Page 1

Tektronix

'*■ *

x^^#^;r^>:^:?r

/v^rT;

2445B/2455B/2465B

Oscilloscope and Options

Operator Manual

070-6860-00

-

r«

.-Tpta-S^i f *

"i -

j*.'<}<*'

Page 2

Tektronix

/

2445B/2455B/2465B

Oscilloscope and Options

Operator Manual

070-6860-00

Please check for change information at the rear

of

this

manual.

First Printing: May 1988

Revised Printing: October 1990

Page 3

Instrument Serial Numbers

Each instrument manufactured by Tektronix has a serial number on a panel

insert or tag, or stamped on the chassis. The first letter in the serial number

designates the country of manufacture. The last five digits of the serial number

are assigned sequentially and are unique to each instrument. Those

manufactured in the United States have six unique digits. The country of

manufacture is identified as follows:

B010000 Tektronix, Inc., Beaverton, Oregon, USA

E200000 Tektronix United Kingdom, Ltd., London

J300000 Sony/Tektronix, Japan

H700000 Tektronix Holland, NV, Heerenveen, The Netherlands

Instruments manufactured for Tektronix by external vendors outside the United

States are assigned a two digit alpha code to identify the country of manufacture

(e.g.,

JP for Japan, HK for Hong Kong, IL for Israel, etc.).

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

Printed in

U.S.A.

Copyright

■!■

Tektronix, Inc., 1988

Page 4

WARRANTY

Tektronix warrants that this product will be free from defects in materials and

workmanship for a period of

three

(3) years from the date of shipment. If any such

product proves defective during this warranty

period,

Tektronix, at its

option,

either

will repair the defective product without charge for parts and

labor,

or

wiii

provide a

replacement in exchange for the defective product.

In order

to

obtain service under this warranty, Customer must notify Tektronix of the

defect before the expiration of the warranty period and make suitable

arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by

Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the

product to Customer if

the

shipment

is

to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all

shipping charges, duties, taxes, and any other charges for products returned to

any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper

use or improper or inadequate maintenance and care. Tektronix shall not be

obligated to furnish service under this warranty

a)

to repair damage resulting from

attempts by personnel other than Tektronix representatives to install, repair or

service the product; b) to repair damage resulting from improper use or connection

to incompatible equipment; or c) to service a product that has been modified or

integrated with other products when the effect of such modification or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS

PRODUCT IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE

DEFECTIVEPRODUCTSISTHESOLEANDEXCLUSIVEREMEDYPROVIDED

TO THE CUSTOMER FOR BREACH OF THIS WARRANTY TEKTRONIX AND

ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF

WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE

POSSIBILITY

OF

SUCH DAMAGES.

Page 5

Certificate of the Manufacturer^lmporter

We hereby certify that the .

2465B/2455B/2445B OSCILLOSCOPE AND ALL INSTALLED OPTIONS

complies with the RF Interference Suppression requirements of

Amtsbl.-Vfg 1046/1984.

The German Postal Service was notified that the equipment is being

marketed.

The German Postal Service has the right to re-test the series and to

verify that it complies.

TEKTRONIX

Bescheinigung des Herstellers/lmporteurs

Hiermit wird bescheinigt, da# der/die/das

2465B/2455B/2445B OSCILLOSCOPE AND ALL INSTALLED OPTIONS

in Ubereinstimmung mit den Bestimmungen der Amtsblatt-Verfugung

1046/1984 funkentstoYt ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses Gerates

angezeigt und die Berechtigung zur Uberprufung der Serie auf Einhalten

der Bestimmungen eingeraumt.

TEKTRONIX

Page 6

NOTICE to the user/operator:

The German Postal Service requires that Systems assembled by the

operator/user of this instrument must also comply with Postal

Regulation, Vfg. 1046/1984, Par. 2, Sect. 1.

HINWEIS fur den Benutzer/Betreiber:

Die vom Betreiber zusammengestellte Anlage, innerhalb derer dies

Gerat eingesetzt

wird,

mu/3

ebenfalls den Voraussetzungen nach Par. 2,

Ziff. 1 der Vfg. 1046/1984 genugen.

NOTICE to the user/operator:

The German Postal Service requires that this equipment, when used in a

test setup, may only be operated if the requirements of Postal

Regulation, Vfg. 1046/1984, Par. 2, Sect. 1.7.1 are complied

with.

HINWEIS fur den Benutzer/Betreiber:

Dies Gerat darf in Meflaufbauten nur betrieben werden, wenn die

Voraussetzungen des Par. 2,

Ziff.

1.7.1 der Vfg. 1046/1984 eingehalten

werden.

Page 7

The

2465B, 2455B,

and 2445B

TheTEKTRONIX 2465B, 2455B, and 2445B portable oscilloscopes have four vertical

channels with DC to 400 MHz, 250 MHz, and 150 MHz bandwidths. Deflection factors

run from 2 mV to 5 V per division, in a 1-2-5 sequence, with either 1 MH or 50 Cl input

resistance, in channels 1 and 2. Either AC or DC input coupling is available at 1 MfL

Channels 3 and 4 give 0.1 V or 0.5 V per division, with 1 MH input resistance, and DC

coupling.

With the standard 10X probes, channels 1 and 2 display 20 mV to 50

V/division and channels 3 and 4 display 1 V or 5 V/division.

The trigger system works automatically for most signals. They operate in various

modes, from any channel, with optimum couplings for a wide range of signals. The

2445B triggers from DC to 250 MHz. The 2455B and 2465B trigger from DC to

500 MHz.

Sweep speeds range from 1.5 s to 1 ns per division on the 2445B and 2455B and to

500 ps per division on the 2465B, including the effects of the X10 magnifier and the

calibrated variable between 1-2-5 steps. Horizontal displays include A-Sweep,

B-Sweep (delayed), A alternated with B, and CH 1 (for X/Y displays).

The SETUP features. AUTO, SAVE, and RECALL, save time and prevent errors.

whether you are a novice operator or a master. AUTO Setup works with almost any

signal.

For repeating measurements, the Save and Recall functions record and restore

as many as 30 instrument setups, including the extended-function options. Setups can

be recalled either immediately or sequentially.

Digital readouts of time, voltage, scale factors, trigger levels, and auxiliary information

also save time and reduce errors.

With Parametric Measurements, common measurements such as frequency, period,

amplitude, pulse width, duty factor, rise time, fall time, and propagation delay can be

made automatically. Each measurement activation displays the results in the CRT

readout. Measurement results remain on-screen until any other button is pressed.

For instruments with serial numbers B049999 and below with firmware Version

11 and above or for instruments serial numbers B050000 and above with firmware

Version 2 and above the following function is available. The RECALL button resets

the instrument into the mode of operation it was in prior to performing the parametric

measurement or AUTO Setup.

With the available Counter/Timer/Trigger (CTT), Option 06 or Option 09,

measurements require even less effort and give better accuracy. The CTT increases

trigger selectivity, especially in digital systems. Option 09 includes the CTTand a 17-bit

Word Recognizer

{WR).

The available TelevisionA/ideo (TV) enhancement, Option 05, can

trigger at any desired point in a frame and it can reduce the effects of ac coupling and

hum in a video signal. The available Digital Multimeter (DMM) measures dc voltage, dc

current, ac rms current, resistance, and temperature with floating inputs.

2465B/2455B/2445B Operators

Page 8

The 2465B, 2455B, and 2445B

The

WR

adds a Word Recognizer Probe connector on the rear panel. The

TV

enhancement adds LINES, FLD1, and FLD2 Trigger Coupling.

The available GPIB interface accesses all controls and digital readings. The interface

adds GPIB status indicators, just above the CRT. See the 24X5B/2467B GPIB (Option 10)

Instrument Interfacing Guide for information on integrating the instrument into a GPIB

system.

The 2465B CT includes C7Tand WR (Option9) and GPIB (Option 10). The

2465B DM adds DMM (Option 01) and also includes CTT and WR (Option 9) and GPIB

(Option 10). The 2465B DV adds TV (Option 05) to the features of the 2465B DM.

Illustrations at the back of the manual show the instrument front and rear panels.

2465B/2455B/2445B Operators

Page 9

Page

Preface i

Illustrations vi

Tables vii

Operators Safety Summary viii

"j Genera! Information

Preparation for Use 1-1

Safety 1-1

Line Voltage Selection 1-1

Line Fuse 1-1

Power Cord 1-3

Instrument Cooling 1-4

Start-up 1-4

Repackaging For Shipment 1-5

2 Operation

Fundamentals 2-1

Parametric Measurements 2-1

Getting a Display 2-2

Assigning Parametric Measurements to Auto Setup 2-3

Vertical 2-4

Horizontal 2-6

Trigger Controls 2-6

Video Triggering 2-9

Readout 2-10

Measurements with Cursors 2-13

Voltage Measurements 2-15

Display Operation 2-15

Signal Connections 2-16

Magnify Waveform Details with Delayed-Sweep 2-17

B-Trigger

Operation 2-18

Delta-Delay-Time 2-19

Single-Delay-Time Measurements 2-20

Time Interval Measurement 2-21

Precision Timing 2-22

Triggered Delta-Delay-Time Measurements 2-23

Time Interval Resolution 2-25

Measurement Updating 2-25

Frequency, Period, and Totalize Counting 2-27

Frequency Measurement with External Reference (Option 1E) 2-28

Delay Sweeps by Event Counts 2-28

Logic Triggering 2-32

Word Recognizer Operation 2-34

The Word Out Signal 2-35

Frequency Limit for Auto Level or Parametric Measurements 2-35

DMM \ 2-35

Save and Recall Operation 2-36

2465B/2455B/2445B Operators iii

Page 10

Contents

3 Applications

Peak-to-Peak Voltage 3-1

Absolute Voltages Using Cursors 3-1

Noise Immunity 3-2

DC Voltage Measurement 3-3

Amplitude Modulation 3-3

Frequency Modulation 3-4

Measuring Video Signals in IRE Units 3-5

Avoiding False Displays with Multi-Mode Signals 3-5

Algebraic Addition to Detect Coincidence or Cancel Interference 3-5

Observing Coincidence of Digital Signals 3-6

Measuring Off-Ground Signals And Cancelling Interference 3-6

Period and Frequency 3-8

Rise Time and Fall Time 3-9

Propagation Delay 3-11

Setup and Hold Times 3-12

Slew Rate 3-13

Time Ratio (Duty Factor) 3-13

Phase Difference Between Two Signals 3-15

Measuring Millivolt Signals 3-17

4 Checks and Adjustments

Introduction 4-1

Initial Setup 4-1

Trace Rotation and Adjustment 4-2

Astigmatism Adjustment 4-2

Auto DC Balance Routine 4-3

Probe Compensation 4-4

Matching Channel 2 Delay 4-5

Amplitude Check 4-6

Timing Check 4-7

Q Controls, Connectors, and Indicators

Introduction 5-1

Power And Display 5-1

Setup and Vertical 5-4

Horizontal 5-12

Delay and Delta Controls 5-15

Rear Panel 5-27

DMM 5-29

DMM Displays 5-33

Display-Mode Interactions 5-33

iv 2465B/2455B/2445B Operators

Page 11

Q

Performance Characteristics

Performance Conditions 6-1

"J Options and Accessories

Introduction 7-1

Option 11 7-1

Option 1R 7-1

Power Cord Options 7-2

Standard Accessories 7-3

Optional Accessories 7-5

f^

Appendix A

Extended Functions with Diagnostic Exercisers A-1

3

Appendix B

Sequence Programming and Operation B-1

Executing Sequences B-3

Q

Appendix C

Power Up Tests C-1

Kernel Test C-1

Confidence Tests C-1

Q

Appendix D

Delta-Time and Delta-Delay-Time Accuracy under Noted

Conditions for theC/T/T Option D-1

Delay-Time Accuracy under Noted Conditions for the

C/T/T Option D-2

2465B/2455B/24-45B Operators

Page 12

Contents

Illustrations

Figure Page

1-1 Line selector switch, line fuse, and detachable power cord 1-3

2-1 Readout display locations 2-11

3-1 Instantaneous voltages 3-2

3-2 Eliminating common-mode signals 3-7

3-3 Measuring rise times 3-10

3-4 Time between two pulses (cursor method) 3-12

3-5 Time ratio (duty factor) 3-14

3-6 Phase difference between two signals 3-16

3-7 Small-angle phase difference 3-16

4-1 Probe low-frequency compensation 4-4

5-1 Power and display controls 5-3

5-2 SETUP and MODE buttons, and CH 1 and CH 2 POSITION controls 5-7

5-3 Channel 1 and Channel 2 controls and connectors 5-8

5-4 CH 3 and CH 4 controls and connectors and CALIBRATOR output 5-11

5-5 Horizontal and delta measurement controls 5-19

5-6 Trigger controls and indicators 5-26

5-7 Rear panel controls and connectors 5-28

5-8 DMM controls and connectors 5-32

6-1 Dimensional drawing 6-39

VI

2465B/2455B/2445B Operators

Page 13

Contents

Tables

Table Page

1-1 Power Cord and Voltage Data 1-2

2-1 Resolution Selections 2-26

2-2 Auto Resolution 2-26

2-3 Delay-by-Events Combinations 2-29

2-4 Sweep Triggering 2-33

6-1 2465A/2455A/2445A Electrical Characteristics 6-2

6-2 Option 01 (DMM) Electrical Characteristics 6-19

6-3 Option 05 (TV) Electrical Characteristics 6-26

6-4 Option 06 (C/T/T) Electrical Characteristics 6-29

6-5 Option 09 (WR) Electrical Characteristics 6-35

6-6 Option 10 (GPIB) Electrical Characteristics 6-37

6-7 Mechanical Characteristics 6-38

6-8 Environmental Requirements 6-40

C-1 Confidence Test Numbers and Affected Functions C-2

2465B/2455B/2445B Operators vii

Page 14

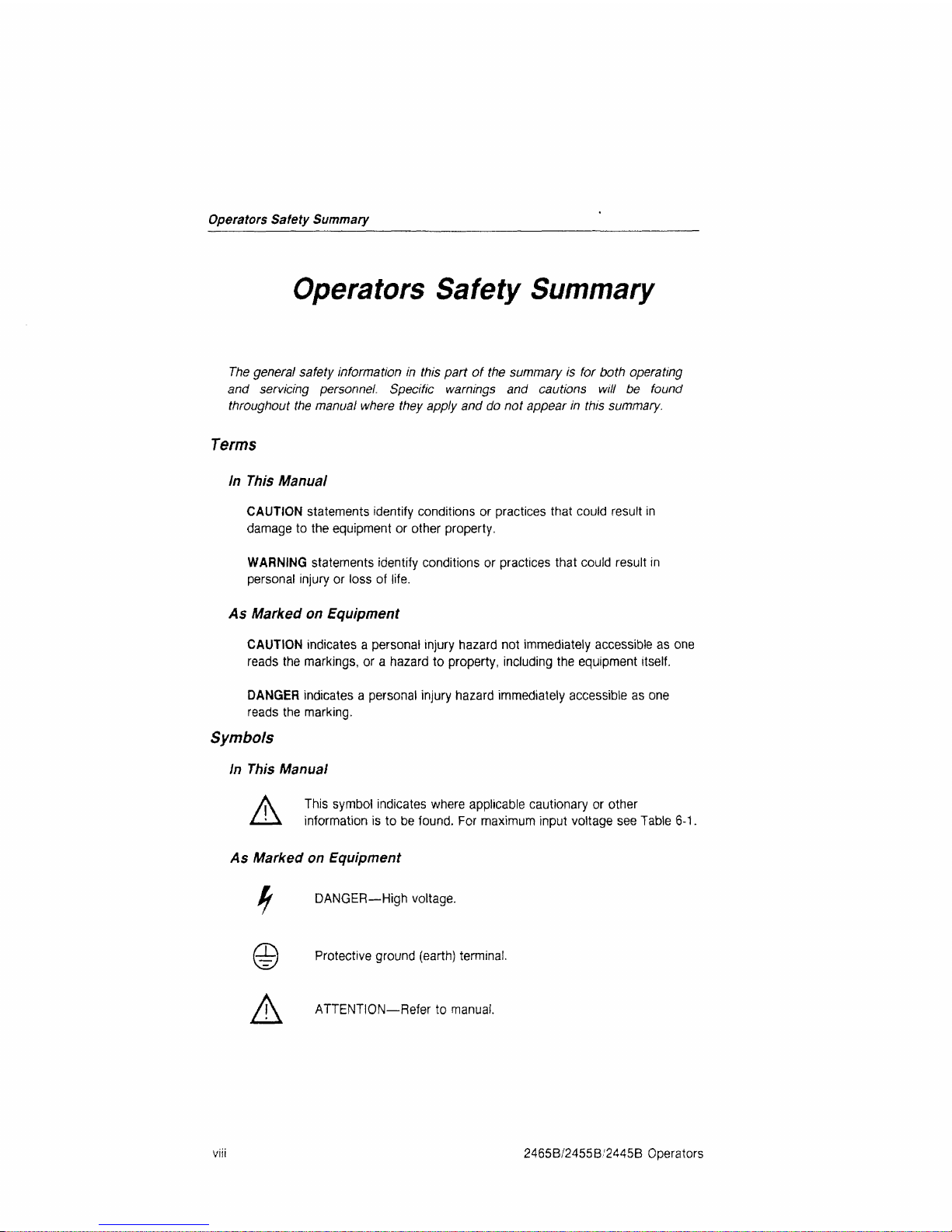

Operators Safety Summary

Operators Safety

Summary

The general

safety

information

in this part of

the summary

is for both

operating

and servicing personnel. Specific warnings and cautions will be found

throughout the manual where they apply

and do not

appear

in this

summary.

Terms

In This Manual

CAUTION statements identify conditions or practices that could result in

damage to the equipment or other property.

WARNING statements identify conditions or practices that could result in

personal injury or loss of life.

As Marked on Equipment

CAUTION indicates a personal injury hazard not immediately accessible as one

reads the markings, or a hazard to property, including the equipment

itself.

DANGER indicates a personal injury hazard immediately accessible as one

reads the marking.

Symbols

In This Manual

A

This symbol indicates where applicable cautionary or other

information is to be found. For maximum input voltage see Table 6-1.

As Marked on Equipment

ff DANGER—High voltage.

A

Protective ground (earth) terminal.

ATTENTION—Refer to manual.

vin

2465B/2455B/2445B Operators

Page 15

Operators Safety Summary

Power Source

This product is intended to operate from a power source that does not apply more

than 250 volts rms between the supply conductors or between either supply

conductor and ground. A protective ground connection by way of the grounding

conductor in the power cord is essential for safe operation.

Grounding

the

Product

This product is grounded through the grounding conductor of the power

cord.

To

avoid electrical shock, plug the power cord into a properly wired receptacle before

connecting to the product input or output terminals. A protective ground

connection by way of the grounding conductor in the power cord is essential for

safe operation.

Danger Arising From Loss

of

Ground

Upon loss of the protective-ground connection, all accessible conductive parts

(including knobs and controls that may appear to be insulating) can render an

electric shock.

Use the

Proper Power Cord

Use only the power cord and connector specified for your product.

Use only a power cord that is in good condition.

For detailed information on power cords and connectors see Table 1-1.

Use the

Proper Fuse

To avoid fire hazard, use only a fuse of the correct type, voltage rating and current

rating as specified in the parts list for your product.

Do Not

Operate

in

Explosive Atmospheres

To avoid explosion, do not operate this product in an explosive atmosphere unless

it has been specifically certified for such operation.

Do Not

Remove Covers

or

Panels

To avoid personal injury, do not remove the product covers or panels. Do not

operate the product without the covers and panels properly installed.

2465B/2455B/2445B Operators

IX

Page 16

HIGH

,jji*;'

,

FtAhGC

41HQ'"' UJ>" tfflWS

DCV

ACV

IIBV

com Hin

WIN.MAX REF

HOU)

mspiAY nisi'LAY

;

/d/'p

'□

.

D a a a a a a ana

>!

" OCA ACA

dllm lOfi

"I

SMOQ1H

MIN MAX

flEF

/,----■.

r% Mn

A

rh

Tektronix 2465B4OOMHZ *?0Z»ltl%»

j-

INTENSITY FOCUS READOUT INTENSITY SCALI: ILLUM

i'iS

POWER*■■■'■■;

MAM IflACf

QFf | flN \

(IND

,,

FK11AIK1N

, ,, v ASIir,

_ i __^ fa \

\t--~r

x^-

-^y

SCALI

\i-^y

btnu — \I-JS t \^LS

rife

*

^■"^

-v-*- mr.rnns ^^ lAtinR.s "^ ? ^~ kw :

SETUP

VERTICAL

TRIGGER

t-'

J

a

ice

7*fK\

STEP/

^..POSITION ^.POSITION | ^POSITION..' XIO iHOLDOFF

„.-;.,„

LEVEL

WHO !H

,tfLV

A

/dfx

- /fK MAG

a ii

o o *

SAVF 4 MODE ~" ^ |

□

if

CM I CH } Cll J CH 4 i| AV At

IRAtK/

*

I

^ 3 4 '!. I/At

imufp

j A/B

IRIG iJIMPr INIlfalEM

-5i;i.

a a u a

!- "a

a' n ii a a D

a

i ■ A111!

I t V i vtlU

III

KE1 p :} . ADD mum-

I:IIIII'/ . IIMM.

] f , AHFF(llini.V

PUS

A

MEASURE.'.

All

HWIIM

I ' *': ,„„ ^^_ » ^

LINE

/i^tt if .

"

UIIM

iH

' ■■ "'

......

' l\ yi * : ~'M '■'<!

t-H j >t

IIEIP

i, ... e ; a

Ql

a a a a

;; f

»c

s pini

INIIIN IUHN

AII

IMISH

B

VOLTS/DIV VOLTS/DIVf A«r SfcC/DIV

hUN/,n

UNI

IINIS

HI) i mr

iv

inn,

AUIV

fin i

""

MODE SOURCE COUPLING

|FASI

|

Q

O

ni;,|i liUHI YALANU rvUAMl":

.- lo V

■ • (fflAi: i i.rtJOiv

O

S

. AC -. . I

RACE

f;Nn

( \ .

J..SEP j ,-..POSITION VOLTS/DIV -^POSITION

«„v <

IMfi

111". -&f ' /F\\ />' IIV\ I 1 i I 1

f.'\V-\

&)

»>

f-1 O < t J

□ : □ t J

ID,.0,0

VOLTS/DIV

, i'f

IW/.IV bV/.IV

j\

o

CH

1onQ

IM.fi l5pF<it(IOV|ik

CH

2

IM!1

l!)|il

5'intlV|ik

CH

3

CA|il

b

^,

AMT

H

?R CH

4

IMfi lf.|)f 54(IOV|ik COMPPnOHKallmi

IMS"! IS||F

54nf>V|ik

iini

(czn)

INH

1

:IWI>

'ifl!;

6860-11

Page 17

CAUTION

TO AVOID ELECTRIC SHOCk

THE

POWER CORD

PROTECTIVE GROUNDING CONDUCTOR MUST

8E

CONNECTED

TO

GROUND

00

NOT

REMOVE COVERS. RtfER SERVICING

TO

QUALIFIED PERSONNEL.

DISCONNECT INPUT POWER DtfORE REPLACING fUSfc.

KIR CONTINUED TIRi PROTECTION REPLACE, ONLY

WITH SPECIFIED TYPE

ANO

RAT

Ell FUSE.

UNE VOUAGE

SELECTION

1ISV

230V

RAN6E

90132V

180 250V

dl I98.GI3AC)

.i X Hi 25UV

■2A fASl

IECI2>

5X?(Jmn1?50V

I.6A (T)

POWER

MAX

WATTS

120

MAX VA

180

FREO.

46

440H;

TEKTRONIX GUERNSEY

LID, L,l

W_-

GP1B CONNECTOR

4EEE

STD 468

PORT

SHV.

AH1.

T6, 13. SRI. RL1.

PPf).'

OGl.

DTjl,

C0. El

^^^

CH Z SIGNAL

OUT

lOmV/OIV INTO 5Qfi

A GATE

OUT

STEP/AUTO 8 GATE

OUT

TtL

Jt {XT

SWITCH

TTL TV.

EXT Z AXIS

.IN

15-25'Vpkl TTL

Jl

BLANKS

~\£

Page 18

||Ejifri~f~li~|ry ilkiiuiwn inrvnmni ivrri

Manual Part No. 070-6860-00 First Printing MAY 1988

Prnrinct- 2445B/2455B/2465B Operators Revised OCT 1990

Manual Insert Status

Date Change Refersnc© Ststu

JUL90 M73008 Effective

r «M »%• W

Pagel of 1

Page 19

•

* * K •■ ■ « »

MANUAL UMANUt INhUHMAI

IUN

COLMTTED

TO

BCH1EN3E

leKtronix

Date:

07-05-90 Change Reference: M73006

Product: 2465B/2455B/2445B Operators Manual Part Number: 070-6860-00

DESCRIPTION Product Group 38

EFFECTIVE SERIAL NUMBERS: 2445B B0600000

PAGE!

Change the first and second paragraphs to:

The TEKTRONIX

2465B, 2455B,

and 2445B portable oscilloscopes have four

vertical channels with DC to 400

MHz,

250

MHz,

and 200 MHz bandwldths...

The trigger systems work automatically for most

signals.

They operate

In

various

modes,

from any

channel,

with couplings for a wide range of

signals.

The 2445B

triggers from

DC

to 300

MHz.

The 2455B and 2465B trigger

from

DC to 500 MHz.

PAGE

6-3,6-5,

and 6-6

Change the 2445B Vertical Deflection System— Channel 1 and

Channel 2, and Vertical Deflection System— Channel 3 and

Channel 4 specifications to:

-3 dB Bandwidth

2445B

+ 15°Cto+35°C DC to 200 MHz.

a

—15°C to +15°C and DC to 175 MHz.

+35°Cto+55°C

-4.7 dB Bandwidth

2445B

+15°Cto+35°C DC to 200 MHz.

a

—15°C to +15°C and DC to 175 MHz.

+35°C to +55°C

Step Response Rise Time

2445B

Page 1 of

2

<1.75ns.

Page 20

Product: 2465B/2455B/2445B Oper Date: JJZ=G5=:9Ghange

Reference:

M73QQ9

PAGE 6-7 and 6-8

Change the 2445B Triggering specifications to:

Minimum P-P Signal Amplitude for Stable Triggering from

Channel 1 or

Channel

2 Source

2445B

DC

Coupled

NOISE REJ Coupled

AC

Coupled

LF REJ

Coupled

Jitter

2445B

0.35 division from dc to 50 MHz;

increasing to 1.0 division at 200 MHz

and 1.5 divisions at 300 MHz.

<1.2 divisions from dc to

50

MHz;

increasing to 3.0 divisions at 200 MHz

and 4.5 divisions at

300

MHz.

0.35 division from 60 Hz to

50

MHz;

increasing to 1.0 division

at 200

MHz

and 1.5 divisions at

300

MHz.

Attenu-

ates signals below

60

Hz.

0.50 division from 80 kHz to

50

MHz;

increasing to 1.0 division at 200 MHz

and 1.5 divisions at 300 MHz.

<100 ps with 5 divisions of 200 MHz

at 1 ns/division.

PAGE 7-3

Change the 2445B Standard Accessories to:

2 Probes (1 OX, 1,3m) with Accessories

PAGE 7-5

Change the 2445B Standard Accessories to:

Probe Package

P6137

P6137

Page 2 of

2

Page 21

1

General Information

Page 22

Preparation

for

Use

Safety

Before connecting the oscilloscope to a power source, read entirely both this

section and the Safety Summary at the front of this manual. Be sure you have the

training required to safely connect the instrument inputs to the signals you will be

measuring. Refer to the Safety Summary for power source, grounding, and other

safety considerations pertaining to the use of the instrument.

Line

Voltage

Selection

This instrument may be damaged if operated with the LINE VOLTAGE

SELECTOR switch set for the wrong applied ac input-source voltage or if

the vsrong tine fuse is installed.

The oscilloscope operates from either a 115-V or a 230-V nominal ac power-line

with any frequency from 48 Hz to 440 Hz. Before connecting the power cord to a

power source, verify that the LINE VOLTAGE SELECTOR switch, located on the rear

panel (see Figure 1 -1), is set correctly (see Table 1-1) and that the line fuse is

correct. To convert the instrument for operation on the other line-voltage range,

move the LINE VOLTAGE SELECTOR switch to the correct nominal ac

source-voltage setting. The detachable power cord may have to be replaced to

match the particular power source.

Line Fuse

To verify the instrument power-input fuse rating, do the following steps:

1.

Press the fuse-holder cap and release it with a slight counterclockwise

rotation.

Pull the cap (with the attached fuse inside) out of the fuse holder.

2.

Verify that the fuse is of the type listed on the back of the instrument. Then

install the proper fuse and reinstall the proper fuse-holder cap. The two

types of fuses listed are not directly interchangeable; they require different

types of fuse caps. For international power cord options, a 5x20 mm fuse

holder cap is included in the accessory pouch for use with 1.6 A, 250 V,

5x20 mm (IEC 127) fuses (not supplied).

2465B/2455B/2445B Operators

1-1

Page 23

General Information

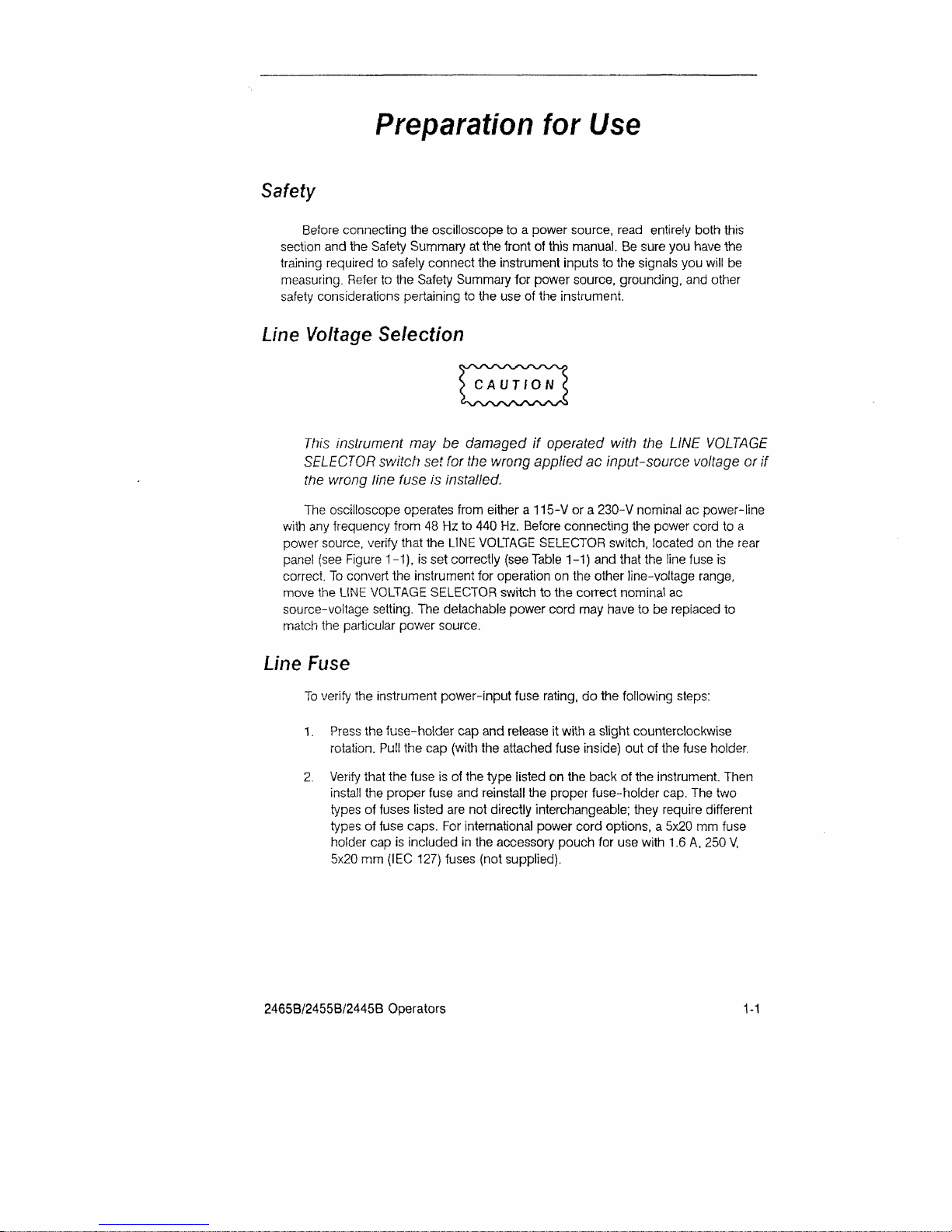

Table 1-1

Power Cord and Voltage Data

Plug

Configuration

t&

"%

"^

Option

U.S.

Std.

A1

A2

A3

A4

A5

Power Cord/

Plug Type

U.S.

120 V

EURO

220 V

UK

a

240 V

Australian

240 V

North

American

240 V

Switzerland

220 V

Line Voltage

Selector

115V

230V

230V

230V

230V

230V

Reference

Standards'

1

ANSIC73.11

NEMA

5-15-P

IEC83

UL 198.6

CEE(7), II, IV, VII

IEC83

IEC 127

BS 1363

IEC 83

IEC 127

ASC112

IEC 127

ANSI C73.20

NEMA

6-15-P

IEC 83

UL 198.6

SEV

IEC 127

a

A 6A, type C fuse is also installed inside the plug of the Option A2 power

cord.

Reference Standards Abbreviations:

ANSI—American National Standards Institute

AS—Standards Association of Australia

BS—British Standards Institution

CEE—International Commission on Rules for the Approval of Electrical Equipment

IEC—International Electrotechnical Commission

NEMA—National Electrical Manufacturer's Association

SEV—Schweiiervischer Elektrotecfmischer Verein

UL—Underwriters Laboratories Inc.

1-2 2465B/2455B/2445B Operators

Page 24

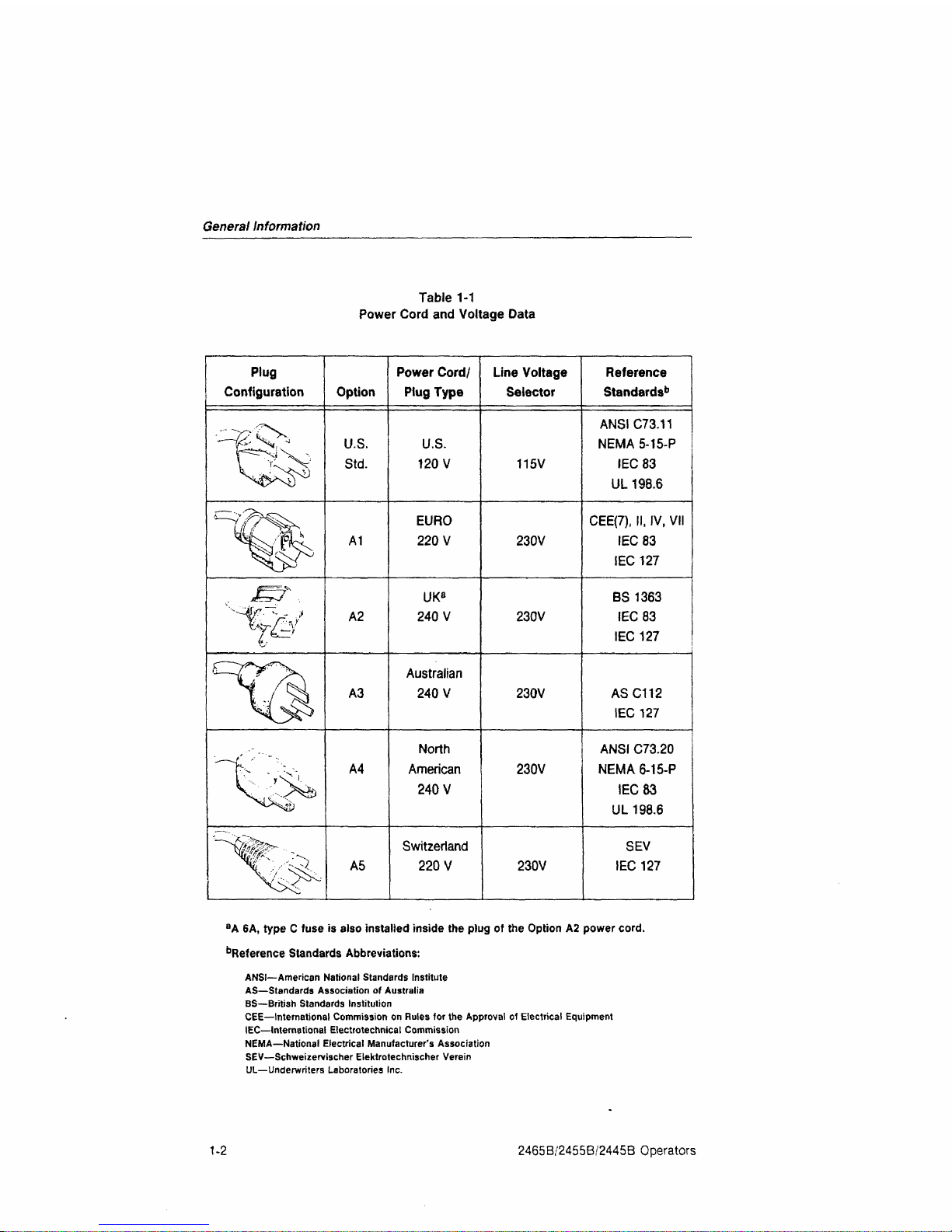

General Information

Figure 1-1. Line selector switch, line fuse, and detachable power cord.

Power

Cord

This instrument has a detachable, three-wire power cord with a three-contact

plug for connection to both the power source and protective ground. The power

cord is secured to the rear panel by a cord-set-securing clamp. The protective-

ground contact on the plug connects through the power-cord to the external metal

parts of the instrument. For electrical-shock protection, insert this plug into a

power-source outlet that has a properly grounded protective-ground contact.

Instruments are shipped with the required power cord as ordered by the

customer. Available power-cord information is presented in Table 1-1, and part

numbers are listed in "Options and Accessories" (Section 7). Contact your

Tektronix representative or iocai Tektronix Fieid Office for additional power-cord

information.

2465B/2455B/2445B Operators

1-3

Page 25

General Information

Instrument Cooling

To prevent instrument damage from internally generated heat, adequate air flow

must be maintained. Before turning on the power, verify that the spaces around the

air-intake holes on the bottom of the cabinet and the fan-exhaust holes in the rear

panel are free of any obstruction to airflow.

Start-up

The oscilloscope automatically performs a set of diagnostic tests each time the

instrument is turned on. These tests warn the user of any available indication that

the instrument may not be fully functional. The tests run for several seconds after

power is applied. If no faults are encountered, the instrument operates normally. A

failure of any of the power-up tests will be indicated by either a flashing TRIG'D

indicator on the instrument front panel or a bottom-line readout on the CRT in the

form:

TEST XX FAIL YY (where XX is the test number and YY is the failure code

of the failed test).

If a failure of any power-up test occurs, the instrument may still be usable for

some applications. To operate the instrument after a power-up test failure, press

the A/B TRIG button. Even if the instrument then functions for your particular

measurement requirement, it should be repaired by a qualified service technician at

the earliest convenience. Additional information on the power-up tests may be

found in Appendix C at the rear of this manual. Consult your service department,

your local Tektronix Service Center, or nearest Tektronix representative if

additional assistance is needed.

1-4

2465B/2455B/2445B Operators

Page 26

General Information

Repackaging

For

Shipment

If this instrument is to be shipped by commercial transportation, it should be

packaged in the original manner. The carton and packaging material in which your

instrument was shipped to you should be retained for this purpose.

If the original packaging is unfit for use or is not available, repackage the

instrument as follows:

1.

Obtain a corrugated cardboard shipping carton having inside dimensions at

least six inches greater than the instrument dimensions and having a carton

test strength of at least 275 pounds.

2.

If the instrument is to be shipped to a Tektronix Service Center for service or

repair, attach a tag to the instrument showing the following: owner of the

instrument (with address), the name of a person at your firm who can be

contacted,

complete instrument type and serial number, and a description of

the service required.

3. Wrap the instrument with polyethylene sheeting or equivalent to protect the

outside finish and prevent entry of packing materials into the instrument.

4.

Cushion the instrument on all sides by tightly packing dunnage or urethane

foam between the carton and the instrument, allowing three inches on each

side.

5. Seal the carton with shipping tape or with an industrial stapler.

6. Mark the address of the Tektronix Service Center and your return address on

the carton in one or more prominent locations.

2465B/2455B/2445B Operators

1-5

Page 27

2

Operation

Page 28

Operation

Operation

Fundamentals

Like any oscilloscope, this instrument draws a graph of voltage as a function of

time.

The VERTICAL controls, marked off by a heavy gray line, define the voltage axis

of the display. SEC/DIV, XI0 MAG, and horizontal POSITION control the time axis of

the display. The TRIGGER controls, marked off by a green box, define the signals

required to initiate sweeps across the time axis. The controls under the CRT affect the

display but not the waveform.

Parametric Measurements

The Parametric Measurement function provided in the instrument gives quick

access to the parameters of your input signal.

To obtain a parametric measurement, simply press the MEASURE button and

select the desired function from the displayed menu. The function is selected by

pressing the button in the VERTICAL MODE area that occupies the same relative

position as the desired menu selection. The measurement function will

automatically scale the input signal before making the measurement.

Parametric measurements require repetitive signals for reliable results.

Measurements on non-repetitive signals will produce unpredictable results.

Repetitive signals that have periodic bursts of signal transitions will also produce

unpredictable results.

Parametric measurements can only be performed on signals in CH 1 or CH 2.

An error message will be displayed if CH 3, CH 4, or ADD are selected for

parametric measurements.

2465B/2455B/2445B Operators

REV NOV 1988

2-1

Page 29

Operation

Getting a Display

1.

Connect a probe from the input of a Vertical channel to a signal.

2.

Select the channel using the Vertical MODE buttons. You may select any

combination of vertical channels. (If you are using the standard accessory

probes, make sure the CH 1 and CH 2 input are not set at 50 IX)

3. Press AUTO Setup to initialize vertical, horizontal, trigger, and display intensity

for a usable display. (If STEP is illuminated, first push RECALL to extinguish it.)

4.

If the resulting display isn't exactly what you want, adjust the appropriate

VOLTS/DIV, SEC/DIV, POSITION, or Trigger controls.

Characteristics of AUTO Setup

With one channel. Auto Setup centers the 0-volt level and makes the vertical

display as large as possible, within the graticule. With more than one channel, the

0-volt levels of CH 1. CH 2, CH 3. and CH 4 are set at +2. 0. -2, and -3 divisions

from center, respectively. When ADD is displayed, the 0-volt level of CH 2 is set at

-2 divisions.

AUTO sets Sec/Div within the range from 20 ns to 2 ms, to show two to five

cycles of most signals. With narrow, low repetition-rate pulses, the sweep runs faster

to stretch out the display, with the appropriate trigger slope.

AUTO Setup sets the trigger for Auto Lvl Mode, Vert Source, DC Coupling, and

Min Holdoff, with level at the midpoint between signal peaks.

The STEP/AUTO EXT SWITCH connector on the rear panel produces the same

functions as the STEP/AUTO button, in response to a switch closure or TTL-low

signal.

The following function is available for instruments with serial numbers

B049999 and below with firmware version 11 and above or for instruments with

serial numbers B050000 and above with firmware version 2 and above (see

Appendix A - EXER04 to determine firmware version). AUTO Setup can also be

activated by pressing any probe ID button if configured to perform an AUTO Setup

using the PROBE Configure menu. The operator can configure the probe ID to

perform one of four possible outcomes (IDENT, AUTO Setup. INIT@50%, or STEP).

Once configured, the instrument will maintain the selection until modified again by

the operator.

The following function is available for instruments with serial numbers

B049999 and below with firmware version 10 and below or for instruments with

serial numbers B050000 and above with firmware version 1 and below (see

Appendix A - EXER04 to determine firmware version). AUTO Setup can also be

activated by pressing any probe ID button twice in 0.5 second.

See "Save and Recall Operation" for the sequence function of Step/Auto.

2-2 2465B/2455B/2445B Operators

Page 30

Operation

Assigning Parametric Measurements to the Auto Setup Function

Any of the Parametric Measurements can be assigned to the Auto Setup

function.

When Auto Setup is activated, the assigned function is performed as

well as the Auto Setup.

To assign a function to Auto Setup:

i. Push MEASURE.

2.

If the CTT is present, select MORE from the menu. Otherwise go to

Step 3.

NOTE

To

select items from a menu, simply press the vertical mode button that

has the same position as the desired item in the menu.

3. Select CONFIGURE from the menu.

4.

Select

AUTO

from the menu.

5. Select the function to be performed with each Auto Setup by pushing

the appropriate MODE button.

Activating AUTO Setup from the Probe

The following function is available for instruments with serial numbers

B049999 and below with firmware version 11 and above or for instruments

with serial numbers B050000 and above with firmware version 2 and above

(see Appendix A - EXER04 to determine firmware version). Pressing the probe

identification button on any Tektronix, Inc. probe will shift the associated trace and

replace the associated scale factor with ID, if IDENT has been selected from the

PROBE CONFIGURE menu.

AUTO Setup, INIT@50% or STEP can also be assigned to the probe ID

function.

To assign a function to probe ID:

1.

Push MEASURE

2.

If CTT is present, select MORE from the menu. Otherwise, go to

Step 3.

2465B/2455B/2445B Operators

2-3

Page 31

Operation

NOTE

To select items from a

menu,

simply

press the vertical mode button that

has the same position

as

the

desired

item

in the menu.

3. Select CONFIGURE from the menu.

4.

Select PROBE from the menu.

5. Finally, select the function to be performed with each probe ID by

pressing the appropriate MODE button. If

AUTO

Setup function is

selected,

any measurement assigned to the AUTO Setup is also

performed.

The following function is available for instruments with serial numbers

B049999 and below with firmware version 10 and below or for instruments

with serial numbers B050000 and above with firmware version 1 and below

(see Appendix A - EXER04 to determine firmware version). Pressing the probe

identification button on any Tek probe will shift the associated trace and replace

the associated scale factor with ID. If the probe identification is pressed twice in

0.5 second, the Auto Setup function is activated. Any measurement assigned to

the Auto Setup function is also performed.

Vertical

For voltage measurements, set VOLTS/DIV

VAR

fully clockwise. For best accuracy,

set VOLTS/DIV for the largest display possible.

Input Coupling

Use 1 MH DC input mode for most applications. This mode is compatible

with the standard accessory, high-impedance probes and it displays logic levels

and dc levels of static signals. Use the pair of buttons near the CH 1 and CH 2

inputs to select input coupling. CH 3 and CH 4 inputs are fixed at 1 MH DC.

GND input mode shows where the

0-volt

level will be displayed with

DC coupling.

Use AC coupling for the special cases where you need to see small signals

on large dc voltages.

Use the 50 Q DC input mode for the best possible vertical performance with

active probes,

50-D,

signal sources, and low-impedance passive probes. A

low-impedance probe can present less than 2 pF load to the signal-source, in

parallel with 500 Cl or 5000 fi with 10X or 100X attenuation.

2-4

2465B/2455B/2445B Operators

Page 32

Operation

Input Conditioning for Video Signals

Video signals can be distorted by ac coupling or by low-frequency

interference. The available Television/Video

(TV)

enhancement adds a TV CLAMP

to the CH 2 input to eliminate such distortion.

To use the TV clamp:

1.

Apply a composite video signal to CH 2.

2.

Select CH 2 Trigger Source and set SLOPE to the displayed polarity of

ihe sync pulses.

3. Set the CH 2 input to TV CLAMP by pressing the upper

input-coupiing button for CH 2 until the readout shows "TVC". The

"back porch" of the video signal will be locked to a fixed level.

Keep the TV Clamp turned off when the trigger source is not composite video

or composite sync, to preserve normal operation of Channel 2. Leave the

rear-panel CH 2 SIGNAL OUT unloaded to avoid a minor distortion in the video

signal when TV Clamp is on.

Channel Selection

Using the Vertical MODE buttons, you can display any combination of the four

vertical channels. To manually switch between CH 1 and another channel, with

minimum button pushing, deselect CH 1 and press the button for the other

channel to turn it on and off; CH 1 is displayed when all other verticals are off.

ADD and

INVERT

Press ADD to display the algebraic sum of CH 1 and CH 2. Select INVERT to

change the sense of the CH 2 waveform or to see the difference between CH 1

and CH 2 on the ADD trace. If you use ADD, the CH 1 and CH 2 VOLTS/DIV

settings should be equal. Parametric measurements will not work if ADD

is selected.

Choosing CHOP or

ALT

With two or more channels, the display is time-shared. Chop mode displays

each channel for a short time and multiplexes during the sweep to give the

appearance of displaying all channels at once. Chop works better than Alt for

sweeps slower than 1 ms/division and for low repetition-rate signals that make the

display flicker, up to 2 jus/division.

Alt mode displays each channel for the duration of a complete sweep. Alt

gives a "cleaner" display of multiple channels than Chop does and is usually

preferred at moderate to high sweep speeds.

20 MHz BW Limit

This mode can give you a sharper trace by eliminating high-frequency

interference. Before using it, check to make sure it doesn't distort the waveform.

2465B/2455B/2445B Operators

2-5

Page 33

Operation

Horizontal

The A Sweep is the only horizontal function you need for most applications. The

A SWP indicator is on when the A-Sweep is displayed. To make sure the A-Sweep is

displayed,

press AUTO Setup and push SEC/DIV in. You can also restore the

A-Sweep display by pushing the SEC/DIV knob in and turning it counterclockwise until

the A SWP indicator lights. If both A SWP and B SWP indicators are off, push

SEC/DIV in and turn it clockwise to escape the X/Y display mode.

The X10 MAGnifier expands the center of the unmagnified waveform.

For best measurement accuracy, set SEC/DIV for the fastest sweep that will

display the interval of interest and set VAR fully clockwise.

See "Delayed Sweep Operation" for more information about B Sweep, B Trigger,

and trace separation.

Trigger Controls

For "hands-off triggering with most signals, select Auto Lvl Mode, Vert Source,

DC Coupling, and MINimum Holdoff.

Auto Lvl mode, with LEVEL in the center half of its range, sets the trigger point

near the midpoint between signal peaks. When LEVEL is set to the - or

■+

end of its

range,

this mode initiates triggering near the 10% or 90% point between signal peaks.

You can select a level anywhere in about the middle 80% of the signal amplitude.

Once set, the level doesn't change unless the signal ceases to trigger the sweep. The

sweep free-runs without a trigger

signal.

With signals below 50 Hz, AUTO LVL may

not find the correct level. If the signal is below 50 Hz but greater than 10 Hz, you can

change the minimum frequency at which Auto Level will work by using the MINFREQ

entry under the measurement CONFIGURE menu. See "Frequency Limit for Auto

Level or Parametric Measurements" for more information.

With Auto Lvl mode and Vert Source, the displayed channel or the first one of a

multichannel display supplies the trigger signal.

Auto mode maintains the trigger level setting and the sweep free-runs if the signal

doesn't meet the triggering requirements.

2-6

2465B/2455B/2445B Operators

Page 34

Operation

Use Auto for monitoring logic signals. Set the LEVEL control to the mean threshold

of the logic system, +1.4 V for TTL. The sweep then triggers on valid transitions and

free-runs to show static highs and lows.

Normal mode produces a sweep only when the trigger signal meets the Level and

Slope criteria.

Use Normal mode for infrequent events and erratic signals.

Sgl Seq mode accepts one trigger for each sweep in the display. Press the lower

Mode button to arm the trigger and illuminate the READY indicator for each sequence.

With a multi-trace display, a sequence comprises up to sixteen sweeps.

Use Sgl Seq to detect a rare event or to eliminate all but the first one of a chaotic

burst of pulses. Set the trigger for the signal of interest in Normal mode. Then press

the lower Mode button to select Sgl Seq and illuminate the READY indicator. To

detect the occurrence of a rare event, display a single trace and arm Sgl Seq with the

trigger set for the event. Periodically check to see if READY is on. If a burst of trigger

events occurs, the sweep runs once for each trace displayed and READY

extinguishes.

Trigger Source

Choose a single trigger source to correctly display the timing relationships

among multiple channels. Choose the channel with the lowest-frequency signal

to avoid ambiguous displays.

With Vert trigger source. Auto Lvl trigger mode or Chop vertical mode

automatically selects a single trigger source, the first one of the displayed

channels.

Use a composite A-Trigger source to compare asynchronous signals. To

generate a composite trigger, select Vert trigger source, a trigger mode other

than Auto Lvl, and Alt vertical mode.

Trigger Coupling

For noisy signals or signals with strongly interfering components, Noise

Reject, HF Reject, and LF Reject coupling give added selectivity. AC coupling

continues triggering when the dc level of the signal changes.

2465B/2455B/2445B Operators

2-7

Page 35

Operation

Trigger Slope

Press SLOPE to select the rising ( + ) or falling (-) edge of the signal to

trigger the sweep.

Trigger Level

INIT@50% sets the trigger level near the midpoint between signal peaks, in

any mode. Some signals below 50 Hz may not produce the correct level setting.

LEVEL gives you complete freedom to choose the most appropriate

threshold voltage on a signal to initiate sweeps, in case neither the Auto Lvl

mode nor INIT@50% provides a suitable threshold.

Trigger Holdoff

With irregular signals such as bursts, the Trigger HOLDOFF setting can

improve display stability. Also, if the signal has a fixed pattern of variation from

cycle to cycle, some modes of the signal may be omitted from the display.

Changing the Holdoff setting can force the instrument to display all the modes

of the signal. Normally, HOLDOFF should be set at MIN. If you must use

HOLDOFF to achieve a stable display, parametric measurements will not

function correctly.

2-8

2465B/2455B/2445B Operators

Page 36

Operation

Video Triggering

The available Television/Video

(TV)

enhancement adds TV LINES. FLD1, and FLD2

Coupling to the A-Trigger. See Appendix A to change the line-number format and the

sync polarity automatically selected when you select TV triggering.

To trigger at the video line rate:

1.

Select a composite video signal as the trigger source.

2.

Select LINES coupling.

3. Set SLOPE to the polarity of the sync.

To trigger at a specific video line:

1.

Select a composite video signal as the trigger source.

2.

Select

FLD1.

FLD2, or ALT coupling.

3. Set SLOPE to the polarity of the sync.

4.

Turn FLD LINE # (A) to the desired line number.

When you increment or decrement the line number outside the range of the

selected

field,

the other field is automatically selected.

With ALT field coupling, the line number is referred to the beginning of both fields.

The trigger level can be adjusted to vary the actual sync trigger point. This can be

useful when triggering on noisy video signals. INIT@50% resets the trigger point to

mid-range.

To compare two video signals with the same format that are not perfectly

synchronized, such as from a camera and a VCR or from the input and output of a time

base corrector:

1.

Display the signals on CH 1 and CH 2, with Alt Vertical mode.

2.

Select VERT Trigger Source, and ALT field trigger coupling.

3. The CH 1 display triggers on field 1 and the CH 2 display triggers on field 2.

TV Lines trigger coupling with multiple vertical channels, Alt Vertical mode, and Vert

Trigger source produce unpredictable results.

A "A" symbol with the line number display shows when the A/FLD LINE # control

can change the line number. If AV, At. or 1/At is on, press a trigger Coupling button to

redirect the control to line number selection. Press AV or At to redirect the control to

cursor or delay adjustment. The first push redirects the control. A second push will

change the A function or trigger coupling.

2465B/2455B/2445B Operators

2-9

Page 37

Operation

If you magnify the vertical display beyond the graticule, the trigger may be

degraded.

To avoid trigger overload, use one channel for display and another channel

with an appropriate video signal as the trigger source. A composite sync signal can be

used for the trigger source as well as composite video.

Readout

To aid waveform interpretation, the readout shows scale factors, delta

measurements, delay times, trigger settings, and other information. To display all readout

information, set the READOUT INTENSITY control clockwise from OFF (SCALE

FACTORS ON). See Figure 2-1.

Trigger Readout

The trigger readout shows which trigger (A or B) is affected by the controls

(Mode, Source, Coupling, Slope, Level, and INIT@50%), which channel (1-4) is

supplying the trigger signal, and the voltage at which triggering takes place, with

the following settings:

Trigger Coupling DC or Noise Reject

Trigger Source Any Single Channel

Vertical Input DC or GND

VOLTS/DIV VAR Fully Clockwise.

If the trigger comes from the word recognizer, which is available with the CTT,

the readout shows the defined word.

For instruments with serial numbers B049999 and below with firmware

version 11 and above or for instruments with serial numbers B050000 and

above with firmware version 2 and above (see Appendix A - EXER04 to

determine firmware version), then all AC trigger couplings (HF Reject, LF

Reject, and AC or AC input coupling provide an indication of the trigger level

setting.

The readout in these modes indicates a reference level (not absolute

value) XXXX and is followed by a "V?" to indicate the relative nature of the

readout.

For instruments with serial numbers B049999 and below with firmware

version 10 and below or for instruments with serial numbers B050000 and

above with firmware version 1 and below (see Appendix A - EXER04 to

determine firmware version), the trigger readout works only when trigger

coupling is DC or Noise Reject, when the trigger source is one, dc-coupled,

vertical channel with VOLTS/DIV VAR in its calibrated position.

Readout Intensity

To display nothing but measurements, set the READOUT INTENSITY control

counterclockwise from OFF (SCALE FACTORS OFF). Rotate the control toward

OFF to decrease readout brightness. When the sweep is faster than

50 jis/division, random 2-jis segments of the waveform may be missing. Set the

control near the center of the word "OFF" to eliminate this interference between

the waveform and the readout.

2-10

2465B/2455B/2445B Operators

Page 38

Operation

Scale

Factors

CH 1 and CH 2 scale factors include "mV" or "V" units indicators. A tilde (~)

over the V indicates AC input coupling. A ground symbol in front of the number

indicates Gnd input coupling. A greater-than symbol (>) indicates the

VOLTS/DIV VAR control is not at its clockwise, calibrated position. A plus sign

{ + )

shows that Add, the algebraic sum of CH 1 and CH 2, is displayed. A down

arrow shows that CH 2 is inverted.

TRIGGER TRIGGER

SOURCE LEVEL

[i,

2.

3 OR

4) INDICATOR

TRIGGER

CURRENTLY

UNDER CONTROL

(A

or B)

INVERT

INDICATOR

W

SWEEP

DELAY TIKE

DELTA VOLTAGE

DELTA TIME

i/DELTA

TIME

PARAMETRIC

MEASUREMENTS

{MENUS

AND

HELP

USE

ALL

FOUR

READOUT LINES)

6860-01

Figure

2-1.

Readout display locations.

CH 3 and CH 4 scale factors assume volts/division units.

The A-Sweep and

B-Sweep

time-scale readouts are always calibrated,

combining the effects of SEC/'DIV, VAR, and X10 MAG. If SEC/DIV VAR is not

at its clockwise setting, the time scale factor includes a decimal point.

2465B/2455B/2445B Operators

2-11

Page 39

Operation

Holdoff Indicator

The holdoff indicator, "HO," is displayed when the HOLDOFF control is not

at minimum.

Parametric Measurements

Parametric measurements (rise time, fall time, frequency, etc.) are displayed

on the second and third lines of the readout. Help and menu information can

use all four lines of the readout.

Probe Effects

Probe attenuation effects are included in scale factors, trigger levels, and

delta volts readouts, if you use the standard accessory probes or other

compatible probes. Pressing the identification button on Tektronix probes

replaces the scale factor for the channel with "ID" and shifts the trace.

2-12

2465B/2455B/2445B Operators

Page 40

Operation

Measurements with

Cursors

The controls in the gray box (AV, At, TRACK/INDEP, A REF OR DLY POS, and A)

operate cursors and sweep delays. With the cursors, you can measure voltage, time,

frequency, ratios, and phase. We often refer to the A REF OR DLY POS control as

"A REF" for convenience.

Cursors are more accurate and easier to use than the graticule. They eliminate the

inconvenience and errors of counting and interpolating graticule markings and they

avoid CRT linearity errors.

For best AV accuracy, display the signal on either CH 1 or CH 2 with VOLTS/DIV

set for three to eight divisions of waveform amplitude. For best At and 1/At accuracy,

use the fastest sweep that will include the interval of interest.

Measure

Voltage

1.

Turn on the AV cursors and readout with the AV button.

2.

Align the cursors with points of interest, such as waveform peaks, using

the A REF and A knobs.

3. The readout shows the voltage between the points marked by the

cursors.

4.

Press AV to turn off the AV cursors and readout.

Measure

Time,

with

A-Sweep

or

B-Sweep

Alone (SEC/DIV

in)

1.

Turn on the At cursors and readout with the At button.

2.

Align the cursors with points of interest, such as waveform zero-

crossings, using the A REF and A knobs.

3. The readout shows the time between the points marked by the cursors.

4.

Press At to turn off the At cursors and readout.

2465B/2455B/2445B Operators

2-13

Page 41

Operation

Measure Frequency with Cursors

1.

Turn on the 1/At cursors and readout by pressing the AV and At

buttons together.

2.

Align the cursors with identical points, such as zero crossings, on

adjacent cycles

of the waveform, using the A REF and A knobs.

3. The readout shows the frequency of the signal.

4.

Press AV and At together or press either A button twice to turn off the

1/At cursors and readout.

Measure

Voltage

Ratio,

Time Ratio (such

as

Duty

Factor),

or

Phase

1.

Set VOLTS/DIV or SEC/DIV so a feature of the waveform which you

consider the 100% reference covers more than five divisions of the

graticule.

2.

Turn the VOLTS/DIV VAR or SEC/DIV VAR counterclockwise from the

detent until the 100% reference feature covers exactly five divisions.

You can use one signal as a reference and compare others to it. For

phase,

set one cycle, which is the 360 degree reference, to five

divisions.

3. Press AV to measure voltage ratio, At for time ratio, or AV and At

together for phase. The VAR must be counterclockwise from the detent

position to turn on the RATIO or PHASE readout.

4.

Turn A REF and A to align the cursors with the portion of the waveform

to be compared to the reference portion. Phase is usually a two-channel

measurement between zero crossings. (Be sure zero crossings for

phase measurements are positioned at the graticule center.)

5. The readout shows the ratio or phase shift.

6. Press the same AV or At button, or

both,

to turn off the cursors and

readout.

Choosing Tracking

or

Independent Delta

Mode

Use the INDEP mode for most measurements, with each cursor

independently adjustable. Use TRACK mode, where the A REF knob moves

both cursors as a pair, to compare waveform features. The A control moves

only the A cursor.

2-14

2465B/2455B/2445B Operators

Page 42

Operation

Voltage Measurements

Automatic voltage measurements can be made through the measurement menus.

Set the oscilloscope up for automatic voltage measurement by:

1.

Pressing the MEASURE button.

2.

Selecting VOLTS from the menu by pressing button number 2.

The +

peak,

-peak, average, and peak-to-peak volts are measured and displayed

in the readout.

If the voltage measured has an extremely small peak-to-peak value, only the

average volts will be displayed.

If the input signal is AC coupled, only the peak-to-peak value will be displayed.

The voltage measurement is sensitive to input frequency. Signal frequencies above

1 MHz will have measurement errors greater than 5%.

For accurate voltage measurements using VOLTS, it is important that a DC

balance has been done at a temperature within 5°C of the operating environment

temperature. See "Auto DC Balance Routine" in the "Checks and Adjustments"

section for more information.

Display

Operation

Set both INTENSITY and READOUT INTENSITY controls for comfortable viewing,

but no brighter than you need. Use high intensity settings to observe low repetitionrate signals, narrow pulses in long time intervals, or occasional variations in

fast signals.

2465B/2455B/2445B Operators

2-15

Page 43

Operation

Signal

Connections

A probe is usually the most convenient way to connect an input signal to the

instrument. Shielded to prevent pickup of electromagnetic interference, the standard

10X probes supplied with the instrument present a high impedance to a circuit under

test. While the 10

U9,

and 11 pF of the probe are a negligible load on most circuits,

very fast circuits or very high impedance circuits may be seriously affected.

Waveform Fidelity

and

Probe Grounds

A probe ground must be used for accurate measurements and observations.

Use the shortest ground connection possible if you want good waveform

fidelity.

The standard-accessory probe is a compensated 10X voltage divider. It

appears resistive at low frequencies and capacitive for high-frequency signal

components. The probe input capacitance can interact with the inductance of

either a long signal lead or a long ground lead to form a series-resonant circuit.

This circuit can affect system bandwidth and can ring if driven by a fast step.

Always keep both the ground lead and the probe signal-input connections as

short as possible to maintain the best waveform fidelity.

In some cases, a separate ground from the unit under test to the ground

receptacle on the oscilloscope front panel can reduce interference from lowfrequency hum and noise. For rough checks of larger signals, such as

5-volt

logic, a ground lead separate from the probe or even the safety ground

connection which is shared with the unit under test may work for a signal

ground.

Fast signal transitions will be highly distorted and extraneous noise will

be induced without the probe ground connection.

Probe Compensation

Misadjustment of probe compensation is a common source of measurement

error. Due to variations in oscilloscope input characteristics, probe

compensation should be checked whenever the probe is moved from one

oscilloscope to another or between channels of a multichannel oscilloscope.

See the procedure in the "Checks and Adjustments" section of the manual.

2-16

2465B/2455B/2445B Operators

Page 44

Operation

Probe Handling

Both the probe and the probe accessories should be handled carefully to

prevent damage. Striking a hard surface can damage both the probe body and

the probe tip. Exercise care to prevent the cable from being crushed, kinked, or

excessively strained.

Coaxial Cables

To maintain good waveform fidelity and accuracy, only high-quality, low-loss

coaxial cables should be used. The instrument is optimized for 50 0 sources,

driving the 50

9.

dc input through 50 U cable. If you use another signal source

impedance, such as 75 ft, use the appropriate coaxial cable and an external

terminator to match, with the input set at 1 MQ. Some high frequency response

will be lost with external termination.

Magnify

Waveform

Details

with

Delayed-Sweep

1.

Display a waveform with the A Sweep, then pull SEC/DIV out to activate B

Sweep and light both the A SWP and B SWP indicators (INTEN mode).

2.

If a B-Trigger Mode indicator is on, select RUN AFT DLY. (If an A-Trigger

Mode indicator is on, the B Trigger has been set previously to RUN AFT DLY.)

3. Set A REF OR DLY POS to place the small intensified zone at a point of

interest. (This zone may be more apparent with a lower Intensity setting.) If the

A Sweep terminates just after the intensified zone, you can move the

HOLDOFF control and set it at MIN. (Two intensified zones appear if you have

selected At or 1/At. See " Delta-Delay-Time.")

4.

Turn SEC/DIV clockwise, with the knob pulled out, to expand the point of

interest on the B Sweep, while observing its relationship to everything else on

the A Sweep (ALT mode). Use TRACE SEP to separate the A-Sweep and

B-Sweep traces.

5. If you want to simplify the display and obtain the best possible view of the

magnified details, push the SEC/DIV knob in to display only the B Sweep. If

you want the brightest trace possible, set HOLDOFF to B ENDS A, which

makes the sweep repetition rate as high as possible.

6. Select AV, At, or 1/At when the SEC/DIV knob is pushed in to measure

waveform details with cursors. The A REF and A controls have no effect on

sweep delay while cursors are displayed.

2465B/2455B/2445B Operators

2-17

Page 45

Operation

B-Trigger

Operation

Use the B Trigger to eliminate jitter in B-Sweep displays. With the available

Counter/Timer/Trigger

(CTT),

the B Trigger locks a delay-time or delta-delay-time

measurement to the signal, so any variations are tracked automatically. However,

without the

CTT,

the B Trigger obscures delay or delta-delay measurements and the

readout includes a question mark.

Distinguishing RUN

AFT

DL Y

and

TRIG

AFT

DL Y

With RUN AFT DLY mode, the A REF OR DLY POS and ^ controls adjust

the delay-time or delta-delay-time. The intensified zones on the A-Sweep trace

move continuously as the controls are adjusted. If the B-Trigger mode is TRIG

AFT DLY and a signal triggers the B Sweep, the delay times and intensified

zones jump to successive B-Trigger points as delay time is adjusted. With TRIG

AFT DLY, the actual delay time is controlled by the signal, as enabled by the

A Sweep and the A REF and A settings.

Setting

the B

Trigger

1.

When the B SWP indicator is on, press A/B TRIG to illuminate a

B-Trigger Mode indicator. (If B-Trigger mode is not RUN AFT DLY, a

B-Trigger Mode indicator will be on when the B SWP indicator is on.)

2.

Select TRIG AFT DLY Mode.

3. Set SOURCE, COUPLING, SLOPE, INIT@50%, and LEVEL controls

as required.

Changing

the A

Trigger while B Trigger is

Active

1.

Press and hold A/B TRIG while adjusting SOURCE, COUPLING,

SLOPE,

INIT@50%, and LEVEL controls for the A Trigger.

2.

Alternatively, choose RUN AFT DLY B-Trigger mode and momentarily

press A/B TRIG, then adjust A Trigger. With RUN AFT DLY B-Trigger

mode or SGL SEQ A-Trigger mode (or an active

CTT function

that uses

the B Trigger), the trigger controls alternate between A Trigger and

B Trigger each time A/B TRIG is momentarily pressed.

2-18

2465B/2455B/2445B Operators

Page 46

Operation

Delta-Delay- Time

Use the delayed (B) sweep to magnify both ends of a time interval for the best

measurement accuracy available. Appendix D gives relative accuracies of the various

time-measurement techniques.

Measure

Time

or

Frequency with Delta-Delay-Time

1.

Display the time interval or signal period with the A Sweep running as

fast as possible, unmagnified, up to one speed slower than the fastest

SEC/DIV setting. If the interval is a propagation delay or other twosignal measurement, display the signals on CH 1 and CH 2 and trigger

A Sweep on the earlier of the two.

2.

Pull SEC/DIV out to activate B Sweep and light the A SWP and B SWP

indicators (INTEN mode). (If you inadvertently chose the fastest

A-Sweep speed, the CH2 Delay Match function will be active. See the

"Operator Checks and Adjustments" section.)

3. If a B-Trigger Mode indicator is on, select RUN AFT DLY. (If an

A-Trigger Mode indicator is on, the B-Trigger has been set previously to

RUN AFT DLY.)

4.

Select At or 1/At while the SEC/DIV knob is out.

5. Adjust A REF OR DLY POS and A to place the pair of intensified zones

at the beginning and end of the interval of interest. If the A Sweep

terminates just after the intensified zones, you can move the HOLDOFF

control and set it at MIN.

6. Turn SEC/DIV clockwise with the knob pulled out to magnify the ends

of the interval on the B Sweep while observing the entire interval on the

A Sweep (ALT mode). Use TRACE SEP to separate the A-Sweep and

B-Sweep traces as desired.

7. Set A REF and A to superimpose the magnified displays of the

beginning and end of the interval. The readout shows the interval.

Without the

CTT,

make delta-delay-time measurements only in the RUN AFT

DLY trigger mode, where the B Sweep runs immediately after the set delays. If

the B Sweep is triggered (TRIG AFT DLY), it waits for a trigger after the set

delay, so the actual delay time may differ from the delay or At readout by as

much as twice the signal period.

2465B/2455B/2445B Operators

2-19

Page 47

Operation

Delta-Delay-Time Measurement Characteristics

A delta-delay-time measurement is valid between a pair of points

superimposed on the pair of B Sweeps, regardless of display positions, Trace

Sep setting, and CRT-distortion errors. In other words, the only points that can

be superimposed are those points that are separated by the delta-time value.

(Good accuracy for short intervals does depend on correct CH 2 DLY

adjustment. See "Operator Checks and Adjustments" section.)

The main sweep trigger event begins the interval of interest for many

measurements. The delta-delay-time measurement can include the A-Sweep

trigger event with A SEC/DIV set faster than 50

us.

If an interval begins less

than 0.05 division from the beginning of A Sweep, the readout shows a

question mark. Move A REF clockwise and change the A-Trigger controls as

required to eliminate the question mark and still see a suitable waveform feature

for the beginning of the interval.

Single-Delay-Time

Measurements

For intervals longer than 10

MS

or for low repetition rate signals that make the

display flicker, you may prefer to use the B Sweep without At. Without At, the display

repetition rate is higher and the Dly readout shows the time from the start of A Sweep

to the start of B Sweep. Compared to delta-delay-time measurements, some accuracy

will be lost, unless you can take the difference between one delay time and another.

1.

Display the time interval with the A Sweep running as fast as possible,

unmagnified. If the interval is a propagation delay or other two-signal

measurement, apply the signals to CH 1 and CH 2. For maximum display

repetition rate, display only the channel with the end of the interval. Trigger

the A Sweep at the beginning of the interval. Turn off At or 1/At.

2.

Pull SEC/DIV out to activate B Sweep and light both the A SWP and B SWP

indicators (INTEN mode).

3. If a B-Trigger Mode indicator is on, select RUN AFT DLY. (If an A-Trigger

Mode indicator is on, the B-Trigger has been set previously to RUN AFT DLY.)

4.

Set A REF OR DLY POS to place the intensified zone at the end of the

interval.

5. Turn SEC/DIV clockwise with the knob pulled out to magnify the end of the

interval on the B Sweep while observing its relationship to the beginning of the

interval on the A Sweep (ALT mode). Use TRACE SEP to separate the

A-Sweep and B-Sweep traces.

6. Set A REF OR DLY POS to align the end of the interval with the left end of the

B Sweep. The DLY reading is the length of the interval.

7. If you want to simplify the display and obtain the best possible view of the end

of the interval, push the SEC/DIV knob in when A and B SEC/DIV settings are

unequal to display only the B Sweep.

2-20 2465B/2455B/2445B Operators

Page 48

Operation

Time

Interval

Measurement

The Parametric Measurement feature automatically makes time interval

measurements between any two selected points. To make a time interval

measurement:

1.

Push the MEASURE button.

2.

Select TIME from the displayed menu by pushing button 6 in the Vertical

mode area.

Before making the first measurement using the Time Function, configure the

measurement by:

1.

Pushing the MEASURE button.

2.

If the Crroption is present, select MORE from the menu. Then, select

CONFIGURE from the displayed menu. Otherwise, select CONFIGURE from

the menu.

3. Select TIME from the menu

4.

Using the A REF OR DLY POS and the A controls select the channel, slope.

and level of the start and stop events that define the time interval.

The A REF OR DLY POS control moves the underlining cursor among the various

items.

When an item is underlined, turning the A control will change its value.

Pressing any one of the VERT mode buttons will exit from this menu, leaving the

time-measurement configuration you have defined.

Pressing MEASURE with a measurement menu displayed will display additional

help messages, if available.

To make-a measurement with these configuration values, press MEASURE, then

select TIME from the menu. The configuration values will remain the same until

changed using the above procedure.

2465B/2455B/2445B Operators

2-21

Page 49

Operation

Precision Timing

The available Counter/Timer/Trigger

(CTT)

directly and precisely measures any

interval defined by the delayed (B) Sweep and the

B-Trigger.

The

CTT also

reduces

the effort required for repetitive measurements or measurements on changing signals.

Direct

and

Indirect Measurements

As the counter completes each

direct

measurement, the last character of the

units symbol blinks. If the readout includes the word "SET," it indicates an

indirect

measurement of delay-time, including delta-delay-time or

1/delta-delay-

time.

Indirect measurements are inferred from the A Sweep and control

settings.

Indirect delay-time measurements are displayed when any Count. Delay-by-

Events, or Logic-Trigger function of the C7Tis active, except B Sweep

triggered by the Word Recognizer. Indirect measurements are also displayed for

a few seconds when A REF or A are adjusted. Moving any control that affects

direct measurements produces an indirect reading until a new, direct

measurement is complete.

Direct, counted measurements may be different from indirect {"SET-')

measurements for any of the following reasons:

1.

Direct measurements are more accurate and show more digits of

resolution;

2.

When B Sweep is triggered, both the waveform display and the direct

measurement respond to the signal. Indirect measurements respond

only to control settings, regardless of the signal, and they include a

question mark when B Sweep is triggered;

3. Both direct and indirect measurements in RUN AFT DLY Mode suffer

from offset errors. Direct delay measurements, without At or 1/At, are

accurately calibrated in TRIG AFT DLY Mode, from the A-Trigger event

to the

B-Trigger

event.

Condition Messages

One of the following messages, indicating the described condition, may

appear instead of a measurement:

AVERAGING The selected resolution requires more sweeps.