Page 1

Service Manual

1503C

Metallic Time-Domain Reflectometer

070-7170-05

This document applies to firmware version 5.04

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved. T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation and Repacking xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Instructions

Operating Instructions 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing to Use the 1503C 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front-Panel Controls 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Selections 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Preparations 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable T est Procedure 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Features (Menu Selected) 1–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Performance Checks

Operator Performance Checks 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Specifications 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Characteristics 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Characteristics 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options and Accessories

Options and Accessories 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 04: YT–1 Chart Recorder 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 05: Metric Default 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 06: EthernetR 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 07: YT–1S Chart Recorder 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 08: T oken Ring Adapter 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 09: Universal Service Ordering Code 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 10: T oken Ring Interface 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Options 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1503C MTDR Service Manual

i

Page 6

Table of Contents

Circuit Descriptions

Circuit Descriptions 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Processor System 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option Port Interface 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Video Processor 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timebase 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Generator/Sampler 5–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 5–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Module 5–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 06 (EthernetR) 5–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration and Adjustments

Calibration 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Performance Check 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Module Check 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Check 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horizontal Scale (Timebase) Check 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vertical Position (Offset) Check 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise Check 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impedance Check 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset/Gain Check 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAM/ROM Check 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Balance Check 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Width Check 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto Pulse Select Check 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jitter Check 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aberrations Check 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Amplitude Check 6–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 04/07: YT-1/YT-1S Chart Recorder Check 6–30. . . . . . . . . . . . . . . . . . . . . . .

Option 05: Metric Default Check 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 06: EthernetR Adapter Checks 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures 6–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Visual Inspection 6–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Checks and Adjustments 6–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Board "12 VDC Check and Adjust 6–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD Check and Adjustment 6–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulser/Sampler Voltage Check 6–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sampling Efficiency Adjustment 6–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1st Blow-By Compensation Adjustment 6–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Impedance Check 6–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 06: EthernetR Adapter Adjustments 6–58. . . . . . . . . . . . . . . . . . . . . . . . . . . .

After Adjustments are Completed 6–59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

1503C MTDR Service Manual

Page 7

Maintenance

Maintenance 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part Removal and Replacement 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Installation 7–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Case Cover Over the Chassis 7–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Replaceable Electrical Parts 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Replaceable Mechanical Parts

Replaceable Mechanical Parts 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary

Index

1503C MTDR Service Manual

iii

Page 8

Table of Contents

List of Figures

Figure 1–1: Rear Panel Voltage Selector, Fuse, AC Receptacle 1–1. . . . .

Figure 1–2: Display Showing Low Battery Indication 1–4. . . . . . . . . . . .

Figure 1–3: 1503C Front-Panel Controls 1–5. . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Display and Indicators 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–5: Vp Set at .30, Cursor Beyond Reflected Pulse

(Setting Too Low) 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–6: Vp Set at .99, Cursor Less Than Reflected Pulse

(Setting Too High) 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–7: Vp Set at .66, Cursor on Rising Edge of Reflected Pulse

(Set Correctly) 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–8: 20-ft Cable at 5 ft/div 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–9: Short in the Cable 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–10: Open in the Cable 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–11: 455-ft Cable 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–12: 455-ft Cable with 20 ft/div, Cursor Off Screen 1–16. . . . . . . .

Figure 1–13: Return Loss 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–14: Reflection Adjusted to One Division in Height 1–17. . . . . . .

Figure 1–15: Display with VIEW INPUT Turned Off 1–18. . . . . . . . . . . . .

Figure 1–16: Display of a Stored Waveform 1–19. . . . . . . . . . . . . . . . . . . .

Figure 1–17: Display of a Stored Waveform and Current Waveform 1–19.

Figure 1–18: Display of a Stored Waveform, Current Waveform,

and Difference Waveform 1–20. . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–19: Waveform Moved to Top Half of Display 1–20. . . . . . . . . . . .

Figure 1–20: Current Waveform Centered, Stored Waveform

Above 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–21: Current Waveform Center, Stored Waveform Above,

Difference Below 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–22: Waveform of Three-Foot Lead-in Cable 1–22. . . . . . . . . . . . .

Figure 1–23: Cursor Moved to End of Three-Foot Lead-in Cable 1–23. . . .

Figure 1–24: Cursor Moved to End of Three-Foot Lead-in Cable 1–23. . . .

Figure 1–25: Cursor Moved to 0.00 ft 1–24. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–26: Incident Pulse at Four Divisions, FILTER at

Desired Setting 1–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–27: Waveform Viewed in Normal Operation 1–25. . . . . . . . . . . . .

Figure 1–28: Waveform Showing Intermittent Short 1–26. . . . . . . . . . . . . .

Figure 1–29: Waveform Display with No Outgoing Pulses 1–26. . . . . . . . .

iv

1503C MTDR Service Manual

Page 9

Table of Contents

Figure 1–30: A Captured Single Sweep 1–27. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Start-up Measurement Display 2–2. . . . . . . . . . . . . . . . . . . .

Figure 2–2: Measurement Display with 10-foot Cable 2–2. . . . . . . . . . .

Figure 2–3: Cursor at End of 10-foot Cable 2–3. . . . . . . . . . . . . . . . . . . .

Figure 2–4: Cursor at End of 10-foot Cable, Vp Set to .30 2–3. . . . . . . .

Figure 2–5: Flatline Display Out to 50,000+ Feet 2–4. . . . . . . . . . . . . . .

Figure 2–6: Waveform Off the Top of the Display 2–4. . . . . . . . . . . . . . .

Figure 2–7: Waveform at the Bottom of the Display 2–5. . . . . . . . . . . . .

Figure 2–8: Waveform with Gain at 57 dB 2–5. . . . . . . . . . . . . . . . . . . . .

Figure 2–9: Distance at –2.00 ft 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–10: Pulse Adjusted to Four Major Divisions in Height 2–7. . . . .

Figure 2–11: Waveform Centered, Cursor at 10.00 ft 2–8. . . . . . . . . . . . .

Figure 2–12: Pulse Adjusted to Four Major Divisions in Height 2–8. . . . .

Figure 2–13: Aberrations Less Than Four Divisions Out to

30.00 ft 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–14: Pulse Adjusted to Four Major Divisions in Height 2–9. . . . .

Figure 2–15: Aberrations Less Than Four Divisions Out to

300.00 ft 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–16: Pulse Adjusted to Four Major Divisions in Height 2–10. . . . .

Figure 2–17: Aberrations Less Than Four Divisions Out to

3000.00 ft 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: A Typical Ethernet System 4–2. . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: N-Type Male T-Connector 4–5. . . . . . . . . . . . . . . . . . . . . . .

Figure 4–3: N-Type Female T-Connector 4–5. . . . . . . . . . . . . . . . . . . . . .

Figure 4–4: System 1 – Tap Hidden by Traffic

(1 avg, 50 ft/div. 35 dB) 4–10. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–5: System 1 – Traffic and Tap Nearly Identical

(4 avg, 50 ft/div, 35 dB) 4–10. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–6: System 1 – Tap Becoming Visible

(16 avg, 50 ft/div, 35 dB) 4–11. . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–7: System 1 – Tap Quite Visible

(128 avg, 50 ft/div, 35 dB) 4–11. . . . . . . . . . . . . . . . . . . . . . .

Figure 4–8: System 1 – No Traffic

(1 avg, 50 ft/div, 35 dB) 4–11. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–9: System 1 – Tap Expanded, No Traffic

(1 avg, 2 ft/div, 35 dB) 4–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–10: System 2 – Cable w/ Revision One Repeater

(1 avg, 200ft/div, 2.25dB) 4–12. . . . . . . . . . . . . . . . . . . . . . . .

1503C MTDR Service Manual

v

Page 10

Table of Contents

Figure 4–11: System 2 – First Tap, No Traffic

(1 avg, 1 ft/div, 44.5 dB) 4–12. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–12: System 2 – Same Tap with 5% Traffic

(1 avg, 1 ft/div, 44.5 dB) 4–13. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–13: System 2 – Same Tap, Increased Averaging

(16 avg, 1 ft/div, 44.5 dB) 4–13. . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–14: System 2 – Farther Out, More Gain

(128 avg, 10 ft/div, 53.5 dB) 4–13. . . . . . . . . . . . . . . . . . . . . .

Figure 4–15: System 2 – 1000-ft Cable at 10 ns

(128 avg, 100 ft/div, 43.75 dB) 4–14. . . . . . . . . . . . . . . . . . . .

Figure 4–16: System 2 – Previous Waveform Expanded

(128 avg, 20 ft/div, 54.75 dB) 4–14. . . . . . . . . . . . . . . . . . . . .

Figure 4–17: System 2 – Next Group of Taps

(128 avg, 20 ft/div, 54.75 dB) 4–14. . . . . . . . . . . . . . . . . . . . .

Figure 4–18: System 2 – Group of Taps Expanded

(128 avg, 10 ft/div, 54.75 dB) 4–15. . . . . . . . . . . . . . . . . . . . .

Figure 4–19: System 2 – Another Group of Taps

(128 avg, 10 ft/div, 54.75 dB) 4–15. . . . . . . . . . . . . . . . . . . . .

Figure 4–20: System 2 – End of Cable

(128 avg, 20 ft/div, 61.25 dB) 4–15. . . . . . . . . . . . . . . . . . . . .

Figure 4–21: Typical Frequency Response Curve with

EthernetR Option 06 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–1: System Block Diagram 5–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–2: Waveform Accumulation Diagram 5–3. . . . . . . . . . . . . . . . .

Figure 5–3: Power Supply Block Diagram 5–4. . . . . . . . . . . . . . . . . . . . .

Figure 5–4: Processor Block Diagram 5–8. . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–5: Option Port Interface Block Diagram 5–11. . . . . . . . . . . . . . .

Figure 5–6: Video Processor Block Diagram 5–13. . . . . . . . . . . . . . . . . . .

Figure 5–7: Video Processor Output 5–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–8: Timebase Block Diagram 5–16. . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–9: Timebase Control 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–10: Combined Effects of Time Delay 5–18. . . . . . . . . . . . . . . . . .

Figure 5–11: Calibration of Delay Zero and 50-ns Analog Delay 5–19. . . .

Figure 5–12: Pulse Generator/Sampler Block Diagram 5–23. . . . . . . . . . . .

Figure 5–13: Front Panel Block Diagram 5–26. . . . . . . . . . . . . . . . . . . . . . .

Figure 5–14: Display Module Block Diagram 5–29. . . . . . . . . . . . . . . . . . .

Figure 5–15: SBE Cell 5–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–16: Row Driver Block Diagram 5–31. . . . . . . . . . . . . . . . . . . . . .

Figure 5–17: Column Driver Block Diagram 5–32. . . . . . . . . . . . . . . . . . . .

Figure 5–18: Row Timing Diagram 5–33. . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

1503C MTDR Service Manual

Page 11

Table of Contents

Figure 5–19: Column Timing Diagram 5–35. . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–20: Shift Register 5–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–21: CPU and Display Memory Interface 5–39. . . . . . . . . . . . . . . .

Figure 5–22: Option 06 (EthernetR) Block Diagram 5–41. . . . . . . . . . . . .

Figure 6–1: Typical Start-Up Display 6–2. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Waveform on the Display 6–2. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–3: Setup Menu 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Main Menu 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Diagnostics Menu 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Front Panel Diagnostic Display 6–5. . . . . . . . . . . . . . . . . . . .

Figure 6–7: Front Panel Diagnostic Display 6–6. . . . . . . . . . . . . . . . . . . .

Figure 6–8: Front Panel Diagnostic Display 6–7. . . . . . . . . . . . . . . . . . . .

Figure 6–9: Front Panel Diagnostic Display 6–7. . . . . . . . . . . . . . . . . . . .

Figure 6–10: Waveform on the Display with No Cable Attached 6–8. . . .

Figure 6–11: Waveform on the Display with 10-ft Cable Attached 6–8. . .

Figure 6–12: Cursor on Rising Edge of Reflected Pulse at 5 ft/div 6–9. . .

Figure 6–13: Cursor on Rising Edge of Reflected Pulse at 1 ft/div 6–9. . .

Figure 6–14: Cursor on Rising Edge of Reflected Pulse with

Vp at .84 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–15: Flatline Display to >50,000 ft 6–10. . . . . . . . . . . . . . . . . . . . .

Figure 6–16: Waveform at Top of the Display 6–11. . . . . . . . . . . . . . . . . .

Figure 6–17: Waveform at Bottom of the Display 6–11. . . . . . . . . . . . . . . .

Figure 6–18: Waveform at Center of the Display 6–11. . . . . . . . . . . . . . . . .

Figure 6–19: Distance Moved Beyond Trailing Edge of Pulse 6–12. . . . . .

Figure 6–20: Noise with Gain at 57 dB 6–13. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–21: Noise Diagnostic Display 6–13. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–22: Service Diagnostic Menu 6–14. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–23: Service Diagnostic Menu 6–14. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–24: Service Diagnostic Menu 6–15. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–25: Pulse Appx. Five Divisions High 6–16. . . . . . . . . . . . . . . . . .

Figure 6–26: Current Waveform Shifted from Stored Waveform 6–17. . . .

Figure 6–27: Initial Pulse 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–28: Pulse Adjusted to Six Divisions High 6–18. . . . . . . . . . . . . . .

Figure 6–29: Cursor on Leading Edge at Center Graticule 6–19. . . . . . . . .

Figure 6–30: Cursor on Trailing Edge at Center Graticule 6–19. . . . . . . . .

Figure 6–31: Initial Pulse with Cursor at 0.00 ft 6–20. . . . . . . . . . . . . . . . .

Figure 6–32: Waveform on Auto Pulse Select 6–21. . . . . . . . . . . . . . . . . . .

Figure 6–33: Initial Pulse Centered on Horizontal Graticule 6–21. . . . . . . .

1503C MTDR Service Manual

vii

Page 12

Table of Contents

Figure 6–34: Gain Increased to 30.00 dB 6–22. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–35: Jitter Apparent Using Max Hold 6–22. . . . . . . . . . . . . . . . . . .

Figure 6–36: Cursor at –2.00 ft 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–37: Pulse Height at Four Divisions at 1 ft/div 6–24. . . . . . . . . . . .

Figure 6–38: Gain Increased to 25.00 dB 6–24. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–39: Pulse Height at Four Divisions at 2 ft/div 6–25. . . . . . . . . . . .

Figure 6–40: Gain Increased to 30.00 dB 6–25. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–41: Pulse Height at Four Divisions at 50 ft/div 6–26. . . . . . . . . . .

Figure 6–42: Gain Increased to 30.00 dB 6–26. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–43: Pulse Height at Four Divisions at 500 ft/div 6–27. . . . . . . . . .

Figure 6–44: Gain Increased to 30.00 dB 6–27. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–45: Oscilloscope Waveform 6–28. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–46: 1503C Waveform of 1000-ns Pulse 6–29. . . . . . . . . . . . . . . .

Figure 6–47: 1503C Waveform of 100-ns Pulse 6–29. . . . . . . . . . . . . . . . .

Figure 6–48: 1503C Waveform of 2-ns Pulse 6–30. . . . . . . . . . . . . . . . . . .

Figure 6–49: Head Alignment Chart Print 6–30. . . . . . . . . . . . . . . . . . . . . .

Figure 6–50: Equipment Setup 6–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–51: Main Menu 6–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–52: Ethernet Menu 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–53: Ethernet Menu 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–54: Ethernet Menu 6–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–55: Ethernet Menu 6–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–56: Ethernet Menu 6–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–57: Circuit Board Locations in the Instrument 6–37. . . . . . . . . . .

Figure 6–58: Power Supply Board 6–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–59: Power Supply Test Points TP1020 and TP1010 6–39. . . . . .

Figure 6–60: Power Supply Test Point TP2030 6–40. . . . . . . . . . . . . . . . .

Figure 6–61: Connector Plug P5040 and Pins J5040 on Bottom of

Main Board 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–62: Power Supply Test Point TP1020 6–41. . . . . . . . . . . . . . . . .

Figure 6–63: Power Supply Test Point TP2030 6–41. . . . . . . . . . . . . . . . .

Figure 6–64: Location of Main Board in Instrument 6–42. . . . . . . . . . . . . .

Figure 6–65: Main Board Probe Points 6–42. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–66: Waveform on Display 6–43. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–67: Battery Connections to Power Supply Board 6–44. . . . . . . . .

Figure 6–68: CR2012 on Power Supply Board 6–44. . . . . . . . . . . . . . . . . .

Figure 6–69: Display Showing Power is Battery 6–45. . . . . . . . . . . . . . . . .

Figure 6–70: Display Showing Battery Voltage is Low 6–45. . . . . . . . . . . .

Figure 6–71: R2012 on Power Supply Board 6–46. . . . . . . . . . . . . . . . . . . .

viii

1503C MTDR Service Manual

Page 13

Table of Contents

Figure 6–72: R1018 on Front Panel Board 6–47. . . . . . . . . . . . . . . . . . . . . .

Figure 6–73: LCD Pattern with Contrast Too Light 6–47. . . . . . . . . . . . . . .

Figure 6–74: LCD Pattern with Contrast Too Dark 6–47. . . . . . . . . . . . . . .

Figure 6–75: LCD Pattern Adjusted for Sharpness 6–48. . . . . . . . . . . . . . .

Figure 6–76: Waveform with Contrast Too Light 6–48. . . . . . . . . . . . . . . . .

Figure 6–77: Waveform with Contrast Adjusted Correctly 6–49. . . . . . . . .

Figure 6–78: Location of Pulser/Sampler Board in Instrument 6–50. . . . . .

Figure 6–79: TP1081 and TP1082 on Pulser/Sampler Board 6–50. . . . . . .

Figure 6–80: VR3020 and VR30212 on Pulser/Sampler Board 6–50. . . . . .

Figure 6–81: Service Diagnostic Menu 6–52. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–82: Location of Pulser/Sampler Board in Instrument 6–52. . . . . .

Figure 6–83: Location of R1080 on Pulser/Sampler Board 6–53. . . . . . . . .

Figure 6–84: Service Diagnostic Efficiency Readout 6–53. . . . . . . . . . . . . .

Figure 6–85: Location of Pulser/Sampler Board in Instrument 6–54. . . . . .

Figure 6–86: Location of R2097 on Pulser/Sampler Board 6–55. . . . . . . . .

Figure 6–87: Over-Compensated 6–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–88: Under-Compensated 6–55. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–89: Correctly Compensated 6–56. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–90: Location of Pulser/Sampler Board in Instrument 6–56. . . . . .

Figure 6–91: Location of C3010, TP3020, and TP3030 on

Pulser/Sampler Board 6–57. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–92: Main Menu 6–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–93: L2010, R1011, and R1013 on Option 06 Board 6–58. . . . . . .

1503C MTDR Service Manual

Figure 7–1: Location of Voltage Selector, Fuse Holder on Rear Panel 7–2

Figure 7–2: Power Supply Module and P/O Rear Panel 7–4. . . . . . . . . .

Figure 7–3: Main Board 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7–4: EPROM on Main Board 7–7. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7–5: Lithium Battery on Main Board 7–8. . . . . . . . . . . . . . . . . . .

Figure 7–6: Display Module/Front Panel Board Screw Locations 7–10. . .

Figure 7–7: Display Module/Front Panel Board Showing Hex Nuts 7–11.

Figure 7–8: Location of Default Jumper on Front Panel Board 7–12. . . . .

Figure 7–9: Default Jumper Positions 7–12. . . . . . . . . . . . . . . . . . . . . . . .

Figure 7–10: Main Board TP1041 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7–11: Main Board TP3040 and Main Board TP3041 7–17. . . . . . . .

Figure 7–12: Main Board TP4040 and Main Board TP6010 7–17. . . . . . . .

Figure 7–13: Main Board TP7010 and Main Board TP9011 7–17. . . . . . . .

Figure 7–14: Main Board TP9041 and Front Panel CABLE

Connector 7–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 14

Table of Contents

Figure 7–15: Installing the Case Cover Over the Chassis 7–20. . . . . . . . . .

Figure 9–1: Special Schematic Symbols 9–3. . . . . . . . . . . . . . . . . . . . . .

Figure 9–2: Component Locator – Main Board 9–15. . . . . . . . . . . . . . . . .

Schematics – Main Board 9–16. . . . . . . . . . . . . . . . . . . . . .

Figure 9–3: Component Locator – Front Panel Board 9–25. . . . . . . . . . . .

Schematics – Front Panel 9–26. . . . . . . . . . . . . . . . . . . . . .

Figure 9–4: Component Locator – Power Supply Board 9–28. . . . . . . . . .

Schematics – Power Supply 9–29. . . . . . . . . . . . . . . . . . . . . .

Figure 9–5: Component Locator – Pulser/Sampler Board 9–31. . . . . . . . .

Schematics – Pulser/Sampler 9–32. . . . . . . . . . . . . . . . . . .

Figure 9–6: Component Locator – EthernetBoard 9–34. . . . . . . . . . . . . . .

Schematics – Ethernet Board 9–35. . . . . . . . . . . . . . . . . . . . .

Figure 10–1: Cabinet 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–2: Frame, Assemblies and Front Panel Controls 10–15. . . . . . . . .

Figure 10–3: Option 06 EthernetR 10–17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–4: Power Supply 10–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

1503C MTDR Service Manual

Page 15

List of Tables

Table of Contents

Shipping Carton Test Strength xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse / Voltage Ratings 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vp of Various Dielectric Types 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impedance of Various Cable Types 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Length / Suggested Pulse / Suggested ft/div 1–14. . . . . . . . . . . . . . . . . .

Operator Performance Checks – Equipment Required 2–1. . . . . . . . . . . . . . .

Specifications: Electrical Characteristics 3–1. . . . . . . . . . . . . . . . . . . . . . . . .

Specifications: Environmental Characteristics 3–3. . . . . . . . . . . . . . . . . . . . .

Specifications: Physical Characteristics 3–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Option 06 Ethernet: Electrical Characteristics 4–16. . . . . . . . . . . . . . . . . . . . .

Option Port Wiring Configuration 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Row Driver Latch Bits 5–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Column Driver Latch Bits 5–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Periods 5–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 06 Ethernet Control Lines 5–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Performance Check – Equipment Required 6–1. . . . . . . . . . . . . .

Pulse Widths with Allowable Tolerances 6–19. . . . . . . . . . . . . . . . . . . . . . . . .

Auto Pulse: Distance per Division and Pulse Width 6–20. . . . . . . . . . . . . . . . .

Option 06 EthernetR Checks – Equipment Required 6–31. . . . . . . . . . . . . . . .

Adjustment Procedures – Equipment Required 6–37. . . . . . . . . . . . . . . . . . . .

Main Board Voltages, Tolerances, Test Point Locations 6–40. . . . . . . . . . . . . .

Pulser/Sampler Voltages and Test Point Locations 6–51. . . . . . . . . . . . . . . . . .

Impedance Range and Specification 6–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance – Equipment Required 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Conductor Color Code 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sealing Materials 7–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1503C MTDR Service Manual

xi

Page 16

Table of Contents

xii

1503C MTDR Service Manual

Page 17

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Power Source

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Use Proper Voltage Setting. Before applying power, ensure that the line selector is

in the proper position for the power source being used.

This product is intended to operate from a power source that will not apply more than

250 volts RMS between the supply conductors or between the supply conductor and

ground. A protective ground connection, by way of the grounding conductor in the

power cord, is essential for safe operation.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

The standard power cord (161-0288-00) is rated for outdoor use. All other optional

power cords are rated for indoor use only.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

1503C MTDR Service Manual

Replace Batteries Properly. Replace batteries only with the proper type and rating

specified.

Recharge Batteries Properly. Recharge batteries for the recommended charge

cycle only.

Use Proper AC Adapter. Use only the AC adapter specified for this product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

xiii

Page 18

General Safety Summary

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in an Explosive Atmosphere.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

xiv

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

1503C MTDR Service Manual

Page 19

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Care When Servicing

With Power On

Disposal of Batteries

Do not perform internal service or adjustments of this product unless another person

capable of rendering first aid and resuscitation is present.

T o avoid electric shock, disconnect the main power by means of the power cord or

the power switch.

Dangerous voltages or currents may exist in this product. Disconnect power, remove

battery, and disconnect test leads before removing protective panels, soldering, or

replacing components.

To avoid electric shock, do not touch exposed connections.

This instrument contains a lead-acid battery . Some states and/or local jurisdictions

might require special disposition/recycling of this type of material in accordance

with Hazardous Waste guidelines. Check your local and state regulations prior to

disposing of an old battery.

T ektronix Factory Service will accept 1503C batteries for recycling. If you choose

to return the battery to us for recycling, the battery cases must be intact, the battery

should be packed with the battery terminals insulated against possible short-circuits,

and should be packed in shock-absorbant material.

1503C MTDR Service Manual

Tektronix, Inc.

Attn: Service Department

P.O. Box 500

Beaverton, Oregon 97077 U.S.A.

For more information, call 1-800-833-9200.

xv

Page 20

Service Safety Summary

xvi

1503C MTDR Service Manual

Page 21

General Information

Product Description

Battery Operation

Options

The Tektronix 1503C Metallic-cable Time-Domain Reflectometer (MTDR) is a

cable test instrument that uses radar principles to determine the electrical

characteristics of metallic cables.

The 1503C generates a half-sine wave signal, applies it to the cable under test, and

detects and processes the reflected voltage waveform. These reflections are

displayed in the 1503C liquid crystal display (LCD), where distance measurements

may be made using a cursor technique. Impedance information may be obtained

through interpreting waveform amplitude.

The waveform may be temporarily stored within the 1503C and recalled or may be

printed using the optional dot matrix strip chart recorder, which installs into the

front-panel Option Port.

The 1503C may be operated from an AC power source or an internal lead-gel

battery, which supplies a minimum of eight hours operating time (see the

Specifications chapter for specifics).

Options available for the 1503C are explained in the Options and Accessories

chapter of this manual.

Standards, Documents,

and References Used

Changes and History

Information

1503C MTDR Service Manual

Terminology used in this manual is in accordance with industry practice.

Abbreviations are in accordance with ANSI Y1.1–19722, with exceptions and

additions explained in parentheses in the text. Graphic symbology is based on ANSI

Y32.2–1975. Logic symbology is based on ANSI Y32.14–1973 and manufacturer’s

data books or sheets. A copy of ANSI standards may be obtained from the Institute

of Electrical and Electronic Engineers, 345 47th Street, New York, NY 10017.

Changes that involve manual corrections and/or additional data will be incorporated

into the text and that page will show a revision date on the inside bottom edge.

History information is included in any diagrams in gray.

xvii

Page 22

General Information

Installation and Repacking

Unpacking and InItial

Inspection

Power Source and Power

Requirements

Before unpacking the 1503C from its shipping container or carton, inspect for signs

of external damage. If the carton is damaged, notify the carrier. The shipping carton

contains the basic instrument and its standard accessories. Refer to the replaceable

parts list in the Service Manual for a complete listing.

If the contents of the shipping container are incomplete, if there is mechanical

damage or defect, or if the instrument does not meet operational check requirements,

contact your local T ektronix Field Office or representative. If the shipping container

is damaged, notify the carrier as well as Tektronix.

The instrument was inspected both mechanically and electrically before shipment.

It should be free if mechanical damage and meet or exceed all electrical

specifications. Procedures to check operational performance are in the Performance

Checks appendix. These checks should satisfy the requirements for most receiving

or incoming inspections.

The 1503C is intended to be operated from a power source that will not apply more

than 250 volts RMS between the supply conductors or between either supply

conductor and ground. A protective ground connection, by way of the grounding

conductor in the power cord, is essential for safe operation.

The AC power connector is a three-way polarized plug with the ground (earth) lead

connected directly to the instrument frame to provide electrical shock protection. If

the unit is connected to any other power source, the unit frame must be connected

to earth ground.

Repacking for Shipment

xviii

Power and voltage requirements are printed on the back panel. The 1503C can be

operated from either 115 VAC or 230 VAC nominal line voltage at 45 Hz to 440 Hz,

or a 12 VDC supply, or an internal battery.

Further information on the 1503C power requirements can be found in the Safety

Summary in this section and in the Operating Instructions chapter.

When the 1503C is to be shipped to a T ektronix Service Center for service or repair,

attach a tag showing the name and address of the owner, name of the individual at

your firm who may be contacted, the complete serial number of the instrument, and

a description of the service required. If the original packaging is unfit for use or is

not available, repackage the instrument as follows:

1. Obtain a carton of corrugated cardboard having inside dimensions that are at

least six inches greater than the equipment dimensions to allow for cushioning.

The test strength of the shipping carton should be 275 pounds (102.5 kg). Refer

to the following table for test strength requirements:

1503C MTDR Service Manual

Page 23

General Information

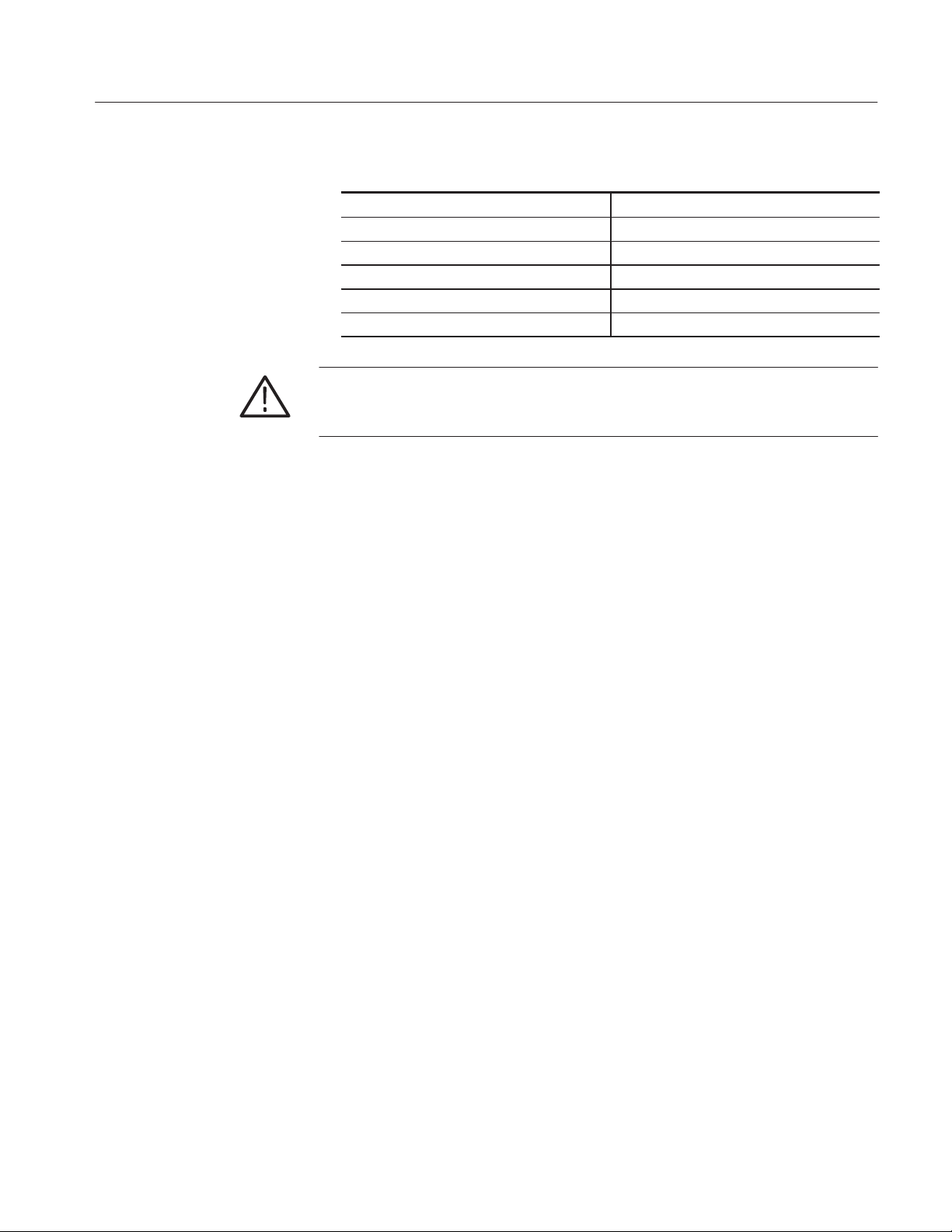

SHIPPING CARTON TEST STRENGTH

Gross Weight (lb)

0 – 10 200

11 – 30 275

31 – 120 375

121 – 140 500

141 – 160 600

CAUTION. The battery should be removed fr om the instrument befor e shipping. If it

is necessary to ship the battery, it should be wrapped and secur ed separately befor e

being packed with the instrument.

2. Install the front cover on the 1503C and surround the instrument with

polyethylene sheeting to protect the finish.

Carton Test Strength (lb)

3. Cushion the instrument on all sides with packing material or urethane foam

between the carton and the sides of the instrument.

4. Seal with shipping tape or an industrial stapler.

If you have any questions, contact your local Tektronix Field Office or

representative.

1503C MTDR Service Manual

xix

Page 24

General Information

Contacting Tektronix

Product

Support

Service

support

Toll-free

Number

Postal

Address

For questions about using Tektronix measurement products, call

toll free in North America:

1-800-833-9200

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your local

Tektronix distributor or sales office.

T ektronix offers a range of services, including Extended Warranty

Repair and Calibration services. Contact your local Tektronix

distributor or sales office for details.

For a listing of worldwide service centers, visit our web site.

In North America:

1-800-833-9200

An operator can direct your call.

Tektronix, Inc.

Department or name (if known)

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

xx

1503C MTDR Service Manual

Page 25

Operating Instructions

Overview

Handling

Powering the 1503C

The 1503C front panel is protected by a watertight cover, in which the standard

accessories are stored. Secure the front cover by snapping the side latches outward.

If the instrument is inadvertently left on, installing the front cover will turn off the

POWER switch automatically.

The carrying handle rotates 325° and serves as a stand when positioned beneath the

instrument.

The 1503C can be stored in temperatures ranging from –62° C to +85° C if a battery

is not installed. If a battery is installed and the storage temperature is below –35°

C or above +65° C, the battery pack should be removed and stored separately (see

1503C Service Manual for instructions on removing the battery). Battery storage

temperature should be between –35° C to +65° C.

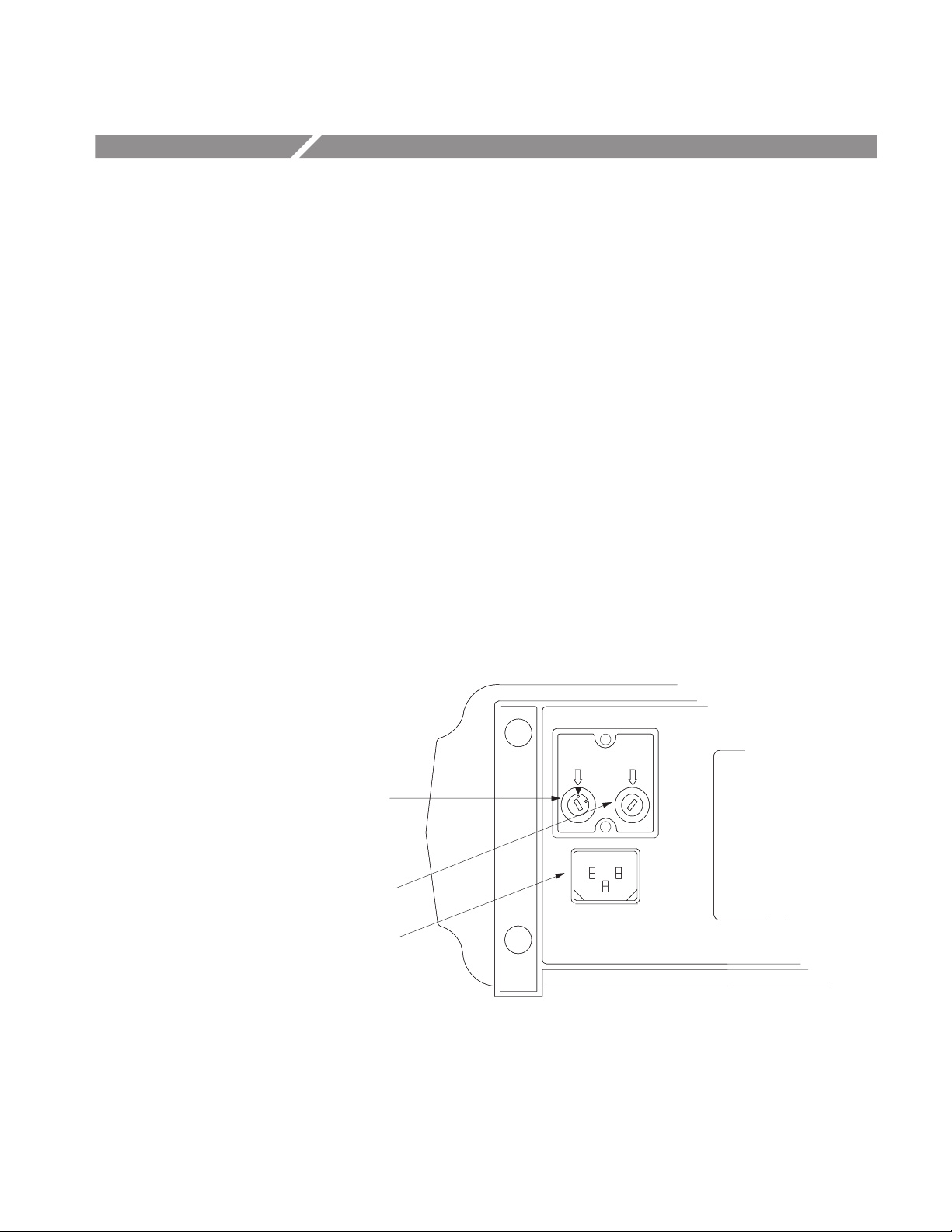

In the field, the 1503C can be powered using the internal battery . For AC operation,

check the rear panel for proper voltage setting. The voltage selector can be seen

through the window of the protective cap. If the setting differs from the voltage

available, it can be easily changed. Simply remove the protective cap and select the

proper voltage using a screwdriver.

REMOVE

CAP TO

REPLACE

FUSE

Voltage

Selector

REMOVE

CAP TO

SELECT

VOLTAGE

1503C MTDR Service Manual

Line Fuse

AC Power

Cord Receptacle

Figure 1–1: Rear Panel Voltage Selector, Fuse, AC Receptacle

The 1503C is intended to be operated from a power source that will not apply more

than 250 V RMS between the supply conductors or between either supply conductor

1–1

Page 26

Operating Instructions

and ground. A protective ground connection by way of the grounding conductor in

the power cord is essential for safe operation.

The AC power connector is a three-way polarized plug with the ground (earth) lead

connected to the instrument frame to provide electrical shock protection. If the unit

is connected to any other power source, the unit frame must be connected to an earth

ground. See Safety and Installation section.

CAUTION. If you change the voltage selector, you must change the line fuse to the

appropriate value as listed near the fuse holder and in the table below.

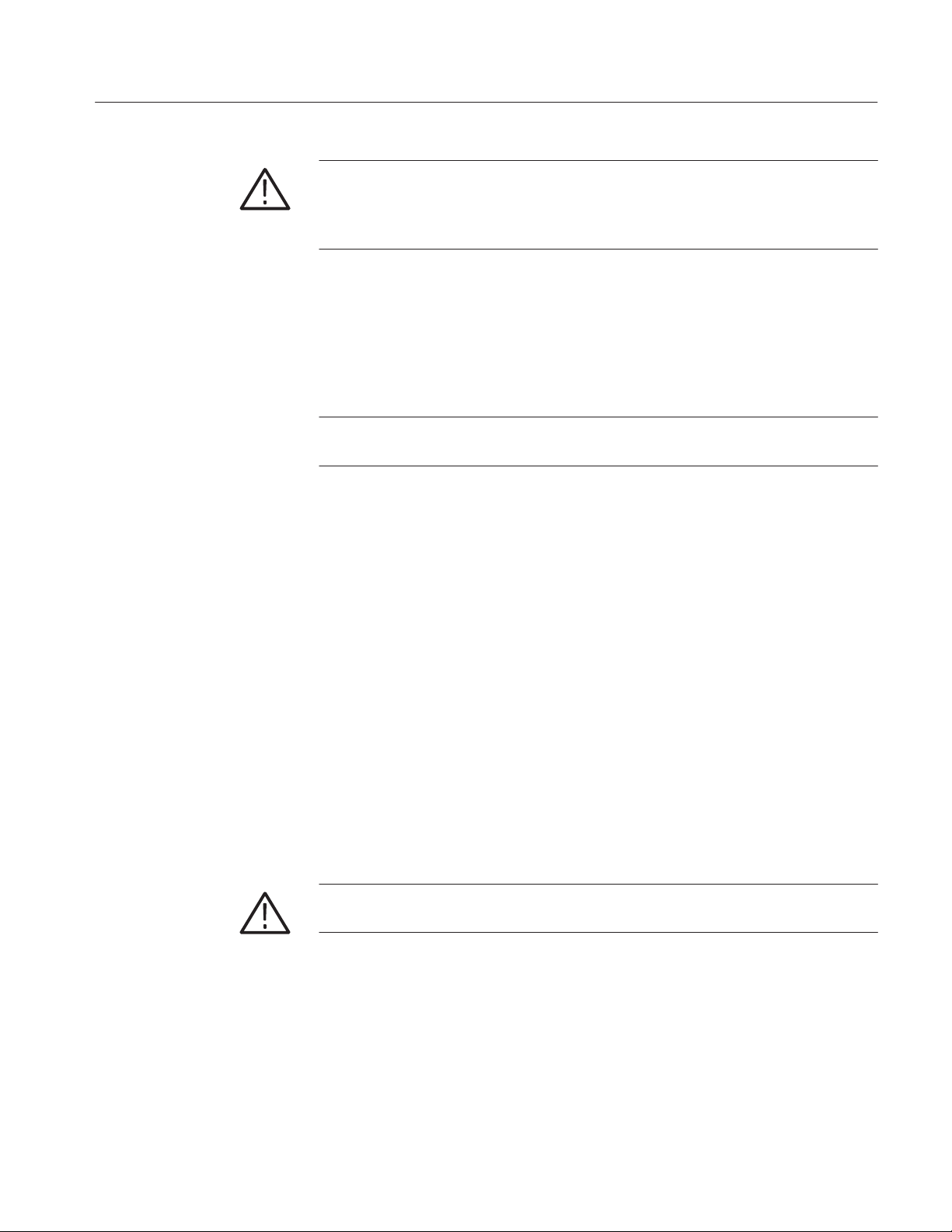

FUSE RATING VOLTAGE RATING

250 V NOMINAL RANGE

0.3 A T 115 VAC (90 – 132 VAC)

0.15 A T 230 VAC (180 – 250 VAC)

Care of the Battery Pack

Battery Charging

CAUTION. Read these instructions concerning the care of the battery pack. They

contain instructions that reflect on your safety and the performance of the

instrument.

The 1503C can be powered by a rechargeable lead-gel battery pack that is accessible

only by removing the case from the instrument. When AC power is applied, the

battery pack is charged at a rate that is dependent on the battery charge state.

The battery pack will operate the 1503C for a minimum of eight continuous hours

(including making 30 chart recordings) if the LCD backlight is turned off.

The battery pack will charge fully in 16 hours when the instrument is connected, via

the power cord, to an AC power source with the instrument turned off. The

instrument may be turned on and operated while the batteries are charging, but this

will increase the charging time. For longest battery life, a full charge is preferred

over a partial charge.

For maximum capacity , the batteries should be charged within a temperature range

of +20° C to +25° C. However, the batteries can be charged within a temperature

range of 0° C to +40° C and operated in temperatures ranging from –10° C to +55° C.

1–2

1503C MTDR Service Manual

Page 27

Battery Removal

Operating Instructions

CAUTION. Do not charge battery pack below 0° C or above +40° C. Do not

discharge battery pack below –10° C or above +55° C. If r emoving the battery pack

during or after exposure to these extreme conditions, turn the instrument off and

remove the AC power cord.

The battery pack should be stored within a temperature range of –35° C to +65° C.

However, the self-discharge rate will increase as the temperature increases.

If the instrument is stored with the battery pack installed, the battery pack should

be charged every 90 days. A fully charged battery pack will lose about 12% of its

capacity in three to four months if stored between +20° C and +25° C.

NOTE. The battery pack in the 1503C is inside the instrument case with no external

access. Refer removal and replacement to qualified service personnel.

1. Ensure that the instrument power is off.

2. If the instrument is connected to an AC power source, remove the AC power

cable from the source and from the instrument.

3. If installed, remove the chart recorder, or other device, from the option port.

4. Loosen the four screws on the back of the case and set the instrument face-up

on a flat surface.

5. Swing the handle out of the way of the front panel.

6. Break the chassis seal by pushing downward with both hands on the handle

pivots on each side of the case.

7. Grasp the case with one hand and tilt the chassis out with the other. Lift by

grasping the outside perimeter of the front panel.

CAUTION. Do not lift the instrument by the front-panel controls. The controls will

be damaged if you do so.

8. Remove the top shield from the instrument by gently lifting the rear edge near

the sides of the instrument.

9. Unplug the battery cable positive lead at the battery.

1503C MTDR Service Manual

10. Unplug the battery cable negative lead at the battery.

11. Unplug the battery cable at the power supply.

1–3

Page 28

Operating Instructions

12. Remove the cable.

13. Remove the two screws mounting the battery clamp to the chassis.

14. Carefully remove the clamp without touching the battery terminals.

15. Lift the battery out.

To re-install or replace the battery, repeat the above steps in reverse order.

Low Battery

If the battery is low, it will be indicated on the LCD (bat/low). If this is the case,

protective circuitry will shut down the 1503C within minutes. Either switch to AC

power or work very fast. If the instrument is equipped with a chart recorder, using

the recorder will further reduce the battery level, or the added load might shut down

the instrument.

bat/low 0.00 ft

O

N

O

F

F

O

F

F

O

F

F

50 W 2 ns

1 avg

0.00 dB 5000 ft

Low Battery

Indicator

Figure 1–2: Display Showing Low Battery Indication

Protection circuits in the charger prevent deep discharge of the batteries during

instrument operation. The circuits automatically shut down the instrument

whenever battery voltage falls below approximately 10 V. If shutdown occurs, the

batteries should be fully recharged before further use.

1–4

Low Temperature

Operation

NOTE. Turn the POWER switch off after instrument shutdown to prevent continued

discharge of the batteries.

When the instrument is stored at temperatures below –10° C, voids might develop

in the liquid crystal display (LCD). These voids should disappear if the instrument

is placed in an ambient temperature w +5° C for 24 hours.

When operating the 1503C in an environment below +10° C, a heater will activate.

The element is built into the LCD module and will heat the display to permit normal

operation. Depending on the surrounding temperature, it might take up to 15

minutes to completely warm the crystals in the LCD. Once warmed, the display will

operate normally.

1503C MTDR Service Manual

Page 29

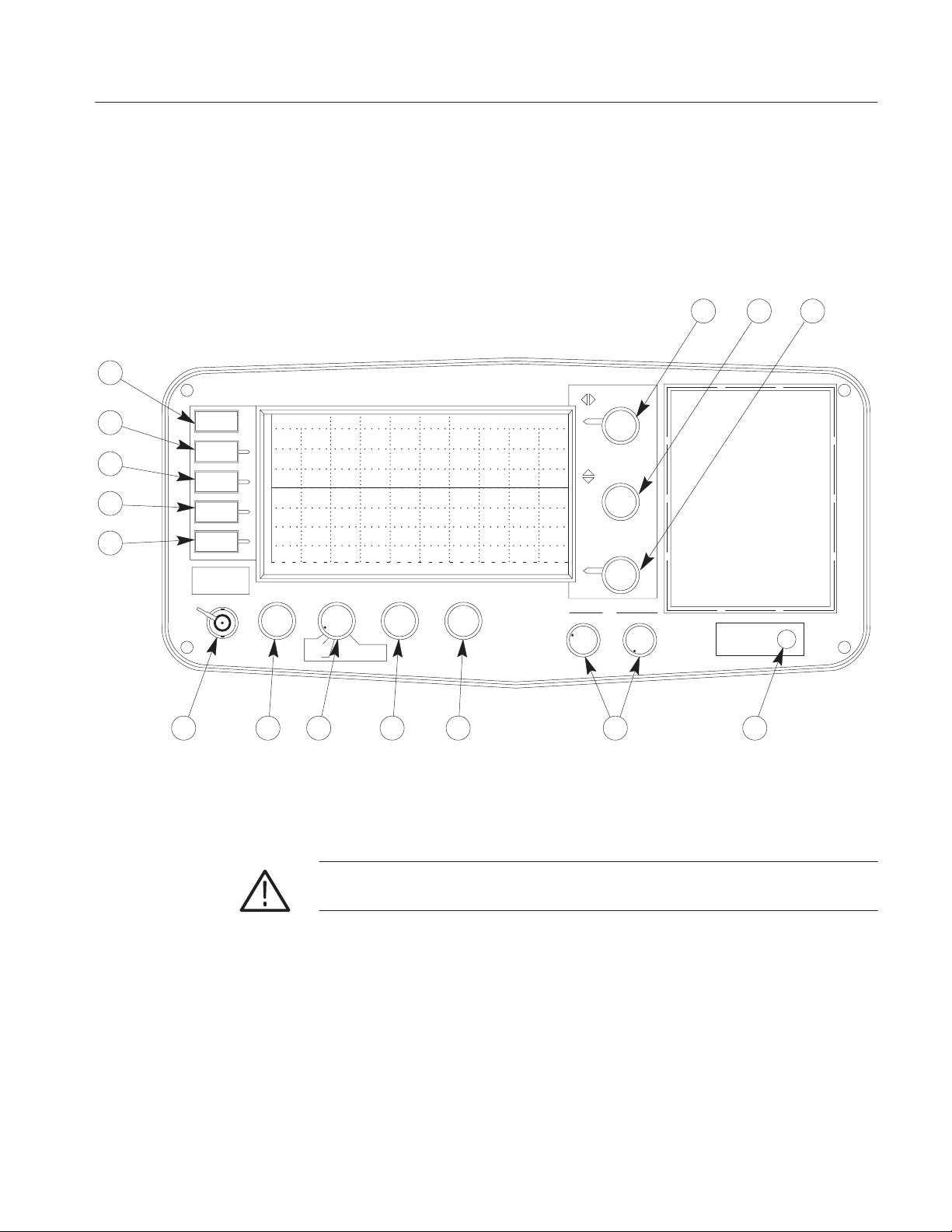

Preparing to Use the 1503C

Check the power requirements, remove the front cover, and you are ready to test

cables. The following pages explain the front-panel controls.

Operating Instructions

11

12

13

14

15

Tektronix

MENU

VIEW

INPUT

VIEW

STORE

VIEW

DIFF

STORE

INPUT PROTECTED

400 V PEAK MAX

CABLE

1 3 4 5 6 7

ac 0.00 ft

O

N

O

F

F

O

F

F

O

F

F

50 Ω

IMPEDANCE

1 avg

NOISE FILTER VERT SCALE DIST/DIV

HORZ

SET REF

VERT

2

1503C

0.00 db

METALLIC TDR

CABLE TESTER

1 ft

2 ns

.3

.4

POSITION

POSITION

PULSE WIDTH

Vp

.5

.6

.03

.7

.02

.8

.01

.9

.04

.05

.06

.07

.08

.09

.00

POWER

(PULL ON)

910

8

Figure 1–3: 1503C Front-Panel Controls

CAUTION. Do not connect to circuits or cables with live voltages gr eater than 400 V

peak. Voltages exceeding 400 V might damage the 1503C front-end circuits.

1503C MTDR Service Manual

1–5

Page 30

Operating Instructions

Display

Power

Type Cursor Waveform

Front-Panel to Cursor

Distance Window

Front-Panel Controls

IMPEDANCE

View Input

Indicator

View Store

Indicator

View Difference

Indicator

Store

Indicator

ac

O

N

O

F

F

O

F

F

O

F

F

50 W 2 ns

Selected

Impedance

1 avg

Selected

Noise Filter

0.00 dB 5000 ft

Selected Selected Selected

Vertical Scale Distance per

Division

0.00 ft

Pulse Width

Figure 1–4: Display and Indicators

1. CABLE: A female BNC connector for attaching a cable to the 1503C for

testing.

2. IMPEDANCE: A four-position rotary switch that selects the output impedance

of the cable test signal. Available settings are 50, 75, 93, and 125 Ohms. The

selected value is displayed above the control on the LCD.

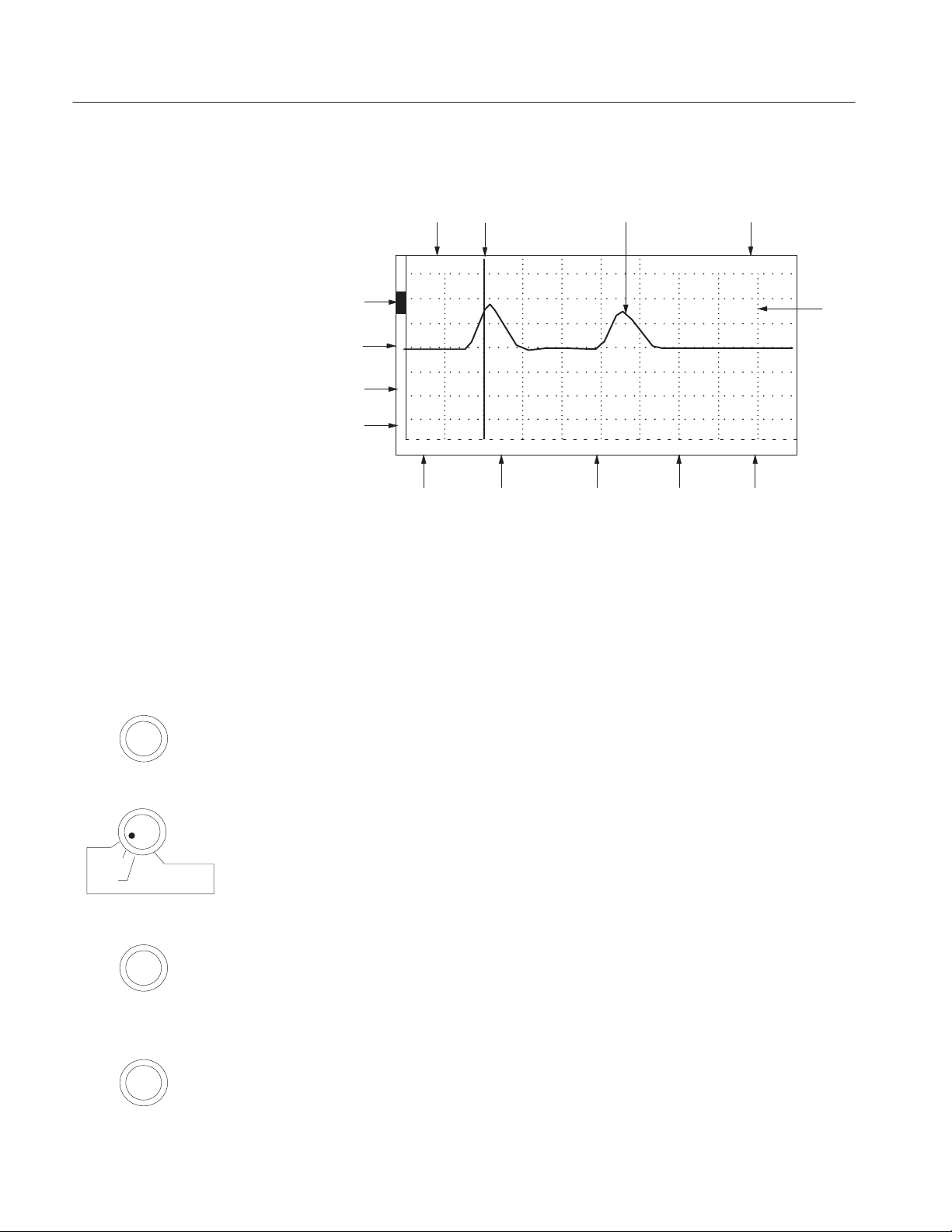

Grid

1–6

NOISE FILTER

VERT SCALE

DIST/DIV

3. NOISE FILTER: If the displayed waveform is noisy, the apparent noise can

be reduced by using noise averaging. A veraging settings are between 1 and 128.

The time for averaging is directly proportional to the averaging setting chosen.

A setting of 128 might take the instrument up to 35 seconds to acquire and

display a waveform. The first two positions on the NOISE FILTER control are

used for setting the vertical and horizontal reference points. The selected value

or function is displayed above the control on the LCD.

4. VERT SCALE: This control sets the vertical gain, displayed in dB, or the

vertical sensitivity, displayed in mr per division. Although the instrument

defaults to dB, you may choose the preferred mode from the Setup Menu. The

selected value is displayed above the control on the LCD.

5. DIST/DIV: Determines the number of feet (or meters) per division across the

display . The minimum setting is 1 ft/div (0.25 meters) and the maximum setting

is 5000 ft/div (1000 meters). The selected value is displayed above the control

on the LCD.

1503C MTDR Service Manual

Page 31

Operating Instructions

A standard instrument defaults to ft/div. A metric instrument (Option 05)

defaults to m/div, but either may be changed temporarily from the menu. The

default can be changed by changing an internal jumper (see Chapter 7).

.3

.4 .5

POWER

(PULL ON)

Vp

.03

.6

.7

.02

.8

.01

.9 .00

PULSE WIDTH

n

POSITION

o

n

o

POSITION

.04 .05

6. Vp: The two Velocity of Propagation controls are set according to the

.06

.07

.08

.09

propagation velocity factor of the cable being tested. For example, solid

polyethylene commonly has a Vp of 0.66. Solid polytetraflourethylene

(Teflon ) is approximately 0.70. Air is 0.99. The controls are decaded: the left

control is the first digit and the right control is the second digit. For example,

with a Vp of 0.30, the first knob would be set to .3 and the second knob to .00.

7. POWER: Pull for power ON and push in for power OFF . When the front cover

is installed, this switch is automatically pushed OFF.

8. PULSE WIDTH: This is a five-position rotary switch that selects the pulse

width of the cable test signal. The available settings are: 2, 10, 100, 1000

nanoseconds, and AUTO. The selected value is displayed on the LCD adjacent

to the control. The AUTO setting sets the pulse width according to the distance

registered at the right side of the LCD. The selected value is displayed to the left

of this control on the LCD.

n

9.

POSITION: This is a continuously rotating control that positions the

o

displayed waveform vertically, up or down the LCD.

n

o

10.

POSITION: This is a continuously rotating control that moves a vertical

cursor completely across the LCD graticule. In addition, the waveform is also

moved when the cursor reaches the extreme right or left side of the display. A

readout (seven digits maximum) is displayed in the upper right corner of the

LCD, showing the distance from the front panel BNC to the current cursor

location.

MENU

VIEW

INPUT

VIEW

STORE

VIEW

DIFF

STORE

1503C MTDR Service Manual

11. MENU: This pushbutton provides access to the menus and selects items chosen

from the menus.

12. VIEW INPUT: When pushed momentarily, this button toggles the display of

the waveform acquired at the CABLE connector. This function is useful to stop

displaying a current waveform to avoid confusion when looking at a stored

waveform. This function defaults to ON when the instrument is powered up.

13. VIEW STORE: When pushed momentarily, this button toggles the display of

the stored waveform.

14. VIEW DIFF: When pushed momentarily , this button toggles the display of the

current waveform minus the stored waveform and shows the difference between

them.

15. STORE: When pushed momentarily, the waveform currently displayed will be

stored in the instrument memory . If a waveform is already stored, pushing this

button will erase it. The settings of the stored waveform are available from the

first level menu under View Stored Waveform Settings.

1–7

Page 32

Operating Instructions

Menu Selections

There are several layers of menu, as explained below.

Main Menu

The Main Menu is entered by pushing the MENU button on the front panel.

1. Return to Normal Operations puts the instrument into normal operation

mode.

2. Help with Instrument Controls explains the operation of each control. When

a control or switch is adjusted or pushed, a brief explanation appears on the

LCD.

3. Cable Information has these choices:

a. Help with Cables gives a brief explanation of cable parameters.

b. Velocity of Propagation V alues displays a table of common dielectrics and

their Vp values. These are nominal values. The manufacturer’s listed

specifications should be used whenever possible.

c. Impedance Values displays impedances of common cables. In some cases,

these values have been rounded off. Manufacturer’s specifications should

be checked for precise values.

d. Finding Unknown Vp Values describes a procedure for finding an

unknown Vp.

4. Setup Menu controls the manner in which the instrument obtains and displays

its test results.

1–8

a. Acquisition Control Menu has these choices:

i. Max Hold Is: On/Off. Turn Max Hold on by pushing MENU then

STORE. In this mode, waveforms are accumulated on the display . Max

Hold can be deactivated by pushing STORE or the mode exited by

using the Setup Menu.

ii. Pulse Is: On/Off. T urns the pulse generator of f so the 1503C does not

send out pulses.

iii. Single Sweep Is: On/Off. This function is much like a still camera; it

will acquire one waveform and hold it.

b. Vertical Scale Is: dB/mr. This offers you a choice as to how the vertical

gain of the instrument is displayed. You may choose decibels or millirho.

When powered down, the instrument will default to decibels when powered

back up.

c. Distance/Div Is: ft/m. Offers you a choice of how the horizontal scale is

displayed. You may choose from feet per division or meters per division.

1503C MTDR Service Manual

Page 33

Operating Instructions

When powered up, the instrument will default to feet unless the internal

jumper has been moved to the meters position. Instructions on changing this

default are contained in Chapter 7.

d. Light Is: On/Off. This control turns the electroluminescent backlight

behind the LCD on or off.

5. Diagnostics Menu lists an extensive selection of diagnostics to test the

operation of the instrument.

a. Service Diagnostics Menu has these choices:

i. Sampling Efficiency Diagnostic displays a continuous efficiency

diagnostic of the sampling circuits.

ii. Noise Diagnostic measures the internal RMS noise levels of the

instrument.

iii. Impedance Diagnostic tests the output impedance circuits in the

instrument.

iv. Offset/Gain Diagnostic reports out-of–tolerance steps in the program-

mable gain stage. This can help a service technician to quickly isolate

the cause of waveform distortion problems.

v. RAM/ROM Diagnostics Menu performs tests on the RAM (Random

Access Memory) and the ROM (Read Only Memory).

vi. Timebase Is: Normal - Auto Correction / Diagnostic - No

Correction. When in Normal - Auto Correction, the instrument

compensates for variations in temperature and voltage. This condition

might not be desirable while calibrating the instrument. While in

Diagnostic - No Correction, the circuits will not correct for these

variations.

b. Front Panel Diagnostics aids in testing the front panel.

c. LCD Diagnostics Menu has these choices:

i. LCD Alignment Diagnostic generates a dot pattern of every other

pixel on the LCD. These pixels can be alternated to test the LCD.

ii. Response Time Diagnostic generates alternate squares of dark and

light, reversing their order. This tests the response time of the LCD and

can give an indication of the effectiveness of the LCD heater in a cold

environment.

1503C MTDR Service Manual

iii. LCD Drive Test Diagnostic generates a moving vertical bar pattern

across the LCD.

iv. Contrast Adjust allows you to adjust the contrast of the LCD. It

generates an alternating four-pixel pattern. The nominal contrast is set

1–9

Page 34

Operating Instructions

internally . When in Contrast Adjust mode, VERT SCALE is used as the

contrast adjustment control. This value ranges from 0 to 255 units and

is used by the processor to evaluate and correct circuit variations caused

by temperature changes in the environment.

d. Chart Diagnostics Menu offers various tests for the optional chart

recorder.

i. LCD Chart allows adjusting the number of dots per segment and the

number of prints (strikes) per segment.

ii. Head Alignment Chart generates a pattern to allow mechanical

alignment of the optional chart recorder.

6. View Stored W aveform Settings displays the instrument settings for the stored

waveform.

7. Option Port Menu contains three items. T wo items allow configuration of the

option port for communicating with devices other than the optional chart

recorder and one item test the option port.

a. Option Port Diagnostic creates a repeating pattern of signals at the option

port to allow service technicians to verify that all signals are present and

working correctly.

b. Set Option Port Timing allows adjustment of the data rate used to

communicate with external devices. The timing rate between bytes can be

set from about 0.05 to 12.8 milliseconds.

c. Option Port Debugging Is Off/On. Off is quiet, On is verbose. This

chooses how detailed the error message reporting will be when communicating with an external device.

It is possible to connect the instrument to a computer through a parallel interface

with a unique software driver. Because different computers vary widely in

processing speed, the instrument must be able to adapt to differing data rates

while communicating with those computers. With user-developed software

drivers, the ability to obtain detailed error messages during the development can

be very useful. For more information, contact your T ektronix Customer Service

representatives. They have information describing the option port hardware and

software protocol and custom development methods available.

The SP-232, a serial interface product, also allows for connection of the 1503C

to other instrumentation, including computers, via the option port. SP-232 is an

RS-232C-compatible interface. For more information, contact your Tektronix

Customer Service Representative. They can provide you with additional details

on the hardware and software protocol.

1–10

8. Display Contrast (Software Version 5.02 and above)

1503C MTDR Service Manual

Page 35

Test Preparations

Operating Instructions

a. Press the MENU button firmly once. If the display is very light or very dark,

you might not be able to see a change in the contrast.

b. T urn the VER TICAL SCALE knob slowly clockwise to darken the display

or counterclockwise to lighten the display . If you turn the knob far enough,

the contrast will wrap from the darkest to lightest value.

c. When the screen is clearly readable, press the MENU button again to return

to normal measurement operation. The new contrast value will remain in

effect until the instrument is turned off.

The Importance of Vp

(Velocity of Propagation)

Vp of Various Dielectric

Types

Vp is the speed of a signal down the cable given as a percentage of the speed of light

in free space. It is sometimes expressed as a whole number (e.g., 66) or a percentage

(e.g., 66%). On the 1503C, it is the percentage expressed as a decimal number (e.g.,

66% = .66). If you do not know the velocity of propagation, you can get a general

idea from the following table, or use the Help with Cables section of the Cable

Information menu. You can also find the Vp with the procedure that follows using

a cable sample.

NOTE. If you do not know the Vp of your cable, it will not prevent you fr om finding

a fault in your cable. However, if the Vp is set wrong, the distance readings will be

affected.

All Vp settings should be set for the cable under test, not the supplied jumper cable.

Dielectric Probable Vp

Jelly Filled .64

Polyethylene (PIC, PE, or SPE) .66

PTFE (Teflon R) or TFE .70

Pulp Insulation .72

Foam or Cellular PE (FPE) .78

Semi-solid PE (SSPE) .84

Air (helical spacers) .98

1503C MTDR Service Manual

1–11

Page 36

Operating Instructions

n

o

Impedance of Various

Cable Types

Finding an Unknown Vp

50 W75 W93 W 125 W

RG–4 RG–6/U RG–7/U RG–23/U

RG–8/U RG–11/U RG–22/U RG–63/U

RG–9/U RG–12/U RG–62/U RG–79/U

RG–58/U RG–13/U RG–71/U RG–89/U

RG–62/U RG–59/U RG–111/U Flat Lead

RG–81 RG–124/U Twisted Pair Twisted Pair

RG–93 RG–140/U

RG–142B/U RG–179/U

RG–225/U 75 Video

RG–303B/U

RG–316/U

RG–393/U

Vertebrae Helix

1. Obtain a known length of cable of the exact type you wish to test. Attach the

cable to the CABLE connector on the front panel.

2. Pull POWER on.

3. Turn the DIST/DIV to an appropriate setting (e.g., if trying to find the Vp of a

three-foot cable, turn the DIST/DIV to 1 ft/div).

4. Turn the

POSITION control until the distance reading is the same as the

known length of this cable.

5. Turn the Vp controls until the cursor is resting on the rising portion of the

reflected pulse. The Vp controls of the instrument are now set to the Vp of the

cable.

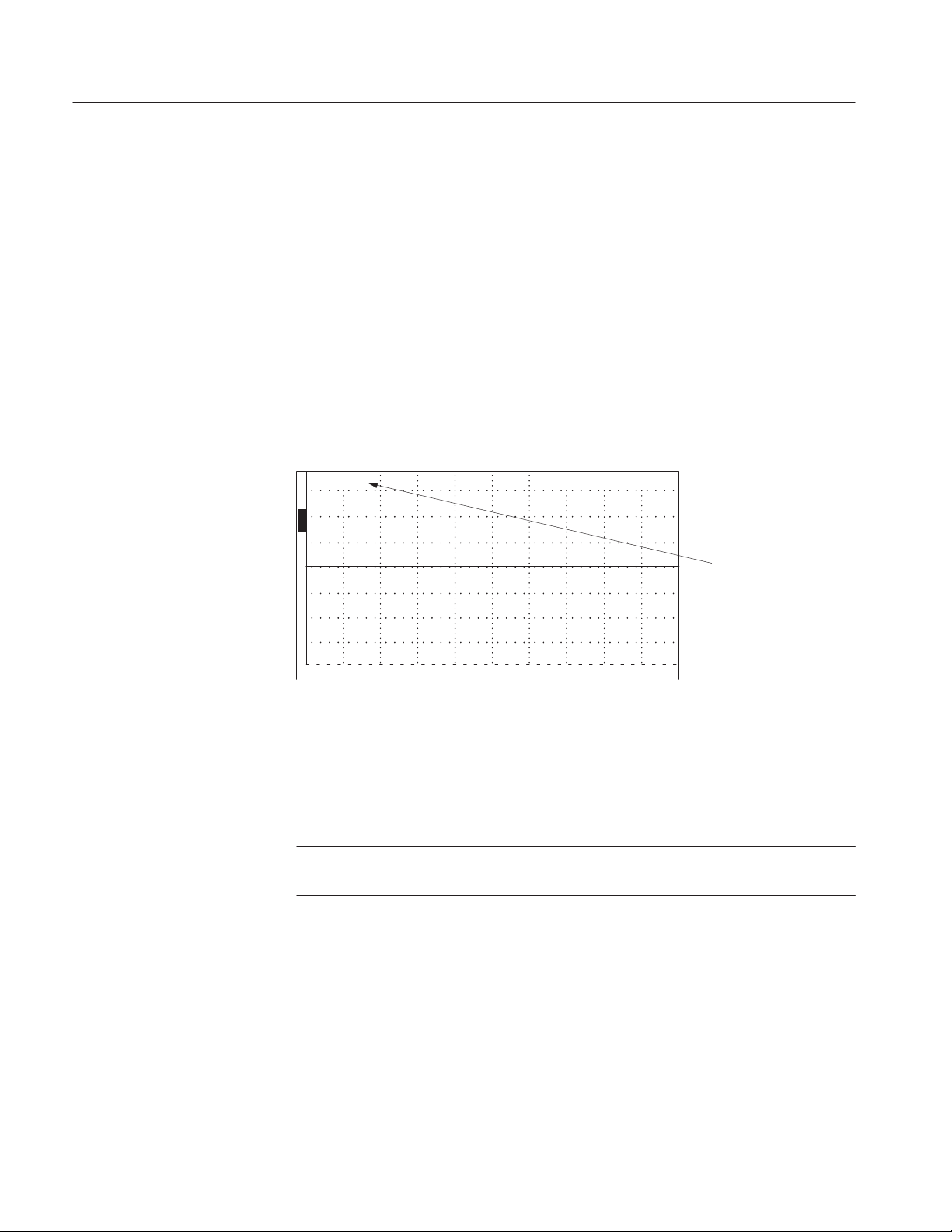

The following three illustrations show settings too low, too high, and correct for a

sample three-foot cable.

ac 3.00 ft

O

N

O

F

F

O

F

F

O

F

F

Figure 1–5: Vp Set at .30, Cursor Beyond Reflected Pulse (Setting Too Low)

1–12

1503C MTDR Service Manual

Page 37

Operating Instructions

ac 3.00 ft

O

N

O

F

F

O

F

F

O

F

F

Figure 1–6: Vp Set at .99, Cursor Less Than Reflected Pulse (Setting Too High)

ac 3.00 ft

O

N

O

F

F

Cable Test Procedure

Distance to the Fault

O

F

F

O

F

F

Figure 1–7: Vp Set at .66, Cursor on Rising Edge of Reflected Pulse (Set Correctly)

Be sure to read the previous paragraphs on Vp.

1. Set the 1503C controls:

POWER On

CABLE Cable to BNC

IMPEDANCE 50

NOISE FILTER 1 avg

DIST/DIV (see below)

Vp (per cable)

PULSE WIDTH (per cable)

2. If you know approximately how long the cable is, set the DIST/DIV

appropriately (e.g., 20-ft cable would occupy four divisions on the LCD if 5

ft/div was used). The entire cable should be displayed.

1503C MTDR Service Manual

1–13

Page 38

Operating Instructions

ac 0.00 ft

O

N

O

F

F

O

F

F

O

F

F

Figure 1–8: 20-ft Cable at 5 ft/div

If the cable length is unknown, set DIST/DIV to 5000 ft/div and continue to decrease

the setting until the reflected pulse is visible. Depending on the cable length and the

amount of pulse energy absorbed by the cable, it might be necessary to increase the

VERT SCALE to provide more gain to see the reflected pulse.

The best pulse width is dependent on the cable length. A short pulse can be

completely dissipated in a long cable. Increasing the pulse width will allow the

reflected pulse to be more visible when testing long cables. AUTO will select the

pulse width for you, depending on the distance on the right side of the LCD.

CABLE LENGTH SUGGESTED PULSE

SUGGESTED ft/div

0 to 100 ft 2 ns 10 ft/div

51 to 500 ft 10 ns 50 ft/div

501 to 5000 ft 100 ns 500 ft/div

5001 to 50,000 ft 1000 ns 5000 ft/div

When the entire cable is displayed, you can tell if there is an open or a short.

Essentially, a drop in the pulse is a short and a rise in the pulse is an open. Less

catastrophic faults can be seen as hills and valleys in the waveform. Bends and

kinks, frays, water, and interweaving all have distinctive signatures.

ac 0.00 ft

O

N

O

F

F

Short

O

F

F

O

F

F

Figure 1–9: Short in the Cable

1–14

1503C MTDR Service Manual

Page 39

ac 20.00 ft

n

o

n

o

O

N

Operating Instructions

O

F

F

O

F

F

O

F

F

Open

Figure 1–10: Open in the Cable

3. To find the distance to the fault or end of the cable, turn the

POSITION

control until the cursor rests on the leading edge of the rising or falling reflected

pulse (see Figure 1–10). Read the distance in the distance window in the upper

right corner of the display.

A more thorough inspection might be required. This example uses a longer cable:

4. When inspecting a 455-foot cable, a setting of 100 ft/div allows a relatively fast

inspection. If needed, turn VERT SCALE to increase the gain. The higher the

gain, the smaller the faults that can be detected. If noise increases, increase the

NOISE FILTER setting.

ac 455.00 ft

O

N