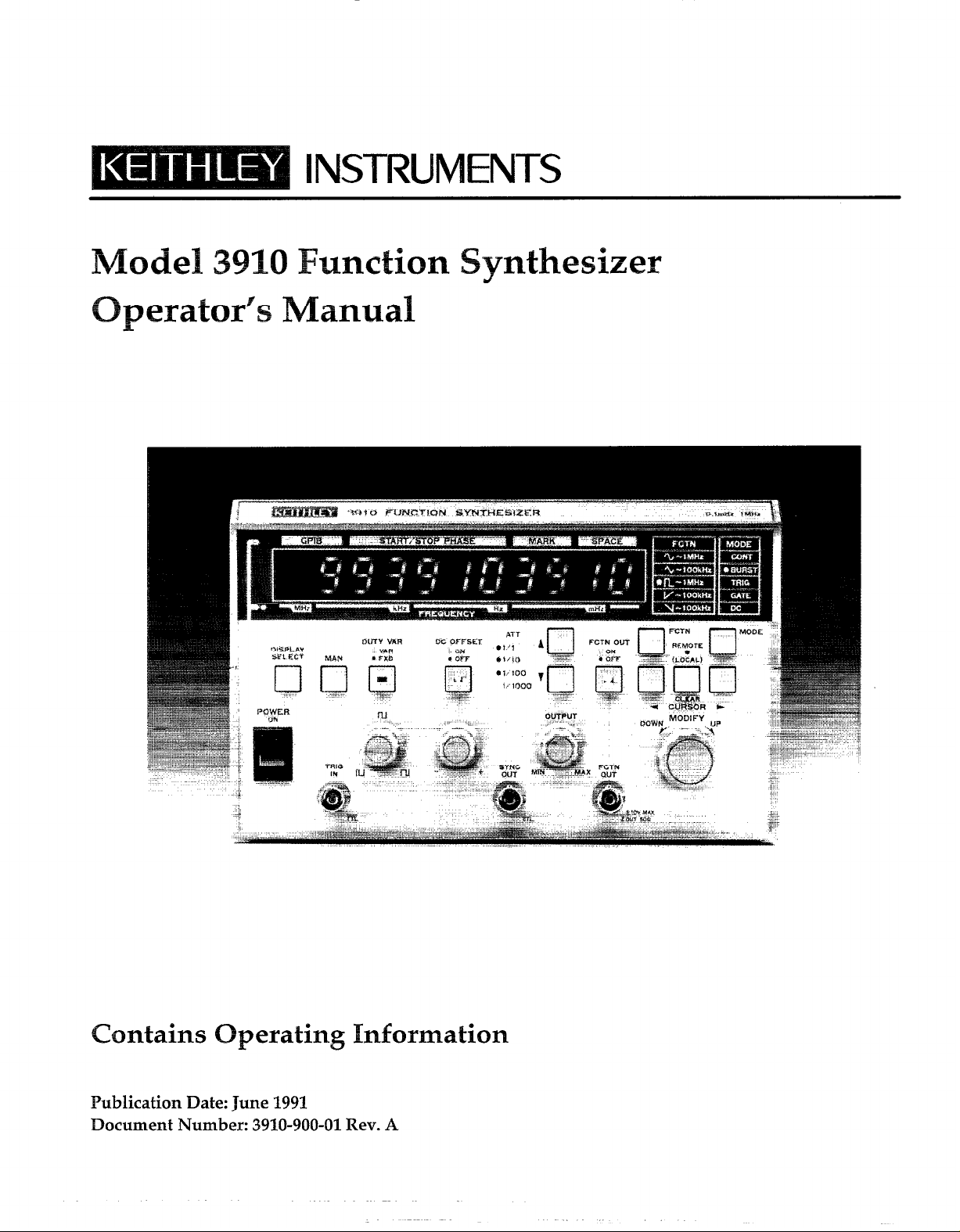

Page 1

ordains

Publication Date: June 1991

Document Number: 3910-900-01 Rev. A

perating

nformation

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation

prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at

least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRAN TIES, EXPRESSED OR IMPLIED, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILIIY OR FlTNESS FOR A PARTICULAR USE. THE

REMEDIES PROVIDED HEREIN ARE BUYERS SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT

OF THE USE OF ITS INSTRUMENTS AND SOFIWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION,

LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

INSTRUMENTS

Instruments Division, Keithley Instruments, Inc. l 28775 Aurora

WEST GERMANY:

GREAT BRITAIN:

FRANCE Keithky Instruments SARL -3 Allee des Garays l B.P. 60.91124 P&iseau/Z.L l I-6-0115 155 l Telex: 600 933 l Fax: l-6-0117726

NEIXERLANDS: Keithley Instruments BV l Avehgen West 49 l 4202 MS Gorinchem l P.O. Box 559 l 4200 AN Gorinciwn l 01830-35333 l Telex: 24 684. Fax: 01830-30821

SWITZERLAND:

AUSTRIA: Keithley Instruments GesmbH L Rosenhugelstrasse 12 l A-1120 Vienna l (0222) CC4 65 48 l Telex: 131677 l Fax: (0222) 8403597

ITALY: Keithky Instruments SRL l Vi&S. Giiignano 4/A 0 20146 Milano l 02-4120360 or 02-4156540 l Fax M-4121249

Keithky Instruments GmbH l Landsbugers&. 65 l D-8034 Gemwring l 089-??49307-0 l Telex: 52-12160 l Fax: 089+?4930759

Keithky Instmments, Ltd. l The Mnster l 58, Portman Road l Reading, Berkshire RG 3 IEA l 01144 734 575 666 l Fax 01144 734 596 469

Keithky Instruments SA l Kriesbachstr. 4 l 8600 Dubendorf l 01-821-V444 l Telex: 828 472 l Fax: 0222-315366

Road l Cleveland, Ohio 44139 l (216) 248-0400 l Fax: 248-6168

Page 3

Operator’s Manual

Model 3910

Function Synthesizer

01991, Keithley Instruments, Inc.

All Rights Reserved

Instruments Division

Cleveland, Ohio, U. S. A.

document Number: 3910-900-01

Page 4

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using the Model 3910 Function Synthesizer and any associated instruments.

This instrument is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read over this manual carefully before using the instrument.

Exercise extreme caution when a shock hazard is present at the test circuit. The American National Standards Institute

(ANSI) states that a shock hazard exists when voltage levels greater than 30V rms or 42.4V peak are present. A good

safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Inspect the connecting cables and test leads for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the test cables or any instruments while power is applied to the circuit under test.

Turn off the power and discharge any capacitors before connecting or disconnecting cables from the instrument.

Do not touch any object which could provide a current path to the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

Instrumentation and

accessories

should not be connected to humans.

Page 6

Table of Contents

SECTION 1

1.1

1.2

1.3

1.4

1.5

1.6

1.6.1

1.6.2

1.63

1.6.4

1.7

1.8

- General Information

INTRODUCTION

FEATURES

WARRANTY INFORMATION

MANUALADDENDA

sAFETyTERMsANDsyMBoLs...........................................:

UNPACKlNGANDREPACKJNG

Unpacking

Shipment Contents

Operatofsb.nual

Repacking For Shipment

OPTIONALACCESSORIES

SPECIFICATIONS

...................................................................

.................................................................

SECTION 2 - Getting

2.1

2.2

2.2.1

2.2.2

2.3

2.3.1

2.3.2

2.3.3

2.4

2.5

2.5.1

2.5.2

2.5.3

INTRODUCTION

INSTALLATION

Installation Location

cooling

LINEPOWERSUPPLY.................,...................~

LINE Voltage Selector Switch ...................................................

Line Receptacle Connection .....................................................

LineFuse

HANDLING PRECAUTIONS .....................................................

BASICOPERATION

Front Panel Summary .........................................................

Typical Test Connections ......................................................

OperatingExamples

....................................................................

..................................................................

..............................................................

....................................................

..........................................................

.................................................

...........................................................

...........................................................

.......................................................

......................................................

.............................................................

Started

..............................................................

..............................................................

..................

............................................................

..........................................................

..C .....................................

.....................

l-1

l-l

1-2

l-2

...... 1-2

1-2

1-2

1-2

1-2

l-2

1-3

l-3

2-1

2-l

2-l

2-l

2-2

2-2

2-2

2-2

2-2

2-3

2-3

2-3

2-4

SECTION 3

3.1

3.2

3.2.1

3.2.2

3.3

3.3.1

3.3.2

3.4

3.5

3.5.1

INTRODUCTION

FRONT PANEL AND REAR PANEL DESCRIPTION ...................................

Front Panel Description

RearPanelDescription

INPUT AND OUTPUT CONNECTIONS ............................................

InputConnection

OutputConnections

STARTUP

OPERATING PROCEDURES

ErrorCodes

- Operation

..............................................................

........................................................

........................................................

............................................................

..........................................................

....................................................................

.....................................................

................................................................

3-1

3-l

3-1

3-4

3-5

3-5

3-5

3-6

3-7

3-7

Page 7

’ 35.2 FrequencySetting

3.5.3 OutputAmplitude

3.5.4

3.5.5 Waveform Selection, Square-Wave Duty Cycle, and Synchronous Output

3.5.6 OscillationMode

3.5.7

DCOffset

Trigger Parameters

..................................................................

............................................................

...........................................................

.............................................................

........................................................... 3-11

..................

‘3-7

3-8

3-8

3-8

3-9

SECTION

4.1 INTRODUCTION

4.1.1 GPIBOverview

4.1.2 Major GPIB Specifications

4.1.3 Bus Line Signals and Operation

4.1.4 GPIBHandshaking

4.1.5

4.1.6

4.1.7 Basic Listener Functions

4.1.8 BasicControllerFunctions

4.1.9 Multi-line Interface Messages

4.2

4.2.1

4.2.2 Specifications

4.3 MODEL 3910 PROGRAM CODES

4.4 TYPICAL EXECUTION TIMES

4.5

4 - GPIB Interface

..............................................................

..............................................................

......................................................

...........................................................

Data Transfer Example

BasicTalkerFunctions

OVERVIEW OF MODEL 3910 GPIB INTERFACE

Introduction

SAMPLEPROGRAMS

................................................................

...............................................................

........................................................

.........................................................

.......................................................

......................................................

.................................................... 4-12

..........................................................

.................................................. 4-1

...................................................

......................................

..................................................

4-l

4-1

4-1

4-2

4-3

4-3

4-3

4-3

4-3

4-6

4-6

4-6

4-9

4-13

Page 8

List of Illustrations

SECTION 2 -

Figure 2-1

Figure 2-2

SECTION 3

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

SECTION 4

Figure 4-1

Figure 4-2 Handshake Timing Diagram

Figure 4-3

Figure 44

Getting Started

Frontpanelsummary...............................................,...... 2-3

TypicalConnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Operation

Model 3910 Front Panel

Mode13910RearPanel

LogicInputCircuit

oLltputCircuit

Phase Relationship between FCTN OUT Waveform and SYNC OUT

Relationship between Trigger Signal and Oscillation in TRIG Mode

Relationship between Trigger Signal and Oscillation in GATE Mode

Definition of Phase of each Waveform

...........................................................

..................................................... 3-2

.....................................................

........................................................

- GPIB Interface

Interface Connector

Data Transfer Example

ProgramCodeSyntax ......................................................

.......................................................

.....................................................

2-4

3-4

3-5

3-6

...................

....................

................... 3-11

.......................................... 3-12

................................................. 4-3

3-9

3-10

4-2

4-4

4-8

Page 9

List of Tables

SECTION 2

Table 2-l

SECTION 4

Table 4-1

Table 4-2

Table 4-3

Table 4-4

Table 4-5

Table 4-6

Table 4-7

- Getting Started

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- GPIB Interface

Multiple-line Interface Message

InterfaceFunctions..

BusDriverSpecifications

Response to Interface Messages

StatusByte..

Model 3910 Main Parameter Setting Messages

TypicalExecutionTimes

............................................................

......................................................

....................................................

..............................................

...................................................

...............................................

....................................

2-2

4-5

4-6

4-6

4-7

4-9

4-10

4-12

Page 10

SECTION 1

t General Information

1 .I INTRODUCTION

The Model 3910 Eunction Synthesizer can generate frequencies between O.lmHz and 1MHz. The Model 3910

can generate the entire band at a resolution of O.lmHz,

with a high-frequency accuracy of f30ppm.

Q 2/,squarelX,ris-

Five AC waveforms, sine

ing sawtooth/l, and falling sawtooth\ are available. A

maximum of tlOV DC can be added onto each output.

Maximum output voltage for all waveforms is 20V p-p/

no load or lOVp-p/5On load.

Since frequencies are synthesized directly by a custom

LSI digital IC, accuracy and stability are high, and the fre-

quencyswitching time is short. Another advantage is the

continuity of phase at frequency switchover.

In addition to continuous oscillation, burst oscillation,

trigger oscillation, and gate oscillation are available. The

Model 3910 also provides a continuous output of direct

current voltage. An external trigger input provides an external trigger signal during trigger or gate oscillation. The

square-wave duty cycle is also variable.

The Model 3910 uses a single line, ll-character LED display to display the values of oscillation frequency, pa-

, triangle

,

rameters, and other values. Settings are easily made using push-button keys and rotary knobs.

A GPIB (IEEE-488) interface is available as an option for

the Model 3910. With the exception of the AMPTD, amplitude setting; DC OFFSET, added quantity setting; and

DUTY VAR, duty ratio setting; a GPIB equipped Model

3910 can be programmed over the bus for the same operating modes and parameters that can be controlled from

the front panel.

1.2 FEATURES

l Wide bandwidth: O.lmHz to 1MHz (resolution

O.lmHz).

0 &30 ppm frequency accuracy.

l Phase continuity, at frequency switchover.

l Five ACwaveformsavailable: %,2/,n,n,andl

l The duty cycle can be set to values between 10% and

90% for frequencies up to 1OOkHz.

l High output: 2OVp-p/no load, lOVp-p/50Qload.

0 Low distortion: 0.3% or less (1OHz to IOOkHz).

l DC output voltages

fiV/5OQ load.

l Burst oscillation mode: Repeats oscillation of wave

number specified by mark wave (l-16) and space wave

number (l-16).

o Trigger oscillation and gate oscillation:

Trigger source: External by front panel BNC plug or

push-button key.

available: flOV/no load,

l-l

Page 11

SECTION 1

General Information

Start/stop phase: -360” to +360”.

Input voltage: ‘ITL level (pulls up 74HC14 input by

5.1K). Minimum pulse width ZOOnsec.

Trigger: Oscillates wave number specified by wave

number (l-16) by trigger signal.

Gate: Integral wave number oscillation by trigger

signal.

Waveform and frequency range:

Sine wave, square wave (duty fixed); O.lmHz to

IMHZ.

Triangle wave, square wave (duty variable), rising

sawtooth wave, falling sawtooth wave; O.lmHz to

lOOkHz, oscillation possible up to 1MHz.

Each parameter setting can be modified using the

MODIFY knob and the CURSOR keys. The single line,

11 character LED display, clearly displays all neces-

sary information; oscillation frequency, GPIB address

(when installed), start/stop phase, mark wave number, and space wave number.

Battery backed-up memory stores the configuration in

effect when power is turned off.

Optional GPIB interface allows the Model 3910 to be

programmed over the GPIB (IEEE-488 interface bus).

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this operator’s manual. Should your Model 3910 require warranty service, contact the Keithley representative or authorized repair facility in your area for further

information. When returning the instrument for repair,

be sure to fill out and include the service form at the back

of this manual in order to provide the repair facility with

the necessary information.

The WARNING heading used in this manual explains

dangers that might result in personal injtuy or death. Always read the associated information very carefully before performing the indicated procedure.

The

CAUTION

hazards that could damage the instrument. Such damage

may invalidate the warranty.

heading used in this manual explains

1.6 UNPACKING AND REPACKING

1.6.1 Unpacking

After carefully unpacking the instrument from its shipping carton, inspect it for any obvious signs of physical

damage. Report any such damage to the shipping agent

immediately. Save the original packing carton for storage

or possible future shipment.

1.62

The following items are included with every Model 3910

order:

l

Model 3910 Function Synthesizer

0 Model 3910 Operator’s Manual

l

Power Cord

l

Fuse (lA, 25OV, 5.2 x 2Omm)

l

BNC to BNC signal cable

l

Additional accessories as ordered.

Shipment Contents

1.4 MANUAL ADDENDA

Any improvement or changes concerning the instrument

or manual will be explained in an addendum included

with the unit. Be sure to note these changes and incorporate them into the manual before using the unit.

1.5 SAFETY TERMS AND SYMBOLS

The following safety terms and symbols are found on the

instrument or used in this manual.

A

The

user should refer to the operating instructions.

l-2

symbol on the instrument indicates that the

1.6.3 Operator’s Manual

If an additional manual is required, order the manual

package, Keithley part number 3910-900-00. The manual

package includes an operator’s manual and any pertinent addenda.

1.6.4 Repacking For Shipment

Should it become necessary to return the Model 3910 for

repair, carefully pack the unit in its original packing carton or the equivalent. If the original carton is not available

or damaged, be sure to use a cardboard box of sufficient

strength and room. Pad the empty spaces in the carton

with adequate packing material to hold the unit firmly in

place.

Page 12

General Information

SECTION 1

Include the following information:

l Advise to the warranty status of the instrument.

l Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

o Fill out and include the service form located at the back

of this manual.

1.7 OPTIONAL ACCESSORIES

The following accessories are available for use with the

Model 3910.

Models 3900-l and 3900-2 Rack Mounting Kits: The

Model 3900-l mounts one Model 3910 in a standard

IPinch rack. The Model 3900-2 mounts two Model 3910s

side by side in a standard 19-inch rack. Both kits include

all necessary hardware for proper rack mounting of the

instruments.

Model 7007 Shielded IEEE-488 Cables:

7007-l (lm, 3.3ft.j and Model 7007-2 (2m, 6.6ft.j can be

used to interface the Model 3910 tothe IEEE-488 bus.

The Model

Model 7051-2 BNC-to-BNC Cable:

50R BNC to BNC cable (RG-58C) 2ft. (0.6m) in length.

The Model 7051-2 is terminated with male BNC connec-

tors on both ends.

Model 7051-5 BNC-to-BNC Cable:

5OQ

BNC to BNC cable (RG-58C) 5ft. (1.2m) in length.

The Model 7051-5 is terminated with male BNC connec-

tors on both ends.

Model 7051-10 BNC-to-BNC Cable:

is similar to the Models 7051-2 and 70516 except that it is

lOft..(2.4m) in length.

Model 7754-3 BNC-to-Alligator Cable:

7754-3 is a 3ft. (0.9m) 5Ofi cable (RGd8C), terminated

with a male BNC connector on one end and two alligator

clips on the other end.

Model 7755 5Oa Feed-Through Terminator:

7755 is a BNC to BNC adapter that is terminated with a

5OQ resistor. VSWR is ~1.1, DC to 25OMHz.

The Model 7051-2 is

The Model 7051-5 is

The Model 7051-10

The Model

The Model

Model 3911 IEEE-488 Interface:

tion a maximum of 15 Model 3910s can be connected on

the same bus, data line transfer uses a 3-line handshake

mefhod, enabling reliable data transfer between data

sending (talkers) and receivers (listeners) having differing data transfer rates.

With the Model 3911 op-

1.8 SPECIFICATIONS

Detailed Model 3910 specifications may be found in Appendix B.

l-3

Page 13

SECTION 2

Gettina Started

2.1 INTRODUCTION

This sections contains basic information on installation,

power line connections, and it also provides typical simple operating examples.

2.2 INSTALLATION

The following paragraphs discuss Model 3910 installation. In particular, use adequate care when installing the

unit. Improper installation will adversely affect the life,

reliability, and safety of the unit.

The Model 3910 weighs about 7 lbs; be careful when carrying the unit or mounting it in a rack.

2.2.1 installation Location

The allowable ambient temperature and humidity

ranges for the Model 3910 are.

Operating: 0 to 4O”C, 10 to 9O%RH

Storage: -10 to 5O”C, 10 to 8O%RH

Be sure to install the unit in a location that satisfies these

temperature and humidity conditions. Also the environ-

ment must be free of dust and vibration, and the Model

3910 must not be exposed to direct sunlight.

The Model 3910 uses a line filter, but pulse noise or strong

magnetic or electric fields may cause incorrect operation

of the unit. Do not install the unit near a source of pulse

noise or strong magnetic or electric fields.

The guard on the rear panel of the unit is designed to protect rear panel connectors and should not be used as a leg

for installation. Do not stand the unit vertically on the

rear guard because it may fall over, causing instrument

damage or personal injury.

2.2.2

The Model 3910 is ‘air-cooled by vents. Insufficient air

flow may cause a component in the unit to fail. Follow the

instructions given below.

l

Cooling

CAUTION

Observe the following precautions to prevent damage to the unit:

A vent is provided on the bottom panel of the

unit. Install the unit on a rigid, flat surface,

and avoid installing it on soft material such

as a cushion. Be careful not to insert foreign

2-l

Page 14

SECTION 2

Geffina Started

material between the bottom of the unit and

the surface underneath. Another vent is located on the top panel of the unit. Be careful

not to block the top vent by placing an object

on top of the unit.

l

Avoid mounting two or more units vertically. Placing one unit on top of another will

obstruct the vents.

2.3 LINE POWER SUPPLY

The Model 3910 operates with a lOOV, 12OV, 22OV, or

240.7 *lo%, 48 to 62Hk, single-phase AC power supply.

The power consumption is approximately 25VA.

2.3.1 LINE Voltage Selector Switch

The LINE voltage selector switch on the rear panel allows

you to change operating voltage of the power supply.

The standard setting of the switch is the same as the volt-

age available in the country to which the unit is shipped.

To change the power supply voltage, first disconnect the

line cord, and set the supply voltage switch in the correct

position. Wait at least five seconds before turning the

power back on after turning it off.

WARNING

The Model 3910 is equipped with a 3-wire

power cord that contains a separate ground

wire and is designed to be used with

grounded outlets. When proper connections

are made, instrument chassis is connected to

the power line ground. If the AC outlet is not

ounded, the rear panel ground terminal

=!= must be connected to safety earth

b

ground using #18AWG (or larger) wire before use.

2.3.3

The line fuse, which is integral with the power line receptacle, protects the instrument from over-current situations. To replace the fuse, first disconnect the line cord,

then pry out the fuse compartment (immediately to the

right of the FUSE marking) with a small screwdriver. A

spare fuse is located in the compartment with the fuse being used. Replace the blown fuse only with the type listed

in Table 2-1, then replace the fuse holder.

Line Fuse

WARNING

To avoid a shock hazard, disconnect the line

cord from the instrument before replacing

the fuse.

CAUTION

Use only a fuse of the rating listed in Table

2-1, or instrument damage may occur.

WARNING

To avoid a shock hazard, disconnect the

power cord from the instrument before

changing the supply voltage setting.

CAUTION

Be sure to set the line voltage switch to the

correct position for the line power voltage to

be used. Operating the instrument on an incorrect voltage may cause damage to the unit.

2.3.2

Connect the supplied power cord to the rear panel Line

receptacle and to a grounded AC power receptacle supplying the correct voltage.

Line Receptacle Connection

2-2

Table 2-1, Fuse Replacement

Fuse Current Keithley

Line Voltage

lOOV, 120v 1A

220,240v

NOTE: Fuses are 5 x2Omm and have UOV, normal blow ratings.

Rating Part No.

FU-96-2

ID-4

FU-96-1

2.4 HANDLING PRECAUTIONS

When the front panel or case becomes

a soft

cloth. If the panel or case is too dirty for cleaning

with a dry cloth, dampen the cloth in mild detergent, and

wipe the panel or case with the damp cloth. Never use

solvents such as thinner or benzene, or chemical dust

cloths to avoid damaging the case or front panel surfaces.

dirty, clean it with

Page 15

SECTION 2

Gettim?

Started

2.5 BASIC OPERATlON

The following paragraphs summarize front panel operat-

ing controls, give typical test connections, and discuss

typical operating examples for the Model 3910.

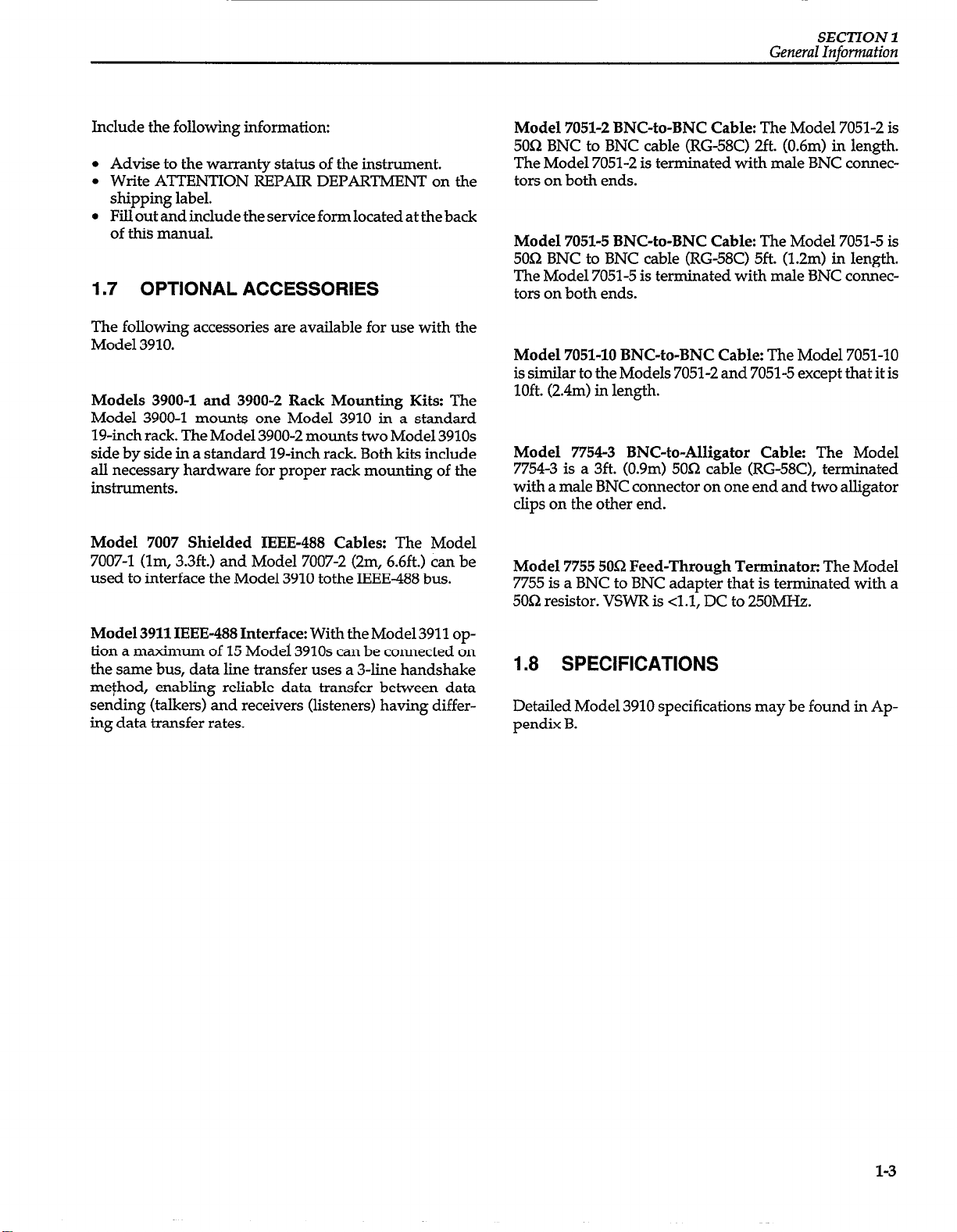

2.5.1 Front Panel Summary

Figure 2-l summarizes each front panel feature. For de-

tailed information on each operating feature, refer to Section 3.

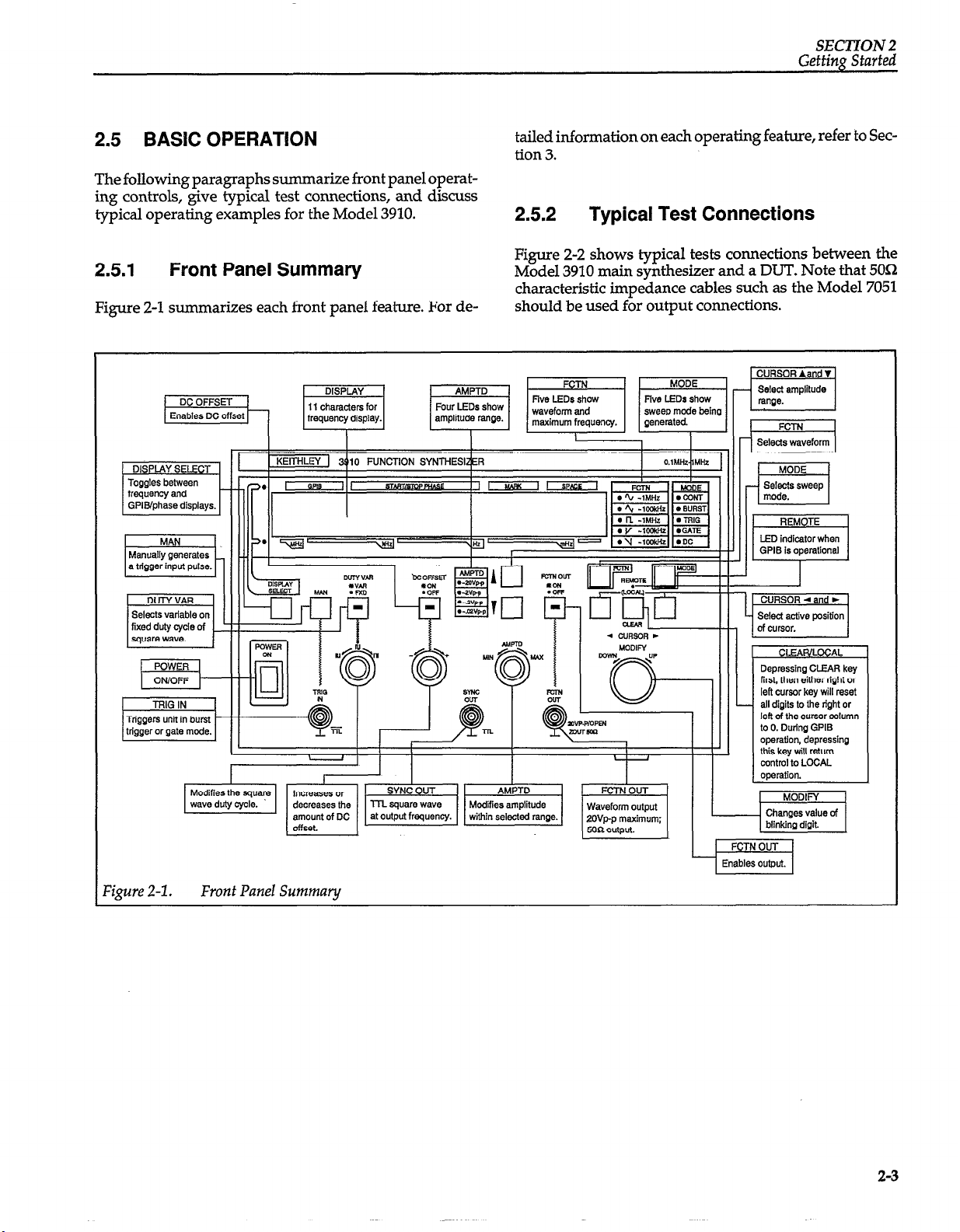

2.5.2

Typical Test Connections

Figure 2-2 shows typical tests connections between the

Model 3910 main synthesizer and a DTJT. Note that 5OL2

characteristic impedance cables such as the Model 7051

should be used for output connections.

%I I11111

LED indicator when

Figure 2-1.

Front Panel Summary

Depressing CLEAR key

first, then either right or

left cursor key will reset

all digits to the right or

left of the cursor column

to 0. Dudng GPIB

operation+ depressing

this key will return

control to LOCAL

mxxn+inn

2-3

Page 16

SECTION 2

Gettim Started

Model 3910

5052 BNC Coaxial cable

(Model 7051 or equivalent)

OUT

Figure 2-2.

Typical Connections

2.5.3 Operating Examples

The following examples give step-by-step instructions

for setting basic Model 3910 operating parameters. The

Model 3910 can be connected to an oscilloscope to view

the results of the various operating examples.

Example 1: Selecting the Waveform Type (Function)

The first sequence will adjust the Model 3910 to output a

sine wave, with a continuous sweep.

1. Press DISPLAY SELECT to indicate frequency

(lower LED).

2. Press FCTN to cycle through the five options until

the LED indicates a SINE wave (top LED).

3. Press MODE to indicate CONT (continuous sweep).

Example 2: Setting the Waveform Frequency or Period

This sequence will set the Model 3910 to a frequency of

5OOHz, without regard to any previous setup. You will

have to determine whether to use step 1 or 2 in this sequence because there is no way to know what setup was

used for the previous test. Since the Model 3910 retains

only one setting in memory, that setting is always the last

one.

1. If the display shows a frequency higher than 500Hz,

use this next sequence. Otherwise skip to step 2.

A. Move the cursor to the seventh position: The sev-

enth position, 1OOHz column, will blink. Press

the CLEAR key and at the same time press the

left cursor key. All digits to the left of the blinking digit will return to 0 (erase).

B. The seventh position, 1OOHz column, will be

blinking. Rotate the MODIFY knob UP (clockwise) to increase or DOWN (counter-clockwise)

to decrease the digit to the correct value, 5 in the

1OOHz column.

C. If any of the lower digits (less significant digits)

in the displayed number are above zero, press

the CLEAR key and at the same time press the

right cursor key. All digits to the right of the

blinking digit will return to 0. The display should

now show the following digits: 5000000

(5OO.OOOOHz).

2. If the display shows a frequency less than 5OOHz

(5000000), use this sequence:

A. Assume the display indicates a frequency of

86Hz. Press the left, or right, cursor as necessary

to make the column to the left of 8 blink. A u will

appear in this column.

B. Rotate the MODIFY knob UP (clockwise) and a

number will appear in the 1OOHz column. Adjust

this number to 5.

C. Press the CLEAR key and at the same time press

the right cursor key. All digits to the right of the

blinking digit will return to 0. The display should

now show the following digits: 5000000

(500.0000Hz).

2-4

Page 17

SECTION 2

Getting Sfarted

NOTE

The frequency may be increased quickly, using the above method, but no similar action is

available to rapidly reduce the frequency setting.

Example 3: Setting the Output Amplitude

This step sets the amplitude of the existing waveform to a

value of lOmVp-p:

Use the cursor down key to set the amplitude range so it

indicates O.O;?Vp-p (2OmVpp). RPotate the AMpTD knob

until the scope indicates lOmVp-p.

Example 4: Changing the Output to a Square Wave

This example changes the output to a square wave with

variable duty cycle, while maintaining the present frequency, in continuous mode.

1. Press FCTN twice to indicate a square wave output.

Note that the output waveform has equal time-on

and time-off.

2. Press DUTY VAR to allow variable duty cycle (LED

on). Rotate the associated knob below the key to cre-

ate square waves with different on- and off-times.

Leave the square wave in some extreme variable position; that is, an obviously unequal on- or off-time.

3. Press DUTY VAR key again. The scope presentation

reverts to a square wave with equal on- and offtimes.

4.

Press the DUTY VAR key again. The scope should

display the unequal duty cycle from the previous

step.

Example 5: Adjust the DC Offset

This step adjusts the DC offset value based on the center-

line (zero or average) voltage level of the existing

waveform.

1. Press the DC OF!ZSET key (LED on). Rotate the associated knob and note the vertical movement of CH A

on the scope. This movement corresponds directly

with the offset voltage applied by the rotation of the

knob. Leave the signal with a significant offset and

go to the next step.

2. Press DC OFFSET again (LED off). The scope presen-

tation reverts to the original value of zero offset.

Press the key again and the offset value re-appears

and the CH A display moves off zero. Press the key

once more to return the scope to zero offset (LED

off).

2-5

Page 18

SECTION 3

Operation

3.1 INTRODUCTION

This section contains detailed information on front panel

operation of the Model 3910. For detailed GPIB (IEEE488

bus) operation, refer to Section 4.

3.2

3.2.1

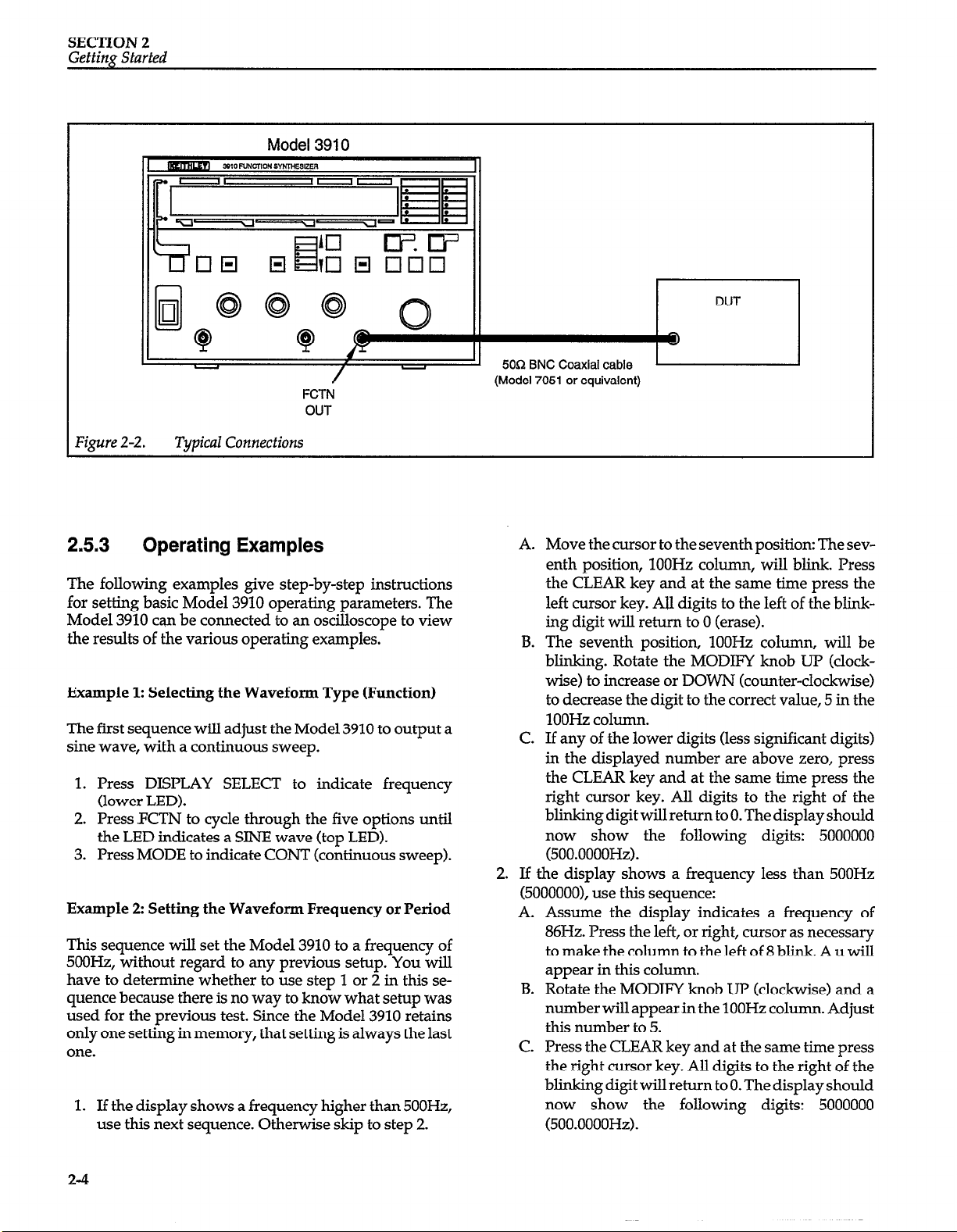

The front panel of the Model 3910 is shown in Figure 3-1.

The front panel is made up of a LED display and a control

panel with various push-button switches and knobs. The

FRONT PANEL AND REAR PANEL

DESCRIPTION

Front Panel Description

LED display presents information useful for the operation of the Model 3910, such as the value of each parameter and the range of permissible parameter values. Along

the bottom edge of the front panel are various input/output BNC connectors.

Most settings are maintained in battery backed-up memory. As a result, the Model 3910 automatically assumes

the previous settings when the power is first turned on.

Each front panel feature is described below. The circled

number to the left of each description corresponds to the

appropriate number shown in Figure 3-1.

3-l

Page 19

SECTION 3

Operation

Figure 3-1.

1

0

2

0

3

0

Model 3910 Front Panel

POWER ON/OFF (Power switch)

POWER controls AC power to the Model 3910.

Push this switch up to turn power on, and push

down to turn power off.

Display

The single-line 1 l-character display shows oscil-

lation frequency, parameter values, and other

important information during operation. An active display also indicates that instrument power

is turned on.

DISPLAY SELECT

Push-button key that selects the parameter dis-

played to either oscillation frequency or GPJB

address (only when GPIB option is installed),

start/stop phase, mark wave number, and space

4

0

wave number. When LED at the lower left of the

display is lit oscillation frequency is selected.

When LED at the upper left of the display is lit

GPIJ3 address, start/stop phase, and mark and

space wave numbers are selected.

DUTY VAR FXD, VAR (Square wave dufy

q&9

,Push-button key to select either variable duty or

fixed square wave output. When LED in center

of key is lit variable duty is selected.

111,111, r&VarlabZe duty ratio adjustment)

Rotating the variable duty adjustment knob allows you to program the square wave duty cycle.

The allowed duty cycle ranges from 5% to 95%

under lOkHz, and from 10% to 90% at 1OkHz to

1oOkHz. In the variable duty mode, the upper

frequency limit for square waves is restricted to

1ookHz.

3-2

Page 20

SECTION3

Operation

6

0

7

0

8

0

9

0

IO

0

11

0

12

0

13

0

+I- (DC offset value adjustment)

Rotating the DC offset value adjustment knob

sets the programmed offset voltage. The allowable DC offset to be added to a waveform is between -lOV and +lOV.

DC OFFSET ON, OFF

Push-button key to select whether or not DC offset is added to the waveform. When LED in center of the key is lit offset is selected.Use the +/offset value adjustment knob to add the determined amount of offset to the waveform.

AMPTD

LEDs light to display the selected amplitude

range. The allowed amplitude range is from

2mVp-p to 2OVp-p. The values for the amplitude

setting are for no-load (open) output conditions.When the output is terminated with a 500

terminal resistor, amplitude range is one half of

the selected range.

V(Amplitude range down key)

When the down cursor key is pressed the maxi-

mum value of the amplitude output signal is re-

duced.

A (Amplitude range up key)

When the up cursor key is pressed the maximum

value of the amplitude output signal is increased.

FCTN

This key allows you to choose the

waveform. Available waveforms include :

(sine wave), 2/ (triangular wave), 111 (square

wave), V(ascending sawtooth wave), 1 (descending sawtooth wave).

The selected waveform is displayed in the function LEDs.

FCTN

Refer to the lit LED to see which wave function

has been selected.

REMOTE

This lamp indicates the remote state when the

GPIB option is installed and listener is specified

from the controller.

(Amplitrrde range display)

(Function:

(Displays the selected function)

(Remote state display)

waveform)

out ut

4J

14

0

15

0

16

0

17

0

18

0

19

0

20

0

21

0

MODE

This key allows you to choose the oscillation

mode. Available modes include: CONT (continuous oscillation), BURST (burst oscillation),

TRIG (trigger oscillation), GATE (gate oscilla-

tion). In addition, it is also possible to select DC

for a continuous output of direct current voltage.

MODE

Refer to the lit LED to see which mode has been

selected.

MAN Manual trigger key)

This key allows the operator to manually gener-

ate a trigger input pulse during trigger or gate

mode of oscillation.

TRIG IN

This BNC connector is an input for external TTLlevel signals, which can be used to trigger the

Model 3910 in TRIG (trigger) and GATE modes

of operation. When this input goes from high

level to low level, it operates as a trigger signal.

SYNC OUT (Synchronous output)

This BNC jack provides a TIL-level signal at the

same frequency as the FCTN OUT output

waveform.

AMPTD MIN,

Turning this knob allows you to set the output

amplitude of the unit when the FCTN OUT key

has been activated. The allowed amplitude

ranges from 2mVp-p to 2OVp-p.

FCTN OUT

FCTN OUT turns the output waveform off or on

to the BNC plug of FCTN OUT. When the output

is off, the main output signal is turned off and

open-circuited. This can be shorted to ground by

switching an internal short plug. The current

status of this key can be determined by the LED

in the center of the key. If lit, FCTN OUT is on.

FCTN OUT

oufpft)

This BNC jack provides the waveform output

signal. The maximum output voltage range is

SOVp-p/open circuit, and the output impedance is 50&J.

(Oscillation mode)

(Displays the selected mode)

(Tuigger input)

MAX (Amplitude adjustment)

ON, OFF (Signal output ON/OFF)

(Function output:

waveform

3-3

Page 21

SECTION 3

Operation

22 4(Left Cursor)

0

This key moves the cursor one column to the left

each time it is pressed. If held continuously for

more than 0.3 seconds, the cursor will continue

moving to the left.

CLEAR (Local)

If this key is pushed first and then either the right

or left cursor key is pushed at the same time, all

digits to the right or left of this column will be reset to 0. In Gl?lB remote mode, this key is a return

to local control key.

24

0

MODIFY UP, DOWN (Modify knob)

This knob is used to increase or decrease the set

value of the display. Turning the knob clockwise

increases the value while turning the knob

counter-clockwise decreases the value. This

knob can be used to set the following parame-

ters: frequency, Gl?lB address (O-301, start/stop

phase (f360.0’), mark wave number (l-16), and

space wave number (1-16).

25 b(Righ t Cursor)

0

This key moves the cursor one column to the

right each time it is pressed. If held continuously

for more than 0.3 seconds,the cursor will continue moving to the right.

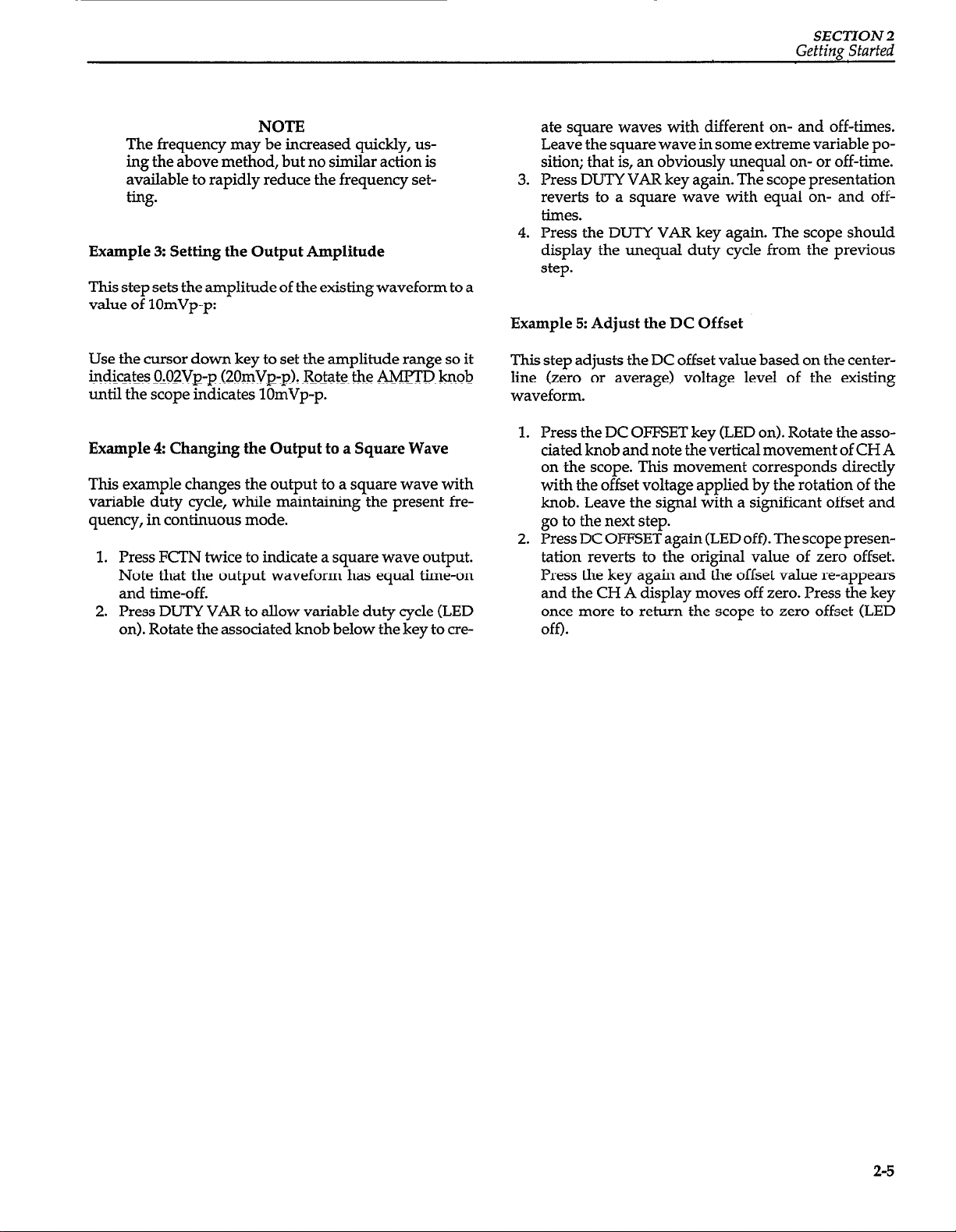

3.2.2

The rear panel of the Model 3910 is shown in Figure 3-2.

Each rear panel feature is described below. The circled

number to the left of each description corresponds to the

appropriate number shown in Figure 3-2.

Rear Panel Description

Figure 3-2.

3-4

Model

3920 Rear

Panel

Page 22

SECTTON 3

Operation

26

0

27

0

GPIB

(General Purpose Interface Bus (option))

This connector is the 24-pin connector used to

connect the Model 3911 option of the Model 3910

to the GPIB (IEEE488 bus). Shielded GPIB cables, such as the Model 7007, are recommended

for bus connectionsThe GPIB address is set by

first selecting the GPlB display. Rotate the MODIFY knob UP (clockwise) to increase or DOWN

(counter-clockwise) to decrease the GPIB address.

LINE Voltage Selector

This switch sets the Model 3910 for the correct

line voltage. Using a flat-blade screwdriver, set

the switch in the proper position for the supply

voltage in your area.

WARNING

To avoid a shock hazard, disconnect the line

cord before changing the switch position.

CAUTION

Operating the Model 3910 on an incorrect

line voltage may result in instrument damage.

(Supply voltage switch)

3.3 INPUT AND OUTPUT CONNECTIONS

3.3.1

One signal can be applied to the BNC connector of the

Model 3910. The specification of that input signal is given

below.

Logic Input

The logic input is TRIG IN (external trigger input).

Input name: TRIG IN (External trigger

Input voltage: TTL level

Allowable input voltage:

circuit: See Figure 3-3, Logic Input

Input Connection

CAUTION

Be careful no to exceed the maximum allowable input voltages, or instrument damage

may occur.

input) external trigger during TRIG, GATE operation

ov to +5.5v

circuit

28

0

@Q

LINE

(Power Input Connector)

The LINE connector is used to connect the instrument to AC power.

WARNING

To avoid the possibility of electric shock,

connect the Model 3910 to grounded AC outlet using the supplied 3-wire power cord or

the equivalent.

(Grounding Terminal)

The grounding terminal is connected to the chas-

sis of the Model 3910. To prevent interference

and for safety, be sure to ground this terminals

WARNING

If the Model 3910 is connected to an ungrounded AC outlet, connect the grounding

terminal to safety earth ground using

#18AWG minimum wire before use to avoid

the possibility of electric shock.

V V

1 Figure 3-3.

Figure 3-3. Logic Input Circuit

3.3.2

3.3.2

Two output signals are available from the BNC connec-

tors of the Model 3910. The specifications of the output

signals are given below.

Be careful not to connect an external signal to

an output connector, or instrument damage

may occur.

Logic

Input

Circuit

Output Connections

Output Connections

CAUTION

3-5

Page 23

SECTION 3

Analog Output

The analog output is FCTN OUT (main waveform out-

put)

Output n&e: FCTN OUT (Main

Waveform Output)

Maximum output voltage:

Output impedance:

Recommended Impedance: 50!2

Short circuit ljrotection See Figure 3-4, Output Circircuit: cuit

ZOVp-p/open,

lOVp-p/son

5on 32%

Analog Output Considerations

The FCTN OUT (main waveform output) impedance is

50!2. To maintain maximum amplitude across the entire

bandwidth, and for maximum square-wave quality, use

a 5OQ cable for connections, and terminate the opposite

end of the cable with a 5OQ impedance. Note that the

Model 3910 displays voltage amplitude for open circuit

conditions. The actual output voltage with a 5OQ termination is about half that for no-load conditions.

Logic Output Considerations

The SYNC OTJT (synchronous output) is driven by a

74LS type logic IC. The maximum load is about 25ksz. Be

careful not to connect a load that exceeds the drive capa-

bility of this type of TTL IC. Also, do not use excessively

long connecting cables, as the resulting capacitance may

have detrimental effects on the output signals.

The SYNC OUT impedance is matched at 5OQ at higher

frequencies. Relatively good waveforms will be obtained

if 5OQ coaxial cables are used; however, cables connected

to this output must not be terminated with a 5OQ impedance.

3.4 STARTUP

1. Check that the supply voltage switch is set at the

proper position for the supply voltage. The allowable supply voltage range is +lO% of the voltage at

which the supply voltage is set.

CAUTION

Operating the Model 3910 in an incorrect

line voltage may result in damage to the unit.

Logic Output

The logic output is SYNC OTJT (synchronous output).

Output name:

Output voltage:

circuit:

SYNC OUT

TTL level

See Figure 3-4, Output Circuit

Figure 3-4. Output Circuit

2. Make sure that the power is off, then plug the supplied power cable firmly into the LINE connector on

the rear panel of the Model 3910. Insert the plug into

a grounded AC power receptacle.

WARNING

To avoid the possibility of electric shock, use

only grounded AC receptacles for power

connections.

Turn on Model 3910 power by pushing the front

panel POWER switch. The power is on when the

POWER switch button is up; power is off when the

POWER switch is down. When the power is on, the

Model 3910 will begin normal operation, and the

LED display will be on.

3. When the power is first turned on, the Model 3910

will return to the previous settings effective prior to

power-off, and the unit will display the main parameters.

If the previous settings were not stored correctly, the

error code “ERR3” will be displayed. In this case, if

the CLEAR key is pushed, the machine goes to the

initial reset state and can be used normally, but the

3-6

Page 24

SECTION 3

Operation

settings prior to turning off the power are lost. This

situation occurs when the backup battery used to

maintain memory is drained and the stored data cannot be maintained or if the power is cut off while the

machine is being set. Fully charged batteries can retain memory for approximately 30 days. This time

period, however, varies slightly with ambient temperature and from one battery to another.

The backup batteries may be discharged when the

Model 3910 is used for the first time after being purchased. If “ERR 3” is displayed during initial operation, replace the batteries using the information provided in the service manual.

The FCTN OUT ON/OFF (function output) state is

not saved. The FCTN OUT ON/OFF setting depends on the setting of the internal short plug. The

factory default setting at power-on is function output on. Consult the service manual for details on setting the internal short plug.

If, at power on, the Model 3910 does not enter the

mode with settings that were effective immediately

before previous power-off (or the preset operating

modes), or if the main display does not appear, contact your Keithley representative or the factory to determine the correct course of action.

ERR2 (RAM error)

l Abnormality in internal RAM of the machine.

ERR3 (Memory backup error)

l Battery backup operation failure.

When “ERRl” and “ERR2” occur, try to turn the power

on again several times. If the error is still displayed, it is

probably a breakdown. Contact your Keithley representative or the factory to determine the correct courseof action.

When “ERR3” is displayed, replace the batteries inside

with new ones. Refer to the service manual for replacement information.

If the CLEAR key is pressed when “ERR3” is displayed,

the machine will be set to its default settings, and will

then go into the operating state, where it can be used normally. However, the settings prior to turning off the

power will be erased.

NOTES:

1. Wait at least five seconds before turning on the

Model 3910 after turning it off or it may not operate

normally.

2. For precise measurement applications, allow the

Model 3910 to warm up for at least 30 minutes to allow internal circuits to stabilize.

3.5 OPERATING PROCEDURES

3.51 Error Codes

When an error occurs, the Model 3910 displays an error

code on the left side of the numerical display.

Displayed error codes and their meanings are summarized below.

ERR1 (ROM error)

l Abnormality in internal ROM of the machine.

3.5.2

Frequency Setting

The frequency setting is used to set the cycles per second

of the waveform selected. To change the frequency setting, first ensure that the frequency display has been selected. To select the frequency display, depress the DISPLAY SELECT button so that the LED indicator is lit next

to MHz on the lower left of the display.

Once this action has been performed the Model 3910 can

now have the frequency set. To move the cursor to the position you wish to change, just use the4 key or the, key.

To change the frequency setting, turn the MODIFY knob

UP (clockwise) to increase the setting or DOWN

(counter-clockwise) to decrease the setting.

The allowed frequency range for the sine and square

waves (with 50% duty cycle) is from O.lmHz to IMHz; for

other waveforms, the upper limit is 1OOkHz for good

quality waveforms. Although waveform quality will be

of reduced quality, oscillations up to 1MHz can be set for

triangle (2/ >,

rising sawtooth (v >, falling sawtooth

(u ), and variable duty square wave (m >.

Page 25

SECTION 3

Operation

3.5.3

The amplitude setting establishes the output voltage

from the FCTN OUT BNC jack. The amplitude range display will display only the maximum possible output

value in the current setting.

To accurately set the output amplitude, first set the de-

sired range using the amplitude range keys. Then rotate

the AMPTD knob to fine tune the output. The output

value can be measured at the FCTN OUT BNC jack with a

voltmeter or by using an oscilloscope. However, take

note of the frequency characteristics of the voltmeter.

Amplitude setting can be performed by using both the

AMPTD knob and the amplitude range keys. The allowed amplitude range is 2mVp-p to 2OVp-p.

When the DC offset is OV, the allowed amplitude range is

2mVp-p to 2OVp-p. If, however, the DC offset is not OV,

the sum of the AC amplitude setting/2 and the DC offset

must not exceed the AC amplitude setting.

Output Amplitude

Using DC

the value that appears at the output jack. Valid offset values are within the range of +lOV to -lOV.

For all AC waveforms, the DC offset is added to the aver-

age

waveform. When adding DC offset to the output

waveform, set them so that the sum does not exceed that

of your AMPTD (amplitude range display). To prevent

errors from oc

offset combinations, first set the offset to OV, change the

AMPTD setting, then set the offset to the desired value.

Settings that exceed the range of the AMM’D are possible, but the waveform will be distorted or clipped. Check

the waveform with an oscilloscope.

3.5.5

as

a mode, the offset voltage is the voltage of

value of the peak-to-peak amplitude of the AC

curring while programming amplitude-

Waveform Selection, Square-Wave

Duty Cycle, and Synchronous Out-

put

Waveform Selection

Pressing the FCTN key advances the present waveform

function on the upper right of the front panel. Available

waveforms include: sine ( s ),tiangle ( 2/ >, s uare

6u ), rising sawtooth (A ), and falling sawtooth ( \ 1.

The variable range of the AMPTD knob is 20dB.

The AMl?TD knob can be used only on AC waveforms;

use the DC OFFSET knob to set the DC output voltage of

the DC waveform. When the DC waveform is selected,

you can still set the amplitude range by using the ampli-

tude range keys.

3.5.4 DC Offset

Pressing the DC OFFSET key selects whether or not DC

offset is added to the waveform. When the LED in the

center of the key is lit the DC offset is active. The current

DC offset setting cannot be observed from the Model

3910 display. The DC offset setting should be made using

a voltmeter or an oscilloscope.

To modify the DC offset, rotate the +/- offset value adjustment knob directly below the DC OFFSET key clockwise to increase the setting and counter-clockwise to decrease the setting.

For all AC waveforms, the p-p value of the amplitude

will remain unchanged when you change the waveform.

Square-Wave Duty Cycle

The duty cycle is the ratio of the time period of the

waveform high-level duration to the time period of one

complete cycle of the waveform expressed as a percentage. For example, assume a 1OkHz square wave has a

time period of 100psec. If the high portion of the

waveform has a period of 30pec, the duty cycle is

30/100x100=30%.

Two square-waveform duty cycles are available: one

with the duty cycle fixed at 50% and the second mode

with a variable duty cycle. The duty cycle applies only to

the square-wave function. When the Model 3910 is in the

variable duty-cycle mode, the upper frequency limit is

1OOkHz and the maximum jitter is 15011s.

To change the duty cycle, press the DUTY VAR FXD,

VAR key. If the LED is lit in the center of the key the vari-

3-8

Page 26

SECTION 3

Operafion

able duty

duty cycle, turn the (variable duty) knob directly below

the DUTY VAR key. The variable range of duty ratio is

between 5% and 95% for frequencies up to 1OkHz. For

frequencies up to 100 kHz, the variable range is between

10% and 90%. It can actually be set until the point where

the waveform is extinguished, but the waveform may become unstable. To select the fixed 50% duty cycle mode,

press the DUTY VAR FXD,VAR key so that the LED in

the center of the key is no longer lit.

Note that the duty cycle setting also changes the duty cycle of the sync out signal.

To extend the duty cycle range, use the trigger oscillation

mode and one square waveform cycle. Refer to paragraph 3.5.6 for details on setting the oscillation mode.

Synchronous Output

Figure 3-5 illustrates the phase relationships between the

FCTN OUT waveform and SYNC OUT (synchronous

output). Note that as the frequency increases, a substan-

range

has been selected. To modify the variable

tial phase differential will result between the waveform

output and the synchronous output signals.

3.5.6 Oscillation Mode

Oscillation Mode Selection

The oscillation mode setting is selected by the MODE

switch on the right side of the front panel. The present oscillation mode is displayed by the lit LED next to the selected mode. Each time the mode key is depressed the

mode is advanced by one. Available oscillation modes include CONT (continuous), BURST, TRIG (trigger), and

GATE. In addition, it is also possible to select DC for a

continuous output of direct current voltage.

CONT (continuous mode)

When the continuous mode is selected, the instrument

generates the selected waveform continuously. Triggering is not required, and the selected burst cycle and internal rate

waveform:

parameters

have no effect on the output

-

Sine wave

Rising sawtooth wave

Waveform

Triangular wave

Falling sawtooth wave

Figure 3-S. Phase Relationship between FCTN OUT Waveform and SYNC OUT

Square wave

Duty variable square wave

3-9

Page 27

SECTION 3

Operation

BURST

In the burst mode, the instrument generates the selected

waveform for the specified mark wave number and

space wave number. No trigger signal is required to initi-

ate the waveforms. The mark wave number and space

wave number can be set by first pressing the DISPLAY

SELECT button so that the LED is lit next to GPIB on the

upper left of the display. When the LED is lit next to

GPIB, the mark wave number and space wave number

can be found on the right side of the display. Then by us-

ing the 4 and b keys advance the cursor to either mark

wave number or space wave number. Turn the MODIFY

knob UP (clockwise) to increase the wave number or

DOWN (counter-clockwise) to decrease the wave num-

ber. The phase where oscillation starts can be set in 0.1”

from +360.0” to -360.0”.

TRIG (trigger)

In the trigger mode, the instrument generates the se-

lected waveform for the number of specified mark wave

numbers each time a trigger comes from the outside. The

trigger signal is effective only while oscillation is

stopped, and trigger signals prior to when the oscillation

finishes are ignored. To set the mark wave number first

press the DISPLAY SELECT button so that the LED is lit

next to Gl?lE on the upper left of the display. When the

LED is lit next to GPIB, the mark wave number can be

found on the right side of the display. Then use the4 and

b keys to advance the cursor to the mark wave number.

Turn the MODIFY knob UP (clockwise) to increase the

mark wave number or DOWN (counter-clockwise) to de-

crease the mark wave number. The phase where oscillation starts can be set in 0.1” units from +360.0” to -360.0”.

Triggering is performed by either using the TRIG IN (external trigger) BNC jack or by pressing the MAN (manual) key on the front of the unit.

Figure 3-6 shows the relationship between the trigger

signal and oscillation in TRIG mode.

GATE

In the GATE mode, the unit generates oscillations as long

as the gate signal (trigger signal) is on. When the gate signal turns oW, the Model 3910 will always stop oscillating

at the end of one complete cycle even if the gate signal

turns off at the mid point of a cycle. Thus, the Model 3910

always provides integral cycles of oscillation. The phase

where the oscillation starts can be set in 0.1” units from

+360.0” to -360.0”.

Triggering is performed by either using the TRIG IN (external trigger) BNC jack or by pressing the MAN (manual) key on the front of the unit.

Figure 3-7 demonstrates how the output waveform always completes the current cycle when the gate signal

turns off.

Ignored

Figure 3-6. Relationship between Trigger Signal and OsciZlation in TRIG Mode

3-10

Page 28

SECTION 3

Ozleration

Figure 3-7.

In the trigger or gate oscillation modes, if the

next trigger is applied at about the same time

the unit terminates oscillation, oscillation may

become unstable. In this situation, temporarily change the oscillation mode, then return

the unit to the original mode. Oscillation will

return to normal.

Relationship between Trigger Signal and Oscillation in GATE Mode

NOTE

DC Mode

DC is a mode in which oscillation from the synthesizer is

stopped. In this mode only a constant voltage is output.

When the MODE is set to DC, DC OFFSET ON/OFF

must be on (LED lit in center of DC OFFSET ON/OFF

key). To alter the output voltage, turn the +/- knob, directly below the DC OFFSET ON/OFF switch, clockwise

to increase the voltage or counter-clockwise to decrease

the voltage. The maximum voltage of the DC output is

HOV, and current is up to lOOmA. Short circuit protection

on the output has been installed.

play. When the LED is lit next to GPIB, the start/stop

phase setting can be found in the center of the display. To

change the current start/stop phase setting, move the

cursor to the start/stop phase by using the4 and, cursor

keys. Then set the start/stop phase by turning the

MODIFY knob UP (clockwise) to increase the setting or

DOWN (counter-clockwise) to decrease the setting. The

allowed range for the start/stop phase parameter is

-360.0” to +360.0” with 0.1” resolution.

The definitions of each waveform and its phase are

shown in Figure 3-8.

The Model3910 generates square waves with a fixed 50%

duty cycle by processing sine waves with a zero-crossing

comparator that has hysteresis.The level of the generated

square wave, therefore, alternates high and low at approximately 0”, +X30’, and &360” (within about ti.3’) depending on the past value of the phase. Thus, to set the

square-wave start/stop level high, set the phase to 90”.

Similarly, the phase should be set to -90” to set the

square-wave start/stop level low.

3.5.7 Trigger Parameters

Start/Stop Phase

The start/stop phase setting is the starting and finishing

position for waveform cycles. To set start/stop phase

press the DISPLAY SELECT button so that the LED indi-

cator light is lit next to GMB in the upper left of the dis-

The Model 3910 also generates the synchronous output

for the sine, triangle, and sawtooth waves by passing

each waveform through a zero-crossing comparator that

has hysteresis. As a result, the synchronous output level

changes at the same points as the square wave when the

phase is approximately 0”, +180’, or &360” for the sine or

triangle waves, or about +180” with the sawtooth wave.

3-11

Page 29

SECTION 3

Oaeration

Center of

waveform

amplitude

Phase O”

Duty ratio fixed square wave

Center of

00

Rising Sawtooth Wave

0 Not including this point

l

Including this point

Center of

waveform

amplitude

I

I I

I I

1800 36il”

Phase O”

Duty ratio variable square wave

Center of

waveform

amDlitude

, I

0" 180" 360”

180” 360”

Phase

Falling Sawtooth Wave

Center of

waveform

amplitude

180” 360”

o Not including this point

l

Including this point

0 Not including this point

Figure 3-8. Definition

3-12

of

Phase

180” 360”

of

each Waveform

Phase

0” 180” 360”

.

Page 30

SECTION 3

Otlerution

Mark Wave Number Setting

The mark wave setting is used to set the number of oscil-

lation cycles the unit generates each time it is triggered in

the BTJRST and TRIG oscillation modes. To set the mark

wave number, press the DISPLAY SELECT button so that

the LED is lit next to GPIB on the upper left of the display.

When the LED is lit next to GPIB, the mark wave number

setting can be found on the right side of the display. To

change the current mark wave number setting, move the

cursor using the 4 and @ cursor keys to the desired number. Then turn the MODIFY knob Ul? (clockwise) to increase the setting or DOWN (counter-clockwise) to decrease the setting. The allowable range for the mark wave

number setting is 1 to 16.

Space Wave Number Setting

The space wave setting is used to set the number of non-

oscillation cycles between each group of oscillation cycles

in the BURST mode. To set the desired space wave num-

ber, press the DISPLAY SELECT button so that the LED is

lit next to GPIB on the upper left of the display. When the

LED is lit next to GPIB, the space wave number can be

found on the far right side of the display. To change the

currents

ing the

turn the MODIFY knob UP (clockwise) to increase the

setting or DOWN (counter-clockwise) to decrease the

setting. The allowable range for the space wave number

is 1 to 16.

ace wave number setting, move the cursor us-

P

and b cursor keys to the desired number. Then

3-13

Page 31

SECTION 4

GPIB Interface

4.1 INTRODUCTllON

4.1 .I GPIB Overview

The GPIB interface is a general-purpose interface bus sys-

tem recognized by the IEEE (Institute of Electrical and

Electronics Engineers) in 1975 and is a method of stan-

dardizing data transfer between measuring instruments

and peripherals. By building each controller and periph-

eral device into an interface conforming to this standard,

it is possible to establish complete hardware compatibil-

ity among devices.

UP to 15 devices may be connected to a single interface

b&, and data transfer is performed by threghandshake

lines, enabling reliable data transfer between data senders (talkers) and receivers (listeners) having differing

data transfer rates.

4.1.2 Major GPIB Specifications

Overall cable length: 20m maximum

Cable lengths between devices: 4m maximum

Number of devices connectable

(including a controller): 15 maximum

Transfer method: 3-line handshake

Transfer rate: 1M bytes/set (maximum>

Data transfer: g-bit parallel

Signal lines:

Data Bus: 8 Lines

Control bus: 8 Lines

(including DAV, NRFD, and NDAC handshake lines

and ATN, REN, IFC, SRQ, and EOI control lines)

Signal/system grounds: 8 lines

Signal logic: Negative

True (low-level): 0.8V maximum

False (high-level): 2.OV minimum

4.1.3 Bus Line Signals and Operation

The GPIB bus consists of 24 lines, including eight data

lines, eight control lines, and eight signal/system ground

lines.

Data Bus (DIOl to DI08)

DIOl through DIO8 are data input/output lines, which

are used to transfer both address and command information (the type of data present on these lines is determined

by the ATN line). DIOl is the least significant bit (LSB).

4-l

Page 32

SECTION 4

GPIB Interface

Handshake Bus (DAV, NRFD, NDAC)

These three lines are handshake lines used to ensure reliable data transfer.

DAV @&a Yalid)

This line indicates that the data on the DIO lines sent

from a talker or the controller are valid.

NRFD &Jot &eady Zoraata)

This line indicates when the listeners are ready to accept

data over the data lines.

NDAC Uot Data Kcepted)

This line indicates the acceptance of data by listeners.

EOI and Qr Jdentify)

This line is used to indicate the end of a multiple-byte

transfer sequence or, in conjunction with ATN, to execute

a parallel poll operation.

4.1.4

GPIB handshaking is performed by checking the status of

all listeners and inhibiting the next data transfer until all

listeners have completed the reception of data, so that the

slowest device on the bus can perform data transfer reliably. The handshaking operations are executed by the

following handshake line logic levels:

NRFD=High level: Alllisteners are ready for accepting

data.

DAV=Low level: A talker has valid data on the data bus.

NDAC=High level: All listeners have completed data re-

ception.

GPIB Handshaking

Control Bus (ATN, REN, IFC, SRQ, EOII

ATN UeNtion)

This line is an output line from the controller, and it indi-

cates whether the information on the data bus is to be interpreted as data or commands.

REN @emote ENable)

This output line from the controller switches devices be-

tween remote control and local control.

IFC (Inter]Eace Q.lear)

This output line from the controller clears the interface of

active talkers and listeners.

SRQ @en&e &eQuest)

DlOl

0102

D103

D104

EOI

DAV

NRFD

NDAC

IFC

SRQ

ATN

SHIELD

. Cable

Receptacle Side

/

D105

D106

D107

D108

REN

DAV GROUND

NRFD GROUND

NDAC GROUND

IFC GROUND

SRQ GROUND

ATN GROUND

LOGIC GROUND

This control line is used by a device to request service

from the controller. The controller detects this signal and

usually executes a serial or parallel poll operation.

4-2

IEEE-488

1

Figure 4-l. Interface Connector

Page 33

SECTION 4

GPIB Inferface

NRFD

(Listener) --I,

DAV I I

(Talker)

NDAC

(Listener)

Data Bus

Signal

Valid Data

I 1

- Data bus disabled

Ready for next data byte.

Data bus enabled

Termination of

data reception

Data not received

(during data reception)

Figure 4-2. Handshake Timing Diagram

The handshaking timing diagram is in Figure 4-2. The

various timing points indicate the following:

4.1.5

Figure 4-3 shows a data transfer example using the threeline handshake process. In this example, the character

string “ABC” is sent, followed by the <CR> <LF> delimiter.

4.1.6

l Only one talker may exist on the GPIB at a time.

l Data is sent to the listeners when the controller ATN

line is high (false).

l Source handshaking is performed automatically.

l A service request (SRQ) is sent to the controller by

other devices.

l The talker function is available with both the local and

remote modes.

l The talker function is canceled by any of the following:

When the talk address of another device is received.

When the device is addressed as a listener.

When the untalk (UNT) command is received.

When the interface clear (IFC) command is received.

Data Transfer Example

Basic Talker Functions

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

Indicates that all listeners are waiting for data.

The talker places the data byte to be sent on the

data lines. Output may have already occurred.

The talker checks NRFD, and, if high, DAV is set

low to indicate to the listener that the data is

valid.

When DAV goes low, the listener reads data, and

NRFD is set low, indicating to the talker that data

processing is in progress. Each listener sets

NDAC high at the completion of data input. The

NDAC logic level is the result of ORing the

NDAC signals from each listener.

When all listeners have completed receiving

data, NDAC goes high, indicating to the talker

that data reception has been completed.

The talker sets DAV high, indicating to the lis-

tener that data on the bus is no longer valid.

The listener checks to see whether DAV is high

and sets NDAC low, completing the handshake.

Indicates that all listeners have completed data

input, and the bus is ready to transfer the next

data byte.

4.1.7 Basic Listener Functions

l Two or more listeners may exist on the GPIB at any

time.

l Data is received from a talker when the controller

ATN signal is high.

l The acceptor handshake is performed automatically.

l The listener function is canceled by any of the follow-

ing:

When the device is addressed to talk.

When the unlisten (UNL) command is received.

When the IFC command is received.

4.1.8 Basic Controller Functions

l Only one controller can be active on the GPIB.

l The controller sets the ATN signal to low to address

devices to listen and talk, and to transmit commands

such as DCL.

0 The controller sends single-line commands such as

IFC and REN.

4.1.9 Multi-line Interface Messages

A multi-line interface message is sent over the data lines

with ATN set low. Table 4-1 summarizes these messages.

4-3

Page 34

SECTION 4

GPIB Interface

DATA

ATN

DAV

NRFD

NDAC L

EOI

UNL Address

Talker

Listener

Address A 0

C CR

LF

Figure 4-3.

Data Transfer Example

4-4

Page 35

1

I

LISTENER ADDRESSES

ASSIGNED TO DEVICES

LISTENER ADDRESSES

ASSIGNED TO DEVICES

TALKERADDRESSES

ASSIGNED TO DEVICES

I I

I I

MEANING DEFINED BY PCG

I I

Page 36

SECTION 4

GPII?

Interface

4.2 OVERVIEW OF MODEL 3910 GPIB

INTERFACE

4.2.1 Introduction

The Model3910 GPIB interface has a wide variety of interfacing functions. These functions allow remote setting

of most of the parameters which can be set from the front

panel. Items that cannot be controlled from GPIB are

AMPTD, amplitude setting; DC offset, added quantity

setting; and DUTY VAR, duty ratio setting; which correspond to regulators other than the MODIFY dial on the

panel. The interface can also transfer setting data and

conditions to an external device, enabling the user to easily configure a sophisticated automatic measurement

system.

Setting data and conditions are sent to the controller as

character strings in ASCII format.

4.2.2

Interface Functions

Table 4-2 shows the interface functions of the Model

3910.

Specifications

Bus Driver

Table 4-3 gives the bus driver specifications.

Table 4-3. Bus Driver Specifications

DIOl to D108

NDAC, NRFD, SRQ

I

DAV

EOI

Codes

Codes which can be received by the Model 3910 in listener mode are in 7-bit ASCII format (bit 7 is ignored).

Codes can be sent using either lower-case or upper-case

letters. In either case, codes are interpreted and executed

identically. The space @OH), tab (09H), and semicolon

“;“(3BH) characters are ignored.

Talker (inquiry) mode transmission codes are also in ‘/bit

ASCII format. All letter characters are sent as upper-case

letters.

Open Collector

I

Three-state

Three-state

I

Table 4-2. Interface Functions

Function

Source Handshake SHl

Acceptor Handshake AH1

Talker T6

Listener

Service Request SRl

Remote/Local

Parallel Poll

Device Clear

Device Trigger DTO

Controller co

Subset Explanation

IA

RLl

PPO

DC1

Sending handshake all functions

Receiving handshake all functions

Basic talker, serial poll, talker cancel by MLA

Basic listener function, listener cancel by MLA

Service request all functions

Remote local all functions

No parallel poll functions

Device clear all functions

No device trigger functions

No controller functions

4-6