Page 1

Programmer Manual

2714 & 2715

Spectrum Analyzer

070-8533-05

This document supports Firmware

Version 10.28.98.

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Introduction

Message Structure

Functional Groups

Introduction to Programming 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Operation (Option 08) 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Over the RS-232 Interface 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up for RS-232 Operation 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Operation (Option 03) 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Over the GPIB 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up for GPIB Operation 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument-Specific Message Structure 2–1. . . . . . . . . . . . . . . . . . . . . . . .

What Is A Message? 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Buffering (RS-232) 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Buffering (GPIB) 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Format 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Groups 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Command/Query List 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command And Query Functional Groups 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command/Query

Status Reporting

Programming

Command and Query Definitions 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ypographical Conventions 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Commands and Queries 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Reporting 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Error Reporting 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Service Request 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Byte 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Event Codes 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction to RS-232 Programming 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Program Examples 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Menu Control 6–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction to GPIB Programming 6–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Beginning Your GPIB Program 6–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Trapping 6–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2714 & 2715 Programmer Manual

i

Page 6

Table of Contents

Appendices

GPIB System Software 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Sample Subroutines 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sample GPIB Controller 6–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: RS-232 Concepts A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction To RS-232 Communications A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Implementation of the RS-232 Interface A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documentation A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: GPIB System Concepts B–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Elements B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Elements B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Elements B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Typical GPIB System B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T alkers, Listeners, and Controllers B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Control Messages B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device-Dependent Messages B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Signal Line Definitions B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Functions and Messages B–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

ii

2714 & 2715 Programmer Manual

Page 7

List of Figures

Table of Contents

Figure 1–1: Two RS-232 System Configurations 1–4. . . . . . . . . . . . . . . . .

Figure 1–2: The RS-232 Port Configuration Menu 1–6. . . . . . . . . . . . . . .

Figure 1–3: Typical Small Instrument System for GPIB 1–14. . . . . . . . . . .

Figure 1–4: Connecting Multiple Instruments on the GPIB 1–16. . . . . . . .

Figure 1–5: The Spectrum Analyzer’s GPIB Port Configuration

Menu 1–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: Format of Curve Data 4–25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Spectrum Analyzer Graticule Coordinates 4–26. . . . . . . . . . .

Figure 6–1: Terminal Display of ID? Query Response 6–3. . . . . . . . . . . .

Figure 6–2: Terminal Display Before CATV XMOD Test Begins 6–26. . . .

Figure 6–3: Terminal Display of CATV XMOD Test Results 6–26. . . . . . .

Figure 6–4: A Remote Menu 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Prompting for a Numeric Entry 6–41. . . . . . . . . . . . . . . . . . . .

Figure 6–6: Specifying a Numeric Value 6–42. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–7: A Remote Submenu 6–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Possible Data Acquisition Scheme 6–54. . . . . . . . . . . . . . . . . . .

Figure 6–9: Possible Data Print/Plot Scheme 6–55. . . . . . . . . . . . . . . . . . . .

Figure A–1: RS-232 Representation of a Character A–1. . . . . . . . . . . . . .

Figure A–2: Rear Panel RS-232 Connector A–3. . . . . . . . . . . . . . . . . . . . .

Figure A–3: 9-pin Female to 9-pin Female Null-Modem Cable A–4. . . . .

Figure A–4: 9-pin Female to 25-pin Female Null-Modem Cable A–5. . . .

Figure A–5: 9-pin Female to 25-pin Male Extension Cable A–6. . . . . . . .

Figure B–1: IEEE Std 488.1 (GPIB) Connector B–2. . . . . . . . . . . . . . . . . .

Figure B–2: Typical GPIB System B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–3: Example of Data Byte Traffic B–11. . . . . . . . . . . . . . . . . . . . . .

Figure B–4: Handshake Timing Sequence, Idealized B–12. . . . . . . . . . . . .

Figure 1–1: Two RS-232 System Configurations 1–4. . . . . . . . . . . . . . . . .

Figure 1–2: The RS-232 Port Configuration Menu 1–6. . . . . . . . . . . . . . .

Figure 1–3: Typical Small Instrument System for GPIB 1–14. . . . . . . . . . .

Figure 1–4: Connecting Multiple Instruments on the GPIB 1–16. . . . . . . .

Figure 1–5: The Spectrum Analyzer’s GPIB Port

2714 & 2715 Programmer Manual

Configuration Menu 1–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 8

Table of Contents

Figure 4–1: Format of Curve Data 4–25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Spectrum Analyzer Graticule Coordinates 4–26. . . . . . . . . . .

Figure 6–1: Terminal Display of ID? Query Response 6–3. . . . . . . . . . . .

Figure 6–2: Terminal Display Before CATV XMOD Test Begins 6–26. . . .

Figure 6–3: Terminal Display of CATV XMOD Test Results 6–26. . . . . . .

Figure 6–4: A Remote Menu 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Prompting for a Numeric Entry 6–41. . . . . . . . . . . . . . . . . . . .

Figure 6–6: Specifying a Numeric Value 6–42. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–7: A Remote Submenu 6–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Possible Data Acquisition Scheme 6–54. . . . . . . . . . . . . . . . . . .

Figure 6–9: Possible Data Print/Plot Scheme 6–55. . . . . . . . . . . . . . . . . . . .

Figure A–1: RS-232 Representation of a Character A–2. . . . . . . . . . . . . .

Figure A–2: Rear Panel RS-232 Connector A–2. . . . . . . . . . . . . . . . . . . . .

Figure B–1: IEEE Std 488.1 (GPIB) Connector B–2. . . . . . . . . . . . . . . . . .

Figure B–2: Typical GPIB System B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–3: Example of Data Byte Traffic B–11. . . . . . . . . . . . . . . . . . . . . .

Figure B–4: Handshake Timing Sequence, Idealized B–12. . . . . . . . . . . . .

iv

2714 & 2715 Programmer Manual

Page 9

List of Tables

Table of Contents

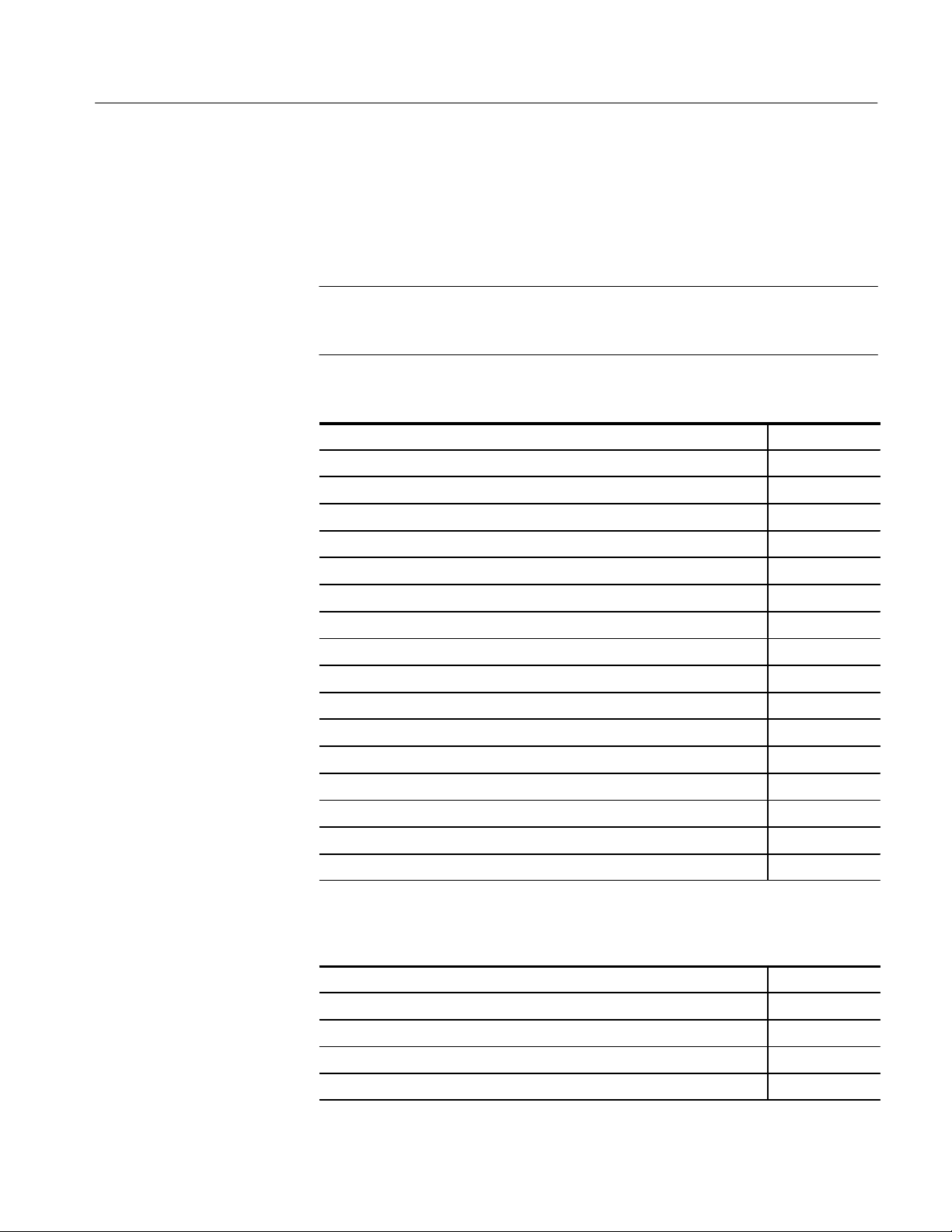

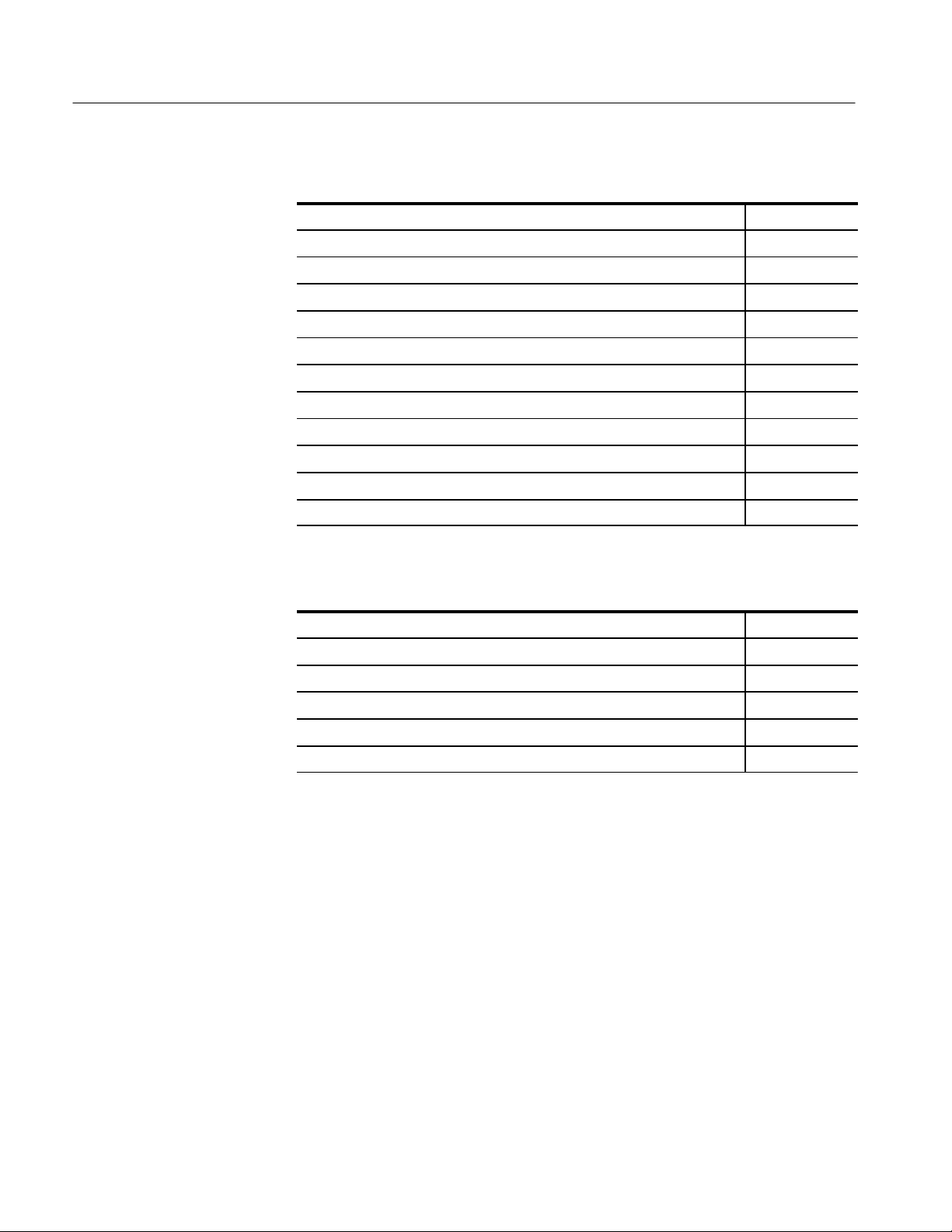

Table 1–1: National Instruments PCII Board Characteristics 1–19. . . . . .

Table 1–2: National Instruments PCIIA Board Characteristics 1–19. . . .

Table 1–3: TEK_SA Device Characteristics 1–20. . . . . . . . . . . . . . . . . . . .

Table 3–1: Commands and Queries 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

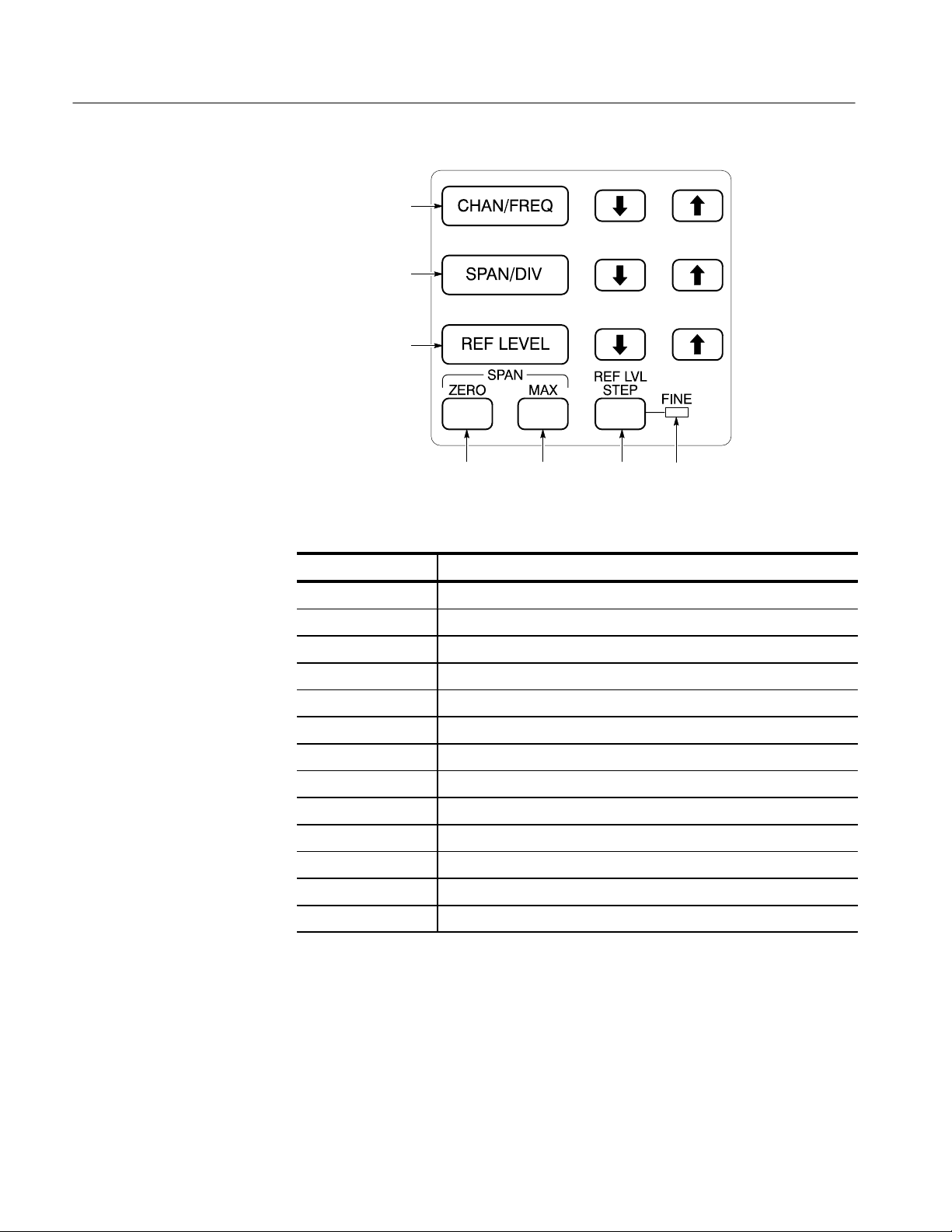

Table 3–2: FREQ/MKRS Front Panel Commands 3–5. . . . . . . . . . . . . . .

Table 3–3: MKR/FREQ Menu Commands 3–6. . . . . . . . . . . . . . . . . . . . .

Table 3–4: FREQUENCY, SPAN/DIV and REF LEVEL Front Panel

Commands 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–5: VERT SCALE, PLOT, and READOUT Front Panel

Commands 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–6: INPUT Menu Commands 3–10. . . . . . . . . . . . . . . . . . . . . . . . . .

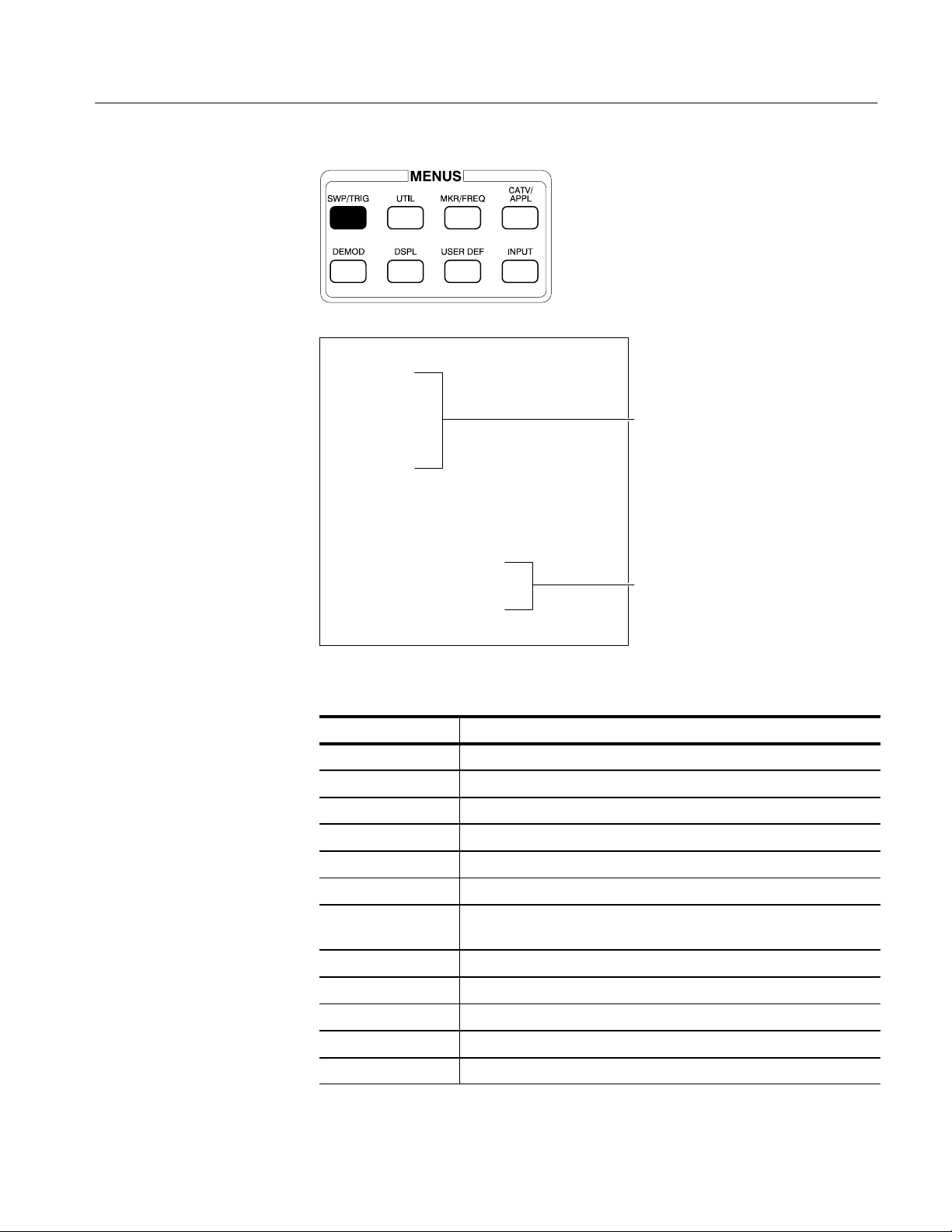

Table 3–7: SWP/TRIG Menu Commands 3–11. . . . . . . . . . . . . . . . . . . . . .

Table 3–8: SWEEP and RES BW Front Panel Commands 3–12. . . . . . . .

Table 3–9: DISPLAY STORAGE Front Panel Commands 3–13. . . . . . . .

Table 3–10: DSPL Menu Commands 3–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–11: CATV/APPL Menu Commands (CATV Mode Active) 3–18.

Table 3–12: CATV/APPL Menu Commands (CATV Mode Inactive) 3–23

Table 3–13: UTIL Menu Commands 3–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–14: DEMOD Menu Commands 3–26. . . . . . . . . . . . . . . . . . . . . . .

Table 3–15: Curve and Waveform Commands 3–27. . . . . . . . . . . . . . . . . .

Table 3–16: System-Related Commands 3–27. . . . . . . . . . . . . . . . . . . . . . .

Table 3–17: Miscellaneous Commands 3–28. . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: CATv Command Arguments 4–10. . . . . . . . . . . . . . . . . . . . . . .

Table 4–2: CATv? Query Arguments 4–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–3: File Types 4–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–4: Valid File Names 4–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–5: Miscellaneous Files 4–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–6: Arguments of the KEY Command 4–44. . . . . . . . . . . . . . . . . . .

Table 4–7: Arguments of the WFMpre? Query 4–91. . . . . . . . . . . . . . . . . .

Table 4–8: Related Formulas 4–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–1: Event Codes 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: General System Status Bytes 5–12. . . . . . . . . . . . . . . . . . . . . . .

Table 5–3: General Device-Dependent Status Bytes 5–12. . . . . . . . . . . . . .

Table 5–4: Specific System Status Bytes 5–12. . . . . . . . . . . . . . . . . . . . . . . .

Table 5–5: Specific Device-Dependent Status Bytes 5–13. . . . . . . . . . . . . .

2714 & 2715 Programmer Manual

v

Page 10

Table of Contents

Table 5–6: Event Priorities 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–7: Event Code Categories 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–1: Variable Names 6–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–2: GPIB System Software Callable Subroutines 6–48. . . . . . . . . .

Table A–1: Back Panel RS-232 Connections A–3. . . . . . . . . . . . . . . . . . . .

Table A–2: 9-pin Female to 9-pin Female Null-Modem Cable A–4. . . . .

Table A–3: 9-pin Female to 25-pin Female Null-Modem Cable A–5. . . .

Table A–4: 9-pin Female to 25-pin Male Extension Cable A–6. . . . . . . . .

Table B–1: Major GPIB Interface Functions B–3. . . . . . . . . . . . . . . . . . .

Table B–2: Interface Messages and Functions: Remote Messages Received .

B–7

Table B–3: Interface Messages and Functions: Remote Messages Sent . . . . .

B–8

Table B–4: ASCII and GPIB Code Chart B–9. . . . . . . . . . . . . . . . . . . . . . .

vi

2714 & 2715 Programmer Manual

Page 11

Introduction

Page 12

Page 13

Introduction to Programming

The Tektronix 2714 or 2715 Spectrum Analyzer allows remote control of its

functions with one of two communication port options. Option 08 provides an

RS-232 data communications interface; Option 03 provides an IEEE Standard

488.1 General Purpose Interface Bus (GPIB) communications interface.

With a desktop computer and an appropriate control program, you can configure

front panel settings (except those intended for local use only, such as INTENSITY) and acquire, transfer, process, and analyze data remotely.

The command set and message structure for the RS-232 and GPIB interfaces are

almost identical. However, a few interface-specific considerations, such as

communications parameters and protocols, are different. The setup for each

interface is described separately in this section.

NOTE. If your instrument is equipped with the RS-232 interface then continue

with the next subsection, RS-232 Operation (Option 08). Otherwise, turn to the

GPIB Operation (Option 03) subsection and follow the instructions there.

RS-232 Operation (Option 08)

NOTE. If your spectrum analyzer is equipped with a GPIB instrument bus, you

can skip this subsection.

The 2714 or 2715 Spectrum Analyzer follows EIA Standard RS-232 when

equipped with the RS-232 interface. This standard establishes electrical levels,

connector configuration, and signal protocols for communication between two

devices called the DCE (data circuit-terminating equipment) and the DTE (data

terminal equipment). The 2714 or 2715 implements the DTE end of the

interface.

Note that the RS-232 interface is NOT a bus. Only one device can be connected

to the instrument’s RS-232 interface. Unlike a GPIB interface, RS-232 does not

support device addresses or serial polling.

For example, if a computer is connected to the spectrum analyzer’s RS-232

interface, a printer or plotter could not be connected to the spectrum analyzer

without first disconnecting the computer. To plot screen data directly from the

spectrum analyzer, you would first have to disconnect the computer and then

connect your printer or plotter.

2714 & 2715 Programmer Manual

1–1

Page 14

Introduction to Programming

The 2714 or 2715’s RS-232 interface requires a minimum of three signal lines

for operation:

H Transmit data (TXD)

H Receive data (RXD)

H Ground (GND)

If hardware handshake is required, additional lines must be supplied in the cable.

Refer to Appendix A: RS–232 Concepts for cabling diagrams.

The section titled Selecting a Data Flow Control Method on page 1–7 describes

the use of the additional lines for hardware flow control.

EIA Standard RS-232 defines other lines typically used for modem control and

handshaking. The 2714 or 2715 can operate using the minimum wiring

configuration. If the appropriate handshake lines are provided, a printer or plotter

that expects handshaking over the RS-232 interface may be used.

Data bits are transferred serially, one bit at a time, over the RS-232 interface.

Data consists of instrument commands and queries, control settings, parameter

values, or display information.

If a computer is connected to the spectrum analyzer by the RS-232 interface, the

computer’s serial interface (called a COM port if the controller is an MS-DOS

computer) must be correctly configured beforehand. Programmed commands and

data can then be transmitted over the interface to the instrument.

If a query such as FREQ? is transmitted, the spectrum analyzer formats its

response immediately and sends it back to the computer. The control program

must be ready to receive the incoming data. In the following subsections you

will learn how to set up your 2714 or 2715 for RS-232 operation. Appendix A:

RS-232 Concepts provides additional information concerning RS-232 implementation for the 2714 or 2715 including wiring for connectors and null-modem

adapters.

1–2

2714 & 2715 Programmer Manual

Page 15

Operation Over the RS-232 Interface

The following equipment is required to operate the 2714 or 2715 Spectrum

Analyzer over the RS-232 interface:

H System controller or terminal

H Software device driver

H 2714 or 2715 equipped with an RS-232 interface (Option 08)

H Interconnecting cable

H Application software

H Printer or plotter (optional)

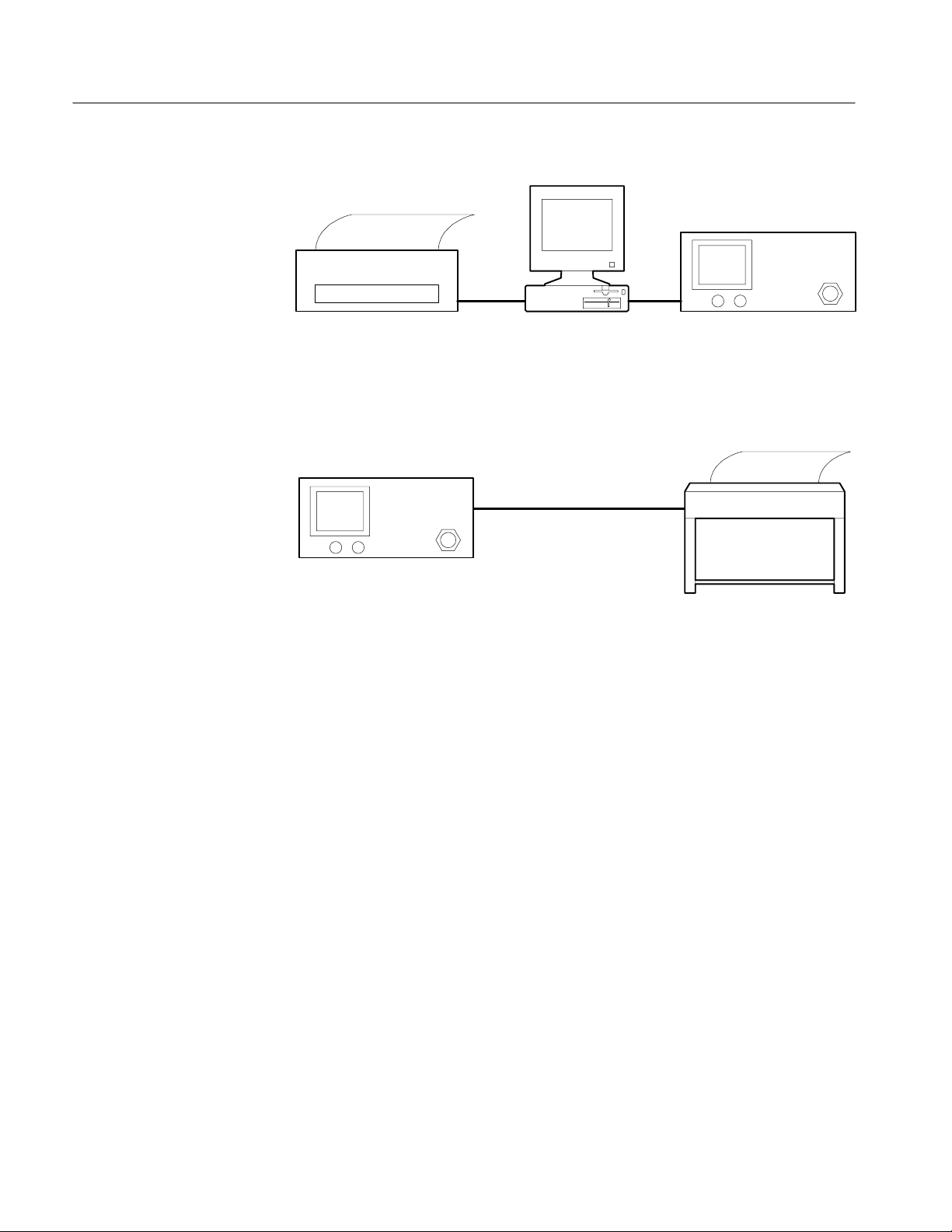

Figure 1–1 shows two typical RS-232 system configurations. The top illustration

shows a computer (PC) controlling the spectrum analyzer over the RS-232

interface; a plotter is connected to the computer over a Centronics interface. The

lower illustration shows the spectrum analyzer connected directly to a plotter by

the RS-232 interface.

Introduction to Programming

System Controller

Software Device Driver

2714 or 2715 Equipped

with RS-232 Interface

(Option 08)

The system controller can be any general purpose computer or terminal equipped

with an RS-232 interface (also called a COM port or serial interface). Specially

built controllers can be used, but are beyond the scope of this manual. The

techniques and programs discussed in this manual are appropriate to the IBM PC

family of computers and their function-alike counterparts that support the

MS-DOS, PC-DOS, or OS/2 environments.

The device driver is a program that handles input and output to the RS-232

interface on your computer. The driver for your system depends on the operating

system and the programming language you are using. For example, if you are

operating a PC, the RS-232 driver configuration may be set with the MS-DOS

MODE command. If your control program is written in the BASIC or QuickBASIC language, optional arguments in the OPEN statement can supply RS-232

configuration settings.

Your 2714 or 2715 Spectrum Analyzer must be equipped with an RS-232 port to

communicate over the RS-232 interface. If your 2714 or 2715 is equipped with

the GPIB interface (Option 03), refer to GPIB Operation later in this section.

Press the key sequence [UTIL] [4] [9] to see a list of the installed options and

capabilities.

2714 & 2715 Programmer Manual

1–3

Page 16

Introduction to Programming

Controller

Hardcopy Device

Spectrum Analyzer

RS-232Centronics

HPGL-Compatible Plotter

or

Epson-Compatible Printer

Spectrum Analyzer

RS-232

Interconnecting Cable

Application Software

Printer or Plotter

(Optional)

Figure 1–1: Two RS-232 System Configurations

An appropriate cable is required to connect between the controller and the

spectrum analyzer. The pinout and connector type on the 2714 or 2715 are

identical to the 9-pin connector used for PC/AT type RS-232 interfaces. Such

cables are available in most computer stores. For some RS-232 devices,

null-modem adapters will be needed. Refer to Appendix A for further information on connectors and adapters.

Application software is the program or programs that control and acquire data

from the spectrum analyzer. You can write your own programs using the

information in this manual. Off-the-shelf software is also available.

A printer or plotter (not both simultaneously) can be connected to the RS-232

interface to provide hard-copy output. A printer is the preferred instrument for

character-based data such as parameter values or instrument settings. Plotters

provide superior results when displaying graphical data.

A printer or plotter cannot be connected to the spectrum analyzer’s interface

when a computer is connected. For this reason you must choose between

computer control or hard-copy output when working directly from the 2714 or

2715’s RS-232 interface. An alternate approach connects the computer to the

1–4

2714 & 2715 Programmer Manual

Page 17

spectrum analyzer interface while using a control program to acquire data from

the spectrum analyzer. A second RS-232 port, a GPIB port, or a Centronics port

on the computer is then used to produce output on a printer or plotter.

Setting Up for RS-232 Operation

Your equipment must be correctly configured before performing RS-232

operations. The following tasks must be completed:

H Installation of cables between the system components

H Configuration of the spectrum analyzer and device driver

H Installation of the device driver into controller memory

H Configuration of the (optional) printer or plotter

This section describes each task in detail.

Introduction to Programming

Connecting the

Equipment

Configuring the

Spectrum Analyzer

Only one device (computer, plotter, or printer) can be attached to the spectrum

analyzer’s RS-232 interface. For systems consisting of a controller and the

spectrum analyzer, simply connect one end of the interconnecting cable to each

device. Figure 1–1 shows two possible configurations. See Appendix A: RS-232

Concepts for the cable configuration appropriate for your system.

Both devices (the computer and spectrum analyzer) in an RS-232 system must be

configured the same way. Before setting up the spectrum analyzer, be sure to

check the configuration settings for the device with which you expect to

communicate.

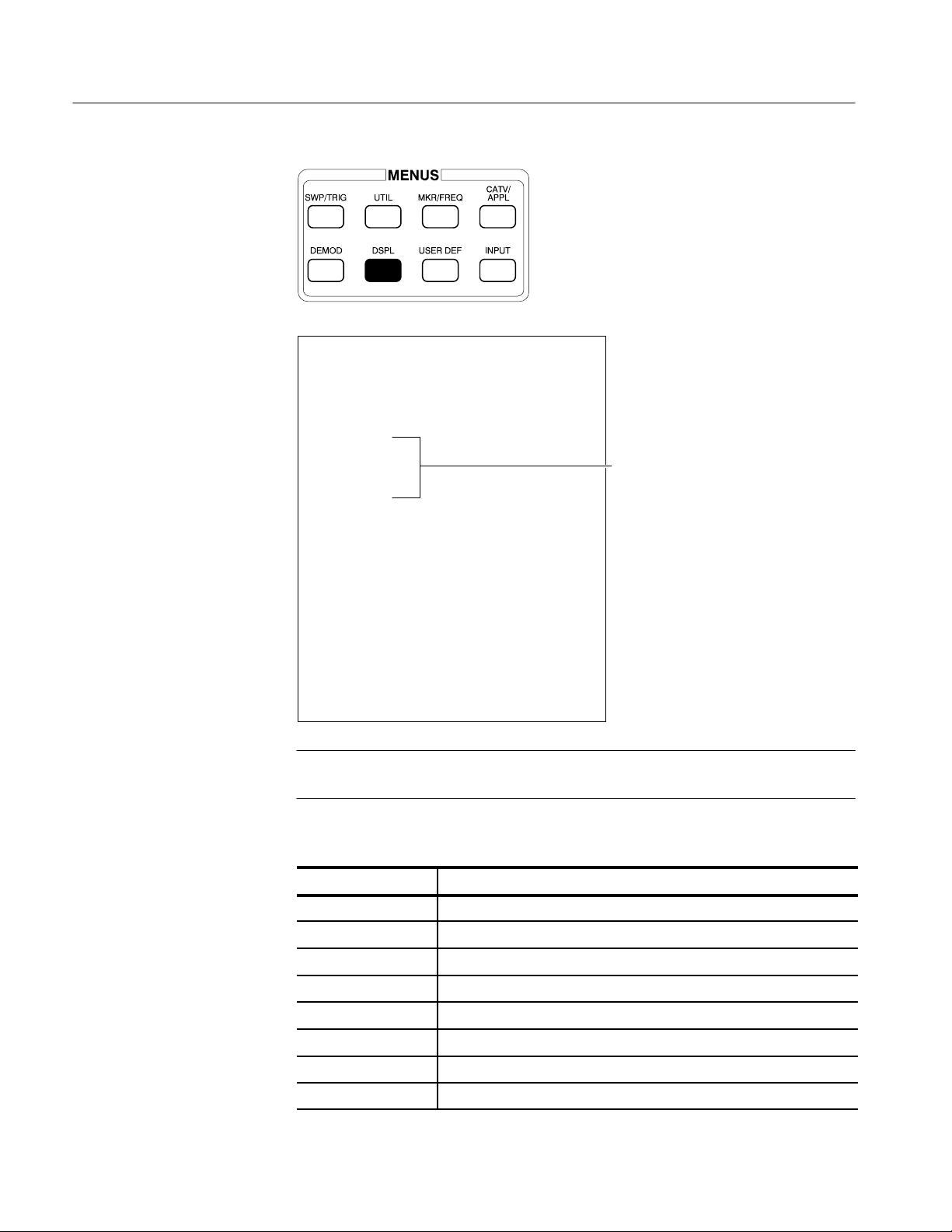

To set the spectrum analyzer configuration settings, turn on the power to the

2714 or 2715 and press the key sequence

[UTIL] [4] [0] [2]

on the spectrum analyzer KEYPAD. An RS-232 PORT CONFIGURATION

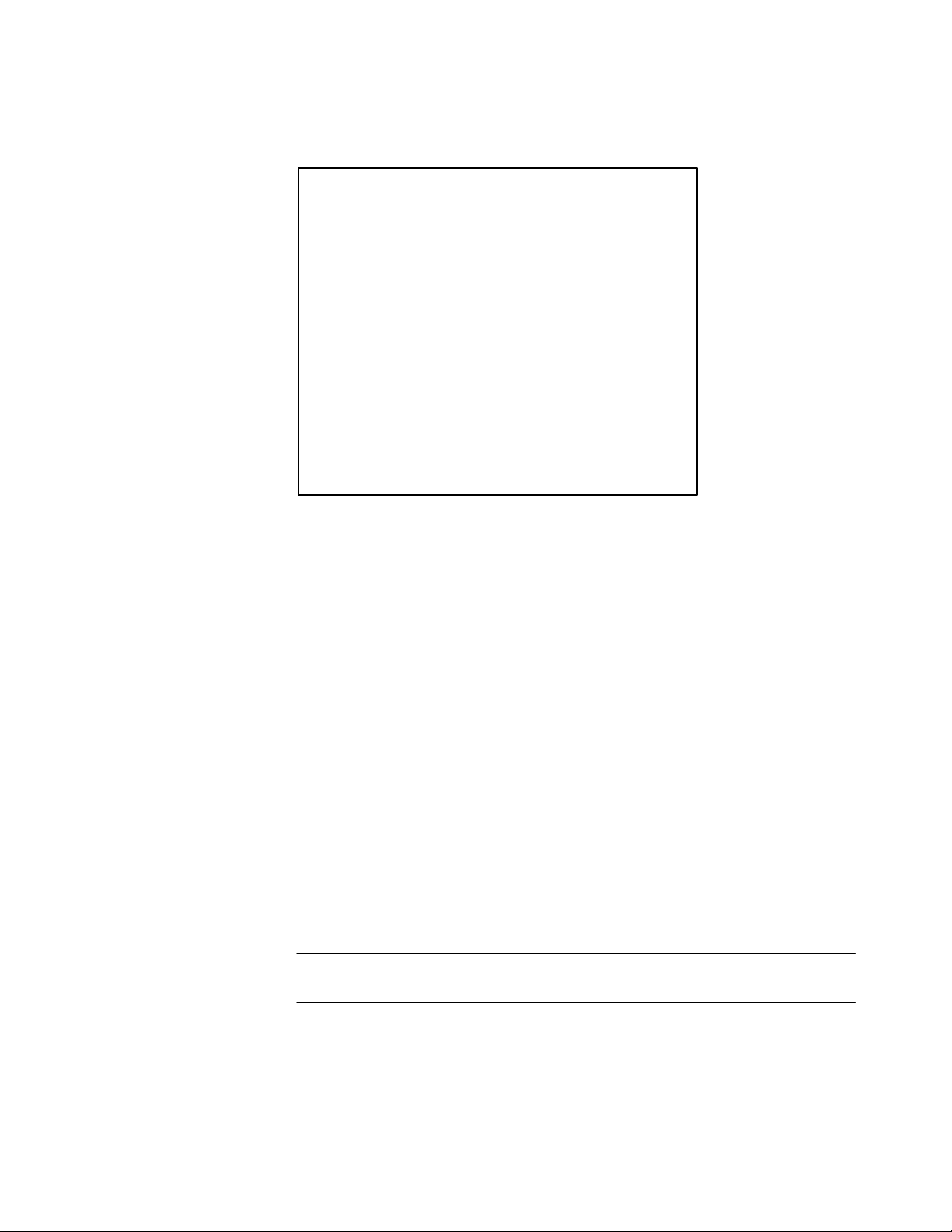

Menu appears that is similar to the one shown in Figure 1–2. This menu allows

for configuration of the spectrum analyzer’s RS-232 parameters. Following are

detailed descriptions of each parameter in the RS-232 PORT CONFIGURATION

Menu.

2714 & 2715 Programmer Manual

1–5

Page 18

Introduction to Programming

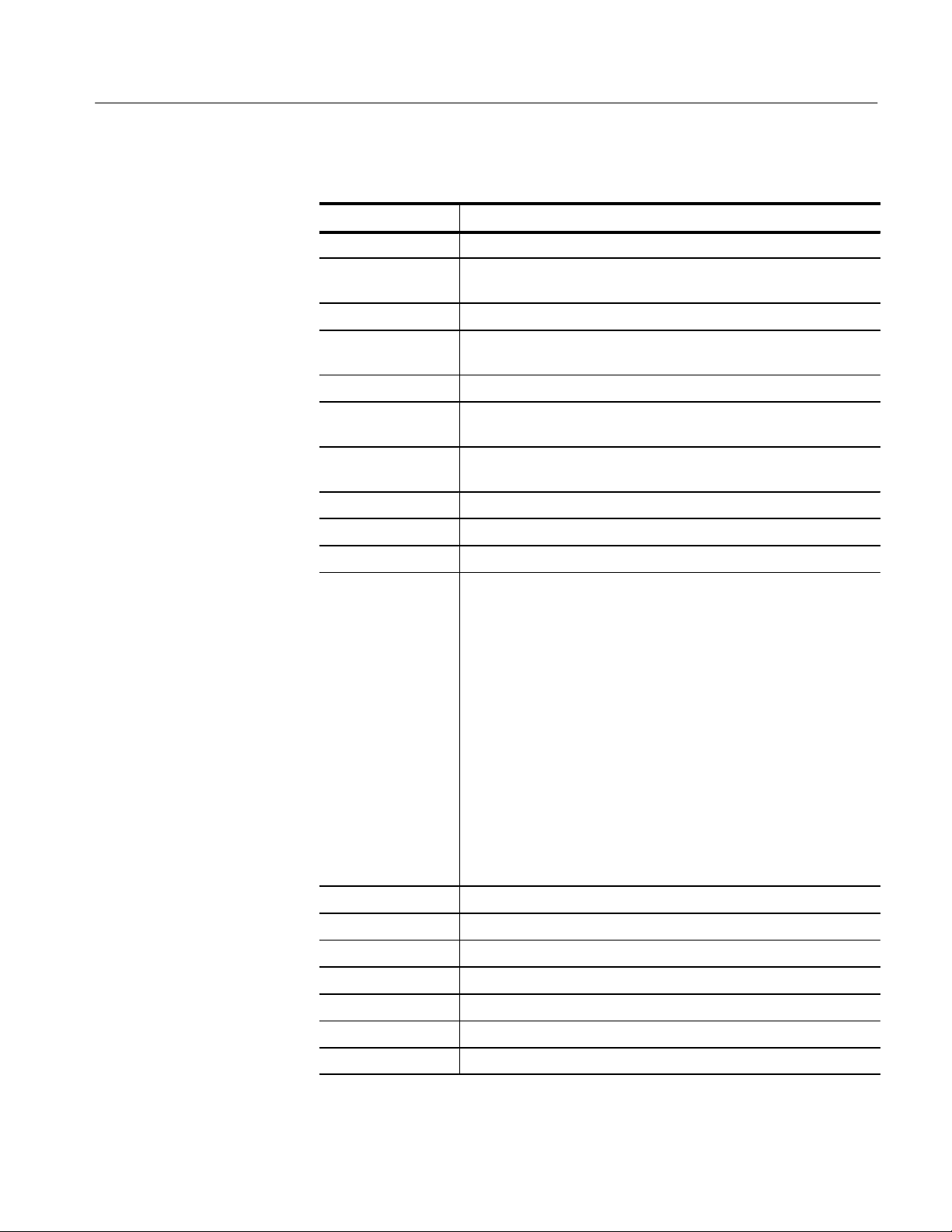

RSĆ232 PORT CONFIGURATION

0 STATUS ONLINE/OFFLINE

1 BAUD RATE 110 Ć 9600

2 DATA BITS 7/8

3 PARITY NONE/ODD/EVEN

4 EOL CR/LF/CR LF

5 FLOW CONTROL HARD/SOFT/NONE

6 ECHO ON/OFF

7 VERBOSE ON/OFF

Figure 1–2: The RS-232 Port Configuration Menu

Placing the 2714 or 2715 Online. Item 0 of the RS-232 PORT CONFIGURATION

Menu, STATUS, controls the RS-232 online/offline status. When the status is set

to OFFLINE, the RS-232 interface is ignored; data is neither received nor

transmitted. After all preparations have been completed and RS-232 operations

are ready to begin, press [0] on the KEYPAD to toggle item 0 until the STATUS

indicates ONLINE. The spectrum analyzer is then ready to exchange information

over the RS-232 interface.

Setting the Baud Rate. Item 1 of the RS-232 PORT CONFIGURATION Menu,

BAUD RATE, sets the baud rate of the spectrum analyzer. Baud rate represents

how fast data is transmitted across the interface. To select a baud rate, repeatedly

press [1] on the KEYPAD until the baud rate you desire is displayed. Baud rates

ranging between 110 and 9600 are available.

The number of stop bits used is automatically selected by the spectrum analyzer

when you change baud rates. If the baud rate is 110, two stop bits are selected.

One stop bit is selected for all other baud rates.

NOTE. The spectrum analyzer baud rate must equal the baud rate of the other

device connected to the RS-232 interface.

1–6

2714 & 2715 Programmer Manual

Page 19

Introduction to Programming

Setting the Number of Data Bits. Item 2 of the RS-232 PORT CONFIGURATION

Menu, DATA BITS, selects the number of data bits sent per character. This is

either seven or eight. Eight bits must be selected for binary transfers. Press [2] on

the KEYPAD to choose between seven or eight data bits.

Setting Parity . Item 3 of the RS-232 PORT CONFIGURATION Menu, PARITY,

determines whether odd or even parity is used for data checking, or it selects no

parity checking. The default setting is NONE. To change the PARITY selection,

repeatedly press [3] on the KEYPAD until ODD, EVEN, or NONE is displayed.

Setting the Message Terminator. Item 4 of the RS-232 PORT CONFIGURATION

Menu, EOL, selects the EOL (end-of-line) indicator used to terminate messages

sent over the spectrum analyzer’s RS-232 interface. The terminator can be CR

(carriage return, ASCII 13), LF (line feed, ASCII 10), or CR LF (carriage return

followed by line feed). To change the EOL status selection, repeatedly press [4]

on the KEYPAD until CR, LF, or CRLF is displayed.

When a controller sends data, the spectrum analyzer interprets either CR or LF as

a terminator, independent of the setting.

Selecting a Data Flow Control Method. Item 5 of the RS-232 PORT CONFIGURATION Menu, FLOW CONTROL, selects between three flow control

methods: SOFT, HARD, or NONE. An explanation of each selection follows.

SOFT: When the spectrum analyzer sends data through the interface and SOFT

flow control is enabled, CTRL-S (ASCII 19, same as pressing [CTRL] and [S]

simultaneously) halts the data stream until CTRL-Q (ASCII 17) is received. Any

other character received in the interim is ignored. This type of flow control can

be used with a 3-wire setup because additional handshake lines are not needed.

When SOFT control is selected, the spectrum analyzer sends CTRL-S when its

input data buffer is within 200 characters of being full. It sends CTRL-Q when

the buffer empties to the point at which additional characters can be safely

accepted (less than 200 characters remain in the buffer). If the input buffer is

allowed to overflow, the spectrum analyzer discards the incoming data and

signals an error (Event 372).

HARD: When HARD flow control is selected, the instrument sends data as long

as the CTS (Clear-To-Send) line is TRUE and stops sending data if CTS goes

FALSE. Additional handshake lines (more than a 3-wire RS-232 implementation) are required to support HARD flow control.

When receiving data and HARD flow control is selected, the spectrum analyzer

asserts RTS (Request-To-Send) TRUE until the input buffer is within 200

characters of being full. It then sets RTS FALSE. Data is received while RTS is

FALSE until the buffer overflows. If the buffer is allowed to overflow, the

spectrum analyzer signals an error (Event 372), and incoming data is discarded.

2714 & 2715 Programmer Manual

1–7

Page 20

Introduction to Programming

NONE: No flow control is used.

Follow these general rules when selecting a flow control method:

H Do not use SOFT flow control when transmitting file or waveform data

(binary transfers) because there is no guarantee that the ASCII-decimal

values corresponding to CTRL-S and CTRL-Q do not appear in the input

stream. Instead, specify HARD flow control or NONE for files and

waveform data.

H If NONE is specified, you must ensure that buffers do not overflow. This can

be done by allocating enough buffer space to handle most contingencies. A

buffer size of 1200 is sufficient for most purposes. The 2714 or 2715 uses a

1200-byte, internal input buffer.

Selecting the Echo Feature. Item 6 of the RS-232 PORT CONFIGURATION

Menu, ECHO, chooses ECHO modes of ON or OFF. ECHO mode is intended

primarily as a means of interacting with the 2714 or 2715 from a “dumb”

terminal, or for testing purposes. Press [6] on the KEYPAD to choose between

ON or OFF.

When ECHO is OFF, the spectrum analyzer does not return the characters it

receives to the controller. For most cases, ECHO should be OFF. However, set

ECHO to ON when using a “dumb” terminal to control the spectrum analyzer.

When ECHO is ON, the spectrum analyzer echoes each character it receives back

to the controller. This can cause problems for the control program if it is not

expecting the characters. Additional time is required to process each returned

character, so it is possible to experience buffer overrun at 9600 baud if the

character rate is too high. After each command or query is completed, the

spectrum analyzer prompts for further input by returning the string “>” to the

controller.

For example, if ECHO mode is ON, “>” appears on the terminal or computer

display screen. If the query “VPO?” is entered, the spectrum analyzer returns

“VPO?” followed by a normal response to the query, such as “VPOLARITY

POSITIVE”. It then appends the “>” to indicate that it is ready to receive

additional commands.

ECHO mode is sometimes useful for interactive testing because it lets you see

each character received by the spectrum analyzer. Following are some important

ECHO mode characteristics:

H If SOFT flow control is enabled, CTRL-S and CTRL-Q are not echoed, but

they perform their normal functions.

1–8

H If either CR or LF is received by the spectrum analyzer, it is echoed as the

currently selected output terminator.

2714 & 2715 Programmer Manual

Page 21

Introduction to Programming

H Any other control character echoes as an up arrow (^) followed by a capital

letter. For example, ^X represents pressing the [CTRL] and [X] keys at the

same time.

H ECHO should not be ON with binary transfers.

H When ECHO is ON the prompt character appears on the display under other

conditions: 1) when the instrument is powered up or placed on-line with

ECHO mode ON, 2) when ECHO is turned on, and 3) after a device clear

(break) is received.

Verbose Mode and Error Handling. Item 7 of the RS-232 PORT CONFIGURATION Menu, VERBOSE, turns VERBOSE mode ON and OFF. This feature

is provided as an alternative to the GPIB SRQ mechanism. It is generally used

when controlling the spectrum analyzer with a “dumb” terminal. Press [7] on the

KEYPAD to choose between ON or OFF.

When ON, VERBOSE mode forces the spectrum analyzer to respond for each

command it receives. The response will be one of the following:

Installing and Configuring

the Device Driver

H An event code for an abnormal condition

H A response for a successful query (FREq?)

H The string “OK” for a successful non-query

Refer to Status Reporting for additional information on error handling for

instruments with the RS-232 interface.

If you are using special applications software or a custom RS-232 driver, follow

the detailed instructions for installing and configuring the device driver included

with it. However, for PC-type controllers running MS-DOS, the driver is part of

the operating system. You can configure a serial communications port with the

MODE command by entering a command similar to the following example:

MODE COM1:9600,n,8,1

This command configures the COM1 interface to run at 9600 baud, no parity, 8

data bits, and 1 stop bit.

NOTE. You must use the same setup information for the controller and the

spectrum analyzer.

A program statement, such as OPEN in the BASIC language, is an alternative way

to configure the driver. This method of driver configuration is recommended

because it sets the driver to a known, and presumably correct, operating state

from within the application program and just prior to actual operation. If the

2714 & 2715 Programmer Manual

1–9

Page 22

Introduction to Programming

MODE command is used, the last settings applied to the interface must be used. If

this data is not used, your program will not work properly.

Configuring the (Optional)

Printer or Plotter

Communicating with the

Spectrum Analyzer

A variety of printers and plotters are available for use with your system. The

serial or parallel printer of your choice may be connected to the appropriate

computer port. For example, the Centronics- or GPIB-compatible, 4-pen

Tektronix HC100 plotter is recommended. Its four pens provide a useful

complement to the four-trace capability of the 2714 or 2715.

A serial printer or plotter, such as the Tektronix HC100 Option 03, can be

attached to the spectrum analyzer’s RS-232 interface instead of a computer

controller. This arrangement enables data transfer directly from the spectrum

analyzer to the printer or plotter with a remote PLOT command when the system

controller is unavailable. Of course, the spectrum analyzer must be correctly

configured using the SCREEN PLOT CONFIGURATION Menu (key sequence

[UTIL] [4] [1]).

Figure 1–1, located earlier in this section, shows two alternative configurations

using a printer. A plotter could be substituted for the printer in either configuration.

The RS-232 interface enables remote or automated control of the 2714 or 2715

Spectrum Analyzer. An application program (often called a test, measurement, or

control program) determines 2714 or 2715 operations by exchanging spectrum

analyzer-specific messages with the instrument.

Preparing the Software

The spectrum analyzer-specific messages are also referred to as device-dependent

messages. They are generally understood by and meaningful to only the

instrument, or class of instruments, for which they are designed. The organization of the spectrum analyzer-specific messages is explained in the next section

of this manual. Functional Groups provides a summary of the messages.

Command and Query Definitions describes the individual messages in detail, and

Programming provides some programming examples.

Programmed commands and data are transmitted over the interface to the

instrument as soon as they are delivered to the driver. If the command is a query

(FREQ? for example), the spectrum analyzer formats a response immediately and

sends it back to the computer. The control program is responsible for handling

incoming data in a timely fashion.

After completing the setup procedures your equipment is ready for RS-232

operation, but you must still provide the software needed to control the spectrum

analyzer. When creating new software this is usually a two step process. The first

step is to establish the programming environment. Next you can create and run

the control program. If you are using ready-made control software, simply follow

the supplier’s instructions.

1–10

2714 & 2715 Programmer Manual

Page 23

The programming requirements for RS-232 control are more complex than those

for GPIB operation. Programming contains a complete example of an interactive

RS-232 control program. This program is functionally similar to the GPIB

program example located later in this section (refer to A GPIB Instrument

Control Program on page 1–23).

GPIB Operation (Option 03)

Option 03 adds a General Purpose Interface Bus (GPIB) port. This GPIB port

conforms to the IEEE 488.1 Standard and to the Tektronix Interface Standard for

GPIB Codes, Formats, Conventions, and Features. This standard promotes ease

of operation and, so far as possible, makes this spectrum analyzer compatible

with other Tektronix instruments and with GPIB instruments from other

manufacturers.

The IEEE 488.1 Standard establishes electrical levels, connector configuration,

and signal protocols for communication between two or more electronic

instruments using a common multi-line bus structure. The bus structure, known

as the GPIB, consists of eight data lines, eight dedicated control signal lines, a

shield, and various grounds.

Introduction to Programming

Data is transferred via eight data lines in a bit parallel, byte serial fashion. That

is, the eight bits of a data byte are placed on the eight data lines simultaneously.

As soon as they are transferred, the next 8-bit data byte is placed on the lines and

is transferred. Data consists of instrument commands and queries, control

settings, parameter values, or display information.

The eight control lines are divided into three transfer control (handshake) lines

and five interface management lines. Handshaking and interface management are

necessary because the bus operates asynchronously. This means that signals can

be generated by one instrument without regard for what other instruments may

be doing, or the rate at which other instruments can carry out an operation. For

instance, two instruments may try to send information simultaneously, or a high

speed instrument may try to send data to a slower instrument.

Instruments connected to the bus are designated as talker, listener, or both talker

and listener. A listener can only receive information over the bus and a talker can

only send information. A talker and listener can do both (but not simultaneously).

One instrument is usually designated as the system controller. This is generally a

computer that determines, through software, when specific instruments are

activated as talkers or listeners. Each instrument is assigned a unique address

between 0 and 30, but only 15 instruments can be connected to the bus

simultaneously.

2714 & 2715 Programmer Manual

1–11

Page 24

Introduction to Programming

The following example illustrates how data transfer typically takes place (except

in the case of abnormal events; see Status Reporting).

1. The instrument on the bus that is designated as system controller determines

(through operator intervention or program control) that it needs to send a

message to one of the other instruments.

2. Using the data and interface management lines, the controller first addresses

the desired instrument as a listener. This is called LISTENING an instrument.

3. Instruments on the bus are normally idle, and they signal using the hand-

shake lines when they are ready to receive data. The controller then places

the first byte of the message on the bus, indicating the type of information it

wants.

4. Next the controller signals, using the handshake lines, that the data byte is

ready.

5. As the listener accepts the data byte, it signals over the handshake lines that

it has done so. The controller then removes the data from the data lines.

6. The process from steps 3, 4, and 5 is repeated until the entire message has

been transferred.

7. The controller indicates that the last data byte has been sent. Depending on

the option selected, one of two methods is used: 1) Signaling over the end or

identify (EOI) interface management line simultaneously with the last data

byte, or 2) Appending the ASCII codes for carriage return (CR) and line feed

(LF) to the end of the message and simultaneously signaling EOI.

8. When the message is complete, the controller normally UNLISTENS the

instrument. If a message requires a response, the controller then addresses

the instrument as a talker (TALKS the instrument).

9. Now the instrument places the first byte of the response on the data bus and

signals that it is ready.

10. After the controller reads the byte, it signals (over the handshake lines) that it

has done so and is ready to receive more data. The process repeats until EOI

is detected, at which point the controller normally UNTALKS the instrument.

The data transfer process is transparent to you. It is carried out by the spectrum

analyzer, the GPIB board in your controller, and the device driver software

(generally supplied with the GPIB board). In the following subsections you will

learn how to set up your spectrum analyzer for GPIB operation. See Appendix B:

GPIB System Concepts for additional information concerning IEEE 488.1 and

the GPIB.

1–12

2714 & 2715 Programmer Manual

Page 25

Operation Over the GPIB

The following equipment is required to operate the 2714 or 2715 Spectrum

Analyzer over the General Purpose Interface Bus (GPIB):

H System controller

H Software device driver

H 2714 or 2715 equipped with the GPIB interface (Option 03)

H Interconnecting cable

H Application software

H Printer or plotter (optional)

Figure 1–3 shows an example of a simple GPIB system consisting of a printer

and plotter.

Introduction to Programming

System Controller

Software Device Driver

The system controller can be any general purpose computer equipped with a

GPIB board. Specially built controllers can also be used, but are beyond the

scope of this manual. The techniques and programs discussed in this manual are

appropriate to the IBM family of personal computers (PCs) and their functionalike counterparts, which support the MS-DOS, PC-DOS, or OS/2 environments.

To function as a controller, your computer must be equipped with a GPIB board.

Tektronix supplies three National Instruments GPIB boards for your convenience:

H PC-GPIB Package provides a PCII/IIA board; order S3FG210

H AT-GPIB Package provides a 16-bit AT Bus interface board; order S3FG220

H MC-GPIB Package provides a 16-bit Micro Channel interface board; order

S3FG230

The device driver is a program (usually supplied with the GPIB board) that tells

your computer how to access the board. For the National Instruments PCII,

PCIIA, or PCII/IIA GPIB boards, the device driver is a file named GPIB.COM. An

additional program is usually supplied that enables you to correctly configure the

driver by providing information such as the instrument address and the type of

message terminator. The National Instruments program is named IBCONF.EXE.

2714 & 2715 Programmer Manual

1–13

Page 26

Introduction to Programming

Controller

Hardcopy Device

Spectrum Analyzer

RS-232Centronics

Plotter

GPIB

2714 or 2715 Equipped

with the GPIB Interface

(Option 03)

Interconnect Cable

Application Software

Figure 1–3: T ypical Small Instrument System for GPIB

Your 2714 or 2715 must be equipped with the Option 03 GPIB interface to

operate over the General Purpose Interface Bus. Refer to RS-232 Operation

(Option 08) on page 1–1 for configuration information if your instrument has

the RS-232 interface. Press the key sequence [UTIL] [4] [9] to see a list of the

installed options and capabilities.

An appropriate interconnect cable is required to connect the controller to the

spectrum analyzer. Cables may be purchased from Tektronix by ordering one of

these part numbers:

H P/N 012-0991-01 (1 meter)

H P/N 012-0630-01 (2 meter)

Application software is the program or programs that control and acquire data

from the spectrum analyzer. You can write your own programs with the

information in this manual. However, you will need the applications interface

software supplied by the GPIB board manufacturer. For the PCII/IIA board and

the QuickBASIC language, these programs have names such as QBIB4.OBJ,

QBIB4728.OBJ, and QBDECL4.BAS. The programs include the BASIC device

function calls which enable you to communicate easily over the GPIB. The

function calls are an integral part of your application programs.

1–14

2714 & 2715 Programmer Manual

Page 27

Introduction to Programming

Printer or Plotter

(Optional)

A printer, a plotter, or both can be added to your system to provide hard-copy

output. Printers are preferred for character-based data such as parameter values or

instrument settings. Plotters provide superior results when displaying graphical

data. A convenient approach is to install a printer on a parallel port of the

controller and a GPIB-compatible plotter on the bus. With this approach,

graphical data can be plotted directly from the spectrum analyzer when the

controller is not available.

See Setting the TALK ONLY Option on page 1–18.

Setting Up for GPIB Operation

Your equipment must be correctly configured before GPIB operations can be

performed. The following tasks must be completed:

H Installation of cables between the system components

H Configuration of the spectrum analyzer and device driver

H Installation of the device driver into controller memory

H Configuration of the (optional) printer and/or plotter

This section describes each task in detail.

Connecting the

Equipment

Configuring the Spectrum

Analyzer

Placing the 2714 or 2715

Online

If your system consists of a controller and spectrum analyzer, you can simply

connect one end of the interconnecting cable to each instrument. A star configuration, daisy chain configuration, or combination of these (Figure 1–4) should be

used when more than two instruments are on the bus. Up to 15 instruments can

be connected.

To maintain electrical performance of the bus, use only one 2-meter cable per

instrument, and ensure that at least 2/3 of the connected instruments are

powered up.

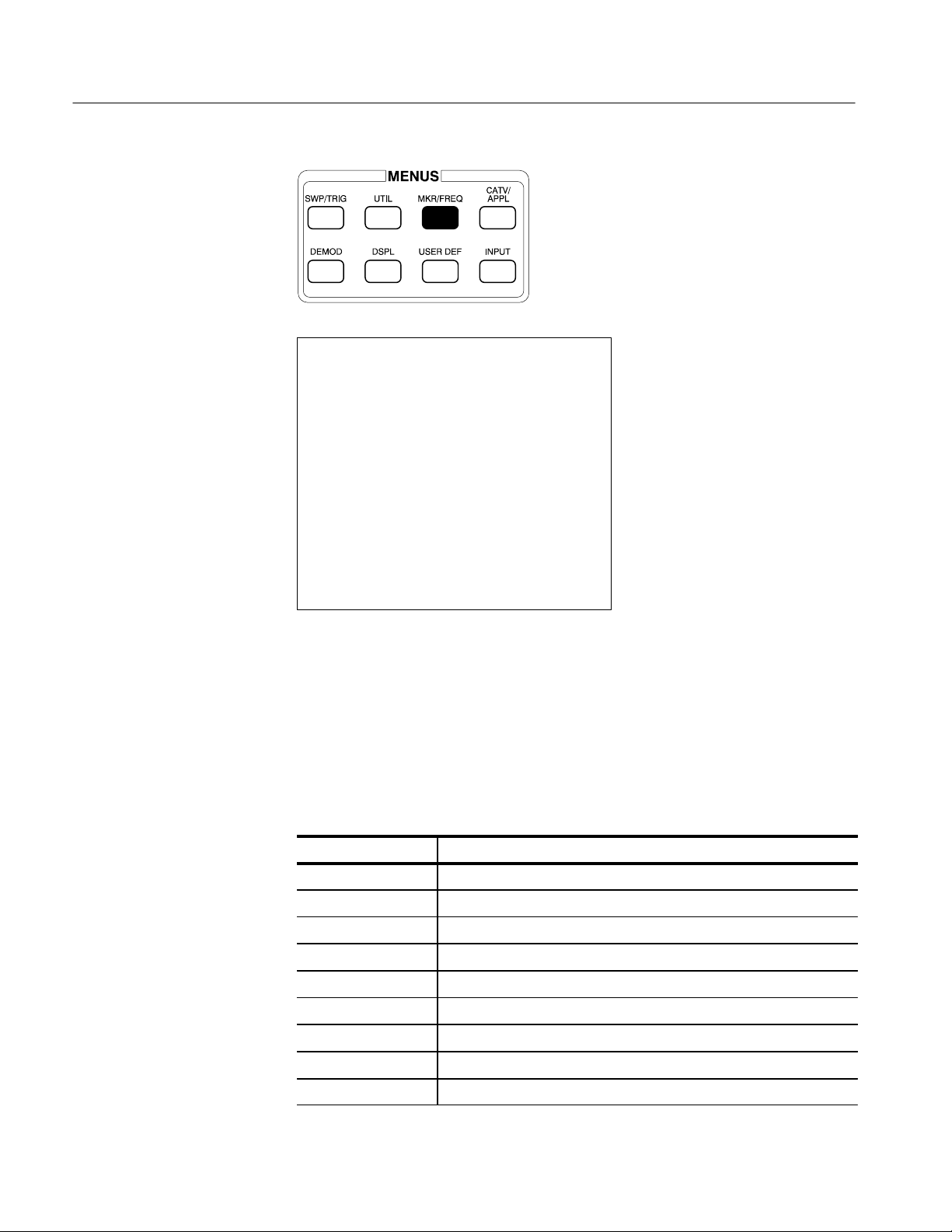

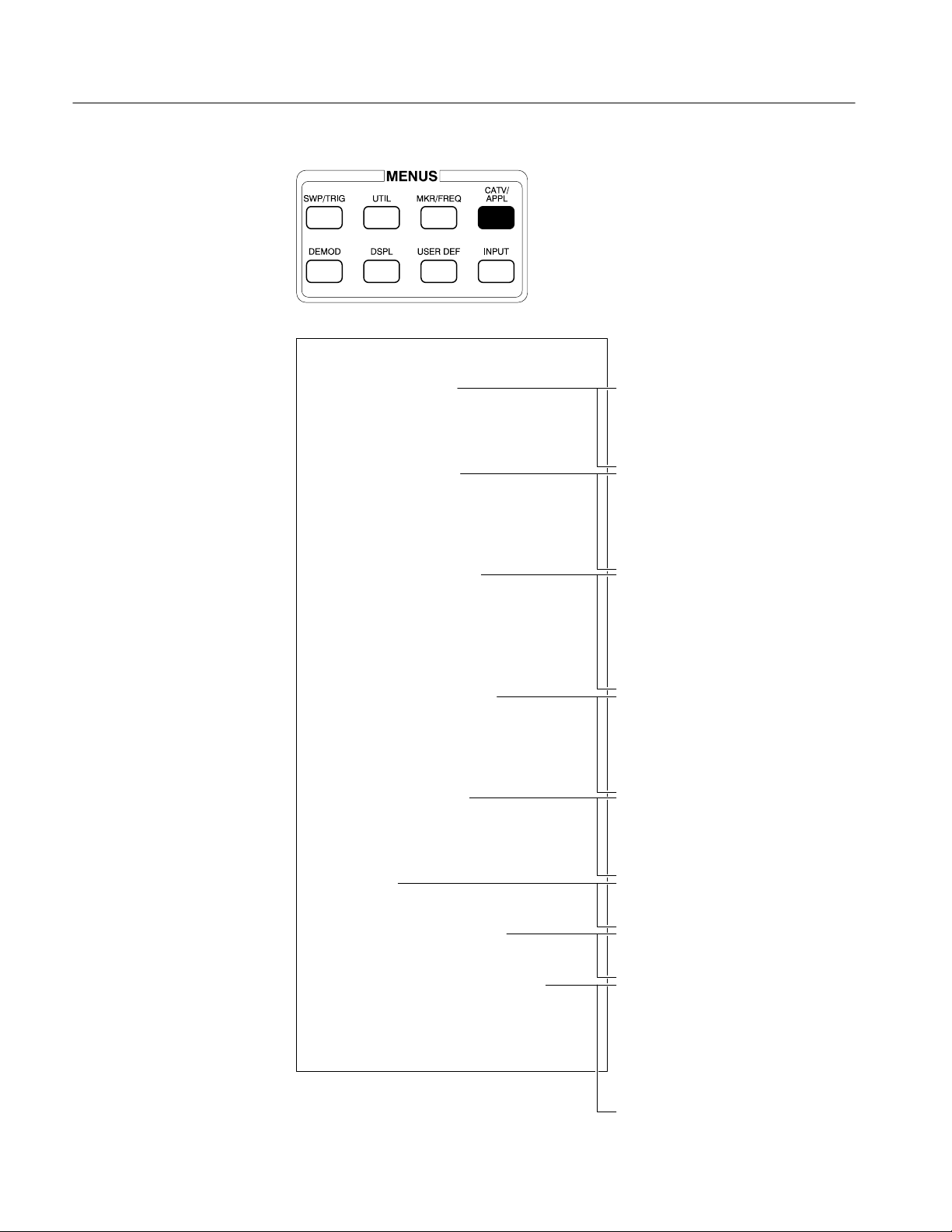

Turn on the power to the spectrum analyzer. Press the key sequence:

[UTIL] [4] [0] [0]

A GPIB PORT CONFIGURATION Menu appears. It should resemble the one

shown in Figure 1–5. You will use this menu to configure the GPIB parameters.

Item 0 of the GPIB PORT CONFIGURATION Menu, STATUS, controls the

GPIB ONLINE/OFFLINE status (see Figure 1–5). After all preparations have

been completed and GPIB operations are ready to begin, press [0] on the

KEYPAD to toggle item 0 until the STATUS indicates ONLINE. The spectrum

analyzer is then ready to exchange information over the GPIB.

2714 & 2715 Programmer Manual

1–15

Page 28

Introduction to Programming

C

B D

A

Setting the GPIB Device

Address

F

A B C D E F

Star

Daisy Chain

E

Figure 1–4: Connecting Multiple Instruments on the GPIB

Item 1 of the GPIB PORT CONFIGURATION Menu, GPIB ADDRESS, sets the

spectrum analyzer’s GPIB device address. You must assign a primary address to

the spectrum analyzer (the 2714 or 2715 does not support secondary addresses).

The address can have a value from 0 through 30. However, addresses 0 and 30

are usually reserved for system controllers.

1–16

2714 & 2715 Programmer Manual

Page 29

Introduction to Programming

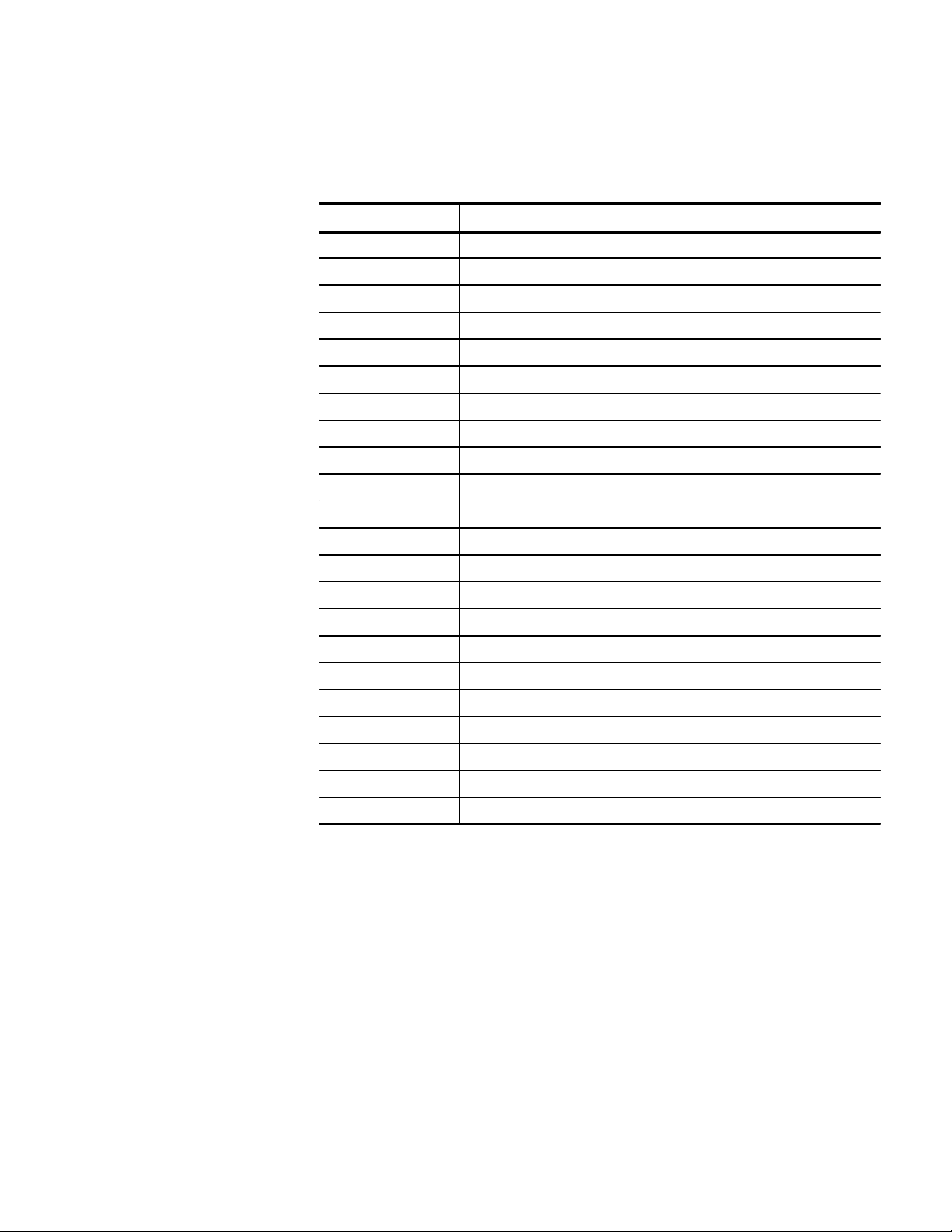

GPIB PORT CONFIGURATION

0 STATUS ON/OFFLINE

1 GPIB ADDRESS 0 Ć 30

2 POWER ON SRQ ON/OFF

3 EOI/LF MODE LF/EOI

4 TALK ONLY MODE ON/OFF

Figure 1–5: The Spectrum Analyzer’s GPIB PORT CONFIGURATION Menu

The Power-On SRQ

The address you assign is not critical, but it must not be the same address used

for any other instrument on the bus.

NOTE. The GPIB address assigned to the spectrum analyzer must be the same as

the one that was used to configure the device driver for the spectrum analyzer.

To assign the address, select item 1, GPIB ADDRESS, from the GPIB PORT

CONFIGURATION Menu. Follow the on-screen prompts to enter the desired

address using the KEYPAD for data entry. If the spectrum analyzer is the only

instrument on the bus, we suggest using 1 as the address. The address you set is

read immediately by the spectrum analyzer and is permanently retained in

non-volatile memory.

Item 2 of the GPIB PORT CONFIGURATION Menu, POWER ON SRQ, causes

the spectrum analyzer to produce an SRQ at power up. To generate a POWER

ON SRQ, press [2] on the KEYPAD until the status changes to ON.

Normally there is no need to have the spectrum analyzer generate an SRQ when

it powers up. Therefore, the default setting of item 2, POWER ON SRQ, is OFF.

However, some test sequences require that the power to the spectrum analyzer is

removed (power down). Under these conditions it may be beneficial for the

program to sense the return of power.

2714 & 2715 Programmer Manual

1–17

Page 30

Introduction to Programming

Setting the Message

Terminator

Setting the TALK ONLY

Option

Item 3 of the GPIB PORT CONFIGURATION Menu, EOI/LF MODE, selects

the message terminator. Whenever a message is transmitted over the bus, the

instrument sending the message must signify to other instruments on the bus

(including the system controller) that the message has been completed. This is

done in one of two ways:

H The interface management line named End Or Identify (EOI) is brought to

its low state simultaneously with the last data byte that is transmitted.

H The ASCII codes for carriage return (CR) and line feed (LF) are appended to

the message string. EOI is still asserted (brought to its low state) simultaneously with the transmission of LF.

All Tektronix instruments and controllers are equipped to use the EOI selection.

You should, therefore, toggle item 3 of the GPIB PORT CONFIGURATION

Menu until its status changes to EOI. The LF OR EOI setting is included for

controllers that do not use the EOI signal line. The selection you choose is

permanently retained in non-volatile memory.

Item 4 of the GPIB PORT CONFIGURATION Menu, TALK ONLY MODE,

selects the spectrum analyzer’s TALK ONLY mode.

TALK ONLY mode must be selected to send the spectrum analyzer’s output

directly to a plotter without the use of a controller. Complete these steps to send

the spectrum analyzer’s display directly to a plotter:

Configuring the Device

Driver

1. Disconnect all instruments except the spectrum analyzer and the plotter from

the bus.

2. Place the plotter in the LISTEN ONLY mode (usually done with controls on

the plotter).

3. Press the key sequence [UTIL] [4] [0] and then press [4] until the TALK

ONLY status indicates ON.

4. Press the front-panel key labelled [PLOT].

TALK ONLY mode must be disabled when the spectrum analyzer is used with a

controller, because the spectrum analyzer must talk to and listen to the controller.

To use the spectrum analyzer with a controller, press [4] on the KEYPAD until

the status indicates OFF. The system controller will determine when the

spectrum analyzer should be addressed as a talker or listener.

Instructions for configuring the device driver should be included with your GPIB

board. For example, complete the following steps when using a National

Instruments PCII/IIA board:

1. Run the IBCONF.EXE program to configure the driver.

1–18

2714 & 2715 Programmer Manual

Page 31

Introduction to Programming

2. Follow the on-screen prompts and ensure that the BOARD CHARACTER-

ISTICS screen resembles one of those shown in Table 1–1 and 1–2.

3. Create or edit the DEVICE CHARACTERISTICS screen for a device named

TEK_SA (see Table 1–3).

NOTE. You must assign the same GPIB address to the spectrum analyzer that

was used when configuring the device driver for the spectrum analyzer. Use the

EOI message terminator for all Tektronix controllers.

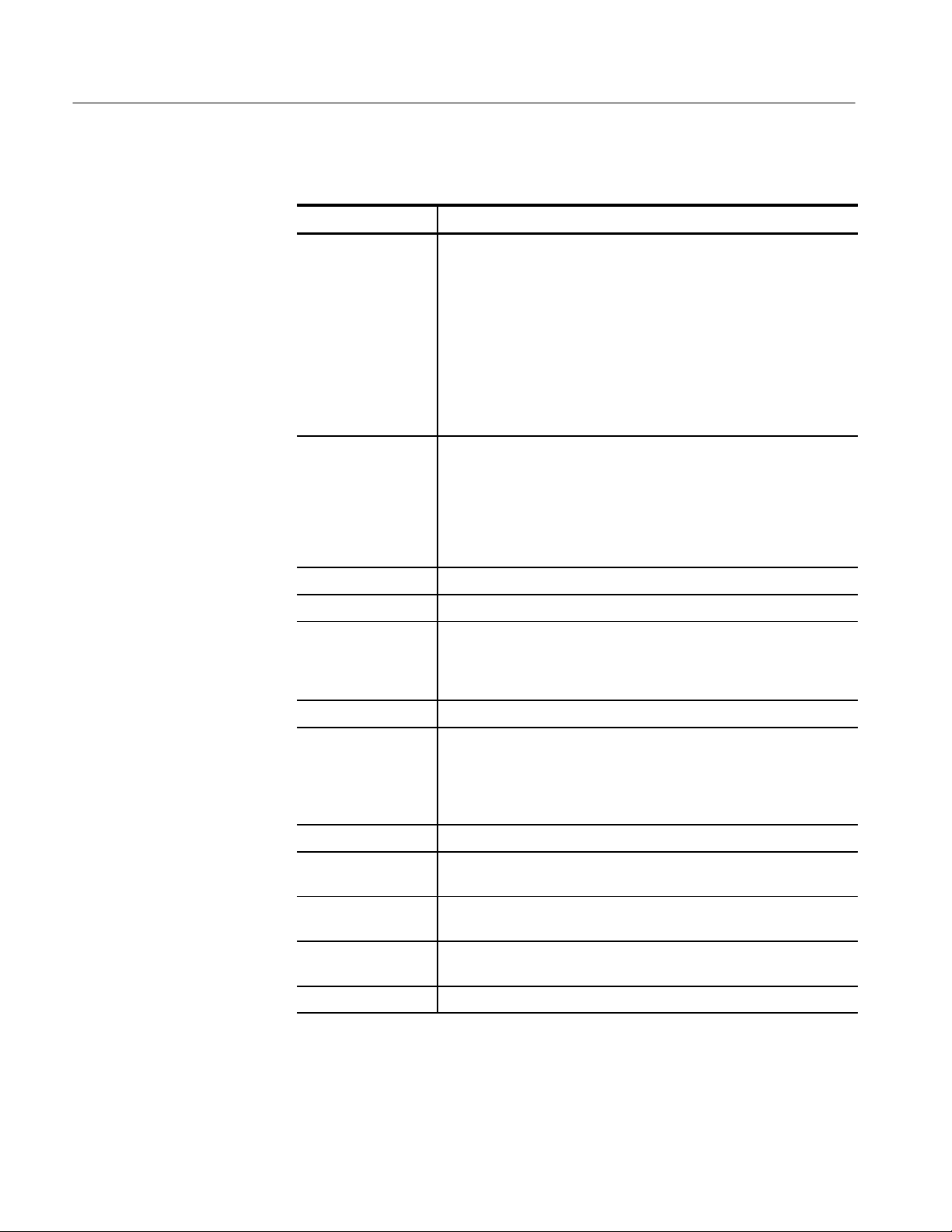

T able 1–1: National Instruments PCII Board Characteristics

Primary GPIB address 0

Secondary GPIB address NONE

Timeout setting T30s

EOS byte 00H

Terminate Read on EOS no

Set EOI with EOS on Write no

Type of compare on EOS 7-bit

Set EOI with last byte of Write yes

GPIB-PC model PC2

Board is system controller yes

Local lockout on all devices no

Disable auto serial polling yes

High-speed timing no

Interrupt jumper setting 7

Base I/O address 2B8H

DMA channel 1

Internal clock freq (in MHz) 8

T able 1–2: National Instruments PCIIA Board Characteristics

Primary GPIB address 0

2714 & 2715 Programmer Manual

Secondary GPIB address NONE

Timeout setting T30s

EOS byte 00H

Terminate Read on EOS no

1–19

Page 32

Introduction to Programming

T able 1–2: National Instruments PCIIA Board Characteristics (Cont.)

Set EOI with EOS on Write no

Type of compare on EOS 7-bit

Set EOI with last byte of Write yes

GPIB-PC model PC2A

Board is system controller yes

Local lockout on all devices no

Disable auto serial polling yes

High-speed timing no

Interrupt jumper setting 7

Base I/O address 02E1H

DMA channel 1

Internal clock freq (in MHz) 6

Installing the Device

Driver

T able 1–3: TEK_SA Device Characteristics

Primary GPIB address 1

Secondary GPIB address NONE

Timeout setting T30s

EOS byte 00H

Terminate Read on EOS no

Set EOI with EOS on Write no

Before your computer can transfer information over the GPIB, it must know how

to access the GPIB board and the spectrum analyzer. The device driver tells it

how. If you are using a National Instruments PCII/IIA board, the device driver is

a program named GPIB.COM created and modified by another National Instruments program named IBCONF.EXE. If you are using a board from another

manufacturer, the appropriate driver should have accompanied your board.

The device driver program must be installed whenever you wish to use the

GPIB. Use the following procedure. Refer to your DOS manual if you need help

creating or modifying files.

1. Copy GPIB.COM to your computer’s root directory.

1–20

2. Add the following line to your CONFIG.SYS file:

device=GPIB.COM

2714 & 2715 Programmer Manual

Page 33

Introduction to Programming

OFF

1

3. If CONFIG.SYS does not already exist in the controller’s root directory, create

a new CONFIG.SYS file.

4. Reboot your controller.

The GPIB device driver is loaded into memory whenever you boot your

computer. It then remains in memory until the computer is turned off or until a

reboot is performed.

Configuring the (Optional)

Printer or Plotter

A variety of printers and plotters are available that can be used with your system.

We recommend a serial or parallel printer connected to the appropriate computer

port, and/or an HPGL-compatible plotter connected to the GPIB. This arrangement allows data to be sent directly from the spectrum analyzer to the plotter

when the system controller is unavailable. The Tektronix HC100 plotter is

recommended. Its four pens provide a useful complement to the four-trace

capability of the 2714 or 2715.

Printer Configuration. Configuration of the printer is independent of the GPIB.

Consult your printer and computer manuals for information on setting up the

printer and corresponding computer communications port.

Plotter Configuration. Plotter configuration procedures vary. Consult your plotter

manual for the configuration appropriate to your plotter.

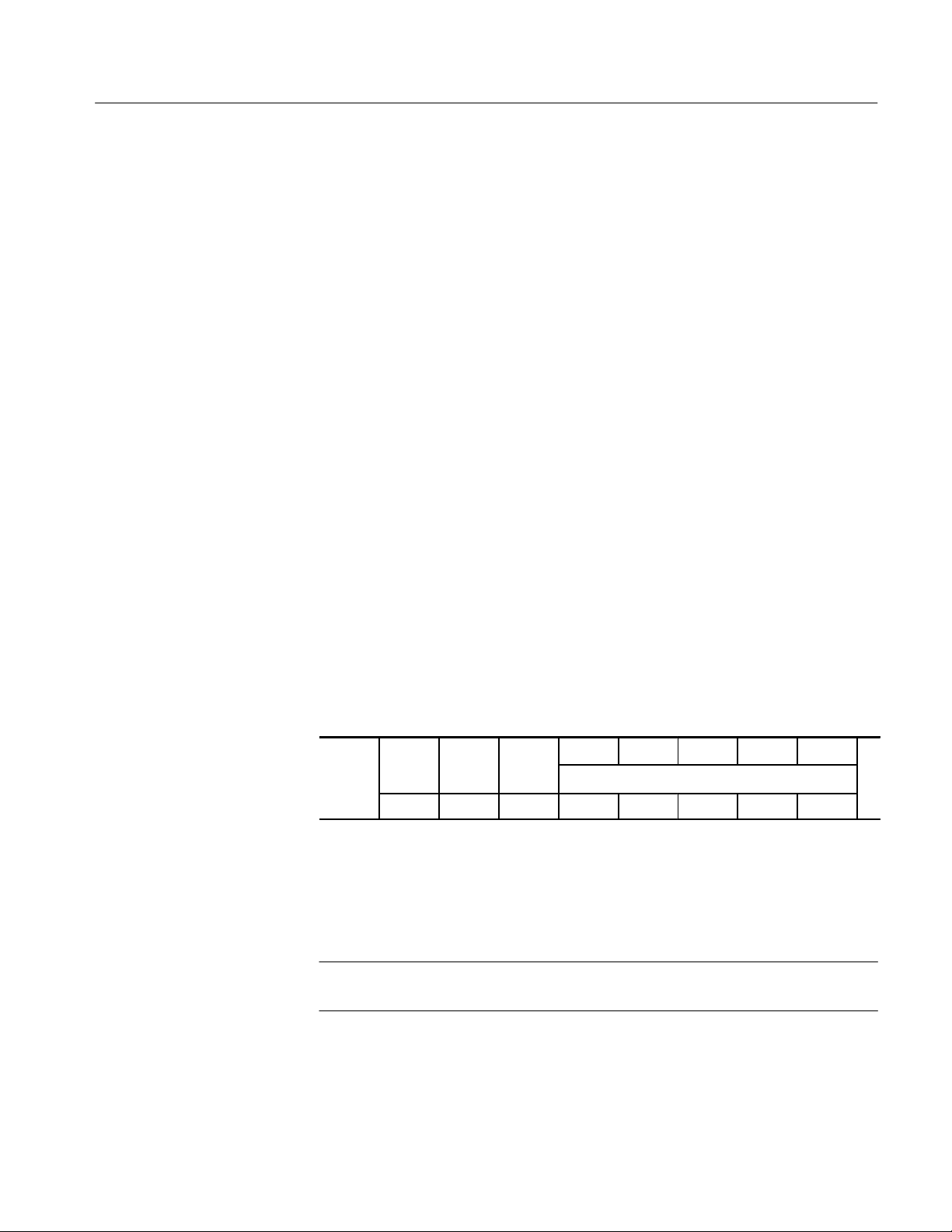

When using a Tektronix HC100 plotter, set its rear-panel DIP switches as

follows:

16 8 4 2 1

ON GPIB HPGL STD

Down Down Down Up Up Up Up Up

Address (Listen Only = 31)

0

All bits should be set when the Tektronix HC100 plotter is in LISTEN ONLY

mode, and its power must be cycled to load the settings into memory. You must

also correctly configure the plotter DEVICE CHARACTERISTICS using the

IBCONF file.

NOTE. Be sure to use the same GPIB address for the HC100 DIP switches and

the DEVICE CHARACTERISTICS.

2714 & 2715 Programmer Manual

1–21

Page 34

Introduction to Programming

Communicating with

the 2714 or 2715

The GPIB enables remote or automated control of instruments on the bus (in this

case, a spectrum analyzer). An application program (often called a test, measurement, or control program) determines spectrum analyzer operations by exchanging messages with the spectrum analyzer. The messages can be of the generic

GPIB type, or they can be instrument-specific.

Generic messages are usually carried out by GPIB hardware and the GPIB device

driver without intervention by the operator or programmer. They typically

implement routine housekeeping chores such as instrument addressing,

handshaking, requesting service, or terminating messages.

The instrument-specific messages are also referred to as device-dependent

messages. They are generally understood by, and meaningful to, only the

instrument or class of instruments for which they are designed. The organization

of the instrument-specific messages is explained in the next section of this

manual. Functional Groups provides a summary of the messages. Command and

Query Definitions describes the individual messages in detail, and Programming

provides some programming examples for the National Instruments GPIB/2714

or 2715 combination working in the QuickBASIC environment.

The spectrum analyzer is addressed as a talker or listener to send or receive

messages, depending on whether messages are being sent to or received from the

system controller. The GPIB system software provided with your GPIB card

automatically addresses the spectrum analyzer as a talker or listener depending

on the callable subroutine used. The device-dependent messages are then

transferred between the controller and the spectrum analyzer over the GPIB as

one or more eight-bit bytes of information. Proficiency in controlling the

spectrum analyzer is the key to programming these messages efficiently.

Preparing the Software

1–22

After completing the setup procedures your equipment is ready for GPIB

operation, but you must still provide the software needed to control the spectrum

analyzer. When creating new software this is usually a two step process. The first

step is to establish the programming environment. Next you can create and run

the control program. If you are using ready-made control software, simply follow

the supplier’s instructions.

When creating your own QuickBASIC software, you must ensure that QuickBASIC has the necessary GPIB information. Use the following procedure. Refer

to your DOS manual if you need help creating or modifying files.

H Copy the files QBIB4.OBJ, GPIB.QLB, GPIB.LIB, BQLB45.LIB, and

QBIB4728.OBJ from the National Instrument’s disk to the QuickBASIC

directory.

H Create the Quick library by typing this command from the DOS command

line:

LINK /Q QBIB4.OBJ QBIB4728.OBJ,GPIB.QLB,,BQLB45.LIB

2714 & 2715 Programmer Manual

Page 35

Introduction to Programming

H To make your QuickBASIC program a stand-alone *.EXE file, you need an

additional library file. Type this command from the DOS command line:

LIB GPIB.LIB + QBIB4.OBJ + QBIB4728.OBJ;

H Start QuickBASIC using this command:

QB /L GPIB.QLB

This procedure ensures that the National Instruments GPIB subroutines needed

to control devices on the bus are present in the QuickBASIC environment. When

using another version of QuickBASIC, use the analogous files and procedures

indicated in the READĆQB.DOC document file from National Instruments.

A GPIB Instrument

Control Program

You will learn more about controlling the spectrum analyzer in Sections 4

through 6 in this manual. However, we have provided a simple program here so

you can check the operation of your system and observe typical interactions

between the controller and spectrum analyzer. Be aware that the program is very

basic; it contains no error checking and may hang up the controller (requiring

you to reboot) if incorrect or unacceptable commands or queries are entered. It

will, however, accept uppercase or lowercase entries.

Alternatively, you can use the IBIC program supplied with the National

Instruments PCII/IIA GPIB board. It enables you to communicate with the

spectrum analyzer, but requires that you learn how to use a few simple subroutines such as IBWRT() and IBRD(). See your National Instruments documentation for details.

Follow these steps to use the Example Program 1-1 located on the following

pages (REM $INCLUDE: 'QBDECL4.BAS').

1. Start QuickBASIC according to the instructions in Installing and Configur-

ing the Device Driver on page 1–9. Enter the program. Be sure to enter the

program exactly as it is written. The spectrum analyzer must be named

TEK_SA by the IBCONF program.

2. Place the spectrum analyzer ONLINE by selecting item 0 from the GPIB

PORT CONFIGURATION Menu (press the key sequence [UTIL] [4] [0]

[0]). The instrument is nominally ONLINE, but is not yet handshaking with

the controller.

3. Start the program. The computer display shows:

2714 & 2715 Programmer Manual

2714 or 2715 SHOULD NOW BE HANDSHAKING

NDAC SHOULD BE DISPLAYED

PRESS ANY KEY TO CONTINUE

When the spectrum analyzer is handshaking with the controller, NDAC (Not

Data ACcepted) is displayed at the lower right of the spectrum analyzer’s

screen. NDAC is asserted most of the time. It is unasserted only briefly

1–23

Page 36

Introduction to Programming

following receipt of a message to indicate that the message has been

accepted (see Appendix B: GPIB System Concepts).

4. Press any key. The word REMOTE should appear at the lower left of the

spectrum analyzer’s screen and the controller should display these messages:

2714 or 2715 SHOULD NOW BE IN REMOTE MODE

PRESS ANY KEY TO CONTINUE

The National Instruments software places the spectrum analyzer in remote

mode whenever a message is sent (the message HDR ON was transmitted).

Unless the GPIB local lockout command is issued, any spectrum analyzer

key which alters its measurement status may be pressed to return the

spectrum analyzer to local mode. (For example, the [MENU] keys do not

change the status, but items selected from a menu may change the status.)

5. Press the [VID FLTR] key twice. The REMOTE message should disappear

from the spectrum analyzer screen.

6. Press any key. This message should appear:

ENTER MESSAGE TO SEND

Enter the message you want to send, which can be either a command or

query. For example, enter this query requesting the spectrum analyzer to

identify itself:

ID?

7. REMOTE should reappear on the spectrum analyzer screen. The word TALKER

or LISTENER will also appear momentarily. These words are displayed when

the spectrum analyzer enters the indicated mode, but because of timing

considerations, they do not always appear for short commands, queries, and

responses. You should see a response similar to the following one on the

controller’s screen:

ID TEK/2714 or 2715,V81.1,"VERSION 02.28.92 FIRMWARE",

"GPIB", "NVM 12.88", "OPT NVM 12.88";

8. The actual response depends on the options in your instrument.

9. You will then be asked:

SEND MORE (Y/N)?

Enter “Y” to send more; other answers end the program.

1–24

2714 & 2715 Programmer Manual

Page 37

Introduction to Programming

NOTE. The 2714 or 2715 must have a spectral display on its screen when any

RS-232 or GPIB program is executed. If the 2714 or 2715 is displaying a menu

when a program is executed, the program will not run properly.

Example: GPIB Test

Program

REM $INCLUDE: 'QBDECL4.BAS'

RD$ = SPACE$(3000)

CLS

CALL IBFIND("GPIB0", BD%)

V%=0

CALL IBSRE(BD%, V%)

CALL IBFIND("TEK_SA", BD%)

PRINT "2714 or 2715 SHOULD NOW BE HANDSHAKING"

PRINT "NDAC SHOULD BE DISPLAYED"

PRINT:PRINT "PRESS ANY KEY TO CONTINUE"

DO WHILE INKEY$ = ""

LOOP

WRT$ = "HDR ON"

CALL IBWRT(BD%, WRT$)

PRINT "2714 or 2715 SHOULD NOW BE IN REMOTE MODE"

PRINT:PRINT "PRESS ANY KEY TO CONTINUE"

DO WHILE INKEY$ = ""

LOOP

SEND.RCV:

CLS

PRINT:PRINT "ENTER MESSAGE TO SEND"

PRINT : INPUT WCALL IBWRT(BD%, WRT$)

QUES = INSTR(1, WRT$, "?")

HOLD.TIME = TIMER

DO WHILE TIMER < HOLD.TIME + 1

LOOP

IF QUES = 0 THEN GOTO MORE

CALL IBRD(BD%, RD$)

PRINT:PRINT "THE REPLY IS:"

PRINT:PRINT MID$(RD$, 1, IBCNT%)

MORE:

PRINT:PRINT

INPUT "SEND MORE (Y/N)? "; Y$

IF Y$ = "Y" THEN GOTO SEND.RCV

END

2714 & 2715 Programmer Manual

1–25

Page 38

Introduction to Programming

1–26

2714 & 2715 Programmer Manual

Page 39

Message Structure

Page 40

Page 41

Instrument-Specific Message Structure

Communications between the system controller and the 2714 or 2715 are

accomplished by instrument-specific messages. Instrument-specific messages

exchanged over the RS-232 or GPIB interface control the measurement and

display functions of the spectrum analyzer. These messages are always transmitted over the data lines (with the exception of the EOI message terminator).

Instrument-specific messages control parameters such as center frequency,

span/division, reference level, and resolution bandwidth. It is the system

programmer’s task to efficiently compile a series of messages in a script

designed to implement specific tests and measurements. The script, or control

program, is written in a conventional computer language and embodies specific

spectrum analyzer commands and queries.

When the GPIB interface is installed, generic GPIB messages are exchanged

between the system controller and the 2714 or 2715 in addition to instrumentspecific messages. Generic GPIB messages exercise control over the bus and

carry out routine system operations such as instrument addressing, handshaking,

requesting service, and terminating messages. GPIB messages may be transmitted over the handshake lines or interface management lines (uni-line

messages), or they may be transmitted over the data lines (multi-line messages).

The GPIB hardware and software usually sends and receives these messages in a

way that is transparent to the system operator or programmer. Refer to

Appendix B: GPIB System Concepts for additional information about uni- and

multi-line messages.

What Is A Message?

An instrument-specific message consists of three or more 8-bit bytes of

information that are transferred between the spectrum analyzer and the system

controller. Each byte represents an ASCII character or binary data. A message

may be an input message or an output message. It may contain one or more

message units.

For instance, here is an example of a message from Mary to John:

2714 & 2715 Programmer Manual

John

dinner Ć put in oven; washing machine Ć start; bank Ć

withdraw how much?; cat Ć let her in

Bye bye

2–1

Page 42

Instrument-Specific Message Structure

John’s response may resemble this one:

Mary

$100

Bye bye

He could also respond this way:

Mary

Withdraw Ć $100

Bye bye

These messages are structured in a similar manner. Each contains a salutation

(John and Mary). Each message consists of one or more message units. For

instance, Mary’s message to John has four units. One of these is a query and is

identified by a question mark (?). Each message unit begins with a “header”

describing what the message is about (such as dinner or cat). The header is

separated from its object or argument by a dash (–), which is the argument

delimiter. Message units are separated or delimited by semicolons (;).

Message Unit

Input Message

Output Message

Each of John’s messages to Mary consist of a single response indicating how

much money she should withdraw. If John thinks Mary will remember her own

question (withdraw how much?), he may simply reply “$100” as in the first

example. However, to relate his response to her question he may answer

“Withdraw - $100” as in the second example. The latter form is equivalent to

receiving a response from the spectrum analyzer when HDR ON is selected (see

Command and Query Definitions). Both messages close with a message

terminator “Bye bye”.

The instrument-specific messages for the 2714 or 2715 are constructed in a

similar way. The following definitions clarify the structure.

A message unit is a single command, query, or response.

An input message is one or more message units, along with any message unit

delimiters (separators) and a message terminator, transmitted from the controller

to the 2714 or 2715.

An output message is one or more message units, along with any message unit

delimiters (separators) and a message terminator, transmitted from the 2714 or

2715 to the controller.

2–2

2714 & 2715 Programmer Manual

Page 43

Instrument-Specific Message Structure

Message Unit Delimiter

Message Terminator

(RS-232)

A semicolon (;) must be used to delimit or separate message units in a message.

Following the last message unit, the use of a delimiter is optional with one

exception. The 2714 or 2715 always appends a message unit delimiter as the last

data byte when it sends a response.

If desired, you may substitute the line feed character for the semicolon in the

case of responses (see the MSGdlm command in Command and Query Defini-

tions). Do not confuse the line feed character with the optional message

terminator discussed next.

When a controller sends data to the 2714 or 2715, the spectrum analyzer

interprets both CR and LF as message terminators. Messages sent by the

spectrum analyzer over the RS-232 interface can be terminated in the following

ways:

H By CR only (carriage return, ASCII 13)

H By LF only (line feed, ASCII 10)

H By CR-LF (carriage return followed by line feed)

See Setting the Message Terminator in the Setting Up for RS-232 Operation part

of Introduction to Programming for instructions about configuring the message

terminator for RS-232 instruments.

Message Terminator

(GPIB)

Command

Messages exchanged over the GPIB interface (Option 03) can be terminated in

one of two ways:

H The EOI interface management line is brought low (asserted) simultaneously

with the last byte of the message.

H ASCII codes for carriage return (CR) and line feed (LF) are appended to the

end of message, and the EOI interface management line is asserted simultaneously with transmission of the LF character.

All Tektronix instruments assert the EOI line. The CR-LF terminator option is

provided for instruments that do not use the EOI line. If you are using such an

instrument, select the CR-LF option (see Setting the Message Terminator in the

Setting Up for GPIB Operation part of Introduction to Programming). Termina-

tor control is handled automatically by the GPIB hardware and software.

A command generally consists of a command mnemonic or header, header

delimiter, argument(s), and argument delimiter. For example, the command

SAVE A:ON, B:ON

enables the SAVE A and SAVE B functions. In this example, SAVE is the

command header. The space between SAVE and A:ON is the header delimiter.

2714 & 2715 Programmer Manual

2–3

Page 44

Instrument-Specific Message Structure

A:ON and B:ON are arguments, and the comma (,) following A:ON is the argument

delimiter.

Some commands have no arguments, or only one argument, and may not require

header or argument delimiters. For instance, the command

GTL