Page 1

Model 7057A Thermocouple Scanner Card Instruction Manual

Contains Operating and Servicing Information

Publication Date: January 1992

Document Number: 7057A-901-01 Rev. D

Page 2

WARRANTY

LIMITATION OF WARRANTY

Page 3

Safety Precautions

The following safety precautioos should be obsewed before using this product and any asnociated instrumcntatioo. Although some inrtromeots and accessories woold nonnally bo used

with nowhazardous voltages, there arc situations wberc hazardous conditions may be present.

This product is intended for use by qualified personnel who rccogoiu: shock hazards and are

familiar with tbc safety pnxaotions rcqoircd to avoid possible injuly. Read lbe operating it]formation carefully before using the product.

‘The types of product users arc:

Kesponsiblc body is tbe iodividunl or group responsible for the USC sod owinleoaoce of

equipment, for ensuring tlnt the equipment ia operated within its spccilications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. Tbey most be trained in electrical safety

procedures and proper use of the iostrument. ‘lhey most be protected from electric shock and

~onmt with hazardous live circuits.

Maintenance personnel perform mutioe procedures oo the product to keep it operadog, for

example, setting the hoc voltage or replacing consumable materials. Maintenance proccdurcs

am dcacribed in the manual. The procedures explicitly state if the operator ~nay perform them.

Othcrwisc, they should be performed only by senice pcnonoel.

Service personnel are trained to work on live circuits, sod perfoonn safe installations sod repairs of products. Ooly properly trained setvice personocl may perform installation and scrvice procedures.

Exercise extreme caution whco a shock hazard is present. Lethal voltage may be present on

cable coonector jacks or test fixtures. 111~ American National Standards lostitute (ANSI)

stam that a shock hazard exists wheo voltage levels greater than 30V RMS, 42.4V peak, or

60VDC are present. A good safety practice is to expect that hazardous voltage is present

in any unknown circuit before measuring.

Users of this product must be protected fmm electric shock at all timer. The responsible body

must eosum thtat wets aw pwented a.cce~s aod/orinsulatcd from every connection point. lo some

cases, conoectiuns most be exposed to potential buman cootact. Product usa io these circuostances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or abovc 1wO volts, no conductive part of the circuit may be exposed.

AY described in the Ioteroational Electratechnical Commission (IEC) Standard IEC 664, digital multimcter measuring circuits (e.g., Keifhley Models 175A, 199, 2OOQ,2COl, 2002, and

2010) are Installation Category II. All other instruments signal tennioals are Installation Category I and must oat be conoected to mains.

Do not conoect switching cards directly to unlimited power circuits. They are inlendcd to bc

used with impedance limited sources. NEVER connect switching cards directly to AC mains.

Wheo conoccting sources to switching cards. iostall protective devices to limit fault current

sod voltage to tbc card.

Before operating ao instrument, make sure the line cord is connected to a properly grounded

power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear,

cracks, or breaks bcforc each oso.

For maximum safety, do not touch the product, test cables, or any other instrumcots while power is applied to the circuit under test. ALWAYS remove power from the entire test system sod

dischuge soy capxitors before: coooccting or disconnecting cables or jumpers, installing 01

Page 4

removing switching cards. or making iotemtil chaogcs, socb as installing or nzmoviog jumpers.

Vu not touch soy object that could provide a con-cot path to tbc common side of the circuit

under test or power line (eatth) ground. Always make measurements witb dry hands while

standing oo a dly, insulated surface capable of withstanding tbc voltage bciog measured.

The instrument and accessories most be used in accordance with its specifications and operatiog iostructioos or tbe safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories. as defined in

tbe speciticationr sod operatiog information, and es show on the instrument or test fixture

panels, or switcbiog cant.

When fores are used in a product, replace with same type sod rntiog forcootioued pmtectioo

against fire hazard.

Cbassir connections must only be used as shield coooectioos for me~suriog circoits, NOT as

safety eaflh ground connections.

If you are using II test fixture, keep the lid closed while power is applied to the device under

test. Safe operation requires tbe we of a lid interlock.

1ra@

screw is present, connect it to safety earth ground uaiog the wire recommended in

the user documentation.

The ! symbol on an iostroment indicates that the user should refer to the operating ill-

n

stmctions located io tbc manual.

The h

symbol on al iostmment shows that it CNI source or IIICRIIUII: loo0 volts or more, illeluding the combined etTect of normal ad common mode voltages. Use stiuldarrl safety precaulions to avoid pcrsooal cootect with these voltages.

TIE WARNING beading in A manual enplaios dangers that might result in personal injury or

death. Always read the associated information wy carefully hcfore ptxformiog the indicated

pC"CCdU~C.

The CAUTION beading in a manual explains hazards that could damage the instrument.

Such damage may invalidate the warrmty.

lostrumcntatioo and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain pmtcctioo from electric shock and ftre, replacement components in mains circoils, including the power transfouner, test leads, and ioput jacks, must he purchased from

Keithley Instruments. Standard fuses, with applicable national safety appmvals, may be used

if the ratiog sod type are the same. Other components that are not safety r&ted may hc por-

chased from other suppliers as long as they are equivalent to tbe original component. (Note

that selected parts should be purchased only through Keithley Iostmmcnts to maiotain accoracy sod fonctiooality of the product.) If you we unsure about the applicability of a replaccment component, call a Keithlcy Instruments office for information.

To clean an instrument. use a damp cloth or mild, water based cleaner. Clean the exterior

of the instrument only. Do not apply cleaner directly tb the instrument or allow liquids to

enter or spill on the instrument. Products that consist of a circuit hoard with no case or cbassis (e.g., data acquisition board for installation into a computer) should neverrequire cleaning if handled according to instructiuns. If the board becomes contaminated sod operation

is affected. the hoard should he returned to the factory for proper cleaninglserviciog.

tie”. 2rB

Page 5

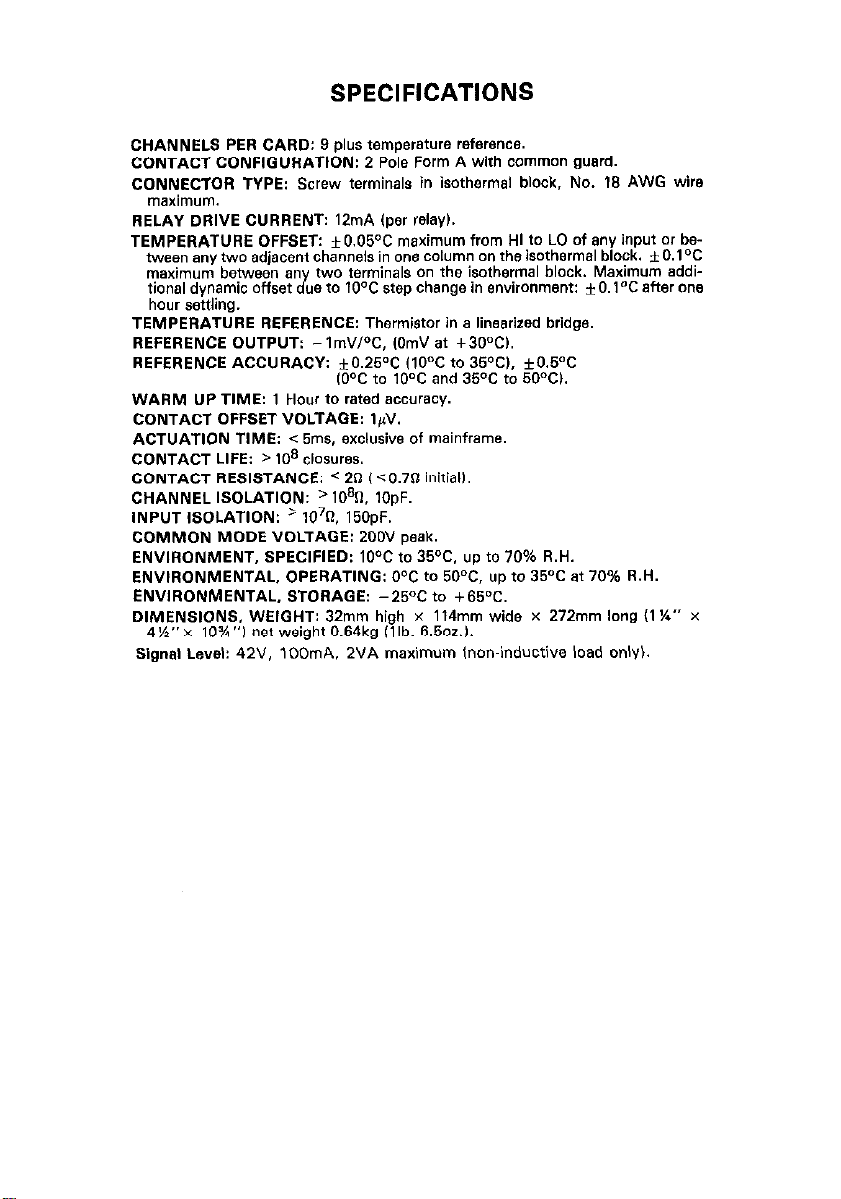

SPECIFICATIONS

CHANNELS PER CARD: 9 plus temperature reference.

CONTACT CONFIGURATION: 2 Pole Form A with common guard.

CONNECTOR TYPE: Screw terminals in isothermal block, No. 18 AWG wire

maximum.

RELAY DRIVE CURRENT: 12mA lper relay).

TEMPERATURE OFFSET: i0.05°C maximum from HI to LO of any input or be-

tween any two adjacent channels in one column on the isothermal block. * O.lOC

maximum between an two ferminals on the isothermal block. Maximum addi-

tional dynamic offset J ue fo 10°C step chsngo in environment: *O.l°C after one

hour settling.

TEMPERATURE REFERENCE: Thermistor in a linearized bridge.

REFERENCE OUTPUT: - ,m”,°C, ,Om” at +3O”CI.

REFERENCE ACCURACY: f0.2S°C ,,O’=C to 35OC,, +0.5OC

WARM UP TIME: 1 Hour to rated accuracy.

CONTACT OFFSET VOLTAGE: I,,“.

ACTUATION TIME: < 5ms, exclusive of mainframe.

CONTACT LIFE: > lo* cbs”res.

CONTACT RESISTANCE: < 2n (<O.,O inidall.

C”ANNEL ISOLATION: ‘109O. 1OpF.

INPUT ISOLATION: a 10’R. 15OpF.

COMMON MODE VOLTAGE: 200” peak.

ENVIRONMENT, SPECIFIED: ,O’=C to 35°C. up to 70% R.H.

ENWRONMENTAL, OPERATING: O°C to 50°C, up to 35OC at 70% R.H.

ENVIRONMENTAL. STORAGE: -25OC to +55”C.

DIMENSIONS, WEIGHT: 32mm high x 114mm wide x 272mm long I1 %*’ x

4%“~ 10%“) net weight 0.54kg Illb. 5,502.).

Signaf Level: 42”. 1DDmA. 2VA maximum Inon-inductive load only).

,O”C to 10% and 35°C to 60°Cl.

Page 6

TABLE OF CONTENTS

SECTION l-GENERAL INFORMATION

Introduction

1.1

Warranty Information

1.2

ManualAddenda

1.3

Safety Symbols and Terms

1.4

SECTION Z-OPERATION

Introduction

Wiring

Operating Considerations,,

2.3

Operating Hints

2.4

Thermocouple Measurement Considerations,

2.5

Measurement Procedure

2.6

SwitchTerminology.. .....................................

2.7

SECTION 3-SERVICING INFORMATION

Calibration Procedure.,

3.1

Calibration Procedures

3.2

Test of Calibration

3.3

Channel Isolation,,

3.4

3.5

Input Isolation, Common Mode

SECTION 4-REPLACEABLE PARTS

introduction,

4.1

ReplaceableParts

4.2

Ordering Information

4.3

FactoryService ..........................................

4.4

4.5

Component Layout and Schematic Diagram

.............................................

.....................................

.........................................

................................

............................................

...................................................

................................

..........................................

..................................

...................................

....................................

........................................

.......................................

............................................

........................................

.....................................

LIST OF FIGURES

Typical Thermocouple Connections

:

Plug-In Board Assembly.

3

Using GUARD Connection

4

Typical Multiple Channel Analog Connections.

Typical Thermocouple Measurements

Switch Terminology

ii

Chsnnel~lsolation Test Setup

Common Mode Isolation Test Setup

;

Model 7057A. Component Location Drawing

9

Model 7057A. Schematic Diagram

10

..................................

.................................

.....................................

.................

.............................

..................

.........................

......................

..............................

.......................

.........................

...............

................

21

;1

21

22

23

ii

23

23

3

4

5

5

6

7

22

22

26

27

LIST OF TABLES

Summary of Temperature Measurement Procedure

:

NBS Quwtic Coefficients for Types S, R, B, E, J, K and T

Recommended Test Equipment.

3

4

Model 7057A Rep!aceab!e parts .:

5

Model 7057A Replaceable Parts ,Mec”a”~ca,, 24

...........................

.. : .,:

.... :

...........

................

7

......

2:

23

Page 7

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 7057A is a thermocouple scanner card which is field-installable in an

appropriate scanner mainframe (e.g. Model 7051. Since it combines the functions of a thermocouple scanner and uniform temperature reference, it is

especially useful for scanning thermocouples. The input terminals aie HI0 alloycopper set in an isothermal block to minimize temperature differences. A thermistor sensor within the isothermal block is used with a bridge network located

on the Model 7057A to give an indication of the temperature reference or cold

junction. The temperature of the heat sink is used to calculate the corrected

thermocouple output. The output voltages of each thermocouple must be converted to temperature PC or OF) using appropriate thermocouple tables or

polynomial equations. In addition any channel may be used for monitoring lowlevel signals. The Model 7057A uses Z-pole form A contacts for witching of

signals up to 35V peak or IOOmA peak. Input and output connections 818 made

through the rear panel of the scanner mainframe using #4 screw terminals on the

Model 7057A.

1.2 WARRANTY INFORMATION

Warranty information is stated on the inside front cover of the manual. If there is

a need for service, contact the Keithley representative or authorized repair facility

in your area. Check the back cover of this manual for addresses. The service

form supplied at the end of this manual should be used to provide the repair

facility with adequate information concerning any difficulty.

1.3 MANUAL ADDENDA

Any improvements or changes to this manual will be explained on an addendum

included with this manual.

1.4 SAFETY SYMBOLS AND TERMS

The symbol

i;;i;TbolN

The WARNING used in this manual explains dangers that could result in

personal injury or death.

The CAUTION used in this manual explains hazards that could damage the

instrument.

denotes that the user should refer to the operating instruc-

A

denotes that a high voltage may be present on the ter-

1

Page 8

SECTION 2

OPERATION

2.1 INTRODUCTION

This section provides information needed to use the Model 7057A with an

*ppropriate scanner mainframe.

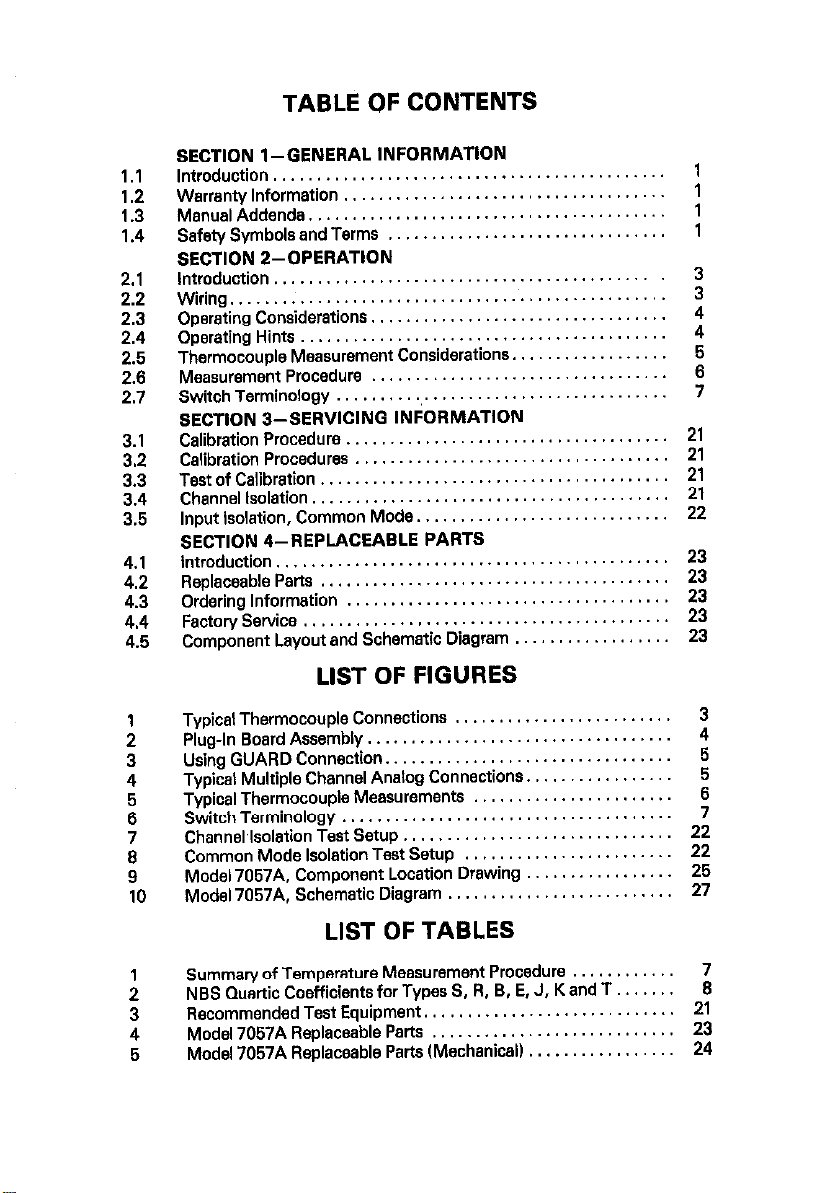

2.2 WIRING AND INSTALLATION

1. Wiring Configuration-The Model 7057A has a Z-pole switching configuration. It may be used to connect one of nine signals to the output. The tenth

scanner position (Channel 1) is used to monitor the temperature of the input

terminals with a thermistor bridge. Bridge power is derived from a non-

isolated internal supply with jumper provisions for an external isolated supply.

A. lnwt and output connections are made to the screw terminals shown in

Fi& 1.

8. Signal path resistance, including both poles of a channel relay, is typically

less than 1.4?, less than 2Q et end of life.

C. A guard surrounds 811 signal paths and is connected to the heat sink

surrounding the input terminals. Connection to the guard is made at the

isothermal block.

2. Installation-Refer to the scanner mainframe instruction manual for scanner

instructions.

I

I-==

Figure 1. Typical Thermocouple Connections.

3

Page 9

2.3 OPERATING CONSIDERATIONS

1. Signal Level-IOV peak, 1OmA peak with a resistive load for expected life.

Maximum peak instantaneous rating is 35V.

2. Contact Potential (Laboratory Environment)-Less than I$/ from input to

output when copper wires are used.

3. Isolation-Guarded interchannel resitanceis nominally@!?. Guarded cap*citance is less than 1OOpF between any two channels.

4. Maximum Levels-A 2OOV peak between channels or from channel to

guard or mainframe (digital) common.

5. Operating Environment-OQC-50°C, up to 35°C at 70% relative humidity.

2.4 OPERATING HINTS

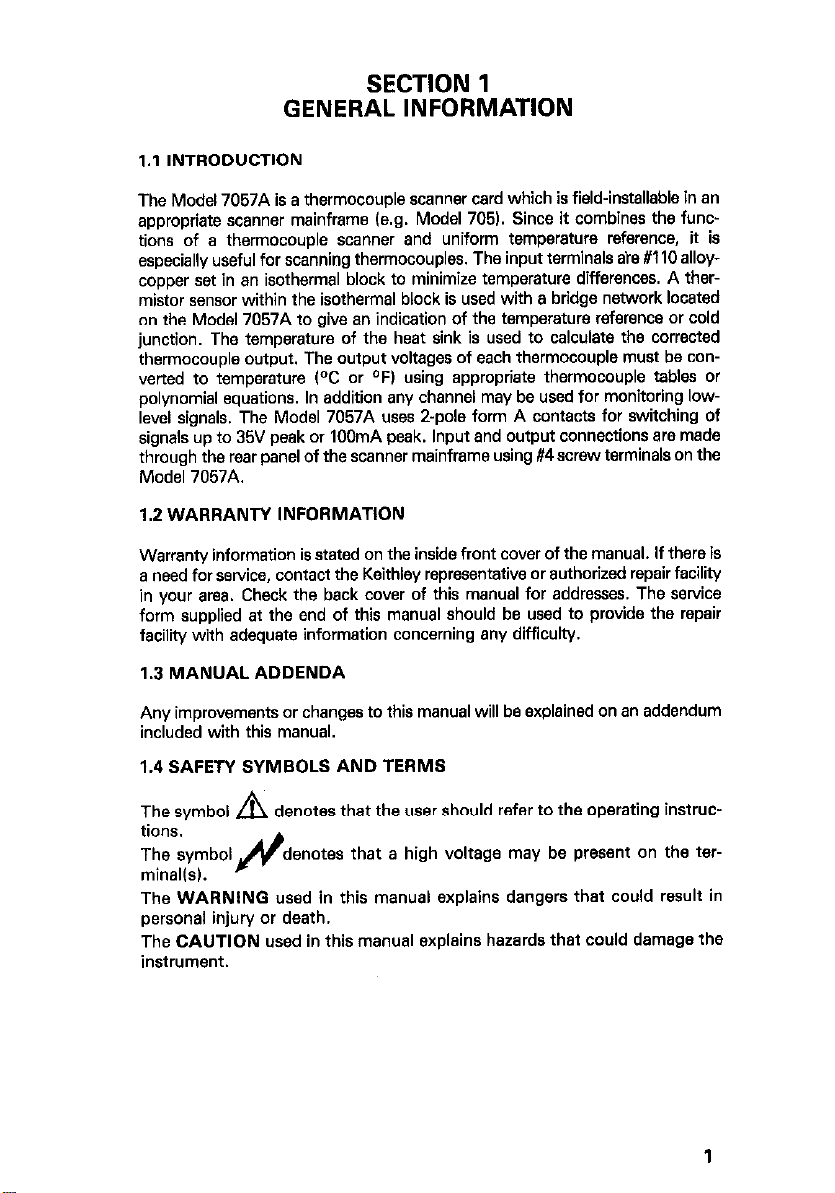

1. The clamp-type screw terminals will accept #I8 to #36 AWG (0.044 to

0.005 inch) wire. Figure 2 shows the mechanical features of the Model

7057A which prevent lead movement after the board is wired.

Figure 2. Plug-h Board Assembly

2. Thermal offset on any given channel is typically repeatable to within a few

hundred nanovolts each time the channel is selected. That is, every time a

channel is selected and allowed to stabilize for a period of time, the channel

will exhibit the same thermal offset to within a few hundred nanovolts. This

offset may be accounted for in the measurement and subtracted from each

reading, to obtain a more precise measurement.

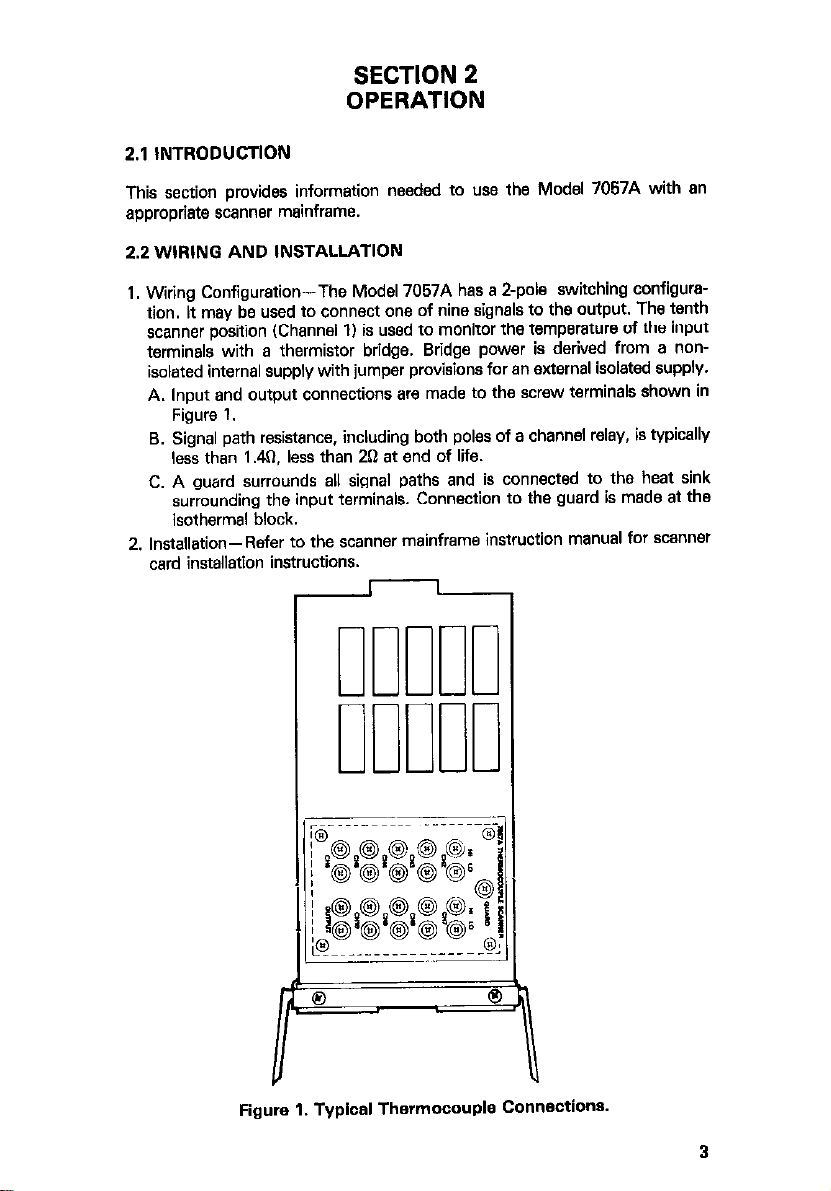

3. To effectively eliminate error voltages produced by leakage current, the

GUARD terminal should be connected to the reference connection on the

channel which is most sensitive to error (that is, the one which has the

lowest source voltage versus the highest resistance). For instance. two

sources are connected to the Model 7057A; one having an equivalent

source voltage of IV with a series resistance of IOOkR and the other having

a source voltage of .lV with a lkn series resistance. The lOOka source

resistance will develop 100 times the error voltage as the lkn Knwze

resistance. Its source voltage however, is only 10 times as great. which

means that the percentage error is 10 times as large on the lV/lOOkn chan-

4

Page 10

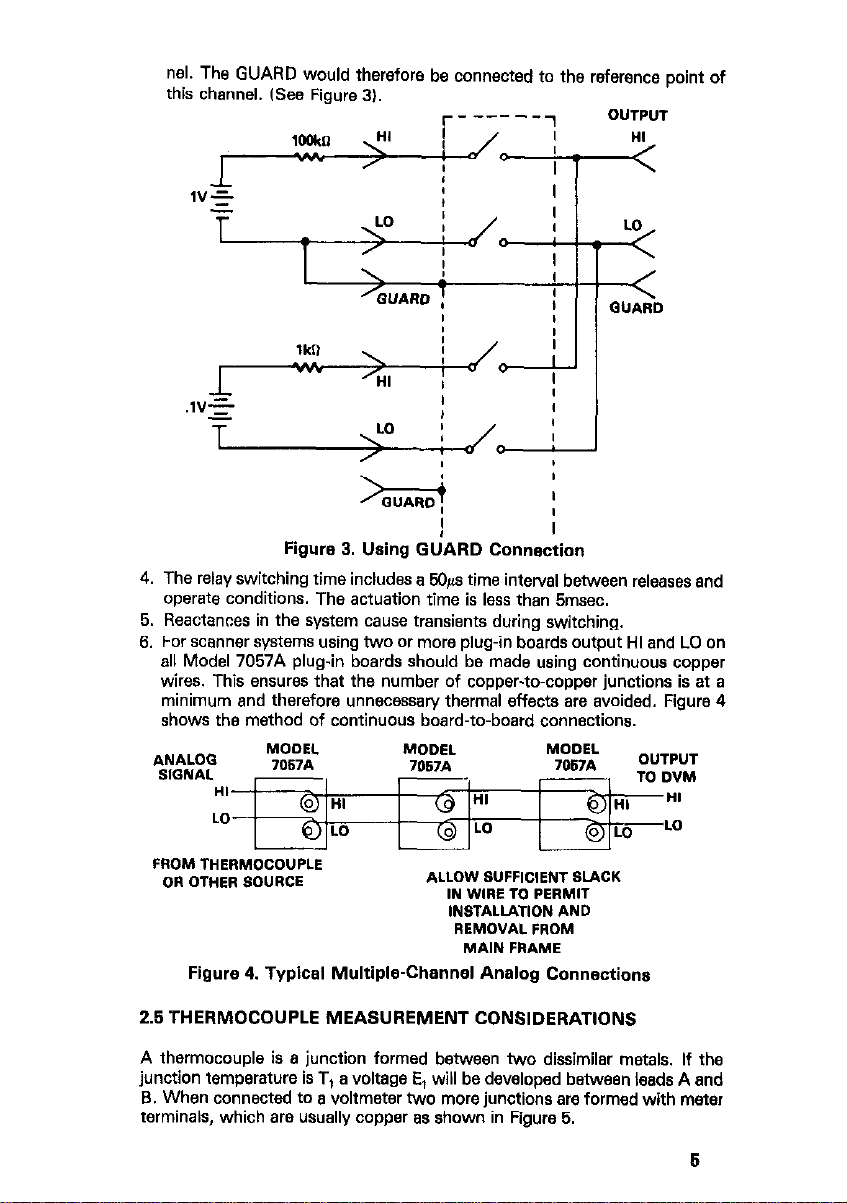

nel. The GUARD would therefore be connected to the reference point of

this channel. ISee Figure 3).

Figure 3. Using GUARD Connection

4. The relay switching time includes a 9&s time interval between releases end

operate conditions. The actuation time is less than 5msec.

5. Reactances in the system cause transients during switching.

6. For scanner systems using two or more plug-in boards output HI and LO on

all Model 7057A plug-in boards should be made using continuous copper

wires. This ensures that the number of copper-to-copper junctions is at a

minimum and therefore unnecessary thermal effects are avoided. Figure 4

shows the method of continuous board-to-board connections.

Figure 4. Typical Multiple-Channel Analog Connections

2.5 THERMOCOUPLE MEASUREMENT CONSIDERATIONS

A thermocouple is B junction formed between two dissimilar metals. If the

junction temperature is T, a voltage E, will be developed between leads A and

B. When connected to B voltmeter two more junctions are formed with meter

terminals, which are usually copper as shown in Figure 5.

Page 11

Figure 5. Typical Thermocouple Measurement

The voltage measured by the voltmeter is proponional to the difference between temperature T, and T2. To determine T,, T2 the thermoelectric properties of the thermocouple are needed. Data is available to determine the voltage

versus temperature relationship based on a reference temperature IT*) of 0°C.

Thus, if the thermocouple-to-copper junctions were maintained at O°C it

would be possible to determine T, directly by referring to thermocouple

reference tables*, which give temperature as a function of the meter reading

V,. If these junctions are different from 0°C a voltage E2 will be introduced,

where V, = E,-E,.

2.6 MEASUREMENT PROCEDURE

In the Model 7057A the reference temperatwre T is measured by a dual thermistor in a bridge circuit. The temperature of a thermocouple connected to

Channels 2 through 10 is determined by the following procedure:

1. Measure the voltage for the reference junction V and calculate Tz. T2 =

30-w, x 1031.

2. Determine the reference junction voltage, E2, either from thermocouple

reference tables’ or by the calculation**:

5 = a0 + A, T + a,p + aaT + a,,+ where T = T2 as determined in step 1

above. Q is expressed in microvolts. The constant a0 through a4 are a

function of the thermocouple type connected to the channel. The coeff-

CiWntS, aO, a,, a?, a3 and a4 are dependent on the thermocouple type and

temperature range under consideration.

3. Measure the thermocouple voltage V, at the channel output. Convert to

microvolts.

4. Add b to V, to determine E,. E, =V, +E, (where V, is expressed in

microvoltsl.

5. Determine the thermocouple temperature, T,, either from thermocouple

reference tables* or by calculation**:

TI = a, + %EI. + %E12r + e,E? + %EI+ (where E, is expressed in microvoltsl.

6. For example, consider a type J iron-constantan thermocouple at 300°C

(T,I. The reference junction temperature will be 6 to 10°C above ambient,

say 36% IT2).

A. The bridge output ichannel II will be -.006V. Since the bridge output is

zero when T, = 30°C this indicates T2 = 36OC.

B. Using NBS Monograph 125 to determine the reference voltage for a type

J thermocouple gives b 4 1649,O@V. Using the most accurate quark

approximation formula (Table 21 for this range gives lB49.085@,

C. The voltage at Channel 1, which is V,, will be 14476,OpV. IV, = E, -b).

D. Add 6 to V, and get E, = 16325.0@,

6

Page 12

E. Using Table A6.2.1 to find the thermocouple temperature gives

300.00°C. Using the formula (Table 2) gives 299.995°C.

* Thermocouple Reference Tables, Based on the IPTS-66 National Bureau

Standards Monograph 125. (SD Catalog No. C13.44~1251

** See also Table 2 which summarizes the quartic coefficients.

Table 1. Summary of Temperature Measurement Procedure

Quantity

channel output V,.

Determine equivalent

V2

bLSl

Tz = 30-I!!, x 103)

Measured desired

Calculate correction

VI

(volts)

F

lCalcuiat~~olt.age E,. )

Calculate equivalent

temperature TV.

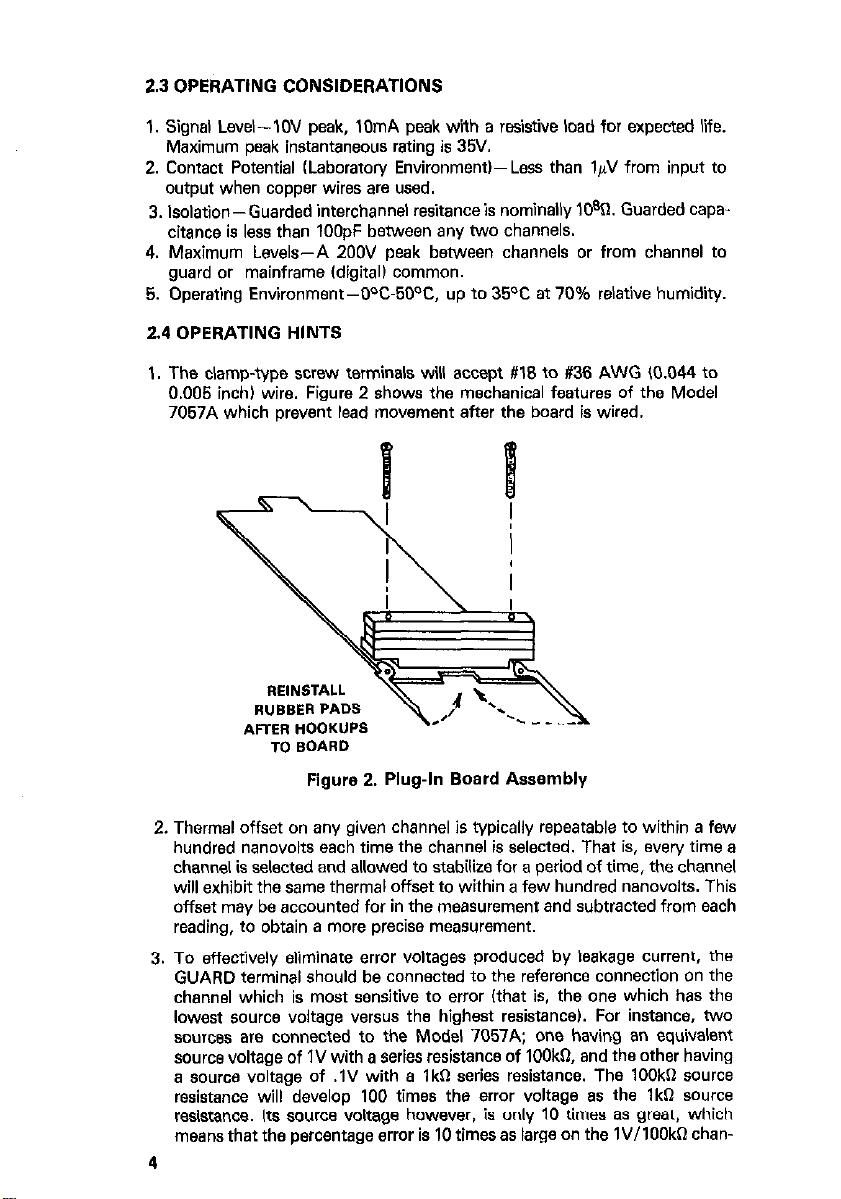

2.7 SWITCH TERMINOLOGY

Throughout this manual the terminology Form A is used. The term Form A is

used in switch terminology and is described as follows:

1. Form A is simply a single pole normally open ISPNOI switch (refer to

Figure 6). A Z-pole switch normally open is classified as 2 Form A.

2. Form B is similar to Form A except that its contacts are normally closed

(refer to Figure 61. A Z-pole switch normally closed is classified as a 2 Form

B.

3. Form C is shown in Figure 6 as a single pole double throw switch. It could

also be a multipole switch such as a Z-pole which would be classified as a 2

-- 1 E, = E2 + V,.x-lO-” 1 mic~v,lts 1

T, = a, + a,E, + a,P, +

*Pl + Wl

T, IW

Figure 6. Switch Terminology

7

Page 13

Reference Junction

1

16% to 176%

Correction

” tn m

Table 2. NBS Quartic Coefficients for Types S. R. B. E. J. K. and T.

Argument hp.

a0

=I

=2

Argument EXP. Arg”me”t Exp. Arg”ment EXP.

5.5439639

5.9791m

6.2516%!3

6.5554!232

Ma34421

8.7228147

9.5827994

9.4531354

2.9873073

3.4129348

6.4091373

3.9952876

*.co4320*

1.3532278

5.3994446 +o 1

I.2467754 -2

a3

Argument Exp.

a4

Exact-Approx.

Error

Range ILNV)

Page 14

c

4.1137317 +1

4.4507790 +1

4.1670535 + 1

-3.0938374 +1

z!2zm7 +7

1.3866867 +2

1.3923740 +2

4.6133695 +3

2.3131446 +4

I

-2.0241757 -5 -2.0241757 -5

-m349c6, -5 -m349c6, -5

-9.cl763455 -6 -9.cl763455 -6

-7.0073775 -6 -7.0073775 -6

-6.319500, -6 -6.319500, -6

-1.8612979 -6 -1.8612979 -6

-,.33496,, -6 -,.33496,, -6

- I .6,62,80 - I .6,62,80 - 6 - 6

-4.9,94442 -6 -4.9,94442 -6

-3.2873314 -6 -3.2873314 -6

4.659nc8 -8 4.659nc8 -8

7.7266682 -8 7.7266682 -8

1.032002 -4 1.032002 -4

4.934,196 -4 4.934,196 -4

Page 15

4rgumem Exp.

80

Zrgumenf Ex*.

a1

-4.0674108 +*

-5.mm84 +*

-5.4505828 +*

1.6618169 +3

1.5132838 +3

2.4m3703 +3

1.5787334 +3

-7.1904948 +4

8.8532076 14

5.4295008 +o

5.7622558 +o

6.1429772 +!I

6.4615269 +o

6.596212u +o

8.7490234 +o

9.673111, +o

9.5942872 +o

2.3048626 +O

*.795%247 +o

4.1604579 -1

*.6321,44 +o

1.94423a3 +*

- ,.5014129 +*

1.1446885 -2

9.2715271 -3

7.1515857 -3

5.7010917 -3

5.1559203 -3

1.7115155 -3

-2.6994046 -4

-1.2813352 -4

8.7635426 -3

8.1571403 -3

1.0549178 -2

8.31co314 -3

- 1.7913090 - 1

9.5376167 -2

-1.1295306 -5

-7.1346883 -6

-3.7639447 -6

-1.8683292 -6

-1.2385309 -6

7.5039035 -7

2.5536988 -6

2.4468512 -6

-2.3016?318 -6

-1.9701159 -6

-3.0383621 -6

-2.0332036 -6

7.9264764 -6

-1.6644901 -5

-0.01 to +o.o,

5.w2w96 -9

2.5877454 -9

9.6963832 -10

2.3636365 -10

1.m3.27643 -11 1.m3.27643 -11

-3.oo96280 -10 -3.oo96280 -10

-8.9155191

-8.915549,

-8.6286758 -10

7.4284923 -11

6.5568964 -12

1.8540516 -10

1.6260416 -11

- 1.3167245 -8

-8.3062870 - 10 -8.3062870 - 10

- 10

- 10

-7 to 16

- 16 to 12

-35to25

-551036

7

-661036

- .4 to .5

-1~7 to 1.6

-2.1 to 1.8

- .05 to .05

- .05 to .05

- 45 to .05

- .05 to .05

-1.0 to 1.3

.05 to .05

Page 16

,rg"ment Exp.

=0

Argument Exp.

a2

Argument Exp.

84

4.5509556 +1

4.9160016 +1

4.8343651 +1

-4.1134469 10

3.7487318 +1

8.0559850 +1

1.4180146 +3

3.176!3333 +3

1.2683437 +4

1.6251434 -1

1.5239494 -1

1.4441607 -1

1.3344190 -1

1.3752efj? -1

1.12ed875 -1

1.1054689 -1

1.1098270 -1

1.2738464 -1

1.1515zc4 -1

1.0442877 -1

9.0181346 -2

-5.m2431 -1

- 2.6747958 + 0

-2.0454379 -5

-1.3755675 -5

-9.5014952 -6

-7.4485484 -6

-6.7661171 -6

-2.86ces78 -6

-2.3559046 -6

-2.4353s9o -6

-4.3132296 -6

-2.9827002 -6

-1.9Enm -6

-7.4069329 -7

5.6190639 -5

2.2334214 -4

2.5404935 -9

1.2610922 -9

6.2073358 -10

3.8266182 -10

3.M2c473 -10

8.6173702 - 11

3.9276246 -11

-1.1767904 -13

-4.4281251 - 14

-1.9622497 -14

-7.4617277 -15

-5.4254672 -15

-1.1440038 -15

3.33-4 -16

1.8172612 -16

-1Ea3798 -15

-3.78Gss57 -16

2.4513433 -16

9.4290495 -16

3.0369250 -14

1.0882779 -13

-13to3

-4to7

-6 to 10

-7to13

-7 to 14

-.0tto.o4

-.08tom

-.lOfO .12

- .m* to .x3*

-.Oll to ,011

-.x05 to .wo5

.wo5 to .ooo5

-.ll to .I8

.ccm to .a307

Page 17

a0

4rg”ment EXP.

=I =*

PIrgument EXp. Argument Exp.

Argument Exp.

a3

1.3740347 +1

-2.5321108 +1

-1.1708354 +*

-9.8446269 +2

1.3702395 + 3

~4.76445Sl +*

- 6.4mas29

‘Quadratic. cubic. and quark approximations f

E=ag+alT+a*T*+a3T3+aqT4where E is in

+ 2

- I.3749133

-3.2914888

-9.9736579

3.smx94

3.367OEsS

~f!Eiy~~

7e dafa as a function Of temperat”le ,Y

:rwolfs and T is in degrees Celsius.

- 1 6.3446673

-1 5.9766638

-2 5.4976533

-1 4.5539656

+o 8.2282215

-3

-3

-3

-3

-4

-5.6339756 -7

-5.9983692 -7 -9.7c41131 -11 -.,*to.*o

- 5.7165679 7

~3.3057S24 -7 -2.w18428 10

-9.1094186 -8 -2.8098361 -10

-8.0141311 -7 - 2.7203972 - 1, - .05 fO .05

-3.6623964 -7 -3.6S6Slcc -10 -2.0 fo 1.8

3.6623964 -7 -3.69691cc -10 -2.010 1.8

*.‘lm1224 -6

3.W5686 -6 -9.4548852 -10 .05 fO .05

2.2417410 -6 ~7.6471224 10

2.4305578 -6 -8.1518033 -10 - .05 to .05

-1.2267180 -6

1 selecied temperat”re ranges. me expansion is 0‘ the form

-1.1808558 -10 -22f0.14

-1.0818193 -10 -.,m,.o

-4to5

-*to9

-7.7901142 -10 .05 ro .05

- $5 fO .05

0.01 fO +o.o,

Page 18

80

E,,W

Range

WV1

EX*Ct-App,OX.

,rgument Ex

-5.7447033 -4

7.2874oE6 -1

5.7822214 -1

4.SS2Slrn -1

1.8946288 4

2.0949015 4

2.2394664 i

3.2188156 4

3.44,5x4 t

4.6255054 -1

3.ux.6136 -1

2.7222162 -1

2.4988761 -1

1.8282378 -1

1.7031473 - 1

1.5828913 -1

1.4979551 - 1

-3.177193, -4

-1.6039309 -4

-1.0349686 -4

-8.2176262 -5

-6.81oo680 -5

~3.6330332 -5

-2.71@33,2 -5

-1.1561743 -5

-8.9696912 -6

-7.0050689 -6

~6.n762S3 -6

-301075

-35row

-45 to 110

-5otom

-50 TO 130

-.09fO,.O

-3to3

-5to5

-.cmro.o03

-.0*5 to .o*o

- .W, 10 .w,

- ,031 to .Wl

1

n is Of the form

Page 19

*0

Argwnent Exp.

*3 *3

\rgument hp. \rgument hp.

aq

*rgument Exp.

‘Cluadr*tic, cubic. and qu ‘Cluadr*tic, cubic. and qu

E=ar,+a,T+a*T2+,3T: E=ar,+a,T+a*T2+,3T:

-8.5384268 +2

-1.383%33 +3

-5.1503130 +4

5.9287179 +1 5.9287179 +1 7.0983783 -2

5.6754764 +1 5.6754764 +1 5.7443085 -2

5.8943714 +1 5.8943714 +1 5.611850, -5

5.8318736 +1 5.8318736 +1 5.4292960 -2

5.m7691 +1 5.m7691 +1 5.3761106 -2

5.8734537 +1 5.8734537 +1

6.5022W +1 6.5022W +1

6.7*111*6 fl 6.7*111*6 fl 3.1669230 -2

-1.6691278 +2 -1.6691278 +2 4.1877018 -1

5.8637565 +1 p4.67*w25 -2

5.0763!?31 -2

3.4354900 -2

5.*421&u -5 5.*421&u -5

-5.GmmTn2 -5 -5.GmmTn2 -5

-5.9506584 -5 -5.9506584 -5

-5.6286941 -5 -5.6286941 -5

-5.2870696 -5 -5.2870696 -5

-4.7621793 -5 -4.7621793 -5

-2.9763494 -5 -2.9763494 -5

-2.9237913 -5 -2.9237913 -5

-3.1228607 -4 -3.1228607 -4

-1.443202 -6

3.8137875 -7

1.3960921 -7

2.2327737 -8

2.0825828 -8

1.5352840 -8

1.465!3118 -8

7.w39401 -9

8.1514671 -9

8.5283044 -8

-5to5

- .5 to .4

-6oto3n

-8704

-3ro4

-,8tol7

-2 to 2.5

- .03 to .03

-.06to.oE

- .12 70 + .24

Page 20

Page 21

I. Ouartic Equation

Error

Range

WV)

-2COt00

-mto76o

-MO to 12cm

-2oto5W

0 20 4cQ

oto780

0t01200

4ooto760

4ooto12w

sooto760

780 to ,209

Reference Junction

Correction

0 to 50

t

-5.7831co5 +3

,.,,2,3,, +3

-2.5724435 +4

3.9264982 +4

5.04cm743 +1

4.8xQ533 + 1

4.,052807 + 1

5.m +,

5.0452399 +1

5.12E8213 +1

5.5881877 +1

9.77l8!35 +1

,.8%9x, +,

2.2151898 +2

-1.47850,7 +2

5.0373743 +1

a2

PIrgument hp.

3.Mo906) -2

3.269em2 -2

2.552650 -2

2.ax2596 -2

2.840913, -2

2.oo40854 -2

1.4207854 -2

-1.18E843n -1

5.3882730 -2

-4.041808, -1

3.647092, -1

3.01670,, -2

a3

Fwgumant 5xp.

-8.3493983 -5

-6.993603, -5

-2.2xl82s5 -5

-8.E&883o5 -5

-8.7558436 -5

-4.~ -5

3.1325181 -5

1.3184454 -4

-2.2171472 -5

4.2749984 -4

~2.7029305 -4

-7.4293513 -5

2.5174022 -7

5.,,,2,2!3 -8

7.1373907 -8

5.3587105 -8

5.ez8zo4a -8

3.281s4wJ -8

-1.5023,,0 -8

-4.8218788 -8

1.8445398 -10

1.6174242 -7

7.2113090 -8

Page 22

a2

4rgument EXP.

a3

Argument Exp.

I 0 0 fO to ,200 400

Wuadratic. cubic. and q~artic approximation*

T=aO+alE+a2E2+a3E3+aqE4where E is in r

0t0760

4OOt07M1

403 fO ,203

6Wt07M1

700 to 1200

!3.2808351 +1

-1.1075293 +2

1.8020713 +2

-6.3828680 +2

1.8843850 -2

2.1155170 -2

2.1676850 -2

1.8745056 -2

1.8750953 -2

1.9323799 -2

1.8134974 -2

5.4483817 -3

2.8651303 -2

-4.5284199 -3

7.4068745 -2

- 3.3513149 -7

-2.1844454 -7

~1.8094256 -7

~I.8512600 -7

-1.03ca20 -7

1.2443!397 -11

3.9094347 -12

7.8771919 - 12

8.3681958 -12

3.7084018 -12

~2.5849263 -14

-1.5227150 -16

- 2.4303017

-1.1897222 -18

-1.328n568 -18

-5.1031937 -17

2.1141718 -17

9.9364476 - 17

-4.9012035 - 18

1.5521511 -18

- 17

Page 23

IAlgUmenf

a2

Argument EXP.

83

Argm-“ant Exp.

1.3223524 +3

-3.6456236 +1

2.1326066 +3

-9.0373649 +2

-2.5972816 +3

3.9676618 +l

3.6478446 fl

3.6762217 +l

4.09B640 * 1

4.0961103 +1

3.9443859 +1

3.0191663 fl

3.8349319 +1

2.5608012 +1

4.0577145 +1

5.M75276 +1

3.1063356 -2

2.8266412 -2

2.4514587 -2

-3.2619221 -3

-1.5!%2510 -4

5.aJ53822 -3

2.76m912 -2

9.9993329 -3

3.7091744 -2

9.5092149 -3

- 1.4576419 -2

-9.16m895 -5

-1.14a8433 -4

-4.3@319%3 -5

S.FJl4137 -6

- 1.252RW.J - 5

-4.2015137 -6

-2.4734437 -5

-8.744446 -6

-3.3517324 -5

-1.0989249 -6

9.4854151 -6

3.0X+3626 -8

-2.8153447 -8

2.5127588 -8

-1.6912373 -9

3.2764725 - 8

I.3317059 -10

6.9798332 -9

1.7108618 -9

9.9607405 -9

-3.0753213 -9

-3.1,x779 -9

-1.1 fO 1.2

-.@3to.o+

-1mtom

-'25 to 45

-25to20

-60 to 110

-.9to1.4

-,2to,,

- .05 fO .o,

- .05 to .I3

- .05 to .05

-.ffito +.14

1 is of the form

Page 24

a0

Argument EXP.

-r

a7

,rgu”lent Exp.

a2

Argument Exp.

a3

Argument EXP.

a4

*rgument Exp.

-270too

-200030

-2ootot?lm

-20t05CC

0 to ml

-2.4707112 t,

6.2300671 TO

-3.w30992 + 1

-3.1617495 CO

2.3615582 +2

1.2329875 -2

2.3763697 -2

2.8346886 -2

2.4363851 -2

2.4383246 -2

2.5132785 -2

2.3465633 -2

2.4655374 -2

3.1425797 -2

2.7115517 -2

1.1066277 -3

-1.4434305 -5

-2.4382217 -6

-5.8008526 -7

5.6206931 -8

9.7830251 - 9

-6.0883423 -8

-3.1332620 -7

-7.8788333 -8

-4.0935633 -7

-2.1941595 -7

8.2516607 -7

4.2824666

6.8203073

2.5720615 11

-3.8825620 -12

3.6276665 -12

5.5358209 -13

6.5075717 - 12

1.3266743 12

8.5462602 -12

4.6762626 - 12

-1.3558849 -11

9

4.2028679 - 13

10

-9.4854031 -14

-3.6813679 -16

3.9120208 17

-2.5756-W -16

9.3720918 18

-3.9663834 -17

1.5580541 -18

-5.5696636 -17

-2.9316611 -17

9.1638500 -17

Page 25

I. Quartie Equafion

Argument

Exp.

3.9439319

+1

-27OtoO

-2cntoo

~200104m

Reference Junction

0 to 403

Correction

0 20 50

ä

3.8749356 +1

3.8621703 i-1

3.64@407 +1

3.8ml239 +1

=,

Argument Exp.

6.2407452 -2

4.5149603 -2

4.5433050 -2

4.6651731 -2

4.1277w -2

=*

-4.7753448 -5

8.0773568 -5

irgument Exp.

2.6846647 -7

-2.5773959 -8

1.4661300 -8

1.5999833 -8

=4

-0.04to t0.081

-9107

- .14 to .I3

-7 to 3.5

-9 to .9

I

Argument

4.3553379 -3

2.3837090 -2

2.6792411 -2

2.5661297~ -2

“Ouadratic. cubic. and qualfic approximarions fo fix data as a tuncti

T = a0 + al E + a2E2 + a3E3 + a4E4 where E is in mi~rovolts and T is in degrees Celsius

Argument EXP.

-2.0325426 -5 -5.4720813 -9

-2.9876839 -6

- 1.0370271 - 6 6.1330327 11

-6.195469 -7 2.2181644 - 11

=2

Argument Exp.

-7.1945810 10

=3

-5.0865527 13

-1.cc41943 -13

-1.39e8335 -15

~3.5500900 -16

I

Page 26

SECTION 3

SERVICING INFORMATION

3.1 RECOMMENDED TEST EQUIPMENT

The recommended test equipment for calibration and performance verification

is given in Table 3. Test equipment other than recommended may be

substituted if specifications at least equal those given in Table 3.

Table 3. Recommended Test Equipment

Itam Description

A 1 DMM

6 Voltage source

C Electrometer

D Scanner Mainframe

3.2 CALIBRATION PROCEDURES

To calibrate the Model 7057A do the following procedure:

1. Remove the green wire on the Model 7057A.

2. Connect DMM across R104 l6.151kQ resistor).

3. Adjust RIO1 for 175.92mV fO.lmV.

4. Remove DMM and reconnect the green wire.

3.3 TEST OF CALIBRATION

Using RFL industries oil bath lor equivalentl, submerge thermistor Ion 7057Al

with temperature standard measuring device (Thermometrics S-10 probe or

equivalent) into the oil. Allow to stabilize and note the difference lat 30°C).

The difference should be less than .2’C.

3.4 CHANNEL ISOLATION

A. This test ~measures the leakage resistance between two channels on the

board. One channel is to be open and the other closed. Set up the test circuit shown in Figure 7.

B. Short the HI and LO connections of each channel on the Model 7057A. Do

not connect the channels together, just short the HI and LO terminals.

C. Set the Model 705 to the Channel mode, Channel 2 and the Step mode.

Set the electrometer to Amps and program the Model 230 to output 1OOV.

Take the electrometer out of ZERO CHECK. Program the channel under

test as open and other channels as closed.

D.Take the reading on the electrometer. The reading should be less than

1 x lo-6A. Using Ohm’s Law calculate the channel isolation. For example:

R = E/I = IOOVll x lo-CA = 1 x lO%?. Due to the capacitance of the circuit, the offset current may be high until the capacitance of the circuit is

charged up. Wait until the readings settle out.

E. Manually scan through channels 2 through 10 repeating step C and D for

each channel.

Channel 1 is the temperature reference channel.

Specifications

I 1OuV resolution

1oov DC

IpA resolution

-

NOTE

21

Page 27

Figure 7. Channel Isolation Test Sat Up

3.5 INPUT ISOLATION, COMMON MODE

A. This test measures the leakage resistance between signal lines and power

line ground. Set up the test circuit shown in Figure 8.

El. Short the input HI and LO terminals of each channel with a short piece of

solid copper wire. Do not connect the channels together, just short the HI

and LO terminals.

C. Insert the Model 7057A into the mainframe and sea the Model 705 to the

Channel mode, Channel 2 and the Step mode.

D. Set the electrometer to Amps and program the Model 230 to output 1OOV.

Take the electrometer out of ZERO CHECK.

E. Take the reading on the electrometer. The reading should be less than

1 x lo-“A. Using Ohm’s Law calculate the isolation ileakaae resistance).

For example: R-=E/I = lOOVl1 x 10m5A = ~lO’n.- Due to the

capacitance of the circuit, the offset current may be high until the

capacitance is charged up. Wait until the readings settle out.

F. Manually scan Channels 2 through 10 repeating step D and E for each

channel.

22

Figure 8. Common Mode Isolation Test Setup

Page 28

SECTION 4

REPLACEABLE PARTS

4.1 INTRODUCTION

This section contains replacement parts information, B schematic diagram

and component layout for the Model 7057A.

4.2 REPLACEABLE PARTS

Parts are listed alpha-numerically in order of their circuit designation. Table 4

contains parts list information for the Model 7057A. Table 5 contains a

mechanical parts list for the Model 7057A.

4.3 ORDERING INFORMATION

To place an order, or to obtain information concerning replacement parts,

contact your Keithley representative of the factory. See the inside front

cover for addresses. When ordering include the following information:

1. Instrument Model Number

2. Instrument Serial Number

3. Part Description

4. Circuit Description (if applicable)

5. Keithley Part Number

4.4 FACTORY SERVICE

If the instrument is to be returned to the factory for service, please complete

the service form which follows this section and return it with the instrument.

4.5 COMPONENT LAYOUT AND SCHEMATIC DIAGRAM

The component layout for the Model 7057A is shown in Figure 9, while

Figure 10 contains the Model 7057A schematic diagram.

Table 4. Modal 705JA Replaceable Parts

23

Page 29

CkCUl

t

Deslg.

Cl01

c102Cl11

KlOl

K102

K103

K104

K105

K106

ix

K109

KllO

RlOl

R102

R103

R104

R105

R106

R107R116

RTlOl

UlOl

Table 4. Model 7057A Replaceable Parts

Description

Capacitor, .l@, 5OOV, Polystyrene

Capacitor, lOpF, 25V, Alummm

Electrolytic

Relay, i Pole Form A

Relay, 2 Pole Form A

Relay, 2 Pole Form A

Relav. 2 Pole Form A

R&i; 2 Pole Form A

Relay, 2 Pole Form A

Relay, 2 Pole Form A

Relay, 2 Pole Form A

Relay, 2 Pole Form A

R&v. 2 Pole Form A

rot,‘ioon

Resistor, 77.77k, 0.02%, %W,

Wirewound

Resistor, 953.4n, O.OZ%, ‘/aW,

Wirewound

Resistor, 6.15kQ 0.02%, XW,

Wirewound

Resistor, 46.590, 0.02%, XW,

Wirewound

Resistor, 12k0, .l%, ‘/,W, Metal

Resistor, 27OQ, 5%, ‘law,

Composition

Thermistor

Low Drift Voltage Reference, AD5803

Film

Ksithley

Part No.

C-238-.1

c-314-10

RL-77

RL-77

E;

RL-77

RL-77

;::g

RL-77

RL-77

Rl-97-100

R-260-77.77k

R-260-953.4

R-260-6.151k

R-260-46.59

R-168-12k

R-76-270

RT-4

IC-151

Table 5. Model 7057A Replaceable Parts Mechanical

Description

Isothermal Block

Isothermal Block. Cover

Clamp Assembl;, Upper

a. Clamp, Upper

b. Strip, Rubber

Clamp Assembly, Lower

a. Clamp Cable, Lower

b. Stiip, Rubber

Handle (2 required)

Rivet (2 required)

Standoff (21 required)

#6-32 x 5116 Phillips Pan Head Screw

(2 required)

X6-32 x 1 inch Phillips Pan Head Screw

(2 required)

#6-32 x ‘X Phillips Pan Head Screw (Heat Sink)

(4 required)

#6-32 x J/4 Phillips Pan Head Screw (Heat Sink

Cover) (4 required)

#6-32 x 318 Phillips Pan Head Screw

Psrt Number

7057A-303

7057A-305

7055-303-06

7055-305

26621

7055-308

7055-307

26621

FA-119

FA-121

ST-139-7

Page 30

Figure 9. Model 7057A Component Location Diagram

26

Page 31

0

Y

Y

0

”

m

3

I;

a

Page 32

Page 33

Loading...

Loading...