Tektronyx

24XSAl2467

Option 10

Instrument Interfacing Guide

70-6282-00

0

-

.

<

. . .--..e

-m.-.. .

TEK . INTER-OFFICE COMlvllJNlCATlON

TO

Sohn Martin

94-540

.-

3:. ’ t

.

Juno 25, 1991

Frank Gray, SO-PAT

FWW

M3KC.T

GIDEP permit request

In response to

Government

Tektronix operator,

Tektronix, Inc. hereby grant6 such permission for distribution

of

such documents to any

in the Metrology Data Interchange Data Base

that

copyright notice and ownership statement exactly a-& it appears

in the original, together with the Legend "Reproduded with

pemieeion,a

aeon% 1[

all copies

This permission has been approved by the Intellectual

Industry

Committee of Tektronix

ded

to GIDEP to grovide’the requested permission.

the request

Exchange

service and

GTDEP

of the original work include the entire

to grant permission to

Pro

ram (GPDEP) to reproduce

nstruction manuals,

P

user that is a full participant

of

GIDEP provided

and

a

copy of this memo may

the

geG&dy

Group Pat&t Counsel Group Patent C&nsal v

Tektronjx

24XSAl2467

Option 10

Instrument Interfacing Guide

070-6282-00

Please check for change information at the rear

of this manual.

First Edition: September 1986

Last Revised: February 1988

_--... -. -- ------

Copyright 0 Tektronix, Inc. 1986. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

Tektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070-1000

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

.......................................................................................................... iv

Tables

Operators Safety Summary

Introduction

1

........................................................................

2 Measurement Capabilities and Ch8racteristics

Cursors..

Frequency and

Time Interval..

Repetitive Time intervals

Non-Repetitive Time Intervals..

Peak Amplitude.

Programming Techniques

3

4

Self-Contained Programs.. .....................................................................

Easy Programs

Full-Power Programs

System

Setting GPIB System Parameters.. .......................................................

Instrument Configuration

IBM PC/XT/AT Configuration

Program Considerations at Power-on.

................................................................................................. 2-l

..........................................................................

Period..

.........................................................................................

..................................................................................... 2-3

.......................................................................................

.......................................................................

.............................................................. 2-3

.............................................................................

Contigur8tion

.......................................................................

................................................................

.................................................. 4-5

Page

V

2-l

2-2

2-2

3-1

3-l

3-2

4-l

4-3

4-4

Communication Between Oscilloscope

5

Output Statements

Query Commands and Responses..

Input Statements.. ..................................................................................

Setup Transfers

Sending and Receiving ASCII Setups

Sending and Receiving Binary Setups.

SRQ and Event Codes

Interface Messages

Local Lockout

Remote Enable (REN). ...........................................................................

Go To Local (GTL)

My Listen Address and My Talk Addresses

Unlisten (UNL) and Untalk (UNT). ..........................................................

Interface Clear (IFC)

Device Clear (DCL).

24X5Al2467 Instrument Interfacing Guide

.................................................................................

.....................................................................................

.......................................................................... 5-5

................................................................................

(LLO)

..............................................................................

................................................................................. 5-7

............................................................................... 5-7

................................................................................

and

Controller

..................................................... 5-2

................................................... 5-4

.................................................

........................................ 5-7

5-1

5-3

5-3

5-5

56

5-6

5-7

5-7

5-8

i

Contwtta

Selected Device Clear (SDC). ................................................................ 5-8

Serial Poll Enable and Disable (SPE and SPD) .................................... 58

Command Handler ................................................................................. 5-8

Service-Request

GPIB Commands

Headers ..................................................................................................

Arguments.. ............................................................................................ 5-10

Command Separator.. ............................................................................ 5-l 1

Queries

Abbreviations ......................................................................................... 5-l 1

GPIB Commends

6

................................................................................................... 5-l 1

Message Terminator.. ............................................................................ 5-l 1

Numeric Arguments

Measurement Techniques

Introduction ............................................................................................ 7-1

Trigger Settings..

Measuring Time Intervals on Repetitive Signals.. ................................. 7-2

Measuring Single-Shot Time Intervals .................................................. 7-4

Measuring Peak Voltages.. .................................................................... 7-5

Measuring

Trigger Level

Programming

Rise and Fall Times ............................................................. 7-6

Pege

Handler ....................................................................... 5-S

................................................................................... 5-10

5-l 0

............................................................................... 5-l 2

.................................................................................... 7-1

Compensation..

Examples.. ....................................................................... 7-10

................................................................

7-10

ii 24X%/2467 Instrument Interfacing Guide

Page

A

Appendix

Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

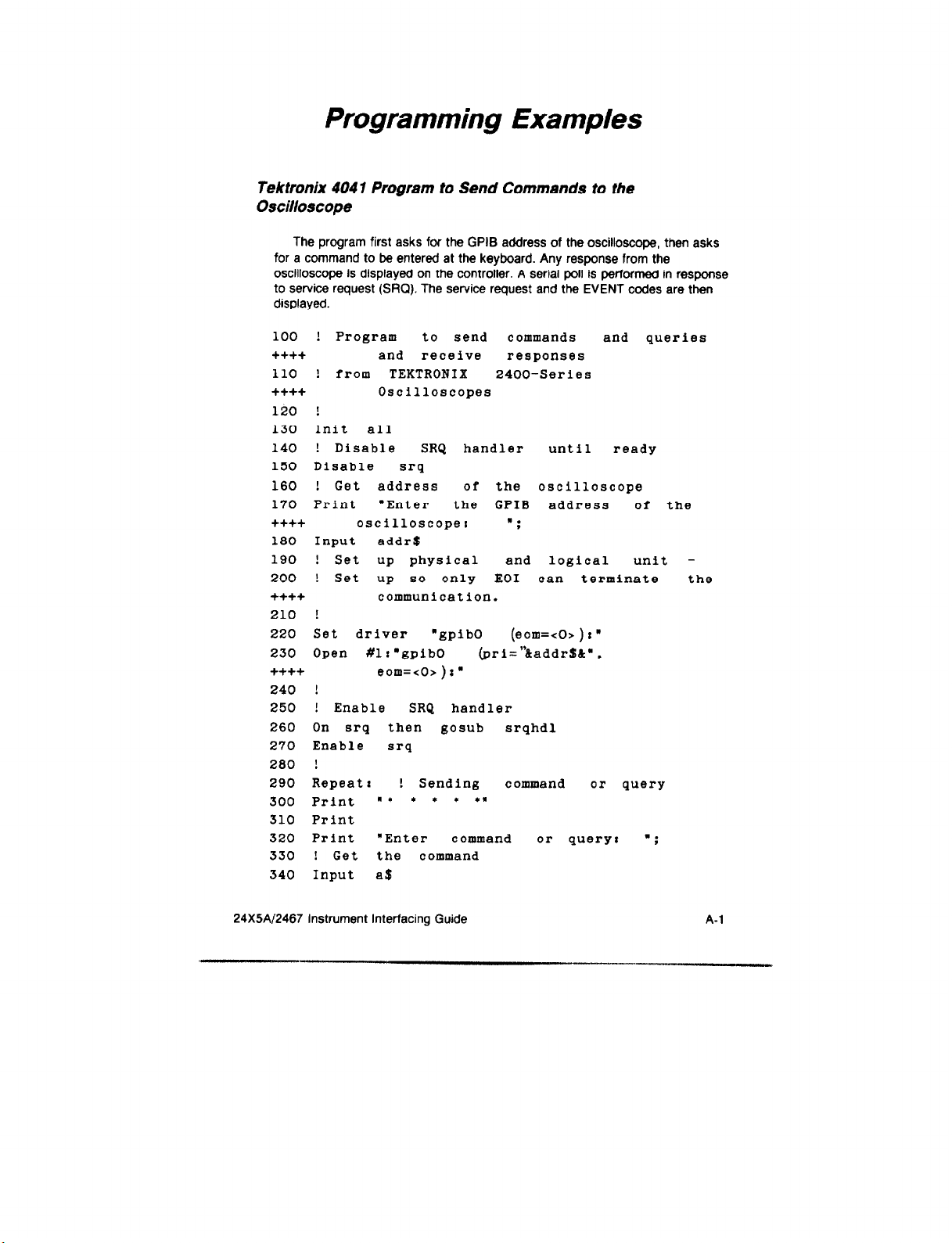

Tektronix 4041 Program to Send Commands to the Oscilloscope

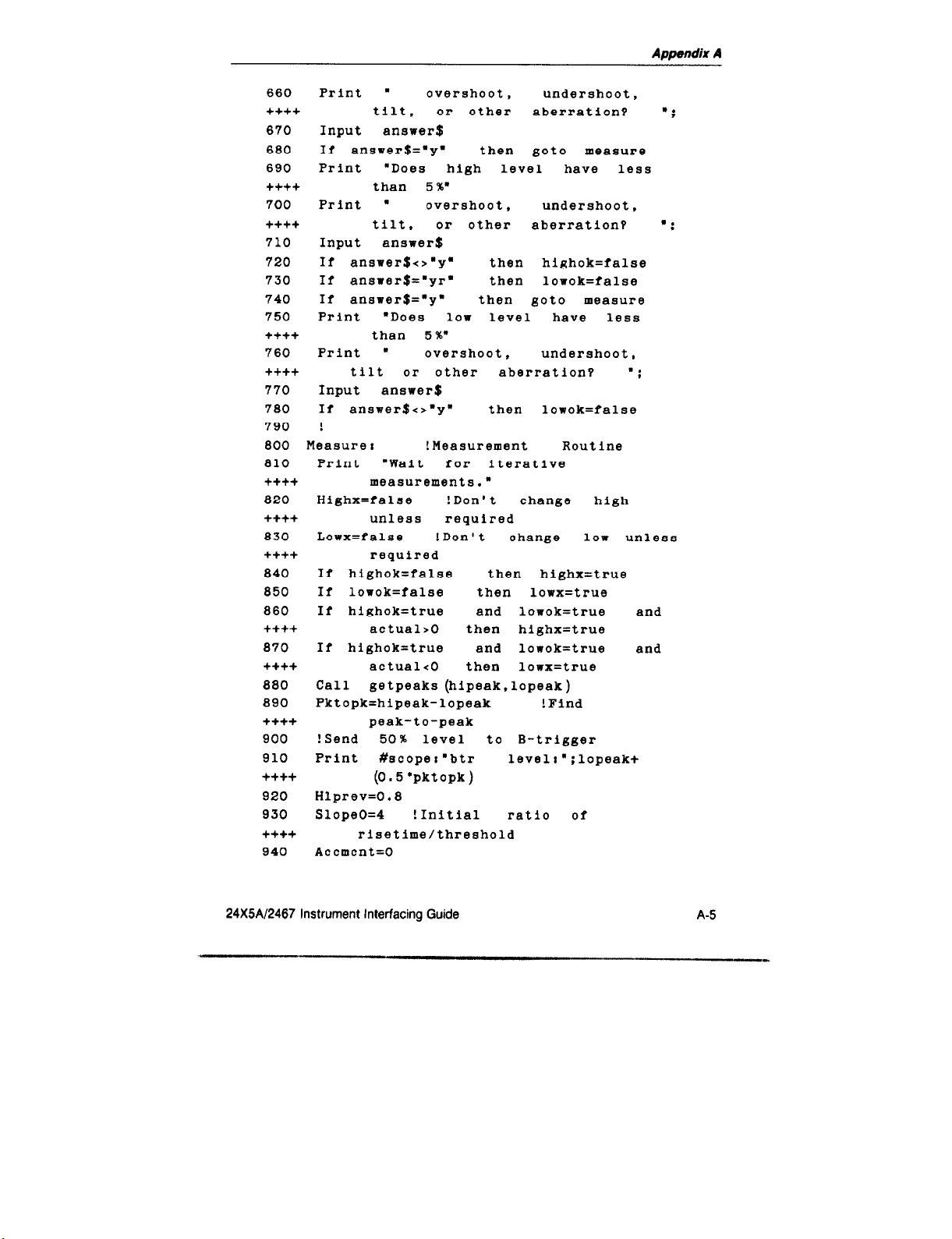

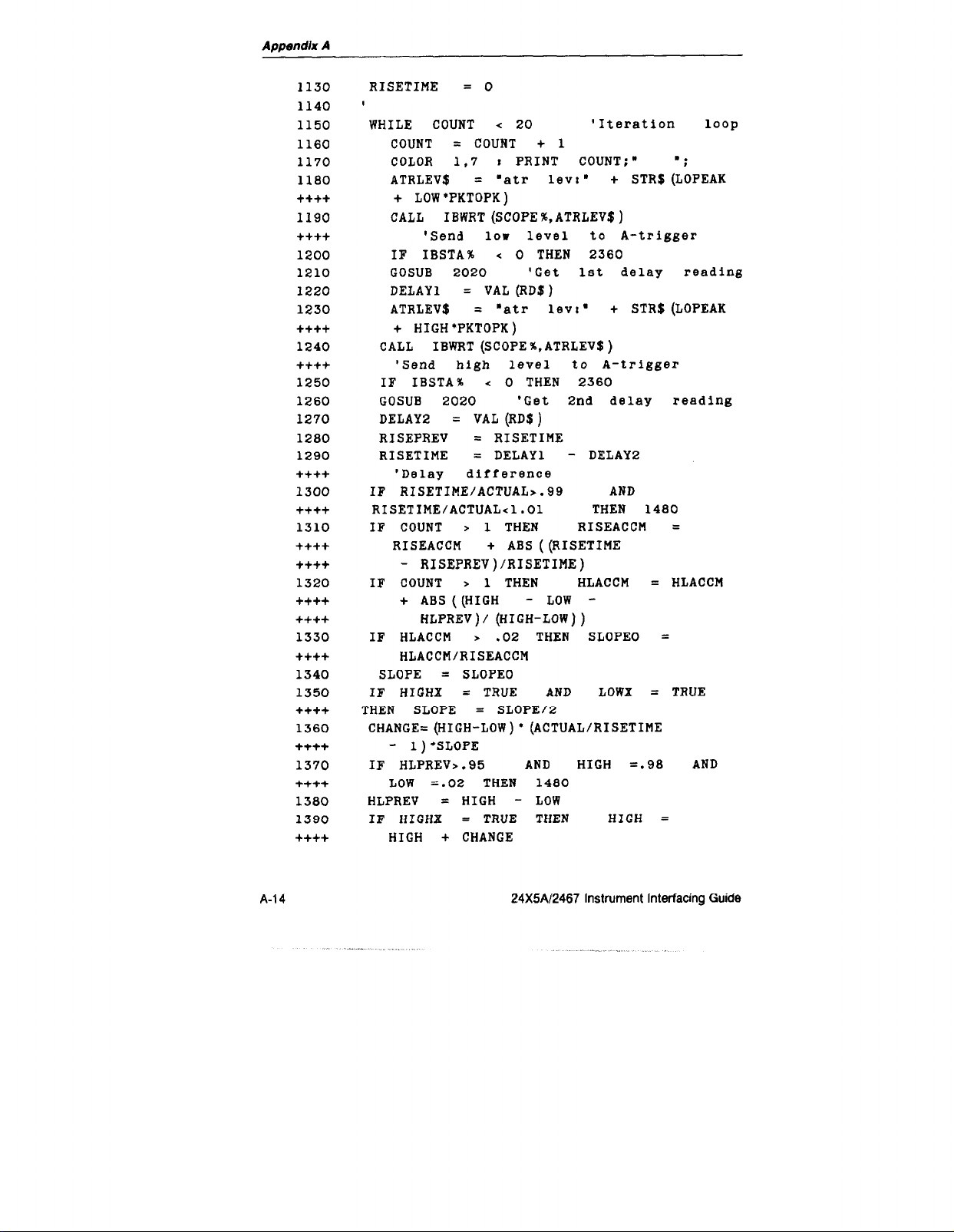

Tektronix 4041 Program to Calibrate Trigger Levels

for Transition

IBM PC/XT/AT Program to Calibrate Trigger Levels

for Transition Time . . . . . . . . . . . . . . . . . . . . . .,.............,.................................. .

HP 98Xx Program to Calibrate Trigger Levels

for Transition Time . . . . . . . . . . . . . . . . . . . . . . . .

Tektronix 4041 Subroutine to Measure

Frequency, Count, and Time

IBM PC/XT/AT Subroutine to Measure Frequency,

Count, and Time

Tektronix 4041 Subroutine to Measure Peak

Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IBM PC/XT/AT Subroutine to Measure Peak

Voltages. . . . . . . . . . . .

HP 98XX Subroutine to Measure Peak Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Appendix B

Status and Error Reporting _..........._........... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

c

Message Command

Appendix D

D

Sweep Speed Command Considerations . .._._.............................................

. . . . . . . . . . . . . . . . . . . ..*..........................

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . , . . , , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . A-33

A-l

A-l

A-2

A-9

A-18

A-28

A-29

A32

A-85

B-l

C-l

D-l

E Appendix E

GPIB Command

Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Appendix F

LLMessage Command Character Translations ._........,............................... F-l

24X5A/2487 Instrument Interfacing Guide

E-l

iii

Tables

Table

Functional Enhancement Options .................................................................. l-l

l-1

5-l Command or Query Byte Counts..

Numeric Argument Format for GPfB Commands

5-2

6-l Vertical Commands

6-2 Horizontal Commands..

6-3 Trigger Commands..

Delay and Delta Commands.. ........................................................................

6-4

6-5 System Commands

GPIB Command Set for the TV Option.. ....................................................... 6-23

6-6

Counter/Timer/Trigger GPIB Commands ...................................................... 6-24

6-7

Word Recognizer GPIB Commands

6-6

GPIB Command Set for the DMM Option .................................................... 6-29

6-9

6-10 Calibration and Diagnostic Commands..

Delay Time and Delta-Delay Time ................................................................. 7-13

7-1

B-l Status Event and Error Categories

B-2 GPIB Status Codes ........................................................................................

C-l MESsage Command Character Translations..

Sweep Speecl Command Results.. ................................................................ D-2

D-l

GPIB Command Summary.. ........................................................................... E-l

E-l

F-l

LLMessage? Query Character Set (Code-Sequenced).

LLMessage Command Character Set .......................................................... F-l

F-2

........................................................................................ 6-1

..................................................................................

.......................................................................................

........................................................................................

................................................................

......................................... 5-l 2

..............................................................

....................................................... 6-33

............................................................... B-2

.............................................. c-2

................................ F-2

Page

5-4

z

6-11

6-13

6-28

B-3

0

24X5Al2467 Instrument Interfacing Guide

Operators Safety Summary

The general safety information in this part of the summary is for both operating

and servicing personnel. Specific warnings and cautions will be round

throughout the manual where

Terms

In This Manual

CAUTION statements identify conditions or practices that could result in

damage to the equipment or other property.

WARNING statements identify conditions or practices that could result in

personal injury or loss of life.

As Marked on Equipment

CAUTION indicates a personal injury hazard not immediately applicable as One

reads the markings, or a hazard to property, including the equipment itself.

DANGER indicates a personal injury hazard immediately applicable as one

reads the marking.

Symbols

In This Manual

they

apply and do

not

appear in this summary

A

As Marked on Equipment

A

24X5A/2467 Instrument interfacing Guide

information is to be found. For maximum input voltage see Table 6-l.

DANGER-High voltage.

Protective ground (earth) terminal.

!

ATTENTION-Refer to manual.

This symbol indicates where applicable cautionary or other

!

V

Operators Safety Summary

Power Source

This product is intended to operate from a power source that does not apply more

than 250 volts rms between the supply conductors or between either supply

conductor and ground. A protective ground connection by way of the grounding

conductor in the power cord is essential for safe operation.

Grounding the Product

This product is grounded through the grounding conductor of the power cord. To

avoid electrical shock, plug the power cord into a properly wired receptacle before

connecting to the product input or output terminals. A protective ground

connection by way of the grounding conductor in the power cord is essential for

safe operation.

Danger Arising From Loss of Ground

Upon loss of the protective-ground connection, all accessible conductive parts

(including knobs and controls that may appear to be insulating) can render an

electric shock.

Use the Proper Power Cord

Use only the power cord and connector specified for your product.

Use only a power cord that is in good condition.

For detailed information on power cords and connectors see Table 1-l.

Use the Proper Fuse

To avoid fire hazard, use only a fuse of the correct type, voltage rating and current

rating as specified in the parts list for your product.

Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate this product in an explosive atmosphere unless

it has been specifically certified for such operation.

Do Not Remove Covers or Panels

To avoid personal injury, do not remove the product covers or panels. Do not

operate the product without the covers and panels properly installed.

vi

24X5A/2467 Instrument Interfacing Guide

Introduction

The Tektronix 2445A, 2455A, 2465A, and 2467 Portable Oscilloscopes have raised

measurement capability and operator efficiency far above previous standards. These

qualities are enhanced by a family of Options. Options are available individually or in

Special Editions which combine them in synergistic packages.

Number

10

09/09

09

01

05

Functional Enhancement Options

Table l-l

Designation

IEEE-488 (GPIB)

Interface

Counter-Timer-Trigger

w-v

Word Recognizer (WR

Digital Multimeter

@MM)

TV/Video Analysis

System (TV)

Adapts the oscilloscope to measurement

systems. (Included in 2465A DV, 2465A

DM, 2465A CT.)

Measures frequency, period, or total;

enhances timing accuracy; delays trigger

by event count; triggers on signal

combinations. (Included in 2465A DV,

2465A Dfvl, 2465A CT.)

Triggers sweep or counter on 17-bit word.

(Included in 2465A DV. 2465A DM, 2465A

CT.)

Measures V,. V,,. A*, A,,, resistance,

continuity, temperature, dB. averages, and

changes, with 4 112 digits (included in

2465A DV, 2465A DM).

Triggers on selected video lines: clamps

‘back porch.” (Included in 2465A DV.)

Function

24X5A/2467 Instrument Interfacing Guide l-l

This Interfacing Guide shows how to use the 24X5A/2467 Oscilloscopes with

Option 10 in a GPIB system. It explains the instruments’ measurement capabilities,

how to set them up for GPIB operation, and how to communicate with the

oscilloscopes and their options with a system controller. Consult the instrument

operators manual for basic measurement techniques.

If your instrument is configured with at least the GPIB and CTT (Options 10 and 06

or Options 10 and 09), it can measure frequency, period, time interval, peak voltages,

rise and fall time, slew rate, duty factor, peak-to-peak voltage, frequency ratio, and

other signal parameters automatically. The DMM adds precise measurements of lowspeed signals to the possibilities for automation.

If your tests are not suited to automation, a measurement system can interact with

an operator through the instrument. The controller sets the scope to display a

waveform and the operator positions AV or At cursors to the points of interest. The

controller men logs the measurement or compares it to limits. In other applications.

the operator adjusts a circuit or device by looking at an automatically displayed

waveform. Cursors can indicate test limits or adjustment targets.

1-2

..x-_..- ..__ -..^.._ l.l-

24X5/\/2467 Instrument Interfacing Guide

Measurement Capabilities

and Characteris tics

cursors

For semiautomatic measurements, the cursors aid communication between the

system and the operator. An operator can align the cursors with specific waveform

features and the controller can assimilate the data. A controller can set the cursors

to nominal starting positions, close to the actual measurement or to limit positions

within which a waveform should fall.

The cursors give excellent accuracies. They eliminate graticule interpolation and

they eliminate CRT geometry errors. Time measurements spanning 4 divisions or

more are accurate within -+ 1.25% of reading with X10 MAG off or 2 1.75% with

Xl 0 MAG on. Low-frequency voltage measurements spanning 3.2 divisions or

more are accurate within + 2.25%. Always use the largest possible display of any

waveform for the best accuracy.

For intervals less than 4 ns, delta-time cursors are more accurate than the

55 ps basic accuracy of counter-based, delta-delay-time measurements.

Frequency and Period

An oscilloscope with the CTT option directly measures frequency or period of

the A-trigger signal, but accurate counting requires greater signal amplitudes than

stable sweep triggering requires. The highest frequency specified for counting is

150 MHz, even though sweep triggering is specified to much higher frequencies.

Two factors cause these differences.

the signal, even though the sweep will trigger on marginal or very-high-frequency

signals that the shaping comparator sometimes misses. Second, the shaping

circuits driving the sweep and the counter may have slightly different thresholds.

To count the frequency or period of a Channel 1 or Channel 2 signal, use DC

trigger coupling and at least 1.5 divisions peak-to-peak signal amplitude, from

0.5 Hz to 50 MHz; use at least 4 divisions up to 150 MHz. Counting from

Channel 3 or Channel 4 requires only half as much display amplitude.

24X5AI2467 Instrument Interfacing Guide 2-l

First, the counter must ‘see” every cycle of

--...- _.____ “,.

MesSUremen! c8p8bitities 8i?d ti8f8CteriStiCS

Time Interval

Automatic time interval measurements depend on the relationship between a

waveform and the sweep generators. This relationship is established by the

horizontal display, sweep delay, and trigger controls. Instruments equipped with

the Counter-Timer-Trigger (Cl-T) measure actual delay time, whether the B Sweep

runs immediately after delay or waits until receiving a trigger signal after delay. If

the B Sweep is triggered after delay, the measurement automatically tracks varying

intervals.

The counter operates with the delayed (B) sweep, in both delay-time and deltadelay-time modes. It counts time-base-clock pulses from the A-Sweep trigger event

to the start of the B Sweep. In the delta-delay-time mode the B Sweep displays a

pair of events that define the interval of interest and the counter determines the

difference between the pair of delay times.

The time resolution you select determines how long you must wait for the

instrument to complete a time interval measurement. AUTO resolution gives the

fastest measurement response, as short as 0.5 second. With 10 ps, 100 ps. or 1

ns resolution, response time depends on how long it takes to accumulate

1 ,OOO,OOO or 10,000 or 100 A Triggers, respectively. Higher signal frequencies give

higher A-Trigger rates, but the minimum trigger period is

the A SECiOlV setting. Increasing HOLDOFF increases the minimum trigger

period.

about

2 ps plus 12 times

Repetitive Time Intervals

The counter measures each of the two delay-times inherent in the deltadelaytime mode; then it determines the equivalent time between the B-Trigger events by

taking the difference between the pair of measured times.

Delta-delay-time mode yields the best possible accuracy for many time

measurements. The difference measurement cancels delay differences between the

A Trigger and the B Trigger. With delta-time, you can measure very short intervals,

down to the resolution limit. However, delta-time measurements require repetitive

signals.

For the best deltadelay-time accuracy, expanded displays of the beginning and

ending of an interval must be visually superimposed. You can disregard

superposition of the ends of the interval, with triggered delta-delay-time, if the

transition times of the signals are short compared to the accuracy you need.

2-2 24X5A/2467 Instrument Interfacing Guide

Meesurement Cepebilities end Cherecteristics

Non-Repetitive Time Intervals

The CTT also measures non-repetitive signals and isolated intervals, by

measuring delay-time. If the A Sweep triggers on one event and the B Sweep

triggers on another, the counter records the time between the events. The two

events could be the rising and falling edges of a single pulse. Using the delay

mode, you can measure pulse widths or propagation delays as short as 70 ns. You

can measure single-shot time intervals with lo-ns resolution.

Peak Amplitude

In response to a command from a GPIB system controller, the oscilloscope can

measure signal peaks. The A-Trigger circuit compares trigger levels to the peaks.

The trigger levels match the signal peaks within + [3% of peak +3% of peakto-peak +O.l division +(0.5 mV X probe attenuation)]. Peak voltage accuracy is

not specified for signals with transition times less than 20 ns. Fortunately, peak

voltages of similar signals can be compared more accurately than the specifications

indicate they can be measured. Differences between signals with similar waveforms

and repetition rates can be accurately determined, even if the signal transitions are

faster than 20 ns.

If the signal period exceeds 20 ms. set SEGiDlV slower than 0.25 times the

signal period. With SEC/DIV from 50 ms to 500 ms, the instrument will measure

the peaks of signals with periods up to 200 ms. If SEClDlV is 5 ms or faster, the

measurement should take no more than 2 seconds, and usually takes much less.

With slower sweeps, to accommodate slower signals, the measurement can take

up to 20 seconds.

24X5A/2467 Instrument Interfacing Guide

2-3

Programming Techniques

Self-Contained Programs

The oscilloscopes in this series can satisfy many repetitive test and

measurement requirements, without external controllers. They can store as many

as 30 setups, with seven-character names, which can be grouped into multiple

sequences. The setups in any of the sequences can be recalled by operating a

single button on the front panel or by operating an external switch, connected to

the instrument’s rear panel.

With the CTT (Option 09 or 06), these setups can measure frequency, period,

time intervals, and slew rate automatically. With some operator interaction you can

measure rise and fall time, duty factor, peak voltage, and other signal parameters.

With the GPIB (Qption lo), the 30 setups can be copied from one oscilloscope to

others, using only a GPIB cable, without a controller or other external device. See

EXER 13 and EXER 14 in Section 4. See the instrument Operators manual for

complete instructions.

Easy Programs

With minimal programming, a system controller can augment the oscilloscope

with conditional sequences, limit testing, data logging, and extended operator

prompting, beyond the seven-character setup names. Test program generators and

executors facilitate this level of programming and relieve the test developer of

writing and debugging code. The test developer sets the instrument manually and

chooses a set of test parameters for each step in a test procedure. The controller

‘learns” the setup and the set of test parameters for future use.

Test program development and execution software from Tektronix includes EZTEK-2400-PC, for the IBM AT/XT/PC and equivalents, and EZ-TEK-2400 and EZTEST, for the Tek 4041 controller. The Tektronix GURU interface package, which

adds GPIB controller capability to the IBM AT/XT/PC and equivalents, also

includes a test program generator.

If you use a test program generator, you can disregard the tables of commands

in this guide. Refer to ‘Setting GPIB System Parameters” to establish compatibility

with your controller.

24X5A/2467 Instrument Interfacing Guide 3-1

Progremming Techniquea

Full-PO wer Programs

If you need to automate voltage measurements and indirect time

measurements, you can take advantage of the versatility of the instrument

command language. Automatic measurements can include rise and fall time, duty

factor, peak voltage, and other signal parameters, by programming specific

instrument commands.

Even if you use the full power of the instrument command language and the

controller language, most tests and measurements can be set up by operating the

instrument manually, then transferring the setup information to the controller for

future use and possible modification. See the ‘LLSET’?” query and ‘LLSET’

directive described in Table 6-5, System Commands. Sample program segments

follow the command tables.

3-2

24X5Al2467 Instrument Interfacing Guide

System Configuration

Setting GPIB System Parameters

To use the oscilloscope with a GPIB controller, system compatibility must be

established by setting a few key parameters. Use the oscilloscope front panel

controls to select the primary address, message terminator, and talk/listen mode.

These selections are accessible through ‘exerciser” routines. GPIB exercisers also

can transfer the set of thirty saved setups from one instrument to one or more

other instruments, without a system controller.

GP EXER 11 Program GPIB Address

GP EXER 12 Program GPIB Message Terminator and Talk/Listen

GP EXER 13 Receive-Setups Mode

GP EXER 14 Send-Setups Mode

To operate these exercisers:

1. Enter the Diagnostic Monitor mode by pressing and holding both AV and

At, then pressing Trigger SLOPE while holding AV and At. The readout will

display ‘DIAGNSTIC. PUSH A/B TRIG TO EXIT,” indicating the Diagnostic

Monitor mode.

2. Repeatedly press the upper or lower Trigger MODE button to sequence

through the TEST and EXER routine labels and select the one you want to

run.

3. Press the upper Trigger COUPLING button to execute the selected

Exerciser.

4. To exit an exerciser, press the lower Trigger COUPLING button.

5. To return to normal instrument operation, press A/B/TRIG (or, with the

available C77, press A/B/MENU).

In the following descriptions, the lines marked with > show what is displayed in

the top row of the readout.

24X5A/2467 Instrument Interfacing Guide 4-l

System Conftgwation

QP EXER 11 Program GPIB Address for Talk and Listen

> GPIB ADDRESS nn

nn = a primary address within 0 to 31. Turn the A control to

select the appropriate address. With address 31, bus data has no

effect on the instrument and is unaffected by the instrument.

The instrument does not have secondary addressing.

GP EXER 12 Program GPIB Message Terminator and Talk/Listen

Press the upper MODE button to select EOI or LF as

message terminator.

Press the upper COUPLING button to select TALWLlSTEN

or LISTEN operation.

> TERMINATOR EOI MODE TALK LISTEN

The instrument accepts only the EOI bus message as the end

of a string of received bytes. The instrument asserts EOI at

the end of a string of transmitted bytes. The instrument can

be addressed either as a talker to send settings and readings

or as a listener to receive control information.

> TERMINATOR LF MODE TALK LISTEN

The instrument accepts either the EOI bus message or an LF

(line feed) character as the end of a string of received

bytes. The instrument asserts CR (carriage return) then LF

with EOI at the end of a string of transmitted bytes.

> TERMINATOR EOI MODE LISTEN ONLY

The instrument will not operate as a bus talker. It will

receive control information. The listen-only mode allows the

instrument to share a GPIB address with another instrument

that talks.

> TERMINATOR LF MODE LISTEN ONLY

4-2

24X5A12467 Instrument Interfacing Guide

System Configuration

GP EXER 13 Receive-Setups Mode

> READY TO RECEIVE SETUPS

1. Connect the instrument to another instrument of the same model and with the

same options by a GPlB cable. If the instrument is a different model in the

following list: 2445A, 2455A, 2465A, 2465ACT, 2465ADM. 2465ADV, and

2467, or one with a different set of options, most setups will be valid, but

some will give unpredictable results.

2. Select GP EXER 14 in the other instrument.

> RECEIVING SETUPS

When the transfer is complete, the instrument will exit EXER 13 automatically.

GP EXER 14 Send-Setups Mode

Before executing this exerciser, make sure the instrument is

connected to another by a GPIB cable and be sure the other

instrument is in the “READY TO RECEIVE SETUPS” state

initiated by GP EXER 13.

> SENDING SETUPS

When the transfer is complete, the instrument will exit

EXER 14 automatically.

Instrument Configuration

1. Select a primary address for the oscilloscope.

2. Set the scope address through the diagnostic exerciser.

NOTE

/f you are using an HP controller, the standard l/O port is 7. Add the value

of the scope address to 700 and use the result as the device identifier in all

calls to the scope.

24X5A/2467 Instrument Interfacing Guide REV SEP 1967 4-3

System Confh7uration

3. Select the message terminator. If you are using an HP controller, the

message terminator must be set to LF. For other controllers, use EOI.

4. Select TALK/LISTEN mode, not LISTEN ONLY.

IBM PC/XT/A T Configuration

For IBM computers, using the Tektronix GURU interface or the National

Instruments IEEE-488 interface, do the following.

1. Determine whether you have a PC2 or PCPA interface board. PC2A has a

clock. Be sure jumpers and switches are set correctly.

2. If you are using the National Instruments interface package, execute

IBSTART, which augments the CONFIG.SYS file on the root drive by

adding a line.

DEVICE=GPIB.COM

If you are using the Tektronix GURU package, be sure the GURU diskette

is in the root drive or else copy the CONFIGSYS file on the GURU diskette

to the root drive, after backing up the original file.

3. Execute the tBCONF program.

l

In the GPIBO menu, be sure the correct card is selected. DMA should be

1. Set any other configuration parameters as required.

l

Choose and enter a name for the oscilloscope. Use ‘02465” if you are

going to use the XTNLEV program.

l

Using the sub-menu of the device name you chose, set the primary

address to the value you selected in step 1 of Instrument Configuration.

l

Save any changes you made and exit IBCONF.

4.

Make sure a copy of the file GPIB.COM exists in the directory your

computer boots up from.

5.

“Boot” the system to initialize it for GPIB operation with the defined device

address(

6.

Be sure the logged drive contains a copy of the file BIB.M, part Of the

interface package.

7.

Execute

8.

Load and execute any valid application program. Each application program

BASICA.

must incorporate at least lines 1-6 of the file DECL.BAS, part of the

interface package.

4-4 24X5A/2467 Instrument Interfacing Guide

System Configurstion

Program Considerations at Power-on

If you are using the self-programming features or a test program generator, you

can disregard the information in this section. At power-on, the instrument restores

the setup in effect at power-off or saved setup number 1, depending on the

selection made by an extended-function exerciser, described in the Operators

manual. The GPIB interface enters the Local State (LOCS).

If service requests were enabled at power-off, the GPIB interface asserts

Service Request (SRQ) at power on. The normal response of a controller to SRQ

is a serial poll, but the instrument will communicate normally on the GPIB whether

or not the controller responds to an SRQ. If the controller performs a serial poll,

the oscilloscope responds with a status byte of 65 decimal, meaning that the

instrument has just powered up.

Some controllers, such as the Tektronix 4051 and 4052 without the 405XA14

GPIB ROM pack, require a program with an SRQ handler. The program should

begin by enabling this handler; otherwise, a power-on SRQ will cause the program

to halt and display the error message ‘NO SRQ ON UNIT.” Examples of SRQ

handler routines for both Tektronix 4041 and 405X series controllers are contained

in the ‘SRQ and EVENT Codes’ section.

24X5A/2467 Instrument Interfacing Guide 4-5

Communication Between

Oscilloscope and Controller

GPIB controllers use high-level languages such as Pascal, C, and BASIC to define

messages and transfer them to and from the oscilloscope. Statements in these

languages usually contain three parts: the input/output keyword (such as ‘PRINT” or

“read”), the GPIB logical unit designator (such as ‘08” or ‘scope”), and a character

string or string variable designator (such as ‘CHl COUPLING:DC”) that forms a

specific instrument command or response. The following statement in Tektronix 4041

BASIC sets CH 1 coupling to dc, if the instrument has been previously identified as

logical unit #8. All program examples are given in Tek 4041 BASIC unless otherwise

noted.

220 PRINT #6: "CHl COUPLINGIDC"

You may prefer to assign the oscilloscope GPIB address to a variable and use that

variable in I/O statements. This can make the code more understandable and reduce

effort and errors when changes are required.

320 Let scope=6

. . .

730 Print

24X5A12467 Instrument Interfacing Guide 5-l

#scope:

“CHl COUPLINGIDC"

Communicetion Between Oscilloscope 8nd Controller

Output Statements

The following examples show output statements in several controller languages.

Any instrument command can take the place of “string” in the examples. Each

statement assumes a prior configuration and declaration of the GPIB port and the

device (oscilloscope) on the bus.

Tek 4041 BASIC:

PRINT #lOI "string"

IBM AT/XT/PC, with Tek GURU GPIB Interface and Microsoft BASIC,

where WRT$ is an output string buffer:

IBM AT/XT/PC, with National GPIB/Pascal Interface and Turbo Pascal,

where wrl is an output string buffer and cnt is the number of bytes

to be sent:

HP 9826A BASIC:

OUTPUT

710: %tring"

Query Commands and Responses

The oscilloscope will transmit measurement or status information after a query

command has been sent to the scope. Query commands are formed by

immediately following a header with a question mark. The query and input

operations can be specified by separate statements. In some controllers, a

prompting input statement can perform both functions. For example, the following

Tek 4041 statement acquires the channel 1 settings, where set$ has previously

been declared an array of 100 characters.

160 Input #lO prompt %Hl? "I sets

The controller addresses the oscilloscope as a listener at primary address #lO

then sends ‘CHl?” over the bus. The controller then reassigns the instrument to

be a talker and inputs the characters into the target variable (set$). The set$

variable then contains the following information, for example:

CHl VOL:SO.OE-~,VARIO.O.POSIO.O,COU:FIF:

5-2 24X5At2467 Instrument Interfacing Guide

.-.... “_

Communication Between Oscilloscope and Controller

If a query includes an argument to specify a parameter, the response is

shortened. For example, if the query ‘CHl? COUPLING” were sent to the

oscilloscope, the response returned to the controller could be:

CHl COUrDC:

input Statements

The following examples show input statements in several controller languages.

The instrument response occupies the S$ or rd$ buffer in the examples. Each

statement assumes a prior configuration and declaration of the GPIB port and the

device (oscilloscope) on the bus. Each input must be preceded by a query to

identify the information desired.

Tek 4041 BASIC:

INPUT #lOrSS

IBM AT/XT/PC, with Tek GURU GPIB Interface and Microsoft

BASIC, where WRT$ is an output string buffer:

IBRD (SCOPE%.RDS)

IBM AT/AT/XT/PC, with National GPlBlPascal Interface and Turbo

Pascal, where wrt is an output string buffer and cnt is the

number of bytes to be sent:

lbrd(scope.rd,cnt):

HP 9826A BASIC:

INPUT 71033s

Setup Transfers

Only rarely should an oscilloscope setup be defined entirely by the commands

in the command tables. Initial setups normally should be copied from a manually

operated instrument, then modified if necessary by a few commands. The

instrument can transfer setups in tour ways. See the operators manual and the

command tables for details,

1. Thirty internally stored setups can be copied directly from one instrument to

another, through a GPIB cable, without a controller.

2. The current setup can be transferred to a controller in response to an

LLSET? query and returned by an LLSET command. The setup is

transmitted compactly, in an eight-bit binary format.

24X5A12467 Instrument Interfacing Guide

5-3

Communication Between Oscilloscope and Conlroller

3. The current setup can be transferred to a controller in response to a SET?

query and returned by a SET command. The setup is described fully in

ASCII characters, as defined in the command tables.

4. Thirty internally stored setups can be transferred to a GPIB controller, in

eight-bit binary format, using the LOADSEQ? query. The setups can be

sent to an oscilloscope with the LOADSEQ command.

Table 5-l

Command or Query Byte Counts

Command Maximum 6yte Count Maximum Byte Count

or Query with GPIB Only with All Options

LONGFORM Oif Ofl Off On

LLSET 90 92 154 156

SET

LOADSEQ

588 a45 a42

4043 4843 4043 4643

1303

Use LLSET? and LLSET to avoid wasting time and memory space, if your

controller can handle binary data.

Sending and Receiving ASCII Setups

To save a setup for future use, request a SET? string from the oscilloscope and

store it in a string variable. To set the instrument up with the stored parameters,

simply send the string back to the instrument.

400 Dim strS

410 Input #a prompt ‘%ETP”:s~~~! Input front

420 Dim atrs to len (strt)! M-dimension

. . .

450 Print m:atrs

5-4 24XW2467

to 1400

! Dimensloa variable

! panel setup into atrs

atr$ to actual

! string

Instrument Interfacing Guide

Communication Between Oscilloscope end Controller

Sending and Receiving Binary Setups

To obtain a Binary front-panel setup from the oscilloscope, send LLSET? and

store the response either in a string variable or in a numeric array according to the

capability of your controller. If the data is stored as an ASCII character string, the

controller must support E-bit ASCII characters or the data will be invalid. The

following 4041 example inputs the LLSET? response to a binary variable. To set

the instrument up with the stored parameters, simply send the array back to the

instrument.

. . .

400 Dim bind to 200 ! Dimension array variable

410 open #BI“GPIB (PRI=~,EOM=~O~)I”

420 Input #a prompt ‘fSET?“rbin$! Input front

! pane1 setup

450 Dim bin$ to len (binj)! Re-dimension bin$

! to actual array

. . .

460 Print #8rbin$

into bin$

SRQ and Event Codes

The most recent RQS ON or RQS OFF command (see Table 6-5, System

Commands) determines whether the instrument will generate the Service Request

(SRQ) message on the GPIB when either an error or a change in status occurs.

The enabling or disabling effect of the RQS command persists through power-off

and power-on, so the power-on SRQ also is controlled by the RQS command. The

SRQ indicator lights when the scope asserts the message on the bus.

If the controller is configured and programmed appropriately, the SRQ

interrupts the normal flow of the program. To service an interrupt, the controller

performs a Serial Poll. In response, the oscilloscope returns a Status Byte (STB),

which reveals the type of event that occurred. It also drops SRQ. If the instrument

has another event to report, it reasserts SRQ. The SRQ indicator extinguishes

when all events are reported. If the controller does not respond to the SRQ

message, the instrument continues to operate and communicate normally, even

though the condition that initiated the SRQ may invalidate a measurement.

The operator can generate SRQ and the user-request event (403). The SWRQS

ON; command enables or disables SRQ on closure of a switch connected to the

rear-panel STEP/AUTO EXT SWITCH connector, if RQS is on. The event is

included in the response to serial poll regardless of RQS. If a Tektronix probe with

an Identify button is connected to a vertical input, pressing the button with RQS on

also generates the SRQ and event 403.

24X5A/2467 Instrument Interfacing Guide

5-5

Communicetion Between Oscilloscope end Controller

To obtain more information about an event, the controller can send an EVENT?

query. The instrument responds with a number which indicates the specific event.

The various status bytes, events codes, and errors are defined in Appendix 6.

This program segment shows how to handle an SRQ, determine the instrument

status, and display the Status Byte and the associated event code on the

controller screen.

800????? ! Simple SRQ Handler

810 poll atb. dev ! poll bus. store status

820 input #dev prompt

830 print

stb; event ! print stb and event on SCI-*8ll

! byte in “stb”

“event?“:event

Interface Messages

This section describes the effects of GPli3 interface messages received by the

oscilloscope from a controller. See ANSI/IEEE Std 488-1978 for detailed

descriptions of interface messages and resultant interface states. These messages

are encoded as single bits or as single bytes. They may be explicitly generated by

the GPIB interface software in the controller or they can be composed in

hexadecimal format according to the IEEE Standard. They can NOT be sent as

character strings in the manner of instrument commands.

Local Lockout (LLO)

The Local Lockout message (LLO) may be received from the controller at any

time, whether the instrument is addressed or not. Once the LLO message has been

received, the My Listen Address (MIA) message locks out the front-panel

and the Go to Local (GTL) message enables them. The LLO message disables the

front-panel controls immediately if the instrument is addressed as a listener when

LLO is received. If the program sends the LLO message, it should also send the

GTL message to a listener-addressed device when the front panel should be active.

The LOCK indicator lights when front-panel operation is suspended.

If the controller sets the Remote Enable (REN) line false or if power is cycled off

and on, the effect of the LLO message is cancelled and the instrument controls

operate normally.

5-6 24X5Al2467 Instrument Interfacing Guide

controls

Communicetion Between Oscilloscope end Controller

Remote Enable (REN)

When the Remote Enable (REN) line is true and the instrument receives its

listen address (MLA), the oscilloscope can receive data from the bus and the

oscilloscope’s REM (remote) indicator lights.

If the REN line goes false, the instrument must receive MLA again before it can

receive commands. If a command is in process when REN goes false, it continues

to execute.

Go To Local (GTL)

If GTL is received, the instrument must receive MLA again before it can receive

commands. If a command is in process when GTL is received, it continues to

execute.

My Listen Address and My Talk Addresses (MLA and

MTA)

These messages condition the instrument to receive commands or respond to

queries and serial polls, respectively. They are received when the Attention (ATN)

line is true and the data on the GPIB is hexadecimal 20 or 40 plus the address

defined by GP EXER 11.

Unlisten (UNL) and Untalk (UN T)

These messages, equivalent to talk and listen address decimal 31, cancel the

MLA and MTA messages, respectively.

Interface Clear (IFC)

Receiving this message is equivalent to receiving both the UNL and the UNT

messages.

24X5A/2467 Instrument Interfacing Guide 5-7

Communication Between Oscilloscope and

Controller

Device Clear @CL)

The DCL message initializes communication between the instrument and the

controller. In response to DCL, the instrument clears any input and output

messages as well as any unexecuted control settings. Any errors and events

waiting to be reported are cleared except the power-on event. The SRO message

is cleared unless it is asserted for power-on.

Selected Device Clear (SDC)

This message performs the same function as DCL, only if the instrument has

been listen addressed.

Serial Poll Enable and Disable (SPE and SPD)

The Serial Poll Enable (SPE) message causes the instrument to transmit its

serial-poll status byte when it is talk-addressed. The Serial Poll Disable (SPD)

message returns the instrument to normal operation.

Command Handler

A command handler establishes communication between the controller and

oscilloscope, sends commands and queries to the oscilloscope, receives responses

from the oscilloscope, and processes the responses as required. The following

outline indicates a general sequence of command-handling functions.

1. Initialize the controller.

2. Disable the service-request handler until the program is ready to handle

them.

3. Get the GPIB address of the oscilloscope.

4. Enable the service-request handler.

5. Send a command to the oscilloscope.

6. Check for a response from the oscilloscope.

7. Process any response as desired.

6 Repeat steps 5 through 7 as desired.

5-8

24X5A/2467 Instrument Interfacing Guide

Communication Between Oscilloscope and Controller

Service-Request Handler

A service-request handler processes the interrupts generated by the SRQ

message on the GPIB. For example, when cursors have bean placed on points of

interest on a waveform, an operator can press a switch connected to the rear

panel which can cause the oscilloscope to assert SRQ. In response the controller

program can verify that the switch closure caused the interrupt, then query the

cursor measurement and compare the measured value to preset limits.

Events at which the oscilloscope asserts SRQ are identified in Appendix 8.

Some controllers can ignore service requests and others require a programmed

response to SRQ. Most controllers ignore service requests until SRQ interrupts are

explicitly enabled.

An SRQ handler needs an interrupt-enabling statement (eg. ON SRQ

statement-label) near the beginning of the program and a serial-poll subroutine with

that label. The ON SRQ statement directs program control to the serial-poll

subroutine whenever an SRQ interrupt occurs. The instrument maintains the

identity of an event that generates an SRQ until a serial poll is executed by the

interrupt-service subroutine.

The following general steps handle service requests from the oscilloscope:

1. Perform a serial poll to determine which device on the bus is requesting

service. The serial poll clears an SRQ generated by the oscilloscope, unless

more than one event has been identified.

2. Send an EVENT? query to the oscilloscope requesting service.

3. If the EVENT? query response is not zero, perform the appropriate

response to the event.

4. Return to the main program.

24X5A12467 Instrument Interfacing Guide 5-9

Communlcetion Between Oscilloscope end Controller

GPB Commands

The GPIB commands set instrument operating states, query the operating

states, and query the results of measurements. These commands are specified in

mnemonics that are related to function names or front-panel control names.

Commands follow the conventions established in the Tektronix Codes and Formats

Standard.

Command messages consist of headers, arguments, separators, and message

terminators.

A command contains at least a header. A few commands are fully specified by

a header. For example:

INIT

Arguments

Most commands require arguments after the headers. An argument must be

separated from its header by at least one space.

DELAY l.OE03

HMODE XY

Some arguments consist of primary and secondary arguments. Primary and

secondary arguments must be separated by a colon.

CHl VOLTS:6

ATRIGGER MODE:AUTOLEVEL

Some headers allow multiple arguments, which must be separated by commas.

A colon still separates primary and secondary arguments.

CHl VOLTS:5,COUPLING:DC,POSlTlON:1.2

VMODE CHl:OFF,CH2:ON,ADD:ON

5-10

_ ..” .“I_ _..._

24X5A/2467 Instrument Interfacing Guide

Communication Between Oscilloscope and Controller

Command Separator

Multiple commands can be combined in one message by separating the

individual commands with semicolons.

CHl VOLTS:5,COUPLING:DC;VMODE ADD:ON

Queries

In a query, the question mark must immediately follow the header, with no

space.

DVOLTS?

ATRIGGER? COUPLING

Message Terminator

Messages can be terminated with either EOt or LF, depending on the system

controller. The GPIB interface can be set to accept either terminator, using EXER

12, as previously explained. With EOI selected, a data byte received with EOI

asserted is recognized as the end of an input message. The instrument also

asserts EOI concurrently with the last byte of an output message. With the LF

setting, either an LF character or any data byte received with EOI asserted is

recognized as the end of an input message. With the LF selection, the instrument

transmits a Carriage Return character followed by Line Feed (LF) with EOI asserted

to terminate an output message.

Abbreviations

The defined words in headers and arguments can be entered at full length or

shortened to reduce typing and bus traffic. The command tables show the essential

characters of headers and arguments in upper-case characters and optional

characters in lowercase. The instrument accepts either upper case or lower case

characters. For example, any of the following commands are acceptable.

VMO?

vmadt

vmode invert

VMODE INVE

24X5A/2467 Instrument Interfacing Guide 5-11

Commuflk8tion Between Osciltoscope and Controlier

Numeric Arguments

The following table depicts the formats for numeric arguments in the GPIB

command set. Both signed and unsigned numbers

numbers are interpreted

as

positive.

are

accepted but unsigned

The symbol tnrx> indicates that

only one specific format is permitted, it is represented by nrl , nr2, or nr3.

any

of the three formats is allowed. When

fable 5-2

Numeric Argument Format for GPIB Commandr

Numeric

Argument

tnrx>

bol Number Format

SYl

<ml>

tnr2> Explicit decimal point

<nr3> Floating point in

Integers

scientific notation

+1,z

-3.2, +5.1, 1.2

+l.E-2, l.OE+2, l.E-2, O.O2E+3

Examples

-1, -10

5-12 24X5Al2467 Instrument Interfacing Guide

GPIB Commands

NOTE

Some commands are valid on/y with 2445A, 2455A, or 2467. These are indica ted by “(A) ” in the descriptions. The other commands are valid with the earlier

2445 and 2465

Table 6-1

Vertical Commands

CHl

CHl?

Header

Argument

Coupling:

POSition:

VARiable:

VOLls:

Coupling

POSition

VARiable

VOLts

Argument

AC

DC

FlFty

GND

tnrx>

tnrx>

tnrx>

Description

Selects Channel 1 vertical parameters.

Sets input coupling.

Sets position to tnrx> divisions from

center. Range extends -+ 11 divisions.

Sets VoltslDiv Var to the approximate

value of <nrx> in the range from 0 to

10. At tnrx> = 0, Vofts/Div is

calibrated.

Sets Volts/Div deflection factor to the

value of <nrx>. If tnrx> is not a

valid. calibrated VoltsiDiv for the

installed probe, the next higher

calibrated Volts/Div or the highest

VoltslDiv is used and an error event is

generated.

Query returns CHl VOL: tnr3>,

VAR:<nrl>. POS:tnr3>.

COU: <argument>;.

Response: CR1 COU:targument>;.

Response: CHl POS:tnR or nr3>;.

Response: CHl VAR: tnrl or nr2>;.

Response: CHl VOL:tnr2 or nr3>;.

PRObe

24X5A12467 instrument Interfacing Guide

CHl? PROBE must be queried

explicitly; it is not included in the CHl?

query response. The response string

indicates the probe attenuation coding:

Xl, X10, Xl00 or X1000.

6-1

GPIB Commands

Table 6-1 (cant)

Header

CH2

CH2?

CH3

CH3?

CH4

CH4?

VMOde

Argument

INVert:

INVert

BWLimit:

cl-lop:

CHI :

CH2:

Argument

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Description

Same as CHl plus INVert: argument.

Turns Channel 2 inversion on or off.

This command has the same effect as

VMOde INVert: <argument>.

Same as Cl-H, except query also

returns INV:<argument>. where

argument is either ON or OFF.

Same as CHl , except Coupling and

VARiable arguments are invalid and

POSition range is + 4 divisions.

Same as CH3.

Selects channels to be displayed, Chop

or Alternate channel-multiplexing mode,

limited or full vertical bandwidth, and

Channel 2 inversion. When all channels

are

off, Channel 1 is

Sets state of bandwidth limit.

Selects Chop or Alternate multiplexing.

Default is Chop (ON).

Turns Channel 1 on or off.

Turns Channel 2 on or off.

displayed.

CH3:

CH4:

ADD:

INVet-t:

6-2 REV OCT 1986 24X5A/2467 Instrument Interfacing Guide

ON

OFF

ON

OFF

ON

OFF

ON Selects normal or inverted Channel 2

OFF

Turns Channel 3 on or off.

Turns Channel 4 on or off.

Turns display of sum of Channel 1 plus

Channel 2 on or off.

display. Default is INV (ON).

Table 6-l (cant)

Header Argument Argument Description

GPl8 Commands

CHOp

CHl

CH2

CH3

CH4

ADD

INVert

BWLimit

Query returns current state of the

vertical display: VMO

CHl:targument>, CH2: <argument>.

CH3: <argument>, CH4: <argument>,

ADD:targument>,

BWL: <argument>, INV: <argument>,

CHO: <argument>.

24X5A/2467 Instrument Interfacing Guide

REV OCT 1986 6-3

GPIB Commands

Table 6-2

Horizontal Commands

Header

HORizontal

Argument

ASEcdiv:

BSEcdiv:

MAGnify:

POSition: <nrx>

Argument

tnrx>

tnrx>

ON

OFF

Description

Selects Horizontal display

parameters.

Selects A-Sweep speed in

seconds per division. Range for

the 2465A and 2467 is from 5E-9

to 1.5. Range for the 2445A and

2455A is from 1 OE-9 to 1.5. If the

selected speed is faster than the

current B Sweep, B-SeclDiv is set

equal to A-Sec/Div. The effects of

MAGnify: are independent of

ASEcdiv:.

Selects B-Sweep speed in

seconds per division. Range for

the 2465A and 2467 is from 5E-9

to 0.15. Range for the 2445A and

2455A is from lOE-9 to 0.15. B-

Sec/Div is updated whether B

Sweep is active or not. If the

selected B-Sec/Div is slower than

the current A-SeciDiv, A-SeclDiv is

set equal to B-SeciDiv. The effects

of MAGnify: are independent of

BSEcdiv:.

Turns Xl 0 sweep magnification on

or off.

Sets the starting position of the

sweep in divisions from the left

edge of the screen over the range

+ 5.46 divisions.

6-4

TRACEsep:

REV SEP 1987 24X5A/2467 Instrument Interfacing Guide

tnrxz

Offsets B Sweep from A Sweep or

b-B Sweep from the B Sweep

with the reference delay by the

indicated amount, in the

approximate range from 0 to -4

divisions.

Table 6-2 (cant)

GPIB Commnnds

Header

HORizontal?

HMOde

HMOde?

Argument

ASEcdiv

BSEcdiv

MAGnify

POSition

TRACEsep

ALTernate

ASWeep

BSWaep

XY

Argument

Description

Query returns the horizontal

selections: HOR ASE: tnrx>,

BSE:<nrS>, MAG:targument>.

POS:tnrS>, TRACE:tnr2>;.

String

is either ON or OFF.

Selects Horizontal display mode.

Choices are mutually exclusive.

Selects both A Sweep and B

Sweep for display. This is

equivalent to pulling the SEC/DIV

knob out.

Selects only the A Sweep for

display.

Selects only B Sweep for display.

If A-SeclDiv and B-SeclDiv are

equal, then a settings conflict error

is generated.

Selects XY mode, where Channel

1 drives the horizontal display.

Query returns HMO string;, where

the string represents one of the

possible Horizontal display modes.

24X5AI2467 Instrument Interfacing Guide

6-5

GPll3 Commends

Table 6-3

Trigger Commands

Header

ATRigger

MODe:

Source:

:

Coupling:

Argument

-EVeI:

Argument Description

Selects A-Trigger parameters.

AUTOBaseline

AUTOLevel

NORmal

SGLseq

Cl-f1

CH2

CH3

CH4

LlNe

VERtical

AC

DC

HFRej

LFRej

NOlserej

FLDl

CLD2

ALTernate

LINES

<nrx>

Selects Mode from the list of

arguments. (AUTOBaseline is

equivalent to AUTO.)

Selects Source from the argument

list.

Selects Coupling from the

argument list. (Use DC for most

applications.)

Only with the available TV option,

selects TV trigger mode.

Sets Trigger Level in volts with

rertical channel sources or in

dimensionless units with LINE

source. The numeric argument is

stored as a target value. Trigger

eve1 is set at the target value or at

I limit value defined by the trigger

;ource. The limits are + 18 times

he VoltslDiv setting for CH 1 and

:H 2, f 9 times the Volts/Div

jetting for CH 3 and CH 4. and

k 10 for LINE. A level query

eturns the value of the current

arqet

6-6 REV SEP 1967 24X5Al2467 Instrument Interfacing Guide

Table 6-3 (cant)

Header

ATRigger?

Argument

INIt

SLOpe:

BENdsa:

HOLdoff:

BENdsa

Coupling

HOLdoff

LEVel

MODe

SLOpe

SOUrce

Argumenr

MINUS

PLUS

ON

OFF

<nrx >

Description

Measures signal peaks at the ATrigger source and sets trigger

level at the midpoint between

peaks. (A)

Selects Slope 01 the A-Trigger

signal.

Sets the B ENDS A mode ON or

OFF.

Sets

Holdoff to the value of

tnrx> in the arbitrary range from

0 to 10, with 0 representing

minimum (normal) holdoff.

Query returns ATR BEN:string,

COU:string, HOL:string,

LEV:tnrP>, MOD:string,

SLO:string. SOU:string.

Arguments MAX, MINI, READY,

and TRIGD must be requested

explicitly, e.g. ATR? MINI,MAX.

MAXimum

24XSA/2467 Instrument Interfacing Guide

Query-only returns ATR

MAX:cnrx>;. The value of

<nrx> represents the most

positive peak voltage, measured in

volts, at the A-Trigger source at

the most recent operation of the

INlT@50% button with the A

Trigger or in response to the most

recent ATRigger INIt command

or the most recent Auto Level

acquisition or the most recant

ATRigger MODe AUTOLevel

command. Normally, the ATRigger

INlt50 command should be sent

just prior to

MAXimum auerv.

REV OCT 1966

an

ATRigger?

6-7

GPIB Commands

Header Argument

MINImum

READY

TRIGD

BTRigger

MODe:

Table 6-3

Argument

RUN

TRIGGERAble

DRTRigger

(cant)

Description

Query-only returns ATR

MINI:tnrx>;. The value of

<nrx> represents the most

negative peak voltage, measured

in volts, under the same conditions

as ATRigger? MAXimum.

Query-only returns ATR

READY:string;. String is ON if the

single-sequence READY indicator

is ON. Otherwise, string is OFF.

Query-only returns ATR

TRIGD:string;. String is ON if

TRIG’D indicator is illuminated.

Otherwise, string is OFF.

Selects B-Trigger parameters.

Selects B-Trigger Mode.

Only with the available CTT,

conditions the instrument to direct

front-panel Slope and Level

controls to the B-Trigger

associated with the A REF delay.

This command forces Delta

ModeTime on unless Delta

ModePertime or Delta

ModeCperfime is on. If Delta

MO& Cpertime is on, the

command forces a change to Delta

ModePertime. (A)

DTRlgger

6-6 24X5A12467 Instrument Interfacing Guide

Only with the available ClT,

conditions the instrument to direct

front-panel Slope and Level

controls to the B-Trigger

associated with the A delay. This

command forces Delta Mode:Time

on unless Delta Mode:Pertime or

Delta Mode:Cpertime is on. If

Delta Mode Cpertirne is on, the

command forces a change to Delta

Mode:Pertime. (A)

”

Table 6-3 (cant)

G/W Commands

Header Argument

SOUroe:

Coupling:

LEVel:

Argument

ALTSlope

CHl

CH2

CH3

CH4

VERtical

AC

DC

HFReJ

LFRej

NOlserej

<nrx>

Description

Only with the available C‘TT,

included only for compatibility with

earlier instruments, and not

recommended for new

applications; conditions the

instrument to direct front-panel

Slope and Level controls to the BTrigger associated with both A

delays, maintaining common levels

and opposite slopes. This

command forces Delta Mode:Time

on unless Delta Mode: Pertime or

Delta Mode:Cpertime is on. If

Delta Mode Cpertime is on, the

command forces a change to Delta

Mode:Pertime. (A)

Selects B-Trigger Source.

Selects B-Trigger Coupling. (Use

DC for most applications.)

Sets Trigger Level in volts. The

numeric argument is stored as a

target value. Trigger level is set at

the target value or at a limit value

defined by the trigger source. The

limits are _+ 18 times the Volts/Div

setting for CH 1 and CH 2 and +9

times the VoltslDiv setting for

CH 3 and CH 4. A level query

returns the value of the current

target.

24X5A12467 Instrument Interfacing Guide

Measures signal peaks at the B-

Trigger source and sets trigger

level at the midpoint between

peaks. (A)

8-9

GPIB Commends

Table 6-3 (cant)

Header

BTRigger?

SLOpe:

DLEVel:

DSLope:

Coupling

LEVel

MODe

SLOpe

SOUrce

DLEVel

I

DSLOpe

-

Argument

Argument

MINUS

PLUS

tnrx>

MINUS

PLUS

Description

Selects Slope of the B-Trigger

signal.

Only with the available ClT, sets

trigger level for the B Sweep

controlled by the A delay setting,

in the same manner as LEVel sets

trigger level for all other B-Trigger

functions. (A)

Only with the available ClT,

selects trigger slope for the B

Sweep controlled by the A delay

setting, in the same manner as

SLOpe sets slope for all other BTrigger functions. (A)

Query returns ETR MOD:string,

COU:string, SLO:string,

SOU:string, LEV:<nrx>;.

BTRigger? query response only

with the available CTT: BTR

MOD: string, DSL:string,

DLEV: <nrx>, COU: string,

SLO:string, SOU:string,

LEV:<nrx>;. (A)

610 24X5Al2467 Instrument Interfacing Guide

Table 6-4

Delay and Delia Commands

GPIB Commands

Header Argument

DELAY <nrx>

DELAY?

DELTa

MODe:

Argument

OFF

CPERTime

CTlMe

Description

Sets sweep delay to tnrx>

divisions in the range from -0.05

to 9.95. This command has the

same effect as DTIME REF:

tnrx>. The value of -0.05

assures that the A-Trigger event is

visible on the B Sweep.

Query returns the current delay

setting in divisions: DELA

tnr2>;. This response is not

included in a SET? query but the

DTIME REF: tnrx> response to

the query contains the equivalent

information.

Sets Delta-display parameters.

Selects or cancels a Delta mode.

Activates l/At cursors with ASweep or B-Sweep display. With

ALT horizontal display, the

command produces an error

response. (A)

Activates A.t cursors with A-Sweep

or B-Sweep display. With ALT

horizontal display, the command

produces an error response. (A)

PERtime

TlMe

24X5Al2467 lntrument Interfacing Guide 6-11

Activates l/At cursors with ASweep display; activates 1 /delta-

delay-time with Alternate or B-

Sweep horizontal display.

Activates At cursors with A-Sweep

display; activates delta-delay-time

with Alternate or B-Sweep

horizontal display.

GPI6 Commands

Table 6-4 (conl)

H88d8r

DELTa?

DTlme

DTlme?

Argument

TRACKing:

MODe

TRACKing

REFerence

DELTa:

REFerence

DELTa

Argument

vous

ON

OFF

tnrx>

tnrxb

D8aCriptiOn

Activates AV cursors.

Selects Tracking or Independent A

REF control mode. Default is

Tracking (ON).

Cluery returns DELT

MOD:string.TAACK:string;.

Sets reference delay, At cursor, or

l/At cursor tnrx> divisions from

A-Sweep start or left edge of the

display, in the range from - 0.05

to 9.95. If Tracking is on, the delta

delay or cursor moves as required

to maintain its distance from the

reference, within the -9.05 to

9.95 range.

Sets delta delay, At cursor, or l/At

cursor <nrx> divisions from the

reference delay or cursdr. The sum

of the reference setting plus the

delta setting must be within -0.05

to 9.95 divisions.

Query returns the Delta Time

settings in divisions: OTI

REF:tnr2>, OELT:tnr2>;.

TOELta?

6-12 24X5A/2467 lntrument Interfacing Guide

Query returns the delta time

setting in seconds, hertz, percent,

or degrees: < nr3> ;. No

‘TOELTA’ header is returned so

high-level input drivers can

process

the response. NOTE: if

the query follows a MESSAGE

command, a DELTA

MODE: <argument> ; command

nust be given again to restore the

delta reading. (A)

Table 6-4 (cant)

GPIB Commsnds

Header

DVOlts

DVOlts?

VDELta?

Argument

REFerence:

DELTa:

REFerence

DELTa

Argument

<nrx>

<nrx>

Description

Sets the reference cursor tnrx>

divisions from the center of the

display, within the +4.O range. If

Tracking is on, the delta delay or

cursor moves as required to

maintain its distance from the

reference, within the + 4.0 range.

Sets the delta cursor tnrx>

divisions from the reference

cursor. The sum of the reference

setting plus the delta setting must

be within

Query returns the delta volts

settings in divisions: DVO

REF:tnrP>,DELT:tnr2>;.

Query returns the delta volts

setting in volts, or percent:

tnrx>;. No ‘VDELTA” header is

returned so high-level input drivers

can process the response. NOTE:

If the query follows a MESSAGE

command. a DELTA

MODE:VOLTS; command must be

given again to restore the delta

reading. (A)

Table 6-5

System Commands

Header

BA Lance

ERRor?

24X5A/2467 Instrument Interfacing Guide

Argument Argument Description

Initiates the vertical DC Balance

procedure. The instrument

initializes after BALANCE (see

INIt).

Query returns ERR <nrl>;.

Response is equivalent to EVEnt?

query. Command is included for

compatibility with earlier

instruments.

6-13

GPIB Commands

Table 6-5 (cant)

Header

EVEnt?

ID?

Argument Argument

Description

Query returns EVE <nrl>;. The

value of tnrl> is the most

severe of the current errors. Errors

are prioritized into three levels, but

only the most

maintained for each level. If no

error is pending, 0 is returned.

Event codes are listed in Tables

B-l and B-2.

Query returns ID

TEK/model,VBl .l .SYS:FVx.

BB:FVy, [string:FVtnrl >,]

GPIB:,FVz;. The word model

stands in place of the strings

2445A, 2455A, 2465A,

The characters x, y, and z stand in

place of the firmware version

numbers of the oscilloscope.

Buffer board, and GPIB option,

respectively. The section in

brackets is repeated for each

installed option, including TV and

CTT. String V61 .l indicates that

the GPIB interface is compatibfe

with the VEtl .l version of the

Tektronix Codes and Formats

standard.

recent error

or 2467.

iS

INlt

6-14 24X5A:2467 InstrumeM Interfacing Guide

Sets the instrument and all options

except the GPIB to an initialized

state equivalent to cycling power

off and on. The GPIB system-

command states (OPC. RQS,

WARning, and LONgform) are not

nitialized. (RQS is not changed by

oower-downlpower-up.) This

:ommand should be the final or

3nly command in a message.

Mditional commands in the same

message give unpredictable

results.

Table 6-5 (cant)

dPlf3

Commends

Header Argument Argument

LLMessage %<byte>tbyte>...

LLMessage?

LLSet % <byte> <byte>...,

Description

Sends binary

of the CRT readout. The

displays the block of binary data

according to the codes in Tables

14 and 15. The first pair of bytes

represent the number of

characters. The last byte is the

two’s complement of the least

significant byte of the sum of the

character codes.

Query returns the contents of the

top line of the CRT readout in a

binary block of data, in the form:

LLM %<byte> <byte> . .

<byte>;. The first two bytes

followlng the % character are a

16-bit count of the bytes

follow.

according to Tables

not ASCII. The last byte of the

block is the two’s complement of

the least significant byte of the

sum of data bytes. (See

MESsage? for ASCII coding of the

readout.)

Returns a previously acquired

setup

Level binary Setup data

generated only by a LLSet? query.

data to the

top line

readout

that

The display is encoded

to the instrument. The Low

14 and 15,

can be

24X5A/2467 Instrument Interfacing Guide 6-l 5

GPIt9 Commands

Table 6-5 (cant)

Header

LLSet?

MESsage

Argument

‘string”

Argument

Description

I-

Query response is a block of

binary data representing the

instrument setup in the form:

LLSET %<byte><byte>.

%tbyte> <byte>;. The block of

data comprises a sub-block for

each installed option. Each sub-

block begins with a % character