Page 1

pp

User Manual

gigaBERT1400

1400 Mb/s Bit Error Rate Tester

Generator and Analyzer

071-0590-00

This document supports firmware version 2.2 and above.

Page 2

Copyright © 2000 Tektronix, Inc. All rights reserved. Licensed software

products are owned by Tektronix or its suppliers and are protected by United

States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set

forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer

Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software - Restricted Rights clause at FAR 52.227-19, as

applicable.

Tektronix products are covered by U.S. and foreign patents, issued and pending.

Information in this publication supersedes that in all previously published

material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070-1000

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

GB1400 User Manualii

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and workmanship for a

period of one (1) year from the date of shipment. If any such product proves defective during this

warranty period, Tektronix, at its option, either will repair the defective product without charge

for parts and labor, or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect

before the expiration of the warranty period and make suitable arrangements for the performance

of service. Customer shall be responsible for packaging and shipping the defective product to the

service center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for

the return of the product to Customer if the shipment is to a location within the country in which

Tektronix service center is located. Customer shall be responsible for paying all shipping charges,

duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish service

under warranty a) to repair damage resulting from attempts by personnel other than Tektronix

representatives to install, repair or service the product; b) to repair damage resulting from

improper user or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT

IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX

AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE

SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH

OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE

NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

GB1400 User Manual iii

Page 4

iv

How to Reach Customer Service

If you have any questions regarding the operation, maintenance, repair,

or application of your Tektronix equipment, contact your local sales

and service office. For a complete list of the Worldwide Sales and

Service Offices contact (800) 426-2200.

Tektronix provides high quality Technical Support on applications,

operation, measurement specifications, hardware, and software by

expert application engineers. For Applications Support, call the

Customer Support Center listed below.

Mailing

Address

Tektronix, Inc.

Measurement Business Division

P.O. Box 500

Beaverton, Oregon 97077-0001

USA

Customer

and Sales

Support

800-TEK-WIDE

or

800-835-9433 Ext 2400

Center

Direct

Fax

503-627-2400

503-627-5695

E-Mail tm_app_supp@tek.com

Web Site http://www.tek.com

Attn. Customer Service

Hours are 6:00 AM to 5:00 PM,

Pacific Time.

After hours Voice Mail is available.

GB1400 User Manual

Page 5

Table of Contents

Safety.................................................................................................. xii

Getting Started

Features............................................................................................... 1-1

Ordering Information ............................................................................ 1-4

gigaBERT comparison chart.................................................................. 1-5

Initial Self-Check Procedure ................................................................. 1-7

Operating Basics

Functional Overview....................................................................................... 2-1

BERT Basics - GB1400 ........................................................................ 2-2

Controls, Indicators, and Connectors...................................................... 2-4

Display Formats ................................................................................... 2-6

Outputs & Inputs.................................................................................. 2-9

Generator OUTPUT ....................................................................... 2-9

Generator CLOCK ......................................................................... 2-10

Generator OUTPUT (Set-up) ........................................................... 2-11

Generator Rear Panel...................................................................... 2-12

Changing the Line Fuse .................................................................. 2-12

Analyzer INPUT............................................................................ 2-13

Analyzer MONITOR ...................................................................... 2-14

Analyzer Rear Panel....................................................................... 2-15

Changing the Line Fuse .................................................................. 2-15

Connectors, Terminations and Levels .............................................. 2-16

Controls & Indicators............................................................................ 2-18

Power Switches .............................................................................. 2-18

Unit Mounting ............................................................................... 2-18

Unit Cooling .................................................................................. 2-18

View Angle and Panel Lock Keys ................................................... 2-18

Reset to Factory Default.................................................................. 2-18

GPIB Controls................................................................................ 2-19

Pattern Controls and Function Keys ................................................. 2-20

Function (Soft) Keys (F1, F2, F3, F4) ............................................... 2-21

GB1400 User Manual v

Page 6

Table of Contents

Generator ERROR INJECT ............................................................ 2-22

Analyzer INPUT............................................................................ 2-23

Analyzer Error History.................................................................... 2-24

Analyzer ERROR DETECTION ..................................................... 2-25

Analyzer SYNC Controls ................................................................ 2-25

Burst Mode Option ............................................................................... 2-26

Burst Mode Usage.......................................................................... 2-27

Specifications for Burst Mode ......................................................... 2-27

PECL Option for GB1400 Tx ................................................................ 2-29

Tutorial........................................................................................................... 2-30

Applications .................................................................................................... 2-38

Method for Very Fast Automatic RX Synchronization

and Eye Width Measurement ......................................................... 2-38

GB700/ GB1400 Optical Component Test........................................ 2-46

Reference

Menu Overview.................................................................................... 3-1

Functions common to TX and RX.......................................................... 3-1

Selecting a Pattern................................................................................ 3-2

Fibre Channel Link Testing Parallel and High-Speed Serial............... 2-47

Testing QPSK Modems, I & Q ........................................................ 2-48

QPSK BER Testing using PRBS Data for 2-Channel I & Q ............... 2-49

AC Power...................................................................................... 3-1

Selecting 115 VAC or 230 VAC operation ....................................... 3-1

Turning Instrument Power ON/OFF................................................. 3-1

LCD Viewing Angle ....................................................................... 3-1

Recalling Default Setup................................................................... 3-2

Locking the Front Panel.................................................................. 3-2

Pattern Definitions.......................................................................... 3-2

PRBS Patterns ............................................................................... 3-2

Word Patterns ................................................................................ 3-3

Selecting an Active Pattern................................................................... 3-3

Selecting PRBS Patterns ................................................................. 3-3

Selecting the Current Word Pattern.................................................. 3-3

Selecting (Recalling) a Saved Word Pattern..................................... 3-4

GB1400 User Manualvi

Page 7

Table of Contents

Word Patterns ...................................................................................... 3-5

Basics............................................................................................ 3-5

Creating Word Patterns using front panel controls ............................. 3-5

Creating Word Patterns using menus................................................ 3-7

Creating Word Patterns using remote control.................................... 3-8

Saving Word Patterns ..................................................................... 3-9

Recalling Word Patterns ................................................................. 3-9

Generator Functions ....................................................................................... 3-10

Clock Source and Frequency................................................................. 3-10

External Clock Input............................................................................. 3-10

Clock Source........................................................................................ 3-10

Step Size and Frequency ....................................................................... 3-10

Saving a Frequency.............................................................................. 3-11

Recalling a Frequency........................................................................... 3-11

Data and Clock Outputs ........................................................................ 3-12

Amplitude and Baseline Offset.............................................................. 3-14

Logically Inverting Output Data (D-INV) .............................................. 3-15

Single-Ended or Differential Operation ................................................. 3-16

Pattern SYNC (PYNC) and CLOCK/4 Outputs ...................................... 3-16

Error Injection ...................................................................................... 3-17

Selection an Error Inject Mode .............................................................. 3-17

Error INJECT Input.............................................................................. 3-18

Analyzer Functions ......................................................................................... 3-19

Automatic Setup Functions (SYNC)...................................................... 3-19

AUTO SEARCH with PRBS Patterns.................................................... 3-20

AUTO SEARCH with "Non-PRBS" Patterns ......................................... 3-21

How to DISABLE Automatic Pattern Resynchonization.......................... 3-21

Relationship between AUTO SEARCH and DISABLE........................... 3-21

Synchronization (LOCK) Threshold ....................................................... 3-22

Clock, Data, and Reference Data Inputs................................................. 3-23

Input Data Delay.................................................................................. 3-24

Input Termination................................................................................. 3-25

Input Decision Threshold ...................................................................... 3-26

Logically Inverting Input Data ............................................................... 3-26

GB1400 User Manual vii

Page 8

Table of Contents

Single-Ended or Differential Operation .................................................. 3-27

Selecting the Reference Data Mode ....................................................... 3-27

Monitor Outputs................................................................................... 3-28

Error Detection Set-up .......................................................................... 3-29

Display Mode: Totalize, Window or Test ............................................... 3-33

Clearing Results and Starting Tests ........................................................ 3-33

Totalize Process Setup.......................................................................... 3-33

Window Process Setup.......................................................................... 3-34

Test Process Setup................................................................................ 3-35

Viewing Results ................................................................................... 3-36

Printing Results (Reports) ..................................................................... 3-37

Result Definitions ................................................................................. 3-42

Error History Indicators ........................................................................ 3-44

CLEAR Control.................................................................................... 3-45

Audio (Beeper) Function....................................................................... 3-45

Analyzer Error Messages...................................................................... 3-45

Starting & Stopping Measurements........................................................ 3-46

Menus ............................................................................................................. 3-48

Functions Performed using the Menu System......................................... 3-48

Menu and Function "Pages".................................................................. 3-48

General Rules for using the Menu System .............................................. 3-51

Menu Summaries.................................................................................. 3-52

Menu Function Definitions.................................................................... 3-55

Word Edit (EDIT) .......................................................................... 3-56

Word Length (LENGTH) ................................................................ 3-57

Word Fill (FILL) ............................................................................ 3-58

Word Order (ORDER).................................................................... 3-59

Word Synchronization Threshold (SYNC) ....................................... 3-60

Buffer............................................................................................ 3-61

Auto .............................................................................................. 3-62

Test Length (LENGTH) .................................................................. 3-63

Test Mode (MODE) ....................................................................... 3-64

Test Reports (REPORT) ................................................................. 3-65

Test Threshold (THRES)................................................................. 3-66

Test Squelch (SQUEL)................................................................... 3-67

GB1400 User Manualviii

Page 9

Table of Contents

Test Print (PRINT)......................................................................... 3-68

Test View Previous (VIEW-PRE).................................................... 3-69

Test View Current (VIEW-CUR) .................................................... 3-70

Window Mode (MODE)................................................................. 3-71

Window Interval in Bits (BITS)....................................................... 3-72

Window Interval in Hrs:Min:Sec (SECOND)................................... 3-73

Window Reports (REPORT) ........................................................... 3-74

RS-232 Baud Rate (BAUD)............................................................ 3-75

RS-232 Parity (PARITY) ................................................................ 3-76

RS-232 Data Bits (SIZE) ................................................................ 3-77

RS-232 End-of-Line Char.(EOL)..................................................... 3-78

RS-232 Xon/Xoff (XON/XOFF)...................................................... 3-79

RS-232 Echo (ECHO) .................................................................... 3-80

GPIB............................................................................................. 3-81

Utility Option (OPTION) ................................................................ 3-82

Utility Version (VER) ..................................................................... 3-83

Time Option (DATE)...................................................................... 3-84

Time Option (TIME)....................................................................... 3-85

Appendices

Specifications .................................................................................................. A-1

BERT Primer/ Technical Articles ................................................................... B-1

Remote Commands ......................................................................................... C-1

Using GPIB, RS-232 ....................................................................................... D-1

Customer Acceptance Test ............................................................................. E-1

Default Settings .............................................................................................. F-1

Cleaning Instructions ..................................................................................... G-1

Pattern Editing Software ................................................................................ H-1

Theory of Operation ....................................................................................... I-1

Glossary.......................................................................................................... Glossary-1

Index .............................................................................................................. Index-1

GB1400 User Manual ix

Page 10

Table of Contents

List of Figures

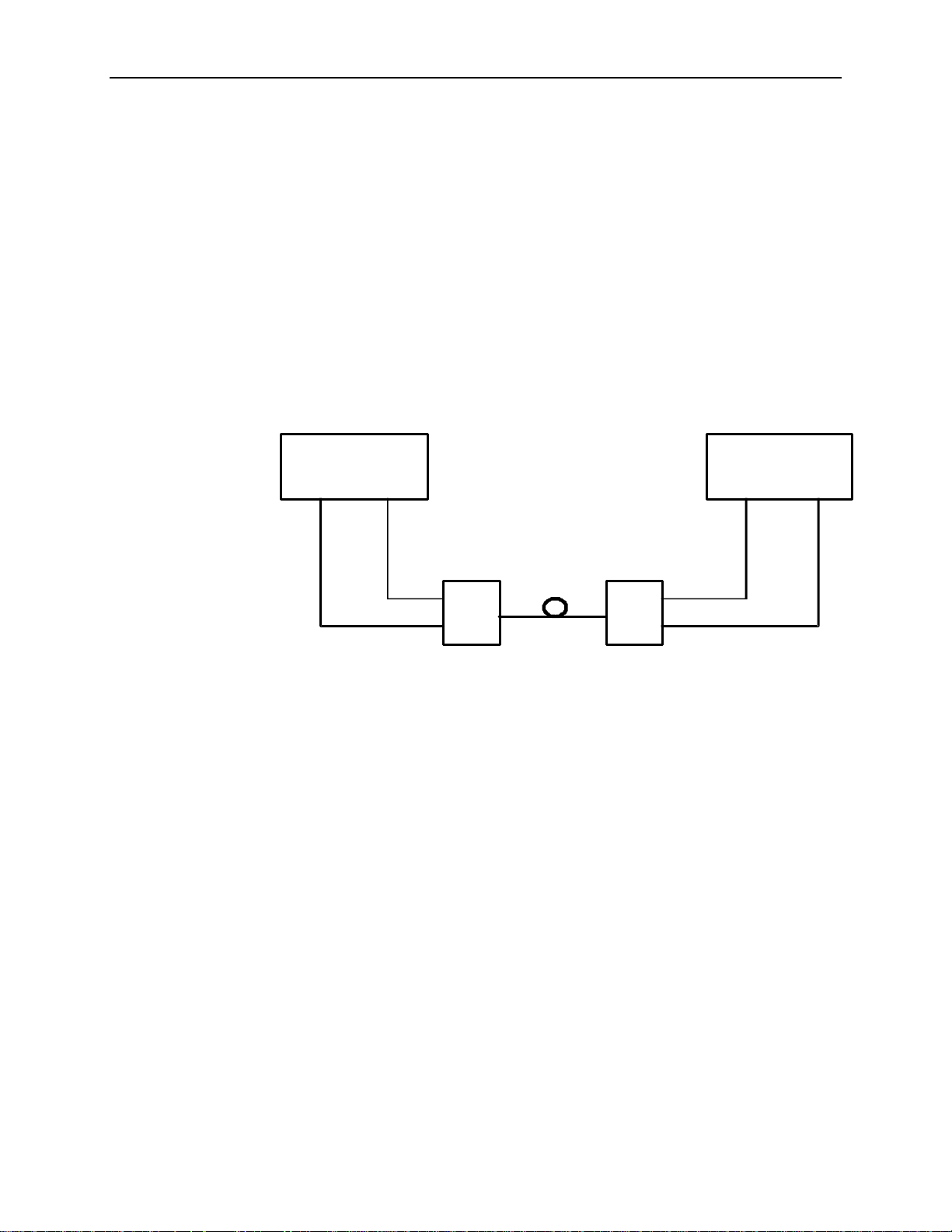

2-1 Example of BERT Application........................................................ 2-2

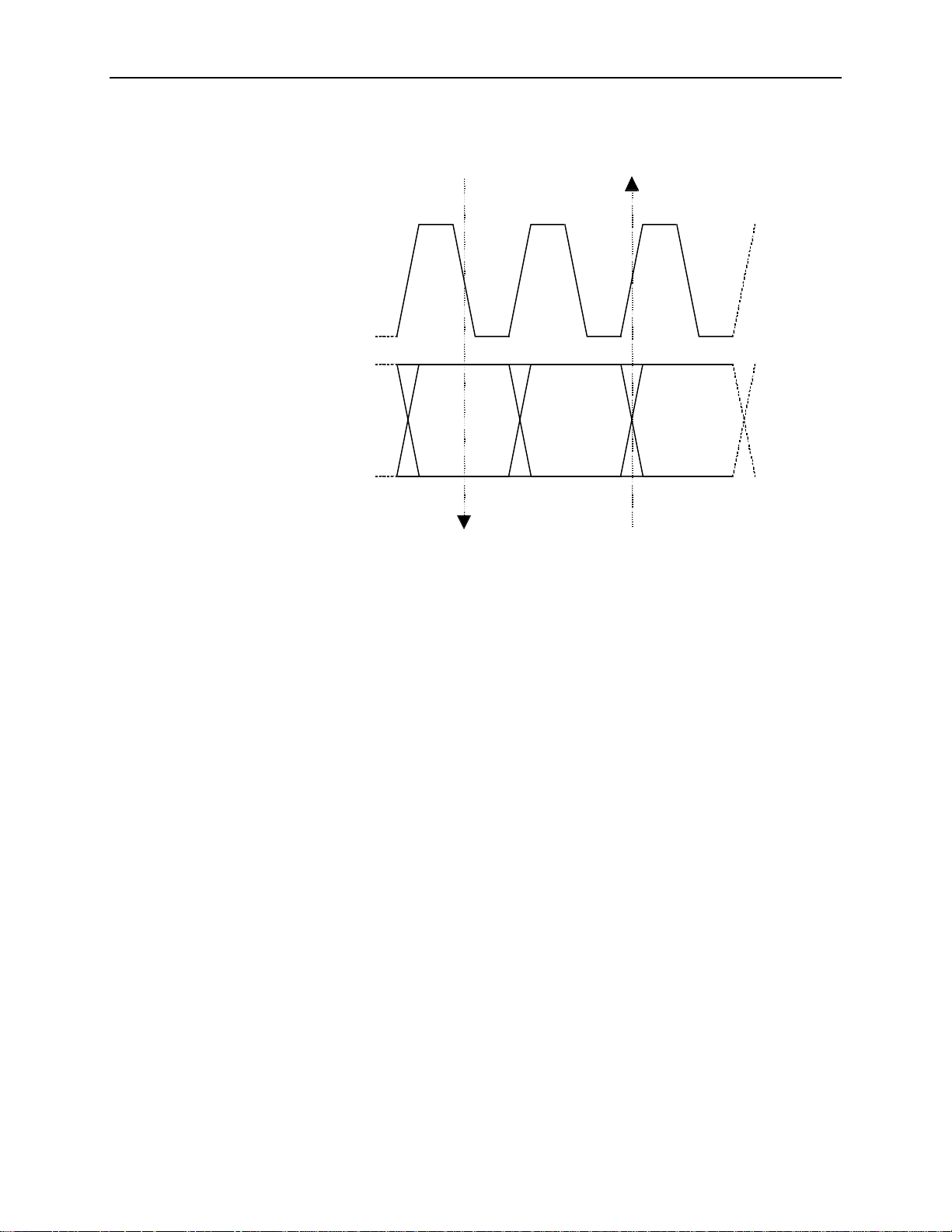

2-2 Nominal Generator NRZ Data and Clock Output Waveforms ........... 2-3

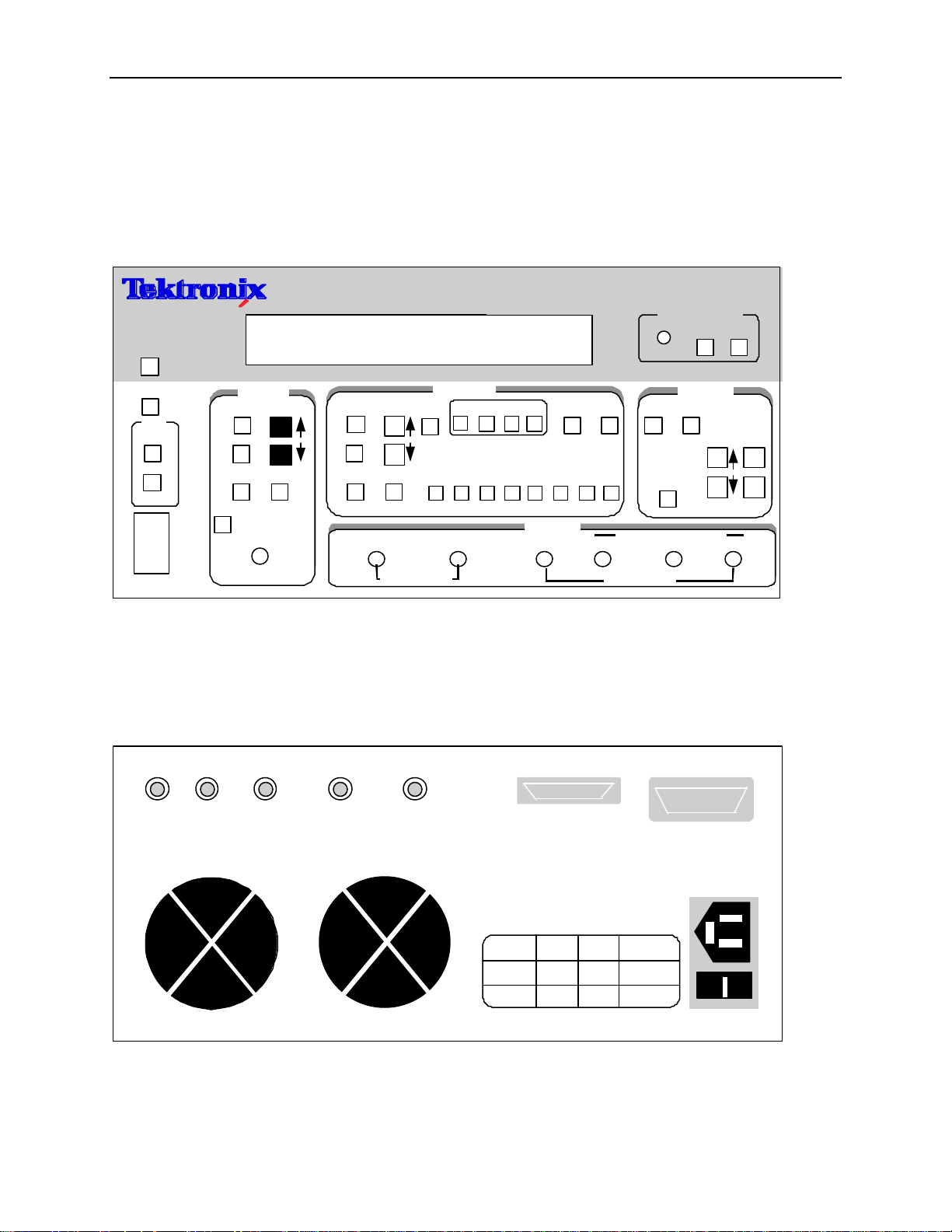

2-3 & 2- 4 Generator (TX) Front & Rear Panels ..................................... 2-4

2-5 & 2-6 Analyzer (RX) Front & Rear Panels ....................................... 2-5

2-7 Generator Display .......................................................................... 2-6

2-8 Analyzer Display........................................................................... 2-7

2-9 Transmitter Burst Mode Operation.................................................. 2-28

2-10 Receiver Burst Mode Operation .................................................... 2-28

3-1 Nominal Generator Clock, Data Waveforms showing Amplitude,

Baseline Offset and Vtop................................................................ 3-13

3-2 Generator Clock and Data Output Equivalent Circuits...................... 3-17

3-3 Analyzer Clock and Data Input Equivalent Circuits .......................... 3-22

3-4 TOTALIZE Measurement Process.................................................. 3-30

3-5 WINDOW Measurements Process.................................................. 3-31

3-6 TEST Measurement Process........................................................... 3-32

B-1 Three-stage PRBS generator .......................................................... B-5

B-2 Four-stage PRBS generator............................................................ B-5

B-3 Seven-stage PRBS generator.......................................................... B-6

I-1 Block Diagram - GB1400 TX.......................................................... I-5

I-2 Block Diagram - GB1400 RX.......................................................... I-6

GB1400 User Manualx

Page 11

List of Tables

2-1 Generator Inputs & Outputs............................................................ 2-16

2-2 Analyzer Inputs & Outputs............................................................. 2-17

3-1 PRBS (2N-1) Test Patterns............................................................. 3-3

3-2 Output Setup Rules vs. Termination Impedance ............................... 3-14

3-3 Data Inhibit Logic .......................................................................... 3-18

3-4 Actions taken by Analyzer when Synchronization is Lost................. 3-20

3-5 Synchronization Threshold ............................................................. 3-22

3-6 How F2, F3 determine Input Set-up ................................................ 3-24

3-7 Input Terminations for CLOCK, DATA, and REF DATA ................ 3-25

3-8 Input Threshold Range as a Function of Termination ........................ 3-26

3-9 How to Tell which Display Mode is Active ...................................... 3-37

3-10 Menu Descriptions ....................................................................... 3-52

Table of Contents

3-11 Analyzer Menu System Overview ................................................. 3-53

3-12 Generator Menu System Overview................................................ 3-54

B-1 PRBS Polynomials and Shift Register feedback taps for PB200........ B-4

B-2 PRBS Polynomials, Shift Register feedback taps, GB700/ GB1400 .. B-4

GB1400 User Manual xi

Page 12

Safety

Safety Terms Used in This User's Guide

CAUTION!

WARNING! Indicates an operation or practice that could result in

Indicates an operation or practice that could harm the

instrument.

personal injury or loss of life.

Safety Labels Found on the Instrument

DANGER

High Voltage

Protective Ground

(Earth) Terminal

ATTENTION

Refer to Manual

AC Power

The instrument is designed to operate from a power source that provides no more

than 250 volts RMS between the two supply conductors or between either supply

conductor and ground.

Ground the Instrument

The GB1400 is grounded through its AC power cord. Plug this power cord only

into a properly grounded, three-conductor outlet. If you operate the instrument

without a proper ground then all metal surfaces on the instrument become

potential shock hazards.

To avoid potential hazards, use this product only as specified.

Use the Proper Fuse

Operating the instrument with an improper fuse creates a fire hazard. The correct

fuses to install in the GB1400 are shown below:

Power Voltage Fuse Type

115 VAC 5A, Slo-Blo

230 VAC 5A, Slo-Blo

Do Not Operate in Explosive Atmospheres

This instrument does not provide protection from static discharges or arcing

components and therefore must not be operated in an explosive atmosphere.

xii GB1400 User Manual

Page 13

Table of Contents

Do Not Remove Instrument Covers

To avoid a shock hazard and to maintain proper air flow, never operate the

GB1400 with any of its outside covers removed.

Static Sensitive Device Notice

GB1400 outputs use a GaAs FET design and therefore are susceptible to damage

from externally applied over-voltage or electrostatic discharge. Never apply

reverse voltage to DATA or CLOCK outputs or voltages that are outside the

range specified in Appendix A of this manual. Operate the instrument only in a

static-controlled environment.

SMA Connectors

Be careful when attaching test cables to SMA connectors. Always tighten the nut

on the SMA connector rather than the cable itself. Never tighten an SMA

connector nut using more than 10 lb.-in. of torque.

Behavior of Outputs - Turning Power On or Off

When the GB1400 Generator is powered or de-powered its DATA and CLOCK

outputs may saturate to their specified positive or negative rail, that is +2 V or - 2

V, for up to 400 milliseconds. If this condition could be harmful to your

equipment, then remove all connections to your GB1400 Generator CLOCK and

DATA outputs before powering or de-powering the instrument.

Unit Mounting

The GB1400 is designed to be placed: (1) flat on a level surface, capable of

supporting its weight, or (2) angled from the surface with the rotating carrying

handle. To change the handle's orientation, press both handle-locking buttons

(located at the hubs of the handle), rotate the handle to the desired angle, and

release the buttons. The handle will click into a locked position. Assure that the

handle is locked before placing the unit on a work surface. A Rack mounting

option is available for installation of the unit into a 19" rackmount. The rack

height for the GB1400 is 7 inches (four RMU).

Unit Cooling

The rear panel fan openings and top-mounted ventilation slots must be kept clear

for proper cooling of the unit. Allow a minimum of two (2) inches of rear panel

clearance, and one (1) inch of top clearance, while operating the unit.

GB1400 User Manual xiii

Page 14

Preface

This manual describes how to use the Tektronix GB1400 Test Set. The product is

also known by the name, gigaBERT1400. This manual is your primary source of

information on how to use the GB1400 functions.

How This Manual is Organized

This manual is divided into four sections: Getting Started, Operating Basics,

Reference, and Appendices.

Getting Started provides an overview of the GB1400 and describes first time

operation.

Operating Basics describes the hardware controls, indicators, connectors, and

display elements for Tx, Rx and the cabling required. There is also a tutorial and

an application note in this section.

Reference describes the LCD Menus and Screens.

The Appendices provide a listing of specifications, a BERT technology primer,

Theory of Operation, Remote Commands, default factory settings, an extensive

Customer Acceptance Test and other useful information.

Conventions

This manual uses the following conventions:

• The names of front-panel controls and menus appear in all upper case letters,

for example, TRANSMIT and HELP.

• Names appear in the same case in this manual as they appear on the display

screens of the GB1400.

• Within a procedure, a specific button to be pressed or a parameter to be

selected appears in boldface print.

Some procedures require several iterations of highlighting parameters and

selecting choices. Some procedures may require more than one menu button or

menu page selection as well.

xiv GB1400 User Manual

Page 15

Related Manuals

The following document is also complementary to the GB1400:

• The GB700 BER Tester User Manual (Tektronix part number

Preface

070-9393-02) describes how to operate the GB700 test set.

GB1400 User Manual xv

Page 16

Preface

GB1400 User Manualxvi

Page 17

Getting Started

Page 18

Getting Started

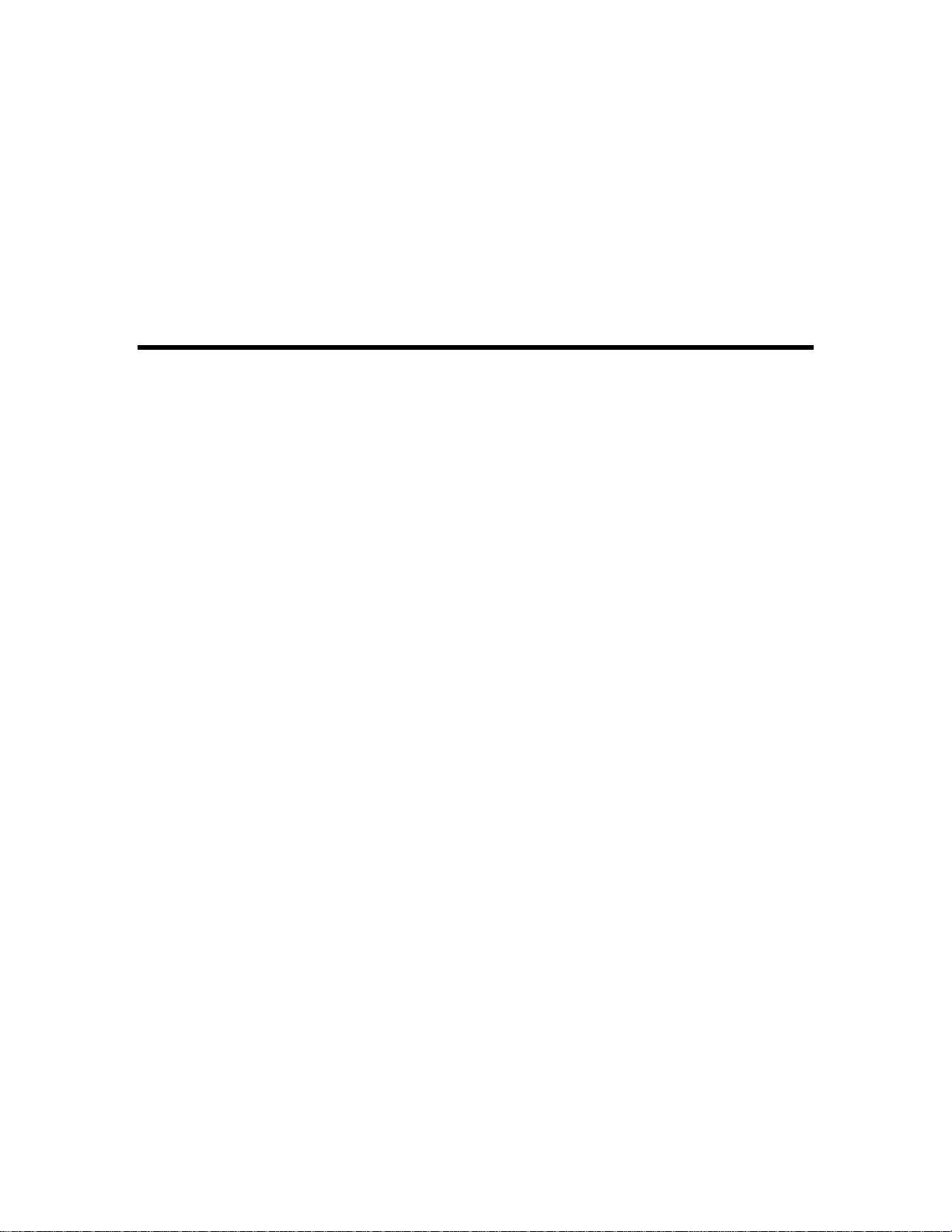

GB1400 Pattern Generator and Error Detector

Features

• Test digital data transmission up to 1400 Mb/s

• Set Data Rate with 1 kHz resolution

• Vary Clock and Data timing with 5 pS

resolution

• Phase-Synchronous Clock and Data Edge

Tracking

• 1-Mbit data pattern memory

• Measure Eye-Width at Specific BER

Automatically

• Auto-Synchronization Rx/Tx Lock-up

• Front panel or computer control operation

The GB1400 is a general-purpose 1400 Mb/s bit error rate tester (BERT) built to

meet the exacting standards of design engineers who need to verify and

characterize high-speed serial data transmission circuits, interfaces and systems.

While primarily a lab instrument, the GB1400’s compact design, full computer

programmability and relatively light weight also enable it to serve in

manufacturing ATE and field test applications.

The quality of a digital link depends on many factors, but everything comes

down to the issue of whether the circuit exhibits a satisfactory BER (bit error

rate) and has sufficient margin to function under stress conditions.

The GB1400 has all of the features you expect in a general-purpose BERT, and

some you expect only in more expensive instruments, such as automated eyewidth measurements at a specified BER, and the ability to accept an external

real-time data stream for bit error testing. Also, the GB1400 has options to add

advanced features, such as Burst Mode (which also extends external clock range

down to 150 kb/s), and a 1-Mbit programmable pattern memory option.

GB1400 User Manual 1-1

Page 19

Getting Started

Symmetrical, Low-Jitter Output Waveforms

The GB1400 generates low-jitter, symmetrical waveforms over its entire

operating frequency range. The clock and data ports provide both true and

inverted output signals. The instrument can drive single-ended or differential

ECL inputs.

Applications

The GB1400 is focused on the research, design, and manufacturing of

telecommunication components, modules, or links operating at data rates to

1400 Mb/s. It is frequently employed in testing and development well under this

top speed rating, where sharp clock and data waveforms are especially desired, or

where additional frequency range is thought to be needed in the future.

Sample Applications

• Development of Gigabit LAN/Data Comm Devices:

• High-Speed Fibre Channel, Ethernet

• Digital Video (MPEG, SDV, HDDV)

• Wideband Satellite Data Links

• SONET/SDH Network Devices up to OC-12e/STM4e

• High-speed GaAs/ECL/E/O device testing

• Test Clock Recovery Circuits

• Parallel-to-Serial Analysis with Tektronix MB100

• Testing of High Speed Fibre Channel links up to 1,063 Mb/s

• Gigabit Ethernet at 1,250 Mb/s.

• Testing of high-speed Optical Busses (Opto Bus, Opto Bahn) at 800 Mb/s per

channel.

• Satellite system testing and TDMA (Burst Mode) at 400, 800 Mb/s

• GaAs, ECL and optical component testing

PRBS Or User-Defined Test Patterns

The GB1400 can generate pseudo-random bit sequences (PRBS) up to 223−1 bits

and others up to 1-Mbit in length, via user-programmable patterns. Patterns can

be created locally using setup menus or externally by using a workstation or PC.

A PC Windows-based MLPE Pattern Editor software package comes with the

1-Mbit Memory Option. Externally created patterns can be downloaded via the

GPIB or RS-232 port. All user patterns are saved in battery-backed RAM.

1-2 GB1400 User Manual

Page 20

Getting Started

Adjustable Inputs For Maximum Flexibility

The clock and data ports on the GB1400 Error Detector accept both true and

inverted inputs. Single-ended or differential signals can be internally terminated.

Input data delay is adjustable over a 4 ns range to accommodate different clock

and data signal path delays.

Auto Search For Easy Setup

Auto search greatly simplifies the Error Detector setup. The GB1400 Error

Detector automatically synchronizes to the incoming signal by 1) Setting the

input data decision voltage to its optimum value; 2) Adjusting input data delay

for an optimum clock/data phase relationship; 3) Selecting the correct PRBS test

pattern; and 4) selecting the correct pattern polarity (normal or inverted).

It synchronizes with any pattern sourced by a gigaBERT Pattern Generator. It

can perform a bit-by-bit comparison of an external data stream via the Reference

Data input. Thus the GB1400 can perform bit error analysis on any data pattern

with a known good reference pattern.

Powerful Analysis And Reporting Functions

The GB1400 performs a full-rate, bit-by-bit analysis of the received signal. Bit

error results are then used to calculate three bit error rate (BER) measures. Total

BER is calculated from the last power-on or reset. Window BER is calculated

over a sliding window specified in terms of time (1 second to 24 hours) or bits

(18- to 116-bits). Test BER is calculated from the start of the current test. A hard

copy of all test results can be generated locally by connecting a printer to the

parallel printer port or GPIB or RS-232 port. Reports may be printed when an

error is detected, at the end of test intervals, or both.

Front Panel Or Automated Operation

The GB1400 provides easy operation augmented by set-up store and recall.

Clear, concise LCD displays of setup and results make it easy to use. The 1

Megabit memory option for both the Pattern Generator and the Error Detector is

sufficient for storing and outputting complex data such as SONET frames, ATM

cells, MPEG digital video, etc, allowing designers to simulate “live” traffic. The

GB1400 Pattern Generator and Error Detector can be controlled via the GPIB or

RS-232 interface ports. The gigaBERT remote command set includes commands

for all setup menus and front panel selections. The status of front panel indicators

and test results can be remotely accessed.

Burst Mode

BURST mode, allows for operation with non-continuous external clocks. Use of

BURST mode requires ECL-level signals with a minimum rate during the burst

of 150 kHz. This is an option to the GB1400. See a write-up on Burst Mode at

the end of the Functional Overview section of Chapter 2.

GB1400 User Manual 1-3

Page 21

Getting Started

Ordering Information

gigaBERT GB1400

1400 Mb/s BERT Generator and Detector. Not available in Europe.

Includes: Power Cord, Manual.

Opt. 02 - 75 Ohm Both Sets.

Opt. 05 - BURST Mode Both Sets.

Opt. 07 - Positive ECL (Pattern Generator Only).

Opt. 08 - 1-Mbit RAM WORD Both Sets & PC Pattern Editor Software.

Opt. 2M - Rack Mounts - 2 rackmount kits

Opt. A3 - Australian 240 V, 50 Hz.

gB1400T

1400 Mb/s BERT Pattern Generator.

Opt. 02 - 75 Ohm Pattern Generator Only.

Opt. 05 - BURST Mode Pattern Generator Only.

Opt. 07 - Positive ECL Pattern Generator Only

Opt. 08 - 1-Mbit RAM WORD, Generator Only, w/ PC Pattern Edit software

Opt. 1M - Rack Mount.

Opt. A3 - Australian 240 V, 50 Hz.

gB1400R

1400 Mb/s BERT Error Detector.

Opt. 02 - 75 Ohm Error Detector Only.

Opt. 05 - BURST Mode Error Detector Only.

Opt. 08 - 1-Mbit RAM WORD, Detector Only w/ PC Pattern Edit Software

Opt. 1M - Rack Mount.

Opt. A3 - Australian 240 V, 50 Hz

1-4 GB1400 User Manual

Page 22

Getting Started

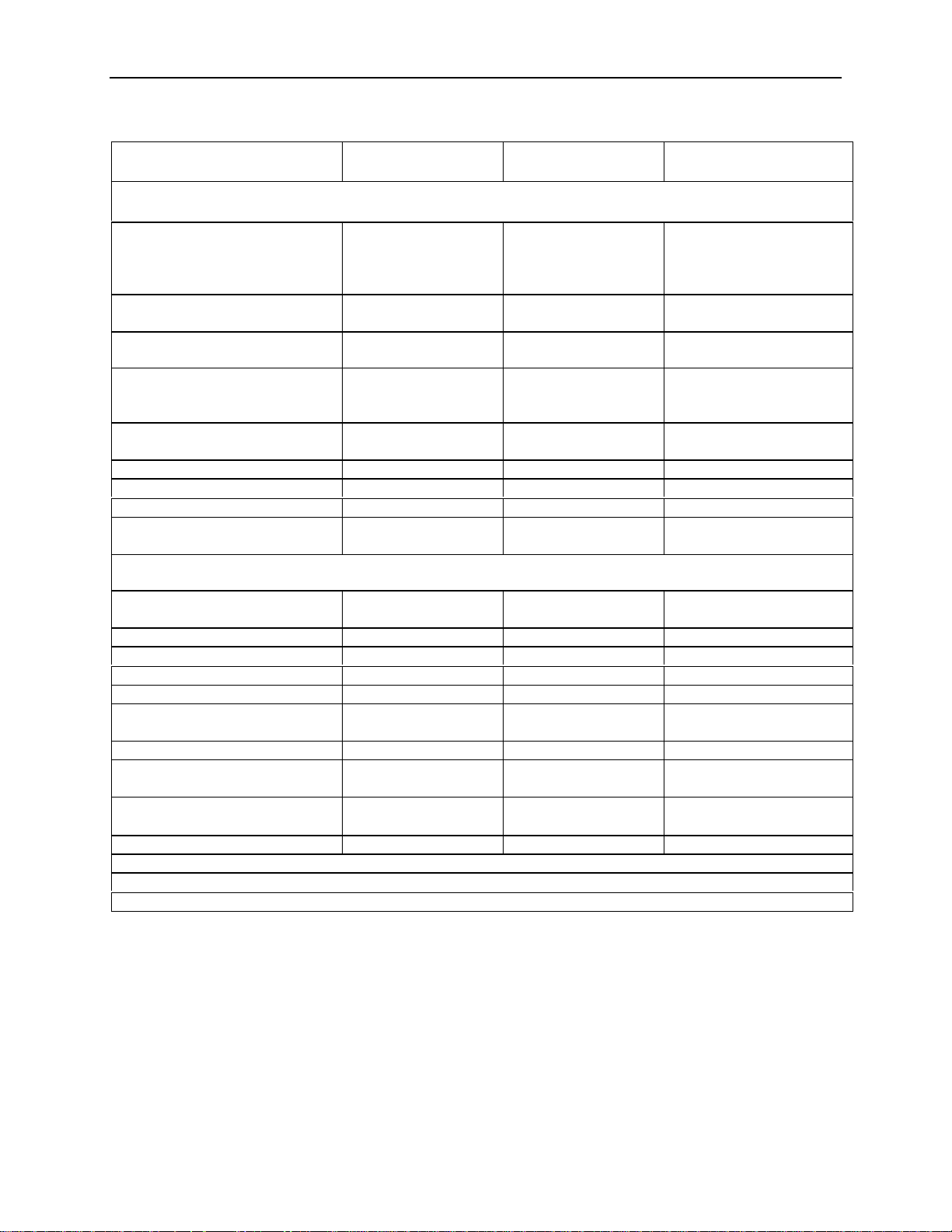

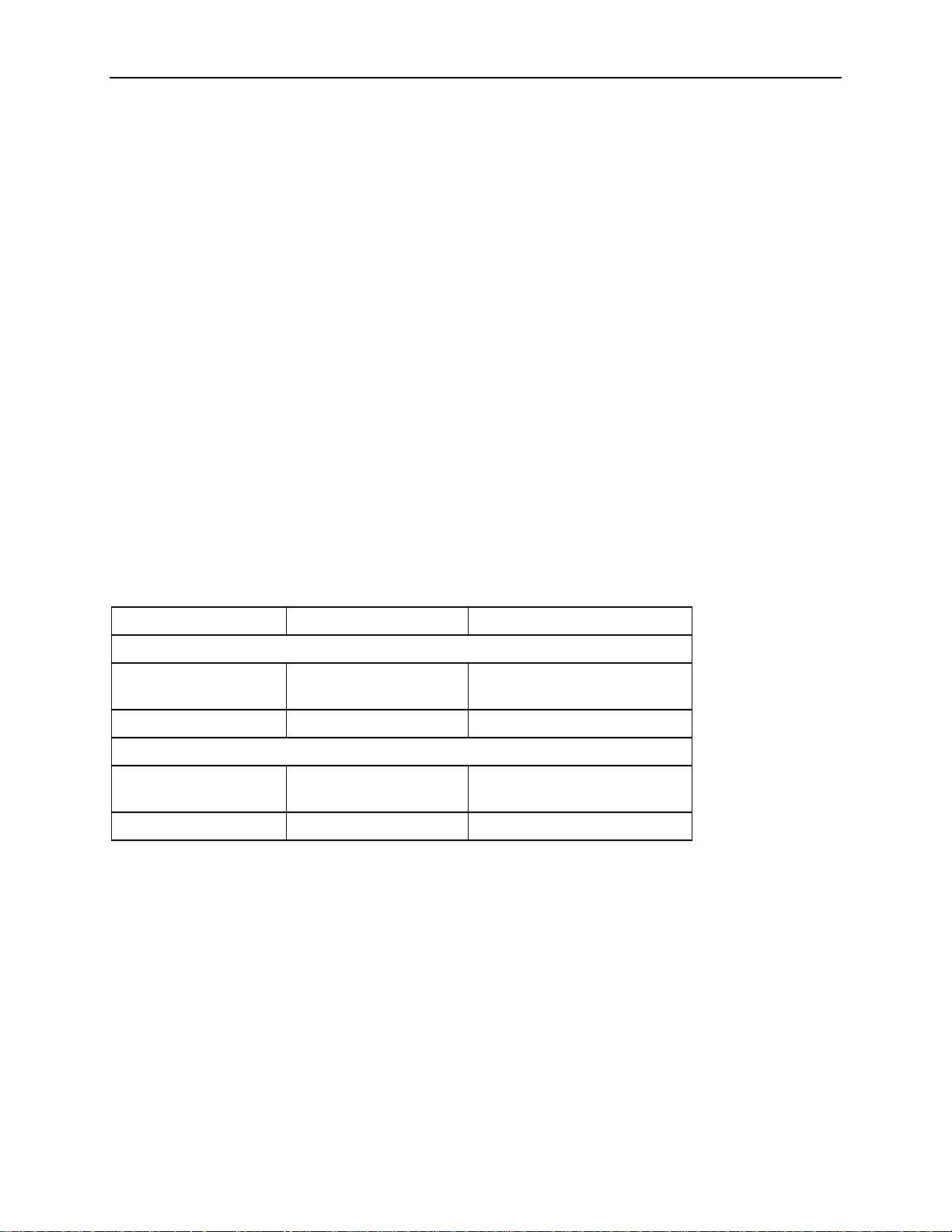

GB Comparison

Feature

Transmitter

Frequency range

Internal Clock Source

External Clock

External Clock w/Burst Mode

Freq Resolution CR/LF

(Internal Clock)

Clock /Data

Output Amplitude

Clock/Data

Output Offset

Clock/Data Threshold

Resolution

Std. Programmable Memory 16 bits 128 Kbits 16 bits

Optional Memory 128 Kbits none 1 Mbit

PRBS Patterns (2n-1) 7,15,17,20,23 7,15,17,20,23 7,15,17,20,23

Burst Mode New Line

(External Clk Only)

Receiver

Frequency range

w/Burst Mode

Burst Mode (Ext Clk Only) Standard Feature Standard Feature Optional Feature

Clock/Data Input levels (max) 500 mV to 6.0 V p-p 500 mV to 6.0 V p-p 500 mV to 2.0 V p-p

Clock Input Threshold -3.00 to +4.5 V -3.00 to +4.5 V Fixed threshold levels

Data Input Threshold -3.00 to +4.5 V -3.00 to +4.5 V -1.5V to 1.0 V

Clock/Data Threshold

Resolution

Clock/Data Input Terminations GND, AC, -2V, +3V GND, AC, -2V, +3V GND, AC, -2V

Single-Ended operation Automatic selection Automatic selection Requires external

Clk/Data Delay Range /

Resolution

1

GB660/CSA907A

Tx and Rx

150 kHz to 700 MHz

150 kHz to 700 MHz

1

150 kHz to 700 MHz

1 kHz 1 kHz 1 kHz (was 10 kHz)

500mV to 2.0 V 500mV to 2.0 V 500mV to 2.0 V

-2.0V to +1.8 V -2.0V to +1.8 V -2.0V to +1.0 V

50 mV steps 50 mV steps 50 mV steps

Standard Feature Standard Feature Optional Feature

150 kHz to 705 MHz

150 kHz to 705 MHz

50 mV steps 50 mV steps 50 mV steps

±4 ns in 100 pS

steps

GB700

Tx and Rx

150 kHz to 705 MHz

150 kHz to 705 MHz

150 kHz to 705 MHz

150 kHz to 705 MHz

150 kHz to 705 MHz

±4 ns in 20 pS steps ±4 ns in 5 pS steps

GB1400

Tx and Rx

1 MHz to 1405 MHz

1 MHz to 1405 MHz

150 kHz to 1405 MHz

-2.0V to +1.8 V with

PECL opt.

1 MHz to 1405 MHz

150 kHz to 1405 MHz

2

cable

Note 1 Burst mode operation requires ECL levels and is DC coupled

Note 2 Single-ended operation requires ext. cable connection from rear panel DATA THRESHOLD SMA

GB1400 User Manual 1-5

Page 23

Getting Started

GB1400 Instrument Configurations - Standard and Burst Option

GB1400 instruments are sold with and without the BURST option. To determine if the burst option is

installed in a GB1400, press the F1 key several times until you get to the UTIL menu. Then select the

OPTION menu. The OPTIONS menu will tell you if the Burst option is installed in the unit. External

indications of the BURST option are unique labels for both transmitter and receiver. See a write-up on

Burst Mode at the end of the Functional Overview section of Chapter 2.

GB1400 with no Burst Option Standard instrument configuration

All standard configuration GB1400 Generators (no burst option) have an AC coupled external clock

input. All standard configuration GB1400 Analyzers (no burst option) have AC coupled paths in the

receiver clock input circuitry.

GB1400 with Burst Option

When the BURST option is installed in the GB1400, the AC coupled paths in both transmitter and

receiver are eliminated. This will also change several specifications listed in the table below. External

clock inputs to the GB1400 transmitter must be ECL levels when the BURST option is installed. Clock

inputs into the GB1400 receiver must be ECL levels and are terminated into 50 Ohms to -2V.

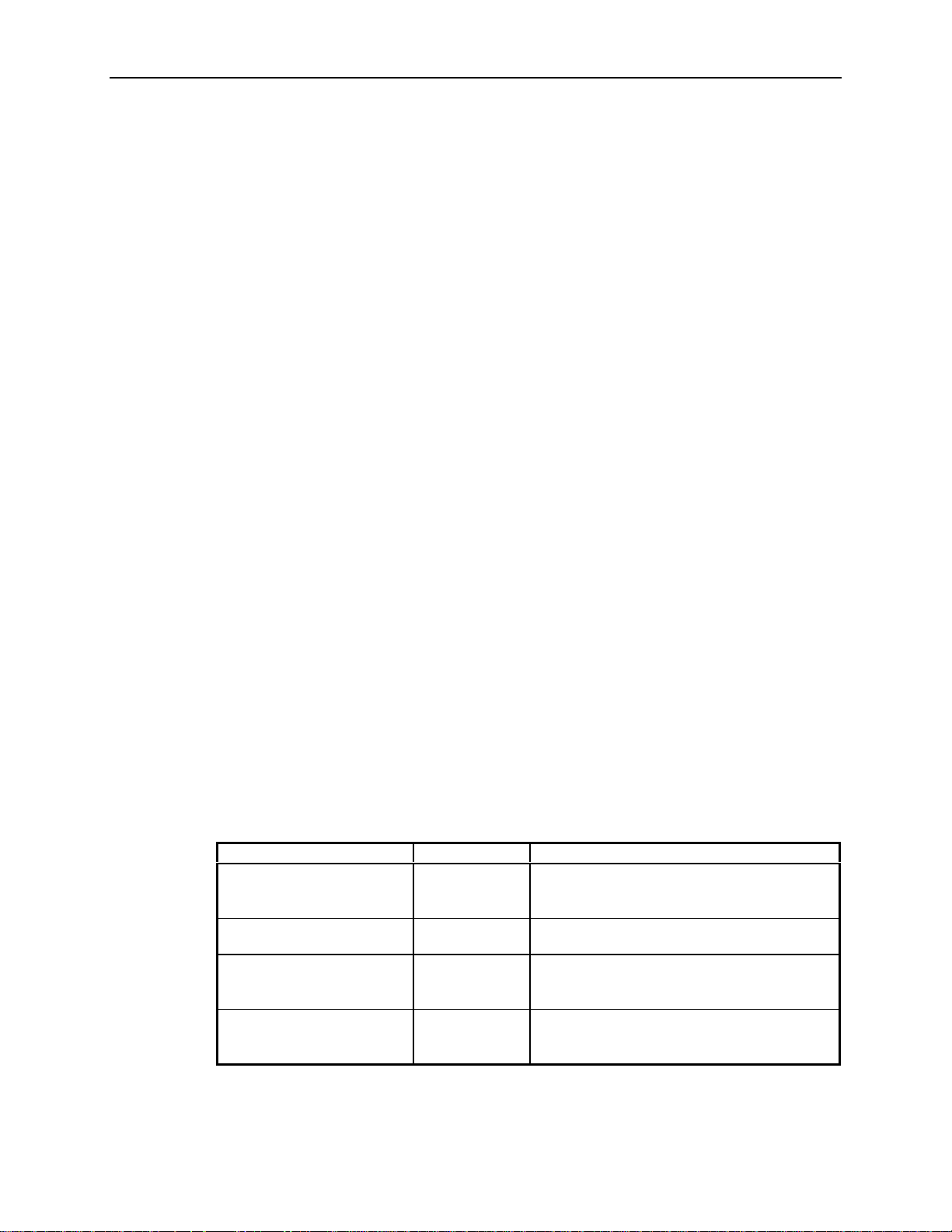

GB1400 Clock Signals for Standard and Burst and Instruments

Standard Coupling Burst (Option) Coupling

GB1400 TX

External Clock Input 50 Ohm, AC coupled,

2V max

GB1400 RX

Clock Input 50 Ohm, AC coupled,

2.0V max

50 Ohm to -2V, DC coupled,

ECL levels

50 Ohm to -2V, DC coupled,

ECL levels

1-6 GB1400 User Manual

Page 24

Initial Self-Check Procedure

You may perform the following procedure as an initial self-check of your

GB1400 Generator and Analyzer. It is also a useful introduction to the basic

features and operation of the GB1400.

The fan openings of the GB1400 needs 2-inches of clearance for proper

ventilation.

Procedure

1. Make sure both the Generator and Analyzer are equipped with the proper

fuse.

2. Make sure that the Generator and Analyzer rear-panel power switches

are ON, and that their front-panel power switches are in the STBY

position.

3. Plug both instruments into grounded (three-conductor) AC power outlets.

4. Connect a 50-Ohm SMA cable from the Generator CLOCK output to the

Analyzer CLOCK input. If using 75-Ohm option, use &5 OHM

SMA/BNC cable.

Getting Started

5. Connect a 50-Ohm SMA cable from the Generator DATA output to the

Analyzer DATA input.

6. Connect a 50-Ohm SMA cable from the Analyzer rear panel DATA

THRESHOLD output to the Analyzer DATA BAR input (required for

single-ended data inputs).

7. Power the Generator while pressing and holding its VIEW ANGLE,

MSB 1 and (PATTERN) CLEAR keys simultaneously. Release the key

after the message Default Settings appears in the display. Repeat this

procedure with the Analyzer. This will force both the Generator and

Analyzer to power up using factory default settings.

8. Set up the Generator clock and data outputs using controls in the

OUTPUT box as follows:

Set this parameter… to this value … using this procedure.

DATA amplitude. 2 volts Press the DATA key.

Press AMPLITUDE up/down keys until

data amplitude is set to 2.00V.

DATA baseline offset -1 volt Press BASELINE OFFSET up/down keys

until data baseline offset is set to -1.00V.

CLOCK amplitude 2 volts Press CLOCK.

Press AMPLITUDE up/down keys until

clock amplitude is set to 2.00V.

CLOCK baseline offset -1 volt Press BASELINE OFFSET up/down keys

until clock baseline OFFSET is set to

-1.00V.

GB1400 User Manual 1-7

Page 25

Getting Started

9. Set Generator pattern to a 223-1 bit PRBS using controls in the

PATTERN box as follows:

a. Press PRBS.

b. Press the pattern up/down keys until PATTERN is set to PN 23.

10. Verify that the Generator error injection rate is off. If the LED in the

error inject RATE key is on, then press RATE one or more times until it

turns off.

11. Verify that the Analyzer auto-search function is enabled. If the LED in

the AUTO SEARCH key is off, then press AUTO SEARCH one time to

turn it on. At this point, verify that the green LOCK LED in the

Analyzer SYNC box is on.

12. Zero all Analyzer error counts by pressing CLEAR in the ERROR

DETECTION group.

13. Reset all Analyzer history LEDs by pressing CLEAR in the ERROR

HISTORY group.

14. Verify GB1400 Analyzer can detect errors by pressing the Generator

error inject SINGLE key several times. Verify that the Number of Errors

count displayed by the Analyzer increments each time the Generator

SINGLE key is pressed.

In effect you are now performing a bit error rate test on the test cables connecting

the GB1400 Generator and Analyzer. In an actual BER test, GB1400 Generator

clock and data outputs would be connected to inputs on a "device under test"

(DUT) while GB1400 Analyzer inputs would be connected to outputs on the

DUT.

1-8 GB1400 User Manual

Page 26

Operating Basics

Page 27

Functional Overview

This section describes how to use and navigate through the basic functions of the

GB1400, including:

• BERT Basics

• Controls, indicators and connectors

• Display Formats

• Outputs and Inputs

Also in this section is:

• Tutorial - "Understand GB1400 instrument setup for BER testing using

PRBS patterns";

• Application Note - Auto Search Synchronization with GB1400; and,

• Application Example - GB700/ GB1400 Optical component test.

GB1400 User Manual 2-1

Page 28

Functional Overview

BERT Basics - GB1400

The GB1400 Generator and Analyzer together comprise a 1400 Mb/s, serial, bit

error rate test system or BERT.

A BERT is an instrument designed to measure the bit error rate (BER)—or more

generally, the error performance—of a digital communications device, module, or

system.

A typical BERT application, for example, would be to measure the error

performance of the electrical-to-optical (E/O) and optical-to-electrical (O/E)

output modules of a high-speed fiber optic transmission system (FOTS), as

shown in the figure below.

GB1400 Generator GB1400 Analyzer

CLOCK DATA

OUT OUT

E/O

O/E

CLOCK DATA

IN IN

Figure 2- 1. Example, BERT Application

The GB1400 is described as a serial BERT because it is designed to test one

digital path at a time. The term serial also distinguishes the GB1400 from

parallel BERTs, such as the Tektronix MB100, which is designed to test multiple

digital signal paths simultaneously.

The GB1400 Generator, also known as the transmitter or "Tx", can generate

various test patterns, including pseudo-random bit sequences (PRBS) and userdefined word patterns. The Generator output consists of a two level, non-return to

zero (NRZ) data signal and its associated clock signal, as illustrated in Figure

2-2. In the NRZ format, the data signal remains at either a logic "1" or logic "0"

level for the entire duration of each bit time slot, except for a small transition

period between time slots containing different data. The corresponding clock

signal is a nominal "square wave" whose frequency defines the bit rate of the test

signal.

2-2 GB1400 User Manual

Page 29

Functional Overview

Falling edge of CLOCK

in middle of DATA "eye"

Rising edge of CLOCK Coincident with DATA transitions

CLOCK

DATA

Figure 2- 2. Nominal Generator NRZ Data and Clock Output

Waveforms

The nominal Generator clock/data phase relationship is fixed so that the falling

edges of the clock signal occur in the middle of bit time slots of the data signal.

The amplitude and baseline offset of the Generator's clock and data outputs are

adjustable to insure compatibility with a wide range of input circuit designs and

logic families including ECL, positive ECL, and GaAs.

The GB1400 Analyzer, also known as the receiver or "Rx", can terminate and

analyze the NRZ output of a digital device, module, or system being tested by the

GB1400 Generator or an equivalent signal source. The decision voltage or

threshold of the Analyzer DATA and CLOCK inputs can be adjusted to

accommodate different logic families. The Analyzer can also add a variable

amount of delay to the input data signal to accommodate different clock/data

phase relationships at the output of the device under test.

The primary measurements made by the GB1400 Analyzer are bit errors and bit

error rate.

GB1400 User Manual 2-3

Page 30

Functional Overview

Controls, Indicators and Connectors

The first four figures in this section identify the controls, indicators and

connectors located on the front and rear panels of the GB1400 Generator (Tx)

and GB1400 Analyzer (RX).

VIEW

ANGLE

FREQUENCY (kHz)

MEMORY

PATTERN

gigaBERT1400 GENERATOR

OUTPUT

AMPL

OFFSET

ERROR INJECT

RATE SINGLE

PANEL

LOCK

GPIB

ADDR

LOCAL

REMOTE

POWER

ON

OFF

CLOCK

FREQUENCY

STEP

RECALL SAVE

EXT

INPUT

50 Ohm 2 V Max

PRBS

WORD

RECALL SAVE

PATTERN SYNC CLOCK/4 CLOCK

(2) (1)

50 Ohm SOURCE

PATTERN

WORD

F1 F2 F3 F4

LENGTH

BIT

MSB

1 2 3 4 5 6 7 8

(1) With Option 2, these outputs are 75 Ohm.

(2) With Option 5, the input is ECL levels only.

Figure 2- 3. Front Panel, GB1400 Generator (Tx)

PHASE A PHASE B CLOCK/2 ERROR INJECT DATA INHIBIT

CLEAR SET CLOCK DATA

OUTPUT

CLOCK

50 Ohm SOURCE

RS-232C

INVERT

DATA

(D-INV)

DATA

OUTPUT

AMPLITUDE

GPIB

OFFSET

DATA

WARNING

ELECTRICAL SHOCK HAZARD

THIS INSTRUMENT MUST BE GROUNDED

DO NOT OPEN INSTRUMENT REFER SERVICING TO

QUALIFIED PERSONNEL

DISCONNECT POWER CORD BEFORE REPLACING

FOR CONTINUED FIRE PRODUCTION REPLACE ONLY

INPUT MAX LINE

VOLTAGE RANGE POWER FUSE

115 90-132V 175W 5A SLOBLO

230 180-250V 175W 5A SLOBLO

AUTO SELECT FREQUENCY 47-63 Hz

FUSE

WITH SPECIFIED FUSES

AC-LINE

Figure 2- 4. Rear Panel, GB1400 Generator (Tx)

2-4 GB1400 User Manual

Page 31

VIEW

ANGLE

DELAY/

MEMORY

FREQUENCY (kHz) ERROR RATE TOTALIZE

Functional Overview

gigaBERT 1400 ANALYZER

ERROR HISTORY

SYNC LOSS

BIT

PHASE

POWER

CLEAR

PANEL

LOCK

GPIB

ADDR

LOCAL

REMOTE

POWER

ON

OFF

INPUT

DELAY

V-TERM V-THRESH

D-INV

DATA DATA

PRBS

WORD

RECALL SAVE

REFERENCE DATA CLOCK

(1) (2)(1)

PATTERN

WORD

LENGTH

MSB

1 2 3 4 5 6 7 8

EXT

(1) With Option 2, this input is 75 Ohm.

(2) With Option 5, the input is ECL levels only.

Figure 2- 5. Front Panel, GB1400 Analyzer (RX)

DATA

THRESHOLD

ERROR INHIBIT RZ ERROR

OUTPUT

PRINTER

F1 F2 F3 F4

CLK REF

BIT

ERROR DETECTION

SYNC

DISPLAY

CLEAR

AUDIO

VOL

MONITOR

CLOCK

50 Ohm SOURCE 50 Ohm, 1.5V MAX 50 Ohm, 2V MAX

CLEAR SET

CLOCK

PATTERN

RS-232C GPIB

RATE

SYNC

AUTO

SEARCH

LOCK

DISABLE

DATA

WARNING

ELECTRICAL SHOCK HAZARD

THIS INSTRUMENT MUST BE GROUNDED

DO NOT OPEN INSTRUMENT REFER SERVICING TO

QUALIFIED PERSONNEL

DISCONNECT POWER CORD BEFORE REPLACING

FOR CONTINUED FIRE PRODUCTION REPLACE ONLY

INPUT MAX LINE

VOLTAGE RANGE POWER FUSE

115 90-132V 175W 5A SLOBLO

230 180-250V 175W 5A SLOBLO

AUTO SELECT FREQUENCY 47-63 Hz

FUSE

WITH SPECIFIED FUSES

AC-LINE

Figure 2- 6. Rear Panel, GB1400 Analyzer (RX)

GB1400 User Manual 2-5

Page 32

Functional Overview

Display Formats

The normal display format for the Generator and Analyzer are explained below.

Note that the "normal" format is simply the format of the display when not in the

menu mode.

Generator (Tx) Display

The Generator has a two-line by 24-character high-contrast liquid crystal display

(LCD). The Generator display in its normal (non-menu) mode is illustrated in the

figure below.

Frequency (kHz) Pattern Output

1405000 PN23 2.00 V

FREQ 0 ERR OFF -1.00 V

Memory

Figure 2- 7. Generator Display in Its Normal (Non-menu) Mode

The function of each field in the normal Generator display format—that is the

format used when the Generator is not in the menu mode - is described below:

• The top left section of the Generator display is used to show the current

frequency of the internal clock in MHz. For example a display of

622.050 indicates a frequency of 622.050 MHz.

• The top middle section normally shows the current test pattern. For example

PN23 INV indicates that the current pattern is an inverted 2

• The top right section of the display shows the amplitude of the CLOCK or

DATA output, depending on which output control ( CLOCK or DATA) is

selected.

• The bottom left section of the Generator display may show either the

presently selected word memory (WORD 0 ... WORD 7) or the selected

frequency memory (FREQ 0 ... FREQ 9).

AMPL

OFFS

23

-1 PRBS.

• The bottom middle section of the display shows the currently selected

Generator error inject mode.

• The bottom right section of the Generator display will normally show the

baseline offset of the CLOCK or DATA output, depending on which output

control (CLOCK or DATA) is selected.

2-6 GB1400 User Manual

Page 33

Analyzer (RX) Display

Like the Generator, the Analyzer has a two-line by 24-character high-contrast

liquid crystal display (LCD).The Analyzer display in its normal (non-menu)

mode is illustrated in the figure below.

Frequency (kHz) Error Rate Totalize

1405000 5.0E-06 2410538

1.2 ns PN23 -0.05 V

Delay/ Memory

Figure 2- 8. Analyzer Display in Its Normal (Non-menu) Mode

Like the Generator, the Analyzer has a two-line by 24-character high-contrast

liquid crystal display (LCD). The function of each field in the normal Analyzer

display format -that is the format used when the Analyzer is not in the menu

mode -is described below:

Functional Overview

• The top left section of the Analyzer display is used to show the measured

frequency of the input clock signal in MHz. For example a display of

622.05 indicates a measured frequency of 622.05 MHz. Note that the

Analyzer frequency display contains five significant digits while the

Generator frequency display contains six. This is because the frequency

shown in the Analyzer display is a measurement result while the frequency

shown in the Generator display is an instrument setup which is known with

more precision.

• The top middle and top right sections of the display normally show measured

bit error rate and bit errors respectively. BER is expressed in exponential or

"E" notation. For example, a display of 1.5E-09 indicates a measured BER

of 1.5 x 10-9. The Analyzer calculates BER and counts bit errors in three

modes simultaneously: Window, Test, and Totalize. The symbol in front of

the BER field indicates which mode has been selected for display. Window

results are preceded by a blank space, that is no symbol. Totalize results will

be preceded by an ∞ (infinity) symbol. Test results will be preceded by a T,

U, or R depending on the selected test mode: timed, untimed, or repeat.

Refer to Chapter 4 for more information on displaying Analyzer results and

starting and stopping tests.

GB1400 User Manual 2-7

Page 34

Functional Overview

• The bottom left section of the Analyzer display can show the following setup

parameters: delay in nanoseconds for the DATA or REF DATA input; the

selected input termination (GND, -2V, or AC) for the CLOCK, DATA, or

REFERENCE DATA input, or the selected word memory (WORD 0 ...

WORD 7), Note that DATA input delay may be set manually by the user, or

automatically by the AUTO SEARCH feature.

To control the delay, termination or threshold settings for the DATA input,

make sure F2 and F3 LEDs are turned OFF.

Pressing F2 places the unit into CLOCK control (F2 LED illuminated). The

V-TERM key is redefined to allow control of the Input CLOCK Termination

voltage. The status of each key LED and LCD displayed value now reflects

the CLOCK Input signal.

Pressing F3 places the unit into REF Data control mode (F3 LED

illuminated). The Delay, V-TERM and V-THRS keys are redefined to allow

control of the Input REF DATA Delay, Termination Volga and Threshold.

The status of each key LED and LCD displayed value now reflects the REF

DATA Input signal.

• The bottom middle section of the display shows the currently selected

Analyzer pattern, for example PN23 indicates a 223-1 PRBS. This section

will also indicate when input pattern inversion is enabled by displaying INV

after the pattern name.

• The bottom right section of the Analyzer display shows the current value of

the input threshold in volts for the CLOCK, DATA, or REF DATA inputs.

Note that the CLOCK and DATA input thresholds may be set manually by

the user, or automatically by the AUTO SEARCH feature.

2-8 GB1400 User Manual

Page 35

Outputs and Inputs

This section introduces all inputs and outputs of the GB1400 Generator and

Analyzer. Unless otherwise indicated, all signal inputs and outputs are equipped

with SMA female connectors and have a nominal input or output impedance of

50 ohms. However, a 75 Ohm Option is available for both the Generator and

Analyzer which changes nominal impedance of key inputs and outputs to 75

ohms.

Note: The same term can be expressed three different ways.

Functional Overview

clock

DATA

= clock bar = NOT clock

= DATA BAR = NOT DATA

The front panel of the GB1400 Tx is divided into nine sections:

LCD Display Error Inject

Clock Pattern

Output Controls GPIB

Power Switch Output Connectors

Generator OUTPUT Connectors Section

The OUTPUT connectors section of the Generator front panel contains the

outputs listed below.

PATTERN SYNC CLOCK/4 CLOCK

OUTPUT

CLOCK

DATA

DATA

50 Ohm SOURCE

50 Ohm SOURCE

• CLOCK and DATA [outputs]: These two connectors comprise the main

test signal output of the Generator. DATA is the NRZ output of the pattern

generator and CLOCK is its corresponding clock signal. The amplitude and

baseline offset of CLOCK and DATA are variable. CLOCK and DATA may

be used to drive single-ended clock and data inputs, respectively.

• CLOCK-BAR and DATA-BAR [outputs]: These are complimentary

outputs to CLOCK and DATA. That is, CLOCK and CLOCK-BAR together

can drive a differential clock input, while DATA and DATA-BAR together

can drive a differential data input. These complementary outputs should be

terminated with a 50 Ohm load (or a 75 Ohm load if the 75 Ohm Option is

GB1400 User Manual 2-9

Page 36

Functional Overview

installed) when not in use—that is, when the Generator is driving singleended inputs.

• CLOCK/4 [output]: This is a clock signal at one quarter the frequency of

CLOCK. This output may be useful when observing generator outputs using

an oscilloscope that does not have the bandwidth to trigger on the CLOCK

output.

• PATTERN SYNC [output]: This is a pulse that occurs once per pattern

frame. This output may be useful as a trigger signal when observing the

Generator data output using an oscilloscope. The location of PATTERN

SYNC is fixed. A pulse is generated at the start of the pattern frame.

Generator CLOCK Section

Controls in the CLOCK section of the Generator are used to select clock mode

(internal or external) and to set up the instrument's internal clock. The CLOCK

section also contains the input connector for an external clock source. These

controls and input are introduced below.

FREQUENCY

STEP

RECALL

SAVE

EXT

INPUT

50 Ohm 2 V Max

(2)

• FREQUENCY: When this key is selected (LED on), the clock up/down

keys may be used to adjust the frequency of the internal Generator clock up

or down. Each press of the frequency up or down key will increment or

decrement frequency by the current step size.

• STEP: Select this key to adjust the frequency adjustment step size from

1 kHz to 100 MHz.

• SAVE: Use this key to save the present frequency into one of 10 frequency

memory locations.

• RECALL: Use this key to recall a previously saved frequency.

• EXT: Press this key to toggle between internal clock mode (LED off) and

external clock mode (LED on).

• INPUT: This is an input for an external clock source. A signal must be

provided to this input when clock mode is set to external. However, when

clock mode is internal, any signal appearing at this input will be ignored.

2-10 GB1400 User Manual

Page 37

Functional Overview

Generator OUTPUT Section

The controls shown below are used to set up the Generator's clock and data

outputs.

OUTPUT

CLOCK DATA

OFFSET

AMPLITUDE

INVERT

DATA

(D-INV)

• CLOCK: Use this key to select clock amplitude and offset set up mode.

• DATA: Use this key to select data amplitude and offset set up mode.

• AMPLITUDE (↑↑, ↓↓): Use these up/down keys to adjust clock or data

output amplitude.

• BASELINE OFFSET (↑↑, ↓↓): Use these up/down keys to adjust clock or

data baseline offset.

• INVERT DATA: Use this key to toggle between output data inverted (LED

on) and non-inverted (LED off) mode.

GB1400 User Manual 2-11

Page 38

Functional Overview

Generator Rear Panel

The rear-panel of the Generator contains the auxiliary signals, remote control,

and AC-power inputs shown below. See the appendix for instruction on how to

set up the RS-232 and GPIB ports, and general information on using external

controllers with the Generator.

PHASE A PHASE B CLOCK/2 ERROR INJECT DATA INHIBIT

• PHASE A: An SMA connector provides signal output for DATA Phase A.

This phase-shifted data pattern provides signals suitable for MUX/DEMUX

testing. Phase A/B outputs are half rate data patterns (alternating bits).

• PHASE B: : An SMA connector provides signal outputs for DATA Phase

B. This phase-shifted data pattern provides signals suitable for

MUX/DEMUX testing.

• CLOCK/2: : An SMA connector provides signal outputs for CLOCK/2.

• ERROR INJECT: An ECL signal applied to this input may be used to

control error injection when the Generator is in the external (EXT ERR)

injection mode. One error will occur for each rising edge of this signal.

• DATA INHIBIT: An ECL signal applied to this input may be used to

asynchronously gate off the data outputs of the Generator.

• RS-232C [input/output]: A two-way serial port that may be connected to

an external controller or serial printer.

• GPIB [input/output]: An IEEE-488 standard I/O port that may be

connected to a GPIB compatible controller. This port is not compatible with

stand-alone GPIB printers.

• AC LINE [power input]: This is the AC power input connector for the

Generator.

Changing the Line Fuse

1. Disconnect the AC line cord.

2. Slide the fuse cover upwards and remove the fuse.

3. Install the correct line fuse into the holder.

115 VAC 5A, Slo-Blo

230 VAC 5A, Slo-Blo

4. Close the fuse cover.

5. Plug in the line cord.

Allow at least two inches of clearance for the rear panel fan opening and at least

one inch of clearance for the top of the unit. This assures proper cooling of the

unit. Do not operate the Generator on its rear side.

2-12 GB1400 User Manual

Page 39

Functional Overview

Analyzer INPUT Section

The INPUT section of the Analyzer front panel contains the test signal NRZ data

and clock inputs shown below.

DATA

DATA

REFERENCE DATA CLOCK

CLOCK

• CLOCK and DATA [inputs]: These inputs comprise the main test signal

input to the Analyzer. DATA is the main NRZ data input to the Analyzer

pattern detector and CLOCK is its corresponding clock signal. Both inputs

have selectable input terminations. In addition, a variable amount of delay

may be added to the DATA input to properly phase-align the clock and data

signals. CLOCK and DATA may be used to terminate singled-ended clock

and data outputs, respectively.

For single-ended applications, the DATA input threshold is programmable.

This requires an external cable connection from the rear panel DATA

THRESHOLD output to the unused DATA input. Only the unused

"DATA-BAR" input needs the threshold signal. The CLOCK input is selfbiasing for single-ended applications.

• CLOCK-BAR and DATA-BAR [inputs]: These are complimentary inputs

to CLOCK and DATA. That is, CLOCK and CLOCK-BAR together

comprise a differential clock input, while DATA and DATA-BAR together

comprise a differential data input. When the Analyzer is connected to

singled-ended clock and data signals, these inputs are not used.

Note: In DIFFERENTIAL applications, the programmed threshold voltage is

not used.

• REFERENCE DATA [input]: This is an input for a reference data signal.

When the external reference mode is selected (LED in EXT key is on), the

signal appearing at the REF DATA input will be used as the reference signal

to perform bit error analysis instead of a (reference) pattern generated by the

Analyzer's error detection circuit. Note that REF DATA uses the same clock

signal as DATA, however different amounts of delay can be added to the

DATA and REF DATA inputs to account for phase differences between the

two signals.

GB1400 User Manual 2-13

Page 40

Functional Overview

Analyzer MONITOR Section

The MONITOR section of the Analyzer front panel contains the auxiliary outputs

shown below. These outputs may be used to monitor the test signal as seen by

the Analyzer.

PATTERN

SYNC

MONITOR

CLOCK

50 Ohm SOURCE

DATA

• CLOCK [output]: A buffered copy of the clock signal received by the

Analyzer.

• DATA [output]: A regenerated (re-clocked) version of the data signal

received by the Analyzer.

• PATTERN SYNC [output]: A train of pulses that occur once per pattern

frame. This output may be used to trigger an oscilloscope to view the

beginning (first bit/byte) of the data pattern.

2-14 GB1400 User Manual

Page 41

Functional Overview

Analyzer Rear Panel

The rear-panel of the Analyzer contains the auxiliary signal, remote control,

printer, and AC-power inputs shown below. See the appendix for instruction on

how to set up the RS-232 and GPIB ports, and general information on using

printers and external controllers with the Analyzer.

DATA

THRESHOLD

ERROR INHIBIT RZ ERROR

OUTPUT

• DATA THRESHOLD OUTPUT: The programmed DATA threshold

voltage is set via the front panel. Connect to DATA BAR input for singleended applications. Requires external cable connection.

• ERROR INHIBIT INPUT: An ECL signal applied to this input may be

used to asynchronously gate on/off the error detection function of the

Analyzer. That is, while the signal at this input is low, errors are counted.

While it is high, error counting is inhibited.

• RZ ERROR OUTPUT: This is an ECL output signal. One pulse will be

generated at this output for each bit error detected. May be connected to an

external recording device, for example, to log the exact times that errors

occur.

• PRINTER [output]: A one-way port that may be connected to a "parallel

printer"—that is, any printer compatible with the parallel port (LPT1 etc.) of

an IBM-compatible PC.

• RS-232-C [input/output]: A two-way serial port that may be connected to

an external controller (e.g. a PC or workstation) or to a serial printer.

• GPIB [input/output]: A two-way, IEEE-488 compatible I/O port that may

be connected to an external controller via a GPIB cable.

PRINTER

RS-232C GPIB

Changing the Line Fuse

1. Disconnect the AC line cord.

2. Slide the fuse cover upwards and remove the fuse.

3. Install the correct line fuse into the holder.

115 VAC 5A, Slo-Blo

230 VAC 5A, Slo-Blo

4. Close the fuse cover.

5. Plug in the line cord.

Allow at least two inches of clearance for the rear panel fan opening and at least

one inch of clearance for the top of the unit. This assures proper cooling of the

unit. Do not operate the Analyzer on its rear side.

GB1400 User Manual 2-15

Page 42

Functional Overview

Connectors, Terminations, and Levels

Tables 2-1 and 2-2 below summarize the physical interface characteristics of all

GB1400 Generator and Analyzer inputs and outputs.

Table 2-1. Generator (Tx) Inputs and Outputs

Connector Label Signal Type Location Connector

Type

DATA output OUTPUT section SMA,

female

CLOCK output OUTPUT section SMA,

female

DATA-BAR output OUTPUT section SMA,

female

CLOCK-BAR output OUTPUT section SMA,

female

CLOCK/4 output OUTPUT section SMA,

female

PATTERN SYNC output OUTPUT section SMA,

female

Impedance, amplitude,

and offset

50 Ohm, see NOTE 1,

variable amplitude and

offset

50 Ohm, see NOTE 1,

variable amplitude and

offset

50 Ohm, see NOTE 1,

variable amplitude and

offset

50 Ohm, see NOTE 1,

variable amplitude and

offset

50 Ohm, 200mV into 50Ω

50 Ohm, 200mV into 50Ω

CLOCK INPUT input CLOCK section SMA,

female

DATA INHIBIT input rear panel BNC,

female

ERROR INJECT input rear panel BNC,

female

RS-232 I/O rear panel 25 pin, D

type

GPIB I/O rear panel GPIB IEEE-488 standard levels

50 Ohm, 2V max, see

NOTE 2

50 Ohm to -2V, ECL

50 Ohm to -2V, ECL

RS-232C standard levels

and impedance

and impedance

Note 1: A 75-Ohm version of the GB1400 is an option.

Note2: BURST Mode units require ECL-level inputs and are terminated with 50-Ohms to -2V.

2-16 GB1400 User Manual

Page 43

Table 2-2. Analyzer (RX) Inputs and Outputs

Functional Overview

Connector Label Signal

Type

DATA/DATA BAR Input INPUT SMA, female 50 Ohm, see NOTE 1, variable

CLOCK/CLOCK

BAR

REF DATA Input INPUT SMA, female 50 Ohm, ECL, variable delay,

PATTERN SYNC output MONITOR SMA, female

CLOCK output MONITOR SMA, female

DATA output MONITOR SMA, female

ERROR INHIBIT

INPUT

RZ ERROR

OUTPUT

Input INPUT SMA, female 50 Ohm, see NOTE 1, fixed

input rear panel BNC, female 50 Ohm, ECL

output rear panel BNC, female

Section Connector

Type

Impedance, threshold, and delay

threshold and delay. Selectable

termination: GND, -2 V, AC

threshold. Selectable termination:

GND, -2 V, AC

selectable termination GND, -2V,

AC

50 Ohm, 200mV into 50Ω

50 Ohm, 200mV into 50Ω

50 Ohm, 200mV into 50Ω

50 Ohm, 200mV into 50Ω

PRINTER output rear panel 25-pin, D male Compatible with PC parallel printers

RS-232C I/O rear panel 25-pin, D male RS-232 levels and impedance

GPIB I/O rear panel GPIB IEEE-488 standard levels and

impedance

Note 1: A 75-Ohm version of the GB1400 is an option.

GB1400 User Manual 2-17

Page 44

Functional Overview

Controls and Indicators

All of the controls, indicators, inputs, and outputs found on the Generator or

Analyzer front or rear panels are discussed in the following section.

Power Switches

The ON/OFF power switch is located on the left side of the test instrument below

the LCD screen. The power switch switches the 120/240 VAC to the system

power supply. When off, a Battery backup circuit powers the non-volatile RAM.

Unit Mounting

The GB1400 is designed to be placed: (1) flat on a level surface, capable of

supporting its weight, or (2) angled from the surface with the rotating carrying

handle. To change the handle's orientation, press both handle-locking buttons

(located at the hubs of the handle), rotate the handle to the desired angle, and

release the buttons. The handle will click into a locked position. Assure that the

handle is locked before placing the unit on a work surface. A Rack mounting

option is available for installation of the unit into a 19" rackmount. The rack

height for the GB1400 is 7 inches (four RMU).

Unit Cooling

The rear panel fan openings must be kept clear for proper cooling of the unit.

Allow a minimum of two (2) inches of rear panel clearance, and one (1) inch of

top clearance, while operating the unit.

View Angle and Panel Lock Keys

The PANEL LOCK and VIEW ANGLE keys are located near the top, left side of

the front panel.

• VIEW ANGLE: Use this key to select the optimum LCD viewing angle.

• PANEL LOCK: Use this key to "lock" and "unlock" the front panel. While

the front panel is locked, all keys that can cause setup changes are disabled.

This feature can help prevent accidental loss of data when performing longterm or critical tests.

RESET to Factory Default

To return the Generator or Analyzer to factory default settings, turn the

instrument OFF and then re-power it while pressing and holding the VIEW

ANGLE, MSB 1, and (PATTERN) CLEAR keys at the same time. Release these

keys after the message Default Setup appears in the display.

2-18 GB1400 User Manual

Page 45

Functional Overview

GPIB Section Controls

There are two keys in the GPIB section:

• ADDR: Key used to set GPIB address in the range 0 to 30.

• LOCAL: The LED in this key indicates whether the instrument is in the

local mode (LED off) or remote mode (LED on). If the LED is on, you can

return the instrument to local mode by pressing the LOCAL key.

Note that these two keys are used only when operating the instrument via its

GPIB port. For more information on the GPIB port and remote control in general,

see the appendix. For detailed descriptions of all remote commands, see the

appendix.

GB1400 User Manual 2-19

Page 46

Functional Overview

Pattern Controls and Function Keys

The PATTERN section of both the Analyzer and Generator front panels contains

two basic types or groups of controls: "pattern" and "function". The four

function or "soft" keys —F1, F2, F3, and F4—have different functions depending

on the current mode of the instrument. A primary function of these controls is to

access and navigate the menu system. Pattern controls, which includes all other

controls in the PATTERN section, are used to select edit, save, and recall test

patterns.

WORD

PRBS

LENGTH

F1 F2 F3 F4

CLEAR SET

WORD

RECALL

SAVE

MSB

1 2 3 4 5 6 7 8

CLK REF

• PRBS: Press this key, and then the pattern up/down keys to select a PRBS

pattern.

• WORD: Press this key either to select a word or ROM pattern or to edit the

current word pattern.

• SAVE and RECALL : Use these keys to save and recall user-created word

patterns to and from non-volatile memory. The standard GB1400 can store

up to ten 16-bit or short word patterns. When equipped with the 1-Mbit

option, the GB1400 Generator and Analyzer can store up to ten (10) 65-kbit

patterns, depending upon the buffer size set for word memory.

• WORD LENGTH: Press this key and then the up/down keys, to adjust the

length of the current word pattern.

• (↑↑,↓↓): These are the pattern up/down keys. Their effect depends on which of