Tektronix 4200A-SCS User manual

Model 4200A-SCS

LPT Library

Programming

4200A-LPT-907-01 Rev. C March 2023

tek.com/keithley

*P4200A-LPT-907-01C*

4200A-LPT-907-01C

LPT Library

Model 4200A-SCS

Programming

© 2023, Keithley Instruments

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments is strictly prohibited.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, LLC. Other brand names are trademarks or registered trademarks of their

respective holders.

Actuate

®

Copyright © 1993-2003 Actuate Corporation.

All Rights Reserve d.

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: 4200A-LPT-907-01 Rev. C March 2023

Safety precaut ions

The following safety precautio ns should be observed before using this product and any associated ins tr um enta tion . Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not conn ect any instru ment to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user docume ntat ion.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is mark ed on the instr u ment .

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains h azard s that coul d dama ge the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purcha sed from o ther

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2018.

Table of contents

Introduction ............................................................................................................... 1-1

LPT library reference ............................................................................................................ 1-1

Lists of LPT library commands ............................................................................................. 1-2

General operation commands ................................................................................................... 1-2

Math operation commands ........................................................................................................ 1-4

SMU commands ........................................................................................................................ 1-4

PGU (pulse only) and PMU (pulse and measure) commands ................................................... 1-5

CVU commands ........................................................................................................................ 1-7

Switch commands ..................................................................................................................... 1-8

LPT Library Status and Error codes ..................................................................................... 1-8

Customized error texts .............................................................................................................. 1-9

Code status or error titles ........................................................................................................ 1-10

Large number reported readings and explanations ................................................................. 1-15

LPT library and Clarius interaction when using UTMs ....................................................... 1-16

LPT commands for general operations ................................................................... 2-1

LPT commands for general operations ................................................................................ 2-2

clrscn ......................................................................................................................................... 2-2

clrtrg .......................................................................................................................................... 2-3

delay ......................................................................................................................................... 2-5

devint ........................................................................................................................................ 2-6

disable ....................................................................................................................................... 2-8

enable ....................................................................................................................................... 2-8

execut ....................................................................................................................................... 2-8

getinstattr .................................................................................................................................. 2-9

getinstid ................................................................................................................................... 2-10

getinstname............................................................................................................................. 2-10

GetKiteCycle ........................................................................................................................... 2-11

GetKiteDevice ......................................................................................................................... 2-11

GetKiteSite .............................................................................................................................. 2-11

GetKiteSubsite ........................................................................................................................ 2-12

GetKiteTest ............................................................................................................................. 2-12

getlpterr ................................................................................................................................... 2-13

imeast ..................................................................................................................................... 2-13

inshld ....................................................................................................................................... 2-13

kibcmd ..................................................................................................................................... 2-14

kibdefclr ................................................................................................................................... 2-15

kibdefdelete ............................................................................................................................. 2-16

kibdefint ................................................................................................................................... 2-16

kibrcv ....................................................................................................................................... 2-17

kibsnd ...................................................................................................................................... 2-18

kibspl ....................................................................................................................................... 2-19

kibsplw .................................................................................................................................... 2-20

kspcfg ...................................................................................................................................... 2-20

kspdefclr .................................................................................................................................. 2-21

kspdefdelete ............................................................................................................................ 2-22

kspdefint .................................................................................................................................. 2-22

ksprcv ...................................................................................................................................... 2-23

kspsnd ..................................................................................................................................... 2-23

PostDataDouble ...................................................................................................................... 2-24

PostDataInt ............................................................................................................................. 2-25

PostDataString ........................................................................................................................ 2-26

rdelay ...................................................................................................................................... 2-26

Table of contents Model 4200A-SCS LPT Library Programming

rtfary ........................................................................................................................................ 2-27

savgX ...................................................................................................................................... 2-27

scnmeas .................................................................................................................................. 2-29

searchX ................................................................................................................................... 2-29

setmode .................................................................................................................................. 2-32

sintgX ...................................................................................................................................... 2-34

smeasX ................................................................................................................................... 2-35

trigcomp .................................................................................................................................. 2-36

trigXg, trigXl............................................................................................................................. 2-37

tstdsl ........................................................................................................................................ 2-40

tstsel ........................................................................................................................................ 2-40

LPT commands for math operations ....................................................................... 3-1

LPT commands for math operations .................................................................................... 3-1

kfpabs ....................................................................................................................................... 3-1

kfpadd ....................................................................................................................................... 3-2

kfpdiv ......................................................................................................................................... 3-2

kfpexp ....................................................................................................................................... 3-3

kfplog ........................................................................................................................................ 3-4

kfpmul ....................................................................................................................................... 3-4

kfpneg ....................................................................................................................................... 3-5

kfppwr ....................................................................................................................................... 3-6

kfpsqrt ....................................................................................................................................... 3-7

kfpsub ....................................................................................................................................... 3-8

LPT commands for SMUs ......................................................................................... 4-1

LPT commands for SMUs .................................................................................................... 4-1

adelay ....................................................................................................................................... 4-1

asweepX ................................................................................................................................... 4-2

avgX .......................................................................................................................................... 4-4

bmeasX ..................................................................................................................................... 4-5

bsweepX ................................................................................................................................... 4-7

devclr ........................................................................................................................................ 4-9

devint ........................................................................................................................................ 4-9

forceX ...................................................................................................................................... 4-11

getstatus.................................................................................................................................. 4-12

intgX ........................................................................................................................................ 4-14

limitX ....................................................................................................................................... 4-16

lorangeX .................................................................................................................................. 4-17

measX ..................................................................................................................................... 4-18

mpulse .................................................................................................................................... 4-20

pulseX ..................................................................................................................................... 4-21

rangeX .................................................................................................................................... 4-23

rtfary ........................................................................................................................................ 4-25

segment_sweepX_list ............................................................................................................. 4-26

setauto .................................................................................................................................... 4-27

ssmeasx .................................................................................................................................. 4-28

sweepX ................................................................................................................................... 4-29

LPT commands for CVUs ......................................................................................... 5-1

LPT commands for the CVUs .............................................................................................. 5-1

adelay ....................................................................................................................................... 5-2

asweepv .................................................................................................................................... 5-3

bsweepX ................................................................................................................................... 5-4

cvu_custom_cable_comp .......................................................................................................... 5-6

devclr ........................................................................................................................................ 5-6

Model 4200A-SCS LPT Library Programming Table of contents

devint ........................................................................................................................................ 5-7

dsweepf ..................................................................................................................................... 5-8

dsweepv .................................................................................................................................. 5-10

forcev ...................................................................................................................................... 5-11

getstatus.................................................................................................................................. 5-12

measf ...................................................................................................................................... 5-13

meass ..................................................................................................................................... 5-14

meast ...................................................................................................................................... 5-15

measv ..................................................................................................................................... 5-15

measz ..................................................................................................................................... 5-16

rangei ...................................................................................................................................... 5-17

rtfary ........................................................................................................................................ 5-18

setauto .................................................................................................................................... 5-19

setfreq ..................................................................................................................................... 5-19

setlevel .................................................................................................................................... 5-20

setmode (4210-CVU or 4215-CVU) ........................................................................................ 5-21

smeasf .................................................................................................................................... 5-23

smeasfRT ................................................................................................................................ 5-23

smeass .................................................................................................................................... 5-24

smeast .................................................................................................................................... 5-25

smeastRT ................................................................................................................................ 5-26

smeasv .................................................................................................................................... 5-26

smeasvRT ............................................................................................................................... 5-27

smeasz .................................................................................................................................... 5-28

smeaszRT ............................................................................................................................... 5-29

sweepf ..................................................................................................................................... 5-30

sweepf_log .............................................................................................................................. 5-32

sweepv .................................................................................................................................... 5-33

Programming examples ..................................................................................................... 5-34

Programming example #1 ....................................................................................................... 5-34

Programming example #2 ....................................................................................................... 5-35

Programming example #3 ....................................................................................................... 5-36

Programming example #4 ....................................................................................................... 5-37

Programming example #5 ....................................................................................................... 5-38

LPT commands for PGUs and PMUs ....................................................................... 6-1

LPT commands for PGUs and PMUs .................................................................................. 6-1

arb_array ................................................................................................................................... 6-3

arb_file ...................................................................................................................................... 6-4

dev_abort .................................................................................................................................. 6-4

devclr ........................................................................................................................................ 6-6

devint ........................................................................................................................................ 6-6

getstatus.................................................................................................................................... 6-8

pg2_init ................................................................................................................................... 6-10

pmu_offset_current_comp....................................................................................................... 6-11

PostDataDoubleBuffer ............................................................................................................ 6-11

pulse_burst_count ................................................................................................................... 6-14

pulse_chan_status .................................................................................................................. 6-15

pulse_conncomp ..................................................................................................................... 6-16

pulse_current_limit .................................................................................................................. 6-17

pulse_dc_output ...................................................................................................................... 6-18

pulse_delay ............................................................................................................................. 6-19

pulse_exec .............................................................................................................................. 6-20

pulse_exec_status .................................................................................................................. 6-21

pulse_fall ................................................................................................................................. 6-22

pulse_fetch .............................................................................................................................. 6-24

pulse_float ............................................................................................................................... 6-28

pulse_halt ................................................................................................................................ 6-29

pulse_init ................................................................................................................................. 6-30

Table of contents Model 4200A-SCS LPT Library Programming

pulse_limits ............................................................................................................................. 6-31

pulse_load ............................................................................................................................... 6-32

pulse_meas_sm ...................................................................................................................... 6-33

pulse_meas_timing ................................................................................................................. 6-34

pulse_meas_wfm .................................................................................................................... 6-36

pulse_measrt ........................................................................................................................... 6-37

pulse_output............................................................................................................................ 6-38

pulse_output_mode ................................................................................................................. 6-39

pulse_period............................................................................................................................ 6-40

pulse_range ............................................................................................................................ 6-41

pulse_ranges ........................................................................................................................... 6-42

pulse_remove .......................................................................................................................... 6-44

pulse_rise ................................................................................................................................ 6-45

pulse_sample_rate .................................................................................................................. 6-46

pulse_source_timing ............................................................................................................... 6-47

pulse_ssrc ............................................................................................................................... 6-48

pulse_step_linear .................................................................................................................... 6-50

pulse_sweep_linear ................................................................................................................ 6-53

pulse_train............................................................................................................................... 6-56

pulse_trig................................................................................................................................. 6-57

pulse_trig_output ..................................................................................................................... 6-58

pulse_trig_polarity ................................................................................................................... 6-59

pulse_trig_source .................................................................................................................... 6-60

pulse_vhigh ............................................................................................................................. 6-62

pulse_vlow .............................................................................................................................. 6-63

pulse_width ............................................................................................................................. 6-65

rpm_config .............................................................................................................................. 6-66

seg_arb_define ....................................................................................................................... 6-67

seg_arb_file............................................................................................................................. 6-69

seg_arb_sequence .................................................................................................................. 6-70

seg_arb_waveform .................................................................................................................. 6-73

setmode (4225-PMU) .............................................................................................................. 6-74

LPT commands for switching .................................................................................. 7-1

LPT commands for switching ............................................................................................... 7-1

addcon ...................................................................................................................................... 7-1

clrcon ........................................................................................................................................ 7-2

conpin ....................................................................................................................................... 7-2

conpth ....................................................................................................................................... 7-3

cviv_config ................................................................................................................................ 7-4

cviv_display_config ................................................................................................................... 7-5

cviv_display_power ................................................................................................................... 7-6

delcon ....................................................................................................................................... 7-6

devint ........................................................................................................................................ 7-7

LPT library and Clarius interaction when using UTMs ............1-16

In this section:

LPT library reference ................................................................1-1

Lists of LPT library commands ..................................................1-2

LPT Library Status and Error codes ..........................................1-8

LPT library reference

The Keithley Instruments Linear Parametric Test Library (LPT library) is a high-speed data acquisition

and instrument control software library. It is the programmer’s lowest level of command interface to

the system instrumentation. You can use the library commands to configure the relay matrix and

instrumentation for parametric tests.

Section 1

Introduction

This section lists the commands included in the LPT library and describes how to use them. The

descriptions include:

• A brief description of the command.

• Usage, which shows how the command should be organized and descriptions of each parameter.

The parameters that you need to supply are shown in italics. For example, for the command

int delay(long n);, replace n with the duration of the delay.

• Detailed information about the command.

• Examples that show a typical use of the command in a test sequence.

The following conventions are used when explaining the commands:

• All LPT library commands are case-sensitive and must be entered as lower case when writing

program code.

• Period strings (...) indicate additional arguments or commands that can be added.

• Periods ( . ) indicate data not shown in an example because it is not necessary to help explain

the specific command.

Section 1: Introduction Model 4200A-SCS LPT Library Programming

i

Current

Amperes

t

Time

Seconds

v

Voltage

Volts

f

Frequency

Hertz

clrscn (on page 2-2)

Clears the measurement scan tables associ at ed with a swee p.

Clears the user-selected voltage or current level that is used to set trigger

once with different levels in a single test sequence.

delay (on page 2-5)

Provides a user-programmable delay in a test sequence.

devint (on page 2-6)

Resets all active instruments in the system to their default states.

disable (on page 2-8)

Stops the timer and sets the time value to zero (0).

enable (on page 2-8)

Provides correlation of real time to measurements of voltage, current,

conductance, and capacitance.

execut (on page 2-8)

Causes the system to wait for the preceding test sequence to be executed.

getinstattr (on page 2-9)

Returns configured instrument attributes.

getinstid (on page 2-10)

Returns the instrument identifier (ID) from the instrument name string.

getinstname (on page 2-10)

Returns the instrument name string from the instrument identifier (ID).

GetKiteCycle (on page 2-11)

Returns the present Clarius cycle number.

GetKiteDevice (on page 2-11)

Returns the device that Clarius is presently testing.

• A capital letter X in a command name indicates that you must select from a list of replacement

suffixes. For example, in forceX, replace the X w ith e ither a v for voltage or i for current. The

following is a table of possible suffixes, the parameter each represents, and the units used

throughout the LPT library for that parameter.

Suffix Parameter Unit

Lists of LPT library commands

These topics list the LPT library commands that are available in the 4200A-SCS. A brief description

and links to full descriptions of each command are provided.

The LPT library commands are grouped as follows:

• General operation commands (on page 1-2)

• Math operation commands (on page 1-4)

• SMU commands (on page 1-4)

• PGU (pulse only) and PMU (pulse and measure) commands (on page 1-5)

• CVU commands (on page 1-7)

• Switch commands (on page 1-8)

General operation commands

General operation commands include commands to control timing, execution, communications, and

test status.

Command Description

clrtrg (on page 2-3)

points. This permits the use of the trigXl or trigXg command more than

1-2 4200A-LPT-907-01 Rev. C March 2023

Model 4200A-SCS LPT Library Programming Section 1: Introduction

GetKiteSite (on page 2-11)

Returns the site number for the site that Clarius is presently testing.

GetKiteSubsite (on page 2-12)

Returns the subsite number for the site that Clarius is presently testing.

GetKiteTest (on page 2-12)

Returns the test that Clarius is presently testing.

getlpterr (on page 2-13)

Returns the first LPT library error since the last devint command.

imeast (on page 2-13)

Forces a reading of the timer and returns the result.

inshld (on page 2-13)

Provided for compatibility with Model S400 LPT library.

kibcmd (on page 2-14)

Enables universal, addressed, and unaddressed GPIB bus commands to be

sent through the GPIB interface.

kibdefclr (on page 2-15)

Defines the device-dependent command sent to an instrument connected to

the GPIB interface.

kibdefdelete (on page 2-16)

Deletes all command definitions previously made with the kibdefclr

device initialize) commands.

kibdefint (on page 2-16)

Defines a device-dependent command sen t to an instrument connected to the

GPIB interface.

kibrcv (on page 2-17)

Reads a device-dependent string from an instrument connected to the GPIB

interface.

kibsnd (on page 2-18)

Sends a device-dependent command to an instrument connected to the GPIB

interface.

kibspl (on page 2-19)

Serial polls an instrument connected to the GPIB inter f ac e.

kibsplw (on page 2-20)

Synchronously serial polls an instrument connected to the GPIB interface.

kspcfg (on page 2-20)

Configures and allocates a serial port for RS-232 communications.

kspdefclr (on page 2-21)

Defines a device-dependent character string sent to an instrument connected

to a serial port.

kspdefdelete (on page 2-22)

Deletes all command definitions previously made with the kspdefclr

Device Initialize) commands.

kspdefint (on page 2-22)

Defines a device-dependent character string sent to an instrument connected

to a serial port.

ksprcv (on page 2-23)

Reads data from an instrument connected to a serial port.

kspsnd (on page 2-23)

Sends a device-dependent command to an instrument attached to a RS-232

serial port.

PostDataDouble (on

page 2-24)

Posts double-precision floa ting -point data from memory into the Clarius

Analyze sheet.

PostDataDoubleBuffer (on

page 6-11)

Posts PMU data retrieved from the buffer into the Clarius Analyze sheet (large

data sets).

PostDataInt (on page 2-25)

Posts an integer-type point from memory to the Clarius Analyze sheet in the

user test module and plots it on the graph.

PostDataString (on page 2-26)

Transfers a string from memory into the Clarius Analyze sheet in the user test

module and plots it on the graph.

rdelay (on page 2-26)

Sets a user-programmable delay.

rtfary (on page 2-27)

Returns the force array determined by the instrument action.

savgX (on page 2-27)

Makes an averaging measurement for every point in a sweep.

scnmeas (on page 2-29)

Makes a single measurement on multiple instruments at the same time.

searchX (on page 2-29)

Used to determine the voltage or current required to get a current or voltage.

setmode (on page 2-32)

Sets instrument-specific operating mode parameters.

sintgX (on page 2-34)

Makes an integrated measurement for every point in a sweep.

smeasX (on page 2-35)

Allows a number of measurements to be made by a specified instrument

are stored in the

defined array.

Command Description

(Keithley GPIB define device clear) and kibdefint (Keithley GPIB define

(Keithley Serial Define Device Clear) and kspdefint (Keithley Serial Define

during a sweepX command. The results of the measurements

4200A-LPT-907-01 Rev. C March 2023 1-3

Section 1: Introduction Model 4200A-SCS LPT Library Programming

trigcomp (on page 2-36)

Causes a trigger when an instrument goes in or out of compliance.

trigXg, trigXl (on page 2-37)

Monitors for a predetermined level of voltage, current, or time.

tstdsl (on page 2-40)

Deselects a test station.

tstsel (on page 2-40)

Enables or disables a test station.

value that is returned to a specified variable.

kfpadd (on page 3-2)

Adds two real numbers and stores the result in a specified variable.

kfpdiv (on page 3-2)

Divides two real numbers and stores the result in a specified variable.

kfpexp (on page 3-3)

Supplies the base of natural logarithms (e) raised to a specified power and stores

the result as a variable.

kfplog (on page 3-4)

Returns the natural logarithm of a real number to the specified variable.

kfpmul (on page 3-4)

Multiplies two real numbers and stores the result as a specified variable.

kfpneg (on page 3-5)

Changes the sign of a value and stores the result as a specified variable.

kfppwr (on page 3-6)

Raises a real number to a specified power and assigns the result to a

specified variable.

kfpsqrt (on page 3-7)

Performs a square root operation on a real number and returns the result to the

specified variable.

kfpsub (on page 3-8)

Subtracts two real numbers and stores their difference in a specified variable.

adelay (on page 4-1)

Specifies an array of delay points to use with asweepX command calls.

Generates a waveform based on a user-defined forcing array (logarithmic sweep or

other custom forcing commands).

avgX (on page 4-4)

Makes a series of measurements and averages the results.

bmeasX (on page 4-5)

Makes a series of readings as quickly as possible. This measurement mode allows

measurement instrument).

bsweepX (on page 4-7)

Supplies a series of ascending or descending voltages or currents and shuts down

the source when a trigger condition is encountered.

devclr (on page 4-9)

Sets all sources to a zero state.

devint (on page 2-6)

Resets all active instruments in the system to their default states.

forceX (on page 4-11)

Programs a sourcing instrument to generate a voltage or current at a specific level.

getstatus (on page 4-12)

Returns the operating state of a specified instrument.

intgX (on page 4-14)

Performs voltage or current measurements averaged over a user-defined period

(usually one ac line cycle).

limitX (on page 4-16)

Allows the programmer to specify a current or voltage limit other than the default

limit of the instrument.

lorangeX (on page 4-17)

Defines the bottom autorange limit.

measX (on page 4-18)

Allows the measurement of voltage, curre nt, or time.

mpulse (on page 4-20)

Uses a source-measure unit (SMU) to force a voltage pulse and measure both the

voltage and current for exact device loading.

Command Description

Math operation commands

Command Description

kfpabs (on page 3-1)

Takes a user-specified positive or negative value and converts it into a positive

SMU commands

Command Description

asweepX (on page 4-2)

for waveform capture and analysis (within the resolution of the

1-4 4200A-LPT-907-01 Rev. C March 2023

Model 4200A-SCS LPT Library Programming Section 1: Introduction

adelay (on page 4-1)

Specifies an array of delay points to use with asweepX command calls.

pulseX (on page 4-21)

Directs a SMU to force a voltage or current at a specific level for a predetermined

length of time.

rangeX (on page 4-23)

Selects a range and prevents the selected instrument from autoranging.

rtfary (on page 2-27)

Returns the array of force values used during the subsequent voltage or frequency

sweep.

segment_sweepX_list

(on page 4-26)

Creates and returns up to a 4-segment linear sweep force table based on userdefined start, stop, and step values.

setauto (on page 4-27)

Re-enables autoranging and cancels any previous rangeX c ommand f or the

specified instrument.

ssmeasX (on page 4-28)

Makes a series of readings until the change (delta) between readings is within a

specified percentage.

sweep consists of a sequence of steps, each with a user-specified duration.

arb_array (on page 6-3)

Used to define a full-arb waveform and name the file.

arb_file (on page 6-4)

Loads a waveform from an existing full-arb waveform file.

dev_abort (on page 6-4)

PGU, PMU. Programmatically ends (aborts) a test from within the user

pulse_exec

devclr (on page 4-9)

Sets all sources to a zero state.

devint (on page 2-6)

Resets all active instruments in the system to their default states.

getstatus (on page 4-12)

Returns the operating state of a specified instrument.

pg2_init (on page 6-10)

Resets the pulse card to the specified pulse mode (standard, full arb, or

Segment Arb) and its default conditions.

pmu_offset_current_comp (on

page 6-11)

PMU. Collects offsets current constants from the 4225-PMU for offset

compensation measurements.

PostDataDoubleBuffer (on

page 6-11)

PMU. Posts PMU data retrieved from the buffer into the Clarius Analyze

sheet (large data sets).

pulse_burst_count (on page 6-14)

For the burst mode, this command sets the number of pulses to output

during a burst sequence.

pulse_chan_status (on pag e 6-15)

PMU. Used to determine how many readings are stored in the data buffer.

pulse_conncomp (on page 6-16)

PMU. Enables or disables connection compen sat ion.

pulse_current_limit (on pag e 6-17)

Channel number of the pulse card: 1 or 2

pulse_dc_output (on page 6-18)

Selects the dc output mode and sets the voltage level.

pulse_delay (on page 6-19)

Sets the delay time from the trigger to when the pulse output starts.

pulse_exec (on page 6-20)

PGU, PMU. Used to validate the test configuration and start test execution.

pulse_exec_status (on page 6-21)

PGU, PMU. Used to determine if a test is running or completed.

pulse_fall (on page 6-22)

Sets the fall transition time for the pulse output.

pulse_fetch (on page 6-24)

PMU. Retrieves enabled test data and temporarily stores it in the data

buffer.

Command Description

sweepX (on page 4-29) Generates a ramp consisting of ascending or descending voltages or currents. The

PGU (pulse only) and PMU (pulse and measure) commands

In the LPT commands, the pulse-only module (4220-PGU) is referred to as VPU1, VPU2, and so on.

The pulse-measure module (4225-PMU) is referred to as PMU1, PMU 2, and so on. The 4210-CVU or

4215-CVU is referred to as CVU1, CVU2, and so on.

Note that the 4225-PMU and 4220-PGU support the PG2 commands.

Command Description

module that was started with the

command.

4200A-LPT-907-01 Rev. C March 2023 1-5

Section 1: Introduction Model 4200A-SCS LPT Library Programming

pulse_float (on page 6-28)

PMU. Sets the state of the floating relay for the given pulse instrument

pulse_halt (on page 6-29)

Stops all pulse output from the pulse card.

pulse_init (on page 6-30)

Resets the pulse card to the default settings for the pulse mode that is

presently selected.

pulse_limits (on page 6-31)

PMU. Sets measured voltage and current thre sh old s at the DUT and sets

the power threshold for each channel.

pulse_load (on page 6-32)

Sets the output impedance for the load (DUT).

pulse_meas_sm (on page 6-33)

PMU. Configures spot mean measurement s.

pulse_meas_timing (on

page 6-34)

PMU. Sets the measurement windows.

pulse_meas_wfm (on page 6-36)

PMU. Configures waveform measurements.

pulse_measrt (on page 6-37)

PMU. Returns pulse source and measure data in pseudo real time.

pulse_output (on page 6-38)

Sets the pulse output of a pulse card channel on or off.

pulse_output_mode (on

page 6-39)

pulse_period (on page 6-40)

Sets the period for pulse output.

pulse_range (on page 6-41)

Sets a pulse card channel for low voltage (fast speed) or high voltage

(slow speed).

PGU, PMU. Sets the voltage pulse range and voltage/current

measure ranges.

pulse_remove (on page 6-44)

PGU, PMU. Removes a pulse channel from the test.

pulse_rise (on page 6-45)

Sets the rise transition time for the pulse card pulse output.

pulse_sample_rate (on

page 6-46)

PMU. Sets the measurement sample rate.

pulse_source_timing (on

page 6-47)

PGU, PMU. Sets the pulse period, pulse width, rise time, fall time, and

delay time.

pulse_ssrc (on page 6-48)

Controls the high-endurance output relay (HEOR) for each output channel

of the PGU.

pulse_step_linear (on page 6-50)

PGU, PMU. Configures the pulse stepping type.

pulse_sweep_linear (on

page 6-53)

PGU, PMU. Configures the pulse sweeping type.

pulse_train (on page 6-56)

PGU, PMU. Configures the pulse card to output a pulse train using fixed

voltage values.

Selects the trigger mode (continuous, burst, or trigger burst) and initiates

the start of pulse output or arms the pulse card.

pulse_trig_output (on page 6-58)

Sets the output trigger on or off.

pulse_trig_polarity (on page 6-59)

Sets the polarity (positive or negative) of the pulse card output trigger.

pulse_trig_source (on page 6-60)

Sets the trigger source.

pulse_vhigh (on page 6-62)

Sets the pulse voltage high level.

pulse_vlow (on page 6-63)

Sets the pulse voltage low value.

pulse_width (on page 6-65)

Sets the pulse width for pulse output.

rpm_config (on page 6-66)

PMU with 4225-RPM. Sends switching commands to the 4225-RPM.

seg_arb_define (on page 6-67)

Defines the parameters for a Segment Arb® waveform.

seg_arb_file (on page 6-69)

Used to load a waveform from an existing Segment Arb® waveform file.

seg_arb_sequence (on

page 6-70)

PGU, PMU. Defines the parameters for a Segment Arb waveform

pulse-measure sequence.

seg_arb_waveform (on

page 6-73)

PGU, PMU. Creates a voltage segment waveform.

setmode (on page 6-74)

PMU. Sets the number of iterations for load-line effect compensation

(LLEC) for the PMU. Also enables or disables offset current compensation.

Command Description

Sets the pulse output mode of a pulse card channel.

pulse_ranges (on page 6-42)

pulse_trig (on page 6-57)

1-6 4200A-LPT-907-01 Rev. C March 2023

Model 4200A-SCS LPT Library Programming Section 1: Introduction

adelay (on page 4-1)

Specifies an array of delay points to use with asweepX command calls.

asweepv (on page 5-3)

Does a dc voltage sweep using an array of voltage values.

bsweepX (on page 4-7)

Supplies a series of ascending or descending voltages or currents and shuts

down the source when a trigger condition is encountered.

cvu_custom_cable_comp (on

page 5-6)

Determines the delays needed to accommodate custom cable lengths.

devclr (on page 4-9)

Sets all sources to a zero state.

devint (on page 2-6)

Resets all active instruments in the system to their default states.

dsweepf (on page 5-8)

Performs a dual frequency sweep.

dsweepv (on page 5-10)

Performs a dual linear staircase voltage sweep.

forcev (on page 5-11)

Sets the dc bias voltage level.

getstatus (on page 5-12)

Returns parameters that describe the state of the 4210-CVU or 4215-CVU.

measf (on page 5-13)

Returns the frequency sourced during a single measurement.

meass (on page 5-14)

Returns the status referenced to a single measure me nt.

meast (on page 5-15)

Returns a timestamp referenced to a measurement or a system timer.

measv (on page 5-15)

Returns the dc bias voltage sourced during a single measurement.

measz (on page 5-16)

Makes an impedance measurement.

rangei (on page 5-17)

Selects an impedance measurement range.

rtfary (on page 4-25)

Returns the array of force values used during the subsequent voltage or

frequency sweep.

setauto (on page 5-19)

Selects the automatic measurement range.

setfreq (on page 5-19)

Sets the frequency for the ac drive.

setlevel (on page 5-20)

Sets the voltage level of the ac drive.

setmode (on page 5-21)

Sets operating modes specific to the 4210-CVU or 4215-CVU.

smeasf (on page 5-23)

Returns the frequencies used for a sweep.

smeasfRT (on page 5-23)

Returns the sourced frequencies (in real time) for a sweep.

smeass (on page 5-24)

Returns the measurement status values for every point in a sweep.

smeast (on page 5-25)

Returns timestamps referenced to sweep measurements or a system timer.

smeastRT (on page 5-26)

Returns timestamps (in real time) referenced to sweep measurements or a

system timer.

smeasv (on page 5-26)

Returns the dc bias voltages used for a sweep.

smeasvRT (on page 5-27)

Returns the sourced dc bias voltages (in real time) for a sweep.

smeasz (on page 5-28)

Performs impedance measurements for a sweep.

smeaszRT (on page 5-29)

Makes and returns impedance measurements for a voltage or frequency sweep

in real time.

sweepf (on page 5-30)

Performs a frequency sweep.

sweepf_log (on page 5-32)

Performs a logarithmic frequency sweep using a 4215-CVU instrument. This is

not available for the 4210-CVU.

sweepv (on page 5-33)

Performs a linear staircase dc voltage sweep.

CVU commands

Command Description

4200A-LPT-907-01 Rev. C March 2023 1-7

Section 1: Introduction Model 4200A-SCS LPT Library Programming

addcon (on page 7-1)

Adds connections without clearing existing connections.

Opens or de-energizes all device under test (DUT) pins and instrument matrix

relays, disconnecting all crosspoint connections.

conpin (on page 7-2)

Connects pins and instruments.

conpth (on page 7-3)

Connects pins and instruments using a specific pathway.

cviv_config (on page 7-4)

Sends switching commands to the 4200A-CVIV Multi-Switch.

page 7-5)

cviv_display_power (on

page 7-6)

Sets the display state of the LCD display on the 4200A-CVIV.

Switch commands

Command Description

clrcon (on page 7-2)

cviv_display_config (on

delcon (on page 7-6) Removes specific matrix connecti ons .

devint (on page 2-6) Resets all active instruments in the system to their default states.

Configures the LCD display on the 4200A-CVIV Multi-Switch.

LPT Library Status and Error codes

Error codes are displayed whenever an invalid parameter or configuration occurs. The messages

associated with the error codes describe the error condition to help the user module programmer or

user determine how to address the error. Once an error occurs, the response of the user module to

the error depends on how the user module is programmed. If a user module does not have any error

handling, an initial error could cause additional errors on following LPT commands.

Library status and error codes are reported in Clarius in the message area.

Codes with positive values are statuses or updates. Codes with negative values are errors and

warnings.

Each error code number is associated with a brief text explanation. However, many of the error texts

are customized with specific information, such as a particular SMU or ID number. See

error texts (on page 1-9) for an explanation of the type of customized data.

Customized

In addition to error codes, some conditions may prevent a valid measurement condition. In these

cases, the reported measurement value reports a condition. This is usually a large number with an

22

exponent of 10

or 1023. See Large number reported readings and explanations (on page 1-15) for

the conditions associated with these large numbers.

1-8 4200A-LPT-907-01 Rev. C March 2023

Model 4200A-SCS LPT Library Programming Section 1: Introduction

%d

Signed decimal number; may be a parameter index or GPIB addr e ss

%g

Double value

%i

Signed decimal number

%s

String, such as "SMU1" or other test resource

%u

Unsigned integer

%04x

Hexadecimal number, 4 places

%08x

Hexadecimal number, 8 places

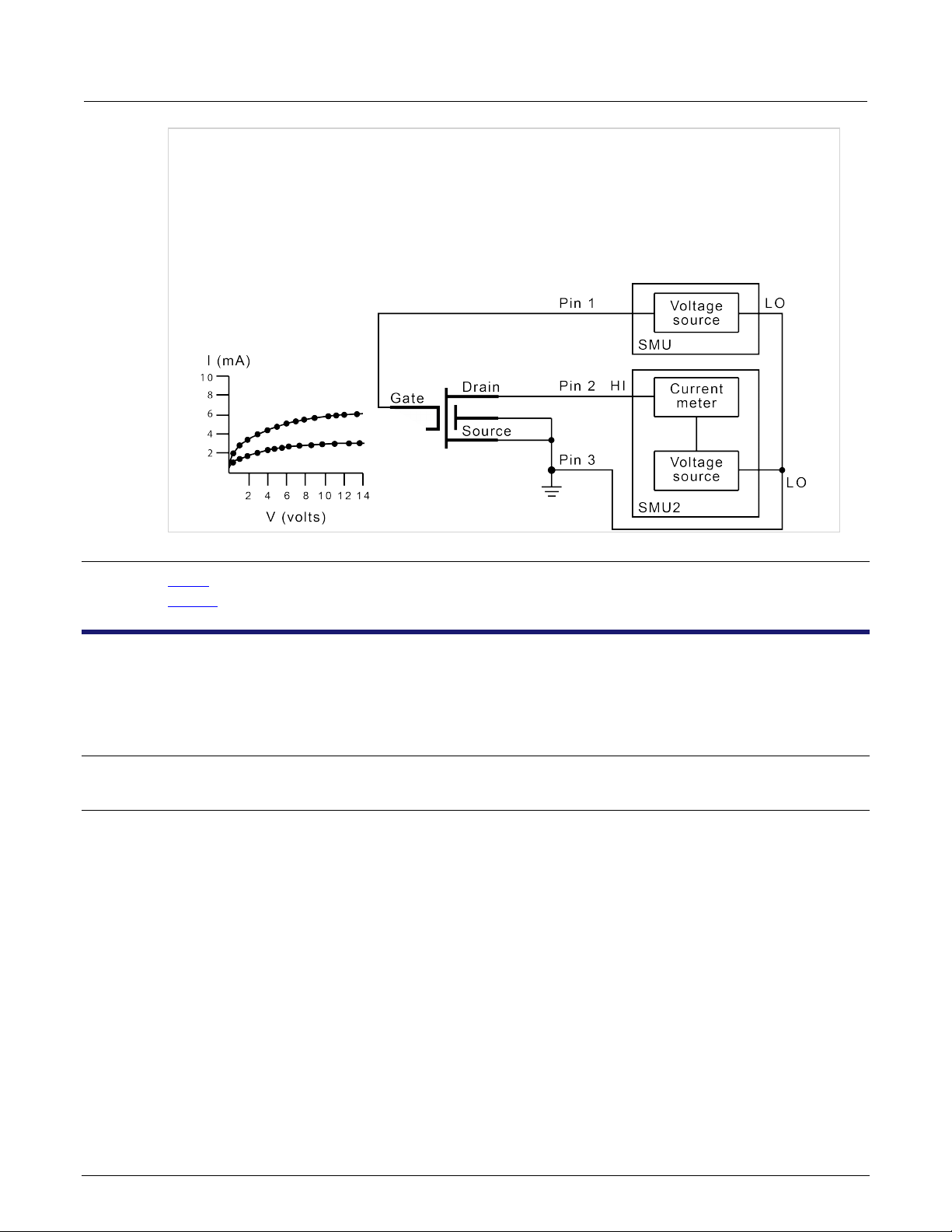

Figure 1: LPT error codes in the Clarius message areas

Customized error texts

Key Explanation

4200A-LPT-907-01 Rev. C March 2023 1-9

Section 1: Introduction Model 4200A-SCS LPT Library Programming

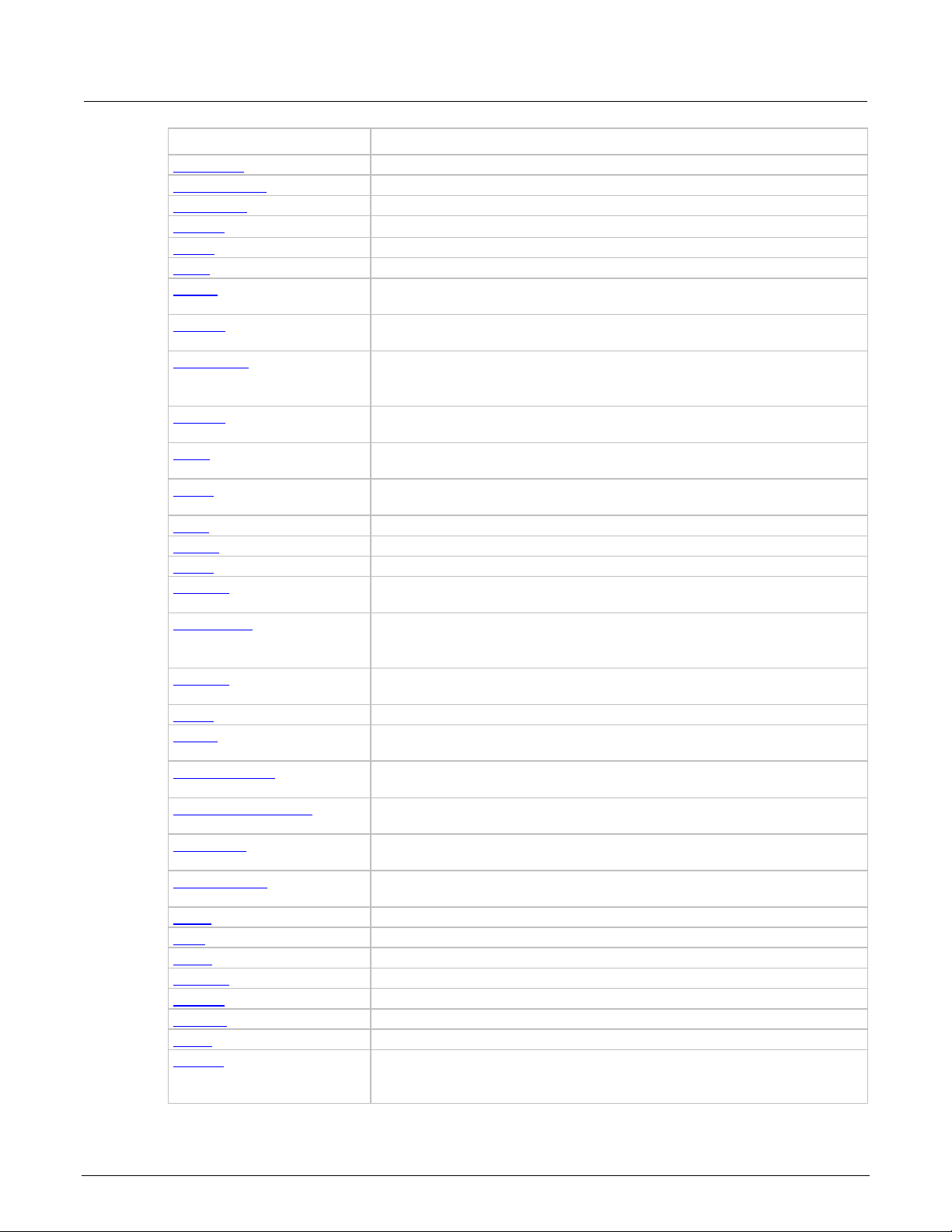

2802 to 2807

RPM: Invalid Configuration Requested

2801

RPM: Returned ID Error Response

2800

RPM: Command Response Timeout

2702

PMU: Temperature Within Normal Range

2701

PMU: High Temperature Limit Exceeded

1905

PMU: Measure Program Error

1904

PMU: Source Program Error

1902

PMU: Transmission to analog from digital error

1901

PMU: Handshake from analog to digital error

1900

PMU: DA Communication Timeout

400 to 402

PMU: Invalid Attributes in SW Command

100

LPTLib is executing function %s on instrument ID %d.

55

%s is no longer in thermal shutdown.

54

%s VXIBus device busy (command ID %04x). Timed out after %g seconds.

53

%s VXIbus transaction recovered after %u timeouts.

52

%s VXIbus transaction (command ID %04x) timed out after %g seconds.

51

Interlock reset.

50

Interlock tripped.

40

%s

24

Config %d-%d complet e for %s (%d).

23

Config %d-%d starting for %s (%d).

22

Binding %s (%d) to driver %s.

21

Loading driver %s.

20

Preloading model code %08x (%s).

15

Executor started.

14

%s channel closed.

13

%s channel starting.

12

TAPI services shutting down.

11

Starting TAPI services.

9

System configuration complete.

8

System configuration starting.

4

System initialization complete.

1

The call was successful (no error).

0

The call was successful (no error).

−4

Too many instruments in configuration file %s.

−5

Memory allocation failure.

−6

Memory allocation error during configuration with configuration file %s.

−20

Command not executed because a previous error was encountered.

−21

Tester is in a fatal error state.

−22

Fatal condition detected while in testi ng state .

−23

Execution aborted by user.

−24

Too many arguments.

−25

%s is unavailable because it is in use by another test station.

−40

%s.

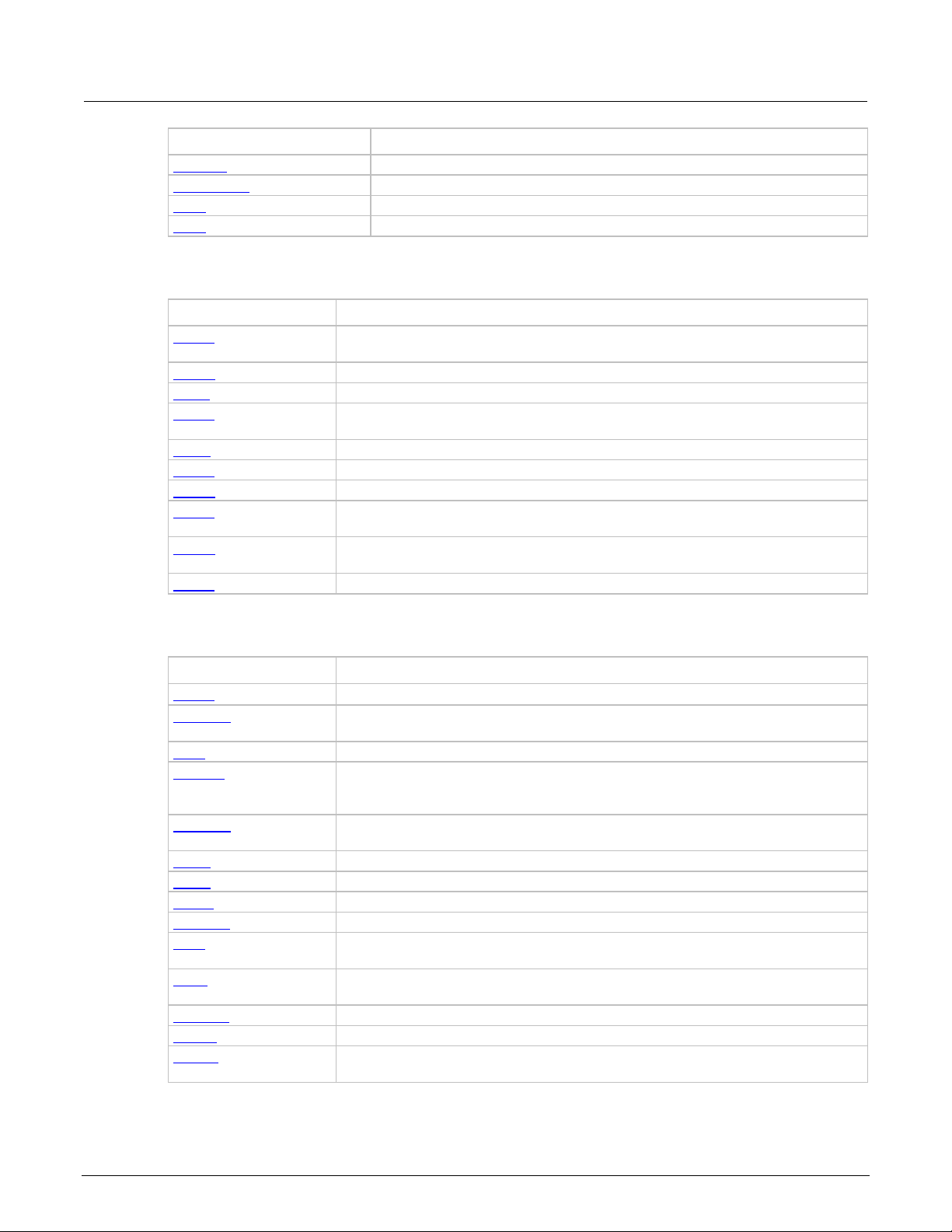

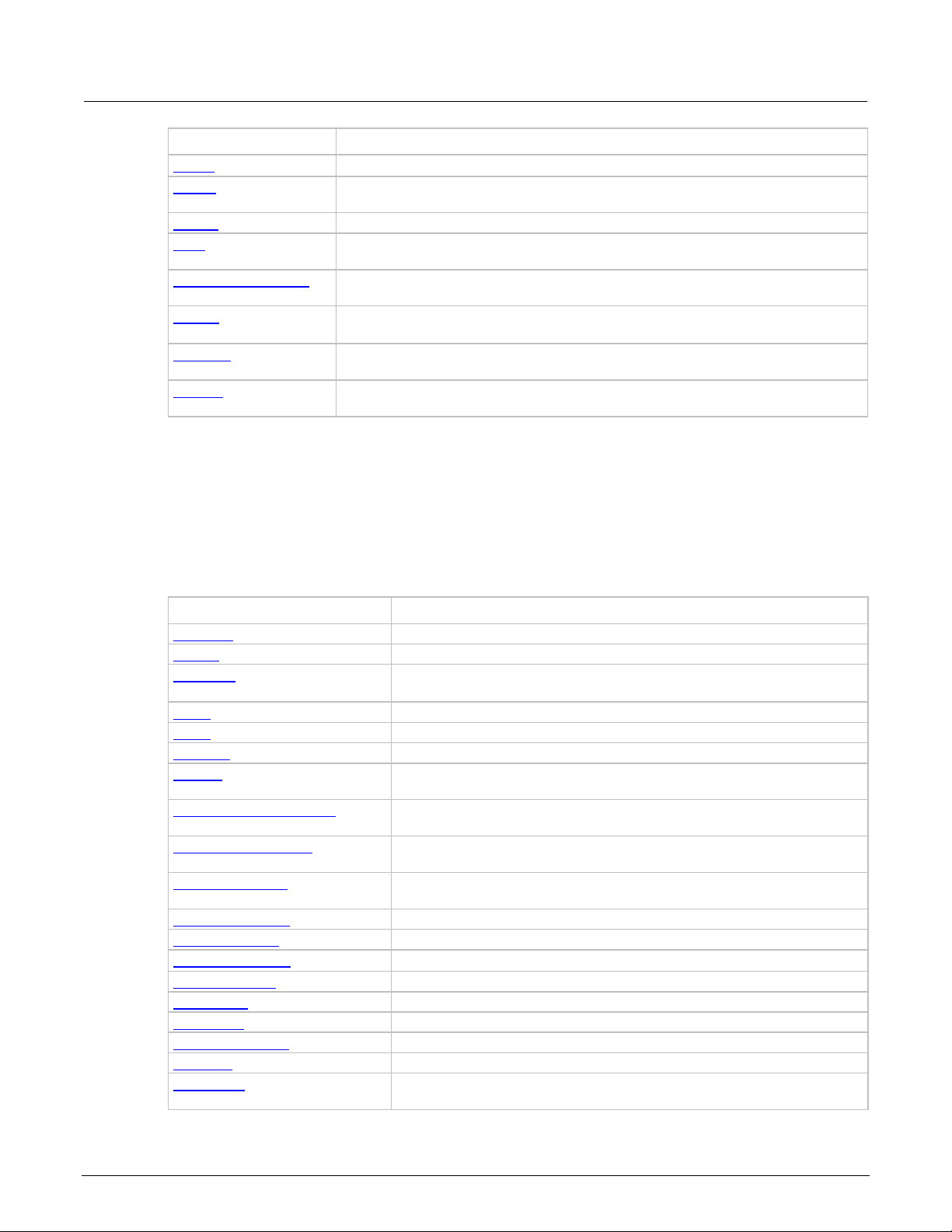

Code status or error titles

Code Status or error titles

1-10 4200A-LPT-907-01 Rev. C March 2023

Model 4200A-SCS LPT Library Programming Section 1: Introduction

−87

Can not load library %s.

−88

Invalid configuration file %s.

−89

Duplicate IDs.

−90

Duplicate instrument addresse s in config ur ati on file %s.

−91

Duplicate instrument slots in config uration file %s.

−93

Unrecognized/missing interface for %s in configuration file %s.

−94

Unrecognized/missing PCI slot number for %s in configuration file %s.

−95

Unrecognized/missing GPIB address for %s in configuration file %s.

−96

GPIB Address out of range for %s was %i in configuration file %s.

−97

PCI slot number out of range for %s was %i in configuration file %s.

−98

Error attempting to load driver for model %s in configuration file %s.

−99

Unrecognized/missing instrument ID in configuration file %s.

−100

Invalid connection count, number of connections passed was %d.

−101

Argument #%d is not a pin in the current configuration.

−102

Multiple connections on %s.

−103

Dangerous connection using %s.

−104

Unrecognized instrument or terminal not connected to matrix, argument #%d.

−105

No pathway assigned to argument #%d.

−106

Path %d previously allocated.

−107

Not enough pathways to complete connection.

−108

Argument #%d is not defined by configuration.

−109

Illegal test station: %d.

−110

A ground connection MUST be made.

−111

Instrument low connection MUST be made.

−113

There are no switching instruments in the system configuration.

−114

Illegal connection.

−115

Operation not allowed on a connected pin: %d.

−116

No physical bias path from %s to %s.

−117

Connection cannot be made because a required bus is in use.

−118

Cannot switch to high current mode while sources ar e acti ve .

−119

Pin %d in use.

−120

Illegal connection between %s and GNDU.

−121

Too many calls were made to trigXX.

−122

Illegal value for parameter #%d.

−124

Sweep/Scan measure table overflow .

−126

Insufficient user RAM for dynamic allocation.

−129

Timer not enabled.

−137

Invalid value for modifier.

−138

Too many points specified in array.

−139

An error was encountered while accessing the file %s.

−140

%s unavailable while slaved to %s.

−141

Timestamp not available because no measurement was made.

−142

Cannot bind, instruments are incompat ibl e.

−143

Cannot bind, services unavailable or in use.

−152

Function not supported by %s (%d).

−153

Instrument with ID %d is not in the current configuration.

−154

Unknown instrument name %s.

Code Status or error titles

4200A-LPT-907-01 Rev. C March 2023 1-11

Section 1: Introduction Model 4200A-SCS LPT Library Programming

−155

Unknown instrument ID %i.

−158

VXI device in slot %d failed selftest (mfr ID: %04x, model number: %04x).

−159

VME device with logical address %d is either non-VXI or non-functional.

−160

Measurement cannot be performed because the source is not operational.

−161

Instrum ent in slot %d has non-functional dual-port RAM.

−164

VXI device in slot %d statically addressed at reserved address %d.

−165

Service not supported by %s (%d).

−166

Instrum ent with model code %08x is not recognized.

−167

Invalid instrument attribute %s.

−169

Instrument %s is not in the current configuration.

−190

Ill-formed connection.

−191

Mode conflict.

−192

Instrument sense connection MUST be made.

−200

Force value too big for highest range %g.

−202

I-limit value %g too small for specified range.

−203

I-limit value %g too large for specified range.

−204

I-range value %g too large for specified range.

−206

V-limit value %g too large for specified range.

−207

V-range value %g too large for specified range.

−213

Value too big for range selection, %g.

−218

Safe operating area for device exceeded.

−221

Thermal shutdown has occurred on device %s.

−224

Limit value %g too large for specified range.

−230

V-limit value %g too small for specified range.

−231

Range too small for force value.

−233

Cannot force when not connected.

−235

C-range value %g too large for specified range.

−236

G-range value %g too large for specified range.

−237

No bias source.

−238

VMTR not allocated to make the measurement.

−239

Timeout occurred attempting measure ment .

−240

Power Limited to 20 W. Check voltage and current range settings.

−250

IEEE-488 time out during data transfer for addr %d.

−252

No IEEE-488 interface in configuration.

−253

IEEE-488 secondary address %d invalid for device.

−254

IEEE-488 invalid primary address: %d.

−255

IEEE-488 receive buffer overflow for address %d.

−261

No SMU found, kelvin connection test not performed.

−262

SRU not responding.

−263

DMM not connected to SRU.

−264

GPIB communication problem.

−265

SRU not mechanically calibrated.

−266

Invalid SRU command.

−267

SRU hardware problem.

−268

SRU kelvin connection problem.

−269

SRU general error.

−270

Floating point divide by zero.

Code Status or error titles

1-12 4200A-LPT-907-01 Rev. C March 2023

Model 4200A-SCS LPT Library Programming Section 1: Introduction

−271

Floating point log of zero or negative number.

−272

Floating point square root of negative number.

−273

Floating point pwr of negative number.

−280

Label #%d not defined.

−281

Label #%d redefined.

−282

Invalid label ID #%d.

−301

PCI ID read back on send error, slot.

−455

Protocol version mismatch.

−510

No command byte available (read) or SRQ not asserted.

−511

CAC conflict.

−512

Not CAC.

−513

Not SAC.

−514

IFC abort.

−515

GPIB timed out.

−516

Invalid function number.

−517

TCT timeout.

−518

No listeners on bus.

−519

Driver problem.

−520

Bad slot number.

−521

No listen address.

−522

No talk address.

−523

IBUP Software configuration error.

−524

No utility function.

−550

EEPROM checksum error in %s: %s.

−551

EEPROM read error in %s: %s.

−552

EEPROM write error in %s: %s.

−553

%s returned unexpected error code %d.

−601

System software internal error; contact the fact or y.

−602

Module load error: %s.

−603

Module format error: %s.

−604

Module not found: %s.

−610

Could not start %s.

−611

Network error.

−612

Protocol error.

−620

Driver load error. Could not load %s.

−621

Driver configuration function n ot fou nd. Dri ver is %s.

−640

%s serial number %s failed diagnostic test %d.

−641

%s serial number %s failed diagnostic test %d with a fatal fault.

−650

Request to open unknown channel type %08x.

−660

Invalid group ID %d.

−661

Invalid test ID %d.

−662

Ill-formed list.

−663

Executor is busy.

−664

Invalid unit ID %d.

−701

Error configuring serial port %s.

−702

Error opening serial port %s.

Code Status or error titles

4200A-LPT-907-01 Rev. C March 2023 1-13

Section 1: Introduction Model 4200A-SCS LPT Library Programming

−703

Call kspcfg before using kspsnd or ksprcv.

−704

Error reading serial port.

−705

Timeout reading serial port.

−706

Terminator not received before read buffer filled.

−707

Error closing serial port %s.

−801

Exception code %d reported from VPU in slot %d, channel %d.

−802

VPU in slot %d has reached thermal limit.

−803

Start and stop values for defined segmented arb violate minimum slew rate.

−804

Function not valid in the present pulse mode.

−805

Too many points specified in array.

−806

Not enough points specified in array.

−807

Function not supported by 4200-VPU.

−808

Solid state relay control values ignored for 4200-VPU.

−809

Time Per Point must be between %g and %g.

−810

Attempts to control VPU trigger output are ignored by the 4200-VPU.

−811

Measure range not valid for %s.

−812

WARNING: Sequence %d, segment %d. Cannot measure with PGUs/VPUs.

−820

PMU segment start value %gV at index %d does not match previous segment stop value of

%gV.

−821

PMU segment stop time (%g) greater than segment duration (%g)

−822

PMU sequence error for entry %d. Start value %gV does not match previous stop value of

%gV.

−823

Start and stop window was specified for PMU segment %d, but no measurement type was

set.

−824

Measurement type was specified for PMU segment %d, but start and stop window is invalid.

−825

%s set to post to column %s. Cannot fetch data that was registered as real-time.

−826

Cannot execute PMU test. No channels defined.

−827