3321

/3322/3330

LCZ

Meter

Calibration

1

Tfus

plied calibration program.

verification procedures covered in Section

show that instrument performance

Dunng calibration,

and the resulting calibration constants are downloaded into the

ments

level.

I

NTRO D UCT

paclung list grves step-by-step procedures for calibrating

are

made using a digital multimeter

If

the calibration procedures cannot be performed successfully, refer to

formation in the service manual unless the

der warranty should be returned to the factory or authorized repair facility for repair.)

I0

N

This

calibration procedure can be performed at specified intervals, or

1

is

not within specifications.

a

set of standard resistances

in

of the Model 3321/3322 Service Manual or Model 3330 Service Manual

is

measured twice, the resulting data

order to calibrate the voltage measurement display function and signal

NOTE

unit

the

Model 3321/3322/3330

LCZ

is

still

2 CALIBRATION PROGRAM REQUIREMENTS

is

processed

meter. For the Model

the

under warranty. (Units

Packing

LCZ

Meter using the sup-

if

the performance

by

the computer,

3330,

additionai measue-

repair in-

strll

un-

List

The supplied calibration program must be used to calibrate the Model

run

on an IBM PC

to

2.1

The

2.1.1

Use the factory default settings with the National Instruments PC-IIA interface board. When using older versions

of the PC-IIA interface (those not equipped with a

use

IIA

change the driver configuration for operation with the PC-IIAboard. See the interface board documentation for details.'

Computer hardware requ-ts

following

IBM-PC

One of the

with

boards, and the driver defaults to the

AT,

National Instruments PC-IIA interface card.

Keithley Metrabyte KM48-ROM interface card.

Using the National Instruments PC-IIA

the

PC-IIA

AT

or compatible computer with appropriate hardware, as covered below.

computer hardware

or compatible computer.

two

following IEEE-488 interfaces for the computer:

card. The older version of the interface software uses a single driver for both the

is

required for calibration:

board

VLSI

PC-II

board.

Use

chip), the interface driver software

the "IBCONEEXE" utibty supplied with the interface to

3321/3322/3330.

Tfus

program

must

be corhgured for

PC-II

is

intended

and PC-

PA-390

Rev.

A

/

12-92

2.1.2 Using

the Keithley Metrabyte KM-488-ROM

board

When using the KM-488-ROM board,

which should be disabled. Refer to the documentation supplied with the interface board for detailed information

on defaults and disabling the on-card ROM.

2.2

The following computer

2.3

Before using the supplied calibration program, first make a backup copy of the diskette, then copy the contents of

the diskette to a convenient subdirectory on

tory before attempting to

The

Computer software requirements

software

MS-DOS or

PC-DOS,

version

Program installation

run

the calibration program.

following programs are supplied on the distribution diskette or created during program execution:

CAL.EXE: Calibration program intended for use in calibrating the Model

use

is

required to

3.30

or later.

the default switch settings for

run

the calibration programs:

your

hard drive. Be

sure

to

select

all

operating modes except for the ROM,

this

subdirectory as the current

3321/3322/3330.

direc-

MAKEFILE.EXE:

of resistance standards to ensure accurate calibration.

SAVESET

must be located

REFDATA:

resistance standards

the calibration program environment data variables, which are specified when the program

A

utility

program that allows you to set up the "REFDATA" file values for

A

file that contains the environment data variables for the calibration program. Note that

in

the same directory as the calibration program, and the filename cannot be changed.

The reference data file that contains the actual resistance, capacitance, and inductance values of the

used

by the calibration program. Note that

ttus

file must be located

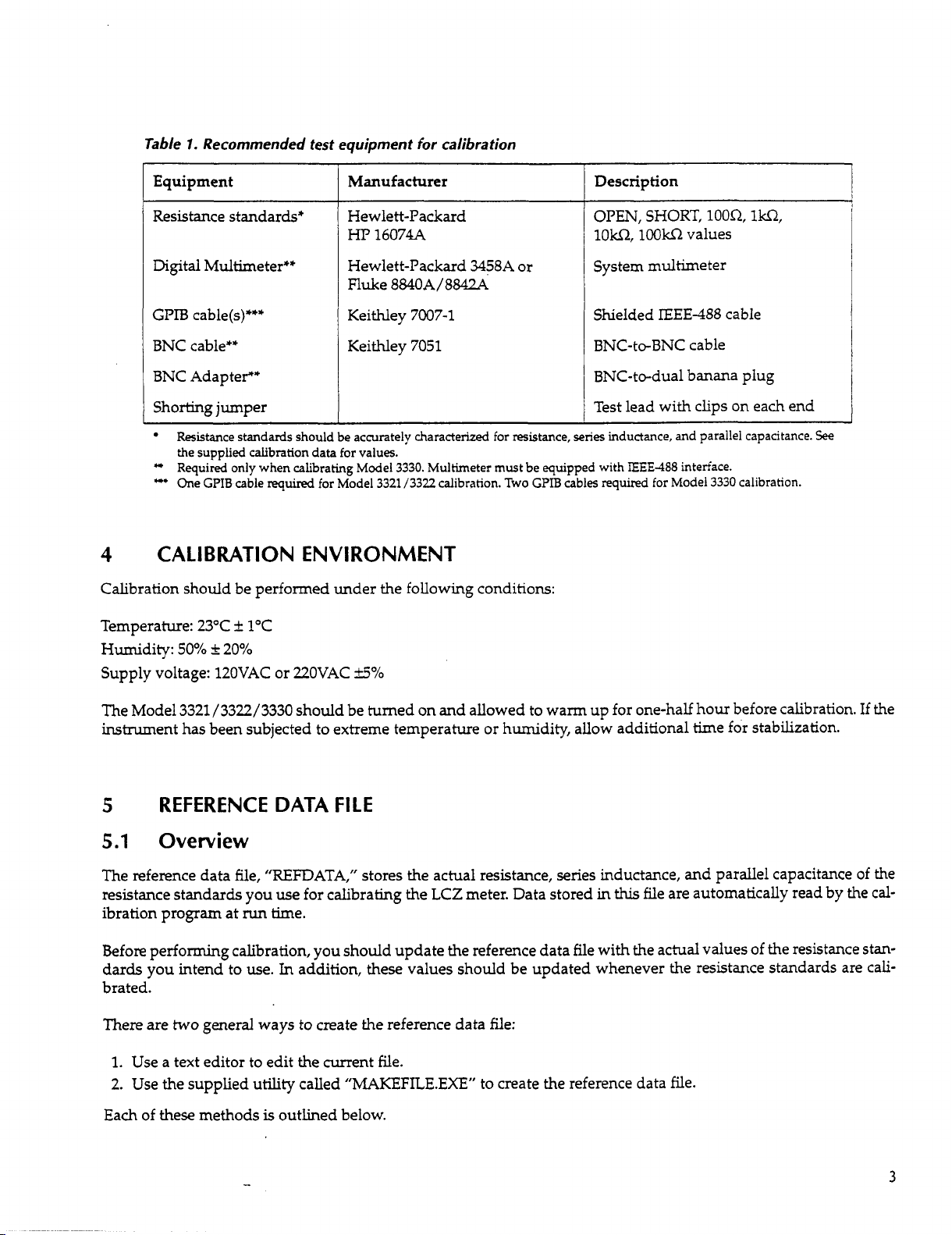

RECOMMENDED CALIBRATION EQUIPMENT

Table 1 summarizes recommended equipment for calibrating the Model

is

computer hardware, which

covered separately

in

paragraph

2.

3321/3322/3330.

your

particular set

in

a path specified by

is

run.

This

list does not include

this

file

Table

1.

Recommended test equipment for calibration

Equipment

Resistance standards*

Digtal Multimeter**

GPTB

cable(s)***

BNC cable**

Manufacturer

Hewlett-Packard

HP

16074A

Hewlett-Packard

Fluke

8840A/8842A

Keithley

Keithley

7007-1

7051

3458A

or

BNC Adapte?

Shorting jumper

Resistance standards should be accurately characterized for resistance,

the supplied calibration data for values.

*

Required only when calibrating Model 3330. Multimeter must be equipped with

**

One

GPIB

cable

4

requkd

CALIBRATION ENVIRONMENT

for Model 3321 /3322 calibration.

Two

GPIB

Calibration should be performed under the following conditions:

Temperature: 23°C

Humidity:

50%

Supply voltage: 12OVAC or 22OVAC

i

k

20%

1°C

*'/o

Description

OPEN,

lorn,

SHORT,

lOOkf2

loon,

values

System multimeter

Shielded

IEEE-488

cable

BNC-to-BNC cable

BNC-to-dual banana plug

Test lead with clips on each end

series

inductance, and parallel capacitance.

cables

reqd

IEEE-488

interface.

for Model 3330 calibration.

1w2,

See

The Model 3321/3322/3330 should be turned on and allowed to warm up for one-half hour before calibration.

instrument has been subjected to extreme temperature or humidity, allow additional time for stabilization.

5

5.1

The reference data file,

resistance standards you use for calibrating the LCZ meter. Data stored in

ibration program at

Before performing calibration, you should update the reference data file with the actual values

dards

REFERENCE DATA

Overview

"REFDATA,"

run

time.

you intend to use.

In

FILE

stores the actual resistance, series inductance, and parallel capacitance of the

this

file are automatically read by the

of

the resistance stan-

addition, these values should be updated whenever the resistance standards are cali-

brated.

two

There are

1.

Use a text editor to edit the current file.

general ways to create the reference data file:

2. Use the supplied utility called "MAKEFILE.EXE" to create the reference data file.

is

Each of these methods

outlined below.

If

the

cal-

3

5.2

Resistance standards values

Resistance standards values are supplied by the manufacturer on a calibration sheet.

will

value, both an inductance and capacitance value

be supplied.

be specified as a negative value. Similarly, the capacitance will be specified

inductive.

Any

negative capacitance or inductance value should be entered as 0 in the reference data file, asoutlined

If

the standard

is

capacitive, the inductance will

as

a

negative value

below.

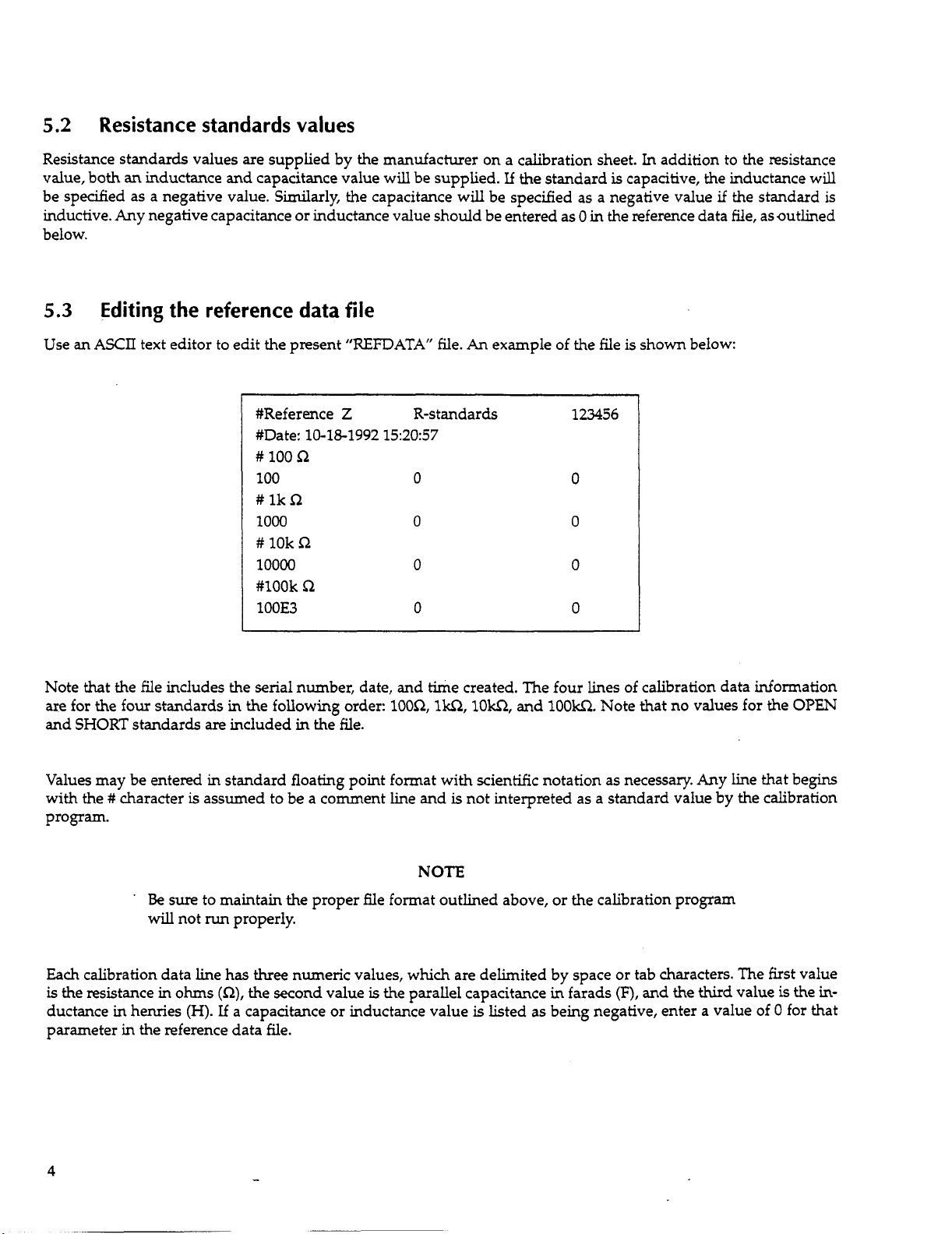

5.3

Use

Editing the reference data file

an

ASCII

text editor to edit the present

#Reference

#Date:

##

100

100

##

lk

n

1000

##

10k

10000

#look

~

100E3

10-18-1992

n

n

C.2

“REFDATA”

Z

R-standards

15:20:57

0

0

0

0

file.

An

example of the file is shown below:

123456

0

0

0

0

In

addition to the resistance

if

the standard

is

Note that the file includes the serial number, date, and time created. The four lines of calibration data information

are for the four standards in the following order:

and SHORT standards

are

included

in

the

file.

Values may be entered in standard floating point format with scientific notation as necessary.

with the

#

character

is

assumed to be a comment line and

100R,

1w1,1Ow1,

and

100W.

is

not interpreted as a standard value by the calibration

Note that no values for the

Any

line that begins

OPEN

program.

NOTE

’

l3e

sure

to maintain the proper file format outlined above, or the calibration program

will

not

run

properly.

Each calibration data line

is

the resistance

in

ohms

ductance in henries (H).

has

three

numeric values, which are delimited by space or tab characters. The first value

(n),

the second value

If

a capacitance or inductance value

is

the parallel capacitance in farads

is

listed

(F),

and the

as

being negative, enter a value of 0 for that

third

value

is

the

in-

parameter in the reference data file.

4

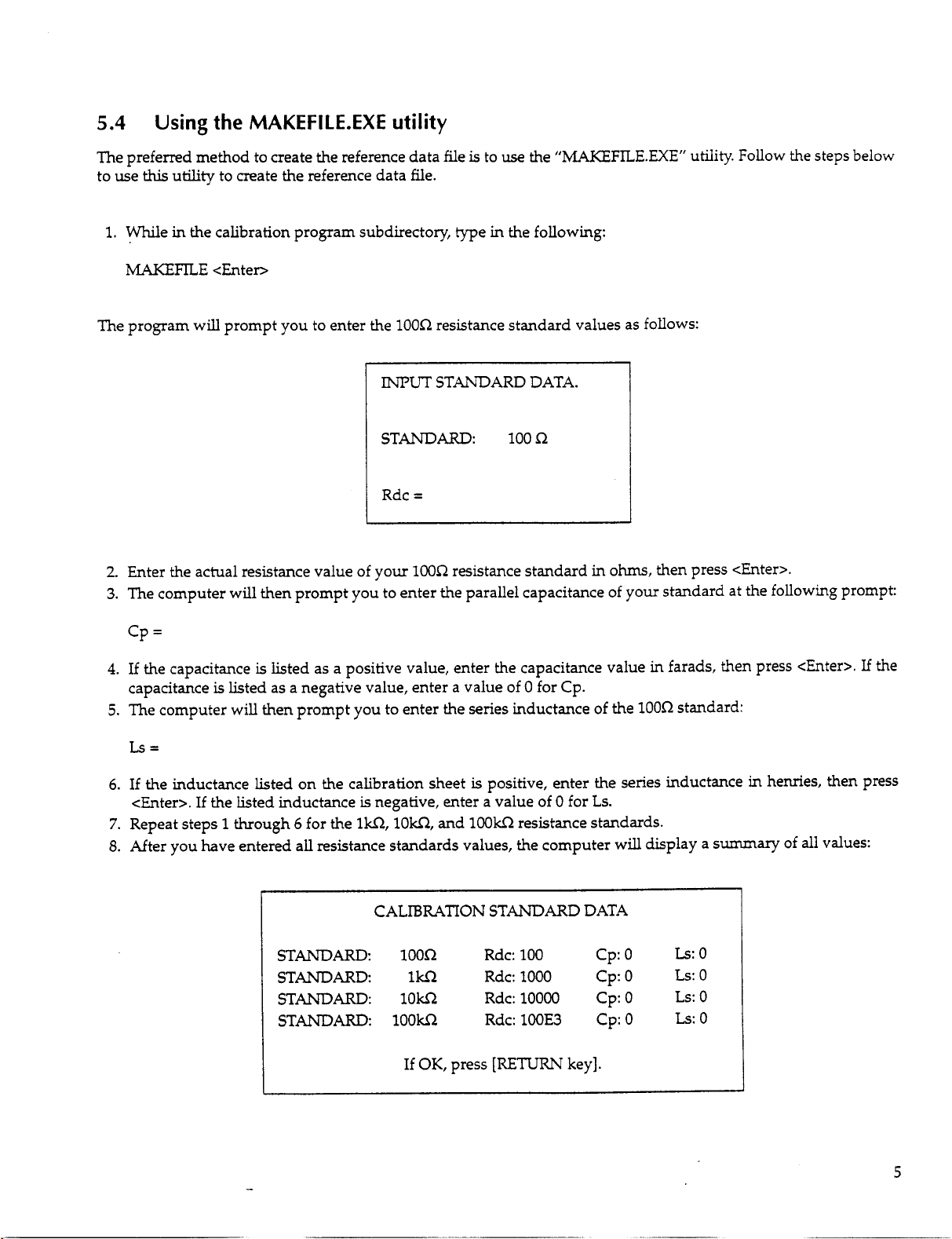

5.4

Using

the

MAKEFILE.EXE

utility

The preferred method to create the reference data file

to

use

this

utility

to create the reference data file.

1.

While in the calibration program subdirectory, type

MAKEFILE

The program will prompt you to enter the

<Enten

lOOR

I"

STANDARD:

Rdc

=

2.

Enter the actual resistance value of

3.

The computer will then prompt you to enter the parallel capacitance of

your

lOOR

is

to

use

the

in

the following:

resistance standard values

STANDARD DATA.

100R

resistance standard

"MAKEFILE.EXE"

as

follows:

in

ohms,

then press <Enter>.

your

standard at the following prompt:

utility. Follow the steps below

cp

=

4.

If the capacitance

capacitance

5.

The computer will then prompt you to enter the series inductance of the

is

listed as a positive value, enter the capacitance value

is

listed as a negative value, enter a value of 0 for Cp.

Ls=

6.

If the inductance listed on the calibration sheet

<Enter>. If the listed inductance

7.

Repeat steps

8.

After

you

1

through

have entered all resistance standards values, the computer will display a

6

STANDARD:

STANDARD

STANDARD:

STANDARD:

for the 1w2,

is

negative, enter a value

lorn,

CALIBRATION STANDARD DATA

lOOR

1w2

low2

1OOw2

If

OK,

and

press

is

positive, enter the series inductance in henries, then press

of

0

for

lOOkR

resistance standards.

Rdc: 100

Rdc: 1000

Rdc:lOOOO

100E3

Rdc:

[RETURN

key].

Ls.

cp:o

cp:o

Cp:O

Cp:O

in

farads, then press <Enter>.

1000

standard:

summary

of

Ls:o

Ls:

0

Ls:O

Ls:O

all

values:

If

the

-

5

9.

Press <Enter>

through 6 above to re-enter values.

10.

After all values are entered

if

all values are correct, or press

any

other key to reenter standards values. Follow steps

and

accepted, the program will prompt you for the reference data filename:

1

STANDARD

File name ’refdata’.

[RETURN]

11.

Simply press <Enter> to use the default “REFDATA” filename, or press any other key, then enter the desired

filename at the prompt.

sponding environment data variable

12. Finally, enter the serial number of your standards set at the prompt, then press <Enter>. The reference data file

will then be saved

6

The following paragraphs will *take you through the procedure necessary to complete calibration of the Model

3321/3322/3330 LCZ Meter. Before performing calibration, you must have previously completed the following:

CALIBRATION PROCEDURE

Installed the calibration software (paragraph 2).

Installed and configured the computer

NOTE:

using

the selected filename, and the program

key to continue. Any other key to change filename

If

you use a filename other

in

FILE

NAME

than

“REFDATA,”

the calibration program. See paragraph 6 for details.

will

end.

IEEE-488

interface.

you

must also change the corre-

Setup the reference data file with the correct resistance standards values (paragraph

6.1

6.1.1

Before performing calibration, the Model 3321/3322/3330 must be connected to the

computer.

If’you

ure

Hardware preparation

Connections

Use

only a shielded

If

you are calibrating multiple units, connect

IEEE-488

one LCZ meter during a calibration session.

are

calibrating the Model 3330, connect the multimeter to the computer and the LCZ meter, as shown

1.

IEEE-488

bus at a time. Manually change bus connections when calibrating more than

cable such as the recommended Keithley Model 7007-1.

NOTE

only

one Model 3321/3322/3330 to the

GPIB

5).

(IEEE-488)

interface of the

in

Fig-

6

II

-

Model

332113322l3330

Figure

6.1.2

Connect

cable shell

~ ~~ ~

Digital

(HP3458A

7.

Calibration connections

Multirneter

or

Fluke

G

to

884ON42A)

Note

:

Multirneter is required

Model

as

display

Power-up procedure

b'

-&

LO

w'

shown

Y

Volts

3330

only

and

signal level (see text).

/

I

BNC

Input

L

BNC/Dual Banana Adapter

LCZ

only

Meter. Connect multirneter

when calibrating voltage

\

H

CUR

Cable

when calibrating

I

Cable

IBM

PC

AT

rl

I/

1.

Turn

on the LCZ meter. The instrument will begin its self-calibration cycle.

2.

The

3.

If

"EEEEE"

been detected, and calibration cannot be performed without clearing the error. Use the following procedure to

clear the error before performing calibration:

A.

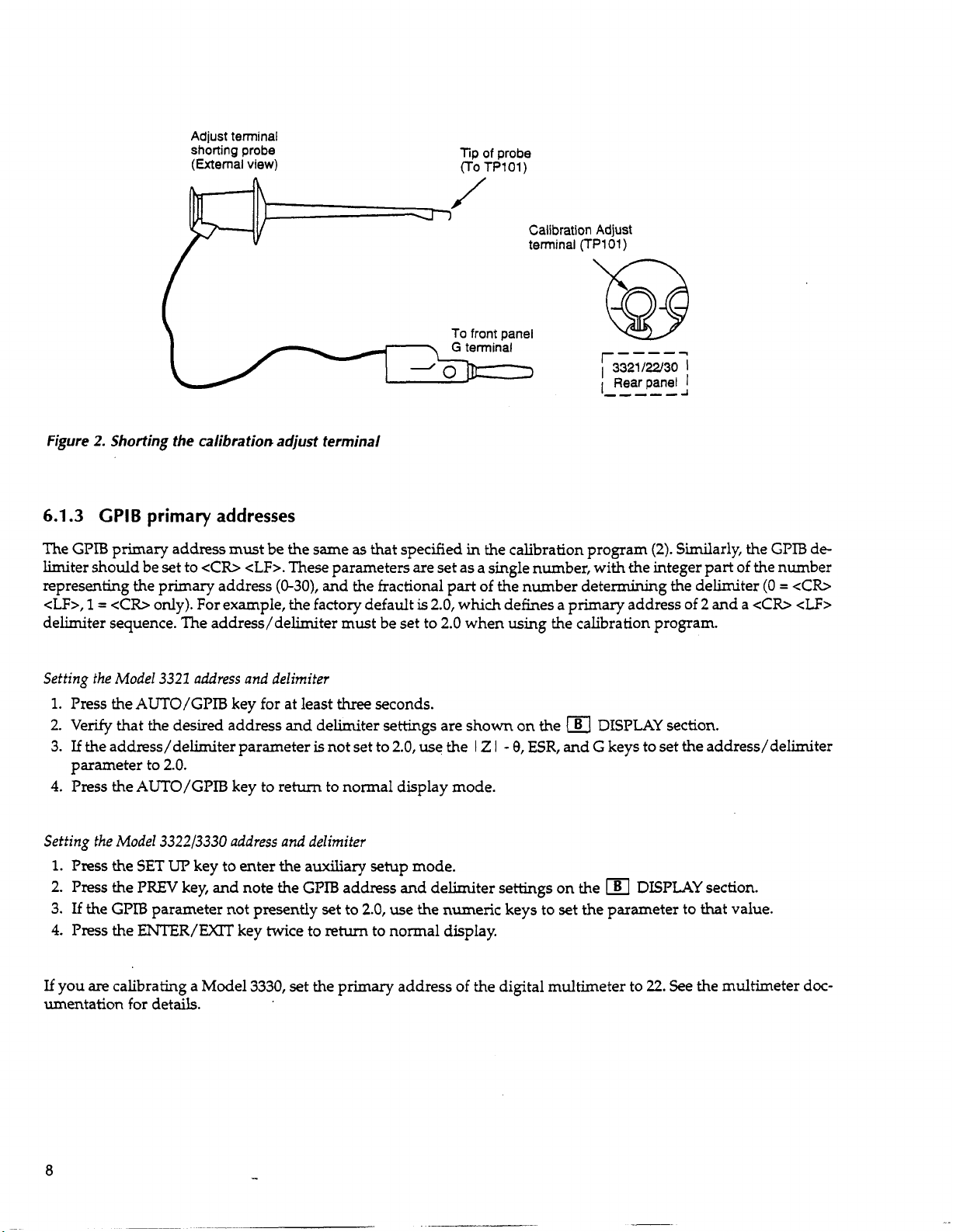

B.

C. Connect one end of

D.

4.

After

DISPLAY will show "CAL," while the

and

"22222"

Leave the instrument tumed on with the "EEEEE" and

PLAY and the DISPLAY.

Remove the rubber plug that covers the access hole on the rear panel of the LCZ meter.

Momentarily touch the other end

the

"EEEEE

mode.

turning

22222"

on the power, allow a =-minute warm-up period before beginning the calibration procedure.

are displayed on the DISPLAY, a calibration constants error has

the

Adjust terminal

of

the probe

error message has been cleared. The instrument will then enter the normal measurement

@l

DISPLAY will count down to

DISPLAY and

shorting

probe

to

"22222"

to

the front panel G terminal, as

TPlOl

through the rear panel access hole, and venfy that

0.

messages still displayed on the

shown

in

/A]

Figure

DIS-

2.

7

Adjust

terminal

shorting

(External

probe

view)

Tip

(To

of

probe

TP101)

Figure

2.

Shorting the calibration adjust terminal

6.1.3

The

limiter should be set to

representing the primary address (0-30), and the fractional

<U>,

delimiter sequence. The address/delimiter must be set to

Setting the Model 3321 address

1.

2.

3.

4.

GPlB

GPIB

1

=

Press the

Venfy that the desired address

If

the addxess/delimiter parameter

parameter to

Press the

primary addresses

primary address must be the same

<Cm

cLF>.

cCR>

only). For example, the factory default

and

delimiter

AUTO/GPIB

2.0.

AUTO/GPIB

key for at least

key to retum

as

that specified

These parameters are set as a single number, with the integer part of the number

is

2.0,

three

seconds.

and

delimiter settings are shown on the

is

not set to

to

normal display mode.

2.0,

use the

Calibration

terminal

Adjust

(TPlO1)

-----

r33211w30

Rearpanel

L,,--d

in

the calibration program

part

of the number determining the delimiter

which defines a primary address of 2 and

2.0

when using the calibration program.

le]

DISPLAY

I Z I - 9,

ESR,

and G keys to set the address/delimiter

I

I

(2).

Similarly, the

section.

GPTB

(0

=

a

<Cb

de-

<Cb

cLF>

Setting the Model 332213330 address and delimifer

1.

Press

the

SET

UP

key to enter the auxiliary setup mode.

2.

Press the

3.

If

the

4.

Press the

If

you

are

umentation for details.

8

PREV

key, and note the

GPIB

parameter not presently set to

ENTER/EXIT

calibrating a Model 3330, set the primary address of the digital multimeter to

key twice to return to normal display.

GPIB

address and delimiter settings on the

2.0,

use the numeric keys

to

set the parameter

DISPLAY

22.

section.

to

that value.

See the multimeter doc-

6.1.4 Calibration adjust terminal

TP101,

calibration.

6.2

which

1.

Remove the rubber plug that covers the rear panel access hole.

2.

Connect a

is

accessible through a hole in the rear panel, must be connected to the front panel G terminal

To

ground

clip

TPlOl,

lead or probe between

complete the following steps:

TPlOl

and the front panel G terminal as shown

Calibration program

in

Figure

6.2.1 Overview

The supplied calibration program

terface. The values of a set

and the correct values stored in the reference data file are calculated. Corrected data are then written to

LCZ

in the

Model

digital multimeter.

meter, and the instrument uses these corrected values during normal measurements.

3330

calibration includes

of

is

used

to

control the

resistance standards are measured, and the deviation between the measured values

an

additional procedure, which calibrates voltage display and signal level using

LCZ

meter to be calibrated from the

PC

over the

6.2.2 Running the calibration program

2.

RAM

during

GPIB

in-

located

a

To

run

the calibration program, change to the directory in which the calibration program

following:

CAL <Enter>

6.2.3 Main menu

When the calibration program

is

located, then type the

is

run,

the following main menu

will

appear on the computer screen:

-

9

Main Menu Screen

3321/3322/3330 Calibration System Ver.

Calibration Process

Save Environment Data

Manipulate Calibration Data

Qm

Key wait sound

Calibration Data PATH

ENVIRONMENT

I

All

menus in the calibration program are regular popup menus. Use the

which will be highhghted. Press the <Enter> key to select or edit

gram

entry

is

the ”Calibration Process” field.

<ARROW - Change Field> <CR - Select Field/Edit>

DATA

Reference Data

GPIB Board present

MULTMETERtype

1.00

(c

4)

FILENAME

(c

+)

(c

+)

four

arrow keys to select the current field,

a

given field. Note that the default field upon pro-

OFF

c:\cal\

refdata

NI-PCIIA

hp3458a

If

an

invalid key

ed), the computer will beep. Pressing <Enter> for the PATH and FEENAME fields in the

section will allow you to edit those fields as appropriate. Simply type

<Enter> key.

6.2.4

Briefly, the main menu selections perform the following operations.

Calibration Process

The “Calibration Process” menu selection begins the actual calibration procedure. Refer to paragraph 6.3

plete details on performing the calibration process procedure.

Save

This

field with the arrows keys

Main menu selections

Enuironmenf

menu selection allows you

Key wait sound: The sound generated while the computer

Calibration Data PATH: The path that describes the location of the reference data file. Recall that the reference

data file contains the actual values of the calibration standards.

is

pressed (for example, pressing left or right arrow while the “Calibration Process” field

ENVIRONMENT

in

the desired path or filename, then press the

Data

to

save environment data variables, which can be changed by selecting the desired

and

then pressing <Enter>. Program environment data variables include:

is

waiting for data during calibration.

is

selectDATA

for

com-

Reference Data FILENAME: The

h

file

is

for

”REFDATA”.

name

of the file that contains the resistance standards values. The default name

GPIB Board present: The field shows the type of GPIB board installed in the computer. The

and

interfaces are the Keithley KM-488-ROM

MLTL??METER

is

used

only when calibrating the Model 3330). The

Model

Environment variables are stored in the

Manipulate Calibration Data

This

computer screen. Refer

QUIT

Selecting

6.3

1.

To

play the following screen to remind you of the required 30-minute warm-up period:

358A

menu selection allows you to read and write the LCZ meter calibration table and display file contents on the

“QUIT”

Calibration

begin calibration, select “Calibration Process” on the main menu, then press <Enter>. The computer will

type:

’&IS

field identifies the type of d@al multimeter to be used for calibration

and the Fluke Model

to

paragraph

exits the calibration program and retums you to the

8840A/42A.

“SAVESET”

6.4

for complete information on data manipulation.

process

Calibration

the National Lnstruments

two

types of meters supported are the Hewlett-Packard

file located in the current directory

Process

Screen

DOS

[l]

PC-IIA

prompt.

boards.

two

supported GPIB

(a

multimeter

dis-

*******

Check that the environment temp.

Power-On all LCZ meters to be calibrated

3330

For

multimeter also.

Press

2.

If

you wish to continue calibration, press

3.

Next, the following screen

will

3321/3322/3330 Calibration System Ver.

CHECK

any

be displayed:

$******

is

23

i

1OC.

calibration, Power-On the ‘hp3458a’

key

to

continue

any

.......

key except

([ESC]

<<ABORT

<Ex>.

To

return to the main menu, press

1.00

>>)

<Esc>.

-

11

1

Calibration Process Screen

3321/3322/3330 Calibration System Ver.

CALIBRATE

[2]

QW

How many LCZ Meters? 3

1.00

Mad-une

Madrune 2 Serial

Machine 3 Serial

1

<ARROW - Change Field>

is

1,

The default number of LCZ meters

ing

the number of LCZ meters will affect the number of serial number fields that are displayed.

4.

After selecting the number

this

main menu at

5.

The next screen will remind

the calibration environment before calibration.

meters have been warming up for at least 30 minutes. Anegative response will cause the program

minute wait state (the program uses the

point, select

of

you

units,

"QUIT"

and you

select "CALIBRATE" to continue calibration.

instead.

that

all

LCZ meters should be allowed to warm up for at least 30 minutes

DOS

Calibration Process Screen

1

Serial

No.

00000

No.

00000

No.

00000

cCR

-

Select/Edit>

can

calibrate up to five units

The

screen

time function to time the length of the waiting period).

first prompts you as to whether or not the

in

a single calibration

If

you

wish to return to the

[3]

run.

to

go

Chang-

in

LCZ

to

a

30-

Note that the current

utes have elapsed,

12

3321 /3322/3330 Calibration System Ver.

Have machines been

30 minutes

Leave machine

before calibrating. ([ESC]

Current Tune

time

and remaining time values

the

next screen will be displayed.

(Y/N)

in

running

powered on state

cc

=

10:30:04

Remaining

will

be continuously updated while waiting. After

for at least

until

ABORT

>>)

=

1.00

10:59:54

00:29:50

30

min-

6. The next screen will remind you about

just terminal:

GPIB

connections, the primary address, and shorting the calibration ad-

I

CAUTION!!

Rear panel

Front panel : Set GPIB address and delimiter

Make sure that GPIB cable

,

7.

Make sure that calibration adjust terminal

Also

make sure the primary address/delimiter setting

8.

If you are calibrating a Model

monitor calibration of the Model

the digital multimeter

connected to the Model

is

3321/3322/3330

Calibration unit No. 1 Serial No. 123456

:

Connect the adjust cable between ADJ and

Press any key to continue

3330,

3330

turned on, and its primary address

3330,

as shown in Figure

Calibration Process

Calibration System Ver.

is

connected between the unit and PC

is

shorted and that the instrument

the next screen

LCZ Meter. Before continuing with

will

1.

.......

([ESC]

is

2.0.

guide you

Screen

[2.0]

cc

is

set to

[4]

1.00

ABORT

through

22.

Also

GND.

>>)

is

properly connected to the GPIB.

signal level calibration

ths

step, you should make sure

make sure that the multimeter

and

voltage

that

is

Calibration Process Screen [4a] (Model

3321/3322/3330

Calibrate the Frequency Response of the

monitor.

Calibrate the signal level of the

Calibrating the signal level.

Connect

The program will allow you to abort the process at various stages. Errors are reported at the bottom of the screen

to

prompt

you

regarding signal cable,

3330

Press

and 'hp3458a' multimeter

any

key to continue

GPIB

Calibration System Ver.

3330's

using

.......

([ESC]

address, etc.

3330.

.

.

SPECIAL

cc

ABORT

3330

1.00

voltage

Only)

JIG.

>>)

13

9.

Press any key except

connect standards using the following screen:

cEso

to continue with calibration.

During

calibration, the computer will prompt you

to

3321/3322/3330 Calibration System Ver.

Modek3321 Unit

Calibration Process Screen

No.

:3 Serial

No.:

123456 Sample Set: 2/2

[5]

1.00

any

Press

10.

During

the LCZ meter twice:

OPEN

SHORT

lOOR

These standards should be connected to the LCZ meter, as shown

tlu

part of the calibration process, you will be prompted

lki2

lOkS2

loom

key to continue

.......

([ESC]

cc

NOTE

Be

sure

to

connect the H and L terminals

LO terminals on the LCZ meter.

Do

not handle the standards excessively, or the resulting increase in temperature may

result

in

inaccurate calibration.

of

each standard to the corresponding

ABORT

>>)

to

connect each of the following standards to

in

Figure 3.

HI

and

IL

H

Standard Resistance

Figure

11.

12.

13. After calibrating the unit(s), the calibration data file is created and written to the computer disk

14.

3.

Calibration standards connections

After connecting each standard, press any key except

to abort the calibration process and return to the main menu.

If

you are calibrating more than one

directory. The filename for

seconds) when calibration

Example: 5/21/92 10:45:03

Filename: "05219210.450"

Values written to the file are

ment model number and serial number will also be written to the file.

When

all

units have been calibrated, the following message screen will be displayed:

this

is

performed.

in

unit,

file

is

derived from the

ASCII

representation

the process will be repeated for each unit.

Calibration Process Screen

3321/3322/3330 Calibration System Ver.

Check

sum

is

being written

<Ex>

to continue with calibration You

Dos

date (month/day/year) and time (hour/minutes/

of

double-precision floating-point numbers. The

[6]

...

can

1.00

press <Eso

in

the current

instru-

15.

Press

Finished calibration for 3 unit(s).

Press

any key to continue

any

key to re6 to

Calibration is now complete. However, new calibration constants do not

until

power

cessful.

the

main menu.

NOTE

is

cycled. See the following paragraph

.....

to

determine

go

into effect

if

calibration was suc-

15

6.3.1

Post calibration

After calibration

ber plug

strument oes through its power-up self-calibration cycle without errors.

on the

up calibration constants

Service Manual or the Model 3330 Service Manual for information on battery replacement and repair.)

To

manual.

6.4

Selecting “Manipulate Calibration Data’’ from the main menu will display the following screen and allow you to

perform the operations described below.

in

venfy calibration accuracy, perform the verification procedures described

Manipulate Calibration Data

has

been completed, remove the jumper clip connected between

the access hole.

and

@l

DISPLAY sections, repeat the calibration procedure.

RAM

I

TPlOl

and

G,

and install the rub-

Turn

off

the power for

may require replacement, or the unit may require repair. (See the Model 3321/3322

Manipulate Calibration Data Screen

3321/3322/3330 Calibration System Ver.

Directory

Write Machine Table

Read Machine Table

Type File

Listing

three

seconds, then

turn

the unit back on, and venfy that the in-

If

the errors

If

the error persists, the battery that backs

in

1.00

“EEEEE”

Section 1 of the respective service

and

“22222“

appear

SPECIFICATION

I

(ARROW

Direct0 y Listing

This

selection will allow you

lected, the program will display the following prompt for the directory

SPECIFICATION

Enter the desired path, then press <Enter>. The default path

Write Machine Table

This

menu selection writes calibration data from a given computer data file to Model 3321/3322/3330

this

menu item

16

>>

is

selected, the computer will prompt you for the name

to

-

-

display a listing of files

>>

-

Change Field>

<CR

-

Select/Edit>

in

a manner similar to the

to

be displayed:

is

the current directory,

of

the calibration data file as follows:

DOS

and

“DIR”

the output

command. When

is

paginated.

RAM.

When

se-

WRlTE

Machine Table FROM file name

>>

-

Type in the name of the file to be loaded, then press <Enter>. Alist of data sets with serial numbers

to

bers will be displayed on the screen. Eriter the number corresponding to the data set

3321 /3322/3330,

Read

Machine Table

This

menu selection reads the calibration table from the

this

item

is

READ

Type in the desired filename, then press <Enter>. The unit will then prompt for the serial number and model num-

ber:

Serial

NO. & Model Type

Type

in

the pertinent information, then

the data wlll be stored in the designated computer data file.

then press <Enter>.

NOTE

The Model

G)

to

ment

selected, the program will prompt you for the filename as follows:

Machine Table TO file name

3321/3322/3330

in

order to write calibration data to the instrument.

is

connected to the

>>

-

must be

GPIB

>>

-

press

in

the calibration adjust mode

interface of the computer.

LCZ

meter and stores data

<Enter>. The calibration table will be read from the instrument, and

Also

be

(-101

sure

be written to the Model

connected

that the

in

a designated disk file. When

and

instru-

model num-

Type File

This

menu selection allows you

item

is

selected, the instrument will prompt you for the name of the

FILESPEC

Type in the name of the file, then press <Enter>. The display will be paginated

>>

-

to

display the contents of a designated

ASCII

file:

QUfl

Selecting

QUIT

will return you to the main menu screen of the calibration program.

file on the computer screen. When

if

necessary.

this

Loading...

Loading...