Page 1

Model 4210-MMPC-W

Keithley Instruments, Inc. Multi-measurement Prober Cable Kit

28775 Aurora Road Quick Start Guide

Cleveland, Ohio 44139

1-888-KEITHLEY

http://www.keithley.com

Overview

The Keithley Instruments Model 4210-MMPC-W multi-measurement prober cable kit (see Figure 1) provides a

collection of matched connection accessories. When properly installed, these accessories have the performance

needed that allow current-voltage (I-V), capacitance-voltage (C-V), and pul se I-V parametric characterization

measurements to be made using a single prober cable setup. This kit has been assembled for u se with a

Wentworth prober.

This prober cable kit requires the Keithley Instruments Articulated Arm (Wentworth Part Number 2026-96509).

Contact your Wentworth representative to obtain the necessary manipulator arm and instru ctions.

Quick Start Guide topics

The guide contains information about the use of this cable kit:

• Model 4200-SCS instrument connections: Explain

to the bulkhead.

• Prober bulkhead to prober pin connections (basic setup): Explains

prober bulkhead to the prober pins.

• Usage scenarios: Provide

o I-V testing (2-pin and 4-pin)

o C-V testing (2-pin and 4-pin)

o Pulse I-V measurements using the Keithley Model 4225-PMU with the Model 4225-RPM

s the following specific prober cable setups:

s how to make connections from the Model 4200-SCS

how to make connections from the

Related documents

The following documents (in PDF format) are located on the Model 4200-SCS Complete Reference CD:

• 4200-SCS Reference Manual: Section 16

The reference manual PDF can be found in the main 4200-SCS Complete Reference. Open the complete

reference web page by double-clicking the Complete Reference icon in the upper-left corner of the 4200

desktop.

• White Paper: Labs’ Demands for Greater Measurement Flexibility Require Cabling Systems Capable of

Accommodating Multiple Measurement Types

This white paper explains the different cabling requirements for I-V, C-V, and pulse I-V testing. It also

describes the concept behind this easy-to-use multi-measurement cabling system.

PA-1085 Rev. A / September 2012 1

Page 2

Model 4210-MMPC-W Quick Start Guide

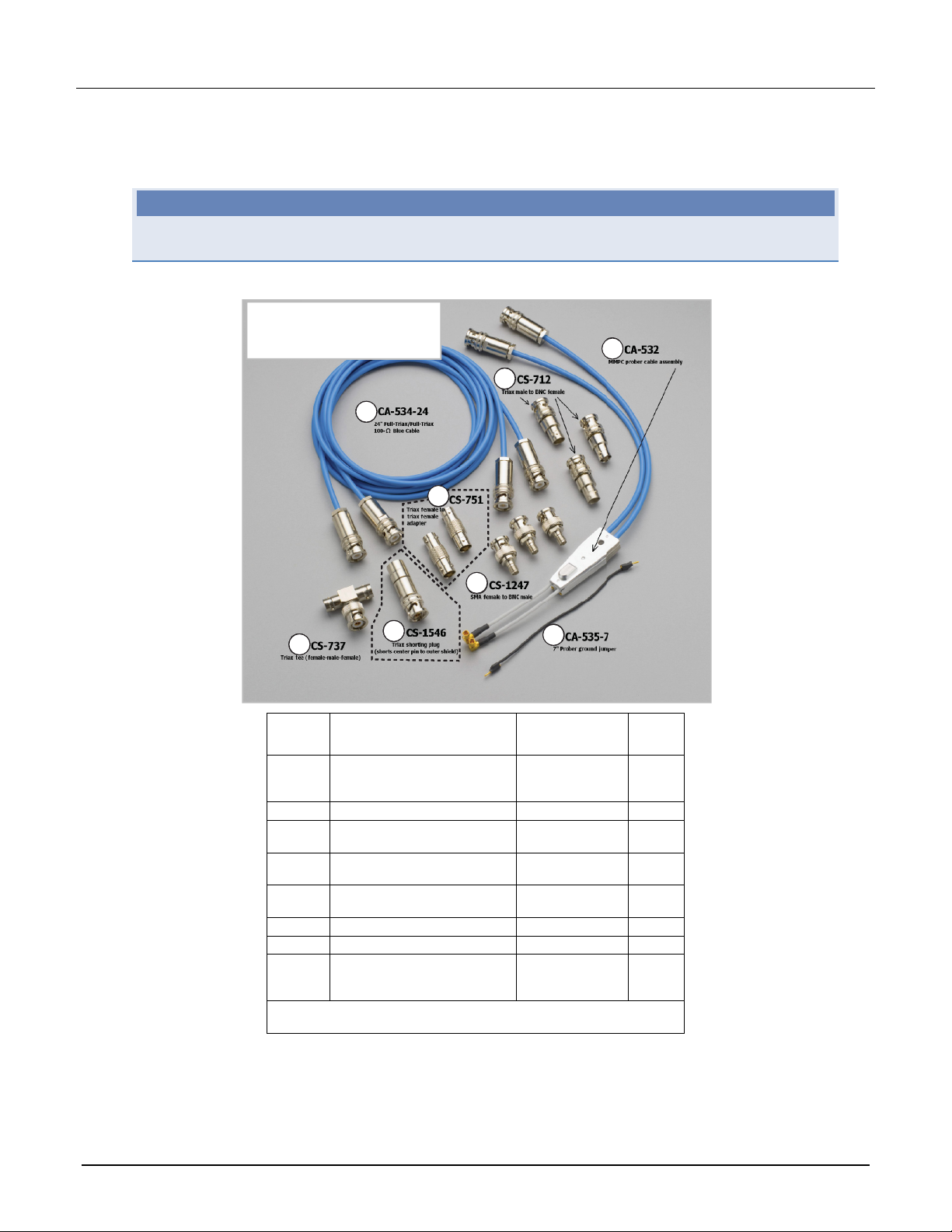

Prober cable kit contents

Figure 1 shows the cables, adapters, and supplies that are included in the Model 4210-MMPC-W

multi-measurement cable kit. This kit also includes the following screw (not shown): M3X12MMSSSOHCBLK

NOTE

Each kit (Model 4210-MMPC-W) supplies the required components to make sense and force

connections to one pin (additional kits are required to make additional connections).

Figure 1: Model 4210-MMPC-W multi-measurement prober cable kit

Model 4210-MMPC-W

1

2

3

4

7

5

6

Item Description Keithley

1* Prober cable assembly with

clamp (blue)

Length: 37.5 cm (14.75 in.)

2 Triaxial to BNC Adapter CS-712 3

3 Triaxial to triaxial cable (blue)

Length: 61.0 cm (24 in.)

4 Triaxial female to triaxial

female, high voltage adapter

5 Triaxial male to triaxial female,

tee

6 Triaxial shorting plug CS-1546 1

7 BNC-SMA adapter CS-1247 3

8 Ground jumper cable

assembly (black)

Length: 17.8 cm (7 in.)

* Not shown black M3X12MM stainless steel socket head cap screw

(Keithley Instruments part number M3X12MMSSSOHCBLK)

8

Part number

CA-532 1

CA-534-24 2

CS-751 2

CS-737 1

CA-535-7 1

Qty

2 PA-1085 Rev. A / September 2012

Page 3

Quick Start Guide Model 4210-MMPC-W

Model 4200-SCS instrument connections

WARNING

To prevent injury or death due to electric shock, remove all power from the Model 4200-SCS

and shut down the Wentworth prober before installing the prober cable kit.

Connect the Model 4200-SCS instruments to the female triaxial connectors located on the prober bulkhead (se e

Figure 2 for an example).

Figure 2. T

ypical prober bulkhead triaxial connectors

1

2

Item Description

1 Female triaxial connectors

2 Bulkhead

I-V testing

For I-V testing, connect the triaxial cables of your Model 4200-SCS source-measure units (SMUs) to the standard

female triaxial connectors on the bulkhead. Figure 3 shows the prober connectio

SMU or Model 4210-SMU).

ns for two SMUs (Model 4200-

NOTE

Figure 3 shows connections to SMUs that do not use preamps. These SMUs use the supplied triaxial

cables that are terminated with a miniature triaxial connector on one end and a standard triaxial

connector on the other end. If your SMUs are equipped with preamps, use the supplied cables that

PA-1085 Rev. A / September 2012 3

are terminated with standard triaxial connectors on both ends. Figure 3 shows both cables.

Page 4

Model 4210-MMPC-W Quick Start Guide

Figure 3: Model 4200-SCS SMU connections to the prober

4200-SCS

SMU-1

SMU-2

SMUs with preamps not installed (as shown):

SMUs with preamps installed:

SENSE

FORCE

SENSE

FORCE

SMU connections to prober bulkhead

Triaxial cable

Triaxial cable

Wentworth prober

bulkhead

Female

triaxial

connectors

Miniature triaxial

connector (male)

Standard triaxial

connector (male)

C-V testing

Two prober cable kits include the cable adapters needed to connect the subm iniature version A (SMA) cables of

the Model 4210-CVU to the female triaxial connectors on the prober's bulkhead.

Figure 4 shows how to make the connections. Use the torque wrench (supplied with the Model 4210-CVU) to

tighten the SMA connectors to the proper specification (8 in. lb.).

Figure 4: Model 4210-CVU prober connections

4200-SCS

4210-CVU

Use supplied torque

wrench to tighten

SMA connections

to 8 in. lb.

HCUR

Wentworth prober

bulkhead

HPOT

LPOT

LCUR

A

A = SMA cable (male to male) supplied with

4200-CVU)

B = SMA female to BNC male (CS-1247)

C = BNC female to triaxial male (CS-712)

C

B

Female

triaxial

connectors

4 PA-1085 Rev. A / September 2012

Page 5

Quick Start Guide Model 4210-MMPC-W

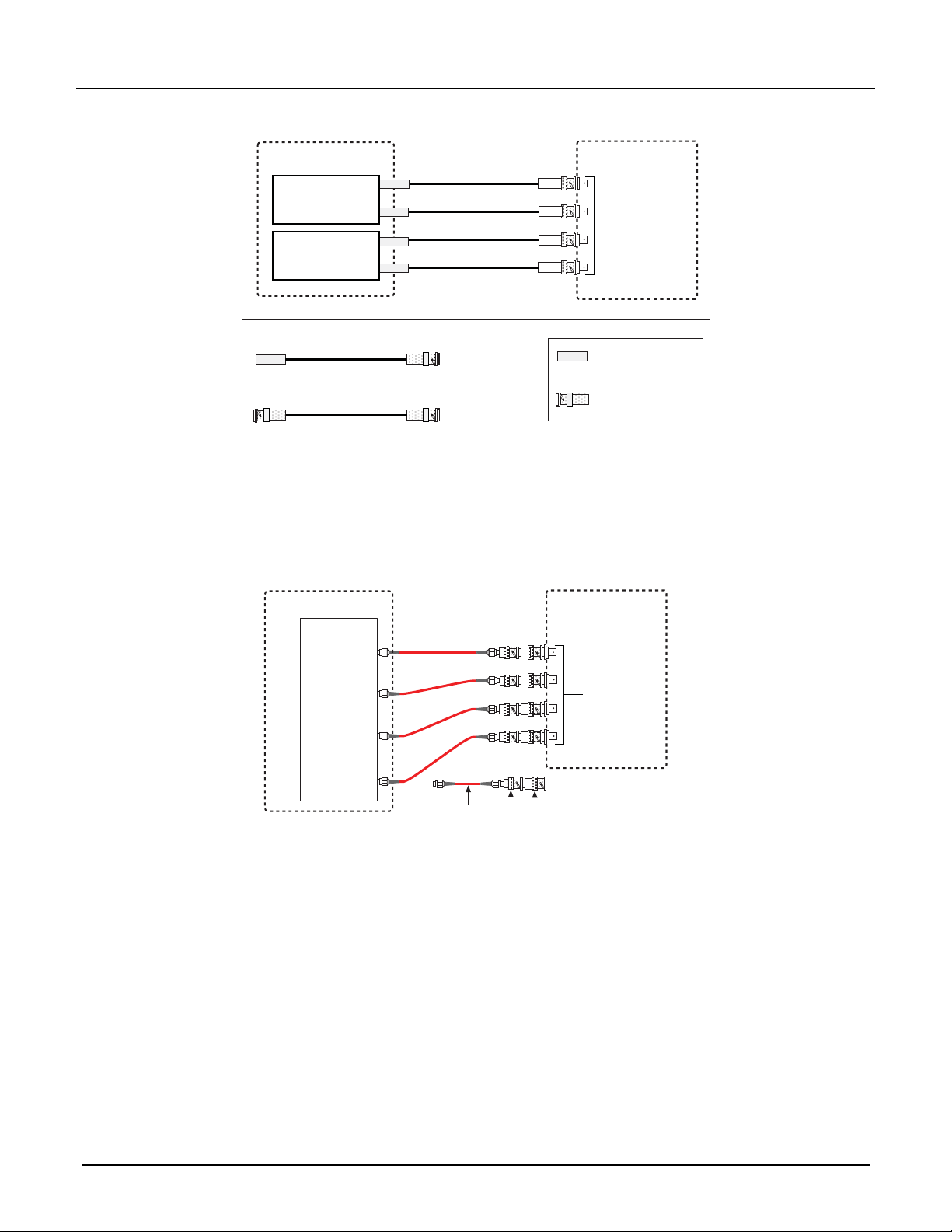

Prober bulkhead to prober pin connections (basic setup)

Figure 5 shows the basic cable setup for the 2-pin I-V and 2-pin C-V testing scenarios described in this guide. The

4-pin I-V and 4-pin C-V testing scenarios require minor setup changes; pulse I-V setup, which is more compl ex, is

described later in this quick start guide.

NOTE

The two-pin setup illustrated below requires two Model 4210-MMPC-W kits.

Figure 5: Basic 2-pin prober cable setup

6

5

4

Item Description Part number Quantity Notes

1 Prober cable

assembly

2 Ground jumper cable

assembly

3 Triaxial female to

triaxial female, high

voltage adapter

4 Prober bulkhead (for

triaxial connectors)

5 Triaxial connectors N.A. 4 Prober bulkhead triaxial connectors

6 Triaxial to triaxial

cable

3

CA-532 2

CA-535-7 2 The jumpers connect the commons

CS-751 4

N.A. 1

CA-534-24 4

1

2

of the two cable assemblies.

1

2*

PA-1085 Rev. A / September 2012 5

Page 6

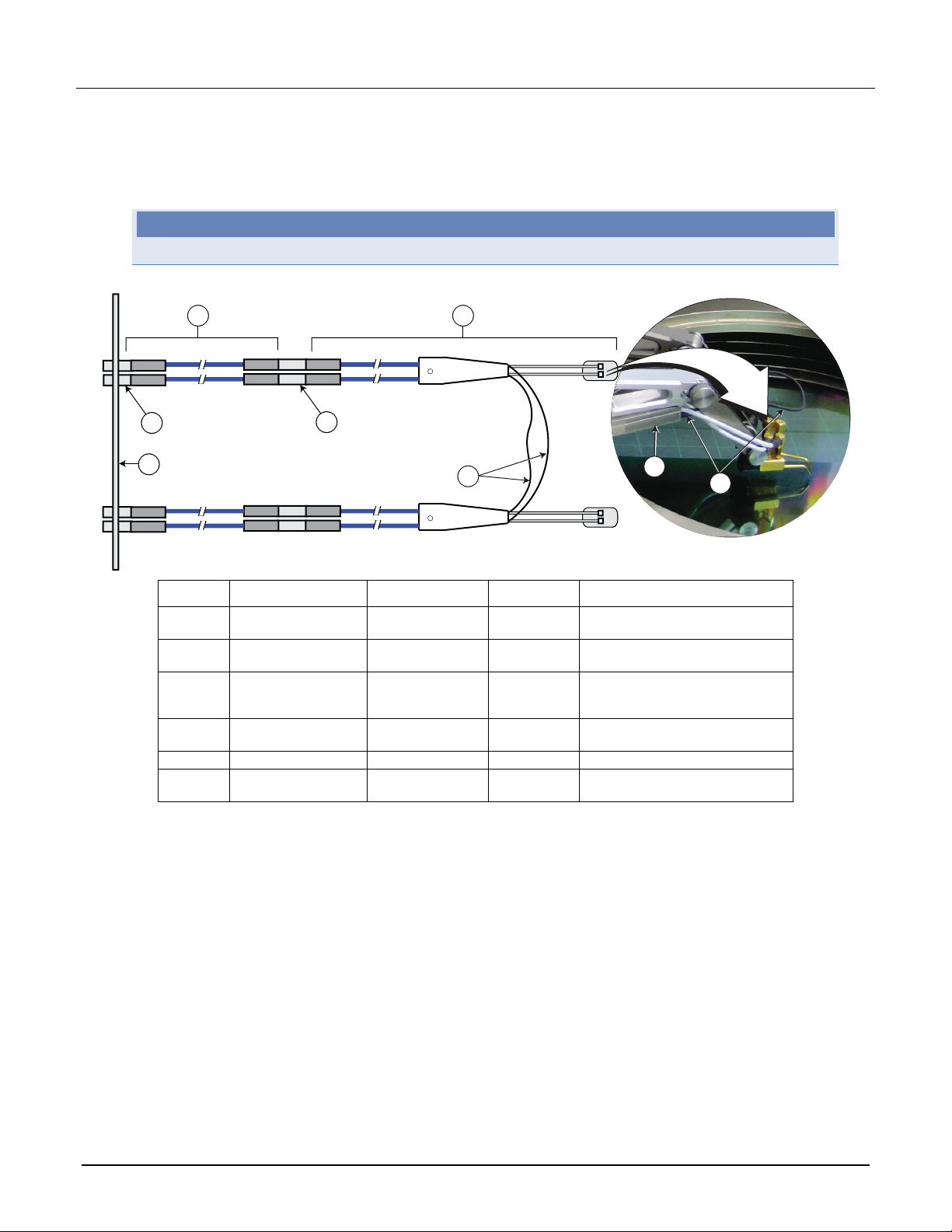

Model 4210-MMPC-W Quick Start Guide

Installation guidelines

Figure 6 shows the prober cable assemblies of two Model 4210-MMPC-W kits installed in a Wentworth prober.

Each blue triaxial cable (CA-587) is secured to the manipulator mounting bracket by one mounting screw (see item

1, Figure 6 for location).

Figure 6: T

wo prober cable kits installed in a Wentworth prober

2

1

3

4

View of cable assembly

underneath manipulator

Guidelines:

• Secure each prober cable assembly to a manipulator using a single mounting screw (1, Figure 6 show s

the locatio

• As shown in Figure 6, route the blue cables (2) along the side

n of the mounting screw). Firmly tighten the cable assemblies to the manipulators.

s of the manipulators.

• Connect a black jumper (3) from one cable assembly to the other. This jumper connects the commons

of the two cable assemblies together. The jumper plugs into the ends of the assembly blocks (4). It is

good practice to install the second jumper. It improves the connection and is a good place to store the

extra jumper (second jumper not shown in Figure 6).

NOTE

Figure 6 shows an example of good routing for the ground jumper wires. When routing the wires,

consider the possible movements of the manipulators, as well as the movements of the camera or

microscope.

6 PA-1085 Rev. A / September 2012

Page 7

Quick Start Guide Model 4210-MMPC-W

Figure 7: Side view of the installed prober cable assemblies

6

1

2

45

To properly attach the cable:

1. Connect the cable wires of the cable assemblies (1) to the APT probe tips (2), as shown in Figure 7.

2.

When routing the wires, consider the possible movements of the manipulators and the microscope. Figure

6 sho

ws an example of good routing for the jumper and cable wires.

3. For each pin, connect the triaxial cable assemblies (3) to the supplied female adapters (4).

4. Connect the triaxial cable assemblies (5) to the triaxial connectors on the bulkhead panel (6).

3

Usage scenarios

I-V testing: 2-pin I-V setup

To perform 2-pin I-V testing, connect two Model 4200-SMUs or Model 4210-SMUs to the prober bulkhead and then

use the setup shown in Figure 8 as a guide to connect to the device under test (DUT). Figure 2 shows typical

triaxial SMU con

nections to the outside of the bulkhead.

NOTE

The setup for 2-pin I-V testing requires two prober cable kits.

PA-1085 Rev. A / September 2012 7

Page 8

Model 4210-MMPC-W Quick Start Guide

Figure 8: Test setup for 2-pin I-V testing

SMU-1

SMU-2

DUT

1

2

1

2*

6

5

4

SMU-1

3

Force

Sense

Signal path

Force

SMU-2

Sense

Item Description Part number Quantity Notes

1 Prober cable

assembly

2 Ground jumper cable

assembly

3 Triaxial female to

triaxial female, high

voltage adapter

4 Prober bulkhead (for

triaxial connectors)

5 Triaxial connectors N.A. 4 Prober bulkhead triaxial connectors

6 Triaxial to triaxial

cable

CA-532 2

CA-535-7 2 The jumpers connect the commons

of the two cable assemblies.

CS-751 4

N.A. 1

CA-534-24 4

I-V testing: 4-pin I-V setup

With four Model 4200-SMUs connected to the prober bulkhead, use the setup shown in Figure 9 to perform 4-pin

I-V testing. Figure 3 shows two SMUs connected to one of the bulkhead

connection panels. Connect two additional

SMUs to the other bulkhead connection panel.

NOTE

The setup for 4-pin I-V testing requires four prober cable kits.

8 PA-1085 Rev. A / September 2012

Page 9

Quick Start Guide Model 4210-MMPC-W

Figure 9: Test setup for 4-pin I-V testing

SMU

SMU

SMU

SMU

DUT

Signal path

SMU

SMU

4-terminal

DUT

Jumper*

1 of 4

The four jumpers connect the

*

commons of the four cable

assemblies.

SMU

SMU

C-V testing: 2-pin C-V setup

NOTE

The setup for 2-pin C-V testing requires two prober cable kits.

With a Model 4210-CVU connected to the prober bulkhead, use the fundamental setup shown in Figure 10 to

perform 2-pin C-V testing. Figure 4 shows the CVU connections to

Figure 10: Test setup for 2-pin C-V testing

Triaxial to triaxial cables

(CA-534-24)

Prober cable assembly

the outside of the bulkhead.

(CA-532)

HI Cur

HI Pot

Connect to

Connect to prober

bulkhead triaxial

connectors

LO Pot

LO Cur

HI Cur

HI Pot

Model

4210-CVU

LO Pot

LO Cur

Triaxial female to triaxial

female adapters

(SC-751)

Signal path

DUT

Jumpers*

(CA-535-7)

The jumpers connect the commons of

*

the two cable assemblies.

prober pin

DUT

PA-1085 Rev. A / September 2012 9

Page 10

Model 4210-MMPC-W Quick Start Guide

C-V testing: 4-pin C-V setup

NOTE

The setup for 4-pin C-V testing requires four prober cable kits.

A typical test for a field effect transistor (FET) is to connect the drain, bulk, and source together and perform the

measurement across the gate. With a Model 4210-CVU connected to the prober bulkhead, use the setup shown in

Figure 11 to perform 4-pin C-V testing.

: Test setup for 4-pin C-V testing

Gate

Drain

4-terminal

DUT

Source

Bulk

L-Pot

L-Cur

*

Jumper*

1 of 4

The four jumpers connect the commons

of the four cable assemblies.

H-Pot

H-Pot

H-Cur

4-terminal

DUT

Drain

Bulk

Source

Signal path

Figure 11

Gate

Setup using the Keithley Model 4225-PMU for pulse I-V measurements

L-Pot

L-Cur

H-Cur

NOTE

The setup for four-pin pulse I-V testing requires four prober cable kits.

The Model 4225-PMU is an Ultra Fast I-V Module that is an instrument card for the Model 4200-SCS. The PMU has

two channels of voltage pulse source with integrated simultaneous voltage and current measurement.

Figure 12 shows the cable and adapters needed to connect a PMU cha

shows a typical prober connection setup for testing a four-pin device.

Figure 12: Cable and adapters used to connect PMU channel to prober bulkhead

Model

4225-PMU

channel

A

A = 2 m SMA cable (male to male)

(supplied with Model 4225-PMU)

B = SMA female to BNC male

(CS-1247)

C = BNC female to triax male

(CS-712)

Prober

B

C

10 PA-1085 Rev. A / September 2012

nnel to the prober bulkhead, and Figure 13

Use the supplied torque

wrench to tighten the SMA

connections to 8 in. lb.

Page 11

Quick Start Guide Model 4210-MMPC-W

Figure 13: Basic four-pin prober setup for PMU

To bulkhead, then connected to

Model 4225-PMU channel 1

B

A

C

E*

C

D

Drain

Gate

4-terminal

DUT

Source

D

NOTE This four-pin setup requires four

Bulk

Model 4210-MMPC-S kits.

(CA-535-7)

To bulkhead, then connected to

Model 4225-PMU channel 2

D

Jumper**

1 of 4

D

C

E*

C

B

A

A = Triaxial tee (CS-737)

B = 24” triaxial to triaxial 100 W cable (CA-534-24)

C = Triaxial female to triax female adapter (CS-751)

D = MMPC prober cable assembly (CA-532)

E = Triaxial shorting plug* (CS-1546)

The triaxial shorting plug (H) connects the

*

center conductor of the triaxial cable to

the outer shield.

to pulse generator low.

The four jumpers connect the commons of the

**

four cable assemblies.

This connects DUT LO

Setup using the Keithley Model 4225-RPM for I-V, C-V, or pulse I-V measurements

NOTE

The setup for three-pin pulse I-V testing requires three prober cable kits. The setups for four-pin

testing require four prober cable kits.

The Model 4225-RPM is a Remote Amplifier/Switch that is an optional item to the Model 4225-PMU. The PMU has

two channels, so each PMU instrument card supports two (2) RPMs. The MMPC cables simplify the conne ction

and re-connection between the instruments and the device under test. The combination of the MMPC cables with

the RPM permits testing I-V, C-V, or pulse I-V automatically, without any manual cable re-connections. When using

only two RPMs on a four-terminal device, some re-cabling is required for certain C-V test configurations.

The Model 4225-RPM has the appropriate connector types at the input and output of the RPM enclosure to

eliminate any adapters when connecting cables to the RPM. On the input side, there are two triaxial connectors for

SMU Force and SMU Sense. There are two SMA connectors for CVU POT and CVU CUR. There is also an RPM

control connector for the control and power of the RPM from the Model 4225-PMU. The output of the RPM is a pair

of triaxial cables (Force and Sense), which connect directly to the MMPC cables as shown in the figures below.

See Section 16 of the 4200 Reference Manual for Model 4225-PMU and Model 4225-RPM information and how to

configure an ITM for a pulse IV test.

PA-1085 Rev. A / September 2012 11

Page 12

Model 4210-MMPC-W Quick Start Guide

2 Channel I-V or Pulse I-V Setup

For most I-V and pulse I-V testing, only two source/measure channels are typically used. The two active signals are

connected to the gate and drain, and the source (and bulk, if present) is connected to ground (see Figure 14 and

Figure 15). For the C-V test setup shown in Figure 16, all four source/measure channels are used.

Figure 14

To SMU1

To CVU HI

To Model 4225-PMU 1,

RPM channel 1

Bulkhead pass-through

for RPM cables

To SMU2

To CVU LO

To Model 4225-PMU 1,

RPM channel 2

: Test setup for three-pin device using two-channel I-V and Pulse I-V

MMPC prober cable assembly

A =

Wentworth prober

bulkhead

Model

4225-RPM 1

SMU Sense

SMU Force

CVU HI Pot

CVU HI Cur

RPM Control

Model

4225-RPM 2

SMU Sense

SMU Force

CVU LO Pot

CVU LO Cur

RPM Control

Black triaxial SMU cables

Red SMA CVU cables (CA-447)

White RPM control cable

(CA-547-2)

Sense

Force

Ground Jumper*

1 of 2

(CA-535-7)

Sense

A

Force

(CA-532)

Triaxial female to triaxial female

B =

adapter (CS-751)

Triaxial shorting plug** (CS-1546)

C =

NOTE This three-pin setup requires three

Model 4210-MMPC-W kits.

A

Drain

Gate

Source

A

The two jumpers connect the

*

commons of the three cable

assemblies.

The triaxial shorting plug (C)

**

connects the center conductor

of the triaxial cable to the outer

shield. This connects DUT LO

to pulse generator low.

B

C**

12 PA-1085 Rev. A / September 2012

Page 13

Quick Start Guide Model 4210-MMPC-W

Figure 15: Test setup for four-pin device using two-channel I-V and Pulse I-V

MMPC prober cable assembly

A =

(CA-532)

Triaxial female to triaxial female

B =

adapter (CS-751)

Triaxial shorting plug** (CS-1546)

C =

NOTE This three-pin setup requires three

Model 4210-MMPC-W kits.

A

The two jumpers connect the

*

Drain

Gate

commons of the three cable

assemblies.

The triaxial shorting plug (C)

**

connects the center conductor

Source

of the triaxial cable to the outer

shield. This connects DUT LO

to pulse generator low.

A

To SMU1

To CVU HI

To Model 4225-PMU 1,

RPM channel 1

Bulkhead pass-through

for RPM cables

To SMU2

To CVU LO

To Model 4225-PMU 1,

RPM channel 2

Wentworth prober

bulkhead

Model

4225-RPM 1

SMU Sense

SMU Force

CVU HI Pot

CVU HI Cur

RPM Control

Model

4225-RPM 2

SMU Sense

SMU Force

CVU LO Pot

CVU LO Cur

RPM Control

Black triaxial SMU cables

Red SMA CVU cables (CA-447)

White RPM control cable

(CA-547-2)

Sense

Force

Ground Jumper*

1 of 2

(CA-535-7)

Sense

A

Force

B

C**

PA-1085 Rev. A / September 2012 13

Page 14

Model 4210-MMPC-W Quick Start Guide

Figure 16: Test setup for four-terminal C-V testing

MMPC prober cable assembly

A =

(CA-532)

Triaxial female to triaxial female

B =

adapter (CS-751)

Ground jumper* (CS-535-7)

C =

NOTE This four-pin setup requires four

Model 4210-MMPC-W kits.

A

C

Drain

Gate

C

The three jumpers (C) connect

*

the commons of the four cable

assemblies.

C

Bulk

Source

A

B

A

B

To SMU1

To CVU HI

To Model 4225-PMU 1,

RPM channel 1

Bulkhead pass-through

for RPM cables

To SMU2

To CVU LO

To Model 4225-PMU 1,

RPM channel 2

Wentworth prober

bulkhead

Model

4225-RPM 1

SMU Sense

4225-RPM 2

SMU Force

CVU HI Pot

CVU HI Cur

RPM Control

Model

4225-RPM 2

SMU Sense

SMU Force

CVU LO Pot

CVU LO Cur

RPM Control

Black triaxial SMU cables

Red SMA CVU cables (CA-447)

White RPM control cable

(CA-547-2)

Sense

Force

Sense

Force

A

14 PA-1085 Rev. A / September 2012

Page 15

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and

Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most

measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or

to voltage sources with high transient overvoltages. Measurement Category II connections require protection for high transient

overvoltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are

for connection to Category I sources unless otherwise marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructi ons, or the safety of

the equipment may be impaired.

09/12

Page 16

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection agains t fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

!

The symbol on an instrument means caution, risk of danger. The user should refer to the operating instructions located in

the user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means caution, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

Hg

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated pr ocedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley Instruments. Standard fuses with applicable national

safety approvals may be used if the rating and type are the same. Other components that are not safety-related may be

purchased from other suppliers as long as they are equivalent to the original component (note that selected parts should be

purchased only through Keithley Instruments to maintain accuracy and functionality of the product). If yo u are unsure about the

applicability of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do n ot app ly

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., a data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

09/12

Loading...

Loading...