Page 1

Model 5802

IEEE-488 Interface

Instruction Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio, You will

be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KFJTHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT AR!? NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Page 3

Model 5802 IEEE-488 Interface

Instruction Manual

0 1985, Keithley Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

July 1987, Second Printing

Document Number: 5802-901-01 Rev. 6

Page 4

Safety Precautions

The following safety precautions should be observed before

using this product and any associated instrumentation. Although sane instruments and accessories would normally be

used with non-hazardous voltages, there are situations where

hazardous conditions may be present.

This product is intended for use by qualified personnel who

recognize shock hazards and are familiar with the safety pre-

cautions required to avoid possible injury. Read the operating

information carefully before using the product.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI)

states that a shock hazard exists when voltage levels greater

than 3OV RMS, 42.4V peak, or 60VDC are present. A good

safety practice is to expect that hazardous voltage is present

in any unknown circuit before measuring.

Before operating an instrument, make sure the line cord is

connected to a properly grounded power receptacle. Inspect

the connecting cables, test leads, and jumpers for possible

wear, cracks, or breaks beforr each use.

For maximum safety, do not touch the product, test cables, or

any other instruments while power is applied to the circuit

under test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers, installing or removing

switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to

the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry bands

while standing on a dry, insulated surface capable of with-

standing the voltage being measured.

Do not exceed the maximum signal levels of the instruments

and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture

rear panel, or switching card.

Do not connect switching cards directly to unlimited power

circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards directly to AC

main. When connecting sources to switching cards, install

protective devices to limit fault current and voltage to the

card.

When fuses are used in a product, replace with same type and

rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections

for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power

is applied to the device under test. Safe operation requires the

use of a lid interlock.

If a @screw is present on the test fixture, connect it to safety

earth ground using #18 AWG or larger wire.

The $ symbol on an instrument or accessory indicates that

1OOOV or more may be present on the terminals. Refer to the

product manual for detailed operating information.

Instrumentation and accessories should not be connected to

humans.

Maintenance should be performed by qualified service personnel. Before performing any maintenance, disconnect the

line cord and all test cables.

Page 5

SPECIFICATIONS/5802

ANALOG OUTPUT

LEVEL: 1” = 10,cal CO”“tS 0” Xl gain.

1” = 100 Counts on Xl00 gain,

Maximurn output voltage = *‘iv.

ACC”RACY: *(0.25% 0, displayed reading +*r”“)~ In x100. 2mV

output = 0.2 displayed aunts.

:EEE-488 BUS IMPLEMENTATION

RESPONSE TIME: FdlOWS d,splay cnnversion rate,

OUTPUT RESISTANCE: 1OOOn~

ISOLATION: ANALOC; OUTPUT LO is connected to ,EEE COM-

MON. Maximum cwnmo” mode voltage from IEEE COMMON to

earth ground is 3W rms al dc. 50 or 6011~~

.l”l.T,LINE COMMANDS: DCL. SK, GET. GTL. UNT. UNL.

WE. 3’“. LLO,

lN,L,NE COMMANDS: IFC, EN, EOI, SRQ, ATN,

NTERFACE FUNCTIONS: SHl. AH,. T5, TEO. L4. LEO, SRI. RLO.

PPO. DC,, DT,, CU. El.

‘ROCRAMMABLE PARAMETERS: Range. DRY CIRCUIT

TEST,Operate, RELative. POLARITY, DRIVE. TRlCger. Calibra-

tian. EOI, SRQ. Status. Data Format. Terminatar~

,E”,CE-DEPENDENT COMMANDS:

RANGE:

RO

;:

R-3 20 n

114 200 n

R5 2k n

Rb 2Ok n

R7 200k n

RELATIVE:

ZO = REL ofi

Z, = REL on

OPERATE:

0” = STBY (Standby1

0, = OPR (Operatv)

POLARITY:

PO = FOL +

Pi = I’OL -

DRIVE:

DO = DRIVE (puked)

D, = DRIVE

DRY ClRCUIT TEST:

CO = NON DRY CIRCUIT TEST

C, = DRY CIRCUIT TEST

D,G,TAL CALIBRATION:

v * n.nn,,,,~ * nn = enter calibratiun value.

STORE:

LO = Store calibration constants.

NON

DRY CIRCUIT

TEST

A”to

2”“rnII

2 R

(dc)

DRY CIRCUIT

TEST

Auto

2OOmll

2 0

20 0

20 0

20 n

20 0

20 0

TRIGGER:

TO = Continuous on Talk

T, = One-shot on Talk

T2 = Continuous ~1” GET

T3 = O”e~shr,t <>n GET

T4 = Cantinuous on X

TZ = One-shut on X

EXECUTE:

X = Exerute drviwdcprndent cwnmands

EO,:

KO = EOI Enabled

K1 = EO, “isabied

STATUS WORD:

ti” = Ourput status word,

DATA FORMAT:

GO = Readings and status word with preiix

C, = Readings and status word withut pretix

SRQ:

MO = Clear SRQ Data Mask

MI = Reading Overthn%

MS i Reading D”“r

M9 = Reading Done or Reading Ovcrfh

Ml6 = BUS)

M,, = Busy ,,T Reading Overflw

M24 = Busy or Reading Dane

M25 = Busy. Reading hne i)r Reading Overflw

M32 = Clear SRQ Ermr Mask

M33 = IDDCO

M34 = IDDC

M3S = ,DDC or IDDCO

M36 = Not in Remote

,437 = Not in Remok or ,DDCCl

M3X = Not in Rem<>tr or ,D,,C

M39 = Not in Remote. lDDC or (“DC0

TERMINATOR:

Y(ASC,I) = ASCII Character

Y(LF) = CR LF

Y(CR) = LF CR

Y(DEL, = None

T,ME FROM TRlGGER TO FlRST BYTE OUT: 350”~s 10 500ms.

ADDRESS MODES: Taik Only. Addressable

Page 6

DATA FORMAT AND STATUS BYTE OUTPUT

DATA FORMAT: STATUS BY-I-E OUTPUT:

TERMINATOR I

EXPONENT

PREF’X -FL u-l

N + DP + I.23456 E + 2 ,cR)(LF,

(pulsed)

D = DRIVE

S=STANDBY J L

N = NORMAL

O=OVERFLOW D=DRY

Z = RELATIVE CIRCUIT TEST

DRY CIRCUIT TEST: N = NON DRY

!-

POLARITY: + = POL +

- =POL -

id4

CIRCUIT TEST

580 D P C 0 R Z K T Md Me H Y

RELATIVE

TRIGGER

SRQ ON DATA

SRQ ON ERROR

LINE FREQUENCY A

TERMINATOR

I

PREFIX

DRIVE

POLARITY

DRY CIRCUIT TEST

OPERATE

RANGE

EOI

Page 7

TABLE OF

SECTION l-GENERAL INFORMATION

CONTENTS

1.1

1.2

1.3

1.4

1.5

1.6 USING THE INSTRUCTION MANUAL

1.7

1.8 UNPACKING AND INSPECTION..

INTRODUCTION

INTERFACE FEATURES

WARRANlY INFORMATION

MANUAL ADDENDA

SAFETY SYMBOLS AND TERMS

SPECIFICATIONS

......

......

......

......

......

......

......

SECTION 2-AN OVERVIEW OF THE IEEE-488 BUS

2.1 INTRODUCTION

2.2

2.3 IEEE-488 BUS LINES

2.3.1 BusManagement Lines

2.3.2 Handshake Lines

2.3.3 Data Lines

2.4 BUS COMMANDS

2.4.1

2.4.2

2.4.3 Addressed Commands

2.4.4 Unaddressed Commands

2.4.5 Device-Dependent Commands

2.5

2.6 COMMAND SEQUENCES

2.6.1 Addressed Command Sequence

2.6.2

2.6.3 Device-Dependent Command Sequence ......................................................

BUS DESCRIPTION

UniIine Commands

Universal Commands

COMMAND CODES

Universal Command Sequence

............................................................................

..........................................................................

.........................................................................

.....................................................................

...........................................................................

.................................................................................

...........................................................................

.........................................................................

.......................................................................

......................................................................

...................................................................

..............................................................

.........................................................................

...................................................................

............................................................. 2-7

..............................................................

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

..,...

1-l

1-l

1-l

1-l

1-l

1-l

l-2

l-2

2.1

2-l

2-2

2-2

2-2

2-3

2.3

2-4

2-4

2-5

2-5

2-5

2.5

2-7

2-8

2-8

SECTION 3-SYSTEM CONFIGURATION

3.1 INTRODUCTION

3.2 HARDWARE CONSIDERATIONS .............................................................

3.2.1 Typical Systems

3.2.2 Bus Connections

3.2.3 Primary Address Selection..

3.3

3.3.1 Controller Interface Routines

3.3.2 HP-85BASIC Statements

3.3.3 InterfaceFunction Codes ....................................................................

3.3.4 Interface Commands

SOFTWARE CONSIDERATIONS .............................................................

............................................................................

............................................................................

...........................................................................

................................................................

................................................................

...................................................................

.......................................................................

3-l

3-l

3-l

3-2

3-4

3-5

3-5

3-5

3-6

3-7

I

Page 8

SECTION 4-OPERATION

4.1

4.2

4.2.1

4.2.2

4.2.3

i.2.4

4.2.5

4.2.6

4.2.7

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.3.7

4.3.8

4.3.9

4.3.10

4.3.11

4.3.12

4.3.13

4.3.14

4.3.15

4.4

INTRODUCTION ..............

GENERAL BUS COMMANDS

REN (Remote Enable). ........

IFC (Interface Clear) ..........

GTL (Go To Local) ...........

LLO (Local Lockout). .........

DCL (Device Clear). ..........

SDC (Selective De&ce Clear)

Serial Polling (SPE, SPD)

DEVICE-DEPENDENT COMMAND PROGRAMMING..

Execute(X) ..........................

Range (R) ...........................

Operate/Standby (0) .................

Dry Circuit Test (C) ..................

Relative (2). .........................

Digital Calibration (V) and Storage (L)

Polarity (P) ..........................

Drive (D) ............................

Triggering (T) ............................

EOI (K) .................................

SRQ Mode (M) and Status Byte Format ....

Status Word (U) or Alternate Output ......

Prefix(G)

Programmable Terminator (Y) .............................................................. 4-14

Data Format .............................................................................. 4.14

TALK ONLY OPERATION ..................................................................

.................................................................................

.......

.......

.......

.......

.......

.......

......

......

......

......

......

......

..........

..........

..........

..........

..........

..........

..........

.................................................

.................................................

.................................................

................................................

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

4-l

4-l

4-l

4-2

4-2

4-2

4-3

4-3

4-3

4-4

4-b

4-6

4-6

4-6

4-7

4-7

4-8

4-8

4-8

4-8

4-9

4-13

4-13

4.15

SECTION 5-ANALOG OUTPUT

5.1

5.2

5.3

5.4

INTRODUCTION ............................................................................

USING THE ANALOG OUTPUT .............................................................

OUTI’UTRESISTANCE ......................................................................

Xl00 RESOLUTION AND ACCURACY

........................................................

SECTION 8-PRINCIPLES OF OPERATION

6.1

6.2

6.2.1

6.2.2 Digital Circuitry..

6.2.3

INTRODUCTION ............................................................................

CIRCUIT DESCRIPTION .....................................................................

Power Supply .............................................................................

..........................................................................

Analog Output .............................................................................

SECTION 7-MAINTENANCE

7.1

7.2

7.3

7.3.1

7.3.2

7.3.3

7.3.4 Calibration. ................................................................................

7.4 SPECIAL HANDLING OF STATIC-SENSITIVE DEVICES

7.5 TROUBLESHOOTING

INTRODUCTION ............................................................................

INSTALLATION .............................................................................

CALIBRATION ..............................................................................

Warm Up .................................................................................

Recommended Calibration Equipment ........................................................

Environmental Conditions ..................................................................

.......................................................................

.......................................

5-l

5-l

5-3

5-3

b-1

6-l

6-l

6-2

6-2

7-l

7-l

7-l

7-l

7-l

7-3

7-3

7-3

7-3

ii

Page 9

SECTION 8--REPLACEABLE PARTS

8.1

8.2

8.3

8.4

8.5

INTRODUCTION ............................................................................

REPLACEABLE PARTS.

ORDERING INFORMATION

FACTORY SERVICE

SCHEMATIC DIAGRAMS AND COMPONENT LOCATION DRAWINGS

......................................................................

.................................................................

.........................................................................

8-l

8-l

8-1

8-l

........................ 8-1

iii

Page 10

LIST OF TABLES

SECTION 2-AN OVERVIEW OF THE IEEE-488 BUS

2-l

2-2

2-3

2-4

IEEE-488 Bus Command Summary .,,,...,,.._...,,,.,..,,,._..................,,............. 2-4

Hexadecimal and Decimal Command Codes.. 2-7

Typical Addressed Command Sequence.. 2-8

Typical Device-Dependent Command Sequence 2-8

SECTION 3-SYSTEM CONFIGURATION

3-l

3-2

3-3

3-4

3-5

IEEE-488 Contact Designations

Primary Address Switch Positions

HP-85 IEEE-488 BASIC Statement

Interface Function Codes

IEEE-488 Command Groups

................................................................

.............................................................

.............................................................

.......................................................

..................................................................

SECTION 4-OPERATION

4-l

4-2

4-3

4-4

4-5

4-6

GeneralBus Commands

Default Values (Status Upon Power Up or After SDC or DCL).

Device-Dependent Command Summary

RangeCommands

SRQMask Commands

Status Byte and Mask Interpretation

......................................................................

........................................................

...........................................................................

.......................................................................

..........................................................

SECTION t&ANALOG OUTPUT

5-l AnalogOutputParameters....................................................................

..................................

.............

3-3

3-4

3-6

3-7

3-7

4-l

4-4

4-5

4-6

4-9

4-10

5-3

SECTION 7--MAINTENANCE

7-1 Static SensitiveDevices.......................................................................

7-2 Model5802InterfaceChecks..................................................................

SECTION 8-REPLACEABLE PARTS

8-l

iv

Model5802Parts List _...._.........................._.,.,.___.,...._.._.__._................ 8-2

7-3

7-4

Page 11

LIST OF ILLUSTRATIONS

SECTION 2-AN OVERVIEW OF THE IEEE-488 BUS

2-l

2-2

2-3

IEEE-488 Bus Configuration ...... .. ......................... ..................... 2-l

Handshake Sequence

Command Codes ............ _......

.........................................................................

SECTION 3-SYSTEM CONFIGURATION

3-l SystemTypes

3-2 IEEE-488 Connector

3-3 IEEE-488 Connections

3-4

3-5

3-6

3-7

Contact Assignments

Rear Panel of Model 580 Showing IEEE-488 Connections and Switches

Typical IEEE-488 Bus Drive (one of 16).

Primary Address Switch (Address 25 Shown)

......................................................

.................................................

...............................................

................................................

SECTION 4-OPERATION

4-l Status Byte Format

4-2

4-3

General Format for UO Command

Data Format

..........................................................................

............................................................

................................................................................

SECTION 5-ANALOG OUTPUT

5-l

5-2

5-3

Analog Output Connections

Xl Analog Output ........................................................................... 5-2

XlOOAnalog Output .._ ...................................................................... 5-3

..................................................................

........................................................

...............................

.........................

2-3

2-6

3-l

3-2

3-2

3-2

3-3

3-3

3-4

4-10

4-11

4-14

5-l

SECTION 6-PRINCIPLES OF OPERATION

6-l

6-2

6-3

Simplified Block Diagram.. ................................................................... 6-l

Memory Map

Xland Xl00 Gains ........................................................................... 6-3

................................................................................

SECTION 7-MAINTENANCE

7-l

Model 5802 Installation

.......................................................................

SECTION 8-REPLACEABLE PARTS

8-l

8-2

Model 5802 Interface, Component Location Drawing, Dwg. No. 5802-100

Model 5802 Interface, Schematic Diagram, Dwg. No. 5802-106

6-2

7-2

......................... 8-4

................................... 8-5

Page 12

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Model 5802 is an IEEE-488 interface for the Model 580

Micro-ohmmeter. This interface, which includes analog

output, adds extra versatility to the Model 580 by allowing the transmission of data and commands over the

IEEE-488 bus. The interface provides all the necessary logic

to interface the Model 580 to the bus using standard

IEEE-488-1978 protocol.

1.2 INTERFACE FEATURES

Important IEEE-488 interface features:

l With the Model 5802 installed, the Model 580 is able to

communicate with other insrmmentation using the same

IEEE-488s1!778 standards.

l A standard IEEE-488 connector that provides easy con-

nection to the IEEE-488 bus.

l An easily-changeable primary address. Although the

Model 580 is shipped from the factory with a primary

address of 25, the customer can change it by using the

five rear panel address switches.

l All Model 580 operation is supported by IEEE-488 pro-

gramming. In addition, numerous other IEEE-488 commands add operating features not available from the front

pSW1.

1.4 MANUAL ADDENDA

Information concerning improvements or changes to the

instrument which occur after the printing of this manual

may be found on an addendum included with this

manual. Review these changes before programming the

Instrument.

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms are used in this

manual and may be found on the instrument.

The A symbol on the instrument indicates that the user

should refer to the operating instructions.

Information associated with the WARNING heading explains dangers that could result in personal injury or

death.

Information following the CAUTION heading explains

hazards that could damage the instrument.

1.6 USING THE INSTRUCTION MANUAL

1.3 WARRANTY INFORMATION

Warranty information may be found on the inside front

cover of this manual. Should it become necessary to exercise the warranty, contact your Keithley representative or

the factory to determine the proper course of action.

Keithley Instruments, Inc. maintains service facilities in the

United States, the United Kingdom and throughout

Europe. Addresses for these facilities may be found inside

the front cover of this manual. Information concerning the

application, operation or service of your instrument may

be directed to the applications engineer at any of these

locations.

This manual contains all the information you need to con-

nect the Model 5802 to the IEEE-488 bus and program the

instrument from a separate bus controller.

The manual is divided into the following sections:

1. Section 2 contains a general description of the IEEE-488

bus and its commands.

2. Section 3 contains information necessary to connect the

instrument to the bus and set the primary address.

3. Section 4 contains the bulk of the programming information. General bus commands as well as commands

unique to the Model 5802 are covered in detail.

1-l

Page 13

4. Section 5 explains the analog output feature of the

Model 5802.

5. Section 6 contains Principles of Operation.

6. Section 7 contains maintenance information such as installation and troubleshooting.

7. Section 8 contains replaceable parts information and applicable schematics and component layouts.

and electrically before shipment. When the Model 5802

arrives, carefully unpack all items and check for any obvious signs of damage.

Report any damage to the shipping agent immediately. Retain and use the original packing material in case reshipment is necessary. The following items are shipped with

every Model 5802 order:

1.7 SPECIFICATIONS

A complete list of IEEE-488 specifications can be found

preceding this section.

1.8 UNPACKING AND INSPECTION

The Model 5802 was carefully inspected both mechanically

Model 5802 IEEE-488 Interface

Hardware necessary for installation

Model 5802 Instruction Manual

Additional accessories as ordered

If you need another manual, order the manual package

(Keithley Part No. 5802-901-01). This package includes an

instruction manual and any pertinent addenda.

l-2

Page 14

2.1 INTRODUCTION

SECTION 2

AN OVERVIEW OF THE IEEE-488 BUS

The IEEE-488 bus is an instrumentation data bus adopted

by the IEEE (Institute of Elechical and Eleckonic Engineers)

in 1975 and given the IEEE-488 designation. The most recent revision of bus standards was made in 1978; hence

the complete description for current bus standards is the

IEEE-488-1978 designation.

The information presented here is not an elaborate description of a complicated set of standards. Rather, this section

briefly describes general bus structure including a bus command outline. Complete IEEE-488 bus information is

available from the IEEE and other sources.

2.2 BUS DESCRIPTION

The IEEE-488 bus is a parallel data transfer medium that

optimizes data transfer without using an excessive number

of bus lines. The bus has only eight data lines, used for

data and certain commands. In addition, the IEEE-488 bus

employs eight signal lines, including five bus management

lines and three handshake lines. Since the bus is of pamlIe

design, all devices connected to the bus have the same in-

formation available simultaneously. Each device processes

information received from the bus depending on its

capabilities.

TO OTHER DEVlCES

/ * \

DATA BYTE

TRANSFER

CONTROL

INTERFACE

T

HANDSHAKE

A typical bus configuration for controlled operation is

shown in Figure 2-l. A typical system has one controller

and one or more instruments that receive commands and

which usually yield data.

BUS

MANAGEMENT

Figure 2-1. IEEE-488 Bus Configuration

2-1

Page 15

AN OVERVIEW OF THE IEEE-488 BUS

Three categories described device operation: controller,

talker, and listener. The controller regulates other devices

on the bus, the talker sends data, and the listener receives

data. A particular device may be a talker only or both a

talker and a listener. A system can have only one controller

(although control may be passed on to an appropriate

device through a special command). Several talkers and

listeners may be present depending on the bus’s

capabilities.

The bus is limited to 15 devices including the controller.

The maximum cable length is 20m.

Several devices may listen simultaneously, but only one

device at a time may be a talker. Otherwise, communication would be garbled.

Before a device can be a talker or a listener, it must be appropriately addressed. Devices are selected according to

their primary address; the addressed device is sent a talk

or listen command derived from its primary address. Each

device on the bus has a unique address so that each may

be addressed individually.

ATN (Attention)-The ATN line is an important management line. ATN line status indicates if controller information on the data bus is to be considered data (set high false)

or a multiline command (set low).

IFC (Interface Clear)-The IFC line, set true (low), sends

the bus to a known state by sending the IFC command.

REN (Remote Enable)-The REN line, set low, sets up in-

struments on the bus for remote operation.

EOI (End or Identify)-The EOI line, set low, sends the

command to terminate a multi-byte transfer sequence.

SRQ (Service Request)-The SRQ line is set low by a device

when it requires service from the controller.

2.3.2 Handshake Lines

The bus uses three handshake lines that operate in an interlocked sequence. This method ensures reliable data

transfer regardless of the transfer rate. Generally, the

slowest active device on the bus determines the data

transfer rate.

Once a device is addressed to talk or listen, appropriate

bus transactions take place. For example, if an instrument

is addressed to talk, it sends its data to the bus one byte

at a time. The listening device reads this information, and

the appropriate software is then used to channel the information to the desired location.

2.3 IEEE-488 BUS LINES

Three types of signal lines are found on the IEEE-488 bus

lines: data lines, which handle bus information, and handshake and bus management lines, which ensure proper

data transfer and bus operation. Each of these bus lines

is “active low” so that approximately zero (0) volts is a logic

one (1). The following paragraphs describe the purpose

of these lines, which are illustrated in Figure 2-l.

2.3.1 Bus Management Lines

The bus management group includes five signal lines that

ensure orderly data transfer. These lines send the uniline

commands described in paragraph 2.4.1.

Of the three bus handshake lines, the data source controls

one and the accepting device controls the other two. The

handshake lines are:

DAV (Data Valid)-The source controls the state of the DAV

line.

NRFD (Not Ready For Data)-The acceptor controls the

state of the NRFD line.

NDAC (Not Data Accepted)--The acceptor controls the state

of the NDAC line.

Figure 2-2 illustrates the complete handshake sequence for

one data byte. Once data is on the bus, the source confirms that NRFD is high, indicating that all devices on the

bus are ready for data. Simultaneously, NDAC is low from

the previous byte transfer. If these conditions are not met,

the source must wait until the NRFD and NDAC lines have

the correct status. If the source is a controller, NRFD and

NDAC must remain stable for at least 1OOnsec after ATN

is low. Some controllers have time-out routines to display

error messages if the handshake sequence stops for any

reason to reduce the possibility of bus hang-up.

2-2

Page 16

DATA

DAV

X

SOURCE

SOURCE

AN OVERVIEW OF THE IEEE-488 BUS

DAV line high, indicating bus data is invalid, and the

NDAC line returns to its low state. Finally, each of the

devices releases the NRFD line at its own rate until it goes

high when the slowest device is ready. The bus is then set

to repeat the sequence with the next data byte.

MRFD

NOAC

VALlD

I

I I

I

I

I

I

I

I

DAiA

TRANSFER

BE61N

I

I

1

I

I

OAt A

TRANBFER

END

ACCEPTOR

ACCEPTOR

Figure 2-2. Handshake Sequence

Once the NRFD and NDAC lines are properly set, the

source sets the DAV line low (data on the bus is now valid).

The NRFD line then goes low, and the NDAC line goes

high after all devices on the bus have accepted the data.

Each device releases the NDAC line at its own rate. The

NDAC line will not go high until the slowest device has

accepted the data byte.

After the NDAC line goes high, the source then sets the

2.3.3 DBtB Lines

The IEEE-488 bus uses eight data lines that allow data to

be transmitted and received in a bit-parallel, byte-serial

manner. The eight lines are labeled DIOl through DI08, are

bidirectional and, as with the remaining bus signal lines,

low is true.

2.4 BUS COMMANDS

This section briefly describes the purpose of the bus commands that control communication between various instruments on the bus. The commands can be divided into

three categories.

Uniline Commands-Sent by setting the associated bus

line low.

Multiline Commands-General bus commands which are

sent over the data lines with the ATN line low.

Device-dependent Commands-Special commands that

depend on device configuration; sent over the data lines

with ATN high.

2-3

Page 17

AN OVERVIEW OF THE IEEE-488 BUS

Table 2-1. IEEE-488 Bus Command Summary

-I-

Command Type

Uniline

Command

REN (Remote Enable)

EOI (End Or Identify)

IFC (Interface Clear)

ATN (Attention)

SRQ (Service Request)

Multiline

Universal

DCL (Device Clear)

WE (Serial Poll Enable)

SI’D (Serial Poll Disable)

Addressed

SDC (Selective Device Clear)

GTL (Go To Local)

GET (Group Execute Trigger)

Unaddressed

UNL (Unlisten)

UNT (Untalk)

Device-dependent**

*X = Don’t Care

*‘See paragraph 4.3 for complete description.

State of

ATN Line*

i

t

X

X

X

Low

X

Low

Low

Low

Low

Low

Low

Low

Low

High

Comme”ts

Set up for remote operation.

Sent by setting EOI’low

Clear interface.

Defines data bus contents.

Controlled by external device.

Returns to default conditions.

Enables serial polling.

Disables serial polling.

Returns unit to default conditions.

Returns to local control,

Triggers device for reading.

Removes all listeners from bus.

Removes all talkers from bus.

Commands for control of the

instrument.

-1

2.4.1 Uniline Commands

Uniline commands are sent by setting the associated bus

line low. The ATN, IFC and REN commands are asserted

only by the system controller. The SRQ command is sent

by either the controller or an external device depending

on the direction of data transfer. The following is a brief

description of each command.

ATN (Attention)-Controller sets ATN when transmitting

addresses or multiline commands. Device-dependent commands are sent with the ATN line high (false).

IFC (Interface Clear)-Clears the bus and sets devices to

a known state. Although device configurations differ, the

IFC command usually places instruments in the talk and

listen idle states.

REN (Remote Enable)-Sets instrument up for remote

operation. The REN command should be sent before attempting to program the instruments over the bus.

EOI (End or Identify)-Positively identifies the last byte

in a multi-byte transfer sequence, and allows variable

length data words to be easily transmitted.

SRQ (Service Request)-Asserted by an external device

when it requires service from the controller. A serial polling sequence, as described in Section 4, must be used in

case of multiple devices to determine which device has requested service.

2.4.2 Universal Commands

Universal commands are multiline commands that require

no addressing. All inshumentation equipped to implement

the command will do so simultaneously when the command is transmitted over the bus. The universal commands, like all multiline commands, are sent over the data

line with ATN low.

LLO (Local Lockout)-The LLO command is used to lock

out front panel controls on devices so equipped.

DCL (Device Clear)-After DCL is sent, instrumentation

equipped to implement the commands will revert to a

known state. Usually, instruments return to their powerup conditions.

2-4

Page 18

AN OVERVIEW OF THE IEEE-488 BUS

Sl’E (Serial Poll Enable)--The SPE command is the first step

in the serial polling sequence. The serial polling sequence

is used to determine which instrument has requested ser-

vice with the SRQ command.

SPD (Serial Poll Disable)-The SPD command is sent by

the controller to remove all instrumentation from the serial

.poll mode.

2.4.3 Addressed Commands

Addressed commands are multiline commands that must

be preceded by a listen command before the instrument

will respond. The listen command is derived from the

device’s primary address. Only the addressed device will

respond to the following commands:

SDC (Selective Device Clear)-The SDC command is

essentially identical to the DCL command except that only the addressed device responds. The addressed instrument usually returns to its default conditions when SDC

is sent.

GTL (Go To Local)-The GTL command removes instruments from the remote operation mode. Also, front

panel operation will usually be restored if LLO was already

sent.

GET (Group Execute Trigger)-The GET command is used

to trigger devices to perform a device-dependent action.

Although GET is considered an addressed command,

many devices respond to GET without being addressed.

2.4.4 Unaddressed Commands

The controller uses two unaddressed commands to

simultaneously remove all talkers and listeners from the

bus. ATN is low when these multiline commands are

asserted.

UNL (Unlisten)-All listeners are immediately removed

from the bus when the UNL command is placed on the

bus.

UNT (Untalk)-The controller sends the UNT command

to clear the bus of all talkers.

2.4.5 Device-Dependent Commands

The instrument determines device-dependent command

definition. Generally, these commands are sent as ASCII

characters that tell the device to perform a specific func-

tion. For example, Zl places the instrument in the relative

mode. For complete information on using these commands

with the Model 5802, refer to Section 4. The IEEE-488 bus

treats device-dependent commands as data with the ATN

line high (false) when the commands are transmitted.

2.5 COMMAND CODES

Each multiline command has a unique code that is

transmitted over the bus as 7 bit ASCII data. This section

briefly explains the code groups which are summarized

in Figure 2-3. Every command is sent with ATN true.

2-5

Page 19

AN OVERVIEW OF THE IEEE-466 BUS

2-6

Figure 2-3. Command Codes

Page 20

AN OVERVIEW OF THE IEEE-466 BUS

Addressed Command Group (ACG)-Address commands

are listed in column O(8) in Figure 2-3. Column O(A) lists

the corresponding ASCII codes.

Universal Command Group (UCG)-Columns l(A) and

l(B) list universal commands and the corresponding ASCII

codes.

Listen Address Group (LAG)-Columns 2(A) and 3(A) list

the ASCII codes corresponding to the primaly addresses

listed in columns 2(B) and 3(B). For example, if the primary

address is set to l2, the LAG byte will correspond to an

ASCII(,) command.

Talk Address Group (TAG)--TAG primary address values

and the corresponding ASCII characters are listed in columns 4(A) through 5(B).

The preceding address groups are combined to form the

Primary Command Group (KG). The bus also has

another group of commands, the Secondary Command

Group (SCG). These are listed in Figure 2-3 for reference

only; the Model 5802 does not respond to these commands, although other devices may have secondary addressing capability.

NOTE

Commands are normally transmitted with the 7

bit code listed in Figure 2-3. The condition of D7

(D108) is usually unimportant, as shown by the

“Don’t Care” indication in the table. Some devices,

however, may require that D7 assume a specific

logic state before it recognizes commands.

Table 2-2. Hexadecimal and Decimal Command

Codes

Command Hex Value’

GTL

01

SDC 04

GET

08

DCL 14

WE 18

SPD 19

LAG 20-3F

TAG 40-5F

UNL 3F

UNT 5F

l-

Decimal Value

32-63

64-95

i

8

20

24

25

63

95

*Values shown with D7 = 0

2.6 COMMAND SEQUENCES

The proper command sequence must be sent by the controller before an instrument will respond as intended. The

universal commands such as LLO and DCL require only

that ATN be set low before the command is sent. Other

commands require that the device be addressed to listen

first. This section briefly describes the bus sequence for

several types of commands.

2.6.1 Addressed Command Sequence

Hexadecimal and decimal values for each of the commands

or command groups are listed in Table 2-2. Each value in

the table assumes that D7 is set to 0.

Before a device will respond to one of these commands,

it must receive a LAG command derived from its primary

address. Table 2-3 shows a typical sequence for the SDC

command. The LAG command assumes that the instrument is set at a primary address of 25 (11001).

2-7

Page 21

AN OVERVIEW OF THE IEEE-488 BUS

Table 2-3. Typical Addressed Command Sequence

Data Bus

Step Command ATN State

UNL Set low

1

LAG* stays low

2

3

4

*Assumes primary address = 25

Note that an UNL command is transmitted before the

LAG, SDC sequence. This removes all other listeners from

the bus first so that only the addressed device responds.

SDC Stays low

Returns hiah

ASCII Hex Decimal

? 3F

9 39

EOT04

63

57

4

2.6.2 Universal Command Sequence

The universal commands are sent by setting ATN true and

then placing the command byte on the bus. For example,

the following gives the DCL command:

2.6.3 Device-Dependent Command Sequence

Device-dependent commands are transmitted with ATN

false. However, the device must be addressed to listen first

before the command is transmitted. Table 2-4 shows the

sequence for the following command:

z 1 ::.::

This command, which sets the Model 58015802 to the

relative mode, is described in detail in Section 4.3.5.

Table 2-4. Typical Device-Dependent Command

Sequence

Data Bus

Step Command ATN State

UNL Set low

1

LAG* stays low

2

3

4

5

Data Set high

Data Stays high

Data Stays high

ASCII Hex Decimal

? 3F

9 39

z 5A

1 31

X 58

63

57

90

49

88

Note that both ATN and DCL are on the bus simultaneously. Also, addressing is not necessary.

*Assumes primary address = 25.

2-8

Page 22

SECTION 3

SYSTEM CONFIGURATION

3.1 INTRODUCTION 3.2.1 Typical Systems

This section deals with important hardware and software The IEEE-488 bus is a parallel interface system. When more

aspects of IEEE-488 bus operation. devices are added, more cables are used to make the

desired connections. This flexible arrangement can accommodate simple to extremely complex systems.

3.2 HARDWARE CONSIDERATIONS

Before the Model 5802 can be used with the IEEE-488 bus,

the device must be connected to the bus with a suitable

connector. Also, the primary address must be selected, as

described in this section. And of course, the Model 5802

IEEE-488 interface must be installed in the Model 580. Refer

to Section 7 for installation instructions.

tlOOEL 980

(A,) SIMPLE SYSTEM

Figure 3-l shows two typical system configurations. Figure bows two typical system configurations. Figure

3-1(A) shows the simplest possible controlled system. The YS the simplest possible controlled system. The

controller sends commands to the instrument, which sends commands to the instrument, which

sends data back to the controller. back to the controller.

CONTROLLER

CONTRoLLER

INSTRWENT

(El ADDITIONAL INSTRUHENTATlON

tlODEL 880

Figure 3-l. System Types

I

INSTRUMENT

3-1

Page 23

SYSTEM CONFIGURATION

The system becomes more complex in Figure 3-1(B), where

additional instrumentation is added. Depending on programming, all data may be routed through the controller,

or transmitted directly from one instrument to another. For

very complex applications, a much larger computer may

be used. Tape drives or disks can then be used to store

data.

INSTRUMENT

INSTRUMENT INSTRUMENT

3.2.2 Bus Connections

The Model 5802 is connected to the bus through an

IEEE-488 connector, which is shown in Figure 3-2. This

connector can be stacked to allow a number of parallel con-

nections to one instrument.

CONTROLLER

Figure 3-3. IEEE-488 Connections

NOTE

The IEEE-488 bus is limited to a maximum of 15

devices. includine the controller. Also, the maximum cable length is 20 meters. F&&to observe

these limits will probably result in erratic

operation.

Custom cables may be constructed using the information

in Table 3-l and Figure 3-4. Table 3-l lists the contact

assignments for the various bus lines, while Figure 3-4

shows the contact designations. Contacts 18 through 24 are

return lines for the indicated signal lines. The cable shield

is connected to contact 12. Each ground line is connected

to digital common in the Model 5802, but contact 12 within

the instrument is left unconnected to avoid ground loops.

Refer to Figure 3-5 to locate the connector on the rear panel

of the Model 580.

L

Figure 3-2. IEEE-488 Connector

NOTE

To avoid possible mechanical damage, it is recommended that not more than three connectors be

stacked on any one instrument. Otherwise the

resulting strain may cause internal damage.

A typical connecting scheme for the bus is shown in Figure

3-3. Each cable normally has the standard IEEE-488 connector on each end. The Keithley Model 7008-6 cable,

which is six feet long, is ideal for this purpose. Once the

connections are made, the screws should be securely

tightened.

3-2

I

CONTACT 12

(

CONTACT I

(

----- -----

---_----_ _

7 2

CONTiCT 24

Figure 3-4. Contact Assignments

CONiACT 13

Page 24

SYSTEM CONFIGURATION

Figure 3-5. Rear Panel of Model 580 Showing IEEE-488 Connections and Switches

Table 3-l. IEEE-488 Contact Designations

Contact IEEE-488

Number Desgination

DIOl

D102

D103

D104

EOI (24)

6

7

8

9

10

11

lz

l3

14

15

16

17

18

19

20

21

22

23

24

DAV

NRFD

NDAC

IFC

SRQ

ATN

SHIELD

D105

D106

D107

DI08

REN (24)’

Gnd, (6)

Gnd, (7)

Gnd, (8)

Gnd, (9)*

Gnd, (IO)*

Gnd, (11)”

,

Gnd. LOGIC

Type

Data

Data

Data

Data

Management

Handshake

Handshake

Handshake

Management

Management

Management

Ground

Data

Data

Data

Data

Management

Ground

Ground

Ground

Ground

Ground

Ground

Ground

WARNING

The voltage between IEEE-488 common and

chassis ground must not exceed 30V or damage

to the instrument may occur.

A typical signal line bus driver is shown in Figure 3-6. With

the configuration shown, the driver has bidirectional

capability. When the I/O control line is high, the line is

configured as an output line. When the control line is low,

the driver is set up for input operation. Note that not all

signal lines have bidirectional capability. Some lines, such

as ATN, will always be configured as an output line in the

controller and as an input line for all other devices on the

bus.

1

*Numbers in parenthesis refer to signal ground retur:

of reference contact number. EOI and REN signal lines

return on contact 24.

Figure 3-6. Typical IEEE-488 Bus Drive (one of 16)

”

3-3

Page 25

SYSTEM CONFIGURATION

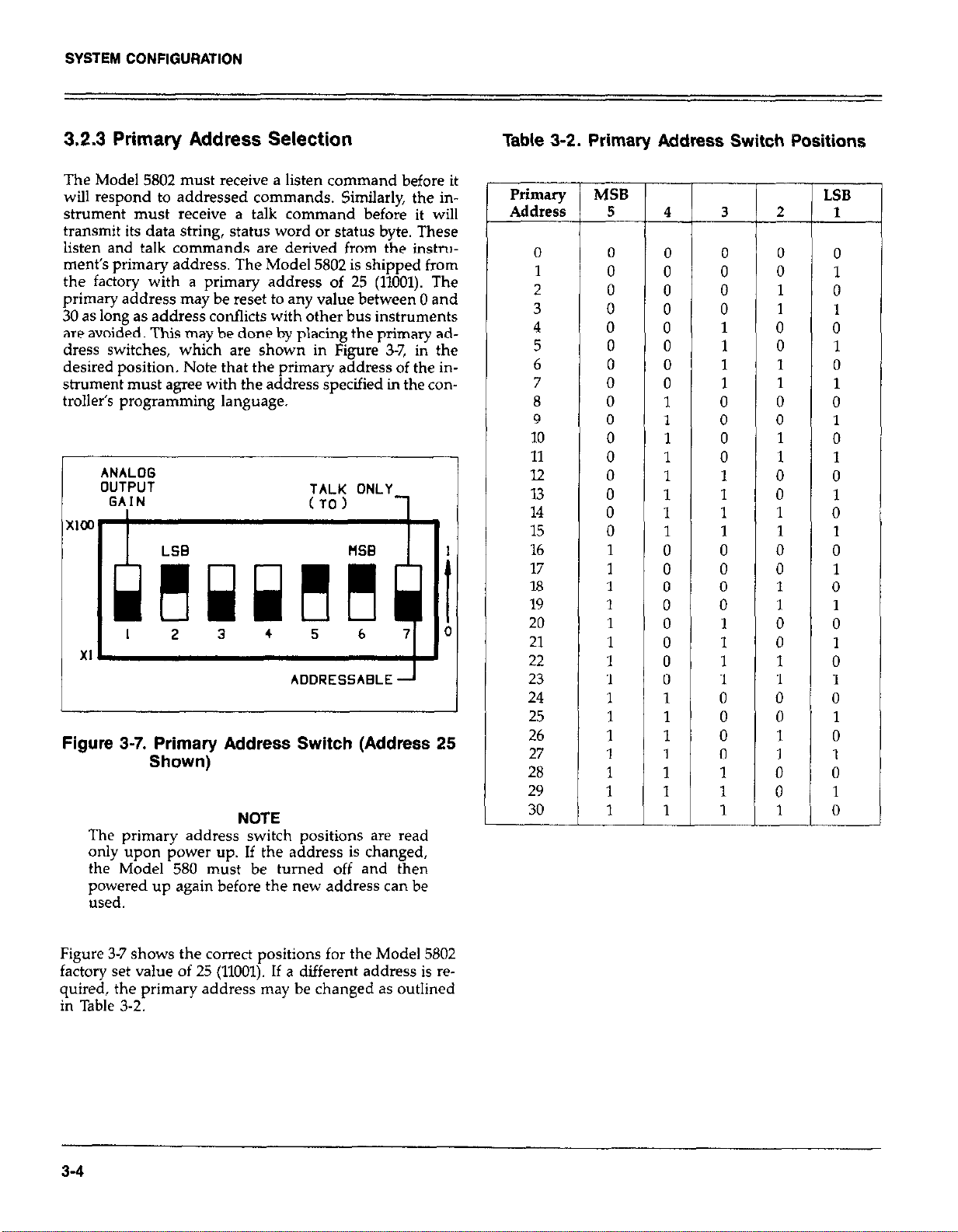

3.2.3 Primary Address Selection

The Model 5802 must receive a listen command before it

will respond to addressed commands. Similarly, the in-

strument must receive a talk command before it will

transmit its data string, status word or status byte. These

listen and talk commands are derived from the instrw

ment’s primary address. The Model 5802 is shipped from

the factory with a primary address of 25 (11001). The

primary address may be reset to any value between 0 and

30 as long as address conflicts with other bus instruments

are avoided. This may be done by placing the primary address switches, which are shown in Figure 3-7, in the

desired position. Note that the primary address of the instrument must agree with the address specified in the controller’s programming language.

ANALOG

OUTPUT

GAIN

TALK ONLY

(TO) 1

..-

LSG MB

h

mwdi

I 2 3 4 5 6 7 0

XI.

ADDRESSABLE -

Figure 3-7. Primary Address Switch (Address 25

Shown)

NOTE

The primary address switch positions are read

only upon power up. If the address is changed,

the Model 580 must be turned off and then

powered up again before the new address can be

used.

Table 3-2. Primary Address Switch Positions

Primary

Address

0 0

1

2 0

3

4 0

5 0

6 0

7

8

9

10

11

12

13 0

14

15 0

16 1

17 1

18 1

19 1

20 1

21 1

22

23 1

24

25 1

26

27

28

29

30

MSB

5

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

LSB

4

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

3

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

P-

__

2

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

Figure 3-7 shows the correct positions for the Model 5802

factory set value of 25 (11001). If a different address is required, the primary address may be changed as outlined

in Table 3-2.

3-4

Page 26

SYSTEM CONFIGURATION

NOTE

If other instrumentation is also connected to the

bus, be sure that each device has a different

primary address. If this precaution is not observed, erratic bus operation will result.

The primary address switches are binary weighted; Al is

the least significant bit, A5 is the most significant bit. For

example, the binary value for the factory set primary address of 25 is 11001. Use the tip of a pencil to operate the

switches.

NOTE Instruments should not be operated with a primary

address of 31 (11111) even though it is possible to set the

Model 5802 address to those positions. This address is

reserved for the UNT and UNL commands; erratic operation may result if primary address 31 is used.

3.3 SOFTWARE CONSIDERATIONS

The necessary handler routines to operate the IEEE-488

bus are described in this section.

3.3.1 Controller Interface Routines

Before a controller can be used with the IEEE-468 interface, make certain that appropriate handler software is present within the controller. The HP-85 interface card for the

HP-85 computer, for example, must be used with an additional 110 ROM, which contains the necessary handler

software.

Other small computers used as controllers have limited

IEEE-488 command capability. The PETKBM computers

are incapable of sending multiline commands from BASIC,

although these commands can be sent through machine

language routines. Other small computers’ capabilities depend on the particular interface being used. Often, little

software “tricks” are required to achieve desired results.

Make sure the proper software is being used with the interface. Often, the user may suspect that hardware is causing a problem when it is actually the software causing the

problem.

3.3.2 HP-85 BASIC Statements

Many of the programming instructions covered in Section

4 use examples written in Hewlett Packard Model 85

BASIC. The HP-85 was chosen for these examples because

it has a large number of BASIC statements that control

IEEE-488 operation. This selection covers those HP-85

BASIC statements essential to Model 58015802 operation.

A list of HP-85 BASIC statements is shown in Table 3-3.

All statements have a one or three digit argument that must

be specified. The first digit is the HP-85 interface select

code which is set to 7 at the factory. The last two digits

of those statements that require a three digit argument

specify primary address. Generally, only those commands

that require an address to be sent over the bus require that

the primary address be specified in the BASIC statement.

3-5

Page 27

SYSTEM CONFlGURATlON

Table 3-3. HP-85 IEEE-488 BASIC Statement

statement

ABORT10 7

CLEAR 7 Send DCL.

CLEAR 725 Send SDC to device 25.

ENTER 725;A$

LOCAL 725

OUTPUT 725;A5 Device 25 addressed to listen.

REMOTE 7 Set REN true.

REMOTE 725

RESET 7

SPOLL(725) Address device 25 to talk.

TRIGGER 7

TRIGGER 725 Address device 25 to listen.

Those statements in the table with three digit arguments

assume that the primary address of the device is set at 25.

Other primary addresses require that the last two digits

be set to the corresponding value. For example, to send

a GTL command to device 25, the following BASIC statement would be used.

Action

I

Send IFC.

Device 25 addressed to talk.

Data placed in A!$.

Send GTL to device 25.

Transmit A$.

Send REN true. Address device 25 to listen

Send IFC, cancel REN.

Conduct serial poll.

Send GET

Send GET.

BUS Command Sequence

F

IFC

ATN-DCL

ATN*UNL;MTA;LAG;SDC

ATN*UNL;MLA;TAG;ATN;data

ATN*UNL;MTA;LAG;GTL

ATN*MTA;UNL;LAG;ATN;data

REN

REN;ATNsL;MTA;LAG

1FC;REN;REN

ATN*UNL;MLA;TAG;SPE;ATN;

status byte;ATN*SPD;UNT

ATN*GET

ATN*UNL;MTA;LAG;GET

dresses sent by the HP-85 to facilitate bus operation in cer-

tain circumstances.

NOTE

The HP-85 address is set to 21 at the factory. Since

each device on the bus must have a unique

primary address, do not set the Model 5802 to the

controller’s address.

-

-

-

Some of the statements in the table have two forms; the

exact configuration used depends on the desired command. For example, CLEAR 7 will cause a DCL to be sent

to all devices on the bus, while CLEAR 725 causes an SDC

to be transmitted to device 25.

The third column of Table 3-3 lists command sequence

mnemonics. While most of these are covered elsewhere,

a couple of points should be noted. The ATN line is set

low by the controller if the data bus contains a multiline

command. This is indicated in the table by ANDing the

ATN mnemonic with the first command on the bus. For

example, ATN GET means that ATN and GET are sent

simultaneously. Two commands not previously covered are

MTA (My Talk Address) and MLA (My Listen Address).

These are ordinary PCG (Primary Command Group) ad-

3-6

3.3.3 Interface Function Codes

The interface function codes are part of the IEEE-488-1978

standards. These codes define an instrument’s ability to

support various functions and should not be confused

with programming commands found elsewhere in this

manual.

Table 3-4. lists the codes for the Model 5802. These codes

are also listed for convenience on the rear panel of the instrument immediately above the IEEE-488 connector. The

numeric value following each one or two letter code

defines Model 5802 capabilities as follows:

Page 28

SYSTEM CONFIGURATION

Table 3-4. Interface Function Codes

T

Code

SHl

AH1

l-5

L4

SRl

RLO

IT0

DC1

lm

co

El

TEO

LEO

SH (Source Handshake Function)-The ability of the

Model 5802 to initiate message/data transfer on the data

bus is provided by SH function.

AH (Acceptor Handshake Function)-Guaranteed proper

reception of message data on the data bus is provided by

the AH function.

T (Talker Function)-The ability of the Model 5802 to send

device-dependent data over the bus (to other devices) is

provided by the T function. Model 5802 talker capability

exists after the instrument has been addressed to talk.

L (Listener Function)-The ability of the Model 5802 to

receive device-dependent data over the bus (from other

devices) is provided by the L function. Listener function

capability of the Model 5802 exists only after the instrument has been addressed to listen.

SR (Service Request Function)-The ability of the Model

5802 to request service from the controller is provided by

the SR function.

RL (Remote Local Function)-The ability of the Model 5802

to be placed in the remote or local modes is provided by

the RL function.

PP (Parallel Poll Function)-The Model 5802 does not have

parallel polling capabilities.

DC (Device Clear Function)-The ability of the Model 5802

to be cleared (initialized) is provided by the DC function.

Interface Function

Source Handshake Capability

Acceptor Handshake Capability

Talker (Basic Talker, Serial Poll, Talk Only

Mode, Unaddressed To Talk On LAG)

Listener (Basic Listener, Unaddressed To

Listen On TAG)

Service Request Capability

No Capability

No Parallel Poll Capability

Device Clear Capability

Device Trigger Capability

No Controller Capability

Open Collector Bus Driver

No Extended Talker Capability

No Extended Listener Capability

DT (Device Trigger Function)-The ability for the Model

5802 to have its basic operation started is provided by the

DT function.

C (Controller Fun&m-The Model 5802 does not have

controller capabilities.

TE (Extended Talker Capability)-The Model 5802 does not

have extended talker capability.

LE (Extended Listener Capability)-The Model 5802 does

not have extended listener capability.

3.3.4 Interface Commands

Interface commands controlling Model 58015802 operation

are listed in Table 3-5. Not included in the table are devicedependent commands, which are covered in detail in Section 4.

Table 3-5. IEEE-488 Command Groups

HANDSHAKE COMMAND GROUP

DAC=DATA ACCEFTED

RFD=READY FOR DATA

DAV= DATA VALID

UNIVERSAL COMMAND GROUP

ATN=ATTENTION

DCL=DEVICE CLEAR

IFC=INTERFACE CLEAR

LLO=LOCAL LOCKOUT

REN=REMOTE ENABLE

SPD=SERIAL POLL DISABLE

SI’E=SERIAL POLL ENABLE

ADDRESS COMMAND GROUP

LISTEN: LAG=LISTEN ADDRESS GROUP

MLA=MY LISTEN ADDRESS

UNL=UNLISTEN

TALK: TAG=TALK ADDRESS GROUP

MTA=MY TALK ADDRESS

UNT=UNTALK

OTA=OTHER TALK ADDRESS

ADDRESSED COMMAND GROUP

ACG=ADDRESSED COMMAND GROUP

GET=GROUl’ EXECUTE TRIGGER

GTL=GO TO LOCAL

SDC=SELECTIVE DEVICE CLEAR

STATUS COMMAND GROUP

RQS=REQUEST SERVICE

SRQ=SERIAL POLL REQUEST

STB=STATUS BYTE

EOI=END

3-713-0

Page 29

SECT

ON 4

OPER

4.1 INTRODUCTION

The Model 5802 is an IEEE-488 interface for the Model 580

Micro-ohmmeter. Since all IEEE-488 operation is done

through commands given over the bus, IEEE-488 operation precludes the use of operating controls in the usual

sense. Instead, all operating functions are controlled by

programming.

This section describes important programming functions

in detail Included are: general bus commands, devicedependent commands, status word and status byte, and

other important information. The information presented

in this manual assumes that the operator is familiar with

all normal aspects of Model 580 operation. For information on front panel operation, refer to the Model 580

Operator’s Manual.

NOTE

mming examples in this section assume that

rrogra

the Model 5802 primary address is set to 25. Those

examples with &dressed commands will not function unless the primary address of the instrument

is set to that value. Refer to Section 3 for information on setting the primary address.

4.2 GENERAL BUS COMMANDS

General bus commands are those commands which have

the same general meaning regardless of instrument configuration. These commands are grouped into two

categories:

lTlON

General bus commands are summarized in Table 4-1,

which also lists the HP-85 BASIC statement that sends each

command. Each addressed command statement assumes

a primary address of 25 (11001).

Table 4-1. General Bus Commands

-

L-

*GET may be sent with or without addressing

4.2.1 REN (Remote Enable)

The remote enable command is sent to the Model 5802 by

the controller to set the instrument up for remote operation. Generally, this should be done before attempting to

program the instrument over the bus. The Model 58015802

indicates that it is in the remote mode by turning on the

front panel RMT annunciator.

To place the Model 58015802 in the remote mode, the con-

troller must perform the following steps:

Addressed Commands-These commands require that the

primary address of the instrument agrees with the primary

address in the controller’s language.

Unaddressed Commands-No primary address is required

for these commands. All devices equipped to implement

these commands will do so simultaneously when the command is sent.

1. Set the REN line true.

2. Address the Model 58015802 to listen

4-1

Page 30

OPERATION

NOTE

Setting the REN true without addressing will not

cause the REMOTE indicator to turn on: however.

once the REN is true, the REMOTE indicator turns

on the next time an addressed command is re-

ceived.

P&ramming Example-This sequence is automatically

sent by the HP-85 when the following is typed into the

keyboard.

After the END LINE key is pressed, the Model 580

REMOTE annunciator (RMT) should hnn on. If not, check

to see that the instrument is set for the proper primary

address. Also check to see that all the bus connections are

tight.

4.2.2 IFC (Interface Clear)

The IFC command is sent by the controller to set the Model

58015802 to the talk and listen idle states.

1. Set ATN true.

2. Address the Model 580/5802 to listen.

3. Place the GTL command on the bus.

Programming Example-If the instrument is not in the

remote mode, enter the following statements into the

HP-85 computer:

Check to see that the RMT annunciator is on. The GTL

command sequence is automatically sent by the HP-85

with the following statement:

Note that the remote (RMT) annunciator on the front panel

turns off.

NOTE

Setting the REN line false with the LOCAL 7 statement will also take the instrument out of the

remote mode

To send the IFC command, the controller need only set

the IFC line true.

Programming Example-Before demonstrating the IFC

command, turn on the front panel remote @MT) annunciator by entering the following statement into the HP-85

computer:

The front panel remote (RMT) annunciator should now

be on. The IFC command can now be sent by typing in

the following statement:

After the END LINE key is pressed, the Model 58015802

is in the talk idle state. Note that the remote mode is not

cancelled.

4.2.3 GTL (Go To Local)

4.2.4 LLO (Local Lockout)

The LLO command may be used to “lock out” front panel

button control on the Model 580. Note that all devices on

the bus equipped to respond to a LLO command will do

so simultaneously. When the Model 58015802 receives a

LLO command, the instrument will no longer respond to

front panel buttons, but can still be controlled over the bus

by the controller.

Programming Example-To put the instrument into local

lockout, enter the following statement into the HP-85

controller:

Note that the RMT and LLO annunciators come on

To get out of local lockout and remote, type:

The GTL command is used to take the instrument out of

the remote mode. To send the GTL command, the controller must perform the following sequence:

4-2

Both annunciators turn off

Page 31

OPERATION

To stay in local lockout but get out of remote (go to

LOCAL), type:

Note that the RMT annunciator turns off, but LLO stays

on.

4.2.5 DCL (Device Clear)

The DCL command may be used to clear the Model 580,

setting it to a known state. Note that all devices on the bus

equipped to respond to a DCL will do so simultaneouslv.

When the Model 58015802 receives a DCL command, it will

return to the default conditions listed in Table 4-2.

To send a DCL command, the controller must perform the

following steps:

1. Set ATN true.

2. Place the DCL command on the bus.

Programming Example-Using the front panel controls,

select POLARITY and the 2012 range. Type in the following statement into the HP-85 computer:

Programming Example-Using front panel controls select

DC drive. Enter the following statements into the HP-85

computer:

Note that the instrument did not respond to the SDC

because the command was sent with a primary address

of five. Now enter the following statement into the HP-85:

This time, the instrument returns to the default conditions

listed in Table 4-2 (pulsed drive).

4.2.7 Serial Polling (SPE, SPD)

The serial polling sequence is used to obtain the Model

58015802 status byte. Usually, the serial polling sequence

is used to determine which of several devices has requested

service over the SRQ line. However, the serial polling sequence may be used at any time to obtain the status byte

from the Model 58015802. For more information on status

byte format, refer to Paragraph 4.3.11.

The serial polling sequence is conducted as follows:

When the END LINE key is pressed after the CLEAR 7

statement, the instrument returns to the default conditions

listed in Table 4-2 (the POLARITY will return to its positive

power up condition).

4.2.6 SDC (Selective Device Clear)

The SDC command performs the same function as the

DCL command except that only the addressed device

responds. This command is useful for clearing only a

selected instrument instead of all instruments at once. The

Model 580 returns to the default conditions listed in Table

4-2 when responding to a DCL command.

To transmit the SDC command, the controller must perform the following steps:

1. Set ATN true.

2. Address the Model 5802 to listen.

3. Place the SDC command on the bus.

1.

The controller sets the ATN line true.

2,

The SPE (Serial Poll Enable) command is placed on the

bus by the controller.

3.

The Model 58015802 is addressed to talk.

4.

The controller sets ATN false.

5.

The instrument then places its status byte on the bus

to be read by the controller.

6.

The controkr sets the ATN line true and places the SPD

(Serial Poll Disable) on the bus to end the serial polling

sequence.

Steps 3 through 5 may be repeated for other instruments

on the bus by using the correct talk address for each instrument. ATN must be true when the talk address is

transmitted and false when the status byte is read.

Programming Example-The HP-85 SPOLL statement

automatically performs the serial polling sequence. Tu

demonstrate serial polling, momentarily power down the

instrument and power it up again. Enter the follo\~ing

statement into the HP-85 computer:

4-3

Page 32

OPERATION

When the END LINE key is pressed after the S=SPOLL

statement, the computer performs the serial polling sequence. When the END LINE key is pressed after the

DISP S statement, the status byte value (0) is displayed

on the CRT. The status byte has a value of 0 with this example because no bits in the byte are set. Paragraph 4.3.11

covers the status byte format in detail.

Table 4-2. Default Values (Status Upon Power Up

or After SDC or DCL)

Mode

Range

Operate

Dry Circuit Test

Relative

Calibration

Polarity

Drive

Trigger

EOI

SRQ

Alternate Output Prefix

Terminator

Value status

-

-

-

zo

-

PO Positive

DO

To

KO

MO No SRQ

GO Send Prefix

Y(CR)(LF) Carriage Return, Line

Reflects front panel

selection

Reflects front panel

selection

Reflects front panel

selection

Off

Off

Pulsed current

Continuous on TALK

EOI is transmitted on

the last byte out

Standard output

Feed

1. Ignore the entire command string.

2. Set appropriate error bits in the status byte.

3. Generate an SRQ if programmed to do so.

These programming aspects are covered in paragraph

4.3.11. HP-85 examples are included throughout this section to clarify programming.

NOTE

Before starting a programming example, it is

recommended that the instrument be set to its

default values by sending a DCL over the bus. See

paragraph 4.2.5 for information on using the SDC

command.

If the HP-65 should become “hung up” at any point (due

to inadvertent command errors, etc.), operation may be

restored by holding down the SHIFT key and then pressing RESET on the keyboard.

In order to send a device-dependent command, the controller must perform the following sequence:

1. Set ATN true.

2. Set the REN line true.

3. Address the Model 58015802 to listen.

4. Set ATN false.

5. Send the command string over the bus one byte at a

time.

4.3 DEVICE-DEPENDENT COMMAND

IEEE-488 device-dependent commands are sent to the

Model 58015802 to control its various operating modes.

Each command is made up of an ASCII alpha character

followed by one or more numbers designating specific

parameters. For example, REL is programmed by sending

an ASCII “Z” followed by a zero or one for turning it off

or on. The IEEE-488 bus treats device-dependent commands as data in that ATN is high when the commands

are transmitted.

A number of commands may be grouped together in one

string. A command string is terminated by an ASCII “X”

which tells the instrument to execute the command string.

If an illegal command or command parameter is present

within a command string the instrument will:

Programming Example-Device-dependent commands are

sent by the HP-85 using the following statement:

A$ in this case contains the ASCII characters that form the

command string.

NOTE

REN must be true when attempting to program

the Model 580. If REN is false, the RMT annunciator will be off.

Commands that affect the Model 580 are listed in Table

4-3. All the commands listed in Table 4-3 are covered in

detail in the following paragraphs.

NOTE

The programming examples that follow assume

that the Model 58015802 primary address is at its

factory setting of 25 (11001).

4-4

Page 33

Table 4-3. Device-Dependent Command Summary

OPERATION

Store Calibration Constants

Polarity

Jn,

EOI

SRQ

Command

f

V