Page 1

NAVAIR 17-20AW-105

TECHNICAL MANUAL

AW-105

INSTRUMENT CALIBRATION PROCEDURE

CURVE-TRACER

TEKTRONIX

576

THIS PUBLICATION SUPERSEDES NAVAIR 17-20AW-105

DATED 1 DECEMBER 2000

DISTRIBUTION STATEMENT C. DISTRIBUTION AUTHORIZED TO U.S. GOVERNMENT AGENC IES AND THEIR

CONTRACTORS TO PROTECT PUBLICATIONS REQUIRED FOR OFFICIAL USE OR FOR ADMINISTRATIVE OR

OPERATIONAL PURPOSES ONLY. OTHER REQUESTS FOR THIS DOCUMENT SHALL BE REFERRED TO

MEASUREMENT SCIENCE DIRECTORATE, CORONA DIVISION, NAVAL SURFACE WARFARE CENTER,

P.O. BOX 5000, CORONA, CA 92878-5000.

DESTRUCTION NOTICE - FOR UNCLASSIFIED, LIMITED DOCUMENTS, DESTROY BY ANY METHOD

THAT WILL PREVENT DISCLOSURE OF CONTENTS OR “RECONSTRUCTION OF THE DOCUMENT.”

AW-105

PUBLISHED BY DIRECTION OF COMMANDER NAVAL AIR SYSTEMS COMMAND

1 AUGUST 2002

Page 2

NAVAIR 17-20AW-105

LIST OF EFFECTIVE PAGES

The purpose of this list is to identify the pages in this document affected by any technical content changes made since the

previous release of the document.

NOTE: On a revised page, with the exception of the Title, the A, and the i pages, the technical changes are indicated by a vertical

line in the outer margin of the page.

Page

No. **

Title 0

A 0

i 0

1 to 29 0

Revision*

Page

No. **

Revision*

Page

No. **

Revision*

A

*Zero in this column indicates an original page.

“R” in this column indicates a revised page.

**All pages not listed are blank pages.

Page 3

NAVAIR 17-20AW-105

TABLE OF CONTENTS

Section Page

1 Introduction and Description ................................................................................................................... 1

2 Equipment Requirements......................................................................................................................... 5

3 Preliminary Operations............................................................................................................................ 6

4 Calibration Process .................................................................................................................................. 6

4.1 Horizontal and Vertical CRT Gain Tests ............................................................................................. 6

4.2 Horizontal and Vertical Displayed Noise Tests.................................................................................... 8

4.3 Display Offset and CAL Pushbutton Tests........................................................................................... 9

4.4 Horizontal Display Accuracy Tests ...................................................................................................... 11

4.5 Vertical Display Accuracy Tests.......................................................................................................... 12

4.6 Step Amplifier Gain Tests.................................................................................................................... 15

4.7 Step Generator and Offset Multiplier Accuracy Tests ......................................................................... 16

4.8 Step Generator Tests ............................................................................................................................ 19

4.9 Collector Supply Tests......................................................................................................................... 20

Navy Calibration Checklist...................................................................................................................... 23

ILLUSTRATIONS

Figure Page

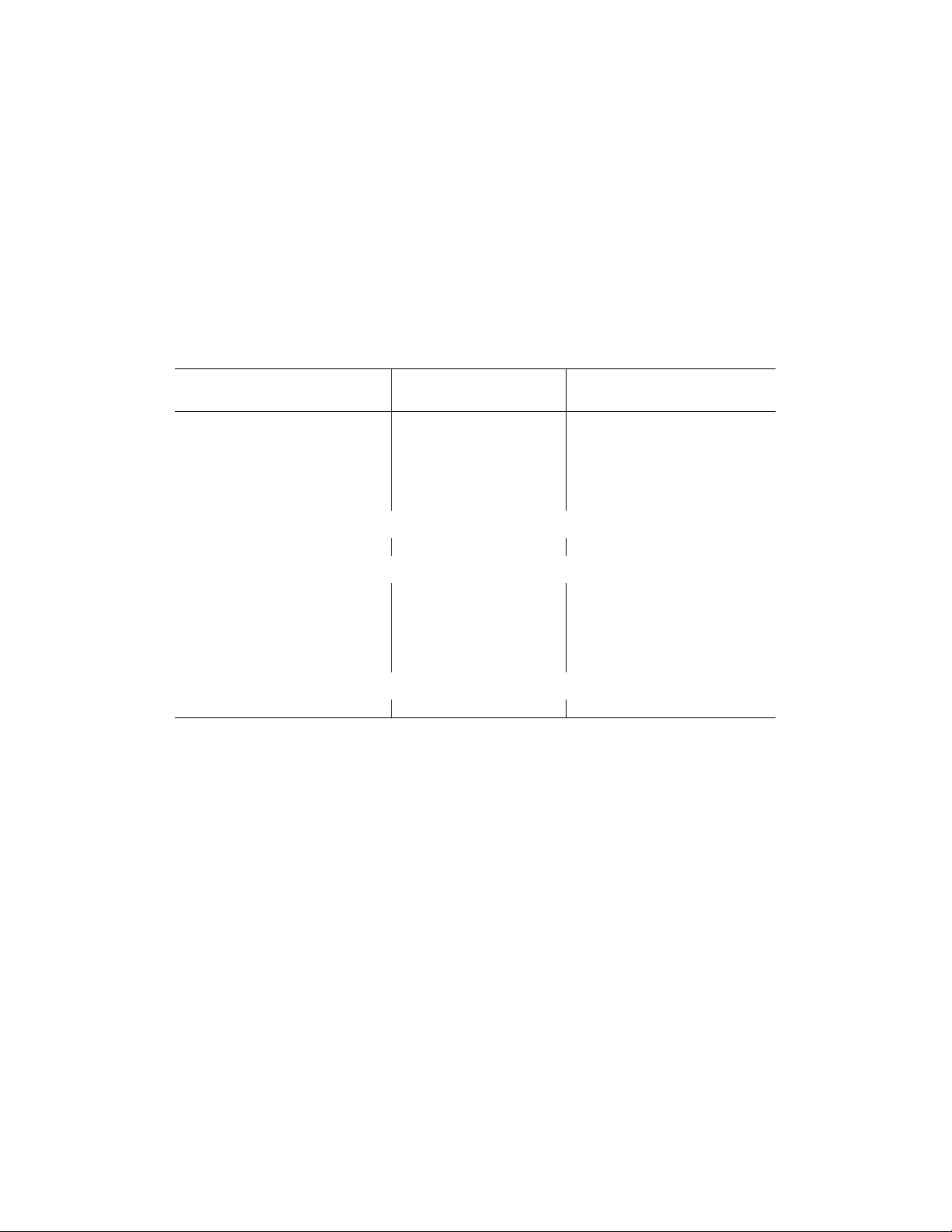

1 TI CRT Graticule Lines........................................................................................................................... 8

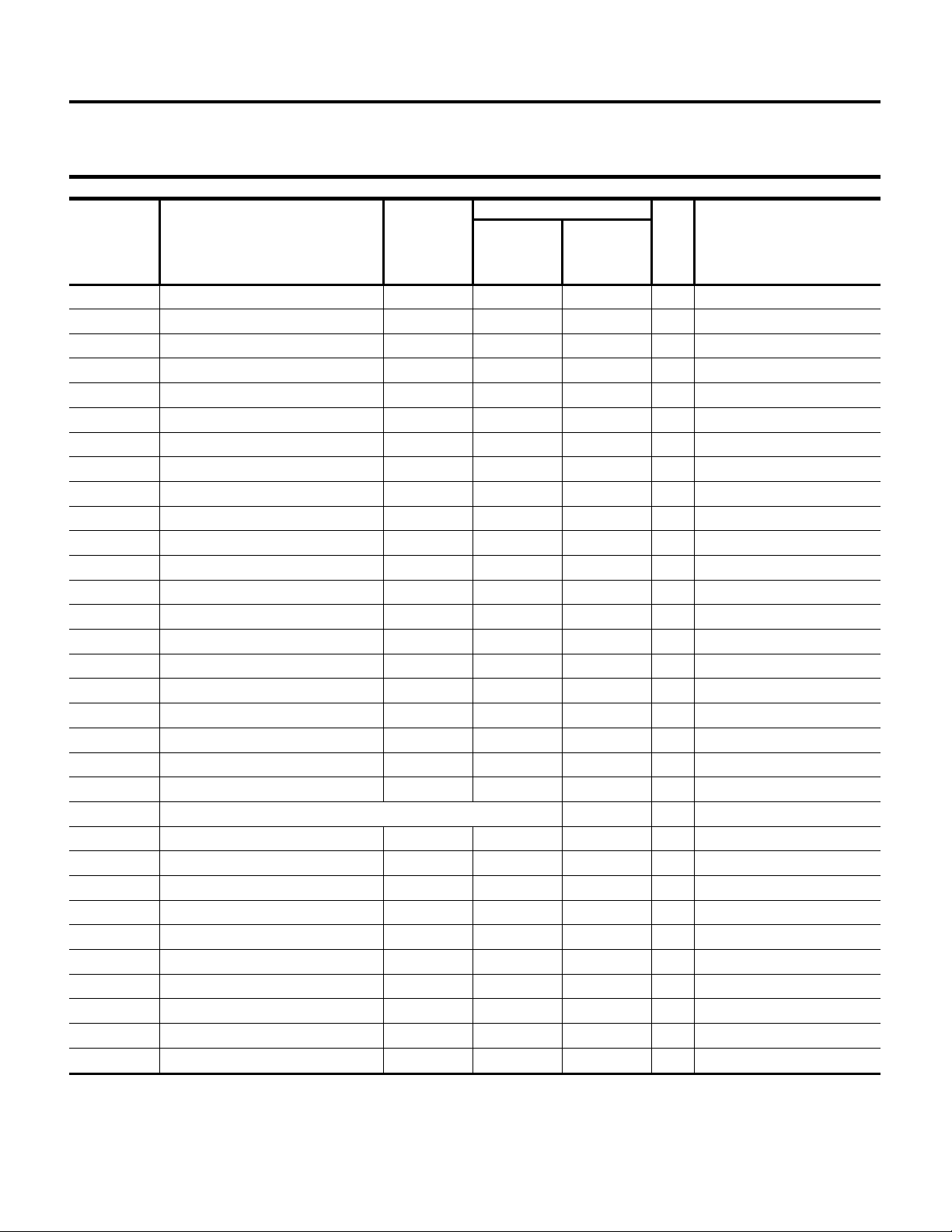

2 Vertical Display Accuracy Test Configuration........................................................................................ 14

TABLES

Table Page

1 Calibration Description............................................................................................................................ 1

2 Equipment Requirements......................................................................................................................... 5

i

Page 4

NAVAIR 17-20AW-105

SECTION 1

INTRODUCTION AND DESCRIPTION

1.1 This procedure describes the calibration of the Tektronix 576 Curve-Tracer. The instrument being calibrated is referred

to herein as the TI (Test Instrument).

1.2 All comments concerning this procedure should be directed to the Measurement Science Directorate, Corona Division,

Naval Surface Warfare Center, P.O. Box 5000, Corona, CA 92878-5000.

1.3 This procedure includes tests of essential performance parameters only. Any malfunctio n noticed during calibration,

whether specifically tested for or not, should be corrected.

Table 1. Calibration Description

TI

Characteristics

Collector supply sweep

modes

Voltages Ranges: 15, 75, 350, and 1500 V

Step generator current or

voltage steps inc lud i ng

offset

Normal AC: At line fre q uency

positive- or negative-going full

wave rectified AC

DC: Positive- or negative-going DC

Ripple: no load, 2% or less of

voltage; or 0.1% or less of full range

voltage

Tolerance: ±35% and -5% peak open

circuit voltages on all ranges

Series resistance: 0.3, 1.4, 6.5, 30,

140, and 650 Ω; 3, 14, 65, and

300 kΩ; 1.4 and 6.5 MΩ

Tolerance: ±5% or 0.1 Ω

Incremental tolerance: ±5% between

any two steps, without the 0.1X

STEP MULT button pressed; and

within ±10% with the 0.1X STEP

MULT button pressed

Absolute tolerance: ±2% of total

output, inc luding any a mount of

offset; or ±1% of AMPLITUDE

switch setting, whichever is greater

Performance

Specifications

Test

Method

Tested by inference.

Not tested.

Tested by observing the CRT

display and by measuring

the TI output with a DVM.

Tested by observing the CRT

display.

Step current o r voltage

amplitudes

OFFSET MULT control

range

One time (or 0.1 times with the STEP

MULT button pressed) the

AMPLITUDE switch setting

0 to 10 times AMPLITUDE switch

setting, either aiding or opposing the

step generato r polarit y

1

Page 5

NAVAIR 17-20AW-105

TI

Characteristics

Current mode Amplitude range: 200 mA to 50 nA,

in a 1-2-5 sequence

Maximum current: 20 times

AMPLITUDE switch setting, except

10 times switch setting when switch

is set to 200 mA, and 15 times

switch setting when the switch is set

to 100 Ma

Maximum voltage: 10 V min.

Maximum opposing offset current:

10 times the AMPLITUDE switch

setting, or between 10 mA and

20 mA, whichever is less

Maximum opposing voltage: between

1 and 3 V

Ripple plus noise: 0.5% or less of

AMPLITUDE switch setting or

1 nA, peak to peak

Voltage mode Amplitude range: 50 mV to 2 V, in a

1-2-5 sequence

Maximum voltage: 20 times

AMPLITUDE switch setting

Maximum current: at least 2A at

10 V or less decreasing linearly to

10 mA at 40 V

Maximum opposing offset voltage:

10 times the AMPLITUDE switch

setting

Maximum opposing current: 5 to

20 mA

Ripple plus noise: 0.5% or less of

AMPLITUDE switch setting; or

2 mV p-p

Performance

Specifications

Test

Method

Tested by observing the CRT

display.

Step rates 1 times .5 X, 2 times NORM, and

4 times 2 X line frequency

Pulsed steps

Number of steps Range from 1 to 10 as selected by the

2

Steps 80 µs wide within +20% to

-5%; or 300 µs wide withi n + 5 % to

15%

NUMBER OF STEPS switch

Page 6

NAVAIR 17-20AW-105

TI

Characteristics

Display amplifiers

Display tolerance (% of

highest on-screen value)

Normal and DC collector

supply modes

Vertical collector

External vertical

(through interface)

Horizontal collector volts 2% 3% 4% 3%

Horizontal base volts 2% 3% 4% 3%

External horizontal

(through interface)

Leakage collector supply mode

Vertical emitter current

(VERTICAL switch set

between 10 nA and 2 mA)

Display magnified (DISPLAY

OFFSET selector switch set to

either VERT X 10 or HORIZ

X 10) and offset between

100 and

40 div

2% 3% 4% 3%

2% 3% 4% 3%

2% 3% 4% 3%

2%

±1 nA

Not applicable

Performance

Specifications

35 and

15 div

3%

±1 nA

10 and

0 div

4%

±1 nA

Display

Unmag

nified

3%

±1 nA

5%

±1 nA

Test

Method

Tested by observing the CRT

display and by measuring the

output on a DVM.

Tested by observing the CRT

display.

Vertical emitter current

(VERTICAL switch set to

5 nA, 2 nA, or 1 nA)

Horizontal collector or base

volts VERTICAL switch set

to: 1 µA or more

100 nA, 10 nA, or 1 nA

500 nA, 50 nA, or 5 nA

200 nA, 20 nA, or 2 nA

Step generator display

Vertical

Horizontal 3% 4% 5% 4%

Reflection factors

Vertical

Collector current

2%

±1 nA

Not applicable

Not applicable

Not applicable

3% 4% 5% 4%

1 µA/div to 2 A/div in a 1-2-5 sequence

3%

±1 nA

4%

±1 nA

3% plus 0.025 V per

vertical di v

3% plus 0.025 V per

vertical di v

3% plus 0.025 V per

vertical di v

3%

±1 nA

Tested by observing an output on an

external oscilloscope.

Tested with an external 10A source

on the 1 and 2A ranges.

Emitter current 1 nA/div to 2 mA/div in a 1-2-5 sequence

3

Page 7

NAVAIR 17-20AW-105

TI

Characteristics

Performance

Specifications

Test

Method

Step generator 1 step/div

Horizontal

Collector volts 50 mV/div to 200 V/div in a 1-2-5 sequence Tested by observing the CRT

display.

Base volts 50 mV/div to 2 V/div in a 1-2-5 sequence

Input impedance

At least 100 MΩ with the HORIZONTAL

switch set to 50, 100, and 200 mV BASE;

1 MΩ within 2% with the switch set to

0.5 V, 1V, and 2 V

Step generator 1 step/div

Maximum displayed noise 1% or less, or the following depending on

the setting of the MAX PEAK VOLTS

Tested by observing the CRT

display.

switch:

Range

Vertical 15 V 75 V 350 V 1500 V

Collector

1 µA 1 µA 2 µA 5 µA

Emitter 1 nA 1 nA 2 nA 5 nA

Horizontal

Collector 5 mV 5 mV 20 mV 200 mV

Base 5 mV 5 mV 5 mV 5 mV

Calibration check 10 div vertical and horizontal deflection

with the DISPLAY OFFSET switch set to

Tested by observing the CRT

display.

NORM (OFF)

Tolerance: ±1.5% with the DISPLAY

OFFSET switch to X10 MAGN IFIER

(horizontal or vertical) the calibration spot

is within 0.5% of the zero spot (graticule

center) with CAL button depressed

PER HORIZ DIV 5 mV to 100 V

PER STEPS 5 nA to 2A and 5 MV to 20 V

B or gm PER DIV

1µ to 500 k

Power requirements Tested by inference.

Low

Medium

High

Line frequency

90 to 110 V

104 to 126 V

112 to 136 V

48 to 66 Hz

4

Page 8

NAVAIR 17-20AW-105

SECTION 2

EQUIPMENT REQUIREMENTS

NOTES

Minimum use specifications are the principal parameters required for performance of the calibration, and are

included to assist in the selection of alternate equipment, which may be used at the discretion of the using

laboratory. Satisfactory performance of alternate items shall be verified prior to use. All applicable

equipment must bear evidence of current calibration.

The instruments utilized in this procedure were selected from those known to be available at Navy calibration

facilities and the listing by make or model number carries no implication of preference, recommendation, or

approval for use by other agencies. It is recognized that equivalent equipment produced by other

manufacturers may be capable of equally satisfactory performance in this procedure.

Table 2. Equipment Requirements

Item Minimum Use

2.1 Oscilloscope

Specifications

Sweep time: 50 µs/div

Triggering : + (plus)

Sensitivity: 0.05 to 5 V/div

Tektronix 7704A MOD 129G

with a 7B53A and a 7A26 or

7A12 plug in unit installed, or

Calibration

Equipment

547 or 545 series with a 1A1

plug in unit

2.2 DVM DV ranges: 10 V with an input impedance of

500 MΩ minimum; 100 and 1000 V ranges

Fluke 8350A, 8800A/AA,

887AB, or 883AB

Uncertainty: ±0.25%

2.3 Power supply 10A DC Hewlett-Packard

6259BOPT026 or 6433B

2.4 Resistor kit

1 and 10 Ω, 3 W; 10 MΩ, 1 W; 100 Ω, 0.5 W;

Local supply

1 and 10 kΩ, 0.25 W; 100 kΩ and 1 MΩ,

0.125 W; 25 and 250 kΩ, and 2.5 and 25 MΩ,

0.125 W

Uncertainty: ±0.25%

2.5 Protective box -- TI accessory

2.6 BNC male to dual binding

-- TI accessory

post adapter

2.7 Patch cords, and

-- Local supply

interconnecting cables

2.8 Current shunt 10 A DC

Uncertainty: ±0.5%

Leeds & Northrup 4360 or 4385

5

Page 9

NAVAIR 17-20AW-105

SECTION 3

PRELIMINARY OPERATIONS

3.1 Ensure that all power switches are set to off, and set all auxiliary equipment controls as necessary to avoid da mage to the

equipment and so that dangerous voltages will not be present on output terminals when the power switches are turned on.

3.2 Connect the auxiliary equipment, and the TI, to the appropriate power source.

3.3 Ensure that the TI Line Voltage Selector Assembly (rear panel) Range Selector is positioned for M (medium) range, the

Voltage Selector is positioned for 115 V operation, and that the 60 Hz-50 Hz switch is set to 60 Hz.

3.4 Turn all power switches on, and allow a sufficient warm-up period for the equipment (the TI requires a 5 minute warm-up

time).

3.5 The Standard Test Fixture referred to in this procedure, is part of the TI from lower control panel.

SECTION 4

CALIBRATION PROCESS

NOTES

Unless otherwise specified, verify the results of each test and take corrective action whenever the test

requirement is not met, before proceeding.

If the TI is a 576 MOD 301W, all instructions pertaining to the Readout Assembly should be disregarded.

4.1 HORIZONTAL AND VERTICAL CRT GAIN TESTS

4.1.1 Set the TI controls as follows:

GRATICULE ILLUM control for graticule lines visible

READOUT ILLUM control for a visible readout

INTENSITY control for a visible spot

FOCUS control centered

VERTICAL switch to 5 mA COLLECTOR

DISPLAY OFFSET switch to NORM (OFF)

CENTERLINE VALUE switch to 5

HORIZONTAL switch to 2 V COLLECTOR

Vertical POSITION switch to Mid-range

Vertical FINE POSITION control centered

Horizontal POSITION switch to mid-range

6

Page 10

Horizontal FINE POSITION control centered

DISPLAY INVERT pushbutton released

DISPLAY ZERO pushbutton released

CAL pushbutton released

MAX PEAK VOLTS switch to 15

PEAK POWER WATTS switch to 0.1

VARIABLE COLLECTOR SUPPLY control fully ccw

POLARITY switch to AC

MODE switch to NORM

LOOPING COMPENSATION control as is

NUMBER OF STEPS switch to 10

CURRENT LIMIT switch to 2 A

AMPLITUDE switch to 2 V

OFFSET ZERO pushbutton depressed

OFFSET MULT dial to 0.00 (fully ccw)

NAVAIR 17-20AW-105

STEPS pushbutton depressed

PULSED STEPS pushbuttons released

STEP FAMILY SINGLE pushbutton depressed

RATE NORM pushbutton depressed

POLARITY INVERT pushbutton released

STEP MULT .1X pushbutton released

LEFT-OFF-RIGHT switch to OFF

Terminal Selector switch to BASE TEM STEP GEN

CAUTION

TO AVOID BURNING THE TI CRT PHOSPHOR DURING THIS PROCEDURE, ALWAYS ADJUST

THE TI INTENSITY CONTROL FOR A DIM, BUT VISIBLE CRT TRACE OR SPOT.

4.1.2 Adjust the TI INTENSITY and FOCUS controls for a dimly lit, and well-defined spot of minimum size.

4.1.3 Set the TI POLARITY switch to +(NPN).

4.1.4 Adjust the TI Horizontal and Vertical POSITION switches and FINE POSITION controls to position the spot to the

zero horizontal and vertical CRT graticule lines (see Figure 1).

7

Page 11

NAVAIR 17-20AW-105

10th

HORIZONTAL

GRATICULE

LINE

9th

8th

7th

6th

Center

4th

3rd

2nd

1st

Zero

Zero 1st 2nd 3rd 4th

VERTICAL GRATICULE LINES

Figure 1. TI CRT Graticule Lines

Center

6th 7th 8th 9th 10th

4.1.5 Set the TI POLARITY switch to -(PNP).

4.1.6 Verify that the TI spot is within 0.1 division of the 10th vertical and 10th horizontal line.

4.1.7 Set the TI POLARITY switch to AC.

4.2 HORIZONTAL AND VERTICAL DISPLAYED NOISE TESTS

4.2.1 Set the TI controls as follows:

HORIZONTAL switch to .0 5 V COLLECTOR

Horizontal POSITION switch to mid-range

Horizontal FINE POSITION CONTROL centered

Vertical POSITION switch to mid-range

Vertical FINE POSITION control centered

DISPLAY OFFSET switch to HORIZ X10

POLARITY switch to AC

SERIES RESISTORS switch to 140 Ω

4.2.2 Install the protective box on the TI Standard Test Fixture and close its lid.

4.2.3 Ensure that the TI CENTERLINE VALUE switch is set to 5, and set the MAX PEAK VOLTS switch to the 15, 75, 350,

and 1500 ranges. Verify that the horizontal width of the CRT spot is not greater than 1 division for the 15 and 75 ranges,

4 divisions for the 350 range, and 40 divisions for the 1500 range. See the following note.

8

Page 12

NAVAIR 17-20AW-105

NOTE

The TI CENTERLINE VALUE switch is set to 5. Measuring the displayed noise with t he MAX PEAK

VOLTS switch set to 1500 V, can be accomplished by setting the CENTERLINE VALUE switch to 4 or 3,

observe the end of the trace reference point, then set the centerline value switch to 6 or 7 and measure the

number of divisions from the reference point to the other end of the trace. Between each full step setting of

the CENTERLINE VALUE switch, the trace will be offset 10 divisions.

4.2.4 Set the TI HORIZONTAL switch to 0.05 BASE, set the LEFT-OFF-RIGHT switch to RIGHT, and connect the 1 MΩ

resistor between the base (B) and emitter (E) jacks on the Standard Test Fixture.

4.2.5 Set the TI MAX PEAK VOLTS switch to the 15, 75, 350, and 1500 ranges. Verify that the horizontal width of the CRT

spot is not greater than 1 division for each range.

4.2.6 Set the TI controls as follows:

VERTICAL CURRENT/DIV switch to 1µ A COLLECTOR

HORIZONTAL switch to 200 COLLECTOR

DISPLAY OFFSET switch to NORM (OFF)

Vertical POSITION switch 1 position cw

POLARITY switch to + (NPN)

VARIABLE COLLECTOR supply control fully cw

LEFT-OFF-RIGHT switch to OFF

4.2.7 Disconnect the 1 MΩ resistor from the TI.

NOTE

The LOOPING COMPENSATION control may have some effect on this check. It may be necessary to make

this check after the looping compensation adjustments have been made. (See manufacturer’s manual for

performing the adjustment of the LOOPING COMPENSATION.)

4.2.8 Set the TI MAX PEAK VOLTS switch to the 15, 75, 350, and 1500 V ranges. Verify that the vertical height of the

CRT spot is not greater than 1 division for the 15 and 75 ranges, 2 divisions for the 350 range, and 5 divisions for the 1500 range.

4.2.9 Set the TI MODE switch to LEAKAGE (EMITTER CURRENT).

4.2.10 Set the TI MAX PEAK VOLTS switch to the 15, 75, 350, and 1500 ranges. Verify that the vertical height of the CRT

spot is not greater than 1 division for the 15 and 75 ranges, 2 divisions for the 350 range, and 5 divisions for the 1500 range.

4.2.11 Disconnect the protective box from the TI Standard Test Fixture.

4.3 DISPLAY OFFSET AND CAL PUSHBUTTON TESTS

4.3.1 Set the TI controls as follows:

VERTICAL switch to 2A COLLECTOR

DISPLAY OFFSET switch to HORIZ X10

CENTERLINE VALUE switch to 0

HORIZONTAL switch to 1 V COLLECTOR

Vertical POSITION switch to mid-range

9

Page 13

NAVAIR 17-20AW-105

OFFSET AID pushbutton depressed

MAX PEAK VOLTS switch to 15

MODE switch to DC

VARIABLE COLLECTOR SUPPLY control fully ccw

LEFT-OFF-RIGHT switch to RIGHT

AMPLITUDE switch to 2V

PULSED STEPS STEPS

STEP FAMILY SINGLE

4.3.2 Connect a patch cord between the TI base (B) and collector (C) jacks (right hand set of jacks).

4.3.3 Connect the DVM between the collector sense (C) and the emitter sense (E) jacks, and adjust it for measurement on the

10V DC range.

4.3.4 Depress the TI DISPLAY ZERO pushbutton, adjust the Horizontal POSITION to center the CRT spot on the center

vertical graticule line, and release the ZERO pushbutton.

NOTE

Upon release of ZERO pushbutton, ensure that the CRT spot is within 0.10 divisions of the center vertical

line. If not, repeat 4.3.4.

4.3.5 Set the TI CENTERLINE VALUE switch to each position shown in the following table. At each setting, adjust the

OFFSET MULT control for the co rresponding DVM voltage ind ications shown, and verify that the CRT spot is within 0.2 5

divisions of the center vertical graticule line.

TI

CENTERLINE VALUE

Switch Setting

.5 0.500

1 1.000

1.5 1.500

2 2.000

2.5 2.500

3 3.000

3.5 3.500

4 4.000

4.5 4.500

5 5.000

5.5 5.500

6 6.000

6.5 6.500

7 7.000

7.5 7.500

8 8.000

8.5 8.500

9 9.000

9.5 9.500

10 10.000

DVM

Voltage Indication

(DC Volts)

10

Page 14

NAVAIR 17-20AW-105

4.3.6 Depress the TI DISPLAY ZERO pushbutton, adjust the Horizontal FINE POSITION control to center the CRT spot on

the center vertical graticule line, release the ZERO pushbutton, and verify that the CRT spot is within 0.5 division of the center

vertical gra ticule line.

4.4 HORIZONTAL DISPLAY ACCURACY TESTS

4.4.1 Set the TI switch to .05 COLLECTOR, and AMPLITUDE switch to .05 V.

4.4.2 Depress the TI ZERO pushbutton, and adjust the Horizontal FINE POSITION control to center the CRT spot on the

center vertical graticule line. Release the ZERO pushbutton.

4.4.3 Set the TI HORIZONTAL and AMPLITUDE switches as shown in the following table. At each setting, adjust the

OFFSET MULT control for the co rresponding DVM voltage ind ication, and verify that the CRT sp ot is within 2 divisions of the

center vertical graticule line.

TI HORIZONTAL

Switch Setting

.05 COLLECTOR .05 0.500

.1 ” .1 1.000

.2 ” .2 2.000

.5 ” .5 5.000

1 ” 1 10.00

Adjust the DVM controls for measurement on the 100 V range.

2 COLLECTOR 2 20.00

Adjust the DVM controls for measurement on the 100 V range.

.05 BASE .05 0.500

.1 ” .1 1.000

.2 ” .2 2.000

.5 ” .5 5.000

1 ” 1 10.00

Adjust the DVM controls for measurement on the 100 V range.

2 BASE 2 20.00

4.4.4 Set the TI LEFT-OFF-RIGHT switch to OFF, and disconnect the patch cord and DVM from the TI.

4.4.5 Set the TI MODE switch to DC (DC ANTI LOOP), and connect the DVM to the collector (C) and emitter (E) jacks.

4.4.6 Set the TI controls as follows:

TI AMPLITUDE

Switch Setting

DVM Voltage Indication

(DC Volts)

CENTERLINE VALUE switch to 10

HORIZONTAL switch to 5 V COLLECTOR

OFFSET ZERO pushbutton depressed

VARIABLE COLLECTOR SUPPLY control fully ccw

MAX PEAK VOLTS switch to 1500

SERIES RESISTORS s witch to 6.5 M

LEFT-OFF-RIGHT switch to RIGHT

4.4.7 Adjust the DVM controls for measurement on the 100 V range.

11

Page 15

NAVAIR 17-20AW-105

4.4.8 Set the TI HORIZONTAL switch as shown in the following table. At each setting, use a non-metallic object to depress

the Interlock switch (located on the Standard Test Fixture left side), adjust the VARIABLE COLLECTOR SUPPLY control for

the corresponding DVM voltage indications shown, and verify that the CRT spot is within 2 divisions of the center vertical

graticule line, except for the 200 COLLECTOR setting the CRT spot must be within 1 division of the center vertical graticule

line.

WARNING

DURING THE FOLLOWING TEST, LETHAL VOLTAGES WILL BE PRESENT ON THE TI

STANDARD TEST FIXTURE CONNECTIONS. AVOID BODY CONTACT.

TI HORIZONTAL

Switch Setting

5 COLLECTOR

10 ”

Adjust the DVM controls for measurement on the 1000 V range.

20 COLLECTOR

50 ”

100* ”

Set the TI CENTERLINE VALUE switch to 5.

200* COLLECTOR 1000*

*It may be necessary to set the TI PEAK POWER WATTS switch to a higher

value to get a 1000 V collector supply output.

4.4.9 Release the TI Interlock switch, set the LEFT-OFF-RIGHT switch to OFF, and disconnect the DVM from the TI.

4.5 VERTICAL DISPLAY ACCURACY TESTS

4.5.1 Set the TI controls as follows:

VARIABLE COLLECTOR SUPPLY control fully ccw

MAX PEAK VOLTS switch to 15

DVM Voltage Indication

(DC Volts)

50.00

100.0

200.0

500.0

1000*

SERIES RESISTORS s witch to .3

MODE switch to NORM

VERTICAL switch to 1 µA

DISPLAY OFFSET switch to VERT X10

CENTERLINE VALUE switch to 10

AMPLITUDE switch to 1 µA

OFFSET AID pushbutton depressed

POLARITY INVERT pushbutton depressed

LEFT-OFF-RIGHT switch to RIGHT

4.5.2 Connect the 100 kΩ resistor between the TI collector (C) and base (B) connectors (use short banana plug-to-alligator

clip leads, if available).

4.5.3 Connect the DVM between the TI collector (C) and base (B) terminals (right side of the Standard Test Fixture), and

adjust the controls for measurement on the 10 V range.

12

Page 16

NAVAIR 17-20AW-105

4.5.4 Depress the TI DISPLAY ZERO pushbutton, and adjust the Vertical FINE POSITION control and Vertical POSITION

switch to center the CRT spot on the center horizontal graticule line. Release the ZERO pushbutton.

4.5.5 Set the TI VERTICAL and AMPLITUDE switches as shown in the following table. At each setting, connect the

resistor shown to the collector (C) and base (B) connectors, adjust the OFFSET MULT control for the corresponding DVM

voltage indications shown, and verify that the CRT spot is within 2 divisions of the ce nter horizontal graticule line. When

disconnecting and connecting resistors, momentarily set the LEFT-OFF-RIGHT switch to OFF.

NOTE

If the CRT spot position cannot be determined due to noise, disconnect the DVM to observe the spot.

DVM Voltage

TI VERTICAL

Switch Setting

1 µA 1 µA 100 kΩ

2 ” 2 ” ” 2

5 ” 5 ” ” 5

10 ” 10 ”

20 ” 20 ” ” 2

50 ” 50 ” ” 5

.1 mA 1 mA

.2 ” .2 ” ” 2

.5 ” .5 ” ” 5

1 ” 1 ”

2 ” 2 ” ” 2

5 ” 5 ” ” 5

10 ” 10 ”

20 ” 20 ” ” 2

50 ” 50 ” ” 5

1.1 A 100 mA

.2 ” 200 ” ” 2

.5 ” */** ” ” ” 2

TI AMPLITUDE

Switch Setting

Resistor

10 kΩ

1 kΩ

100 Ω

10 Ω

1 Ω

Indication

(Volts)

1

1

1

1

1

*Set the TI CENTERLINE VALUE switch to 4.

**The tolerance limits, for the .5A VERTICAL switch setting, are within 0.4 division of the

center line.

4.5.6 Set the TI LEFT-OFF-RIGHT switch to OFF, and disconnect the resistor and DVM from the TI.

4.5.7 Connect the equipment as shown in Figure 2.

13

Page 17

NAVAIR 17-20AW-105

POWER

SUPPLY

+

+

-

DVM

-

+

*RIGHT SIDE OF THE

STANDARD TEST FIXTURE

TI

4.5.8 Set the TI controls as follows:

VERTICAL switch to 1A

CENTERLINE VALUE switch to 10

LEFT-OFF-RIGHT switch to RIGHT

4.5.9 Adjust the power supply controls for a 10.00A DC output current as indicated on the DVM using the appropriate

multiplier for the current shunt. Verify that the CRT spot is within 2 divisions of the horizontal center graticule line.

4.5.10 Set the TI VERTICAL switch to 2A, and the CENTERLINE VALUE switch to 5.

+

*C

-

*E

Figure 2. Vertical Display Accuracy Test Configuration

G

+

POT.

G

CURRENT

SHUNT

LINE

4.5.11 Verify that the TI CRT spot is within 1 division of the horizontal center graticule line.

4.5.12 Adjust the power supply controls for minimum output, set the TI LEFT-OFF-RIGHT switch to OFF, and disconnect

all equipment from the TI.

4.5.13 Connect the 25 MΩ resistor between the TI base (B) jack and emitter (E) jack, and connect the DVM between the base

(B) jack and GROUND jack.

4.5.14 Set the TI controls as follows:

VERTICAL switch to 1 nA EMITTER

DISPLAY OFFSET switch to NORM (OFF)

CENTERLINE VALUE switch to 10

AMPLITUDE switch to .5 V

OFFSET MULT control to 0.00

POLARITY INVERT pushbutton released

MODE switch to LEAKAGE (EMITTER CURRENT)

LEFT-OFF-RIGHT switch to RIGHT

14

Page 18

NAVAIR 17-20AW-105

4.5.15 Adjust the TI OFFSET MULT control clockwise until the CRT spot is on the 10th horizontal graticule line (if the CRT

spot has noise, adjust the center of the spot to the 10th horizontal graticule line).

4.5.16 Verify that the DVM indication is between 0.425 and 0.575 V.

4.5.17 Set the TI VERTICAL switch to 2 and 5 nA. At each setting, adjust the OFFSET MULT control to center the CRT

spot on the 10th horizontal graticule line, and verify that the DVM indication is between 0.900 and 1.100 V for the 2 nA setting,

and between 2.325 and 2.675 V for the 5 nA setting.

4.5.18 Set the TI DISPLAY OFFSET switch to VERTICAL X10, disconnect the 25 MΩ resistor, and connect the 2.5 MΩ

resistor in its place.

4.5.19 Set the TI VERTICAL switch as shown in the following table. At each setting, connect the appropriate resistor as

shown, and then depress the DISPLAY ZERO pushbutton an d adjust the Vertical POSITION switch and FINE POSITION

control to center the CRT spot on the center horizontal graticule line. Release the ZERO pushbutton, adjust the TI OFFSET

MULT control to center the CRT spot on the center horizontal graticule line, and verify that the DVM indication is within the

tolerance limits listed.

TI VERTICAL

10 nA

20 ” ” 0.975 to 1.025

50 ” ” 2.445 to 2.555

.1 µA 250 kΩ

.2 ” ” 0.980 to 1.020

.5 ” ” 2.450 to 2.550

1 ”

2 ” ” 0.980 to 1.020

5 ” ” 2.450 to 2.550

4.5.20 Disconnect the DVM and the resistor from the TI.

4.6 STEP AMPLIFIER GAIN TESTS

4.6.1 Set the TI controls as follows:

MODE switch to NORM

VERTICAL switch to 2A

CENTERLINE VALUE switch to 10

Switch Setting

2.5 MΩ

25 kΩ

Resistor

Tolerance Limits

(Volts)

0.485 to 0.515

0.490 to 0.510

0.490 to 0.510

HORIZONTAL switch to 1V BASE

NUMBER OF STEPS switch to 10

AMPLITUDE switch to 1 V

STEP FAMILY REP pushbutton depressed

POLARITY INVERT pushbutton released

DISPLAY OFFSET switch to HORIZ X10

4.6.2 Depress the TI DISPLAY ZERO pushbutton and adjust the Horizontal FINE POSITION control to center the CRT spot

on the center vertical graticule line. Release the ZERO pushbutton.

4.6.3 Verify that the CRT spot is within 2 divisions of the center vertical graticule line.

15

Page 19

NAVAIR 17-20AW-105

4.6.4 Depress the TI AID OFFSET pushbutton, and verify that the CRT spot is within 2 divisions of the center vertical

graticule line.

4.6.5 Set the TI CENTERLINE VALUE switch to 0.

4.6.6 Depress the TI OPP OSE OFFSET pushbutton, and verify that the CRT spot is within 2 d ivisions of the center vertical

graticule line.

4.7 STEP GENERATOR AND OFFSE T MULTIPLIER ACCURACY TESTS

4.7.1 Set the TI controls as follows:

VERTICAL switch to 2A

DISPLAY OFFSET switch to HORIZ X10

CENTERLINE VALUE switch to 0

HORIZONTAL switch to 1V B ASE

AMPLITUDE switch to 1V

OFFSET MULT control to 10.00

STEP FAMILY REP pushbutton depressed

MAX PEAK POWER WATTS switch to 220

POLARITY switch to + (NPN)

OFFSET ZERO

4.7.2 Depress the TI ZERO pushbutton, and adjust the Vertical FINE POSITION control to center the CRT spot on the center

horizontal graticule line.

4.7.3 Release the TI ZERO pushbutton and verify that the CRT spot is within 0.1 division of the center horizontal graticule

line.

4.7.4 Depress the TI ZERO pushbutton, and adjust the Horizontal FINE POSITION control to center the CRT spot on the

center vertical graticule line. Release the ZERO pushbutton.

4.7.5 Set the TI CENTERLINE VALUE switch as shown in the following table. At each setting, verify that the CRT spot is

centered on the center vertical graticule line within the tolerance limits listed.

TI

CENTERLINE VALUE

Switch Setting

2 0.5 div

4 ”

6 ”

8 ”

10 2 div

Tolerance Limits

(divisions)

4.7.6 Depress the TI AID OFFSET pushbutton, and verify that the CRT spot is within 2 divisions of the center vertical

graticule line.

4.7.7 Adjust the TI OFFSET MULT control one complete revolution at a time, set the CE NTERLINE VALUE switch

clockwise two positions at a time, and verify that the zero step voltage level continuously decreases.

16

Page 20

NAVAIR 17-20AW-105

4.7.8 Adjust the TI OFFSET MULT control to 10.00, depress the OFFSET OPPOSE pushbutton, and verify that the C RT

spot is within 2 divisions of the center vertical graticule line.

4.7.9 Set the TI controls as follows:

HORIZONTAL switch to .1V B ASE

OFFSET ZERO pushbutton depressed

STEP MULT .1X pushbutton depressed

4.7.10 Depress the TI DISPLAY ZERO pushbutton, and adjust the Vertical and Horizontal FINE POSITION controls to

center the CRT spot on the center horizontal and vertical lines.

4.7.11 Release the TI ZERO pushbutton, and verify that the CRT spot is within 0.1 division of the center horizontal graticule

line.

4.7.12 Set the TI CENTERLINE VALUE switch as shown in the following table. At each setting, verify that the CRT spot is

centered on the center vertical graticule line within the tolerance limits listed.

TI

CENTERLINE VALUE

Switch Setting

2 1 div

4 ”

6 ”

8 ”

10 2 div

Tolerance Limits

(divisions)

4.7.13 Set the TI controls as follows:

HORIZONTAL switch to 200 COLLECTOR

AMPLITUDE switch to 2V

OFFSET AID pushbutton depressed

STEP MULT .1X pushbutton released

STEP FAMILY SINGLE pushbutton depressed

4.7.14 Connect the DVM between the TI base (B) and emitter (E) jacks on the right side of the Standard Test Fixture.

4.7.15 Adjust the DVM cont rols for mea surement on the 10 V range .

4.7.16 Set the TI LEFT-OFF-RIGHT switch to RIGHT.

4.7.17 Set the TI AMPLITUDE switch as shown in the following table. At each setting, verify that the DVM indication is

within the tolerance limits listed.

17

Page 21

NAVAIR 17-20AW-105

TI AMPLITUDE

Switch Setting

.05 V 0.490 to 0.510

.1 V 0.980 to 1.020

.2 V 1.960 to 2.040

.5 V 4.90 to 5.10

1 V 9.80 to 10.20

Adjust the DVM controls for measurement on the 100 V range.

2 V 19.60 to 20.40

4.7.18 Adjust the DVM cont rols for mea surement on the 10 V range .

4.7.19 Set the TI LEFT-OFF-RIGHT switch to OFF.

4.7.20 Connect the 1 MΩ resistor between the TI base (B) and emitter terminals on the Standard Test Fixture.

4.7.21 Set the TI AMPLITUDE switch as shown in the following table. At each setting, connect the corresponding resistor

(when connecting the resistor, set the LEFT-OFF-RIGHT switch to OFF, then set the switch to RIGHT before continuing), and

verify that the DVM indication is within the tolerance limits listed.

Tolerance Limits

(Volts)

NOTE

If resistors are connected using leads, ensure that the interconnecting leads are as short as possible.

TI AMPLITUDE

Switch Setting Resistor

.05 µA 1 MΩ

.1 ” ” 0.980 to 1.020

.2 ” ” 1.960 to 2.040

.5 ”

1 ” ” 0.980 to 1.020

2 ” ” 1.960 to 2.040

5 ”

10 ” ” 0.980 to 1.020

20 ” ” 1.960 to 2.040

50 ”

.1 ” ” 0.980 to 1.020

.2 ” ” 1.960 to 2.040

.5 ”

1 ” ” 0.980 to 1.020

2 ” ” 1.960 to 2.040

5 ”

10 ” ” 0.980 to 1.020

20 ” ” 1.960 to 2.040

50 ”

100 ” ” 0.980 to 1.020

200 ” ” 1.960 to 2.040

100 kΩ

10 kΩ

1 kΩ

100 Ω

10 Ω

1 Ω

0.490 to 0.510

0.490 to 0.510

0.490 to 0.510

0.490 to 0.510

0.490 to 0.510

0.490 to 0.510

0.490 to 0.510

Tolerance Limits

(Volts)

4.7.22 Set the TI LEFT-OFF-RIGHT switch to OFF, and disconnect the resistor and DVM from the TI.

18

Page 22

NAVAIR 17-20AW-105

4.8 STEP GENERATOR TESTS

4.8.1 Set the TI controls as follows:

HORIZONTAL switch to 1 BASE

AMPLITUDE switch to 1 V

OFFSET ZERO pushbutton depressed

RATE .5X pushbutton depressed

POLARITY switch to + (NPN)

NUMBER OF STEPS switch to 10

4.8.2 Connect the BNC male to dual binding post adapter to the oscilloscop e vertical input connector. Connect a patch cord

from the TI STEP GEN OUTPUT (red binding post) connector and the ground connector on the Standard Test Fixture to the dual

binding post.

4.8.3 Depress the TI STEP FAMILY REP pushbutton, adjust the oscilloscope for a sweep, and verify that there is a 10 step

oscilloscope display.

4.8.4 Depress the TI 2X RATE pushbutton, and set the NUMBER OF STEPS switch to 1.

4.8.5 Adjust the oscilloscope controls for + triggering, 50 µs/div sweep time (calibrated), and 0.2V/div vertical deflection.

4.8.6 Depress the TI 300 µs PULSED STEPS pushbutton and verify that the oscilloscope display is a pulsed step with a 5.7 to

7.2 division pulse width. For serial numbers 172570 and higher, the pulse width should be 5.1 to 6.3 divisions. Release the

pushbutton.

4.8.7 Depress the TI 80 µs PULSED STEPS pushbutton, and verify that the display is a pulsed step with a 1.52 to

1.92 division pulse width.

4.8.8 Disconnect the oscilloscope from the TI.

4.8.9 Set the TI controls as follows:

DISPLAY OFFSET switch to HORIZ X10

CENTERLINE VALUE switch to 10

HORIZONTAL switch to .05 BASE

AMPLITUDE switch to .05 µA

OFFSET AID pushbutton depressed

OFFSET MULT control to 0.00

STEPS pushbutton depressed

STEPS FAMILY SINGLE pushbutton depressed

POLARITY switch to + (NPN)

4.8.10 Connect the 10 MΩ resistor between the TI BASE and EMITTER jacks (right side of the TI Standard Test Fixture).

4.8.11 Set the TI LEFT-OFF-RIGHT switch to RIGHT.

4.8.12 Depress the TI DISPLAY ZERO pushbutton, and adjust the Horizontal and Vertical POSITION controls to center the

spot on the CRT Vertical and Horizontal graticule lines. Release the ZERO pushbutton.

4.8.13 Adjust the TI OFFSET MULT control until a spot appears on the CRT display, and verify that the spot has a

horizontal width of less than 4.0 divisions (less than 1 nA p-p).

19

Page 23

NAVAIR 17-20AW-105

4.8.14 Set the TI LEFT-OFF-RIGH T switch to OFF, the OFFSET MULT contr ol to 10.00, and the AMPLITUDE switch to

.05 V.

4.8.15 Verify that the TI CRT spot width is less than 0.4 divisions (less than 2 mV p-p).

4.8.16 Disconnect the 10 MΩ resistor from the TI.

4.9 COLLECTOR SUPPLY TESTS

4.9.1 Set the TI controls as follows:

VERTICAL switch to 5 mA COLLECTOR

DISPLAY OFFSET switch to NORM (OFF)

CENTERLINE VALUE switch to 5

HORIZONTAL switch to 2 V COLLECTOR

Vertical POSITION switch to mid-range

Vertical FINE POSITION control centered

Horizontal POSITION switch mid-range

Horizontal FINE POSITION control centered

DISPLAY INVERT pushbutton released

ZERO pushbutton released

CAL pushbutton released

MAX PEAK VOLTS switch to 15

PEAK POWER WATTS switch to 220

VARIABLE COLLECTOR SUPPLY control fully ccw

POLARITY switch to AC

MODE switch to NORM

LOOPING COMPENSATION control as is

NUMBER OF STEPS switch to 10

CURRENT LIMIT switch to 2A

AMPLITUDE switch to 2 V

OFFSET ZERO pushbutton depressed

OFFSET MULT control to 0.00

STEPS pushbutton depressed

PULSED STEPS pushbuttons released

STEP FAMILY SINGLE pushbutton depressed

RATE NORM pushbutton depressed

POLARITY INVERT pushbutton released

STEP MULT .1X pushbutton released

LEFT-OFF-RIGHT switch to OFF

Terminal Selector switch to BASE TERM STEP GEN

4.9.2 Install the protective box (item 2.5) on the TI Standard Test Fixture and close its lid.

20

Page 24

NAVAIR 17-20AW-105

4.9.3 Depress the TI DISPLAY ZERO pushbutton and adjust the Horizontal and Vertical POSITION switches and FINE

POSITION controls to center the spot on the CRT vertical and horizontal graticule lines. Release the ZERO pushbutton.

4.9.4 Adjust the TI VARIABLE COLLECTOR SUPPLY control clockwise to obtain a 10 division CRT display trace, and

verify that the trace extends out from both sides of the center vertical graticule line.

4.9.5 Set the TI POLARITY switch to -(PNP), adjust the VARIABLE COLLECTOR SUPPLY control fully cw, and verify

that the trace originates at the 10th vertical graticule line and extends to the left.

4.9.6 Set the TI POLARITY switch to +(NPN), and verify that the trace originates at the 0 vertical graticule line and extends

to the right.

CAUTION

DURING THE FOLLOWING TEST, ALWAYS SET THE HORIZONTAL SWITCH FIRST TO AVOID

DAMAGE TO THE HORIZONTAL AMPLIFIER.

4.9.7 Set the TI HORIZONTAL and MAX PEAK VOLTS switches as shown in the following table. At each setting, verify

that the trace length from the 0 vertical graticule line (see Figure 1, if required) is within the corresponding tolerance limits listed.

Then set the TI DISPLAY OFFSET switch to HORIZ X10, the MODE switch to DC, adjust the CENT ERLINE VALUE switch

to position the spot on the CRT, and verify that the spot width does not exceed the tolerance limits listed. Set t he DISP LAY

OFFSET switch to NORM (OFF), the MODE switch to NORM, and the CENTERLINE VALUE switch to 5 before setting the

HORIZONTAL and MAX PEAK VOLTS switches to the next settings.

Tolerance Limits

TI HORIZONTAL

Switch Setting

2 V 15 V 7.13 to 10.1 1.5 max

10 V 75 V 7.13 to 10.1 1.5 ”

50 V 350 V 6.65 to 9.4 1.4 ”

200 V 1500 V 7.15 to 10.1 1.5 ”

4.9.8 Set the TI DISPLAY OFFSET switch to NORM (OFF), the MODE switch to NORM, and the VARIABLE

COLLECTOR SUPPLY fully ccw.

4.9.9 Lift the protective box lid and connect a patch cord between the collector and emitter jacks (right side of the Standard

Test Fixture). Close the lid.

4.9.10 Set the TI LEFT-OFF-RIGHT switch to RIGHT.

4.9.11 Depress the TI ZERO pushbutton and adjust the Horizontal and Vertical POSITION switches and FINE POSITION

controls as required to place the spot on the CRT zero graticule lines. Release the ZERO pushbutton.

DURING THE FOLLOWING TEST, ALWAYS SET THE VERTICAL SWIT CH FIRST TO AVOID

DAMAGE TO THE VERTICAL AMPLIFIER. ALSO, DO NOT EXCEED THE CURRENT (IN

DIVISIONS) SHOWN, AND RETURN THE VARIABLE COLLECTOR SUPPLY CONTROL TO IT S

FULLY CCW POSITION AFTER REACHING THE CURRENT SHOWN.

TI MAX PEAK VOLTS

Switch Setting

CAUTION

Trace Length

(Divisions)

Spot Width

(Divisions)

21

Page 25

NAVAIR 17-20AW-105

4.9.12 Set the TI VERTICAL and MAX PEAK VOLTS switches as shown in the following table. At each setting, adjust the

VARIABLE COLLECTOR SUPPLY control clockwise until the peak current shown is reached (do not exceed the current), then

return the VARIABLE COLLECTOR SUPPLY control to its fully ccw position. Verify that each current minimum can be

reached.

TI VERTICAL

Switch Setting

*

TI MAX PEAK VOLTS

Switch Setting

Tolerance Limits

(Divisions)

20 mA 1500 10 div (20 mA) min

.1 A 350 10 div (1A) min

.5 A 75 8 div (4A) min

2 A 15 10 div (20A) min

*See CAUTION note above.

4.9.13 Set the TI LEFT-OFF-RIGHT switch to OFF, lift the protective box lid and remove the patch cord, and close the lid.

4.9.14 Unless other measurements are to be performed, set all power switches to off, and disconnect the setup.

22

Page 26

NAVAIR 17-20AW-105

CALIBRATION CHECKLIST

TEST INST(S) Tektronix 576 Curve-Tracer

PROC. NO. NA 17-20AW-105 MFR MODEL SER. NO.

PROCEDURE MEASURED VALUES OUT

STEP FUNCTION TESTED NOMINAL FIRST RUN SECOND RUN OF CALIBRATION TOLERANCES

NO TOL

(1) (2) (3) (4) (5) (6) (7)

4.1 Horizontal and Vertical CRT Gain Tests

4.1.6 vertical 10th line -- ck ( ) within 0.1 div

” horizontal 10th line -- ck ( ) ”

4.2 Horizontal and Vertical Displayed Noise Tests

4.2.3 Horizontal Width

” 15 range -- ck ( ) 1 div max

” 75 ” -- ck ( ) ”

” 350 ” -- ck ( ) 4 div max

” 1500 ” -- ck ( ) 40 div max

4.2.5 Horizontal Width

” 15 range -- ck ( ) 1 div max

” 75 ” -- ck ( ) ”

” 350 ” -- ck ( ) ”

” 1500 ” -- ck ( ) ”

4.2.8 Vertical Height

” 15 range -- ck ( ) 1 div max

” 75 ” -- ck ( ) ”

” 350 ” -- ck ( ) 2 div max

1500 ” -- ck ( ) 5 div max

4.2.10 Vertical Height

” 15 range -- ck ( ) 1 div max

” 75 ” -- ck ( ) ”

” 350 ” -- ck ( ) 2 div max

1500 ” -- ck ( ) 5 div max

4.3 Display Offset and Cal Pushbutton Tests

4.3.4 Zero adj -- ck ( ) NA adjust to center spot

4.3.5 CENTERLINE VALUE

” .5 -- ck ( ) within 0.25 div of center

Page 1 of 7

23

Page 27

NAVAIR 17-20AW-105

CALIBRATION CHECKLIST

TEST INST(S) Tektronix 576 Curve-Tracer

PROC. NO. NA 17-20AW-105 MFR MODEL SER. NO.

PROCEDURE MEASURED VALUES OUT

STEP FUNCTION TESTED NOMINAL FIRST RUN SECOND RUN OF CALIBRATION TOLERANCES

NO TOL

(1) (2) (3) (4) (5) (6) (7)

4.3.5 CENTERLINE VALUE

” 1 -- ck ( ) within 0.25 div of center

” 1.5 -- ck ( ) ”

” 2 -- ck ( ) ”

” 2.5 -- ck ( ) ”

” 3 -- ck ( ) ”

” 3.5 -- ck ( ) ”

” 4 -- ck ( ) ”

” 4.5 -- ck ( ) ”

” 5 -- ck ( ) ”

” 5.5 -- ck ( ) ”

” 6 -- ck ( ) ”

” 6.5 -- ck ( ) ”

” 7 -- ck ( ) ”

” 8 -- ck ( ) ”

” 8.5 -- ck ( ) ”

” 9 -- ck ( ) ”

” 9.5 -- ck ( ) ”

” 10 -- ck ( ) ”

4.3.6 Zero adj -- ck ( ) adjust to center spot

” spot centered -- ck ( ) within 0.5 div of center

4.4 Horizontal Display Accuracy Tests

4.4.2 Zero adj -- ck ( ) NA adjust to center spot

4.4.3 .05 COLLECTOR -- ck ( ) within 2 div of center

” .1 ” -- ck ( ) ”

” .2 ” -- ck ( ) ”

” .5 ” -- ck ( ) ”

” 1 ” -- ck ( ) ”

” 2 ” -- ck ( ) ”

” .05 BASE -- ck ( ) ”

” .1 ” -- ck ( ) ”

Page 2 of 7

24

Page 28

NAVAIR 17-20AW-105

CALIBRATION CHECKLIST

TEST INST(S) Tektronix 576 Curve-Tracer

PROC. NO. NA 17-20AW-105 MFR MODEL SER. NO.

PROCEDURE MEASURED VALUES OUT

STEP FUNCTION TESTED NOMINAL FIRST RUN SECOND RUN OF CALIBRATION TOLERANCES

NO TOL

(1) (2) (3) (4) (5) (6) (7)

4.4.3 .2 BASE -- ck ( ) within 2 div of center

” .5 -- ck ( ) ”

” 1 ” -- ck ( ) ”

” 2 ” -- ck ( ) ”

4.4.8 5 COLLECTOR -- ck ( ) within 2 div of center

” 10 ” -- ck ( ) ”

” 20 ” -- ck ( ) ”

” 50 ” -- ck ( ) ”

” 100 ” -- ck ( ) ”

” 200 ” -- ck ( ) within 1 div of center

4.5 Vertical Display Accuracy Tests

4.5.4 Zero adj -- ck ( ) adjust to center spot

4.5.5

1 µA

-- ck ( ) within 2 div of center

” 2 ” -- ck ( ) ”

” 5 ” -- ck ( ) ”

” 10 ” -- ck ( ) ”

” 20 ” -- ck ( ) ”

” 50 ” -- ck ( ) ”

” .1 mA -- ck ( ) ”

” .2 ” -- ck ( ) ”

” .5 ” -- ck ( ) ”

” 1 ” -- ck ( ) ”

” 2 ” -- ck ( ) ”

” 5 ” -- ck ( ) ”

” 10 ” -- ck ( ) ”

” 20 ” -- ck ( ) ”

” 50 ” -- ck ( ) ”

” .1 A -- ck ( ) ”

” .2 ” -- ck ( ) ”

” .5 ” -- ck ( ) within 0.4 div of center

Page 3 of 7

25

Page 29

NAVAIR 17-20AW-105

CALIBRATION CHECKLIST

TEST INST(S) Tektronix 576 Curve-Tracer

PROC. NO. NA 17-20AW-105 MFR MODEL SER. NO.

PROCEDURE MEASURED VALUES OUT

STEP FUNCTION TESTED NOMINAL FIRST RUN SECOND RUN OF CALIBRATION TOLERANCES

NO TOL

(1) (2) (3) (4) (5) (6) (7)

4.5.9 VERTICAL 1 A -- ck ( ) within 2 div of center

4.5.11 VERTICAL 2 A -- ck ( ) within 1 div of center

4.5.16 VERTICAL 1 nA 0.500 V 0.425 to 0.575 V

4.5.17 ” 2 nA 1.000 V 0.900 to 1.100 V

” ” 5 nA 2.500 V 2.325 to 2.675 V

4.5.19 VERTICAL 10 nA 0.500 V 0.485 to 0.515 V

” ” 20 ” 1.000 V 0.975 to 1.025 V

” ” 50 ” 2.500 V 2.445 to 2.555 V

”

” .1 µA

0.500 V 0.490 to 0.510 V

” ” .2 ” 1.000 V 0.980 to 1.020 V

” ” .5 ” 2.500 V 2.450 to 2.550 V

” ” 1 ” 0.500 V 0.490 to 0.510 V

” ” 2 ” 1.000 V 0.980 to 1.020 V

” ” 5 ” 2.500 V 2.450 to 2.550 V

4.6 Step Amplifier Gain Tests

4.6.2 Zero adj -- ck ( ) adjust to center spot

4.6.3 VERTICAL 2 A -- ck ( ) within 2 div of center

4.6.4 AID OFFSET -- ck ( ) ”

4.6.6 OPPOSE OFFSET -- ck ( ) ”

4.7 Step Generator and Offset Multiplier Accuracy Tests

4.7.2 Zero adj -- ck ( ) adjust to center spot

4.7.3 OFFSET MULT 10.00 -- ck ( ) within 0.1 div of center

4.7.4 Zero adj -- ck ( ) adjust to center spot

4.7.5 CENTER LINE VALUE

” 2 -- ck ( ) within 0.5 div of center

” 4 -- ck ( ) ”

” 6 -- ck ( ) ”

” 8 -- ck ( ) ”

” 10 -- ck ( ) within 2 div of center

Page 4 of 7

26

Page 30

NAVAIR 17-20AW-105

CALIBRATION CHECKLIST

TEST INST(S) Tektronix 576 Curve-Tracer

PROC. NO. NA 17-20AW-105 MFR MODEL SER. NO.

PROCEDURE MEASURED VALUES OUT

STEP FUNCTION TESTED NOMINAL FIRST RUN SECOND RUN OF CALIBRATION TOLERANCES

NO TOL

(1) (2) (3) (4) (5) (6) (7)

4.7.6 AID OFFSET -- ck ( ) within 2 div of center

4.7.7 Zero voltage level -- ck ( ) continuously decreases

4.7.8 OFFSET OPPOSE -- ck ( ) within 2 div of center

4.7.10 Zero adj -- ck ( ) adjust to center spot

4.7.11 OFFSET MULT 10.00 -- ck ( ) within 0.1 div of center

4.7.12 CENTERLINE VALUE 2 -- ck ( ) within 1 div of center

” ” 4 -- ck ( ) ”

” ” 6 -- ck ( ) ”

” ” 8 -- ck ( ) ”

” ” 10 -- ck ( ) within 2 div of center

4.7.17 AMPLITUDE .05 V 0.500 V 0.490 to 0.510 V

” ” .1 V 1.000 V 0.980 to 1.020 V

” ” .2 V 2.000 V 1.960 to 2.040 V

” ” .5 V 5.00 V 4.90 to 5.10 V

” ” 1 V 10.00 V 9.80 to 10.20 V

” ” 2 V 20.00 V 19.60 to 20.40 V

4.7.21

”

”

”

”

”

”

”

”

”

AMPLITUDE .05 µA

” .1 µA

” .2 µA

” .5 µA

” 1 µA

” 2 µA

” 5 µA

” 10 µA

” 20 µA

” 50 µA

0.500 V 0.490 to 0.510V

1.000 V 0.980 to 1.020 V

2.000 V 1.960 to 2.040 V

0.500 V 0.490 to 0.510 V

1.000 V 0.980 to 1.020 V

2.000 V 1.960 to 2.040 V

0.500 V 0.490 to 0.510 V

1.000 V 0.980 to 1.020 V

2.000 V 1.960 to 2.040 V

0.500 V 0.490 to 0.510 V

” ” 1 mA 1.000 V 0.980 to 1.020 V

” ” .2 mA 2.000 V 1.960 to 2.040 V

” ” .5 mA 0.500 V 0.490 to 0.510 V

” ” 1 mA 1.000 V 0.980 to 1.020 V

” ” 2 mA 2.000 V 1.960 to 2.040 V

Page 5 of 7

27

Page 31

NAVAIR 17-20AW-105

CALIBRATION CHECKLIST

TEST INST(S) Tektronix 576 Curve-Tracer

PROC. NO. NA 17-20AW-105 MFR MODEL SER. NO.

PROCEDURE MEASURED VALUES OUT

STEP FUNCTION TESTED NOMINAL FIRST RUN SECOND RUN OF CALIBRATION TOLERANCES

NO TOL

(1) (2) (3) (4) (5) (6) (7)

4.7.21 AMPLITUDE 5 mA 0.500 V 0.490 to 0.510 V

” ” 10 mA 1.000 V 0.980 to 1.020 V

” ” 20 mA 2.000 V 1.960 to 2.040 V

” ” 50 mA 0.500 V 0.490 to 0.510 V

” ” 100 mA 1.000 V 0.980 to 1.020 V

” ” 200 mA 2.000 V 1.960 to 2.040 V

4.8 Step Generator Tests

4.8.3 10 steps -- ck ( ) 10 step display

4.8.6

”

4.8.7

300 µs PULSED STEPS

300 µs (ser. 172570 up)

80 µs PULSED STEPS

6 div 5.7 to 7.2 div

6 div 5.1 to 6.3 div

1.6 div 1.52 to 1.92 div

4.8.12 Zero adj -- ck ( ) adjust to center spot

4.8.13 1 nA p-p -- ck ( ) <4.0 div

4.8.15 2 mV p-p -- ck ( ) <0.4 div

4.9 Collector Supply Tests

4.9.3 Zero Adj -- ck ( ) adj to center spot

4.9.4 Trace test -- ck ( ) extends from center

4.9.5 -(PNP) -- ck ( ) extends to left

4.9.6 +(NPN) -- ck ( ) extends to right

4.9.7 2 V Trace Length 7.5 div 7.13 to 10.1 div

” 2 Spot Width -- ck ( ) 1.5 div max

” 10 V Trace Length 7.5 div 7.13 to 10.1 div

” 10 Spot Width -- ck ( ) 1.5 div max

” 50 V Trace Length 7.0 div 6.65 to 9.4 div

” 50 Spot Width -- ck ( ) 1.4 div max

” 200 V Trace Length 7.5 div 7.15 to 10.1 div

” 200 Spot Width -- ck ( ) 1.5 div max

Page 6 of 7

28

Page 32

NAVAIR 17-20AW-105

CALIBRATION CHECKLIST

TEST INST(S) Tektronix 576 Curve-Tracer

PROC. NO. NA 17-20AW-105 MFR MODEL SER. NO.

PROCEDURE MEASURED VALUES OUT

STEP FUNCTION TESTED NOMINAL FIRST RUN SECOND RUN OF CALIBRATION TOLERANCES

NO TOL

(1) (2) (3) (4) (5) (6) (7)

4.9.11 Zero adj -- ck ( ) adjust to center spot

4.9.12 20 mA -- ck ( ) 10 div min

” .1 A -- ck ( ) 10 div min

” .5 A -- ck ( ) 8 div min

” 2 A -- ck ( ) 10 div min

Page 7 of 7

29

Loading...

Loading...