Page 1

TM 9-6625-2801-14&P

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL,

DIRECT SUPPORT, AND GENERAL SUPPORT

MAlNTENANCE MANUAL (INCLUDING MAINTENANCE REPAIR PARTS LIST)

FOR

TEST SET,

TEKTRONIX

NSN 6625-04-084-3855

TEKTRONIX, INC.

ELECTRICAL

TYPE 1502-1

HEADQUARTERS, DEPARTMENT OF THE ARMY

AUGUST 1981

Page 2

WARNING

DRY CLEANING SOLVENT

Dry cleaning solvent or mineral spirits paint thinner is flammable

and should not be used near an open flame.

should be provided when these materials are used.

Fire extinguishers

Use only in

well-ventilated areas.

WARNING

Be extremely careful when working in the vicinity of batteries

when the battery case is open.

Do not use uninsulated tools.

Do not wear rings or watches. Metal articles will, if allowed

to contact connectors, cause severe arcing with possible injury

to personnel and damage to the battery.

Page 3

TM 9-6625-2801-14&P

TECHNICAL MANUAL

NO. 9-6625-2801-14&P

DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE MANUAL (INCLUDING MAINTENANCE REPAIR PARTS LIST)

You can help improve this manual. If you find any mistake

or if you know of a way to improve the procedures, please

let us know.

Changes to Publication and Blank Forms) , or DA Form

2028-2 located in the back of this manual direct to:

Commander, U.S. Army Armament Materiel Readiness

Command, ATTN:

A reply will be furnished to you.

HEADQUARTERS

DEPARTMENT OF THE ARMY

Washington, DC, 20 August 1981

OPERATOR’S , ORGANIZATIONAL,

FOR

TEST SET, ELECTRICAL

TEKTRONIX TYPE 1502-1*

REPORTING OF ERRORS

Mail your letter, DA Form 2028 (Recommended

DRSAR-MAS , Rock Island, IL 61299.

1

CHAPTER

Section

CHAPTER

Section

CHAPTER

Section

*NOTE

Throughout the text,

is in lieu of the authorized Federal nomenclature.

INTRODUCTION

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.

II.

Description . . . . . . . . . . . . . . ....... . . . .

2

OPERATING INSTRUCTIONS

I.

Controls and Indicators . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . .......

II.

3

SERVICE AND PREVENTIVE MAINTENANCE

I.

Service on Receipt of Material . . . . . . . . . . . . . . .

II. Repair Parts,

III.

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV.

Preventive Maintenance . . . . . . . . . . . . . . . . .

this is referred to as a Time Domain Reflectometer or a TDR. This

Special Tools and Equipment . . . . . .

Paragraph

1-1

1-6

2-1

2-2

3-1

3-3

3-4

3-5

Page

1-1

1-1

2-1

2-3

3-1

3-1

3-1

3-1

i

Page 4

TM 9-6625-2801-14&P

CHAPTER

Section

CHAPTER

Section

CHAPTER

Section

CHAPTER

Section

CHAPTER

Section

4

5

I.

II.

III.

6

I.

II.

7

I.

II.

8

I.

II.

9

I.

II.

III.

Paragraph

FUNCTIONAL ANALYSIS . . . . . . . . . . . . . . . . . . . . 4- 1

PERFORMANCE CHECKS/FAULT ISOLATION

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Performance Checks . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Fault Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

MAINTENANCE INSTRUCTIONS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . 6-2

REPAIR INSTRUCTIONS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Repair of TDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

FINAL INSPECTION

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Final Inspection Checks. . . . . . . . . . . . . . . . . . . . . 8-2

PREPARATION FOR SHIPMENT AND STORAGE

Preparation for Travel.. . . . . . . . . . . . . . . . . . . . . 9-1

Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Page

4-1

5-1

5-1

5-11

6-1

6-1

7-1

7-1

8-1

8-1

9-1

9-1

9-1

APPENDIX

A

REFERENCES

B

MAINTENANCE ALLOCATION CHART (MAC)

C

MAINTENANCE REPAIR PARTS LIST

A-1

B-1

C-1

A-1

B-1

C-1

ii

Page 5

LIST OF ILLUSTRATIONS

TM 9-6625-2801-14&P

Figure

1-1

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

4-1

4-2

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

7-1

C-1

C-2

Title

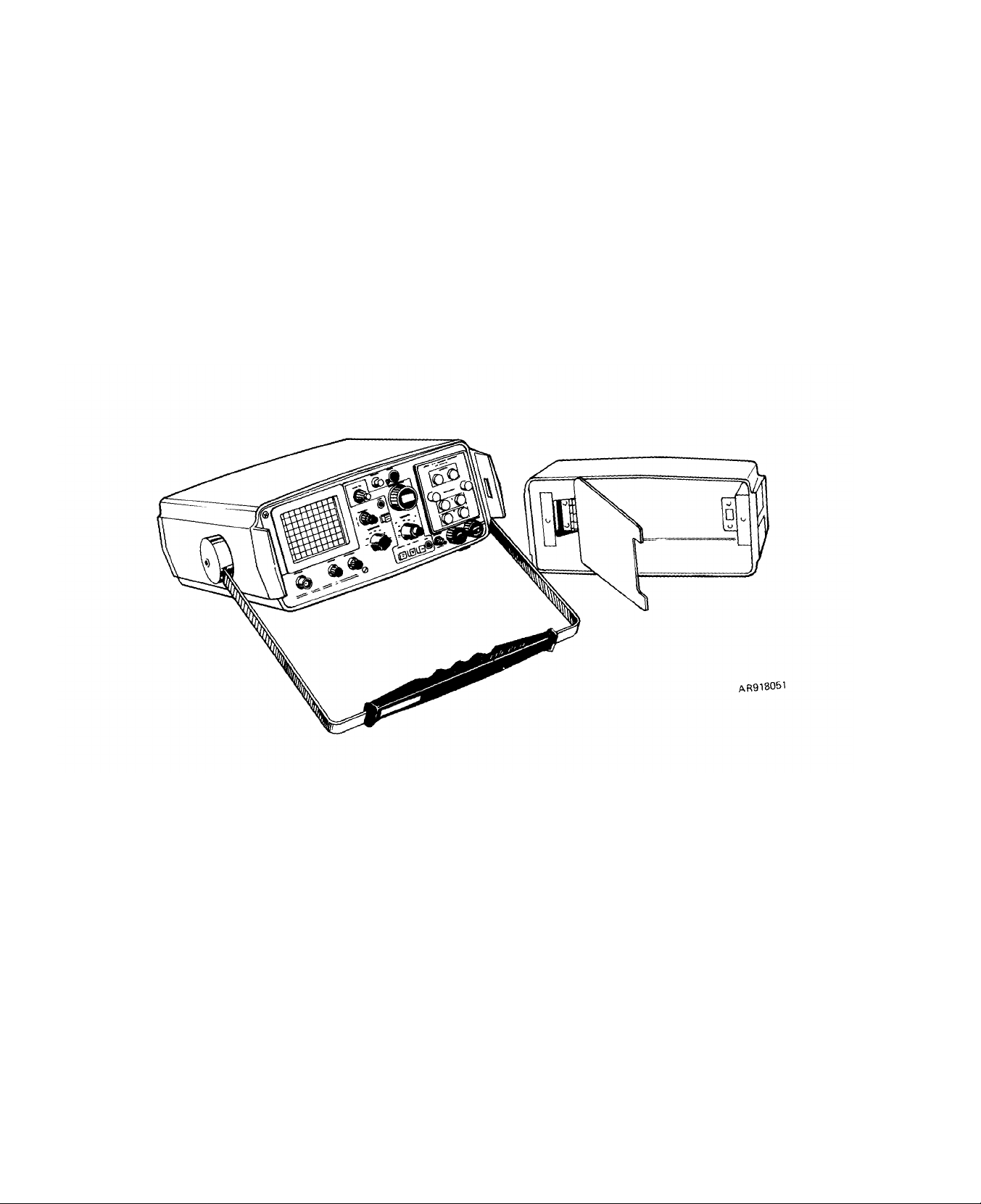

Time domain reflectometer, Tektronix 1502-1, cover removed. . . . . .

TDR front panel controls and indicators . . . . . . . . . . . . . . . . . . . . . .

Battery connector polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

230 Vac transformer wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Incident and reflecting pulses.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X-Y output module strap.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crt display of pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDR display of R

vs ZO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L

Impedance nomograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open able . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........

Shorted cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crimped cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frayed cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Simplified block diagram.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Simplified sampling diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse display . . . . . . . . . . . . . . . . . . . . . . . . . . . ...... . . . . . . . . .

Jitter check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Position check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise time and fall time... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply board test points and adjustments . . . . . . . . . . . . . . .

Pulse display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loop gain adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PC board location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vertical amplifier/slow ramp board . . . . . . . . . . . . . . . . . . . . . . . . . .

Output amplifier board fog adjustment . . . . . . . . . . . . . . . . . . . . . . . .

Power supply board DC fuse location . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable electrical parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard accessories . . . . . . . . . . . . . . . .. . ..... .......

Page

1-0

2-1

2-4

2-4

2-5

2-6

2-8

2-9

2-9

2-10

2-10

2-10

2-11

4-1

4-2

5-2

5-3

5-4

5-4

5-6

5-7

5-8

5-9

5-9

5-10

7-1

C-4

C-5

Number

1-1

1-2

2-1

5-1

6-1

8-1

C-1

C-2

LIST OF TABLES

Title

Page

TDR accessories storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...2-2

Tabulated data system... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-2

TDR front panel controls and indicators . . . . . . . . . . . . . . . . . . . . . . . 2-2

TDR troubleshooting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-11

Maintenance effort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6-1

TDR final inspection checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-1

Replaceable electrical parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..C-3

Standard accessories . . . . . . . ............. ...... .. . . C-3

This technical manual is an authentication of the manufacturers’

commercial literature and does not conform with the format and

content specified in AR 310-3, Military Publications. This

technical manual does, however, contain available information

that is essential to the operation and maintenance of the

equipment.

iii/(iv blank)

Page 6

Page 7

TM 9-6625-2801-14&P

INSTRUCTIONS FOR REQUISITIONING PARTS

NOT IDENTIFIED BY NSN

When requisitioning parts not identified by National Stock Number, it

is mandatory that the following information be furnished the supply

officer.

1

- Manufacturer’s Federal Supply Code Number - 80009

2

- Manufacturer’s Part Number exactly as listed herein.

Nomenclature exactly as listed herein, including

3-

dimensions, if necessary.

4

- Manufacturer’s Model Number. Tektronix Type 1502-1

5-

Manufacturerfs Serial Number (End Item)

6

- Any other information such as Type, Frame Number, and

Electrical Characteristics, if applicable.

7

- If DD Form 1348 is used, fill in all blocks except 4, 5,

6, and Remarks field in accordance with AR 725-50.

Complete Form as Follows:

(a) In blocks 4, 5,

Supply Code Number - 80009, followed by a colon and

manufacturer’s Part Number for the repair part.

(b) Complete Remarks field as follows:

Noun:

For:

Manufacturer:

Model:

Serial: (of end item)

Any other pertinent information such as Frame

Number, Type, Dimensions, etc.

1502-1

and 6, list manufacturer's Federal

(nomenclature of repair part)

NSN:

Tektronix, Inc.

P.O. Box 500

Beaverton, Oregon 97005

6625-01-084-3855

v

Page 8

TM 9-6625-2801-14&P

1-0

Figure 1-1. Time domain reflectometer, Tektronix1502-1, cover removed

Page 9

CHAPTER 1

INTRODUCTION

TM 9-6625-2801-14&P

Section I.

1-1. Scope.

a. Purpose.

ual is to provide information and instruction for the direct support maintenance

of the Time Domain Reflectometer, Tek-

tronix 1502.1 (hereafter referred to as

the TDR) including accessory equipment

and external test cable assemblies (see

figure 1-1),

b. Content Summary. This manual

contains the following information:

(1)

A description of the equipment.

Corrective and preventive main-

(2)

tenance

dures.

tions (appendix A).

instructions.

Checkout procedures.

(3)

(4)

Repair instructions.

(5)

Shipment and storage proce-

(6)

References to all related publica-

(7) Maintenance allocation chart

The purpose of this man-

GENERAL

defining maintenance level responsibilities (appendix B).

(8) Maintenance repair parts list

(appendix C).

1-2. Forms and Records. Refer to TM 38750 for instructions on the use of

appropriate forms, records and reports.

1-3. Calibration.

for the TDR are provided in Technical

Bulletin TB 11-6625-2860-35.

1-4. Destruction of Material to Prevent

Enemy Use.

tion of materiel to prevent enemy use refer to TM 750-244-2.

1-5. Reporting Equipment Improvement

Recommendations (EIR). EIR’s will be

prepared using SF 368, Quality Deficiency

Report (QDR).

EIR’s are provided in TM 38-750, The

Army Maintenance Management System

(TAMMS).

to Commander, U.S. Army Armament Materiel Readiness Command, Attention:

DRSAR-MAO, Rock Island, IL 61299. A

reply will be furnished directly to you.

For information on destruc-

EIR’s should be mailed directly

Calibration procedures

Instructions for preparing

Section II.

1-6. Description.

General.

a.

portable Time Domain Reflectometer which

uses radar principles to test cables and

provides a visual display of cable faults.

The test pulses are transmitted via the

CABLE output jack. Reflections are received at the same jack and displayed on

the cathode-ray tube (crt).

The Tektronix 1502-1 is a

DESCRIPTION AND DATA

Calibrated distance controls allow an operator to examine up to 100 feet of cable

with segments as small as 1 foot displayed

horizontally across the 10-division crt

screen.

feet may be examined at 100 feet per division or 200 feet per division. The horizontal crt scale is calibrated directly in distance units from 0. 1 foot per division to

200 feet per division in a 1-2-5 sequence.

Low-loss cables as long as 2000

1-1

Page 10

TM 9-6625-2801-14&P

A 3-digit, direct reading dial indicates

the distance to any cable discontinuity

when the dial is used to horizontally posi–

tion the discontinuity’s reflection to a crt

reference line.

b. Description.

(1) Main case.

gedized portable instrument that can be

used in the field as well as in the labora–

tory.

Class 2, Style A instrument as specified

in MIL-T-28800 were used as a guideline

for the environmental specifications. The

TDR has a ruggedized case that provides

protection when the instrument is stored

in exposed areas.

is not being used, the accessories, including

the Operators manual, may be packed in

the front of the instrument. Table 1-1

indicates which accessories may be placed

in the cover of the TDR.

The requirements for a Type II,

(2) Accessories. When the instrument

The TDR is a rug-

1 TDR Slide Rule

1 TDR Application Note #1

1 X-Y Output Module

1 Instruction Manual 070-1792-00

1-7. Tabulated Data. The characteristics

given in table 1-2 apply after the instrument has been calibrated and will perform

to the requirements given in Chapter 5.

Termination

Pulse Amplitude

Into 50 Load

Accessories Not Stored in Cover

Accessory

Table 1-2.

Characteristics

Tabulated Data System

Tektronix part

number

003-0700-00

062-1538-00

016-0606-00

Performance

50 within ±2%.

225 mV Nominal.

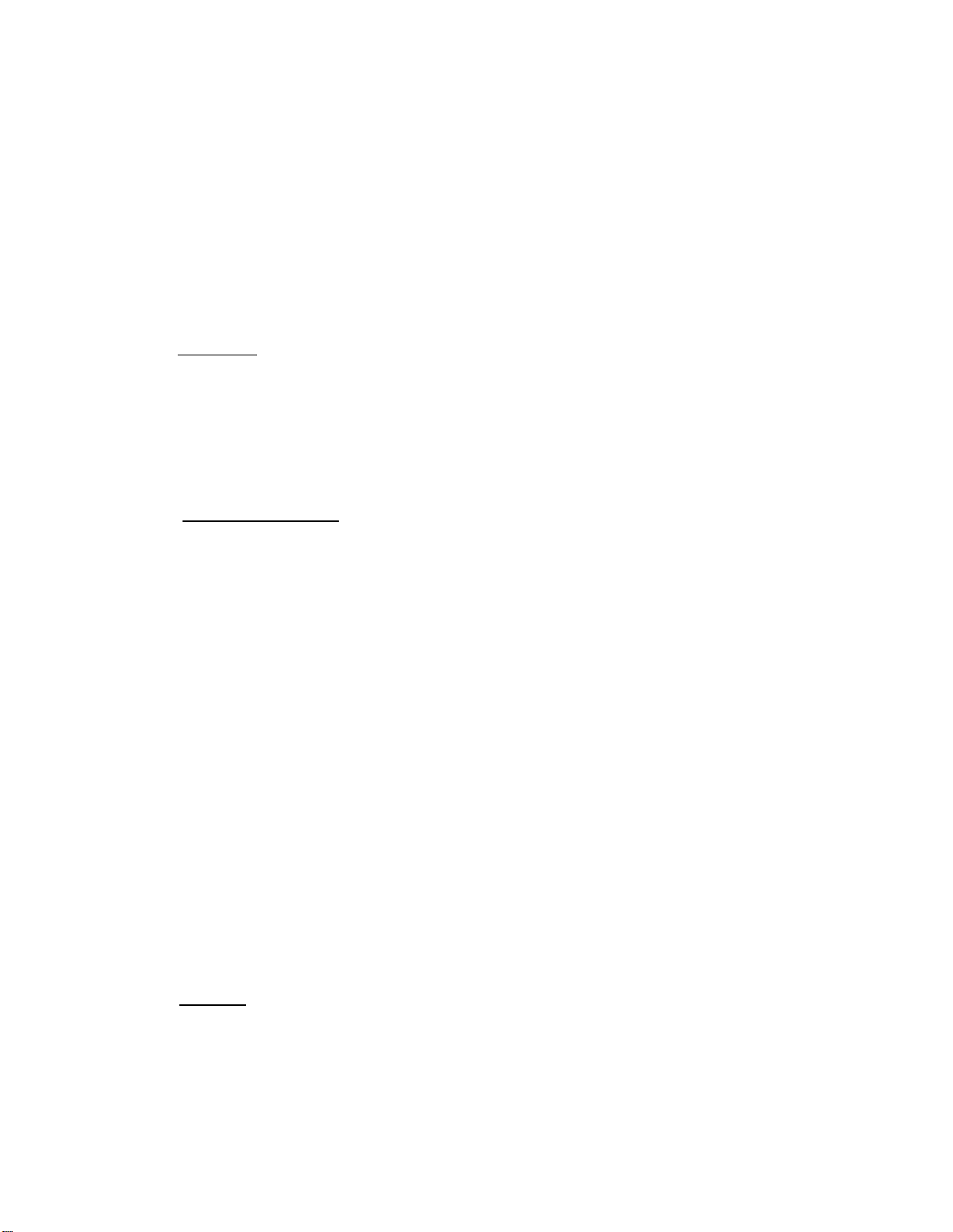

Table 1-1.

Accessories Stored in Cover

Accessories

1 50 BNC Terminator

1 Precision 50 Cable

1 Viewing Hood

1 Operators Manual

1 BNC Connector

Female-to-Female

2 Replacement Fuses

(for front panel)

For 115 Vac

Operation

or

For 230 Vac

Operation (Option 6)

1 Power Cord

1 Filter, Mesh (crt)

TDR Accessories Storage

Tektronix parts

number

011-0123-00

012-0482-00

016-0297-00

070-1790-00

103-0028-00

159-0029-00

159-0054-00

161-0066-00

378-0055-00

Vertical System

Deflection Factor

(7 steps, 1-2-5

sequence)

Accuracy

Gain (screwdriver

control)

Displayed Noise

Low Noise Operation

Horizontal System

Distance Controls

5 /div to 500

/div.

Within ±3%.

At least 3.5:1

from calibrated

point.

±5 or less,

NOISE FILTER

switch “Out”.

±2 or less,

NOISE FILTER

switch “In”.

0 to 2000 feet

total.

1-2

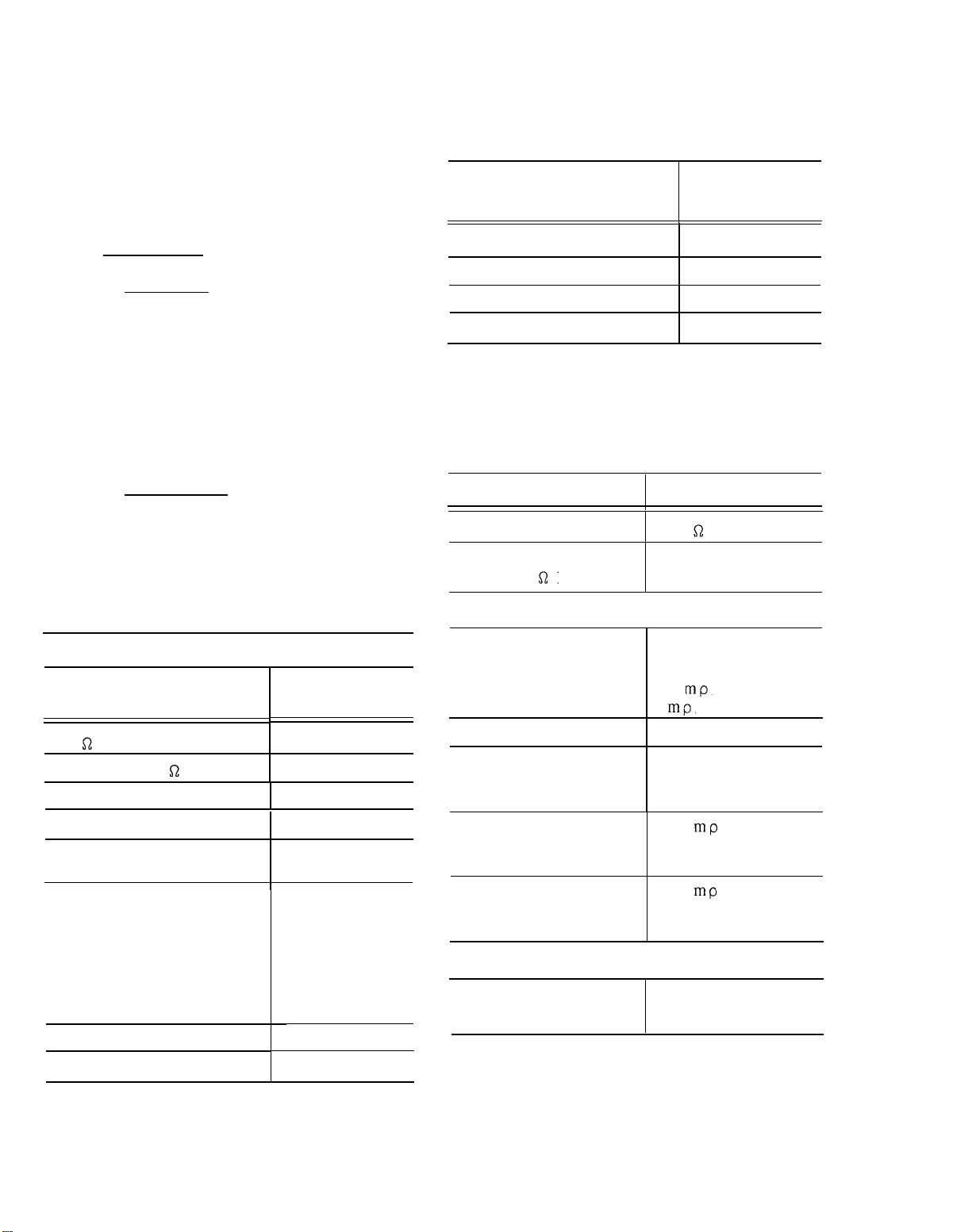

Page 11

TM 9-6625-2801-14&P

Table 1-2.

Tabulated Data

System - Continued

Horizontal System - Continued

Characteristics

Distance Dial

At X1 Multiplier

Range

Accuracy

I

At X1 Multiplier

Range

Accuracy

FEET/DIV Control

At X.1 Multiplier

Range

Scales

(8 steps,

1-2-5

sequence)

Accuracy

(All scale

settings)

(With scale

set at 20

ft/div)

At X1 Multiplier

Range

Scales

(8 steps,

1-2-5

sequence)

Accuracy

All scale

settings Within ±2%.

200 ft/div

scale

Dielectric Scales

SOLID PTFE Vp/V

SOLID POLY

Performance

0 to 100 feet.

Within ±2%, ±0.5

foot.

0 to 1000 feet.

Within ±2 %, ±1

Digit.

To 20 feet/div

0.1 foot/div to 20

feet/div.

Within ±2%.

Within ±1%

To 200 feet/div.

1 foot/div to 200

feet/div.

Within ±1%.

= 0.70

air

V

p/Vair

= 0.66

Characteristics

OTHER-VAR

Accuracy

Recorders

External Recorder

Interface for X-Y

Recorders

Horizontal

Vertical

Pen Lift

Mode 1

Source V

Sink

Mode 2 (inverted

Mode 1)

Source

Sink

Line Voltage

Battery Pack

(C size, 9 cell)

Operation

(+20oC to +25°C

charge and dis–

charge temperature)

Full Charge Time

Performance

V

= 0.55 to 1

p/Vair

Within ±2%.

0.1 V/div;

(source impedance

10 K ).

0.09 to 0.13 V/div

adjustable (source)

impedance 10 k

= 5 V Nominal

s

with R

< 10 mA (V out

< 0.5 V).

Vs = 5 V Nominal

with R

< 0.5 mA (V out

<0.6V).

—

Power System

117 Vac ±20%, 48

to 410 Hz; fused

at 0.3 A.

234 Vac ±20%, 48

to 410 Hz; fused

at 0.15 A.

At least 5 hours.

16 hours

= 10 k

s

= 10 k

s

1-3

Page 12

TM 9-6625-2801-14&P

Table 1-2.

Tabulated Data - Continued

Power System - Continued

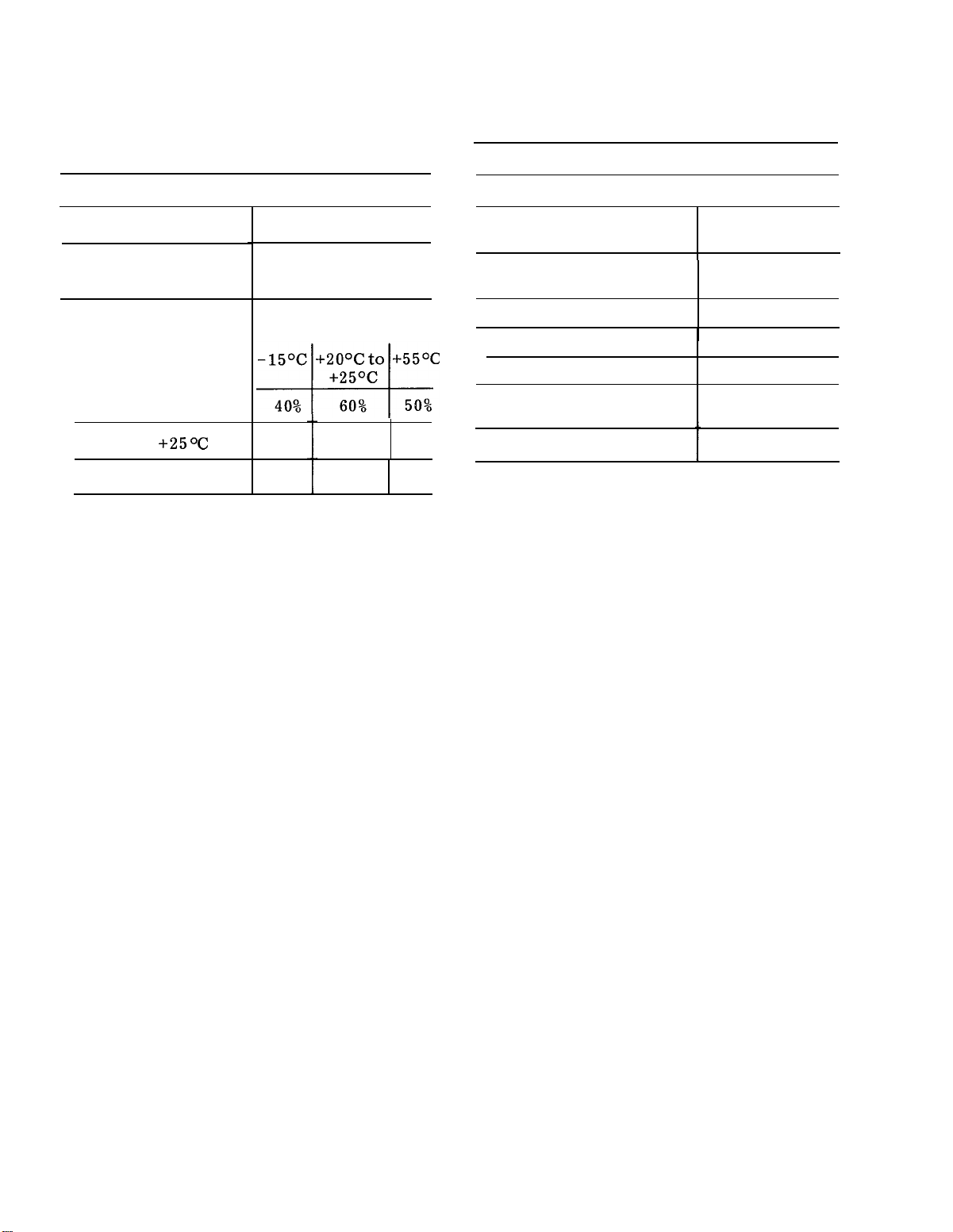

Characteristics

Typical Charge

Capacity

Charge Temperature

0oC

o

C to +25°C

+20

o

C

+40

Description

Discharge Temperature

65% 100% 85%

40%

65% 55%

Physical Characteristics

Characteristics

Description

Weight with panel cover 18 pounds

and accessories

Without panel cover

16 pounds

and accessories

Height

Width with handle

Without handle

Depth including panel

5.0 inches

12.4 inches

11.8 inches

16.5 inches

cover

Handle extended

18.7 inches

1-4

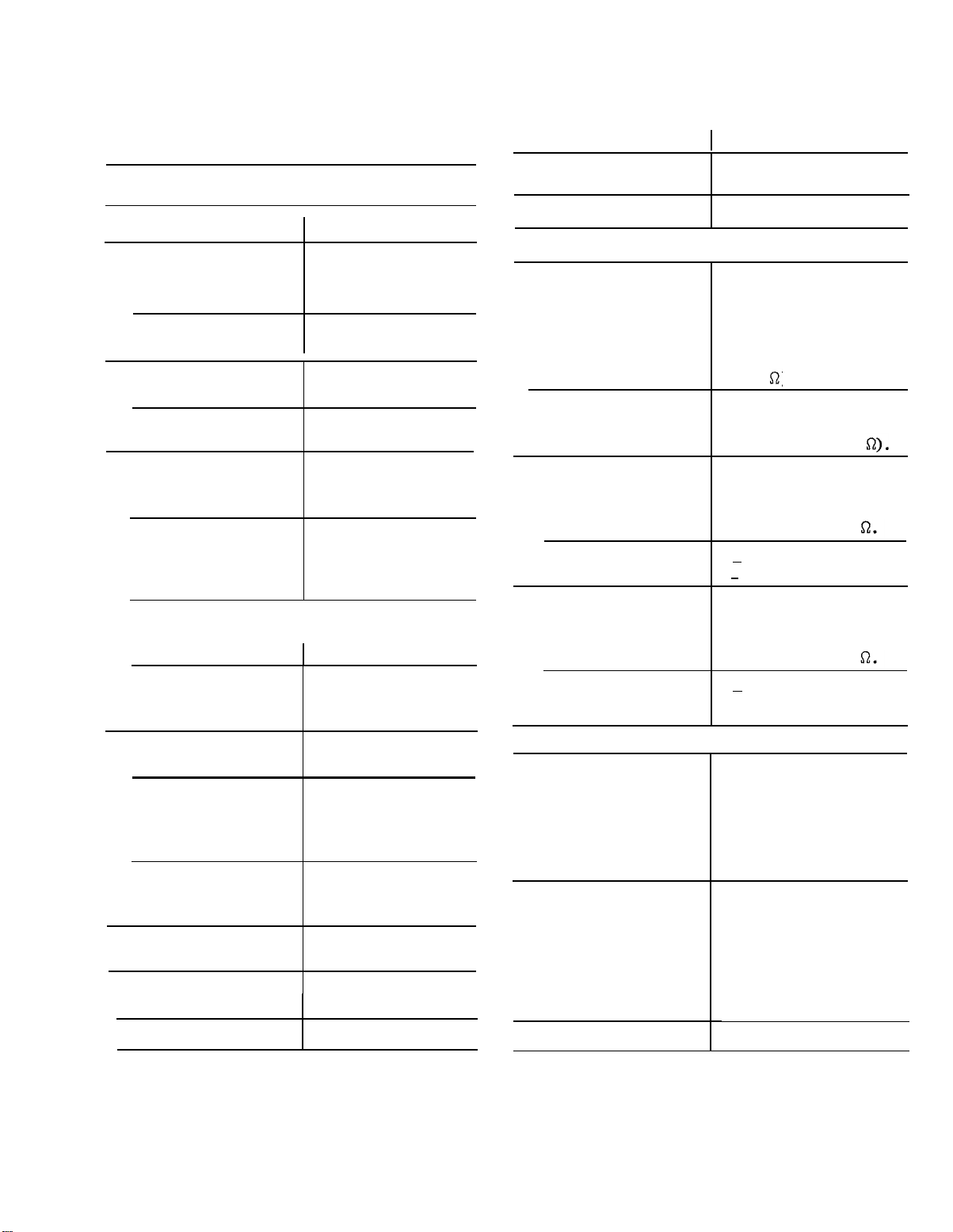

Page 13

CHAPTER 2

OPERATING INSTRUCTIONS

TM 9-6625-2801-14&P

Section I.

2-1.

tors.

pose of each front panel connector,

pushbutton,

Front Panel Controls and Indica-

A brief description of the pur-

control, and screwdriver

CONTROLS AND INDICATORS

adjustment follows.

controls of the plug-in module is also

included.

location.

Refer to figure 2-1 for their

A description of the

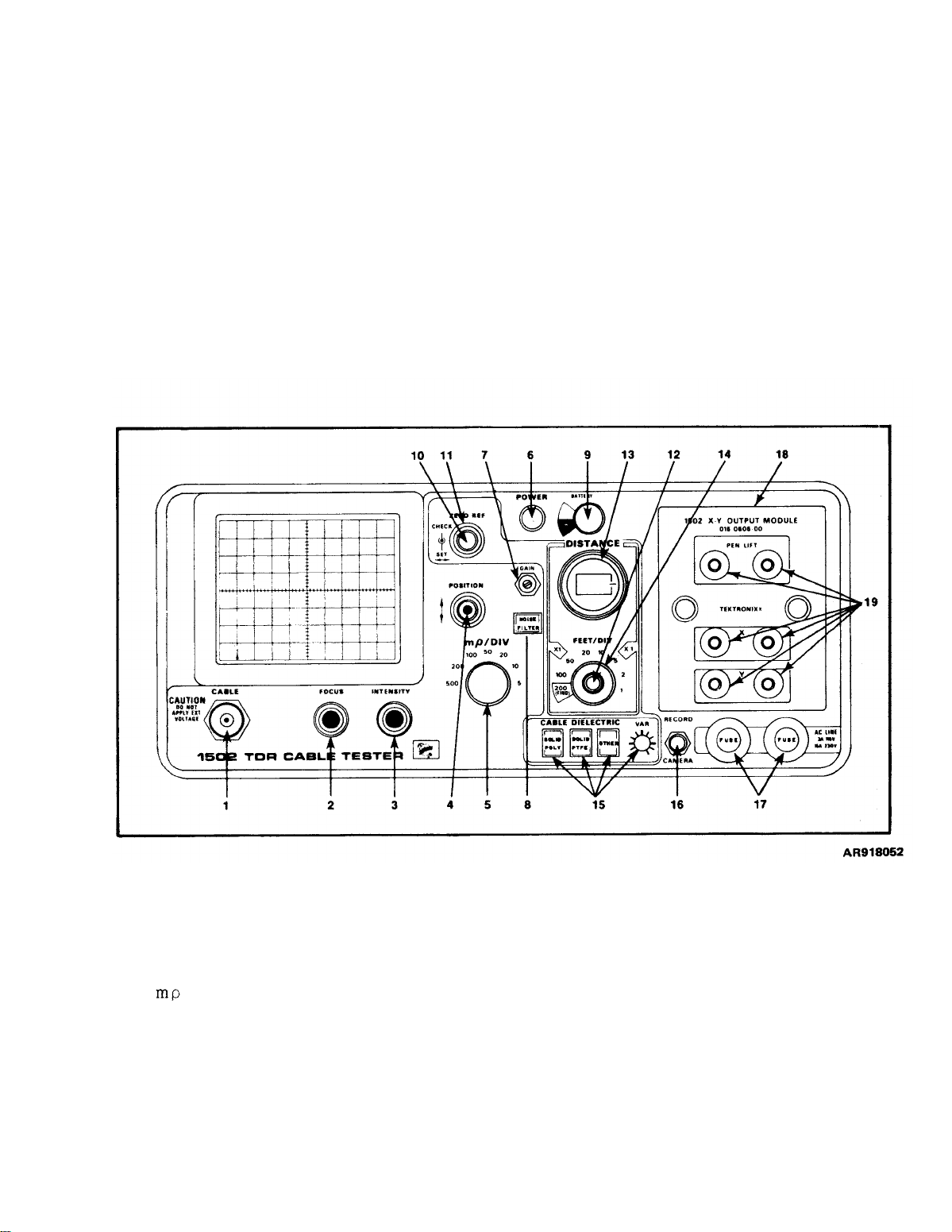

Legend for fig. 2-1:

1.

CABLE connector

FOCUS control

2.

3.

INTENSITY control

4.

POSITION control

5.

/DIV switch

6.

POWER switch

7.

GAIN adjustment

8.

NOISE FILTER switch

9.

BATTERY meter

10.

ZERO REF CHECK switch

Figure 2-1.

11.

ZERO REF SET control

12.

multiplier switch

13.

DISTANCE control

14.

FEET/DIV switch

15.

CABLE DIELECTRIC switches and

control

16.

RECORD/CAMERA switch

17.

AC LINE fuses

18.

X-Y OUTPUT MODULE

19.

External

TDR front panel controls and

chart recorder controls

indicators

2-1

Page 14

TM 9-6625-2801-14&P

Table 2-1.

Figure 2-1

index no

1

2

3

4

5

6

7

8

TDR Front Panel Controls

and Indicators

Control or

indicator

CABLE

FOCUS

INTENSITY

POSITION/

FINE

/DIV

POWER

GAIN

NOISE

FILTER

Function

BNC Connectordelivers 110 ps

risetime pulse to

the test cable and

receives the re–

fleeted return

pulse.

Adjusts the focus

of the crt elec–

tron beam.

Controls the

brightness of crt

display.

Controls vertical

position of the crt

display. The

outer control is a

coarse adjust–

ment and the

inner control is

a fine adjustment.

Selects the vertical deflection

factor--5 /div

to 500 /div

(5-2-1 sequence).

Push-pull, off-on

switch (pull for

on) – does not

affect the battery

charging circuit.

Screwdriver ad-

just to set the

gain of the verti-

cal amplifier.

Reduces displayed

noise.

rate is reduced by

a factor of 10.

Display

Figure 2-1

index no.

9

10

11

12

13

Control or

indicator

BATTERY

ZERO

REF

CHECK

ZERO

REF

SET

MULTI-

PLIER

DISTANCE

Function

Meter to indicate

the relative charge

of the power pack.

Momentary contact

Pushbutton. When

pushed, checks

the horizontal location of the inci–

dent pulse on the

crt when the DISTANCE dial is

being used.

horizontal pulse

position control

for crt display.

Sets the incident

pulse edge to a

vertical reference

line of the crt

when the DIS-

TANCE dial is at

000 or the ZERO

REF CHECK but-

ton is pushed.

Two-position

switch (red con–

trol) for X.1 or

X1 multiplier.

Affects both the

DISTANCE dial

and the FEET/

DIV control.

Inicates the dis-

tance from the

TDR to the point

on the cable where

the display win-

dow begins. Two

ranges:

at X.1 or 1000

feet at X1. Dis-

abled when the

FEET/DIV is at

200 (FIND).

100 feet

2-2

Page 15

TM 9-6625-2801-14&P

Table 2-1.

Figure 2-1

index no

14

15

16

TDR Front Panel Controls

and Indicators – Continued

Control or

indicator

FEET/DIV

CABLE

DIELECTRIC

SOLID

POLY

SOLID

PTFE

OTHER

VAR

RECORD/

CAMERA

Function

Selects the horizontal deflection

factor:

X1=1 - 200 ft/

div.

X.1=0.1 - 20

ft/div.

Three pushbuttons

and a screwdriver

adjust.

the proper velocity

of propagation.

VAR from 0.55 to

1.0 when the

OTHER pushbutton

is pressed. Fully

cw if for air die–

lectric.

trol has reference

marks every 30°

to indicate relative propagation

constants.

Two-position lever

switch; pushed up

and then released,

it initiates X-Y

Recorder or a

Selects

VAR con-

Figure 2-1

index no.

17

18

19

Control or

indicator

AC LINE

FUSES

X-Y

OUTPUT

MODULE

X, Y,

and PEN

LIFT

Function

Chart Recorder;

pushed down, it

floods the crt during retrace to

display graticule

for photography.

Protection fuses

for line power

and battery charging circuits (0.3

A fuses for 115

Vac; 0.15 A fuses

for 230 Vac).

The standard plugin module for the

TDR. Used to

drive an external

X-Y Chart Recorder.

Six front panel

jacks used for

driving an ex-

ternal X-Y recorder.

are for horizontal drive.

are for vertical

drive.

jacks are for pen

control.

X jacks

Y jacks

PEN LIFT

Section II.

Be extremely careful when working

in the vicinity of batteries when the

battery ease is open. Do not use

uninsulated tools. Do not wear

rings or watches. Metal articles will,

if allowed to contact connectors,

cause severe arcing with possible

injury to personnel and damage to

the battery.

OPERATION

2-2. Operating Power Selection.

When substituting a dc power

supply or external battery for

the battery pack, be sure the

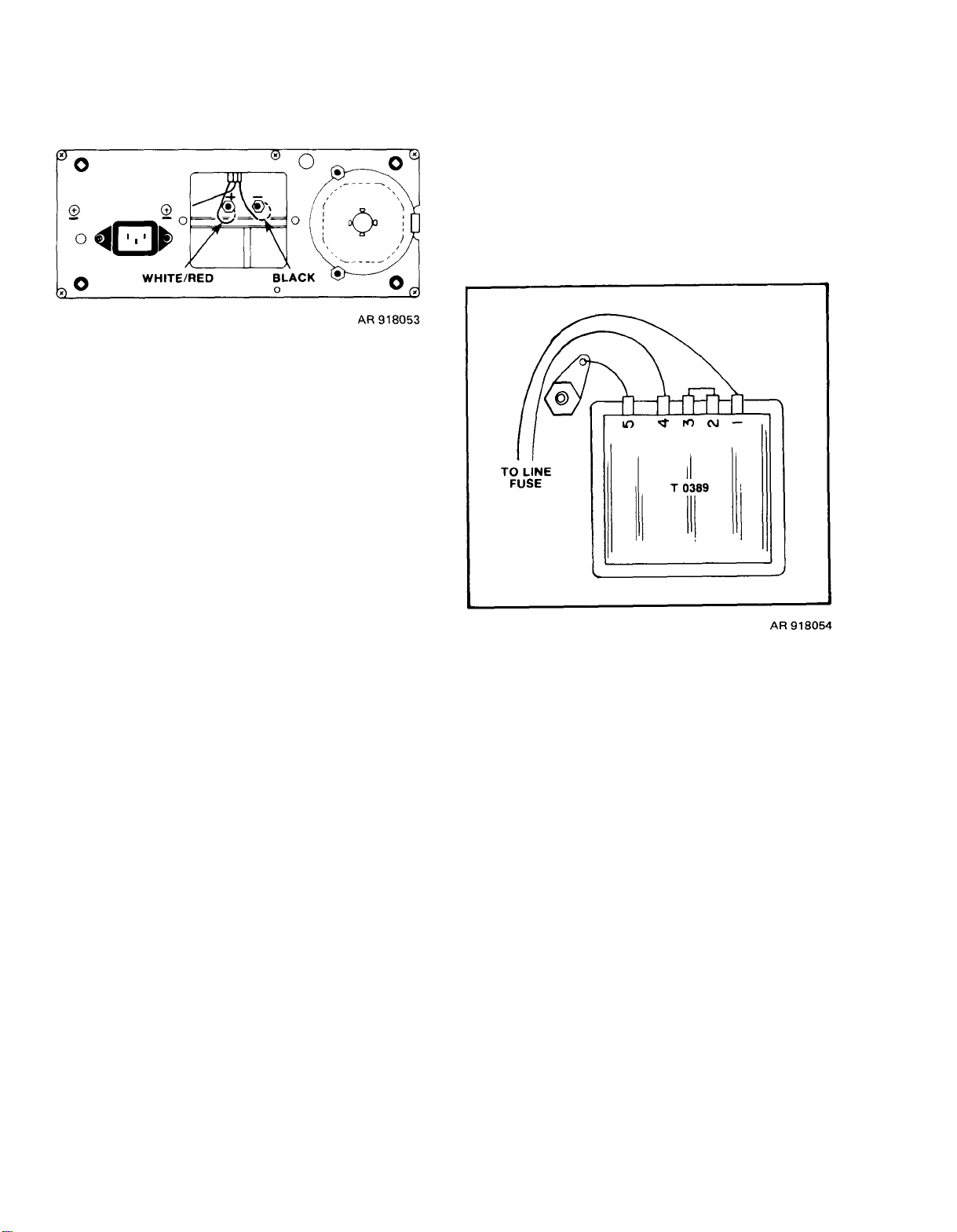

polarity is correct (see figure

2-2).

2-3

Page 16

TM 9-6625-2801-14&P

Figure 2-2. Battery connector polarity

a.

Battery Connections. A 12 Vdc

power supply may be substituted for the

TDR battery pack by removing the pack

from the unit and connecting the power

supply to the terminals inside the battery

pack compartment.

The power pack can be stored at any

temperature between -40oC and +50°C

with the battery cells either fully or

partially charged.

rate of the cell increases with increased

temperature.

will lose about 50% of its charge in 3 to 4

months if stored at +20°C to +25°C.

Therefore, the battery pack should be

completely recharged before using if it

has been stored without power supplied

to its charging circuit for more than a

month.

A fully charged battery

The self-discharge

2-3. Turn-on Procedures.

If crt displays no signal, check

fault isolation paragraph 5-6.

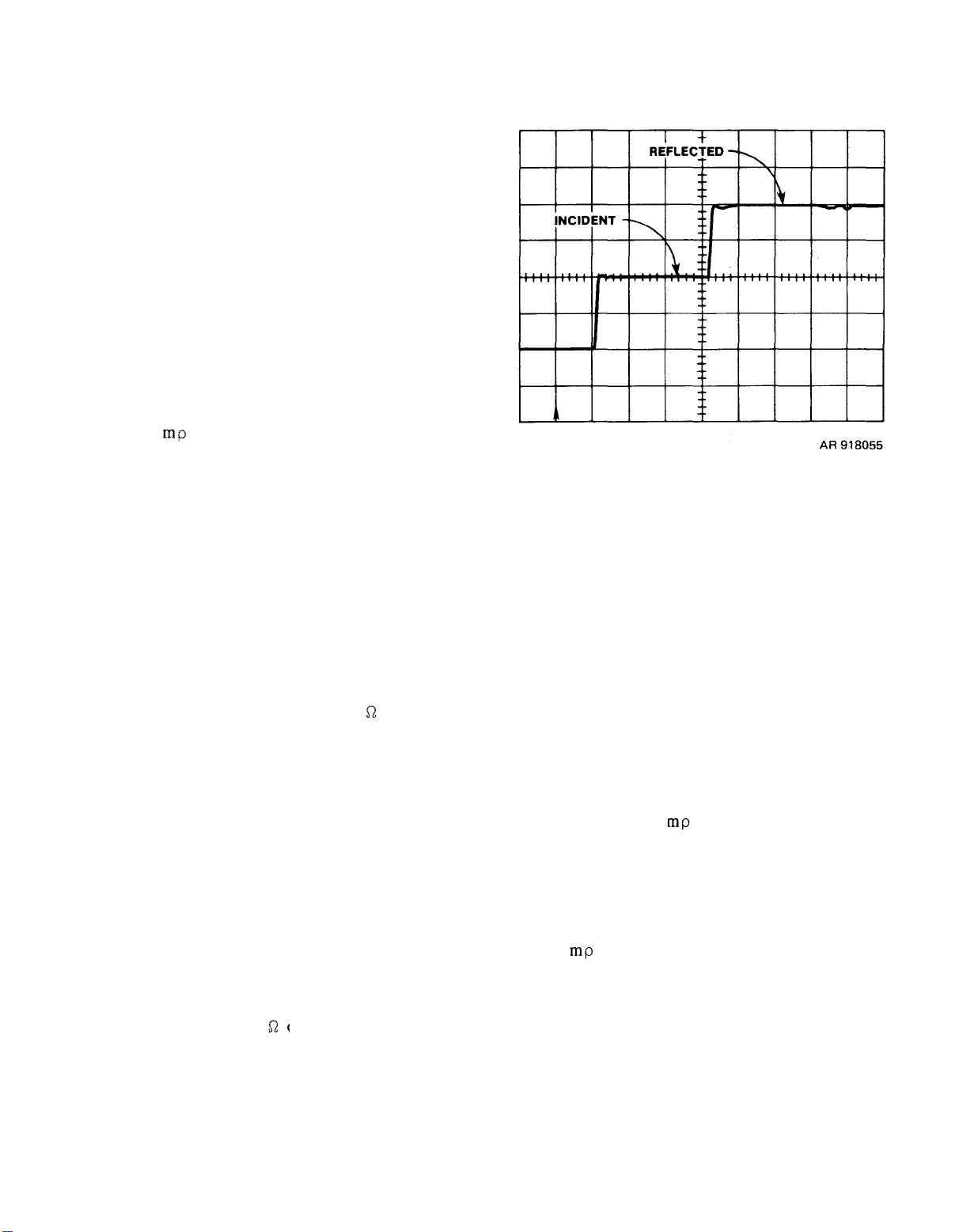

Figure 2-3.

Preparation.

a.

NOTE

230 Vac transformer wiring

When the TDR is wired for 230

Vac, be sure that the two front

panel fuses are changed to 230 V,

0.15A slow-blow fuses and the

proper plug is installed on the

ac cable.

b.

230 Volt Operation. The battery

charger is factory wired for 115 Vac or

230 Vac if Option 6 is ordered. The

standard 115 Vac unit can be changed to

230 Vac operation by rewiring the line

transformer.

per wiring configuration for 230 V operation.

Figure 2-3 shows the pro-

2-4

(1) To gain access to the front panel,

pull the two side latches forward and re-

move cover.

TDR as a stand, position it to raise the

unit to a convenient operating position

(figure 1-1).

(2) The battery pack is fully charged

in 16 hours when connected to an ac power

source and the unit is switched off. The

TDR may be operated while the battery

pack is charging; however, the charging

time will increase.

overcharge if the charger is left on long-

er than 16 hours.

may remain connected to an ac source

without damaging the batteries. Approxi-

mately once a month or every 15 -charge–

discharge cycles, the batteries should be

charged for approximately 24 hours.

Using the handle of the

The batteries will not

Therefore, the TDR

Page 17

Approximately 30 minutes of operating

time can be expected from a 1-hour partial

charge. To avoid reverse charging, the

full 16 hour charge should be completed

in preference to a partial charge whenever possible.

Control Settings (TDR).

b.

(1) Set front panel controls as

follows:

TM 9-6625-2801-14&P

FOCUS

INTENSITY

ZERO REF

POSITION

/DIV

DISTANCE

FEET/DIV

X1-x1

CABLE DIE-

LECTRIC

POWER

(2) Adjust INTENSITY and FOCUS

controls for a clear bright trace.

(3) Adjust POSITION controls to set

trace 2 divisions below horizontal center–

line.

(4) Attach precision 50 cable (012-

0482-00) to CABLE connector (stored in

cover).

(5) Turn ZERO REF SET button ccw

until incident pulse edge is located on a

vertical reference line. The incident

pulse edge is the initial rise of the step

pulse. The vertical reference line may be

any line you choose from center line to

left side of crt graticule. An arrow in

the second vertical line indicates a

commonly used reference line.

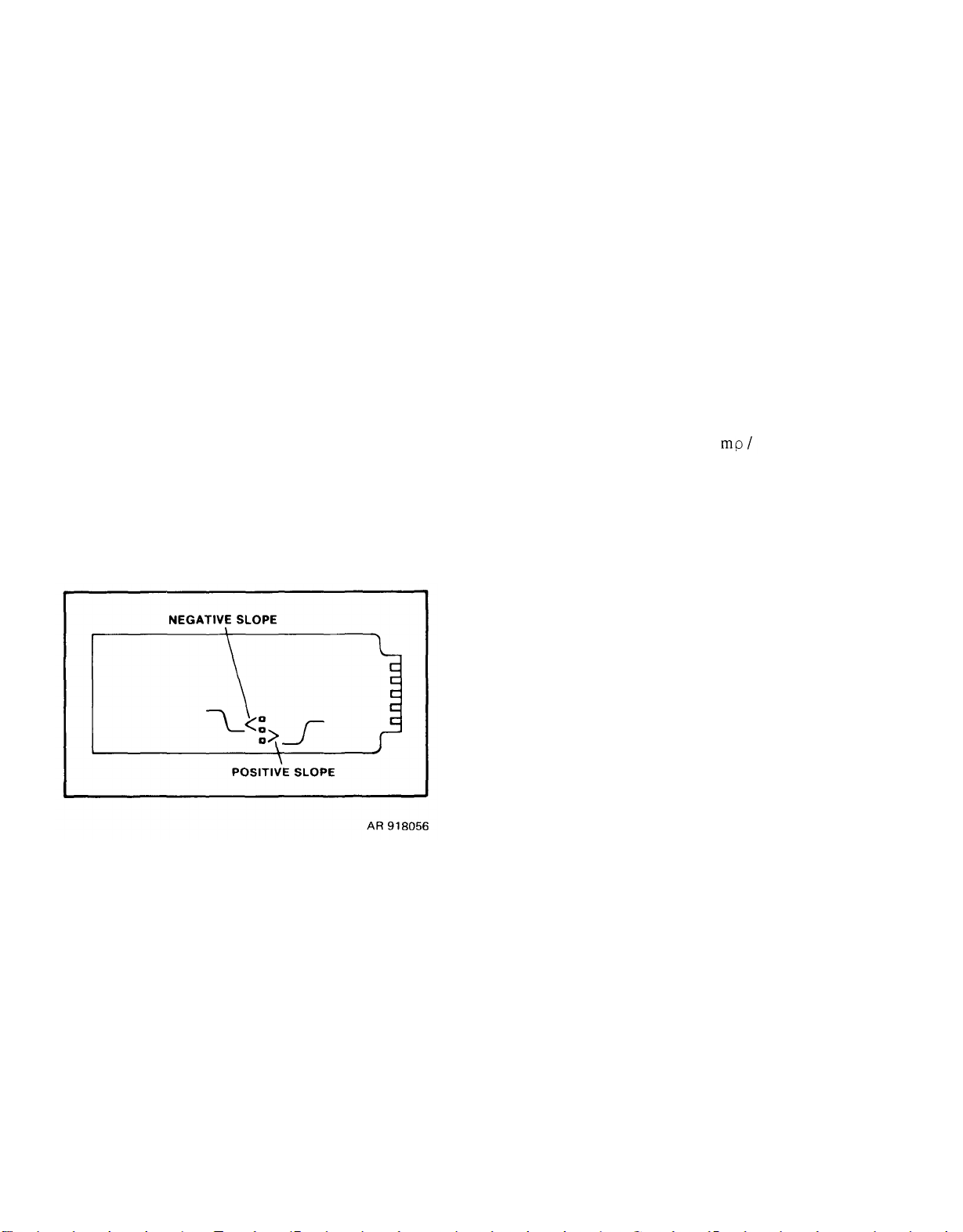

The reflected pulse from the open

end of the 50 cable should ap-

pear three horizontal divisions to

right of reference line. Open end

of cable is indicated by start of a

second rise in trace (see figure

2-4).

Midrange

Full range

Fully cw

Midrange

500

000

1

X1

SOLID POLY

ON

NOTE

Figure 2-4. Incident and reflected pulses

(6) Turn ZERO REF SET button

throughout its range to see that the inci–

dent pulse edge can be set on any vertical graticule line.

edge on vertical reference line.

(7) Set DISTANCE dial to 050 and

check that top of step (open cable re–

flection) is displayed.

(8) Press ZERO REF CHECK button

and check that incident pulse edge returns to vertical reference line of graticule.

POSITION controls so top of incident

pulse is on horizontal centerline.

and check for a reduction in displayed

noise as well as a reduction in scan rate.

Reset /DIV to 500, and release (by

depressing a second time) NOISE FILTER

button.

Note crt display; entire crt should be

flooded on retrace to illuminate graticule

when taking photographs. Release

CAMERA switch.

Reset DISTANCE dial to 000.

(9) Change /DIV to 50 and adjust

(10) Press NOISE FILTER pushbutton

(11) Press and hold CAMERA switch.

Set incident pulse

2-5

Page 18

TM 9-6625-2801-14&P

(12) Lift up and hold RECORD switch.

Check that bright spot appears at left

edge of crt.

(13) Release RECORD switch. Slow

scan of spot will trace displayed waveform.

automatically return to its normal mode

of scanning.

When scan is complete TDR will

c.

Control Settings (Accessories).

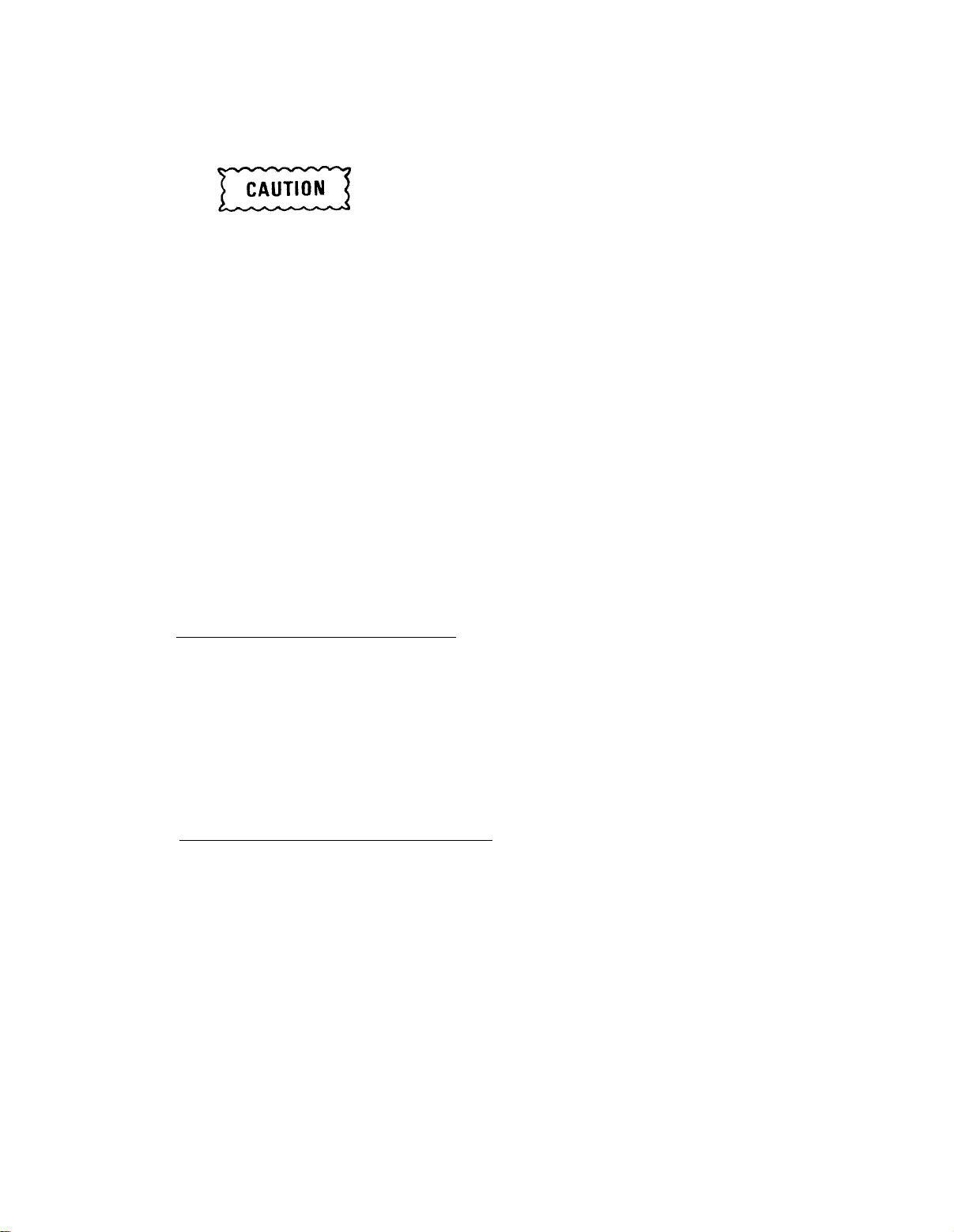

NOTE

The X-Y OUTPUT MODULE is

wired for either a positive or

negative pen lift signal. Be-

fore using the X-Y OUTPUT

MODULE , be sure that the pen

lift circuit on the etched circuit board is properly connected.

Figure 2-5 shows the proper

connection for either a positive

or negative pen lift signal.

(4) To position stylus at desired

position on paper, adjust STYLUS POSITION screw while RECORD/CAMERA

switch is in the RECORD position.

(5) Release RECORD/CAMERA to

precede with recording. Chart record

circuits automatically shut off when recording is completed.

NOTE

In evaluating a graph, the dis-

tance between two dark hori-

zontal lines corresponds to one

vertical division of the crt dis–

play with respect to the

DIV setting; the distance between two dark vertical lines

corresponds to one horizontal

division of the crt display with

respect to the FEET/DIV setting.

d. Use of Accessories.

Figure 2-5.

(1) If not already in place, install

X-Y OUTPUT MODULE into its compartment on front panel of TDR.

(2) Connect X, Y, and PEN LIFT

inputs of recorder to corresponding

jacks of X-Y OUTPUT MODULE.

(3) Position and hold RECORD/

CAMERA switch to RECORD to prepare

for recording.

X-Y output module strap

(1) Mesh Filter for the crt. A mesh

filter is provided with the TDR which

makes viewing of the crt easier when the

unit is being used in the sunlight. This

filter is placed over the crt by sliding it

onto the slots of the crt bezel.

provides shading for the crt and can be

installed over the crt by sliding it down

over the crt bezel sides.

must be removed before the viewing hood

will connect to the crt bezel.

If a Camera Adapter (Tektronix Part

Number 016-0327-00) is attached to the

crt bezel of the TDR, a C–30A/31 cam–

era can be used to take photographs of

the crt display.

illumination, the RECORD/CAMERA

switch must be pushed down and held

while the photograph is being taken.

After the trace is completed the entire crt

is flooded to provide a light background

to allow the dark graticule to appear in

the photograph.

.

(2) Viewing Hood. The viewing hood

The mesh filter

(3) Using a Camera with the TDR.

To obtain graticule

2-6

Page 19

TM 9-6625-2801-14&P

2-4.

the TDR to the BNC connector (CABLE)

on the front panel.

ter as required.

Cable Testing.

Do not connect live circuit cables

to the input of the TDR. Voltages in excess of 5 volts can damage the sampling gate or tunnel

diode.

Bleed cables before connecting

them to the TDR to remove static

charge from them. The 50 ohm

termination and BNC adapter

supplied may be used to bleed

any cable charge.

When testing antennas, be sure

that you are not close to trans-

mitters that can be keyed at the

antennas receiving frequency.

Keying of transmitters in close

proximity can cause damage to

the TDR.

Connecting a Cable for Testing.

a.

(1) Connect cables to be tested by

Use connector/adap-

150 feet long, set

and the multiplier

Use the X.1 multiplier whenever

possible to lessen the effects of

jitter.

(2) Measure the distance between

the incident pulse rise and the reflected

pulse rise.

The distance from the sampling

bridge to the CABLE connector

(2. 5 inches) should be taken into account when measuring

cables less than 2 feet in length.

(3) To more accurately locate the

discontinuity, set the FEET/DIV control

to a lower setting. (The reflected

pulse does not need to be in the display

window).

button and adjust the ZERO REF SET

control so that the incident pulse rise is

set at a convenient vertical reference

graticule line.

contol may have to be readjusted when

changing the FEET/DIV control.

Push the ZERO REF CHECK

the FEET/DIV to 200

at X.1.

NOTE

NOTE

The ZERO REF SET

(2) Adjust FOCUS and INTENSITY

controls for a sharp and bright display

on the crt.

b. Locating a Discontinuity in a Cable.

The DISTANCE dial and the FEET/DIV

control make it possible to evaluate cables

as long as 2000 feet. The entire length

can be displayed directly on the crt if

desired.

only that portion of the trace seen on the

crt will be recorded on the graph. To

check cables using the crt, proceed as

follows:

(1) Set crt display window so it is

longer than the cable under test by set-

ting the FEET/DIV control and the X1/

X.1 control,

If a chart recorder is used,

For example, if the cable is

NOTE

Always set the incident and reflected pulse to the 10% points of

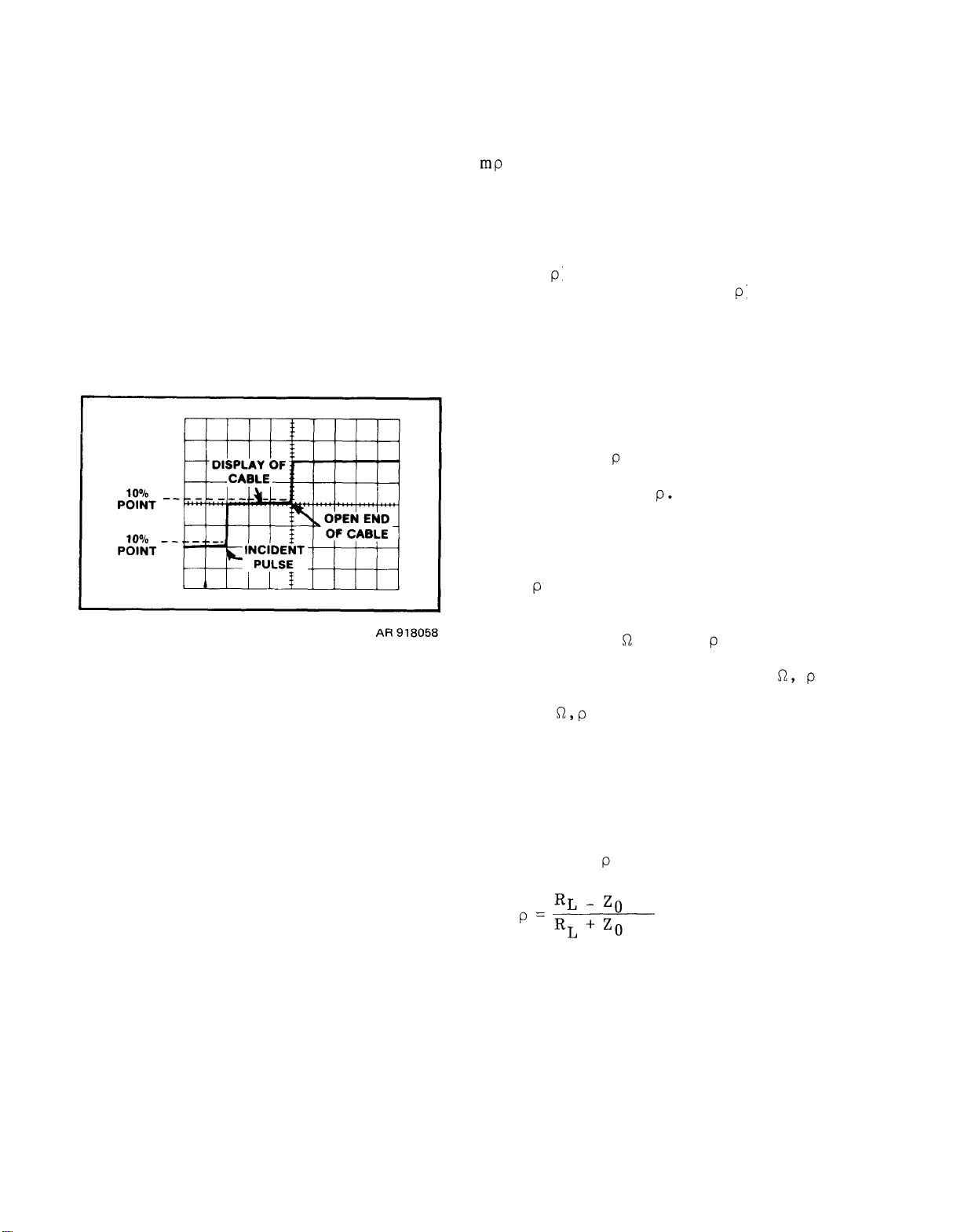

their amplitude (see figure 2-6).

(4) Turn the DISTANCE dial clock-

wise until the reflected pulse is located

on the reference graticule line. The

reading on the DISTANCE dial times the

multiplier gives the length from the

CABLE connector to the end of the cable

(or to the discontinuity).

NOTE

When checking cables longer

than 1000 feet, adjust the DISTANCE dial until the reflected

pulse reaches the right-hand

2-7

Page 20

TM 9-6625-2801-14&P

edge of the graticule, then

add the graticule display distance to that on the DISTANCE

dial for the total length. The

reading of the DISTANCE dial,

plus the number of divisions

(from the reference line) across

the graticule times the FEET/

DIV setting gives the total

length of the cable. Remember

that in the 200 FEET/DIV setting the DISTANCE dial is inoperative.

Figure 2-6. Crt display of pulse

(5) The CABLE DIELECTRIC push-

buttons allow the TDR to accurately locate discontinuities in cables of various

relative propagation velocity constant

(Vp).

brated to check solid polyethylene dielectrics which have a Vp of 0.66. The

SOLID PTFE button is calibrated to check

solid polytetrafluoroethylene (Teflon)

which has a Vp of 0.70. The OTHER

button is variable from 0.55 to 1.00 and

is controlled by the screwdriver adjust–

ment control VAR.

control is turned to the fully clockwise

position, it is calibrated for air dielectrics

which have a Vp of 1.00. If all three of

the CABLE DIELECTRIC buttons are

released, a default condition leaves the

instrument calibrated for air dielectrics

(Vp) = 1.00).

The SOLID POLY button is cali-

When this screwdriver

/DIV control determines the vertical

deflection that can be seen on the crt or

recorded on a graph if a chart recorder

is used.

measure the ratio of the reflected signal

amplitude to the incident signal amplitude

in rho ( ), which is called the voltage

reflection coefficient.

measurement of reflected signal amplitude

and can be used to determine the im–

pedance of a discontinuity. Note that no

reflection is obtained from a cable that

has no discontinuities if the cable is ter-

minated with its characteristic impedance.

If a cable has an open, i.e., a break

(infinite impedance), the reflected step

amplitude is +1 ;

short (zero impedance), the reflected

step amplitude is -1

of a TDR display labeled to identify the

incident and reflected voltage signals.

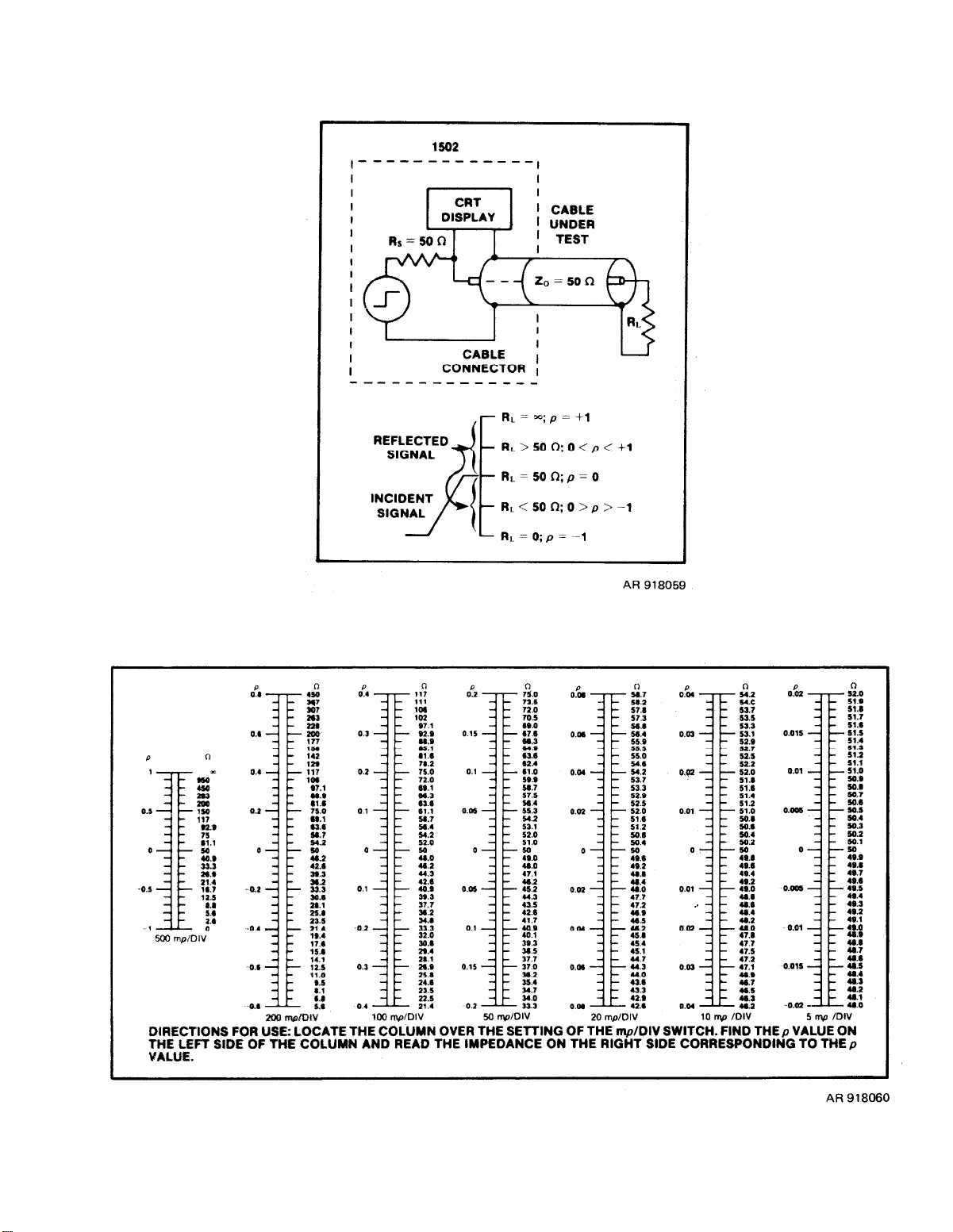

When =0, the transmission line is ter-

minated by a resistance equal to its

characteristic impedance (Z0) which, in

this case, is 50

the transmission line load is a short. If

the line is terminated by RL > 50

is positive and if the line is terminated by

RL < 50 is negative.

ting reflected pulse amplitude to impe-

dance.

teristic impedance, Z0, of the cable under

test and the load (or the impedance of

the discontinuity), R

Therefore, a can also be defined as:

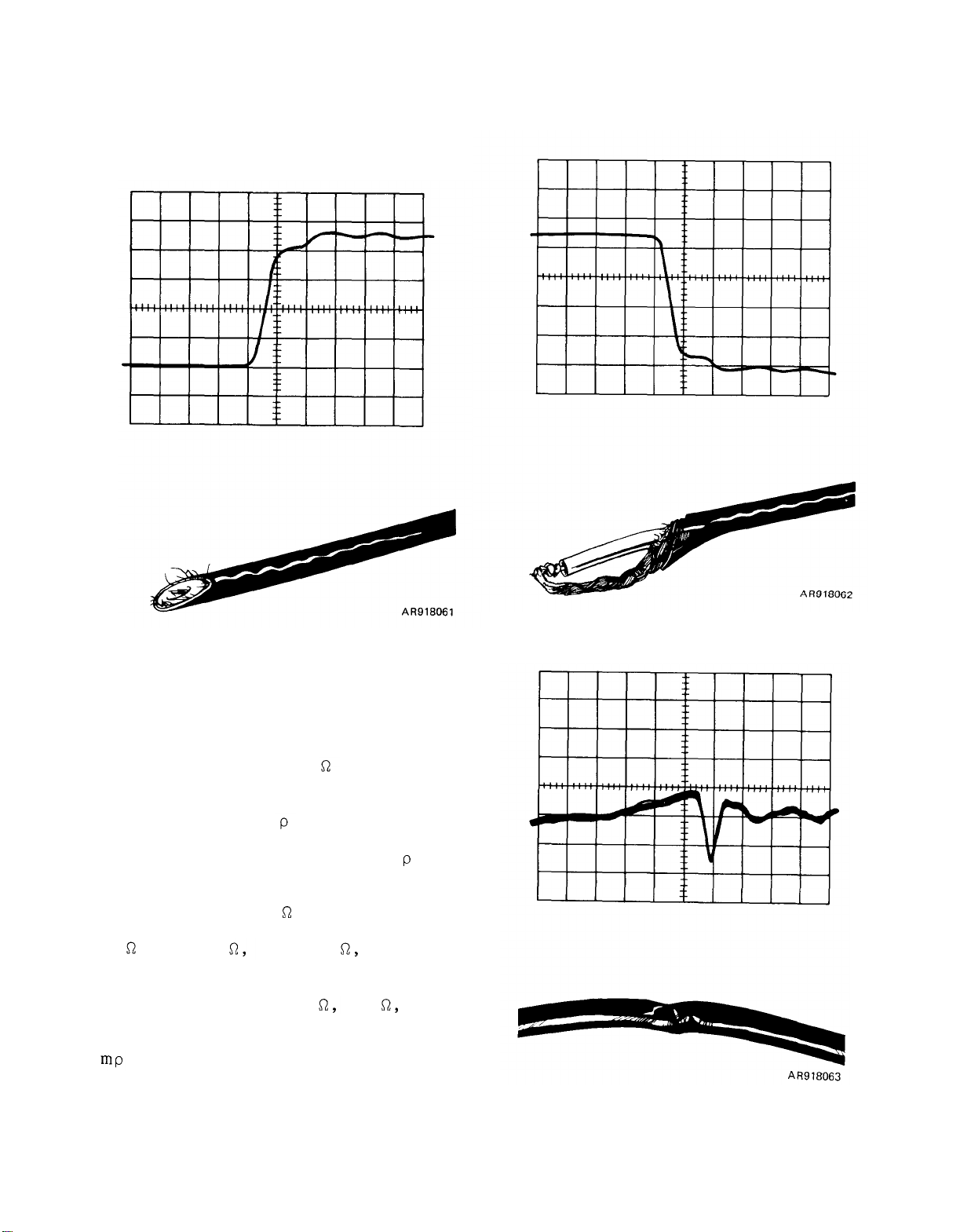

the cable problems that can be analyzed

with the TDR include opens, shorts, pin-

holes in the cable shield, opens in the

shield, kinks in the cable, mismatched

connectors, and corroded connectors.

c.

Evaluating a Discontinuity. The

This control is calibrated to

Rho ( ) is the

and if a cable has a

(1) Figure 2-7 shows the two parts

.

When equals +1,

(2) Figure 2-8 is a chart for conver-

Rho is dependent on the charac-

, on the cable.

L

Typical Cable Problems. A few of

d.

2-8

Page 21

TM 9-6625-2801-14&P

Figure 2-7.

TDR display of RL vs Z

O

Figure 2-8.

Impedance nomograph

2-9

Page 22

TM 9-6625-2801-14&P

Figures 2-9 through 2-12 show typical

examples of these problems.

Figure 2-9. Open cable

e.

Checking Cables with Other than

50 Ohms Impedance.

(1) Cables with a characteristic

impedance other than 50 can be evalu-

ated by adjusting the GAIN control

(screwdriver adjust) to correct the re-

flected pulse for +1 at the open end of

a cable.

incident pulse will no longer be 1

dance other than 50 , either connect

an impedance–matching adapter (50 to

75 , 50 to 93 50 to 125 etc.) to the

CABLE connector and connect a short

length of cable (with impedance the same

as the adapter, i.e., 75 125 etc.)

to the adapter or connect the cable to be

tested to the CABLE connector. With the

/DIV control set at 500, position the

trace on the graticule so that the display

of the cable appears in the display. Now

When the GAIN is changed, the

.

(2) To reset the GAIN for an impe-

Figure 2-10.

Figure 2-11. Crimped cable

Shorted cable

2-10

Page 23

TM 9-6625-2801-14&P

adjust the GAIN control so that the open

end display (reflected pulse) is set 2

divisions above the cable display (hori-

zontal centerline). This sets the reflected pulse to +1 from the characteristic impedance.

NOTE

If an impedance adapter is not

used, secondary reflections

will re–appear as discontinuities beyond the open end of

the cable.

Figure 2-12.

Frayed cable

2-11/(2-12 blank)

Page 24

Page 25

CHAPTER 3

SERVICE AND PREVENTIVE MAINTENANCE

TM 9-6625-2801-14&P

Section I.

3-1. Unpacking and Inspection. When the TDR is

received, it will be packed in a corrugated cardboard carton. Inside packing and re-enforcement is

also fabricated from corrugated cardboard. Gain

access to the TDR by carefully cutting the sealing

tape on top of the carton, open carton, remove the

top packing, and withdraw TDR from carton,

Carton should be stored for future use in reshipping. Visually inspect the TDR for

Section II.

3–3. Repair Parts. Repair parts are

listed in Appendix C of this manual.

SERVICE UPON RECEIPT OF MATERIAL

damage.

panel and controls for damage. Open inside cover. Remove, unwrap and check

for all items listed in table 1-1 and inspect all items for damage.

3-2. Checkout Procedures. Perform

procedures given in paragraphs 2-3 a

and b to ensure the equipment is in operational condition.

REPAIR PARTS , SPECIAL TOOLS AND EQUIPMENT

Section III.

LUBRICATION

Release cover and inspect front

3-4. General. This equipment does not

require periodic lubrication.

Section IV.

Dry cleaning solvent or mineral

spirits paint thinner is flammable

and should not be used near an

open flame. Fire extinguishers

should be provided when these

materials are used.

ventilated areas.

Use only in well

PREVENTIVE MAINTENANCE

3-5. General.

consists of cleaning, visual inspection,

etc. Preventive maintenance performed

on a regular basis will help improve the

reliability of the instrument. The se-

verity of the environment to which the

TDR is subjected determines the fre-

quency of needed maintenance. A convenient time to perform preventive

maintenance is preceding recalibration of

the instrument.

Preventive maintenance

3-1

Page 26

TM 9-6625-2801-14&P

3-6. Cleaning.

a.

General. Accumulation of dirt in

the instrument can cause overheating and

component breakdown. Dirt on components acts as an insulting blanket and

prevents efficient heat dissipation. It

also provides an electrical conduction

path.

b.

Interior.

in a manner that protects the interior of

the instrument from dust.

When the cabinet is removed,

the watertight integrity may be

compromised.

tions (in this section) on removing and replacing the cabinet.

Therefore, the interior of the TDR

should not require cleaning unless the

unit has been left with the front cover

removed and the plug–in compartment

empty.

terior is to blow off the accumulated dust

with low–pressure air.

that remains with a soft brush or a cloth

dampened with a mild detergent and

water solution.

cator is useful for cleaning in narrow

spaces on circuit boards.

The best way to clean the in-

The TDR is constructed

NOTE

See the instruc-

Remove any dirt

A cotton-tipped appli-

rinsed with clear water.

cumulated on the front panel is best

removed with a small brush or a soft

cloth dampened with a mild detergent and

water solution.

not be used on the front panel.

d.

CRT Implosion Shield. The face of

the crt can be cleaned by using isopropyl

alcohol applied and wiped very gently

dry with lens paper (NSN 6640-00-559-

1385).

3-7.

pack should be inspected every two

months.

be replaced if venting or corrosion has

occurred.

3-8. Water-tight Seals. The TDR is prepared to be operated in any weather

(rain, snow, dust, etc.). To prevent

moisture and dust from getting inside the

instrument, special seals are used around

the pushbuttons,

and rotary controls.

the components on the front panel will

require special resealing procedures to

retain their water–tight integrity.

3-9. Calibration.

measurements, check the calibration

every 120 days.

Procedure Technical Bulletin for Time

Domain Reflectometer, Tektronix Type

1502-1, TB 11-6625-2860-35 for calibration procedures.

Servicing battery. The battery

The entire battery pack should

Abrasive cleaners should

crt, power switches,

To ensure accurate

Refer to Calibration

Loose dust ac-

Removal of any of

Avoid the use of chemical cleaning agent which might damage

the plastics used in this instrument.

contain benzene, toluene, xy–

lene, acetone or similar solvents.

c.

can be washed with soap and water and

Avoid chemicals which

Exterior.

The cabinet exterior

3-2

Page 27

CHAPTER 4

FUNCTIONAL ANALYSIS

TM 9-6625-2801-14&P

4-1.

TDR uses radar principles to check cable

conditions.

the pulses down the cable under test,

and the sampler circuits sample the echos

and provide the vertical signal for display on the crt.

tunnel diode in a 50 ohm strip line (cavity). It contains all biasing and timing

circuits required for operation of tunnel

diode CR1703.

Simplified Circuit Analysis. The

The pulser circuits transmit

Pulser. The pulser is basically a

a.

b.

Sampling.

(1) Sequential equivalent-time sampling is used to develop a display (see

figure 4-1).

a fast ramp and a slow ramp. The fast

ramp is compared to the slow ramp or a

fixed reference to generate trigger pulses for the sampler and the pulser respectively.

the pulser and sampler comparators.

These comparisons are made by

Two ramps are generated,

Figure 4-1.

Simplified block diagram

4-1

Page 28

TM 9-6625-2801-14&P

(2) A short time after the pulser

transmits the step pulse into the cable

under test, depending on the amplitude

of the slow and fast ramps, a sampling

trigger from the sampler comparator

causes the sampler to sample–and–hold

the voltage level appearing at that time.

This voltage is taken at the point where

the sampler is connected to the 50 ohm

strip line.

fied and sent through the vertical amplifiers to the crt.

(3) The slow ramp generator pro-

vides the horizontal sweep for the crt

and, combined with the vertical sample,

This voltage sample is ampli-

provides a display of the sampled value.

Ensuing sampling triggers taken later

during the next fast ramp time, cause

additional samples to be displayed next to

the first one, until a line of very short

dashes is formed across the crt, appearing as a solid line (figure 4-2).

c.

Chart Recorder.

(1) The amplified vertical and ramp

signals are also sent to X–Y interface

connectors. These signals, along with a

pen lift control signal, provide the information for driving external X-Y record-

ers.

4-2

Figure 4-2.

Simplified sampling diagram

Page 29

CHAPTER 5

PERFORMANCE CHECKS/

FAULT ISOLATION

Section I. GENERAL

TM 9-6625-2801-14&P

5-1. Introduction.

detailed performance checks for the TDR.

Performance checks may be made without

5-2. Preparation for Performance Checks.

a.

Ensure that a battery is installed in

the TDR.

b. Connect TDR to ac power source.

c.

Pull the POWER switch to turn the

unit on.

the relative level of charge on the battery

pack. If the battery pack is fully charged

(charged for 16 hours), the BATTERY

meter needle will be approximately at the

top mark on the meter.

5– 3. Performance Checks.

a.

graph 5-2 and then set front panel con-

trols as follows:

INTENSITY

ZERO REF

POSITION Midrange

/DIV

DISTANCE

NOISE FILTER

FEET/DIV

MULTIPLIER X1

CABLE DIELECTRIC

b. Preset the POSITION and GAIN con-

trols so the trace is on screen and the

BATTERY meter will indicate

Perform procedures given in para-

SOLID POLY

SOLID PTFE

Other

VAR

This chapter provides

Section II.

Fully cw

Fully cw

500

000

Out

200

In

Out

Out

Fully cw

PERFORMANCE

any test equipment. Performing the

checks will also identify a fault present

in the

equipment.

CHECKS

amplitude is approximately 4 divisions.

Adjust the FOCUS and INTENSITY controls for a clear, bright trace.

FEET/DIV

MULTIPLIER

CABLE DIELECTRIC

SOLID POLY

SOLID PTFE

Other

VAR

b. Preset the POSITION and GAIN

controls so the trace is on screen and the

amplitude is approximately 4 divisions.

Adjust the FOCUS and INTENSITY con-

trols for a clear, bright trace.

c.

Adjust the GAIN control so that the

total amplitude of the display is exactly 4

divisions.

depot for repair.

d.

MULTIPLIER to X1.

e.

counterclockwise to locate the pulse at

center screen.

form as shown in figure 5-1a. If the

display is not correct, forward TDR to

depot for repair.

f. Connect the precision 50 terminator

(Tektronix Part No. 011-0123-00) to the

CABLE connector. Turn the GAIN control

fully counterclockwise and note the

If incorrect, forward TDR to

Set FEET/DIV control to 2 and

Turn the ZERO REF SET control

Check for correct wave-

200

X1

In

Out

Out

Fully cw

5-1

Page 30

TM 9-6625-2801-14&P

amplitude of the pulse. Turn the GAIN

control fully clockwise. The amplitude

should be 4 times greater than the ampli-

Figure 5-1.

tude with the GAIN control fully counterclockwise.

as necessary.)

Pulse display

(Adjust the POSITION control

g.

Set the /DIV control to 200, the

FEET/DIV control to 20 and the MULTIPLIER control to X1.

h.

Adjust the ZERO REF SET control

so that the pulse is at the center of the

screen.

actly 5 divisions of amplitude.

i.

and remove the 50 terminator.

litude of the pulse must be 4 divisions

±0.12 division (±0.6 minor division). If

not, forward the TDR to depot for repair.

j.

adjust the ZERO REF SET control so the

leading edge of the incident pulse is set

on the vertical centerline.

k.

X1.

pulse must be within 1 division of the

vertical centerline. (If not, check the X1

Position calibration, para. 5-5k (5). If still

incorrect, forward TDR to depot for repair.

Adjust the GAIN control for ex-

Change the /DIV control to 500

The amp-

Set the FEET/DIV control to 1 and

Change the MULTIPLIER control to

The leading edge of the incident

l. Attach the 3 foot precision cable

(Tektronix Part No. 012-0482-00) to the

CABLE connector and change the FEET/

DIV control to 5.

SET control to locate the incident pulse on

the graticule reference line (as indicated

by the arrow on the graticlde line). The

reflected pulse should be 6.3 divisions to

the right of the incident pulse.

m.

reflected pulse is located on the graticule

reference line.

read 031.5 ± 1 digit.

n.

the incident pulse should return to the

graticule reference line. If the incident

Adjust the ZERO REF

Adjust the DISTANCE dial until the

The DISTANCE dial should

NOTE

When using the more sensitive ranges of the FEET/DIV control, the

0.3 foot between the CABLE connector and the sampler must be taken

into consideration.

Push the ZERO REF CHECK button;

5-2

Page 31

TM 9-6625-2801-14&P

pulse does not return to the graticule re-

ference line, adjust the ZERO REF SET

control so that the incident pulse is located

on the graticule reference line. Release

the ZERO REF CHECK control and check

that the reflected pulse is located on the

graticule reference line. Adjust the DISTANCE dial if necessary; it must remain

031.5±1 digit.

(If incorrect, forward TDR

to depot for repair). Return the DISTANCE

dial to 000 when this step is completed.

NOTE

To more accurately check the DISTANCE dial, a known length of solid

polyethylene (V

=0.66) cable (1000 to

p

1600 feet) should be used.

o.

Change the FEET/DIV control to 20,

the MULTIPLIER control to X1, and the

/DIV control to 200. Adjust the ZERO

REF SET control so that the reflected

pulse is located exactly on the eighth graticule line from the left-hand edge of the

graticule.

of graticule).

The DISTANCE dial should

read between 167 and 173. Push in the

OTHER button (VAR control must be fully

C

w) and locate the reflected pulse on the

0 graticule line with the DISTANCE dial.

The DISTANCE dial should read between

240 and 250. (If incorrect, forward TDR

to depot for repair). Return the DISTANCE dial to 000 when this step is completed.

s.

Change the FEET/DIV control to 1,

the MULTIPLIER control to X1, disconnect

the 3 foot cable from the CABLE connector,

and connect the precision 50 terminator

to the CABLE connector.

Adjust the ZERO

REF SET control to locate the pulse on the

graticule center.

Adjust the POSITION

control to center the pulse on the graticule.

Check that the jitter is not greater

t.

than 0.1 division (200 ps) (see figure 5-2),

Adjust the DISTANCE dial to locate

p.

the reflected pulse on each graticule line.

The DISTANCE dial should read as follows

(if incorrect, forward TDR to depot for

repair):

Graticule Line

8

7

6

5

4

3

2

1

0

Return the DISTANCE dial to 000,

q.

Distance Dial Reading

000

020±1 digit

040±1

060±1.2

080±1.6

100±2

120±2.4

140±2.8

160±3.2

change the MULTIPLIER control to X1 and

repeat the above step.

r.

Push the SOLID PTFE button (do

not readjust the ZERO REF SET control)

and adjust the DISTANCE dial so that the

reflected pulse is located on the 0 graticule line (first vertical line at left edge

Figure 5-2. Jitter check

Change the MULTIPLIER control to

u.

X1 and adjust the ZERO REF SET control

to locate the pulse on the graticule center.

Check that the jitter is not greater than

0.2 division (40 ps). If not, forward TDR

to depot for repair.

Change the /DIV control to 50,

v.

and turn the POSITION control counterclockwise to display the top of the trace

on the graticule,

then adjust the ZERO

5-3

Page 32

TM 9-6625-2801-14&P

REF SET control to locate the pulse on

the reference graticule line.

w.

Set the DISTANCE control to 500

and adjust the POSITION controls to cen–

ter the trace on the graticule, then return

the DISTANCE dial to 000.

x.

While viewing the trace, adjust the

DISTANCE dial from 000 to 100. The

trace must remain within ±1 division of the

centerline (±5% peak for the first 10 feet of

rise) (see figure 5-3).

set the DISTANCE dial to 500, re–center

the trace, then return the DISTANCE

dial to 100.

DISTANCE dial from 100 to 999.

trace must remain within ±1 division of

the centerline (0. 5% peak beyond 10 feet).

and push the NOISE FILTER button. While

viewing the trace,

dial from 100 to 999. The trace must remain within ±0.4 division of the centerline

(0.2% peak beyond 10 feet with noise filter).

If there is a problem with aberrations or

noise,

return the DISTANCE dial to 000, and set

the /DIV control to 200.

entire incident pulse is displayed on the

crt and check that the rise time is less

than 0.55 division (100ps or 0.055 foot).

See figure 5-4 for definition of rise time.

Change the /DIV control to 5,

y.

z.

While viewing the trace, adjust the

The

aa.

Return the DISTANCE dial to 100

adjust the DISTANCE

forward TDR to depot for repair.

ab.

Release the NOISE FILTER button,

ac.

Adjust the POSITION control so the

Figure 5-3. Position check

Figure 5-4.

ad.

Remove the 50 terminator from

the CABLE connector and connect a

shorted terminator to the CABLE

Rise time and fall time

5-4

Page 33

TM 9-6625-2801-14&P

connector.

so the entire reflected pulse is on the crt.

Check that the fall time is less than 0.7

division. Remove the shorted terminator

from the CABLE connector.

ae. Push the RECORD/CAMERA switch

to CAMERA and see that fogging oscilla-

tions fill the entire crt during retrace.

(If fogging does not occur, return to de-

pot.)

5-4. Detailed Performance Checks.

a.

Introduction.

the detailed procedure recommended for

verif

ying that a TDR performs according

to specifications.

DULE will be covered in this procedure.

b. Equipment Required. Digital multi-

meter, Fluke Model 8000A or equivalent.

This will be referred to as DM 8000A or

DM.

c.

Preliminary Connections and Set-Up.

(1) Remove the battery pack from the

rear of the TDR case. Remove the front

cover of the TDR.

Adjust the POSITION controls

This paragraph gives

The X-Y OUTPUT MO-

INTENSITY

ZERO REF SET

POSITION

/DIV

NOISE FILTER

GAIN

DISTANCE Dial

FEET/DIV

MULTIPLIER

FOCUS

CABLE DIELECTRIC

SOLID POLY

SOLID PTFE

Other

VAR

(6) Set the DM 8000A RANGE/FUNC-

TION control of the digital multimeter to

200 DC VOLTS.

the V- common INPUT terminals.

d. Power Supply Checks. Power supply

checks are not to be considered performance checks.

points are shown in figure 5-5. See table

D-1 for location of board. Measure the

supply voltages with the digital multimeter

(Fluke 8000A).

Voltage Measurements.

e.

Connect the test leads to

The location of the test

Fully cw

Fully cw

Midrange

500

Out

Fully cw

000

200 (FIND)

X1

Adjust for a

clear trace

In

Out

Out

Fully cw

(2) Loosen the four screws at the

rear of the case and set the unit face up,

Push down on the handle to break the

seal;

surface.

case and pull free.

then place it face down on a flat

Take hold of the sides of the

(3) Remove the EMI shields from the

top and bottom of the unit. Place the

battery pack in the rear of the TDR,

taking care that the polarity is correct.

Connect the ac power cord to the ac

outlet, at the rear of the unit, and to a

115 Vac (230 Vac for Option 6) power

source.

(4) Pull the POWER switch to turn

the unit on and allow 20 minutes warm-up

before proceeding with checks.

(5) Preset the front panel controls

as follows:

(1)

Connect the lead from the common

terminal

the TDR

terminal

voltmeter reads +25 V (±0.25) V.

to TP6411 (violet test point).

switch to 20 Vdc.

voltmeter reads +10 V, ±0.1V.

to TP6227 (green test point) and check

that the voltmeter reads +5 V ±0.25V.

to TP 6332 (black test point) on

power supply board.

Connect the lead from the V-

(2)

to TP 6256 (red test point).

Adjust R6358 (HV ADJ) so the

(3)

(4) Move the test lead from TP6256

(5) Change the RANGE/FUNCTION

(6) Adjust R6514 (+10 ADJ) so the

(7) Move the test lead from TP6411

5-5

Page 34

TM 9-6625-2801-14&P

Figure 5-5.

(8) Move the test lead from TP6227 to

TP6218 (orange test point) and check

that the voltmeter reads -5 V ±0.25 V.

(9) Change the RANGE/FUNCTION

switch to 200 Vdc.

(10) Move the test lead from TP6218

to connector P66 pin 6 (see figure 5-5)

and check that the voltmeter reads +100V;

tolerance +20 V, -5V.

(11) Move the test lead from P66 pin

6 to P66 pin 7 and check that the voltmeter

reads +165 V; tolerance +25 V, –5V.

f. CRT Check.

(1) Attach the precision cable to the

CABLE output.

(2) Check for a step pulse on the crt.

Power supply board test points and adjustments

Trance Focus and Astigmatism.

g.

(1) Set the FEET/DIV to 2 with the

MULTIPLIER control to X1.

(2) Locate the trace with the ZERO

REF SET at the center of the graticule.

(3) Set the front panel FOCUS con-

trol for the clearest possible trace.

(4) Remove the precision cable.

h. Trace Rotation.

(1) Set the /DIV

(2) Turn the ZERO

clockwise and adjust the

trols so that the trace is located on the

horizontal centerline.

control to 200.

REF SET fully

POSITION con-

5-6

Page 35

TM 9-6625-2801-14&P

(3) Check that the trace aligns with

horizontal centerline. focus.

the

i.

Trace Geometry.

(1) Move the trace with the POSITION

controls so that it is located 3 divisions

below the horizontal centerline.

(2) Check that the trace aligns with

the graticule line (has no bow).

(3) Move the trace with the POSITION

controls so that it is located 3 divisions

above the horizontal centerline.

(4) Check that the trace aligns with

the graticule line (has no bow).

(5) Recheck the trace rotation and

Vertical Checks.

j.

(1) Pulse Strobe and Rise Time.

(a) Set the /DIV control to

500.

(b) Use the ZERO REF SET and

POSITION controls to locate the pulse

at the graticule center.

(c) Check that the incident and

reflected pulse both have equal amplitudes (see figure 5-6 for the correct

display).

Figure 5-6.

(2) Loop Gain.

(a) Set the FEET/DIV to 200, MUL-

TIPLIER to X1, and /DIV to 200.

(b) Connect the precision 500

terminator (Tektronix Part No. 011-0123-

00) to the CABLE connector.

(c) Use the ZERO REF SET control to

locate the pulse on the graticule. Use the

POSITION controls as necessary to locate

Pulse display

AR918079

the entire pulse step on the graticule.

(d) Adjust the front-panel GAIN

screw driver control for a pulse amplitude

of 5 divisions. (Adjust the POSITION

controls as necessary.)

(e) Check that the rise of the pulse

occurs within 0.1 division horizontally

and there is no spike at the top of the

pulse.

incorrect displays.

Figure 5-7 illustrates correct and

5-7

Page 36

TM 9-6625-2801-14&P

(3) Noise.

(a) Set the /DIV to 5 and adjust

the POSITION controls so the top of the

trace is located on the horizontal center-

line.

(b) Check that the peak-to-peak

noise is not greater than 5 (1 division).

(c) Push the NOISE FILTER button

in and check that the peak–to–peak noise

is less than 2 (0.4 division).

(d) Change the FEET/DIV control

to 20.

(e) Use the POSITION controls to

set the bottom of the noise pulse at the

horizontal centerline.

(f) Check that the peak-to-peak

noise is less than 2

(g) Release the NOISE FILTER button and check that the peak-to-peak noise

is less than 5

(4) DC Balance.

(a) Set the /DIV to 100.

(b) Use the POSITION controls to

locate the base of the pulse at the hori-

zontal centerline.

(c) Remove the 50 terminator and

check that the trace shift is less than 1/2

division.

(5) Vertical Attenuation.

the /DIV to 500, and turn the DIS-

TANCE dial completely clockwise.

switch to 2 on the DC VOLTS scale.

Replace 50 terminator.

(a) Remove the 50 terminator, set

(b) Set the DM RANGE/FUNCTION

Figure 5-7.

5-8

Loop gain adjustments

(c) Connect the lead from the DM

common terminal to the

of C2137 (on the VERT

board, figures 5-8 and

grounded terminal

AMP/SLOW RAMP

5-9).

Page 37

TM 9-6625-2801-14&P

Figure 5-8.

PC board location

(d) Connect the lead from the Vterminal to the left end of R2229. See

figure 5-9 for the proper connection

points.

(e) Set the TDR POSITION controls

so that the DM reads 1.000 ±0.008 volt.

(f) Move the test lead from R2229

to R2326 (see figure 5-9). The DM

should read 0.400 ±0.008 volt.

(g) Move the test lead from R2326

to R2325 (see figure 5-9). The DM

should read 0.199 ±0.004 volt.

(h) Move the test lead from R2325

to R2323 (see figure 5-9). The DM

should read 0.991 ±0.002 volt.

(i) Move the test lead from R2323

to R2322 (see figure 5-9). The DM

should read 0.405 ±0.0008 volt.

Figure 5-9. Vertical amplifier/

slow ramp board

(j) Move the test lead from R2322

to R2321 (see figure 5-9). The DM

should read 0.200 ±0.0004 volt.

5-9

Page 38

TM 9-6625-2801-14&P

(k) Move the test lead from R2321

to R2223 (see figure 5-9). The DM

should read 0.0100 ±0.0002 volt.

(l) Remove the test leads from the

TDR and turn the DISTANCE dial fully

counterclockwise.

k. Horizontal Checks.

(1) DISTANCE dial.

(a) Set controls as

/DIV

FEET/DIV 1

MULTIPLIER X1.

Attach the precision cable to the CABLE

output.

(b) Set the front panel DISTANCE

dial to exactly 031.5. Check that the leading

edge of the reflected pulse is located on the

graticule reference line within 0.1 division.

follows:

500

to locate the leading edge of the incident

pulse on the graticule reference line.

the reflected pulse is 6.3 divisions ±0.1

division away from the incident pulse.

MULTIPLIER control X1.

the TDR.

so that the leading edge of the incident

pulse is set on the vertical centerline.

the incident pulse is located within 1 divi-

sion of the vertical centerline when the

MULTIPLIER control is changed to X1.

(b) Use the ZERO REF SET control

(c) Check that the leading edge of

(3) X1 Positioning.

(a) Set the FEET/DIV to 1 with the

(b) Remove the 3-foot cable from

(c) Adjust the ZERO REF SET control

(d) Check that the leading edge of

(c) Push the ZERO REF CHECK

button; the incident pulse should return

to the graticule reference line. If this

check fails, adjust the ZERO REF SET

button, while holding the ZERO REF

CHECK button in, so the incident pulse

is located on the graticule reference line.

(2) X1 MULTIPLIER Control.

(a) Set the DISTANCE dial to 000

and FEET/DIV to 5.

l.

Fogging Circuit Adjustments.

(1) Push the CAMERA/RECORD

switch to CAMERA and see that bright

(fogging) oscillations appear across the

entire crt screen during retrace.

(2) Adjust the R3237 (FOG) located on

the OUTPUT AMPS board, (figures 5-8 and

5-10) while holding the CAMERA/RECORD

switch to CAMERA, until fogging vertically

covers the entire crt screen during retrace.

5-10

Figure 5-10.

Output amplifier board fog adjustment

Page 39

TM 9-6625-2801-14&P

m.

X-Y Output Module Checks.

(1) Pen Lift Signal.

(a) Set the Digital Multimeter

RANGE/FUNCTION control to 20 on the

DC VOLTS scale.

(b) Turn the TDR upright.

(c) Place the terminal connection

link of the OUTPUT MODULE board on the

negative slope terminals (see figure 2-5).

(d) Connect the lead from the DM

V- terminal to the X-Y OUTPUT MODULE

PEN LIFT red terminal and the lead from

the DM common terminal to the X-Y OUTPUT MODULE PEN LIFT black terminal.

(e) Check that the DM shows

approximately +5 volts.

(f) Momentarily push the RECORD/

CAMERA switch to RECORD, then release

the switch.

to +0.5 volt or less and returns to approximately +5 volts at the end of the sweep.

(g) Move the terminal connection

link to the positive slope terminals on the

X-Y OUTPUT MODULE board.

(h) Check that the DM reads ap-

proximately -0.5 volt.

Check that the voltage goes

(i) Push the RECORD/CAMERA

switch to RECORD and check that the DM

reads +4 volt or greater, then returns to

approximately 0.5 volt at the end of the

sweep.

(2) Y Output.

(a) Move the test leads from the

PEN LIFT terminals to the corresponding

Y terminals of the X-Y OUTPUT MODULE.

(b) Set the TDR ZERO REF SET

completely clockwise.

(c) Push the RECORD/CAMERA

switch to RECORD and adjust the TDR

POSITION controls so that the DM reads

0.0 volt.

(d) Turn the TDR ZERO REF SET

completely counterclockwise and check

that the DM reads approximately +0.04

volt .

terminals.

CAMERA switch to RECORD, then re–

lease.

from 0 to 1 V (100 mV/div) as the dot

moves across the screen.

Release the RECORD switch.

(e) Move the test leads to the X

(f) Momentarily press the RECORD/

(g) Check that the voltage reads

Section III.

5-5. Introduction.

be confined to power failure. A power

failure indication would be no display on

the crt or no indication on the battery

meter.

does not restore power, forward TDR to

depot for repair.

Para.

ref.

7-4b

2-3a

If the required corrective action

Trouble shooting will

Parts location drawings

Table 5-1.

No CRT display

No battery indication

Battery does not charge

TDR Troubleshooting Procedure

Symptom

FAULT ISOLATION

are referenced in the troubleshooting

tables as required. Replacement parts

are listed in Appendix C. Procedures

for parts replacement are given in Chapter 6.

paragraph 5-2 and perform troubleshooting

given in table 5-1.

Perform procedures given in

Corrective Action

Check fuses

Charge battery

Replace battery

5-11/(5-12 blank)

Page 40

Page 41

CHAPTER 6

MAINTENANCE INSTRUCTIONS

TM 9-6625-2801-14&P

Section I.

6-1. General.

direct support maintenance level person- (d) install; (e) replace the equipment.

nel.

level personnel are shown in the Maintenante Allocation Chart (MAC) in Appendix accordance with TB 11-6625-2860-35 for

B.

6-2. Maintenance Efforts. Table 6-1

lists the various maintenance efforts re-

quired, the frequency of performance,

and references to the actual procedures

to be performed.

The maintenance functions of the DS

The maintenance functions are to:

The TDR is maintained by

Section II.

MAINTENANCE INSTRUCTIONS

Table 6-1.

Maintenance effort

Frequency of performance

GENERAL

(a) inspect; (b) test; (c) service;

Calibration of the TDR is performed by

a separate calibration/repair facility in

the TDR.

Battery pack replacement. See

a.

figure C-1 for location. Loosen the two

thumbscrews and pull out the battery

pack.

secure the two thumbscrews.

Insert new battery pack and

Maintenance Efforts

Reference

Installation, replacement

Inspect and services:

Preventive mainte-

nance

Battery maintenance

Preparation for ship-

ment and storage

Tests

Repair

On receipt of equipment

As required

Every 30 days

As required

Every 30 days or

after repair and

service

As required

Para 3-1

Paras 3-6, 3-7

Para 3-7

Chapter 9

Para 5-3, 5-4

Chapter 7

6-1/(6-2 blank)

Page 42

Page 43

CHAPTER 7

REPAIR INSTRUCTIONS

TM 9-6625-2801-14&P

Section I.

7-1. Responsibilities. Repair at the direct support (DS) level consists of replacing damaged or malfunctioning compo-

nents found during inspection and

checkout.

is performed only to the extent necessary

to accomplish the required repairs. Refer to the Maintenance Allocation Chart

(MAC) in appendix B

level of responsibility

7-3. General.

structions for removal and replacement

of assemblies and parts that need repair.

Refer to appendix C for location of parts.

7-4. Repair and Replacement Instructions.

Removal of major assemblies

to determine the

for maintenance

Section II.

This section contains in-

REPAIR OF TDR

GENERAL

functions. Items not identified in the

MAC, such as accessory equipment, may

be repaired by direct support maintenance personnel, if authorized by pertinent directives.

7-2. Depot Repaired Components. Items

that cannot be repaired or disposed of

at DS should be sent to depot for repair

or disposition.

Refer to the MAC.

a. Fuses.

on the front panel. All dc fuses and

spares are located on the power supply

board inside the instrument. Remove

the TDR from its case (See paragraph

5-4c).

the top of the unit. The fuses are up-

right plug-in types located near the

center of the instrument (see figures

7-1 and C-1).

b.

ease on the TDR proceed as follows:

adapters from the cable connector.

Remove the aluminum shield from

When the cabinet is removed high

voltages may be present.

Replacing Case. To replace the

(1) Remove any termination and

All ac line fuses are located

Figure 7-1.

(2) Remove the battery pack and

power cord from the back of the TDR.

Power supply board DC fuse

location

7-1

Page 44

TM 9-6625-2801-14&P

(3) Place the EMI shields on the top

and bottom of the TDR.

(4) Stand the TDR on its face.

(5) Slide the case over the back of

the unit, until it has reached the sub-

panel.

(6) Tighten the four screws on the

back of the case until the case is aligned

with the groove at the back of the sub–

panel.

(7) Make sure the case is in the

groove; then, using a torque screwdriver, tighten the four screws to 10

inch–pounds.

NOTE