NAVAIR 17–20AW–232

TECHNICAL MANUAL

INSTRUMENT CALIBRATION PROCEDURE

SPECTRUM ANALYZERS

TEKTRONIX

494, 494P, 494POPT08,

494POPT30, 494AP

AND

INTERSTATE ELECTRONICS

7185400

THIS PUBLICATION SUPERSEDES NAVAIR 17–20AW–232

DATED 1 MARCH 1991

DISTRIBUTION STA TEMENT C. DISTRIBUTION AUTHORIZED TO U.S. GOVERNMENT AGENCIES AND THEIR

CONTRACTORS TO PROTECT PUBLICA TIONS REQUIRED FOR OFFICIAL USE OR FOR ADMINISTRA TIVE OR

OPERA TIONAL PURPOSES ONL Y . OTHER REQUESTS FOR THIS DOCUMENT SHALL BE REFERRED TO NA VY

MEASUREMENT SCIENCE DIRECTORATE, NAVAL WARFARE ASSESSMENT DIVISION, P.O. BOX 5000

CORONA, CA 91718–5000

DESTRUCTION NOTICE– FOR UNCLASSIFIED, LIMITED DOCUMENTS, DESTROY BY ANY METHOD

THAT WILL PREVENT DISCLOSURE OF CONTENTS OR “RECONSTRUCTION OF THE DOCUMENT.”

PUBLISHED BY DIRECTION OF COMMANDER NAVAL AIR SYSTEMS COMMAND

1 APRIL 1997

NAVAIR 17–20AW–232

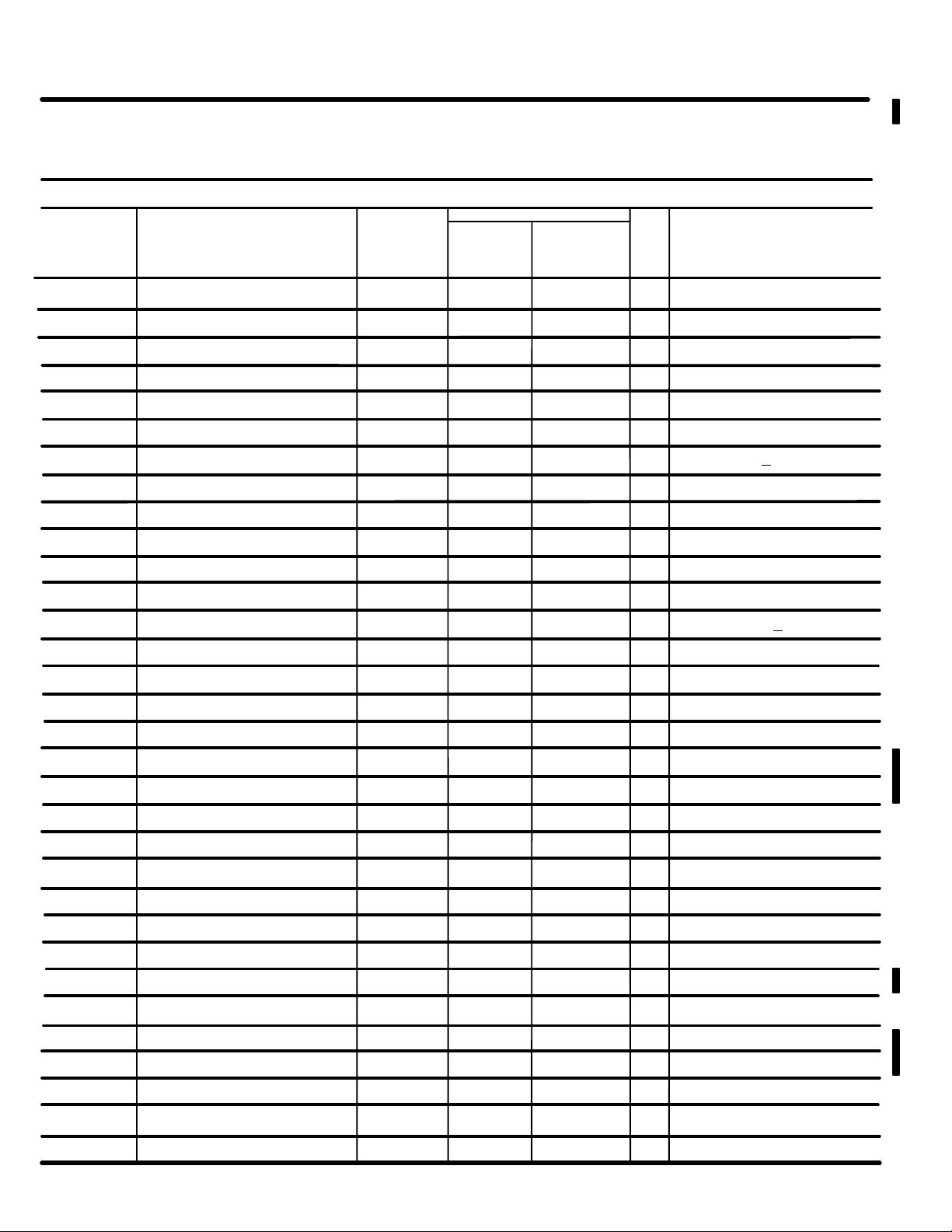

LIST OF EFFECTIVE PAGES

The purpose of this list is to identify the pages in this document affected by any technical content changes made since

the previous release of the document.

NOTE: On a revised page, with the exception of the Title, the A, and the i pages, the technical changes are indicated by

a vertical line in the outer margin of the page.

Page

No.

Title R

AR

i0

1, 2 R

3, 4 0

5 to 9 R

10, 11 0

12 to 16 R

17 0

18 to 35 R

36 0

37 R

Revision*

Page

No.

Revision*

Page

No.

Revision*

38, 39 0

40 to 43 R

44 (blank) 0

45 to 53 R

54 (blank) 0

55 to 64 R

* Zero in this column indicates an original page.

“R” in this column indicates a revised page.

A

NAVAIR 17–20AW–232

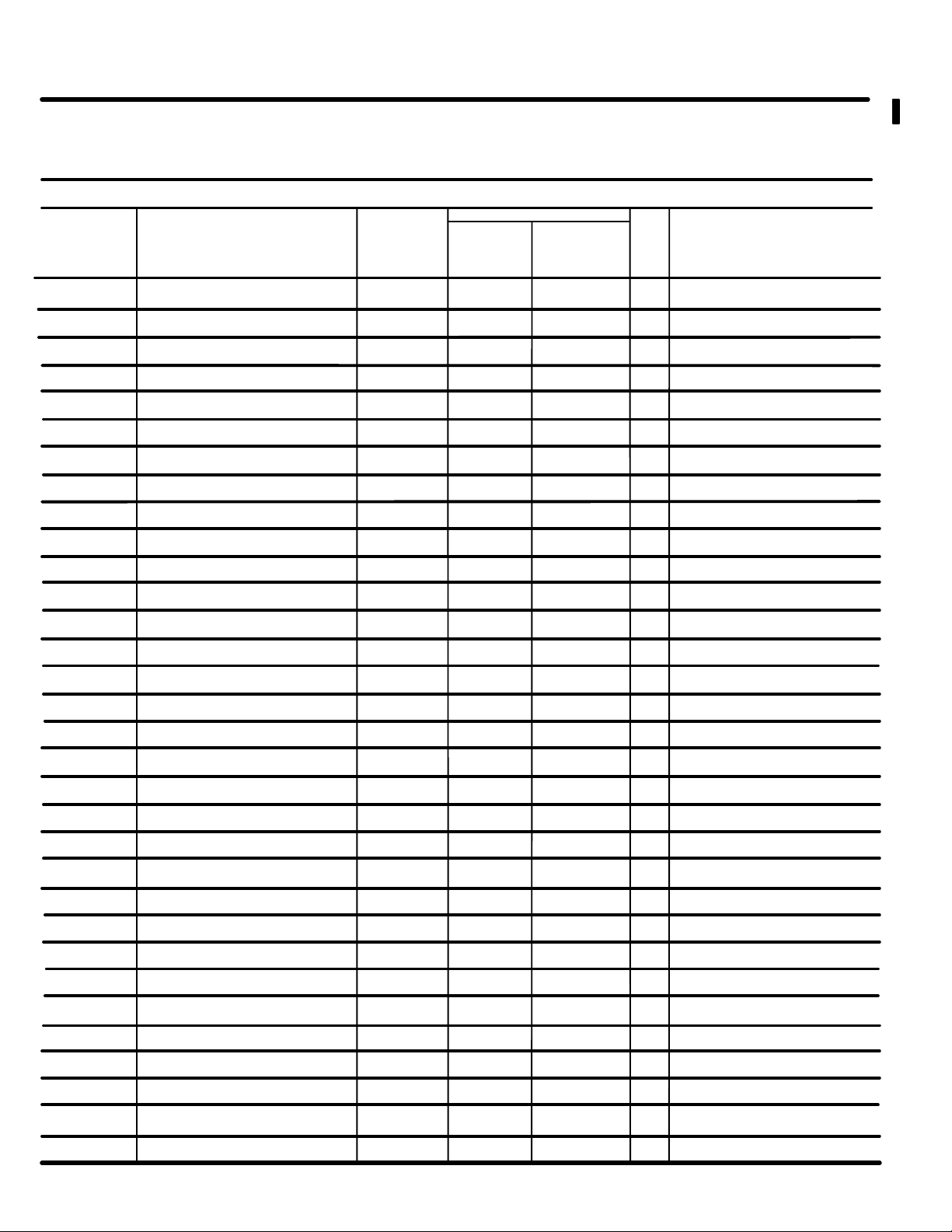

TABLE OF CONTENTS

Section Page

1 Introduction and Description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Equipment Requirements 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Preliminary Operations 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Calibration Process 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Calibrator Tests 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Counter Readout Tests 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Center Frequency Tests 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 CRT Display Tests 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Frequency Span Tests 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 RF Attenuator Tests 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 IF Gain Tests 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Frequency Response Tests 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Equivalent Input Noise Sensitivity Tests 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Intermodulation Distortion T ests 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 Harmonic Distortion T est 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Noise Sidebands T est 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 Residual Response T ests 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 Residual FM T ests 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 Resolution Bandwidth T ests 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 IEEE Bus Tests (494P and 494AP Models only) 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Navy Calibration Checklist 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ILLUSTRATIONS

Figure Page

1 Calibrator T est Configuration 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Counter Readout T est Configuration 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 CR T Display Test Configuration 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Frequency Span T est Configuration 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 RF Attenuator T est Configuration 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Frequency Response T est Configuration 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Intermodulation Distortion T est Configuration 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Third Order Intermodulation Display 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Sideband Noise Level Measurement Display 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Calculating Slope for Residual FM Measurement 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Residual FM Measurement Display 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Resolution Bandwidth and Shape Factor Measurement Displays 41. . . . . . . . . . . . . . . . . . . . . . . . . .

TABLES

T able Page

1 Calibration Description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

NAVAIR 17–20AW–232

SECTION 1

INTRODUCTION AND DESCRIPTION

1.1 This procedure describes the calibration of the T ektronix 494, 494P, 494POPT08, 494POPT30, 494AP and

Interstate Electronics 7185400 Spectrum Analyzers. The instrument being calibrated is referred to herein as the

TI (Test Instrument).

1.2 All comments concerning this procedure should be directed to Navy Measurement Science Directorate,

Naval Warfare Assessment Division, P .O. Box 5000, Corona, CA 91718–5000.

1.3 This procedure includes tests of essential performance parameters only. Any malfunction noticed during

calibration, whether specifically tested for or not, should be corrected.

1.4 If the TI is the Interstate Elecectronics 7185400, the T ektronix 494P test tolerances apply.

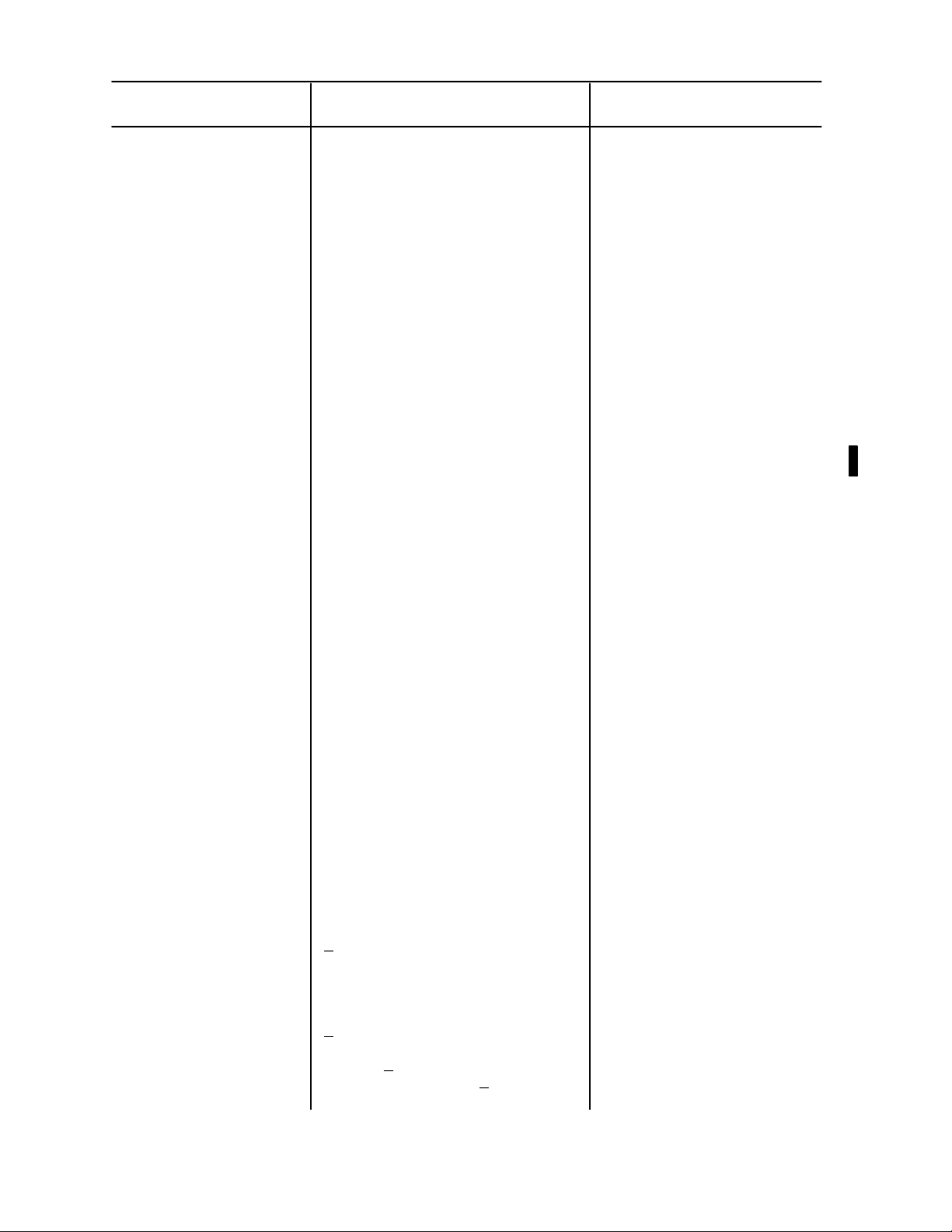

T able 1. Calibration Description

TI

Characteristics

Calibrator

Counter read–out

Performance

Specifications

Frequency: 100 MHz

T olerance: +

10 Hz

Output level: –20 dBm

T olerance: +

0.3 dB

Range: 10 kHz to 21 GHz

T olerance: +

x 1 x 10

[(counter frequency

7

–

) + [(10 + 2N) Hz] +

1 LSD], all 494 series and for

delta frequency mode if TI is a

494A series; +

x 1 x 10

[(counter frequency

7

–

) + [(5 + N) Hz] +

1 LSD], frequency accuracy mode

if TI is a 494A series

Where N=1 for Bands 1

through 3, and N=3 for Bands 4

and 5; and where:

BAND 1 = 0 to 1.8 GHz

BAND 2 = 1.7 to 5.5 GHz

BAND 3 = 3.0 to 7.1 GHz

BAND 4 = 5.4 to 18 GHz

BAND 5 = 15 to 21 GHz

T est

Method

Measured with an electronic

counter.

T ested using the TI display

by measuring, with a power

meter, the output level of a

signal generator that had

been set to the same power

level as the TI calibrator

signal.

T ested with the TI CAL

OUT markers and a signal

source.

1

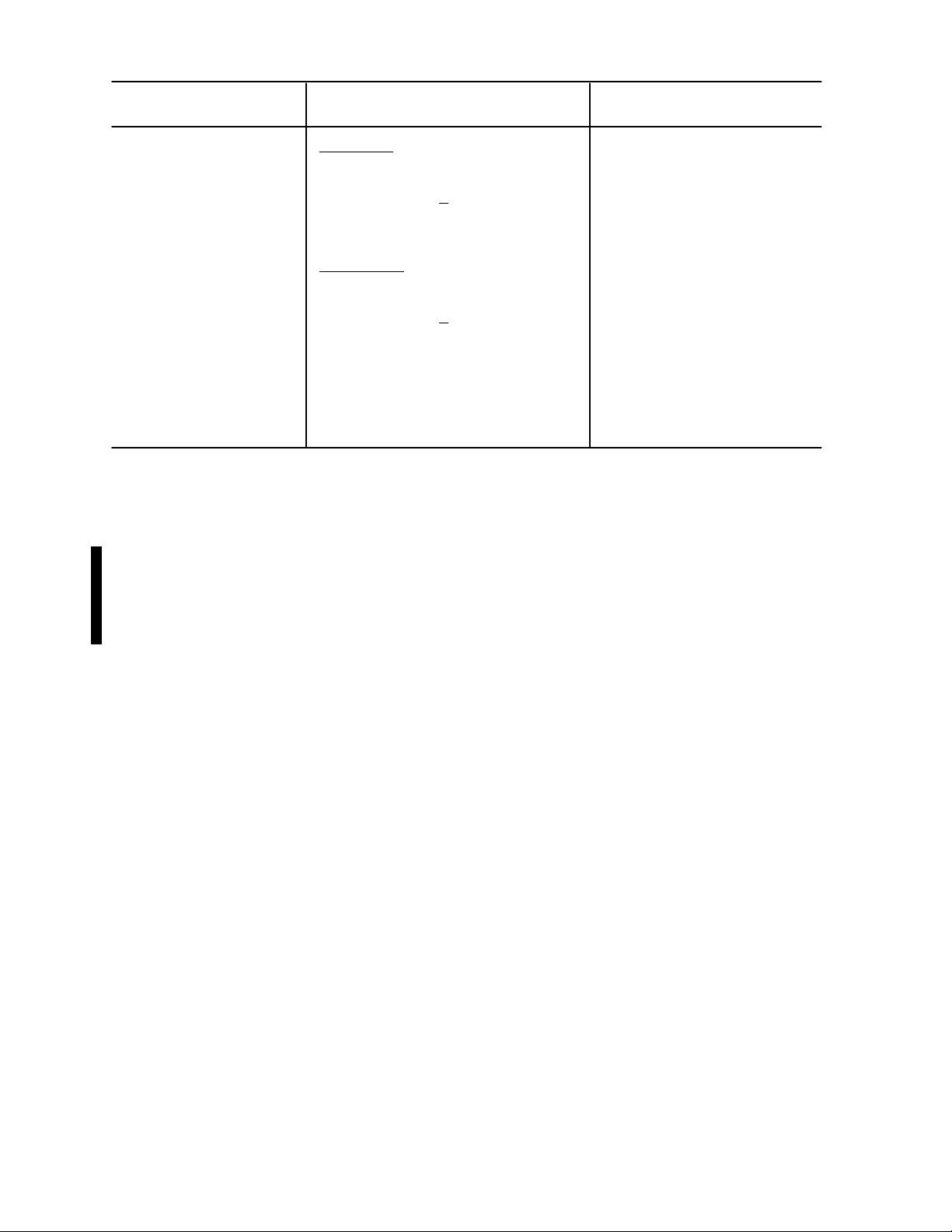

NAVAIR 17–20AW–232

TI

Characteristics

Center frequency

accuracy

CR T display

Performance

Specifications

Range: 10 kHz to 21 GHz

T olerance: +

Res. BW, whichever is greater) +

(center frequency x 1 x 10

[(20% of span/div or

7

–

) +

{(N x 15) kHz}] for Bands 1 and 5

with span/div >200 kHz, and

Bands 2 through 4 with span/div

>100 kHz; +[(20% of span/div or

Res. BW, whichever is greater) +

(center frequency x 1 x 10

7

–

) +

{(2N + 25) Hz}] for Bands 1 and 5

with span/div <200 kHz, and

Bands 2 through 4 with span/div

<100 kHz

Range: 80 dB (log) or 8 divisions

(linear)

T olerance: +

maximum of +

range; +

maximum of +

range; +

1.0 dB/10 dB to a

2 dB over 80 dB

0.4 dB/2 dB to a

1.0 dB over 16 dB

5% fullscale over linear

range

Test

Method

T ested with a signal source.

T ested using a signal

generator and step

attenuators.

Frequency span/div

RF attenuator

494 Models

Range (in a 1, 2, 5 sequence):

50 Hz/div to 200 MHz/div for

Bands 1 to 3; 50 Hz/div to

500 MHz/div for Bands 4 and 5

494A Models

Range (in a 1, 2, 5 sequence):

10 Hz/div to 100 MHz/div for

Band 1; 10 Hz/div to

200 MHz/div for Bands 2 and

3; 10 Hz/div to 1 GHz/div for

Band 4; 10 Hz/div to

500 MHz/div for Band 5

T olerance: +

5% of frequency

span/div setting over center

8 div of CRT display,

50 Hz/div bandwidth settings

>

494 Models

Range: 0 to 60 dB in 10 dB steps

T olerance: +

maximum of +

0.3 dB/10 dB to a

0.7 dB, over the

60 dB range from DC to 4 GHz;

+0.5 dB/10 dB to a maximum

of 1.4 dB, over the 60 dB range

from 4 to 18 GHz

T ested using a comb

generator for spans of

500 MHz/div down to

500 kHz/div, and then

using a function generator

to modulate the comb

generator to test the span

from 200 kHz/div down to

2 kHz/div; or tested using

an accurate (frequency)

signal generator, or signal

source.

T ested at 1, 10, and 15 GHz

by noting the change in the

signal generator level (as

measured by a calibrator)

that is required to regain a

reference as the TI

attenuators are switched in.

2

NAVAIR 17–20AW–232

Characteristics

RF attenuator

(cont.)

IF gain

TI

Performance

Specifications

494A Models

Range: 0 to 60 dB in 10 dB steps

T olerance: +

maximum of +

60 dB range to 1.8 GHz;

+1.5 dB/10 dB to a maximum

3.0 dB, over the 60 dB

of +

range from 1.8 to 18 GHz;

+

3 dB/10 dB to a maximum

6 dB, over the 60 dB

of +

range from 18 to 21 GHz

Range: 97 dB

(107 dB, 494A models)

T olerance: +

maximum of +

except at the decade transitions

from –19 to –20 dBm, –29 to

–30 dBm, –39 to –40 dBm,

–49 to –50 dBm, and –59

to –60 dBm, where an

additional +

a total of +

(with add maximum error of

+2 dB over the full range)

0.5 dB/10 dB to a

1.0 dB, over the

0.2 dB/dB to a

0.5 dB/9 dB,

0.5 dB can occur for

1.0 dB per decade;

Test

Method

T ested at 100 MHz by

noting the change in signal

generator level (as

measured by a calibrator)

that is required to regain a

reference as the TI IF gain

is varied.

Frequency response

Frequency response (about the

mid–point between two

extremes):

Band 1: +

1.8 GHz; +

1.8 GHz; (494 models only)

Band 1: +

1.8 GHz, (494A models only)

Band 2: +2.5 dB

Band 3: +

Band 4: +

Band 5: +

Frequency response (referenced

to 100 MHz):

Band 1: +

1.8 GHz; +

1.8 GHz, (494 models only)

Band 1: +2.5 dB, 10 kHz to

1.8 GHz, (494A models only)

Band 2: +

Band 3: +

Band 4: +

Band 5: +

1.5 dB, 50 kHz to

2.0 dB, 10 kHz to

1.5 dB, 10 kHz to

2.5 dB

3.5 dB

5.0 dB

2.5 dB, 50 kHz to

3.0 dB, 10 kHz to

3.5 dB

3.5 dB

4.5 dB

6.5 dB

T ested by noting the TI

indication of test signal that

are held constant in level

and verifying that the TI

indications, when

compared to each other,

are acceptable.

3

NAVAIR 17–20AW–232

TI

Characteristics

Equivalent input noise 494 Models:

Sensitivity:

Bands 1–3 (50 kHz to 7.1 GHz):

–80 dBm at 1 MHz res. BW;

–90 dBm at 100 kHz res. BW;

–100 dBm at 10 kHz res. BW;

–110 dBm at 1 kHz res. BW ;

–118 dBm at 100 Hz res. BW;

–121 dBm at 30 Hz res. BW

Bands 4 (5.4 kHz to 12.0 GHz):

–65 dBm at 1 MHz res. BW;

–75 dBm at 100 kHz res. BW;

–85 dBm at 10 kHz res. BW;

–95 dBm at 1 kHz res. BW;

–103 dBm at 100 Hz res. BW;

–106 dBm at 30 Hz res. BW

Band 4 (12.0 to 18.0 GHz):

–60 dBm at 1 MHz res. BW;

–70 dBm at 100 kHz res. BW;

–80 dBm at 10 kHz res. BW;

–90 dBm at 1 kHz res. BW;

–98 dBm at 100 Hz res. BW;

–101 dBm at 30 Hz res. BW

Band 5 (15.0 to 21.0 GHz):

–55 dBm at 1 MHz res. BW;

–65 dBm at 100 kHz res. BW;

–75 dBm at 10 kHz res. BW;

–85 dBm at 1 kHz res. BW;

–93 dBm at 100 Hz res. BW;

–96 dBm at 30 Hz res. BW

Performance

Specifications

Test

Method

Tested by verifying that the

TI average noise level does

not exceed the rated

sensitivity of the TI at the

test frequency.

494A Models

Sensitivity:

Band 1:

–80 dBm at 3 MHz res. BW;

–85 dBm at 1 MHz res. BW;

–95 dBm at 100 kHz res. BW;

–105 dBm at 10 kHz res. BW;

–115 dBm at 1 kHz res. BW ;

–125 dBm at 100 Hz res. BW;

–134 dBm at 10 Hz res. BW

Bands 2 & 3:

–74 dBm at 3 MHz res. BW;

–79 dBm at 1 MHz res. BW;

–89 dBm at 100 kHz res. BW;

–99 dBm at 10 kHz res. BW;

–109 dBm at 1 kHz res. BW;

–119 dBm at 100 Hz res. BW;

–125 dBm at 10 Hz res. BW

Band 4 (5.4 to 12 GHz):

–60 dBm at 3 MHz res. BW;

–65 dBm at 1 MHz res. BW;

–75 dBm at 100 kHz res. BW;

–85 dBm at 10 kHz res. BW;

–95 dBm at 1 kHz res. BW;

–105 dBm at 100 Hz res. BW;

–111 dBm at 10 Hz res. BW

4

NAVAIR 17–20AW–232

TI

Characteristics

Equivalent input noise

(Cont.)

Intermodulation

distortion

Harmonic distortion

Performance

Specifications

Band 4 (12 to 18 GHz) and 5:

–55 dBm at 3 MHz res. BW;

–60 dBm at 1 MHz res. BW;

–70 dBm at 100 Hz res. BW;

–80 dBm at 10 kHz res. BW;

–90 dBm at 1 kHz res. BW;

–100 dBm at 100 Hz res. BW;

–107 dBm at 10 Hz res. BW

Third order products: at least

–70 dB below any two on–screen

signals within any frequency span

Harmonic distortion:

at least –60 dBc for full screen

signal (to 1.8 GHz): at least

–100 dBc (1.7 to 21 GHz)

(494 models only);

not discernible, (494A models

only)

T est

Method

T ested using two signals

which are 1 MHz apart at

approximately 1 GHz, and

verifying with the TI display

that the 3rd order products

are within specifications.

The TI is set for a fullscale

display of –30 dBm

(–40 dBm, 494A models). A

precise 100 MHz signal from a

signal generator is adjusted for

a fullscale display on the TI.

Next, the TI is adjusted to

center the harmonic of

200 MHz on the display. A

filter is inserted to reject the

external 200 MHz harmonic

signal and the TI display is

verified to be at least 60 dB

below fullscale.

Noise sidebands

Residual response

LO emission out

Residual FM (short

term) after 1 hour

warm–up

At least –75 dBc at 30 times the

resolution bandwidth offset

(–70 dBc at 30 times the

resolution bandwidth offset for

100 Hz resolution bandwidth or

less)

Responses: –100 dBm or less

(no input signal, referenced to

mixer input)

Maximum output: –70 dBm

(referenced to input mixer)

(7 x N) kHz total excursion in

<

20 ms; Band 1 and 5 with

span/div >200 kHz and Bands

2 through 4 with span/div

>100 kHz (phaselocked off)

(10 + 2N) Hz total excursion in

<

20 ms; Bands 1 and 5 with

span/div <200 kHz and Bands 2

through 4 with span/div <

(phaselocked on)

100 kHz

T ested with the TI CAL OUT

signal.

T ested in 100 MHz increments

using the TI display by

verifying that all observed

residual responses are below

–100 dBm.

T ested by inference during

residual response tests.

T ested using the TI display

and the TI CAL OUT signal.

5

NAVAIR 17–20AW–232

TI

Characteristics

Resolution bandwidth

IEEE data bus (494P

and 494AP models

only)

1.4 This procedure does not perform tests for vertical output, horizontal output, trigger sensitivity, external

sweep, time/div , and preselector rejection.

494 Models

Range: 30 Hz, and then 100 Hz to

1 MHz in decade steps

T olerance: Within +20% of

bandwidth at 6 dB down

Shape factor: <7.5:1; <15:1 at 30 Hz

Res. BW

494A Models

Range: 10 Hz to 1 MHz in decade

steps, and then 3 MHz

T olerance: Within +20% of

bandwidth at 6 dB down

Shape factor: <7.5:1; <12:1 at 10 Hz

Res. BW

Conforms to IEEE std. 488–1978

for Talker and Listener

Performance

Specifications

Test

Method

T ested using the TI CAL

OUT signal and the CRT

display.

Checked using an IEEE bus

tester program.

NOTE

If the TI is used for applications only up to 18 GHz, calibrate the TI only up to 18 GHz;

otherwise, if the TI is used for applications up to 21 GHz, calibrate the TI fully up to

21 GHz as directed in the procedure.

SECTION 2

EQUIPMENT REQUIREMENTS

NOTE

Minimum use specifications are the principal parameters required for performance of the

calibration, and are included to assist in the selection of alternate equipment, which may be used

at the discretion of the using laboratory. Satisfactory performance of alternate items shall be

verified prior to use. All applicable equipment must bear evidence of current calibration.

The instruments utilized in this procedure were selected from those known to be available at

Navy calibration facilities, and the listing by make or model number carries no implication of

preference, recommendation, or approval for use by other agencies. It is recognized that

equivalent equipment produced by other manufacturers may be capable of equally satisfactory

performance in this procedure.

6

NAVAIR 17–20AW–232

Item

2.1 Microwave

counter*

2.2 Low pass filter

2.3 Signal generator

(2 required)

2.4 Power meter

2.5 Power sensor*

Minimum Use

Specifications

Frequency: 100 MHz to 21 GHz

Uncertainty: +

2.5 x 10

8

–

Sensitivity: –20 dBm

Resolution: 1 Hz

Cutoff frequency: 135 MHz

Insertion loss: 1 dB max. at 100 MHz

Rejection: at least 40 dB at 200 MHz

Impedance: 50

Frequency: 20 MHz to 1 GHz

(and 200 MHz to 1.8 GHz is used

for frequency span/div tests)

Uncertainty: NA**

Stability: +

0.001%/hr max.

Output: +12 to –85 dBm

Power display range: 0 to –20 dBm

Uncertainty: +

1% fullscale

Frequency: 100 MHz to 21 GHz

Power range: 0 to –20 dBm

Cal. factor uncertainty: +

2.5% max.

SWR: 1.40 max.

Must be compatible with power meter

(item 2.4)

Calibration

Equipment

Hewlett–Packard

5351BOPT001 or

5343AOPT001, 011

T elonic TLC135–7EE2;

or Sierra 184–135

Hewlett–Packard

8642BOPT001, 710,

907, 8642BOPT001,

907, or 8640BOPT001,

002, 003***; or

Fluke 6062AOPT130 or

6071AOPT130***

Hewlett–Packard

436AOPT022, 436A, or

435A

100 MHz to 18 GHz

Hewlett–Packard 8481A

18 to 21 GHz

Hewlett–Packard 8485A

2.6 Signal source

CW frequency: 100 MHz to 21 GHz

Uncertainty: NA**

Resolution: 10 Hz

Hewlett–Packard

83630AOPT001, 008, H53,

8340B or 8340A

Output: +10 to –85 dBm

Sweep frequency range: 10 MHz to

21 GHz

Output: +6 dBm to –10 dBm

Capable of being externally leveled to

0.375 dB

+

2.7 Step attenuators

(one of each

value required)

Overall attenuation: 0 to 80 dB in 1 dB

steps

Consisting of attenuation: 0 to 12 dB in

1 dB steps;

and

Attenuation: 0 to 80 dB in 1 0dB

steps

Hewlett–Packard

355COPT001,

355COPTC08, or 355C

Hewlett–Packard

355DOPT001,

355DOPTC08, or 355D

* If the TI is to be calibrated up to 18 GHz, the top frequency requirement of these items is

only 18 GHz.

** If the signal generator or signal source is to be used for the TI frequency span/div tests instead of

the comb generator, then the frequency uncertainty of the signal generator or signal source should

8

1 x 10

–

.

be +

*** Not applicable, if the signal generator is to be used for the TI frequency span/div tests.

7

NAVAIR 17–20AW–232

Item

2.8 Comb

generator***

2.9 Function

generator

2.10 T ee

2.11 10 dB

attenuator

(2 required)

2.12 Power splitter*

2.13 Calibrator*

Minimum Use

Specifications

Frequency comb: 1, 10, and 100 Mhz

increments

Uncertainty: +

Capable of being externally modulated

Frequency range: 2 kHz to 200 kHz

Uncertainty: +

BNC T ee, Coaxial

Attenuation: 10 dB

Frequency: 30 MHz to 1 GHz

SWR: 1.20 max.

Frequency range: 0 to 21 GHz

Input SWR: 1.20 max.

Output SWR: 1.10 max.

Output tracking between arms:

0.15 dB max.

Insertion loss: 6 dB nom.

Frequency range: 30 to 1000 MHz

Power range: +20 to –80 dBm

Uncertainty: +

0.01%

0.01%

0.35 dBm absolute

Calibration

Equipment

Hewlett–Packard 8406A

Hewlett–Packard

33120AOPT001 or 3314A

Amphenol UG274AU

Weinschel 2–10; or

Hewlett–Packard

8491BOPT010

0 to 18 GHz

Weinschel 1870A; or

Hewlett–Packard 11667A

18 to 21 GHz

Weinschel 1579; or

Hewlett–Packard 11667B

Hewlett–Packard

8902AOPTE04 (consists

of : HP 8902A;

8672AOPT001, 008;

11792AOPT001, H04;

and 11793AOPTH04)

2.14 Oscillator

2.15 3 dB attenuator*

2.16 Instrument

controller**

* If the TI is to be calibrated up to 18 GHz, the top frequency requirement of these items is

only 18 GHz.

** These items are required only if the TI is a 494P or 494AP series.

*** Not required if the signal generator or the signal source is to be used for the TI

frequency span/div tests.

Frequency range: 10 kHz to 10 MHz

Output: 0.141 V rms (–4 dBm)

Output meter frequency response: +

Attenuation: 3 dB

Frequency range: 0 to 21 GHz

SWR: 1.20 max.

Programmable using diskette NAVAIR

17–20MSYS–036D, version 2 or 3,

IEEE–488 GPIB test for use with

Fluke 1720A/AP or 1722A/AP

4%

Hewlett–Packard

33120AOPT001 or

Fluke 6011AOPT01, 03, 05

or 6011AOPT01, 02, 05

0 to 18 GHz

Weinschel 2–3; or

Hewlett–Packard

8491BOPT003

18 to 21 GHz

Hewlett–Packard

8493COPT003

Fluke 1722A/AP or

1720A/AP

8

NAVAIR 17–20AW–232

Item

2.17 Interface bus

cable*

2.18 Coaxial

termination

* These items are required only if the TI is a 494P or 494AP series.

3.1 Ensure that all power switches are set to off, and set all auxiliary equipment controls as necessary to avoid

damage to the equipment and so that dangerous voltages will not be present on output terminals when the power

switches are turned on.

Meets IEEE Std. 488–1978 and FCC

regulation 79–555–14686

50 ohms, 1 watt

SWR: <

Frequency range: DC to 18 GHz

Minimum Use

Specifications

Local supply

W einschel M1404N

1.02 + 0.0023f (GHz)

SECTION 3

PRELIMINAR Y OPERATIONS

Calibration

Equipment

3.2 Connect the auxiliary equipment, and the TI, to the appropriate power source.

3.3 Turn all auxiliary power switches to on and allow a sufficient warm–up time for the equipment.

NOTES

The 1st and 2nd LO OUTPUTS must be terminated into 50 at all times.

At times throughout this procedure, it may be necessary to activate the TI BASELINE CLIP

function in order to see the TI read–out on the bottom of the TI CRT.

3.4 Initial TI Turn–on.

3.4.1 Set the TI POWER switch to ON.

NOTE

When the TI POWER is switched on, the internal TI processor will run a memory and I/O test.

If a problem exists, a failure message will appear on the TI CRT screen. The program will be

ready to operate if there is no problem.

3.4.2 Verify that the TI passed the memory and I/O test (no failure messages).

3.4.3 Ensure that the TI CRT read–out is functioning. If necessary, activate the TI READOUT function and

adjust the INTENSITY control for the desired brightness.

9

NAVAIR 17–20AW–232

TI functions can be toggled active/inactive by pressing the function pushbutton. A TI function is

considered active when its pushbutton is illuminated and inactive when its pushbutton is not

illuminated, Throughout this procedure, when instructed to activate a TI function that is

currently active, first deactivate that function then activate it.

3.4.4 Ensure that the TI BASELINE CLIP function is deactivated.

3.4.5 Allow a 1 hour TI warm–up time before proceeding.

3.5 Internal Calibration

3.5.1 Activate the TI CAL function (SHIFT, FINE pushbuttons) to start the TI internal calibration routine.

During the TI processor generated calibration procedure, the technician should observe the TI

CR T for instructional messages and take action accordingly. The first message should instruct

the technician to connect the TI CAL OUT to the TI RF INPUT and to ensure that the TI

PEAK/AVERAGE knob is fully counterclockwise. Subsequent messages on the TI CRT will

direct the technician on how to adjust the vertical and horizontal POSITION, CAL AMPL, and

LOG controls. This sets the absolute Reference Level for the 1 MHz resolution bandwidth filter.

An automatic calibration is then run by the TI processor, which measures and corrects frequency

and amplitude errors of the other filters with respect to the 1 MHz filter and the reference

frequency .

NOTE

NOTE

3.5.2 Press the TI FINE pushbutton to continue with the calibration routine.

3.5.3 Verify that the TI passed the calibration routine.

NOTE

If the TI processor completes the routine, the TI control settings will return to normal operation

(no CALIBRATION FAILED message).

3.6 Set the TI controls as follows:

CENTER FREQUENCY control to 100 MHz

FREQUENCY SPAN/DIV control to 200 kHz

VER TICAL DISPLAY to 10 dB/div

MIN RF ATTEN switch to 0 dB

REF LEVEL to 0 dBm

AUTO RESOLN function to ON (activated)

VIDEO FILTER to NARROW

10

NAVAIR 17–20AW–232

TIME/DIV switch AUTO

DIGITAL STORAGE VIEW A function to ON (activated)

DIGITAL STORAGE VIEW B function to ON (activated)

TRIGGERING to FREE RUN

MIN NOISE function to OFF (deactivated)

3.7 H–P 8902A Calibrator Sensor Module Zeroing and Reference Calibration

3.7.1 Ensure that the calibrator system is interconnected as appropriate.

3.7.2 Press the calibrator INSTR PRESET (Blue key, Green AUTOMATIC OPERATION key), set the calibrator

to measure RF POWER.

3.7.3 Connect the calibrator sensor module input to the calibrator RF POWER output.

3.7.4 Press the calibrator ZERO key, and after the calibrator momentarily displays 0.000 W followed by a small

measurement value, press the CALIBRATE key.

3.7.5 Select the calibrator SAVE CAL function (Blue key, CALIBRATE key) and then press the CALIBRA TE

key. The calibrator sensor module is now zeroed and reference calibrated. Disconnect the calibrator sensor

module input from the calibrator RF POWER output.

SECTION 4

CALIBRATION PROCESS

NOTES

Unless otherwise specified, verify the results of each test and take corrective action whenever

the test requirement is not met, before proceeding.

Unless otherwise specified, make all measurements with the TI PEAK/AVERAGE knob fully

counterclockwise.

4.1 CALIBRATOR TESTS

4.1.1 Connect the TI CAL OUT through the low pass filter to the appropriate microwave counter input for a 100

MHz frequency.

4.1.2 Set the microwave counter for automatic frequency measurement with 1 Hz resolution, maximum sample

rate, and 50 input impedance. Verify that the microwave counter indication is between 99.999990 and

100.000010 MHz (100 MHz +

4.1.3 Disconnect the TI CAL OUT from the low pass filter, and disconnect the low pass filter from the

microwave counter.

10 Hz).

4.1.4 Connect the TI CAL OUT to the TI RF INPUT.

11

NAVAIR 17–20AW–232

4.1.5 Set the TI VERTICAL DISPLAY to 2 dB/div and set the TI REF LEVEL to –15 dBm.

4.1.6 Set the TI RESOLUTION BANDWIDTH to 1 MHz, and adjust the TI CENTER FREQUENCY control to

center the calibrator signal.

4.1.7 Depress the TI DIGITAL STORAGE SAVE A pushbutton.

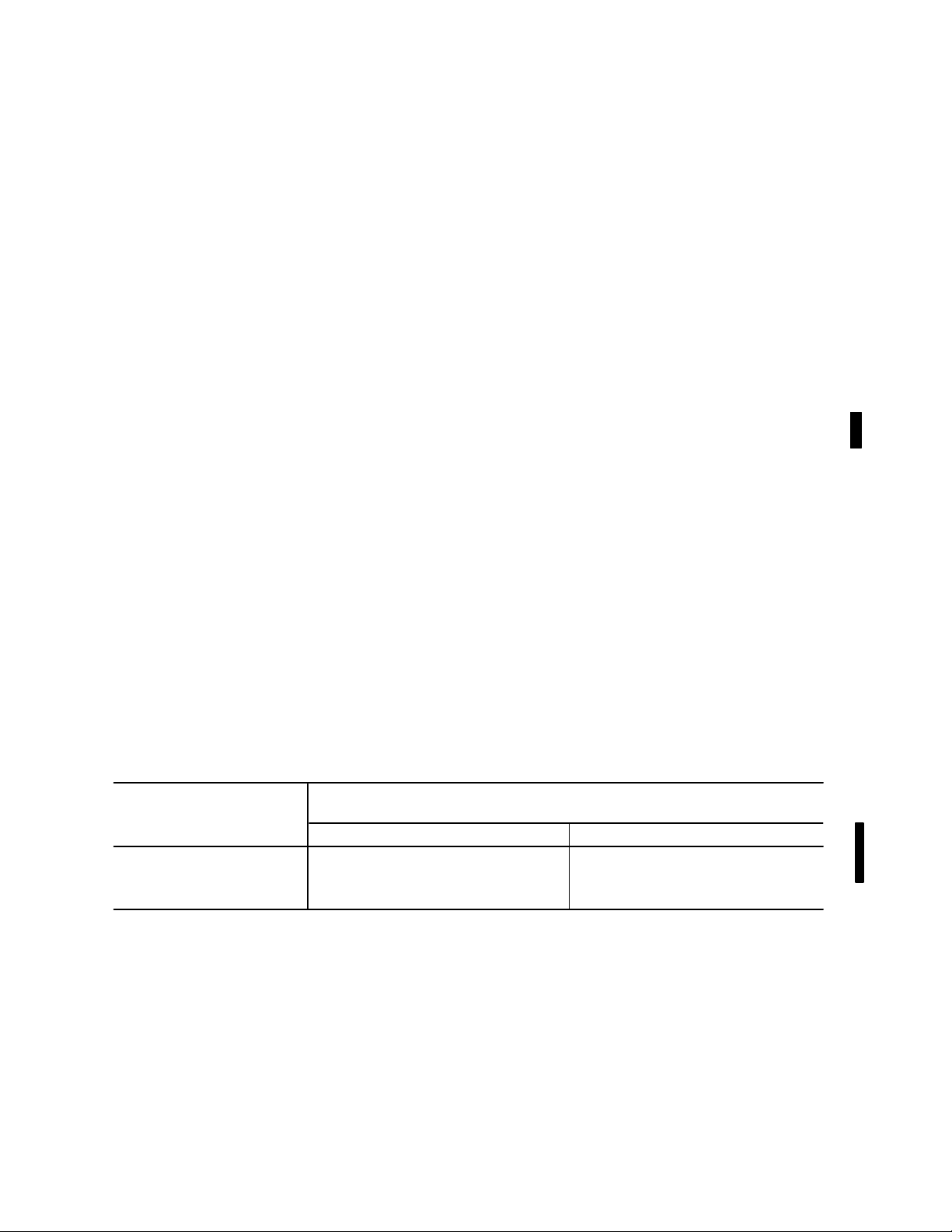

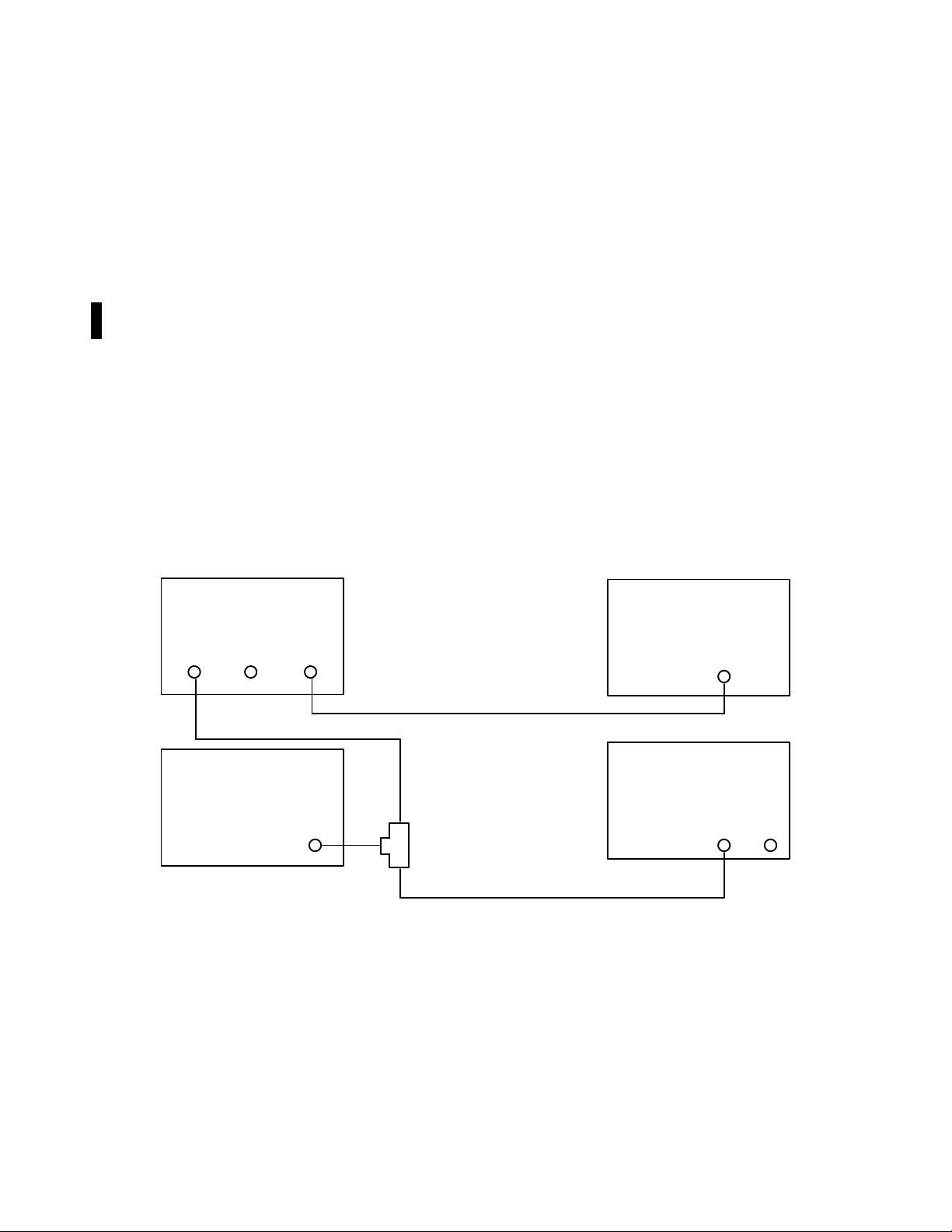

4.1.8 Disconnect the TI CAL OUT from the TI RF INPUT. Connect the equipment as shown in Figure 1.

2.3

SIGNAL

GENERATOR

RF

OUTPUT

2.2

LOW P ASS FILTER

IN OUT

TI

RF

INPUT

Figure 1. Calibrator T est Configuration

4.1.9 Adjust the signal generator controls for a 100 MHz output at –20 dBm.

4.1.10 Adjust the signal generator frequency controls to center the signal on the TI CRT.

4.1.11 Adjust the signal generator output level to align the amplitude of the signal generator signal with that of

the stored TI calibrator signal.

4.1.12 Disconnect the TI RF INPUT from the low pass filter.

4.1.13 Zero and reference calibrator, the power meter, the power sensor (capable of 0 to 18 GHz operation), and

then set the power meter CAL FACTOR switch to the power sensor calibration factor corresponding to 100 MHz

(or as close as possible).

4.1.14 Connect the power meter and power sensor to the low pass filter output.

4.1.15 Verify that the power meter indicates between –19.7 and –20.3 dBm.

4.1.16 Adjust the signal generator amplitude controls for minimum output and disconnect the test setup.

4.2 COUNTER READOUT TESTS

4.2.1 Set the TI controls as follows:

CENTER FREQUENCY control to 100 MHz

FREQUENCY SPAN/DIV control to 20 kHz

VER TICAL DISPLAY to 10 dB/div

MIN RF ATTEN switch to 0 dB

12

NAVAIR 17–20AW–232

REF LEVEL to 0 dBm

AUTO RESOLN function to ON (activated)

VIDEO FILTER to WIDE

DIGITAL STORAGE SAVE A function to OFF (deactivated)

DIGITAL STORAGE VIEW B function to OFF (deactivated)

MIN NOISE function to ON (activated)

4.2.2 Activate the TI COUNT RESOLN function (SHIFT, COUNTER pushbuttons) and enter 1 Hz via the TI

Data Entry keypad.

4.2.3 Connect the TI CAL OUT to the TI RF INPUT.

4.2.4 Center the 100 MHz marker under the dot marker using the TI CENTER FREQUENCY control.

4.2.5 Activate the TI COUNTER function. Note the indication over several counts, and verify that the TI

COUNTER indications are between 99,999,987 and 100,000,013 Hz (99,999,993 and 100,000,007 Hz, 494AP

Models). Deactivate the TI COUNTER function.

4.2.6 Set the TI FREQUENCY SPAN/DIV control to 500 kHz and repeat steps 4.2.4 and 4.2.5.

4.2.7 Activate the TI COUNT RESOLN function (SHIFT, COUNTER pushbuttons) and enter

1 kHz for a TI counter resolution of 1 kHz.

4.2.8 Activate the TI COUNTER function. Note the indication over several counts, and verify that the TI

COUNTER indications are between 99,999 and 100,001 kHz. Deactivate the TI COUNTER function.

4.2.9 Set the TI FREQUENCY SPAN/DIV control to 200 kHz and repeat steps 4.2.4 and 4.2.8.

4.2.10 Set the TI FREQUENCY SPAN/DIV control to 500 kHz. Activate the TI COUNT RESOLN function

(SHIFT, COUNTER pushbuttons) and enter 1 Hz via the TI Data Entry keypad.

4.2.11 Repeat steps 4.2.4 and 4.2.5 for the following TI CAL OUT marker frequencies and verify that the TI

COUNTER indications are within the tolerance limits listed (adjust the TI REF LEVEL as necessary).

TI CAL OUT

Marker Frequency

(MHz)

500 499,999,987 to 500,000,013 499,999,993 to 500,000,007

1000 999,999,987 to 1,000,000,013 999,999,993 to 1,000,000,007

4.2.12 Disconnect the TI CAL OUT from the TI RF INPUT and connect the equipment as shown in Figure 2.

494 Models

T olerance Limits

(Hz)

494AP Models

13

NAVAIR 17–20AW–232

2.6

SIGNAL SOURCE

RF

OUTPUT

2.1

MICROWAVE

COUNTER

RF

INPUT

* USE POWER SPLITTER CAPABLE

OF 0 TO 18 GHz OPERATION,

AS APPLICABLE.

2.12*

POWER

SPLITTER

TI

RF

INPUT

Figure 2. Counter Readout T est Configuration

4.2.13 Set the signal source controls for a 1.7 GHz CW output at –10 dBm, and set the microwave counter for

automatic frequency measurement with maximum resolution and maximum sample rate. Set the TI REF LEVEL

+10 dBm.

4.2.14 Set the signal source for the following microwave counter indications. At each setting, use the methods

from steps 4.2.4 and 4.2.5 and verify that the TI COUNTER indications are within the tolerance limits listed

(adjust the TI REF LEVEL as necessary).

Microwave

Counter Indication

(GHz)

494 Models 494A Models

T olerance Limit

(Hz)

1.7 1,699,999,817 to 1,700,000,183 1,699,999,823 to 1,700,000,177

3.0 2,999,999,687 to 3,000,000,313 2,999,999,693 to 3,000,000,307

5.0 4,999,999,487 to 5,000,000,513 4,999,999,493 to 5,000,000,507

8.0 7,999,999,183 to 8,000,000,817 7,999,999,191 to 8,000,000,809

12.0 11,999,998,783 to 12,000,001,217 11,999,998,791 to 2,000,001,209

15.0 14,999,998,483 to 15,000,001,517 14,999,998,491 to 15,000,001,509

18.0 17,999,998,183 to 18,000,001,817 17,999,998,191 to 18,000,001,809

21.0* 20,999,997,883 to 21,000,002,117 20,999,997,891 to 21,000,002,109

* Skip this test if TI is only to be calibrated to 18 GHz.

14

NAVAIR 17–20AW–232

4.3 CENTER FREQUENCY TESTS

4.3.1 Set the signal source output level to 0 dBm, and the frequency for a 500 MHz microwave counter

indication.

4.3.2 Set the TI controls as follows:

CENTER FREQUENCY control to 500 MHz

FREQUENCY SPAN/DIV control to 500 kHz

MIN RF ATTEN switch to 0 dB

REF LEVEL to +15 dBm

VIDEO FILTER to NARROW

RESOLUTION BW to 1 MHz

4.3.3 Press the TI COUNT –> CF pushbutton and wait until the TI COUNT –> CF light extinguishes. Change

the TI RESOLUTION BANDWIDTH to 10 kHz.

4.3.4 Verify that the signal is within +115.05 kHz (+0.23 divisions) from the TI CRT center vertical graticule

line.

4.3.5 Set the TI FREQUENCY RANGE and the signal source for the following settings. At each setting, use

the methods described in steps 4.3.3 and 4.3.4 and verify that the difference between the TI CRT center vertical

graticule line and the signal is within the tolerance limits listed.

TI

FREQUENCY RANGE

Setting

(GHz)

0 to 1.8 1.0 1.0 +

0 to 1.8 1.5 1.5 ”

1.7 to 5.5 3.5 3.5 ”

3.0 to 7.1 5.0 5.0 ”

5.4 to 18 10.0 10.0 +

5.4 to 18 15.0 15.0 ”

15 to 21 18.0 18.0 ”

15 to 21* 21.0 21.0 ”

* Skip this test if the TI is only to be calibrated to 18 GHz.

4.3.6 Set the TI RESOLUTION BANDWIDTH to 10 kHz and the FREQUENCY SPAN/DIV switch to 100

kHz.

CENTER

FREQUENCY

(GHz)

Signal Source

Frequency

(GHz)

T olerance Limits

(GHz)

0.23

0.29

4.3.7 Set the TI FREQUENCY RANGE, to the following settings. Adjust the signal source for a frequency

counter indication of the following value. At each setting press the TI COUNT –> CF pushbutton and wait until

the TI COUNT –> CF light extinguishes, and verify that the difference between the TI CRT center vertical

graticule and the signal is within the following tolerance limits.

15

NAVAIR 17–20AW–232

FREQUENCY RANGE

0 to 1.8 0.5 0.5 +0.20

0 to 1.8 1.0 1.0 +

0 to 1.8 1.5 1.5 +0.21

1.7 to 5.5 3.5 3.5 +

3.0 to 7.1 5.0 5.0 +

5.4 to 18 10.0 10.0 +

5.4 to 18 15.0 15.0 +0.35

15 to 21 18.0 18.0 +

15 to 21 * 21.0 21.0 +

* Skip this test if the TI is only to be calibrated to 18 GHz.

4.3.8 Set the signal source output amplitude control for minimum output and disconnect the test setup.

Setting

(GHz)

TI

CENTER

FREQUENCY

(GHz)

Signal Source

Frequency

(GHz)

T olerance Limits

(Div)

0.21

0.24

0.25

0.30

0.38

0.41

4.4 CRT DISPLAY TESTS

4.4.1 Set the TI controls as follow:

CENTER FREQUENCY control to 100 MHz

FREQUENCY SPAN/DIV control to 20 kHz

REF LEVEL to +10 dBm

MIN RF ATTEN to 0 dB

MIN NOISE to Activated

PEAK/AVERAGE control to Full clockwise position

RESOLUTION BW to 10 kHz

VIDEO FILTER to NARROW

4.4.2 Connect the equipment as shown in Figure 3.

2.3

SIGNAL

GENERATOR

RF

OUTPUT

TI

RF

INPUT

16

STEP ATTENUATOR

2.7

Figure 3. CRT Display Test Configuration

NAVAIR 17–20AW–232

4.4.3 Set the signal generator controls for a 100 MHz output at +10 dBm, and set both of the step attenuators to

0 dB.

4.4.4 Carefully adjust the signal generator output so that the signal peak is aligned with the top TI CRT

graticule line.

4.4.5 Increase the external attenuation with the step attenuators to 80 dB in 10 dB steps. Verify that the

displayed signal steps down in 10 dB steps (+

4.4.6 Verify the the maximum cumulative error over the TI CRT display from top to bottom does not exceed

2.0 dB.

+

4.4.7 Return the external attenuation to 0 dB. Set the TI VERTICAL DISPLAY to 2 dB/div, and deactivate the

TI MIN NOISE function.

4.4.8 Set the TI RESOLUTION BANDWIDTH to 100 kHz, and carefully adjust the signal generator output so

that the signal peak is aligned with the top TI CRT graticule line.

4.4.9 Increase the external attenuation with the step attenuators to 16 dB in 2 dB steps. Verify that the

displayed signal steps down in 2 dB steps (+

4.4.10 Verify that the maximum cumulative error over the TI CRT display from top to bottom does not exceed

1.0 dB.

+

1 dB/10 dB).

0.4 dB/2 dB).

4.4.11 Return the external attenuation to 0 dB, and set the TI VERTICAL DISPLAY to LIN.

4.4.12 Carefully adjust the signal generator output so that the signal peak is aligned with the top TI CRT

graticule line.

4.4.13 Increase the external attenuation with the step attenuators to 6 dB. Verify that the displayed signal steps

down to within +

4.4.14 Increase the external attenuation with the step attenuators to 12 dB. Verify that the displayed signal steps

down to within +

4.4.15 Increase the external attenuation with the step attenuators to 18 dB. Verify that the displayed signal steps

down to within +

4.4.16 Set the TI VERTICAL DISPLAY to 10 dB/div, and disconnect the equipment from the TI.

0.4 div of the center TI CRT horizontal graticule.

0.4 div of the TI CRT quarter screen (2 division above the TI CRT bottom).

0.4 div of the TI CRT eighth screen (1 division above the TI CRT bottom).

17

NAVAIR 17–20AW–232

4.5 FREQUENCY SPAN TESTS

If the comb generator is to be used, proceed with step 4.5.1. If the signal generator or signal

source is to be used, skip to step 4.5.2.

4.5.1 Frequency Span T ests Using a Comb Generator

4.5.1.1 Set the TI controls as follows:

CENTER FREQUENCY control to 1.0 GHz (2.0 GHz if the

FREQUENCY SPAN/DIV control to 200 MHz

REF LEVEL to –20 dBm

AUTO RESOLN function to ON (activated)

MIN NOISE function to ON (activated)

NOTE

TI is a 494A series)

PEAK/AVERAGE control to Fully ccw

4.5.1.2 Connect the equipment as shown in Figure 4.

2.8

COMB

GENERATOR

MODULATION OUTPUT

2.9

FUNCTION

GENERATOR

2.10

TEE

TI

RF

INPUT

2.1

MICROWAVE

COUNTER

INPUTOUTPUT

18

Figure 4. Frequency Span T est Configuration

4.5.1.3 Set the comb generator frequency controls to 100 MC, adjust the interpolation amplitude–1 MC control

to off and the output amplitude control for a TI signal display of approximately 3 div amplitude.

4.5.1.4 Adjust the TI CENTER FREQUENCY control to position the second comb signal (at 200 MHz) at the

second from the left TI vertical graticule line.

NAVAIR 17–20AW–232

NOTE

The first comb signal (at 100 MHz) should be positioned halfway between the TI CRT leftmost

vertical graticule and second from the left vertical graticule.

4.5.1.5 Verify that the TI indicates that the 18th comb signal is between 7.6 and 8.4 divisions from the second

comb signal.

4.5.1.5.1 If the TI is a 494A series, set the CENTER FREQUENCY to 1.0 GHz.

4.5.1.6 Set the TI FREQUENCY SPAN/DIV switch and the comb generator frequency controls to the following

settings. At each setting, adjust the TI CENTER FREQUENCY control to position the indicated comb signal at

the given TI vertical graticule line, and verify that the TI indicates that the difference between the listed comb

signals is within the tolerance limits listed.

NOTE

Adjust the comb generator output amplitude, the TI REF LEVEL, and the RESOLUTION

BANDWIDTH as necessary to maintain a clear comb display.

TI

FREQUENCY

SPAN/DIV

Switch Setting

Comb Generator

Frequency Setting

(MC)

Difference Between

Comb Signals

(numbers)

T olerance Limits

(divisions)

100 MHz 100 2 – 10 ** 7.6 to 8.4

50 ” 100 1 – 5* ”

20 ” 10 3 – 19 *** ”

10 ” 10 2 – 10 ** ”

5 ” 10 1 – 5* ”

2” 1 3–19 *** ”

1” 1 2–10 ** ”

500 kHz 1 1 – 5* ”

* Align the first comb signal with the second from the left TI CRT vertical graticule line.

** Align the second comb signal with the second from the left TI CRT vertical graticule line.

*** Align the third comb signal with the second from the left TI CRT vertical graticule line.

4.5.1.7 Set the comb generator frequency controls to 10 MC, and adjust the interpolation amplitude

– 1 MC control to mid position.

4.5.1.8 Adjust the function generator frequency controls for a 200.0 kHz electronic counter indication.

4.5.1.9 Set the TI FREQUENCY SPAN/DIV switch to 200 kHz, adjust the function generator amplitude, and

the comb generator interpolation amplitude–1 MC, controls to obtain the best possible TI comb signal display.

4.5.1.10 Adjust the TI CENTER FREQUENCY control to position the second comb signal at the second from

the left TI vertical graticule line. Verify that the TI indicates that the tenth comb signal is between 7.6 and 8.4

divisions from the second comb signal.

19

NAVAIR 17–20AW–232

4.5.1.11 Set the TI FREQUENCY SPAN/DIV switch to the following settings and adjust the function generator

frequency control for the electronic counter indications listed. At each setting, adjust the TI CENTER

FREQUENCY control to position the indicated comb signal at the given TI vertical graticule line, and verify that

the TI indicates that the difference between the listed comb signals is within the tolerance limits listed.

Adjust the comb generator interpolation amplitude and the function generator output amplitude

controls as necessary to maintain a good comb display.

FREQUENCY

SPAN/DIV

Switch Setting

100 MHz 200 1 – 5 ** 7.6 to 8.4

50 ” 50 2 – 10 * ”

20 ” 20 2 – 10 *** ”

10 ” 20 1 – 5** ”

5” 5.0 2–10 * ”

NOTE

TI

Comb Generator

Frequency Setting

(MC)

2” 2.0 2–10 *** ”

Difference Between

Comb Signals

(numbers)

T olerance Limits

(divisions)

* Align the first comb signal with the second from the left TI CRT vertical graticule line.

** Align the second comb signal with the second from the left TI CRT vertical graticule line.

4.5.1.12 Adjust the function generator and comb generator amplitude controls for minimum output and

disconnect the equipment from the TI.

4.5.1.13 Skip to subsection 4.6.

4.5.2. Frequency Span T ests Using a Signal Generator or Signal Source

4.5.2.1 Set the TI controls as follows:

CENTER FREQUENCY control to 1.0 GHz (2.0 GHz if the

TI is a 494A series)

FREQUENCY SPAN/DIV control to 200 MHz

REF LEVEL to –20 dBm

AUTO RESOLN function to ON (activated)

MIN NOISE function to ON (activated)

PEAK/AVERAGE control to Fully ccw

20

NOTE

Select the signal generator (item 2.3) or signal source (item 2.6) as applicable to the test

frequency .

NAVAIR 17–20AW–232

4.5.2.2 Connect the signal generator/source output to the TI RF INPUT.

4.5.2.3 Set the signal generator/source for a –25 dBm signal at 200 MHz (1.2 GHz if the TI is a 494A series).

4.5.2.4 Adjust the TI CENTER FREQUENCY control to position the signal generator/source signal at the

second from the left TI vertical graticule line.

NOTE

All TI CRT vertical graticule references count the far left graticule as the first (1st) graticule,

which would imply that the far right graticule is the eleventh (11th) graticule.

4.5.2.5 Set the signal generator/source frequency to 1.8 GHz (2.8 GHz if the TI is a 494A series).

4.5.2.6 Verify that the TI indicates that the signal generator/source signal (at the 10th vertical graticule line

from the left) is within +0.4 divisions of the 10th vertical graticule line.

4.5.2.6.1 If the TI is a 494A series, set the CENTER FREQUENCY to 1.0 GHz.

4.5.2.7 Set the TI FREQUENCY SPAN/DIV switch to the following settings. At each setting, first set the

signal generator/source for the “Left” frequency, adjust the TI CENTER FREQUENCY control to position the

indicated “Left” signal at the second TI vertical graticule line, then set the signal generator/source frequency to

the “Right” frequency settings and verify that the signal is within +0.4 divisions of the 10th vertical graticule.

NOTE

Adjust the TI REF LEVEL and RESOLUTION BANDWIDTH as necessary to maintain a clear

signal display.

TI

FREQUENCY

SPAN/DIV

Switch Setting

100 MHz 600.000 1400.000

50 ” 800.000 1200.000

20 ” 920.000 1080.000

10 ” 960.000 1040.000

5 ” 980.000 1020.000

2 ” 992.000 1008.000

1 ” 996.000 1004.000

500 kHz 998.000 1002.000

200 ” 999.200 1000.800

100 ” 999.600 1000.400

50 ” 999.800 1000.200

20 ” 999.920 1000.080

10 ” 999.960 1000.040

5 ” 999.980 1000.020

2 ” 999.992 1000.008

“Left”

Frequency Setting

(MHz)

Signal Generator/Source

“Right”

Frequency Setting

(MHz)

4.5.2.8 Adjust the signal generator/source amplitude controls for minimum output and disconnect the equipment

from the TI.

21

NAVAIR 17–20AW–232

4.6 RF ATTENUATOR TESTS

4.6.1 Connect the equipment as shown in Figure 5.

Use the shortest cable possible in the connection between the power splitter and the TI RF

INPUT connector. Do not use adapters.

NOTE

TI

RF

INPUT

* USE POWER SPLITTER CAPABLE

OF 0 TO 18 GHZ OPERATION, AS APPLICABLE.

4.6.2 Set the TI controls as follows:

CENTER FREQUENCY control to 1 GHz

2.3

SIGNAL

GENERATOR

RF

OUTPUT

IN

2.12*

POWER

SPLITTER

Figure 5. RF Attenuator T est Configuration

2.13

CALIBRATOR

2.11

10 DB ATTEN.

SENSOR

MODULE

P/O

2.13

FREQUENCY SPAN/DIV control to 500 kHz

RESOLUTION BANDWIDTH to 100 kHz

REF LEVEL to +21 dBm

MIN RF ATTEN switch to 0 dB (60 dB on TI CRT display)

VER TICAL DISPLAY to 10 dB/div

WIDE VIDEO FILTER to ON (activated)

MIN NOISE to OFF (deactivated)

4.6.3 Set the signal generator for a +12 dBm signal at 1 GHz.

4.6.4 Program the calibrator INSTR PRESET function (BLUE Shift and GREEN Automatic Operation buttons).

Enter on the calibrator: 27.3 SPCL 0 MHz, and ensure that the calibrator indication is approximately 1000 MHz.

Set the calibrator for TUNED RF LEVEL measurements with log (dBm) display, enter 39.9 SPCL, and press the

CALIBRATE button.

4.6.5 Decrease the signal generator output level until the calibrator displays RECAL. Press the calibrator

CALIBRATE button.

22

NAVAIR 17–20AW–232

4.6.6 Decrease the signal generator output level again until the calibrator displays RECAL. Again, press the

calibrator CALIBRATE button.

4.6.7 Adjust the signal generator output level for a –9 dBm calibrator indication.

4.6.8 Adjust the TI CENTER FREQUENCY control to center the displayed signal. Decrease the TI

FREQUENCY SPAN/DIV setting to 20 kHz, while keeping the signal centered on the display with the TI

CENTER FREQUENCY control.

4.6.9 Adjust the signal generator output level to align the signal displayed on the TI CRT with the nearest TI

CR T horizontal graticule line. Note this line as the reference.

4.6.10 Program the calibrator SET REF function (BLUE Shift and ZERO keys). Ensure that the calibrator

indicates 0.00 dB (+

4.6.11 Set the TI REF LEVEL control for a +11 dBm CRT readout. Decrease the signal generator output level

to align the signal to the same TI CRT graticule line noted in step 4.6.9.

4.6.12 Verify that the calibrator indication is between –9.7 and –10.3 dB (–9.5 and –10.5 dB if the TI is a 494A

series). Note the calibrator indication.

4.6.13 Set the TI REF LEVEL control for a +1 dBm CRT readout. Decrease the signal generator output level to

align the signal to the same TI CRT graticule line noted in step 4.6.9.

0.01 dB).

4.6.14 Verify that the calibrator indication is between –19.4 and –20.6 dB (–19.0 and –21.0 dB if the TI is a

494A series). Note the calibrator indication.

4.6.15 Repeat steps 4.6.13 and 4.6.14 for the following TI REF LEVEL control settings. At each setting, verify

that the calibrator indication is within the tolerance limits listed. Note the calibrator indication.

TI

REF LEVEL

Control Setting

(dBm)

–9 –29.3 to –30.7 –29.0 to –31.0

–19 –39.3 to –40.7 –39.0 to –41.0

–29 –49.3 to –50.7 –49.0 to –51.0

–39 –59.3 to –60.7 –59.0 to –61.0

4.6.16 Verify that the difference between any two adjacent calibrator indications noted in steps 4.6.12, 4.6.14,

and 4.6.15 is 9.7 to 10.3 dB (–9.5 and –10.5 dB if the TI is a 494A series).

4.6.17 Repeat step 4.6.2, except set the TI CENTER FREQUENCY to 10 GHz.

4.6.18 Set the signal generator output to minimum, and replace the signal generator in the test setup with the

signal source.

Model 494

Calibrator

T olerance Limits

(dB)

Model 494A

Calibrator

T olerance Limits

(dB)

4.6.19 Set the signal source for a +8 dBm signal at 10 GHz.

4.6.20 Program the calibrator INSTR PRESET function (BLUE Shift and GREEN Automatic Operation

buttons). Set the external LO of the calibrator to 10120.53 MHz. Enter on the calibrator: 27.3 SPCL 10120.53

MHz, and ensure that the calibrator indication is approximately 10000 MHz. Set the calibrator for TUNED RF

LEVEL measurements with log (dBm) display, enter 39.9 SPCL, and press the CALIBRATE button.

23

NAVAIR 17–20AW–232

4.6.21 Repeat steps 4.6.5 through 4.6.15, except use the signal source and verify that the calibrator indication is

within the following tolerance limits for the TI REF LEVEL control settings listed.

TI

REF LEVEL

Control Setting

(dBm)

+11 –9.5 to –10.5 –8.5 to –11.5

+1 –19.0 to –21.0 –17.0 to –23.0

–9 –28.6 to –31.4 –27.0 to –33.0

–19 –38.6 to –41.4 –37.0 to –43.0

–29 –48.6 to –51.4 –47.0 to –53.0

–39 –58.6 to –61.4 –57.0 to –63.0

4.6.22 Verify that the difference between any two adjacent calibrator indications noted in step 4.6.21 is 9.5 to

10.5 dB.

4.6.23 Repeat step 4.6.2, except set the TI CENTER FREQUENCY to 15 GHz.

4.6.24 Set the signal source for a +8 dBm signal at 15 GHz.

4.6.25 Program the calibrator INSTR PRESET function (BLUE Shift and GREEN Automatic Operation

buttons). Set the external LO of the calibrator to 15120.53 MHz. Enter on the calibrator: 27.3 SPCL 15120.53

MHz, and ensure that the calibrator indication is approximately 10000 MHz. Set the calibrator for TUNED RF

LEVEL measurements with log (dBm) display, enter 39.9 SPCL, and press the CALIBRATE button.

Model 494

Calibrator

T olerance Limits

(dB)

Model 494A

Calibrator

T olerance Limits

(dB)

4.6.26 Repeat steps 4.6.21 and 4.6.22.

4.6.27 Adjust the signal source output level for minimum output but do not disconnect the test setup. Replace

the signal source in the test setup with the signal generator.

4.7 IF GAIN TESTS

4.7.1 Set the TI controls as follows:

CENTER FREQUENCY control to 100 MHz

FREQUENCY SPAN/DIV control to 10 kHz

REF LEVEL to –10 dBm

VER TICAL DISPLAY to 1 dB/div

VIDEO FILTER to WIDE

RESOLUTION BANDWIDTH switch to 10 kHz

MIN NOISE to OFF (deactivated)

4.7.2 Set the signal generator for a +5 dBm signal at 100 MHz.

24

NAVAIR 17–20AW–232

4.7.3 Program the calibrator INSTR PRESET function (BLUE Shift and GREEN Automatic Operation buttons).

Enter on the calibrator: 27.3 SPCL 0 MHz, and ensure that the calibrator indication is approximately 100 MHz.

Set the calibrator for TUNED RF LEVEL measurements with log (dBm) displays, enter 39.9 SPCL, and press the

CALIBRATE button.

4.7.4 Decrease the signal generator output level until the calibrator displays RECAL. Press the calibrator

CALIBRATE button.

4.7.5 Decrease the signal generator output level again until the calibrator displays RECAL. Press the calibrator

CALIBRATE button.

4.7.6 Adjust the signal generator output level for a –12 dBm TI CRT display (signal is two graticules below top

TI CRT graticule). Note this graticule as the reference.

4.7.7 Activate the TI MIN NOISE function and verify that the signal amplitude change is <+

(<0.4 minor divisions) on the TI CRT.

4.7.8 Adjust the signal generator output level to reposition the signal level to the TI CRT reference line, if

necessary.

4.7.9 Program the calibrator SET REF function (BLUE Shift and ZERO buttons). Ensure that the calibrator

indicates 0.00 dB (+

4.7.10 Set the TI REF LEVEL control to following settings. At each setting, decrease the signal generator

output level to align the signal to the same TI CRT graticule line noted in step 4.7.6, and verify that the calibrator

indication is within the tolerance limits listed, Note the exact calibrator relative indication at each TI REF

LEVEL setting.

0.01 dB).

TI CRT REF LEVEL

Readout Indication

(dBm)

–11 –0.8 to –1.2

–12 –1.6 to –2.4

–13 –2.5 to –3.5

–14 –3.5 to –4.5

–15 –4.5 to –5.5

–16 –5.5 to –6.5

–17 –6.5 to –7.5

–18 –7.5 to –8.5

–19 –8.5 to –9.5

–20 –9.0 to –11.0

T olerance Limits

(dB)

0.8 dB

4.7.11 Verify that the difference between any two calibrator relative indications recorded in step 4.7.10 for

adjacent steps of the TI REF LEVEL from –11 to –19 dBm is between 0.8 and 1.2 dB.

4.7.12 Verify that difference between any two calibrator relative indications recorded in step 4.7.10 for the TI

REF LEVEL settings of –19 and –20 dBm is between 0.5 and 1.5 dB.

4.7.13 Adjust the signal generator output level to reposition the signal level to the TI CRT reference line, if

necessary.

4.7.14 Program the calibrator SET REF function (BLUE Shift and ZERO buttons). Ensure that the calibrator

indicates 0.00 dB (+

0.01 dB).

25

NAVAIR 17–20AW–232

4.7.15 Set the TI REF LEVEL control to following settings. At each setting, decrease the signal generator

output level to align the signal to the same TI CRT graticule line noted in step 4.7.13, and verify that the calibrator

indication is within the tolerance limits listed. Note the exact calibrator relative indication at each TI REF

LEVEL setting.

* Activate the TI NARROW VIDEO FIL TER function.

** Decrease the TI RESOLUTION BANDWIDTH to 1 kHz and the FREQUENCY SP AN/DIV

to 200 Hz, while keeping the displayed signal centered on the TI display using the TI

CENTER FREQUENCY control. Adjust the signal generator output level to reposition the

signal level to the TI CRT reference line, if necessary.

4.7.16 Verify that the difference between any two calibrator relative indications in step 4.7.15 for adjacent steps

of the TI REF LEVEL from –30 to –80 dBm is between 9.0 and 11.0 dB.

TI CRT REF LEVEL

Readout Indication

(dBm)

–30 –9.0 to –11.0

–40 –18.0 to –22.0

–50 –28.0 to –32.0

–60 –38.0 to –42.0

–70 * –48.0 to –52.0

–80 ** –58.0 to –62.0

T olerance Limits

(dB)

4.7.17 Adjust the signal generator output level controls for minimum and disconnect the test setup.

4.8 FREQUENCY RESPONSE TESTS

4.8.1 Set the TI controls as follows:

CENTER FREQUENCY control to 250 kHz

FREQUENCY SPAN/DIV control to 50 kHz

MIN RF ATTEN switch to 30 dB

REF LEVEL to 0 dBm

TIME/DIV switch to AUTO

VER TICAL DISPLAY to 1 dB/div

RESOLUTION BANDWIDTH to 10 kHz

MIN NOISE function to OFF (deactivated)

4.8.2 Ensure that the oscillator amplitude controls are set to minimum and connect the oscillator 50 output to

the TI RF INPUT.

4.8.3 Set the oscillator output frequency to 100 kHz. Adjust the oscillator output level controls to set the 100

kHz signal for a TI CRT 4.0 division signal display. Note the TI CR T horizontal graticule associated with the

signal level as the reference graticule, and the oscillator output level indication.

26

4.8.4 Activate the TI VIEW A, and MAX HOLD functions.

4.8.5 Adjust the oscillator frequency slowly from 10 kHz to 500 kHz, while maintaining the oscillator output

level noted in step 4.8.3.

NAVAIR 17–20AW–232

4.8.6 Note the TI frequency response (amplitude deviation above and below the reference graticule established

in step 4.8.3). Verify that the frequency response is within +

1.5 dB of the reference graticule from 50 kHz to 500

kHz, and +2.0 dB from 10 kHz to 500 kHz (+1.5 dB from 10 kHz to 500 kHz, for TI 494A Models). Deactivate

the TI MAX HOLD function.

4.8.7 Set the TI CENTER FREQUENCY control to 5 MHz, the FREQUENCY SPAN/DIV control to

1 MHz, and the AUTO RESOLN function to ON (activated).

4.8.8 Set the oscillator output frequency to 2 MHz. Adjust the oscillator output level controls to set the

2 MHz signal for a TI CRT 4.0 division signal display. Note the TI CR T horizontal graticule associated with the

signal level as the reference graticule, and the oscillator output level indication.

4.8.9 Activate the TI VIEW A, and MAX HOLD functions.

4.8.10 Adjust the oscillator frequency slowly from 500 kHz to 10 MHz, while maintaining the oscillator output

level noted in step 4.8.8.

4.8.11 Note the TI frequency response (amplitude deviation above and below the reference graticule established

in step 4.8.8). Verify that the frequency response is within +

1.5 dB of the reference graticule from 500 kHz to 10

MHz. Deactivate the TI MAX HOLD function.

4.8.12 Adjust the oscillator output level controls for minimum and disconnect the test setup.

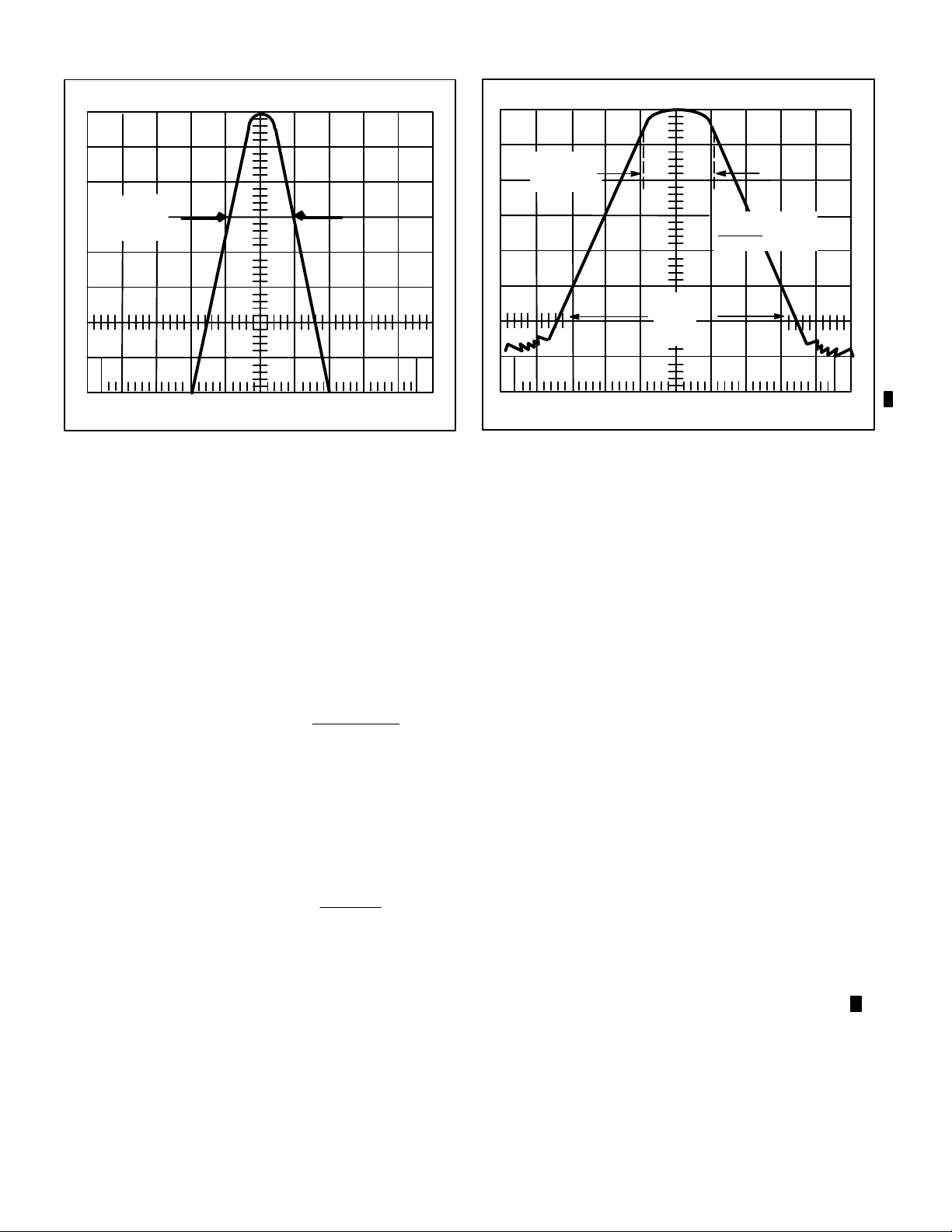

4.8.13 Connect the equipment as shown in Figure 6.

Use cables of minimum length in the test setup.

2.6

SIGNAL

SOURCE

EXTERNAL

LEVELING

(EXT ALC)

RECORDER

OUT

RF

OUTPUT

2.4

POWER METER

NOTE

2.15*

3 DB ATTEN.

2.5*

POWER

SENSOR

IN

2.12*

POWER

SPLITTER

TI

RF

INPUT

* USE THE ITEMS CAPABLE

OF 0 TO 18 GHZ OPERATION,

UNLESS OTHERWISE INSTRUCTED.

Figure 6. Frequency Response T est Configuration

27

NAVAIR 17–20AW–232

4.8.14 Set the TI controls as follows:

CENTER FREQUENCY control to 1 GHz

FREQUENCY SPAN/DIV control to 200 MHz

4.8.15 Set the signal source controls for external (meter) leveling.

4.8.16 Adjust the signal source controls for a 1 GHz, 4 division TI CRT signal display. Note the TI CR T

horizontal graticule associated with the signal level as the reference graticule. Set the power meter RANGE

HOLD button to ON (depressed), if applicable.

4.8.17 Set the signal source controls for a 10 MHz to 1.8 GHz, 100 second sweep (or slowest time possible),

and activate the TI VIEW A, and MAX HOLD functions.

4.8.18 Note the TI frequency response (amplitude deviation above and below the reference graticule established

in step 4.8.16). Verify that the frequency response is within +

1.8 GHz. Deactivate the TI MAX HOLD function.

NOTE

T o view the signal, it may be necessary to increase the TI INTENSITY momentarily.

1.5 dB of the reference graticule from 10 MHz to

4.8.19 Set the TI VERTICAL DISPLAY to 2 dB/div.

4.8.20 Use the methods described in steps 4.8.16 through 4.8.18 for the following TI FREQUENCY RANGE,

CENTER FREQUENCY, and signal source sweep range. Verify that the TI frequency response is within the

tolerance limits listed.

NOTE

Prior to testing the frequency response on each TI FREQUENCY RANGE, set the signal source

for CW output at the TI CENTER FREQUENCY setting and set the signal source output level

for a 4 division TI CRT signal display (it may be necessary to increase the TI INTENSITY

momentarily, to view the signal) and then activate the TI AUTO PEAK function. Note the TI

CR T horizontal graticule associated with the signal level as the reference graticule. Set the

power meter RANGE HOLD button to OFF (released) and then back to ON (depressed), if

applicable.

TI

FREQUENCY

RANGE Setting

(GHz)

1.7 to 5.5 2.7 1.7 to 3.7 +2.5

” 4.5 3.5 to 5.5 +

3.0 to 7.1 4.0 3.0 to 5.0 +

” 6.0 5.0 to 7.0 +

5.4 to 18 7.9* 5.4 to 10.4 +

” 12.9 10.4 to 15.4 +

” 15.5 13.0 to 18.0 +

5 to 21 16.5 15.0 to 18.0 +

” ** 19.5 18.0 to 21.0 +

CENTER

FREQUENCY

(GHz)

Signal Source

Sweep Range

(GHz)

T olerance Limits

(dB)

2.5

2.5

2.5

3.5

3.5

3.5

5.0

5.0

28

* Set the TI FREQUENCY SPAN/DIV control to 500 MHz.

** Prior to this test, reconnect the equipment shown in Figure 6, except use the items capable of

18 to 21 GHz operation, only if the TI is to be calibrated to 21 GHz; otherwise skip this test.

4.8.21 Adjust the signal source amplitude controls for minimum output and disconnect the test setup.

4.9 EQUIVALENT INPUT NOISE SENSITIVITY TESTS

NOTE

If the TI is a Model 494, then proceed with step 4.9.1. If the the TI is a Model 494A, then skip

to step 4.9.2.

4.9.1 Equivalent Input Noise Sensitivity T est For TI 494 and 494P Models

4.9.1.1 Set the TI controls as follows:

CENTER FREQUENCY control to 1000 MHz

FREQUENCY SPAN/DIV control to 5 MHz

VER TICAL DISPLAY to 10 dB/div

MIN RF ATTEN switch to 0 dB

REF LEVEL to –60 dBm

NAVAIR 17–20AW–232

RESOLUTION BANDWIDTH to 1 MHz

VIDEO FILTER to WIDE

TIME/DIV switch to 1 s

MAX HOLD function to OFF (deactivated)

PEAK/AVERAGE control to full clockwise position

4.9.1.2 Verify that the TI CRT display average noise level is –80 dBm maximum.

4.9.1.3 Set the TI FREQUENCY SPAN/DIV control to 1 MHz, and the RESOLUTION BANDWIDTH control

to 100 kHz.

4.9.1.4 Verify that the TI CRT display average noise level is –90 dBm maximum.

4.9.1.5 Set the TI RESOLUTION BANDWIDTH to 10 kHz. Verify that the TI CRT display average noise level

is –100 dBm maximum.

4.9.1.6 Set the TI controls as follows:

FREQUENCY SPAN/DIV control to 10 kHz

TIME/DIV switch to AUTO

RESOLUTION BANDWIDTH to 1 kHz

VIDEO FILTER to NARROW

4.9.1.7 Verify that the TI CRT display average noise level is –110 dBm maximum.

4.9.1.8 Set the TI controls as follows:

REF LEVEL to –70 dBm

FREQUENCY SPAN/DIV control to 100 Hz

RESOLUTION BANDWIDTH to 100 Hz

29

NAVAIR 17–20AW–232

4.9.1.9 Verify that the TI CRT display average noise level is –118 dBm maximum.

4.9.1.10 Set the TI FREQUENCY SPAN/DIV control to 50 Hz, and the RESOLUTION BANDWIDTH control

to 30 Hz.

4.9.1.11 Verify that the TI CRT display average noise level is –121 dBm maximum.

4.9.1.12 Repeat steps 4.9.1.1 through 4.9.1.11 for the following TI FREQUENCY RANGE and CENTER

FREQUENCY settings. Verify that the TI CRT display average noise level is within the tolerance limits listed.

TI

FREQUENCY

RANGE Setting

(GHz)

1.7 to 5.5 3.6 1 MHz <

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 30 ” <

3.0 to 7.1 5.0 1 MHz <

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 30 ” <

5.4 to 18.0 8.7* 1 MHz <

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 30 ” <

5.4 to 18.0 15.0* 1 MHz <

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 30 ” <

15.0 to 21.0 18.0* 1 MHz <

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 30 ” <

CENTER

FREQUENCY

(GHz)

RESOLUTION

BANDWIDTH

T olerance Limits

(dB)

–80

–90

–100

–110

–118

–121

–80

–90

–100

–110

–118

–121

–65

–75

–85

–95

–103

–106

–60

–70

–80

–90

–98

–101

–55

–65

–75

–85

–93

–96

30

* Set the TI REF LEVEL to –50 dBm before performing the noise level test in this frequency band.

4.9.1.13 Skip to subsection 4.10.

4.9.2 Equivalent Input Noise Sensitivity T est For TI 494A Models

4.9.2.1 Set the TI controls as follows:

CENTER FREQUENCY control to 100 MHz

FREQUENCY SPAN/DIV control to 5 MHz

VER TICAL DISPLAY to 10 dB/div

MIN RF ATTEN switch to 0 dB

REF LEVEL to –60 dBm

RESOLUTION BANDWIDTH to 3 MHz

VIDEO FILTER to WIDE

TIME/DIV switch to 1 s

MAX HOLD function to OFF (deactivated)

PEAK/AVERAGE control to full clockwise position

4.9.2.2 Verify that the TI CRT display average noise level is –80 dBm maximum.

NAVAIR 17–20AW–232

4.9.2.3 Set the TI FREQUENCY SPAN/DIV control to 1 MHz, the RESOLUTION BANDWIDTH control to 1

MHz, and verify that the TI CRT display average noise level is –85 dBm maximum.

4.9.2.4 Set the TI RESOLUTION BANDWIDTH to 100 kHz. Verify that the TI CRT display average noise

level is –95 dBm maximum.

4.9.2.5 Set the TI RESOLUTION BANDWIDTH to 10 kHz. Verify that the TI CRT display average noise level

is –105 dBm maximum.

4.9.2.6 Set the TI controls as follows:

FREQUENCY SPAN/DIV control to 10 kHz

TIME/DIV switch to AUTO

RESOLUTION BANDWIDTH to 1 kHz

VIDEO FILTER to NARROW

4.9.2.7 Verify that the TI CRT display average noise level is –115 dBm maximum.

4.9.2.8 Set the TI controls as follows:

REF LEVEL to –70 dBm

FREQUENCY SPAN/DIV control to 100 Hz

RESOLUTION BANDWIDTH to 100 Hz

4.9.2.9 Verify that the TI CRT display average noise level is –125 dBm maximum.

4.9.2.10 Set the TI FREQUENCY SPAN/DIV control to 10 Hz, the RESOLUTION BANDWIDTH control to

10 Hz, and verify that the TI CRT display average noise level is –134 dBm maximum.

31

NAVAIR 17–20AW–232

4.9.2.11 Repeat steps 4.9.2.1 through 4.9.2.10 for the following TI FREQUENCY RANGE and CENTER

FREQUENCY settings. Verify that the TI CRT display average noise level is within the tolerance limits listed.

TI

FREQUENCY

RANGE Setting

(GHz)

1.7 to 5.5 3.6 3 MHz <

””1 ”<

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 10 ” <

3.0 to 7.1 5.0 3 MHz <

” ” 1 ” <

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 10 ” <

5.4 to 18.0 8.7* 3 MHz <

””1 ”<

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 10 ” <

5.4 to 18.0 15.0* 3 MHz <

” ” 1 ” <

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 10 ” <

15.0 to 21.0 18.0* 3 MHz <

””1 ”<

” ” 100 kHz <

” ” 10 ” <

””1 ”<

” ” 100 Hz <

” ” 10 ” <

CENTER

FREQUENCY

(GHz)

RESOLUTION

BANDWIDTH

T olerance Limits

(dB)

–74

–79

–89

–99

–109

–119

–125

–74

–79

–89

–99

–109

–119

–125

–60

–65

–75

–85

–95

–105

–111

–55

–60

–70

–80

–90

–100

–107

–55

–60

–70

–80

–90

–100

–107

32

* Set the TI REF LEVEL to –50 dBm before performing the noise level test in this frequency band.

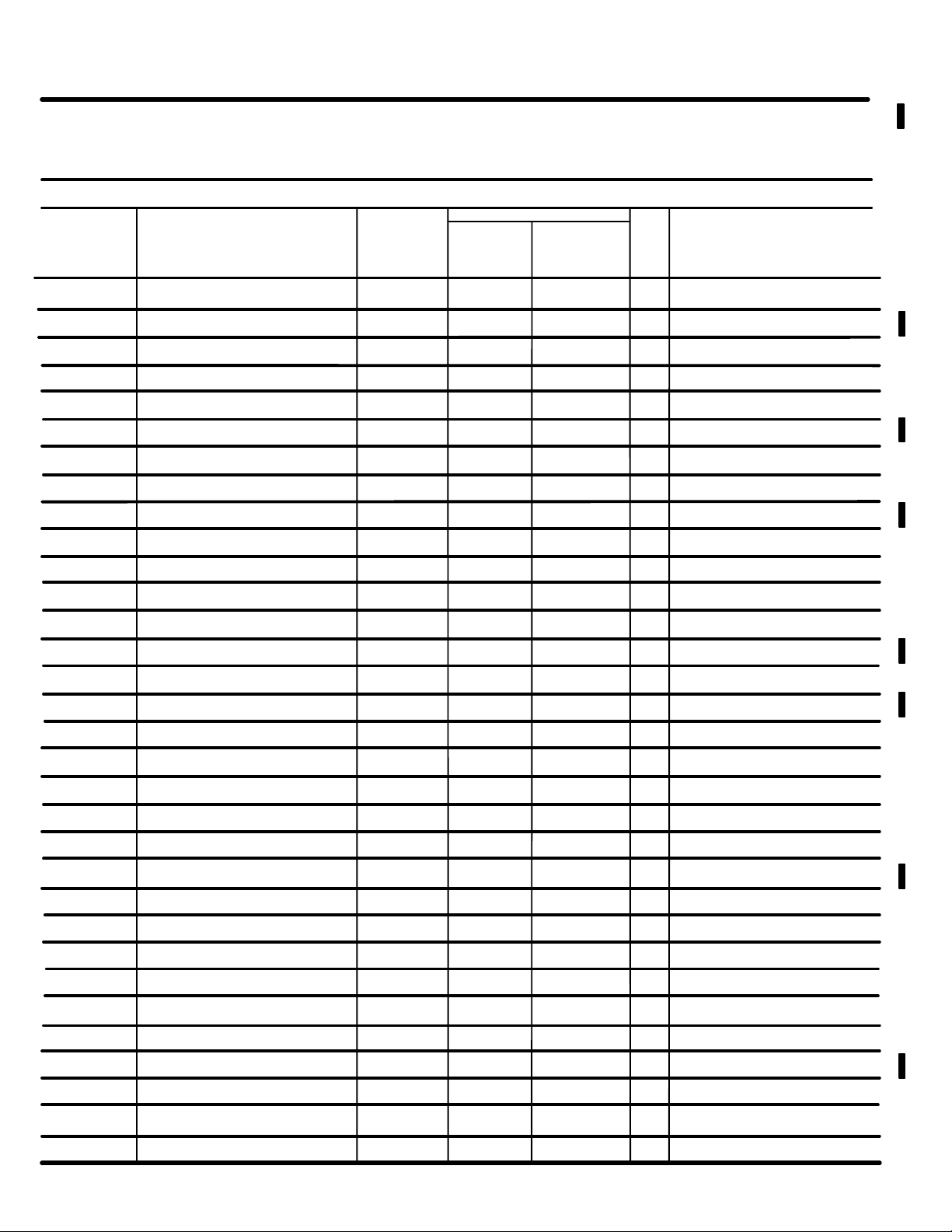

4.10 INTERMODULATION DISTOR TION TESTS

4.10.1 Set the TI controls as follows:

CENTER FREQUENCY control to 1 GHz

FREQUENCY SPAN/DIV control to 50 MHz

REF LEVEL to –30 dBm

RESOLUTION BANDWIDTH to 100 kHz

VIDEO FILTER to off (no filter activated)

PEAK/AVERAGE control to Fully ccw

4.10.2 Connect the equipment as shown in Figure 7.

NAVAIR 17–20AW–232

2.3

SIGNAL

GENERATOR

RF

OUTPUT

2.11

10 DB

ATTEN.

* USE POWER SPLITTER CAPABLE

OF 0 TO 18 GHZ OPERATION, AS APPLICABLE.

RF

INPUT

SPLITTER

TI

IN

2.12*

POWER

2.11

10 DB

ATTEN.

2.3

SIGNAL

GENERATOR

RF

OUTPUT

Figure 7. Intermodulation Distortion T est Configuration

4.10.3 Adjust the frequency controls of the two signal generators so one is set at 999.5 MHz and the other is set

to 1000.5 MHz. Set the output levels of both of the signal generators to –20 dBm.

4.10.4 Set the TI FREQUENCY SPAN/DIV switch to 500 kHz, and the RESOLUTION BANDWIDTH control

for a 10 kHz CRT read–out, while keeping both signals on the TI CRT using CENTER FREQUENCY control.

4.10.5 Adjust the output level controls of both signal generators to align the signal with the TI CRT top

graticule line.

4.10.6 Set the TI VIDEO FILTER to WIDE.

NOTE

Intermodulation products may not appear unless the input signal level is off the screen. Use the

TI VIDEO FILTER and very slow sweep speed rates to help resolve these sidebands.

33

NAVAIR 17–20AW–232

This test cannot be performed using signal generators with excessive FM.

By momentarily increasing each signal generator output by 10 dB (or 20 dB), a false

intermodulation product can be observed on the TI CRT display at either 2f

Figure 8). After noting where to look for intermodulation products, return the signal generator

output levels to the settings established in step 4.10.5.

4.10.7 Verify that the third order intermodulation products are more than 70 dB down from the input signals

(refer to Figure 8).

NOTES

or 2f2–f1 (see

1–f2

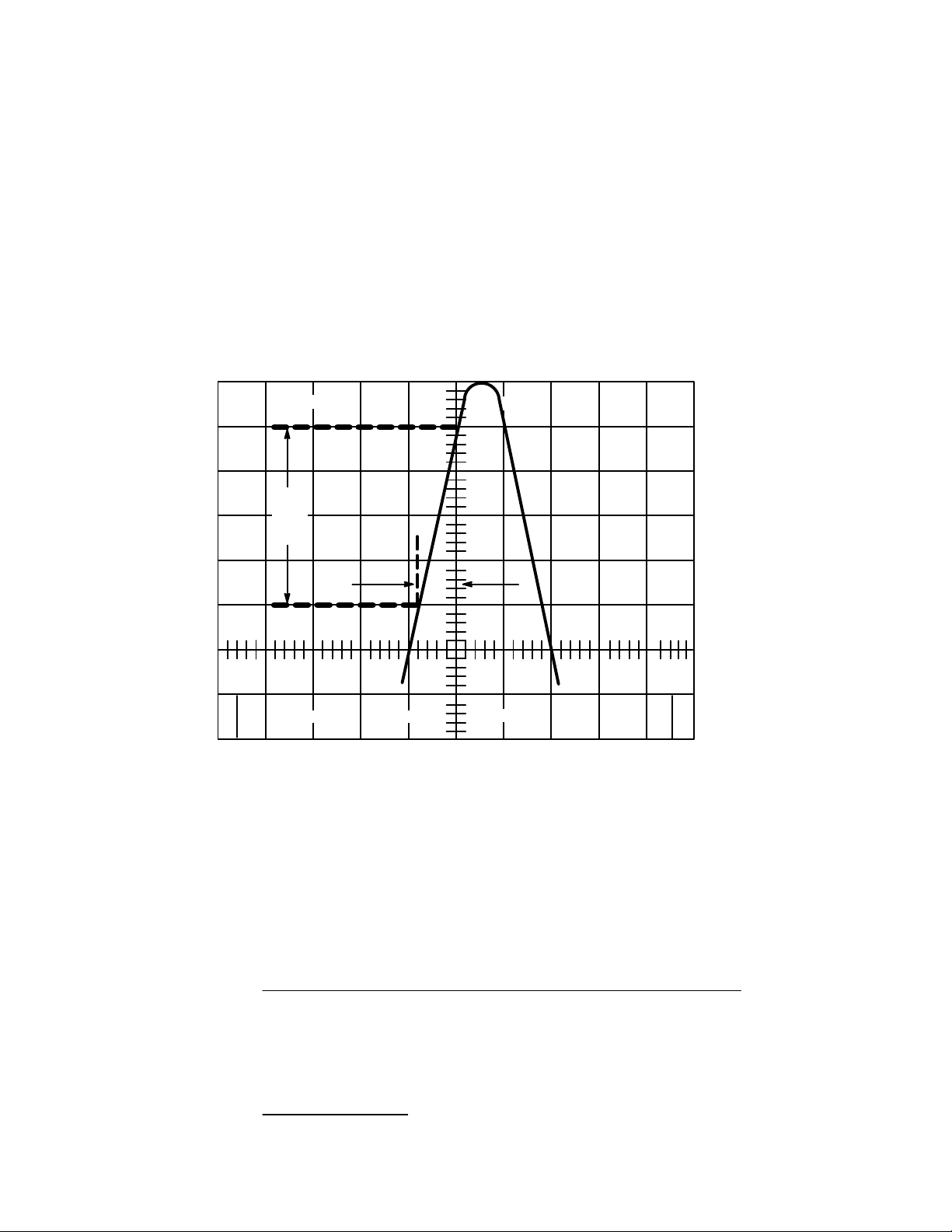

f

1

> 70 dB > 70 dB

–

2f

f

1

2

f

2

–

2f

2

REF.LEVEL

f

1

3RD ORDER

PRODUCTS

Figure 8. Third Order Intermodulation Display

4.10.8 Adjust the output levels of both signal generators for minimum output and disconnect the test setup.

4.11 HARMONIC DISTORTION TEST

4.11.1 Set the TI controls as follows:

34

CENTER FREQUENCY control to 100 MHz

FREQUENCY SPAN/DIV control to 5 MHz

REF LEVEL to –30 dBm (–40 dBm,

494A models)

RF ATTEN to 0 dB

RESOLUTION BANDWIDTH to 1 MHz

VER TICAL DISPLAY to 10 dB/div

MIN DISTORTION to ON (activated)

VIDEO FILTER to off (no filter activated)

MIN DISTORTION to ON (activated)

NAVAIR 17–20AW–232

4.11.2 Connect the signal generator output through the low pass filter to the TI RF INPUT.

4.11.3 Set the signal generator frequency controls to 100 MHz and adjust the output level to align the signal

with the TI top horizontal graticule line.

4.11.4 Decrease the TI FREQUENCY SPAN/DIV control to 10 kHz, and the RESOLUTION BANDWIDTH to

1 kHz, while keeping the signal centered on the TI CRT display using the TI CENTER FREQUENCY control.

4.11.5 Set the TI CENTER FREQUENCY control to 200 MHz.

4.11.6 Set the TI VIDEO FILTER to WIDE and verify that any harmonic distortion is more than 60 dB down

from the TI CRT top horizontal graticule line.

NOTE

If necessary , momentarily increase the signal generator output level by 10 dB (or 20 dB) to

identify on the TI CRT display where a harmonic distortion product might occur. Then return

the signal generator output level to its original setting.

4.11.7 Adjust the signal generator output level for minimum output and disconnect the test setup.

4.12 NOISE SIDEBANDS TEST

4.12.1 Set the TI controls as follows:

CENTER FREQUENCY control to 100 MHz

FREQUENCY SPAN/DIV control to 10 MHz

REF LEVEL to –20 dBm

AUTO RESOLN switch to ON (activated)

VIDEO FILTER to NARROW

MIN DISTORTION to OFF (deactivated)

4.12.2 Connect TI CAL OUT connector to the TI RF INPUT connector.

4.12.3 Decrease the TI FREQUENCY SPAN/DIV switch to 10 kHz and the RESOLUTION BANDWIDTH

control for a 1 kHz TI CRT read–out. Keep the 100 MHz signal centered on the TI CRT display using the TI

CENTER FREQUENCY control.

4.12.4 Set the TI REFERENCE LEVEL control for –40 dBm TI CRT read–out. This places the signal peak 20

dB above the TI CRT top graticule line.