Page 1

Service Manual

3026

3 GHz Real Time Spectrum Analyzer

071-0420-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to the Safety Summary prior to

performing service.

Page 2

Copyright E Sony/T ektronix Corporation. All rights reserved.

Copyright E Tektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in Japan.

Sony/T ektronix Corporation, P.O.Box 5209, Tokyo Int’l, T okyo 100–31 Japan

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Overview 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W arranted Characteristics 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ypical Characteristics 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nominal Traits 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certification and Compliances 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplying Operating Power 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Environment 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applying and Interrupting Power 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installed Options 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Instructions 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparations 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning On the Power 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Observing Spectrum 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dividing the Display Area and Changing the Display Mode 2–12. . . . . . . . . . . . . . .

Using the Block Mode to Acquire Data 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Dual Markers 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger and Mask Pattern 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Display Frame 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutting Power Off 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Theory of Operation 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Overview 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3026 3 GHz Real Time Spectrum Analyzer Service Manual

i

Page 6

Table of Contents

Performance Verification

Performance Verification 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance T ests 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 MHz Reference Output T est 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 MHz Reference Input T est 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Center Frequency Accuracy T est 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flatness and Aliasing T est 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attenuator T est 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span and Center Frequency T est 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frame Update Interval T est 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Trigger Test 4–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Trigger Test 4–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C/N T est 4–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Reference Level T est 4–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Flatness T est 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Record 4–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

Maintenance

Adjustment Procedures 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements for Adjustments 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Maintenance Procedures 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedures 6–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Access Procedure 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for External Modules 6 –19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for Internal Modules 6–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for Board Modules 6–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for Power Supply Modules 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures for Rear Panel Modules 6–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedure 6–59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 6–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symptoms and Faulty Modules 6–78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing the BIOS 6–81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the BIOS Parameters 6–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backing Up the System Files 6–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 7

Options

Electrical Parts List

Diagrams

Mechanical Parts List

Table of Contents

Options and Accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Parts List 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Parts List 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3026 3 GHz Real Time Spectrum Analyzer Service Manual

iii

Page 8

Table of Contents

List of Figures

Figure 2–1: Power switch 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: RF INPUT connector 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: System information 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Initial screen 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: START/STOP button 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: Typical spectrum display (16 MHz center frequency

and 10 MHz span) 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–7: Buttons in DISPLAY area 2–12. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: Spectrogram display (upper) and spectrum display

(lower) 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–9: SELECT button 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–10: Waterfall display and spectrum display 2–14. . . . . . . . . . . . .

Figure 2–11: ROLL BLOCK button 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–12: Data acquisition in the Block mode 2–16. . . . . . . . . . . . . . . . .

Figure 2–13: Displaying dual markers 2–17. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–14: MARKER TOGGLE button 2–18. . . . . . . . . . . . . . . . . . . . . .

Figure 2–15: Measurement of frequency difference with dual

markers 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–16: Creation of trigger region 2–21. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–17: Created trigger mask (blue region) 2–22. . . . . . . . . . . . . . . . .

Figure 2–18: Waveform display before triggering 2–23. . . . . . . . . . . . . . . .

Figure 2–19: Frame in which trigger occurred 2–25. . . . . . . . . . . . . . . . . .

Figure 4–1: Display of the self test results 4–3. . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: CAL NEED indication in status indication area 4–5. . . . . . .

Figure 4–3: Initial test hookup 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–4: Initial test hookup 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–5: Modified test hookup 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–6: Initial test hookup 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–7: Initial test hookup 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–8: Initial test hookup 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–9: Initial test hookup 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–10: Initial test hookup 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–11: Initial test hookup 4–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–12: Creating a trigger mask 4–27. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–13: Initial test hookup 4–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 9

Table of Contents

Figure 4–14: Initial test hookup 4–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–15: Initial hookup for setting up the power meter and

sensor 4–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–16: Hookup for calibrating the power sensor 4–35. . . . . . . . . . . .

Figure 4–17: Hookup for setting the signal generator 4–36. . . . . . . . . . . . .

Figure 4–18: Hookup for checking the reference level accuracy 4–36. . . .

Figure 4–19: Initial test hookup 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–20: Running the RF flatness check program on PC 4–39. . . . . .

Figure 5–1: Accessing the A5 Baseband board 5–5. . . . . . . . . . . . . . . . . . .

Figure 5–2: Adjustment and connector location 5–6. . . . . . . . . . . . . . . . .

Figure 5–3: Test hookup 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–4: Initial test hookup 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–5: Loading the adjustment file from the floppy disk 5–9. . . . . .

Figure 5–6: Calibration & Set Constant menu 5–10. . . . . . . . . . . . . . . . . . .

Figure 5–7: Initial hookup for setting up the power meter and

sensor 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–8: Hookup for calibrating the power sensor 5–12. . . . . . . . . . . . .

Figure 5–9: Test hookup 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–10: Initial hookup for setting up the power meter and

sensor 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–11: Hookup for calibrating the power sensor 5–15. . . . . . . . . . . .

Figure 5–12: Test hookup 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–13: Running the SG flatness measurement program on

PC 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–14: Label location 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–15: Serial number entry 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–16: Test hookup 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–1: 3026 orientation 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Guide to removal procedures 6–13. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–3: External modules 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Internal modules 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Board modules 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Power supply modules 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–7: Rear panel modules 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Front-panel knob removal 6–20. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–9: Line cord removal 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–10: Rear cover and cabinet removal 6–23. . . . . . . . . . . . . . . . . . .

Figure 6–11: Trim ring and menu buttons removal 6–25. . . . . . . . . . . . . . .

3026 3 GHz Real Time Spectrum Analyzer Service Manual

v

Page 10

Table of Contents

Figure 6–12: Front-panel assembly removal 6–26. . . . . . . . . . . . . . . . . . . .

Figure 6–13: Disassembly of front-panel assembly 6–27. . . . . . . . . . . . . . .

Figure 6–14: Front-panel connectors removal 6–29. . . . . . . . . . . . . . . . . . .

Figure 6–15: Opening the top chassis 6–31. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–16: Fan and fan frame removal 6–32. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–17: Floppy disk drive removal 6–33. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–18: Opening the down-converter chassis 6–34. . . . . . . . . . . . . . .

Figure 6–19: Hard disk drive and solid state disk removal 6–35. . . . . . . . .

Figure 6–20: Display module removal 6–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–21: Board retainer and shield cover removal 6–39. . . . . . . . . . . .

Figure 6–22: Daughter boards removal 6–42. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–23: A1 Mother board removal – Top side 6–44. . . . . . . . . . . . . . .

Figure 6–24: A1 Mother board removal – Bottom side 6–45. . . . . . . . . . . .

Figure 6–25: Down-converter and A5 Baseband board removal 6–47. . . .

Figure 6–26: A13 Filter board removal 6–49. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–27: A11 and A12 DC Power boards removal 6–51. . . . . . . . . . . .

Figure 6–28: A10 Sub Power board and Power Supply removal 6–53. . . .

Figure 6–29: Power supply removal 6–54. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–30: Rear panel modules removal 6–57. . . . . . . . . . . . . . . . . . . . . .

Figure 6–31: Rear BNC cable assembly removal 6–58. . . . . . . . . . . . . . . . .

Figure 6–32: Troubleshooting procedure 1 — Power supply

modules 6–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–33: Troubleshooting procedure 2 — Signal processing

modules 6–64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–34: Troubleshooting procedure 3 — Clock modules 6–66. . . . . .

Figure 6–35: Troubleshooting procedure 4 — LCD display modules 6–68

Figure 6–36: Troubleshooting procedure 5 — CPU modules 6–69. . . . . . .

Figure 6–37: Troubleshooting procedure 6 — Front panel modules 6–70.

Figure 6–38: Location of the A11 and A12 DC Power boards 6–71. . . . . .

Figure 6–39: Location of the A5 Baseband and A13 Filter board 6–72. . .

Figure 6–40: Location of the A6 FFT board 6–73. . . . . . . . . . . . . . . . . . . . .

Figure 6–41: Location of the A7 DDC board 6–74. . . . . . . . . . . . . . . . . . . .

Figure 6–42: Location of the A8 Memory board 6–75. . . . . . . . . . . . . . . . .

Figure 6–43: U100 down-converter location 6–76. . . . . . . . . . . . . . . . . . . . .

Figure 6–44: LCD wire location 6–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–45: Connecting the keyboard 6–82. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–46: BIOS SETUP screen 6–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–47: STANDARD CMOS SETUP screen 6–84. . . . . . . . . . . . . . . .

Figure 6–48: BIOS FEATURES SETUP screen 6–85. . . . . . . . . . . . . . . . . .

vi

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 11

Table of Contents

Figure 9–1: Block diagram 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–2: Interconnect diagram 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–1: External modules 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–2: Front panel modules 10–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–3: Internal modules 10–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–4: Power supply modules 10–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–5: Board modules – 110–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–6: Board modules – 210–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–7: Cables 10–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3026 3 GHz Real Time Spectrum Analyzer Service Manual

vii

Page 12

Table of Contents

List of Tables

Table 1–1: Warranted characteristics — Frequency 1–4. . . . . . . . . . . . .

Table 1–2: Warranted characteristics — Amplitude 1–4. . . . . . . . . . . . .

Table 1–3: Warranted characteristics — Realtime span 1–5. . . . . . . . . .

Table 1–4: Warranted characteristics — Trigger/Acquisition 1–5. . . . .

Table 1–5: Warranted characteristics — Installation requirements 1–6

Table 1–6: Warranted characteristics — Environmental 1–6. . . . . . . . .

Table 1–7: T ypical characteristics — Amplitude 1–7. . . . . . . . . . . . . . . .

Table 1–8: T ypical characteristics — Filter 1–7. . . . . . . . . . . . . . . . . . . .

Table 1–9: T ypical characteristics — Trigger/Acquisition 1–7. . . . . . . .

Table 1–10: T ypical characteristics — Installation requirements 1–7. .

Table 1–11: Nominal traits — Frequency 1–9. . . . . . . . . . . . . . . . . . . . . .

Table 1–12: Nominal traits — Amplitude 1–9. . . . . . . . . . . . . . . . . . . . . .

Table 1–13: Nominal traits — FFT 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–14: Nominal traits — Filter 1–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–15: Nominal traits — Trigger/Acquisition 1–11. . . . . . . . . . . . . .

Table 1–16: Nominal traits — System control 1–12. . . . . . . . . . . . . . . . . .

Table 1–17: Nominal traits — AC line power 1–12. . . . . . . . . . . . . . . . . . .

Table 1–18: Nominal traits — Mechanical 1–12. . . . . . . . . . . . . . . . . . . . .

Table 1–19: Certifications and compliances 1–13. . . . . . . . . . . . . . . . . . . . .

viii

Table 2–1: Power-cord conductor identification 2–2. . . . . . . . . . . . . . . . .

Table 2–2: Power cord identification 2–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Performance tests 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–2: Test equipment 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–3: Level accuracy 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–4: The instrument settings for the span and center

frequency test 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–5: The instrument settings for the RF reference level test 4–37. .

Table 5–1: Adjustments 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: Test equipment 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–1: Relative susceptibility to static-discharge damage 6–3. . . . . .

Table 6–2: External inspection check list 6–5. . . . . . . . . . . . . . . . . . . . . . .

Table 6–3: Internal inspection check list 6–6. . . . . . . . . . . . . . . . . . . . . . .

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 13

Table of Contents

Table 6–4: Summary of procedures 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–5: Tools required for module removal 6–11. . . . . . . . . . . . . . . . . .

Table 6–6: Normal supply voltage 6–72. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–7: Symptoms and faulty modules 6–78. . . . . . . . . . . . . . . . . . . . . .

Table 6–8: 3026 system files 6–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–1: Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–2: Standard accessories 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–3: Optional accessories 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3026 3 GHz Real Time Spectrum Analyzer Service Manual

ix

Page 14

Table of Contents

x

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 15

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Use Proper Voltage Setting. Before applying power, ensure that the line selector is

in the proper position for the power source being used.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

xi

Page 16

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

xii

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 17

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

xiii

Page 18

Service Safety Summary

xiv

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 19

Preface

Manual Structure

This is the service manual for the 3026 Real Time Spectrum Analyzer. The

manual contains information needed to service the analyzer to the module level.

This manual is divided into sections, such as Specifications and Theory of

Operation. Further, some sections are divided into subsections, such as Product

Description and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures.

Be sure to read these introductions because they provide information needed to

do the service correctly and efficiently. The following contains a brief description

of each manual section.

H

Specifications contains a description of the analyzer and the characteristics

that apply to it.

H

Operating Information includes general information and operating

instructions.

H

Theory of Operation contains circuit descriptions that support service to the

module level.

H

Performance Verification contains procedures for confirming that the

analyzer functions properly and meets warranted limits.

H

Adjustment Procedures contains a collection of procedures for adjusting the

analyzer to meet warranted limits.

H

Maintenance contains information and procedures for performing preventive

and corrective maintenance of the analyzer. These instructions include

cleaning, module removal and installation, and fault isolation to the module.

H

Options contains information on servicing factory-installed options.

H

Electrical Parts List contains a statement referring you to Mechanical Parts

List, where both electrical and mechanical modules are listed.

H

Diagrams contains an block diagram and an interconnection diagram.

H

Mechanical Parts List includes a table of all replaceable modules, their

descriptions, and their Tektronix part numbers.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

xv

Page 20

Preface

Manual Conventions

This manual uses certain conventions that you should become familiar with.

Some sections of the manual contain procedures for you to perform. To keep

those instructions clear and consistent, this manual uses the following conventions:

H

Names of front panel controls and menus appear in the same case (initial

capitals, all uppercase, etc.) in the manual as is used on the analyzer front

panel and menus. Front panel names are all upper-case letters; for example,

DISPLAY, MEASURE, SETUP etc.

H

Instruction steps are numbered unless there is only one step.

Modules

Safety

Throughout this manual, any replaceable component, assembly, or part of the

analyzer is referred to generically as a module. In general, a module is an

assembly (like a circuit board), rather than a component (like a resistor or an

integrated circuit). Sometimes a single component is a module; for example, the

chassis of the analyzer is a module.

Symbols and terms related to safety appear in the Safety Summary near the

beginning of this manual.

Finding Other Information

Other documentation for the 3026 includes:

H

H

The 3026 Real Time Spectrum Analyzer User Manual contains a tutorial to

quickly describe how to operate the analyzer. It also includes an in-depth

discussion on how to more completely use the analyzer features.

The 3026 Real Time Spectrum Analyzer Programmer Manual explains how

to use the GPIB and LAN interfaces to remotely control the analyzer.

xvi

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 21

Contacting Tektronix

Preface

Product

Support

Service

Support

For other

information

To write us

Website

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Tektronix offers extended warranty and calibration programs as

options on many products. Contact your local Tektronix

distributor or sales office.

For a listing of worldwide service locations, visit our web site.

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

Tektronix, Inc.

P.O. Box 1000

Wilsonville, OR 97070-1000

USA

Tektronix.com

3026 3 GHz Real Time Spectrum Analyzer Service Manual

xvii

Page 22

Preface

xviii

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 23

Introduction

This manual contains information needed to properly service the 3026 Real Time

Spectrum Analyzer as well as general information critical to safe and effective

servicing.

To prevent personal injury or damage to the analyzer, consider the following

before attempting service:

H

The procedures in this manual should be performed only by a qualified

service person .

H

Read the General Safety Summary and the Service Safety Summary,

beginning on page xi.

H

Read Preparation for Use in section 2, Operating Information.

When using this manual for servicing, be sure to follow all warnings, cautions,

and notes.

Performance Check Interval

Strategy for Servicing

Generally, the performance check described in section 4, Performance Verification, should be done every 12 months. In addition, performance check is

recommended after module replacement.

If the analyzer does not meet performance criteria, repair is necessary.

Throughout this manual, the term, module, refers to any field-replaceable

component, assembly, or part of the analyzer.

This manual contains all the information needed for periodic maintenance of the

analyzer (Examples of such information are procedures for checking performance).

Further, it contains all information for corrective maintenance down to the

module level. To isolate a failure to a module, use the fault isolation procedures

found in Troubleshooting, part of section 6, Maintenance. To remove and replace

any failed module, follow the instructions in Removal and Installation Proce-

dures, also part of section 6. After isolating a faulty module, replace it with a

fully-tested module obtained from the factory. Section 10, Mechanical Parts

List, contains part number and ordering information for all replaceable modules.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

xix

Page 24

Preface

xx

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 25

Specifications

Page 26

Page 27

Product Overview

The 3026 is a portable real time 3 GHz spectrum analyzer with real-time

frequency analysis functions.

The incorporated 3 GHz down converter enables you to perform spectrum

analysis, time domain analysis, and analog modulation analysis of Radio

Frequency (RF) signals without connecting any external devices.

The 3026, with the adoption of new architecture, can acquire time and frequency

domain data simultaneously. It can also accurately capture various kinds of

signals with a wide variety of triggering functions.

Real-time trigger functions in frequency domain allow you to trigger on

instantaneous events such as the starting point of a burst signal.

Using the trigger functions in time domain, triggering is available on impulse

noises which are barely captured in frequency domain.

In addition, the 3026 provides measurement functions that can evaluate the

performance of radio devices with simple operation. Moreover, four types of data

display functions offered in the system can allow you to analyze the acquired

data more precisely.

Features

The 3026 has the following features:

H

Measurement frequency range: 50 Hz to 3 GHz

H

Measurement span: 100 Hz to 3 GHz

H

Complete real time frequency analysis

H

Concurrent processing of real time frequency analysis and analog modulation analysis

H

Provides comprehensive measurement functions to evaluate radio devices

such as occupied bandwidth (OBW), adjacent channel leakage power (ACP)

and power consumption.

H

Four types of data display:

H

Spectrum display

H

Spectrogram display

H

Waterfall display

H

Analog demodulation display (AM, PM, FM, and FSK)

3026 3 GHz Real Time Spectrum Analyzer Service Manual

1–1

Page 28

Specifications

H

A range of trigger functions:

H

Mask pattern trigger

H

Level trigger

H

External trigger

H

Simultaneous data acquisition in frequency domain and time domain

H

6.5 inch full-color TFT display

H

Equipped with a hard disk drive and a 3.5 inch floppy disk drive

H

A selection of interface ports:

H

GPIB port

H

10 BASE-T port

H

VGA output port

Targets

H

Printer port

The 3026 can perform complete real time analysis for the following:

H

Analog modulation analysis (AM, PM, FM, and FSK)

H

Variation analysis in PLL frequency:

Jitter in reference oscillator of a mobile telephone, localization of a radio set,

HD read-out jitter, etc.

H

Analysis of momentary noise: Mixed noise, EMI measurement, etc.

H

Multi-path measurement: Measurement of electric wave environment

H

Electric wave interference: Radar interference

H

Electric wave analysis: Burst signals

1–2

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 29

Specifications

The specifications on the 3026 Real Time Spectrum Analyzer can be classified

into three sub-sections: Warranted Characteristics, Typical Characteristics and

Nominal Traits. Certifications and Compliances are also found at the last page in

this section.

Warranted Characteristics

This section lists the various warranted characteristics that describe the 3026

Real Time Spectrum Analyzer. Electrical and environmental characteristics are

also included.

Warranted characteristics are described in terms of quantifiable performance

limits which are warranted.

As stated above, this section lists only warranted characteristics. A list of typical

characteristics starts on page 1–7.

Performance Conditions

The performance limits in this specification are valid with these conditions:

H

The analyzer must have been calibrated/adjusted at an ambient temperature

_

between +20

H

The analyzer must be in an environment with temperature, altitude,

humidity, and vibration within the operating limits described in these

specifications.

H

The analyzer must have had a warm-up period of at least 20 minutes.

H

The analyzer must be operating at an ambient temperature between +10

and +40

C and +30_ C.

_

C.

_

C

3026 3 GHz Real Time Spectrum Analyzer Service Manual

1–3

Page 30

Specifications

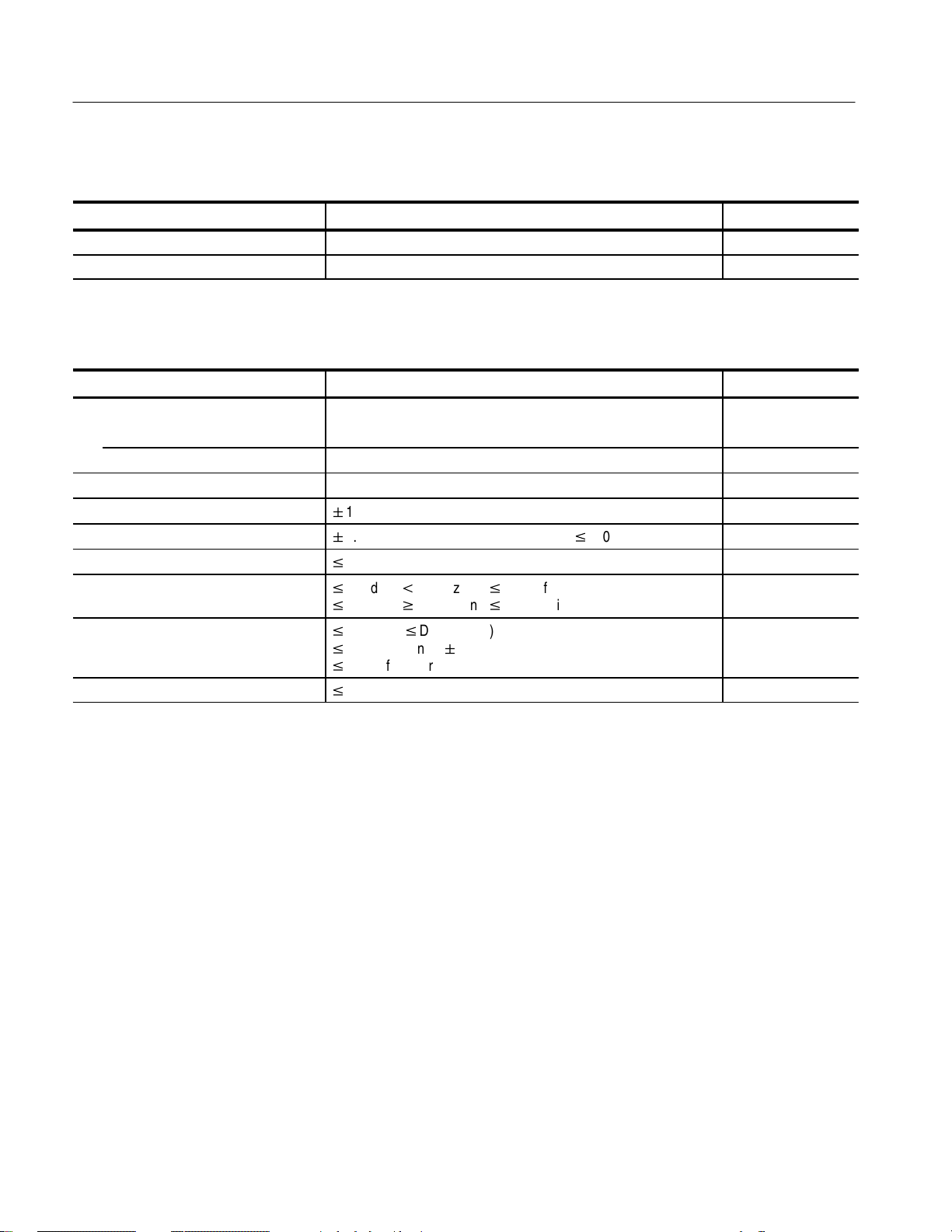

Table 1–1: Warranted characteristics — Frequency

Characteristics Description PV reference page

Center frequency setting characteristic 0.1 Hz step

Spectrum purity –100 dBc/Hz (10 kHz offset) 4–32

Table 1–2: Warranted characteristics — Amplitude

Characteristics Description PV reference page

Reference level range

RF mode –50 dBm to +30 dBm

BASEBAND mode –30 dBm to +30 dBm

Maximum nondestructive input voltage +30 dBm

Internal gain calibration accuracy

Flatness

2-nd harmonic distortion

3-rd order distortion

Residual response

Image suppress

"

1.0 dB (at 25 MHz) 4–34

"

2.0 dB (>500 Hz), +2.0 dB and –5.0 dB (v500 Hz) 4–16, 4–38

v

–70 dBc (–10 dBfs input level)

v

–60 dBc (t20 MHz and v–10 dBfs input level)

v

–70 dBc (w20 MHz and v–10 dBfs input level)

v

–40 dBfs (vDC +10 bins)

v

–65 dBfs (center "2 bins)

v

–70 dBfs (other than above)

v

–70 dB

1–4

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 31

Specifications

Table 1–3: Warranted characteristics — Realtime span

Characteristics Description PV reference page

Minimum spectral frame update interval 4–23

1024-point analysis 160ms (500 kHz to 5 MHz span)

400ms (50 kHz to 200 kHz span)

4 ms (5 kHz to 20 kHz span)

40 ms (500 Hz to 2 kHz span)

100 ms (200 Hz span)

200 ms (100 Hz span)

256-point analysis 40ms (500 kHz to 2 MHz span)

400ms (50 kHz to 200 MHz span)

4 ms (5 kHz to 20 kHz span)

40 ms (500 Hz to 2 kHz span)

100 ms (200 Hz span)

200 ms (100 Hz span)

Realtime span

v

2 MHz

Table 1–4: Warranted characteristics — Trigger/Acquisition

Characteristics Description PV reference page

Internal trigger 4–26

Level

Maximum 0 dBfs

Minimum –55 dBfs

Frequency resolution Span/800 (5 MHz span, 1024 points)

Span/640 (v2 MHz span, 1024 points)

Span/160 (v2 MHz span, 256 points)

Time resolution Same as the spectral frame update interval.

External trigger 4–30

Input voltage range 0 to 5 V

3026 3 GHz Real Time Spectrum Analyzer Service Manual

1–5

Page 32

Specifications

Table 1–5: Warranted characteristics — Installation requirements

Characteristics Description

Heat emission

Maximum power 300 W

Maximum line current 4.0 Arms (at 50 Hz)

AC line source

Primary circuit dielectric voltage

withstand

Grounding impedance Verify the continuity of grounding connection, by any suitable means, between a

15 s for 1,500 Vrms at 50 Hz

representative part required to be grounding and attachment-plug cap grounding pin.

(0.1 W at 30 A)

Table 1–6: Warranted characteristics — Environmental

Characteristics Description

Atmospherics

Temperature

Operating +10 _C to +40 _C

Non-operating –20 _C to +60 _C

Relative humidity

Operating 20 % to 80 % (no condensation), Maximum wet-bulb temperature 29.4 _C

Non-operating 5 % to 90 % (no condensation), Maximum wet-bulb temperature 40.0 _C

Altitude

Operating Up to 4.5 km (15,000 ft).

Non-operating Up to 15 km (50,000 ft)

Dynamics

Random vibration

Operating 0.27 g rms, from 5 Hz to 500 Hz, 10 minutes

Non-operating 2.28 g rms, from 5 Hz to 500 Hz, 10 minutes

Shock

Non-operating 294 m/s2 (3.0G), half-sine, 11 ms duration, three times in every axis direction.

Maximum working temperature decreases by 1 _C at 300 m increments when the altitude

exceeds 1.5 km.

1–6

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 33

Typical Characteristics

This subsection contains tables that list the various typical characteristics which

describe the 3026 Real Time Spectrum Analyzer.

Typical characteristics are described in terms of typical or average performance.

Typical characteristics are not warranted.

Table 1–7: Typical characteristics — Amplitude

Characteristics Description

Input equivalent noise –140 dBm/Hz at 1 GHz

Spurious response

Table 1–8: Typical characteristics — Filter

v

–65 dBc

Specifications

Characteristics Description

Stopband attenuation 90 dB

Bandpass ripple 0.2 dB

Table 1–9: Typical characteristics — Trigger/Acquisition

Characteristics Description

Roll mode update rate 10 frames/s

Table 1–10: Typical characteristics — Installation requirements

Characteristics Description

Surge current 30 A (at 100 VAC)

15 A (at 200 VAC)

3026 3 GHz Real Time Spectrum Analyzer Service Manual

1–7

Page 34

Specifications

1–8

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 35

Nominal Traits

This section contains a collection of tables that list the various nominal traits

that describe the 3026 Real Time Spectrum Analyzer. Electrical and mechanical

traits are included.

Nominal traits are described using simple statements of fact such as “Four, all

identical” for the trait “Output Channels, Number of,” rather than in terms of

limits that are performance requirements.

Table 1–11: Nominal traits — Frequency

Characteristics Description

Range

RF mode 10 MHz to 3 GHz

BASEBAND mode 50 Hz to 10 MHz

Span

RF mode 100 Hz to 3 GHz

BASEBAND mode 100 Hz to 10 MHz

Stability of Frequency Standard

Residual FM Maximum 3 Hz

"5

10–9/day

Specifications

Table 1–12: Nominal traits — Amplitude

Characteristics Description

Input impedance 50

Input VSWR

A/D converter 12 bits, 25.6 MS/s

Input anti-aliasing filter

W

v

1.5 (reference level w–20 dBm)

"

0.3 dB (v10 MHz), –60 dB (w15.5 MHz)

3026 3 GHz Real Time Spectrum Analyzer Service Manual

1–9

Page 36

Specifications

Table 1–13: Nominal traits — FFT

Characteristics Description

Number of FFT points 1024 or 256

FFT window Blackman-Harris

Hamming

Rectangle

Operation Accuracy 16-bit

Block-floating point

Overlapping

1024 points 512 points (at 2 MHz span)

768 points (at 1 MHz span)

896 points (at 500 kHz span)

896 points (at 200/20/2 kHz span)

960 points (at 100/10/1 kHz span)

992 points (at 50/5 kHz span)

992 points (at 500/200/100 Hz span)

256 points 128 points (at 2 MHz span)

192 points (at 1 MHz span)

224 points (at 500 kHz span)

128 points (at 200/20/2 kHz span)

192 points (at 100/10/1 kHz span)

224 points (at 50/5 kHz span)

224 points (at 500/200/100 Hz span)

1–10

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 37

Table 1–14: Nominal traits — Filter

Characteristics Description

Filter type

5 MHz span 134-tap FIR filter

2 MHz span 201-tap FIR filter

1 MHz span 268-tap FIR filter

500 kHz span 317-tap FIR filter

200 kHz span 391-tap FIR filter

100 kHz span 503-tap FIR filter

50 kHz span 503-tap FIR filter with 4-stage comb filter

20 kHz span 503-tap FIR filter with 4-stage comb filter

10 kHz span 503-tap FIR filter with 4-stage comb filter

5 kHz span 459-tap FIR filter with 4-stage comb filter

2 kHz span 503-tap FIR filter with 4-stage comb filter

1 kHz span 459-tap FIR filter with 4-stage comb filter

500 Hz span 459-tap FIR filter with 4-stage comb filter

200 Hz span 459-tap FIR filter with 4-stage comb filter

100 Hz span 503-tap FIR filter with 4-stage comb filter

FIR filter coefficient length 20 bits

Specifications

Table 1–15: Nominal traits — Trigger/Acquisition

Characteristics Description

Trigger mode Auto, Normal

Trigger source Internal or External

Internal trigger

Resolution 19 bits

External trigger

Input level 1.6 V "0.2 V

Acquisition mode Block or Roll

Maximum block length

1,024 FFT points 1,000 frames

256 FFT points 4,000 frames

3026 3 GHz Real Time Spectrum Analyzer Service Manual

1–11

Page 38

Specifications

Table 1–16: Nominal traits — System control

Characteristics Description

Bus type ISA

CPU type 486 DX4-100 MHz

Main memory 32 M bytes

Hard disk drive 2.5 inches, 3 M bytes, solid-state disk

2.5 inches, 2.1 G bytes, hard disk

Floppy disk drive 3.5 inches, 2HD (1.44 M bytes)

Table 1–17: Nominal traits — AC line power

Characteristics Description

Line voltage 100 to 240 VAC

Line frequency 48 Hz to 63 Hz

Table 1–18: Nominal traits — Mechanical

Characteristics Description

Dimensions Height 165 mm

Width 376 mm (handle included)

length 495 mm

Net weight 13.0 kg

1–12

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 39

Specifications

Certification and Compliances

The certification and compliances for the 3026 Real Time Spectrum Analyzer are

listed in Table 1–19.

Table 1–19: Certifications and compliances

Characteristic Description

EC Declaration of Conformity – EMC Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance

was demonstrated to the following specifications as listed in the Official Journal of the

European Union:

EN 55011 Class A Radiated and Conducted Emissions

EN 50081-1 Emissions:

EN 61000–3–2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

EN61000–4–2 Electrostatic Discharge Immunity

EN61000–4–3 RF Electromagnetic Field Immunity

EN61000–4–4 Electrical Fast Transient/Burst Immunity

EN61000–4–5 Power Line Surge Immunity

EN61000–4–6 Conducted Disturbances Induced by RF Fields

EN61000–4–8 Power Frequency Electromagnetic Field

EN61000–4–11 Power Line Interruption Immunity

Australia/New Zealand Declaration of

Conformity – EMC

Complies with EMC provision of Radiocommunications Act per the following

standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

EC Declaration of Conformity – Low Voltage Compliance was demonstrated to the following specification as listed in the Official

Journal of the European Union:

Low Voltage Directive 73/23/EEC, amended by 93/69/EEC

EN 61010-1:1993 Safety requirements for electrical equipment for

measurement control and laboratory use.

U.S. Nationally Recognized Testing Laboratory

Listing

Canadian Certification CAN/CSA C22.2 No. 231 CSA safety requirements for electrical and electronic

Additional Compliance ANSI/ISA S82.01:1994 Safety standard for electrical and electronic test,

UL3111-1 Standard for electrical measuring and test equipment.

measuring and test equipment.

measuring, controlling, and related equipment.

IEC61010-1 Safety requirements for electrical equipment for

measurement, control, and laboratory use.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

1–13

Page 40

Specifications

Table 1–19: Certifications and compliances (Cont.)

Characteristic Description

Installation (Overvoltage) Category Terminals on this product may have different installation (overvoltage) category

designations. The installation categories are:

CAT III Distribution-level mains (usually permanently connected). Equipment at this

level is typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this level includes

appliances, portable tools, and similar products. Equipment is usually

cord-connected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Pollution Degree A measure of the contaminates that could occur in the environment around and within

a product. Typically the internal environment inside a product is considered to be the

same as the external. Products should be used only in the environment for which they

are rated.

Pollution Degree 1 No pollution or only dry, nonconductive pollution occurs.

Products in this category are generally encapsulated,

hermetically sealed, or located in clean rooms.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by

condensation must be expected. This location is a

typical office/home environment. Temporary

condensation occurs only when the product is out of

service.

Pollution Degree 3 Conductive pollution, or dry, nonconductive pollution that

becomes conductive due to condensation. These are

sheltered locations where neither temperature nor

humidity is controlled. The area is protected from direct

sunshine, rain, or direct wind.

Pollution Degree 4 Pollution that generates persistent conductivity through

conductive dust, rain, or snow. Typical outdoor locations.

Safety Certification Compliance

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 1010-1, Annex H) – grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 1010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 1010-1). Note: Rated for indoor use only.

1–14

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 41

Operating Information

Page 42

Page 43

Installation

Supplying Operating Power

NOTE. Read all information and heed all warnings in this subsection before

connecting the analyzer to a power source.

WARNING. AC POWER SOURCE AND CONNECTION. The analyzer operates

from a single-phase power source. It has a three-wire power cord and two-pole,

three-terminal grounding type plug. The voltage to ground (earth) from either

pole of the power source must not exceed the maximum rated operating voltage,

250 volts.

Before making connection to the power source, be sure the analyzer has a

suitable two-pole, three-terminal grounding-type plug.

GROUNDING. This instrument is safety Class 1 equipment (IEC designation).

All accessible conductive parts are directly connected through the grounding

conductor of the power cord to the grounded (earthing) contact of the power

plug.

WARNING. The power input plug must be inserted only in a mating receptacle

with a grounding contact where earth ground has been verified by a qualified

service person. Do not defeat the grounding connection. Any interruption of the

grounding connection can create an electric shock hazard.

For electric shock protection, the grounding connection must be made before

making connection to the instrument’s input or output terminals.

Power Cord Information

3026 3 GHz Real Time Spectrum Analyzer Service Manual

A power cord with the appropriate plug configuration is supplied with each

analyzer. Table 2–1 gives the color-coding of the conductors in the power cord. If

you require a power cord other than the one supplied, refer to Table 2–2, Power

cord identification.

2–1

Page 44

Installation

Table 2–1: Power-cord conductor identification

Conductor Color Alternate color

Ungrounded (Line) Brown Black

Grounded (Neutral) Light blue White

Grounded (Earthing) Green/Yellow Green

Table 2–2: Power cord identification

Plug configuration Normal usage Option number

North America

125 V

Europe

230 V

United Kingdom

230 V

Australia

230 V

North America

230 V

Switzerland

230 V

Standard

A1

A2

A3

A4

A5

2–2

Operating Voltage

This analyzer operates with any line voltage from 85–264 VAC

with any line

RMS

frequency from 47–66 Hz. Before plugging the cord in the outlet, be sure that the

power supply voltage is proper.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 45

Operating Environment

Installation

The following environmental requirements are provided to ensure proper

operation and long instrument life.

Operating Temperature

Ventilation Requirements

Operate the analyzer where the ambient air temperature is from 10_ C to +40_ C

with no diskette in the floppy drive. Store the analyzer in ambient temperatures

from –20_ C to +60_ C with no diskette in the floppy drive. After storage at

temperatures outside the operating limits, allow the chassis to stabilize at a safe

operating temperature before applying power.

The analyzer has a exhaust fan on its left side panel. Air enters the cabinet

through the air intakes on the right side, and exhausts through the exhaust fan.

To allow air circulation, leave the following space around the analyzer.

When used on a bench top:

Top and bottom surfaces 2.5 cm or more. . . . .

Left and right surfaces 15 cm or more. . . . . . .

Rear surface 7.5 cm or more. . . . . . . . . . . . . . .

When mounted on 19 inch rack:

Top and bottom surfaces 2.5 cm or more. . . . .

Left and right surfaces 5 cm or more. . . . . . .

Rear surface 7.5 cm or more. . . . . . . . . . . . . . .

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–3

Page 46

Installation

Applying and Interrupting Power

Consider the following information when you power on or power off the

instrument, or when power is interrupted due to an external power failure.

Power On

To turn on the power to the analyzer, turn on the ON/STBY button located at the

bottom left corner of the front panel. When you turn on the power, Windows 95

is booted and the system software is subsequently started.

Upon power on, the analyzer runs a power-on self check. See Section 6,

Maintenance, for information on diagnostics and fault isolation.

ON/STBY

button

2–4

Power Off

Figure 2–1: Power switch

When you place the ON/STBY button on the front panel in the STAND-BY

position, the internal software detects the condition of the power switch and

shuts down the system before powering off the analyzer. You need not terminate

the application software of the analyzer or Windows 95 before the shutdown.

CAUTION. When turning on or off the power, be sure to use the ON/STBY button

on the front panel. While the power cord remains unplugged from the AC outlet,

or no voltage is being supplied to the AC outlet, be sure to keep the ON/STBY

button in the STAND-BY position.

Placing the front panel power switch in the STAND-BY position does not cause

the master mains to be off completely. To turn it off, unplug the power cord from

the outlet.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 47

Repackaging Instructions

If you ship the analyzer, pack it in the original shipping carton and packing

material. If the original packing material is not available, package the instrument

as follows:

1. Obtain a corrugated cardboard shipping carton with inside dimensions at

2. If you are shipping the instrument to a Tektronix field office for repair, attach

3. Wrap the instrument with polyethylene sheeting or equivalent material to

4. Cushion the instrument in the shipping carton by tightly packing dunnage or

Installation

least 15 cm (6 inches) taller, wider, and deeper than the instrument. The

shipping carton must be constructed of cardboard with 170 kg (375 pound)

test strength.

a tag to the instrument showing the instrument owner and address, the name

of the person to contact about the instrument, the instrument type, and the

serial number.

protect the finish.

urethane foam on all sides between the carton and the analyzer. Allow

7.5 cm (3 in) on all sides, top, and bottom.

Installed Options

5. Seal the shipping carton with shipping tape or an industrial stapler.

NOTE. Do not ship the instrument with a diskette inside the floppy disk drive.

When the diskette is inside the drive, the disk release button sticks out. This

makes the button more prone to damage than otherwise.

Your instrument may be equipped with one or more instrument options. Except

for the line-cord options described by Table 2–2 on page 2–2, all options and

optional accessories are listed and described in Section 7, Options. For further

information and prices of instrument options, see your Tektronix Products

catalog or contact your Tektronix Field Office.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–5

Page 48

Installation

2–6

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 49

Operating Instructions

Before doing service, read the following operating instructions. These instructions are at the level appropriate for servicing these analyzer. The User Manual

contains more complete operating instructions.

Additional instructions are integrated into the service procedures found in later

sections of this manual. For instance, the procedures found in the section

Performance Verification contain instructions for making the front-panel settings

required to check each instrument characteristic included there. Also, the general

instructions for operating the analyzer’s internal diagnostic routines are found in

Section 6, Maintenance. You may also find the Product Description in Section 1

useful for understanding how the analyzer functions.

Preparations

To start this tutorial, the following devices are required:

H

Signal generator or function generator

Example: Arbitrary Waveform & Function Generator

Sony Tektronix AFG320

H

Two BNC cables

H

One N–BNC conversion connector (standard accessory)

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–7

Page 50

Operating Instructions

Setup

1. First, make preparations for outputting. AM modulation signals from the

signal generator.

a. Connect the CH2 output of the signal generator to AM IN on the rear

panel of the signal generator with a BNC cable.

b. Set up the signal generator as follows:

CH1 output:

Function SINE. . . . .

Frequency 16 MHz. . . .

Amplitude 0.1 V. . .

Modulation AM. . .

CH2 output:

Function SINE. . . . .

Frequency 1 MHz. . . .

Amplitude 1.0 V. . .

2. Use the other BNC cable and BNC–N conversion connector to connect the

CH1 output of the signal generator with the RF INPUT connector on the

3026 front panel. (See Figure 2–2).

RF INPUT connector

2–8

Figure 2–2: RF INPUT connector

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 51

Turning On the Power

Operating Instructions

1. Press the ON/STBY button on the front panel of the 3026.

When you press the ON/STBY button, the system comes up and performs

Power-on self test. When the test is complete, system information appears at

the center of display. (See Figure 2–3.)

Figure 2–3: System information

In this condition, if you press any front panel button, or turn the general purpose

knob, the system information will be removed and the initial screen appears as

shown in Figure 2–4.

Figure 2–4: Initial screen

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–9

Page 52

Operating Instructions

Observing Spectrum

SUMMARY. This section describes how to change the basic settings to view the

spectrum after the system has been installed.

Acquiring Data

When power is turned on, the initial settings are 100 MHz center frequency and

2 MHz span. First, change these settings to view the spectrum.

1. Press the START/STOP button. (See Figure 2–5.)

The LED on the top left of the button lights up, and a trace appears on the

display.

START/STOP button

2–10

Figure 2–5: START/STOP button

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 53

Operating Instructions

2. Press the FREQ button.

H

Use the general purpose knob or value entry keys to set the center

frequency to 16 MHz.

You should have obtained the spectrum display. The current span is set to 2

MHz. Next, change the span.

3. Press the SPAN button.

H

Set the span to 10 MHz by using the general purpose knob or value entry

keys. Pressing the Span 10 MHz bottom button will produce the same

result.

Figure 2–6 shows a typical spectrum display with the center frequency set to

16 MHz and the span set to 10 MHz.

Figure 2–6: Typical spectrum display (16 MHz center frequency and 10 MHz span)

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–11

Page 54

Operating Instructions

Dividing the Display Area and Changing the Display Mode

SUMMARY. This section describes how to divide the display area into two and

observe the data in different display modes.

Dividing the Display Area

To divide the display area and change the display mode, use the buttons located

in the DISPLAY area. (See Figure 2–7.)

Figure 2–7: Buttons in DISPLAY area

4. Press the

The display area is divided into two. The upper section displays the

spectrogram and the lower section displays the spectrum, as shown in Figure

2–8.

button located in the DISPLAY area.

2–12

Figure 2–8: Spectrogram display (upper) and spectrum display (lower)

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 55

Operating Instructions

Changing the Display

Mode

Next, change the upper section into the waterfall display.

5. Press the SELECT button located at the bottom right of the general

purpose knob. (See Figure 2–9.)

SELECT button

Figure 2–9: SELECT button

The color of upper scale of the spectrogram display changes from gray to

blue. This indicates that the active area (that for which setting changes and

operations are valid) has been switched to the upper section.

NOTE. If the display area has been split, check which area is active before you

change the settings.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–13

Page 56

Operating Instructions

6. Press the

spectrogram display to waterfall display.

button in the DISPLAY area. The upper half is changed from

Figure 2–10: Waterfall display and spectrum display

Next, return the display to the previous condition.

7. Press the SELECT button.

The color of the top part of the lower scale changes from gray to blue.

8. Press the

button in the DISPLAY area.

2–14

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 57

Using the Block Mode to Acquire Data

SUMMARY. This section describes how to acquire data by using the Block mode.

In the Block mode, all the data is acquired and then it is displayed, unlike the

Roll mode in which each frame it displayed directly after it is acquired.

Operating Instructions

Changing the Basic

Settings

Acquiring Data

The Block mode is valid for a span setting of 2 MHz or lower. Therefore, first

change the span setting. In addition, change the trigger mode to auto mode

because the trigger function is not used in this example.

9. Press the Span 2 MHz bottom button. Alternatively, the general purpose

knob or value entry keys may be used.

10. Press the TRIG button.

11. Press the Mode bottom button.

12. Press the Trig Mode side button to select Auto.

The above steps complete the preparation for data acquisition in the Block mode.

13. Press the ROLL BLOCK button.

ROLL BLOCK button

Figure 2–11: ROLL BLOCK button

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–15

Page 58

Operating Instructions

During data acquisition, a dialog box titled “Processing Data... Please Wait” is

indicated on the display. After the completion of data acquisition, the waveform

is displayed. (See Figure 2–12.)

Unlike the Roll mode, there is noticeable delay before data is displayed in the

Block mode. This is because data is displayed after sufficient data is acquired to

match the length specified by the block size and block count. Once the all the

data is acquired, acquisition ends and the data is displayed.

2–16

Figure 2–12: Data acquisition in the Block mode

When data has been acquired in the Block mode, return the data acquisition

mode to the Roll mode.

14. Press the ROLL BLOCK button.

The LED at the top left of the button turns off, which indicates that the data

acquisition mode has changed to the Roll mode.

15. Press the START/STOP button.

The LED at the top left of the button turns on and data acquisition is

resumed.

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 59

Using Dual Markers

Operating Instructions

SUMMARY. This section describes the procedure of using dual markers to

measure the frequency difference between two peaks in the spectrum.

Before starting the operation, return the span setting to 10 MHz.

16. Press the SPAN button.

17. Press the Span 10 MHz bottom button.

Displaying Dual Markers

Place markers on the waveform as follows:

18. Press the MARKER button.

19. Press the Marker Setup bottom button.

20. Press the Dual Marker side button.

This operation places two markers on the waveform: a “[x]” marker

(MARKER1) and a “+” marker (MARKER2). (See Figure 2–13.)

Of these two markers, the “[x]” marker is highlighted and the “+” marker is

dimmed. This indicates that the “[x]” marker is the active one: the marker which

a/'

can be moved by the general purpose knob or the

buttons.

Figure 2–13: Displaying dual markers

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–17

Page 60

Operating Instructions

Moving Markers

Next, move the two markers to the peaks which are located on the right and left

of the center peak.

21. Using the general purpose knob or the

a/'

button, move the “[x]” marker to

the peak located on the left of the center spectrum. The value entry keys may

be used to enter the value directly.

22. Press the MARKER TOGGLE button located at the top right of the general

purpose knob. (See Figure 2–14.)

MARKER TOGGLE button

Figure 2–14: MARKER TOGGLE button

This operation toggles the active marker to the “+” marker located on the

center spectrum. The “+” marker will be highlighted.

a/'

23. Using the general purpose knob or the

button, move the “+” marker to

the peak located on the right of the center spectrum. The value entry keys

may be used to enter the value directly.

NOTE. A more sophisticated way of moving a marker to a peak in the spectrum is

to use the Peak Find feature.

The frequency and amplitude differences between the two markers are displayed

as the DELTA readout. Further, the frequency difference is indicated as a

negative value because the marker value is calculated based on the position of

active marker. When you toggle the position of active marker, the frequency will

change to a positive value.

2–18

3026 3 GHz Real Time Spectrum Analyzer Service Manual

Page 61

Operating Instructions

24. Press the MARKER TOGGLE button again.

The active marker is toggled and the frequency difference is indicated as a

positive value. (See Figure 2–15.)

Figure 2–15: Measurement of frequency difference with dual markers

3026 3 GHz Real Time Spectrum Analyzer Service Manual

2–19

Page 62

Operating Instructions

Trigger and Mask Pattern

SUMMARY. Using a trigger mask pattern, triggering is available in two

dimensions: frequency and level. How to create a trigger mask pattern and how

to receive a trigger are described below.

In this tutorial, a trigger is made to occur by turning from the CH2 output of the