Page 1

Service Manual

2715

Spectrum Analyzer

Volume 1

070-9096-06

This document supports firmware version

12.01.95 and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a repl acement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of t he

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center de signated by Tektronix, with shipping charges prepaid.

Tektronix shall pay for the return of the product to Customer i f the shipment is to a location within the country in which the

Tektronix service center is located. Custome r shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS W ARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS W ARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary ix...................................

Service Safety Summary xi....................................

Preface xv...................................................

Electrical Characteristics 1-1..........................................

Instrument Description 2-1............................................

Conformance to Industry Standards 2-2..................................

Product Service 2-2..................................................

Instrument Construction 2-3...........................................

Installation and Preparation for Use 2-3..................................

Power Cord 2-3.....................................................

Replacing the Fuse 2-4...............................................

Selected Components 2-4.............................................

Assembly and Circuit Numbering 2-4...................................

Accessories 2-4.....................................................

Menus 2-4.........................................................

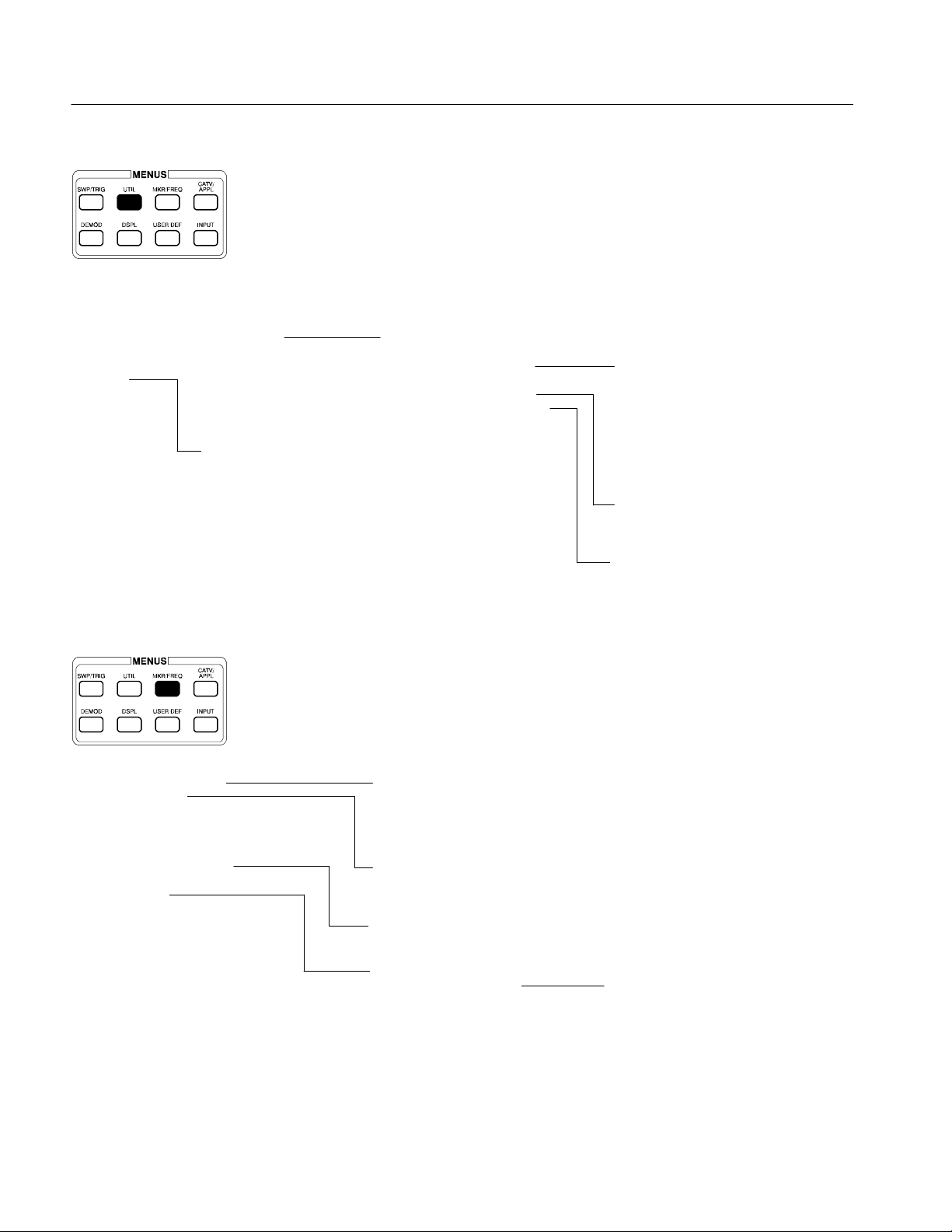

SWP/TRG Menu Structure 2-6.........................................

UTIL Menu Structure

(1 of 2) 2-7.....................................................

UTIL Menu Structure

(2 of 2) 2-8.....................................................

MRK/FREQ Menu Structure 2-8.......................................

CATV/APPL CATV Measurements Page 1 Menu Structure (1 of 3) 2-9........

CATV/APPL CATV Measurements Page 1 Menu Structure (2 of 3) 2-10........

CATV/APPL CATV Measurements Page 1 Menu Structure (3 of 3) 2-11........

CATV/APPL CATV Measurements Page 2 Menu Structure (1 of 2) 2-12........

CATV/APPL CATV Measurements Page 2 Menu Structure (2 of 2) 2-13........

CATV/APPL Applications Menu Structure 2-14............................

DEMOD Menu Structure 2-14..........................................

DSPL Menu Structure 2-15............................................

USER DEF Menu Structure 2-15........................................

INPUT Menu Structure 2-16...........................................

Theory of Operation

Block Diagram Description 3-1........................................

Center Frequency Control 3-5.........................................

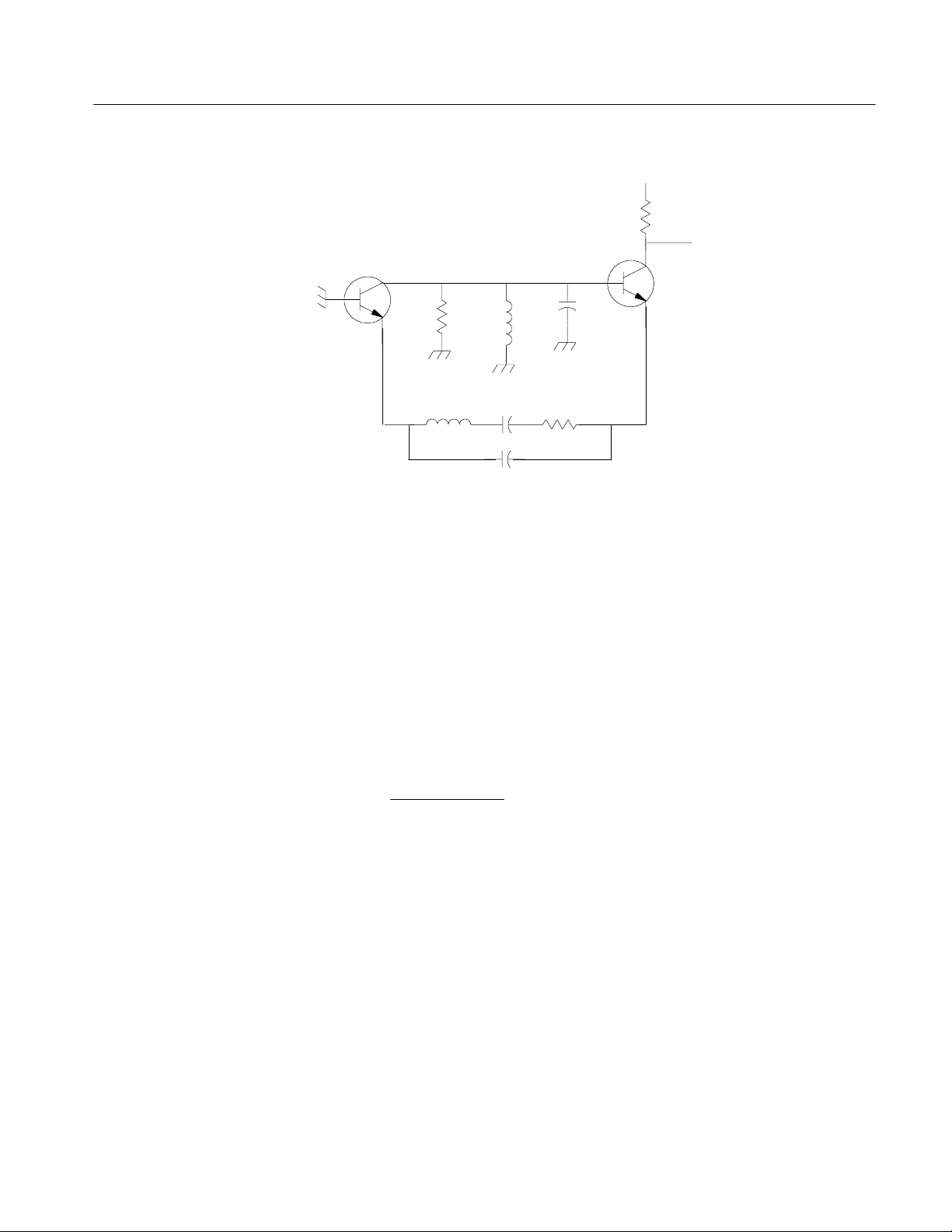

1st LO Buffer 3-7...................................................

Sweep 3-7.........................................................

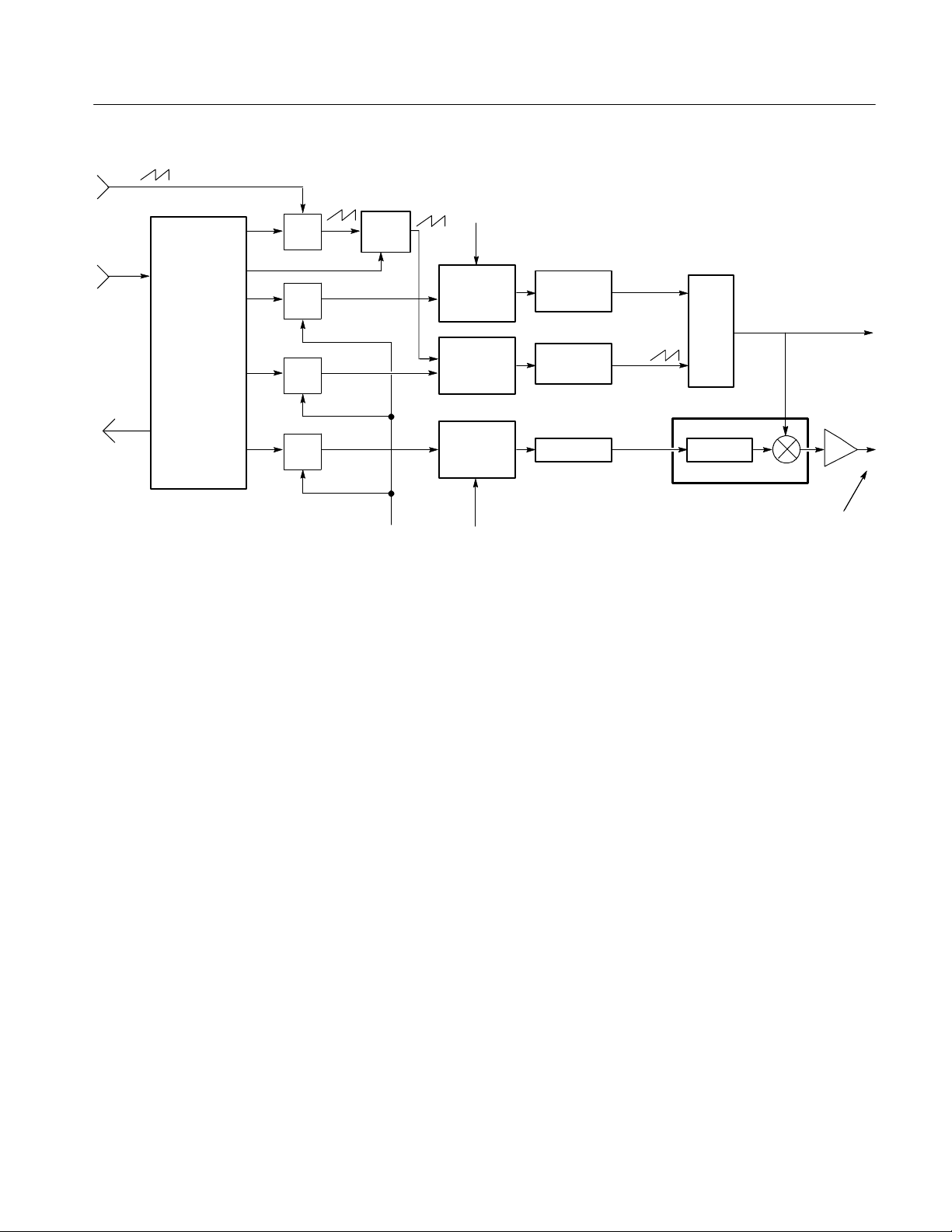

Display System 3-8..................................................

Circuit Description 3-9........................................

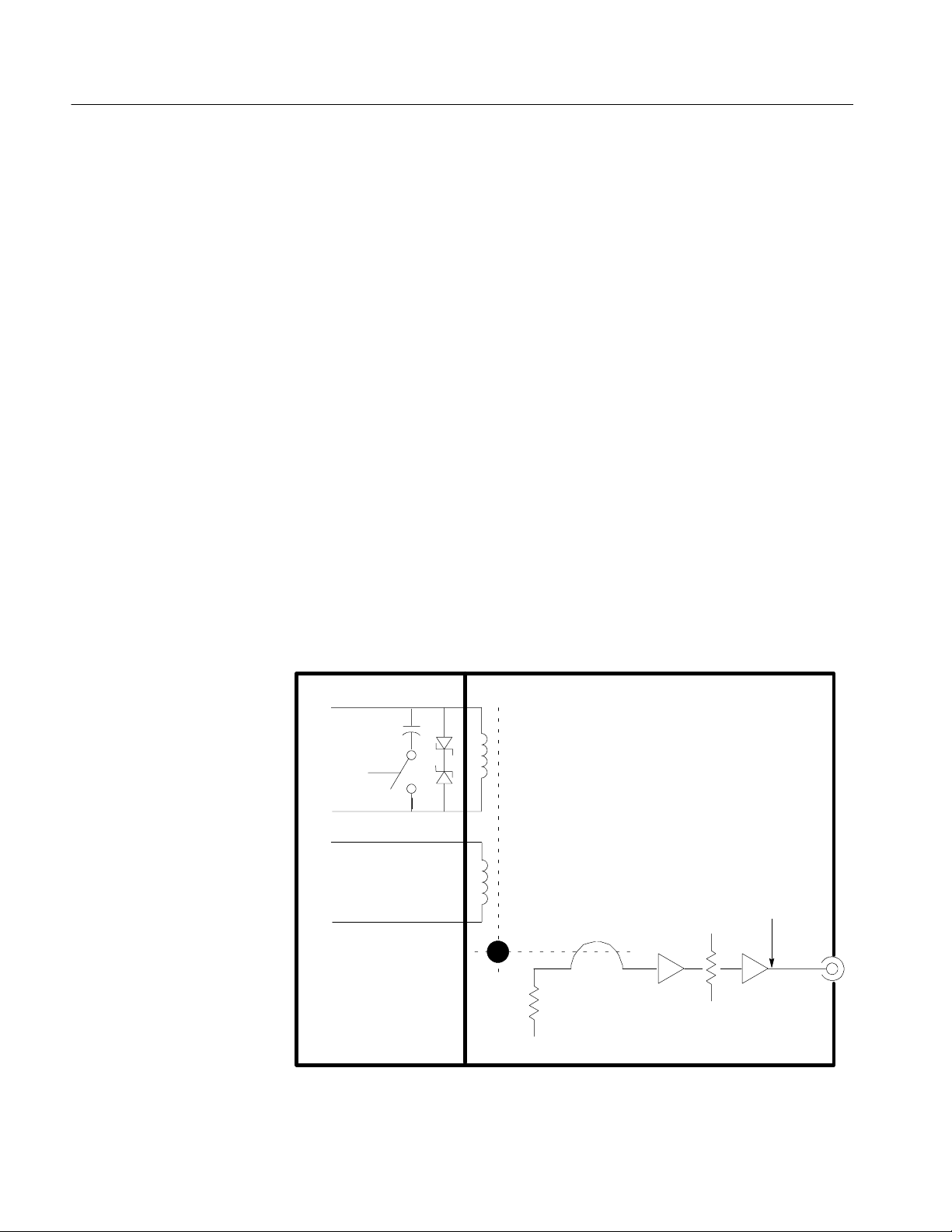

Attenuator and 1st Converter 3-9.......................................

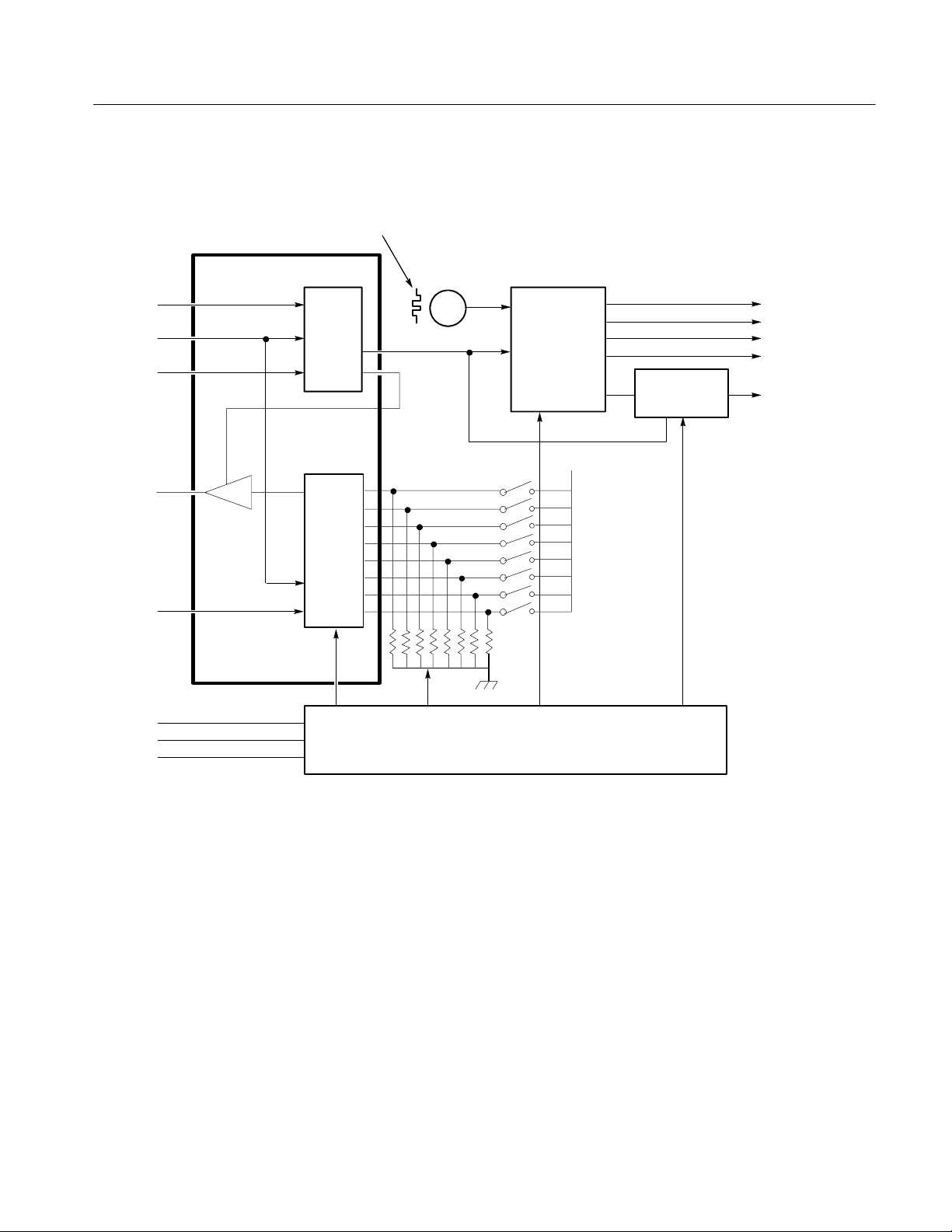

RF Mother Board and Phase Locked 2nd LO 3-12..........................

2715 Spectrum Analyzer Service Manual

i

Page 6

Table of Contents

1st LO Interface, 1st LO, and 1st LO Buffer Amplifier 3-14..................

Reference Oscillator 3-16..............................................

Phase Lock Assembly (Center Frequency Control System) 3-21...............

Variable Resolution Module 3-33........................................

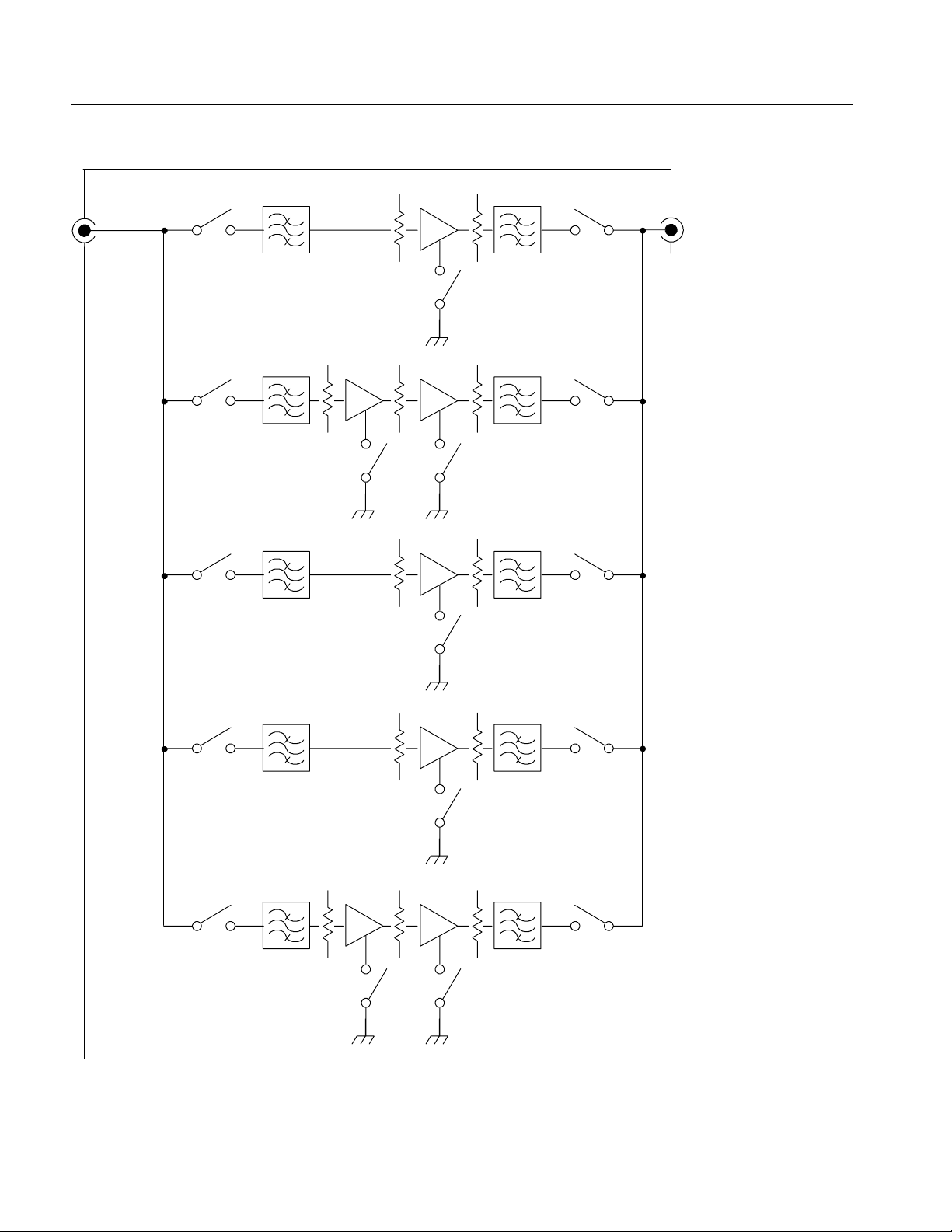

RF Options 3-35.....................................................

Log Amplifier 3-38...................................................

Display Storage 3-40..................................................

Microprocessor 3-60..................................................

GPIB, RS-232, Real Time Clock, NVRAM, and Gated Measurement Functions 3-74

Video Demodulator 3-78...............................................

Sweep 3-80.........................................................

Front Panel 3-83.....................................................

Power Supply (Primary and Secondary) 3-87..............................

Power Supply (Display) 3-91...........................................

Performance Verification

Incoming Inspection Test 4-1..........................................

Verification of Tolerance Values 4-1....................................

History Information 4-1..............................................

Equipment Required 4-2..............................................

Power-Up Procedure 4-3..............................................

Front Panel Operation 4-4.............................................

Performance Check Procedure 4-4......................................

Adjustment Procedures

Static Discharge Precautions 5-1.......................................

Recommended Test Equipment 5-2.....................................

Preparation 5-4.....................................................

Adjustments Requiring Flatness Correction 5-4...........................

Instrument Bottom View 5-5..........................................

Adjustments 5-6....................................................

Maintenance

Static Sensitive Components 6-1.......................................

Preventive Maintenance 6-2...........................................

Troubleshooting 6-6.................................................

Cal Debug Flags 6-8.................................................

Corrective Maintenance 6-13...........................................

Assembly Replacement Requiring Flatness Correction 6-17...................

Removing and Replacing Assemblies and Subassemblies 6-17................

Maintenance Adjustments 6-33.........................................

Options

Replaceable Electrical Parts

Diagrams

Replaceable Mechanical Parts

ii

2715 Spectrum Analyzer Service Manual

Page 7

List of Figures

Table of Contents

Figure 1-1: Typical Accuracy Limits for Carrier-to-Noise

Measurement 1-7..........................................

Figure 1-2: Typical Accuracy Limits for CTB Measurement 1-7......

Figure 1-3: Typical Accuracy Limits for Nongated CSO

Measurement 1-8..........................................

Figure 1-4: Typical Accuracy Limits for Gated CSO

Measurement 1-8..........................................

Figure 1-5: Typical ACL Measurement Limits for 2 dB Accuracy 1-9..

Figure 1-6: Typical D/U Measurement Range Limits for

2 dB Accuracy 1-9.........................................

Figure 1-7: Typical Digital Signal CSO Measurement Range Limit

for 2 dB Accuracy 1-10......................................

Figure 1-8: Typical Digital Signal CTB Measurement Range

Limit for 2 dB Accuracy 1-10.................................

Figure 2-1: 2715 Front Panel Keys 2-5............................

Figure 3-1: Main Block Diagram 3-2.............................

Figure 3-2: Display System Diagram 3-8..........................

Figure 3-3: Attenuator and 1st Converter Diagram 3-10..............

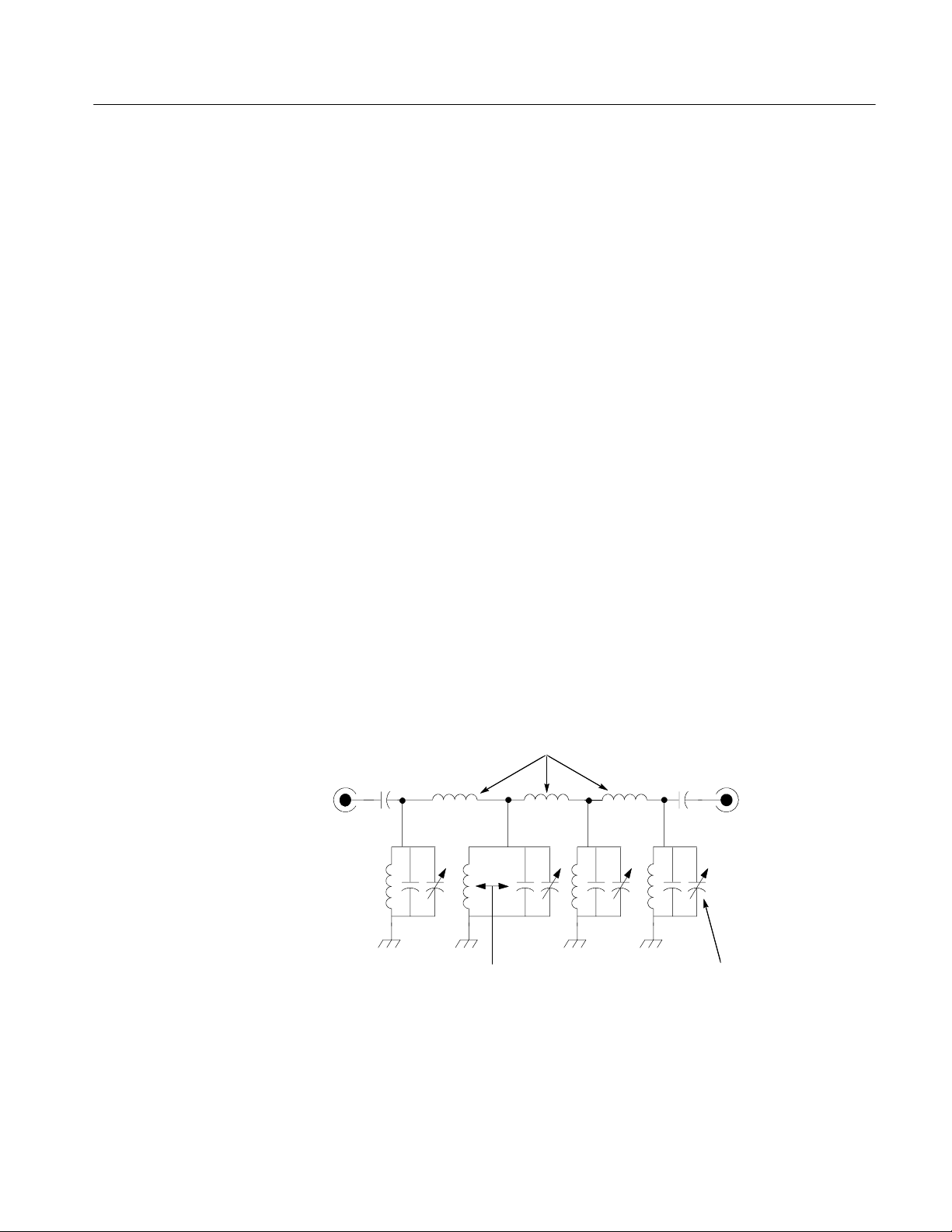

Figure 3-4: Equivalent Circuit for the Bandpass (4 Cavity)

Filter 3-11.................................................

Figure 3-5: Block Diagram of RF Mother Board 3-12................

Figure 3-6: 1st LO Interface and 1st LO Diagram 3-14...............

Figure 3-7: 1st LO Buffer Amplifier Diagram 3-15..................

Figure 3-8: Reference Oscillator Diagram 3-17......................

Figure 3-9: Crystal Heater and 15 V Regulation Circuit 3-18..........

Figure 3-10: Oscillator AC Equivalent 3-19........................

Figure 3-11: Oscillator DC Equivalent 3-20........................

Figure 3-12: Phase Lock Center Frequency Control

Configuration for Wide Spans (Unlocked, Sweep Main Coil) 3-28..

Figure 3-13: Phase Lock Center Frequency Control Configuration

for Moderate Spans (Unlocked, Sweep FM Coil) 3-29.............

Figure 3-14: Phase Lock Center Frequency Control Configuration

for Narrow Spans (Locked, Sweep VCO) 3-30...................

Figure 3-15: Variable Resolution Module Diagram 3-34..............

Figure 3-16: RF Options Diagram 3-36............................

2715 Spectrum Analyzer Service Manual

iii

Page 8

Table of Contents

Figure 3-17: Timing Diagram for a Typical Write to the Control

Register 3-50...............................................

Figure 3-18: Timing Diagram of a Typical Sweep for the Horizontal

Tracking A/D Converter 3-51.................................

Figure 3-19: Sequence of Events When Writing Data to the

Waveform Memory 3-54.....................................

Figure 3-20: How a Vertical Scan is Performed 3-56.................

Figure 3-21: The Display of a Single Vector of a Waveform 3-57.......

Figure 3-22: A Single Column of Character Dots 3-57................

Figure 3-23: Vertical Output Integrator 3-58.......................

Figure 3-24: Microprocessor Block Diagram 3-61...................

Figure 3-25: Microprocessor Counter System (CPU) 3-62.............

Figure 3-26: Front Panel Block Diagram 3-83......................

Figure 3-27: How the Debounce Circuit Reacts to Key Closure 3-85....

Figure 3-28: Power Supply Primary Block Diagram 3-88.............

Figure 3-29: Display Amplifiers Block Diagram 3-91................

Figure 4-1: 3rd Order IM Test Setup (25 MHz Separation) 4-17.......

Figure 4-2: Harmonic Distortion Test Equipment Setup 4-18..........

Figure 4-3: 1 dB Compression Point Test Setup 4-20.................

Figure 4-4: Accessory Connector (J103) 4-22.......................

Figure 4-5: Test Equipment Setup for Checking Return Loss 4-28.....

Figure 4-6: Test Signal on Video Line 17 4-32.......................

Figure 4-7: Video Gating Check Waveform (NTSC Illustrated) 4-34....

Figure 4-8: IF Gating Check Waveform (NTSC Illustrated) 4-35......

Figure 5-1: Instrument Bottom View 5-5..........................

Figure 5-2: Display Storage Board Adjustment Locations 5-13........

Figure 5-3: Properly Adjusted Checkerboard Pattern 5-14...........

Figure 5-4: Locked 2nd LO and 5 MHz Bandpass Filter

Adjustments 5-16...........................................

Figure 5-5: Phase Lock CFC Module Adjustment and Test Point

Locations 5-17.............................................

Figure 5-6: Log Board Adjustment and Test Point Locations 5-21.....

Figure 5-7: CAL Level Adjustment on Reference Oscillator Board 5-26.

Figure 5-8: RF Option Adjustment Locations 5-28..................

Figure 5-9: Variable Resolution Module Adjustment Locations 5-29....

Figure 5-10: Flatness adjustment test setup (all instruments

except Option 50) 5-34.......................................

iv

2715 Spectrum Analyzer Service Manual

Page 9

Table of Contents

Figure 5-1 1: Presetting the Flatness Adjustments on the

Log Board 5-35............................................

Figure 5-12: Gain Step Reference Test Setup 5-36...................

Figure 5-13: Internal Ref Ampltd Test Setup 5-38...................

Figure 5-14: SW410 on the Reference Oscillator Board 5-39..........

Figure 5-15: Adjustment and Test Point Locations on the

Sweep Board 5-41..........................................

Figure 5-16: Typical FM Adjustment Waveform 5-42................

Figure 5-17: HPF Tuning Criteria (at TP110M) 5-45.................

Figure 5-18: Typical Video Waveform 5-48.........................

Figure 5-19: Horizontal Sync Output 5-49.........................

Figure 5-20: Vertical Sync Output Waveform 5-50..................

Figure 5-21: E/O Output Waveform 5-51..........................

Figure 5-22: Test Equipment Characterization Using a Dual

Channel Power Meter for split75 5-59..........................

Figure 5-23: Test Equipment Characterization Using a

Single Channel Power Meter to Characterize the Power Meter

Output for split75 5-59......................................

Figure 5-24: Test Equipment Characterization Using a

Single Channel Power Meter to Characterize the DUT

Output for split75 5-59......................................

Figure 5-25: Test Equipment Characterization Using a Dual

Channel Power Meter for split50 5-60..........................

Figure 5-26: Test Equipment Characterization Using a

Single Channel Power Meter to Characterize the Power Meter

Output for split50 5-60......................................

Figure 5-27: Test Equipment Characterization Using a

Single Channel Power Meter to Characterize the DUT

Output for split50 5-60......................................

Figure 5-28: Flatness Test Setup (75 W) 5-62.......................

Figure 5-29: Flatness Test Setup (50 W) 5-62.......................

Figure 6-1: Main Extender and Secondary Extender 6-4............

Figure 6-2: Signal Steering Square Pins 6-5.......................

Figure 6-3: Surface Mounted Components Lead Configuration 6-14...

Figure 6-4: Top View of Assemblies and RF Deck 6-18...............

Figure 6-5: Assemblies Seen from the Bottom of the Spectrum

Analyzer 6-19..............................................

Figure 6-6: Removing the Front Panel 6-22........................

Figure 6-7: Locations of J510 and J550 on the Phase Lock

Assembly 6-23.............................................

2715 Spectrum Analyzer Service Manual

v

Page 10

Table of Contents

Figure 6-8: Connector Locations on the RF Deck 6-24...............

Figure 6-9: RF Deck Screws and Nuts 6-25.........................

Figure 6-10: Fan and Fan Mounting Springs Detail 6-29.............

Figure 6-11: Power Supply Assembly Removal (Bottom View) 6-31....

Figure 6-12: Removing Power Supply Attaching Nuts 6-32...........

Figure 6-13: Location of R602 on the Phase Lock CFC Board 6-34.....

Figure 7-1: Option 15 Installation 7-3............................

Figure 10-1: Cabinet 10-7.......................................

Figure 10-2: Front Panel 10-11....................................

Figure 10-3: Power Supply 10-15..................................

Figure 10-4: Chassis #1 10-18.....................................

Figure 10-5: Chassis #2 10-22.....................................

Figure 10-6: Accessories 10-25....................................

vi

2715 Spectrum Analyzer Service Manual

Page 11

List of Tables

Table of Contents

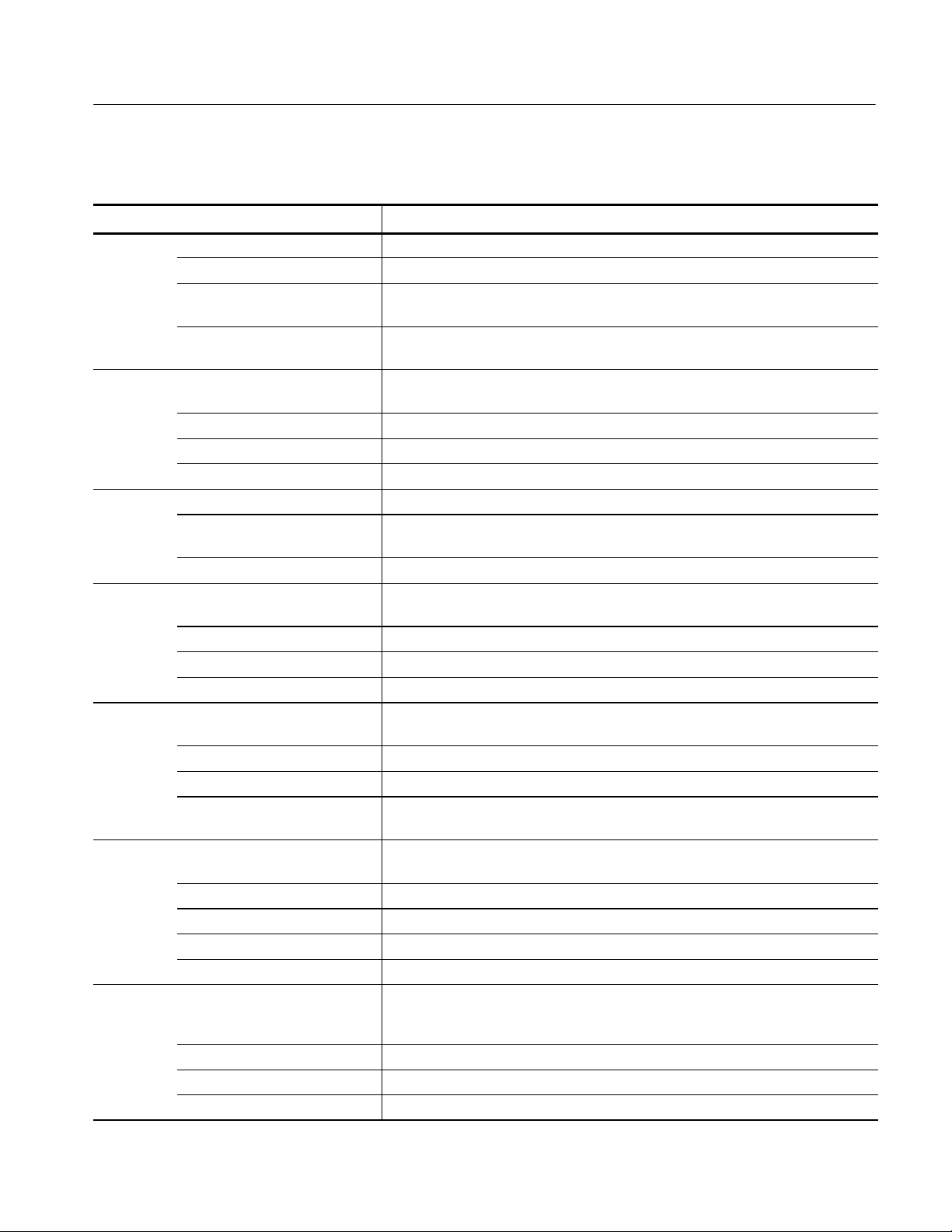

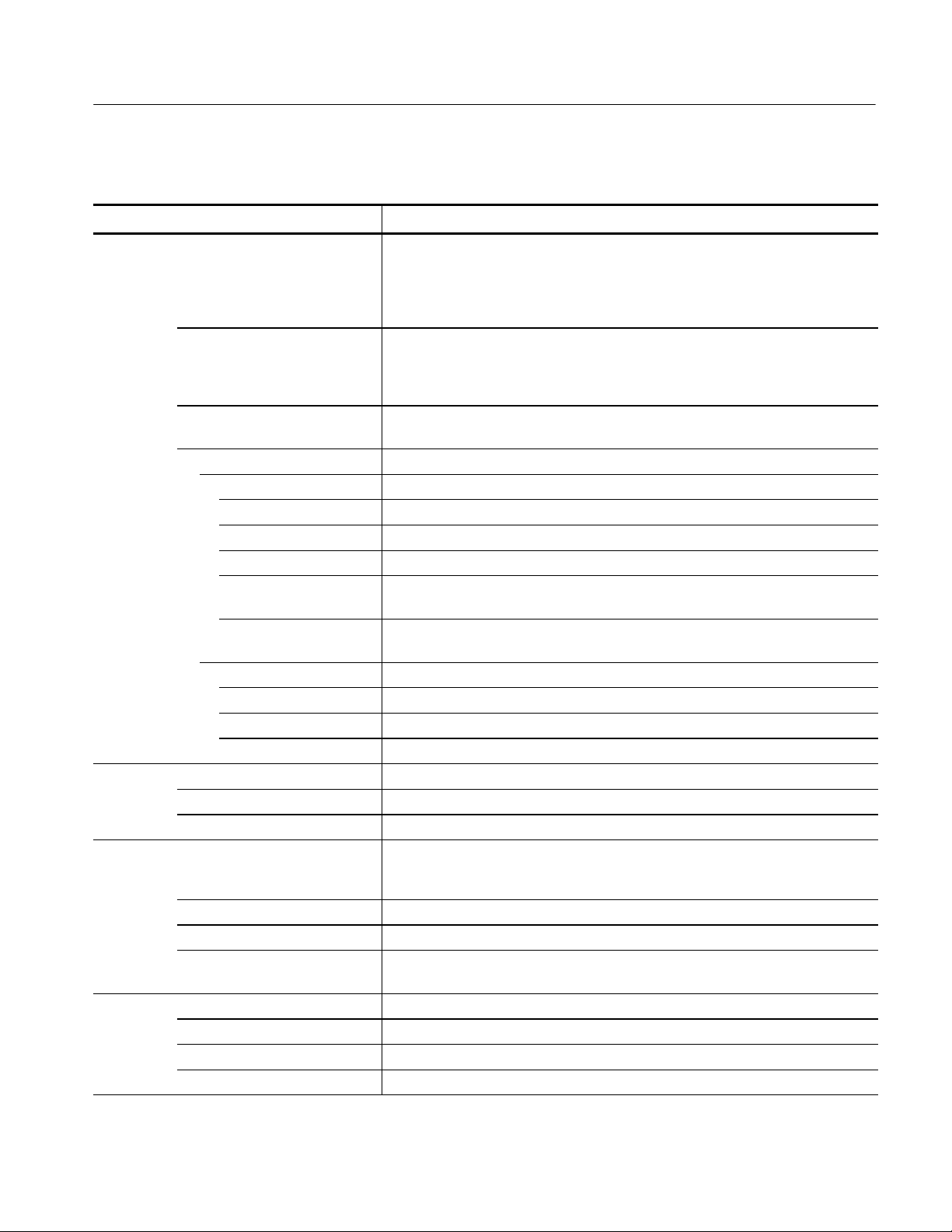

T able 1-1: CA TV Characteristics 1-2............................

Table 1-2: Frequency-Related Characteristics 1-11..................

Table 1-3: Frequency/Amplitude Related Characteristics 1-13........

T able 1-4: Amplitude-Related Characteristics 1-14..................

Table 1-5: Input/Output Signal Characteristics 1-17................

Table 1-6: Power Requirements 1-19.............................

Table 1-7: Supplementary Characteristics Due to Options 1-19.......

T able 1-8: General Characteristics 1-20...........................

Table 1-9: Environmental Characteristics 1-21.....................

Table 1-10: Physical Characteristics 1-22.........................

Table 1-11: Certifications and Compliances 1-23....................

Table 1-12: Safety Certification Compliance 1-24...................

Table 1-13: Safety Standards 1-24................................

Table 3-1: Input and Output Bit Definition 3-21....................

Table 3-2: Mode Control Register 1 3-41..........................

Table 3-3: Mode Control Register 2 3-42..........................

T able 3-4: Truth Table for the B,C-Save A Display Screen

Offset 3-43...............................................

T able 3-5: Truth Table for the Acquisition Modes 3-43..............

Table 3-6: Mode Control Register 2 3-43..........................

Table 3-7: Enhanced Mode MKRWFM[3..2] Bit Assignment 3-44.....

Table 3-8: Enhanced Mode MKRWFM[1..0] Bit Assignment 3-45....

Table 3-9: Display Control Register 3-45..........................

Table 3-10: Scroll Register 3-46..................................

Table 3-11: Memory Map for the Display Storage Board 3-48.........

Table 3-12: Control Register Latch and Tristate Buffer

Reference Designators and Microprocessor I/O Port

Address Location 3-49......................................

Table 3-13: Input Conditions Required to Write Either the

Max or Min Accumulators to Waveform Memory 3-53...........

Table 3-14: Page Number/Waveform Relation 3-55.................

Table 3-15: Interrupt Controller Input Connections 3-63............

Table 3-16: Configuration of Jumpers/Wires for Various

Memory IC Sizes 3-65......................................

Table 3-17: Definition of Software Jumpers 3-66....................

2715 Spectrum Analyzer Service Manual

vii

Page 12

Table of Contents

Table 3-18: Power Supply and Serial Bus Connector (J10)

Signal Names and Definitions 3-68............................

Table 3-19: Microprocessor Interface Connector (J550)

Signal Names and Definitions 3-69............................

T able 3-20: Microprocessor Counter Section Connector

Signal Names and Definitions 3-70............................

Table 3-21: Connectors and Signal Names for the Frequency

Counter Section 3-70.......................................

Table 3-22: Pinout for the 24-Pin DIN Connector (J10) Between the

Microprocessor Board, Power Supply Interconnect,

and Serial I/O 3-71.........................................

Table 3-23: Pinout for the Microprocessor Board Test

Connector (J150) 3-71......................................

Table 3-24: Pinout for the 50 Pin Connector (J550) Between

the Microprocessor, Display Storage, and Digital Options

Boards 3-73...............................................

Table 3-25: Real Time Clock Functions 3-75.......................

Table 4-1: Equipment Required 4-2.............................

Table 4-2: Settings for Shape Factor Check 4-5....................

Table 4-3: Settings for the Noise Sidebands Check 4-7..............

Table 4-4: Front Panel Span Accuracy Settings 4-8................

Table 4-5: Maximum Range in 10 dB/Div 4-11.....................

Table 4-6: Resolution Bandwidth Filter Display Dynamic

Range Settings 4-12........................................

T able 4-7: Sensitivity Settings at 110 MHz 4-13.....................

Table 4-8: Sensitivity Settings at 1800 MHz 4-14....................

T able 4-9: Sensitivity Settings at 2.15 GHz 4-15....................

Table 5-1: Test Equipment 5-2..................................

Table 5-2: Power Supply Tolerances 5-7..........................

Table 5-3: Power Supply Tolerances 5-10..........................

Table 5-4: Correction Bit Values 5-39.............................

Table 5-5: Television Channels 5-40..............................

Table 6-1: Relative Susceptibility to Static Discharge Damage 6-2....

Table 6-2: Cal Debug Messages and Meanings 6-9.................

Table 6-3: Servicing Tools for Boards With Surface

Mounted Components 6-15..................................

viii

2715 Spectrum Analyzer Service Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

2715 Spectrum Analyzer Service Manual

ix

Page 14

General Safety Summary

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

x

CAUTION

Refer to Manual

Double

Insulated

2715 Spectrum Analyzer Service Manual

Page 15

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

2715 Spectrum Analyzer Service Manual

xi

Page 16

Service Safety Summary

xii

2715 Spectrum Analyzer Service Manual

Page 17

Preface

This manual contains service information for the 2715 Spectrum Analyzer. The

service information is located in two volumes. Volume 1 contains the maintenance procedures and parts lists. Volume 2 contains the component locators and

schematic diagrams.

This manual is divided into the following sections.

H Section 1: Specifications, contains characteristic tables detailing Electrical

Characteristics, Mechanical Characteristics, and Environmental Character-

istics.

H Section 2: Operating Information, contains information on how to install and

operate the product.

H Section 3: Theory of Operation, contains both a general and detailed circuit

description of the various modules that make up the instrument.

H Section 4: Performance Verification, is a procedure to ensure, when passed,

that the product operates properly and meets its advertised performance

levels.

H Section 5: Adjustment Procedures, is a procedure to ensure that, when

performed, the product can meet the performance levels for characteristics

listed in Section 1, Specifications.

H Section 6: Maintenance, contains instructions for removal and replacement

of internal modules or components.

H Section 7: Options, describes all options available for this instrument.

H Section 8: Replaceable Electrical Parts, is a list of replaceable assemblies

and electrical components.

H Section 9: Diagrams, Refer to the 2715 Spectrum Analyzer Service Manual

Volume 2.

H Section 10: Replaceable Mechanical Parts, is a list of replaceable assemblies

and mechanical components. Exploded-view illustrations are included to

relate assemblies to the parts list.

The following manuals are also available for the 2715 Spectrum Analyzer.

H 2715 User Manual provides information necessary to operate the 2715

Spectrum Analyzer.

H 2714 & 2715 Programmer Manual includes all GPIB commands, queries,

and responses for the instrument.

H The Cable TV RF Measurement Software Manual describes how to use the

Cable TR RF Measurements Software, a test system that measures cable TV

parameters.

2715 Spectrum Analyzer Service Manual

xiii

Page 18

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

xiv

2715 Spectrum Analyzer Service Manual

Page 19

Specifications

This section lists the electrical, physical, and environmental characteristics of the

spectrum analyzer, specifies the performance requirements for those characteristics, and provides supplementary information.

Electrical Characteristics

Unless otherwise stated, the following tables of electrical characteristics and

features apply to the spectrum analyzer after a 15 minute warm-up period (within

the environmental limits) and after all normalization procedures have been

carried out.

Information in the Performance Requirement column of Tables 1--2 through 1--8

is guaranteed and verifiable unless otherwise noted. Supplemental Information is

intended to further explain a characteristic, its performance requirement, or to

describe characteristic performance that is impractical to verify. Supplemental

Information is not guaranteed and may not be supported by a performance check

procedure.

Changes to a characteristic because of the addition of an option are included in

Table 1--7.

2715 Spectrum Analyzer Service Manual

1- 1

Page 20

Specifications

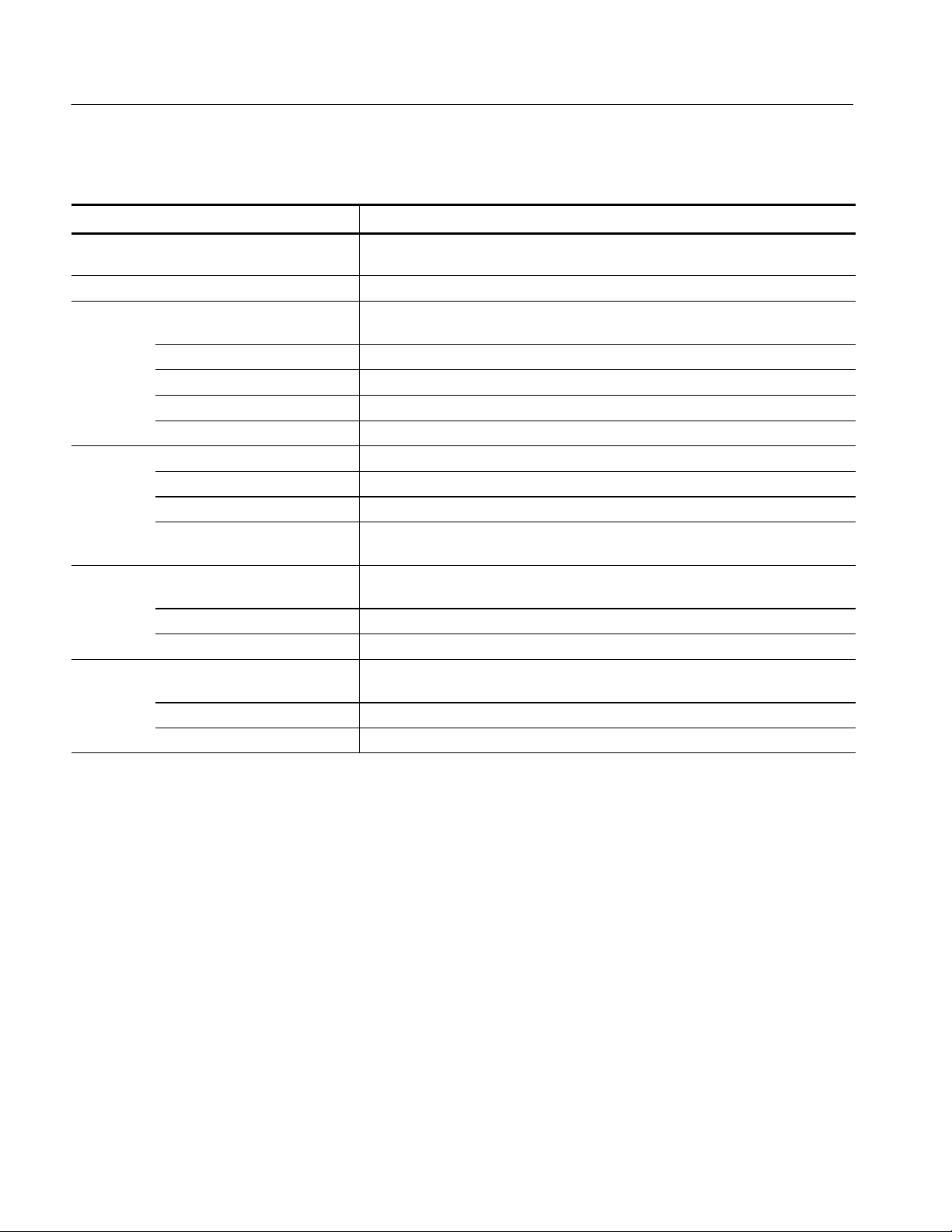

Table 1- 1: CATV Characteristics

Characteristic Description

Input Configuration

All except Option 50 75 Ω Female F connector

Option 50 50 Ω Type N connector

Channel Selection The visual and aural carriers are displayed when the channel number is entered, or

either [ y ] or [ b ] next to [CHAN/FREQ] is pressed

Tune Configuration STD (73.603), HRC (73.605), IRC (73.612), and Custom

Channel Range 0to999

Frequency Range

(except Opt 50 and Opt 75)

Frequency Range

(Opt 50 and Opt 75)

Visual Carrier Frequency

Measurement

Method Internal Counter

Resolution 1Hz

Accuracy 5 × 10-7× Carrier Frequency ±10 Hz, ±1 Least Significant Digit

1

1MHzto1.8GHz2, Preamp limited to 600 MHz

1 MHz to 2.15 GHz2, Preamp limited to 600 MHz

Accuracy is dependent on the accuracy of the spectrum analyzer — see Frequency

Accuracy in Table 1--2.

@ 55.25 MHz (Ch 2) worst case is ±38 Hz

@ 325.25 MHz (Ch 41) worst case is ±173 Hz

@ 643.25 MHz (Ch 94) worst case is ±332 Hz

1

Visual-to-Aural Carrier Frequency Measurement Aural carrier measured relative to the visual carrier

Method Internal Counter

Difference Range 1 MHz to 10 MHz3for an amplitude difference of ≤30 dB and aural C/N ≥15 dB

(300 kHz RBW)

Resolution 1Hz

Accuracy ±15 Hz for visual-to-aural carrier difference ≤8MHz

Visual Carrier Peak Level Measurement Absol ute peak amplitude of visual carrier measured with PREAMP OFF

Accurate Frequency and

Amplitude

Visual carrier frequency measurement

Visual-to-aural carrier frequency measurement

Visual carrier peak level measurement

Visual-to-aural carrier level difference measurement

Accurate Amplitude Only Visual carrier peak level measurement

Visual-to-aural carrier level difference measurement

Fast Amplitude Only Carrier amplitudes are measured using marker values in 10 dB/div vertical scale

Amplitude Range --18 dBmV to +58.8 dBmV4for visual C/N ≥30 dB (300 kHz RBW)

1

Configured using Cable TV RF Measurements Software.

2

Dependent on selected channel table. Frequencies above 1.8 GHz are not supported by the Cable TV RF Measurements

Software.

3

Dependent on selected channel table.

4

Total input power (all signals included) cannot exceed +70 dBmV.

1- 2

2715 Spectrum Analyzer Service Manual

Page 21

Specifications

Table 1- 1: CATV Characteristics (Cont.)

Characteristic Description

Frequency Range 15 to 1015 MHz

Resolution 0.1 dB

Absolute Accuracy ±2.5 dB for visual C/N ≥30 dB (300 kHz RBW) and for FM signal C/N ≥33 dB (100

kHz RBW) assumes flatness corrections are present

Relative Accuracy ±0.5 dB relative to adjacent channel

±1.2 dB relative to all other channels

Visual-to-Aural Carrier Level

Difference Measurement

Difference Range 0 to 30 dB for aural C/N ≥15 dB (300 kHz RBW)

Resolution 0.1 dB

Accuracy ±0.75 dB for aural C/N ≥15 dB (300 kHz RBW)

Averaged Power (Typical) Averaged amplitude measured with preamp off

Accuracy ±2.5 dB for input levels above --30 dBmV, up to +37 dBmV (multichannel) or

Resolution 0.1 dB

Modulation Depth

Measurement (Typical)

AM Range 50% to 95%

Resolution 0.1%

Accuracy ±2% for visual C/N ≥40 dB (300 kHz RBW)

HUM/LFD Measurement (Typical) Power line frequency is measured on an unmodulated visual carrier, and low

AM Range 1% to 10% peak-to-peak

Resolution 0.1%

Accuracy ±1% for Hum ≤5% and visual C/N ≥25 dB (300 kHz RBW)

Carrier-to-Noise (C/N)

Measurement (Typical)

Optimum Input Range See Figure 1--1 on page 1--7

Maximum Range See Figure 1--1 on page 1--7

Resolution 0.3 dB

Accuracy See Figure 1--1 on page 1--7

In-Service C/N (typical) Noise density is measured at 2 MHz offset (by default) from visual carrier during

Optimum Input Range See Figure 1--1 on page 1--7

Maximum Range See Figure 1--1 on page 1--7

Resolution 0.3 dB

Aural carrier level measured relative to the visual carrier

+52 dBmV (preselector in use)

Percent AM measured from sync tip to lowest white level found in 10 sweeps (the

VITS line is used if it is defined in the channel table)

frequency disturbance (LFD) is measured on the modulated carrier

±2% for Hum <10% and visual C/N ≥25 dB (300 kHz RBW)

Default noise floor is a normalized 4 MHz bandwidth measured relative to the visual

carrier peak

quiet lines in the vertical interval, then normalized to 4 MHz BW and expressed as

dBc

2715 Spectrum Analyzer Service Manual

1- 3

Page 22

Specifications

Table 1- 1: CATV Characteristics (Cont.)

Characteristic Description

Accuracy See Figure 1--1 on page 1--7

Desired-to-Undesired Ratio (Typical) Channel averaged power is divided by total noise plus distortion in the channel

Resolution 0.1 dB

Accuracy ±2 dB within the limits shown in Figure 1--6 on page 1--9

CTB Measurement (Typical) Composite triple beat (CTB) is measured relative to the visual carrier peak according

to the NCTA recommended spectrum analyzer settings — SINGLE-SWEEP mode

does not use all the NCTA recommended settings

Maximum Range See Figure 1--2 on page 1--7

Resolution 0.3 dB

Accuracy See Figure 1--2 on page 1--7

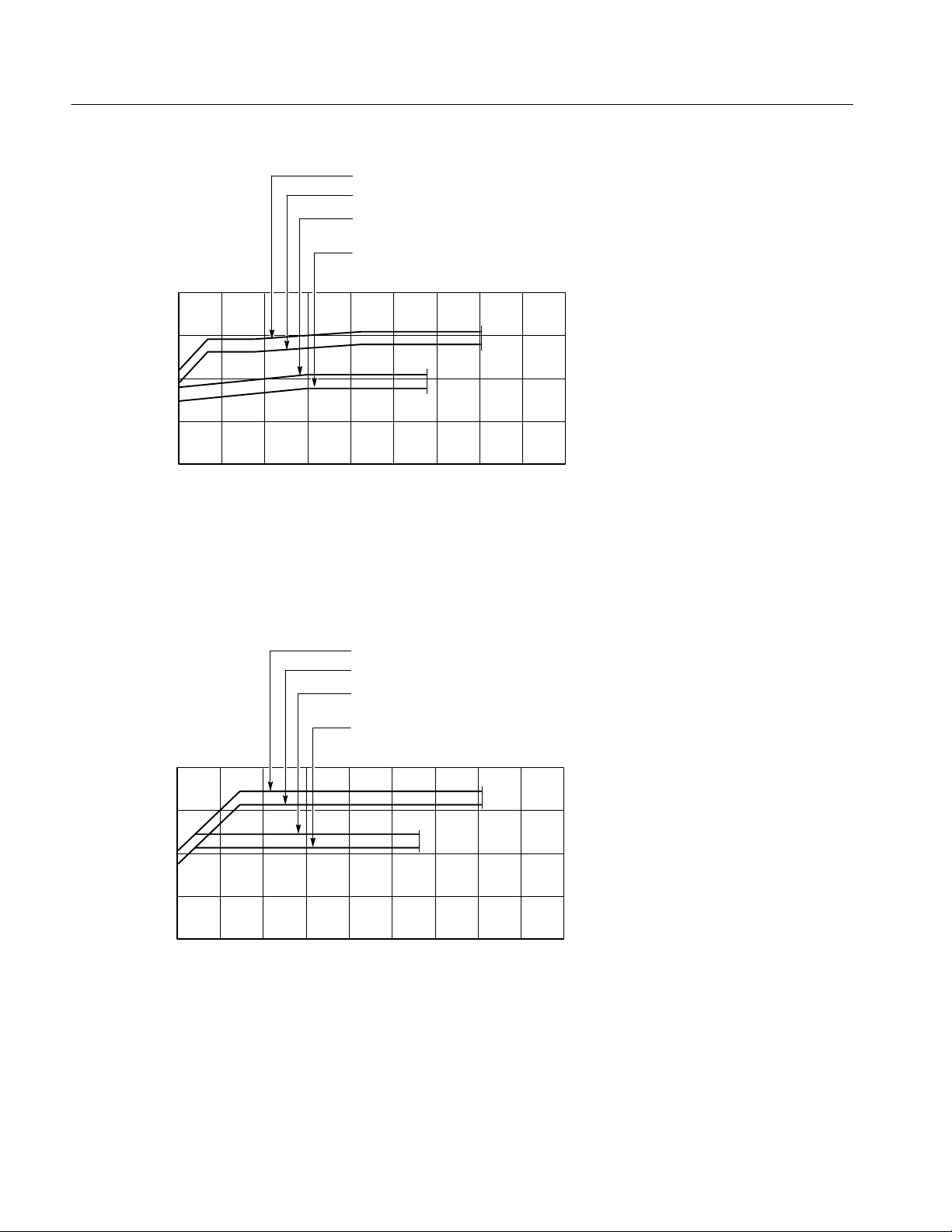

Digital Channel CTB (Typical) Measured relative to the averaged power of the test channel

Resolution 0.3 dB

Accuracy ±2 dB within the limits shown in Figure 1 --8 on page 1 --10

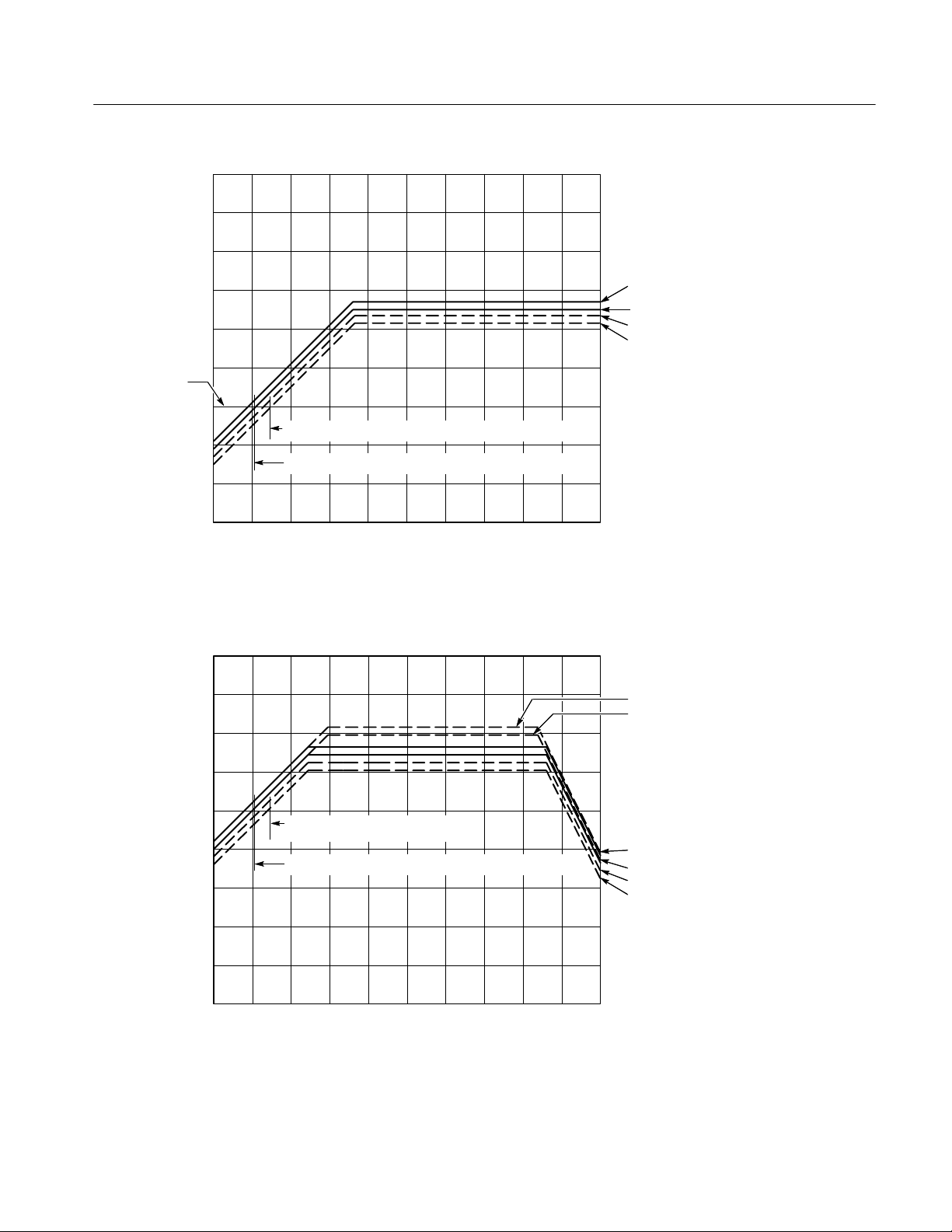

CSO Measurement

(Typical)

Optimum Input Range See Figure 1--3 on page 1--8

Maximum Range See Figure 1--3 on page 1--8

Resolution 0.3 dB

Accuracy See Figure 1--3 on page 1--8

In-Service CSO (Typical) CSO products are measured per NCTA recommendations during quiet lines in the

Optimum Input Range See Figure 1--4 on page 1--8

Maximum Range See Figure 1--4 on page 1--8

Resolution 0.3 dB

Accuracy See Figure 1--4 on page 1--8

Digital Channel CSO (Typical) Measured relative to the averaged power of the test channel

Resolution 0.3 dB

Accuracy ±2.0 dB within the limits shown in Figure 1 --7 on page 1--10

Frequency Response

Measurement (Typical)

Reference Trace Storage

(Nonvolatile)

Range 5 dB/div, fixed

Resolution 0.2 dB

Trace Flatness Accuracy ±0.75 dB

Composite second order (CSO) is measured relative to the visual carrier peak

according to the NCTA recommended spectrum analyzer settings — SINGLESWEEP and CONTINUOUS modes do not use all the NCTA recommended settings

vertical interval, then expressed as dBc

For fixed-amplitude scrambling or no scrambling, system amplitude variations

(flatness) are measured relative to a reference trace (stored during the frequency

response reference setup)

Up to 10 traces with spectrum analyzer states

1- 4

2715 Spectrum Analyzer Service Manual

Page 23

Specifications

Table 1- 1: CATV Characteristics (Cont.)

Characteristic Description

Carrier Survey Absolute peak amplitude of each visual carrier measured and each associated aural

carrier level measured relative to the measured visual carrier for the selected

channels — characteristics are identical to the frequency (visual and aural) and level

measurements (frequency is counted only if ACCURATE FREQUENCY AND AMPL

is on)

Accurate Frequency and

Amplitude

Accurate Amplitude Only Visual carrier peak level measurement

Fast Amplitude Only Carrier amplitudes are measured using marker values in 10 dB/div vertical scale

Visual Carrier

Amplitude Range --18 dBmV to +58.8 dBmV5for C/N ≤30 dB (300 kHz RBW)

Frequency Range 15 MHz to 1015 MHz

Resolution 0.3 dB

Absolute Accuracy ±2.7 dB for visual C/N ≥30 dB (300 kHz RBW) and for FM signal C/N ≥33 dB (100

Relative Accuracy ±0.8 dB relative to adjacent channel

Aural Carrier

Difference Range 0to30dBforC/N≥15 dB (300 kHz RBW)

Resolution 0.3 dB

Accuracy ±1.1 dB for C/N ≥15 dB (300 kHz RBW)

Aural <FM> Deviation (Typical) Peak FM deviation measured for the selected channel

Range 10 kHz to 50 kHz, usable to 80 kHz

Accuracy ±4 kHz

Cross Modulation (Typical) The third order distortion at the horizontal sync frequency (AM) measured on the

Range 48 dB

Resolution 0.1 dB

Accuracy ±2 dB for cross modulation <36 dB

Listen (Typical) The aural carrier for the selected channel is demodulated

Output Speaker or headphones with volume control

Demodulation Type FM

Sweep Displays instantaneous peak FM deviation

5

Total input power (all signals included) cannot exceed +70 dBmV.

Visual carrier frequency measurement

Visual-to-aural carrier frequency measurement

Visual carrier peak level measurement

Visual-to-aural carrier level difference measurement

Visual-to-aural carrier level difference measurement

kHz RBW) assumes flatness corrections are present

±1.5 dB relative to all other channels

unmodulated visual carrier, as corrected to the NCTA recommended synchronous

square wave modulation procedure

±3 dB for cross modulation <48 dB

2715 Spectrum Analyzer Service Manual

1- 5

Page 24

Specifications

Table 1- 1: CATV Characteristics (Cont.)

Characteristic Description

View Picture (Typical) The visual carrier, NTSC or PAL format depending on the selected channel, is

demodulated

View Modulation (Field) (Typical) One video field of the selected channel video is displayed

View Modulation (Line) (Typical) The VITS line is displayed — if no VITS line is specified in the channel table, line 17

is displayed

TV Line Selection Selectable using the FREQ/M KRS knob during View Line Modulation function

Line Format NTSC or PAL

Line Range 1 to 525 (NTSC), 1 to 625 (PAL)

Sweep Time 10 s/div

In-Channel Response

Range ±3 dB (the auto test is run in 1 dB/div)

Resolution 0.1 dB

Accuracy ±0.5 dB, Auto mode

±0.8 dB, Interactive mode

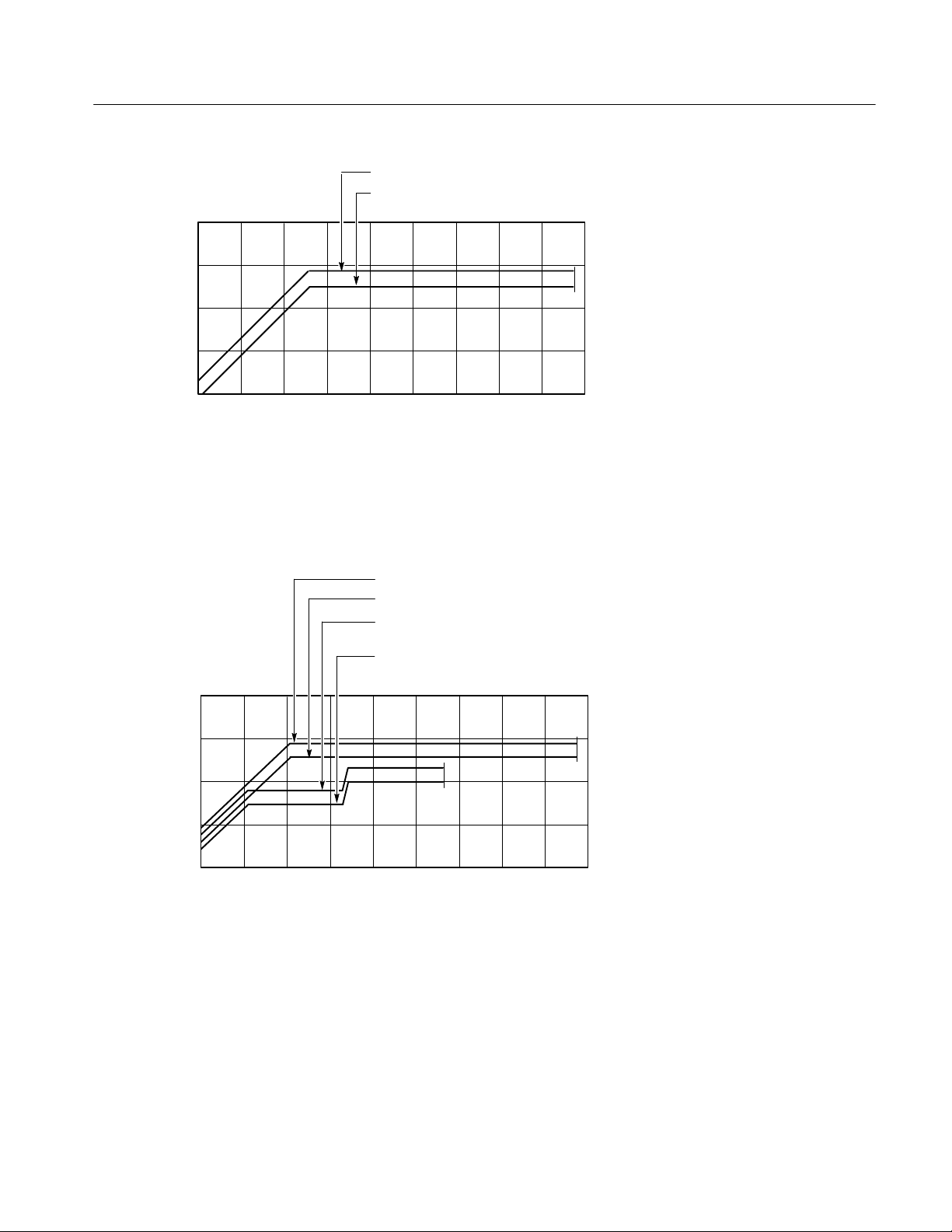

Adjacent Channel Leakage (Typical) Averaged power in adjacent channel(s) is divided by averaged power for the test

channel

Resolution 0.1 dB

Accuracy ±2.0 dB within limits shown in Figure 1--5 on page 1--9

In-Service In-Channel Response (Typical) Standard vertical interval test signal (line sweep, ghost-canceller, multiburst) is

measured within gate which excludes active video; result is expressed as dB P-P

Resolution 0.2 dB

Accuracy ± 0.5 dB assuming test signal is flat at head end

1- 6

2715 Spectrum Analyzer Service Manual

Page 25

-- 9 0

-- 8 0

-- 7 0

Specifications

-- 6 0

Measurement

Minimum C/N

measurements

C/N

Limit (dBc)

for gated

-- 5 0

-- 4 0

-- 3 0

-- 2 0

-- 1 0

Minimum signal level for gated measurement (at 1000 MHz)

Minimum signal level for gated measurement (to 500 MHz)

0

-- 2 0

-- 3 0

--100 102030 4050 6070

VISUAL CARRIER PEAK (dBmV)

Figure 1- 1: Typical Accuracy Limits for Carrier-to-Noise Measurement

-- 9 0

-- 8 0

-- 7 0

± 4dBto500MHz

± 2dBto500MHz

± 4 dB at 1000 MHz

± 2 dB at 1000 MHz

Note: 60 channel

flat system

± 4dBto500MHz(Note1)

± 2dBto500MHz(Note1)

-- 6 0

CTB

Measurement

Limit (dBc)

-- 5 0

-- 4 0

-- 3 0

-- 2 0

-- 1 0

Minimum signal level for gated

measurement (at 1000 MHz)

Minimum signal level for gated measurement (to 500 MHz)

0

-- 2 0

-- 3 0

--100 102030 4050 6070

VISUAL CARRIER PEAK (dBmV)

Figure 1- 2: Typical Accuracy Limits for CTB Measurem ent

2715 Spectrum Analyzer Service Manual

± 4dBto500MHz(Note2)

± 2dBto500MHz(Note2)

± 4 dB at 1000 MHz (Note 2)

± 2 dB at 1000 MHz (Note 2)

Note 1

Approximate extended limits if

preselector is used and mixer input

level is set to --20 dBm.

Note 2

Normal limits without preselector and

mixer input level set to default setting

of --30 dBm in a 60 channel flat

system.

1- 7

Page 26

Specifications

-- 9 0

-- 8 0

-- 7 0

-- 6 0

CSO

Measurement

Limit (dBc)

-- 5 0

-- 4 0

-- 3 0

-- 2 0

-- 1 0

Minimum signal level for gated

measurement (at 1000 MHz)

Minimum signal level for gated measurement (to 500 MHz)

0

-- 2 0

-- 3 0

--100 102030 40506070

VISUAL CARRIER PEAK (dBmV)

Figure 1- 3: Typical Accuracy Limits for Nongated CSO Measurement

-- 9 0

-- 8 0

-- 7 0

± 4dBto500MHz(Note1)

± 2dBto500MHz(Note1)

± 4dBto500MHz(Note2)

± 2dBto500MHz(Note2)

± 4 dB at 1000 MHz (Note 2)

± 2 dB at 1000 MHz (Note 2)

Note 1

Approximate extended limits if

preselector is used and mixer

input level is set to --20 dBm.

Note 2

Normal limits without preselector

and mixer input level set to default

setting of --30 dBm. in a 60 channel

flat system

-- 6 0

CSO

Measurement

Limit (dBc)

-- 5 0

-- 4 0

-- 3 0

-- 2 0

-- 1 0

Minimum signal level for gated

measurement (at 1000 MHz)

Minimum signal level for gated measurement (to 500 MHz)

0

-- 2 0

-- 3 0

--100 102030 40506070

VISUAL CARRIER PEAK (dBmV)

Figure 1- 4: Typical Accuracy Limits for Gated CSO Measurement

1- 8

± 4dBto500MHz(Note1)

± 2dBto500MHz(Note1)

± 4dBto500MHz(Note2)

± 2dBto500MHz(Note2)

± 4 dB at 1000 MHz (Note 2)

± 2 dB at 1000 MHz (Note 2)

Note 1

Approximate extended limits if

preselector is used and mixer

input level is set to --20 dBm.

Note 2

Normal limits without preselector

and mixer input level set to default

setting of --30 dBm in a 60 channel

flat system.

2715 Spectrum Analyzer Service Manual

Page 27

-- 6 5

-- 5 5

Specifications

To 500 MHz

500 MHz to 1000 MHz

Measurement

Limit (dBc)

-- 4 5

-- 3 5

-- 2 5

-- 2 0

--10 0 1020 30 40 506070

INPUT LEVEL (dBmV) FOR SINGLE-SIGNAL TEST ENVIRONMENT

Figure 1- 5: Typical ACL Measurement Limits for 2 dB Accuracy

To 500 MHz using preselector

500 MHz to 1000 MHz using preselector

To 500 MHz in 60-channel flat system dominated by analog signals

10 dB stronger than average power of channel under test

500 MHz to 1000 MHz in 60-channel flat system dominated by analog

signals 10 dB stronger than average power of channel under test

65

55

Measurement

Limit (dB)

45

35

25

-- 2 0

--10 0 1020 30 40 506070

CHANNEL UNDER TEST INPUT LEVEL (dBmV)

Figure 1- 6: Typical D/U Measurement Range Limits for 2 dB Accuracy

2715 Spectrum Analyzer Service Manual

1- 9

Page 28

Specifications

To 500 MHz using preselector

500 MHz to 1000 MHz using preselector

To 500 MHz in 60-channel flat system dominated by analog signals

10 dB stronger than average power of channel under test

500 MHz to 1000 MHz in 60-channel flat system dominated by analog

signals 10 dB stronger than average power of channel under test

-- 6 5

-- 5 5

Measurement

Limit (dBc)

-- 4 5

-- 3 5

-- 2 5

-- 2 0

--10 0 1020 30 40 506070

INPUT LEVEL (dBmV)

Figure 1- 7: Typical Digital Signal CSO Measurement Range Limit for 2 dB Accuracy

To 500 MHz using preselector

500 MHz to 1000 MHz using preselector

To 500 MHz in 60-channel flat system dominated by analog signals

10 dB stronger than average power of channel under test

500 MHz to 1000 MHz in 60-channel flat system dominated by analog

signals 10 dB stronger than average power of channel under test

-- 6 5

-- 5 5

Measurement

Limit (dBc)

-- 4 5

-- 3 5

-- 2 5

-- 2 0

--10 0 1020 30 40 506070

INPUT LEVEL (dBmV)

Figure 1- 8: Typical Digital Signal CTB Measurement Range Limit for 2 dB Accuracy

1- 10

2715 Spectrum Analyzer Service Manual

Page 29

Specifications

Table 1- 2: Frequency-Related Characteristics

Characteristic Performance Requirement Supplemental Information

Channel Tuned with keypad, [CHAN/FREQ] [ y ],

or [CHAN/FREQ] [ b ],accordingtothe

selected channel table

Frequency

Range All except Option 50 and Option 75:

9 kHz to 1.8 GHz

Option 50 and Option 75: 9 kHz to

2.15 GHz

Accuracy 5 × 10

Drift

Long Term (One Year) ±2 PPM/year

Short Term (SPAN/DIV ≤20 kHz) All except Option 50 and Option 75:

Readout Resolution 1 kHz or 1 Hz (counter readout), menu

Frequency Span/Div

Range Using

Accuracy/Linearity Within 3% Measured over the center 8 divisions

Flatness

(Relative to the Reference Level at 100 MHz)

-- 7

of center frequency ±10 Hz ±1

least significant digit

≤400 Hz up to 1.8 GHz

Option 50 and Option 75: 500 Hz above

1.8 GHz

All instruments:

±2dB9KHzto1.8GHz

Option 50 and Option 75: ±3 dB above

1.8 GHz

Tuned with keypad, [CHAN/FREQ] [ y ],

[CHAN/FREQ] [ b ], FREQ/MARKERS

knob, UTIL menu, or MKR/FREQ menu

Assumes zero drift since last

normalization procedure

With frequency corrections enabled

selectable

[SPAN/DIV] [ y ] and [SPAN/DIV] [ b ]

buttons, selections in a 1--2--5 sequence

Using the keypad or UTIL menu,

select any value from

100 MHz/div to 1 kHz/div.

In MAXSPAN,

180 MHz/div (All except Option 50 and

Option 75) or

215 MHz/div (Option 50 and Option 75)

In ZERO SPAN, 0 Hz/div

Measured with 10 dB of RF Attenuation

and PREAMP off

Flatness is affected by:

H Input voltage standing-wave ratio

(VSWR)

H Gain variation

H Mixer conversion

2715 Spectrum Analyzer Service Manual

1- 11

Page 30

Specifications

Table 1- 2: Frequency-Related Characteristics (Cont.)

Characteristic Supplemental InformationPerformance Requirement

Residual FM

With SPAN/DIV ≤20 kHz All except Option 50 and Option 75:

≤100 Hz peak-to-peak total excursion in

20 ms up to 1.8 GHz

Option 50 and Option 75: ≤120 Hz

peak-to-peak total excursion in 20 ms

(above 1.8 GHz)

With SPAN/DIV >20 kHz All except Option 50 and Option 75:

≤2 kHz peak-to-peak total excursion in

20 ms up to 1.8 GHz

Option 50 and Option 75: ≤2.4 KHz

peak-to-peak total excursion in 20 ms

above 1.8 GHz

Resolution Bandwidth (6 dB down) Resolution bandwidth selections are:

Shape Factor (60 dB/6 dB) 7:1 or less for all resolution bandwidths

≤1MHz

Noise Sidebands All except Option 50 and Option 75:

≤--70 dBc at 30X Resolution Bandwidth

for all resolution bandwidths ≤100 kHz

Option 50 and Option 75: ≤–69 dBc at

30X Resolution Bandwidth for all

resolution bandwidths ≤100 kHz

Video Filter Reduces video bandwidth to about 1% of

Short term, after 1 hr warm-up, and with

PHASELOCK in AUTO mode

5 MHz, 1 MHz, 300 kHz, 100 kHz,

30 kHz, 10 kHz, 3 kHz, 1 kHz, and

300 Hz for the spectrum analyzer

the selected resolution bandwidth; or one

of 12 video filters (3 Hz, 10 Hz, 30 Hz,

100 Hz, 300 Hz, 1 kHz, 3 kHz, 10 kHz,

30 kHz, 100 kHz, 300 kHz, or WIDE) can

be selected from the UTIL menu

1- 12

2715 Spectrum Analyzer Service Manual

Page 31

Specifications

Table 1- 2: Frequency-Related Characteristics (Cont.)

Characteristic Supplemental InformationPerformance Requirement

Resolution Bandwidth (6 dB down) Resolution bandwidth selections are:

5 MHz, 1 MHz, 300 kHz, 100 kHz,

30 kHz, 10 kHz, 3 kHz, 1 kHz, and

300 Hz for the spectrum analyzer

Shape Factor (60 dB/6 dB) 7:1 or less for all resolution bandwidths

≤1MHz

Noise Sidebands ≤--70 dBc at 30X Resolution Bandwidth

for all resolution bandwidths ≤100 kHz

Video Filter Reduces video bandwidth to about 1% of

the selected resolution bandwidth; or one

of 12 video filters (3 Hz, 10 Hz, 30 Hz,

100 Hz, 300 Hz, 1 kHz, 3 kHz, 10 kHz,

30 kHz, 100 kHz, 300 kHz, or WIDE) can

be selected from the UTIL menu

Table 1- 3: Frequency/Amplitude Related Characteristics

Characteristic Performance Requirement Supplemental Information

Marker The frequency and amplitude values of

the marker position are displayed and

are preceded by the letter M

[MKR] [ ' ] and [MKR] [ a ] position the

marker to the next right or left signal

peak, respectively

Accuracy

Frequency Same as SPAN/DIV

Amplitude A function of the reference level, vertical

scale factor, and normalizations (see

Display Dynamic Range on page 1--15)

Also, flatness corrections while in CATV

mode for range of 15 MHz to 1.105 GHz

Delta Marker When activated, a second marker is

displayed at the same frequency as the

first marker. This is the “Reference

Marker”

Accuracy

Frequency 1 PPM ±10 Hz of the higher marker

frequency

Amplitude Same as Marker

The FREQ/MARKERS control may be

used to position the first marker; the

frequency and amplitude differences

between markers are readouts preceded

by the letter D

With both signals counted

2715 Spectrum Analyzer Service Manual

1- 13

Page 32

Specifications

Table 1- 3: Frequency/Amplitude Related Characteristics (Cont.)

Characteristic Supplemental InformationPerformance Requirement

Center Measure When activated, the signal nearest

center screen (or nearest marker if

marker is on) and above a preset

threshold level, is moved to center

screen

The frequency and amplitude values are

preceded by the letter C

Readout Resolution 1 kHz or 1 Hz Readout resolution is selectable

Signal Tracking When activated, the centered signal is

held at center screen

Signal tracking requires a signal strength

greater than the threshold level

If the strength of a signal being tracked

decreases below the threshold level, the

instrument displays the message NO

SIGNAL FOUND ABOVE THRESHOLD

Table 1- 4: Amplitude-Related Characteristics

Characteristic Performance Requirement Supplemental Information

Vertical Display Mode 10 dB/div, 5 dB/div, 1 dB/div, and Linear

Reference Level

Range Top of g r a t icul e

Log Mode --21.2 dBmV to +68.8 dBmV

(--41.2dBmVto+48.8dBmVwiththe

PREAMP enabled)

Linear Mode 10.83 V/div to 342.33 mV/div

(1.08 nV div to 34.23 mV/div with the

PREAMP enabled)

Steps

Log Mode 1dBor10dB

Linear Mode 1--2--5 sequence: 10.83 V/div to

342.33 mV/div

FINE REF LVL STEP Activated ≥0.2 division per increment

Accuracy Dependent on:

H Normalizations

H Calibrator accuracy

H Frequency response

1- 14

2715 Spectrum Analyzer Service Manual

Page 33

Table 1- 4: Amplitude-Related Characteristics (Cont.)

Characteristic Supplemental InformationPerformance Requirement

Specifications

Display Dynamic Range

Accuracy

10 dB/div Mode ±1.0 dB/10 dB to a maximum cumulative

5 dB/div Mode ±1.0 dB/10 dB to a maximum cumulative

1 dB/div Mode ±1 dB m aximum error over the 8 dB range

Linear Mode ±5% of full scale

RF Attenuator Range 0to50dBin2dBsteps

All except Option 50 and Option 75:

80 dB maximum (Log)

8 divisions (Linear)

error of ±2.0 dB over the 70 dB range and

a maximum cumulative error of ±4.0 dB

over the 80 dB range

error of ±2.0 dB over the 40 dB range

Log Mode Display Dynamic Range is

dependent upon the selected Resolution Bandwidth.

The accuracy specifications apply for

amplitude measurements done with the

marker only, since marker measurements are corrected for logging errors.

Option 50 and Option 75:

Baseline will rise to indicated value,

typically 10 dB to 20 dB below signal

level applied near frequency of

2.11 GHz.

Display Dynamic Range is reduced if

there is signal energy at or near

2.11 GHz.

10 dB/div accuracy and range is

affected by the signal-to-noise ratio of

the selected Resolution Bandwidth

filter. See following table for maximum

specified range.

Resolution

Bandwidth dB Down

5MHz 40

1MHz 40

300 kHz 50

100 kHz 50

30 kHz 60

10 kHz 60

3 kHz 80

1 kHz 80

300 Hz 80

2715 Spectrum Analyzer Service Manual

1- 15

Page 34

Specifications

q

p

1.8GHzrefertotheOption50and

Abov

fromapproximately10MHzto9kHz.

y

y

p

600MHz.

Table 1- 4: Amplitude-Related Characteristics (Cont.)

Characteristic Supplemental InformationPerformance Requirement

Sensitivity without Preamp Equivalent maximum input noise for

Resolution Bandwidth @110 MHz @ 1.8 GHz @ 2.15 GHz*

5MHz --36 dBmV --28 dBmV –26 dBmV

(--85 dBm) (--77 dBm) –75 dBm)

1MHz --43 dBmV --35 dBmV –33 dBmV

(--92 dBm) (--84 dBm) –82 dBm)

300 kHz --48 dBmV --40 dBmV –38 dBmV

(--97 dBm) (--89 dBm) –87 dBm)

100 kHz --53 dBmV --45 dBmV –43 dBmV

(--102 dBm) (--94 dBm) –92 dBm)

30 kHz --58 dBmV --50 dBmV –48 dBmV

(--107 dBm) (--99 dBm) –97 dBm)

10 kHz --63 dBmV --55 dBmV –53 dBmV

(--112 dBm) (--104 dBm) –102 dBm)

3 kHz --68 dBmV --60 dBmV –58 dBmV

(--117 dBm) (--109 dBm) –107 dBm)

1 kHz --73 dBmV --65 dBmV –63 dBmV

(--122 dBm) (--114 dBm) –112 dBm)

300 Hz --78 dBmV --70 dBmV –68 dBmV

(--127 dBm) (--119 dBm) –117 dBm)

Sensitivity with Preamp NOTE. Sensitivity with the Preamp

Resolution Bandwidth @110 MHz @ 1.8 GHz and 2.15 GHz

5MHz --48 dBmV Not Specified

(--95 dBm)

1MHz --55 dBmV Not Specified

(--104 dBm)

300 kHz --60 dBmV Not Specified

(--109 dBm)

100 kHz --65 dBmV Not Specified

(--114 dBm)

30 kHz --70 dBmV Not Specified

(--119 dBm)

10 kHz --75 dBmV Not Specified

(--124 dBm)

3 kHz --80 dBmV Not Specified

(--129 dBm)

1 kHz --85 dBmV Not Specified

(--134 dBm)

300 Hz --90 dBmV Not Specified

(--139 dBm)

each resolution bandwidth.

*Performance measurements above

1.8 GHz refer to the Option 50 and

Option 75 instruments only.

Sensitivity decreases linearly approximately 8 dB from 9 KHz to 1.8 GHz.

e 1.8 GHz sensitivitydecreases

linearly approximately 10 dB.

NOTE: Sensitivity degrades as the

FREQUENCY setting is decreased

Maximum loss in sensitivity is approximately 20 dB.

enabled is not specified above

1- 16

2715 Spectrum Analyzer Service Manual

Page 35

Specifications

Table 1- 4: Amplitude-Related Characteristics (Cont.)

Characteristic Supplemental InformationPerformance Requirement

Spurious Responses

Residual (no input signal) All except Option 50 and Option 75:

≤ --51 dBmV (≤--100 dBm) except at

1780 MHz where the spurious response is

≤--41 dBmV (≤--90 dBm).

Option 50 and Option 75: ≤--26 dBmV

(≤--75 dBm) at 2.0 GHz.

3rdOrder IM (Intermodulation) Products All except Option 50 and Option 75: ≤-- 7 0

dBcupto1.8GHz

Zero Frequency Spur ≤+39 dBmV (≤--10 dBm) Referenced to input with 0 dB RF

2ndHarmonic Distortion ≤--66 dBc Measured with 1stmixer input level of

LO (Local Oscillator) Emission All except Option 50 and Option 75: ≤ -- 7 0

≤--21 dBmV (≤--70 dBm)

With 0 dB RF attenuation

From any two on-screen signals within

any frequency span

Option 50 and Option 75:

Typically ≤--65 dBc at 2.15 GHz

attenuation

≤+9 dBmV

With 0 dB RF attenuation and preamp

off.

Option 50 and Option 75:

When frequency is below 90 MHz:

Typically <+29 dBmV (–20 dBm)

When frequency is above 350 MHz:

Typically ≤--21 dBmV (≤--70 dBm)

Table 1- 5: Input/Output Signal Characteristics

Characteristic Performance Requirement Supplemental Information

RF Input Type F male connector or

type N female connector

VSWR with RF Attenuation ≥10 dB 1.5:1 maximum Checked to 1 GHz

VSWR with 0 dB RF Attenuation All except Option 50 and Option 75:

2:1maximumupto1GHz

3.5:1 maximum up to 1.8 GHz

Option 50 and Option 75:

4:1maximumupto2.15GHz

Maximum Safe Input +70 dBmV (0.1 W or 2.2 V) continuous

peak

100 VDC blocking capacitor

Caution: Do not apply more than

100 VDC or 100V peak AC to the RF

Input

1 dB Compression Point (minimum) +34 dBmV (--15 dBm) With no RF Attenuation and 1stmixer at

+19 dBmV (--30 dBm )

2715 Spectrum Analyzer Service Manual

1- 17

Page 36

Specifications

Table 1- 5: Input/Output Signal Characteristics (Cont.)

Characteristic Supplemental InformationPerformance Requirement

Ext Trig (J102) BNC connector, 10 kΩ, DC coupled for

external trigger signals

Voltage Range

Minimum Typically at least 100 mV

1MHz

Maximum 50 V (DC + peak AC)

Pulse Width 0.1 s minimum

Accessory Connector (J103) DB-15 female connector

Pin 1: External Video Input Typically 100 ohm, DC coupled, 0 -

50 kHz, 0 -- 1.6 V (200 mV/div) signal

input for vertical deflection of the CRT

beam. The signal is processed through

the video filters and the 1 dB, 5 dB, and

10 dB scale factor circuits on the Log

board. Display storage may be bypassed.

Pin 2: Sweep Gate

+2.0 V minimum (high)

0.8 V maximum (low)

TTL-compatible signal that goes to a

logic high level while the CRT beam is

sweeping.

Pin 3: Chassis and Signal Ground

Pin 4: Sweep Output

+1.3 V

-- 1 . 3 V

Provides a nominal +1.3 V to --1.3 V

negative-going ramp, proportional to the

horizontal sweep (output impedance

≤50 Ω).

Pin 5: Log Video Output Provides 0 V to +1.6 V of video signal,

inversely proportional to the vertical

display amplitude. 0 V is the top of the

screen. Impedance is 1 kΩ.

Pin 6: CLK0 Output Clock output to Option 05 (External

Tracking Generator). CMOS logic levels

typically +3.5 V high, +1.5 V low.

Pin 7: Data I Input Data input from Option 05 (External

Tracking Generator). Typically +5 V high,

+0.1 V low.

Pin 8: Data O Output Data output to Option 05 (External

Tracking Generator). CMOS logic levels,

typically +3.5 V high, +1.5 V low.

Pin 9: ~EXTGLATCH Logic output to Option 05 (External

Tracking Generator). CMOS logic levels,

typically +3.5 V high, +1.5 V low.

Pin 10: 26.38 MHz Input Input from Option 05 (External Tracking

Generator); typically a 0.5 V

centered at +3.7 VDC.

,15Hzto

peak

p-p

sine wave

1- 18

2715 Spectrum Analyzer Service Manual

Page 37

Specifications

Table 1- 5: Input/Output Signal Characteristics (Cont.)

Characteristic Supplemental InformationPerformance Requirement

Pin 11: VLVL Output DC output to Option 05 (External

Tracking Generator); typically 9.5 V

with TG level set to ON.

Pin 12: SWPSLOPE Output Negative going ramp output to Option 05

(External Tracking Generator); typically

5 V with analyzer set to max span.

Pins 13 through 15 Not used

Digital Communications Port (J104) RS-232 or GPIB connector

Table 1- 6: Power Requirements

Characteristic Performance Requirement Supplemental Information

Input Voltage

Line Voltage Range 90 VAC to 250 VAC

Line Frequency Range 48 Hz to 63 Hz

Line Voltage Range 90 VAC to 132 VAC

Line Frequency Range 48 Hz to 440 Hz

Line Fuse 2ASlow-Blow

Input Power 90 W (1.2 A) for standard instrument

105 W (1.4 A) maximum with options

(115 W maximum at 90 V and 440 Hz)

Leakage Current 3.5 mA

At 115 V and 60 Hz

maximum or 5 mA

RMS

maximum

peak

Table 1- 7: Supplementary Characteristics Due to Options

Characteristic Performance Requirement Supplemental Information

Option 03 Provides a GPIB interface port at J104 to

replace RS-232

Option 08 Provides a RS-232 serial interface port at

J104 to replace GPIB

Option 15 Adda1stLO output

1stLO Output Level ≥+48.8 dBmV (≥0.0 dBm) At spectrum analyzer frequencies

≥100 kHz

2715 Spectrum Analyzer Service Manual

1- 19

Page 38

Specifications

Table 1- 8: General Characteristics

Characteristic Performance Requirement Supplemental Information

Sweep Normal, Single Sweep, and Manual Scan

Sweep Rate 1 s/div to 2 s/div in a 1--2--5 sequence

Accuracy ±10% over the center 8 divisions

Triggering Free Run, Internal, External, Line,

TV Line, and TV Field

Internal Trigger Level 1 division or more of signal

External Trigger Level See EXT TRIG in Table 1--5

Nonvolatile Memory (Battery-Backed Up) Instrument settings, waveforms, and

normalization results are stored in

NVRAM

Battery Life (Lithium)

At +55_ C Ambient Temperature 1to2years

At +25_ C Ambient Temperature At least 5 years

Temperature Range for Retaining Data -- 1 0 _ Cto+75_ C

Internal Calibrator Provides 100 MHz marker for amplitude

calibration and comb of 100 MHz

markers for frequency and span calibration

Amplitude and Accuracy +18.8 dBmV (--30 dBm), ±0.3 dB, at

100 MHz, ±2 kHz

Drift ±2 PPM/year

IF Gate Rise and Fall Times 7 s nominal

Off Isolation >60dB

1- 20

2715 Spectrum Analyzer Service Manual

Page 39

Specifications

Table 1- 9: Environmental Characteristics

Characteristic Description

The Description column describes how most characteristics were derived and a description of the characteristic. This instrument meets

MIL-T-28800E, Type III, Class 5, Style C Specifications.

Electromagnetic Interference (EMI)

Emissions: EN50081--1 Radiated Emissions, 30 MHz--1 GHz

EN55022 Class B (CISPR 22B)

Conducted Emissions, 150 kHz--30 MHz

EN55022 Class B (CISPR 22B)

Conducted Emissions, Power Line Harmonics, 0--2 kHZ

IEC 555-2/3

Immunity: EN50082--1 Electrostatic Discharge, 8 kV

IEC 801-2

Radiated Immunity, 27 MHz--500 MHz

IEC 801-3

Performance Requirement:

No responses above --90 dBm ina3V/meterfield

Fast Transients, Capacitive Clamp, 1 kV Power Leads,

500 V Control Leads

IEC 801-4

Power Line Surge, 1 kV Differential Mode,

2kVcommonmode

IEC 801-5

Temperature

Operating 0_ Cto+50_ C

Nonoperating

1

-- 5 5 _ Cto+75_ C

2

Humidity

Operating 95% RH ± 5% + 30_ C and below

75% RH ± 5% + 31_ C through + 40_ C

45% RH ± 5% + 41_ C through + 50_ C

Nonoperating Five cycles (120 hours) in accordance with MIL-STD-28800E, class 5

Altitude

Operating 15,000 ft (4.57 km)

Nonoperating 50,000 ft (15.24 km)

1

After storage at temperatures below - 15_ C, the instrument may not reset when power is first turned on. If this happens,

allow the instrument to warm up for at least 15 minutes, then turn power off for 5 seconds an back on.

2

NVRAM is lost below - 10_ C.

2715 Spectrum Analyzer Service Manual

1- 21

Page 40

Specifications

Table 1- 9: Environmental Characteristics (Cont.)

Characteristic Descri pti on

Vibration

Operating

(Instrument secured to a vibration

platform during test)

Shock (Operating and Nonoperating) Three guillotine-type shocks of 30 g, one-half sine, 11 ms duration each direction

Transit Drop (Free Fall) 8 in (203.2 mm), one per each of 5 faces and 4 corners (instrument is tested and

MIL-T-28800E, Method 514 Procedure X (modified) 15 minutes along each of 3

major axes at a total displacement of 0.015 in (0.38 mm) peak-to-peak (2.4 g at

55 Hz), with frequency varied from 10 Hz to 55 Hz in 1-minute sweeps

Hold for 10 minutes at 55 Hz

All major resonances must be above 55 Hz (resonance is defined as an excursion

greater than 2X the input displacement)

along each major axis, total of 18 shocks; no drops allowed on the front surface and

front corners

meets drop height of 12 in (304.8 mm)

Table 1- 10: Physical Characteristics

Characteristic Performance Requirement

Weight

With Standard Accessories 25 lbs (11.34 kg)

Without Standard Accessories 22.5 lbs (10.21 kg)

Dimensions

Height with Feet and Handle 5.4 in (137.16 mm)

Width

With Handle 14.2 in (360.68 mm)

Without Handle 12.9 in (327.66 mm)

Depth

With Front Panel Cover 17.5 in (444.50 mm)

Without Front Panel Cover 16.85 in (427.99 mm)

With Handle Extended 20.1 in (510.54 mm)

1- 22

2715 Spectrum Analyzer Service Manual

Page 41

Table 1- 11: Certifications and Compliances

Category Description

Specifications

EC Declaration of Conformity -EMC

EC Declaration of Conformity -Low Voltage

Approvals UL1244 -- Standard for Electrical and Electronic Measuring and Testing Equipment

Installation Category Descriptions Terminals on this product may have different installation category designations. The installation

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

IEC 801-5 Power Line Surge Immunity

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Low Voltage Directive 73/23/EEC

EN 61010-1:1993 Safety requirements for electrical equipment for measurement,

control, and laboratory use

CAN/CSA C22.2 No. 231 – Safety Requirements for Electrical and Electronic Measuring and

Testing Equipment

categories are:

CAT III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location

CAT II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected

CAT I Secondary (signal level) or battery operated circuits of electronic equipment

2715 Spectrum Analyzer Service Manual

1- 23

Page 42

Specifications

Table 1- 12: Safety Certification Com pliance

Category Description

Temperature (operating) +5° Cto+50° C

Altitude (maximum operating) 2000 meters (6562 ft.)

Relative Humidity (maximum operating)

Equipment Type Test and Measuring

Safety Class Class I (as defined in IEC 1010-1, Annex H)—grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 1010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 1010-1)

80% for temperatures up to 31° C, decreasing linearly to 50% at 40° C

Note: Rated for indoor use only.

Table 1- 13: Safety Standards

Category

U.S. Nationally Recognized

Testing Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 231 – Safety Requirements for Electrical and Electronic Measuring and Test

European Union Compliance Low Voltage Directive 73/23/EEC, as Amended by 93/68/EEC

Additional Compliance UL3 111-1 – Standard for Electrical Measuring and Test Equipment

UL1244 -- Standard for Electrical and Electronic Measuring and Testing Equipment

Equipment

EN61010-1/A1 – Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use

IEC1010-1 – Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use

Standards

1- 24

2715 Spectrum Analyzer Service Manual

Page 43

Operating Information

This section contains the following:

H Instrument description

H Conformance to industry standards

H Product service information

H Instrument construction

H Installation and preparation for use

H Power cord

H Fuse replacement

H Assembly and circuit numbering

H Accessories

H Menus

Instrument Description

This instrument is a compact and portable Spectrum Analyzer for the 9 kHz to

1.8GHzfrequencyrange(upto2.15GHzwithOption50orOption75

installed). Microprocessor control of most functions simplifies and enhances

operation.

The Spectrum Analyzer’s main features are:

H Precision Measurements Menu selectable routines provide directions for

normalizing the internal reference (calibrator signal) to external frequency

and amplitude references. After the internal reference is normalized, other

menu selections provide for normalizing any instrument measurement

parameter.

H Menu Operation Menu-selectable routines provide diagnostics, normaliza-

tion, adjustments, and setup of basic parameters such as center frequency,

frequency span, reference level, vertical scale factor, resolution bandwidth,

etc. These menus are described in Section 6: Spectrum Analyzers Menus of

the 2715 Spectrum Analyzer Users Manual.

2715 Spectrum Analyzer Service Manual

2- 1

Page 44

Operating Information

H Single and ∆ Markers A single marker can be enabled to show the

frequency and amplitude of a specific point on the display. Delta (∆)markers

show the difference frequency and amplitude between any selected two

points on the displayed waveform.

H Tracking Signal tracking holds a drifting signal to center screen.

H Center Measure When this function is activated, the instrument completes

the sweep and centers the signal nearest center screen or, with markers

activated, the signal nearest the marker. A readout of center frequency and

amplitude is displayed.

H Display In the Spectral mode, the numerical values of signals and setup

parameters are displayed. In the Menu mode, a menu with its selections and

prompts is displayed. Any error, warning, or information messages are

displayed in both modes.

Conformance to Industry Standards

Product Service

This Spectrum Analyzer conforms with the following industry safety standards

and regulatory requirements.

CAN/CSA C22.2, No. 231

UL 1244 (3rd Edition) Measuring Testing Equipment

To ensure adequate product service and maintenance for our instruments,

Tektronix has established Field Offices and Service Centers at strategic points

throughout the United States and in countries where our products are sold.

Several types of maintenance or repair agreements are available.

For example, for a fixed fee, a maintenance agreement program provides

maintenance and recalibration on a regular basis. Tektronix will remind you

when a product is due for recalibration and perform the service within a specified

time.

Contact your local Tektronix Service Center, representative, or sales engineer for

details regarding product service.

2- 2

2715 Spectrum Analyzer Service Manual

Page 45

Instrument Construction

Modular construction provides ready access to the major circuits. Each circuit

board containing RF sensitive circuits is mounted in a casting, with feed through

connectors through the compartment walls. Most boards and assemblies plug

onto a common interconnect board. Most adjustments and test points are

accessible while the instrument is operational and without need of a circuit board

extender.