Page 1

TM 11-6625-3135-12

TECHNICAL MANUAL

OPERATOR’S AND ORGANIZATIONAL

MAINTENANCE MANUAL

OSCILLOSCOPE

AN/USM-488

(NSN 6625 -01-1 87-7847)

4

This copy is a reprint which includes current

pages from Change 1.

HEADQUARTERS, DEPARTMENT OF THE ARMY

1 OCTOBER 1986

Page 2

TM 11-6625-3135-12

SAFETY STEPS TO FOLLOW IF SOMEONE IS THE VICTIM OF

ELECTRICAL SHOCK

DO NOT TRY TO PULL OR GRAB THE INDIVIDUAL

IF POSSIBLE, TURN OFF THE ELECTRICAL POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL POWER, PULL,

PUSH, OR LIFT THE PERSON TO SAFETY USING A WOODEN POLE

OR A ROPE OR SOME OTHER INSULATING MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF CONTACT WITH THE

SOURCE OF ELECTRICAL SHOCK, MOVE THE PERSONA SHORT

DISTANCE AWAY AND IMMEDIATELY START ARTIFICIAL

RESUSCITATION

A

Page 3

TM 11-6625-3135-12

WARNING

HIGH VOLTAGE

is used in the operation of this equipment

DEATH ON CONTACT

may result if personnel fail to observe safety precautions

Never work on electronic equipment unless there is another person nearby who is familiar with the

opera! ion and hazards of the equipment and who is competent in administering first aid. When the

technician is aided by operators, they must be warned about dangerous areas.

A periodic review of safety precautions in TB 385-4, Safety Precautions for Maintenance of

Electrical/Electronic Equipment, is recommended. When the equipment is operated with covers

removed, DO NOT TOUCH exposed connections or components. MAKE CERTAIN you are not

grounded when making connections or adjusting components inside the test instrument.

Be careful not to contact high-voltage connections or 115 volt ac input connections when

installing or operating this equipment.

Whenever the nature of the operation permits, keep one hand away from the equipment to reduce

the hazard of current flowing through the body.

WARNING Do not be misled by the term “low voltage”. Potentials as low as

50 volts may cause death under adverse conditions.

For Artficial Respiration. refer to FM 21-11.

B

Page 4

TM 11-6625-3135-12

Technical Manual

No. 11-6625-3135-12

DEPARTMENT OF THE ARMY

Washington, DC, 1 October 1986

HEADQUARTERS

OPERATOR’S AND ORGANIZATIONAL MAINTENANCE MANUAL

FOR

OSCILLOSCOPE AN/USM-488

(NSN 6625-01-187-7847)

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes or if you know of a way to improve the

procedures, please let us know. Mail your letter, DA Form 2028 (Recommended Changes to

Publications and Blank Forms), or DA Form 2028-2 located in the back of this manual direct to:

Commander, US Army Communications-Electronics Command and Fort Monmouth, ATTN:

AMSEL-LC-LM-LT, Fort Monmouth, New Jersey 07703-5000. In either case, a reply will be

furnished direct to you.

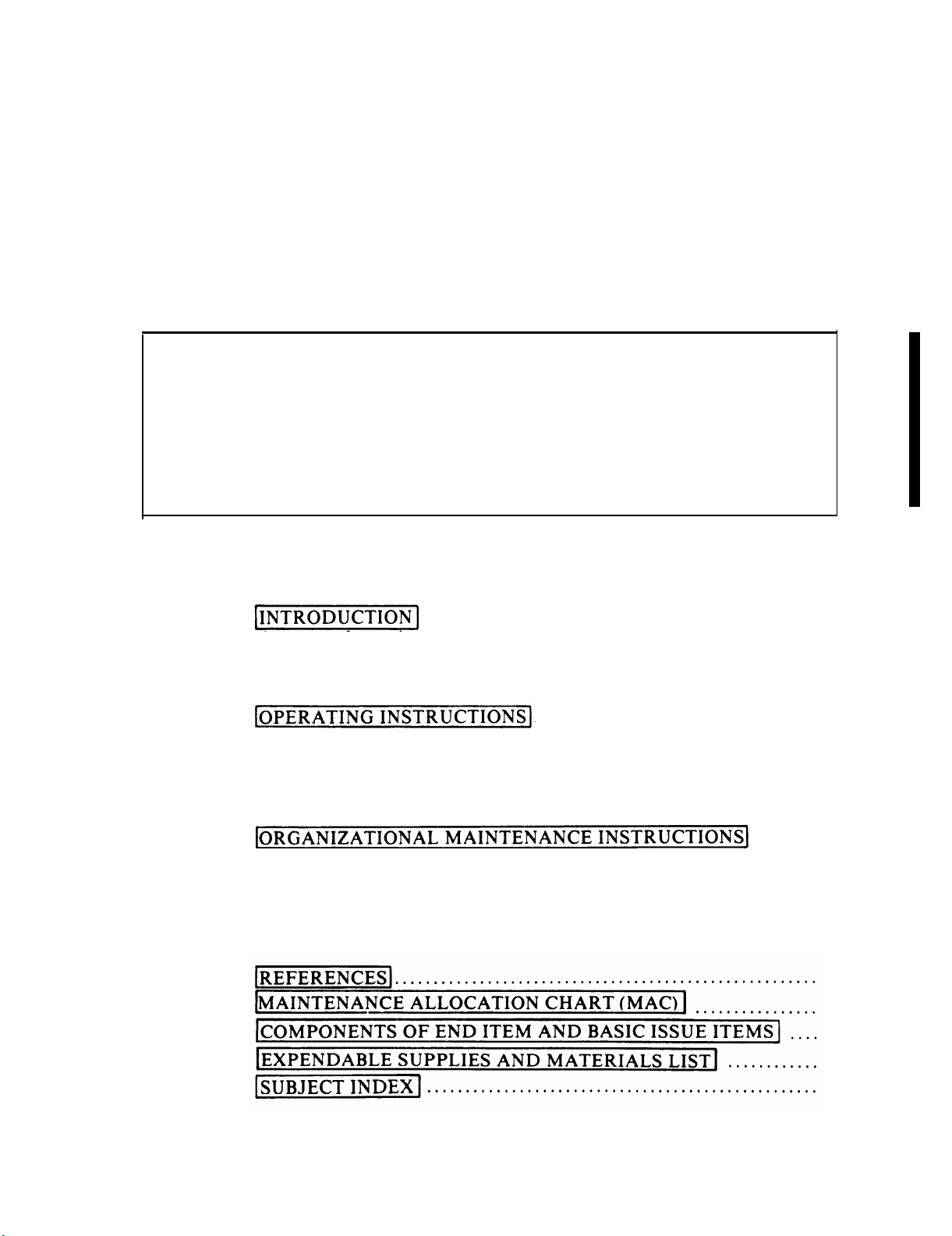

Page

HOW TO USE THIS MANUAL . . . . . . . . . . . . . . . . . . . . .

CHAPTER 1

INTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Section I General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II EQUIPPMENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III Technical Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

1-1

1-1

1-4

1-10

CHAPTER 2

OPERATING INSTRUCTIONS

. . . . . . . . . . . . . . . . .

Section I Description and Use of Operator’s Controls and Indicators . . . . . . . . . .

II Operator Preventive Maintenance Checks and Services (PMCS) . . . . . .

III Operation Under Usual Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV Operation Under Unusual Conditions

CHAPTER 3

Section I

II

III

IV

V

ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Repair Parts, Special Tools; (TMDE); and Support Equipment . . . . . .

Service Upon Receipt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation for Storage or Shipment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX A

B

C

D

SUBJECT INDEX

. . . .

2-1

2-2

2-8

2-11

2-44

3-1

3-1

3-2

3-3

3-5

3-12

A-1

B-1

C-1

D-1

I-1

Change 1

i/(ii blank)

Page 5

Page 6

TM 11-6625-3135-12

HOW TO USE THIS MANUAL

This manual tells you about your Oscilloscope AN/USM-488 and

contains instructions about how to use it while testing and maintaining

other equipment.

The technical manual for the equipment you are maintaining will give

you some guidance in the correct method to make certain connections

when testing and troubleshooting with the oscilloscope.

When you first receive your oscilloscope, start at the front of the

manual and go all the way through to the back, and become familiar

with every part of the manual and the oscilloscope.

This manual has an edge index which will help you find specific

information in a hurry. Simply spread the pages on the right edge of the

manual until the printed blocks can be seen. Open the manual where the

block on the edge of the page lines up with your selected topic printed in

the front cover block.

iii

Page 7

TM 11-6625-3135-12

1-0

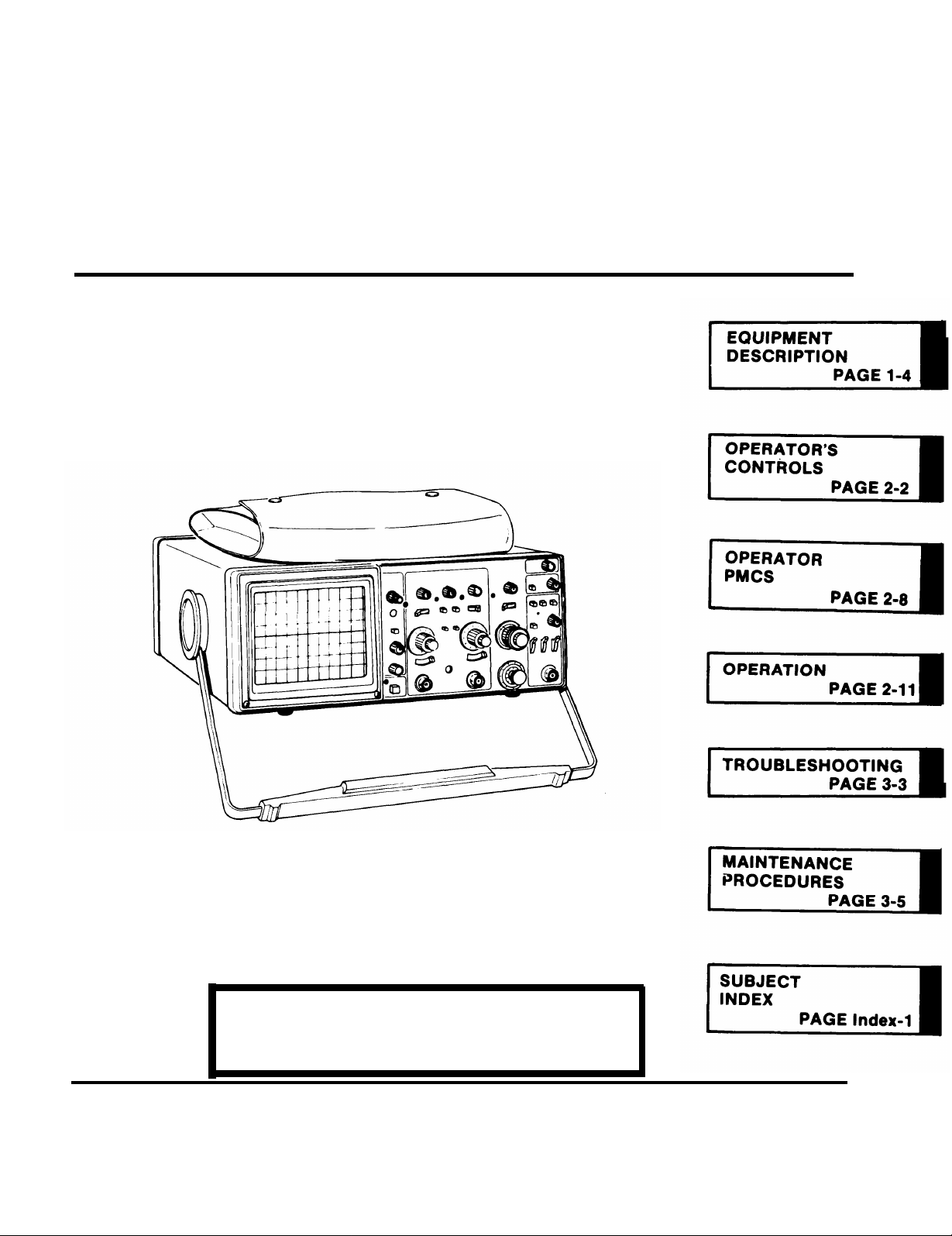

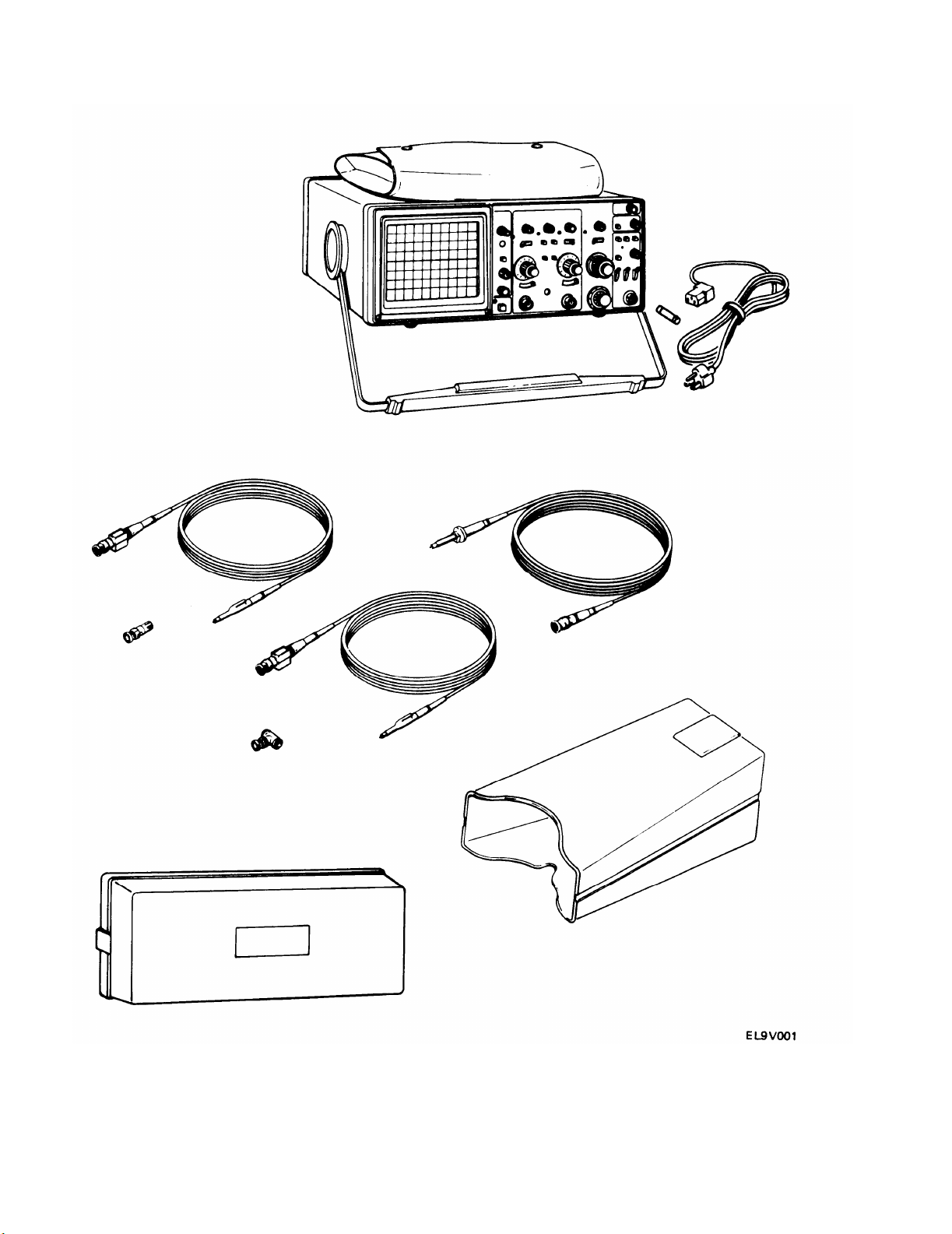

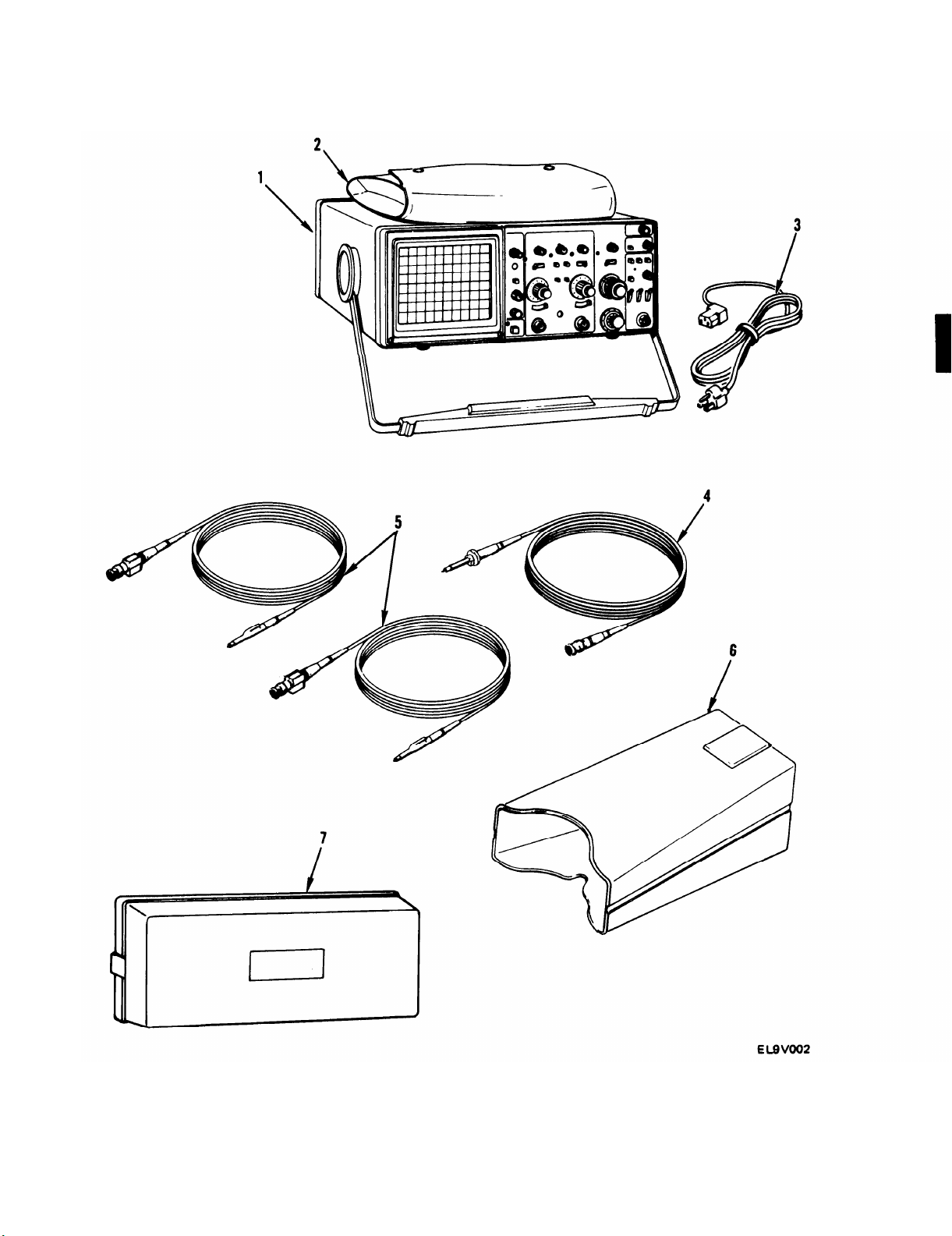

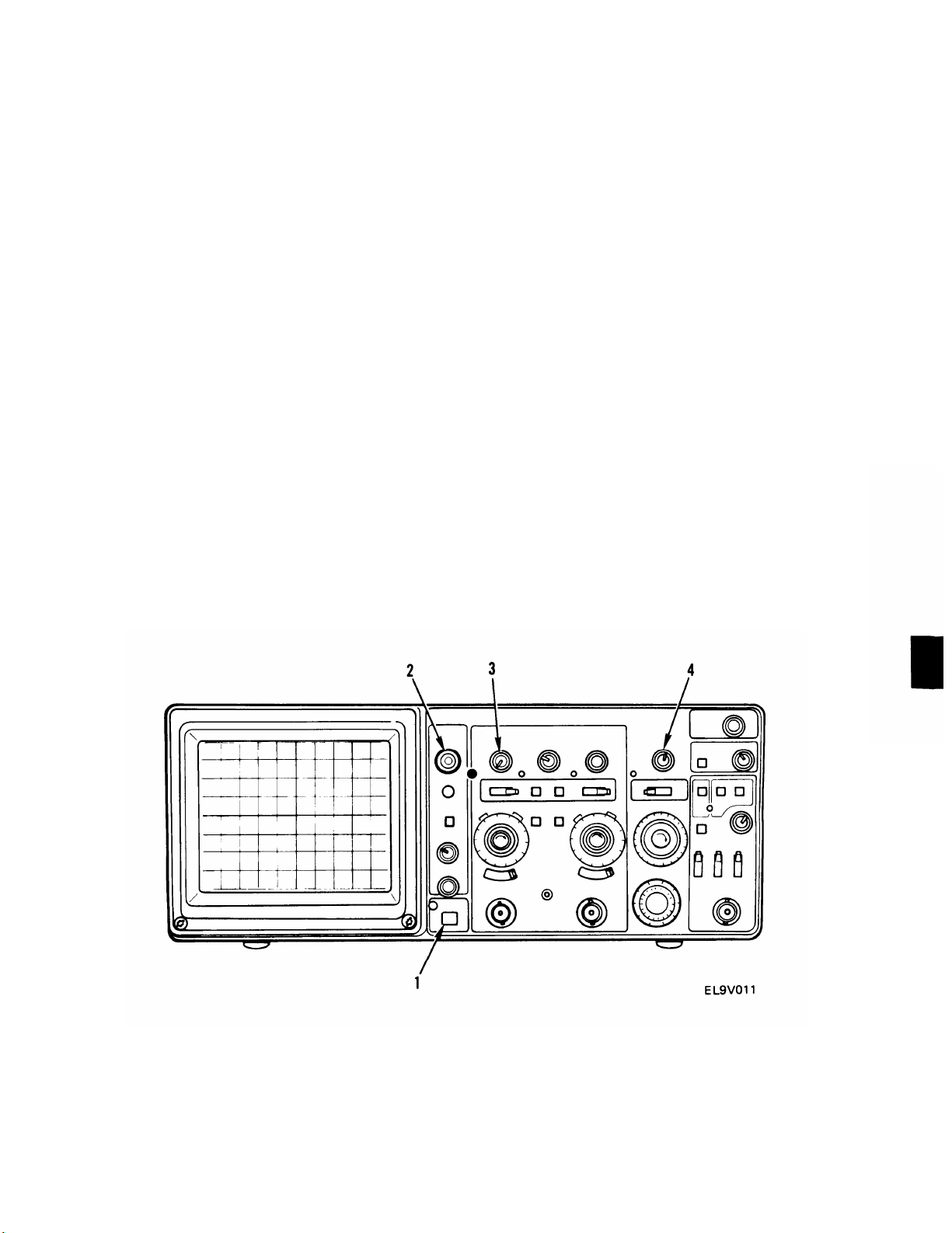

Figure 1-1. Oscilloscope AN/USM-488

Page 8

TM 11-6625-3135-12

CHAPTER 1

INTRODUCTION

Para Page

1-1

Consolidated Index of Army Publications and Blank Forms. . . . . . . . . . . . . . . . .

Destruction of Army Materiel to Prevent Enemy Use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Euipment Characteristics, Capabilities, and Features. . . . . . . . . . . . . . . . . . . . . . . .

Euipment Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location and Description of Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Forms,Records,and Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nomenclature Cross-Reference List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation for Storage or Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reporting Equipment Improvement Recommendations (EIR) . . . . . . . . . . . . . .

Safety, Care, and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1-4

1-11

1-13

1-14

1-10

1-12

1-3

1-7

1-5

1-8

1-6

1-1

1-9

1-1

1-4

1-6

1-10

1-3

1-4

1-1

1-1

1-1

1-1

1-1

1-1

1-2

Section I. GENERAL INFORMATION

1-1.SCOPE

This manual describes the Oscilloscope AN/USM-488 (oscilloscope) and provides instructions for operation, cleaning,

inspection, and maintenance. Testing, troubleshooting, and repair procedures are provided for organizational

maintenance personnel. The oscilloscope (fig. 1-1) is a portable, bench-type oscilloscope designed for general purpose

waveform measurements using single-or dual-trace displays with normal or delayed sweep.

1-2. CONSOLIDATED INDEX OF ARMY PUBLICATIONS AND BLANK FORMS

Refer to the latest issue of DA Pam 25-30 to determine whether there are new editions, changes, or additional publications

pertaining to the equipment.

1-3. MAINTENANCE FORMS, RECORDS, AND REPORTS

a.

Reports of Maintenance and Unsatisfactory Equipment. Department of the Army forms and

procedures used for equipment maintenance will be those prescribed by DA Pam738-750, as contained in Maintenance

Management Update.

b.

Reporting of ltem and Packaging Discrepancies. Fill out and forward SF 364 (Report of Discrepancy

(ROD)) as prescribed in AR 735-11-2/DLAR 4140.55/SECNAVINST 4355.18/AFR 400-54/MCO 4430.3J.

C

.

Transportation Discrepancy Report (TDR) (SF 361). Fill out and forward Transportation Discrepancy

Report (TDR) (SF 361) as prescribed in AR 55–38/NAVSUPINST 4610.33C/AFR 75-18/MCO P4610.19D/DLAR

4500.15.

1-4. DESTRUCTION OF ARMY ELECTRONICS MATERIEL TO PREVENT ENEMY USE

Destruction of Army electronics materiel to prevent enemy use shall be in accordance with TM 750-244-2.

1-5. PREPARATION FOR STORAGE OR SHIPMENT

Storage and shipment procedures are in Chapter 3, Section V.

1-6. SAFETY, CARE, AND HANDLING

Observe all WARNINGS, CAUTIONS, and NOTES in this manual. This equipment can be extremely dangerous if

these instructions are not followed.

1-7. NOMENCLATURE CROSS-REFERENCE LIST

This listing identifies approved nomenclature usage that is different from the official nomenclature:

Common Name

Osccilloscope . . . . . . . . . . . . . . . . . . . . . . . . . .Oscilloscope AN/USM-488

Official Nomenclature

Change 1 1-1

Page 9

TM 11-6625-3135-12

1-8. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR)

If your oscillscope needs improvement, let us know. Send us an EIR. You, the user, are the only one who can tell us what

you don’t like about your equipment. Let us know why you don’t like the design or performance. Put it on an SF 368

(Product Quality Deficiency Report). Mail it to: Commander, US Army Communications-Electronics Command and

Fort Monmouth, ATTN: AMSEL-ED-PH, Fort Monmouth, New Jersey 07703-5000. We’ll send you a reply.

1-9. WARRANTY INFORMATION

Oscilloscope AN/USM488 is warranted by Tektronix Inc. for 1 year. The warranty starts on the date of purchase by the

original owner. Report all defects immaterial or workmanship to your supervisor who will take appropriate action through

your organizational maintenance shop.

1-2

Page 10

TM 11-6625-3135-12

1-10. LIST OF ABBREVIATIONS

This list identifies abbreviations, and descriptions that are used in this manual,

Abbreviation

AN/USM. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

AR

. . . . . . . . . . . . . . . . . . .

BII

. . . . . . . . . . . . . . . . . . . . .

BW

. . . . . . . . . . . . . . . . . . . . . .

C

. . . . . . . . . . . . . . . . . . .

cm

crt . . . . . . . . . . . . . . ..

DA . . . . . . . . . . . . . . . . . . .

DOD . . . . . . . . . . . . . . . . .

DISREP . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

div

EAR . . . . . . . . . . . . . . . . . .

Hz

. . . . . . . . . . . . . . . . . . .

kHz . . . . . . . . . . . . . . . . . .

MAC . . . . . . . . . . . . . . . .

MHz . . . . . . . . . . . . . . . . .

mV

. . . . . . . . . . . . . . . . ..

...... . . . . . . . . . .

ns

NON . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . ....

o

pF. .... . . . . ... . . . .

P-P.

. . . . . . . . . . . . . . . . . . . . . .

PMCS . . . . . . . . . . . . . . .

rqr . . . . . . . . . . . . . . . . . . .

. ..... . . . .... . ...

s

sec/div . . . . . . . . . . . . . . .

SIR . . . . . . . . . . . . . . . . .

TAMES . . . . . . . . . . . . .

TIDE . . . . . . . . . . . . . . .

U/M . . . . . . . . . . . . . . . . .

us

..... ... ... ...

uV

. . . . . . . . . .

VITS . . . . . . . . ..... .

Army-Navy/General utility-special-maintenance

Army Regulation

basic issue item

Bandwidth

operator/crew

centimeter

cathode ray tube

Department of the Army

Department of Defense

discrepancy in shipment report

division

equipment improvement recommendation

hertz (formerly cps)

kilohertz

maintenance allocation chart

megahertz

millivolt

nanosecond

National/NATO stock number

organizational maintenance

picofarad

peak-to-peak

preventive maintenance checks and services

required

second

seconds per division

source, maintainability, and recoverability

The Army Maintenance Management System

test, measurement, and diagnostic equipment

unit of measure

microsecond

microvolt

vertical interval test signal

Term

1-3

Page 11

TM 11-6625-3135-12

Section Il. EQUIPMENT DESCRIPTION

1-11. EQUIPMENT CHARACTERISTICS, CAPABILITIES, AND FEATURES

The oscilloscope is a rugged, lightweight, dual-channel instrument allowing visual evaluation of

electrical circuits.

a. Characteristics.

Measures ac voltage and dc voltage

Measures frequency

Measures nondelayed time

Measures rise and fall times

Algebraically adds signals applied to channels 1 and 2

b. Capabilities and Features.

Vertical system provides calibrated deflection factors from 2 inV per division to 5 V per division

Trigger circuits enable stable triggering over full bandwidth of vertical system

Horizontal system provides calibrated sweep speeds from 0.5s per division to 50 ns per division

Horizontal system provides delayed sweep feature

. Magnifier circuit extends maximum sweep speed to 5 ns per division

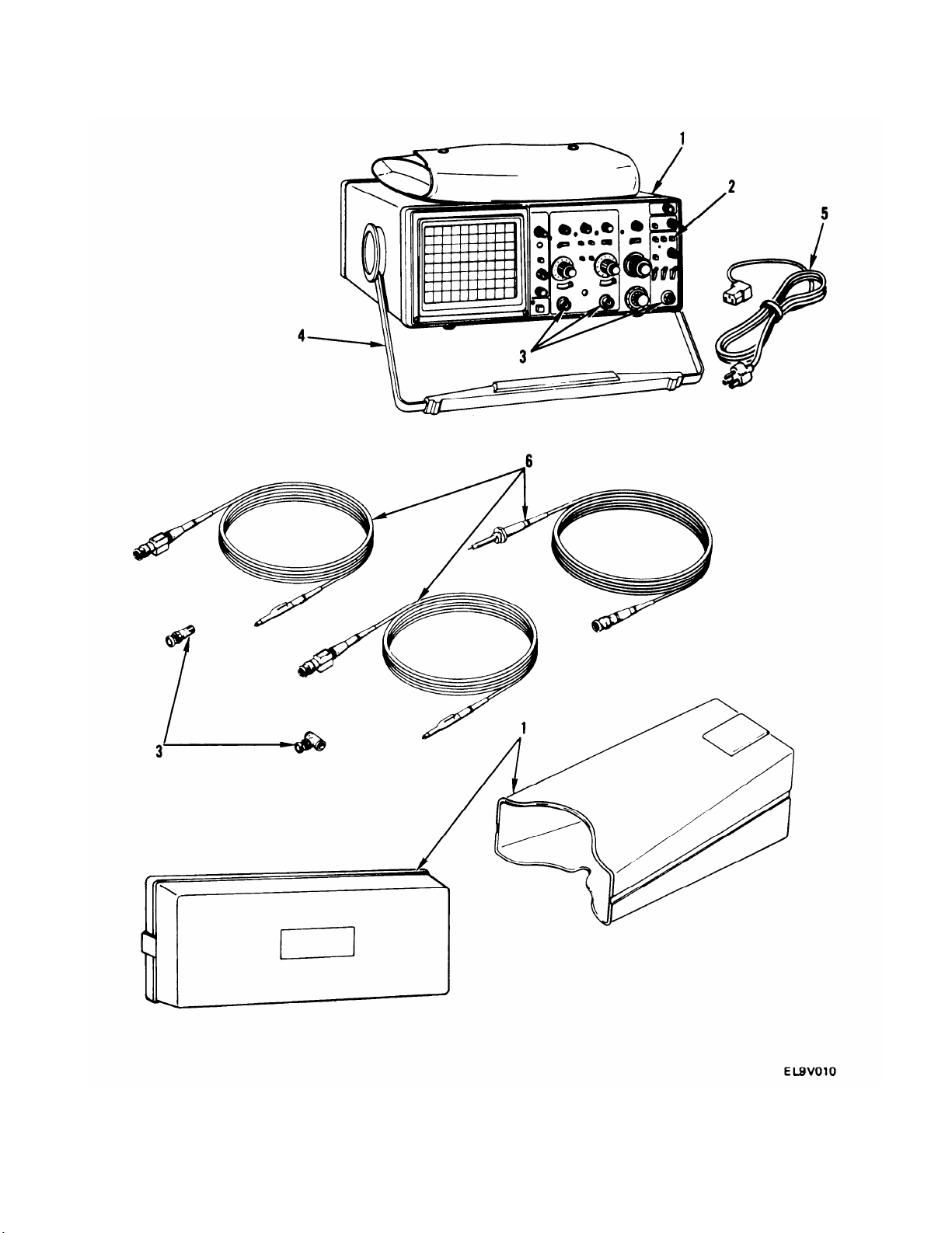

1-12. LOCATION AND DESCRIPTION OF MAJOR COMPONENTS

OSCILLOSCOPE (1)

evaluation of electrical circuits. It measures and indicates various electrical characteristics needed to

test and troubleshoot electrical equipment. The handle can be adjusted as a stand.

POUCH (2)

AC POWER CORD (3)

1X PROBE PACKAGE (4) —

— Provides storage for probes and small components.

— A self-contained, multi-range measuring instrument that allows visual

— Provides for operation from the ac power line.

Provides nonattenuated input to oscilloscope.

10X PROBE PACKAGE (5) –

VIEWING HOOD (6) —

COVER (7)

1-4

— Protects crt screen and front panel controls.

Allows operator to view crt display in bright light.

Attenuates input signal by factor of 10.

Page 12

TM 11-6625-3135-12

1-5

Page 13

TM 11-6625-3135-12

1-13. EQUIPMENT DATA

VERTICAL DEFLECTION SYSTEM:

Deflection Factor

Range

Accuracy at 52-95°F(15-350C) ±2%

Accuracy at 32-122°F(0-50

Range of VOLTS/DIV Control . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

0

C). . . . . . . .. ±3%

2 m V to 5 V per division

Continuously variable between settings, Increases

deflection factor by at least 2.5 to 1

Step Response (Rise Time)

32-95° F (0-35° C)

5 mV to 5 V per Division . . . . . . . . . . . . . . . . . 3.5 ns or less

2 m V per Division . . . . . . . . . . . . . . . . . . . . . . . . 3.9 ns or less

52-122° F (35-50° C)

5 mV to 5 V per Division . . . . . . . . . . . . . . . . . 3.9 ns or less

2 m V per Division, . . . . . . . . . . . . . . . . . . . . . . . 4.4 ns or less

Aberrations (Positive-going Step)

2 m V to 0.5 V per Division . . . . . . . . . . . . . . . . . 4% peak-to-peak

1 V to 5 V per Division . . . . . . . . . . . . . . . . . . . . . 12% peak-to-peak

Bandwidth (-3 dB Point)

32-95° F (0-35° C)

5 m V to5 V per Division ..... . . . . . . . . . . . dc to at least 100 MHz

2 m V per Division . . . . . . . . . . . . . . . . . . . . . . . . dc to at least 90 MHz

95-122° F (35-500C)

5 m V to 5 V per Division . . . . . . . . . . . . . . . . . dc to at least 90 MHz

2 m V per Division . . . . . . . . . . . . . . . . . . . . . . . . dc to at least 80 MHz

AC Coupled Lower Limit . . . . . . . . . . . . . . . . . . . 10 Hz or less at -3 dB

Bandwidth Limiter

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper limits (-3 dB bandpass at 20 MHz, ± 10%)

Chop Mode Switching Rate . . . . . . . . . . . . . . . . . . . 500 kHz ±30%

Input Characteristics

Resistance

.. . . . . . . . . .

Capacitance

. . . . ... . . . . ..... . . . . . . . . . . .

1 Megohm ±2%

20 pF ±2 pF

Maximum Safe Input Voltage

DC Coupled

. . . . . . . . . . . . . . . . . . .. . ..

400 V (dc + peak ac) or 800 V peak-to-peak to 10

kHz or less

AC Coupled . . . . . . . . . . . .. . . . .. . .

400 V (dc + peak ac) or 800 V peak-to-peak to 10

kHz or less

Common Mode Rejection Ratio . . . . . . . . . . . . . . At least 20 to 1 at 80 MHz

Input Current . .. . . .. . . . . . . . . . . . .

1.0 nA or less (0.5 division trace shift at 2 m V per

division)

Trace Shift with VOLTS/DIV Switch

Rotation

. . . . . . . . . . . . .

0.75 division or less

Trace Shift as VOLTS/DIV Variable Control

is Rotated

. . .. . . . . . . . . . . . . . . . . . . .

1.0 division or less

Trace Shift With Invert. . . . . . . .. . .. . .. . .. . 1.5 divisions or less

Channel Isolation

POSITION Control Range .............

. . . . . . . . . . . .

Greater than 100 to 1 at 50 MHz

At least ±11 divisions from graticule center

1-6

Page 14

TRIGGER SYSTEM:

A Trigger Sensitivity

P-P AUTO/TV LINE and NORM Modes

Internal . . . . . . . . . . . . . . . . . . . . . . ..

0.35 division at 10 MHz, 1.0 division at 60 MHz,

1.5 divisions at 100 MHz

External

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35 m V at 10 MHz, 120 m V at 60 MHz, 150 m V at

100 MHz

High-Frequency Rejection . . . . . . . . . . . . . . . .

Attenuates signals above 40 kHz

(-3 dB point at 40 kHz ±25%)

Low-Frequency Rejection . . . . . . . . . . . . . . . .

Attenuates signals below 40 kHz

(--3 dB point at 40 kHz ±25%)

Lowest Useable Frequency in P-P

AUTO Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TV FIELD Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 Hz with 1.0 division internal or 100 m V external

1.0 division of composite sync

External Trigger Input

Maximum Input Voltage . . . . . . . . . . . . . . . . . . .

Input Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Coupled . . . . . . . . . . . . . . . . . . . . . . . . . . .

400 V (dc + peak ac) or 800 V ac peak-to-peak

1 Megohm ±2%

20 pF ±2.5 pF

10 Hz or less at lower -3 dB point

Level Control Range

A TRIGGER (Normal)

INT . . . . . .

. . . . ... . . . . . . . . . . . . . . .

. . . . . . . . . .

Can be set to any point of the trace that can be

displayed

EXT. DC

EXT. DC 10

. . . . . . . . . . . . . . . . . . . . . . .... . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

B TRIGGER (Internal) . . . . . . . . . . . . . . . . . . . . .

At least+ 1.6 V (3.2 V peak-to-peak)

At least ±16 V (32 V peak-to-peak)

Can be set to any point of trace that can be

displayed

VAR HOLDOFF Control

. . . . . . . . . . . . . . . . . .

Increases A sweep holdoff time by at least a

factor of 10

TM 11-6625-3135-12

TRIGGER VIEW SYSTEM:

Deflection Factor

Internal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ...... .

Same as vertical

External

AC and DC

. . . . . . . . . . . . . . . . . . . ...... ...

DC 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

100 m V per division

1 V per division

±20%

Delay Difference Between EXT INPUT and

Either Vertical Channel . . . . . . . . . . . . . . ...

Less than 2.0 ns

1-7

Page 15

TM 11-6625-3135-12

HORIZONTAL DEFLECTION SYSTEM:

Sweep Rate Calibrated Range

A sleep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.5 second to 0.05 us per division. X10 magnifier

extends maximum sweep speed to 5 ns per

division

B Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50 ms to0.05us per division. X10 magnifier

extends maximum sweep speed to 5 ns per

division

Sweep Rate Accuracy at 59-95° F (15-35° C)...

Sweep Rate Accuracy at 32-122° F (0-50° C)...

POSITION Control Range . . . . . . . . . . . . . . . . . . . .

±2% unmagnified, ±3% magnified

±3% unmagnified, ±4% magnified

Start of sweep to 10th division will position past

center vertical graticule line in X1 or 100th

division in X10

Sweep Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±5%

Variable Control Range . . . . . . . . . . . . . . . . . . . . . . .

Continuously variable between calibrated

settings. Reduces A and B sweep speeds by at

least a factor of 2.5

Sweep Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Greater than 10 divisions

A/B SWP SEP Range . . . . . . . . . . . . . . . . . . . . . . . . ±3.5 divisions or greater

Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dial Control Range . . . . . . . . . . . . . . . . . . . . . . . . .

Jitter . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

Applies to 0.5 us per division and slower

<0.5 + 300 ns to >10 divisions

0.005% of the maximum delay time

Time Measurement Accuracy

59-95° F (15-350 C) . . . . . . . . . . . . . . . . . . . . . . . . ±1%+ 0.01 major dial division

32-122° F (0-50

0

C) . . . . . . . . . . . . . . . . . . . . . . . . ±2%+ 0.01 major dial division

X-Y OPERATION:

Deflection Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Same as vertical deflection system (with

VOLTS/DIV variable controls in CAL detent)

Accuracy

X-Axis at 59-95° F (15-35

X-Axis at 32-122° F (0-50

Y-Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0

C) . . . . . . . . . . . . . . . ±3%

0

C) . . . . . . . . . . . . . . . ±4%

Same as vertical deflection system

Bandwidth (--3 dB Point)

X-Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dc to at least 2.5 MHz

Y-Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Same as vertical deflection system

Phase Difference Between X- and Y-Axis

Amplifiers, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±3%from dcto150kHz

AMPLITUDE CALIBRATOR:

Output Voltage of AMP CAL Connector . . . . . 0.5V ±2%

Repetition Rate................ . . . . . . . . . . . 1 kHz ±20%

Z-AXIS INPUT:

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 V causes noticeable modulation. Positive-going

input decreases intensity. Useable frequency range

is dc to 20 MHz.

Maximum Safe Input Voltage . . . . . . . . . . . . . . . . .

30 V (dc + peak) or 30 V ac peak-to-peak at

1 kHz or less

Input Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 kilo hms ±10%

1-8

Page 16

POWER SOURCE:

Line Voltage Ranges . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Power Consumption . . . . . . . . . . . . . . .

Line Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

90 V ac to 250 V ac

48 to 440 Hz

40 W (70 VA)

1.0 A, 250 V, Slow-blow

CATHODE RAY TUBE:

Display Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Phosphor

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Nominal Accelerating Voltage . . . . . . . . . . . . . . . . .

80mmx100mm

P31

14 kV

ENVIRONMENTAL CHARACTERISTICS:

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . .

Nonoperating Temperature . . . . . . . . . . . . . . . . . . .

Operating Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32-122° F (0-50° C)

-67 to +167°F (--55 to + 75°C)

Up to 15,000 ft (4,500m). Maximum temperature

decreased 1° C per 1,000 ft above 5,000 ft

Nonoperating Altitude . . . . . . . . . . . . . . . . . . . . . . . .

Operating Humidity

. . . . . . . . . . . . . . . . . . . . ... . . .

Nonoperating Humidity . . . . . . . . . . . . . . . . . . . . . . .

Vibration (Operating) . . . . . . . . . . . . . . . . . . . . . . . . .

To 50,000 ft (15,000 m)

95% at 86-122° F (30-50° C)

95% at 86-140° F (30-60° C)

Can withstand total displacement of 0.01 5 inch

p-p (2.4 g’s at 55 Hz) along all three axes, with

frequency varied from 10 Hz to 55 Hz, for period

of 15 minutes

Electromagnetic Interference . . . . . . . . . . . . . . . . . .

Meets requirements of MIL STD-461B Pt 4

TM 11-6625-3135-12

PHYSICAL CHARACTERISTICS:

Weight with Accessories . . . . . . . . . . . . . . . . . . . . . . .

Weight without Accessories . . . . . . . . . . . . . . . . . . .

Domestic Shipping Weight . . . . . . . . . . . . . . . . . . . .

Height with Empty Pouch . . . . . . . . . . . . . . . . . . . . .

Height without Pouch . . . . . . . . . . . . . . . . . . . . . . . . .

Width with Handle

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width without Handle . . . . . . . . . . . . . . . . . . . . . . . .

Length with Front Cover . . . . . . . . . . . . . . . . . . . . . .

Length without Front Cover.. . . . . . . . . . . . . . . . .

Length with Handle Extended . . . . . . . . . . . . . . . . .

20.0 lb (9.1 kg)

13.5 lb (6.1 kg)

24.1 lb (10.9 kg)

5.9 in. (150 mm)

5.4 in. (137 mm)

14.2 in. (360 mm)

12.9 in. (328 mm)

17.5 in. (445 mm)

17.3 in. (440 mm)

20.1 in. (511 mm)

1-9

Page 17

TM 11-6625-3135-12

Section Ill. TECHNICAL PRINCIPLES OF OPERATION

1-14. FUNCTIONAL DESCRIPTION

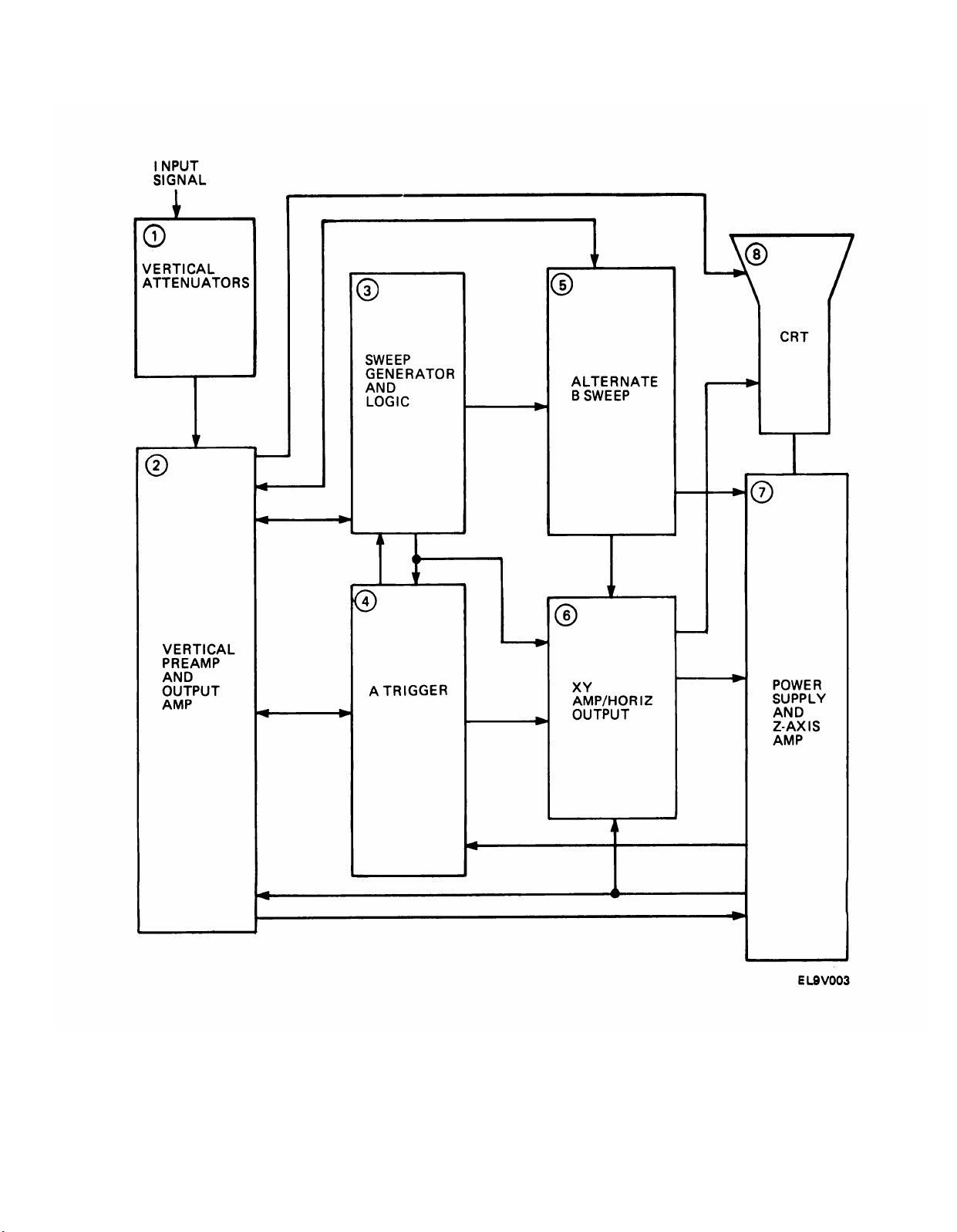

The following is a basic functional description of the oscilloscope. Refer to fig. 1-2 for a block

diagram.

There are two vertical attenuators (one for each channel). The attenuator circuits provide

control of input coupling, vertical deflection factor, and variable volts-per-division gain. An

invert circuit in the channel 2 attenuator allows you to invert the channel 2 input signal.

The vertical preamp and output circuit amplifies the input signals. This makes the signal level

high enough for vertical deflection of the electron beam in the crt. The dynamic range of the

amplifier can be limited with the beam find switch. The amplifier also intensifies the trace and

limits horizontal deflection.

The A sweep generator and logic circuit produces a linear voltage ramp for horizontal

deflection of the crt beam. The sweep generator also produces signals that generate correct

timing of the crt unblinking and intensity levels.

The A trigger circuitry uses either an internal signal, external trigger, or ac line trigger signal to

develop a gate signal for the A sweep generator. The B trigger circuitry uses only the internal

trigger signal to gate the B signal generator.

The alternate B sweep circuitry produces a linear voltage ramp that is amplified by the

horizontal amplifier. This provides the B sweep horizontal deflection on the crt. The alternate

B sweep circuitry also produces sweep-switching signals that control the display of the A and

B sweeps, and gate signals used to establish the crt unblinking and intensity levels for the A

intensified and B sweep displays.

The X-Y amplifier amplifies the channel 1 signal from the internal circuit and applies it to the

horizontal amplifier. The horizontal amplifier provides output signals to drive the crt

horizontal deflection plates.

The power supply converts ac power-line voltage into voltages needed for oscilloscope

operation. The Z-axis amplifier uses several input signal sources to control the crt intensity

level.

The crt provides a visual display of the electrical properties of the circuit or signal under

examination.

1-10

Page 18

TM 11-6625-3135-12

Figure 1-2. AN/USM-488 Oscilloscope Block Diagram

1-11/(1-12 Blank)

Page 19

Page 20

CHAPTER 2

OPERATING INSTRUCTIONS

TM 11-6625-3135-12

Para

General Operator Preventive Maintenance Checks and Services . . . . . . . . .

Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation in Unusual Weather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PMCS Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-3

2-4

2-2

Page

2-8

2-11

2-44

2-8

2-1

Page 21

TM 11-6625-3135-12

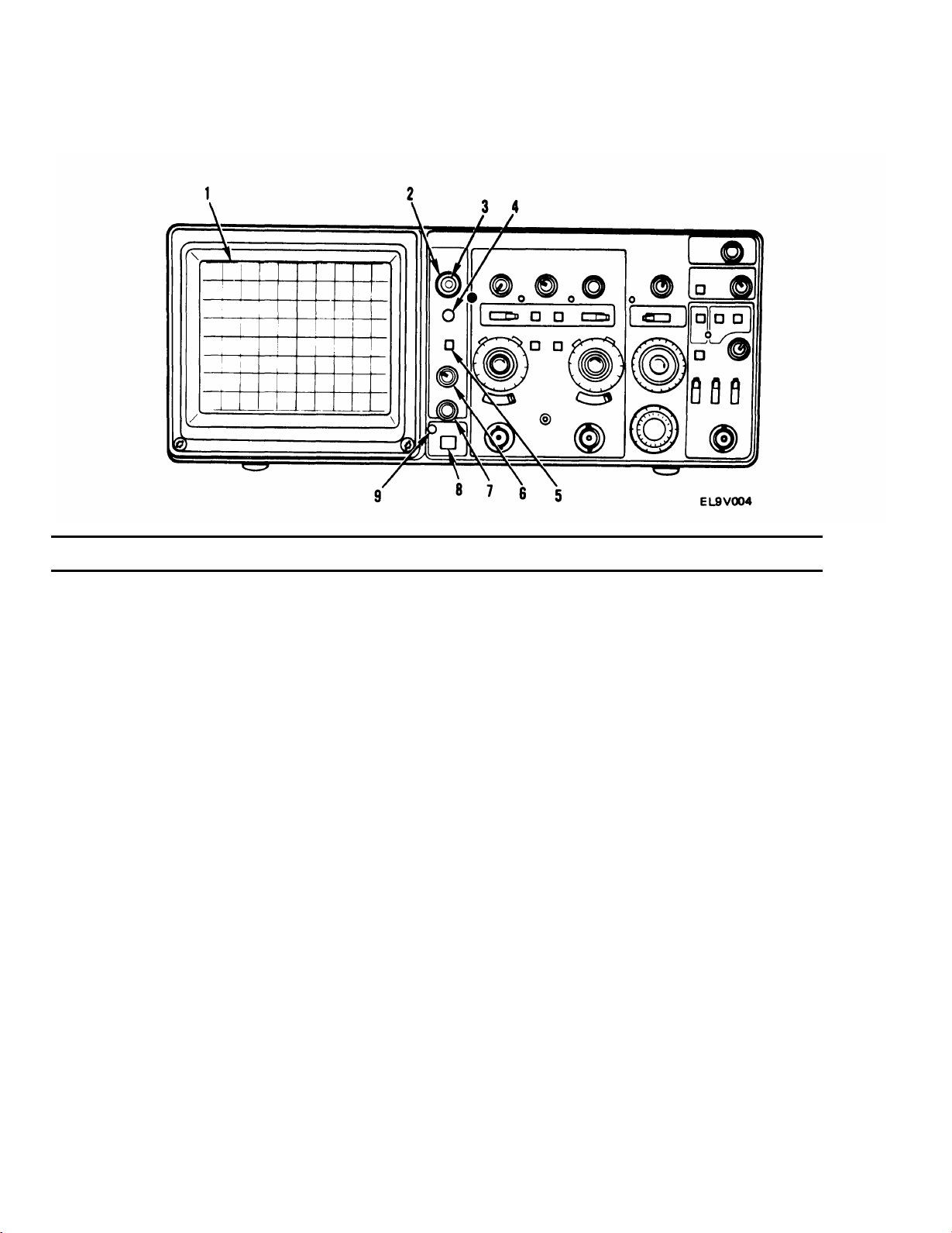

Section I. DESCRIPTION AND USE OF OPERATOR’S CONTROLS

AND INDICATORS

Key

1

2

3

4

5

6

7

Control Or Indicator

Cathode Ray Tube

A INTENSITY

Control

B INTENSITY

Control

TRACE ROTATION

Control

BEAM FIND Switch

SCALE ILLUM

Control

FOCUS Control

Function

Provides visual display of electrical properties of circuit

under examination

Controls brightness of A sweep trace

Controls brightness of B sweep trace

Screwdriver adjustment used to align trace with horizontal

graticule line

When held depressed, compresses display to within graticule

area to aid in locating off-screen displays

Adjusts brightness of graticule illumination

Adjusts for optimum display definition

2-2

8

POWER Switch

POWER Indicator

9

Turns oscilloscope power on and off

When illuminated, indicates power applied to oscilloscope

Page 22

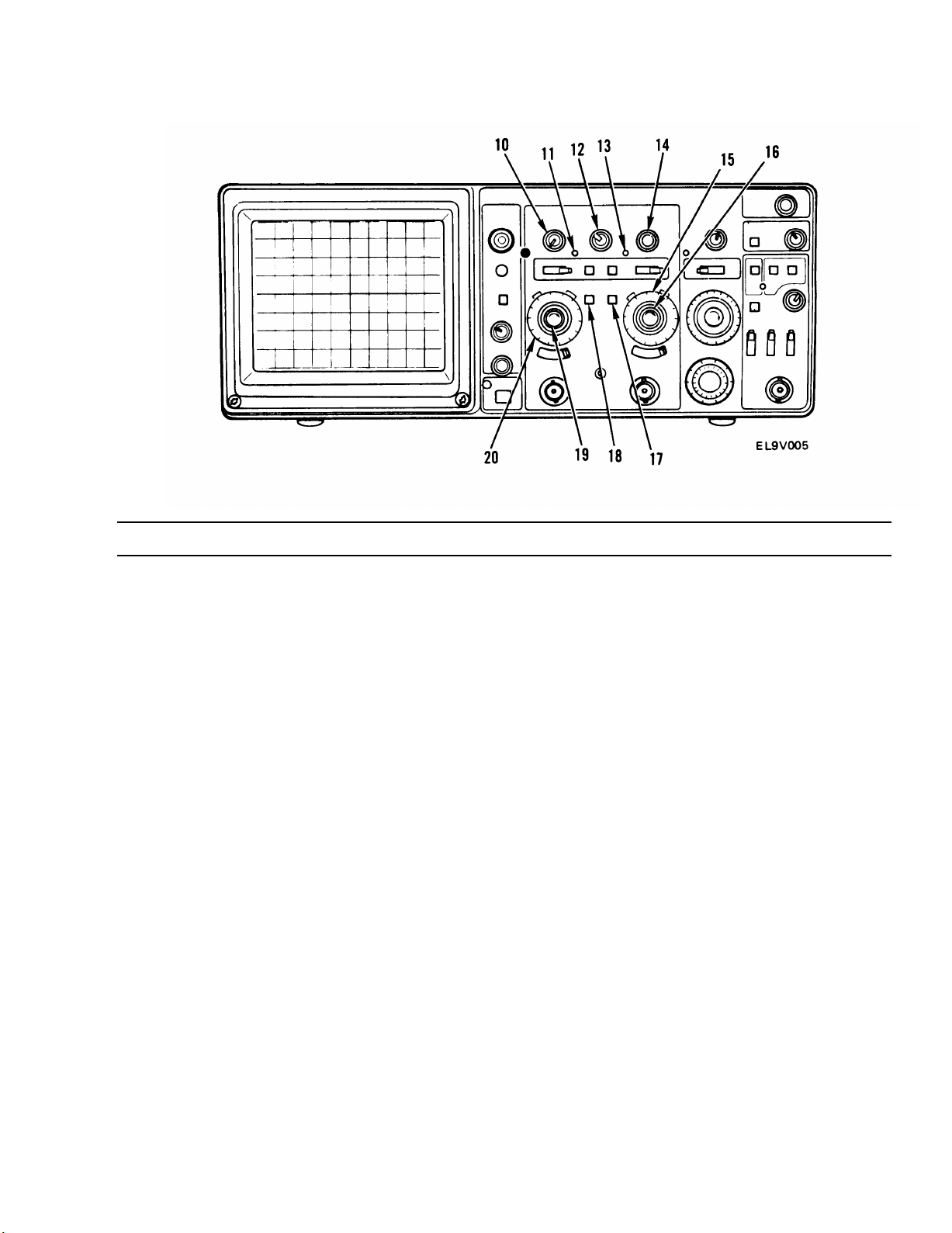

TM 11-6625-3135-12

Key

10

11

12

13

14

15

16

17

18

Control Or Indicator

POSITION Control

UNCAL Indicator

A/B SWP SEP Control

UNCAL Indicator

POSITION Control

CH 2 VOLTS/DIV

Switch

CH 2 VOLTS/DIV

Variable Control

BW LIMIT Switch

TRIG VIEW Switch

Function

Controls vertical position of channel 1 display

When illuminated, indicates channel 1 VOLTS/DIV control

not in calibrated position

Vertically positions B sweep trace with respect to A sweep

trace when HORIZONTAL ALT mode is selected

When illuminated, indicates channel 2 VOLTS/DIV control

not in calibrated position

Controls vertical position of channel 2 display

Used to select channel 2 vertical deflection factor

When rotated out of detent, provides variable, uncalibrated

deflection factors between calibrated settings of channel 2

VOLTS/DIV switch

When depressed, limits bandwidth of vertical amplifier and

A trigger system to approximately 20 MHz

While held in, sample of signal present in A trigger amplifier

displayed on crt

19

CH 1 VOLTS/DIV

Variable Control

20

CH 1 VOLTS/DIV

Switch

When rotated out of detent, provides variable, uncalibrated

deflection factors between calibrated settings of channel 1

VOLTS/DIV switch

Used to select channel 1 vertical deflection factor

2-3

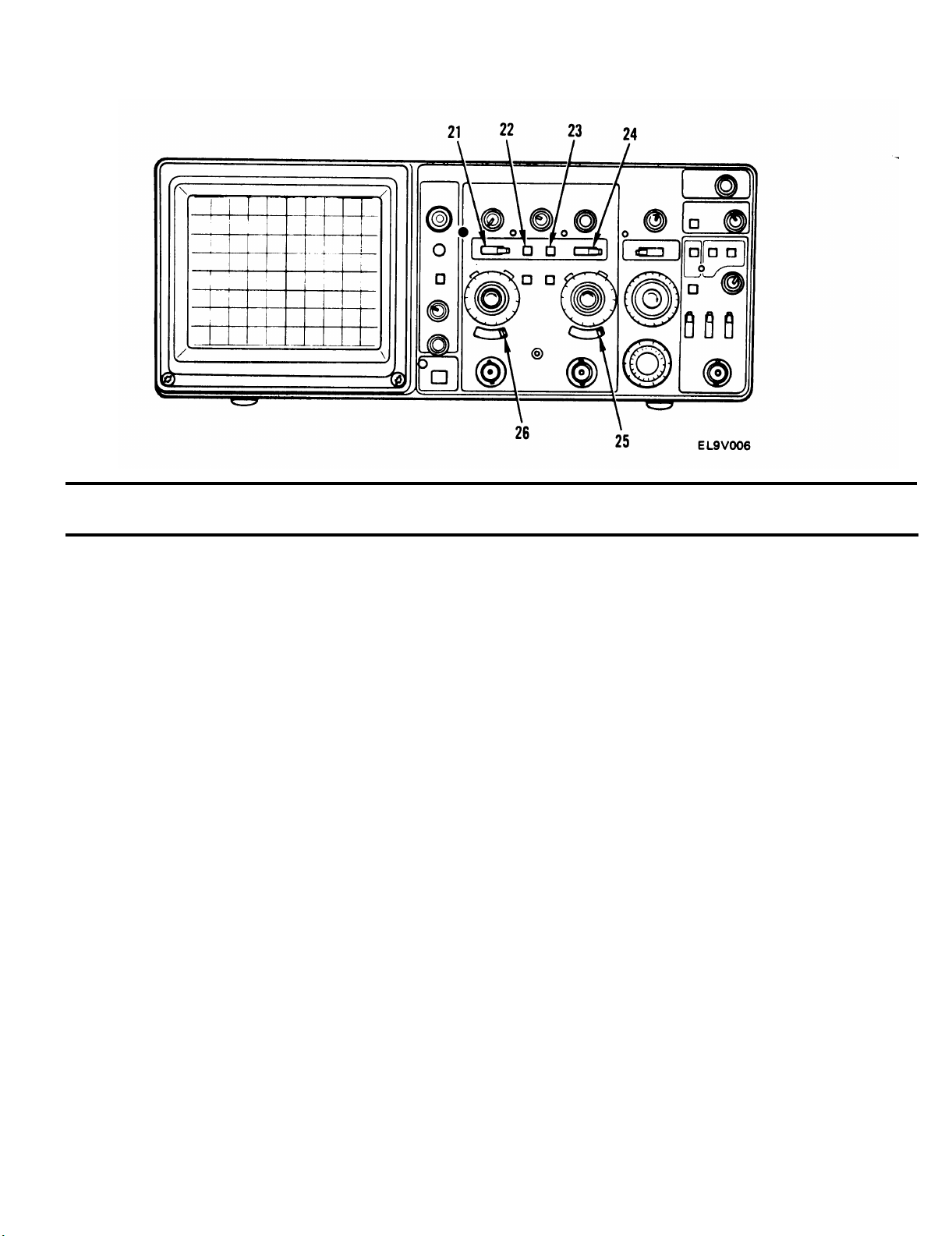

Page 23

TM 11-6625-3135-12

Key

21

Control Or Indicator

VERTICAL MODE

CH 1/BOTH/CH

Switch

22 CH 1 TRIGGER

SOURCE Switch

22-23 COMPOSITE

23

CH 2 TRIGGER

SOURCE Switch

VERTICAL MODE

24

ADD/ALT/CHOP

Switch

Function

When set to CH 1, selects only channel 1 input signal

2

for display. When set to BOTH, selects both channel 1

and channel 2 input signals for display. When set to CH 2,

selects only channel 2 input signal for display

When depressed, selects signal applied to CH 1 OR X

INPUT connector as trigger source

When CH 1 and CH 2 switches are either both depressed or

both released, composite trigger source is selected, Trigger

source is then determined by signals selected for display by

the VERTICAL MODE switches

When depressed, selects signal applied to CH 2 OR Y

INPUT connector as trigger source

When set to ADD, displays algebraic sum of channel 1

and channel 2 input signals. When set to ALT, displays

channel 1 and channel 2 input signals alternately at end of

each trace. When set to CHOP, displays channel 1 and

channel 2 input signals alternately during sweep time

2-4

25

26

AC/GND/DC Switch

AC/GND/DC Switch

Three-position switch to select method of coupling input

signal to channel 2 deflection system. It also establishes DC

ground reference line on crt.

Three-position switch to select method of coupling input

signal to channel 1 deflection system. It also establishes DC

ground reference line on crt.

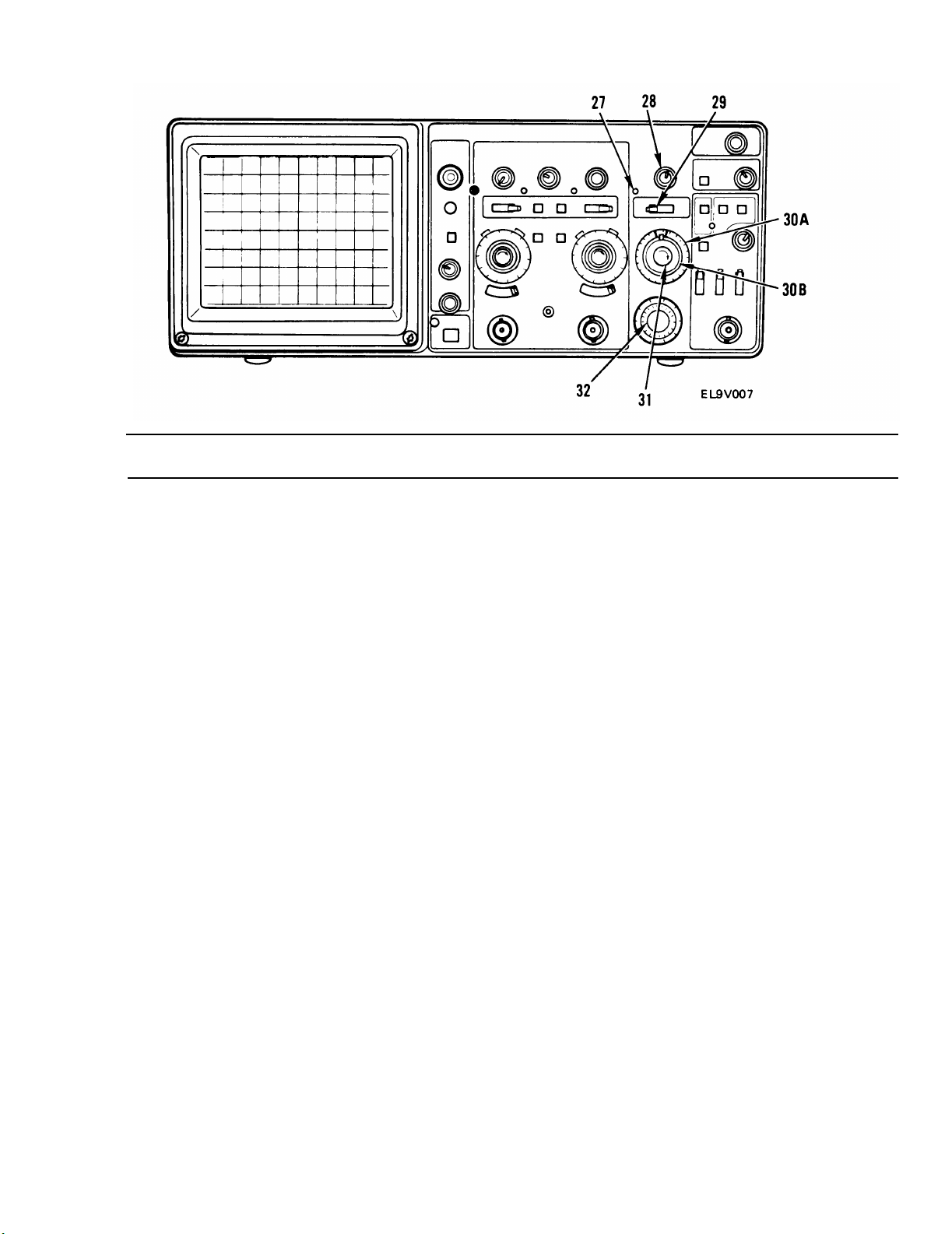

Page 24

TM 11-6625-3135-12

Key

27

28

29

30A

30B

Control Or Indicator

UNCAL Indicator

POSITION Control

HORIZONTAL MODE

A/ALT/B Switch

A SEC/DIV Switch

B SEC/DIV Switch

Function

When illuminated, indicates SEC/DIV variable control is

not in calibrated position

Moves A sweep and B sweep displays horizontally and

horizontally positions X-axis in X-Y mode of operation

Determines mode of operation for horizontal deflection

system. When set to A, horizontal deflection is provided by

A sweep generator. When set to ALT, display alternates

between A sweep and B delayed sweep. When set to B,

horizontal deflection is provided by B sweep generator

Used to select sweep speeds for A and B sweep generators in

a 1, 2, 5 sequence. To lock A and B sweeps together, pull the

B SEC/DIV switch out and align the pointer on the B

SEC/DIV switch between the two markers on the A

SEC/DIV switch, then release the switch. If the two

switches are not locked together, B sweep can be delayed.

Setting A SEC/DIV switch to X-Y locks the A sweep in

horizontal mode.

31

SEC/DIV Variable

Control and X10

Multiplier Switch

B DELAY TIME

32

POSITION Control

Provides continuously variable, uncalibrated sweep speeds.

Pulling control out actuates X 10 magnifier switch, which

expands crt display by a factor of 10

Selects amount of delay time between start of A sweep and

start of B sweep. Delay time is variable from 0.5 to 10 times

A SEC/DIV switch setting

2-5

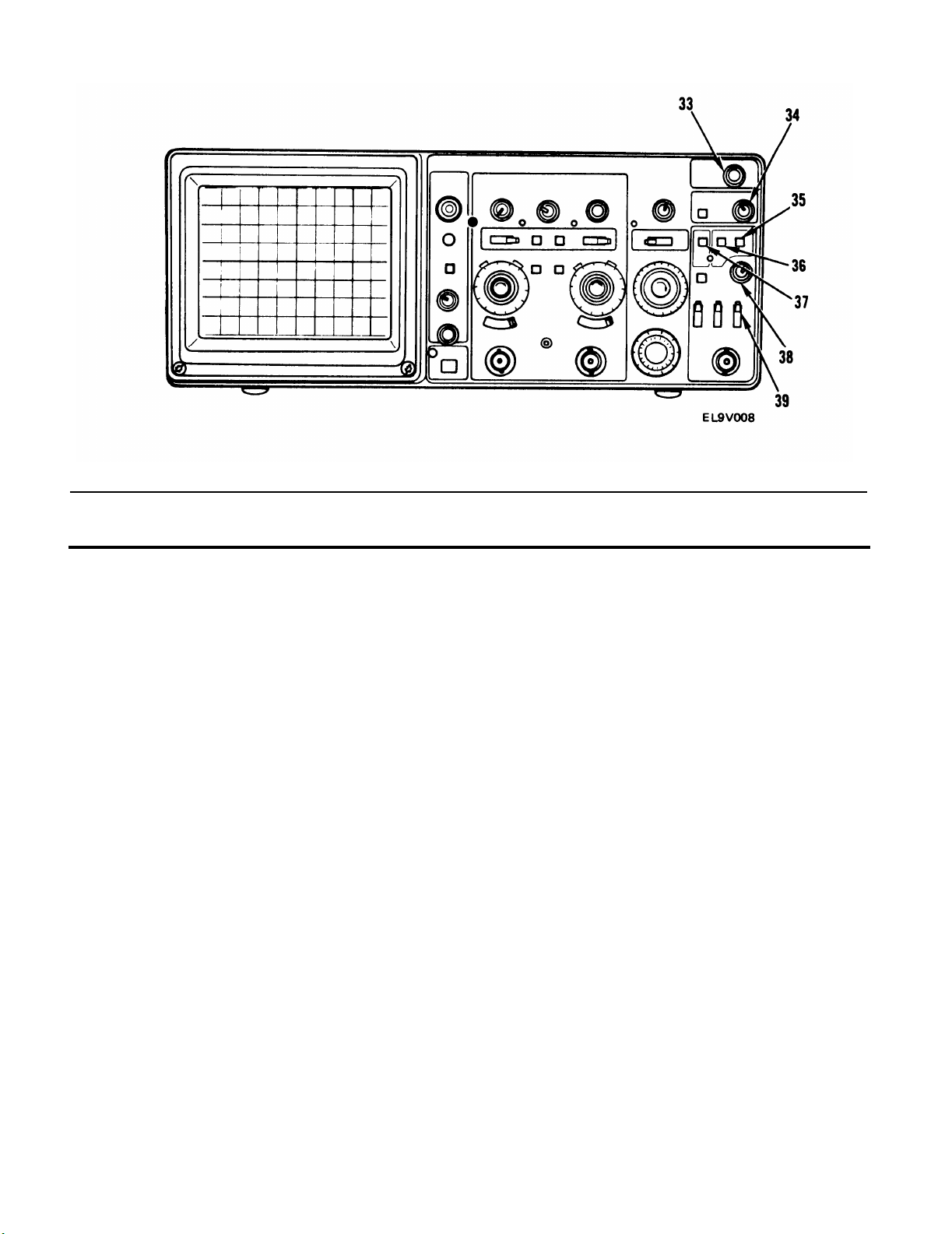

Page 25

TM 11-6625-3135-12

Key

33

34

35

35-36

36

37

Control Or Indicator

VAR HOLDOFF

Control

B TRIGGER LEVEL

Control

A TRIGGER NORM

Switch

TV FIELD

A TRIGGER

P-P AUTO/TV LINE

Switch

A TRIGGER SGL SWP

RESET Switch

Function

Provides continuous control of hold off time between sweeps

and increases hold off time by at least a factor of 10

Selects amplitude point

on trigger signal at which B sweep is

triggered

When depressed,

sweep

is initiated when adequate trigger

signal is applied

Depressing both P-P

permits triggering on

AUTO and NORM pushbuttons

television field signals

Permits triggering on waveforms and television lines having

repetition rate of at least 20 Hz. Sweep free-runs in absence

of adequate trigger signal

When momentarily depressed, arms A trigger circuit for

single-sweep display

2-6

A TRIGGER LEVEL

38

Control

39

A EXT

COUPLING

Switch

Selects amplitude point on trigger signal at which A sweep is

triggered

Three-position switch that determines method used to

couple external signals from EXT INPUT connector to A

trigger circuit

Page 26

TM11-6625-3135-12

Key

40

Control Or Indicator

B TRIGGER SLOPE

Switch

TRIG’D/READY

41

Indicator

42 A TRIGGER SLOPE

Switch

43

A SOURCE Switch

44 A TRIG BW Switch

Function

Selects slope of signal that triggers B channel sweep

Illuminates when either P-P AUTO or NORM trigger mode

is selected

Selects slope of signal that triggers A channel sweep

Three-position switch that determines source of trigger

signal coupled to input of A trigger circuit. When set to

INT, permits triggering on signal applied to CH 1 OR X

connector or CH 2 OR Y connector. When set to LINE,

selects ac line voltage as trigger signal. When set to EXT,

permits triggering on signals applied to EXT INPUT

connector

Three-position switch that selects trigger bandpass

frequencies for A trigger circuit. When set to FULL, allows

all frequency components to pass. When set to HF REJ,

attenuates all trigger signals above approximately 40 kHz.

When set to LF REJ, attenuates all trigger signals below

approximately 40 kHz

2-7

Page 27

TM 11-6625-3135-12

Section Il. OPERATOR PREVENTIVE MAINTENANCE CHECKS

AND SERVICES (PMCS)

2-1. GENERAL

Operator Preventive Maintenance Checks and Services (PMCS) is the required inspection and care

of your equipment necessary to keep it in good operating condition.

a. Before You Operate.

Always keep in mind the CAUTIONS and WARNINGS. Perform your

before - PMCS.

b. While YOU Operate. Always keep in mind the CAUTIONS and WARNINGS. Perform your

during - PMCS.

c. After Y

OU Operate. Be sure to perform your after-operation PMCS.

d. If Your Equipment Falls to Operate. Troubleshoot with proper equipment. Report any

deficiencies using the proper forms. See DA PAM 738-750.

2-2. PMCS TABLE

The PMCS are shown in table 2-1.

a. Item Number Column. The numbers appearing in this column are in the order the work

should be performed. The numbers are keyed to fig. 2-1 to identify work locations. This column shall

also be used as a source of item numbers for the TM Number Column on DA Form 2404 (Equipment

Inspection and Maintenance Worksheet) in recording results of PMCS.

Interval Column.

b.

This column indicates whether PMCS are performed before operation (B),

during operation (D), after operation (A), or weekly (W).

c.

Item to be Inspected Column.

Procedures Column.

d.

This column contains a brief description of the check or service to be

This column identifies the item to be inspected.

performed and step-by-step procedures.

e.

Equipment is Not Ready If Column.

equipment from being ready for operation.

2-8

This column identifies the condition that prevents the

Page 28

TM 11-6625-3135-12

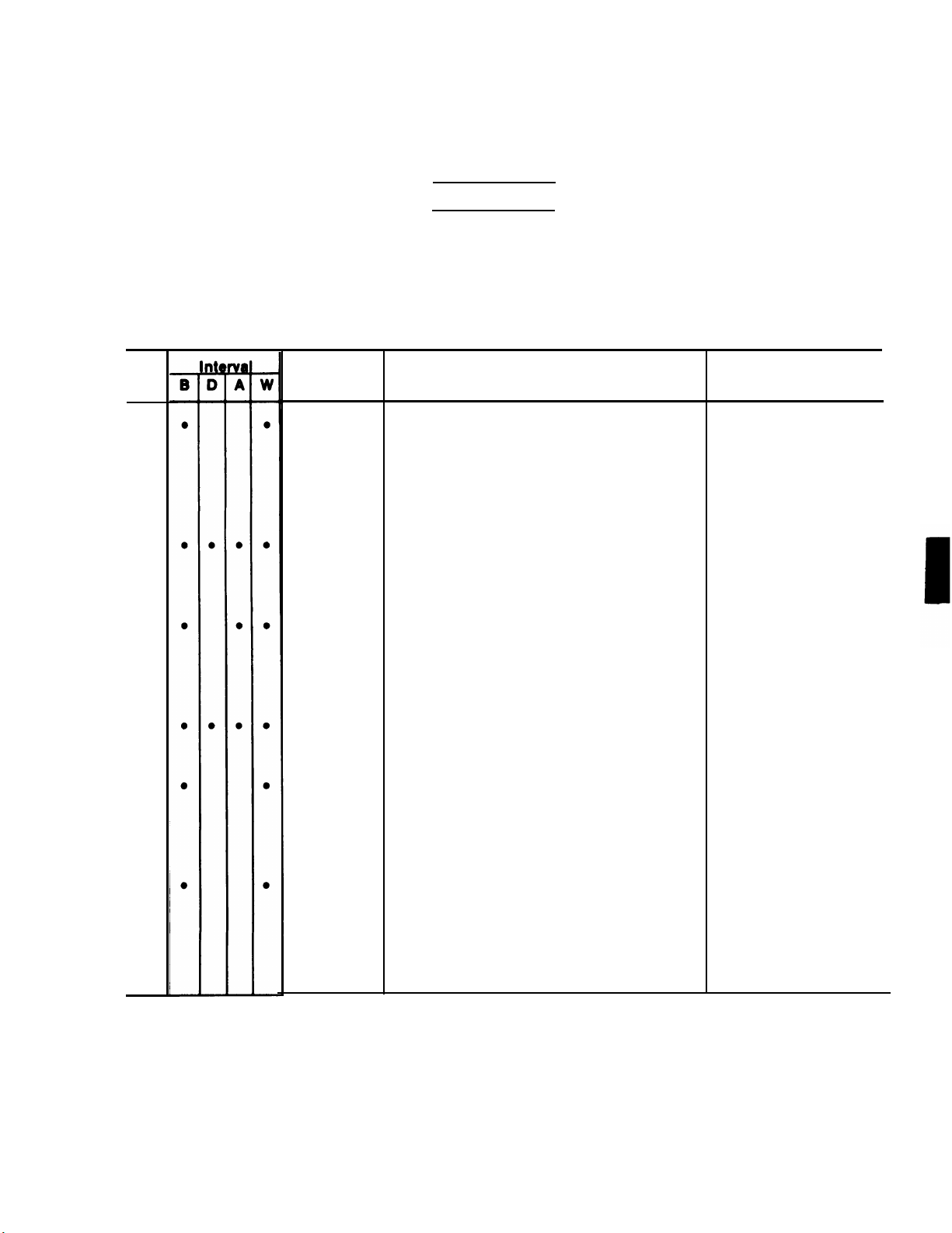

Table 2-1. Operator Preventive Maintenance Checks and Services

WARNING

High voltage is used in the operation of this equipment. Death on

contact may result if you fail to observe safety precautions. Learn where

there may be dangerous voltages present.

Item

No.

1

2

3

4

B = Before

Item to be

Inspected

Cabinet

Front

Panel, and

Viewing

‘Hood

Front

Panel

Controls

Connectors

Carrying

Handle

D = During

A = After

Procedure

Inspect case, viewing hood, cover,

and front panel for cracks, scratches,

deformation, loose or missing

hardware or gaskets.

Inspect for missing, loose, or

damaged knobs, buttons, and

controls.

Inspect for broken shells, cracked

insulation, deformed contacts,

and dirt in connector.

Inspect for correct operation.

W = Weekly

Equipment is

Not Ready if:

Cabinet or front

panel is badly

damaged.

Knobs, buttons, or

controls missing or

damaged.

Connector shell is

broken, insulation is

cracked, or contacts

deformed.

5

AC Power

Cord

Inspect for frayed, broken, or

abraded insulation, broken wires,

Cord shows any

signs of damage.

or damaged connectors. Replace

if damaged.

6

Probe

Package

Inspect for missing items, bent

pins, broken or frayed cables, and

damaged connectors. Replace if

damaged.

Cables frayed or

broken, pins

broken, or

connectors

damaged.

2-9

Page 29

TM 11-6625-3135-12

2-10

Figure 2-1. Oscilloscope PMCS Location Diagram

Page 30

TM 11-6625-3135-12

Section Ill. OPERATION UNDER USUAL CONDITIONS

2-3. OPERATING PROCEDURES

After becoming familiar with the capabilities of the oscilloscope, an operator can easily develop

convenient methods for making measurements. The following paragraphs provide recommended

methods for making basic measurements, such as probe compensation, voltage measurement,

non-delayed time measurement, obtaining television displays, delayed sweep magnification, and

delayed sweep time measurements.

a. Obtaining Baseline Trace.

1.

Set POWER ON/ OFF switch (1) to OFF and plug power cord into ac source.

2.

Preset front panel controls as shown in table 2-2.

3.

Depress POWER ON/ OFF switch (1) to ON.

4.

Adjust A INTENSITY control (2) to desired brightness of display.

Adjust channel 1 vertical POSITION control (3) to center trace vertically on screen.

5.

Adjust horizontal POSITION control (4) to center trace horizontally on screen.

6.

2-11

Page 31

TM 11-6625-3135-12

Table 2-2. Controls, Preset Positions

Control

Display

A AND B INTENSITY

FOCUS

Vertical (Both Channels)

POSITION

POSITION and INVERT (Channel 2 only)

VERTICAL MODE CH 1/BOTH/CH 2

TRIGGER SOURCE

BW LIMIT

VOLTS/DIV Switch

VOLTS/DIV Variable Control

AC/GND/DC

Horizontal

A/B SWP SEP

POSITION

MODE

A AND B SEC/DIV Switch

SEC/DIV Variable Control

X10 Multiplier

B DELAY TIME POSITION

Position

Fully counterclockwise

Midrange

Midrange

Midrange and pushed in

CH 1

COMPOSITE (both in or both out)

Off (button out)

50 mV

CAL detent

AC

Midrange

Midrange

A

0.5 ms

CAL detent

Off (knob in)

Fully counterclockwise

Trigger

B

SLOPE

LEVEL

A Trigger

VAR HOLDOFF

TRIGGER MODE P-P AUTO/TV LINE

SLOPE

LEVEL

A TRIG BW

A SOURCE

A EXT COUPLING

out

Fully clockwise

NORM

In

out

Midrange

FULL

INT

AC

2-12

Page 32

b. Probe Compensation.

Misadjustment of probe compensation is a common source of measurement error. To ensure optimum measurement accuracy, always

compensate the oscilloscope probes before making measurements.

TM 11-6625-3135-12

NOTE

1.

Obtain baseline trace as described in para 2-3a.

2.

Connect one 10X probe to CH 1 OR X connector (1) and one 10X probe to CH 2 OR Y

connector (2).

Set both CH 1 and CH 2 VOLTS/DIV switches (3 and 4) to 0.1 10X PROBE.

3.

4.

Set both AC/GND/DC switches (5 and 6) to DC.

5.

Set VERTICAL MODE CH 1/BOTH/CH 2 switch (7) to CH 1.

Insert tip of channel 1 probe into AMP CAL connector (8) and adjust CH 1 VOLTS/DIV

6.

variable control (9) to obtain display amplitude of five vertical divisions.

Set A SEC/DIV switch (10) to display 5 cycles of AMP CAL signal.

7.

Using channel 1 vertical POSITION control (11), vertically center display on crt screen.

8.

9.

Using low-reactance alignment tool, adjust low-frequency compensation control on probe

compensation box to obtain best wave orm with flattest top.

2-13

Page 33

TM 11-6625-3135-12

10. Set VERTICAL MODE CH 1/BOTH/CH 2 switch (7) to CH2.

11. Insert tip of channel 2 probe into AMP CAL connector and adjust CH 2 VOLTS/DIV

variable control (12) to obtain display amplitude of five vertical divisions.

12. Set A SEC/DIV switch (10) to display five cycles of AMP CAL signal.

13. Using channel 2 vertical POSITION control (13), vertically center disp

14. Using low-reactance alignment tool, adjust low-frequency compensation

compensation box to obtain best waveform with flattest top.

15. Probes are now properly compensated.

2-14

lay on crt screen.

control on probe

Page 34

TM11-6625-3135-12

C. Peak-To-Peak Voltage Measurements.

1.

Obtain baseline trace as described in para 2-3a.

2. Apply ac signal to either CH 1 OR X connector (1) or CH 2 OR Y connector (2) and set

VERTICAL MODE CH 1/BOTH/CH 2 switch (3) to display channel used.

3.

Set CH 1 or CH 2 VOLTS/DIV variable control (4 or 5) for appropriate channel to CAL

detent position, and set appropriate VOLTS/DIV switch (6 or 7) to display about five

vertical divisions of waveform.

4.

Adjust A TRIGGER LEVEL control (8) to obtain stable display.

5.

Set A SEC/DIV switch (9) to position that allows several cycles of waveform to be

displayed.

6. Rotate appropriate vertical POSITION control (10 or 11) until waveform negative peak

coincides with one horizontal graticule line.

Rotate horizontal POSITION control (12) until one positive peak coincides with center

7.

vertical graticule line.

2-15

Page 35

TM 11-6625-3135-12

Measure deflection from negative point A to positive point B.

8.

If amplitude measurement is critical or trace is thick because of noise or

hum on the signal, a more accurate value can be obtained by measuring

from the top of the peak to the top of the valley. This eliminates trace

thickness from the measurement.

NOTE

9.

Calculate the voltage, using the following formula:

vertical

volts (p-p) = deflection

(divisions)

VOLTS/DIV switch setting indicated

x 1X (or 10X PROBE when 10X probe is

used)

EXAMPLE: Measured peak-to-peak vertical deflection is 4.6 divisions, a 10X attenuator

probe is used and VOLTS/DIV switch is set to 5 at the 10X PROBE setting. Substituting

the given values:

volts (p-p) = 4.6 div x 5 volts/div = 23 volts

2-16

Page 36

d. Instantaneous Voltage Measurement.

1.

Obtain baseline trace as described in para 2-3a.

This procedure can be used to measure instantaneous voltage

for any input waveform. The example shown here is for a

square wave.

2.

Apply signal

VERTICAL

to either CH 1 OR X connector (1) or CH 2 OR Y connector (2) and set

MODE CH 1 /BOTH/CH 2 switch (3) to display channel used.

TM 11-6625-3135-12

NOTE

Set CH 1 or CH 2 VOLTS/DIV variable control (4 or 5) to CAL detent position, and set

3.

appropriate VOLTS/DIV switch (6 or 7) for desired deflection.

4.

Set AC/GND/DC switch (8 or 9) to GND.

Rotate channel 1 or channel 2 vertical POSITION control (10 or 11) until baseline trace

5.

falls on center horizontal graticule line. This establishes ground reference location.

Set AC/GND/DC switch (8 or 9) to DC. Points on waveform above ground reference are

6.

positive; those below are negative.

If necessary, repeat step 5 using different reference line which allows waveform obtained

7.

in step 6 to be displayed on crt screen.

2-17

Page 37

TM 11-6625-3135-12

If using channel 2, ensure that channel 2 vertical POSITION control (11) is pushed in.

8.

Adjust A TRIGGER LEVEL control (12) to obtain stable display.

9.

10.

Set A SEC/DIV switch (13) to position that allows several cycles of waveform to be

displayed.

Count number of divisions of vertical deflection between ground reference line and point

11.

on waveform at which voltage level is to be determined.

Calculate voltage using formula:

12.

VOLTS/DIV switch setting indicated

by 1X (or 10X PROBE when 10X probe

is used)

instantaneous =

voltage

Vertical

deflection x polarity x

(divisions) (+ or --)

EXAMPLE: Vertical deflection from reference line is 4.6 divisions. The waveform point is

above the reference line, a 10X attenuator probe is used, and VOLTS/ DIV switch is set to 2

at the 10X PROBE position. Substituting given values:

instantaneous voltage

= 4.6 div x (+1) x 2 volts/div = +9.2 volts

2-18

Page 38

e. Algebraic Addition.

1.

Obtain baseline trace as described in para 2-3a.

2.

Set VERTICAL MODE CH 1/BOTH/CH 2 switch (1) to BOTH.

3.

Set VERTICAL MODE ALT/ADD/CHOP switch (2) to ADD.

TM 11-6625-3135-12

CAUTION

Do not exceed maximum safe input voltage rating (para 1-13).

NOTES

Signals that

settings may

To obtain sim

switches must

4.

Connect one signal to CH 1 OR X connector (3) and one signal to CH 2 OR Y connector (4).

exceed about eight times the

distort the display.

lar response from each

be set to the same position.

VOLTS/DIV switch

, both AC/GND/DC

2-19

Page 39

TM 11-6625-3135-12

5.

Set VERTICAL MODE CH 1/BOTH/CH 2 switch (1) to CH 1 and adjust channel 1

vertical POSITION control (5) to center display vertically on crt screen.

6.

Set VERTICAL MODE CH 1/BOTH CH 2 switch (1) to CH 2 and adjust channel 2

vertical POSITION control (6) to center display vertically on crt screen.

7.

Set VERTICAL MODE CH 1/BOTH/CH 2 switch (1) to BOTH.

If the channel 2 vertical POSITION control is pushed in, the

resultant waveform is the sum of the two applied signals.

If the channel 2 vertical POSITION control is pulled out, the

resultant waveform is the difference between the two signals.

NOTES

2-20

Page 40

f. Common-Mode Rejection.

1.

Obtain baseline trace as described in para 2-3a.

This procedure can be used to measure instantaneous voltage for any

input waveform. The example shown here is for a square wave.

2.

Connect signal containing unwanted line-frequency components to CH 1 OR X connector (1).

Connect line-frequency signal to CH 2 OR Y connector (2).

3.

For maximum cancellation, the signal connected to channel 2 must be

in phase with the unwanted line-frequency component connected to

channel 1.

TM 11-6625-3135-12

NOTE

NOTE

4.

5.

6.

VERTICAL MODE CH 1/BOTH/CH 2 switch (3) to BOTH.

Set

VERTICAL MODE ADD/ALT/CHOP switch (4) to ALT.

Set

both CH 1 and CH 2 VOLTS/DIV switches (5 and 6) to produce displays four or five

Set

divisions in amplitude.

7.

Adjust either CH 1 or CH 2 VOLTS/DIV switch (5 or 6) and appropriate VOLTS/DIV

variable control (7 or 8) so that both displays are of equal amplitude.

2-21

Page 41

TM 11-6625-3135-12

Adjust CH 2 VOLTS/DIV switch (6) and CH 2 VOLTS/DIV variable control (8) so that

8.

channel 2 display amplitude is approximately same amplitude as undesired portion of

channel 1 display.

9.

Set VERTICAL MODE ADD/ALT/CHOP switch (4) to ADD.

10.

Pull out channel 2 vertical POSITION control (9) to invert signal.

11.

Slightly readjust CH 2 VOLTS/DIV variable control (8) for maximum cancellation of

unwanted signal.

2-22

Page 42

g. Amplitude Comparison (Ratio).

Obtain baseline trace as described in para 2-3a.

1.

TM 11-6625-3135-12

2.

Connect known

connector (2).

Set VERTICAL MODE CH 1/BOTH/CH 2 switch (3) to channel to which reference

3.

signal is connected.

reference signal to either CH 1 OR X connector (1) or CH 2 OR Y

4.

Adjust CH 1 or CH 2 VOLTS/DIV switch (4 or 5) and appropriate VOLTS/DIV variable

control (6 or 7) for display amplitude of five vertical divisions.

5.

Disconnect reference signal connected in step 2 and connect unknown signal to same

connector.

6.

Rotate channel 1 or 2 vertical POSITION control (8 or 9) until bottom edge of waveform

0%

just touches

Rotate horizontal POSITION control (10) until topmost feature of waveform crosses

7.

center vertical graticule line.

line on crt.

2-23

Page 43

TM 11-6625-3135-12

8.

Read percent ratio directly from graduations of center vertical graticule line, referring to

0% and 100% marks on left edge of graticule. (One minor division equals 4% for fivedivision display.)

2-24

Page 44

h. Time Duration Measurement.

1.

Obtain baseline trace as described in para 2-3a.

This procedure can be used to measure instantaneous voltage for any

input waveform. The example shown here is for a square wave.

2.

Connect signal to either CH 1 OR X connector (1) or CH 2 OR Y connector (2).

3.

Set VERTICAL MODE CH 1/BOTH/CH 2 switch (3) to appropriate channel.

TM 11-6625-3135-12

NOTE

4.

Adjust A TRIGGER LEVEL control (4) to obtain stable display.

5.

Set A and B SEC/DIV variable control (5) to CAL detent, and set A SEC/DIV switch (6)

to display one complete cycle of waveform.

Rotate channel 1 or channel 2 vertical POSITION control (7 or 8) until time measurement

6.

points fall on center horizontal graticule.

7.

Count horizontal divisions between time measurement points.

2-25

Page 45

TM 11-6625-3135-12

8. Calculate time duration using formula:

time

duration =

horizontal

distance x

(division)

magnification factor

A SEC/DIV

switch

setting

EXAMPLE: The distance between time measurement points is 8.3 divisions. The A

SEC/DIV switch is set to 2 ms per division, and the X 10 multiplier is off. Substituting

given values:

time duration = 8.3 div x2 ms/div

16.6 ms

=

1

2-26

Page 46

i. Frequency Measurement.

Measure time duration of one cycle of waveform as described in paragraph 2-3h.

1.

2.

Calculate reciprocal of time duration determined in step 2-3h(8) to determine frequency of

waveform.

EXAMPLE: The signal obtained has a time duration of 16.6 ms. Substituting given values:

TM 11~6625-3135-12

j. Rise

1.

2.

3.

4.

5.

frequency =

1=1

time duration

q 60 Hz

16.6 ms

Time Measurement.

Obtain baseline trace as described in paragraph 2-3a.

Set BW LIMIT switch (1) to off (pushbutton out).

Connect signal to either CH 1 OR X connector (2) or CH 2 OR Y connector (3).

Set VERTICAL MODE CH 1/BOTH/CH 2 switch (4) to appropriate channel.

Set appropriate CH 1 or CH 2 VOLTS/DIV switch (5 or 6) and VOLTS/DIV variable

control (7 or 8) for an exact five-division display.

2-27

Page 47

TM 11-6625-3135-12

6. Rotate channel 1 or channel 2 vertical POSITION control (9 or 10) until zero reference of

0%

waveform touches

7. Rotate horizontal POSITION control (11) until 10% point on waveform intersects second

vertical graticule line.

graticule and top of waveform touches 100% graticule,

8. Determine horizontal distance between 10% and 90% points (points A and B) and calculate

time duration using formula:

horizontal

distance x

rise time =

EXAMPLE: The horizontal distance between the 10% and 90% points is five divisions,

The A SEC/DIV switch setting is 1 us and the magnification factor is 1. Substituting the

given values:

rise time =

(division)

magnification factor

5 div x 1 us/div

A SEC/DIV

switch

setting

= 5 us

1

2-28

Page 48

k. Rise Time Measurement in Delayed-Sweep Mode.

1.

Obtain baseline trace as described in para 2-3a.

2.

Connect signal to either CH 1 OR X connector (1) or CH 2 OR Y connector (2).

Set VERTICAL MODE CH 1 /BOTH/CH 2 switch (3) to selected channel.

3.

4.

Set appropriate CH 1 or CH 2 VOLTS/DIV switch (4 or 5) and VOLTS, DIV variable

control (6 or 7) to provide display amplitude of exactly five divisions.

Rotate appropriate channel 1 or 2 vertical POSITION control (8 or 9) until zero reference

5.

line of waveform touches 0% graticule line and top of waveform touches 100% graticule

line.

Set SEC/DIV variable control (10) to CAL detent position and set A SEC/DIV switch

6.

(11) so one rise time of interest is displayed.

7.

Set HORIZONTAL MODE switch (12) to ALT.

TM 11-6625-3135-12

8.

Adjust B DELAY TIME POSITION control (13) to intensify rise time of interest on A

trace.

2-29

Page 49

TM 11-6625-3135-12

9.

Set B SEC/DIV switch (11) so portion of A trace being measured is spread as much as

possible on B sweep.

10.

Set HORIZONTAL MODE switch (12) to B.

11.

Adjust B DELAY TIME POSITION control (13) until display intersects 10% point at

center vertical graticule line. Record B DELAY TIME POSITION control dial reading.

THE 10% POINT ON THE WAVEFORM INTERSECTS

THE CENTER VERTICAL GRATICULE LINE.

Adjust B DELAY TIME POSITION control (13) until display intersects the 90% point at

12.

THE

90%

POINT ON THE WAVEFORM INTERSECTS

THE CENTER VERTICAL GRATICULE LINE.

EL9V043

center vertical graticule line. Record B DELAY TIME POSITION control dial reading.

Calculate rise time using the formula:

13.

time

second

first

difference = dial – dial x

(duration)

setting

setting setting

A SEC/DIV

switch

EXAMPLE: A SEC/ DIV switch is set to 1 us per division, first B DELAY TIME

POSITION control is set to 2.50, and second B DELAY TIME POSITION control is set

to 7.50. Substituting given values:

rise time =(7.03 - 2.50)(1 us/div) = 5 us

\

/.

/

2-30

Page 50

1.

Phase Difference Measurement.

1.

Obtain baseline trace as described in para 2-3a.

2. Depress CH 1 TRIGGER SOURCE switch (1).

3.

Set

both

AC/GND/DC switches (2 and 3) to desired positions and ensure that both are set

to same position.

or

4. Using either probes

1 OR X connector

5.

Set both CH 1 and CH 2 VOLTS/DIV switches

6. Set VERTICAL MODE CH 1/BOTH/CH 2 switch (8) to BOTH.

7.

Set VERTICAL MODE ADD/ALT/CHOP switch (9) to either ALT or CHOP,

depending on frequency of input signals.

cables with equal time delays, connect known reference signal to CH

(4)

and comparison signal

to

(6

CH 2

and

OR

7)

for four- or five-division display.

TM 11-6625-3135-12

Y connector (5).

NOTE

The reference signal should precede the comparison signal in time.

8.

If two signals are opposite polarities, pull out channel 2 vertical POSITION control (10) to

invert channel 2 display.

2-31

Page 51

TM11-6625-3135-12

Adjust both CH 1 and CH 2 VOLTS/DIV variable controls (1 1 and 12) until two displays

9.

are equal in amplitude.

10.

Adjust A TRIGGER LEVEL control (13) for stable display.

Set A SEC/DIV switch (14) to sweep speed setting which provides display of one full cycle

11.

of reference signal.

Using horizontal POSITION control (15), center display.

12.

Adjust SEC/DIV variable control (16) until one reference signal cycle occupies exactly

13.

eight horizontal graticule divisions at 50% rise-time points. Each graticule division now

represents 45° and graticule calibration can be stated as 45° per division.

2-32

Determine horizontal difference between corresponding points on waveforms at common

14.

horizontal graticule line and calculate phase difference using formula:

horizontal

phase difference =

horizontal

difference x calibration

(divisions) (deg/div)

EXAMPLE: The horizontal difference is 0.6 division with a graticule calibration of 45° per

division. Substituting given values:

Phase difference = 0.6 div x 45° / div = 27°

Page 52

m.

Magnified B Sweep Runs After Delay.

Obtain baseline trace as described in para 2-3a.

1.

Connect signal to either CH 1 OR X connector (1) or CH 2 OR Y connector (2).

2.

Set VERTICAL MODE CH 1/BOTH/ CH 2 switch (3) to selected channel.

3.

TM 11-6625-3135-12

Set appropriate CH 1 or CH 2 VOLTS/DIV switch (4 or 5) to provide display amplitude of

4.

two or three divisions.

Set A SEC/DIV switch (6) to sweep speed setting which provides display of at least one

5.

complete waveform cycle.

Set HORIZONTAL MODE switch (7) to ALT.

6.

Adjust B INTENSITY control (8) to display B trace.

7.Adjust appropriate vertical POSITION control (9 or 10) and A/BSWP SEP control (11)

8.

to display A trace above B trace.

Adjust B DELAY TIME POSITION control ( 12) to position start of intensified zone to

9.

portion of display to be magnified.

10.

Set B SEC/DIV switch (6) to setting which intensifies full portion of A trace to be

magnified. Intensified zone is displayed as B trace.

2-33

Page 53

TM 11-6625-3135-12

11. Calculate apparent sweep magnification using formula:

apparent

delayed sweep =

magnification

A SEC/DIV switch setting

B SEC/DIV switch setting

EXAMPLE: Determine the apparent delayed sweep magnification of a display with an A

SEC/DIV switch setting of 0.1 ms per division and a B SEC/DIV switch setting of 1 us per

division. Substituting the given values:

apparent

delayed sweep = — =

magnification

1 x 101 x 10-

4

102 = 100

6

2-34

Page 54

n. Pulse Jitter Time Measurement.

1.

Perform Magnified Sweep Runs After Delay, para 2-3m, steps 1 through 10.

Determine number of divisions difference between points C and D and calculate pulse

2.

jitter time using formula:

TM 11-6625-3135-12

pulse jitter time =

horizontal difference (divisions) x B SEC/ DIV switch setting

2-35

Page 55

TM 11-6625-3135-12

p. Triggered Magnified Sweep Measurement.

1.

Perform Magnified Sweep Runs After Delay, para 2-3m, steps 1 through 10.

NOTE

The intensified zone seen in the ALT HORIZONTAL MODE display

will move from trigger point to trigger point as B DELAY TIME

POSITION CONTROL is rotated.

2. Adjust B TRIGGER LEVEL control (1) to stabilize intensified portion of A trace.

3. Calculate apparent magnification factor using formula:

apparent

magnification =

factor

A SEC/DIV switch setting

B SEC/DIV switch setting

EXAMPLE: Determine apparent magnification factor of a display with an A SEC/DIV

switch setting of 0.1 ms per division and a B SEC/DIV switch setting of 1 us per division.

Substituting given values:

apparent

1 x 10

magnification = — =

factor

1 x 10

-4

-6

10

2

= 100

2-36

Page 56

TM 11-6625-3135-12

q. Time Difference Measurement on

Obtain baseline trace as described in para 2-3a.

1.

2. Connect signal to either CH 1 OR X connector (1) or CH 2 OR Y connector (2).

Set VERTICAL MODE CH 1/ BOTH/ CH 2 switch (3) to selected

3.

5)

to provide display amplitude of

4.

Set appropriate CH 1 or CH 2 VOLTS/ DIV switch (4

or

two or three divisions.

channel.

2-37

Page 57

TM 11-6625-3135-12

5.

Ensure that SEC/DIV variable control (6) is in CAL detent position and set A SEC/DIV

Switch (7) to sweep speed setting that displays measurement points on waveform.

Set HORIZONTAL MODE switch (8) to ALT.

6.

7.

Adjust B INTENSITY control (9) to display trace.

Adjust appropriate channel 1 or 2 vertical POSITION control (10 or 11) and A/B SWP

8.

SEP control ( 12) to display A trace above B trace.

9.

Set B SEC/DIV control (7) to fastest sweep speed that provides visible

intensified zone.

10.

Adjust B DELAY TIME POSITION control (13) to move intensified zone to leading edge

of first point of interest on A trace; then fine adjust until selected portion on B trace is

centered on any vertical graticule line. Record B DELAY POSITION control reading.

Adjust B DELAY TIME POSITION control clockwise to move intensified zone to leading

11.

edge of second point of interest on A trace, then fine adjust until rising portion on B trace is

centered at same vertical graticule used in step (10). Record B DELAY TIME POSITION

control (13) dial reading.

2-38

12.

Calculate time difference between repetitive pules using formula

time

second

difference = dial (duration) setting

first

dial x

A SEC/DIV

switch

setting setting

EXAMPLE: A SEC/DIV switch is set to 0.2 ms per division, first B DELAY TIME

POSITION control is set to 1.20, and second B DELAY TIME POSITION control is set

to 9.53. Substituting given values:

Time difference = (9.53 - 1.20)(0.2 ms/div) = 1.666 ms

Change 1

Page 58

TM 11-6625-3135-12

r. Measurement of Time Difference Between Pulses on Time-Related Signals.

1.

Obtain baseline trace as described in para 2-3a.

2. Depress CH 1 TRIGGER SOURCE switch (1).

3. Set both AC/ GND/ DC switches (2 and 3) to desired position and ensure that both are set

to same position.

4. Using either probes or cables with equal time delays, connect known reference signal to CH

1 OR X connector (4) and comparison signal to CH 2 OR Y connector (5).

5. Set both CH 1 and CH 2 VOLTS/ DIV switches (6 and 7) for four- or five-division display.

Set VERTICAL MODE CH 1/BOTH/CH 2 switch (8) to BOTH.

6.

Set VERTICAL MODE ADD/ALT/ CHOP switch (9) to either ALT or CHOP,

7.

depending on frequency of input signals.

If two signals are opposite polarities, pull out channel 2 vertical POSITION control (10) to

8.

invert channel 2 display.

2-39

Page 59

TM 11-6625-3135-12

Adjust A TRIGGER LEVEL control (11) for stable display.

9.

10.

Set A SEC/DIV switch (12) to sweep speed setting which provides three or more divisions

of horizontal separation between reference points on two displays.

Rotate both vertical POSITION controls (10 and 13) to vertically center both displays.

11.

Determine horizontal distance between two signal reference points and calculate time

12.

difference using formula:

EXAMPLE: The A SEC/DIV switch is set to 50 us per division, the X10 magnifier is on

(button out), and horizontal difference between signal measurement points is 4.5 divisions.

Substituting the given values:

A SEC/DIV horizontal

switch setting x difference (divisions)

time difference =

magnification factor

time difference =

50 us/div x 4.5 div = 22.5 us

10

2-40

Page 60

TM 11-6625-3135-12

S. Time Difference Measurement Between Two Pulses on Two Time-Related Signals in

Delayed Sweep Mode.

1.

Obtain baseline trace as described in para 2-3a.

2.

Depress CH 1 TRIGGER SOURCE switch (l).

3.

Set VERTICAL MODE CH 1/BOTH/ CH 2 switch (2) to BOTH.

4.

Set VERTICAL MODE ADD/ ALT/ CHOP switch (3) to ALT.

Using either probes or cables with equal time delays, connect known reference signal to CH

5.

1 OR X connector (4) and comparison signal to CH 2 OR Y connector (5).

6.

Set both CH 1 and CH 2 VOLTS/DIV switches (6 and 7) for two- or three-division display.

7.

8.

9.

A SEC/DIV switch (8) to display measurement points within graticule area.

Set

HORIZONTAL MODE switch (9) to ALT.

Set

VERTICAL MODE CH 1/BOTH/CH 2 switch (2) to CH 1.

Set

2-41

Page 61

TM 11-66Z5-3135-12

10.

Adjust B INTENSITY control (10) to display trace.

11.

Adjust channel 1 vertical POSITION control (11) and A/B SWP SEP control (12) to

display A trace above B trace,

Rotate B DELAY TIME POSITION control ( 13) to move intensified zone to appropriate

12.

edge of comparison signal on A trace, then fine adjust until edge of reference signal on B

trace is centered at any convenient vertical graticule line. Record B DELAY TIME

POSITION control dial reading.

13.

Set VERTICAL MODE CH 1 /BOTH/CH 2 switch (2) to CH 2.

Adjust channel 2 vertical POSITION control (14) and A/B SWP SEP control (12) to

14,

display A trace above B trace.

Rotate B DELAY TIME POSITION control (13) to move intensified zone to appropriate .

15.

edge of comparison signal on A trace, then fine adjust until edge of reference signal on B

trace is centered on same vertical graticule line used in step 14. Do not move horizontal

POSITION control. Record B DELAY TIME POSITION dial reading.

242

Page 62

TM 11-6625-3135-12

16. Calculate time difference between reference signal and comparison

time

difference =

(duration) setting setting

EXAMPLE: A SEC/DIV switch is set to 50 us per division, first B DELAY TIME

POSITION control is set to 2.60, and second B DELAY TIME POSITION control is set

to 7.10. Substituting given values:

time difference = (7.10 - 2.60)(50 us/div) = 225 us

second

dial - dial x

first

A SEC/DIV

switch

setting

signal using formula:

2-43

Page 63

TM 11-6625-3135-12

Section IV. OPERATION UNDER UNUSUAL CONDITIONS

2-4. OPERATION IN UNUSUAL WEATHER

The oscilloscope was designed as a bench-type instrument to be used in a controlled environment. It

does not have a weatherproof or waterproof case. It may be used outdoors as long as it is protected

from extreme heat, excessive cold, water, sand, mud, or similar conditions. Refer to chapter 1, para

1-13, for oscilloscope specifications that should not be exceeded.

2-44

Page 64

CHAPTER 3

ORGANIZATIONAL MAINTENANCE

TM 11-6625-3135-12

Para

A and B Intensity Knobs Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A and B SEC/DIV Knob Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CH 1 VOLTS/DIV and CH 2 VOLTS/DIV Knob Replacement . . . . . . . . . .

Checking Unpacked Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Checks, Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation for Storage or Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools, TMDE, and Support Equipment

Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Storage. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

3-11

3-13

3-12

3-5

3-14

3-1

3-6

3-10

3-9

3-15

3-3

3-7

3-2

3-8

3-16

3-4

Page

3-8

3-10

3-9

3-2

3-11

3-1

3-2

3-7

3-5

3-12

3-1

3-3

3-1

3-3

3-12

3-2

Section I. REPAIR PARTS, SPECIAL TOOLS; TEST, MEASUREMENT,

AND DIAGNOSTIC EQUIPMENT (TMDE); AND SUPPORT EQUIPMENT

3-1. COMMON TOOLS AND EQUIPMENT

Common tools and equipment required for organizational maintenance of Oscilloscope AN/USM-

488 are listed in Appendix B (Maintenance Allocation Chart).

3-2. SPECIAL TOOLS, TMDE, AND SUPPORT EQUIPMENT

No special tools, TMDE, or support equipment are required.

3-3. REPAIR PARTS

Repair parts are listed and illustrated in the Repair Parts and Special Tools List (TM 11-6625-

3135-24P).

3-1

Page 65

TM 11-6625-3135-12

Section II. SERVICE UPON RECEIPT

3-4. UNPACKING

The oscilloscope is shipped assembled in its original packing container. Unpack carefully and do not

damage the container while unpacking. Save the container for use in reshipment.

3-5. CHECKING UNPACKED EQUIPMENT

a. Inspect the equipment for damage incurred during shipment. If the equipment has been

damaged, report the damage on Form SF 364, Report of Discrepancy.

b. Check the equipment against the packing slip to see if the shipment is complete. Report all

discrepancies in accordance with the instructions of DA PAM 738-750.

c. Check to see whether the equipment has been modified.

3-6. INITIAL CHECKS, ADJUSTMENTS AND TESTS

a.

Checks.

b.

Adjustments.

c.

Tests.

Perform complete operational test detailed in para 3-9.

Check that installed fuse in 1.0 amp, 250 volt, slow-blow.

Compensate probes as described in para 2-3b.

3-2

Page 66

TM 11-6625-3135-12

Section Ill. TROUBLESHOOTING

3-7. SAFETY PRECAUTIONS

WARNING

High voltage is used in the operation of this equipment. Death on

contact may result if you fail to observe safety precautions.