Page 1

INSTRUCTION MANUAL

MODEL 660

GUARDED DC

DIFFERENTIAL

VOLTMETER

Page 2

WARRANTY

We warrant each of our products to be free

from defects in material and workmanship. Our

obligation under this warranty is to repair or

replace any instrument or part thereof (except

tubes and batteries) which, within a year after

shipment, proves defective upon examination.

To exercise this warranty, contact your Keithley

field engineering representative. You will be

given assistance and shipping instructions.

REPAIRS AND RECALIBRATION

Keithley Instruments and its internat.ional dis-

tributors maintain complete repair facilities.

To insure prompt repair or recalibration service,

please contact your Keithley field representative

before returning the instrument.

Estimates for repairs, normal recalibrations, and

calibrations traceable to the National Bureau of

Standards are available upon request.

Page 3

MODEL 660 DIFFERERTIAL VOLTMETER

TABLE OF CONTENTS

CONTENTS

Section

GENERAL DESCRIPTION. . . . .

1.

l-l.

Description. . . . . .

1-2. Operating Modes. . . .

l-3.

Applications . . . . .

1-4. Accessories. . . . . .

l-5. Specifications . . . .

l-6.

Equipment Shipped. . .

2. OPERATION. . . . . . . . . .

2-l. Front Panel Controls

and Terminals . . . .

2-2. Rear Controls and

Terminals . . . . . ,

2-3.

Preliminary Procedures

2-4. Operating Procedures .

2-5.

Model 6601A High

Voltage Divider . . .

2-6.

Recorder Output. . . .

2-7. Measuring Resistances.

2-8. Effects Due to Kelvin-

Varley Divider Gut-

put Resistance. . . .

2-9. loading and Off-Null

Resistance. . . . . .

2-10. Thermal EMF Precau-

tions . . . . . . . .

2-11. AC Effects on Measure-

ment. . . . . . . . .

2-12. Rack Mounting. . . . .

2-13. Placing in Rack. , . .

2-14. 234-Volt Operation . .

Page

1

5

5

5

5

6

8

8

LO

11

12

12

12

12

14

14

Section

Page

3-3. Kelvin-Varley Divider. . 16

3-4. Null Detector. . . . . . 16

3-5. Guarding . . . . . . . . 17

4. MAINTENANCE. . . . . . . . . . 19

4-l.

General......... 19

4-2. Parts Replacement. . . . 19

4-3. Troubleshooting. . . . . 19

4-4. Adjustment of

km

Balancing Controls. . . 22

4-5. Zener Current Test . . . 23

4-6. Calibration Procedures , 24

4-7. Kelvin-Varley Divider

Verification. . . . . . 24

4-8. Range Calibration. . . . 25

4-9. Reference Voltage Sup-

ply Stability Test. . . 29

REPLACEABLE PARTS. . . . . . . 37

5.

5-1. Replaceable Parts List . 37

5-2.

How to Order Parts . . . 37

Model 660 Replaceable

Parts List. . . . . . . 38

Model 6601A Replaceable

Parts List. . . . . . . 44

Model 660 Schematic

Diagram 15199B. . . . . 47

Model 6601A Schematic

Diagram 16321B. . . . . 48

* Change Notice

3. CIRCDIT DESCRIPTION. . . . .

3-l. General, . . . . . . .

3-2. Reference Voltage

Supply. . . . . . . .

0664R

15

15

15

Wellow Change Notice sheet is in-

cluded only for instrument modifications affecting the Instruction Manual.

i

Page 4

GENERAL DESCRIPTION

MODRL 660 DIFFERENTIAL VOLTMETER

.

FIGURE 1.

ii

Keithley Instruments Model 660 Guarded DC Differential Voltmeter.

0564R

Page 5

MODEL 660 DIFFERENTIAL VOLTMETER

GENERAL DESCRIPTION

SECTION 1.

l-l. DESCRIPTION.

The Keithley Model 660 Guarded DC Differential Voltmeter is a convenient,

8.

self-contained potentiometric system that accurately measures dc voltages. It

has 20.02% limit of error from 100 millivolts to 500 volts full scale, 0.005%

repeatability, and a reference supply stable to 0.005% indefinitely without

manual standardization.

resolution is within 2 microvolts.

Features for convenient use include:

b.

automatically lighted decimal points;

input polarity switch; floating operation up to 500 volts off ground; fast

overload recovery; better than 45 decibels of 60-cps rejection.

l-2. OPERATING MODES.

a conventional vacuum tube voltmeter. As a potentiometer, it can measure

from 100 millivolts to 500 volts full scale with 20.02% limit of error and

from 100 microvolts to 100 millivolts full scale within 20 microvolts. As

a VTVM, the Model 660 can measure from 100 microvolts to 500 volts full

scale with an accuracy of *3% of full scale.

tances from 10 megohms to 50,000 megohms within *5%.

Maximum null sensitivity is 2100 microvolt6 full scale;

The Model 660 can be used as a potentiometer or as

GENERAL DESCRIPTION

five in-line readout dials with

10 to 25-millivolt recorder output;

It can also measure resis-

l-3. APPLICATIONS.

The Model 660 is used for measurements over a wide range. Typical ap-

a.

plications in the microvolt region are the matching of semi-conductors and

the monitoring of noise, transients and drift.

tions include power supply and meter calibration, and tube potential measure-

ments.

Overall stability of 0.01% indefinitely makes the Model 660 useful in

b.

measurements of extended duration.

stability, long-term drift runs, and monitoring during environmental and

reliability tests are possible uses.

The null-detector output permits use with potentiometric recorders and

c.

digital voltmeters equipped with automatic print-out. The Model 660 is useful in quality control, product development, inspection and production.

Floating operation to 500 volts is provided for measurements such as

d.

plate potential differences of balanced amplifiers.

l-4.

range of the Model 660 to 5000 volts.

its input resistance is 10 megohms. The overall limit of error of the Model

660 with the Model 6601A is 20.03%.

for the Divider,

ACCESSORIES.

a. Model 6601A High Voltage Divider is a 1OO:l divider which extends the

Measurements of long-term power supply

The divider accuracy is tO.Ol% and

Paragraph 2-5 gives operating instructions

High level voltage applica-

0664R

Page 6

GENERAL DESCRIPTION

Model 4000 Rack Mounting Kit, containing two brackets and a top cover,

b.

adapts the Model 660 for standard 19-inch rack mounting.

the Model 660 is 19 inches wide x 13-l/2 inches deep x 5 inches high.

to paragraph 2-12 for installing instructions.

l-5. SPECIFICATIONS.

AS AN ULTRA-STABLE POTENTIOMETER:

MODEL 660 DIFFERENTIAL VOLTMETER

For rack mounting,

Refer

LIMIT OF ERROR:

after 15-minute warm-up.

er,

REPEATABILITY: Within 0.005%.

COMBINED STABILITY OF KELVIN-VARLEY DIVIDER AND REFERENCE VOLTAGE SUPPLY:

?O.Ol% indefinitely,

exceed 0.002% per OC.

MAKIm NULL SENSITIVITY:

resolution.

INPUT RESISTANCE: Infinite at null, from 0 to 500 volts.

POLARITY:

FLOATING OPERATION:

(chassis ground).

RESISTANCE - LOW TO GROUND: lo8 ohms shunted by 0.05 microfarad.

RESOLUTION CHART:

Input Voltage

Range

(volts)

Positive or negative, selectable by switch.

20.02% of input voltage or 20 microvolts, whichever is great-

after l-hour warm-up. Temperature coefficient does not

100 microvolts full scale with 2.0-microvolt

May be operated with up to 500 volts between LO and GND

Maximum Usable

Maximum Dial

Resolution

(millivolts)

Full-Scale Null

Sensitivity

(millivolts)

Maximum Meter

Resolution

(microvolts)

10 10

1 1

0.1

0.01 0.1

5

- 500

- 50

- 5

- 0.5

500 volts

50 volts

5 volts

0.5 volt

50

0.5

0

AS A SENSITIVE VTVM:

Voltage Ranges (oositive or negative)

0.1

100

10

2

2

@out Resistance

10 megohms

10 megohms

10 megohms

10 megohms

0664R

Page 7

MODEL 660 DIFFEXENTIAL VOLTMETER

GENERAL DESCRIPTION

Null Rannes

100 volts

10 volts

1 volt

100 millivolts

10 millivolts

1 millivolt

0.1 millivolt

NOTE:

Input resistance on O.l-millivolt range

Input Resistance (Slewind

10 megohms

10 megohms

10 megohms

1 megohm

1 megohm

1 megohm

100 kilohms

can be increased; see paragraph 2-8.

VTVM ACCURACY: +3% of full scale on all ranges.

DRIFT: Less than 10 microvolts, non-cumulative, after 15-minute warm-up.

60 CPS REJECTION:

Greater than 45 db.

GENERAL CHARACTERISTICS:

STABILITY OF REFERENCE VOLTAGE SUPPLY: +0.005% indefinitely, after l-hour

wan-up.

STABILITY OF ZENER REFERENCE:

20 ppm per year and five ppm per 'C.

LINE TRANSIENT REGULATION:

Less than 5 ppm for 10% variation from 117 volts.

ACCURACY OF DIVIDER: 0.005%.

CHARACTERISTICS OF NULL DETECTOR OUTPUT:

Output:

Output Resistance:

Adjustable 10 to 25 millivolts dc full scale, all ranges.

300 ohms maximum.

Noise: 2 microvolts peak-to-peak (referred to input).

Note:

Recorder used must have input fully isolated - 10"

minimum leakage.

CONNECTORS:

Input: Binding posts on front panel.

Output: Banana jacks on rear.

TUBE COMPLEMENT:

One OG3, five 12AX7, one 12BH7, two 12B4A, one 6CMS.

POWER: 105-125 volts or 210-250 volts, 50-60 cps, 75 watts.

DIMENSIONS (Bench):

5-l/2 inches high x 17-l/2 inches wide x 13-l/2 inches

deep.

NET WEIGHT: 24 pounds.

ohm

l-6. EQUIPMENT SHIPPED.

The Model 660 Guarded DC Differential Voltmeter is

factory-calibrated and is shipped with all components in place. All units are

shipped for bench use.

to paragraph 2-12 for assembly instructions.

Model 4000 Kit may be ordered for rack mounting; refer

The shipping carton also contains

the Instruction Manual.

0664R

3

Page 8

GENERAL DESCRIPTION

MODEL 660 DZFFF.RENTIAL VOLTMETER

FIGURE 2.

Model 660 Front Panel Controls and Terminals.

Designations refer to Parts List.

._ . ..-. IT -.,,

--

-m-

m-

-T-

-.

.

:

FIGURE 3. Model 660 Rear Controls and Teminals.

4

0564R

Page 9

MODEL 660 DIFFERENTIAL VOLTMETER

OPERATION

SECTION 2.

2-1. FRONT PANEL CONTROLS AND TERMINALS. (See Figure 2.)

a. POLARITY Switch.

the input polarity.

voltage supply so both positive and negative voltages may be measured; it does

not reverse the meter polarity.

b. NULL Switch.

decade ranges from 0.1 millivolt to 100 volts full scale. When the Switch is

in the VTVM position,

voltmeter for the four ranges of the RANGE Switch.

c. RANGE Switch. The RANGE Switch adjusts the sensitivity of the VTVM in

four steps: 0.5, 5, 50 and 500 volts full scale, It also determines the

voltage across the Kelvin-Varley divider and the position of the decimal point

light - which also serves as a pilot light - between the five Reference

Voltage Dials.

Reference Voltage Dials.

d.

panel set the reference voltage when the Model 660 is used as a potentiometer.

The POLARITY Switch turns the instrument on and selects

The Switch reverses the polarity of the internal reference

The NULL Switch sets the null detector sensitivity for seven

the Model 660 operates as a conventional vacuum tube

Five in-line dials at the top of the front

OPERATION

e. METER ZERO Control.

zero. The control is needed on only the 0.1 and l.O-millivolt null ranges; on

the other ranges, the pointer will normally be on zero without adjustment.

The control has a range of approximately +50 microvolts.

Input Terminals.

f.

is to be connected to the low impedance terminal of the unknown voltage and

the red HI terminal is to be connected to the high impedance termiual. A

second set of terminals marked Lo and GND is provided for grounding the LC

input terminal to the chassis when desired.

together internally.

2-2. REAR CONTROLS AND TJBMLNALS. (See Figure 3.)

a. Fuse.

fuse. For 210-250 volt operation,

Power Cord.

b.

unless otherwise specified on the rear panel. A three-wire power cord is used.

c. NULL DETECTOR OUTPUT. Two terminals, marked + and -, supply a dc signal

from the null detector.

d.

OUTPUT ADJUST. '

justs the null detector output between 10 and 25 millivolts full scale.

For 105-125 volt operation,

The Model 660 is for a 105-125 volt, 50-60 cps line source,

The METER ZERO Control adjusts the meter pointer to

At the lower left front panel, the black LO terminal

The LO terminals are connected

the Model 660 uses a l-ampere 3 AG

the Model 660 uses a 0.5-ampere 3 AG fuse.

A screwdriver control next to the OUTPUT terminals ad-

2-3.

0664R

PRELIMINARY PROCEDURES.

a. Connect the Model 660 power cord to a 105-125 volt, 50-60 cps line

5

Page 10

OPERATION

MODEL 660 DIFFBRENTIAL VOLT?fETER

source.

Set the controls as follows:

RANGE

500

NULL VTVM

POLARITY

Reference Voltage Dials

+

Zero

The decimal light between the third and fourth dials will light.' Allow the

instrument to warn up for 15 minutes to meet the specified accuracy on all ranges,

With the input terminals open, set the NDLL Switch to 0.1 MV and zero the

b.

meter with the METER ZERO Control.

no adjustment should be required in eight hours after a 15-minute warm-up.

The stability of the Model 660 is such that

Then

return the NULL Switch to VTVM.

2-4.

OPERATING PROCEDURES.

a. The Model 660 is used first as a VTVM to determine the approximate value of

the unknown voltage.

It is then used in the potentimetric mode to determine the

voltage to ti.O2%.

VTVM Operating Procedures.

b.

Eleven full-scale ranges are available for VTVM operation. When the

1.

NIJLL Switch

ranges.

is

at VTVM, the RANGE Switch determines one of four full-scale

By putting the five Reference Voltage Dials at zero, the Model 660

can then operate as a VTVM on the seven null ranges,

Connect the unknown voltage to the input terminals, using the LO term-

2.

inal for the low impedance terminal of the unknown. Refer to Figure 4.

LH $C

,

I

Unknavn

Voltage =

0000

Off-Grou,,d’=r

Potential -

B

FIGIJRE 4. Input Connections to Model 660.

The two diagrams show the input

circuit for measuring at ground and for floating.

In A, the unknown voltage has one terminal at ground.

The shorting link

is between the LO and GND terminals of the Model 660.

In B, the unknown voltage has both terminals off ground potential. Note

this floating or off-ground potential mst be less than 500 volts. Also

note the shorting link is not used.

6

0664R

Page 11

MODEL 660 DIFFRRENTIAL VOLTMRTER

Switch the RANGE Switch to the most sensitive range lor an on-scale

3.

'~meter deflection.

c. Potentiometric Operating Procedures.

NOTE

Avoid large overload voltages on the null detector. No permanent

damage will occur even with 500-volt overloads, but some open circuit offset will be caused in the null detector.

to the polarization of the input filter capacitors, will disappear

after about an hour.

Leave the RANGE Switch at the last setting used in the VTVM operation.

1.

If the VTVM reading is negative, reverse the POLARITY Switch.

Set the first two Reference Voltage Dials to the first two digits of

2.

the unknown voltage found in the VTVM operation.

Set the NULL Switch to the initial null setting shown in Table 1.

3.

Adjust the Voltage Reference Dials progressively for zero meter deflection

while increasing the null detector's sensitivity with the NULL Switch.

Deflections to the right indicate the voltage being measured is more

positive than the Reference Voltage Dial setting.

The offset, due

OPERATION

RANGE Initial NULL

Setting Setting

I

500 volts 100 volts

50 volts

~ 5 volts 1 volt

0.5 volt 100 millivolts

/

TABLE 1. Recommended Null Sensitivities and Settings.

The most accurate resistors in the Kelvin-Varley divider are in

the first two Reference Voltage Dials. Therefore,

most accurate readings, use the first tm dials whenever possible.

The value of the unknown voltage is read directly from the Reference

4.

Voltage Dials.

a) The Dial reading will be within the specified limit of error

if the NULL Switch is at the most sensitive setting (Table 1) for the

range used and if the meter is as close to null as possible.

need not be actually at null.

b) For Dial settings below 499910, only the five Dials need be

read to be within specifications. However,

an approximation of a sixth digit.

10 volts

NOTE

the meter may be read as

Most Sensitive

NULL Setting

10 millivolts

1.0 millivolt

0.1 millivolt

0.l millivolt

to obtain the

The meter

For Dial settings above 499910, the first Dial is not used and

c)

the voltage is read directly from the remaining four Dials.

0664R

7

Page 12

OPERATION

MODEL 660 DIFFERENTIAL VOLTMETER

d) Use the meter asa null indicator when balancing voltages. For

Dial..settings above 499910, the meter approximates a fifth dial reading.

However, the loading effect of the Kelvin-Varley divider on the meter

causes some quantative inaccuracies when the meter is off null.

paragraph 2-8).

(See

2-5. MODEL 6601A

a. The Model 6601.A extends the range

scale.

The ratio of the Divider is lOO:l, ?O.Ol%; the input resistance is

10 megohms.

HIGH

VOLTAGE DIVIDER.

of

the Model 660 to 5000 volts full

The limit of error when the Model 660 is used with the Model

6601A is 20.03%.

NOTE

Maximum input into the Model 66Ol.A is 5000 volts.

Set the Model 660 RANGE Switch to 50 volts. The meter will read to 5000

b.

volts full scale.

Connect the HI and LO Divider terminals to the HI and Lx)

Voltmeter terminals, respectively. Connect the unknown voltage to the Divider

INPUT, and use the Model 660 as outlined in paragraph 2-4.

FIGURE 5.

Model 6601A High Voltage Divider.

2-6. RECORDER ODTPwr.

a. Reconsaended recorders for use with the Model 660 are the F.L. Moseley Auto-

graf 680 series recorder and the Minneapolis Honeywell recorder (lOmv-0-101~ scale,

50 kilohms input

resistance).

Any recorder used must be able to float 500 volts

off ground and its input nest be fully isolated (1010 ohm minimum leakage resistance to ground).

Before attaching the recorder, set all Reference Voltage Dials to zero.

b.

Disconnect the unknown voltage and short both Model 660 input terminals.

Set

the NULL Switch to 10 MV. Connect the recorder to the OUTPUT terminals on the

Model 660 rear panel.

0664R

Page 13

MODEL 660 DIFFRRRRTIAL VOLTMETER

Set the Reference Voltage Dials to 10 millivolts to apply an accurate

c.

OPERATION

ID-millivolt potential to the null detector on the lo-millivolt null range.

This will provide a full-scale recorder output which can be matched to the

recorder’s range between 10 and 25 millivolts by adjusting the OUTPUT ADJUST

Control.

To obtain accurate results and/or to prevent damage to the instruments,

d.

the recorder must be able to float off-ground with the Model 660. Leakage

and pickup between the two instruments should also be minimized.

Make sure neither recorder terminal is grounded. Use a 3-wire

1.

grounded power line for the recorder.

If a Z-wire line is used, connect

the recorder chassis and the Model 660 chassis with a separate lead.

Minimize all sources of leakage between the output terminals, the

2.

recorder and ground. Use polystyrene or Teflon-insulated wire where

possible.

If the connecting wires are shielded,

connect

the shield to

the LO terminal.

Avoid long leads between the Model 660 and the recorder.

3.

If difficulty is encountered in off-ground measurements, such as

4.

unstable readings, connect a lo-microfarad capacitor between the LO and

GND terminals on the Model 660 front panel.

NOTE

Do not short either Model 660 output terminal to the case;

this may damage the Kelvin-Varley divider.

e. If there is substantial recorder

jitter

on the O.l-millivolt null

range, place a filter between the Model 660 and the recorder. Refer to Figure

6 for this connection.

Rote the filter must also be insulated from ground.

Terminals

FIGURE 6.

Recorder Filter.

A filter between the Model 660 and the

recorder may be necessary when using the O.l-millivolt null detector range.

0664R

9

Page 14

OPERATION

MODEL 660 DIFFEREXTIAL VOLTMETER

2-7. MJ?ASURING RRSISTANCES.

Procedure&: The Model 660 can be used to rapidly measure resistances

frzm 10 megohms to 50,000 megohms with an accuracy of 25%.

tance,

connect the resistor across the Model 660 RI and LO terminals.

To measure resis-

Use a

short isolated lead to the HI terminal to prevent measuring leakage between

the leads.

Set the RANGE Switch to 500.

Then determine the value of the

resistor as follows:

For resistances between 10 megohms and 100 megohms, set the NULL Switch

1.

to 10 volts; adjust the Reference Voltage Dials to obtain a full-scale meter

deflection.

Subtract 10.000 from the dial setting to obtain the value of

the resistor in megohms.

For resistances between 100 megohms and 1,000 megohms, set the NULL

2.

Switch to 1 volt; adjust the Reference Voltage Dials to obtain a full-scale

meter deflection. Subtract 1.0000 from the dial setting and multiply the

difference by ten to obtain the value of the resistor in megohms.

For resistances between 1,000 megohms and 50,000 megohms, set the NULL

3.

Switch to 1 volt; adjust the Reference Voltage Dials to obtain a convenient

deflection on the meter. Calculate the value of the resistor using,

Q = 10 Rd

megohms

v

Where R, is the unknown resistance;

Ed is the Reference Voltage Dial setting in volts;

V is the null detector meter reading in volts.

FIGURE 7. Simplified Model 660 Circuit for Measuring Resistances. Rr is

the unknown resistance. R,, is the input resistance of the null detector;

V is the null detector; Ed is the buckout voltage.

Theory: The above method for determining the value of an unknown resistor

b.

is based upon the equation for the circuit (see Figure 7).

If an unknown resis-

tance is across the Model 660 input terminals, then

=i C&+&-J

Ed

Es.

2

10 0664R

Page 15

MODEL 660 DIFFRRRRTIAL VOLTMETER OPERATION

where Ed is the Reference Voltage Dial setting in volts;

i is the current in the circuit;

R, is the unknown resistance;

Rn is the input resistance of the null detector meter in ohms.

The current can be written i = V/R.,.,,, where V is the null detector meter

reading in volts.

If measurements are made on the 1 to loo-volt null ranges, the input resist-

ance, Rn, is 10 megohms. Equation 3 becomes

Equation 2 now becomes

Eq. 3

Eq. 4

2-a.

last Reference Voltage Dial may appear to be inaccurate, The apparent error

is due to a voltage drop across the Kelvin-Varley divider. This effect involves only the null detector sensitivity and not the accuracy of the dial

setting. When the Model 660 is as near to null as possible, the Reference

Voltage Dial setting is correct within the instrument's specifications.

There is no error

millivolt off-null setting of the reference voltage will not produce a full-

scale deflection on the meter. The output resistance of the Kelvin-Varley

divider is significant compared to the shunt resistance across the null

detector meter, and the IR drop across the divider will cause the meter to

be in error from 1% to 36%.

setting of 100, 10 and 1 millivolt off-null respectively, can show up as

an error of up to 6% for Reference Voltage Dial settings near 25000. The

effect cannot be observed on the other null ranges of the Model 660.

EFFECTS DUE TO KELVIN-VARLEY OUTPUT RESISTANCE.

a. When the Model 660 is used for nulling on the O.l-millivolt range, the

at

null.

The effect is most apparent on the O.l-millivolt null range, A O.l-

b.

On the 100, 10 and l-millivolt null ranges, a

c. The amount of deflection on the meter is equal to the ratio

R,

+ NW

51

where R,., is the shunt resistance across the meter (10 megohms for the 100 to

l-volt null ranges, 1 megohm for the 100 to l-millivolt null ranges,

and 100 kilohms for the O.l-millivolt null range);

Rkv is the output resistance of the Kelvin-Varley divider, which is

a maximum of 62.4 kilohms at settings of 24545 and 25455 and a

minimum of 100 ohms at settings of 49998 and 00002.

d. The input resistance on the O.l-millivolt range may be increased by

substituting a l-megohm, l/Z-watt resistor (Keithley Part No. R12-1M) for

the lOO-kilohm input resistor, Rl003, if the source resistance is not more than

0664R 11

Page 16

OPERATION

MODEL 660 DIFFRRRNTIAL VOLTMETER

100 kilohms.

instrument open circuited only.

The higher input resistor will increase the input noise of the

The effect of line transients will also be

more apparent.

2-9. LOADING AND OFF-NULL RESISTANCE.

a. The input resistance of the voltmeter for the seven null ranges varies

from 10 megohms to 100 kilohms a8 given in the Specifications. This resist-

ance, however, is not the effective input resistance of the Model 660. Its

input resistance is considerably higher due to the potentiometric principle

of operation.

The Vehe is

given by

where Rin is the effective input resistance of the Model 660;

Rd is the voltage indicated on the Reference Voltage Dials;

Rn is the shunt resistance or input resistance of the null detector meter;

V is the null detector meter reading.

To find the loading effect the Model 660 will have on a circuit, equa-

b.

tion 5 may be used to compute the effective input resistance of the instrument.

At null, the input resistance is infinite.

Off null, the input resistance is

usually high compared to the internal resistance of the unknown voltage, and

the loading will not be enough to affect the accuracy of the measurement. For

example, the Model 660 input resistance is 1010 ohms if the Reference Voltage

Dials are set at 1.0000 volt on the l-millivolt null range for a reading off

null by 10% of full scale.

2-10.

THERMAL RMF PRRCAUTIONS. Observe standard thermocouple techniques to

reduce thermal emf errors for measurements using the most sensitive null ranges.

Since the Model 660 can read to 0.5 microvolt, thermal emf's can intro-

duce considerable error8 into the measurements. In general, use pure copper

lead8 throughout the system when measuring in the microvolt range. For extensive measurements in the microvolt region, request the article, DC Microvolt

Measurements, from Keithley Instruments, Inc.

2-11. AC EFFECTS ON MRASUFEMRNTS. To minimize errors from ac signals present

in the unknown voltage, the Model 660 employs a chopper-stabilized null detector

operating at a 42-cps chopping rate with a two-section R-C filter at the input.

Very large ac components on the measuring lines, however, may reduce off-null

sensitivity. Also, heavy 60-cps pickup will be observed as needle quiver. If

ac components affect measurements by the Model 660, additional filtering is required. For an ac signal of a single frequency, a twin T filter is effective.

For an ac variable frequency, an ordinary low-pass filter may be used.

2-12.

RACK MOUNTING. (See Figure 8.)

a. The tide1 660 is shipped for bench use with four feet and a tilt-bail.

The

Model

4000

Rack Mounting

Kit

converts the instrument to rack mounting

to the standard RIA (RRTMA) lV-inch width.

To convert the Model 660, remove the four screws at the bottom of each

b.

side of the instrument case.

Lift off the top cover assembly with the handles;

12

0664R

Page 17

MODEL 660 DIFFRRRNTIAL VOL'JMETRR

OPERATION

save the four screws. To remove the feet and tilt bail from the bottom cover

assembly, turn the two screws near the back.

The two pawl-type fasteners

will release the cover and allow it to drop off. Remove the feet and the tilt

bail and replace the cover (2).

c. Attach the pair of rack angles (3) to the cabinet with the four screws

(4) previously removed.

Insert the top cover assembly (1) in place and fasten

to the chassis with the two pawl-type fasteners at the rear. Store the top

cover with handles, feet and tilt-bail for future use.

Item,

See Fig. 8) Description

1

Cover Assembly

2 Cover Assembly, Bottom (Supplied with

Model 660) 14590B 1

3

Angle, Rack

4 Screw, Slot Head, IO-32 URC-2x1/4

(Supplied with Model 660)

5

Front Panel (Supplied with Model

660) ---

TABLE 2. Parts List for Model 4000 Rack Mounting Kit.

Keithley

Part No.

Quantit!

14623B

14624B

-_-

,/OCOVER ASSEMBLY

1

2

4

1

0664R

@ZOVER ASSEMBLY

FIGURE 8.

Exploded View for Rack Mounting.

13

Page 18

OPERATION

MODEL 660 DIFFERRNTIAL VOLTMETER

2-13. PLACING IN RACK.

fits into the rack.

rack enclosure in which the Model 660 is mounted.

state a 0.002% per OC temperature coefficient.

The Model 660, once converted for rack mounting, easily

It is recomended, however, that a blower be used in the

The instrument specifications

A temperature rise of 5 oC

(9 OF) will cause a 0.01% error.

2-14. 234-VOLT OPERATION. The Model 660 can be quickly and easily converted to

operate from a 234-volt line source.

It is normally supplied with the power

transformer primary windings connected in parallel for 117-volt operation. To

convert,

diagram:

0.5~ampere fuse.

reconnect the primary windings in series as shown on the schematic

the brown lead to

Power line frequency'can be 50 to 400 cps for either

the

black-white. Replace the l-ampere fuse with a

voltage.

14

0664R

Page 19

MODEL 660 DIFFERENTIAL VOLTMETER

SECTION 3. CIRCUIT DESCRIPTION

CIRCUIT DESCRIPTION,

3-l.

GENERAL.

potentiometric method.

The Model 660 Differential Voltmeter measures voltage by the

The ultra-stable SOO-volt reference voltage supply

(see Figure 9) is used with the 5-dial Kelvin-Varley divider to null the

unknown voltage.

voltage is indicated by the null detector

The difference between the divider output and the unknown

- a chopper-stabilized vacuumtube voltmeter. At null the unknavn voltage equals the reference voltage

and can be directly read from the five in-line dials of the Kelvin-Varley

divider.

The input and null detector are fully guarded to avoid leakage.

NOTE

The circuit designations referred to in the following paragraphs are

for the schematic diagram 15199B found at the back of this manual.

INPUT

TERMINALS

GUARDED

NULL

DETECTOR

KELVIN.VARLEY

DIVIDER

I

REFERENCE

VOLYAGE

SUPPLY

1

5DDv

SUPPLY

Gin

“lll”l”Cl

l-l

LO 0

FIGURE 9.

I I

1 1

Simplified Circuit Diagram of the Model 660.

I

3-2. REFERENCE POWER SUPPLY.

a. Unregulated voltage from the transformer T3001 is rectified by a sili-

con half-wave rectifier, D3004, and is filtered by capacitors C3003, C3004

and C3005. The voltage then is applied to the preregulator series pass tube,

v3005.

The output voltage of V3005 is regulated by comparing a sample voltage

b.

from divider string, R3015, R3016 and R3017, to the reference, regulator tube

v3007.

The difference between the two potentials is amplified by V3006. The

amplifier output drives the grid of V3005 in the proper phase to nullify input variations. The ac feedback loop, containing capacitor C3007, is used

for better high frequency and transient response.

0664R

15

Page 20

CIRCUIT DESCRIPTION

c.. The regulated output of V3005 is applied to the second series tube,

V3004, for final regulation, To obtain a stable, accurate voltage, the SOO-volt

output of V3004 is sampled by a divider network of wirewound resistors, R3034,

R3036, R3037, R3049 and 83050.

tentiometer R3035 to better than 0.01%.

sample voltage from the divider network to the voltage across the ultra-stable

zener diode, D3009. Any difference between the sampled voltage and the

voltage of D3009 is chopped by E3002 and amplified by a two-stage ac-coupled

amplifier, V3001.

by light modulator, E3001, and then is amplified by the two-stage differential dc amplifier, V3002 and V3003.

grid of the series tube, V3004, in the.proper phase to nullify input variations. Capacitor C3009 is used in the ac feedback circuit,

The temperature-compensated zener diode, D3009, was used as the circuit's

d.

basic reference since typical variations are limited to less than 20 ppm per

year and 5 ppm per 'C. Thus, a highly stable reference is provided with re-

spect to both time and temperature. The sener diode will also withstand extre-

me shock and vibration.

e. The regulated 500 volts from V3004 either is applied directly to the

Kelvin-Varley divider or it is divided to 50, 5, or 0.5 volts by very stable

wirewound resistor networks. The RANGE Switch, S3002, determines which network is used. The 50-volt range divider network consists of R3040, R3041 and

R3042; the 5-volt, of R3040, R3044 and R3045; and the 0.5-volt, of R3040,

R3047 and R3048.

set the voltage division on each range.

The amplified output of V3001 is converted to a dc signal

Potentiometers R3041, R3044 and R3047 are used to accurately

The divider network ratio is adjusted with po-

The amplifier output is applied to the

MODEL 660 DIFFERENTIAL VOLTMETER

Light modulator E3002 compares the

3-3.

nulling an unknown voltage. It is, in effect, a constant input impedance

decade potentiometer consisting of resistors R3051 through R3099.

within each decade are matched; the decades are matched for each instrument.

through R3056, parallels two resistors of the preceeding string.

two contacts of the first Reference Voltage Switch, 53003, the total resis-

tance is 40 kilohms (80 kilohms in parallel with the 80 kilohms total resistance of the four remaining strings).

volts dc will appear across the contacts of Reference Voltage Switches S3004,

10 volts across S3005, 1 volt across S3006, and 0.1 volt across S3007.

3-4.

amplifier.

two-stage R-C filter. The signal is then amplified and measured by the null

detector meter.

1 and 10 millivolts. Above the lo-millivolt range, the input is divided by

resistorsR1002 through R1007 to the lo-millivolt level.

sensitivities are determined by which of three feedback resistors, R1037,

R1038 or R1039, is in the circuit.

KELVIN-VARLEY DIVIDER.

The Kelvin-Varley divider precisely divides the reference voltage for

a.

The resistors

Each decade of the Kelvin-Varley divider, except the first, R3051,

b.

Between the

With the RANGE Switch set at 500, 100

NULL DETECTOR.

a. The Model 660 uses a null detector with a chopper stabilized, feedback

The input signal is attenuated, if necessary, and sent through a

The null detector has basically three full-scale sensitivities, 0.1,

b.

The full-scale

A two-stage R-C filter, consisting of

16

0664R

Page 21

MODEL 660 DIFFERENTIAL VOLTMETER

CIRCUIT DESCRIPTION

R1008, ClOOl, R1009 and C1002, is used to decrease the ac input components.

The input filter attenuation ratio is 35db at 60 cps. The light modulators

are driven by a 42-cps multi-vibrator. Using a drive source harmonically

unrelated to the standard line frequency minimizes 60-cps pickup effects.

c. The light modulators El001 and El002 convert the difference between

the filtered input voltage and the output of the Kelvin-Varley divider into

an ac voltage, which is fed,to a four-stage ac coupled amplifier, VlOOl and

v1002. The output of the amplifier is then demodulated by light modulator

El003 and applied to an R-C filter, R1034 and C1017. The null detector meter,

MlOOl, indicates the value of the filtered signal.

One arm of the feedback network is formed by resistors R1043, R1040,

d.

R1041, R1042 and one of the feedback range resistors, R1037, R1038 or Rl039.

Resistor R1036 forms the second shunt arm. The feedback is applied to light

modulator E1002. The low end of Cl001 is also returned to the feedback point

for faster speed of response.

e. A zero-control network is across resistor R1009 to buck out thermal

emf's at the input on the two most sensitive ranges.

The network consists of

a 1.32-volt mercury battery, BTlOOl, and resistors RlOlO through R1013.

The zero control on the front panel, R1013, has approximately a lOO-microvolt

span.

The null detector output is obtained across resistors R1040 and R1043,

f.

which are in the feedback network. Potentiometer R1043 adjusts the output

from 10 to 25 millivolts at full scale. The output voltage is proportional

to the full-scale meter reading.

3-5.

GUARDING.

Guarding is accomplished by floating the null detector and

the input circuitry at a voltage equal to the input voltage from a low impe-

dance source.

This full guarding eliminates leakage between the input ter-

minal and ground. Such leakage in an unguarded circuit is difficult to avoid,

even under laboratory conditions, and can result in sizeable errors.

For

example, in an unguarded circuit with a 1-megohm source, leakage of 108 ohms

will introduce 0.1% error.

error.

The effectiveness of guarding in the Model 660 is demonstrated by

A guarded circuit eliminates this element of

setting the null detector on the O.l-millivolt range, with the input circuit

open, and the Reference Voltage Dials set to 500 volts,

condition there is no deflection on the meter,

demonstrating there is no leakage.

Even at this extreme

0664R

17

Page 22

MODEL 660 DIFFERENTIAL VOLTMETER

SECTION 4. MAINTENANCE

4-l. GRNBRAL.

I'lAINTBIiANCE

a. Section 4 contains the maintenance,

procedures for the Model 66b. It is recoannended that these procedures be

followed as closely as possible to maintain the accuracy and stability of

the instrument.

The Model 660 needs no periodic maintenance beyond the normal care re-

b.

quired of high-quality electronic equipment.

limit of error should show if adjustments or calibration are needed.

4-2.

the electrical components in the Model 660. Replace components only as nec-

essary, and use only reliable replacements which meet the specifications.

Replace the resistors in the Kelvin-Varley divider, switches S3004 through

53007, only with Keithley matched resistors.

4-3.

which might occur in the Model 660.

and use only specified replacement parts. Table 3 lists equipment recormaended

for troubleshooting. If the trouble cannot be readily located

contact Keithley Instruments or its representatives.

proceeding with the troubleshooting, check the vacuum tubes in the instru-

ment. Normally, replacing tubes will clear up the difficulty.' All tubes

can be readily tested on a grid-modulated tube tester. If replacing a tube

does not correct the trouble, continue the procedures. Replacing tubes does

not necessitate recalibration of the instrument.

PARTS PBPLACKMENT.

TROUBLRSHOOTING.

a. The following procedures give instructions for repairing troubles

Paragraph 2-12 describes how to remove the Model 660 cover. Before

b.

The Replaceable Parts List is Section 5 describes

Use these procedures to troubleshoot

troubleshooting and calibration

Occasional verification of the

or

repaired,

Table 4 contains the more common troubles which might occur with the

c.

instrument,

the difficulty will have to be found through a point-by-point check of the

circuits. Refer to the circuit description in Section 3 to find the more

crucial components and to determine their function in the circuit. The complete circuit schematic, Diagram 15199H, is found in Section 5.

Keithley Model 503 Milliobnrneter Ohsureter for resistors less than 1 Icn

Keithley Model 610A Electrometer

Keithley Model 662 Guarded dc

Differential Voltmeter Test Kelvin-Varley divider resistors

Grid-modulated tube tester Test vacuum tubes

TABLE 3.

Use these instruments or their equivalents.

0664R

If the repairs indicated in the table do not clear up the trouble,

Instrument

DC voltmeter and ohnxneter

Equipment Recommended for Troubleshooting Model 660.

Use

19

Page 23

MAINTENANCE

MODEL 660 DIFFERENTIAL VOLTMETER

0664R

Page 24

MODEL 660 DIFFERENTIAL VOLTMETER

MAINTENANCE

0664R

21

Page 25

MODEL 660 DIFFERENTIAL VOLTMETER

4-4. ADJUSTMENT OF RuM BALANCING CONTROLS.

a. Adjusting Trimmer C1018.

Trimmer Cl018 nulls out residual ac components in the power transformer,

1.

T3001.

If this adjustment is not properly set, null sensitivity decreases.

on the O.l-millivolt null range, however, it is normal to have a maximm

sensitivity of 62% of full scale when the Reference Voltage Dials are set near

25000.

This is due to the loading of the null detector by the Kelvin-Varley

divider (paragraph 2-8).

FIGURE 10.

Attaching Oscilloscope Leads for Adjusting Trinnner. The oscillo-

scope is attached to the LC input terminal and the guard circuit.

2. To adjust the trinuser,

remcve the bottom ccver and attach an oscillo-

scope between the I.0 input terminal and the guard circuit (see Figure 10).

With the Reference Voltage Dials set for either 24545 or 25455, the wave

form should be similar to that shown in Figure 11. Adjust trinnner Cl018

(Figure 19) until the wave form is correct.

NOTE

Trimmer Cl018 and resistor R1045 are normally used in each instrument.

In scme instruments, however, component parameters

are

such that this

adjustment is unnecessary and Cl018 and R1045 are disconnected et

manufacture.

22

0664R

Page 26

MODEL 660 DIFFERENTIAL VOLTMETER MAINTENANCE

Q

FIGURE 11. Wave Forms for Adjusting Trimmer.

The wave form with Cl018

b

properly adjusted is shown in (a). The wave form with trimmer misadjusted

is shown in (b).

A Tektronix Type 503 Oscilloscope was used; horizontal

sweep was 20 mseclcm; vertical, 10 mvlcm.

Adjusting HUM BAL Potentiometer R1046.

b.

Potentiometer R1046 minimizes 60-cps pickup in the null detector.

1.

Misadjustment will reduce sensitivity and cause needle quiver.

To adjust the potentiometer,

2.

zero and short the input terminals.

set the Reference Voltage Dials to

Attach an oscilloscope to the junction

of capacitor Cl014 and resistor R1034 (from-pin 6 of V1002). Figure 12

shows the wave form if potentiometer R1046 is adjusted for minimum output.

FIGURE

Type 50

20 msec

4-5.

prw=ly ,

1

,:

ZENER CURRENT TEST.

When the reference voltage supply is operating

the zensr current will be 10 milliamperes and the voltage across

R3031 should be 100 millivolts.

0664R

ronix

1aaS

7.3

Page 27

MAINTENANCE

MODEL 660 DIFFERENTIAL VOLTMETER

4-6. CALIBRATION PROCEDURES.

a. The following procedures are recommended for calibrating the Model 660.

Use the equipment reconrmended in Table 5. If proper facilities - especially

important for calibrating an T0.02% instrument - are

difficulty is encountered,

contact Keithley Instruments or its representatives

not

available or if

to arrange for factory calibration.

Three procedures are covered:

b.

Kelvin-Varley divider verification, voltage

range calibration, and reference voltage supply stability test.

c. If the Model 660 is not within specifications after the calibrations,

follow the troubleshooting procedures or contact Keithley Instruments or its

representatives.

Instrument

Electra Scientific Industries Model

Range Voltage Calibrator

Use

SV-194B Voltage Calibrator, ?-0.005%

accuracy with corrections on certificate

Electra Scientific Industries Model

RV-722 Kelvin-Varley Divider, linearity:

Voltage divider for range calibration

settings of 0.1 to 1, Certificate Cor-

rected to r0.2 ppm

Keithley Instruments Model 150A Micro-

voltmeter

Keithley Instruments Model 241 Regulated

High Voltage Supply

Null detector for range calibration

Power supply for range calibration

Keithley Instruments Model 662 Guarded

DC Differential Voltmeter

Mosley Instruments Model 680 Direct

Reading Recorder

Weston Instruments Model 3 Type 7

Saturated Standard Cell

Weston Instruments Model 66 Oil Bath

Check voltages in Kelvin-Varley

divider

Recorder for reference voltage

supply stability

Range calibration and reference

voltage supply stability

Range calibration and reference

voltage supply stability

TABLE 5.

Recommended Equipment for Model 660 Calibration. Use these

instruments or their equivalents.

4-7.

KELVIN-VARLEY DIVIDER VERIFICATION.

a. There is no in-field calibration for the Kelvin-Varley divider; its accuracy

can only be verified.

switches.

At manufacture,

The divider accuracy depends upon matching resistors and

each resistor within the first two Reference Voltage

switches, S3003 and S3004, is matched to 20.005%. The resistors in the switches

are checked as a set to an accuracy of better than 0.005%.

Individual resistors

24

0664R

Page 28

MODEL 660 DIFFERENTIAL VOLTMETER

cannot be replaced without rematching the entire divider deck.

Kelvin-Varley Divider Accuracy Verification Procedures.

b.

Use the Model 662 Differential Voltmeter or equipment with better

1.

limit of error to match

the

Model 660 under test. Connect the wiper arm

of Switch 53007 of the instrument under test to the HI terminal of the

Model 662.

Connect both M terminals.

NOTE

Be careful of high voltages when working within the Model 660.

Up to 900 volts dc is present at various points.

MAINTENANCE

Set the dials to random settings on both instruments.

2.

should match to +0.02%.

Kelvin-Varley divider accuracy.

This procedure, however, only indicates the

The errors of the two instruments may

be additive, causing a false verification.

The Most accurate way is to

Settings

use standard procedures for checking a Kelvin-Varley divider or to return

the Model 660 to the factory.

If any resistor fails to test out,

3.

the entire divider string will

have to be rematched.

4-8.

RANGE CALIBRATION.

a. The reference voltage supply has a 500-volt output which can be attenuated to 50, 5 or 0.5 volts.

Varley divider to provide the accurate buckout voltage.

This voltage is then divided by the Kelvin-

Each of the four

voltage ranges is set by internally adjusting potentiometers R3035, R3041,

R3044 and R3048 (Figure 15).

The ranges are calibrated by applying an accurate voltage to the

b.

Model 660 for each setting of the RANGE Switch.

furnish the equivalent buckout voltage,

and the internal range potentiometer

The Model 660 is set to

is adjusted until the voltmeter indicates a null.

The accuracy of the ModeL 660 calibration will be no greater than

the accuracy of the voltage

source

used for calibrating.

Unless

the user is familiar with techniques for obtaining greater accuracy

than 0.01% (100 ppm),

it is better to return the Model 660 to the

factory for range calibration.

The most critical part in range calibration is establishing a reference

s&ce whose accuracy exceeds 0.01%.

for the 500, 50, 5 and 0.5-volt outputs.

Use the Model SV-194B Voltage Calibrator

Establish the accuracy of these

outputs by determining the corrections for the calibrator's CALIBRATION and

OUTPUT dials at these outputs.

The system's accuracy can be determined to

approximately 10 ppm. Added to the accuracy of the standard cell, total

accuracy should be approximately 20 ppm.

Note, this will depend upon

properly executed procedures.

0664R

25

Page 29

Procedures to Establish System Accuracy.

d.

MODEL 660 DIFFERENTIAL VOLTMETER

Set up the system shown in Figure 13.

1.

only the 0.5 and 5-volt outputs.

Have the Model SV-194B certified by the

Use the 9.9-megohm extender for

manufacturer to accuracy.

Establish the corrections for the CALIBRATION dial setting for Model

2.

SV-194B outputs of 500, 50, 5 and 0.5 volts.

the Model 241 which is 0.05% accurate) to 500 volts.

Set the Power Supply (preferably,

Set the Kelvin-Varley

Divider to a voltage equal to that of the standard cell. Adjust the Model

SV-194B ratio dial until the Null Detector indicates a null.

The difference

between the settings of the Kelvin-Varley Divider and the ratio dial is the

Model SV-194B correction factor at 500 volts,

With this correction, the 500

volts may be set to within 20 ppm.

Connect the Null Detector to the 50, 5 and 0.5-volt taps of the Model

3.

SV-194B Calibrator in that order.

ponding voltages.

Use the 9.9 megohm extender for the 5 and 0.5-volt outputs.

Set the Kelvin-Varley Divider to corres-

(See Figure 13.) The difference read on the Null Detector is the correction

factor for each of the three voltages.

These voltages may also be set to

within 20 ppm.

Use the four correction factors for calibrating the Model 660 range

4.

settings.

FIGURE 13.

ibration.

Block Diagram to Establish System Accuracy for Model 660 Range Cal-

Fully guard the entire system to prevent leakage errors.

1-kilohm copper resistor to shunt the Null Detector.

ded equipment.

26

Use a

See Table 5 for recosssen-

0664R

Page 30

MODEL 660 DIFFERENTIAL VOLTMETER MAINTENANCE

FIGURE 14.

Block Diagram for Model 660 Range Calibration. Fully guard entire

system to prevent leakage errors. See Table 5 for recomended equipment.

Procedures for Range Calibration.

e.

Set up the system shown in Figure 14. The standard cell should be

1.

certified to 10 ppm.

Use the dial correction factors found for each output.

If the system accuracy was properly determined, the input voltage to the

Model 660 should be correct to 20 ppm.

2. 500-volt Range Calibration: Set the Model 660 as follows:

RANGE 500

Reference Voltage Dials 499.9=

NDlL VTVM

POLARITY +

Adjust the Voltage Calibrator to apply 500 volts dc to the Model 660. Turn

the Model 660 NULL Switch to 10 MV and adjust the 500 V CAL potentiometer

R3035 (Figure 15) for null on the Model 660.

50-Volt Ranee Calibration: Set the Model 660 as follows:

3.

RANGE

Reference Voltage Dials :;.99E

NULL

POLARITY

10 MV

+

Adjust the Voltage Calibrator to apply 50 volts dc to the Model 660.

Adjust the 50 V CAL potentiometer R3041 (Figure 15) for an off-null read-

ing on the Model 660 equal to the correction factor at 50 volts.

0664R

27

Page 31

MAINTENANCE

BBIDEZ 660 DIFPERENTIAL VOLTMETER

4. S-Volt Range Calibration: Set the Model 660 as follows:

RANGE 5

Reference Voltage Dials 4.999E

NULL 1MV

POLARITY +

Adjust the Voltage Calibrator to apply 5 volts dc to the Model 660. Adjust

the 5 V CAL potentiometer R3044 (Figure 15) for an off-null reading on the

Model 660 equal to the correction factor at 5 volts.

0.5-Volt Range Calibration: Set the Model 660 as follows:

5.

RANGE

0.5

Reference Voltage Dials .49995

NULL

0.1 Mv

POLARITY +

Adjust the Voltage Calibrator to apply 0.5 volt dc to the Model 660. Adjust

the 0.5 V CAL potentiometer R3047 (Figure 15) for an off-null reading on the

Model 660 equal to the correction factor at 0.5 volt.

-

._

28

FIGURE 15. Model 660 Internal Controls. (Top View.)

0664R

Page 32

MODEL 660 DIFFERENTIAL VOLTMETW

Model 660

Reference

Voltage

SUPPlY

---------‘I

MAINTENANCE

9

Recorder

- I

L

T

--------mm---?

- ,

1

FIGURE 16.

Circuit Diagram for Reference Voltage Supply Stability Test. The

voltage across the 250-ohm resistor is slightly higher than the standard cell.

Use the lo-kilobm potentiometer to shunt the divider voltage down. All re-

sistors are wirewound. See Table 5 for recommended equipment.

4-9.

RRFRRENCE VOLTAGE SUPPLY STABILITY TEST.

The reference voltage supply,

a.

consisting of the power transformer, the

main supply (printed circuit PC55), and the reference section (printed circuit

PC61), is factory calibrated for an output of 500 volts dc r.O05%.

Its sta-

bility is ?0.005% indefinitely after a l-hour warm-up. The 500-volt output

is adjustable to meet specifications.

If the stability of the supply is not

within specifications, then troubleshooting for a faulty component or replacing the supply is probably required.

Routine calibration of the Model 660 does not require a stability test

b.

of the reference voltage supply. However, a stability test is recmended if

one of the components in the.supply is replaced.

For the 24-hour test, the 500-volt output of the reference voltage

c.

supply is divided and compared to a 1.02-volt saturated standard cell using

a sensitive null detector.

Variations between the reference voltage supply

and the standard cell are detected by the Model 150A and are recorded on a

recorder.

Refer to Figure 16 for the block diagram of the test circuit.

J

In using the test circuit,

d.

Saturated standard cells,

1.

the following points are important.

though extremely stable with time, have a

high temperature coefficient and require a controlled environment during use.

Therefore, the Weston Oil Bath, which is maintained at +35OC ti.05°C, is

used for the test. Unsaturated standard cells have a lower temperature

coefficient, but they do not have the long term stability required for this

test.

0664R

29

Page 33

MAINTENANCE

The resistor divider network is constructed from wire of the same

2.

MODRL 660 DIFFERENTIAL VOLTMETER

spool for an extremely close temperature coefficient match (4 ppm, typically).

Additional stability results when the resistors are inssersed in an oil bath

to hold the ambient temperature variations to ?O.Ol%.

e. Procedures for the Reference Voltage Supply Stability Test.

After the saturated standard cell and the resistor divider network are

1.

placed in the oil bath and connected to the circuit, allow sufficient time

for the cell to stabilize at +35oC.

(Consult Keithley Instruments for details.)

Set the Model 660 controls as follows:

RANGE

500

Reference Voltage Dials 499.910

NULL

POLARITY

10 MV

OFF

Connect the resistor divider network across the Model 660's reference voltage

supply,

the positive side of the divider input to the wiper arm of the last

Reference Voltage Switch, 53007, and the negative side of the divider to the

LO terminal on the Model 660 front panel.

Connect the Model 150A and the recorder as shown in Figure 16.

2.

Model 150A to the 3-volt range.

Advance the Model 660 POLARITY Switch to +

to put 500 volts across the divider.

If the Model 150A reads two volts, the

Set the

standard cell and the divider voltages are improperly connected in series.

If the circuit is correct,

Model 150A's sensitivity to the O.l-millivolt range.

20 microvolts,

adjust the lo-kilohm potentiometer shunting the divider.

the Model 150A will read zero.

If it reads more than

Increase the

NOTE

Any adjustment of potentiometer R3035 requires all other ranges

be calibrated.

After a l-hour warm-up,

3.

the drift of the entire system should not exceed

r50 microvolts in 24 hours (Figure 17).

FIGDRF, 17.

chart covers

Stability Strip Chart for Model 660 Reference Voltage Supply. The

over

15 hours.

is non-cumulative.

conditions was made.

30

Fluctuations are well within ?O.OOS%. Note drift

No compensation for variations of line voltage or other

0664R

Page 34

MODEL 660 DIFFERENTIAL VOLTMETER

MAINTENANCE

FIGURE 18. Top View of Model 660 Chassis.

printed circuits is shown above.

0664R

Refer to Parts List for circuit designations.

Location of components and

31

Page 35

MAINTENANCE

MODEL 660 DIFFERENXAL VOLTMETER

FIGURE 19.

shown in the figure.

32

Bottom View of Model 660 Chassis.

Location of components is

Refer to Parts List for circuit dhsignations.

0664R

Page 36

MODEL 660 DIFFERENTIAL VOLTMETER

MAINTENANCE

FIGURE 20. Resistor Locations on Printed Circuit 54. Other components

are shown in Figure 21.

Refer to Parts List for circuit designations,

FIGURE 21.

Battery, Capacitor, Modulator,

Printed Circuit 54.

0664R

Diode and Tube Locations on

Resistors are shown in Figure 20.

33

Page 37

MAINTENANCE

MODEL 660 DIFFF&ENTlAL VOLTMETER

FIGURE 22.

Resistor Locations on Printed CFrcuFt 55. Other components are

shown in Figure, 23.

FIGURE 23. Capacitor, Modulator, Diode and Tube Locations on Printed Circuit

Resistors are shown in Figure 22.

55.

34

0664R

Page 38

MODEL 660 DIFFERENTIAL VOLTMETER

MAINTENANCE

FIGURE 24.

Resistor Locations on Printed Circuit 36.

Resistor R1049 is not used in the Model 660.

E3 02

P

0664R

FIGURE 25. Component Locations on Printed Circuit 61.

The values of resistors R3049 and R3050 are determined

at factory calibration.

35

Page 39

MAINTENANCE

MODEL 660 DIFFERENTIAL VOLTMETER

36

FIGURE 26.

Model 66Ol.A Component Locations.

0664R

Page 40

MODEL 660 DIFFERENTIAL VOLTMETER REPLACEABLE PARTS

SECTION 5.

5-1. REPLACEABLE PARTS LIST.

ppnents of the Models 660 and 660%

The Replaceable Parts List describes the com-

REPLACEABLE PART5

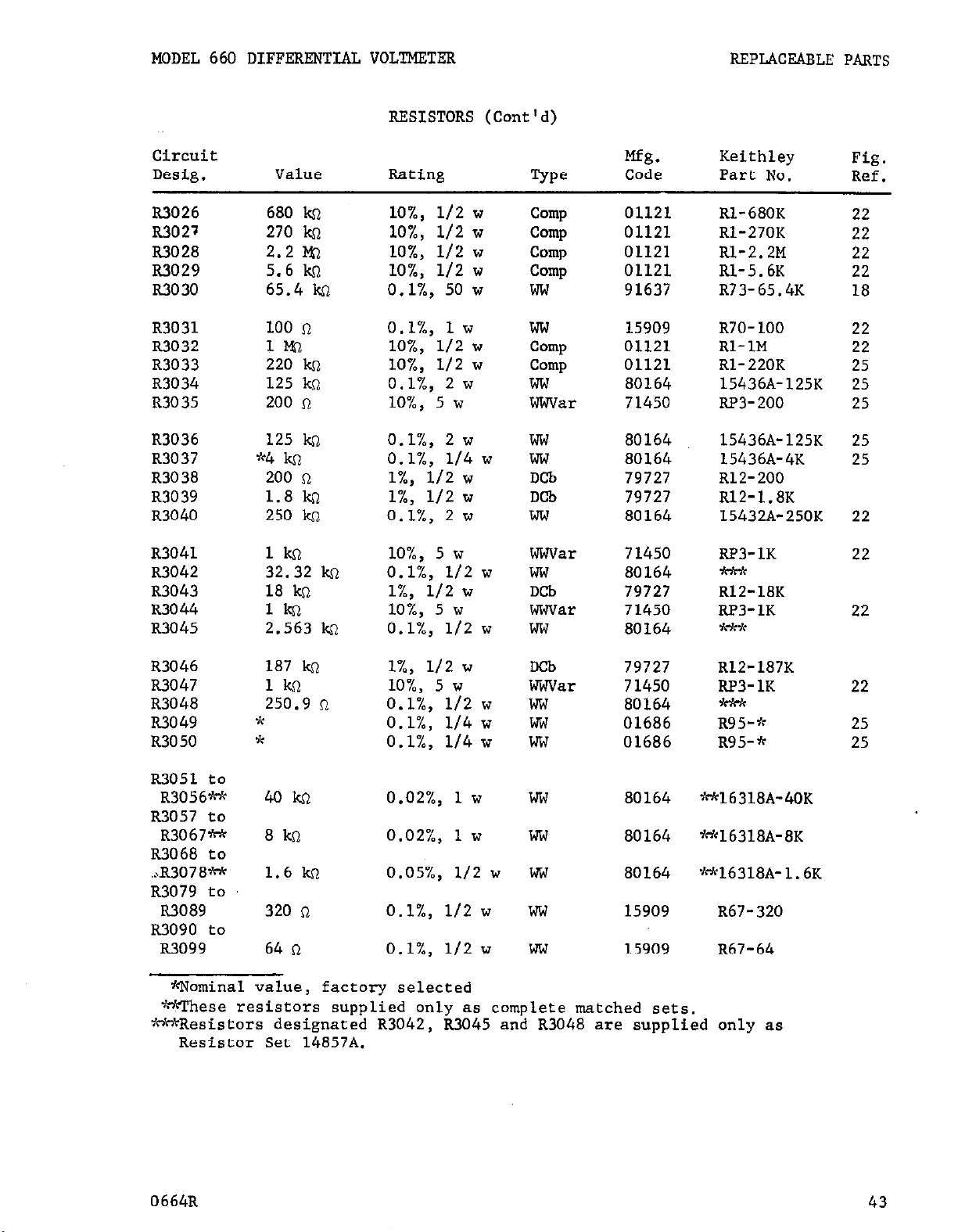

The List gives the circuit designation,

the part description, a suggested manufacturer and the Keithley Part Number.

The last column indicates the figure picturing the part. The name and address of the manufacturers listed in the "Mfg. Code" colunm are contained in

Table 7.

5-2.

HOW TO ORDER PARTS.

a. For parts orders,

include the instrument's model and serial number, the

Keithley Part Number, the circuit designation and a description of the part.

All structural parts and those parts coded for Keithley manufacture (80164)

must be ordered from Keithley Instruments, Inc.

In ordering a part not

listed in the Replaceable Parts List, completely describe the part, its

function and its location.

Order parts through your nearest Keithley distributor or the Sales

b.

Service Department, Keithley Instruments, Inc.

amP

CbVar

CerD

camp

DCb

EMC

ETB

El!T

f

k

M or meg

kg.

ampere MtF Metal Film

Carbon Variable

Ceramic, Disc

Mil. No.

KY

Military Type Numbe

Mylar

Composition

n

ohm

Deposited Carbon

Poly Polystyrene

Electrolytic, metal cased

P

pi.20 (10-q

Electrolytic, tubular

Electrolytic, tantalum

w

farad v

micro

volt

(10-6)

Var Variable

kilo (103)

w

mega (106) or megohms

ww

milli (10-3) WWVar

watt

Wirewound

Wirewound Variable

Manufacturer

TABLE 6. Abbreviations and Symbols.

0664R

37

Page 41

REPLACEABLE PART8

(Refer to Schematic Diagram 15199B for circuit designations)

MODEL 660 DIFFEWNTIAL VOLTMETER

MODEL 660 REPLACEABLE PARTS LIST

CAPACITORS

Circuit

Desig. Value Rating

CL001

Cl002

Cl003

Cl004

CL005

CL006

Cl007

Cl008

Cl009

Cl010

Cl011

Cl012

CL013

Cl014

Cl015

Cl016

CL017

Cl018

1.0 pf

1.0 pf

.05 pf

80 vf

200 IJ.f

LO pf

.l pf

.05 pf

40/?0 IJ.f

.047 pf

.002 pf

10 pf

.1 Pf

.25 pf

100 pf

4 wf

560 pf

1.517 pf

600 v

600 v MtF 13050

600 v

350 v

3v

15 " ETB

600 v MtF 02777

600 v

450 v

1000 v Poly 96733

600 v CerD

15 v ETB

600 v

400 v MtF 13050 C73-.25M

15 v ETB

250 v EMC

6v

500 v Trimer

Mfg.

Vr=

Code Part No. Ref.

MtF 13050

Keithley

C12-L.OM 21

C12-L.OM 21

MY

56289

EMC 53021

F&K

14655 C48-200M 21

56289

C62-.05M

C32-80M 21

C3-10M 21

C47-O.LM 21

MY

56289 C62-.05M 21

ENC 56289 C36-40/20M

C67-.047M 19

72982

C22-.002M 21

56289 C3-10M

MtF 02777

C47-O.lM 21

56289 C3-LOOM

14655

C27-4M

ETT 12065 C95-560M

71590 C76-1.5/7P

Fig.

21

21

21

21

21

21

21

19

CZOOL

c2002

C2003

c3001

C3002

c3003

c3004

c3005

C3006

c3007

C3008

c3009

c3010

C3OLL

C3012

c3013

c3014

c3015

Not Used

.022 pf

.022 I.rf

.OOL pf

1000 iJ.f

20 pf

20 pf

20140 pf

330 pf

.Ol pf

.OL pf

1.0 pf

.05 I.lf

4 Ilf

50 pf

.0047 pf

.022 pf

.05 pf

400 "

MtF

13050 C73-.022M

400 v MtF 13050 c73-,022M

600 v

15 "

CerD 72982

EMC 56289 C4-1000M

450 v EMC 37942

C22-.OOlM

C36-20M 23

450 v JIMC 37942 C36-20M

450 v RMC 56289

600 v

2000 v

600 v

1000 v

600 v

250 v

6v

600 v

200 v

1600 v

CerD

CerD

CerD

MtF

MY

EMC

EMC

CerD

MtF

MY

72982

56289 C88-.OIM

72982

13050 C14-l.OM

56289

14655 C27-4M

56289 C17-50M

01121 C22-.0047M

13050 C6-.022M

14655

C36-40/20M

C22-330P

C22-.OlM

C62-.

05M

C87-.OSM 19

23

23

19

23

23

23

23

23

23

23

23

23

23

23

25

38

0664R

Page 42

MODEL 660 DIFFERENTIAL VOLTMETER REPLACEABLE PARTS

DIODES

Circuit

Desig.

DlOOl

D1002

D1003

D1004

D3001

D3002

D3003

D3004

D3005

D3006

D3007

D3008

D3009

Circuit

Desig.

BTlOOl

Mfg.

Type

Not Used

Not Used

Silicon lN645 01295

Silicon

Silicon

Not Used

Not Used

Silicon lN2378 08520 RF-25

Silicon

Silicon

Silicon

Zener lN1601

Zener

Description

Battery, 1.32~volt Mercury (Mfg.

No. PK13T2)

Number

lN645

lN3256 02735

lN3256 02735 RF-22

lN1563A 04713 RF-19

lN1563A 04713 RF-19

63440 81483 DZ-8

MISCELLANEOUS PARTS

Code

01295 RF-14

81483

Keithley

Part No.

RF-14

RF-22

DZ-9

Mfg.

Code Part No. Ref.

37942

Keithley

BA-12

Fig.

Ref.

21

21

21

23

23

23

23

23

25

Fig.

21

DS2001

DS2002

DS2003

DS2004

El001

El002

El003

E3001

E3002

FL001 (117~)

FlOOl (234~)

---

JlOOl

51002

51003

51004

---

---

Neon Pilot Light (Mfg. No. NE-2P)

Neon Pilot Light (Mfg. No. NE-2P)

Neon Pilot Light (Mfg. No. NE-2P) 08804

Neon Pilot Light (Mfg. No. NE-2P)

Light Modulator

Light Modulator

Light Modulator

Light Modulator

Light Modulatdr

Fuse, 1.0 amp, 3 AG (Mfg. No. MDL)

Fuse, 0.5 amp, 3 AG (Mfg. No. MDL)

Fuse Holder (Mfg. No. 34201)

Binding Post, HI (Mfg. No. DF31RC)

Binding Post, LO (Mfg. No. DF3LBC)

Binding Post, LCI (Mfg. No. DF31BC)

Binding Post, GND (Mfg. No. DF3LBC)

Shorting Link (Mfg. No. 938-L)

Banana Jack, Red, NULL DETECTOR OUT-

PUT (Mfg. No. 108-745-l) 74970

08804

08804

08804

80164

80164

80164

80164

80164

71400

71400

75915

58474

58474

58474

58474

24655

PL-2

PL-2

PL-2

PL-2

1510

1510

1511

1510

1510

FU-10

FU-6

FH-3

BP-8R

BP-8~

BP-8B

BP-8B

BP-6

BJ-3

21

21

21

23

25

3

3

2

2

2

2

3

0664R

Page 43

PLACEABLE PARTS

MODEL 660 DIFFERENTIAL VOIXMFXER

MISCELLANEOUS PARTS (Cont'd)

Circuit

Desig.

Ml001

PlOOl

-__

SlOOL

e-m

--_

53001

w-m

_--

53002

m-m

m-m-s

Description

Banana Jack, Black, NULL DETECTOR OUTPUT

(Mfg. No. 108-745-2)

Meter

Line Cord (Mfg. No. 4638-13)

Clamp

Rotary Switch, Assembly less components,

MTLL

Switch Assembly with components, NULL

Skirted Knob Assembly, Null Switch

Rotary Switch less components, POLARITY

Switch Assembly with components, POLARITY

Skirted Knob Assembly, Polarity Switch

Rotary Switch less components, RANGE

Switch Assembly with components, RANGE

Skirted Knob Assembly, Range Switch

Skirted Knob Assembly, Meter Zero Po-

tentiometer

Mfg.

Code Part No. Ref.

74970

80164 ME-38

82879

80164

80164

80164 15136B

80164

80164 SW-119

80164 15138B

80164 148388

80164 SW-116

80164 L5137B

80164 14838A

80164

Keithley Fig.

BJ-4

co-2.

cc-7

L5135B

15LLOA

14838A

3

18

3

19

19

19

s3003

_-m

53004

---

s3005

---

53006

-em

s3007

-em

T3001

Circuit

Desig.

RlOOl 10 m-l L%, l/2 w Dch 79727 R12-10M 24

R1002 1.25 m l%, l/2 w MtF 75042 R61-1.25M 24

RL003 100 kn l%, 7 w w 91637 R43-1OOK 24

R1004 9010 n L%, l/2 w DCb 79727 Rl2-9010 24

R1005 93 kl l%, l/2 w DCb 79727 RL2-93K 24

Switch Assembly with components, Readout

Dial Assembly, O-4 Readout

Switch Assembly with components, Readout

Dial Assembly, O-9 Readout

Switch Assembly with components, Readout

Dial Assembly, O-9 Readout

Switch Assembly with components, Readout

Dial Assembly, O-9 Readout 80164

Switch Assembly with components, Readout

Dial Assembly, O-10 Readout

Transformer

RESISTORS

Value Rating

5w

80164

80164

80164

80164

80164

80164

80164

80164

80164

80164

Mfg.

Code

14869B

14827A

15114B

148288

15112B

148288

15111B

14828A

15115B

14829A

TR-50

Keithley

Part No.

2

2

2

2

2

18

Fig.

Ref.

40

0664R

Page 44

MODEL 660 DIFFERENTIAL VOLTMETER REPLACEABLE PARTS

RESISTORS (Cont'd)

Circuit

De&g. Value

R1006

1.11 m

R1007

RlOO8

R1009

RlOlO

RlOll

R1012

R1013

R1014

R1015

R1016

R1017

R1018

R1019

R1020

R1021

R1022

R1023

R1024

R1025

:0E.Q

100 kQ

5krl

5kI-l

5m

10 kfl

1M-l

lItI

10 kfl

1.5 wl

330

kc?

1.5

m

15

ko

10 m

100 kG

woo krl

"Cl l$l

Not Used

Rating

l%, l/2 w

l%, l/2 w

lO%, l/2 w

lO%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

lO%, 2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

l%, l/2 w

l%, l/2 w

Keithley

Type

DCb

Mfg.

Code Part No.

79727 R12-l.llM

DCb 79727 R12-1K

camp 01121 Rl-100K

COmp

DCb

01121 Rl-100K

79727

R12-5K

DCb 79727 R12-5K

DCb 79727 R12-5M

Fig.

Ref.

24

24

20

20

20

20

20

WWVar 12697 RP27B-10K 19

camp 01121 Rl-1M

ComP

camp 01121

camp

01121 Rl-1M

Rl-1OK

75042

R61-1.5M

camp 01121 Rl-330K

COW

COmp

01121 Rl-1.5M

01121 Rl-15K

camp 01121 Rl-1OM

camp 01121 Rl-100K

DCb

DCb

79727

79727 R12-1M

R12-100K

20

20

20

20

20

20

20

20

20

24

24

R1026

R1027

R1028

R1029

R1030

R1031

R1032

R1033

R1034

R1035

R1036

R1037

R1038

R1039

R1040

R1041

R1042

R1043

R1044

R1045

10 M

8.2

ko

1.5

m-l

IN-2

3.3

M

1.2

k.0.

100 ko

220

kri

6.8

kn

1kIl

2&l

*40

ko

*400 kn

4m

80

R

500

R

1.5

kfl

200

0

10 k-i

*10 M

lO%, l/2 "

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

lo%, l/2 w

l%, lw

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, lw

lO%, 5 w

l%, 1 w

lO%, 2 w

lO%, l/2 w

lO%, l/2 w

camp 01121 Rl-1OM

Comp 01121 Rl-8.2K

Comp

Comp 01121

Comp 01121

01121 Rl-1.5M

Rl-

1M

Rl-3.3M

Comp 01121 Rl-1.2K

Comp 01121 Rl-100K

Comp 01121 Rl-220K

Comp

Comp 01121

ww 15909

DCb

DCb

DCb

ww 15909

WWVar

ww 15909

WWVar

Comp 01121

01121 Rl-6.0K

Rl-1K

R58-2K 20

79727

79727

79727

71450

R12-40K

R12-4OOK

R12-4M

R58-80 20

RP3-500 20

R58-1.5K

71450

Rp22-200

Rl-1OK 19

Comp 01121 Rl-1OM

20

20

20

20

20

20

20

20

20

20

24

24

24

20

18

19

*Nominal value, factory selected

0664R

41

Page 45

REPLACEABLE PARTS

MODEL 660 DIFFERENTIAL VOLTMETER

RESISTORS (Cont'd)

Circuit

De&g. Value

R1046

R1047

R1048

R2001

R2002

R2003

R2004

R2005

R2006

R200

7

l&l

113.6 ti

100 Mz 20%, l/2 w

180 k0

150 kQ lO%, l/2 w

270 kn

l&-l

27.

k5-l

22 k5-l

1Wl

R2008 *52 kn

R2009

R2010

R2011

R2012

R2013

R2014

150 kll

180 kn lO%, l/2 w Comp 01121 Rl-180K

270 ko lO%, l/2 w

270 kn

270 kn lO%, l/2 w Comp 01121 Rl-270K

270 k~

Rating

5Pe

20%, 0.2 w CbVar

l%, l/2 w

DCb

Camp

lO%, l/2 w

ComP

Camp

lO%, l/2 w

l%, l/2 w

lO%, 2 w

lO%, 2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

Camp

DCb

COmp

ComP

DCI,

DCb

DCb

Comp

lO%, l/2 w

lO%, l/2 w

Camp

Camp

Mfg.

Keithley

Code Part No.

71450 RP31-1K

79727

R12-113.6K

Fig.

Ref.

20

24

75042 R37-100M 19

01121

01121

01121

79727

Rl-18dK

Rl-150K

Rl-270K

Rl2-1M

01121 R3-22K

01121

79727

79727

79727

R3-22K

R12-1M

R12-52K

R12-150K

22

22

22

22

22

22

22

22

22

22

01121 Rl-2JOK

01121

Rl-270K

22

22

22

01121

RI-2JOK

22

R3001 220 0

R3002 100 kQ

R3003

R3004

R3005

R3006

R3007

1B-l

1Wl

1El

1M-l

5n

R3008 470 n

R3009 150 kfl

R3010

R3011

R3012

R3013

R3014

R3015

R3016

R3017

R3018

R3019

R3020

R3021

R3022

R3023

R3024

R3025