Page 1

Models 7018-S and 7018-C

28-Channel3-Pole Multiplexer Cards

Instruction Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Kcithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of I year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

baitcries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithlcy headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated sewice

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products arc warranted for

the balance of the original warranty period, or at least 90 days.

LlMlTATlON OF WARRANTY

This warranly does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTIIER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THI? REMEDIES I’ROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUHNTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFI-WARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Kcithley Instruments, Inc. * 28775 Aurora Road - Cleveland, OH 44139 - 440-24X-0400 - Fax: 440-248-6168 9 http://www.kcithley.com

Page 3

Models 7018-S and 7018-C

Instruction Manual

01993, Keithley Instruments, Inc.

All Rights Reserved

Cleveland, Ohio, U. 5. A.

First Printing, October 1993

Document Number: 7018-901-01 Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately

into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated

with the previous Revision of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 7018~901.01) October 19%

Page 5

Safety Precautions

l‘hc following safciy prccaulions should hc ohscrvcd heforc using

this producl and any associated instrumcnlation. Although some in~mmxmis and accessories would normally hc used with non-hazardous voltages, thcrc are siluations whcrc hazardous conditions

may hc prcscnl.

This product is imended for USC by queiilicd pcrsonncl whn rcwg~

nix shock hazards and arc familiar with :hc safety prccaulions rc~

quired Lo avoid possihlc injury. Kcad tbc “peraiing informalion

carclully hefore using the pruducl.

The types “C product users arc:

Responsible body is lhc individual or group rcsponsihlc lor the USC

and mainlenancc or equipmcnl. r”r ensuring that the equipment is

operated within its specilicauons and “pcrating limits. and for cn~

swing lhal “pcratnrs arc adcquatcly waincd.

Operators us” the product for ils imendcd runclion. They must he

trained in clcctrical salety procedures and proper US” of lhc instrumcnt. They must hc protcctcd from electric shock and con&i wilb

hazardous live circuits.

Maintenance personnel perform routine proccdurcs on the producl

to keep it “pcrating, for example. setting the line vollagc or replacing consumahic materials. Maintenance proccdurcs arcdcscrihcd in

the manual. The proccdurcs cxplicidy stat” if ~hc opcralor may pcrSourm Ihem. Otherwise, they should bc pcrrormcd only by service

personnel.

Service personnel arc lraincd 1” work on live circuits. and pcrlurm

safe installations and repairs or

vice personnel may perform installation and service proccdurcs.

lixcrcise extreme caution when a shock hazard is prcscnt. Lcihal

vol~agc may be present on cable connector jacks or test Axturcs. The

American National Slandards lnstitule (ANSI) BIZBES thdl B shock

hazard exists when voltage levels grcatcr than 30V RMS. 42.4V

peak. or 60VDC arc prcsen~. A goud safety practice is to fx-

pect that hazardous vnltage is present in any un-

known circuit before measuring.

products.

Only properly trained scr-

Page 6

The insmmcnt and accessories mu bc used in accordance with its

spccilicalions and operating inslrucLinns OT the safely of Ihc cquipmcnt may be impeircd.

Do ml exceed the maximum signal lcvcls ofthc inswmcnls and acccssorics, as defined in the specificaliuns and operating information, and as shown on Ihc insliumcnt OT test fixlurc panels, or

switching card.

The

WARNING

rcsul~ in persrmal injury or death. Always read the asocialed i&rmaCon very carefully bclore performing ~hc indicated procedure.

The

CAUTION

damage the inslrumcnl. Such damage may invatidaw the wananty.

Inavumenlalian and acccssorics shall nol hc connected 10 humans.

hcading in a manual explains dangcrs that might

hcading in a manual cxplains haxds Lhat could

When fuses BTC used in B produa, replace with same type and Ming

I’m continued prolcclion againsl fire harard.

Chassis conncclions must only be used as shield ConnecLions for

measuring circuits, NOT as safely carlh ground conneclions.

II you arc using a test fixurc, keep the lid closed while power is applied IO the device under test. Sale operalion rcquircs the use of a

lid intcriock.

Ira 0..

wire recommended in lhc user documentalion.

Then

rccr to the operating inslruclions located in lhc manual.

Then.

suc 1000 volls or more, including Lhc combined elfal of normal

and common mode voltages. Use standard safculy precautions 10

avoid pcrsonai contact with these vol~agcs.

ww is present mnm it LO sareely earth ground using the

symbol on an instrument indicates Hal the USCT should TC-

~ymhol on an instrumcnl shows Lhal il can swrcc OT mca-

Bcrorc pcribrming any maimcnancc, discoonccl the lint cord and

all test cahlcs.

To maintnin protcclion from elcc~ric shock and fire, rcplaccmcm

components in mains circuils, including lhc power Iransrormcr, test

leads, and input jacks, musL bc purchased from Kcithlcy Instrumcnts. Slandard rusts, wilh applicable national sarcly approvals,

may be used if the rating and type ari: Lhc same. Other components

that are not safety related may hc purchased from oLhcr suppliers as

long as Lhcy arc cquivalenl LO Ihc original componcnl. (Note thal set

lcclcd patts should bcpurchased only through Kcithlcy lnstrumenls

LO maintain accuracy and functiunalily of the producl.) If you arc

unsure about the applicabilily (11 a rcptaccmem componcm, call a

Kcithlcy Insmunents

To clean an insvumenl. USC B damp clolh or mild, water based

cleaner. Clean the exlerior of the instwmcnl only. Do not apply

ctcancr dircclly Lu Lhc instrument or aliow liquids LO enLcr or spilt

on the instrumenl. Products that consisL of a circuit board wilh no

case or chassis (c.g., dala acquisition board for installation into a

computer) should ncvcr rcquirc cleaning if handled according LO in-

sLruclions. I( Ihc board bccomcs cantaminaled and apcratian is a[-

f&cd, the board should be retuned Lo lhc factory for proper

clcaninglservicing.

dficc

for infonna~ion.

Page 7

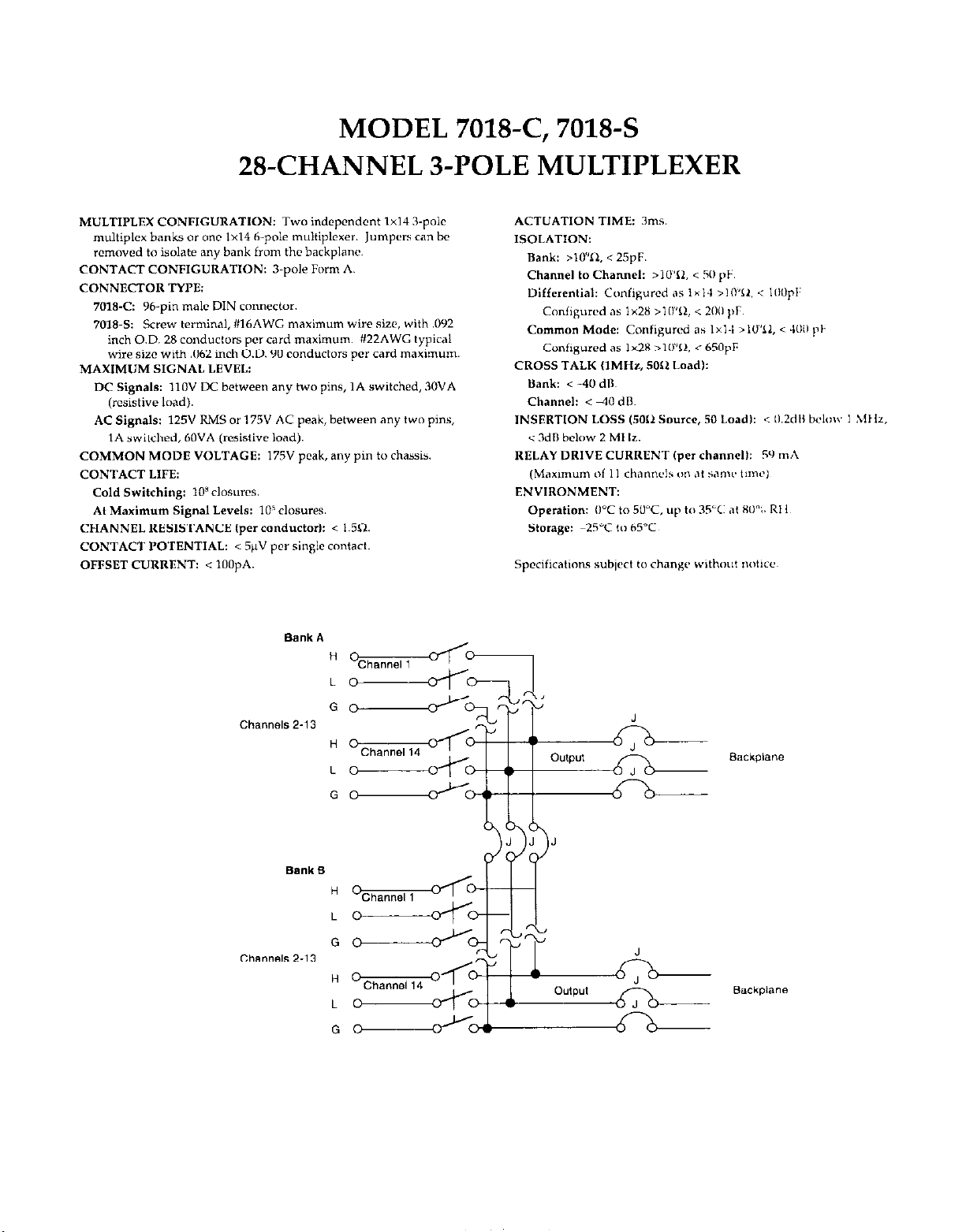

MODEL 7018-C, 7018-S

2%CHANNEL 3-POLE MULTIPLEXER

MULTIPLEX CONFIG”RATION: TWO indepcndcnt 1x14 3.pole

multiplex banks or 0°C 1x14 h-poic muitiplcxer. Jumpers can be

rcmovcd to isolate any bank from the backplane.

CONTACT CONFIG”RATION: 3~poIe Form A.

CONNECTOR TYPE:

AC Signals: 125” RMS or 175” AC peak, between any two pins,

IA switched, 60VA (rcsistivc land).

COMMON MODE VOLTAGE: 175” peak, any pin to chassis.

CONTACT LIFE:

Cold Switching: IOx closures.

At Maximum Signal Levels: 10’ CIOSureS.

CHANNEL RESlSTANCE ,per eonductor~: < 1.50.

CONTACT POTENTIAL: < SpV per single contact.

OFFSET CLlRRENT: < 100pA.

Page 8

Page 9

Table of Contents

1

1.1

1.2

1.3

I .4

1.5

1.6

1.7

1.7.1

1.7.2

1.7.3

1.7.4

1.8

General Information

Introduction

Features

WalTanty

Manual

Safety

Specifications..

Unpacking

Inspection for damage .................................................................................................................................

Shipping contents ........................................................................................................................................

Instruction manual

Repacking for shipment

Optional accessories

.........................................................................................................................................................

...............................................................................................................................................................

lnformatlo”.

addenda.. ................................................................................................................................................

symbols and terms ...................................................................................................................................

and inspcctio”.

.........................................................................................................................................

....................................................................................................................................................

.......................................................................................................................................

............................................................................................................................................

2 Multiplexing Basics

2.1

2.2

2.2.1

2.2.2

2.3.2

2.3.3

2.3

2.3. I

2.3.4

2.3.5

2.4.2

2.4

2.4. I

Introduction

Basic multtplexer configurations

Multiplexer bank-to-bank jumpers..

Backplane jumpers. .....................................................................................................................................

Differential switching .................................................................................................................................

Sensing ........................................................................................................................................................

Typical

Single-cndcd switching.. .............................................................................................................................

3.pole connections

h-pole connections ......................................................................................................................................

Mainframe multiplexer expansion

Multiplexer expansion..

Multiple-card swttchlng systems

.........................................................................................................................................................

multiplexer swtchlng schemes..

.......................................................................................................................................

..................................................................................................................................

..............................................................................................................................

?-I

........................................................................................................................

............................................................................................................

............................................................................................................

......................................................................................................................................

..............................................................................................................

................................................................................................................

2~ I

2-Z

2~3

2-J

2-J

2-4

2~4

2~5

2-S

2~1

2-7

Z-7

3

3.1

3.2

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.4

3.4.1

3.4.2

Card Connections & Installation

Introduction

Handling precautions

Connections

Bank-to-bank jumpers .................................................................................................................................

Backplane jumpers.. ....................................................................................................................................

Screw terminal connector card

Multi-pin (mass termination)

Typical connection schemes

Single-card system ......................................................................................................................................

Two-card system..

.........................................................................................................................................................

..........................................................................................................................................

.........................................................................................................................................................

....................................................................................................................

connector card..

...............................................................................................................................

.....................................................................................................................................

............................................................................................

3~ I

3 I

3~ I

3-X

3-3

3-3

3-5

3-9

3-5

3-I I

Page 10

3.4.3

35.1

3.5

3.5.2

3.5.3

Two-mainframe system .............................................................................................................................

Ground screw .............................................................................................................................................

Model 7018 installation and removal

Multiplexer card installation. .....................................................................................................................

Multiplexer card removal

................................................................................................................ 3-14

.......................................................................................................................... 3-15

3- 12

3 I4

3- 15

4

4.1

4.2

4.2. I

4.2.2

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.4

4.4.1

4.4.2

4.4.3

4.5

4.5. I

4.5.2

4.5.3

4.5.4

4.5.5

4.5.6

4.5.1

5

5.1

5.2

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.1

5.3.8

5.4

5.5

5.5.1

5.5.2

5.5.3

5.5.4

5.6

5.6.1

56.2

5.6.3

Operation

Introduction

Operational constraints..

Maximum signal levels ................................................................................................................................

Channel hmdatlons .........................................................................................................................................

Mainframe control of multiplexer card

Channel assignments

Front panel control ......................................................................................................................................

IEEE-488 bus operation ..............................................................................................................................

Selecting 3-pale/6-pole operation ................................................................................................................

Multiplexer applications ......................................................................................................................................

Resistor testing ............................................................................................................................................

Transistor current gain testing .....................................................................................................................

Testing with matrix cards ............................................................................................................................

Measurement considerations ...............................................................................................................................

Path isolation ...............................................................................................................................................

Magnetic tields ..........................................................................................................................................

Radio frequency interference ....................................................................................................................

Ground loops .............................................................................................................................................

Keeping connectors clean.. ........................................................................................................................

AC frequency response.. ............................................................................................................................

Thermoelectric potentials ..........................................................................................................................

......................................................................................................................................................... 4-l

......................................................................................................................................

...............................................................................................................

...................................................................................................................................

4-l

4-l

4-l

4-l

4 -I

4-3

4-4

4-4

4-5

4-S

4-6

4-7

4-9

4-9

4 -10

4-10

4 -10

4-l 1

4-l 1

4-l I

Service Information

Introductio” .........................................................................................................................................................

Handling and cleaning precautions .....................................................................................................................

Performance verification .....................................................................................................................................

Environmental conditions.. ..........................................................................................................................

Recommended equipment ...........................................................................................................................

Multiplexer card connections ......................................................................................................................

Channel resistance tests.. .............................................................................................................................

Offset current tests.. ..................................................................................................................................... 5-3

Contact potential tests.. ................................................................................................................................

Bank and channel-to-channel isolation tests

Differential and common-mode ..................................................................................................................

Special handling of static-sensitive devices

Principles of operation .......................................................................................................................................

Block diagram ...........................................................................................................................................

ID data circuits ..........................................................................................................................................

Relay control .............................................................................................................................................

Relay power control ..................................................................................................................................

Troubleshooting.. ...............................................................................................................................................

Troubleshooting equipment.. .....................................................................................................................

Troubleshooting access .............................................................................................................................

Troubleshooting procedure.. ......................................................................................................................

...............................................................................................

......................................................................................................

5-l

5-l

5-l

5-2

5-2

5-2

5-3

5-5

5-6

5-8

5 -IO

5-l I

S-1 I

5 -I I

5-l I

5-12

5-12

5-l 2

5.12

S-12

ii

Page 11

6.1

6.2

6.3

6.4

6.5

Replaceable Parts

Introduction

Parts lists

Ordering information ..........................................................................................................................................

Factory service

Component layouts and schemetic ......................................................................................................................

.........................................................................................................................................................

.............................................................................................................................................................

h- I

6-I

b- I

....................................................................................................................................................

h-l

6 -I

iii

Page 12

Page 13

2 Multiplexing Basics

Figure 2. I

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-X

Figure 2-9

Figure 2-l 0

Figure 2. I I

Figure 2. I2

Figure 2. I3

Model 7018 simplified schematic..

Dual 1 x 14 multiplexer configuration (jumpers not installed)

Single I x 28 multiplexer configuration (jumpers installed)

Model 7001/7002 analog backplane ...........................................................................................................

Bank connections to backplane ,.,..................................., ............................................................................

Single-ended switching example

Differential switching example..

Sensing example

3.pole connections

6.~01~ connections

Two separate multiplexer systems..

Multiplexer input cxpension example

Mixed card type cxamplc ...... ..................................

........................................................................................................................................ 7-5

............ . .....

............

List

.............................................................................................................

.._

............

......... .... .... .............. .......... .. .... ... ....

................................................................................................................. 2-h

.._

................................................................................................................ 1-h

. .

.._

.....

.....................................................................................

...............................................................................................

.........

of

.............................................................................................. 2~8

..............................................................................

Illustrations

................................................................... 2-2

...................................................................... 2-3

.. ........

............................

2-2

2~3

2-J

........... 2-J

1-5

............

2-7

2~8

3

Figure 3-I

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-X

Figure 3-9

Figure 3-10

Figure 3-l I

Figure 3-12

Figure 3-13

Figure 3-14

Figure 3-15

Figurc 3-16

Figure 3-17

Figure 3-18

Figure 3-19

4

Figure 4-l

Figure 4-2

Figure 4-3

Card Connections & Installation

Bank-to-bank jumper locations ..,.......,.._ .....................................................................................................

Bank-to-bank jumpcr terminal identtficatton ,......................................., .....................................................

Bank-to-bank jumper installation

Backplane jumpers ._...............,,..,., ..............................................................................................................

Model 7018 screw terminal connector card..

Typical screw terminal connections..

Cable clamp for screw terminal connector card..

Multi-pin card terminal identif~catlon.. ... .. .... .. ... ......... ... .......

Typical round cable connection techniques ,.....,.,...,.,...._ ............................................................................

Model 701 1 -MTR connector pinout

Model 701 I-KIT-R (with/cable) assembly

Single-card system example (multi-pin connector card) _...,

Single-card system example (screw terminal connector card).

Two-cud system example (multi-pin connector card) .._.._

Two-card system example (screw terminal connector card)

Two-mainframe system example (multi-pin connector card)

Two-mainframe system example (screw terminal connector card)

Model 7018 card installation in Model 7001

7018 card installation in Model 7002 ..... ...................................

..

........ ....

.._............................................. ................................................... 3-i

........................................................................ 3-J

.._.......,

...........

.......................................................................................................... 3-J

.. ..... ........... ......... .....

......................................................................................................

....

......................................

.....................................................................

................................................................. 3-l I

....................................................................... 3-l I

..................................................................... 3- I2

..........................................................

.._

......

..........................................................

..... .. .. ......... ........

.........................................................

..............................................

......................................................

.......................................................... 3-9

...................................................

3-1

3-Z

3-3

3~5

3~7

3-X

i-X

3 -IO

3~ I3

3- IJ

3-15

3 16

Operation

Channel status display .._..............,.,,...........................,.,....., .......................................................................

Display organization for Model 7018 multiplexer inputs..

Model 7018 programming channel assignments

.._..,,, ..........................................................................

....

..............................................................

... ....

J-2

J-2

J-3

Page 14

Figure 4-4

Figure 4-5

Figure 4-6

Figure 4-7

Figure 4-8

Figure 4-9

Figure 4-10

Figure 4-l I

Figure 4. I2

Four-wire resistance

testing.. .......................................................................................................................

Low resistance testing .................................................................................................................................

Configuration for current gain test ..............................................................................................................

cards together .....................................................................................

Connecting multiplexer and

Path isolation resistance

Voltage attenuation

by path isolation resistance

Power line ground loops

matrix

..............................................................................................................................

.......................................................................................

............................................................................................................................

Eliminating ground loops ..........................................................................................................................

Thermoelectric

generation.. .......................................................................................................................

4-6

4.7

4.8

4-9

4-9

4.10

4-I 0

4-l I

4-l

I

5

Figure 5-l

Figure 5-2

Figure 5-3

Figure 5-4

Figure 5-5

Figure 5-6

Figure 5-7

Figure 5-X

Figure 5-9

Figure 5-10

Service Information

Path resistance

Offset current

test connections.. .................................................................................................................

test connections ....................................................................................................................

Contact potential test connections.. .............................................................................................................

Bank isolation

Channel-to-channel

Differential isolation test connections..

Common-mode

Model 7018 block diagram..

Start and stop sequences

Transmit and acknowledge sequence..

test connections ...................................................................................................................

isolation test connections

..

lsolatmn test connections..

............................................................................................

.....................................................................................................

...............................................................................................

......................................................................................................................

............................................................................................................................

......................................................................................................

5-3

5-4

5.5

5-7

5-7

5.10

IO

5

5 -I

5 -1 I

5 -I I

I

vi

Page 15

List

of Tables

3

Table 3. I

Table 3-2

Table 3-3

4

Table 4-l

5

Table 5-l

Table 5-2

Table 5-3

Table 5-4

Table 5-5

Table 5-6

Card Connections & Installation

Bank-to-bank jumpers (on connector cuds) ~..~ 3~2

Backplane jumpcrs (on r&y cards) ~.~ 3~3

Mass termmatton accessories . 3-5

Operation

Paired Channels in 4.pole Operation .,.........................,,,,....,.,..,,....,,.......................................................... 4-S

Service Information

Verification equipment .... ~.,

Bank isolation test summary ..,..,.....,............................,...................................................................~.......... S-7

Channel-to-channel isolation test summary 5-X

Differential and common-mode isolation testing ~.~...~~.~

Recommended troubleshooting equipment 5. I2

Troubleshooting procedure 5- I3

6 Replaceable Parts

Table 6-I Verification equipment

Table 6-2

Table 6-3

Bank isolation test summary

Channel-to-channel isolation test summa~

5~2

SL)

Page 16

General Information

1.1

This section contains general information about the Model

7018 28.Channel 3.Pole Multiplexer Card.

There are two basic versions of this multiplcxcr card; the

Model 7018-S and the Model 7018-C. The Model 701X-S asscmbly consists of a screw terminal connector card and a relay card. External test circuits arc wired directly to the screw

terminals of the connector card. Also available from Keithley is the Model 7018.ST. This accessory is an extra screw

terminal connector card. With an extra connector card, you

can wire a second test system without disturbing the wiring

configuration of the first test system.

The Model 7018-C assembly consists of a multi-pin (mass

termination) connector card and the relay card. External test

circuit connections to the multiplexer are made via the 96.

pin male DIN connector on the connector card. Keithley offers a variety of optional accessories that can be used to make

connections to the connector card (see paragraph I .a).

The rat of Section I is arranged in the following manner:

1.2 Features

1.3 Warranty information

1.4 Manual addenda

1.5 Safety symbols and terms

1.6 Specifications

introduction

I.8 Optional accessories

1.2 Features

The Model 7018 is a three-pole.

card. Some of the key features include:

* Low contxt potential and offset current for Iminimal cf-

fats on low-Icvcl signals.

. The connector board detaches fronl the rulq board

allowing easy access to the screw terminals (.Modcl

7018-S) and jumpers.

* Easy jumper configuration of one or two multiplcxcr

banks(I x28or2x 14).

* Backplane jumpers. Cutting jumpers disconnects muIt&

plcxcr hank outputs from the Model 700117002 imalog

backplane.

.

l-pole or 6-p& operation.

2X-cbanncl multiplc*cr

1.3 Warranty information

Warranty information is located on the inside front cover ot

this instruction manual. Should your Model 7018 rcquirc

warranty scrvicc. contiict the Keithlcy rcpresentatiw or

authorized repair facility in your area for further informotion. When returning the multiplexer card for repair. be

sure to till out and include the service form at the back of this

manual in order to provide the repair facility with the

necessary information.

1.7 Unpacking and inspection

l-1

Page 17

1.4 Manual addenda

Any improvements or changes concerning the multiplexer

card or manual will be explained in an addendum included

with the card. Addenda are provided in a page replacement

format. Simply replace the obsolete pages with the new

pa&X.

2. When not installed in a Model 7001/7002 mainframe,

keep the card in the anti-static bag, and store it in the original packing carton.

After removing the card from its anti-static bag, inspect it for

any obvious signs of physical damage. Report any such damage to the shipping agent immediately.

1.5

The following symbols and terms may be found on an instro-

ment or used in this manual.

The L!?!, symbol on an instrument indicates that the user

should refer to the operating instructions located in the instruction manual.

The

more may be present on the terminal(s). USC standard safety

precautions to avoid personal contact with these voltages.

The WARNING heading used in this manual explains dangers that might result in personal injury or death. Always

read the associated information very carcfully before performing the indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage the multiplexer card. Such damage

may invalidate the warranty.

Safety symbols and terms

f

symbol on an instrument shows that IOOOV or

1.7.2 Shipping contents

The following items are included with every Model 7018 ordcr:

- Model 7018 2%channel 3-pole Multiplexer Card

- Model 7018 Instruction Manual

- Additional accessories as ordered

1.7.3 instruction manual

The Model 7018 Instruction Manual is three-hole drilled so

that it can be added to the three-ring bindcr of the Model

700117002 instruction Manual. After removing the plastic

wrapping, place the manual in the binder following the mainframe instruction manual. Note that a manual identification

tab is included and should precede the multiplexer card in-

stnrction manual.

If an additional instruction manual is required, order the

manual package, Keithlcy part number 701X-901-00. The

manual package includes an instruction manual and any per-

tinent addenda.

1.6 Specifications

Model 7018 specifications are found at the front of this man-

ual. These specifications are exclusive of the switching

mainframe specifications.

1.7 Unpacking and inspection

1.7.1 inspection for damage

The Model 7018 is packaged in are-sealable, anti-static bag

to protect it from damage due to static discharge and from

contamination that could degrade its performance. Before rcmoving the card from the bag, observe the following precautions on handling.

Handling Precautions:

I. Always grasp the card by the side edges and shields. Do

not touch the board surfaces or components.

1-2

1.7.4 Repacking for shipment

Should it become necessary to return the Model 7018 for repair, carefully pack the unit in its original packing carton or

the equivalent, and include the following information:

- Advise as to the warranty status of the multiplexer card.

. Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

* Fill out and include the service form located at the back

of this manual.

1.8 Optional accessories

The following accessories are available for use with the

Model 7018:

Page 18

Model 701%ST - This screw terminal connector card is

identical to the one provided with the Model 7018-S assembly. An extra screw terminal connector card allows you to

wire a second test system without disturbing the wiring conliguration of the first connector card.

Model 701 l-MTC-Z-This 2.mctcr round cable assembly

is terminated with a 96.pin female DIN connector on each

end. It will mate directly to lbc connector on the Model

701X-C and to a standard Y6-pin male DIN bulklaid com~cctar (see Model 701 I-MTR).

Model 7011-KIT-R-This connection kit includes a 96.pin

fcmalc DIN connector that will mate directly to the conncctar on the Model 7018-C or to a standard Yh-pin male DIN

bulkhead connector (see Model 701 I -MTR). This connector

uses solder cups for connections to external circuitry. It includes an adaptcr for a round cable and the housing.

Model 701 I-MTR - This Y&pin malt DIN bulkhead con

ncctor uses solder cups for connections 10 e.xtemal circuitr).

It wilt mate to the Model 701 I -KIT-K connector. and !vI~niel

701 t -MTC-2 cable assembly.

Page 19

2

Multiplexing Basics

2.1 Introduction

This section covers the basics for multiplex switching and is

arranged as follows:

2.2 Basic multiplex configurations: Covers the basic

multiplex configurations: dual I x 14 configuration

and single I x 28 configuration. The backplane jumpers are also covered here.

2.3 Typical multiplexer switching schemes: Explains

some of the basic ways a multiplexer can be used for

switching. Covers sin&cndcd switching, diffcrcntiat

(floating) switching, sensing, and 3-pale/6-pole operation.

2.4 System expansion: Discusser the various configor;tlions that arc possible by using multiple cwds.

2.2 Basic multiplexer configutations

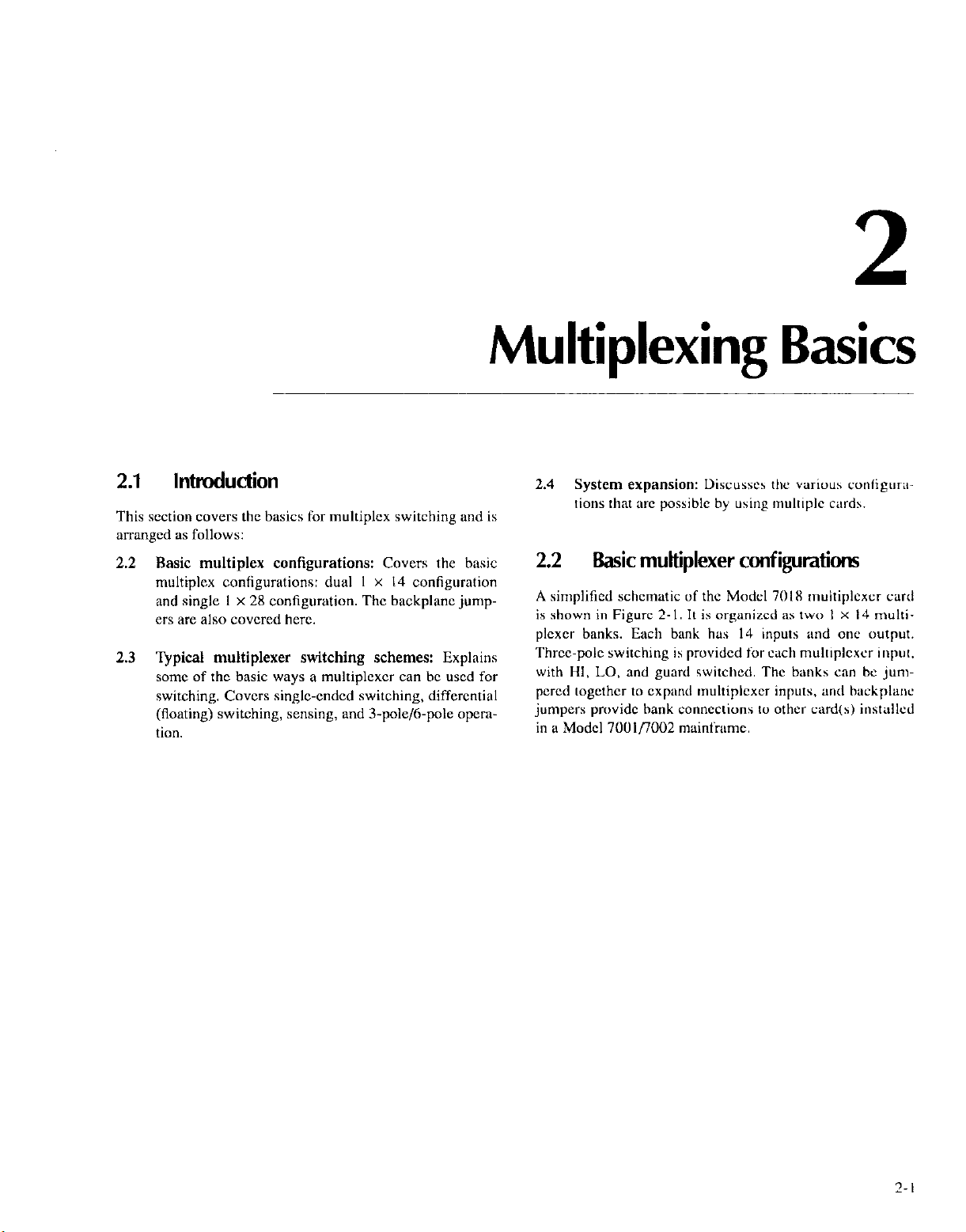

A simplified schematic of the Model 70 t 8 multiplexer card

is shown in Figure 2. I. It is organized ns two I x t 4 multiplexer banks. Each bank has 14 inputs and one output.

Three-potc switching is provided for each mult~plcxcr input.

with HI. LO, and guard switcbcd The banks can bc junlpercd together to expand muttiplcxcr inputs, and beckplanc

jumpers provide bank connections to other card(s) installed

in a Model 7001/7002 mainframe.

2-t

Page 20

r-----

-----_-______-------------

7018

1

Note : Factory Config”ration shown

Figure 2- 1

Model 7018 simplified schematic

2.2.1 Multiplexer bank-to-bank jumpers

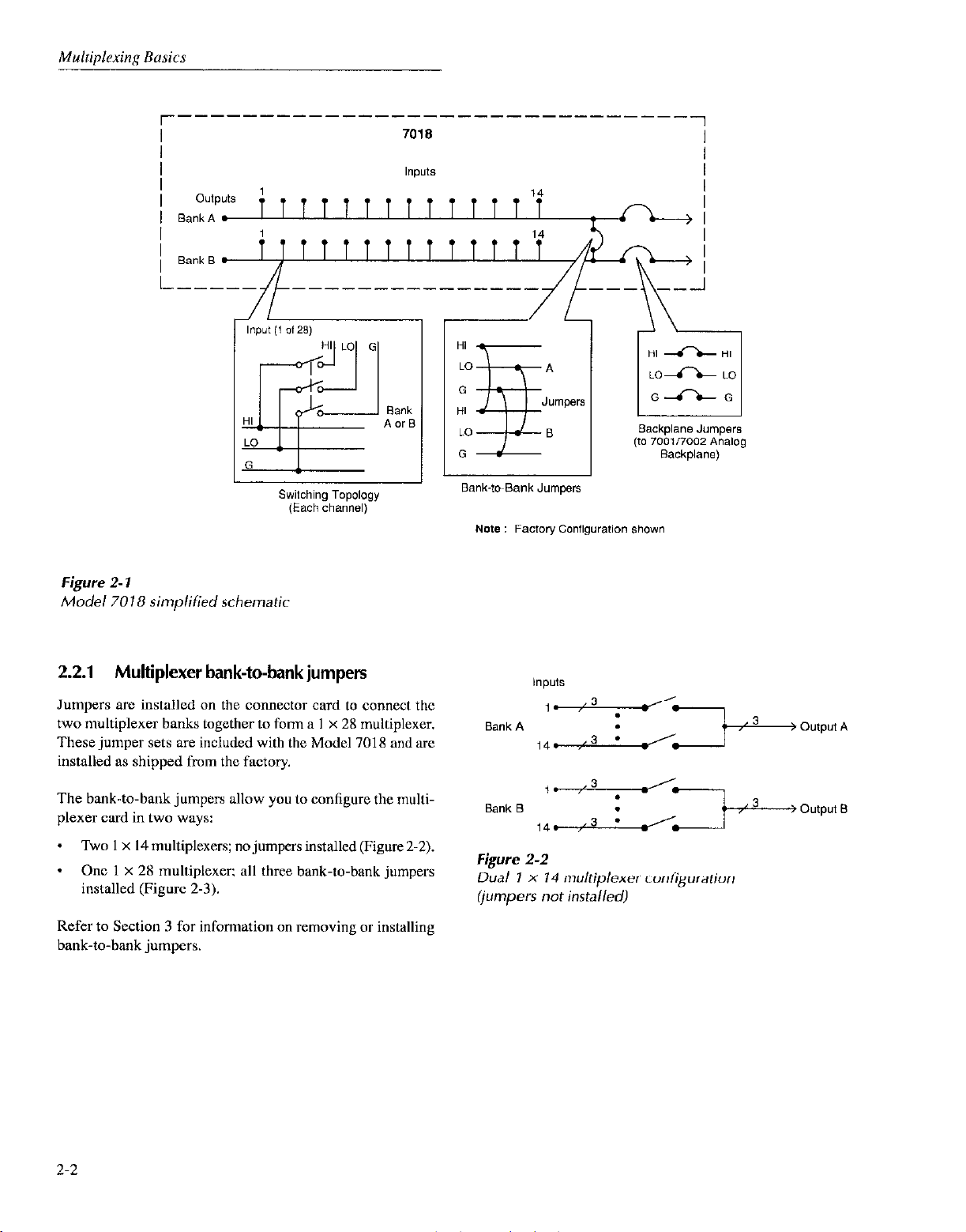

Jumpers arc installed on the connector card to connect the

two multiplexer banks together to form a I x 28 multiplexer.

These jumper sets are included with the Model 7018 and are

installed as shipped from the factory.

The bank-to-bank jumpers allow you to configure the multi-

plexer card in two ways:

* Two 1 x I4 multiplexers; no jumpers installed (Figure 2-2).

* One 1 x 2X multiplexer; all three bank-to-bank jumpers

installed (Figure 2-3).

Refer to Section 3 for information on removing or installing

bank-to-bank jumpers.

Figure 2-2

Dual 1 X 14 multiplexer configuration

(jumpers not installed)

2-2

Page 21

Figure 2-3

Single1 x28 multiplexer configuration (jumpers installed)

2.2.2 Backplane jumpers

NOTE

When the backplane jumpers nrc installed.

connecting the banks together on one card

will automatically connect the banks of

cards in other slots to~cther.

Figure 2-5 shows how each bank of the Model 701X i> cons

ncctcd to the backpbmc. The Model 70 IX is shipped fro111 the

factory with the backplxx jumpers installed.

&moving (cutting) the beckphuw .jumpws isrrlatcs the card

from the beckplanc. and subsequently. any card installed in

the other slot. For information on rcmoviny the jumpcr~. rcfcr to Section 3.

There arc six backplane jumpers located on the relay card

(three for each bank). With the jumpers instelled, the banks

of the multiplexer card are connected to the analog backplane of the Model 7OOl/7002, allowing expansion with other 7001/7002 card(s) installed in the mainframe. With the

jumpers removed (cut), the multiplexer card is isolated from

other card(s) installed in the mainframe.

The three-pole analog backplane of the Model 700117002

mainframe is shown in Figure 2-4. Through this analog

backplane, the banks of a Model 7018 multiplexer card, in-

stalled in one slot, can be connected to the banks (or rows) of

n compatible card installed in another slot of the mainframe.

Model 7001/7002

Analog

Backplane

Row 2 or Bank B

r----

l

Card 1

l r----

I I

&------!‘L

G\!-?G

I

I I

H)I

NOTE

The Model 7(101I7002 dots not provide itn

analog backplane for the non-701X scrics

cards. As a result, any of these c;irds installed in one slot in the nwinfrwnc is clectrically isoletcd from any card instidlcd io

another slot. The only way to connect il

Model 701X to one of thcsc cards is to wire

them togcthcr cxtemelly,

Card 2

I

KH

I

I

I

L------------.

Figure 2-4

Model 7001/7002 analog backplane

L\/t,

Gi-10

H = High

L= LOW

G = Guard

L----- -------

ROW = Matrix Card (7012,

Bank = MUX Card 17018,

Page 22

7018

Bank

(1 Of 2)

700117002

Analog

Backplane

I

, BankAorS I

Input l-14 r---)

,- I

H‘A., H

L‘A L

G>

H = High

i= LOW

G = Guard

Figure 2-5

Bank connections to backplane

2.3

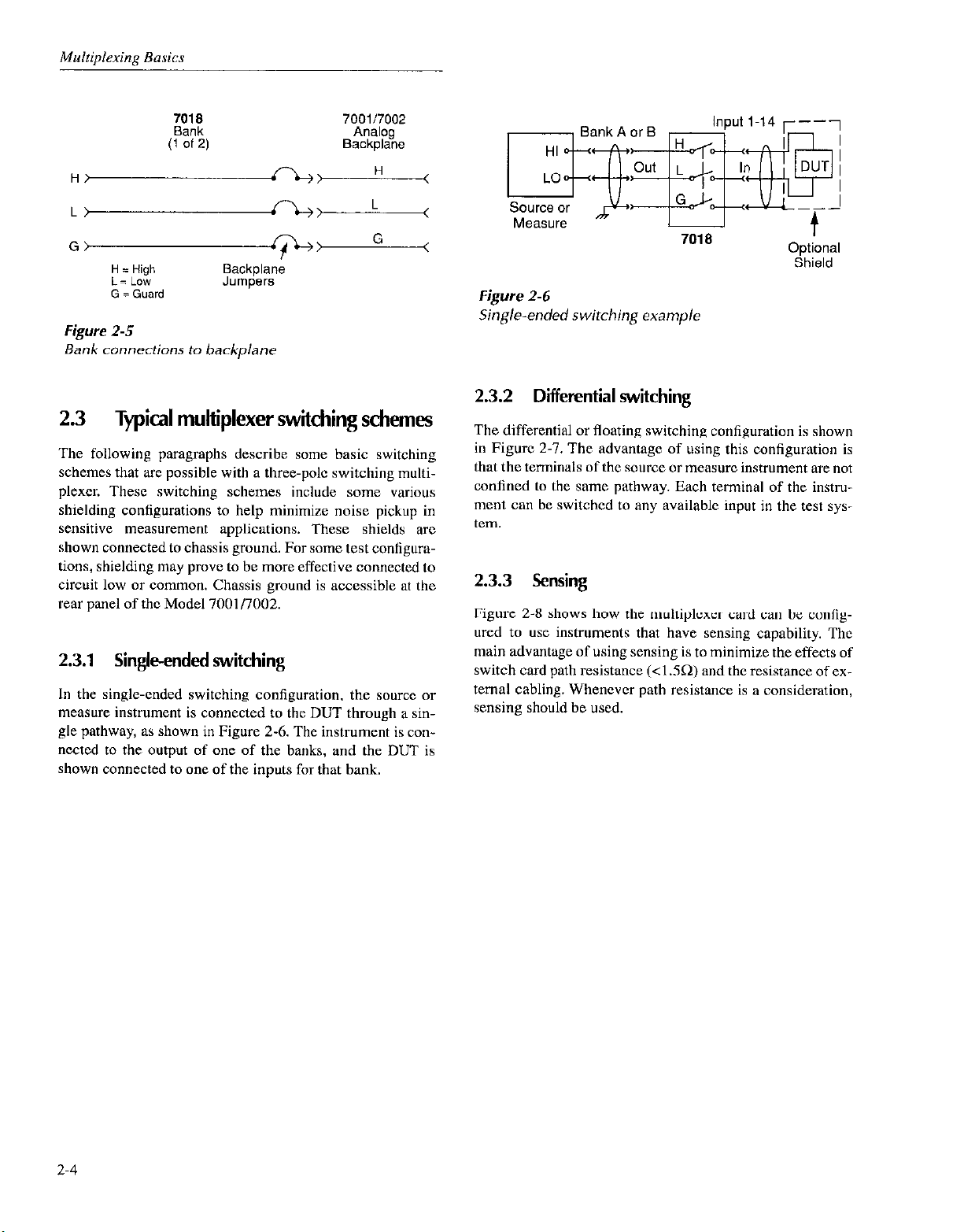

The following paragraphs describe some basic switching

schemes that are possible with a three-pole switching multiplexer. These switching schemes include some various

shielding configurations to help minimize noise pickup in

sensitive measurement applications. These shields are

shown connected to chassis ground. For some test configurations, shielding may prow! to be more effective connected to

circuit low or common. Chassis ground is accessible at the

rear panel of the Model 7001/7002.

Typical multiplexer switching schemes

Jumpers

9::

Backplane

G

<

<

<

2.3.1 Single-ended switching

In the single-ended switching configuration, the source or

measure instrument is connected to the DUT through a single pathway, as shown in Figure 2-6. The instrument is connected to the output of one of the banks, and the DUT is

shown connected to one of the inputs for that bank.

Measure or

Figure2-6

Sing/e-ended switching example

t

Optional

Shield

2.3.2 Differential switching

The differential or floating switching configuration is shown

in Figure 2-l. The advantage of using this configuration is

that the terminals of the source or measure instrument are not

confined to the same pathway. Each terminal of the instrument can be switched to any available input in the test system.

2.3.3 Sensing

Figure 2-8 shows how the multiplexer card can be configured to use instruments that have sensing capability. The

main advantage of using sensing is to minimize the effects of

switch card path resistance (<I .SQ) and the resistance of ex-

ternal cabling. Whenever path resistance is a consideration,

sensing should be used.

2-4

Page 23

Figure 2-7

Differential switching example

3”“ICtl “I -

Sense HI

Figure 2-8

Sensing example

I-

701

Input I-14

a

7018

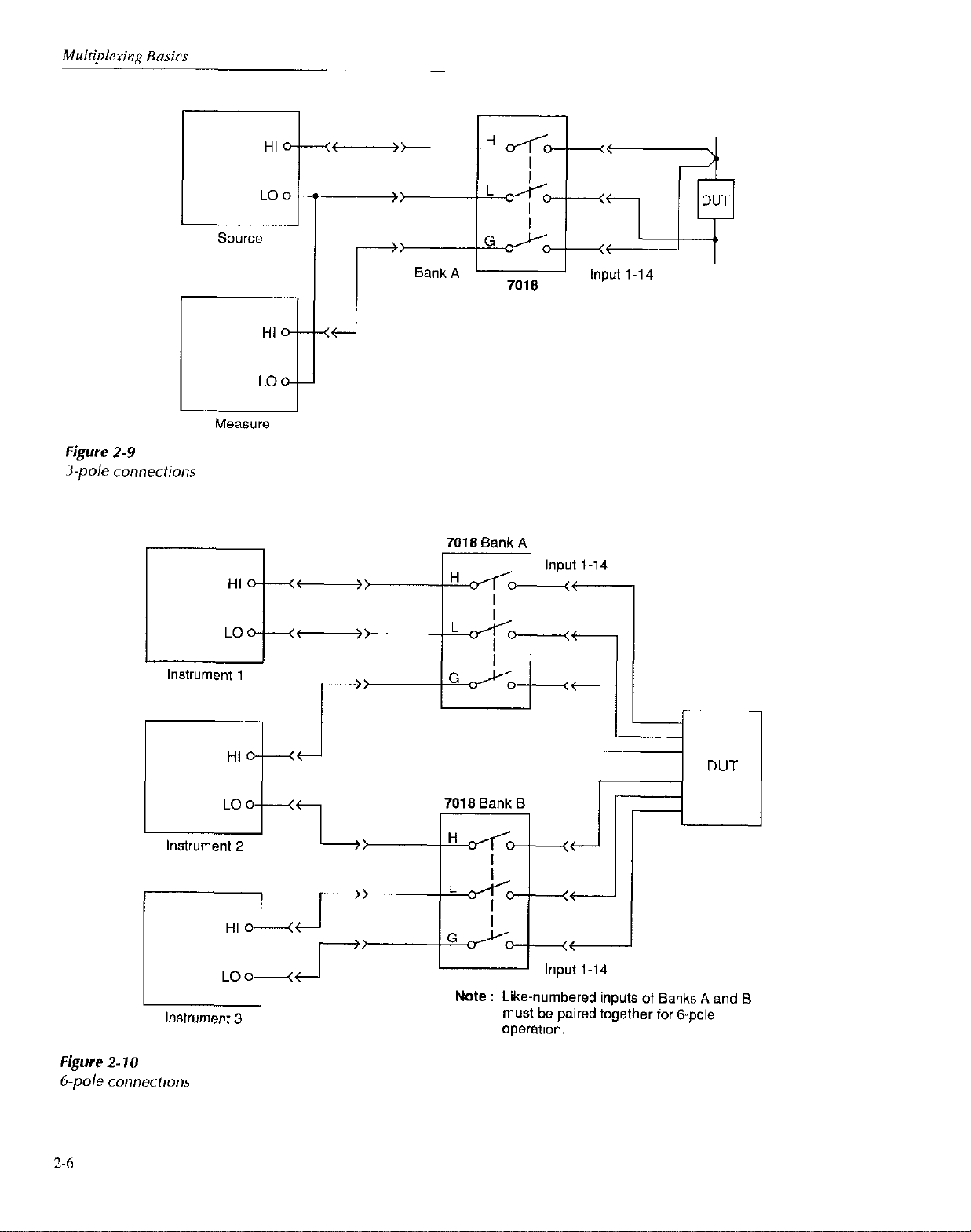

2.3.4 3-pole connections

Figure 2-9 shows typical 3-p& connections using a single

channel to switch both source and measure instruments to

the DUT. In this example, source HI and measure HI arc

routed separately to the DUT, while the LO terminals xc

connected together externally.

2.3.5

6-pole connections

The Model 7018 can also be used for h-pole switching for

testing more complex DUTs. Figure 2. IO shows typical Opole connections. In order to use h-pole switching. Ihc tikc-

numbcrcd channels of Banks A and I3 must bc paired togcther (Bank A, Input I with Bank B. Input I, etc.,. See ,>a~graph 4.3.4 f& informalion on sclting up the switching

mainframe for h-potc operation.

Page 24

Figure 2-9

3-p& connections

HI 0

LO

ci

HI

LO

--

t---j-

Lit )

Instrument 1

r

Instrument 3

1 DUT

Note : Like-numbered inputs of Banks A and Et

must be paired together for &pole

operation.

Figure 2- 10

6.pole

2-6

connections

Page 25

2.4 Multiplexer expansion

With the USC of additional switching cards and mainframes.

larger systems can be configured. Each Model 7001 Switch

System mainframe will accommodate up to two cards. and

each Model 7002 Switch System can hold up to IO cards.

2.4.1 Multiple-card switching systems

hank jumpcrs for either card were installed. the rewh would

be a single I x 5h muhiplexcr.

Mixing card types

Different types of cards cw bc used togcthcr to create some

vcrsatilc switching systems. For cxemplc. you could have it

Model 7018 multiplexer card instellcd in one slot and ii Modcl 7012 matrix card installed ill imothcr slot.

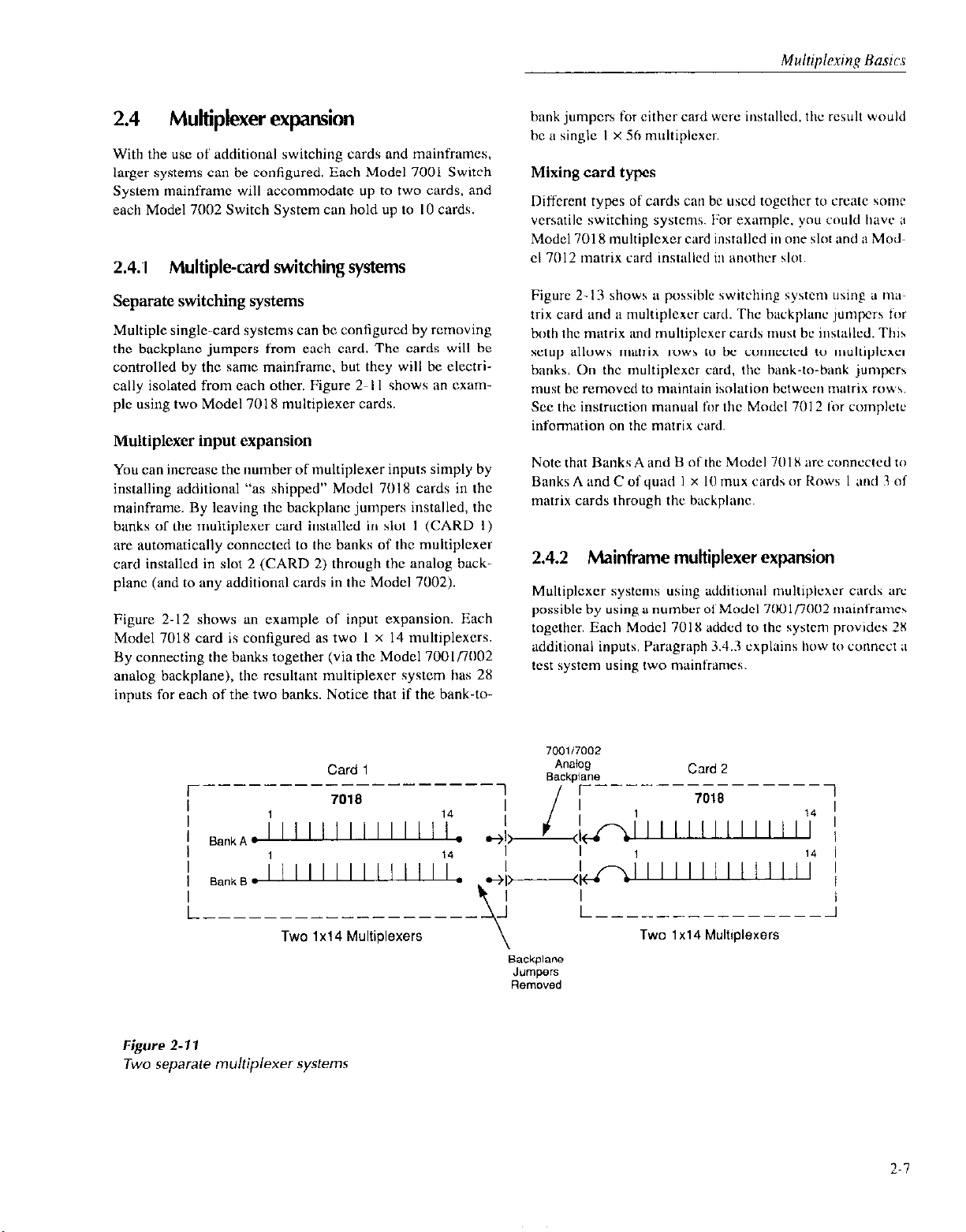

Separate switching systems

Multiple single-card systems can be configured by removing

the backplane jumpers from each card. The cards will be

controlled by the sane mainframe, but they will be clcctrially isolated from each other. Figure 2-l I shows an exemplc using two Model 7018 multiplexer cards.

Multiplexer input expansion

You can incrcasc the number of multiplexer inputs simply by

installing additional “as shipped” Model 7018 cards in the

mainframe. By leaving the backplane jumpers installed, the

banks of the multiplexer card installed in slot I (CARD I)

arc automaticttlly conncctcd to the banks of the multiplexer

card installed in slot 2 (CARD 2) through the analog backplane (and to any additional cards in the Model 7002).

Figure 2-12 shows an example of input expansion. Each

Model 7018 card is configured as two I x I4 multiplcxers.

By connecting the banks together (via the Model 7OOlflOO2

analog backplane), the resultant multiplexer system has 28

inputs for each of the two banks. Notice that if the bank-to-

Card 1

7018

r----

______---------

Figure 2-13 shows a possible switching system using a nw

trix card and a muhiplcxcr card. The bxkphmc jumpus for

both the matrix and multiplcxcr cards must bc installcd. Thih

setup allows mntrix rows to be conncctcd to multiplexer

banks. On the muhiplcxcr card. the bank-to-bank jumpers

must be removed to maintain isolation hctwccn matrix IOU\.

See the instruction Manuel fur the Model 7012 ior complctc

information on the matrix card.

Note that Banks A and B of the Model 70 IX arc connected tiz

Banks A and C of quad 1 x IO mux cards or Rows I and 3 of

matrix cards through the backplane.

2.4.2

Muhiplcxcr systems using udditional muhiplexcr cards arc

possible by using a number of Model Xi) l/7002 n~~inframc~

together. Each Model 701X added to the system provides 2X

additional inputs. Paragraph 3.4.3 cxphlins hwv tu connc~t a

wst system using two mainframes.

1

I

Mainframe multiplexer

700117002

A”CliOg

Backpiane

r----

I I

_----------

Card 2

7018

expansion

1

I

Figure 2-11

Two

separate multiplexer systems

Two 1x14 Multiplexers Two 1 x14 Multiplexers

Page 26

r-----

----------____

Card 1

700117002

Dual 1 xl 4 Multiplexers

Figure 2- 12

Multiplexer input expansion example

Card 1

r---I

7012

Dual 1 x 28 Multiplexer

1

I I

r----

Dual 1x14 Multiplexers

Card 2

-------__

7018

---

Bank A ’

Bank B I

----

1

I

I

Figure 2- 13

Mixed card type example

2-x

Page 27

3

Card Connections & Installation

3.1 Introduction

WARNING

The procedures in this section are intended only for qualified service personnel. Do not perform these procedures

unless qualified to do so. Failure to recognize and observe normal safety pre-

cautions could result in personal injury

or death.

The information in this section is arranged as follows:

3.2 Handling precautions: Explains precautions that

must be followed to prevent contaminetion to the multiplexer card assembly. Contamination could degrade

the performance of the multiplexer card.

3.3 Connections: Covers the basics for connecting external circuitry to the two available connector cards for

the multiplexer; the screw terminal connector card and

the multi-pin connector card.

3.4 Typical connection schemes: Provides some typical

connection schemes for single card, two-card, and

two-mainframe system configurations.

3.5 Model 7018 installation: Provides a procedure to install the multiplexcrcardassembly in the Model 70011

7002 mainframe.

3.2 Handling precautions

To maintain high impedance isolation. care should be taken

when handling the curd to avoid contamination from such

foreign materials as body oils. Such contamination can suhrtantially lower leakage rcsist;mccs. thus dcgwding pwformance.

To avoid possible contaminailfion. always grasp the r&y and

connector cuds by the side edges or shields. Do not touch

the board surfaces or components. On cwux-cto~\. do not

touch areas adjacent to tbc clcctricul COIIIBCIS. Din build-up

over a period of time is anotbcr possihlc source of contam~

station To avoid this problem. opcratc the mainframe and

multiplexer card in a clean en\‘ironment.

If a card becomes contaminated, it should he tborougbl)

cleaned as explained in paragraph 5.2.

3.3 connections

This paragraph provides the basic information needed to

connect your cxtemnl test circuitry to the multiplcxcr card. It

includes the instnlletion of the bank-to-bank jumpers 011 the

connector card, installation/remov;lI of backplane jumper)

on the relay card. and detailed information on making extcr-

nal connections to the two available connector cards.

WARNING

The following connection information is

intended to be used by qualified service

personnel. Failure to recognize and ob-

serve standard safety precautions could

result in personal injury or death.

3-l

Page 28

3.3.1 Bank-to-bank jumpers

As explained in paragraph 2.2.1, the two banks of the multi-

plexer card can he connected together (using plug-in jump-

ers) to form a larger multiplexer. The locations of the bankto-bank jumper terminals for both connector cards are shown

in Figure 3-1. The Model 7018 is shipped from the factory

with the bank-to-bank jumpers installed.

Terminal identification is provided by Figure 3-2. On the

drawing, the three terminal pairs arc labeled WlOl through

w103.

Figure 3-2

Bank-to-bank jumper terminal identification

Referring to Figure 3-l for jumper locations. perform the following steps to remove or install bank-to-bank jumpers:

Table 3-1

Bank-to-bank jumpers (on connector cardsi

~.~-~ ~~.

Installed

jumper*

WI01

WI02

WI03

Connection

Connect Bank A G to Bank B G

: Connect Bank A HI to Bank B HI

/ Connect Bank A LO to Bank B LO

I, If mated together, separate the relay card from the con-

nector card by removing the mounting screw and pulling the two cards away from each other. Remember to

handle the cards only by the edges and shields to avoid

contamination.

2. Refer to Figure 3-2 to determineJumper location.

3. Using Figure 3-3 as a guide, install or remove the jumpers on all three terminal pairs.

A. Screw Terminal Connector

Card (Model 7018-S)

Figure 3- 1

Bank-to-bank jumper locations

3-2

0

-1

P

I_~~~~~~~~.~~ . .._..........,....,....,..,..,..,...,.,,.,.,..,.. ~.,~.,.~A

_I,_l.w.“l-i

6. Multi-pin Connector Card

(Model 7018-C)

Page 29

-Jumper

Figure 3-3

Bank-to-bank jumper

installation

3.3.2 Backplane jumpers

The Model 7001/7002 mainframe has an analog backplane

that allows the banks of a Model 7018 multiplexer to be internally connected to B compatible switching card installed

in another slot (see paragraph 2.4.1 for details).

The backplane jumpers for the multiplexer card assembly are

located on the relay card as shown in Figure 3-4. The card is

shipped from the factory with the jumpers installed.

Card Connections &

lnstallalion

2. Use Figure 3-4 and Table 3-2 to locntc the jumper(s) thut

arc to be removed.

3. It is not necessary to unsolder the jumpers from the PC

board. Using a pair of wire cutters, cut both cuds of each

jumper, then remove the cut jumper scgmcnt complctcly.

Table 3-2

Backplane jumpers (on relay cards)

ran

~ Jumper* ~ Connection

I

WI01 ~ Bank AMI

: WI112

WI03

WI04

WI05

WI06

Bank AL0

Bunk A G

Bank B HI

Bank B 1.0

Bank B G

*see I:igurc 3-4 fur kwilm

Jumper

installation

Referring to Figure 3-4 forjumper locations. perform the following steps to install backplane row jumpers:

I. If mated together. scparatc the relay card from rhc cow

ncctor card by removing the mounting screw und pulling the two curds sway from each other. Rcn~emhcr to

handle the cards only by the edges and shields to avoid

contamination.

2. Physically remove cut jumper ends by unsoldering them

from the PC board.

3. Install a new #22 AWG jumper wire (Keithlcy P/N J-

15), and solder it to the PC board.

4.

Remove the solder flux from the PC boerd The cleaning

procedure is explained in paragraph 5.2.

Figure 3-4

Backplane jumpers

Jumper removal

Perform the following steps to remove backplane jumpers:

1. If mated together, separate the relay card from the connector card by removing the mounting screw and pull-

ing the two cards away from each other. Remember to

handle the cards only by the edges and shields to avoid

contamination.

3.3.3

Screw terminal connector card

The screw terminal connector curd is shown in Figure 3-5.

Connections are made directly to the screw tcrminuls of the

twelve terminal blocks. Each screw tenninnl will uccommodate #16-22 AWG wire. Note that the inputs for channels I

14ofhothBankAand BankB urc Inbelled INI through IN14

respectively.

Each input and output has three tcrminuls labelled II. Land

G for HI, LO and guard respectively.

NOTE

Although the G tcnninitl is called guard. it

is not a guard terminal uud should not bc

considcrcd a guard in the usual sense. All

3-3

Page 30

three pathways for each input have the

same electrical characteristics. Chassis

ground is available at the rear panel of the

mainframe.

Wiring procedure

Perform the following procedure to wire circuitry to the

screw terminal connector card:

WARNING

Make sure all power is off and any

stored energy in external circuitry is discharged. All DUT connections must be

insulated to prevent electric shock. The

recommended minimum wire insulation

rating is 175V RMS.

1. If mated together, separate the connector card from the

relay card by removing the mounting screw and pulling

the two cards away from each other. Remember to only

handle the cards only by the edges and shields to avoid

contamination.

2. Using an insulated screwdriver, connect the circuitry to

the appropriate terminals. Figure 3-6 shows how the

output of Bank A would be connected to a DMM.

Figure 3-5

Model 7018 screw terminal connector card

Warnlng:All DUTconnections mwt

be insulated. Recommended

minimum insulation rating is 175V

RMS.

Figure 3-6

Typical

3. Referring to Figure 3-1, remove the top half of the cable

4. Route wires under the wire guide/connector shim.

5. Route the wires through the bottom half of the cable

screw terminal connection.5

clamp as f0ll0ws:

A. Loosen the cable clamp screw enough to disengage

it from the bottom half of the cable clamp.

B. Using your thumb and forefinger, press the retaining

clips inward, and, with your other hand, remove the

top half of the clamp.

&tIlp.

3-4

Page 31

electrical characteristics. and they ciul bc

used intcrch;mgeably.

Keithlcy has B variety of cable and connccmr accessories

available to accommodi~tc con~~cctio~~s from the conncc~or

card to test instrumentation and DUT (devices under wst,. In

gcncral, these ucccssories, which arc summwizcd in Tahlc J3, utilize a round cable assembly for connections.

Cautkm: External strain relief should be used

with large wire bundles

Figure 3-7

Cable clamp for screw

terminal

connector card

6. Replace the top half of the clamp. It simply snaps onto

the bottom half of the clamp. Tighten the cable clamp

SCTCW. The clamp serves as a strain relief for terminal

block wires.

CAUTION

An external strain relief should be used

with large wire bundles to prevent damage to the card.

7. Mate the connector card to the relay card. The Model

7018 is now ready to be installed in the Model 70011

7002 meinframe. See paragraph 3.5 for details.

3.3.4 Multi-pin (masstermination) connector card

WARNING

All DUT connections must be insulated

to prevent electric shock. The recommended minimum wire insulation rat-

ing is 17SV RMS.

CAUTION

An external strain relief should be used

with large wire bundles to prevent damage to the card.

Since connections to external circuitry we made at the 96.

pin male DIN bulkhead connector. there is no wed to scparate the connector card from the relay card. If the connector

card is separated from the relay card, carefully mate them together, and install the supplied 4-40 mounting screw. Make

sure to handle the cards by the edges and shields to avoid

contamination.

Terminal identification for the DIN connector of the multipin connector card is provided by Figure 3-8. This connector

will mate to a 96-pin female DIN coonc~to~. Each input Rod

output has three terminals, HI, LO and G (guard).

NOTE

Although the G terminal is called guard, it

is not a guard in the usual sense. All three

pathways of each input have the same

Qpical connection techniques

All external circuitry, such as instrumenmtion sod DUTs.

that you wish to connect to tbe multiplexer card murt be tcrminated with u single 96.pin fcmalc DlZ cwncctor. The Ibl~

lowing connection techniques provide some guidehoer and

suggestions for wiring your circuitry.

WARNING

Before beginning any wiring procedures, make sure all power is off and

any stored energy in external circuitry is

discharged.

3-s

Page 32

Card Connections & Installation

NOTE

External circuitry should be connected

(plugged in) only with the mainframe

power off, after the Model 7018 assembly

is installed in the Model 7001/7002 mainfranc. Installation is covered in paragraph

3.5.

Output relay+The multi-pin connector card uses a relay

for each of the two output banks. These output relays arc normally open to prevent any hazardous voltages (via the mainframe backplane) from appearing on the pins of the male

DIN connector. The output relays will only close when the

Model 701 I -MTC-2 cable assembly is connected to card. If

building you own cable assembly, you must make sure that it

shorts pins la to lb of the card connector (Figure 3-8) when

it is mated to the card. Shorting pins la to I b allows the output relays to close.

Round cable assemblies-Figure 3-Y shows typical round

cable connection techniques using accessories available

from Keithley.

In Figure 3.YA, connections are accomplished using a Model

701 I-MTC-2 cable and a Model 701 I-MTR bulkhead con-

ncctor. The two-meter round cable is terminated with a 96.

pin female DIN connector at each end. This cable mates directly to the multi-pin connector card and to the bulkhead

connector. The bulkhead connector has solder cups to allow

direct connection to instrumentation and DUT. Figure 3-10

provides the pinout for the bulkhead connector.

In Figure 3.9B, connections are accomplished using a Model

7011.MTC-2 cable assembly that is cut in half. The 96.pin

female DIN connector on one end of the cable mates directly

to the multi-pin connector card. The unterminated end of the

cable is wired directly to instrumentation and DUT. The other half of the cable assembly could bc used for a second

switching card,

In Figure 3.YC, connections are accomplished using a custom-built cable assembly that consists of a Model 7011.KITR connector and a suitable round cable. Hitachi cable part

number N2807-P/D-SOTAB is a 50.conductor cable. Two of

these cables can be used to supply 100 conductors.The connector has solder cups to accommodate the individual wires

of the unterminated cable. Figure 3-l I provides an exploded

view of the connector assembly and shows how the cable is

connected. The connector end of the resultant cable assembly mates directly to the multi-pin connector card. The unterminated end of the cable assembly is wired directly to

instrumentation and DUT.

3-6

Page 33

Pins of the Model 701 B~C mass termination connector can be identified in one of three ways:

1. MUX terminal, consisting of banks A-B and inputs i-14.

2. Connector description, consisting of rows a-c and columns l-32.

3. Schematic and component layout designation (l-96).

The following pinout diagrams show the correspondence between these arrangements:

Carrl Connections & Insrallation

.................................

.

................................

.................................

MUX

Terminal

Bank A Bank A

Input 1 HI

Input * HI

Input3 HI 4a

Input4 HI

Input 5 HI

Input 6 HI 78

Input7 HI

Notes:

1. Pins 9a and 9b (pins 9 and 41 on schematic) are shield.

2. Short pins la to 1 b an the mating connector (pins 1 and 33 an schematic) to allow the output relays on the connector card 10 close

Desig.

la-32~

*a

LO

G

LO

G

LO

G

LO

G 5b

LO 6C

G

LO 7c

G

LO

G 8b

2c

2b

38

3c

3b

4c

4b

5a

5c

6a

6b

7b

*a

BC

onnect

:cllem.

or S

I

hslg. MUX

1-96 Terminal

2l LC

66

34 I

3 Input9 HI

67 LC

36 G

4 Input lOti

68 LC

36 G

5 Input 11 HI

69 LC

37 G

6

70 LC

3s

7 Input 13HI

71 LC

39 G

8 Input 14HI

72 LC

40 G

Input8 HI

G

lnpu, 12HI

G

output HI

LC

G

~Onnectol

Desig.

18-32s

Bank B

Ill Input 1 HI

74 LO

42 G

11

75

43

12 Input 3 HI

76 LO

44 G

13 Input4 Hi

77 LO

45 G

Input 6 HI

LO

G

Input 7 HI

LO

G

COnneCtOl

DC&g.

ts-32~

178

17c

17b

19a

19c

19b

20a

2oc

20b

22a

22c

22b

2%

2%

23b

View from pin side

of connector

:hem. i

esig. / MUX

l-96 ~ Terminal i 18-32~ ~ t-96

/Bank B

I

85

53 28b

InoUt 13HI /

22

~ connector 1 Schem.

~ Desig. Deaig.

-~-

24a 24

24c 66

24b 56

25s 25

2%

25b 57

2&l 26

26C 90

26b

27a 27

27c 91

27b 59

ma

LOI

G 1

Lo: 29c

G

26C

29a

29b

ma

97 1

55

G 30b

ou,put HI

G

3oc

LOI

32a

LO 32c

32b

69

58

28

All DUT connections must be insulated. Recommended minimum insulation rating is 175V RMS.

External strain relief should be used for large wire bundles

Figure 3-8

Multi-pin card terminal identifkation

WARNING

CAUTION

Page 34

Card Connections & Installation

Figure 3-9

Typical round cable connection techniques

Note

: See Figure 3-8 for terminal

identification.

Figure 3- 10

Model 70 11 -MTR connector pinout

3-8

View from solder

cup side of

connector

Page 35

Figure 3-

Model 701 I-KIT-R (with/cab/e) assembly

3.4

The following information provides some typical conacction

schemes for single-card, two-card and two-mainframe system configurations. Connection schemes for the multi-pin

connector card use some of the techniques presented in paragraph 3.3.2. Keep in mind that these arc only cxamplcs to

demonstrate various ways to wire a test system. Connection

details for both connector cards (multi-pin and screw termi-

nal connector cards) are provided in paragraph 3.3.

11

Typical connection schemes

3.4.1 Single-card system

Card Connections & Installation

(Model 7018-C). This single-card system is conligurcd as

two I x 14 multiplcxcrs. To accomplish this. the bank-tom

bank jumpers must bc rcmovcd.

Instrumentation and DUTs arc bard-wired to the Model

701 1 -MTR male bulkhead cormcctor. This connector has

solder cups thtat will accept wire size up to #24 AWG. The

test system is conncctcd to the multiplexer using the Mudci

701

I -MTC-2 round c;iblc wembly. This cahlc ~natc\ dircct~

ly to both the externill hulkhead connector and the Llodcl

701X-C multiplcxcr card assctnbly. Uoticc that the bulkhcxd

connector is shown mounted to it lixturc to help keep tbc oil-

bling stable during the test.

The single-card system in Figure 3-l 3 is identical to the sys-

tem in the previous illustration. cxccpl for the connection

scheme. The system in Figure 3-l 3 uses the screw tcrmirtal

connector card (Model 7018-S). With this curd. single-cow

ductor connections are made directly from the terminal

blocks of the connector card to instrumentntion and I)l:Ts.

When using a single-card system. mskc sure th;lt the card rcmains clcctrically isolated from any other switching cwd.

There arc several ways to ensure isolation for a sinflc card

in the Model 7001/7Gil2 mainfmmc:

I, Vacate other mainframe slot(s). If thcrc is a Model 70 IX

card installed in another slot, rermwc it.

2. Remove the backplane jumpcrs on the multiplcxr card.

Doing so will disconnect the card from the mulog hackplane of the mainfrnme.

3. Remove the bnckplanc jumpers from switching card(s)

installed in other slot(s).

4. Remove backplune jumpers from the Model 7002 hacks

pltNlC.

Figurc 3.12 shows how external connections can be made to

a single-card system that uses the multi-pin connector card

Page 36

. . .

L

r----

Simplified Equivalent Circuit

Figure 3- 12

Sing/e-card system example (multi-pin connector card)

3-10

Page 37

Figure 3- 13

Sing/e-card system example hcrew

terminal connector

Card Connecrionr & Inutallarion

cardi

Figure 3- 14

Two-card system example

3.4.2

Two-card system

(multi-pin connector card)

Both Figure 3-14 and Figure 3-15 show a system using two

multiplexer cards installed in one Model 7001 mainframe to

configure a single 1 x 56 multiplexer system. Each card is

configured as a single I x 28 multiplexer. To accomplish this,

bank-to-hank jumpers are installed to connect Banks A and

B together. By leaving the backplane jumpers of both cards

installed, the banks of Card 1 are connected to the banks of

Card 2 through the analog backplane of the Model 7001

mainframe resulting in the I x 56 configuration.

Figure 3. I4

shows how extcmnl connections can he made

for the multi-pin connector cards. In this exnmplc. a single

Model 7011.MTC-2 round cable asscmhly is cut in halt. to

provide two cables. each of which is untem~inated at ore

end. The unterminated ends of the two cahlcs iwc herd-wired

to the instrument and DUT as shown in the drawing. The other ends of these cables mate directly to the Modct 701X-C

multiplexer card assemblies.

Figure 3-15 shows how cxtcmal connections can be made

for the screw tcnninal connector card. Single conductor cow

ncctions are made directly from the screw tcmlinals 01’ the

connector card to tbc instrument sod DUT.

7-l I

Page 38

Card Connections & Installation

.

Simplified Equivalent Circuit

Figure 3- 15

Two-card system example (screw

. . .

/ Ill

DUT Test Fixture

terminal connector

I Ill

28 29

card)

. . . . . . . . .

56

3.4.3 Two-mainframe system

Both Figure 3- 16 and Figure 3-17 show a system using three

multiplexer cards installed in two Model 7001 mainframes to

configure a single I x 84 multiplexer system. Each card is

configured as a single 1 x 28 multiplexer. To accomplish this,

bank-to-bank jumpcrs of all at least one card must be installed to connect Banks A and B together.

By leaving the backplane jumpers of the cards in mainframe

#l installed, the hanks of Card 1 are connected to the hanks

of Card 2 through the analog backplane of the Model 7001

3.12

mainframe resulting in a 1 x 56 configuration. External bank

connections from the instrument to the card in the second

mainframe connect the banks of all three cards together to

form the 1 x 84 multiplexer system. This system is similar to

the Two-card System (see previous paragraph) except that a

third multiplexer card (installed in a second mainframe) is

added.

Figure 3-16 shows the connection scheme for the multi-pin