Page 1

TBktronix

®

COMMfTTED TO EXCELLENCE

Tektronix, Inc.

P.O. Box 500

Beaverton,

Oregon 97077 Serial Number

PLEASE CHECK FOR CHANGE INFORMATION

AT THE REAR OF THIS MANUAL.

5A14N

FOUR CHANNEL

AMPLIFIER

INSTRUCTION MANUAL

070-1229-00 First Printing OCT 1972

Product Group

52

Revised OCT 1987

Page 2

Copyright © 1971 Tektronix, Inc. All rights reserved. Contents of this

publication may not be reproduced in any form without the written

permission of Tektronix, Inc.

Products of Tektronix, Inc. and its subsidiaries are covered by U.S. and

foreign patents and/or pending patents.

TEKTRONIX, TEK, SCOPE-MOBILE, and ® are registered trade-

marks of Tektronix, Inc. TELEQUIPMENT is a registered trademark of

Tektronix U.K. Limited.

Printed in

U.S.A.

Specification and price change privileges are

reserved.

INSTRUMENT SERIAL NUMBERS

Each instrument has a serial number on a panel insert, tag, or stamped

on the chassis. The first number or letter designates the country of

manufacture. The last five digits of the serial number are assigned

sequentially and are unique to each instrument. Those manufactured in

the United States have six unique digits. The country of manufacture is

identified as follows:

BOOOOOO Tektronix, Inc., Beaverton, Oregon, USA

1000000 Tektrnoix Guemsey, Ltd., Channel Islands

2000000 Tektronix United Kingdom, Ltd., London

3000000 Sony/Tektronix, Japan

7000000 Tektronix Holland, NV, Heerenveen, The Netherlands

Page 3

5A14N Instruction

TABLE OF CONTENTS

Operators Safety Summary ii

Servicing Safety Summary. Jii

Frontispiece iv

SECTION

1—OPERATING

Instrument Description 1-1

Controls and Connectors. 1-1

Basic Operation 1-1

General Information 1-2

Electrical Characteristics 1-4

Repackaging for Shipment 1-4

THE FOLLOWING SERVICING INSTRUCTIONS ARE FOR USE BY QUALIFIED PERSONNEL

ONLY. TO AVOID PERSONAL INJURY, DO NOT PERFORM ANY SERVICING OTHER THAN

THAT CONTAINED IN OPERATING INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO SO,

INSTRUCTIONS

Preparation 1-1

C3aln Check (All Channels) 1-2

Applying Signals 1-2

Channel Sequence Logic 1-3

Input Coupling 1-3

Deflection Factor 1-3

Display Modes 1-3

Trigger Source 1-3

Oscllloscxjpe Applications 1-3

Performance Conditions 1-4

Display Modes 1-4

Bandwidth (-3 dB) 1-4

Deflection Factor 1-4

Maximum Safe Input Voltaga 1-4

Channel Isolation 1-4

Input RC 1-4

WARNING

SECTION

SECTION

SECTION 4—DIAGRAMS AND PARTS LISTS

2—THEORY

Introduction 2-1

Plug-In Logic 2-1

Input Coupling 2-1

Input Attenuator 2-1

Amplifier 2-1

Cfiannel Switching 2 2

Probe Sensing 2-2

3—CALIBRATION

Test Equipment Requried 3-1

Procedure 3-1

OF OPERATION

Inti-oduction. 3-1

Instrument Maintenance 3 1

Service Available 3-1

General 3 1

Calibration Equipment Alternatives 3 1

Special Calibration Fixtures. 3-1

Test Instruments 3-1

Accessories 3 1

Preparation 3-3

Initial Control Settings 3-3

1.

Step Attenuator Balance 3-3

2.

Input and Attenuator Compensation .3-3

3. Amplifier Gain and VOLTS/DIV Accuracy 3-3

4.

Amplifier Bandwidth 3-4

REV MAR 1987

Page 4

5A14N Instruction

OPERATORS SAFETY SUMMARY

The general safety information in this part of the summary is for tx)th operating and servicing personnel. Specific warnings and

cautions will be found throughout the manual where they apply, but may not appear

in

this summary.

TERMS

In This Manual

CAUTION statements identify conditions or practices that

could result in damage to the equipment or other property.

WARNING statements identify conditions or practices that

<x)uld result

in

personal injury or

loss

of life.

As Marked On Equipment

CAUTION indicates a personal injury hazard not immediately

accessible as one reacJs the marking, or a hazard to property

including the equipment

DANGER indicates a personal injury hazard immediately

accessible as one reads the marking.

itself.

SYMBOLS

In This Manual

^p Static-Sensitive Devices.

|\ This symtxjl indicates where applic:able cautionary

A

or other information

is

to

be

fourid.

As Marked On Equipment

Use the Proper Power Cord

Use only the power cord and connector specified for your

product. Use only a power

Refer cord and connector changes to qualified personnel.

cord

that is in gcxjd condition.

Grounding the Product

This product is grounded through the grounding conductor

of the mainframe power

the power cord into a properly wired receptacle before

connecting to the product input or output terminals. A

protective-ground connection, by way of the grounding

conductor

in

the power

cord.

To avoid electric shock, plug

cord,

is essential for safe operation.

Danger Arising From Loss of Ground

Upon loss of the protective-ground connection, all

accessible conductive parts (including knobs and controls

that may appear to be insulating), can render an electric

shock.

Do Not Operate In Explosive

Atmospheres

To avoid explosion, do not operate this product in an

atmosphere of explosive gasses unless it has been

specifically certified for

such

operation.

^ DANGER—High voltage.

^Q Protective ground (earth) terminal.

/!\ ATTENTION—refer to manual.

WARNINGS

Power Source

This prcxjuct is intended to operate in a mainframe

connected to a power source that will not apply more than

250 volts rms between the supply conductors or between

either supply conductor and ground. A protective ground

connection, by way of the grounding conductor in the power

cord,

is essential for safe operation.

Do Not Remove Covers or Panels

To avoid personal injury, do not rennove the protective

covers or panels. Do not operate the product without

the

covers

and

panels properiy installed.

Do Not Operate Without Covers

(For TM 500 Plug-Ins Only)

To avoid personal injury, do not operate this product without

covers or panels installed. Do not apply power to the plug-in

via a plug-in extender.

REV MAR 1987

Page 5

5A14N Instruction

SERVICING SAFETY SUMMARY

FOR QUALIFIED SERVICE PERSONNEL ONLY

Refer also to

the preceding

Operators Safety Summary

Use Care When Servicing Do Not Service Alone

With Power On

Do not perform internal servrce or adjustment of this prcxiuct

Dangerous voltages exist at several points in this product. To unless another

avoid personal injury, do not touch exposed connections resuscitation

and

components while power

Disconnect power before removing protective panels,

soldering,

or replacing components.

is

on.

person

is

present,

capable of rendering first aid and

REV MAR 1987

jjj

Page 6

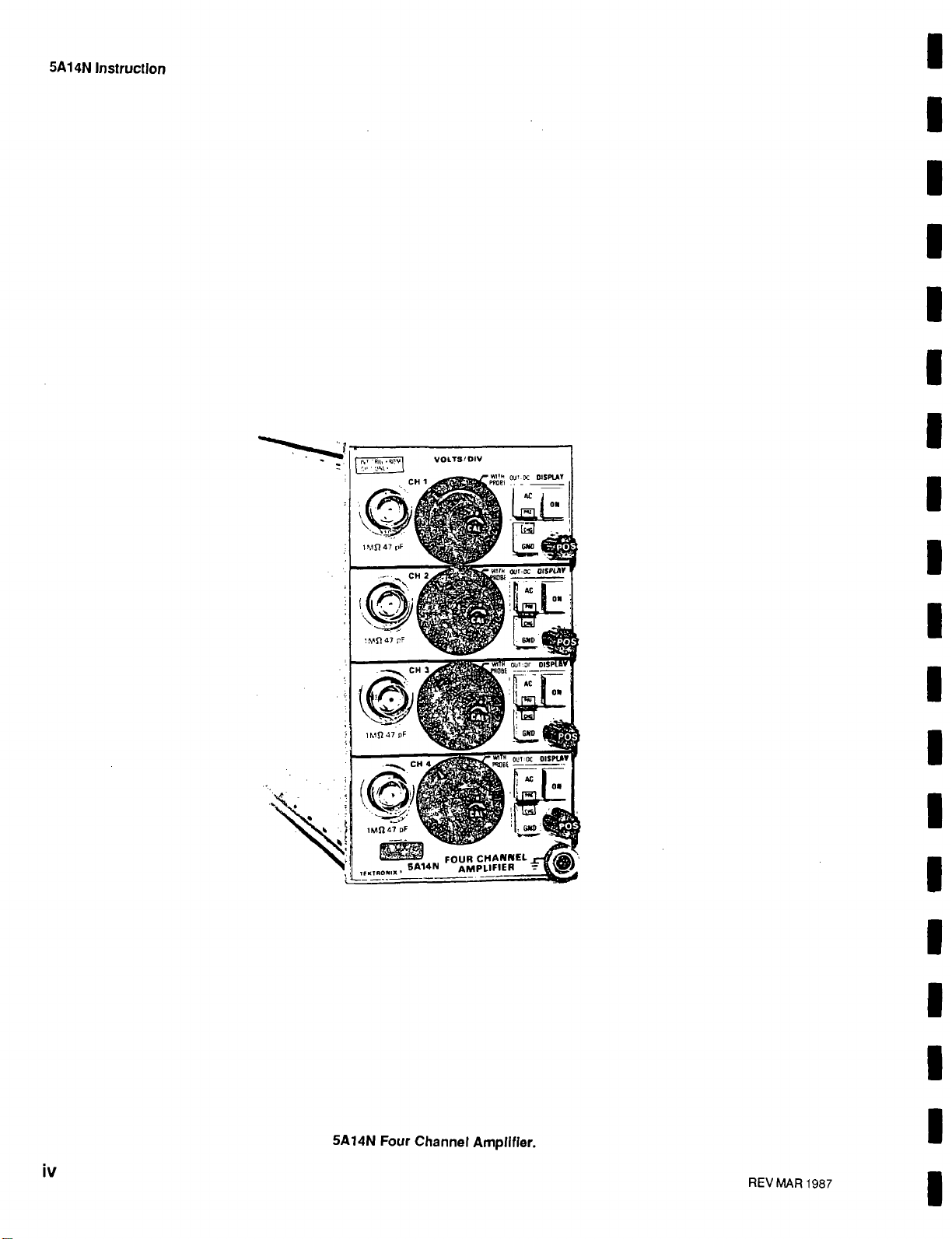

5A14N Instruction

VOLTS'DIV

«"'« OU!.K OlSPUY

IV

„«,.o.,..

FOURCHANIKEL^

8*^*" AMPLIFIER rr

5A14N Four Channel Amplifier.

REV MAR

1987

Page 7

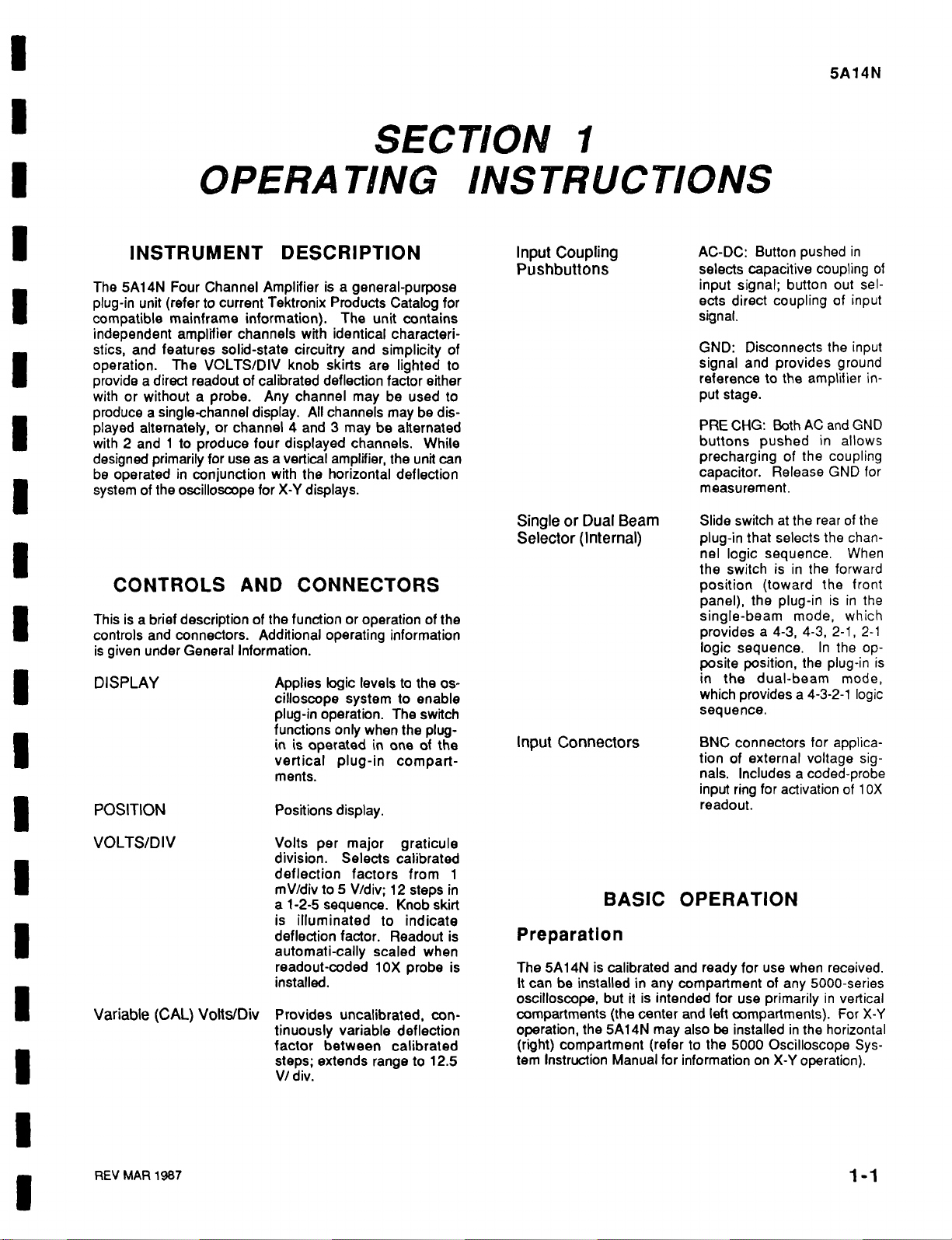

SECTION 1

OPERATING INSTRUCTIONS

5A14N

INSTRUMENT DESCRIPTION

The 5A14N Four Channel Amplifier is a general-purpose

plug-in unit (refer to current Tektronix Products Catalog for

compatible mainframe information). The unit contains

independent amplifier channels with identical characteristics,

and features solid-state circuitry and simplicity of

operation.

provide a direc^t readout of calibrated deflection factor either

with or without a probe. Any channel may be used to

produce a single-channel display. All channels may be displayed alternately, or channel 4 and 3 may be alternated

with 2 and 1 to produce four displayed channels. While

designed primarily for use as a vertical amplifier, the unit can

be operated in conjunction with the horizontal deflection

system of the oscilloscope for X-Y displays.

The VOLTS/DIV knob skirts are lighted to

CONTROLS AND CONNECTORS

This is a brief description of the function or operation of the

controls and connectors. Additional operating information

is given under General Information.

DISPLAY

POSITION

Applies kigic levels to the oscilloscope system to enable

plug-in operation. The switch

functions only when the

in is operated in one of the

vertical plug-in compartments.

Positions display.

plug-

Input Coupling

Pushbuttons

Single or Dual Beam

Selector (Internal)

Input Connectors

AC-DC: Button pushed in

selects capacitive coupling of

input signal; button out

ects direct coupling of input

signal.

GND:

Disconnects the input

signal and provides ground

reference to the ampliiier input stage.

PRECHG: Both AC and GND

buttons pushed in allows

precharging of the coupling

capacitor. Release GND for

measurement.

Slide switch at the rear of the

plug-in that selects the chan-

nel logic sequence. When

the switch is in the forward

position (toward the front

panel), the plug-in is in the

single-beam mode, which

provides a 4-3, 4-3, 2-1, 2-1

logic sequence. In the opposite position, the plug-in is

in the dual-beam mode,

which provides a 4-3-2-1 logic

sequence.

BNC connectors for application of external voltage

nals.

Includes a coded-probe

input ring for activation of 10X

readout.

sel-

sig-

VOLTS/DIV

Variable (CAL) Volts/Div

REV MAR 1987

Volts per major graticule

division.

deflection factors from 1

mV/div to 5 V/div; 12 steps in

a 1-2-5 sequence. Knob skirt

is illuminated to indicate

deflection factor. Readout is

automati-cally scaled when

readout-coded 10X probe is

installed.

Provides uncalibrated,

tinuously variable deflection

factor between calibrated

steps;

V/ div.

Selects calibrated

con-

extends range to 12.5

BASIC OPERATION

Preparation

The 5A14N is calibrated and ready for use when received.

It can be installed in any compartment of any 5000-series

oscilloscx}pe, but it is intended for use primarily in vertical

cxjmpartments (the center and left compartments). For X-Y

operation,

(right) compartment (refer to the 5000 Oscilloscope System Instruction Manual for information on X-Y operation).

the 5A14N may also be installed in the horizontal

1-1

Page 8

Operating Instructions—5A14N

NOTE

// the oscilloscope system receives no DISPLAY ON logic levels from the vertical plug-ins,

ii is designed to display the unit in the left

compartment

To install, align the upper and lower rails ofthe 5A14N with

the plug-in compartment tracks and fully insert it (the

in panel must be flush with the oscilbscope panel). To remove,

pull the release latch to disengage the 5A14N from

the oscilloscope.

The first few steps of the following procedure are intended

to quickly obtain a trace on the screen and prepare the instrument for immediate use. The remainder of the steps

demonstrate some of the basic functions of the 5A14N.

Operation of the other instruments in the system is described in the instruction manuals for those units.

1.

Insert the unit all the way into the oscilloscope system

plug-in compartment.

2.

Turn the oscilloscope Intensity control fully counter-

clockwise and turn the oscilloscope power on. Preset the time-base and triggering controls for a 2-ms/

division sweep rate and automatic triggerng.

3. Set the 5A14N front-panel controls as follows:

CH 1 through CH 4

DISPLAY

POSITION

VOLTS/DIV

Input Coupling

Adjust the Intensity control for normal viewing of the

four traces.

Position the traces two divisions apart with the

TION controls.

Apply a 400-miHivolt peak-to-peak signal (available at

the oscilloscope Calibrator loop) through a test lead

or IX probe to the CH 1 input connector.

Release the CH 1 GND pushbutton. The display

should be square waves approximately two divisions

in amplitude, with the bottom of the display at the

reference established in step 5. Adjust trigger Level,

if necessary, to obtain a stable display. Rotate the

CAL control throughout its range, observing a

reduction of the display amplitude. Return the CAL

control to the detent (calibrated Volts/Div) position).

The preceding procedure applies for each

channel.

for the time-base plug-in is obtained from CH 1

only.

However, the internal trigger signal

ON (deflection factor

illuminated)

Midrange

0.2 V (Calibrated)

DC,

GND

NOTE

plug-

POSI-

To demonstrate AC-coupled operation, position

(with the POSITION control) the bottom of the display

to the graticule centeriine.

Push in the AC button and note that the display

shifts downward to its average level.

Gain Check (All Channels)

The vertical and horizontal deflec:tion system of the 5000series oscilloscopes are gain-standardized to permit a

in to be moved from one oscilloscope to another (or from

one compartment to another within the oscilloscope)

out the need to recheck the calibration each time.

This completes the basic operating procedure for the

5A14N.

that need further explanation are discussed under General

Instrument operations not explained here or those

Information.

plug-

with-

GENERAL INFORMATION

Applying Signals

When measuring DC voltage, use the largest deflection

factor (5 V/Div) when first connecting the 5A14N to an un-

known voHage source. H Ihe deflection is loo small to make

the measurement, switch to a smaller deflection factor.

In general probes offer the most convenient method of

connecting a signal lo the input of the 5A14N. Tektronix

probes are shielded to prevent pickup of electrostatic

interference. A 10X attenuator probe oilers a high input

impedance and allows the circuit under test to perform very

close to normal operating conditions. The 5A14N is de-

signed for compatibility with coded probes,. The input

connector has an outer ring to which the coding ring on the

probe connector makes contact. This type of probe allows

the vertical deflection factor indicated by the readout to

correspond with the actual deflection factor at the probe tip,

eliminating the need to consider the attenuation factor of

the probe when measuring the signal amplitude on the

graticule scale. See your Tektronix, Inc., catalog lor

characteristics and compatibility of probes for use with this

system.

Sometimes unshielded test leads can be used to connect

the 5A14N to a signal source, particularly when a high-level,

low-frequency signal is monitored at a low-impedance

point. However, when any of these factors is missing, it

becomes increasingly important to use shielded signal

cables. In all cases, the signal transporting leads should be

kept as short as practical. Be sure to establish a common

ground connec:tion between the device under test and the

5A14N.

signal probe provides an adequate common ground

nection.

The shield of a coaxial cable or ground strap of a

con-

1-2

REV MAR

1987

Page 9

Operating Instructions—5A14N

Channel Sequence Logic

The 5A14N has two channel-sequence modes selected by

the internal Single Beam/Dual Beam selector. In the forward or Single Beam position (toward the front panel), the

channels are displayed in a 4-3, 4-3,

the rear or Dual Beam position, the channels are displayed

in a

4-3-2-1,

quence is necessary in order to display all channels when

operating with a single-beam oscilloscope where each vertical compartment is given two time slots in sequence

before the other compartment receives its two time slots.

Since a possible four channels per compartment may be

desired,

sary. The Dual Beam sequence is useful when only one

vertical compartment of a single-beam oscilloscope is being

used,

any YT mcxie.

4-3-2-1 sequence. The Single Beam se-

a double count of each 4-3 and 2-1 pair is neces-

or when a dual-beam oscilloscope is being used in

2-1,

2-1 sequence. In

Input Coupling

The AC-DC pushbutton switch allows a choice of input

coupling.

coupling used.

DC coupling (button out) can be used for most applica-

tions.

larger than the AC component, AC coupling (button in) will

probably provide a better display. DC coupling should be

used to display AC signals below atout 2 hertz as they will

be attenuated in the AC position.

In the AC position, the DC component is blocked by a capacitor in the input circuit. The low-frequency response in

the AC position is about 2 hertz (-3 dB point). Therefore,

some low-frequency attenuation can be expected near this

frequency limit. Distortion will also appear in square waves

which have low-frequency components.

The type of display desired will determine the

However, if the DC component of the signal is much

b. Wait about one second for the coupling capacitor to

charge.

c. Remove the ground from the coupling capacitor

(GND button out). The display will remain on-screen

and the AC component can be measured in the

usual manner.

Deflection Factor

The amount of trace deflectbn produced by a signal is determined by the signal amplitude, the attenuation factor (if

any) of the probe, the setting of the VOLTS/DIV switch,

and the setting of the Variable control. The deflection factors indicated by the VOLTS/DIV switch are calibrated only

when the CAL control is rotated fully clockwise to the detent position.

The range of the CAL control is at least

uncalibrated deflection factors covering the full range between the fixed settings of the VOLTS/DIV switch. The

control can be set to extend the deflection factor to at least

12.5 volts/division.

2.5:1.

It provides

Display Modes

SINGLE TRACE. To display a single channel, apply the

signal to the desired input and press the DISPLAY button

to display the corresponding channel.

FOUR TRACE. To display all four channels, press all the

DISPLAY buttons.

The GND pushbutton provides a ground reference at the

amplifier input. The signal applied to the input connector is

presented with a one-megohm

put is grounded. This eliminates the need to externally

ground the input to establish a DC ground reference.

Pre-charging. To minimize surge currents in the circuit under test when using deflection factors of 50 mV/div

through 1 mV/div and a test lead or IX probe, use the ACDC and GND pushbuttons to take advantage of the precharging circuit permits charging the coupling capacitor to

the DC source voltage when the AC and GND buttons are

pressed in, and also limits surge current to the coupling capacitor from the signal source. The procedure for using

this circuit is as follows:

a. Before connecting the 5A14N to a signal containing

a DC component, push in the AC and GND buttons.

Then connect the input to the circuit under test.

REV MAR 1987

load,

while the amplifier in-

Trigger Source

The internal trigger signal lor the time-base plug-in unit is

obtained from the Channel 1 display only. Select the

ger source by pushing the CH 1 DISPLAY button.

trig-

Oscilloscope Applications

Refer to the Operating Instructions of a 5000-series

Oscilloscope System manual for basic oscilloscope

applications, including peak-to-peak AC voltage meas-

urements, instantaneous DC voltage measurements,

comparison measurements, time-duration measurements,

determining frequency, rise time measurements, X-Y

measurements, etc.

1-3

Page 10

Operating Instructions—5A14N

ELECTRICAL CHARACTERISTICS

In this manual the word Volts/Div or division refers to major

graticule division.

Performance Conditions

The following charac^teristics apply when the 5A14N is operating within the environment described in the 5000series Oscilloscope System manual. In addition, the

5A14N must have been calibrated at an ambient temperature between -i-220° C and •i-30° C.

Display Modes

Selectable by switch on rear panel. All four channels displayed alternately, i.e.,

alternated with 2 and 1, i.e.,

vides a lull display of left ancl right vertical channels when

the 5A14N is usecd in a 3 plug-in single-beam system.

4-3-2-1

-4-3-2-1,

4-3-4-3-2-1-2-1,

or channel 4 and 3

which pro-

Bandwidth (-3 dB)

REPACKAGING FOR SHIPMENT

If the Tektronix instrument is to be shipped to a Tektronix

Servk^ Center for service or repair, attach a tag showing:

owner (wKh address) and the name of an individual at your

firm that can be contacted. Include complete instrument

serial number and a description of the service required.

Save and re-use the package in whk:h your instrument was

shipped.

available, repackage the instrument as foltows:

Surround the instrument with polyethylene sheeting to

protect the finish of the instrument. Obtain a carton of

corrugated cardboard of the corre<:t carton strength and

having inside dimensions of no less than six inches more

than the instrument dimensions. Cushton the instrument

by tightly packing three inches of dunnage of urethane

foam t>etween carton and instrument, on all sides. Seal

carton with shipping tape or industrial stapler.

The carton test strength for your instrument is 200 pounds.

If the original packaging is unfit for use or not

DC (DIRECT) COUPLED: DC to at least 1 MHz.

AC (CAPACITIVE) COUPLED: 2 Hz or less to at least

1 MHz.

Deflection Factor

1 mV/Divto 5 V/div within 2% in a 12 step, 1-2-5 sequence.

Uncalibrated, continuously variable between steps and to

12.5 V/div.

Maximum Safe Input Voltage

DC (DIRECT) COUPLED: 350 V (DC + peak AC).

AC (CAPACITIVE) COUPLED: 350 VDC.

Channel Isolation

At least 50 dB with any displayed combination.

input RC

1 Mn paralleled by =47 pF.

1-4

REV MAR

1987

Page 11

WARNING

THE FOLLOWING SERVICING INSTRUCTIONS

ARE FOR USE BY QUALIFIED PERSONNEL

ONLY. TO AVOID PERSONAL INJURY, DO NOT

PERFORM ANY SERVICING OTHER THAN THAT

CONTAINED IN OPERATING INSTRUCTIONS

UNLESS YOU ARE QUALIFIED TO DO SO.

REFER TO OPERATORS SAFETY SUMMARY

AND SERVICE SAFETY SUMMARY PRIOR TO

PERFORMING ANY SERVICE.

Page 12

SECTION 2

THEORY OF OPERATION

5A14N

INTRODUCTION

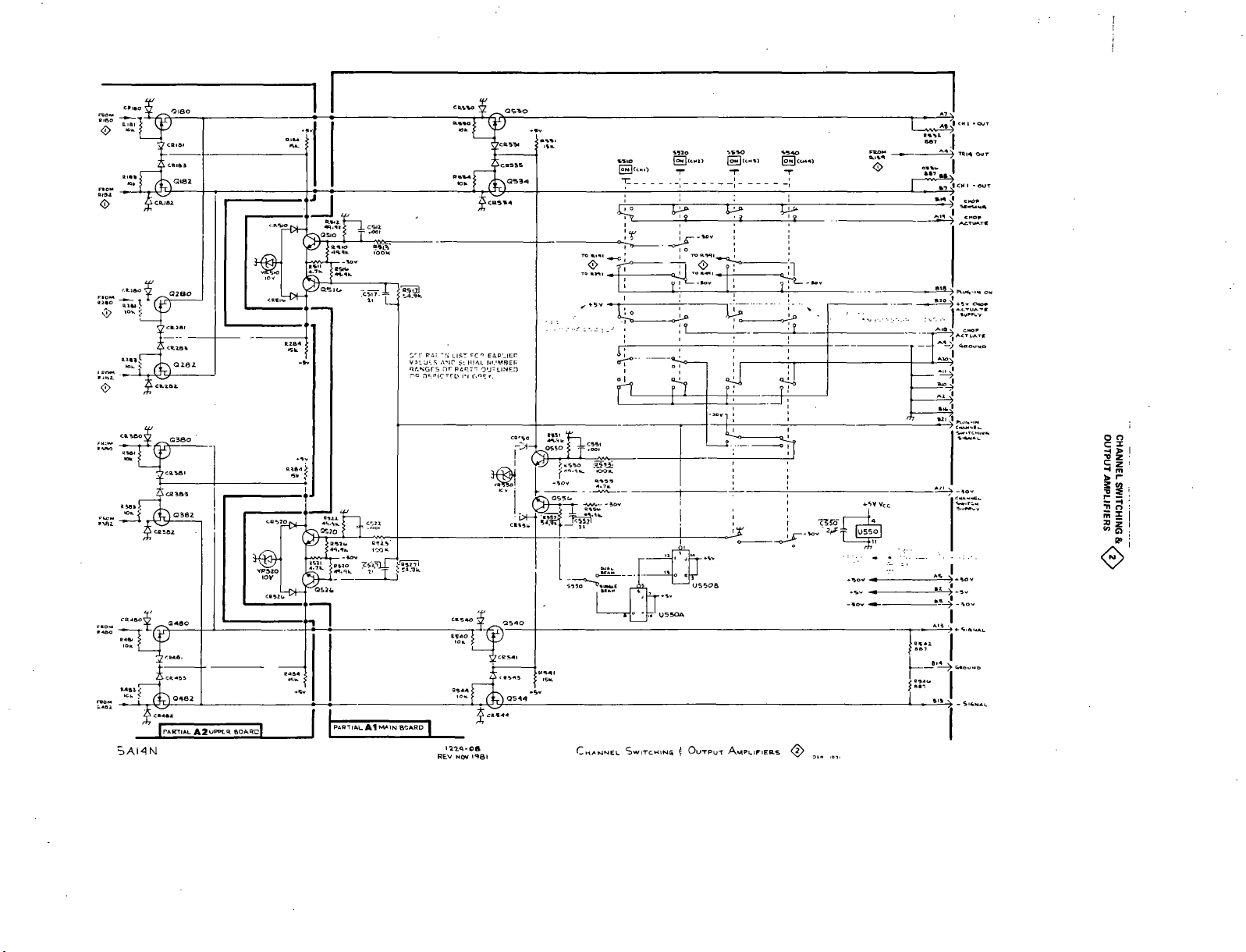

This section contains an electrical description of the circuits

in the 5A14N Four Channel Amplifier unit. A complete

block and schematic diagram is given on a pullout page at

the back of the manual.

The four channels are nearly identical except for Trigger

Pickoff, which occurs in Channel 1 only. Thus, this discussion concerns only Channel 1 except for the Channel

Switching portion, which necessarily involves all the chan-

nels.

PLUG-IN LOGIC

When the DISPLAY button, S510, is pressed, a logic level

is applied to the electronic switching circuit in the oscilloscope to enable plug-in operation (this button has no effect

when the plug-in is inserted in a horizontal plug-in

compartment). Power is applied to illuminate the frontpanel knob-skirt readout lamps, indicating the ON mcxJe.

INPUT COUPLING

Signals applied to the front-panel input connectors may be

capacitive coupled (AC), direct coupled (DC), or internally

disconnected (GND). Provision is made to precharge (or

discharge) the input capacitor to protect delicate circuitry

under test. When both the AC and GND buttons are

pressed,

input capacitor is pre-charged through a one-megohm

resistor to the level of the applied input signal.

the input to the amplifier is grounded and the

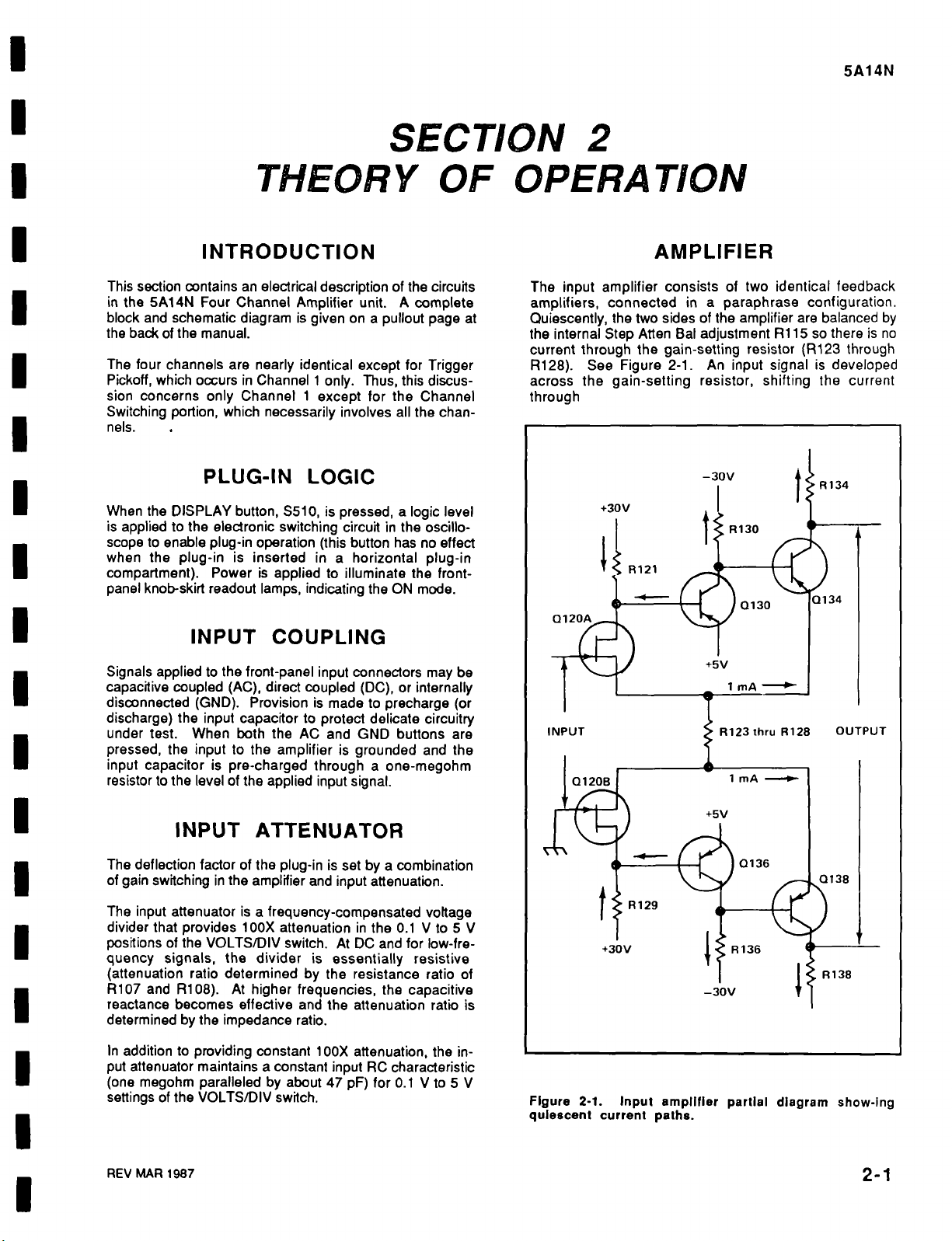

AMPLIFIER

The Input amplifier consists of two identical feedback

amplifiers, connected in a paraphrase configuration.

Quiescently, the two sides of the amplifier are balanced by

the internal Step Atten Bal adjustment Rl 15 so there is no

current through the gain-setting resistor (R123 through

R128). See Figure 2-1. An input signal is developed

across the gain-setting resistor, shifting the current

through

-sov

130

Q120A,

INPUT R123thru R128 OUTPUT

Q120B

O130

1 mA

1 mA

(134

Q134

INPUT ATTENUATOR

The deflection factor of the plug-in is set by a combination

of gain switching in the amplifier and input attenuatbn.

The input attenuator is a frequency-compensated voltage

divider that provides 100X attenuation in the 0.1 V to 5 V

positions of the VOLTS/DIV switch. At DC and for tow-frequency signals, the divider is essentially resistive

(attenuation ratio determined by the resistance ratio of

R107 and R108). At higher frequencies, the capacitive

reactance becomes effective and the attenuation ratio is

determined by the impedance ratio.

In addition to providing constant 10OX attenuation, the input attenuator maintains a constant input RC characteristic

(one megohm paralleled by about 47 pF) for 0.1 V to 5 V

settings of the VOLTS/DIV switch.

REV MAR 1987

+5V

VT\

j > R129 ^^

+30V 1136

Figure 2-1. Input amplifier partial diagram show-ing

quiescent current paths.

0136

0138

-30V

2-1

Page 13

Theory of Operation—5A14N

Q134 and Q138 by the amount established through R123R128,

and developing a push-pull output signal across

R134 and R138. The gain of this amplifier ranges from

about one to fifty, and is primarily determined by the ratio of

the gain-setting resistor to the sum of R134 and R138.

The push-pull signal voltage from 0134 and 0138 collectors then passes through emitter followers 0142 and Q146

and is transformed to a signal current by 0160 and 0162.

The Variable VOLTS/DIV (CAL) potentiometer R168, and

the Gain-setting potentiometer R166, reduce the gain in

the Q160-Q162 stage by developing an adjustable amount

of signal voltage between their emitters.

Q150,

0156 and 0158 in Channel 1 only receive the pushpull signal and provide a single-ended trigger signal out.

0177 and Q178 provide positioning current.

CHANNEL SWITCHING

When only the CH 1 DISPLAY button S510 is pressed,

0510 is biased off, turning on Channel 1 switches 0180

and 0182 and albwing a signal to pass.

When only the CH 2 DISPLAY button S520 is pressed,

Q510 is biased on, switching Q516 off. This action turns

Channel 2 switches Q280 and 0282 on.

When both CH 1 and CH 2 buttons are pressed (dual-trace

mode), the state of O510 and 0516 is determined by the

channel-switching signal generated in the oscilloscope

mainframe. The form of this signal is selected on the sweep

plug-in by the Alternate-Chop Mode button.

Channels 3 and 4 operate as a switched pair just as Channels 1 and 2. Thus, the Channel 3 switches Q380 and

0382 are controlled by Q520, and the Channel 4 switches

Q480 and 0482 are controlled by Q526. When both

Channels 3 and 4 are ON, they are either alternated or

chopped as a pair through Q520 and 0526 by the channelswitching signal.

Channels 1 and 2 are displayed as a composite pair when

their composite switches Q530 and 0534 are turned on.

This occurs when Q550 is biased off. Channels 3 and 4

composite switches Q540 and 0544 are similariy turned on

when 0556 is biased off. When one or two channels from

each composite pair are ON, U550 switches between the

two pairs at either 1/2 or 1/4 the Alternate or Chop rate of

the channel-switching signal. U550 divides the channel-

switching signal by 2 in the Dual Beam position or by 4 in

the Single Beam position of S550. The divided channel-

switching signal from S550 determines the state of Q550

and Q556 when 1 or 2 channels from each composite pair

are

ON.

PROBE SENSING

Either of two lamps located behind the VOLTS/ DIV knob

skirt illuminates the selected deflection factor to provide a

direct readout. Normally, DS190 is lit; connection of a

readout-coded 10X probe extinguishes DS190 and lights

DS196. This changes the knob skirt readout by a factor of

10 to reflect the probe attenuation, eliminating possible

operator error.

2-2

REV MAR

1987

Page 14

SECTION 3

CALIBRATION

5A14N

Introduction

This section of the manual contains a procedure to return

the circuits of the 5A14N within their designed operating

capabilities. Calibration is generally required alter a repair

has been made, or after long time intervals in which normal

aging of components may affect instrument accuracy. For

initial inspection, verify instrument operation by performing

the procedures described under Basic Operation in Section 1.

Instrument Maintenance

Before complete calibration, thoroughly clean and inspect

this instrument as outlined in the Maintenance section of

the Oscilloscope System manual. Also, the System manual

contains information for general maintenance of this instrument, including preventive maintenance, component

identification and replacement, etc.

Service Available

Tektronix, Inc. provides complete instrument repair and

calibration at local Field Service Centers and at the Factory

Sen/ice Center. Contact your local Tektronix Field Office or

representative for further information.

test equipment are not given in this procedure. Refer to

the instruction manual for the test equipment if more infor-

mation is needed.

Special Calibration Fixtures

Special Tektronix calibration fixtures are used in this procedure only where they facilitate instrument calibration.

These special fixtures are available from Tektronix, Inc. Order by part number through your local Tektronix Field

Office or representative.

Test Instruments

1.

5000-series oscilloscope system. For this proce-

dure,

a 5110 Oscilloscope with a 5B10N Time-Base

plug-in is used.

2.

Constant amplitude sine-wave generator. Fre-

quency, 2 Hz to 1 MHz; output amplitude, about 0.5

V to at least 4 V P-P. Tektronix FG 501 Function

Generator recommended (requires a TM 500-series

power module).

3. Standard amplitude calibrator. Output signal, 1 kHz

square wave; output amplitude, 5 mV to at least 20 V;

accuracy, within 0.25%. Tektronix PG 506 Calibration

Generator recommended (requires a TM 500-series

power module).

TEST EQUIPMENT REQUIRED

General

The following test equipment and accessories, or the

equivalent are required for complete calibration of the

5A14N.

the minimum necessary for accurate calibration. Therefore,

some of the specifications listed may be less rigorous than

the actual performance capabilities of the test equipment.

All test equipment is assumed to be correctly calibrated and

operating within the listed specifications.

Specifications given for the test equipment are

Calibration Equipment Alternatives

If other test equipment is substituted, control settings or

set-up may need altering to meet the requirements of the

equipment used. Detailed operating instructions for the

REV MAR 1987

Accessories

1.

Coaxial cable, Impedance,

connectors, BNC. Tektronix Part No.

2.

Input RC normalizer. RC time constant, 47 ms

x 47 pF); connectors, BNC. Tektronix Calibration

Fixture 0067-0541-00 recommended.

3. In-line termination. Impedance, 50 il, accuracy,

within 2%; connectors, BNC. Tektrnoix Part No.

0049-01 recommended.

4.

Plug-in extension for the 5000-series oscilloscope

system.

(not mandatory for this procedure).

Tektrnoix Calibration Fixture 0067-0645-03

50fi;

length, 42 inches;

012-0057-01.

(1

Mi2

011

3-1

-

Page 15

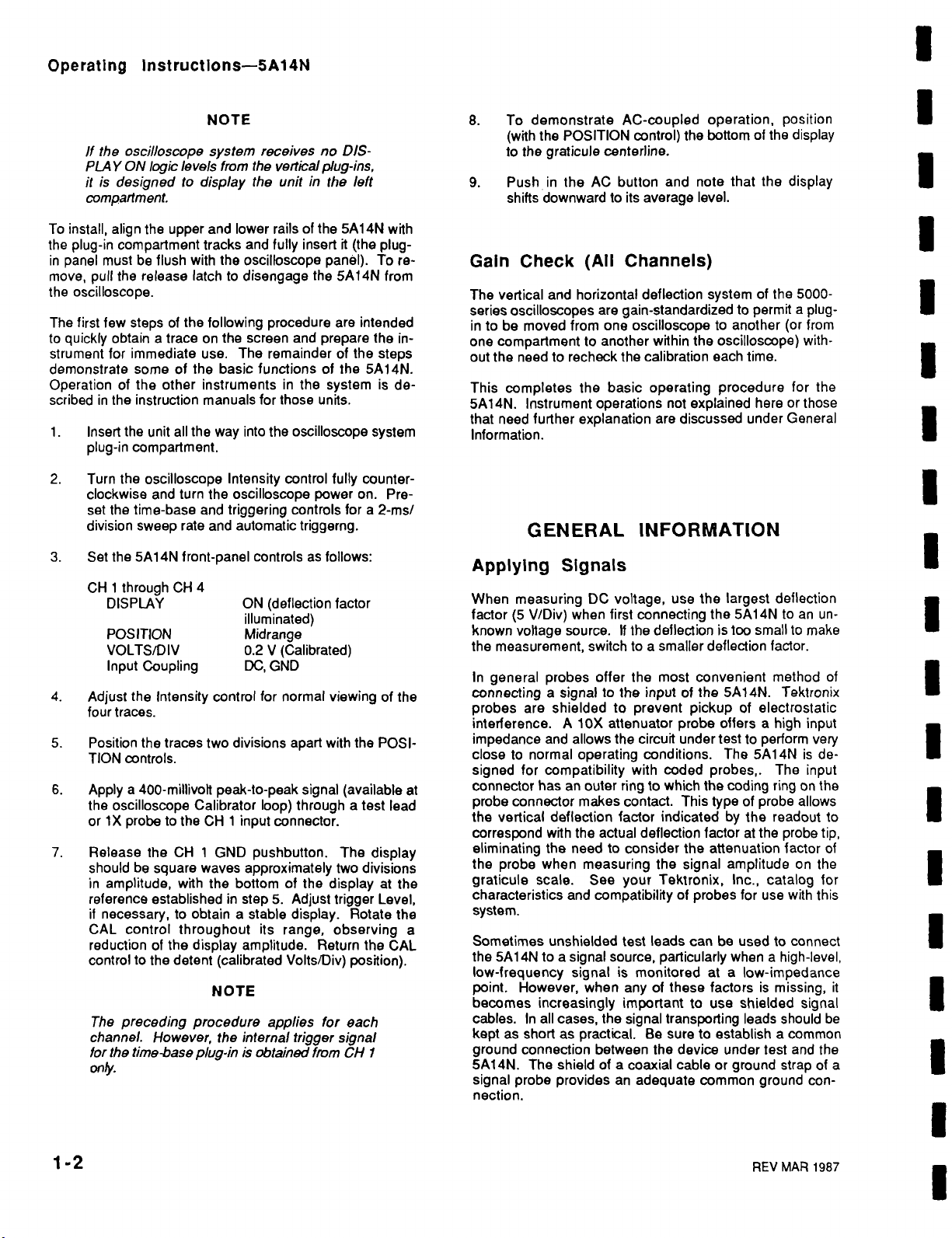

Calibration—5A14N

3-2

^OUOOOO

:C3-

.an

'•CID

Q'^O'OOQQO

is.^

^

>^-l.y>

OO

OOOOQ

-T^_T

c—n

e a

^i^^

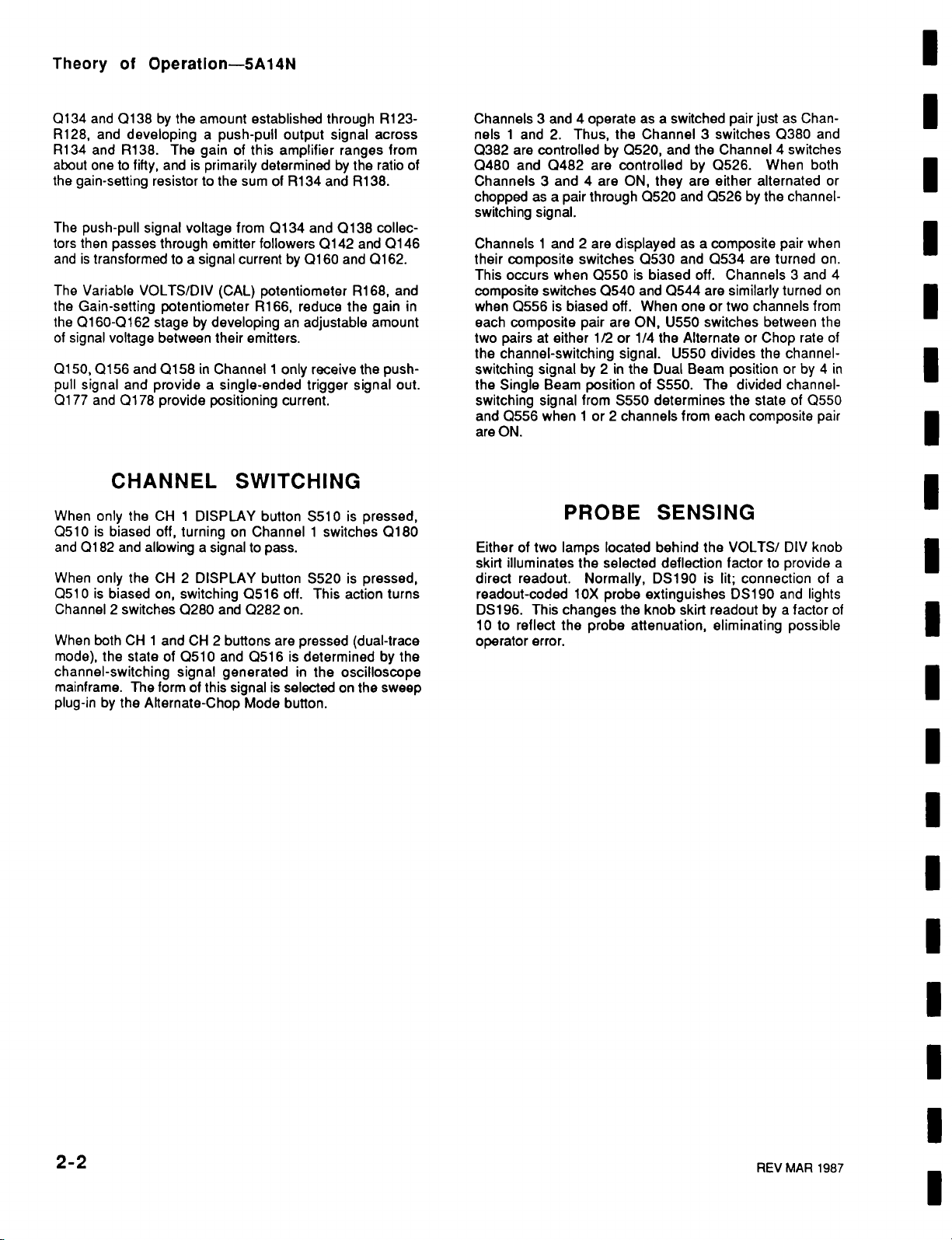

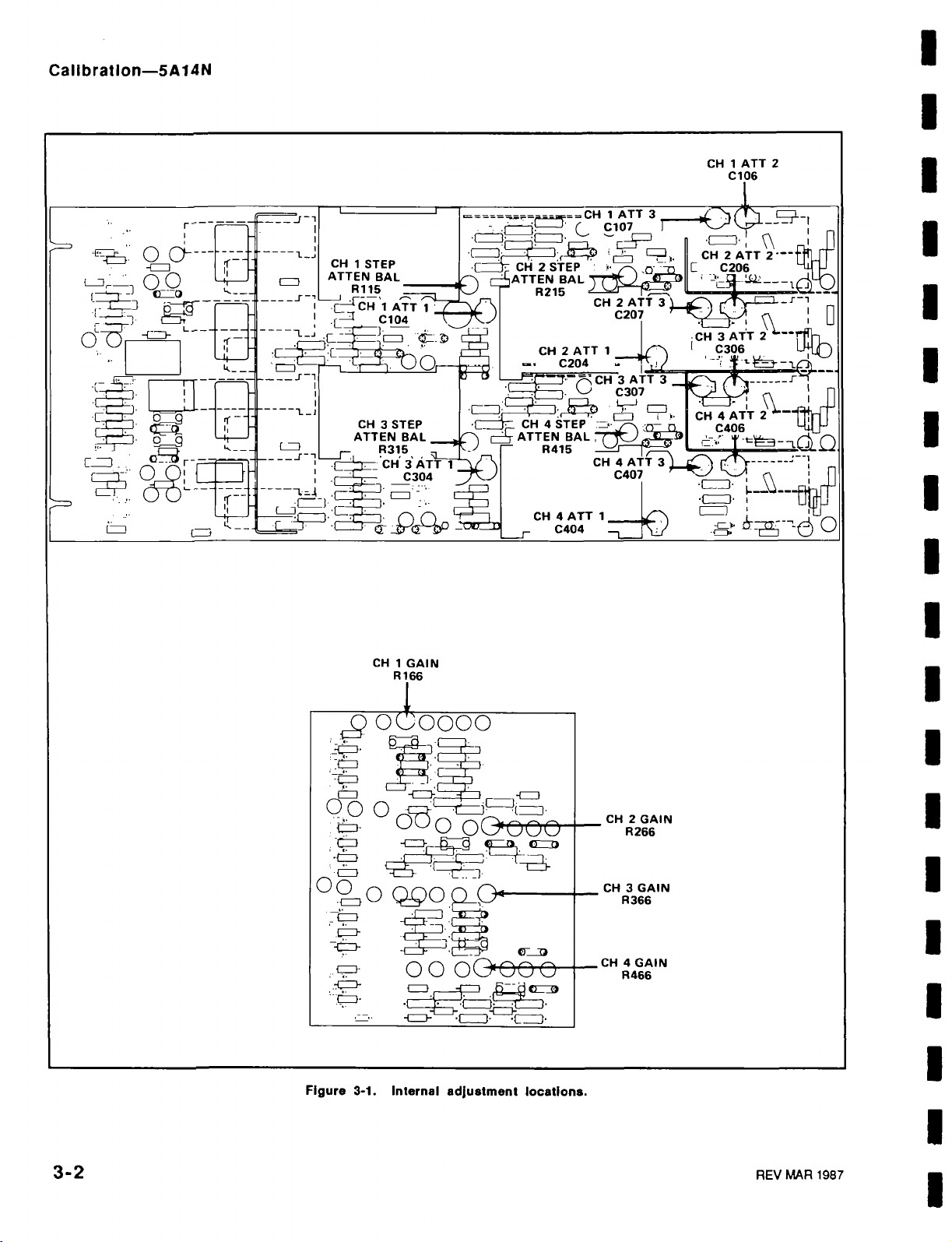

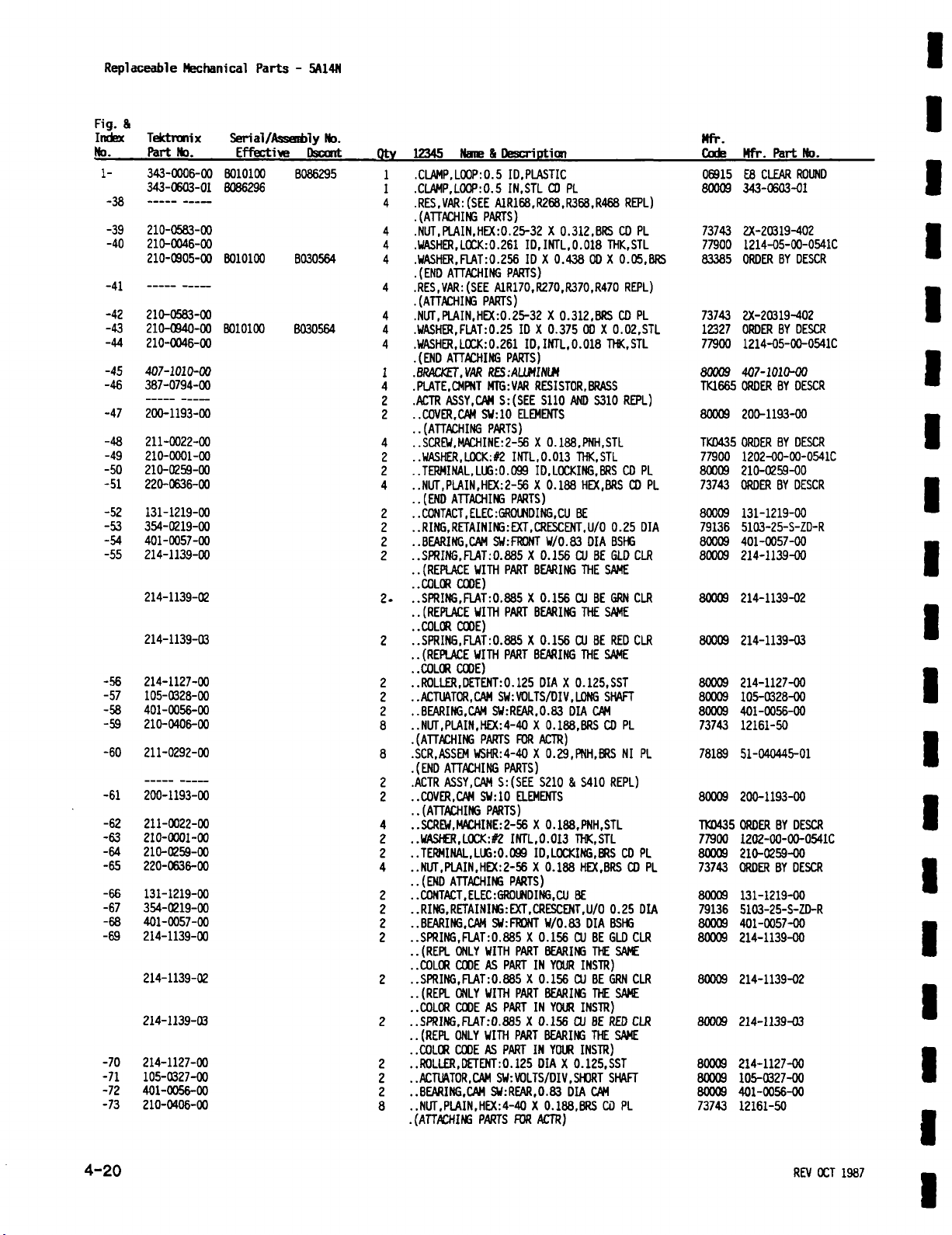

Figure 3-1. Internal adjustment locations.

CH 2 GAIN

R266

CH 3 GAIN

R366

.CH 4 GAIN

R466

REV MAR 1987

Page 16

PROCEDURE

Calibration—5A14N

1.

Step Attenuator Balance

Preparation

1.

Remove the protective cover from the left side of the

5A14N and also the left side panel from the 5000series oscilloscope. (The plug-in extender can be

used to gain access to the internal adjustments rather

than by removing the oscilloscope side panel.) Insert

the 5A14N into the left plug-in compartment, and the

5B10N into the right compartment.

2.

Connect the oscilloscope to the power source for

which it is wired. Set the controls as described under

Initial Control Settings. Refer to Figure 3-1 for location of internal adjustments and test points.

NOTE

This instrument should be calibrated at an ambient temperature between +20° C and

(+68° F and -^86° F) for best accuracy.

-1-30°

C

Initial Control Settings

NOTE

Do not preset internal controls unless they are

known to be significantly out of adjustment, or

unless repairs have been made in the circuit. In

these instances, the internal control scan be

set to midrange.

5A14N (All Channels)

a. Position the CH 1 trace to graticule center and adjust

R115 (CH 1 STEP ATTEN BAL) for no trace shift

when the VOLTS/DIV switch is turned throughout its

range.

b. Turn the CH 1 CAL control throughout its range and

check for less than 1 division of trace shift. Return

the CAL control to the fully cw (detent) position.

c. Repeat the preceding procedure for CH 2 through

CH 4. Adjust R215, R315, and R415 respectively.

2.

Input and Attenuator Compensation

a. Set all VOLTS/DIV switches to 0.1. Apply a 1 volt

signal from the Standard Amplitude Calibrator, using

the HIGH AMPL mode, through the Input RC

Normalizer to the 5A14N CH 1 input. Adjust the time

base triggering Level control for a stable display.

b. Adjust Cl

for a square leading corner on the square-wave display.

c. Set CH 1 VOLTS/DIV to 50 m and the Standard Am-

plitude Calibrator for a 0.5 volt output. Adjust C106

(ATT 2) for a square leading corner on the display.

d.

Set CH 1 VOLTS/DIV to 0.1 and the Standard Am-

plitude Calibrator for a 1 volt output. Adjust C107

(ATT 3) for a square leading corner on the display.

e. Repeat the preceding procedure for the remaining

channels. Adjust the attenuator capacitors that correspond to those adjusted in channel 1.

04,

Cl

06,

and Cl 07 (CH 1 ATT 1,2, and 3)

POSITKDN

DISPLAY

VOLTS/DIV

INPUT COUPLING

All other pushbuttons

CAL

Seconds/Div

Position

Level

Triggering Source

Trigger Mode

All other pushbuttons

REV MAR 1987

Centered

On

50 m

GND

Out

In detent (fully cw)

Time Base (5B10N)

0.5 m

Centered

Fully

CW

Left/Right

(Composite)

Auto Trig

Out

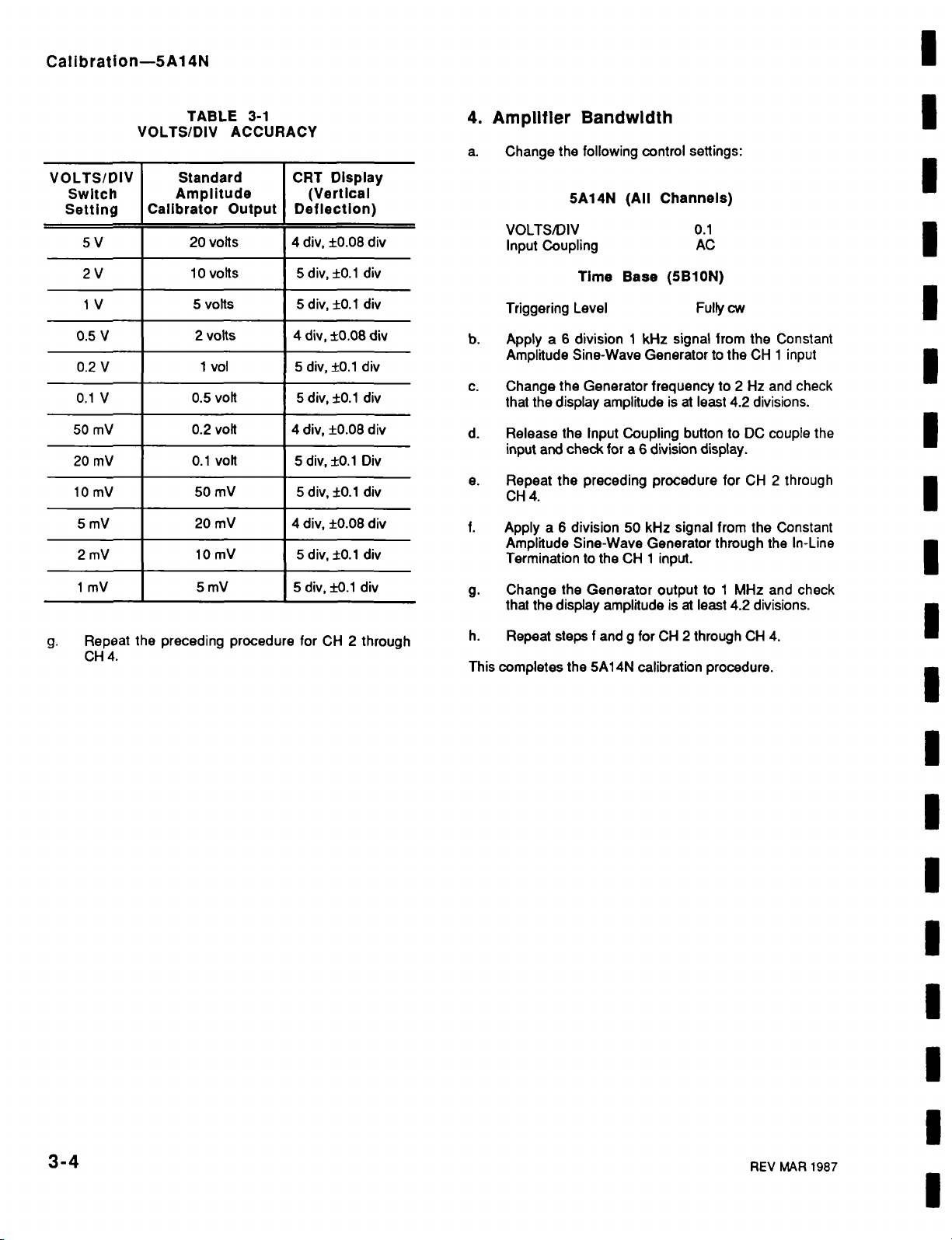

3. Amplifier Gain and VOLTS/DIV

Accuracy

a. Set all VOLTS/DIV switches to 1 and connect the

Standard Amplitude Calibrator, using the STD AMPL

mode,

through the Coaxial Cable to the CH 1 input.

b. Set Standard Amplitude Calibrator for a 5 volt square-

wave output and adjust the time-base triggering

Level control for a stable display.

c. Adjust R166 (CH 1 GAIN) for exacfly 5 divisions of

display.

d.

Repeat the preceding procedure for CH 2 through

CH 4. Adjust R266, R366, and R466 respectively.

e. Set all VOLTS/DIV switches to 5 and connect the

Standard Amplitude Calibrator the CH 1 input.

f. Check the VOLTS/DIV accuracy as outlined in Table

3-1.

3-3

Page 17

Calibration—5A14N

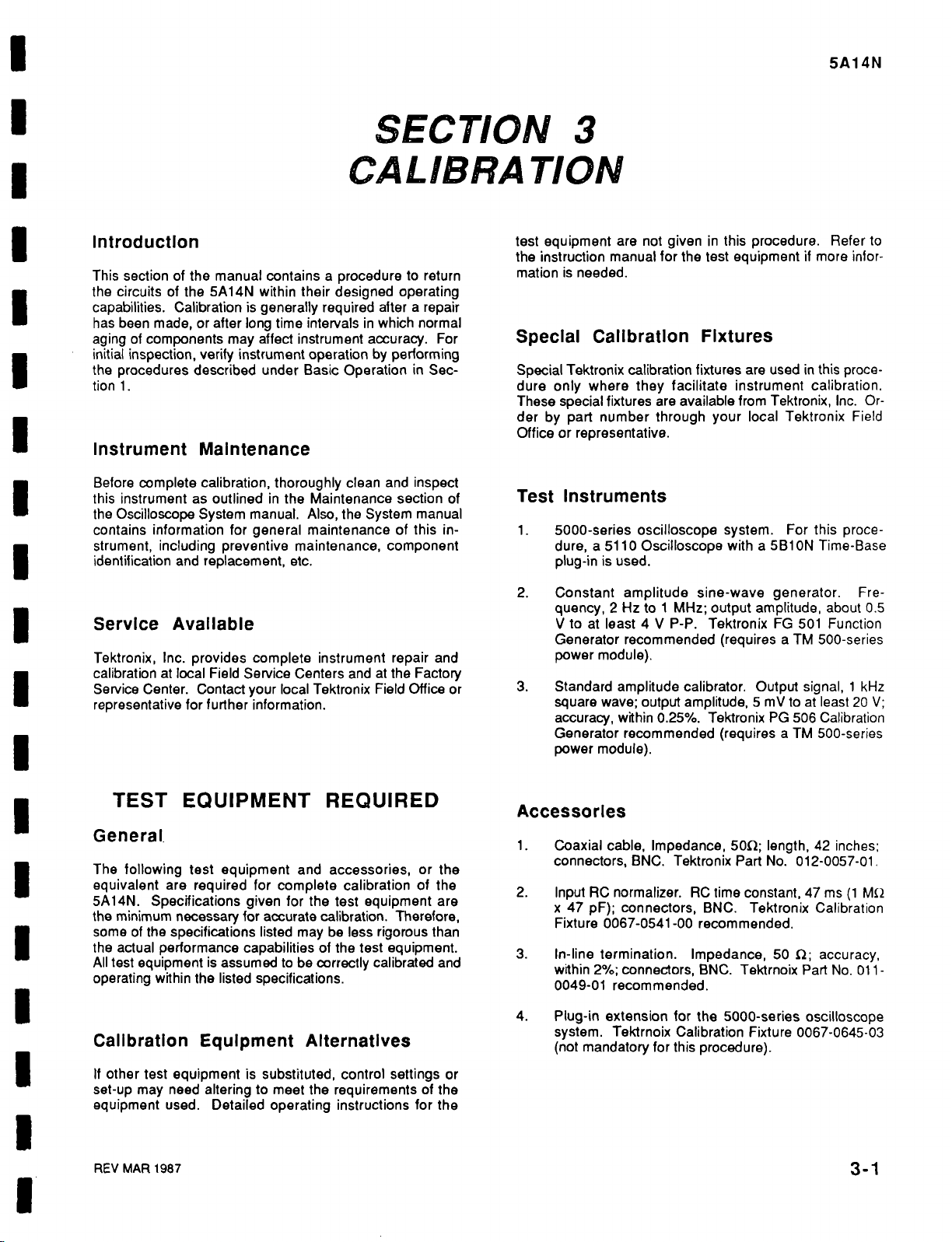

VOLTS/DIV

Switch

Setting

5V

2V

1 V

O.SV

0.2 V

0.1 V

50 mV

20 mV

10 mV

5mV

2mV

TABLE 3-1

VOLTS/DIV ACCURACY

Standard

Amplitude

Calibrator Output

20 volts

10 volts

5 volts

2 volts

1 vol

0.5 volt

0.2 volt

0.1 volt

50 mV

20 mV

10 mV

CRT Display

(Vertical

Deflection)

4 div, ±0.08 div

5

div,

5

div,

4 div, ±0.08 div

5 div,

5

div,

4 div, ±0.08 div

5 div,

5

div,

4 div, ±0.08 div

5

div,

±0.1

±0.1

±0.1

±0.1

±0.1

±0.1

±0.1

div

div

div

div

Div

div

div

4.

Amplifier Bandwidth

Change the following control settings:

a.

5A14N (All Channels)

VOLTS/DIV

Input Coupling

Time Base (5B10N)

Triggering Level Fully cw

b. Apply a 6 division 1 kHz signal from the Constant

Amplitude Sine-Wave Generator to the CH 1 input

c. Change the Generator frequency to 2 Hz and check

that the display amplitude is at least 4.2 divisions.

d.

Release the Input Coupling button to DC couple the

input and check for a 6 division display.

e. Repeat the preceding procedure for CH 2 through

CH4.

f. Apply a 6 division 50 kHz signal from the Constant

Amplitude Sine-Wave Generator through the In-Line

Termination to the CH 1 input.

0.1

AC

ImV

Repeat the preceding prcx:edure for CH 2 through

CH4.

5mV

5 div,

±0.1

div

g.

Change the Generator output to 1 MHz and check

that the display amplitude is at least 4.2 divisions.

h. Repeat steps f and g for CH 2 through CH 4.

This completes the 5A14N calibratbn procedure.

3-4

REV MAR 1987

Page 18

DIAGRAMS AND PARTS LISTS

Symbols and Reference Designators

Electrical components shown on the diagrams are in the following units unless noted otherwise:

Capacitors = Values one or greater are in picofarads (pF).

Values less than one are in microfarads

Resistors = Ohms (£2).

Graphic symbols and class designation letters are based on ANSI Standard Y32.2-1975.

Logic symbology is based on ANSI Y32.14-1973 in terms of positive logic. Logic symbols depict the logic

function performed and may differ from the manufacturer's data.

The overline on a signal name indicates that the signal performs its intended function when it goes to the low state.

Abbreviations are based on ANSI Y1.1-1972.

Other ANSI standards that are used in the preparation of diagrams by Tektronix, Inc. are:

Y14.15, 1966 Drafting Practices.

Y14.2,

1973 Line Conventions and Lettering.

Y10.5,

1968 Letter Symbols for Quantities Used in Electrical Science and

Electrical Engineering.

The following prefix letters are used as reference designators to identify components or assemblies on the diagrams.

Assembly,

A

AT

B

BT

C

CB

CR

DL

DS

E

F

FL

separable or repairable

(circuit

board,

Attenuator,

Motor

Battery

Capacitor,

Circuit

Diode,

Delay

Indicating

Spark

Fuse

Filter

tixed or variable

tixed or variable

breaker

signal or rectitier

line

device (lamp)

Gap. Ferrite bead

etc)

H

HR

HY

J

K

L

M

P

O

R

RT

Heat

dissipating device (heat sink,

heat

radiator, etc)

Heater

Hybrid

Circuit

Connector,

Relay

Inductor,

Meter

Connector,

Transistor

rectitier

Resistor,

Thermistor

stationary portion

tixed or variable

movable portion

or silicon-controlled

tixed or variable

The following special symbols may appear on the diagrams:

Strap or Link

Cam Switch

I ^'^ [BALf^ Indicators

- V I

Closure Chart

(Dot indicates

switch closure

SEL Value Selected

at Factory

(/JF).

S

T

TC

TP

U

V

VR

W

Y

Z

Switch

or contactor

Transtormer

Thermocouple

Test

point

Assembly,

inseparable or non-repairable

(integrated

Electron

Voltage

Wirestrap

Crystal

Phase

circuit, etc )

tut>e

regulator (zener

or cable

shitter

diode,

Plug to EC. Board

Identifies Panel

Controls, Connectors and

Modified Component—See

Parts List (Depicted in grey,

or with grey outline)

Plug Index

Refer to Waveform

5A14N

etc 1

Test Voltage

Internal

Screwdriver

Adjustment

Assembly Number

Board Name

REV. A JUL 1977

Refer to Diagram Number

Coaxial Connector

Shielding

Heat Sink

Decoupled or Filtered

Voltage

Etched Circuit Board

Outlined in Black

VERTIC^L AMPL1F1ER<|>-^ fnSSbe'

Schematic Name

r

4-1

Page 19

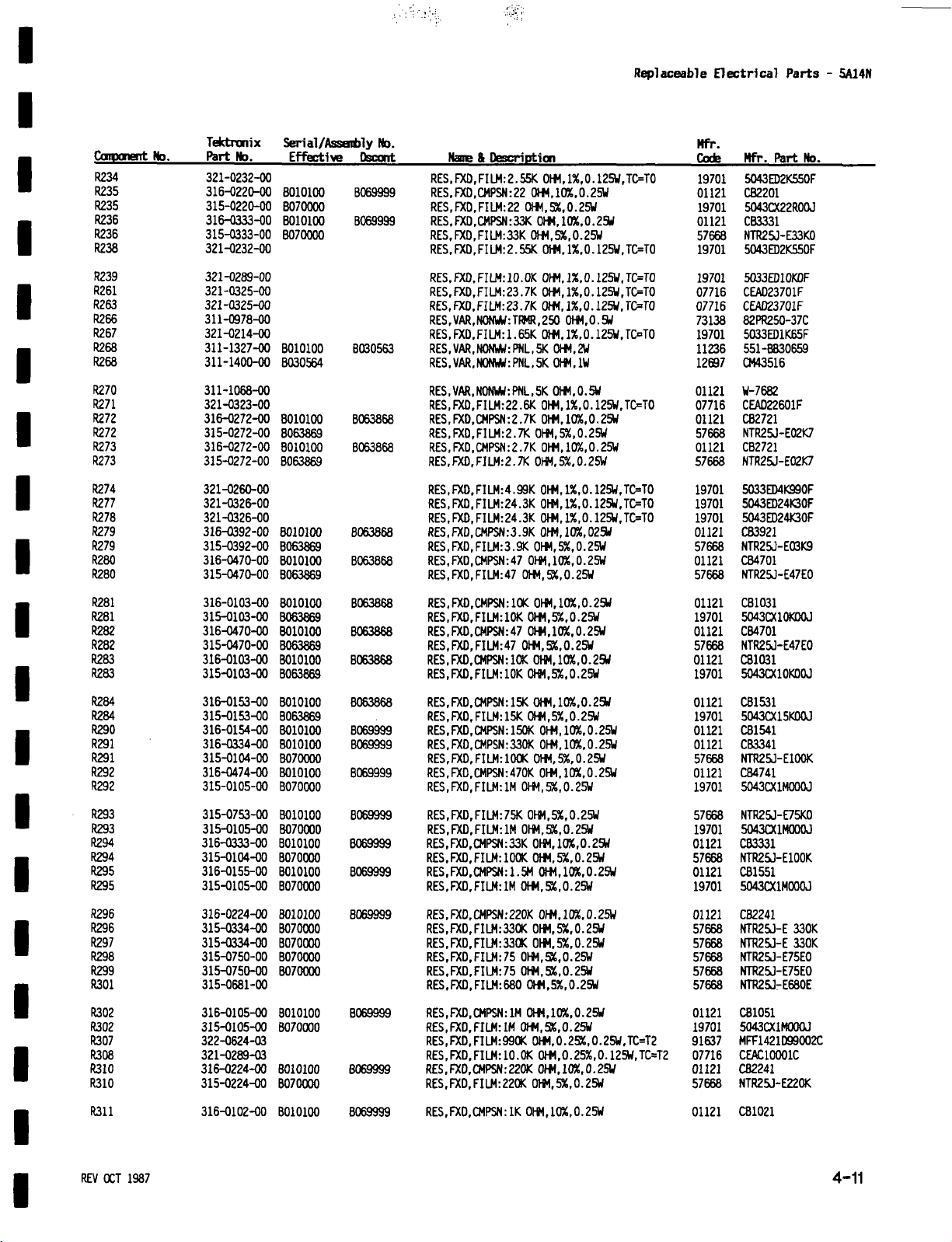

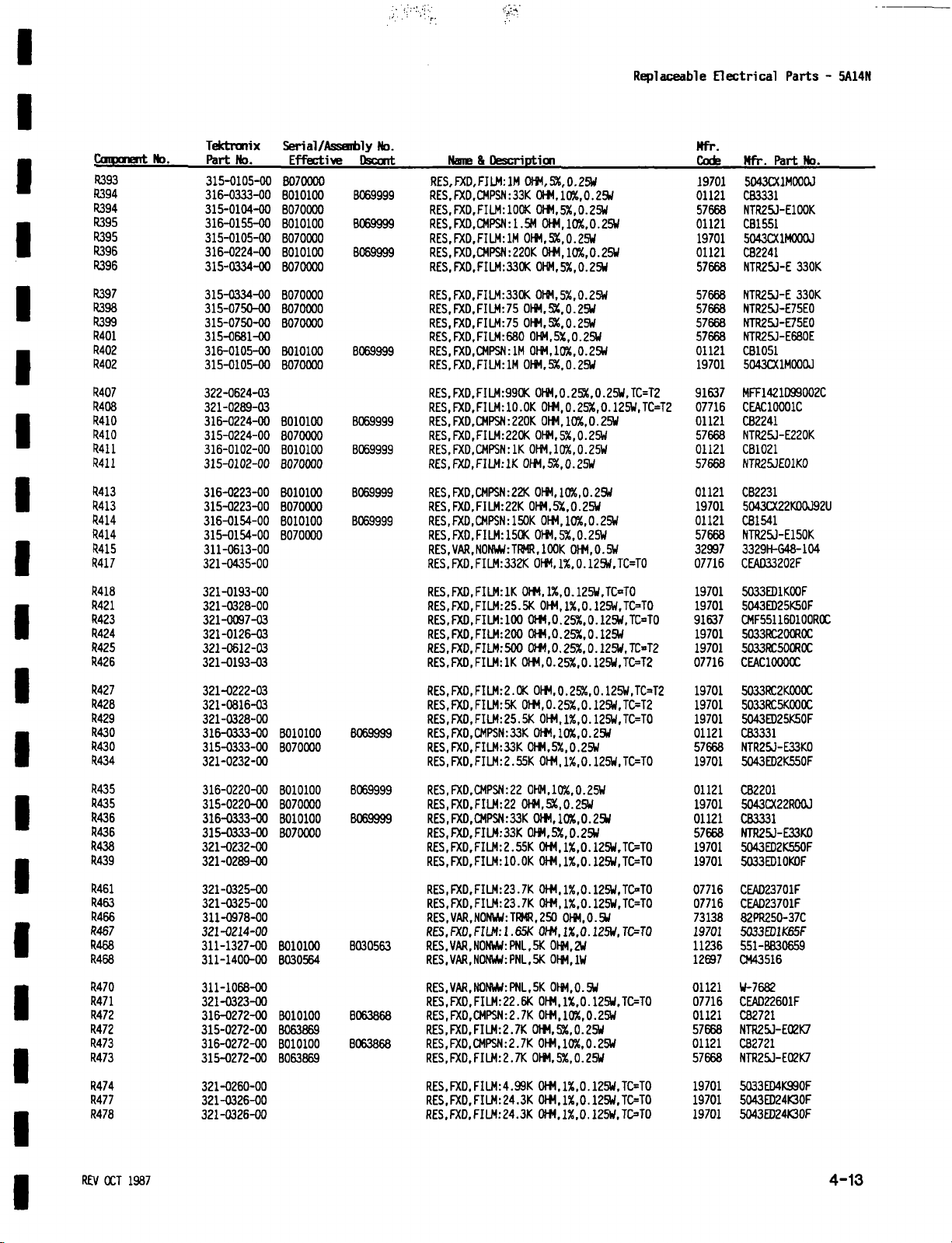

REPLACEABLE

ELECTRICAL PARTS

PARTS ORDERING INFORMATION

Replacement parts are available from or through your local Tektronix, Inc. Field Office

or representative.

Changes to Tektronix instruments are sometimes made to accommodate improved

components as they become available, and to give you the benefit of the latest circuit

improvements developed in our engineering department. It is therefore important, when

ordering parts, to include the following Information in your

type or number, serial number, and modification number if applicable.

If a part you have ordered has been replaced with a new or improved part, your local

Tektronix, Inc. Field Office or representative

will

contact you concerning any change in pari

number.

order;

Part number, instrument

Section 4—5A14N

Change information, if any, is located at the rear of this manual.

SPECIAL NOTES AND SYMBOLS

XOOO Part first added at this serial number

OCX Part removed after this serial number

rTEM NAME

In the Parts List, an Item Name is separated from the description by a colon (:).

Because of space limitations, an Item Name may sometimes appear as incomplete. For

further Item Name identification, the U.S. Federal Cataloging Handbook H6-1 can be

utilized where possible.

ABBREVIATIONS

ACTR

ASSY

CAP

CER

CKT

COMP

CONN

ELCTLT

ELEC

INCAND

LED

NONWIR

ACTUATOR

ASSEMBLY

CAPACITOR

CERAMIC

CIRCUIT

COMPOSITION

CONNECTOR

ELECTROLYTIC

ELECTRICAL

INCANDESCENT

LIGHT EMITTING DIODE

NON WIREWOUND

PLSTC

QTZ

RECP

RES

RF

SEL

SEMICOND

SENS

VAR

WW

XFMR

XTAL

PLASTIC

QUARTZ

RECEPTACLE

RESISTOR

RADIO FREQUENCY

SELECTED

SEMICONDUCTOR

SENSITIVE

VARIABLE

WIREWOUND

TRANSFORMER

CRYSTAL

REV B. MAY 1979

4-3

Page 20

Replaceable Electrical Parts - SA14N

CROSS INDEX - MFR. CODE NUMBER TO MANUFACTURER

Mfr.

Code

00853

01121

01295

03508

04222

04713

05397

07263

07716

11236

12697

14433

15238

15513

19701

24546

24931

31918

32997

52763

53944

55680

57668

59660

71590

73138

74970

79727

80009

91637

^famifBctur^

SANGAMO WESTON INC

SANGAMO CAP/CITOR DIV

ALLEN-BRADLEY CO

TEXAS INSTRIWENTS INC

SEMIC0NDl£T0R GROUP

GENERAL ELECTRIC CO

SEMI-CONDUCTOR PRODUCTS OEPT

AVX CERAMICS DIV OF AVX COKP

MOTOROLA INC

SEMICONDUCTOR GROUP

W<ION CARBIDE CORP MATERIALS SYSTEMS

DIV

FAIRCHILD CAMERA AND INSTRIHENT CORP

SEMICONDUCTOR DIV

TRW INC

TRW ELECTRONICS COMPONENTS

TRW IRC FIXED RESISTORS/BURLINGTON

CTS OF BERNE INC

CLAROSTAT MFG CO INC

ITT SEMICONDUCTORS DIV

in SEMICONDUCTORS

A DIVISION OF INTERNATIONAL

TELEPHONE ANO TELEGRAPH CORP

DATA DISPUY PRODUCTS

MEPCO/ELECTRA INC

A NORTH AMERICAN PHILIPS CO

CORNING GLASS WORKS

SPECIALTY COWIEaOR CO INC

in SCHADOW INC

BOURNS INC

TRIfPOT DIV

STLIINER ELECTRONICS INC

GLOW LITE CORP

NICHICON mmCA/ CORP

mmcQKP

TUSONIX INC

GLOBE-UNION INC

CEN7RALAB ELECTRONICS DIV

BECKMAN INSTRUMENTS INC HELIPOT DIV

JOHNSON E FCO

C-W INDUSTRIES

TEKTRONIX INC

DALE ELECTRONICS INC

Address

SANGAMO RD

P 0 BOX 128

1201 SOUTH 2ND ST

13500 N CENTRAL EXPRESSWAY

P 0 BOX 225012 K/S

W GENESEE

19TH AVE SOUTH

P 0 80X867

5005 EMCOOWaLRD

11901 MADISON AVE

464 ELLIS

2850 MT PLEASANT AVE

406 PARR ROAD

LOWER WASHINGTON

500 BROADWAY

P 0 BOX 168

303 N OAK ST

P 0 BOX 760

550 HIGH

2620 ENDRESS PUCE

P 0 BOX

8081 WALLACE RD

1200 coLureiA AVE

6135 AIRWAYS BLVD

PO BOX 21947

BOX 698

927 E STATE PKY

16931 MILLIKEN AVE

2155 N FORBES BLVD

HWY 20

P0B0X858

2500 HARBOR BLVD

299 lOm AVE S

550 DAVISVILLE RD

P 0 BOX 96

4900

P 0 BOX 500

POBQX 609

ST

ST

ST

D

W

S W

GRIFFITH OR

49

ST

W

City. State. Zip Code

PICKENS SC 29671

MILWAUKEE WI 53204

DALLAS TX 75265

AUBURN NY 13021

MYRTLE BEACH SC 29577

PHOENIX AZ 85008

aEVELAND OH 44101

MOUNTAIN VIEW CA 94042

BURLINGTOI IA 52601

BERNE IN 46711

DOVER NH 03820

WEST PALM BEACH

LAWRENCE MA 01841

LOS ANGELES CA 90302

MINERAL WaLS TX 76067

BRADRKD PA 16701

GREENWOOD IN 46142

EDEN PRAIRIE MN 55343

RIVERSIDE CA 92507

CHAHANOOW TN 37421

PAULS VALLEY OK 73075

SCHAUMBURG IL 80195

IRVINE CA 92713

TUCSON, ARIZONA 85705

FORT DODGE IA 50501

FULLERTON CA 92634

WASECA MN 56093

WARMINSTER PA 18974

BEAVERTON OR 97077

COLUMBUS NE 68601

R.

4-4

REV XT 1987

Page 21

Replaceable Electrical Parts - 5A14N

Al

Al

Al

A2

ClOl

C104

C106

C107

C108

Clio

Clio

C113

C130

C135

C136

C139

C167

C177

C178

C190

C201

C204

C206

C207

C208

C210

C210

C213

C218

Tektronix

f^rt No.

670-1891-00

670-1891-01

670-1891-02

670-1892-00

285-0603-00

281-0166-00

281-0166-00

281-0166-<K)

283-0605-00

283-0068-00

281-0614-00

283-0177-00

281-0700-00

290-0247-00

281-0700-00

283-0204-00

281-0628-00

283-0023-00

283-0023-00

283-0068-00

285-0603-00

281-0166-00

281-0166-00

281-0166-00

283-0605-00

283-0068-00

281-0614-00

283-0177-00

283-0204-00

Serial/Assently

Ef=fiBctive

BOlOlOO

B070000

B080000

BOlOlOO

B063739

BOlOlOO

BOlOlOO

B063739

~

B069999

B079999

B063738

B069999

B063738

No.

uscont

Hane & Descriptiai

CIRCUIT

BD

CIRCUIT

CIRCUIT

CIRCUIT

CAP,FXD,PLASTIC:0.1UF,3.5%,600V

CAP.VAR.AIR 01:1.9-15.7 PF,250V

CAP.VAR.AIR 01:1.9-15.7 PF,250V

CAP,VAR,AIR 01:1.9-15.7 PF,250V

CAP.FXD.MICA DI:678PF,1%,300V

CAP.FXD.CER DI:0.01UF,+100-0%,500V

CAP.FXD.CER DI:6800PF,-t80-20%,500V

CAP,FX0,CER DI:lUF,-i«)-20%,25V

CAP.FXD.CER DI:3.3PF.-i-/-0.33PF.500V

CAP.FXD.ELCTLT:5.6UF,10%,6V

CAP.FXD.CER DI:3.3PF.•^/-0.33PF.500V

CAP.FXD.CER DI:0.01UF,20%.50V

CAP.FXD.CER OI:15PF.5%.500V

CAP.FXD.CER DI:0.1UF,-t80-20%,12V

CAP.FXD.CER DI:0.1UF,-t80-20%,12V

CAP.FXD.CER DI:0.01UF,-H00-0%.5OOV

CAP,FXD,PLASTIC.O.1UF,3.5%,600V

CAP.VAR.AIR 01:1.9-15.7 PF.250V

CAP.VAR.AIR 01:1.9-15.7 PF,250V

CAP.VAR.AIR 01:1.9-15.7 PF.250V

CAP.FXD.MICA DI:678PF,1%.300V

CAP.FXD.CER DI:0.01UF.+100-0%.500V

CAP.FXD.CER DI:6800PF,+80-20%,500V

CAP,FXD.CER DI:1UF.+60-20%.25V

CAP.FXD.CER DI:0.01UF.20%,50V

(CHANNEL 2 ONLY)

ASSY:MAIN

BD

ASSY:MAIN

BD

ASSY:MAIN

BD

ASSY:SECONDARY

Mfr.

Code

80009 670-1891-00

80009 670-1891-01

80009 670-1891-02

80009 670-1892-00

80009

74970

74970

74970

00853

59660

52763

04222

52763

05397

52763

04222

52763

71590

71590

59660

80009

74970

74970

74970

0flR53

59660

52763

04222

04222

Hfr.

Part

No.

285-C603-00

187-0109-055

187-0109-055

187-0109-055

D153PB78OF0

871-533E103P

2RDPLZ007 6N80Z6

SR302E105ZAATR

2RDPLZ007 3P30KS

T322B565K006AS

2RDPLZ007 3P30KS

SR155E103MAA

2RDPLZ007 15P0JC

2DDU668104Z

2DDU668104Z

871-533E103P

285-0603-00

187-0109-055

187-0109-055

187-0109-055

0153F678OF0

871-533E103P

2RDPLZ007 6N80Z6

SR302E105ZAATR

SR155E103MAA

C230

C235

C236

C239

C267

C277

C278

C290

C301

C304

C306

C307

C308

GIO

GIO

C313

G30

C335

C336

cm

C367

C377

G78

C390

C401

C404

C406

281-0700-00

290-0247-00

281-0700-00

283-0204-00

281-0628-00

283-0023-00

283-0023-00

283-0068-00

285-0603-00

281-0166-00

281-0166-00

281-0166-00

283-0605-00

283-0088-00

281-0614-00

283-0177-00

281-0700-00

290-0247-00

281-0700-00

283-0204-00

281-0628-00

283-0023-00

283-0023-00

283-0068-00

285-0603-00

281-0166-00

281-0166-00

BOlOlOO

BOlOlOO

B063739

BOlOlOO

B069999

B063738

B069999

CAP.FXD.CER DI:3.3PF,+/-0.33PF.500V

CAP,FXD,ELCTLT:5.6UF.10%.6V

CAP.FXD.CER DI:3.3PF.+/-0.33PF.500V

CAP.FXD.CER DI:0.01UF,20%.50V

CAP.FXD.CER DI:15PF.5%.500V

CAP.FXD.CER DI:0.1UF,+60-20%.12V

CAP.FXD.CER 01:0.1UF,+80-20%.12V

CAP.FXD.CER OI:0.01UF.+100-0%.500V

CAP,FXO.PLASTIC:0.lUF.3.5%.600V

CAP.VAR.AIR 01:1.9-15.7 PF,250V

CAP.VAR.AIR 01:1.9-15.7 PF.250V

CAP.VAR.AIR 01:1.9-15.7 PF.250V

CAP.FXD.MICA DI:678PF,1%,300V

CAP.FXD.CER DI:0.01UF.+100-0%.500V

CAP.FXD.CER DI:6800PF.+80-20%.500V

CAP.FXD.CER DI:1UF.+80-20%.25V

CAP.FXD.CER DI:3.3PF.+/-0.33PF.500V

CAP.FXO.ELCTLT:5.6UF.10%.6V

CAP.FXD.CER DI:3.3PF.+/-0.33PF.500V

CAP.FXD.CER DI:0.01UF.20%.50V

CAP.FXD.CER DI:15PF,5%.5O0V

CAP.FXD.CER DI:0.1UF.+8O-2O%.12V

CAP.FXD.CER 0I:0.1UF.+8O-20%.12V

CAP.FXD.CER DI:0.01UF.+100-0%,500V

CAP.FXD.PLASTIC:0.1UF,3.5%.600V

CAP.VAR.AIR 01:1.9-15.7 PF.250V

CAP.VAR.AIR 01:1.9-15.7 PF.250V

52763

05397

52763

04222

52763

71590

71590

59660

80009

74970

74970

74970

onas3

59660

52763

04222

52763

05397

52763

04222

52763

71590

71590

59660

80009

74970

74970

2RDPLZ007 3P30KS

T322B565K006AS

2RDPLZ007 3P30KS

SR155E103MAA

2R0PLZ007 ISPOJC

2D0U66B104Z

2DDU668104Z

871-533E103P

285-0603-00

187-0109-055

187-0109-055

187-0109-055

D153F6780F0

871-533E103P

2RDPLZ007 6N80Z6

SR302E105ZAATR

2RDPLZ007 3P30KS

T322B565KD06AS

2RDPLZ007 3P30KS

SR155E103MAA

2RDPLZ007 15P0X

2DDU66B104Z

200U668104Z

871-533E103P

285-0603-00

187-0109-055

187-0109-055

REV OCT 1987

4-5

Page 22

Replaceable Electrical Parts - 5A14N

C407

C408

C410

C410

C413

C430

C435

C436

C439

C467

C477

C478

C490

C512

C517

C517

C522

C527

C527

C550

C551

C557

C557

C590

CR113

CR130

CR136

CR180

CR181

CR182

CR183

Tektronix

Part No.

281-0166-00

283-0605-00

283-n0fi8-00

281-0614-00

283-0177-00

281-0700-00

290-0247-00

281-0700-00

283-0204-00

281-0628-00

283-0023-00

283-0023-00

283-0068-00

283-0000-00

281-0628-00

281-0579-00

283-0000-00

281-0628-00

281-0579-00

283-0212-00

283-0000-00

281-0628-00

281-0579-00

290-0480-00

152-0246-00

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

Serial/Assed)ly No.

Effective "^ "

6010100

B063739

BOlOlOO

BOlOlOO

B051983

BOlOlOO

B051983

B080000

BOlOlOO

B051983

BOlOlOO

B063738

8069999

B051982

B051982

B051982

6069999

u A n 1 1.J

Mane & Description

CAP.VAR.AIR 01:1.9-15.7 PF.250V

CAP.FXD.MICA DI:678PF,1%.300V

CAP.FXD.CER DI;0.01UF,+100-0%,500V

CAP.FXD.CER DI:6800PF,+eO-20%,500V

CAP.FXD.CER DI:lUF.+60-20%.25V

CAP.FXD.CER DI:3.3PF,+/-0.33PF.500V

CAP.FXO.ELCTLT:5.6UF.10%.6V

CAP.FXD.CER DI:3.3PF,+/-0.33PF,500V

CAP.FXD.CER DI:0.01UF.20%.5OV

CAP.FXD.CER DI:15PF.5%.500V

CAP.FXD.CER DI:0.1UF,+80-20%.12V

CAP.FXD.CER 0I:0.1UF,+«)-20%,12V

CAP.FXD.CER DI:0.01UF.+100-0%.500V

CAP.FXD.CER DI:0.001UF.+100-0%,500V

CAP.FXD.CER DI:15PF.5%.500V

CAP.FXD.CER OI:21PF.5%.500V

CAP.FXD.CER DI:0.001UF.+100-0%.500V

CAP.FXD.CER 0I:15PF.5%.5O0V

CAP.FXD.CER 01:21PF.5%.500V

CAP.FXD.CER DI:2UF.2(K.50V

CAP.FXD.CER OI:0.0011F.+100-0%.500V

CAP.FXD.CER 01:15PF.5%.500V

CAP.FXD.CER DI:21PF,5K,5O0V

CAP.FXD,ELCTLT:0.5UF.+50-10%.200V

SEMICOND DVC.DI:SW,SI.40V.200m.DO-7

SEMICOW) DVC.0I:SW.SI.30V.150m.30V.DO-35

SEMICOND DVC.DI:SW,SI,30V.150m,30V.0O-35

SEMICOND DVC.DI:SW.SI.30V.15flMA.30V.0O-35

SEMICOND DVC.DI:SW.SI.30V.150MA.30V.DO-35

SEMICOND DVC.0I:SW.SI,30V.150m,30V,DO-35

SEMICOND DVC.DI:SW.SI.30V.150m,30V,DO-35

Mfp.

Code

74970

onfW3

59660

52763

04222

52763

05397

52763

04222

52763

71590

71590

59660

59660

52763

52763

59660

52763

52763

04222

59660

52763

52763

55680

14433

03508

03508

03508

03508

03508

03508

Mfr. Part No.

187-0109-055

D153F6780F0

871-533E103P

2RDPLZ007 6N80Z6

SR302E105ZAATR

2RDPLZ007 3P3(KS

T322B565K00fiAS

2RDPLZ007 3P3a(S

SR155E103MAA

2R0PLZ007 15P0X

2D01lfifiR104Z

2DDU66B104Z

871-533E103P

831-610-Y5U0102P

2RDPLZ007 ISPOJC

2RDPLZ007 21PQJC

831-610-Y5U0102P

2RDPLZ007 ISPOJC

2RDPLZ007 21P0X

SR405E205MAA

831-610-Y5U0102P

2RDPLZ007 ISPOX

2RDPLZ007 21P0JC

THU20R4rTAA

WGISSTTK

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

0A2527 (1N4152)

DA2527 (1N4152)

CR190

CR195

CR213

CR230

CR236

CR280

CR281

CR282

CR283

CR290

CR295

CR313

CR330

CR336

CR380

CR381

CR382

CR383

CR390

CR395

CR413

CR430

CR436

CR480

CR481

CR482

CR483

152-0141-02

152-0141-02

152-0246-00

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0246-00

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0246-00

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

BOlOlOO

BOlOlOO

BOlOlOO

BOlOlOO

BOlOlOO

BOlOlOO

B068999

B069999

8069999

B069999

B069999

8069999

SEMICOND DVC.DI:SW.SI.30V.150MA.30V.DO-35

SEMICOND DVC.DI:SW.SI.30V.150m.30V.DO-35

SEMICOND DVC.0I:SW.SI.40V.200m.DC-7

SEMICOfO 0VC.DI:SW.SI.30V.150MA.30V.DO-35

SEMICOMD 0VC.OI:SW.SI.3OV,150MA.30V.DO-35

SEMICOND DVC,DI:SW.SI.30V.150W.30V.DO-35

SEMICOND DVC.DI:SW.SI.30V.150W.30V.DO-35

SEMICOND DVC.DI:SW.SI.30V.150W.30V.DO-35

SEMICOND DVC.DI:SW.SI,30V,150m,30V.DO-35

SEMICOND 0VC.DI:SW.SI.3OV.15flW,30V,0O-35

SEMICOND DVC.DI:SW.SI,30V.15CHA,30V.DO-35

SEMICOND DVC.DI:SW.SI.40V.20(WA.DO-7

SEMia»ID OVC.DI:SW.SI.30V.15flMA,30V.DO-35

SEMICOND 0VC.DI:SW.SI,30V.150MA,30V.00-35

SEMICOND DVC.DI:SW,SI.30V.150MA,30V.DO-35

SEMICOND DVC.DI:SW,SI,30V,150MA,30V.DO-35

SEMICOND DVC.DI:SW.SI.30V.150MA,30V.DO-35

SEMICOND DVC.DI:SW.SI.30V.150MA.30V.0O-35

SEMICOfO 0VC.DI:SW,SI.3OV.150m.30V.DO-35

SEMICOW) 0VC,DI:SW.SI.30V.15(»1A.30V,DO-35

SEMICOND 0VC,DI:SW.SI.40V.20(»W.D0-7

SEMICOND DVC.DI:SW.SI.30V.15(WA,30V.D0-35

SEMICOND DVC.DI:SW.SI.30V.15flMA,30V.D0-35

SEMICOND DVC.DI:SW.SI.30V.150MA.30V,DO-35

SEMICOND DVC.OI:SW.SI,30V.150m,30V,DO-35

SEMICOND DVC.DI:SW.SI.30V.150MA.30V.DO-35

SEMICOND DVC.DI:SW,SI.30V.15flMA.30V.DO-35

03508

03508

14433

03508

03508

03508

03508

03508

03508

03508

03508

14433

03508

03508

03508

03508

03508

03508

03508

03508

14433

03508

03508

03508

03508

03508

03508

DA2527 (1N4152)

DA2527 (1N4152)

W61537TK

DA2527 (1N4152)

DA2527 1N4152)

DA2527 1N4152)

OA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (IN4152)

DA2527 (1N4152)

W61537TK

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

0A2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

WG1537TK

DA2527 (1N4152

0A2527 (1N4152

DA2527 (1N4152

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

4-6

REV OCT 1987

Page 23

Replaceable Electrical Parts - 5A14N

Cuiixxuit

CR490

CR495

CR510

CR516

CR520

CR526

CR530

CR531

CR534

CR535

CR540

CR541

CR544

CR545

CR550

CR556

DS190

DS190

OS 196

0S196

0S290

DS290

0S296

0S296

DS390

0S390

DS396

0S396

0S490

DS490

No.

Tektronix

Part

No.

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

152-0141-02

150-0111-00

150-1064-00

150-0111-00

150-1064-00

150-0111-00

150-1064-00

150-0111-00

150-1064-00

150-0111-00

150-1064-00

150-0111-00

150-1064-00

150-0111-00

150-1064-00

Soial/Assartily

Effective

BOlOlOO

BOlOlOO

BOlOlOO

6069999

8069999

B069999

B070000

BOlOlOO

8069999

8070000

8010100

8069999

8070000

BOlOlOO

8069999

8070000

BOlOlOO

B069999

8070000

BOlOlOO

8069999

8070000

8010100

B069999

B070000

No.

Dscont

Nane & Description

SEMICOND DVC.DI:SW.SI.30V.15OMA.30V.0O-35

SEMICOND DVC.DI:SW.SI.30V.150MA.30V.D0-35

SEMICOfC DVC.DI:SW.SI.30V.150MA.30V.DO-35

SEMICOND OVC.DI:SW.SI.30V.150MA.30V.DO-35

SEMICOND DVC.DI:SW,SI.30V,150MA.30V,DO-35

SEMICOND DVC.DI:SW.SI.30V.150m.30V.DO-35

SEMICOND OVC.DI

SEMICOND DVC.OI

SEMICOND DVC.OI

SEMICOND DVC.OI

SEMICOND DVC.OI

SEMICOND DVC.OI

:SW.SI.30V.150MA.30V,DO-35

:SW.SI.SOV.150m.30V.00-35

:SW.SI.30V.150MA.30V.DO-35

:SW.SI.30V.150MA.30V.0O-35

:SW.SI.30V.150W\.30V.DO-35

:SW.SI,30V.150^W.30V.DO-35

SEMICOND 0VC.DI:SW.SI,30V.150m.30V.DO-35

SEMICOND DVC,DI:SW.SI,30V.150MA.30V.0O-35

SEMICOND DVC,DI:SW.SI,30V.150MA.30V.DO-35

SEMICOND OVC.DI:SW.SI,30V.150MA.30V.D0-35

LAMP.GLOW:125V MAX.1.5MA.2AC-AT.WIRE

LT

EMITTING 0I0:YELLCW,585NM.40

MA MAX

LAMP.GLDW:125V MAX.1.5MA.2AC-AT.WIRE

LT

EMITTING DIO:YELL0W.585NM.4O

MA MAX

LAMP.GLOW:125V MAX.1.5MA.2AC-AT.WIRE

LT

EMiniNG DIO:YELL0W.585NM.4O

MA MAX

LAMP.GLOW:125V MAX,1.5MA.2AC-AT.WIRE

LT

EMITTING DI0:YELL0W,585NM,40

LAMP.aOW:125V

LT

EMITTING 0IO:YELL0W.585NM,4O

MAX.

1.5MA.2AC-AT.WIRE

MA MAX

MA MAX

LAMP,GL0W:125V MAX.1.5MA.2AC-AT.WIRE

LT

EMiniNG DI0:YELL0W.585NM.4O

MA MAX

LAMP.GLOW:125V MAX.1.5MA.2AC-AT.WIRE

LT

EMiniNG DI0:YELL0W.585»1.40

MA MAX

Mfr.

Code

03508

03508

03508

03508

03508

03508

03508

03508

03508

03508

03508

03508

03508

03508

03508

03508

53944

15513

53944

15513

53944

15513

53944

15513

53944

15513

53944

15513

53944

15513

Mfr.

Part

No.

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152I

DA2527 (1N4152)

0A2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

DA2527 (1N4152)

AlB-9

SP840113

AlB-9

SP840113

AlB-9

SP840113

AlB-9

SP840113

AlB-9

SP840113

AlB-9

SP840113

AlB-9

SP840113

DS496

0S496

JlOl

JlOl

J201

J201

J301

J301

J401

J401

Q120

Q130

Q134

Q136

Q138

Q142

Q146

Q150

Q156

0158

Q160

0162

Q177

Q178

Q180

Q182

Q190

150-0111-00

150-1064-00

131-0679-00

131-0679-02

131-0679-00

131-0679-02

131-0679-00

131-0679-02

131-0679-00

131-0679-02

151-1049-00

151-0342-00

151-0342-00

151-0342-00

151-0342-00

151-0341-00

151-0341-00

151-0341-00

151-0341-00

151-0341-00

151-0341-00

151-0341-00

151-0342-00

151-0342-00

151-1005-00

151-1005-00

151-0347-00

BOlOlOO

8070000

8010100

8031129

8010100

B031129

BOlOlOO

B031129

BOlOlOO

B031129

BOlOlOO

B069999

B031128

B031128

8031128

8031128

8069999

LAMP.GL0W:125V MAX.1.5MA.2AC-AT.WIRE

LT

EMiniNG 0I0:YELL0W.585W1.40

MA MAX

CONN.RCPT.ELEC:BNC,MALE.3 CONTACT

CONN.RCPT.ELEC:BNC.MALE.3 CONTACT

CONN.RCPT.ELEC:BNC.MALE.3 CONTACT

CONN.RCPT.ELEC:BNC.MALE.3 CONTACT

C0im.RCPT.EL£C:8NC.MALE.3 CONTACT

CONN.RCPT.ELEC:BNC.MALE.3 CONTACT

COW.RCPT.ELEC:BNC.MALE.3 CONTAa

COW.RCPT,ELEC:BNC.MALE.3 CONTACT

TRANSISTOR:FET.N-CHAN.SI.TO-71

TRANSIST0R:PNP.SI.T0-92

TRANSISTOR:PNP,

TRANSISTOR:PNP,

TRANSISTOR:PNP,

TRANSISTOR:NPN,

TRANSISTOR:NPN,

TRANSISTOR:NPN,

TRANSISTOR:

TRANSISTOR:

TRANSISTOR:

TRANSISTOR:

TRANSISTOR:

TRANSISTOR:

TRANSIST0R:FET.N-CHAN.SI.T0-106

TRANSISTOR:FET.N-CHAN,SI.T0-106

TRANSISTOR:NPN.SI.TO-92

SI.TO-92

SI.TO-92

SI.TO-92

SI.T0-106

SI.TO-106

SI,TO-106

NPN,SI,TO-106

NPN.SI.TO-106

NPN.SI.TO-106

NPN.SI.TO-106

PNP.SI.TO-92

PNP.SI.TO-92

53944

15513

24931

24931

24931

24931

24931

24931

24931

24931

04713

07263

07263

07263

07263

04713

04713

04713

04713

04713

04713

04713

07263

07263

04713

04713

04713

AlB-9

SP840113

28JR168-1

28JR270-1

28JR168-1

28JR270-1

28JR168-1

28JR270-1

28JR168-1

28JR270-1

Sn31049

S035928

S035928

S035928

S035928

SPS6919

SPS6919

SPS6919

SPS6919

SPS6919

SPS6919

SPS6919

S035928

S035928

SPF685

SPF685

SPS7951

REV XT 1987

4-7

Page 24

Replaceable Electrical Parts - 5A14N

CunxjiKaiL

Q190

Q196

Q196

0220

Q230

Q234

Q236

Q238

Q260

Q262

0277

Q278

Q280

Q282

Q290

Q290

Q296

Q296

Q320

Q330

0334

Q336

Q338

Q360

0362

0377

0378

Q380

0382

0390

Q390

No.

Tektronix

Part

No.

151-0254-00 8070000

151-0347-00 8010100

151-0254-00 8070000

151-1049-00

151-0342-00

151-0342-00

151-0342-00

151-0342-00

151-0341-00

151-0341-00

151-0342-00

151-0342-00

151-1005-00

151-1005-00

151-0347-00

151-0254-00

151-0347-00

151-0254-00

151-1049-00

151-0342-00

151-0342-00

151-0342-00

151-0342-00

151-0341-00

151-0341-00

151-0342-00

151-0342-00

151-1005-00

151-1M5-00

151-0347-00

151-0254-00

Serial/Assentily

Effective Osoont

BOIOIX

X700X

XIOIOO

B070X0

XIOIOO

8070X0

No.

8069999

8069999

8069999

8069999

Name & Description

TRANSIST0R:[»RLINGT0N.NPN,SI.625MW.TO-92

TRflNSISTOR:NPN.SI.TO-92

TRANSIST0R:DARLINGT0N.NPN,SI.625MW.T0-92

TRANSISTOR:FET.N-CHAN.SI.TO-71

TRANSISTOR:PNP,SI,TO-92

TRANSISTOR:PNP.SI,TO-92

ISTOR:

PNP.SI.TO-92

PNP.SI.TO-92

NPN.SI.TO-IX

NPN.SI.TO-IX

PNP.SI.TO-92

PNP.SI.TO-92

FET.

N-CHAN.

NPN. SI.

TO-IX

FCT.

N-CHAN.

SI,

SI.

TO-IX

TO-IX

TRANSISTOR:

TRANSISTOR:

TRANSISTOR;

TRANSISTOR;

TRANSISTOR;

TRANSISTOR;

TRANSISTOR:

TRANSISTOR:FET,N-CHAN,SI .TO-IX

TRANSISTOR:NPN,SI,TO-92

TRANSIST0R:QARLINGT0N,NPN,SI,625MW,T0-92

TRANSISTOR:NPN.SI.TO-92

TRANSIST0R:QARLINGT0N.NPN.SI.K5MW.T0-92

TRANSISTOR:FET.N-CHAN.SI.TO-71

TRANSISTOR:PNP.SI.TO-92

TRANSISTOR:FNP.SI.TO-92

TRANSISTOR:PNP.SI.TO-92

TRANSISTOR:PNP,SI.TO-92

TRANSISTOR:

TRANSIST(»:NPN.SI.T0-1X

TRANSISTOR:PNP,SI,TO-92

TRANSISTOR:PNP,SI,TO-92

TRANS

TRANSISTOR:FET,N-CHAN.SI.TO-IX

TRANSISTOR:NPN,SI,TO-92

TRANSISTOR:DARLINGTON,NPN,SI.625MW.T0-92

Mfr.

Code

03508

04713

03508

04713

07263

07263

07263

07263

04713

04713

07263

07263

04713

04713

04713

03508

04713

03508

04713

07263

07263

07263

07263

04713

04713

07263

07263

04713

04713

04713

03508

Mfr.

Part

X38L3118

SPS7951

X38L3118

SFD1049

S035928

S035928

S035928

S035928

SPS6919

SPS6919

S035928

S035928

SPF685

SPF685

SPS7951

X38L3118

SPS7951

X38L3118

SFD1049

S035928

S035928

S035928

S035928

SPS6919

SPS6919

S035928

S035928

SPF685

SPF685

SPS7951

X.'Hfll

3118

No

0396

Q396

Q420

Q430

0434

0436

Q438

046O

Q462

Q477

Q478

Q480

Q482

0490

Q490

0496

Q496

Q510

Q516

0520

0526

Q530

Q534

Q540

Q544

Q550

Q556

151-0347-00

151-0254-00

151-1049-00

151-0342-00

151-0342-00

151-0342-00

151-0342-00

151-0341-00

151-0341-00

151-0342-00

151-0342-00

151-1X5-00

151-1X5-X

151-0347-00

151-0254-X

151-0347-X

151-0254-M

151-034HX)

151-0341-X

151-0341-X

151-0341-X

151-1X5-00

151-1X5-X

151-1X5-X

151-1X5-X

151-0341-X

151-0341-X

XIOIOO

M700X

XIOIX

B0700X

XIOIX

M700X

8069999

8069999

8069999

TRANSISTORrNPN.SI.TO-92

TRANSIST0R:DARLINGT0N.NPN.SI.625MW.T0-92

TRANSISTOR:PFT.N-CHAN.SI.TO-71

TRANSISTOR:PNP.SI.TO-92

TRANSISTOR:PNP.SI.TG-92

TRANSISTOR:PNP.SI.TO-92

TRANSISTOR:PNP.SI.TO-92

TRANSISTOR:NPN,SI,TO-106

TRANSISTOR

TRANSISTOR:PNP,SI.TO-92

TRANSISTOR:PNP.SI.TO-92

TRANSISTOR:FET.N-CHAN.SI .TO-IX

TRANSISTOR:

TRANSISTOR:NPN.SI.TO-92

TRANSIST0R:aARLINGT0N.NPN.SI,625MW.TO-92

TRANSISTOR:NPN,SI.TO-92

TRANSISTOR:QARLINGTON,NPN,SI.625MW.TO-92

TRANSISTOR:NPN.SI.TO-106

TRANSISTOR:NPN.SI.TO-IX

TRANSISTOR:NPN,SI,TO-IX

TRANSISTOR:NPN.SI.TO-IX

TRANSISTOR:FET.N-CHAN.SI.TO-IX

TRANSISTOR:FET.N-CHAN.SI.TO-IX

TRANSISTOR:FET.N-CHAN,SI.TO-IX

TRANSISTOR:

TRANSISTOR:NPN,SI,TO-IX

TRANSISTOR:NPN,SI,TO-IX

:l«^,

SI,

T0-106

FET.

N-CHAN.

FET.N-CHAN.SI,TO-IX

SI

.TO-IX

04713

03508

04713

07263

07263

07263

07263

04713

04713

07263

07263

04713

04713

04713

03508

04713

03508

04713

04713

04713

04713

04713

04713

04713

04713

04713

04713

SPS7951

X38L3118

SFD1049

S035928

S035928

S035928

S035928

SPS6919

SPS6919

S035928

S035928

SPF685

SPF685

SPS7951

X38L3118

SPS7951

X38L3118

SPS6919

SPS6919

SPS6919

SPS6919

SPF685

SPF685

SPF685

SPF685

SPS6919

SPS6919

4-8

REV XT 1987

Page 25

Replaceable Electrical Parts - 5A14N

RlOl

R102

R102

R107

RIX

RllO

RllO

Rill

Rill

R113

R113

R114

R114

R115

R117

R118

R121

R123

R124

R125

R126

R127

R128

R129

R130

R130

Tektronix

Part No.

315-0681-00

316-0105-X

315-0105-X

322-X24-03

321-0289-03

316-0224-X

315-0224-X

316-0102-X

315-0102-X

316-0223-X

315-0223-X

316-0154-X

315-0154-X

311-0613-X

321-0435-X

321-0193-X

321-X28-X

321-0X7-03

321-0126-X

321-X12-03

321-0193-03

321-0222-X

321-X16-03

321-0328-X

316-0333-X

315-a\^3-X

Seria1/Ass8rt)ly No.

Effective ~

BOlOlX

uscont

6069999

B0700X

BOlOlOO

8069999

M70X0

MIOIOO

8069999

M70X0

BOIOIX

8069999

M7OX0

BOlOlOO

B069999

M700X

BOlOlOO

B069999

M70X0

NatB & Description

RES,FXD.FILM:680 0HM.5%.0.25W

RES.FXD.CMPSN:1M 0I*1.10%.0.25W

RES.FXD.FILM:lMOIt1.5%,0.25W

RES,FXD,FILM:990K Om.0.25%.0.25W.TC=T2

RES.FXD.FILM:10.0KOIt1.0.25%.0.125W.TC=T2

RES,FXD,CMPSN:220K Olt1.10%.0.25W

RES,FXD.FILM:220K 0IW.5%.0.25W

RES.FXD.CMPSN:1K Ot*1.10%.0.25W

RES.FXD.FILM:lK0tf1.5%.0.25W

RES.FXD.CMPSN:22K Off1.10%.0.25W

RES.FXD.FILM:22K 0HM.5%,0.25W

RES,FXD.CMPSN:150K 0t«.10%.0.25W

RES.FXD.FILM:150K 0HM.5%,0.25W

RES,VAR,N0NWW:TRM?,100K Olti.O.SW

RES,FXD,FILM:332K OHM.l%,0.125W.TC=TO

RES.FXD.FILM:IK 0I»1.1%.0.125W.TC=T0

RES.FXD.FILM:25.5KOfW.l%.0.125W,TC=T0

RES.FXD.FILM:IX OHM.0.25%.0.125W,TC=TO

RES.FXD.FILM:2X 0IW.0.25%.0.125W

RES.FXD,FILM:500 OHM.0.25%.0.125W.TC=T2

RES.FXD.FILM:IK Om.0.25%,0.125W.TC=T2

RES.FXD.FILM:2.OK OHM.0.25%.0.125W.TC=T2

RES,FXD.FIU1:5K 01*1.0.25%.0.125W.TC=T2

RES,FXD,FILM:25.5K 0W,1%,0.12W,TC=T0

RES,FXD.CMPSN:33K 0>«.10%.0.25W

RES.FXD.FILM:33K 0I*I.5%.0.25W

nil .

Code

57668

01121

19701

91637

07716

01121

57668

01121

57668

01121

19701

01121

57668

32997

07716

19701

19701

91637

19701

19701

07716

19701

19701

19701

01121

57668

Mfr.

Part

No.

NTR25J-E680E

CB1051

5043aiM000J

MFF1421D99X2C

CEACIOXIC

CB2241

NTR25J-E220K

CB1021

NTR25JE01K0

CB2231

5043CX22K00J92U

CB1541

NTR25J-E150K

3329H-648-104

CEAD33202F