Page 1

Model 2460

www.tek.com/keithley

Interactive SourceMeter

®

Instrument

Calibration and Adjustment Manual

2460-905-01 Rev. A / January 2016

*P2460-905-01A*

2460-905-01

A Greater Measure of Condence

A Tektr onix Company

Page 2

Model 2460

Calibration and Adjustment Manual

© 2016, Keithley Instruments

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments is strictly prohibited.

®

TSP

, TSP-Link®, and TSP-Net® are trademarks of Keithley Instruments. All Keithley Instruments

product names are trademarks or registered trademarks of Keithley Instruments. Other brand

names are trademarks or registered trademarks of their respective holders.

The Lua 5.0 software and associated documentation files are copyright © 1994 - 2015, Lua.org,

PUC-Rio. You can access terms of license for the Lua software and associated documentation at

the Lua licensing site (http://www.lua.org/license.ht ml) .

Document number: 2460-905-01 Rev. A / January 2016

Page 3

Safety precaut ions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are measurement, control, and data I/O

connections, with low transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high

transient overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 4

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The

user documentation in all cases where the symbol is mark ed on the instr u ment .

The

contact with these voltages.

The

The

If this

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains h az ards that coul d dama ge the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mai ns cir cu its — inc lud ing the power

transformer, test leads, and input jacks — must be purchased from Keithley Instruments. Standard fuses with applicable national

safety approvals may be used if the rating and type are the same. Other components that are not safety-related may be

purchased from other suppliers as long as they are equivalent to the original component (note that selected parts should be

purchased only through Keithley Instruments to maintain accuracy and functionality of the product). If you are unsure about the

applicability of a replacement component, call a Keithley Instruments office for information.

symbol on an instrument means caution, risk of danger. The user must refer to the operating instructions located in the

symbol on an instrument means caution, risk of electric shock. Use standard safety precautions to avoid personal

symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

symbol indicates a connection terminal to the equipment frame.

symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., a data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Safety precaution revision as of January 2013.

Page 5

Table of Contents

Introduction ............................................................................................................... 1-1

Welcome .............................................................................................................................. 1-1

Introduction to this manual ................................................................................................... 1-1

Extended warranty ............................................................................................................... 1-2

Contact information .............................................................................................................. 1-2

Factory service ..................................................................................................................... 1-2

Preparing for calibration verification and adjustment ........................................... 2-1

Calibration verification and adjustment test requirements ................................................... 2-1

Environmental conditions .......................................................................................................... 2-1

Recommended test equipment ................................................................................................. 2-2

Calibration and adjustment connections .............................................................................. 2-3

Connections for the 200 mV to 100 V ranges............................................................................ 2-4

Connections for the 1 µA to 1 A ranges .................................................................................... 2-5

Connections for the 4 A to 7 A ranges ...................................................................................... 2-5

Connections for resistance cali brat io n verifi cat ion and adj ustment ........................................... 2-6

Remote communications connections ....................................................................................... 2-7

Calibration verification and adjustment considerations ........................................................ 2-7

Calibration ................................................................................................................. 3-1

Introduction .......................................................................................................................... 3-1

Calibration verification limits ................................................................................................ 3-2

Example source limits calculati on ............................................................................................. 3-2

Example measure limits calculation .......................................................................................... 3-2

Setting the measurement range ........................................................................................... 3-3

Taking the Model 2460 out of a limit overflow state ............................................................. 3-3

Remote calibration verificat ion pr ocedure............................................................................ 3-3

Step 1. Prepare the Model 2460 for calibration verification ....................................................... 3-3

Step 2. Voltage calibration verification ...................................................................................... 3-3

Step 3. Current calibration verification ...................................................................................... 3-5

Step 4. Resistance measurement calibration ............................................................................ 3-8

Adjustment ................................................................................................................ 4-1

Introduction .......................................................................................................................... 4-1

Unlocking calibration for adjustment .................................................................................... 4-1

Changing the password ....................................................................................................... 4-2

Resetting the calibration password ...................................................................................... 4-3

Querying calibration and adjustment dates and count ......................................................... 4-3

Adjustment errors ................................................................................................................. 4-3

Front-panel error reporting ........................................................................................................ 4-3

Remote error reporting .............................................................................................................. 4-3

Page 6

Table of Contents

justment Manual

Model 2460 Calibration and Ad

Remote adjustment .............................................................................................................. 4-4

Calibration and adjustment commands summary ..................................................................... 4-7

Remote adjustment procedure ............................................................................................. 4-7

Step 1. Prepare the Model 2460 for adjustment ........................................................................ 4-7

Step 2. Voltage adjustment ....................................................................................................... 4-8

Step 3. Current adjustment ..................................................................................................... 4-10

Step 4. Program calibration verification and adjustment dates................................................ 4-16

Step 5. Save calibration constants .......................................................................................... 4-16

Step 6. Lock-out adjustment.................................................................................................... 4-16

Single-range adjustment .................................................................................................... 4-16

Command reference ................................................................................................. 5-1

Introduction .......................................................................................................................... 5-1

Model 2460 calibration verification and adjustment commands .......................................... 5-1

:CALibration:ADJust:COUNt? ................................................................................................... 5-1

:CALibration:ADJust:DATE ....................................................................................................... 5-2

:CALibration:ADJust:SENSe ..................................................................................................... 5-3

:CALibration:ADJust:SENSe:DATA? ......................................................................................... 5-4

:CALibration:ADJust:SOURce ................................................................................................... 5-5

:CALibration:ADJust:SOURCe:DATA? ..................................................................................... 5-6

:CALibration:LOCK .................................................................................................................... 5-6

:CALibration:PASSword ............................................................................................................ 5-7

:CALibration:SAVE .................................................................................................................... 5-8

:CALibration:UNLock ................................................................................................................. 5-9

:CALibration:VERify:DATE ........................................................................................................ 5-9

Routine maintenance ................................................................................................ 6-1

Introduction .......................................................................................................................... 6-1

Line fuse replacement .......................................................................................................... 6-1

Page 7

Factory service ......................................................................... 1-2

Welcome

Section 1

Introduction

In this section:

Welcome .................................................................................. 1-1

Introduction to this manual ....................................................... 1-1

Extended warranty ................................................................... 1-2

Contact information .................................................................. 1-2

Thank you for choosing a Keithley Instruments product. The Model 2460 High-Current Interactive

®

SourceMeter

Instrument is a precise, low-noise instrument that combines a stable DC power supply,

high-current source, electronic load, and a high-impedance multimeter. The design of this instrument

features intuitive setup and control, enhanced signal quality and range, and better resistivity and

resistance capabilities than similar products on the market.

The Model 2460 can source up to 7 A, and features 1 A, 4 A, 5 A, and 7 A ranges. With 0.012 percent

basic accuracy at 6½-digit resolution, the Model 2460 is a good solution for testing a wide variety of

materials and devices in applications such as power semiconductors, solar energy, high brightness

LEDs, power conversion, electrochemistry, batteries, and more.

Introduction to this manual

This manual provides instructions to help you calibrate and adjust your Keithley Instruments Model

2460. In this manual, the term "calibration" refers to the process of verifying that the accuracy of the

instrument is within its one-year accuracy specifications. The term "adjustment" refers to the process

of changing the calibration constants so that the accuracy of the instrument is within its one-year

accuracy specifications.

This manual presents calibration information, adjustment information, and command descriptions for

the calibration and adjustment commands.

For additional command descriptions, refer to the Model 2460 Reference Manual, which is available

on the Downloads, Manuals, and Documentation web page at http://www.tek.com/downloads

(http://www.tek.com/downloads).

Page 8

Section

Calibration and Adjustment Manual

1: Introduction Model 2460

Extended warranty

Additional years of warranty coverage are available on many products. These valuable contracts

protect you from unbudgeted service expenses and provide additional years of protection at a fraction

of the price of a repair. Extended warranties are available on new and existing products. Contact your

local Keithley Instruments office, sales partner, or distributor for details.

Contact information

If you have any questions after you revie w the infor mation in this documentation, please contact your

local Keithley Instruments office, sales partner, or distributor. You can also call the corporate

headquarters of Keithley Instruments (toll-free inside the U.S. and Canada only) at 1-800-935-5595,

or from outside the U.S. at +1-440-248-0400. For worldwide contact numbers, visit the

Instruments website (http://www.tek.com/keithley).

Factory service

To return the instrument to Keithley Instruments for repair:

Keithley

• Call the Repair Department at 1-800-833-9200 or send an email to

RMAREQUEST@tektronix.com for a Return Material Authorization (RMA) number.

• Carefully pack the instrument in the original packing carton.

• Write ATTENTION REPAIR DEPARTMENT and the RMA number on the shipping label.

1-2 2460-905-01 Rev. A / January 2016

Page 9

Calibration verification and adj ustm ent con si derat ions ............ 2-7

Section 2

Preparing for calibration verification and adjustment

In this section:

Calibration verification and adj ustm ent test requir e ment s ........ 2-1

Calibration and adjustment connections .................................. 2-3

Calibration verification and adjustment test requirements

The following topics describe what you must do to prepare the Model 2460 for calibration verification

and adjustment.

Environmental conditions

To ensure accurate results, the calibration verification and adjustment environment must meet the

following conditions.

Temperature and relative humidity

Conduct the calibration verification and adjustment procedures in a test environment with:

• An ambient temperature of 18 °C to 28 °C (65 °F to 82 °F).

• A relative humidity of less than 70 percent, unless otherwise noted.

Warm up period

Allow the Model 2460 to warm up for at least one hour before conducting the calibration verification or

adjustment procedures.

If the instrument has been subjected to temperatures outside of the ranges stated above, allow

additional time for the internal temperature of the instrument to stabilize. Typically, allow one extra

hour to stabilize an instrument that is 10 °C (18 °F) outside the specified temperature range.

Also, allow the test equipment to warm up for the minimum time specified by the manufacturer.

Line power

The Model 2460 requires a line voltage of 100 V to 240 V and a line frequency of 50 Hz or 60 Hz.

Calibration verification and adjustment should be done within this range.

The instrument automatically senses the line frequency at power up.

Page 10

Section

Calibration and Adjustment Manual

Keithley Instruments Model 2002 Digital Multimeter

200 mV

100 V

Digital multimeter

DC current

1 A

For better accuracy on the 4 A, 5 A, and 7 A ranges, you can use shunt

on the Model 2460 one-year accuracy specifications.

4 A

Resistance calibrator

Resistance

Fluke 5730A High-Performance Multifunction Calibrator

20 Ω

20 MΩ

2: Preparing for calibration verification and adjustment Model 2460

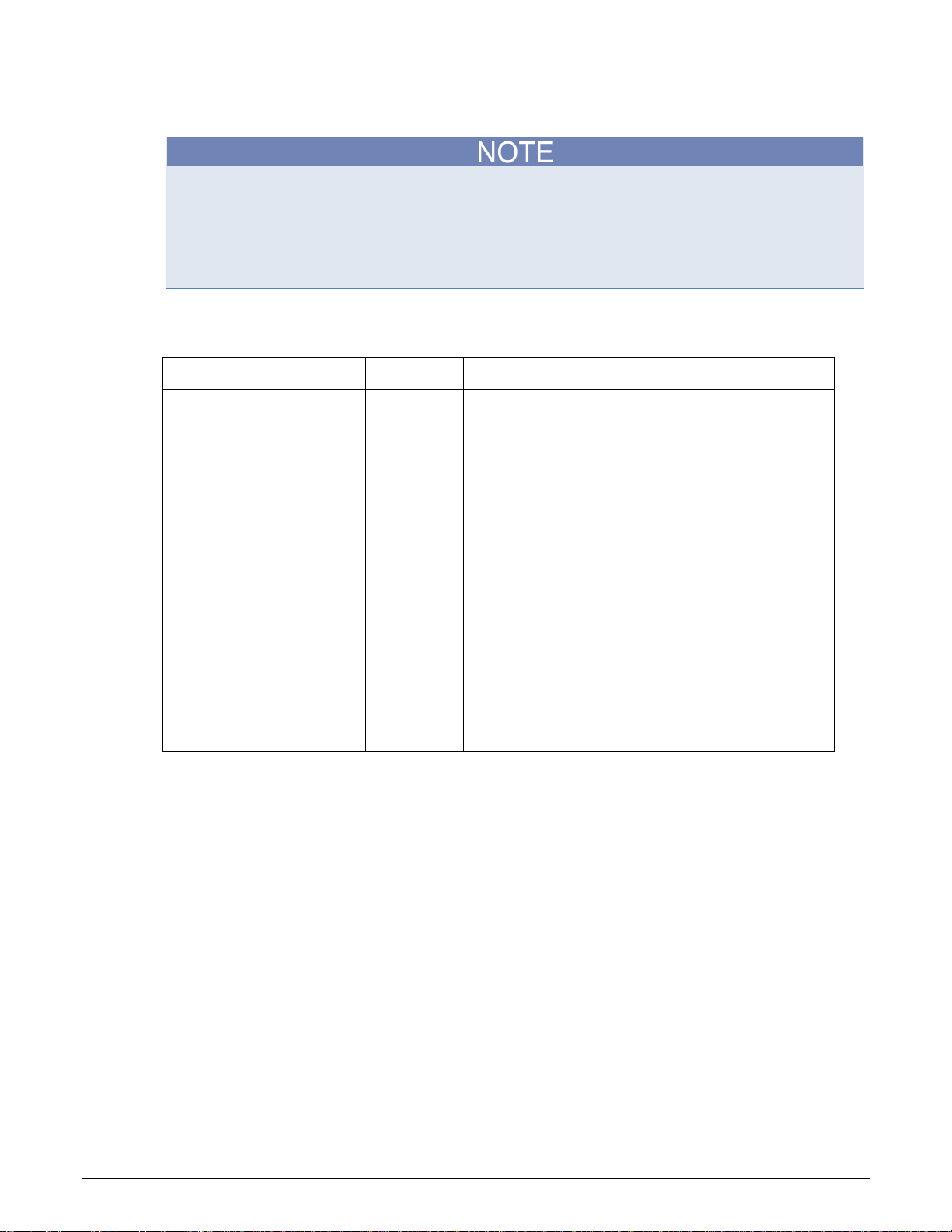

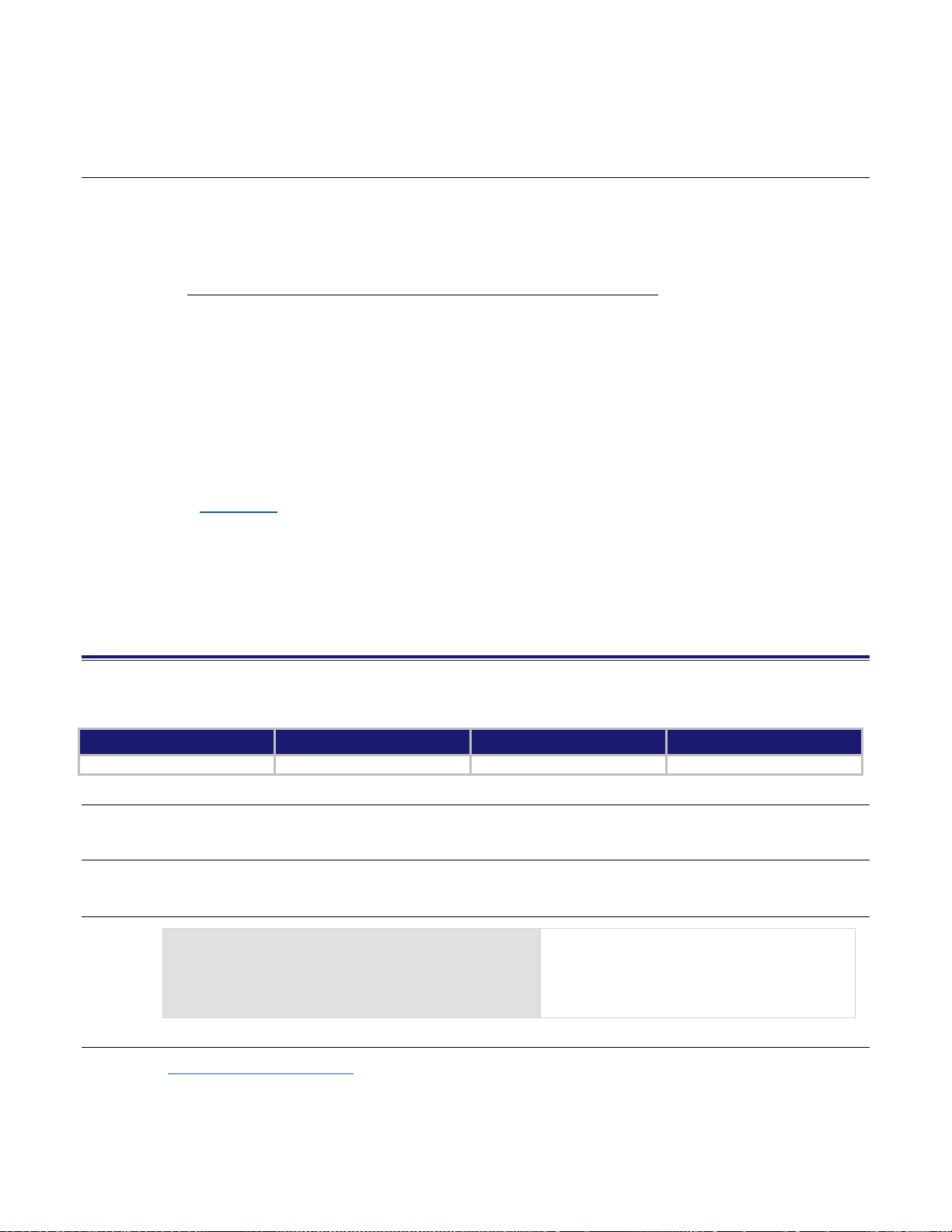

Recommended test equi pm e nt

The following table summarizes recommended calibration verification and adjustment equipment.

Test equipment uncertainty adds to the uncertainty of each measurement. Generally, test equipment

uncertainty should be at least four times smaller than the corresponding Model 2460 specifications.

Refer to the test equipment manufacturer's specifications to calculate the uncertainty, which varies

for each function and range test point.

Description Ranges

Digital multimeter DC voltage

2 V

7 V

10 V

20 V

Any digital multimeter with a test uncertainty ratio (TUR) of 4:1 or better 1 µA

10 µA

100 µA

1 mA

10 mA

100 mA

resistors if the combined uncertaint ies for the test set up stil l meet the

required test uncertainty ratio of 4:1 or better. This ratio should be based

5 A

7 A

200 Ω

2 KΩ

20 KΩ

200 KΩ

2 MΩ

2-2 2460-905-01 Rev. A / January 2016

Page 11

Model 2460

ion and adjustment

Calibration and Adjustment Manual Section 2: Preparing for calibration verificat

Calibration and adjus tment connections

Connections for Model 2460 calibration verification and adjustment are the same. The following topics

describe the connections you should use for the different ranges and functions.

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the Model 2460

while the instrument is powered on. Turn off the equipment from the front panel or

disconnect the main power cord from the rear of the Model 2460 before handling cables.

Putting the equipment into standby does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

The maximum common-mode voltage (voltage between LO and chassis ground) is 250 V

peak

.

Exceeding this value may cause a breakdown in insulation, creating a shock hazard.

The front and rear terminals of the Model 2460 are rated for connection to circuits rated

Installation Category I only. Do not connect the Model 2460 terminals to CAT II, CAT III, or

CAT IV circuits. Connection of the SourceMeter® instrument input/output terminals to

circuits higher than CAT I can cause damage to the equipment or expose the operator to

hazardous voltage.

The maximum voltage between input/output HI and LO or 4-wire sense HI and LO is 210 V

peak

. The

maximum voltage between input/o utput HI and 4-wire sense HI or between input/output LO and 4wire sense LO is 5 V. Exceeding these voltages may result in instrument damage.

2460-905-01 Rev. A / January 2016 2-3

Page 12

Section

Calibration and Adjustment Manual

2: Preparing for calibration verification and adjustment Model 2460

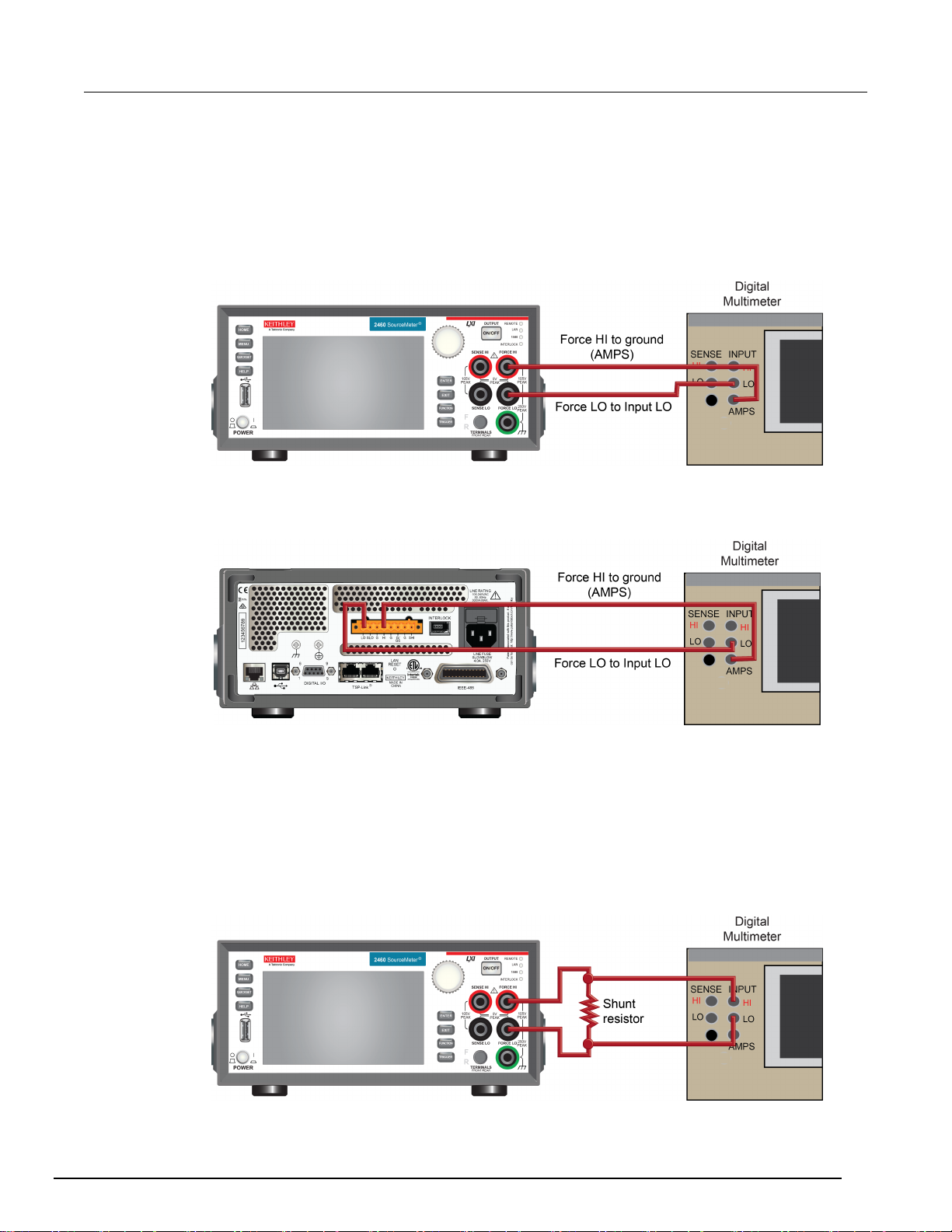

Connections for the 200 mV to 10 0 V range s

For calibration verification or adjustment on the 200 mV to 100 V ranges, use either the front-panel or

rear-panel connections shown in the following figures.

The default voltage source protection value is 40 V. Before testing the 100 V range, be sure to assert

the interlock. Without the interlock asserted and the green interlock light on, the Model 2460 is

limited to 40 V. For more information on the Model 2460 interlock, see the “Using the Interlock”

section in the Model 246 0 Refer ence Manual.

Figure 1: Front-panel connections for the 200 mV to 100 V ranges

Figure 2: Rear-panel connections for the 200 mV to 100 V ranges

2-4 2460-905-01 Rev. A / January 2016

Page 13

Model 2460

Preparing for calibration verification and adjustment

Calibration and Adjustment Manual Section 2:

Connections for the 1 µA to 1 A ranges

For calibration verification or adjustment on the 1 µA to 1 A ranges, use either the front-panel or

rear-panel connections shown in the following figures.

Figure 3: Front-panel connections for the 1 µA to 1 A ranges

Figure 4: Rear-panel connections for the 1 µA to 1 A ranges

Connections for the 4 A to 7 A ranges

For calibration verification or adjustment on the 4 A to 7 A ranges, use either the front-panel or

rear-panel connections shown in the following figures.

Figure 5: Front-panel connections for the 4 A to 7 A ranges

2460-905-01 Rev. A / January 2016 2-5

Page 14

Section

Calibration and Adjustment Manual

2: Preparing for calibration verification and adjustment Model 2460

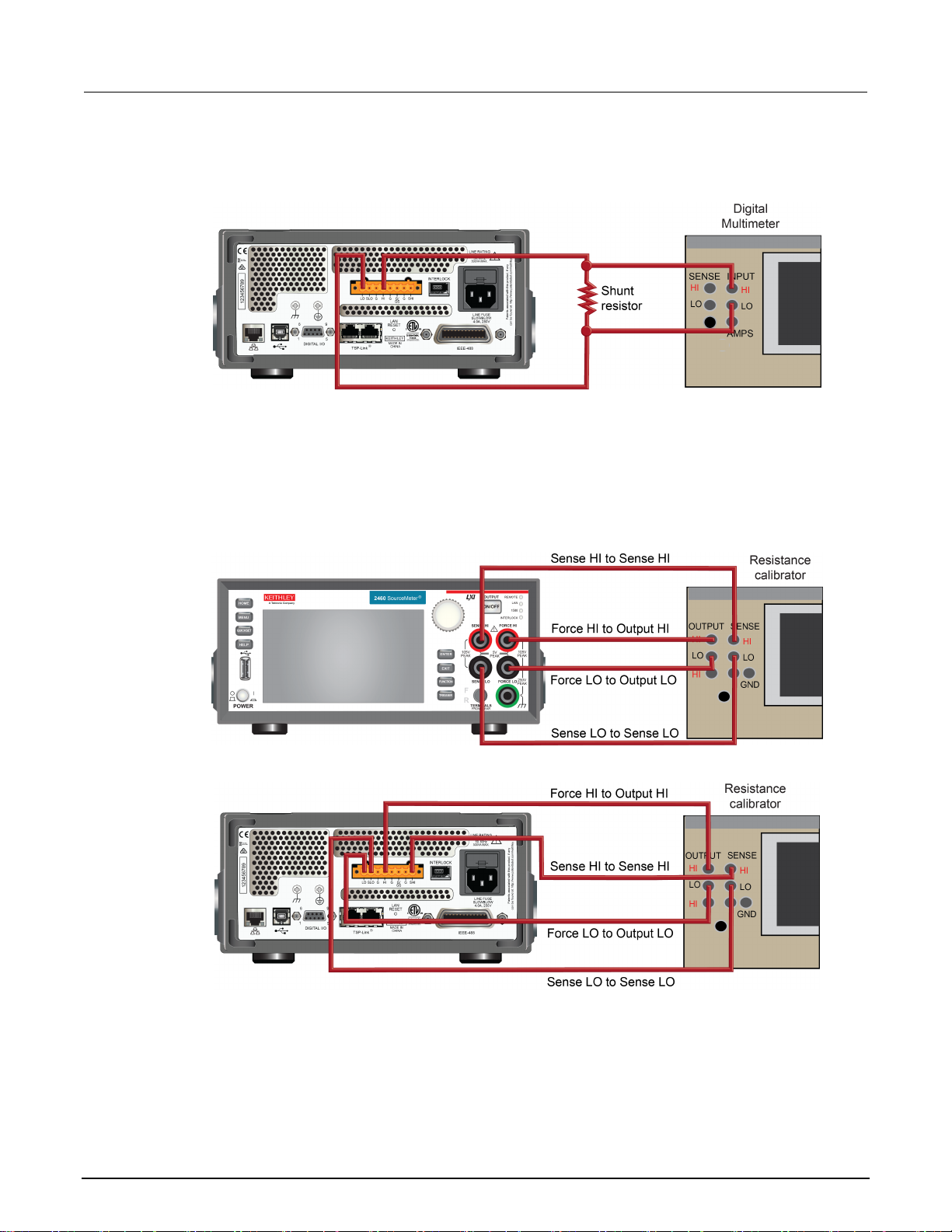

Figure 6: Rear-panel connections for the 4 A to 7 A ranges

Connections for resistance calibration verification and adjustment

For resistance calibration verification or adjustment, use either the front-panel or rear-panel

connections shown in the following figures.

Figure 7: Front-panel resistance connections

Figure 8: Rear-panel resistance connections

2-6 2460-905-01 Rev. A / January 2016

Page 15

Model 2460

paring for calibration verification and adjustment

Calibration and Adjustment Manual Section 2: Pre

Remote communications c onne c t ions

The procedures in this manual use SCPI commands sent to the Model 2460 from a remote interface.

Select one of the remote interface connections shown below. The instrument automatically detects

the connection. For more detailed information about the remote communications connections, see

"Remote communications interfaces" in the Model 2460 Reference Manual.

Figure 9: Remote communications interfaces

If you are using the IEEE-488 interface, make sure the primary address of the Model 2460 is the

same as the address specified in the program you will be using to send commands.

Calibration verification and adjustment considerations

When performing the calibration verification or adjustment procedures:

• Make sure that the test equipment is properly warmed up and connected to the Model 2460 input

and output jacks. Ensure that either the front-panel or rear-panel terminals are selected

(depending on your connections) with the TERMINALS FRONT/REAR button or using the

:ROUTe:TERMinals <FRONt or REAR> SCPI command.

• Make sure the Model 2460 is set to the correct source range.

• Make sure the Model 2460 output is turned on before making measurements.

• Make sure the test equipment is set up for the proper function and range.

• Allow the Model 2460 output signal to settle before making a measurement or adjusting each

point.

• When using a shunt resistor for current calibration verification and adjustment, make sure the

shunt is properly rated for the current and power being measured. Also, consider temperature

coefficient and other resistance uncertainty contributors in the overall measurement uncertainty

calculation.

• Do not connect test equipment to the Model 2460 through a scanner, multiplexer, or other

switching equipment.

2460-905-01 Rev. A / January 2016 2-7

Page 16

Remote calibration verification procedure ................................ 3-3

In this section:

Introduction .............................................................................. 3-1

Calibration verification limits ..................................................... 3-2

Setting the measurement range ............................................... 3-3

Taking the Model 2460 out of a limit overflow state ................. 3-3

Introduction

Use the procedures in this section to verify that Model 2460 accuracy is within the limits stated in the

instrument’s one-year accuracy specifications. Specifications and characteristics are subject to

change without notice; refer to the Downloads, Manuals, and Documentation web page

(http://www.tek.com/downloads

Section 3

Calibration

(http://www.tek.com/downloads)) for the most recent specifications.

You can use these calibration verification procedures to:

• Make sure that the instrument was not damaged during shipment

• Verify that the instrument meets factory specifications

• Determine if adjustment is required

• Verify that adjustment was done properly

The information in this section is intended for qualified service personnel only. Do not

attempt these procedures unless you are qualified to do so. Some of these procedures may

expose you to hazardous voltages, which could cause personal injury or death if contacted.

Use appropriate safety precautions when working with hazardous voltages.

If the instrument is still under warranty and its performance is outside specified limits, please contact

your local Keithley Instruments office, sales partner, or distributor. You can also call the corporate

headquarters of Keithley Instruments (toll-free inside the U.S. and Canada only) at 1-800-935-5595,

or from outside the U.S. at +1-440-248-0400. For worldwide contact numbers, visit the Keithley

Instruments website (http://www.tek.com/keithley).

Page 17

Section

Calibration and Adjustment Manual

3: Calibration Model 2460

Calibration verification limits

Before performing the calibration verification test procedures, you must calculate the calibration

verification limits using the Model 2460 specifications. The most recent version of the specifications is

on the Downloads, Manuals, and Documentation web page at http://www.tek.com/downloads

(http://www.tek.com/downloads).

In the Model 2460 Specifications document, source specifications are expressed as a percent of

setting plus voltage, current, or ohms offset. Measure specifications are expressed as a percent of

reading plus voltage, current, or ohms offset.

The calculation for calibration verification limits is:

Specification toleranc e = ± [(setting × percent of setting specification) + offset specification

To calculate the calibration verification limits for a range:

1. Select the test setting to verify.

2. Multiply the setting by the percent of setting (for source verification) or percent of reading (for

measure verification) value listed in the specification for that range.

3. Add the absolute value of that calculation to the offset specification for the range.

4. Calculate the low limit by subtracting the result of step 3 from the setting value.

5. Calculate the high limit by adding the result of step 3 to the setting value.

Example source limits calc ulation

As an example of how source limits are calculated, assume you are testing the 20 V DC range using

a 95 percent of scale signal value, and the Model 2460 one-year accuracy specification.

Use ±(0.015 % of setting + 2.4 mV offset) to get the calculated output limits:

Output limits = 19 V ± [(19 V × 0.015 %) + 2.4 mV]

Output limits = 19 V ± (0.00285 + 0.0024)

Output limits = 19 V ± 0.00525 V

Output limits = 18.99475 V to 19.00525 V

Example measure limits calculation

When you verify the measure functions (voltage, current, and resistance), calculate the upper and

lower test limits relative to the reference nominal value determined by the reference instrument. For

voltage and current, the reference nominal value is generally a reading from a reference digital

multimeter (DMM). For resistance, the reference value is the characterized value of the resistance

source.

The calculation of upper and lower test limits is identical to the source limit calculation, except the

reference value is used instead of the nominal setting.

As an example, assume that you are testing the 20 kΩ range, and the actual value of the nominal

19 kΩ calibrator resistor is 19.025 kΩ. Using a one-year normal accuracy specification of ±(0.063 %

of reading + 3 Ω), the recalculated reading limits are:

Specification tolerence = [(19.025 kΩ × 0.063 %) + 3 Ω]

Reading limits = 19.025 kΩ ±(11.99 kΩ + 3 Ω)

Reading limits = 19.025 kΩ ±14.99 Ω

Reading limits = 19.01001 kΩ to 19.03999 kΩ

3-2 2460-905-01 Rev. A / January 2016

Page 18

Model 2460

Calibration

Calibration and Adjustment Manual Section 3:

Setting the measurement range

When simultaneously sourcing and measuring either voltage or current, the measure range is

coupled to the source range, and you cannot independently control the measure range. As a result,

you do not set the range when testing voltage or current measurement accuracy.

When selecting the source range, be sure that the limit is set to the appropriate maximum value for

that range.

Taking the Model 2460 out of a limit overflow state

Calibration verification measurements should not be made when the Model 2460 is in a limit overflow

state. For purposes of the calibration verification tests, the Model 2460 can be taken out of an

overflow state by raising the limit value.

Do not take the instrument out of an overflow state by decreasing the source value or changing the

range. Always use the recommended range and source settings when verifying the instrument.

Remote calibration verification procedure

Use the following procedure to verify instrument calibration by sending SCPI commands over the

IEEE-488, USB, or LAN connections.

Step 1. Prepare the Model 2460 for calibration verification

Verify that the calibration verification environment, instrument, and test equipment are set up as

described in Preparing for calibration verification and adjustment (on page 2-1

Step 2. Voltage calibration verification

Follow the steps below to verify that Model 2460 voltage source-measure accuracy is within specified

limits. This test involves setting the output voltage to each full-range value and measuring the

voltages with a precision digital multimeter (DMM).

1. With the source output off, connect the Keithley Model 2460 to the DMM as shown in

Connections for the 200 mV to 100 V ranges (on page 2-4

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the Model 2460

while the instrument is powered on. Turn off the equipment from the front panel or

disconnect the main power cord from the rear of the Model 2460 before handling cables.

Putting the equipment into standby does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

).

).

2460-905-01 Rev. A / January 2016 3-3

Page 19

Section

Calibration and Adjustment Manual

1

*RST

Restore default settings.

2

:SOUR:FUNC VOLT

Select the source function.

3

:FUNC "VOLT"

Select the measure function.*

4

:SOUR:VOLT:RANG <Range>

Set the source range.**

5

:SYST:RSEN OFF

Disable remote sensing.***

6

Select the front-panel or rear-panel terminals to

match your test setup.

7

:SOUR:VOLT <Level>

Program the source value.

8

:OUTP:STAT ON

Turn on the source output.

9

Make DMM reading.

Read the actual output of the Model 2460 using

the external DMM.

:READ?

source output.

11

:OUTP:STAT OFF

Turn off the source output.

step 9.

13

Calculate the measure error.

Calculate the difference between step 9 and

step 10.

14

Validate source accuracy.** **

Compare the result of step 12 to the source

specification.

specification.

* The measure range is coupled to the source range when simultaneously sourcing and measuring voltage,

Model 2460 (not the programmed value).

3: Calibration Model 2460

2. Turn on the source output.

If the Model 2460 is not already warmed up, allow it to warm up for at least one hour before

continuing to the next step.

Complete the range calibration verification steps listed in the following table for each voltage range.

For each voltage range, perform the complete procedure at 95 percent of the range's positive

full-scale value, then at 0 V, then at 95 percent of the range's negative full scale value, and then again

at 0 V. For example, for the 200 mV range, complete the procedure four times using each of the

following values, in this order: +190 mV, 0 V, −190 mV, 0 V.

Voltage calibration verification procedure

Step Command or procedure Description

:ROUT:TERM <FRONT or REAR>

10

Have the Model 2460 measure and return its

12 Calculate the source error. Calculate the difference between step 7 and

15 Validate measure accuracy.** ** * Compare the result of step 13 to the measure

so you do not neet to set the measure range.

** Where <Range> = 0.2, 2, 7, 10, 20, and 100.

*** With remote sense off, you may need to add a relative offset to compensate for cable noise.

**** The source limits are calculated based on the programmed source value of the Model 2460 for each range

(not the actual value).

***** The measure limits are calculated based on a precise measurement of the programmed value of the

3-4 2460-905-01 Rev. A / January 2016

Page 20

Model 2460

Calibration

Calibration and Adjustment Manual Section 3:

Step 3. Current calibra t ion verification

Keithley Instruments recommends two different connection configurations for current calibration

verification:

For the 1 µA to 1 A ranges, use the connection diagrams in Connections for the 1 µA to 1 A

ranges (on page 2-5).

For the 4 A to 7 A ranges, use the connection diagrams in Connections for the 4 A to 7 A ranges

(on page 2-5).

The following topics describe how to do current calibration verification for each of these

configurations.

Current calibration verification for the 1 µA to 1 A ranges

Follow the steps below to verify that Model 2460 current source-measure accuracy is within specified

limits. In this test, you set the output current to each full-range value and measure the current with a

precision digital multimeter (DMM).

To calibrate the 1 µA to 1 A ranges:

1. With the source output off, connect the Model 2460 to the DMM using the connection

configuration in Connections for the 1 µA to 1 A ranges (on page 2-5

).

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the Model 2460

while the instrument is powered on. Turn off the equipment from the front panel or

disconnect the main power cord from the rear of the Model 2460 before handling cables.

Putting the equipment into standby does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

2. Turn on the Model 2460 source output.

If the Model 2460 is not already warmed up, allow it to warm up for at least one hour before

continuing to the next step.

3. Complete the range calibration steps listed in the following table for each current range. For each

current range, perform the complete procedure at 95 percent of the range's positive full-scale

value, then at 0 A, then at 95 percent of the range's negative full scale value, and then again at

0 A. For example, for the 1 mA range, complete the procedure four times using each of the

following values, in this order: +0.95 mA, 0 A, -0.95 mA, 0 A.

2460-905-01 Rev. A / January 2016 3-5

Page 21

Section

Calibration and Adjustment Manual

1

*RST

Restore default settings.

:SOUR:FUNC CURR

3

:FUNC "CURR"

Select the measure function.*

4

:SOUR:CURR:RANG <Range>

Set the source range.**

5

:SYST:RSEN OFF

Disable 4-wire remote sensing.

6

:ROUT:TERM <FRONT or REAR>

Select the front-panel or rear-panel terminals to

match your test setup.

7

:SOUR:CURR <Level>

Program the source value.

8

:OUTP:STAT ON

Turn on the source output.

9

Make DMM reading.

Read the actual output of the Model 2460 using

the external DMM.

10

:READ?

Have the Model 2460 measure and return its

11

:OUTP:STAT OFF

Turn off the source output.

12

Calculate the source error.

Calculate the difference between step 7 and

step 9.

13

Calculate the measure error.

Calculate the difference between step 9 and

step 10.

specification.

15

Validate measure accuracy.** **

Compare the result of step 13 to the measure

specification.

* The measure range is coupled to the source range when simultaneously sourcing and measuring current,

Model 2460 (not the programmed value).

3: Calibration Model 2460

Current calibration verification procedure for the 1 µA to 1 A ranges

Step Command or procedure Description

2

Select the source function.

source output.

14 Validate source accuracy.** * Compare the result of step 12 to the source

so you do not need to set the measure range.

** Where <Range> = 1e-6, 10e-6, 100e-6, 1e-3, 10e-3, 100e-3, and 1.

*** The source limits are calculated based on the programmed source value of the Model 2460 for each range

(not the actual value).

**** The measure limits are calculated based on a precise measurement of the programmed value of the

3-6 2460-905-01 Rev. A / January 2016

Page 22

Model 2460

Calibration

Calibration and Adjustment Manual Section 3:

Current calibration verification for the 4 A to 7 A ranges

Follow the steps below to verify that Model 2460 current source-measure accuracy is within specified

limits. In this test, you set the output current to each full-range value and measure the voltage drop

across a shunt resistor with a precision digital multimeter (DMM) and then calculate the current.

When verifying the 4 A to 7 A ranges using a shunt resistor, use the following formula to calculate

the current:

Current (I) = Voltage (V) / Resistance (R)

Where:

Resistance is either the value stated by the specifications for the shunt resistor, or for greater

measurement accuracy, resistance is the measured resistance value of the shunt resistor.

1. With the source output off, connect the Model 2460 to the DMM using the connection

configuration in Connections for the 4 A to 7 A ranges (on page 2-5

).

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the Model 2460

while the instrument is powered on. Turn off the equipment from the front panel or

disconnect the main power cord from the rear of the Model 2460 before handling cables.

Putting the equipment into standby does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

2. Turn on the Model 2460 source output.

If the Model 2460 is not already warmed up, allow it to warm up for at least one hour before

continuing to the next step.

3. Complete the range calibration verification steps listed in the following table for each current

range. For each current range, perform the complete procedure at 95 percent of the range's

positive full-scale value, then at 0 A, then at 95 percent of the range's negative full scale value,

and then again at 0 A. For example, for the 5 A range, complete the procedure four times using

each of the following values, in this order: +4.75 A, 0 A, -4.75 A, 0 A.

2460-905-01 Rev. A / January 2016 3-7

Page 23

Section

Calibration and Adjustment Manual

1

*RST

Restore default settings.

2

:SOUR:FUNC CURR

Select the source function.

3

:FUNC "CURR"

Select the measure function.*

4

:SOUR:CURR:RANG <Range>

Set the source range.**

5

:SYST:RSEN OFF

Disable 4-wire remote sensing.

6

Select the front-panel or rear-panel terminals to

match your test setup.

7

:SOUR:CURR <Level>

Program the source value.

8

:OUTP:STAT ON

Turn on the source output.

9

Make DMM reading.

Read the actual output of the Model 2460 using

the external DMM.

11

:READ?

Have the Model 2460 measure and return its

source output.

12

:OUTP:STAT OFF

Turn off the source output.

13

Calculate the source error.

Calculate the difference between step 7 and

step 10.

step 11.

15

Validate source accuracy.** *

Compare the result of step 13 to the source

specification.

16

Validate measure accuracy.** **

Compare the result of step 14 to the measure

specification.

* The measure range is coupled to the source range when simultaneously sourcing and measuring current.

Model 2460 (not the programmed value).

3: Calibration Model 2460

Current calibration verification procedure for the 4 A to 7 A ranges

Step Command or procedure Description

:ROUT:TERM <FRONT or REAR>

10 (calculated I) = (DMM V reading) / R Calculate the shunt current.

14 Calculate the measure error. Calculate the difference between step 10 and

*** Where <Range> = 4, 5, and 7.

**** The source limits are calculated based on the programmed source value of the Model 2460 for each range

(not the actual source value).

***** The measure limits are calculated based on a precise measurement of the programmed value of the

Step 4. Resistance measurement calibration

Follow the steps below to verify that Model 2460 resistance measurement accuracy is within specified

limits. In this procedure, you apply accurate resistances from a resistance calibrator and then verify

that Model 2460 resistance measurements are within required limits.

1. With the source output off, connect the Model 2460 to the resistance calibrator using the

connection configuration in Connections for resistance calibration verification and adjustment

page 2-6).

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the Model 2460

while the instrument is powered on. Turn off the equipment from the front panel or

disconnect the main power cord from the rear of the Model 2460 before handling cables.

Putting the equipment into standby does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

(on

3-8 2460-905-01 Rev. A / January 2016

Page 24

Model 2460

Calibration

1

*RST

Restore default settings.

2

:FUNC "RES"

Select the resistance function.

3

:RES:RANG:AUTO OFF

Disable autoranging.

4

:RES:RANG <Range>

Set the resistance range.

5

:RES:RSEN ON

Enable 4-wire remote sensing.

match your test setup.

7

Program calibrator value.

Set the resistance calibrator value.

8

:OUTP:STAT ON

Turn on the source output.

9

:READ?

Have the Model 2460 measure and return its

source output.

10

:OUTP:STAT OFF

Turn off the source output.

11

Calculate the measure error.

Calculate the difference between step 7 and

step 9.

12

Validate measure accuracy.

Compare the result of step 11 to the calibrator

* Perform the complete procedure for each range, where <Range> = 20, 200, 2K, 20K, 200K, 2M, 20M, and 200M.

Calibration and Adjustment Manual Section 3:

2. Turn on the Model 2460 source output.

If the Model 2460 is not already warmed up, allow it to warm up for at least one hour before

continuing to the next step.

3. On the resistance calibrator, select the external sense mode.

4. Send the commands summarized in the following table in the order listed to verify resistance

measurement accuracy.

Resistance calibration verification procedure using a resistance calibrator*

Step Command or procedure Description

6

:ROUT:TERM <FRONT or REAR>

Select the front-panel or rear-panel terminals to

specification.

It may not be possible to set the resistance calibrator to the specified value. Use the closest possible

setting and modify reading limits accordingly.

2460-905-01 Rev. A / January 2016 3-9

Page 25

Section

Calibration and Adjustment Manual

20 Ω

19 Ω

200 Ω

190 Ω

2 kΩ

1.9 kΩ

20 kΩ

19 kΩ

200 kΩ

190 kΩ

2 MΩ

1.9 MΩ

20 MΩ

19 MΩ

200 MΩ

100 MΩ

3: Calibration Model 2460

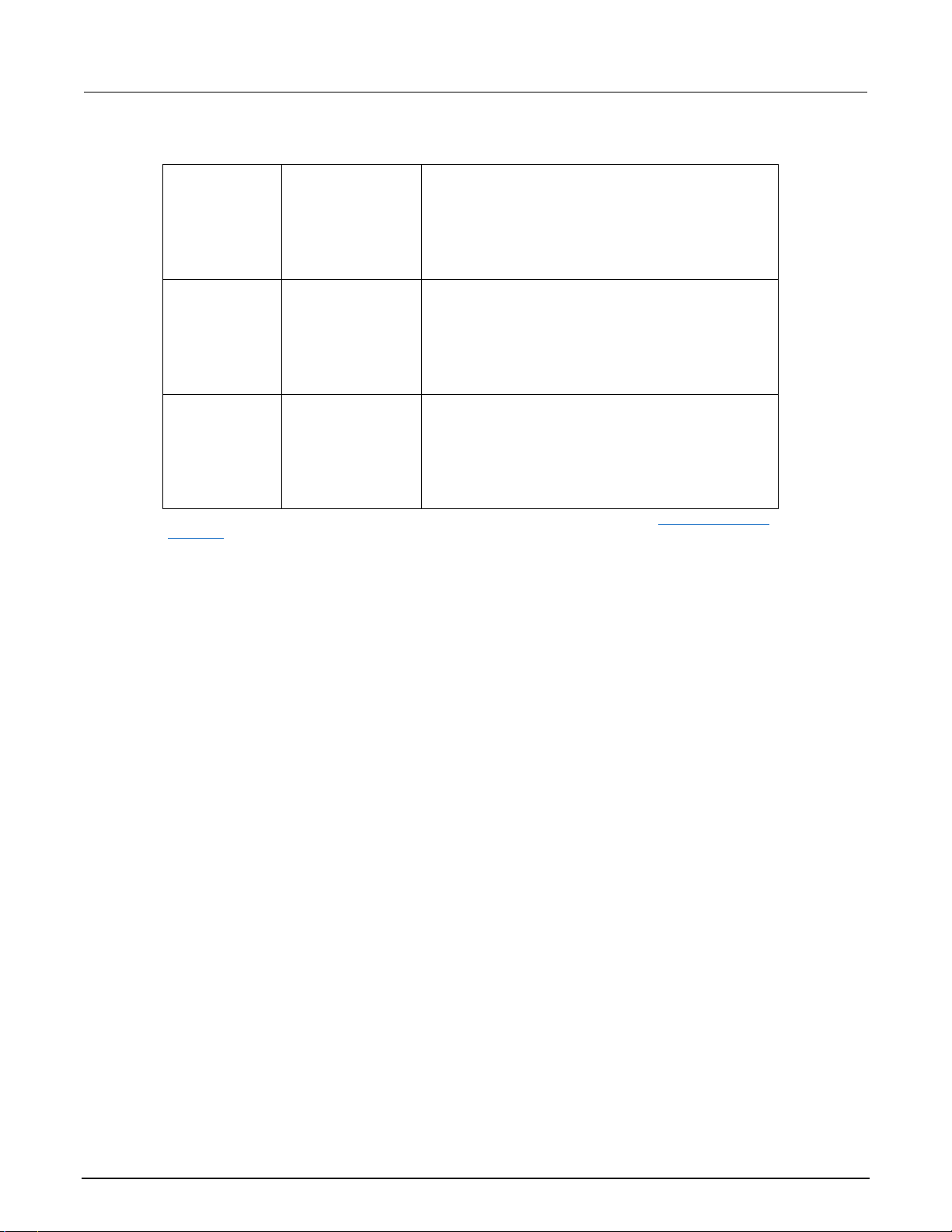

5. Verify that the Model 2460 resistance reading is within the limits in the following table.

Ohms measurement accuracy limits

Model 2460 range Calibrator resistance*

* Nominal resistance value.

3-10 2460-905-01 Rev. A / January 2016

Page 26

Single-range adjustment ........................................................ 4-16

In this section:

Introduction .............................................................................. 4-1

Unlocking calibration for adjustment ........................................ 4-1

Changing the password ........................................................... 4-2

Resetting the calibration password .......................................... 4-3

Querying calibration and adjustment dates and count ............. 4-3

Adjustment errors ..................................................................... 4-3

Remote adjustment .................................................................. 4-4

Remote adjustment procedure ................................................. 4-7

Introduction

Section 4

Adjustment

Use the procedures in this section to adjust the Model 2460. These procedures require accurate test

equipment to measure precise DC voltages and currents. Adjustment can be completed either from

the front panel or by sending SCPI calibration and adjustment commands over the IEEE-488, USB, or

LAN port using a computer. This manual describes using SCPI commands from a remote interface to

adjust the instrument.

The information in this section is intended for qualified service personnel only. Do not

attempt these procedures unless you are qualified to do so. Some of these procedures may

expose you to hazardous voltages, which could cause personal injury or death if contacted.

Use appropriate safety precautions when working with hazardous voltages.

Unlocking calibration for adjustment

Before adjusting the Model 2460, you must unlock the calibration constants by entering or sending a

password using the following command (KI002400 is the default pass wor d; if you have cha nge d

your password, use it instead):

CALibration:UNLock "KI002400"

When calibration constants are unlocked, the instrument is in the state shown in the following table. If

you try to change any of these settings with calibration unlocked, error +510, “Not permitted with cal

unlocked” is returned.

Page 27

Section

Calibration and Adjustment Manual

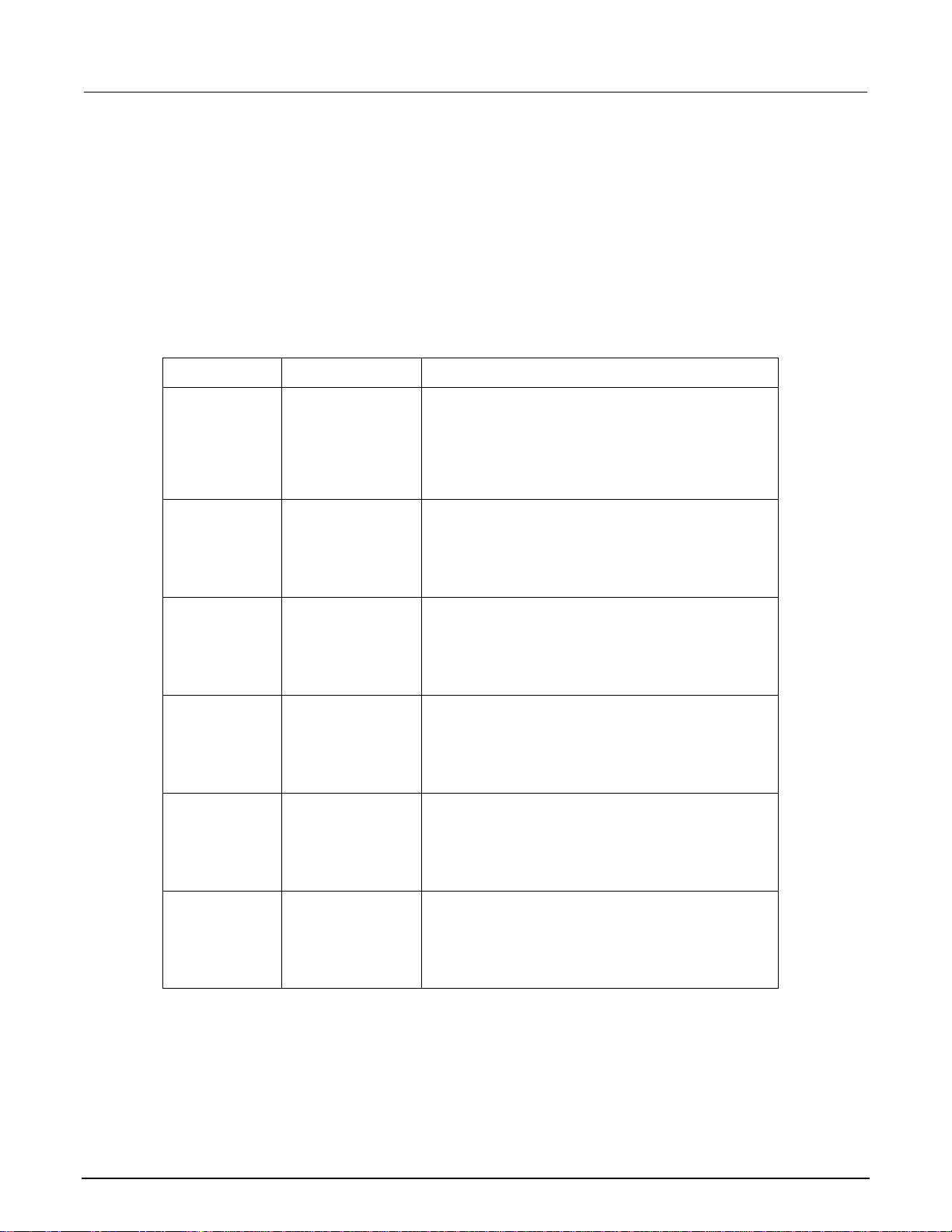

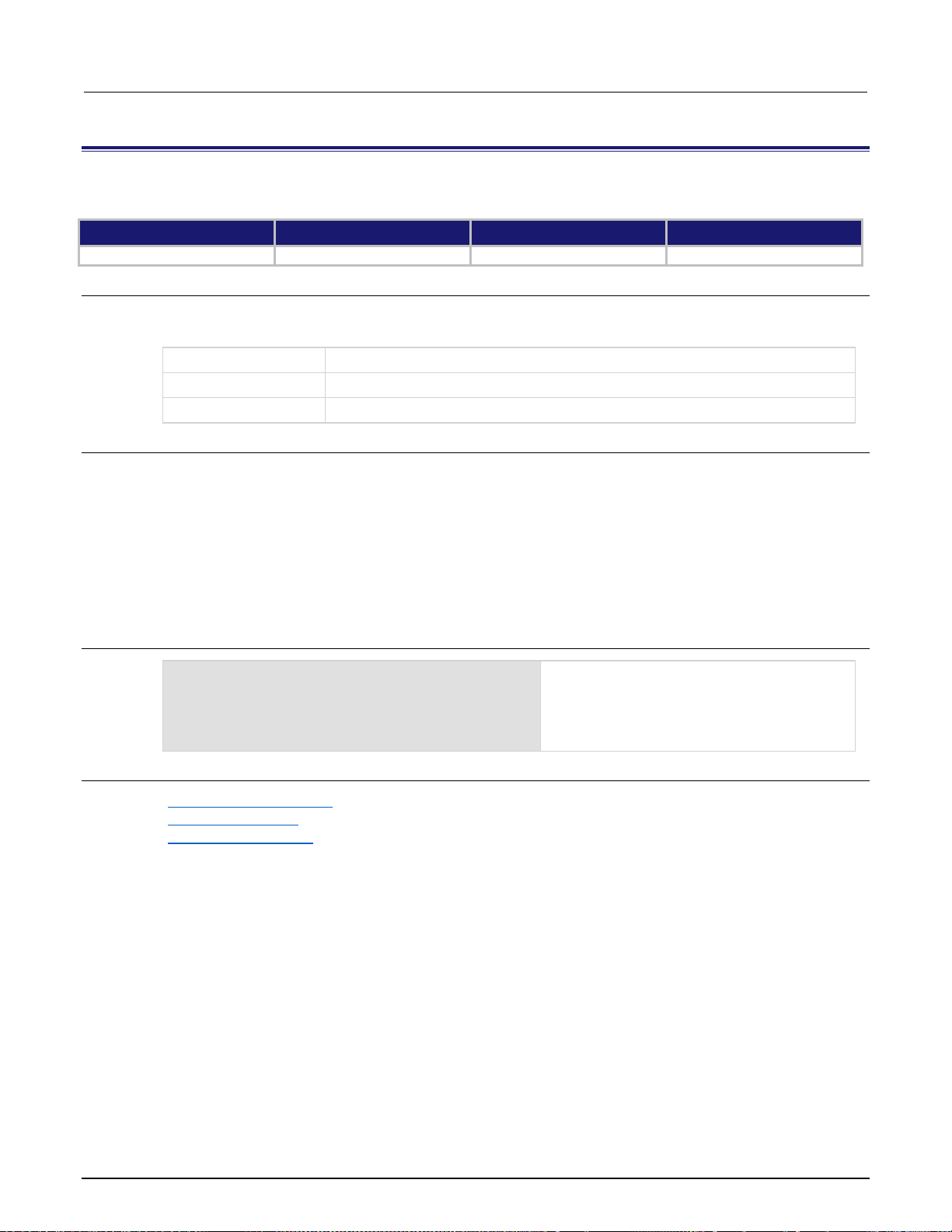

Concurrent functions

Off

:SENSe:FUNCtion:CONCurrent Off

Sense function sense

Source

:SENSe:FUNCtion <source_function>

:SENSe:VOLTage:NPLC 1.0

:SENSe:VOLTage:RANGe <source_v_range>

Current NPLC sense

1.0

:SENSe:CURRent:NPLC 1.0

Current measure range

Same as

range value

:SENSe:CURRent:RANGe <source_i_range>

Count

10

:SENSe:AVERage:COUNt 10

Filter control

Repeat

:SENSe:AVERage:TCONtrol Repeat

Filter averaging

On

:SENSe:AVERage:STATe On

Source V mode

Fixed

:SOURce:VOLTage:MODE Fixed

Volts autorange

Off

:SOURce:VOLTage:RANGe:AUTO Off

Source I mode

Fixed

:SOURce:CURRent:MODE Fixed

Current autorange

Off

:SOURce:CURRent:RANGe:AUTO Off

Autozero

On

:SYSTem:AZERo On

4: Adjustment Model 2460

With calibration unlocked, the sense function and the source function and range are the same. For

example, when :SOURce:FUNCtion is set to VOLTage, the :SENSe:FUNCtion setting is

"VOLTage:DC". When :SOURce:FUNCtion is set to CURRent, the :SENSe:FUNCtion setting is

"CURR:DC". This also applies to the range settings (for example,

:SOURce:VOLTage:RANGe and :SENSe:VOLTage:RANGe;

SOURce:CURRent:RANGe and :SENSe:CURRent:RANGe).

Calibration unlocked states

Mode State Equivalent remote command

Volts NPLC sense 1.0

Volts measure range Same as

source V

range value

Changing the password

You can change the default password from the front panel or using a remote interface.

To change the calibration password using SCPI commands, first send the present password, and

then send the new password.

For example, the following command sequence changes the password from the "KI002400" default

password to "KI_CAL":

CALibration:PASSword "KI002400"

CALibration:PASSword "KI_CAL"

source I

You can use any combination of letters and numbers up to a maximum of eight characters.

4-2 2460-905-01 Rev. A / January 2016

Page 28

M

odel 2460 Calibration and Adjustment Manual Section 4:

Adjustment

Resetting the calibration password

If you change the Model 2460 calibration password and forget it, you must return the Model 2460 to

the local Keithley Worldwide Service Center to be reset. There is no user-serviceable procedure to

restore the default calibration password on the Model 2460.

Querying calibration and adjustment dates and count

To query the adjustment date, send the following SCPI command:

CALibration:ADJust:DATE?

To query the number of times the Model 2460 has been adjusted, send the following SCPI command:

CALibration:ADJust:COUNt?

To query the calibration verification date, send the following SCPI command:

CALibration:VERify:DATE?

You can also view the calibration verification and adjustment dates and adjustment count on the front

panel by pressing the MENU key and selecting System Information.

Adjustment errors

The Model 2460 checks for errors after each adjustment step, minimizing improper adjustment due to

operator error.

Front-panel error rep orting

If an error is detected during adjustment, the instrument displays an appropriate error message. Once

the error is displayed, you can dismiss the error message and repeat the adjustment step that caused

the error with the corrected parameter or corrected command syntax.

Remote error reporti ng

You can detect errors while using a remote interface by testing the state of the Error Available Bit

(EAV) (bit 2) in the status byte (use the *STB? query to request the status byte). Query the

instrument for the type of error by using the appropriate :SYSTem:ERRor? query. The Model 2460

will respond with the error number and a text message describing the the error.

2460-905-01 Rev. A / January 2016 4-3

Page 29

Section

Calibration and Adjustment Manual

0.2 V

+200.00 mV

____________________________ mV

+000.00 mV

____________________________ mV

____________________________ mV

2 V

+2.0000 V

____________________________ V

+0.0000 V

____________________________ V

____________________________ V

7 V

+7.000 V

____________________________ V

+0.000 V

____________________________ V

____________________________ V

10 V

+10.00 V

____________________________ V

+0.000 V

____________________________ V

____________________________ V

____________________________ V

20 V

+20.000 V

____________________________ V

____________________________ V

____________________________ V

100 V

+100.00 V

____________________________ V

____________________________ V

____________________________ V

* DMM reading used in corresponding adjustment step. See procedure.

4: Adjustment Model 2460

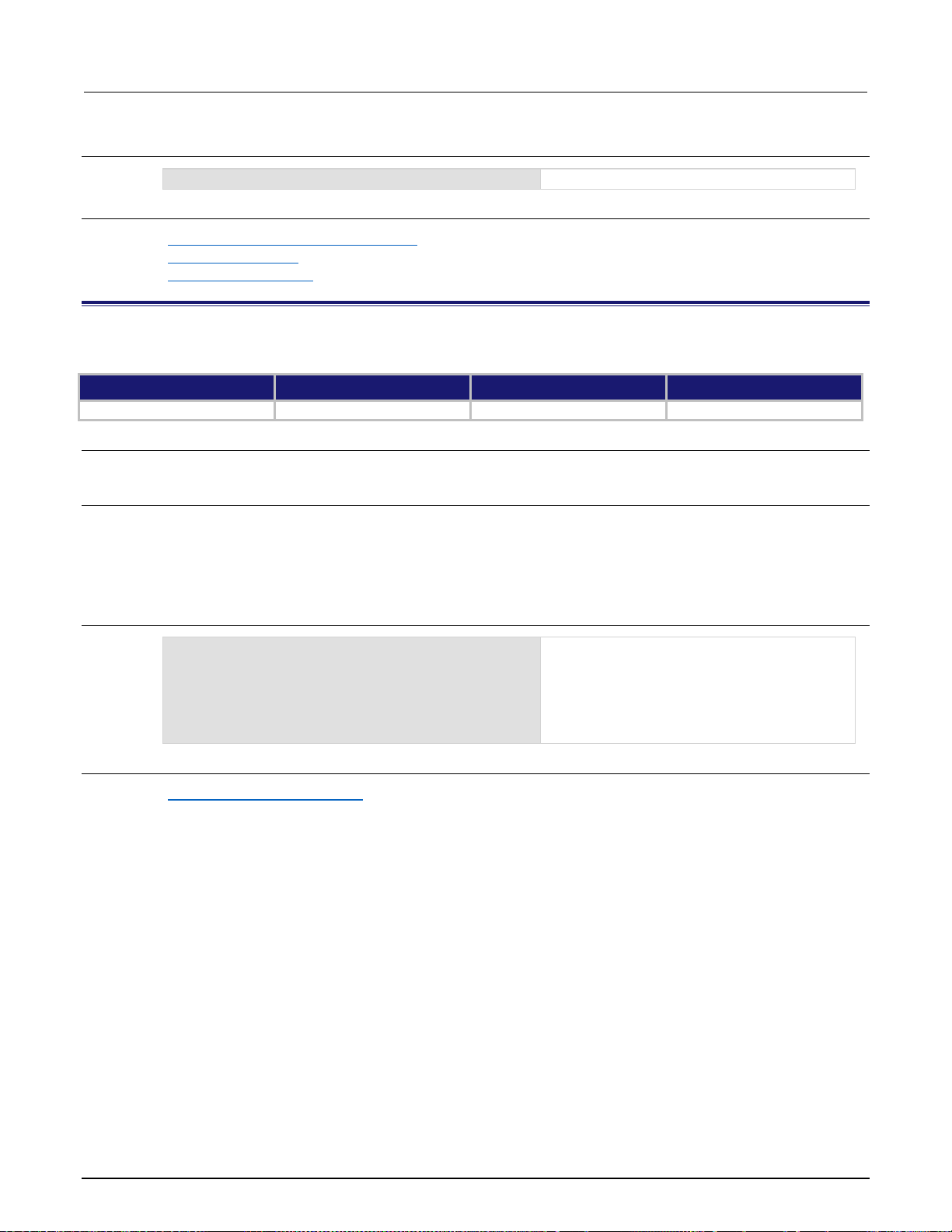

Remote adjustment

Use the following procedure to perform remote adjustment by sending SCPI commands over the

IEEE-488, USB, or LAN connection. The remote commands and appropriate parameters are

separately summarized for each step.

You can use the following tables to document each calibration adjustment value as the calibration

adjustment procedure is executed.

Voltage calibration adjustment data table

Source range Source voltage Digital multimeter (DMM) voltage reading*

+00.000 V ____________________________ V

−200.00 mV

−000.00 mV

−2.0000 V

−0.0000 V

−7.000 V

−0.000 V

−10.00 V

−0.000 V

−20.000 V

−00.000 V

____________________________ mV

____________________________ V

____________________________ V

+000.00 V ____________________________ V

−100.00 V

−000.00 V

4-4 2460-905-01 Rev. A / January 2016

Page 30

Model 2460

Adjustment

+0.0000 μA

____________________________ μA

____________________________ μA

+00.000 μA

____________________________ μA

____________________________ μA

100 μA

+100.00 μA

____________________________ μA

+000.00 μA

____________________________ μA

____________________________ μA

1 mA

+1.0000 mA

____________________________ mA

____________________________ mA

____________________________ mA

10 mA

+10.000 mA

____________________________ mA

____________________________ mA

____________________________ mA

100 mA

+100.00 mA

____________________________ mA

____________________________ mA

____________________________ mA

1 A

+100.00 mA

____________________________ A

+000.00 mA

____________________________ A

____________________________ A

Calibration and Adjustment Manual Section 4:

Current calibration adjustment data table

Source range Source current DMM current reading*

1 μA +1.0000 μA ____________________________ μA

−1.0000 μA

−0.0000 μA

____________________________ μA

10 μA +10.000 μA ____________________________ μA

−10.000 μA

−00.000 μA

____________________________ μA

−100.00 μA

−000.00 μA

____________________________ μA

+0.0000 mA ____________________________ mA

−1.0000 mA

−0.0000 mA

+00.000 mA ____________________________ mA

−10.000 mA

+00.000 mA ____________________________ mA

2460-905-01 Rev. A / January 2016 4-5

−00.000 mA

−10.000 mA

−00.000 mA

−100.00 mA

−000.00 mA

____________________________ A

Page 31

Section

Calibration and Adjustment Manual

4 A

+4.0000 A

____________________________ A

+000.00 A

____________________________ A

____________________________ A

5 A

+5.0000 A

____________________________ A

+000.00 A

____________________________ A

____________________________ A

+000.00 A

____________________________ A

____________________________ A

* DMM reading used in corresponding adjustment step. See the adjustment procedure in Remote adjustment

4: Adjustment Model 2460

−4.0000 A

____________________________ A

−000.00 A

−5.0000 A

−000.00 A

____________________________ A

7 A +7.0000 A ____________________________ A

−7.0000 A

procedure (on page 4-7).

−000.00 A

____________________________ A

4-6 2460-905-01 Rev. A / January 2016

Page 32

Model 2460

Adjustment

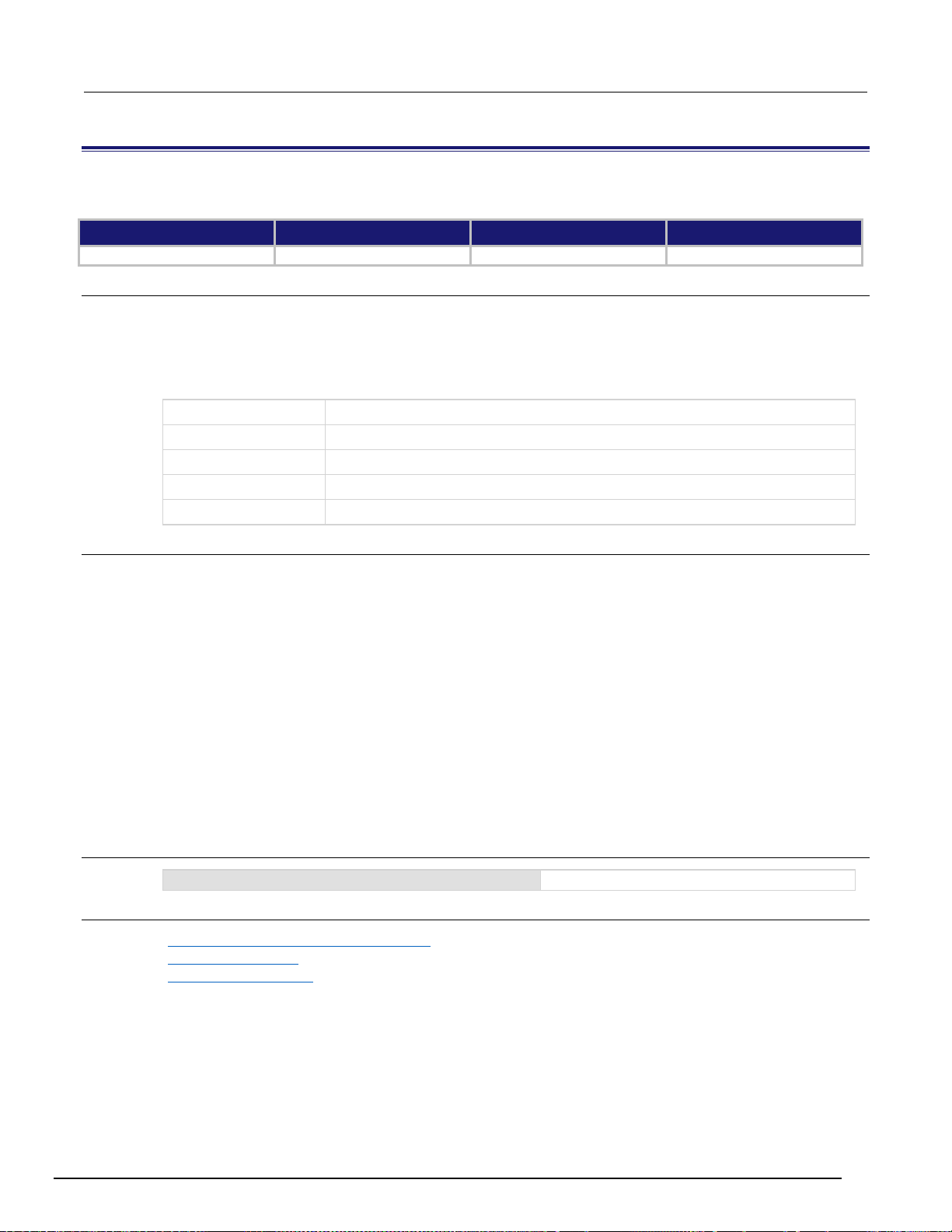

:CALibration:PASSword

Unlock calibration:

default password is KI002400.

:CALibration:ADJust:COUNt?

Query the number of times the Model 2460

at the Keithley Instruments factory.

:CALibration:ADJust:DATE

:CALibration:ADJust:DATE?

Set or query the date the Model 2460 calibration

constants were last adjusted (year, month, day).

:CALibration:VERify:DATE

:CALibration:VERify:DATE?

Set or query the date the Model 2460 calibration

constants were last verified (year, month, day).

:CALibration:LOCK

:CALibration:LOCK?

Set or query whether or not the Model 2460

:CALibration:UNLock <password>

Unlock the Model 2460 calibration constants.

:CALibration:SAVE

Save the updated calibration constants to

nonvolatile memory.*

:CALibration:ADJust:SENSe

Set the new adjusted sense data value.

:CALibration:ADJust:SENSe:DATA?

:CALibration:ADJust:SOURce

Set the new adjusted source data value.

:CALibration:ADJust:SOURce:DATA?

Query the new adjusted source data.

* Adjustment data is not saved if calibration constants were not unlocked with the

:CALibration:UNLock <password>

Calibration and Adjustment Manual Section 4:

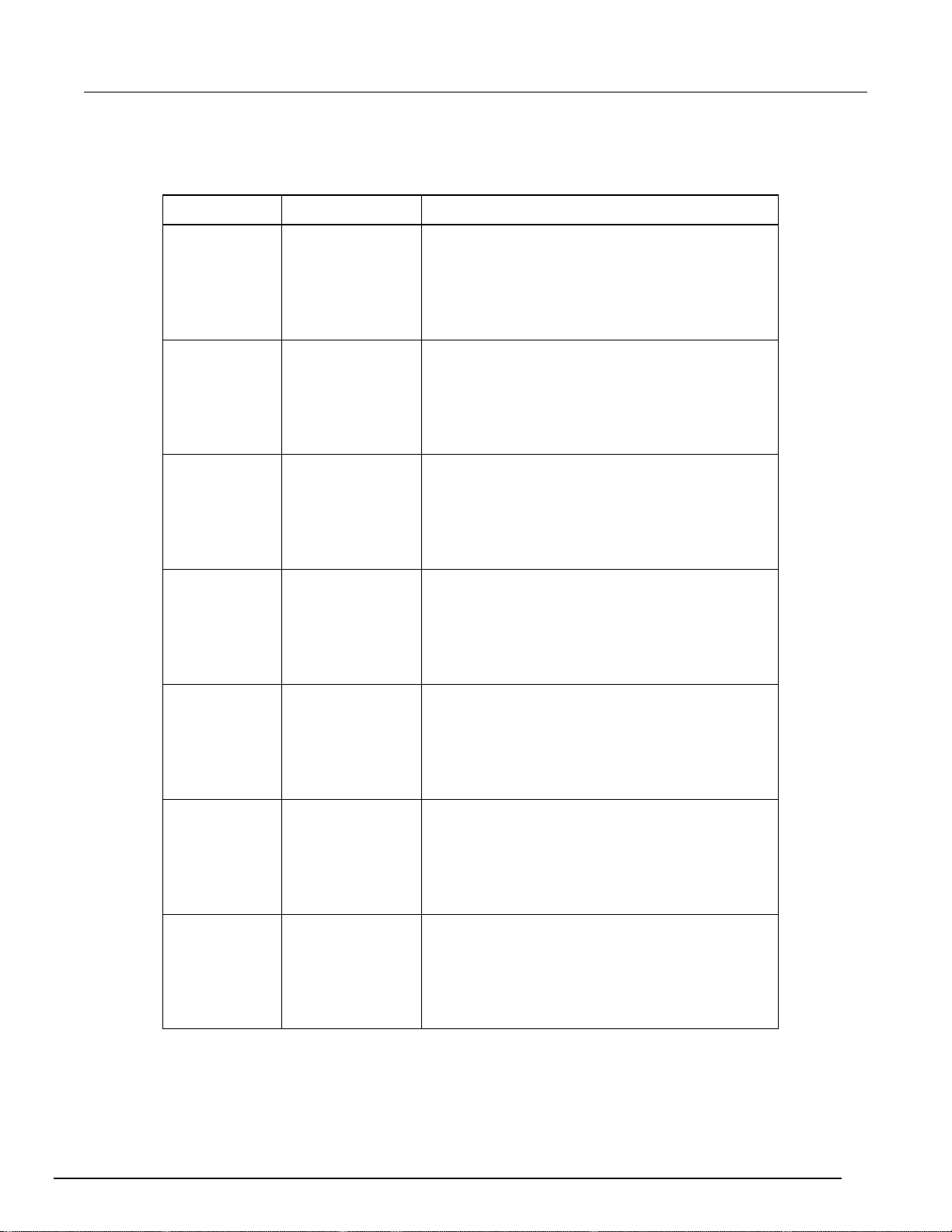

Calibration and adjust m e nt comm a nds summ a ry

The following table summarizes the Model 2460 calibration and adjustment commands. For more

detailed descriptions of the commands, see the Command reference (on page 5-1

SCPI command Description

* Changes the password if

<change code to unlock>

calibration constants are already unlocked. The

calibration constants have bee n adjust ed.

Note: The adjust count is incremented

automatically each time a customer adjustment

is completed. The adjust count can only be reset

calibration constants are locked or unlocked.

) section.

command.

If you change the default calibration password and you forget the new password, you must return the

Model 2460 to the Keithley Worldwide Service Center to reset the calibration password. This

password is unique to calibration and is not the same as the instrument password that is described in

the Model 2460 Reference Manual.

Remote adjustment procedure

Use the following procedure to adjust the Model 2460.

Step 1. Prepare the Model 2460 for adjustment

Verify that the adjustment environment, instrument, and test equipment are set up as described in

Preparing for calibration verification and adjustment (on page 2-1

Query the new adjusted sense data.

).

2460-905-01 Rev. A / January 2016 4-7

Page 33

Section

Calibration and Adjustment Manual

*RST

Restore instrument defaults.

:SOUR:FUNC VOLT

Activate the voltage source.

:SENS:CURR:RANG 0.1

Make sure the 1 A range is not active.

:SOUR:VOLT:PROT:LEV NONE

:SYST:RSEN OFF

Disable remote sensing.*

:CAL:UNL "KI002400"

Unlock the calibration constants.

match your test setup.

:OUTP:STAT ON

Turn the source output on.

4: Adjustment Model 2460

Step 2. Voltage adjustment

1. With the source output off, connect the Keithley Model 2460 to the digital multimeter (DMM) as

shown in Connections for the 200 mV to 100 V ranges (on page 2-4

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the Model 2460

while the instrument is powered on. Turn off the equipment from the front panel or

disconnect the main power cord from the rear of the Model 2460 before handling cables.

Putting the equipment into standby does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

2. Turn on the Model 2460 source output.

If the Model 2460 is not already warmed up, allow it to warm up for at least one hour before

continuing to the next step.

3. On the DMM, select the DC volts function.

4. Initialize voltage adjustment by sending the commands summarized in the following table in the

order listed.

).

When the :CALibrate:UNLock command is sent, the instrument assumes the operating states

listed in the "Calibration unlocked states" table in Unlocking calibration for adjustment (on page 4-1).

Voltage adjustment initialization commands

Command Description

Allow maximum source voltage.

:ROUT:TERM <FRONT or REAR>

* Remote sensing may be used if desired, but is not essential when using recommended digital multimeter.

Select the front-panel or rear-panel terminals to

4-8 2460-905-01 Rev. A / January 2016

Page 34

Model 2460

Adjustment

Calibration and Adjustment Manual Section 4:

5. Complete the range adjustment steps listed in the following table for each range. Do the following

for each range:

Send the :SOURce:VOLTage:RANGe command to select the source and sense range to

adjust. For example, for the 2 V range, send the following command:

:SOUR:VOLT:RANG 2

Program the source to output the negative full-range value using the :SOURce:VOLTage

command. For example, send the following command:

:SOUR:VOLT -2

Record the DMM reading in the "Voltage calibration adjustment data" table in Remote

adjustment (on page 4-4).

Use the DMM reading as the parameter for the :CALibration:ADJust:SOURce and

:CALibration:ADJust:SENSe commands. For example, typical values for the 2 V range

would be:

:CAL:ADJ:SOUR -1.998

:CAL:ADJ:SENS -1.998

Set the voltage source to 0 V output using the :SOURce:VOLTage command:

:SOUR:VOLT 0.0

Record the DMM reading in the "Voltage calibration adjustment data" table in Remote

adjustment (on page 4-4).

Send the source and sense calibration adjustment commands using the DMM reading for the

parameter. For example:

:CAL:ADJ:SOUR 0.001

:CAL:ADJ:SENS 0.001

Set the source to the positive full-range value using the :SOURce:VOLTage command. For

example:

:SOUR:VOLT 2

Record the DMM reading in the "Voltage calibration adjustment data" table in Remote

adjustment (on page 4-4).

Send the source and sense commands using the DMM reading as the parameter. For

example:

:CAL:ADJ:SOUR 1.997

:CAL:ADJ:SENS 1.997

Send the :SOURce:VOLTage command to set the source voltage to 0 V:

:SOUR:VOLT 0.0

Record the DMM reading in the "Voltage calibration adjustment data" table in Remote

adjustment (on page 4-4).

Send the :CALibration:ADJust:SOURce command using the DMM reading as the

command parameter. For example:

:CAL:ADJ:SOUR -1.02e-3

2460-905-01 Rev. A / January 2016 4-9

Page 35

Section

Calibration and Adjustment Manual

1

:SOUR:VOLT:RANG <Range>

Select the source range.

2

:SOUR:VOLT -<Range>

Establish negative polarity.

3

DMM reading 1.**

Read the actual output value on the DMM.

4

:CAL:ADJ:SOUR <DMM_Reading1>

Adjust the source function negative full scale.

5

:SYST:ERR?

Check Model 2460 for errors.

6

:CAL:ADJ:SENS <DMM_Reading1>

Adjust the sense function negative full scale.

7

:SYST:ERR?

Check Model 2460 for errors.

8

:SOUR:VOLT 0.0

Set the output to 0 V.

9

DMM reading 2.**

Read the actual output value on the DMM.

10

:CAL:ADJ:SOUR <DMM_Reading2>

Adjust the source function negative zero.

11

:SYST:ERR?

Check Model 2460 for errors.

12

:CAL:ADJ:SENS <DMM_Reading2>

Adjust the sense function negative zero.

13

:SYST:ERR?

Check Model 2460 for errors.

14

:SOUR:VOLT +<Range>

Establish positive polarity.

15

DMM reading 3.**

Read the actual output value on the DMM.

16

CAL:ADJ:SOUR <DMM_Reading3>

Adjust the sense function positive full scale.

17

:SYST:ERR?

Check Model 2460 for errors.

18

CAL:ADJ:SENS <DMM_Reading3>

Adjust the source function positive full scale.

19

:SYST:ERR?

Check Model 2460 for errors.

20

:SOUR:VOLT 0.0

Set the output to 0 V.

21

DMM reading 4.**

Read the actual output value on the DMM.

22

:CAL:ADJ:SOUR <DMM_Reading4>

Adjust the source positive zero.

23

:SYST:ERR?

Check Model 2460 for errors.

<DMM_Readingn>

4: Adjustment Model 2460

Voltage range calibration and adjustment commands

Step Command Description

* Perform the complete procedure for each range, where <Range> = 0.2, 2, 7, 10, 20, and 100.

** The

parameter is the DMM reading from the previous step.

Each range requires:

Four CAL:ADJ:SOURce commands (full scale and zero for each polarity)

Three CAL:ADJ:SENSe commands (full scale for each polarity, and zero)

Step 3. Current adjustme nt

Keithley Instruments recommends two different connection configurations for current adjustment:

For the 1 µA to 1 A ranges, use the connection diagrams in Connections for the 1 µA to 1 A

ranges (on page 2-5).

For the 4 A to 7 A ranges, use the connection diagrams in Connections for the 4 A to 7 A ranges

(on page 2-5).

The following topics describe how to do current adjustment for each of these configurations.

4-10 2460-905-01 Rev. A / January 2016

Page 36

Model 2460

Adjustment

*RST

Restore instrument defaults.

:SOUR:FUNC CURR

Select the source current mode.

:FUNC "CURR"

Select the measure function.*

:CAL:UNL "KI002400"

Unlock the calibration constants.

your test setup.

:OUTP:STAT ON

Turn source output on.

* The measure range is coupled to the source range when simultaneously sourcing and measuring current,

Calibration and Adjustment Manual Section 4:

Current adjustment for the 1 µA to 1 A ranges

1. With the source output off, connect the Model 2460 to the digital multimeter (DMM) using the

connection configuration in Connections for the 1 µA to 1 A ranges (on page 2-5

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the Model 2460

while the instrument is powered on. Turn off the equipment from the front panel or

disconnect the main power cord from the rear of the Model 2460 before handling cables.

Putting the equipment into standby does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

2. Turn on the Model 2460 source output.

If the Model 2460 is not already warmed up, allow it to warm up for at least one hour before

continuing to the next step.

3. On the DMM, select the DC current function.

4. Send the commands summarized in the following table in the order listed to initialize current

adjustment.

Current adjustment initialization commands

).

Command Description

:ROUT:TERM <FRONT or REAR>

so you do not need to set the measure range.

Select the front-panel or rear-panel terminals that match

2460-905-01 Rev. A / January 2016 4-11

Page 37

Section

Calibration and Adjustment Manual

4: Adjustment Model 2460

5. Adjust each current range using the procedure summarized in the following table. Do the

following for each range:

Send the :SOURce:CURRent:RANGe command to select the source and sense range to

adjust. For example, for the 1 mA range, the command is:

:SOUR:CURR:RANG 1e-3

Program the source to output the negative full-range value using the :SOURce:CURRent

command. For example:

:SOUR:CURR -1e-3

Record the DMM reading in the "Current calibration adjustment data" table in Remote

adjustment (on page 4-4).

Use the DMM reading as the parameter for the :CALibration:ADJ:SOURce and

:CALibration:ADJ:SENSe commands. For example, a typical value for the 1 mA range

would be:

:CAL:ADJ:SOUR -1.025e-3

:CAL:ADJ:SENS -1.025e-3

Set the current source to 0 A output using the :SOURce:CURRent 0.0 command.

Record the DMM reading in the "Current calibration adjustment data" table in

adjustment (on page 4-4).

Remote