Page 1

x

370B

Programmable Curve Tracer

ZZZ

Service Manual

*P070A84250*

070-A842-50

Page 2

Page 3

xx

370B

Programmable Curve Tracer

ZZZ

Service Manual

Revision C

Warning

The servicing instructions are for use by qualified personnel only. To

avoid personal injury, do not perform any servicing unless you are

qualified to do so. R efer to all safety summaries prior to performing

service.

www.tektronix.com

070-A842-50

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 5

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement i n exchange for the

defective product. Parts, modules and replacement products used by Tektronix for warranty work may be new or

reconditioned to like new performance. All replaced parts, m odules and products become the property of Tektronix.

In order to obtai n service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid.

Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furni sh servi ce under this warranty a) to repai r damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or c onne ction to incompatible equipment; c) to repair any dam age or malfunction

caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or i ntegration increases the time or difficulty of servicing the product.

THIS W ARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER W ARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENT AL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 6

Page 7

Table of Contents

Specifications

Operating Information

General Safety Summary vii...................................

Service Safety Summary ix....................................

Preface xi...................................................

Introduction xv..............................................

Product Overview 1--1.........................................

Specifications 1--3.............................................

Performance Conditions 1--3...........................................

Electrical Specifications 1--4...........................................

Mechanical Specifications 1--17.........................................

Functional Specifications 1--18.........................................

Environmental Specifications 1--19......................................

GPIB Interface 1--22..................................................

Operating Information 2--1.....................................

Installation 2--1.....................................................

Kelvin Sense 2--5....................................................

Rackmounting Information 2--7........................................

Repacking for shipment 2--13...........................................

Theory of Operation

Theory of Operation 3--1.......................................

Block Diagram Description 3--1........................................

Circuit Operation 3--6................................................

Maintenance

Maintenance 4--1..............................................

Preventive Maintenance 4--1...........................................

Corrective Maintenance 4 --4...........................................

Performance Verification

Performance Verification 5--1...................................

Using Procedure 5--3.................................................

Power Supply 5--12...................................................

CRT 5--17...........................................................

Display 5--26........................................................

Horizontal 5--44......................................................

Vertical 5--54........................................................

Step Generator 5--71..................................................

Collector Supply 5--104.................................................

AUX Supply 5--119....................................................

370B Service Manual i

Page 8

Table of Contents

Instrument Options

Electrical Parts List

Diagrams

Mechanical Parts List

Configuration 5--122...................................................

Key Operation and Floppy Disk Drive 5--129................................

Options 6--1........................................................

Accessories 6--2.....................................................

Replaceable Electrical Parts 7--1.................................

Parts Ordering Information 7 --1.........................................

Using the Replaceable Electrical Parts List 7--2............................

Diagrams 8--1.................................................

Mechanical Parts List 9--1......................................

Parts Ordering Information 9 --1.........................................

Using the Replaceable Parts List 9--2....................................

ii 370B Service Manual

Page 9

List of Figures

Table of Contents

Figure 2--1: Example of Kelvin sense connection 2--6................

Figure 2--2: Location of the Rackmount Latch Release 2--7...........

Figure 2--3: Rackmount hole spacing 2--8..........................

Figure 2--4: Rackmounting Length and Clearance 2--8..............

Figure 2--5: Rackmounting Hardware 2--9.........................

Figure 2--6: Mounting Stationary Rackmount Sections 2--10...........

Figure 2--7: Cabinet-to-Rackmount Conversion 2--12.................

Figure 3--1: 370B Block Diagram 3--3.............................

Figure 5--1: Diagnostic test pattern display 5--32.....................

Figure 5--2: Looping compensation display 5--40....................

Figure 5--3: Checking Collector high current range 5--67..............

Figure 5--4: Examining and Adjusting for Step Generator Offset 5--73..

Figure 5--5: Adjusting for Current Amplifier Bias 5--75...............

Figure 5--6: Checking for Maximum OFFSET of 200 mA Range 5--83..

Figure 5--7: Checking for Maximum Current Output of 100 mA

and 200 mA range 5--96......................................

Figure 5--8: Adjusting for Collector Supply Amplifier Offset 5--105......

Figure 5--9: Examining for DC and LEAKAGE operation 5--113........

Figure 8--1: 370B circuit board locator 8--1........................

Figure 9--1: Cabinet, Rear 9--9...................................

Figure 9--2: Display, Front 9--10..................................

Figure 9--3: Chassis Circuit Boards 9--17...........................

Figure 9--4: Power Supply 9--18...................................

Figure 9--5: Front Panel: L-O-R 9--27..............................

Figure 9--6: LV, L-O-R, Looping Circuit Boards 9--28................

Figure 9--7: FDD, Config. Relay, Sense Circuit Boards 9--35...........

Figure 9--8: Accessories 9--36.....................................

370B Service Manual iii

Page 10

Table of Contents

List of Tables

Table 1--1: Collector Supply 1 -- 4.................................

Table 1--2: Step Generator 1--7..................................

Table 1--3: AUX Supply 1--10....................................

Table 1--4: Non-store Vertical Deflection System 1--10................

Table 1--5: Digital Storage Vertical Acquisition 1--12.................

Table 1--6: Non-store Horizontal Deflection System 1--13.............

Table 1--7: Digital Storage Horizontal Acquisition 1--14..............

Table 1--8: CRT and Readout 1--15...............................

Table 1--9: Adapter Connectors 1--16..............................

Table 1--10: Power Supply 1--17..................................

Table 1--11: Surge Current 1 -- 17..................................

T able 1--12: Mechanical Specification 1--17.........................

Table 1--13: Digital Storage Acquisition Mode 1--18.................

Table 1--14: Text Display 1--18...................................

Table 1--15: Environmental Specification 1--19......................

Table 1--16: Certifications and Compliances 1--20...................

Table 1--17: Installation category and Pollution degree Descriptions 1--21

Table 1--18: GPIB Interface 1--22.................................

Table 2--1: Line voltage ranges 2--1...............................

Table 2--2: Power Cord Color Conductor Identification 2--2..........

Table 2--3: Power cord identification 2--3.........................

Table 4--1: Power-on System Error Messages 4--24..................

Table 4--2: Front Panel Control Identification 4--25..................

Table 5--1: Performance Check and Adjustment Procedure Options 5--2

T able 5--2: Performance Check Summary 5--4.....................

Table 5--3: Test Equipment 5--10.................................

Table 5--4: Voltage Regulation and Ripple 5--13.....................

Table 5--5: Base/Emitter Voltage Accuracy 5--48.....................

T able 5--6: Collector Voltage Accuracy 5--50........................

Table 5--7: Displayed Horizontal Noise 5--53........................

T able 5--8: Emitter Current Accuracy 5--61........................

T able 5--9: Collector Current Accuracy 5--63.......................

T able 5--10: Collector High Current Accuracy 5--67.................

iv 370B Service Manual

Page 11

Table of Contents

Table 5--11: Displayed Vertical Collector Noise in CONFIGURATION

BASE to COLLECTOR SUPPLY mode 5--70...................

Table 5--12: OFFSET Voltage 5--79...............................

Table 5--13: OFFSET Voltage 5--80...............................

Table 5--14: OFFSET Current 5--82...............................

Table 5--15: Max Peak Volts 5--108.................................

Table 5--16: Max Peak Volts 5--109.................................

Table 5--17: Maximum Peak Currents 5--111........................

Table 5--18: Auxiliary Supply Accuracy 5--120.......................

T able 6--1: Standard accessories 6--2.............................

Table 6--2: Optional accessories 6--2..............................

T able 6--3: Recommended accessories 6--3.........................

370B Service Manual v

Page 12

Table of Contents

vi 370B Service Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Use Proper Voltage Setting. Before applying power, ensure that the line selector is

in the proper position for the power source being used.

Connect and Disconnect Pr operly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Rat ings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

370B Service Manual vii

Page 14

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

viii 370B Service Manual

Page 15

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

370B Service Manual

ix

Page 16

Service Safety Summary

370B Service Manual

x

Page 17

Preface

Manual Structure

This is the service manual for the 370B Programmable Curve Tracer. The manual

contains information needed to service the 370B to the module level.

This manual is divided into sections, such as Specifications and Theory of

Operation. Further, some sections are divided into subsections, such as Product

Description and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures.

Be sure to read these introductions because they provide information needed to

do the service correctly and efficiently. The following contains a brief description

of each manual section.

H Specifications contains a description of the 370B Programmable Curve

Tracer and the characteristics that apply to it.

H Operating Information includes general information and operating

instructions.

H Theory of Operation contains circuit descriptions that support service to the

module level.

H Performance Verification contains procedures for confirming that the 370B

Programmable Curve Tracer functions properly and meets warranted limits.

H Adjustment Procedures contains a collection of procedures for adjusting the

370B Programmable Curve Tracer to meet warranted limits.

H Maintenance contains information and procedures for performing preventive

and corrective maintenance of the 370B Programmable Curve Tracer. These

instructions include cleaning, module removal and installation, and fault

isolation to the module.

H Options contains information on servicing factory-installed options.

H Electrical Parts List contains a statement referring you to Mechanical Parts

List, where both electrical and mechanical modules are listed.

H Diagrams contains an block diagram and an interconnection diagram.

H Mechanical Parts List includes a table of all replaceable modules, their

descriptions, and their Tektronix part numbers.

370B Service Manual xi

Page 18

Preface

Manual Conventions

This manual uses certain conventions that you should become familiar with.

Some sections of the manual contain procedures for you to perform. To keep

those instructions clear and consistent, this manual uses the following conventions:

H Names of front panel controls appear in the same case (initial capitals, all

uppercase, etc.) in the manual as is used on the 370B Programmable Curve

Tracer front panel. Front panel names are all upper-case letters; for example,

REF, SAVE, VIEW etc.

H Instruction steps are numbered unless there is only one step.

Modules

Safety

Throughout this manual, any replaceable component, assembly, or part of the

370B Programmable Curve Tracer is referred to generically as a module. In

general, a module is an assembly (like a circuit board), rather than a component

(like a resistor or an integrated circuit). Sometimes a single component is a

module; for example, the chassis of the 370B Programmable Curve Tracer is a

module.

Symbols and terms related to safety appear in the Safety Summary near the

beginning of this manual.

Finding Other Information

Other documentation for the 370B includes:

H The 370B Programmable Curve Tracer User Manual contains a tutorial to

quickly describe how to operate the370B Programmable Curve Tracer. It also

includes an in-depth discussion on how to more completely use the 370B

Programmable Curve Tracer features.

xii 370B Service Manual

Page 19

Preface

370B Service Manual xiii

Page 20

Preface

xiv 370B Service Manual

Page 21

Introduction

This manual contains information needed to properly service the 370B Programmable Curve Tracer as well as general information critical to safe and effective

servicing.

To prevent personal injury or damage to the analyzer, consider the following

before attempting service:

H The procedures in this manual should be performed only by a qualified

service person

H Read the General Safety Summary and the Service Safety Summary,

beginning on page vii

H Read Preparation for Use in section 2, Operating Information

When using this manual for servicing, be sure to follow all warnings, cautions,

and notes.

Performance Check Interval

Strategy for Servicing

Generally, the performance check described in section 4,

Performance Verification, should be done every 12 months. In addition,

performance check is recommended after module replacement.

If the analyzer does not meet performance criteria, repair is necessary.

Throughout this manual, the term, module, refers to any field-replaceable

component, assembly, or part of the analyzer.

This manual contains all the information needed for periodic maintenance of the

370B Programmable Curve Tracer (Examples of such information are procedures

for checking performance.)

Further, it contains all information for corrective maintenance down to the

module level. To isolate a failure to a module, use the fault isolation procedures

found in Troubleshooting, part of section 6, Maintenance. To remove and replace

any failed module, follow the instructions in Removal and Installation

Procedures, also part of section 6. After isolating a faulty module, replace it with

a fully-tested module obtained from the factory. Section 9, Mechanical Parts

List, contains part number and ordering information for all replaceable modules.

370B Service Manual xv

Page 22

Introduction

Tektronix Service Offerings

Tektronix provides service to cover repair under warranty as well as other

services that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well trained to service the waveform

generator. They have access to the latest information on improvements to the

370B as well as new options.

Warranty Repair Service

Self Service

Tektronix warrants this product for one year from date of purchase. The warranty

appears on the back of the title page in this manual. Tektronix technicians

provide warranty service at most Tektronix service locations. The Tektronix

product catalog lists all worldwide service locations or you can visit our Web site

for service information: www.tektronix.com.

Tektronix supports repair to the module level by providing Module Exchange.

Module Exchange. This service reduces down-time for repair by allowing you to

exchange most modules for re-manufactured ones. Each module comes with a

90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the repair or adjustment services just

described.

xvi 370B Service Manual

Page 23

Specifications

Page 24

Page 25

Product Overview

The 370B Programmable Curve Tracer is a high-performance, GPIB-programmable digital storage curve tracer that provides static and dynamic semiconductor device testing. This versatile instrument stimulates, measures, and displays

the semiconductor characteristics of a variety of two-, three-, and four-terminal

devices; including bipolar transistors, field effect transistors, silicon-controlled

rectifiers, diodes, thyristors, opto-isolators, wafers, integrated circuits, etc.

A variety of measurements can be performed using either grounded-emitter or

grounded-base configurations.

The side, top, and bottom cabinet panels provide protection to personnel from

operating potentials present within the instrument. In addition, they reduce

radiation of electromagnetic interference from the instrument. The cabinet panels

are held in place by screws and four plastic panel retainers. To remove the

panels, remove the four plastic retainers and three additional securing screws at

the rear of the instrument. Pull each panel back to release the front edge. then lift

the panels away from the instrument. Operate the instrument with the panels in

place to protect the interior from dust, and to maintain cooling airflow.

The collector supply produces AC, rectified AC, or DC voltages ranging from 0

to 2000 volts. This high voltage, combined with a current sensitivity of

100 pA/div, permits extended breakdown measurements of a device under test. A

step generator produces voltage or current steps of either polarity for application

to the base or emitter terminal. The step generator may also be operated in a

pulsed mode to control the power dissipated by the DUT.

370B Service Manual

In addition to conventional curve tracer performance, the 370B Programmable

Curve T racer includes the following features:

H Digital storage capability that allows bright and stable display and useful

cursor measurements. The 370B has a mass storage system consists of

non-volatile IC memory and 3.5-inch floppy disk drive. Up to 64 families of

characteristic curves and front-panel setups can be stored in a floppy disk.

Up to 16 families of characteristic curves and front-panel setups can also be

stored in non-volatile IC memory. The stored characteristic curves can be

recalled for additional analysis and comparison.

H Two extended acquisition modes, called Averaging and Envelope. Averaging

reduces display noise in high sensitivity ranges. Envelope mode displays

only the maximum and minimum vertical or horizontal excursion of each

curve, which is useful for detecting long-term variations such as thermal

drift.

1- 1

Page 26

Product Overview

H Almost all of the 370B front-panel settings can be controlled by GPIB

commands. (Exceptions are those controls intended only for manual

operation, such as INTENSITY, FOCUS, GRAT ILLUM, etc.) Also, curve

data can be sent to or received from an external controller through the GPIB.

H The printer interface permits sending displayed curve data and digital

on-screen readouts to a printer without an external controller.

H Other features include an auxiliary voltage supply, cursor measurement

readout, and diagnostic routines.

1- 2

370B Service Manual

Page 27

Specifications

This section contains the 370B Programmable Curve Tracer specifications. All

specifications are guaranteed unless labeled “typical”. Typical specifications are

provided for your convenience but are not guaranteed.

Performance Conditions

The performance limits in this specification are valid with these conditions:

H The 370B Programmable Curve Tracer must have been calibrated/adjusted at

H The 370B Programmable Curve Tracer must be in an environment with

H The 370B Programmable Curve Tracer must have had a warm-up period of

H The 370B Programmable Curve Tracer must be operating at an ambient

an ambient temperature between +20

temperature, altitude, humidity, and vibration within the operating limits

described in these specifications.

at least 20 minutes.

temperature between +10

_C and +40 _C.

_C and +30 _C.

Warranted characteristics are described in terms of quantifiable performance

limits which are warranted.

370B Service Manual

1- 3

Page 28

Specifications

Electrical Specifications

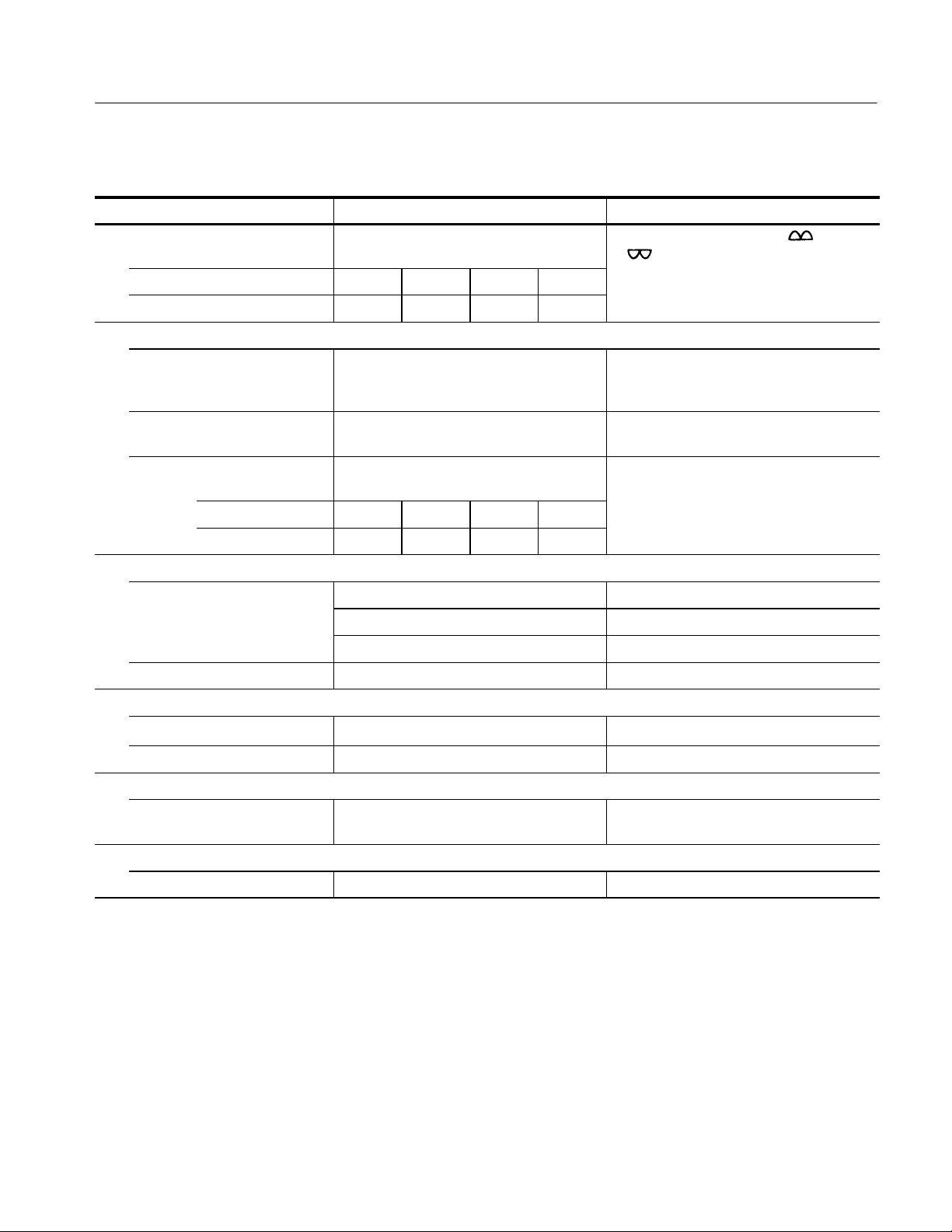

Table 1- 1: Collector Supply

Characteristic Performance Requirement Operating Information

Polarity

+ LEAKAGE Applies positive DC voltage to the collector or

base terminal. Measures emitter current.

Sensitivity is increased 1000 times.

+DC Applies positive DC voltage to the collector or

base terminal. Measures collector or base

current.

+ Applies positive swept voltage to the collector

or base terminal. Measures collector or base

current.

AC Applies line-frequency sine wave to the

collector or base terminal. Measures collector

or base current.

-- Applies negative swept voltage to the

collector or base terminal. Measures collector

or base current.

-- D C Applies negative DC voltage to the collector

or base terminal. Measures collector or base

current.

-- LEAKAGE Applies negative DC voltage to the collector

or base term inal. Measures emitter current.

Sensitivity is increased 1000 times.

DC mode ripple

(no load)

Less than 2% of output voltage. VARIABLE COLLECTOR SUPPLY at 30% or

higher

Less than 0.5% of output voltage. VARIABLE COLLECTOR SUPPLY at 30% or

less

1- 4

370B Service Manual

Page 29

Specifications

availa

c

V*V/(4R)

W

P=VV/(4R)for<220W

Table 1- 1: Collector Supply (Cont.)

Characteristic Operating InformationPerformance Requirement

Max peak volts

Max peak voltage 16 V, 80 V, 400 V, 2000 V Selected by the MAX PEAK VOLTS buttons.

Voltage accuracy Peak open circuit voltage on all ranges within

+15%, --0%.

Current available In PULSE mode of STEP GENERATOR,

Peak volts 16 V 80 V 400 V 2000 V In PULSE mode of STEP GENERATOR,

Range 10 A 2A 0.4 A 0.05 A

Max peak current 20 A 4A 0.8 A 0.1 A

Series Resistance Available Selection of 0.26 Ω,1.3Ω,6.4Ω,32Ω,

Min/Max resistance

peak volts range

Minimum series

resistance (Ω)

Maximum series

resistance (Ω)

Resistance accuracy Within 5% or 0.2 Ω.

Peak power watts available Derived from nominal peak open-circuit

16, 80 and

400 V range

2000 V range 50 W, 10 W, 2 W, 0.4 W, 0.08 W

16 V 80 V 400 V 2000 V

0.26 6.4 160 20 k

800 20 k 500 k 12.5 M,

220 W, 50 W, 10 W, 2 W, 0.4 W, 0.08 W

At MAX PEAK POWER of 50 W.

available current is two times of DC mode.

blecurrent is two times ofDC mode.

160 Ω, 800 Ω,4kΩ,20kΩ, 100 kΩ,

500 kΩ,2.5MΩ, 12.5 MΩ

ollectorvoltageand nominalseries

resistance values.

P=

P = (V--I*R)*I for 220 W

for < 220

Variable collector supply

0 -- 100.0% % of maximum peak voltage value is

displayed in the CRT readout area. Provides

uncalibrated variable collector supply

amplitude control from 0 to 100% in 0.1%

increments.

Safety interlocks The protective cover must be in place over

test terminals and lid shut before voltage can

be applied to the terminals.

When protective cover is open, collector

supply is not operated.

Warning indicator Red light indicates dangerous voltage is

applied to collector or base terminal.

Limiting indicator Indicates that internal sensing circuit

automatic protection is operating.

Looping compensation

Range At least 100 pF. Cancels stray capacitance between DUT

terminal and ground.

370B Service Manual

1- 5

Page 30

Specifications

Table 1- 1: Collector Supply (Cont.)

Characteristic Operating InformationPerformance Requirement

Sweep start voltage accuracy

Applicable to FULL WAVE mode. Due to

stray capacitance between collector and

ground terminals, zero-volt-error may occur

because of charged offset voltage.

16, 80, 400 V range

2000 V range

Thermal cutoff (typical)

Operating temperature

Current limit

Operating point At least 2.0 A, 1.2 A and 0.2 A of primary

Voltage limit

Operating point 50%, 25%, 5% of Max Peak Volts. Depends on Horizontal and Max Peak Volts

Arc killer Collector supply is disabled at least one cycle

Output control Circuit Breaker mounted on the front panel

2% of MAX Peak Voltage.

15% of MAX Peak Voltage.

70 _C 2.8 _C

current of collector transformer.

For Collector Supply Amplifier and Series

Resistors.

Depends on Vertical and Max Peak Volts

settings.

settings.

while the relays or switches are operated.

enables and disables Collector supply,Step

Generator and AUX source.

No trip for 1.5 A of Collector Transformer

primary current. (100% rating of circuit

breaker)

Trip occurs between 3 second and 80 second

for 2.025 A of Collector Transformer primary

current. (135% rating of circuit breaker)

NOTE: The collector supply is limited to a maximum continuous peak current operating time under the following duty cycle and ambient

temperature conditions:

50 W. Maximum continuous operating time at rated current (100% duty cycle) into a short circuit is 20 minutes at 25_C ambient, or

10 minutes at 40_C ambient.

220W. Maximum continuous operating time at rated current(, 100% duty cycle) into a short circuit is 3 m inutes at 25_C ambient, or

90 seconds at 40_C ambient.

Alternatively, the duty cycle may be limited to 50% at 25_C ambient or 25% at 40_C ambient. (A normal family of transistor curves will

produce a duty cycle effect to 50% or less, even if operated continuously.)

Collector Supply over-dissipation temporarily shuts off the power, and prints a message on the screen. Collector Supply over-current

trips the OUTPUTS breaker, prints a message on the screen, and reset the Collector Supply output to 0%. No damage results when

over-dissipation occurs.

1- 6

370B Service Manual

Page 31

Specifications

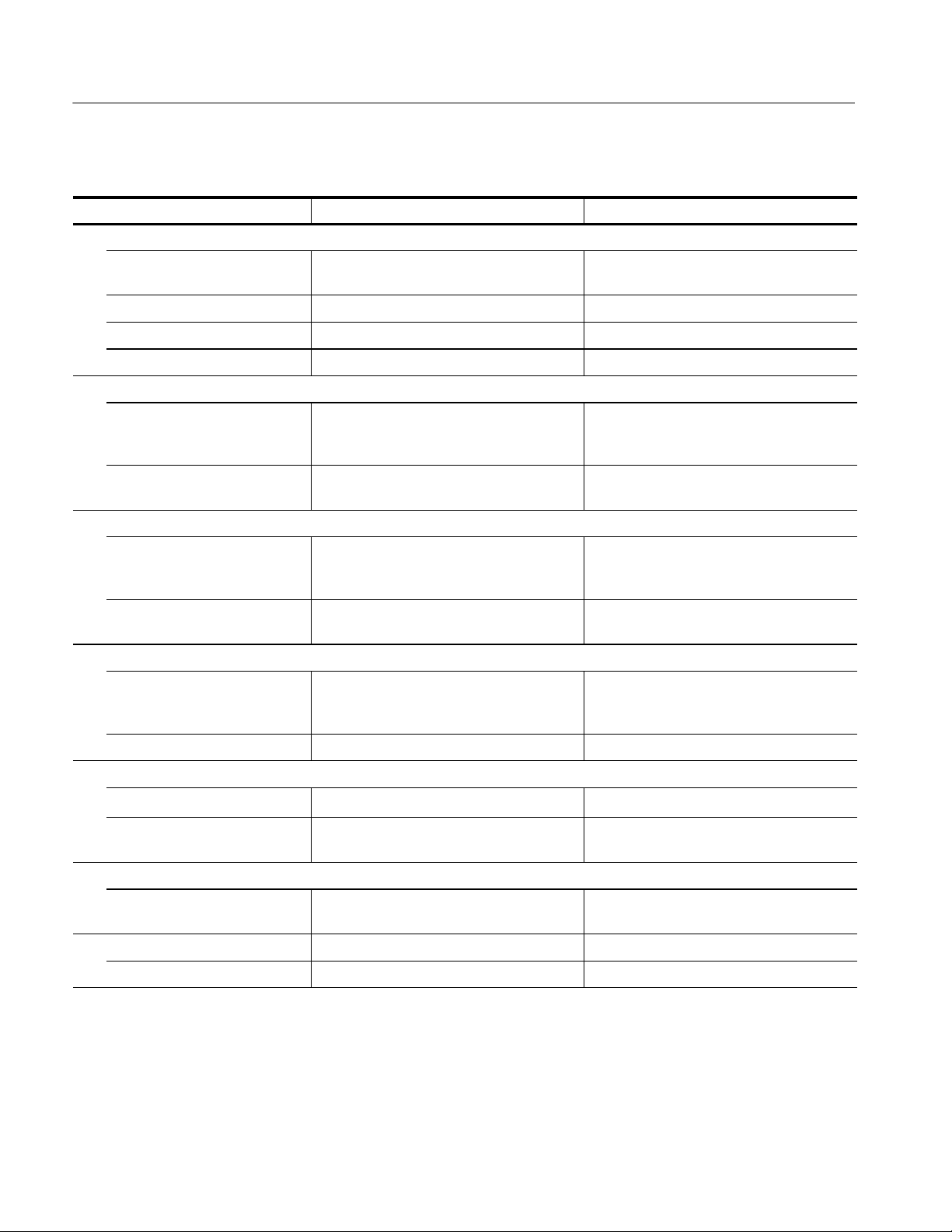

Table 1- 2: Step Generator

Characteristic Performance Requirement Operating Information

Accuracy Current or Voltage Steps including Offset.

Incremental 1.5%

Absolute Less than 1.5% of total output + 3% x STEP

AMPLITUDE setting + 1 mV or 1 nA.

Less than 1.5% of total output + 10% x STEP

AMPLITUDE setting + 1 mV or 1 nA.

Offset control range Variablefrom--10to+10timesSTEP

AMPLITUDE.

Resolution STEP AMPLITUDE setting x 1%

Step transition timing (typical) Within 3% of collector peak volts including

jitter.

Current mode

Amplitude range 50 nA to 200 mA in a 1 --2--5 sequence of

21 steps.

Maximum current 20 x STEP AMPLITUDE setting, except 10 x

STEP AMPLITUDE when control is set to

200 mA.

Maximum voltage At least 10 V. Steps and aiding offset.

Maximum opposing offset current 10 x STEP AMPLITUDE.

Maximum opposing volts Less than 15 V. When the voltage limiter is working in

Ripple plus noise Less than 0.5% x STEP AMPLITUDE +

10 nA.

With .1X STEP MULTI pressed.

Polarity is in AC mode.

Steps and aiding offset.

opposing current setting condition, the step

generator output current value is not

guaranteed.

BW = 20 MHz, with open circuit.

1

Maximum inductive load (typical) 1 H

Output impedance (typical) More than 1/(0.3% of STEP AMPLITUDE

current setting per volt) Ω

Fall and rise time (typical) Within 25 s for 1 step or 100 s for 10

steps.

Overshoot and undershoot

(typical)

Within 10% of transition amplitude. 1kΩ load, 100 A/step.

370B Service Manual

1kΩ load, 100 A/step.

1- 7

Page 32

Specifications

Table 1- 2: Step Generator (Cont.)

Characteristic Operating InformationPerformance Requirement

Voltage Mode

Amplitude switch range 50 mV to 2 V, in a 1--2--5 sequence of

6 steps

Maximum voltage 20 x STEP AMPLITUDE

Maximum current At least 500mA at 10V or less, at least

200mA at 15 V, at least 10 mA at 40 V.

Short circuit current limiting 500 mA, +50%, --20%

Maximum opposing offset volts 10 x STEP AMPLITUDE

Maximum opposing current Less than 20 mA

Ripple plus noise Less than 0.5% x STEP AMPLITUDE

+10mV

Maximum capacitive load

(typical)

Output Impedance (typical) 200 mΩ or less

Fall and rise time (typical) Within 50 s for 1 step or 100 sfor

Overshoot (typical) Within 10% of transition amplitude. 1 kΩ

Step rates 2 x li ne frequency (1 x line frequency in AC

Pulsed steps

Steps and offset polarity Corresponds to Collector Supply Polarity

0.01 F

10 steps. 1 kΩ load, 2 V/step.

load, 2 V/step.

collector supply mode). Steps occur at 0

collector voltage.

80 s or 300 s wide, 10%

when STEP GENERATOR POLARITY

INVERT is disabled.

Opposite to Collector Supply Polarity when

STEP GENERATOR POLARITY INVERT is

selected or CONFIGURATION switch is set

to BASE COMMON.

BASE COMMON configuration disables

STEP GENERATOR POLARITY INVERT.

2

BW = 20 MHz, with open circuit.

1kΩ load at 2 V/step

1kΩ load at 2 V/step

At mesial line, with 1 kΩ load, 1 mA /STEP

Number of steps Ranges from 0 to 10.

1- 8

370B Service Manual

Page 33

1

Available max current of Step Generator in 100 mA and 200 mA/step.

Specifications

Step Generator Current

2A

0A

0V 8V 10V

Load Voltage

2

Step Generator max voltage output, in 2 V/step.

0.01 A, 40 V

40 V

Step Generator Voltage

8V,2A

0.2A,15V

15 V

10 V

0V

10 mA

0.2 A

0.5A,10V

0.5 A

Load Current

370B Service Manual

1- 9

Page 34

Specifications

Table 1- 3: AUX Supply

Characteristic Performance Requirement Operating Information

Range From --40 to +40 volts, with 20 mV step

resolution.

Accuracy Within 50 m V + 1.5% of total output.

Output current

At least 100 mA at 20 V. At least 10 mA at

40 V.

Ripple pulse noise Less than 50 mV

3

Max voltage output and current of AUX SUPPLY.

40 V

AUX Supply Voltage

20 V

0V

10 mA

3

p--p.

0.01 A, 40 V

0.1A,20V

100 mA

Load Current

Table 1- 4: Non-store Vertical Deflection System

Characteristic Performance Requirement Operating Information

Cursor WINDOW

Accuracy (typical) Within 0.06 division.

Collector/Base current

Range 1 A/div to 2 A/div in a 1--2--5 sequence.

x10 MAG extends maximum sensitivity to

100 nA/div (1 nA resolution).

Accuracy (typical) Within 2% of WINDOW cursor readout + 0.1

x VERT/DIV setting.

1- 10

370B Service Manual

Page 35

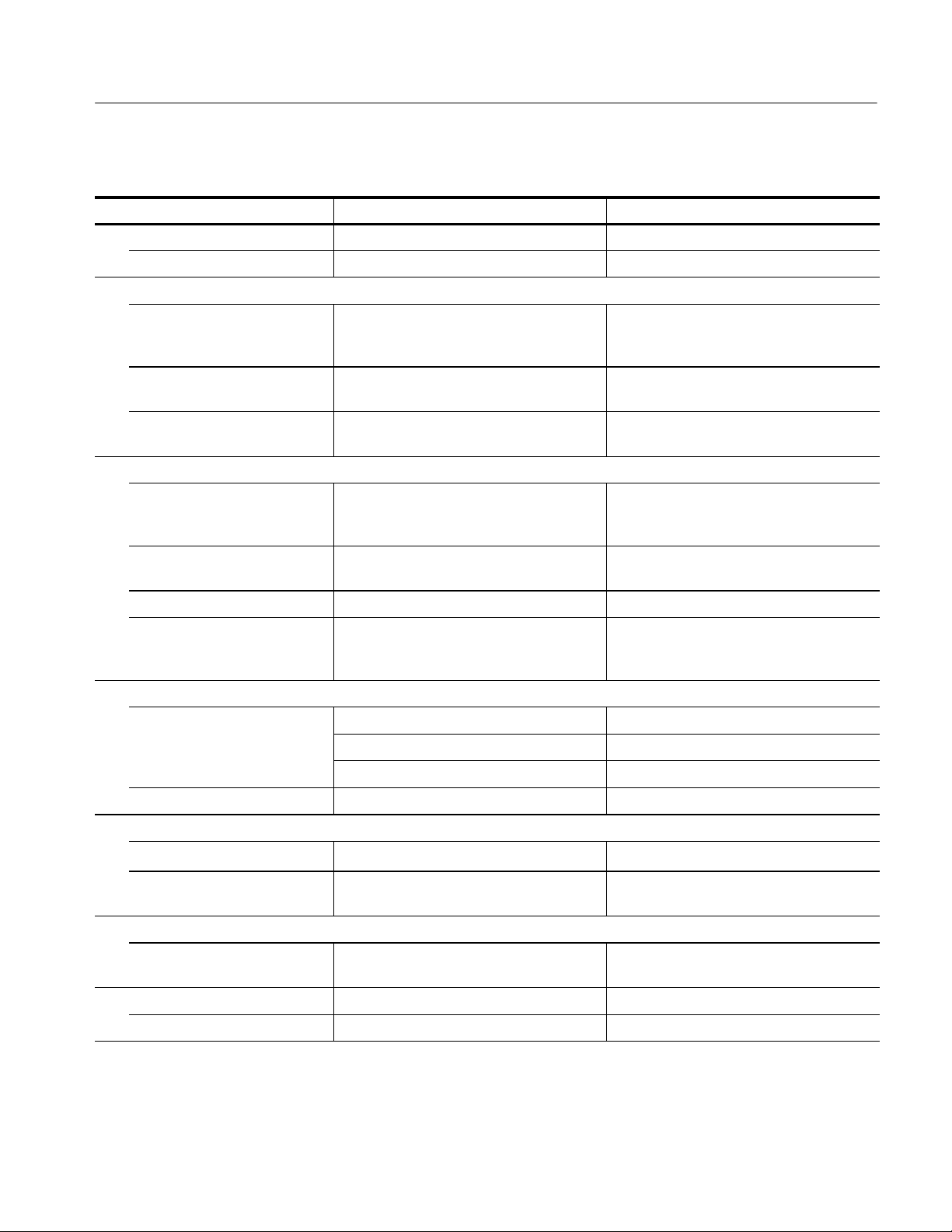

Table 1- 4: Non-store Vertical Deflection System (Cont.)

Characteristic Operating InformationPerformance Requirement

Maximum displayed noise or

ripple

Max volts range 16 V 80 V 400 V 2000 V

Specifications

Except tor switching noise at + and

-- mode.

Noise or ripple 1 A

p--p

1 A

p--p

2 A

p--p

Emitter current

Range 1 nA/div to 2 mA/div in a 1--2--5 sequence.

x10 MAG extends maximum sensitivity to

100 pA/div.

Accuracy Within 2% of WINDOW cursor readout +0.1 x

VERT/DIV settings + 1 nA

Maximum displayed noise or

Depending on setting of MAX PEAK VOLTS

ripple

Max Volts Range 16 V 80 V 400 V 2000 V

Noise or Ripple 1nA

p--p

1nA

p--p

2nA

p--p

Step generator display

Range (typical) 1 step/division

1 step/10 divisions With x10 MAG

10 steps/division With STEP MULTI .1 x

Accuracy Within 0.3 division.

Display offset (typical)

Range

10 divisions with 0.1 div resolution.

Accuracy Within .% of offset + 0.1 x VERT/DIV setting

5 A

5nA

p--p

Collector Supply Polarity is either +LEAKAGE or --LEAKAGE mode.

p--p

Display x10 MAG (typical)

Accuracy Within 1.5% of window cursor readout + 0.3

x VERT/DIV setting.

Display invert (typical)

Accuracy Within 0.1 x VERT/DIV setting

370B Service Manual

1- 11

Page 36

Specifications

Table 1- 5: Digital Storage Vertical Acquisition

Characteristic Performance Requirement Operating Information

A/D converter

Resolution 10 bits for 10.24 divisions, 100 counts per

division.

Max data points 1024

Max sampling rate Line frequency x 1024

Min sampling rate Line frequency x 2

Collector/Base current

Range 1 A/div to 2 A/div in a 1 -- 2--5 sequence.

x10 MAG extends maximum sensitivity to

100 nA/div (1 nA resolution).

Accuracy Within 1.5% of DOT cursor readout + 0.05 x

VERT/DIV setting.

Emitter current

Range 1 nA/div to 2 mA/div in a 1--2--5 sequence.

x10 MAG extends max sensitivity to

100 pA/div (1 pA resolution).

Accuracy Within 1.5% of DOT cursor readout + 0.05 x

VERT/DIV setting + 1 nA.

Step generator display

Range 1 step/division

1 step/10 divisions

10 steps/division

Accuracy Within 0.3 division.

Display offset

Range

Accuracy Within 1.5% of offset +0.06 x VERT/DI V

Display x10 MAG

Accuracy Within 1.5% of DOT cursor readout +0.3 x

Display invert

Accuracy Within 0.04 x VERT/DIV setting.

10 divisions in 0.1 division resolution.

setting.

VERT/DIV setting.

Collector supply polarity is either +LEAKAGE

or -- LEAKAGE

With x10 MAG

With STEP MULTI .1 x

1- 12

370B Service Manual

Page 37

Table 1- 6: Non-store Horizontal Deflection System

Characteristic Performance Requirement Operating Information

Cursor WINDOW Cursor

Accuracy (typical) Within 0.06 division.

Collector volts

Range 50 mV/div to 500 V/div in a 1 --2--5 sequence.

x10 MAG extends maximum sensitivity to

5 mV/div (50 V resolution).

Accuracy (typical) Within 2% of WINDOW cursor readout + 0.1

x HORIZ/DIV setting.

Maximum displayed noise Less than 0.02% of MAX PEAK VOLTS

setting.

Base/Emitter volts

Range 50 mV/div to 5 V/div in a 1--2--5 sequence.

x 10 MAG extends maximum sensitivity to

5 mV/div (50 V resolution).

Specifications

Accuracy (typical) Within 2% of WINDOR cursor readout + 0.1 x

HORIZ/DIV setting.

Input impedance At least 100 MΩ.

Maximum displayed noise Less than 10 mV

Step generator display

Range 1 step/division

1 step/10 division With x10 MAG

10 steps/division With STEP MULTI .1 x

Accuracy Within 0.3 division.

Display offset

Range

Accuracy Within 1.5% of offset + 0.1 x HORIZ/DIV

Display x10 MAG

Accuracy Within 1.5% of window cursor readout + 0.3 x

Display invert

10 divisions in 0.1 division steps.

setting.

HORIZ/DIV setting.

p--p.

With 1 MΩ resistor connected between Base

and Emitter terminals, BASE OPEN

configuration, and 0 Number of Steps.

Accuracy Within 0.1 x HORIZ/DIV setting.

370B Service Manual

1- 13

Page 38

Specifications

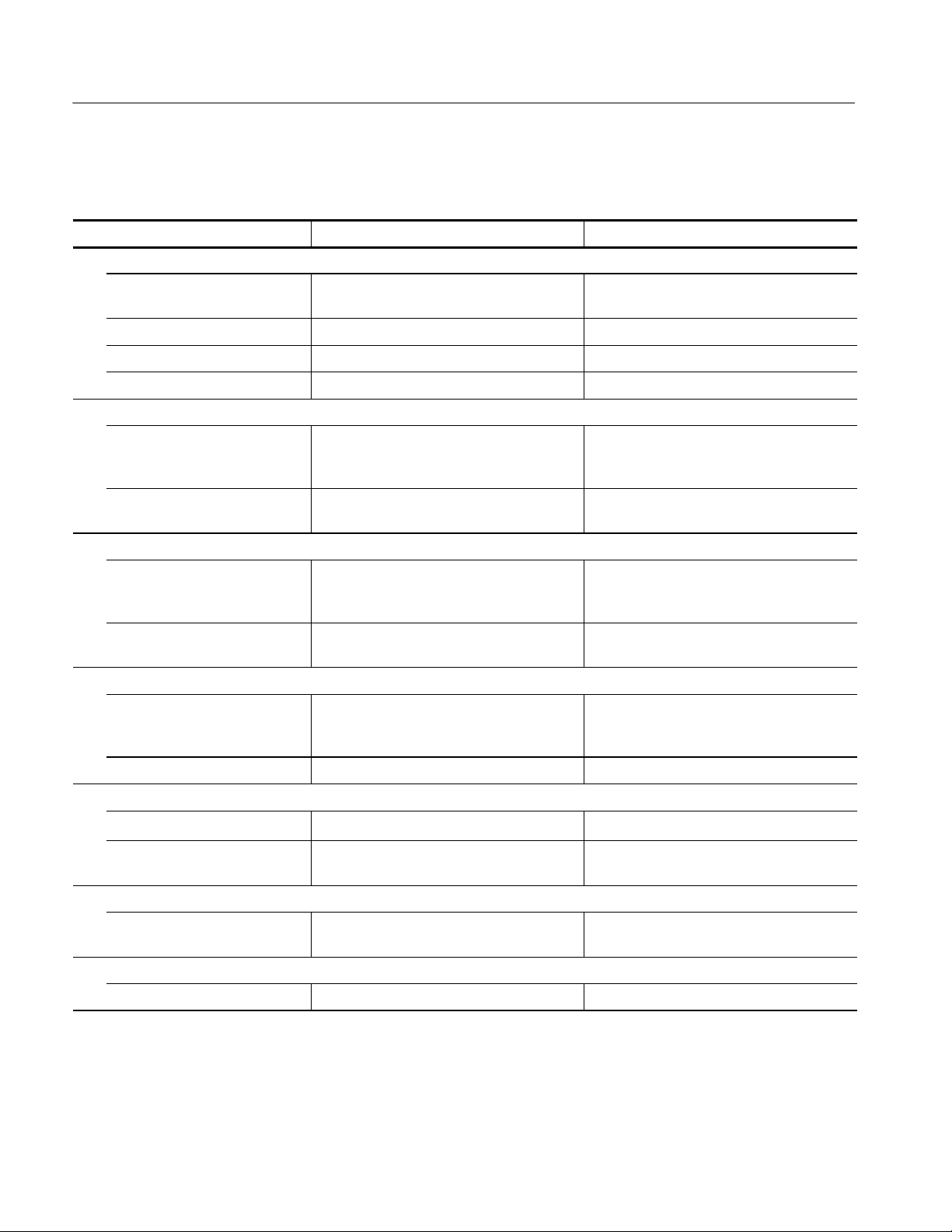

Table 1- 7: Digital Storage Horizontal Acquisition

Characteristic Performance Requirement Operating Information

A/D converter

Resolution 10 bits for 10.24 divisions. 100 counts per

division.

Max data points 1024

Max sampling rate Line frequency x 1024

Min sampling rate Line frequency x 2

Collector volts

Range 50 mV/div to 500 V/div in a 1--2--5 sequence.

X10 MAG extends maximum sensitivity to

5 mV/div (50 V resolution).

Accuracy Within 1.5% of dot cursor readout + 0.05 x

HORIZ/DIV setting.

Base/Emitter volts

Range 50 mV/div to 5 V/div in a 1--2--5 sequences.

x 10 MAG extends maximum sensitivity to

5 mV/div (50 V resolution)

Accuracy Within 1.5% of dot cursor readout + 0.05 x

HORIZ/DIV setting.

Step generator display

Range 1 step/division

1 step/10 divisions

10 steps/division

Accuracy (typical) Within 0.3 division.

Display offset

Range

Accuracy Within 1.5% of DOT cursor readout + 0.01 x

Display x10 MAG

Accuracy Within 1.5% of DOT cursor readout + 0.3 x

Display invert

Accuracy Within 0.04% x HORIZ/DIV setting.

10 divisions in 0.1 division resolution.

HORIZ/DIV setting.

HORIZ/DIV setting.

With X10 MAG

With STEP MULTI .1 x

1- 14

370B Service Manual

Page 39

Table 1- 8: CRT and Readout

Characteristic Performance Requirement Operating Information

CRT

Type Electrostatic deflection

Phosphor P31

Acceleration potential 12 kV typical

Screen size 178mm(7 in) diagonal internal graticule and

on-screen scale factor readout.

Specifications

Total addressable points

1000 x 1000

(graticule area)

Geometry 0.5 minor division or less of tilt or bowing;

0.75 minor division or less of keystone.

Resolution At least 10 lines/div

Spot size Within 0.95 mm at screen center; elsewhere

on screen: within twice center value.

Orthogonality 90_,within0.3_

Trace rotation range (typical)

At least 3_

READOUT Automatic on-screen display. Over range

shown by a flashing display.

VERT/DIV 100 pA to 2 A

HORIZ/DIV 5mVto500V.

PER STEP 5nAto200mA,and5mVto2V.

OFFSET 4-digit value.

β or gm/DIV 500 x 10

50 x 10

-- 9

to 400 x 106for β and

-- 9

S to 400 S for gm

CURSOR 4-digit Horizontal and Vertical values without

x 10 MAG, 5-digit with MAG.

% of COLLECTOR PEAK VOLTS 0.0% to 100.0% in 0.1% step.

Aux Supply -- 40.00 V to + 40.00 V

370B Service Manual

1- 15

Page 40

Specifications

Table 1- 9: Adapter Connectors

Characteristic Performance Requirement Operating Information

Collector

Collector Sense

Maximum output voltage

Maximum output current

Base

Base Sense

Maximum output voltage

Maximum output current

Emitter

Emitter Sense

Maximum output voltage

Maximum output current

Step Gen Out connector

Maximum output voltage

Maximum output current

Aux Supply Connector

Maximum output voltage

and current

2000 V

20 A

400 V

20 A

40 V

20 A

40 V

2A

40 V @ 10 mA, or

20 V @ 100 mA.

Ext Base or Emitter Connector

Maximum input voltage

Maximum input current

1- 16

40 V

2A

370B Service Manual

Page 41

Table 1- 10: Power Supply

Characteristic Performance Requirement Operating Information

Rating voltage 115 VA C / 2 3 0 VAC

Line voltage range

115 VA C High 107 VAC to 132 VAC

Low 90 VAC to 110 VAC

230 VAC High 214 VAC to 250 VAC

Low 180 VAC to 220 VAC

Frequency range 48.0 to 63.0 Hz

Power consumption Max. 400 W, 3.5 A

Typical 120 W, 1.3 A at 115 V, 50 Hz

Fuse

115 VA C 125 V, 4 A, Sl ow-Blow

230 VAC 250 V, 2 A, Slow-Blow

Specifications

Table 1- 11: Surge Current

Characteristic Description

Surge current

80 A peak (25_C) for 5 line cycles, after product has been turned off for at least 30 s.

Mechanical Specifications

Table 1- 12: Mechanical Specification

Characteristic Performance Requirement Operating Information

Net weight

Standard instrument Approx. 37 k g (82 lb)

Option 1R Approx. 38 k g (84 lb)

Dimensions

Height 326 mm (12.8 in) with feet

310 mm (12.2 in) without feet

Width 429 mm (16.9 in)

Depth 635 mm (25.0 in)

370B Service Manual

1- 17

Page 42

Specifications

Functional Specifications

Table 1- 13: Digital Storage Acquisition Mode

Characteristic Performance Requirement Operating Information

Normal Acquires and displayed each curve.

Envelope

Vertical envelope Acquires and displays the maximum and

minimum vertical excursion of each curve.

Horizontal envelope Acquires and displays the maximum and

minimum horizontal excursion of each curve.

Averaging Acquires and displays the average of last 16

acquisitions.

Table 1- 14: Text Display

Characteristic Performance Requirement Operating Information

Alphanumeric character

Set (1)

Alphanumeric character

Set (2)

Maximum text string length 24 characters

Character size Approximately 3 mm height, 2 mm width.

ASCII character set except double quote (”),

u is recognized as )

GPIB-accessible with the TEXT command.

A,B,....,Y,Z,(Space),m, u,

n,o,,,0,........,9,--,*,(,),

Accessible with the Position Control buttons.

1- 18

370B Service Manual

Page 43

Environmental Specifications

Table 1- 15: Environmental Specification

Characteristic Performance Requirement

Temperature

Operating +10 _Cto+40_C

Non-operating -- 2 0 _Cto+60_C

Transportation -- 4 0 _Cto+65_C

Temperature gradient

Specifications

Operating

Non-operating

Humidity

Operating and Non-operating Five cycles (120 hours) with equipment tested at 80% relative humidity. Tested on-operating

Relative Humidity

Operating 20% to 80% (no condensation)

Storage 10% to 90% (no condensation)

Transportation 5% to 95% (no condensation)

Altitude

Operating Up to 3.0 km (10000 feet).

Non-operating Up to 15 km (50000 feet).

Vibration

Operating 2.352 m/s2(0.24 G

Shock (non--operating) 196 m/s2(20 G), hal f-sine, 11 ms duration.

≤15 _C per hour (no condensation)

≤30 _C per hour (no condensation)

at 60 _C and operating to meet MIL-STD-810C method 507.1 procedure IV, modified as

specified in MIL-T-28800B paragraph 4.5.1.1.2.

Maximum wet bulb temperature shall be 29 _C.

Maximum wet bulb temperature shall be 40.0 _C.

Maximum wet bulb temperature shall be 45.0 _C.

Maximum operating temperature decreases 1 _C each 1,000 feet above 1.5 km (5,000 feet).

),5Hzto500Hz

rms

Three shocks per axis in each direction (18 shocks total)

Bench handling

Operating Drop from 10 cm (4 in) tilt, or 45 _ which ever less (Tilt not to balance to point.)

Packaged transportation drop Meets the limits of the National Safe Transit Association test procedure 1A--B--2; 10 drops of

61 cm (24 in).

Packaged transportation vibration Meets the limits of the National Safe Transit Association test procedure 1A--B--1 ;excursion of

2.5 cm (1 in) p--p at 4.63 Hz 10.8ms/s

2

(1 .1 G) for 60 minutes.

370B Service Manual

1- 19

Page 44

Specifications

Table 1- 16: Certifications and Compliances

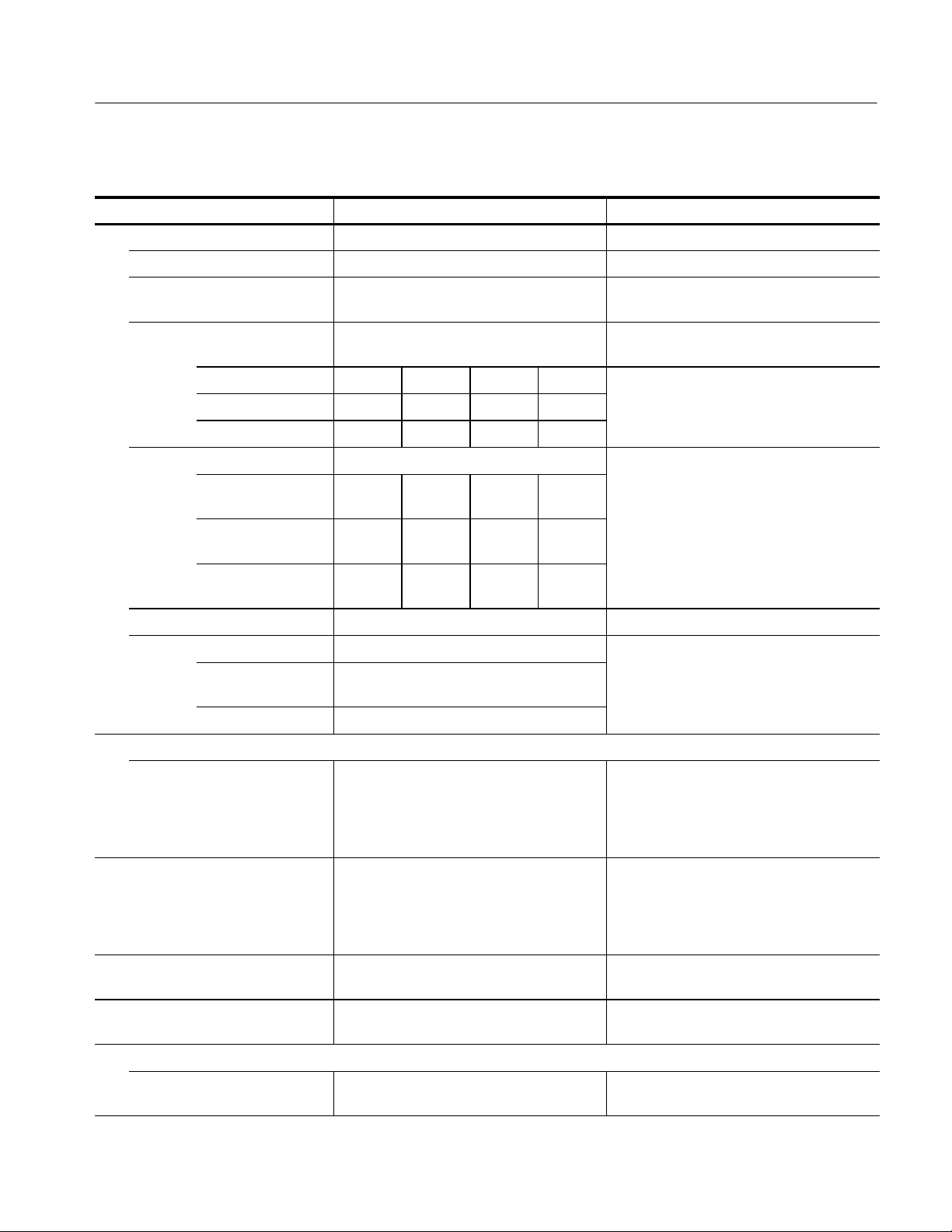

Category Standards or description

EC Declaration of Conformity -EMC

Emissions EN 55011 Class A Radiated and Conducted Emissions

Immunity EN 61000-4-2 Electrostatic Discharge Immunity

Australia/New Zealand

Declaration of Conformity -- EMC

Safety UL3111-1

Self-Declaration EN 61010-1 with second amendment

Installation Category Power input -- Installation Category II (as defined in IEC 61010--1, Annex J)

Meets intent of Directive 89/336/EEC, amended by 93/68/EEC;

EN 61326-1: 1997 Product Family Standard for Electrical Equipment for Measurement,

Control, and Laboratory Use-EMC Requirement.

EN 61000-3-2 Power Line Harmonic

EN 61000-3-3 Line Voltage Alteration and Flicker

EN 61000-4-3 Radiated RF Electromagnetic Field Immunity

Note: The output level of Step Generator may vary in this test.

EN 61000-4-4 Electrical Fast Transient/Burst Immunity

EN 61000-4-5 Surge Immunity

Note: The output level of collector supply may decrease in this test.

EN 61000-4-6 Conducted Disturbance induced by RF Field Immunity

EN 61000-4-8 Power Frequency Electromagnetic Field Immunity

EN 61000-4-11 Voltage Drop, Short Interruptions and Voltage Variations Immunity

Note: The output of Collector Supply is disabled after this test.

Complies with EMC provision of Radio Communications Act per the following standard:

Industrial, Scientific, and Medical Equipment: 1992

CAN/CSA C22.2 NO. 1010.1

Pollution Degree Pollution degree 2 (as defined in IEC 61010--1)

1- 20

370B Service Manual

Page 45

Specifications

Table 1- 17: Installation category and Pollution degree Descriptions

Characteristics Description

Installation category Terminals on this product may have different installation category designations. The

installation categories are:

Category Descriptions

CAT III Distribution-level mains (usually permanently connected).

Equipment at this level is typically in a fixed industrial

location

CAT II Local-level mains (wall sockets). Equipment at this level

includes appliances, portable tools, and similar products.

Equipment is usually cord-connected

Pollution degree

CAT I

A measure of the contaminates that could occur in the environment around and within a

product. Typically the internal environment inside a product is considered to be the same

as the external. Products should be used only in the environment for which they are rated.

Category Descriptions

Pollution Degree 1 No pollution or only dry, nonconductive pollution occurs.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs.

Pollution Degree 3

Pollution Degree 4 Pollution that generates persistent conductivity through

Secondary (signal level) or battery operated circuits of

electronic equipment

Products in this category are generally encapsulated,

hermetically sealed, or located in clean rooms.

Occasionally a temporary conductivity that is caused by

condensation must be expected. This location is a typical

office/home environment. Temporary condensation occurs

only when the product is out of service.

Conductive pollution, or dry, nonconductive pollution that

becomes conductive due to condensation. These are

sheltered locations where neither temperature nor humidity is

controlled. The area is protected from direct sunshine, rain,

or direct wind.

conductive dust, rain, or snow. Typical outdoor locations.

370B Service Manual

1- 21

Page 46

Specifications

GPIB Interface

The IEEE-488-1978 (GPIB) standard defines the GPIB interface functions and

the allowed subsets of those functions.

Table 1- 18: GPIB Interface

Function Implemented As

Source handshake SH1

Acceptor handshake AH1

Tal k er T6

Listener L4

Service request SR1

Remote local RL2

Parallel poll PP0

Device clear DC1

Device trigger DT0

Controller C0

1- 22

370B Service Manual

Page 47

Operating Information

Page 48

Page 49

Operating Information

This section provides the following information:

H Initial inspection procedure

H Installation procedures

H Kelvin Sense

H Rackmounting Information

H Repackaging procedure for shipment

Installation

Initial Inspection

Power Source Information

This instrument was thoroughly inspected for mechanical and electrical defects

before shipment. It should be free of mars or scratches and meet or exceed all

electrical specifications. To confirm this, inspect the instrument for physical

damage incurred in transit and test the electrical performance by following the

First Time Operation in the 370B Programmable Curve Tracer User Manual.

This instrument operates from a power source having a neutral or near ground

(earth) potential. It is not intended for operation from two phases of a multiphase system, nor across legs of a single phase, three wire system. This

instrument can be operated from either a 115 volt or 230 volt nominal supply

source, 48 to 63 Hz. Table 2-- 1 is a listing of the line voltage ranges, line

frequency range, and power consumption.

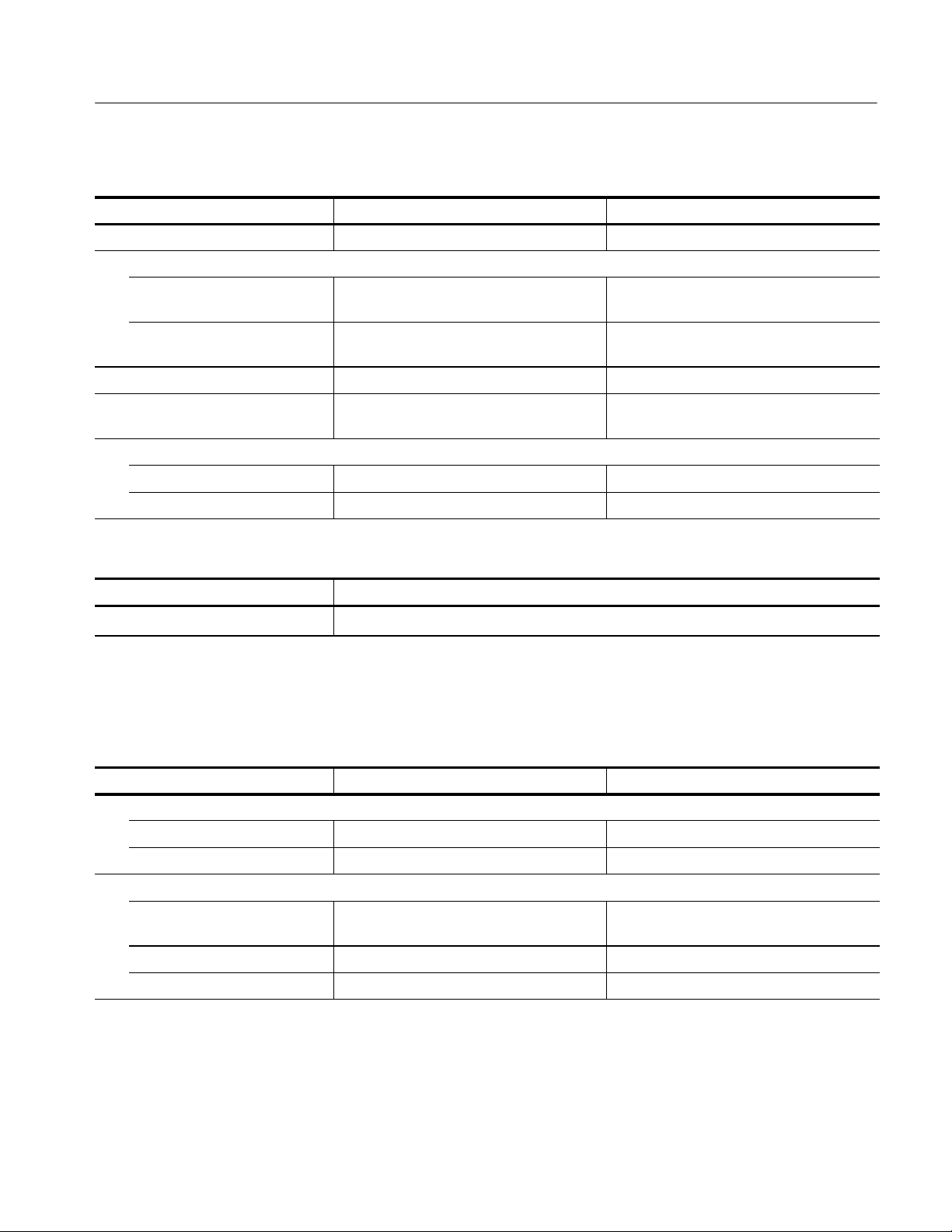

Table 2- 1: Line voltage ranges

RANGE switch NORM AL switch

115 VA C 230 VAC

HIGH 107 VAC to 132 VAC 214 VAC to 250 VAC

LOW 90 VAC t o 110 VAC 180 VAC to 220 VAC

Power consumption

370B Service Manual

Max. 400 W, 3.5 A at 132 V, 60 Hz

Typical 120 W, 1.3 A at 115 V, 50 Hz

2- 1

Page 50

Getting Started

Operating Voltage

Selection and Line Fuse

Verification

The LINE VOLTAGE SELECTOR switches (NOMINAL and RANGE, located

on the rear panel) allow selection of the operating line voltage. To select the

correct operating line voltage:

1. Disconnect the 370B from the AC power source before changing the

operating voltage.

2. Select the nominal AC power source voltage with the NOMINAL switch,

and

3. Select the operating line voltage with the RANGE switch.

CAUTION. To prevent damage to the instrument, always check the settings of the

LINE VOLTAGE SELECTOR switches located on the rear panel of the 370B

before connecting the instrument to the line voltage source.

To verify that the power input fuse is for the nominal AC source voltage

selected, perform the following:

1. Use the small straight slot screwdriver to pry the cap (with the attached fuse

inside) out of the fuse holder.

2. Verify proper fuse value:

Power Cord Information

Nominal voltage 230 V 2 A medium blow

Nominal voltage 115 V 4 A medium blow

3. Install the proper fuse and reinstall the fuse holder cap.

A power cord with the appropriate plug configuration is supplied with each

instrument. The color coding of the power cord conductors appears in Table 2--2.

Also, should you require a power cord plug other than that supplied, refer to

Table 2--3, Power Cord Identification.

Table 2- 2: Power Cord Color Conductor Identification

Conductor Color Alternate

Ungrounded (Line) Brown Black

Grounded (Neutral) Light Blue White

Grounded (Protective Ground) Green / Yellow Green / Yellow

2- 2

370B Service Manual

Page 51

Getting Started

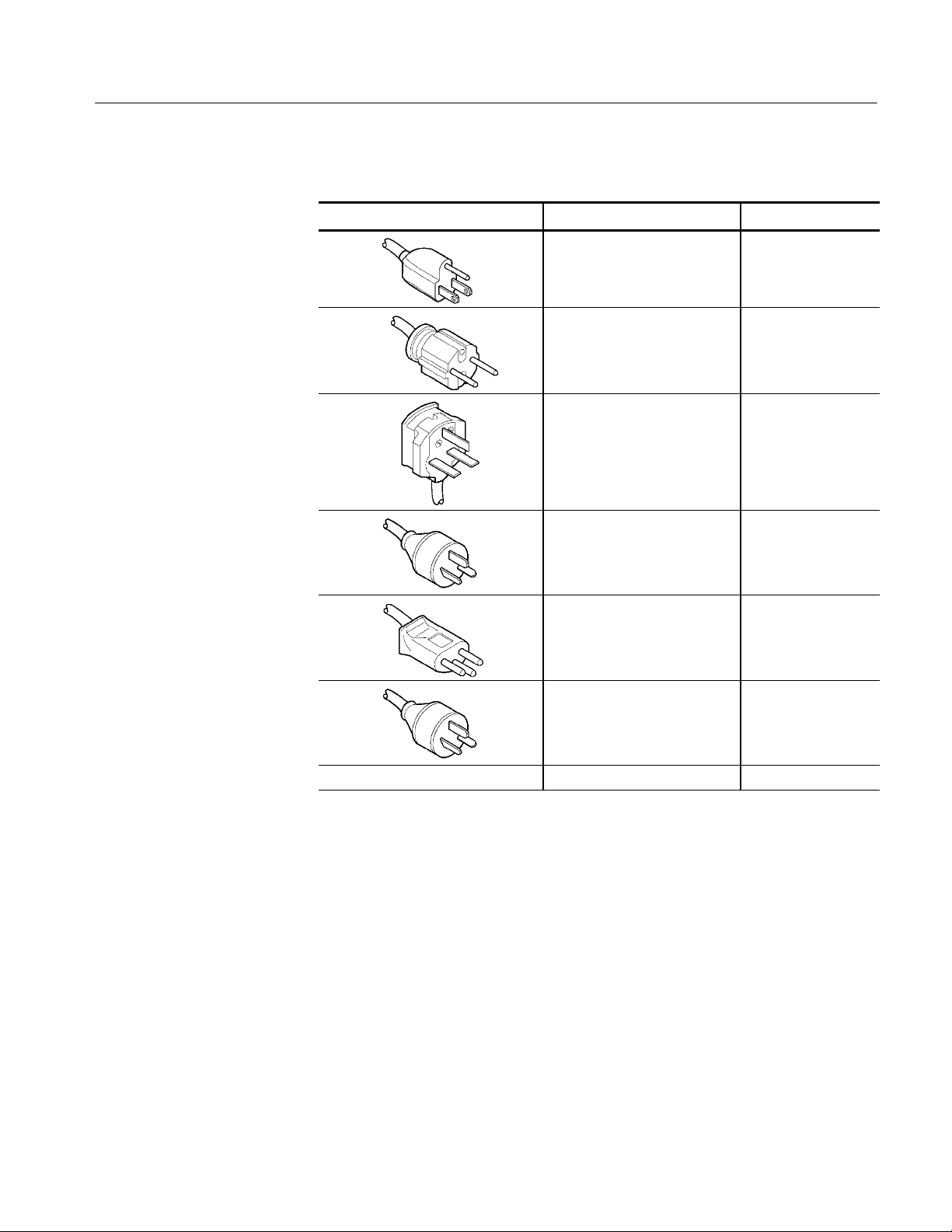

Table 2- 3: Power cord identification

Plug configuration Normal usage Option number

North America

125 V

Europe

220 V

United Kingdom

240 V

Australia

240 V

Switzerland

220 V

China

240 V

Standard

A1

A2

A3

A5

AC

370B Service Manual

No power cord supplied. A9

2- 3

Page 52

Getting Started

WARNING. This instrument operates from a single phase power source, and has a

detachable three-wire power cord with a two-pole, three-terminal grounding type

plug. The voltage to ground (earth) from either pole of the power source must

not exceed the maximum rated operating voltage (250 volts rms).

Before making connection to the power source, make sure that the instrument is

set for the pow er source voltage, and is equipped with a suitable plug (two-pole,

three-terminal, grounding type).

This instrument is safety class 1 equipment (IEC* designation). All accessible

conductive parts are directly connected through the grounding conductor of the

power cord to the grounding contact of the pow er plug. Therefore, the power

plug must only be inserted in a mating receptacle with a grounding contact. Do

not defeat the grounding connection. Any interruption of the grounding

connection can create an electric shock hazard.

For electric shock protection, connect the instrument to ground before connecting to the instrument input or output terminals.

* International Electrotechnical Commission.

Operating Temperature

The 370B can be operated where the ambient air temperature is between +10

and +40

_C. After storage at temperatures outside the operating limits, allow the

_C

chassis temperature to reach the safe operating limits before applying power. The

370B is cooled by air drawn in through the air filter on the rear panel and blown

out through holes in the side panels. For proper instrument cooling, provide

adequate clearance on the rear and sides of the instrument to ensure free air flow

and dissipation of heat away from the instrument.

WARNING. Following use of the 370B at high power settings, the device, fixture,

or protective cover may be hot enough to cause injury. Avoid touching any of

these items until cooled.

2- 4

370B Service Manual

Page 53

Getting Started

Test adapter and

Protective cover

To use the 370B to display and measure the characteristic curves of most

devices, a test adapter and the protective cover must be installed. Four test

adapters are provided as standard accessories. Six other test adapters are

available as optional accessories. The test adapter is inserted into the adapter

connectors provided on the front panel. These connectors allow two devices to

be set up at a time.

WARNING. Dangerous voltage may appear at the front panel collector and base

terminals. To avoid injury or equipment damage, do not remove the protective

cover.

CAUTION. Double-wide test adapters are designed to fit in the left set of adapter

connectors. If you try to forcibly install a double-wide test adapter in the right

side, you might damage the connector. The connectors are identified by the

following numbers:

A1006

A1007

A1009

A1010

Kelvin Sense

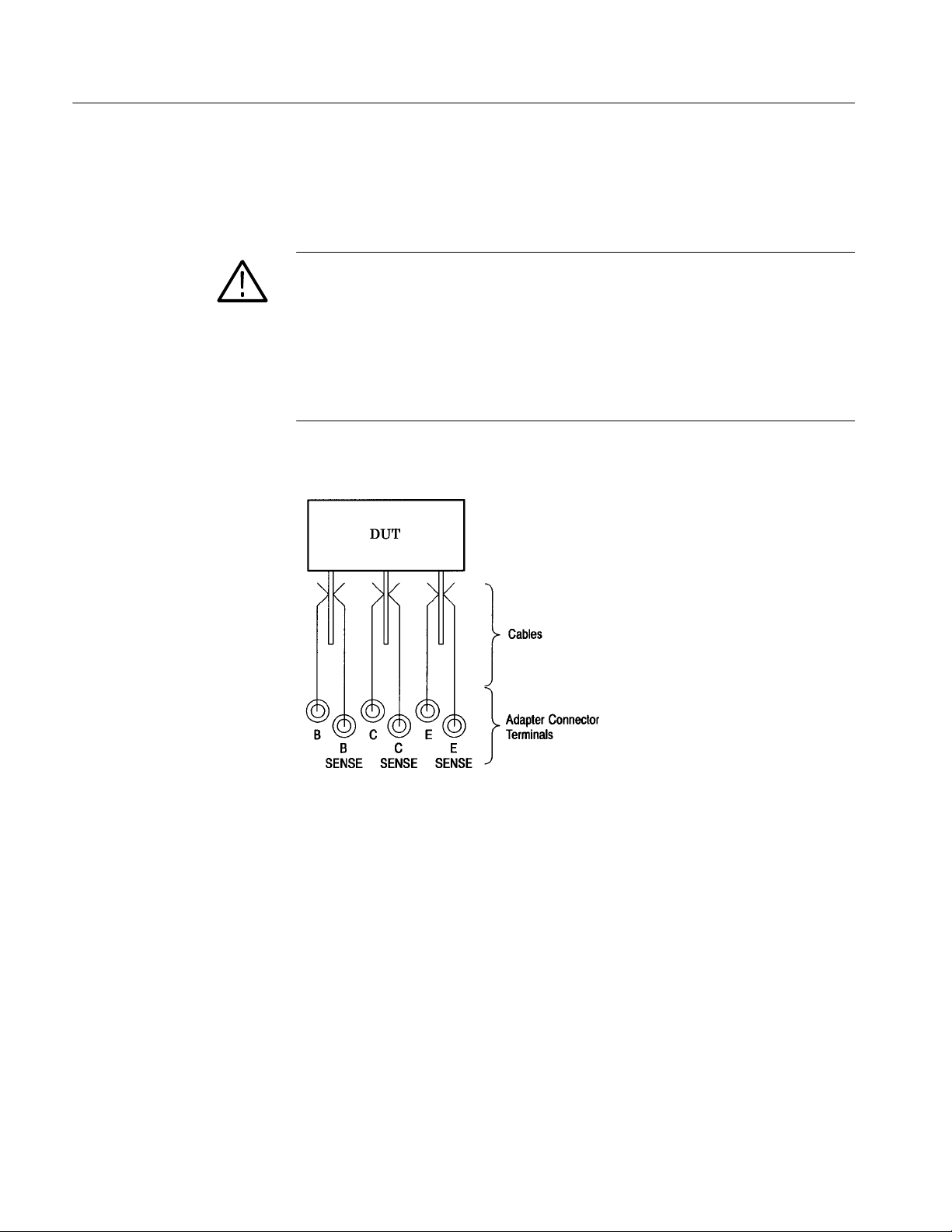

The 370B provides the adaptor connector equipped with Kelvin sense terminals.

The Kelvin sense is the way to measure voltage with two independent terminals

connecting to each of DUT leads; the Force terminal that supplies power and the

Sense terminal senses the voltage. By using the Kelvin sense mechanism, you

can make a high precision measurement because that the effect of conductance

from the contact between the cables and DUT leads is suppressed to a minimum.

The Sense terminals in the 370B adaptor connector and the A1001 through

A1005 test adaptors are for Kelvin sensing. The measurement can be performed

without Sense terminals, however, if you need high precision measurement, use

the those terminals.

370B Service Manual

2- 5

Page 54

Getting Started

Connections for Kelvin

Sensing

When a DUT does not fit in any of the test adaptors and you prepare a specific

test adaptor, for example, use cables to connect terminals and DUT leads as

shown in Figure 2--1 for Kelvin sensing.

CAUTION. Confirm that the the DUT leads and the force terminals: C, B and E

are firmly connected. Making improper connections may cause the DUT to be

broken. Before a measurement, also verify that the cables are not down and the

contact between the terminals and cables are made properly. To avoid electric

shock and damage to the instrument, perform measurement only within the

protective cover. Do not disable the interlock mechanism and/or do not take the

cables out of the protective cover to perform measurement without or outside the

cover.

2- 6

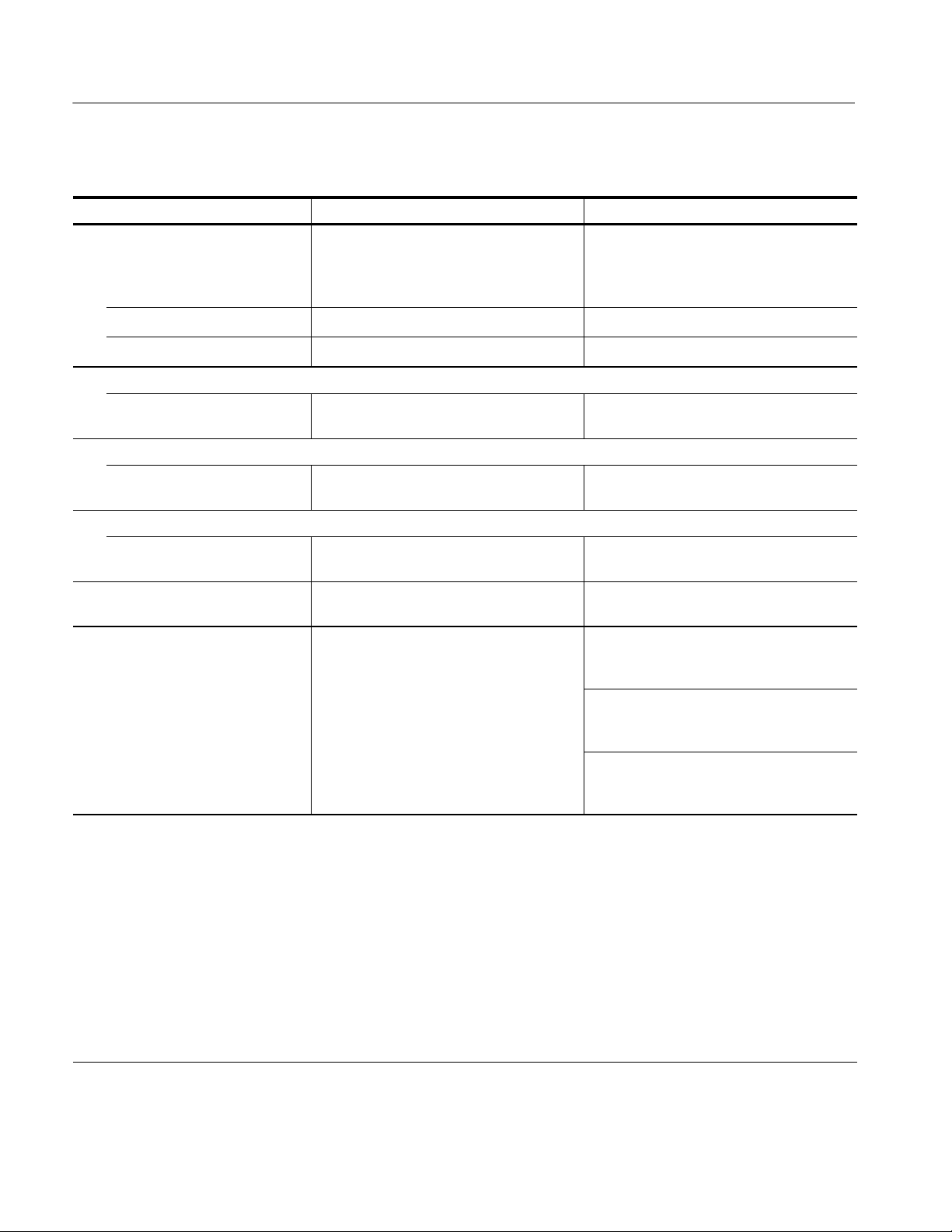

Figure 2- 1: Example of Kelvin sense connection

370B Service Manual

Page 55

Rackmounting Information

Getting Started

Latching

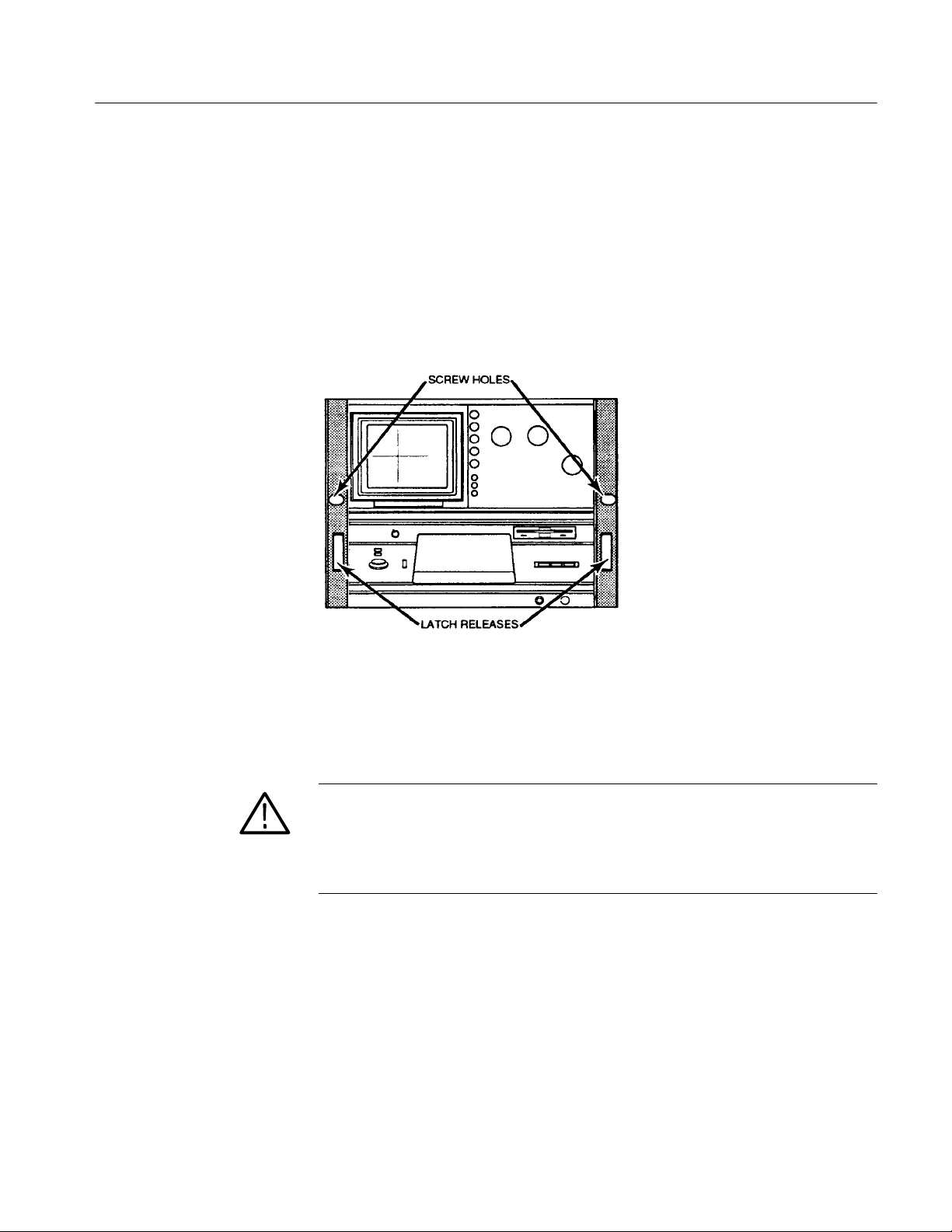

The 370B incorporates a spring-latch design built into the rackmounting ear. To

release, pull the rackmount latch release (see Figure 2--2). To relatch, push the

rackmount latch release until the spring latches engage.

For those applications that require additional rackmounting security, the

rackmounting ears of the 370B are drilled for screw fasteners (see Figure 2--2).

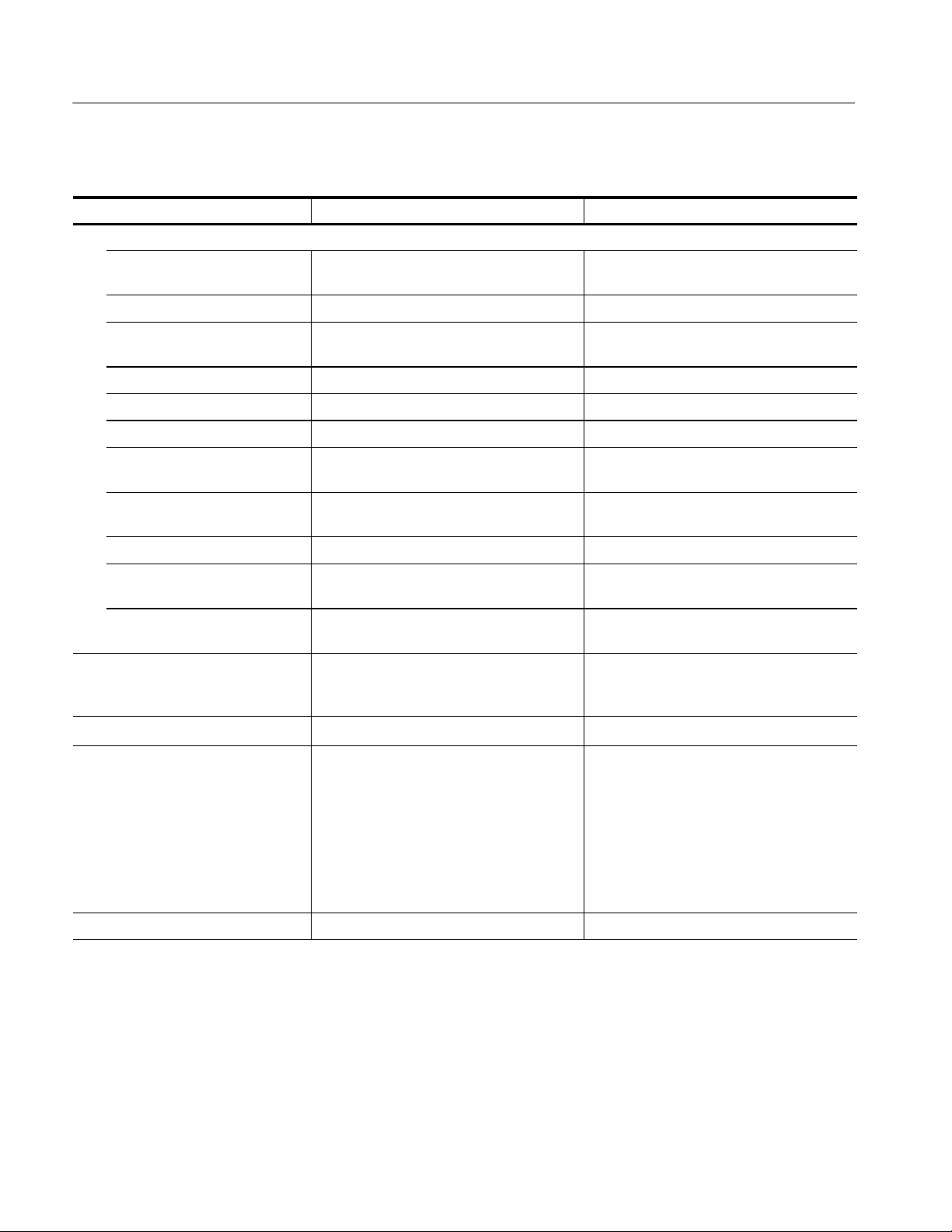

Figure 2- 2: Location of the Rackmount Latch Release

Rackmounting

370B Service Manual

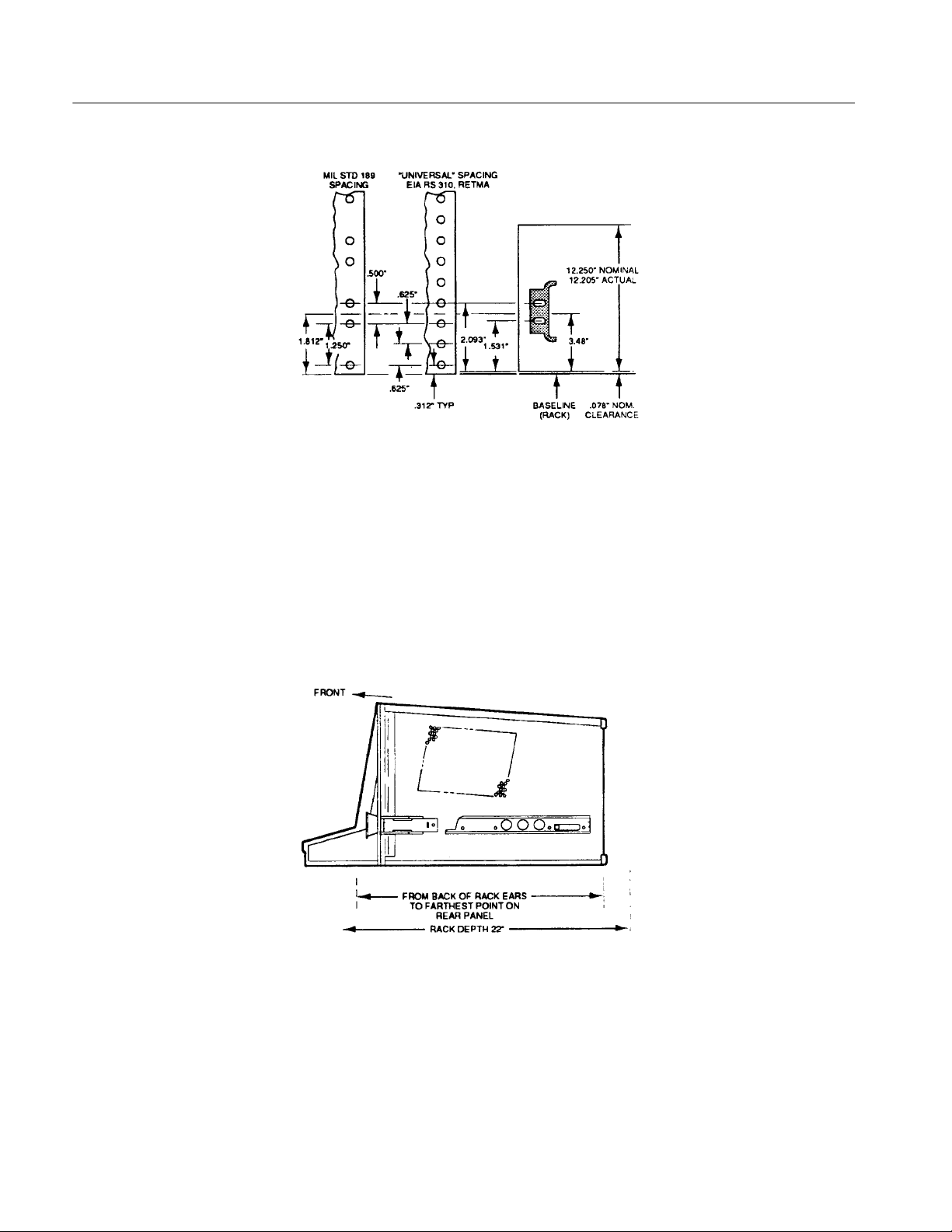

The 370B fits most commercial consoles and 19-inch racks with rail holes that

conform to universal spacing. See Figure 2--3 for hole spacing details.

WARNING. The 370B weighs more than 36Kg(80 lb). To avoid personal injury,

use care when lifting the instrument, and where required, seek help in lifting and

positioning the 370B into the rack. Once the 370B is installed in a rack, use care

that when extended, the 370B does not tip the rack forward, causing personal

injury or instrument damage.

2- 7

Page 56

Getting Started

Figure 2- 3: Rackmount hole spacing

When rackmounting the 370B, take note of the following: Allow one inch clearance above and below, and on the left and right sides of the 370B for air circulation. Allow at least three inches of clearance between the 370B rear panel and the

rack enclosure for adequate cooling air and to provide cable clearance. The depth

of the 370B from behind the rack ears to the rear panel is 480mm (18.9 in).

The rack depth must be at least 559 mm (22 in) (see Figure 2--4) to meet the rear

clearance requirement.

2- 8

Figure 2- 4: Rackmounting Length and Clearance

The 370B is 312 mm (12.25 in) high, a multiple of 45 mm (1.75 in) (the

standard rack spacing). If the 370B is installed in a rack with standard hole

spacing, and positioned some multiple of 45 mm (1.75 in) from the bottom or

top, all holes should line up and no drilling should be required.

370B Service Manual

Page 57

Getting Started

The slide-out tracks mount easily to the rack front and rear vertical mounting

rails if the inside distance between the rails is within 503 mm (19.8 in) to

674 mm (26.5 in). If the tracks are to be installed in a rack having other

dimensions, provide extra support (for example, extensions to the rear mounting

brackets) for the rear ends of the slide-out tracks.

The front rack rails must be at least 17 inches apart. The front lip of the

stationary-track section mounts in front of the rail. (Use bar nuts behind

untapped front rails.) The front lip of the stationary track section must mount in

front of the front rail to allow the 370B spring latch to function properly.

The slide-out tracks consist of two assemblies, one for each side of the instrument. Each assembly consists of three sections (see Figure 2--5). The stationary

section of each track attaches to rack rails as shown in Figure 2--6. The chassis

section mounts on the instrument and is installed at the factory. The intermediate

section fits between the other two sections, allowing the instrument to be fully

extended out of the rack.

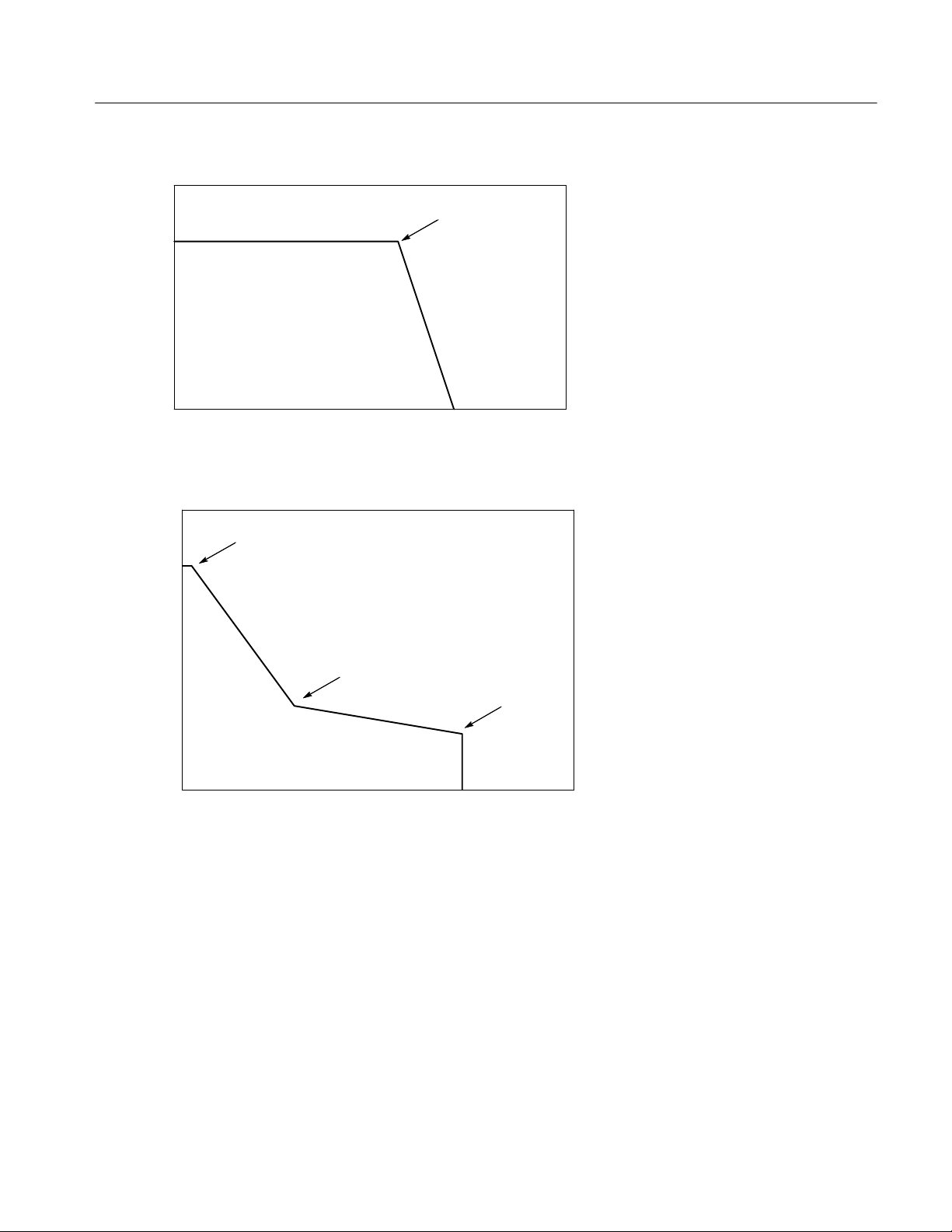

Figure 2- 5: Rackmounting Hardware

370B Service Manual

2- 9

Page 58

Getting Started

The stationary and intermediate sections for both sides are shipped as a matched

set and should not be separated. The package includes matched sets for both

sides and mounting hardware. To identify the assemblies, note that the automatic

latch and intermediate section latch stop holes are located near the top when the

matched sets are properly mated to the chassis sections.

To mount the instrument in a rack, perform the following:

1. Select the appropriate holes in the rack rail, using Figure 2--3 as a guide.

2. Mount the stationary-track sections to the front rack rails with truss head

screws (and bar nuts, if necessary).

3. Mount the stationary-track sections to the rear rails, using one of the

methods depicted in Figure 2--6. Note that the rear mounting bracket can be

installed to fit either deep or shallow cabinet racks.

4. After mounting the instrument in the slide-out tracks, adjust for proper width

by loosening the front and rear screws and allowing the slides to seek the

proper width. Center the instrument, then tighten the screws.

Figure 2- 6: Mounting Stationary Rackmount Sections

2- 10

370B Service Manual

Page 59

Getting Started

5. Push the instrument into the rack, and check that the automatic spring latch

engages the spring latch catch to hold the instrument in place.

6. Extend the instrument out of the rack by pulling the rackmount latch releases

on the front panel (see Figure 2--2) out to disengage the spring latches. Then,

pull the instrument out.

7. Once the instrument is out of the rack, press the latch release and push the

instrument back into the rack.

Rackmount to Cabinet

Conversion

To convert the 370B rackmount version to a cabinet model, use the following

procedure (see Figure 2-- 7):

1. Remove the bracket from each comer of the instrument rear panel.

2. Replace the left and right side panels with cabinet model side panels.

3. Mount a carrying handle assembly on the left and right sides of the top.

4. Fasten a foot at each corner on the bottom of the instrument.

370B Service Manual

2- 11

Page 60

Getting Started

Cabinet to Rackmount

Conversion

To convert the 370B cabinet model to a rackmount version, use the following

procedure (see Figure 2-- 7):

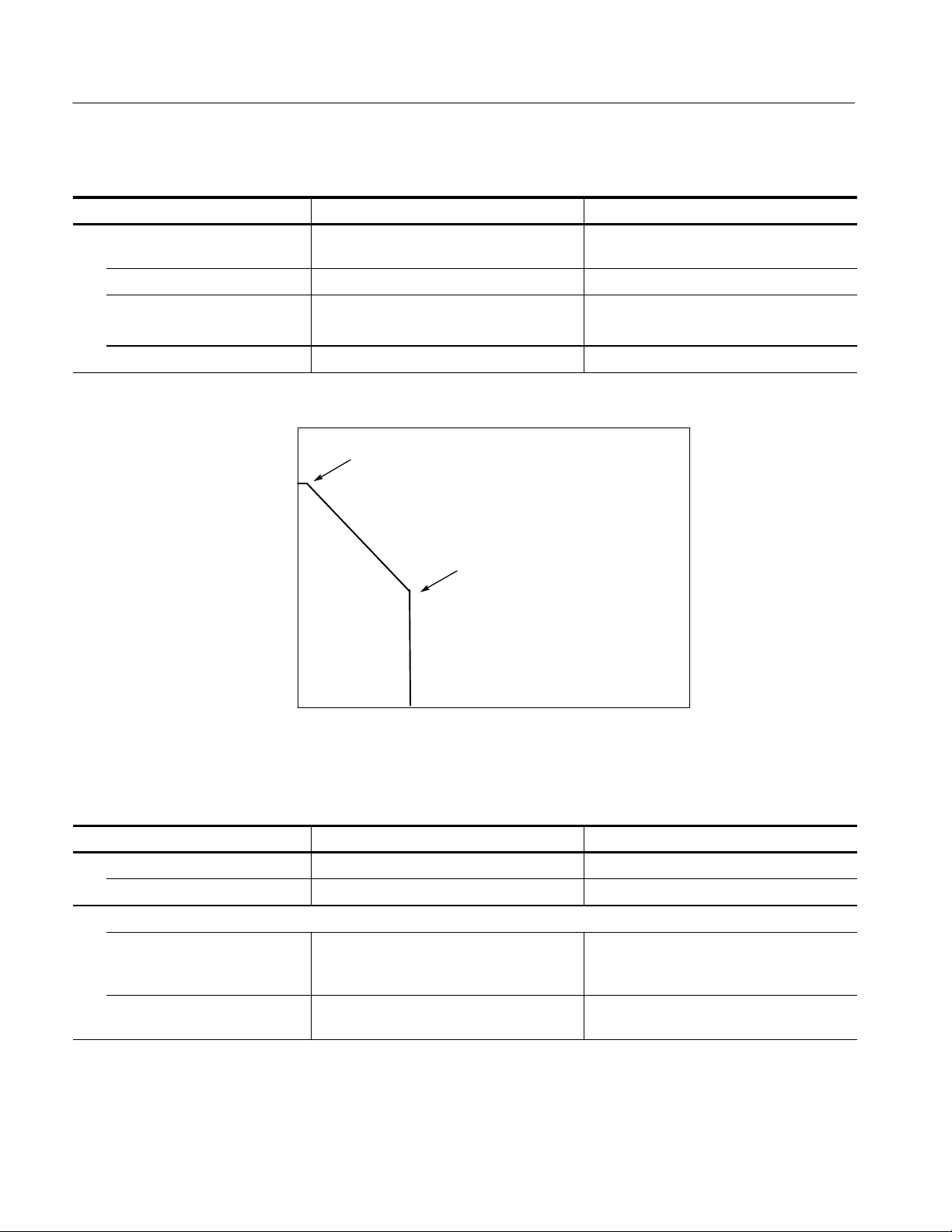

Figure 2- 7: Cabinet-to-Rackmount Conversion

1. Remove the bracket from each comer on the rear panel.

2. Replace the side panels with rackmount version side panels.

3. Attach brackets at each comer on the rear panel.

4. Remove both carrying handle assemblies:

a. Remove the plastic retainer caps that conceal the screws located at each

end of the handle.

b. Remove the screw, spacer and bar nut, then lift off the carrying handle

assembly.

2- 12

370B Service Manual

Page 61

Repacking for shipment

Getting Started

If this instrument is to be shipped long distances, we recommend that the

instrument be repackaged the same as when it arrived. The cartons and packaging material in which your instrument was shipped should be saved and used for

this purpose.

If your instrument is to be shipped to a Tektronix Service Center for service or

repair, attach a tag to the instrument showing the following:

Owner of the instrument (with address)

Name of a person at your firm to contact

Instrument type

Instrument serial number

Description of the service required

If the original packaging is unfit for use or not available, package the instrument

as follows:

1. Obtain a corrugated cardboard shipping carton with a 170kg(375lb) test

strength that has inside dimensions at least six inches greater than the

instrument dimensions.

2. Surround the instrument with polyethylene sheeting to protect the finish.

3. Cushion the instrument on all sides by tightly packing dunnage or urethane

foam between the carton and the instrument, allowing three inches on all

sides.

4. Seal the carton with shipping tape or with an industrial stapler.

5. Write the address of the Tektronix Service Center and your return address on

the carton in one or more prominent locations.

370B Service Manual

2- 13

Page 62

Getting Started

2- 14

370B Service Manual

Page 63

Theory of Operation

Page 64

Page 65

Theory of Operation

This section describes the operation of the 370B Programmable Curve Tracer

circuits. The section is divided into two parts: Block Diagram Description and

Detailed Circuit Operation.

Block Diagram Description

The following description is an overview of the 370B operation. Figure 3--1 on

page 3--3 is an overall block diagram of the 370B. The numbers enclosed in

diamonds within each block in Figure 3--1 indicate the schematic diagrams

associated with the block.

The 370B is a static and dynamic semiconductor tester that displays and allows

measurement of static and dynamic semiconductor characteristics obtained under

simulated operating conditions.

The 370B consists of five major functional sections:

H Collector Supply

H Data Acquisition and Display

H Control and Processing

H Interface

H Power Supply

370B Service Manual 3-1

Page 66

Theory of Operation

Stimulus Generators

The Stimulus Generators simulate operating conditions for the DUT by

producing voltages and currents that are applied to the DUT. They include the

Collector Supply, the Step Generator, the Aux Supply, and the PLL and Clock

Circuits.

The Collector Supply produces sine-wave ac, full-wave rectified sine waves

(positive and negative), and positive and negative DC voltages. The amplitude of

the output can be varied from 0 to 2000 volts. The Collector Supply output is

applied to either the collector or the base (or equivalent) terminal of the device

under test.

The Step Generator Circuit produces ascending or descending steps of current or

voltage at a normal rate of one step for each half-sine wave of the Collector

Supply. The amount of current or voltage per step, total number of steps and

offset voltage and current can be controlled. This Step Generator output may be

applied to either the base or the emitter (or equivalent) terminals of the device

under test.

The Auxiliary Supply produces auxiliary power for the DUT. The output voltage

range is 0 to 40 volts. This output can be applied to any terminal of the DUT.

3- 2 370B Service Manual

Page 67

Theory of Operation

Figure 3- 1: 370B Block Diagram

370B Service Manual 3-3

Page 68

Theory of Operation

The PLL and Clock Circuit generates a synchronous signal for the Step

Generator and the Sine Wave generator. This Circuit also generates synchronous

signals for the Acquisition Circuits.

This block consists of the following circuits.

AUX GEN Circuit

STEP GEN Circuit

SIN GEN Circuit

PLL and CLOCK Circuit

AUX SUPPLY Circuit

Collector Supply Amp Circuit

Step Amp Circuit

H.V. Module Circuit

L.V. Relay Circuit

Collector Terminal Circuit

Data Acquisition and

Display

These circuits sense, acquire, and display the effect of the Collector Supply and

Step Generator on the DUT. The block consists mainly of the Sense Circuit, the

Acquisition Circuit, the Digital Display Circuit, and the Display Circuit.

The Sense Circuit senses and amplifies voltages and currents of each terminal of

the DUT. This circuit also compensates for errors produced by IR drops between

the DUT terminals and the supply. The amplifier sensitivity is controllable.

The Acquisition Circuit converts sensed analog data into digital data, that is, the

fetch and A/D convert functions. This acquired data is sent to the CPU Circuit.

The Digital Display Circuit converts digital data into analog display signals. This

digital data includes stored curve and operating information.

The Display circuit selects store or non-store data and displays curves and 370B

operating information.

The Data Acquisition and Display Circuits consist of the following:

Acquisition Circuit

Display Counter Circuit

Display D/A Converter Circuit

Display Offset Circuit

Display Select Circuit

Vertical Sense Circuit

Sense Board Interface Circuit

Horizontal Sense Circuit

CRT Output Circuit

H.V. Power Supply Circuit

3- 4 370B Service Manual

Page 69

Theory of Operation

Control and Processing

These circuits control the 370B and process acquired data. They include the CPU

Circuit, the Front Panel Circuit, and Floppy Disk Circuit.

The CPU Circuit controls an operations of the 370B, including Collector Supply

and Step Generator Control, Sense Circuit Control. CRT Display Control, Front