Tektronix 3910 Service Manual

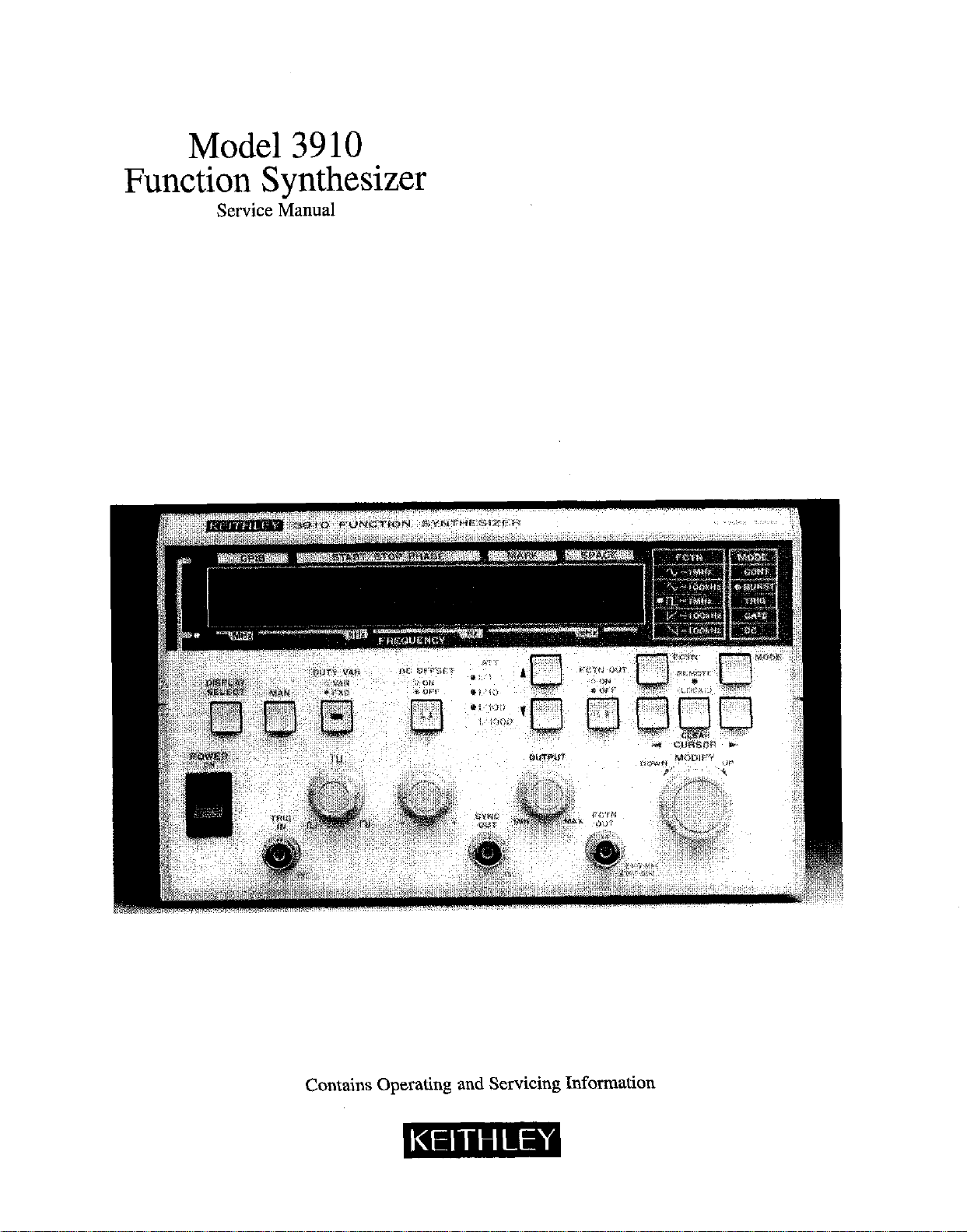

Model 3910

Function Synthesizer

Service Manual

Contains Operating and Servicing Information

WARRANTY

Kcithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Kcithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batlcrics,

diskettes. and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, 01‘ contact Keithley hcadquaxters in Cleveland, Ohio. You will

bc given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will bc made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANN

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or part. This wzuranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Model 3910 Function Synthesizer

Service Manual

8 1991, Keithley Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

October 1991, First Printing

Document Number: 3910-902-01 Rev. A

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision

Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new Revision is created. all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (oc.c”me”, Number 39 10.902-01) ,....,,,.,....,..................................................................... October ,991

Safety Precautions

The following safety precautions should be observed before

using this product and any associated instrumentation. Although some instruments and accessories would normally be

used with non-hazardous voltages, there are situations where

hazardous conditions may be present.

This product is intended for use by qualified personnel who

recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating

information carefully before using the product.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI)

states that a shock hazard exists when voltage levels greater

than 30V RMS, 42.4V peak, or 60VDC are present. A good

safety practice is to expect that hazardous voltage is present

in any unknown circuit before measuring.

Before operating an instrument, make sum the line cord is

connected to a properly grounded power receptacle. Inspect

the connecting cables, test leads, and jumpers for possible

wear, cracks, or breaks before each use.

For maximum safety, do not touch the product, test cables, or

any other instruments while power is applied to the circuit

under test. ALWAYS renwve power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers, installing or removing

switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to

the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands

while standing on a dry, insulated surface capable of withstanding the voltage being measured.

Do not exceed the maximum signal levels of the instruments

and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture

rear panel, or switching card.

Do not connect switching cards directly to unlimited power

circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards directly to AC

main. When connecting sources to switching cards, install

protective devices to limit fault current and voltage to the

card.

When fuses are used in a product, replace with ~arne type and

rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections

for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power

is applied to the device under test. Safe operation requires the

use of a lid interlock.

If a @screw is present cm the test fixture, connect it to safety

earth ground using #18 AWG or larger wire.

‘Ihef y bl B m o on an instrument or accessory indicates that

IOOOV or more may be present on the terminals. Refer to the

product manual for detailed operating information.

Instrumentation and accessories should not be connected to

humans.

Maintenance should be performed by qualified service personnel. Before performing any maintenance, disconnect the

line cord and all teat cables.

HOW TO USE THIS MANUAL

Details procedures to verify that the Model 3910 Function

Synthesizer

Describes basic operating principles for the various circuits in

the Model 3910.

Covers fuse replacement, battery replacement, calibration

and repair of the instrument, and lists replacement parts.

meets stated

specifications.

WARNING

The information in this manual is intended for qualified service personnel who can recognize possible shock hazards. Do

not attempt these procedures unless you are qualified to do 80.

SECTION 1

Performance Verification

SECTION 2

Principles of Operation

SECTION 3

Service Information

Table of Contents

SECTION 1 - Performance Verification

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.7.1

1.7.2

1.7.3

1.7.4

1.7.5

INTRODUCTION

ENVIRONMENTAL CONDITIONS ...

INITIAL CONDlTIONS

LINEPOWER

RECOMMENDED TEST EQUIPMBNT .

VERIFICATION LIMITS

VERIFICATION PROCEDURES

Frequency Accuracy

Maximum Output Amplitude

DCOffset

FrequencyResponse..

Total Harmonic Distortion

.................

............

....................

............

......

.............

.............................

............................................

..................................

...............................

SECTION 2 - Principles of Operation

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

INTRODUCTION

BLOCK DIAGRAM

CIRCUITOPERATION

ControlSection

Display and Keyboard Section

Synthesizer

AnaIogSection

PowerSupply

GPIB Interface.

.................................

...............................

.............................

.................................

......................

....................................

.................................

..................................

.................................

......................

......................

......................

.......................

......................

......................

......................

. . . . .

1-l

1-l

1-l

1-l

l-1

1-z.

l-2

l-2

l-3

l-4

l-4

l-6

2-l

2-l

.

2-l

2-l

2-l

2-l

2-l

2-l

2-2

SECTION 3 - Service Information

3.1

3.2

3.3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.4.8

3.4.9

3.4.10

INTRODUCTION

LINE FLJSE REPLACEMENT

BAWRY RBPLACEMENT

CALIBRATION

EnvironmentaI Conditions

Initial Conditions

LinePower

Recommended Calibration Equipment

Cover Removal

Calibration Adjustment Locations

DC Offset Calibration

Amplitude Calibration

Square Wave Duty Cycle Calibration

Cover Replacement

.............................

.....................

..............................

...........................

................................

.............................

........................

.......................

..........................

....................

....................

...............

.............

...........

3-l

3-1

3-2

. . 3-2

. . . . 3-3

.

..,.. 3-3

. . . . .

. . . 3-6

3-3

3-3

3-3

3-4

3-4

3-8

. . 3-8

3.5

3.5.1

3.5.2

3.6

3.6.1

3.6.2

3.7

3.7.1

3.7.2

3.8

3.8.1

3.8.2

FCTN OUT JUMPERS

Waveform Output On/Off Selection

FCTN OUT Open/Short Selection

GI’IB INTERFACE INSTALLATlON

Installation Precautions .............................

Board Installation .................................

REPAIR ..........................................

Factory Service ...................................

BoardRemoval

REPLACEABLE PARTS ..............................

PartsList .......................................

OrderingParts

...............................

...................

.....................

.....................

...................................

...................................

........

........

........

........

........

........

........

........

........

........

........

3-8

3-8

3-9

3-9

3-9

3-9

3-12

3-12

3-12

3-15

3-15

3-15

APPENDICES

A TypicalData.................................................................. A-l

B Model 3910 and 3910/11 Specifications

B-l

List of Illustrations

SECTION 1

Figure l-l

Figure 1-2

Figure l-3

Figure 14

- Performance Verification

Connections for Frequency Accuracy Test .

Connections for Output Amplitude and DC Offset Tests

Connections for Frequency Response Tests . . . .

Connections for Distortion Tests . . . .

SECTION 2 - Principles of Operation

Figure 2-l

Block Diagram

,..............................

SECTION 3 - Service Information

Figure 3-l

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-S

Figure 3-9

Figure 3-10

Figure 3-l 1

Figure 3-12

Figure 3-13

Figure 3-14

Figure 3-15

Figure 3-16

Figure 3-17

Fuse Replacement ...........................

Battery Replacement .........................

CoverRemoval .............................

Calibration Adjustments (Main Board)

Connsctions for TP2 Offset Calibration

Connections for FCI’N OUT Offset Calibration

Connections for Amplitude Calibration

Connections for Square Wave Duty Cycle Calibration

Jumper Installation ..........................

Model 3911 Interface Installation

Cover Removal ........................

KnobRemoval ........................

Connector Removal ....................

Removal of 3-Terminal Regulator Screws

Connecting Wires ......................

Main Board Mounting Screws .............

Display Board Connector and Screw Locations

...........

...........

...........

................

....

.....

..........................

..........................

..........................

...................

..........................

..........................

..........................

.................

................. 14

.................

.................

. . . . . . . . . . . . . . . . . 2-2

.......................

.......................

.......................

.......................

......................

......................

......................

....................

....................

.......

l-3

l-5

l-6

3-l

3-2

34

3-5

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-12

3-13

3-13

3-14

3-15

List of Tables

SECTION 1 - Performance Verification

Table l-l Recommended Test Equipment for Performance Verification

Table l-2 Reading Limits for Output Amplitude Tests

Table l-3 Reading Limits for Frequency Response Tests

.................................

................................

SECTION 3 - Service Information

Table 3-l

Table 3-2

Table 3-3

Table 3-4

RecommendedLineFuses

Recommended Test Equipment for Calibration

Relationship Between R29 Value and Amplitude

Relationship Between R4 Value and Square Wave Amplitude

...............................................

...............................

..............................

....................

....................

l-2

l-3

l-5

3-l

3-3

3-7

3-7

SECTION 1

Performance Verification

1.1 INTRODUCTION

This section covers procedures to verify accuracy of the

Model 3910. Verification can be performed when the in-

shument is first received to verify that the Model 3910

meets its stated accuracy specifications, and it can also be

performed following calibration, if desired. If the lnshument fails to meet stated specifications, refer to the calibration and repair information in Section 3 unless the

unit is still under warranty (less than one year from the

date of shipment).

NOTE

Inshuments still under warranty should be

rehuned to the factory for calibration or repair.

1.2 ENVIRONMENTAL CONDITIONS

All measurements should be made at 18-28°C (65-82°F)

and at less than 70% relative humidity.

1.3 INITIAL CONDITIONS

The Model 3910 and the test equipment should be turned

on and allowed to warm up for one hour before making

test measurements. If the instrument has been subjected

to extreme temperature or humidity, allow additional

time for stabilization. Typically, it take one additional

hour to stabilize an instrument that is 10°C outside the allowed temperature range.

1.4 LINE POWER

Before testing, be sure the rear panel line voltage is set to

the correct operating voltage. The Model 3910 should be

tested while operating at a line voltage within flO% of

the line voltage switch setting and at a line frequency

from 48Hz to 62Hz.

1.5 RECOMMENDED TEST EQUIPMENT

Table 1-l summarizes recommended equipment for the

verification procedures. Similar equipment may be used

as long as corresponding specifications are comparable.

l-l

Loading...

Loading...