Page 1

4510-QIVC and 4511-QIVC Quad IV Cards

User’s Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PRO

VIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

-

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF

ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF

INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

Belgium: Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02-363 00 64 • www.keithley.nl Italy: Milano • 02-48 39 16 01 • Fax: 02- 48 39 16 28 • www.keithley.it

China: Beijing • 8610-82251886 • Fax: 8610-82251892 • www.keithley.com.cn Japan: Tokyo • 81-3-5733-7555 • Fax: 81-3-5733-7556 • www.keithley.jp

Finland: Helsinki • 09-5306-6560 • Fax: 09-5306-6565 • www.keithley.com Korea: Seoul • 82-2-574-7778 • Fax: 82-2-574-7838 • www.keithley.com

France: Saint-Aubin • 01-64 53 20 20 • Fax: 01-60 11 77 26 • www.keithley.fr Netherlands: Gorinchem • 0183-635333 • Fax: 0183-630821 • www.keithley.nl

Germany: Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34 • www.keithley.de Singapore: Singapore • 65-6747-9077 • Fax: 65-6747-2991 • www.keithley.com

Great Britain: Theale • 0118 929 7500 • Fax: 0118 929 7519 • www.keithley.co.uk Sweden: Solna • 08-509 04 600 • Fax: 08-655 26 10 • www.keithley.com

India: Bangalore • 080 212 8027 • Fax: 080 212 8005 • www.keithley.com Tai wa n : Hsinchu • 886-3-572-9077 • Fax: 886-3-572-9031 • www.keithley.com.tw

2/04

Page 3

4510-QIVC and 4511-QIVC Quad IV Cards

User’s Manual

Microsoft® Windows, Microsoft® Excel, and Visual Basic®

are either registered trademarks or trademarks of

Microsoft

®

Corporation in the United States and/or other countries.

LabView

®

, LabWindows® are registered trademarks

©2003, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

First Printing, December 2003

Document Number: 451XQIVC-900-01 Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately into

the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the new Revision of the manual. Each new Revision includes a

revised copy of this print history page.

Revision A (Document Number 451XQIVC-900-01).................................................................... December 2003

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some in

struments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for en

suring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instru

ment. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or replacing consumable materials. Maintenance procedures

are described in the manual. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed

only by service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained ser

vice personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Measurement Category I and Measurement Category II, as

described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O sig

nals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient overvoltages. Measurement Category II connections require protection

for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless other

wise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a

shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present. A good safety practice is to ex

pect that hazardous voltage is present in any unknown circuit

before measuring.

Operators of this product must be protected from electric shock at

-

all times. The responsible body must ensure that operators are pre

vented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human con

tact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When con

necting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power dis

connect device must be provided, in close proximity to the equip-

ment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jump

ers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equip

ment may be impaired.

Do not exceed the maximum signal levels of the instruments and

accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

-

-

-

-

-

-

-

5/03

Page 6

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment

frame.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that se

lected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to in

structions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

-

-

Page 7

1 Getting Started

Introduction ........................................................................................................................................................ 1-2

General information ........................................................................................................................................... 1-2

Features ...................................................................................................................................................... 1-2

Intended applications ................................................................................................................................. 1-3

Supported operating system ....................................................................................................................... 1-3

Supported software platforms .................................................................................................................... 1-3

Supplied software ....................................................................................................................................... 1-3

Specifications ............................................................................................................................................. 1-3

Warranty information ................................................................................................................................. 1-3

Contact information ................................................................................................................................... 1-4

Safety symbols and terms .......................................................................................................................... 1-4

Unpacking and Inspection .......................................................................................................................... 1-4

Optional accessories ........................................................................................................................................... 1-7

Card configuration ............................................................................................................................................. 1-7

Card side view ............................................................................................................................................ 1-7

Card edge view ........................................................................................................................................... 1-9

2 Installation & Connections

Introduction ........................................................................................................................................................ 2-2

Connection precautions ...................................................................................................................................... 2-2

Card installation ................................................................................................................................................. 2-2

Cover removal ............................................................................................................................................ 2-2

Installation procedure ................................................................................................................................. 2-3

Card removal .............................................................................................................................................. 2-5

Card configuration ..................................................................................................................................... 2-5

Software installation .......................................................................................................................................... 2-5

Connections ........................................................................................................................................................ 2-6

Connector terminal designations ................................................................................................................ 2-6

Block diagram ............................................................................................................................................ 2-7

DUT connections ....................................................................................................................................... 2-7

Output states ............................................................................................................................................... 2-8

Reverse current bias and laser diode considerations ................................................................................ 2-11

Using both I-Source and V-Source subchannels with a single DUT ....................................................... 2-11

Interlock ........................................................................................................................................................... 2-13

Interlock events ........................................................................................................................................ 2-13

Interlock connections ............................................................................................................................... 2-13

Interlock connector and cables ................................................................................................................. 2-14

Interlock terminal designations ................................................................................................................ 2-15

Multiple card interlock connections ......................................................................................................... 2-16

Table of Contents

i

Page 8

3 Basic Operation

Introduction ........................................................................................................................................................ 3-2

Environmental conditions ................................................................................................................................... 3-2

Temperature and humidity ......................................................................................................................... 3-2

Warm-up period .......................................................................................................................................... 3-2

Basic software operation .................................................................................................................................... 3-2

4500-MTS folder ........................................................................................................................................ 3-2

Enabling the emulation mode ..................................................................................................................... 3-3

Using the Embedded Sweep Example program ................................................................................................. 3-4

Overview .................................................................................................................................................... 3-4

Running the 4500-MTS Embedded Sweep Example program .................................................................. 3-5

Connecting to the 4500-MTS ..................................................................................................................... 3-6

Building a new channel group .................................................................................................................... 3-7

Removing a channel from a channel group ................................................................................................ 3-9

Configuring a channel ................................................................................................................................ 3-9

Running a test ........................................................................................................................................... 3-14

Saving test data to a file ............................................................................................................................ 3-15

4 Programming

Introduction ........................................................................................................................................................ 4-2

Operation overview ............................................................................................................................................ 4-2

Channel designation description ................................................................................................................. 4-2

Channel groups ........................................................................................................................................... 4-3

Sweep and sourcing terminology ............................................................................................................... 4-4

Immediate mode ......................................................................................................................................... 4-7

Memory capacity ........................................................................................................................................ 4-8

Using the 4500 driver with various programming environments ..................................................................... 4-10

References to online help ......................................................................................................................... 4-10

Basic assumptions .................................................................................................................................... 4-10

Using specific programming environments .............................................................................................. 4-10

User programming ............................................................................................................................................ 4-12

Remote mode ............................................................................................................................................ 4-12

Driver details ............................................................................................................................................ 4-12

Source code .............................................................................................................................................. 4-13

Driver functions ........................................................................................................................................ 4-13

A Specifications

B Terms, Concepts, and Definitions

Introduction ....................................................................................................................................................... B-2

C Output Control Relay Lifetime

Output control relay ........................................................................................................................................... C-2

Lifetime rating ................................................................................................................................................... C-2

ii

Page 9

List of Illustrations

1 Getting Started

Figure 1-1 QIVC cable (4500-CQIV-2) ...................................................................................................................... 1-5

Figure 1-2 QIVC Interlock Cable (4500-CILK-2) ...................................................................................................... 1-5

Figure 1-3 15 pin D-sub female solder-cup connector (4500-CIV-KIT-1) ................................................................. 1-5

Figure 1-4 QIVC Test Lead Set (Model 4500-QIVC-TLS) ........................................................................................ 1-6

Figure 1-5 Interlock override plug (4500-ILK-PLUG) ............................................................................................... 1-6

Figure 1-6 451x-QIVC card side view ........................................................................................................................ 1-8

Figure 1-7 451x-QIVC card edge view ....................................................................................................................... 1-9

2 Installation & Connections

Figure 2-1 Case cover removal .................................................................................................................................... 2-4

Figure 2-2 Flat plate removal ....................................................................................................................................... 2-4

Figure 2-3 Card installation ......................................................................................................................................... 2-5

Figure 2-4 Card block diagram .................................................................................................................................... 2-7

Figure 2-5 DUT connections ....................................................................................................................................... 2-8

Figure 2-6 Output On state ........................................................................................................................................ 2-10

Figure 2-7 Output Off_Shorted state ......................................................................................................................... 2-10

Figure 2-8 Output Off_Open state ............................................................................................................................. 2-11

Figure 2-9 LED forward bias simultaneous I-Source and V-Source connections ..................................................... 2-12

Figure 2-10 LED reverse bias simultaneous I-Source and V-Source connections ...................................................... 2-12

Figure 2-11 Connections directly to card interlock connector .................................................................................... 2-14

Figure 2-12 Connections to interlock cable 9-pin connector ....................................................................................... 2-15

Figure 2-13 Multiple card interlock connections ......................................................................................................... 2-17

3 Basic Operation

Figure 3-1 Typical 4500-MTS folder contents ............................................................................................................ 3-3

Figure 3-2 4500-MTS control panel System Settings tab ............................................................................................ 3-4

Figure 3-3 Running VB Embedded Sweep Example program using Start menu ........................................................ 3-5

Figure 3-4 Embedded sweep example program initial window .................................................................................. 3-6

Figure 3-5 Typical card configuration window ........................................................................................................... 3-7

Figure 3-6 Typical channel group configuration window ........................................................................................... 3-8

Figure 3-7 Group configuration window after group creation .................................................................................... 3-8

Figure 3-8 Typical card properties window ................................................................................................................. 3-9

Figure 3-9 I Linear Sweep settings ............................................................................................................................ 3-11

Figure 3-10 I-Bias settings ........................................................................................................................................... 3-12

Figure 3-11 I-List Sweep settings ................................................................................................................................ 3-12

Figure 3-12 Typical Sweep Results ............................................................................................................................. 3-15

iii

Page 10

4 Programming

Figure 4-1 Subchannel block diagram ......................................................................................................................... 4-2

Figure 4-2 Channel designation example ..................................................................................................................... 4-3

Figure 4-3 Current source output during sweep ........................................................................................................... 4-4

Figure 4-4 Block diagram example of a Linear Sweep ................................................................................................ 4-5

Figure 4-5 Block diagram of an Immediate Mode test ................................................................................................ 4-7

Figure 4-6 Remote Mode connection block diagram ................................................................................................. 4-12

B Terms, Concepts, and Definitions

Figure B-1 RTM System Tray Icon ............................................................................................................................. B-2

Figure B-2 Four channel nested sweep example ......................................................................................................... B-4

Figure B-3 Four channel parallel sweep example ........................................................................................................ B-5

iv

Page 11

List of Tables

2 Installation & Connections

Table 2-1 Connector terminal designations (each channel) ....................................................................................... 2-6

Table 2-2 Output states for KE4500_EnableOutputs() command ............................................................................. 2-9

Table 2-3 Interlock connector and cable terminal designations ............................................................................... 2-15

3 Basic Operation

Table 3-1 Valid current source and voltage source output states ............................................................................. 3-10

B Terms, Concepts, and Definitions

Table B-1 Subchannel measure capabilities .............................................................................................................. B-7

Table B-2 Subchannel source capabilities ................................................................................................................. B-7

v

Page 12

1

Getting Started

Page 13

1-2 Getting Started 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Introduction

This user’s manual describes operation of the 4510-QIVC and 4511-QIVC Quad IV cards. After

reading this document, you should be able to perform the following tasks:

• Open up the mainframe.

• Plug a card into the mainframe.

• Connect the hardware necessary to operate a card with the mainframe.

• Use the Keithley 4510-QIVC and 4511-QIVC Embedded Sweep Example program.

• Perform basic programming tasks to control and take measurements with the card using the

supplied library of driver calls.

General information

Features

The 4510-QIVC and 4511-QIVC cards are intended to provide parallel real-time source/measure

capability in a cost-effective, compact, and scalable platform. These applications typically take

two forms: multi-channel I-V test or multi-channel intelligent power supply. Applications requir

ing multi-channel I-V capability include on wafer test of LEDs, VCSELs, and Optoelectronic ICs

where a large number of channels need to perform I-V sweeps in parallel or in coordination with

each other. Applications that require multi-channel intelligent power supply capability include

accelerated life test and functional device test that require large numbers of channels to sourcing

currents or voltages while monitoring power consumption.

-

The 4510-QIVC provides three current source ranges: 30mA, 100mA, and 500mA, at up to 6V

compliance. The 4511-QIVC is a higher current unit also providing three source current ranges

at 100mA, 300mA, and 1A without compromising instrument specifications or functionality.

Both cards also have a programmable ±10V voltage source with source read-back and precision

three-range (10µA, 500µA, 10mA) current measurement. Together these cards provide coverage

for a wide variety of source/measure applications.

The following list summarizes the major features of 4510-QIVC and 4511-QIVC:

• Channel Density — The channel density provided by the 4510-QIVC and 4511-QIVC

allows for testing of up to 36 channels in a single 4500-MTS chassis. Channel density allows

you to perform massively parallel tests to accelerate throughput.

• Source/Measure Combinations — The 4510-QIVC and 4511-QIVC plug-in cards offer

modular precision source-measure capability. Each card provides four channels, and each

channel includes a current source subchannel and a voltage source subchannel. Each channel

also includes an instrument grade A/D converter for highest possible throughput without

compromising precision.

• Integrated Test System — The internal PC and Windows® 2000 Operating System of the

4500 system allow users to eliminate the test system controller from new test stands. With

ethernet interface capability, the 4500-MTS can interface directly with facility databases for

transfer of test data.

• User Safety — The 4510-QIVC and 4511-QIVC provide for user safety (electrical and

optical) for the target component types. Voltage source capability will not exceed 48V on any

circuit. The system also provides for software and hardware abort capability upon interlock.

• High Test Throughput and Accuracy — The 4510-QIVC and 4511-QIVC provide fast and

accurate measurements.

Page 14

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Getting Started 1-3

• User Interface — The 4500 comes with standard drivers for the LabView,

LabWindows/CVI, Visual C/C++, and Visual Basic® programming environments. In

addition, application demo programs in LabView, LabWindows/CVI, and Visual Basic

provided to supplement the development of test programs.

• Sweep and Immediate Data Measurement Retrieval — The 4510-QIVC and 4511-QIVC

cards provide sweep capability along with immediate data measurement retrieval.

®

are

Intended applications

The 4510-QIVC and 4511-QIVC cards are designed for multi-channel I-V test and multi-channel

intelligent power supply applications where source requirements are limited to 1A or 10V per

channel.

Supported operating system

The 451x-QIVC driver software is compatible with the following operating system:

• Windows® 2000 Workstation (required for 4500-MTS)

Supported software platforms

The 451x-QIVC drivers are compatible with the following test software platforms:

• MS Visual Basic® Version 5 and 6

• MS Visual C/C++ (32 bit)

• NI LabView Version 5.1 and higher

• NI LabWindows/CVI Version 5.5 and higher

Supplied software

The following software is supplied with the 451x-QIVC cards:

• Win32 DLL driver for the card that supports the above software platforms.

• Embedded Sweep Example Software that demonstrates card sweep capabilities and allows

you to perform simple tests.

• Example application programs.

Specifications

Detailed specifications are located in Appendix A. For the latest specifications, check

www.keithley.com.

Warranty information

Warranty information is located at the front of this manual. Should your Model 4510-QIVC or

4511-QIVC require warranty service, contact the Keithley representative or authorized repair

facility in your area for further information. When returning the instrument for repair, be sure to

fill out and include the service form at the back of this manual to provide the repair facility with

the necessary information.

Page 15

1-4 Getting Started 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Contact information

Worldwide phone numbers are listed at the front of this manual. If you have any questions,

please contact your local Keithley representative or call one of our Application Engineers at

1-800-348-3735 (U.S. and Canada only).

Safety symbols and terms

If a screw is present, connect it to safety earth ground using the wire recommended in the

user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions

located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more,

including the combined effect of normal and common mode voltages. Use standard safety

precautions to avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment frame.

The WA R NI N G heading in a manual explains dangers that might result in personal injury or

death. Always read the associated information very carefully before performing the indicated

procedure.

The CAUTION heading in a manual explains hazards that could damage the instrument. Such

damage may invalidate the warranty.

.

Unpacking and Inspection

Inspection for damage

The Model 451x-QIVC card was carefully inspected electrically and mechanically before

shipment. After unpacking all items from the shipping carton, check for any obvious signs of

physical damage that may have occurred during transit. Report any damage to the shipping

agent immediately. Save the original packing carton for possible future shipment.

Package content

The following items are included with every Model 451x-QIVC card order:

• Model 4510-QIVC Low Power Quad I/V Card or 4511-QIVC High Power Quad I/V card.

• QIVC Cable (4500-CQIV-2) signal connecting cable (2m) with MDR connectors for QIVC

to 4 male 15 pin D-sub connectors (

• QIVC Interlock Cable (4500-CILK-2) cable (2m) with MDR connector to male 9 pin D-Sub

(

Figure 1-2).

• 15 pin D-sub female solder-cup connector (4500-CIV-KIT-1, Qty: 4). Mates to 4500-CQIV-*,

provided for DUT connection (Figure 1-3).

• QIVC Test Lead Set (Model 4500-QIVC-TLS), 15 pin D-sub to 8 alligator clips, provided.

for temporary DUT connection and troubleshooting (

• Interlock override plug (4500-ILK-PLUG). 9 pin D-sub mates to 4500-CILK-* interlock

cable, overrides the interlock functionality on all four channels (

• Additional accessories as ordered.

Figure 1-1).

Figure 1-4).

Figure 1-5).

Page 16

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Getting Started 1-5

Figure 1-1

QIVC cable (4500-CQIV-2)

Figure 1-2

QIVC Interlock Cable (4500-CILK-2)

Figure 1-3

15 pin D-sub female solder-cup connector (4500-CIV-KIT-1)

Page 17

1-6 Getting Started 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 1-4

QIVC Test Lead Set (Model 4500-QIVC-TLS)

Figure 1-5

Interlock override plug (4500-ILK-PLUG)

Page 18

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Getting Started 1-7

Optional accessories

For more information on optional accessories, refer to www.keithley.com.

The following cables are available:

• 4500-CQIV-* — This cable has a 40-pin connector that mates with the 451x-QIVC card signal connector on one end and a 15-pin D-Sub connector for each of the four channels on the

other end.

NOTE This cable is available in 0.5, 1, 2, and 3 meters. 0.5 to 2 meter lengths

are recommended for use with the 4511-QIVC. 3 meter length is recom

mended for use only with the 4510-QIVC.

• 4500-CILK-* — This cable has a 14-pin male connector that mates with the 451x-QIVC

card interlock on one end and a 9-pin D-Sub female connector at the other end.

NOTE This cable is available in 0.5, 1, 2, and 3 meters.

• 4500-ILK-KIT-1 — This kit contains a mating connector and housing for interlock wiring.

The connector mates to the 451x-QIVC card interlock connector for a single card.

• 4500-CIV-KIT-1 — This kit contains a mating connector for wiring. This kit is for use with

the 4500-CQIV-*.

• 4500-QIVC-TLS — This test lead set adapts the 15 pin D-sub, for a single channel, to eight

alligator clips. It provides a quick method for initial DUT connections.

-

Card configuration

Card side view

Figure 1-6 shows the 451x-QIVC card side view. Key components include:

• DUT signal connector — provides connections to the DUTs using the supplied connecting

cable (see

• Interlock connector — connects to a test fixture interlock (see “Interlock,” page 2-13).

• Edge connectors — connects the card to the PCI bus, analog power bus, and trigger bus of

the mainframe (see Section 2 of the 4500-MTS Mainframe User’s Manual).

•Heat sink — cools power output stages of card.

WARNING The heat sink may be hot after extended operation at higher power

“Connections,” page 2-6).

levels. Do not touch the heat sink or adjacent power components

until the card has cooled sufficiently.

Page 19

1-8 Getting Started 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 1-6

451x-QIVC card side view

Heat sink

DUT signal

connector

Interlock

connector

Edge connectors

Page 20

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Getting Started 1-9

Card edge view

Figure 1-7 shows the edge view of the card. Key components include:

• DUT connector — provides signal connections for all four channels to the DUTs using the

supplied connecting cable (see

• INTLK (interlock) connector — provides connections to a test fixture interlock for safety

purposes (see

Section 2).

• Rear mounting plate — secures card to rear panel of mainframe (see Section 2).

Figure 1-7

451x-QIVC card edge view

Section 2).

KEITHLEY

4510

QIVC

DUT

INTLK

DUT Signal

Connector

Interlock

Connector

Rear

Mounting

Plate

Page 21

2

Installation & Connections

Page 22

2-2 Installation & Connections 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Introduction

This section includes information on card installation, software installation, and connecting

DUTs (Device Under Test) to the card.

Connection precautions

WARNING Read all safety precautions listed at the beginning of this manual. The

following safety practices must be used to protect operators and other

users of this product from potential exposure to electrical hazards:

• Operators must be protected from electrical hazards at all times.

• The interlock is required for safe operation. The test fixtures

must ensure that the interlock circuit is disabled (source outputs

inhibited) so that an operator is not exposed to any harmful

conditions. See

• Maximum isolation from earth ground is ±20V. Exceeding this

value may result in a shock hazard.

• When making connections, do not leave any exposed

connections. Be sure that all external circuits are properly

insulated.

“Interlock,” page 2-13 for interlock information.

Card installation

Cover removal

WARNING The following information is intended only for qualified service per-

sonnel. Do not attempt these procedures unless you are qualified to

do so. Some of these procedures may subject you to electric shock,

possibly causing personal injury or death.

NOTE The 4500-MTS mainframe is shipped from the factory with ordered mea-

surement cards already installed. The following procedure is intended

for those who wish to install additional cards in the field.

WARNING Disconnect the line cord and all other cables from the mainframe

before removing the cover.

Tools Required

#1 Tip Phillips Screwdriver

Wrist ground strap

Procedure

1. Remove the six (6) screws that secure the cover to the case (located on the bottom side of

chassis (

2. Carefully remove the cover from the case by sliding it off the top of the chassis.

3. Loosen the twelve (12) screws that secure the flat cover plate to the chassis (Figure 2-2,

page 2-4), slide the plate toward rear of chassis about 0.25" and lift off.

Figure 2-1, page 2-4).

Page 23

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Installation & Connections 2-3

WARNING The safety shield that covers the fan and front area should not be

removed for card installation/removal or cover removal, and it

should be removed only for servicing. Hazardous voltages will be

exposed when the shield is removed. Rotating fan blades can cause

minor cuts or injury. Keep hands clear when servicing.

4. To re-install, install the flat cover plate and tighten the twelve (12) screws, place the cover on

the case, then attach it with the six (6) screws.

Installation procedure

Install a 4510-QIVC or 4511-QIVC card using the procedure below and Figure 2-3 on page 2-5

as a guide. This procedure assumes that the case cover is already removed as previously discussed.

CAUTION Handle the card only by the edges to avoid contamination that

could affect measurement quality. Do not touch PC board traces or

edge connector contacts. Use a ground strap and proper grounding

techniques to avoid damage caused by static discharge.

NOTE A maximum of eight 4511-QIVC cards should be installed in a

4500-MTS mainframe. Operation with nine 4511-QIVC cards is not

recommended.

1. Remove the desired slot cover plate from the rear panel by removing the securing screw (1)

and bracket.

2. Remove the PCI card retainer by loosening the three (3) retaining screws and sliding the

bracket off.

3. Carefully remove the card from its antistatic (shipping) bag.

4. Position the card above the appropriate PCI slot, aligning the card with the card edge rails

and rear slot opening. Line up the edge connectors with the slot connectors on the backplane,

and then carefully insert the card into those connectors. Make sure the card is properly seated

in all connectors by applying firm, even pressure to the top edge of the card.

5. Install the screw (1) at the rear panel location to secure the card.

6. Re-install the PCI card retainer; retighten the three (3) screws.

7. Replace the mainframe top cover plate and cover.

Page 24

2-4 Installation & Connections 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 2-1

Case cover removal

Case Cover

Slide Cover Off Carefully

Figure 2-2

Flat plate removal

Slide Cover Toward Rear of Chassis 0.25”.

Lift Flat Cover Plate Off.

Remove Six (6) Screws

Loosen Twelve (12) Screws

Flat Cover Plate

Page 25

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Installation & Connections 2-5

Figure 2-3

Card installation

4510-QIVC or

4511-QIVC Card

PCI Retainer Bracket

Remove Securing Screw and Bracket

Reuse Screw to Secure 45XX-QIVC Card

Install Card in Desired

PCI Slot

Loosen Three (3) Screws

Card removal

To remove a card, first disconnect all cables connected to the card, remove the rear plate screw,

and then remove the card from the slot.

Card configuration

The operating system software will automatically recognize and configure the card the next time

the mainframe power is turned on. Card operation is covered in

Software installation

NOTE The software will be already installed on the 4500-MTS hard drive. The

1. Install CD. Setup.exe should run automatically. Accept all of the installation defaults.

2. Reboot the 4500-MTS and login.

3. Exit (close) the 4500-MTS Real-Time Manager.

4. Upgrade the QIVC firmware through the Control Panel applet labeled 4500-MTS.

5. In Start->Settings->Control Panel, double-click the 4500-MTS icon, and select the

Flash Upgrade tab. After pressing the Start Flash Upgrade button, navigate to the

C:\Program Files\Keithley Instruments\4500-MTS\bin\QIVC Flash Upgrade folder and

select the file named 4510-QIVC-*.fx for the 4510-QIVC, or 4511-QIVC-*.fx for the

4511-QIVC. Select Open. After a few seconds, the applet should signal completion with a

series of three beeps and a status message.

Section 3.

procedure below should be used to re-install or upgrade software.

Page 26

2-6 Installation & Connections 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

6. Upgrade the Digital FPGA image. Repeat step 5 using the *.dx file type selector and the file

named 45xx-QIVC-*.dx in the same directory.

7. Upgrade the Analog FPGA image. Repeat step 5 using the *.ax file type selector and the file

named 45xx-QIVC-*.ax in the same directory.

8. Start the 4500-MTS Real-Time Manager located in the 4500-MTS folder.

9. Run the VB Embedded Sweep Example program located in the 4500-MTS folder.

10. Click Connect, and confirm the digital FPGA, analog FPGA, and firmware were successfully programmed. Version information is displayed in the Card Identification field. Repeat

steps 4 through 7 if incorrect.

Connections

WARNING The following information is intended only for qualified service per-

sonnel. Do not attempt these procedures unless you are qualified to

do so. Some of these procedures may subject you to electric shock,

possibly causing personal injury or death.

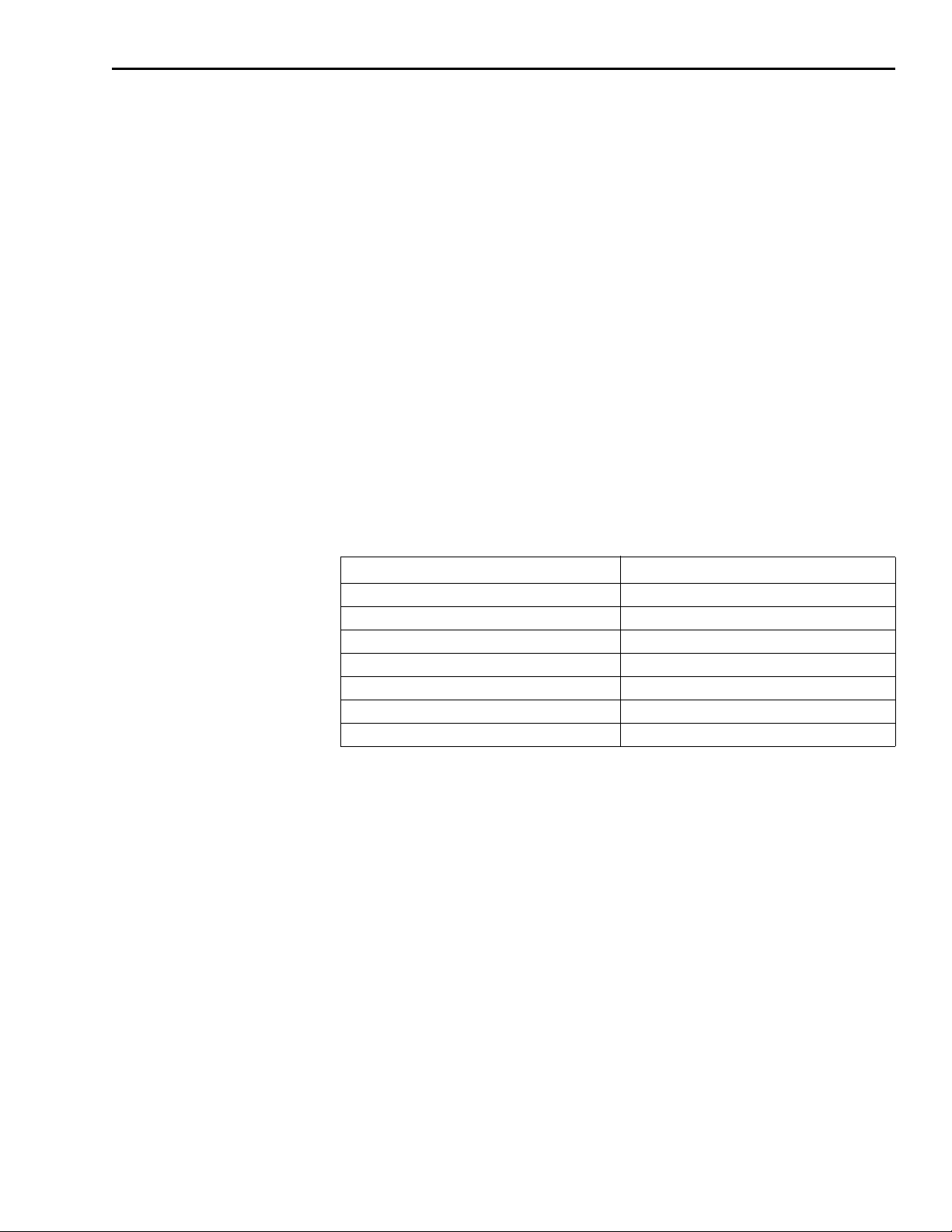

Connector terminal designations

The supplied 4500-CQIV-2 signal connecting cable is designed to mate with the DUT signal

connector on the card. The cable branches out to four connectors on the other end, one for each

of the four identical channels, labeled A through D.

Table 2-1 lists card connector terminal des-

ignations for each of the four channels.

Table 2-1

Connector terminal designations (each channel)

Signal Connector pin(s)

I-SOURCE HI

V-M E A SUR E HI

V-MEASURE LO

I-SOURCE LO

V-BI A S HI

GUARD

V-BI A S SE N SE L O

V-BI A S LO

1. Current source connections

2. Voltage source connections

1

1

1

1

2

2

2

2

3 and 11

4

12

5 and 13

1

2

10

9

Page 27

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Installation & Connections 2-7

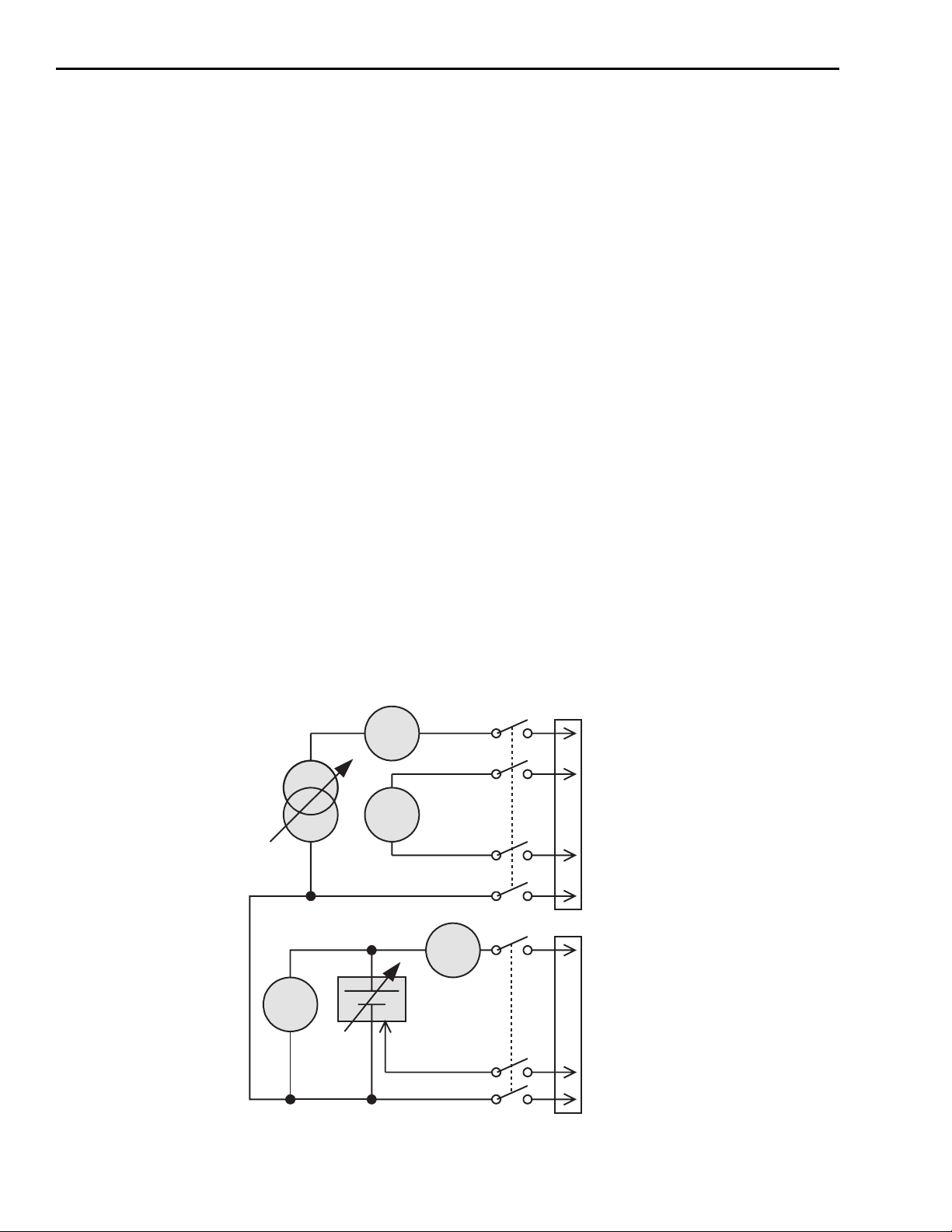

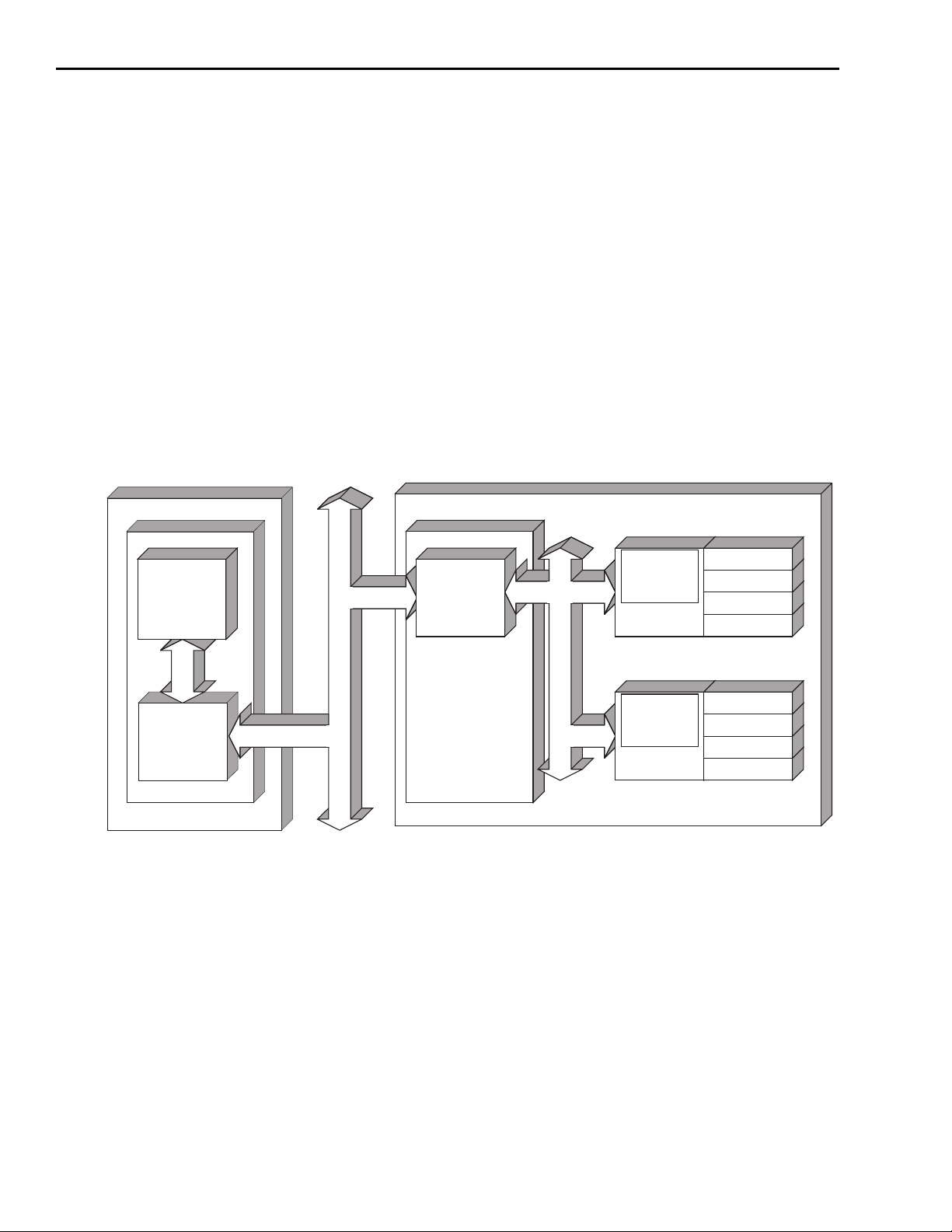

Block diagram

Figure 2-4 shows a block diagram of one channel of the 451x-QIVC cards. Each of the four

channels is identical.

Each of the four channels has two subchannels: I-Source and V-Source. In addition to sourcing

current, the I-Source subchannel measures the voltage and, optionally, the current (current read

back). The current source subchannel is useful for testing many types of DUTs. The current

source sections include circuitry for current readback, voltage measurement, and compliance,

while the voltage source section has current measurement and voltage readback circuits. Both

sections include output relays that control connections to the DUTs.

Figure 2-4

Card block diagram

-

I-READBACK

I-SOURCE

NOTE: The I-SOURCE circuit is bi-polar. It can source positive or negative current.

I-MEASURE

V-SOURCE

NOTE: The V-SOURCE circuit is bi-polar.

It can source positive or negative voltage.

V-MEASURE &

V-COMPLIANCE

High impedance pathways. Negligible

current flow.

V-READBACK

X1

Output

control

relays

Output

control

relays

Pin 3 & 11 : I-SOURCE HI

Pin 4: V-MEASURE HI

Pin 12: V-MEASURE LO

Pin 5 & 13: I-SOURCE LO

QIVC cable pin-out

(Channel A-D)

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15

Pin 1: V-SOURCE HI

Pin 2: GUARD

Pin 10: V-SOURCE SENSE LO

Pin 9: V-SOURCE LO

DUT connections

Figure 2-5 shows DUT connections. I-SOURCE HI and V-MEASURE HI are connected to the

diode anode (DUT A), while I-SOURCE LO and V-MEASURE LO are connected to the diode

cathode. V-SOURCE HI is connected to the diode anode (DUT B), while V-SOURCE LO

and V-SOURCE SENSE LOW are connected to the diode cathode. GUARD is connected to

the shield of the cable connected to V-SOURCE HI to shield the sensitive signal path against

interference. The GUARD connection may be required when high quality low current

(10µA range) measurements are required.

Page 28

2-8 Installation & Connections 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 2-5

DUT connections

I-SOURCE HI

I-READBACK

V-MEASURE HI

DUT A

V-MEASURE LO

I-SOURCE LO

I-SOURCE

V-MEASURE &

V-COMPLIANCE

Output

control

relays

V-SOURCE

Output states

I-MEASURE

V-READBACK

X1

Output

control

relays

V-SOURCE HI

GUARD

DUT B

V-SOURCE SENSE LO

V-SOURCE LO

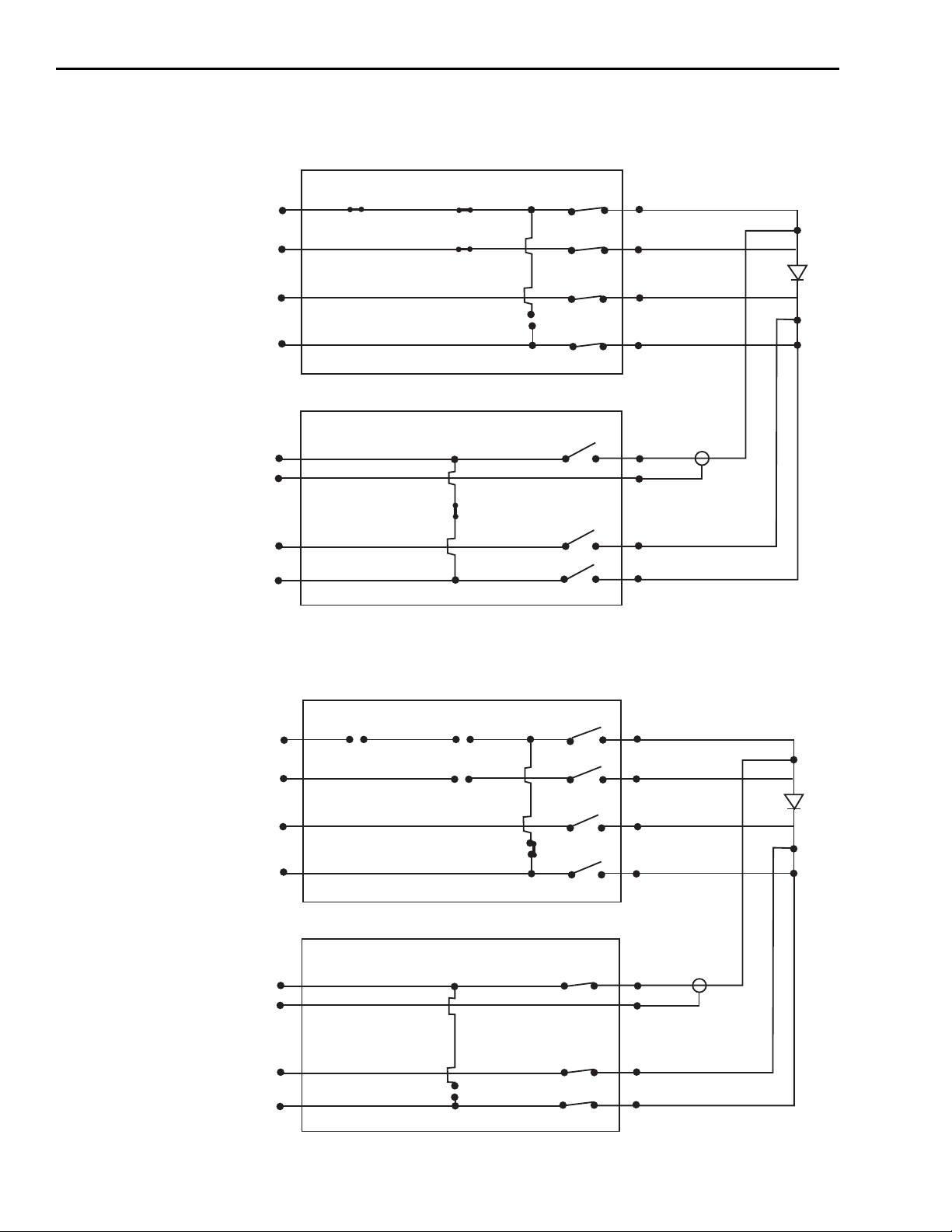

There is one output On state and two Off states. Figure 2-6 shows the On state compared with

the Off_Shorted and Off_Open states in Figure 2-7 and Figure 2-8 respectively. Table 2-2 sum-

marizes the available Output states.

NOTE See Section 4 for a description of the KE4500_EnableOutputs() command.

Output ON state

When the output is turned on (Figure 2-6), the internal terminal shorts (I-Source and V-Source )

are opened, and the I-SOURCE terminals are connected to DUT A and the V-SOURCE terminals

are connected to DUT B.

Output Off_Shorted state

When the output is in the Off_Shorted state (Figure 2-7), the I-SOURCE is disconnected from

DUT A, and the DUT terminals are shorted together. DUT B terminals are also shorted together

by internally connecting V-SOURCE HI and V-SOURCE LO.

Page 29

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Installation & Connections 2-9

Output Off_Open state

As shown in Figure 2-8, the I-Source and V-Source subchannel connections can be completely

isolated. Table 2-2 summarizes allowed states for the I-Source and V-Source subchannels. When

the output is in the Off_Open state, all source and measure connections are isolated (also

referred to as the high impedance off state).

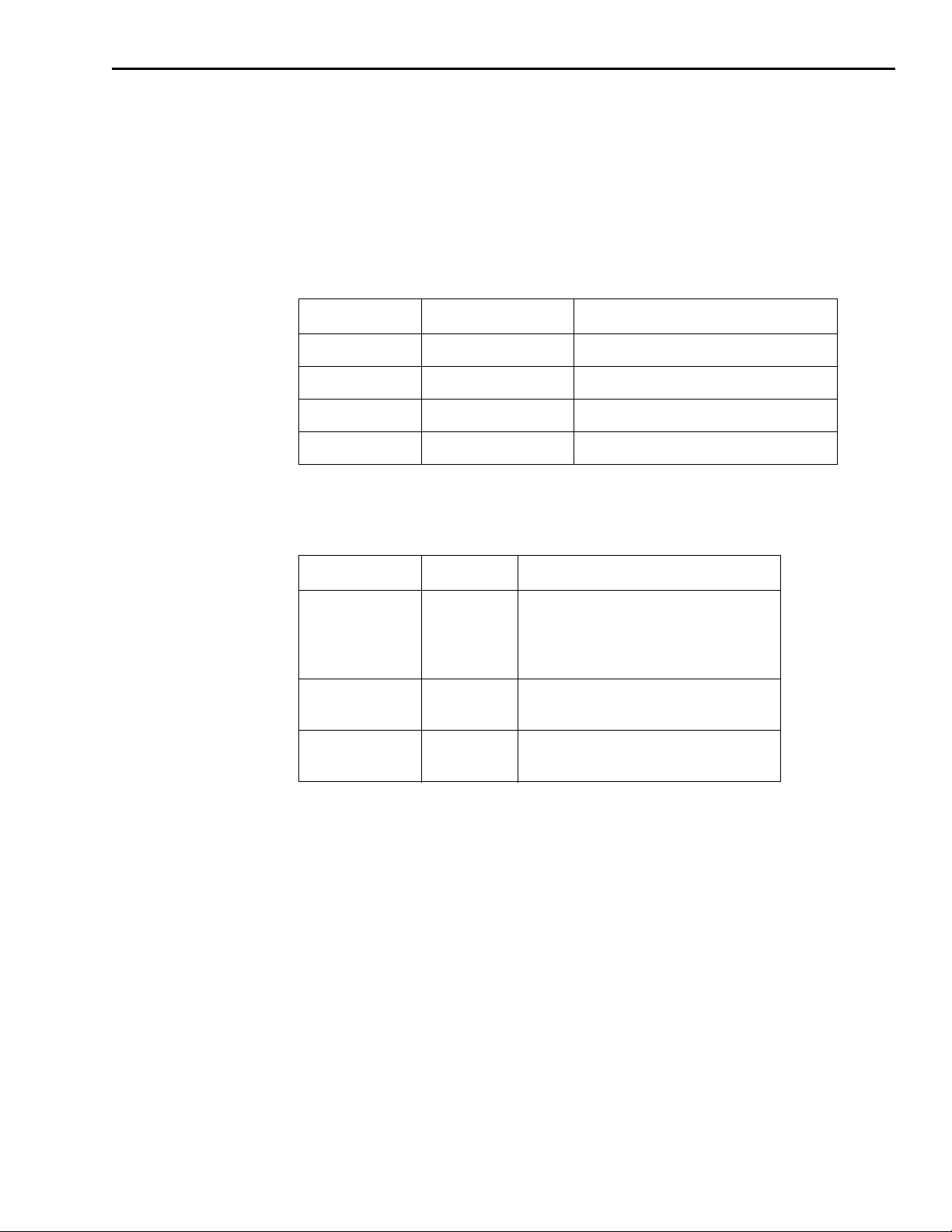

Table 2-2

Output states for KE4500_EnableOutputs() command

I-Source subchannel V-Source subchannel

Off_Shorted

1

Off_Shorted

ON ON

ON Off_Shorted

Off_Shorted

1

ON

ON Off_Open

Off_Open

Off_Open

2

2

ON

Off_Open

1

1

2

2

1. Off_Shorted: I Source HI and LO leads shorted together and

V Source HI and LO leads shorted together. See

2. Off_Open: All Source and Measure leads isolated from each

other and from QIV cable. This mode may also be referred to

as “isolated” or “high-impedance (Hi-Z)”. See

Figure 2-7.

Figure 2-8.

NOTE Be aware that the Guard pin is not isolated in the OFF_OPEN state.

Page 30

2-10 Installation & Connections 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 2-6

Output On state

Internal Signals

I-SOURCE HI

I-SOURCE Output Control Relays (OUTPUT ON)

External Signals

I-SOURCE HI

V-MEASURE HI

V-MEASURE LO

I-SOURCE LO

V-SOURCE HI

GUARD

V-SOURCE SENSE LO

V-SOURCE LO

Figure 2-7

Output Off_Shorted state

Internal Signals

I-SOURCE HI

V-SOURCE Output Control Relays (OUTPUT ON)

I-SOURCE Output Control Relays (OUTPUT OFF_SHORTED)

V-MEASURE HI

V-MEASURE LO

I-SOURCE LO

V-SOURCE HI

GUARD

V-SOURCE SENSE LO

V-SOURCE LO

External Signals

I-SOURCE HI

DUT A

DUT B

V-MEASURE HI

V-MEASURE LO

I-SOURCE LO

V-SOURCE HI

GUARD

V-SOURCE SENSE LO

V-SOURCE LO

V-MEASURE HI

DUT A

V-MEASURE LO

I-SOURCE LO

V-SOURCE Output Control Relays (OUTPUT OFF_SHORTED)

V-SOURCE HI

GUARD

DUT B

V-SOURCE SENSE LO

V-SOURCE LO

Page 31

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Installation & Connections 2-11

Figure 2-8

Output Off_Open state

I-SOURCE HI

V-MEASURE HI

V-MEASURE LO

I-SOURCE LO

V-SOURCE HI

GUARD

V-SOURCE SENSE LO

V-SOURCE LO

I-SOURCE Output Control Relays (OUTPUT OFF_OPEN)

I-SOURCE HI

V-MEASURE HI

DUT A

V-MEASURE LO

I-SOURCE LO

V-SOURCE Output Control Relays (OUTPUT OFF_OPEN)

V-SOURCE HI

GUARD

DUT B

V-SOURCE SENSE LO

V-SOURCE LO

Reverse current bias and laser diode considerations

Some diode-like devices, laser diodes in particular, may tolerate very little reverse current. The

QIVC specifications show that there is a small ambiguity of the current source at zero current,

which is given as the offset portion of the current source accuracy specification (

This offset current is unsigned, meaning it may be a negative, or reverse, current. If this current

may cause problems with the device under test, adjust the source value slightly positive by this

offset when the desired output current would be normally be set to zero.

Using both I-Source and V-Source subchannels with a single DUT

The Off_Open state isolates the subchannels individually. By using this subchannel isolation, it

is possible to connect both the I-Source and V-Source leads to the same DUT and power the

DUT with either subchannel.

As an example, for LED testing, both QIV subchannels provide unique capabilities. Figure 2-9

shows forward bias connections, while Figure 2-10 shows reverse bias connections. In Figure 2-9,

the I-Source subchannel is used to power the LED for forward voltage and other emission-oriented

measurements. In

surements.

Figure 2-10, the V-Source subchannel is used for reverse voltage leakage mea-

Appendix A).

Page 32

2-12 Installation & Connections 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 2-9

LED forward bias simultaneous I-Source and V-Source connections

Internal Signals

I-SOURCE HI

V-MEASURE HI

V-MEASURE LO

I-SOURCE LO

V-SOURCE HI

GUARD

V-SOURCE SENSE LO

V-SOURCE LO

I-SOURCE Output Control Relays

V-SOURCE Output Control Relays

External Signals

I-SOURCE HI

V-MEASURE HI

V-MEASURE LO

I-SOURCE LO

V-SOURCE HI

GUARD

V-SOURCE SENSE LO

V-SOURCE LO

DUT

Figure 2-10

LED reverse bias simultaneous I-Source and V-Source connections

Internal Signals

I-SOURCE HI

V-MEASURE HI

V-MEASURE LO

I-SOURCE LO

V-SOURCE HI

GUARD

V-SOURCE SENSE LO

V-SOURCE LO

I-SOURCE Output Control Relays

V-SOURCE Output Control Relays

External Signals

I-SOURCE HI

V-MEASURE HI

V-MEASURE LO

I-SOURCE LO

V-SOURCE HI

GUARD

V-SOURCE SENSE LO

V-SOURCE LO

DUT

Page 33

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Installation & Connections 2-13

Interlock

Each card is equipped with an interlock connector that can be used to inhibit the source outputs

of each individual channel when an external switch is open.

WARNING The interlock should always be used to protect operators and other

users from potential safety hazards.

Interlock events

When an interlock event occurs:

1. Set I-SOURCE subchannel to 0A and set V-SOURCE subchannel to 0V.

2. The source relay states are changed immediately for that channel’s interlock line, the

I-SOURCE is disconnected from the output terminals, and the DUT terminals are

shorted together. The V-SOURCE terminals are shorted together by internally connecting

V-SOURCE HI and V-SOURCE LO.

3. An interrupt is generated, and the test sequence is halted for the channel group containing

that channel, passing the event to the Real-Time Manager.

4. The test cannot be resumed. The test must be re-initiated after the interlock is recovered.

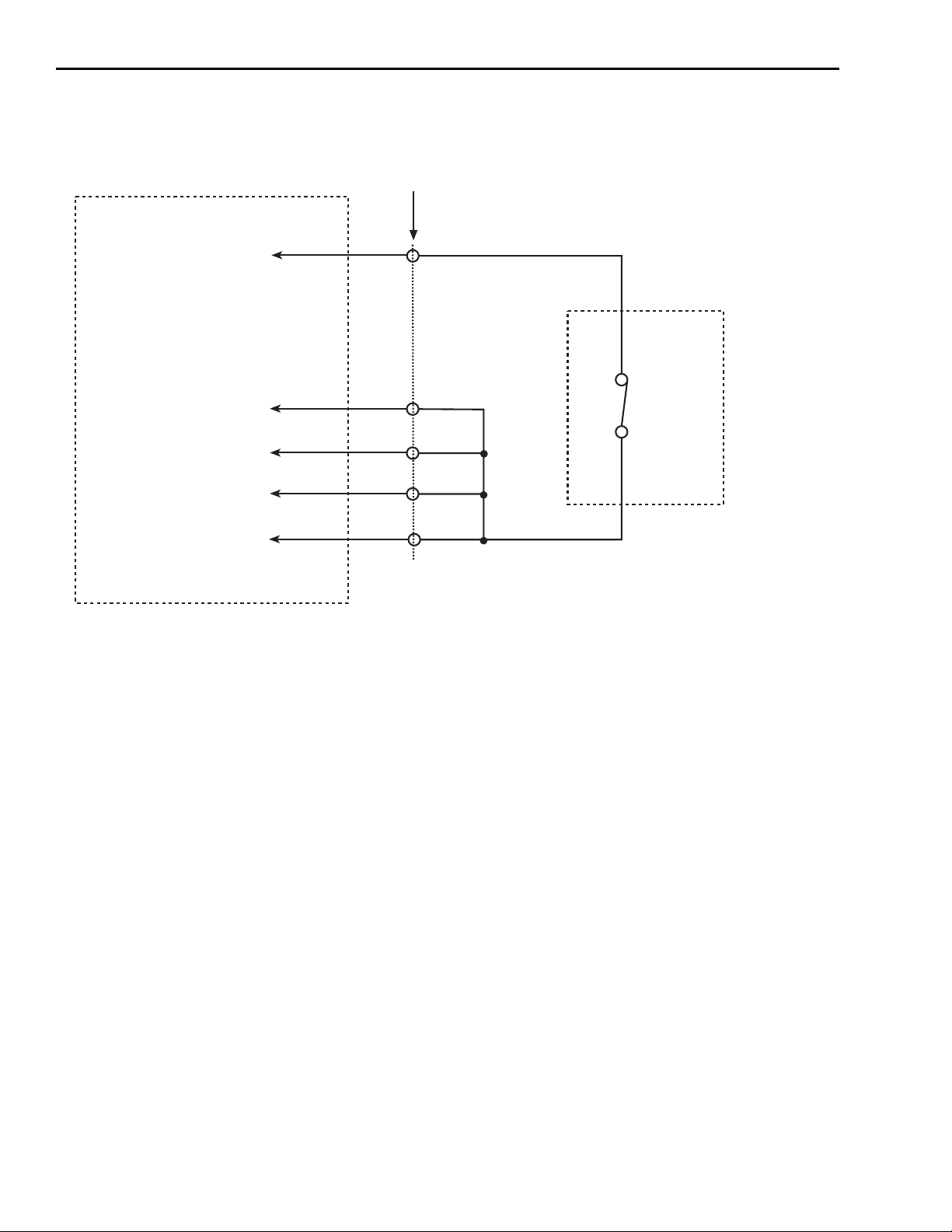

Interlock connections

Figure 2-11 shows typical connections directly from the 451x-QIVC card interlock connector to

an interlock switch in a test fixture. In this instance, a single interlock switch is connected to the

enable lines of all four channels. Other applications that require the output of each channel to be

individually controlled will require a separate switch for each channel. In either case, outputs

will be enabled (turned on) when the switch is closed. When the switch is open, output(s) will be

turned off (as described in Step 2 above) and cannot be turned on. See Figures

for output on and the two output off states.

CAUTION Under no circumstances should the interlock lines be intentionally

NOTE The +5V line on the interlock connector (pin 1) is internally protected

2-8 through 2-10

shorted to chassis ground. Improper operation will result.

The interlock is not designed to protect the DUT during an interlock

event. In the interest of protecting the operator, the output relays of

the interlock circuit close immediately and before the output is

driven to a low voltage potential. As a result, the DUT will see the

energy in the DUT cable. This energy may display as a significant

negative (opposite polarity of the source current) voltage at the

DUT. Activating the interlock may damage the DUT.

with a 0.75A fuse. Inadvertently shorting this line to chassis ground will

trip the fuse, disabling the interlock control circuits, and outputs cannot

be turned on. The fuse will automatically reset a few minutes after the

overload condition is removed.

Page 34

2-14 Installation & Connections 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 2-11

Connections directly to card interlock connector

4510-QIVC or 4511-QIVC Card

+5V

Channel A Enable

Channel B Enable

Channel C Enable

Channel D Enable

Pin 1

Pin 4

Pin 5

Pin 6

Pin 7

Card

interlock

connector

terminals

Switch

Channel outputs are enabled

when switch is closed, disabled

when switch is open.

Test

fixture

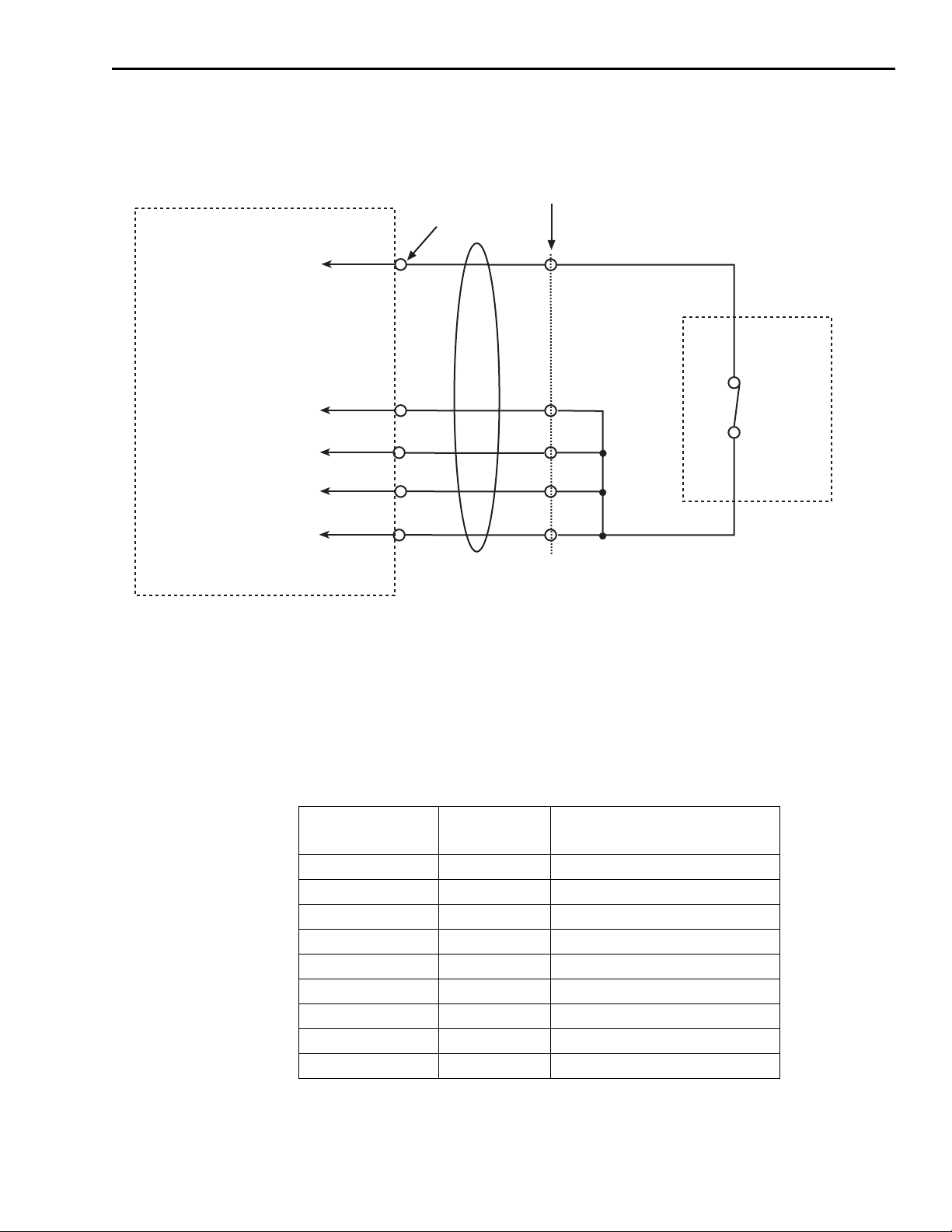

Interlock connector and cables

To facilitate interlock connections, the following connector and cable kit are available:

• Mating connector for rear panel interlock connector — Keithley model number

4500-ILK-KIT-1

• Interlock cable kit — Keithley model # 4500-CILK-*, where * relates to available cable

lengths (0.5, 1, 2, 3 meters). See

end of this cable.

Figure 2-12 for connections to the 9-pin connector on the

Page 35

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Installation & Connections 2-15

Figure 2-12

Connections to interlock cable 9-pin connector

4510-QIVC or 4511-QIVC Card

+5V

Channel A Enable

Channel B Enable

Channel C Enable

Channel D Enable

Pin 1

Pin 4

Pin 5

Pin 6

Pin 7

Card interlock

connector

terminals

4500-CILK-*

interlock

cable

Interlock

cable 9-pin

connector

terminals

Pin 1

Pin 7

Pin 3

Pin 8

Pin 4

Switch

Channel outputs are enabled

when switch is closed, disabled

when switch is open.

Test

fixture

Interlock terminal designations

Table 2-3 summarizes terminal designations for the 14-pin interlock connector on the

451x-QIVC and the 9-pin connector on the interlock cable.

Table 2-3

Interlock connector and cable terminal designations

14-pin interlock

connector

1 1 +5VD (+5V digital supply)

2 6 DIAG – RX (not implemented)

3 2 DIAG – TX (not implemented)

4 7 Interlock Channel A Enable

5 3 Interlock Channel B Enable

6 8 Interlock Channel C Enable

7 4 Interlock Channel D Enable

8 9 D – GND (digital ground)

9 – 14 N.C. ——

9-pin cable

connector

Signal description

Page 36

2-16 Installation & Connections 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

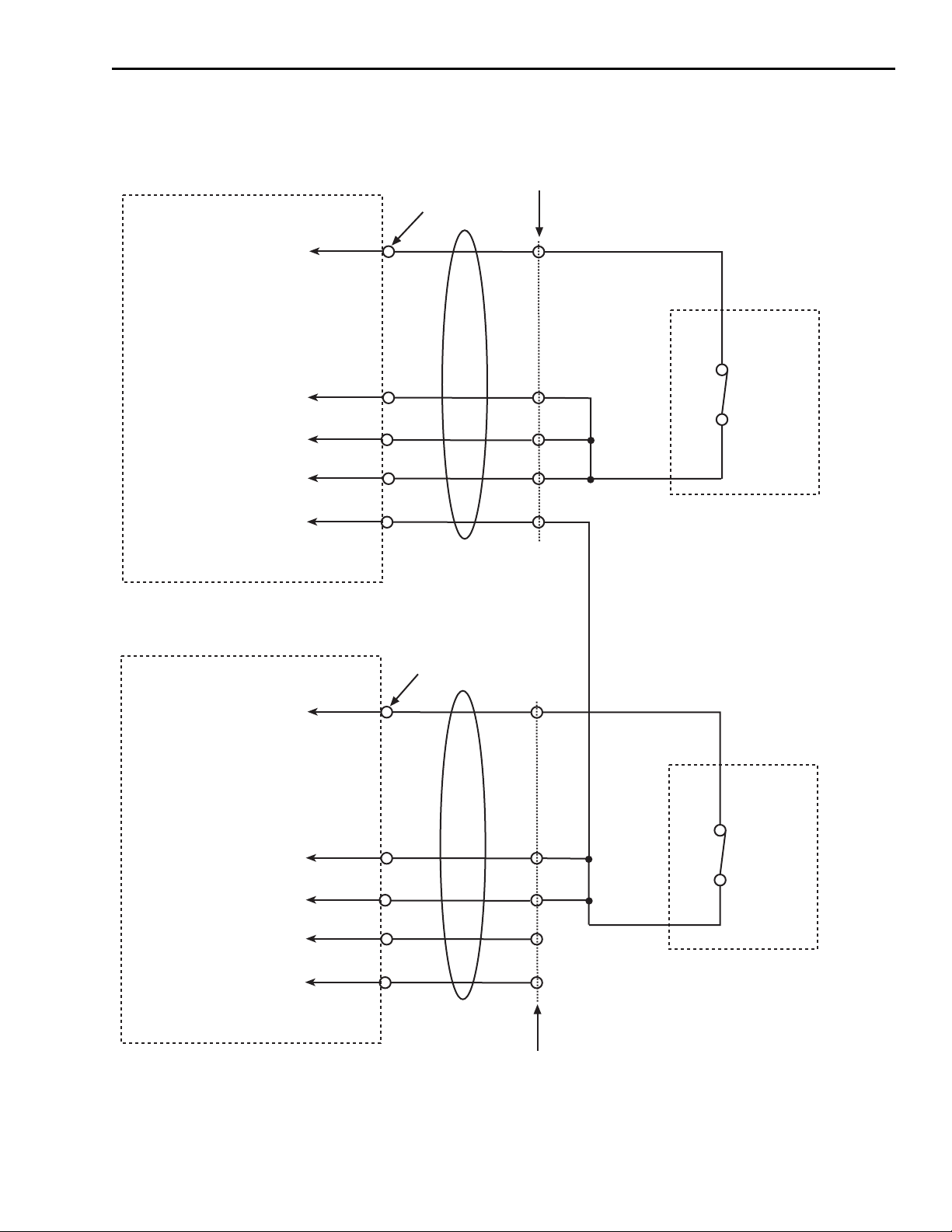

Multiple card interlock connections

When channel groups span cards, interlocks may be tied together across cards. For more than

four channels, use a separate +5V fused line (pin 1) for every four channel interlock enable

lines.

An example of multiple card interlock connections is shown in Figure 2-13. This example has

two channel groups:

•Group 1— Card 1 Channel A, Card 1 Channel B, Card 1 Channel C.

•Group 2 — Card 1 Channel D, Card 2 Channel A, Card 2 Channel B.

Page 37

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Installation & Connections 2-17

Figure 2-13

Multiple card interlock connections

451x-QIVC Card #1

+5V

Channel A Enable

Channel B Enable

Channel C Enable

Channel D Enable

Pin 1

Pin 4

Pin 5

Pin 6

Pin 7

Card interlock

connector

terminals

4500-CILK-*

interlock

cable

Interlock

cable 9-pin

connector

terminals

Pin 1

Pin 7

Pin 3

Pin 8

Pin 4

Switch

Closing switch enables Card 1

Channels A, B, and C.

Test

fixture #1

451x-QIVC Card #2

+5V

Channel A Enable

Channel B Enable

Channel C Enable

Channel D Enable

Pin 1

Pin 4

Pin 5

Pin 6

Pin 7

Card interlock

connector

terminals

4500-CILK-*

interlock

cable

Pin 1

Pin 7

Pin 3

Pin 8

Pin 4

Interlock

cable 9-pin

connector

terminals

Switch

Closing switch enables Card 1, Channel D,

Card 2, Channels A and B.

Test

fixture #2

Page 38

3

Basic Operation

Page 39

3-2 Basic Operation 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Introduction

This section contains basic information for using the 4510-QIVC and 4511-QIVC Quad IV

cards, including environmental conditions, and basic software operation when using the

embedded sweep example program.

NOTE See Appendix B for detailed terms, concepts, and definitions.

Environmental conditions

Temperature and humidity

For optimum accuracy, the 4510-QIVC and 4511-QIVC cards should be operated at an ambient

temperature of 18°C to 28°C at a relative humidity of 5% to 60%. For operating environments

outside these ranges, accuracy specifications must be derated (see specifications).

Warm-up period

For optimum accuracy, turn the system on and allow a one-hour warm-up period before use.

Basic software operation

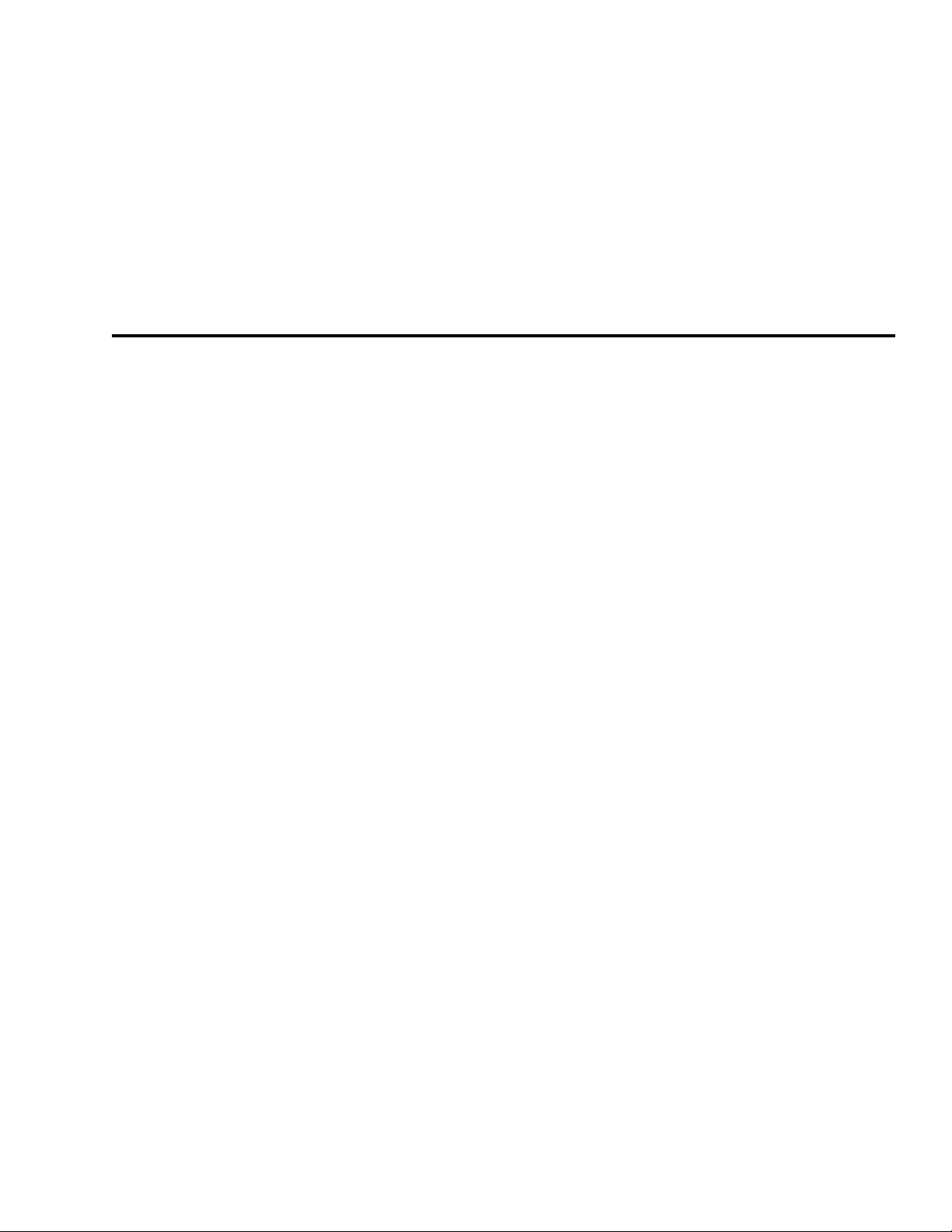

4500-MTS folder

Figure 3-1 shows the typical contents of the 4500-MTS folder located on the main desktop.

NOTE Actual 4500-MTS folder contents may vary, depending on installed

cards and software version.

Be sure to refer to the release notes and help files for updated software

information not contained in this manual.

Briefly, contents include:

• Release notes — Includes information on this particular version of 4500-MTS software.

•Help files — Contains detailed information for using card driver function calls for the soft-

ware platforms supported by the 4500-MTS. The C Help File covers using the 4500 software

with C-based platforms, while the VB Help File has details for use with Visual Basic

• 4500-MTS Real-Time Manager — The real-time manager, which runs in the background,

is launched when the system boots and the user logs in. Note that the real-time manager task

will automatically execute when the system boots. The Real-Time Manager must be running

to access and control the QIV cards.

• Reset 4500 — Resets the chosen QIV card(s) to power-on conditions.

• VB Embedded Sweep Example — A Visual Basic® application that demonstrates

embedded sweep capabilities.

®

.

Page 40

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Basic Operation 3-3

Figure 3-1

Typical 4500-MTS folder contents

Enabling the emulation mode

There are two basic operating modes for the 4500-MTS system: emulation mode and real mode.

The emulation mode provides pretend cards for running existing 4500 programs or developing

new ones. The Real mode (Emulation mode disabled) lets programs control 4500 cards in the

system.

To select the operating mode, double-click on the 4500-MTS icon in the Windows Control

Panel, click on the System Settings tab, and then Enable or Disable the emulation mode as

desired. Click OK to select.

4500-MTS Mainframe User’s Manual for other mainframe settings.

NOTE Emulation mode provides basic QIV functionality, but is not a complete

emulation of a QIV card. All measurements are simulated, operation

and test times are invalid, and there is no interlock functionality (the

interlock is always over-ridden).

Figure 3-2 shows the control panel System Settings tab, refer to the

Page 41

3-4 Basic Operation 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 3-2

4500-MTS control panel System Settings tab

Using the Embedded Sweep Example program

Overview

Example program capabilities

The supplied Visual Basic Embedded Sweep Program demonstrates 4510-QIVC and

4511-QIVC sweep capabilities. If the emulation mode is enabled, the embedded sweep example

program will operate without any cards in the system. If the emulation mode is disabled (real

mode), you can use the example program to control card(s) installed in the mainframe, set

source values, perform sweeps, and take measurements.

NOTE The included Embedded Sweep Example program provides sweep con-

trol of the 4500 with QIV card(s), but is not intended as a comprehensive

interface to all of the functionality available in the 4500-MTS system.

See

Section 4 for details on controlling the 4500-MTS using a program-

ming environment.

Multiple channel groups

A single instance of the 4500-MTS Embedded Sweep Example program can be used to configure different channel groups. However, it can only run one channel group at a time. Multiple

channel groups can only be run sequentially after the previous test has stopped. If you would

like to run a simultaneous test on another channel group, run a second instance of the Embedded

Sweep Example program, and configure another channel group.

Embedded sweep example software overview

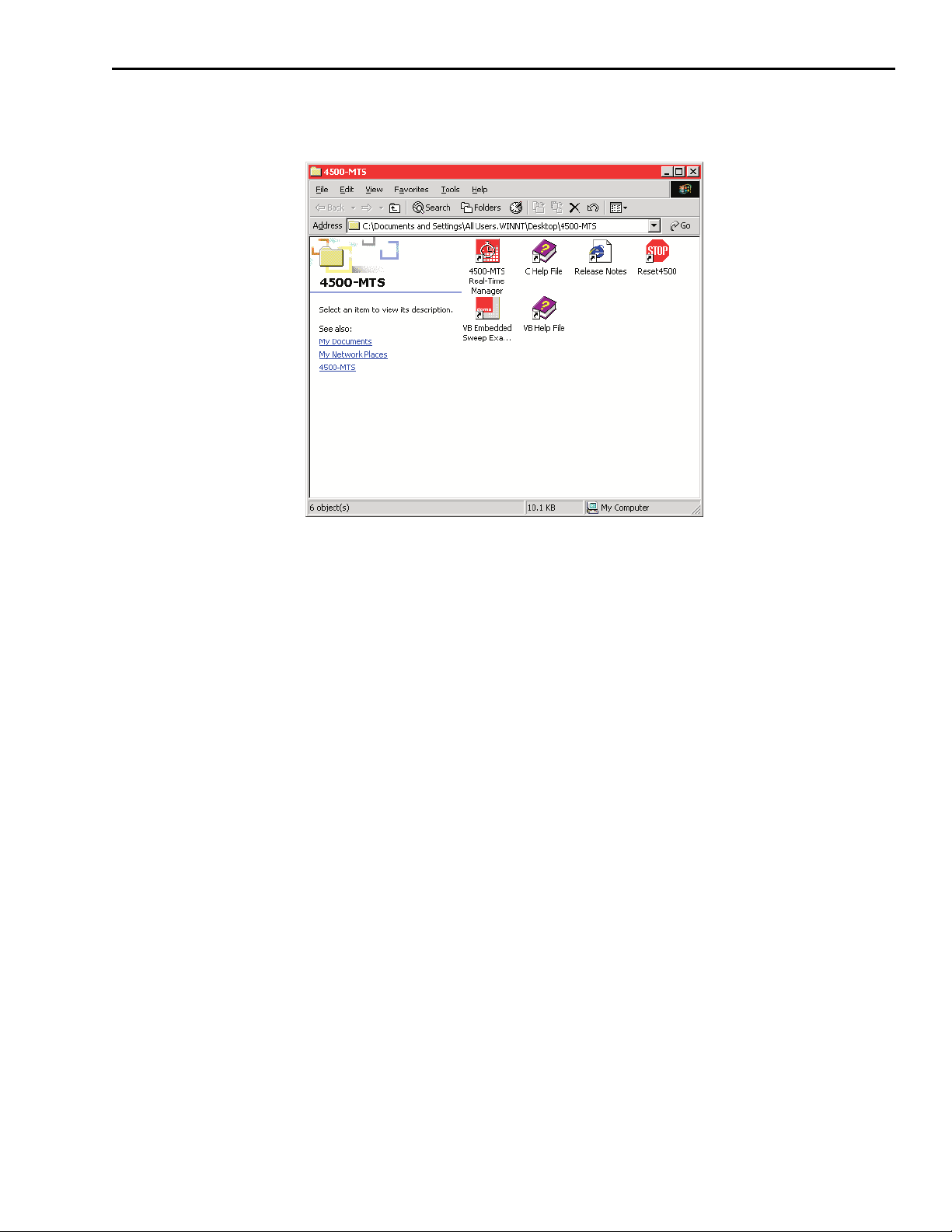

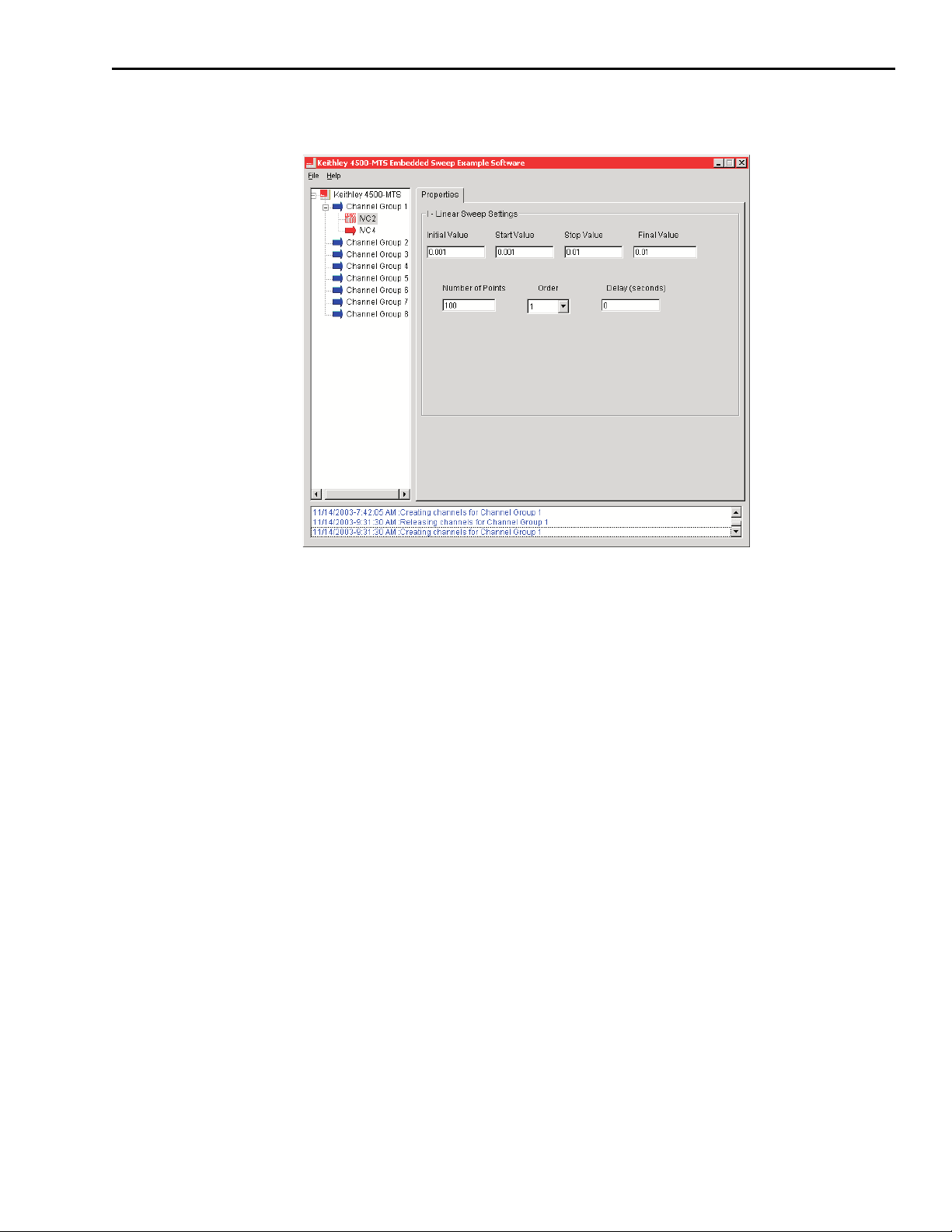

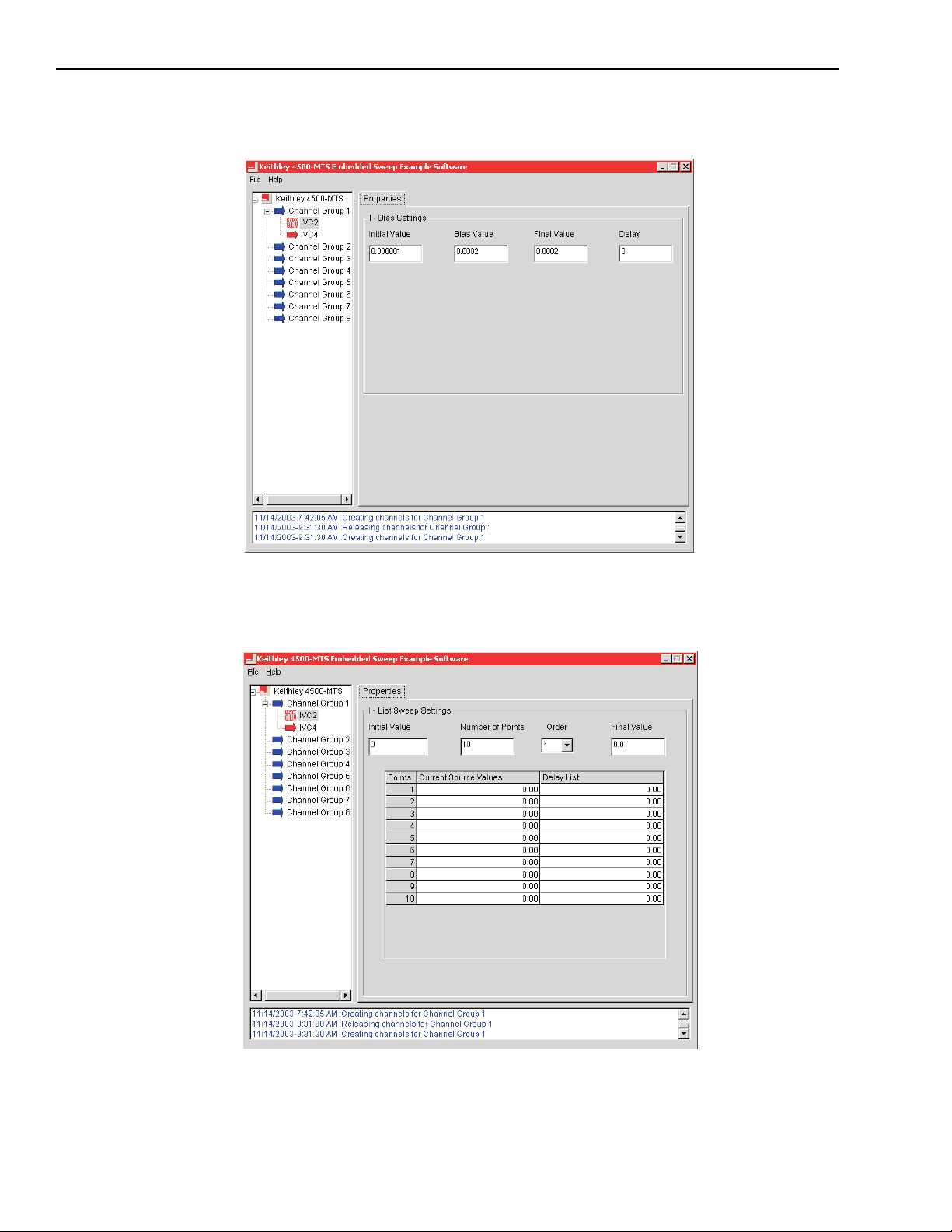

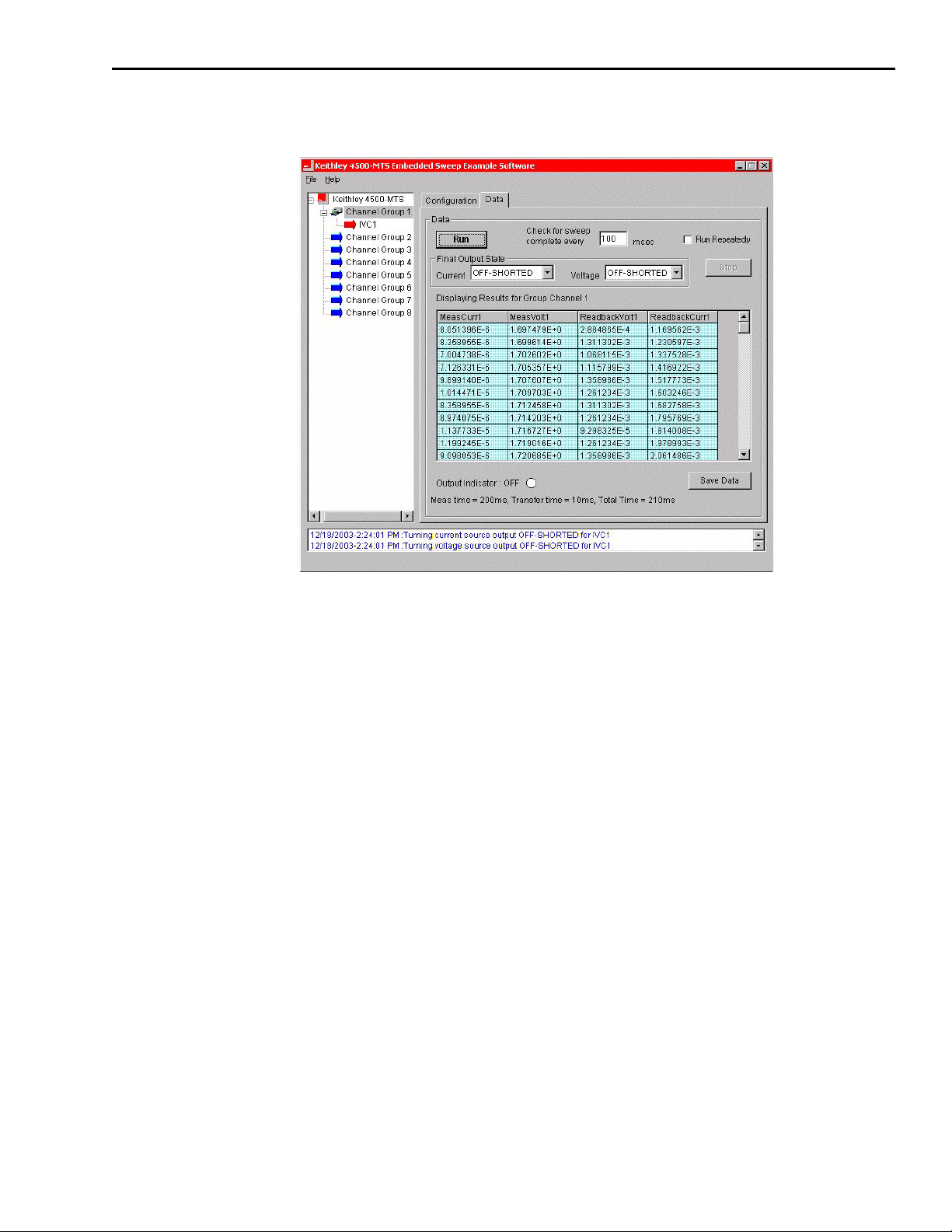

As shown in Figure 3-4, the 4500-MTS Embedded Sweep Example Software screen contains

three areas: the Channel Tree on the left side of the screen showing the Channel Groups, context-sensitive configuration tab(s) on the right side, and a status message area at the bottom.

The first action is to make a connection to the 4500-MTS by clicking Connect. After the connection is made, the fields on the right side are populated to show what 4500 cards are present in the

system. By clicking on one of the channel groups in the tree and clicking on the Configuration tab

on the right side, you can see which channels are available (

unused channels and clicking on Add to Group, you can start to build a new channel group.

Figure 3-6). By selecting one of the

Page 42

4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual Basic Operation 3-5

Clicking Apply creates the Channel Group, and the tree shows the new channel group and the

channels in the group (

The tab control will show an appropriate dialog to configure the type of channel you select.

Figure 3-8 shows a typical card properties window.

By selecting one of the channel groups in the tree, you can run a test and retrieve data into a grid

control (

Figure 3-12). You can save this data to a file for future analysis.

Figure 3-7). You can configure channels by selecting them in the tree.

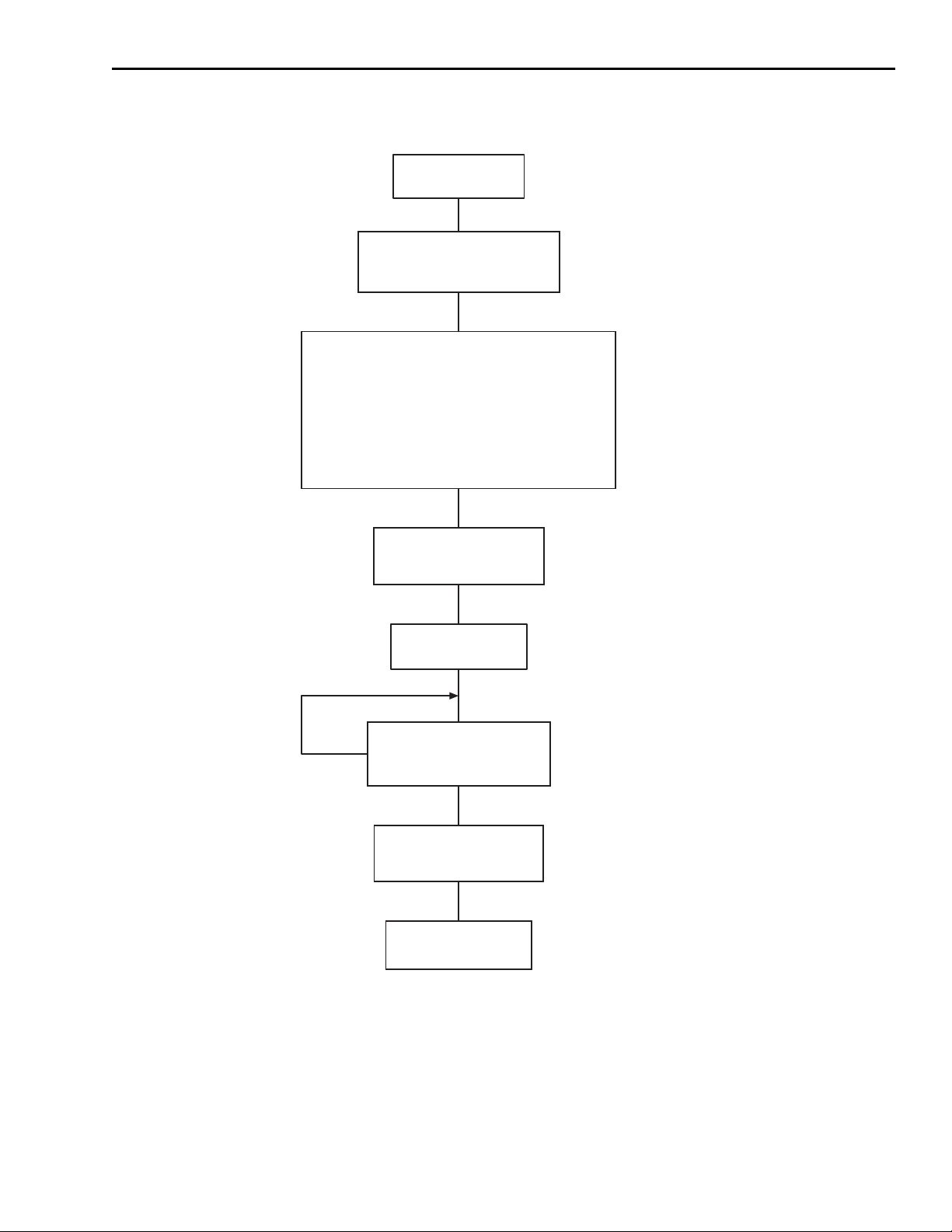

Running the 4500-MTS Embedded Sweep Example program

To run the 4500-MTS Embedded Sweep Example program, perform the following steps.

1. To run the example program using the emulation mode, click on the System Settings tab in

the 4500-MTS control panel located in the Windows Control Panel, and then Enable the

emulation mode. To run the software in the real mode, click on the System Settings tab in

the control panel, and then Disable the emulation mode. Click OK to complete your selec

tion. If you are using the real mode, make sure at least one 4500 card is present in the mainframe.

2. You can run the example program in one of two ways: (1) select Start > Programs > Keithley

Instruments > 4500-MTS > VB Embedded Sweep Example (

VB Embedded Sweep Example in the 4500-MTS folder to start the program and display

the initial window (

Figure 3-4).

Figure 3-3), or (2) double-click

-

Figure 3-3

Running VB Embedded Sweep Example program using Start menu

Page 43

3-6 Basic Operation 4510-QIVC and 4511-QIVC Quad IV Cards User’s Manual

Figure 3-4

Embedded sweep example program initial window

Channel Tree

shows group configuration

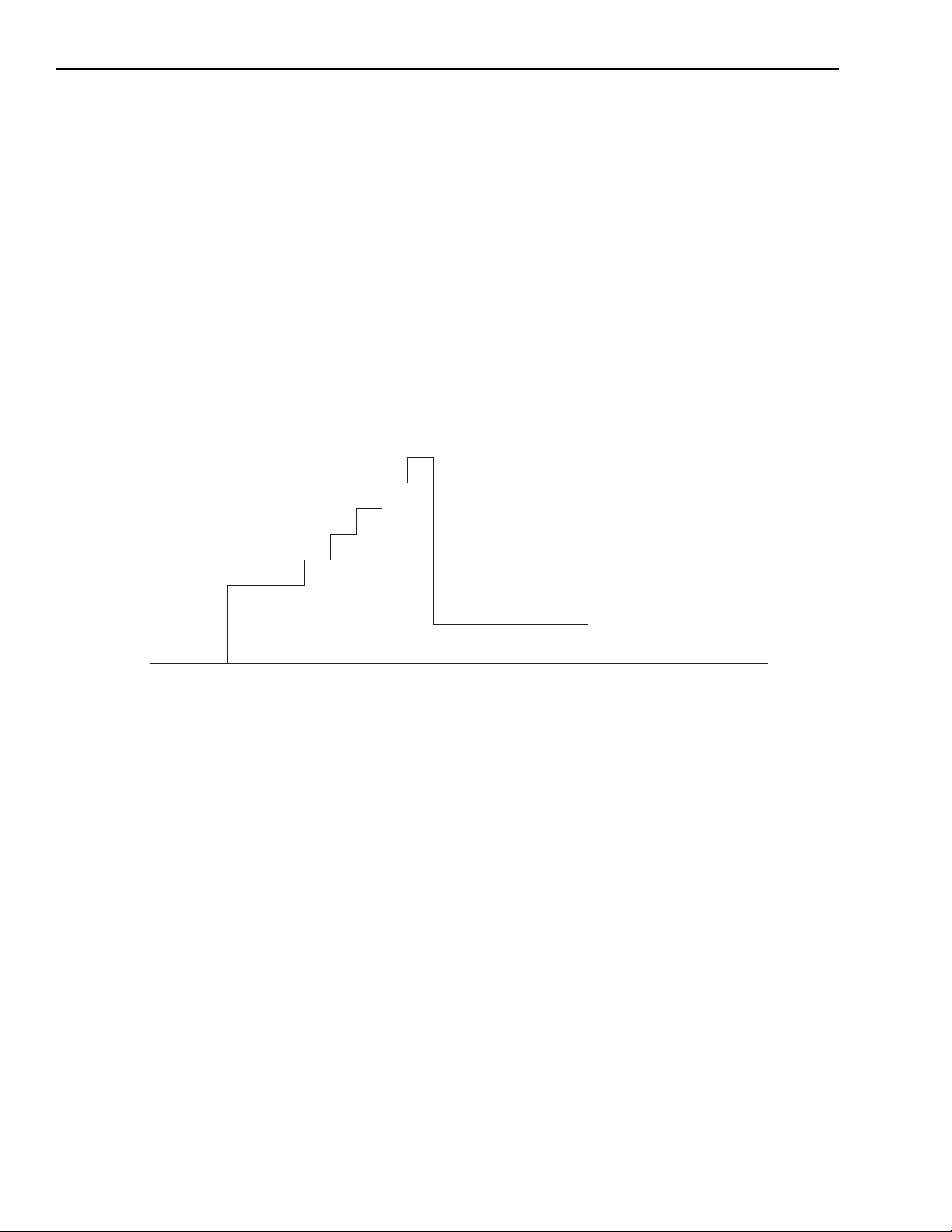

Tabbed area shows

context sensitive settings

Connecting to the 4500-MTS

The Embedded Sweep Demo (the Application) can run with a Controller Mode 4500-MTS that is

on the same computer as the 4500-MTS. Alternatively, the Application can connect to slave

(remote) units via ethernet and TCP/IP. The first step in QIV card control is to establish a soft

ware connection to the Real-Time Manager.

To establish a connection to the QIV card(s), perform the following steps:

1. In the Configuration tab control dialog, select either KE4500 (local) or a remote connection

from the Connection Type drop-down box. The default connection type is Ke4500, a local

connection. A local connection means that the Application is running on the 4500-MTS or

another computer using the emulation mode.

2. If you select Remote, enter an IP address: xxx.xxx.xxx.xxx.

3. Click Connect to populate the following fields in the 4500-MTS Configuration tab

(

Figure 3-5):

• System Identification — For the Keithley Instruments Inc., Model 4500-MTS, this field

provides information about the Operating System Version, Platform Version, Serial

Number, and System Software Version.

• Card — Identifies the card in a given slot as being a 4510-QIVC or 4511-QIVC card.