Page 1

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST)

TM 9-6625-963-14-1

GRAPHICAL DISPLAY SYSTEM,

TEKTRONIX TYPE 561 SERIES

This copy is a reprint which includes current

pages from Change 1.

HEADQUARTERS, DEPARTMENT OF THE ARMY

OCTOBER 1972

Page 2

NOTE

This manual is an authentication of the manufacture’s commercial literature which, through

usage, has been found to cover the data required to operate and maintain this equipment.

Since the manual was not prepared in accordance in with military specifications, the format

has not been structured to considered level of maintenance nor to include a formal section

on depot overhaul standards.

This manual contains copyrighted information. Reproduced by permission of Tektronix,

Incorporated. All rights reserved.

Page 3

CHANGE TM 9-6625-963-14-1

Change 2

No. 2 HEADQUARTERS

DEPARTMENT OF THE ARMY

WASHINGTON, DC, 12 August 1986

OPERATOR’S ORGANIZATIONAL, DIRECT SUPPORT AND

GENERAL SUPPORT MAINTENANCE MANUAL,

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST:

GRAPHICAL DISPLAY SYSTEM

TEKTRONIX TYPE 561 SERIES (NSN 4931-0(1-910-8164)

Current as of 16 April 1986

TM 9-6625-963-14-1, 11 October 1972, is changed as follows:

1. Remove old pages and insert new pages as indicated below. New or changed material is indicated by a vertical bar in the margin

of the page.

Remove pages Insert pages

0 -1 and 0 -2 0 -1 and 0 -2

12 - 1 through 12 - 11 12 - 1 through 12 - 16

2. File this change sheet in front of the publication for reference purposes.

By Order of the Secretary of the Army:

JOHN A. WICKHAM, JR.

General, United States Army

Chief of Staff

Official:

R. L. DILWORTH

Brigadier General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with DA Form 12-34C, Block No. 319, requirements for calibration procedures publications.

Page 4

TM 9-6625-963-14-1

CHANGE 1

CHANGE HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 1 WASHINGTON, D.C. 20 MARCH 1975

TM 9-6625-963-14-1, 11 October 1972, is changed as follows:

1. The title is changed to read as shown above.

2. Remove old pages and insert new pages as indicated below. New or changed material is indicated by a vertical bar in the margin

of the page.

}

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

AND SUPPORT MAINTENANCE MANUAL,

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST:

GRAPHICAL DISPLAY SYSTEM, TEKTRONIX

TYPE 561 SERIES (NSN 4931-00-910-8164)

Current as of 11 September 1974

Remove pages Insert pages

i and ii i and ii

12-1 through 12-11

3. File this change sheet in front of the publication for reference purposes.

Page 5

TM 9-6625-963-14-1

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 9-6625-963-14-1 Washington, D.C.

SECTION 0 INTRODUCTION................................................................................................................................................0-1

1A TYPE R561B SPECIFICATION......................................................................................................................1-1A

2A OPERATING INSTRUCTIONS R561B...........................................................................................................2-1A

3A CIRCUIT DESCRIPTION R561B....................................................................................................................3-1A

4A MAINTENANCE R561B..................................................................................................................................4-1A

5A PERFORMANCE CHECK VIRGULE MAINTENANCE CALIBRATION R561B...............................................5-1A

10 PREVENTIVE MAINTENANCE INSTRUCTIONS............................................................................................10-1

11 RACKMOUNTING............................................................................................................................................11-1

12 REPAIR PARTS LIST......................................................................................................................................12-1

Appendix A REFERENCES..................................................................................................................................................A-1

B BASIC ISSUE ITEMS LIST AND ITEMS TROOP INSTALLED OR AUTHORIZED LIST..................................B-1

C MAINTENANCE ALLOCATION CHART...........................................................................................................C-1

}

OPERATOR’S ORGANIZATIONAL, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS SPECIAL TOOL LIST

GRAPHICAL DISPLAY SYSTEM,

TEKTRONIX TYPE 561 SERIES

(NSN 4931-00-910-8164)

1 CHARACTERISTICS RM561A...........................................................................................................................1-1

2 OPERATING INSTRUCTIONS RM561A............................................................................................................2-1

3 CIRCUIT DESCRIPTION RM561A....................................................................................................................3-1

4 MAINTENANCE RM561A..................................................................................................................................4-1

5 PERFORMANCE CHECK RM561A...................................................................................................................5-1

6 MAINTENANCE CALIBRATION RM561A..........................................................................................................6-1

PARTS LIST ABBREVIATIONS......................................................................................................................7-0.1

7 ELECTRICAL, PARTS LIST...............................................................................................................................7-1

8 MECHANICAL, PARTS LIST.............................................................................................................................8-1

9 DIAGRAMS........................................................................................................................................................9-1

11 October 1972

Page

Change 1 i

Page 6

TM 9-6625-963-14-1

Figure 1-1A. Type RM561A Oscilloscope

ii

Page 7

SECTION 0

INTRODUCTION

TM 9-6625-963-14-1

Scope

The manual includes installation and operation

instructions and covers organizational, direct support (DS),

and general support (GS) maintenance. It describes Graphical

Display System, Tektronix Type 561 Series. The basic issue

items list appears in appendix B. Appendix ’B is current as of

1 September 1972.

Indexes of Publications

DA Pam 310-4.

to determine if there are any new editions, changes, or

additional publications pertaining to the equipment.

DA Pam 310-7.

whether there are Modification Work Orders (MWO) pertaining

to the equipment.

Forms and Records

Refer to the latest issue of DA Pam 310-4

Refer to DA Pam 310-7 to determine

Reports of Maintenance and Unsatisfactory Equipment.

Use equipment forms and records in accordance with

instructions given in TM 38750.

Change 2 0-1

Report of Packaging and Handling Deficiencies

6). Fill out and forward DD Form 6 as prescribed in AR 700-8

(Army), NAVSUP Pub 378 (Navy), AFR 71-41 (Air Force), and

MCO P4030.29 (Marine Corps).

Discrepancy in Shipment Report.

Discrepancy in Shipment Report (SF 361) as prescribed in AR

55-38 (Army), NAV SUPINST 4610.33 (Navy), AFM 7-18 (Air

Force), and MCO P4610.19A (Marine Corps).

Fill out and forward

Reporting of Equipment Publication Improve

reporting of errors, omissions, and recommendations for

improving this publication by the individual user is encouraged.

Reports should be submitted on DA Form 2028

(Recommended Changes to Publications) and forwarded

direct to: Commander, U. S. Army TMDE Support Group,

ATTN: AMXTM-LML, Redstone Arsenal, AL 35898-5400.

(DD Form

ments. The

Page 8

Fig. 1-1. Type R561B Oscilloscope.

0-2

Page 9

SECTION 1

CHARACTERISTICS

General Information

The Tektronix Type RM561A Oscilloscope is essentially

an indicator unit with provision for two plug-in units. The plugin unit in the right-hand opening controls the horizontal (X-axis)

deflection, and the plug-in unit in the left-hand opening

controls the vertical (Y-axis) deflection. The plug-in units con

be selected from any of the Tektronix ’2’ Series or ’3’ Series

groups to provide the desired oscilloscope performance.

Cathode-Ray Tube

Type - T5032-31-1 (rectangular ceramic-envelope).

Phosphor-P31.

Unblanking - Deflection type, dc-coupled, with grid

intensification.

Graticule - Variable edge lighted "no parallax" internal

graticule. Marked in 8 vertical and 10 horizontal divisions with

each major division divided into 5 minor divisions on

centerlines.

Accelerating voltage - 3.5 kv.

Useable viewing area - 8 divisions vertical by 10

divisions horizontal.

Deflection meters - 18.5 to 20.5 volts per centimeter

vertical, and 17.5 to 19.3 volts per centimeter horizontal.

Calibrator

Waveform - Square waves at line frequency.

RM561A

Output voltage - 1 millivolt to 100 volts, peak-to-peak, in 6

steps. The 1 v position provides an output of 0.1 volt into 50

ohms.

Accuracy - Peak-to-peak amplitude within 3% of indicated

voltage.

Rise-time - Typically 5 microseconds.

Power Supplies

Electronically regulated for stable operation with normal line

voltage variations and widely varying loads. The low voltage

supplies hold regulation within ± 1% of value.

Line voltage requirements - 105 to 125 volts, or 210 to 250

volts, rms, 50 to 60 cps, single-phase ac.

Fuse requirements - 3-amp slow-blowing type for 117 volts,

1.25-amp slow-blowing type for 234 volts.

Ventilation

Forced air cooled. Automatic-resetting thermal cutout

interrupts instrument power if internal temperature exceeds about

123° F.

Construction

Aluminum-alloy chassis.

Photo-etched anodized front panel.

Weight - 30-1/2 pounds, indicator unit only.

Dimensions - see Dimension Drawing at rear of manual.

1-1

Page 10

SECTION 1A

TYPE R561B SPECIFICATION

Introduction

The Type R561B Oscilloscope is compatible with

Tektronix 2-Series and 3-Series plug-in units (see following

table and Section 2 for exceptions); thus, it con be used in a

variety of applications including differential, multi-trace, wideband, delayed sweep, sampling and spectrum analysis.

This instrument will perform to the specifications listed in

this section in a laboratory environment with ambient

temperature range between 0°C and +50°C, except as

indicated. Warm-up time for rated accuracy is 5 minutes

(certain plug-ins may require additional warmup time). The

Performance Check instructions outlined in Section 5 provide

a convenient method of checking the performance of this

instrument.

ELECTRICAL CHARACTERISTICS

DISPLAY

Characteristics Performance

Plug-in Compatibility 2- and 3-Series plug-ins, except the

3S6, 3T6, 385 (horizontal only)

CRT Type Electrostatic deflection

Graticule Area 8 x 10 cm

Phosphor P31

Typical CRT

Accelerating Voltage

EXTERNAL INPUTS AND OUTPUTS

CRT Cathode Input

(AC Coupled)

Low - 3 dB

Frequency 1.8 kHz or less

Z Axis Modulation 10 V or less (P-P) gives useful

Maximum Input

Voltage

Calibrator

Output Voltages Into

High Impedance (1

MΩ or greater)

Into 50.0Ω

Current Loop 10mA DC or 10mA (P-P) square

3.5 kV

intensity variation

150 V

+4 mV, +40 mV, +0.4 V, +40 V

(ground to peak) square wave and

40 VDC (within 1-1/2%, +20°C to

+30° ;2 %, 0°C to +50°C

+2mV, +20mV, +0.2V (ground to

panel) square wave (within 1-1/2%,

+20°C to +30° C; 2%, 0° C to

+50°C

wave (within 1-1/2%, +20°C to

+30°C; 2%, 0°C to +50°C

Type R561B

Frequency 1 kHz within 1%

Duty Factor 48% to 52%

Rise-time and Fall-time

Line Voltage 115 VAC

Low 90 V to 110 V 180 V to 220 V

Medium 104 V to 126 V 208 V to 252 V

High 112 V to 136 V 224 V to 272 V

Line Frequency Range 48 Hz to 66 Hz

Maximum Power

Consumption at 115 VAC,

60 Hz

ENVIRONMENTAL CHARACTERISTICS

Characteristics Performance

Temperature

Non-operating

Operating

Altitude

Non-operating To 50,000 feet

Operating To 15,000 feet

Finish Lacquered aluminum panels.

Dimensions

Height

Width

Length

Accessories

Standard accessories supplied with the Type R561B are

listed on the last pullout page of the Mechanical Parts List

illustrations. For optional accessories available for use with this

instrument, see the current Tektronix, Inc. catalog.

1 µs or less at all voltages with

load capacitance of 100pF or

less, except 40 V, 2.5µs or less

at 40 V with load capacitance at

100 pF or less

POWER SUPPLY

230 VAC

186 W, 2.02 A

-40°C to +65°C

0°C to +50°C

PHYSICAL

Anodized aluminum front panel

≅ 7 inches

≅ 19 inches

≅ 20-1/2 inches

(A)

1-1A

Page 11

SECTION 2

OPERATING INSTRUCTIONS

RM561A

Introduction

Before operating the Type RM561A Oscilloscope, be sure

that the instrument will cool properly, the proper line voltage is

used and the crt deflection potentials are correct. Function of

front-panel controls and operating considerations are given in

this section.

Cooling

A fan at the rear of the Type RM561A provides cooling.

The entire fan assembly is in a snap-in mounting that can be

mounted to exhaust air at the rear of the instrument or draw air

in at the rear and blow it throughout the instrument. Direction

of air flow con be changed to meet the operating conditions.

The Type RM561A can operate in ambient temperatures

up to 50°C. If the instrument overheats, the thermal cutout

turns off the power. When the internal temperature drops to a

safe operating level, power is automatically restored. If wired

for 117-volt operation, the fan will continue to operate when

the thermal cutout opens. On 234-volt operation, power for

the fan is turned off when the thermal cutout opens.

Line Voltage

The Type RM561A can be wired for either 117-volt or

234-volt operation. It will operate properly between 105 and

125 volts when wired for 117-volt operation and between 210

and 250 volts when wired for 234-volt operation. Converting

from one operating voltage to the other requires a change in

the power transformer primary connections, fan connections,

fuse and line cord plug. Figs. 2-1 and 2-2 indicate the

transformer primary and fan connections for

117-volt and 234-volt operation. A 3-amp slow-blow type fuse is

required for 117-volt operation and a 1.25-amp slow-blow type

fuse is required for 234-volt operation.

Front Panel Controls

The POWER ON switch and SCALE ILLUM. control permit

turning the instrument power on or off and provide adjustment of

the brightness of the graticule markings.

The FOCUS control adjusts the trace or spot focus.

The ASTIG. control is used in conjunction with the FOCUS

control, to assure proper focus over the entire crt display.

The INTENSITY control adjusts the crt display brightness.

The ALIGNMENT control permits electronic alignment of the

crt trace to match the horizontal graticule markings.

The 7-position CALIBRATOR switch determines the peak-topeak amplitude of the signal at the CAL. OUT connector. It also

turns the Calibrator on or off.

Rear Panel Controls

The CRT CATHODE SELECTOR switch permits the operator

to select either (1) internal DUAL-TRACE CHOPPED BLANKING

to remove dual-trace chopped mode switching transients from the

crt display, or (2) Z-axis intensity modulation by external signals.

Operation

Operation of the Type RM561A Oscilloscope with two plug-in

units in place is much the same as that of a Tektronix oscilloscope

with corresponding vertical and horizontal deflection systems built

into the main frame. The plug-in

Fig. 2-1. Power transformer primary connections for

operation at (a) 117 volts or (b) 234 volts.

(A)(A)

Fig. 2-2. Fan terminal strip located near thermal cutout. (a) 117

volts, (b) 234 volts

.

2-1

Page 12

Operating Instructions--Type RM561A

units are the vertical and horizontal deflection systems; their

outputs connect directly to the deflection plates of the cathoderay tube. The plug-in units can be selected to give the Type

RM561A Oscilloscope the degree and type of performance

required for a particular application.

The controls and switches on the Type RM561A affect the

display; however, the plug-in units determine the major

characteristics of the system.

Calibrator Output

The Calibrator output signal of the Type RM561A provides

a convenient signal source for setting the gain of an amplifier

plug-in unit or the basic timing of a time-base plug-in unit. The

1 V position also provides a 0.1 volt amplitude signal when

connected to a 50-ohm system. This is very useful for

calibrating sampling plug-in units. See the plug-in unit

Instruction Manual for complete adjustment procedure.

In addition to these applications, the Calibrator output

signal can be used as a convenient square-wave signal source

for other applications.

NOTE

When using the Calibrator output

signal as a signal source for a system

sharing a common ground with the

Type RM561A (including plug-ins

used in the instrument) be sure that the

outer conductor of the CAL. OUT

connector is connected to the chassis

(or ground). Otherwise, the current

through the Calibrator ground resistor,

R899, may cause an incorrect

Calibrator output signal.

CRT CATHODE SELECTOR Switch

The CRT CATHODE SELECTOR switch provides two

modes of operation; CHOPPED BLANKING for dual-trace

amplifier plug-ins and EXT CRT CATHODE for intensity

modulation of the display.

The CRT CATHODE SELECTOR switch should be left in

the CHOPPED BLANKING position except when external

intensity modulation is used. For normal operation the

shorting plug should connect the EXT CRT CATHODE jack to

ground. Remove the plug for Z-axis modulation:

Display Combinations

The plug-in unit in the right opening of the Type RM561A

controls the horizontal (X-axis) deflection of the crt beam. The

unit in the left opening controls the vertical (Y-axis) deflection.

Conventional Display. To obtain the conventional display of

a horizontal sweep with vertical deflection by the input signal,

insert a time-base plug-in unit in the right-hand opening and

an amplifier unit in the left. If a vertical sweep is desired with the

input signal displayed horizontally, reverse the plug-ins. However,

in this manner, the sweep retrace will not be blanked. Retrace

blanking is provided only when a time-base unit is inserted in the

right side of the Type RM561A.

X-Y Display. To obtain an X-Y display, insert amplifier plug-in

units in both plug-in openings. Plug-in units with equal

characteristics should be used.

Intensity Modulated Display. The crt beam can be intensity

modulated, (Z-axis modulated) by applying a signal to the EXT

CRT CATHODE jack on the rear panel. Depending on the setting

of the INTENSITY control, the crt beam can be turned on with a

negative pulse, or off with a positive pulse.

To intensity modulate the display remove the shorting strap

from between the EXT CRT CATHODE and GND jacks. Set the

CRT CATHODE SELECTOR switch to the EXT CRT CATHODE

position and apply the modulating signal to the EXT CRT

CATHODE jack.

Changing Plug-in Units

Before inserting a plug-in unit into the Type RM561A

Oscilloscope, make sure the latching bar (bottom front) is not

pointing down., Then, push the plug-in unit all the way into the

opening. Turn the aluminum knob at the bottom center of the unit

clockwise until it is tight. To remove the unit, turn the knob

counterclockwise several turns and pull the unit out of the plug-in

compartment.

CAUTION

Although most plug-in units can be

inserted or removed without damage when

the power is on, best protection is

provided for all units by turning the power

off before changing units.

Different plug-in units apply slightly different dc voltages to

the crt deflection plates. The Type RM561A crt has higher

horizontal deflection sensitivity than vertical deflection sensitivity.

Also, changing one plug-in unit con affect the accuracy of the

other unit installed. Therefore, if one or both of the units are

replaced, check the gain of both units. If a plug-in needs

adjustment, follow the directions in the applicable Instruction

Manual to adjust gain or sweep timing.

When the plug-in units are changed, the FOCUS and ASTIG,

controls on the Type RM561A may need readjustment.

The Type RM561A can be operated with only one plug-in unit

if desired. For example, moving film recording may be used in

place of a sweep plug-in unit. To operate with only one plug-in

unit, it will be necessary to elevate the unconnected crt deflection

plates to about +170 to +210 volts dc vertical or +150 to +180

volts dc horizontal. This will provide proper action of the FOCUS

and ASTIG. controls.

(A)(A)

2-2

Page 13

SECTION 2A

OPERATING INSTRUCTIONS R561B

Type R561B

Introduction

To effectively use the Type R561B, the operation and

capabilities of the instrument must be understood. This

section of the manual describes the operation of the frontand rear-panel controls and connectors, and gives first time

and general operating information.

Rack-mounting

Complete information for rack-mounting installation of the

Type R561B is given on the Rack-mounting fold-out pages at

the back of this manual.

Line Voltage

The Type R561B can be operated from either a 1 5-volt

or a 230-volt nominal line-voltage source. The Line Voltage

Selector assembly on the rear panel converts the instrument

from one operating range to the other. In addition, this

assembly changes the primary connections of the power

transformer to allow selection of one of three regulating

ranges. The assembly also includes two fuses to provide the

correct protection for the instrument; both fuses are connected

for 230-volt nominal operation, and only one fuse is

connected for 115-volt nominal operation. Use the following

procedure to obtain the proper line voltage and regulating

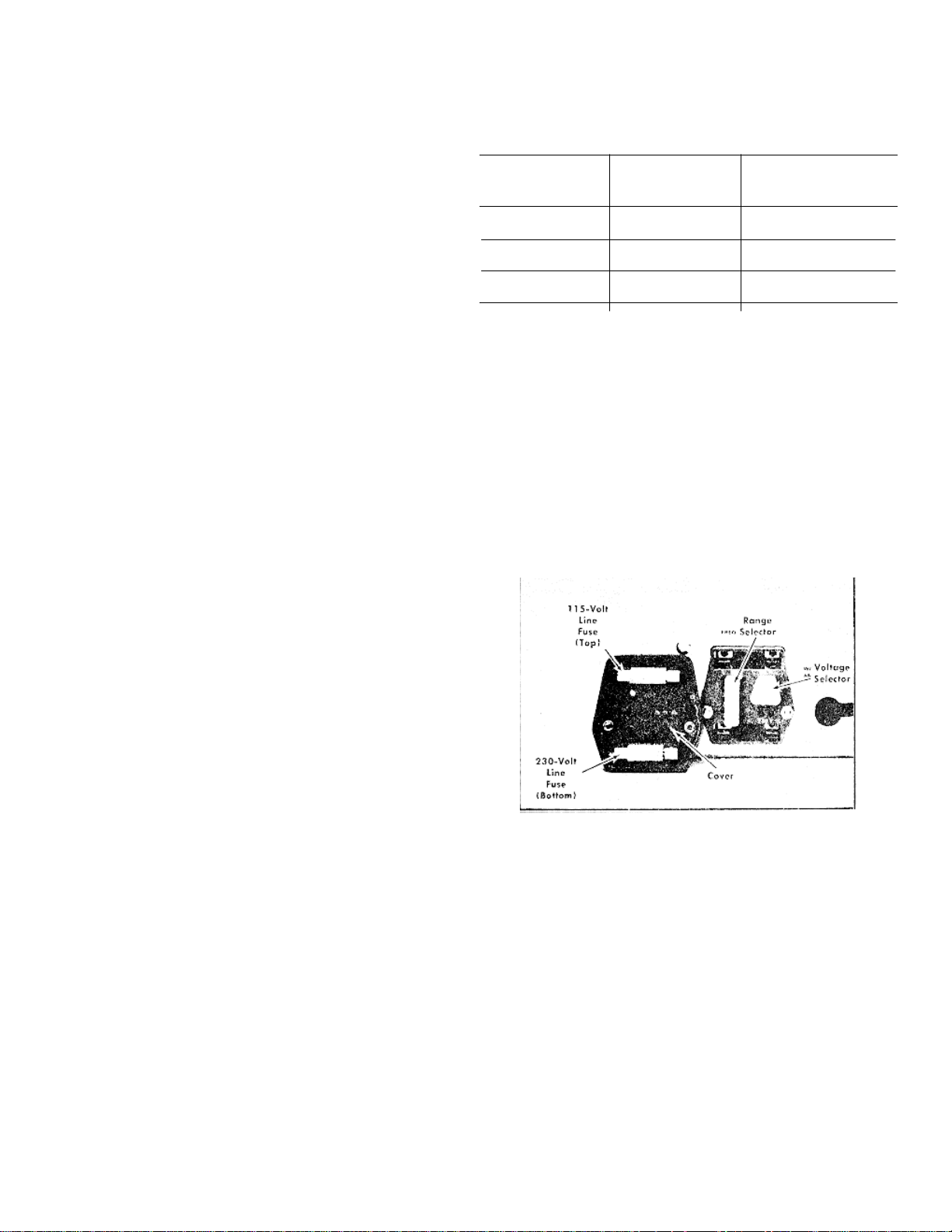

range settings of the Line Voltage Selector.

1. Disconnect the instrument from the power source.

2. Loosen the two captive screws which hold the cover

onto the voltage selector assembly; then pull to remove the

cover.

3. To convert from 115 volts nominal to 230 volts

nominal line voltage, pull out the Voltage Selector switch bar

(see Fig. 2-1); turn it around 180- and plug it back into the

remaining holes. Change the line-cord power plug to match

the power-source receptacle or use a 115- to 230-volt

adapter.

4. To change regulating ranges, pull out the Range

Selector switch bar (see Fig. 2-1); slide it to the desired

position and plug it back in. Select a range which is centered

about the average line voltage to which the instrument is to be

connected (see Table 2-1).

5. Re-install the cover and tighten the two captive

screws.

6. Before applying power to the instrument, check that

the indicating tabs on the switch bars are protruding through

the correct holes for the desired nominal line voltage and

regulating range.

TABLE 2-1

Regulating Ranges

Regulating Range,

Range Selector 115-Volts 230-Volt

Switch Position Nominal Nominal

LO (switch bar in 90 to 110 volts 180 to 220 volts

left holes)

M (switch bar in 104 to 126 volts 208 to 252 volts

middle holes)

HI (switch bar in 12 to 13 volts 224 to 272 volts

right holes)

Operating Temperature

The Type R561B can be operated where there ambient air

temperature is between 0°C and +50°C. The instrument can be

stored in ambient temperatures between -40°C and +65°C. After

storage at a temperature beyond the operating limits, allow the

chassis temperature to come within the operating limits before

power is applied.

A fan at the rear of the Type R561B provides forced air

cooling of the instrument. For proper circulation of air the

instrument should normally be operated with the top and bottom

covers in place. Do not block or restrict the air flow through the

instrument.

A thermal cutout provides thermal protection and disconnects

the power to the instrument if the internal temperature exceeds a

safe operating level. This device will automatically reapply power

when the temperature returns to a safe level.

Fig. 2-1. Line Voltage Selector assembly on the rear panel

(shown with cover removed).

CAUTION

Damage to the instrument may result from

incorrect Line Voltage Selector settings.

(A)

2-1A

Page 14

Operating Instructions--Type R561B

SELECTION OF PLUG-IN UNITS

General Information

The Type R561B is designed to use Tektronix 2-series

and 3 series amplifier and time-base plug-in ’units for

amplifying the vertical input signal and producing the timebase sweep. The use of plug-in permits the selection of

display modes, bandwidth, sensitivity and number of inputs so

that the oscilloscope performance can be changed to meet

changing measurement needs.

NOTE

Programmable plug-in Types 3S6 and 3T6

are not compatible with the Type R561B.

However, the capability of these plug-ins

is available (without programmability)

with Types 3S5 and 3T5. Use the Type

3B5 in the right-hand (horizontal)

compartment only. Refer to the

instruction manual of the plug-in unit for

specific information.

To install a plug-in unit in the Type R561B, push it all the

way in to the plug-in compartment, then turn the locking knob

,at the bottom of the front panel) clockwise until it is tight. To

remove the unit, turn the knob counterclockwise until the latch

releases, then pull the unit out.

The accuracy of measurements made with the Type

R561B depends on the calibration of the plug-in units used.

Since the plug-in units drive the deflection plates directly, each

unit must be adjusted to match the deflection sensitivity of the

particular CRT that it drives. Therefore, the gain or sweep

timing adjustment must be checked each time a plug-in unit, is

changed. On most units, gain or timing calibration is made

with a front-panel screwdriver adjustment. (Sampling units

require special adjustment procedures.) Refer to the plug-in

unit instruction manual for the required procedure. Since the

various plug-in units present different output voltage levels to

the deflection plates, the FOCUS and ASTIGMATISM controls

will also require re-adjustment.

Plug-in units can be changed without turning off the

instrument power, but it is recommended that the power be

turned off while the change is made.

Either or both of the plug-in units can be operated on

special extension cables for troubleshooting. For normal

operation, power, the units must be installed in the

oscilloscope. If the instrument is operated with the plug-in

units on extension cables, the high-frequency response and

fast sweep rates will be affected.

Display Combinations

The plug-in unit in the left plug-in compartment controls

the vertical (Y-axis) deflection of the CRT beam, and the unit in

the right plug-in compartment controls the horizontal (X-axis)

deflection. The following paragraphs discuss some of the

display combinations that con be obtained.

Time-Base Displays. To produce a conventional timebase, or Y-T display, an amplifier plug-in unit is used in the

vertical (left) plug-in compartment and a time-base plug-in unit

is used in the horizontal (right) plug-in compartment.

If a vertical sweep is desired with the input signal

displayed horizontally, the time-base unit is inserted in the left

compartment

and the amplifier unit in the right compartment. However, if a

vertical sweep is used, there is no retrace blanking, no

chopped blanking multi-trace displays and the delaying-sweep

intensification does not operate because these circuits are

associated with the horizontal (right) plug-in compartment.

X-Y Displays. Two amplifier units may be used to

produce either a single or a multiple X-Y display (for example,

for phase comparison measurement). Plug-in units with

equal phase shift will produce an accurate X-Y display;

however, for high-frequency X-Y operation, use of two units of

the some type is recommended. Careful factory adjustment of

deflection-circuit capacitance to a standard value in the Type

R561B minimizes the high-frequency phase-shift between two

plug-in units of the same type. For multiple X-Y displays, both

synchronization and automatic pairings are provided for

some amplifier units. Refer to the instruction manual of the

plug-in unit to be used.

Multi-Trace Displays. The use of a dual-trace or multitrace amplifier unit permits almost simultaneous viewing of two

or more signals. For a multi-trace amplifier unit with single

channel trigger capability ("Channel 1 Trigger"), the trigger

signal is applied through the Type R531B to the trigger circuit

in the time-base unit. This permits triggering from a single

input signal and the CRT display shows the time relationship

between the various signals. When using a plug-in without

single-channel triggering, an external trigger is recommended

to establish time relationship in multi-trace displays. In

chopped mode, the multi-trace blanking pulses from the

amplifier unit are applied internally through the Type R561 B to

the CRT cathode to blank the CRT beam while it is switched

from one channel to another (with the amplifier unit in the left

compartment and the time-base unit in the right compartment,

and with the rear panel CRT CATHODE SELECTOR switch in

the CHOPPED BLANKING position).

Delayed Sweep. A delayed-sweep time-base unit is

convenient for detailed viewing of pulse-train segments that

occur a relatively long time after the maximum-amplitude

(triggering) portion of the signal. The portion of the pulse train

to be displayed by the delayed sweep may be intensified on

the delaying-sweep display. A delayed-sweep unit that has a

calibrated time delay can also be used for making very

accurate (within 1%) time measurements

Raster Generation. A roster display can be presented by

using two time-base units, one in each compartment. Intensity

modulation can be achieved through the Z-axis of the CRT by

applying the signal to the EXT INPUT connector on the rear

panel and setting the CRT CATHODE SELECTOR to the EXT

INPUT position.

Sampling. The apparent bandwidth of the oscilloscope

can be increased to as much as one Gigahertz through the

use of sampling plug-in units. A sampling time-base unit must

be used with a sampling amplifier unit in the Type R561 B in

order to produce the sampling display (even for X-Y

operation). Generally, sampling and conventional plug-in units

cannot be used together in the oscilloscope. However, Type

3S1 and 3S2 sampling amplifiers do have limited compatibility

with conventional time-base units and the Type 3T5 sampling

time-base unit con generate a real-time staircase sweep

usable with conventional amplifiers.

Spectrum Analysis. Spectrum analyzer plug-in units

can be used in conjunction with conventional time-base units

2-2A (A)

Page 15

Operating Instruction--Type R561 B

to produce a spectral display ( a graph of the relative

amplitude distribution as a function of frequency).

FUNCTIONS OF CONTROLS AND

CONNECTORS

A brief description of the function or operation of the frontand rear-panel controls and connectors follows. See Fig. 2-2

for locations.

Front Panel

ASTIGMATISM Used in conjunction with FOCUS

(Screwdriver control to obtain a well-defined display.

adjustment)

FOCUS Control Used to optimize focus.

INTENSITY Control Controls display brightness.

TRACE ALIGNMENT Permits alignment of the trace with

(Screwdriver respect to the horizontal graticule lines.

adjustment)

SCALE ILLUM Varies illumination of the graticule grid

Control lines.

POWER Switch Used to apply or remove instrument

input power.

POWER Indicator Lamp bulb which indicates that AC

power is applied to the instrument.

CALIBRATOR Switch Provides selection of one of several

values of square wave voltage or a

calibrated DC voltage. A calibrated DC

or square wave current can also be

selected.

CAL OUT Connector BNC connector at which calibrator

output voltage is available.

10 mA Current Loop Convenient means for calibrating

current probes.

Rear Panel

CRT CATHODE Permits .election of normal CRT

SELECTOR operation, chopped blanking (blanking

Switch of the between-channel switching

transients when using multi-channel

plug-in units in the chopped mode) and

external CRT cathode input (permitting

intensity modulation of the CRT by an

external signal).

EXT INPUT BNC connector by which an external signal

Connector can be applied to the CRT cathode.

Line Voltage Provides quick method of changing

Selector transformer taps to allow instrument to

operate over a wide range of line voltages.

Horizontal and Permit installation of auxiliary inputs

Vertical and outputs through rear panel.

Connector Holes

FIRST TIME OPERATION

The following procedure, using normal single-channel timebase mode, will demonstrate the basic operation of this instrument

and its plug-in units.

1. Install a 2-Series or 3-Series amplifier plug-in unit in the

vertical (left) plug-in compartment and a 2-Series or 3-Series timebase plug-in unit in the horizontal (right) plug-in compartment.

Lock the plug-in units in place with their locking screws.

2. Set the POWER switch to the off position (pushed in).

3. Connect the power cord from the Type R561B to the

proper line voltage.

NOTE

The LINE VOLTAGE SELECTOR assembly on

the rear panel should be checked to be sure

the Voltage Selector and Range Selector

switch bars are in the proper positions for

the line voltage applied.

4. Set the instrument controls as follows:

Type R561B

INTENSITY Counterclockwise

FOCUS Centered

SCALE ILLUM Counter-clockwise

ASTIGMATISM Centered

(Screwdriver adjustment)

CALIBRATOR 4 V

CRT CATHODE SELECTOR NORM

(rear panel)

Amplifier Unit

(For example: Type 3A6)

Position Centered

Mode Normal (Channel 1)

Volts/Div 2

Variable (Volts/Div) Calibrated

Input Coupling DC

Time-Base Unit

(For example: Type 3B3)

Position Centered

Time/Div .5 ms

Variable (Time/Div) Calibrated

Magnifier Off

Sweep Mode Normal

(A)

2-3A

Page 16

Operating Instructions--Type R561 B

Fig. 2-2. Front-and rear-panel controls and connectors.

2-4A

(A)

Page 17

Normal-Single Sweep Normal

Level Free run (clockwise)

Triggering Source Internal

Slope +

Coupling Auto

5. Connect a patch cord from the CAL OUT connector to

the Channel 1 input connector of the amplifier plug-in unit.

6. Set the POWER switch to ON (pulled out) and allow a

few minutes for warm up.

7. Adjust the INTENSITY control to obtain a display of

moderate brightness. The amplifier unit Position control may

have to be adjusted to position the free running trace on the

CRT screen. Do not turn the intensity higher than is

necessary for adequate observation of the display.

8. Trigger the display by adjusting the time-base Level

control.

9. Set the SCALE ILLUM control so the graticule

illumination is approximately equal to the intensity of the

display.

10. Adjust the time-base Position control to position the

start of the trace at the left edge of the graticule.

11. Adjust the FOCUS and ASTIGMATISM controls for a

sharp well-defined display over the entire trace length. (If a

focused display cannot be obtained, see Astigmatism

Adjustment later in this section under General Operating

Information.)

12. Adjust the TRACE ALIGNMENT screwdriver

adjustment to align the display with the graticule lines.

13. Check the gain and DC balance of the amplifier unit

and the timing adjustment (Sweep Cal) of the time-base unit

as given in the instruction manuals for those units before

making any voltage or time measurements. (In this

demonstration, the calibrator waveform should be displayed as

two divisions per cycle and two divisions in amplitude.)

GENERAL OPERATING INFORMATION

General

Refer to the amplifier unit manual for the following:

Compensation of probes, selection and use of input cables,

coupling and attenuation, and measurement of input signal

voltage and phase (X-Y). Refer to the time-are unit manual for

selection of triggering sources and coupling, and for

measurements of time intervals, frequency and phase (linear

measurement).

Scale Illumination

The CRT graticule is edge-lighted by three small lamps at

the bottom. The lighting can be adjusted to suit the ambient

light conditions by means of the SCALE ILLUM control.

Rotating the control clockwise increases the brightness of the

graticule scale markings.

Intensity Control

The setting of the INTENSITY control may affect the

correct focus of the display. Slight adjustment of the FOCUS

control may be necessary when the intensity level is changed.

(A)

Operating Instruction--Type R561B

Do not leave a bright, sharply focused spot on the CRT

screen for a prolonged period. An excessively bright stationary

spot may damage the CRT phosphor.

Astigmatism Adjustments

For most displays, the trace can be adequately focused using

only the front-panel FOCUS control. However, whenever a large

change is made in the beam intensity (to offset large changes in

sweep rates or triggering repetition rates), or when plug-in units

are changed, adjustment of the ASTIGMATISM control may also

be required for a sharp display.

To check for proper setting of the ASTIGMATISM adjustment,

slowly turn the FOCUS control through the optimum setting with a

signal displayed on the CRT screen. If the ASTIGMATISM

adjustment is correctly set, the vertical and horizontal portions of

the trace will come into sharpest focus at the same position of the

FOCUS control.

To set the ASTIGMATISM adjustment, use the following

procedure:

1. Connect a 4 V Calibrator signal to the vertical input and

set the corresponding Volts/Div switch to present 2.5 divisions of

vertical deflection.

2. Set the Time/Div switch .2 ms.

3. Adjust the INTENSITY control so that the rising portion of

the display can be seen.

4. Alternately adjust the FOCUS and ASTIGMATISM

controls so that the horizontal and vertical portions of the display

are equally focused.

Graticule

The graticule of the Type R561B is marked with eight vertical

and 10 horizontal divisions. Each division is one centimeter

square. In addition, each major division is divided into five minor

divisions on the center vertical and horizontal lines. With the

vertical gain and horizontal timing calibrated to the graticule,

accurate measurements can be made from the CRT. The

illumination of the graticule lines can be varied with the SCALE

ILLUM control.

Trace Alignment Adjustment

If a free-running trace is not parallel to the horizontal graticule

lines, set the TRACE ALIGNMENT adjustment as follows: position

the trace to the center horizontal line, and adjust the TRACE

ALIGNMENT adjustment so the trace is parallel with the horizontal

graticule lines.

1 kHz Calibrator

The 1 kHz Calibrator provides a convenient source of square

waves of known amplitude at an accurate frequency of one

kilohertz. The output square-wave voltages available at the CAL

OUT connector are 4 mV, 40 mV 0.4 V, 4 V and 40V. The loading

of a terminated 50Ω system at the CAL OUT connector will

provide output square-wave voltages of 2 mV, 20 mV and 0.2 V.

A constant 40-volt DC level is also provided.

2-5A

Page 18

Operating Instructions--Type R561 B

The current link provides 10 milliamperes, available as

either DC or a square-wave current signal, which can be used

to check and calibrate current probe systems. This current

signal is obtained by clipping the probe around current loop.

The arrow indicates conventional current (i.e., positive to

negative).

Intensity (Z-Axis) Modulation

Intensity modulation can be used to relate other voltage

information to the display signal without changing the shape of

the waveform. The modulating signal is AC-coupled to the

CRT cathode through the rear-panel EXT INPUT connector

and the CRT CATHODE SELECTOR switch. With the

INTENSITY

control set correctly, a positive excursion will dim or blank the

CRT beam, and a negative excursion will brighten the beam

(see Section 1 for amplitudes).

Time markers may be applied for direct time reference of

the display or for establishing the sweep rate when

uncalibrated deflection is used. Fast-rise pulses of short

duration provide best resolution with respect to time. If the

markers are not time-related to the displayed wave-form, a

single sweep display is required. If sine waves are used for

Z-axis modulation, the minimum usable frequency is about

250 hertz, due to AC coupling at the input. Be sure the CRT

CATHODE SELECTOR is in the NORMAL position when the

EXT INPUT connector is not in use, to avoid random intensity

modulation from stray signals.

(A)

2-6A

Page 19

SECTION 3

CIRCUIT DESCRIPTION

Introduction

The Tektronix Type RM561A Oscilloscope has a lowvoltage power supply circuit, a cathode-ray tube circuit, and a

calibrator.

The low-voltage power supply circuit provides the

regulated and unregulated power used by the instrument and

the plug-in units.

The crt circuit has the necessary controls and input

facilities needed to give a sharp trace of useable intensity.

Two negative high-voltage power supply outputs are used

for the cathode, focus element, and control grid of the crt.

The calibrator produces amplitude-calibrated square

waves.

LOW-VOLTAGE POWER SUPPLY

The low-voltage power supply circuits have regulated

outputs of -100, -12.2, +125, and -300 volts, and unregulated

output of +420 volts. These circuits use silicon diode rectifiers

and series-regulators. Each regulator circuit has a vacuum

tube (or transistor, in the case of the -12.2-volt supply) in

series with the load. This tube’s series plate resistance (and

current) is controlled to maintain a constant voltage drop

across the load. For example, if the load increases the series

tube plate resistance decreases to pass more current to the

load. If the load decreases it passes less current. In both

cases, the voltage across the load remains the same.

The -100-, +125-, and +300-volt regulated supplies

require shunt resistors when supplying more current than can

be handled by the series tube. A shunt allows some of the

load current to bypass the supply-series-regulator tube. The

size of the shunt is very important. If the shunt resistance is

too high, the series tube can overheat; if the resistance is too

low, the supply can fail to regulate. If a plug-in draws an

amount of current that calls for a supply shunt, the correct

shunt resistance is located in that plug-in unit. When the unit

is plugged into the Type RM561A, the shunt is connected

around the series regulator tube. The plug-in portion of the

shunt is always in series with a resistor located in each power

supply circuit.

Power for the Type RM561A Oscilloscope and its plug-in

units is supplied through the power transformer T601. The two

primary windings of T601 are connected in parallel for 117-volt

operation, or in series for 234-volt operation, as shown on the

schematic diagram.

RM561A

The series tube plate resistance changes to hold the load voltage

constant. R616, -100 VOLTS adjustment, determines the

percentage of the total divider voltage applied to the grid of V634A

and thus controls the output voltage. When this control is properly

adjusted, the output is exactly -100 volts.

Should the output voltage tend to change because of a

change in input voltage or a change in load current, the potential

at the grid of V634A will change a proportional amount. Any

change at the grid of V634A is amplified by V634A and Q624 and

applied to the grid of V627. The resulting grid change at V627 will

cause its plate resistance to change in the direction needed to

bring the output back to --100 volts. C616 improves the response

of the regulator to sudden changes in output voltage R628 is part

of the series tube shunt. connected by some plug-in units.

+ 125-Volt Supply

The -100-volt supply serves as a reference for the +125 volt

supply. With the R651 end of the divider R650-R651 fixed at -100

volts, any change in the +125-volt output produces a proportional

change at the grid of V654. This change is amplified and supplied

to the grid of the series regulator tube, V667A. The change at the

grid of V667A changes its plate resistance to bring the output

voltage back to 4-125 volts. R656, the +125 VOLTS control,

determines the percentage of total divider voltage applied to the

grid of V654 and permits adjustment of the output voltage. W hen

this control is properly adjusted, the output is exactly +125 volts.

C650 improves the response of the regulator to sudden changes

in output voltage. .R666 is port of the series tube shunt.

+ 300-Volt Supply

The + 300-volt supply works the some as the + 125-volt

supply. To supply the voltage for the + 300-volt regulator, rectified

voltage from the transformer pins 21 and 22 is added to the

voltage supplying the + 125-volt regulator. R676, the -+ 300

VOLTS control, adjusts the output voltage. The + 300-volt supply

has an unregulated output of + 420-volts for the crt circuit.

- 12.2-Volt Supply

Operation of the --12.2-volt regulating circuit is essentially the

same as that of the other regulating circuits, except that

transistors are used instead of vacuum tubes. The base of Q734

is fixed near ---12 volts by the voltage divider R731-R732

between ---100 volts and ground. Any variation of the --12 2-volt

output at the emitter of Q734 is amplified by 0734 and 0744 to

change the collector resistance of 0757 which is in series with the

lead R730, the -12.2 VOLTS control, allows adjustment of the

voltage applied to the base, of Q734 and thus the output voltage.

- 100 Volt Supply

Reference voltage for the -100-volt supply is established

by the gas diode, V609. The constant voltage drop across

V609 establishes a fixed potential of about --85 volts at the

grid of V634B. Voltage at the grid of V634A is established by

the divider R616, R617, and R618. The difference in voltage

between the two grids of V634 determines the plate current cf

V634A. Plate current of V634A determines the base voltage

of transistor Q624 which in turn determines the grid voltage of

the series tube, V627.

(A)(A)

3-1

Page 20

Circuit Description--Type RM561A

When this control is properly adjusted, the output is exactly -

12.2 volts. F720 protects Q757 in case of an overload on the -

-12.2-volt supply.

CRT CIRCUIT

The crt circuit contains the cathode-ray tube and two highvoltage supplies (one for the crt and focus element, the other

for the control grid). The circuit also contains the necessary

controls and signal input facilities.

Cathode-Ray Tube

A Tektronix T5032-31-1 ceramic-envelope cathode-ray

tube is used in the Type RM561A. The accelerating voltage is

approximately 3500 volts, developed by about -3300 volts at

the cathode and an average deflection plate voltage of about

+200 volts. With this accelerating voltage, the nominal vertical

and horizontal deflection factors are 19.5 and 18.4 volts per

centimeter respectively.

Deflection blanking of the crt beam is used in the Type

RM561A. The crt contains a special set of deflection plates,

pins 6 and 7, for this purpose. Both plates are connected to

+125 volts; however pin 6 is also driven by the horizontal plugin unit.

During sweep time, or if no plug-in unit is installed, both

plates rest at +125 volts and permit the electron beam to pass

on to the crt phosphor. During sweep retrace, however, pin 6

is driven considerably away from +125 volts by the right-hand

plug-in unit. This scatters the beam and prevents it from being

displayed.

High-Voltage Supplies

Energy for both high-voltage supplies is furnished by

T801. V800, the primary of T801, and the stray circuit

capacitance form a Hartley oscillator which operates at about

45 kc.

The output of one secondary winding of T801, rectified by

V822, provides voltage for the crt cathode and focus element.

This voltage is about -3300 volts at the crt cathode, and

between about -2200 and -3000 volts at the focusing element,

depending on the setting of the FOCUS control. The 6.3-volt

crt heater is elevated to the cathode potential by R851.

The output of the other secondary winding of T801 is

rectified by V832 for the control grid. The grid voltage ranges

from -3200 to -3450 volts, depending on the setting of the

INTENSITY control. The reference to ground for this supply is

determined by the voltage at the junction of diodes D838 and

D839. The voltage at this junction, plus the setting of the

INTENSITY control, determines the crt bias and therefore the

intensity of the display.

Two neon bulbs, B856 and B857, keep the voltage

between the grid and cathode of the crt within safe limits. If

the voltage exceeds about 140 volts, the neons fire and the

voltage reduces to about 120 volts.

Regulation of the -3300-volt supply is accomplished through

feedback from the arm of R841. The -3450-volt supply is

regulated indirectly by mutual coupling in T801. If, because of

loading or a change in input voltage, the output of the -3300-volt

supply changes, a proportionate change occurs at the arm of

R841. This change is amplified by V814 and is coupled to the

screen of V800. The resulting change in screen voltage of V800

will increase or decrease the amplitude of oscillations in V800,

changing the output voltage of T801 in the direction needed to

return the high voltage to the correct level. The HIGH VOLTAGE

control, R841, permits adjustment of the output voltage by setting

the bias on V814B.

Deflection Signals

Push-pull signals for the deflection plates appear at pins 17

and 21 of the plug-in connector. The effective deflection circuit

capacitance these signals see at the connector affects the bandpass and phase shift of each plug-in unit. C760 and C761

(Interconnecting Socket diagram) are set at the factory.

Intensifying Signals

Two signals may be used to modulate the intensity of the crt

display. First, intensifying signals from a two-sweep (delayingsweep) time-base plug-in unit are applied to the grid supply

through pin 14 of the right-hand Interconnecting Socket. W hen

the overall display intensity is reduced with the INTENSITY

control, positive intensifying pulses from a two-sweep time-base

plug-in unit will brighten any desired portion of the display.

The ground return for the crt grid supply can be either through

D838 in the case where the plug-in unit does not supply

intensifying signals or through D839 to a negative voltage in the

intensifying circuit of the plug-in unit. In the second case D838 is

back-biased and the junction of D838 and D839 is at a low

negative voltage. With the same setting of the INTENSITY

control, the first case will provide a brighter display. The second

case provides a slightly dimmer display due to the plug-in unit

negative voltage. Intensification results when the plug-in unit

positive pulse turns D839 off and the crt grid supply return again

becomes D838. R837 and C837 then couple the leading edge of

the intensifying pulse directly to the crt grid.

Other external intensifying signals can be fed to the crt

cathode through the EXT CRT CATHODE jack. Depending on the

setting of the INTENSITY control, a negative pulse of 5 volts or

more will turn the crt beam on.

Crt Controls

The INTENSITY control, R833, has a range of about 250 volts

to control the crt bias and permit changing the intensity of the

display.

The FOCUS control, R844, adjusts the focus of the crt by

varying the voltage at the focusing anode through a range from

about -2200 to -3000 volts.

The ASTIG. control, R864, has a 300-volt adjustment range.

3-2 (A)(A)

Page 21

Circuit Description--Type RM561A

The GEOMETRY control, R865, adjusts the geometry by

varying the voltage of the crt isolation shield through a range

from +180 to +246 volts.

The TRACE ALIGNMENT control, R860, rotates the

display so it can be aligned with the graticule.

CALIBRATOR

The calibrator for the Type RM561A Oscilloscope

produces line-frequency amplitude-calibrated square waves.

The 6.3-volt (approximately 18 volts peak-to-peak) ac heater

voltage for V884 is supplied through C876 to the cathode of

V884A. The signal at the plate of V884A is coupled to the grid

of V884B to turn that tube on and off.

(A)(A)

Regenerative feedback from the plate of V884B to the grid of

V884A speeds up the switching action, and drives V884A into and

out of cutoff.

The voltage present at the cathode of V884B during the time

that V884B is conducting is adjusted to exactly 100 volts with the

CAL. AMPL. adjustment, R871.

The voltage divider in the cathode circuit of V884B contains

precision resistors to provide an output accuracy of 3% or better

at the various settings of the CALIBRATOR control.

When the CALIBRATOR control is set to the IV position, there

will be a 0.1-volt output when the CAL. OUT connector is

terminated in 50 ohms.

3-3

Page 22

SECTION 3A

CIRCUIT DESCRIPTION

Type R561B

R561B

Introduction

This section of the manual contains a description of the

circuitry used in the Type R561B Oscilloscope. Each circuit is

described in detail using a detailed block diagram to show the

interconnections between the stages in each major circuit and

the relationship of the front-panel controls to the individual

stages. Complete schematic diagrams are located at the rear

of this manual.

LOW-VOLTAGE POWER SUPPLY

General

The Low-Voltage Power Supply circuit provides the

operating power for this instrument from four regulated

supplies. Electronic regulation is used -to provide stable, lowripple output voltages. Each regulated supply contains a short

protection circuit to prevent instrument damage if a supply is

inadvertently shorted to ground or to another supply. The

voltage input stage includes the Voltage Selector Assembly

which allows selection of the nominal operating voltage and

regulating range for the instrument. Fig. 3-1 shows a detailed

block diagram of the Low-Voltage Power Supply.

Power Input

Power is applied to the primary of transformer T1 through

fuse F1, POWER switch SW1, thermal cutout TK1, Voltage

Selector switch SW2 and Range Selector switch SW3. SW2

connects the split primaries of T1 in parallel for 115-volt

nominal operation, or in series for 230-volt nominal operation.

SW3 allows three ranges of regulation by changing the taps

on the primary windings to fit different line requirements. A

second fuse, F2, is connected into the circuit when SW2 is set

to the 230V position to provide the correct protection for 230volt operation.

Thermal cutout TK1 provides thermal protection by

interrupting the power if the instrument overheats. When the

temperature returns to a safe level, TK1 automatically closes

to re-apply the power.

- 100 Volt Supply

The -100-Volt Supply provides the reference voltage for

the remaining supplies. The output from the secondary of T1

is rectified by bridge rectifier D8A-D. This voltage is filtered by

C9, then applied to the -100-Volt Series Regulator stage to

provide a stable output voltage. The Series Regulator can be

compared to a variable resistance which is changed to

stabilize the output voltage. The conductance

of the Series Regulator stage is controlled by the Error Amplifier to

provide the correct regulated output voltage.

The Error Amplifier consists of Q12 and Q14, which are

connected as a comparator. The output at the collector of Q14

indicates any voltage variations which occur at the base of Q14

relative to the fixed voltage at the base of Q12. Zener diode D10

maintains a fixed 9-volt drop, setting the base of Q12 at about -9

volts. The base level of Q14 is determined by the voltage divider

network R18-R19-R20-R21-R23. R23, the -100 Volts adjustment,

allows the operating point of the Error Amplifier to be adjusted to

set the output voltage of the supply at -100 volts. R13 is the

emitter resistor for both comparator transistors and the current

through it divides between Q12 and Q14. The output current of

the Error Amplifier stage controls the conduction of the Series

Regulator stage. This is accomplished as follows: Assume that

the output voltage increases (becomes more negative) because of

a change in load or an increase in line voltage. This negativegoing voltage change at the output is applied to the base of Q14,

reducing the conduction of Q14. As current through Q14 is

reduced, Q24 base current increases. This results in increased

Q24 collector current, increasing the voltage drop across R25 and

R26 and pulling the base of Q28 negative. The emitter of Q28

follows the base; hence, the base of Q32 is also pulled negative.

Reduced current through Series Regulator Q32 decreases current

through the load, causing the output voltage to decrease (become

less negative) to its correct level. These changes occur rapidly,

and the effect is to maintain unchanged output voltage. In a

similar manner, the Series Regulator and Error Amplifier stages

compensate for output changes due to ripple. As will be seen in

subsequent paragraphs, R33 determines the limit current for the

Series Regulator stage, and thus for the load. Transients beyond

the frequency range of the regulator are filtered by C31 to prevent

their appearance on the output voltage.

When the power switch is activated, diode D25 provides a

base current path for Q28, allowing the -100-Volt Supply to turn on

first, since all the other supplies are dependent upon its output.

As the -100-Volt Supply output builds up to its correct level, D25 is

reverse biased and remains off during normal operation of the

instrument.

The Short-Protection Amplifier stage, Q30, protects the -100Volt Supply if the output is shorted, and also serves to limit the

current demanded from the Series Regulator under excessive

load. During normal operation, divider R30-R31 sets the base of

Q30 to a point below the turn-on level of the transistor. When

excess current is demanded from Series Regulator Q32 due to an

overload or short circuit, the additional current through R33 raises

the emitter of Q32 more positive. This produces a

corresponding change at the base of Q32, which is connected

through R30

(A)

3-1A

Page 23

Circuit Description--Type R561B

Fig. 3-1. Power Supply detailed block diagram.

3-2A

(A)

Page 24

Circuit Description--Type R561B

to the base of Q30. This positive-going change biases Q30

into conduction. As a result, less current is available to Q28,

to Q32 and to the load, thus causing the supply to lose

regulation. R31 senses the decrease in load voltage and adds

to increasing base current of Q30. As the collector of Q30

goes negative, conduction of Q28 and Q32 is further

decreased. Thus the output current is decreased and remains

low until the excessive load is removed. D19, together with

divider R18-R19-R20, provides protection to the --12.2-Volt

supply in the event the -100-Volt Supply is shorted to the -

12.2-Volt Supply by causing the -100-Volt Supply to lose

regulation, and therefore lose reference voltage for the -12.2Volt Supply. D31 protects the -100-Volt Supply from

damaging polarity reversal if it is shorted to either the +125Volt Supply or the +300-Volt Supply.

- 12.2-Volt Supply

Rectified voltage for operation of the -12.2-Volt Supply is

provided by D35A-B, filtered by C36 and applied to the -12.2Volt Supply Series Regulator stage. Reference voltage for this

supply is provided by voltage divider R42-R43 between the

regulated -100-Volt Supply and ground. If the -12.2-volt output

changes, a sample of the change appears at the base of Q46

as an error signal. Regulation of the output voltage is

controlled by Error Amplifier Q44-Q46-Q49 and Series

Regulator Q51 in a manner similar to that described for the 100-Volt Supply. Transients beyond the frequency range of

the regulator are filtered by C47.

Short protection is provided by Q38 and R38. For normal

operation, the emitter-base voltage of Q38 is not enough to

bias it into conduction. However, when the output is shorted,

the high current demanded from the -12.2-Volt Supply is

drown through R38, producing a voltage drop sufficient to

forward bias Q38. Q38 collector current then produces an

increased voltage drop across R40, reducing the conduction of

both Q49 and Q51 to limit the output current. R39 protects

Q38 from sudden current surges by limiting the base current.

D47 protects the -12.2-Volt Supply from damage if it is shorted

to either the +;125-Volt Supply or the +300-Volt Supply.

+ 125-Volt Supply

Rectified voltage for operation of the +125-Volt Supply is

provided by D53A-D, filtered by C54 and applied to the +125Volt Supply Series Regulator stage. The +125-volt output is

summed with the -100-volt reference through divider R62-R63,

and the summation is applied through R61 to the base of Q60

and compared to the grounded base of Q58. If the +125-volt

output changes, a sample of the change appears at the base

of Q60 as an error signal. Regulation of the output voltage is

controlled by Error Amplifier Q58-Q60-Q66-Q68 and Series

Regulator Q74 in a manner similar to that described for the 100-Volt Supply. Transients beyond the frequency range of

the regulator are filtered by C97B-C to prevent their

appearance on the output voltage.

Short protection for this supply is provided by the ShortProtection amplifier stage, Q70, which functions in a manner

similar to that described for Q30 in the --10Volt Supply. D62

protects the Error Amplifier from damage if the output of the

+125-Volt Supply collapses or goes negative, causing C62 to

rapidly discharge and reverse bias 060. Diode D75 protects

electrolytic capacitor C97B-C and the transistors in the circuit from

damaging polarity reversals in the event the +300-volt output is

shored to ground or to one of the negative supplies. D76 causes

the +125-Volt Supply to go into current limiting when the +300-Volt

Supply is shorted to ground or to one of the negative supplies.

+ 300-Volt Supply

Rectified voltage for operation of the +300-Volt Supply is

provided by D77A-D, filtered by C78 and applied from the

negative side of the rectifier to the +300-Volt Supply Series

Regulator stage. The +300-volt output is summed with the -100volt reference through divider R80-R81, and the summation is

applied through R83 to base of Q84 and compared to the

grounded base of Q86. If the +300-volt output changes, a

sample of the change appears at the base of Q84 as an error

signal. Regulation of the output voltage is controlled by Error

Amplifier Q84-Q86-Q88-Q90 and Series Regulator Q96 in a

manner similar to that described for the -100-Volt Supply.

Transients beyond the frequency range of the regulator are filtered

by C97A. The load current through Series Regulator Q96 also

posses through the +125-Volt Supply Series Regulator, Q74.

However, this does not affect the limit current of the +125-Volt

Supply.

Shorting protection for this supply is provided by the ShortProtection Amplifier stage, Q91, which functions in a manner

similar to that described for Q30 in the -100-Volt Supply. D80

protects the Error Amplifier from damage if the output of the +300Volt Supply collapses or goes negative, and D95 protects the

transistors in the circuit from damaging polarity reversals in the

event the +125-Volt Supply is shorted to ground or to one of the

negative supplies.

6.5-Volt RMS AC Source

The four 6.5-volt RMS secondary windings of T1 provide

power for the CRT heater, the plug-in heaters via J11 and J21, the

pilot light, B7, and the scale illumination lights, B4, B5, and B6.

Current through the scale illumination lights is controlled by the

SCALE ILLUM control, R4, to change the brightness of the

graticule lines.

DEFLECTION CIRCUITS

horizontal and vertical signals for deflecting the CRT beam are

received through pins 17 and 21 of each plug-in unit and applied

to the respective deflection plates of the CRT. The effective

deflection circuit capacitance encountered by each of these

signals at the plug-in connector affects the bandwidth and phase

shift of the plug-in unit. Compensating capacitors C102 and C109

(shown on the Plug-In Connectors diagram) are factory-adjusted

to set the effective capacitance at a standard value of 14.3

picofarads to ensure plug-in compatibility.

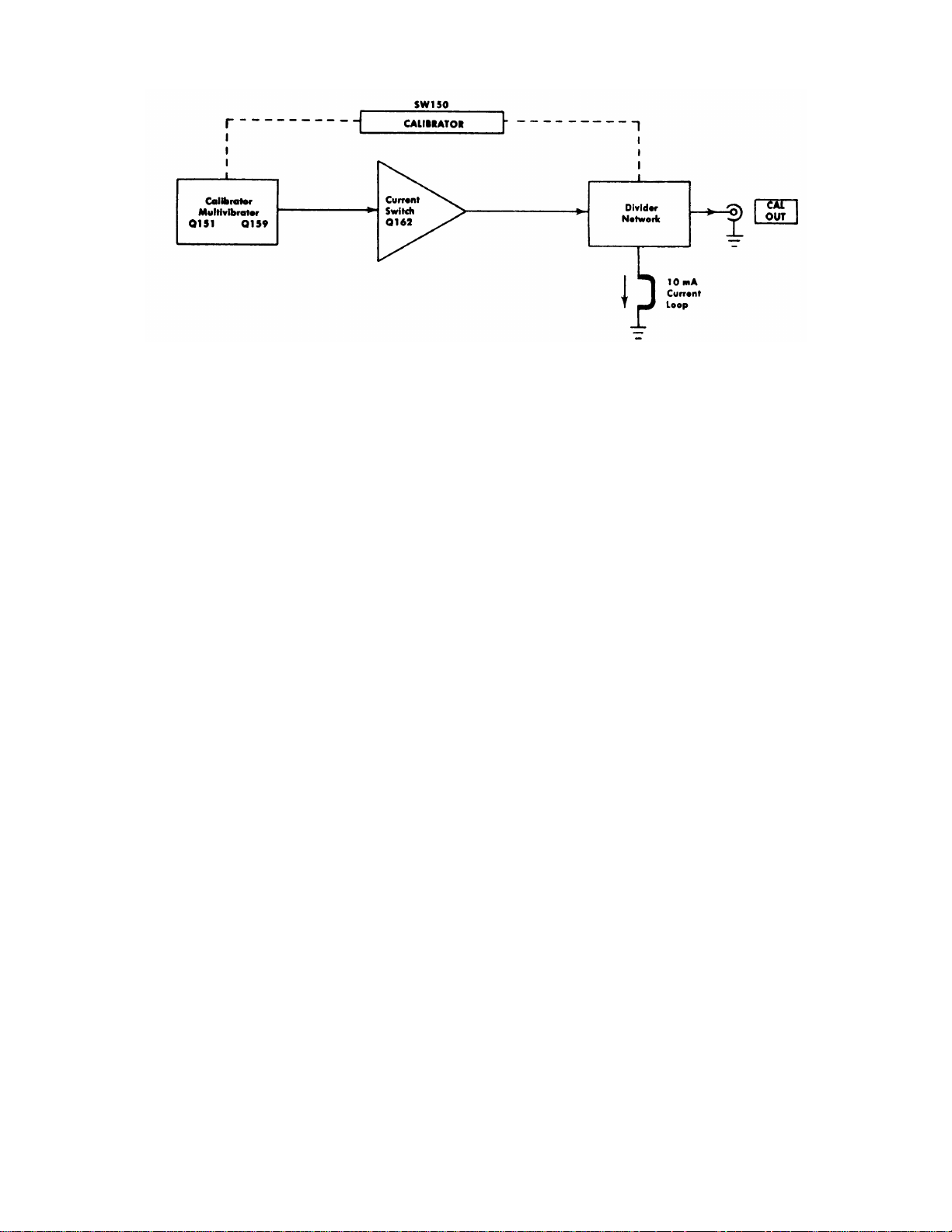

1 kHz CALIBRATOR

General

The 1 kHz Calibrator circuit produces a square-wave output

with accurate amplitude and frequency. This output is available

as a square-wave voltage at the CAL OUT connector or as a

square-wave current through the 10 mA probe current

(A)

3-3A

Page 25

Circuit Description--Type R561B

Fig. 3-2. 1 kHz Calibrator detailed block diagram.

loop. An accurate +40 volts DC level is also available. The

CALIBRATOR switch selects the attenuation of the output

signal to provide square-wave voltage outputs between 40

volts and 4 millivolts (between 0.2 volts and 2 millivolts into 50

ohms) peak to peak. Fig. 3-2 shows a detailed block diagram

of the 1 kHz Calibrator circuit.

Calibrator Multivibrator

The Calibrator Multivibrator is comprised of Q151 and

Q159, and is a free-running emitter-coupled multivibrator. The

circuit operates in a symmetrical manner and the output is an

accurate one-kilohertz square wave. Only an approximate 9volt change is exhibited at the emitters of Q151 and Q159, so

that an essentially constant current of about 0.8 mA is

maintained through resistors R150 and R1 58.

Refer to the wave shapes shown in Fig. 3-3 for this

discussion. With the CALIBRATOR switch, SW150, in all

positions except 1 mA DC and OFF, the emitters of Q151 and

Q159 are returned to the +125-volt supply through D151-R150

and D159-R158. Assume that the multivibrator has just

switched states; Q151 is off and Q159 is on. This is To in Fig.

3-3. The base potential of Q159 is set to about -11.0 volts by

voltage divider R153-R154-R156 to ensure that Q159 will not

saturate. The voltage at the anode of D159 is about -9.8 volts

because of the voltage drop across two forward biased

junctions. Capacitor C157 had about a 2-volt charge as

switching occurred; thus, the voltage at the anode of D151 is

about -7.8 volts, cutting off Q151. C157 begins to charge

toward the +125-volt supply via R150. Total current through

Q159 is about 1.6 mA; 0.8 mA through R158 and 0.8 mA

through C157 and R150.

After about 0.5 milliseconds (corresponding with T, in Fig.

3-3), C157 has charged to the turn-on level of Q151 and D151.

At this point, the capacitor has a charge of about 11 volts and

the potential at the anode of D151 is about +1.2 volts. The

capacitor charging current through Q159 ceases as Q151 and

D151 begin

to conduct. As the collector of Q151 (hence the base of Q159)

rises, Q159 and D159 are switched off and C157 begins to

discharge through R158. The C157-R158 current sums with R150

current through Q151, producing an approximate 9-volt positivegoing step at the base of Q159.

C157 continues to discharge, and after 0.5 milliseconds (T,

in Fig. 3-3), the voltage at the anode of D159 has risen to

forward-bias Q159 and D159. As Q159 begins to conduct, the

anode of D159 is clamped at about 0.8 volts and discharge action

of C157 is halted. The current through Q151 decreases, causing

its collector to introduce a negative-going step, which is connected

through the Q159 base-emitter junction and D159 to C157.

Because C157 cannot obtain an instantaneous charge, the anode

of D151 is pulled negative to reverse bias D151 and Q151. Q151

turns off, and its collector falls rapidly to about -11.0 volts,

resulting in an approximate 9-volt negative-going step applied

through Q159 and D159 to C157. The anode of D151 is pulled

down to about -7.8 volts, completing the cycle.

The Calibrator Multivibrator circuit has been designed to

repeat the preceding sequence at an accurate one-kilohertz

frequency. However, since a tolerance range of the passive

components does exist, the frequency can be adjusted by varying

slightly the amplitude across C157 during the charge-discharge

cycle. This is accomplished by adjustment of R154, Frequency,

which determines the potential on D159 anode at the instant the

diode turns on. For example, with greater amplitude, longer

charge and discharge times are required, thus lowering the

frequency.

Output Stage

The output stage consists of the Current Switch, Q162, and

the Divider Network. During the half cycle that Q159 is

conducting, current is injected into the base of Q162. Q162

saturates and its collector drops to about -12 volts, reverse

biasing D168. With D18 off, there is no current through R170 and

R171, and the output level at the cathode of D168 drops to zero

volts.

(A)

3-4A

Page 26

When Q159 turns off, Q162 turns off and D161 turns on to

protect the Q162 base-emitter junction from reverse-bias

breakdown. D164 and D168 turn on, and the output of the

circuit (at D168 cathode) is dependent upon voltage divider

R166-R167-R170-R171 between +125 volts and ground. This

output level is set to exactly +40 volts by adjustment of R166,

Amplitude. When this adjustment is made, the current through

the divider is an accurate 10 mA, which is available at the

current probe loop in the 10 mA positions of the CALIBRATOR

switch.

The signal voltage available at the CAL OUT connector is

determined by the divider network (made up of precision

resistors) and the setting of the CALIBRATOR switch. In the

10 mA DC (40 VDC) position, the Calibrator Multivibrator is

inoperative so that a +40-volt DC output level is produced.

R173 is placed in series with the R166-R167-R170-R171

resistance to obtain an effective resistance of 450 ohms with 4

volts applied, as seen by the CAL OUT connector in the 4 V

position of the switch. This effective resistance becomes port

of the output voltage divider in the positions of 0.4 V and below

(these positions have an accurate 50- ohm output resistance,

which when terminated by 50 ohms can further divide the

outputs by two, providing outputs of 0.2V, 20 mV and 2 mV).

In the 10 mA position, the CAL OUT connector is grounded.

R183, which is about ten times the resistance of the braid

of a 42-inch coaxial cable, cancels any ground loop current

that may exist between the CAL OUT connector and some

other instrument chassis.

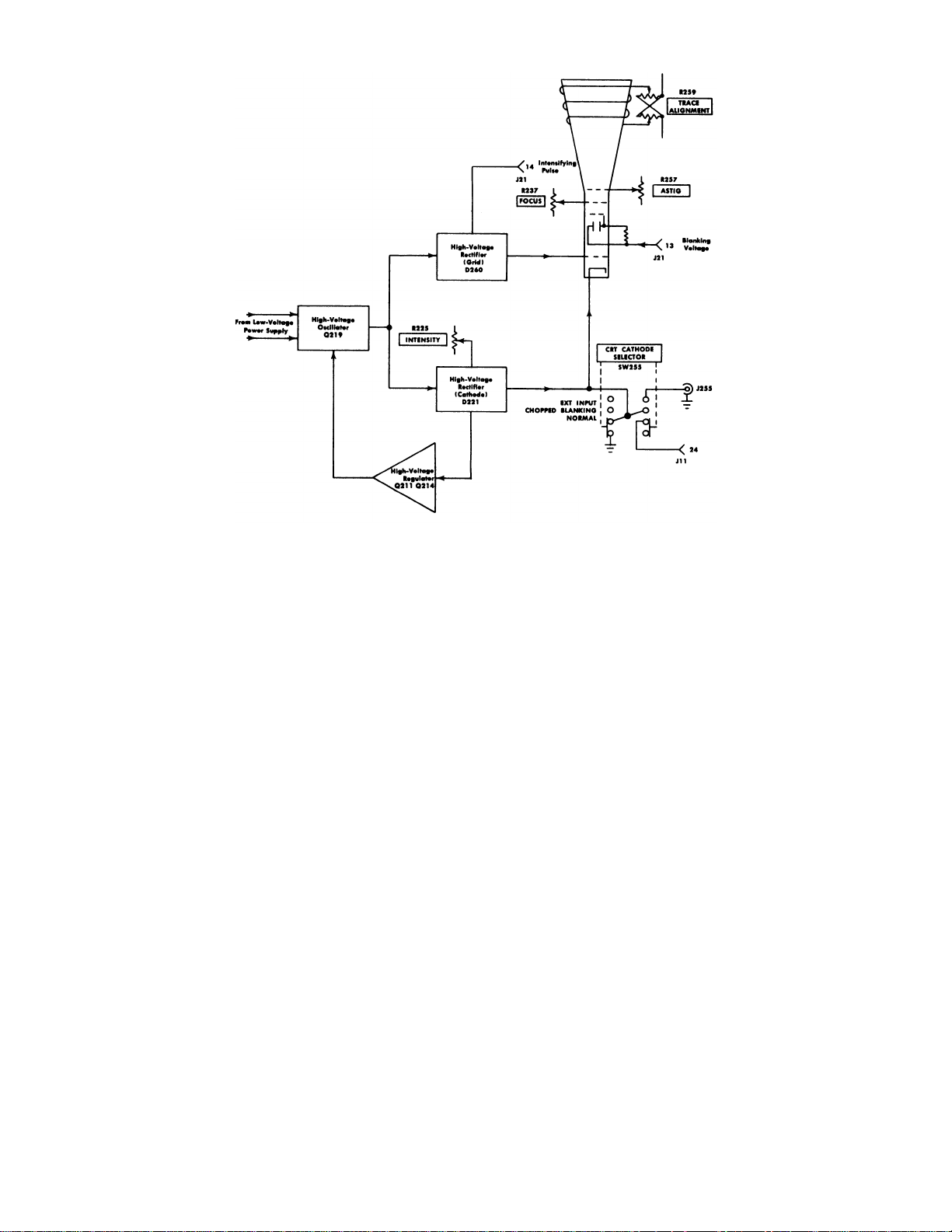

CRT CIRCUIT

General

The CRT Circuit provides the high voltage and control

circuits necessary for operation of the cathode-ray tube (CRT).

Fig. 3-4 shows a detailed block diagram of the CRT Circuit.

High Voltage Oscillator

Q219 and its associated circuitry comprise a class C

oscillator to provide the drive for the high-voltage transformer,

T220. When the instrument is turned on, conduction of Q214

provides a base current path for Q219. The collector current

of Q219 increases and a voltage is developed across the

collector winding of T220. This produces a corresponding

voltage increase in the feedback winding of T220 which is

connected to the base of Q219, causing it to conduct harder.

While Q219 is conducting, C217 charges negatively to the

peak to peak voltage of the feed-back winding. Eventually the

rate of collector current increase in Q219 becomes less than

that required to maintain the voltage across the collector

winding and the voltage drops.This turns off Q219 by way of

feedback voltage to the base. During the interval that Q219 is

not conducting, the negative charge on C217 is partially

removed through Q214. Q219 remains off until the feedback