Page 1

e

eratof

mual

perating

Publication Date: March 1991

Document Number: 3933A-900-01 Rev. A

nformation

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation

prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at

least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIE S, EXPRESSED OR IMPLIED, INCLUDING

ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE

REMEDIES PROVIDED HEREIN ARE BUYERS SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENT S, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQ

UENTIAL DAMAGES ARISING OUT

OF THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION,

LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

INSTRUMENTS

Instruments Division,

WEST GERMANY: KeithIey Instruments GmbH l Heiglhofsk. 5 l Munchen 70 l 089-71002-0

GREAT BRITAIN:

FRANCE KeitbIey Inskuments SARL -3 AlIee des Garays l BP. 60 l 91124 PaIaiseau/ZL l 1-6-OI15 155 l Telex M)O 933 l Fax l-6-0117726

NETHERLANDS:

SWITZERLAND: Keithley Inskunents SA l Kriebacbsk. 4 l 8600 Dubendorf

AUSTRIA: KeitbIey Inskuments GesmbH l Rosenbugelskasse 12 l A-1120 Vienna l (0222) 84 65 48 l Telex: 131677 l Fax (0222) S403597

ITALY: KeitbIey Instruments SRL l Vi&S. G~gnano 4/A l u)146 Milano l 02-4120360 or M-4156540 l Fax: 02-4121249

Keithley Instruments, Inc. l 28775 Aurora Road l Cleveland, Ohio 44139 l (216) 248-0400 l Fax: 248-6168

KeitbIey Instruments, Ltd. l The Minster l 58, Porknan Road l Reading, Berkshire RG 3 IFA -01144 734 575 666 l Fax: 01144 734 596 469

Keitbley Instruments BV l AveIingen West 49 l 4202 MS Gorinchem . P.0. Box559 l 4200 AN

.01-821-9444 l

l Telex 52-12160 l

Telex 828 472. Fax 0222-315366

Fax: 089-7100259

GorInchem .01830-35333 l

Telex: 24 684. Fax OlS30-30821

Page 3

Operator’s Manual

Model 3933A

Phase Shifter

01991, Keithley Instruments, Inc.

All Rights Reserved

Instruments Division

Cleveland, Ohio, U. S. A.

Document Number: 3933A-900-01

Page 4

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using the Model 3933A Phase Shifter and any associated

instruments.

This instrument is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read over this manual carefully before using the instrument.

Exercise extreme caution when a shock hazard is present at the test circuit. The American National Standards Institute

(ANSI) states that a shock hazard exists when voltage levels greater than 30V rms or 42.4V peak are present. A good

safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Inspect the connecting cables and test leads for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the test cables or any instruments while power is applied to the circuit under test.

Turn off the power and discharge any capacitors before connecting or disconnecting cables from the instrument.

Do not touch any object which could provide a current path to the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

Do not apply more than 42V peak between the outer shell of any BNC connector and chassis ground.

Instrumentation and accessories should not be connected to humans.

Page 6

Table of Contents

SECTION 1

1.1 SUMMARY

1.2 FEATURES.......................................~

1.3 WARRANTYINFORMATION

1.4 ~ALADDENDA

1.5

1.6 TJNPACKINGANDREPACKING

1.6.1 Unpacking

1.6.2 ShipmentContents..

1.6.3 InstructionManual

1.6.4

1.7

1.8

SECTION 2

2.1 INTRODUCTION....‘.

2.2 INSTALLATION

2.2.1 InstallationLocation..

2.2.2 Fan..

2.3 LINE POWER SUPPLY AND GROUNDING

2.3.1

2.3.2

2.4

2.5

2.5.1

2.5.2 TypicalTestConnections

2.5.3 OperatingExamples

- General Information

..................................................................

....................................................

..........................................................

SAFETYTERMSANDSMLlBOLS

.................................................................

.........................................................

...........................................................

Repacking For Shipment

OPTIONALACCESSORIES

SPECIFICATIONS

.............................................................

....................................................... l-2

......................................................

- Getting Started

.........................................................

..............................................................

........................................................

.....................................................................

LinePowerSupply

Grounding

HANDLINGPRECAUTIONS

BASICOPERATION

Front Panel Summary

.................................................................

...........................................................

.....................................................

............................................................

......................................................... 2-3

......................................................

..........................................................

..................................................

.................................................

...........................

..........................................

l-1

l-l

1-2

1-2

1-2

1-2

1-2

1-2

1-2

l-2

1-3

2-l

2-l

2-l

2-l

2-2

2-2

2-3

2-3

2-3

2-3

2-3

SECTION 3

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.3

3.4

3.4.1

LNTRODUCTION

FRONT PANEL AND REAR PANEL DESCRIPTION

Input and Output Connections

InputConnections

Output Connections

GPIB Bus (Input/output Connector)

FrontPanelDescription

RearPanelDescription

STARTUP

OPERATINGPROCEDURES

Setting Parameters Using Numeric Keys

- Operation

..............................................................

..................................................

...........................................................

..........................................................

..............................................

........................................................

........................................................

....................................................................

.....................................................

...................................

.........................................

; .

3-1

3-l

3-l

3-1

3-3

3-4

3-4

3-11

3-14

3-15

3-15

Page 7

3.4.2 Setting Parameters with the MODIFY Controls

3.4.3 ErrorCodes

3.4.4 Amplitude Units Conversion

3.4.5 Amplitude Programming

3.4.6

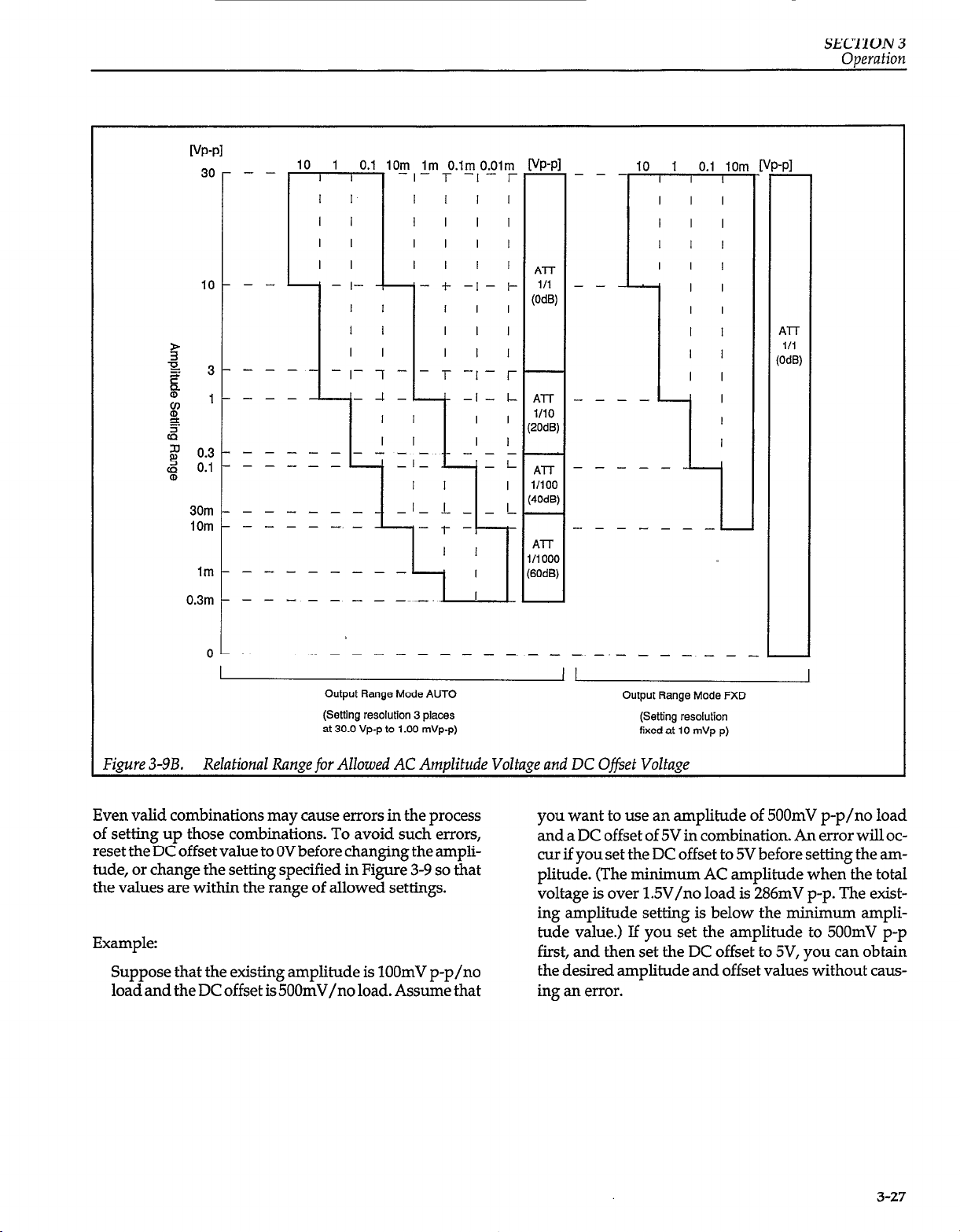

3.4.7 AC Amplitude and DC Offset Relational Restrictions

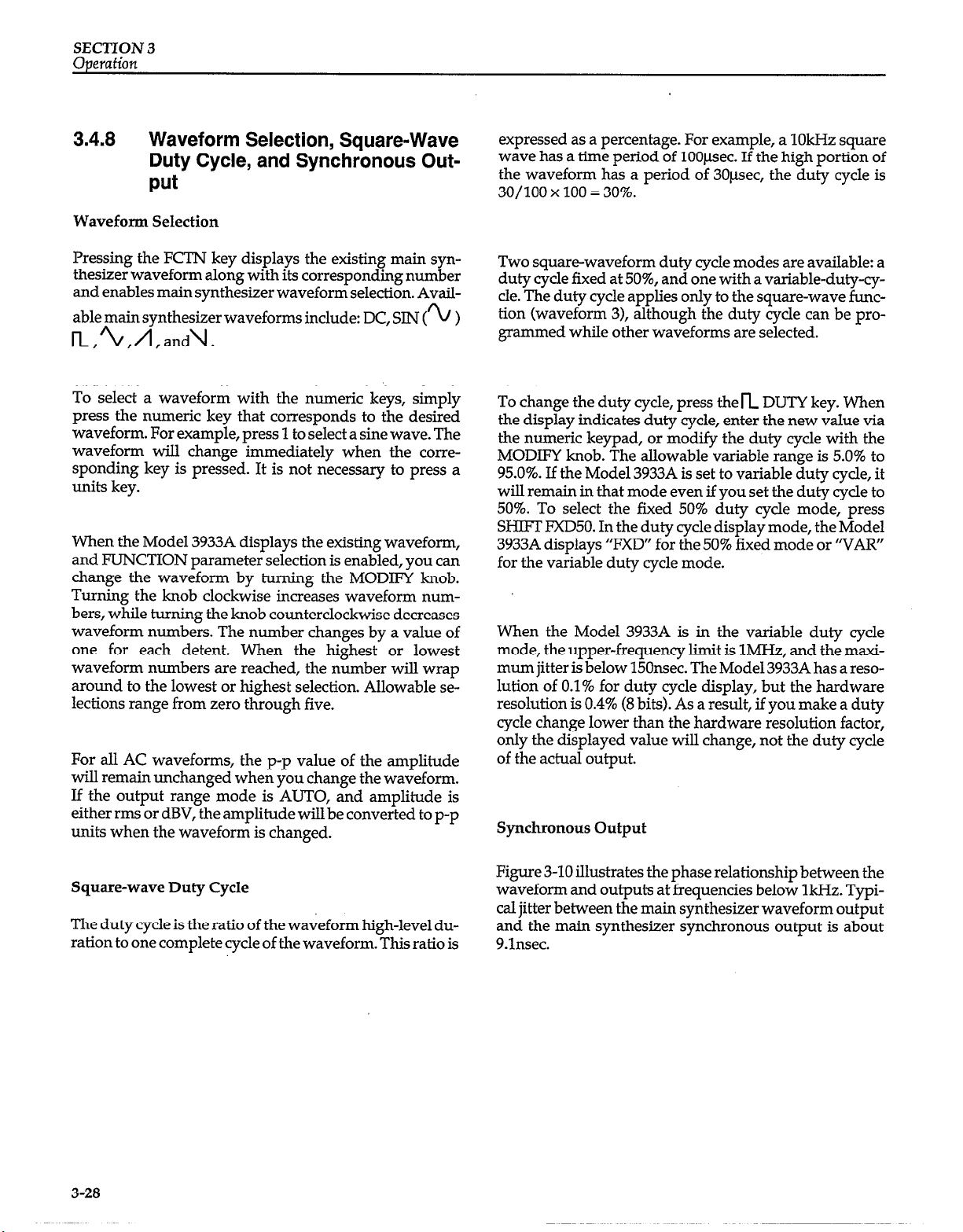

3.4.8 Waveform Selection, Square-Wave Duty Cycle, and Synchronous Output

3.4.9

3.5

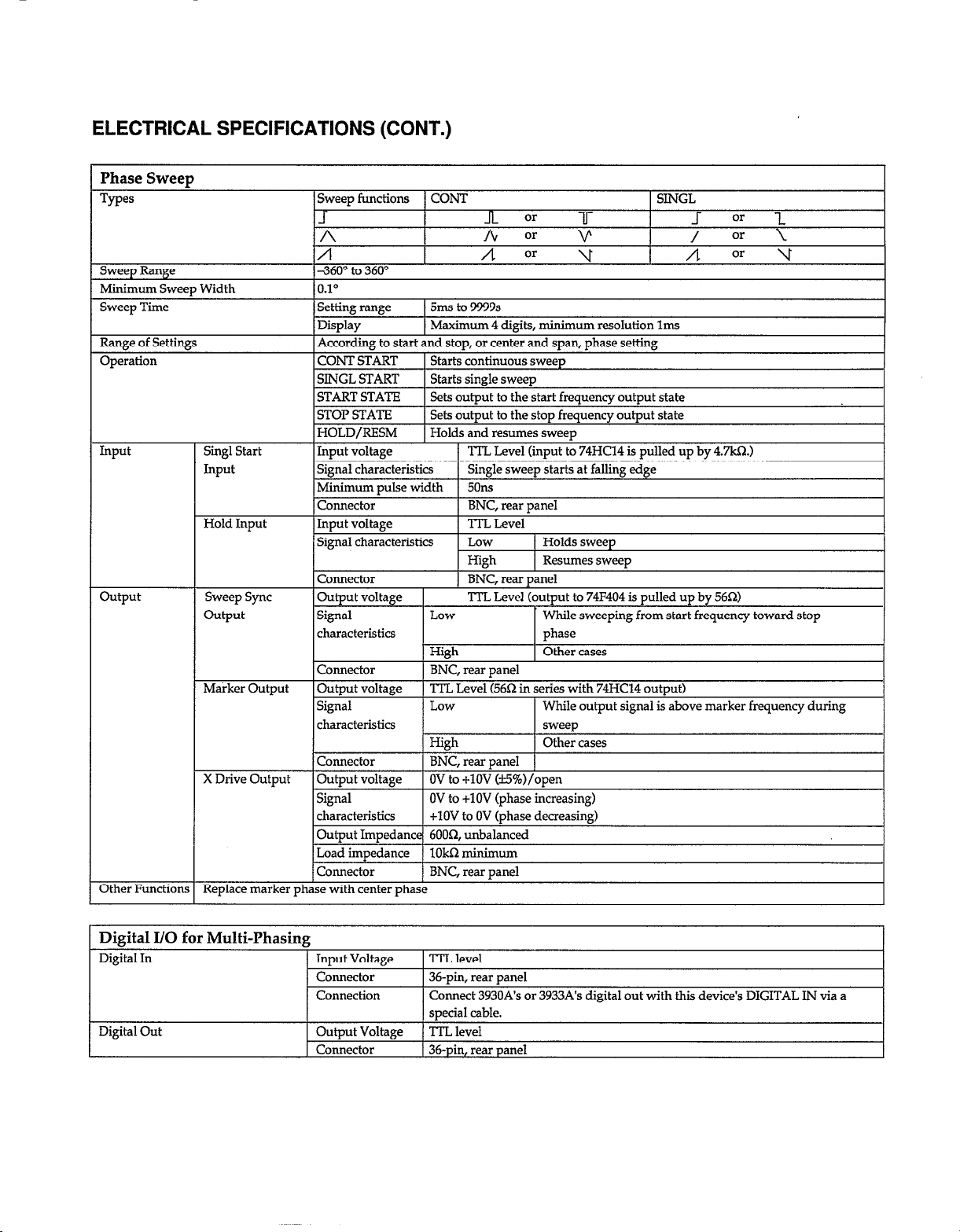

3.5.1 Sweep Phase and Sweep Output Relationships

3.5.2

DC Offset Progr amming .......................................................

Mark, Span, and Phase Parameter Programming

SWEEPOPERATIONS..

OutputRangeMode..

.............................................

...................................................

......................................................

........................................................

.......................................................

......................................

................................. 3-25

..................................... 330

......................................

.

..................

..................

3-16

3-17

3-22

3-25

3-25

3-28

3-30

3-32

3-33

Page 8

List of Illustrations

SECTION 2

Figure 2-l

Figure 2-2

Figure 2-3

SECTION 3

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-9

Figure 3-10

- Getting Started

LineFilter ...............................................................

FrontPanelSummary

TypicalConnections

......................................................

.......................................................

- Operation

LogicInputCircuit ........................................................

AnalogInputCircuits ......................................................

Typical Digital I/O Interconnections

Sweep Marker and Sweep Synchronous Outputs

Waveform Synchronous Outputs

Model3933AFrontPanel ...................................................

Model3933ARearPanel ....................................................

Waveforms and Their Phase Definitions

Relational Range for Allowed AC Amplitude Voltage and DC Offset Voltage

Phase Relationship Between Waveform and Output

...........................................

..................................

.............................................

........................................

...............................

............

2-3

2-4

2-5

3-1

3-2

3-2

3-3

3-3

3-5

3-12

3-24

3-26

3-29

Page 9

List of Tables

SECTION

Table 2-l

SECTION

Table 3-l

Table 3-2

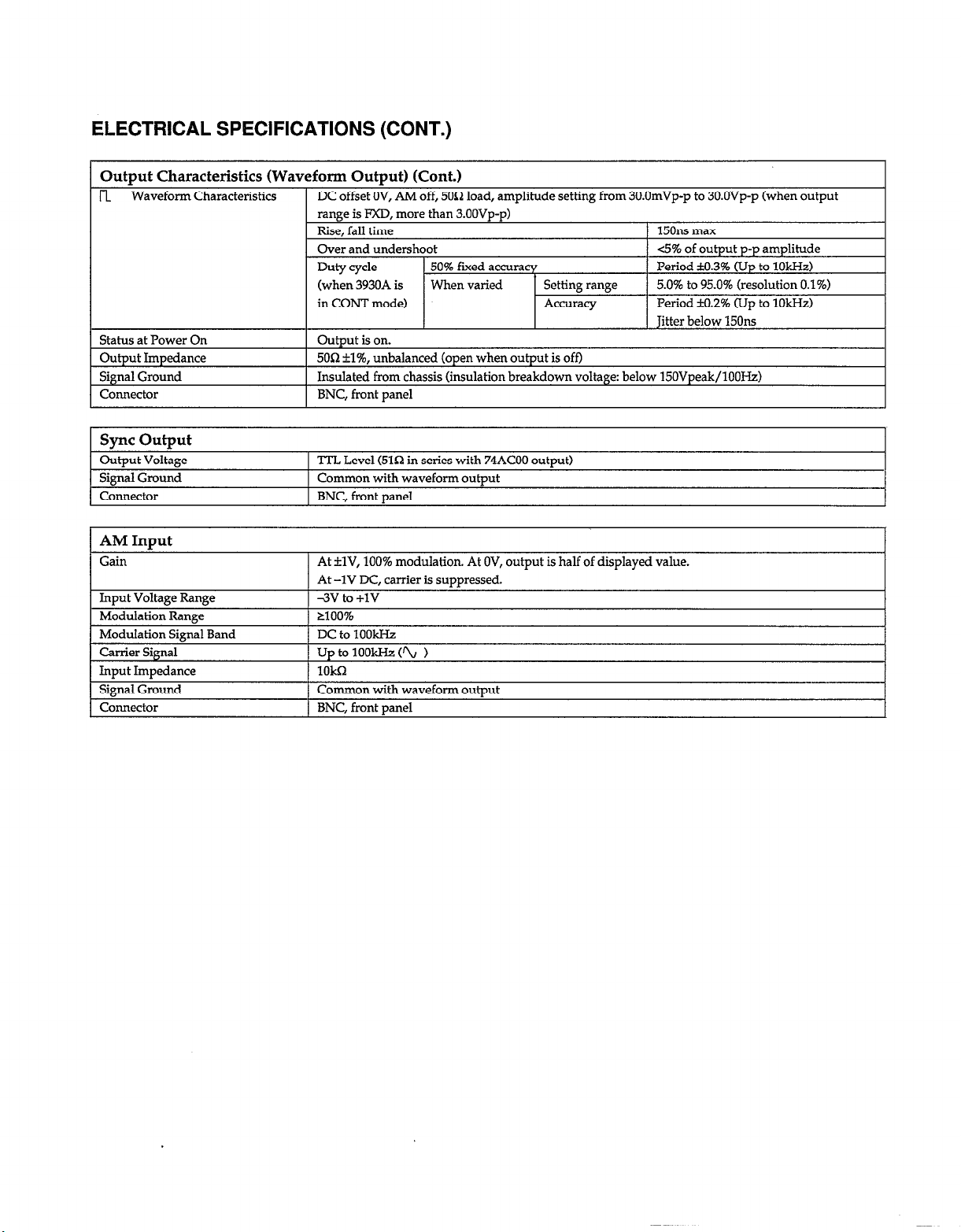

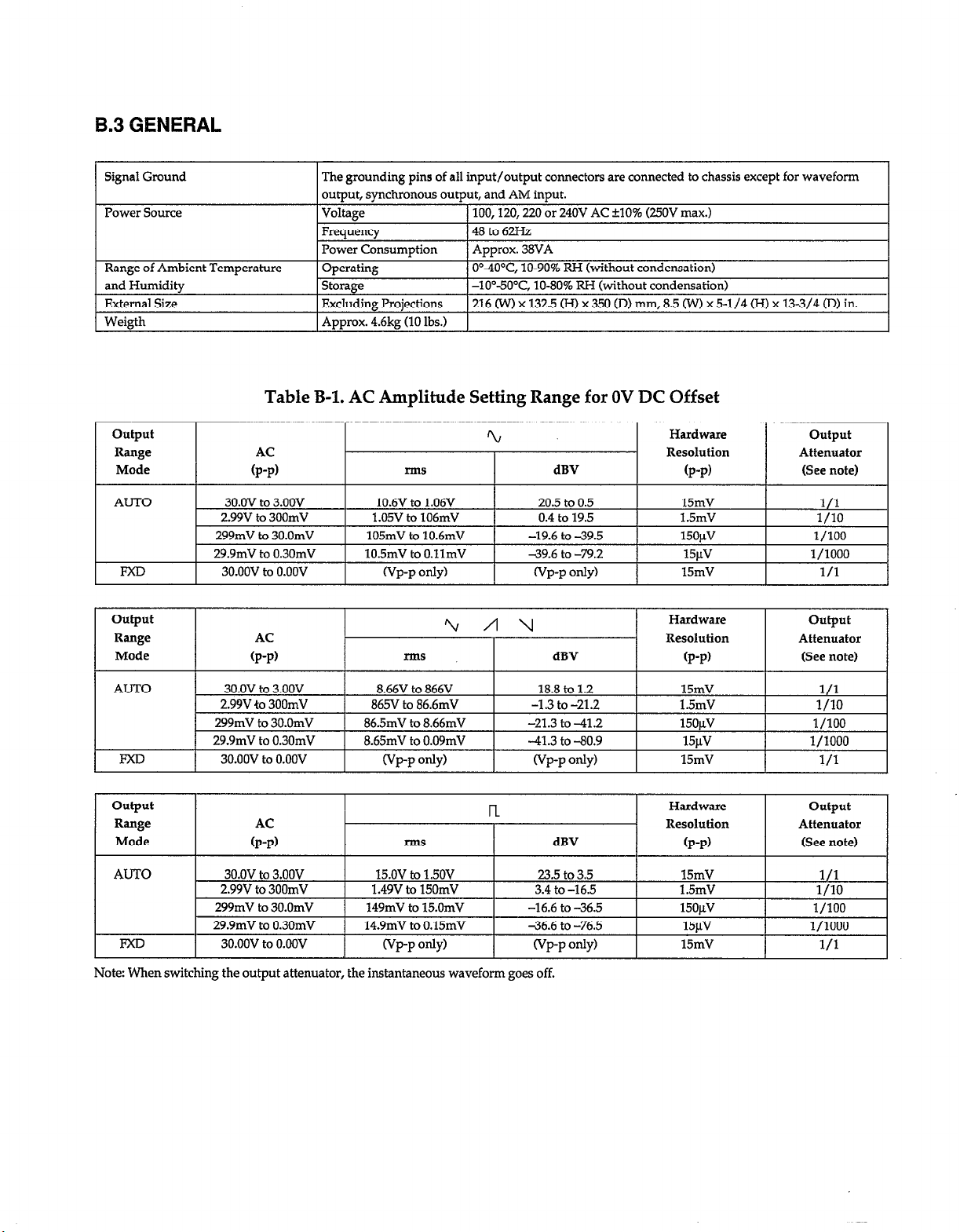

Table 3-3 AC + DC Minimum Amplitude, Resolution, and Accuracy (open load)

2 - Getting Started

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 - Operation

Main Synthesizer Amplitude Range When DC Offset is 0 Volts

DC-only Voltage Setting Range, Resolution, and Accuracy (open load, 18 to 28°C)

....................... 3-18

.................

2-3

......... 3-18

3-19

Page 10

SECTION

General Information

1 .l SUMMARY

The Model 3933A Phase Shifter is designed for use in conjunction with a Model 3930A Multifunction Synthesizer.

Together, Mode13933A and Model 3930A form a variable

phase, multi-phase oscillator with a phase setting range

from -360 to 360”. Phase resolution is 0.1”. The frequency

range is the same as the Model 3930A.

Five output waveforms,

available. Each waveform has a maximum output of 30V

p-p (no-load) and 15V p-p into 5OQ. Waveform and amplitude may be set independently of the Model 3930A or

another Model 3933A. Waveform output is isolated from

the Model 393OA, or another Model 3933A, allowing a

wide range of applications. Multiple 3933A units may be

combined with a single 3930A to create a multi-phase oscillator system.

Phase output is directly synthesized by a custom LSI digital IC, resulting in high accuracy and stability, and short

phase switching time.

In addition to phase sweep and amplitude modulation

(AM), variable square-wave duty cycle is also provided.

Parameter settings are easily made using either the front

panel keys and/or the modify knob.

$,2/,-rL,n,and\jare

The Model 3933A is equipped with a standard GPIB

(IEEE-488) interface, and can be programmed over the

bus to produce the same operating modes and parame-

ters that can be controlled from the front panel.

The Model 3933A uses a two-line, 40-character liquid

crystal display to indicate selected functions, parameters,

and pertinent messages.

1.2 FEATURES

Wide phase setting range: -360” to 360”, with resolution of 0.1”.

High output and high AC voltage accuracy: 30V p-p

(no load), 15V p-p into 5OQ ti.5% (-5OkHz, sine wave,

above 3V p-p).

A total of 5 units of Model 3933A may be combined

with a Model 3930A to provide up to a 6-phase oscillator system.

Two-line, 40-character liquid crystal display.

Five output waveforms:

Variable square wave duty cycle (5% to 95%, below

100 kHz).

Multiple phase sweep functions. Each setting digitally

synthesized according to input from the front panel

numeric keypad or the modify dial.

Low distortion ratio (<O.l%, 1OHz to lOOkI&, above

30.0mV p-p, AUTO output range mode).

Isolated waveform output.

Battery backed-up memory can retain up to 10 groups

of parameters. At power-on, it will automatically set

%,2/,l,n,and\l.

l-l

Page 11

SECTION 1

General Information

itself according to those parameters which were in effect immediately prior to the last power shut-off.

GPIB interface included as standard equipment.

Output mode switchable from automatic (AUTO) to

fixed (FXD).

A wide range of front and rear panel I/O interconnections to control or modify signal operations and parameters.

, .3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this instruction manual. Should your Model 3933A require warranty service, contact the Keithley representative or authorized repair facility in your area for further

information. When returning the instrument for repair,

be sure to fill out, and include, the service form at the back

of this manual in order to provide the repair facility with

the necessary information.

1.4 MANUAL ADDENDA

1.6 UNPACKING AND REPACKING

1.6.1

After carefully unpacking the instrument from its shipping carton, inspect it for obvious signs of physical dam-

age. Report any such damage to the shipping agent im-

mediately. Save the original packing carton for storage or

possible reshipment.

1.6.2

The following items are included with every Model

3933A order:

l

Model 3933A Phase Shifter

l

Model 3933A Instruction Manual

l

Power Cord

l

Fuse 0.5A, WOV, 5.2 x 20mm (FU-96-2)

l

Digital I/O interconnection cable (CA-941

l

BNC to BNC signal cable (Keithley Model 7051-2, -5, or

-10)

l

Additional accessories as ordered

Unpacking

Shipment Contents

Any improvements or changes concerning the instrument or manual, will be explained in an addendum included with the unit. Be sure to note these changes and

incorporate them into the manual before using or servicing the unit.

1.5 SAFETY TERMS AND SYMBOLS

The following safety terms and symbols are found on the

instrument, or used in this manual.

The A 1 symbol on the instrument indicates that the

user should refer to the operating instructions.

The WARNING heading used in this manual explains

dangers that might result in personal injury or death. Always read the associated information carefully before

performing the indicated procedure.

1.6.3

Instruction Manual

If an additional instruction manual is required, order the

manual package, Keithley part number 3933A-901-00.

The manual package includes an instruction manual and

any pertinent addenda.

1.6.4

Repacking For Shipment

Should it become necessary to return the Model 3933A

for repair, carefully pack the unit in its original packing

carton or the equivalent. Be sure to use a cardboard box of

sufficient strength.

Include the following information:

l

Advise as to the warranty status of the instrument.

l

Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

o Fill out and include the service form located at the back

of the manual.

The CAUTION heading used in this manual explains

hazards that could damage the instrument card. Such

damage may invalidate the warranty.

l-2

1.7 OPTIONAL ACCESSORIES

The following accessories are available for use with the

Model 3933A.

Page 12

General Information

SECTION 1

Models

3900-l and 3900-2 Rack Mounting Kits:

The

Model 3900-l mounts one Model 3933A in a standard 19

inch rack. The Model 3900-2 mounts two Model 3933A’s,

side by side, or one Model 3933A and one Model 3940A

side by side. Both kits include all necessary hardware for

proper rack mounting of the instruments.

Model 7007 Shielded IEEE-488 Cables:

The Model

7007-l (lm, 3.3ft.) and Model 7007-2 (2m, 6.6 ft.) can be

used to interface the Model 3940 to the IEEE-488 bus.

Model 7051-2 BNC-to-BNC Cable:

The Model 7051-2 is a

50 Ohm BNC-to-BNC cable (RG-58C), 2 feet (0.6m) in

length. The Model 7951-2 is terminated with male BNC

connectors at both ends.

Model 7051-5 BNC-to-BNC Cable: The Model 7051-5 is a

50 Ohm BNC-to-BNC cable (RG-58C), 5 feet (1.2m) in

length. The Model 7951-5 is terminated with male BNC

connectors at both ends.

Model 7051-10 BNC-to-BNC Cable:

The Model 7051-10

is a 50 Ohm BNC-to-BNC cable (RG-58C), 10 feet (2.4m)

in length. The Model 7951-10 is terminated with male

BNC connectors at both ends.

1.8 SPECIFICATIONS

Detailed Model 3933A specifications may be found in

Appendix A.

l-3

Page 13

SECTION 2

Getting Started

2.1 INTRODUCTION

This section contains basic information on installation

and power line connections. It also provides typical sim-

ple operating examples. The Model 3933A uses an in-line electrical noise filter, but

2.2 INSTALLATION

The following paragraphs discuss Model 3933A installa-

tion. Improper installation will adversely affect the life,

reliability, and safety of the unit.

The Model 3933A weighs about 10 pounds. Be careful

when carrying the unit or mounting it in a rack.

ment must be free of dust and vibration, and the Model

393314 must not be exposed to direct sunlight.

pulse noise or strong magnetic or electric fields may

cause incorrect operation of the unit. Do not install the

unit near a source of pulse noise or strong magnetic or

electric fields.

WARNING

The guards on the rear panel of the

designed to protect rear panel connectors

and should not be used as legs for installation. Do not stand the unit vertically on the

rear guards, because it may fall over, causing

instrument damage or personal injury.

unit are

2.2.1 Installation Location

The allowable ambient temperature and humidity

ranges for the Model 3933A are:

Operating: 0” to 4O”C, 10 to 9O%RH

Storage: -10” to 5O”C, 10 to 8O%RH.

2.2‘2

The Model 3933A is air-cooled by a fan. Insufficient air

flow may cause a component in the unit to fail. Follow the

instructions given below.

Fan

Be sure to install the unit in a location that satisfies these Observe

temperature and humidity conditions. Also, the environ-

vent damage to the unit:

CAUTION

the following precautions to pre-

2-l

Page 14

SECTION 2

Getting Started

An air intake port is provided on the rear

panel of the unit. Allow a space of at least

four inches between the rear panel and a

wall or other obstruction.

An exhaust port is provided on the bottom

panel of the unit. Install the unit on a rigid,

flat surface, and avoid installing it on soft

material, such as a cushion. Be careful not to

insert foreign material between the bottom

of the unit and the surface underneath. Another exhaust port is located on the top panel

of the unit. Be careful not to block the top

port by placing an object on top of the unit.

Avoid mounting two or more units vertically

(for example, when using two or more units

synchronously). Placing one unit on top of

another will obstruct the exhaust port.

Dust collecting in the fan filter will prevent

sufficient air flow. In a clean operating envi-

ronment, wash the filter with a mild detergent every three months. When operating

the unit in a dusty environment, wash the filter with a mild detergent at least once a

month.

Immediately turn off the power to the unit if

the fan ceases to operate. Operating the instrument with an inoperative fan may result

in damage to the instrument.

2.3

LINE POWER SUPPLY AND

GROUNDING

position. Wait at least five seconds before turning the

power back on after turning it off.

WARNING

Disconnect the power cord from the instrument before changing the supply voltage

setting.

CAUTION

Be sure to set the line voltage switch to the

correct position for the line power voltage to

be used. Operating the instrument on an incorrect voltage may cause damage to the unit.

LINE Receptacle Connection

Connect the supplied power cord to the rear panel LINE

receptacle and to a grounded AC power receptacle supplying the correct voltage.

WARNING

The Model 3933A is equipped with a 3-wire

power cord that contains a separate ground

wire and is designed to be used with

grounded outlets. When proper connections

are made, instrument chassis is connected to

the power line ground. If the AC outlet is not

grounded, the rear panel ground terminal

must be connected to safety earth ground using #lSAWG (or larger) wire before use.

2.3.1 Line Power Supply

The Model 3933A operates with lOOV, 12OV, 22OV, or

24OV, &lo%, 48 to 62Hz, single-phase AC power supply.

The power consumption is about 38 VA.

Line Voltage Selector Switch

The Line Voltage Selector switch on the rear panel allows

you to change the operating voltage of the power supply.

The standard setting of the switch is the same as the voltage in the country to which the unit is shipped.

To change the power supply voltage, first disconnect the

line cord, and set the supply voltage switch in the correct

2-2

LineFuse

The line fuse protects the instrument from over-current

situations. To replace the fuse, first disconnect the line

cord, then unscrew the center cap with a small screwdriver. Replace the blown fuse only with the type listed in

Table 2-1, then replace the fuse cap.

WARNING

Disconnect the line cord from the instrument before replacing the fuse.

CAUTION

* Use only a fuse of the rating listed in Table

2-1, or instrument damage may occur.

Page 15

SECTION2

Getting Starfed

Table 2-l. Fuse Replacement

220,240V

NOTE: Fuses are 5 x 20mm and have 25OV, normal blow ratings.

2.3.2

To prevent the possibility of electrical interference,

the Model 3933A using the grounding terminal

If the Model 3933A is not connected to a

grounded AC outlet, be sure to connect the

grounding terminal on the rear panel to

safety earth ground using minimum

#18AWG wire before use.

1 0.5A

Grounding

WARNING

1 FU-96-1

When the panel or case becomes dirty, clean it with a soft

cloth. If the panel or case is too dirty for cleaning with a

dry cloth, lightly dampen the cloth in mild detergent solution, and wipe the panel or case with the damp cloth.

Never use solvents such as thinner or benzene, or chemi-

cal dust cloths, as these

panel surfaces.

may

damage the case or front

2.5 BASIC OPERATION

The following paragraphs summarize front panel operating controls, give typical test connections, and discuss

typical operating examples for the Model 3933A.

2.5.1 Front Panel Summary

Figure 2-2 summarizes each front panel feature. For detailed information on each operating feature, refer to Section 3.

2.5.2

Typical Test Connections

The Model 3933A uses the line filter circuit shown in Figure 2-l. The maximum leakage current at 250V/60Hz is

1mA rms. Touching the metallic part of the chassis of the

unit may, therefore, cause an electric shock if the Model

3933A is not properly grounded.

I- II

1 -I-l*

-1 I

Power

inpur

Figure 2-1. Line Filter

transformer

2.4 HANDLING PRECAUTIONS

A flat keyboard, coated with a polyester film, forms the

control panel surface of the Model 3933A. Be careful not

to damage the keyboard surface by cutting it with a sharp

instrument or touching it with a hot object.

Figure 2-3 shows typical tests connections between the

Model 3933A Phase Shifter and a device under test. Note

that 50 ohm characteristic impedance cables, such as the

Model 7051, should be used for all signal connections.

2.5.3 Operating Examples

The following examples give step-by-step instructions

for setting basic Model 3933A operating parameters,

Example 1: Selecting the Waveform Type (Function)

The waveform type can be selected using the FCTN key,

of the ENTRY group, as follows:

1. Press FCTN and note that the instrument displays

the existing function and the available functions

(sine, triangular, square, sawtooth, DC).

2. Press the number key corresponding to the desired

function (O-5), or rotate the MODIFY knob until the

desired function number is displayed. For example,

press 3 to select the square wave function. The

waveform will immediately change to the selected

function.

3. Press DSPL to return to the normal display mode.

2-3

Page 16

SECTION 2

Getting Started

SYNC OUT

DISPLAY

,*I

MODIFY

Changes

parameters,

I--

selections

3

AM IN: Enables or

;;k$Ies AM

I s

SHIFT

Adds shifted function

to some other keys

I

2 DUTY FXDBO

t-i- DUTY: Allows setting squarewave -

duty cycle

FXDBO: Fixed 50% duty cycle

RUB OUT: Deletes current

L

1

ENTRY

PHASE: Sets phase parameters

AMPTD: Sets output amplitude

OFFSET: Sets DC offset (main only)

I

-1

J

FCTN: Sets waveform type

L

SWEEP

START. Programs start

STOP. Programs stop

CTR: Sets center

SPAN: Sets span

SWEEP FCTNI Sets function

SWEEP TIME: Sets time

SWEEP OFF: Cancels sweet mode

I

. S&marker

SWEEP OPR

START: Starts sinole or

caltinuous sweep

L

I

,

1

4 e STEP SIZE

Used with modify

keys to change

parameter values

1 DSPL 1

Returns display

to normal

Sets applicable units

definition value for

parameters set with

Figure 2-2.

2-4

Front Panel Summary

Page 17

SECTlON 2

Getting

Started

Model 3933A

Function

output

Figure 2-3. TypicaZ Connections

Example 2: Setting the Output Amplitude.

Use the AMPTD key, of the ENTRY group, to set the output voltage amplitude as follows:

Press AMPTD, and note that the instrument displays

1.

the existing amplitude and allowed amplitude

range.

2. To enter a completely new amplitude value in p-p

units, press the keys for the desired numeric value,

then press V or mV, as required. For example, to enter a 30mV p-p amplitude, press the following three

keys: 3 0 mV.

To simply modify the existing amplitude value, use

3.

the cursor keys and the MODIFY knob to set the

value as required.

Press DSPL to return to normal display.

4.

Example 3: Programming the DC Offset

The OFFSET key allows you to set the DC or average level

of the main synthesizer output waveform, as in the following example:

1. Press OFFSET and note that the instrument displays

the existing offset value and allowed range.

2. Either press the numeric keys for the desired offset

value, or use the MODIFY knob and/or cursor keys

to change the value.

3. Press DSPL to return to normal display.

Example 4: Setting Phase Shift

The PHASE key allows you to set the amount of phase

shift, in degrees, of the main synthesizer output wave-

form, as in the following example:

1. Press PHASE and note that the instrument displays

the existing phase value and the allowed range.

2. Enter the desired phase shift value, or use the MODIFY KNOB and/or cursor keys to change the existing

value.

3. Press DSPL to return to normal display.

2-5

Page 18

CTION 3

Operatio

3.1 INTRODUCTION

This section contains detailed information on front panel

and rear panel operation of the Model 3933A. For detailed GPIB (IEEE-488 bus) operation, refer to Section 4,

GPIB Operation, in the manual for the Model 3930A Multifunction Synthesizer.

3.2 FRONT PANEL AND REAR PANEL

DESCRIPTION

3.2.1

Input and Output Connections

CAUTION

Restrictions apply to input and output signal

levels and signal types. Adhere to signal

level and load characteristics as described

below. or the instrument may be seriously

damaged.

3933A: LOGIC and ANALOG. The specifications of the

input signals are given below.

BNC LOGIC INPUTS (Rear Panel)

Logic inputs include SWEEP SINGL START IN (singlesweep start input), and SWEEP HOLD IN (sweep hold

input). Important specifications for these inputs include:

Input voltage: TTL level

Allowable maximum input voltage: OV to +5V

Circuit: See Figure 3-1, Logic Input Circuits.

(SWEEP) SINGL START IN

(SWEEP) HOLD IN

3.2.2 Input Connections

Two types of input signals may be applied through the

front and rear panel BNC input connectors of the Model

1 Fiaure 3-l.

Loaic Invut Circuit

Page 19

SECTION 3

Operation

BNC ANALOG INPUT (Front Panel)

The AM IN BNC can be used to apply an external analog

input signal which controls the amplitude of the

waveform.

Input voltage range: -3V to +lV

Allowable maximum input voltage: rtl5V.

Input phase range: DC to 1OOkHz.

Input impedance: Approximately 1OkQ.

Signal ground: insulated from ground.

Circuit: See Figure 3-2, Analog Input Circuit.

+6.3V

AM IN

DIGITAL INPUT CONNECTOR (Rear Panel)

A third type of input is the DIGITAL INPUT. One digital,

36-pin, D-type input connector transfers MAIN SYNTHESIZER signals from a master Model 3930 to a Model

3933A slave unit, and between successive Model 3933A’s

in a chain of phase shifters. A jumper cable, CA-94 is required to interconnect units.

The main synthesizer signal from a Model 3930A (master

unit) is applied to the DIGITAL IN connector on the rear

panel of a Model 3933A (slave unit). If an additional

phase shifter unit is chained to provide multiple phase

operation, a second cable (CA-941 is connected from the

DIGITAL OTJT of the first slave, to the DIGITAL IN on

the rear panel of the second slave unit. This may be repeated until a maximum of 5 (five) slave units are tied to a

single master synthesizer. The DIGITAL IN and DIGITAL OUT signals at the rear panel of the slaves are identical to the master main synthesizer output signal.

Figure 3-2.

Analog Input Circuits

3930A

CA-94

3933A

Figure 3-3. Typical Digital I/O Interconnections

Cable

Interconnection details are shown below, in Figure 3-3.

,

3933A

I

\

Next

3933A

3-2

Page 20

SECTION 3

Operation

3.2.3 Output Connections

Five output signals are available from various BNC connectors on the Model 3933A. The specifications for the

output signals are given below.

CAUTION

Be careful not to connect an input signal to

an output connector, or instrument damage

may occur.

BNC LOGIC OUTPUTS (Rear Panel)

Logic outputs include the SWEEP SYNC OUT (sweep

synchronous output) and SWEEP MKR OUT (sweep

marker output). Specifications for these outputs are summarized below.

Output voltage: TTL level

Sweep MKR OUT and Sweep SYNC OUT are connected

to ground.

Circuits: See Figure 3-4.

Circuits: See Figure 3-5.

SYNC OUT

Figure 3-5.

DIGITAL OUTPUT CONNECTOR (Rear Panel)

Waveform Synchronous Outputs

One digital, 36-pin, D-type input connector transfers signals among several Model 3933A’s (up to 5) in a chain of

phase shifters. A jumper cable, CA-94 is required to interconnect units.

BNC ANALOG OUTPUT (Rear Panel)

Sweep X Drive Out (Sweep X

Axis

Drive Output)

Output voltage: OV to +lOV/no load

+5v

Figure 3-4.

9

Sweep Marker and Sweep Synchronous

SWEEP MKR OUT

SWEEP SYNC OUT

outputs

BNC LOGIC OUTPUT (Front Panel)

Waveform SYNC OUT (front panel synchronous output)

Output voltage: TTL level

Waveform SYNC OUT is electrically isolated from chassis ground.

Output impedance: 6OOQ

Recommended load impedance: lOkG! or more

BNC ANALOG OUTPUT (Front Panel)

Fctn Out (Waveform Output)

Maximum output voltage: &15V/no load, *7V/5OQ load

Output impedance: 50R

Recommended load impedance: 5OQ or more

OUTPUT CONSIDERATIONS

All logic outputs are driven by a 7400 family IC. Be careful not to connect a load that exceeds the drive capability

of this TTL IC. Also, do not use excessively long connecting cables; the resulting capacitance may have detrimental effects on the output signals.

The interconnection between the Model 3930A Waveform Synthesizer (master), and the Model 3933A Phase

3-3

Page 21

SECTION 3

Shifter (slave), requires the special cable CA-94. Chaining

multiple phase shifters requires the same cable.

The waveform synthesizer output impedance is 5OQ. To

maintain maximum amplitude across the entire bandwidth, and for maximum square-wave quality, use a 5OQ

coaxial cable for connections. Terminate the receiving

end of the cable with a 5OQ impedance. The actual output

voltage will be displayed by the Model 3933A if the out-

put amplitude display is set for 5Of2 loads.

3.2.4 GPIB Bus (Input/output

Connector)

A GPIB connector on the rear panel permits remote control of all parameters which are normally accessed

through phase shifter controls. The GPIB bus is both an

input and an output system. See Section 4, GPIB Operation, in the Model 393019 Multifunction Synthesizer manual, for details.

3.2.5

The Model 3933A front panel, shown in Figure 3-6, contains the following:

l

A two-line, 40-character liquid crystal display.

l

A front panel with a built-in flat keyboard.

l

3

0 A rotary knob to modify certain parameters.

l

A POWER ON/OFF button.

The liquid crystal display presents information useful for

the operation of the Model 3933A, such as the value of

each parameter and the range of permissible parameter

values.

The flat keyboard includes a SHIFT key, which gives cer-

tain other keys a secondary function. Any key which is

Front Panel Description

BNC I/O connectors.

shaded with the same background color as the SHIFT

key, requires that you press SHIFT first before accessing

the function of that particular key.

Most settings are maintained in battery backed-up memory. As a result, on power-up, the Model3933A automatically assumes the settings which were in effect immedi

ately prior to the last power shut-down.

Key Representations

This section uses special representations such as [SHIFI],

[MODIFYI, or [SIZE] in the explanation of certain keys.

For example, if &iODIFYl appears by itself, then it is the

only one that applies. If both [MODIFYI and [SIZE] are

shown, then both functions apply to that parameter.

These representations indicate the following:

[SHra

Press the SHIFT key, then press the

applicable key to access the shifted

key function. The liquid crystal display indicates “SHIFT” in the upper

left corner when the Model 3933A is

in the shift mode.

[MODIFY]

Enter the desired value using the

DATA keys or change a given parameter value with the MODIFY

knob. When WODIFYI alone applies, the up/down step size, while

incrementing or decrementing a

value, is fixed at 1, and the cursor position is also fixed.

[MODIFY] [SIZE]

Both lMODIFYj and [SIZE] functions apply to this parameter. Specify

the digit to be modified by placing

the cursor under the desired digit,

using 4 or b. Then change the modify up/down increment using the

STEP SIZE key.

3-4

Page 22

SECTION 3

Operation

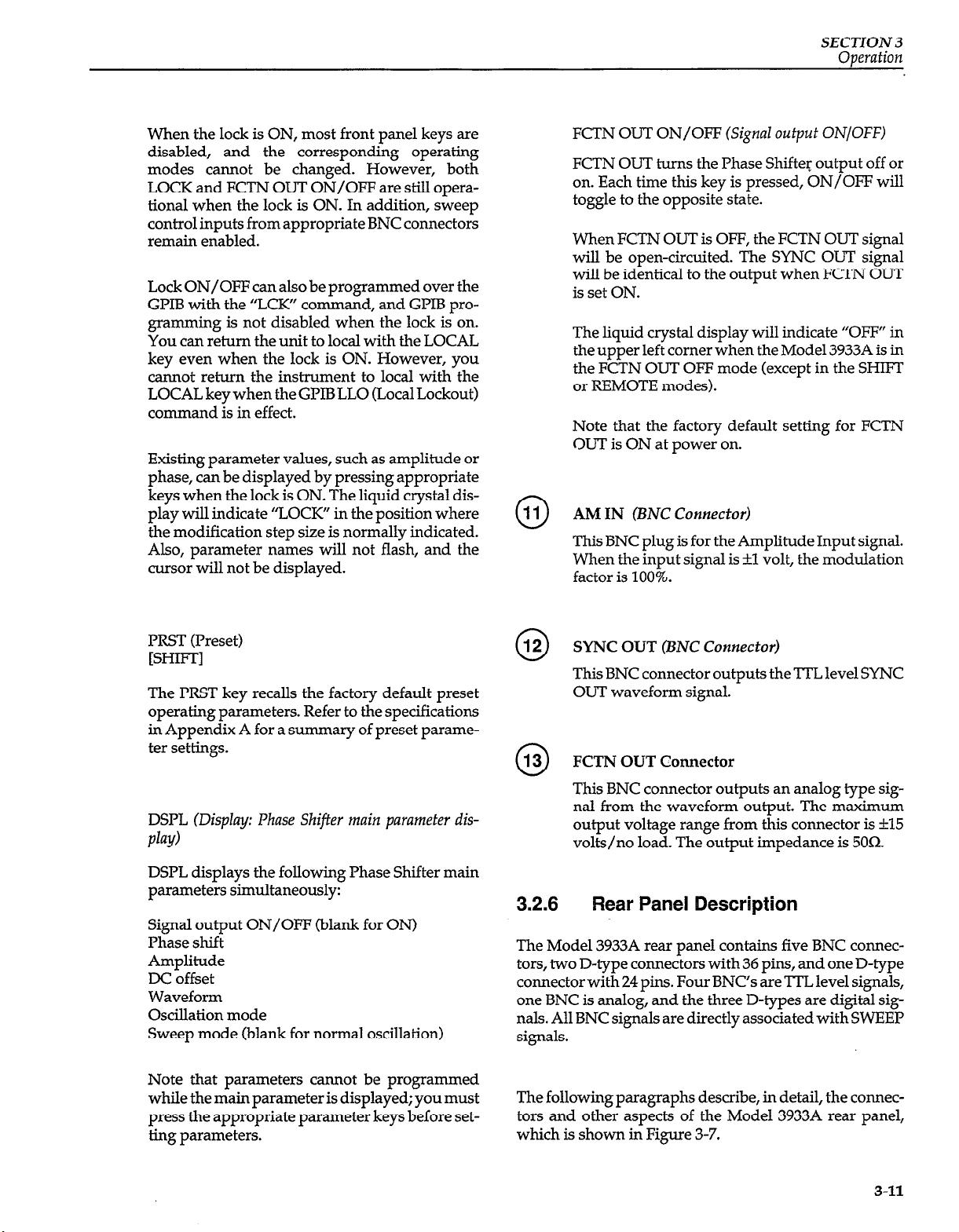

Figure 3-6.

Detailed Descriptions

Each front panel feature is described below. The circled

number to the left of each description corresponds to the

appropriate number shown in Figure 3-6.

1

0

POWER ON/OFF

POWER controls AC power to the Model 3933A.

Press this switch once to turn power on. Press

POWER a second time to turn the power off. An

active display also indicates the instrument

power is turned on.

Model 3933A Front Panel

(Power switch)

2

0

3

0

L

Display

The two-line, 40-character display shows parameter values and other important information

during operation.

SWEEP

The various SWEEP keys are used to program

sweep functions such as start and stop phase,

center, marker, span phase, sweep function and

sweep time. The paragraphs below summarize

the operation of these keys. Refer to the specifications located in Appendix A for details on the

sweep range.

(Power Indicator)

(Phase sweep keys)

3-5

Page 23

SECTION 3

START PHASE (Start phase)

CMODIFYI BZEI

The START PHASE key allows you to set the

sweep start phase. You can specify a start phase

that is either higher or lower than the stop phase.

The relationship between the start and stop

phase values determines the sweep direction. If

the start phase is higher than the stop phase, the

sweep will be performed in a descending direction. If the start phase is lower than the stop

phase, the sweep will be performed in the ascending direction.

STOP PHASE (Stop phase)

[MODIFYI [SIZE]

The STOP PHASE key allows you to set the stop

phase of the phase sweep. You can specify a stop

phase that is either higher or lower than the start

phase. If the stop phase is higher than the start

phase, the sweep will be performed in ascending

order. If the stop phase is lower than the start

phase, the sweep will be performed in descending order.

SPAN (phase span)

MODIFY] NZ-J3

This key allows you to set the phase span of the

phase sweep. The relationship between the start

and stop phase values determines the sweep direction. If the phase span is changed, the start

and stop phase will be changed so that the sweep

range is determined by the new phase span and

the existing center phase. The existing center

phase will not change.

MKR (Marker phase)

[SHIFT], [MODIFYI BZEI

This key allows you to set the marker phase of

the phase sweep. Note that you can specify only

one marker phase. While the oscillation frequency is higher than the programmed marker

frequency during a sweep, the marker output

signal available at the rear panel MKR OUT jack

will be set low. The marker output signal at MKR

OUT will be set high at all other times.

SWEEP FCTN (Sweep function)

[MODIFY]

If the stop phase is changed, the sweep range will

be determined by the new stop phase and the existing start phase.

CTR (Center phase)

[MODIFY] iTSIZE

The CTR key allows setting of the center phase of

the sweep.

The relationship between the existing start and

stop phase values determines the sweep direction. If the center phase is changed, the start and

stop phase will be changed, but the span phase

will remain constant.

CTR 4 (Substitute ten ter phase for marker phase)

EHIFU

The CTR 4 key substitutes the center phase for

the marker phase. The sweep direction and span

phase are affected in the same manner as when

using the center phase setting. If the substituted

center phase is different than the marker phase,

the start and stop phase will change accordingly.

The SWEEP FCTN key allows you to select the

sweep function. Available sweep functions include: step (11, linear triangular wave and saw-

tooth wave (A or n ), and log triangular wave

or sawtooth wave (A or n >.

With the step sweep function, the output phase

simply changes between the start phase and stop

phase at intervals determined by the sweep time.

With the linear and log functions, the phase increases or decreases linearly or logarithmically,

respectively.

SWEEP TIME (Sweep time)

[MODIFY] HZEI

The SWEEP TIME key allows you to set the

sweep time, which is the time from the start

phase to the stop phase. The allowed sweep time

range is: 5msec to 9,999sec.

SWEEP

SlNGL START (Single start: singZe-sweep start)

This key starts a single sweep. Only one sweep

will be generated per key press.

OPR (Sweep Operation)

3-6

Page 24

SECTION 3

Oi7eruticm

CONT START (Continuous start: repeated sweep

sfart)

L3-F-U

This key starts repeated sweeps, which will be

generated continuously until halted with the

HOLD/RESM or SWEEP OFF keys.

SWEEP OFF (Sweep off)

SWEEP OFF cancels the sweep mode. The phase

will remain at the existing phase when this key is

pressed, and the MKR OUT, SWEEP SYNC

OUT, and X DRIVE OUT signals on the rear

panel are set to high level, high level, and OV, respectively.

START STATE (Sweep start state: start phase outpuf)

This key resets the sweep and sets the output

phase to the start phase.

5

0

Pressing HOLD/RESM while sweep is in pro-

gress will halt the sweep with the PHASE, MKR

OUT, SWEEP SYNC OUT, and X DRIVE OUT

signals present at that time maintained at their

present values. Pressing HOLD/RESM with the

sweep halted resumes the sweep, using the previous signal conditions.

ENTRY (Main parameter setting keys)

PHASE Phase)

[MODIFY] [SIZE]

Pressing PHASE allows you to set the output

phase of the unit. The allowed phase range is

from -360” to 360”. The amount of phase depends on the signal from the Model 3930A main

synthesizer. The phase difference between the

master Model 3930A signal and Model 3933A

slave signal is:

(Model 3933A phase setting) - (Model 3930A

start/stop phase setting)

When START STATE is pressed, the MKR OUT

and SWEEP SYNC OUT signals on the rear panel

will be set high. The X DRIVE OUT signal is set to

OV when the start phase is lower than the stop

phase; the X DRIVE OUT signal is set to 1OV

when the start phase is higher than the stop

phase. These signals can be used for scale adjustments of XY recorders.

STOP STATE (Sweep stop state: stop state)

[SHIW

STOP STATE performs the opposite function of

the START STATE key in that it sets the output

phase to the stop phase.

When STOP STATE is pressed, the MKR OUT

and SWEEP SYNC OUT signals on the rear panel

are set high. The X DRIVE OUT signal is set to OV

when the start phase is higher than the stop

phase; it is set to 1OV when the start phase is

lower than the stop phase.

If the Model 3930A’s start/stop phase is anything other than 0”, the difference between the

settings for both units does not change, regardless of the Model 3930A’s oscillation mode.

m (AmpIifude)

[MODIFYI [SIZE]

Pressing AMPTD

amplitude of the unit. The allowed amplitude

ranges from 0.30mV p-p/no load to 3O.OV p-p/

no load when the DC offset is OV and the output

range mode is AUTO. The range becomes

O.OOVp-p to 3O.OVp-p in the FXD mode. In other

cases, the upper and lower limits are restricted to

the range specified in Table 3-1. The values for

the amplitude setting are for no-load output conditions. The unit can be set to display either the

no-load or 5Ofi amplitude value (see below).

In the AUTO mode, amplitude setting may be set

to rms or dBV value, as well as p-p.

allows you to set the output

HOLD/RESM iHoZd/resumer kmpomry stop -und

resume)

This key alternately stops and resumes the

sweep.

Vmr ran cnnrihr thn sn7r\mnr;stn ,rn;tc hv ~VPCE-

L “- -. “r-“-J

ing the appropriate ENTER units key when entering the amplitude. Use mV or V for p-p values,

mVrms or Vrms for rms values, and dBm for dB

values.

CALL uyyL”yALuw. cuuca “J y’“as-

3-7

Page 25

SECTION 3

Operation

OFFSET (DC offset)

[MODIFY] [SIZE]

The OFFSET key enables DC offset voltage programming. The allowed offset is between -15V/

no load and 15V/no load for a DC waveform. For

other waveform types, the offset range is restricted to the values specified in Table 3-l. All

specified offset ranges are for no-load condi-

tiOIlS.

FCTN (Function: waveform)

MODIFY1

This key allows you to choose the output

waveform of the phase shifter. Available

waveforms include: DC, SIN Q (sine wave),

2/ (triangular wave), ll- (square wave), /l (as-

cending sawtooth wave), A (descending sawtooth wave).

If the output range is AUTO, and the waveform

changes, p-p amplitude values are set automati-

dY*

DATA (Numeric keys for parameter entry)

The DATA key set consists of numeric keys for

entering a value and ENTER (units) keys for setting the units of the entered value. The. (decimal

point) key and the +/- (sign inversion) key do

not affect parameters for which they have no

function.

Parameters which are selected with one numeric

character, such as waveform and oscillation

mode, do not require that any ENTER key be

pressed. Such parameters are set simply by entering one numeric character (or by rotating the

MODIFY knob as required).

For other parameters, enter the required value

with the numeric keys, then press the appropriate ENTER units key to enter the units (deg, V,

etc.>.

The display will indicate the entered values and

the cursor will flash beneath the least significant

whole number. The MODIFY knob will allow

you to change the value in the column indicated,

while the cursor is flashing. After you have made

any necessary modifications, press DSPL to return to the main parameter display and begin

operation of the Model 3933A under the new settings.

If, while using the DATA numeric keypad, you

enter an incorrect value, you will notice that the

cursor is not visible. This indicates the MODIFY

knob is not operational at this time.

For example, when changing PHASE, you want

to set a new phase of 124 degrees, via the DATA

keypad, but you erroneously enter “142”. Since

you haven’t pressed the “deg” key on the ENTER pad, you have several options for changing

the numeric input.

You can press the RUB OUT (delete) key. RUJ3

OUT deletes the numeric character or decimal

point from the rightmost position. Two strokes

on the RUB OTJT key will delete the Y”, then the

“4”, leaving the “1” next to the decimal point. At

this point, you simply enter Y”, then “4”, followed by the “deg” key. The display indicates

“124 deg”. Pressing DSPL completes the entry.

Keep in mind, RUB OUT only works prior to entering the parameter units (V, deg, etc.).

If you have already pressed one of the ENTER

keys, you will notice that the cursor is displayed

and is blinking. You now have the option of using the MODIFY knob and the cursor movement

keys (4 and b >. Place the cursor under the value

to be changed and turn the MODIFY knob

counter-clockwise to reduce the numeric value

indicated by the cursor. A clockwise rotation will

increase the value. The amount of increase or decrease depends on the setting of STEP SIZE (if

applicable).

Another option is to simply press PHASE again

(or any other appropriate ENTRY key), which

will wipe out all your existing entries in the pre-

sent display (other settings - AMPTD, OFFSET,

FCTN - remain unaffected). Now, re-enter the

proper numbers, plus “deg”, then DSPL.

Pressing any appropriate ENTER key will enter

the values for the MARK and SPAN waveform

cycles and phase parameters, where only one

type of unit is used. This also applies to the GPlB

address, which does not contain parameter

* units. The Model 3933A will automatically select

the appropriate unit value designation when

two unit types are identified on one keypad face.

For amplitude, where parameters can be entered

in different types of units, select the appropriate

3-8

Page 26

SECTlON 3

Ot7eration

7

0

units key from the ENTER key to complete entry

of the value.

The units keys also have a units conversion function. This feature is available for unit conversions such as amplitude p-p/rms/dBV/dBm

conversions. When the units key of the unit to be

changed is pressed with the present setting displayed, the display will be changed to reflect the

newly-selected units. Note, however, that the actual output remains unchanged.

0 (Oufput Range Mode)

[SHIFT] [MODIFY

The numeral “0” (zero) on the numeric key-pad

has a second function when used in conjunction

with the SHIFT key. An entry of [SHIFT] “0”

brings up the output range mode display. The

existing setting is displayed, with an option to

toggle between AUTO and FXD. The display

toggles between settings according to whether a

“1” (one) or “0” (zero) is pressed. See section

3.5.2, Output Range Mode for details.

MODIFY

In addition to using the numeric keys, you can

set any parameter, except the GPIB address, delimiter, and memory number, by using the

MODIFY knob.

(Modify operation knob)

8

0

clockwise, or multiply the parameter by 2 by

turning the knob clockwise.

Similarly, when the step size is x+10, you can divide or multiply the parameter by 10 by rotating

the knob counter-clockwise or clockwise respectively. Note that the cursor will not be displayed

when the step size is x+2 or x+10.

4 CL@ cursor)

This key moves the cursor to the left by one digit

each time it is pressed.

@ (Right cursor)

This key moves the cursor to the right by one

digit each time it is pressed.

STEP SIZE (UP/DOWN sfep size)

STEP SIZE changes the MODIFY knob UP/

DOWN step size value. For parameters with values that can be changed using variable step sizes,

the step size will cycle in the following order

each time this key is pressed: +l x+2 x-i-10 . . . rtl.

MISCELLANEOUS KEYS

LOCAL (Xefurn to local)

The MODIFY knob is operational under the following two conditions:

The Model 3933A is in the appropriate parame-

ter-entry mode.

And the displays indicates the present parame-

ter value.

MODIFY (Modify knob)

When the step size is 51, or &5, you can select the

digit to increase or decrease by placing the cursor

under the appropriate digit (use 4 or b ) and

turning the MODIFY knob to the right or left.

Each knob increment increases or decreases the

selected digit by a value of 1 (or 5).

When the step size is x+2, you can divide the selected parameter by 2 by turning knob counter-

LOCAL cancels remote, and returns the instrument to the local mode, when used over the

GPIB.

GPIE3 (GPIB Address: GPIB address, delimiter)

rsH=v

The GPIB key allows you to program the GPIB

primary address and the output delimiter used

when the Model 3933A is acting as a GPIB talker.

Only the numeric keys can be used for setting

these parameters (the MODIFY knob cannot be

used). The allowed range for the primary address is from 0 to 30, and the delimiter can be selected for CR/LF or CR (CR and LF or CR only).

The GLIB pAmary address is the integer part of

this parameter, and the delimiter is defined by

the fractional part. For example, a parameter of

2.0 indicates a primary address of 2 and defines

CR/LF as the delimiter. Similarly, a parameter of

3-9

Page 27

SECTION 3

Operation

4.1 indicates a primary address of 4 with CR as

the delimiter.

To change only the primary address, enter only

the integer part of the number; the delimiter will

remain unchanged. To change only the delimiter, enter the decimal point followed by the fraction (0 or 1); the primary address value will remain unchanged.

When programming the primary address and/

or delimiter, remember that you must press any

one of the ENTER keys to complete the entry

process.

Note: when using multiple units in remote GPIB

mode, it is necessary to program each unit with a

unique address. The default is 2.0, which allows

all units to acknowledge any GPIB command

sent over the IEEE-488 bus.

This programming is achieved by pressing

SHIFT, then pressing LOCAL/GPIB. When the

display shows the 2.0 address, modify the parameter with the MODIFY knob or the DATA

numeric keys to enter a unique address.

9

0

SHIET

The SHIFT key adds a secondary function to

many other front panel keys. Those keys which

have shifted functions are indicated by having a

brown background color that matches the color

of the SHIFT key. Keys with shifted functions include STOP STATE, CONT START, PRST, CTR

4, MKR, GPIB, FXD50, and 0.

When the SHIFT key is first pressed, the unit en-

ters the shift mode, and the liquid crystal display

indicates “SHIFT” in the upper left corner. The

shift mode is canceled when any key, including

the SHIFT key, is pressed. If a key with a shift

function is pressed, the unit enters that mode;

otherwise, it returns to the mode it was in before

SHIFT was pressed.

MEMORY

The MEMORY keys allow you to store and recall

instrument setups. Ten groups of memory settings, numbered 0 through 9, are available for

setup storage.

ST0 (Store: store sefup in memory)

(Memo y operation keys)

(Beep sound)

[SHIF--U, MODIFY]

This key controls the beep that sounds when you

press front panel keys and when errors occur.

You can tum the beep OFF (0) or ON (1).

DUTY (Square-wave Dufy Cycle)

[MODIFY] [SEE1

The DUTY key allows you to program the

square-wave duty cycle. The allowed duty cycle

ranges from 5.0% to 95.0%.

Two duty-cycle modes are available: 50% fixed

and variable. In the variable mode, the upper frequency limit is restricted to 1MHz even if the

duty cycle is set at 50%.

FXD50 (Fixed 50% Duty Cycle)

[Srn

This key fixes the square-wave duty cycle at 50%.

10

0

The ST0 key stores the displayed instrument setup parameters in the selected memory location

(O-9). You can use only numeric keys to store setups (the MODIFY knob cannot be used). Pressing the numeric key will immediately store the

existing parameter values in the selected memory location and erase the previous setup in that

sa,me memory 1ocat;on.

RCL (Recall: read sefup from memory)

RCL reads instrument setups from the desired

memory location (O-9) and displays them. Numeric keys are the only means of selecting memory locations to recall (the MODIFY knob cannot

be used). Pressing RCL, followed by a single numeric key will immediately read the contents of

the selected memory location into the display.

Previous instrument settings will change accordingly.

ADDITIONAL KEYS AND CONNECTORS

LOCK Uock out fionf panel keys)

This key allows you to disable most front panel

keys. Available modes are ON (1) and OFF (0).

3-10

Page 28

SECTION 3

Oaemtion

When the lock is ON, most front panel keys are

disabled, and the corresponding operating

modes cannot be changed. However, both

LOCK and FCTN OUT ON/OFF are still operational when the lock is ON. In addition, sweep

control inputs from appropriate BNC connectors

remain enabled.

Lock ON/OFF can also be programmed over the

GPIB with the “LCK” command, and GPIB programming is not disabled when the lock is on.

You can return the unit to local with the LOCAL

key even when the lock is ON. However, you

cannot return the instrument to local with the

LOCAL key when the GPIB LLO (Local Lockout)

command is in effect.

Existing parameter values, such as amplitude or

phase, can be displayed by pressing appropriate

keys when the lock is ON. The liquid crystal display will indicate “LOCK” in the position where

the modification step size is normally indicated.

Also, parameter names will not flash, and the

cursor will not be displayed.

11

0

FCTN OUT ON/OFF (Signal oufput ON/OFF)

FCTN OUT turns the Phase Shifter output off or

on. Each time this key is pressed, ON/OFF will

toggle to the opposite state.

When FCTN OUT is OFF, the FCTN OUT signal

will be open-circuited. The SYNC OTJT signal

will be identical to the output when FCTN OUT

is set ON.

The liquid crystal display will indicate “OFF” in

the upper left corner when the Model 3933A is in

the FCTN OUT OFF mode (except in the SHIFT

or REMOTE modes).

Note that the factory default setting for FCTN

OUT is ON at power on.

AM IN @NC

This BNC plug is for the Amplitude Input signal.

When the input signal is &l volt, the modulation

factor is 100%.

Connector)

PRST (Preset)

rsm1

The PRST key recalls the factory default preset

operating parameters. Refer to the specifications

in Appendix A for a summary of preset parameter settings.

DSPL (Display: Phase Shifier main parameter dis-

play)

DSPL displays the following Phase Shifter main

parameters simultaneously:

Signal output ON/OFF (blank for ON)

Phase shift

Amplitude

DC offset

Waveform

Oscillation mode

Sweep mode (blank for normal oscillation)

Note that parameters cannot be programmed

while the main parameter is displayed; you must

press the appropriate parameter keys before setting parameters.

12 SYNC

0

This BNC connector outputs the TTL level SYNC

OTJT waveform signal.

13

0

FCTN OUT

This BNC connector outputs an analog type signal from the waveform output. The maximum

output voltage range from this connector is rt15

volts/no load. The output impedance is 5OQ.

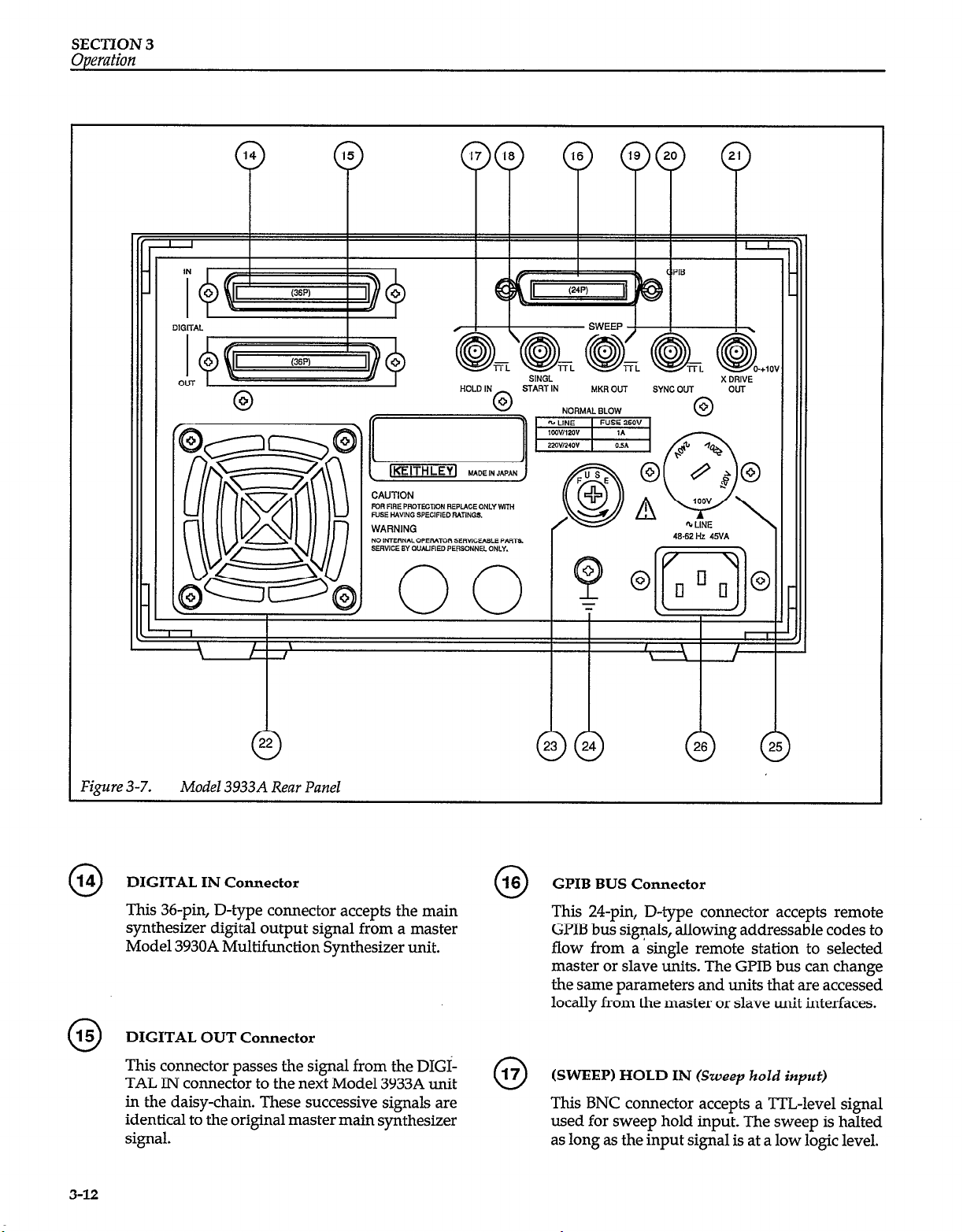

3.2.6

The Model 3933A rear panel contains five BNC connectors, two D-type connectors with 36 pins, and one D-type

connector with 24 pins. Four BNC’s are TTL level signals,

one BNC is analog, and the three D-types are digital signals. All BNC signals are directly associated with SWEEP

signals.

The following paragraphs describe, in detail, the connectors and other aspects of the Model 3933A rear panel,

which is shown in Figure 3-7.

OUT

(BNC Connector)

Connector

Rear Panel Description

3-11

Page 29

SECTION 3

Operation

IN

DIGKA

I

(3W

SINGL

X DRIVE

t

-+1ov

Figure 3-7.

14

0

Model 393314 Rear Panel

DIGITAL IN Connector

This 36-pin, D-type connector accepts the main

synthesizer digital output signal from a master

Model 3930A Muhifunction Synthesizer unit.

18

0

48-62 Hz 4SVA

I/,n,

GPIB BUS Connector

This 24-pin, D-type connector accepts remote

GPIB bus

flow from a single remote station to selected

master or slave units. The GPIB bus can change

the same parameters and units that are accessed

locally from the master or slave unit interfaces.

sipals,

allowing addressable codes to

15

0

3-12

DIGITAL OUT Connector

This connector passes the signal from the DIGITAL IN connector to the next Model 3933A unit

in the daisy-chain. These successive signals are

identical to the original master main synthesizer

signal.

17

0

(SWEEP) HOLD IN

This BNC connector accepts a TTL-level signal

used for sweep hold input. The sweep is halted

as long as the input signal is at a low logic level.

(Sweep hold input)

Page 30

SECTION 3

Operation

18

0

19

0

20

0

21

0

(SWEEP) SINGL START IN

start input)

This BNC connector accepts a TTL-level signal

used to start a single sweep. A single sweep

starts at the falling edge of the input signal.

(SWEEP) MKR OUT (Sweep

This BNC connector provides a TTL-level signal

used for sweep marker output. This signal goes

low when the frequency rises above the marker

frequency during a sweep. It remains high at all

other times.

(SWEEP) SYNC OUT (Sweep synchronous out-

put)

This BNC connector provides a TTL-level signal

for sweep synchronous output. This signal is at

low level while a sweep is progressing from the

start phase to the stop phase. It is at a high level at

all other times.

(SWEEP) X DRIVE OUT

output)

(SingZe-sweep

marker output)

(Sweep X-axis drive

CAUTION

Immediately turn off the power to the unit if

the fan ceases to operate. Be careful not to obstruct the exhaust ports on the upper and

lower panels. Failure to observe these precautions may result in instrument damage.

FUSE

23

0

24

0

0

If the Model 3933A is connected to an ungrounded AC outlet, connect the grounding

terminal to safety ground using #18AWG

minimum wire before use.

(Line Fuse)

The fuse holder cap can be removed with a

Philips screwdriver. Turn the cap counterclockwise to access the fuse. Always use a fuse with an

electrical rating that matches the input line voltage setting in use.

-L

(Grounding terminal)

The grounding terminal is connected to the chassis of the Model 3933A. To prevent interference

and for safety, be sure to ground this terminal.

WARNING

.

22

0

This BNC connector provides the signal for

sweep X-axis drive output. The output voltage

ranges from OV to lOV, and it increases and decreases according to the sweep direction, as the

sweep is generated. This output signal is intended for use as the X-axis drive for an oscilloscope or XY recorder.

AIR INTAKE PORT

An air intake port is on the rear panel for cooling.

Allow at least four inches of clearance behind the

port and any obstruction.

When the air filter becomes dirty, pull out on the

central plastic section of the air filter housing

cover and remove the filter element. Clean the

filter element with pressurized air or wash it

with a mild detergent. Make sure that the filter is

completely dry before re-installing it in the unit.

The filter should be cleaned at least once every

three months when used in a clean environment,

or at least once a month in a dirty environment.

25

0

26

0

LINE VOLTAGE SELECTOR

switch)

This switch sets the Model 3933A for the correct

line voltage. Using a flat-blade screwdriver, set

the switch in the proper position for the supply

voltage in your area.

WARNING

Disconnect the line cord before changing

setting the switch position.

CAUTION

Operating the Model 3933A on an incorrect

line voltage may result in instrument damage.

LINE

(Power input connector)

The LINE connector is used to connect the instrument to AC power.

(SuppZy voltage

3-13

Page 31

SECTION 3

Operation

WARNING

To avoid the possibility of electric shock,

connect the Model 3933A to grounded AC

outlet.

The fuse holder is located above, and to the left

of, the LINE connector. The fuse can be replaced

by disconnecting the line cord and unscrewing

the fuse holder cap with a screwdriver. Replace

only with the type indicated below.

Fuse Keithley

Line

Voltage

1 lOV, 120v 1A

220,240V

NOTE Fuses are 5 x 20mm and have 25OV, normal blow ratings.

Current Part

Rating Number

0.5A

c

I-

FU-96-2

F-U-96-1

3.3 STARTUP

1. Check that the supply voltage switch is set at the

proper position for the supply voltage. The allowable supply voltage range is flO% of the voltage at

which the supply voltage switch is set.

CAUTION

Operating the Model 3933A in an incorrect

line voltage may result in damage to the unit.

2. Make sure that the power is off, then plug the supplied power cable firmly into the LINE connector on

the rear panel of the Model 3933A. Insert the power

plug into a grounded AC power receptacle.

WARNING

To avoid the possibility of electric shock, use

only a grounded AC receptacle for the power

connection.

Turn on Model 3933A power by pressing in on the

front panel POWER switch. Power is ON when the

POWER switch button is depressed (in); power is

OFF when the POWER switch button is released

(out). When the power is turned on, the Model

3933A will begin normal operation, and the liquid

crystal display backlight will turn on.

3. When the power is first turned on, the Model 3933A

will return to the settings in effect prior to the last

power-off, and the unit will display the phase shif-

ter’s main parameters.

If the previous settings were not stored correctly, the

error code “Er MEMOll” message is displayed, fac-

tory preset parameters will be placed into effect and

displayed. At this point, parameters in effect prior to

the preceding power-off will be lost. This situation

occurs when the memory backup battery has insufficient charge, and memory data cannot be maintained.

A fully-charged battery can retain memory for approximately 60 days. This period, however, varies

slightly with ambient temperature and from one battery to another. Approximately 50 hours, with the

unit connected to line power, are required to fully

charge a dead battery.

When the battery no longer sustains sufficient

charge for practical use, contact your Keithley representative or the factory for information on obtaining

a replacement.

4. The backup battery may be discharged when the

Model 3933A is used for the first time after being

purchased, or if the unit has not been connected to

line power for a considerable length of time. Connect

the unit to line power for at least several hours to

charge the battery.

5. Sweep operation mode parameters are not stored

when the power is turned off. Therefore, turning the

power off during sweep operation, sweep hold, end

of single sweep, start phase output, or stop phase

output, will result in a loss of sweep state information the next time power is turned on. At next powerup, the LCD will, however, indicate the output

phase at the moment of previous shut-down.

Waveform output is not saved at shut-down and the

Model 3933A is shipped with waveform output set

to the “on” state during power-up sequencing. This

can be set to “off” via an internal jumper pin. See the

Model 3933A Service Manual for details.

6. If, at power-on, the phase shifter beeps and displays

error code “Er NODTW and the error message “NO

SYNTH DATA COMING”, there is a missing, or improper, digital signal at the rear panel of the slave

Model 3933A.

This situation can arise under the following condi-

tions:

0 Master Model 3930A power switch is in the “OFF”

position.

3-14

Page 32

SECTION 3

Operafion

.

A cable is not connected between the slave Model

3933A and a master Model 3930A.

0

A digital cable is missing, or disconnected, between

successive Model 3933A units in a phase shifter

chain.

7.

If, at power-on, the Model 3933A displays the error

code “ER FRDTO7”, it indicates:

0

The last time the power was turned off the waveform

setting was “variable-duty-cycle” square wave.

.

The master Model 3930’s frequency exceeded

lookH.z.

.

In this case, the setting will automatically change to

duty-cycle fixed 50%.

8.

If, at power on, the Model 3933A fails to operate in

one or more of the following conditions, contact

your Keithley representative or the factory to determine the correct course of action.

.

Unit does not power-up according to the mode and

settings in effect immediately before last power-off.

.

Unit does not power-up according to the preset operating modes.

0

Main display does not appear.

Note: After turning off Model 3933A, wait at least

five seconds before turning it on.

NOTE

For precise measurement applications, allow

the Model 3933A to warm up for at least 30

minutes to allow internal circuits to stabilize.

the unit is in the GPIB remote mode, or when the front

panel lock is enabled.

Some parameters, such as waveform, can be selected by

pressing a single numeric character. Changes are made

by simply pressing the numeric key corresponding to the

desired setting, as shown in the display. An error message will be displayed if the entered value is outside the

allowed range. Other displays and internal settings remain unchanged when an error occurs. Values may be

changed as many times as desired, without leaving the

present display. Pressing DSPL returns the display to the

main settings and the final change will be indicated.

Example: Changing the waveform type from the present

sine wave) to I-L (square wave) or to A (triangular

QC

wave).

Key Operation 1 Display Result

I

Press FCTN.

Press 3

Existing waveform selection

if

ed.

>3

(<SIN>11 will be displa

Waveform changes to <

(square wave).

Press 2

Waveform changes to < A >2

(triangle wave).

Press 3

Waveform changes back to <n >3

(square wave)

Press DSPL

Display indicates main settings,

including final choice CL >3

(square wave).

Parameters, such as amplitude and phase, which require

units (deg, V, dbV, etc.) can be changed as follows:

3.4 OPERATING PROCEDURES

3.4.1 Setting Parameters Using Numeric

Keys

When the appropriate parameter key such as FCTN,

AMPTD, OFFSET, or PHASE is pressed, the parameter

narne and the present parameter value will be indicated

in the upper part of the liquid crystal display. The allowed range of the parameter setting and useful help information will appear in the lower part of the liquid crystal display.

The parameter value can be changed when the parameter

name indicated in the upper part of the liquid crystal display is flashing. The parameter name will not flash when

l

Press appropriate ENTRY key to select the desired pa-

rameter.

l

Enter new numeric value (for phase or amplitude)

with the numeric keys.

l

Press appropriate ENTER key to add designator (V,

deg, mV, etc.).

While entering the new value, the existing parameter

value, unit display, and modification step size will disappear from the display,

and the new value will be dis-

played. To correct an entered value during the entry

process, press the RUB OUT key, which will delete one

character at the units position (immediate left of decimal

point) of the entered number. To re-enter the entire parameter value from the beginning, press the same parameter key to return to the corresponding parameter

setting.

3-15

Page 33

SECTION 3

Operation

For amplitude, which has several unit value options, select and press the appropriate units key to complete the

entry process. For phase and marker phase parameters,

which have only single parameter units, press any one of

the ENTER keys to complete entry.

Regardless of the number of digits for the entered value

and the size of the units (set, msec, V, mV, etc.), the predetermined number of digits, resolution, and units will

be properly adjusted and displayed. When values below

the display resolution are entered with the numeric keys,

a beep tone will sound, an error message will be displayed. and the display will return to the previous value.

Internal settings will remain unchanged when an error

condition occurs.

Example: Change amplitude from a existing value of

+178” to a new value, -98”, and then correct an erroneous

entry of “95.”

Key

Operation

Press PHASE

Press 9

Press 5

Press Phase

Press -I-

Press 9

Press 8

Press deg

Press DSPL

3.4.2

Setting Parameters with the

1 Display Presentation

I

Existing parameter, “178 deg”, will

be displayed.

The value of the key pressed, (9),

will appear.

The display now shows erroneous

figure: “95”.