INSTRUCTION MANUAL

Tektronix, Inc. S.W. Millikan Way P. O. Box 500 Beaverton, Oregon Phone MI 4-0161 Cables: Tektronix Tektronix International A.G. Terrassenweg 1A Zug, Switzerland PH. 042-49192 Cable: Tekintag, Zug Switzerland Telex 53.574 070-163

WARRANTY

All Tektronix instruments are warranted against defective materials and workmanship for one year. Tektronix transformers, manufactured in our own plant, are warranted for the life of the instrument.

Any questions with respect to the warranty mentioned above should be taken up with your Tektronix Field Engineer.

Tektronix repair and replacement-part service is geared directly to the field, therefore all requests for repairs and replacement parts should be directed to the Tektronix Field Office or Representative in your area. This procedure will assure you the fastest possible service. Please include the instrument Type and Serial number with all requests for parts or service.

Specifications and price change privileges reserved.

Copyright © 1960 by Tektronix, Inc., Beaverton, Oregon. Printed in the United States of America. All rights reserved. Contents of this publication may not be reproduced in any form without permission of the copyright owner.

| 20 | B.I' | r E | R. I | 76 |

|---|---|---|---|---|

| N | ||||

| Section 1CharacteristicsSection 2Operating InformationSection 3ApplicationsSection 4Circuit DescriptionSection 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 1CharacteristicsSection 2Operating InformationSection 3ApplicationsSection 4Circuit DescriptionSection 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Warranty | ||

|---|---|---|---|---|

| Section 2Operating InformationSection 3ApplicationsSection 4Circuit DescriptionSection 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 2Operating InformationSection 3ApplicationsSection 4Circuit DescriptionSection 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 1 | Characteristics | |

| Section 3ApplicationsSection 4Circuit DescriptionSection 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 3ApplicationsSection 4Circuit DescriptionSection 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 2 | Operating Information | |

| Section 4Circuit DescriptionSection 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 4Circuit DescriptionSection 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 3 | Applications | |

| Section 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 5MaintenanceSection 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 4 | Circuit Description | |

| Section 6 Calibration Procedure Section 7 Accessories Section 8 Parts List and Circuit Diagrams | Section 6Calibration ProcedureSection 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 5 | Maintenance | |

| Section 7AccessoriesSection 8Parts List and Circuit Diagrams | Section 7 Accessories Section 8 Parts List and Circuit Diagrams | Section 6 | Calibration Procedure | |

| Section 8 Parts List and Circuit Diagrams | Section 8 Parts List and Circuit Diagrams | Section 7 | Accessories | |

| Section 8 | Parts List and Circuit Diagrams |

SECTION 1

CHARACTERISTICS

General Information

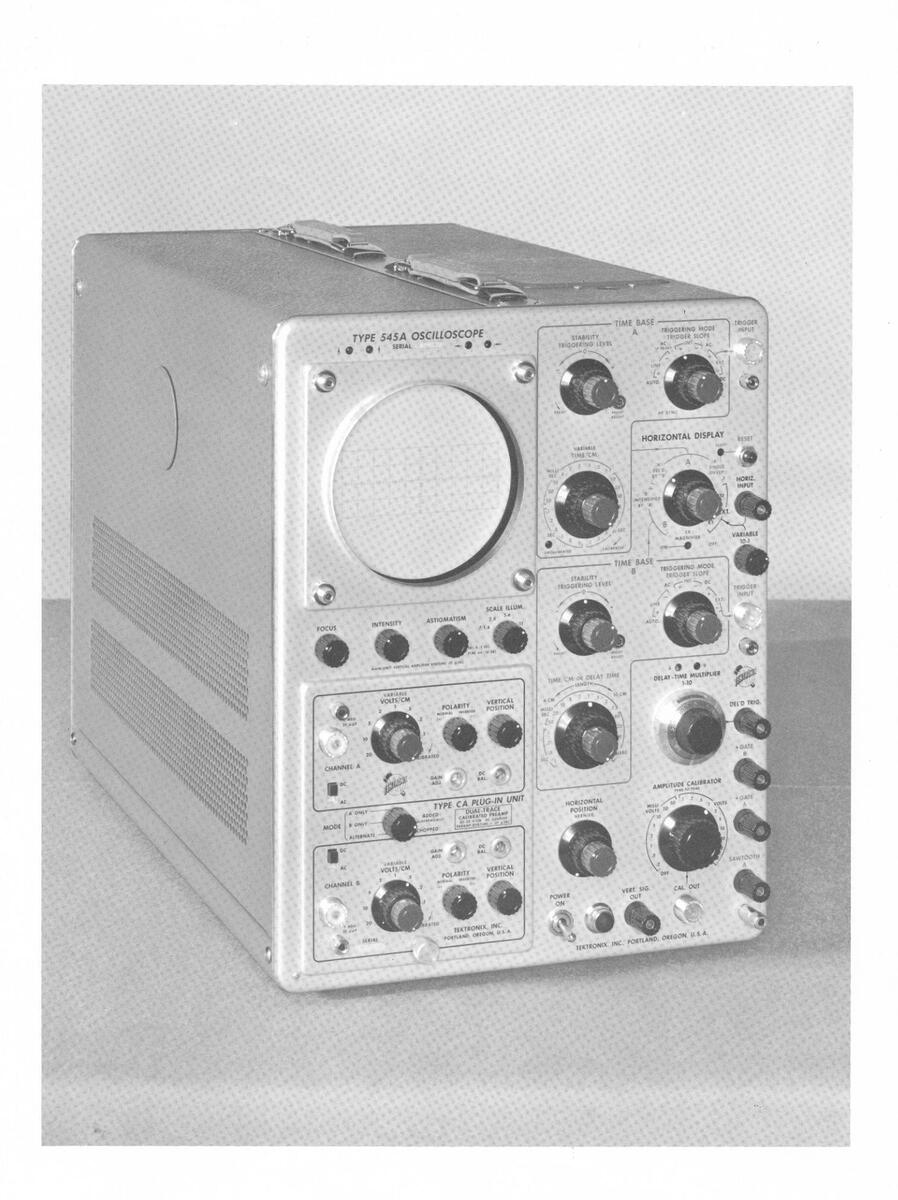

The Tektronix Type 545A Oscilloscopes are wide-range general-purpose laboratory instruments. The Type 545A provides accurate measurements in the dc to 30 mc range. The instrument can be operated with any Tektronix letterseries plug-in unit to satisfy the requirements for virtually any application.

Special circuits incorporated in the Type 545A Oscilloscope permit an accurate, continuously variable delay in the presentation of the sweep from 1 microsecond to 10 seconds after receipt of a triggering impulse. This feature permits observation of a small portion of the normal sweep, accurate measurement of waveform jitter, precise time measurements, as well as many other uses.

Vertical-Deflection System

All specifications for the Vertical-Deflection System of the Type 545A Oscilloscope depend upon the plug-in unit used with the instrument. The following specifications are given assuming that a Type K Plug-In Unit is used.

Type 545A:

| Bandpass | DC to 30 mc (3 db down at 30 mc |

|---|---|

| ± ¼ db. | |

| Risetime | 0.012 microseconds |

Triggering Modes

TimeBase A—Automatic, AC, DC, AC Low Frequency Reject, and High Frequency Sync.

Time Base B—Automatic, AC, and DC.

Triggering Signal Requirements

Internal triggering—a signal producing 2 millimeters of vertical deflection.

External triggering-a signal of 0.2 volts to 10 volts.

Sweep will trigger on larger signals, but TRIGGERING LEVEL control operates over a ±10 volt range.

High Frequency Sync.—Assures a stable display of sine wave signals to approximately 30 mc. Requires a signal producing 2 centimeters of vertical deflection or an external signal of more than 2 volts.

Sweep Rates

Time Base A-0.1 microseconds to 5 seconds per centimeter in 24 accurately calibrated steps. An uncalibrated control permits sweep rates to be varied continuously between 0.1 microseconds and approximately 12 seconds per centimter.

Calibrated sweep rates are typically within 1%, and in all cases within 3%, of the indicated sweep rate.

Time Base B—2 microseconds to 1 second per centimeter in 18 accurately calibrated steps. Sweep rates are typically within 1%, and in all cases within 3%, of the indicated sweep rate.

Magnifier

Provides a 5-times magnification of the center 2-centimeter portion of the oscilloscope display. Extends the fastest Time Base A sweep rate to 0.02 microseconds per centimeter and the fastest Time Base B sweep rate to 0.4 microseconds per centimeter.

External Horizontal Input

Deflection factor-approximately 0.2 to 15 volts per centimeter, continuously variable.

Frequency response—from dc to 240 kc. Response down 3 db at 240 kc. When variable control is full right and multiplier is on X1.

Horizontal input connector characteristics—1 megohm paralleled by approximately 47 µµf.

Delayed Sweep

Sweep delay continuously variable from 1 microsecond to 10 seconds. Actual delay steps (between 1.00 and 10.00) are within 1% of the indicated delay from 2 µsec/cm to 0.1 sec/cm; within 3% from 0.2 sec/cm to 1 sec/cm. Incremental delay accuracy is within 0.2%.

Time jitter—1 part in 20,000.

Cathode-Ray Tube

Type 545A Oscilloscope—Type T543P2.

Phosphors—Type P2 phosphor normally supplied; P1, P7, and P11 phosphors optional. Other phosphors available on special order.

Unblanking—dc coupled.

Characteristics — Type 545A

Accelerating potential-10,000 volts.

Usable viewing area:

Type 545A Oscilloscope-4 by 10 centimeters.

Graticule

Illumination—variable edge lighting.

Type 545A graticule markings—marked in 4 vertical and 10 horizontal 1-centimeter divisions with 2-millimeter markings on the centerlines.

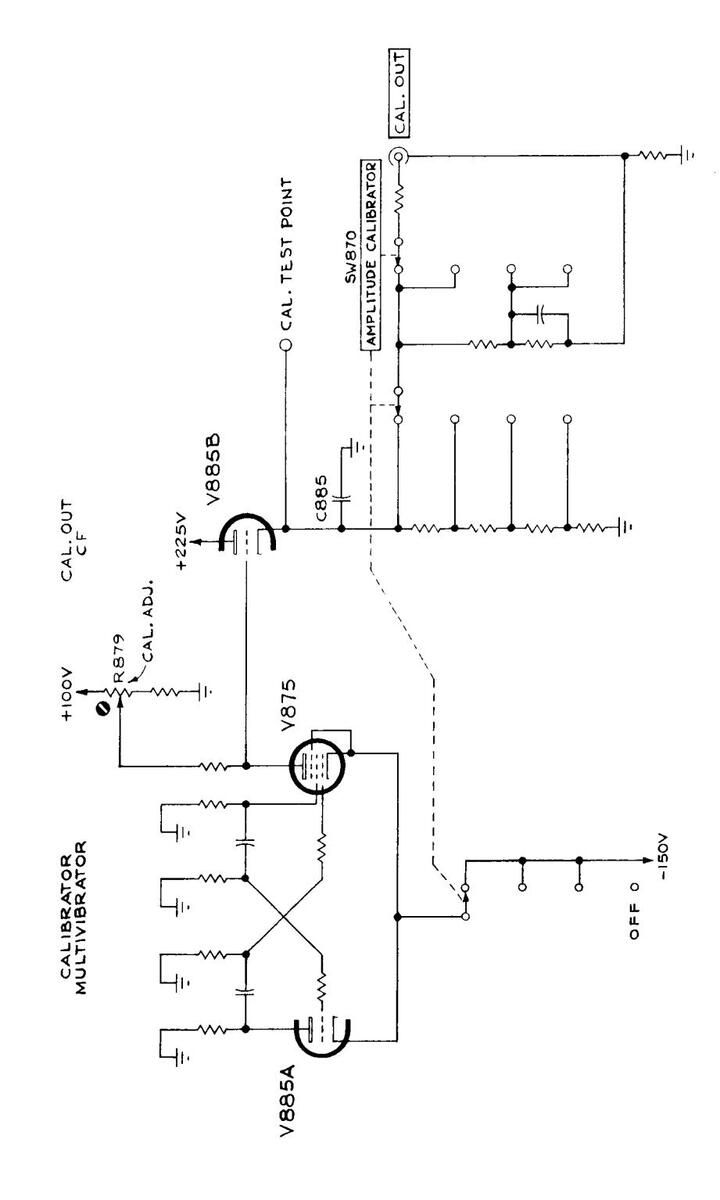

Amplitude Calibrator

Waveform-square-waves at approximately 1,000 cycles.

Output voltage—0.2 millivolts peak-to-peak to 100 volts peak-to-peak in 18 steps.

Accuracy—peak-to-peak amplitudes of square-waves within 3% of indicated voltage.

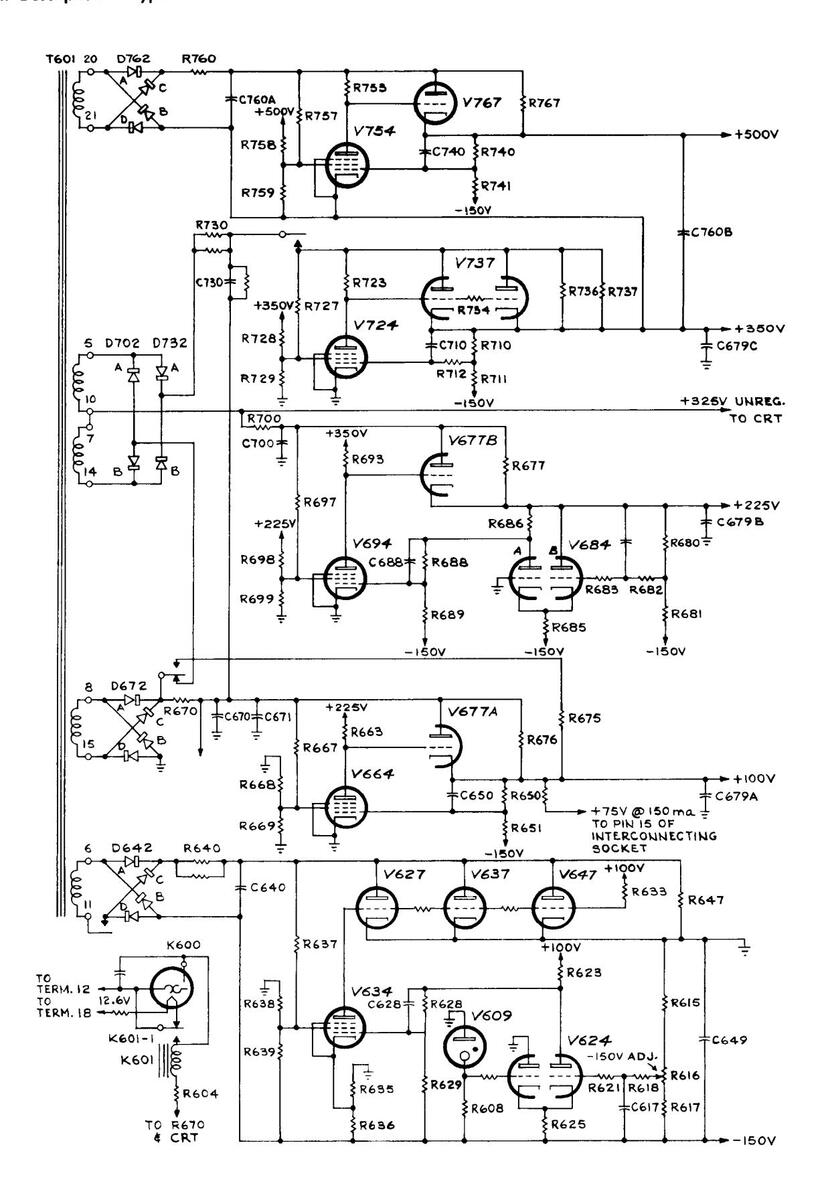

Power Supplies

Electronically regulated for stable operation with widely varying line voltages and loads.

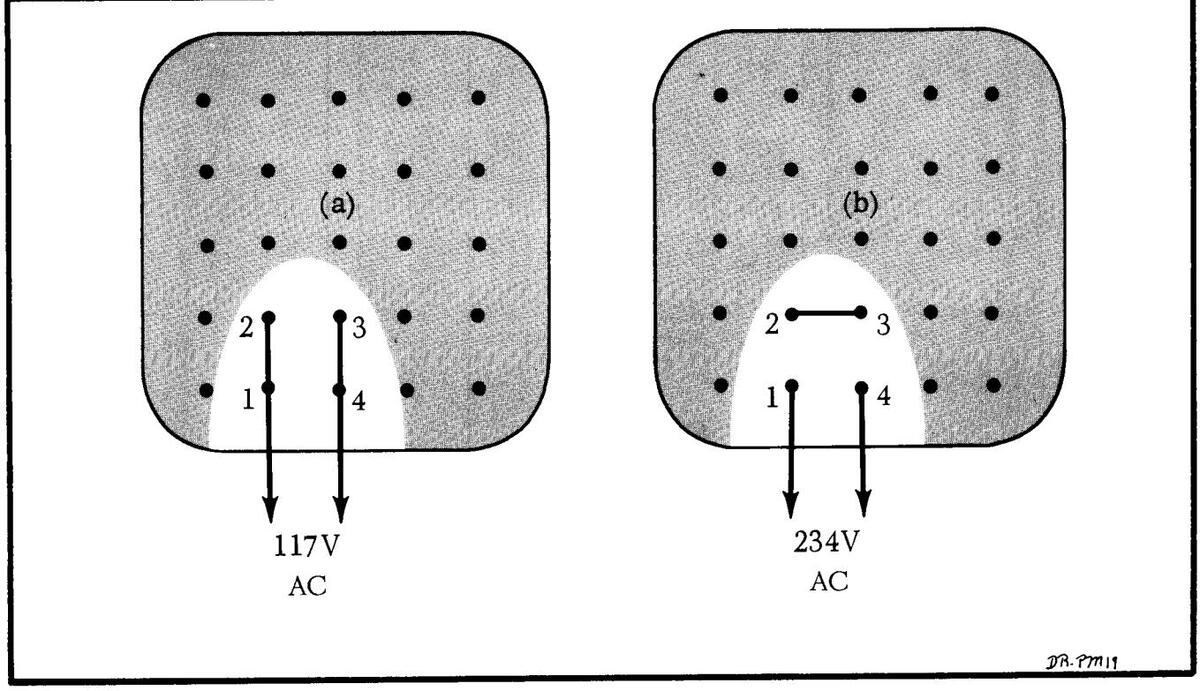

Line voltage requirements—105 to 125 volts, or 210 to 250 volts.

Power—approximately 500 watts with a Type CA Plug-In Unit installed.

Line frequency—50 to 60 cycles.

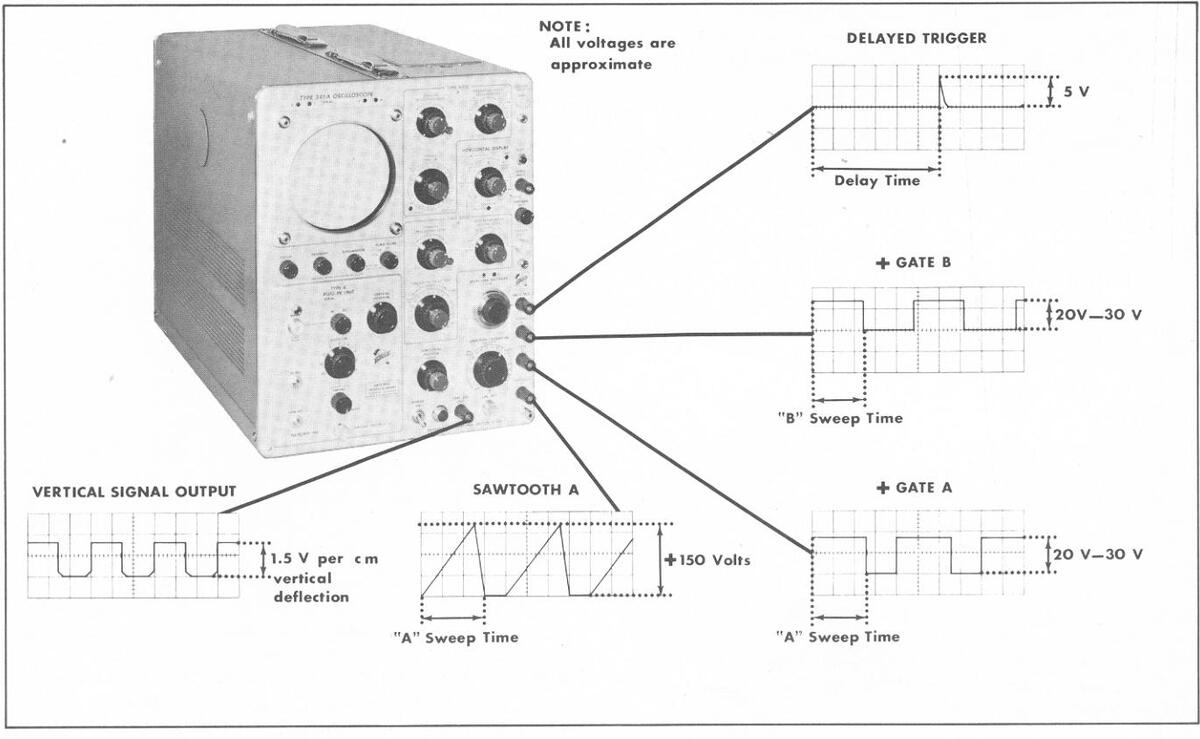

Output Waveforms Available

Delayed trigger pulse—approximately 5 volts in amplitude, occurring at the end of the delay period.

Positive Gate B—approximately 20 volts peak-to-peak with same duration as sweep B.

Positive Gate A—approximately 20 volts peak-to-peak with same duration as sweep A.

Sawtooth A—sweep A sawtooth waveform, approximately 150 volts peak.

Vertical signal output—output from vertical deflection system. Approximately 1.5 volts peak-to-peak per centimeter of vertical deflection.

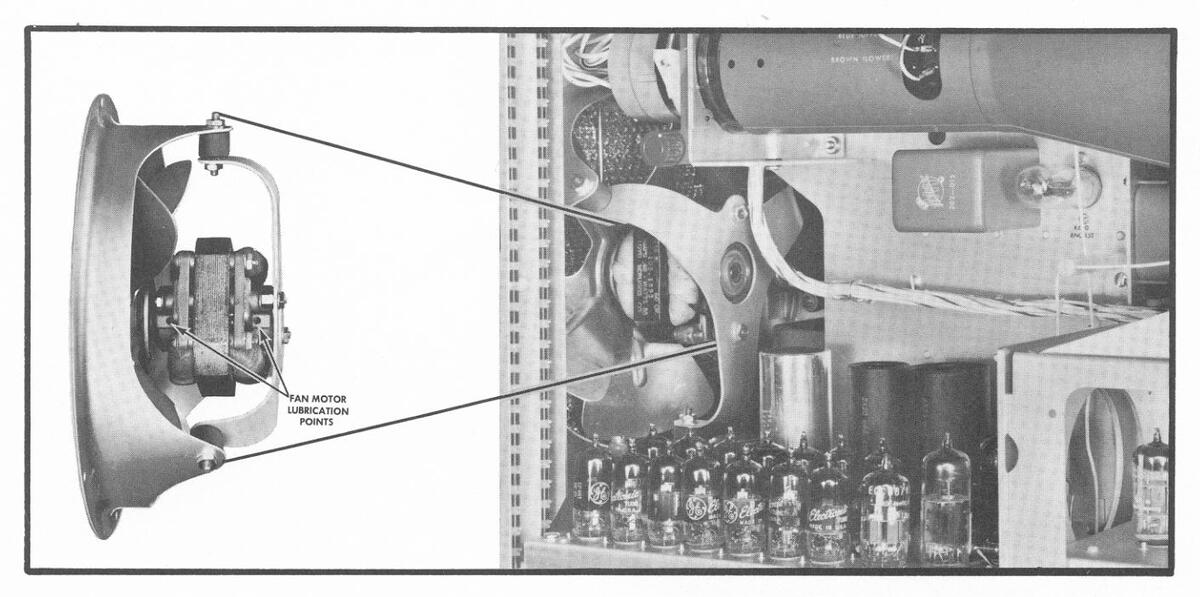

Ventilation

Forced filtered air. Thermal relay interrupts instrument power in the event of overheating.

Fig. 1-1. Output waveforms available at the Oscilloscope front panel.

Construction

Aluminum-alloy chassis and three-piece cabinet. Photo etched anodized panel, blue wrinkle-finished cabinet.

Dimensions—see Figure 1-2.

Weight—65 pounds.

Accessories

- 1—3 to 2-wire Adapter, 103-013

- 2—Type P6006 Probes, 010-127

- 2-Binding Post Adapter, BNC, 103-033

- 1—Test Lead (012-031).

- 1—Type F510-5 Green Filter (3/8-514)

- 2—Operator's Manuals.

- 1—Operator's Handbook.

- 1—3-conductor power cord, 161-010

Fig. 1-2. Type 545A Oscilloscope Dimensions.

Type N

The Type N Sampling Unit is designed for use with Tektronix plug-in type Oscilloscopes. The sampling system thus formed permits the display of repetitive signals with fractional nanosecond (10-9 second or nsec) risetime. By taking successive samples at a slightly later time at each recurrence of the pulse under observation, the Type N reconstructs the pulse on a relatively long time-base. Specifications of the Type N include a risetime of 0.6 nsec, corresponding to a maximum bandpass of approximately 600 mc; a sensitivity of 10 mv/cm with 2 mv or less noise; and a dynamic range of ±120 mv minimum linear range before overloading results.

Accidental overload of ±4 volts dc is permissible.

Type P

The Type P Plug-In Unit generates a fast-rise stepfunction test signal of known waveform, simulating the output of an ideally compensated Type K Unit driven with a Tektronix Type 107 Square-Wave Generator. The Type P permits the standardization of the main-unit vertical amplifier transient response of a Tektronix convertible oscilloscope. Risetime of the Type P is approximately 4 nanoseconds when it is used to standardize a Type 540-Series Oscilloscope. Pulse repetition rate is 240 step functions per second, with either positive or negative polarity. Step function amplitude is continuously adjustable between 0 and 3 major graticule divisions.

Type Q

The Type Q Plug-In Unit permits any Tektronix convertible oscilloscope such as the Type 545A to be operated with strain gages and other transducers. Excitation voltages for the strain gages and transducers are provided by the plug-in unit. The unit provides high gain, low noise, and extremely low drift. Frequency response of the Type Q Plug-In Unit is DC to 6 kc; risetime is approximately 60 microseconds. Strain sensitivity is calibrated in 10 steps from 10 microstrain per major graticule division to 10,000 microstrain per division, and is continuously variable between steps.

Type R

The Type R Plug-In Unit is a combined power supply and pulse generator which is used to measure the high-frequency characteristics of junction transistors by the pulse-response method. When the Type R is used in an oscilloscope having a delay line; delay time, risetime, storage time, and falltime may be displayed simultaneously. A pushbutton switch connects a front-panel terminal directly to the input of the oscilloscope for observing externally derived waveforms.

Pulse risetime of the Type R unit is less than 5 nanoseconds, so measurements depend on the risetime of the oscilloscope used. Pulse amplitudes are in 8 fixed, calibrated steps from .05 to 10 volts, adjustable between steps. Pulse recurrence frequency is 120 pulses per second.

Type S

The Type S Plug-In Unit is designed for use with Tektronix Wide-Band convertible oscilloscopes. The slower risetime of the Tektronix 530-Series Oscilloscopes will affect the ability of the S Unit to analyze fast semiconductor diodes. Using the Type S, voltage across a test diode is displayed as a function of time.

Certain diode parameters, such as junction resistance, junction capacitance, and the stored charge at the junction, can be measured readily and reliably from the display. Performance of a diode in a particular circuit can be predicted by analyzing the recovery and "turn-on" characteristics. Since it is essentially a means for plotting voltage across an element while passing constant current through it, the unit can be used for other applications as well. For

Characteristics — Type 545A

| PLUG-IN TYPE |

CALIBRATED

DEFLECTION FACTOR |

PASSBAND | RISETIME |

INPUT

CAPACITANCE |

|---|---|---|---|---|

|

Type A

Wide-Band DC Coupled |

0.05 v/cm to 20 v/cm |

dc to 14 mc

dc to 20 mc |

18 nsec | 47 pf |

|

TYPE B

Wide-Band |

5 mv/cm to 0.05 v/cm | 2 c to 12 mc | 30 nsec | 47 pf |

|

High Gain

DC Coupled |

0.05 v/cm to 20 v/cm | dc to 20 mc | 18 nsec | |

|

TYPE CA

Dual-Trace DC Coupled |

0.05 v/cm to 20 v/cm | dc to 24 mc | 15 nsec | 20 pf |

|

TYPE D

High-Gain DC Coupled Differential |

1 mv/cm to 50 v/cm | dc to 2 mc | 0.18 µsec | 47 pf |

|

Type E

Low-Level AC Coupled Differential |

50 µv/cm to 10 mv/cm | 0.06 cycles to 60 kc | 6 μsec | 50 pf |

|

TYPE G

DC Coupled Differential Wide-Band |

0.05 v/cm to 20 v/cm | dc to 20 mc | 18 nsec | 47 pf |

|

TYPE H

DC Coupled High-Gain Wide-Band |

5 mv/cm to 20 v/cm | dc to 15 mc | 23 nsec | 47 pf |

|

TYPE K

Fast-Rise DC Coupled |

0.05 v/cm to 20 v/cm | dc to 30 mc | 12 nsec | 20 pf |

|

TYPE L

Fast-Rise |

5 mv/cm to 2 v/cm | 3 c to 24 mc | 15 nsec | 20 pf |

|

High-Gain

DC Coupled |

0.05 v/cm to 20 v/cm | dc to 30 mc | 12 nsec | |

|

TYPE N*

Pulse Sampling |

10 mv/cm | 600 mc | 0.6 nsec |

Input Impedance

50 ohms |

| TYPE P* is a fast-rise | e step-function test signal unit. | |||

|

TYPE Q*

Strain Gage |

10 μstrain/div to

10,000 μstrain/div |

dc to 6 kc | 60 µsec | Adjustable |

|

TYPE R*

Transistor Risetime |

0.5 ma/cm to 100 ma/cm | 12 nsec | ||

|

TYPE S*

Semiconductor Diode Recovery |

0.05 v/cm and 0.05 v/cm | |||

|

TYPE T*

Time-Base Generator |

||||

|

TYPE Z*

DC Coupled Differential Comparator |

0.05 v/cm to 25 v/cm | dc to 13 mc | 27 nsec | 27 pf |

PLUG-IN PREAMPLIFIER CHARACTERISTICS FOR TYPE 545A OSCILLOSCOPES

*More data available on the special purpose plug-in units in the following paragraphs.

example: observing the junction characteristics of transistors, or measuring the resistance, capacitance or inductance of circuit components.

The Type S offers calibrated forward currents in five fixed steps from 1 to 20 milliamps, and reverse currents calibrated in six steps from 0 to 2 milliamps. Diode shunt capacitance is 9 picofarads, and deflection factors are 0.05 v/cm and 0.5 v/cm, calibrated.

Туре Т

The Type T Time-Base Generator provides sawtooth sweep voltages from 0.2 µsec/div to 2 sec/div. The trigger source may be line frequency, external, ac or dc coupled, automatic or high-frequency sync. The triggering point can be on either rising or falling slope of the waveform, and triggering level is adjustable. A signal of 0.2 to 50 volts is required for triggering.

Туре Z

The Type Z Plug-In Unit extends the accuracy of oscilloscope voltage measurements. It can be used in three modes of operation: (1) as a conventional preamplifier, (2) as a differential input preamplifier, or (3) as a calibrated differential comparator. With sensitivity of 50 mv/cm and insertion voltage range of ±100 volts, the effective scale range is ±2000 cm. Maximum resolution of the Type Z Unit is .005%.

As a conventional preamplifier, the Type Z Unit offers a passband of dc to 13 mc for the 545A for signals that do not overscan the screen. The deflection factors are 0.05 volts/cm to 25 v/cm in 9 fixed, calibrated steps.

As a differential input preamplifier, the Type Z accepts a common-mode signal level ±100 volts with input attenuation X1, and offers a common-mode rejection ratio of 40,000 to 1. Maximum input signal is 1 volt/7 nsec, or -1 volt/5 nsec.

As a calibrated differential comparator, the Type Z makes available three comparison voltage ranges; from zero to ±1 volt, zero to ±10 volts, zero to ±100 volts.

NOTES

SECTION 2

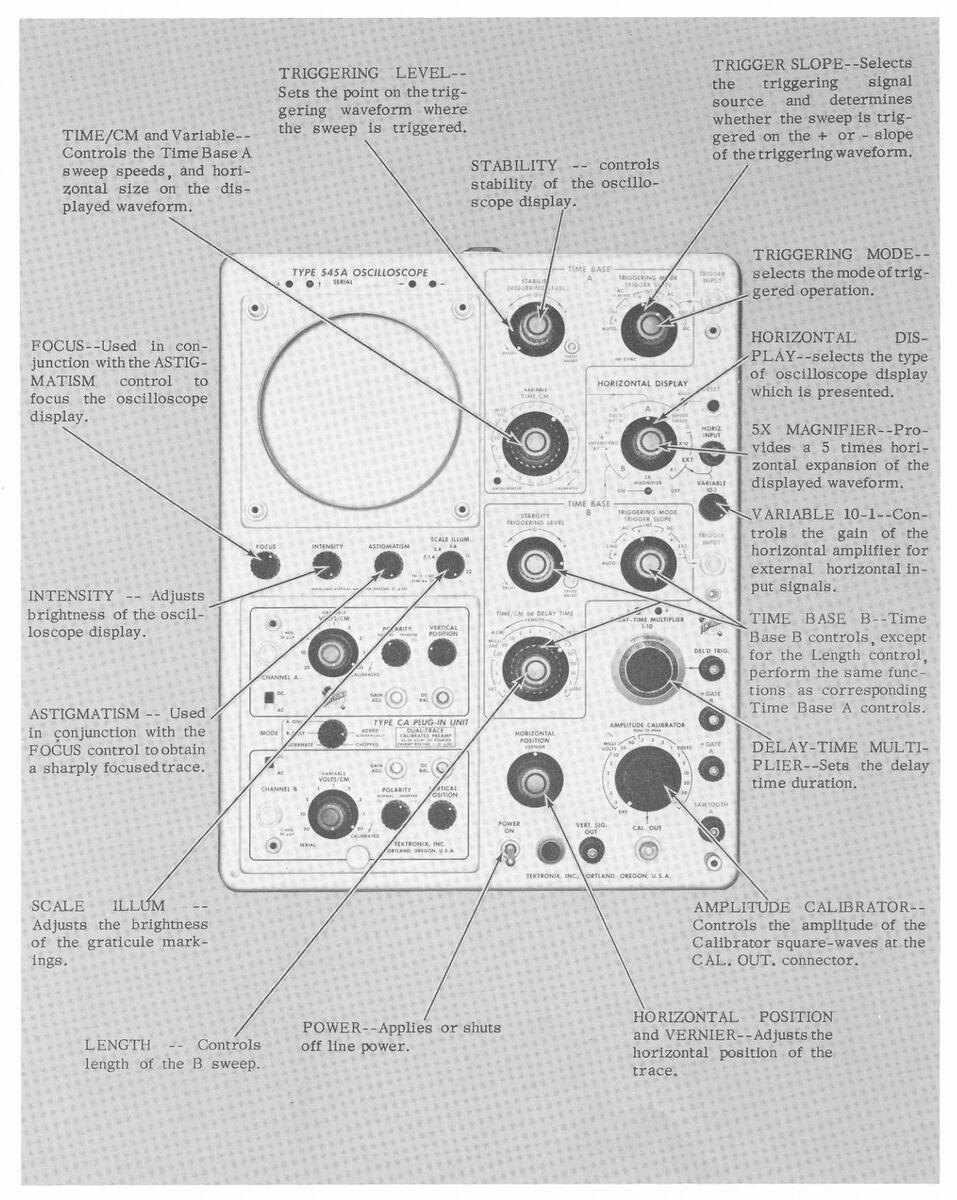

The Type 545A Oscilloscope is an extremely versatile instrument which is adaptable to a great number of applications. However, to make use of the full potentialities of the instrument, it is necessary that you understand completely the operation of each control. This portion of the Instruction Manual is intended to provide you with the basic information that you require. If you are familar with other Tektronix Oscilloscopes, you should have very little difficulty in understanding the operation of the Type 545A since the function of many controls is the same as the function of corresponding controls on other Tektronix instruments.

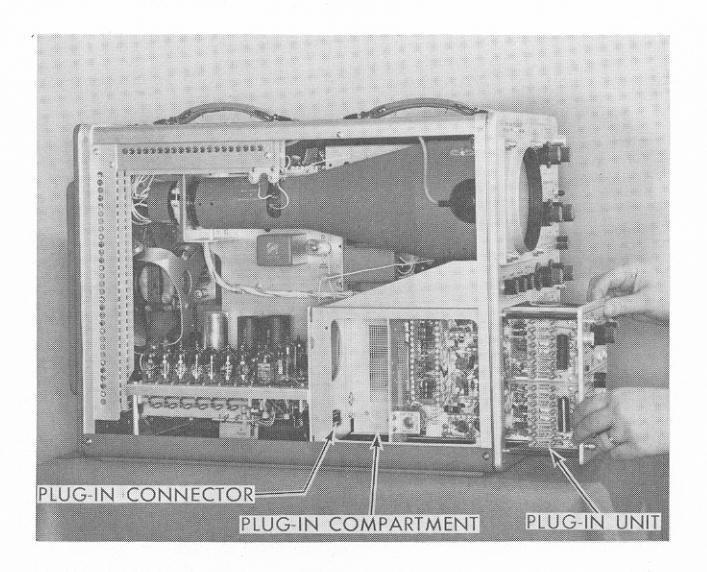

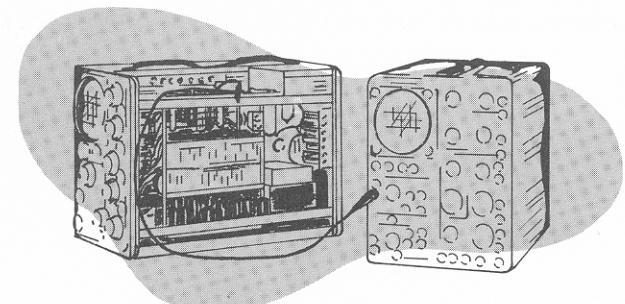

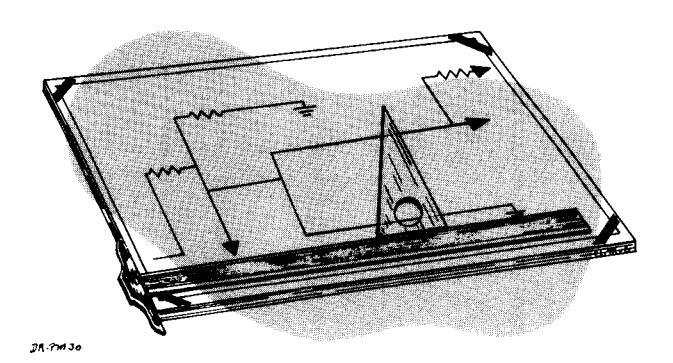

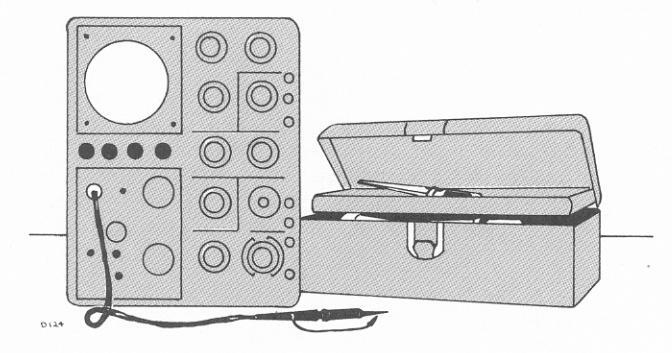

Plug-In Units

The Type 545A Oscilloscope is designed to operate with any one of the Tektronix letter-series plug-in units. The particular plug-in unit used must be selected by you to satisfy the requirements of your application. In selecting the plug-in unit for any particular application, you must consider the bandpass, sensitivity, and the type of input required for that application. The plug-in units available will satisfy the requirements for most applications.

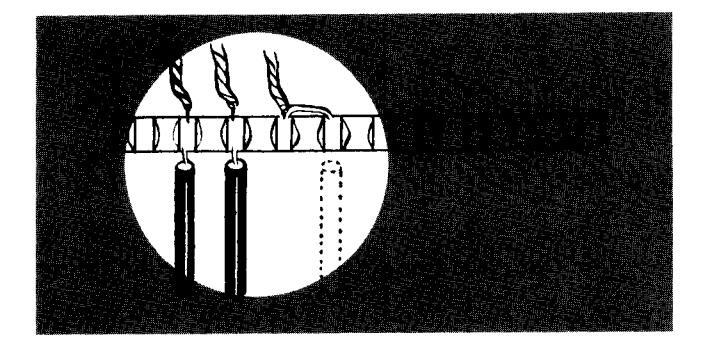

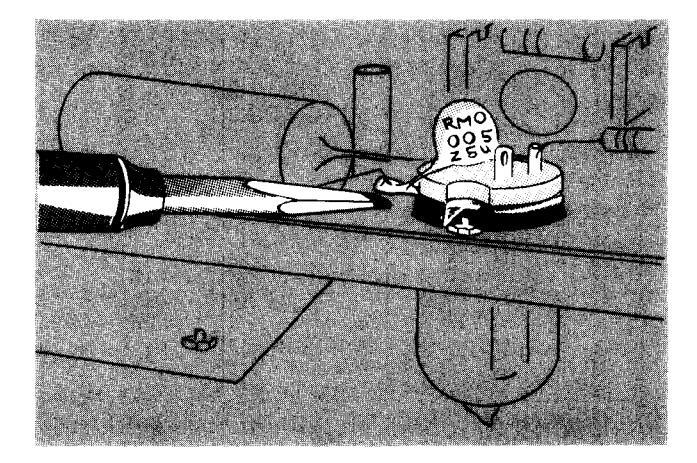

Fig. 2-1. Inserting the selected plug-in unit into the oscilloscope plug-in unit compartment.

OPERATING INSTRUCTIONS

Preparation for use

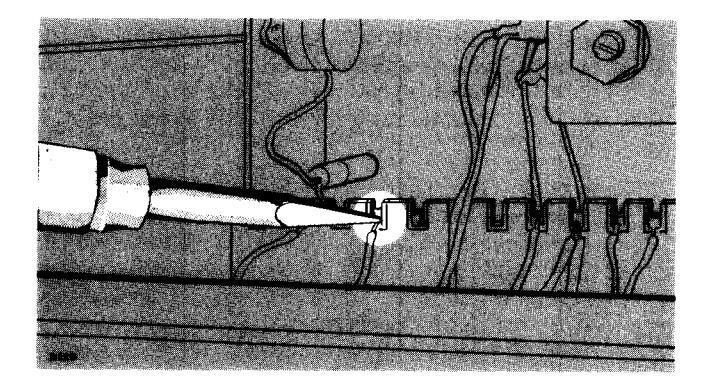

When the plug-in unit has been selected, insert it into the plug-in compartment of the oscilloscope and press firmly to insure that the connectors make proper contact (see Figure 2-1). Tighten the plug-in unit locking control to hold the unit securely in place and turn the oscilloscope INTENSITY control fully counterclockwise. Connect the power cord to the rear of the instrument and to the power line and place the POWER switch in the ON position.

Time Delay

Time delay relays used in Type 545A Oscilloscopes delay operation of the instrument for approximately 25 seconds after the POWER switch is turned on to allow a brief tubewarmup period. The delay allows the tubes sufficient time to heat before the dc operating voltages are applied.

If the ac power is off for only an instant, the normal 25second delay will occur before the instrument returns to full operation. This delay will occur regardless of whether the ac power is off because of a momentary power failure or is turned off with the POWER switch.

Focus and Astigmatism Contols

The FOCUS and ASTIGMATISM controls operate in conjunction with each other to allow you to obtain a sharp, clearly defined spot or trace. The proper setting of the ASTIGMATISM control is obtained by rotating the FOCUS control fully clockwise, setting the HORIZONTAL DISPLAY switch to EXT. X10, and adjusting the INTENSITY control to obtain a spot on the screen. After positioning the spot to the center of the screen, the ASTIGMATISM control is adjusted for the most nearly circular spot possible. The FOCUS control is then adjusted to reduce the spot diameter as much as possible. (You must be certain that all input signals to the oscilloscope are disconnected when you adjust the FOCUS and ASTIGMATISM controls.)

Intensity Control

The INTENSITY control is used to adjust the brightness of the oscilloscope display. This permits you to compensate for changes in brightness resulting from changes in the sweep or triggering rate. The INTENSITY control is rotated clockwise to increase brightness and counterclockwise to decrease brightness. Care must be taken when using the INTENSITY control that the brightness is not turned up to

Operating Instructions — Type 545A

the point where the face of the cathode-ray tube is permanently damaged. If the intensity of the beam is turned up too far, the phosphor on the face of the crt may be burned. The intensity of the beam should never be turned up to the point where a halo forms around the spot.

Graticule Illumination Control

The graticule used with the Type 545A Oscilloscope is accurately marked with 10 horizontal and 4 vertical 1centimeter divisions with 2-millimeter markings on the centerlines. These graticule markings allow you to make time and voltage measurements from the oscilloscope screen.

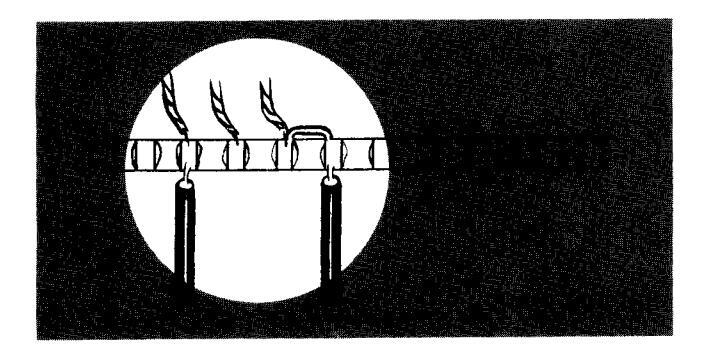

The graticule is illuminated by two lamps located at the top edge of the graticule. This illumination can be controlled so that the graticule markings appear either red or white, as desired. The graticule markings are changed from red to white or from white to red by removing the graticule cover and rotating the graticule through 180° about an axis through the center of the graticule (see Figure 2-2). As a general rule, white graticule markings are superior to red for photographic purposes.

Fig. 2-2. Rotating the graticule to change the color of the graticule markings from red to white or from white to red.

Graticule illumination is adjusted by the SCALE ILLUM control located just under the oscilloscope screen. Rotating the control clockwise increases the brightness of the graticule markings and rotating the control counterclockwise decreases the brightness. For convenience in photographic work, the SCALE ILLUM control is marked in approximate f-stops. These f-stops can be used with a shutter speed of 1 second when TRI X film is used or with a shutter speed of 10 seconds when Type 44 Polaroid film is used. Regardless of the type of film used, white graticule markings should be used. To obtain satisfactory waveform photographs, the intensity of the trace must approximately match the brightness of the graticule markings.

2-2

Positioning Controls

Three controls are used with the Type 545A Oscilloscope to allow you to position the trace to the desired point on the oscilloscope screen. Two of these controls are used to set the horizontal position of the trace and are located on the front panel of the instrument. The third control is used to set the vertical position of the trace and is located on the front panel of the plug-in unit used with the oscilloscope. (The Type 53/54C and Type CA Dual-Trace Plug-In Units have two Vertical Positioning controls.)

The two HORIZONTAL POSITION controls cause the trace to move to the right when they are rotated in the clockwise direction and to the left when they are rotated counterclockwise. The combination of the two controls has a total positioning range of approximately 12 centimeters with the sweep magnifier off or approximately 60 centimeters with the sweep magnifier on. The black HORIZONTAL POSITION control has approximately three times the range of the red VERNIER control. The fine range of adjustment of the VERNIER control makes this control particularly useful whenever fine horizontal positioning is required, as for example, when the sweep magnifier is used.

The vertical positioning control has sufficient range to allow the trace to be positioned completely off the top or bottom of the screen or to any intermediate point. The trace moves up when the control is rotated clockwise and down when the control is rotated counterclockwise.

Beam Position Indicators

Four small indicator lights located just above the oscilloscope screen indicate the position of the spot or trace. When one of these lamps is lit, it indicates that the trace is off-centered in the direction of the arrow. These four lights allow you to position the spot to the center of the screen even though the intensity is so low that the trace is not visible. When the sweep is running, the spot moves from the left side of the screen to the right and may cause both horizontal lamps to light each time the sweep runs.

Input Signal Connections

The electrical waveform to be observed is applied to one of the plug-in unit input connectors. The waveform is then connected through the vertical-deflection system of the plug-in unit and the oscilloscope to cause the spot to be deflected vertically and to trace out the waveform on the screen of the crt. The vertical size of the displayed waveform is adjusted with the plug-in unit VOLTS/CM switch. The VOLTS/CM switch is an accurately calibrated control which, when used with the graticule, allows you to make precise voltage measurements from the displayed waveforms. The operation of other plug-in unit controls varies between plug-in units. For information regarding the operation of these controls, refer to the instruction manual for the plug-in unit you are using.

Certain precautions must be taken when you are connecting the oscilloscope to the input signal source to insure that accurate information is obtained from the oscilloscope display. This is particularly true when you are observing low-level signals or waveforms containing high- or extremely

low-frequency components. For applications where you are observing low-level signals, unshielded input leads are entirely unsatisfactory due to their tendency to pick up stray signals which produce erroneous oscilloscope displays. Shielded cables should be used whenever possible, with the shield connected to the chassis of both the oscilloscope and the signal source. Regardless of the type of input lead used, leads should be kept as short as possible.

Distortion of the input waveform may result if very lowfrequency input signals are ac coupled into the oscilloscope, if high-frequency waveforms are not properly terminated, or if the input waveform contains high-frequency components which exceed the pass band of the oscilloscope and plug-in unit combination. You must be aware of the limitations of the instrument.

In analyzing the displayed waveform, you must consider the loading effect that the oscilloscope has on the inputsignal source. In most cases this loading effect is negligible; however in some applications, loading caused by the oscilloscope may materially alter the results obtained. In such cases you may wish to reduce the amount of loading to a negligible amount through the use of a probe.

Use of Probes

Occasionally connecting the input of an oscilloscope to a signal source loads the source sufficiently to adversely affect both the operation of the source and the waveform displayed on the oscilloscope. In such cases an attenuator probe may be used to decrease both the capacitive and resistive loading caused by the oscilloscope to a negligible value.

In addition to providing isolation of the oscilloscope from the signal source, an attenuator probe also decreases the amplitude of the displayed waveform by the attenuation factor of the probe. Use of a probe allows you to increase the vertical-deflection factors of the oscilloscope to observe large-amplitude signals which are beyond the normal limits of the oscilloscope and plug-in combination. Signal amplitudes, however, must be limited to the maximum allowable value of the probe used.

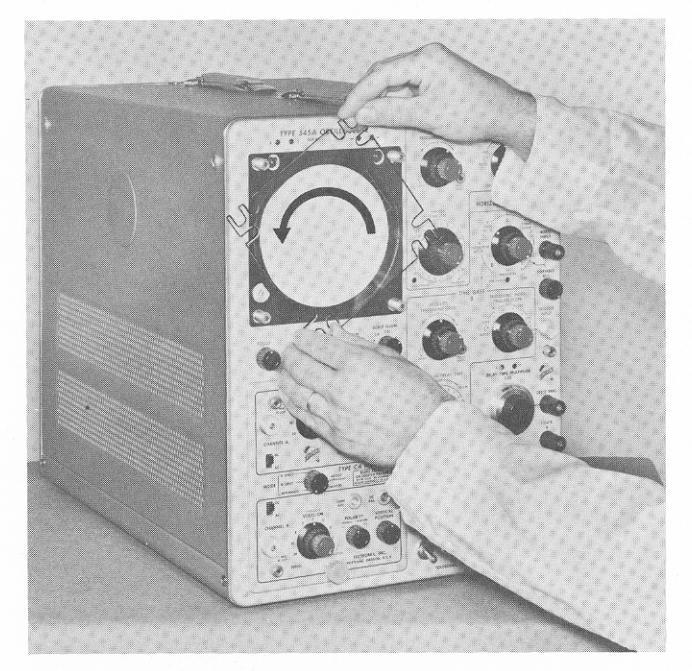

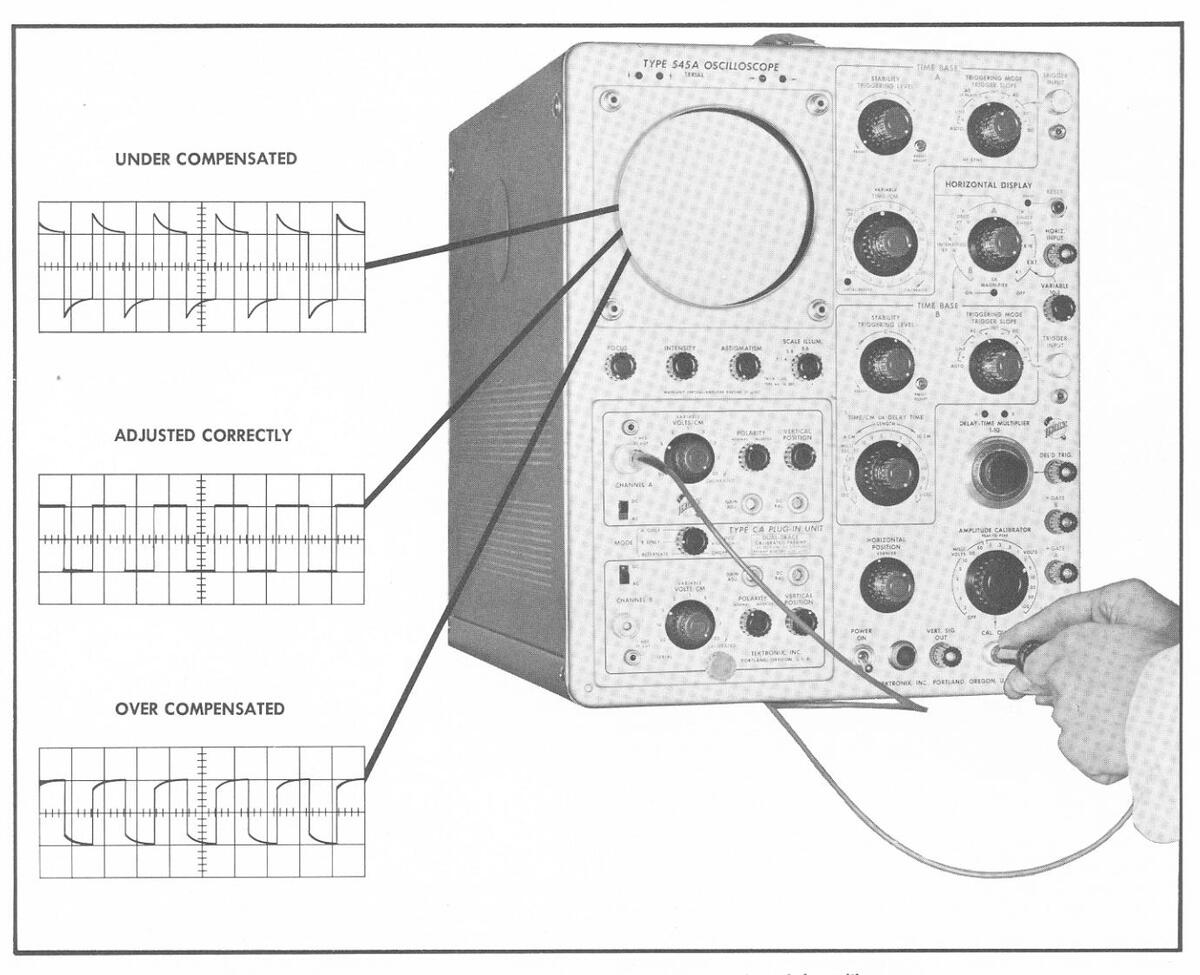

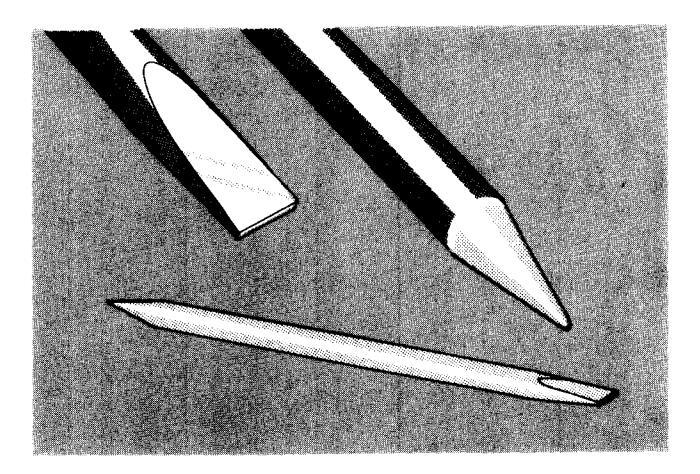

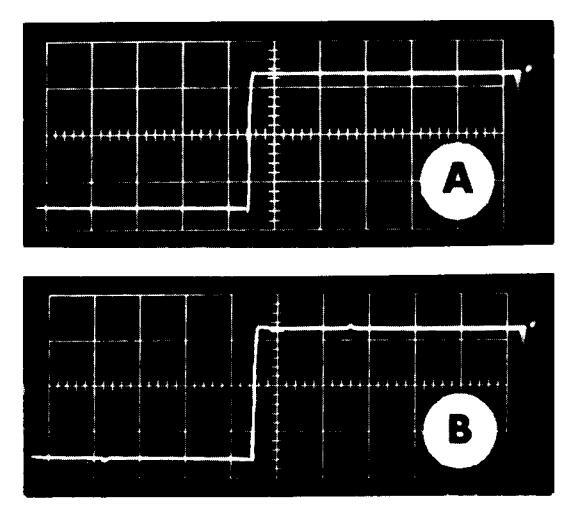

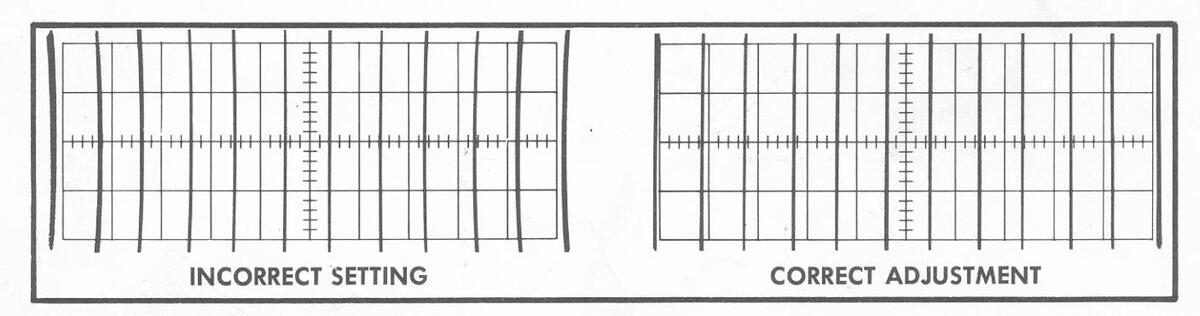

Before using a probe you must check (and adjust if necessary) the compensation of the probe to prevent distortion of the applied waveform. To adjust the probe compensation control, place the HORIZONTAL DISPLAY switch to A, the

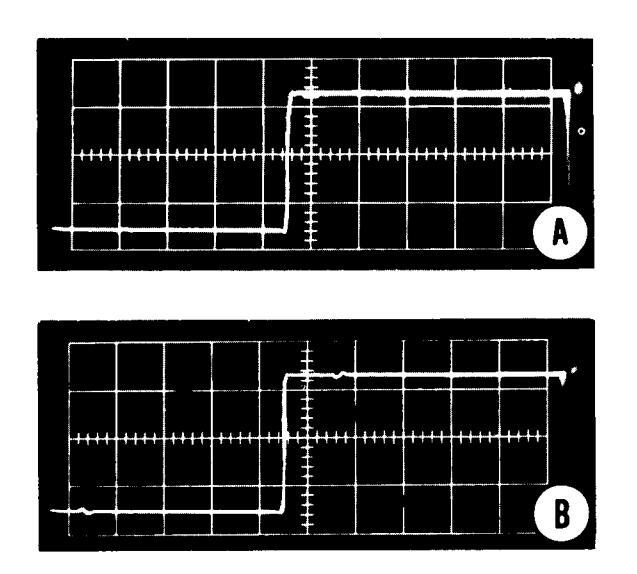

Fig. 2-3. When compensating the probe it is adjusted to obtain an undistorted presentation of the calibrator square-waves.

Operating Instructions --- Type 545A

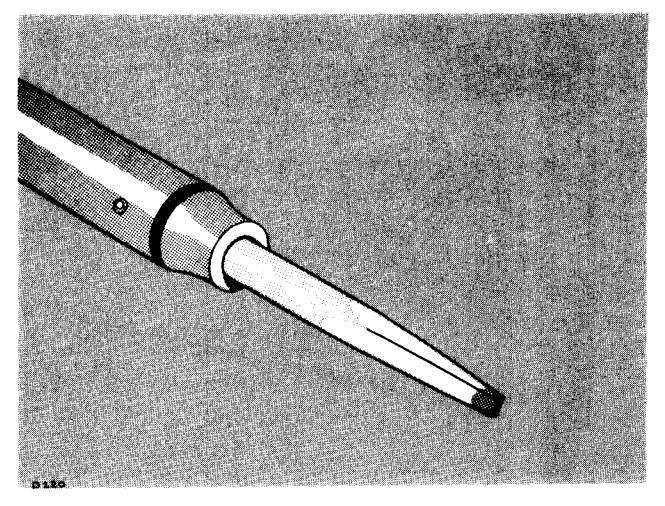

TIME BASE A TRIGGERING MODE switch to AUTO, and the TIME BASE A TRIGGER SLOPE switch to +INT. Turn up the intensity until the trace is visible and connect the probe tip to the CAL OUT connector. Set the AMPLITUDE CALI-BRATOR switch for 2 centimeters of displayed signal. Set the TIME BASE A TIME/CM switch to display approximately 3 or 4 cycles of the Calibrator waveform and adjust the probe compensation control to obtain flat tops on the displayed Calibrator square-waves (see Figure 2-3).

First unlock the Locking Sleeve by turning it counterclockwise. The probe is then compensated by rotating the probe body while watching the oscilloscope display for the desired waveform. When compensation is completed, carefully turn the Locking Sleeve clockwise to lock it without disturbing the adjustment of the probe.

Horizontal Sweep

The usual oscilloscope display is a graphical presentation of instantaneous voltage versus time. Voltage information is presented by vertical deflection of the trace and time information is presented by horizontal deflection. To obtain a useful display, it is necessary for the spot formed by the electron beam to be deflected horizontally at a known rate so that any horizontal distance on the screen represents a definite known period of time. The trace formed by the deflection of the spot across the screen is known as the horizontal sweep. Since the horizontal deflection of the spot bears a definite relationship to time and provides the means for making time measurements from the screen, the horizontal sweep is also known as the time base.

The Type 545A Oscilloscope features two independent time-base units: Time Base A and Time Base B. Either of the two time bases may be displayed on the oscilloscope screen at any time. Controls affecting Time Base A and Time Base B operation are in the correspondingly labeled blocks on the oscilloscope front panel. The HORIZONTAL DISPLAY switch determines which time base is used and the type of display to be presented. Time Base A is selected when the HORIZONTAL DISPLAY switch is in position A and Time Base B is selected when the switch is in position B.

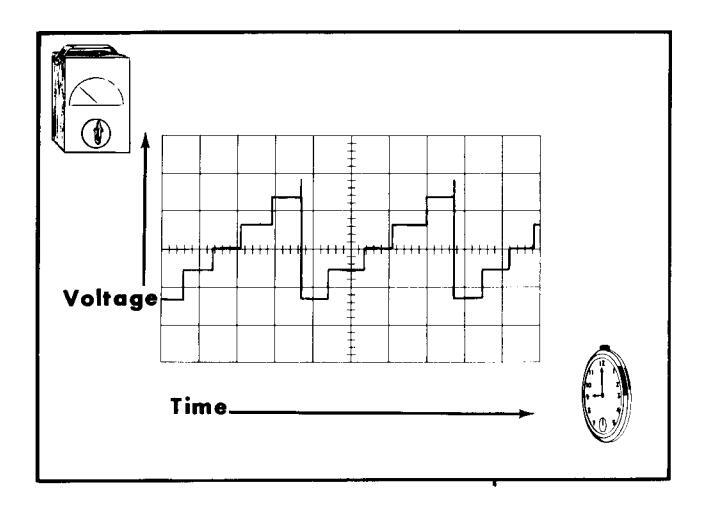

Fig. 2-4. The oscilloscope plots instantaneous voltage versus time, thereby serving both as a voltmeter and a timer.

The rate at which the spot is deflected across the screen is accurately controlled by the setting of the appropriate TIME/CM controls. The settings of the TIME/CM controls determine the sweep speed and the horizontal size of the displayed waveform. The controls are set to display the portion of the waveform you wish to observe.

Time Base A has 24 accurately calibrated sweep rates ranging from .1 microsecond to 5 seconds per centimeter. These calibrated sweep rates are obtained only when the VARIABLE TIME/CM control is in the fully clockwise position. The VARIABLE TIME/CM control permits you to vary the sweep rate continuously between .1 microsecond and approximately 12 seconds per centimeter. All sweep rates obtained with the VARIABLE TIME/CM control in any position but fully clockwise are uncalibrated. Uncalibrated sweep rates are indicated when the UNCALIBRATED lamp is lit.

Time Base B has sweep rates ranging from 2 microseconds to 1 second per centimeter in 18 steps. There is no VARI-ABLE TIME/CM control for Time Base B. The red LENGTH control adjusts the sweep length between approximately 4 and 10 centimeters.

Sweep Triggering

The oscilloscope display is formed by the repetitive sweep of the spot across the oscilloscope screen. If the sweeps are allowed to occur at random or at a rate unrelated to the rate of occurrence of the input waveform, the displayed waveform will be traced out at a different point on the screen each time the sweep runs. This will either cause the waveform to drift across the screen or to be indistinguishable.

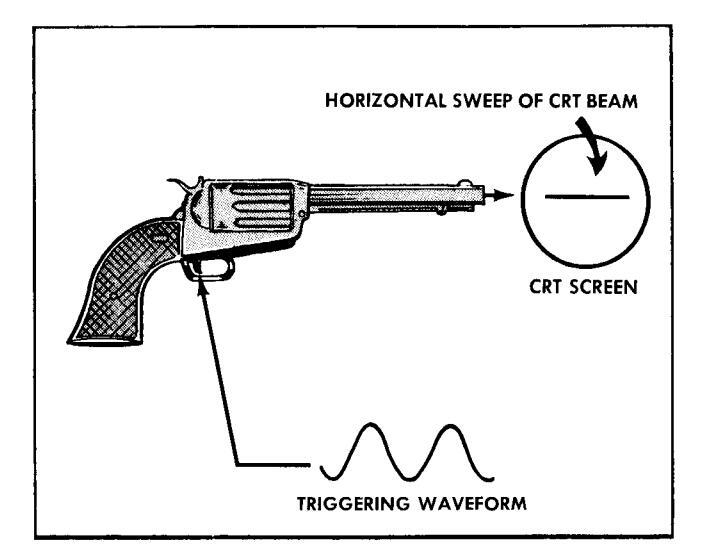

In most cases it is desirable for a repetitive waveform to appear stationary on the oscilloscope screen so that the characteristics of the waveform can be examined in detail. As a necessary condition for this type of display, the start of the sweep must bear a definite, fixed-time relationship to the appearance of the input waveform. This means that the sweep must be synchronized with the input waveform. In the Type 545A Oscilloscope this is accomplished by starting (triggering) the sweep with the displayed waveform or with another waveform bearing a definite time relationship to the displayed waveform.

The following paragraphs outline the means for selecting the triggering source, triggering slope, and triggering level with specific information regarding the operation of the controls affecting triggering. Triggering controls for Time Base A and Time Base B are virtually identical so that the following information is applicable to both time-base units. Triggering of the sweep is adjusted by the respective STABILITY, TRIGGERING LEVEL, TRIGGERING MODE, and TRIGGER SLOPE controls.

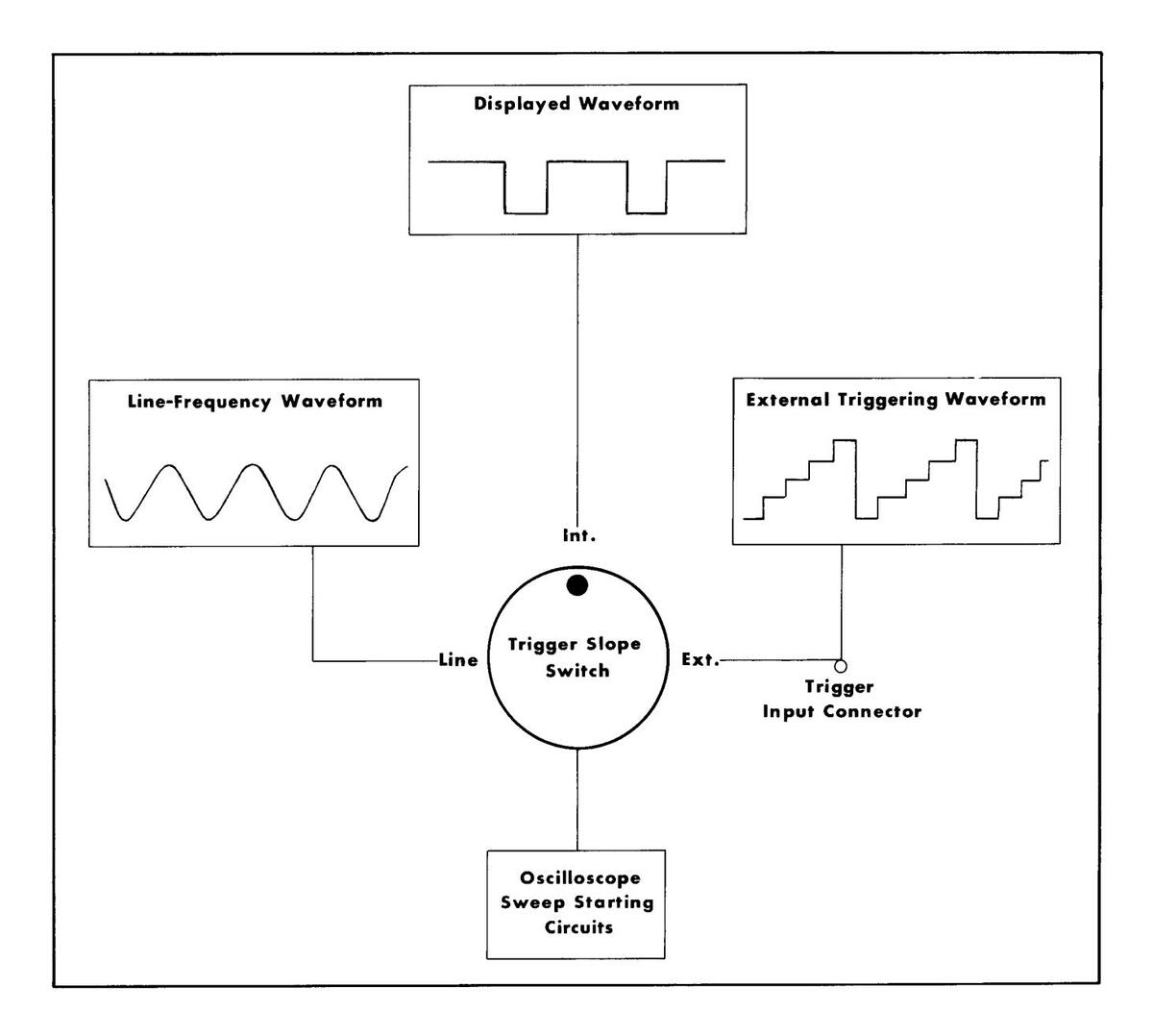

Selecting the Triggering Source

In preparing the Type 545A Oscilloscope for triggered operation of the sweep, it is first necessary to select the triggering signal source which will provide the best display for the particular application. The sweep can be triggered by the displayed waveform, a line-frequency waveform,

or by an externally derived waveform. This selection is made by the setting of the TRIGGER SLOPE control. Each type of triggering has certain advantages for some applications.

Triggering from the displayed waveform is the method most commonly used. The displayed waveform is selected when the TRIGGER SLOPE control is in either the +INT. or -INT. position. Internal triggering is convenient since no external triggering connections are required. Satisfactory results are obtained in most applications.

When you are observing a waveform which is related to the line frequency, you may wish to trigger the sweep from a line-frequency waveform. This can be done by placing the TRIGGER SLOPE switch in either the +LINE or the -LINE position. This type of triggering is particularly useful in observing waveforms which bear a definite relationship to the line frequency. The shape and the amplitude of the triggering waveform remains constant to provide extremely stable triggering.

To trigger the sweep from some external waveform connect the triggering waveform to the appropriate TRIG-GER INPUT connector and place the TRIGGER SLOPE switch in either the +EXT, or -EXT, position, External triagering provides definite advantages over other methods of triggering in certain cases. With external triggering, the triggering signal usually remains constant in amplitude and shape. It is thereby possible to observe the shaping and amplification of a signal in an external circuit without resetting the oscilloscope triggering controls for each observation. Also, time and phase relationships between the waveforms at different points in the circuit can be seen. If for example the external triggering signal is derived from the waveform at the input to a circuit, the time relationship and phase of the waveforms at each point in the circuit are compared to the input signal by the display presented on the oscilloscope screen.

When you are using external triggering and a stable triggering signal, it is possible to observe and accurately measure jitter of the displayed waveform. This is not possible when the sweep is triggered internally.

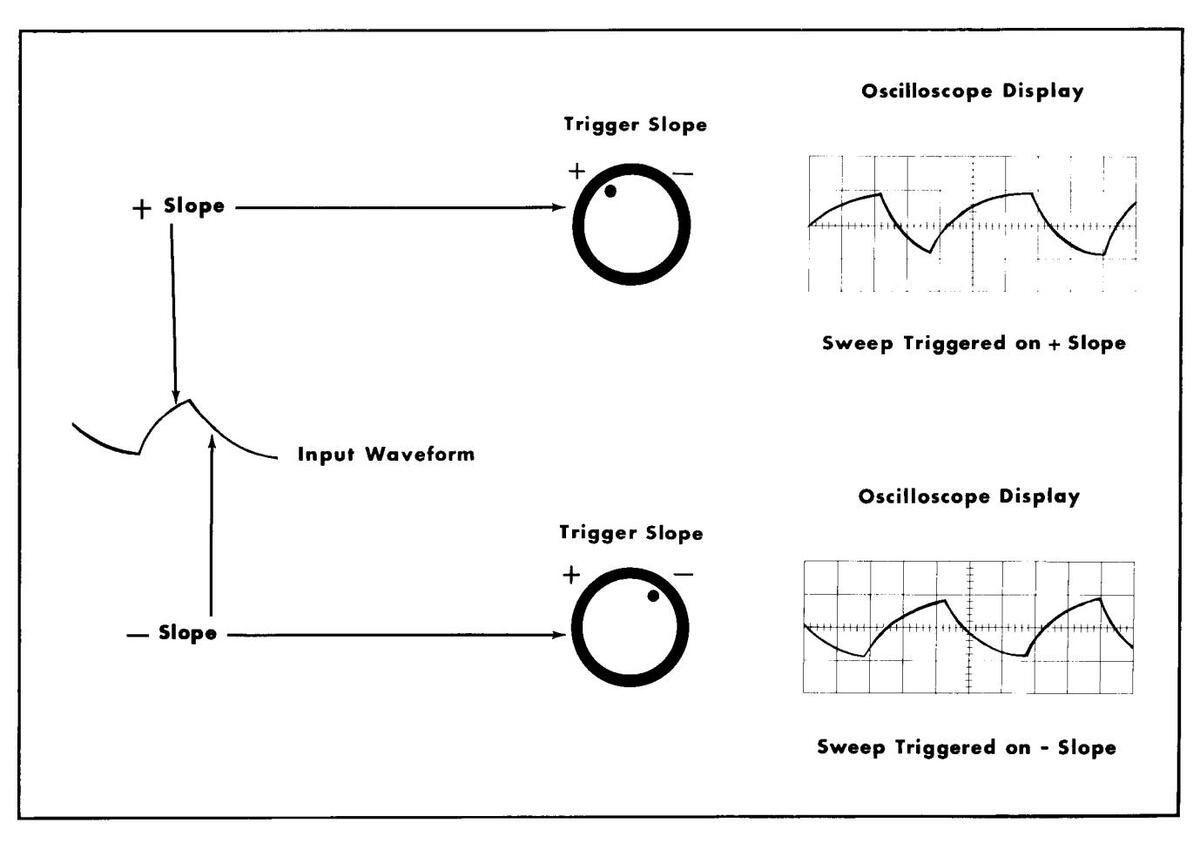

Selecting the Triggering Slope

The horizontal sweep can be triggered on either the rising (+slope) or falling (-slope) portion of the triggering waveform as determined by the position of the TRIGGER SLOPE switch. When the switch is in one of the + positions, the sweep is triggered on the rising portion of the triggering waveform; when the TRIGGER SLOPE switch is in one of the - positions, the sweep is triggered on the falling portion of the waveform (see Figure 2-7).

In many applications the triggering slope is not important since triggering on either slope will provide a display which is suitable to the application. However, in many other cases, such as pulse measurements, the triggering slope is very important. If, while using a fast sweep, you may wish to observe the rise of a pulse, it will be necessary for you to trigger the sweep on the rising portion of the waveform by placing the TRIGGER SLOPE switch in one of the + positions. To observe the fall of a pulse at a fast sweep rate, it will be necessary to trigger the sweep on the falling portion of the waveform by placing the TRIGGER SLOPE switch in one of the — positions. In either case, selection of the wrong triggering slope will make it impossible for you to observe the portion of the waveform you wish to check.

Selecting the Triggering Mode

After selecting the triggering source and triggering slope, it is next necessary to select the triggering mode which will allow you to obtain the desired display. Time Base A has five triggering modes while Time Base B has three. Not available for Time Base B are the HF SYNC and AC LF REJECT triggering modes.

Each of the triggering modes is designed to provide stable triggering from a certain type of waveform. For most applications, however, several of the triggering modes will work equally well. For applications of this type, the triggering mode used is purely a matter of choice. The primary thing to consider in choosing the triggering mode is whether or not it allows you to obtain the display you want.

To determine the best mode of operation for a particular application, it is usually best to try each triggering mode in the application. The AUTOMATIC mode should be tried first since this triggering mode provides stable triggering in most applications without the necessity of setting the STABILITY or TRIGGERING LEVEL controls. If the AUTO-MATIC mode does not provide the desired display, it will then be necessary for you to try one or more of the other triggering modes.

Automatic Triggering Mode

The AUTOMATIC mode is most frequently used because of its ease of operation. This mode is useful in obtaining stable triggering from waveforms with frequencies of from approximately 60 cycles to 2 megacycles. The principal advantage of this type of operation is that it is not necessary to adjust either the STABILITY or TRIGGERING LEVEL controls to obtain a stable display. This permits you to observe a large number of waveforms with different shapes

and amplitudes without adjusting any of the triggering controls. In the absence of a triggering signal, the sweep continues to run to provide a convenient reference trace on the oscilloscope screen.

The AUTOMATIC triggering mode is selected by placing the TRIGGERING MODE switch in the AUTO. position. The triggering source and slope is then selected and the input signal is applied to the oscilloscope. No other control adjustments are required. Since the TRIGGERING LEVEL control has no effect on the display when AUTOMATIC trig-

gering is used, it is impossible to select the point on the triggering waveform where the sweep is triggered. Each sweep is instead triggered at the average voltage point of the waveform.

DC Triggering Mode

The DC triggering mode is selected by placing the TRIG-GERING MODE switch in the DC position. This mode permits excellent triggering on all types of waveforms in the

Fig. 2-7. Effects on the oscilloscope display produced by + and — settings if the TRIGGER SLOPE control.

frequency range from dc to approximately 5 mc. The DC mode also permits the selection of the point on the triggering waveform where the sweep is triggered through the use of the TRIGGERING LEVEL control.

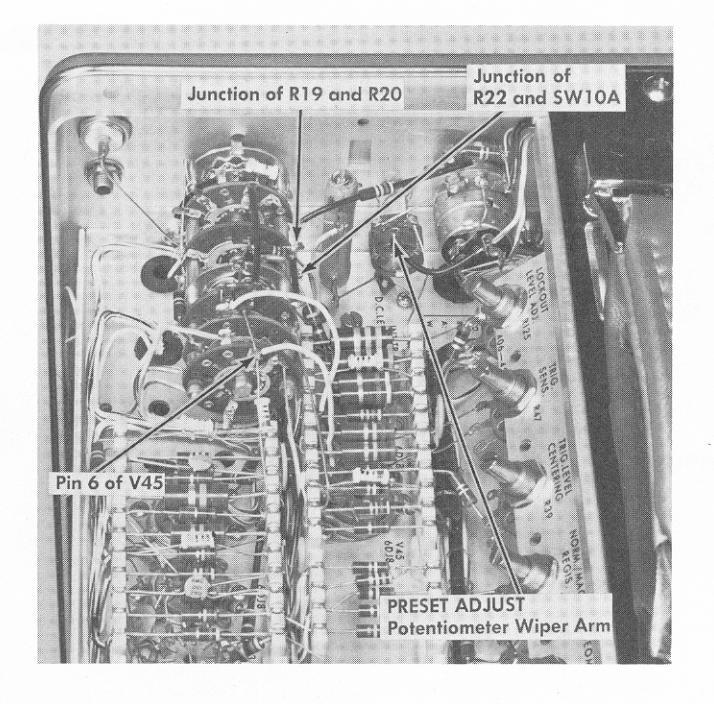

To use the DC triggering mode you must set the STA-BILITY and TRIGGERING LEVEL controls after first selecting the triggering signal source and slope. The method used to set the STABILITY and TRIGGERING LEVEL controls is the same for the DC mode, AC mode, and AC Low Frequency Reject mode. The STABILITY control must be set properly before the TRIGGERING LEVEL control can be adjusted.

The STABILITY control has a PRESET position at the fully counterclockwise setting of the control. This position permits proper triggering in most applications without necessitating additional adjustment of the STABILITY control. If it becomes impossible or difficult for you to obtain proper triggering with the STABILITY control at PRESET, you must then adjust the control. This is done with the TRIGGERING LEVEL control fully counterclockwise. The STABILITY control is rotated clockwise from the PRESET position until a trace appears on the screen. The proper setting for the control is then obtained by rotating the knob slowly counterclockwise until the trace just disappears.

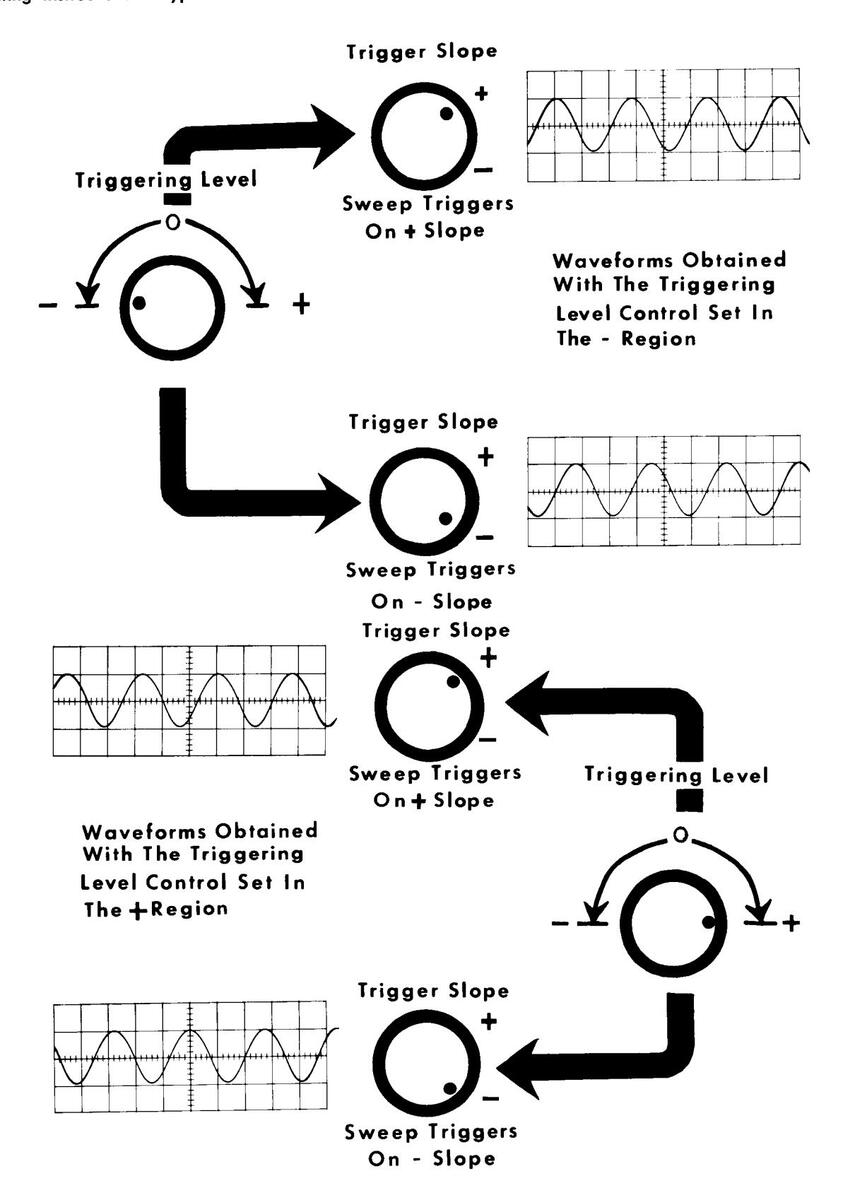

The TRIGGERING LEVEL control determines the point on the triggering waveform where triggering of the sweep occurs. This control is set to provide the display you want

while at the same time causing stable triggering. Rotating the control clockwise causes the sweep to trigger at more positive points on the waveform while rotating the control counterclockwise causes the sweep to trigger at more negative points. If the displayed waveform is vertically centered under the graticule, setting the TRIGGERING LEVEL control at 0 will cause the sweep to start at approximately the midvoltage point of the waveform. In the DC mode, rotating the vertical position control will change the point on the triggering waveform where the sweep is started.

The + and — markings for the TRIGGERING LEVEL control should not be confused with similar markings for the TRIGGER SLOPE control. The markings on the TRIGGER SLOPE control indicate only whether triggering occurs on the rising or falling portion of the triggering waveform. The markings for the TRIGGERING LEVEL control indicate whether triggering occurs on the upper portion or lower portion of the waveform.

AC Triggering Mode

Selection of the AC triggering mode is made by placing the TRIGGERING MODE switch in the AC position. This mode provides useful triggering in the frequency range of approximately 15 cycles to 5 mc. These frequency limits vary slightly depending upon the shape and amplitude of

Fig. 2-8. Effects on the oscilloscope display produced by + and — settings of the TRIGGERING LEVEL control. When the TRIGGERING LEVEL control is set in the + region, the sweep is triggered on the upper portion of the input waveform; when it is set in the - region, the sweep is triggered on the TRIGGER SLOPE control determines whether the sweep is triggered on the rising portion or the falling portion of the input waveform.

the triggering waveform. In the AC mode, triggering is unaffected by the dc components of the triggering signal or by the vertical positioning of the trace. The triggering level can be selected to provide the desired display using the STABILITY and TRIGGERING LEVEL controls. These two controls are set as described for the DC triggering mode.

AC Low Frequency Reject Triggering Mode

The AC Low Frequency Reject triggering mode is used when the TRIGGERING MODE switch is in the AC LF REJECT position. This mode is similar to the AC mode except that low-frequency waveforms are rejected by the triggering circuit. This triggering mode works well with highfrequency waveforms, but it may be difficult to obtain stable triggering with frequencies below approximately 1000 cycles.

Occasionally you may be required to obtain stable triggering from a fairly high-frequency waveform that is mixed with a great deal of low-frequency noise or line-frequency pickup. In such cases the additional noise and pickup can make it very difficult to obtain a stable display. If this occurs, you can select the AC Low Frequency Reject triggering mode, thereby eliminating the effects of the low frequency noise and pickup. The low frequencies are blocked from the triggering circuit while the high-frequency triggering waveform is passed to produce the stable triggering that you require. In all other respects the AC Low Frequency Reject triggering mode is identical to the AC mode.

High Frequency Synchronization Mode

The High Frequency Synchronization Mode permits stable displays of waveforms with frequencies higher than approximately 5 mc. Stability of the display is adjusted with the STABILITY control. The TRIGGERING LEVEL control is not used. To use the High Frequency Synchronization Mode, place the TRIGGERING MODE switch in the HF SYNC position. Rotate the STABILITY control clockwise until a trace appears. Continue to adjust the STABILITY control until a stable display is obtained.

Although the synchronization signal source is selected with the TRIGGER SLOPE control, the slope cannot be selected. Also you cannot use the PRESET position of the STABILITY control in this mode.

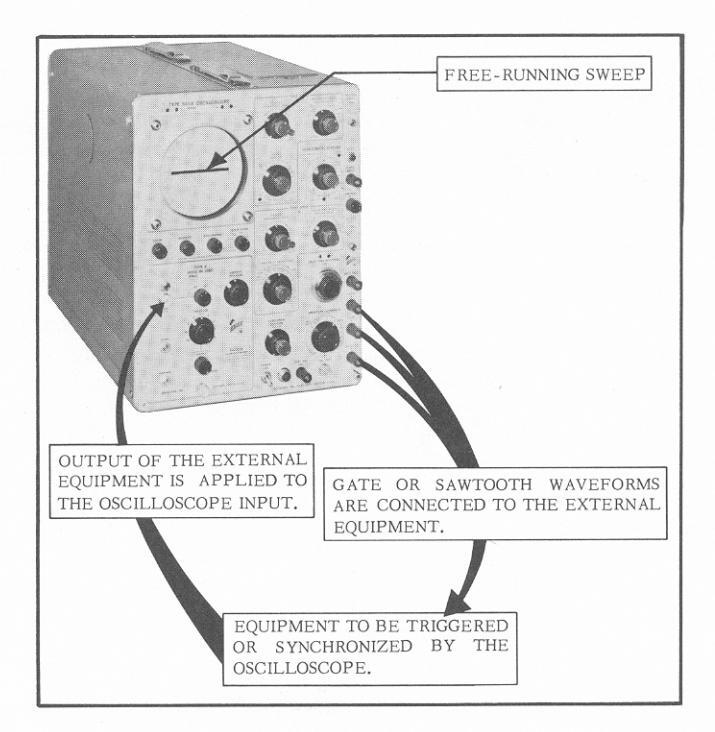

Free-Running Sweep Operation

In the usual oscilloscope application, the sweep is triggered or synchronized by the input waveform. However, in some applications it may be more desirable to reverse the process and initiate the input waveform through use of a periodically recurrent waveform from the oscilloscope. In this type of application the sweep is caused to free-run and an output from either the +GATE or SAWTOOTH connectors is used to trigger or synchronize the input waveform (see Figure 2-9).

The sweep can be made to free run with any setting of the TRIGGERING mode switch by rotating the STABILITY

Fig. 2-9. Using the + Gate or Sawtooth output waveforms to synchronize or trigger external equipment.

control fully clockwise. In all positions of the TRIGGERING MODE switch except AUTO, the number of sweeps per second is determined by the setting of the TIME/CM controls. In the AUTO, position, the sweep repetition rate remains at approximately 50 sweeps per second regardless of the setting of the TIME/CM control.

In addition to providing the means for controlling an applied waveform, a free-running sweep also provides a convenient reference trace on the oscilloscope screen without requiring an input signal. This trace can then be used to position the sweep or to establish a voltage reference line.

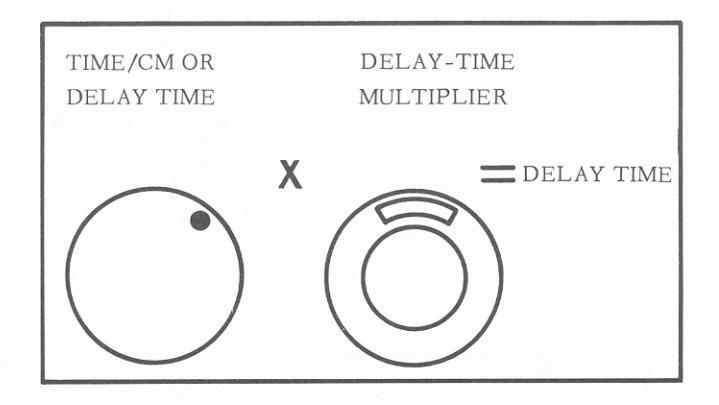

Delayed Sweep

With the Type 545A Oscilloscope the start of the horizontal sweep can be delayed for a period of from 1 microsecond to 10 seconds after application of the triggering

Fig. 2-10. Calculating delay time.

Operating Instructions — Type 545A

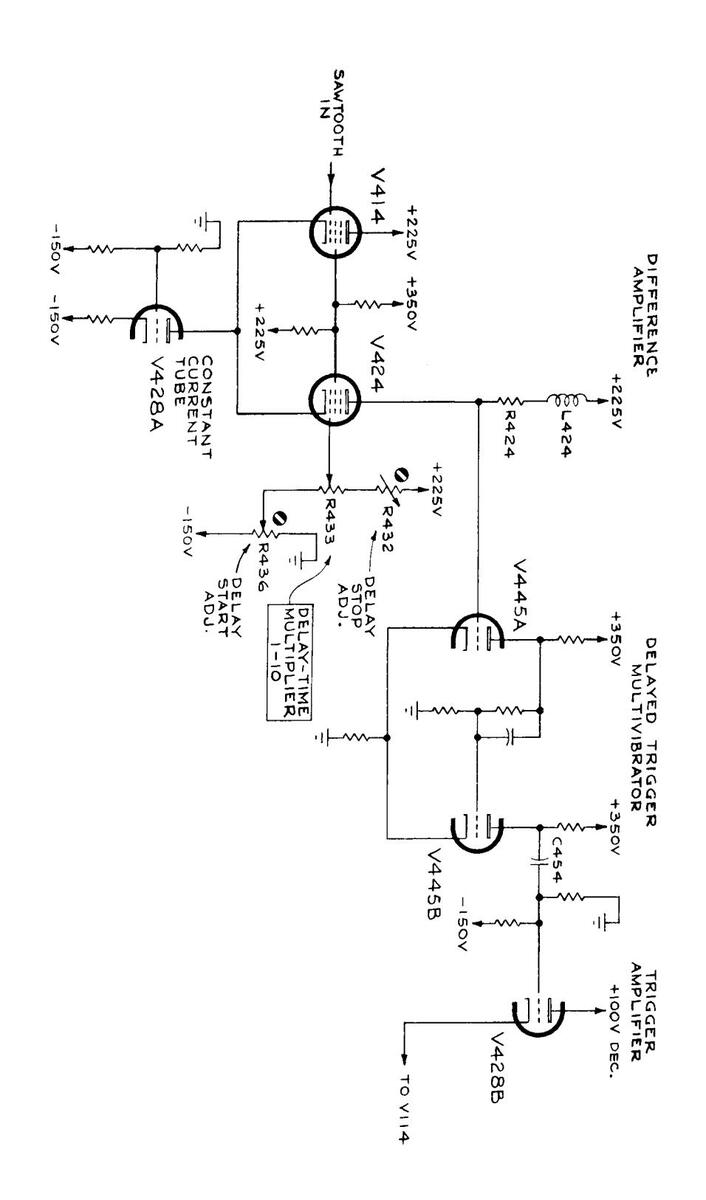

waveform. This is done through simultaneous use of Time Base A and Time Base B. In this application Time Base B is used to provide the accurate time delay while Time Base A presents a normal horizontal sweep at the end of the delay period. The duration of the sweep delay is controlled by the Time Base B TIME/CM OR DELAY TIME switch and the DELAY_TIME MULTIPLIER control

The delayed sweep feature of the Type 545A Oscilloscope can be used in a number of special applications to increase the versatility of the instrument. Such applications include high magnification of a selected portion of an undelayed sweep, accurate time measurements, and accurate measurements of waveform jitter. Also, it is possible to pick off and display any desired line of a television scan or to check pulse-time modulation. In addition, the delayed sweep feature is readily adaptable to a great number of other applications.

The delayed sweep is selected when the HORIZONTAL DISPLAY switch is in the 'A' DEL'D BY 'B' position. The amount of delay occurring from the application of the triggering waveform until the sweep runs is indicated directly by the settings of the TIME/CM OR DELAY TIME switch and the DELAY TIME MULTIPLIER control. The settings

of the two controls are multiplied together to obtain the actual delay time. For example, if the TIME/CM OR DELAY TIME switch is set at 1 MILLISEC and the vernier dial of the DELAY TIME MULTIPLIER control indicates 6.75, the delay time is 6.75 milliseconds. When the Time Base A STABILITY control is in the fully clockwise position, the horizontal sweep starts immediately at the completion of the delay period at a rate determined by the settings of the Time Base A TIME/CM controls.

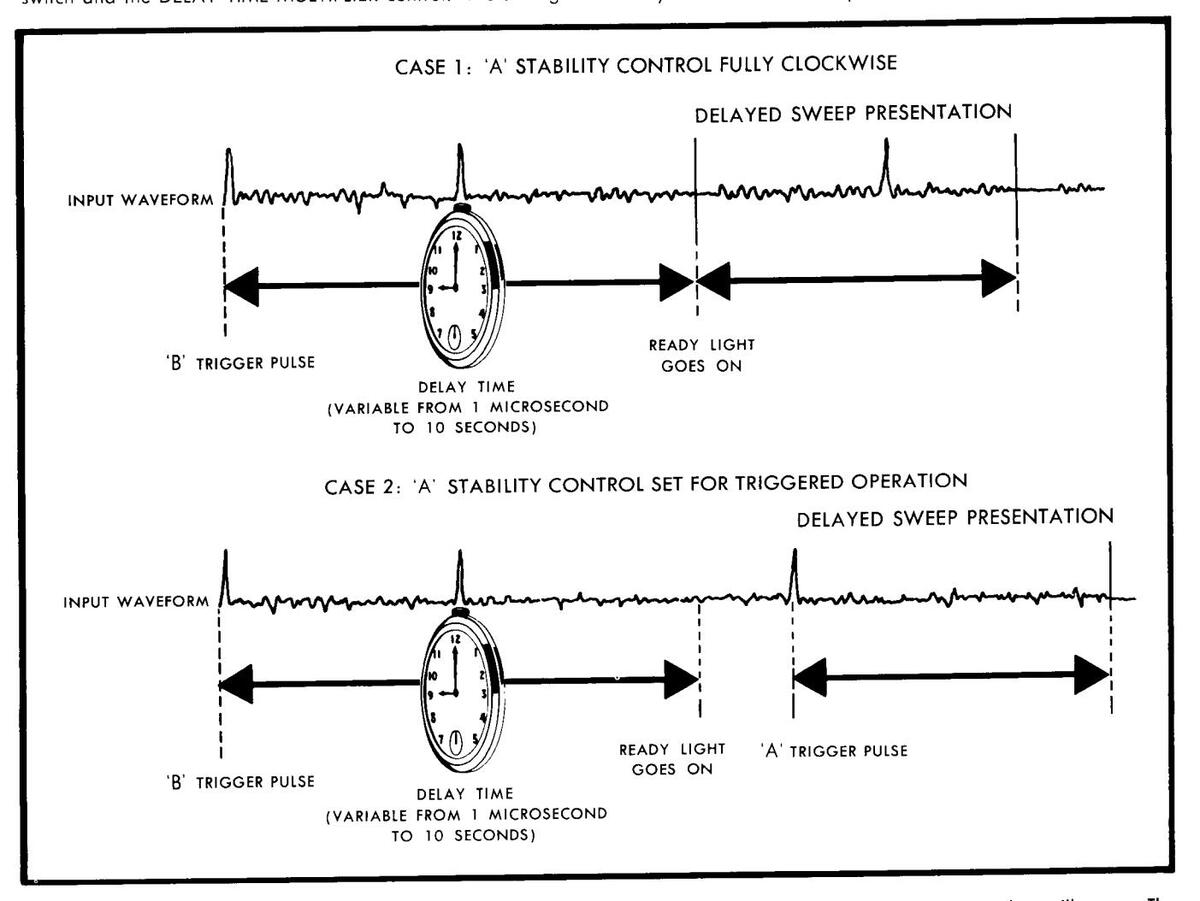

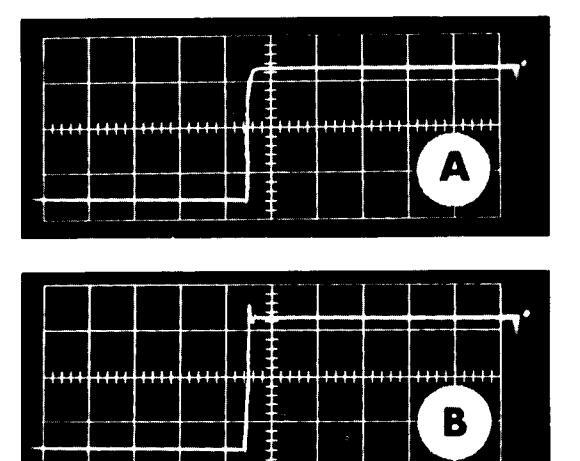

There are actually two modes of delayed sweep operation available in the Type 545A Oscilloscope (see Figure 2-11). In one mode the delayed sweep is started immediately after the completion of the delay time. This is the mode described previously and is obtained with the Time Base A STABILITY control fully clockwise. This mode permits you to select continuously variable delay times and is the mode of operation used to make accurate time and waveform jitter measurements as well as most other measurements.

The second delayed-sweep mode is different from the first in that the sweep does not start at the completion of the delay time until a triggering waveform is applied to Time Base A. The delay time in this mode is not continuously variable and is dependent not only on the settings of

Fig. 2-11. Comparison of the two delayed-sweep modes. In each case the waveform shown represents the input to the oscilloscope. The waveform shown in the delayed-sweep presentation boxes represents the portion of the input waveform that is actually displayed on the oscilloscope screen. Note that in Case 2 an additional triggering pulse is required before the delayed sweep will occur.

Fig. 2–12. Correlation of the 'B' INTENSIFIED BY 'A' and 'A' DEL'D BY 'B' positions of the HORIZONTAL DISPLAY switch.

the delay-time controls, but on the occurrence of the Time Base A triggering waveform as well. The primary purpose of this mode is to eliminate jitter from the displayed waveform. Since the sweep is triggered by the input waveform, jitter is eliminated from the display even though it is inherent in the input waveform.

The second delayed-sweep mode is also obtained with the HORIZONTAL DISPLAY switch in the 'A' DEL'D BY 'B' position. In this mode, however, the Time Base A triggering controls are set to provide normal triggering. The STABIL-ITY control is not placed in the fully clockwise position.

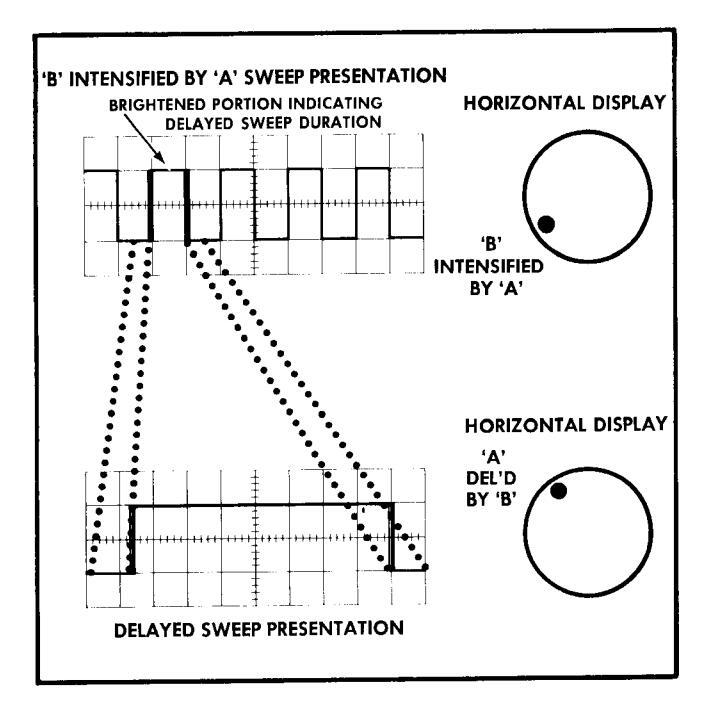

When the HORIZONTAL DISPLAY switch is placed in the 'B' INTENSIFIED BY 'A' position, you can obtain a normal sweep presentation using Time Base B. If all other controls are set for delayed sweep operation and the Time Base A TIME/CM switch is set for a faster sweep rate than the Time Base B control, a portion of the displayed waveform will be brightened. The start of this brightened portion indicates the start of the delayed sweep and the length of the brightened portion indicates the delayed sweep duration. The start of the brightened portion can be positioned left or right with the DELAY-TIME MULTIPLIER control. The length of the brightened portion can be adjusted with the Time Base A TIME/CM control. Using these two controls, it is possible to include any portion of the displayed waveform in the brightened area.

To expand a portion of the display obtained with the HORIZONTAL DISPLAY switch in the 'B' INTENSIFIED BY 'A' position, adjust the DELAY-TIME MULTIPLIER and Time Base A TIME/CM controls to include the portion you wish to expand in the brightened area (see Figure 2-12). Then place the HORIZONTAL DISPLAY switch in the 'A' DEL'D BY 'B' position. This expands the brightened portion to the full width of the screen. The amount of magnification is the ratio of the Time Base B TIME/CM OR DELAY TIME control

setting to the Time Base A TIME/CM control setting. For example, if the Time Base B TIME/CM OR DELAY TIME switch is set at 1 MILLISEC and the Time Base A TIME/CM switch is set at 1 µSEC, the brightened portion of the sweep is magnified horizontally 1,000 times. Using this method, practical sweep magnifications up to approximately 10,000 times are attainable.

At times when you are using the delayed sweep with high magnification, the intensity of the trace will be so low that it is difficult to see. In many of these cases the intensity cannot be improved significantly with the INTENS-ITY control. However, the intensity can often be increased by using the Time Base B SWEEP LENGTH control to increase the duty cycle. To set the SWEEP LENGTH control, place the HORIZONTAL DISPLAY switch in the 'B' INTENSI-FIED BY 'A' position. Adjust the SWEEP LENGTH control until the sweep runs to a point just past the brightened portion of the trace. Then return the HORIZONTAL DISPLAY switch to the 'A' DEL'D BY 'B' position.

Fig. 2-13. Occurrence of the delayed triggering pulse. The delay time is adjusted with the DELAY-TIME MULTIPLIER control. The delayed triggering pulse occurs at the end of the delay time.

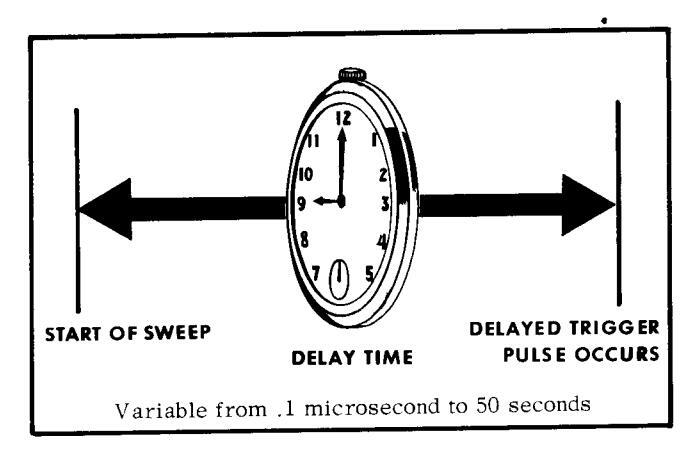

Delayed Trigger

A delayed triggering pulse can be obtained from the DEL'D TRIG. connector of the oscilloscope any time from .1 microsecond to 50 seconds after the start of a sweep. When the oscilloscope is set for delayed sweep operation, the delayed trigger occurs at the start of the delayed sweep. This delayed triggering pulse can be used to initiate some action after a known time interval, and when used with the delayed sweep, permits you to observe the resulting action.

In the B, 'B' INTENSIFIED BY 'A', 'A' DEL'D BY 'B', EXT. X1, and EXT. X10 positions of the HORIZONTAL DISPLAY switch, the delayed trigger is controlled by Time Base B. In the other two positions of the HORIZONTAL DISPLAY switch, the delayed trigger is controlled by Time Base A.

To obtain a delayed trigger you must first adjust the appropriate time-base unit for triggered operation or for free-running operation, depending upon the application. The delay is then set with the appropriate TIME/CM control and the DELAY-TIME MULTIPLIER. The lights above the DELAY-TIME MULTIPLIER control indicate which time-base unit is used to produce the delayed trigger with each setting of the HORIZONTAL DISPLAY switch.

Fig. 2-14. Comparison of single sweep and repetitive sweep presentation of a damped sine wave. In the repetitive sweep presentation, it is difficult to determine what is being presented. However, in the single sweep presentation the damped sine wave can be clearly seen.

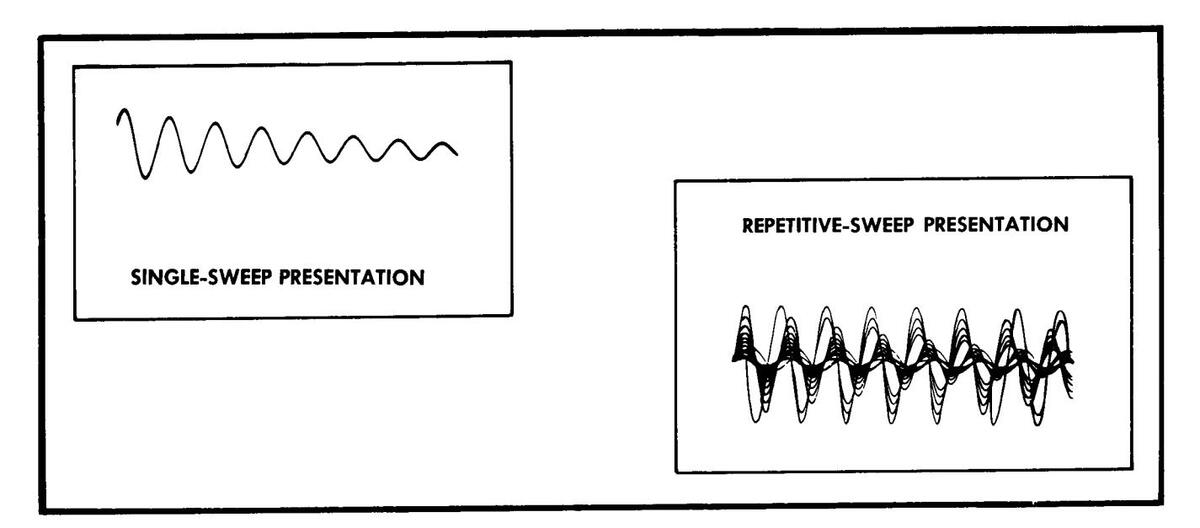

Single Sweep

The usual oscilloscope display formed by a repetitive sweep is entirely satisfactory for most applications. However, in applications where the displayed waveform is not repetitive or varies in amplitude, shape, or time interval, a repetitive sweep produces a jumbled display. When observing a waveform of this type, it is usually advantageous to use a single-sweep presentation.

The Type 545A Oscilloscope permits you to obtain a single-sweep presentation and to eliminate all subsequent sweeps so that information is clearly recorded without the confusion resulting from multiple traces. The single-sweep feature is selected by placing the HORIZONTAL DISPLAY switch in the 'A' SINGLE SWEEP position. In this position, only Time Base A is used. The RESET button controls the start of the single sweep.

When the STABILITY control is set fully clockwise or the TRIGGERING MODE switch is in the AUTO. position, a single sweep runs immediately each time the RESET button is depressed. However, if Time Base A is set for triggered operation with the TRIGGERING MODE switch in other than AUTO. or HF SYNC positions, the single sweep does not occur when the RESET button is depressed unless a triggering signal is applied to Time Base A. Instead the READY lamp lights to indicate that the sweep is ready to be triggered. When a triggering signal occurs, the single sweep runs and the READY light goes out. Each time the RESET button is depressed the procedure is repeated.

External Horizontal Input

For special applications you can deflect the trace horizontally with some externally derived waveform. This allows you to use the oscilloscope to plot one function versus another.

To use an external horizontal input, connect the externally derived waveform to the HORIZ. INPUT connector and place

the HORIZONTAL DISPLAY switch in either EXT. position. The horizontal deflection factor is continuously variable from approximately .2 to approximately 15 volts per centimeter with the VARIABLE 10-1 control and the HORIZONTAL DISPLAY switch.

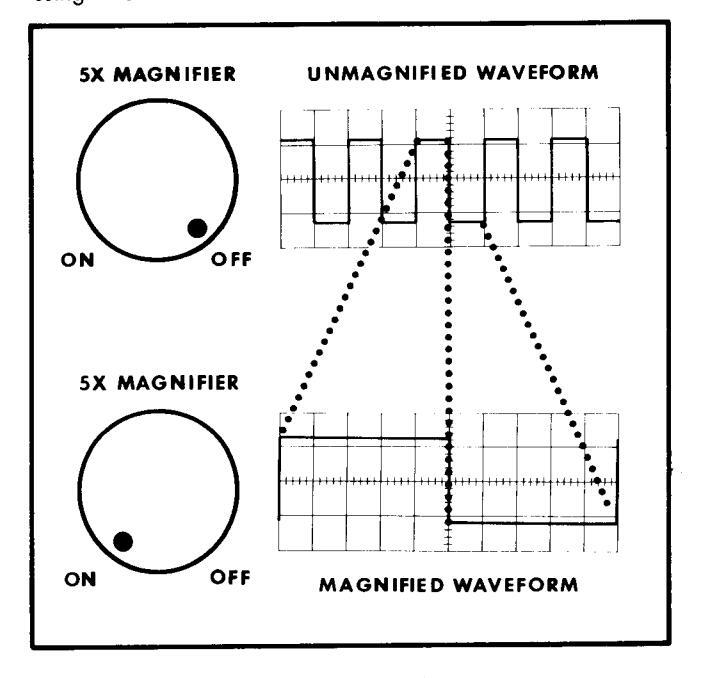

Sweep Magnifier

The sweep magnifier allows you to expand any twocentimeter portion of the displayed waveform to the full ten-centimeter width of the graticule. This is done by first using the HORIZONTAL POSITION control to move the

Fig. 2-15. Operation of the sweep magnifier.

portion of the display you wish to expand to the center of the graticule, then placing the 5X MAGNIFIER switch in the ON position. When the 5X MAGNIFIER switch is at ON, the 5X MAGNIFIER lamp lights to indicate the magnifier is on. Any portion of the original unmagnified display can then be observed by rotating the HORIZONTAL POSI-TION controls. The sweep magnifier can be used with either time base unit

In magnified sweep operation, the sweep speed indicated by the position of the TIME/CM control is divided by 5 to obtain the actual time required for the spot to move one centimeter. For example, if the TIME/CM control is set at 5 MILLISEC, the actual time per centimeter is 5 milliseconds divided by 5, or 1 millisecond per centimeter. The actual time per centimeter must be used for all measurements of time.

Amplitude Calibrator

The amplitude calibrator provides a convenient source of square waves of known amplitude at a frequency of approximately 1 kc. The square waves are used primarily to adjust probes and to verify the calibration of the vertical-deflection system of the oscilloscope and plug-in unit

Calibrator square-waves are adjustable from .2 millivolts, peak-to-peak, to 100 volts, peak-to-peak, in 18 steps. The amplitude is controlled by the setting of the AMPLITUDE CALIBRATOR switch and is accurate within 3% of the AMPLITUDE CALIBRATOR switch setting when the output is connected to a high impedance load.

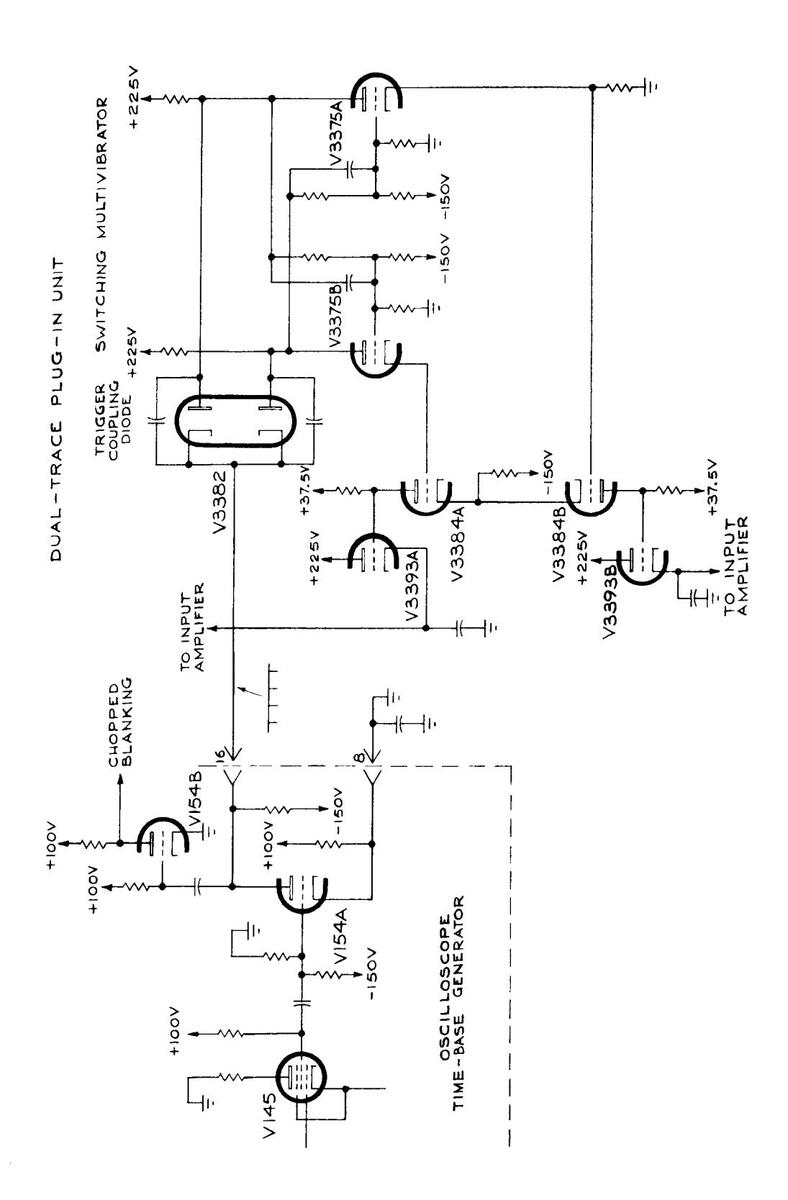

Dual-Trace Displays

The Type CA Plug-In Unit allows you to obtain two separate traces on the face of the crt. This permits you to display two functions simultaneously. Detailed instructions for operating the Type CA Unit in conjunction with the Type 545A Oscilloscope are contained in the Instruction Manual for the Type CA Unit.

When you are using the Type CA Unit in the chopped mode to obtain a dual-trace presentation, switching transients will be displayed on the screen. You can eliminate these switching transients by placing the CRT CATHODE SELECTOR switch on the rear of the instrument in the DUAL-TRACE CHOPPED BLANKING position.

Intensity Modulation

The crt display of the Type 545A Oscilloscope can be intensity modulated by an external signal to display additional information. This is done by disconnecting the grounding bar from the EXTERNAL CRT CATHODE con nector at the rear of the instrument and connecting the external signal to this terminal. The CRT CATHODE SELEC-TOR switch must be in the EXTERNAL CRT CATHODE position

When you wish to make very accurate time measurements from the crt display, you can intensity modulate the beam with time markers and make your measurements directly from the time markers presented on the screen. A positive signal of approximately 25 volts is required to cut off the beam from normal intensity.

Operating Instructions — Type 545A

Fig. 2-16. Functions of the Type 545A Oscilloscope front panel controls.

SECTION 3

APPI ICATIONS

38-7m32

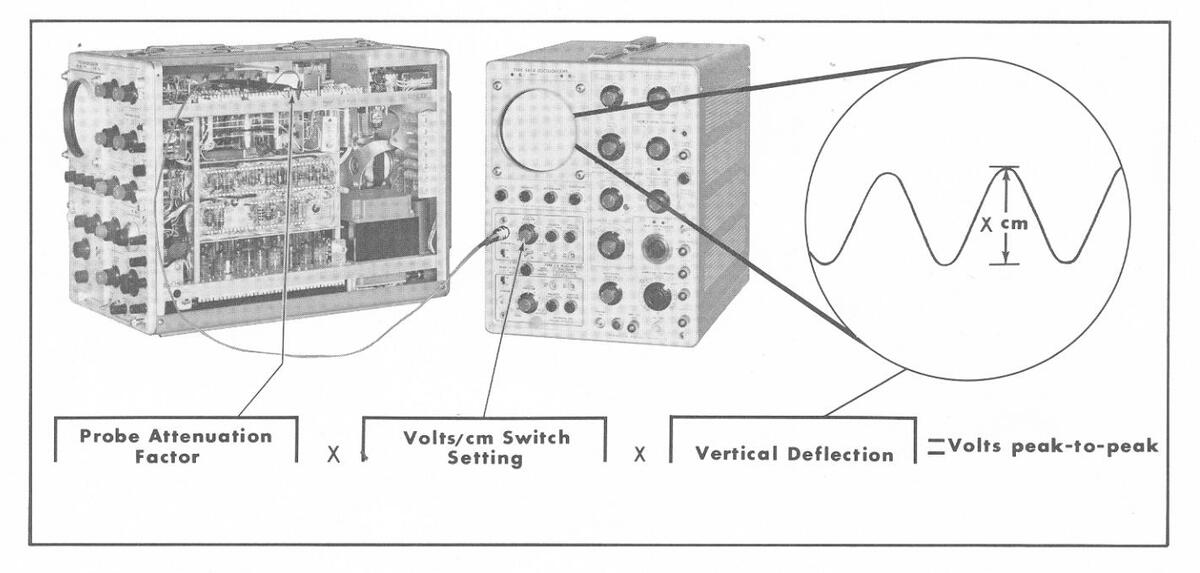

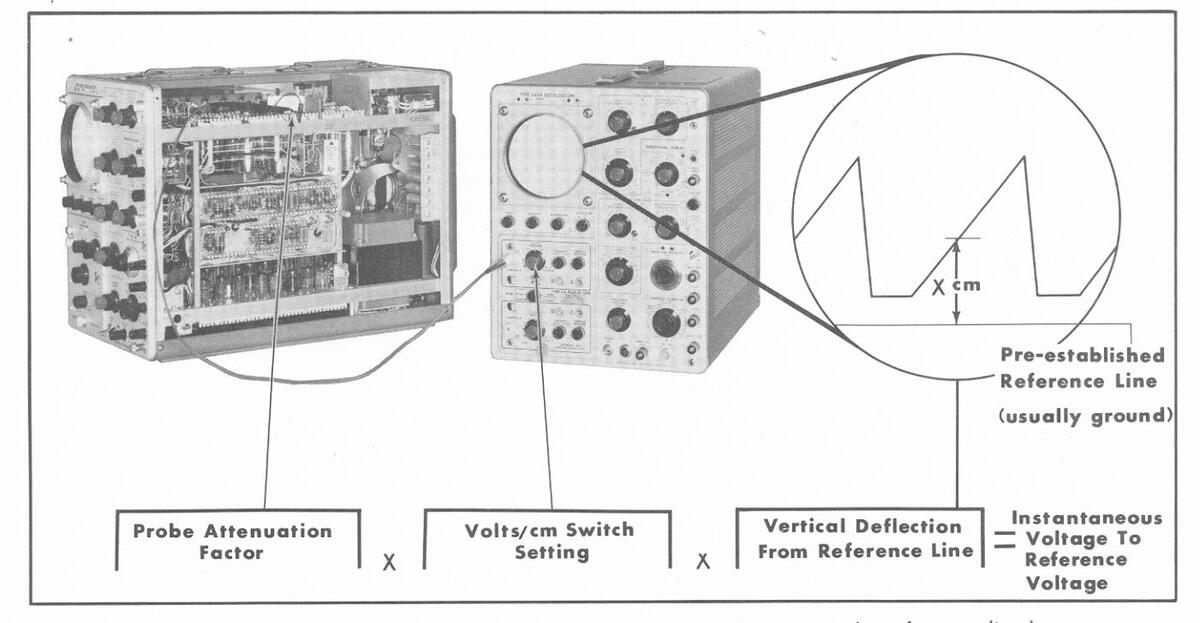

Voltage Measurements

The Type 545A Oscilloscope can be used to measure the voltage of the input waveform by using the calibrated vertical-deflection factors of the instrument and associated plug-in unit. The method used for all voltage measurements is basically the same although the actual techniques vary somewhat depending on the type of voltage measurements required. Essentially there are two types of voltage measurements: ac-component voltage measurements and instantaneous voltage measurements with respect to some reference potential. Many waveforms contain both ac and dc voltage components. It is often necessary to measure one or both of these components.

When making voltage measurements, you should display the waveform over as large a vertical portion of the screen as possible for maximum accuracy. Also, it is important that you do not include the width of the trace in your measurements. You should consistently make all measurements from one side of the trace. If the bottom side of the trace is used for one reading, it should be used for all succeeding readings. The VARIABLE VOLTS/CM control must be in the CALIBRATED position.

AC Component Voltage Measurements

To measure the ac component of a waveform, the plug-in unit input selector switch should usually be set to one of the AC positions. In these positions only the ac components of the input waveform are displayed on the oscilloscope screen. However, when the ac component of the input waveform is of very low frequency it is necessary for you to make voltage measurements with the input selector switch in one of the DC positions to prevent errors.

To make a peak-to-peak voltage measurement on the ac component of a waveform, perform the following steps (see Figure 3-1):

1. With the aid of the graticule, measure the vertical distance in centimeters from the positive peak to the negative peak.

2. Multiply the vertical distance measured by the setting of the plug-in unit VOLTS/CM control to obtain the indicated voltage.

3. Multiply the indicated voltage by the attenuation factor of the probe used to obtain the actual peak-to-peak voltage.

Fig. 3-1. Measuring the peak-to-peak ac component voltage of an applied waveform.

Applications — Type 545A

As an example of the method, assume that using a 10X probe and a deflection factor of 1 volt per centimeter, you measure a vertical distance between peaks of 4 centimeters. In this case then, 4 centimeters multiplied by 1 volt per centimeter gives you an indicated voltage of 4 volts peak-to-peak. The indicated voltage multiplied by the probe's attenuation factor of 10 then gives you the true peak-to-peak amplitude of 40 volts.

When sinusoidal waveforms are measured, the peak-topeak voltage obtained can be converted to peak, rms, or average voltage through use of standard conversion factors.

Instantaneous Voltage Measurements

The method used to measure instantaneous voltages is virtually identical to the method described previously for the measurement of the ac components of a waveform. However for instantaneous voltage measurements the plug-in unit input selector switch must be placed in one of the DC positions. Also since instantaneous voltages are measured with respect to some potential (usually ground) a reference line must be established on the oscilloscope screen which corresponds to that potential. If, for example, voltage measurements are to be made with respect to +100 volts, the reference line would correspond to +100 volts. In the following procedure the method is given for establishing this reference line as ground since measurements with respect to ground are by far the most common type. The same general method may be used to measure voltage with respect to any other potential, however, so long as that potential is used to establish the reference line.

To obtain an instantaneous voltage measurement with respect to ground, perform the following steps (see Figure 3-2):

1. To establish the voltage reference line, touch the probe tip to an oscilloscope ground terminal (or if the reference line is to represent a voltage other than ground, to a source of that voltage) and adjust the oscilloscope controls to obtain a free-running sweep. Vertically position the trace to a convenient point on the oscilloscope screen. This point will depend on the polarity and amplitude of the input signal, but should always be chosen so that the trace lies along one of the major divisions of the graticule. The graticule divisions corresponding to the position of the trace is the voltage reference line and all voltage measurements must be made with respect to this line. (Do not adjust the vertical positioning control after the reference line has been established.)

2. Remove the probe tip from ground and connect it to the signal source. Adjust the triggering controls for a stable display.

3. Using the graticule, measure the vertical distance in centimeters from the desired point on the waveform to the voltage reference line.

4. Multiply the setting of the VOLTS/CM control by the distance measured to obtain the indicated volage.

5. Multiply the indicated voltage by the attenuation factor of the probe you are using to obtain the actual voltage with respect to ground (or other reference voltage).

As an example of this method, assume that you are using a 10X probe and deflection factor of .2 volts per centimeter. After setting the voltage reference line at the second from the bottom division of the graticule, you measure a distance of 3 centimeters to the point you wish to check. In this case then, 3 centimeters multiplied by .2 volts per centimeter gives you an indicated .6 volts. Since the voltage point is above the voltage reference line the polarity is

** Fig. 3-2. Measuring the instantaneous voltage with respect to ground (or some other reference voltage).

Fig. 3-3. Measuring time interval between events displayed on the oscilloscope screen.

indicated to be positive. The indicated voltage multiplied by the probe's attenuation factor of 10 then gives you the actual voltage of positive 6 volts.

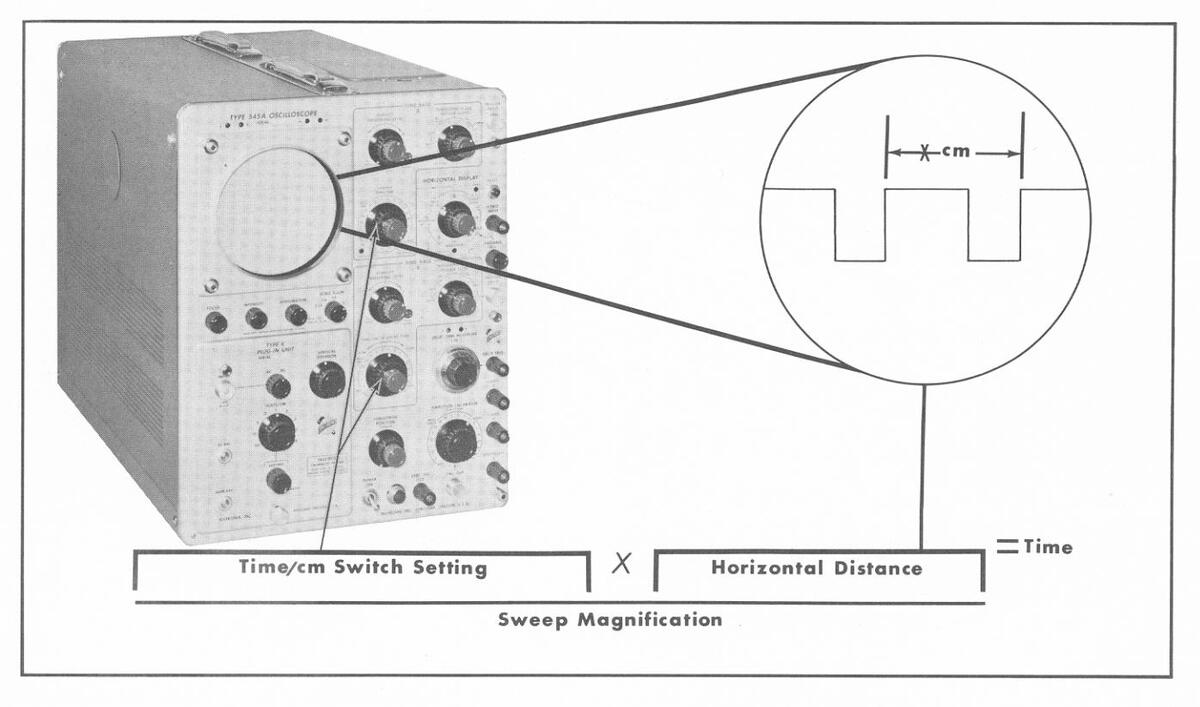

Timé Measurements

The calibrated sweeps of the Type 545A Oscilloscope cause any horizontal distance on the screen to represent a definite known interval of time. Using this feature you can accurately measure the time lapse between two events displayed on the oscilloscope screen. One method which produces sufficient accuracy for most applications is as follows (see Figure 3-3):

1. Using the graticule, measure the horizontal distance between the two displayed events whose time interval you wish to find.

2. Multiply the distance measured by the setting of the appropriate TIME/CM control to obtain the apparent time interval. (The VARIABLE TIME/CM control must be in the CALIBRATED position).

3. Divide the apparent time interval by 5 if the magnifier is on, and 1 if the magnifier is off, to obtain the actual time interval.

For example, assume that the TIME/CM switch setting is 1 MILLISEC, the MAGNIFIER is ON, and that you measure a horizontal distance of 5 centimeters between events. In this example then, 5 centimeters multiplied by 1 millisecond per centimeter gives you an apparent time interval of 5

milliseconds. The apparent time divided by 5 then gives you the actual time interval of 1 millisecond.

Another method for measuring time intervals involves the use of the delayed sweep feature of the Type 545A Oscilloscope. In this method the HORIZONTAL DISPLAY switch is placed in the 'B' INTENSIFIED BY 'A' position to brighten a portion of the trace. The brightened portion of the trace and the DELAY-TIME MULTIPLIER control are then used to make the time measurements. This method provides a very high degree of accuracy when care is taken in making the measurements. The method is summarized as follows:

1. Place the HORIZONTAL DISPLAY switch in the 'B' INTENSIFIED BY 'A' position and adjust the Time Base B triggering controls for a stable display of the input waveform. Adjust Time Base A for free-running operation.

2. Turn the intensity down until the brightened portion of the trace is easily distinguishable. Adjust the Time Base A TIME/CM controls to reduce the brightened area to a small spot or to cover as small a portion of the trace as possible.

3. Using the DELAY-TIME MULTIPLIER control, position the start of the brightened portion of the beginning of the interval you wish to measure. Record the setting of the DELAY-TIME MULTIPLIER control.

4. Using the DELAY-TIME MULTIPLIER control, position the start of the brightened portion of the trace to the end of the interval you wish to measure. Again record the setting of the DELAY-TIME MULTIPLIER control.

Fig. 3-4. Measuring the frequency of a repetitive input signal.

5. Subtract the first DELAY-TIME MULTIPLIER control setting from the second and multiply the result by the setting of the Time Base B TIME/CM control. The figure obtained is the time interval between the two events. The figure obtained is correct regardless of whether the magnifier is on or off.

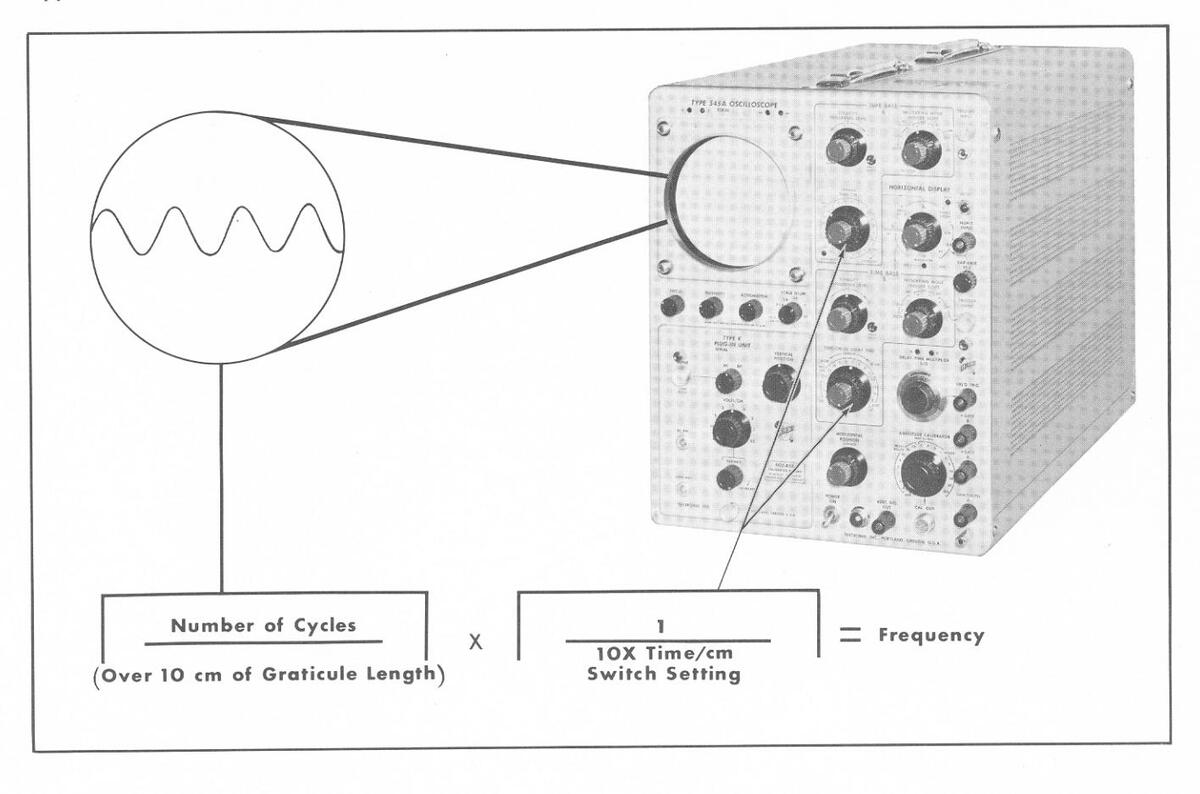

Frequency Measurements

Using the methods described in the previous section, you can measure the period (time required for one cycle) of a recurrent waveform. The frequency of the waveform can then easily be calculated since frequency is the reciprocal of the period. For example, if the period of a recurrent waveform is accurately measured and found to be 0.2 microseconds, the frequency is the reciprocal of 0.2 microseconds, or 5 mc.

At any given oscilloscope sweep rate, the number of cycles of the input waveform that is displayed on 10 centimeters of the screen is dependent on the frequency of the input waveform. Frequencies can usually be measured faster by the following method than by the one given in the last paragraph.

If you divide the cycles per unit of length by the time required for the input waveform to sweep this unit of length, you get the frequency. The total number of cycles are found for 10 cm for greater accuracy. Since the TIME/CM switch gives time for 1 cm, multiply this setting by 10 to have the time required for 10 cm. (See Fig. 3-4).

To obtain the frequency of a repetitive input signal, perform the following steps:

1. Adjust the TIME/CM control to display several cycles of the input waveform. Insure that the VARIABLE TIME/CM control is in the CALIBRATED position.

2. Count the number of cycles of the waveform shown on the 10 centimeters of the graticule.

3. Divide this number by 10 times the TIME/CM switch setting. This gives you the frequency of the input waveform.

For example, assume that when you are using a sweep rate of 50 milliseconds per centimeter, you count 7.2 cycles in 10 centimeters. The frequency is 7.2 cycles divided by 50 milliseconds times 10, or 500 milliseconds. 500 milliseconds are 500 x .001 seconds, or .5 seconds. 7.2 cycles per 1/2 second gives you 14.4 cycles per second.

SECTION 4

CIRCUIT

VERTICAL DEFLECTION SYSTEM

General

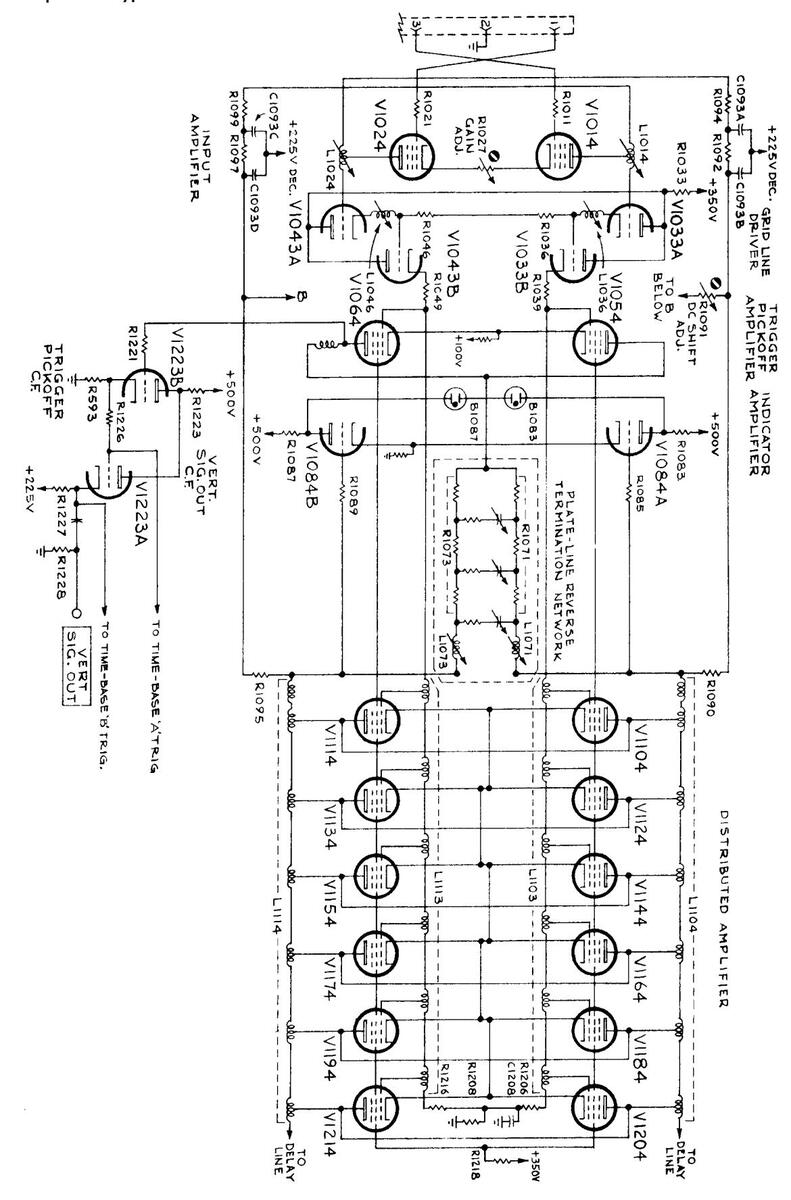

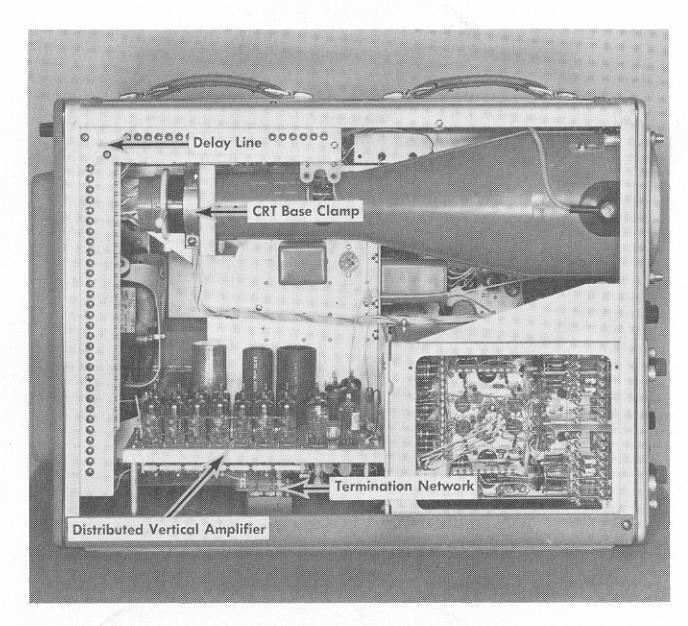

The dc-coupled, push-pull, main Vertical Amplifier provides the necessary gain to drive the Delay Line and the vertical deflection plates of the crt. The main units of the Vertical Amplifier are the Input Amplifier stage V1014 and V1024, the cathode follower stages V1033 and V1043, and the 6-section Distributed Amplifier output stage. Other circuits of importance are the Trigger Pickoff Amplifier V1054 and V1064, the Trigger Pickoff C.F. V1223B, the Vert. Sig. Out. C.F. V1223A, and the Indicator Amplifiers and lamps, V1084A and B1083, and V1084B and B1087, respectively.

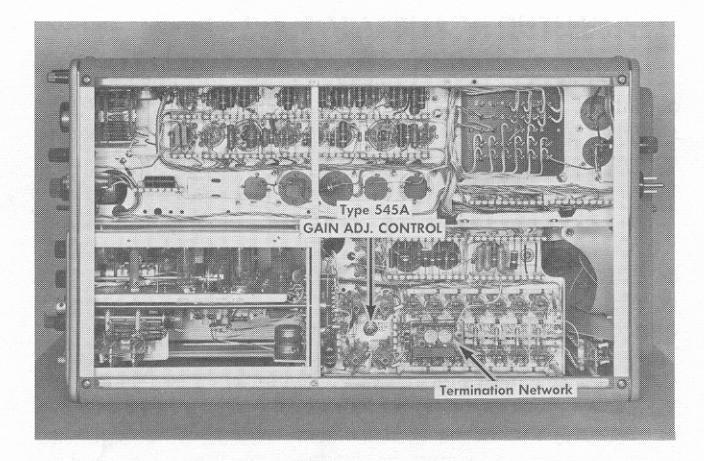

Input Circuit

The signal input from the plug-in unit is coupled through terminals 1 and 3 of the interconnecting plug to the grids of the Input Amplifier stage. GAIN ADJ., R1027 varies the cathode degeneration, and thus sets the gain of the stage to agree with the Preamplifier's front-panel calibration when the VARIABLE knob is in the CALIBRATED position.

The Input Amplifier is coupled to the Distributed Amplifier by the cathode followers V1033 and V1043. The cathode followers isolate the Distributed Amplifier from the Input Amplifier, and provide the necessary low-impedance drive for the Distributed Amplifier's grid line.

High-frequency compensation for the Input Amplifier is provided by the variable peaking coils L1014 and L1024. Variable inductors L1036 and L1046 provide additional peaking at the very high frequencies.

Output Stage

The output stage is a 6-section Distributed Amplifier. The tapped inductors in the transmission line, between each grid and between each plate, isolate each section from the capacitance of the adjacent sections.

The input signal for each tube is obtained from the grid line, which is driven by the cathode followers V1033 and V1043. The amplified signal at each plate, fed to the plate line, becomes an integral part of the wave traveling down the line toward the deflection plates.

The vertical signal is delayed 0.2 microsecond between the input to the grid line and the vertical deflection plates.

This delay insures that the very "front" of fast vertical signals can be observed. About 0.015 microsecond of the total delay time occurs in the Distributed Amplifier; the remaining 0.185 microsecond occurs in the Delay Line.

The tapped inductors between each section of the Distributed Amplifier provide about 0.003 microsecond of delay. By making the delay time in the grid and plate lines equal, the signal arriving at each plate, through the electron stream of the tube, will be synchronous with the signal moving down the plate line from the preceding sections.

DC Shift Compensation

DC shift in the amplifiers — a condition whereby the dc and very low-frequency transconductance is less than at mid-frequencies — is compensated for in two ways. R1090 and C1093B in plate line L1104, and R1095 and C1093D in plate line L1114, form a low-frequency boost network; the time constant of this network is such that the termination resistance of the line is increased in the range from very low-frequencies to dc. A longer time constant, for extremely low-frequency and dc compensation is provided by R1092, R1094 and C1093A in one plate line, and by R1097, R1099 and C1093C in the other, which provide a small amount of positive feedback from the plate lines to the plate circuits of the Input Amplifier. A variable resistor R1091, the DC SHIFT ADJ. control, is connected between the two networks to adjust for the proper amount of compensation.

Beam-Position Indicators

The beam-position indicators B1083 and B1087 located on the front panel above the crt, indicate the relative vertical position of the trace with respect to the center of the graticule. When the beam is centered vertically, the potential across either neon is insufficient to light it. As the beam is positioned up or down the screen, however, the current through the Indicator Amplifiers, and hence the voltage across the neons will change. The voltage across one will increase, causing it to light, and the voltage across the other will decrease, causing it to remain extinguished. The neon that lights will indicate the direction in which the beam has been moved.

Trigger Pickoff

When internal triggering of the Time Base Generator is desired (black TRIGGER SLOPE knob on either the + or

Fig. 4-1. Simplified Vertical Amplifier.

-INT. position), a "sample" of the vertical signal is used to develop the triggering pulse. This "sample" is obtained from the trigger pickoff circuit consisting of the Trigger Pickoff Amplifier V1054 and V1064, and Trigger Pickoff C.F. V1223B.

This "sample" of the vertical signal is also ac-coupled through V1223A and C1228, to a front-panel binding post labeled VERT, SIG, OUT.

Delay Line

The output signal from the Vertical Amplifier is coupled through the Balanced Delay Line to the vertical deflection plates of the crt. The function of the Delay Line is to retard the arrival of the waveform at the deflection plates until the crt has been unblanked and the horizontal sweep started. This delay, as mentioned previously, insures that the very "front" of fast vertical signals can be observed. The line is adjusted, by means of the variable capacitors connected across the line, for optimum transient response.

The entire Delay Line, which includes the plate line in the Distributed Amplifier, is reverse-terminated in its characteristic impedance. The Termination Network, shown on the Vertical Amplifier diagram, is designed to dissipate both the dc and signal energy in the line by presenting a constant resistance over the frequency range of the amplifier. The terminating resistors R1071 and R1073 are specially made, wirewound, noninductive, distributed resistors. The 600 ohms total resistance in each is "tapered", or distributed in steps. The largest segment of the terminating resistance appears nearest the line; the smallest segment appears at the opposite end. Each step of the resistance is then tuned, by means of the variable capacitors, so the network will present an optimum load to the line.

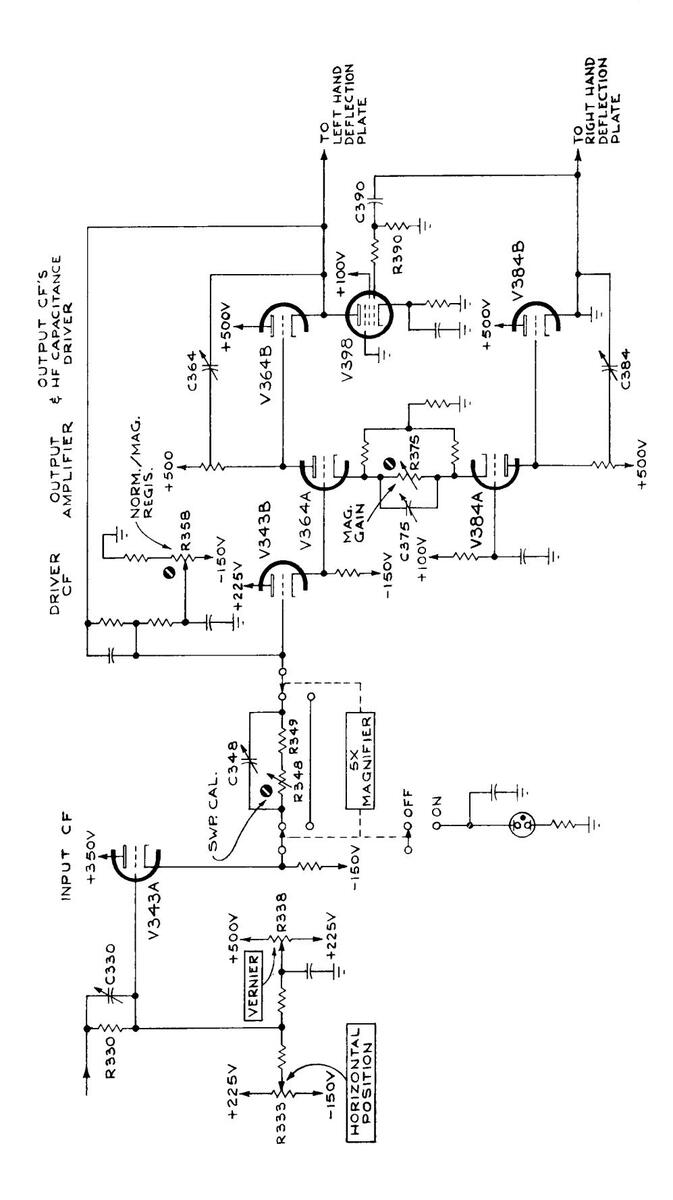

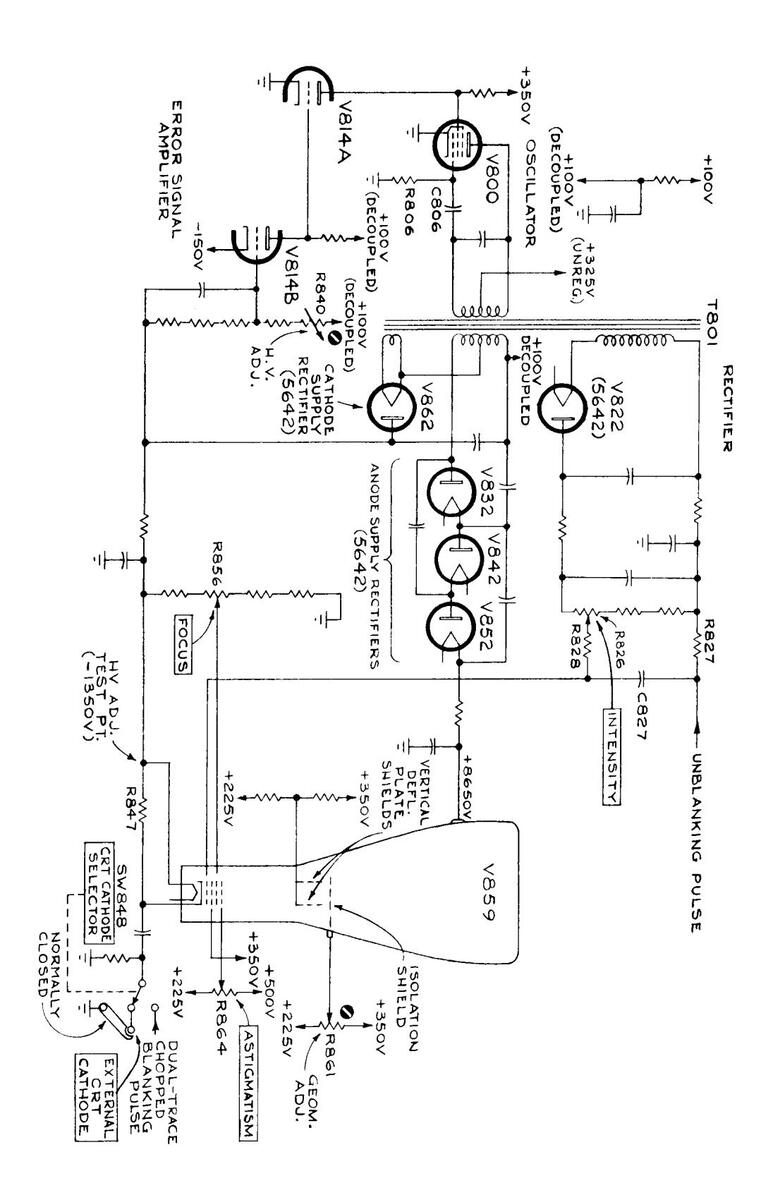

HORIZONTAL DEFLECTION SYSTEM

Time-Base Trigger

General

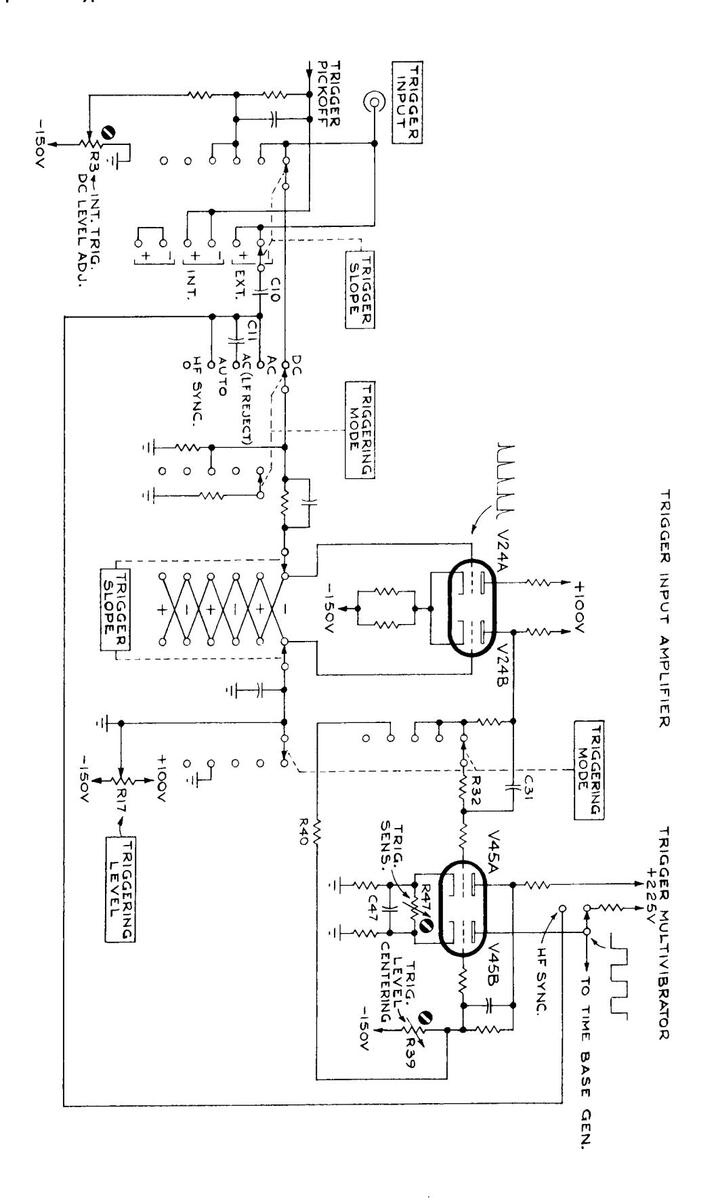

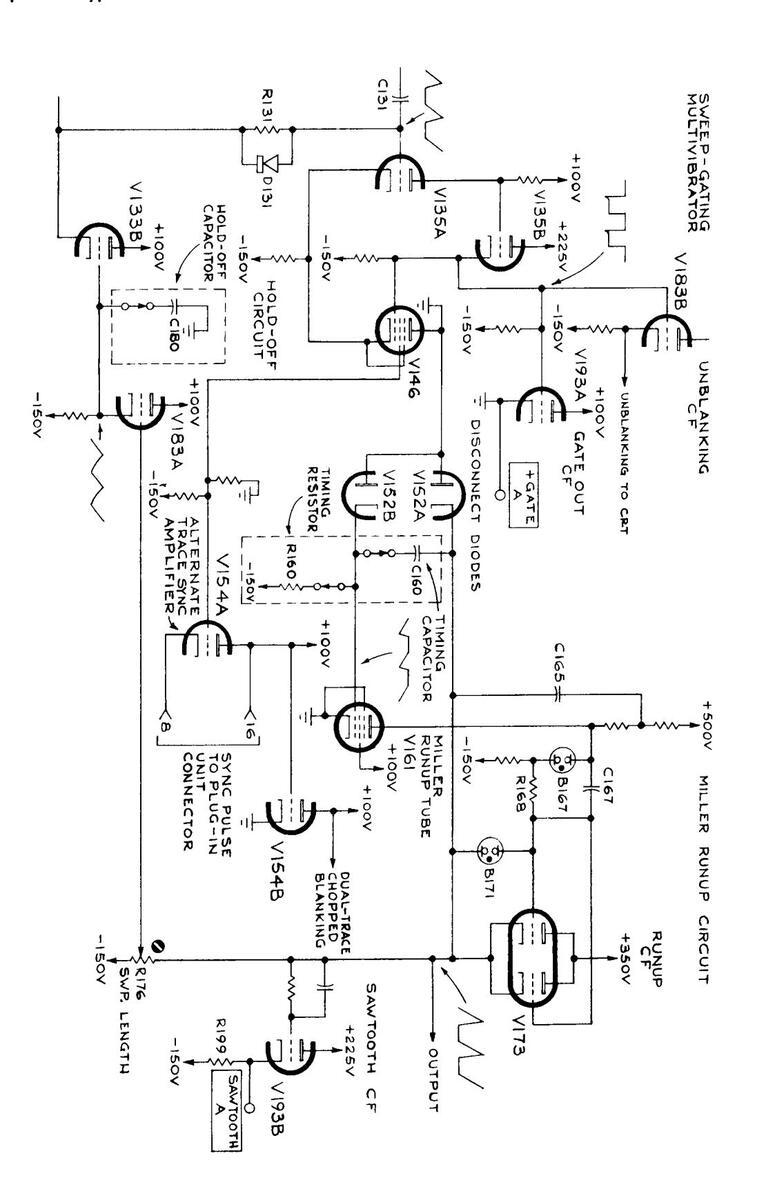

The Time-Base Trigger developes a pulse which will initiate a cycle of action in the Time Base Generator. To display signals below five megacycles, a TRIGGERING MODE switch allows the operator to select the type of triggered operation most suitable for the waveform to be displayed. A second switch, the TRIGGER SLOPE switch, allows the operator to select the "slope", either positive or negative, which will cause triggered operation of the sweep. To display signals above five megacycles, the Time Base Trigger is bypassed, and the signal is applied to the Sweep-Gating Multivibrator in the Time-Base Generator. (HIGH FREQUENCY SYNC. mode.) No choice of triggering slope is available in this mode.

Trigger-Input Amplifier

Triggering signals may be developed from several sources. The most common source of triggering signals utilizes the internal circuitry of the oscilloscope to sample the signal present in the vertical amplifier. Using an internal source

of triggering signal, either triggered operation in the various triggering modes, or synchronized operation, is available

Triggered or synchronized operation of the time-base circuitry may also be effected from external sources. Operation in any of the available modes is possible with external signals.

In +Line or —Line positions of the TRIGGER SLOPE switch a voltage at the power line frequency is used to develop the triagering signal.

The Trigger-Input Amplifier is a polarity-inverting, cathode-coupled amplifier. It serves two basic functions in the Time-Base Trigger. First, it provides a source of negative-going signal to drive the following stage. Secondly, by means of the TRIGGERING LEVEL control, it enables the operator to select the signal at which triggered operation of the Time-Base will occur.

To trigger from a negative-going signal, the grid of the V24A section is connected to the input signal source. The grid of the V24B section is connected to a dc bias source, which is adjustable with the TRIGGERING LEVEL control. This bias voltage establishes the voltage present at the plate under no-signal conditions.