Model 4200A-SCS

Prober and

External Instrument Control

4200A-913-01 Rev. B June 2022

tek.com/keithley

*P4200A-913-01B*

4200A-913-01B

Parameter Analyzer

Model 4200A-SCS

Prober and External Instrument Cont rol

© 2022, Keithley Instruments

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments is strictly prohibited.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, LLC. Other brand names are trademarks or registered trademarks of their r espective

holders.

Actuate

®

Copyright © 1993-2003 Actuate Corporation.

All Rights R eserved.

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: 4200A-913-01 Rev. B June 2022

Safety precaut ions

The following safety precautio ns should be observed before using this product and any associated ins tr um enta tion . Altho ugh

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specification s.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is mark ed on the instr u ment .

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazar ds that mi ght result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains h azard s that coul d dama ge the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, repl ace m ent comp one nts in mai ns cir cu its — inc lud ing the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purchased from other

suppliers as long as they are equivalent to the original component (not e that se lect ed part s shou ld be purch ase d only thro ugh

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2018.

Table of contents

Introduction ............................................................................................................... 1-1

Introduction .......................................................................................................................... 1-1

Using switch matrices .............................................................................................. 2-1

Typical test systems using a switch matrix .......................................................................... 2-1

Matrix card types ....................................................................................................................... 2-2

Switch matrix mainframes ......................................................................................................... 2-6

Switch matrix connections.................................................................................................... 2-6

Typical SMU matrix card connections ....................................................................................... 2-6

Typical preamplifier matrix card connections ............................................................................ 2-8

Typical CVU matrix card connections ....................................................................................... 2-9

Typical CVU test connections to a DUT .................................................................................. 2-11

Connection scheme settings .............................................................................................. 2-12

Row-column or instrument card settings ................................................................................. 2-12

Switch matrix control .......................................................................................................... 2-16

Signal paths to a DUT ........................................................................................................ 2-16

4200A-SCS signal paths ......................................................................................................... 2-17

C-V Analyzer signal paths ....................................................................................................... 2-20

Keysight Model 8110A pulse generator signa l pat h ................................................................ 2-23

Use KCon to add a switch matrix to the system ................................................................ 2-24

Step 1. Exit Clarius and open KCon ........................................................................................ 2-24

Step 2. Add a test fixture or probe station ............................................................................... 2-25

Step 3. Add switching system mainframe ............................................................................... 2-27

Step 4. Set GPIB address ....................................................................................................... 2-28

Step 5. Configure the instrument connection scheme ............................................................. 2-29

Step 6. Assign switch cards to mainframe slots ...................................................................... 2-29

Step 7. Set matrix card properties ........................................................................................... 2-30

Step 8. Save configuration ...................................................................................................... 2-31

Step 9. Close KCon and open Clarius ..................................................................................... 2-31

Switch matrix control example ........................................................................................... 2-31

Set up and run a switch matrix in Clarius ................................................................................ 2-32

Matrixulib user library ......................................................................................................... 2-33

ConnectPins user module ....................................................................................................... 2-33

Configure and use a Series 700 Switching System ................................................ 3-1

Introduction .......................................................................................................................... 3-1

Equipment required .............................................................................................................. 3-2

Device connections .............................................................................................................. 3-2

Connect the 7072 to the DUT.................................................................................................... 3-3

Connect the 4200A-SCS to the 7072 ........................................................................................ 3-4

Update the switch configuration in KCon ............................................................................. 3-5

Set up the measurements in Clarius .................................................................................... 3-9

Create a new project ............................................................................................................... 3-10

Add a device ........................................................................................................................... 3-10

Add the connectpins action ..................................................................................................... 3-11

Configure the connectpins action ............................................................................................ 3-11

Table of contents Model 4200A-SCS Prober and External Instrument Control

Search for and add existing tests from the Test Library .......................................................... 3-13

Run the project and view the tests .......................................................................................... 3-14

Using a Model 590 C-V Analyzer .............................................................................. 4-1

Introduction .......................................................................................................................... 4-1

C-V measurement basics ..................................................................................................... 4-1

Capacitance measureme nt tes ts ......................................................................................... 4-2

Connections ......................................................................................................................... 4-2

Signal connections .................................................................................................................... 4-3

Triaxial connectors .................................................................................................................... 4-3

GPIB connections ..................................................................................................................... 4-4

Cable compensation ............................................................................................................ 4-4

Cable compensation user modules ........................................................................................... 4-5

Using KCon to add a 590 C-V Analyzer to system .............................................................. 4-5

Model 590 test examples ..................................................................................................... 4-5

Cable compensation example ................................................................................................... 4-6

C-V sweep example ................................................................................................................ 4-10

KI590ulib user library ......................................................................................................... 4-12

CableCompensate590 user module ........................................................................................ 4-12

Cmeas590 user module .......................................................................................................... 4-15

CtSweep590 user module ....................................................................................................... 4-18

CvPulseSweep590 user module ............................................................................................. 4-22

CvSweep590 user module ...................................................................................................... 4-26

DisplayCableCompCaps590 user module .............................................................................. 4-30

LoadCableCorrectionConstants .............................................................................................. 4-32

SaveCableCompCaps590 user module .................................................................................. 4-33

Using a Keysight 4284/4980A LCR Meter ................................................................ 5-1

Introduction .......................................................................................................................... 5-1

C-V measurement basics .......................................................................................................... 5-1

Capacitance measurement tes ts ............................................................................................... 5-2

Signal connections .................................................................................................................... 5-3

GPIB connections ..................................................................................................................... 5-5

Using KCon to add a Keysight LCR Meter to the system .................................................... 5-6

Model 4284A or 4980A C-V sweep test example ................................................................ 5-6

HP4284ulib user library ........................................................................................................ 5-8

CvSweep4284 User Module...................................................................................................... 5-9

Cmeas4284 User Module........................................................................................................ 5-11

Using a Model 82 C-V System .................................................................................. 6-1

Introduction .......................................................................................................................... 6-1

Capacitance measureme nt tes ts ......................................................................................... 6-2

C-t measur ements ..................................................................................................................... 6-2

Simultaneous C-V measurements ............................................................................................. 6-3

Cable compensation ............................................................................................................ 6-5

Cable compensation user modules ........................................................................................... 6-6

Connections ......................................................................................................................... 6-6

Model 4200A-SCS Prober and External Instrument Control Table of contents

Front-panel connections ............................................................................................................ 6-6

Rear-panel connections ............................................................................................................ 6-7

Make power and GPIB connections .......................................................................................... 6-8

Using KCon to add Model 82 C-V System ........................................................................... 6-9

Model 82 projects ................................................................................................................. 6-9

Cable compensation tests ....................................................................................................... 6-10

Capacitance tests .................................................................................................................... 6-13

Formulas for capacitance tests ............................................................................................... 6-21

Choosing the right parameters ........................................................................................... 6-25

Optimal C-V measurement par amet ers ................................................................................... 6-25

Determining the optimal delay time ......................................................................................... 6-27

Correcting residual errors ........................................................................................................ 6-29

ki82ulib user library ............................................................................................................ 6-30

Abortmodule82 ........................................................................................................................ 6-31

CableCompensate82 user module .......................................................................................... 6-31

CtSweep82 user module ......................................................................................................... 6-34

DisplayCableCompCaps82 user module ................................................................................ 6-37

QTsweep82 user module ........................................................................................................ 6-39

SaveCableCompCaps82 user modu le .................................................................................... 6-42

SIMCVsweep82 user module .................................................................................................. 6-45

Simultaneous C-V analysis ................................................................................................ 6-48

Analysis methods .................................................................................................................... 6-48

Basic device parameters ......................................................................................................... 6-49

Doping profile .......................................................................................................................... 6-55

Interface trap density ............................................................................................................... 6-57

Mobile ion charge concentration ............................................................................................. 6-58

Generation velocity and generation lifetime (Zerbst plot) ........................................................ 6-61

Constants, symbols, and equations used for analysis ............................................................. 6-63

Summary of analysis equations .............................................................................................. 6-65

References .............................................................................................................................. 6-67

Bibliography of C-V Measurements ......................................................................................... 6-67

Articles and Papers ................................................................................................................. 6-68

Using a Keysight 8110A/8111A Pulse Generator .................................................... 7-1

Introduction .......................................................................................................................... 7-1

Pulse generator tests ........................................................................................................... 7-2

Signal connections ............................................................................................................... 7-2

Triaxial connections .................................................................................................................. 7-2

Probe station and test fixture connectio ns ................................................................................ 7-3

Switch matrix connections ......................................................................................................... 7-3

GPIB connections ................................................................................................................ 7-5

Using KCon to add a Keysight pulse generator to the system ............................................ 7-5

HP8110ulib user library ........................................................................................................ 7-5

PguInit8110 user module .......................................................................................................... 7-6

PguSetup8110 user module ...................................................................................................... 7-7

PguTrigger8110 user module .................................................................................................... 7-9

Set up a probe station .............................................................................................. 8-1

Prober control overview ....................................................................................................... 8-1

Supported probers .................................................................................................................... 8-4

PRBGEN user modules ............................................................................................................ 8-4

Table of contents Model 4200A-SCS Prober and External Instrument Control

Example test execution sequence: prob esi tes proj ect .............................................................. 8-6

Example test execution sequence: probesubsites project ......................................................... 8-6

Understanding site coordinate information .......................................................................... 8-7

Reference site (die) ................................................................................................................... 8-7

Probe sites (die) ........................................................................................................................ 8-8

Chuck movement ...................................................................................................................... 8-8

PRBGEN user library ......................................................................................................... 8-11

PrInit ........................................................................................................................................ 8-11

PrChuck .................................................................................................................................. 8-12

PrSSMovNxt ............................................................................................................................ 8-13

PrMovNxt ................................................................................................................................ 8-14

Tutorial: Control a probe station ......................................................................................... 8-16

Test system connections ......................................................................................................... 8-17

KCon setup ............................................................................................................................. 8-17

Test flow .................................................................................................................................. 8-18

Using a Cascade Microtech PA200 Prober ............................................................. 9-1

Cascade Microtech PA200 prober soft war e ........................................................................ 9-1

Software versions ...................................................................................................................... 9-1

Probe station configuration .................................................................................................. 9-3

Set up communications ........................................................................................................ 9-3

Make connections between the 4200A-SCS and the prober ..................................................... 9-3

GPIB control connector terminals .............................................................................................. 9-5

Set up communications on the 4200A-SCS .............................................................................. 9-6

Set up communications on the prober ....................................................................................... 9-8

Set up wafer geometry ....................................................................................................... 9-11

Create a site definition and define a probe list ................................................................... 9-13

Load, align, and contact the wafer ..................................................................................... 9-14

Aligning the wafer .................................................................................................................... 9-16

Start the Alignment Wizard...................................................................................................... 9-16

Verify wafer alignment ............................................................................................................. 9-17

Set the chuck heights .............................................................................................................. 9-18

Clarius probesubsites project example .............................................................................. 9-19

Set the wafer map ................................................................................................................... 9-21

Use KCon to add a prober....................................................................................................... 9-22

Running projects ..................................................................................................................... 9-23

Clarius ..................................................................................................................................... 9-23

Commands and error symbols ........................................................................................... 9-25

Using a Micromanipulator 8860 Prober ................................................................. 10-1

Micromanipulator 8860 prober software ............................................................................ 10-1

Software versions .................................................................................................................... 10-1

Probe station configuration ................................................................................................ 10-2

Set up communications ........................................................................................................... 10-2

Set up wafer geometry ............................................................................................................ 10-6

Create a site definition and define a probe list ........................................................................ 10-8

Load, align, and contact the wafer .......................................................................................... 10-9

Probesites Clarius project example ................................................................................. 10-18

Set spline pattern (optional) .................................................................................................. 10-19

Use KCon to add a prober..................................................................................................... 10-21

Model 4200A-SCS Prober and External Instrument Control Table of contents

Clarius ................................................................................................................................... 10-22

Probesubsites Clarius project example ............................................................................ 10-23

Use KCon to add a prober..................................................................................................... 10-26

Clarius ................................................................................................................................... 10-27

Commands and error symbols ......................................................................................... 10-29

Using a manual or fake prober............................................................................... 11-1

Using a manual or fake prober software ............................................................................ 11-1

Manual prober overview ..................................................................................................... 11-1

Fake prober overview ......................................................................................................... 11-2

Modifying the prober configuration file ............................................................................... 11-2

Probesites Clarius project example ................................................................................... 11-5

Use KCon to add a prober....................................................................................................... 11-5

Clarius ..................................................................................................................................... 11-6

Probesubsites Clarius project example .............................................................................. 11-7

Use KCon to add a prober....................................................................................................... 11-8

Clarius ..................................................................................................................................... 11-9

Using a Cascade Summit-12000 Prober ................................................................ 12-1

Cascade Summit 12000 prober software........................................................................... 12-1

Software version ..................................................................................................................... 12-1

Probe station configuration ................................................................................................ 12-2

Set up communications ........................................................................................................... 12-2

Set up wafer geometry ............................................................................................................ 12-8

Create a site definition and define a probe list ...................................................................... 12-11

Load, align, and contact the wafer ........................................................................................ 12-13

Probesites Clarius Project example ................................................................................. 12-17

Nucleus UI or Velox software ................................................................................................ 12-17

Use KCon to add a prober..................................................................................................... 12-17

Clarius ................................................................................................................................... 12-19

Probesubsites Clarius Project example ........................................................................... 12-20

Velox prober control software................................................................................................ 12-20

Nucleus UI prober control software ....................................................................................... 12-20

Use KCon to add a prober..................................................................................................... 12-22

Clarius ................................................................................................................................... 12-24

Commands and error symbols ......................................................................................... 12-25

Using a Signatone CM500 Prober .......................................................................... 13-1

Signatone CM500 prober software .................................................................................... 13-1

Software versions .................................................................................................................... 13-1

Probe station configuration ................................................................................................ 13-1

Set up communications ........................................................................................................... 13-2

Modify the prober configuration file ......................................................................................... 13-3

Set up wafer geometry ............................................................................................................ 13-4

Load, align, and contact the wafer .......................................................................................... 13-6

Set up programmed sites without a subsite ............................................................................. 13-9

Set up programmed sites with a subsite ............................................................................... 13-10

Table of contents Model 4200A-SCS Prober and External Instrument Control

Clarius project example for probe sites ............................................................................ 13-11

CM500 .................................................................................................................................. 13-11

Use KCon to add a prober..................................................................................................... 13-12

Clarius project example.................................................................................................... 13-13

Probesites Clarius project example ................................................................................. 13-17

Probesubsites Clarius project example ............................................................................ 13-18

Commands and error symbols ......................................................................................... 13-19

Using an MPI Probe Station ................................................................................... 14-1

MPI prober software ........................................................................................................... 14-1

Software version ..................................................................................................................... 14-1

Probe station configuration ................................................................................................ 14-1

Set up communications ........................................................................................................... 14-2

Load, align, and contact the wafer .......................................................................................... 14-3

Set up wafer geometry ............................................................................................................ 14-3

Create a site definition and define a probe list ........................................................................ 14-4

Clarius probesites and probes ubs ites pr ojec t example ..................................................... 14-4

MPI Sentio setup ..................................................................................................................... 14-4

Use KCon to add a prober....................................................................................................... 14-4

Clarius ..................................................................................................................................... 14-6

Commands and error symbols ........................................................................................... 14-8

Introduction ...............................................................................1-1

In this section:

Introduction

This document contains information about using switch matrices, probers, and other external

equipment with the 4200A-SCS.

Section 1

Introduction

Matrixulib user library ..............................................................2-33

Using switch matrices

In this section:

Typical test systems using a switch matrix................................2-1

Switch matrix connections.........................................................2-6

Connection scheme settings ...................................................2-12

Switch matrix control ...............................................................2-16

Signal paths to a DUT .............................................................2-16

Use KCon to add a switch matrix to the system ......................2-24

Switch matrix control example ................................................2-31

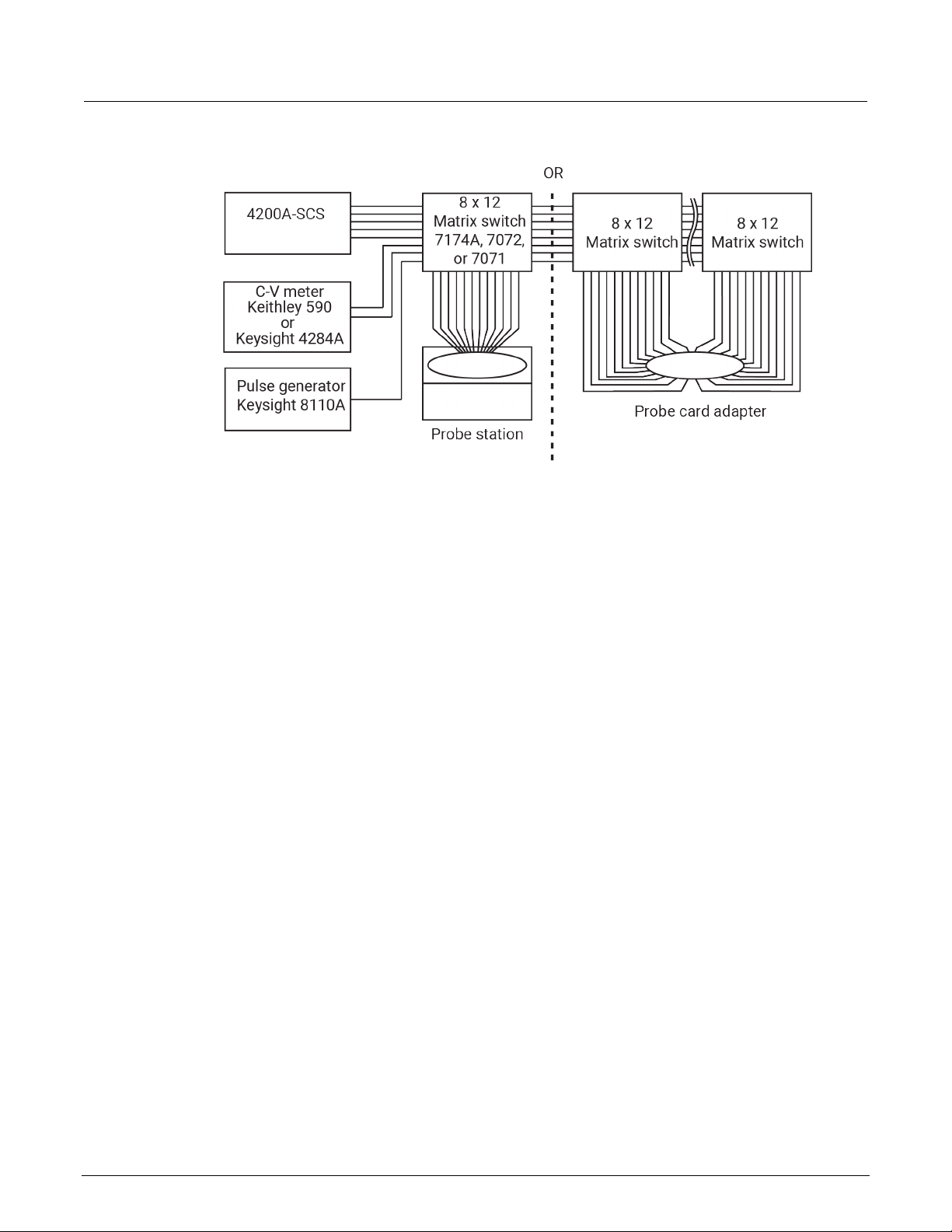

Typical test syste ms using a switch matrix

Section 2

A switch matrix enhances the connectivity of the 4200A-SCS by allowing any SMU or preamplifier

signal to be connected to any DUT pin. The following paragraphs summarize recommended switching

mainframes and matrix cards, and also show typical connecting schemes with SMUs and

preamplifiers.

A switch matrix provides automatic switching for test instrumentation and devices under test (DUTs).

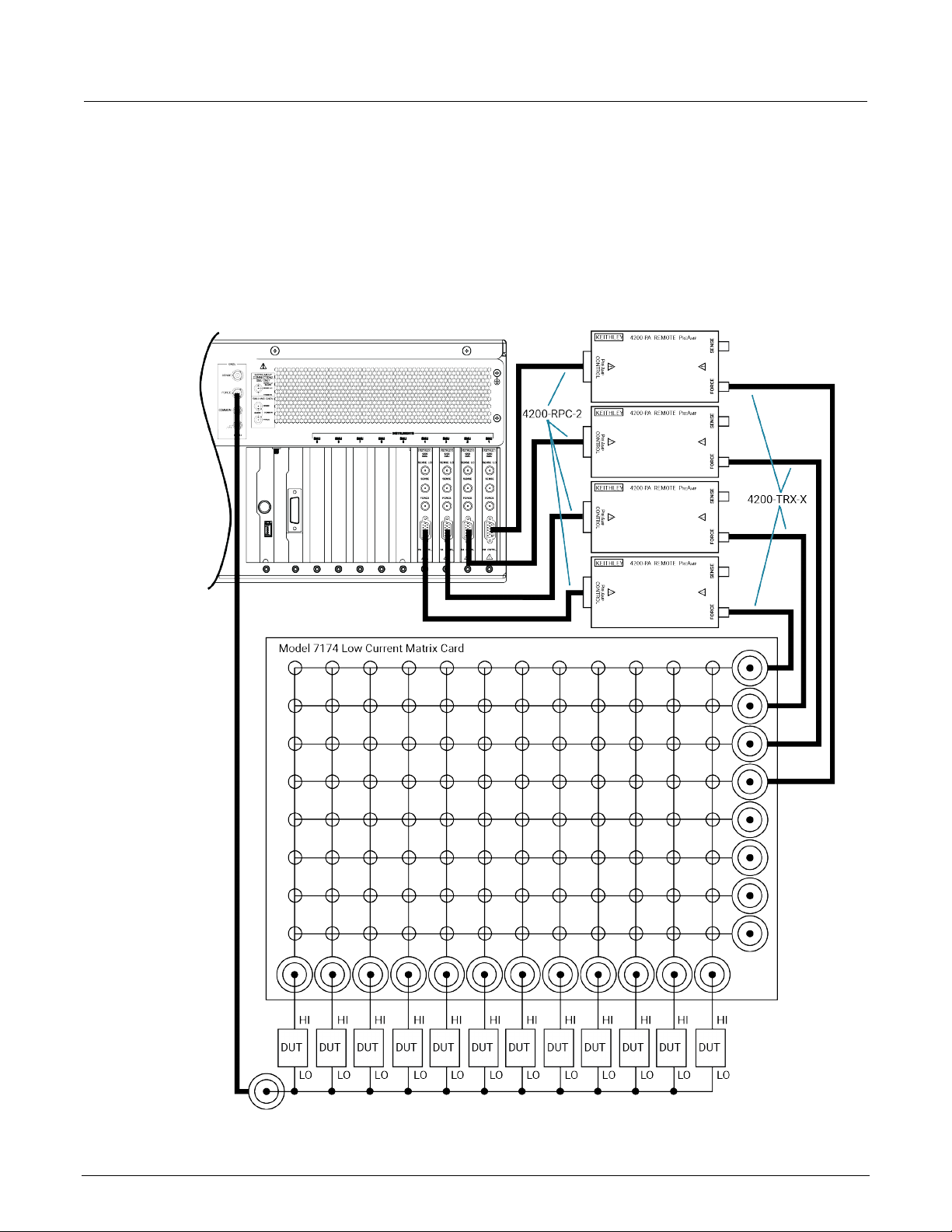

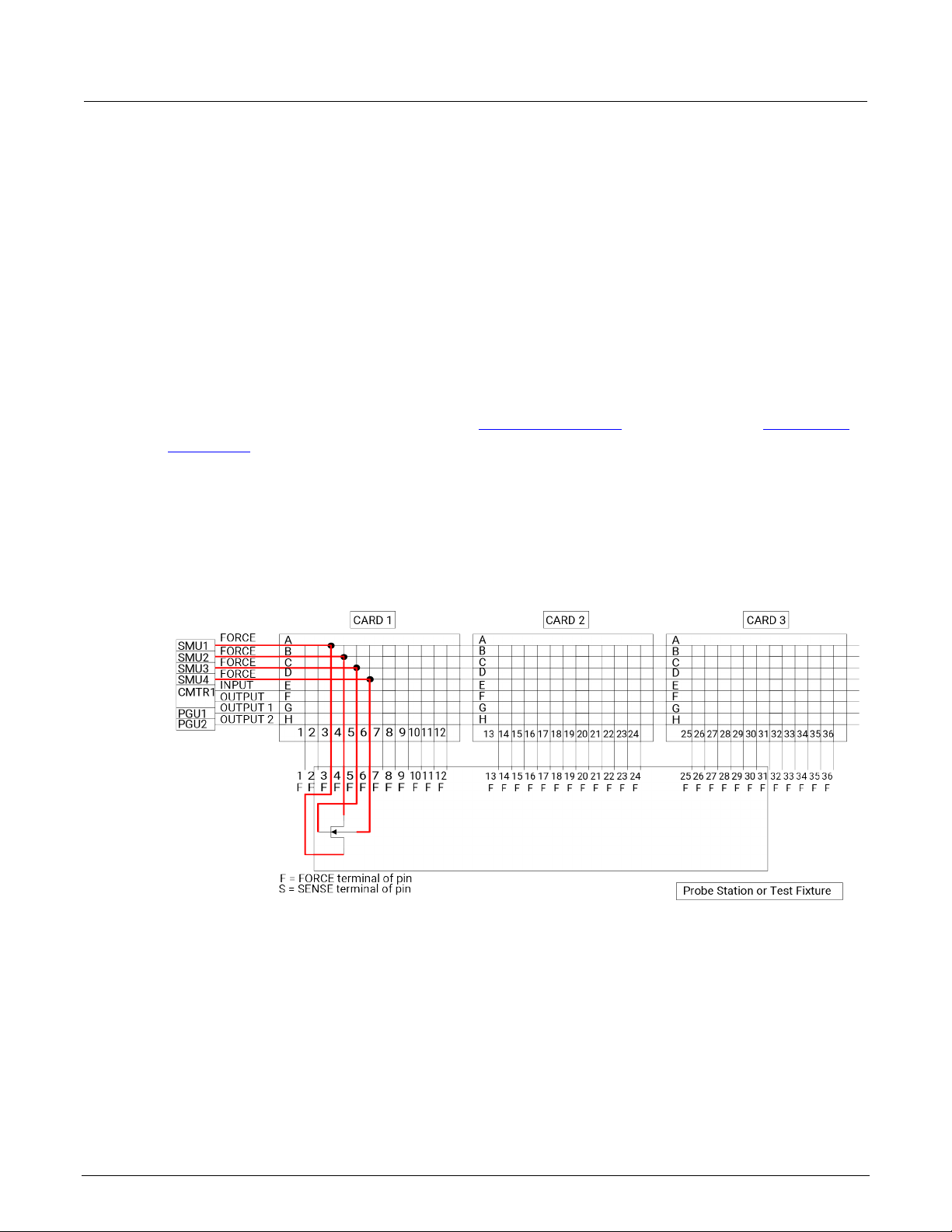

Typical switch matrix systems are shown in the following figure.

The 4200A-SCS supports the Keithley Instruments Series 700 Switching System as external

instruments. This series includes the 707, 707A, and 707B, which have six slots for matrix cards. This

provides up to 72 pins of switching. This series also includes the 708, 708A, and 708B, which support

a single matrix card for 12 pins of matrix switching.

When using a switch matrix, one probe station or one test fixture must be present in the system

configuration because the probe station or test fixture establishes the number of test-system pins.

The matrix is cabled to the test system pins, and instrument terminals are routed through the matrix to

the pins using the user modules in the Matrixulib user library.

The following figure shows switch matrix cards connected to a probe station in order to test a wafer.

However, a probe station could be replaced by a test fixture to test discrete devices.

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Figure 1: Typical systems using a switch matrix

Matrix card types

The recommended Keithley Instruments matrix cards are:

• Model 7072 8 x 12 Semiconductor Matrix Card, <1 pA offset current

• Model 7174A 8 x 12 Low Current Matrix Card, <100 fA offset current

Note that a key characteristic of these cards is low offset current to minimize the negative effects of

offset currents on low-current measurements.

7072 Semiconductor Matrix Card

The 7072 provides two two-pole low-current paths that have <1 pA offset current (rows A and B), two

one-pole CV paths for characterization from DC to 1 MHz (rows G and H), and four two-pole paths for

general purpose switching (rows C, D, E, and F). The card is equipped with 3-lug triaxial connectors

for signal connections. The maximum signal level is 200 V, 1 A. The maximum leakage is 0.01 pA/V

and the 3 dB bandwidth is 5 MHz (CV channels).

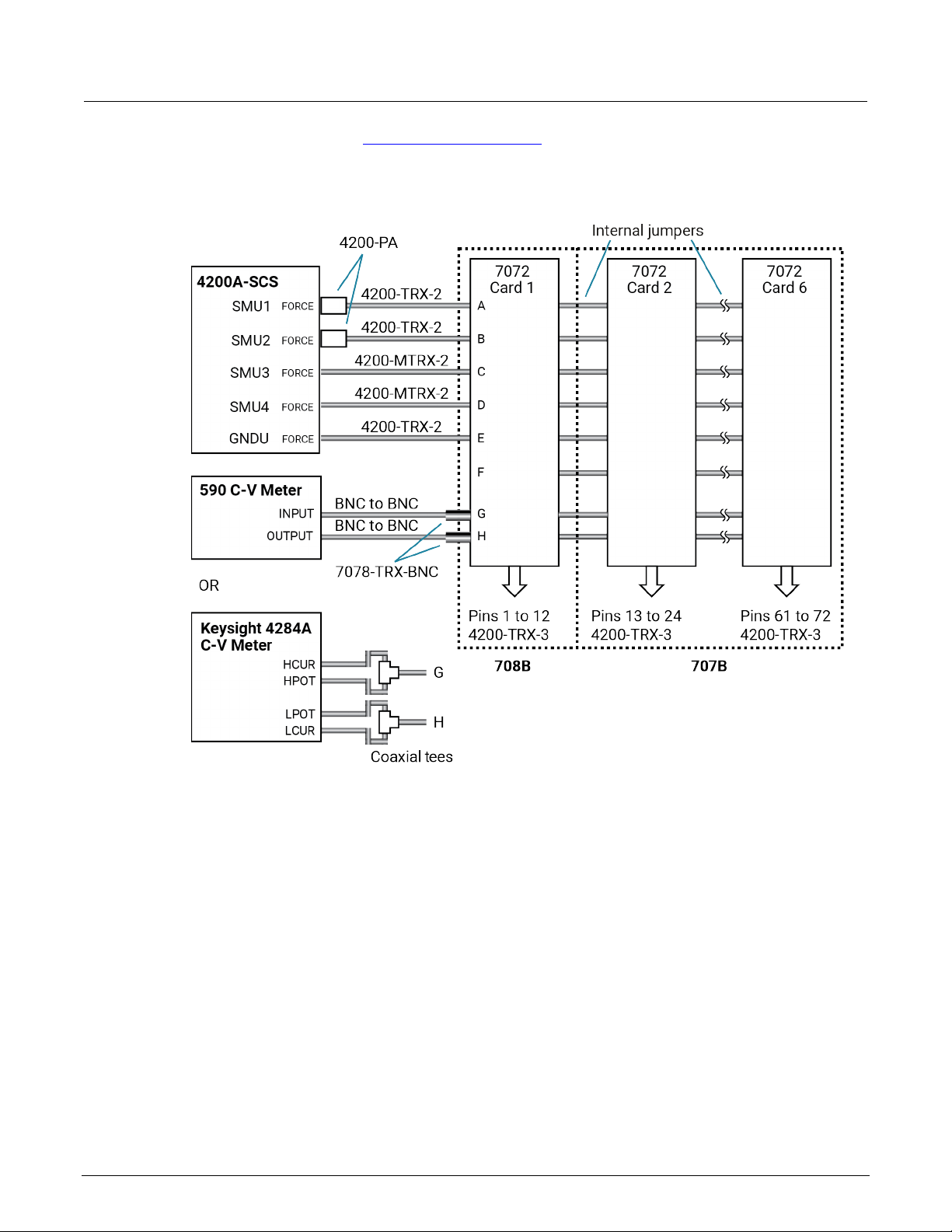

The following figure shows a test system using 7072 matrix cards. The connection requirements for

this card are the same as the connection requirements for the 7174A. Notice that the C-V meter is

connected to rows G and H. These two rows are optimized for C-V measurements.

If using preamplifiers with the 4200A-SCS, they should be connected to the first two rows of the 7072

matrix card.

2-2 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

The following figure and the C-V Analyzer signal pat h s (on page 2-20) figures show how signals are

routed through 7072 matrix switches to a DUT.

Figure 2: Test system using 7072 matrix cards

7174A Low Current Matrix Card

The 7174A provides high quality, high performance switching of I-V and C-V signals. This matrix card

uses 3-pole switching (HI, LO, Guard) with 10 fA typical offset current. The card is equipped with 3lug triaxial connectors for signal connections.

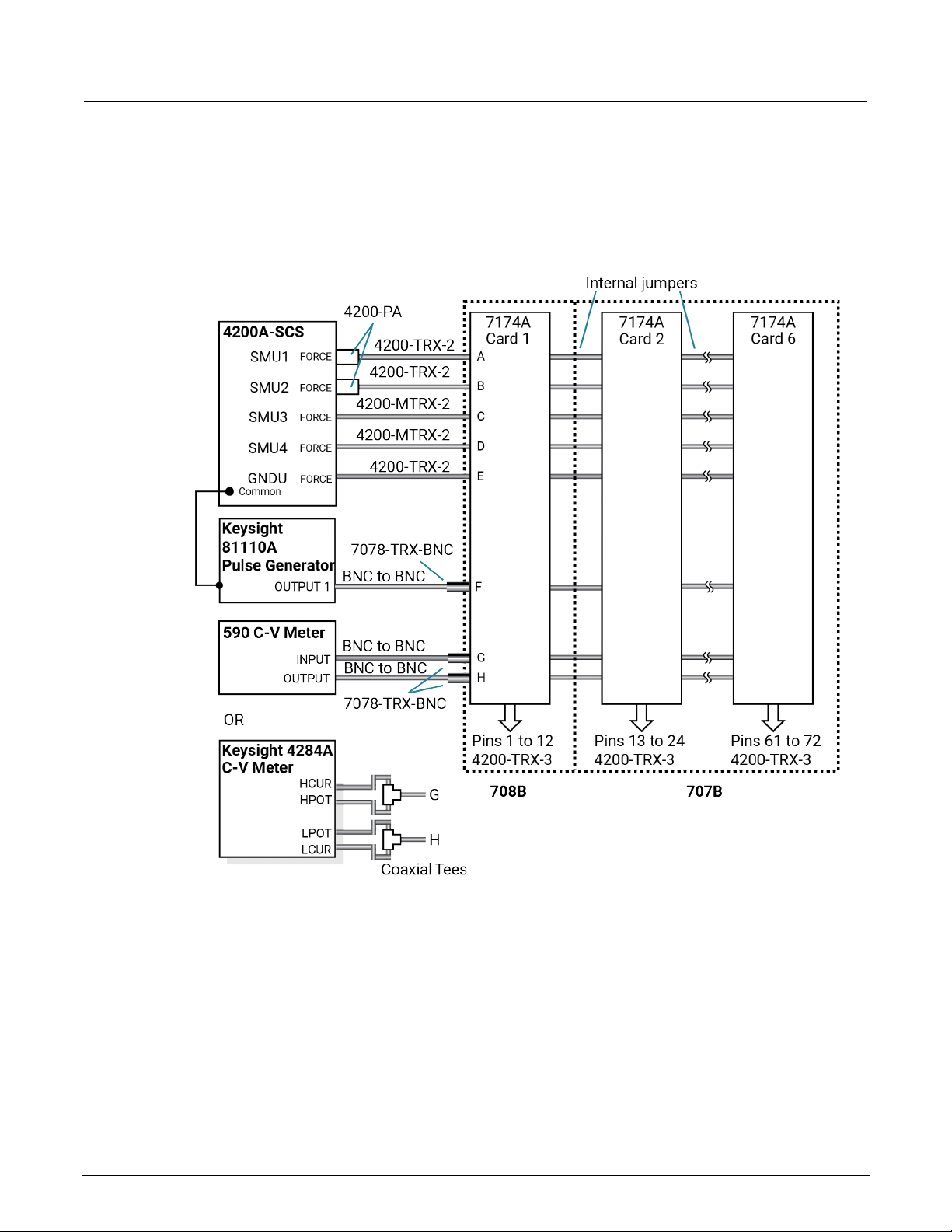

The following figures show test systems using 7174A matrix cards. The supplied triaxial cables

connect the 4200A-SCS directly to matrix rows. The other instruments in the system are fitted with

BNC connectors that require the use of BNC-to-triaxial adapters.

4200A-913-01 Rev. B / June 2022 2-3

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

7174A connections for local sensing

The following figure shows a system that uses local sensing. Coaxial tees adapt the Keysight 4284A

C-V meter for two-term in al operat io n.

Figure 3: Test system using 7174A matrix cards

7174A connections for remote sensing

The following figure shows how to connect instrumentation for remote sense operation. Since there

are not enough matrix rows, the instruments are connected to the matrix columns. In this

configuration, two switch relays are closed to complete a path from an instrument to a device under

test (DUT). With five DUT matrix cards installed in a Series 700 Switching System mainframe, up to

30 DUT pin-pairs can be used.

2-4 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

In the following figure, the C-V Analyzer signal paths (on page 2-20) for the Keysight Model 4980A

and Keysight Model 8110A pulse generator signal path (on page 2-23) show how signals are routed

through 7174A matrix switches to a DUT.

In this example, the instrumentation is connected to matrix columns, so the switch matrix is rotated

90° for i

llustration purposes.

Figure 4: Remote sense test system using 7174A matrix cards

4200A-913-01 Rev. B / June 2022 2-5

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Switch matrix mainframes

The 4200A-SCS provides a user library that contains preconfigured data acquisition and control user

modules for the Series 700 Switch System.

You can use the 4200A-SCS with switch matrices from other vendors. However, you will need to

+

develop software to control these matrices from Clarius

Extension Programming (4200A-KULT-907-01) for inf ormation about developing user modules

and libraries.

Card installation

Refer to the instructions for your matrix card for card installation instructions.

GPIB connections

The 4200A-SCS controls the switch matrix using the GPIB interface. Connect the GPIB port of the

switch matrix to the 4200A-SCS using a shielded GPIB cable.

. See Model 4200A-SCS KULT and KULT

Switch matrix connections

A switch matrix enhances the connectivity of the 4200A-SCS by allowing any SMU or preamplifier

signal to be connected to any DUT pin. Typically, devices are connected to columns and instruments

are connected to rows. The following topics summarize recommended switching mainframes and

matrix cards. They also show typical connection schemes with SMUs and preamplifiers.

Typical SMU matrix card connections

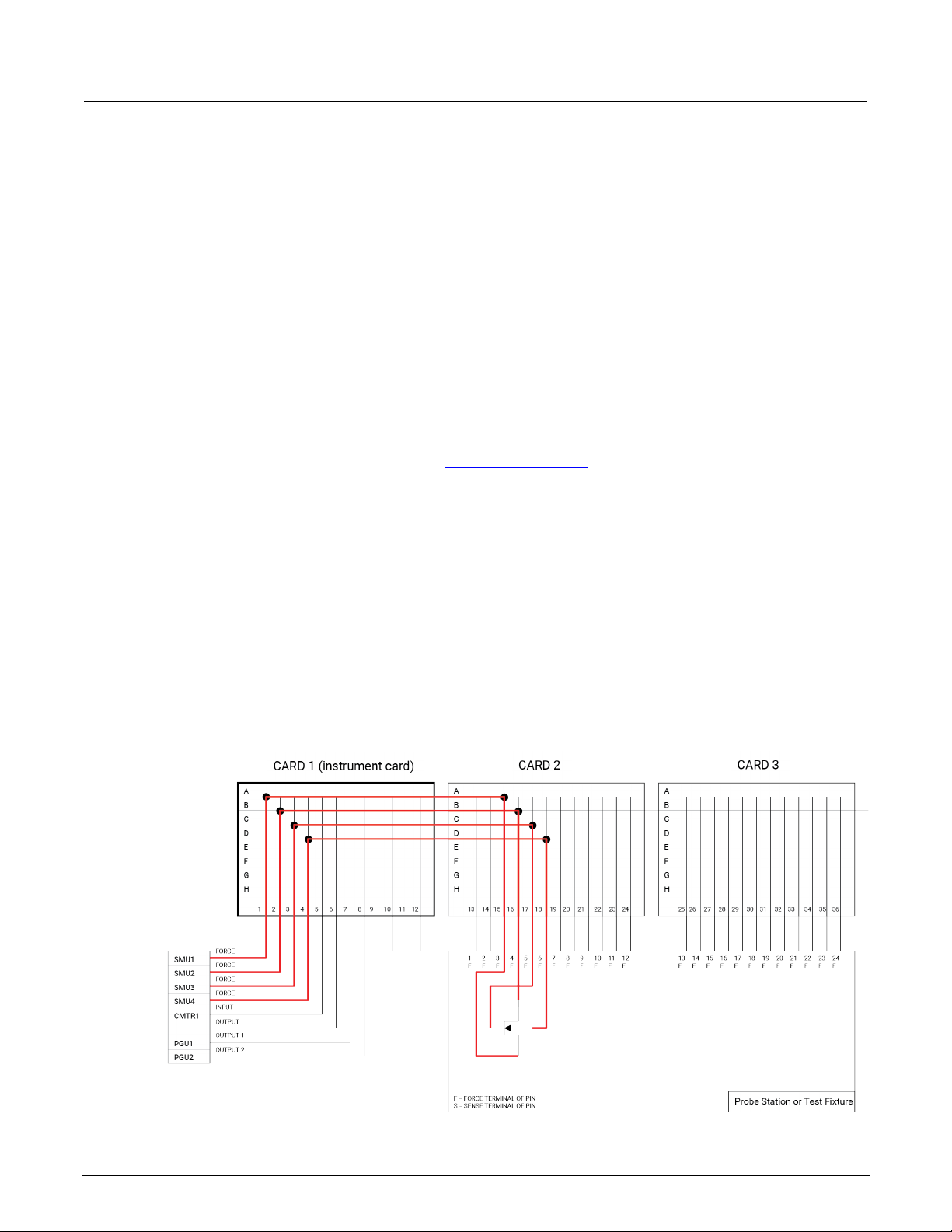

The following figure shows typical SMU matrix card connections using local sensing. The four SMU

FORCE terminals are connected to the matrix card rows, while the DUT HI terminals are connected to

the matrix card columns. All 12 DUT LO terminals are connected together, and the DUT LO signal is

connected to the ground unit FORCE terminal. Any SMU FORCE terminal can be connected to any

DUT HI terminal simply by closing the appropriate matrix crosspoint.

2-6 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

Figure 5: Typical SMU matrix card connections

4200A-913-01 Rev. B / June 2022 2-7

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

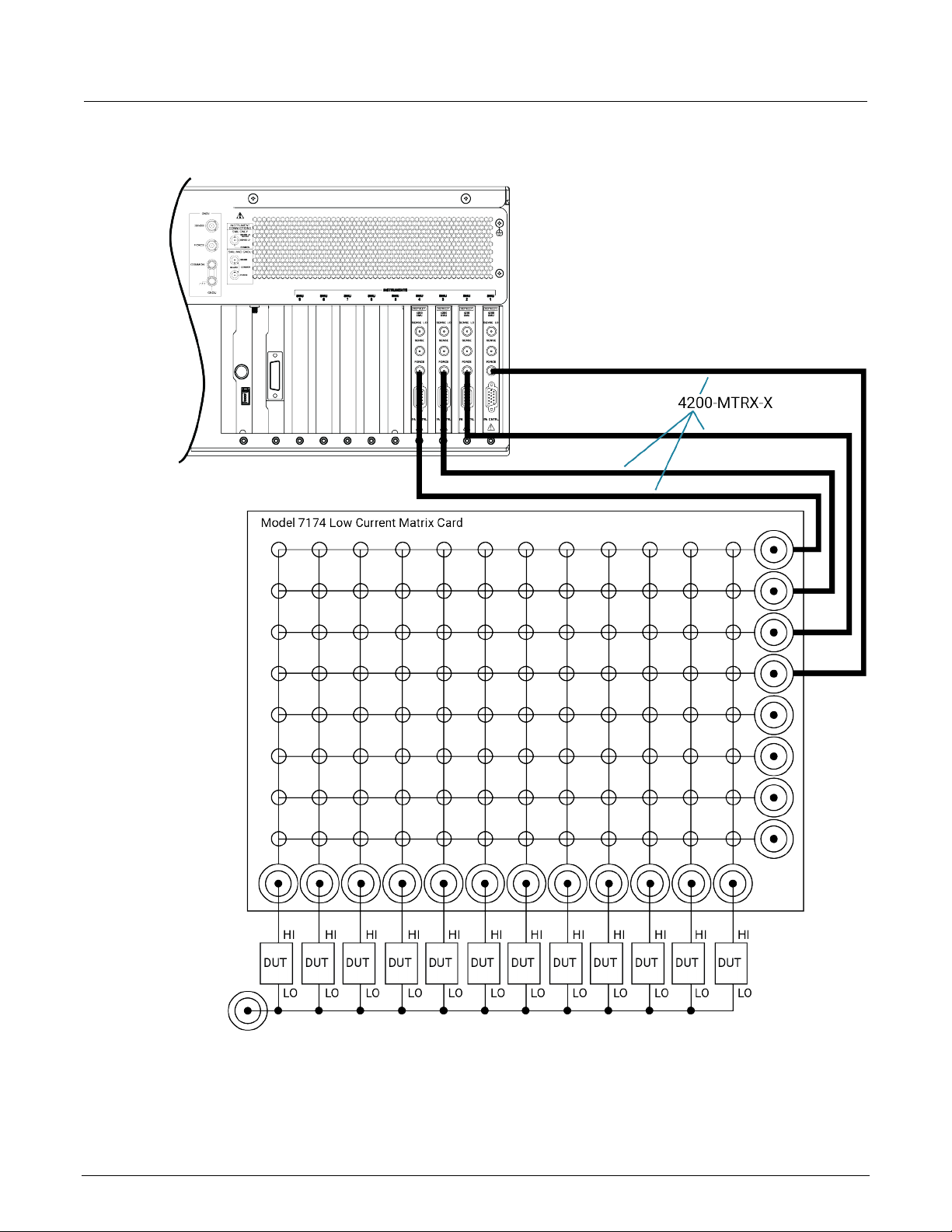

Typical preamplifier matrix card connections

The following figure shows typical preamplifier matrix card connections using local sensing. This

configuration is similar to the SMU configuration shown in the previous figure, except that

preamplifiers are added for low-current source-measure capabilities. The preamplifier FORCE

terminals are connected to the matrix card rows, while the DUT HI terminals are connected to the

matrix card columns. All 12 DUT LO terminals are connected together, and the common DUT LO

signal is connected to the ground unit FORCE terminal. Any preamplifier FORCE terminal can be

connected to any DUT HI terminal by closing the appropriate matrix crosspoint.

Figure 6: Preamplifier matrix card connections

2-8 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

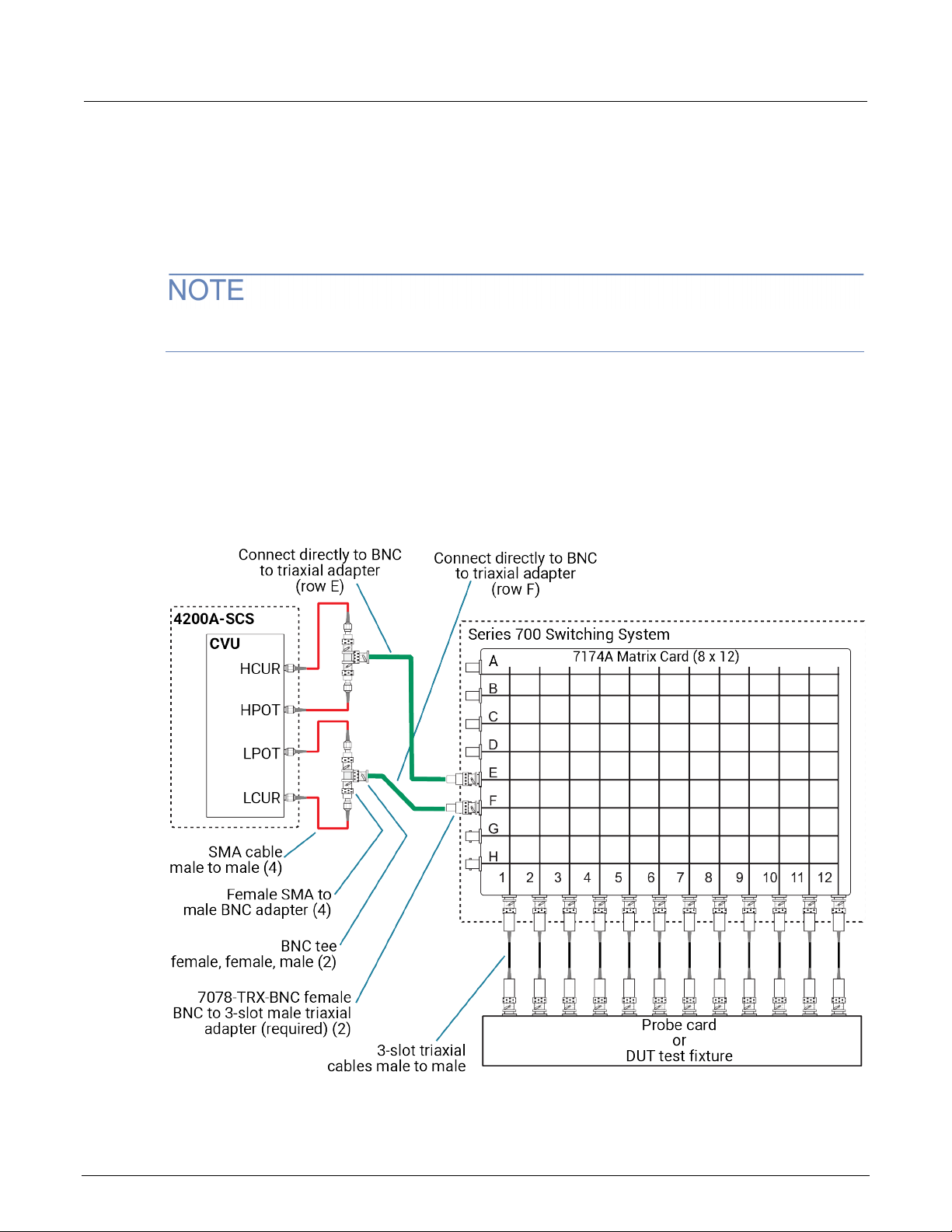

Typical CVU matrix card connections

In your project, you can automate the use of a CVU and other instrumentation using a switching

matrix and actions to control the switching. When the project is run, the switching matrix automatically

makes the required instrument connections for each test in the project.

The next figures show typical connections for a switch system using a Series 700 Switching System

with the 7174A Matrix Card installed.

You can also use the 7072 Matrix Card for C-V t

G and H and local (2-wire) s ensing.

The SMA cables and adapters shown in the following figures are supplied with the CVU or the 4200CVU-PROBER-KIT. The triaxial and BNC cables are not supplied. The prober kit includes two types

of BNC-to-triaxial adapters that connect directly to the rows of the matrix. The 7078-TRX-BNC has the

guard connected to the inner shield of the adapter. The 7078-TRX-GN D has the guard dis connected.

This figure shows connections for local (2-wire) sensing with the CVU connected to rows E and F of

the matrix. This is the connection scheme for the cap-iv-cv-matrix project. For details, see “capiv-cv-matrix” in the Model 4200A-SCS Capacitance-Voltage Unit (CVU) User's Manual.

Figure 7: Test connections for a switch matrix - local (2-wire) sensin g

esting. If you are using the 7072, you must use rows

4200A-913-01 Rev. B / June 2022 2-9

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

The following figure shows connections for remote (4-wire) sensing.

Figure 8: Test connections for a switch matrix - remote (4-wire) sensing

The 7078-TRX-BNC adapters must be used in order to extend SMA shielding through the matrix

card.

The shields of the SMA cables must be connected together and extended as far as possible to the

DUT, as shown in Typical CVU test connections to a DUT (on page 2-11).

2-10 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

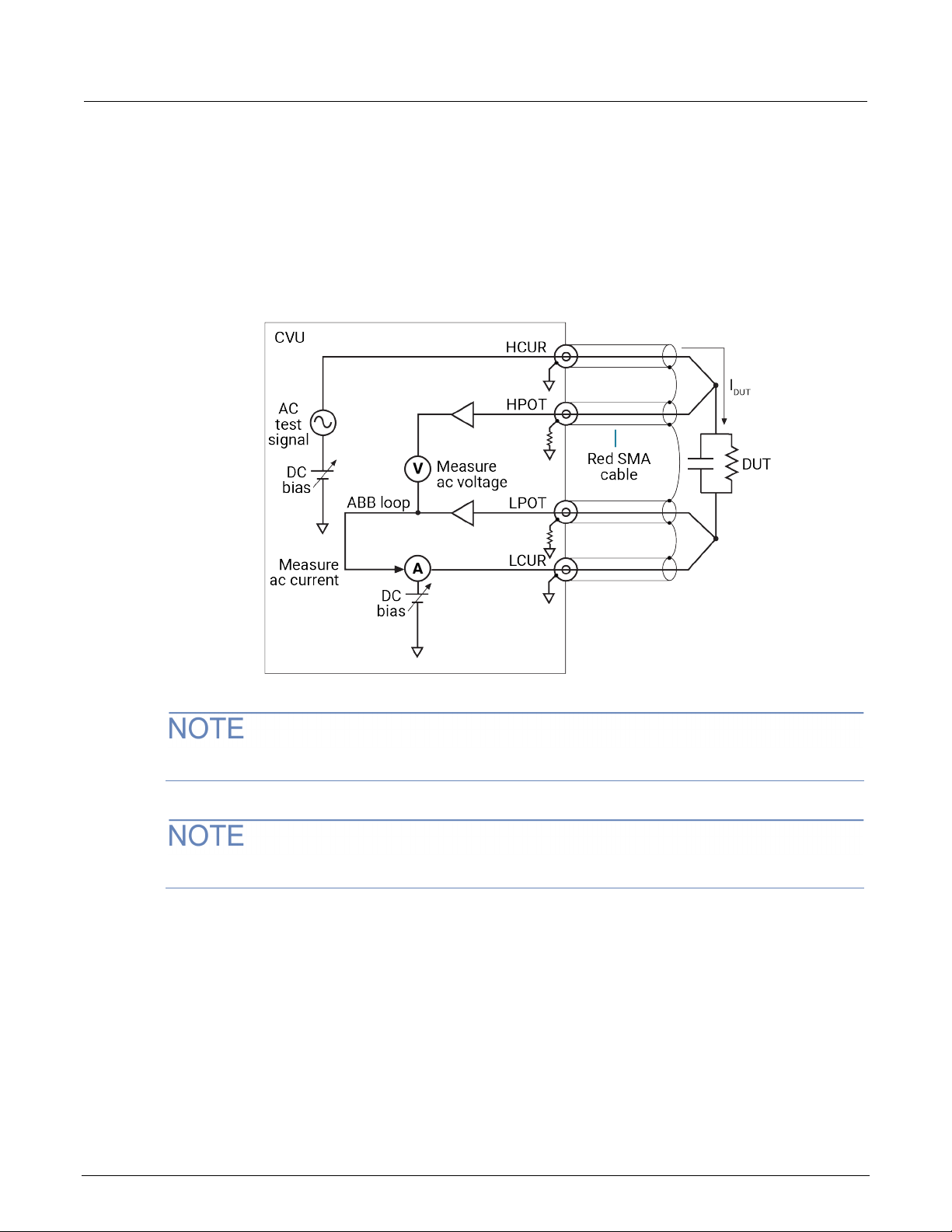

Typical CVU test connections to a DUT

The shields of the SMA cables must be connected together and extended as far as possible to the

device under test (DUT), as shown in the following figure.

Use the supplied torque wrench to tighten the SMA connections to 8 in. lb.

Figure 9: Measurement circuit (simplified)

You can swap the HCUR and HPOT and LCUR and LPOT terminal functionality in Clarius.

The shields of the red SMA cables must be connected together near the DUT.

4200A-913-01 Rev. B / June 2022 2-11

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

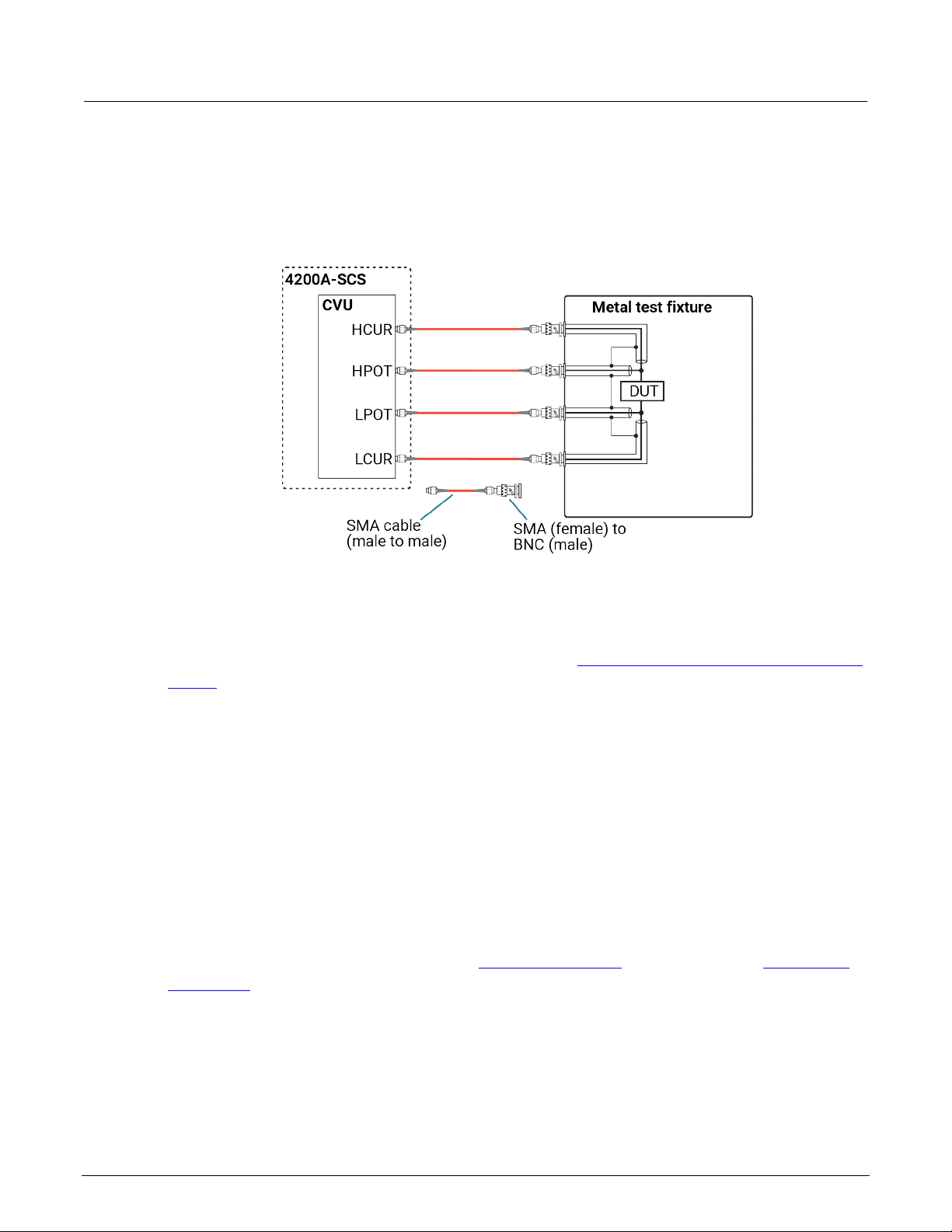

The following figure shows typical connections to a DUT installed in a test fixture that has BNC

bulkhead connectors. Use a conductive test fixture with the bulkhead connectors mounted directly to

the test fixture. Do not use insulators between the connectors and test fixture. The cables and

adapters shown are the ones supplied with the 4210-CVU or 4215-CVU.

Figure 10: Typical CVU connections to a DUT in a test fixture

Connection scheme settings

The following connection scheme settings are set from the Keithley Configuration Utility (KCon) when

the switch matrix is added to the system configuration. See Using KCon to add a switch matrix to the

system (on page 2-24).

Row-column or instrument card settings

You select the scheme for interconnections between the instruments, the switch-matrix rows and

columns, and the test system (prober or test fixture). You can select:

• Row-Column: Connect instruments to rows and prober or test fixture to columns.

• Instrument Card: Both instruments and prober or test fixture are connect ed to col umns . Matr ix

rows are not used.

The row-column setting is the simplest connection scheme. In this scheme, instruments are

connected to the switch-matrix rows. The prober/test fixture pins or the device under test (DUT) are

connected to the switch-matrix columns (see Switch matrix control (on page 2-16) and

signal paths (on page 2-17)).

4200A-SCS

2-12 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

When you set up a matrix, you also select the sense. You can select:

• Local sense: 2-wire connections. Connections are only to instrument FORCE terminals.

• Remote sense: 4-wire connections. Connections are to both instrument FORCE and SENSE

terminals.

For more information regarding local and remote sense, refer to “Remote sensing” in the Model

4200A-SCS Source -Measure Unit (SMU) User's Manual.

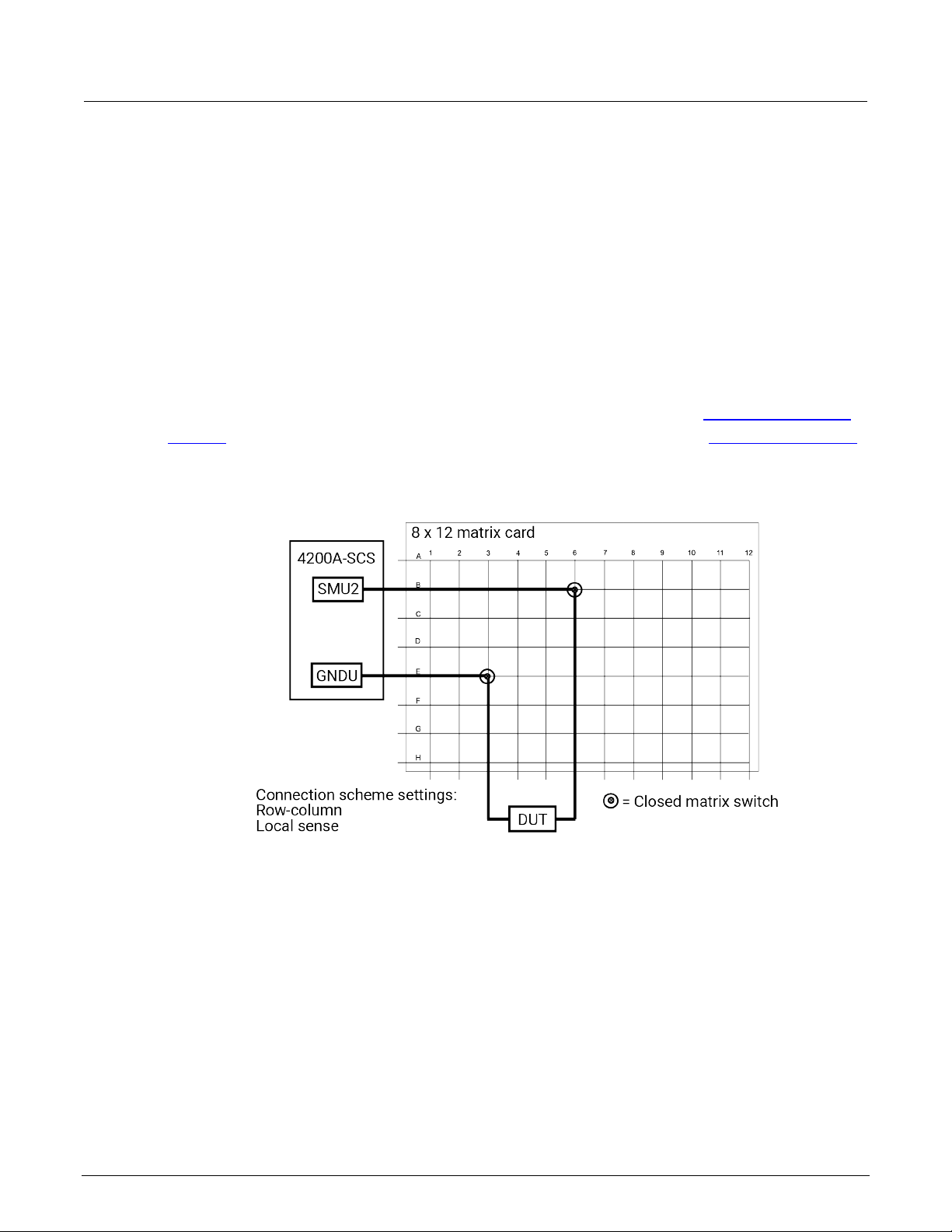

Row-column scheme

The row-column setting is the simplest connection scheme. In this scheme, instruments are

connected to the switch-matrix rows. The prober/test fixture pins or the device under test (DUT) are

connected to the switch-matrix columns (see Switch matrix control (on page 2-16) and 4200A-SCS

signal paths (on page 2-17)).

Instrument signals can route to prober/test-fixture pins through only one matrix card, as shown in the

following figure. However, the row-column scheme limits the number of external instruments. If the

instrumentation requirements exceed eight paths (rows), you must use the instrument

card configuration.

Figure 11: Row-Column, Local Sense Connection Scheme example

4200A-913-01 Rev. B / June 2022 2-13

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Instrument card scheme for l ocal sense

Use local sense when the measurement-pathway resistance is small and the associated voltage

errors are negligible. The measurement pathway is comprised of the following conductors, connected

in series:

• The cables used to connect the instruments to the matrix

• The internal matrix-card signal path

• The cables used to connect the matrix to the prober or test fixture

Current flowing through the measurement pathway creates a voltage drop (an error voltage) that is

directly proportional to the pathway resistance. This error voltage is present in all local sense voltage

measurements.

When local sense is selected, only the connection paths specified by the connected action are

completed. For example, in the figure in Switch matrix control (on page 2-16

connection paths would be:

• SMU2, 6 (connect SMU2 to Pin 6)

• GNDU, 3 (connect GNDU to Pin 3)

), the specified

For the instrument card scheme, both the instrumentation and the prober/text-fixture pins or DUT are

connected to switch-matrix columns. No external conn ec tions ar e made to matr ix r ows . In this

configuration, two switch relays are closed to complete a path from an instrument to a DUT.

Instrument signals route to the prober/test-fixture pins through two or more matrix cards, as shown in

the following figure. This connection scheme can support large systems with numerous instruments

by removing the eight-row instrument connection limitation.

Figure 12: Instrument Card, Local Sense Connection Scheme example

2-14 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

Row A paired with row B

Column 1 paired with Column 2

Row C paired with row D

Column 3 paired with Column 4

Row E paired with row F

Column 5 paired with Column 6

Row G paired with row H

Column 7 paired with Column 8

Column 9 paired with Column 10

Column 11 paired with Column 12

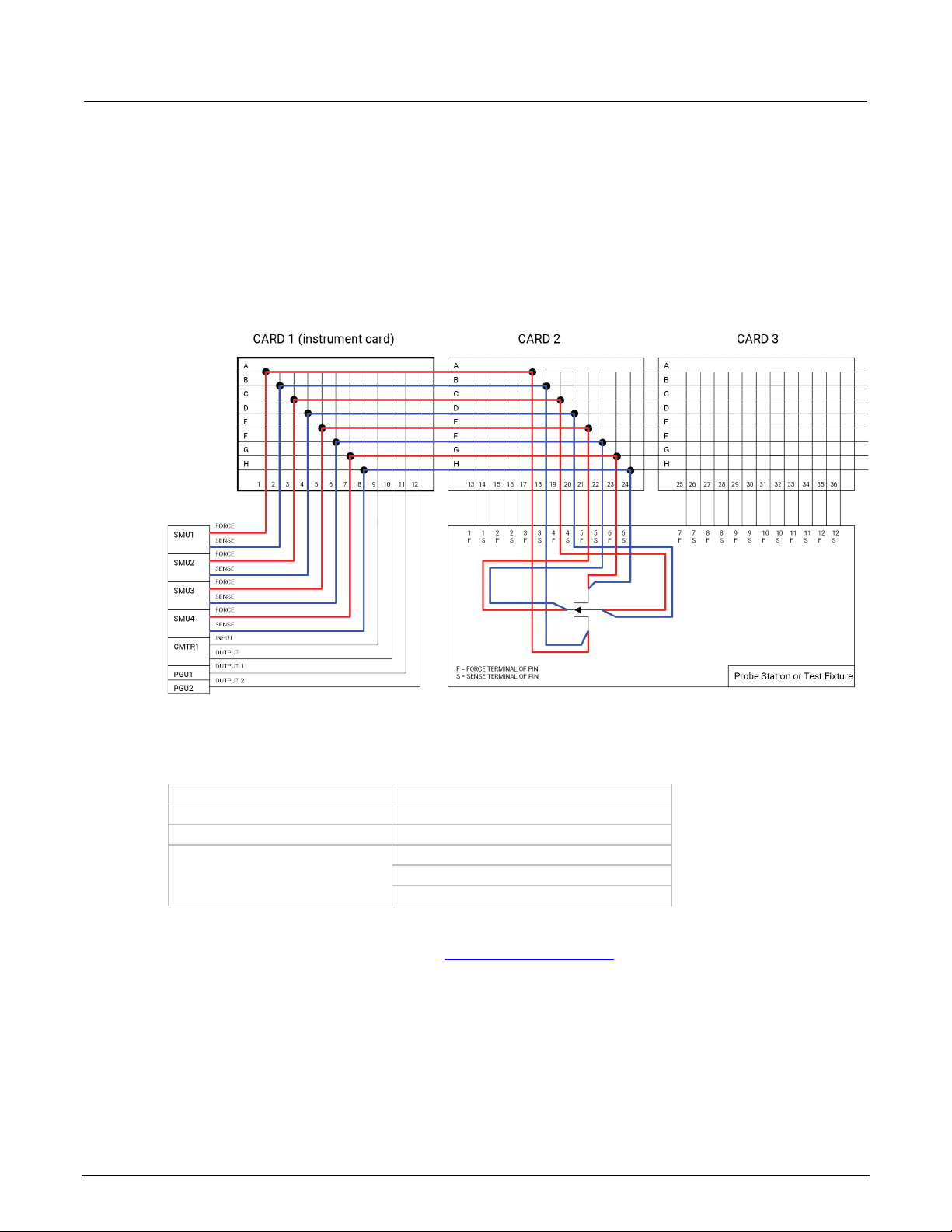

Instrument card scheme for remote sense

Use remote sense to eliminate the effects of measurement pathway resistance. The following figure

illustrates the use of remote sense in an instrument card configuration. Note that remote sense

requires twice as many measurement pathways. The FORCE pathways (in red) are the currentcarrying pathways, and the SENSE pathways (in blue) are the meas urem ent path way s .

Figure 13: Instrument Card, Rem o te Sense Connection Scheme example

When remote sense is selected, rows and columns are paired together as shown in the following

table.

When you specify a connection path in the connect action, the paired connection path is also

completed. For example, in the figure in 4200A-SCS signal paths ( on pag e 2-17), the specified

connection paths would be:

• SMU1, 4 (connect SMU1 to Pin 4)

• GNDU, 3 (connect GNDU to Pin 3)

4200A-913-01 Rev. B / June 2022 2-15

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Switch matrix control

To control switching, you can use the connect action in the ivcvswitch project. You can also use

the ConnectPins user module in the Matrixulib user library.

The connect action uses the ConnectPins user module to control a switch matrix. You specify t

i

nstrument terminal and pin pairs. For example, for the row-column connection scheme shown in the

following figure, you set the parameters:

he

• TermIDStr2 to SMU2 and Pin2 to 6, which connects SMU2 to pin 6.

• TermIDStr8 to GNDU and Pin8 to 3, which connects GNDU (ground unit) to pin 3.

A matrix control example using the ConnectPins user module is provided in Switch matrix control

example (on page 2-31). Detailed information for ConnectPins is provided in Matrixulib user library

(on page 2-33).

Figure 14: Row-column connection scheme

Signal paths to a DUT

The following figures show signal path examples from the various test instruments through the matrix

switches to a DUT.

2-16 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

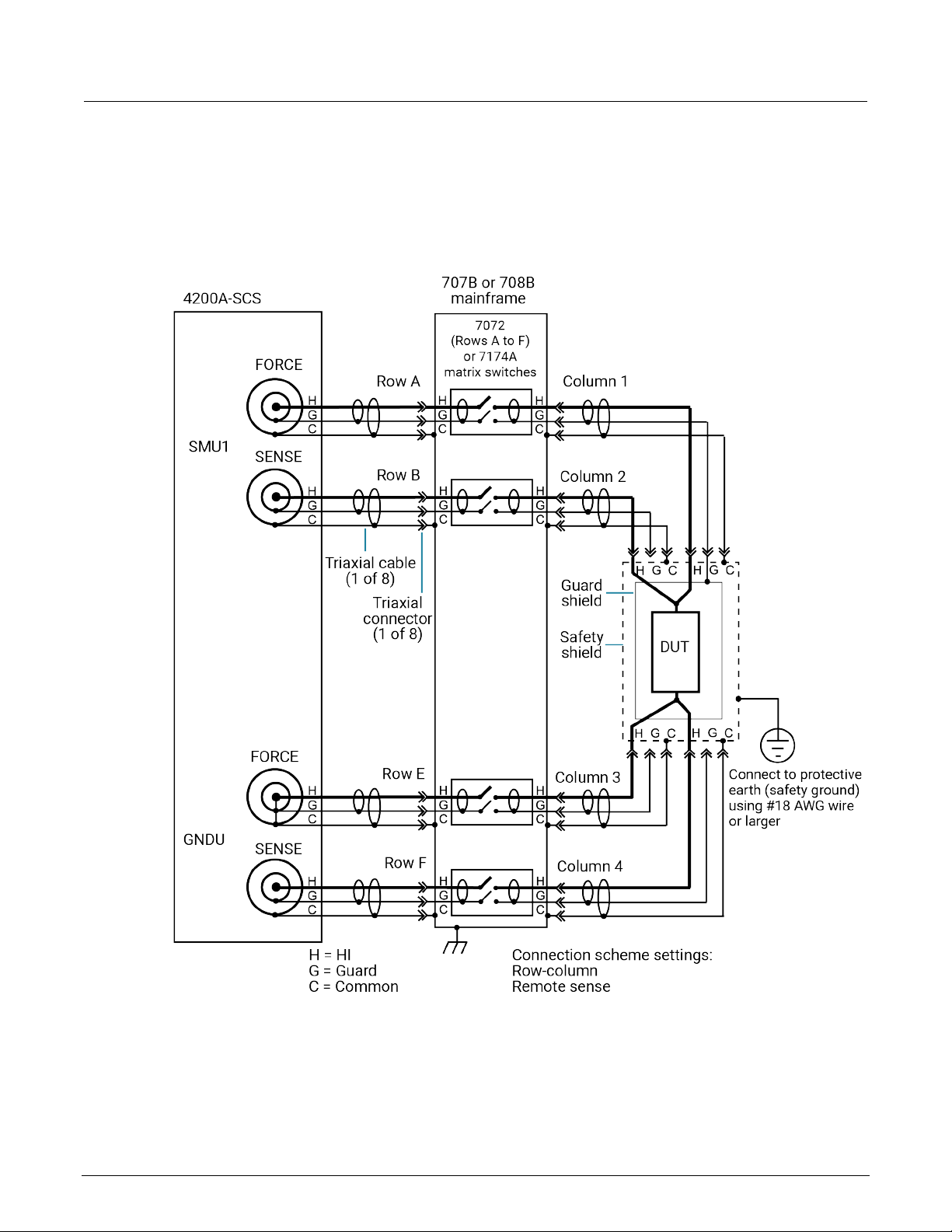

4200A-SCS signal paths

The following figure shows remote sensing (4-wire) signal paths through a matrix card using two-pole

switching. Two-pole switching is provided by the 7174A and 7072 (rows A through F).

Figure 15: 4200A-SCS signal paths through a two-pole matrix card using remote sensing

4200A-913-01 Rev. B / June 2022 2-17

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Row A (force) paired with row B (sense)

Column 1 (force) paired with column 2 (sense)

Row E (force) paired with row F (sense)

Column 3 (force) paired with column 4 (sense)

Sense setting

To make the connections shown in 4200A-SCS signal paths (on page 2-17), you must select remote

sensing.

When remote sensing is selected, the rows and columns are paired together as follows:

When the FORCE matrix switches are closed by the ConnectPins user module, the SENSE matrix

switches are also closed.

For local sensing (2-wire), the connections from the SENSE terminals of the 4200A-SC S ar e

not used.

For more information regarding local and remote sense, refer to “Remote sensing” in the Mode

4200A-SCS Source -Measure Unit (SMU) User's Manual.

Connection setting

The row-column setting must be used when connecting instrumentation to matrix rows, as shown in

4200A-SCS signal paths (on page 2-17).

The maximum number of rows available to the test system is eight. If instrumentation needs more

than eight pathways, they must be connected to matrix columns, and the instrument card setting must

be used.

The following figure shows a test system with both the instruments and the DUT connected to

matrix columns.

See Connection scheme settings (on page 2-12

settings. The connection scheme settings shown in this figure are Instrument Card and

Remote Sense.

) for details on the row-col

umn and instrument card

l

2-18 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

Figure 16: Instrument card connection scheme

The 4200A-SCS automatically selects the first available rows to make connections to the DUT. In

this example, rows A through D are the first available rows.

The following shows 4200A-SCS signal paths through a 3-pole 7071 matrix card using remote

sensing. Note that for this configuration, each FORCE and SENSE connector does not use a

separate path (row). Unlike the configuration shown in 4200A-SCS signal paths (on page 2-17), each

FORCE/SENSE connector pair is routed through a single 3-pole matrix switch. Since row pairing is

not required, the local sense setting must be used.

For two-wire local sense connections, do not use the SENSE connectors of the 4200A-SCS

.

To avoid high voltage exposure that could result in personal injury or death, whenever the

inte

rlock of the 4200A-SCS is asserted, the FORCE and GUARD term inals of the SMUs and

preamplifier should be considered to be at high voltage, even if they are programmed to a

nonhazardous voltage current.

4200A-913-01 Rev. B / June 2022 2-19

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Figure 17: 4200A-SCS signal paths through a 3-pole matrix card using remote sensing

C-V Analyzer signal paths

The following figures show local sense C-V Analyzer signal paths through rows B and H of a 7072

matrix card. A C-V analyzer can be used with any of the three matrix card types; however, rows G

and H of the 7072 are optimized for C-V measurements.

2-20 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

Figure 18: 590 signal paths through 7072 matrix card using local sensing

Figure 19: Keysight Model 4980A signal paths through 7072 matrix card using local sensing

4200A-913-01 Rev. B / June 2022 2-21

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

The following figure shows the remote sense signal paths for the Keysight Model 4980A LCR meter

through a 2-pole matrix card. Since row pairing is required, the remote sense setting must be used.

Figure 20: Keysight Model 4980A signal paths through a two-pole matrix card using remote

sensing

2-22 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

Keysight Model 8110A pulse generator signal path

The following figure shows the HI signal path through the 7174A matrix card. However, the pulse

generator can also be used with other matrix card types.

Note that the pulse generator LO is not routed through the matrix card. A separate external return

path is required. The chassis of the pulse generator is output LO. As shown in the following figure,

use a banana plug cable that is terminated with a spade lug on one end. Connect the banana plug

end of the cable to the Common banana jack of the GNDU, and attach the spade lug end to a chassis

screw on the pulse generator.

Figure 21: Keysight Model 8110A signal path through a 7174A matrix card

4200A-913-01 Rev. B / June 2022 2-23

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Use KCon to add a sw itch matrix to the system

You use Keithley Configuration Utility (KCon) to manage the configuration of all instr umen tat ion

controlled by the 4200A-SCS software. To use the 4200A-SCS to control a switch matrix, you must

add the switch matrix to the system configuration using KCon.

If you are testing discrete device under test (DUTs), you must use the switch matrix with a test fixture.

If you are testing a wafer, you must use the switch matrix with a probe station. The test fixture or

probe station is also added to the system configuration using KCon.

You specify physical instrument-to-card and card-to-prober or fixture connections in KCon.

These and other KCon switch matrix settings result in simplified matrix connections. Initially, you

need to:

• Add the test fixture or probe station.

• Configure the Instrument Connection Scheme and Switch Cards areas.

• Specify the physical instrument-to-card and card-to-prober/fixture connections.

• Physically make the specified instrument-to-card and card-to-prober/fixture connections.

After the initial setup, you can specify instrument-to-prober/fixture connections by specifying the

corresponding terminal and prober/fixture pins in a Clarius user test module (UTM). You do not need

to specify matrix cross points. The 4200A-SCS automatically routes the signals through the matrix.

For additional detail on KCon, refer to the Model 4200A-SCS Setup and Maintenance User's Manual.

If you are using a 707B or 708B Switching System, you must use the control panel on the front of

y

our switching system to enable DDC and change the command set to 70XB by following these

steps:

1. Select Menu.

2. Select DDC.

3. Select Enable.

4. Select 70XB-VERSION.

This allows the switching system to be controlled by the 4200A-SCS.

Step 1. Exit Clarius and open KCon

To exit Clarius and open KCon:

1. Exit Clarius.

2. On the Windows desktop, select the KCon icon.

2-24 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

Step 2. Add a test fixture or probe station

You must use a test fixture or a probe station with the switch matrix. However, both cannot be in the

system configuration together. If you need to remove a component, refer to “Remove an external

instrument” in Model 4200A-SCS Paramet er Analy zer Setu p and Mai nte nanc e .

Add a test fixture

To add a test fixture to the system configuration:

1. Select Add External Instrument

2. S

elect Test Fixture.

3. Select OK.

4. In the System Configuration list, select the test fixture (prefix is TF).

.

Figure 22: Add test fixture

5. From the Model list, select the appropriate test fixture.

6. Enter the number of pins. You can enter 2 to 72 pins.

The number of pins defined in the test fixture properties determines the pins that are available to

ign to a switch matrix card column. Make sure the number of pins assigned is appropriate for

ass

your system.

4200A-913-01 Rev. B / June 2022 2-25

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Add a probe station

Supported probe stations include:

• Fake Prober

• Manual Prober

• Micromanipulator 8860 Prober

• Cascade Microtech PA200 Prober

• Cascade Summit-12000 Pr ober

• Signatone CM500 (WL250) Prober

• MPI TS2000, TS2000-D P, TS2 0 00-HP, TS2000-SE, TS3000, and TS3000-SE Pr obe rs

Contact Keithley for the most up-to-date list of supported probers. If you are using an unsupported

prober, you must create a user library and module to control it.

To add a probe station to the system configura tion:

1. Select Add External Instrument

2. S

elect Probe Station.

3. Select OK.

4. In the System Configuration list, select the probe station. The Properties are displayed.

.

Figure 23: Probe station properties

2-26 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

5. From the Model list, select the prober.

6. Enter the Number of Pins / Positioners.

7. Select the options that are appropriate for your prober.

The number of pins defined in the probe station properties determines the pins that are available to

assign to a switch matrix card column. Make sure the number of pins assigned is appropriate for

your system.

Step 3. Add switching system mainframe

The default GPIB address for the Series 700B Switching systems is 16.

To add a switching system mainframe:

1. Select Add External Instrument

2. S

elect the Keithley 707/707A/707B Switching Matrix or Keithley 708/708A/708B Switching

Matrix.

3. Select OK.

4. In the System Configuration list, select the switching matrix. The properties are displayed. T

ollowing figure shows the properties for the 707/707A/707B. If the 708/708A/708B mainframe is

f

selected, there is only one switch card slot.

.

he

4200A-913-01 Rev. B / June 2022 2-27

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Figure 24: KCon MTRX1 Properties

Step 4. Set GPIB address

The GPIB address setting in the properties must match the actual GPIB address of the mainframe.

The address for the switch system mainframe is briefly displayed during its power-on sequence.

To set the GPIB address:

1. Select the GPIB Address from the list. Addresses that are in use are displayed with asterisks (*)

next to them. The range of addresses is 0 to 30 (GPIB address 31 is reserved as the 4200A-SCS

c

ontroller address). If the selected GPIB address conflicts with the GPIB address of another

system component, a red exclamation-point symbol (!) is displayed next to the selected address.

2. Select Save to save the change.

You can programmatically read the GPIB address and other instrument properties from the system

conf

iguration using the LPT library getinstattr function. Proper use of getinstattr allows y

o develop user libraries that are independent of the configuration. For more information, refer to

t

Model 4200A-SCS KULT and KULT Extension Pr ogra mmi ng (4200A-KULT-907-01).

ou

2-28 4200A-913-01 Rev. B / June 2022

Model 4200A-SCS Prober and External Instrument Control Section 2: Using switch matrices

Step 5. Configure the instrument connection scheme

To configure the instrument connection scheme:

1. Select the Connection Scheme from the list:

If you are connecting the instrumentation to matrix rows and the device under test (DUT) t

matrix columns, select Row-Column.

If all connections (instrumentation and DUT) are made to matrix columns only, select

Instrument Card.

2. Select Local Sense or Remote Sense:

For 2-wire connections to the DUT, select Local Sense.

For 4-wire connections to the DUT, select Remot e Se nse.

Step 6. Assign switch cards to mainframe slots

To assign switch cards to mainframe slots:

1. For each slot that contains a matrix card, select the model number of the matrix card.

2. For each slot that is empty, select Empty.

You cannot mix matrix card models. For example, if you set slot 1 to Keithley 7174 Low Current

Matrix Card, all other slots can only be set to the 7174 or Empty. To select a different model, you

must set all slots to Empty and then make the new selection.

o

Figure 25: Assign switch cards to slots

4200A-913-01 Rev. B / June 2022 2-29

Section 2: Using switch matrices Model 4200A-SCS Prober and External Instrument Control

Step 7. Set matrix card properties

The matrix card properties set the connections:

• Between the measurement instrumentation and the matrix card

• Between the matrix card and the test system (prober or test fixture)

The number of pins defined in the properties for a probe station or test fixture determines the pins

that are available to assign to a switch matrix card column. Make sure the number of pins assigned

is appropriate for your system. Refer to Add a test fixture (on pag e 2-25) or Add a probe station (on

page 2-26) for additional information.

To set matrix card properties:

1. In the System Configuration list, expand the switching matrix.

2. Select the card. The properties are displayed. Each row and column has a list to set the card

properties. If the row-column connection scheme is selected, instruments are assigned to t

ows and the test fixture pins or probe pins are assigned to the columns. If the instrument car

r

c

onnection scheme is selected, both instrumentation and test fixture/probe pins are assigned t

olumns.

c

he

d

o

The following figure shows the 7071 Matrix Card Properties settings that are required to support

the physical connections that are shown in Row-column or instrument card settings (on page

12).

3. Select from the lists to connect the rows and columns to instrument terminals and prober or test

fixture pins. Note that card properties must match the actual physical connections to th

mat