Page 1

Model 4200A-SCS

Capacitance-Voltage Unit (CVU)

User's Manual

tek.com/keithley

4200A-CVU-900-01 Rev. B

March 2023

*P4200A-CVU-900-01B*

4200A-CVU-900-01B

Page 2

Capacitance-Volt age Unit (CVU)

Model 4200A-SCS

User's Manual

Page 3

© 2023, Keithley Instruments

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments is strictly prohibited.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, LLC. Other brand names are trademarks or registered trademarks of their

respective holders.

Actuate

®

Copyright © 1993-2003 Actuate Corporation.

All Rights Reserved.

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: 4200A-CVU-900-01 Rev. B March 2023

Page 4

Safety precaut ions

The following safety precautio ns should be observed before using this product and any associated ins t rum enta tion. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associate d with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specif icat ion s, opera ting manual, and instrument labels, do not connect any instru ment to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 5

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment ma y be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a

The

screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentatio n.

symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is mark ed on the instr u ment .

The

symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The

If this

symbol indi cates a connection terminal to the equipment frame.

symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains h azard s that coul d dama ge the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the

symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the as soc iate d infor mation very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purcha sed fr om ot her

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2018.

Page 6

Table of contents

Introduction .............................................................................................................. 1-1

Introduction .......................................................................................................................... 1-1

Capacitance-Voltage Unit (CVU) ......................................................................................... 1-1

Test signal ............................................................................................................................ 1-2

Connections ............................................................................................................. 2-1

CVU connections ................................................................................................................. 2-1

Connection notes ...................................................................................................................... 2-1

Prober accessories for the CVU ................................................................................................ 2-2

Typical CVU test connections to a DUT .................................................................................... 2-3

Simplified model of a DUT......................................................................................................... 2-4

Typical test connections to a probe card ................................................................................... 2-5

Typical CVU matrix card connections ....................................................................................... 2-5

Connection compensation ................................................................................................... 2-8

Generate open connection compensat ion dat a ......................................................................... 2-8

Generate short connection compen sat ion data ....................................................................... 2-11

Generate load connection compensatio n dat a ........................................................................ 2-13

Compensation data ................................................................................................................. 2-15

Enable compensation .............................................................................................................. 2-15

ABB unbalance errors ............................................................................................................. 2-17

CVU Confidence Check ..................................................................................................... 2-17

Run an open check and short check ....................................................................................... 2-18

CVU Real-Time Measurement ........................................................................................... 2-19

Setting up CVUs in Clarius ...................................................................................... 3-1

CVU project example ........................................................................................................... 3-1

Select a project ......................................................................................................................... 3-1

Configure the test ...................................................................................................................... 3-3

Run the test and review results ................................................................................................. 3-3

Selecting the DC Operation Mode ....................................................................................... 3-5

Voltage Bias .............................................................................................................................. 3-5

Voltage Linear Sweep ............................................................................................................... 3-5

Voltage List Sweep ................................................................................................................... 3-5

Voltage Step.............................................................................................................................. 3-6

DC Gnd operation mode - CVU ................................................................................................. 3-6

Selecting the Freq Operation Mode ..................................................................................... 3-6

Frequency Single Freq .............................................................................................................. 3-6

Frequency Linear Sweep .......................................................................................................... 3-6

Freq Log Sweep ........................................................................................................................ 3-7

Freq List Sweep ........................................................................................................................ 3-7

Freq Step .................................................................................................................................. 3-7

Making additional test settings ............................................................................................. 3-8

Typical test setups with timing diagrams ............................................................................. 3-9

DC bias function and sweep characteristics .............................................................................. 3-9

CVU using voltage bias ........................................................................................................... 3-11

CVU using voltage sweep ....................................................................................................... 3-12

CVU using voltage li st sweep .................................................................................................. 3-13

Page 7

Table of contents

User's Manual

Model 4200A-SCS Capacitance-Voltage Unit (CVU)

CVU using a dc voltage bias and a frequency sweep ............................................................. 3-15

CVU frequency sweep - DC step ............................................................................................ 3-17

CVU voltage linear sweep - f requency step ............................................................................ 3-19

Force-measure timing ........................................................................................................ 3-22

Bias function timing ................................................................................................................. 3-22

Sweep function timing ............................................................................................................. 3-23

CVU - all terminal parameters ............................................................................................ 3-23

Presoak ................................................................................................................................... 3-23

Start ........................................................................................................................................ 3-23

Stop ......................................................................................................................................... 3-23

Step (voltage sweep) .............................................................................................................. 3-23

List Values............................................................................................................................... 3-24

Freq Operation Mode .............................................................................................................. 3-24

Start (Freq Operation Mode) ................................................................................................... 3-24

Stop (Freq Operation Mode) ................................................................................................... 3-24

Step (Freq Operation Mode) ................................................................................................... 3-24

Frequency Points (Freq Operation Mod e) ............................................................................... 3-25

AC Drive Signal ....................................................................................................................... 3-25

Points ...................................................................................................................................... 3-25

Points (list or segment sweep) ................................................................................................ 3-25

Dual Sweep ............................................................................................................................. 3-25

DC Bias ................................................................................................................................... 3-26

Frequency ............................................................................................................................... 3-26

Parameters.............................................................................................................................. 3-26

Param1 Column Name ............................................................................................................ 3-27

Param2 Column Name ............................................................................................................ 3-28

Report Test Conditions ........................................................................................................... 3-28

DCV Column Name ................................................................................................................. 3-28

Freq Column Name ................................................................................................................. 3-28

Report Status (CVU) ............................................................................................................... 3-29

Open ....................................................................................................................................... 3-29

Short ....................................................................................................................................... 3-29

Load ........................................................................................................................................ 3-29

Cable Length ........................................................................................................................... 3-29

CVU Terminal Settings Advanced settings and circuits ..................................................... 3-30

AC Source V ........................................................................................................................... 3-31

AC Measure I Range ............................................................................................................... 3-31

DC Source V ........................................................................................................................... 3-32

DC Offset ................................................................................................................................ 3-32

Capacitance Range Estimator ................................................................................................. 3-32

CVU test settings ............................................................................................................... 3-32

CVU speed settings ................................................................................................................ 3-33

Report Timestamps ................................................................................................................. 3-37

Test Mode ............................................................................................................................... 3-38

Sweep Delay ........................................................................................................................... 3-39

Interval .................................................................................................................................... 3-39

Number of Samples ................................................................................................................ 3-39

Hold Time ................................................................................................................................ 3-39

Disable outputs at completion - CVU ...................................................................................... 3-40

Output Values ......................................................................................................................... 3-40

C-V projects .............................................................................................................. 4-1

C-V projects ......................................................................................................................... 4-1

BJT Capacitance Tests (cvu-bjt) .......................................................................................... 4-3

cvu-bjt connections ................................................................................................................... 4-3

Formulas and constants ............................................................................................................ 4-5

Page 8

Model 4200A

contents

-SCS Capacitance-Voltage Unit (CVU) User's Manual Table of

c-cb0 test................................................................................................................................... 4-5

c-ce0 test................................................................................................................................... 4-5

c-be0 test .................................................................................................................................. 4-6

BJT I-V and C-V Tests Using 4200A-CVIV Multi-Switch Project (cvu-bjt-cviv) ................... 4-7

Capacitor I-V and C-V Measurements with Series 700 Project (cap-iv-cv-matrix) .............. 4-8

cap-iv-cv-matrix project summary ............................................................................................. 4-9

cap-iv-cv-matrix connections ................................................................................................... 4-10

Formulas and constants .......................................................................................................... 4-11

connect test ............................................................................................................................. 4-11

iv-cap test ................................................................................................................................ 4-11

connect-cv test ........................................................................................................................ 4-12

cv-capacitor test ...................................................................................................................... 4-12

Capacitor Measurements (cap-measurements) ................................................................ 4-13

cvu-capacitor connection s ....................................................................................................... 4-13

Formulas and constants .......................................................................................................... 4-13

cv-10 pF test ........................................................................................................................... 4-13

cf-10 pF test ............................................................................................................................ 4-14

Carbon Nanotube Transistor Characterization Project (cntfet -characterization) ............... 4-14

Demo project (default) ........................................................................................................ 4-15

cv-nmosfet test ........................................................................................................................ 4-15

cv-diode test ............................................................................................................................ 4-15

cv-cap test ............................................................................................................................... 4-15

Diode Project (diode) ......................................................................................................... 4-16

diode connections ................................................................................................................... 4-17

diode project formulas and constants ...................................................................................... 4-18

diode-cvsweep test ................................................................................................................. 4-19

diode-c-2vsv test ..................................................................................................................... 4-20

diode-dopingprofile test ........................................................................................................... 4-21

High-Voltage C-V Tests Project (cvu-highv) ...................................................................... 4-21

High Voltage C-V Tests Using 4200A-CVIV Bias Tee Project (cviv-bias-highv) ............... 4-22

MOS Capacitor C-V Project (cvu-moscap) ........................................................................ 4-23

MOS capacitor C-V curves ...................................................................................................... 4-24

Accumulation region ................................................................................................................ 4-24

Depletion region ...................................................................................................................... 4-25

Inversion region ....................................................................................................................... 4-25

cvu-moscap connections ......................................................................................................... 4-26

cvu-moscap project formulas .................................................................................................. 4-27

cvu-moscap project constants ................................................................................................. 4-34

moscap-cvsweep test .............................................................................................................. 4-35

moscap-c-2vsv test ................................................................................................................. 4-35

moscap-dopingprofile test ....................................................................................................... 4-37

Compensating for series resistance ........................................................................................ 4-38

Extracting MOS device parameters from C-V measurements ................................................. 4-40

MOS Capacitor Lifetime Test Project (moscap-lifetime) .................................................... 4-46

moscap-lifetime connections ................................................................................................... 4-46

moscap-lifetime formulas and constants ................................................................................. 4-47

c-v test .................................................................................................................................... 4-50

c-t test ..................................................................................................................................... 4-51

gni-w-wf test ............................................................................................................................ 4-51

MOS Capacitor Mobile Ion Project (moscap-mobile-ion) ................................................... 4-54

moscap-mobile-ion connections .............................................................................................. 4-57

Formulas and constants .......................................................................................................... 4-57

Run the project ........................................................................................................................ 4-58

cv-vfb1 test .............................................................................................................................. 4-58

Page 9

Table of contents

User's Manual

Model 4200A-SCS Capacitance-Voltage Unit (CVU)

bias-pos test ............................................................................................................................ 4-59

hotchuck action ....................................................................................................................... 4-60

cv-vfb2 test .............................................................................................................................. 4-60

bias-neg test ............................................................................................................................ 4-60

hotchuck action ....................................................................................................................... 4-61

cv-vfb3 test .............................................................................................................................. 4-61

MOSFET 3-Terminal C-V Tests Using the 4200A-CVIV Bias Tees (mosfet-cviv-cv-bias-tees and

mosfet-cviv-cv-bias-tees-400V) ......................................................................................... 4-62

MOSFET I-V and C-V Tests Using 4200A-C VIV Multi-Switch Project (mosfet-cviv)......... 4-62

MOSFET Project (mosfet) .................................................................................................. 4-63

mosfet connections ................................................................................................................. 4-64

mosfet formulas and constants ............................................................................................... 4-65

g-to-sdb and mosfet-dopingprofile Analyze sheet ................................................................... 4-70

Solar Cell Project (solarcell) ............................................................................................... 4-70

solarcell connections ............................................................................................................... 4-71

solarcell formulas and constants ............................................................................................. 4-72

fwd-ivsweep test ...................................................................................................................... 4-76

rev-ivsweep test ...................................................................................................................... 4-76

solarcell-cvsweep test ............................................................................................................. 4-77

solarcell-c-2vsv test ................................................................................................................. 4-77

cfsweep test ............................................................................................................................ 4-78

Interconnect Capacitance C-V Sweep test (cv-sweep) ..................................................... 4-79

cv-sweep connections ............................................................................................................. 4-79

Formulas and constants .......................................................................................................... 4-79

Analyze sheet .......................................................................................................................... 4-80

Nanowire tests ................................................................................................................... 4-80

cvu-nanowire connection s ....................................................................................................... 4-80

Formulas and constants .......................................................................................................... 4-81

cv-gd and cv-sd tests .............................................................................................................. 4-82

Make C-V measurements on a MOSCAP ................................................................ 5-1

Introduction .......................................................................................................................... 5-1

Equipment required .............................................................................................................. 5-1

Device connections .............................................................................................................. 5-2

Connect the 4200A-SCS to the DUT ......................................................................................... 5-2

Set up the measurements in Clarius .................................................................................... 5-4

Search for and select a project .................................................................................................. 5-4

Configure the test ...................................................................................................................... 5-5

Perform offset compensation .................................................................................................... 5-8

Run the test ............................................................................................................................. 5-11

View and analyze the test results ............................................................................................ 5-11

Page 10

Test signal ................................................................................ 1-2

In this section:

Introduction .............................................................................. 1-1

Capacitance-Voltage Unit (CVU) .............................................. 1-1

Introduction

This document provides information about the 4210-CVU and 4215-CVU capacitance-v olta ge unit s,

including:

• Connections (on page 2-1): Basic information on connecting CVUs to DUTs, making test

equipment connections, making control and data connections, and configuring the system

in KCon.

Section 1

Introduction

• Setting up CVUs in Clarius (on page 3-1): Provides a brief example of setting up CVUs in Clarius

and descriptions of the terminal and test settings.

• C-V projects (on page 4-1): Provides descriptions of the C-V projects in Clarius.

• Make C-V measurements on a MOSCAP (on page 5-1): Presents a step-by-step

application example.

Capacitance-Vo l tage Unit (CVU)

The 4210-CVU and 4215-CVU Multi-Frequency Capacitance-Voltage Units are impedance

measurement modules that can be installed in the 4200A-SCS.

Capacitance-voltage (C-V) measurements are often used to characterize the gate oxide thickness,

oxide defect density, and doping profile of MOSFETs. In these measurements, as the gate voltage

varies, the capacitance of the gate to the drain and source changes. Capacitance measurements are

typically made using an ac technique. The CVUs measure ac impedance by applying a dc bias

voltage and sourcing an ac voltage across the device under test (DUT) and then measuring the

resultant ac current and phase angle.

The 4210-CVU operates from 1 kHz to 10 MHz. The ac test signal (10 mV

dc voltage biased from −30 V to +30 V.

to 100 mV

RMS

) can be

RMS

The 4215-CVU operates from 1 kHz to 10 MHz at 1 kHz resolution. The ac test signal (10 mV to

1 V

) can be dc voltage biased from −30 V to +30 V.

RMS

Page 11

Section

User's Manual

1: Introduction Model 4200A-SCS Capacitance-Voltage Unit (CVU)

Test signal

The test signal can be set for the following frequencies.

For the 4210-CVU:

• 1 kHz to 10 kHz in 1 kHz increments

• 10 kHz to 100 kHz in 10 kHz increments

• 100 kHz to 1 MHz in 100 kHz increments

• 1 MHz to 10 MHz in 1 MHz increments

The ac signal output level can be set from 10 mV

to 100 mV

RMS

impedance is 100 Ω (typical). The ac voltage measure range is 100 mV

RMS

(1 mV

RMS

resolution). The output

RMS

.

The ranges available to measure current are 1 μA, 30 μA, or 1 mA. With autorange selected, range

selection is done automatically.

For the 4215-CVU:

• 1 kHz to 10 MHz in 1 kHz increments

The ac signal output level can be set from 10 mV

RMS

to 1 V

impedance is 100 Ω (typical). The ac voltage measure range is 1 mV

The ranges available to measure current are 1 μA, 30 μA, or 1 mA. With autorange selected, range

selection is done automatically.

RMS

(1 mV

resolution). The output

RMS

.

RMS

1-2 4200A-CVU-900-01 Rev. B March 2023

Page 12

CVU Real-Time Measurement ............................................... 2-19

In this section:

CVU connections ..................................................................... 2-1

Connection compensation ........................................................ 2-8

CVU Confidence Check ......................................................... 2-17

CVU connections

The CVU is shipped with four red 1.5 m SMA cables (plug-to-plug, 100 Ω). These characterized

cables must be used for connection to the CVU to achieve optimum performance.

Section 2

Connections

If you have the 4200-CVU-PROBER-KIT, you also have four red 3 m SMA cables

(plug-to-plug, 100 Ω).

If you have the 4225-RPM Remote Amplifier/Switch Module (available as an accessory for the

4225-PMU UltraFast Pulse Measure Unit), you can use the RPM for switching between SMUs, CVUs,

and PMUs. For switching connection information, refer to “Use the RPM to switch the SMU, CVU, and

PMU” in Model 4200A-SCS Pulse Card (PGU and PMU) User’s Manual (4200A-PMU-900-01).

Connection notes

• Use only the supplied red SMA cables for connections to the 4210-CVU or 4215-CVU.

• Do not use a mix of cable lengths on different CVU terminals.

• Use the supplied torque wrench to tighten SMA cable connectors to 8 in. lb.

• In Clarius, the cable length setting of a test must match the length of the SMA cables used for

your setup.

• If you need to run connection compensation, do it after setting up connections or after making

changes to existing connections, but before running any tests. See the Connection compensation

(on page 2-8) topic.

• When making connections from the CVU to the device under test (DUT), make sure the shields of

the SMA cables are connected as close as possible to the DUT.

• Use coaxial cables to extend SMA shielding to the DUT, then connect them.

Page 13

Section

User's Manual

Keithley part number or

A 4 CA-446

Red SMA cables, male to male, 100 Ω, 3 m

B 4 CS-565

BNC female to BNC female adapter

C 4 7078-TRX-GND

Triaxial male to BNC female adapter (with guard remov ed)

D 4 7078-TRX-BNC

Triaxial male to BNC female adapter (with guard conne cted

to the inner shield of the adapter)

E 4 237-TRX-BAR

Triaxial female to triaxial female adapter

F 4 CS-1247

SMA female to BNC male adapter

G 2 CS-1391

SMA Tee adapter (female, male, female)

H 2 4200-PRB-C

SMA to SSMC dual (with local ground)

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

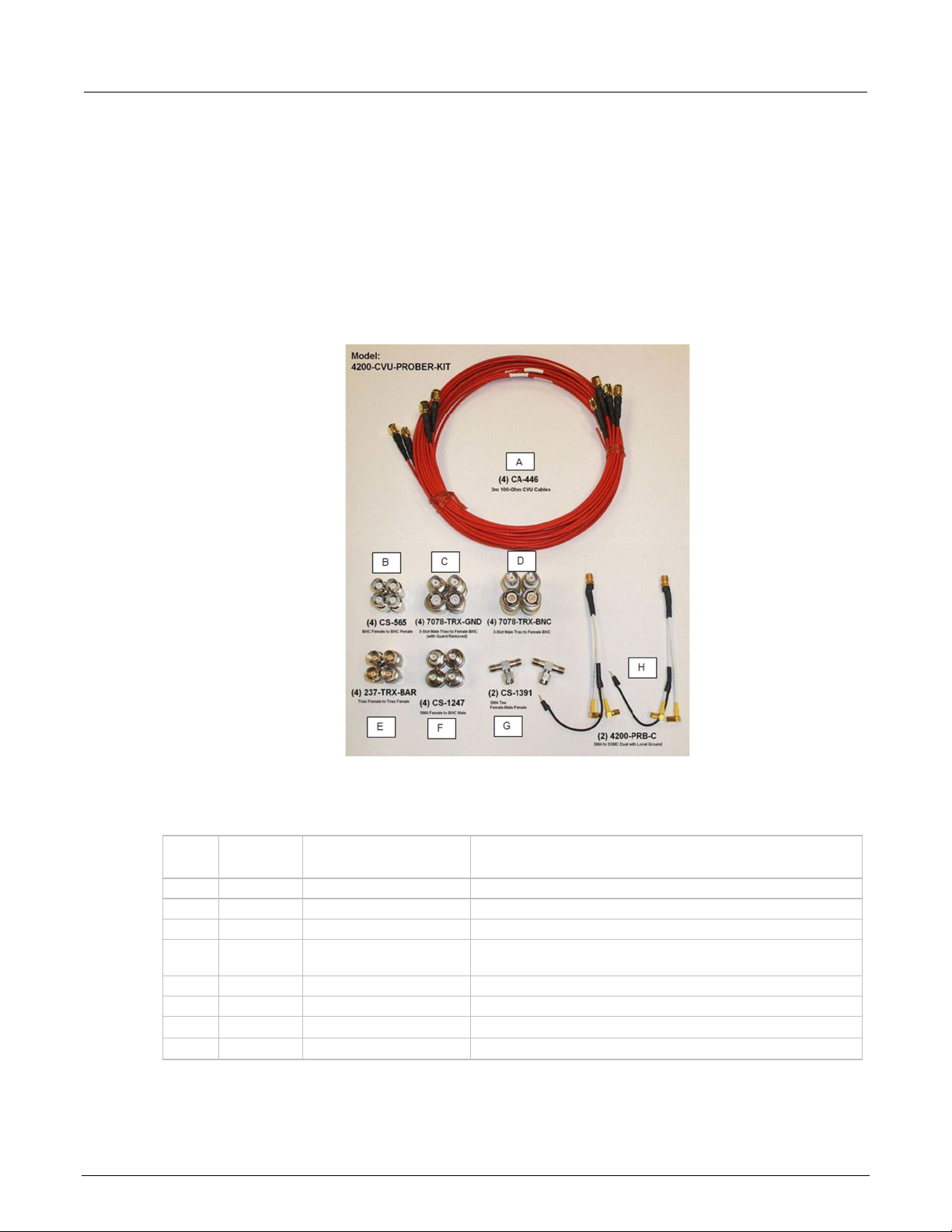

Prober accessories for the CVU

The Model 4200-CVU-PROBER-KIT is an accessory kit that provides connections to a wide variety of

prober and manipulator types. This kit contains a combination of triaxial and BNC adapters and

barrels that accommodate most prober connection requirements.

The following figure shows the accessories that are included in the kit.

Figure 1: Model 4200-CVU-PROBER-KIT

The following table lists the cables and adapters provided with the prober kit.

Supplied cables and adapters for the Model 4200-CVU-PROBER-KIT

Item Quantity

model number Description

When using the Model 4200-PRB-C cables (item H), be sure you jumper the shields together at the

probe tips. Each stackable black banana plug is connected to the outer shield of the cables.

2-2 4200A-CVU-900-01 Rev. B March 2023

Page 14

Mo

del 4200A-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2:

Connections

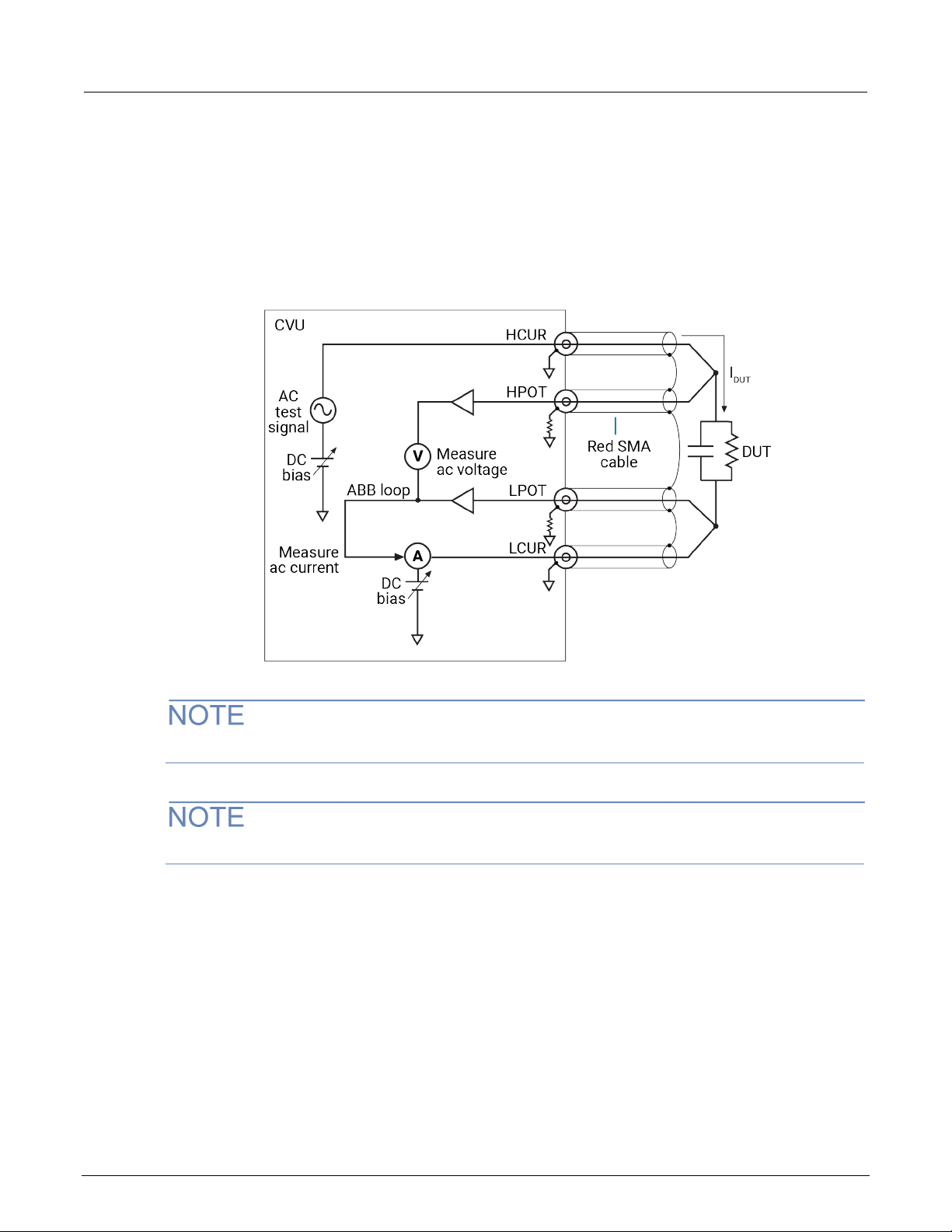

Typical CVU test connections to a DUT

The shields of the SMA cables must be connected together and extended as far as possible to the

device under test (DUT), as shown in the following figure.

Use the supplied torque wrench to tighten the SMA connections to 8 in. lb.

Figure 2: Measurement circuit (simplified)

You can swap the HCUR and HPOT and LCUR and LPOT terminal functionality in Clarius.

The shields of the red SMA cables must be connected together near the DUT.

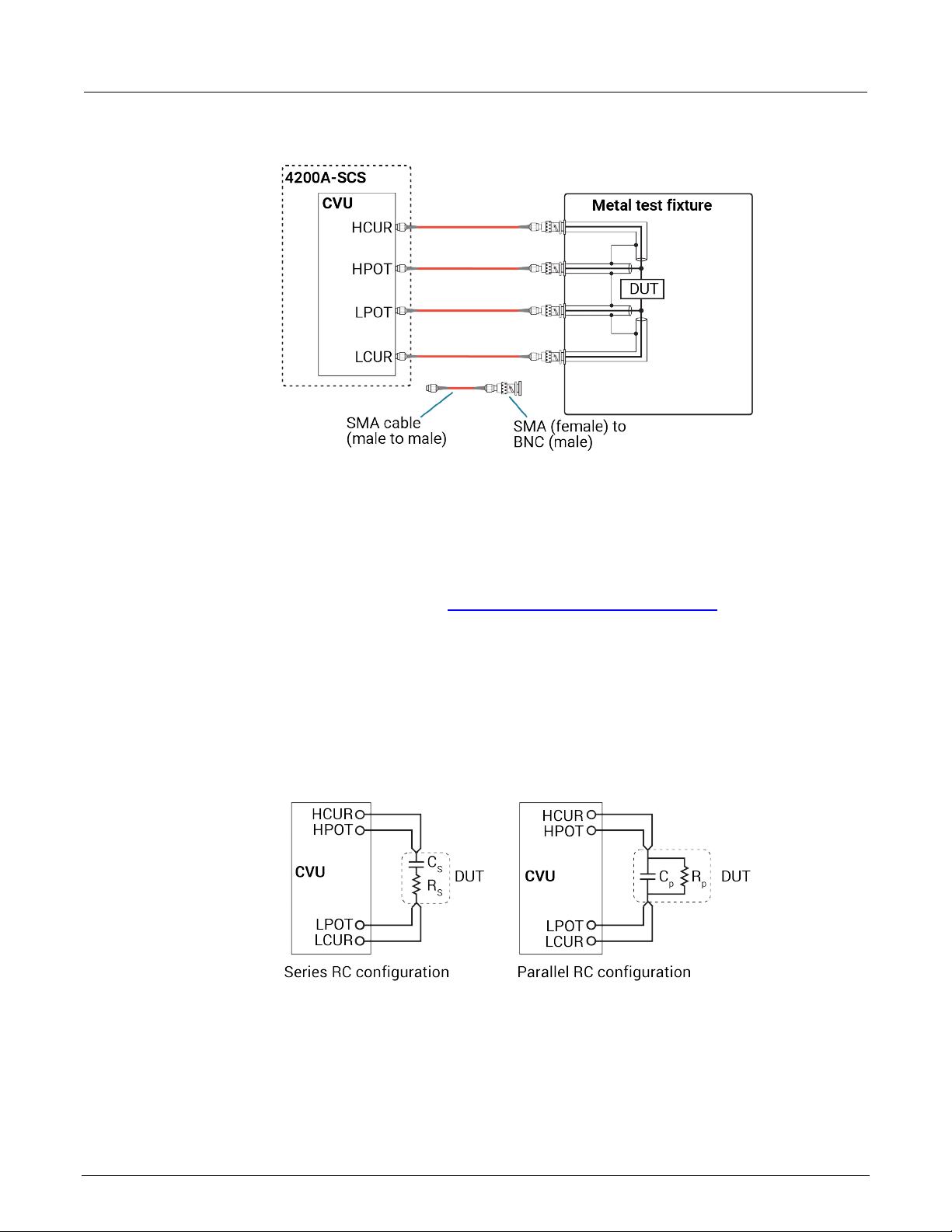

The following figure shows typical connections to a DUT installed in a test fixture that has BNC

bulkhead connectors. Use a conductive test fixture with the bulkhead connectors mounted directly to

the test fixture. Do not use insulators between the connectors and test fixture. The cables and

adapters shown are the ones supplied with the 4210-CVU or 4215-CVU.

4200A-CVU-900-01 Rev. B March 2023 2-3

Page 15

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

Figure 3: Typical CVU connections to a DUT in a test fixture

Simplified model of a DUT

The CVU makes ac impedance measurements (Z

) of the device under test (DUT) by sourcing an

DUT

ac test voltage across the device and measuring the resulting ac current and ac voltage.

The ac current is measured as shown in Typical CVU test connections to a DUT (on page 2-3

).

The HCUR/HPOT and LCUR/LPOT terminal pairs are interchangeable. Each provides the full

capability of the other pair.

The simplified model of a DUT is a resistor and a capacitor. As shown in the following figure, the CVU

can measure the DUT as a series configuration of the resistor-capacitor (RC) or as a parallel

RC configuration.

Figure 4: Measure models (simplified)

2-4 4200A-CVU-900-01 Rev. B March 2023

Page 16

Model 4200A

Connections

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2:

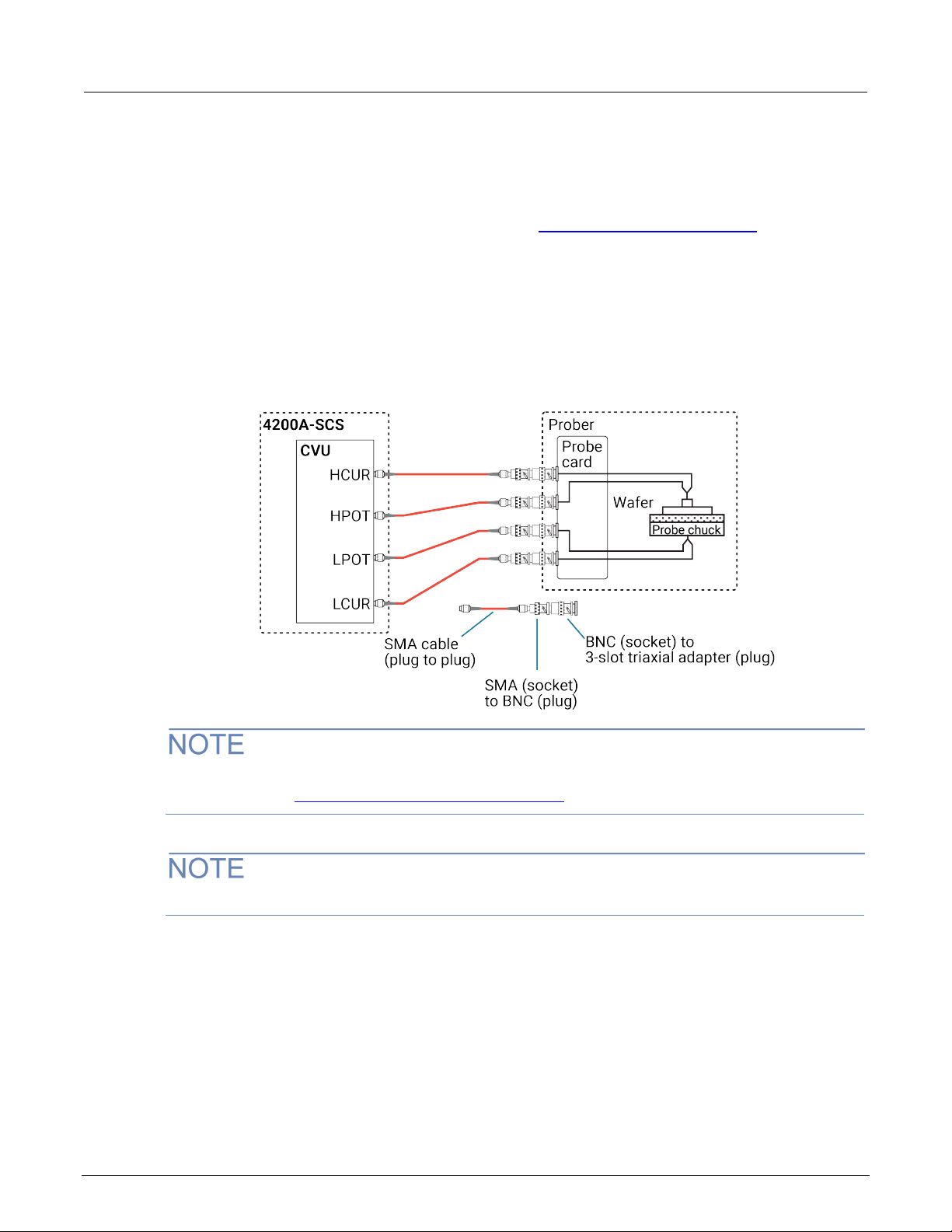

Typical test connections to a probe card

The 4200-CVU-PROBER-KIT includes 3 meter SMA cables and connection accessories to connect

the 4210-CVU or 4215-CVU to a probe card. Refer to Prober accessories for the CVU (on page 2-2

for a list of the supplied items.

The following figure shows typical test connections to a probe card. The connections use triaxial

socket connectors. The probe kit includes two types of BNC to triaxial adapters. The 7078-TRX-BNC

has the guard connected to the inner shield of the adapter. The 7078-TRX-GND has the guard

disconnected. In most applic ations , the 707 8-TRX-BNC is the preferred adapter.

Figure 5: Typical connections to a probe card

)

The shields of the SMA cables must be connected together and extended as far as possible to the

DUT, as shown in Typical CVU test connections to a DUT (on page 2-3

If the probe card uses BNC (socket) connectors, you do not need the BNC-to-triaxial adapters.

Typical CVU matrix card connections

In your project, you can automate the use of a CVU and other instrumentation using a switching

matrix and actions to control the switching. When the project is run, the switching matrix automatically

makes the required instrument connections for each test in the project.

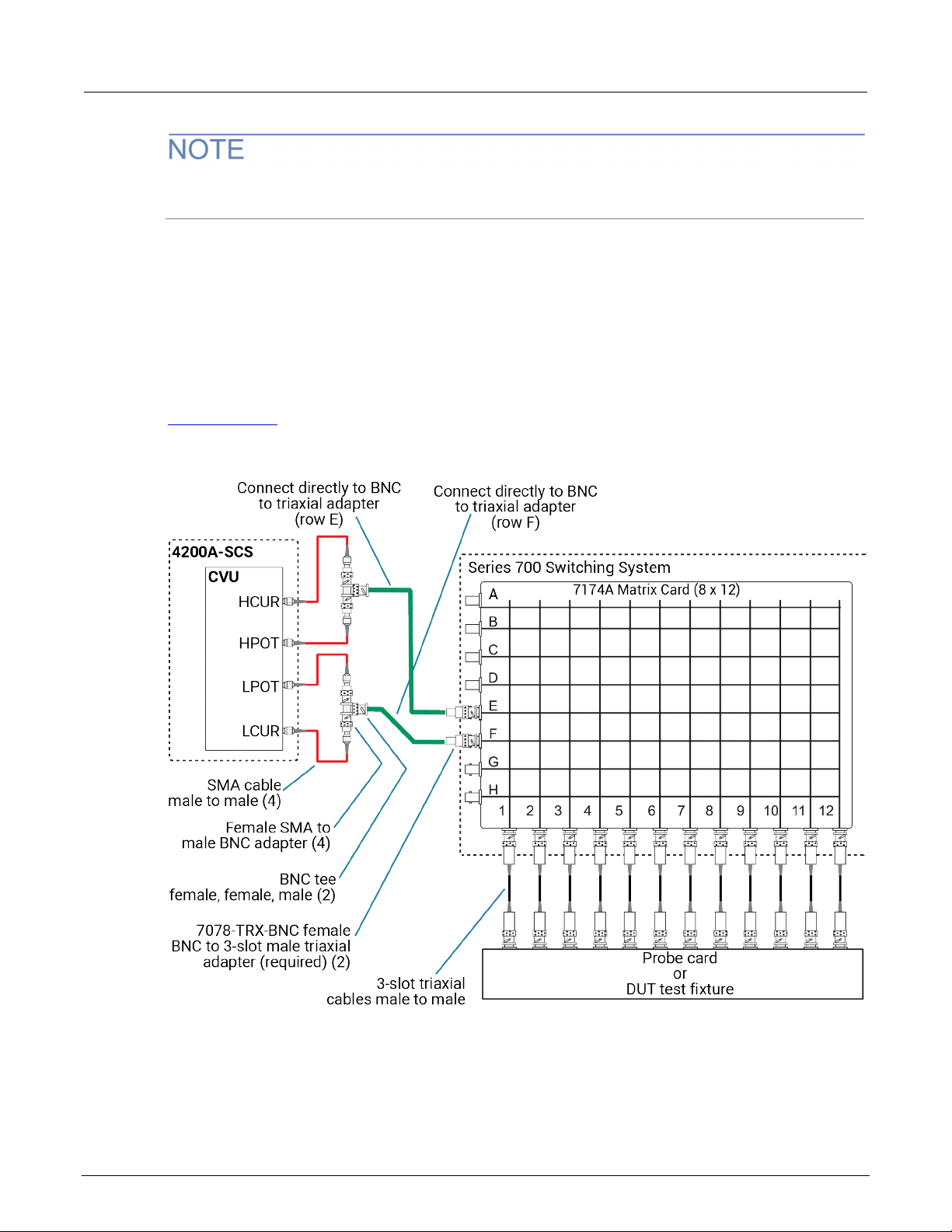

The next figures show typical connecti ons for a switch s y stem using a Series 700 Switch in g Syste m

with the 7174A Matrix Card installed.

).

4200A-CVU-900-01 Rev. B March 2023 2-5

Page 17

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

You can also use the 7072 Matrix Card for C-V testing. If you are using the 7072, you must use rows

G and H and local (2-w ir e) s ens ing.

The SMA cables and adapters shown in the following figures are supplied with the CVU or the

4200-CVU-PROBER-KIT. The triaxial and BNC cables are not supplied. The prober kit includes two

types of BNC-to-triaxial adapters that connect directly to the rows of the matrix. The 7078-TRX-BNC

has the guard connected to the inner shield of the adapter. The 7078-TRX-GND has the guard

disconnected.

This figure shows connections for local (2-wire) sensing with the CVU connected to rows E and F of

the matrix. This is the connection scheme for the cap-iv-cv-matrix project. For details, see

cap-iv-cv-matrix (on page 4-8

).

Figure 6: Test connections for a switching matrix - local (2-wire) sensing

2-6 4200A-CVU-900-01 Rev. B March 2023

Page 18

Model 4200A

Connections

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2:

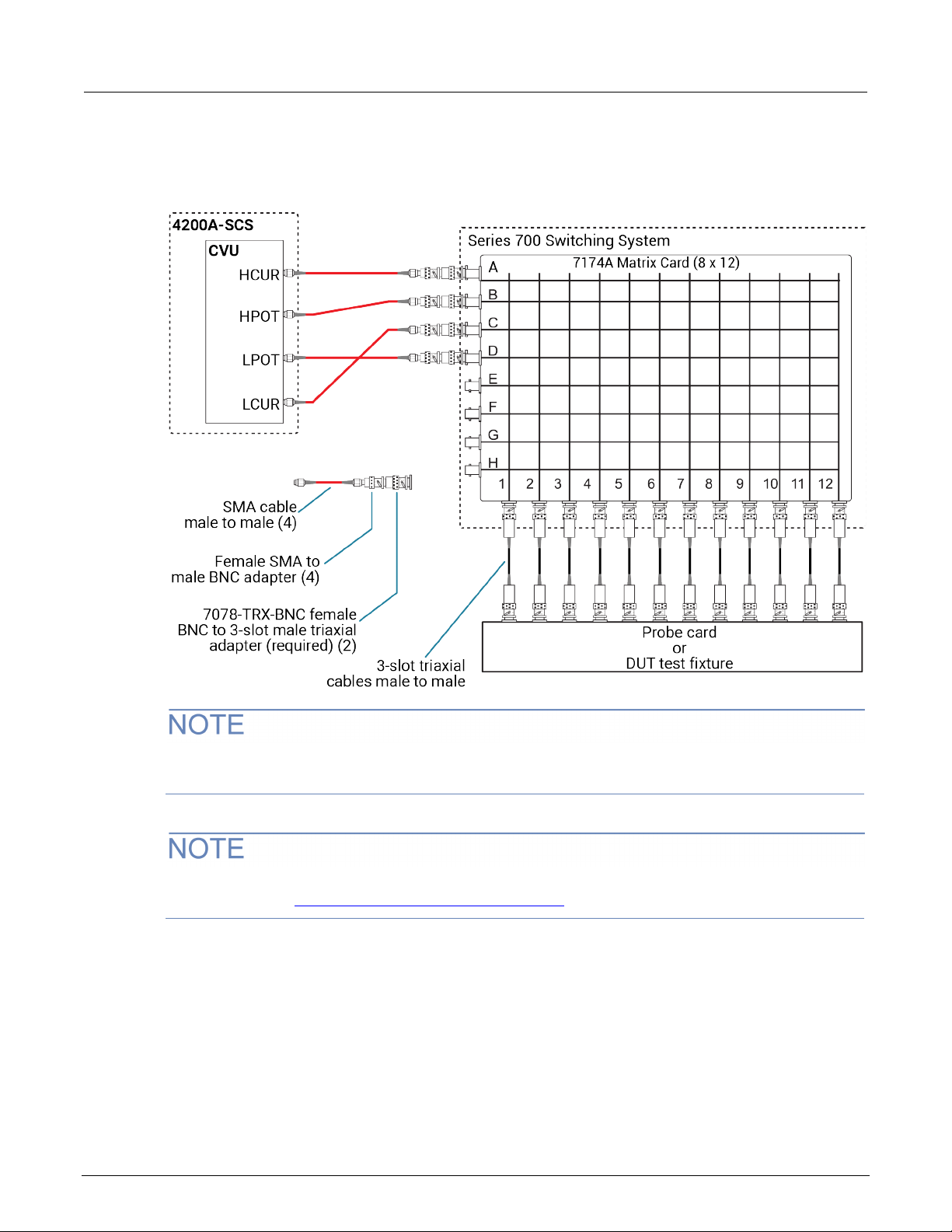

The following figure shows connections for remote (4-wire) sensing.

Figure 7: Test connections for a switching matrix - remote (4-wire) sensing

The 7078-TRX-BNC adapters must be used in order to extend SMA shielding through the

matrix card.

The shields of the SMA cables must be connected together and extended as far as possible to the

DUT, as shown in Typical CVU test connections to a DUT (on page 2-3

).

4200A-CVU-900-01 Rev. B March 2023 2-7

Page 19

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

Connection compensation

You can correct offset and gain errors caused by the connections between the CVU and the device

under test (DUT) by using connection compensation. To use correction, you:

• Generate connection compensation data for open, short, and load conditions.

• Enable CVU connection compensation.

When a test is run, the enabled compensation values are factored in by each measurement.

If open, short, or load compensation is disabled, those compensation values are not used by the test.

Once compensation values are stored, they are available to any project that uses a CVU.

Update connection compensation any time the connection setup is changed or disturbed. Changes

in temperature or humidity do not affect connection compensation.

If the CVU is connected to a 4200A-CVIV Multi-Switch, run the cvu-cviv-comp-collect action.

Refer to the Model 4200A-CVIV Multi-Switch User’s Manual for detail.

Use the following general guidelines to determine which correction needs to be done:

• Open correction: Offset correction for small capacitances (>1 MΩ, large impedance).

• Short correction: Offset correction for large capacitances (<10 Ω, small impedance).

• Load correction: Resistive load correction for gain error. Keithley recommends a load that is as

close in impedance to the cabling system (100 Ω) as possible. The load must have an impedance

versus frequency characteristic that is purely resistive over the frequency range of

subsequent measurements.

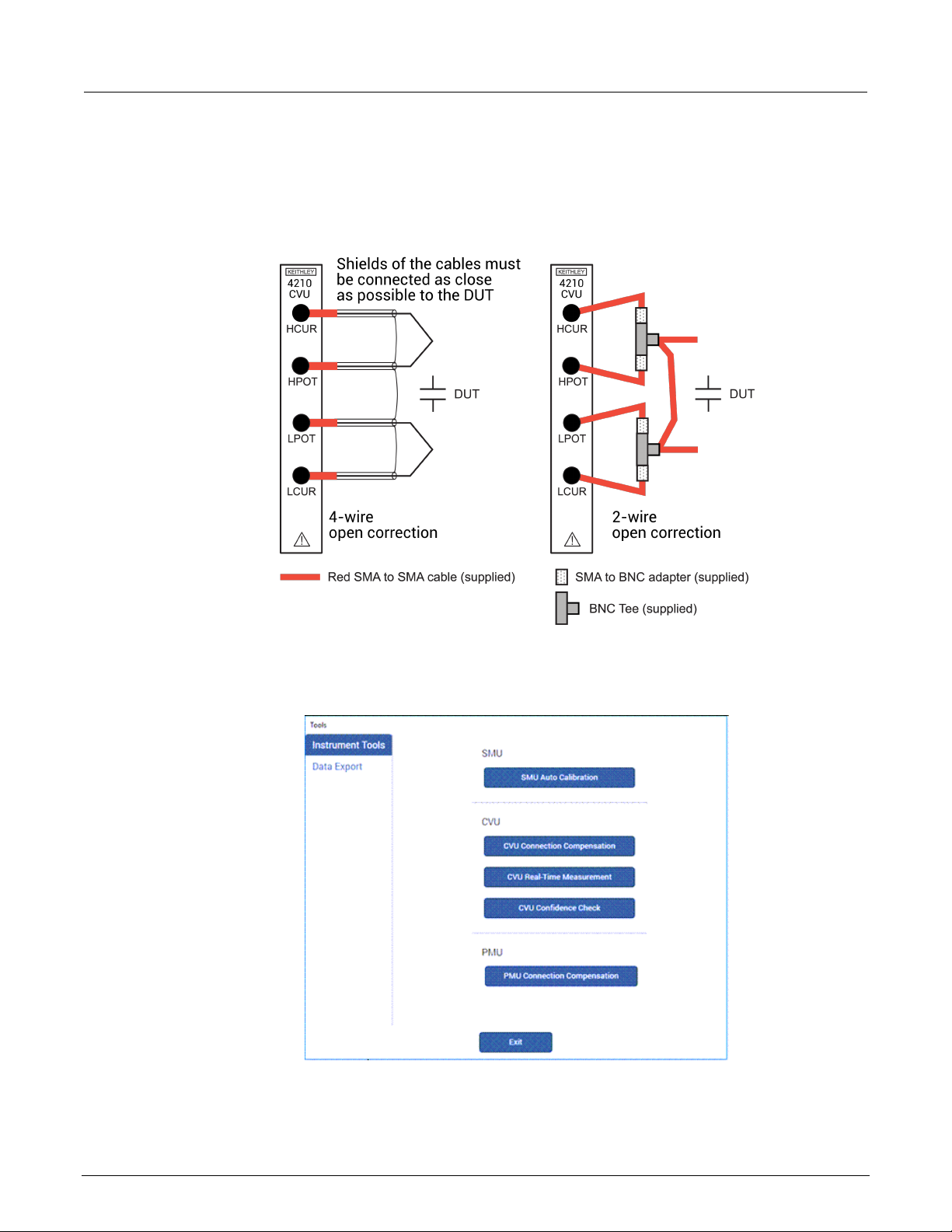

Generate open connection compensation data

Open connection compensation is usually done to offset correction for small capacitances.

Open compensation is done with all the cables, adapters, switch matrices, and other hardware

connections connected to the device under test in the test circuit. The probes must be lifted up or the

device must be removed from the test fixture.

2-8 4200A-CVU-900-01 Rev. B March 2023

Page 20

Model 4200A

Connections

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2:

To generate open connection compensation da ta:

1. Make the connections to the CVU, as shown in the following figure. For remote (4-wire) sensing,

the shields of the four SMA cables must be connected as close as possible.

Figure 8: Connections for open connection compensation CVU

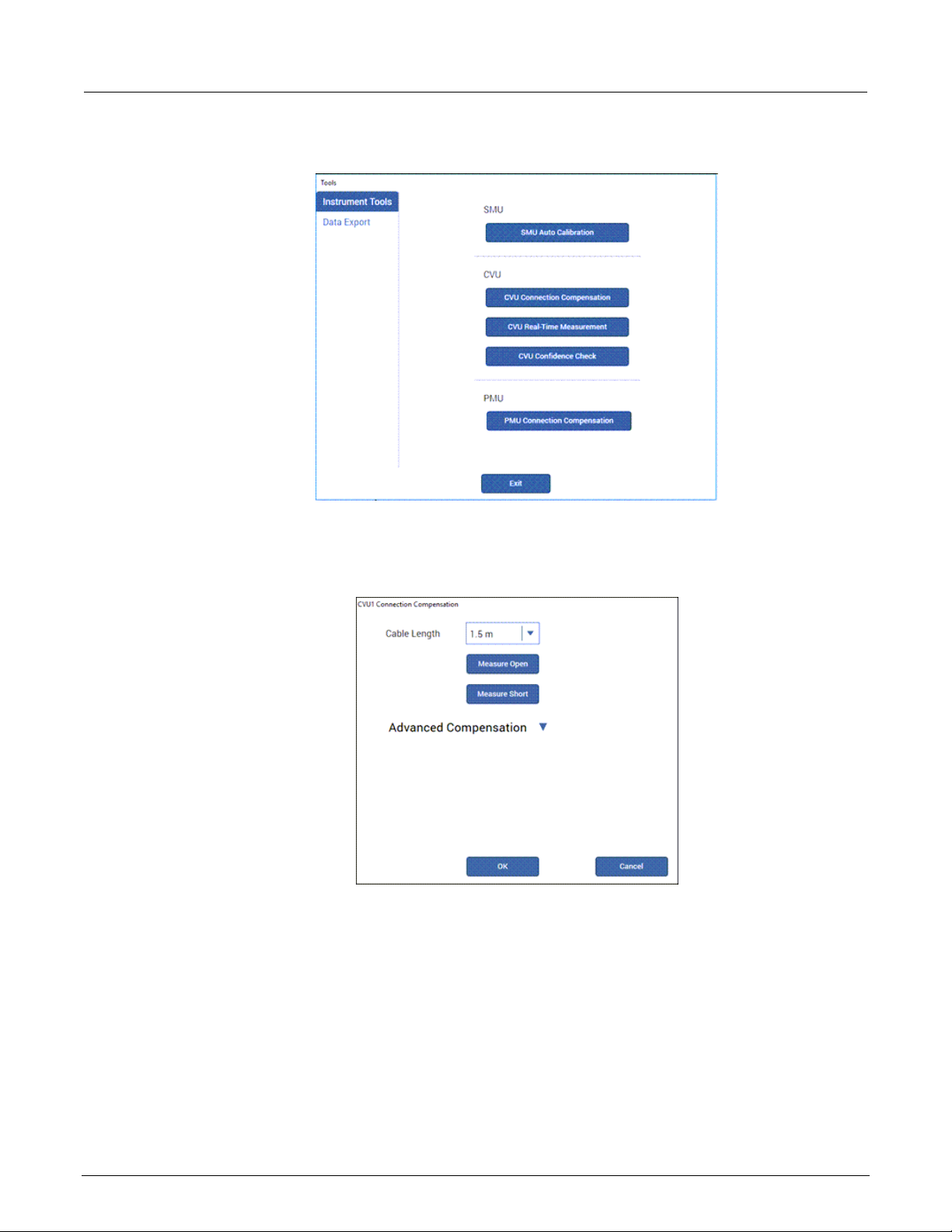

2. In Clarius, select Tools. The Clarius Tools dialog opens.

Figure 9: Clarius Tools dialog

4200A-CVU-900-01 Rev. B March 2023 2-9

Page 21

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

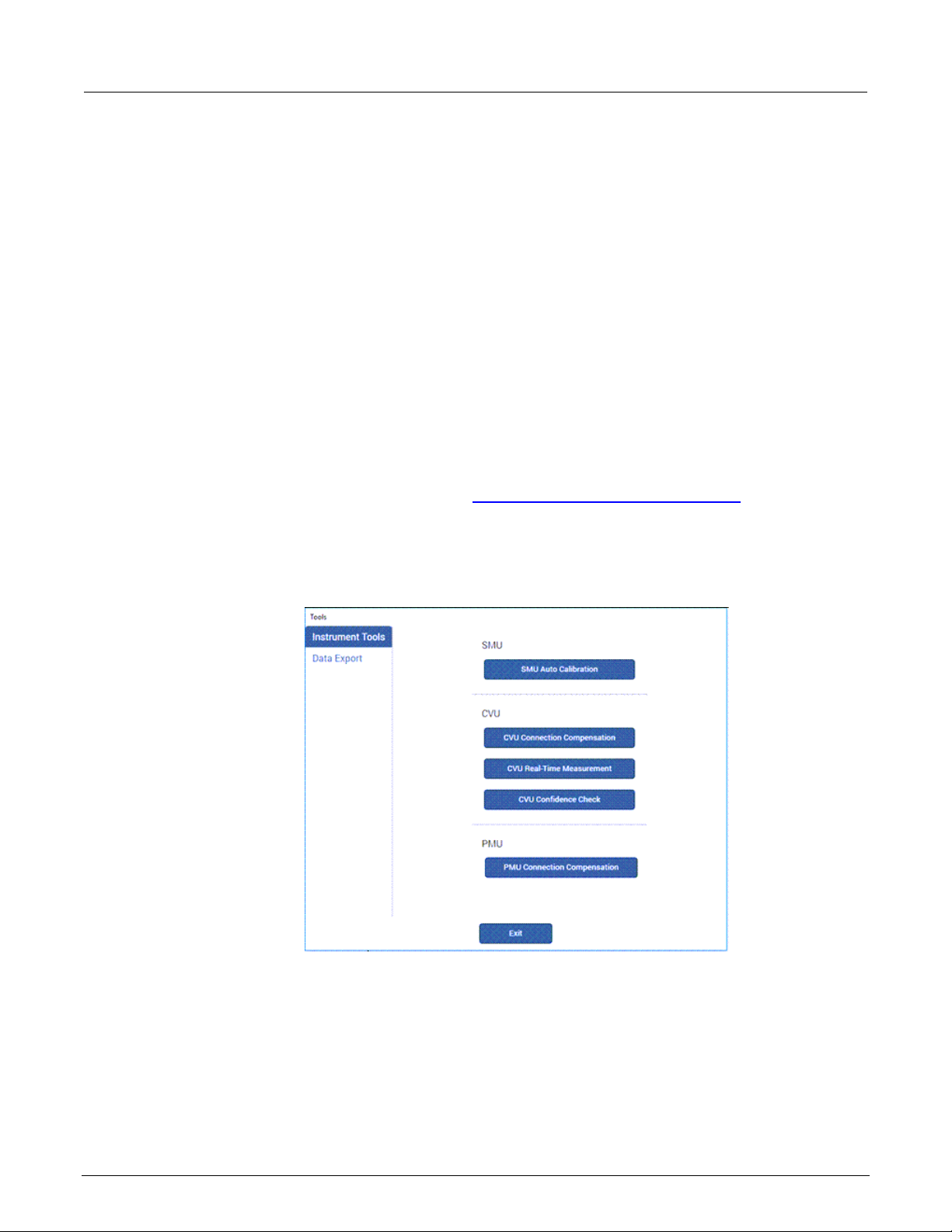

3. Select CVU Connection Compensation.

Figure 10: CVU Connection Compensation dialog

4. Select the cable length. You can select:

0 m: Use if measurements are made at the terminals of the CVU (no cables).

1.5 m: Use with the standard red SMA cables (part number CA-447A) that are supplied with

the CVU.

3 m: Use with the red SMA cables (part number CA-446) that are supplied with the

4200-CVU-PROBER-KIT. You can also use this setting if you are using a switching matrix.

Custom: Cable length coefficients are measured by the user using the Measure Custom

Cable Length option under Advanced Compensation.

5. If you selected Custom cable length, select Advanced Compensation and select Measure

Custom Cable Length. Follow the on-screen instructions.

6. If you are using a switching matrix, close the matrix switches that connect the CVU to the open.

Refer to “Using Switch Matrices” in Model 4200A-SCS Prober and External Instrument Control.

7. In the Clarius CVU Connection Compensation dialog, select Measure Open.

8. Follow the instructions.

9. Select OK.

2-10 4200A-CVU-900-01 Rev. B March 2023

Page 22

Model 4200A

Connections

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2:

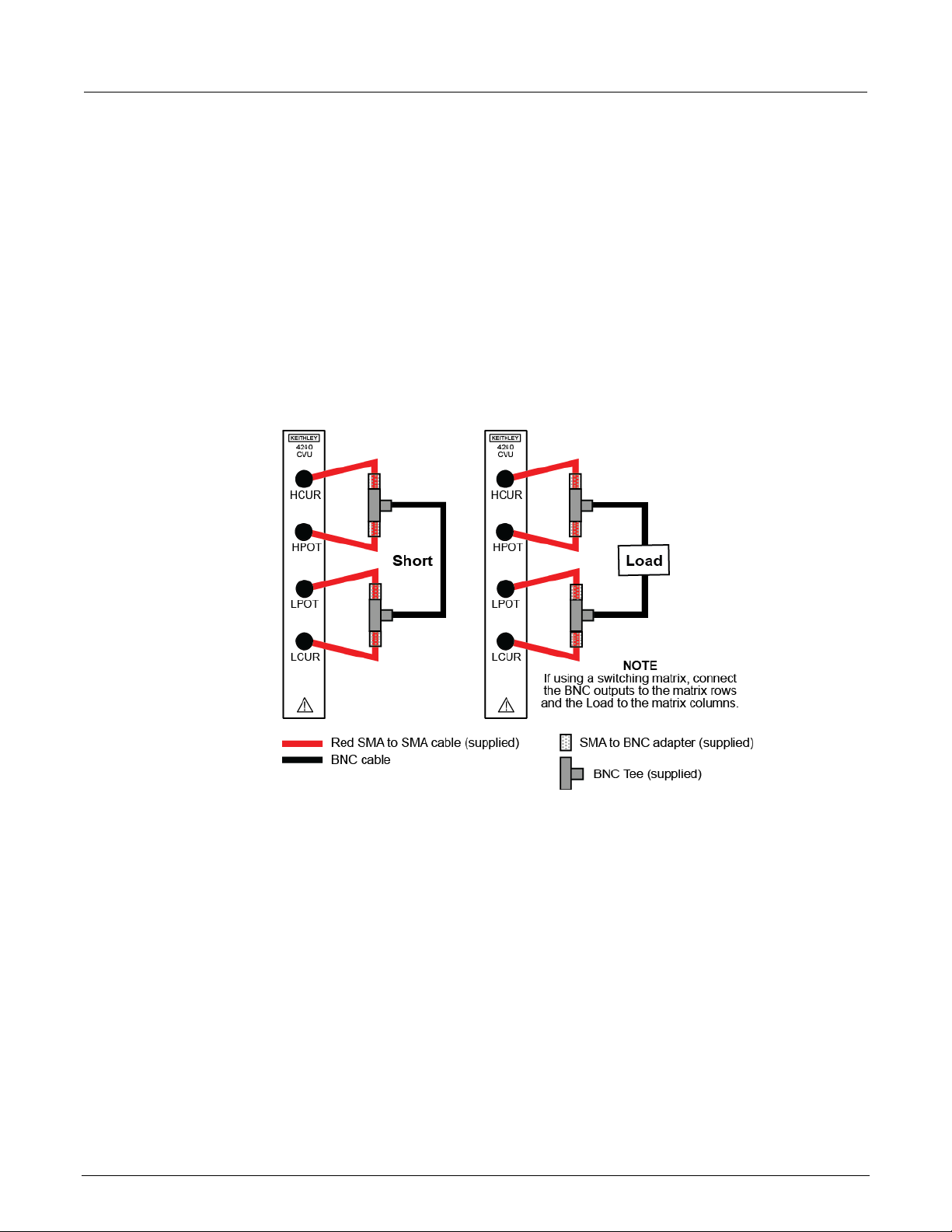

Generate short connection compensation data

Short connection compensation is usually done to offset correction for large capacitances.

Short compensation is done by connecting all the CVU terminals directly together. A known short is

connected to the CVU terminals through all the cables, adapters, and probes that may be in the test

circuit. You can make a short at the wafer level by shorting all probes together.

To generate short connection compensatio n data:

1. Make the connections to the CVU, as shown in the following figure. For remote (4-wire) sensing,

the shields of the four SMA cables must be connected.

Figure 11: Connections for short and load connection compensation

2. In Clarius, select Tools. The Clarius Tools dialog opens.

4200A-CVU-900-01 Rev. B March 2023 2-11

Page 23

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

Figure 12: Clarius Tools dialog

3. Select CVU Connection Compensation.

Figure 13: CVU Connection Compensation dialog

4. Select the cable length. You can select:

0 m: Use if measurements are made at the terminals of the CVU (no cables).

1.5 m: Use with the standard red SMA cables (part number CA-447A) that are supplied with

the CVU.

3 m: Use with the red SMA cables (part number CA-446) that are supplied with the

4200-CVU-PROBER-KIT. You can also use this setting if you are using a switching matrix.

Custom: Cable length coefficients are measured by the user using the Measure Custom

Cable Length option under Advanced Compensation.

2-12 4200A-CVU-900-01 Rev. B March 2023

Page 24

Model 4200A

Connections

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2:

5. If you selected Custom cable length, select Advanced Compensation and select Measure

Custom Cable Length. Follow the on-screen instructions.

6. If you are using a switching matrix, close the matrix switches that connect the CVU to the open.

Refer to “Using Switch Matrices” in Model 4200A-SCS Prober and External Instrument Control.

7. In the Clarius CVU Connection Compensation dialog, select Measure Short.

8. Follow the instructions.

9. Select OK.

Generate load connection compensation data

Loads are reference resistors, typically 50 or 100 Ω or less, that must be resistive and constant over

the entire frequency range (1 kHz to 10 MHz). A load is connected to the output terminals using all

the cables, adapters, probes, and other hardware in the test circuit.

To generate load correction data:

1. Make the connections to the CVU. See “Test connections for a switching matrix (on page 2-5

the Model 4200A-SCS Capacitance-Voltage Unit (CVU) User's Manual.

2. In Clarius, select Tools. The Clarius Tools dialog opens.

Figure 14: Clarius Tools dialog

)” in

4200A-CVU-900-01 Rev. B March 2023 2-13

Page 25

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

3. Select CVU Connection Compensation.

Figure 15: CVU Connection Compensation dialog

4. Select the cable length. You can select:

0 m: Use if measurements are made at the terminals of the CVU (no cables).

1.5 m: Use with the standard red SMA cables (part number CA-447A) that are supplied with

the CVU.

3 m: Use with the red SMA cables (part number CA-446) that are supplied with the

4200-CVU-PROBER-KIT. You can also use this setting if you are using a switching matrix.

Custom: Cable length coefficients are measured by the user using the Measure Custom

Cable Length option under Advanced Compensation.

5. If you selected Custom cable length, select Advanced Compensation and select Measure

Custom Cable Length. Follow the on-screen instructions.

6. If you are using a switching matrix, close the matrix switches that connect the CVU to the open.

Refer to “Using Switch Matrices” in Model 4200A-SCS Prober and External Instrument Control.

7. If it is not open, select Advanced Compensation.

8. In Measure Load, enter the value of the load in ohms.

9. Select Measure Load.

10. Follow the instructions.

11. Select OK.

2-14 4200A-CVU-900-01 Rev. B March 2023

Page 26

Model 4200A

Connections

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2:

Compensation data

You can view the compensation data. Clarius lists R and jX compensation values for every test

frequency and measurement range for open, short, and load.

To view the data generated by connection compensation:

1. In Clarius, select Tools.

2. Select CVU Connection Compensation.

3. Select Advanced Compensation.

4. Next to View Compensation Data, select the data you would like to display: Open, Short, or

Load.

5. Select View Compensation Data.

6. Select the HI tab to review the high side values.

7. Select the LO tab to review the low side values.

Figure 16: Open compensation values example

Enable compensation

To use the values generated by connection compensation, you need to enable compensation for

each test.

When compensation is enabled, the most recently acquired CVU compensation data is applied.

Compensation values can be gathered using the CVU Connection Compensation option in Tools or

through actions and user modules.

4200A-CVU-900-01 Rev. B March 2023 2-15

Page 27

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

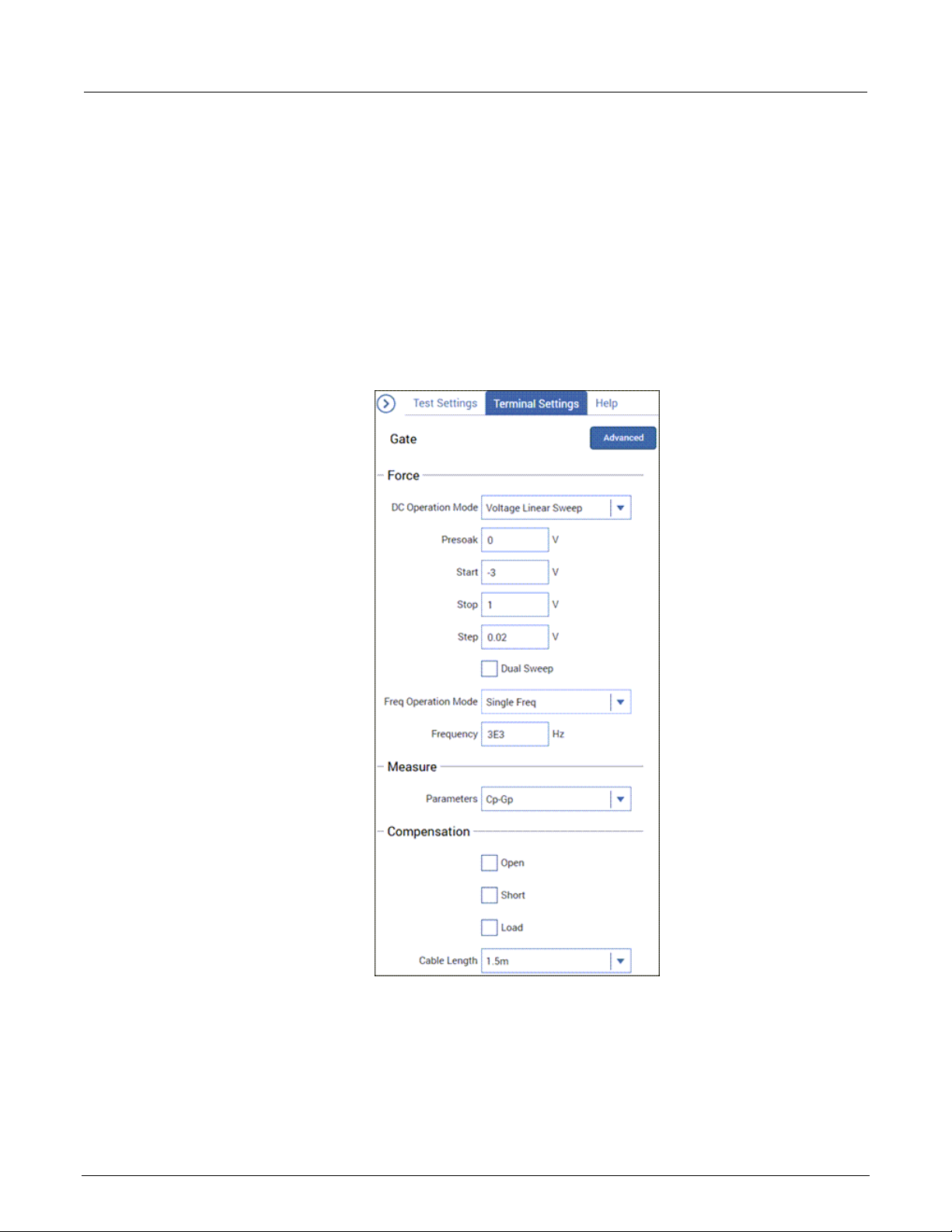

To enable compensation:

1. Select the test from the project tree.

2. Select Configure.

3. Select the terminal in the center pane.

4. In the right pane, select Terminal Settings.

5. Under Compensation, select the types of compensation as needed.

6. Make sure Cable Length is the same as the setting that was used in the Tools > CVU

Connection Compensation dialog to generate connection compensation data.

Figure 17: Enable connection compensation

2-16 4200A-CVU-900-01 Rev. B March 2023

Page 28

Model 4200A

Connections

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2:

ABB unbalance errors

The CVU uses the autobalancing bridge (ABB) technique to achieve accurate impedance

measurements. ABB creates a virtual ground at the DUT to minimize measurement error. Every CVU

measurement is made with ABB active. The ABB always attempts to lock the low side of the DUT to

virtual ground.

If the ABB fails to lock, the measurement is made, but may be out of specification. If this occurs, the

returned data is flagged and shown in yellow on a blue background on the Analyze sheet.

The most common reasons that ABB fails to lock are:

• The cable lengths on the CVU terminals are not the same

• HPOT or LPOT terminals were disconnected

• Excessive noise on the LPOT terminal

• High frequency sources

• Physical cable lengths do not match the cable length set in Clarius

• Improperly torqued SMA cables

• Sub-optimal I

RANGE

setting

• Too much parasitic load on the low side of the DUT

You can use CVU Confidence Check to help troubleshoot ABB errors. Refer to

and short check (on page 2-18) for instructions on performing a confidence check.

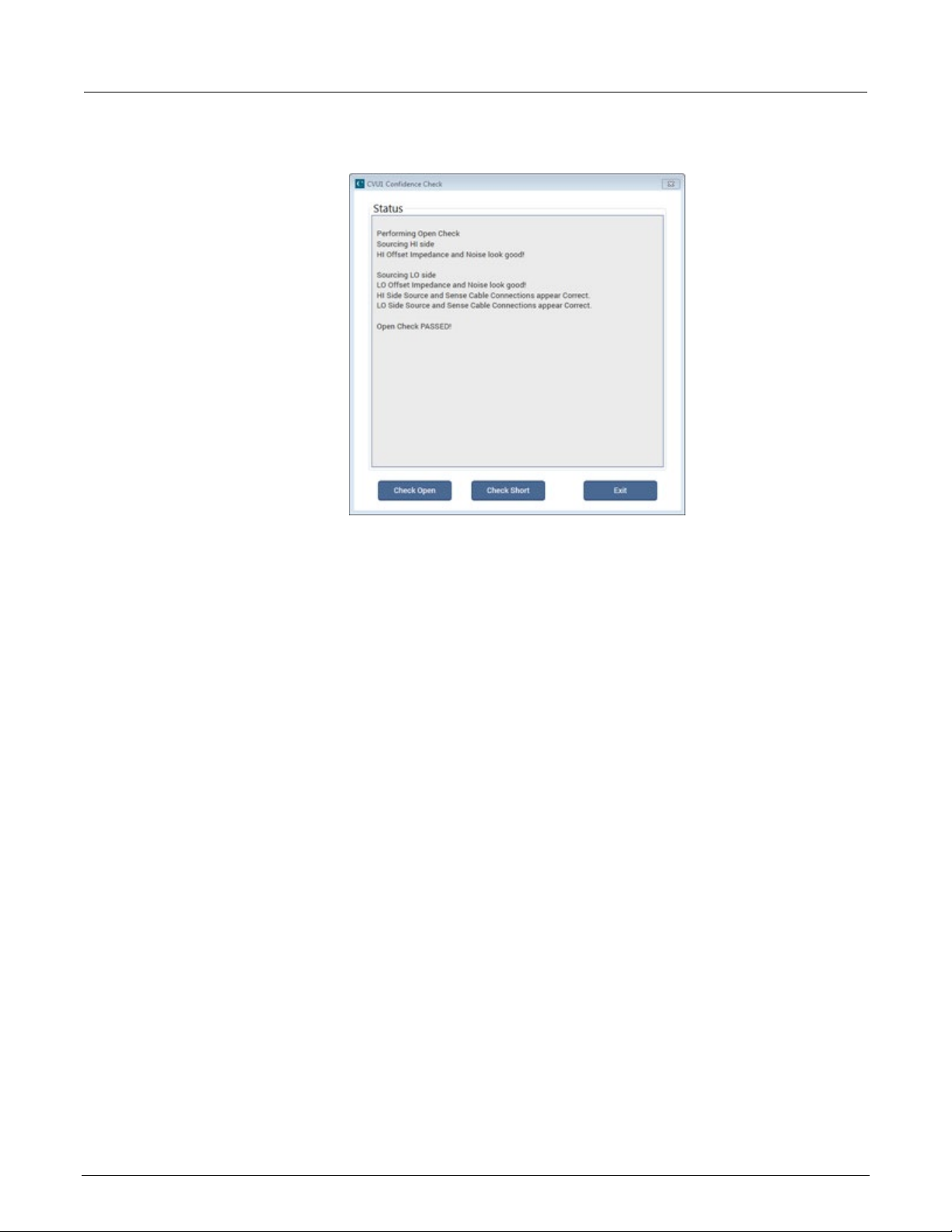

CVU Confidence Check

CVU Confidence Check is a diagnostic tool that allows you to check the integrity of open and short

connections and connections to a device under test (DUT). When the CVU is connected to the DUT,

the Confidence Check displays the measured readings in real time in the Messages area of Clarius.

An open or short confidence check makes a measurement on the high and the low sides of the

test circuit.

The open check is not compatible with the 4200A-CVIV Bias Tee configurations.

To get the best results from a confidence check:

• Use the red CA-446A or CA-447A cables or equivalent.

Run an open check

• If applicable, make sure the prober chuck is connected.

• If you are using a switching matrix, make sure all channels are closed.

4200A-CVU-900-01 Rev. B March 2023 2-17

Page 29

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

Run an open check and short check

To run a CVU confidence check:

1. If you are using a switching matrix, connect the switching matrix to the CVU and DUT or the short

as explained in Test connections for a switching matrix (on page 2-5

2. For the short check, close the matrix switches to connect the CVU to the DUT or short. For the

open check, also close the matrix switches, but lift the probes or disconnect the DUT.

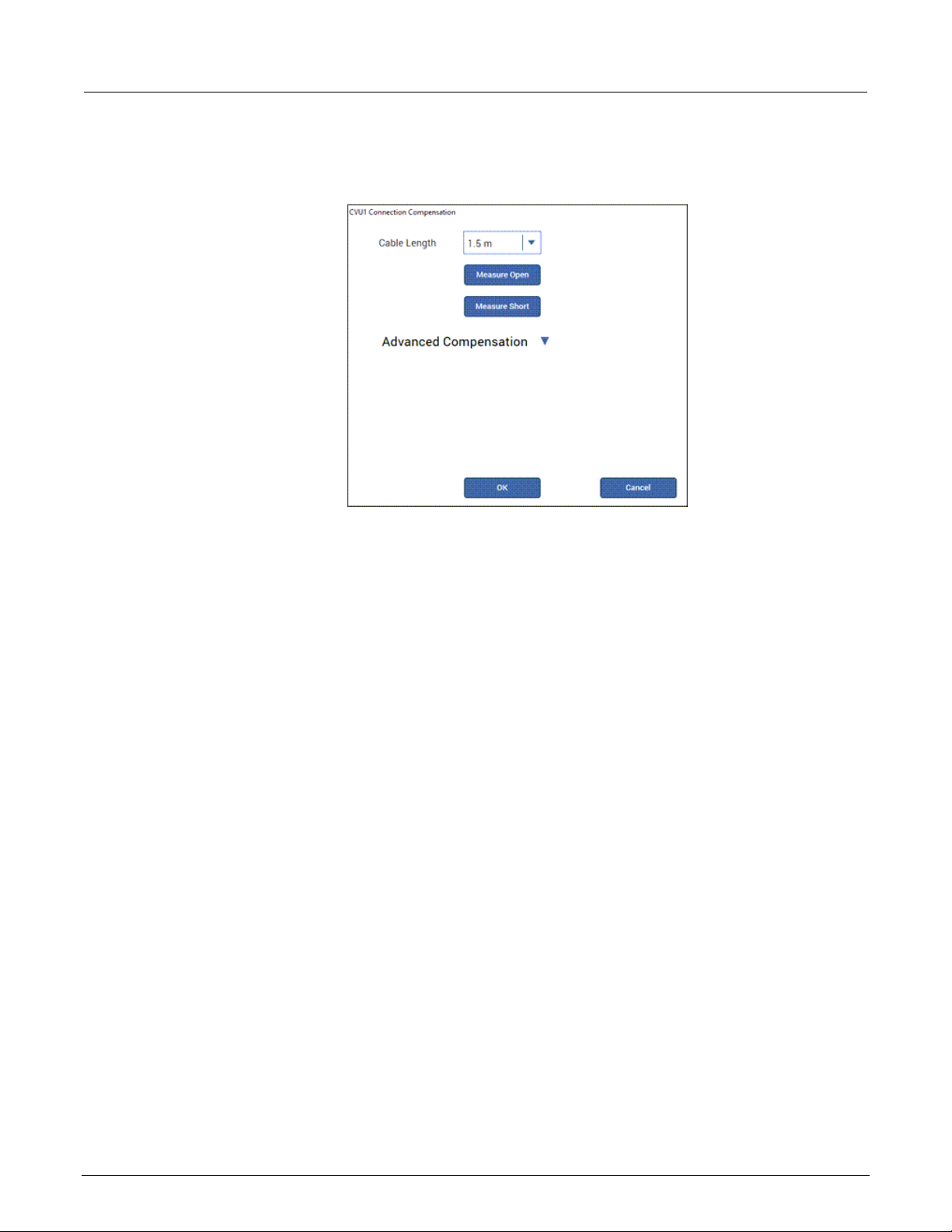

3. In Clarius, select Tools. The Clarius Tools dialog opens.

Figure 18: Clarius Tools dialog

).

4. Select CVU Confidence Check.

5. Select Check Open or Check Short.

2-18 4200A-CVU-900-01 Rev. B March 2023

Page 30

Model 4200A

ions

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 2: Connect

Figure 19: CVU Confidence Check dialog

6. Follow the instructions and select OK.

When the check is complete, the dialog displays the results of the test. If the test failed, the results

include suggestions for troubleshooting.

CVU Real-Time Measureme nt

The CVU Real-Time Measurement provides a direct real-time user interface to the CVU to help you

set up and debug your system. For example, you can use it to confirm that contact has been made

with the pads on a wafer. The measurements are independent of the open and short

confidence checks.

To make real-time measurements:

1. In Clarius, select Tools. The Clarius Tools dialog opens.

4200A-CVU-900-01 Rev. B March 2023 2-19

Page 31

Section

User's Manual

2: Connections Model 4200A-SCS Capacitance-Voltage Unit (CVU)

Figure 20: Clarius Tools dialog

2. Select Instrument Tools.

Figure 21: Real-Time Measurement dialog

3. Select CVU Real-Time Measurem en t.

4. Select the parameters for which you want to return results.

5. Set the Speed, AC Drive Conditions, and DC Bias Conditions for the conditions you want to test.

6. Select Run. The results for the selected parameters are displayed at the top of the dialog.

2-20 4200A-CVU-900-01 Rev. B March 2023

Page 32

CVU test settings ................................................................... 3-32

Section 3

Setting up CVUs in Clarius

In this section:

CVU project example ............................................................... 3-1

Selecting the DC Operation Mode ............................................ 3-5

Selecting the Freq Operation Mode ......................................... 3-6

Making additional test settings ................................................. 3-8

Typical test setups with timing diagrams .................................. 3-9

Force-measure timing ............................................................ 3-22

CVU - all terminal parameters ................................................ 3-23

CVU Terminal Settings Advanced settings and circuits ......... 3-30

CVU project examp le

The following example shows you how to use the 4210-CVU or 4215-CVU in a project to make a

capacitance measurement.

The example assumes you have a CVU connected to a test fixture as described in

connections to a DUT (on page 2-3).

In this test, you sweep the dc bias from −5 V to 5 V in 0.2 V steps, with a 1 MHz capacitance

measurement made at each step.

Select a project

Select a project:

1. Start Clarius.

2. Run Connection compensation (on page 2-8

the connections.

3. Choose Select.

4. Select Projects to display the Project Library in the center pane.

5. Search for demo. The Demo Project is displayed, as shown in the following figure.

Typical CVU test

) to correct for offset and gain errors caused by

Page 33

Section

User's Manual

3: Setting up CVUs in Clarius Model 4200A-SCS Capacitance-Voltage Unit (CVU)

Figure 22: Demo Project selected

6. Select Create. You are prompted to replace the existing project.

7. Select Yes. The project is displayed in the project tree.

Figure 23: Demo Project (default) in the project tree

3-2 4200A-CVU-900-01 Rev. B March 2023

Page 34

Model 4200A

Setting up CVUs in Clarius

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 3:

Configure the test

This example uses the cv-cap test, which measures the capacitance as a function of a linear voltage

sweep of a capacitor.

Configure the cv-cap test:

1. In the project tree, select the cv-cap test.

2. Select Configure. The key parameters are displayed in the center pane.

Figure 24: cv-cap key parameters

3. Verify the settings for CVH1:

Operation Mode: Voltage Linear Sweep

Start: −5 V

Stop: 5 V

Step: 0.2 V

Frequency Operation Mode: Single Freq

Frequency: 1 MHz

Run the test and review results

To run the cv-cap test and review the results:

1. Select Run.

2. Select Analyze. The test results are shown as data in a spreadsheet and on the graph, as shown

in the figure below.

3. To export the data, select Save Data.

4200A-CVU-900-01 Rev. B March 2023 3-3

Page 35

Section

User's Manual

3: Setting up CVUs in Clarius Model 4200A-SCS Capacitance-Voltage Unit (CVU)

4. To save the information in the Run sheet, select Save Sheet. The information is saved in a

®

Microsoft

Excel® spreadsheet format.

5. To save the information in the graph, select the Graph File Format and select Save Graph1.

The graph is saved into the selected file type.

Note that the extracted NOISE parameter is displayed on the graph.

For information on changing how the graph is displayed, refer to “Change the graph settings” in the

Model 4200A-SCS Clarius User's Manual.

Figure 25: cv-cap test results

3-4 4200A-CVU-900-01 Rev. B March 2023

Page 36

Model 4200A

Setting up CVUs in Clarius

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 3:

Selecting the DC Ope r a t ion Mo de

DC Operation Mode selects the most common settings for the selected test type. Selecting the

appropriate mode simplifies terminal and test configuration. The following topics describe the

operation modes that are available when a CVU is selected as the instrument.

For descriptions of the parameters that you can set for the operation modes, refer to

terminal parameters (on page 3-23).

Voltage Bias

The Voltage Bias operation mode maintains a selected constant-voltage state at the terminal.

Voltage Linear Sweep

When you select the Voltage Linear Sweep operation mode, the test increments through a series of

constant voltage steps. You define the start and stop voltages and the voltage size between each

step. An example is shown in the following figure.

CVU - all

Figure 26: Example linear sweep

The voltage sweep generates parametric curve data that is recorded in the Analyze pane.

Voltage List Sweep

The Voltage List Sweep operation mode allows you to customize the voltage values for each step of

the sweep. List Sweeps allow you to make measurements only at selected forced voltages. For

example, they allow you to skip unimportant measurement points or to synthesize a custom sweep

that is based on a special mathematical equation. You can also use list sweeps to make pulsed

measurements to avoid overheating of sensitive devices. The following figure illustrates a possible

list sweep.

4200A-CVU-900-01 Rev. B March 2023 3-5

Page 37

Section

User's Manual

3: Setting up CVUs in Clarius Model 4200A-SCS Capacitance-Voltage Unit (CVU)

The voltage list sweep generates parametric curve data that is recorded in the Analyze pane.

Voltage Step

The Voltage Step operation mode increments through evenly-spaced, constant voltage steps over a

range that you specify. The time interval for each step is determined automatically by the time

required to complete a sweep.

Figure 27: Example voltage list sweep

For each step, parametric curve data is generated. The data is recorded in the Analyze pane.

DC Gnd operation mode - CVU

Automatically selected for the CVL terminal.

Selecting the Freq Operation Mode

The Frequency Operation Mode selects the most common settings for the selected test type.

Selecting the appropriate mode simplifies terminal and test configuration.

If you have a 4210-CVU, you can select Single Freq, Freq Linear Sweep, or Freq Step. If you have a

4215-CVU, you can also select Freq Log Sweep or Freq List Sweep.

The following topics describe these operation modes.

Frequency Single Freq

The CVU makes a single frequency reading.

Frequency Linear Sweep

When performing a frequency sweep, the CVU steps through all the frequency points from start to

stop at the frequency intervals set by the step.

3-6 4200A-CVU-900-01 Rev. B March 2023

Page 38

Model 4200A

Setting up CVUs in Clarius

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 3:

Freq Log Sweep

This sweep is similar to the linear sweep except that the steps are done on a logarithmic scale.

Freq List Sweep

The Freq List Sweep operation mode allows you to customize the voltage values for each step of the

sweep. List Sweeps allow you to make measurements only at selected frequencies. For example,

they allow you to skip unimportant measurement points or to synthesize a custom sweep that is

based on a special mathematical equation.

Freq Step

When the Freq Step operation mode is selected, the CVU sweeps through all the frequency points

from start to stop for each dc step.

Figure 28: Frequency sweep - DC step operation mode

For example, if the:

• Start frequency is 800 kHz

• Stop frequency is 3 MHz

• The dc start value is −1

• Stop value is 1

• Step value is 0.5

The CVU sweeps through the frequency points 800 kHz, 900 kHz, 1 MHz, 2 MHz, and 3 MHz for dc

biases −1 V, −0.5 V, 0 V, 0.5 V, and 1 V.

4200A-CVU-900-01 Rev. B March 2023 3-7

Page 39

Section

User's Manual

3: Setting up CVUs in Clarius Model 4200A-SCS Capacitance-Voltage Unit (CVU)

When this test is run, the following sequence occurs:

1. The dc source goes to the Presoak voltage.

2. After the hold time (set in the Test Settings), dc bias goes to the Start voltage.

3. After the delays, the CVU makes a measurement for the Start Frequency point. The ac signal is

applied before the start of the measurement.

4. The CVU sweeps through the frequency points until it reaches the Stop Frequency point.

5. The dc bias goes to the next voltage as defined by the Step value.

6. Steps 4 and 5 are repeated until the dc bias reaches the Stop value.

Making additional test settings

You can refine your test settings using the Test Settings tab in the right pane.

Figure 29: CVU Test Settings pane

From the Test Settings pane, you can open additional options by selecting Advanced.

3-8 4200A-CVU-900-01 Rev. B March 2023

Page 40

Model 4200A

Setting up CVUs in Clarius

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 3:

Figure 30: CVU Advanced Test Settings Pane

Refer to CVU Test Settings (on page 3-32) for descriptions of the test settings.

Typical test setups with timing diag r ams

The following topics describe typical test setups with the related timing diagrams.

DC bias function and sweep characteristics

The ac test signal can be biased with a static dc level (−30 V to +30 V), or a voltage sweep (up or

down). You can also perform a frequency sweep (up or down).

The following figure shows an example of dc bias waveform. In this example, the dc bias is set to 0 V,

but you can set it to any valid dc bias level. You specify the number of measurements to make.

Figure 31: DC Bias waveform (example)

4200A-CVU-900-01 Rev. B March 2023 3-9

Page 41

Section

User's Manual

3: Setting up CVUs in Clarius Model 4200A-SCS Capacitance-Voltage Unit (CVU)

The following figure shows an example of dc voltage sweep. You specify the start voltage, stop

voltage, and step voltage. The number of measure points is calculated by the CVU.

Figure 32: DC voltage sweep (example)

The following figure shows an example of a frequency sweep. You specify the start frequency and the

stop frequency. The CVU calculates the number of measure points.

Figure 33: Frequency sweep example

If you are setting up a voltage list sweep, you specify the voltage levels for the sweep.

If you are setting up a voltage step frequency sweep, the sweep includes voltage stepping. A

frequency sweep is performed for every voltage step point.

If you are setting up a frequency step voltage sweep, the sweep includes frequency stepping. A

voltage sweep is performed for every frequency point.

The following examples are examples of these setups in Clarius.

3-10 4200A-CVU-900-01 Rev. B March 2023

Page 42

Model 4200A

Setting up CVUs in Clarius

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 3:

CVU using voltage bias

Make the following Test Settings for a dc bias with a single frequency. This sweep measures CP-Gp.

• Speed: Normal

• Report Timestamps: Selected

• Mode: Sampling

• Interval: 0.25 s

• Number of Samples: 10

• Hold Time: 1 s

Make the following Terminal Settings for CVH1:

• DC Operation Mode: Voltage Bias

• Presoak: 5 V

• DC Bias: 1 V

• Frequency Operation Mode: Single Freq

• Frequency: 100000 Hz

• Parameters: Cp-Gp

• Compensation as needed

When this test is run, the following force-measure sequence occurs:

1. The dc source goes to the Presoak voltage of 5 V for the hold time (1 s).

2. The dc source goes to the dc bias voltage of 1 V.

3. After the built-in system delay and interval (0.25 s), the CVU makes a measurement. The ac test

signal is applied just before the start of the measurement. The ac drive is turned off after the

measurement is completed. This step is repeated for every sample.

Figure 34: CVU Voltage Bias output

4200A-CVU-900-01 Rev. B March 2023 3-11

Page 43

Section

User's Manual

3: Setting up CVUs in Clarius Model 4200A-SCS Capacitance-Voltage Unit (CVU)

CVU using voltage sweep

Make the following Test Settings:

• Speed: Normal

• Report Timestamps: Selected

• Mode: Sweeping

• Sweep Delay: 0.1 s

• Hold Time: 1 s

For this test, make the following Terminal Settings for CVH1:

• DC Operation Mode: Voltage Linear Sweep

• Presoak: 5 V

• Start: 5 V

• Stop: 3 V

• Step: 1 V

• Frequency Operation Mode: Single Freq

• Frequency: 100000 Hz

• Dual sweep: Selected

• Parameters: Cp-Gp

• Compensation as needed

The following figure shows the Advanced terminal settings for a voltage linear sweep. This sweep

measures Cp-Gp.

Figure 35: 4215-CVU Voltage Linear Sweep

3-12 4200A-CVU-900-01 Rev. B March 2023

Page 44

Model 4200A

Setting up CVUs in Clarius

-SCS Capacitance-Voltage Unit (CVU) User's Manual Section 3:

When this test is run, the following force-measure sequence occurs:

1. The dc source goes to the presoak voltage of −5 V for the hold time.

2. The dc bias voltage goes to the first step of the sweep (1 V).

3. After the built-in system delay and sweep delay, the 4210-CVU or 4215-CVU makes a

measurement. The ac test signal is applied before the start of the measurement. The ac drive is

turned off after the measurement is made.

4. Steps 2 and 3 are repeated for the 2 V and 3 V dc bias voltage steps. The sweep delay repeats at

the beginning of each subsequent step.