Page 1

DEPARTMENT OF THE ARMY TECHNICAL BULLETIN

CALIBRATION PROCEDURE FOR

OSCILLOSCOPE,

TEKTRONIX TYPES 317 (AN/USM-154)

AND RM17

Headquarters, Department of the Army, Washington, DC

22 September 1975

TB 9-6625-1172-35, 30 August 1974, is changed as follows:

TB 9-6625-1172-35

Change 1

The title is changed as shown above.

1. Remove old pages and insert new pages as indicated below. New or changed material is

indicated by a vertical bar in the margin of the page.

Remove pages Insert Pages

1 through 6 1 through 6

2. File this change sheet in front of the publication for reference purposes.

By Order of the Secretary of the Army:

FRED C. WEYAND

General, United States Army

Official: Chief of Staff

PAUL T. SMITH

Major General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with DA Form 12-34A (qty rqr block No. 75), requirements

for Calibration Procedures Publications.

This publication is a courtesy quick copy from the UNITED

STATES ARMY ADJUTANT GENERAL PUBLICATIONS

CENTER, ST. LOUIS, MISSOURI, to meet your needs while we

are replenishing our regular stock.

Page 2

TB 9-6625-1172-35

10. Crt Geometry and Astigmatism graticule line.

fig. 2) until markers are parallel with vertical

a. Performance Check

(1) Connect time-mark generator (A6) to TI

VERTICAL INPUT, using cable (B5) and if necessary,

adapter (B2). Adjust time-mark generator for .1 mS

marker output.

(2) Adjust TI POSITIONING controls to aline

top of markers with top horizontal graticule line and

extending across full horizontal range of crt. If markers

displayed on crt are not parallel with vertical graticule

lines, perform b(l) below.

(3) Reposition TI waveform to display both

the baseline and markers. If sharp focus of crt display

cannot be obtained by adjusting front panel FOCUS

control, perform b(2) below.

b. Adjustments

Table 4. Calibrator Accuracy

Test Instrument Ac/Dc Voltmeter Indications

VOLTS PEAK-TO-PEAK

Switch Settings. Min Max

in conjunction with FOCUS control for sharpest focus of

displayed baseline and markers.

11. Calibrator Accuracy

position) and remove V875 (fig. 3), or for TI's with S/N

280 and above V883 (fig. 3) (V573, fig. 4).

CAL OUT connector and chassis ground, using leads

supplied with ac/dc voltmeter and, if necessary, adapter

(B 1).

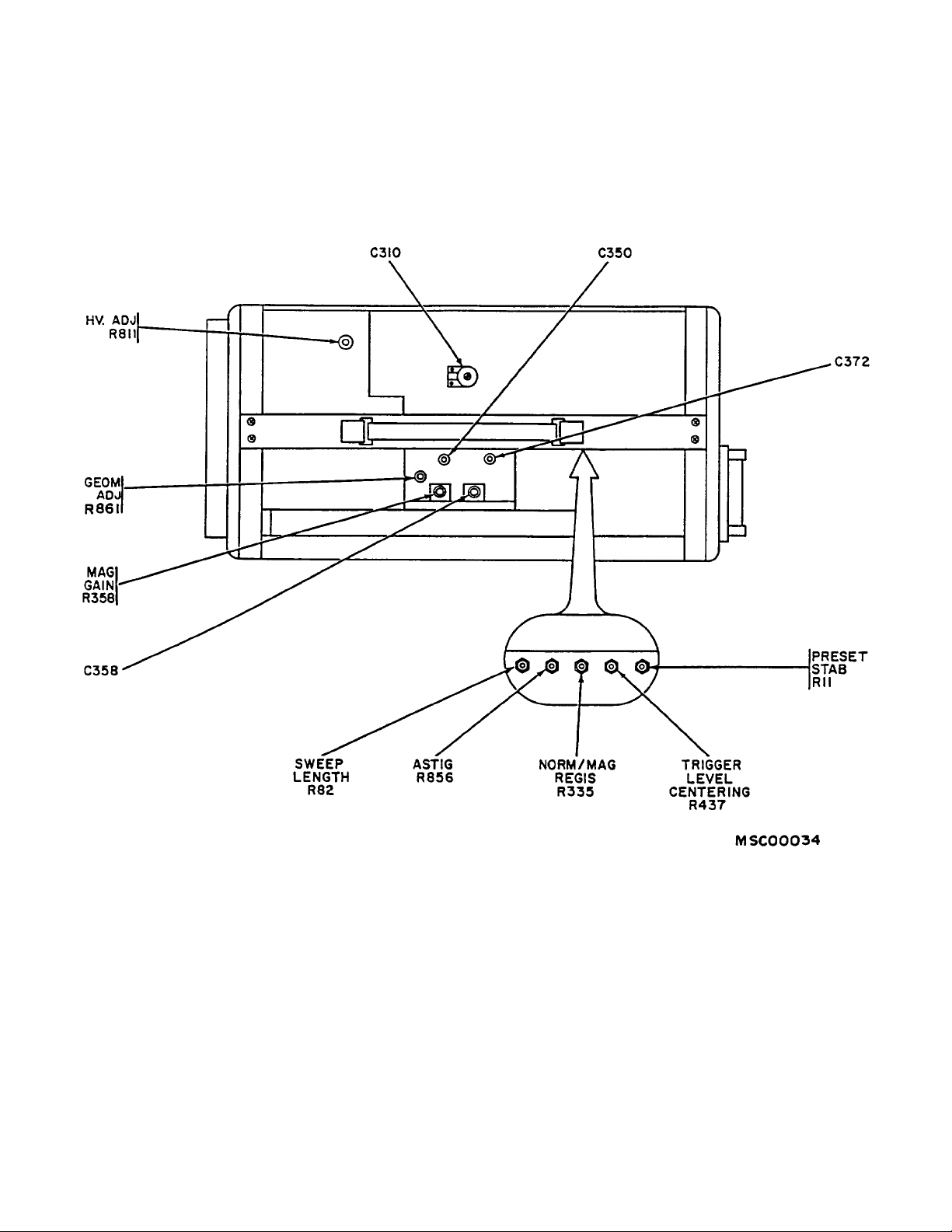

(1) Adjust R861 (fig. 1) (GEOM ADJ R861,

(2) Adjust R860 (fig. 1) (ASTIG R856, fig. 2)

a. Performance Check

(1) Turn TI POWER switch to off (down

(2) Turn TI POWER switch to ON.

(3) Connect ac/dc voltmeter (A2) between TI

(vdc).

50 48.5 51.5

20 19.4 20.6

10 9.7 10.3

5 4.85 5.15

2 1.94 2.06

1 0.97 1.03

.5 0.485 0.515

.2 0.194 0.206

.1 0.097 0.103

.05 0.0485 0.0515

(4) Turn TI VOLTS PEAK-TO-PEAK switch (6) Turn TI POWER switch to off (down) and

to 100. If ac/dc voltmeter does not indicate bet- replace vacuum tube removed in (1) above.

ween 97 and 103 volts dc, perform b below. (7) Turn TI POWER switch to ON and VOLTS

PEAK-TO-PEAK switch to OFF.

(5) Repeat technique of(4) above for settings b. Adjustments. Adjust CAL ADJ R879 (fig. 3)

and indications listed in table 4. Ac/dc voltmeter. (CAL. ADJ. R566, fig. 4) for a 100-volt dc indicawill indicate within limits specified. tion on ac/dc voltmeter (R).

¶¶ U.S. GOVERNMENT PRINTING OFFICE: 19754656681174

6

Page 3

DEPARTMENT OF THE ARMY TECHNICAL BULLETIN

CALIBRATION PROCEDURE FOR

OSCILLOSCOPE,

TEKTRONIX TYPES 317 AND RM17

Headquarters, Department of the Army, Washington, D.C.

30 August 1974

SECTION I. IDENTIFICATION AND DESCRIPTION

Test instrument identification ------------------------------------------------------------------- 1 2

Calibration data card, DA Form 2416--------------------------------------------------------- 2 2

Reporting of errors ---------------------------------------------------------------------------------- 3 2

Calibration description ----------------------------------------------------------------------------- 4 2

II. EQUIPMENT REQUIREMENT FOR OSCILLOSCOPE, TEKTRO -

NIX TYPES 317 AND RM17 (A-LEVEL)

Equipment required --------------------------------------------------------------------------------- 5 3

Accessories required ------------------------------------------------------------------------------- 6 3

III. PRELIMINARY OPERATIONS FOR OSCILLOSCOPE, TEKTRO-

NIX TYPES 317 AND RM17 (A-LEVEL)

Preliminary instructions --------------------------------------------------------------------------- 7 5

Equipment setup ------------------------------------------------------------------------------------- 8 5

IV. CALIBRATION PROCESS FOR OSCILLOSCOPE, TEKTRONIX

TYPES 317 AND RM17 (A-LEVEL)

Crt mechanical alinement ------------------------------------------------------------------------- 9 5

Crt geometry and astigmatism ----------------------------------------------------------------- 10 6

Calibrator accuracy --------------------------------------------------------------------------------- 11 6

Vertical dc balance ---------------------------------------------------------------------------------- 12 7

Vertical amplifier and preamplifier gain, attenuation, and stability --------------- 13 8

Attenuator compensation ------------------------------------------------------------------------- 14 11

Sweep triggering -------------------------------------------------------------------------------------- 15 12

Magnifier gain and registration ----------------------------------------------------------------- 16 12

Horizontal amplifier and sweep length ------------------------------------------------------ 17 13

Sweep timing ------------------------------------------------------------------------------------------- 18 13

Rise time ------------------------------------------------------------------------------------------------ 19 14

Power supply ------------------------------------------------------------------------------------------- 20 14

Final procedure --------------------------------------------------------------------------------------- 21 15

V. EQUIPMENT REQUIREMENTS FOR OSCILLOSCOPE, TEK-

TRONIX TYPE 317 (C-LEVEL)

Equipment required --------------------------------------------------------------------------------- 22 15

Accessories required ------------------------------------------------------------------------------- 23 16

VI. PRELIMINARY OPERATIONS FOR OSCILLOSCOPE, TEKTRO-

NIX TYPE 317 (C-LEVEL)

Preliminary instructions --------------------------------------------------------------------------- 24 17

Equipment setup ------------------------------------------------------------------------------------- 25 17

*TB 9-6625-1172-35

Paragraph Page

*This bulletin supersedes TB 9-6625-787-50, 8 December 1969, and TB 9-6625-1172-50, 31 May 1968., including all

changes.

1

Page 4

VII. CALIBRATION PROCESS FOR OSCILLOSCOPE, TEKTRONIX

TYPE 31 7 (C-LEVEL)

Calibrator ----------------------------------------------------------------------------------------------- 26 17

Crt alinement ------------------------------------------------------------------------------------------ 27 18

Crt astigmatism --------------------------------------------------------------------------------------- 28 18

Crt geometry ------------------------------------------------------------------------------------------- 29 18

Sweep triggering ------------------------------------------------------------------------------------- 30 19

Magnifier gain ----------------------------------------------------------------------------------------- 31 20

Horizontal amplifier gain -------------------------------------------------------------------------- 32 20

Sweep length ------------------------------------------------------------------------------------------ 33 20

Magnifier registration ------------------------------------------------------------------------------- 34 20

1 µSEC sweep timing ------------------------------------------------------------------------------ 35 20

10 µSEC/DIV sweep timing ---------------------------------------------------------------------- 36 21

2 µSEC/DIV linearity ------------------------------------------------------------------------------- 37 21

.5 µSEC/DIV sweep timing ----------------------------------------------------------------------- 38 21

.2 µSEC/DIV linearity ------------------------------------------------------------------------------ 39 21

.04 µSEC/DIV sweep timing and linearity -------------------------------------------------- 40 21

Variable attenuator balance --------------------------------------------------------------------- 41 22

Amplifier gain and attenuation ------------------------------------------------------------------ 42 23

Attenuator high-frequency compensation -------------------------------------------------- 43 23

Attenuator input capacitance -------------------------------------------------------------------- 44 23

Preamplifier low-frequency compensation ------------------------------------------------- 45 24

Delay line high-frequency response ---------------------------------------------------------- 46 24

Amplifier bandwidth---------------------------------------------------------------------------------- 47 25

Preamplifier bandwidth ---------------------------------------------------------------------------- 48 26

Power supply ------------------------------------------------------------------------------------------- 49 26

Final procedure --------------------------------------------------------------------------------------- 50 27

TB 9-6625-1172-35

Paragraph Page

IDENTIFICATION AND DESCRIPTION

1. Test Instrument Identification

This bulletin provides instructions for the A-level

calibration of Oscilloscope, Tektronix Types 317 and

RM17 and C-level calibration of Oscilloscope, Tektronix

Type 317. The manufacturer's instruction manuals were

used as the prime data source in compiling these

instructions. The oscilloscope will be referred to as the

"TI" (test instrument) throughout this bulletin.

a. Model Variations. Type RM17 is the

rackmounted version of type 317. Wherever difference

exists between types, adjustments and parameters for

type 317 are listed in parenthesis for A-level calibration.

b. Time and Technique. The time required for this

calibration is approximately 3 hours, using the dc and

low frequency technique.

2. Calibration Data Card, DA Form 2416.

a. Forms, records, and reports required for

calibration personnel at all levels are prescribed by

TM 38-750. DA Form 2416 must be annotated

SECTION I

in accordance with TM 38-750 for each calibration

performed.

b. Adjustments to be reported on DA Form 2416

are designated (R) at the end of the sentence in which

they appear. When adjustments are in tables, the (R)

will follow the designated adjustment. Report only those

adjustments made and designated with (R).

3. Reporting of Errors

The reporting of errors, omissions, and

recommendations for improving this publication by the

individual user is encouraged. Reports should be

submitted on DA Form 2028, Recommended Changes

to Publications, and forwarded direct to Commander,

U.S. Army Missile Command, ATTN: AMSMI-MFPA,

Redstone Arsenal, AL 35809.

4. Calibration Description

TI parameters and performance specifications which

pertain to this calibration are listed in table 1.

2

Page 5

Table 1. Calibration Description

Test Instrument Parameters Performance Specifications

Power input requirements 115 vac ±10% (or 230 vac +10%), 50 to 60 Hz, 200 w

Calibrator:

Output 6.05 to 100 v p-p in 11 steps

Accuracy

Waveform

1

±3%

Square waves at approx 1 kHz

Vertical deflection system:

Deflection factor 0.01 to 50 v/cm p-p in 12 steps; 0.1 to 50 v/cm dc coupled

and 0.01 v/cm to 50 v/cm ac coupled.

Accuracy

±3%

Frequency response Dc to 10 MHz; 0.1 to 50 v/cm, dc coupled; 2 Hz to 10 MHz,

0.1 to 50 v/cm, ac coupled; 2 Hz to 9 MHz, 0.01 to 0.05

v/cm, ac coupled.

1 megohm, 38 pf, direct connection

Input impedance

1

Rise time 35 nsec

TB 9-6625-1172-35

Horizontal deflection system:

Deflection factor

1

Approx 1.3 v/cm

Frequency response Dc to 500 kHz

Sweep speeds:

Time base

0.2 µAsec/cm to 2 sec/cm, in 22 steps; 5X magnifier extends

fastest sweep rate to 0.04 µsec/cm.

1

This specification Is for information only and is not verified in this bulletin.

SECTION II

EQUIPMENT REQUIREMENTS FOR OSCILLOSCOPE,

TEKTRONIX TYPES 317 and RM17

(A-LEVEL)

5. Equipment Required

listed in table 2 provide a four-to-one ratio between the

standard and TI. Where the four-to-one ratio cannot be

Table 2 identifies the specified equipment used for A-

level calibration. This equipment is issued with the

met, the actual accuracy of the equipment selected is

shown in parenthesis.

secondary transfer calibration standards set and is to be

used in performing this procedure. Alternate items may

6. Accessories Required

be used by the calibrating activity when the equipment

listed in table 2 is not available. The items selected

must be verified to perform satisfactorily prior to use and

must bear evidence of current calibration. The

equipment must meet or exceed the minimum use

specifications listed in table 2. The accuracies

The accessories listed in table 3 are issued with the

secondary transfer calibration standards set and are to

be used for A-level calibration. When necessary, these

items may be substituted by equivalent items unless

specifically prohibited.

3

Page 6

TB 9-6625-1172-35

Table 2. Minimum Specifications of Equipment Required

Item Common Name Minimum Use Specifications Manufacturer, Model, and Part Number

A1 AC CALIBRATOR Range: 13.7158 my rms to Hewlett-Packard, Model

72.826 v rms at 1 kHz. 745A (MIS-10342).

Accuracy: ±0.75%

A2 AC/DC VOLTMETER Range: -153 to +309 vdc Dana, Model 5703-S-2127

(7912606).

Accuracy: ±0.75%

A3 AUTOTRANSFORMER Range: 105 to 125 vac General Radio, Model

W10MT3AS3 (7910809).

Accuracy: ±0.75%

A4 DC VOLTMETER Range: -1261 to -1339 vdc Electrical Instruments Ser-

vice, Model ESV (MIS-10276).

Accuracy: ±0.75%

A5 SQUARE-WAVE Range: 50 Hz to 1 MHz Tektronix, Type 106

GENERATOR. (MIS-10284).

Rise Time: Less than 35 nsec

A6 TIME-MARK GENERATOR Range: 20 nsec to 1 sec Tektronix, Type 184MOD

markers. 146B (7912042-2).

Accuracy: ±0.75%

Table 3. Accessories Required

Item Common Name Description and Part Number

B1 ADAPTER BNC plug to double banana posts (7909401)

B2 ADAPTER BNC jack to UHF plug (10519439)

B3 ADAPTER UHF jack to BNC plug (8109698)

B4 CABLE 36-in., RG-580/U; BNC plug and double banana plug termina-

tions (7907471).

B5 CABLE 30-in., RG-580/U; BNC plug terminations (7907467)

B6 CAPACITANCE 5 to 80 pf, variable (SKD-4850-44)

STANDARDIZER.

B7 LEAD 24-in., No. 18 AWG; single banana plug terminations (red)

(7907497).

B8 LEAD 24-in., No. 18 AWG; single banana plug terminations (black)

(7907498).

B9 PROBE Test hook, banana plug to miniature hook (SKC-4850-14)

4

Page 7

SECTION III

PRELIMINARY OPERATIONS FOR OSCILLOSCOPE,

TEKTRONIX TYPES 317 AND RM17 (A-LEVEL)

TB 9-6625-1172-35

7. Preliminary Instructions

a. The instructions outlined in this section are

preparatory to the calibration process. Personnel should

become familiar with the appropriate sections before

beginning the calibration.

b. Items of equipment used in this procedure are

referenced within the text by common name and item

identification number as listed in tables 2 and 3. For the

identification of equipment referenced by item numbers

prefixed with A, see table 2, and for prefix B, see table 3.

WARNING

HIGH VOLTAGE is used during the

performance of this calibration.

DEATH ON CONTACT may result if

personnel fail to observe safety

precautions.

8. Equipment Setup

a. Remove protective cover from TI.

b. Connect TI to autotransformer (A3).

c. Connect autotransformer to 115-volt

SECTION IV

ac source and adjust controls for 115 volts ac.

d. Position TI controls as listed in (1) through (15)

below:

(1) INTENSITY control to midrange.

(2) FOCUS control to midrange.

(3) CALIBRATOR switch to OFF.

(4) HORIZONTAL DISPLAY switch to NORM.

(5) TRIGGER SELECTOR switch (black) to

+INT.

(6) TRIGGER SELECTOR switch (red) to

AUTO.

(7) TRIGGERING LEVEL control to 0 (zero).

(8) STABILITY control fully clockwise.

(9) TIME/DIV switch to .1 MILLISEC.

(10) VARIABLE TIME/DIV control to

CALIBRATED.

(11) VERTICAL POSITIONING control to

midrange.

(12) HORIZONTAL POSITIONING control to

midrange.

(13) VOLTS/DIV switch to .1.

(14) VARIABLE VOLTS/DIV control to

CALIBRATED.

(15) AC DC switch to AC.

e. Turn POWER switch to ON and allow sufficient

time for equipment to warm up and stabilize.

NOTE

Unless otherwise specified, verify the

results of each test and take

corrective action whenever the test

requirement is not met before

continuing with the calibration.

NOTE

When indications specified in

paragraphs 9 through 19 are not

within tolerance, perform the power

supply check prior to making

adjustments. After adjustments are

made, repeat paragraphs 9 through

19, Do not perform power supply

check if all other parameters are

within tolerance.

9. Crt Mechanical Alinement

a. Performance Check

(1) Position TI controls as listed in (a) through

(c) below:

(a) SCALE ILLUM control as desired.

CALIBRATION PROCESS FOR OSCILLOSCOPE,

TEKTRONIX TYPES 317 AND RM17 (A-LEVEL)

(b) INTENSITY and FOCUS controls for

sharp trace.

(c) HORIZONTAL POSITION control

for start of trace at left edge of graticule.

(2) Adjust VERTICAL POSITION control for

start of trace alined with center horizontal graticule line.

If end of trace is not within M small division of center

horizontal graticule line, perform b below.

b. Adjustments

WARNING

HIGH VOLTAGE is present in area of

crt base; use extreme caution when

making the following adjustments.

(1) Loosen crt base clamp and rotate crt with

positioning handle for indication as specified in a(2)

above.

(2) Tighten crt base clamp and repeat a(2)

above.

5

Page 8

TB 9-6625-1172-35

10. Crt Geometry and Astigmatism

fig. 2) until markers are parallel with vertical graticule

a. Performance Check

(1) Connect time-mark generator (A6) to TI

VERTICAL INPUT, using cable (B5) and if necessary,

adapter (B2). Adjust time-mark generator for .1 mS

marker output.

(2) Adjust TI POSITIONING controls to aline

top of markers with top horizontal graticule line and

extending across full horizontal range of crt. If markers

displayed on crt are not parallel with vertical graticule

lines, perform b(1) below.

(3) Reposition TI waveform to display both

the baseline and markers. If sharp focus of crt display

cannot be obtained by adjusting front panel FOCUS

control, perform b(2) below.

b. Adjustments

Table 4. Calibrator Accuracy

Test Instrument Ac/Dc Voltmeter Indications

VOLTS PEAK-TO-PEAK

Switch Settings. Min Max

line.

in conjunction with FOCUS control for sharpest focus of

displayed baseline and markers.

11. Calibrator Accuracy

position) and remove V875 (fig. 3), or for TI's with SIN

280 and above V883 (fig. 3) (V573, fig. 4).

CAL OUT connector and chassis ground, using leads

supplied with ac/dc voltmeter and, if necessary, adapter

(B1).

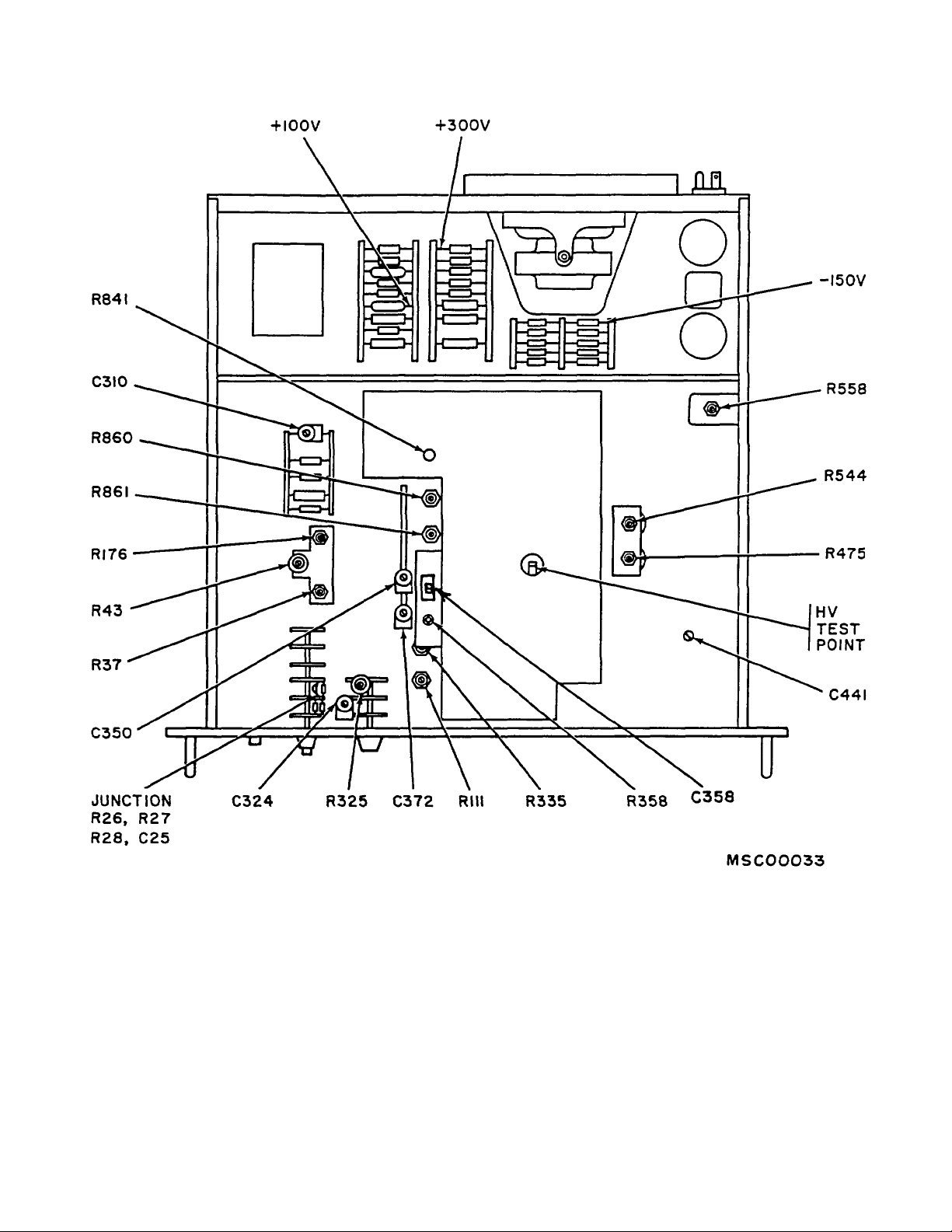

(1) Adjust R861 (fig. 1) (GEOM ADJ R861,

(2) Adjust R860 (fig. 1) (ASTIG R856, fig. 2)

a. Performance Check

(1) Turn TI POWER switch to off (down

(2) Turn TI POWER switch to ON.

(3) Connect ac/dc voltmeter (A2) between TI

(vdc).

50 48.5 51.5

20 19.4 20.6

10 9.7 10.3

5 4.85 5.15

2 1.94 2.06

1 0.97 1.03

.5 0.485 0.515

.2 0.194 0.206

.1 0.097 0.103

.05 0.0485 0.0515

(4) Turn TI VOLTS PEAK-TO-PEAK switch to

100. If ac/dc voltmeter does not indicate between 97

and 103 volts dc, perform b below.

(5) Repeat technique of (4) above for settings

and indications listed in table 4. Ac/dc voltmeter will

indicate within limits specified.

(6) Turn TI POWER switch to off (down) and

replace vacuum tube removed in (1) above.

(7) Turn TI POWER switch to ON and VOLTS

PEAK-TO-PEAK switch to OFF.

b. Adjustments. Adjust CAL ADJ R879 (fig. 3)

(CAL. ADJ. R566, fig. 4) for a 100-volt de indication on

ac/dc voltmeter (R).

6

Page 9

TB 9-6625-1172-35

Figure 1. Oscilloscope-bottom view (type RM17).

12. Vertical Dc Balance

a. Performance Check

(1) Connect TI VERTICAL INPUT to chassis

ground, using lead (B 7), and if necessary, adapter (B1).

(2) Position TI controls as listed in (a) through

(c) below:

(a) AC/DC switch to DC.

(b) STABILITY control fully clockwise.

(c) VERTICAL POSITION control to

aline trace behind horizontal graticule center line.

(3) Turn VARIABLE VOLTS/DIV control from

fully clockwise to fully counterclockwise

7

Page 10

TB 9-6625-1172-35

Figure 2. Oscilloscope - top view (type 317).

position. If trace does not remain behind center

horizontal graticule line, perform b below.

b. Adjustments. Adjust VARIABLE ATTEN. BAL.

(front panel) for minimum vertical movement of trace

while turning VARIABLE VOLTS/DIV control throughout

its range.

13. Vertical Amplifier and Preamplifier Gain,

Attenuation. and Stability

8

a. Performance Check

(1) Connect ac calibrator (Al) output to TI

VERTICAL INPUT, using cable (B4) and, if necessary,

adapter (B2).

(2) Turn TIME/DIV switch to 1 mSEC and

VARIABLE VOLTS/DIV switch to CALIBRATED.

Page 11

TB 9-6625-1172-35

(3) Adjust ac calibrator for 1 kHz and

amplitude for 4 major divisions of vertical deflection on TI

crt. If ac calibrator does not indicate between 137.158

and 145.642 millivolts rms, perform b(1) below.

(4) Turn VOLTS/DIV switch to .01 and adjust

ac calibrator for 4 major divisions of vertical deflection on

TI crt. If ac calibrator does not indicate

between 13.7158 and 14.5642 millivolts rms, perform

b(2) below.

(5) Vary autotransformer (A3) between 105

and 125 volts. Ac calibrator will remain between limits

specified in (4) above.

(6) Adjust autotransformer for 115 volts.

(7) Repeat technique of (4) above, using

settings listed in table 5. Ac calibrator will indicate

between limits specified.

Figure 3. Oscilloscope-top Mew (type RM17).

9

Page 12

Table 5. Vertical Amplifier and Preamplifier Gain and Attenuation

Test Instrument Ac/Dc Voltmeter Indications

VOLTS/DIV (vdc).

Switch Settings.

Min Max

.02 27.4316 mv 29.1284 mv

.05 68.579 mv 72.821 mv

.2 274.316 mv 291.284 mv

.5 685.79 mv 728.21 mv

1 1.37158 v 1.45642 v

2 2.74316 v 2.91284 v

5 6.8579 v 7.2821 v

10 13.7158 v 14.5642 v

20 27.4316 v 29.1284 v

50 68.579 v 72.821 v

TB 9-6625-1172-35

b. Adjustments

(1) Adjust ac calibrator for 141.4 millivolts rms

output. Adjust R544 (fig. 1) (GAIN ADJ R244, fig. 5) for

4 major divisions of vertical deflection on crt (R).

(2) Adjust ac calibrator for 14.14 millivolts rms

output. Adjust PREAMP GAIN ADJ R454 (fig. 3)

(PREAMP GAIN ADJ R154, fig. 5) for 4 major divisions

of vertical deflection crt (R).

10

Figure 4. Oscilloscope - right-side view (type 317).

Page 13

TB 9-6625-1172-35

14. Attenuator Compensation

a. Performance Check

(1) Connect square-wave generator (A5) to TI

INPUT, using cable and termination supplied with

square-wave generator, and adapter and capacitance

standardizer (B2 and B6) and, if necessary, adapter

(B3).

(2) Turn TI VOLTS/DIV switch to .01 and

TIME/DIV switch to .5 MILLISEC.

and amplitude for approximately 4 major divisions of

vertical display on TI cit.

optimum square-wave display on TI crt.

VOLTS/DIV switch setting listed in table 6. If square

wave displayed on TI crt does not have flat tops and

square corners, perform the appropriate adjustments

(3) Adjust square-wave generator for 1 kHz

(4) Adjust capacitance standardizer for

(5) Repeat technique of (3) above for each

listed in table 6.

Table 6. Attenuator Compensation Adjustments

Test Instrument Adjustments (fig. 3 or 5)

VOLTS/DIV Flat Top Square Corner

Switch Settings.

.2 C430 (C130) (R) C432 (C132) (R)

.5 C424 (C124) (R) C426 (C126) (R)

1 C416 (C116) (R) C418 (C118) (R)

10 C410 (C110) (R) C412 (C112) (R)

.02 C441 1 (R) ---

2

.05

1

Refer to figure 1 for location.

2

Turn TI TIME/DIV switch to 5 mSEC and adjust square-wave generator to 50 Hz.

R475 1 (R175) (R) ---

Figure 5. Oscilloscope-left-side view (type 317).

11

Page 14

TB 9-6625-1172-35

b. Adjustments. No further adjustments can be

made.

15. Sweep Triggering

a. Performance Check

(1) Connect CAL OUT to VERTICAL INPUT,

using lead (B7) or cable (B5).

(2) Position TI controls as listed in (a) through

(e) below:

(a) TRIGGER SELECTOR switch (red)

to AC.

(b) TIME/DIV switch to .5 MILLISEC.

(c) VOLTS/DIV switch to 1.

(d) VOLTS PEAK-TO-PEAK switch to

.5.

(e) STABILITY switch to PRESET.

(3) Connect junction of R26, R27, R28, and

C25 (fig. 1) (or R426 and R427, fig. 4) to chassis ground,

using probe (B9).

(4) Adjust VOLTS/DIV VARIABLE control for

1 minor division of vertical deflection on TI crt.

(5) Position crt trace on horizontal graticule

center line.

(6) Alternately switch TI TRIGGER

SELECTOR (black) control back and forth from +INT to INT. If sweep does not have stable triggering in both

+INT and -INT positions, perform 6(1) through (3) below.

(7) Remove short connected in (3) above.

(8) Turn TI TRIGGERING LEVEL control to

position where stable triggering occurs in both +INT and

-INT positions. If stable triggering does not occur when

TRIGGERING LEVEL control is in 0 (zero) position,

perform b(4) below.

(9) Turn TI TRIGGERING SELECTOR (red)

switch to DC.

(10) It may be necessary to adjust TI

VERTICAL POSITIONING control until sweep appears

on crt.

(11) Adjust VOLTS/DIV VARIABLE control for

1.5 minor divisions of vertical display on TI crt. If crt

display is not positioned at the center horizontal graticule

line, while TI TRIGGER SELECTOR (black) switch is

turned from +INT to -INT, perform b(5) below.

(12) Turn TI VOLTS PEAK-TO-PEAK switch to

OFF.

(13) Remove lead (B7) or cable (B5)

connected in (1) above.

(14) Turn TI TRIGGER SELECTOR (red)

switch to AUTO. IF stable waveform does not occur,

perform b(6) through (8) below.

b. Adjustments

(1) Adjust TI TRIGGER LEVEL CENTERING

R37 (fig. 1) (R437, fig. 2) until stable triggering is

obtained in both +INT and -INT positions.

12

(2) Reduce amplitude of crt display, using

VOLTS/DIV VARIABLE control until display becomes

unstable. Adjust R43 (fig. 1) on TI's with S/N 203 and

above (TRIGGER SENSITIVITY ADJ. R443, fig. 4) until

stable triggering is obtained in both +INT and -INT

positions.

(3) Repeat (1) and (2) above until no further

adjustments are required.

(4) Loosen setscrew on TRIGGERING

LEVEL knob and adjust to 0 (zero) position without

turning potentiometer shaft. Tighten setscrew.

NOTE

Do not disturb setting of

TRIGGERING LEVEL control

established in a(8) above.

(5) Adjust R558 (fig. 1) (INT TRIG DC LEVEL

ADJ R258, fig. 5) in conjunction with VERTICAL

POSITIONING control until sweep is positioned at center

horizontal graticule line as TRIGGER SELECTOR

(black) switch is turned from -INT to +INT.

(6) Turn R111 (fig. 1) (PRESET STAB R11,

fig. 2) fully counterclockwise; then, turn slowly clockwise

until trace appears on TI crt. Note position of R111

(R11) shaft.

(7) Continue turning R111 (R11) clockwise

until trace brightens. Note position of R111 (R11) shaft.

(8) Adjust R111 (R11) to a position that is

midway between positions noted in (6) and (7) above.

16. Magnifier Gain and Registration

a. Performance Check

(1) Connect time-mark generator (A6) to TI

VERTICAL INPUT, using cable (B5) and, if necessary,

adapter (B2). Set time-mark generator to 1 mS markers.

(2) Position TI controls as listed in (a) through

(i) below:

(a) VARIABLE VOLTS/DIV control to

CALIBRATED.

(b) AC/DC switch to AC.

(c) TRIGGER SELECTOR (red) switch

to AC.

(d) TRIGGER SELECTOR (black)

switch to +INT.

(e) HORIZONTAL DISPLAY switch to

MAG.

(t) TIME/DIV switch to 5 MILLISEC.

(g) STABILITY and TRIGGERING

LEVEL controls for a stable display.

(h) VERTICAL POSITIONING control to

center trace vertically.

(i) HORIZONTAL POSITIONING

control

Page 15

TB 9-6625-1172-35

for second marker alined behind second vertical

graticule line. If 10th marker is not displayed within 1.5

minor divisions of 10th vertical graticule line, perform

b(1) below.

(3) Adjust HORIZONTAL POSITIONING

control to aline first marker behind center vertical

graticule line.

(4) Turn HORIZONTAL DISPLAY switch to

NORM. If first marker does not remain alined behind

center vertical graticule line, perform b(2) and (3) below.

b. Adjustments

(1) Adjust R358 (fig. 1) (MAG GAIN R358, fig.

2) for one marker per major division on TI crt (R).

(2) Adjust R335 (fig. 1) (NORM/MAG REGIS

R335, fig. 2) to aline first marker behind center vertical

graticule line (R).

(3) Repeat a(2)(e), (3), (4), and b(2) above

until indication specified in a(4) above is obtained.

17. Horizontal Amplifier and Sweep Length

a. Performance Check

(1) Adjust time-mark generator (A6) for .1 mS

markers.

(2) Turn TIME/DIV switch on TI to .1

MILLISEC.

(3) Adjust TI HORIZONTAL POSITIONING

control to aline second marker behind second vertical

graticule line. If 10th marker is not displayed within ± 1.5

minor divisions of 10th vertical graticule line, perform

b(1) below.

(4) Adjust time-mark generator for 50 µS

markers.

(5) Adjust TI HORIZONTAL POSITIONING

control to aline first marker behind first vertical graticule

line. If trace on TI crt does not extend one marker past

11th graticule line, perform b(2) below.

b. Adjustments

(1) Adjust R325 (fig. 1) (HORIZ GAIN ADJ.

R325, fig. 4) until one time marker per centimeter is

displayed between second and 10th vertical graticule

lines (R).

(2) Adjust R176 (fig. 1) (SWEEP LENGTH

R82, fig. 2) for sweep length extending one marker past

right edge of graticule.

18. Sweep Timing

a. Performance Check

(1) Adjust time-mark generator (A6) to 10 µS

markers.

(2) Turn TI TIME/DIV switch to .1 MILLISEC

and HORIZONTAL DISPLAY switch to MAG.

(3) Position first marker behind center vertical

graticule line.

(4) Turn TI TIME/DIV switch to 50 µSEC. If

first marker does not remain behind center vertical

graticule line, perform b(1) and (2) below.

(5) Turn TI TIME/DIV switch to 5 µSEC and

adjust time-mark generator for 1 µS markers.

(6) Adjust TI HORIZONTAL POSITIONING

Table 7. Sweep Timing

Test Instrument Time-Mark Markers Adjustments

TIME/DIV Generator Per cm. (fig. 3 or 4).

Switch Settings. Settings.

1 µSEC 1 µS

10 µSEC 10 µS

20 µSEC 10 µS

50 µSEC 50 µS

.2 µSEC

.2 µSEC

1

1 3

.1 µS

.1 µS

2 µSEC .1 µS

.5 µSEC .5 µS

1 --1 C160E (R)

2 --1

2

4/10 cm

2

1 C160A (R)

.1 MILLISEC .1 mS 1 --.2 MILLISEC .1 mS 2 --.5 MILLISEC .5 mS 1 --1 MILLISEC .1 mS 1 --2 MILLISEC .1 mS 2 ---

See footnotes at end of table.

2

4

5

13

Page 16

TB 9-6625-1172-35

Table 7. Sweep Timing-Continued

Test Instrument Time-Mark Markers Adjustments

TIME/DIV Generator Per cm. (fig. 3 or 4).

Switch Settings. Settings.

5 MILLISEC 5 mS 1 --10 MILLISEC 10 mS 1 --20 MILLISEC 10 mS 2 --50 MILLISEC 50 mS 1 --.1 SEC .1 S 1 --.2 SEC .1 S 2 --.5 SEC .5 S 1 --1 SEC 1 S 1 --2 SEC 1 S 2 ---

1

Turn TRIGGER SELECTOR switch (red) from AC to HF SYNC for this check only.

2

If TI crt does not display 2 markers per cm, adjust C324 (fig. 1 or 4) (R). Then, adjust C358 (fig. 1 or 2) for the most

linear display over the first few divisions (R). If necessary, repeat adjustment of C324 and C358 to obtain optimum

display.

3

Turn HORIZONTAL DISPLAY switch to MAG for this check only.

4

Adjust C350 and C372 (fig. 1 or 2) in equal Increments until four cycles of sine wave are within 10 major divisions of

horizontal deflection (R).

5

If an out-of-tolerance indication is observed, repeat footnote 2 above.

control to aline second marker behind second vertical

graticule line. If TI crt does not display one marker per

centimeter, perform b(3) below.

(7) Turn TI HORIZONTAL DISPLAY switch to

NORM and repeat technique of (5) and (6) above for TI

TIME/DIV switch and time-mark generator settings listed

in table 7. If TI crt does not display markers as

specified, perform the appropriate adjustment listed in

table 7.

b. Adjustments

(1) Adjust C310 (fig. 1 or 2) until first market

remains behind center vertical graticule line (R).

(2) Repeat a(2) through (4) above.

(3) Adjust C160C (fig. 3 or 4) for one marker

per centimeter on TI crt (R).

NOTE

Due to interaction between C310 and

C160C, repeat a(1) through (6) above

for optimum conditions.

19. Rise Time

a. Performance Check

(1) Connect square-wave generator (A5)

+OUTPUT to TI VERTICAL INPUT, using cable and

termination supplied with square-wave generator and, if

necessary, adapter (B2).

(2) Position TI controls as listed in (a) through

(d) below:

(a) TIME/DIV switch to .2 ,SEC.

(b) HORIZONTAL DISPLAY switch to

MAG.

(c) VOLTS/DIV switch to .1.

(d) AC/DC switch to DC.

(3) Adjust square-wave generator for 1 MHz

and amplitude for 4 divisions of vertical deflection on TI

crt.

(4) Measure rise time, using standard risetime

technique. Rise time will not exceed 35 nanoseconds.

b. Adjustments. No adjustments can be made.

20. Power Supply

NOTE

Do not perform power supply check if

all other parameters are within

tolerance.

a. Performance Check

(1) Connect ac/dc voltmeter (A2) between 150V test point (fig. 1 or 6) and chassis ground. If ac/dc

voltmeter does not indicate between -147 and -153 volts

dc, perform b(l) below.

(2) Repeat technique of (1) above, using test

points listed in table 8. Ac/dc voltmeter will indicate

within limits specified.

14

Table 8. Low-Voltage Power Supply

Test Instrument Ac/De Voltmeter Indications (v)

Test Points

(fig. 1 or 6). Min Max

+100 V +97 +103

+300 V +291 +309

Page 17

TB 9-6625-1172-35

(3) Connect dc voltmeter (A4) between HV

test point (fig. 1 or 5) and chassis ground. If dc

voltmeter does not indicate between -1261 and -1339

volts dc, perform b(2) below.

b. Adjustments

(1) Adjust -150 ADJ. R617 (fig. 3) (-150 ADJ.

R617, fig. 4) for a -150-volt indication on ac/dc voltmeter

(R).

(2) Adjust R841 (fig. 1) (H.V. ADJ. R811,

fig. 2) for a -1300-volt dc indication on dc voltmeter (R).

21. Final Procedure

a. Deenergize and disconnect all equipment and

replace TI within protective cover.

b. In accordance with TM 38-750, annotate and

affix DA Label 80 (U.S. Army Calibration System).

When the TI cannot be adjusted within tolerance,

annotate and affix DA Form 2417 (Unserviceable or

Limited Use tag).

Figure 6. Oscilloscope-bottom view (type 317).

SECTION V

EQUIPMENT REQUIREMENTS FOR OSCILLOSCOPE, TEKTRONIX TYPE 317 (C-LEVEL)

22. Equipment Required

a. Minimum use specifications are the principal

parameters required for performance of C-level

calibration, and are included to assist in the selection of

alternate equipment. Satisfactory performance of

alternate items must be verified prior to use. All

applicable equipment must bear evidence of current

calibration.

b. The instruments used for C-level calibration

were selected from those known to be available in

AN/TSM-55(V) 2 and TOE 29-134. The listing by make

or model number carries no implication of

preference, recommendations, or approval by the

Department of Defense for use by other agencies. It is

recognized that equivalent equipment produced by other

manufacturers may be capable of equally satisfactory

performance in the procedure.

c. Items of equipment used for C-level calibration

are referenced within the text by common name and

item identification number as listed in table 9. For the

identification of equipment referenced by item numbers

prefixed with A, see table 9.

15

Page 18

TB 9-6625-1172-35

23. Accessories Required

The accessories used for C-level calibration were

selected from those known to be available in AN/TSM55(V)2 and TOE 29-134 and are to be used in this

calibration procedure. When necessary, these items

may be substituted by equivalent items unless

specifically prohibited. Accessory items used in this

procedure are referenced within the text by common

name and item identification number as listed in table

10. For the identification of accessories referenced by

item numbers prefixed with B, see table 10.

Table 9. Minimum Specifications of Equipment Required

Item Common Name Minimum Use Manufacturer and

Specifications. Model Number.

A1 AUTOTRANSFORMER Range: 105 to 125 vac General Radio, Model

Accuracy: ±3%

W10MT3A (TF-510/U).

A2 METER Range: 350 mw to 36 vac, John Fluke, Model 760A

CALIBRATOR. 400 Hz. (TS-2734/U).

Accuracy: ±1%

A3 MULTIMETER Range: -1339 to +309 vdc J-Omega, Model 217A

Accuracy: ±0.5%

(ME-333/U).

A4 RATIO Range: 0 to 36 vac at 400 Hz Gertsch, Model RT-60

TRANSFORMER. Ratio: .0194 to .776 to 1 (TS-515/U).

Accuracy: ±-0.3%

A5 SIGNAL Range: 50 kHz to 10 MHz Tektronix, Type 191

GENERATOR. (AN/USM-272).

Accuracy: ±-1%

A6 SQUARE-WAVE Range: 1 to 400 kHz Fairchild, Model 791

GENERATOR. (AN/USM-256).

Rise time: Less than

0.020 µsec.

A7 TIME-MARK Range: 1 sec to 50 nsec Tektronix, Type 184

GENERATOR. markers. (AN/USM-271).

Accuracy: ±1%

Table 10. Accessories Required.

Item Common Name Manufacturer, Model Number, and Description

B1 ADAPTER

B2 ADAPTER

1

1

H. H. Smith, Model 301; banana jack to alligator clip

Pomona Electronics, Model 1296 (UG-1888/U); binding post to

BNC plug.

B3 ADAPTER Pomona Electronics, Model 201A/U; BNC jack to N plug

B4 CABLE

B5 LEAD

1

1

Pomona Electronics, Model 2241-C-36 (CG-3572/U); BNC plug to

red and black banana plugs.

Pomona Electronics, Model B-24 (red); 24-in., single banana

plug to single banana plug.

B6 LEAD

1

Pomona Electronics, Model B36 (black); 36-in., single banana

plug to single banana plug.

B7 LEAD

1

Pomona Electronics, Model B-36 (red); 36-in., single banana

plug to single banana plug.

1

Two required.

16

Page 19

SECTION VI

TB 9-6625-1172-35

OSCILLOSCOPE, TEKTRONIX TYPE 317 (C-LEVEL)

PRELIMINARY OPERATIONS FOR

24. Preliminary Instructions

The instructions outlined in this paragraph are

preparatory to the calibration process. Personnel should

become familiar with the applicable sections of this

bulletin before beginning the calibration.

WARNING

HIGH VOLTAGE is used during the

performance of this calibration.

DEATH ON CONTACT may result if

personnel fail to observe safety

precaution.

CAUTION

To avoid possible burning of crt

screen, keep intensity control set to a

normal level and never allow a bright

spot to remain in the same position

for lengthy periods of time.

NOTE

Unless otherwise specified, verify the

results of each test and take

corrective action whenever the test

requirement is not met before

continuing with the calibration.

NOTE

When indications specified in

paragraphs 26 through 48 are not

within tolerance, perform the power

supply check prior to making

adjustments. After adjustments are

made, repeat paragraph 26 through

48, Do not perform power supply

check if all other parameters are

within tolerance.

25. Equipment Setup

a. Energize equipment and allow sufficient time for

equipment to warm up and stabilize.

b. Adjust autotransformer (A1) output voltage

control to minimum.

c. Connect TI power cord to autotransformer.

d. Adjust autotransformer output voltage control for

a meter indication of 115 volts ac.

e. Turn TI INTENSITY control fully

counterclockwise.

f. Position TI controls as follows:

(1) TRIGGER SELECTOR (black) switch to

+INT.

(2) TRIGGER SELECTOR (red) switch to AC.

(3) STABILITY control fully counterclockwise,

but not PRESET.

(4) TRIGGER LEVEL control to 0 (zero).

(5) TIME/DIV switch to .5 MILLISEC.

(6) VARIABLE control to CALIBRATED.

(7) HORIZ DISPLAY switch to NORM.

(8) POSITIONING VERTICAL control to

midrange.

(9) POSITIONING HORIZONTAL control to

midrange.

(10) VOLTS/DIV switch to 1.

(11) VARIABLE VOLTS/DIV switch to

CALIBRATE.

(12) AC-DC switch to AC.

(13) CALIBRATOR VOLTS PEAK-TO-PEAK

switch to 100.

SECTION VII

CALIBRATION PROCESS FOR OSCILLOSCOPE,

TEKTRONIX TYPE 317 (C-LEVEL)

26. Calibrator

a. Performance Check

(1) Remove tube V573 (fig. 4) from TI.

CALIBRATOR CAL OUT connector and chassis ground,

using leads (B6 and B7).

(3) Set TI CALIBRATOR VOLTS PEAK-TO-

PEAK switch to positions listed in table 11. If multimeter

(2) Connect multimeter (A3) between TI

does not indicate within limits specified. perform b

below.

Table 11. Calibrator Output

Test Instrument Multimeter

CALIBRATOR VOLTS Indications

PEAK-TO-PEAK (volts).

Switch Settings. Min Max

1

See footnote at end of table

100

1

97.0 103.0

17

Page 20

Table 11. Calibrator Output-Continued

Test Instrument Multimeter

CALIBRATOR VOLTS Indications

PEAK-TO-PEAK (volts).

Switch Settings. Min Max

50 48.5 51.5

20 19.4 20.6

10 9.70 10.30

5 4.85 5.15

2 1.94 2.06

1 0.970 1.030

.5 0.485 0.515

.2 0.194 0.206

.1 0.0970 0.1030

.05 0.0485 0.0515

1

Adjust autotransformer output voltage control for 105, 125, and 115 volts ac.

TB 9-6625-1172-35

(4) Disconnect equipment.

(5) Install tube V573 into TI.

b. Adjustments

(1) Set TI CALIBRATOR VOLTS PEAK-TO-

PEAK switch to 100.

(2) Adjust TI CAL ADJ R566 (fig. 4) for

multimeter indication of 100.0 volts ac (R).

27. Crt Alinement

a. Performance Check

(1) Position TI controls as follows:

(a) TIME BASE STABILITY control fully

clockwise.

(b) INTENSITY control for TI crt display.

(c) POSITION VERTICAL control to

position TI crt display at center horizontal division line.

(2) If TI crt display does not aline parallel to

center horizontal division line, perform b below.

b. Adjustments

WARNING

HIGH VOLTAGE is present in area of

crt base; use extreme caution when

making the following adjustments.

(1) Loosen screw on TI crt base clamp (fig. 5)

and turn TI crt to aline trace parallel with center

horizontal division line.

(2) Tighten TI crt base clamp.

28. Crt Astigmatism

a. Performance Check

(1) Connect TI CALIBRATOR CAL OUT

connector to VERTICAL INPUT connector, using lead

(B5).

(2) Position TI controls as follows:

(a) TIME BASE TRIGGER SELECTOR

(red) switch to AUTO.

(b) TIME BASE TIME/DIV switch for TI

crt display of 5 cycles.

(c) CALIBRATOR VOLTS PEAK-TO-

PEAK switch to 5.

(3) Adjust TI INTENSITY and FOCUS

controls for TI crt display of optimum focus. If TI crt

display is not evenly focused throughout the length of

display, perform b below.

(4) Disconnect lead (B5).

b. Adjustments. Adjust TI ASTIG R856 (fig. 2) for

crt display with even focus throughout the length of

display.

29. Crt Geometry

a. Performance Check

(1) Connect time-mark generator (A7) to TI

VERTICAL INPUT, using cable (B4). Adjust time-mark

generator for 0.1 mS markers.

(2) Position TI controls as follows:

(a) VERTICAL VOLTS/DIV switch to .2.

(b) TIME BASE TIME/DIV switch to .2

MILLISEC.

(c) POSITIONING VERTICAL control to

position top and bottom of display to top and bottom

division lines.

(3) If TI crt does not display straight vertical

division lines as shown in figure 7, perform b below.

18

Page 21

Figure 7. Crt geometry waveform.

TB 9-6625-1172-35

(4) Disconnect equipment.

b. Adjustments. Adjust TI GEOM ADJ R861 (fig. 2)

for TI crt display of straight vertical lines parallel to the

vertical division lines, as shown in figure 7.

30. Sweep Triggering

a. Performance Check

(1) Connect TI CAL OUT to TI INPUT, using

lead (B7) and, if necessary, two adapters (B2).

(2) Position TI controls as follows:

(a) TRIGGER SELECTOR switch (red)

to AC.

(b) TIME/DIV switch to .5 MILLISEC.

(c) VOLTS/DIV switch to 1.

(d) VOLTS PEAK-TO-PEAK switch to

.5.

(e) STABILITY SWITCH TO PRESET.

(3) Connect junction of R426 and R427 (fig.

4) to chassis ground, using lead (B5) and two adapters

(B1).

(4) Adjust VOLTS/DIV VARIABLE control for

1 minor division of vertical deflection on TI crt.

(5) Position crt trace on horizontal graticule

center line.

(6) Alternately switch TI TRIGGER

SELECTOR (black) control back and forth from +INT to INT. If sweep does not have stable triggering in both

+INT and -INT positions, perform b(1) through (3) below.

(7) Remove short connected in (3) above.

(8) Turn TI TRIGGERING LEVEL control to

position where stable triggering occurs in both +INT and

-INT positions. If stable triggering does not occur when

TRIGGERING LEVEL control is in 0 (zero) position,

perform b(4) below.

(9) Turn TI TRIGGERING SELECTOR (red)

switch to DC.

(10) It may be necessary to adjust TI VERTI-

CAL POSITIONING control until sweep appears on crt.

(11) Adjust VOLTS/DIV VARIABLE control for

1.5 minor divisions of vertical display on TI crt. If crt

display is not positioned at the center horizontal graticule

line, while TI TRIGGER SELECTOR (black) switch is

turned from +INT to -INT, perform b(5) below.

(12) Turn TI VOLTS PEAK-TO-PEAK switch to

OFF.

(13) Remove lead and adapters connected in

(1) above.

(14) Turn TI TRIGGER SELECTOR (red)

switch to AUTO. If stable waveform does not occur,

perform b(6) through (8) below.

b. Adjustments

(1) Adjust TI TRIGGER LEVEL CENTERING

R437 (fig. 2) until stable triggering is obtained in both

+INT and -INT positions.

(2) Reduce amplitude of crt display, using

VOLTS/DIV VARIABLE control until display becomes

unstable. Adjust TRIGGER SENSITIVITY ADJ R443

(fig. 4) until stable triggering is obtained in both +INT and

-INT positions.

(3) Repeat (1) and (2) above until no further

adjustments are required.

(4) Loosen setscrew on TRIGGERING

LEVEL knob and adjust to 0 (zero) position without

turning potentiometer shaft. Tighten setscrew.

NOTE

Do not disturb setting of

TRIGGERING LEVEL control

established in a(8) above.

(5) Adjust INT TRIG DC LEVEL ADJ R258

(fig. 5) in conjunction with VERTICAL POSITIONING

control until sweep is positioned at center horizontal

graticule line as TRIGGER SELECTOR (black) switch is

turned from -INT to +INT.

19

Page 22

TB 9-6625-1172-35

(6) Turn TI PRESET STAB R11 (fig. 2) fully

counterclockwise; then, turn slowly clockwise until grace

appears on TI crt. Note position of R11 shaft.

(7) Continue turning R11 clockwise until trace

brightens. Note position of R11 shaft.

(8) Adjust R11 to a position midway between

positions noted in (6) and (7) above.

31. Magnifier Gain

a. Performance Check

(1) Position TI controls as follows:

(a) TRIGGER SELECTOR (black)

switch to +INT.

(b) TRIGGER SELECTOR (red) switch

to AC.

(c) HORIZONTAL DISPLAY switch to

MAG.

(d) TRIGGERING LEVEL control to 0

(zero).

(e) STABILITY control to PRESET.

(f) TIME/DIV switch to 1 MILLISEC.

(g) TIME/DIV VARIABLE control to

CALIBRATED.

(2) Connect time-mark generator (A7) to TI

VERTICAL INPUT connector, using cable (B4). Adjust

time-mark generator for .1 mS marker output.

(3) Adjust TI VOLTS/DIV controls for TI crt

display of 2 divisions. Center display on TI crt with

POSITIONING VERTICAL control.

(4) Adjust TI POSITIONING HORIZONTAL

control for a marker alined with first vertical division line.

If TI crt does not display 2 markers per division and the

16th marker from first division line is not within -2.5

minor divisions of the ninth division line, perform b

below.

b. Adjustments.

(1) Adjust TI POSITIONING HORIZONTAL

control for TI crt display of marker alined with first

division vertical line.

(2) Adjust TI MAG GAIN R358 (fig. 2) for TI

crt display with marker from first division line alined with

ninth vertical division line (R).

32. Horizontal Amplifier Gain

a. Performance Check

(1) Set TI TIME/DIV switch to .1 MILLISEC

and HORIZ DISPLAY switch to NORM.

(2) Adjust TI POSITIONING HORIZONTAL

control for a crt display of second marker at first vertical

division line. If TI crt does not display the 10th marker

within -l.5 minor divisions of the ninth vertical division

line, perform b below.

b. Adjustments. Adjust TI HORIZ GAIN ADJ R325

(fig. 4) for TI crt display with 10th marker alined with

ninth vertical division line (R).

33. Sweep Length

a. Performance Check. Turn TI STABILITY and

TRIGGERING LEVEL controls fully clockwise. If TI crt

does not display a trace 10.5 divisions in length, perform

b below.

b. Adjustments. Adjust TI SWEEP LENGTH R82

(fig. 2) for TI crt display of 10.5 divisions.

34. Magnifier Registration

a. Performance Check

(1) Position TI controls as follows:

(a) STABILITY control to PRESET.

(b) TRIGGER SELECTOR (red) switch

to AUTO.

(c) HORIZ DISPLAY switch to MAG.

(2) Adjust POSITIONING HORIZONTAL

control for TI crt display of first marker at center vertical

division line.

(3) Set TI HORIZ DISPLAY switch to NORM.

If TI crt display shifts horizontally, perform b

below.

b. Adjustments. Adjust TI NORM/MAG REGIS

R335 (fig. 2) for no horizontal shift in TI crt display as TI

HORIZ DISPLAY switch is alternately set to MAG and

NORM.

35. 1 µSEC Sweep Timing

a. Performance Check

(1) Position TI controls as follows:

(a) TIME/DIV (black) switch to 5 ASEC.

(b) HORIZ DISPLAY switch to MAG.

(2) Adjust time-mark generator (A7) controls

for 1 AS marker output.

(3) Adjust TI POSITIONING HORIZONTAL

control for TI crt display of last 10 markers with a marker

alined on first vertical division line. If crt does not display

I marker per division and eighth marker from first division

line is not within -1.5 minor divisions of ninth vertical

division line, perform b(1) and (2) below.

(4) Adjust TI POSITIONING HORIZONTAL

control for TI crt display of first ten markers. If crt does

not display 1 marker per division, and eighth marker

from first division line is not within 1.5 minor divisions of

ninth vertical division line, perform b(3) and (4) below.

b. Adjustments

(1) Repeat a(3) above.

(2) Adjust TI C160C (fig. 4) for TI crt display

of 1 marker per division and ninth marker, from first

division line, alined with ninth vertical division line (R).

20

Page 23

TB 9-6625-1172-35

(3) Adjust C310 (fig. 2) for TI crt display of

first 10 markers alined with vertical division lines (R).

(4) Repeat performance check.

36. 10 µSEC/DIV Sweep Timing

a. Performance Check

(1) Set TI HORIZ DISPLAY switch to NORM

and TIME/DIV switch to 10 ASEC.

(2) Adjust time-mark generator (A7) controls

for 10 µS markers.

(3) Adjust TI POSITIONING HORIZONTAL

control for TI crt display of second marker alined with

first vertical division line. If TI crt does not display 1

marker per division and 10th marker is not within ±1.5

minor divisions of ninth vertical division line, perform b

below.

b. Adjustments. Adjust C160E (fig. 4) for crt

display of 1 marker per division and 10th marker alined

with ninth division vertical line (R).

37. 2 µSEC/DIV Linearity

a. Performance Check

(1) Set TI TIME/DIV switch to 2 µSEC.

(2) Adjust time-mark generator (A7) for 1 µS

marker output. If TI crt does not display 2 markers per

division and the position of markers within the first 2

divisions are not the same as the remaining divisions,

perform b below.

b. Adjustments. Adjust C324 (fig. 4) for 2 markers

per division (R).

38. .5 µSEC/DIV Sweep Timing

a. Performance Check

(1) Set TI TIME/DIV switch to .5 µSEC.

(2) Set TI TRIGGER SELECTOR (red) switch

to AC.

(3) Adjust time-mark generator (A7) for .5 µS

marker output.

(4) Adjust TI TIME BASE STABILITY and

TIME BASE TRIGGERING LEVEL controls for stable TI

crt display.

(5) Adjust TI POSITIONING HORIZONTAL

control to aline second marker with first division vertical

line. If TI crt does not display 1 marker per division and

10th marker is not within ±1.5 minor divisions of ninth

vertical division line, perform b below.

b. Adjustments. Adjust C160A (fig. 4) for crt

display of 1 marker per division and 10th marker alined

with ninth vertical division line (R).

39. .2 µSEC/DIV Linearity

a. Performance Check

(1) Position TI controls as follows:

(a) TRIGGER SELECTOR (red) switch

to HF SYNC.

(b) TRIGGER SELECTOR (black)

switch to +INT.

(c) HORIZ DISPLAY switch to NORM.

(d) TIME/DIV switch to .2 ,SEC.

(e) VARIABLE TIME/DIV control to

CALIBRATED.

(f) POSITIONING VERTICAL control to

midrange.

(g) POSITIONING HORIZONTAL

control to midrange.

(2) Adjust time-mark generator (A7) for .1 µS

marker output.

(3) Adjust TI VOLTS/DIV and STABILITY

controls for stable display of 2 divisions on TI crt. If crt

does not display 2 markers per division and is not linear,

perform b below.

b. Adjustments

(1) Adjust C358 (fig. 2) for crt display of 2

markers per division and best linearity (R).

(2) If C358 will not adjust for proper timing

and linearity, repeat 2 ,SEC/DIV linearity, paragraph 37

above and .2 ±/SEC/DIV linearity, paragraph 39 above.

40. .04 µSEC/DIV Sweep Timing and Linearity

a. Performance Check

(1) Connect time-mark generator (A7)

TRIGGER OUTPUT to TI TRIGGER INPUT, using cable

(B4).

(2) Adjust time-mark generator for .1 µS

markers and 1 µS trigger output.

(3) Position TI controls as follows:

(a) HORIZONTAL DISPLAY switch to

MAG.

(b) TRIGGER SELECTOR (black)

switch to +INT.

(4) Adjust VOLTS/DIV and STABILITY

controls for crt display of 3 divisions amplitude.

(5) Adjust TI POSITIONING HORIZONTAL

control to aline a marker with extreme left vertical

division line. If TI crt does not display 1 marker every

2.5 divisions, and fifth marker is not within ±0.5 division

of extreme right vertical division line, perform b below.

(6) Disconnect equipment.

b. Adjustments

(1) Adjust C372 (fig. 2) for crt display of 1

marker every 2.5 divisions and fifth marker alined with

extreme right vertical division line (R).

(2) Repeat performance check.

21

Page 24

TB 9-6625-1172-35

41. Variable Attenuator Balance

a. Performance Check

(1) Position TI controls as follows:

(a) TRIGGER SELECTOR (black)

switch to +INT.

(b) TRIGGER SELECTOR (red) switch

to AUTO.

(c) HORIZONTAL DISPLAY switch to

NORM.

(d) TRIGGERING LEVEL control fully

clockwise.

(e) STABILITY control to PRESET.

(f) TIME/DIV switch to .5 MILLISEC.

(g) VARIABLE TIME/DIV control to

CALIBRATED.

(h) POSITIONING VERTICAL control to

midrange.

(i) POSITIONING HORIZONTAL

control to midrange.

(j) VOLTS/DIV switch to 1.

(k ) VARIABLE VOLTS/DIV control to

CALIBRATED.

(I) AC-DC switch to DC.

(2) Adjust TI VARIABLE VOLTS/DIV control

fully counterclockwise. If TI crt display shifts vertically as

VARIABLE VOLTS/DIV control is turned throughout its

range, perform b below.

(3) Set TI VARIABLE VOLTS/DIV control to

CALIBRATED.

b. Adjustments

(1) Adjust TI VARIABLE ATTEN BAL (front

panel) adjustment for TI crt display of no vertical.

22

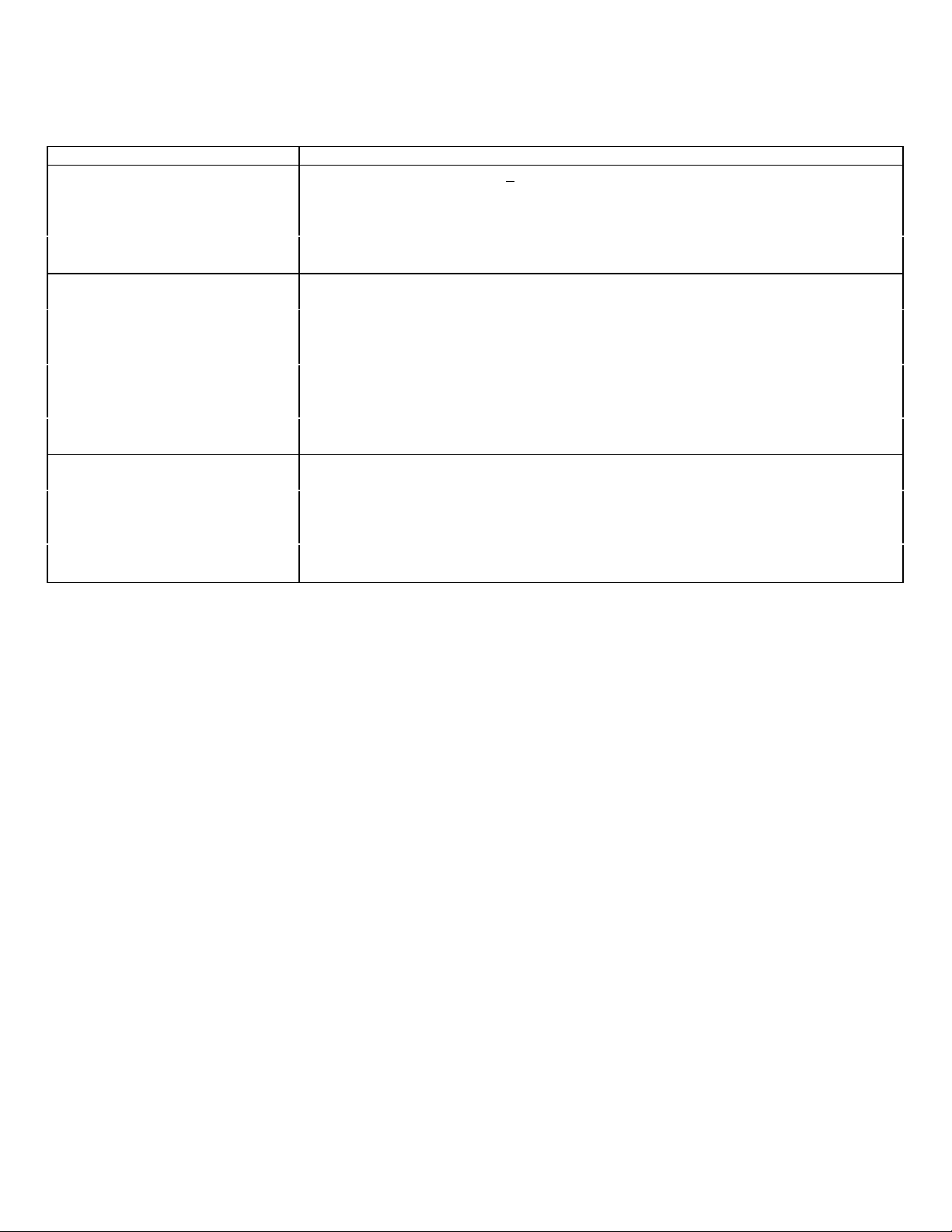

Figure 8. Amplifier gain and attenuation-equipment setup.

Page 25

TB 9-6625-1172-35

shift as VARIABLE VOLTS/DIV control is turned

throughout its range.

(2) Set TI VARIABLE VOLTS/DIV control to

CALIBRATED.

42. Amplifier Gain and Attenuation

a. Performance Check

(1) Connect equipment as shown in figure 8.

(2) Set TI AC-DC switch to DC.

Table 12. Amplifier Gain and Input Attenuator

Test Instrument Meter Calibrator Ratio Transformer

VOLTS/DIV Decade Dials Decade Dials

Switch Settings. Settings. Indications.

Min Max

.05 000.3535 19400 20600

.1 000.3535 38800 41200

.2 000.3535 77600 82400

.5 003.5350 19400 20600

1 003.5350 38800 41200

2 003.5350 77600 82400

/’;[P-0°•5

10 035.3500 38800 41200

20 035.3500 77600 82400

035.3500 19400 20600

in table 12 and perform the following:

dials to settings listed.

controls for 400 Hz and null indication on output meter.

dials for TI crt display of 4 divisions peak-to-peak. If

ratio transformer does not indicate within limits specified,

perform b below.

(3) Set TI VOLTS/DIV switch to settings listed

(a) Set meter calibrator (A2) decade

(b) Adjust meter calibrator output

(c) Adjust ratio transformer (A4) decade

(4) Adjust met er calibrator output controls for

zero indication.

(5) Disconnect equipment.

b. Adjustments

(1) Set TI VOLTS/DIV switch to .1.

(2) Adjust ratio transformer decade dials for

.40000.

(3) Adjust meter calibrator output controls for

000.3535 volt ac at 400 Hz.

(4) Adjust TI GAIN ADJ R244 (fig. 5) for crt

display of 4.0 vertical divisions (R).

(5) Adjust ratio transformer decade dials for

.20000.

(6) Set TI VOLTS/DIV switch to .05.

(7) Adjust II PREAMP GAIN ADJ R154 (fig.

5) for TI crt display of 4.0 vertical divisions

(R).

(8) Repeat performance check.

43. Attenuator High-Frequency Compensation

a. Performance Check

(1) Connect square-wave generator (A6)

OUTPUT to TI VERTICAL INPUT, using cable (B4).

(2) Adjust square-wave generator for 1 kHz

output.

(3) Set TI VOLTS/DIV switch to .2, .5, 1, and

10. At each setting, adjust square-wave generator for crt

display of 4 vertical divisions. If crt does not display an

optimum square wave as shown in figure 9C, perform b

below.

b. Adjustments. Set TI VOLTS/DIV switch to

settings listed in table 13. Adjust TI adjustments listed

for crt display of optimum square wave as shown in

figure 9C.

Table 13. Attenuator High-Frequency Compensation

Adjustments.

VOLTS/DIV Adjustments

Switch Settings. (fig. 5).

.2 C132 (R)

.5 C126 (R)

1 C118 (R)

10 C112 (R)

44. Attenuator Input Capacitance

a. Performance Check

(1) Connect 10X probe (provided with TI) to

TI VERTICAL INPUT connector. Connect probe

23

Page 26

TB 9-6625-1172-35

tip and ground clip to square-wave generator (A6)

output, using adapter (B3).

(2) Set square-wave generator SOURCE

IMPEDANCE switch to INTERNAL 50Ω TERMINATION

and TI VOLTS/DIV switch to .1.

(3) Adjust TI 10X probe variable capacitor (in

Table 14. Attenuator Input Capacitance

Test Instrument Square-Wave Adjustments

VOLTS/DIV Crt Display IMPEDANCE

Switch Settings. Amplitude Switch Settings.

(Divisions).

.2 4 NORM C130 (R)

.5 4 NORM C124 (R)

1 4 NORM C116 (R)

10 Approx 0.5 NORM C110 (R)

.01 4

b. Adjustments. No further adjustments can be

made.

45. Preamplifier Low-Frequency Compensation

a. Performance Check

(1) Set TI TIME/DIV switch to 10 MILLISEC

and TI VOLTS/DIV switch to .01 AC ONLY.

(2) Adjust square-wave generator controls for

crt display of 5 square waves of 4 vertical divisions. If TI

crt does not display a square wave with optimum flat top

as shown in figure 11A, perform b below.

(3) Disconnect equipment.

b. Adjustments. Adjust LOW-FREQ COMP R175

(fig. 5) for crt display of square wave with optimum flat

top as shown in figure 11A (R).

46. Delay Line High-Frequency Response

a. Performance Check

(1) Position TI cont rols as follows:

(a) TRIGGER SELECTOR (black)

switch to -INT.

(b) TRIGGER SELECTOR (red) switch

to AC.

(c) HORIZONTAL DISPLAY switch to

NORM.

(d) TRIGGERING LEVEL control to 0

(zero).

(e) STABILITY control to PRESET.

(f) TIME/DIV switch to 1 MILLISEC.

(g) VARIABLE TIME/DIV control to

CALIBRATED.

probe body) for crt display of square wave with optimum

flat top as shown in figure 10C.

generator SOURCE IMPEDANCE switch to positions

listed in table 14. Adjust TI adjustments listed for crt

display of square wave with optimum flat top as shown in

figure 10C.

Generator (fig. 5)

SOURCE

INTERNAL 50Ω

TERMINATION (fig. 6)

midrange.

control to midrange.

CALIBRATED.

PEAK switch to OFF.

OUTPUT to TI VERTICAL INPUT, using cable (B4).

IMPEDANCE switch to INTERNAL 50Ω TERMINATION.

for 1 square-wave display and adjust amplitude for 4

centimeters of vertical deflection on TI crt.

stable crt display. If TI crt does not display square wave

with flat top (does not slope), no bumps or dips, and

optimum square corner, as illustrated in figure 12A,

perform b below.

MAG and TRIGGER SELECTOR (black) switch to +INT.

control for TI crt display of leading edge of square wave.

technique. Rise time will be less than 0.9 minor

divisions between 10 and 90 percent points.

(4) Set TI VOLTS/DIV switch and squarewave

C141 (R)

(h) POSITIONING VERTICAL control to

(i) POSITIONING HORIZONTAL

(j) VOLTS/DIV switch to 1.

(k ) VARIABLE VOLTS/DIV control to

(l) AC-DC switch to DC.

(m) CALIBRATOR VOLTS PEAK-TO-

(2) Connect square-wave generator (A6)

(3) Set square-wave generator SOURCE

(4) Adjust square-wave generator frequency

(5) Adjust TI TRIGGERING LEVEL control for

(6) Set TI HORIZONTAL DISPLAY switch to

(7) Adjust TI POSITIONING HORIZONTAL

(8) Measure rise time, using standard risetime

24

Page 27

TB 9-6625-1172-32

b. Adjustments

(1) Adjust TI L150, L177 (fig. 6), L213, L227

L244, and L254 (fig. 6 or 13) for crt display or minimum

rise time and optimum square corner (fig. 12A) (R).

(2) Adjust TI delay line capacitors (22 in line)

for TI crt display of optimum flat-top square wave with no

bumps or dips.

(3) Adjust TI L293, L294 (fig. 13), and C295

for crt display of flat top square wave (R).

Figure 9. Attenuator high-frequency compensation waveforms.

NOTE

C295 is located in same vicinity as

L293 and L294.

(4) Repeat (1) through (3) above for optimum

TI crt square-wave display.

(5) Repeat performance check.

47. Amplifier Bandwidth

a. Performance Ch eck

(1) Position TI controls as follows:

Figure 10. Attenuator input capacitance waveform.

Figure 11. Preamplifier low-frequency compensation waveforms.

25

Page 28

Figure 12. High-frequency response waveform.

(a) TRIGGER SELECTOR (black)

switch to +INT.

(b) TRIGGER SELECTOR (red).

switch to AUTO.

(c) HORIZONTAL DISPLAY switch to

NORM.

(d) TRIGGERING LEVEL control fully

clockwise.

(e) STABILITY control to PRESET.

(f) TIME/DIV switch to 1 MILLISEC.

(g) VARIABLE TIME/DIV control to

CALIBRATED.

(h) POSITIONING VERTICAL control to

midrange.

(i) POSITIONING HORIZONTAL

control to midrange.

(j) VOLTS/DIV switch to .1.

(k ) VARIABLE VOLTS/DIV control to

CALIBRATED.

(l) AC-DC switch to AC.

(m) CALIBRATOR VOLTS PEAK-TO-

PEAK switch to OFF.

(2) Connect signal generator (A5) output to TI

VERTICAL INPUT, using cable and adapter supplied

with signal generator, and adapter (B3).

(3) Adjust signal generator for 50 kHz and

amplitude for 6 vertical divisions on TI crt.

(4) Adjust signal generator to increase

frequency for a 4.25-vertical division display on TI crt.

Signal generator will indicate 10 MHz or greater.

b. Adjustments. No adjustments can be made.

48. Preamplifier bandwidth

a. Performance Check

(1) Set TI VOLTS/DIV switch to .01.

(2) Adjust signal generator (A5) for 50 kHz

and amplitude for 6 vertical divisions of crt display.

26

TB 9-6625-1172-35

Figure 13. High-frequency response--adjustment

locations.

(3) Adjust signal generator for an increase in

frequency for a 4.25-vertical division crt display. Signal

generator will indicate 10 MHz or greater.

b. Adjustments. No adjustments can be made.

49. Power Supply

NOTE

Do not perform power supply check if

all other parameters are within

tolerance.

a. Performance Check

(1) Connect multimeter (A3) between -150V

test point (fig. 6) and chassis ground, using leads (B6

and B7) and two adapters (B1). If multimeter does not

indicate between 147 and 153 volts dc, perform b(1)

below.

(2) Repeat technique of (1) above, using test

points listed in table 15. Multimeter will indicate within

limits specified.

Page 29

TB 9-6625-1172-35

(3) Connect multimeter between HV test point

(fig. 5) and chassis ground, using leads (B6 and B7) and

two adapters (B1). If multimeter does not indicate

between -1261 and -1339 volts dc, perform b(2) below.

Table 15. Low-Voltage Power Supply

Test Instrument Multimeter Indications (v)

Test Points

(fig. 6). Min Max

+100 V +97 +103

+300 V +291 +309

50. Final Procedure

a. Deenergize and disconnect all equipment.

b. In accordance with TM 38-750, annotate and

b. Adjustments

(1) Adjust -150 ADJ R617 (fig. 4) for a -150-

volt indication on multimeter (R).

(2) Adjust H.V. ADJ R811 (fig. 2) for a -1300-

volt dc indication on multimeter (R).

affix DA Label 80 (U.S. Army Calibration System).

When the TI cannot be adjusted within tolerance,

annotate and affix DA Form 2417 (Unserviceable or

Limited Use tag).

27

Page 30

By Order of the Secretary of the Army:

CREIGHTON W. ABRAMS

General, United States Army

Official: Chief of Staff

VERNE L. BOWERS

Major General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with DA Form 12-34, Section II, (qty rqr block No. 75) requirements for Calibration

Procedures Publications.

¶U.S. GOVERNMENT PRINTING OFFICE: 1974-640-042/5005

Page 31

PIN: 011297-000

Loading...

Loading...