Page 1

Model 590 CV Analyzer

Quick Reference Guide

A GREATER MEASURE OF CONFIDENCE

Page 2

INTRODUCTION

This quick reference guide contains dascriptions of various

features and information concerning the operation of the

Model 590. Also included are programming examples using various controllers.

01986, Keithley Instruments, Inc.

instrument Division

Document Number: 690-903-01 Rev. A

Cleveland, Ohio, U.S.A.

1

Page 3

CONTENTS

Front Panel Operation

Control Group ........................... 4

Trigger Group ............................

Bias Group

Platter Group ........................... 11

Data Group

Miscellaneous Functions, .................. 16

Mathematical Functions ................... 18

Displays. .............................. 19

Connections

Waveform Definitions ..................... 24

IEEE466 Programming ....... , , .. ~, .. ~, ...... 34

Device-Dependent Commands .............. 34

Data Format ........................... 43

SRQ Mask and Status Byte

UO to U26 Status Word Formats ............ 46

Translator ............................. 64

Pmgrams .................................. 67

IBM PC or XT .......................... 68

Apple ,, ............................... 70

HP-ES.. .............................. 72

HP.9616 ............................ 74

HP-9825A

DEC LSI 11 ............................ 76

PET/CBM 2001 ......................... 80

.............................

............................

.............................

.........................

...........................

Fotmat

14

20

........... 45

76

4

7

9

2

Page 4

SAFETY PRECAUTIONS

1. Before operation, ground the instrument through a properly earth grounded power receptacle.

2. Before servicing, disconnect the instrument from the

power line and all other equipment, and consult the Model

690 Instruction Manuai.

3. Do not touch any terminals while the instrument i8 turned on or connected to any other test equipment.

For additional safety information, see the

“Safety Precautions” pages in the back

of this manual.

3

Page 5

FRONT PANEL OPERATION

LOCAL-Pressing this key when the unit is in remote

(REMOTE onl returns the instrument to the local mode

(REMOTE off) and restoros operation of other front panel

controls unless LLO (local lockout) is in effect.

POWER-Controls AC line power to the instrument.

CONTROL GROUP

CONTROL

RANGE

q

0

AUTO

0x10

Page 6

RANGE-Press RANGE briefly to manually select range.

Pressing and holding RANGE for more than % second places

the unit in autoranging. Press RANGE again to cancel auto

and stay on present range. SHIFT RANGE switches in X10

attenuator to extend lOOkliz measurement range to 20nF

with external optional input adapter (Model 69041.

FREQ-Press FRE‘, to select test frequency, lOOkH2 or

1MHz 8, 15mV RMS. An error message will be displayed

if the appropriate modules are not installed, or if you attempt to “se the X10 atten”ato, at IMHz. FREQ is also used

to disconnect the test signal from the test jacks. IThe display

‘will show DISCONNECT.1

MODEL-MOOEL selects series or parallel device model

(series resistance and capacitance or parallel conductance

and capacitance).

2

PS

20 ps

200 ps

2mS

20mS

FILTER-FILTER toggles the single-pole 37 Hz low-pass

analog filter on and off. Note that the filter incroasss instru-

ment response time.

2Mn

??I “kII

2 kn

200 n

2Mfl

200 kll

20 kfl

2 kn

Page 7

RATE-Press RATE then A/v ior RATEI to scroll through

the rate selection menu: 1, 10. 75, or 1000 readings per

second (or press the numeric key Indicated below). Press

ENTER to select RATE, or QUIT to return to the previous

rate. The slower rates will provide more resolution and

quieter readings, as indicated below.

Nominal

Key # lute

Aesolutlon Readings Filtering

0 1000/set 3 1% * c only

: 75/set 3 K * C.G,V

10/set 4Ya

3

I/%%

4%

C.G.V

C.G,V

DIgItal

NO

NO

YOS

Yes

‘Data displayed only after sweep is finished.

NOTE: Rates are nominal; see instruction manual for actual

rstes.

ZERO-ZERO provides means for supression of B constant

value from the readings, or it can be used to cancel lnternal offsets to maximize ~cccuracy. Note that enabling zero

can reduce the dynamic range of the measurement.

CAL-Pressing CAL performs an automatic one point

calibration of the selected module on the current range using an internal 2OpF or 2OOpF Idapending on range)

capacitor and is intended to compensate for shoe-term thermal drift. CAL should be used for each range at both frequenoies for optimum accuracy of those ranges.

NOTE

Do not press and hold CAL when power is first

turned on, as the instrument will go into its

diagnostic program.

6

Page 8

TRIGGER GROUP

MANUAL-Pressing MANUAL will initiate a one-shot or

sweep sequence depending on the selected trigger mode.

This key is always operational regardless of the selected

trigger sourca Pressing MANUAL while a reading or sweep

is in progress will result in a trigger owrrun error messega

Dashss in the display indicates that a trigger is required.

MODE-Press MODE then A/T. MODE, or numeric key (see

list below) to select a trigger mode: one shot or sweep, then

press ENTER. In one-shot. the instrument will procss6 one

reading per trigger. while in sweep the unit will process a

complete reading sweep.

Page 9

SOURCE-Press SHIFT SOURCE then MODE 01 A/V to

scroll through available trigger sources (or press the spy

propriate numeric key in the list below). and then press

ENTER.

Front panel modes and 80wces include:

Numeric Dlaplay

Key # Message

0 TRIGGER MODE

I-SHOT

1 TRIGGER MODE

SWEEP

0

TRIGGER SOURCE FP Front Panel MANUAL

One reading per

trigger

one sweep pw

trigger

button’

1 TRIGGER SOURCE

EXT

TRIGGER SOURCE

2

External trigger pulse

IEEE talk command

TALK

3 TRIGGER SOURCE

IEEE GET command

GET

4 TRIGGER SOURCE X

IEEE X command

“Always enabled regardless of selected source.

8

Page 10

WAVEFM1M

0

PARAMETER

0

ON-The ON key turns the internal or external bias voltage,

which is applied through the OUTPUT jack, on or off.

WAVEFORM -Selects the type of bias waveform to be programmed. or the external bias 8ourc~. as indicated below.

Use WAVEFORM, A/T, or appropriate numeric key to select

the waveform type, then press ENTER.

3

Page 11

Available waveforms include:

Numeric Dlsplay

Keyif Messaga DBSCrlpllon

0 DC

Constant DC level in the range of

f20V.

1 STAIR

2 DSTAIR

%&staircase lstsp either up or

Dual staircase lstep up then down

or down then upl.

PULSE

3

Pulse train lconstant level or step

up or down).

4 EXT

Voltage from external source IEIAS

INPUT jsckl.

PARAMETER-Use PARAMETER or A/T to ~elecf para-

meter to be programmed, then key In the value using the

numeric keys. Press ENTER when finished programming all

ptWWllt?t~1S.

Progremmeble paremeters include:

Display

Message

START TIME

STOP TIME

STEP TIME

FIRST BIAS V

LAST BIAS V

STEP BIAS V

DEFAULT BIAS V

COUNT’

Llmlls Resolution

lmssc to 65ssc lmsec

lmsec to 05sec lmssc

lmsec to 65sec lmsec

-20v to +2ov 5mV

-20v to tzov 5mV

-20v to tzov 5mv

-20v to t2ov 5mV

I-450 Il.360 et

1,000/set rate1

10

Page 12

“Selscts number of readings storsd for external and DC

GRID

bias waveforms.

“‘Voltages may be programmed in ImV 8teps. but are set

in 5mV steps.

NOTE: Multiply programmed times by 1.024 for actual time

interwals.

PLOTTER GROUP

0

SETUP

0

ABORT

I

11

Page 13

PLOT-Pressing PulT plots the date located in the selscted

buffer IA or SI on a” intelligent plotter over the IEEE-488

bus using the current SETUP paremetsrs. The plotter must

be set tc the eddresssble mode using e primary address

of 6. The controller must be disconnected from the bus for

stand-alone plotting.

GRID-Pressing GRID draws labels, .%~a. end other perameters as appropriate for the selected buffer and the SETUP

pem”leters.

SETUP-Pressing SETUP enters the plotter setup menu

which allows selection of the parameters below. Use increment or decrement tc ~crcll through menu selections the”

press the appropriate “umber (belcwl when desired selectic” is dlsplayed, then ENTER.

ABORT-Press SHIFT ABORT tc ceeso plotting or grid

generation.

12

Page 14

Page 15

DATA GROUP

Increment iAl)-Increment is used to scroll through menu

selections for other front panel operating modes such as

TRIGGER MODE, PLOTTER SETUP, and BIAS WAVEFORM.

Inclement is also used to scroll through buffer locations

when displaying buffer data.

Decrement /II-Liks the increment key, decrement is used to scroll through parameter menus and buffer locations.

but in the opposite direction.

ENTER-ENTER is used as the last step in the menu or

pmamefer selwction process fa actually perform the opera-

tion being programmed.

14

Page 16

WIT-Pressing WIT when scrolling through a pwameter

menu will rsturn the instrument tc the normal front panel

display and restcres the previouslv programmed mode. CJJIT

also exits the buffer.

BUFFER-Pressing BUFFER allows You tc view the contents

of buffer A or buffer B on the front panel displays. Once

in this mode, select the desired buffer (A or 8) and use increment or decrement tc sequentially access various buffer Iccations. The BUFFER LED will be on while the unit is

displaying buffer data. Pressing BUFFER while accessing

the buffer displays the last valid buffer location. Pressing

ENTER displays the first valid buffer location gocation #I).

A -B-Places the entire ccntents of buffer A into buffer

8. including capacitance, conductance, and bias voltage

values. Buffer A is the buffer into which A/D readings are

stored. Buffer A will be cleared after the data is transferred.

SHIFT-SHIFT adds a secondary function tc certain other

front panel keYs. including BUFFER. If You press a key which

has no second function after enabling shift, the primary

function of that key will bs performed.

NUMERlC DATA KEYS 10.9, +, -)-These keys are used

to enter numsric data when programming such item8 as bias

parametsrs. If You wish tc restore the previously prcgrammsd values, press the QUIT key instead of ENTER.

Pressing the -

key scrolls the curser to the right.

Page 17

MISCELLANEOUS FUNCTIONS

To access the following modes, press SHIFT before the key

in question.

CABLE CAL-Pressing this key performs open-circuit cable

correction only at 1MHz. Note that the opposite ends of

the connecting cables must be left open during the ccrrec~

tic” process. Once the correction is complete, you will be

given an opportunity to store the correction scheme for the

particular cable IO-S1 you we using at the update option.

Note that cable correction reduces the dynamic range of

the measurements

CABLE #-Use this key to select which of seven previously

stored cable correction setups obtained above that you wish

to USB IO-8). Once selected, the unit will automatically use

the previously stored cable correction parameters when

making measurements. Note that correction setup #7 turns

off cable correction and installs default values to the front

panel.

SELF TEST-Use this key to perform B self test on many

internal ocmpcnents, including display and the hardware

multiplier.

SAVE-SAVE allows you to save up to seven ccmplsre in-

strument configurations in NVRAM. To use this feature,

simply select the operating configuration and then press

the SAVE button. Key in the position (O-61 that you wish

to save. Note that state 0 is the configuration the unit will

*ssume upon power up.

16

Page 18

RECALL-Use RECALL to assume machine operating configurations that wnre stored with the SAVE key, or the factory configuration. Upon entering this mode, you will be

prompted for a configuration number. Key in the YSIUB (O-7)

and press ENTER. Note that state 7 is a factory default can-

figuration permanently stored in ROM and cannot be altered.

State 0 is the configuration the instrument assume8 upon

power up.

The following modes can be saved and recalled.

Mode

Factory Default

2nF

100kHz’

On

Rate

zero

Trigger Mods

Trigger Source

Bias Source

Waveform

Start, stop. step time

First. last. step, default bias

count

10,sec

Off

SVW3p

Front Panel

Off

DC

1msec

ov

450

“59O/lOOk or 690/100k/lM

IEEE-Press IEEE to verify or program the IEEE-489 primarv

address. Use the number keys to select a primary address

value 03Ol. Press ENTER to program the new address. The

programmed address will go into effect immediately, and

is stored in non-volatile RAM.

Page 19

MATHEMATICAL FUNCTIONS

The following calculations are performed on data presently

stored in the data buffers and are not stored in memory.

In order to use these functions, You must select buffer

display with the SUFFER key.

K-Pressing l/C’ inverts the capacitance value in each

data word of the selected buffer and then squares it; the

value for each point will be displayed as you access that

word location.

C/Co-This feature allows you to display normalized capaci-

tance data. The maximum capacitance YSIUB is used for C,.

C...-Pressing c...

value stored in the selected buffer.

C,-Co-This key allows you to subtract each capacitance

value in buffer El from the corresponding values in buffer A.

IV,-V,IC=CONST.-This function rotates the C-V plot axis

by go0 and gives a display of the change in voltage (AVI

as 8 function of constant capacitance.

C vs t-While in C vs t, you can use A/v to scroll through

various buffer locations. The buffer location number will

be shown in the bias voltage display. You can calculate the

time at a specific location for DC and staircase waveforms

as follows:

ts= Itstart + ,tstep + l/RI ,Sll x 1.024

displays the maximum capacitance

18

Page 20

Where: t9 = time at B specific buffer location

tstert = programmed stert time

tstep = progemmed step time

R = reading rate Ireadings per second)

9 = buffer location number

Use actual reading ret88 as described in instruction manual.

NOTE

DISPLAYS

CAPACITANCE DISPLAY-The normal capacitance display

is e 4% digit +21,999, -19,999 count value with engineer-

ing units in pF or nF. Note that display resolution is 3% digits

et the 76 and 1000 reading per second rates.

CONDUCTANCE DISPLAY-The nominal conductance

display is a 4% digit 13% digits et the 75 end 1000 reeding

per second rates), t21.999. -19,999 count value, with

engineering units else displayed in pS or mS for conductance (parallel model1 or kR or Mll for resistance fseries

model).

BIAS VOLTAGE DISPLAY-The 4% digit bias voltage display indicetes the programmed or actual measured velue

of the internal +2OV bias ~wrce or the applied external

bias voltage (*2OOV). While programming bias parameters.

the display will show the progwnmsd value. When the unit

is displaying readings or stored buffer valufa the display

will show the biss voltage as measured by an internal A/D

converter. This display will also show buffer location in C

vs t. Note that display resolution is 3% digits at the 75 and

1000 reading per second ret%

19

Page 21

CONNECTIONS

FRONT PANEL

Test INPUT and OUTPUT-Connect the device under test

to ths test INPUT and OUTPUT jacks as shown in Figure

1. Use RG-58 coaxial cable for best results. Cable correcdon should bs used when measuring at 1MHz for optimum

Bccvrac”.

20

Page 22

Page 23

REAR PANEL

VOLTAGE BIAS INPUT-This SNC connector is intended to

apply external bias voltage up to -tZOOV DC, 50mA maximum. Note that the input is internally fused to protect the

instrument from over current conditions.

VOLTAGE BIAS OUTPUT-This BNC output jack provides B

means to monitor the selected bias voltage fextemal or internal) applied to the circuit under test.

CONDUCTANCE ANALOG OUTPUT-This output jack provides B scaled voltage proportional to the conductance

reading. The rsnge of the output is 0.2V, full scale. For 8xample, the nominal output value will be IV with a 1011s

reading on the 2OpF12OfiS range.

CAPACITANCE ANALOG OUTPUT-This SNC jack provides

B scaled output voltage that is proportional to the capaci-

tance reading. The output range of the CAPACITANCE out-

put is 0-2V full scale. For example, the nominal outfwt

voltage with B 14OpF reading on the 2OOpF12OOpS range

will be 1.4V.

EXTERNAL TRIGGER INPUT-A SNC jack to be used for applying a trigger pulse to initiate a one-shot or sweep reading.

Pulse specifications are shown in Figure 2.

EXTERNAL TRIGGER OUTPUT-This BNC jack provides 8

pulse when the instrument completes a one-shot reading

or reading sweep, depending on the selected trigger mode.

Output pulse specifications are shown in Figure 3.

22

Page 24

I

Ffgure 2. ExIernaf Ttlgger Input Pulse Specifioatlons

Flgure 3. External Trigger Output Pulse Speclflcations

23

Page 25

WAVEFORM DEFINITIONS

Figure 4. DC, One-Shot

24

Page 26

I

Figure 5. DC, SWWP

25

Page 27

- 1;

Ffgum 6. Single, Staircase, One-Shot

26

1

9

4

Page 28

Figure 7. Single StaIrcase, Sweep

27

Page 29

Figure 8. Dual Staircase, One-Shot

28

Page 30

29

Page 31

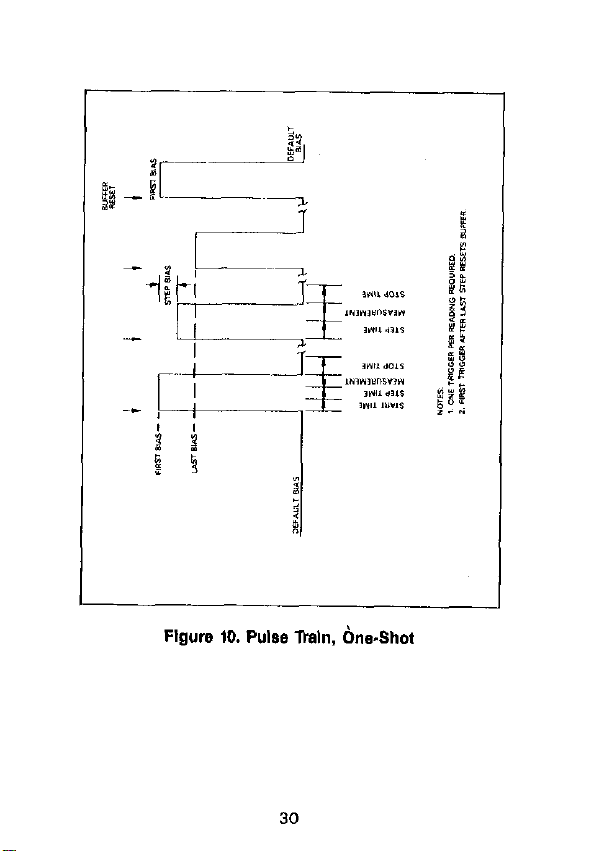

Flgure ID. Pulse lkaln, bne.Shot

30

Page 32

I-

Flgure 11. Pulse lhln, Single SW-P

31

Page 33

Flwm 12. External, OneShot

32

Page 34

Flgure 13. External, SInglO-SWeEP

33

Page 35

IEEE-488 PROGRAMMING

DEVICE-DEPENDENT COMMANDS

Plotter (A)

A0

Al

A2, plot

A3. grid

Plot: O=C YS V: 1 =G YS V;

Z=l/C’w3V; 3=c/c,vsv;

4=c “St; 5=lC,-C,l “9 v;

S=IV,-V.IC=CONST

Grid: 0 = Full grid: 1 = Axis

A4. buffer

A5, pen

AE. line

A7. label

A8.n. Xmin, Xmax

A9.n. Ymin, Ymsx

1 “,%r O=A/D buffer IAl:

1 =Plot buffer @I

Pen: O=No pen; 1 =Pen #I:

2=Pen #2

Line: 0 = DOT at points;

1 = Spaced dots; 2 = Dashes:

3=Long dash: 4=Dash dot;

5=Long dash, short dash;

B=Long, short. long dash;

7=Solid line

Label: O=Full labels; 1 =Label

axls and divisiona; 2 = Label

axis only

X axis limits. n = 0: Autoscsling lminimum/msximum bias).

n = 1: Program X axis

minlmum IXminl and maximum

IXmaxl values.

Y axis limits. n=O: Default

values, 0 to full scale. ” = 1:

Program Y axis minimum

W;;J and maximum fYmaxl

34

Page 36

Save/Recall Cable Setups (C)

C0.n

C1.n

Recall cable #n (Osna71

save csbk #n IOSll56

~

35

Page 37

tm Button (Ii)

Emulate button press:

H12

HI5

H16

HZ0

H23 ZNUAL

H25

HZ6

HZ7

H29 RANGE

H30

H31 MODEL

Cable Parsmeters (I)

IO Measure cable p~mmeter~

Il. “1. “2, “3. “4 Assign cable parameters

12. “1. “2. “3. “4, Assign test output cable

n6, fl6, n7, “6 Ch5tin6L Dh7 tjn6l

13. n1, n2, n3, n4

n5, n6, n7, “6

I:. C, G

IS. C, G

SHIFT

ENTER

(A-6)

ZERO

CAL

FILTER

FRED

(driving point1

KOlnl +jn21, Klln3+jn4)

parameters: Ah1 +jn21.

Bin3+jn4l.

Assign test INPUT cable

parameters: Ah1 +jn2,.

Wn3+in41, Ch5+jn*I

Din7+jn61

Zero cable open

Measure SOlKCB pa,afneterS.

step 1

Measure SOU,CB ,,a,arnefer~.

st*p 2

36

Page 38

Sell

Test

(J)

Jl Perform self test

EOI disabled. hold-off enabled

EOI enabled. hold-off disabled

Bias Control (N)

i’:

t

Bias off

Bias on

37

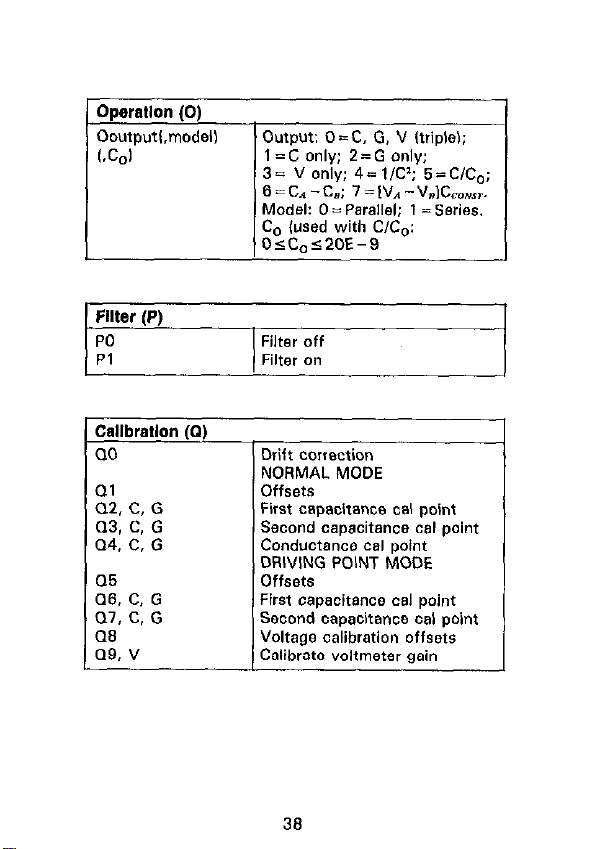

Page 39

!llter (P)

E

PO

Pl

Callbratlon (a)

00

Ql

Q2. C, G

(13, C. G

Q4. C, G

06

Q6. C, G

07. C. G

cm

a9, v

6 = CA -CL; 7 = IV1 - V.IC,,r.

Model: 0 = Parallel: t = Series.

C, (used with C/C,:

05Co~20E-9

Filter off

Filter on

Drift correction

NORMAL MODE

First capacitance oal point

Second capacitance cal point

Conductance cal point

DRIVING POINT MODE

First capacitance cal point

Second capacitance cal point

Voltage calibration offsets

36

Page 40

I

Range (R)

(100kHr

RO

Rl

R2

R3

R4

R5

R6

R7

R6

R9

Resdlng Rate (S)

so

w 75/set. 3% diuits

si

s3

54

NOTE: Reading rates are nCminal

Autorange on Autorange on

2pF/2pS ZOpFlZOOfiS

ZOpF/ZO,,S

2OOpF/2OOpS 200pF12mS

2nF/2mS

RI x10 on

R2 x10 on EWCf

R3 x10 on EWX

R4 x10 on

Autorange off. stay on range

lOOO/sec, 3% digits

tS/ssc, 4% digits

lO/sec, 4% digits

lisec. 4% digits

1

IMHz

2OpF/200,~S

2nF/20mS

Error

EtKX

One-shot on external pulse

sweep on external pulse

One-shot C” front panel

sweep on front panel

39

Page 41

S

c1

F

Ui

U2

u3

u4

U6

I u9

“10

Ull

U12

u13

u14

u15

Buffer A zen, gr&p

Buffer A bias group

Buffer A bias voltage

Buffer A bias time

Buffer A position and time

Buffer B range group

Buffer B triaaer arouo

Buffer B zero group

Buffer B bias group

Buffer B bias voltage

Buffer B bias time

Buffer B position and times

Buffer A maximum/minimum

cao*citance

Biffer A maximum/minimum

conductance

Buffer A maximum/minimum

Voltage

Buffer 6 maximum/minimum

cepscitance

Buffer 6 msximum/minimum

conductance

Buffer B maximum/minimum

Voltage

Global parameters

fseries/psrallel, Co value)

Plotter parameters lplot, grid,

line, etc.1

IEEE cutput parameters IO, G,

B, Y, KI

IEEE input parameters IL. C, H,

K. MI

40

Page 42

Not used

mnslator reserved word list

Translator NEW/OLD state

First=first bias; Last=last

4=External; Start=start time;

r]OTE: Multiply programmed time6 by 1.024 to obtain BC-

tual times

Execute (X)

X

Execute Commands

41

Page 43

Terminator (Y)

YO

Yl

Y2

Y3

<CR> <LF>

<LF> <CR>

<CR>

<LF>

42

Page 44

L

Flgure 14. Data Format

43

Page 45

44

Page 46

SRQ MASK AND STATUS BYTE FORMAT

Flgure 16. SRQ Mask and Status Byte Format

46

Page 47

UO426 STATUS WORD FORMATS

I

Flgure 17. UO Status Word Format

(Hardwam/Sottware Ftevlslon)

46

Page 48

n

Figure 18. Ul Error Status Word Format

47

-

Page 49

Flgure 19. U2 Status Word Format (Sulfer A Range Group)

Flgure 20. U3 Status Word Format (BufferA lklgger Gmup)

49

Page 50

Figure 21. U4 Status Word Format (Butter A Zero Group)

Flgure 22. U5 Status Word Format (Sutter A Bias Group)

49

Page 51

Flgum 23. LIB Status Word Formal (BufferA Bias Voltages)

50

Page 52

Flgure 24. II7 Status Word Format (Buffer A Bias Times)

Flgure 25. Ug Status Word Format

(Buffer A Posltlon and Time)

51

Page 53

Flgum 26. LIB Status Word Format (Suffer B Range Gmup)

I

Flgum 27. UIO Status Word FOrmat

(Buffer B ltlgger Group)

52

Page 54

Figure 29. U12 Status Word Format (Buffer B 819s Group)

53

Page 55

Flgure 30. U13 Status Word Format

(Butter B Bias Voltages)

Page 56

Figure 31. U14 Status Word Format (Butter B Bias Times)

I

Figure 32. U15 Status Word FOrmat

(Butter B Po8ltlon and The)

55

Page 57

Figure 33. U16 Status Word Fcrmat (Suffer A

Maximum and Mlnlmum Capacitance)

Figure 34. U17 Status Word Format (Buffer A

MaxImum and Mlnlmum Conductance)

56

Page 58

I

Flgure 35. U18 Status Word Fcrmat (Suffer A

Maxlmum and Mlnlmum Voltage)

I

Figure 38. Ul9 Statue WC?d FCrCtCl @Utter B

B Maxlmum and Mlnlmum Capacitance)

67

Page 59

Flgure 37. U20 Status Word Fcrmat (Suffer S

Maxlmum and Mlnlmum Conductance)

Flgure 39. U21 Status Word Fcrmat (Buffer B

MaxImum and Mlnlmum Voltage)

55

Page 60

Figure 39. U22 Statue Word Format

(Global Prog~ittttdng PmVttetem)

59

Page 61

I I

I

Flgurs 40. U23 Statue Word Format

(Plotter Prcgrsmmlng Parameters)

60

I

Page 62

FAA

Figure 4,. U24 StSt”8 Word Format

(IEEE Output PSrSmStSm)

61

Page 63

Flgurs 42. U25 Ststus Word Format

(IEEE Input Psrsmstsrs)

62

Page 64

Flgurs 43. U28 Ststus Word Format

(Cable CorrectIon Psrsmstsrs)

63

Page 65

TRANSLATOR

Table 1. ltsnslstcr Reserved Words and Characters

word or

Character Descrlptlcn

I

ALIAS

NEW

OLD

LIST

FORGET

Define words, enable Translator

Enable Translator, combine words

Disable Translator

Get list of Translator words

Erase Translator words

Terminate Translator definition string

Wildcard to define parameter position

Figure 44. U27 Status Wclrl Format

(Trsnslstcr User Nsms List)

64

Page 66

L

I

I35

Page 67

-

66

Page 68

PROGRAMS

The following programs are designed to be B simple aid to

the usw They are not intended to suit specific needs.

Detailed programming information can be found in the

manual.

67

Page 69

IBM PC or XT

(Keithley Model 8573A Interface)

The following program sends a command string to the

Model 590 from an IBM PC or XT computer and displays

the instrument reading string on the CRT. The computer

must bs equipped with the Keifhley Model 6573A IEEE-469

tnterface and the DOS 2.00 operating system. Model

9573A software must be installed and configured as

described in the inStruction manual.

DIRECTIONS

1. Using the front panel IEEE key. set the primary address

of the Model 590 to 16.

2. With the power off, connect the Model 590 to the

IEEE-496 interface installed in the IBM computer.

3. Type in SASICA on the computer keyboard to get into

the IBM interpretive BASIC language.

4. Place the interface software disc in the default drive, type

LOAD”DECL”. and press the return key.

5. Add the lines below to lines 1-6 which are now in

memory. Modify the address in lines 1 and 2, as described in the Model 6673A Instruction Manual.

6. Run the program and type in the desired command string.

Far example, to place the instrument in autorange and

lMHz frequency, type in ROFlX and press the return

key.

7. The instrument reading string will then appear on the

display. For example, the display might show

NCPM+ 1,2345E- 12.

6. To exit the program, type in EXIT at the command

prompt and press the return key.

66

Page 70

PROGRAM

COMMENTS

Clear screen.

Find board descriptor.

Find instrument

descriptor.

Set primary address to

15.

Set timeouts.

set REN *rUtI.

Prompt for command.

See if program is to be

halted.

Check for null input.

Add space for proper

hold off.

NOTE: For conversion to numeric variable. make the following changes:

130 RD=“AL<MIrJ*<HI!s,SI

15))

135 PKINTRO

69

Page 71

APPLE II (APPLE II IEEE-488 Interface)

The following program sends a command string to the

Model 690 from an Apple II computer and displays the in-

sfrument reading string on the computer CRT.

The computer must be equipped with the Apple II IEEE-488

lnterfsce installed in slot 5. Note that the program 86sumes

;lit&h;, computer is running under Apple DOS 3.3 of

DIRECTIONS

1, Using the front panel IEEE key, 8et the primary address of

the Model 590 to 15.

2. With the ower off. connect the Modal 590 TV the

IEEE-488 interface ik&lled in the Apple II computer.

3. Enter the lines in the progrsm below. using the RETURN

key after each line.

4. Run the program and type in the desired command string

at the command prompt. For example, to place the instrument in the autorange and 1MHz modes, type in

ROFIX and press the return key.

5. The instrument reading string will then appear on the

CRT, A typical display is: NCPK + 1.2345E- 12.

70

Page 72

PROGRAM

1, If conversion to numeric variable is required. make the

following changes:

COMMENTS

-

Terminator.

Define address, slot

variables.

Input command string.

Set oufp”t to IEEE-488

bus.

Define input from

IEEE-488 bus.

Enable remote.

Line feed on.

Address 690 to listen.

send string.

Address 690 to talk.

input data.

Untalk the bus.

Define output to CRT.

Define input from

keyboard.

Display string.

2. The Apple II INPUT statement terminates on commas.

To avoid problems, program the Model 590 for the 01,

02, or 03 data format to eliminate commas.

71

Page 73

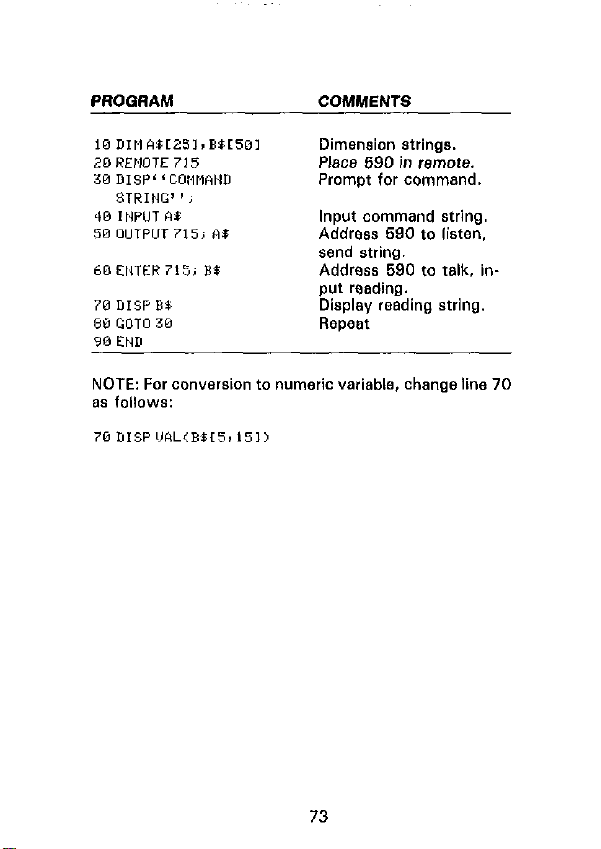

HP 85

The fallowing program sends a command string tc the

Model 590 from an HP-95 computer and displays the in-

strwnent reading string on the computer CRT. The com-

puter must be equipped with the HP82937 GPIS Interface

and an l/O ROM.

DIRECTIONS

1. Using the front panel IEEE key, set the primary address

of the Model 590 to 15.

2. With the pcwer off. ccnnect the Model 590 tc the

HPS2937A GPIB interface installed in the HP-86

ccnlpw3,.

3. Enter the lines in the program below, using the END LINE

key after each line.

4. Press the HP-85 RUN ksy and type in the desired ccmmand string at the command prompt. For example, to

place the Instrument in the autorange and 1 MHz modes.

type in ROFlX and press the END LINE key.

5. The instrument reading string will then appear on the

CRT. A typical display is: NCPM + 1.2345E - 12.

72

Page 74

PROGAAM

COMMENTS

Dimension strings.

Place 690 in remote.

Prcmot for command,

Input command string.

Address 590 to listen.

send string.

Address 590 to talk. in-

NOTE: For conversion to numeric variable, change line 70

zls fcllcws:

73

Page 75

HP 9818

The following program sends a command string to the

Model 590 from a Hewlett-Packard Model 9816 ccmpwer

and displays the instrument reading string on the computer

CAT. The computer must be equipped with the HP82937

GPIS Interface and BASICA 2.0.

DIRECTIONS

1, Using the front panel IEEE key. set the primary address

of the Model 590 to 15.

2. With the power off, connect the Model 690 to the

HPS2937A GPIB interface installed in the 9616

computer.

3. Type EDIT and press the EXEC key.

4. Enter the lines in the program below. using the ENTER

key after each line.

5. Press the 9816 RUN key and type in the desired ccmmand string at the command prompt. For example, to

place the instrument In the autorange and IMHz modes,

type in ROFIX and press the ENTER key.

S. The instrument reading string will then appear on the

CRT. A typical display is: NCPM + I .2346E - 12.

74

Page 76

PROGRAM

COMMENTS

Place 590 in remote.

Dimension string.

Prompt far and input

command.

Address 590 to listen,

send string.

Address 590 to talk, input reading.

Display reading string.

Repeat.

NOTE: For conversion to a numeric variable, change the

prcgrsm as fcllcws:

75

Page 77

HP 9825A

Use the following program to send a

the Model 590frcm a Hewlett-Packard Model 9825A and

display the instrument reading string on the computer

printer. The computer must be equipped with the

HP98034A HPIB Interface and a SS72A extended I/O ROM.

DIRECTIONS

1. From the front panel, set the primary address of the

Model 590 to 16.

2. With the power off, connect the Model 590 to the

S8034A HP18 interface installed in the 9925A.

3. Enter the lines in the program below, using the STORE

key after each line. Line numbers are automatically

assigned by the 982%

4. Press the 9825A RUN key and type in the desired ccmmand string at ths command prompt. For example. to

place the instrument in the furorange and 1 MHz modes,

type in ROFlX and press the CONT key.

5. The instrument reading string will then appear on the

computer print cut. A typical display is:

NCPM -1-t .2345E - 12.

command

string to

76

Page 78

PROGRAM

COMMENTS

@dim wL501.B*r201

Dimension data strings.

IdB”“590”,715 Define 590 at address

16.

2 rein* 05% ’ Place 690 in remote.

a mt c C*~,wwO STKIHG’ 3, Prompt for command

Be string.

4 Lvrt ‘540’ ’ I BE

Address 590 to listen.

send string.

5red“598”,** Address 590 to talk, in6 pr* A$

p”, data.

Print data string on

printer.

7 gto 3 RepWat.

NOTE: For conwrsion to numeric variable. modify the program a* follows:

6 prt Val(R%[51)

77

Page 79

DEC LSI 11

The following program sends a command string to the

Model 590 from a DEC LSI 11 minicomputer and displays

the instrument reading string on the DEC CRT terminsl. The

LSI 11 must be configured with f6K words of RAM and

an IBV If IEEE-499 interface. The software must be configured with the I6 software as well as FORTRAN and the

RT 11 operating system.

DIRECTIONS

1. Using the front panel IEEE key, set the primary address

of the Model 590 to 16.

2. With the power off, connect the Model 690 to the IBV

? 1 IEEE-499 interface cable.

3.

Enter ths program below, using the editor under RT 1 1

and the name IEEE.FOR.

4. Compile using the FORTRAN compiler a8 follows: FOR

TRAN IEEE.

5. Link with the system and IB libraries 8s follows: LINK

IEEE,lBLIB.

6. Type RUN IEEE snd press the RETURN key.

7. The display will read “ENTER ADDRESS”.

S.Type in 16 and press the RETURN key.

9. The display will read “TEST SETUP”.

10. Type in the desired command string and press the

RETURN key. For example, to program the instrument

for the autorange and 1 MHz modes, type in ROF 1X and

press RETURN.

11. The instrument data string will appear on the computer

display. A typical display is: NCPM + 1.2345E- 12.

78

Page 80

PROGRAM

COMMENTS

Allow 5 error 15’s.

Allow 1 sscond bus

timeout.

Set line feed 88

terminator.

Turn on remote.

Input primary address.

Prompt for command

string.

79

Page 81

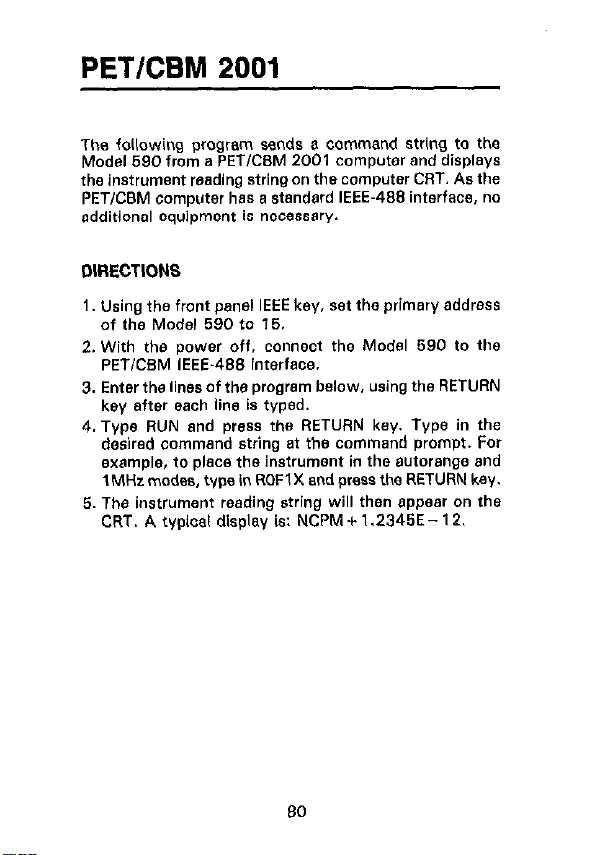

PETKBM 2001

The following program sands a command string to the

Model 690 from a PETKSM 2001 computer and displays

the instrument wading string on the computer CRT. As the

PETlCBM computer has a standard IEEE-498 interface, no

additional equipment is necessw.

DIRECTIONS

1. Using the front panel IEEE key. ?a the primary address

of the Model 590 fo 16.

2. With the power off. connect the Model 590 to the

PETiCBM IEEE-489 interface.

3. Enter the lines of the program below. using the RETURN

key after each line is typed.

4. Type RUN and press the RETURN key. Type in the

desired command string at the command prompt. For

example, to place the instrument in the autorange and

1 MHz modes, type in ROFl X and press the RETURN key.

5. The instrument reading string will then appear on Ihe

CRT. A typical display is: NCPM + 1.2345E- 12.

80

Page 82

PROGRAM

COMMENTS

Open file 1, primary address 15.

Prompt for, input Ccmmand string.

Address 590 tc listen.

send stri”Q.

Address 690 fc talk. inp”t data.

If bus timeout. input

again.

Display reading string.

Repeat.

NOTES:

1. If conversion fc numeric variable is requirsd. modify the

P,OQKW BS fOllOWS:

2. The PET INPUT# statement terminates on a Comma.

Thus. when WadlnQ Model 690 strings which include

ccrntnas, ycu should input each portion of the string intc 8 separate string variable. For example, in the 00

mode, tc obtain and display resdinQs. the program above

CB” be modified as fallows:

81

Page 83

Safety Precautions

The following safety precautions should be observed before

using this product and any associated instrumentation. Although some instruments and accessories would normally

be used with non-hazardous voltages, there are situations

where hazardous conditions may be present.

This product is intended for use by qualified personnel who

recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read and follow all installation, operation, and maintenance information

carefully before using the product. Refer to the manual for

complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body

the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating

limits, and for ensuring that operators are adequately trained.

Operators

must be trained in electrical safety procedures and proper use

of the instrument. They must be protected from electric

shock and contact with hazardous live circuits.

Maintenance personnel

product to keep it operating properly, for example, setting the

line voltage or replacing consumable materials. Maintenance

procedures are described in the manual. The procedures explicitly state if the operator may perform them. Otherwise,

they should be performed only by service personnel.

Service personnel

perform safe installations and repairs of products. Only

properly trained service personnel may perform installation

and service procedures.

Keithley products are designed for use with electrical signals that are rated Installation Category I and Installation

is the individual or group responsible for

use the product for its intended function. They

perform routine procedures on the

are trained to work on live circuits, and

5/02

Page 84

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category

I and must not be directly connected to mains voltage or to

voltage sources with high transient over-voltages. Installation Category II connections require protection for high

transient over-voltages often associated with local AC mains

connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless

otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present.

Lethal voltage may be present on cable connector jacks or

test fixtures. The American National Standards Institute

(ANSI) states that a shock hazard exists when voltage levels

greater than 30V RMS, 42.4V peak, or 60VDC are present.

A good safety practice is to expect that hazardous voltage

is present in any unknown circuit before measuring.

Operators of this product must be protected from electric

shock at all times. The responsible body must ensure that

operators are prevented access and/or insulated from every

connection point. In some cases, connections must be exposed to potential human contact. Product operators in these

circumstances must be trained to protect themselves from

the risk of electric shock. If the circuit is capable of operating at or above 1000 volts,

cuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited

sources. NEVER connect switching cards directly to AC

mains. When connecting sources to switching cards, install

protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is

connected to a properly grounded power receptacle. Inspect

the connecting cables, test leads, and jumpers for possible

wear, cracks, or breaks before each use.

When installing equipment where access to the main power

cord is restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

no conductive part of the cir-

Page 85

For maximum safety, do not touch the product, test cables,

or any other instruments while power is applied to the circuit

under test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers, installing or removing

switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while

standing on a dry, insulated surface capable of withstanding the

voltage being measured.

The instrument and accessories must be used in accordance

with its specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments

and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type

and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires

the use of a lid interlock.

If or is present, connect it to safety earth ground

using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user

should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source

or measure 1000 volts or more, including the combined effect

Page 86

of normal and common mode voltages. Use standard safety

precautions to avoid personal contact with these voltages.

The

WARNING

might result in personal injury or death. Always read the associated information very carefully before performing the

indicated procedure.

The

CAUTION

could damage the instrument. Such damage may invalidate

the warranty.

Instrumentation and accessories shall not be connected to

humans.

Before performing any maintenance, disconnect the line

cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power

transformer, test leads, and input jacks, must be purchased

from Keithley Instruments. Standard fuses, with applicable

national safety approvals, may be used if the rating and type

are the same. Other components that are not safety related

may be purchased from other suppliers as long as they are

equivalent to the original component. (Note that selected

parts should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a

replacement component, call a Keithley Instruments office

for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter

or spill on the instrument. Products that consist of a circuit

board with no case or chassis (e.g., data acquisition board for

installation into a computer) should never require cleaning if

handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

heading in a manual explains dangers that

heading in a manual explains hazards that

Page 87

Specifications are subject to change without notice.

All Keithley trademarks and trade names are the property of

Keithley Instruments, Inc. All other trademarks and trade names

are the property of their respective companies.

Keithley Instruments, Inc.

28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) www.keithley.com

© Copyright 2000 Keithley Instruments, Inc.

Printed in the U.S.A. 04/2001

Loading...

Loading...