Model 515A

Megohm Bridge

Instruction Manual

Contains Operating and Servicing Information

WARRANTY

We warrant each of our products to be free from defects in material and workmanship. Our obligation under this warranty is to repair

or replace any instrument or part thereof which, within a year after

shipment, proves defective upon examination. We will pay domestic surface freight costs.

To exercise this warranty, call your local field representative or the

Cleveland factory, 440-248-0400. You will be given assistance and

shipping instructions.

REPAIRS AND RECALIBRATION

Keithley Instruments maintains a complete repair service and stan-

dards laboratory in Cleveland, and has an authorized field repair

facility in Los Angeles and in all countries outside the United States

having Keithley field representatives.

To insure prompt repair or recalibration service, please contact your

local field representatives.

To insure prompt repair or recalibration service, please contact your

local field representative or the plant directly before returning the

instrument.

Estimates for repairs, normal recalibrations, and calibrations traceable to the National Bureau of Standards are available upon request.

Model 515A Megohm Instruction Manual

0Keithley Instruments, Inc

All rights reserved.

Cleveland, Ohio, U.S.A.

MODEL 515A MEGOHM BRIDGE

CONTENTS

CONTENTS

Section

1.

2.

3.

4.

5.

Page

ii

1

4

15

17

20

29

31

1072R

SPECIFICATIONS

MODEL 515A MEGOHM BRIDGE

SPECIFICATIONS

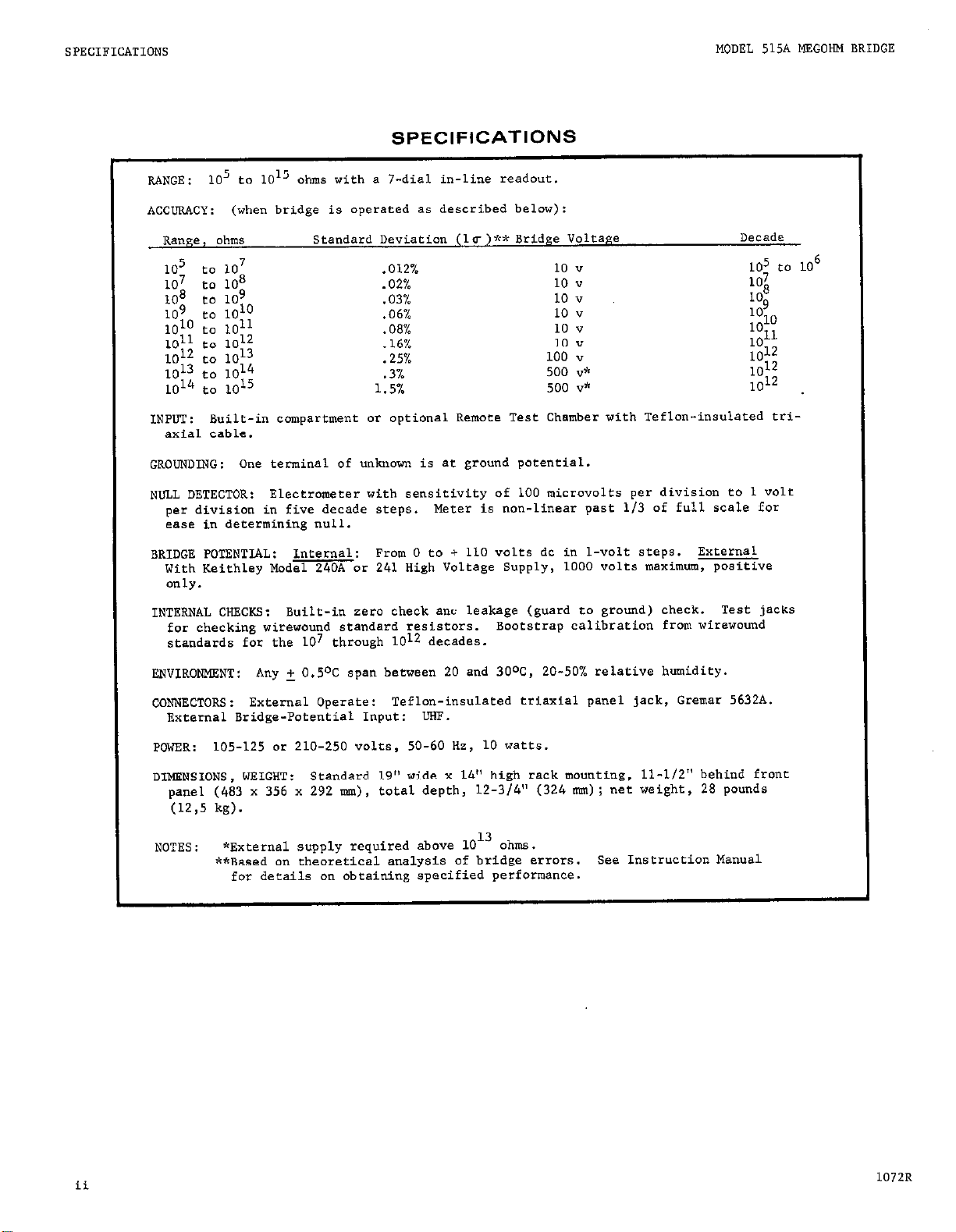

RANGE: 105 to d5

ACCURACY: (when bridge is operated es described below):

Range, ObnlS

105

co lo7 .012%

107

to 108

to 109

100

109

1o1o ;: :$

1011 eo

1012

1012 to 1013

1013 to 1014

1014 to 1015

ohms with a 7-dial in-line readout.

Standard Deviation (lr)r* Bridge Voltage

10 "

.02%

.03%

.06%

.08%

.16%

.25%

.3%

1.5%

10 "

10 "

10 "

10 "

10 "

100 Y

500 "*

500 v*

Decade

105 to 106

107

10;

lOlO

$1

$f

INPUT: Built-in comparfmenf or optional Remote Test Chamber with Teflon-insulated tri-

axial cable.

GROUNDING: One terminal of unknown is at ground potential.

NULL DETECTOR: Electrometer with sen*itivity of 100 microvoles per division to 1 volt

per division in five decade steps.

Meter is non-linear past l/3 of full scale for

ease in determining null.

BRIDGE POTENTIAL:

Internal: Prom 0 to + 110 volts dc in l-volt steps. External

With Keithley Model 240A or 241 High Voltage Supply, 1000 volts maximum, positive

only.

INTERNAL CHECKS: Built-in zero check anu leatige (guard fo ground) check. Test jacks

for checking wirewound standard resistors.

Bootstrap calibration from wirewound

standards for the 10' through 1012 decades.

ENVIRONMENT:

CONNECTORS: External Operate:

Any i O.S°C span between 20 and 3OOC, 20-50% relative humidity.

Teflon-insulated triaxial panel jack, Gremar 56328.

External Bridge-Potential Input: UHF.

POWER: 105-125 or 210-250 volts, SO-60 Hz, 10 "atts.

DIMENSIONS, WEIGHT:

Standard 19" wide x 14" high rack mounting, 11-l/2" behind front

panel (483 x 356 x 292 m), total depth, 12-314" (324 mm); net weight, 28 pounds

(12,s kg).

13

NOTES : *External supply required above

**Based an theoretical analysis of bridge errors.

10

ohms.

See Instrucrion

Manual

for details on obtaining specified performance.

ii

1072R

GENERAL DESCRIPTION

SECTION 1.

1-l. GENERAL. The Model 515A Megohm Bridge is an

instrument

for measuring resistance from lo4 ohms to

GENERAL DESCRIPTION

Source spans a range from 1 to 110 volts in l-volt

steps.

lOI5 ohms with a limit of error from .05 to 1%. Ie

comprises a solid-state, guarded, electrometer null

detector; an ultra-stable, highly-regulated dc voleage ~o”rce, and B Wheatstone bridge.

c.

Shielded Compartment: Connection to the bridge

is made using a guarded terminal in the shielded

compartment which minimizes noise pickup.

1-2. FEATURES

d. Standardize Mode: This mode can be selected

a. Accuracy Verification: Accuracy is traceable

to the National Bureau of Standards by use of the

Model 5155 resistance standards available as an

for quick calibration of bridge elements eo correct

for slight changes in the standard high megohm

resistors.

optional accessory.

e. Guard Leakage Check: A quick self check of the

b. Selectable Bridge Volcage: An internal voltage guard to ground resistance can be made using test

jacks on the front panel (inside the measuring cow

pWCme”t.

1070

1

GENERAL DESCRIPTION MODEL 515A MEGOHM BRIDGE

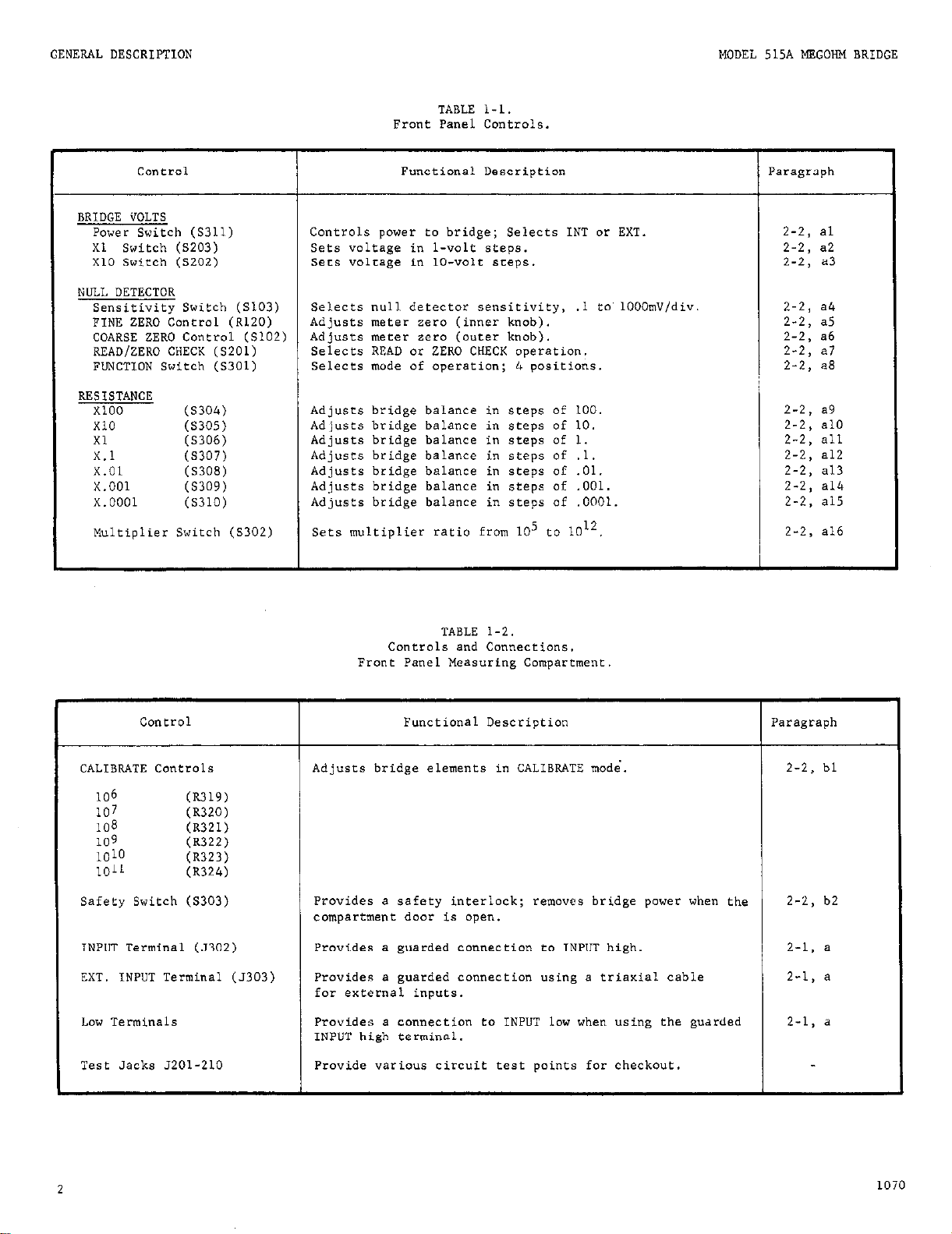

TABLE 1-l.

Front Panel Controls.

Control

Functional Description Paragraph

BRIDGE VOLTS

Power Switch (S311)

Controls power to bridge; Selects INT or EXT.

Xl Switch (S203) Sets voltage in l-volt steps.

X10 Switch (5202) sets vo1rage in IO-volt steps.

NULL DETECTOR

Sensitivity Switch (S103)

FINE ZERO Control (R120)

CO*RSE ZERO Control (5102)

READ/ZERO CHECK (S201)

FUNCTION Switch (S301)

RESISTANCE

x100 (5304)

X10 (5305)

Xl

X.1

X.01 (5308)

x.001

(5306)

(5307)

(S309)

x.0001 (S310)

Selects null detector sensitivity, .I to'lOOOmV/div.

Adjusts meter zero (inner knob).

Adjusts meter zero (outer knob).

Selects READ or ZERO CHECK operation.

Selects mode of operation; 4 positions.

Adjusts bridge balance in steps of 100.

Adjusts bridge balance in steps of 10.

Adjusts bridge balance in steps of 1.

Adjusts bridge balance in steps of .I.

Adjusts bridge balance in steps of .Ol.

Adjusts bridge balance in steps of ,001.

Adjusts bridge balance in steps of .OOfll.

Multiplier Switch (S302) Sets multiplier ratio from lo5 to 1012,

2-2,

al

2-2, a2

2-2, a3

2-2, a4

2-2, a5

2-2, a6

2-2, a,

2-2, as

2-2, a9

2-2, a10

2-2, all

2-2, al2

2-2, a13

2-2, a14

2-2, a15

2-2, a16

Controls and Connections,

TABLE 1-2.

Front Panel Measuring comparement.

Control Functional Description Paragraph

CALIBRATE Controls

106 (R319)

107 (R320)

108 (R321)

109 (R322)

1010

1011 (R324)

(R323)

Safety Switch (~3303)

Adjusts bridge elements in CALIBRATE mode‘.

Provides a safety interlock; rernow~ bridge power when the

2-2,

2-2,

compartment door is open.

INPUT Terminal (5302) Provides a guarded connection to INPUT high.

EXT. INPUT Terminal (5303)

Provides a guarded connection using a triaxial cable

2-1, a

2-1, a

for external inpllts.

Low Terminals Provides a connection to INPUT low when using the guarded 2-1, a

INPUT high terminal.

Tesr Jacks X01-210 Provide various circuit test paints for checkout.

bl

b2

2

1070

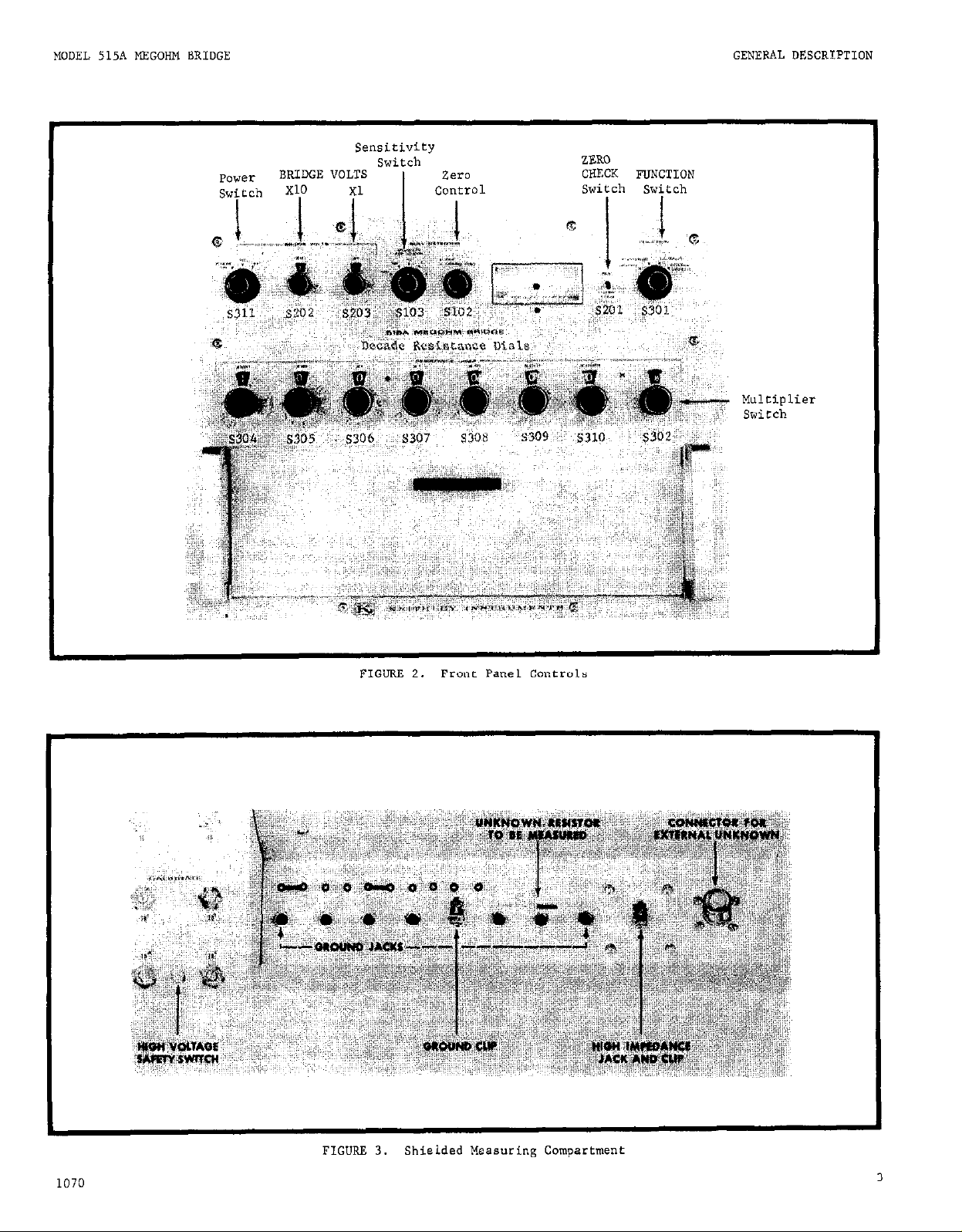

MODEL 515A MEGOHM BRIDGE

GENERAL DESCRIPTION

Power

Swftch

Sensitivity

“RIO”,, VOLTS Switch Zero

Control

I Y1

I

ZERO

CHECK FUNCTION

Switch

S”:rch

Multiplier

Switch

FIGURE 2. FronC Panel Controls

FIGURE 3. Shielded Measuring Compartment

OPERATION

MODEL 515A MEGOHM BRIDGE

SECTION 2.

2-1. MEASUREMENT CONSIDERATIONS.

a. Connections.

Shielded Test Compartment. The Test Compart-

1.

ment shown in Figure 3 permits measurement of high

resistance while minimizing noise pickup and the

effects of leakage paths. Input connections can be

made using a triaxial receptacle (EXTERNAL INPUT

5303) or a guarded INPUT high receptacle (5302).

a.) High Megohm Resistors.

can be easily measured by connecting TV the INPUT

receptacle and any one of eight INPUT low resep-

tacles. The receptacles are designed for use with

test clips such as Grayhill 82-l which have a banana plug on one end and a spring clip on the other.

The INPUT low receptacles are spaced one inch

apart for resistors up to 8 inches long. A typical

resistor connection is shown in Figure 3.

b.) External Connections. A teflon-insulated,

guarded, triaxial receptacle (EXTERNAL INPUT 3303)

is provided for external connections. The receptacle is a Gremar Type 56328 triaxial connector

which mates with a Gremar Type 7991-1 triaxial

plug (Keithley CS-69). A? optiQna1 accessory

cable is available (Keithley MaJel 5153) for external connections; a 60" triaxial cable with CS-

69 connector on one end. The Keithley Model 5152

Remote Test Chamber permits external shielded

measurements (with a 60" triaxial cable and CS-69

connector).

Discrete resistors

OPERATION

External Voltage Source. An external voltage

2.

source can be connected to the bridge using the

rear panel UHF coaxial receptacle (5211). This

connector is a Gremar Type 6804 UHF receptacle

(Keithley CS-64) which mates with a Gremar Type

5127 plug (Keithley CS-49).

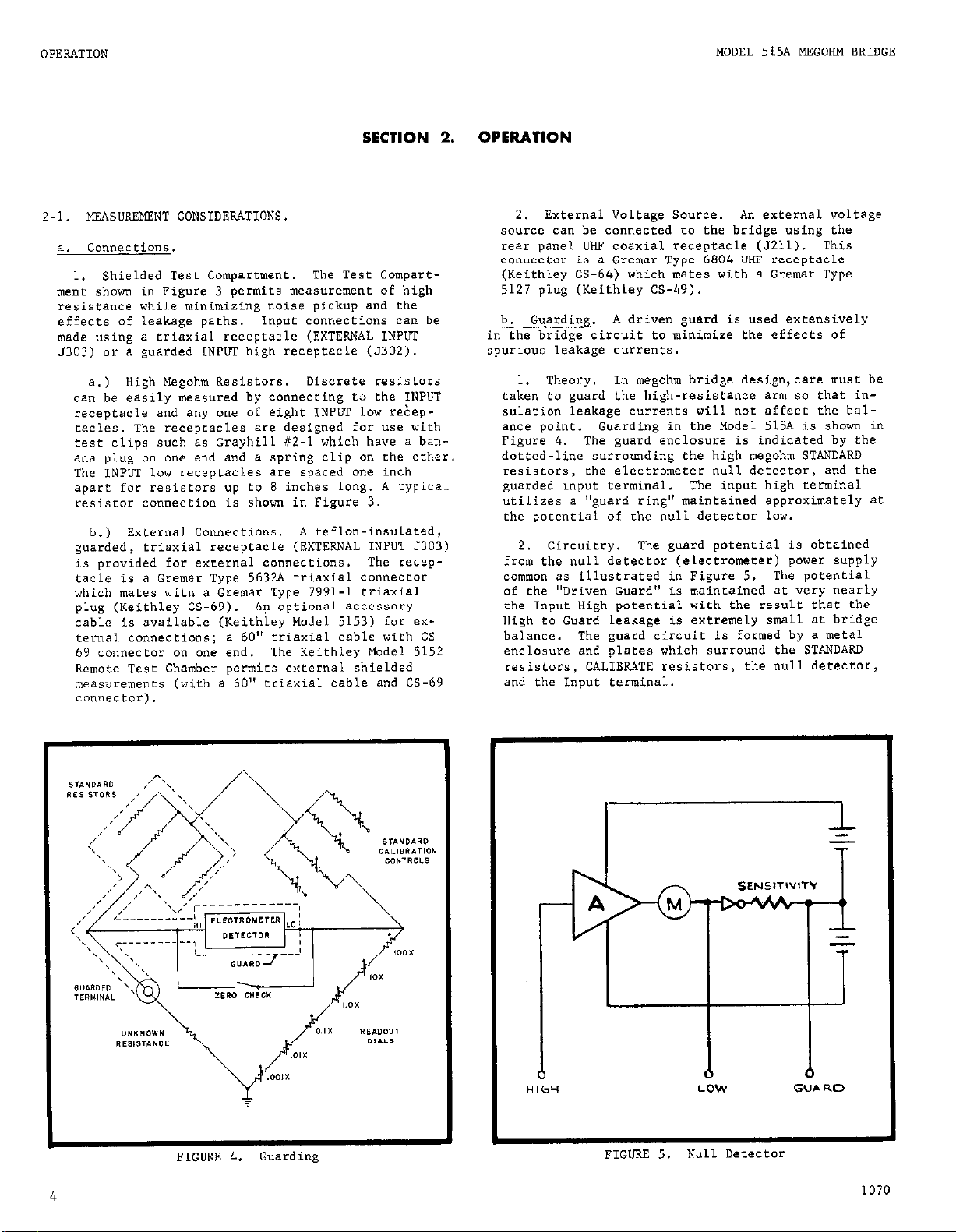

Guarding. A driven guard is used extensively

b.

in the bridge circuit to minimize the effects of

spurious leakage currents.

1. Theory.

taken to guard the high-resistance arm so that insulation leakage currents will not affect the balance point. Guarding in the Model 51% is shown in

Figure 4. The guard enclosure is indicated by the

dotted-line surrounding the high megohm

resistors, the electrometer null detector, and the

guarded input terminal. The inpur high terminal

utilizes a "guard ring" maintained approximately at

the potential of the null detector law.

2. Circuitry. The guard potential is obtained

from the null detector (electrometer) power supply

common as illustrated in Figure 5.

of ehe "Driven Guard" is maintained at very

the Input High potential with the result that the

High to Guard leakage is extremely small at bridge

balance. The guard circuit is formed by a metal

enclosure and plates which surround the STANDARD

resistors, CALIBRATE resistors, the null detector,

and the Input terminal.

In megohm bridge design,care must be

STANDARD

The potential

nearly

FIGURE 5.

Null Detector

1070

OPERATION

3. "se of the Guard.

a.) connections to guard.

(5302) is a guarded receptacle (Gremar, Type

The INPUT terminal

6804)

with a center High contact and an outer Guard

ring. The EXTERNAL INPUT terminal (5303) is a

guarded rriaxial receptacle (Gremar, Type

5632A)

with a center High cmtact, an inner Guard confact

and an outer Low confact. A drawing of the connector construction is shown in Figure

b.) Applications.

The driven guard can be used

6.

for external measurements when it is necessary to

minimize the effects of spurious leakage currents

across the insulation. A rypical external

measurement can be accomplished using Keiehley

Model 5152 Remote Test Chamber and teflon-insulated

triaxial cable. The “se of the Model 5152 is

complerely described in Section 4, Accessories.

c.) Guard to Ground Leakage. The design of the

guard circuit in the Model 515A maintains the Guard

fo Low (ground) resistance greater than 1011 ohms.

The Guard to Ground resistance should be high with

respect to the resistance from floating low to

ground so that the shunting effects across the

Readout Resistance will not be significant. Far

example the worst-case condition would be a Readout Resistance of 10 megohms or lo7 ohms with a

0.02%

tolerance.

If the Guard to Ground fe.sistaxe were 1011 ohms, an additional error of 0.01

% would result.

c. Leakage. The Input terminals of the Model 515A

have been designed using teflon insulation between

High and Guard and Guard and Ground. In order eo

maintain the high insularion resistance, the terminals

must be kept clean and dry.

Preferred cleaning materials include: Chemically pure alcohol, sterile

cotton swabs (to prevent contamination of alcohol),

and a drying agent such as nitrogen. Leakage paths

across the terminal can create intermitrant errors or

difficult bridge balance. The user should also take

care to insure that the unknown resistor, holding

fixtures and case are insulated properly. Glass

envelopes (high.megohm resistors) can be contaminated

by oil and salts from improper handling. Paper base

bakeliee insulation can be degraded by improper

handling and exposure to moisture. The humidity of

the laboratory environment can also affect the measurement of very high resistances. See Specificarians.

d. Noise. Noise pickup from ac electric and mag-

netic fields is minimized by the unit construction

of rhe chassis and the use of a closed, shielded

measuring compartment. When using an external unknown

resistance, care should be taken to:

1. Use shielded cables such as Keithley Model

5153 triaxial cable.

2.

Fasten dawn the cables so that flexure noise

is minimized.

3. Maintain Guard to Ground insulation using

teflon insulation.

FIGURE 6. Triaxial Receptacle

4. Use an external shielded test box such as

Keithley Model 5152 Remote Test Chamber.

e. Accuraw.

1. Specification. The specified accuracy for

measurements on various ranges is valid for the

following conditions.

a.) Minimum Bridge Potential. This potential

is the minimum voltage required for resolution.

b.) Environment. The ambient temperature and

relative humidity must be controlled within

limits stated.

c.) Standardization. The Standardization

procedure should be performed prior to very

critical measurements.

d.) Proper Operating Technique. Care must be

taken when connecting the unknown (See Measure-

ment Considerations, Paragraph 2-1) and balancing

the bridge (See Accuracy Considerations, Para-

graph Z-7).

2. Verification. The Model 515A accuracy can

be verified using the Model 5155 Megohm resistance

standards.

1072R

5

OPERATION

10

3.

Technique for Measuring 10

to 1015 Ohm

Resisrances.

Set Canrrols as Indicated:

BRIDGE VOLTS: 0

FUNCTION SWITCH:

MULTIPLIER:

OPERATE OR EXTERNAL OPERATE

1010, 1011, or 1012

RESISTANCE DECADE DIAL X100: lo

READ/ZERO SWITCH:

Insert unknwn resistor.

ZERO

Set READ/ZERO Switch m

READ and note offset of null deeector with MULTIPLIER

setring to be used in measurement. Allow approx-

imately 15 minutes for reading t” stabilize. The

affser of the null detector is due to offset current

from the null derecror and from stressing of Teflon

insulation surrounding the Hi terminal of the bridge.

Use the offset reading as null for measuring the

unknown.

Ser READ/ZERO Switch to ZERO.

Select the Bridge

potential for the measurement based on desired

accuracy as described in derail in the OPERATION

secfion af the manual. Set READ/ZERO Switch m

READ and balance bridge using Resistance decade

dials.

?IETER NOISE: I” balancing the bridge when measuring

resistances greater than lolo ohms there is meter

noise present due to l/f noise, alpha particle noise,

It may be noted fhat the meter indication has

etc.

a base-line from which meter fluctuations diverge.

The actual null detector reading is this base-line

when balancing the bridge.

NOTE

Care should be taken m allow enaugh time for

bridge to stabilize fc, a reading. This rime will

vary from one measurement to another however, a

minimum time of 15 minures is advisable to decermine final null reading.

2-2. CONTROLS AND SWITCHES.

a. Front Panel.

1. Power Switch (5311). This switch controls

the power to the bridge including the bridge

porenrial and null detector supplies. The INT

position permits a setting of the bridge potential

from 1 to 110 volts using the Xl and X10 BRIDGE

VOLTS switches.

The EXT position connects the

external voltage input (5211) so that a bridge

potential up to 1000 V can be applied “sing an

external voltage supply such as Keithley Model

241.

2.

Xl Switch (S203). This switch permits a set-

ting af the bridge p@zential in l-volt increments

up to 10 volts.

3. X10 Switch (S202). This switch permits a

setting of the bridge potential in lo-volt incre-

nle*tS up to 100 volts.

4. Sensitivity Switch (S103). This switch se-

lects the null detector sensitivity from .l to 1000

milliu0lts per division.

MODEL 515A

5. FINE Control (Rl20).

This control is the

inner knob af a dual-concentric canerol. The FINE

Control permits adjustment of the meter zero.

6.

COARSE ZERO Switch (S102). This switch is

the Outer knob af a dual-concentric control. The

COARSE Switch permits adjustment of the meter zero

in 10 steps.

7.

READ/ZERO CHECK Switch (S201). This switch

selects READ or ZERO CHECK operation for the meter

circuit. In ZERO CHECK position the null deeecmr

High and Low ‘are shorted together.

8. FUNCTION Switch (5301). This switch selects

the mode of Operation in 4 position,

OPERATE,

STANDARDIZE, CALIBRATE, and EXTERNAL OPERATE. A complete

discussion of these modes is given in paragraph 2-3.

9. Xl00 Resistance Switch (5304). This switch

adjusts the “Readout” am of the bridge in steps

of 100.

10. X10 Reeietance Switch (S305). This switch

adjusts the “Readout” am of the bridge in seeps

of 10.

11. Xl Resistance Switch (5306). This switch

adjusts the “Readout” arm of the bridge in steps

of 1.

12. X.1 Resistance Switch (5307). This switch

adjusts the “Readout” arm of the bridge in steps

of .l.

13. X.01 Resistance Switch (S308). This switch

adjusts the “Readaut” am of the bridge in steps

of .Ol.

14.

X.001 Resistance Switch (S309). This switch

adjusts the “Readout” am of the bridge in steps

Of .OOl.

15. X.0001 Resistance Switch (S310). This switch

adjusts the “Reabou:” arm of the bridge in steps

Of .OOOl.

16.

Multiplier Switch (S302). This switch sets

the multiplier ratio from 105 to 1012.

b. Measuring Cmpartment.

1. CALIBRATE Confmls. These controls are used

to adjust the bridge when the FUNCTION Switch is

set to CALIBRATE. The use of these controls is de-

scribed in paragraph 2-4, d (Standardization pro-

cedure).

2.

Safety Switch (5303). This switch is a normally-open interlock which remwee bridge power

when the compartment door is open. The safety in-

terlock is defeated when the FUNCTION switch is set

to EXTERNAL OPERATE.

c. Rear Panel.

117-234V Line Switch (5312). This

switch sets the Model 515A far either 117V or 234V

rms line power,

50-60

Hz.

6

1072R

MODEL 515A

OPERATION

2-3. MODES OF OPERATION.

a. operate.

This mode of operation permits meas-

urements of high megohm resistances when connected to

the INPUT receptacle.

FUNCTION switch to OPERATE.

To select this mode, set the

Either the internal voltage source (bridge potential) or an external voltage

source up to 1000 volts can be used. The safety

interlock switch prevents operation of the bridge

whenever the compartment door is open.

If the unknown

resisCa”ce must he measured externally, “se the External Operate mode.

b. External operate.

This mode of operation permits resistance measurements the same as for the

Operate mode.

To select this mode set the FUNCTION

switch to EXTERNAL OPERATE.

WARNING

When the FUNCTION Switch is set to

EXTERNAL OPERATE the safety inter-

lock feature is defeated. Therefore

the bridge voltage (up to 1000 volts)

is present at ehe Guard circuit at

receptacle 5303.

The user should be

ca”tio”s when “sing very high bridge

voltages. For maximum safety, the

Power Swifch (S311) should be set to

INT when not making a measurement.

c.’ Standardize/Calibrate. These modes of operation permit adjustment of the bridge elements to

compensate for slight variations of the standard high

megohm resistors. To select either made set the

FUNCTION Switch to STANDARDIZE or CALIBRATE as described in paragraph 2-4, d.

2-4.

PRELIMINARY PROCEDURES

1. COARSE ZERO Switch (S102) (Outer Knob). This

switch has eleven positions for adjustment of meter

zero.

2. FINE ZERO Control (R120).

This control provides fine (potentiometer) adjustment of the meter

zero.

c. Warmup. The instrument should be allowed to

stabilize with power on (at least 30 minutes). If

the instrument has been exposed to an extreme ambient

temperature change the warmup time should be extended

fo

24

hours or more.

Standardize Procedure. For critical measure-

d.

ments the instrument should be standardized prior to

each measuremene to compensate for slight changes of

the standard high megohm resistors due to temperature

variations and aging with time. The Standardize procedure should be performed as described in Table 2-l.

A complete discussion of the Standardization technique

is given in paragraph 2-5.

2-5. MEASUREMENT PROCEDURE

a. Connect Unknown Resistance. Determine the method of connection to the unknown as discussed in paragraph 2-l.

b. Select the Bridge Potential. The minimum Bridge

Potential should be determined for rated acc”racv as

stated in the specifications. The voltage can b; applied internally (with Power Switch set to INT) or

externally as described in paragraph 2-l.

c. Standardize Bridge. For measurements where the

effects of variations of the bridge elements must be

minimized, the Standardization procedure should be

performed as described in paragraph 2-3, d.

a. Power.

1. Line Voltage. This inscrumenc can be connect-

ed to 117 volt, 50-60 Hz line power when the Line

Voltage Switch (on the rear panel) is set to 117”.

The fuse should be a type 3AG, 1/4A, SLO-BLO. When

using

234V

power, set the Line Voltage Switch to

234V and replace fuse with a type 3AG, 1/8A, SLO-BLO.

2. Accessory Outlet. A three terminal power

outlet (5301) is provided on the rear panel far

operation of an accessory such as an external power

S”PPlY.

and is not controlled by the Power Switch.

3.

This outlet is wired to rhe line power cord

Power Cord. A three wire power cord is supplied (6 feet long). A third prong is used far

earth ground connection for the chassis. An adapter is supplied for converting to a two prong outlet,

but should only be used when a solid, earth-connec-

tion is made by some other means.

b. Meter Zero. The meter circuit can be zeroed by

adjustment of COARSE ZERO and FINE ZERO Controls. The

READ/METER ZERO Switch (S201) should be -et to METER

ZERO.

1072R

d. Meter Zero. Adjust meter zero as necessary.

iiridge Balance.

e.

With the FUNCTION Switch set

to OPERATE, proceed to balance the bridge (set the

READ/ZERO Switch ea READ).

Increase the null sensi-

riviey as necessary to obtain a precise bridge balance.

f. External Operate. If the unknown resistance is

connected externallv the FUNCTION Switch should be set

to

EXTERNAL

2-6.

a.

OPERATE before bridge balance is attempfed.

STANDARDIZE.

Purpose of Standardization Technique. Wirewound

resistors have the greatest accuracy and keep their

calibrations over long periods of time. Values greater

than about one megohm, however, are too large and coo

expensive to be widely used. Film type resistors pravide values up to lOI ohms and higher with reasonable

SUCCESS and this type resistor is used in rhe Model

515A. B”t the value of these resistors changes with

time, sometimes one percenr per year.

The Keithley

Model 51% Megohm Bridge has been designed so that

frequent compensations can be made for variations of

its high-megohm standard resistors. This process is

called Standardization and is carried out as in paragraph 2-4, d.

7

OPERATION

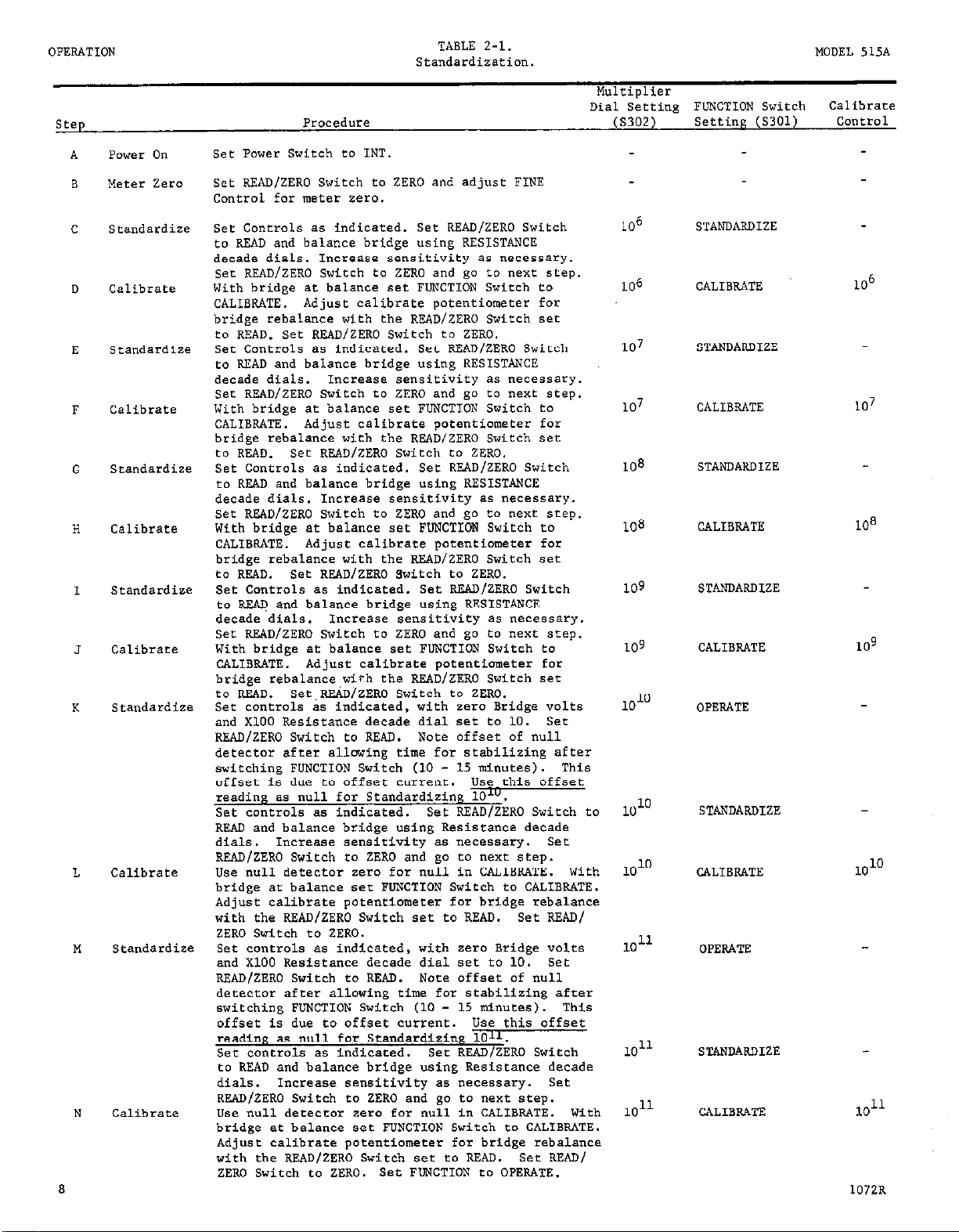

TABLE 2-l.

Standardization.

MODEL 515A

Step

A

B

c

D

E

F

G

H

I

J

K

L

M

N

8

Power On

Meter Zero

Standardize

Calibrate

Standardize

Calibrate

Standardize

Calibrate

Standardize

Calibrate

Srandardize

Calibrate

Standardize

Calibrate

Procedure

Set Power Switch to INT.

Set READ/ZERO Switch to ZERO and adjust FINE

control for meter zero.

Set Controls as indicated. Set READ/ZERO Switch

to READ and balance bridge using RESISTANCE

decade dials. Increase sensitivity as necessary.

Set READ/ZERO Switch to ZERO and go to next step.

With bridge at balance set FUNCTION Switch to

CALIBRATE. Adjust calibrate potentiometer for

bridge rebalance with the READ/ZERO Switch set

to READ. Set READ/ZERO Switch to ZERO,

Set Controls as indicated. Set READ/ZERO Switch

to READ and balance bridge using RESISTANCE

decade dials. Increase sensitivity as necessary.

Set READ/ZERO Switch to ZERO and go to next step.

With bridge at balance set FUNCTION Switch to

CALIBRATE. Adiust calibrate potentiometer for

bridge rebalance with the R&/ZERO Switch set

to READ.

Set Controls as indicated. Set READ/ZERO Switch

to READ and balance bridge using RESISTANCE

decade dials. Increase sensitivity as necessary.

Set READ/ZERO Switch to ZERO and go to next step.

With bridge at balance set FUNCTION Switch to

CALIBRATE. Adjust calibrate potentiometer for

bridge rebalance with the READ/ZERO Switch set

to READ.

Set Controls as indicated. Set READ/ZERO Switch

to READ and balance bridge using RESISTANCE

decade dials. Increase sensitivity as necessary.

Set READ/ZERO Switch to ZERO and go to next step.

With bridge at balance set FUNCTION Switch to

CALIBRATE. Adjust calibrate potentiometer for

bridge rebalance with the READ/ZERO Switch set

to WAD. Set READ/ZERO Switch to ZERO.

Set controls as indicated, with zero Bridge volts

and Xl00 Resistance decade dial set to 10. Set

READ/ZERO Switch to READ. Note offset of null

detector after allowing time for stabilizing after

switching FUNCTION Switch (10 - 15 minutes). This

offset is due to offset current. Use this offset

reading as null for Standardizing 10'".

Set controls as indicated. Set READ/ZERO Switch to

READ and balance bridge using Resistance decade

dials. Increase sensitivity as necessary. Set

READ/ZERO Switch to ZERO and go to next step.

Use null detector zero for null in CALIBRATE. With

bridge at balance set FUNCTION Switch to CALIBRATE.

Adjust calibrate potentiometer far bridge rebalance

with the READ/ZERO Switch set to READ. Set READ/

ZERO Switch to ZERO.

Set conrrals as indicated, wirh zero Bridge volts

and Xl00 Resistance decade dial set to 10. set

READ/ZERO Switch to READ. Note offset of null

detector after allowing time for stabilizing after

switching FUNCTION Switch (10 - 15 minutes). This

offset is due to offset current. Use this offset

reading as null for Standardizing 1011.

Set controls as indicated. Set READ/ZERO Switch

to READ and balance bridge using Resistance decade

dials. Increase sensitivity as necessary.

READ/ZERO Switch co ZERO and go to next step.

Use null detector zero for null in CALIBRATE. With

bridge at balance set FUNCTION Switch to CALIBRATE.

Adjust calibrate potentiometer for bridge rebalance

with the READ/ZERO Switch set to READ. Set READ/

ZERO Switch to ZERO. Set FUNCTION to OPERATE.

Set READ/ZERO Switch to ZERO.

Set READ/ZERO Switch to ZERO.

Dial Seefing FUNCTION Switch

Set

Multiplier

(S302) Setting (S301)

10’5

106

107

107

108

108

109

109

lOlO

1010

lOlO

loll

loll

loll

STANDARDIZE

CALIBRATE

STANDARDIZE

CALIBRATE

STANDARDIZE

CALIBRATE

STANDARDIZE

CALIBRATE 109

OPERATE

STANDARDIZE

CALIBRATE

OPERATE

STAND*RDIZE

CALIBRATE

Calibrate

Control

106

107

108

lOlO

loll

1072R

MODEL 51524

b. Description of circuit and technique.

I. A simplified bridge circuit with FUNCTION

switch in ST*NDARoIZE is shown in Figure 9.

2. With Resistance Multiplier Switch eef et lo6,

then the bridge null is obtained for the condition

s6,S, = B6/A, where “S,j”, s’S7’1, “B6”, and “A” are

defined as follows:

= Standard resistor (lo6 ohm, .02%) selected

"'6"

“ST?<

"'6"

,,*,,

by resistance multiplier switch set at 106.

= Standard resistor (lo7 ohm, 1.0%).

= 105 ohm, .02%.

= Resistance decade potentiometer adjusted

for null (106 ohms).

NOTE

This technique is used ta determine the ratio of

r?,611 to ‘37” accurately as read by resistance

decade dials.

3. A simplified bridge circuit with FUNCTION

switch in CALIBRATE is shown in Figure 10

4. In the CALIBRATE position, a resistance ratio

network of 1:lO is connected in place of “56” and

*‘S7”. The bridge null is obtained far the condition R = +/A, where “R”, “S7”, and “A” are defined

as follaws:

“Ru

= Ratio network of ‘I:10 with .005% accuracy.

OPERATION

2-7.

THEORY OF OPERATION.

Bridge Theory. The Megohm Bridge has been de-

a.

signed to measure very high resistances using a

Wheatstone Bridge and a sensitive null detector. The

Wheatstone Bridge circuit basically consists of four

arms, identified as A, 8, S, and X as shown in Figure

11. (A

thorough

discussian of bridge meaeurement is

available in Electrical Measurement, F. K. Harris,

Wiley, New York, 1952). The equation for the bridge

at balance can be described by the equation:

x = s x A/B

b. Null Detector Sensitivity. The sensitivity of

the bridge can be described by the equation:

e = Sd

OL

xE

e = sensitivity in volts

d = incremental unbalance (in terme of the unknown)

E = bridge potential

S = standard resistance

X = unknown resistance.

C. Voltage Across the Unknown. The Voltage acr~se

the unknown resistance can be determined for a given

set of conditions where:

E =

bridge potential (bridge volts setting)

standard resistance (multiplier setting)

s =

x =

unknown resistance (approximate value of the

“IlkFlOWn )

“87” = Calibrate potentiometer.

= Resistance decade p@zentiometer adjusted

“A”

previously in b2.

NOTE

This technique is used to set the calibrate

paentiometer “8,”

such that errcx in “57”

is compensated.

5. A simplified bridge circuit with FUNCTION

switch in OPERATE is shown in Figure 11.

6.

In the OPERATE position, the bridge null is

obtained for the condition ST/X = 07/A. when resistance decade potentiometer “A” is properly

adjusted.

7. A simplified bridge circuit with FUNCTION

Switch in OPERATE and resistance multiplier 106

is shown in Figure 8.

TEST JACKS

5201 2 3 4 5 6

oegoouooo

7 8 9 10

JUMPERS (NORMAL POSITION)

FIGURE 7.

Test Jack Identification.

“, =

voltage across x = E x

X+S

2-a. GuARo LEAKAGE CHECK.

The fallowing procedure should be used to verify the

guard to ground resistance. The teet jacks are identified in Figure 7.

Procedure :

1. Connect power cord to line voltage.

2. Place

3.

iumers

3203

and j204

5205

and 5206

set 515‘4 controls

between the followine

as foliows.

test

iacks.

BRIDGE POWER - EXT

MILLI"0l.T PER DIVISION

- 1000

FUNCTION - OPERATE

MULTIPLIER - 105

READ/ZERO CHECK

- ZERO CHECK

Xl00 DIAL - 1

DOOR

4.

Connect Keithley Model 240A Power Supply to

- CLOSED

EXTERNAL INPUT on the rear panel.

Set Model 240A to 1000 volts with

5.

6.

Set READ/ZERO CHECK switch to READ.

Allow

7.

five minutes for the Made1 515A reading to

OUTPUT to +.

stabilize. Reading shall be less than 1000 mV.

NOTE.

The meter indicates the voltage drop acrcse

a 108 resistox in series with the leakage path.

Leakage resistance from GUARD to

GROUND

is deter-

mined as fallows.

Leakage current = (Voltage drop : lo* ohms)

Leakage resistance = (1OOOV + leakage current)

Typical GUARD to GROUND resistance is greater

than 1011 ohms.

9

OPERATION

MODEL 515A MEGOHM BRIDGE

Calibrate Position, lo6 Multiplier.

10

. _ _ _ .._

Operate Position, lo7 Multiplier.

MODEL 515A

OPERATION

2-9. ACCURACY

Standard Deviation.

a.

the bridge eiven in the Soecifications is defined as

the “standard deviation” br lo-level.

- I

CONSIDERATIONS.

The overall accuracy of

In a system

where several components of error make up the total

error, it is grossly unfair (when specifying the

system) to use worst-case limits in describing accuracy.

In many cases, the error so described may have

a probability of less than one in a billion while

human error (usually neglected in such an analysis)

can easily contribute gross errors on the order of

one in a thousand.

It is far more reasonable to use

a limit between one in a thousand (99.9% or 3.3) and

one in ten thousand (99.99% or 3.9) as a specification

of system accuracy.

If the 3rlimits of two or more

normally distributed (n) randomly occurring corn-

poqents of error are summed in quadrature (G12T

1 ) the sum is the 3Uerrar for the group. If

=2

three uniformly distributed (-) randomly occurring

components of error have equal limits, the arithmetic

sum of these limits will closely represent the 30

points of the near normal error distribution generated

by the interaction of these error components. These

TABLE 2-2.

3 r Error Computation.

(All numbers in % of Reading with minimum bridge potential specified and dials between 1 and 10).

31r limits may then be used to sum in quadrature with

the 3s limits of other normally distributed error

components. The effect of error components which are

not randomly distributed but are fixed or have a fixed

rate of change (systematic errors) must be added

directly to the random errors. If one component Of

error occurs more than once and does not have random

change to have changed, it must be summed directly

far the number of times occurred before being added

in quadrature to other errors.

b. Error Analysis. The various factors which can

be identified as sources of error include the follow-

ing .

1. Bridge Arm. The errors pertaining to the

bridge arm consist of the decade dial errors and

the fixed arm to decade ana ratio.

a.) Decade Dial. The decade dial errors include the worst case dial setting within the

decade span used, the inherent resistor error,

the temperature and time stability of the resistors, and the effect of leakage resistance.

Range zero

ohms

105 - 10’

107 108

108

- 109

Check Null

,006 .006 - .03 .OOl .031

,006 ,006 .02 .04 .002 ,009 ,005 .03

.006 .006 .03 .08 ,004 .012

109 - lOlo ,006 .012

1010 - 1011

1011 - 1012 ,006

1012 - 1013

1013 - 1014 .006

1014 - 1015 .06 0.6 .07 .72 .064 .04 .030 .03 0.1

.006 .012 .04 .24

.03 .05 .48 ,022

.006 .12 .07 .72 .064

.24 .07 .72 .064 .04 ,030 .03 .Ol .77 500 *

Temp. volt

Coef.

Coef. Coef.

Temp.

Null

R&b

Bridge

AKIllS

.OlO .03 .OOl

.03 .16 ,006 .015 .015 .03

.OlO

.020

,024 .025 .03 ,001 .49

.04 .030 .03

.020 .03 .OOl .25

Leakage %

Ladderinn

Total

Error

Minimum

Bridge

Potential

10

,001

.056 10

,085

10

.OOl .17 10

10

10

.OOl .74 100

1.1

500 *

* ~a obtain this accuracy specification an external voltage supply is required. Accuracy (30) for

1015

range would be + 6% at a bridge potential of 110 V.

1072R

11

OPERATION

MODEL 515A

b.) Fixed arm to decade arm ratio. The errors

associated with the ratio accuracy include the

basic Standard resistance error, the accumulative

laddering error and the temperature and voltage

coefficient of the Standard resistor.

2. Null Uncertainty. The errors pertaining to

null uncertainty include the null detector sensi-

tivify, the bridge voltage, the bridge ratio, and

the l/f noise.

c. Error Computation. The computation of total

error at rhe 3D-level is sham in Table 2-2 far each

NOTE

The assumptions made to simplify the error

analysis include the following.

individual resistors are within their tolerance limits and have a uniform random

distribution between these limits.

temperature coefficient and voltage coefficient an wirewound resistors are negligible in the face of other errors.

to-peak null detector meter excursions

observed over several fime constants represent

the +3Ulimit of a normally distributed random

null certainty.

1. All

2. The

3. Peak-

d. Error Factors.

1. Worst Case Dial Setting. Far the "optimumuse range" between 1.0000 to 9.9999, the worse

case dial setting would be 1.0999. Since each dial

setting of 9 represents 3 resistors, the total

contribution of dial settings .0999 would be:

3uerror =~(.005)2+(.0025)2+(.001)2 : +.006%.

If this error is added to the base tolerance of .OI%

and divided by the higher resistor value (1.0999),

the result is:

% error = * - .015%

If this error is separated into components, then

the uniformly distributed error = .Ol% while the

normally distributed error = .005%.

2. Resistor Accuracy.

the various dials is given in Table 2-3.

Dial

Resistance Xl00 10 1 .1 .Ol .OOl

TDleratKe

I

1

3. Temperature Coefficient. The temperature coefficients for the Standard resistors are given in

Table 2-4 (assuming a +.5'C temperature).

1.0999

The resistor accuracy for

TABLE 2-3.

Dial Resistor Accuracy.

.OOOl

. 5% .Ol% .Ol% .Ol% .05% .25% 1%

I

I

12

1072R

MODEL 515A MEGOHM BRIDGE

OPERATION

TABLE 2-4.

Leakage Resistance.

4.

since the Readout Dials are shunted by approximately

1011 ohms. The error should be added directly since

it is a relatively fixed systematic errm.

VOltage Coefficient. The valtage coefficient

5.

for each Standard resista is given in Table 2-5.

Voltage Coefficient (l-lOV)/V. in %.

IResistance lo7 1OB lo9 lOlo 1011 101’1

Coefficient -.005

I

6. Null Resolution. Null uncertainty is approxirately the ratio of the smallest voltage drop eceoss

the bridge arm to the null resolution. AS the bridge

ratio departs from 1:l the null uncertainty becomes

mre significant.

-.005

Leakage causes an error

TABLE 2-5.

-.Ol

-.Ol

-.03 -.03

7. Laddering. Laddering is the process of using

the bridge Co calibrate itself. Several errars

compound during this process to increase the error

of the bridge at higher resistances. The process

consists of two modes:

I* CALIBRATE Mode: ~6 = &

where R6 is the 106 miltiplier (20.01%) and R7 is

the 107 multiplier resistor (+O.Ol%), B6 is the

“fixed” arm associated with the 106 multiplier and

D is the dial setting.

In STANDARDIZE Mode: R, =

where

Ra/Rb

is the 1:lO ratio pair (20.005%) and B7

I

I

is the “fixed” arm associated with the lo7 multi-

plier (adjusted for proper ratio).

Thus, B7 = ~6 R,

laddering. The

tion and only 3 resistive error factors ere included,

~6, R6

ey at 106

(use 0.006%) muef be included.

If can be shown that further nullings give

and Ra/Rb. In addition, a nulling uncertain-

x r at the end of the first

diai accuracy

and a nulling uncertainty at low impedance

STANDARDIZE and CALIBRATE.

7 D

87

K

b

0

a

drops from considera-

Teble 2-6 gives the null uncertainty for the caee

where the ratio is 1O:l and the bridge voltage is

10”. (1OO:l @ 100” for lOI4 range and 1OOO:l @ SOOV

for 1015 range).

Null Uncerrainey-Null Detecmr Resolution.

105 106

Range

% Error ,006 .006

N.D. Resolution

In” f<

+

I

*With a 10” bridge potential.

to to to to to

106 107

.05 .05

107

108 109

,006 .006 ,012 ,012

.05 .05 .lO .10

108

TABLE 2-6.

109

1o1o $11

thue adding one mme Ra/Rb uncerraincy, one mre

low impedance null uncertainty and an additional

null uncertainty at IO7 ohms. The voltage acmes

1010

1011

;;12 $3

.03 .12 .24 .6

.25 1.0

1012

1013 1014

:;14 ;;15

1070

13

OPERATION

MODEL 515A MEGOHM BRIDGE

the hi-meg changes from about 10 volts in “STAND-

ARDIZE” pcxition to about 1 volt in ehe next “CAL-

ISRATE” position. Since the voltage coefficiene is

always negative, these errors must be added together

prior to the sunning procedure in quadrature wieh

ocher random variable. The effect of voltage co-

I

Range

Range Time to Calibrate Temp. Change

W/V

,005

,005

.Ol

.Ol

.03

.03

Temperature Errors During Laddering.

TABLE 2-7.

TABLE 2-8.

efficient need only be accounted for one time.

Table 2-7 shows the sum of the voltage coefficienr

errors on each range during laddering. For ladder-

ing the meaaamnent time can be assumed short with

respect to ineernal temperature changes. (The

thermal time constant for the Model 515A is about

10 minutes). Table 2-S shows the total error for

temperature changes

v “C Error “C ErT-21

8”

8V

8”

8”

av

8V

TC Total Error TC *

.04

.04

.08

.08

.24

.24

107

108

Jt

TC represents the “root square sum” or total error for each range due to temperature coefficient errors

during laddering.

1 min

1 min

1 min

2 min

5 min

10 min

Range

r

107

108

109

(a) Normal Distribution.

(b) Uniform Distribution.

(c) Ra/Rb will not change so addition of subsequent errors is direct, not in quadrature.

,:;

.04 ,002 1x.006%

.08 ,004 2x.006

16

124

.48 ,022 5x.006

.72 .064 6x.006

(a;

.006 3x.006

.OlO

o,05°c

0.05%

0.05oc

O.lOC

0.2QC 10 .02% ,022

0.4OC :15 .06% .064

TABLE 2-9.

Lo 2 nulls

4x.006

Hi

3x.006-.012 =.020

3x.006-2x.012 =.024 2x.01 5x.005 = .025

3x.006-2x.012-.03 =.040 2x.01 6x.005 = ,030

.04

.06 .003%

.Ol .0035% ,006

.08 .008%

7. nulls

.006 =.009 2x.01 lx.005 = .005

2x.006 =.012 2x.01 2x.005 = ,010

3x.006 =.015 2x.01 3x.005 = ,015

.002%

nulls ~61~6

(a) (b)

2x.01

RaIRb

4x.005 = ,020

,002

,004

.OlO

RI

9 (a) cc

14 1070

MODEL 515A MEGOHM BRIDGE

CIRC”rf DESCRIPTION

SECTION 3.

3-1. GENERAL. The Model 515A comprises a solid-state,

guarded, electrometer null detector; an ultra-stable,

highly-regulated dc voltage source, and a Wheatstone

Bridge.

3-2. N”LL DETECTOR. A simplified diagram of the

null detector circuit is shown in Figure 12. The null

detector utilizes a Keithley Model 302 Electrometer

Amplifier and a 3 &/division meter (MlOl). Power is

supplied by 212 volt regulated supplies.

graph 3-4.) The Sensitivity Switch (5103) has five

positions which provide sensitivity from 1000 mVi

division to 0.1 mVldivision. The meter will indicate

a center scale (zero) if there is no potential across

the Sensitivity Switch resistors. With switch 5201

set to ZERO CHECK, any offset indicated by the meter

is due to the Model 302 offset voltage.

COARSE (5102) and FINE (R120) zero canrrols the meter

can be adjusted for center scale indication (thus the

zero controls can be used to compensate for amplifier

offset). With switch S201 set to READ, the potential

difference between High and Low causes a current flow

through the meter. A voltage is developed across the

sensitivify resistor such that Ifl= e/Y+, where I, =

meter current, RS = sensitivity resistor and e = unbalance potential.

the meter, and diodes 0103 and DlO4 are used to ob-

tain a non-linear meter response beyond five divisions.

The voleane developed across RlO2 will forward bias

either diode so thet diode so that diode conduction

occurs.

giving a logarithmic meter sensitivity.

The current is shunted around meter thus

Resistor. R102, in series with

(See para-

By use of fhe

The null de-

CIRCUIT DESCRIPTION

tector ‘rDriven Guard” is the Cownon of the 212 volt

supplies. The ac potential of the “Driven Guard”

follows the ac poeential of the input High so that

guarding of rhe input High can be used.

3-3. WHEATSTONE BRIDGE. The bridge circuit utilizes

four resistance’arms identified as Standard Resistor

Arm “S”, Unknown Resistor Arm “X”, Calibrated Resistance Arm “Cl’, and Read-out Re?,isCance Arm “A”.

a. Standard Resistor Arm. The Standard resistors

R304 through R311 are connected to the Multiplier

Switch S302. Resistors R304 and R305 are 0.01% wirewound eypes; resistors R306 and R307 are 1% deposifed

carbon types; resistors R308 through R311 are specially

selected High-Meg types. A 1O:l (.005%) ratio divider composed of R301 and R302 is used in the Stand-

ardization procedure. (See paragraph 2- 4).

b. Unknown Resistor Arm. The unknow,, resistance

“X” is connected at the Input connector (5302 or 3303).

Calibrated Resistance Arm.

C.

resistance arm consists of a 94.5 kilohm, 1% deposited

carbon type in series with a 10 kilohm, wirewound

variable resistor. Resistors R313 through R318 and

potentiometers R319 through R324 are connected to the

Multiplier Switch 5302. The Calibration potentiometers

can be adjusted during the Standardization procedure

and are accessible an the front panel (inside the

shielded enclosure).

d. Readour Resistance Arm.

composed of Resistance Dials S304 through 5310

The calibrated

The Readout Arm is

1070

t*

0

HIGH

READ

ZERO

CHECK

0

LOW

FIGURE 12. Null Detector.

.

DRIVEN

GUARD

15

POWER SUPPLY. ,The payer supply consists of a

3-4.

series regulated supply for Bridge Voltage and a

floating 212 V supply for the null detector circuitry.

T-201 is the power transformer operating from power

line, switch selectable for 117V-234V operation. One

secondary is center-tapped and supplies a floating

plus and minus voltage for the regulator amplifier.

This secondary also drives the isolation transformer

T101. The other secondary is full wave rectified to

supply the unregulated voltage to series pass trans-

istor Q206. Q201 and Q202

form a difference amplifier

which compares the regulated output voltage to a reference voltage supplied by 0203 in a resistance programable power supply with the Bridge volts Adjustment setting a ha current ehru the reference divider

string. Q203 and Q204 are used as amplifier and

driver for Q206, correcting far any change in load

current or line voltage.

The secondary of TlOl is

center-tapped and full-wave rectified to supply unregulated plus and minus voltage to QlOl and Q102 re-

spectively which supply a constant load current. Zener

diodes D103 and D104 set the null detector supply

voltages to a nominal i12 volts respectively. TlOl

is especially well insulated to provide the necessary

insulation of guard to ground in the bridge circuit.

MODEL 515A MEGOHM BRIDGE

External Voltage mode only. Thus if both dials are

set to zero the diode is directly across the bridge.

For an external voltage greater than 100 volts, the

zener will conduct. When using a current-limited

voltage supply (such as Keithley Models 240A or 241)

the diode will limit the voltage to 100 volts and

prevent over-heating of the Dial resistors.

WARNING

If the voltage supply used does not have current

limiting (1O~mA approximately), the zener pro-

tection diode could be overheated causing possible

damage co the Dial resistors.

3-5.

OVER-VOLTAGE PROTECTION CIRCUIT.

The Model 51%

utilizes a zoner diode (D301) eo prevent damage ea the

readout resiseors (Xl and lower) from excessive bridge

voltage from an external voltage source.

The diode is

connected (through auxiliary.contacts on the Xl00 and

X10 dials) across the bridge voltage terminals when in

,

I

C203 -

i 101

R220

r j

’ L-

I

- K218

0201 -, ,.

___ D220

J ---*02,6 R224-

~ 0219

-

FIGURE 13. Null Detector, K-233.

*

.

.

~7201

(““4 .

/D223\

c21:

R230

D2t6 - :.

f

R231 --~

0212 T----- ‘0

+

Cl21?

ivl0

c201

0205

l --

C206 -‘-

FIGURE 14. Bridge Voltage Supply, PC-244

- ‘* D213

1070

MODEL 515A MEGOHM BRIDGE

SECTION 4.

4-l. GEl33UL. The fallowing Keithley accessories can

be used with the Model 515A to provide additional convenience and versatility.

Mndel 5151

Description:

The Node1 5151 is a bench mounting kit. The end frames

provide convenience when carrying the instrument.

End Frames

ACCESSORIES

4-2.

OPERATING INSTRUCTZONS. A separate Insrruction

Manual is supplied with each accessory giving complete

operating information.

Model 5152 Remote Test Chamber

The Model 5152 is a shielded test chamber for remote

resistance measurements. A 60 inch triaxial cable is

provided.

Application:

The Model 5152 can be used for resistance measurements

when the self-contained test compartmenr on the Model

515A is not useable. A separate GUARD eerminal is

provided an the Test Chamber.

Model 5153 Triaxial Cable

Description:

the Model 5153 is a triaxial cable 60” long which

mates with the EXT. INPUT connector on the Model 515.4.

Application:

The Model 5153 can be used for external measurements

which require a shielded and guarded cable.

1070

17

ACCESSORIES

MODEL 515A MFGOHM BRIDGE

Model 241 Regulated High Voltage SUDP~V

he Node1 241 is a very stable, accurate high voltage

over supply especially useful as a laboratory refer-

rice.

,pplication:

'he Model 241 can be used as an external voltage supply

or the Model 515.4 when applications require a bridge

otential from 110" to 1000". The Model 241 can be

asily rack mounted with the Model 515A by use of the

.odel 5154 Cabinet.

pecifications:

Voltage: 0 to 1000 volts dc in O.Ol-volt steps.

CUrrelIt: 20 milliamperes dc maximum.

Polarity: Positive 01 negative.

Floating: 50 volts maximum off chassis ground.

.CCUlUCY: ~0.05% of dial setting or +l millivolt,

whichever-is greater.

*SOLUTION: A "Trim" potentiometer permits interpola-

tion between steps with a reso1urion of better than

100 “icro”olts.

ESETABILITY: ~0.025%.

TABILITY: +0.005% per hour with constant load, line

and ambient temperature.

EMPERATURE COEFFICIENT OF REFiRENCE: 210 ppm/OC.

,INE REGULATION: +0.003% or 1 millivolt far 10% line

change.

,OAD REGULATION: +O.OOS% from no load to full load.

,IPPLE AND NOISE: Less than 1 millivolt rms above 5

HZ.

"'PUT IMPEDANCE: Less than 0.05 ohm at dc.

.ECO"ERY TIME: No load eo full load, less than 1 sec-

ond to raced accuracy.

8VERLOAD PROTECTION: Output is disconnected within

50 milliseconds if current exceeds approximately

24 milliamperes.

:ONNECTORS: Output: Teflon-insulated type UHF type.

'OWER:

IIMENSIONS, WEIGHT:

CCESSORIES SUPPLIED: Mating connectors.

105-125 or 210-250 volts, 50-60 Hz, 105 watts.

7" high x 19" wide x 12" deep,

net weight, 26 pounds.

Model 5154 Cabinet

Description:

The Model 5154 is a rack style cabinet with dimensions

25" high x 21" wide x 16-l/2" deep.

Application:

The Model 5154 can be used to rack mount the Model

515.4 with an auxilliary power supply such as the

Keithley Model 241.

18

Parts List:

Item

NO.

1

2

3

Description

Cabinet 14343c

Panel, Blank 14203B

Cable, UHF-UHF 166398

Part No.

1070

MODEL 515.4 MEGOHM BRIDGE

ACCESSORIES

Model 5155 High Meg&m Resiseance Standards

!scripeion:

ie Model 5155 has been developed t0 verify rhe cali-

cation of the Keithley 515A Meg&m Bridge with trace~ility to rhe Nafionai Bureau of Scanda;ds. These

lits are convenient LO use, since they plug directly

I~O the 515A. The 5155 consists of six individually

leased high megohm resistors with values af 108 thro:h 1013 ahms in decade steps. A certificate is inLuded showing the actual value af each resistor with

I accuracy limited by the maximum accuracy certified

i Naeional Bureau of Standards.

Each resistor’s

mperature coefficient, voltage coefficient and hisfry of measured values is also given.

,ecifications:

3SISTOR V*LUES: Sin resistors 100, 109, lOlO, loll,

1012, 1013 ohms 215%.

:CUPJ.CY: ~0.2% af certified value except 1013 ohms

which is ~0.5% (relative to I1.B.S. certified stanCiZlL-dS).

CABILITY: Less than ~0.1% change in value per thou-

sand haurs.

ILTAGE COEFFICIENT: -.

<MPERAT”RE COEFFICIENT:

03% per volt, nominal.

-0.1% per OC, nominal.

JARDING: Case is a~ guard potential when the resist-

or Standard is used in a Keithlev Model 515A Mee~hm

Bridge.

OS”LATION: Teflon.

DIMENSIONS: Each resistor standard is 4” long x 2”

deep x 1” wide.

WEIGHT: Each resistor Standard is approximately 6

ounces. Six Standards in carrying case, 3-l/2 lbr

SERVICE AVAILABLE: Recertification traceable t0

National Bureau of Standards.

Resistor Installation:

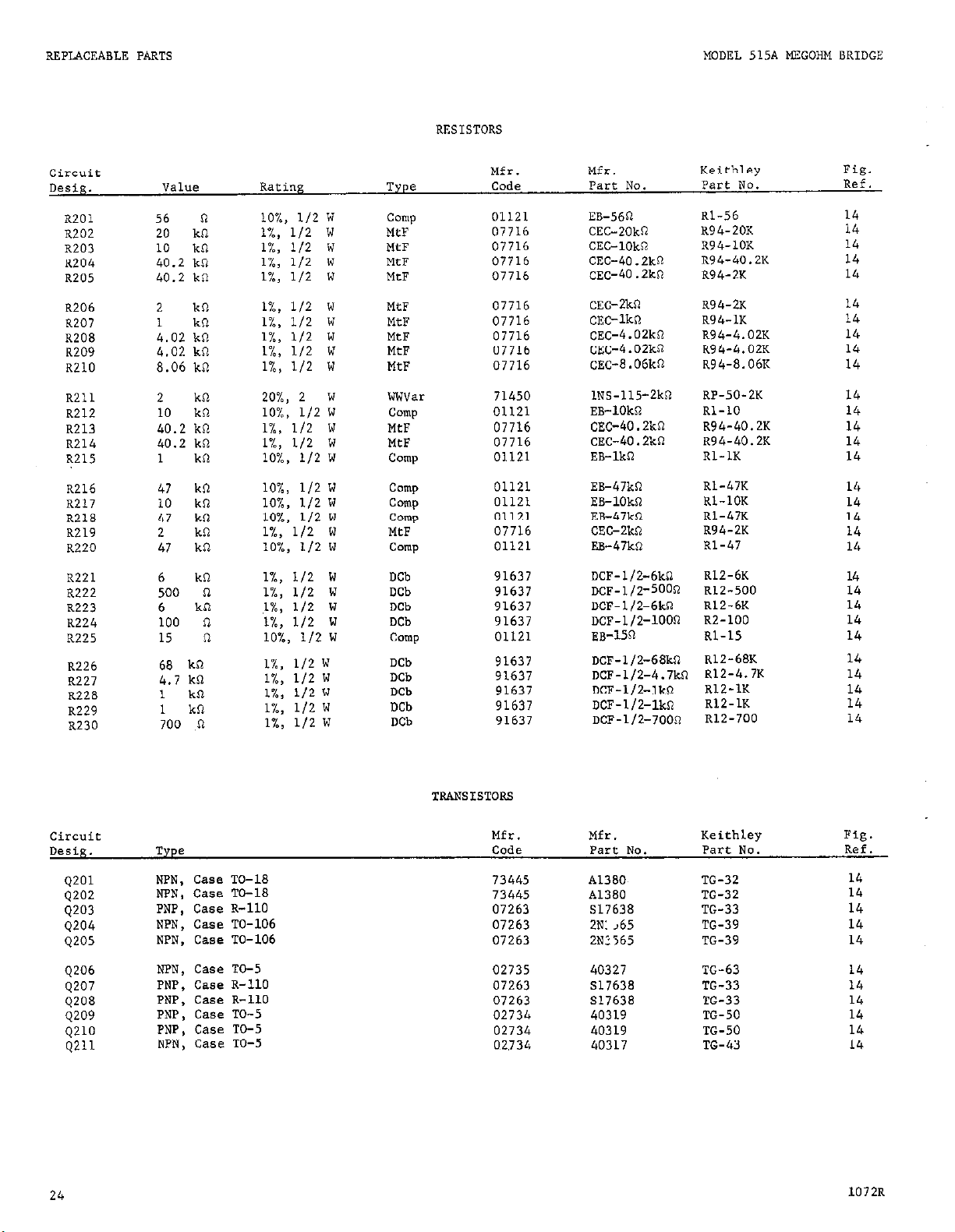

REPLACEABLE PARTS

MODEL 515A MEGoHM BRZDGE

SECTION 5.

5-1. REPLACEABLE PARTS LIST: This section contains

a list of componenets used in this instrument for

user reference. The Replaceable Parte List describes

the individual parts giving Circuit Designation,

Descriptian, Suggested Manufacturer (Code Number),

Abbreviations end Svmbols

A

Cb”ar Carbon Variable

CerD Ceramic Disc

Cer Trinnner Ceramic Trimmer

camp Cmnp0sifion

DCb

Desig.

EAL

ETB

ETT

ampere

Deposited Carbon

Designaeion

Electrolytic, Aluminum

Electrolytic, tubular

Electrolytic, tantalum

F

Fig

GCb

k

P

M

Mfr.

MS

MY

REPLACEABLE PARTS

Manufacturer’s Part

Number. Also included is a Figure Reference Number

where applicable. The complete name and address of

each Manufacturer is listed in the CODE-TO-NAME

Listing following the parts list.

TABLE 5-1.

farad

Figure

Glass enclased Carbon

kilo (10 3,

micro (10-6)

Meg (106)

Manufacturer

Metal Film

Mylar

Number

Number,

end the Keithley Parr

a

P

PC

j ohm

: PlCO (lo-l2)

i Printed Circuit

Paly : Polystyrene

Ref.

i Refere”ce

TC” i Tinner Copperweld

v ; volt

w

ww

i watt

: Wirewound

WWVar i Wirewound Variablt

5-2. ELECTRICAL SCHEMATICS AiW DIAGRAMS. Schematics

and diagrams ere included to describe the electrical

circuits as discussed in Sectian 3. Table 5-2

idenfifies all schematic part numbers included.

5-3. HOW To USE THE REPLACEABLE PARTS LIST. This

Parts List is arranged such that the individual types

of components are listed in alphabetical order. Main

Chassis pares are listed followed by printed circuit

boards and ocher subassemblies.

HOW TO ORDER PARTS.

5-4.

a. Replaceable parts may be ordered through the

TABLE 5-2.

Circuit Designation

Description

t

Description

I

Megohm Bridge Megohm Bridge

Circuit Designation Schematic

PC-233, PC-244 PC-233, PC-244

* *

Sales Service Department, Keithley Instruments, Inc.

or yaur nearest Keithley representative.

b. When ordering parts, include the following

infarmetion.

1. Instrument Model Number.

2. Instrument Serial Number.

3. Part Description.

Schema+zif Circuit Designation.

4.

5. Keithley Part Number,

c. All parts listed are maintained in Keithley

Spare Parts Stock. Any part not listed can be made

available upon request. Parts identified by the

Keithley Manufacturing Cade Number 80164 should be

ordered directly from Keithley Instruments, Inc.

I

Schematic

24820E 24820E

1

I I

20

1070

MODEL 515A MEGOHM BRIDGE

REPLACEABLE PARTS

NULL DETECTOR PARTS LIST

(X-233)

CAPACITORS

Keithley

Value

Rating Type

Mfr.

Code

Mfr.

Part NO. Pare No.

Cl01 .02 &F 1000 " cerLl 56289 loss-s20 C64-.02M

__

Cl02 Not Used --

Cl03 100 pF 40 EAI. 73445 C437ARIGlOO C15O-1OOM

Cl04 100 &F 40 SAL 73445 C437ARIGlOO C150-100M 13

Circuit

Desig.

0101

D102

D103

0104

D105

D106

D107

D108

Type

Transistor, NPN, Case TO-106

Transistor, NW, Case TO-106

Silicon

Silicon

zener

Ze"er

Si1iC.X'

Silicon

-- -- --

Mfr. Mfr.

Keithley

Code Part NO. Part No.

07263 2N3565 TG-39

07263 2N3565 TG-39

01295 1N645 RF-14

01295 lN645 RF-14

12954 lN706 LIZ-1

12954 lN706 02-l

01295 lN645 RF-14

01295 lN645 RF-14 13

0109 Silicon 01295 1N645 RF-14 13

Ill10

0111

0112

Silicon 01295 lN645 RF-14 13

(TG-39*) Transistor, NPN, Case TO-106

(TG-39*)

Transistor, NPN, Case

TO-106

07263

07263

2N3565

2N3565

24220‘4"

24220A*

Fig.

Ref.

1;

Fig.

Ref.

13

13

13

13

13

*Selected. Order from factory.

Circuit

oesig.

TlOl

Ml01

s102

s103

PlOl

JlOl

5102

P102

Transformer

Meter

Rotary Switch, COARSE ZERO

Rotary Switch, Null Detector

Connector,

Connector, Female, 15 Pins

Comector, Female, 15 Fins

Connector, Male, 15 Pins

Type

Male,

Circuit

oesig.

Value

RlOl 10 MO

R102

RI03

R104

R105

12.1 kQ

333 kn

33.3 k!l

3.33 kll

MlSCELwEO"S PARTS

Sensivity ---

15 Fins

Rating Type

lO%, l/Z W CO"P

l%, l/8 w MCF

l%, l/2 w MCF

l%, l/2 w MtF

l%, l/2 w

MtF 07716

Mfr.

Code Part NO.

80164 ___ m-121

80164 ___ ME-86

--- --- SW-294

27264 1625-15P CS-227

27264 1625-15R CS-228

27264 1625-15R B-228

27264 1625-15P CS-227

RESISTORS

Mfr.

Code

01121 EB-1OM

07716

07716

07716

Mfr.

Keithley

Part No.

___

Mfr.

Part No.

SW-292

Keithley

Part No.

RI-10"

CEA-lZ.lkn-1% R88-12.1K

CEC-333kR-1%

R94-333K

CEC-33.3k+1% R94-33.3K

CEC-3.33kQ-1% R94-3.33K

Fig.

Ref.

14

Fig.

Ref.

1072R

21

P.EPLACF.ABLE PARTS

MODEL 515A MEGOHM BRIDGE

RESISTORS (cont'd)

Circuie

Lksip.

R106

RI07

R108

R109

RllO

Rlll

R112

Value

33.3

33.3

2.7

1 kfi

1 k0

1 ki2

1 kfl

R113 1 k*

R114 1

R115 1 kR

RI16

R117

R118

R119

R120

R121

R122

RI23

R124

R125

R126

R127

1 kD

1 kfi

1 k0

1 k0

10 kR

4.7

2.7

700

4.99

4.99

700

15k n 1%. l/8 w

0

n

k#

kfl

kfi

kR*

n

kn

k0

a l%, l/2 w

Rating Type

1%,

l/2

l%,

l/2

1%,

l/2

l%, l/2 w

l%, 112 GI

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%, l/2 w

l%,

If2

1%,

l/2

l%,

l/2

l%,

l/2

5%,2

l%, l/2 w

l%, l/2 w

l%,

l/2

l%, l/2 w

l%, l/2 w

*Nominal value, selected in final test.

w

w

w

w

w

w

w

W

w

Mfr.

Code

McF

07716

MtF 07716

DCb

MtF

91637

07716

MCF 07716

MtF

MtF

07716

07716

MtF 07716

MtF 07716

M-LF

MfF 07716

MtF 07716

MeF 07716

MtF

wwvar

07716

07716

12697

DCb 91637

DCb

DCb 91637

MtF

MtF

DCb

MtF

91637

07716

07'716

91637

07716

TRANSISTORS

Mfr. Keithley Fig.

Part No. Part NO. Ref.

CEC-33.3kR

CEC-33.3k0

R94-33.3K

R94-33.3K

DCF-l/2-2.7kn RlZ-2.7K

CRC-lkn R94-1K

CEC-lkll R94-1K

CEC-1kQ

CEC-lk0

R94-1K

R94-1K

CEC-lkn R94-1K

CEC-lkn

R94-1R

CRC-1kR R94-1K

CEC-1kQ

CRC-lkn

CEC-lk&i

CRC-lkR

62JA-10kR

R94-1K

R94-1K

R94-1K

R94-1K

RP42-10K

DCF-l/2-4.7k0 RlZ-4.7K

DCF-l/2-2.7kR RlZ-2.7K

DCF-l/2-700~7

RlZ-700

CEC-4.99k0 R94-4.99K

CEC-4.99kn

R94-4.99K

DCF-l/2-700D RlZ-700

cm-15&l%

R88-15K

13

Circuit

tIesip.

QlOl

Q102

Circuit

Desip.

c201

c202 .0015 LlF 600

C203 0.1 pF 400

C204

C205

C206

C207

C208

C209

c210

c211

Type

PNP, Case R-110

NFN, Case

TO-106

Value RafinR

0.5

UF

100 UF

100 b

100 p3

100 p

Not Used

20

z

100

0.047

"F

BRIDGE VOLTAGE SUPPLY PARTS LIST

(PC-244)

CAPACITORS

400

v

” CAD 72982

v MY 13050

40

v

40

” EAL 73445

40

” F.AL 73445

40

”

450

v EMC 37942

40

v

100 v

MY

EAL

EAL

EAL

P&y

Mfr.

Code

07263

07263

Mfr.

Code

13050

73445

73445

73445

Mfr. Keithley

Part NO.

S17638

2N3565

Mfr.

Part: NO.

Pal-e NO.

TG-33

TG-39

Keifhley

Part NO.

SMlA-0.5uF C117-.5M

ED-.0015 CZZ-.OOlSM 14

Fig.

Ref.

13

13

Fig.

Ref.

14

SMlA-O.lpF C73-.lM 14

C437AR/GlOO C150-100M

14

C437ARfGlOO C150-100M 14

C437AR/GlOO c150-1OOM 14

C437ARiGlOO C150-1OOM

FP144-20uF

C36-20M 14

14

C437ARfGlOO c150-1OOM 14

Mw9410473

C67-0.047M

22

1072R

MODEL 515A MEGOHM BRIDGE

REPLACEABLE PARTS

DIODES

CirC”it

Desig.

Type

D201 SiliCO”

D202 Silicon

D203 Zt!"er

0204 zener

0205 zener

D206 zener

D207 Silicon

0208 Silicon

0209 Silicon

0210 Silicon

0211 Not Used

0212 Silicon

0213 SiliCO"

D214 Silicon

0215 zener

Mfr.

Code

Mfr.

Part NO.

02735 IN3255

02735 lN3255

04713 lN936

12954 lN718

12954 lN706

12954 lN718

01295 lN645

01295 lN645

01295 lN645

01295 113645

-_

__

01295 IN645

01295

01295

lN645

1~645

12954 lN723 DZ-17

D216 zener 12954 lN723

D217

Silicon 02735

lN3255

D218 Silicon 02735 lN3255

D219

Silicon 02735

lN3255

D220 Silicon 02735 lN3255

0221 Silicon 01295 113645

D222 Silicon 01295

lN645

0223 Silicon 01295 lN645

0224 Silicon 01295 1~645

Keithley

Part NO.

Fig.

Ref.

RF-17

m-17

D7.-5

DZ-18

m-1

DZ-18

RF-14

RF-14

w-14

RF-14

14

14

14

-_

w-14

RF-14

RF-14

14

14

14

14

m-17 14

RF-17 14

RF-17 14

RF-17 14

RF-17 14

RF-14 14

RF-14 14

w-14 14

RF-14 14

Circuit

Lksig.

5211

s201

5201

5202

5203

5204

J205

3206

3207

5208

5209

5210

SL201

SL201

s203

s202

K201a

K201b

T201

K202

Type

Kecepcacle, UHF

'Toggle Switch, ZERO CHECK

Test Jack

Test Jack

Test Jack

Test Jack

Test Jack

Test Jack

Test Jack

Test Jack

Test Jack

Text Jack

Shorting Link

Shorting Link

votary Switch, X1 BRIDGE VOLTS

Rotary Switch, Xl0 BRIDGE VOLTS

Solenoid, ZERO CHECK

Reed Relay, SPST

Tl-a"SfO~~X

Relay, INTERLOCK

MISCELLANEOUS PARTS

Mfr.

Code

91737

80164

71279

71279

71279

71279

71279

71279

71279

71279

71279

71279

71279

71279

80164

80164

-_95348

SO164

_--

Mfr.

*art No.

6804

-__

4352-l-0319

4352-l-0319

4352-l-0319

4352-l-0319

4352-l-0319

4352-l-0319

4352-l-0319

4352-I-0319

4352-l-0319

4352-l-0319

3771-20310

3771-20310

El55

"R406

TR-120

KAllDY

Keithley

Part No.

Fig.

Ref.

CS-64

SW-236 2

TJ-9 3

TJ-9 3

TJ-9 3

TJ-9 3

TJ-9 3

TJ-9 3

TJ-9 3

TJ-9 3

TJ-9 3

TJ-9 3

TJ-10

TJ-10 3

SW-291 2

SW-291 2

SOL-2

RL-25B

TR-120 14

RL-36

3

7.3

REPLACEABLE PARTS

MODEL 515A MEGOHM BRIDGE

RESISTORS

CitTUif

Desig.

R201

R202

R203

R204

R205

R206

R207

R208

R209

R210

R211

R212

R213

R214

R2l5

R216

R217

R218

R2l9

R220

R221

R222

R223

R224

R225

R226

R227

R228

R229

R230

Value Rating

56 0

20 k.Q

10 kc2

40.2 k0

40.2 kfi

2

kR

1

kfl

4.02 kfl

4.02 k.0

8.06 kfl

2 kI2

10 kn

40.2 kR

40.2 kfi

1

kil

47 k0

10 kfi

47 kR

2 kn

47 kR

6

kn

500 n

6 kR

100 0

15 n

68 k!?

4.7 k0

1

k,?

1

kfl

700 ,n

lO%, l/2 w

l%, l/2 w

l%, l/2 w

l%, 112 w

1%, l/2 w

1%. 112 w

l$ I;* w

l%, l/2 w

l%, l/2 w

l%, l/2 w

20%, 2 w

lO%, l/2 w

1%, l/2 w

l%, l/2 w

lo%, 112 w

lO%, l/2 w

lO%, l/2 w

lO%, l/2 w

l%, l/2 w

lO%, l/2 w

l%, l/2 w

l%, l/2 w

L%, l/2 w

l%, l/2 w

lO%, l/2 w

l%, l/2 w

l%, l/2 w

1%, l/2 w

l%, l/2 w

l%, l/2 w

Type

camp

MtF

MtF

MCF

MfF

MtF

MtF

MtF

MtF

MtF

WWVW

conlp

MtF

MeF

Camp

Camp

camp

camp

MtF

camp

DCb

DCb

DCb

DCb

Camp

DCb

DCb

Deb

DCb

Mfr. Mfr.

Code Part No.

01121

07716

07716

07716

07716

ES-560

CEC-20kn

CRC-lOkQ

CEC-40.2kn

CEC-40.2kO

07716 cm?-2kQ

07716 CEC-lkn

07716

07716

07716

CEC-4.02kn R94-4.02K

CEC-4.02kO

CEC-8.06kO R94-8.06K

71450 lNS-115-2kn

01121

07716

07716

RB-1OkQ RI-10

CRC-40.2kQ R94-40.2K

CEC-40.2kn R94-40.2K

01121 EB-lkn

01121

01121

01121

07716

01121

91637

EB-47kn

EB-1Okn

EB-47kR

CEG2kR

BB-47kn

DCF-l/2-6k0

91637 ~~~-112-50On

91637 DCF-l/2-6kn

91637 DCF-l/2-1000

01121

91637

EB-15n

DCF-l/2-68kR

91637 DCF-l/2-4.7kn

91637 DCF-l/2-lkn

91637 DCF-l/2-1kQ

91637 DCF-l/2-7000

Keiehley

Part No.

RI-56

R94-20K

R94-10K

R94-40.2K

R94-2K

R94-2K

R94-1K

R94-4.02K

RP-50-2K

Rl-1K

Rl-47K

Rl-1OK

RI-47K

R94-2K

Rl-47

RlZ-6K

RlZ-500

RlZ-6K

R2-100

Rl-15

R12-68K

RlZ-4.7K

R12-1K

Rl2-1K

R12-700

Fig.

Ref.

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

14

Q201

Q202

Q203

Q204

Q205

Q206 NPN,

0207 PNP,

0208 PNP,

Q209 PNP,

4210

Q211

24

NPN, Case TO-18

WN, Case TO-18

PNP, case R-110

NPN, Case TO-106

NPN, Case TO-106

Case TO-5

Case R-110

case R-110

case TO-5

PNP,

Case

Case

TO-5

TO-5

NW,

TRANSISTOQ

Mfr.

Code

73445

73445 Al380 TC-32

07263

07263

07263

02735

07263

07263

02734

02734

02,734

Mfr.

Part NO.

A1380

Keithley Fig.

Part No. Ref.

TG-32

14

14

S17638 TG-33

14

2N:,65 TG-39 14

2N1565 TG-39

40327 TG-63

S17638 TG-33

S17638 m-33

40319 TG-50

40319

TG-50

40317 TG-43

14

14

14

14

14

14

14

1072R

MODEL 515A MlxOHM BRIDGE

SWITCHING ASSEMBLIES

MISCELLANEOUS PARTS

Mfr. Keithley

Pat? NO.

Part NO.

REPLACEABLE FART8

0301 Diode, zener, loo", SW 04713

OS301

F301

F301

5301

Lamp, 24v, clear

Fuse, SLO-BLO, .25A, 3AC

Fuse, SLO-BLO, l/8.4, 3AG

Receptacle, 3-Prong

03508

75915

71400

___

3302 Receptacle, INPUT Hieh, UHF 91737

3303

P301

Recebtacle; Triaxial; EXT. INPUT

Power Cord, b ft.

RESISTORS

CiPC”it Mfr.

wsig.

It301

R302

R303

R304

R305

R306

R307

R308

R309

R310

R311

R312

R313

R314

R315

Value Rating

10 kR

1O:l Divider Network, .005% 80164

100 kR

10 kn

100 kfl

1

Mn

10

MD

100 MR

109 n

1010

1011 :

1ol2 n

100 kn

94.5 kn

94.5 kR

94.5 kn

I%, 112 w

.Ol%, 1 w

.Ol%, 1 w

l%, l/2 w

1%,2 w

Selected

Selected

Selected

SekCWd

.Ol%, 1 w

1%, l/2 w

l%, l/2 w

l%, l/2 w

Type

Code

MEF 07716

ww 15909

ww 15909

DCb 91637

DCb 91637

-__ 80164

___

___

80164

80164

___ 80164

ww 15909

DCb 91637

DCb 91637 DCF-l/2-94.5k0 R12-94.W

DCb 91637

lN5378-8 DZ-46

1450

PL-53

313.250 FU-17

MDL

1604

6804

5632Al5321Alh CS-67

-__

F"-20

CS-248

CS-64

CO-5

Mfr. Keithley

Part NO. Part NO.

__

2365:;s

CEC-1OkR R94-10K

1252-100kR

1252-lMQ

DCF-l/tlOMI1

DC-2-lOOMi?

___

R154-100K

R154-1M

R12-10M

R14-100M

241598

24160~4

241618

___

241628

1252-lOOk R154-100K

DCF-l/2-94.5kn R12-94.5K

DCF-t/2-94.5kQ RlZ-94.5K

R316

R317

R318

R319

R320

R321

R322

R323

R324

R325

R326

R327

R328

R329

R330

R331

R332

R333

R334

R335

1072R

94.5 kfi

94.5 ks-I

94.5 k0

10

kn

10 kR

10 kR

10 kR

10 k0

10 kR

20 MO

4 MO

4 M*

200 kR

100 ki,

400 k0

l%, l/2 w

l%, l/2 w

l%, l/2 w

20%, 114 w

20%, l/4 w

al%, l/4 w

20%, l/4 w

20%, l/4 w

2o%, l/4 w

.5%, 2 w

.5%, 2 W

.5%,2 w

.5%, 2 w

.Ol%, 2 w

.Ol%, 2 w

.Ol%, 2 w

.Ol%, 2 w

.Ol%, 1 w

.Ol%, 1 w

.Ol%, 1 w

DCb 91637

DCb 91637

DCb

DCb

DCb

91637

71450

71450

DCb 71450