Page 1

Model 251 I-V Test Software

Instruction Manual

Contains Operating Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be

defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transporta-

tion prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation

prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at

least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of any product or part. This warranty also does not apply to fuses, software, nonrechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYERS SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE

USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN

ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES

SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES

SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Test Instrumentation Group, Keithley Instruments, Inc. l 28775 Aurora Road * Cleveland, Ohio 44139 l (216) 248-0400 l Fax: (216) 248-6168

AUSTRIA:

FRANCE:

GERMANY:

GREAT BRITAIN:

ITALY

JAPAN:

NETHERLANDS:

SWITZERLAND:

TAIWAN:

Keithley Instruments GesmbH l Rosenhiigelstrasse lKeithley Instruments SARL l 3 All& des Garays l B.l? 60 l 91121 Palaiseau C&+x l 0160-1151-55 l Fax: 01-60-11-77-26

Keithley Instruments GmbH l Landsberger Sh. 65 l D-8034 Gemwring l 089-849307-O l Fax: 089-84930759

Keithley Instruments, Ltd. l The Minster l 58 Portman Road l Reading, Berkshire RG3 IEA l 07X-575666 l Fax 0734-596-l69

Keithley Instruments SRL l Viale S. Gimignano 38 l 20146 Milano l 02-&8303008 l Fax: 0248302274

Keithley Instruments Far Fast KK l Sumiyoshi 24 Bldg., Room 201 l 2-X-2Sumiyoshi-cho l Naka-ku, Yokohama 231 l 81-45-201-2246 l Fax: 81-45-201-2247

Keithley Instruments BV l Avelingen West -19 l 4202 MS Gorinchem l Postbus 559 l 4200 AN Gcxinchrm l 01830-35333 l Fax: 01830-30821

Keithley Instruments SA l Kriesbachstrasse 4 l 8600 Dilbendorf l 01-821-9444 l Fax: 01-820-3081

Keithley Instruments Taiwan l 3rd Floor, Spring Plaza 6 l Section 3, Min Chuan East Road l Taipei, R.O.C. l 8R6-2-501-7065 l Fax: S866-2-509-5329

7 l A-1120 Wien .0222-804-6548 . Fax: 0222-804-3597

Page 3

hstructionManual

Model 251

I-V Test Software

61990, Keithley Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

Document Number: 251-901-01 Rev. B

Page 4

AI1 Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other btand and product names are trademarks or registered trademarks of their respective holders

Page 5

Model 251 I-V Test Software

OVERVIEW

INSTRUMENTS CONTROLLED: Model 236/237/238 Source Measure

Units (SMU),Model213QuadVoltageSource,Model707MahixSwitch.

Model 2361 Trigger Controller is required for 2 or more SMUs.

TESTS: Control instruments to source and measure current or voltage.

CurveFarnR~SWEEP,SYNCHSWEEP,STEP,andupto3BIASchannels,

Linear, log, linear pulsed and log pulsed sweeps.

DC Source-Meas& Up to 6 BIAS Channels.

GPIB CONTROL: Provides basic control of any GPIB instrument. Useful

for controlling sources, switch matrices, hot chucks, and probers.

707 MATRIX SUPPORT: Upload and download setups (up to 100

memories).

DATA DISPLAY: Graphic or list display.

XY or XYY Graph Axer Manual or auto scale, linear or log, labeled, X-

axis and Y-axis invert.

Overlay two sets of reference data on original.

GRAPHIC ANALYSIS: Dual data curve markers with data value readout.

Line Display Between markers. Readout slope, l/slope, X- and Y-

intercept. Zoom between markers. Filter data curve.

Gain/Ratio Calculation: DC or differential. Data array or point. Graphic

display or readout referenced to marker position. Used for Beta, g,,, or

resistsnce.

PRINT/FLOTr Hardcopy output of any screen to printer,or output graphic

display to plotter.

FILES: Data File: Contains Data, test, GPIB and display parameters.

Test Setup File: Contains Test, GPIB and display parameters.

l~dw.rnrn, P,%nGm.e+inn lxia. Prm+*;na r”rk...... ..I. ..*..7-

. ..“.a-.-... b”.Y.~w.mU”‘. a Y.G. b”AIba.AW uwucullell, ,mn,sa,

GPIB addresses, Trigger Controller channels.

Test Sequence Files: Contains the user’s pre-programmed test

sequence 64!XlI file).

787 Filer Contains 707 matrix setups.

Data Ex~ort/Irnportr Contains Da& array names and units. Lotus

(.WKl) and ASCII (.ASC).

AUTOMATICTESTSEQUENCES:Programanysequenceoftests,prints,

plots, 707 downloads, data save/acport, prompts and display, for attendedorunattendedoperation. Printingorplottingcanbedoneoff-line

(after acquisition).

MEASUREMENT CAPACITY LIMITS: A curve in the Curve Family Test

may contain up to 1000 points. Up to six source arrays and up to six

measurement arrays can be created by each test. Each array is limited to

4000 Points. The maximum number of arrays and tests is limited only by

the available disk storage space.

HELP: On-line, context sensitive, with index.

SYSTEM REQUIREMENTS

MINIMUM HOST COMFUTERr IBM compatible 80386,640kb Conven-

tional RAM (53Ok or 542720 bytes free) plus 1Mb of LIM expanded

memory, hard drive (2MB free), 720kb 3v2 inch or 1.2Mh 5v, inch floppy

drive, Intel 80387 math coprocessor, EGA color monitor and graphics

card, parallel Port.

OFERATING SYSTEM: M!3-DOS or PC-DOS 3.2 kninhum).

GRAPHICS ADAPTER EGA or VGA color, VGA monochrome.

COMPATIBLE PRINTERS: IBM Graphics Printers, Epson or compatible,

HP LaserJet, IBM Proprinter, and Okidata Microline 182.

COMPATIBLE PLOTTERS HP7440, HP7470, HP7475.

COMFATIBLE MOUSE: Microsoft or Logitech.

IEEE-488 (GPIB) INTERFACE CARDS SUPPORTED

Advantech PCL 748

B&C PC488A

BBS GPIB-1000

CaPital Equipment rcc>4u,4x488, P5-9488

Contec GPIB (PC)

Hewlett Packard HPIB

IBM GPIB board

ICS 488-PC1

IOtech GP488, GP488/2

Keithley PC488CEC, 4-488-CEC-OM, 4+488-CEC-lM, P%W-CEC

MetraByte IE-488

National Instruments GPIB-PC, GPIB-PC& GPIB-PCRA, GPIB-PClII,

MC-GPIB, AT-GPIB

Qua Tech MXI-100, I&XI-1000

Scientific Solutions IEEE 488 LM, MC-IEEE 488

Ziatech ZT 1444,ZT/2

.- an

SUPPLIED TEST LIBRARY

The Test Library provides default settings for the Test, 707 Matrix, GPIB

Control, Data Display and Graphic Analysis screens.

FET TESTS: Curve Family, Threshold Voltage, Transconductance, Break-

down, and Leakage.

BIPOLAR TESTS: Curve Family, Gummel Plot, Current Gain, Break-

down, and Leakage (linear and pulsed sweeps).

DIODE TESTS: I-V Curve, Reverse Breakdown, Zener Voltage.

COMPONENT TESTS: Capacitor Leakage, Resistor Voltage Coefficient.

EXAMPL.E GPIB CONTROL: 213 Quad Voltage Source, 707 Switching

Matrix and hot chuck.

TEST SEQUENCES: Bipolar tests, multiple diodes.

MATERIALS PROVIDED

Instruction Manual

Diskettes: 720kb 3tis inch and 1.2Mb 5v, inch containing installation,

program, test library, and sample data.

Specifications subject to change without notice.

Page 6

INTRODUCTION

This addendum to the Model 251 Instruction Manual is being provided to supply you with the

latest information in the least possible time. Please incorporate the following information into the

manual.

LOADING AND SAVING FILES

An enhancement to the Model 251 I-V Test Software is its ability to perform file operations from

the CURVE FAMILY TEST and DC SOURCE-MEASURE TEST forms. You no longer have to return to the main menu to load/save data, test setup, instrument configuration, and 707 files, or

import/export ASCII and Lotus formatted files. (Loading sequence files remains a main menu operation.)

This load/save enhancement is implemented with function keys. The 4% key loads (and imports) files and the <F3> key saves (and exports) file.

When the cl% key is pressed from the CURVE FAMILY TEST or DC SOURCE-MEASURE TEST

form, the following pop-up is displayed:

Load Data File

I

Load Test File

Load Inst. Cf. File

Load 707 File

hn~ortm File

Imbort Lotus File 1

Use the cursor to select the desired operation and press <Enter>. When loading test setup and data

files, you are reminded that loading overwrites old test parameters and data. If you continue, the

next screen prompts for a file name in the usual manner. After the tile is loaded or imported you

are returned to the appropriate test form.

Page 7

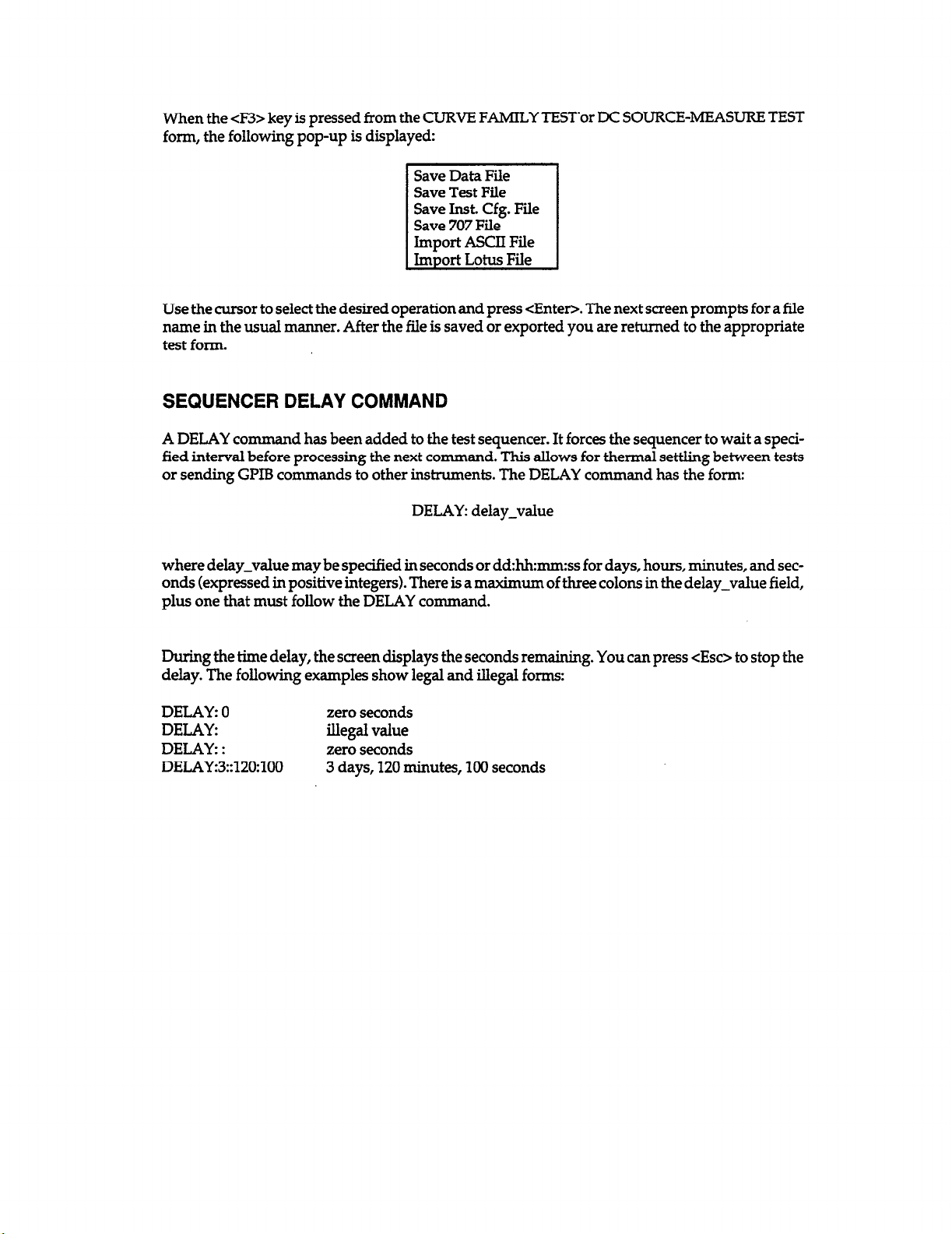

When the <F3> key is pressed from the CURVE FAMILY TESTor DC SOURCE-MEASURE TEST

form, the following pop-up is displayed:

Save Data File

Save Test File

Save Inst. Cfg. File

Save 707 File

Import ASCII File

Import Lotus File

Use the cursor to select the desired operation and press <Enter>. The next screen prompts for a file

name in the usual manner. After the file is saved or exported you are returned to the appropriate

test form.

SEQUENCER DELAY COMMAND

A DELAY co

mmand has been added to the test sequencer. It forces the sequencer to wait a specified interval before processing the next command. This allows for thermal settling between tests

or sending GPIB commands to other instruments. The DELAY command has the form:

DELAY: delay-value

where delay-value may be specified in seconds or dd:hh:mrn:ss for days, hours, minutes, and seconds (expressed in positive integers). There is a maximum of three colons in the delay-value field,

plus one that must follow the DELAY command.

During the time delay, the screen displays the seconds remaining. You can press <Eso to stop the

delay. The following examples show legal and illegal forms:

DELAY: 0 zero seconds

DELAY: illegal value

DELAY: : zero seconds

DELAY:3::120:100 3 days, 120 minutes, 100 seconds

Page 8

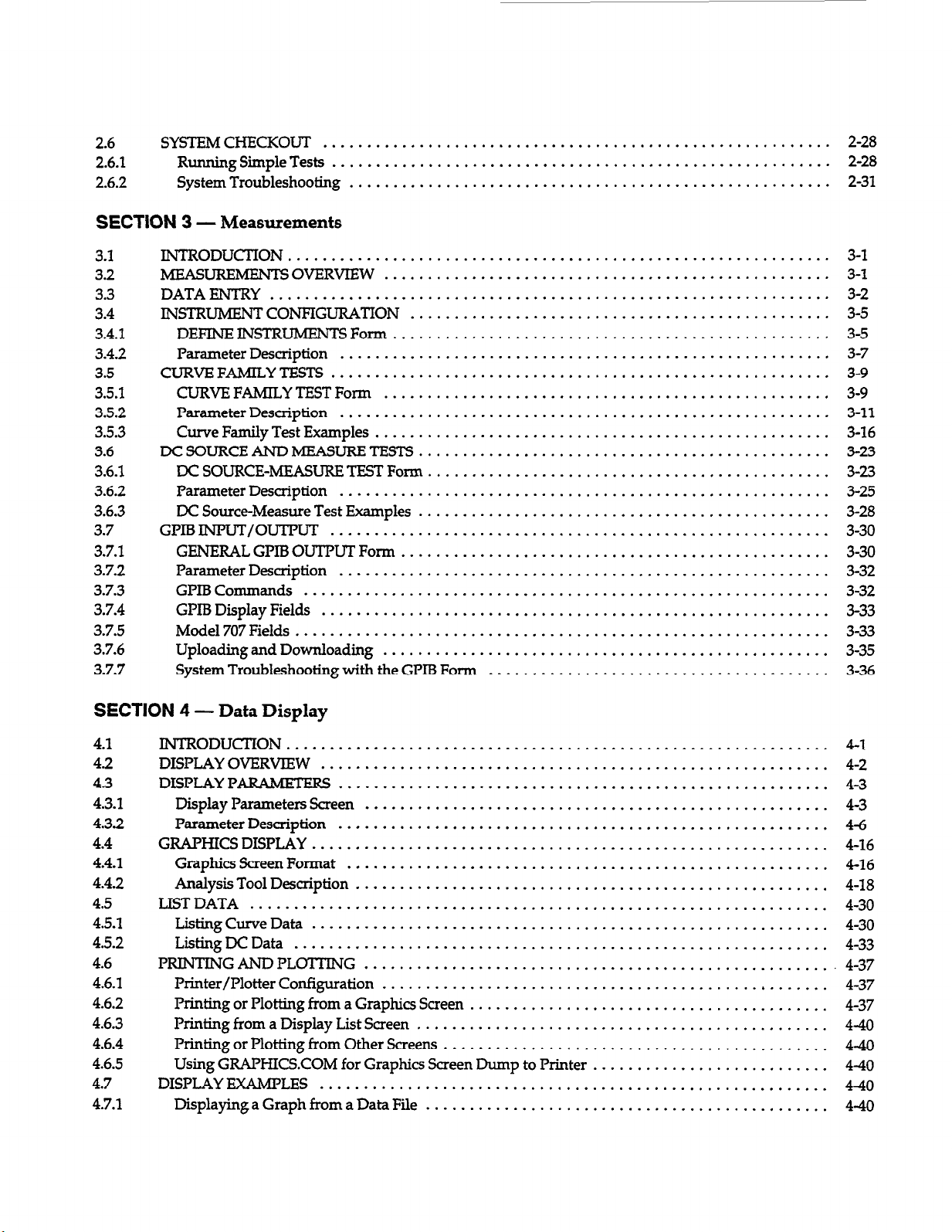

Table of Contents

SECTION 1

1.1

1.2

1.3

1.4

1.5

1.6

1.6.1

1.6.2

1.6.3

1.7 COMPUTERREQ

1.7.1 ComputerHardware

1.7.2 IEEE-488Interfaces..

1.7.3 Printers and Plotters

- General Information

INTRODU~ON

FEATURES

WARRANTYINFORMATION

MANUALADDENDA

sAFETysyMBoLsANDTERMs

UNFACKINGANDINSPECTION..

UnpackingProcedure..

Shipment Contents

InstructionManual

..............................................................

...................................................................

....................................................

..........................................................

..................................................

.......................................................

...........................................................

...........................................................

UIREMENTS ...................................................

..........................................................

.........................................................

..........................................................

...............................................

SECTION 2 - Getting Started

2.1

2.2

2.2.1

2.2.2

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.4 COMPUTERHARDWARE AND SOWARE INSTALLATION

2.4.1 IEEE-488 Interface Card Installation

2.4.2

2.4.3 Software Backup

2.4.4 Software Installation and Configuration

2.4.5 Software Reconfiguration

2.5

2.5.1 RunningtheSoftware..

2.5.2

2.5.3 ExpandedMemoryRequirement

2.5.4

2.5.5

2.5.6

2.5.7

2.5.8

2.5.9

~ODUCTION

HARDWARECONFIGURATION

SystemBlockDiagram

system coNlections

sYsTEMPowER-ulJ

Instrument Power Requirements

PowerConnections

EnvironmentalConditions

Warm-upperiod

Power-upprocedure

CopyProtedionBlock

OPERATIONOVERVIEW

DosMemoryRequirement

Setting Up Printers and Plotters

MainMenuOptions

UsingFunctionKeys

HowtoGetHelp

Configuring the IEEE-488 Card

ConfiguringtheInstruments

..............................................................

.................................................

........................................................

..........................................................

...........................................................

.................................................

...........................................................

.....................................................

.............................................................

..........................................................

..............................................

.........................................................

.............................................................

...........................................

......................................................

.......................................................

.......................................................

.....................................................

.................................................

................................................. 2-21

..........................................................

..........................................................

.............................................................

..................................................

....................................................

...........................

l-l

1-l

l-2

l-2

l-2

l-2

l-2

l-2

l-2

l-3

l-3

l-3

l-3

2-l

2-l

2-l

2-4

2-13

2-13

2-13

2-13

2-13

2-13

2-15

2-15

2-16

2-16

2-17

2-18

2-19

2-19

2-20

2-21

2-22

2-24

2-25

2-26

2-27

Page 9

2.6

2.6.1

2.6.2

SYSTEM CHECKOUT

Running Simple Tests

SystemTroubleshooting .......................................................

..........................................................

SECTION 3 - Measurements

.........................................................

2-28

2-28

231

3.1

3.2

3.3

3.4

3.4.1

3.4.2

3.5

3.5.1

3.5.2

3.5.3

3.6

3.6.1

3.6.2

3.6.3

3.7

3.7.1

3.7.2

3.7.3

3.7.4

3.7.5

3.7.6

3.7.7

INTRODUclTION

MEAS~OVFRVIEW ...................................................

DATAENTRY ................................................................

INSTRUMENTCONFIGURATION

DEFINE INSTRUMENTS Form

ParameterDescription ........................................................

CURVEFAMILYTESTS .........................................................

CURVEFAMILYTESTForm

ParameterDescription ........................................................

Curve Family Test Examples ....................................................

DcsOuRcEANDMEAsuRETESTs ...............................................

DcSOuRcE-MEAsuRETEsTFo~

ParameterDescription ........................................................

DC Source-Measure Test Examples ...............................................

GPlBINPUT/OTJTPUI .........................................................

GENERALGPIBOUTPUTForm .................................................

ParameterDescription ........................................................

GPIBCommands ............................................................

GPIB Display Fields ..........................................................

Model707Fields .............................................................

Uploading and Downloading

System Troubleshooting with the GPlB Form .......................................

..............................................................

................................................

..................................................

...................................................

..............................................

...................................................

3-l

3-l

3-2

3-5

3-5

3-7

3-9

3-9

3-11

3-16

3-23

3-23

3-25

3-28

3-30

3-30

3-32

3-32

3-33

3-33

3-35

3-36

SECTION 4 - Data Display

4.1

4.2

4.3

4.3.1

4.32

4.4

4.4.1

4.4.2

4.5

4.5.1

4.5.2

4.6

4.6.1

4.6.2

4.6.3

4.6.4

4.6.5

4.7

4.7.1

INTRODUcIloN ..............................................................

DISl?LAYOVERVIEW ..........................................................

DISPLAYPV.. ......................................................

DispIayParametersScreen .....................................................

Parameter Description

GRAPHICSDISPLAY ...........................................................

Graphics Screen Format .......................................................

AnalysisToolDescription ......................................................

LISTDATA ..................................................................

ListingCurveData ...........................................................

ListingDCData .............................................................

PRINTINGANDPLOITING .....................................................

Printer/PlotterConfiguration

Printing or Plotting from a Graphics Screen

Printing from a Display List Screen

Printing or Plotting from Other Screens

Using GRAPHICS.COM for Graphics Screen Dump to Printer

DISPLAYEXAMPLES ..........................................................

DisplayingaGraphfromaDataFiIe

........................................................

........................................... .

.........................................

...............................................

............................................

...........................

..............................................

.......

4-l

4-2

4-3

4-3

4-6

4-16

4-16

4-18

4-30

4-30

4-33

4-37

4-37

4-37

4-40

4-40

4-40

440

4-40

Page 10

4.7.2

4.7.3

4.7.4

4.7.5

4.7.6

Graphical Analysis Example

GraphOverlay

SecondYAxis(Y2)Graphing

ListingData

Printing/PlottingData

..............................................................

................................................................

SECTION 5 - File Operations

....................................................

...................................................

........................................................

4-42

446

4-48

4-48

5.1

5.2

5.2.1 TestSetupFiles

5.2.2

5.2.3

5.2.4 Import/ExportFormatFiles

5.2.5

5.3

5.4

5.5 RENAMINGnES

5.6 DELETINGFnES

5.7 EXPORT/IMPORTDATA

5.7.1

5.7.2

5.7.3

5.7.4

INTRODUCTION

FILETYPES

DataFiles

InstrumentConfigurationFiles

DefaultDirectories

LOADINGFILES

SAvINGFnES

ExportData

ImportFiles

Export/Import Data Format

ASCIIExport/ImportDataFormat

..............................................................

..................................................................

..............................................................

..................................................................

...........................................................

..............................................................

................................................................

.............................................................

..............................................................

................................................................

................................................................

SECTION 6 - Test Sequencer

6.1

6.2

6.3

6.3.1

6.3.2

6.3.3

6.3.4

6.3.5

6.3.6

63.7

6.3.8

6.4

6.5

6.6

~ODU~ON

TESTSEQUENCEROVERVIEW

TESTSEQUENCEFILE

TestSequenceGrammar

MessageS~eens

METACommands

TESTCommand.. ...........................................................

LOOP...ENDLOOPComman d

CONFIGCommand

PROMpTCommand

707FILECommand..

PARSER

ERRORFnES

SAMPLETESTSEQUENCE . . . . ..-...............................................

.....................................................................

..............................................................

.........................................................

.............................................................

...........................................................

..........................................................

..........................................................

.........................................................

.................................................................

..................................................

....................................................

.......................................................

....................................................

...............................................

...................................................

.......................................................

..................................................

5-l

5-l

5-2

5-2

5-2

5-3

5-3

5-3

54

5-5

5-5

5-5

5-6

5-6

5-7

S-10

6-l

6-l

6-2

6-2

65

6-5

6-6

6-8

6-10

6-10

6-12

6-13

6-14

6-14

A SoftwareStructure .............................................................

B

C

D

ErrorMessages

Model 2361 Trigger Controller

TestLibrary ..................................................................

................................................................

....................................................

A-l

B-l

C-l

D-l

Page 11

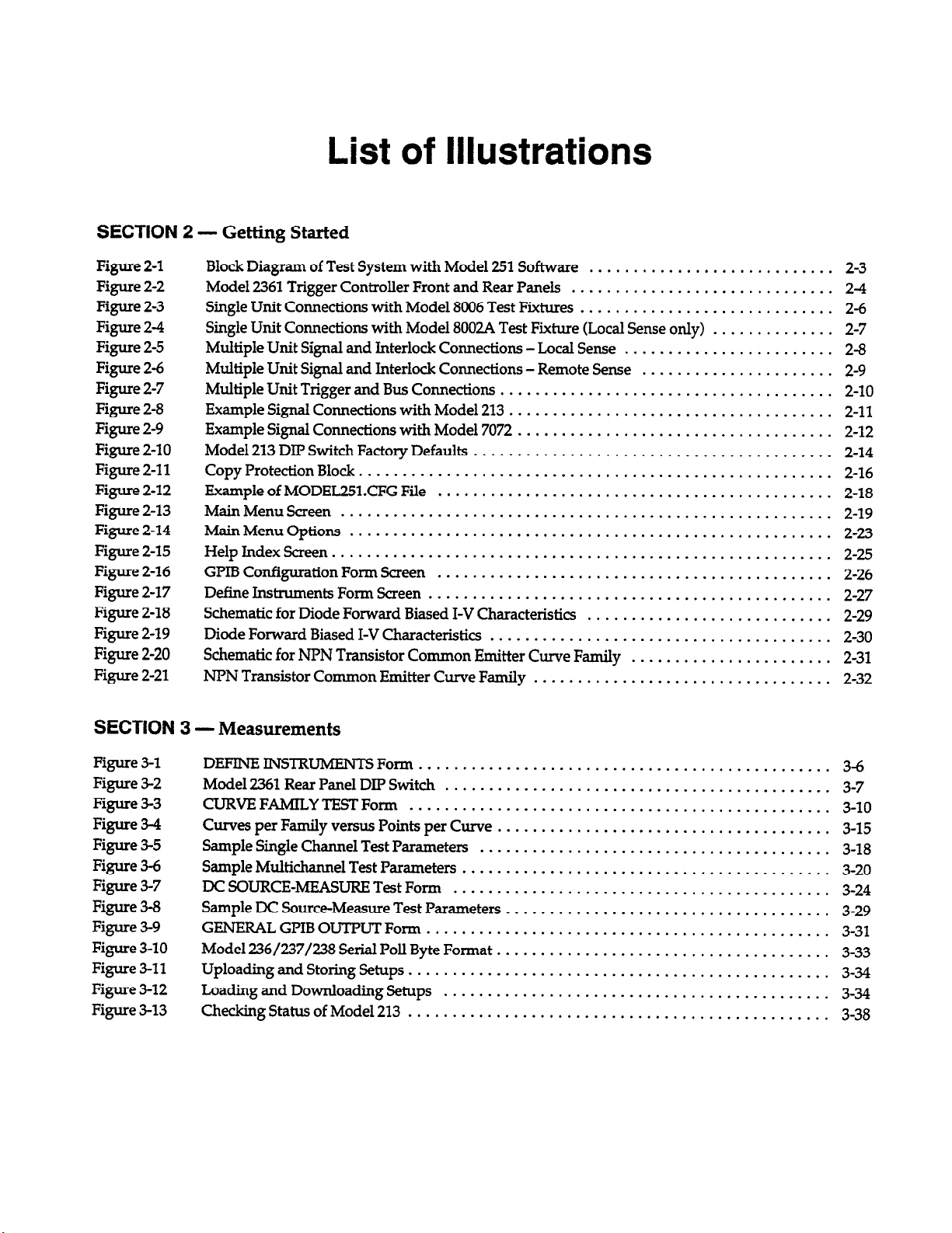

List of Illustrations

SECTION 2 - Getting Started

Figure 2-l

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-l 0

Figure 2-l 1

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure 2-16

Figure 2-17

Figure 2-l 8

Figure 2-l 9

Figure 2-20

Figure 2-21

BlockDiagramofTestSystemwithModel251Software

Model 2361 Trigger Controller Front and Rear Panels

Single Unit Connections with Model 8006 Test Fixtures

Single Unit Connections with Model 8002A Test Fixture (Local Sense only)

Multiple Unit Signal and Interlock Connections - Local Sense

Multiple Unit Signal and Interlock Connections - Remote Sense

Multiple Unit Trigger and Bus Connections

Example Signal Connections with Model 213

Example SignaI Connections with Model 7072

Model 213 DIP Switch Factory Defaults

Copy Protection Block

Example of MODEL25KFG File

MainMenuScreen ........................................................

MainMenuOptions .......................................................

HelpIndexScreen

GPIB Configuration Form Screen

Define Instruments Form Screen

Schematic for Diode Forward Biased I-V Characteristics

Diode Forward Biased I-V Characteristics

Schematic for NPN Transistor Common Emitter Curve Family

NPN Transistor Common Emitter Curve Family

......................................................

.............................................

.........................................................

.............................................

..............................................

......................................

.....................................

....................................

.........................................

.......................................

..................................

............................ 2-3

..............................

.............................

........................

......................

............................

.......................

..............

2-4

2-6

2-7

2-8

2-9

2-10

2-l 1

2-12

2-14

2-16

2-18

2-19

2-23

2-25

2-26

2-27

2-29

2-30

231

2-32

SECTION 3 - Measurements

Figure 3-l

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-9

Figure 3-10

Figure 3-l 1

Figure 3-12

Figure 3-13

DEFINE INSTR UMENTsForm

Model 2361 Rear Panel DIP Switch

CURVEFAMILYTESTForm ................................................

Curves per Family versus Points per Curve

Sample Single Channel Test Parameters

Sample MuItichannel Test Parameters

DC SOURCE-MEASURE Test Form

Sample DC Source-Measure Test Parameters

GENERAL GPIB OUTPUT Form

Model 236/237/238 Serial PoII Byte Format

Uploading and Storing Setups

Leading and Downloading Setups

CheckingStatusofModel213

...............................................

............................................

......................................

........................................

..........................................

...........................................

.....................................

..............................................

...................................... 3-33

................................................

............................................

................................................

3-6

3-7

3-10

3-15

3-18

3-20

3-24

3-29

331

3-34

3-34

3-38

Page 12

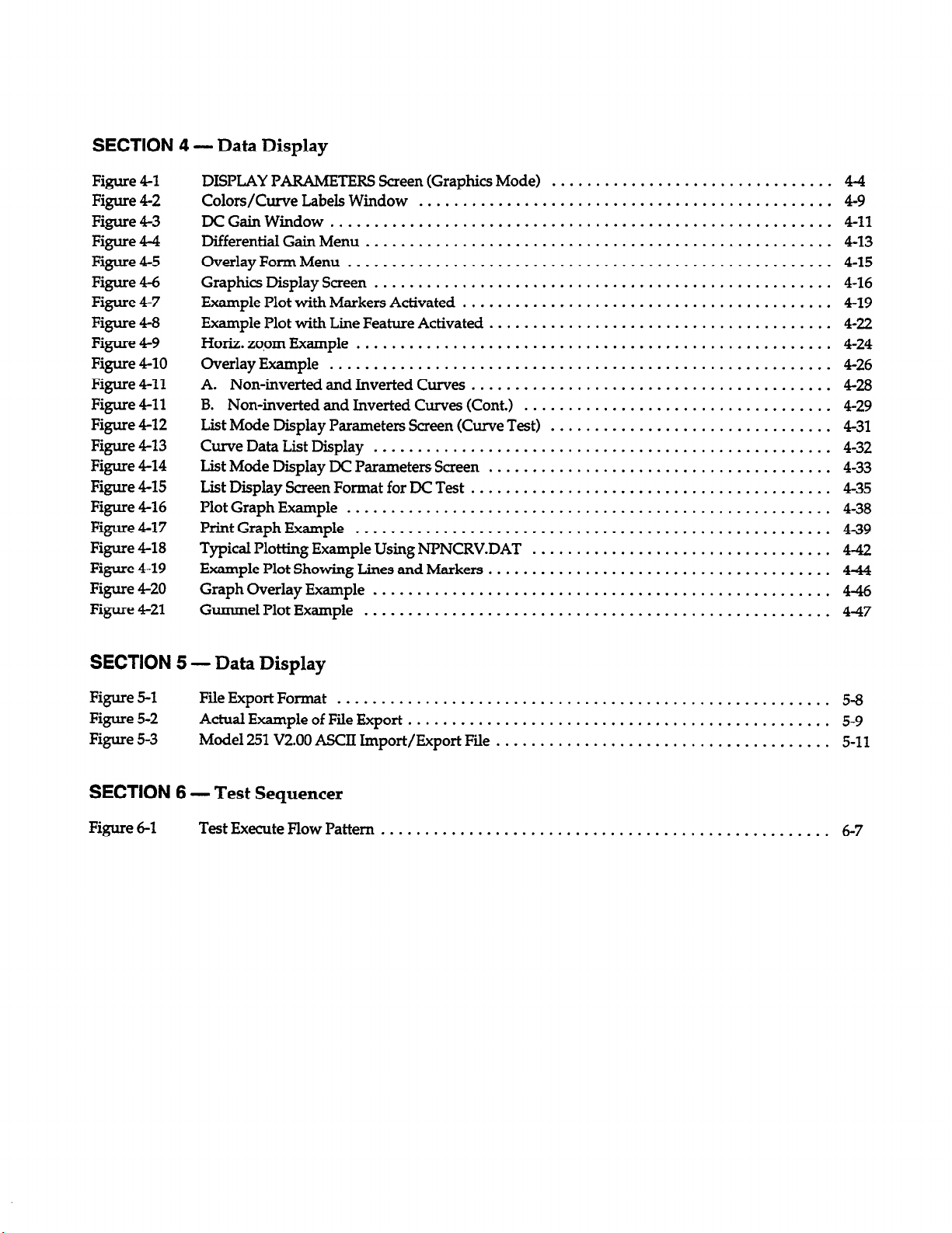

SECTION 4 - Data Display

Figure 41 DISPLAY PARAME

Figure 42 Colors/Curve Labels Window

Figure 43

Figure 44

Figure 4-5

Figure 46

Figure 47 Example Plot with Markers Activated

Figure 48

Figure 49

Figure 410

Figure 411 A.

Figure 411

Figure 412

Figure 413

Figure 414

Figure 415

Figure 416

Figure 417

Figure 418

Figure 419

Figure 420

Figure 421

DCGainWindow

Differential Gain Menu .....................................................

OverlayFormMenu

Graphics Display Screen ....................................................

Example Plot with Line Feature Activated

Horiz. zo,om Example ......................................................

OverlayExample

Non-inverted and Inverted Curves .........................................

Non-inverted and Inverted Curves (Cont.) ...................................

B.

List Mode Display Parameters Screen (Curve Test)

Curve Data List Display ....................................................

L&t Mode Display DC Parameters Screen

ListDisplayScreenFormatforDCTest

Plot Graph Example .......................................................

PrintGraphExample

Typical Plotting Example Using NPNCRV.DAT

Example Plot Showing Lines and Markers

Graph Overlay Example ....................................................

Gummel Plot Example .....................................................

TEES Screen (Graphics Mode)

...............................................

.........................................................

.......................................................

.........................................................

......................................................

................................

..........................................

.......................................

................................

.......................................

.........................................

..................................

.......................................

44

49

4-11

4-13

4-15

4-16

4-19

4-22

4-24

426

428

4-29

431

4-32

4-33

435

4-38

4-39

442

4-44

4-46

4-47

SECTION 5 - Data Display

Figure 5-l

Figure 5-2

Figure 53

FileExportFormat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actual Example of File Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 251 V2.00 ASCII Import/Export File . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 - Test Sequencer

Figure 6-l

Test Execute Flow Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8

5-9

5-11

6-7

Page 13

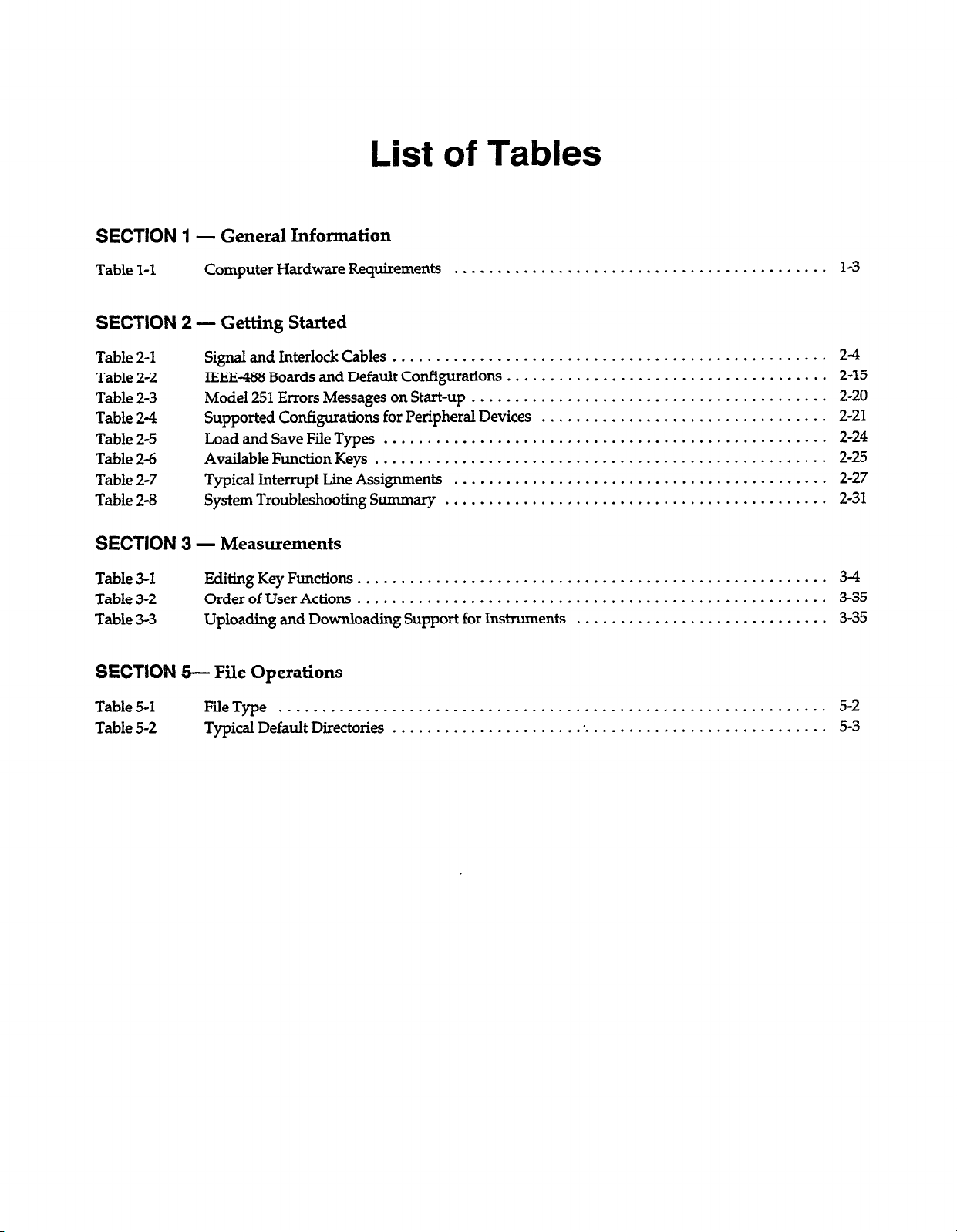

List of Tables

SECTION 1

Table 1-l

- General Information

Computer Hardware Requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 - Getting Started

Table 2-l

Table 2-2

Table 2-3

Table 2-4

Table 2-5

Table 2-6 AvailableFunctionKeys..

Table 2-7 Typical Interrupt Line Assignments

Table 2-8 System Troubleshooting Summary

Signal and Interlock Cables

IEEE-488 Boards and Default Configurations

Model 251 Errors Messages on Start-up

Supported Configurations for Peripheral Devices

LoadandSaveFileTypes

..................................................

.....................................

.........................................

.................................

...................................................

..................................................

...........................................

............................................

SECTION 3 - Measurements

Table 3-l

Table 3-2

Table 3-3 Uploading and Downloading Support for Instruments

EditingKeyFunctions

Order of User Actions

......................................................

......................................................

SECTION 5- File Operations

.............................

l-3

24

2-15

2-20

2-21

2-24

2-25

2-27

2-31

3-4

3-35

3-35

Table 5-l

Table 5-2

FileType . . . . . . . . . . . . . . . .

Typical Default Directories . . . . . . . . . . . . . . . . . . . . . . f. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2

53

Page 14

SECTION 1

General Information

1 .i INTRODUCTION

This section contains overview information for the

Model 251 I-V Test Software system and is arranged as

follows:

1.2 Features

1.3 Warranty Information

1.4 Manual Addenda

1.5 Safeiy!i$nbols and Terms

--- --r

1.7 Computer Requirements

‘0 ..a... a...y~~.a.“‘S

1.2 FEATURES

Model 251 I-V Test Software is a program that controls a

system of instruments designed to measure I-V characteristics of semiconductors. Model

to support the following instruments:

l

Model 236/237/238 Source Measure Units

e Model 2361 Trigger Controller

l

Model 213 Quad Voltage Source

l

Model 707 Switching Matrix

251 can

be configured

Other Keithley and non-Keithley instruments are supported with user-programmed device-dependent commands.

Key Model 231 features include:

l

The menu-driven software allows easy data collection

of parameters from semiconductors and other components. No computer programming knowledge is necessary to operate the system

l

The data is displayed on the computer monitor and

can be printed or plotted on a hardcopy peripheral.

l

craphi& analysis caiabilit& i&cl&e m&kers, line

slope, zooming, and smoothing.

l

A library of tests is included for resistors, capacitors,

diodes, bipolar transistors, and FEIS. Test setup and

sample data files are included on disk.

l

A test sequencing procedure lets you chain multiple

tests without operator interventions.

l

Full Model 213 support provides an easy method of interfacing a four-channel voltage bias source.

l

Model 707 support for uploading and downloading of

up to 100 setups expands the capability to run multiple

tests on multiple devices.

l

The Model 2361 Trigger Controller that is available

simplifies trigger connections and optimizes trigger

response times among the source measure units.

l-l

Page 15

SECTION 1

General Information

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this instruction manual. Should you require warranty

service, contact your Keithley representative or the fac-

tory for further information.

1.4 MANUAL ADDENDA

Any improvements or changes concerning Model 251 I-V

Test Software or this instruction manual will be explained on a separate addendum supplied with the documentation. Please be sure to note these changes and incorporate them into the manual before operating the system.

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms may be found on

the instruments or used in this manual:

A

The ’

should consult the operating instructions in the associated manual.

symbol on an instrument indicates that you

A CAUTION heading outlines dangers that could damage an instrument. Such damage may invalidate the warranty.

1.6 UNPACKING AND INSPECTION

1.6.1

Upon receiving the Model 251, carefully unpack it from

the shipping carton and inspect all items for any obvious

physical damage. Report any such damage to the shipping agent at once. Save the original packing carton for

possible future reshipment.

1.6.2

The following items are included with every Model 251

order:

Model 251 distribution disks (XM-byte, 5-l/4” and

72OK-byte, 3-l /2”)

Copy protection block

Model 251 Instruction Manual

Unpacking Procedure

Shipment Contents

The t symbol on an instrument shows that high voltage

may be present on the terminal(s). Use standard safety

precautions to avoid personal contact with these volt-

ages.

A WARNING heading in this and other manuals cautions against possible hazards that could lead to personal

injury or death. Always read the associated information

very carefully before performing the indicated procedure.

NOTE

Model 251 distribution disks are available

upon request in the 36OK-byte, 5-l/4” format.

Contact Keithley’s Applications department.

1.6.3 Instruction Manual

If an additional instruction manual is required, order the

manual package, 251-901-00. The manual package includes an instruction manual and any applicable addenda.

l-2

Page 16

General Informafion

SECTION 2

1.7 COMPUTER REQUIREMENTS

The following paragraphs discuss minimum and recommended computer requirements, supported interface

cards, printers, and plotters.

1.7.1 Computer Hardware

Model 251 I-V Test Software is intended to run on an IBM

Personal System/2 (80386) or IBM compatible 80386

computer. Table l-l summarizes the computer configuration.

NOTE

Although Model 251 software will run on an

80286-based computer, an 80386based computer is recommended for speed considerations.

1.7.2

The computer must be equipped with a suitable IEEE-488

interface so that it can communicate with the instruments. IEEE-488 interfaces supported by Model 251 software are listed below:

IEEE-488 Interfaces

IBM GPIB board

ICS 488-PC1

IOtech GP488, Gl’488/2

Keithley PC-488-CEC, 4-488-CEC-OM, 4-488-CEC-lM,

PS-488-CEC

MetraByte IE-488

National Instruments GPIB-PC, GPIB-PCII,

GPIB-PCJIA, GPIB-PCm, MC-GPIB, AT-GPIB

Qua Tech MXI-100, MXI-1000

Scientific Solutions IEEE 488 LM, MC-IEEE 488

ziatech ZT 1444, zT/2

1.7.3

To obtain hard copies of your curves, it will be necessary

for you to connect a suitable printer (serial or parallel) or

plotter (serial or IEEE-4881 to your computer. Compatible

printers and plotters for Model 251 software are as follows:

Printers

IBM Graphics Printer, Epson or compatible

HP LaserJet

IBM Proprinter

Okidata Microline 182

Printers and Plotters

Advantech PCL 748

B&C PC488A

BBS GPIB-1000

Capital Equipment PCc488,4x488, PSo488

Contec GPIB (PC)

Hewlett Packard HPlB

Table l-l.

Description

Computer

Coprocessor

Disk drives

Monitor/graphics card

Mouse

Operating system

Requirements

IBM compatible 80386 with parallel port

64OKB conventional memory (53OKB free), 1MB of LlM expanded memory

Intel 80387

Hard drive, 72OKB 3-l /2” or 1.2MB 5-l /4” floppy drive

EGA or VGA color, VGA monochrome

Microsoft or Lotitech mouse

MS-DOS or PC-“m 3.2

Plotters

HP 7440

HP 7470

HP 7475

Computer Hardware Requirements

l-3

Page 17

SECTION 2

Getting Stc[&cJ

2.1 INTRODUCTION

5eciion 2 contains introductory information to help you

get your system up and

Section 3 contains more detailed information on using

the Model 251 I-V Test Software.

5ection 2 is organized as follows:

22 Hardware Configuration: Details the system hardware contiguration, cable connections, and trigger controller.

2.3 System Power-up: Covers the power-up procedure

for a typical system, environmental conditions, and

warm-up periods.

2.4 Computer Hardware and Software Installation:

Outlines installing the IEEE-488 interface and Model 251

software, including configuring the software for a graphics adapter, printer, and plotter.

2.5 Operation Overview: Describes the overall structure

of the Model 251 I-V Test Software and details configuring the software for the IEEE-488 interface and instruments.

2.6 System Checkout: Gives the procedure for checking

out the system to ensure that everything is working properly, including

running sample tests.

running as quickly as possible.

2.2 HARDWARE CONFIGURATION

2.2.1

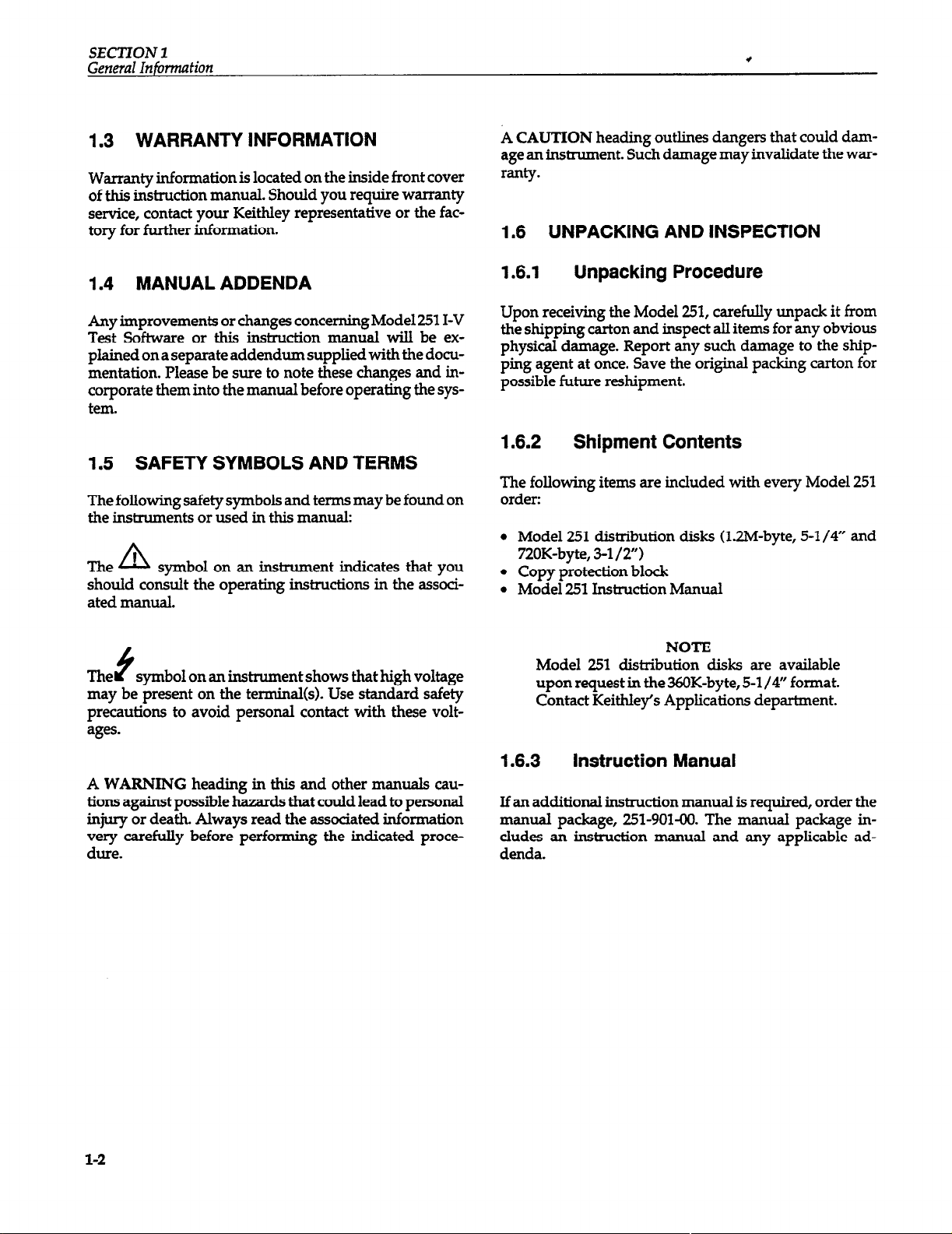

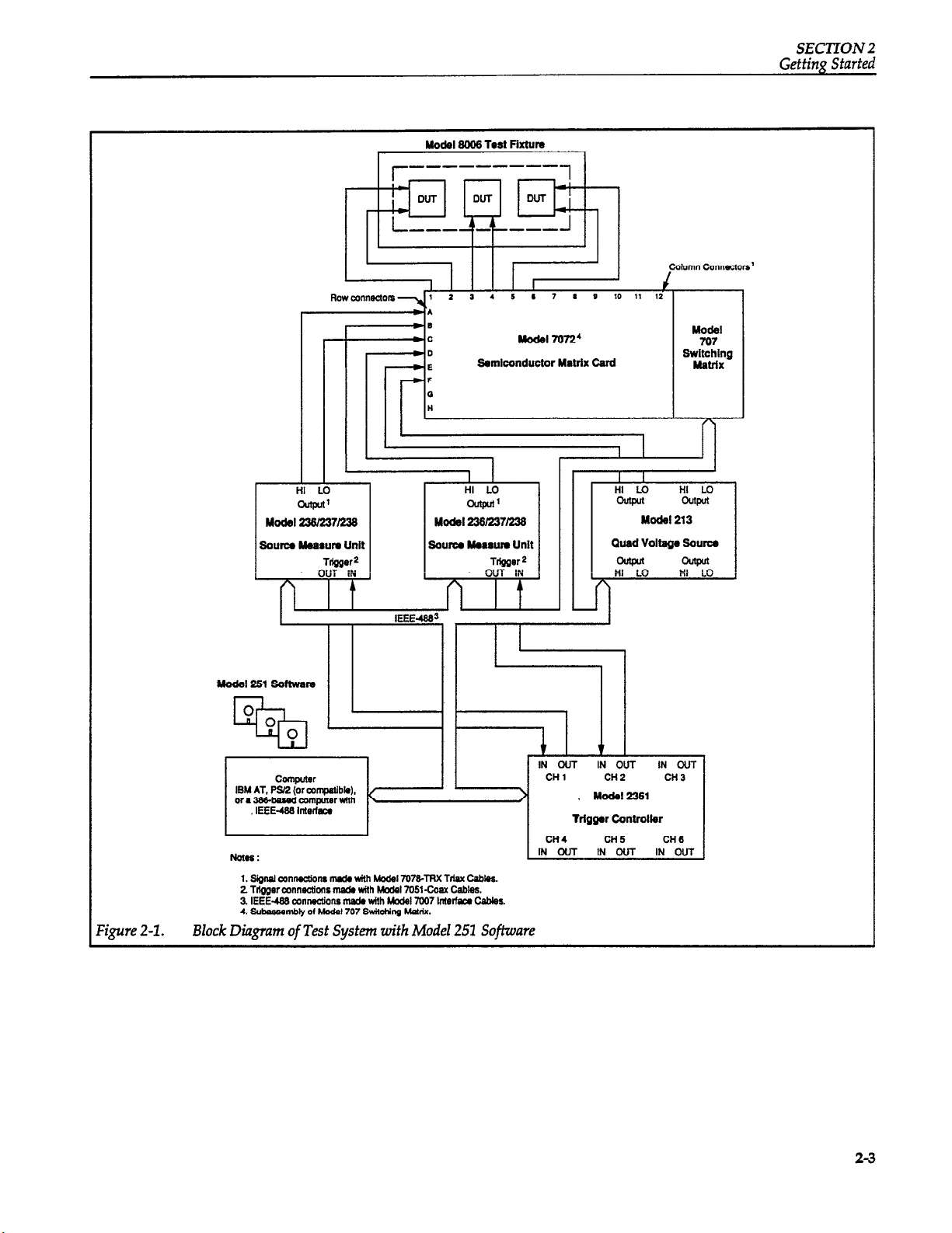

An overall block diagram of a system for running Model

251 software is shown in Figure 2-l. This configuration

with two source measure units, a quad voltage source,

and a switching card and mainframe, is a typical system

with switching, yours may differ. The various system

components perform the following functions:

Model 236/237/238 Source Measure Units - Each

source measure unit can source voltage and simultaneously measure current, or source current and simultane

ously measure voltage. One unit is necessary to run twoterminal device tests, while two units are required to run

bipolar transistor and FET tests. If a substrate bias is required, a third source measure unit, a quad voltage

source, or a current or voltage source will be necessary.

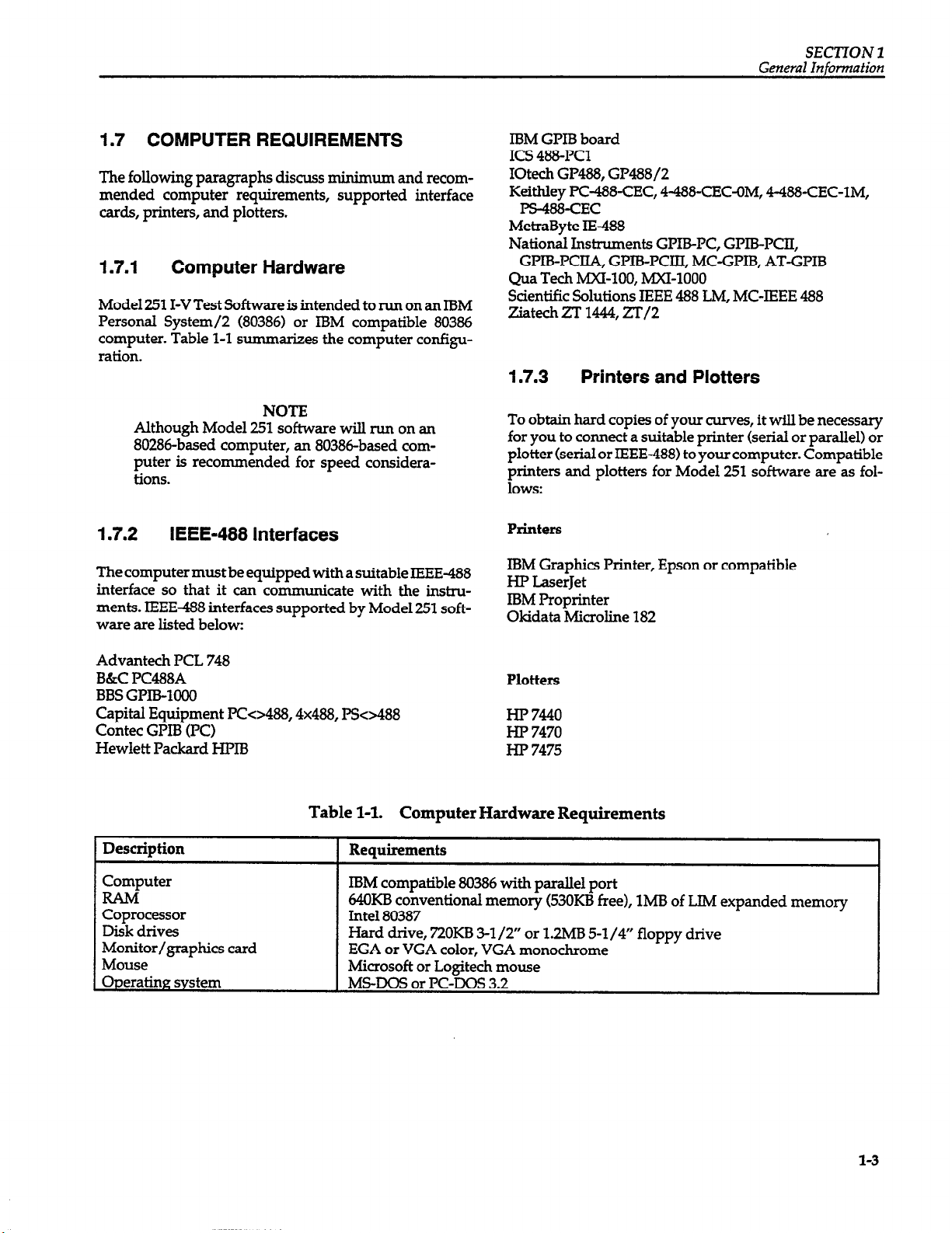

Model 2361 Trigger Controller - A Model 2361 Trigger

Controller is a bus-programmable instrument that is required for all tests where more than one source measure

unit is configured to measure (including synchronized

sweeps). The unit can handle the triggering needs of up

to six source measure units. It not only simplifies system

trigger connections, but it also coordinates the trigger

schemes needed for ah tests. The front and rear panels of

the Model 2361 are shown in Figure 2-2. Refer to Appendix C for more information on the Model 2361.

System Block Diagram

2-l

Page 18

SECTION 2

Getting Started

Model 213 Quad Voltage Source - The Model 213 is a

quad output digital to analog converter interface for the

IEEE-488 bus. Each port can be programmed for full scale

output of *lV, i5V, or flOV.

Model 707 Switching Matrix - The Model 707 is a programmable switch for connecting signal paths in a matrix

or multiplex topology. It is for large-scale switching applications (up to 576 crosspoints per mainframe). Plug-in

cards are available for general purpose and special purpose switching.

Model 8006 Component Test Fixture -The test fixture is

the interface between the DUT (device under test) and

the instruments. The Model 8006 includes sockets for axial-component, TO packages, and 24-pin DIP package devices. A Model 8007 Semiconductor Test Fixture or a user-supplied test fixture could also be used.

Computer - An IBM F’S/2 (or compatible), or a

386-based computer, equipped with an IEEE-488 interface card, controls the test sys tern.

Page 19

SECTION 2

Getting Started

Figwe2-2.

m i

I I

II

I

HI I

L

MO&l 251 sonwara

0

0

Q&l

IBM AT, P.Y2 (or compafibb).

ora336+wdoompufsrtih

fdOl@S:

4. subosse~ Of Model 707 swwing Maftfx.

0

Cwnputer

IEEE-488 Inferfaa

1. signal conlwctiotls mada wifh kdel707fJ-TRX Tfiax cabbs.

2 1-r connecUonr male wifh Model 7OWCoax Cab!+%

3. IEEE-483 contwclionr mada wifh Model 7007 Inferfax C&k

(

Semiconductor Matrix Card

I -1

IN OUT

>

IN OUT

Block Diagram of Test System with Model 251 Software

I-

t I

CHl

. Modsl23s1

Trlggsf Controller

CH4

t I

IN OUT IN OUT

CH2

CH5

IN OUT IN OUT

CH3

CHfi

J

2-3

Page 20

SECl’TOiVP

Getting Started

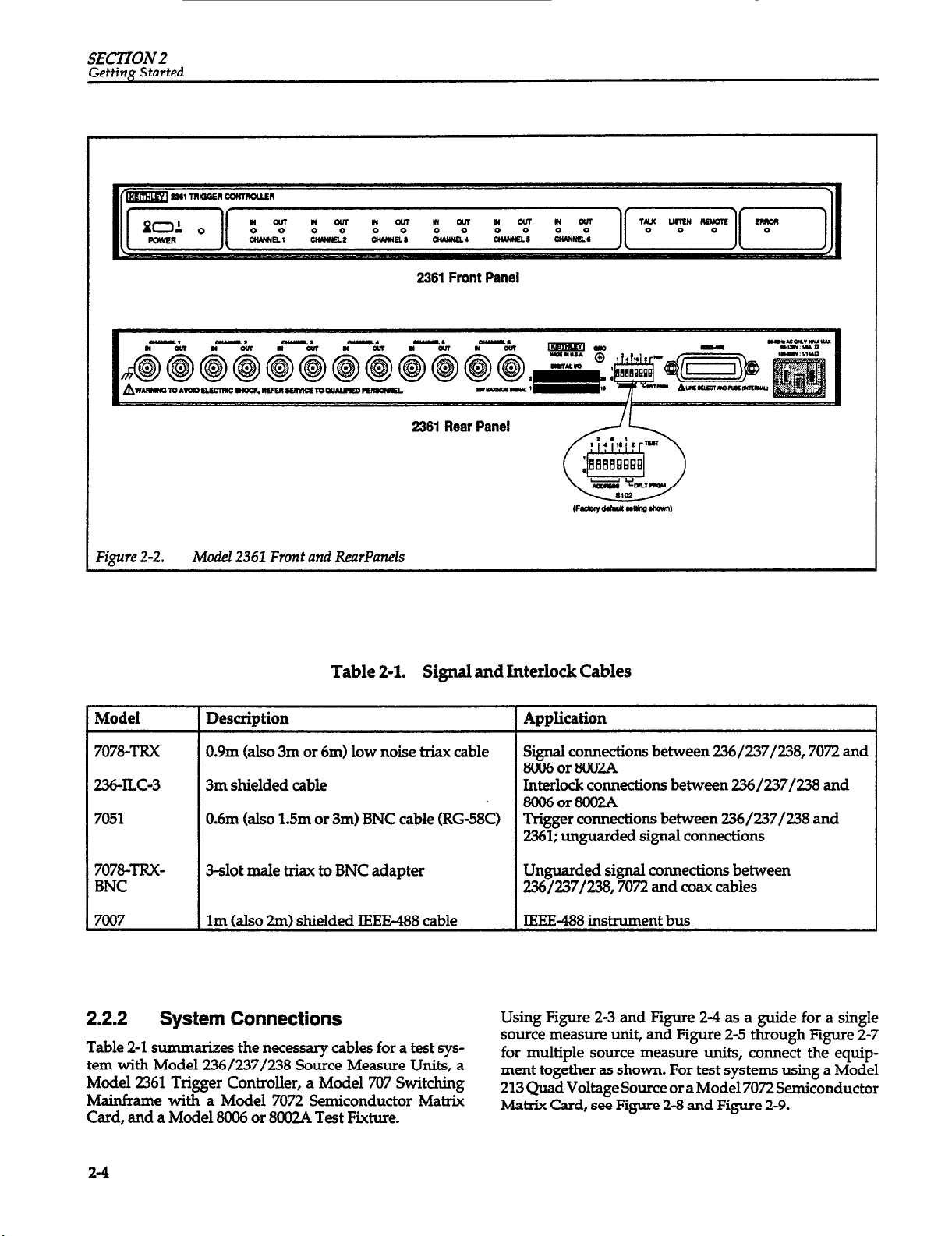

2361 Front Panel

2361 Rear Panel

Figure 2-2. Model 2361 Front and RearPanels

Table 2-l. Signal and Interlock Cables

Model

7078TRX

236-TLC-3

7051

707&TRx-

Description Application

0.9m (also 3m or 6m) low noise triax cable

3m shielded cable

0.6m (also 1.5m or 3m) BNC cable fRG38C) Trigger

3-slat male triax to BNC adapter

BNC

7007

lm (also 2m) shielded IEEE-488 cable

Signal connections between 236/237/238,7072 and

8006or8002A

Interlock

co~eCtions

between 236/237/238 and

8006or8OOL4

COM~C~~OIIS

2361; unguarded signal

between 236/237/238 and

COMWtiOIlS

Unguarded signal connections between

236/237/238,7072 and coax cables

IEEE-488 instrument bus

2.2.2

System Connections

Table 2-l summarizes the necessary cables for a test sys-

tem with Model 236/237/238 Source Measure Units, a

Model 2361 Trigger Controller, a Model 707 Switching

Mainframe with a Model 7072 Semiconductor Matrix

Card, and a Model 8006 or 8002A Test Fixture.

24

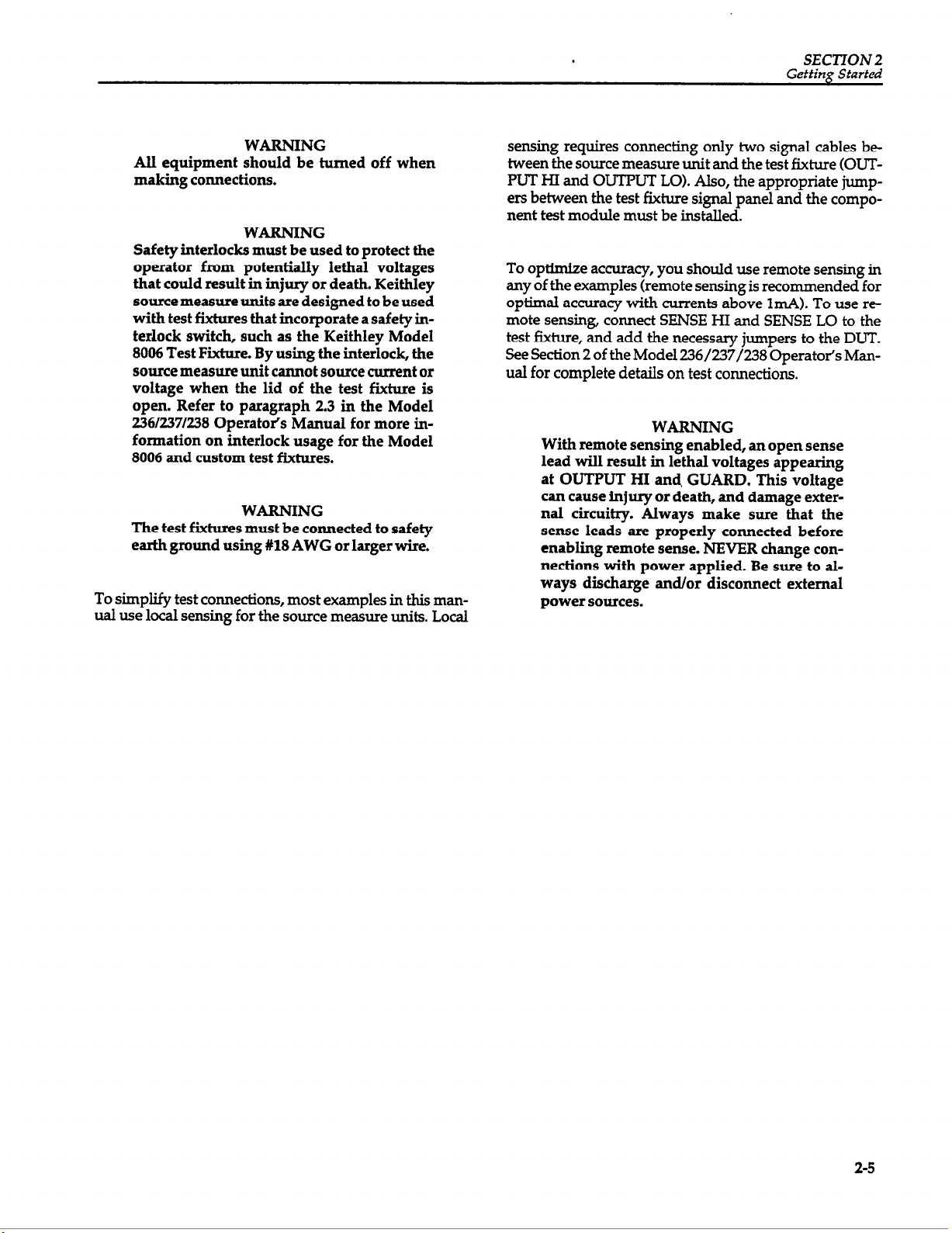

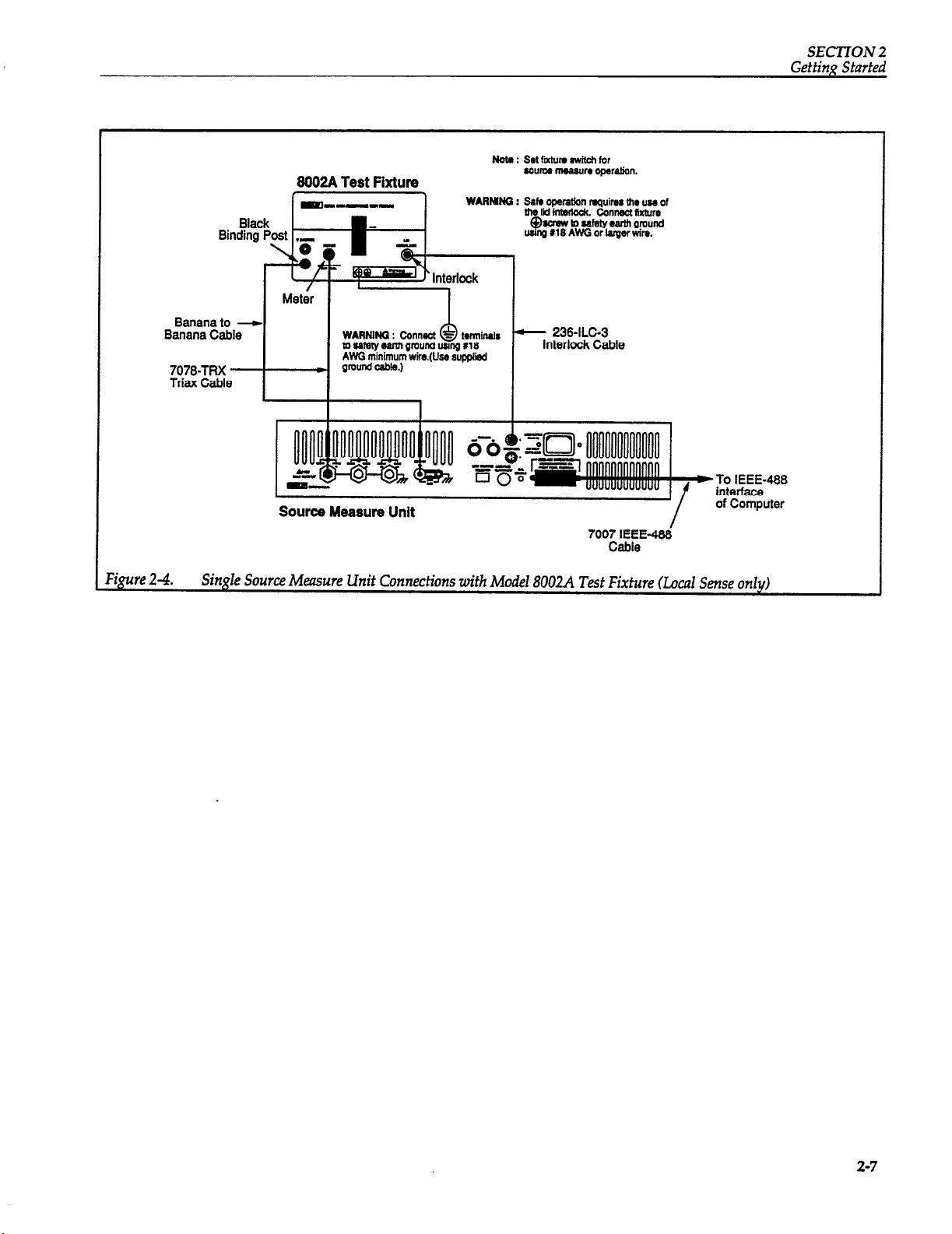

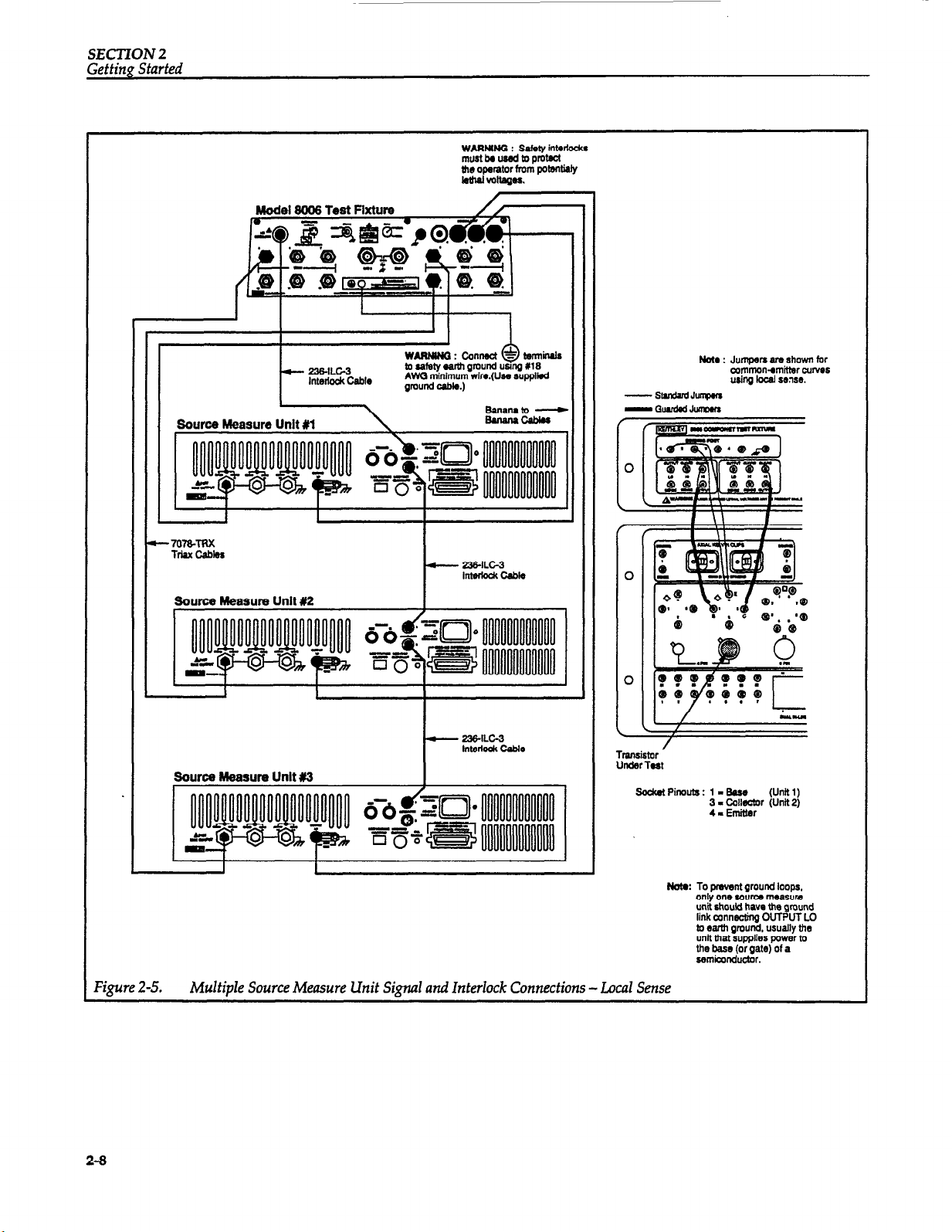

Using Figure 2-3 and Figure 2-4 as a guide for a single

source measure unit, and Figure 2-5 through Figure 2-7

for multiple source measure units, connect the equipment together as shown. For test systems using a Model

213 Quad Voltage Source or a Model 7072 Semiconductor

Matrix Card, see Figure 2-8 and Figure 2-9.

Page 21

SECTION 2

Getting Started

WARNING

All equipment should be turned off when

making connections.

WARNING

Safety interlocks must be

used

to protect the

operator from potentially lethal voltages

that could result in injury or death. Keithley

source measure units are designed to be used

with test fixtures that incorporate a safety interlock switch, such as the Keithley Model

8006 Test Fixture. By using the interlock, the

source measure unit cannot source current or

voltage when the lid of the test fixture is

open. Refer to paragraph 2.3 in the Model

23612371238 Operatois Manual for more information on interlock usage for the Model

8006 and custom test fixtures.

WARNING

The test fixtures must be connected to safety

earth ground using 818 AWG or larger wire.

To simplify test connections, most examples in this manual use local sensing for the source measure units. Local

sensing requires connecting only two signal cables between the source measure unit and the test fixture (OUTF’UT HI and OUTPUT LO). Also, the appropriate mpers between the test fixture signal panel and the compo-

nent test module must be installed.

To optimize accuracy, you should use remote sensing in

any of the examples (remote sensing is recommended for

optimal accuracy with currents above ImA). To use remote sensing,

connect

SENSE HI and SENSE LO to the

test fixture, and add the necessary jumpers to the DUT.

See Section 2 of the Model 236/237/238 Operator’s Man-

ual for complete details on test connections.

WARNING

With remote sensing enabled, an open sense

lead will result in lethal voltages appearing

at OUTPUT HI and, GUARD. This voltage

can cause injury

or

death, and damage external circuitry. Always make sure that the

sense leads are properly connected before

enabling remote sense. NEVER change connections with power applied. Be sure to al-

ways discharge and/or disconnect external

power sources.

2-s

Page 22

SECTION 2

A. Local Sense

source Measure Unit 1

I I

7007 IEEE468

l%tM

To IEEE438 Interfisca

of Computer

Figure 2-3.

2-6

I

Source Measure Unit

6. Remote Sense

Single Source Measure Unit Connections with Model 8006 Test Fixtures

To IEEE- Intedaa

of czoqwter

Page 23

8002A Test Fixture

1

------ 1

I-

Source Measure Unit

Not.: Setfbttunswflohfor

sounx nmasum opnraffon.

WARMNQ : Safe oaftmfbn rwuinr the use of

ctewbsafatveafthamu

.-.

_ _..__. -

700;7lE&E48Ei

SECTION 2

Getting Started

e g;;ol-488

of Computer

Figure24

Single Source Measure Unit Connections with Model 8002A Test Fixture @ma1 Sense only)

2-7

Page 24

SECTION 2

Getting Started

WARNINQ : Safetv interbxks

-SImdadJunlm

Not. : Jumpers am shown for

03mmon-emitter curves

urkg local SeXI.

+707&TRx

Figure 2-5.

Triax Cabkr

Sourca Measure Unit #2

1

t-

236-lLC-3

klmdookcabls

Transistor

Under -rest

Source Measure Unit #3

SocketPimuts: 1 -Etaso (Unit 1)

Multiple Source Measure Unit Signal and Interlock Connections - Local Sense

3 - yieco (Unit 2)

I

Notei To ptwent ground loops.

only on* some measure

unit Shou!d have the Qmund

link connect&g OUTPUT LO

to earth amund. usuallv the

unit thatsupplies pow& to

the base (or gate) of a

remiconduotor.

2-8

Page 25

SECTION 2

Gefting Sfarfed

Model 8008

23WLC-3

InterId C&k

Source Measure Unit 81

Test Fixture

terminals

common-emitter curves

I

-8MdrrdJurpwr

--Jurprr

r-z

using mmte sense.

?gure 2-6.

IL

236-lLC-3

InMock C&la

Source Measure4 Unit x3

Multiple Source Measure Unit Signal and Interlock Connections - Remote Sense

ScdwtPinout8: 1 =Base

NOW: To prevent gmurd loop.

; = h&o (Unit 2)

I

only ona souma masure

unit slwkl havcr tlw gmund

link mnneoGng OUTPUT LO

I0 earth gmund. usualy me

unk that supplii paver to

(Unit 1)

2-9

Page 26

SECTION 2

Getting Started

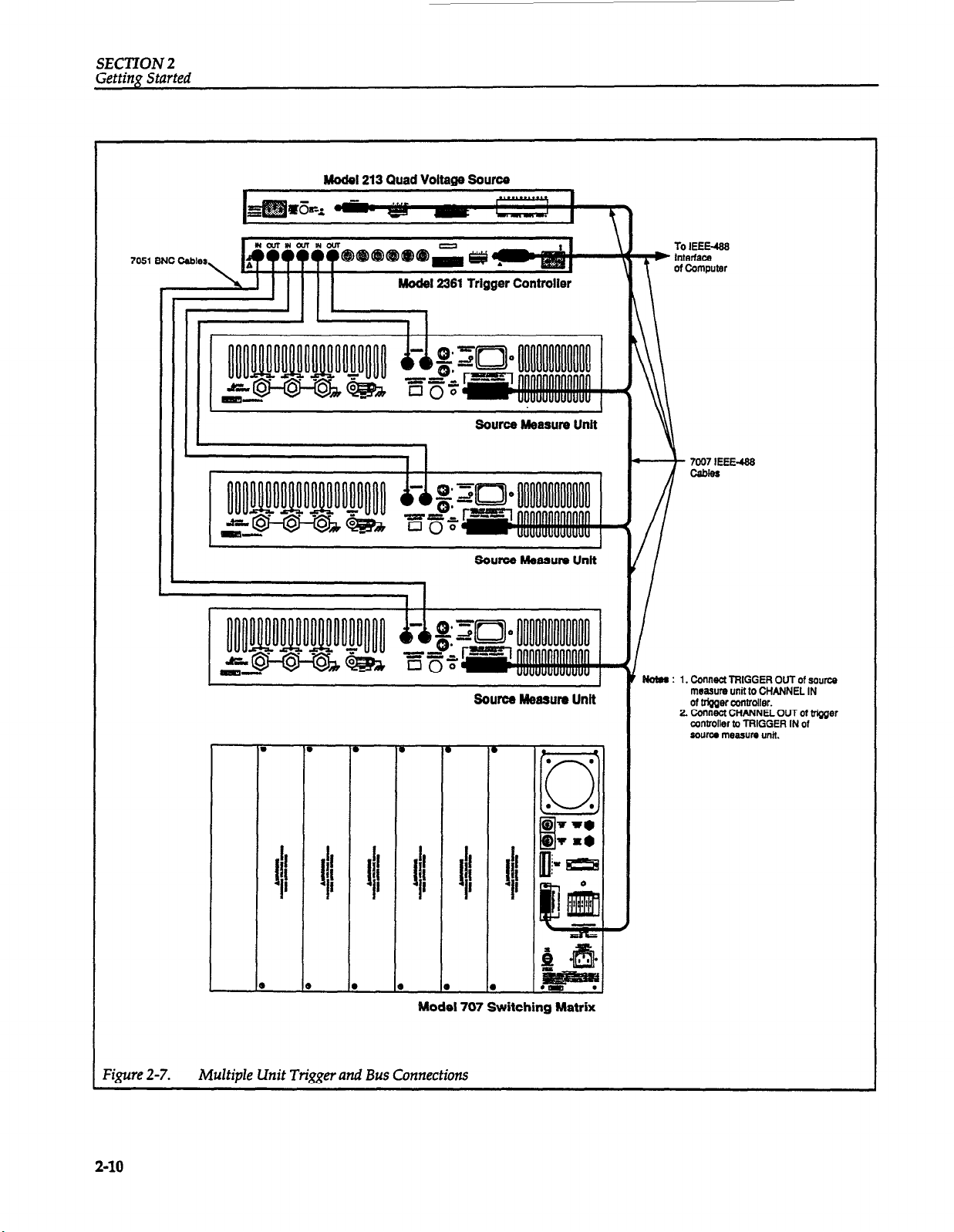

7051 BNC cables

r

~IIIII

II

Model 213 Quad Voltage Source

To IEEE-488

lnterfaca

\

of Computer

Modal 2361 Trigger Controller

I

Source Measure Unit

7007 IEEE-488

cables

I

I

Source Measure Unit

I

r

I !

Sourca Maasum Unlt

Notee : 1. Conneot TFttGGER OUT of source

messura unit to CHANNEL IN

of t@Qer c0ntroiler.

2 Conneot CHANNEL OUT of tr&er

controller to TRIGGER IN of

soura measure unft.

Figure 2-7.

2-10

Model 707 Switching Matrix

Multiple Unit Trigger and Bus Connections

Page 27

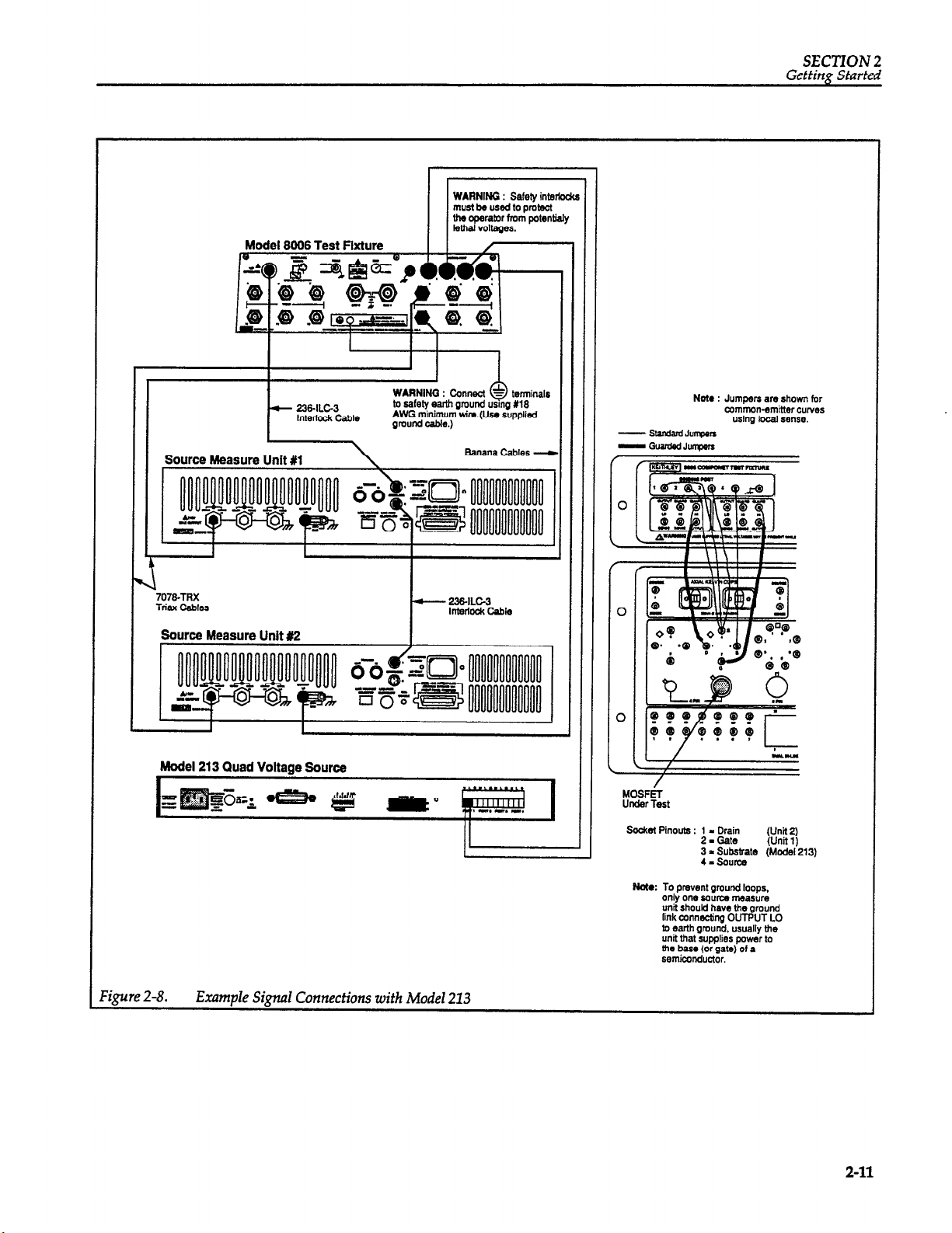

WARNING : Safety inbxla

must be used to pmtect

the operator fmm potenlial

lelhal voltages.

SECTlON 2

Getting Started

Source hhasure Unit Wl

I

‘707ETRx

Tliax oables

Source Measure Unit Y2

,

I

I

I

Model 213 Quad Voltaae Source

Banana Cables -

Noto : Jumpers

common-emitter curves

- StsMard Jumrws

-Gw&mtJwrpen

\ ,.

/

MOSFET

Under Test

Socket Pinouts : 1 I Drain

Note: To plwrNlt ground loops.

2=Gate

I

3 Substrate l?A’f)213)

4-soulcfl

only one sour03 measure

unit should have the ground

link connectiq OUTPUT LO

to earth gmund. usually +Jw

unit

that supplies power to

the base (or gate) of

semiconduotor.

am

shown for

using local sense.

(Unit 2)

a

Figure 2-8.

Example Signal Connections with Model 213

2-11

Page 28

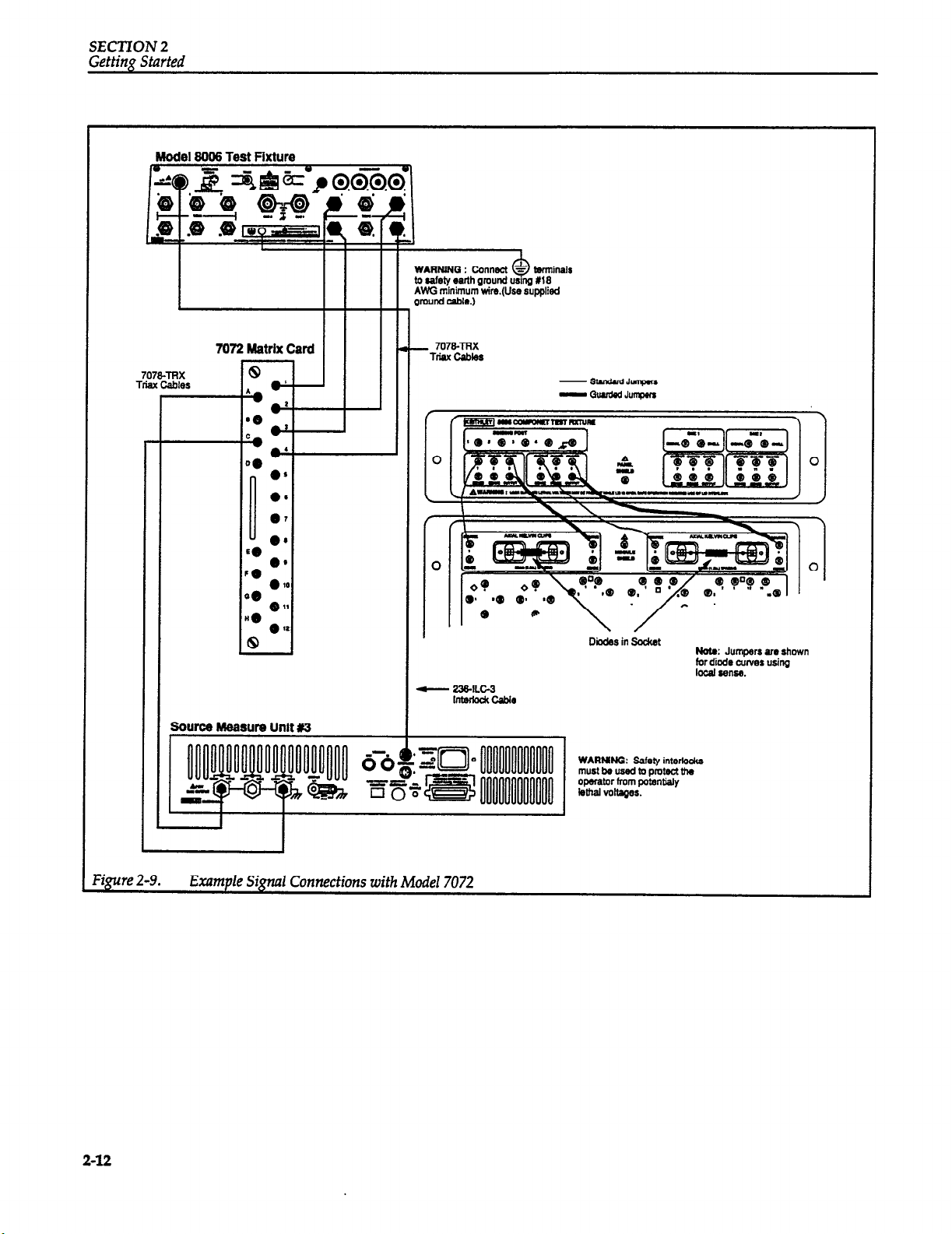

SECTION 2

Getting Started

Model 8006 Test Fixture

terminals

X18

lyaied

707BTAX

Trlax Cables

II

Source

I I,

@ .’

A

Measure Unit #3

c- z3wLc-3

lntedookceblr

I

!

--JIMQMIX

-auudedJ~mpm

I

Noto: Jumpers am shown

fXd$b3~NBS USit-kJ

!?gure 2-9.

2-12

Example Signal Connections with Model 7072

Page 29

SECTION 2

Gettim Started

2.3 SYSTEM POWER-UP

2.3.1

The Model 236/237/238 Source Measure Units are de-

signed to operate from 105-125V or 210~250V line power

ranges. A special transformer may be instaIled (at the factory) for 90-1lOV and 195~235V ranges. A slide switch on

the rear panel indicates the present operating voltage. If

the line voltage needs to be changed, refer to the Model

236/237/23S Operator’s Manual.

Both the Model 2361 Trigger Controller and Model 213

Quad Voltage Source operate from 90-125V or 180-250V

line power ranges. The present operating voltage is indicated on the rear panel. If the line voltage needs to be

changed, a slide switch is located inside the unit (refer to

Appendix B or the appropriate instruction manual).

The Model 707 Switching Matrix operates from 105125V

or 210-250V line power ranges. It can be rewired at the

factory for the 90-1lOV and 180-220V ranges. A slide

switch on rear panel indicates the selected line voltage.

To change the selection, refer to the Model 707 Switching

Matrix Instruction Manual.

Instrument Power Requirements

WARNING

As a safety precaution, it is recommended

that all instruments in a rack be connected to

a single power outlet strip. The strip should

be wired to a panel-mounted emergency

stop switch within easy access of the user. A

red push-pull mushroom switch should be

mounted to the top front of the instrument

rack. The switch must be UL recognized and

have sufficient break current capacity for the

load. To specify the break current of the

switch, add up the total VA of the rack instruments and divide by the line voltage.

Multiply the total by 125% to yield the minimum break current specification for an inductive load.

2.3.3 Environmental Conditions

For maximum accuracy, all measuring instruments and

the test fixture must be operated at an ambient temperature between 18 and 28°C at a relative humidity less than

70%. (See specifications in Models 236/237/238 Operatofs Manual.)

2.3.4

Warm-up Period

CAUTION

Do not attempt to operate an instrument on a

supply voltage outside the allowed range, or

instrument damage may occur.

2.3.2

Each instrument should be connected to a grounded AC

outlet using the supplied AC power cord or the equivalent.

Power Connections

WARNING

Each instrument must be connected to a

grounded outlet to ensure protection from

electric shock Failure to use a grounded outlet and a 3-wire power cord may result in personal injury or death because of electric

shock.

The system can be used immediately when all instru-

ments are

tem accuracy, all instruments should be turned on and allowed to warm up for at least one hour before use.

2.3.5

Follow the general procedure below to power up a Model

251 I-V Test system:

1. Connect the instruments together as outlined in

2 Examine the rear panel DIP switches on the Model

3. Turn on each instrument by pressing in its power

first turned on, however, to achieve rated sys-

Power-up Procedure

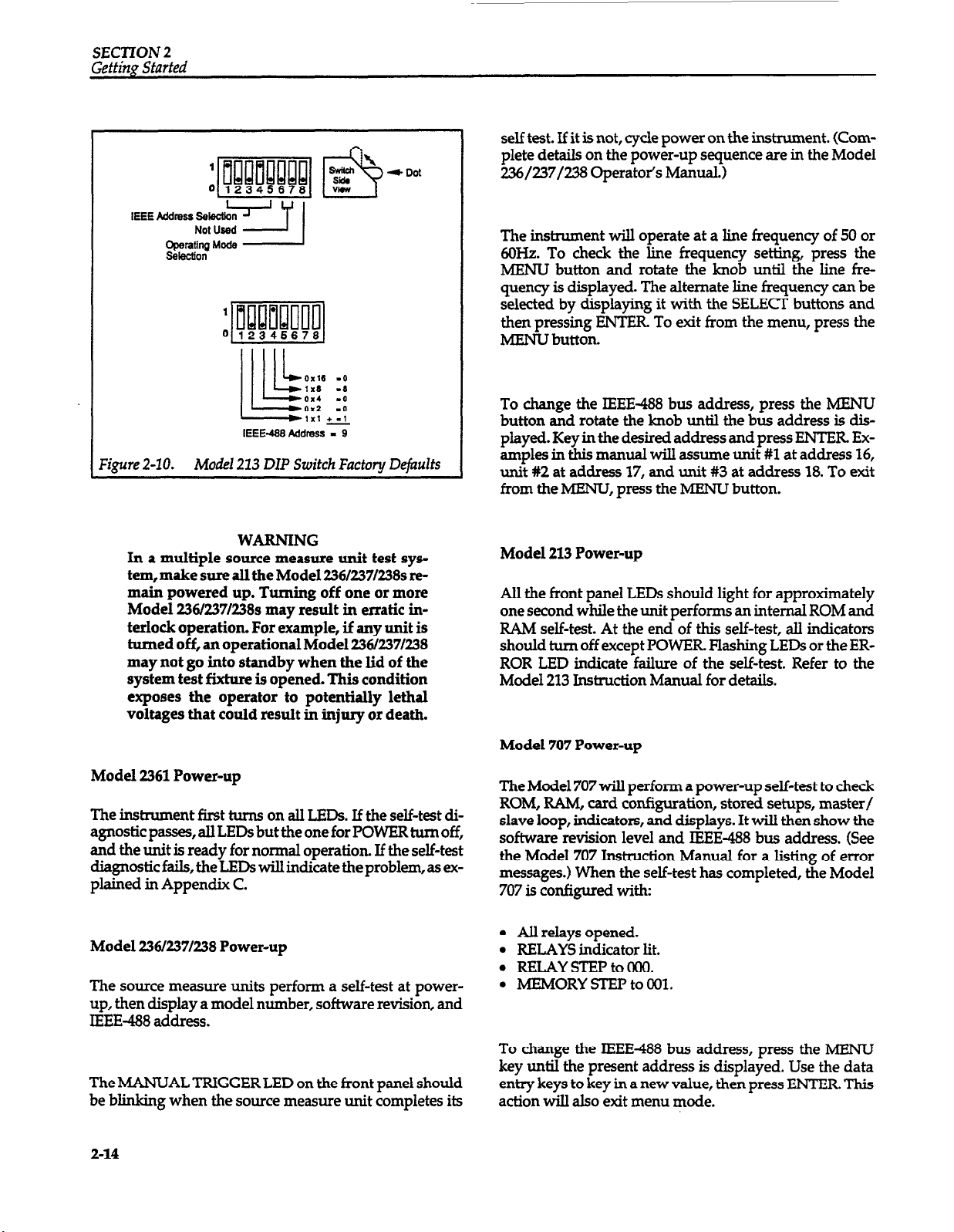

paragraph 2.2.3.

2361 and Model 213. Set switches to desired

IEEE-488 bus addresses. The factory default setting

(15) of the Model 2361 is shown in Figure 2-2. The default setting (9) of the Model 213 is shown in

Figure 2-10.

switch. Verify that each instrument goes through its

normal power-up routine, as described below.

2-13

Page 30

SECTION 2

Geffing Sfarfed

OX16

-0

1x0 -6

0x4 -0

0x2 -0

IX1 + -1

IEEEJ89Address I 9

i

Figure 2-10. Model 213 DIP Switch Facto y Defaults

-

self test. If it is not, cycle power on the instrument. (Complete details on the power-up sequence are in the Model

236/237/238 Operator’s Manual.)

The instrument will operate at a line frequency of 50 or

6OHz. To check the line frequency setting, press the

MENU button and rotate the knob until the line frequency is displayed. The alternate line frequency can be

selected by displaying it with the SELECT buttons and

then pressing ENTER. To exit from the menu, press the

MENU button.

To change the IEEE-438 bus address, press the MENU

button and rotate the knob until the bus address is displayed. Key in the desired address and press ENTER. Examples in this manual will assume unit #l at address 16,

unit #2 at address 17, and unit #3 at address 18. To exit

from the MENU, press the MENU button.

WARNING

In a multiple source measure unit test system, make sure all the Model 236/237/23t3s remain powered up. Turning off one or more

Model 236l237I2389 may result in erratic in-

terlock operation. For example, if any unit is

turned off, an operational Model 236/237/238

may not go into standby when the lid of the

system test fixture is opened. This condition

exposes the operator to potentially lethal

voltages that could result in injury or death.

Model 2361 Power-up

The instrument first turns on all LEDs. If the self-test di-

agnostic passes, all LEDs but the one for ROWER turn off,

and the unit is ready for normal operation. If the self-test

diagnosticfails,theLEDswillindicatetheproblem,asexplained in Appendix C.

Model 236/237/238 Power-up

The source measure units perform a self-test at powerup, then display a model number, software revision, and

IEEE-488 address.

Model 213 Power-up

All the front panel LEDs should light for approximately

one second while the unit performs an internal ROM and

RAM self-test. At the end of this self-test, all indicators

should turn off except POWER Flashing LEDs or the ERROR LED indicate failure of the self-test. Refer to the

Model 213 Instruction Manual for details.

Model 707 Power-up

The Model 707 will perform a power-up self-test to check

ROM, RAM, card configuration, stored setups, master/

slave loop, indicators, and displays. It will then show the

software revision level and IEEE-488 bus address. (See

the Model 707 Instruction Manual for a listing of error

messages.) When the self-test has completed, the Model

707 is configured with:

l

All relays opened.

l

RELAYS indicator lit.

l

RELAYsTErtoOoo.

. MEMORYSTEl’toOOl.

The MANUAL TRIGGER LED on the front panel should

be blinking when the source measure unit completes its

2-14

To change the IEEE-488 bus address, press the MENU

key until the present address is displayed. Use the data

entry keys to key in a new value, then press ENTER. This

action will also exit menu mode.

Page 31

SECTION 2

Gettina Started

2.4 COMPUTER HARDWARE AND

SOFTWARE INSTALLATION

2.4.1 IEEE-488 Interface Card

Installation

Model 251 software can be used with the IEEE-488 interfaces listed in Table 2-2.

Note the configuration settings of your IEEE-488 inter-

face card (also referred to as a GPIB card). If necessary,

see the documentation supplied with the interface card

for interpretation of the switch and jumper settings. Depending-on the pa&~& card, you &-iII be

Table 2-2.

IEEE-488 Boards and Default Configurations

Board Name

Advantech PCL-748

B&CPC488A

BBS GPIB-1000

Capital Equipment PC0488

Capital Equipment PSo488

Capital Equipment 4 x 488

Contect GPIB (PC)

Hewlett-Packard HPIB

IBM GPIB board

ICS48WCl

IOtech GP488

IOtech GP488/2

Keithky PC-488-CEC

Keithky4-488-CEC-OM~ 4-4&3S-CEC-1M

Keithky PS488-CEC

MetraByte IE-488

National Instruments AT-GPIB

National

National

National

National

National

Instruments GPIB-PC

Instruments GPIB-PCII

Instruments GPIB-PCIIA

Instruments GPIB-PCIII

Instruments MC-GPIB

Qua Tech MXI-100

;2ua Tech MXI-1000

Scientific Solutions IBEE 488 LM

Scientific Solutions MC-IEEE 488

Ziatech ZT 1444

Ziatech ZT/2

NA = feature not available on this board

NC = not configured from factory

prom&-d

for kaIIation procedures.

these parameters when Model 251 software is configured

for an IEEE-&38 card

l

I/O port address

l

Memory address

0 System controkr setting

l

Interrupt Iine number

l

Interrupt level

After noting the card configuration, install it in the computer. See the interface card documentation for detaiIed

1

Fault SC

IRQ #

ing;

DMA#

1

cwo&fEM)

2El

390

2B8

2B8

2B8

rzhMEA4

2El

coooMEM)

2El

SE

2B8

2B8

300

2co

2B8

2B8

2El

280

EOO

318

200

2El

2B8

210

800

E

NC

NC

3

NC

7

5

k

NC

is

NC

3

5

11

7

7

7

7

3

z

7

5

GE

LC

NA

1

1

1

1

2

1

kJC

4

1

1

1

:

1

1

1

Ii

3

3

1

0

NC

1

NU’E~yMii5YCliGneI boards can use multiple DMA channels. Non&iicro Channel boards

must use DMA channel number 1 except for the Hewlett-Packard board which uses DMA channel 2. Also note that the Ziatech ZT/2 board cannot use DMA channels 4-7.

2-15

Page 32

SECTION 2

Getting Started

2.4.2

Model 251 I-V Test so&are is copy protected. To run

Model 251 software, you must install the copy protection

block that was shipped with the software. The copy pro-

tection block attaches to any parallel port on the back of

your computer. Figure 2-l 1 shows a block installed on a

computer.

To install the copy protection block, first remove from the

parallel port any device cable, such as a printer cable, if

one is currently attached. Then insert the block into the

port and reattach the device cable. The block will not interfere with the performance of the device attached to the

parallel port. Note that a device does not need to be connected to the block in order to run Model 251 software.

2.4.3

before instalhng Model 251 software on your hard disk,

make backup copies of each of the distribution floppy

disks.Todoso,bootupDOS,thenusetheDOScommand

Copy Protection Block

Software Backup

DISKCOPY, which automaticahy formats blank disks.

(Remember that the DISKCOPY comman

the current directory or path.) For systems with two

floppy disks, the

DISKCOPY A: 8: cEnten

Follow the prompts on the screen to complete copying of

all supplied disks.

Similarly, the comman d for systems with one floppy disk

is:

DISKCOPY A: A: <Enter>

Again, follow the prompts on the screen to copy all supplied disks.

After copying, put the original disks away for safekeeping.

co mmand syntax is:

dfilemustbein

Figure 2-11. Copy Protection Block

1

2-16

Page 33

2.4.4 Software Installation and Configuration

Model 251 software is installed on a hard disk drive by

the program called INSTALL, which is supplied on the

distribution floppy disks. This program creates subdirectories and copies files for initial installation. It may also be

used to reconfigure the software after a change in the

computer configuration (see paragraph 2.4.5). Follow the

procedure below in the order presented to install the software. Press &so at any time to abort installation.

1.

Place the backup copy of the Model 251 Installation

Disk in drive A and enter the following

A: <Enter>

TYPE READMEDOC <Enter>

This file explains the latest changes and how experienced DOS users can install the software without

reading the following instructions.

2.

Type in:

INSTALL &ten

The title screen of the INSIALL program is dis-

played.

SECTION 2

Getting Started

You are then prompted to choose a target hard disk

4.

drive for Model 251 software. The listed options depend on what is available on your computer. The IN-

STALL program will display an error message if the

selected drive does not have at least 3M-bytes of free

disk space.

The next series of questions asks you to select directories for the Model 251 software. The default names

for the root directory and three subdirectories are:

\MODEL251

\MODEIl\DATA

\MODEL251\TESTS

\MODEL251 \CONFIG

(for data files)

(for test setup files)

(for instrument configura-

tion files)

\MODEL251\707

WODEL251 \SEQ

6,

You are then prompted for your computer’s graph-

(for Model 707 files)

(for test sequencer files)

ics adapter type:

EGA or VGA

7.

You are next prompted to select an IEEE-488 (GPIB)

interface card from a displayed list. The INSTALL

procedure will copy the necessary IEEE-488 driver.

The card parameters (I/O port address, memory address, etc.) are not entered until Model 251 software

At this time, the program checks for a minimum

computer configuration:

l

EGA or VGA graphics adapter

l

DOS version 3.2 or higher

l

Math coprocessor

0 At least 64oK-bytes RAM

If minimum requirements are not present, the IN-

STALL program will display an error message.

3.

Press <Eso to quit or any other key to continue. The

next screen asks you if this is a first-time installation

or a reconfiguration of previously installed software.

Select the first option to install Model 251 for the first

time. The second option is used when it is necessary

to reconfigure Model 251 software for different default directories, graphics adapter, IEEE-438 card,

printer, or plotter.

8.

%Grinter and plotter types are then requested. Select appropriate models, and if a plotter was chosen,

the interface type (serial or GPIB) and address.

NOTE

Printer and plotter configuration is further

discussed in paragraph 2.5.3.

After your response, the INSTALL program creates

directories and copies files as they are listed on the

computer screen.

9.

As the INSTALL program is copying files, you will

be prompted to insert Model 251 Program Disks.

When the program has completed, remove any disks

and put them away.

Unless the INSTALL procedure was aborted, you will be

returned to the drive and directory where Model 251

Software is installed.

2-17

Page 34

SECTION2

Getting Started

2.4.5

Software Reconfiguration

As part of a first-time installation, the text file

MODEL251.CFG is created by the INSTALL program to

define the selected subdirectories and computer hardware configuration. MODEL251CFG is placed in the

Model 251 root directory (default name is \MODEL251).

An example file is shown in Figure 2-12.

If any changes are made in the computer hardware, the

“Reconfigure” option of the INSTALL program must be

selected to

change the parameters of the

MODEL251.CFG file. (Although MODEL251CFG is an

Model 251 system configuration file V2.00

GPIB card not configured

C:WODEK51\DATA\

C:WODEKSl\TESTS\

C:\MODEK51\CONFIG\

C:\MODEK51\707\

C:\MODEK51\SEQ\

VGA

;P7470 GPIB 5

C:!MODEK51kONFIG\TESTLlB.CFG

Y File header

- GPIB card not configured during install

- Path for data files

- Path fortest setup files

- Path for configuration files

C--------- Path for Model 707 files

- Path for test sequencer files

- Graphics adapter

- Printer number (IBM Graphics Printer, Epson or Compatible)

- Plotter type

- Default instrument configuration file to use at power up. Set to

ASCII file, do not attempt to edit it as line and character

spacing are exact.)

Since the INSTALL program minimizes the hard disk

space required by only copying the IEEE-488 driver soft-

ware that is needed, it also may be necessary to run the

INSTALL program after changing the IEEE-488 card. As

explained in paragraph 2.5.6, the IEEE-488 card must be

configured through a menu selection. If the desired interface card is not highlighted in the list of available cards,

run the INSTALL program to select the new card before

configuring it through the menu selection.

TESTLIB.CFG during installation.

1 Fimre 2-12. Example

of

MODEL251 .CFG FiZe

2-18

Page 35

SECTION 2

Getting Sfaarfed

Operation Overview

2.5 OPERATlON OVERVIEW

2.5.1

Once the software is installed, running the program is

simply a matter of typing in the following from the

MODEL251 (or other) subdirectory:

MODEL,251 <Enter>

Runnlng the Software

KEITHLEY MODEL 251 I-V TEST SOFTh'm

v2.00

bcurve Family Test

DC Source-Measure Test

File Operations

System Configuration

Getting Started

Exit to DOS

The Model 251 software will read the MODEL2!XCFG

file to configure itself to the computer hardware selections made during installation, then, if everything checks

out, display a logo screen and then the screen shown in

Figure 2-13.

Fl-Help F4-Print

Figure 2-13. Main Menu Screen

Arrow Keys & <Enter> Select Operation

ESC-Exit Current Menu

Page 36

SECTION2

Getting

Started

Table 2-3.

Message

Cant find parallel port copy protect block -

exiting ASYST.

Not enough free DOS memory to run Model

251. Suggestion i Remove any memory resident

Model 251 Ekrors Messages on Start-up

Cause

The copy protect block is missing or is not securely attached to

a parallel port of the computer.

The computer must have 53OK-bytes(542,720 bytes) of free

DOS memory. See paragraph 2.5.2.

programs not necessary for operation to free up

more memory.

System does not have enough expanded memory to boot. Model 251 requires a minimum of

The computer must have lM-byte of free expanded memory.

See paragraph 2.5.3.

lM-byte of expanded memory to operate.

System tie (file name) not found. Run INSTALL

A Model 251 file is missing. You must m-install the software.

to ensure all system files are present.

None Computer must have 53OK-bytes of free DOS memory. (Com-

puter may lock up if this memory is not available; see paragraph 2.5.2.) Or, the copy protect block is missing or is not securely attached to a

parallel port

of the computer.

NOTE

The first time Model 251 software is executed,

a screen telling you that a GPIB card must be

selected is displayed before the main menu

screen. Refer to paragraph 2.5.8.

Note that the version number of the software is listed in

the title bar. Knowing the software version is useful

when discussing problems with the Applications Department at Keithley Instruments.

Possible error conditions for software start-up are listed

in Table 2-3.

2.5.2 DOS Memory Requirement

Model 251 software needs 53OK-bytes (542,720 bytes) of

free DO!3 memory to run. If you

ory to run Model 251 software, follow these guidelines:

Examine your present AUTOEXEC.BAT and CON-

1.

FlG.SYS files to determine which device drivers and

terminate and stay resident (TSR) programs are necessary. For example, a mouse driver, an IEEE488

board driver, and a LIM expanded memory driver

must free

up more mem-

are probably necessary. A network driver or a batch

file for a DOS shell are probably not necessary.

2. Copy your present AUTOEXEC.BAT and CONFIGSYS files to make backups:

COPY AUTOEXEC.BAT AUTOEXEC.SAV

COPY CONFIG.SYS CONFIG.SAV

3.

Create an AUTOEXEC.251 and a CONFIG. in

your root directory to run Model 251 software, including any lines determined necessary in Step 1 and

the following suggested lines:

AUTOEXEC.251

COl’.JFIG.251

4.

Create batch files to switch back and forth between

echo Model 251 Boot Up

buffers = 20

files=20

boot up configurations:

M251.BAT

copy autoexec.251 autoexecbat

copy config. config.sys

MINE.BAT

copy autoexec.sav autoexecbat

copy config.sav config.sys

5. To configure the computer to run Model 251 software enter the following command:

M251

2-20

Page 37

SECTTON 2

Getting Started

This batch file copies the AUTOEXEC and CONF’IG

files you just created with a 251 extension to ones

that will be read on boot up.

6. Reboot the computer.

7. Enter the following from the MODEL251 subdirectory to start Model 251 software:

MODEL251 <Enter>

To configure the computer with your original

AUTOEXEC and CONHG files, follow this procedure:

1. Return to the root directory of your computer’s boot

up drive and type in

MINE’

This batch file copies your original AUTOEXEC and

CONPIG files to ones that will be read on boot up.

2. Reboot the computer.

2.5.4

Setting Up Printers and Plotters

Mode1251 software supports only the peripheral devices

and communications ports shown in Table 24.

Table 2-4. Supported Configurations for

Peripheral Devices

Printer

None

None

None

Parallel

Parallel

Parallel

serial

Plotter

None

serial

IEEE-488

None

Serial

IEEE-488

None

serial IEEE-488

Paral.lel printers and IEEE-488 plotters are completely

configured during the INSTALL program. Serial printers

and plotters need additional configuration.

2.5.3 Expanded Memory Requirement

Model 251 software is compatible with L&us/Intel/

Microsoft (LIM) Expanded Memory, versions 3.2 and 4.0.

Model 251 needs lM-byte of free expanded memory to

run. There are numerous combinations of hardware and

software to attain this requirement. Among them are:

0 DOS 4.0

l

Add-in memory boards offer LIM support in hardware or software.

l

Computers purchased with 2M-byte RAM often include a utility program to convert extended memory

to LIM expanded memory. A free utility for this pur-

pose is available from many computer bulletin boards.

l

Commercially available memory management utilities include QEMM-386 (Quarterback Office Systems)

for 386-based computers.

contains built-in LIM 4.0 support.

After installing or reconfiguring Model 251 software for

serial output devices, it is necessary to properly configure a serial port for the device and, in the case of printers,

to redirect output from a parallel port to a serial port. This

is accomplished by using the DOS MODE command in

your AUTOEXEC2Sl Sle.

Example 1. Connecting an HP 7470A plotter with a

serial interface.

Your AUTOEXEC file will need a MODE command to

configure the baud rate, parity, data bits, and stop bits of

serial port COMl. Assuming 2400 baud, no parity, 8 data

bits, and 1 stop bit, the MODE command in your

AUTOEXEC file would be one of the following:

mode coml: 2400, n, 8,1, p

mode coml: 2400, n, 8,1, b

(for DOS version 3.3)

(for DOS version 4.0)

2-21

Page 38

SECTION 2

Getfing Started

Example 2 Connecting an Epson compatible printer

with a serial interface.