Page 1

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

AND GENERAL SUPPORT MAINTENANCE MANUAL

LOGIC ANALYZER

TEKTRONIX MODELS 318/338

TM 11-6625-3145-14

HEADQUARTERS, DEPARTMENT OF THE ARMY

12 SEPTEMBER 1985

Page 2

TM 11-6625-3145-14

5

1

2

3

4

SAFETY STEPS TO FOLLOW IF SOMEONE IS THE VICTIM OF ELECTRICAL SHOCK

DO NOT TRY TO PULL OR GRAB THE INDIVIDUAL

IF POSSIBLE, TURN OFF THE ELECTRICAL POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL POWER, PULL, PUSH, OR LIFT THE

PERSON TO SAFETY USING A DRY WOODEN POLE OR A DRY ROPE OR SOME OT HER

INSULATING MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF CONTACT WITH THE SOURCE OF

ELECTRICAL SHOCK, MOVE THE PERSON A SHORT DISTANCE AWAY AND

5

IMMEDIATELY START ARTIFICIAL RESUSCITATION

A

Page 3

THE FOLLOWING SERVICING INSTRUCTIONS ARE FOR USE BY QUALIFIED

PERSONNEL ONLY. TO AVOID PERSONAL INJURY, DO NOT PERFORM ANY

SERVICING OTHER THAN THAT CONTAINED IN OPERATING INSTRUCTIONS

UNLESS YOU ARE QUALIFIED TO DO SO.

Copyright c 1984 Tektronix, Inc. All rights reserved. Contents of this publication

may not be reproduced in any form without the written permission of Tektronix, Inc.

Products of Tektronix, Inc. and its subsidiaries are covered by U.S. and foreign

patents and/or pending patents.

TEKTRONIX, TEK, SCOPE-MOBILE, and are registered trademarks of

Tektronix, Inc. TELEQUIPMENT is a registered trademark of Tektronix U.K. Limited.

Printed in U.S.A. Specification and price change privileges are reserved.

Tektronix, Inc.

Walker Road Industrial Park

P.O. Box 4600

Beaverton, Or. 97075

WARNING

WARNING

B

Page 4

The comm ercial manuals cited in paragraph la c ontain copyright material reproduced by perm ission of the T EKTRONIX,

INC., BEAVERTON, OR 97075

TM 11-6625-3145-14

TECHNICAL MANUAL ) HEADQUARTERS

) DEPARTMENT OF THE ARMY

No. 11-6625-3145-14 ) Washington, DC, 12 September 1985

OPERATOR’S, ORGANIZATIONAL,

DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE MANUAL

LOGIC ANALYZER

TEKTRONIX MODELS 318/338

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes, or if you know of a

way to improve the procedures, please let us know. Mail your letter, DA Form 2028

(Recommended Change to Publications and Blank Forms), or DA Form 2028-2

located in the back of this manual direct to: Commander, US Army

Communications-Electronics Command and Fort Monmouth, ATTN: AMSEL-MEMP, Fort Monmouth, NJ 07703-5007.

In either case, a reply will be furnished direct to you.

i

Page 5

TM 11-6625-3145-14

TABLE OF CONTENTS

Section Page

0 INTRODUCTION

0-1 Scope....................................................................................................................................0-1

0-2 Consolidated Index of Army Publications and Blank Forms .................................................0-1

0-3 Maintenance Forms, Records and Reports ..........................................................................0-1

0-4 Reporting Equipment Improvement Recommendations (EIR)..............................................0-1

0-5 Administrative Storage..........................................................................................................0-1

0-6 Destruction of Army Electronics Material..............................................................................0-1

ii

Page 6

TM 11-6625-3145-14

MANUAL REVISION STATUS

PRODUCT: 318/338 Logic Analyzer Service Manual

This manual supports the following versions of this product: All

REV DATE DESCRIPTION

JAN 1984 Original Issue

NOV 1984 Revised Printing: Pages-X1, 1-3, 5-2,-15,-49,-50 and -51, Tab-Fig. 4 Accessories page, Fig. 9-11,

Electrical Parts List, Diagrams < 5>and <6>

iii/(iv blank)

Page 7

TM 11-6625-3145-14

TABLE OF CONTENTS

Page

LIST OF ILLUSTRATIONS........................................................................................................................................... xv

LIST OF TABLES.........................................................................................................................................................xix

OPERATOR’S SAFETY SUMMARY............................................................................................................................ xxi

SERVICE SAFETY SUMMARY...................................................................................................................................xxiii

Section 1 INTRODUCTION AND SPECIFICATIONS

INTRODUCTION...................................................................................................................................1-1

DESCRIPTION......................................................................................................................................1-1

MODES OF OPERATION.....................................................................................................................1-1

CONFIGURATIONS..............................................................................................................................1-2

RELATED DOCUMENTS......................................................................................................................1-2

STANDARD AND OPTIONAL ACCESSORIES....................................................................................1-3

Standard Accessories ...................................................................................................................1-3

Options..........................................................................................................................................1-3

Optional Accessories.....................................................................................................................1-3

SPECIFICATIONS................................................................................................................................. 1-4

Section 2 OPTIONS

Section 3 OPERATING INSTRUCTIONS

INTRODUCTION...................................................................................................................................3-1

INSTALLATION.....................................................................................................................................3-1

Power Requirements.....................................................................................................................3-1

Power Cord....................................................................................................................................3-1

MENU CHARACTERISTICS.................................................................................................................3-2

Power-Up Configuration Display...................................................................................................3-2

Menus and Submenus ..................................................................................................................3-2

Menu Default Displays...................................................................................................................3-2

Menu Fields and the Edit Cursor...................................................................................................3-2

Error Message and Acquisition Status Readout............................................................................3-3

Major Mode Selection Field...........................................................................................................3-3

Inputs During Acquisition...............................................................................................................3-3

MENU FUNCTIONS..............................................................................................................................3-3

Setup Menu...................................................................................................................................3-3

Threshold Menu ............................................................................................................................3-3

Trigger Menu.................................................................................................................................3-4

State Table Menu..........................................................................................................................3-4

Timing Diagram Menu (Parallel Only)...........................................................................................3-4

Character Menu (Serial Only) (318S1/338S1)...............................................................................3-4

Remote (RMT) Menu (318S1/338S1) ........................................................................................... 3-4

Non-Volatile (NVM) Menu (318S1/338S1)....................................................................................3-4

v

Page 8

TABLE OF CONTENTS (cont.)

Section 3 OPERATING INSTRUCTIONS (cont.)

DIAGNOSTICS....................................................................................................................................... 3-5

Power-Up Self Test ........................................................................................................................ 3-5

Diagnostics Menu........................................................................................................................... 3-6

User-Changeable Fields for Each Test’s Display........................................................................... 3-6

Diagnostic Test Descriptions.......................................................................................................... 3-8

KBD Test................................................................................................................................ 3-8

CRT Test................................................................................................................................ 3-8

CLK Test .............................................................................................................................. 3-10

WR Test ............................................................................................................................... 3-10

ACQ Test.............................................................................................................................. 3-11

SQRAM Test........................................................................................................................ 3-11

N&DLY Test ......................................................................................................................... 3-12

SEQ Test.............................................................................................................................. 3-12

THRSH Test......................................................................................................................... 3-13

External Clock Probe Compensation................................................................................... 3-13

P6107 Probe Assignment and Compensation for the

318S1 and 338S1 ........................................................................................................ 3-14

SER Test.............................................................................................................................. 3-15

RMT Test ............................................................................................................................. 3-16

NVM Test ............................................................................................................................. 3-17

TM 11-6625-3145-14

Section 4 THEORY OF OPERATION

SECTION ORGANIZATION................................................................................................................... 4-1

DIGITAL LOGIC CONVENTIONS.......................................................................................................... 4-1

GENERAL SYSTEM DESCRIPTION..................................................................................................... 4-1

Acquisition Module.................................................................................................................................. 4-2

Parallel Data Inputs (A01 AND A02).............................................................................................. 4-2

P6451 Parallel Data Probe..................................................................................................... 4-2

P6107 External Clock Probe.................................................................................................. 4-2

Data Buffers, Delay Lines, and First Lactches.......................................................................4-3

External Clock Circuit............................................................................................................. 4-3

Clock Selector........................................................................................................................ 4-3

Word Recognizer ................................................................................................................... 4-3

Threshold Circuit.................................................................................................................... 4-3

Acquisition Control Board (A03)............................................................................................................. 4-3

Qualifier Selector.................................................................................................................... 4-3

Strobe Generator.................................................................................................................... 4-3

Trigger Sequencer.................................................................................................................. 4-3

Event/Delay Counter.............................................................................................................. 4-3

Acquisition Memory Board (A04).................................................................................................... 4-3

100 MHz Oscillator................................................................................................................. 4-3

Sampled Data RAM and Glitch RAM ..................................................................................... 4-3

Acquisition Address Counter and Carry Flag F-F................................................................... 4-3

Output Multiplexer.................................................................................................................. 4-3

v

Page 9

TABLE OF CONTENTS (cont.)

Section 4 THEORY OF OPERATION (cont.)

Mainframe............................................................................................................................................... 4-4

ROM/Threshold Board (A05).......................................................................................................... 4-4

ROM....................................................................................................................................... 4-4

Threshold Circuit.................................................................................................................... 4-4

MPU/Display Board (A06).............................................................................................................. 4-4

Microprocessor....................................................................................................................... 4-4

RAMs...................................................................................................................................... 4-4

Display Controller and Character ROM.................................................................................. 4-4

Bus Buffer............................................................................................................................... 4-4

Key Control Logic................................................................................................................... 4-4

Mother Board (A08)........................................................................................................................ 4-4

Keyboard (A09) .............................................................................................................................. 4-4

CRT Board (A10)............................................................................................................................ 4-4

CRT ....................................................................................................................................... 4-4

CRT Circuit............................................................................................................................. 4-4

Power Supply (A11 AND A12)........................................................................................................ 4-5

Left-Side Panel............................................................................................................................... 4-5

318S1/338S1 (A07)........................................................................................................................ 4-5

Serial Input Comparator......................................................................................................... 4-5

Serial I/O Controller................................................................................................................ 4-5

DETAILED CIRCUIT DESCRIPTIONS FOR THE 318 .......................................................................... 4-5

318 A01 Input A Board <1> <2> A02 Input B Board <3> <4>............................................................... 4-5

Overview ....................................................................................................................................... 4-5

Address Decoder <2> .................................................................................................................... 4-6

External Clock Input <4>................................................................................................................ 4-6

External Clock Comparator <4>..................................................................................................... 4-6

Clock Selector <4>......................................................................................................................... 4-6

Glitch Control <2> <3> <4>............................................................................................................ 4-7

Pipeline Register <1> <3>.............................................................................................................. 4-7

Word Recognizer <1> <2> <3>...................................................................................................... 4-7

Data Threshold Buffer <4>............................................................................................................. 4-7

Probe Compensation <4> .............................................................................................................. 4-8

318 A03 ACQ Control Board <5> <6> <7>............................................................................................. 4-8

I/O Address Decoder <6>............................................................................................................. 4-10

Qualify/SQRAM Data Register <5>.............................................................................................. 4-11

Qualify Logic <5> <6>.................................................................................................................. 4-12

START/STOP Logic <6>.............................................................................................................. 4-12

Trigger Qualify Flip-Flop <6>........................................................................................................ 4-12

Retiming Clock <6>...................................................................................................................... 4-12

Clock Qualify Flip-Flop <6>.......................................................................................................... 4-12

Strobe Generator <6>................................................................................................................... 4-12

External or Glitch Trigger Circuit <7>........................................................................................... 4-13

Retiming Flip-Flop <6>................................................................................................................. 4-13

Address Buffer <7> ...................................................................................................................... 4-14

Trigger Sequencer RAM <7> ....................................................................................................... 4-14

TM 11-6625-3145-14

vii

Page 10

TABLE OF CONTENTS (cont.)

Section 4 THEORY OF OPERATION (cont.)

Trigger Sequencer Flag <7> ........................................................................................................ 4-14

N Flag Circuit........................................................................................................................ 4-14

TRIG’D Flag Circuit.............................................................................................................. 4-15

SUCCEED Flag Circuit......................................................................................................... 4-15

STOP Flag Circuit ................................................................................................................ 4-15

SQRAM Data/Word Recognizer Data Multiplexer <7>................................................................. 4-15

LSI-A A03U158 <7>..................................................................................................................... 4-15

Address Decoder.................................................................................................................. 4-15

N Register ............................................................................................................................ 4-16

DL Register .......................................................................................................................... 4-16

Mask Register ...................................................................................................................... 4-16

Event/Delay Counter............................................................................................................ 4-16

ACQ Status Logic................................................................................................................. 4-16

318 A04 ACQ Memory Board <8> <9>................................................................................................. 4-17

Acquisition Memory and ACQ Address Counter <8>................................................................... 4-17

Chip Select Latch................................................................................................................. 4-17

Acquisition Memory.............................................................................................................. 4-18

ACQ Address Counter and Carry Latch............................................................................... 4-18

Timebase and MPU Bus Interface <9>........................................................................................ 4-19

TTL-to-ECL Translator ......................................................................................................... 4-19

Address Decoder.................................................................................................................. 4-19

Oscillator .............................................................................................................................. 4-19

Divider, Timer, and Slow Clock Detector ............................................................................. 4-19

INTCLK Buffer...................................................................................................................... 4-19

Data Selector........................................................................................................................ 4-19

ECL-to-TTL Translator and TTL Bus Buffer.........................................................................4-19

Full Valid Flag Latch............................................................................................................. 4-20

LSI-B (A04U 140)................................................................................................................. 4-20

318/338 A05 ROM/Threshold Board --<10>......................................................................................... 4-24

ROM Circuitry............................................................................................................................... 4-24

Threshold Circuit .......................................................................................................................... 4-25

D/A Converter....................................................................................................................... 4-25

Analog Switches................................................................................................................... 4-25

318/338 A06 MPU/Display Board <11>................................................................................................ 4-27

MPU .....................................................................................................................................4-27

RAM .....................................................................................................................................4-27

Bus Drivers................................................................................................................................... 4-27

Keyboard and Keyboard Controller.............................................................................................. 4-27

Interrupt Gates ............................................................................................................................. 4-27

Display Controller......................................................................................................................... 4-27

318/338 A07 Serial, Non-Volatile Memory, RS-232C <17> <18>........................................................4-30

Serial Input <17>.......................................................................................................................... 4-30

Input Comparator ................................................................................................................. 4-30

Offset Adjust......................................................................................................................... 4-30

Clock-Level Translator . ....................................................................................................... 4-30

TM 11-6625-3145-14

viii

Page 11

TABLE OF CONTENTS (cont.)

Section 4 THEORY OF OPERATION (cont.)

Non-Volatile Memory <17>........................................................................................................... 4-30

Threshold Voltage Detector.................................................................................................. 4-30

Chip Select Controller .......................................................................................................... 4-30

Battery Switch....................................................................................................................... 4-31

Battery Voltage Checker ...................................................................................................... 4-31

Random Access Memory..................................................................................................... 4-31

Serial Data Acquisition <18>........................................................................................................ 4-32

Data Bus Buffer.................................................................................................................... 4-32

I/O Selector .......................................................................................................................... 4-32

Baud-Rate Selector.............................................................................................................. 4-32

External Trigger Latch and Data Polarity............................................................................. 4-33

Serial I/O Controller.............................................................................................................. 4-33

RS-232 Control <18>.................................................................................................................... 4-34

Baud-Rate Selector.............................................................................................................. 4-34

Level Converter.................................................................................................................... 4-34

Serial I/O Controller.............................................................................................................. 4-34

318/338 A10 CRT Board <14>............................................................................................................. 4-35

Z-Axis Amplifier ............................................................................................................................ 4-35

Horizontal Sweep Generator........................................................................................................ 4-36

Vertical Sweep Generator............................................................................................................ 4-37

318/338 A11 Power Supply <15> <16>................................................................................................ 4-37

Line Input <15>............................................................................................................................. 4-37

Inverter Start Network <15>......................................................................................................... 4-38

Inverter Control <16>.................................................................................................................... 4-39

Regulator.............................................................................................................................. 4-39

Dead Time Controller........................................................................................................... 4-39

Over/Under Voltage Protection <16>........................................................................................... 4-39

Low Voltage Rectifiers and Regulators <16>............................................................................... 4-39

+12 Volt and -12 Volt Supplies............................................................................................. 4-39

-3.3 Volt Supply.................................................................................................................... 4-39

+5 Volt Supply...................................................................................................................... 4-40

Fan Circuit and Fan <16>............................................................................................................. 4-40

DETAILED CIRCUIT DESCRIPTIONS FOR THE 338 ........................................................................ 4-40

338A01 Input A Board <19> <20> A02lnputBBoard <21> <22>......................................................... 4-40

Overview ..................................................................................................................................... 4-40

Address Decoder <20> ................................................................................................................ 4-40

Glitch Control (CH 0-7) <21>........................................................................................................ 4-41

Word Recognizer <19> <21>...................................................................................................... 4-42

Threshold Buffer <22>.................................................................................................................. 4-42

Probe Compensation <21> <22>................................................................................................. 4-42

338 A03 ACQ Control Board <5> <6> <7>........................................................................................... 4-42

I/O Address Decoder <6>............................................................................................................. 4-44

Qualify/SQRAM Data Register <5>.............................................................................................. 4-45

Qualify Logic <5>.......................................................................................................................... 4-46

TM 11-6625-3145-14

ix

Page 12

TABLE OF CONTENTS (cont.)

Section 4 THEORY OF OPERATION (cont.)

START/STOP Logic <6>.............................................................................................................. 4-46

Trigger Qualify Flip-Flop <6>........................................................................................................ 4-46

Retiming Clock <6>...................................................................................................................... 4-46

Clock Qualify Flip-Flop <6>.......................................................................................................... 4-46

Strobe Generator <6>................................................................................................................... 4-47

External or Glitch Trigger Circuit <7>........................................................................................... 4-47

Retiming Flip-Flop <6>................................................................................................................. 4-47

Address Buffer <7> ...................................................................................................................... 4-48

Trigger Sequencer RAM <7> ....................................................................................................... 4-48

Trigger Sequencer Flag <7> ........................................................................................................ 4-48

N Flag Circuit........................................................................................................................ 4-49

TRIG’D Flag Circuit.............................................................................................................. 4-49

SUCCEED Flag Circuit......................................................................................................... 4-49

STOP Flag Circuit ................................................................................................................ 4-49

SQRAM, Data/Word Recognizer, Data Multiplexer <7>............................................................... 4-49

LSI A A03U158 <7>...................................................................................................................... 4-49

Address Decoder.................................................................................................................. 4-50

N Register ............................................................................................................................ 4-50

DL Register .......................................................................................................................... 4-50

Mask Register ...................................................................................................................... 4-50

Event/Delay Counter............................................................................................................ 4-50

ACQ Status Logic................................................................................................................. 4-50

338 A04 ACQ Memory Board <8> <9>................................................................................................. 4-52

Acquisition Memory and ACQ Address Counter <8>................................................................... 4-52

Chip Select Latch................................................................................................................. 4-52

Acquisition Memory.............................................................................................................. 4-52

ACQ Address Counter and Carry Latch............................................................................... 4-53

Timebase and MPU Bus Interface <9>........................................................................................ 4-53

TTL-to-ECL Translator ......................................................................................................... 4-53

Address Decoder.................................................................................................................. 4-53

Oscillator .............................................................................................................................. 4-53

Divider, Timer, and Slow Clock Detector ............................................................................. 4-53

INTCLK Buffer...................................................................................................................... 4-53

Data Selector........................................................................................................................ 4-53

ECL-to-TTL Translator and TTL Bus Buffer.........................................................................4-55

Full Valid Flag Latch............................................................................................................. 4-55

LSI-B A04U140 .................................................................................................................... 4-55

TM 11-6625-3145-14

x

Page 13

TABLE OF CONTENTS (cont.)

Section 5 VERIFICATION AND ADJUSTMENT PROCEDURES

INTRODUCTION.................................................................................................................................... 5-1

318/338 MULTI-PROBE TEST FIXTURE .............................................................................................. 5-1

TEST SETUP INFORMATION............................................................................................................... 5-4

Suggested Test Instruments .......................................................................................................... 5-4

FUNCTIONAL CHECK PROCEDURES FOR THE 318......................................................................... 5-6

Index of Functional Checks............................................................................................................ 5-7

Mainframe and Parallel Analyzer.................................................................................................... 5-7

Check 1. Power-up Diagnostics............................................................................................ 5-7

Check 2. Keyboard................................................................................................................ 5-7

Check 3. CRT........................................................................................................................ 5-8

Check 4. Threshold Voltage.................................................................................................. 5-9

Check 5. Parallel Data Acquisition with Test Output........................................................... 5-11

Check 6. Glitch Data Acquisition with Test Output.............................................................. 5-18

Check 7. Serial State Analyzer Check for the 318.............................................................. 5-19

ADJUSTMENT PROCEDURES FOR THE 318................................................................................... 5-22

Introduction................................................................................................................................... 5-22

Index of Adjustment Steps ........................................................................................................... 5-23

Mainframe .................................................................................................................................... 5-23

Parallel Analyzer........................................................................................................................... 5-27

Serial State Analyzer.................................................................................................................... 5-39

PERFORMANCE CHECK FOR THE 318............................................................................................ 5-43

Index of Performance Checks...................................................................................................... 5-43

The Performance Checks ............................................................................................................ 5-43

Test 1. Threshold Voltages ................................................................................................. 5-43

Test 2. Parallel Data Acquisition Word Recognition and Trigger

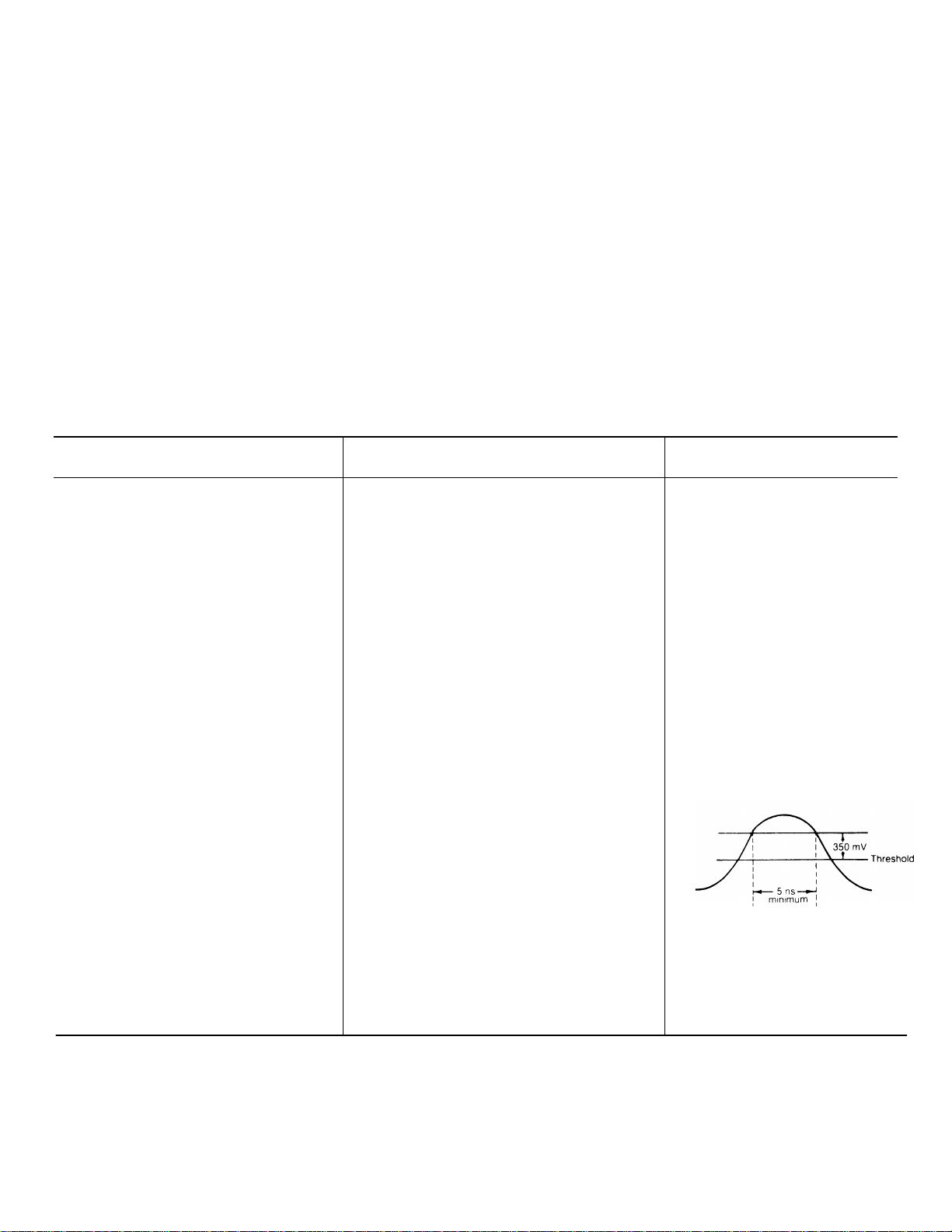

Sequencer Check with External Clock Minimum Period...................................................... 5-47

Test 3. Glitch Data Acquisition and Glitch Trigger .............................................................. 5-55

Test 4. Start Output and Trigger Output Test...................................................................... 5-58

Test 5. External Trigger Input Test...................................................................................... 5-59

Test 6. Serial State Analyzer (318S1)................................................................................. 5-60

FUNCTIONAL CHECK PROCEDURES FOR THE 318....................................................................... 5-63

Index of Functional Checks.......................................................................................................... 5-63

Mainframe and Parallel Analyzer.................................................................................................. 5-64

Check 1. Power-up Diagnostics.......................................................................................... 5-64

Check 2. Keyboard.............................................................................................................. 5-64

Check 3. Crt ........................................................................................................................ 5-64

Check 4. Threshold Voltage................................................................................................ 5-66

Check 5. Parallel Analyzer Check with Test Output............................................................ 5-67

Check 6. Glitch Data Acquisition Using Test Output........................................................... 5-74

Check 7. Serial State Analyzer Check for the 338S1.......................................................... 5-75

ADJUSTMENT PROCEDURES FOR THE 338................................................................................... 5-77

Introduction................................................................................................................................... 5-77

Index of Adjustment Steps ........................................................................................................... 5-78

TM 11-6625-3145-14

xi

Page 14

TABLE OF CONTENTS (cont.)

Section 5 VERIFICATION AND ADJUSTMENT PROCEDURES (cont.)

Mainframe .................................................................................................................................... 5-79

1. Adjust Power Supplies .................................................................................................... 5-79

2. Adjust CRT Circuit........................................................................................................... 5-81

3. Adjust Threshold Voltages on the A05 ROM Board....................................................... 5-82

Parallel Analyzer........................................................................................................................... 5-84

4. Adjust Threshold Voltages on the A02 Input-B Board.................................................... 5-84

5. Probe Compensation for the P6107 External Clock Probe............................................. 5-86

6. Adjust Ext Clk ↑ and Ext Clk ↓ Delay............................................................................. 5-87

7. Adjust delay of RET CLK, WE, ADRS CLK and TRIG CLK............................................ 5-89

Serial State Analyzer.................................................................................................................... 5-93

8. Adjust Threshold Voltages on the A07 Board................................................................. 5-93

9. Adjust Input Capacitance and Serial Data Probe Compensation.................................... 5-95

10. Adjust Non-Volatile Memory Battery Backup Threshold............................................... 5-98

PERFORMANCE CHECK FOR THE 338........................................................................................... 5-98

Index of Performance Checks...................................................................................................... 5-98

Test 1 - Threshold Voltages......................................................................................................... 5-99

Setup.................................................................................................................................... 5-99

Threshold Level TTL .......................................................................................................... 5-101

Threshold Levels V1, V2, and V3....................................................................................... 5-101

Test 2 - Parallel Data Acquisition, Word Recognition, and Trigger

Sequencer Checks with External Clock Minimum Period .......................................................... 5-102

Test 3 - Glitch Data Acquisition and Glitch Trigger .................................................................... 5-111

Setup.................................................................................................................................. 5-112

Negative Glitch................................................................................................................... 5-114

Test 4 - Start Output and Trigger Output.................................................................................... 5-114

Test 5 - External Trigger Input.................................................................................................... 5-116

Test 6 - Serial State Analyzer (338S1)....................................................................................... 5-117

TM 11-6625-3145-14

Section 6 MAINTENANCE: GENERAL INFORMATION

TROUBLESHOOTING TREES .............................................................................................................. 6-1

TEST EQUIPMENT REQUIRED FOR MAINTENANCE........................................................................ 6-1

TOOLS REQUIRED FOR MAINTENANCE ........................................................................................... 6-1

MAINTENANCE PRECAUTIONS .......................................................................................................... 6-1

Soldering ........................................................................................................................................ 6-1

Light-Emitting Diodes (LEDs)......................................................................................................... 6-2

Static Precautions........................................................................................................................... 6-2

Lithium Battery Replacement......................................................................................................... 6-3

PREVENTIVE MAINTENANCE.............................................................................................................. 6-3

Exterior Cleaning............................................................................................................................ 6-3

Interior Cleaning............................................................................................................................. 6-4

Cleaning Guidelines....................................................................................................................... 6-4

Inspection....................................................................................................................................... 6-4

xii

Page 15

TABLE OF CONTENTS (cont.)

Section 6 MAINTENANCE: GENERAL INFORMATION (cont.)

CORRECTIVE MAINTENANCE............................................................................................................. 6-5

Obtaining Replacements................................................................................................................ 6-5

Acquisition Boards and Probes...................................................................................................... 6-5

Repairing Multi-Conductor Connectors.......................................................................................... 6-5

Circuit Board Pin Replacement...................................................................................................... 6-6

DISASSEMBLY/INSTALLATION PROCEDURES................................................................................. 6-7

General Disassembly Precautions................................................................................................. 6-7

Circuit Board Locations.................................................................................................................. 6-7

Component Locations .................................................................................................................... 6-7

Removing and Replacement Instructions....................................................................................... 6-8

Removing the Cabinet............................................................................................................ 6-9

Removing the Front Panel...................................................................................................... 6-9

Removing the Keyboard....................................................................................................... 6-10

Removing the Power Supply Circuit Boards........................................................................ 6-10

Removing the CRT Circuit Board......................................................................................... 6-12

Removing the Cathode-Ray Tube (CRT)............................................................................. 6-12

Section 7 MAINTENANCE: TROUBLESHOOTING

TM 11-6625-3145-14

318 DIAGNOSTIC TEST DESCRIPTIONS............................................................................................ 7-1

Index of 318 Diagnostic Test Descriptions..................................................................................... 7-1

318 Diagnostic Test Common Signal Paths................................................................................... 7-1

Mainframe ...................................................................................................................................... 7-3

1. Keyboard Test................................................................................................................... 7-3

2. CRT Test........................................................................................................................... 7-4

3. Jump Table ROM Test...................................................................................................... 7-6

4. Display RAM Test.............................................................................................................. 7-7

5. System RAM Test ............................................................................................................. 7-8

6. ROM Test.......................................................................................................................... 7-9

Parallel Analyzer........................................................................................................................... 7-11

7. Clock Test ....................................................................................................................... 7-11

8. Word Recognizer Test .................................................................................................... 7-13

9. Acquisition RAM Test...................................................................................................... 7-17

10. Sequence RAM Test..................................................................................................... 7-20

11. N & Delay Test.............................................................................................................. 7-23

12. Threshold Test .............................................................................................................. 7-26

13. SEQ Test....................................................................................................................... 7-28

318S1 Serial Analysis/RS232C/NVM........................................................................................... 7-29

14. Battery Test................................................................................................................... 7-29

15. Non-Volatile Memory Test............................................................................................. 7-30

16. RS-232 Test.................................................................................................................. 7-30

17. Serial Test..................................................................................................................... 7-32

Option I/O Function List................................................................................................................ 7-33

318 TROUBLESHOOTING TREES ..................................................................................................... 7-39

xiii

Page 16

TABLE OF CONTENTS (cont.)

Section 7 MAINTENANCE: TROUBLESHOOTING (cont.)

338 DIAGNOSTIC TEST DESCRIPTIONS.......................................................................................... 7-93

Index of 338 Diagnostic Test Descriptions................................................................................... 7-93

338 Diagnostic Test Common Signal Paths................................................................................. 7-93

Mainframe .................................................................................................................................... 7-95

1. Keyboard Test................................................................................................................. 7-95

2. CRT Test......................................................................................................................... 7-96

3. Jump Table ROM Test.................................................................................................... 7-98

4. Display RAM Test............................................................................................................ 7-99

5. System RAM Test ......................................................................................................... 7-100

6. ROM Test...................................................................................................................... 7-100

Parallel Analyzer................................................................................................................................. 7-104

7. Clock Test ..................................................................................................................... 7-104

8. Word Recognizer Test .................................................................................................. 7-106

9. ACQ RAM Test.............................................................................................................. 7-110

10. SQRAM Test............................................................................................................... 7-113

11. N & DELAY Test.......................................................................................................... 7-116

12. Threshold Test ............................................................................................................ 7-119

13. SEQ Test..................................................................................................................... 7-121

338S1 Serial Analysis/RS232C/NVM......................................................................................... 7-122

14. Battery Test................................................................................................................. 7-122

15. Non-Volatile Memory Test........................................................................................... 7-122

16. RS-232 Test................................................................................................................ 7-123

17. Serial Test................................................................................................................... 7-124

Option I/O Function List.............................................................................................................. 7-126

338 TROUBLESHOOTING TREES ................................................................................................... 7-133

TM 11-6625-3145-14

Section 8 REPLACEABLE ELECTRICAL PARTS................................................................................................ 8-1

Section 9 DIAGRAMS............................................................................................................................................ 9-1

Section 10 REPLACEABLE MECHANICAL PARTS............................................................................................. 10-1

Appendix A REFERENCES.......................................................................................................................................A-1

Appendix B INTRODUCTION....................................................................................................................................B-1

Appendix C ERROR AND ACQUISITION STATUS MESSAGES.............................................................................C-1

Appendix D MAINTENANCE ALLOCATION.............................................................................................................D-1

Appendix E ERROR CODES.....................................................................................................................................E-1

xiv

Page 17

TM 11-6625-3145-14

LIST OF ILLUSTRATIONS

Figure Page

3-1 Failure in the power-up Self Test .................................................................................................................. 3-6

3-2 Successful completion of the power-up Self Test ......................................................................................... 3-6

3-3 Diagnostics menu: first display...................................................................................................................... 3-7

3-4 Display sample with ALL/SINGLE and data entry fields................................................................................ 3-7

3-5 Display sample with LOOP and DISP fields.................................................................................................. 3-7

3-6 Display for KBD tests..................................................................................................................................... 3-8

3-7 CRT test: first display.................................................................................................................................... 3-8

3-8 CRT test: second display .............................................................................................................................. 3-9

3-9 CRT test: third display................................................................................................................................... 3-9

3-10 CRT test: fourth display................................................................................................................................. 3-9

3-11 Display for CLK tests..................................................................................................................................... 3-10

3-12 Display for word recognizer’s RAM tests....................................................................................................... 3-10

3-13 Display for acquisition’s RAM tests............................................................................................................... 3-11

3-14 Display for trigger sequencer’s RAM tests.................................................................................................... 3-11

3-15 Display for N counter or DLY counter tests................................................................................................... 3-12

3-16 Display for overall tests on parallel acquisition.............................................................................................. 3-12

3-17 Display for threshold tests............................................................................................................................. 3-13

3-18 Setup of probe compensation....................................................................................................................... 3-13

3-19 Display for probe compensation.................................................................................................................... 3-14

3-20 Setup for serial tests...................................................................................................................................... 3-15

3-21 Display for serial tests................................................................................................................................... 3-15

3-22 Setup for remote tests................................................................................................................................... 3-16

3-23 Display for remote tests................................................................................................................................. 3-16

3-24 Display for non-volatile memory tests........................................................................................................... 3-17

4-1 318 Input A and Input B block diagram......................................................................................................... 4-8

4-2 318 Simplified diagram of the ACQ control circuitry on schematics <5> and <6>........................................ 4-9

4-3 318 Simplified diagram of the ACQ control circuitry on schematic <7>........................................................ 4-10

4-4 318 SQRAM data register format.................................................................................................................. 4-11

4-5 318 Qualify register format............................................................................................................................ 4-11

4-6 318 Simplified diagram of the acquisition memory and ACQ address counter circuit .................................. 4-18

4-7 318 Simplified diagram of the timebase and MPU bus interface circuit........................................................ 4-23

4-8 318 Timing diagram of the slow-clock detector and timer circuit ..................................................................4-24

4-9 318/338 Simplified diagram of the ROM and threshold circuits.................................................................... 4-26

4-10 318/338 Simplified diagram of the MPU/Display board................................................................................. 4-29

4-11 318/338 Simplified diagram of the serial acquisition and RS-232C circuit.................................................... 4-31

4-12 318/338 Simplified diagram of the CRT circuit.............................................................................................. 4-35

4-13 318/338 Simplified diagram and waveform of the horizontal sweep generator............................................. 4-36

4-14 318/338 Simplified diagram of the power supply circuit................................................................................ 4-38

4-15 338 Input A and Input B block diagram......................................................................................................... 4-41

4-16 338 Simplified diagram of the ACQ control circuitry on schematics <5> and <6>........................................ 4-43

4-17 338 Simplified diagram of the ACQ control circuity on schematic <7>......................................................... 4-44

4-18 338 SQRAM data register format.................................................................................................................. 4-45

xv

Page 18

TM 11-6625-3145-14

LIST OF ILLUSTRATIONS (cont.)

Figure Page

4-19 338 Qualify register format............................................................................................................................ 4-45

4-20 338 Simplified diagram of the acquisition memory and ACQ address counter circuit .................................. 4-52

4-21 338 Simplified diagram of the timebase and MPU interface circuit............................................................... 4-54

4-22 338 Timing diagram of the slow-clock detector and timer circuit .................................................................. 4-55

5-1 Test fixture construction diagram.................................................................................................................. 5-2

5-2 Assembled test fixture................................................................................................................................... 5-3

5-3 318 Successful power-on diagnostic display................................................................................................. 5-7

5-4 318 Keyboard test display............................................................................................................................. 5-7

5-5 318 CRT test cross-hatch pattern ................................................................................................................. 5-8

5-6 318 CRT test white pattern............................................................................................................................ 5-8

5-7 318 CRT test parallel acquisition character fonts.......................................................................................... 5-8

5-8 318 CRT test serial acquisition character fonts............................................................................................. 5-8

5-9 318 Parallel data acquisition check setup..................................................................................................... 5-11

5-10 318 External trigger check setup................................................................................................................... 5-13

5-11 318 Trigger qualifier check setup.................................................................................................................. 5-16

5-12 318 Setup for serial data analysis................................................................................................................. 5-20

5-13 318 Setup for RS-232C control..................................................................................................................... 5-21

5-14 318 Power supply adjustment....................................................................................................................... 5-24

5-15 318 CRT adjustment..................................................................................................................................... 5-25

5-16 318 Threshold voltage adjustment on the ROM board (A05)....................................................................... 5-27

5-17 318 Threshold voltage adjustments on the Input B board (A02)................................................................... 5-29

5-18 318 Test equipment setup for the clock delay adjustment............................................................................ 5-32

5-19 318 EXT CLK and DLD CLK signal adjustment locations............................................................................. 5-33

5-20 318 RET CLK, WE, ADRS CLK, and TRIG CLK adjustments..................................................................... 5-38

5-21 318 Capacitor adjustment oscilloscope setup waveform.............................................................................. 5-38

5-22 318 Capacitor adjustment waveform............................................................................................................. 5-38

5-23 318 Serial analysis/RS-232C/NVM test points and adjustment locations..................................................... 5-39

5-24 318 Side view of A07, Serial analysis’RS-232C/,’NVM board....................................................................... 5-40

5-25 318 Input capacitance adjustment setup....................................................................................................... 5-42

5-26 318 Input capacitance waveform................................................................................................................... 5-42

5-27 318 Threshold voltage check setup............................................................................................................... 5-44

5-28 318 Parallel data acquisition test setup......................................................................................................... 5-48

5-29 318 Parallel data acquisition test waveform #1............................................................................................. 5-50

5-30 318 Parallel data acquisition test waveform #2............................................................................................. 5-50

5-31 318 Glitch data acquisition test setup............................................................................................................ 5-56

5-32 318 Glitch data acquisition test waveform #1................................................................................................ 5-57

5-33 318 Glitch data acquisition test waveform #2................................................................................................ 5-57

5-34 318 Serial state analyzer performance test setup......................................................................................... 5-61

5-35 338 Successful power-on diagnostic display................................................................................................. 5-64

5-36 338 Keyboard test display............................................................................................................................. 5-64

5-37 338 CRT test cross hatch display.................................................................................................................. 5-65

5-38 338 CRT test white pattern............................................................................................................................ 5-65

5-39 338 CRT test parallel acquisition character fonts.......................................................................................... 5-65

5-40 338 CRT test serial acquisition character fonts............................................................................................. 5-65

5-41 338 Parallel data acquisition check setup..................................................................................................... 5-69

xvi

Page 19

TM 11-6625-3145-14

LIST OF ILLUSTRATIONS (cont.)

Figure Page

5-42 338 External trigger check setup................................................................................................................... 5-71

5-43 338 Trigger qualifier check setup.................................................................................................................. 5-73

5-44 338 Setup for serial data analysis................................................................................................................. 5-76

5-45 338 Setup for RS-232C control..................................................................................................................... 5-77

5-46 338 Power supply adjustment....................................................................................................................... 5-80

5-47 338 CRT adjustment..................................................................................................................................... 5-81

5-48 338 Threshold voltage adjustment on the ROM board ................................................................................. 5-83

5-49 338 Threshold voltage adjustment on the (A02) Input B board..................................................................... 5-85

5-50 338 Test equipment setup for the clock delay adjustment............................................................................ 5-89

5-51 338 RET CLK, WE, ADRS CLK, and TRIG CLK adjustments...................................................................... 5-91

5-52 338 Capacitor adjustment oscilloscope setup waveform.............................................................................. 5-93

5-53 338 Capacitor adjustment waveform............................................................................................................. 5-93

5-54 338 Serial analysis/RS-232C/NVM test points and adjustment locations..................................................... 5-94

5-55 338 Side view of A07, Serial analysis/RS-232C/NVM board......................................................................... 5-95

5-56 338 Input capacitance adjustment................................................................................................................. 5-97

5-57 338 Input capacitance waveform................................................................................................................... 5-97

5-58 338 Threshold voltage check setup............................................................................................................... 5-100

5-59 338 Parallel data acquisition test setup......................................................................................................... 5-106

5-60 338 Parallel data acquisition test waveform #1............................................................................................. 5-106

5-61 338 Parallel data acquisition test waveform #2............................................................................................. 5-106

5-62 338 Glitch data acquisition test setup............................................................................................................ 5-112