Page 1

Section

5

Adjustment

Procedure

Adjustment

f ntroductio

n

Procedure

lf

instrument

the

pafiicular

appropriate

performance

repeating

Allow

temperature

illustrations in

construed as

Adjustment

circuit or steps.

STATIC

COMPANENTS USED

Many

static

immediately

characteristics. Devices

JFETS,

damaged

reliability will

reduced

characteristic,

that

instrument

the

DISCHARGE

semiconductor components,

discharge.

and

by

performance

adjustment

specification.

part

of +20o C

the

being representative

steps thal

apparent. lt

high impedance

parts

have

obseruing

the Performance

of

warm

to

to +30" C before

adjustment

interact

CAN

IN THIS INSTRUMENT.

Damage may

may

operate

been severely

the

is nol within

determine

procedure

After

DAMAGE

usually appears as a degradation

that are

following

the cause, repair

to return

any adjustrnent, verify

for

up

at least

procedure

of

flagged

are

especially

nat

be catastrophic and,

particularly

operational amplifiers

within

accepted

impaired.

specified

the instrument

Check.

one hour,

making

may

specilication

MANY

precautions.

any adjustrnents. Waveform

be

and references

SEMICONDUCTOR

MOS

susceptible

limits

Damage

requirements for

if necessary,

performance

in

an ambient

idealized

tolerances.

types,

therefore, not

are: MOS,

(FET

input

over a

can

a

then use

operation

and should

made

can

be

of

the

stages). The

short

be significantly

to

by

not

to the affected

damaged

semiconductor

CMOS,

period,

but

the

be

by

their

492AlP

& 4gzBlP Service,

1 .

Handle

free

work

wrist

2. All

to eafih

Minimize

3.

until

from

4. Hold

Use containers

5.

material for

containers.

returned

one

Vol. 1 5-1

static-sensitive

surface.

plane

strap.

test equipment,

ready

their circuil

the

with

Work

such

as

The

work

ground.

handling

lor

lC

devices

storage

Tektronix,

to

anti-static

by

use.

boards.

made

Any

static sensitive

packaging

station

conductive

accessories,

Minimize

by

and transportation. Avoid

cornponents

areas should contain a

plane

should be connected

keeping

their body

of conductive

Inc.,

the

the

should be

material.

circuit

or

polyethylene

and soldering

components in

removal

rather

material

part

or assembly

packaged

assemblies

sheeting

tools

installation

and

than the

f

illed with

or

using ordinary

in its

at or

static-free

and

to

their

terminals.

(circuit

ground.

earth

should

original

of

conductive

board) that

original

on a static-

bench cover or

grounding

a

be connected'

containers

semiconductors

plastic

is

to be

container

or

Page 2

Adjustment

Equipment

Procedu re

Required

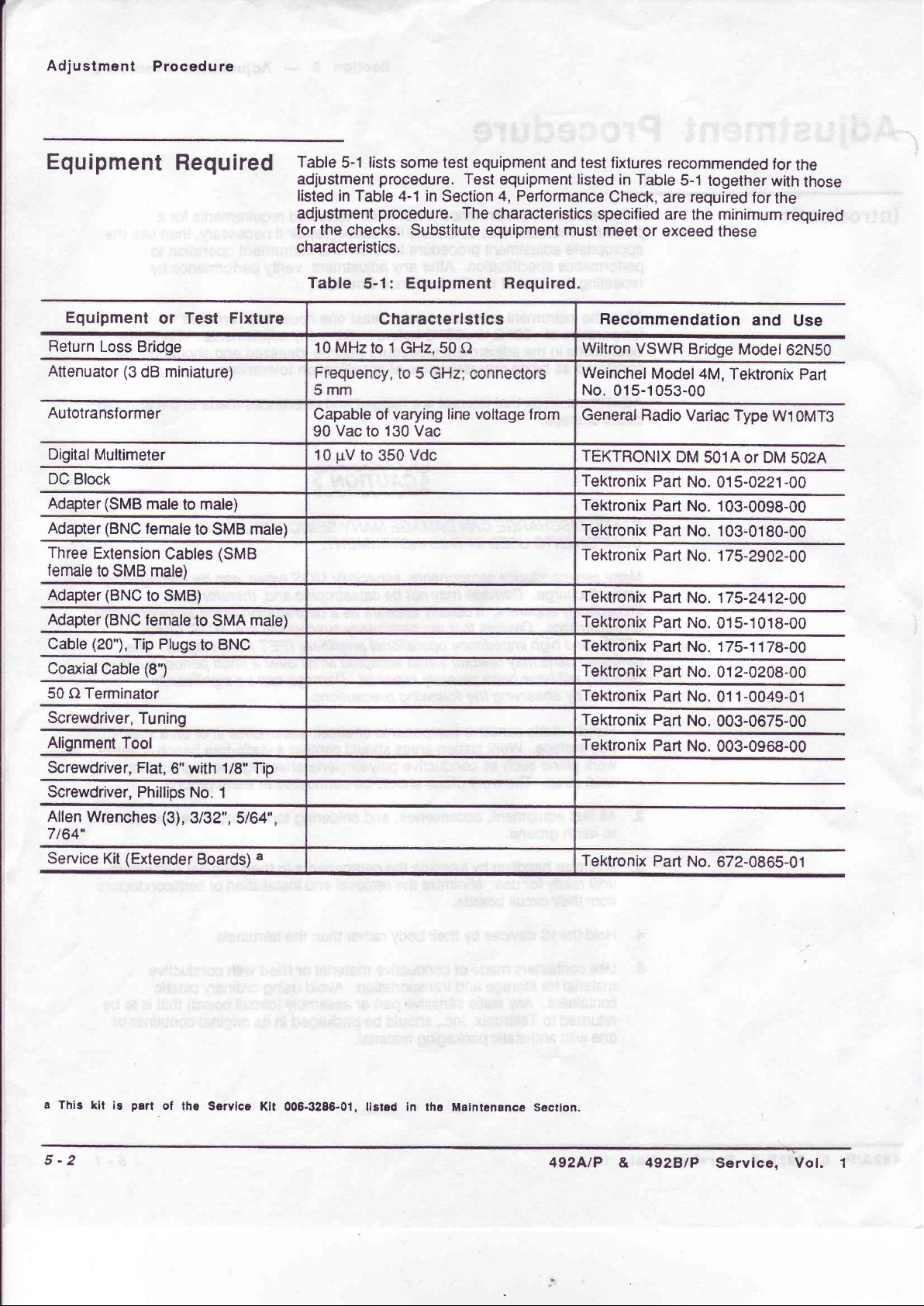

Table

5-1 lists

adjustment

listed in

adiustment

for

the

checks. Substitute

some test equipment and test fixtures

procedure.

Table 4-1 in

procedure.

characteristics.

Test

Section

4, Performance

The

characteristics

equipment

equipment

listed

must

in

Table

Check,

specified

meet

are

are

or exceed

recommended

5-1

together

required

minimum

the

for

for

with

the

these

the

those

required

Equipment

Return

Loss Bridge

Attenuator

(3

dB

or

miniature)

Autotransformer

Digital

DC

Adapter

Adapter

Three

female

Adapter

Adapter

Cable

Coaxial

Multimeter

Block

(SMB

(BNC

Extension

to

SMB male)

(BNC

(BNC

(20"),

Tip

Cable

male

female

Cables

to SMB)

female

Plugs

(8")

50 O Tenninator

Screwdriver,

Alignment

Screwdriver, Flat,

Screwdriver,

Alfen

Wrenches

Tuning

Tool

6"

Phillips

(3),

7164"

Service

(Extender

Kit

Test Flxture

male)

to

to SMB

mate)

(SMB

to SMA

to

male)

BNC

with 1/8" Tip

No.

1

3132",5164"

Boards)

"

Table

10 MHz

Capable

Vac

90

pV

10

to

Equlpment Required.

5-1:

Characterlstlcs

to 1 GHz. 50

varying line voltage

of

130 Vac

to

Vdc

350

C)

from

Flecommendation

Wiltron VSWR

Weinchel

No.

015-1053-00

General Radio

TEKTRONIX

Tektronix

Tektronix

Tektronix

Tektronix

Tektronix

Tektronix

Tektronix

Tektronix

Tektronix Part

Tektronix

Tektronix

Tektronix

Bridge

Model

4M,

Variac

DM

5O1A

Part

No.

Part

No.

Part

No. 103.0180-00

Part

No. 175-2902-00

Part

No.

Part

No.

Part

No.

Part

No.

No.

Part

No.

Part

No.

Part

No.

and

Use

Model

OZN50

Tektronix Part

Type

W10MTo

DM

or

5O2A

015-0221-00

103-0098-00

175-2412-00

015-1018-00

175-1178-00

012-0208-00

011-0049-01

003-0675-00

003-0908-00

672-0865-01

a

This

5-2

kit is

psrt

of

the

Servlce

Klt 006-3286-01, llsted in tha

f,tatntenance Seolon.

492AlP

&

492BlP

Service, Vol. 1

Page 3

P reparatio

n

plepare

To

the

Options

rackmount model for

the

section of this

manual

adjustment,

(Section

8).

Adjustment

refer

to

the

Procedure

Rackrnount

part

of

Remove

1

.

Set the

2.

Loosen

Pull

3.

4. Place

Some circuit boards

gain

to

power

1. Adjust

R6028

This

high-efficiency

kHz. The frequency

66

oscillator components;

procedure.

assembly.

the cabinet

instrument

lour

the

the cover up

instrument

the

access

olf

to some test

before

removing

Low Voltage

and R6061

Parl2

on

screws through

and

or assemblies must

on the

power

adjustment is normally required

therefore, Part

of this step should

follows:

as

face

its

otf.

on the bench

points

the assembly.

front

or

the

or adjustments.

Power

Power

supply

Supply

uses an

1 is

only

panel.

back

reconnect

and

removed

be

Supply

board.

internal

the

required

be

rubber

and

When

oscillator

normal

feet.

power

the

placed

this

only after

adjustment

after repair

cord.

on extenders

is

done, turn

with

a

and

the

frequency

replacing

check

of the

of

Since

the Spectrum

primary

transformer, with

used between

receptacle.

The

ground

suitable transformer.

ground

the

lf

bench,

power

and C6111.

potential

Pan

a.

ground patential

transformer must

through

side

to chassis

input

filter

power

the

Connect

power

the Z-Axis

supply

hazardous

is

disconnected.

A relaxation

exceeds

-

1

Check and

a

input

Analyzer

a turns

power

the

input

the

FL301) .

is

potentials

80

voltage-variable

and set

and

Sweep

WARNING

uses

different

ratio

of

source

have

a three-wire input

and output. Stancor

jumper

A

ground

separated

exisf within

This

is

oscillator

V.

Adiust

the transformerfor 117 Yac. Remove

boards.

high

a

from

1:1

and

should

(emitter

from

due to the

ligltts D55112

Low

transformer

efficiency

cfiassrs or

and a 500

the

Spectrum

also be

of Q2061 and

instrument

the

the supply for

slow

voltages.

in line with

power

ground,

earth

minimum

VA

Analyzer

and output

G1521000

connected

the

and operated

several secands

discharge

(nextto

the

connector

is

between

ground

of capacitars C6101

Spectrum

supply,

rating,

an exampte

C6111)

with

isolation

an

should

power

input

with

the

terminal of

on the

when

Analyzer

the coverover

the

be

a

of

primary

after

the

492AlP

& 492BlP Service,

Vol. 1

5-3

Page 4

Adjustment

Procedure

Table

Supply

+9V

-5V

-7V

-15

V

+5V

+17 V

+100

V

+300 V

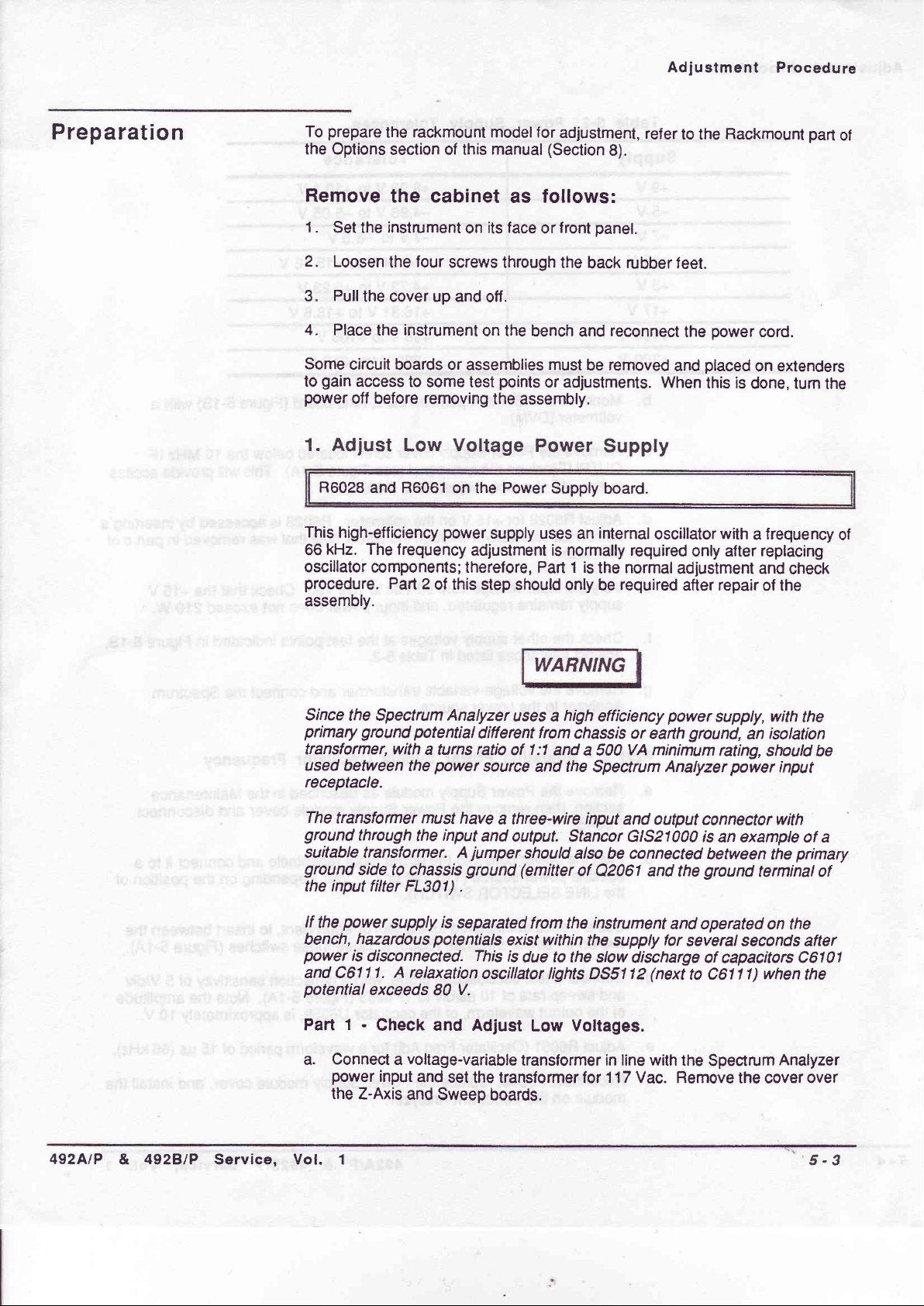

Monitorthe

b.

voltmeter (DVM).

Remove

c.

OUTPUT

to the

Adjust

d.

narrow-bit

this step.

5-2:

+15

R6028 for

Power

the

jack

Supply

point

v

+15

test

Power

V

screwdriver

Supply

the

rear

on

supply adjustment,

V

+15

on the voltmeter.

through

Tolerances.

Tolerance

+8.92

V

lo

-4.96

V

to

-7

-14.84

+4'.73 V

+16.81

+95

+280

on

-€.5

V

to

V

V

V

to +105 V

V

to +310 V

Z-Axis

the

to

to +5.23

to

;

cover

screw

panel

(see

Figure

R6028.

the

screw

+10.1

V

-5.05

V

V

-1

5. 1 6 V

V

+18.6

board

located

5-1A).

R6028

hole

that

V

(Figure

berow

This

is

accessed

was

with

5-18)

the 1

0

provide

will

MHz lF

by

removed

a

access

inserting

part

in

c bt

a

vary

e.

t.

the input voltage

supply

Check

remains

the other

against tolerances listed

g.

Remove

Analyzer

Part 2

a. Remove

section,

the voltage-variable

to the

-

Adiustlng

Power

the

remove

then

P3045.

Plug

b.

suitable_p_oryel

the

c. Use

two on/off

d.

Connect

power

the

LINE

SELECTOR

plastic

a

power

test

a

gource

or

oscilloscope

and sweep rate

of the

output

wavelorm,

from

regulated,

supply

and input

voltages

in Table

power

source.

Power

Supply

Power

the

into

cord

the

(1

15 Vac

SwlTCFl).

insulated

switches

of 10

tuning

(S300)

ps/divto

of the oscillator

vac

90

to 1

82

power

at the test

5-2.

transformer

Supply

module

and

Osclllator

as described

Supply module

power

input

receptacle

or 230

Vac,

tool or equivalent,

to close

probe,

with

TP6053

a deflection

(Figure

U6059,

vac.

check

does not

points

indicated

connect

Frequency

in

cover

depending

to

these

switches

5-1A).

is

approximately

that

the +'t 5 V

exceed 210

the

Spectrum

in

Figure

w.

the Maintenance

and

disconnect

and

connect

on the

insert

(Figure

sensitivity of 5

Note

it

to

position

between the

5-1A).

V/div

the amptitude

10

V.

5-18,

a

of

5-4

Adjust

e.

Reconnect

t.

module

R6061

(Oscillator

P3045,

replace

on the Spectrum

Freq Adj)

Power

the

Analyzer.

492AlP &

waveform

for

a

Supply module

period

492BlP

ps

15

of

cover, and

Service,

(66

kHz).

install

Vol.

the

1

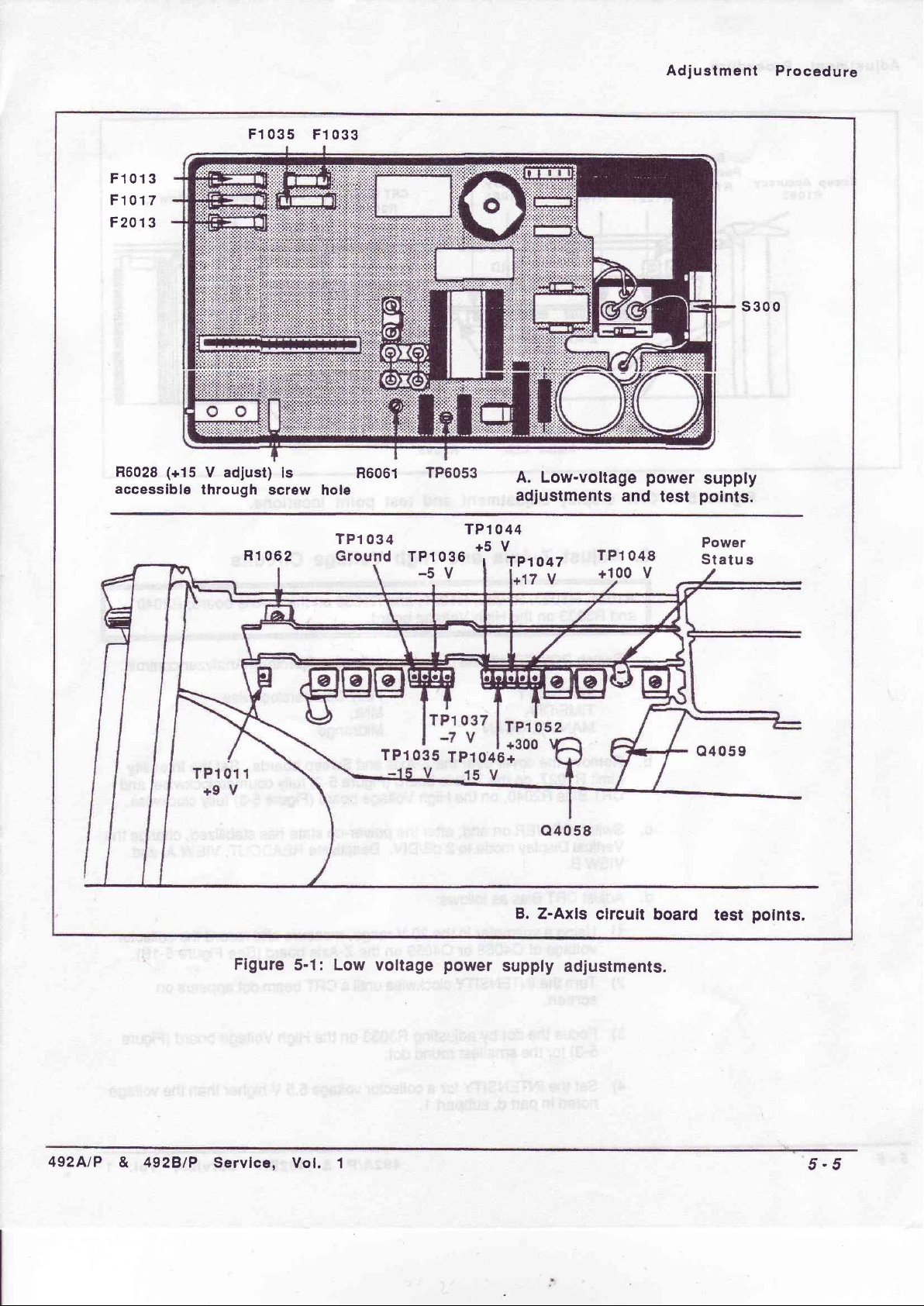

Page 5

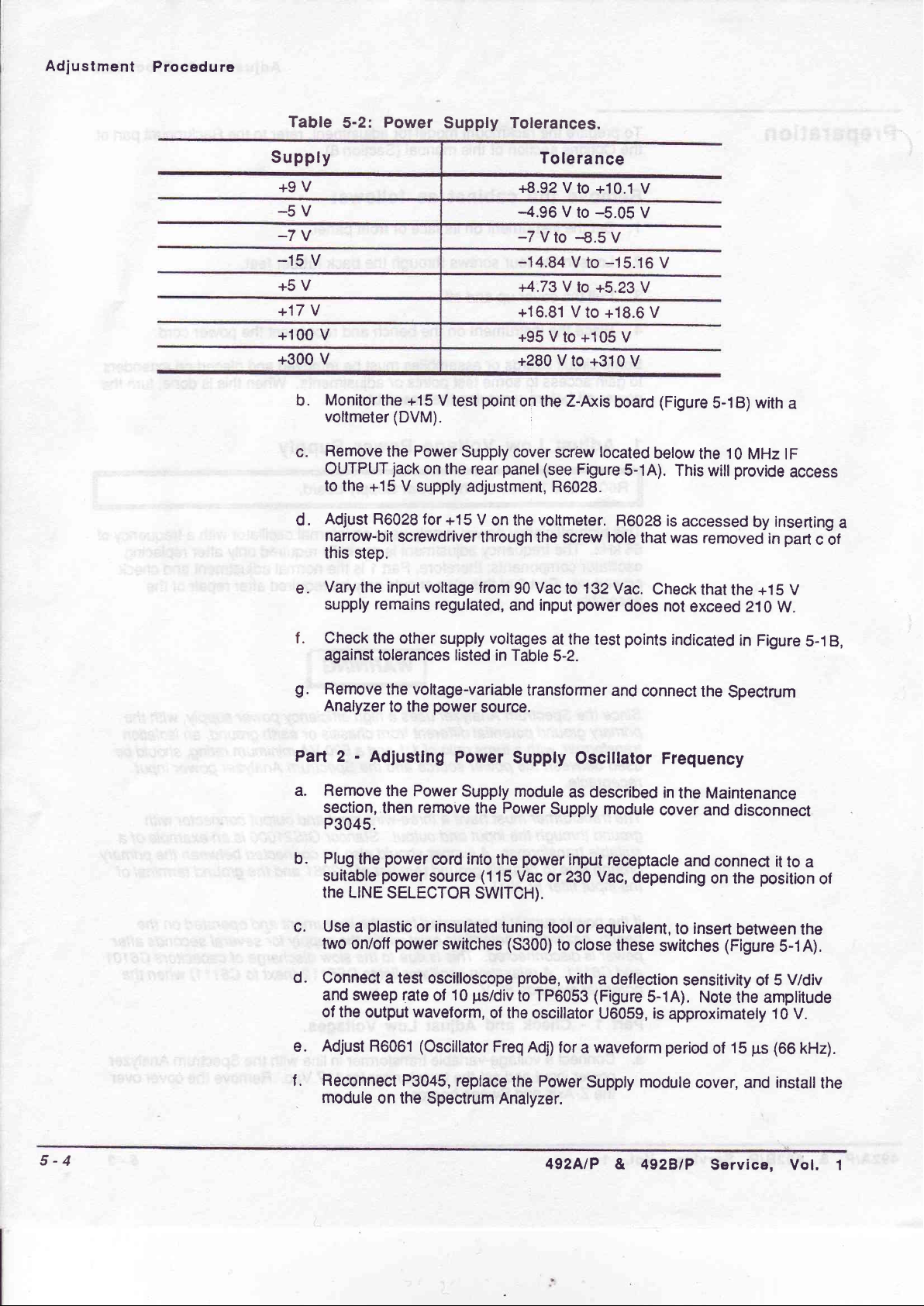

F1013

F1017

F201

3

F1

035

Adjustment Procedure

F1 033

s300

R6028

accessible

(+15

V adJust)

through

R1062

is

screw

hole

TP1

Ground

H6061

03 4

TP1035

TP6053

TP1 044

TP1036

-5V

TP1046+

A. Low-voltage

adjustments

*,u Ur,

1047

17V

Q4058

B.

Z-Axls

and

TP1

048

+100

circuit

power

test

V

board

supply

points.

Power

Statu s

Q4059

test

polnts,

492AlP

& 4928/P

Figure

Servlce,

5-1: Low

Vo

l. 1

voltage

power

supply

adiustments.

5-5

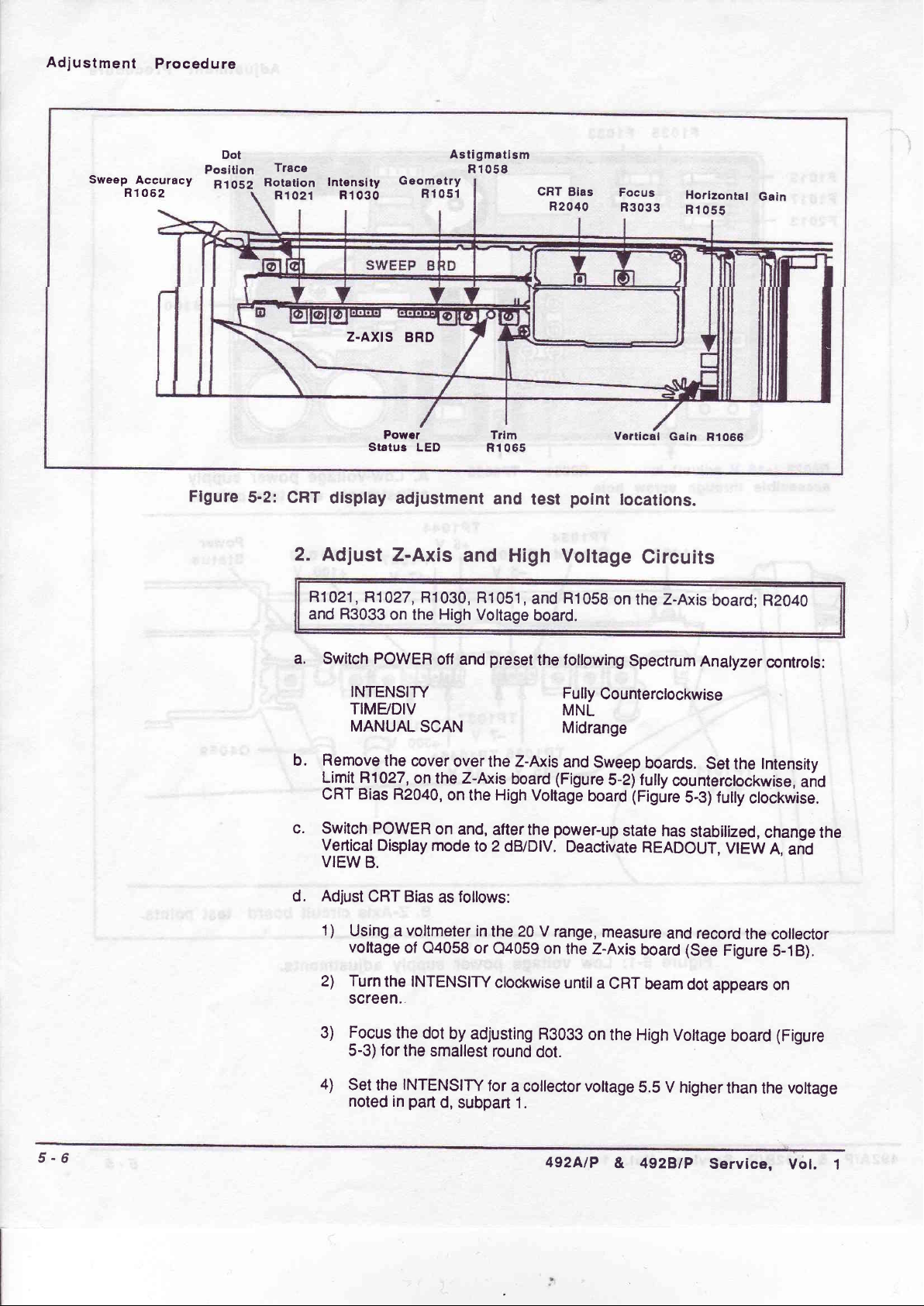

Page 6

Adjustment

Procedure

Sweep

R1

Accuracy

062

Dot

Positlon

R1052

Flgure

Trace

Rotation

Rl

5-2:

Intensity

R1

021

Z.AXIS

cRT

dlsplay adjustment

2.

Adjust

R1021

R3033

and

Geometry

030

Power

Status

Z-Axis

R1027,

,

on the

Rl 051

BRD

LED

R1030,

High

Astigmatlsm

R1058

Trim

R106s

and

and

High

R1051

Voltage

CRT

R2040

test

Voltage

and

,

board.

Bias

Focus

Vertical

potnt

R1OsB

on the Z-Axis

R3033

Horlzontal

R1055

Gain

locations.

Circuits

Gain

R1066

board; R2040

a.

Switch

POWER

INTENSITY

TIME/DIV

MANUAL

b. Remove

the

Limit R1027,

Bias

CRT

c.

d.

Switch

Velical

VIEW

Adjust

1)

POWER

Display mode

B.

CRT Bias

Using a

voltage

2l rurn

the INTENSITY

screen.

Focus

3)

for

5-3)

4l

set

the

noted in

off and

SCAN

epver

over

on

R2040,

Z-Axis

the

on the

on

and,

follows:

as

voltmeter

of

Q4058

the dot

by

adjusting

the smallest

INTENSITY

part

d,

subpart 1.

preset

following

the

Fully

MNL

Midrange

the Z-Axis

board

High

after

to 2

dB/DlV.

in

the 20 V range,

or

Q4059 on

clockwise

and Sweep

(Figure

Voltage

po_wer-up

lhe

Deactivate

the Z-Axis

untir

R3033

round

dot.

for

a collector

Spectrum

Analyzer

Counterctockwise

5-2)

board

state

boards.

fully

(Figure

Set the

counterclockwise,

5-B)

has

stabilized,

READour,

measure

a

cRT

on

the High

voltage

5.5

board

beam dot

record

and

(see

Voltage

v

higher

controls:

Intensity

lully

clockwise.

change the

vlEW

A,

the collector

Figure

s-18).

appears on

(Figure

board

than

the

and

ari'd

voltage

5-6

492AlP

& 492BlP

ServicE,

Vol.

1

Page 7

Adlustment Procedure

Flgure

5)

6)

7)

Adjust

e.

Adjustment

5-3:

m odu le.

use

counterclockwise

beam

with

Turn

dot

(Figure

and sharpest

Turn

non-metallic

the

until

just

dot

the

extinguishes

adjustment

the INTENSITY

with

the Focus

for

5-2)

adjustment,

round

a

dot.

the INTENSITY

and again measure

should

less,

repeat

the

CRT

egualor

lhe

cathode

exceed

procedure

and

screwdriver

the

fully

counterclockwise,

clockwise

point

test

to

adjust

CRT beam is

(with

screen

until

a dot is

R3033.

dot; then

refocus

counterclockwise

the

collector voltage

part

set

for

setting

as

in

CRT

follows:

that

current

tocations

cRT Bias,

visible,

then

shaded). lf

will

this

visible:

Adjust

Astigmatism

with R3033

until

the

dot

at

Q4058 or

d, subpan

bias.

Hlgh

on

R2040,

clockwise

no

dot

appears,

be

the

bias setting.

then defocus

Fl105B

for

the

smallest

just

disappears,

Q4059.'Voltage

A.

lf

voltage

the

vottage

until the

the

is-

492AlP

&

492glP

Sarvice,

Vot.

2)

Connect

lug

on the CRT

3)

Switch

2

dB/DlV

4l

Adlglt

TP4028.

at

5)

Switch

board. Turn

1

voltmeter

the

shield.

POWER

and

switch

Intensity

Limit

POWER

POWER

back

Digital

off

and

between

After

on.

Storage

R1027

(Figure

reinstall

on

and

TP4028 (Figure

the instrument

off.

5-2) for a voltage

jumper

the

adjust

INTENSIW

the

5-3)

initializes,

P4036

on the High Vottage

lor normal

and the

activate

reading

ground

V

of 0.9

viewing.

5-7

Page 8

Adjustment

Procedure

f .

Appfy

controls as

the CAL

follows:

OUT

signal

to the

RF INPUT

and set

Spectrum

lhe

Analyzer

'\

FREQUENCY

FREQUENCY

AUTO

REF LEVEL

MIN RF ATTEN O dB

VERTICAL

NARROW VIDEO

VIEW

TIMSDIV

TRIGGERING FREE RUN

g.

Activate ZERO

approximately

5-2) so

Activate VIEW

h.

positioned

adjust

bottom of the screen.

i.

Change the

Vertical

the

just

visible.

j.

Adjust Delta

characters

visible

iust

setting

INPUT.

RESOLN

A/B

the

trace

at the top then bottom of the screen,

Geometry

REF LEVEL

Display mode

is

after the

photograph purposes.

for

1OO MHZ

SPAN/DIV

DISPLAY

FILTER

SPAN and

mid-screen; then adjust

is

aligned

A

and

R1051

Intensity R1030

slightly

trace

adjust

with

VIEW

(Figure

position

to

of 2 dBlDlV.

higher than the trace. Fleadout

has disappeared. This ratio

10

ON

-20

2

ON

Off

AUTO

REFERENCE

graticule

the

B,

then

5-2) for the

(Figure

Disconnect

MHz

dBm

dB/DIV

LEVEL

Trace Rotation

the

lines.

PEAK/AVERAGE

the

use

as

straightest

the trace within

Adjust

5-2)

INTENSITY

the

so

brightness

CAL

until the trace

R1021

reference

a

lrace

at top and

graticule

the

so the

of

characters

provides

OUT

signal

(Figure

cursor,

line

to

area

trace

readout

the

should be

the

best

from

the

is

with

is

RF

-

Adjust Deflection

3

Respo

C4057, C4061 , C5021,

lection Amplif

Def

C1040, C1030,

492BlP Deflection

When

must be connected

rather than as

ACCESSORIES

manner.

connect

a.

1 ms. Position the

Set the

b.

amplitude

Select

nse

adjusting

shown

the

Function

of

and Ground

ier

C3080, C3060,

Option

to the

in Figura 5-4.

connector

eguipment as shown

test

generator

0 to

+4

Amplifier

C5104,

board.

Amplifier

R1055,

R1055, R1066, R5020,

board.

NOTE

42 instruments,

PEN LIFT

Be sure to

when

using the

trace on

V. Connect a

respectively)

the

bottom

controls for

Gain

and

the output of the

connector

PEN

in Figure

graticule

a 500 Hz

jumper

the ACCESSORIES connector.

on

and Frequency

R1066

at

ground pin

between

on the 492AlP

Function

rear

the

LIFT

connector

5-4. set the

line.

sinewave

pins

and

of

the

t

of the

1

R5030

instrument,

in this

TlMHDlv to

signal,

and 5

the

on

Generator

with

an

(Ext

Video

5-8

4gzLtP &

gzBtP

Servlce,'Vol.

1

Page 9

justment

Ad

Procedure

c

ooo

oo

Time illark

Ganarator

BNC

Partial

J104

T-Connector

(Rear

Accessory

Panel)

Oscllloscope

Showing

Gonnector

c

MARKER/vIDEo

Input

Spectrum

1 3'\

Analyzer

2 5

i

14

Under

1

Test

I

Jumper

Pln

1 to

Pin

5

Figure

5-4: Test

equipment

Deactivate

c.

produce

d.

fliu9t

492BlP

Disconnect

e.

t.

g.

jurnper

the

Triggering

calibrate

1)

Set

2) Monitor

Multimeter).

3)

{Ojugt

(rP2).

4l

Set the

Reset

the

setup

vert

(Figure

TIMHDIV

for

VIEW

a

stable

Gain,

the 500

between

FREE

to

the cenler

TP2

MANUAL

the

horizontal

MANUAL

adjusting

A

and VIEW

sinewave

R1060

5-6) for

Io MNL.

on

for

a

Hz

signalfrom

pins

1

RUN.

of the

the Sweep

SCAN

POSITION

scAN

the

Deflectlon

B,

and sel TRIGGERING

on

the

spectrum

492Np (Figure

the

full-screen

the MARKER/VIDEO

and

5 of the ACCESSORIES

screen for

control for

0 Vorts

(Figure

board

control

controlto

a

analyzer

display.

as

5-9) with

for

0.0

center the

reading

follows:

V

of +5

Amplifier.

lNT. This

to

display.

5-5) or R1066

input.

c6nnector. Reset

voltmeter

a

reading

on the

CRT beam

v

Tp2.

at

should

for

the

Remove

(Digital

voltmeter

(dot).

492AlP

& 4928/P

Servlce,

Vol.

1

5-9

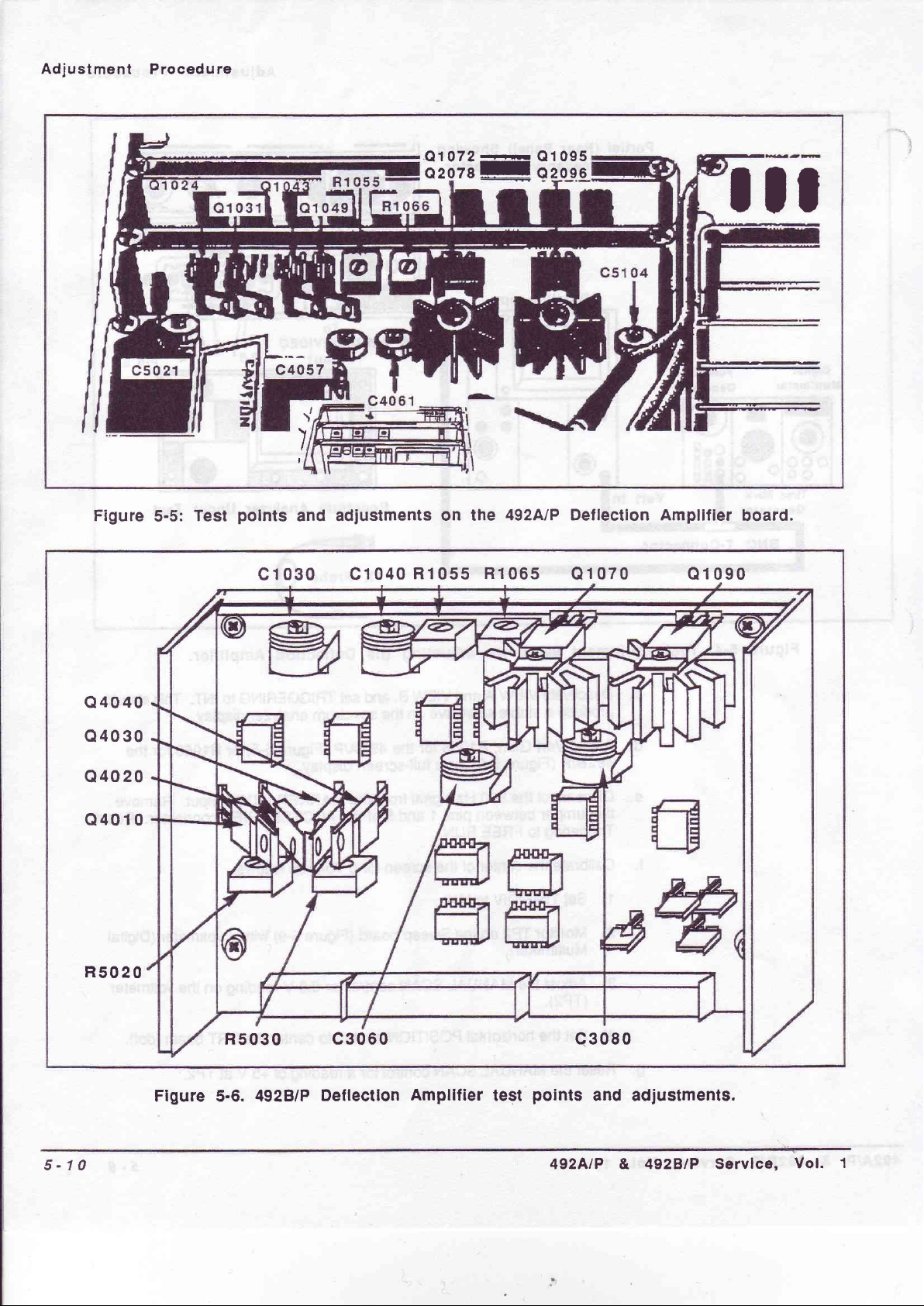

Page 10

justment

Ad

Procedu

re

c4057

,

Y

)

I

ltiii'-3133:

ill

Figure

Q4040

Q40 30

Q4020

Q4010

5-5:

Test

polnts

c1030

adjustments

and

c1040

on t'he

R1055 R1065

492AlP

Deflection

Q1070

Ampllfier

Q1090

board.

R5020

5-10

Figure

R5030 c3060

5.6.

4928/P

Deflecilon

Ampllfier

test

Q3080

points

492AlP &

and adiustments.

492BlP

Servlce,

Vol.

1

Page 11

Adjustment

Procedure

h.

fliu_st_Holz

492BlP

(10th

i.

Set

the

graticule

j

Disconnect

Press

k.

t.

Adjust

C3080

shape

Adjust

c1040 for

character

n.

Check

readout,

and readjust

Only

complete

R1055 for

Gain,

(Figure

graticule

MANUAL

line

<Blue-SHIFT>

c5021

for

(no

c4061

5-6), to

line).

SCAN

and check that

voltmeter

the

RESET

and c4057 tor

4928/P

the

overshoot

or

and C5104

the 492BlP

shape.

the appearance

and

the

letter

as needed

part

when

o

rhe 4g2vp

position

the

control to

voltage

the

and set

(Figure

TIME/D|V

restore

to

492AiP (Figure

the

5-6)

roll-off).

for

the 492AlP

(Figure

of lhe

"X"

for

letter

in

MAX

best

5-o)

vertical

NOTE

adjusting the

(Figure

CRT

beam

position

at Tp2

the

for

the

(Figure

for

the best

"7"

in

GHZ

Frequency

of the

and

4928/P

5-5)

on the right

the

CRT

is now

AUTO.

to

power-up

R1055

or

(dot)

beam

-s.0

settings.

graticute

v

5-5) or c3060

best

vertical

horizontal

readout

5-5)

or C1080

readout

of the FREQUENCY

SPAN/DIV

horizontal

Deflection

readout

Amptifier.

for

the

on

the left

t0,z

v.

and

character

and

readout,

shape,

edge

o. Adjust

R5020, R/O

the readout

1)

For

standard instruments,

below

above

2)

For

Option 43

slightly

slightly

4.

Adjust

R1040,

R1033,

a.

R1050,

R1034,

ltanthe

PULSE

STRETCHER,

the instructions

1)

Adjust

Digital

vefiical

the

2l Adjust

Digital

the horizontal

Gain,

and

characters.

the top

the

graticule

baseline.

line,

(reduced graticule),

above

the top

below the

Digital

R1055,

R1045

Digital

Storage Calibration routine

that are

Output

Storage

Output

Storale

Offset

board

graticule

Offset

board

graticule

graticule

baseline.

Storage

R1060

and

and R1046

and

select

displayed on

R1040

place

to

lines.

R1045

place

to

lines.

R5030, R/O

place

and

Offset, for

the

top two rows

place

the

set

the top two rows

line,and

Calibration

on

on the Vertical

itern

and Output

the risers

and

the

2

the

Output

the

steps of

(DIGITAL

Horizontar

by

CRT.

bottom

place

the

storage

pressing

STORAGE

R1050

Gain

of the

adjustment

R1033

Gain

the

adjustment

the best

placement

of readout

readouts

bottom

storage

slightly

readout

of

readouts

board.

6oard.

<Blue-SHIFT>

CAL).

on the

pattern

the

on

pattern

of

slightly

Fonow

Horizontal

on

Vertical

on

492AlP

&

492BlP

Servlce,

Vol.

1

5-11

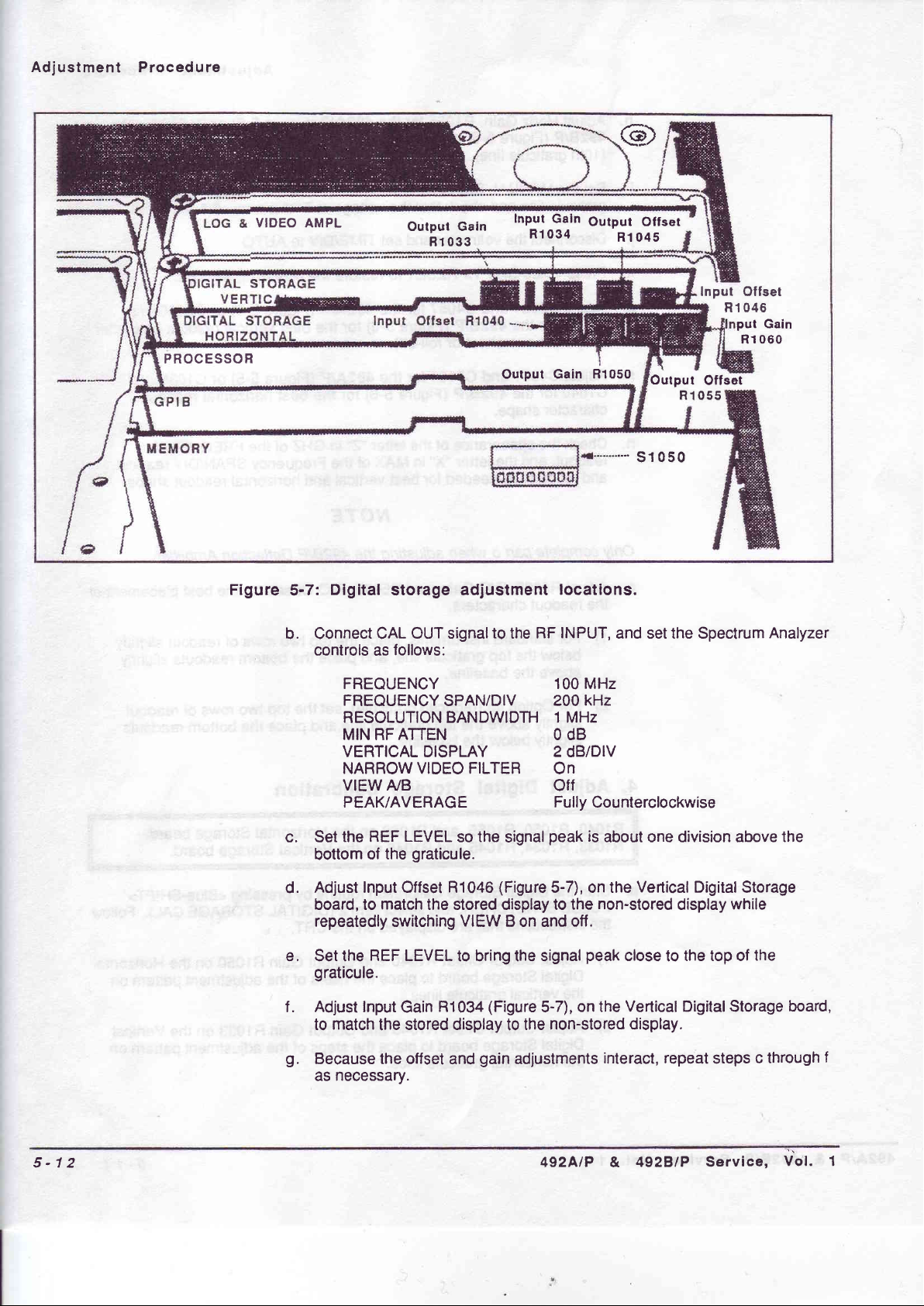

Page 12

Adjustment

Procedure

G)

VIDEO AMPL

PROCESSOR

Figure

Digital

5-7:

storage adjustment

b. Connect CAL

controls as

follows:

Oulpul Galn

B1 033

OUT

signalto

Input

Galn

Rl034

Output Gain

locations.

RF INPUT,

the

gugpgl

R1050

Offset

R1 04S

Output

.-'

s1050

Input Offset

Offset

R1055

and setthe Spectrum

R1046

put

Rl 060

Gain

Analyzer

FREQUENCY 100 MHz

FREQUENCY

RESOLUTION

MIN

ATTEN

RF

VERTICAL DISPLAY

NARROW VIDEO

VIEW A/B

PEAK/AVERAGE

c, Set

d.

e. Set the

the REF

the

bottom

Adjust

board, to

repeatedly

of

Input Offset R1046

match

switching

REF LEVEL

graticule.

f . Adjust Input

match

to

g.

Because the offset

as

the

necessary.

SPAN/DIV

BANDWIDTH

FILTER

LEVEL

so the

signal

graticule.

(Figure

the stored display to

VIEW

B on and

to bring the signal

and

(Figure

to

gain

H1034

Gain

stored display

kHz

2A0

1 MHz

O dB

2

dB/DIV

On

Off

Fully

Counterclockwise

peak

is

about

5-7), on the

non-stored

the

off .

peak

on the

5-7),

non-stored display.

the

adjustments

interact, repeat

one division above the

Vertical

close

Digital

display

the top of

to

Storage

while

the

Vertical Digital Storage board,

steps

c through

f

5-12

4g2AlP

&

4gz}lP

Service,

Vol. 1

Page 13

h.

Select

these

settings:

Adjustment

Procedure

FREOUENCY

FREQUENCY

RESOLUTION

REF

LEVEL

MIN

RF ATTEN

VERTICAL

NARROW

VIEW

A/B

PEAK/AVERAGE

Adjust

match

signal

k.

f{ust

5-7),

stored

5. Adjust

R1062

When

must

rather

ACCESSORIES

Input

oflset,

the horizontal

at center

Input

Gain, R1060

match

to

signal

Sweep

on the Sweep

adjusting

be connected

than as

Option 42 instruments,

shown in

connector when

manner.

SPAN/DIV

BANDWIDTH

DISPLAY

VIDEO FILTER

R1055

on the

position

screen.

on

horizontal

the

near

the

right

edge of

Timing

board.

to

PEN

the

Figure

LIFT

5-4. Be

600 MHz

100

MHz

Auto

-20

dBm

O dB

1O

dB/DIV

Off

Off

Fully

Countercfockwise

Horizontal

of

the

stored

Horizontal

the

position

ol lhe

the screen.

NOTE

the

output of

connector

sure to

using the PEN

Digitar

signal

to that

Digital

stored

the

rear

at the

ground

L\FT

Storage board,

of the non,stored

Storage

signal

pin

connectar

board

to

that of

Functian

instrument,

of

the

I

of the

in

Generator

this

to

(Figure

non-

thb

a.

Connect

the test

Spectrum Analyzer

FREQ

TIMSDIV

TRIGGERING

b.

Connect

jumper

a

respectively)

c. set

e_ditpt_Sryeep

d.

492BlPr,

the

Time

for

align markers

e.

Check

the

accuracy

center eight

f .

Reset

AUTO

mark

pins

moved in

TlMgDlV

the

RESOLN.

generator

1

and 5 of the ACCESSORIES

part

equipment

controls :

SPAN/DIV

between

on

Mark

1 marker

with

ACCESSORIES

the

Generator

Timing,

R1062

per

graticule

of

the

divisions must

AUTO

to

Return Triggering

from

the Spestrum

d.

as shown in

10 MHz

10

EXT

pins

1

and 5

controls for 10

(see

Figure

division.

lines.)

remaining

not

(Use

exceed x5

FREQ

and

to

Analyzer.

conneclor.

Figure

less

or

ms

(Ext

Video

connector.

ms

for 492NP

5-9

Horizontal

TlMgDlV

%.

SPAN/D|V

FREE

RUN.

Remove

5-8.

Set

the

Select

and Ground

time marks.

and

Position

selections.

Error

to MAX,

Disconnect

jumper

the

Reposition

the trace

following

Figure

5-5

adjustment to

over

the

and activate

the time-

between

if

for

492AlP

& 492glP

Service,

Vo

l.

1

5-13

Page 14

Adjustment

Procedure

To

MARKER/VIDEO

Time Mark

Generator

I

Trigger

Marker

Out

Out

-\l/

: ::

Partial

Accessory

Back Panel

To HORIZ/TRf

Showing J104

Connector

g

Connect

Between

G

rtttlG?rt

cltrtlrrtilFrEt-

-n-EtILg

u

J

Pins

t3

mper

1

rarlt

&

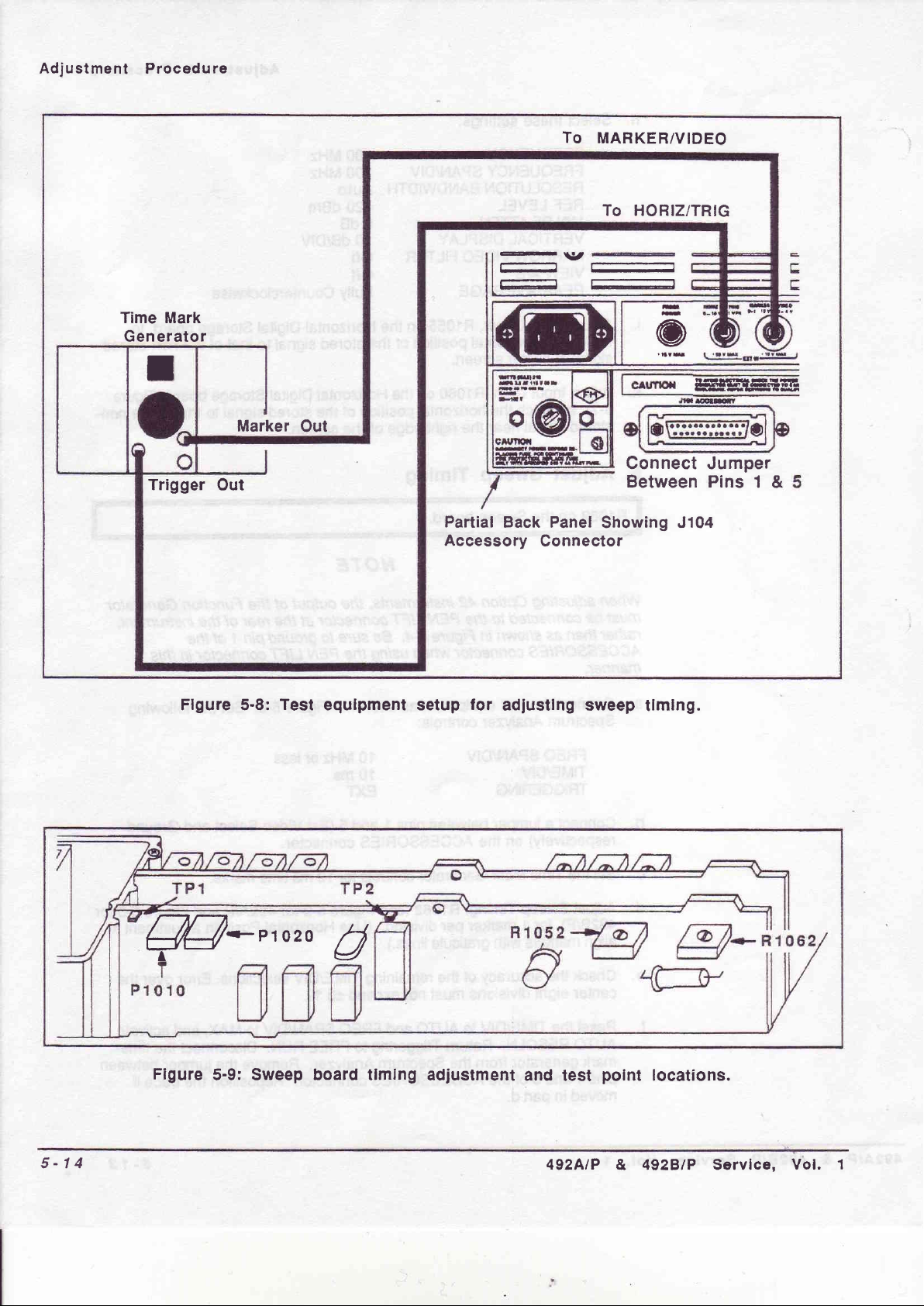

Flgure 5-8:

Test

W*P1o2o

Figure

5-9: Sweep

equlpment setup

U

board tlming

adjustment

for

adlustlng sweep

and

test

polnt

tlmlng.

locations.

5-14

492AlP

&

492BlP

$ervice,

Vol,

1

Page 15

Adjustment Procedure

R3040:

Figure

rP1o3s

{l

e

R4040-

H1031 R1 034

5-10: Frequency

6,

R1063,

R1031, R1032,

R1028, R1

board.

C1013

R1062

Sweep

R1028

R1 032

control system

Adjust

R1065,

032, R3040,

C201 1 on the

on

the Sweep board.

Offset

R1 063

Frequency

R1067,

and

1st LO

Swee

2nd LO

test

Tune

R1065

Sweep

point

Control

R1071

and

R1034

on

F14040

and

Controlled

1st

Sweep

R1067

LO FM

H1071

T F;E,BOArd

Coll

IT

032

Rl

and

on

the 1st LO Driver

on the

oscillator

JJ\

TP1 0s8

I

lfl-'

adjustment

System

the Span

board.

Center

board.

Cotl

I

Sp"n Attenuator

lc"n,",,

Control

I

1st

LO Driver

Board

I

I

I

r-i

locatlons.

Attenuator

Frequency

board.

Frequency

Board

Controf

The

Spectrum Analyzer

frequency

not

error message. lf

routine.

Test

and

a. Select

h.

c.

d. Remove

control

be adjusted

equipment required

Frequency

FREQUENCY

FREQUENCY

TRIGGERING

Connect a shorting

chassis

Adjust

STRETCHER

(OVERALL

directed

BOARD

properly,

Counter.

following

the

ground

Sweep

the

SYSTEM) from

("coNNEcT

AND

procedure

has

a

system.

this

(Figure.S-tO).

Offset

shorting

and select

GROUND"),

However,

which

may cause

occurs,

SPAN/DIV 5 MHz

bypass the

forthis

Spectrum Analyzer

strap

step arc a

from TP1035,

R1063

straplrom

item 1

the

A

DVM

etc.

in firmware

possible

it is

the microcomputer

step

and

Voltmeter,

settings:

MHz

O.O

FREE

RUN

on the

Monitor

(Figure

(FREOUENCY

menus. Perform

TO

TP1073 with

for

5-10)

TP1035.

Tp1

Press

058 ON THE 1ST

for

calibrating the

that some

return

Time Mark

Span

0.00

<Blue-SHIFT>

LOOPS

the

adjustments

to display

to the

calibration

Attenuator

the

Digital

V.

CAL), then

calibration steps as

LO DBTVER

may

an

Generator,

board, to

Vottmeter.

PULSE

item

0

4gzAlP

&

gzBlP

Service,

Vol,

1

5-15

Page 16

justment

Ad

Procedu

re

e.

1) tf

Adjust

1)

2)

3)

4\

5)

6)

"cALlBRATtoN

a

displayed, bypass

to

the adjustment and try

problem persists,

System, in

the SPANIDIV accuracy as

Apply

the cAL

MHZ, FREQ

600

display the

fdiust

5-10)

graticule.

rnarkers.

Remove

Mark

Set

FREQUENCY to

Adjustthe

markerldivision

Set the

Time

Tune

for

one

Reset

the

Generator to

FREQ

the

1st

FREQ

Mark

Generator.

srEP cANNoT

the

refer

Maintenance

the

OUT signal ro rhe RF INPUT,

SPAN/DIV

markers.

Swp R1065,

Coil

marker

CAL

LO

per

the

CENTER FREQUENCY

OUT signal

the

SPAN/DIV

about

FM

over

the

SPAN/DIV

perform

step,

tg bring

Troubleshooting

to

section.

tO

division over

and

RF

INPUT.

to 5

10

MHz.

Coil Swp

center eight divisions

to 20

BE

the other

the

follows:

1OO

MHZ,

on the

apply 0.2

MHz,

REF LEVEL

R1071

kHz

and

OOMPLETED"

adjustments

adjustment

ANd

Span

the

center

(Figure

apply 50

in

range.

Frequency

the

set

the

SEt thE

Attenuator

eight divisions

necessary

as

ps

time mafts

to +10

5-10)

of

the display.

ps

message

Control

FREQUENCy

REF

LEVEL

board

to

from

dBm, and

for

1

markers from

is

then return

lf

the

to

tO

(Figure

ot tne

align

the

Time

the

the

7)

Adjust

center

f . Adjust

1)

Disconnect

2l Press <Blue-SHIFT>

Adiust

3)

the

Adjust

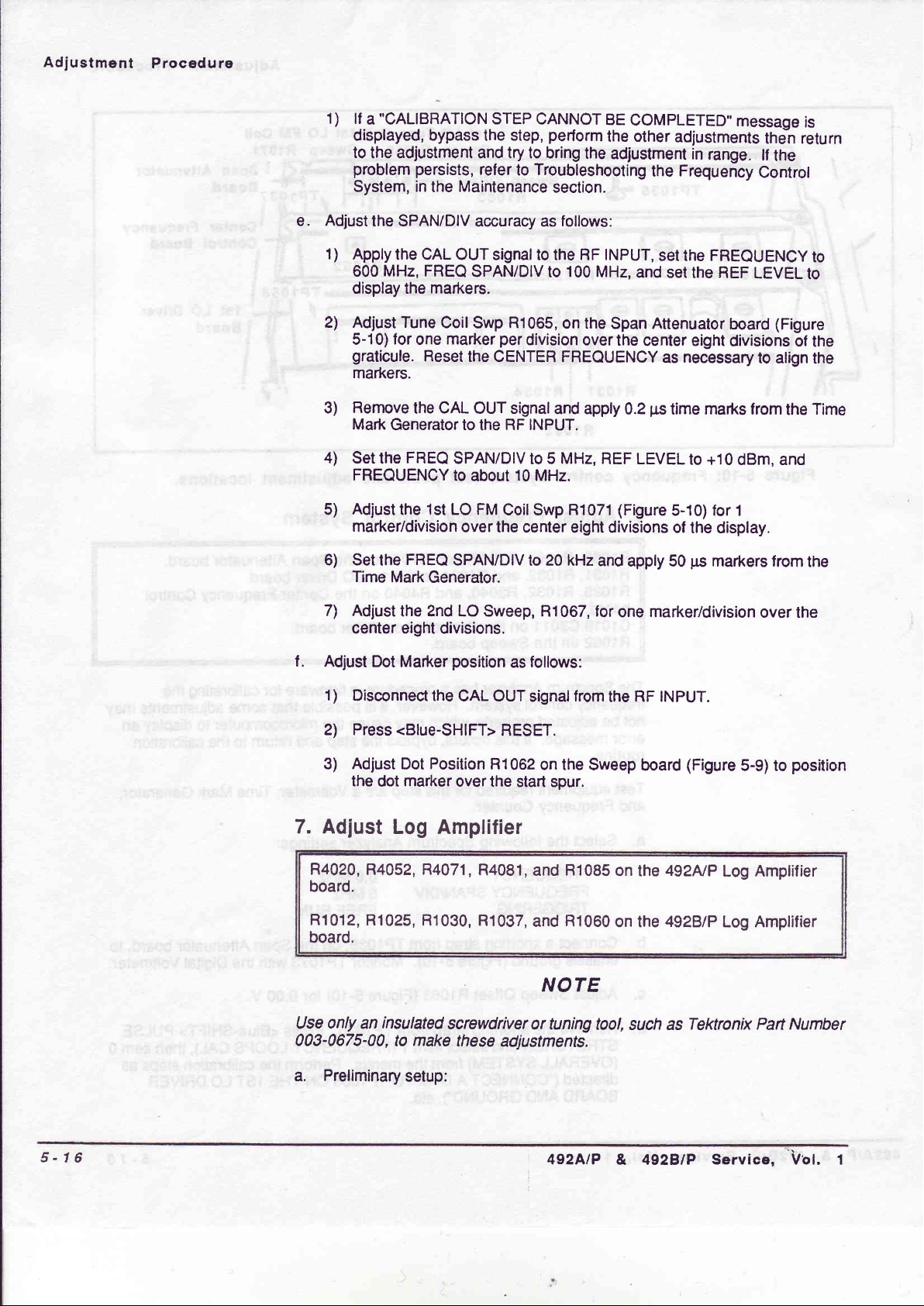

7.

R4020,

board.

R1012,

board.

only

Use

003-0675-00,

the 2nd LO

eight

divisions.

Dot Marker

Dot Position R1062

marker

dot

position

the CAL OUT

over

Log Amplifier

R4052,

R1025,

an

R4471,

R1030,

insulated

to

screwdriver

make

Sweep, R1067, for

follows:

as

signal

RESET.

on the

the start spur.

R4081,

R1037,

and

and

NOTE

or tuning

these

adjustments.

from

the

Sweep

R1085

R1060

tool,

markerldivision

one

RF INPUT.

(Figure

board

on the

on the

49?NP

492BlP

such as

Tektronix

over

5-9) to

Amplifier

Log

Arnplifier

Log

Part Number

the

position

5-16

Preliminary

a.

setup:

4gZAlP

& AgzBtP

Service, Vol. 1

Page 17

Adjustment Procedure

1)

lpttle

SHIFT>

selecting

(sET

2)

Remove

(Figure

3)

Switch POWER

4)

Remove

instrument;

5) Replace

connect

b.

removed in

5-13.)

c.

Set the

FREQUENCY

FREQUENCY

AUTO

REF

MIN RF

VERTICAL

VIEW A/B

TIMSDIV

r_qg-

4ryp,1,lgr_qollegtion

PULSE

item

STRETCHER

(INTERNAL

5

RESULTS TO

Leveler Disable

5-11).

off.

the Log Amplifier

then

the

assembly

the test

equipment

order to access

Spectrum

Analyzer

SPAN/DIV ZMHz

RESOLN

LEVEL

ATTEN

DISPLAY

"UNCALED").

plug

and

remove

in

the

the

as shown

J621 on

controls

factors

(DIAGNOSTIC

MEASUREMENT

P3035

Detector

shield so

instrument

in

zero

ro

by

FUNCTIONSJ

RESULTS),

on the Video Processor

board

assembry from

adjustments

and switch

Figure

5-12.

the Log Amplilier

lollows:

as

2MHz

On

-60

dBm

0dB

10

dB/Dtv

off

10

ms

pressing

<Btueand

then

item

board

the

are accessible.

POWER

(P621

board,

back

must

See

be

Figure

2

on.

d.

Center

signal

attenuators

Position

e.

control;

the two

generator

the display

then switch

for

front

50

steps.

f.

Adiust

g.

set

the REF LEVEL

attenuation.

h.

Increase

ro 70

4oiqst

5-13)

of change

the f ront

dB.

the Log

so each

panel

Reset

attenuation

the

Gain,

10

on

the

Reset vgrlic_alnosition

vertical

Return

k.

4djgsl

5-13) for

settings

10

POSITION

the step

Input

minimum

while

dB/DlV

and 2

attenuator

Ref

alternately

panel

LOG

controls for

and Alri'PL

a 10 MHz/+6

dB of attenuation.

graticule

at a

REF

the

LOG

-20

to

vertical

through

R4020

increment

dB

reference

LEVEL from

CAL so each

dBm and

position

to a

the

tar 492AlP

of attenuation results

display.

by temporarily removing

control to

align

the

to 0 dB.

Lvl,

n4a71 for 492AtP

amplitude change

switching

the

dB/DlV.

CAL

adjustments.

dBm output.

line with

-60

dBm to

10

dB

step

the

step attenuators

graticule

step

attenuators

line

or R102s

the

baseline to

the bottom

or R1097

betweenthe

10

vERTICAL

Set

the

vertical

the

-110

dBm in

equals

one

for

if

necessary.

in

10

dB increments

tor

49zB/p

in

one major

signal

and

graticule

for 4928/p

dB/DtV

DlSpLAy

anO a OA/OIV

between

Set the

step

PO$|T|ON

decade

division.

0 dB

(Figure

division

setting the

line.

(Figure

492AlP

& 492glP

Servlce,

Vot.

1

5-17

Page 18

Adjustment

Procedure

Figure

10

MHz

Leveled

Generator,

0 to

5-11 : P3035

Slgnal

-10

dBrn

@"@"@,@"@

0n

the video

BNC

processor

to smb

board.

Adapter

Spectrum Analyzer

To

J621

Vldeo

on Log

Ampl

Board

Under Test

&

5-18

Flgure

10

5'12:

dB

Test

Step

Attenuator

equlpment

setup for

dB

Step Attenuator

adjusting

492AlP

the Log

& 492BlP

Amplifler.

Servlce.

Vol.

1

Page 19

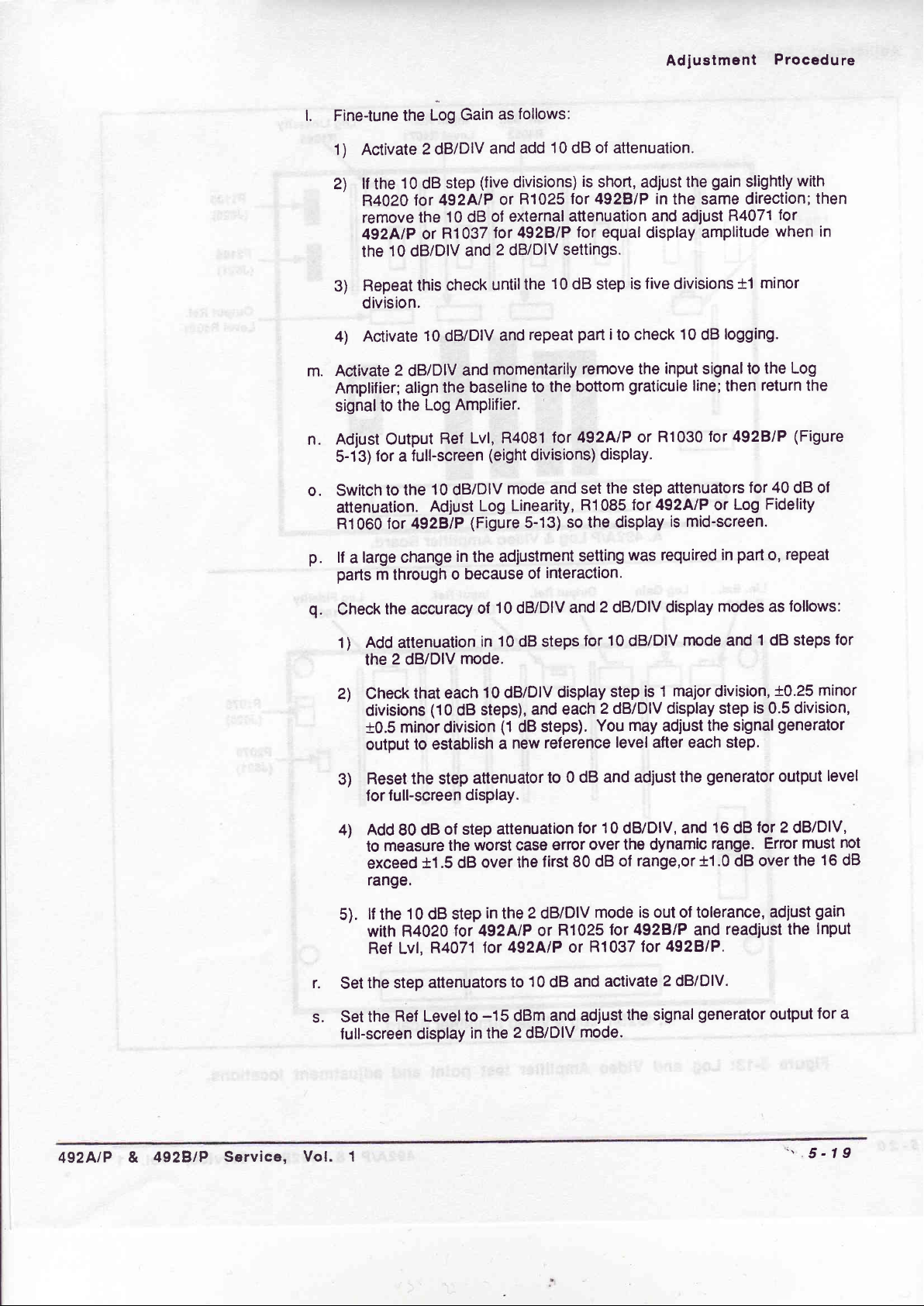

l.

Fine-tune

1) Activate

the

2

Gain

iog

dBlDlV

as

and

follows:

10

add

of

dB

attenualion.

Adjustment

Procedure

lf

Zt

the

R4020

remove the

gZAlP

10

the

Repeat this

3)

division.

Activate

4)

m. Activate

Amplifier;

signal to

Adjust output

n.

lor a full-screen

5-13)

o.

Switch

to

attenuation.

R1060

p.

lf a large change

parts

q.

Check

for 4928/P

m

through

the

step

10

dB

492AlP

for

10 dB

R1 A37

or

dB/DlV

check

10

dB/DlV

2

dB/DlV

the baseline

align

Log

the

Rel

10 dB/DlV

the

Adjust

accuracy

(five

divisions)

R1025

or

of external

492BlP

br

2 dB/DlV settings.

and

until the

repeat

and

momentarily

and

to

AmPlifier.

R4081

Lvl,

(eight

divisions)

mode

Log Linearity,

(Figure

in

the adjustment

because

o

of

5-13)

10

dB/DlV

of

is

short, adjust

for

4928/P in

the same

attenuation and adiust

for

equal

display

10

dB step

part

remove the

bottom

the

492AlP or

for

five

is

ito

check

graticule

divisions

10

input

R1030

display.

and set

the step attenuators

492AlP

R1085

so the

setting

for

display

was

required

is mid-screen.

interaction.

2 dB/DlV display

and

gain

the

slightly

direction;

R4071

amplitude

t1

logging.

dB

to

signal

line;

then

for

4928/P

Log

or

part

in

modes as

for

when

minor

the Log

return the

(Figure

for 40

dB of

Fidelity

repeat

o,

follows:

with

then

in

Add

1)

the

Z) Check that

divisions

+0.5

output

Reset

A)

full-screen

for

Add

4,t

'

measure

to

exceed

range.

lf

the

5).

with R4020

Ref

r.

s.

Set

Set

the

the

full-screen

attenuation

2

dB/DlV

rnode.

each

(10

dB

minor

division

to establish

the step

attenuator

disPlaY.

of step

80 dB

the

worst

*1.5 dB

10 dB

step

for

R4071

Lvl,

attenuators

step

Ref

Levelto

display

in the

10

in

10

steps),

steps

dB

dB/DlV

and

(1

steps).

dB

new

a

reference

attenuation

case

2

the

492A

10

to

dBm

2

dB/DlV

first 80

dB/Dlv

or

over the

in

492AlP

for

-15

10

lor

display

each

step is

2 dB/DlV

You may

level

and adjust the

0 dB

to

for 10

dB/DlV,

over the dynamic

error

of

dB

mode

R1037

activate

and

for

the signal

R1025

lP or

dB

and adjust

mode.

1

dB/DlV

mode

1 majordivision,

display step

the signal

adjust

after each

generator

16

and

and

step.

dB

steps

dB

t0.25 minor

is

0.5

generator

output

tor 2

dB/DlV,

range. Error

range,or

+1.0

dB over the

is out of tolerance, adiust

4928/P

4928/P.

for

2

dB/DlV.

readjust the

and

generator

output

for

division,

level

not

must

16 dB

gain

Input

for a

492AlP

&

492BlP

Serviee,

Vol.

1

".5-19

Page 20

Adjustmenl

Procedu

re

Log Galn

R4020

I-t

l-r

A. 492AlP

Un. Bel.

F4052 Level R4071

Log & Video

lnput Ref.

Amptifier

Board.

Log

Unearity

R1085

P1105

(J620)

P2105

(J621)

Output

Level

Ref.

R4081

Lln.

81012

T

T

Bal.

Log

Gain

R1025

B.492BlP

Output

Ref.

Level Rl030

Log

& Video

Input

Ret

Level

R1037

Amplifler

Board.

Log Fidelity

R1

060

5-20

Figure

5-13: Log

and Video

Amplifler

test

point

and adjustment

492AtP

&

492BlP

locailons.

Service,

'Vol.

1

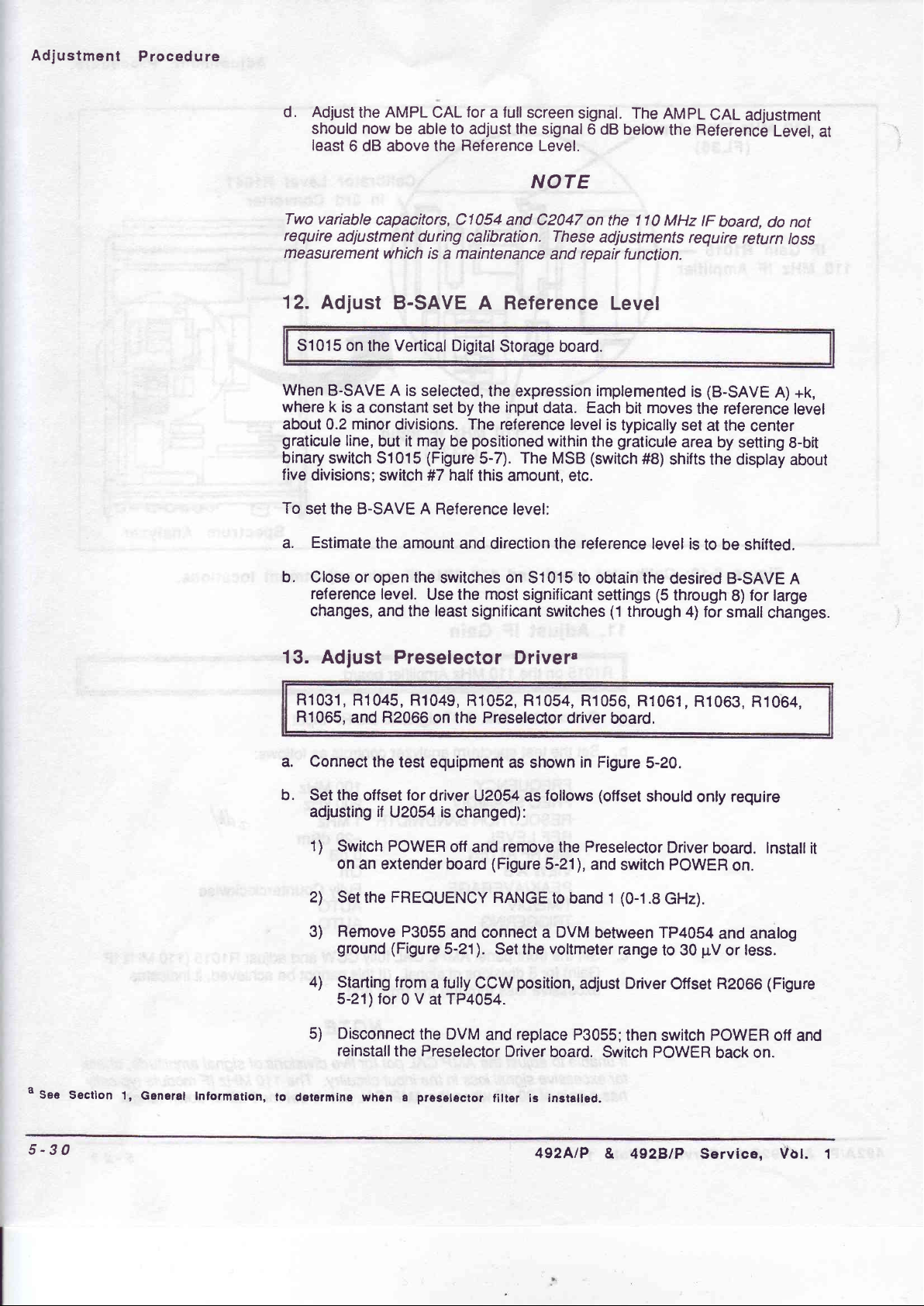

Page 21

Adiustment Procedure

From

3rd

Converter

(A)

10

MHz

@-25

(B)

Figure

dBm

5-14:

Test

equlpment setup

t.

U.

V.

J683

Press

LIN and

492BlP

and

Check

and

+4.4

(Figure

10

dB/DlV display

LIN display linearity

note

divisions.

Remove

jack

and

order to

install

VR 2nd

Filter

for

adjustlng

adjust

Lin

for a full-screen

5-13)

should now be

the display

the signal

step

generator

replace P621,

lhe circuit

Select

Varlable

the

Mode

Balance,

display.

the same.

by adding

down

6 dB,

from full

screen

signal connection to the

and

repeat

part

a

board.

Resolutlon module.

R4052

12

tlg2AlP

for

Amplitude

dB, and

to,

18

410.4,

or

of LlN, 2

dB of attenuation

+0.4,

6

Log Amplifier

subparts 2 through 5

R1012tor

dBlDlV,

andT

input

reverse

in

Adjust

8.

492AlP

R3015, R3029,

C1026, C1033, C2037,

VR 1st

492BlP

R3029, R3033,

Resolution

adjustments

R3033,

Filter

Select.

adiustments

R4025

and

-

C1022,

and

C3023, C3035, C3050,

-

C5055,

on the

C1034, C1044, C1046, C2030,

1st

VR

The

wider

Before

correction

selecting

The 1A0 kHz

applied through

filter

to compensate

each

Filter

Select.

3 dB down bandwidth of each

the 6 dB down

than

calibrating the

factors

item

5; then item 2.

filters

both

shape and

bandwidth.

for

filter in

small

to

in

another

increments.

point

Variable Resolution Bandwidth

zero

each

the

pressing

by

section are

first

and

Because of

filter

Bandwidth and

C2026,

R4025

on the

C5048,

VR 2nd

C3030,

filter

of the combined two

<Blue-SHIFT>

C5055, C5048,

VR

Znd

R2025,

C3041 , R1065,

Filter

Select board.

C3039,

section

C3045,

should

NOTE

second

is

that

aligned

out

separately;

sections.

interaction, it

of

adjustment;

Shape

Factor

C3041,

Filter

Select board

R3035

and

R3015,

R1027

and

wide

be as

filter

sections.

or slightly

and Gain, set the

PULSE

The final

is

STRETCHER

a signal

then

adjustments

to

easy

offset

therefore, only adiust

R1065,

on the

the

on

and

is

trim

filter

one

492AtP

492BlP Service,

&

Vol.

1

5-2I

Page 22

Adjustment

Procedu re

a.

Equipment

1)

setup

Remove

the

is

shown

Variable

Resolution

in Figure

5-144.

module

and

install

it

on

an

extender.

2) Remove

section of the rnodule).

3)

Using smb

(output

4)

Using SMB male-to-male

(10

of

MHz

to second

5) Apply

the

Analyzer

FREQUENCY

FREQUENCY

RESOLUTION

REF LEVEL

MIN

RF ATTEN

VERTICAL

b. Reset

c.

d. Disconnect

the REF

Adjust

(Figure

down,

Third

LEVEL

C5055,

5-15) for

that is

Converter

as

the 10 MHz

needed

the cable

plug

male-to-male

module)

the

output

controls

from

section

cAL

our

the Third

module).

of

signat to

follows:

as

SPAN/DIV

BANDWIDTH

DISPLAY

LEVEL for

C5048, and

the

centered

100

best

around mid-screen).

Third

output

to J693

to maintain

connected

adapters

to

J621, the

adapters

to

and

and

Converter, with red

RF |NPUT,

the

100

MHz

kHz

50

100 kHz

-20

dBm

O dB

2

dB/DIV

a

seven division

C3041

on the

kHz

filter response

Converter

(Figure

5-148).

a 7-division

(input

J683

coaxial

input

cables,

to the

coaxial

and

(100

kHz

(300

kHz

excursion.

VR

2nd Filter

(100

Refer

to

signal from

Set the

display.

to the

connect

Log Amptif

cables,

connecl

band)

set

the spectrum

tor

Oprion

for

Oprion

Select

kHz

bandwidth,

Figure

J683

S-16.

and connect

REFERENCE

second

JOB2

ier.

P6gg

to

J683

07)

07)

board

(input

dB

O

the

Adjust

e.

C3030

screen

f

Sfeps

proceed

t.

through i

to

Change

BANDWIDTH

amplitude

g.

{djust

h.

Change

the

(FL36)

is

centered

BANDWIDTFI

amplitude

i.

Adjust

5-18)

C1034,

for

mid-screen).

c3023,

for

(Figure

part

the

c3035,

4928lP)

5-17).

anly

apply to

j.

FREQ

SPAN/DIV

tor

to 3 MHz. Reset

lo about 7

four

tuning

for

the

best

3

about mid-screen.

FREQ

the

SPAN/DIV

to 1 MHz.

to

about 7

C1044,

the

best

1 MHz

c3050

the

on

best

NOTE

4928/P.

the

to 1 MHz

the

divisions.

screws

MHz

divisions.

(capacitors)

filler

response

to

Reset

the

and C1046

filter response

4gzAtp

the

100

kHz response

your

lf

and

REF

LEVEL

on the

(3

MHz

200 kHz

on the

REF

and

LEVEL

VB 1st

(1

MHz 6 dB

(C3045,

instrument

RESOLUTTON

the

to bring

110

1600 kHz,

C3039,

centered

around

is a 4g2Np,

the signal

MHz

Bandpass Filter

6 dB

the RESOLUTTON

to

the

bring

Filter Select

down,

signal

board

centered

and

mid-

down) that

(Figure

about

5-22

4gZAtP & 4gZBtP Servlce, Vol.

1

Page 23

Y

r

J683

R3o2e

O

R4025

R106s

s6'Jj",

S

Adjustment Procedure

JoB2----->

Figure

5-15:

Adjustments

iSFENEilCE

IARKEi LEI'EL

-1gDBM

tw

s

?3,,,t I tl lt rl ,l ,,rr a a

aa t r

I I tt tr tt

zDBI

VEFT

olsplAY

on the front

15'81

TT'NE

*

t::\

t:

I I

I

I

t

I

20DB

FF

ltttN

of the

CEilfER FNEOUETICY

IAAKEN FBEOUE}ICY

100.000MH2

492BlP Varlable

4 \

I

\

, ,\, ll It tt I i arrf

i. tt,

0-1.8

FREO

nalroE

INT

itt

osc

aP^'{/Dn

sOKHZ

\ -tl

.I

tt tl tt I f I rt I

100KHZ

vtoEo

NL?gF

BE$OLUNOH

SAlilgwtO?H

Hesolutlon

BE'

-14

module.

492AlP

& 492BlP

Service,

Flgure

Vol. 1

5-16: 100 kHz

fllter

centered.

5-23

Page 24

Adjustment

Procedure

NOTE

Parts

i

?nd

part

to

j.

l.

change rhe

BANDWIDTH

amplitude

k.

{djust

(FL36)

is

centered

l.

change

BANDWIDTH

amplitude

m. Adjust

response

N.

SEt

thE

200 Hz.

Adjust

o.

p.

Check

the

100 kHz

be

adjusted

k

only

apply

to the

FREQ

spAN/DtV

to 1 MHz.

to about 7

the thre.e

forthe

best

about

FREQ

the

to 10

to

about

C2a37

for

centered

divisions.

tunlng

MHz filter

3

mid-screen.

SPAN/D|V

kHz.

7

divisions,

492A/P (c2090

about

RESOLUTION

Reset

the REF

R4025

the

(Figure

shape,

5-15)

bandwidth,

f ilter is required,

separately.

492NP.

ro

Reset

screws

your

lf

soo kHz

the REF

(capacitors)

response (1

kHz

2

to

Reser

the

REF

for 492Btp)

the 1 kHz

BANDWIDTH

LEVEL

reference

IO 1OO

for

a 7

for maximum

and centering

1st

the

Figure

5-18

and

shows

instrument

and the

LEVEL

on

and

the

LEVEL

RESoLUTtoN

to

bring

the 110

+200

MHz

RESoLUTtoN

to

for

(Figure

HZ

ANd

division

display.

signat

amptitude.

of

each

Znd Filter

typical respense

is

a 4gZB/p, proceed

the

signal

MHz

Bandpass

kHz,

6

dB

bring

the

signal

the

besr 10

5-17),

FREQ

Select

filter.

SPAN/DIV

lf

adjustment

boarijs

shapes.

down)

kHz

tO

shoufd

Filter

that

of

q.

Level

1)

2)

3)

Table

5.3: Filter

Filter

MHz

MHz

(492BlP

(492BlP

3

1

1 MHz (492AtP

10

kHz

1

kHz

100

Hz

gain

the

Select

of

the

these

FREQUENCY

FREQ

SPAN/DIV

RESOLUTION

REF

LEVEL

VIEW A/B

Activate

reference

4qig{

FREQ

SAVE A

for

all other

allfilters

SPAN/DIV

Gain

Ad

R1027

Onty)

H1065

R3029

R3015

filters

follows:

as

settings:

BANDWIDTH

to store

the

filters.

to the 100

kHz level

as necessary

Leveling

Adfustments.

just

100

MHz

20 kHz

100

kHz

-20

dBm

on

100 kHz

as

maintain

to

Locat ion

Figure

Figure

Figure

Figure

Figure

Figure

(300

kHzlorOption

f ilter

amplitude.

perthe

a suitable

5-15

5-17

5-15

5-15

5-15

5-15

This is

following

tabte.

display.

07)

the

Change

5-24

492AlP

& 492BlP

Service,

Vot.

1

Page 25

Input

I

Y

J693

@

R2045

(4e2BtP

From

3rd Converter

only)

c1034

046

c1

c1044

Adjustment

H2060

@

10 dB Gain

Procedure

Flgure

@

5-17; Adjustments

Preset

9.

Level

R2038

R3035

Rza23

R2031

czoso 10

on

(R1030

on the

and R2060

0n

rear

the

the

g

i n

for 492B/P)

10

the VR

dB

kHz

of

the

Variable

on the

Steps

Gain

(R2045

#2 Mother

for 492BlP)

board.

Variable

Resolutlon

Resolution

Post

VR Amptifier

board.

on

the

Output

On VR#2

Gain

20

dB

To

module.

Band

and

board.

Gain

Steps

J683

board.

492AlP

&

492BlP

Servlee,

The

Log Amplifier

gqiry

gettings.

MHz

10

screen

Resistor

a.

Vol. 1

signal to the

display

R2025 is

Before

correclion factors

and

selecting

must be calibrated

Amplifier

Log

input

with

the

not

used

adjusling the

to

menu item

calibration can

(J621),

nEF

LEVEL

for

the

Variable

zero

pressing

by

"SET

2

NOTE

before

of the Log Amplifier,

at

492NP

Resolution

RESULTS

adjusting

verified

be

-20

dBm.

and 4928/P

gain

and

<Blue-SHIFT>

TO

UNCALED".

any Variabte Resolutian

by applying a +6

and

checking for

Epectrum Analyzers.

band leveling,

PULSE

dBm,

futt

the

set

STRETCHER

5-25

Page 26

Adjustment

Procedu

re

Adjust

Flat Top

<0.5

Ripple

al

For

dB

lB

A. Response

Fl.t

of 1 0

BW

t29o/o

Down

kHz

filter.

{.756

=

10 kHz

6 clB

lmg

ta.itf,

BW

BW

to|

B.

Response

*tl

1 MHz

Fl

lter

rt.ntrt

Fl.l

of

100

Fllter

10

kHz

Fllter

100 ktlz

na

kHz

Inf,

f ilter.

Flgure

d

Response

C,

5-18:10 kHz, 100

Test

b.

equipment setup is

controls

FREQ

follows:

as

SPAN/DIV 1 MHz

RESOLUTION

REF

LEVEL

MIN RF ATTEN

VERTICAL

c. set the

Band

ccw.

gain

The

d.

ra':,

p*.;ormed

pedorm

of the

through

on this

following

the

10 kHz

Fllter

|-l.f

of 1

MHz fllter.

kHz, and 1 MHz

shown

in

BANDWIDTH

DISPLAY

1

the

R2031

Gain

Post VR

Variable

stage,

vR

on

Amplifier

Resolution

or

the

signal

steps.

ll|c

fltter response.

Figure

-20

KHz

1OO

dBm

5-14.

Set

O dB

2 dB/DIV

Mother

should be 20

board

stages.

gain

through

ll

#2

dB

any

the Spectrum Analyzer

(Figure

for

maintenance

the

5-15) lully

best signalto-noise

has

been

module is incorrect,

5-26

4gZAtP & Ag2BlP Servlce,

'Vol.

1

Page 27

rle

vf

signa.l

may

adjustments.

gain

should

be

due

1)

Remove

the

2)

Apply

of

jumper

the

is

che.cked

produce

to improper

a

amplifier.

a

the

cover

connector

10

MHz,-14

b-y

?pptying

full-scre,en

catibration

forthe

VR

to the input

dBm

signal

NOTE

q-gs dBm,

disptay.

of ihe'resoiution

2nd

Filter

of

from

r0

Signat

Select

post

the

a

50 ohm

MHz

Adjustment

signat

loss

thio,ugn

band*idth

board,

VR

signal

to

ne

fiter

and disconnect

Amplitiei

source,

Procedure

J69s.

module

ciit"'ring

.1.11.

lpin

to

This

pin

JJ

3) Adjust

4)

e.

Set

f.

Disconnect

-25

to J693.

amplitude

not

module.)

1)

2)

g.

set the

h.

switch

the

REF

10

dB

Gain R2038

screen

Remove

!!e

Replace

the front

dBm

within

!!lte

R2038

amplitude.

lf.the

step.

display.

the

jymper

front

MIN

LEVEL

Gain

connecrorro

the

panel

P69B

signal,

Set the

should

these limits,

signalamptitude

tor

492Alp

signal

amplitude

panet

NolsE

board

for

signal

from

cover

for

AM,PL

(Figure

from

generator

be

A[4pL

qt:20

(Figure

S-17)

the

between

it

indicates a gi

(R1030

cAL for

off,

decrease

dBrn,

5-17')so

492A/P

the input

plllJjJ

the vR

CAL fr,rlly

signal

is

is

2nd

CCW.

and

a<

gene

freguency

3.5

ani

over

s

divisions,

for

4gzB,tp,)foia

less

than

7

a

the

and

adjust

the

(R1030

to

allfe

Filter

5

division

generator

signal

for

the

Post

inpur

select

adjust

divisions,

signal.

rhe

10

amptirudi

the 4928

VR

Amplilier

p6st

ro

the

board.

the

S-division

proceed

output

dB'cain

to

is

tor

tp)

and replace

VR

Amptirier.

post

vR

Gain

signal

part

to

-85

dBm, leave

R3ffi5;on

ToivGions.

futl

a

g

of this

the

492AlP

& 492Blp

Service,

t.

an{adjust

5-17)

change

t.

q{d

20

k.

set

check

a.nd

signal

necessary.

t.

Remove

Vol.

change

1

the

for

a

the.generatoroutpq!

goiust the 10

dB

Gain

the

REF

tor a 7-divis.ion

dBT input

;Q5

verify

to

the 10

gener?loloytp_ut

the

20

dB

Gain

7-division

dB

step

board

LEVEL

levels.

that

the

MHz

Rz}zg

signal

amplitude.

Gain

R2060_for

(Figure

-90

to

dBm

signal.amptitude.

Note

gain

of

signal

to

-4s

to

to

each

J693

dBm,

on

the

-65

dBm,

s-17)

for

and

that

each

gain

and connect

rhe

REF

ao

dB

Gain

the REF

492!tP (R2045

7-division

a

generator

the

n-epeat

stage

this

detting

maintains

is-10

p698.

Oe.-

LEVEL

step

ooird

LEVEL

toligzB/p)

signat

ampritroe.

output

chrick

ieadiust

to

for-4s,

-40

to

to

ine 7-division

(Figure

-60

-35

dBm,

dBm,

on

dBm.

-5s,

gain

5-27

ine

if

Page 28

Adjustment

Procedure

m. Press

<Blue-SHIFT>

correction factors.

The

band

level

Tracki7g

mean

10.

R1041

The

used

the

a.

@hen

level for

Adjust

on the

CAL

OUT

verify

to

generatar

signal

Apply

g

through

-20

ol

dBm

10_0 MHz

a 3 dB

adjusting

adiustments

preselector

each

band

CAL

100

OUT

MHz

output level

the output

must

signal

attenuator,

on the

the

CAL

Pow_er

OUT

CAL

rerun

to

performed

are

installed

is

sef

to the

Output Level

Osc

and

3rd

NOTE

is

matched

level

of

the

greater

be

from

the signal

and

sellhe

meter.

output

level.

a calibration

NOTE

after catibrating

a)

and checking

level

of Band

Converter

knawn

to a

reference

than

This

signat

40

dB

generatorto

generator

sets

up

routine

freq-uency

I .

board.

reference.

generator.

from

dowi

the

output level