Page 1

www.keithley.com

Model 6487 Picoammeter/Voltage Source

Reference Manual

6487-901-01 Rev. D October 2020

*P648790101D*

6487-901-01

A Greater Measure of Confidence

Page 2

Model 6487 Picoammeter / Voltage Source

Reference Manual

Page 3

© 2020, Keithley Instruments, LLC

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, LLC, is strictly prohibited.

These are the original instructions in English.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, LLC. Other brand names are trademarks or registered trademarks of their respective

holders.

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: 6487-901-01 Rev. D October 2020

Page 4

Safety precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 5

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purchased from other

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2017.

Page 6

Introduction .............................................................................................................. 1-1

Welcome .............................................................................................................................. 1-1

Extended warranty ............................................................................................................... 1-1

Contact information .............................................................................................................. 1-1

General information .............................................................................................................. 1-2

Unpacking and inspection ................................................................ ......................................... 1-2

Package contents ...................................................................................................................... 1-2

Additional references ................................................................................................................ 1-3

Power-up .............................................................................................................................. 1-3

Line power connection .............................................................................................................. 1-3

Line frequency ........................................................................................................................... 1-4

Power-up sequence .................................................................................................................. 1-6

Front panel operation ........................................................................................................... 1-7

Status and error messages .................................................................................................. 1-7

Default settings .................................................................................................................... 1-8

Front panel setup operation ...................................................................................................... 1-8

Remote setup operation ............................................................................................................ 1-9

Menus................................................................................................................................. 1-11

Main menus............................................................................................................................. 1-11

Configuration menus ............................................................................................................... 1-12

SCPI programming ............................................................................................................. 1-13

Optional command words........................................................................................................ 1-13

Query commands .................................................................................................................... 1-13

Measurement concepts and connections .............................................................. 2-1

Connection fundamentals .................................................................................................... 2-1

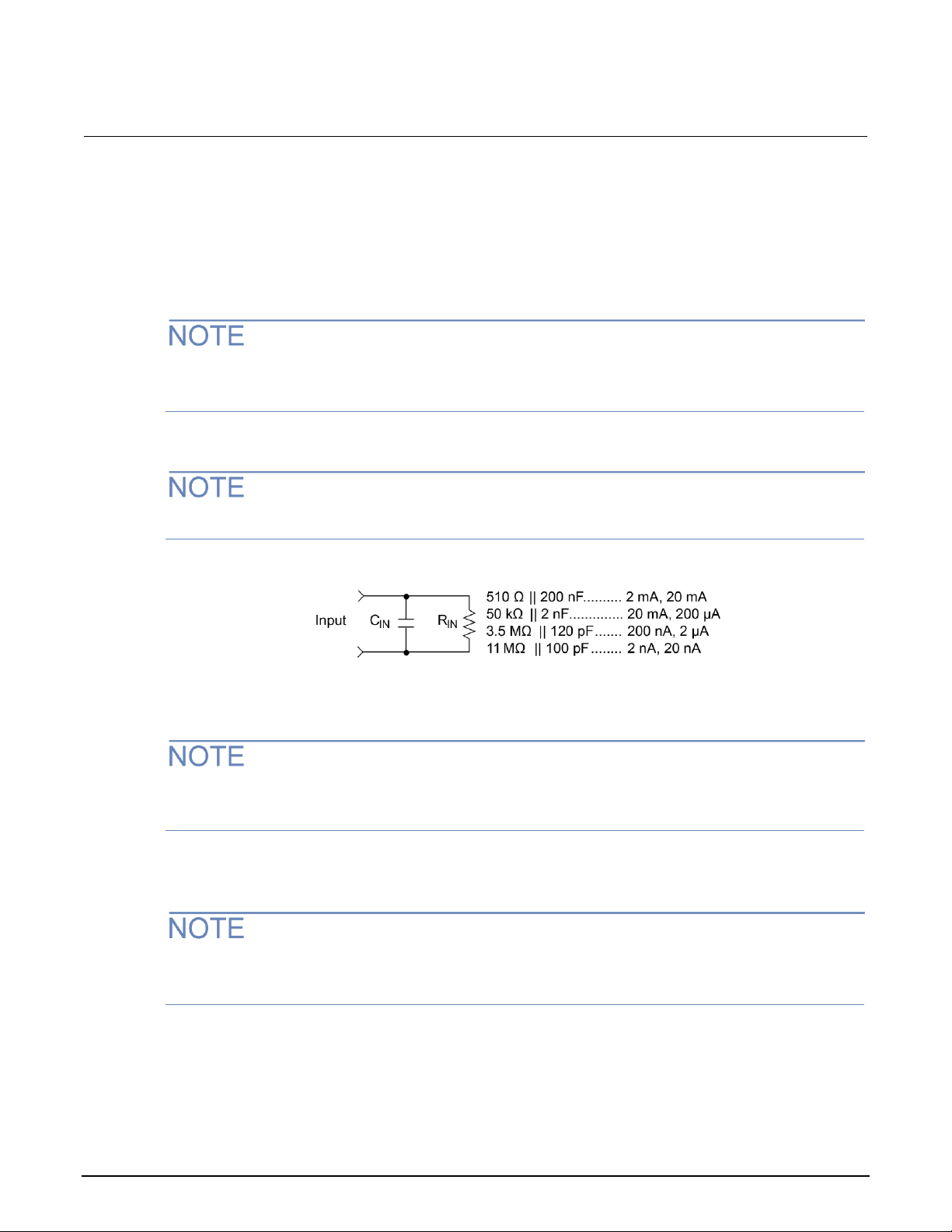

Input connector ......................................................................................................................... 2-1

Voltage source output connectors ............................................................................................. 2-1

Maximum input levels ................................................................................................................ 2-2

Low-noise input cables .............................................................................................................. 2-2

Voltage source test leads .......................................................................................................... 2-3

Basic connections to the DUT .............................................................................................. 2-3

Current measurement connections ........................................................................................... 2-4

Ohms measurement connections .............................................................................................. 2-4

Voltage source connections ...................................................................................................... 2-5

Voltages greater than 505 V...................................................................................................... 2-6

Noise and safety shields ........................................................................................................... 2-7

Using a test fixture ............................................................................................................... 2-8

General purpose test fixture ...................................................................................................... 2-8

Model 8009 resistivity test fixture ............................................................................................ 2-11

Floating measurements ........................................................................................................... 2-12

Interlock .............................................................................................................................. 2-13

Interlock connections .............................................................................................................. 2-14

Interlock operation ................................................................................................................... 2-14

Interlock programming ............................................................................................................ 2-15

Analog output ..................................................................................................................... 2-15

Table of contents

Page 7

Table of contents Model 6487 Picoammeter / Voltage Source Reference Manual

Measurement considerations ............................................................................................. 2-17

Measurement and sourcing voltage ....................................................................... 3-1

Measurement overview ........................................................................................................ 3-1

Current measurements ............................................................................................................. 3-1

Voltage source .......................................................................................................................... 3-1

Performance considerations ................................................................................................ 3-2

Warm-up period ........................................................................................................................ 3-2

Voltage offset correction ........................................................................................................... 3-2

Autozero .................................................................................................................................... 3-3

Zero check and zero correct...................................................................................................... 3-4

Current measurements ........................................................................................................ 3-8

Procedure.................................................................................................................................. 3-8

SCPI programming - current measurements ........................................................................... 3-11

Programming example - current measurements ..................................................................... 3-12

Ohms measurements ......................................................................................................... 3-12

Overview ................................ ................................................................ ................................. 3-12

Procedure................................................................................................................................ 3-13

SCPI programming - ohms measurements ............................................................................. 3-16

Programming example - ohms measurements........................................................................ 3-17

Voltage source operation ................................................................................................... 3-17

Voltage source edit keys ......................................................................................................... 3-17

Configuring the voltage source ................................................................................................ 3-18

Sourcing voltage ..................................................................................................................... 3-18

Operate considerations ........................................................................................................... 3-20

Compliance indication ............................................................................................................. 3-21

Open interlock indication ......................................................................................................... 3-21

SCPI commands - voltage source ........................................................................................... 3-22

Programming example — voltage ........................................................................................... 3-23

Alternating voltage ohms mode ......................................................................................... 3-24

Overview ................................ ................................................................ ................................. 3-24

Storing A-V ohms readings ..................................................................................................... 3-26

Recalling A-V ohms readings .................................................................................................. 3-31

Operating considerations ........................................................................................................ 3-32

SCPI commands — A-V ohms ................................................................................................ 3-35

Programming example — A-V ohms measurements .............................................................. 3-39

Range, units, digits, rate, and filters ....................................................................... 4-1

Range, units, and digits........................................................................................................ 4-1

Range ....................................................................................................................................... 4-1

Units .......................................................................................................................................... 4-3

Digits ......................................................................................................................................... 4-3

SCPI programming for range and digits .................................................................................... 4-4

Rate ...................................................................................................................................... 4-5

SCPI programming — rate ........................................................................................................ 4-6

Programming example - rate ..................................................................................................... 4-6

Damping ............................................................................................................................... 4-6

Filters.................................................................................................................................... 4-7

Median filter............................................................................................................................... 4-8

Median filter control ................................................................................................................... 4-8

Page 8

Model 6487 Picoammeter / Voltage Source Reference Manual Table of contents

Digital filter ................................................................................................................................ 4-8

SCPI programming — filters.................................................................................................... 4-10

Programming example - rate ................................................................................................... 4-10

Relative, mX+b, m/X+b, and log .............................................................................. 5-1

Relative ................................................................................................................................ 5-1

Setting and controlling relative .................................................................................................. 5-1

SCPI programming — relative ................................................................................................... 5-3

mX+b, m/X+b (reciprocal), and logarithmic.......................................................................... 5-4

mX+b and m/X+b ...................................................................................................................... 5-4

Configuring and controlling mX+b and m/X+b ........................................................................... 5-5

Logarithmic................................................................................................................................ 5-6

SCPI programming — mX+b, m/X+b, and log........................................................................... 5-7

Buffer and sweeps ................................................................................................... 6-1

Store ..................................................................................................................................... 6-1

Buffer operations .................................................................................................................. 6-2

Recall ................................................................................................................................... 6-2

Buffer timestamps ................................................................................................................ 6-3

Buffer statistics ..................................................................................................................... 6-4

SCPI programming ............................................................................................................... 6-5

:TRACe:FREE? ......................................................................................................................... 6-6

:TRACe:FEED <name> ............................................................................................................. 6-6

:TRACe:FEED:CONTrol <name> .............................................................................................. 6-6

:TRACe:TSTamp:FORMat <name> .......................................................................................... 6-6

:TRACe:DATA? ......................................................................................................................... 6-7

:FORMat:ELEMents <list>......................................................................................................... 6-7

:CALCulate3:FORMat <name> ................................................................................................. 6-7

:CALCulate3:DATA? ................................................................................................................. 6-8

Programming example ......................................................................................................... 6-8

Voltage sweeps .................................................................................................................... 6-8

Overview ................................ ................................................................ ................................... 6-9

Sweep operation ..................................................................................................................... 6-10

Recalling sweep data .............................................................................................................. 6-10

Operating considerations ........................................................................................................ 6-11

Sweep example ....................................................................................................................... 6-12

SCPI programming — sweeps ................................................................................................ 6-12

Programming example ............................................................................................................ 6-15

Triggering ................................................................................................................. 7-1

Trigger models ..................................................................................................................... 7-1

Idle, initiate, and operation ................................................................ ........................................ 7-4

Event detectors and control sources ......................................................................................... 7-5

Trigger delay ............................................................................................................................. 7-6

Measure action .......................................................................................................................... 7-6

Output triggers .......................................................................................................................... 7-6

Counters.................................................................................................................................... 7-7

Trigger model configuration — front panel ................................................................................ 7-7

SCPI programming ............................................................................................................... 7-9

Page 9

Table of contents Model 6487 Picoammeter / Voltage Source Reference Manual

ABORt ..................................................................................................................................... 7-10

INITiate, FETCh, and READ? ................................................................................................. 7-10

ARM:SOURce <name> ........................................................................................................... 7-10

ARM:DIRection <name> ......................................................................................................... 7-10

ARM:ILINe <NRf> and ARM:OLINe <NRf> ............................................................................. 7-10

TRIGger:CLEar ....................................................................................................................... 7-10

Programming example ............................................................................................................ 7-11

External triggering .............................................................................................................. 7-11

Input trigger requirements ................................................................ ....................................... 7-12

Output trigger specifications .................................................................................................... 7-12

External trigger example ......................................................................................................... 7-13

Limit tests and digital I/O ......................................................................................... 8-1

Limit testing .......................................................................................................................... 8-1

Binning ................................................................................................................................. 8-4

Component handler interface .................................................................................................... 8-6

Component handler types ................................................................ ......................................... 8-7

Digital output clear pattern ........................................................................................................ 8-8

Digital I/O port .................................................................................................................... 8-10

Sink mode — controlling external devices .............................................................................. 8-12

Source mode — logic control .................................................................................................. 8-14

Setting digital output lines ....................................................................................................... 8-15

SCPI programming — digital output pattern ............................................................................ 8-15

Front panel operation — limit tests .................................................................................... 8-16

Limit test configuration ............................................................................................................ 8-16

Performing limit tests .......................................................................................................... 8-17

Step 1. Configure test system ................................................................................................. 8-17

Step 2. Configure measurement ............................................................................................. 8-17

Step 3. Configure limit tests .................................................................................................... 8-17

Step 4. Start testing process ................................................................................................... 8-17

SCPI programming — limit tests ........................................................................................ 8-18

:FEED <name> ....................................................................................................................... 8-19

<NDN> and <NRf> parameters ............................................................................................... 8-19

:FAIL? ..................................................................................................................................... 8-20

:DATA? and :DATA:LATest? ................................................................................................... 8-21

:ARM:SOURce <name> .......................................................................................................... 8-21

Programming example ............................................................................................................ 8-22

Remote operation ..................................................................................................... 9-1

Selecting and configuring an interface ................................................................................. 9-1

Interfaces .................................................................................................................................. 9-1

Languages ................................................................................................................................ 9-2

Interface selection and configuration ......................................................................................... 9-2

GPIB operation and reference................................................................................................... 9-4

RS-232 interface reference ................................................................................................ 9-16

Sending and receiving data ..................................................................................................... 9-16

RS-232 settings ....................................................................................................................... 9-16

RS-232 connections ................................................................................................................ 9-18

Error messages ....................................................................................................................... 9-19

Page 10

Model 6487 Picoammeter / Voltage Source Reference Manual Table of contents

Status structure...................................................................................................... 10-1

Overview ............................................................................................................................ 10-1

Clearing registers and queues ................................................................................................ 10-3

Programming and reading registers ................................................................................... 10-4

Programming enable registers ................................................................................................ 10-4

Reading registers .................................................................................................................... 10-5

Status byte and service request (SRQ) ............................................................................. 10-6

Status byte register ................................................................................................................. 10-7

Service request enable register ............................................................................................... 10-8

Serial polling and SRQ ............................................................................................................ 10-8

Status byte and service request commands............................................................................ 10-9

Programming example — set MSS (B6) when error occurs .................................................... 10-9

Status register sets .......................................................................................................... 10-10

Register bit descriptions ........................................................................................................ 10-10

Queues ............................................................................................................................. 10-17

Output queue ........................................................................................................................ 10-17

Error queue ........................................................................................................................... 10-18

Programming example — read error queue .......................................................................... 10-19

Common commands .............................................................................................. 11-1

Common commands .......................................................................................................... 11-1

IDN? ........................................................................................................................................ 11-2

OPC and OPC? ....................................................................................................................... 11-2

SAV <NRf> and RCL <NRf> ................................................................................................... 11-3

RST ......................................................................................................................................... 11-3

TST? ....................................................................................................................................... 11-3

WAI ......................................................................................................................................... 11-4

SCPI signal-oriented measurement commands ................................................... 12-1

SCPI signal-oriented measurement commands ................................................................ 12-1

CONFigure[:<function>] ..................................................................................................... 12-2

FETCh? .............................................................................................................................. 12-2

READ? ............................................................................................................................... 12-3

MEASure[:<function>]? ...................................................................................................... 12-3

DISPlay, FORMat, and SYSTem ............................................................................ 13-1

DISPlay, FORMat, and SYSTem ....................................................................................... 13-1

DISPlay subsystem ................................................................................................................. 13-1

FORMat subsystem ................................................................................................................ 13-3

SYSTem subsystem ................................................................................................................ 13-8

SCPI reference tables ............................................................................................ 14-1

General notes ..................................................................................................................... 14-1

CALCulate command summary ......................................................................................... 14-1

Page 11

Table of contents Model 6487 Picoammeter / Voltage Source Reference Manual

DISPlay command summary ............................................................................................. 14-4

FORMat command summary ............................................................................................. 14-5

:SENSe command summary .............................................................................................. 14-5

:SOURce command summary ........................................................................................... 14-7

:STATus command summary ............................................................................................ 14-9

:SYSTem command summary ......................................................................................... 14-10

:TRACe subsystem .......................................................................................................... 14-12

:TRIGger command summary .......................................................................................... 14-13

Performance verification ....................................................................................... 15-1

Introduction ........................................................................................................................ 15-1

Verification test requirements ............................................................................................ 15-2

Environmental conditions ........................................................................................................ 15-2

Warm-up period ...................................................................................................................... 15-2

Line power............................................................................................................................... 15-2

Recommended test equipment .......................................................................................... 15-3

Verification limits ................................................................................................................ 15-4

Example reading limits calculation .......................................................................................... 15-4

Calibrator voltage calculations ........................................................................................... 15-4

Performing the verification test procedures ....................................................................... 15-5

Test considerations ................................................................................................................. 15-5

Restoring factory defaults........................................................................................................ 15-5

Offset voltage calibration.................................................................................................... 15-6

Current measurement accuracy ......................................................................................... 15-6

20 µA through 20 mA range accuracy ..................................................................................... 15-7

2 nA through 2 µA range accuracy .......................................................................................... 15-8

Voltage source output accuracy ......................................................................................... 15-9

Calibration .............................................................................................................. 16-1

Introduction ........................................................................................................................ 16-1

Environmental conditions ................................................................................................... 16-1

Temperature and relative humidity .......................................................................................... 16-1

Warm-up period ...................................................................................................................... 16-2

Line power............................................................................................................................... 16-2

Calibration considerations .................................................................................................. 16-2

Calibration cycle ................................................................................................................. 16-3

Recommended calibration equipment ............................................................................... 16-3

Calibration errors ................................................................................................................ 16-4

Calibration menu ................................................................................................................ 16-4

Aborting calibration ............................................................................................................ 16-5

Page 12

Model 6487 Picoammeter / Voltage Source Reference Manual Table of contents

Current calculations ........................................................................................................... 16-5

Calibration procedure ......................................................................................................... 16-5

Preparing for calibration .......................................................................................................... 16-5

Offset voltage calibration ......................................................................................................... 16-6

Current calibration ................................................................ ................................................... 16-6

Voltage source calibration ....................................................................................................... 16-9

Entering calibration dates and saving calibration .................................................................. 16-10

Locking out calibration .......................................................................................................... 16-11

Calibration support ........................................................................................................... 16-11

Changing the calibration code ............................................................................................... 16-11

Resetting the calibration code ............................................................................................... 16-12

Displaying calibration dates................................................................................................... 16-12

Displaying the calibration count ............................................................................................. 16-12

Routine maintenance ............................................................................................. 17-1

Introduction ........................................................................................................................ 17-1

Setting line voltage and replacing line fuse........................................................................ 17-1

Front panel tests ................................................................................................................ 17-2

DISP test ................................................................................................................................. 17-3

KEY test .................................................................................................................................. 17-3

Status and error messages ................................................................................... 18-1

Status and error messages ................................................................................................ 18-1

Eliminating common SCPI errors ....................................................................................... 18-5

-113, "Undefined header" ........................................................................................................ 18-5

-410, "Query INTERRUPTED" ................................................................................................ 18-6

- 420, "Query UNTERMINATED" ............................................................................................ 18-6

DDC emulation commands .................................................................................... 19-1

DDC language .................................................................................................................... 19-1

Command notes ...................................................................................................................... 19-9

Sweeps or A-V ohms in DDC mode ...................................................................................... 19-11

Status words ......................................................................................................................... 19-12

Status byte format ................................................................................................................. 19-14

IEEE-488 bus overview .......................................................................................... 20-1

Introduction ........................................................................................................................ 20-1

Bus description ................................................................................................................... 20-2

Bus lines ............................................................................................................................. 20-3

Data lines ................................................................................................................................ 20-3

Bus management lines ............................................................................................................ 20-4

Handshake lines ...................................................................................................................... 20-4

Bus commands .................................................................................................................. 20-6

Uniline commands ................................................................................................................... 20-8

Universal multiline commands ................................................................................................. 20-8

Addressed multiline commands .............................................................................................. 20-9

Address commands ................................................................................................................ 20-9

Page 13

Table of contents Model 6487 Picoammeter / Voltage Source Reference Manual

Unaddress commands ............................................................................................................ 20-9

Common commands ............................................................................................................. 20-10

SCPI commands ................................................................................................................... 20-10

Command codes ................................................................................................................... 20-10

Typical command sequences ................................................................................................ 20-11

IEEE command groups ......................................................................................................... 20-12

Interface function codes ................................................................................................... 20-13

IEEE-488 and SCPI conformance information...................................................... 21-1

Introduction ........................................................................................................................ 21-1

GPIB 488.1 protocol ........................................................................................................... 21-3

Selecting the 488.1 protocol .............................................................................................. 21-3

Protocol differences ........................................................................................................... 21-4

Message exchange protocol (MEP) ........................................................................................ 21-4

Using SCPI-based programs................................................................................................... 21-5

NRFD hold-off ......................................................................................................................... 21-5

NDAC hold-off ......................................................................................................................... 21-6

Trigger-on-talk ......................................................................................................................... 21-6

Message available .................................................................................................................. 21-7

General operation notes .......................................................................................................... 21-7

SRQ when buffer fills with 200 readings ................................................................................. 21-8

Remote calibration ................................................................................................. 22-1

Introduction ........................................................................................................................ 22-1

Calibration commands ....................................................................................................... 22-1

Remote calibration overview .............................................................................................. 22-2

Applications guide ................................................................................................. 23-1

Measurement considerations ............................................................................................. 23-1

Leakage currents and guarding............................................................................................... 23-2

Input bias current .................................................................................................................... 23-3

Voltage burden ........................................................................................................................ 23-3

Noise and source impedance .................................................................................................. 23-4

Electrostatic interference and shielding ................................................................................... 23-7

Making connections ................................................................................................................ 23-9

Typical range change transients ........................................................................................... 23-11

Steps to minimize impact of range change transients ........................................................... 23-13

Zero check on and zero check off response ......................................................................... 23-15

Applications ...................................................................................................................... 23-16

Diode leakage current ........................................................................................................... 23-16

Capacitor leakage current ................................................................ ..................................... 23-16

Measuring high resistance .................................................................................................... 23-17

Alternating voltage ohms measurement ................................................................................ 23-18

Cable insulation resistance ................................................................................................... 23-18

Surface insulation resistance (SIR) ....................................................................................... 23-19

Photodiode characterization prior to dicing ........................................................................... 23-21

Focused ion beam applications ............................................................................................. 23-23

Using switching systems to measure multiple current sources ............................................. 23-24

Page 14

In this section:

Welcome ...................................................................................1-1

Extended warranty ....................................................................1-1

Contact information ...................................................................1-1

General information ..................................................................1-2

Power-up...................................................................................1-3

Front panel operation ................................................................1-7

Status and error messages .......................................................1-7

Default settings .........................................................................1-8

Menus .....................................................................................1-11

SCPI programming .................................................................1-13

Welcome

The 6487 is a high resolution bus-programmable (RS-232 and IEEE-488) picoammeter. The 6487

has eight current measurement ranges from 20 mA to 2 nA.

The 6487 also has a built-in ± 500 V dc voltage source and an ohms function that includes an

alternating voltage mode for enhanced high resistance measurement accuracy.

Extended warranty

Additional years of warranty coverage are available on many products. These valuable contracts

protect you from unbudgeted service expenses and provide additional years of protection at a fraction

of the price of a repair. Extended warranties are available on new and existing products. Contact your

local Keithley Instruments office, sales partner, or distributor for details.

Contact information

If you have any questions after you review the information in this documentation, please contact your

local Keithley Instruments office, sales partner, or distributor. You can also call the Tektronix

corporate headquarters (toll-free inside the U.S. and Canada only) at 1-800-833-9200. For worldwide

contact numbers, visit tek.com/contact-us.

Section 1

Introduction

Page 15

Section 1: Introduction Model 6487 Picoammeter / Voltage Source Reference Manual

1-2 6487-901-01 Rev. D October 2020

General information

Warranty information is located at the front of this manual. Should your 6487 require warranty service,

contact the Keithley Instruments representative or authorized repair facility in your area for further

information. When returning the instrument for repair, be sure to fill out and include the service form

at the back of this manual to provide the repair facility with the necessary information.

Unpacking and inspection

The 6487 was carefully inspected electrically and mechanically before shipment. After unpacking all

items from the shipping carton, check for any obvious signs of physical damage that may have

occurred during transit. There may be a protective film over the display lens, which can be removed.

Report any damage to the shipping agent immediately. Save the original packing carton for possible

future shipment. Before removing the 6487 from the bag, observe the following handling precautions.

Handling precautions

• Always grasp the 6487 by the covers.

• After removing the 6487 from its anti-static bag, inspect it for any obvious signs of physical

damage. Report any such damage to the shipping agent immediately.

• When the 6487 is not installed and connected, keep the unit in its anti-static bag and store it in

the original packing carton.

Package contents

• Model 6487 Picoammeter with line cord

• Protective triaxial shield cap (CAP-31)

• 7078-TRX-3 triaxial cable

• Model 8607 1 kV Source banana cable set

• CS-459 4-Pin Female interlock connector

• Accessories as ordered

• Certificate of calibration

Page 16

Model 6487 Picoammeter / Voltage Source Reference Manual Section 1: Introduction

6487-901-01 Rev. D October 2020 1-3

Additional references

While reading this document, you may find it helpful to consult the following documentation for

reference:

• Model 6487 User’s Manual: Available from the tek.com website.

• Low-Level Measurements handbook: Available from the tek.com website.

Power-up

Line power connection

To connect the Model 6487 to line power and turn on the instrument:

1. Check to see that the line voltage indicated in the window of the fuse holder assembly is correct

for the operating voltage in your area.

Operating the instrument on an incorrect line voltage may cause damage to the instrument,

possibly voiding the warranty.

Figure 1: Rear panel

Page 17

Section 1: Introduction Model 6487 Picoammeter / Voltage Source Reference Manual

1-4 6487-901-01 Rev. D October 2020

2. Before plugging in the power cord, make sure that the front panel power switch is in the off (O)

position.

3. Connect the female end of the supplied power cord to the AC receptacle on the rear panel.

Connect the other end of the power cord to a grounded AC outlet.

The power cord supplied with the 2601B-PULSE contains a separate protective earth (safety

ground) wire for use with grounded outlets. When proper connections are made, the

instrument chassis is connected to power-line ground through the ground wire in the power

cord. In addition, a chassis ground connection is provided through a screw on the rear panel.

This terminal should be connected to a known protective earth. In the event of a failure, not

using a properly grounded protective earth and grounded outlet may result in personal injury

or death due to electric shock. Do not replace detachable mains supply cords with

inadequately rated cords. Failure to use properly rated cords may result in personal injury or

death due to electric shock.

4. Turn on the instrument by pressing the front-panel power switch to the on (I) position.

Hazardous voltages may be present in the test system. To prevent injury or death, remove

power from the instrument or test system and discharge any energy storage components (for

example, capacitors or cables) before changing any connections that might allow contact

with an uninsulated conductor.

Line frequency

The 6487 operates at line frequencies of 50 Hz or 60 Hz. When auto detect is enabled (factory

default), line frequencies are automatically sensed and set accordingly, therefore there are no

switches to set. Use the :SYSTem:LFRequency? command (query) to read the line frequency. The

factory default setting is Auto-Detect enabled.

If the power line is noisy, auto detect may not be able to lock in on a frequency. If this occurs, set the

frequency manually. This may be accomplished using the front panel or over the bus.

Page 18

Model 6487 Picoammeter / Voltage Source Reference Manual Section 1: Introduction

6487-901-01 Rev. D October 2020 1-5

Front panel procedure

To set the line frequency from the front panel:

1. Press MENU.

2. Scroll to the LFREQ: menu item using the up and down RANGE keys. The present settings are

displayed.

3. Press the right arrow cursor key.

4. Use the up and down RANGE keys to scroll to the desired line frequency: AUTOXX 50 or AUTOXX

60.

5. Press ENTER.

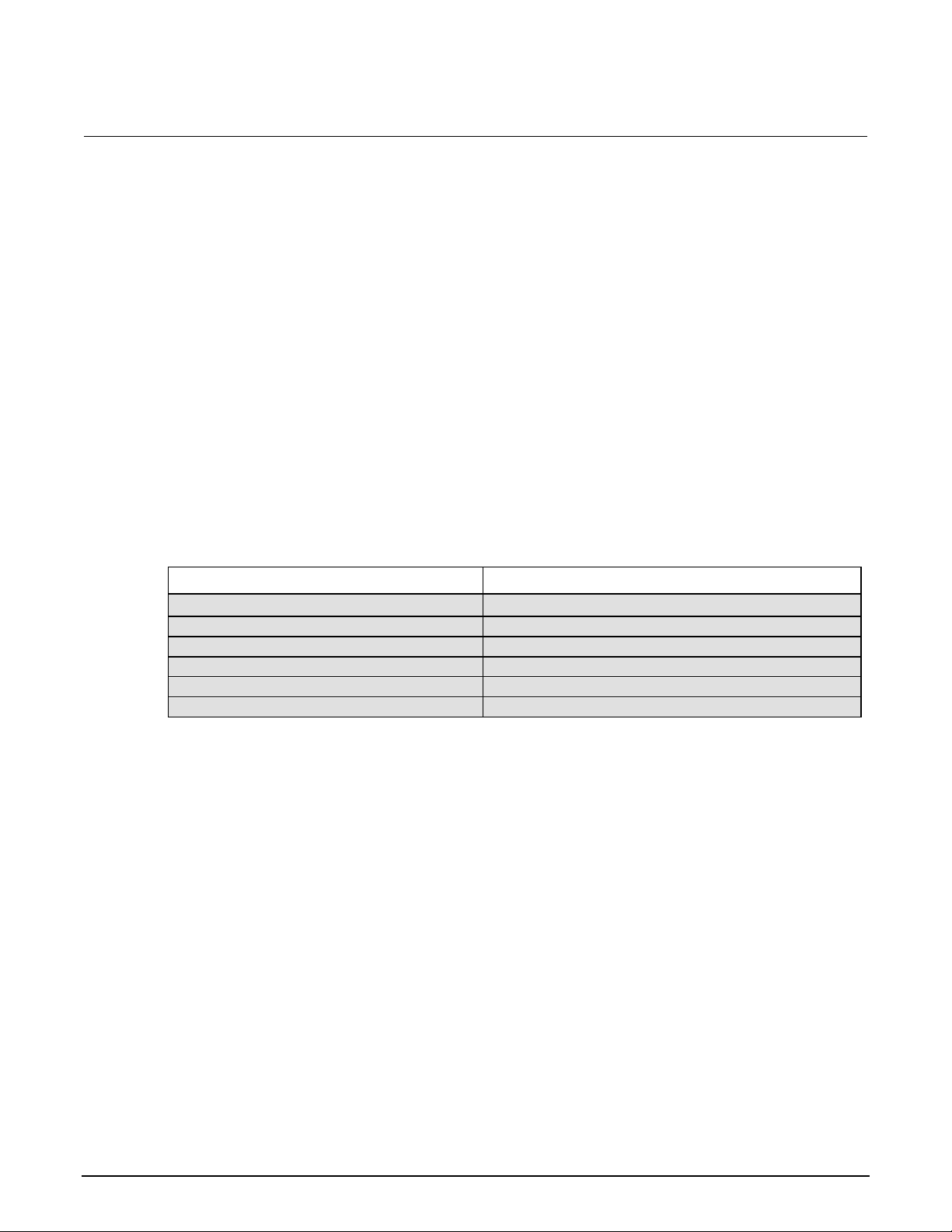

SCPI programming - line frequency

Command

Description

SYSTem

SYSTem subsystem:

:LFRequency <freq>

Set power line frequency (in Hz) to 50 or 60.

:AUTO <b>

Turn automatic frequency detection ON or OFF.

:AUTO?

Read the present automatic detected line frequency

state (1 = on, 0 = off).

[:STATE]

[:STATE]?

:LFRequency?

Read present line frequency setting.

Page 19

Section 1: Introduction Model 6487 Picoammeter / Voltage Source Reference Manual

1-6 6487-901-01 Rev. D October 2020

Power-up sequence

The following power-up sequence occurs when the Model 6487 is turned on.

1. The 6487 performs EPROM and RAM self-tests with all digits and annunciators turned on. If a

failure is detected, the instrument displays an error message and the ERR annunciator turns on.

2. If the instrument passes the self-tests, the firmware revision levels are displayed. For example:

6487 A01

3. After the firmware revision levels are displayed, the detected line frequency is displayed. For

example:

FREQ: 60Hz

4. After the detected line frequency is displayed, information on the selected remote interface is

displayed:

a. If the GPIB is the selected interface, the instrument will display the selected language (SCPI, 488.1, or

DDC) and primary address.

SCPI ADDR: 22

DDC ADDR: 22

b. If RS-232 is the selected interface, the instrument will display the baud rate setting.

RS-232: 9600b

5. If the factory setup is selected as the power-on setup, the unit is placed in the default reading

mode after the communication information is displayed. If a setup other than FACTory is selected,

the configured setup will be displayed. For example, if the USR1 setup (User Setup #1) is

selected:

USING USR1

To configure the power-on set up:

1. From the PWR-ON: menu, press CONFIG and then SETUP.

2. Use the up and down RANGE keys to scroll through the menu items.

3. Press ENTER to select or EXIT to quit without changing power-on setup.

Page 20

Model 6487 Picoammeter / Voltage Source Reference Manual Section 1: Introduction

6487-901-01 Rev. D October 2020 1-7

Front panel operation

The following figure shows the front panel of the 6487. The controls, indicators, and display are

described later in this section of the manual.

Figure 2: Front panel

Status and error messages

Status and error messages are displayed momentarily. During operation and programming, you will

encounter a number of front panel messages. Typical messages are for either status or errors.

Messages, both status and error, are held in queues. For information on retrieving messages from

queues, see Status structure (on page 10-1).

Page 21

Section 1: Introduction Model 6487 Picoammeter / Voltage Source Reference Manual

1-8 6487-901-01 Rev. D October 2020

Default settings

The 6487 can be restored to one of five setup configurations:

• Factory default (FACT)

• Three user-saved setups (USR0, USR1, and USR2)

• Bus default (GPIB).

As shipped from the factory, the 6487 powers up to the factory default settings. Factory default

settings provide a general purpose setup for front panel operation, while the bus default (GPIB)

settings do the same for remote operation.

The instrument will power up to whichever default setup was saved as the power-on setup.

At the factory, the factory default setup is saved into the USR0, USR1, and USR2 setups.

Front panel setup operation

To save a user setup:

1. Configure the 6487 for the desired measurement application.

2. Press SAVE to access the save setup menu.

3. Use the up or down RANGE key to display the desired memory location (0 = USR0, 1 =

USR1, 2 = USR2).

4. Press ENTER.

To restore any setup:

1. Press SETUP to display the restore menu:

2. Use the up or down RANGE key to display the desired setup (FACT, USR0, USR1, USR2, or

GPIB).

3. Press ENTER.

To select power-on setup:

1. Press CONFIG and then SETUP to display the power-on menu.

2. Use the up or down RANGE key to display the desired setup (FACT, USR0, USR1, USR2, or

GPIB).

3. Press ENTER.

Page 22

Model 6487 Picoammeter / Voltage Source Reference Manual Section 1: Introduction

6487-901-01 Rev. D October 2020 1-9

Remote setup operation

Saving and restoring user setups

The *SAV and *RCL commands are used to save and recall user setups. These commands are

documented in Common commands (on page 11-1).

Restoring factory or GPIB default setups

The SYSTem:PRESet command returns the 6487 to the factory defaults and the *RST command

returns it to the GPIB defaults. The *RST command is documented in Common commands (on page

11-1) and SYSTem:PRESet is covered in DISPlay, FORMat, and SYSTem (on page 13-1).

Selecting power-on setup

The SYSTem:POSetup command is used to select which setup to return to on power-up. The

SYSTem:POSetup command is documented in DISPlay, FORMat, and SYSTem (on page 13-1).

Page 23

Section 1: Introduction Model 6487 Picoammeter / Voltage Source Reference Manual

1-10 6487-901-01 Rev. D October 2020

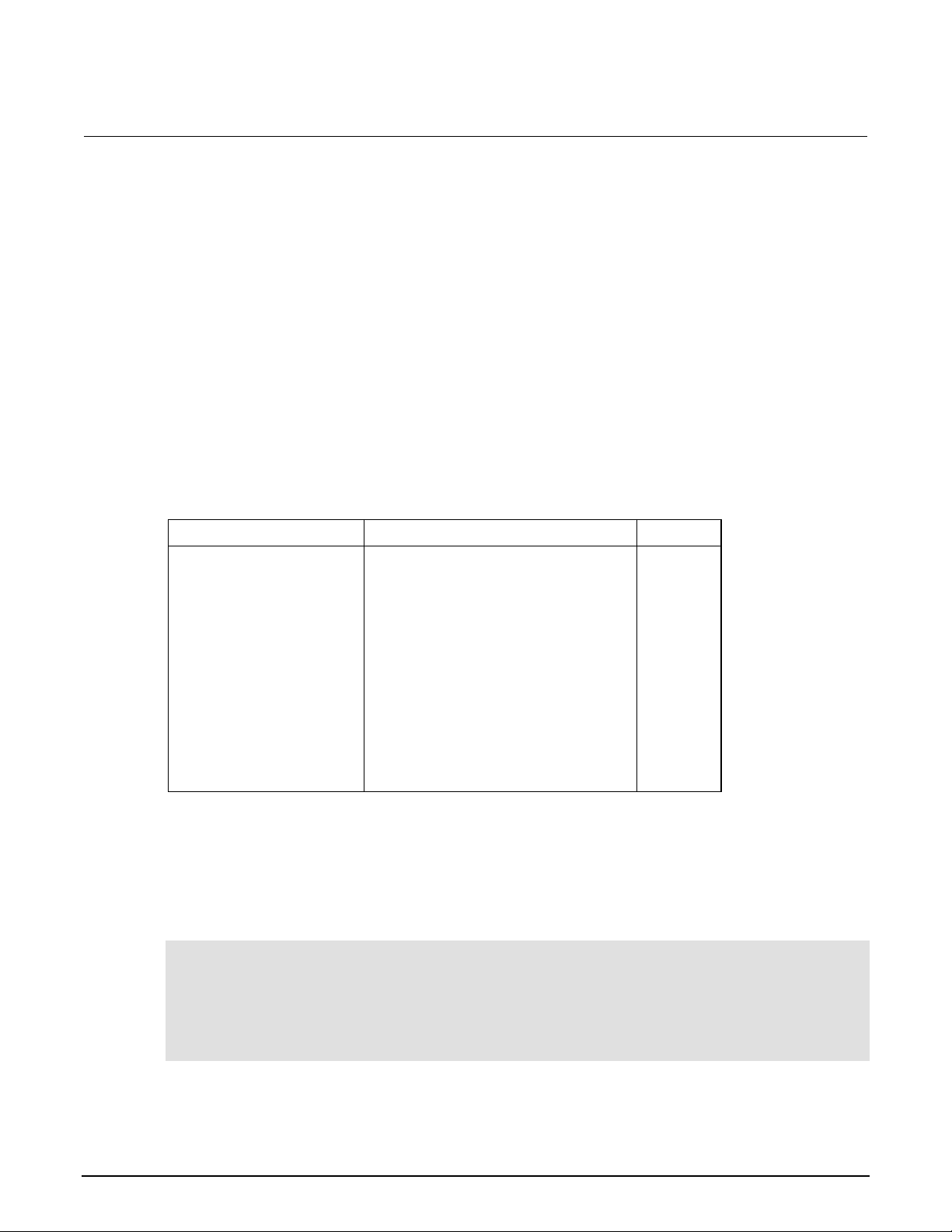

Setting

Factory

(:SYStem:PRESet)

GPIB

(*RST)

Arm Layer (CONFIG ARM):

Arm-In Source Event Arm Count

Input Trigger Link Line Source

Bypass

Output Trigger Link Line Output

Trigger

IMM INF 1

NEVER 2

Off

* 1

*

*

*

*

Buffer (STORE):

Count

Disabled

No effect

*

*

Damping (DAMP)

On

*

Digital Filter (FILT):

Count Type

Off

10

Moving

*

*

*

Display Resolution (DIGITS)

5H-digits

*

Format byte order

Swapped

Normal

Function

Amps

*

GPIB:

Address Language

No effect (On at factory)

No effect (22 at factory) No effect

(SCPI at factory)

*

*

*

Limit Tests:

Limit 1 and Limit 2: HI and LO

Values

Disabled

1, -1

*

*

*

Log (MATH)

OFF

*

Median Filter (FILT):

Rank

Off 1 *

*

MX+B (MATH):

"M" Value "B" Value Units

Disabled

1.0

0.0

X

*

*

*

*

M/X+B (MATH)

"M" Value "B" Value Units

Disabled

1.0

0.0

X

*

*

*

*

Ohms Mode

Normal

*

Range

AUTO

*

Rate:

NPLC

Slow

6.0 (60 Hz) or 5.0 (50 Hz)

*

*

Rel:

Rel Value (VAL)

Off

0.0 * *

RS-232:

All Settings

No effect (Off at factory)

No effect

*

*

Page 24

Model 6487 Picoammeter / Voltage Source Reference Manual Section 1: Introduction

6487-901-01 Rev. D October 2020 1-11

Setting

Factory

(:SYStem:PRESet)

GPIB

(*RST)

Trigger Layer (CONFIG TRIG):

Trig-In Source Event Trigger

Count Trigger Delay

Input Trigger Link Line Source

Bypass

Output Trigger Link Line

IMM 1

0

1

NEVER 2

*

*

*

*

*

*

*

Units

No effect

*

Voltage Source:

Operate Amplitude Range Current

Limit

10 V Range Interlock Sweeps:

Start Voltage Stop Voltage Step

Voltage Center Voltage Span

Voltage Delay

Off 0 V

10 V

25 mA

Off

0 V

10 V

1 V

5 V

10 V

1 s

*

*

*

*

*

*

*

*

*

*

*

Zero Check

Enabled

*

Zero Correct

Disabled

*

*This factory (:SYStem:PRESet) and bus (*RST) GPIB defaults are the same. Bus settings that are different

from factory reset are as shown.

Menus

Main menus

Many aspects of operation are configured through the main menus summarized in the next table.

Refer to the section listed in the next table for in-depth information. To access the main menus, press

the MENU key. Use the up and down RANGE keys to scroll through the menu items and the left and

right keys to change options. Press ENTER to save any changes made and leave the menu. Press

EXIT to leave the menu without saving changes.

The MENU key is used to access the menu structure. However, if in remote for IEEE-488 bus

operation (REM annunciator is lit), pressing the menu key has no effect. Press the LOCAL key to

place the unit in local operation, then press the MENU key to access the menu items.

Page 25

Section 1: Introduction Model 6487 Picoammeter / Voltage Source Reference Manual

1-12 6487-901-01 Rev. D October 2020

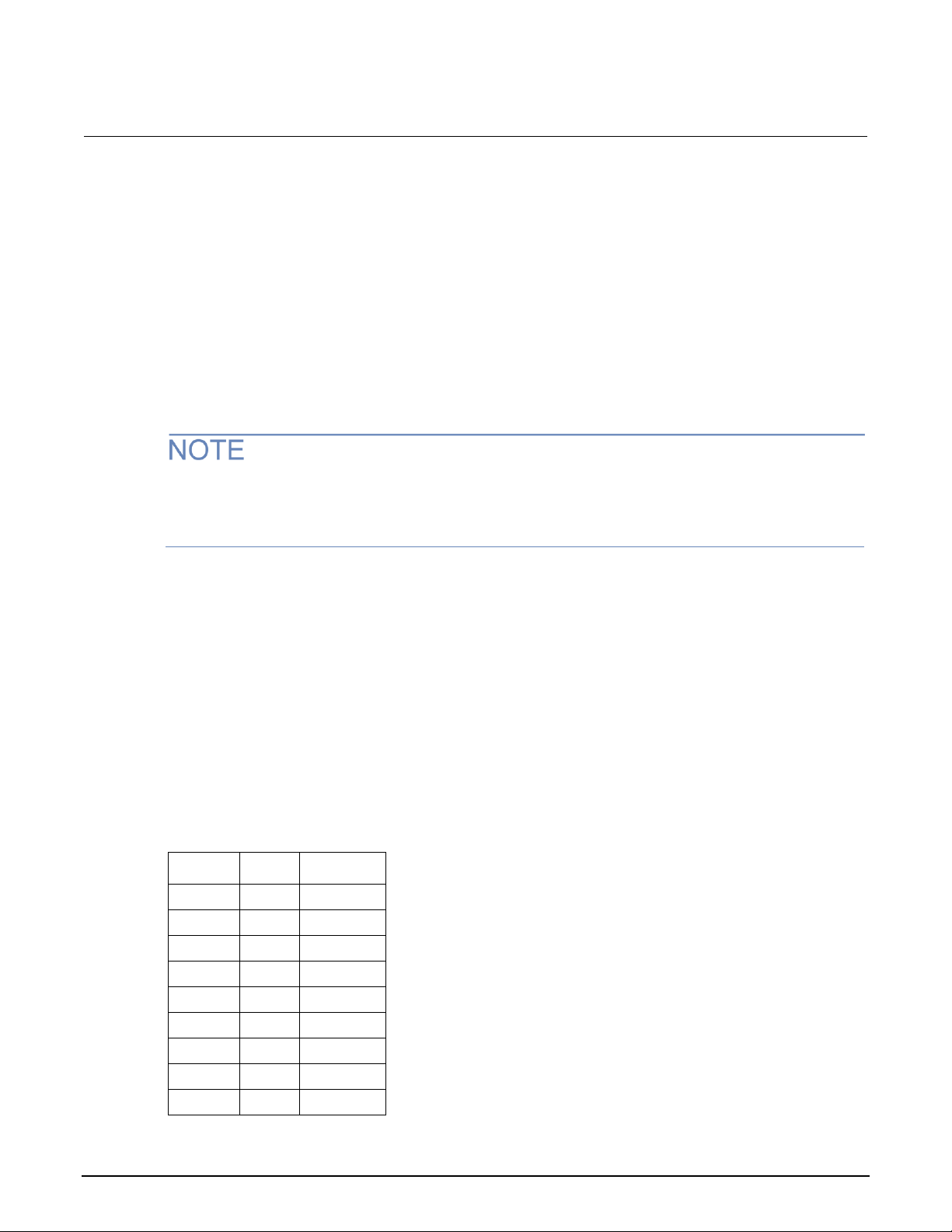

See the following table for the main menu structure.

Menu item

Description

CAL

Provides path to the following calibration submenu items:

VOFFSET, COUNT, RUN, VSRC-RUN, DATES,

UNLOCK, LOCK, and SAVE. See reference section for

verification and calibration information.

TSTAMP

Timestamp format can be ABSolute or DELTa.

UNITS

Readings can be displayed in ENGineering units or

SCIentific notation.

TEST

Run display or key tests.

SNUM

Displays the units serial number.

LFREQ

Line frequency can be manually set to 50 Hz, 60 Hz, or

AUTOmatically set. The number after AUTO indicates

present detected frequency value.

Configuration menus

Many keys have configuration menus that allow you to configure various 6487 operating modes. The

following table summarizes the various configuration menus. To access a configuration menu, press

CONFIG and then the corresponding front panel key.

Key

Description

I | Ù

Configure normal or alternating voltage ohms modes.

MATH

Set up MX + B, M/X + B, and LOG math functions.

FILT

Configure median and average filters.

REL

Enter relative value.

OPER

Select DC or SWEEP mode, set source amplitude and

current limit.

COMM

Configure GPIB or RS-232 interface.

TRIG

Configure trigger parameters.

LIMIT

Set up and enable limit tests.

RATE

Set integration rate in number of power line cycles (NPLCs).

SETUP

Select power-on setup.

STORE

Select number of readings to store in buffer.

RANGE (arrow up)

Set upper auto range limit.

RANGE (arrow down)

Set lower auto range limit.

Page 26

Model 6487 Picoammeter / Voltage Source Reference Manual Section 1: Introduction

6487-901-01 Rev. D October 2020 1-13

SCPI programming

SCPI programming information is integrated with front panel operation throughout this manual. SCPI

commands are listed in tables and additional information that pertains exclusively to remote operation

is provided after each table. The SCPI tables may reference you to other sections of this manual.

Most SCPI tables in this manual do not include most optional command words and query commands.

Optional command words and query commands are summarized as follows.

Optional command words

The 6487 accepts optional command words to conform with the IEEE-488.2 and SCPI standards. Any

command word that is enclosed in brackets ([ ]) is optional and does not need not be included in the

program message. For example:

:INITiate[:IMMediate]

These brackets indicate that :IMMediate is implied and does not have to be used. The above

command can be sent as either :INITiate or :INITiate:IMMediate.

Query commands