INSTRUCTION MANUAL

Digital Multimeter

Model 5900

WARRANTY

We warrant each of our products to be free from defects in material

and workmanship. Our obligation under this warranty is to repair

or replace any instrument or part thereof which, within a year after

shipment, proves defective upon examination. We will pay local

domestic surface freight costs.

To exercise this warranty, write or call your local Keithley repre-

sentative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and shipping instructions,

REPAIRS AND

CALIBRATION

Keithley Instruments maintains a complete repair and calibration

service as well as a standards laboratory in Cleveland, Ohio. A

service facility is also located in Los Angeles for our west coast

customers.

A Keithley service facility at our Munich, Germany office is

available for our customers throughout Europe. Service in the

United Kingdom’can be handled at our office in Reading. Addition-

ally, Keithley representatives in most countries maintain service

and calibration facilities.

To insure prompt repair or recalibration service, please contact

your local field representative or Keithley headquarters directly

before returning the instrument. Estimates for repairs, normal

recalibrations and calibrations traceable to the National Bureau of

Standards are available upon request.

KEITHLEY

The measurement engineers.

Keithley Instruments, inc., 28775 Aurora Road, Cleveland, Ohio 44139. (216) 248-0400

European Headquarters: Heiglhofstrasse 5, D-8000 Munchen 70 West Germany, (0811) 7144065

Unlted Kingdom: 1 Boulton Road, Reading, Berkshire, (0734) 861287

France: 44 Rue Anatole France. F-91121 Palaiseau (01) 928-00-48

FOR YOUR SAFETY

Before undertaking any maintenance procedure, whether it

be a specific troubleshooting or maintenance procedure

described herein or an exploratory procedure aimed at

determining whether there has been a malfunction, read the

applicable section of this manual and note carefully the

WARNING and CADTlON notices contained therein.

The equipment described in this manual contains voltages

hazardous to human life and safety and which is capable of

inflicting personal injury. The cautionary and warning

notes arc included in this manual to alert operator and

maintenance personnel to the electrical hazards and thus

prevent personal injury and damage to equipment.

If this instrument is to be powered from the AC Mains

through an autotransformer (such as a Vartac or equivalent)

ensure that the instrument common connector is connected to the ground (earth) connection of the power

mains.

Before operating the unit ensure that the protective conductor (green wire) is connected to the ground (earth)

protective conductor of the power outlet. Do not defeat

the protective feature of the third protective conductor in

the power cord by using a two conductor extension cord or

a three-prong/two-prong adapter.

Maintenance and calibration procedures contained in this

manual sometimes call for operation of the unit with power

appliedandprotective covers removed. Read the procedures

carefully and heed Warnings to avoid “live” circuit points

to ensure your personal safety.

Before operating this instrument,

1. Ensure that the instrument is configured to

operate on the voltage available at the power

source See Installation section.

Ensure that the proper fuse is in place in the

2.

instrument for the power source on which the

instrument is to be operated.

3. Ensure that all other devices connected to or in

proximity to this instrument are properly grounded

or connected to the protective third-wire earth

ground.

COPYRIGHT

0

Copyright

States of America.

not be reproduced in any form without written permission of the

publishers.

1976 by Keithley Instruments, Inc. Printed in the United

All rights reserved. This book or parts thereof may

PROPRIETARY NOTICE

This document and the technical data herein disclosed, are proprietary

to Keithley Instruments, Inc., and shall not, without express written

permission of Keithley Instruments, Inc., be used, in whole or in part

to solicit quotations from a competitive source or used for manufacture

by anyone other than Keithley Instruments, Inc. The information

herein has been developed at private expense, and may only be used for

operation and maintenance reference purposes or for purposes of

engineering evaluation and incorporation into technical specifications

and other documents which specify procurement of products from

Keithley Instruments, Inc.

TABLE OF CONTENTS

Section

1

1.1

1.7

1.9

1.11

1.13

1.15

1.17

1.19

I .26

I .32

2

2.1

2.4

2.6

2.8

2.12

2.13

2.16

2.18

2.19

2.21

2.23

2.24

2.28

2.42

2.44

2.46

2.48

2.50

2.54

2.56

2.59

2.60

2.62

2.64

2.66

2.68

2.70

2.72

2.75

2.77

GENERALDESCRIPTION

Introduction

Options .’

Model 42 Remote Programming

Rear Input Options(-I, -1s)

Rack-Mounting Flanges (403402)

High-Voltage Probe

Current Shunt Set (651)

Electrical Description

MechonicalDescription

Specifications

mSTALLATION& OPERATION

Unpacking and Inspection

Bench Operation

Rack Mounting

Power Connections

Input/Output Cabling

Binding Posts

Rear Input Connector

Manual Operation

Controls

Display ...............

Measurement Connections.

Basic Voltage Measurement

Ohms Measurement

Ratio Measurements

System Capabilities

Printer Output

Program Input.

Logic Levelsand Electronic Interface

Driving the Inputs

TTL Loading Conditions

Exceptions to Input Loading Conditions

‘ITL Output Capabilities

Thning Sequence

Other Read CommandOptions

Reading Rates.

Superfast

Printer Output

Numerical Data

Function Data.

Range Data.

............

............

............

.............

. JZOI .........

.............

............

............

.........

............

..........

.........

...........

........

.......

..........

..........

...........

...........

..........

........

........

...........

......

...........

...........

...........

Title Page

. .

.....

...

I-1

1-l

I-I

I-1

I-1

1.2

1-2

l-2

1-2

I.3

l-3

2-1

2-l

2-l

2-1

2-l

2-2

2-2

2-2

2-2

2-2

2-2

2.4

24

24

2-7

2-7

2-8

2-8

2-8

2-B

2-8

2.10

2-10

2.10

2.11

2-12

2.12

2-13

2-13

‘2.14

2.14

111

980453

Section

TABLE OF CONTENTS (continued)

2.79

2.81

2.83

2.84

2.86

2.88

2.90

2.93

2.95

2.97

“NO” Indication

Status Output Lines

Input Control Lines

System Direct Command

Remote Programming

SystemControl

Function Programming

Range Programming

+ Five Volts

Hold

2.99 Read Commands

2.101

2.103

2.105

2.107

2.109

Timeouts

Data Inhibit

Program Storage

Superfast

Adding/Removing Accessories

3 SPECIFICATIONTESTS .....

3.1

3.4

3.6

4

4.1

4.3

4.5

4.7

General ...........

Required Equipment ......

Procedure ..........

THEORY OF OPERATION

General

Mechanical Description

Electrical Description

Signal Conditioning Section

4.10 Switching Board

4.14

4.18

4.2 1

4.24

4.28

4.30

4.33

4.35

4.37

4.52

4.54

4.56

4.70

4.12

4.74

OhmsConverter

Scaling Atnplifier

Averaging AC Converter

RMSACConverter

Attenuator

Isolator

Switching Bypass.

Integration

Digitizer,

Ratio, Standard

Ratio,Option

Display Board

Main Logic and Control Circuitry

Control Logic

Program Cycle

. .

2.14

2.15

2-15

2.16

2.16

2.16

2.16

2.17

2.17

2-17

2.17

2.17

2-17

2-17

2.18

2.18

3.1

3-l

3-l

3-1

4.1

4-l

4-l

4-l

4-1

4-l

4-1

4.3

4.9

4-9

4.9

4.9

4-9

4-9

4.12

4-14

4.15

4.15

4.17

4-17

4.19

iv

TABLE OF CONTENTS (continued)

980453

Section

4.76 Display Logic

4.78 Superfast

4.80

4.82

5

5.1

5.3

Power Supplies

Program.

CALIBRATION

scope

General

5.5

5.7

5.10

5.19

5.23

Preliminary Procedure

5.24

5.26

5.28

5.30

5.32

Recalibration Procedure .

5.34

5.35

5.36

5.38

DC Range Calibration

Ohms Calibration.

5.39

5.40

5.41

Ohms Range

AC Calibration (Model 33).

5.42

5.43

5.44

5.45

5.46

RMS AC Calibration (Model 32)

4-Wire Ratio Calibration

Troubleshooting

5.48

5.50

5.52

5.54

5.55

5.86

Board Revision

..................

...................

.................

...................

.................

....................

Required Equipment

..............

Fabricated Calibration Equipment

DC Voltage Sources

AC Voltage Sources

...............

...............

...............

Warmup.

Familiarization

Calibration Points

Environmental Considerations

Isolator Zero

..................

................

...............

...........

.................

DC Voltage Zero and Gain.

................

ohms Zero

..................

..................

AC Converter Zero

Frequency Response

...............

..............

..............

.................

Troubleshooting Equipment

Power Supply Check

Operational Check

...............

Preliminary Instrument Setup

Circuit Descriptions

...............

............

...............

...........

.................

Title

..........

4-19

4.19

4.19

4.20

5-1

5-l

5-l

5-l

5-l

5-l

5-4

5-4

s-4

54

54

5-4

54

5-6

5-6

5-6

5-6

5.6

5-7

5.7

5.7

s-7

5-9

s-10

s-10

s-10

S-10

5-l 1

5-1 1

5.11

s-14

1

DRAWINGS . . . . .

PARTS LIST . . . . . . . . . . .

6-1

7-1

v/vi blank

LIST OF ILLUSTRATIONS

Figure

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

4.15

4.16

4.17

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

1.1

1.2

Block Diagram -Model 5900

Dimensions,

Rack Mount Installation’

Cabling Diagram, Binding Posts

Cabling Diagram, Rear Input

Readout

Front Panel

Basic Voltage Measurement Connections

Maximum RMSlnput Voltage

Two Wire Ohms Measurements

Four Wire Ohms Measurement

Rear Panel

Measurement Sequence.

Command Timing

Minimum Read Rate vs. Input

Superfast Read Rate (Worst Case)

Pin Assignments 5201 PRINTER OUT

Pin Assignments 5202 PROGRAM INPUl

Jumper Location

Mechanical Assembly

Signal Flow, Loaded DVM.

Switching Board

Signal Flow of Switching Board

Ohms Converter

OhmsMeasurement Systems

Scaling Amplifier

Averaging AC Converter

RMS AC Converter

Attenuator/Isolator DC.

Signal Flow, Switching Bypass

Digitizer.

Integration Timing Diagram

4.Wire Ratio Option

Display Board

Main Logic&Control Block Diagram

Program Block Diagram.

10 Volt Source

Generating Accurate DC Levels

AC Source

Adjustment Locations

Ohms Input Connection

Connections for Ohms Range Adjustment

4.Wire Connections

AC Adjustment Locations

4.Wire Ratio Adjustment Locations

Title Page

l-2

l-3

2-l

2-2

2-2

2-2

2-3

2.4

2-4

2-s

2-6

2-8

2-9

2-11

2.12

2.13

2-14

2-16

Z-IX

4-2

4.3

4-4

4.5

4-6

4-7

4-R

4-8

4.10

4.11

4.12

4-13

4.14

4-1s

4.15

4-18

4-20

5-2

s-2

s-3

s-s

S-6

5.7

s-7

S-8

S-IO

vii

980453

LIST OF ILLUSTRATIONS (continued)

Figure

6.1

Layout, Logic and Interconnection

6.2 Layout, Readout

6.3

6.4

6.5

6.6

6.7

6.8

Schematic, Logic and Interconnection ..........

Schematic, Power Supply

Layout, Attenuator

Schematic, Attenuator

Layout, Switching

Schematic, Switching

6.9 Layout, Isolator

6.10

6.11

6.12

Schematic, Isolator

Layout, IOV Reference Amplifier

Layout, Digitizer

.................

..............

................

...............

................

...............

.................

................

.................

...........

...........

6.13 Schematic, Digitizer and 1OV Reference Amplifier ......

6.14

Layout, Program

6.15 Schematic, Program

6.16

layout, Display

6.17 Schematic, Display

6.18

6.19

6.20

Layout, AC Converter

Schematic, AC Converter

Layout, RMS Converter

6.21 Schematic, RMS Converter

6.22

6.23

Layout, Scaling Amplifier

Schematic, Scaling Amplifier

6.24 Layout, Ohms Converter

6.25 Schematic, Ohms Converter

6.26

Layout, 4.Wire Ratio

6.27 Schematic, 4.Wir-s Ratio

6.28 Layout,RearPanel

.................

................

.................

................

...............

..............

..............

.............

..............

.............

..............

.............

...............

..............

................

6.29 Layout, Parallel Front-Rear Input (-1) ..........

6.30 Layout, Switchable Front.Rear Input (-IS) ........

Title

Page

6-3

6.3

6-S

6-7

6.8

6.9

6-10

6-11

6.12

6-13

6.14

6.14

6-15

6.16

6.17

6.18

6.19

6.20

6-21

6.22

6.23

6.24

6.25

6-26

6-27

6.28

6.29

6.30

6.3 1

6-32

viii

LIST OF TABLES

Table

1.1

1.2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

4.1

4.2

4.3

4.4

4.5

4.6

4.7

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

7.1

7.2

Measurement Capability

Specifications

Operating Controls

Maximum Input Voltage

Positive True Logic Relationships

Range Codes(Printer Output)

Function Programming

Range Codes(Programmet)

Timeouts

Maximum Input Voltage

Required Equipment

DC Range Check(Low Ranges)

DC Range Check (High Ranges)

3.Wire Ratio Check

4.Wire Ratio Check

DC Input Resistance.

Model 33 AC Converter Range Check

Model 32 AC Converter Range Check

Ohms-Megohms Range Check.

Common Mode Rejection (In DC Volts Function)

Normal Mode Noise Rejection (In DC Volts Function)

Common Mode Rejection (In AC Volts Function)

Switching Board Range Decode

Range Switch Code

Autorange Logic

Relay Logic Coding

Annunciator Logic

“NO” Annunciator Logic

Program Logic Conversion

Required Calibration Equipment

Fixed Voltage Dividers

DC Source Accuracies

AC Source Accuracies

Power Supply Check

OperationalCheck

Trollblesllooting Guide

Troubleshooting Chart-Digitizer and 1OV Reference Amplifier

Troubleshooting Chart. Isolator and Attenuator Boards

Troubleshooting Chart

Table7.1

List of Suppliers

................

...............

....................

...............................

.............................

..........................

.............. 1 1 : : 1 1 1 1 1 1 1 1 1 :

..........................

............... : : : : : : : : : : : ,: : : : :

..................

................

.......... : : : : : : : : : : : : : : : :

.....................

........................

...............

...............

...........................

......................

................

..................

....................

...................

............................

............................

..........................

..........................

.......................

...........................

...........................

...........................

.........................

...........................

Optional Accessories

...............

..............

...................

: : : : : : : : : : : : : : :

............. : : :

: : : : : : : : : : : : : : :

................

: : : : : : : : :

: : : : : : : : : : : : :

: : : : : :

: : : :

: : : : : : : : :

.............

Page

1-1

1-4

2.3

2.4

2-a

2.15

2.17

2.17

2-18

2.18

3-1

3.2

3-3

3-4

3-s

3.6

3-7

3-8

3-9

3-10

3-11

3.12

4-1

4.16

4-16

4.16

4.17

4.17

4-2 1

5-a

S-l

s-3

s-4

S-II

s-1 1

s-12

s-13

s-14

s-14

7-1

7-l

980453

ix

SECTION 1

GENERAL DESCRIPTION

1.1 INTRODUCTION.

The Model 5900 Digital Multimeter is a five-decade

1.2

instrument with a sixth digit providing 60% overrange. The

basic instrument is equipped for dc and dc/dc ratio measurements on five ranges. With the addition of the optional

AC Converter, a-c and ac/dc ratio measurements on four

ranges are available. The Ohms Converter, also optional,

adds ohms measurements on eight ranges. Complete measurement capability of a fully equipped instrument is tabulated in table 1 .l.

Table 1 .I - Measurement Capability

r

DC & Dc/Dc

RATIO

Range (Basic 5900)

.lV I x I

1vI x I

I

1ov X

FUNCTION

OhIllS

(Model 52

Ohms

Converter)

I

AC & AC/DC

RATIO

(Model 32

or 33

AC Converter)

1

IOOV I x I

ooov I x I

100.

I

.I KS2 X

I x

until a single reading is commanded by an external command. The new measurement is then held until the next

external command. In Periodic mbde (RATE control CW),

measurements are made automatic+ly at the rate of approximately four per second.

1.5 The basic Model 5900 includes an analog output

voltage that is proportional to the parameter being measured (except ratio). The voltage, at 20 volts maximum, is

available at a rear panel connector.

Also included as standard equipment is a solid-state

1.6

isolated BCD output. TTL-compatible output levels of the

reading, function, range, etc., plus a print command are

provided. An additional line enables a new reading to be

commanded externally. An optional isolated remote pro.

gramming unit (Model 42) allows all operating commands to

be made extcmally.

1.7 OPTIONS.

1.8 All optional accessories having model numbers are

plug-in circuit boards that may be added at any time. A

calibrated accessory board can be installed without affecting the d-c calibration of the basic instrument. An

instrument shipped without PCB accessories will not be

equipped with a Function Switching PCB assembly. This

board must be added when accessory boards are installed.

Analog accessories are identified in table 1 .l.

1Kn

10Kn 1

100 K$-l 1

000 KS2 1

lOMa/

lOOMa 1

1.3 Range can be selected manually or automatically

(autorange).

ular measurement is selected automatically (full scale is defined as “100000” on any range). The instrument “up

ranges” at 16U% of full scale and “downranges” at 15% of

full scale. Polarity selection is also automatic and is displayed on the readout.

1.4

(RATE control on EXT), a measurement is held (displayed)

In AUTO range, the proper range for a partic-

Two operating modes are provided. In Hold mode

X

I x

I x

I x

I x

I x

Model 42 Remote Programming.

1.9

The Model 42 Remote Programming accessory al-

1.10

lows the selection of function, range, filter, read command,

etc., to be made externally. Auto range selection is also

provided and appropriate timeouts are generated internally

when ranging takes place. Remote Programming “overrides”

all manual control settings to prevent erratic selections.

Complete isolation of the programming unit is achieved by

the use of photoauplers and pulse transformers.

1.11 Rear Input Options (-1, -lB, -1s. -1SB).

1.12

5900 DMM. The option designated -1 or -IB consists of

connector 5204 on the back panel with input lines +

INPUT, + CURRENT, and GUARD wired in parallel with

the front panel input terminals; the option designated -1s

or -1SB is the same as the -1 or -lB except that the front or

rear inputs are selectable by a switch on the front panel.

Two rear input options are available for the Model

b

I-I

980453

T T

1.13 Rack-Mounting Flanges (403402).

1.14 Rack.Mounting Flatages are used where 1111’ IIIS~~U-

ment is to be installed in a relay-rack or cabinet.

1.15 High-Voltage Probe (641).

1.16 The High.Voltage Probe extends the voltage range of

the instrument up to 10,000 volts (or 7SOOV rms). It is an

insulated prube containing a 1000: 1 voltage divider.

l-2

1.17 Current Shunt Set (651).

I .I8 The Current Shunt Set consists of six precision

sIllill assemblies witb values selected to produce a voltage

drop that, n~e:tsured in millivolts. Ins a numerical value

cqual to 111~ current Ilow in milliamps or micro;tmps.

1.19 ELECTRICAL DESCRIPTION.

1.70

1be Model 5900 DMM is a dual slope integration

instrument consisting of three main functional areas: signal

9804.53

conditioning, integrating, and control/display. A block diagram of the instrument is shown in figure I, 1.

1.21 The signal conditioning section includes the

Switching p-c board, AC Converter, Ohms Converter,

Attenuator, and Isolator. The function of these circuits is

to convert the incoming signal to 10 MC, full scale into the

integrator.

1.22 The Integrating section consists of the Integrator

amplifier, Null Detector and + reference voltages. The

function of these circuits is to convert the conditioned in.

put signal to an equivalent time period and to transmit this

iime period to the display portion of the DMM.

1.23 Dual slope integration operates as follows in a

sequence of program (PCM) states:

a. Signal Integration (KM-A). The integrator capaci-

tor charges to a voltage proportional to the input

voltage during a 20 msec sampling period.

b. Reference Integrate (KM-C). During this period,

the integrator capacitor discharges at a constant current. The time that the integrator requires to discharge (full discharge detected by the Null Detector)

is measured by the counter. The data in the counter

at the end of PCM.C is proportional to the input

voltage.

1.28 The Function Switching board is used only when

either or both of the options (AC and Ohms) are installed.

With no options installed, the Function Switching board is

replaced with the Switching Bypass board. The Switching

Bypass merely connects the + Input (from input connector)

directly to the Isolator input and the - Input to ground.

1.29 At the rear edge of the Logic and Interconnection

assembly is a PCB connector that extends to the rear panel

and serves as the BCD output connector 1201. If the

optional Remote Program board is installed, it is mounted

on stand-offs above the Logic and Interconnection board

with the PROGRAM INPUT connector (J202) available at

the rear panel above the BCD OUTPUT connector.

1.30 The POWER input connector 1203, the power transformer, and power transistors for the power supply are

mounted on the rear panel of the instrument. Other power

supply components are mounted on the Logic and Inter-

connection assembly. Also mounted on the rear panel, in

addition to .I201 and 1202, is the rear INPUT connector

J204, the ANALOG OUTPUT connector and common, the

EXTernal REFerence connector and common, and the line

fuse F201,

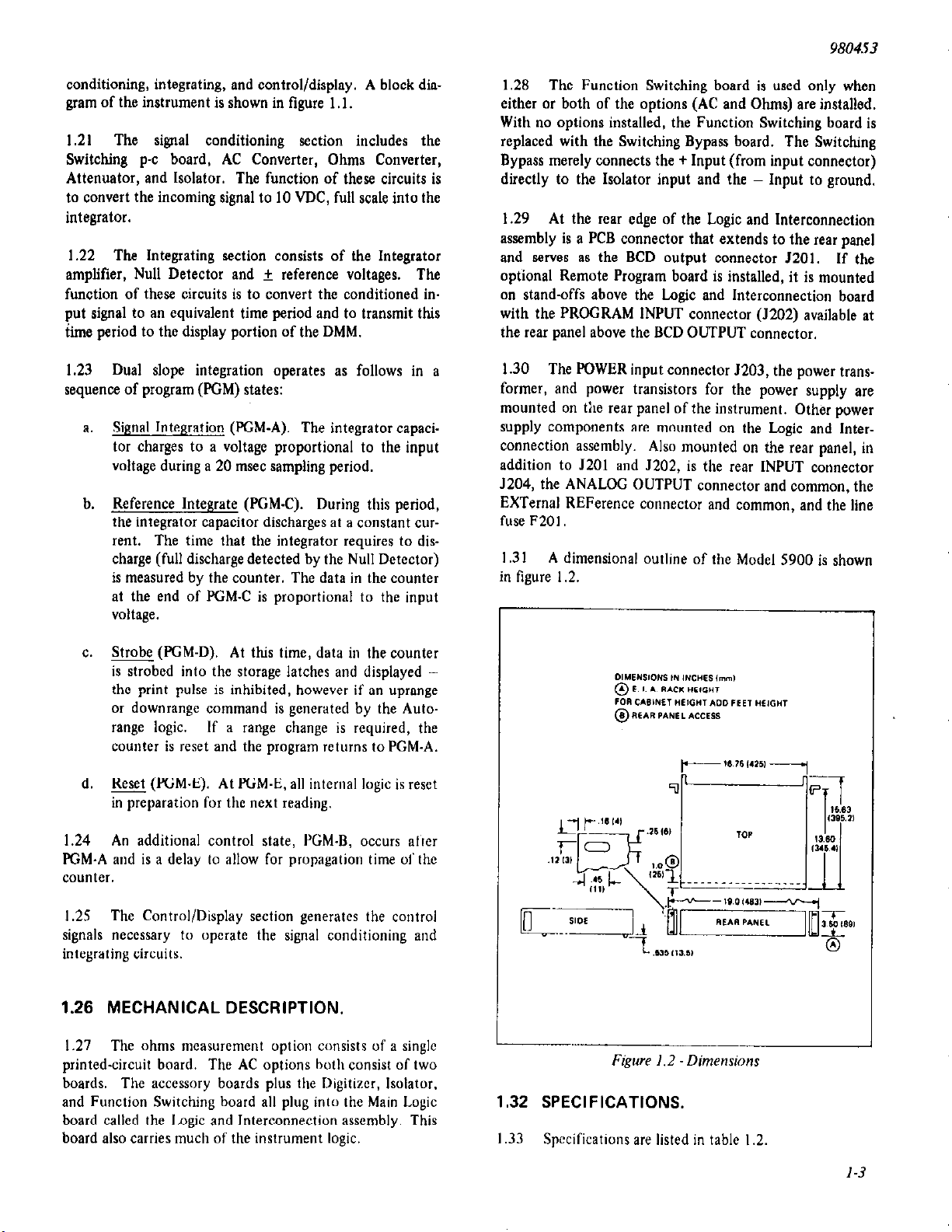

1.31 A dimensional outline of the Model 5900 is shown

in tigure 1.2.

c. Strobe @CM-D). At this time, data in the counter

is strobed into the storage latches and displayed -

the print pulse is inhibited, however if an uprange

or downrange command is generated by the Autorange logic. If a range change is required, the

counter is reset and the program returns to PGM-A.

d. Reset @‘CM-E). At PCM-E, all internal logic is reset

in preparation for the next reading.

1.24 An additional control state, PGM.B, occurs after

PGM-A and is a delay to allow for propagation time of the

counter.

1.25 The Control/Display section generates the control

signals necessary to operate the signal conditioning and

integrating circuits.

1.26 MECHANICAL DESCRIPTION.

1.21 The ohms measurement option consists of a single

printed-circuit board. The AC options both consist of two

boards. The accessory boards plus the Digitizer, Isolator,

and Function Switching board all plug into the Main Logic

board called the Logic and Interconnection assembly. This

board also carries much of the instrument logic.

Figure 1.2 Dimensions

1.32 SPECIFICATIONS.

1.33 Specifications are listed in table 1.2.

1-3

980453

Table 1.2 - Specifications

SPECIFICATIONS, MODEL SSOO

AS A DC VOLTMETER IBASIC INSTRUMENTl

RATIO tdcldc. mVldc. acldc)

SPECIFICATIONS CONTINUED NEXT PAOE

Table 1.2 -Specifications (continued)

980453

l-5

SECTION 2

2.1 UNPACKING AND INSPECTION.

INSTALLATION & OPERATION

2.2

plastic-foam form within a cardboard carton for shipment.

The plastic form holds the DMM securely in the carton and

absorbs any reasonable external shock normally encountered

in transit. Prior to unpacking, examine the exterior of the

shipping carton for any signs of damage. Carefully remove

the DMM from the carton and inspect the exterior of the

instrument for any signs of damage. If damage is found,

notify the carrier immediately.

2.3 Included with the instrument in the packing container are the instruction manual, power cord, and rear input and BCD output mating connectors. With instruments

equipped with remote programming, a mating connector

for that accessory is included.

2.4 BENCH OPERATION.

2.5 Each Model 5900 is equipped with a tilt bail or

“kickstand” to enable the front of the instrument to be

elevated for convenient bench use. The tilt bail is attached

to the two front supporting “feet” at the bottom of the

instrument. For use, the bail is pulled down to its supporting position.

The Model 5900 DMM is packed in a molded

2.6 RACK MOUNTING.

2.1 The instrument can be mounted in a standard 19.

inch rack with the optional rack-mounting flanges (403402,

includes attaching hardware). To install the flanges, proceed as follows:

a. With instrument on its side, remove four Phillips-

head screws holding bottom cover. Remove cover.

Remove screws holding feet (and bail) in place. Replace bottom cover.

b. Place one of the supplied screws through each of

the two holes in the mounting flange (figure 2.1).

Thread a securing nut onto each screw just enough

to attach it to the screw (approximately one turn).

c. Place the mounting flange onto the mounting slot

in the instrument side panel so that the securing

nuts fit entirely into the slot. Be sure the rackmount slots on the flange are toward the front of

the instrument.

d. Tighten screws. The securing nuts will rotate and

hold the flange securely in place.

2.6 POWER CONNECTIONS.

2.9 Standard units operate on either 1 IS volts or 230

volts, SO to 60 Hz (400 Hz available). Power consumption

is less than 40 watts. Operation on either of the two line

voltages is selectable by a slide switch on the rear panel.

Operation on lOO/ZOO volts or 1201240 volts is possible by

simple rewiring of the power transformer secondary wires:

WARNING

Disconnect the instrument from the AC Power source

before attempting to change power connections.

Potentially lethal voltages are exposed when covers

are removed.

a. For operation on 100/200 volts, cut the brown wire

1” from the transformer and splice it to the red

wire on the transformer; cut the blue wire 1” from

the transformer and splice it to the violet wire.

b. For operation on 120/240 volts, cut the brown

wire 1” from the transformer and splice it to the

black wire; cut the blue wire and splice it to the

yellow wire on the transformer.

2-I

980453

2.10 A standard power cable having a three-pin plug is

supplied with the instrument. It connects to POWER con.

nectar 5203. The ground pin (round) is attached to the

instrument case. It is important that this pin be connected

to a good quality earth ground.

2.1 I

Fuse receptacle F20l on the rear panel is equipped

with a .5 amp fuse in domestic units.

2.12 INPUT/OUTPUT CABLING.

2.13 Binding Posts.

2.14 Several connectors on the Model 5900 consist of a

pair of binding posts spaced so as to accept standard

“banana” plugs. The connectors are:

I

Front Panel

I

Rear Panel

+ INPUT f. ANALOG OUTPUT

+ OHMS CURRENT

?1 REFerence INput

2.15 Input cables to fit this type of connector can be

ordered from Keithley (P/N 5900-402190). Figure 2.2 is a

wiring diagram of this cable included for assistance to users

desiring to construct their own cables.

panel binding posts. The rear-panel input lines are wired in

parallel with the front-panel input lines. It is recommended

that the cable for the mating connector be constructed as

shown in figure 2.3 using two two-conductor shielded

cables. Other configurations may be desirable depending

on the ohms measuring method to be used (see paragraph 2.28).

I

2.18 MANUAL OPERATION.

2.19 Controls.

2.16 Rear Input Connector.

2.17 Instruments equipped with the -I or -IS rear input

option are supplied with 5204 7.pin input connector

(Keithley P/N 5900-600673) and a mating connector

(Keithley P/N 5900-600616). The instrument acceptsinputs

applied to this connector or inputs applied to the front-

2.20 All operating controls are located on the front panel

of the instrument. They are shown in figure 2.5 and their

operation described in table 2.1. Description of Systems

operation begins in paragraph 2.44.

2.21 DISPLAY.

2.22 The Pisplay consists of 6 LED decimal readout

devices with moving decimal point. The decimal point

moves in conjunction with the range switchor automatically

in auto range. Maximum usable readout with overrange is

159999. Overload is indicated by a NO and 160000 readout. A non-compatible range and function is indicated by

a NO. However, mechanical interlocks are provided to prevent illegal combinations from the front panel. Figure 2.4

illustrates the readout, NO indicator, polarity sign and the

DC MO

+

r /--- r-7 ,---I ,---I ,--1 AC

- I L-, L-4 L-4 L-,’ L-4 PGM

NO,’ --J. ,’

Fiwe 2.4 . Readout

: : :

KO

n

FIL R

2-2

Figure 2.5 -Front Panel

Table 2.1 . Operating Controls

Control

POW1

(rocker switch)

Function Select

(rotary switch)

Range Select

(rotary switch)

DATA OUTPUT

(pushbutton)

Position

ON (UP)

OFF (down)

ACT

DC

AUTO

Other Positions

Depressed

Function

Applies power to instrument

Removes power from instrument

Selects the measurement of AC voltages on the I, IO, 100, and

1000 volt ranges (max. input, 1OOOV RMS)

Selects the measurement of DC voltages on the .l, 1, IO, 100,

and 1000 volt ranges (max. input, IlOOV)

Selects the measurement of resistance on the 10 ohm range; on

the.1,1,10,100,andlOOOkilohmsranges;oronthe10or100

Megohm ranges

Selects Auto Range in which the optimum range is selected automatically by internal circuits. Uprange occurs at 160% of full

scale; downrange occurs at 15% of full scale

Enables manual selection of fiied ranges. Ranges permissible for

each function are inscribed on the parlel

,Enables the print pulse causing BCD data at P201 to be recorded

by printer, or other output device. (Output data is present at

P201 regardless of the position of this switch.)

PROGRAM CONTROL

(pushbutton)

Depressed

Enables the selection of range, function, and mode to be made

externally through the remote programming connector and dis.

ables all front panel controls (requires programming option)

RATIO

(pushbutton)

Depressed

Selects a ratio measurement in which the readout represents the

ratio of the input to an external d-c reference voltage (applied at

terminals on the rear panel) multiplied by 10: Ein/ERafx 10

FILTER

Depressed

Adds an active four.pole filter across the input circuit

(pushbutton)

RATE EXT (ccw)

(pot)

cw

FRONT/REAR FRONT

Selects the Hold mode. A new reading is initiated through the

remote program input

Increase periodic read rate to a maximum of four readings/second

Connects front panel data input terminals to instrument

(slide switch)

REAR

Connects rear panel data input terminals to instrument

*NOTE: Ohms input terminals are open in AC or DC function.

TNOTE: For inputs greater than lSOV, Filter should be “IN”.

980453

2.23 MEASUREMENT CONNECTIONS.

NOTE

Before taking any measurements, refer, to the list of

maximum input voltages, table 2.2.

Table 2.2 - hlaximum Input Voltage

CAUTION

Do not exceed the following maximum inputs:

DC

AC

1lOOVDCor 1OOOVRMSAC

1OOOV RMS decreasihg to 20V RMS at

1 MHz (see figure 2.7)

n

+SOOV peak between +I and -I(lOOOV

RMS if in DC or AC function.)

RATIO

Input: same as function selected

Reference: +lO.SV, -0.5V

achieved by ‘placing a shorting bar between - INPUT and

GUARD and shorting the single banana plug (shield) to the

-

INPUT side of the double banana plug at the input connector. This arrangement is adequate for measuring all but

low voltage (mV) levels and/or in high-noise environments.

2.27 When making “floating”voltage measurements(both

measurement points above ground potential), do not connect GUARD to measurement ground without making sure

that the voltage between GUARD and - INPUT does not

exceed 250 volts.

Y

‘RMS

GUARD

Voltage between GUARD and - INPUl

must not exceed 250 volts or damage

to the instrument may result

2.24 Basic Voltage Measurement.

2.25 An ac or dc voltage measurement connection recommended to minimize the effects of noise requires a twoconductor shielded cable connected as shown in figure 2.6.

t

Figure 2.6. Basic Voltage Measurement Connections

2.26 For all voltage measurements, the GUARD lead ar

Id

the - INPUT lead are connected to the measurement point

nearest ground potential.

Somewhat less shielding is

2.28 Ohms Measurement.

2.29

Ohms measurement in the Model 5900 consists of

the application of a known current through the unknown

resistance (Rx) and measuring the ratio of the voltage drop

across Rx to the drop across an internal “full-scale” resistor

(Eh/EFS). Current through Rx is applied through leads

from the f. OHMS CURRENT terminals. The voltage drop

is sensed by the + INPUT terminals.

2.30 TWO.WIRE MEASUREMENTS.

2.31

Connections for a simple two-wire shielded ohms

measurement are shown in figure 2.8a. It consists simply of

a single-conductor shielded cable with the conductor serving

as both the t CURRENT and + INPUT leads and the shield

2.4

(4

(b)

Y&v453

lNP”T CVRRENT

Figure 2.8 - Two Wire Ohms Measurements

RX

2-s

980453

2-6

Figure 2.9 - Four Wire Ohms Measurement

980453

carrying - CURRENT and - INPUT. While reasonably

accurate measurements can be made with this method,

shunt leakage problems result from the parallel combinations

of Rx and the cable impedance. This causes loss of accuracy,

especially at high resistance (100 Ma range). Also, lead

resistance becomes a factor in the 10 and 100 ohms ranges;

the four wire measurement system is recommended for

these ranges.

2.32 A more accurate two-wire measurement connection

is shown in figure 2.6b. The + INPUT and + CURRENT,

-

INPUT and - CURRENT terminals are again tied to-

gether. But now, the positive side is a single-conductor,

shielded cable with the shield tied to Ohms Guard. Ohms

Guard is the low ANALOG OUTPUT terminal on the rear

panel of the Model 5900 when ohms is selected. The negative

side is a single wire connected as shown. Guard current is

present in the low side, but the leakage problems of the

first configuration are eliminated.

2.33 In high noise-level environments, the configuration

shown in figure 2.8~ is recommended. This method also

eliminates error due to shunt leakage, but provides more

complete shielding. The positive terminals are tied together

and carried in a single-conductor, double-shielded cable with

the inner shield tied to OhmsGuard (-ANALOG OUTPUT).

The outer shield is tied to GUARD. The negative terminals

are tied together and carried in a single-conductor shielded

cable with the shield tied to GUARD. This configuration

eliminates guard current sensitivity, thereby increasing

guarding characteristics.

2.36 This configuration, although shielded, places the

shield capacitance and cable leakage in parallel with Rx.

This results in loss of accuracy and slow measurements. In

addition, it is very responsive to the triboelectric effect at

high resistance measurements.

2.39 Better guarding is achieved by the use of the configuration shown in figure 2.9b. Here again, RG196U teflon

dielectric cable (either single-conductor shielded or twoconductor shielded) is used on the positive terminals. The

shield(s) are connected to Ohms Guard (low ANALOG

OUTPUT terminal). The negative leads are single wires with

the - INPUT terminal tied to GUARD.

2.40 This eliminates much of the shunt leakage problem

of the previous configuration since guard current now flows

through the low side of the measurement circuit. Measurement is much faster since the shield capacity is driven by

the guard current.

2.41 A high-noise environment calls for the “super”

configuration shown in figure 2.9~. Here, a two-conductor,

double-shielded cable is used as the positive leads. The inner

shield is tied to Ohms Guard. A twoanductor shielded

cable is used as the negative leads. Its shield is tied to

GUARD and to the outer shield of the positive cable. The

shield is also tied to CURRENT at the measurement point.

This configuration maintains high guarding characteristics

while eliminating guard current sensitivity.

2.42 Ratio Measurements.

2.34 FOUR-WIRE MEASUREMENTS

2.35 In most system applications, the device to be measured is located at B remote location requiring interconnection

by cables of lengths from several to possibly hundreds of

feet. When measuring low resistance values over long cables,

most lead resistance problems can be solved by the use of a

four-wire measurement system.

2.36 For high resistance measurements over long cables,

other problems are encountered: noise pick-up, leakage

resistance, and capacitive loading of the system. These

problems can be minimized by proper shielding and the use

of ohms guard.

2.37 Figure 2.9a shows a basic shielded four-wire ohms

measurement configuration. This method uses two singleconductor shielded teflon cables. The conductors carry the

positive sides of the INPUT and CURRENT lines while each

shield carries the low side.

2.43 Ratio measurements are made by applying a positive

d-c voltage to the reference input terminals on the rear panel

and an input signal of any function at the front input

terminals. For DC/DC or AC/DC ratios, the reference

voltage must be within the range of +IV to +lO.SV. Input

signal limitations (numerator) are the same as tbosc given

for conventional measurement of the particular function

(table 2.2). The readout is the ratio multiplied by ten:

Einput/Ereference x 10. In the standard instrument the

INPUT terminal is internally connected to the REF input terminal; in instruments equipped with the option 62

4-wire ratio, both reference inputs arc floating (IO Ma

between - REF and -SIGNAL).

2.44 SYSTEM CAPABILITIES.

2.45 The 5900 has two system interface connectorsdesignated as 3201 (PRINTER OUTPUT) and 5202 (PROGRAM

INPUT) mounted on the rear panel of the instrument (fig

ure 2.10). The following is a brief description of the capabilities of each connector.

2-7

980453

Printer Output - 5201.

2.46

2.47 Through this connector the 5900 supplies BCD

representations of the decimal display; various flags or

indicators of the mode of operation, function and range;

and a print command. Provision has also been made for 60

Hz instruments to accept a fast (20 readings per second

maximum) or a superfast (I 01 readings per second minimum)

read command. In 50 Hz units, the fast command obtains

I7 readings per second, minimum, and the superfast com-

mand 93 readings per second.

2.48 Program Input.

2.49

Through this connector the 5900 receives externally

generated signals that select the function, range, mode of

operation, and initiate the read commands.

2.50 LOGIC LEVELS AND ELECTRONIC IN-

TERFACE.

TTL-compatible positive-true logic levels are used

2.5 1

in the 5900. In some instances, however, complementary

signals are used. These terms are more specifically defined

below:

other words, the complement of X is x. The truth table

shows that the two signals X and x, are by definition, in

opposite logic states (see table 2.3).

Table 2.3 - Positive True Logic Relationships

Voltage Level of

Voltage Level of

Signal Logic State Output Line “x” Output Line “p

“X” True or “1” 2.4 - 5.0

False or “0” 1 0.0-0.4

2.53

As seen above, if gate A has a true or “1” level on

Volts 0.0.0.4

Volts 1

2.4.5.0

output X, its voltage level is the most positive of the two

ranges present, and output x must be in a false or “0”

state with the lowest or most negative voltage range present.

The reverse would be true for a false or “0” level on output

X.

2.54 Driving the Inputs.

2.55 All inputs are TTL compatible and most are the

equivalent of one 7400 series TTL input with a pull-up

resistor for contact closure operation.

Signals and Their Complements -

2.52

If the non-inverting output of gate A is defined as

signal X, then it follows that the inverting output is ???; in

Figure 2. IO - Rear Panel

0

2.56 TTL Loading Conditions,

2.57 To input a “I” level the pull.up resistor will supply

the necessary source current (40 /.tA) to maintain the minimum 2.4 volts. In fact, the pull-up resistor will maintain a

2-8

980453

Figure 2.11 Measurement Sequence

2-9

980453

one level as long as the input source resistance (RI) to

ground is greater than ISK ohms.

2.58 To input a “0” level, at least 2.0 ma of current must

be sinked maintaining the input voltage below 0.4 volts.

This requires a resistance to ground of 200 ohms or less.

Exceptions to Input Loading Conditions.

2.59

a.

Program Storage Input (5202, pin B.15) is the

equivalent of 3 TTL inputs and requires a minimum

5.8 ma sinking current, or 68 ohms or less to common.

b.

Maximum input voltage level, referenced to common,

must not exceed 5.5 volts peak. Otherwise, gate

destruction will occur.

c.

The Direct and Time Out Commands are AC coupled

with pullap resistors to t5 volts. These inputs are

compatible with TTL outputs or contact closures

to ground. The AC coupling does require that rise

and fall times be less than 100 peconds. This input

circuit is illustrated below:

ts” +5V

P 9

2.62 Timing Sequence.

2.63 The standard remote mode of operation of the 5900

is to initiate a reading sequence with each Direct Command

received through the programmer, providing

time has been allowed between commands for the reading

to be completed. This reading sequence is illustrated in

figure 2. I I

TI .To

T2-TI

T3-T2

T4.T3

During this period the input signal must finish settling to within the desired accuracy.

Any control changes involving the 25 msec

relay settling time (a) can he completed;

other logic control inputs (b) can also be

changed.

The Direct Comma signal, which is AC

coupled, must meet the following conditions:

a. Rise and fall times less than 100 /.wc.

b.

Signal must stay in the logical “0”

state for at least 3.4 /&ec. If these

conditions are met, the internal read

command is sustained at T2 and the

signal integrate period is started.

The period of signal integration lasts for

16.2/3 mw (60 Hz line frequency; 20 mw

in 50 Hz units). During this time the integrator charges to a voltage proportional to

the input voltage. This is the input sampling

period.

During this period, the integrator is isolated

from the input signal, and is discharged at a.

precise current. The time the integrator requires to discharge to a level equal to its

voltage at T2 is proportional to the input

voltage. This time is measured by an internal

counter and stored.

that

sufficient

d. Digital output common can be floated as high as

200 VDC above power line ground.

2.60. TTL Output Capabilities.

2.61 The 5900 electrical outputs are specified to drive

two ‘ITL inputs such as described in the TTL loading section.

Summary:

False: 0 to tO.4V

True: t2.4 to +S.OV

Fanout: 2minimum ,

Maximum Capacitance Load: 500 pF

2-10

T5.T4

To-TS

TI -To

This I.7 /J.W period is required to strobe the

new reading from the internal counter into

the readout latches.

This 5 mseconds (&IO%) is required to reset

the internal logic for the next reading.

If the next read command is a Direct

Command, this period must be made long

enough to allow for the condition covered in

the first cycle; however, if the next command

is a Timeout Command, this period can

approach zero since the necessary timeout to

satisfy these conditions are automatically

programmed.

980453

Figure 2.12. Command Timing

2.64 Other Read Command Options.

2.65 In addition to the Direct Command, there are two

other programmable read commands, as illustrated in figure 2.12.

a.

Time Out Command: Again, this is an AC coupled

input which must have rise and fall times of less

than 100 weconds but must remain in a “0” state

for at least 0.1 @second. The timeouts given in

table 2.7 for various combinatioris of ranges and

functions ranging from 30 mseconds to 500 msec.

onds will be automatically inserted before the internal read command is generated. If this command

is wired to the m on J2Ol - pin

All, fully automatic reading with timeouts is

achieved.

The 5 msec internal delay is not adequate for settling

time on the 100 VDC, 1000 Ka 10 MS1, IO0 MS1

ranges, or any AC range. Therefore, the timeout command, providing timeout delays listed in table 2.7,

must be used to initiate accurate readings on these

ranges unless a fixed range and function have been

programmed and the input has been present longer

than the timeout period.

System Direct Command: While the other two read

b.

commands were AC coupled and programmed

through the Program Input Connector (J202), this

command is DC coupled and programmed through

2-11

980453

Figure 2.13. Minimum Read Rate vs. Input

the Printer Output Connector (5201). The $&%

Direct Command must remain in the “0” state for

at least 3.4 /.&seconds to generate the internal read

command. This delay, as in the Direct Command, is and internal reset remain fixed while the reference integrate

to prevent noise from triggering the readings. If this period can vary from 0 to 32 mseconds. Therefore the

command is tied to ground, the 5900 will recycle at maximum read rate could very from 17.4 to 45 reading per

its maximum reading rate with no timeouts. second.

2.66 Reading Rates.

2.67 In figure 2.13, integrator operation with three different input signal levels is illustrated: half scale, full scale,

2-12

and 160% of full scale (full scale is defined as 100000 on any

range). The figure shows that the maximum reading rate is

a function of the input signal. The signal integrate period

2.66 Superfast.

2.69 The Superfast reading mode (programmed through

either the PRINTER OUT or PROGRAM INPUT connector)

980453

Figure 2.14

- Superfast

increases the minimum reading rate from 20.5 to 102

readings per second (50 Hz: 17.4 to 93 r/s). This is done at

the expense of losing the least-significant digit which is reset to zero (blanked out on readout). The signal integration

period is reduced from 16.2/3 msec to I -2/3 msec (SO Hz:

20

msec to 2 msec). This and the resulting reference integrate period reduce the maximum recycle time from 48.8

msec to 9.8 msec (SO Hz: 57.5 msec to 10.7 msec), thereby

yielding the 107 reading per second figure (93 r/s with 50

Hz). Timing changes are shown in figure 2.14.

2.70 PRINTER OUTPUT.

2.71 The printer output connector is a double-edged

PCB connector (extension of Interconnection and Logic

board) with pins Al through A22 on the bottom edge and

pins B I through B22 on the top edge. Pin assignments are

shown in figure 2.15. All outputs are referenced to digital

ground pin B I.

Read Rate (Worst Case)

2.72 Numerical Data

2.73 Numerical data appears as positive true, four-line

BCD code, as shown in figure 2.15. The designator of each

line identifies the digit and weight. For example: Pins Al8,

19, 20, and 21 are designated 12. Ig, 14. and I, consecutively. The 1 indicates these lines correspond to the units

or least significant display; the 2, 8, 4, and I subscripts

indicate the hinary weight of each line.

CAUTION

True output lines arc not short-circuit proof. Accidental grounding may damage the output circuitry.

2.13

980453

Figure 2.15 . Pin Assignments 5201 PRINT.!?R OUT

2.74

Polarity is indicated in positive true format on pin

A9 (positive) and pin A10 (negative). The positive polarity

line is true when the function output is AC or .lK through

IK OHMS ranges. Negative polarity is true with Ohms on

the IOK through lOOMranges. If the instrument overranges,

the polarity bit is not updated since no axis-crossing has

occurred.

2.76 Function Data.

2.76

Function outputs appear on pins Al, 2, 3 and B2 in

their true format. For example: with AC function selected,

2-14

AC is true and is indicated by B true level on the corresponding line.

2.77 Range Data.

2.78

Range data appears in four-line BCD code on pins

Al4 through Al7. Range codes are described in table 2.4.

2.79 “NO” Indication.

2.80 The NO line (pin AI2) is the same as the

NO indicator on the readout. The line is true if a function

Table 2.4 - Range Codes (Printer Output)

980453

or range is selected for which the particular instrument is

not equipped. Overrange is indicated by a true NO line plus

a numerical data output of 160000.

2.81 Status Output Lines.

2.82 The following outputs indicate the status of the

conversion process within the instrument.

DATA READY. This line (pin Al 1) remains true

during the signal and reference integration periods

plus any overrange time, if required. The line drops

to the false level to indicate to the printer that the

measurement is complete and output data can be

printed (PrinterCommand). With front-panel operation, DATA READY ‘is enabled only when the

DATA OUTPUT switch (on front panel) is de-

pressed. Minimum false level time is 4.5 mseconds.

HOLD FLAG. A true level on this line (pin A4)

indicates that the instrument is in the Hold mode.

A reading can be initiated by one of the following

commands:

SYSTEM DIRECT COMMAND (J201.A8)

1.

2. bIRECT COMMAND (3202.A15)

d.

SIGNAL INTEGRATE. This line (pin B 1 I) becomes

true at the end of the signal integration period. After

this time, the input signals may be changed in prepa-

ration for the next reading. The input signal need

remain constant only while the instrument is in

Signal Integrate, indicated by this line in the false

state. For example, the l-2/3 msec sample time in

Superfast could be used in slow sample and hold

applications.

2.83

Input Control Lines.

a.

DATA DISABLE. A contact closure to ground or a

false logic level applied to this line (pin A7) inhibits

the DATA READY output (Print) pulse.

SYSTEM CONTROL. A contact closure to ground

b.

or a false logic level on this line (pin B6) &sables

all front panel operating controls. Operation of the

instrument is then under control of the Remote

Program input. This command duplicates operation

of the PROGRAM CONTROL switch on the front

panel. It is necessary that one of these commands

be initiated during Autorange to inhibit extraDATA

READY pulses.

TIMEOUT COMMAND (JZOZ-B IO)

3.

RATE Control (front panel)

4.

SYSTEM READY. This line (pin AS) drops to a

false level to indicate that the instrument can now

initiate a new reading at the first available read com-

mand.

c.

SUPERFAST. A contact closure to ground or a

false logic level applied to this line (J20l-A6 or

1202.A7) decreases the conversion time of the

instrument while sacrificing the least-significant

digit. This mode is described in paragraph 2.68.

Because of the superfast read rate, do not use this

mode with Autorange.

Z-15

980453

r

Figure 2.16 -Pin Assignments 5202 PROGRAM INPUT

2.84 SYSTEM DIRECT COMMAND.

2.85 To externally initiate a measurement with this command, the instrument must be in the Hold mode. Then, a

contact closure to ground or a false logic level to this line

(pin A8) generates a read command. Minimum false level

time is 3.4 r.oec. Continuous readings at the maximum read

rate are obtained by tying this line to ground. Read com-

mands delayed by 5 msec f 10% (for settling time) are then

generated automatically.

2.86 REMOTE PROGRAMMING.

2.87 The instrument accepts commands made through

PROGRAM INPUT connector J202 on the rear panel. Pin

assignments of 5202 are shown in figure 2.16. Commands

2-16

are made by a switch closure from the appropriate pin to

ground or by standard TTL logic levels as described earlier.

2.88 SYSTEM CONTROL.

2.89

A contact closure to ground or a false logic level

applied to pin 86 disables all front panel operating controls.

Operation of the instrument is then under control of the

remote program input. This line duplicates the PROGRAM

CONTROL switch on the front panel.

2.90 Function Programming.

2.91 The desired function is selected by applying a

ground or false logic level to the appropriate pin (table 2.5).

980453

Table 2.5 -Function Programming

FE

I

2.92

settling time on the 100 VDC, 1000 Kilohm, IO Megohm,

100 Megohm, and all AC ranges. Therefore, the timeout

command, providing timeout delays listed in table 2.7, must

be used to initiate readings on these ranges unless the input

is fixed with range and function predetermined.

2.93 Range Programming.

2.94 Range programming is selected by applying false

logic levels in BCD code to the four range lines described in

table 2.6 below. With no lines programmed, Autorange is

automatically selected.

2.95 + Five Volts.

z

OHMS pin A9

RATIO

FILTER pin B7

The 5 msecond internal delay is not adequate for

I

NC

nin A8

pin 88

2.99 Read Commands.

2.100 Either of two read command lines can be selected

by a contact closure to ground or by a negative logic

level applied to the appropriate pin. Pin AIS, DIRECT

COMMAND, commands a new measurement if applied after

a five millisecond reset delay, and if the command is present for 3.4 peconds. Pin BIO, TIMEOUT COMMAND,

starts a new measurement after five milliseconds plus a

timeout delay to allow for internal settling time of the

measured signal. TIMEOUT COMMAND may be commanded before the previous 5 mw delay since the timeout

generator stores the reading.

2.101 Timeouts.

2.102 Timeout periods for each function are listed in

table 2.7. In Autorange, the indicated delays are taken

following each range change.

2.103 Data Inhibit.

2.104 A contact closure or false logic level on pin B9

inhibits DATA READY OUTPUT (Print pulse) from being

generated.

This voltage, +5 volts + 5%, from the logic power

2.96

supply isavailable at pin Al3 for external use. Current output is .lA, maximum.

2.97 Hold.

2.98

position of the front panel RATE potentiometer and is

selected by a contact closure or a false logic level on pin

commands.

The Hold line parallels the operation of the ccw

Hold is required when using either of the two read

AIO.

Table 2.6 _ Range Codes (Rogrammer)

2.105 Program Storage.

2.106 A false level (equivalent to three TTL inputs) on

pin BIS will stoIe all the programmed inputs except the

Direct and Timeout commands as they existed on the

negative edge of this command (see diagram below).

PROGRAM STORAGE

c’

at this time the program

is stored

980453

2.107 SUPERFAST. 2.109 ADDING/REMOVING ACCESSORIES.

2.108 A contact cloture to ground or a false logic level

applied to pin A7 decreases the signal integrate and the

reference integrate times (see paragraph 2.68). This provides the maximum reading rate in the Direct COMMAND

mode of operation. Because of the high reading rate, Supafast

must

be programmed with a fixed range rather than

AUTORANGE.

Table 2.7 . Timeouts

DC

I Ohm to I Meaohm 130 msec

IO Meg*

100 Megohm

Filter

30 rmec

1

30 msec

300 msec

470 msec (plus function timeout)

ACffixed rawznofilter) 180 msec

AC+Filter(&Autorange) 650 msec

*Use filter for <.Ol%

error

I

Table 2.8 -Maximum Input Voltage

CAUTION

Do not exceed the following maximum inputs.

2.110 The AC and Ohms options may be added or removed at any time in the field without modification to the

basic instrument. Note that the switching board (403625)

is required whenever the plug-in options are used. Access

to the mounting connectors is by removal of the top cover,

held down by captive screw in each of the four corners,

and by removal of the shield, mounted by four flat head

screws.

2.1 I I When an option is added or removed from the

instrument, a jumper corresponding to the option is removed or added to allow proper operation of the NO cir-

cuitry. The two jumpers (WI Ohms and W2 AC) are

located on the display board, shown partially in figure 2.17.

When an option is added, the corresponding jumper is

added; conversely, whw iin wxcssory is removed, the

jumper is rcmovcd

DC

1000 MC or RMS AC

All ranges

AC

1000 RMS to 20 kHz decreasing 20 dB/

decade to 20V RMS at 1 MHz

RATIO Input: same as function selected

Rcfercnce: +10.5V. -0.5V

) OHMS ) +5OOV DC or Peak AC

GIJARD Voltage between GUARD AND - INPUT

mutt not exceed 250 volts or damage

1

1 / to the instrument may result

Figure 2. I7 - Jumper Location

2.18

SECTION 3

3.1 GENERAL.

3.2 This section contains procedures that compare the

operation of the instrument against the published specifications found at the front of this manual. It is intended to

be used for incoming inspection and as a periodic check

determine if recalibration of the instrument is warranted.

3.3

proper operation and that the instrument is within the 90

day accuracy limits. Covers of the instrument are not re-

moved for any of the tests.

temperature of the environment is 23” + 5°C.

3.4 REQUIRED EQUIPMENT.

3.5

checking the instrument. The equipment in this table, with

The procedures provide sufficient checks to verify

The required ambient

In Table 3.1 is a list of equipment necessary for

Table 3.1 - Required Equipment

to

SPECIFICATION TESTS

the exception of those in the OTHER category, is the same

as required for recalibration and is explained in detail in

Section 5.

3.6 PROCEDURE.

3.7

ment end the test equipment as shown in the figure supplied

with each accuracy check. Select the controls and inputs as

called out in the tables and monitor the instrument readout

for the indicated values. If the instrument is equipped

with the rear panel selectable input option, set the FRONT/

REAR switch to the FRONT position for all procedures

presented in this section

Allow one hour for warmup. Convert the instru-

ES1 SRI with corrections

ES1 SRl with corrections

ES1 SRI with corrections

ES1 SRI with corrections

ES1 SRI with corrections

ES1 SRI with corrections

DVM INPUT SIGNAL

FUNCTION

Table 3.2. DC Range Check (Low Ranges)

DC

RANGE VOLTAGE

STANDARD

DIVIDER

SETTING

NOMINAL

READING

TOLERANCE

NOTE

DC

.lV I0.00000

IV 10.00000

STANDARD CELL

.01000 .1ooooo .099992 - .I00008

.10000 I .ooooo

0.99997 - 1.00003

(1” VOLT SOVRCE,

23% + PC

(After zeroing)

Table 3.3 - DC Range’Check (High Ranges)

( “fooooo

980453

+

3-3

980453

Table 3.4 -3.Wire Ratio Check

TOLERANCE

Table 3.5 -4-Wire Ratio Check

980453

DVM

FUNCTION

DC

RATIO

I

INPUT SIGNAL

RANGE “OLYAGE

STANDARD

10

10

+ 2.ooooov

+ 1 o.ooooov

-1o.ooooov

I

NOMINAL

READING

tlO.OOOO

+10.0000

+10.0000

I

TOLERANCE

9.9980

9.9996

9.9996

- 10.0020

-

- 10.0004

I

~O.OOO~

NOTE

23% + 5°C

(After zeroing)

3-5

I

980453

Table 3.6 - DC Input Resistance

TOLERANCE

*Adjust the DC Voltage

Standard to produce the

DVM DISPLAY reading.

l--+T-1-1

O”ARDTERMlNAL

STRAPPED TO LOW

lNP”T TERMINAL

DC “OLTAGE STANDARD

0000000

Table 3.7 - Model 33 AC Converter Range Check

980453

TOLERANCE

formation on use

3-7

980453

Table 3.8 - Model 32 AC Converter Range Check

DVM

FUNCTION

-__AC

INPUT SIGNAL

IT111

0000000

3-8

L

0

0

0 0

c

0

ZACo 0 0

0

u

000

l_;i

I

i

Table 3.9. Ohms-Megohms Range Check

TOLERANCE

TOLERANCE

(Same as Standard)

3-9

Table 3.10 -Common Mode Rejection (In DC Volts Function)

TOLERANCE

DMM’s readout

in the “nominal

Table 3.11 - Normal Mode Noise Rejection (In DC Volts FuKtion)

DVM

FUNCTION RANGE

t

DC

FILT. OUT

FILT. IN

DC

IO osv

IV

0.w 2V*, 60 Hz?

INPUT SIGNAL

AC

iOV*, 60 Hz? 00.5000

*peak

t50 Hz (Option 04)

NOMINAL

READING

0.50000

TOLERANCE

~400 digits

? 2 digits

NOTE

3-1 I

980453

Table 3.12 _ Common Mode Rejection (In AC Volts Function)

TOLERANCE

NOTE

Enter reading with

shorted input in

nominal column

before beginning

3-12

SECTION 4

4.1 GENERAL,

4.2

This section describes the operation of the main

circuitry of the Model 5900 DVM, briefly covering the

mechanical organization and then the electrical operation of

the instrument. The simplified drawings provided in this

section are for the purpose of illustration, and supplement

the complete schematics of Section 6.

4.3 MECHANICAL DESCRIPTION.

4.4

The Model 5900, shown in figure 4.1, consists of a

large, single, printed circuit Logic and Interconnection

board (Main Logic) with as many as 12 separate PC boards

plugging directly or indirectly (by means of cables) into the

Main Logic board. The electronics are housed in a sturdy

die cast and stamped aluminum package with the readout,

input terminals, and allmanual controlslocated on the front

panel. On the back panel is located the power cable input,

all data output, optional remote input, analog output,

external reference, and optional rear inputs.

4.5 ELECTRICAL DESCRIPTION.

4.6

The instrument is divided into three functional

groups. These are the Signal Conditioning section, the

Analog-to-Digital Conversion section, and the Display/

Control Logic section.

by the options. The interconnection of the Switching board

with the options and the other components of the Signal

Conditioning section is shown in block diagram form in

figure 4.2.

4.12 The control of signal flow through the Switching

board, shown in simplified form in figure 4.3, is by means of

two relays Kl ‘and K2. The three possible signal routes

provided by the board are illustrated in figure 4.4. Referring to this figure, with the- dc function selected,

neither of the relays is energized and the signal flow is as

shown in (a); with the ac functiowselected, relay Kl is

energized and the signal flow is as shown in(b); with ohms

function selected, relay K2 is energized and the signal flow

is as shown in (c).

4.13 The range control of the option boards uses analog

supply voltages and require isolation from the digital

supplies and decoding. This is provided on the Switching

board by three Optically Coupled Isolators (OCI) and a

BCD to TEN line driver. The decoding of the range logic is

given in table 4.1.

Table 4.1 -Switching Board Range Decode

4.7 SIGNAL CONDITIONING SECTION.

4.8

The Signal Conditioning section for a fully equipped

instrument consists of: the Switching Board, the Ohms

Converter, the Averaging AC Converter or the RMS AC

Converter, the Attenuator, and the Isolator. The basic

instrument consists of the Switching Bypass Board, the

Attenuator, and the Isolator.

4.9,

The Signal Conditioning section routes, scales, filters

and, when required, converts the input signal into a stable

lOvolt full scale dc level for use by the measurement portion

of the DVM.

4.10 Switching Board.

4.11 The Switching board is a single printed circuit

board and occupies conne&ors J5 and 36 on the Main Logic

board. The Switching board is used with instruments

equipped with either the Ohms Converter or either of the

available ac converters and is necessary for the generation

and isolation of range data and for signal routing required

4.14 Ohms Converter.

4.15 The Ohms Converter circuitry is mounted on a

single printed circuit board and occupies connector JIO on

the Main Logic board. The circuitry, shown simplified in

figure 4.5, consists of a high gain amplifier and a relay

operated positive current source that is capable of producing any one of eight precise current levels depending on

the range selected.

4-l

LOGIC AND

INTERCONNEC

READOUT

DISPLAY

TION

J2

J4

PROGRAM (LOCATION -

J3

BOARD NOT SHOWNI

I

Jl4 II-WIRE RATIO (LOCATION

BOARD NOT SHOWN)

J7 ATFENUATOR

J8 ISOLATOR

J9 DIGITIZER

JlO OHMS CONVERTER

‘INSTRUMENTSHOWN IS EOUIPPED~WITH RMSCONVERTER,

Figure 4.1 -M&mid Assenrbly

Jl, RMS BYPASS’ OR

AC CONVERTER

J12 RMS CONVERTER* OR

SCALtNG AMPLlFlER

980453

4.16 The Ohms Converter, in conjunction with the

Switching board, the Attenuator, and the Isolator, converts

the resistance to be measured into a proportional dc voltage

that can be measured by the DVM. The current produced

for each range, when applied to a resistance equal to the

range selected, generates a voltage et the output of the

resistance measurement network of 10 volts.

4.17 The resistance measurement network assumes two

forms, depending on the range being measured, as shown in

figure 4.6. The basic technique used consists of effectively

connecting the resistance to be measured (Rx) as a negative

feedback path of an operational amplifier, with the amplifier

provided by the Ohms Converter and the input to the

operational amplifier formed by the current generator. In

this hookup, the current through Rx equals the current

generated by the current SOIIIC~. Referring to configuration

(a). used for the ranges 10 kilohm through 100 megobm, the

voltage developed across Rx is monitored through the - IN

front panel connector and buffered by the isolator

in a

gainof-one mode. The full scale output for these ranges, as

shown in the table, is -10 volts. Referring to figure (b),

the isolator is connected in a potentiometric configuration

but with the input at an effective ground potential and the

reference end of the feedback nehvork tied to the voltage

developed across Rx. The low impedance provided by the

isolator feedbacknetwork is offset by the current compensa-

tion circuit (CL). This circuit monitors the output potential

of the isolator and produces a current drain precisely equal

to the current produced by the feedback network. The result is that the feedback network appears to have an

extremely high input impedance. The configuration used

in (b) reduces normal the gain of the isolator by I, thereby

producing gains of 99 and 9 as shown in the table.

4.18 Scaling Amplifier.

4.19 The Scaling Amplifier, shown simplified in fig

ure 4.7, is used in conjunction with the Averaging AC

Converter and occupies position J12. It provides isolation

between the signal being measured end the signal converting

circuitry and it scales the input signal to a level suitable for

the converter (1V RMS output for a full scale input).

4.20 The Scaling Amplifier consists of an AC coupled

operational amplifier with four possible gain settings (XI,

X.1, X.01, and X.001). The gain control network is con-

trolled by three relays and these are operated from decoded

data from the range logic. A change in the roll off of the

amplifier is provided when the 1 volt range is selected.

4.3

980453

4-4

Figure 4.3. Switching Board

la) DC Routing

P6

.1v + 1” ,+ INPUT,

H

, .I + 1” ,- INPUT,

6 0

980453

0

0

K1

lb) AC Routing

c) Ll Routing

980453

*

I

4-6

Figure 4.5 - Ohms Converter

980453

980453

Figure 4.7 - Scaling Amplifier

4-8

Figure 4.8 _ Averaging AC Converter

YKfJ453

4.21 Averaging AC Converter.

4.22 The Averaging AC Converter receives the scaled input from the Scaling Amplifier and generates a positive dc

equivalent for the DVM, measurement section. The circuitry

is mounted on a single printed circuit board and occupies

location 111 on the Main Logic board. The circuitry, shown

simplified in figure 4.8, consists of an active rectifier, a