Page 1

tek.com/keithley

Models 2450-EC, 2460-EC, and 2461-EC

Potentiostats and Galvanostats

User’s Manual

077110403 / March 2020

*P077110403*

077110403

Page 2

Model 2450-EC, 2460-EC, and 2461-EC

Potentiostats and Galvanostats User's

Manual

Page 3

© 2020, Keithley Instruments, LLC

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, LLC, is strictly prohibited.

These are the original instructions in English.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, LLC. Other brand names are trademarks or registered trademarks of their respective

holders.

The Lua 5.0 software and associated documentation files are copyright © 1994 - 2015, Lua.org,

PUC-Rio. You can access terms of license for the Lua software and associated documentation at

the Lua licensing site (https://www.lua.org/license.html).

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: 077110403 / March 2020

Page 4

Safety precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 5

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purchased from other

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2017.

Page 6

Introduction .............................................................................................................. 1-1

Table of contents

Introduction .......................................................................................................................... 1-1

Getting started ...................................................................................................................... 1-2

Power the instrument on or off .................................................................................................. 1-3

Select the high-impedance, output-off state .............................................................................. 1-4

Copy a script to the instrument .................................................................................................. 1-5

Cable assembly details ........................................................................................................ 1-7

Connections and usage ....................................................................................................... 1-7

Make the SMU connections ...................................................................................................... 1-8

Make the device connections .................................................................................................... 1-9

Attach the alligator clips .......................................................................................................... 1-10

Prepare the analyte and assemble the test cell....................................................................... 1-10

Connect to the DUT ................................................................................................................ 1-10

Home and Menu screen overview ........................................................................................... 1-11

Cyclic voltammetry ................................................................................................ .. 2-1

Cyclic voltammetry ............................................................................................................... 2-1

Test application parameters ...................................................................................................... 2-2

Run the cyclic voltammetry test application............................................................................... 2-3

Review the menu controls ......................................................................................................... 2-4

Define the potential scan parameters ........................................................................................ 2-5

Define the scan settings ............................................................................................................ 2-7

Modify the measure settings ..................................................................................................... 2-8

Save or load the test parameter data ...................................................................................... 2-11

Run the test and view the graph .............................................................................................. 2-13

Acquire the open-circuit potential (Eoc) .................................................................................. 2-14

Save the test data to the flash drive ........................................................................................ 2-15

View the results saved to the flash drive ................................................................................. 2-15

View the test reading table ...................................................................................................... 2-16

View the event log ................................................................................................................... 2-16

End the test application ........................................................................................................... 2-17

Cyclic voltammetry theory ....................................................................................................... 2-17

Open-circuit potential .............................................................................................. 3-1

Open-circuit potential ........................................................................................................... 3-1

Test application parameters ...................................................................................................... 3-2

Run the open-circuit potential test application ........................................................................... 3-2

Review the menu controls ......................................................................................................... 3-4

Adjust the measure settings ...................................................................................................... 3-4

Save or load the test parameter data ........................................................................................ 3-6

Run the test and view the graph ................................................................................................ 3-8

Save the test data to the flash drive .......................................................................................... 3-9

View the results saved to the flash drive ................................................................................... 3-9

View the reading table or measurement statistics ................................................................... 3-10

View the event log ................................................................................................................... 3-10

End the test application ........................................................................................................... 3-11

Potential pulse and square wave ............................................................................ 4-1

Potential Pulse and Square Wave ....................................................................................... 4-1

Test application parameters ...................................................................................................... 4-2

Page 7

Table of contents 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

Run the potential pulse and square wave test application ........................................................ 4-3

Review the menu controls ......................................................................................................... 4-4

Configure the pulse settings ...................................................................................................... 4-5

Adjust the end conditions .......................................................................................................... 4-8

Save or load the test parameter data ...................................................................................... 4-10

Run the test and view the graph .............................................................................................. 4-11

Save the test data to the flash drive ........................................................................................ 4-12

View the results saved to the flash drive ................................................................................. 4-13

View the reading table or measurement statistics ................................................................... 4-13

View the event log ................................................................................................................... 4-14

End the test application ........................................................................................................... 4-14

Current pulse and square wave .............................................................................. 5-1

Current pulse and square wave ........................................................................................... 5-1

Test application parameters ...................................................................................................... 5-2

Run the current pulse and square wave test application ........................................................... 5-3

Review the menu controls ......................................................................................................... 5-4

Configure the pulse settings ...................................................................................................... 5-5

Adjust the end conditions .......................................................................................................... 5-8

Save or load the test parameter data ...................................................................................... 5-10

Run the test and view the graph .............................................................................................. 5-11

Save the test data to the flash drive ........................................................................................ 5-12

View the results saved to the flash drive ................................................................................. 5-13

View the reading table or measurement statistics ................................................................... 5-13

View the event log ................................................................................................................... 5-14

End the test application ........................................................................................................... 5-14

Chronoamperometry ................................................................................................ 6-1

Chronoamperometry ............................................................................................................ 6-1

Test application parameters ...................................................................................................... 6-2

Run the chronoamperometry test application ............................................................................ 6-3

Review the menu controls ......................................................................................................... 6-4

Configure the step and measure settings .................................................................................. 6-4

Save or load the test parameter data ........................................................................................ 6-8

Run the test and view the graph ................................................................................................ 6-9

Save the test data to the flash drive ........................................................................................ 6-10

View the results saved to the flash drive ................................................................................. 6-11

View the reading table or measurement statistics ................................................................... 6-11

View the event log ................................................................................................................... 6-12

End the test application ........................................................................................................... 6-12

Chronopotentiometry............................................................................................... 7-1

Chronopotentiometry ............................................................................................................ 7-1

Test application parameters ...................................................................................................... 7-2

Run the chronopotentiometry test application ........................................................................... 7-3

Review the menu controls ......................................................................................................... 7-4

Configure the step and measure settings .................................................................................. 7-4

Save or load the test parameter data ........................................................................................ 7-8

Run the test and view the graph ................................................................................................ 7-9

Save the test data to the flash drive ........................................................................................ 7-10

View the results saved to the flash drive ................................................................................. 7-11

View the reading table or measurement statistics ................................................................... 7-11

View the event log ................................................................................................................... 7-12

End the test application ........................................................................................................... 7-12

Page 8

In this section:

Introduction .............................................................................. 1-1

Getting started .......................................................................... 1-2

Cable assembly details ............................................................ 1-7

Connections and usage ........................................................... 1-7

Introduction

Section 1

Introduction

The Keithley Instruments Models 2450-EC, 2460-EC, and 2461-EC Potentiostat/Galvanostat systems

are alternatives to traditional electrochemistry potentiostats and galvanostats. Your instrument

features a full-color, high-resolution touchscreen, which lets you configure tests and immediately view

results.

The following electrochemistry test applications are loaded in the memory of your instrument:

• Cyclic voltammetry: Potential is swept at a user-programmable scan rate between two to four

defined potential vertices, and the resulting current is measured at specified intervals during the

sweep.

• Open-circuit potential: Measures the cell potential difference between two electrodes with high

input impedance as a function of time.

• Potential pulse and square wave with current measure: Sources potential at programmable

peak and base levels. The resulting current at the pulse peak level is recorded.

• Current pulse and square wave with potential measure: Sources current at programmable

peak and base levels. The resulting potential at the pulse peak level is recorded.

• Chronoamperometry: Potential is stepped to a programmed value and the resulting current is

measured as a function of time.

• Chronopotentiometry: Current is stepped to a programmed value and the resulting potential is

measured as a function of time.

Page 9

Section 1: Introduction 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

1-2 077110403 / March 2020

This kit is not intended to be used with a SMU interlock enabled. To prevent electric shock

and possible damage to the test cable assembly or test setup, do not activate the Keithley

Instruments 2450, 2460, or 2461 interlock.

When the interlock is not engaged on the 2450, 2460, or 2461 the nominal output is limited to

±42 V. However, review the "Safety Precautions" section of this document to ensure

responsible operation.

Getting started

In addition to your SourceMeterTM instrument, you should have received the following items:

• One electrochemistry interface cable that connects the instrument to a 2-, 3-, or 4-terminal

electrochemical cell

• Four insulated miniature alligator clips

• One flash drive that contains the test applications and supporting documentation.

• Six electrochemistry test applications

Before you can run an electrochemistry test, you will need to configure the instrument and make basic

connections. The following topics will explain how to set up and configure your instrument.

The 2450-EC or 2460-EC instrument must have firmware version 1.5.0 or later to run the

electrochemistry test applications. The 2461-EC must have firmware version 1.6.0 or later.

Scripts with version numbers lower than 189427 are compatible with firmware versions 1.5.0 (1.6.0

for 2461) to 1.6.7. Scripts with version numbers of 189427 and higher are compatible with

firmware versions 1.5.0 (1.6.0 for 2461) to 1.6.7 and version 1.7.2 and higher. The script version

number is displayed near the top right corner of an application's Home screen.

To view the firmware version, press the MENU key, then select Info/Manage under System. The

firmware version is at the upper-left of your display. The latest firmware is available from the

Keithley Instruments website (tek.com/keithley).

Page 10

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 1: Introduction

077110403 / March 2020 1-3

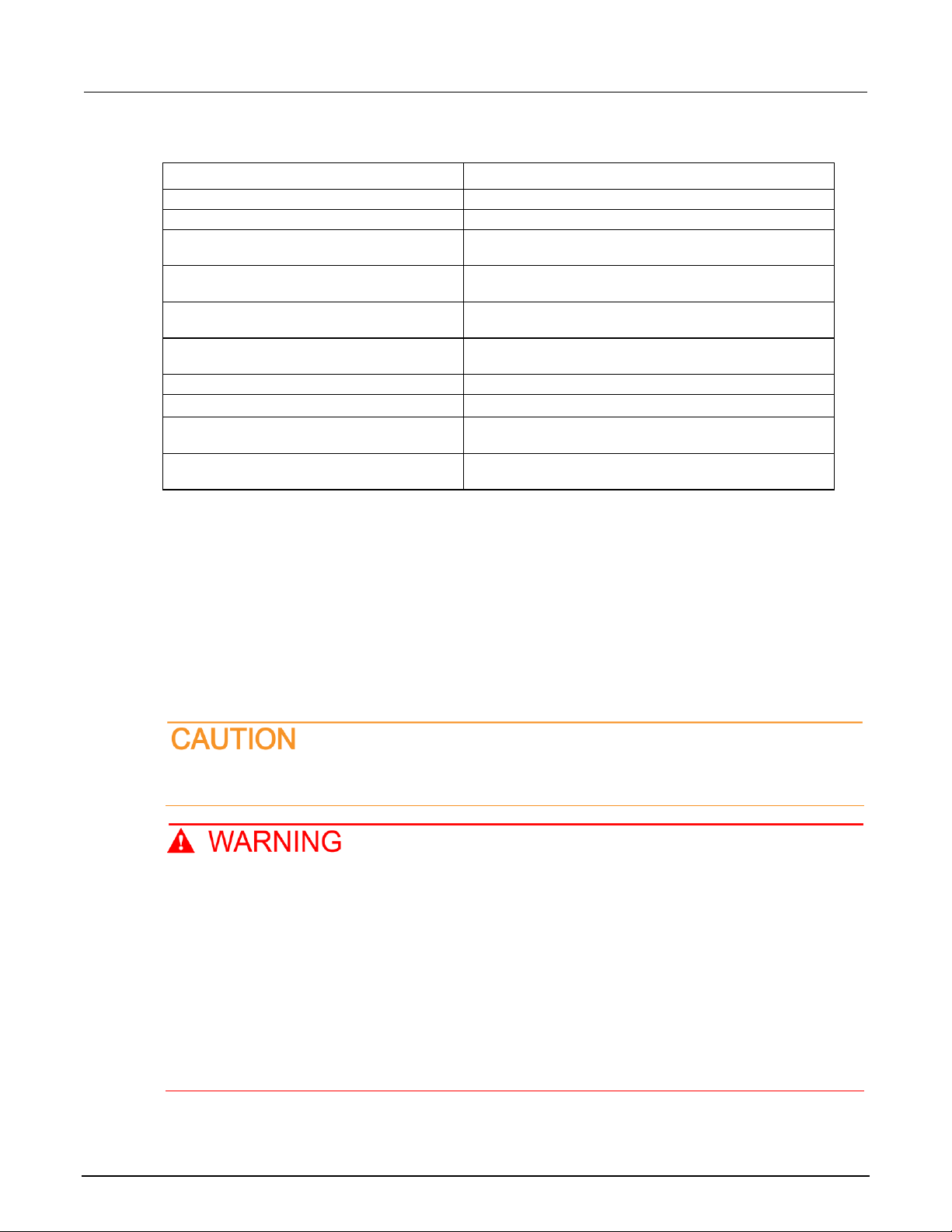

The following files are loaded onto the flash drive:

File

Description

CyclicVoltammetry.tsp

Application to perform cyclic voltammetry

OpenCircuitPotential.tsp

Application to measure the open-circuit potential

Chronoamperometry.tsp

Application to measure the current as a function of time at

a constant potential

Chronopotentiometry.tsp

Application to measure the potential as a function of time

at a constant current

CurrentPulseAndSquareWave.tsp

Application to output a current pulse or square wave while

measuring the potential

PotentialPulseAndSquareWave.tsp

Application to output a current pulse or square wave while

measuring the current

EC_Images.tsp

Potentiostat application images

EC_Framework.tsp

Potentiostat application framework

07711040x_2450-EC.pdf

Models 2450-EC, 2460-EC, and 2461-EC Potentiostats

User's Manual (this document)

07134730x_ECHEM-KIT.pdf

SMU Potentiostats and EC-UPGRADE Kit Quick Start

Guide

Power the instrument on or off

Follow the steps below to connect the 24xx-EC to line power and turn on the instrument. The

24xx-EC operates from a line voltage of 100 V to 240 V at a frequency of 50 Hz or 60 Hz. It

automatically senses line voltage and frequency. Make sure the operating voltage in your area is

compatible.

You must turn on the 24xx-EC and allow it to warm up for at least one hour to achieve rated

accuracies.

Operating the instrument on an incorrect line voltage may cause damage to the instrument,

possibly voiding the warranty.

The power cord supplied with the 2450-EC, 2460-EC, and 2461-EC contains a separate

protective earth (safety ground) wire for use with grounded outlets. When proper connections

are made, the instrument chassis is connected to power-line ground through the ground wire

in the power cord. In addition, a redundant protective earth connection is provided through a

screw on the rear panel. This terminal should be connected to a known protective earth. In

the event of a failure, not using a properly grounded protective earth and grounded outlet

may result in personal injury or death due to electric shock.

Do not replace detachable mains supply cords with inadequately rated cords. Failure to use

properly rated cords may result in personal injury or death due to electric shock.

Page 11

Section 1: Introduction 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

1-4 077110403 / March 2020

To connect the power cord:

1. Make sure that the front-panel POWER switch is in the off (O) position.

2. Connect the female end of the supplied power cord to the AC receptacle on the rear panel.

3. Connect the male end of the power cord to a grounded AC outlet.

To turn the instrument on or off:

1. Before turning the instrument on, disconnect any devices under test (DUTs) from the instrument.

2. To turn your instrument on, press the front-panel POWER switch to place it in the on (|) position.

The instrument displays a status bar as it powers on. The home screen is displayed when power

on is complete.

3. To turn your instrument off, press the front-panel POWER switch to place it in the off (O) position.

On some sensitive or easily damaged devices under test (DUTs), the instrument power-up and

power-down sequence can apply transient signals to the DUT that may affect or damage it. When

testing this type of DUT, do not make final connections to it until the instrument has completed its

power-up sequence and is in a known operating state. When testing this type of DUT, disconnect it

from the instrument before turning the instrument off.

To prevent any human contact with a live conductor, connections to the DUT must be fully insulated

and the final connections to the DUT must only use safety-rated safety jack socket connectors that do

not allow bodily contact.

Select the high-impedance, output-off state

Before making physical connections from the instrument to the test cell, set the output of the

instrument to the high-impedance, output-off state. When the high-impedance output-off state is

selected, the output relay opens, disconnecting the instrument from the load.

To set the output of your SMU to the high-impedance output-off state:

1. Press the MENU key.

2. Under Source, select Settings.

3. Select Output Off.

4. Choose High Z (high impedance).

You may receive a notification about making measurements with the output turned off. Select OK to

clear the message or select Details to see more information.

Page 12

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 1: Introduction

077110403 / March 2020 1-5

Copy a script to the instrument

Your SMU is shipped with all test applications and supporting scripts loaded into memory.

If you accidentally delete a test application or a supporting script (EC_Framework.tsp or

EC_Images.tsp), you can copy the files from the flash drive to your instrument.

If you are upgrading your SMU with the EC-UPGRADE kit, you can run the test applications from the

flash drive or copy the files from the flash drive to the instrument. If you choose to copy the

applications, you must also copy the support files (EC_Framework.tsp and EC_Images.tsp) to

your SMU.

To copy a script to the SMU:

1. Insert the USB flash drive into the USB port on the front panel.

2. Press the MENU key.

3. Under Scripts, select Manage. The Manage Scripts menu opens. Your list of Internal Scripts may

appear different than the following figure.

Figure 1: Manage Scripts menu

Page 13

Section 1: Introduction 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

1-6 077110403 / March 2020

4. In the USB Scripts list, select the test script you want to copy to the SMU. For this example, you

will copy the cyclic voltammetry test script.

Figure 2: Selecting the test script to be copied

5. Select <. The test script is transferred to the instrument, and the corresponding filename is

displayed in the Internal Scripts list.

Figure 3: Copying the file to the instrument

Page 14

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 1: Introduction

077110403 / March 2020 1-7

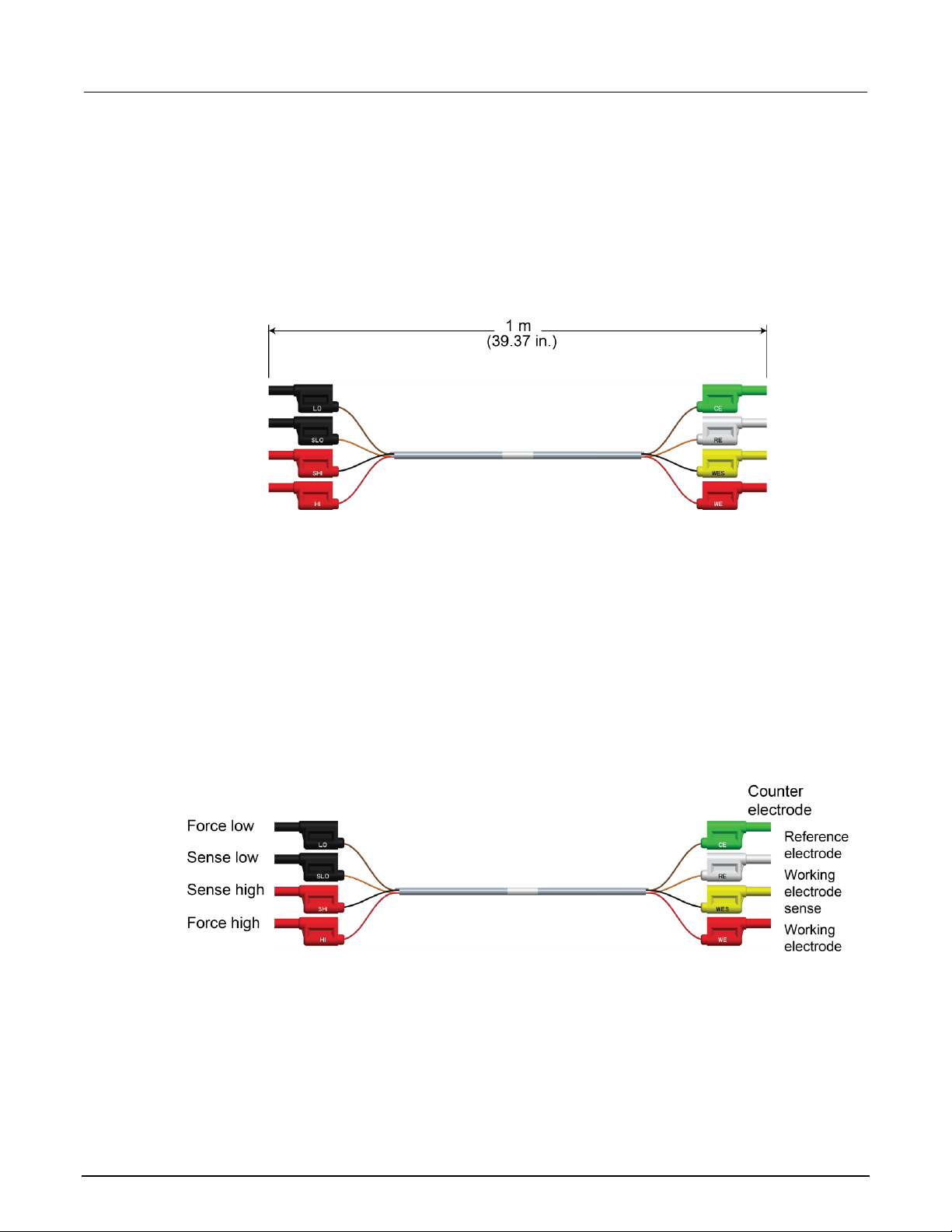

Cable assembly details

Maximum voltage (assembly):

42 V

Maximum current (assembly):

7 A on HI and LO, less than 1 mA on SHI and SLO

The cable is an electrically-shielded 1 m (39.37 in.) assembly with stackable, safety banana plugs on

both ends. This cable simplifies the connections between your SMU potentiostat or galvanostat and

an electrochemical test cell.

Figure 4: ECHEM accessory cable dimensions

Electrical characteristics

Connections and usage

The cable assembly can be used with Keithley SMUs for electrochemistry applications. Each

connector of the assembly is labeled according to its function:

Figure 5: Cable assembly connector labels and definitions

Page 15

Section 1: Introduction 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

1-8 077110403 / March 2020

Make the SMU connections

To connect to the instrument (all tests):

The front panel of your SMU has four banana-style input and output jacks. You use the supplied

cable to connect your electrochemical cell to these jacks.

The SENSE terminals are used to measure voltage at the device under test (DUT). When you use

sense leads, the voltage drop across the force leads is eliminated from a measurement. This

produces more accurate voltage sourcing and measurement at the DUT. Plug the SHI and SLO

connectors into the SENSE terminals.

The FORCE terminals are used to source or sink voltage or current to or from a DUT. Plug the HI and

LO connectors into the FORCE terminals.

Plug the four SMU-side cable connectors into the front of your SMU instrument as shown in the below

graphic.

Figure 6: Connecting SMU-side cable connectors to the SMU front-panel inputs

Page 16

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 1: Introduction

077110403 / March 2020 1-9

Make the device connections

The test cable lets you make connections to test cells with two, three, or four electrodes.

For two-electrode applications, the device-side cable connectors are used in stacked pairs. Connect

the WE and WES pair to the working electrode of your electrochemical cell, and connect the CE and

RE pair to the counter electrode of the cell.

Figure 7: Two-electrode cell testing cable connections

For three-electrode applications, the WE and WES connectors are stacked and attached to the

working electrode. The CE and RE connectors connect to the counter electrode and reference

electrode, respectively.

Figure 8: Three-electrode cell testing cable connections

For four-electrode applications, each device-side cable connector is used separately.

Figure 9: Four-electrode cell testing cable connections

Page 17

Section 1: Introduction 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

1-10 077110403 / March 2020

Attach the alligator clips

Four insulated alligator clips are supplied. You can attach these clips to the ends of the device-side

connectors, as shown in the following graphic. The clips provide a safe, secure way to connect to

your device.

Figure 10: Alligator clip attached to accessory cable connector

For small cells and electrodes, you can use commercially available banana-to-microclip connectors

by plugging them directly into the cable connectors.

Once the appropriate connectors or clips are attached, you are ready to connect to the test cell.

Prepare the analyte and assemble the test cell

Before connecting to the DUT, make sure to prepare the analyte and assemble the test cell for your

test.

Connect to the DUT

The next figure shows the connections from a SMU to a three-electrode test cell.

Figure 11: Front panel connections

Page 18

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 1: Introduction

077110403 / March 2020 1-11

Home and Menu screen overview

Before you run a test application, the default Home and Menu screens of your SourceMeter

instrument appear like those in the next graphic. Press the HOME or MENU keys on your instrument

to access these screens.

Figure 12: SMU Home and Menu screens in standard mode

When you run an electrochemistry test application, the default Home and Menu screens are replaced

by application-specific Home and Menu screens. These screens vary, depending on the potentiostat

or galvanostat test application. You can access these screens with the HOME and MENU keys. You

will see examples of these screens later in this manual.

When a test application is running, you must select End App to exit the test and return to normal

SMU operation.

For more information on using your SMU, see your Interactive SourceMeter® Instrument Reference

Manual.

Page 19

In this section:

Cyclic voltammetry ................................................................... 2-1

Section 2

Cyclic voltammetry

Cyclic voltammetry

Cyclic voltammetry, a type of potential sweep method, is the most commonly-used measurement

electrochemical technique.

In a cyclic voltammetry experiment, the working electrode potential is ramped linearly versus time.

The current that flows through the circuit is measured. The resulting I-V data provides important

electrochemical properties about the analyte under investigation.

You can make cyclic voltammetry measurements from the front panel of the instrument using the

cyclic voltammetry test application.

The cyclic voltammetry test application has adjustable parameter settings and enables real-time

graphing of a voltammogram on the display of the SMU potentiostat without using a computer. Test

parameters are input at source and measure setting screens that the user selects from an

application-specific menu. After the test executes, the data can be stored on a flash drive inserted in

the USB port on the front panel of the instrument.

The following topics describe how to set up and run the CyclicVoltammetry.tsp test application.

To ensure proper instrument operation, the potential difference between the reference electrode (RE)

and counter electrode (CE) terminals and between the working electrode (WE) and working

electrode sense (WES) terminals should not exceed 5 V.

Page 20

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-2 077110403 / March 2020

Test application parameters

You must enter test parameters that are consistent with the following values. Otherwise, you

may receive unsettled and inaccurate measurements.

The cyclic voltammetry test application parameters are listed below.

Model 2450-EC

• Potential range: – 20 V ≤ E ≤ +20 V

• Current measure ranges: 10 μA, 100 μA, 1 mA, 10 mA, 100 mA, 1 A

• Source limit (compliance): 100% of selected current range

• Scan rate: 0.1 mV per second to 3500 mV per second

• Potential step size during scanning:

▪ 100 μV (0.1 mV per second ≤ scan rate < 35 mV per second)

▪ 1 mV (35 mV per second ≤ scan rate < 350 mV per second )

▪ 10 mV (350 mV per second ≤ scan rate ≤ 3500 mV per second)

• Number of cycles: 1 to 100

• User-selectable sampling intervals:

▪ Points per test (10 to 10,000)

▪ Points per cycle (10 to 10,000)

▪ Seconds per point (0.01 to 100)

▪ Points per second (0.01 to 100)

• Maximum total number of samples: 100,000

• High-capacitance mode

Models 2460-EC and 2461-EC

• Potential range: –20 V ≤ E ≤ +20 V

• Current measure ranges: 1 mA, 10 mA, 100 mA, 1 A, 4 A, 5 A, 7 A

• Source limit (compliance): 100% of selected current range

• Scan rate: 0.1 mV per second to 3500 mV per second

• Potential step size during scanning:

▪ 100 μV (0.1 mV per second ≤ scan rate < 35 mV per second)

▪ 1 mV (35 mV per second ≤ scan rate < 350 mV per second )

▪ 10 mV (350 mV per second ≤ scan rate ≤ 3500 mV per second)

Page 21

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-3

• Number of cycles: 1 to 100

• User-selectable sampling intervals:

▪ Points per test (10 to 10000)

▪ Points per cycle (10 to 10000)

▪ Seconds per point (0.01 to 100)

▪ Points per second (0.01 to 100)

• Maximum total number of samples: 100,000

• High-capacitance mode

Run the cyclic voltammetry test application

To run the test application:

1. Press the HOME key.

2. Select the active script indicator at the top of your home screen. If there is no script activity, the

indicator displays No Script.

Figure 13: Active script indicator

3. Select the preloaded cyclic voltammetry test script (potentiostats and galvanostats only) or

connect the supplied USB drive to your SMU instrument to locate the included cyclic voltammetry

test. If you connect the USB drive, scripts on the drive are displayed with usb1/ before the script

file name.

Figure 14: Selecting the cyclic voltammetry test application

Page 22

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-4 077110403 / March 2020

4. Select CyclicVoltammetry. The test application begins to run immediately and the cyclic

End App

Select this control to immediately stop the test and return to normal SMU

operation.

Autoscale

Select this control to define the graph based upon the plotted data. This is

useful for constraining all of the data to the screen's viewing size.

Start Test

Select this control to immediately begin the test. This option becomes Stop

Test when the test runs.

Save Data

Select this control to save the test data to a .csv file on a flash drive. This

option is only visible after the test runs.

Cursor

Select this control to cycle through the available cursor placements: None,

Vertical, Horizontal, and Both.

voltammetry home screen is displayed.

Figure 15: Cyclic voltammetry home screen

The test home screen controls include:

Review the menu controls

You have different options in the Menu screen, depending on the application. The following graphic

shows the cyclic voltammetry main Menu. You will learn the function for each option later in this

section.

Figure 16: Cyclic voltammetry main Menu

Page 23

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-5

Define the potential scan parameters

You will define the potential scan parameters: Number of vertices, vertex potentials, potential

reference, scan rate, and number of cycles.

An example of a potential scan performed during a cyclic voltammetry test is shown in the next figure.

You can select up to four voltage potential vertices, which are defined as E1 (or E initial), E2, E3, and

E4 in the next figure. The slope of the lines is determined by the scan rate that you use. You will set

the scan rate later in this step of the test.

Figure 17: Potential sweep versus time of cyclic voltammetry example

For this step, you will set the Number of vertices, define their potentials, and specify the potential

reference.

To select the Number of Vertices:

1. Press the MENU key, then select Scan Settings.

2. Select Number of Vertices.

Figure 18: Scan Settings menu

Page 24

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-6 077110403 / March 2020

3. Enter the number of potential vertices. You can define two, three, or four vertices.

4. The vertex selections will change based on the number of vertices you choose. Select each

vertex to enter its potential. For this example, you will define four vertices.

Figure 19: Scan Settings menu, defining four vertices

5. Enter each vertex value in the range of ±20 V.

After you define the vertices, select the potential reference: Eref or Eoc. If you select Eref, the applied

potential is relative to the potential at the reference electrode. If you select Eoc, the applied potential

is relative to the open-circuit potential of the cell (Eoc), which is measured immediately before the

scan begins.

To select the potential reference:

1. From the Scan Settings menu, select Reference.

Figure 20: Scan Settings menu, selecting Reference

2. Select Eref or Eoc.

Page 25

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-7

Define the scan settings

You can specify the scan rate in units of millivolts per second. The scan rate, defined as the change

of the potential as a function of time (∆E/∆t), determines the rate at which the potential is linearly

scanned during the experiment. You can select a scan rate of 0.1 mV per second to 3500 mV per

second.

To select the scan rate:

1. From the scan Settings menu, select Scan Rate

Figure 21: Scan Settings menu, selecting Scan Rate

2. Enter a value.

3. Select OK.

After entering the scan rate, you will choose the number of cycles, from 1 to 100. The number of

cycles determines how many times each scan is repeated.

To select the number of scan cycles:

1. From the Scan Settings screen, select Number of Cycles.

Figure 22: Scan Settings menu, selecting the Number of Cycles

2. Enter a value.

3. Select OK.

Page 26

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-8 077110403 / March 2020

The following figure shows an example of a potential versus time graph showing three cycles of a

Sampling rate unit

Description

Sampling rate range of values

points/test

The number of points acquired during a test,

regardless of how many cycles

10 to 10,000

points/cycle

The number of points acquired in each cycle

10 to 10,000

s/point

The number of seconds per each point

0.01 to 100

points/s

The number of points taken per second

0.01 to 100

three-vertex voltage sweep.

Figure 23: Example potential versus time graph

Modify the measure settings

Specify how often to make measurements during the scan by selecting one of the sampling rate units

shown in the following table and setting a value for the sampling rate. The acquired measurements

are stored in the active buffer of the instrument, cvBuffer. The buffer can hold a maximum of

100,000 readings.

The following table describes the available interval units and accompanying range of values.

To select the sampling rate units:

1. From the Menu screen, select Measure Settings.

2. Select Sampling Rate Units.

Page 27

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-9

Figure 24: Measure Settings menu, selecting Sampling Rate Units

3. Select the units you want to use for the test. You can now set a sampling rate.

To set the sampling rate:

1. From the Measure Settings screen, select Sampling Rate.

2. Enter a value.

3. Select OK.

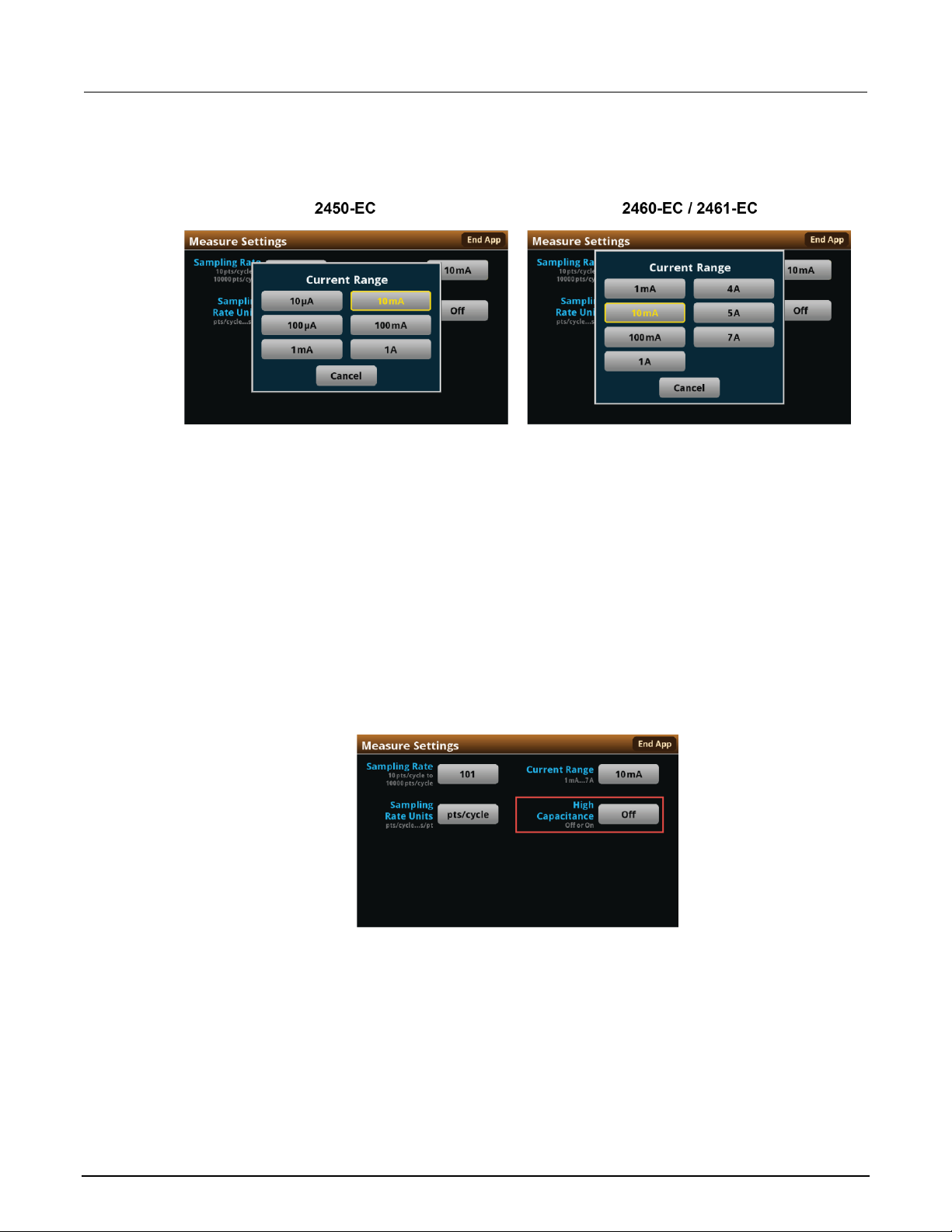

Now you will select the current range to measure the current from the scan. Choose the range based

upon the largest current magnitude you expect during the test.

To select the current measurement range:

1. From the Measure Settings screen, select Current Range.

Figure 25: Measure Settings menu, selecting Current Range

When the test runs, your potentiostat will limit the magnitude of the maximum current that can flow in

the test circuit to 100 percent of the selected current range. This could affect your experiment results.

If your expected current is near the full scale of a range, select the next highest current range to

minimize the influence of your potentiostat on the test.

Page 28

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-10 077110403 / March 2020

2. Choose a value. Note that the choices are different depending on your potentiostat model.

Figure 26: Selecting the current range

Although rare, you may encounter overshoot, ringing, or other instability on the output of your SMU

potentiostat depending the electrical impedance of your chemical cell. This is particularly an issue

when the impedance is capacitive and you are forcing voltage and measuring relatively low currents,

as with the cyclic voltammetry test.

In these cases, you can use the high-capacitance mode to minimize overshoot, ringing, and instability.

See your 24XX Interactive SourceMeterTM Reference Manual for more information.

To select the high-capacitance mode:

1. From the Menu screen, select Measure Settings.

2. Select High Capacitance.

Figure 27: High Capacitance Mode selection

3. Select Off or On.

Page 29

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-11

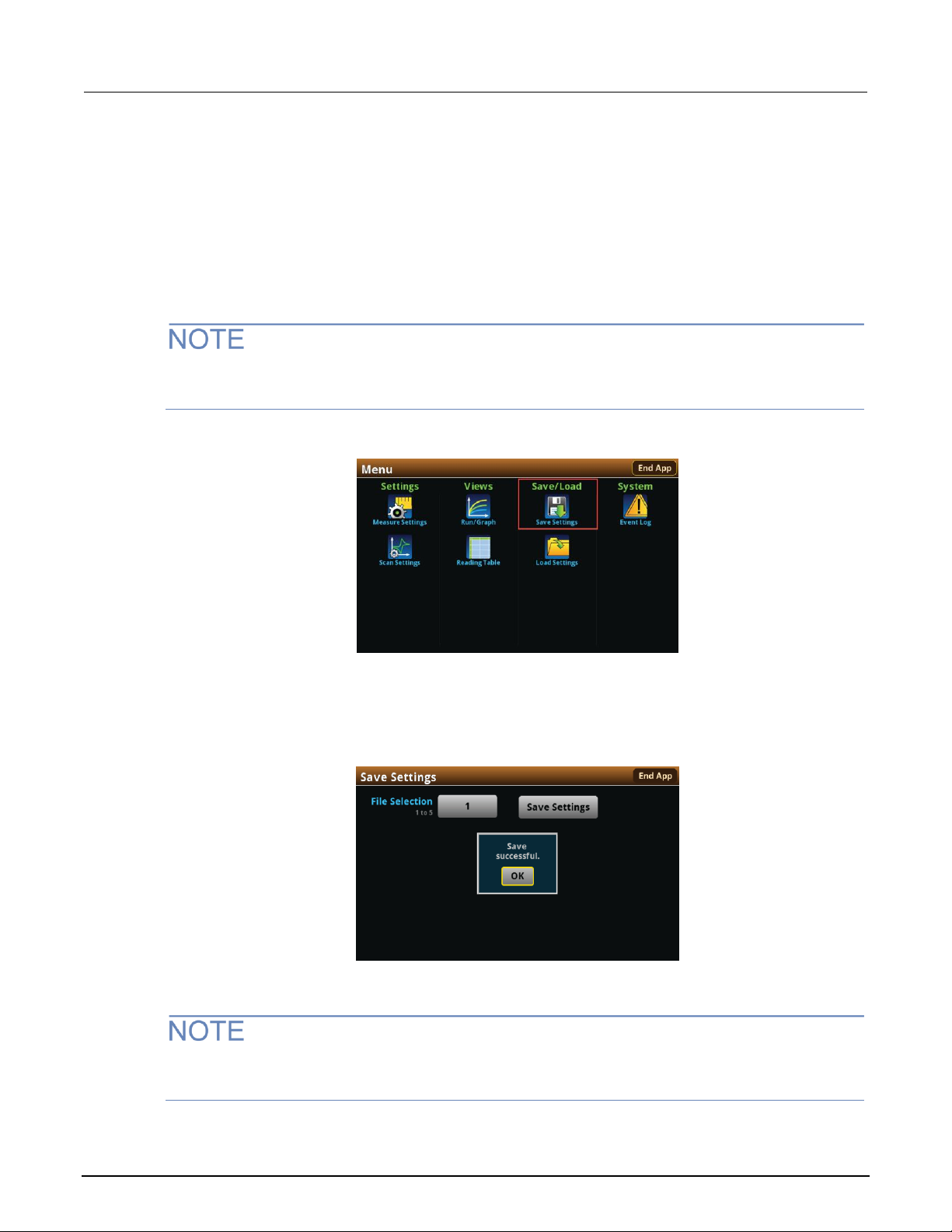

Save or load the test parameter data

You can save your test parameters to the front-panel flash drive at any time. Up to five test parameter

configurations can be stored.

To save the test parameters:

1. From the Menu screen, select Save Settings.

If you have saved a settings file previously with the same File Selection number, you will be

prompted to overwrite it.

Figure 28: Selecting Save Settings

2. Select a file number and then select Save Settings. You are notified when the save is complete,

as shown in the next figure. Select OK to clear the prompt.

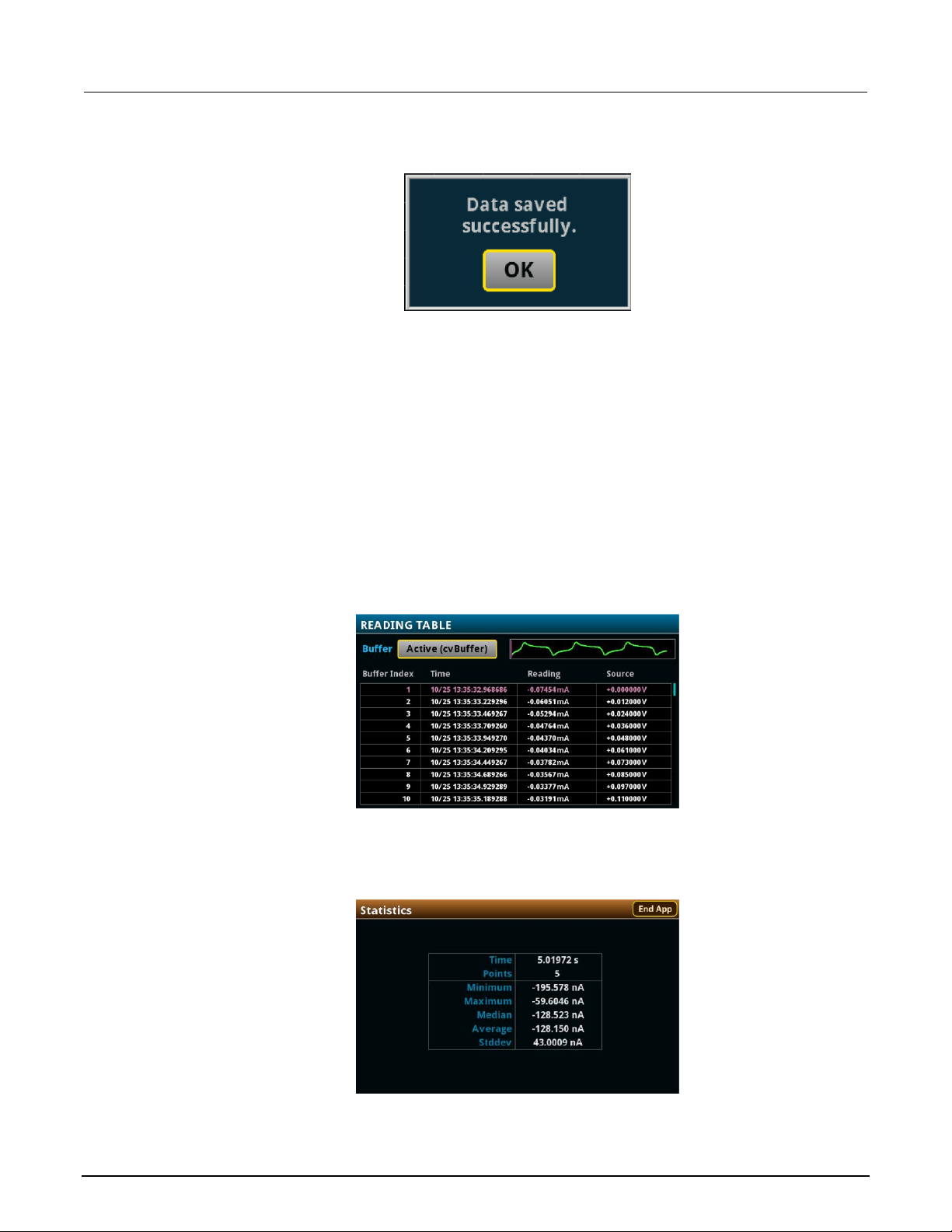

Figure 29: Successful file save

To load saved test parameters:

Test parameters can only be loaded to the same instrument model on which they were created and

saved. For example, you cannot load test parameter settings created with a 2450-EC to a 2460-EC.

Page 30

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-12 077110403 / March 2020

1. From the Menu screen, select Load Settings.

Figure 30: Selecting Load Settings

2. Select a file by choosing File Selection and then a file number.

Figure 31: Choosing a file to load

3. Select Load Settings. You are notified when the load completes. Select OK to clear the prompt.

Page 31

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-13

Run the test and view the graph

To run the test and view the graph:

1. Press the HOME key.

2. Select Start Test. The output turns on automatically, and the display shows the current

measurements plotting in real time, along with a progress bar at the bottom of the screen. The

Start Test control also changes to Stop Test for the duration of the test.

The output turns off when the test completes. The following graphic shows the test home screen

during the test. You can return to this home screen at any time when the test is running by selecting

the Run / Graph option from the Menu screen.

Figure 32: Cyclic voltammetry test results graph

You can use the touchscreen to manipulate the graph or add cursors. See your Interactive

SourceMeterTM Instrument Reference Manual for more information.

You can save a screen capture to a flash drive inserted into the USB port of the potentiostat by

simultaneously pressing the HOME key and the ENTER key. The file name has the format

imgmmdd_hhmmss.png, where hhmmss represents the instrument hour (in 24-hour notation), month,

and day.

To end the test before the run completes, select Stop Test at any time. This stops the test and turns

off the potentiostat output. You can then select End App to exit the test and return to normal SMU

operation. If there is a long interval between consecutive samples, there may be a long delay

between selecting Stop Test and when the test stops, as the current operation must complete.

Page 32

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-14 077110403 / March 2020

Make sure to select Stop Test before selecting End App. Stop Test turns off the instrument's

output.

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the instrument

while the power is turned on. Turn off the equipment from the front panel or disconnect the

main power cord from the rear of the instrument before handling cables. Putting the

equipment into an output-off state does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

Acquire the open-circuit potential (Eoc)

If you selected Eoc as the potential reference for the scan, then the open-circuit potential will be

measured immediately after starting the test. You are prompted by the test application, as shown in

the next figure.

Figure 33: Prompt for Eoc measurement

If you select Yes, the instrument measures the open-circuit potential (Eoc) of your electrochemical

cell. If you select No, the test stops. After the Eoc is measured, the value is displayed in a prompt, as

shown in the next figure.

Figure 34: Eoc measurement displayed

Page 33

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-15

If this value is acceptable, then select Yes to start the scan. If you select No, the test will stop. The

measured Eoc value is saved in the eocBuffer internal buffer of the instrument.

Save the test data to the flash drive

You can save the data generated from the test to the front-panel flash drive. The data is stored in

a .csv file that also includes instrument information and parameter settings.

If there are more than 10,000 measurements stored, the process of saving the data may take several

minutes.

To save the test data to the flash drive:

1. Make sure your flash drive is inserted into the front-panel USB port.

2. From the test application home screen, select Save Data.

3. Specify a file name, then select OK.

4. Select OK on the confirmation message.

Figure 35: Test results saved successfully

View the results saved to the flash drive

To view the test results, open the saved file in a spreadsheet program on a computer. Current,

voltage, time, and general parameters for the test are included in the file.

Page 34

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-16 077110403 / March 2020

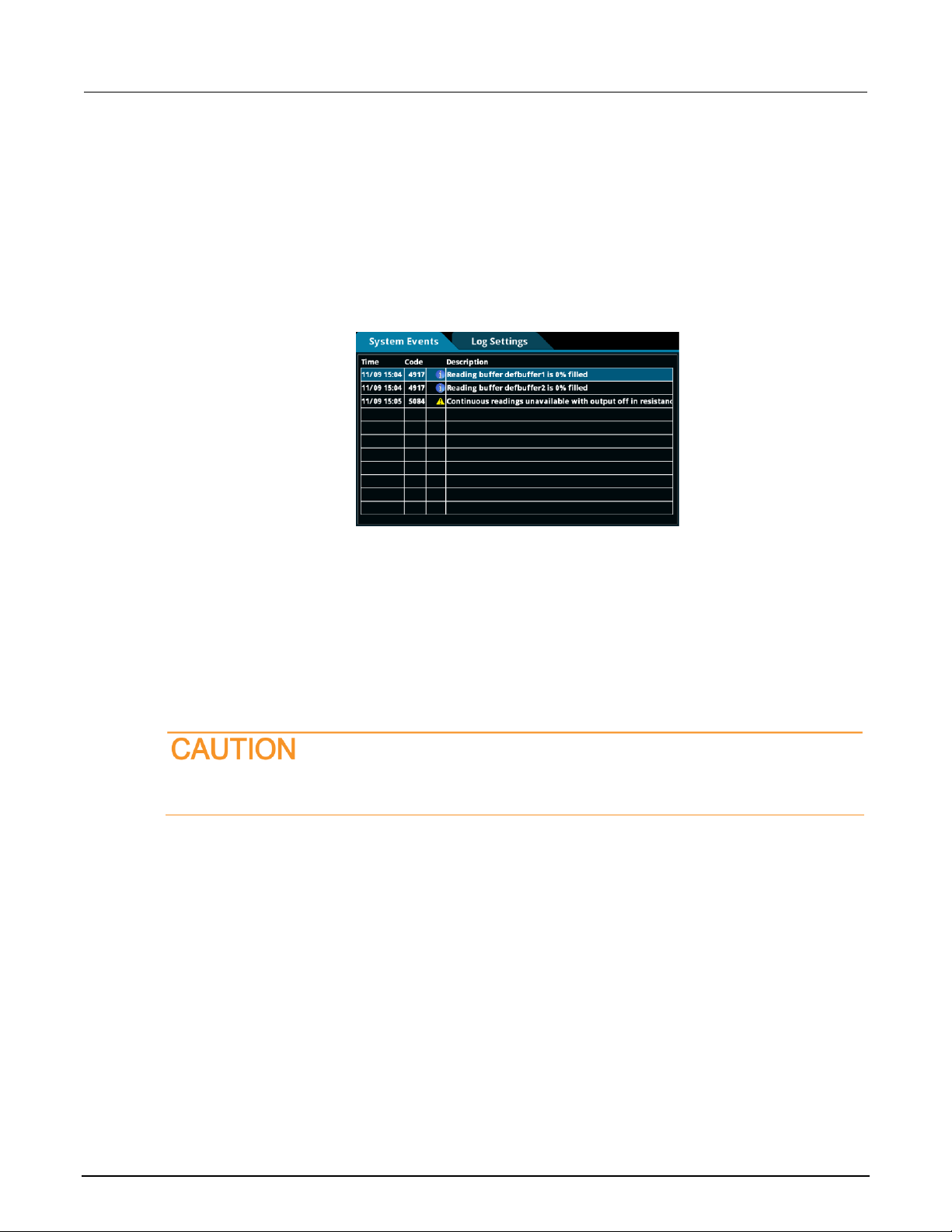

View the test reading table

You can view the individual data points by selecting Reading Table from the Menu screen. See the

next figure.

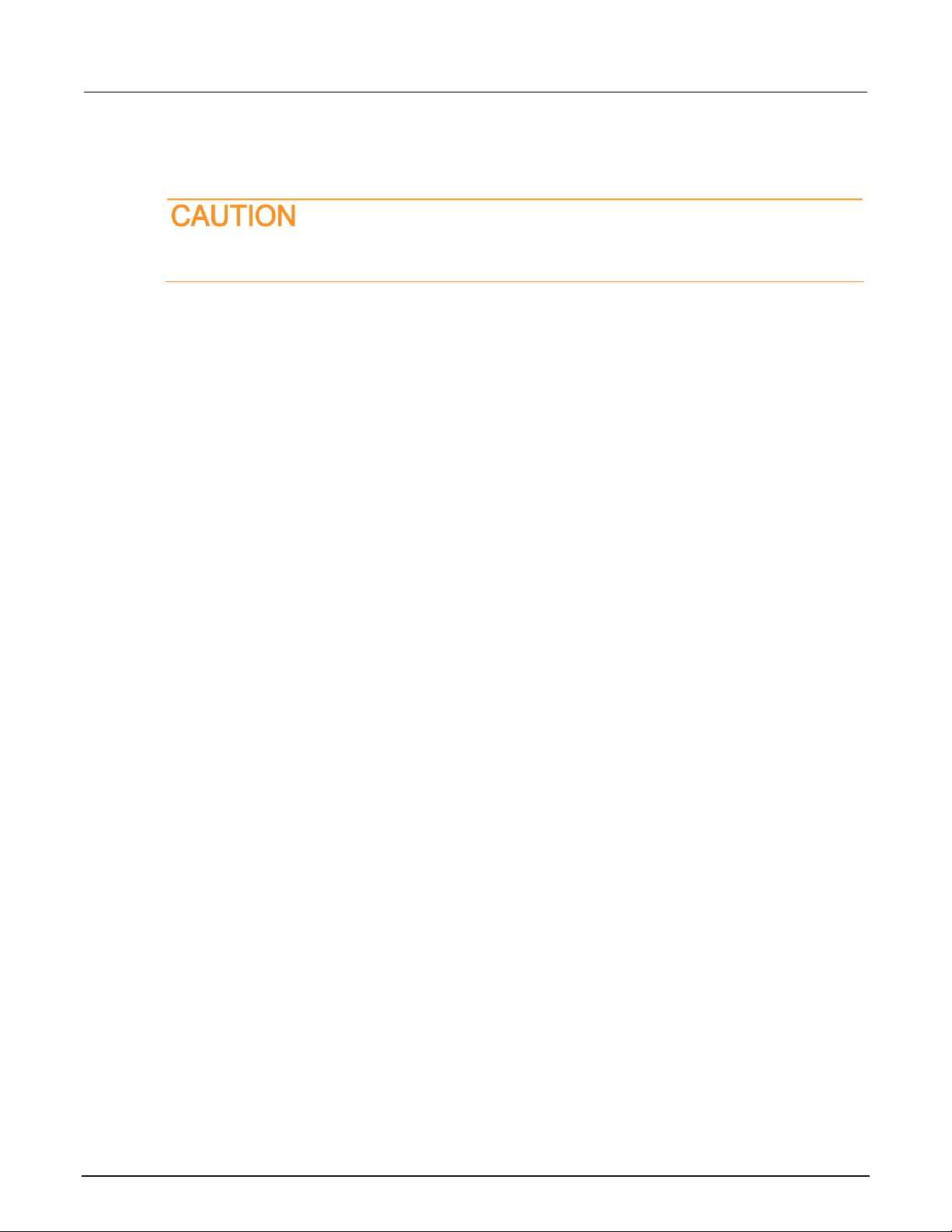

View the event log

From the main Menu, you can select Event Log. The event log records events, which can be errors,

warnings, and information reported by your instrument. Through the Event Log menu, you can view

these events. You can also specify which events are shown in the event log, which ones are logged,

and which ones generate popup messages.

Figure 36: Viewing the Reading Table

Figure 37: Viewing the Event Log

See your Keithley Instruments 2450, 2460, or 2461 Interactive SourceMeter® Instrument Reference

Manual for further details on the Event Log.

Page 35

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-17

End the test application

When you are finished making measurements, select End App to exit the test and return to normal

SMU operation.

Make sure to always select

instrument's output.

Cyclic voltammetry theory

A typical electrochemical measurement circuit, which consists of an electrochemical cell, an

adjustable voltage source (VS), an ammeter (AM), and a voltmeter (VM), is shown in the following

figure.

Figure 38: Simplified measurement circuit for performing cyclic voltammetry

Stop Test

before selecting

End App. Stop Test

turns off the

The three electrodes of the electrochemical cell are the working electrode (WE), reference electrode

(RE), and the counter, or auxiliary, electrode (CE). The voltage source (VS) for the potential scan is

applied between the working electrode and the counter electrode. The potential (E) between the

reference electrode and the working electrode is measured with the voltmeter (VM). The overall

voltage (Vs) is adjusted to maintain the targeted potential at the working electrode with respect to the

reference electrode. The resulting current (i) flowing to the working electrode is measured with the

ammeter (AM). This process is usually repeated for a range of E.

Page 36

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-18 077110403 / March 2020

An example procedure to make a measurement for each point in the scan (Ei):

1. Select a potential (E) for RE with respect to WE.

2. Adjust the voltage across the entire cell (CE to WE) to get desired E (closed loop control).

3. Measure i.

4. Step to a new E and repeat the procedure until the scan is finished. The procedure can be a

single sweep between two potentials (linear sweep voltammetry) or one in which the sweep is

inverted when a certain potential is reached (cyclic voltammetry). This cycle may be repeated

multiple times during an experiment.

Once the experiment is finished, the measured current is plotted as a function of the potential in a

graph known as a voltammogram. The example voltammogram in the following figure shows four

voltage vertices:

• E1 (initial potential)

• E2 (second, switching potential)

• E3 (third, switching potential)

5. Plot the results and derive parameters of interest from the data.

• E4 (final potential)

The voltage peaks in the waveform are the anodic (Epa) and the cathodic (Epc) peak potentials.

Figure 39: Example voltammogram generated by a 2450-EC

Page 37

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-19

In this example, the scan begins at E1 and the potential becomes more positive, causing the anodic

current (to rise rapidly and peak at the anodic peak potential (Epa).

At E2, the scan direction switches to negative for the reverse scan. As the current becomes more

negative, cathodic current flows as the electrode process is reduced. A cathodic peak potential occurs

at Epc.

At E3, the direction reverses again and the voltage is swept until it reaches E4. From the potential

sweep, important information about the experiment can be derived and analyzed.

Keithley galvanostat scan theory

The 2450-EC, 2460-EC, and 2461-EC digital potentiostats do not output a truly linear voltage; they

output very small, digitized steps from 0.1 mV to 10 mV for a specified time (dt), depending upon the

scan rate. See the next figure. While this will not cause significant errors in normal geometry cells

(such as 10 mL analytic and most galvanic cells), there might be errors when using micro and

ultramicro electrodes. The voltage step sizes used are calculated during scanning based on the user

set scan rate:

• 100 μV (0.1 mV per second ≤ scan rate < 35 mV per second)

• 1 mV (35 mV per second ≤ scan rate < 350 mV per second)

• 10 mV (350 mV per second ≤ scan rate ≤ 3500 mV per second)

Figure 40: Potential scan

Page 38

Section 2: Cyclic voltammetry 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

2-20 077110403 / March 2020

Analog integration current method

To measure the resulting current at each step, many digital potentiostats make a single current

measurement at a fixed point (t) for each discrete voltage step, which may not be at the same time for

each step. See the following figure.

Figure 41: Voltage step measurements

Conversely, the 2450-EC, 2460-EC, and 2461-EC use an internal analog integrator to integrate

current over most of the voltage step and report the average current over the aperture time (dt) of the

voltage step. See the following figure. This average current is used in the generation of the

voltammogram.

Figure 42: Current integration

Page 39

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 2: Cyclic voltammetry

077110403 / March 2020 2-21

Open-circuit potential theory

When the open-circuit potential is measured, no current or voltage is applied to the cell. This voltage

measurement is made using the galvanostat to source current and measure voltage (see the next

figure). The instrument sources 0 A on the 1e-6 range using a 4-wire configuration.

Figure 43: Measuring open-circuit potential of an electrochemistry cell

You can use this potential measurement as the zero measurement when defining the voltage vertices.

When you do this, the Eoc measurement gets added to the voltage.

Page 40

In this section:

Open-circuit potential ............................................................... 3-1

Section 3

Open-circuit potential

Open-circuit potential

The open-circuit potential (OCP) of an electrochemical cell is the voltage between the reference and

working electrodes. When the open-circuit potential is measured, a voltmeter with high impedance is

used to measure the voltage with no current or voltage applied to the cell.

Because of its high input impedance, your galvanostat can be used to make OCP measurements

when configured for 4-wire measurements, as shown in the next figure. In this setup, the instrument is

configured to source 0 A and measure voltage.

If you measure the OCP before performing any test, you do not have to change any test leads

between measurements because your potentiostat or galvanostat can automatically change

functions.

Figure 44: Measuring the open-circuit potential

Page 41

Section 3: Open-circuit potential 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

3-2 077110403 / March 2020

To ensure proper instrument operation, the potential difference between the reference electrode (RE)

and counter electrode (CE) terminals and between the working electrode (WE) and working

electrode sense (WES) terminals should not exceed 5 V.

Test application parameters

You must enter test parameters that are consistent with the following values. Otherwise, you

may receive unsettled and inaccurate measurements.

The open-circuit potential test application parameters are listed below.

Model 2450-EC

• Potential measure ranges: 20 mV, 200 mV, 2 V, 20 V

• Sample interval: 0.75 s ≤ sample interval ≤ 100 s

• Number of samples: 1 to 100,000

Models 2460-EC and 2461-EC

• Potential measure ranges: 200 mV, 2 V, 7 V, 10 V, 20 V

• Sample interval: 0.75 s ≤ sample interval ≤ 100 s

• Number of samples: 1 to 100,000

Run the open-circuit potential test application

To run the test application:

1. Press the HOME key.

2. Select the active script indicator at the top of your home screen. If there is no script activity, the

indicator displays No Script.

Figure 45: Active script indicator

Page 42

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 3: Open-circuit potential

077110403 / March 2020 3-3

3. Select the preloaded OCP test script (potentiostats and galvanostats only) or connect the

End App

Select this control to immediately stop the test and return to normal SMU

operation.

Autoscale

Select this control to define the graph based upon the plotted data. This is

useful for constraining all of the data to the screen's viewing size.

Start Test

Select this control to immediately begin the test. This option becomes Stop

Test when the test runs.

Save Data

Select this control to save the test data to a .csv file on a flash drive. This

option is only visible after the test runs.

Cursor

Select this control to cycle through the available cursor placements: None,

Vertical, Horizontal, and Both.

supplied USB drive to your SMU instrument to locate the included OCP test. If you connect the

USB drive, scripts on the drive are displayed with usb1/ before the script file name.

Figure 46: Selecting the open-circuit potential test application

4. Select OpenCircuitPotential. The test application begins to run immediately and the OCP

home screen is displayed.

Figure 47: Open-circuit potential test home screen

The test home screen controls include:

Page 43

Section 3: Open-circuit potential 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

3-4 077110403 / March 2020

Review the menu controls

You have different options in the Menu screen, depending on the application. The following graphic

shows the open-circuit potential main Menu. You will learn the function for each option later in this

section.

Figure 48: Open-circuit potential main Menu

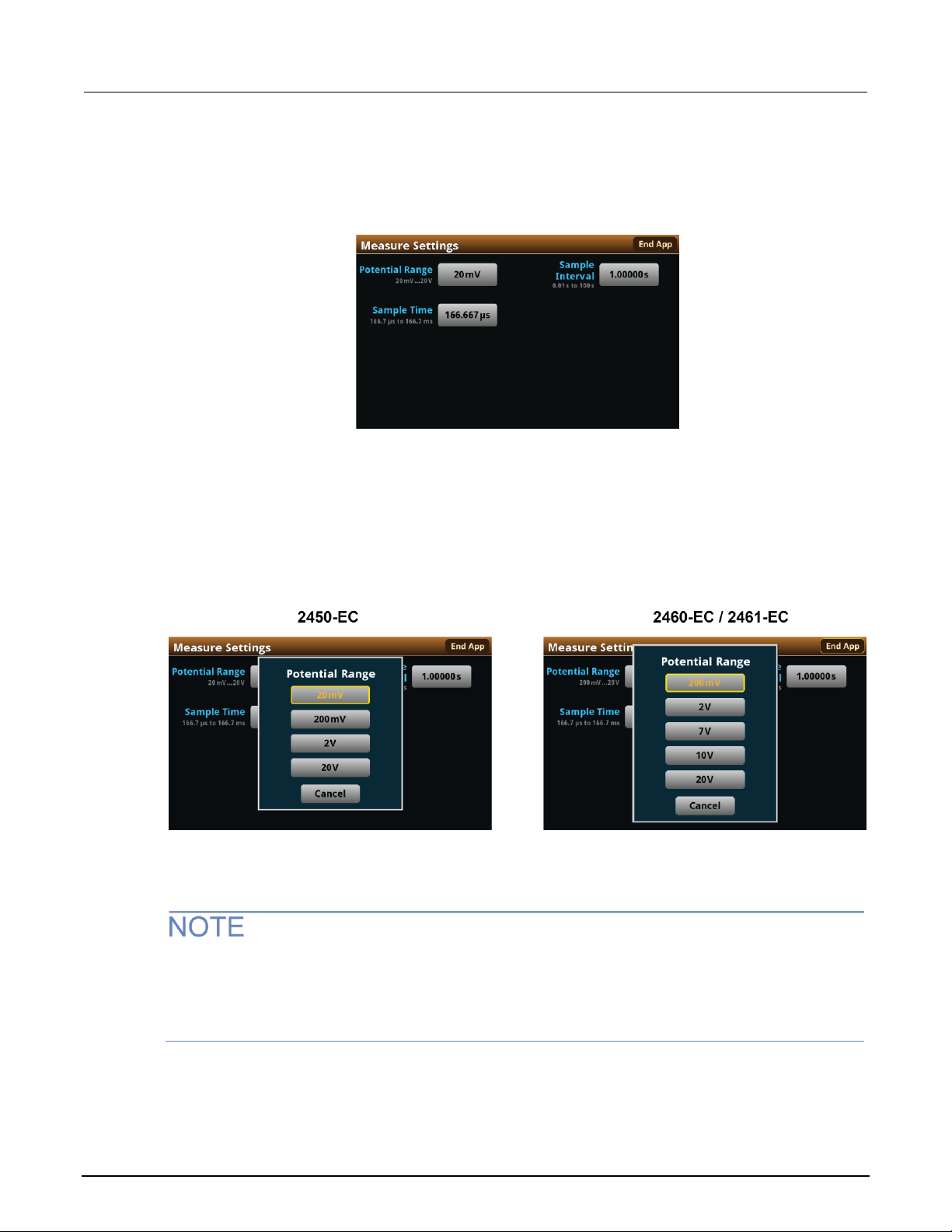

Adjust the measure settings

When you run the test application, you must define the parameters for the open-circuit potential

measurements. These parameters are the Potential range, Sample Count, and the Sample Interval.

To select the Potential Range:

1. Press the MENU key, then select Measure Settings.

2. Select Potential Range.

Figure 49: Measure Settings menu, selecting Potential Range

Page 44

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 3: Open-circuit potential

077110403 / March 2020 3-5

3. Choose a value. Note that the choices are different depending on your galvanostat.

Figure 50: Selecting the Potential Range

Next, specify the number of open-circuit potential measurements to make. This is called the Sample

Count. You can set the Sample Count from 1 to 100,000.

To set the number of samples:

1. From the Measure Settings screen, select Sample Count.

Figure 51: Measure Settings menu, selecting Sample Count

2. Enter a value.

Now you will specify the sample interval time in seconds per point. The sample interval time is

illustrated in the next figure. You can choose an interval from 0.75 to 100 seconds per point.

Figure 52: Sample Interval time, graphic description

Page 45

Section 3: Open-circuit potential 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

3-6 077110403 / March 2020

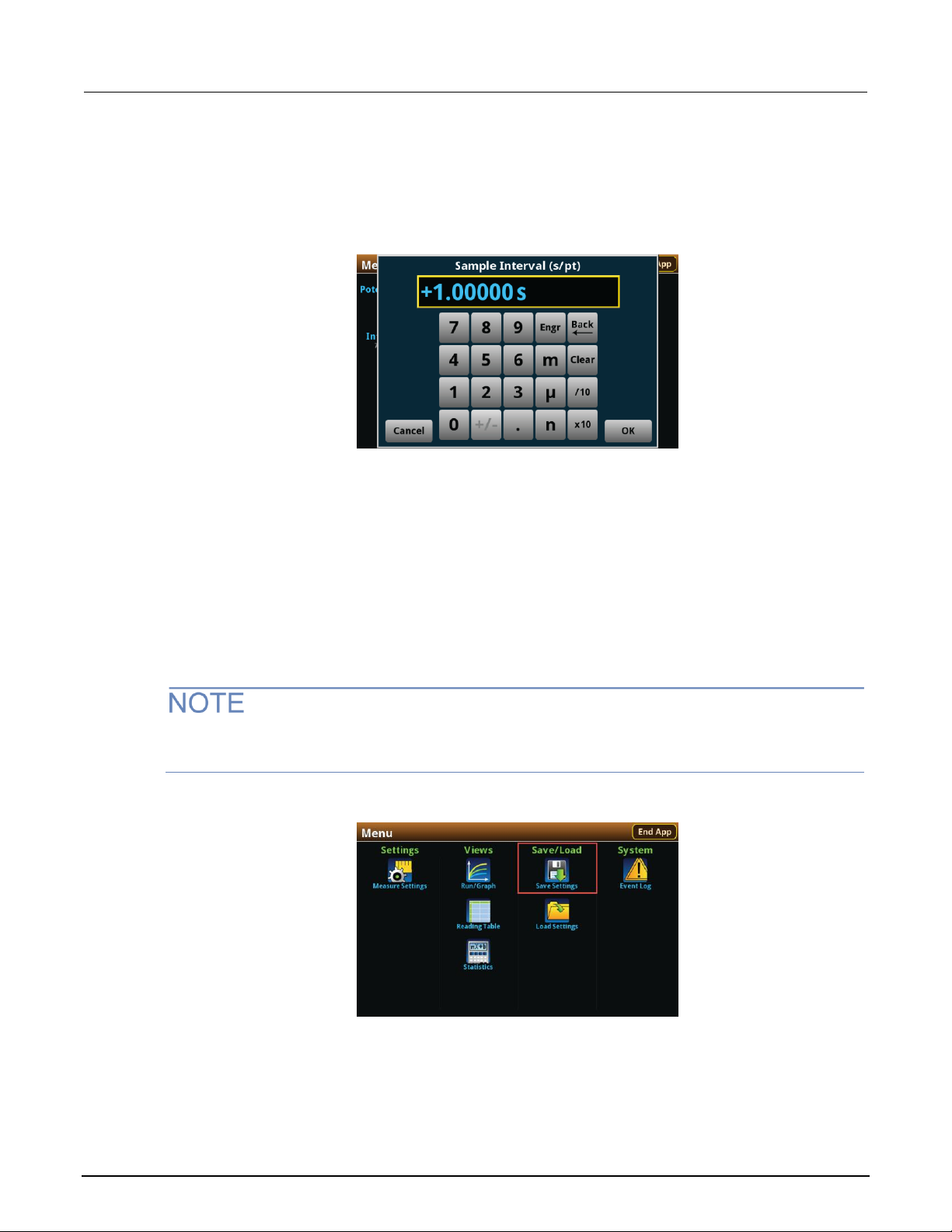

To specify the Sample Interval:

1. From the Measure Settings screen, select Sample Interval (s/pt).

2. Enter a value.

Figure 53: Entering the Measurement Interval

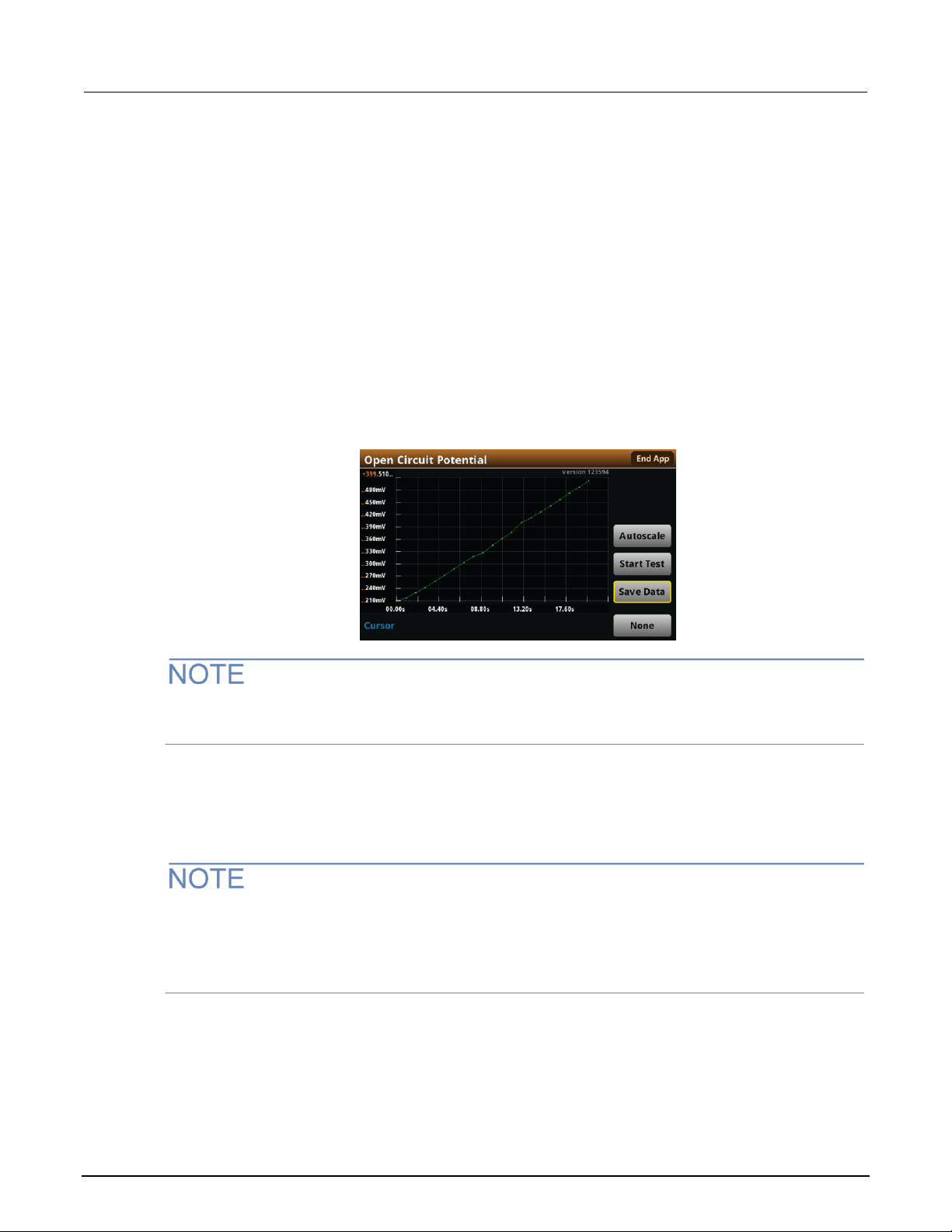

Save or load the test parameter data

You can save your test parameters to the front-panel flash drive at any time. Up to five test parameter

configurations can be stored.

To save the test parameters:

1. From the Menu screen, select Save Settings. Note that your Menu screen options are different

depending on the test you are running.

If you have saved a settings file previously with the same File Selection number, you will be

prompted to overwrite it.

Figure 54: Selecting Save Settings

Page 46

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 3: Open-circuit potential

077110403 / March 2020 3-7

2. You are notified when the save is complete. Select OK to clear the prompt.

Figure 55: Successful file save

To load saved test parameters:

Test parameters can only be loaded to the same instrument model on which they were created and

saved. For example, you cannot load test parameter settings created with a 2450-EC to a 2460-EC.

1. From the Menu screen, select Load Settings.

2. Select a file by choosing File Selection and then a file number.

Figure 56: Choosing a file to load

3. Select Load Settings. You are notified when the load completes.

4. Select OK to clear the prompt.

Page 47

Section 3: Open-circuit potential 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

3-8 077110403 / March 2020

Run the test and view the graph

To start the experiment and view the graph or data:

1. Press the HOME key.

2. Select Start Test. The output turns on and the display automatically shows the potential

measurements plotting in real time, along with a progress bar at the bottom of the screen. The

Start Test control also changes to Stop Test for the duration of the test.

The output turns off when the test completes. The following graphic shows the home screen after the

test finishes. You can return to this home screen at any time when the test is running by selecting the

Run / Graph option from the Menu screen.

Figure 57: Open-circuit potential test results graph

You can use the touchscreen to manipulate the graph or add cursors. See your Interactive

SourceMeterTM Instrument Reference Manual for more information.

You can save a screen capture to a flash drive inserted into the USB port of the galvanostat by

simultaneously pressing the HOME key and the ENTER key. The file name has the format

imgmmdd_hhmmdd.png, where hhmmdd represents the instrument hour, month, and day.

To end the test before the run completes, select Stop Test at any time. This stops the test and turns

off the galvanostat output. You can then select End App to exit the test and return to normal SMU

operation. If there is a long interval between consecutive samples, there may be a long delay

between selecting Stop Test and when the test stops, as the current operation must complete.

Page 48

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 3: Open-circuit potential

077110403 / March 2020 3-9

Make sure to select Stop Test before selecting End App. Stop Test turns off the instrument's

output.

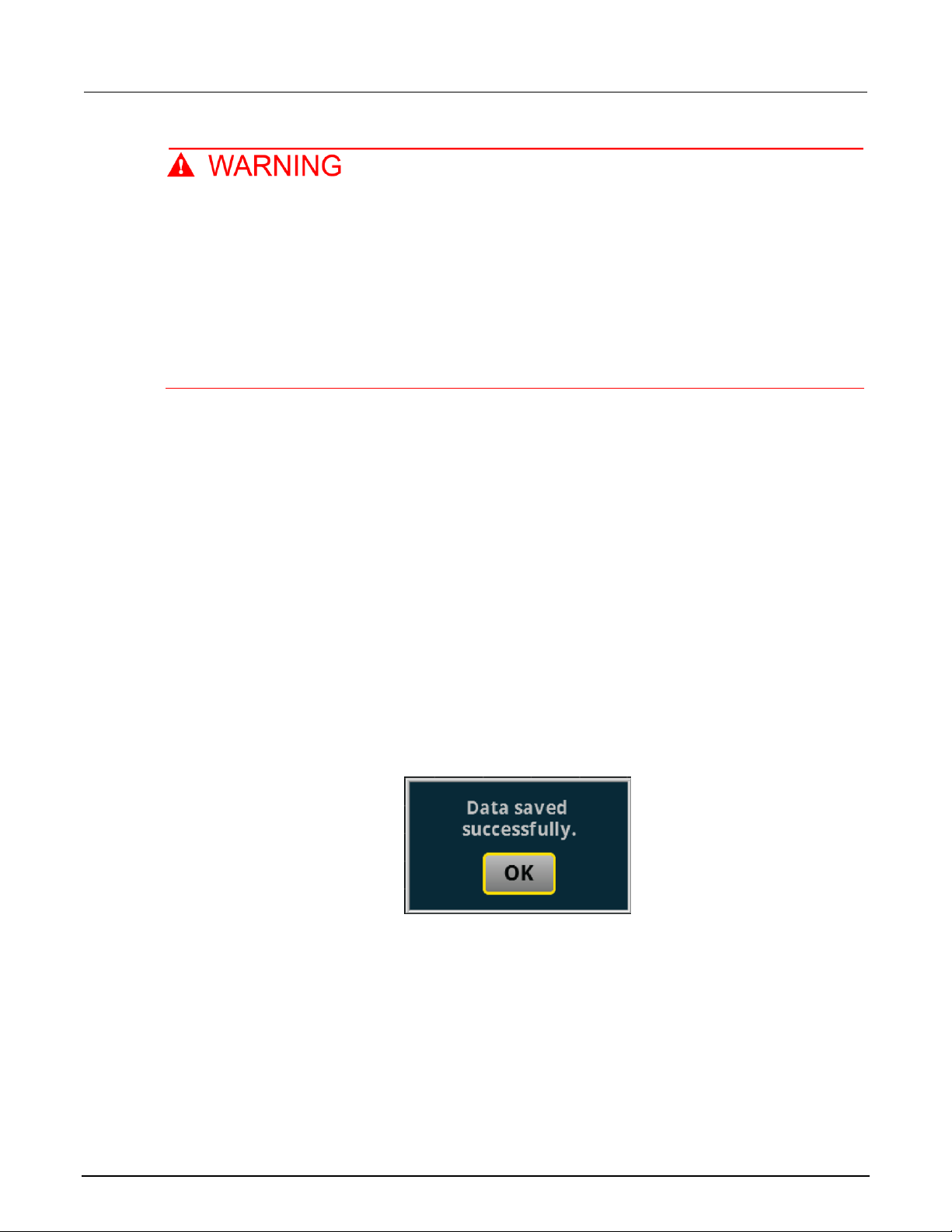

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the instrument

while the power is turned on. Turn off the equipment from the front panel or disconnect the

main power cord from the rear of the instrument before handling cables. Putting the

equipment into an output-off state does not guarantee that the outputs are powered off if a

hardware or software fault occurs.

Save the test data to the flash drive

You can save the data generated from the test to the front-panel flash drive. The data is stored in

a .csv file that also includes instrument information and parameter settings.

If there are more than 10,000 measurements stored, the process of saving the data may take several

minutes.

To save the test data to the flash drive:

1. Make sure your flash drive is inserted into the front-panel USB port.

2. From the test application home screen, select Save Data.

3. Specify a file name, then select OK.

4. Select OK on the confirmation message.

Figure 58: Test results saved successfully

View the results saved to the flash drive

To view the test results, open the saved file in a spreadsheet program on a computer. Current,

voltage, time, and general parameters for the test are included in the file.

Page 49

Section 3: Open-circuit potential 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

3-10 077110403 / March 2020

View the reading table or measurement statistics

When the test completes, you can view the individual data points on the instrument by selecting

Reading Table from the Menu screen.

Figure 59: Viewing the Reading Table

You can also view the measurement statistics. Select Statistics from the Menu screen.

Figure 60: Viewing measurement Statistics

View the event log

From the main Menu, you can select Event Log. The event log records events, which can be errors,

warnings, and information reported by your instrument. Through the Event Log menu, you can view

these events. You can also specify which events are shown in the event log, which ones are logged,

and which ones generate popup messages.

Page 50

2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual Section 3: Open-circuit potential

077110403 / March 2020 3-11

See your Keithley Instruments 2450, 2460, or 2461 Interactive SourceMeter® Instrument Reference

Manual for further details on the Event Log.

End the test application

When you are finished making measurements, select End App to exit the test and return to normal

SMU operation.

Figure 61: Viewing the Event Log

Make sure to always select

Stop Test

before selecting

End App. Stop Test

turns off the

instrument's output.

Page 51

In this section:

Potential Pulse and Square Wave ............................................ 4-1

Section 4

Potential pulse and square wave

Potential Pulse and Square Wave

In the Potential Pulse and Square Wave test, the SMU potentiostat supplies a series of up to 100,000

potential pulses. At the end of each pulse, the SourceMeter instrument measures the resulting current.

You can select both the peak and base levels of the pulses, as well as the period, pulse width, and

sample time.

Various parameters of the pulse wave are displayed in the figure below. Though not pictured, there is

also a brief latency period between the end of the measurement and the end of the pulse to allow the

instrument’s analog-to-digital converter to finish processing the reading.

Figure 62: Potential versus time

To ensure proper instrument operation, the potential difference between the reference electrode (RE)

and counter electrode (CE) terminals and between the working electrode (WE) and working

electrode sense (WES) terminals should not exceed 5 V.

Page 52

Section 4: Potential pulse and square wave 2450-EC, 2460-EC, and 2461-EC Potentiostats and Galvanostats User's Manual

4-2 077110403 / March 2020

Test application parameters