Page 1

*TB 9-6625-2240-35

DEPARTMENT OF THE ARMY TECHNICAL BULLETIN

CALIBRATION PROCEDURE FOR

OSCILLOSCOPE

OS261U (TEKTRONIX, TYPE 475),

OS261A(V)1U (TEKTRONIX, TYPE 475 OPTION 7),

OS261B(V)1U (TEKTRONIX, TYPE 475 OPTION 4),

OS261C(V)1U (TEKTRONIX, TYPE 475 OPTION 4/7),

TEKTRONIX, TYPE 475A (TEKTRONIX,

Headquarters, Department of the Army, Washington, DC

20 August 2001

Approved for public release; distribution is unlimited.

REPORTING OF ERRORS AND SUGGESTED IMPROVEMENTS

You can help improve this publication. If you find any mistakes or if you know of a

way to improve the procedure, please let us know. Mail your letter or DA Form 2028

to: Commander, U. S. Army Aviation and Missile Command, ATTN: AMSAM-MMCMA-NP, Redstone Arsenal, AL 35898-5230. A reply will be furnished to you. You may

also send in your comments electronically to our e-mail address:

2028@redstone.army.mil, or FAX 256-842-6546/DSN 788-6546

Paragraph Page

SECTION I. IDENTIFICATION AND DESCRIPTION

Test instrument identification ..........................

Forms, records, and reports ..............................

Calibration description ......................................

II. EQUIPMENT REQUIREMENTS

Equipment required ..........................................

Accessories required .........................................

Preliminary instructions ...................................

Equipment Setup ..............................................

Vertical deflection..............................................

Main sweep timing ............................................

Delay time and differential time measurement..

Risetime and bandwidth.....................................

Calibrator..........................................................

Power Supply ....................................................

Final procedure.................................................

III. CALIBRATION PROCESS

TYPE R475A)

1 2

2 2

3 2

4 3

5 3

6 4

7 4

8 5

9 8

10 12

11 15

12 20

13 22

14 23

AND

__________

*This bulletin supersedes TB 9-6625-2240-35, dated 7 November 1990.

Page 2

TB 9-6625-2240-35

SECTION I

IDENTIFICATION AND DESCRIPTION

1. Test Instrument Identification. This bulletin provides instructions for the

calibration of Oscilloscope, OS261U (Tektronix, Type 475), OS261A(V)1U (Tektronix,

Type 475 Option 7), OS261B(V)1U (Tektronix, Type 475 Option 4), OS261C(V)1U

(Tektronix, Type 475 Option 4/7) and Tektronix, Type 475A (Tektronix, Type R475A).

The manufacturer's manuals were used as the prime data sources in compiling these

instructions. The equipment being calibrated will be referred to as the TI (test

instrument) throughout this bulletin.

a. Model Variations. Model variations are identified in the text.

b. Time and Technique. The time required for this calibration is approximately 4

hours, using the dc and low technique.

2. Forms, Records, and Reports

a. Forms, records, and reports required for calibration personnel at all levels are

prescribed by TB 750-25.

b. Adjustments to be reported are determined (R) at the end of the sentence in

which they appear. When adjustments are in tables the (R) follows the designated

adjustment. Report only those adjustments made and designated with (R).

3. Calibration Description. TI parameters and performance specifications which

pertain to this calibration are listed in table 1.

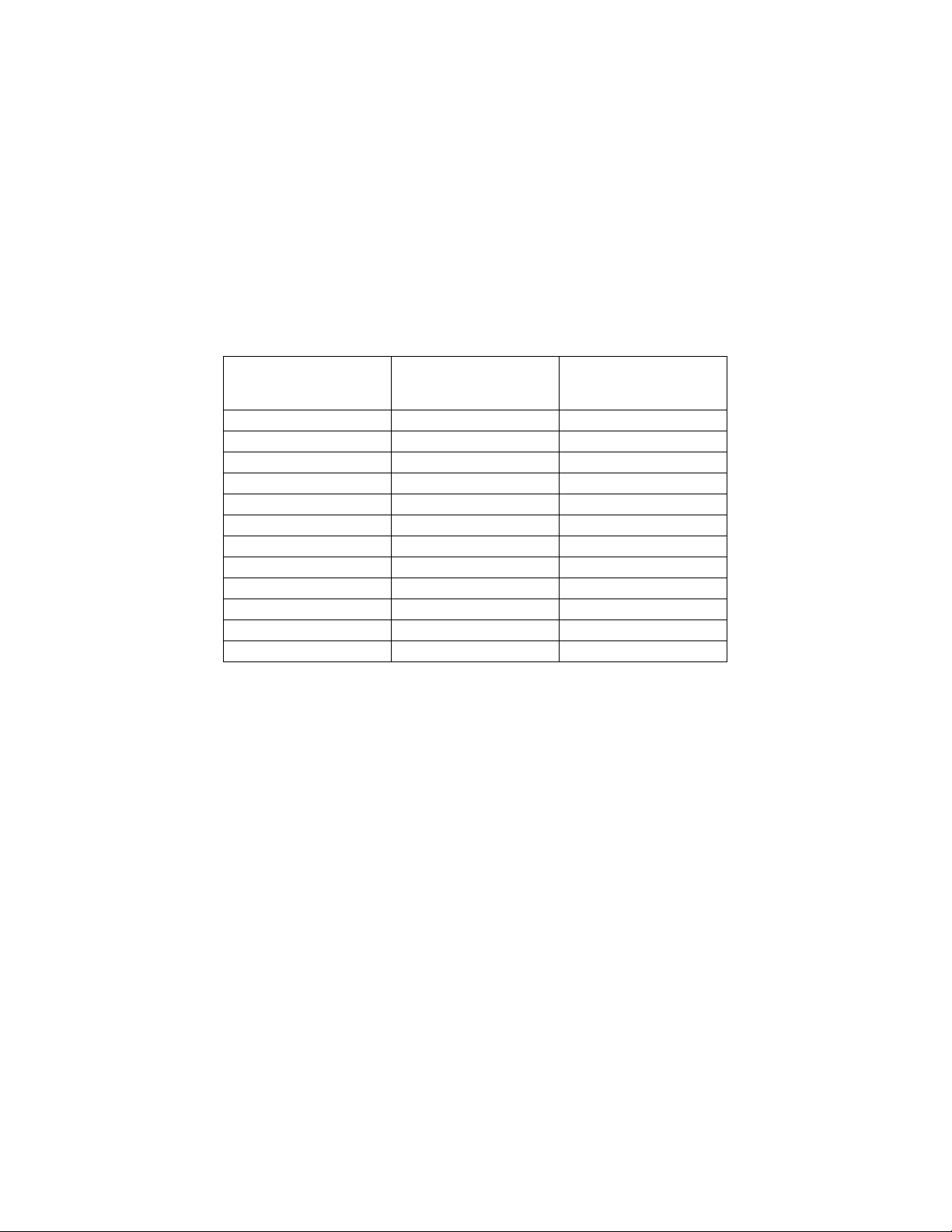

Table 1. Calibration Description

Test instrument

parameters

Vertical deflection Range: 2 mV/div to 5 V/div in 11 steps (5 mV/div to 10 V/div for Tektronix, Type 475A)

Accuracy: ±3% with gain set at 5 mV/div

Time and linearity

A sweep or B

DLY’D sweep

A delaying sweep

(A intensified

sweep)

Range: Unmag: 0.5 s/div to 0.01 µs/div in 24 steps

Mag: 0.5 s/div to 1 ns/div in 24 steps

Accuracy: 5 ms/div to 0.01 µs/div

Unmag: ±1%

Mag: ±2% 0.5 s/div to 10 ms/div

Unmag: ±2%

Mag: ±3%

Range: 0.5 s/div to 0.05 µs/div in 22 steps

Accuracy: Unmag: ±2%

Mag: ±3%

Performance specifications

2

Page 3

TB 9-6625-2240-35

Table 1. Calibration Description - Continued

Test instrument

parameters

Delay time and

differential time

measurement

Risetime Range: 1.75 ns with aberrations not to exceed +4% or -4%, and total p-p of 4%

Bandwidth Dc to 200 MHz (Dc to 250 MHz for Tektronix, Type 475A)

Calibrator Range: 300 mV, ±l%

Range: 5 s to 0.05 µs after start of delaying A sweep

Accuracy: ±0.01 major dial divisions between dial settings of one major division or less

over entire range

(1.4 ns for Tektronix, Type 475A)

±1% between dial settings of more than 1 major dial division, increasing to

Performance specifications

±

0.5%

SECTION II

EQUIPMENT REQUIREMENTS

4. Equipment Required. Table 2 identifies the specific equipment to be used in this

calibration procedure. This equipment is issued with Secondary Transfer Calibration

Standards Set AN/GSM-286. Alternate items may be used by the calibrating activity.

The items selected must be verified to perform satisfactorily prior to use and must bear

evidence of current calibration. The equipment must meet or exceed the minimum use

specifications listed in table 2. The accuracies listed in table 2 provide a four-to-one

ratio between the standard and TI.

5. Accessories Required. The accessories required for this calibration are common

usage accessories, issued as indicated in paragraph 4 above, and are not listed in this

calibration procedure. The following peculiar accessory is also required for this

calibration: 5-80 pF standardizer.

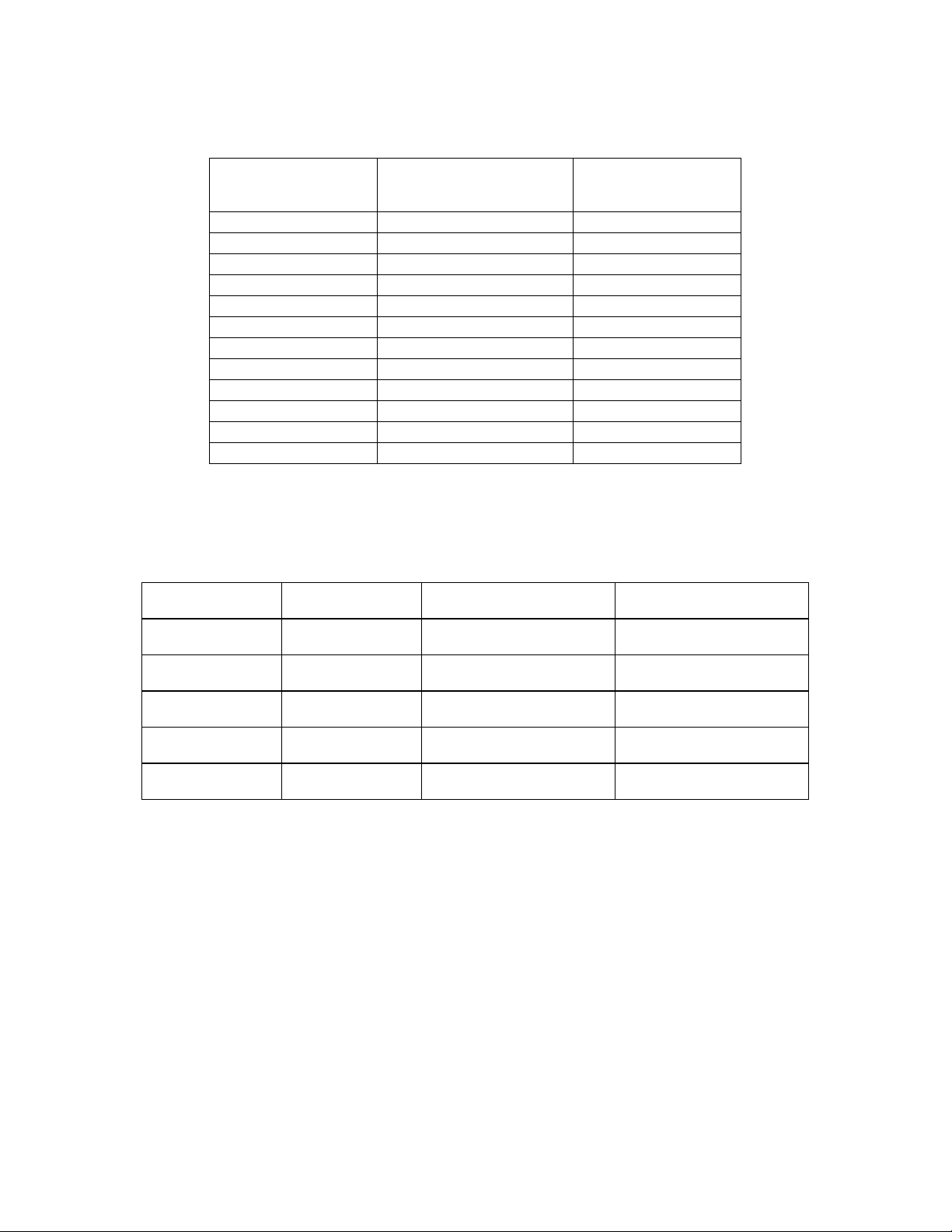

Table 2. Minimum Specifications of Equipment Required

Common name

OSCILLOSCOPE

CALIBRATOR

DIGITAL

MULTIMETER

Minimum use specifications

Voltage output:

Range: 12 mV to 60 V

Frequency: 1 kHz

Accuracy: ±0.75%

Time markers:

Range: 1 ns to 0.5 s

Accuracy: ±.25%, .01 µs to 5 ms

±0.5%, 10 ms to 0.5 s

Risetime: 437.5 ps

Aberrations: ±1%

Level sine wave:

Reference frequency: 50 kHz

Amplitude: 30 mV

Capacity: >200 MHz

Voltage input:

Range: -15.23 to +113 V dc

Accuracy: ±.375%

John Fluke, Model 5820A, (5820A-5C-GHZ),

MIS-38938

John Fluke, Model 8840A/AF-05/09,

(AN/GSM-64D)

Manufacturer and model

(part number)

3

Page 4

TB 9-6625-2240-35

SECTION III

CALIBRATION PROCESS

6. Preliminary Instructions

a. The instructions outlined in paragraphs 6 and 7 are preparatory to the

calibration process. Personnel should become familiar with the entire bulletin before

beginning the calibration.

b. Items of equipment used in this procedure are referenced within the text by

common name as listed in table 2.

c. Unless otherwise specified, verify the result of each test and, whenever the test

requirement is not met, take corrective action before continuing with this calibration.

Adjustments required to calibrate the TI are included in this procedure. Additional

maintenance information is contained in the manufacturer's manual for this TI.

d. When indications specified in paragraphs 8 through 12 are not within tolerance,

perform the power supply check prior to making adjustments. After adjustments are

made, repeat paragraphs 8 through 12. Do not perform power supply check if all other

parameters are within tolerance.

e. Unless otherwise specified, all controls and control settings refer to the TI.

7. Equipment Setup

WARNING

HIGH VOLTAGE is used or exposed during the performance

of this calibration. DEATH ON CONTACT may result if

personnel fail to observe safety precautions. REDUCE

OUTPUT(S) to minimum after each step within the

performance check where applicable.

a. Remove TI protective cover as required for adjustment.

b. Position CH1 and CH2 controls as listed in (1) through (7) below:

(1) FOCUS, vertical POSITION, and SCALE ILLUM controls to midrange.

(2) VOLTS/DIV switches to 5 m (10 m for Tektronix, Type 475A) and VAR

controls fully cw (detent).

(3) VERT MODE CH1 pushbutton pressed (in).

(4) AC-GND-DC switches to GND.

(5) INTENSITY control fully ccw.

(6) INVERT pushbutton out.

4

Page 5

TB 9-6625-2240-35

(7) 20 MHz BW/TRIG VIEW pushbutton pressed in and released to full

bandwidth.

c. Position A and B triggering controls as listed in (1) through (7) below:

(1) A TRIGGER LEVEL control to 0 and SLOPE switch to + (positive).

(2) B (DLY'D) TRIGGER LEVEL control to 0 and SLOPE switch to + (positive).

(3) A TRIGGER SOURCE switch to NORM.

(4) B TRIGGER SOURCE switch to STARTS AFTER DELAY.

(5) A and B triggering COUPLING switches to AC.

(6) TRIG MODE AUTO pushbutton pressed (in).

(7) A TRIG HOLDOFF switch to NORM.

d. Position TI A and B sweep controls as listed in (1) through (5) below:

(1) A and B TIME/DIV switches to 1 ms and VAR control fully cw (detent).

(2) HORIZ DISPLAY A (A LOCKS KNOBS for all models SN B250000 and

above) pushbutton pressed (in).

(3) DELAY TIME dial to 0.00.

(4) X10 MAG pushbutton out.

(5) Horizontal POSITION (FINE) controls to midrange.

e. Connect TI to ac power source.

f. Pull POWER switch to ON and allow at least 20 minutes for warm -up.

g. Adjust INTENSITY, FOCUS, and ASTIG controls for suitable display.

8. Vertical Deflection

a. Performance Check

(1) Ensure CH1 VOLTS/DIV switch is set to 5 m (10 m for Tektronix, Type

475A).

(2) Adjust CH1 POSITION control to align trace on center horizontal graticule

line.

(3) Set CH1 VOLTS/DIV switch to 2 m (5 m for Tektronix, Type 475A). If trace

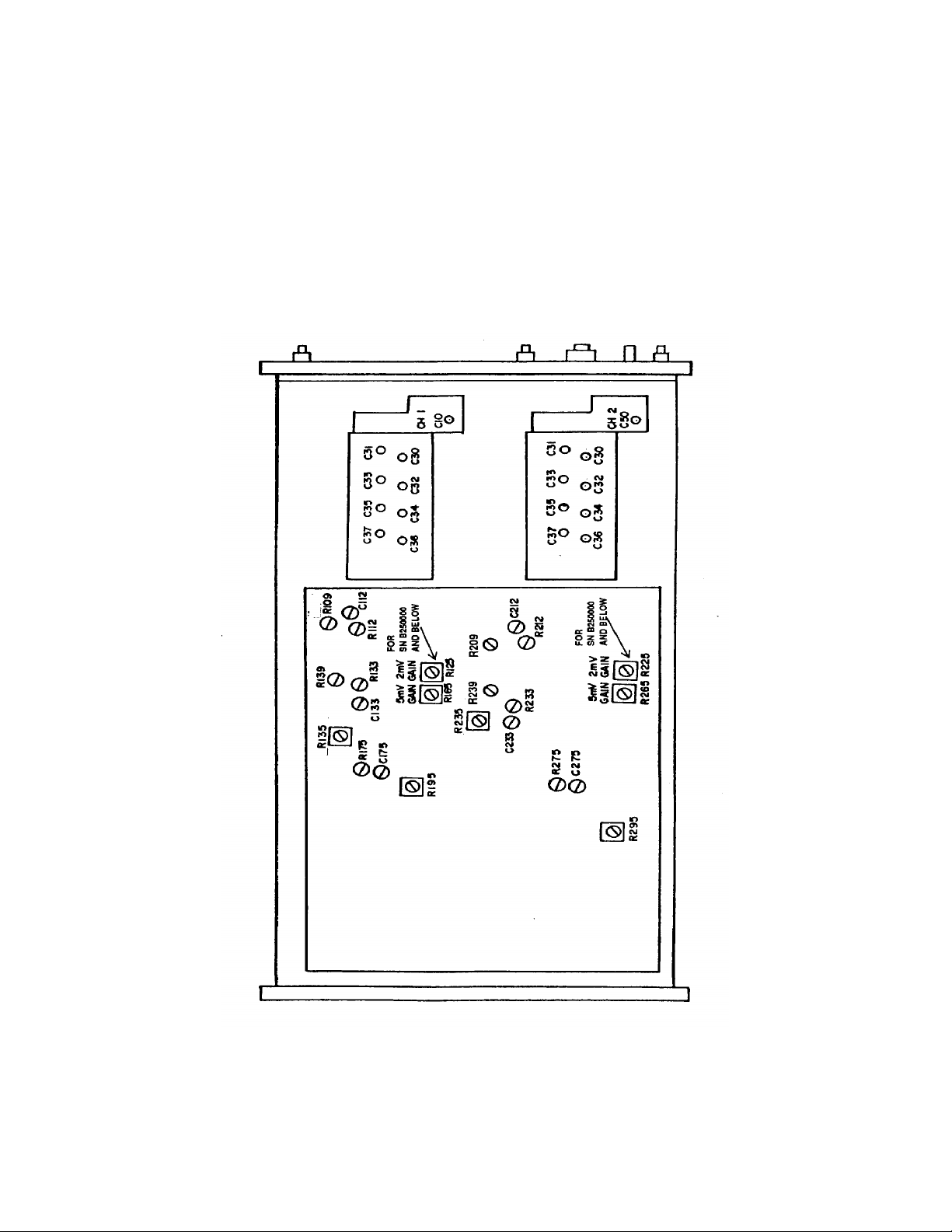

does not remain aligned with center horizontal graticule line, adjust R135 (fig. 1) to align

trace with center horizontal graticule line.

(4) Repeat (1) through (3) above for minimum trace shift when changing CH1

VOLTS/DIV switch from 5 m to 2 m (10 m to 5 m for Tektronix, Type 475A).

(5) Press VERT MODE CH2 pushbutton.

5

Page 6

TB 9-6625-2240-35

(6) Repeat technique of (1) thr ough (4) above using CH2 POSITION control and

adjusting R235 (fig. 1).

(7) Press VERT MODE CH1 pushbutton and set CH1 AC -GND-DC switch to

DC.

(8) Set CH1 VOLTS/DIV switch to 2 m (5 m for Tektronix, Type 475A) and

connect TI CH1 to oscilloscope calibrator CHAN 1.

(9) Press oscilloscope calibrator VOLTAGE pushbutton to illuminate green LED

and set frequency to 1 kHz.

6

Figure 1. Left side view.

Page 7

TB 9-6625-2240-35

(10) Perform steps a through c below:

(a) Use technique of (b) and (c) below for TI VOLTS/DIV switch settings and

oscilloscope calibrator VOLTAGE outputs listed in table 3.

(b) Rotate CH 1 POSITION knob to center trace on TI crt.

(c) Rotate oscilloscope calibrator knob located below EDIT FIELD

pushbutton to obtain 6 divisions of vertical display. Oscilloscope calibrator err display

will indicate within limits specified in table 3; if not, perform b below.

Table 3. Channel 1 Vertical Deflection Accuracy

1

Test instrument

VOLTS/DIV

Switch settings

2 m 12 mV 3

5

10 m 60 mV 3

20 m 120 mV 3

50 m .3 V 3

.1 V .6 V 3

.2 V 1.2 V 3

.5 V 3.0 V 3

1 V 6.0 V 3

2 V 12.0 V 3

5 V 30.0 V 3

10 V1 60.0 V 3

For Tektronix, Type 475A.

1

m 30 mV 3

Oscilloscope calibrator

Voltage output

Oscilloscope calibrator

Err display limits

(±%)

(11) Move TI connection from CH1 to CH2.

(12) Press VERT MODE CH2 pushbutton and set CH2 AC -GND-DC switch to

DC.

(13) Set CH2 VOLTS/DIV switch to 2 m (5 m for Tektronix, Type 475A).

(14) Press oscilloscope calibrator VOLTAGE pushbutton to illuminate green LED

and en sure frequency is set to 1 kHz.

(15) Perform steps (a) through (c) below:

(a) Use technique of (b) and (c) below for TI VOLTS/DIV switch settings and

oscilloscope calibrator VOLTAGE outputs of those listed in table 4.

(b) Rotate TI CH 2 POSITION knob to center trace on crt.

(c) Rotate oscilloscope calibrator knob located below EDIT FIELD

pushbutton to obtain 6 divisions of vertical display. Oscilloscope calibrator err display

will indicate within limits specified in table 4.

7

Page 8

TB 9-6625-2240-35

Table 4. Channel 2 Vertical Deflection Accuracy

1

Test instrument

VOLTS/DIV

switch settings

2 m 12 mV

51 m 30 mV

10 m 60 mV

20 m 120 mV

50 m .3 V

.1 V .6 V

.2 V 1.2 V

.5 V 3.0 V

1 V 6.0 V

2 V 12.0 V

5 V 30.0 V

10 V1 60.0 V

For Tektronix, Type 475A.

Oscilloscope calibrator

Voltage output

Oscilloscope calibrator

Err display limits

± %

3

3

3

3

3

3

3

3

3

3

3

3

b. Adjustments. Set oscilloscope calibrator to required parameter listed in table 5

for particular TI you are calibrating. Perform appropriate adjustments listed in table 5

for 6 divisions of vertical display on TI.

Table 5. Adjustment Guide

Parameter

(mV gain)

2 475 Below B250000 CH 1 R125

2 475 B250000 and up CH 1 R195

5 475 All SN’s CH 1 R165

5 475A --- CH 1 R195

10 475A --- CH 1 R165

Tektronix

type

Serial number

Adjustments

(fig. 1) (R)

CH 2 R225

CH 2 R295

CH 2 R265

CH 2 R295

CH 2 R265

9. Main Sweep Timing

NOTE

For oscilloscopes with digital multimeters attached, refer to

calibration section of digital multimeter manual at this point.

a. Performance Check

(1) Press VERT MODE CH1 pushbutton and set VOLTS/DIV switch to .5 V.

(2) Perform steps (a) through (d) below:

(a) Press oscilloscope calibrator MARKER pushbutton to illuminate green

LED and ensure oscilloscope calibrator output is set to 1.000 ms.

(b) Connect oscilloscope calibrator CHAN 1 to TI CH1 through 50Ω

termination.

8

Page 9

TB 9-6625-2240-35

(c) Press oscilloscope calibrator OPR/STBY pushbutton for OPR indication

on oscilloscope calibrator display.

(d) Ensure TI TIME/DIV is set to 1 ms.

(3) Rotate POSITION knob to align 1st time marker to 1st verticule graticule line

on TI crt.

(4) Rotate oscilloscope calibrator knob located below EDIT FIELD pushbutton

for 1 time marker per division on crt. Oscilloscope calibrator err display will ind icate

within limits specified in table 6.

(5) Repeat technique of (3) and (4) above for TI settings and oscilloscope

calibrator MARKER outputs listed in table 6. Perform TI adjustments for each

TIME/DIV switch position listed in table 6 as needed.

Table 6. Timing Accuracy

Oscilloscope

calibrator

MARKER

output settings

1 ms 1 ms Out 1 b1

1 µs 10 µs In 2

10 µs 10 µs Out 1 C1064 (fig. 2)

1 µs 10 µs In 2

.1 µs .1 µs Out 1 C1009 (fig. 3)

10 ns .1 µs In 2

Test instrument

switch settings

TIME/DIV

Test instrument

X10 MAG

pushbutton

settings

Oscilloscope

calibrator err

display limits

(±%)

Adjustments

(R)

1Type 475 with SN B250000-up.

2Optional with SN B250000-up

Figure 2. Adjustment locations - top view.

9

Page 10

TB 9-6625-2240-35

+15 V

R1430

+50 V

-15 V

C1179

C1253

R1155

R1515

R950

R936

R938

+ 50 V

+110 V

TP

Figure 3. Adjustments locations - bottom view.

+5 V

-8 V

C1233

C1009

(6) Perform steps (a) through (d) below:

(a) Set TI A COUPLING switch to LF REJ.

(b) Set TI A SOURCE switch to CH1.

(c) Press TI X10 MAG pushbutton to on (in).

(d) Press TRIG MODE NORM pushbutton to (in).

NOTE

You may need to adjust A TRIGGER SLOPE LEVEL for a

stable display in step (8) below.

(7) Set oscilloscope calibrator output and TI to settings listed in table 7.

(8) Adjust horizontal POSITION control to align 1 marker per division. TI will

indicate as listed in table 7 .1 marker per division. Perform adjustments listed in table

7 if required.

Table 7. Delay Time and Differental Measurement

Test

instrument

VOLTS/DIV

switch

settings

.5 V .05 µs .05 µs 5 ns 2 b(2)

Test instrument

switch settings

TIME/DIV

A B

Oscilloscope

calibrator

MARKER

output

Test

instrument

indications

1 per division

± minor

divisions

Test

instrument

adjustments

(9) Set A SOURCE switch to NORM, and A COUPLING switch to AC.

(10) Press X10 MAG (IN) pushbutton to off (out).

10

Page 11

TB 9-6625-2240-35

(11) Use technique of (12) and (13) below for TI TIME/DIV switch settings and

oscilloscope calibrator MARKER settings listed in table 8. Perform adjustments as

needed listed in table 8.

(12) Adjust horizontal POSITION control to align 1st time marker with 1st

graticule line.

(13) Rotate oscilloscope calibrator knob located below EDIT FIELD pushbutton to

obtain 1 marker per division on TI. Oscilloscope calibrator err display will indicate

within limits specified in table 8.

b. Adjustments

(1) Set oscilloscope calibrator MARKER output to .1 ms. Press oscilloscope

calibrator OPR/STBY pushbutton for OPR indication on oscilloscope calibrator display

and adjust R1155 (fig. 3) for 1 marker per division (R).

NOTE

Interaction exists between C1233, C1253, and C1179 (fig. 3).

Adjust for best in-tolerance condition.

(2) Adjust C1233 and C1253 (fig. 3) in equal amounts until TI displays 1 marker

per division (R).

(3) Set oscilloscope calibrator MARKER output to 20 ns . Adjust C1179 (fig. 3)

for 1 marker per division (R).

Table 8. Sweep Timing Accuracy

Test instrument

TIME/DIV

switch settings

.02 µs .02 µs 1 b(3)

.01 µs 10 ns 1

.05 µs 50 ns 1

.2 µs .2 µs 1

.5 µs .5 µs 1

1 µs 1 µs 1

2 µs 2 µs 1

5 µs 5 µs 1

20 µs 20 µs 1

50 µs 50 µs 1

.1 ms .1 ms 1

.2 ms .2 ms 1

.5 ms .5 ms 1

1 ms 1 ms 1

2 ms 2 ms 1

5 ms 5 ms 1

Oscilloscope calibrator

output settings

MARKER

Oscilloscope

calibrator err

display limits

(±%)

Test instrument

adjustments

11

Page 12

TB 9-6625-2240-35

Table 8. Sweep Timing Accuracy - Continued

Test instrument

TIME/DIV

switch settings

10 ms 10 ms 2

20 ms 20 ms 2

50 ms 50 ms 2

.1 s .1 s 2

.2 s .2 s 2

.5 s .5 s 2

Oscilloscope calibrator

output settings

MARKER

Oscilloscope

calibrator err

display limits

(± %)

Test instrument

adjustments

10. Delay Time and Differential Time Measurement

a. Performance Check

(1) Position controls as listed in (a) through (g) below:

(a) HORIZ DISPLAY A INTEN pushbutton pressed (in).

(b) DELAY TIME POSITION dial to 1.00.

(c) Press TRIG MODE AUTO pushbutton to (in).

(d) Press X10 MAG (IN ) pushbutton to (in).

(e) Ensure oscilloscope calibrator CHAN 1 is connected to TI CH1 through

50Ω feedthrough termination.

(f) Set TI VOLTS/DIV, TIME/DIV switch settings and oscilloscope

calibrator MARKER output as listed in table 9.

(g) Adjust A TRIGGER SLOPE LEVEL as needed for a stable trace on crt.

NOTE

For Tektronix, Type 475, SN B250000, and above, and

Tektronix, Type 475A, perform (3) below then proceed to (4).

For all other models, proceed to (4) below.

(2) Adjust horizontal POSITION control to align 1st time marker with 1st

graticule line. Rotate oscilloscope calibrator knob located below EDIT FIELD output to

obtain 1 marker per division on TI. Oscilloscope calibrat or err display will be within

limits specified in table 9. Perform adjustments, if required, listed in table 9.

Table 9. Delay Time and Differental Measurement

Test instrument

VOLTS/DIV

switch settings

.5 1 µs 10 µs 1 µs 2 b(1)

Test instrument

switch settings

TIME/DIV

A B

Oscilloscope

calibrator

MARKER

output

Oscilloscope

calibrator err

display limits

(±%)

Test

instrument

adjustments

12

Page 13

TB 9-6625-2240-35

(3) Press HORIZ DISPLAY B DLY'D pushbutton (in).

(4) Press X10 MAG (IN) pushbutton to (out).

(5) Set TI VOLTS/DIV, TIME/DIV switch settings and oscilloscope calibrator

output as listed in table 10.

(6) Adjust horizontal POSITION control to align start of sweep with center

vertical graticule line. Leading edge of displayed time marker will be aligned with the

center vertical graticule line; if not, perform adjustment listed in table 10.

Table 10. Delay Time and Differental Measurement

Test

instrument

VOLTS/DIV

switch

settings

.5 10 µs 0.1 µs 10 µs b(2)

Test instrument

switch settings

TIME/DIV

A B

Oscilloscope

calibrator

MARKER output

settings

Test instrument

adjustment

(7) Set TI VOLTS/DIV, TIME/DIV switch and oscilloscope calibrator output as

listed in table 11.

(8) Rotate DELAY TIME POSITION dial to 9.00. Leading edge of displayed

time marker will be aligned with center vertical graticule line; if not, perform

adjustment listed in table 11.

Table 11. Delay Time and Differental Measurement

Test

instrument

VOLTS/DIV

switch

settings

.5 10 µs 0.1 µs 10 µs

Test instrument

switch settings

TIME/DIV

A B

Oscilloscope

calibrator

MARKER

output settings

Test instrument

DELAY TIME

POSITION

dial limits

(±)

.05

Test

instrument

adjustment

b(3)

(9) Rotate DELAY TIME POSITION dial to 1.00.

(10) Set TI VOLTS/DIV, TIME/DIV switch settings and oscilloscope calibrator

output as listed in table 12.

(11) Adjust horizontal POSITION control to align 1st marker with center vertical

graticule line using test instrument settings and oscilloscope calibrator MARKER

output setting listed in ta ble 12.

(12) Rotate DELAY TIME POSITION dial to align 9th time marker with center

vertical graticule line. DELAY TIME POSITION dial will indicate as listed in table 12.

If not, perform test instrument adjustments listed in table 12.

13

Page 14

TB 9-6625-2240-35

Table 12. Delay Time and Differental Measurement

Test

instrument

VOLTS/DIV

switch setting

.5 10 µs 10 µs 10 µs 8.95 9.05 b(4) through (7)

Test instrument

TIME/DIV

switch setting

A B

Oscilloscope

calibrator

MARKER

output setting

Test instrument

DELAY TIME

POSITION

dial limits

Min Max adjustments

Test instrument

NOTE

You may need to adjust A TRIGGER SLOPE LEVEL for a

stable display.

(13) Set TI VOLTS/DIV, TIME/DIV switch settings and oscilloscope calibrator

output as listed in table 13.

(14) Rotate DELAY TIME POSITION dial to 1.00.

(15) Set TI VOLTS/DIV, TIME/DIV switch settings and oscilloscope calibrator

output as listed in table 13.

(16) Adjust horizontal POSITION control to align 1st marker with center vertical

graticule line using test instrument settings and oscilloscope calibrator MARKER

output setting listed in table 13.

(17) Rotate DELAT TIME POSITION dial to align 9th time marker with center

vertical graticle line. DELAY TIME POSITION dial will indicate between 8.95 and

9.05; if not, perform adjustments listed in table 13.

(18) Rotate DELAY TIME POSITION knob to 0.0 .

Table 13. Delay Time and Differental Measurement

Test

instrument

VOLTS/DIV

switch settings

.5 0.1 µs 0.1 µs 0.1 µs 8.95 9.05 b(8) through (11)

Test instrument

switch settings

TIME/DIV

A B

Oscilloscope

calibrator

MARKER

output settin gs

Test instrument

DELAY TIME

POSITION

dial limits

Min Max

Test instrument

adjustments

b. Adjustments

(1) Adjust R950 (fig. 3) for 1 time marker per division (R).

(2) Adjust R938 (fig. 3) until start of sweep is aligned with the leading edge of the

displayed time marker (R).

NOTE

Interaction occurs between R936 and R938 (fig. 3). Readjust

as necessary for best in-tolerance condition.

(3) Adjust R936 (fig. 3) until start of sweep is aligned with the leading edge of the

displayed time marker (R).

14

Page 15

TB 9-6625-2240-35

(4) Set DELAY TIME POSITION dial to 1.00.

(5) Adjust C1023 (fig. 2) to align time marker with center vertical graticule line

(R).

(6) Set DELAY TIME POSITION dial to 9.00.

(7) Readjust C1023 (fig. 2) for best in-tolerance condition between DELAY TIME

POSITION dial readings of 1.00 and 9.00 to align time marker with center vertical

graticule line (R).

(8) Set DELAY TIME POSITION dial to 1.00.

(9) Adjust C1025 (fig. 2) to align time marker with center vertical graticule line

(R).

(10) Set DELAY TIME POSITION dial to 9.00.

(11) Readjust C1025 (fig. 2) for best in-tolerance condition between DELAY TIME

POSITION dial readings of 1.00 and 9.00 to align time marker with center vertical

graticule line (R).

11. Risetime and Bandwidth

a. Performance Check

(1) Press HORIZONTAL DISPLAY A (A LOCKS KNOBS for SN B250000 and

above) pushbutton (in). Connect oscilloscope calibrator CHAN 1 to TI CH1 through 10x

attenuator and 50Ω termination.

(2) Press and release 20 MHz BW/TRIG VIEW pushbutton to full bandwidth

and press VERT MODE CH1 pushbutton (in).

(3) Set TI VOLTS/DIV CH1 switch to 5m (10m for Tektronix, Type 475A).

(4) Use technique of step 5 below for TI settings and oscilloscope calibrator

output settings listed in table 14.

(5) Rotate oscilloscope calibrator knob below EDIT FIELD pushbutton to adjust

amplitude for 5 divisions of vertical deflection on TI. Square wave will have aberrations

not more than those listed in table 14; if not, perform adjustment as listed in table 14.

Table 14. High Frequency Compensation Adjustments

Oscilloscope calibrator

EDGE settings

Amplitude

200 mVpp 1 MHz 0.1

200 mVpp 100 kHz .5 µs 1 C471, C4773 (fig. 2) Top and corner

See footnotes at end of table.

Frequency

TIME/DIV

switch

settings

(µs)

0.05

Aberration limits

minor division or

minor division

pk-pk

(<)

1 C175, R175 (fig. 1)

Test instrument

CH1

adjustments

(R)

C133, R133 (fig. 1)

C112, R112 (fig. 1)

Portion of

waveform

affected

10 ns from

leading edge

2 ns from

leading edges

Front corner

15

Page 16

TB 9-6625-2240-35

Table 14. High Frequency Compensation Adjustments - Continued

Oscilloscope calibrator

EDGE settings

AMPLITUDE

FREQUENCY

TIME/DIV

switch

settings

(µs)

200 mVpp 10 kHz 20

10

5

1

1

Test instrument with SN B250000 and above.

2

Optional on some test instruments.

3

Affect both CH1 and CH2. Readjust as necessary.

Test instrument

Aberration limits

minor div ision or

minor division

pk-pk

(<)

1 R109 (fig. 1)

CH1

adjustments

(R)

R139 (fig. 1)

R475 (fig. 2)

R494 (fig. 2)3

1

2,3

Portion of

waveform

affected

Top and corner

(6) Remove TI connection from CH1 and connect to CH2 and press VERT

MODE CH2 pushbutton (in).

(7) Set TI VOLTS/DIV CH2 switch to 5m (10m for Tektronix, Type 475A).

(8) Use technique of step 9 below for TI settings and oscilloscope calibrator

output listed in table 15.

(9) Rotate oscilloscope calibrator knob below EDIT FIELD pushbutton to adjust

amplitude for 5 divisions of vertical deflection on TI. Square wave will have aberrations

not more than those listed in table 15, if not perform adjustment listed in table 15.

Table 15. High Frequency Compensation Adjustments

Oscilloscope calibrator

EDGE

settings

AMPLITUDE

FREQUENCY

TIME/DIV

switch settings

(µS)

200 mVpp 1 MHz 0.1

0.05

Abberation limits

minor division or

minor division pk-

pk

(<)

1 C275, R275 (fig. 1)

Test

instrument

CH2

adjustments

(R)

C233, R233 (fig. 1)

C212, R212 (fig. 1

Portion of

waveform

affected

10 ns from

leading edge

2 ns from

leading edges

Front corner

200 mVpp 100 kHz 0.5 1 C471, C4773 (fig. 2) Top and corner

200 mVpp 10 kHz 20

10

5

1

1

Test instrument with SN B250000 and above.

2

Optional on some test instruments.

3

Affect both CH1 and CH2. Readjust as necessary.

1 R209 (fig. 1)1

R239 (fig. 1)

R475 (fig. 2)

R494 (fig. 2)3

Top and corner

2,3

16

Page 17

TB 9-6625-2240-35

(10) Connect oscilloscope calibrator CHAN 1 to TI CH1 through 10x attenuator,

50Ω feedthrough termination, and 5 - 80 pF standardizer.

(11) Pull 20 MHz /TRIGVIEW pushbutton out to 20 MHz.

(12) Set TI TIME/DIV switch to .2 ms

(13) Oscilloscope calibrator output to 500 mV at 1 kHz.

(14) Set CH1 VOLTS/DIV switch to 5 m (10 m for Tektronix, Type 475A) and

press VERT MODE CH1 pushbutton (in).

(15) Rotate oscilloscope calibrator knob below EDIT FIELD pushbutton to adjust

amplitude for 5 divisions of vertical deflection on TI. Adjust standardizer for optimum

square wave presentation. If optimum square wave presentation cannot be obtained,

perform adjustments listed in table 16.

(16) Repeat technique of (15) above for remaining TI VOLTS/DIV switch settings

listed in table 16 (do not readjust standardizer). If optimum square wave presentation

cannot be obtained, perform adjustments listed in table 16.

Table 16. Voltage Compensation

Oscilloscope

calibrator

EDGE VOLTS/DIV Tektronix, Type 475 Tektronix, Type 475A

settings settings Square corner Flat top Square corner Flat top

500 mV pp 5 m --- C10 (CH1)1

1 V pp 10 m C36 C37 --- C10 (CH1)

1 V pp 20 m2 C34 C35 C36 C37

250 mV pp 50 m3 C32 C33 C34 C35

500 mV pp .1 --- --- C32 C33

1.25 V pp4 .5 C30 C31 --- ---

1.25 V pp

1

Adjust for optimum results between square corners and flat tops.

2

Remove termination from setup.

3

Attenuators from setup.

4

Maxium amplitude for oscilloscope calibrator. Make adjustments as best as possible.

5

Adjust A TRIGGER for stable display if required.

4,5

1 --- --- C30 C31

Test

instrument

Test instrument

CH1 and CH 2 adjustments

(fig. 1) (R)

--- ---

C50 (CH2)1

1

C50 (CH2)2

(17) Connect oscilloscope calibrat or CHAN 1 to TI CH2 through 10x attenuator,

50Ω feedthrough termination, and 5 - 80 pF standardizer.

(18) Set TI TIME/DIV switches to .2 ms.

(19) Set oscilloscope calibrator output to 500 mV at 1 kHz.

(20) Set CH2 VOLTS/DIV switch to 5 m (10 m for Tektronix, Type 475A) and

press VERT MODE CH2 pushbutton (in).

17

Page 18

TB 9-6625-2240-35

(21) Rotate oscilloscope calibrator knob below EDIT FIELD pushbutton to adjust

amplitude for 5 divisions of vertical deflection on TI. Adjust standardizer for optimum

square wave presentation. If optimum square wave presentation cannot be obtained,

perform adjustments listed in table 17.

(22) Repeat technique of (21) above for remaining TI VOLTS/DIV switch settings

listed in table 17 (do not readjust standardizer). If optimum square wave presentat ion

cannot be obtained, perform adjustments listed in table 17

Table 17. Voltage Compensation

Oscilloscope

calibrator

EDGE VOLTS/DIV Tektronix, Type 475 Tektronix, Type 475A

settings settings Square corner Flat top Square corner Flat top

500 mV pp 5 m --- C10 (CH1)1

1 V pp 10 m C36 C37 --- C10 (CH1)

1 V pp 20 m2 C34 C35 C36 C37

250 mV pp 50 m3 C32 C33 C34 C35

500 mV pp .1 --- --- C32 C33

1.25 V pp4 .5 C30 C31 --- ---

1.25 V pp

1

Adjust for optimum results between square corners and flat tops.

2

Remove termination from setup.

3

Attenuators from setup.

4

Maxium amplitude for oscilloscope calibrator. Make adjustments as best as possible.

5.

Adjust A TRIGGER for a stable display if required.

4,5

1 --- --- C30 C31

Test

instrument

Test instrument

CH1 and CH 2 adjustments

(fig. 1) (R)

--- ---

C50 (CH2)1

1

C50 (CH2)2

(23) Connect oscilloscope calibrator CHAN 1 to TI CH1 through 50Ω feedthrough

termination.

NOTE

Ensure 50Ω feedthrough termination, wattage, and

frequency ratings are adequate for test below.

(24) Position controls as listed in (a) through (d) below:

(a) TRIG MODE AUTO pushbutton pressed (in).

(b) X10 MAG pushbutton pressed to on (in).

(c) Press and release 20 MHz BW/TRIG VIEW pushbutton to full

bandwidth.

(d) VERT MO DE CH1 pushbutton pressed (in).

NOTE

Ensure oscilloscope calibrator FASTEDG and TDPULSE

are off when performing steps below.

18

Page 19

TB 9-6625-2240-35

(25) Perform steps (a) through (c) below:

(a) Ensure oscilloscope calibrator EDGE pushbutton green LED is

illuminated.

(b) Set TI VOLTS/DIV, TIME/DIV switch settings and oscilloscope

calibrator EDGE output to settings listed in table 18. Use technique of step (c) below for

TI switch settings and oscilloscope calibrator EDGE output settings listed in table 18.

(c) Rotate oscilloscope calibrator knob located below EDIT FIELD

pushbutton to adjust amplitude for 5 divisions on TI crt and measure risetime using

standard risetime technique. Risetime limits are listed in table 18.

Table 18. Channel 1 Risetime Measurement

Test instrument

switch settings

VOLTS/DIV TIME/DIV Amplitude Frequency (≤)

5 m 0.01 µs 25

10 m

(Tektronix,

Type 475A)

0.01 µs 25

Oscilloscope calibrator

output settings

mVpp

mVpp

EDGE

10 MHz 1.75 ns

10 MHz 1.4 ns

Test instrument

risetime

limits

(26) Move connection on TI to CH2 and press VERT MODE CH2 pushbutton (in).

NOTE

Ensure CH2 VOLTS/DIV AC CND DC switch is set to DC

for steps below.

(27) Set TI VOLTS/DIV, TIME/DIV settings and oscilloscope calibrator EDGE

output to settings listed in table 19. Use technique of step (28) below for TI switch

settings and oscilloscope calibrator EDGE output settings listed in table 19.

(28) Rotate oscilloscope calibrator knob located below EDIT FIELD pushbutton to

adjust amplitude for 5 divisions on TI crt and measure risetime using standard risetime

technique. Risetime limits are listed in table 19.

Table 19. Channel 2 Risetime Measurement

Test instrument

switch settings

VOLTS/DIV TIME/DIV Amplitude Frequency (≤)

5 m 0.01 µs 25 mV pp 10 MHz 1.75 ns

10 m

(Tektronix,

Type 475A)

0.01 µs 25 mV pp 10 MHz 1.4 ns

Oscilloscope calibrator

EDGE

output settings

Test instrument

risetime

limits

19

Page 20

TB 9-6625-2240-35

(29) Press VERT MODE CH1 pushbutton (in), and set X10 MAG pushbutton

(out).

(30) Connect CH1 through 50Ω feedthrough termination to oscilloscope calibrator

CHAN 1.

(31) Press oscilloscope calibrator LEVEL SINE pushbutton to illuminate green

LED.

(32) Set TI VOLTS/DIV, TIME/DIV settings and oscilloscope calibrator LEVEL

SINE output to settings listed in table 20.

(33) Rotate oscilloscope calibrator knob below EDIT FIELD pushbutton to adjust

amplitude for 6 divisions of verticle deflection on TI.

Table 20. Bandwidth Measurement Setup

Test instrument

switch settings

VOLTS/DIV TIME/DIV Amplitude Frequency (≥)

5 m 0.1 ms 30 mV pp 50 kHz

10 m

(Tektronix,

Type 475A)

0.1 ms 60 mV pp 50 kHz

Oscilloscope calibrator

LEVEL SINE

output settings

to

200 MHz

to

250 MHz

Test instrument

amplitude limits

(divisions)

4.2

4.2

NOTE

To perform the step below, press EDIT FIELD pushbutton

as required to place underline under one of the frequency

digits.

(34) Rotate oscilloscope calibrator knob below EDIT FIELD pushbutton to sweep

oscilloscope from 50 KHz to 200 MHZ while observing displayed waveform amplitude

on TI crt. Displayed waveform will be 4.2 divisions or greater in amplitude throughout

entire range to 200 MHz (250 MHz for Tektronix, Type 475A).

b. Adjustments. No further adjustments.

12. Calibrator

a. Performance Check

(1) Connect TI CALIBRATOR (front panel) to TI CH1.

(2) Press VERT MODE CH1 pushbutton (in).

(3) Press oscilloscope calibrator VOLTAGE pushbutton to illuminate green LED.

(4) Set TIME/DIV to .2 ms and CH1 VOLTS/DIV switch to 50 m. Adjust CH1

VOLTS/DIV VAR control for 6 divisions of vertical deflection on TI.

20

Page 21

TB 9-6625-2240-35

(5) Remove connection at TI CALIBRATOR and connect to oscilloscope

calibrator CHAN 1.

21

Page 22

TB 9-6625-2240-35

(6) Set TI switch settings and oscilloscope calibrator output as listed in table 21.

(7) Rotate oscilloscope calibrator knob below EDIT FIELD pushbutton to adjust

for 6 divisions of vertical deflection on TI. Oscilloscope calibrator err display will

indicate as specified in table 21, if not perform b below.

Table 21. TI Calibrator Output Check

Test instrument

switch settings

VOLTS/DIV TIME/DIV Amplitude Frequency (±%)

50 m .2 ms 300 mV pp 1 kHz 1

Oscilloscope calibrator

VOLTAGE

output settings

Test instrument

Err

display limits

b. Adjustments

(1) Set oscilloscope calibrator DEVIATION switch to OFF.

(2) Adjust TI VOLTS/DIV controls for 6 divisions of vertical deflection on TI.

(3) Disconnect oscilloscope calibrator from TI and connect TI CALIBRATOR

(front panel) and (ground) (front panel) to TI CH1 input.

(4) Adjust R1515 (fig. 3) for 6 divisions of vertical deflection on TI (R).

13. Power Supply

NOTE

Do not perform power supply checks if all other parameters

are within tolerance.

a. Performance Check

(1) Connect digital multimeter to TI test point +50 V (fig. 3) and chassis ground.

Digital multimeter will indicate as listed in table 22 below; if not, perform b below.

(2) Repeat technique of (1) above for TI test points and voltage indications listed

in table 22. Digital multimeter will indicate within limits specified in table 22.

Table 22. Power Supply Voltage

Test instrument

test points

(fig. 3) Min Max

+50 V +49.75 +50.25

+110 V +107 +113

+15 V +14.77 +15.23

+5 V +4.92 +5.08

-15 V -14.77 -15.23

-8 V -7.88 -8.12

Digital mu ltimeter indications

(V dc)

b.

+50

Adjustments

V (R).

. Adjust R1430 +50 V (fig. 3) for digital multimeter indication of

22

Page 23

TB 9-6625-2240-35

14. Final Procedure

a. Deenergize and disconnect all equipment and reinstall protective cover on TI.

b. Annotate and affix DA label/form in accordance with TB 750-25.

23

Page 24

By Order of the Secretary of the Army:

TB 9-6625-2240-35

0120708

Distribution:

To be distributed in accordance with IDN 344233, requirements for calibration procedure TB 9-66252240-35.

PIN: 045981-000

Loading...

Loading...