Page 1

Series 2400 SourceMeter®

Quick Start Guide

2400S-903-01 Rev. E / September 2011

moc.yelhtiek.www

ECNEDIFNOC FO ERUSAEM RETAERG A

Page 2

Series 2400 SourceMeter

Quick S tart Guide

®

©2011, Keithley Instruments, Inc.

Document Number:

All rights reserved.

Cleveland, Ohio, U.S.A.

2400S-903-01 Rev. E / September 2011

Page 3

Page 4

The following safety precautions should be observed before using this product an d any associated instrumentation. Although some

instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may

be present.

n

This product is intended for use by qualified personnel who recog

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer

to the user documentation for complete product specifications.

ize shock hazards and are familiar with the safety precautions required

Safety Precautions

If the product is used in a manner not sp

The types of product users are:

Responsible body is the

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use

They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routin

replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to

personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient

over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the user documentation.

Exercise extreme caution when a shock hazard is prese

American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak,

or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

the

individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is

product for its intended function. They must be trained in electrical safety procedures and proper use of the instrument.

ecified, the protection provided by the product warranty may be impaired.

e procedures on the product to keep it operating properly, for example, setting the line voltage or

work on live circuits, perform safe installations, and repair products. Only properly trained service

are rated Measurement Category I and Measurement

n

t. Lethal voltage may be present on cable connector jacks or test fixtures. The

c

Operators of this product must be protected from ele

prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact.

Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of

operating at or above 1000V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits

connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current

and voltage to the card.

Before operating an instrument, ensure that the line cord is con

cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

tric shock at all times. The responsible body must ensure that operators are

. They are intended to be used with impedance-limited sources. NEVER

nected

to a properly-grounded power receptacle. Inspect the connecting

04/09

Page 5

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power

!

disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments

AL W AYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers,

installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common

make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in a

equipment may be impaired.

Do not exceed the maximum signal levels of the instrument

and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rati

Chassis connections must only be used as shield connections for measuring

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the u

interlock.

If a screw is present, connect it to safety earth ground u

The symbol on an instrument means caution, risk of danger. The user should refer to the operating instructions located in the user

documentation in all cases where the symbo

The symbol on an instrument means caution, risk of danger. Use standard safety precautions to avoid personal contact with these

voltages.

ccordance with its specifications and operating instruct ions, or the safety of the

s and accessories, as defined in the specifications and operating information,

sing the wire recommended in the user documentation.

l is marked on the instrument.

side of the circuit under test or power line (earth) ground. Always

ng for continued protection against fire hazard.

circuits, NOT as safety earth ground connections.

while power is applied to the circuit under test.

se of a lid

The symbol on an instrument shows that the

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in

disposed of according to federal, st

The WARNING he

associated information very carefully before performing the indicated procedure.

The CAUTION head

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

T o maintain protection from electric shock and fire, replacement compon

and input jacks - must be purchased from Keithley Instruments. Standard fuses with applicable national safety approvals may be used if

the rating and type are the same. Other components that are not safety-related may be purchased from other suppliers as long as they

are equivalent to the original component (note that selected parts should be purchased only through Keithley Instruments to maintain

accuracy and functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley Instruments

office for information.

To clean an instrument, use a damp cloth or mild, water-based clea

directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis

(e.g., a data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the

board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

ading in the user documentation explains dangers that might result in personal injury or death. Always read the

ing in the user documentation explains hazards that could damage the instrument. Such damage may invalidate the

ate, and local laws.

surface may be hot. Avoid personal contact to prevent burns.

the display lamp. Please note that the lamp must be properly

ents in mains circuits - including the power transformer, test leads,

ner

. Clean the exterior of the instrument only. Do not apply cleaner

Page 6

Table of Contents

Section T opic Page

Introduction................................................................................................. 1-2

Source-measure ca

Front and rear panels......

Navigating menus and entering numeric data.....

Menu navigation.....

Numeric data entry (EDIT keys).......

Editing source and compliance values......

Editing keys......

Editing procedure......

Toggling the source and measure display fields .................................. 1-5

Basic connections......

Front/rear terminals se

2-wire connections ....

4-wire connections ............................................................................... 1-7

Cable guard......

Ohms guard .....

Remote command programming........................................................ 1-10

Basic SourceMeter operations......

Source-measure.....

Measure only (V or I)....

Measure ohms ................................................................................... 1-12

Remote command programming......

Settings to optimize performance....

Range................................................................................................. 1-

Speed................................................................................................. 1-18

Digits.................................................................................................. 1-

Filter................................................................................................... 1-

Rel (nulling offsets)....

Remote command programming......

Features to enhance DUT testing.......

Data store.....

Sweep operation....

Performing sweeps....

Limit testing......

Math functions.....

Pulse mode (Model 2430 only) .....

pabilities ...................................................................... 1-2

........................................................................... 1-3

....................................... 1-4

.............................................................................. 1-4

.................................................... 1-4

................................................. 1-4

.................................................................................... 1-4

........................................................................... 1-5

................................................................................. 1-6

lection............................................................... 1-6

........................................................................... 1-6

.................................................................................... 1-8

.................................................................................... 1-9

............................................................ 1-10

............................................................................ 1-10

...................................................................... 1-11

.................................................. 1-14

......................................................... 1-17

17

18

18

......................................................................... 1-19

.................................................. 1-20

..................................................... 1-20

...................................................................................... 1-20

............................................................................ 1-22

......................................................................... 1-26

.................................................................................. 1-30

............................................................................... 1-33

..................................................... 1-36

Page 7

Table of Contents Series 2400 SourceMeter® Quick Start Guide

2 2400S-903-01 Rev. E / September 2011

Page 8

Quick start topics

Topic Page

Introduction ....................................................................................1-1

Source-measure capabilities..........................................................1-2

Front and rear panels............................................................... ... ...1-3

Navigating menus and entering numeric data................................ 1-4

Editing source and compliance values...........................................1-4

Basic connections..........................................................................1-6

Basic SourceMeter operations.....................................................1-10

Section 1

Introduction

Settings to optimize performance............................... ..................1-17

Features to enhance DUT testing................................................1-20

Page 9

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Introduction

This guide is designed to familiarize users with fundamental operation (front panel and remote) of

the Keithley 2400 Series SourceMeters. For comprehensive information on all aspects of

SourceMeter operation, refer to the 2400 Series SourceMeter User’s Manual.

Operation information in this guide is divided into fo

operations, (2) Settings to optimize performance, (3) Features to enhance DUT testing and (4)

More testing techniques. This format allows a new user to easily progress from basic simple

operation to more complex procedures.

Remote command programming - For

guide, the related SCPI commands for remote operation are summarized in tables. Most

commands have a query form. For example, :OUTPut ON turns the output on, while :OUTPut?

requests the present state of the output. Note that the SourceMeter must be addressed to talk after

sending a query command.

For operations where command sequence is impor tant, prog ramming examples are provided. The

ac

t programming syntax will depend on the test program language.

ex

Source-measure capabilities

Model 2400:

• Source voltage from 5µV to 210V; measure voltage from 1µV to 211V.

• Source current from 50pA to 1.05A; measure current from 10pA to 1.055A.

• Measure resistance from 100µΩ (<10

• Maximum source power is 22W.

Model 2400-LV and 2401:

• Source voltage from 5µV to 21V; measure voltage from 1µV to 21V.

• Source current from 50pA to 1.05A; measure current from 10pA to 1.055A.

• Measure resistance from 100µΩ (<10

• Maximum source power is 22W.

ur parts; (1) Fundamental source-measure

the various SourceMeter operating modes covere d in this

0µΩ

in manual ohms) to 211MΩ.

in manual ohms) to 211MΩ.

0µΩ

NOTE The Model 2401 does not use the digital output lines of the Digital I/O

port. Therefore, it cannot be used with a component handler to

perform binning operations.

Model 2410:

• Source voltage from 5µV to 1100V; measure voltage from 1µV to 1100V.

• Source current from 50pA to 1.05A; measure current from 10pA to 1.055A.

0µΩ

• Measure resistance from 100µΩ (<10

• Maximum source power is 22W.

Model 2420:

• Source voltage from 5µV to 63V; measure voltage from 1µV to 63.3V.

• Source current from 500pA to 3.15A; measure current from 100pA to 3.165A.

10µΩ in manual ohms) to 21.1MΩ.

• Measure resistance from 10µΩ (

• Maximum source power is 66W.

1-2 Return to Section Topics 2400S-903-01 Rev. E / September 2011

<

in manual ohms) to 211MΩ.

Page 10

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

2400 SourceMeter

250V

PEAK

5V

PEAK

HI

LO

OUTPUT

250V

PEAK

250V

PEAK

EDIT

TOGGLE

POWER

RANGE

INPUT/

OUTPUT

4-WIRE

SENSE

DISPLAY

ON/OFF

TERMINALS

FRONT/

REAR

AUTO

RANGE

EXIT ENTER

CONFIG MENU

SWEEP

TRIG

REL

LOCAL

FILTER

LIMIT

DIGITS SPEED

V

Ω

MEAS

I

FCTN

V

I

SOURCE

230

1

67

89

4

+/-

5

STORE

RECALL

EDIT

Model 2425:

• Source voltage from 5µV to 105V; measure voltage from 1µV to 105.5V.

• Source current from 500pA to 3.15A; measure current from 100pA to 3.165A.

<

• Measure resistance from 10µΩ (

10µΩ in manual ohms) to 21.1MΩ.

• Maximum source power is 110W.

Model 2430:

• Source DC or pulse voltage from 5µV to 105V; measure voltage from 1µV to 105.5V.

• Source DC current from 500pA to 3.15A; measure DC current from 100pA to 3.165A.

• Source pulse current from 500pA to 10.5A; measure pulse current from 100 pA to 10.55A.

<

• Measure resistance from 10µΩ (

10µΩ in manual ohms) to 21.1MΩ.

• Maximum DC source power is 110W.

• Maximum pulse source power is 1.1kW.

Model 2440:

• Source voltage from 5µV to 42V; measure voltage from 1µV to 42V.

• Source current from 500pA to 5.25A; measure current from 100pA to 5.25A.

<

• Measure resistance from 10µΩ (

1 0 µΩ in manual ohms) to 21.1 M¾.

• Maximum source power is 55W.

Front and rear panels

The front and rear panels of the Mode l 2400 So urceMeter are shown in Fig ures 1 a nd 2. The fro nt

and rear panels of the other SourceMeter models are similar. The use of the various instrument

controls and connectors will be explained throughout this guide.

Figure 1-1

Front Panel

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-3

Page 11

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

WARNING: NO INTERNAL OPERATOR SERVICABLE PARTS, SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION: FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE FUSE WITH SAME TYPE AND RATING.

MADE IN

U.S.A.

INPUT/

OUTPUT

250V

PEAK

250V

PEAK

TRIGGER

LINK

4-WIRE

SENSE

HI

LO

LINE RATING

100-240VAC

50, 60, Hz

190VA MAX.

RS-232

IEEE-488

(ENTER IEEE ADDRESS

WITH FRONT PANEL MENU)

250V

PEAK

5V

PEAK

5V

PEAK

5V

PK

V, Ω,

GUARD

GUARD

SENSE

LINE FUSE

SLOWBLOW

2.5A, 250V

OUTPUT

ENABLE

FUSE DRAWER

L

U

CUS

LISTED

SourceMeter

4ZA4

CAT I

!

Figure 1-2

Rear Panel

Navigating menus and entering numeric data

Menu navigation

Many operating modes for the SourceMeter are configured using front panel menus. Throughout

this guide, menu navigation will be presented as a sequence of key presses and menu item

selections. For example, the following sequence selects the auto ohms source mode:

Press CONFIG > press MEAS Ω > select SOURCE > select AUTO

The above sequence is explained as follows:

1. Press the CONFIG key.

2. Press the MEAS Ω key

.

3. Select the SOURCE menu item.

4. Select the AUTO ohms source mode.

A menu item is selected by placing the cursor

The left and right arrow keys control cursor position.

Numeric data entry (EDIT keys)

Numeric values must to be entered for some menu items. Numeric entry is also used to set source

and compliance values. The edit keys for numeric entry include the EDIT arrow keys to control

cursor position, EDIT arrow keys to increment or decrement the digit value, and the number keys.

After a value is keyed in, press ENTER to select it. No

number to its minimum value.

o

n it and pressing the ENTER key.

te that pressing MENU resets a displayed

Editing source and compliance values

Editing keys

Use the following keys to edit source and compliance values:

1-4 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 12

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

• DISPLAY EDIT — Selects the source or compliance display field for editing. A blinking

cursor will appear in the field to be edited. If no key is pressed within a few seconds, the edit

mode will be cancelled automatically.

• EDIT arrow keys — Places the display cursor on the display digit to be changed.

• SOURCE arrow keys

that pressing either of these keys will automatically enable the source edit mode.

•RANGE arrow keys

• Numeric keys (0-9) — Allow you to directly enter source or compliance values.

• EXIT — Exits the edit mode without waiting for the time-out period.

— Increments or decrements the source or compliance value. Note

— Selects the source or compliance range.

Editing procedure

1. Press the DISPLA Y EDIT key to place the blinki ng cursor in e ither the sour ce or compliance

display field to be edited.

2. If desired, use the RANGE arrow keys to select the desired source or compliance range.

3. To simply increment or decrement the display value, use the EDIT arrow

blinking cursor on the digit to be changed, then increment or decrement the value with the

SOURCE arrow keys. Note that the source or compliance value will be updated immediately; you need not press ENTER to complete the process.

4. To enter the source or compliance value directly, simply key in the desired value with the

numeric keys while the cursor is blinking. Again, the source or compliance value will be

updated immediately.

keys to place the

T oggling the source and measure display fields

Normally, the measured reading value will appear in the upper, main display line, while the source

and compliance values will appear in the left and right fields respectively of the lower display line.

You can toggle the source and measure display fields by pressing the DISPLAY TOGGLE key to

place the source and measure values in the desired display fields.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-5

Page 13

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Basic connections

WARNING The SourceMeter uses safety jacks for signal connections. To avoid

electric shock:

• Do not leave exposed connections.

• Properly insulate all external circuits.

• The front and rear terminals of the SourceMeters are rated for

connection to circuits rated Installation Category I only. Do not

connect the SourceMeter terminals to CAT II, CAT III, or CAT IV

circuits. Connection of the SourceMeter Input/Output terminals,

to circuits higher than CAT I, can cause damage t o the equipmen t

or expose the operator to hazardous voltages.

• Hazardous voltages may be present on the output and guard

terminals. To prevent elect r ical shock that could cause injury or

death, NEVER make or break connections to the SourceMeter

while the unit is on. Power off the equipment fro m the fr ont panel

or disconnect the main power cord from the rear of the

SourceMeter before handling cables connected to the outputs.

Putting the equipment into standby mode does not guarantee th e

outputs are not powered if a hardware or software fault occurs.

The three basic connection configurations for the SourceMeter include 2-wire local sensing, 4-wire

remote sensing, and cable guard.

NOTE Connections and details for in-circuit ohms measurements (ohms

guard) are covered in the “Advanced operation” section of this guide.

Front/rear terminals selection

The input/output and sense terminals are accessible from bo th the fr ont and re ar p anels, while the

guard terminals and chassis ground are only accessible from the rear panel. On the front panel,

press the FRONT/REAR key to toggle between front and rear. The REAR annunciator indicates

that the rear terminals are selected. With REAR off, the front terminals are selected.

2-wire connections

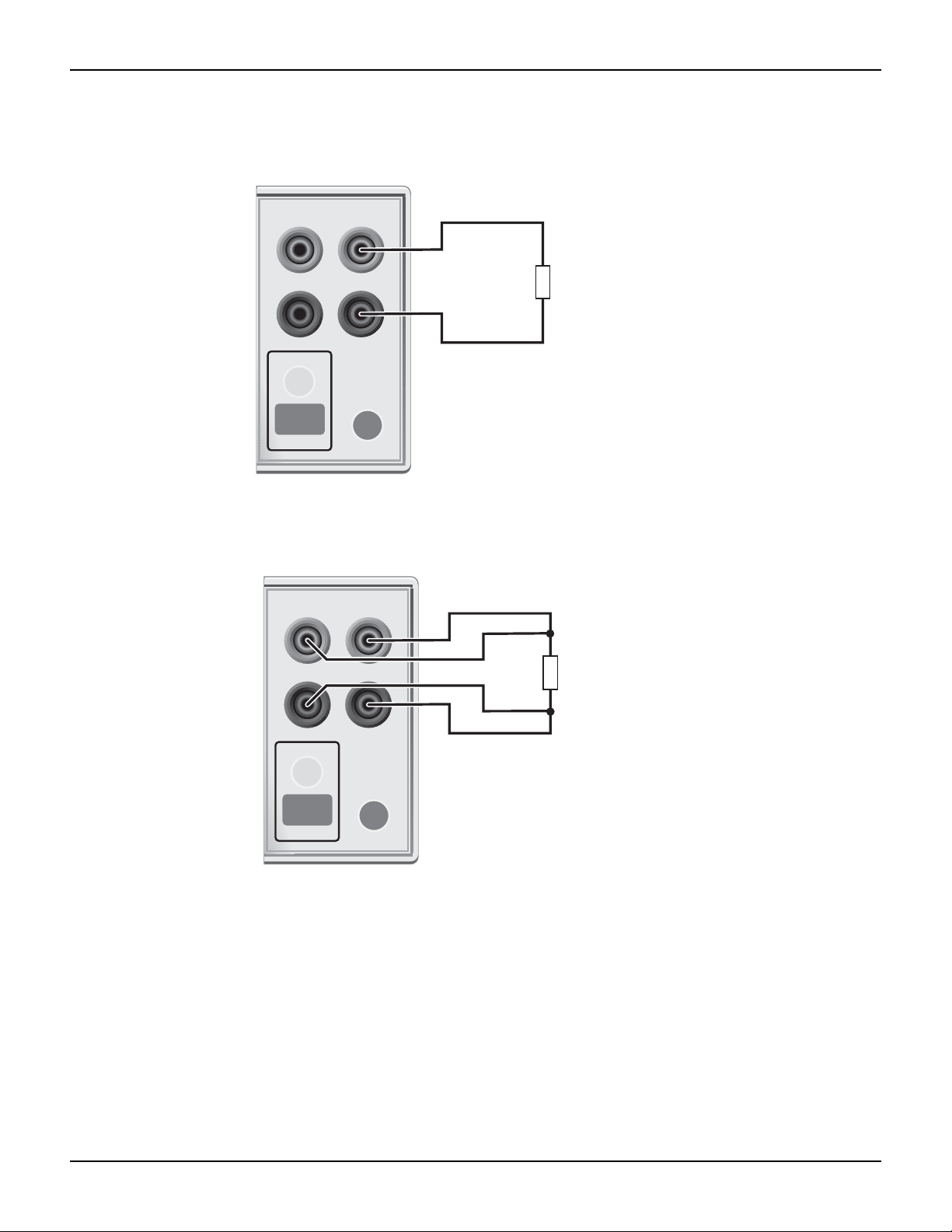

Connections for 2-wire local sensing are shown in Figure 3. The followin g menu sequ ence select s

2-wire local sensing:

Press CONFIG > select SOURCE V (or ΜΕ ΑS Ω) > select SENSE MODE > select 2-WIRE

1-6 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 14

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

HI

LO

OUTPUT

INPUT/

OUTPUT

4-WIRE

SENSE

ON/OFF

TERMINALS

FRONT/

REAR

DUT

SourceMeter Front Panel

Sense Selection: 2-wire

FRONT/

REAR

HI

LO

OUTPUT

INPUT/

OUTPUT

4-WIRE

SENSE

ON/OFF

TERMINALS

FRONT/

REAR

DUT

SourceMeter Front Panel Sense Selection: 4-wire

FRONT/

REAR

Figure 1-3

2-wire connections

Figure 1-4

4-wire connections

4-wire connections

Connections for 4-wire local sensing are shown in Figure 4. Use 4-wire remote sensing for the

following source-measure conditions:

• Test circuit impedance is <1kΩ.

• Optimum ohms, V-source, and/or V-measure accuracy is required.

With 4-wire sensing selected, the 4W annunciator is o

wire remote sensing:

n. The following menu sequence selects 4-

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-7

Press CONFIG > select SOURCE V (or MEAS Ω) > select SENSE MODE > select 4-WIRE

Page 15

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

INPUT/

OUTPUT

4-WIRE

SENSE

HI

LO

IEEE-488

(ENTER IEEE ADDRESS

WITH FRONT PANEL MENU)

V, Ω

GUARD

GUARD

SENSE

WARNING:NO INTERNAL OPERATOR SERVICAB

CAUTION:FOR CONTINUED PROTECTION AGAINST FIR

RS232

DUT

Connect to earth safety ground

using #18 AWG wire or larger.

Guard Shield

Test Fixture

Figure 1

Cable guard connections

NOTE Specified accuracies for both source and measure are achieved only

using 4-wire remote sensing.

Cable guard

When testing high-impedance DUT (>1GΩ), cable guard is used to drive the shields of cables and

test fixtures to minimize leakage currents and input capacitance. A typical connection scheme

using cable guard is shown in Figure 5. The following menu sequence select s cable guard:

Press CONFIG > press SOURCE V (or

The guard terminal of the SourceMeter is at virtually

SOURCE I or MEAS Ω) > select GUARD > select CABLE

the same potential as input/output HI.

Therefore, if there is hazardous voltage at input/outpu t HI, it is also present on the gu ard shield for

the test circuit.

WARNING To prevent injury from electric shock, the guard shield must be

enclosed in a safety shield (i.e., test fixture) that is connected to

safety earth ground (as shown in Figure 5).

1-8 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 16

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

INPUT/

OUTPUT

4-WIRE

SENSE

HI

LO

IEEE-488

(ENTER IEEE ADDRESS

WITH FRONT PANEL MENU)

V, Ω

GUARD

GUARD

SENSE

WARNING:NO INTERNAL OPERATOR SERVICAB

CAUTION:FOR CONTINUED PROTECTION AGAINST FIR

RS232

DUT

Connect to earth safety ground

using #18 AWG wire or larger.

Guard Shield

Test Fixture

Figure 1-5

Cable guard connections

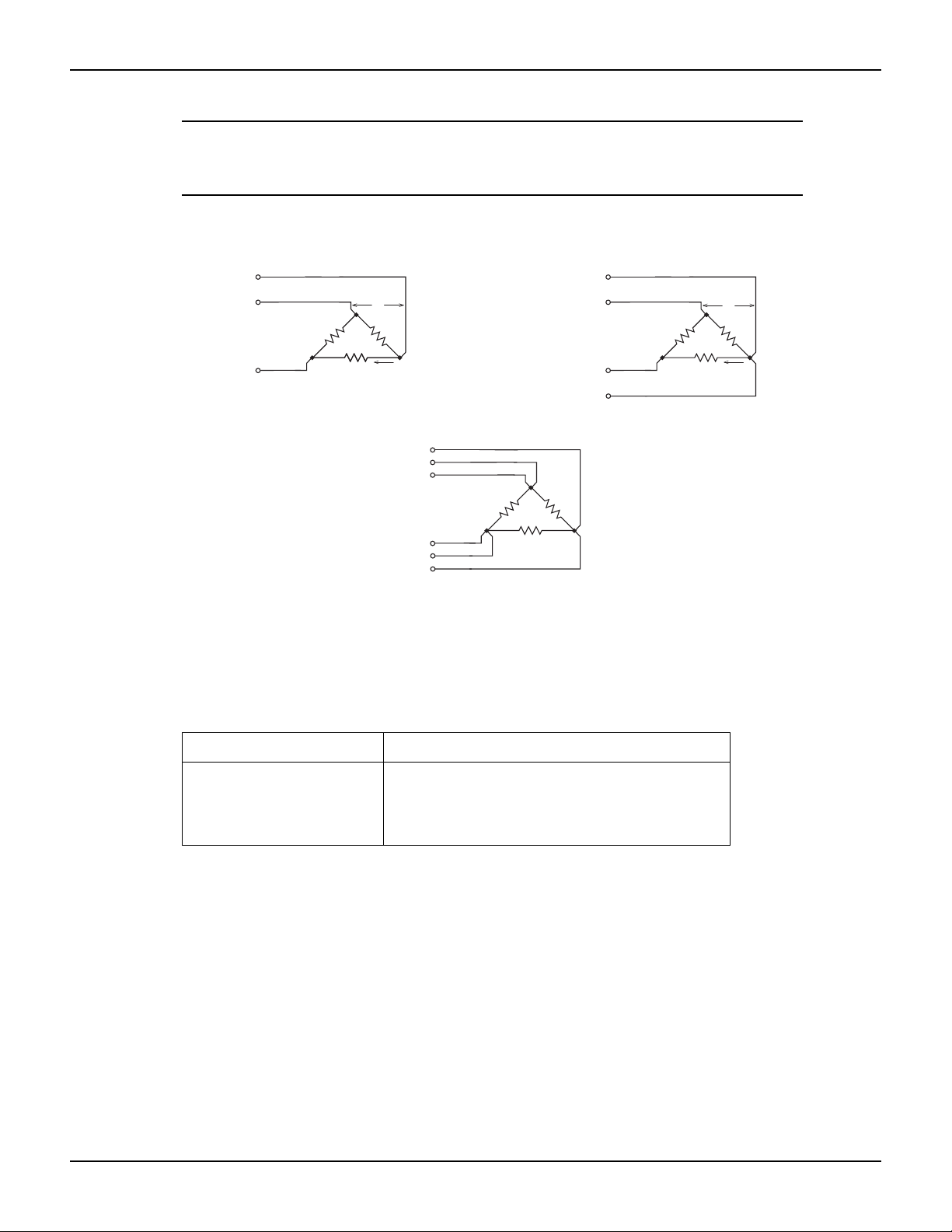

Ohms guard

Ohms guard allows in-circuit resistance measurements on DUT where other parasitic leakage

devices are present. Connection schemes for a Delta DUT configuration is shown in Figure 6.

NOTE Ohms guard cannot be used for high current (>100mA) ranges.

Ohms guard cannot be selected if already on a high current range.

Conversely, if ohms guard is already selected, a high current ra nge

The following menu sequence selects ohms guard:

Press CONFIG > press MEAS Ω (or SOURCE V or SOURC

Basic connections for ohms guard is shown in Figure 6A. With V, Ω Guard and In/Out HI at virtually

the same potential,

be 0A. Virtually all the current from In/Out HI will flow through the DUT resulting in an accurate

measurement.

If the guard resistance path (R

such that a significant voltage drop appears across R. The resultant leakage current through R will

corrupt the measurement of the DUT.

Guard Sense is used to cancel the ef

6B. Guard Sense regulates the guard voltage to ensure that the same potential appears on either

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-9

side of R.

For DUT <1kΩ, 4-wire sensing should be used as shown in Figure 6C.

cannot be selected.

the voltage drop across R will be 0V, and therefore, the current through R will

E I) > select GUARD > select OHMS

) is <1kΩ, IR drop in the V , Ω Guard test lead could be high enough

G

fect of IR drop in the V, Ω Guard test lead as shown in Figure

Page 17

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

DUT

V, Ω Guard

Sense HI

In/Out HI

In/Out LO

Sense LO

Guard Sense

Sense Mode: 4-wire

C. 6-wire connections

DUT

V, Ω Guard

In/Out HI

In/Out LO

Sense Mode: 2-wire

A. Basic connections

DUT

V, Ω Guard

In/Out HI

In/Out LO

Guard Sense

Sense Mode: 2-wire

B. Connections using guard sense

<1kΩ

RG

IG

≥1kΩ

RG

IG

R

0V

R

0V

NOTE Guard current (IG) must never exceed 50mA. If it does, guard voltage

will become less than the output voltage and corrupt the

measurement.

Figure 1-6

Guarded ohms measurements

Basic SourceMeter operations

Remote command programming

Table 1 lists the SCPI commands to select terminals, sense, and cable guard.

Table 1-1

SCPI commands; terminals, sense, and cable guard

Command Description

:ROUTe:TERMinals <name> Selects terminals; <name> = FRONt or REAR.

:SYSTem:RSENse <b> Selects sense mode; <b> = ON (4-wire) or OFF (2-

:SYSTem:GUARd <name> Selects guard mode; <name> = CABLe or OHMS.

Fundamental SourceMeter operations include source- measure, measure only (V or I) and

measure ohms.

Source-measure

There are four source-measure combinations for the SourceMeter:

Source V, Measure I

Source I, Measure V

Source V, Measure V

Source I, Measure I

The basic procedure to source-measure is p rovided in Table 2. It assumes that the DUT is already

connected

to the SourceMeter as explained in Basic connections.

wire).

1-10 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 18

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

Table 1-2

Source-measure procedure

Procedure Details

1. Select source function. Press SOURCE V or SOURCE I.

2. Set source level. Use DISPLAY EDIT key to place cursor in source

field (Vsrc or Isrc), use RANGE

select range, use edit keys to key in source

value, then press ENTER.

3. Set compliance limit. Use DISPLAY EDIT key to place cursor in Cmpl

field, use RANGE arrow keys to select range, use

edit keys to key in limit value, then press ENTER.

4. Select measurement function. Press MEAS V or MEAS I.

arrow keys to

5. If not measuring the source, select

measure range or use auto range (see

Notes 1 and 2).

6. Turn output on and take readings

from display.

7. Turn output off when finished. Press ON/OFF OUTPUT key. Red OUTPUT indi-

Notes:

1. When measuring source (i.e., Source I, Measure I), you

enable auto range. The measure range is determined by the source range.

2. When not measuring the source (i.e., Source I, Measur

maximum measurement range that can be selected.

Sink operation

When operating as a sink (V and I have opposite polarity), the SourceMeter is dissipating power

rather than sourcing it. An external source can force operation into the sink region. The

SourceMeter can be used to charge/discharge (source/sink) batteries. For oper ation information

on battery charging/discharging (and the associated precautions), see Section 3, Sink operation

of the 2400 Series SourceMeter User’s Manual.

Measure only (V or I)

Use RANGE arrow keys to manually select

range. Or press AUTO RANGE (AUTO annunciator on) to enable auto range.

Press ON/OFF OUTPUT key. Red OUTPUT indicator on.

cator off.

cannot change the measure range or

e I), the compliance range determines the

The SourceMeter can be used to measure voltage only (voltmeter) or current only (ammeter). The

procedure to measure only is provided in Table 3.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-11

Page 19

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Table 1-3

Measure only (V or I) procedure

Procedure Details

1. Select source-measure

functions.

2. Set source level to zero. Use DISPLAY EDIT key to place cursor in source field

3. Set compliance higher

than the expected measurement (see CAUTION 1).

4. Select measurement

range (see Note).

5. Connect voltage or cur-

rent to be measured.

6. Turn output on and take

reading from display.

7. Turn output off when

finished.

Note:When measuring current, auto range can be used. When measuring voltage, DO NOT use auto

range (see CAUTION 2).

To measure voltage, press SOURCE I and MEAS V. To

measure current, press SOURCE V and MEAS I.

(Vsrc or Isrc), use RANGE down arrow key to select lowest range, press MENU to display zero source level, then

press ENTER.

Use DISPLAY EDIT key to place cursor in Cmpl field, use

RANGE arrow keys to select range, use edit keys to key in

compliance value, then press ENTER.

Use RANGE arrow keys to select a fixed measurement

range. For best accuracy, use the lowest possible range.

Connect DUT to SourceMeter using 2-wire connections

(see Figure 3).

Press ON/OFF OUTPUT key. Red OUTPUT indicator on.

Press ON/OFF OUTPUT key. Red OUTPUT indicator off.

CAUTION When using the SourceMeter as a voltmeter only, voltage compliance must

CAUTION When using the SourceMeter as a voltmeter only, DO NOT use auto range

Measure ohms

Measurement methods

There are two methods to measure resistance; auto ohms and manual ohms. In auto ohms, the

SourceMeter operates as a conventional constant-cu rrent sour ce ohmmeter. You simply select an

ohms measurement range (or auto range) and t ake the reading from the display.

In manual ohms, the SourceMeter uses the V/I meas

(V or I) and selecting a voltage or current measurement range, the Ω measurement function will

splay the calculated V/I ohms reading.

di

be set higher than the voltage that is being measure d. Failure to do so

could result in instrument damage due to excessive current that will flow

into the SourceMeter.

and NEVER select a measurement range that is below the applied signal

level. Otherwise, high current drawn from the external source could

damage the external source or the test circuit.

urement method. After configuring the sour ce

1-12 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 20

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

Use the following menu sequence to select the auto ohms or ma nua l oh ms meas ure ment metho d:

Press CONFIG > press MEAS Ω > select SOURCE > select AUTO or MANUAL

Ohms source readback

With source readback enabled, the SourceMeter measures both V and I and uses these values for

the ohms calculation. This feature provides optimum accuracy for front panel operation since the

measured source value is more accurate than the programmed source value. For remote

operation, the user specifies the functions to measure.

Use the following menu sequence to enable or disable source readback:

Press CONFIG > press MEAS Ω > select SRC RDBK > select ENABLE or DISABLE

Ohms measurement procedures

The auto ohms and manual ohms measurement procedures are provided in Tables 4 and 5. They

assume that the DUT is already connected to the SourceMeter . (See Basic con nections.) Note that

resistance accuracy specifications are based on 4-wire sensing.

Table 1-4

Auto ohms measurement procedure

Procedure Details

1. Select ohms measurement

function.

2. Select auto ohms

measurement method.

3. Select measurement range. Use RANGE arrow keys to manually select

4. Turn output on and take

readings from display.

5. Turn output off when finished. Press ON/OFF OUTPUT key. Red OUTPUT

Press MEAS Ω.

Press CONFIG > press MEAS Ω > select

SOURCE > select AUTO.

range. Or press AUTO RANGE (AUTO

annunciator on) to enable auto range.

Press ON/OFF OUTPUT key. Red OUTPUT

indicator on.

indicator off.

Table 1-5

Manual ohms measurement procedure

Procedure Details

1. Select ohms measurement

function.

2. Select manual ohms measure-

ment method.

3. Select source, set source level,

and set compliance limit.

4. Select measurement range (see

Notes 1 and 2).

5. Turn output on and take readings

from display.

6. Turn output off when finished. Press ON/OFF OUTPUT key. Red OUTPUT indi-

Notes

1. If sourcing I, you will be selecting the V measure range. If sour

measure range.

2. The compliance range determines the maximum measurement range that can be selected.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-13

Press MEAS Ω.

Press CONFIG > press MEAS Ω > select SOURCE

> select MANUAL.

See steps 1, 2, and 3 of Table 2.

Use RANGE arrow keys to manually select range.

Or press AUTO RANGE (AUTO annunciator on) to

enable auto range.

Press ON/OFF OUTPUT key. Red OUTPUT indicator on.

cator off.

cing V, you will be selecting the I

Page 21

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Offset-compensated ohms

Thermal EMFs can corrupt low-resistance measurements. An offset-compensated Ω

measurement cancels out unwanted offset by performing the following 2-point measurement

process:

Offset-Compensated Ω = ΔV / ΔI

where:ΔV = V2 - V1

ΔI = I2 - I1

V1 and I1 are V and I measurements with the source set to a specific level.

V2 and I2 are V and I measurements with the source set to zero .

1. Select the Ω function, and select the auto or manual ohms measurement method.

2. Enable offset compensation by using the following menu sequence:

3. Press CONFIG > press MEAS Ω > select OFFSET COMPENSATION > select ENABLE

4. If using auto ohms, go to the next step. For manual ohms, configure the desired source (V

or I) to output an appropriate source leve l. Set compliance and select a measurement range

(or use auto range).

5. Turn the output on and observe the offset-compensated ohms reading on the display. Note

that the source value alternates between the set output level and zero.

6. When finished, turn the output off and disable offset compensation.

NOTE Manual offset-compensated ohms is also available as a math

function (FCTN). This math function allows you to specify both source

levels (see “Math functions” in “Features to enhance DUT testing.”

In-circuit ohms measurements

Ohms guard allows you make accurate in-circuit ohms measurements on resistor networks. These

measurements are covered in Advanced operation.

Remote command programming

Data string

The :READ? command is typically used to trigger a source-measure action and request the data

string. The data string is sent to the computer when the SourceMeter is addressed to talk.

The data string is typically made up of five element

the voltage reading, the second is the current reading, and the third is the resistance reading. For

voltage and current, the reading could be source or measure depending on how the instrument is

configured. For example, if sourcing voltage and measuring curren t, the voltage element is the

source reading and the current element is the measured reading. The NAN (not a numb er) value

of +9.91e37 is used for a function that is not enabled.

The fourth data element is the timestamp and the

subsystem, of the 2400 Series SourceMeter User’s Manual for details on all aspects of the data

format.

s separated by commas. The first element is

fif

th is the status word. See Section 18, FORMat

1-14 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 22

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

NOTE The five element data string is the GPIB default cond itio n.

SCPI commands

SCPI commands to source-measure and measure only are provided in Table 6, and the

commands to measure ohms are provided in Table 7.

Table 1-6

SCPI commands; source-measure and measure only

Command

2

Description

1

:SOURce:FUNCtion <name> Select source function; <name> = VOLTage or CURRent.

:SOURce:xxx:MODE FIXed Select fixed V or I sourcing mode.

:SOURce:xxx:RANGe <n> Select measurement range for V or I source; <n> = range.

:SOURce:xxx:LEVel <n> Set source amplitude; <n> = amplitude in volts or amps.

[:SENSe]:FUNCtion <name> Select measure function; <name> = “VOLTage” or “CUR-

Rent”.

[:SENSe]:xxx:PROTection <n> Set V or I compliance; <n> = compliance.

[:SENSe]:xxx:RANGe <n> Select V or I measure range; <n> = range.

[:SENSe]:xxx:RANGe:AUTO

Enable or disable auto range; <b> = ON or OFF.

<b>

:OUTPut <b> Turn output on or off; <b> = ON or OFF.

:READ? Trigger and acquire one data string.

1. For measure only, the following rules apply (Table 9 provides an example to measure I only):

a. To measure V only, you must source I. To measure I only

b. The source must be set to 0V or 0A.

c. When measuring V only, DO NOT use auto range.

d. When measuring V only, voltage compliance MUST be set higher th

2. :xxx = :VOLTage or :CURRent.

, you must source V.

an the volt

age being measured.

Table 1-7

SCPI commands; measure ohms

Command Description

[:SENSe]:FUNCtion “RESistance” Select ohms function.

[:SENSe]:RESistance:MODE <name> Select ohms mode; <name> = AUTO or MANual*.

[:SENSe]:RESistance:OCOMpensated

Enable/disable offset compensation.

<b>

[:SENSe]:RESistance:RANGe <n> Select range for auto ohms; <n> = range.

[:SENSe]:RESistance:RANGe:AUTO

<b>

:OUTPut <b

> Turn output on or off; <b> = ON or OFF.

Enable or disable auto range for auto ohms; <b> =

ON or OFF.

:READ? Trigger and acquire one data string.

*For manual ohms, you must configure the SourceMeter to source-measure. T able 11 provides a programming

example to measure ohms using the manual ohms method.

Programming examples

Source-measure example — Table 8 shows a typical command sequence to source 10V and

measure current on the 10mA range.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-15

Page 23

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Measure-only example — Table 9 shows a typical command sequence to measure current only.

Table 1-8

Command sequence for source-measure example

Command* Comments

*RST Restore GPIB defaults (one-shot source-measure

mode).

:SOUR:FUNC VOLT Select voltage source function.

:SOUR:VOLT:MODE FIX Select fixed voltage source mode.

:SOUR:VOLT:RANG 20 Select 20V source range.

:SOUR:VOLT:LEV 10 Set source output level to 10V.

:SENS:FUNC “CURR” Select current measurement function.

:SENS:CURR:PROT 10e-3 Set compliance limit to 10mA.

:SENS:CURR:RANG 10e-3 Select the 10mA measurement range.

:OUTP ON

Turn the output on.

:READ? Trigger and acquire one data string.

*SourceMeter must be addressed to talk after sending :READ? to trigger and acquire data.

Table 1-9

Command sequence for measure current only example

Command* Comments

*RST Restore GPIB defaults (one-shot measure mode).

:SOUR:FUNC VOLT Select voltage source function.

:SOUR:VOLT:MODE FIX Select fixed voltage source mode.

:SOUR:VOLT:RANG 0.2 Select 200mV source range.

:SOUR:VOLT:LEV 0 Set source output level to 0.000mV.

:SENS:FUNC “CURR” Select current measurement function.

:SENS:CURR:PROT 100e-3 Set compliance limit to 100mA.

:SENS:CURR:RANG 10e-3 Select the 10mA measurement range.

:OUTP ON

:READ? Trigger and acquire one data string.

*SourceMeter must be addressed to talk after sending :READ? to trigger and acquire data.

Turn the output on.

Auto ohms example — Table 10 shows a typical command

sequence to use auto ohms to

measure resistance. Note that 4-wire sensing is used for this example. See Basic connections for

details on sensing.

Manual ohms example — Table 11 shows a typical command sequence to use manual ohms to

measur

e resistance. This example uses auto range for current measurements. If you were to use

manual ranging, you should select the lowest possible current rang e for the measurement. For

example, to measure a 1MΩ resistor with the source set to 2V, the 1µA measure range should be

cted

sele

ex

1-16 Return to Section Topics 2400S-903-01 Rev. E / September 2011

to achieve the best accuracy (2V/1µA = 2MΩ). Note that 2-wire sensing is used for this

ample. See Basic connections for details on sensing.

Page 24

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

Table 1-10

Command sequence for auto ohms example

Command* Comments

*RST Restore GPIB defaults (one-shot measurement mode).

:SENS:FUNC “RES” Select ohms measurement function.

:SENS:RES:RANG 200 Select 200Ω range.

:SENS:RES:MODE AUTO Select the auto ohms measurement method.

:SYST:RSEN ON Select 4-wire sense mode.

:OUTP ON

:READ? Trigger and acquire one data string.

*SourceMeter must be addressed to talk after sending :READ? to trigger and acquire data.

Turn the output on.

Table 1-11

Command sequence for manual ohms example

Command* Comments

*RST Restore GPIB defaults (one-shot measurement mode).

:SENS:FUNC “RES” Select ohms measurement function.

:SENS:RES:MODE MAN Select the manual ohms measurement method.

tion.

:SOUR:FUNC VOLT Select voltage source fun

:SOUR:VOLT:MODE FIX Select fixed voltage sourcing mode.

:SOUR:VOLT:RANG 2 Select 2V source range.

:SOUR:VOLT:LEV 2 Set source level to 2V.

:SENS:CURR:PROT 10e-3 Set current compliance to 10mA.

:SENS:CURR:RANG:AUTO ONSelect auto range for current measurements.

c

:SYST:RSEN OFF Select 2-wire sense mode.

:OUTP ON

:READ? Trigger and acquire one data string.

*SourceMeter must be addressed to talk after sending :READ? to trigger and acquire data.

Turn the output on.

Settings to optimize performance

Range

To achieve best accuracy, the SourceMeter should be on the lowest possible measurement range.

In most situations, auto range can be used to automatically select the best range. Auto range is

controlled (enabled/disabled) by the AUTO rang e key (AUTO annunciator indicates auto range is

enabled).

RANGE

disables auto range.

arrow keys are used for manual range selection. Note that pressing either of these keys

NOTE Basic ranging information (including the SCPI commands for remote

operation) is covered in “Fundamental source- measure operations.”

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-17

Page 25

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Speed

Measurement speed is set by setting the integration time of the A/D converter (period of time the

input signal is measured). Integration time affect s the usable digits, readin g noise, and the ultimate

reading rate of the instrument. It is specified in parameters based on the number of power line

cycles (NPLC), where 1 PLC for 60Hz is 16.67msec (1/60), and 1 PLC for 50Hz and 400Hz is

20msec (1/50).

Digits

In general, the fastest speed setting (FAST; 0.01 PLC) results in increased

display digits. The slowest speed (HI ACCURACY; 10 PLC) provides the best commo n- mod e and

normal-mode noise rejection. In between settings are a compromise between speed and noise.

Press SPEED and select one of the followi

FAST Sets speed to 0.01 PLC and display resolution to 3H-digits.

MED Sets speed to 0.10 PLC and display resolution to 4H-digit

NORMAL Sets speed to 1.00 PLC and display resolution to 5H-digit

HI ACCURACY Sets speed to 1.00 PLC and display resolution to 5H-digit

OTHER Use to set speed to any PLC value from 0.01 to 10. Display reso-

lution is not changed after speed is set with this option.

NOTE After setting speed, display resolution can be changed using the

DIGITS key.

The SourceMeter can display readings at 3H-digit, 4H-digit, 5H-digit or 6H-digit resolution. In situations

where the last digits of the reading are noisy, you can turn those digits off by decreasing display

resolution.

ng speed setting options:

noise and fewer usable

s.

s.

s.

Filter

To set display resolution, press the

Another way to set display resolution is with the following menu sequence:

Press CONFIG > press DIGITS > select 3.5, 4.5, 5.5, or 6.5.

NOTE Changing DIGITS does not affect measurement SPEED, but

changing measurement speed does affect DIGITS.

Filtering is used to stabilize noisy readings. In general, the more filtering that is applied, the more

stable (and accurate) the reading. However, more filtering also means slower speed.

The filtering process consists of filling a stack wi

(filter count), and then averaging them to yield a filtered reading. The SourceMeter has two filter

types; moving and repeating.

DIGITS key until the desired number of digits are displayed.

th the specified number of reading conversions

Repeating filter

The stack is filled with the specified number of reading conversions. The reading conversions are

averaged to yield a filtered reading. The stack is then cleared, and the process starts over. Use

this filter for sweeping so readings for other source levels are not averaged with the present

source level.

1-18 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 26

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

Moving filter

The first reading conversion is placed in the stack, and is copied to the other stack locations to fill

it. Therefore, the first filtered reading is the same as the first reading conversion. The stack type is

first-in, first-out. Each subsequent conversion replaces one of the copied readings in the stack,

which is then averaged to yield the next filtered reading. Note th at as this process continues, a true

average is not yielded until the stack is filled with new reading conversions (no copies in stack).

Once the stack is filled, each subsequent conversion placed into the st

conversion. The stack is re-averaged, yielding a new filtered reading.

Response time

Filter type and count have the following effects on the time needed to display, store, or output a

filtered reading:

• Filter type: The moving filter type yields faster filtered readings

the entire stack (as is the case for the repeating filter) .

• Filter count: Speed and accuracy are trade-of

filtering to achieve acceptably stable readings.

Filter configuration

Filter type — Use the following menu sequence to select filter type:

Press CONFIG > press FILTER > select AVERAG

Filter count — Us

Press CONFIG > press FILTER > select AVERAG

Rel (nulling offsets)

The rel (relative) feature allows you to null offsets. With the offset displayed (measure d) , en ab lin g

rel acquires the offset reading as the rel value and zeroes the display as follows:

ack replaces the oldest

since it doesn’t have to re-fill

fs. T

ypically , you will want to apply just enough

E MODE > select MOVING or REPEAT

e the following menu sequence to select the amount of filtering:

E COUNT, set count value (1 to 100)

Displayed Reading = Actual Input - Rel Value

Since the actual input (offset) and the rel value are th

Rel is enabled by pressing the REL key (REL annunciator on). Pressing REL a second time

disa

bles it. Perform the following steps to null out an offset:

1. Connect your test circuit

2. Select the source function that you are going to use for your test.

3. Select the lowest source range and set the source level to zero.

4. Select the measure function that you are going to use for your test, and select the lowest

range.

5. Turn the output on to measure the offset.

6. With the offset reading displayed, press REL (REL annunciator on) to zero the display. Turn

the output off and configure the selected source and measure functions for your test.

7. Turn the output back on. The displayed test readings will not include the nulled offset.

8. When finished, turn the output off.

If the offset drifts, disable rel and repe at the above procedure to null out the new offset.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-19

to the SourceMeter.

e same, the displayed reading is zero.

Page 27

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

NOTE Rel can also be used to establish a baseline reading. The baseline

reading will be subtracted from present and future readings. See

“Relative” in Section 8 of the 2400 Series SourceMeter User’s

Manual for details.

Remote command programming

The SCPI commands for speed, digits, filter, and rel are listed in Table 12. The commands for

ranging are listed in Tables 6 and 7.

Table 1-12

SCPI commands; speed, digits, filter, and rel

Command Description

1

Speed commands

[:SENSe]:CURRent:NPLCycles <n> Set measurement speed; <n> = 0.01 to 10.

[:SENSe]:VOLTage:NPLCycles <n> Set measurement speed; <n> = 0.01 to 10.

[:SENSe]:RESistance:NPLCycles

<n>

:

Set measurement speed; <n> = 0.01 to 10.

Digits command:

:DISPlay:DIGits <n> Set display resolution; <n> = 4, 5, 6, or 7.

Filter commands:

[:SENSe]:AVERage:TCONtrol

<name>

[:SENSe]:AVERage:COUNt <n> Set filter count; <n> = 1 to 100.

[:SENSe]:AVERage <b> Enable/disable filter; <b> = ON or OFF.

2

Rel command

:CALCulate2:NULL:STATe <b> Enable/disable rel; <b> = ON or OFF.

1. The speed setting is global for all functions. Therefore, you can use any of the three commands to set speed.

1. The commands to acquire a rel value are not listed in this table (see Section 8, Relative in

t

he 2400 Series SourceMeter User’s Manual).

:

Features to enhance DUT testing

Data store

The data store (buffer) can store from 1 to 2500 readings, and provides statistical data on the

stored readings.

Select filter type; <name> = REPeat or MOVing.

Storing readings

To store readings, press STORE, key in the number of readings to store, and press ENTER. The

star (*) annunciator indicates that the buffer is enabled. To start the storage process, turn the

output on and (if necessary) trigger the unit. The star (*) annunciator turns off after storage is

completed.

1-20 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 28

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

Recalling readings

To recall readings, press the RECALL key. The buffer location number is the memory location of

the recalled reading. Location #0000 indicates that the displayed reading is stored at the first

memory location. To display other stored readings, use the edit keys to change the buffer location

number. To exit from the recall mode, press EXIT.

Timestamp — Just

below the buffer location number is the timestamp (in seconds) for the

reading. It can be referenced to the first reading stored in the buf fer ( absolute tim estamp ), or it ca n

indicate the time between buffer readings (delt a timestamp). If the absolute timestamp is selected,

the @ symbol precedes the timestamp value. If the delta timestamp is selected, the δ symbol

r

ecedes the timestamp value. Regardless of which timestamp is selected , the first reading is

p

always timestamped at zero seconds.

To change the timestamp, exit from the recall mode

Press CONFIG > press STORE > select ABSOLUTE or DEL

and use the following menu sequence:

TA

NOTE While in the recall mode, buffer statistics (minimum, maximum, peak-

to-peak, average and standard de viati on) can be displa yed u sing the

TOGGLE key . Details about buffer statistics are provided in Section 9

of the 2400 Series SourceMeter User’s Manual.

Remote command programming

SCPI commands

SCPI commands to configure and control the buffer are listed in Table 13.

NOTE Table 13 does not provide a complete listing of buffer commands.

Documentation for all buffer commands (including the ones for buffer

statistics) can be found in Section 9 of the 2400 Series SourceMeter

User’s Manual.

Table 1-13

SCPI commands; data store

Command Description

:TRACe:POINts <n> Specify buffer size; <n> = 1 to 2500

:TRACe:FEED <name> Specify reading source; <name> = SENSe (raw

ing

s), CALCulate (math readings), or

read

CALCulate2 (limits readings).

:TRACe:TSTamp:FORMat <name> Select timestamp format;

DELTa.

:TRACe:FEED:CONTrol <name> Enable/disable buffer; <name> = NEXT (fill buffer

stop) or NEVer (disable buffer).

and

:TRACe:DATA? Read contents of buffer.

:TRACe:CLEar Clear buffer.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-21

<name> = ABSolute

or

Page 29

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Programming example

Table 14 shows a typical command sequence to store and recall readings from the buffer.

Table 1-14

Command sequence for data store example

Command* Comments

*RST Restore GPIB defaults.

:SOUR:VOLT 10 Set voltage source to 10V.

:TRAC:POINts 10 Set buffer size to 10.

:TRIG:COUN 10 Trigger count equals number of readings.

:TRAC:FEED SENS Set to store raw readings.

:TRAC:FEED:CONT NEXT Enable buffer.

:OUTP ON Turn on output.

:INIT Trigger readings.

:TRAC:DATA? Request raw buffer readings.

*SourceMeter must be addressed to talk after sending :TRAC:DATA? to acquire data.

Sweep operation

Sweep types

The four available sweep types are linear staircase, logarithmic staircase, custom, and source

memory.

Linear staircase sweep

When the sweep shown in Figure 7 is triggered to start, the output w

source level. The bias level is the initial source level prior to the start of the sweep. The output will

then change in equal steps until the stop source level is reached . With trigger delay set to zero, the

time duration at each step is determined by the source delay and the time it takes to perform the

measurement.

With the desired source (V or I) selected, use the follo

and step source levels:

Press CONFIG > press SWEEP > select TYPE > select

After selecting STAIR, you will be prompted to enter the STAR

ill go from the bias level to the

win

g menu sequence to set the start, stop

STAIR

T, STOP and STEP levels.

1-22 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 30

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

Delay

Delay

Delay

Delay

Start

Bias

Stop

Step

Step

Step

Measure Measure Measure Measure

X = Measurement point

X

X

X

X

Figure 1-7

Linear staircase sweep

Logarithmic staircase sweep

This sweep is similar to the linear staircase sweep. The steps, however, are done on a logarithmic

scale. The symmetrical log

points for the steps are determined by the specified number of sweep

points. Figure 8 shows a 5-point log sweep from 1 to 10V.

With the desired source (V or I) selected, use the following menu sequence to set the start and

stop levels, and

Press CONFIG > press SWEEP > select TYPE > select

After selecting LOG, you will be prompted to enter the STAR

the number of sweep points (2 to 2500):

LOG

T and STOP levels, and the NO OF

POINTS.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-23

Page 31

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Delay

Delay

Delay

Delay

Start

Bias

Stop

(10)

Measure

#1

Measure

#2

Measure

#3

Measure

#5

X = Measurement Point

X

X

X

X

Delay

X

Measure

#4

Log Points = 5

1

10

5.6234

3.1623

1.7783

Volts

Log

Scale

Figure 1-8

Logarithmic staircase sweep (example)

Custom sweep

For a custom sweep, the user specifies the number o

f point in a sweep, and the source level at

each point. Figure 9 shows a 6-point, 50% duty cycle pulse sweep. The specified voltage level at

points P0, P2 and P4 is 1V, while the voltage level at P1, P3 and P5 is 0V.

With the desired source (V or I) selected, use the fo

llowing menu sequence to specify the number

of sweep points and the source level at each point:

Press CONFIG > press SWEEP > select TYPE > select

After selecting CUSTOM, these menu items will be

# POINTS - Use to specify the number of points in the sweep (1 to 2500)

ADJUST POINTS - Use to set the source level at each point in t

sweep is P0000. After setting the level for P0000, incr ement the pointer to P0001 and set the level

for that point. In a similar manner, set the level for each point in the sweep.

INIT - This option allows you to set a consecutive rang

selecting INIT, you will be prompted to enter the source VALUE, the START PT (point), and the

STOP PT (point). For example, if you want points 10 through 15 to be 1V, set VALUE to 1V, START

CUSTOM

displayed:

he sweep. The first point in the

e of sweep points to a specified level. After

PT to 10, and STOP PT to 15.

1-24 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 32

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

Delay

P1

Measure

#1

P0

Measure

#2

Delay

Delay

P3

Measure

#3

P2

Measure

#4

Delay

Delay

P5

Measure

#5

P4

Measure

#6

Delay

Bias 0V

1V

Bias

Figure 1-9

Custom pulse sweep (example)

Source memory sweep

For a source memory sweep, up to 100 setup configurations can be saved in memory. When the

sweep

is run, the setup at each memory point is recalled. This allows multiple functions and math

expressions to be used in a sweep.

A SourceMeter setup configuration is saved in memor

y by performing the following menu

sequence:

Press MENU > select SAVESETUP > select SO

After selecting SAVE, you will be prompted to enter the memory loc

URCE MEMORY > select SAVE

ation where you want to store

the setup.

After saving all your test setups in concurrent memor

y locations, use the following menu sequence

to configure the sweep:

Press CONFIG > press SWEEP > select TYPE >

After selecting SRC MEMORY, the followi

ng menu items will be displayed:

START - Use this menu item to set the starting memory location

select SRC MEMORY

for the sweep. For example, if

your first setup is stored in memory location 001, set the start point to 001.

# POINTS - Use to specify the number of points (memor

y locations) in the sweep. For example, if

there are 10 points in the sweep, set the number of points to 010.

NOTE NPLC caching can be used to speed up source memory sweeps. See

“NPLC caching” in Section 3 of the 2400 Series User’s Manual.

Sweep count

For front panel operation, a sweep can automatically repeat a specified number of times (finite

sweep count) or it can repeat continuously (infinite sweep count).

For a finite count sweep, the readings ar

e automatically stored in the buffer . The maximum numbe r

of finite sweeps that can be performed is determined as follows:

Maximum finite sweep count = 2500 /

For an infinite sweep count, the readings are no

Use the following menu sequence to set sweep count:

Press CONFIG > press SWEEP > select SWEEP COUNT > select FINITE or

# points in sweep.

t stored in the buffer.

INFINITE

If you select FINITE, you will be prompted to enter the sweep count.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-25

Page 33

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Source ranging

There are three options to control source ranging for a sweep; fixed, best fixed, and auto range.

With the fixed option selected, the SourceMeter stays on the source range that is selected at the

start of the sweep.

With best fixed selected, the largest

example, if sweeping from 1V to 15V, the best fixed option will select the 20V range.

With the auto range option selected, the SourceMeter will s

source value. For example if sweeping from 1V to 15V in 1V steps, the SourceMeter will source 1V

and 2V on the 2V range, and source the remaining source values on the 20V range.

Use the following menu sequence to select the source ranging option:

Press CONFIG > press SWEEP > select SOURCE RANGING >

RANGE or FIXED

source value in the sweep determines the range. For

elect the most sensitive range for each

select BEST FIXED, AUTO

Source delay

Source delay allows the source to settle before a measurement is performed. As shown in Figures

6, 7, and 8, the delay occurs on each step (level) of the sweep. The delay can be set automatically

by the SourceMeter (auto delay) or it can be set manually.

With auto delay selected, the delay setting will be1ms, 2ms or 3ms

range and source function is being used (see Section 3, Source delay in the 2400 Series

SourceMeter User’s Manual). Manually, the source delay can be set from 0000.0000 to 9999.9980

sec.

Use the following menu sequence to set source delay:

Press CONFIG > press SOURCE V

If DELAY is selected, you will be prompted to enter the delay

is selected, you will be prompted to DISABLE or ENABLE auto delay.

(or I) > select DELAY or AUTO DELAY

depending on which current

value (in seconds). If AUTO DELAY

Performing sweeps

Performing a linear staircase sweep

Perform the following steps to run a linear staircase sweep:

1. Configure the source and measure functions. The so

level for the sweep. T ypically, 0V or 0A is used as the bias level.

2. Configure the linear staircase sweep, including start, stop, and step values, as previously

explained.

3. Set the source delay as required.

4. Turn the output on. The SourceMeter will output the bias level.

5. Run the sweep by pressing the SWEEP key. When finished, turn the output off.

urce level you set becomes the bias

1-26 Return to Section Topics 2400S-903-01 Rev. E / September 2011

Page 34

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

The readings will be stored in the buffer if a finite count sweep was run.

Performing a log staircase sweep

Perform the following steps to run a log staircase sweep:

1. Configure the source and measure functions. The so

level for the sweep.

2. Configure the log staircase sweep, including start and stop values and number of points, as

previously explained.

3. Set the source delay as required.

4. Turn the output on. The SourceMeter will output the bias level.

5. Run the sweep by pressing the SWEEP key. When finished, turn the output off.

buf

The readings will be stored in the

fer if a finite count sweep was run.

urce level you set becomes the bias

Performing a custom sweep

Perform the following steps to run a custom sweep:

1. Configure the source and measure functions. The so

level for the sweep.

2. Configure the custom sweep by choosing the number of points and initial value. Also be

sure to adjust individual sweep points as required.

3. Set the source delay.

4. Turn the output on. The SourceMeter will output the bias level.

5. Run the sweep by pressing the SWEEP key. When finished, turn the output off.

buf

The readings will be stored in the

fer if a finite count sweep was run.

urce level you set becomes the bias

Performing a source memory sweep

Perform the following steps to run a source memory sweep:

1. Configure and save source and measure functions for each sweep point in individual source

memor

2. Configure the source memory sweep by choosing the start me mory location and num ber of

points.

3. Turn the output on.

4. Run the sweep by pressing the SWEEP key. When finished, turn the output off.

The readings will be stored in the

y locations, as previously explained.

fer if a finite count sweep was run.

buf

Remote command programming

SCPI commands

SCPI commands for linear, logarithmic and custom sweeps are listed in Table 15.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-27

Page 35

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

NOTE Table 15 does not provide a complete listing of sweep commands.

Documentation for all sweep commands can be found in Section 10

of the 2400 Series Source-Meter User’s Manual

.

Table 1-15

SCPI commands; sweeping

Command

:SOURce:xxx:MODE <name> Select source mode; <name> = FIXed, LIST or

:SOURce:DELay <n> Set source delay; <n> = 0 to 9999.9980 (sec).

:SOURce:DELay:AUTO <b> Enable/disable auto delay; <b> = ON or OFF.

:TRIGger:COUNt <n> Set trigger count; <n> = Number of points in

Linear and logarithmic sweeps:

:SOURce:SWEep:SPACing

ame>

<n

:SOURce:SWEep:RANGing

ame>

<n

:SOURce:xxx:STARt <n> Specify sweep start level; <n> = V or I source

:SOURce:xxx:STOP <n> Specify sweep stop level; <n> = V or I source

:SOURce:xxx:STEP <n> Specify linear sweep step level; <n> = V or I

:SOURce:SWEep:POINts <n> Set number of sweep points; <n> = 2 to 2500.

*

Description

SWEep.

sweep.

ct sweep scale; <name> = LINear or

Sele

LOGarithmic.

Select source ranging: <name> = BEST

or

FIXed.

value.

value.

source

value.

, AUTO,

Custom (list) sweep:

:SOURce:LIST:xxx <list> Define source list; <list> = value1, value2, ...

valueN.

= value1, value2,

:SOURce:LIST:xxx:APPend <list> Add source list value(s); <l

...

valueN.

:SOURce:LIST:xxx:POINts? Query length of source list.

Source memory sweep:

:SOURce:FUNCtion MEM Select source memory sweep mode.

:SOURce:MEMory:SAVE <n> Save setup in memory location; <n>

:SOURce:MEMory:RECall <n> Return to specified setup; <n> = 1 to 100.

:SOURce:MEMory:STARt <n> Set source memory start location; <n> = 1 to 100.

:SOURce:MEMory:POINts <n> Specify number of sweep points; <n> = 1 to 100.

*:xxx = :VOLTage or :CURRent.

1-28 Return to Section Topics 2400S-903-01 Rev. E / September 2011

ist>

= 1 to 100.

Page 36

Series 2400 SourceMeter® Quick Start Guide Section 1: Introduction

Programming examples

Programming examples for a linear, logarithmic, custo

m, and source memory sweep are provided

in Table 16.

Table 1-16

Command sequences for sweep examples

Command* Comments

Linear staircase sweep: See Figure 6

*RST Restore GPIB defaults (source V, measure I).

:SOUR:VOLT 0 Set bias level to 0V.

:SOUR:DEL 0.1 Set delay to 100ms.

:SOUR:SWE:RANG BEST Select best source ranging.

:SOUR:VOLT:MODE SWE Select the sweep source mode.

:SOUR:SWE:SPAC LIN Select the linear sweep scale.

:SOUR:VOLT:STAR 1 Set start level to 1V.

:SOUR:VOLT:STOP 10 Set stop level to 10V.

:SOUR:VOLT:STEP 1 Set step level to 1V.

:TRIG:COUN 10 Set trigger count to 10.

:OUTP ON Turn output on.

:READ? Trigger sweep and acquire data.

Logarithmic staircase sweep: See Figure 7

*RST Restore GPIB defaults (source V, measure I).

:SOUR:VOLT 0 Set bias level to 0V.

:SOUR:DEL 0.1 Set delay to 100ms.

:SOUR:SWE:RANG BEST Select best source ranging.

:SOUR:VOLT:MODE SWE Select the sweep source mode.

:SOUR:SWE:SPAC LOG Select the log sweep scale.

:SOUR:VOLT:STAR 1 Set start level to 1V.

:SOUR:VOLT:STOP 10 Set stop level to 10V.

:SOUR:SWE:POIN 5 Set number of sweep points to 5.

:TRIG:COUN 5 Set trigger count to 5.

:OUTP ON Turn output on.

:READ? Trigger sweep and acquire data.

Custom (list) sweep: See Figure 8

*RST Restore GPIB defaults (source V, measure I).

:SOUR:VOLT 0 Set bias level to 0V.

:SOUR:DEL 0.1 Set delay to 100ms.

:SOUR:SWE:RANG BEST Select best source ranging.

:SOUR:VOLT:MODE LIST Select the list source mode.

:SOUR:LIST:VOLT 1, 0, 1, 0, 1, 0 Specify source list (1V, 0V, 1V, 0V, 1V and 0V).

:TRIG:COUN 6 Set trigger count to 6.

:OUTP ON

:READ? Trigger sweep and acquire data.

*SourceMeter must be addressed to talk after sending :READ? and :CALC:DATA? to acquire data.

2400S-903-01 Rev. E / September 2011 Return to Section T o pics 1-29

Turn output on.

Page 37

Section 1: Introduction Series 2400 SourceMeter® Quick Start Guide

Table 1-16 (cont.)

Command sequences for sweep examples

Command* Comments

Source memory sweep: Three point sweep; source V, calculate power,

source I.

‘Memory location 001 setup:

*RST Restore GPIB defaults

:SOUR:VOLT:LEV 15 Set voltage source to 15V.

:SOUR:MEM:SA VE 1 Save setup in memory location 001.

‘Memory location 002 setup: