Page 1

Installation Manual

TLA 700 Series

Logic Analyzer

070-9774-02

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

TEKTRONIX SERVICE OPTIONS

T ektronix offers the following service options. These options are modular, flexible, and easy to order with your instrument. Designed to ease installation and start up, to support tracking of calibration to requirements of ISO9000, and

to provide for extended repair coverage, these options help fix your long-term maintenance costs and eliminate unplanned expenditures. And these options can be converted from service at T ektronix service depots to service on-site

(see Option S3), which helps keep downtime to a minimum.

Product installation service

1

Option IN Provides initial installation of the product and

familiarizes new users with some of its operation features

Three years of calibration services Option C3 Provides initial Certification on delivery, plus

two more annual calibrations from your service center

Test data Option D3 Provides test data on delivery and when annu-

al calibration services are provided (three total, requires Option C3)

Three years repair coverage Option R3 Provides three years of repair coverage for the

instrument, including displays and accessories

sold with the instrument

One year uplift to on–site service

1,2

Option S1 Converts the standard one year, “return to de-

pot” warranty to provide service on site for

one year

Three year uplift to on-site service

1,2

Option S3 Converts any C3, D3, and R3 options pur-

chased to on-site services for three years

Tektronix Service Options are available at the time you order your instrument. Contact your local Tektronix Sales

Office for more information.

1

Availability of installation and on-site services depends on the type of product and may vary by geography.

2

Uplift options are ordered with the mainframe products and cover individual modules.

Page 4

Page 5

Table of Contents

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documentation x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Offerings xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Installation 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check the Shipping List 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check the Environmental Requirements 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Modules 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Empty Slots 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect the Standard and Other Accessories 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect the Probes 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power On the Logic Analyzer 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powering Off the Logic Analyzer 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perform the Incoming Inspection 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create an Emergency Startup Disk 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Back Up User Files 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Microprocessor Support Software 15. . . . . . . . . . . . . . . . . . . .

The Next Step 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Online Help 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA 700 Series QuickStart Training Board and Manual 17. . . . . . . . . . . . . . . . . . .

Other Documentation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In Case of Problems 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Problems 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Problems 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA 700 Startup Sequence 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Podlets on the P6417 Logic Analyzer Probe 25. . . . . . . . . . . . . . . . . . .

Appendix A: Merging Logic Analyzer Modules 33. . . . . . . . . . . . . . . . . .

Equipment Required 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Merge Procedure 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Merged Modules in the Logic Analyzer 37. . . . . . . . . . . . . . . . . . . .

Removing Merged Modules from the Logic Analyzer 38. . . . . . . . . . . . . . . . . . . .

Storing the Merge Cable 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Upgrades 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upgrading Software 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing TPI 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Updating Module Firmware 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller BIOS Setup 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reinstalling Software 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customizing TLA 700 Series Setups 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: Power Cord and Line Fuse Requirements for the

Benchtop Mainframe 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA 700 Series Installation Manual

i

Page 6

Table of Contents

List of Figures

Figure 1: Location of ground connections 4. . . . . . . . . . . . . . . . . . . . . . .

Figure 2: Installing modules 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3: Installing the empty slot panel covers 6. . . . . . . . . . . . . . . . . .

Figure 4: Locations of external connectors 7. . . . . . . . . . . . . . . . . . . . . .

Figure 5: Connecting the logic analyzer probes 9. . . . . . . . . . . . . . . . . .

Figure 6: Line fuse and power cord connector locations 10. . . . . . . . . . .

Figure 7: On/Standby switch locations 11. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8: TLA 700 startup sequence 24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9: Moving probe podlets 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10: Disassembling the probe cable 27. . . . . . . . . . . . . . . . . . . . . . .

Figure 11: Removing the faulty channel from the probe cable

header housing 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 12: Removing a podlet cable from the rubber comb 29. . . . . . . .

Figure 13: Replacing a podlet in the podlet holder 30. . . . . . . . . . . . . . .

Figure 14: Installing the color-coded ring 31. . . . . . . . . . . . . . . . . . . . . . .

Figure 15: Installing the cable in the cable header housing 32. . . . . . . .

Figure 16: Removing the cover 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 17: Feeding the Merge cable through the cover 35. . . . . . . . . . . .

Figure 18: Seating the cover on the chassis 36. . . . . . . . . . . . . . . . . . . . . .

Figure 19: Lining up the two modules 37. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 20: Dressing the Merge cable before installing the cover 39. . . .

Figure 21: Flash programming pins 50. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 22: Power cord identification chart 66. . . . . . . . . . . . . . . . . . . . . .

ii

TLA 700 Series Installation Manual

Page 7

List of Tables

Table of Contents

Table 1: Mainframe operating requirements 3. . . . . . . . . . . . . . . . . . . .

Table 2: Additional accessory connection information 8. . . . . . . . . . . .

Table 3: Line fuses 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4: Troubleshooting 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5: Software not covered by the TLA 700 Series software setup 41

Table 6: Controller BIOS setups for the TLA 700 application 53. . . . .

Table 7: Power for instrument modules 65. . . . . . . . . . . . . . . . . . . . . . . .

TLA 700 Series Installation Manual

iii

Page 8

Table of Contents

iv

TLA 700 Series Installation Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the instrument.

Read the General Safety Summary in other system manuals for warnings and

cautions related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

TLA 700 Series Installation Manual

v

Page 10

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

vi

TLA 700 Series Installation Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

TLA 700 Series Installation Manual

vii

Page 12

Service Safety

viii

TLA 700 Series Installation Manual

Page 13

Preface

The TLA 700 Series Installation Manual is intended to help you install your

TLA 700 Series Logic Analyzer. Although your TLA 700 Series Logic Analyzer

may arrive with all modules installed, you should still follow the steps in this

manual to complete the installation process.

The manual consists of the following sections:

Basic Installation describes the hardware installation process and provides

information to start the logic analyzer the very first time.

Installing Microprocessor Support Software describes the steps for installing

microprocessor support software that does not come installed on your logic

analyzer.

The Next Step provides information on other TLA 700 Series documentation

that you may need to operate your TLA 700 Series Logic Analyzer.

In Case of Problems provides information on handling problems or

difficulties that may occur during the installation process. It also provides

procedures for replacing probe podlets and a list of phone numbers for

Tektronix product support.

Appendix A: Merging Logic Analyzer Modules provides the procedures for

combining two logic analyzer modules to create a single, wider module.

Appendix B: Upgrades provides information on upgrading software,

installing TPI, (TLA 700 Programmatic Interface), upgrading firmware for

the individual modules, and for using the BIOS setup for the controller in

your logic analyzer.

Appendix C: Power Cord and Line Fuse Requirements for the Benchtop

Mainframe provides information on selecting the proper power cord and line

fuse for the benchtop mainframe.

TLA 700 Series Installation Manual

ix

Page 14

Preface

Related Documentation

In addition to this installation manual, the following documentation is available

for your TLA 700 Series logic analyzer:

The TLA 700 Series Logic Analyzer User Manual provides basic operating

information for the TLA 700 Series Logic Analyzer.

The online help provides information about the TLA 700 Series user

interface. To view the online help, select Help Topics from the Help menu.

A series of microprocessor support instruction manuals provide operating

and service instructions for the individual microprocessor support packages.

The TLA 7QS Training Manual provides training exercises to help you learn

key features of the TLA 700 Series Logic Analyzer. The training manual is

designed to be used with the TLA 700 Series QuickStart training board.

The TLA 7QS Technical Reference Manual provides technical and service

information for the TLA 700 Series QuickStart training board.

The TLA 700 Series Performance Verification and Adjustment Technical

Reference Manual provides performance verification and adjustment

procedures for the major components of the TLA 700 Series Logic Analyzer.

The manual includes the performance verification and adjustment software.

The TLA 711 Color Benchtop Chassis Service Manual provides module-lev-

el service information for the benchtop chassis.

The TLA 711 Color Benchtop Controller Service Manual provides module-

level service information for the benchtop mainframe controller module.

The TLA 704 Color Portable Mainframe Service Manual provides module-

level service information for the portable mainframe.

The TLA 7Lx/TLA 7Mx Logic Analyzer Service Manual provides module-

level service information for the logic analyzer module.

The TLA 7Dx/TLA 7Ex Digitizing Oscilloscope Service Manual provides

module-level service information for the DSO module.

x

TLA 700 Series Installation Manual

Page 15

Service Offerings

Preface

Tektronix provides service to cover repair under warranty as well as other

services that are designed to meet your specific service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well equipped to service the TLA 700

Series Logic Analyzers. Tektronix technicians train on Tektronix products; they

have access to the latest information on improvements to the TLA 700 Series

Logic Analyzers as well as the latest new product upgrades. Services are

provided at Tektronix Services Centers and on-site at your facility, depending on

your location.

Warranty Repair Service

Calibration and Repair

Service

Tektronix warrants this product for one year from date of purchase. (The

warranty appears behind the title page in this manual.) Tektronix technicians

provide warranty service at most Tektronix service locations worldwide. The

Tektronix product catalog lists all service locations worldwide or you can visit us

on our Customer Services World Center web site at http://www.tek.com/Mea-

surement/Service. See our latest service offerings and contact us by email.

In addition to warranty repair, Tektronix Service offers calibration and other

services which provide cost-effective solutions to your service needs and qualitystandards compliance requirements. Our instruments are supported worldwide by

the leading-edge design, manufacturing, and service resources of Tektronix to

provide the best possible service.

The following services can be tailored to fit your requirements for calibration

and/or repair of the TLA 700 Series Logic Analyzers.

Service Options. Tektronix Service Options can be selected at the time you

purchase your instrument. You select these options to provide the services that

best meet your service needs. These service options are listed on the Tektronix

Service Options page following the title page of this manual.

Service Agreements. If service options are not added to the instrument purchase,

then service agreements are available on an annual basis to provide calibration

services or post-warranty repair coverage for the TLA 700 Series Logic

Analyzers. Service agreements may be customized to meet special turn-around

time and/or on-site requirements.

Service on Demand. Tektronix also offers calibration and repair services on a

“per-incident” basis that is available with standard prices for many products.

TLA 700 Series Installation Manual

xi

Page 16

Preface

Contacting Tektronix

Self Service. Tektronix supports repair to the replaceable-part level by providing

for circuit board exchange.

Use this service to reduce down-time for repair by exchanging circuit boards for

remanufactured ones. Tektronix ships updated and tested exchange boards. Each

board comes with a 90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the Calibration and Repair Services just

described.

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

xii

TLA 700 Series Installation Manual

Page 17

Basic Installation

Check the Shipping List

This chapter describes all of the steps needed to install the TLA 700 Series Logic

Analyzer. It is written from the perspective that you purchased most of the items

uninstalled and you intend to install all of the pieces. If you purchased a logic

analyzer with modules already installed, you should still review all of the

information in this chapter and perform those steps that apply to your specific

situation.

This chapter deals mainly with hardware installation. The basic operating

software is already installed on the internal hard disk. However, if you ordered

additional software, such as microprocessor support software, you must install

that software yourself. Refer to Installing Micropr ocessor Support Software on

page 15.

Verify that you have received all of the parts of your logic analyzer. Use the

shipping lists that came with your logic analyzer to compare against the actual

contents of your order. You should also verify the following:

Verify that you have the correct power cords for your geographical area.

Verify that you have backup copies of the installed software. Store the

backup software in a safe location where you can easily retrieve the software

for maintenance purposes.

NOTE. Keep the software packaging available because you will need it to enter

the Windows 95 software registration number when you first power on the logic

analyzer. (See Step 6 under Power on the Logic Analyzer on page 11.)

Verify that you have the correct module types and probes.

Verify that you have all the standard and optional accessories that you

ordered.

Remember to fill out and send in the customer registration card. The registration

card is packaged with this manual.

TLA 700 Series Installation Manual

1

Page 18

Basic Installation

Check the Environmental Requirements

Read this section before attempting any installation procedures. This section

describes site considerations, power requirements, and ground connections for

your logic analyzer.

Site Considerations:

Portable Mainframe

Site Considerations:

Benchtop Mainframe

The portable mainframe is designed to operate on a bench or on a cart in the

normal position (on the bottom feet). For proper cooling, at least two inches

(5.1 cm) of clearance is recommended on the rear and sides of the mainframe.

You can also operate the mainframe while it rests on the rear feet. If you operate

the mainframe while it is resting on the rear feet, make sure that you properly

route any cables coming out of the rear of the mainframe to avoid damaging

them.

CAUTION. Keep the bottom of the mainframe clear of obstructions to ensure

proper cooling.

The benchtop mainframe is designed to operate on a bench or in a rackmount

environment. For proper cooling, at least two inches (5.1 cm) of clearance is

recommended on the rear and sides of the mainframe.

WARNING. Because of the size and weight of the benchtop mainframe, use care

when lifting or moving the mainframe to avoid personal injury while performing

the installation procedures. Use two people to lift or move the mainframe.

2

TLA 700 Series Installation Manual

Page 19

Basic Installation

Operating Requirements

Table 1 lists the operating requirements for the logic analyzers. Refer to the

TLA 700 Series Logic Analyzer User Manual for a complete specification list.

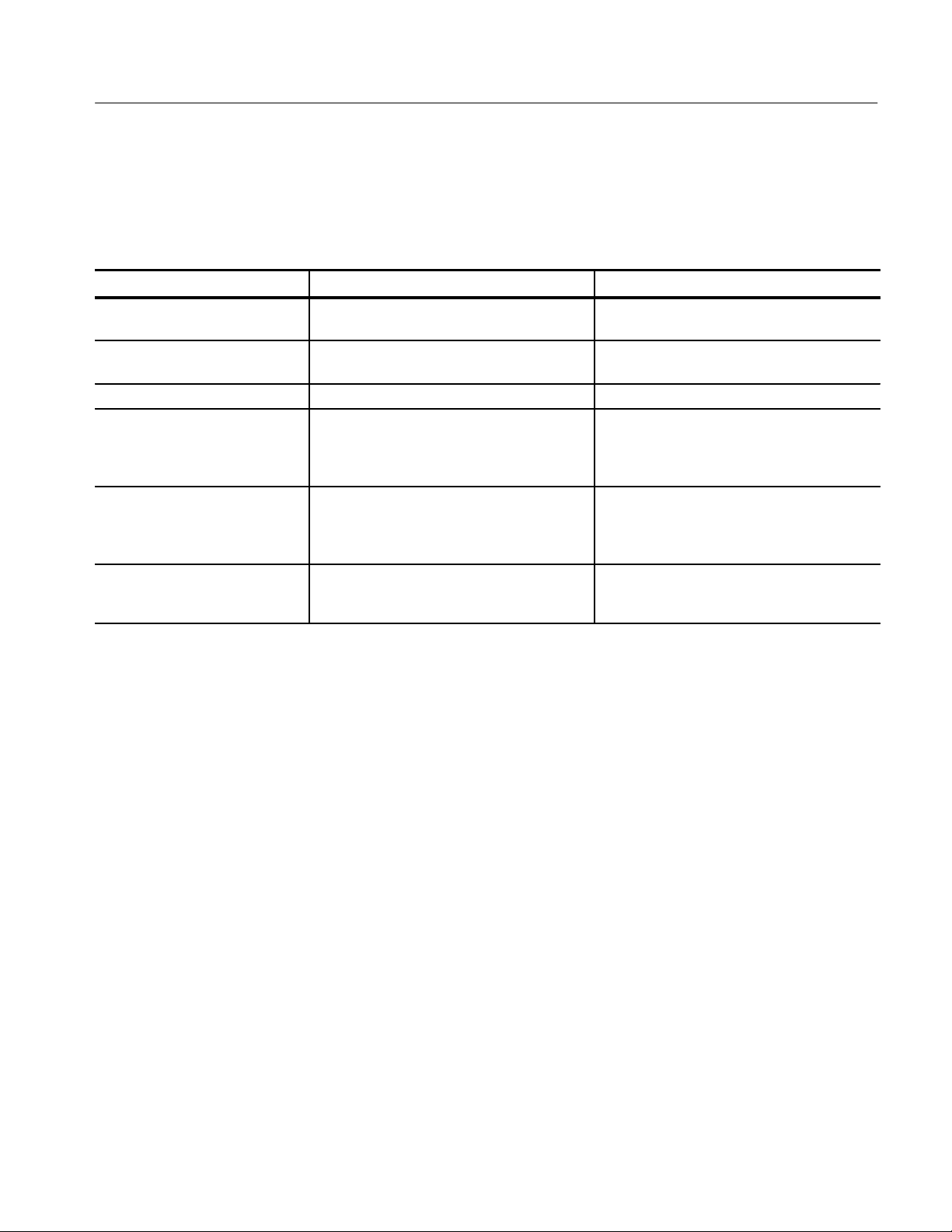

T able 1: Mainframe operating requirements

Requirement TLA 704 Color Portable mainframe TLA 71 1 Color Benchtop mainframe

Source voltage 90–250 V

100–132 V

Steady state input current 6 A

RMS

Maximum power consumption 600 W 1350 W line power

Temperature

(No media in floppy disk drive)

+5° C to +50° C (+41° to +122° F), 15° C/hr

(55° F/hr) maximum gradient, noncondensing

(derated 1° C (34° F) per 1000 ft (304.8 m)

above 5000 ft (1524 m))

Humidity

(No media in floppy disk drive)

20% to 80% relative humidity, noncondensing.

Maximum wet bulb temperature: +29° C

(84° F) (derates relative humidity to ~22% @

50° C (+122° F))

Altitude To 10,000 ft (3,040 m)

(derated 1° C (34° F) per 1000 ft (304.8 m)

above 5000 ft (1524 m))

, 45–66 Hz, continuous range

RMS

, 360–440 Hz, continuous range

RMS

90–250 V

100–132 V

, maximum 15 A

6.3 A

+5° C to +50° C (+41° to +122° F), 15° C/hr

(55° F/hr) maximum gradient, noncondensing

(derated 1° C (34° F) per 1000 ft (304.8 m)

above 5000 ft (1524 m))

20% to 80% relative humidity, noncondensing.

Maximum wet bulb temperature: +29° C

(84° F) (derates relative humidity to ~22% @

50° C (+122° F))

To 10,000 ft (3,040 m)

(derated 1° C (34° F) per 1000 ft (304.8 m)

above 5000 ft (1524 m))

, 45–66 Hz, continuous range

RMS

, 360–440 Hz, continuous range

RMS

, maximum at 90 VAC

RMS

, maximum at 207 VAC

RMS

TLA 700 Series Installation Manual

3

Page 20

Basic Installation

Chassis Ground

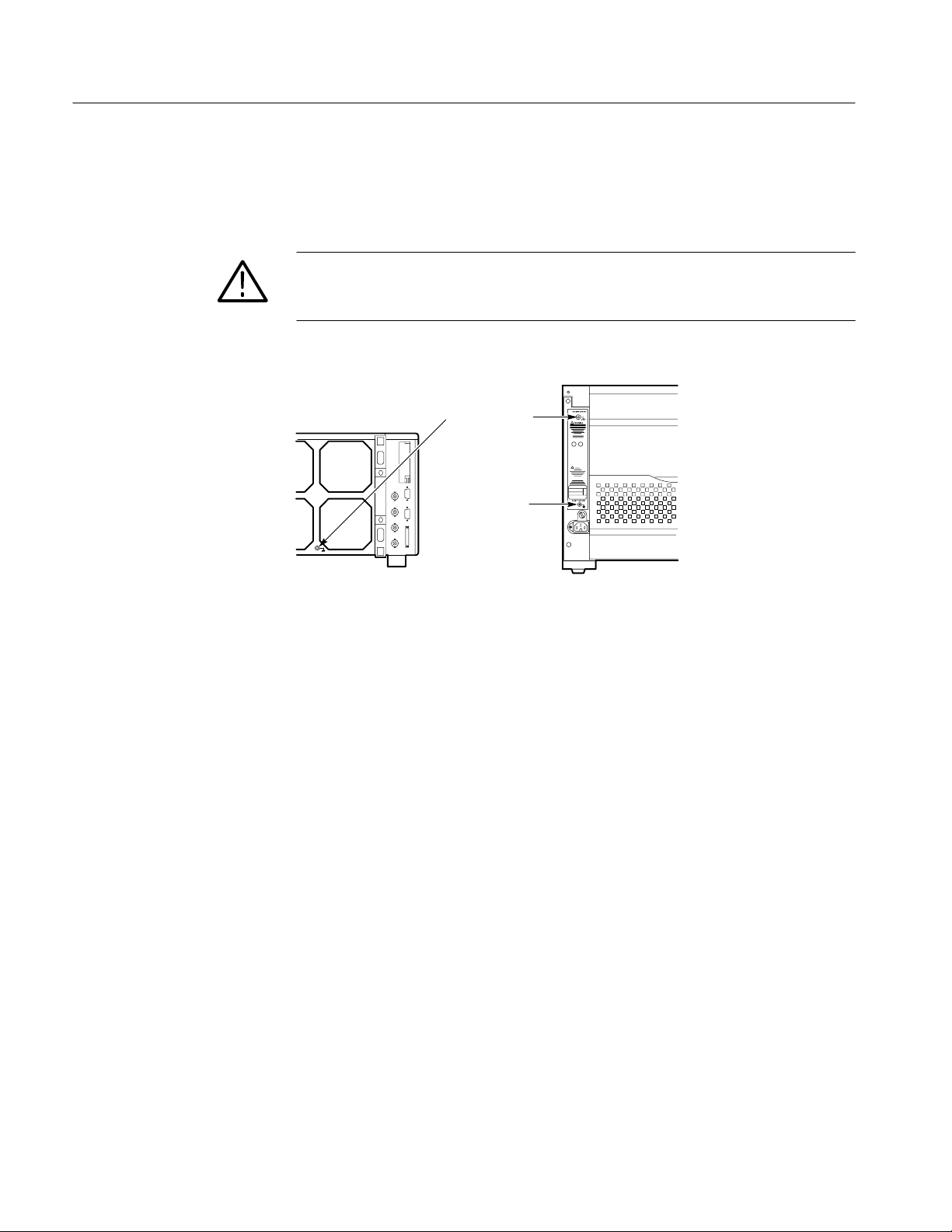

Connections

Figure 1 shows chassis ground connections. Use the chassis ground connections

to connect the grounds of one or more instruments to the logic analyzer to ensure

a common ground connection between instruments.

WARNING. Do not remove the safety ground screw from the benchtop mainframe.

The safety ground screw must always be in place to ensure the proper bonding of

the power supply to the mainframe.

Chassis ground

Safety ground

(Benchtop

mainframe only)

Figure 1: Location of ground connections

4

TLA 700 Series Installation Manual

Page 21

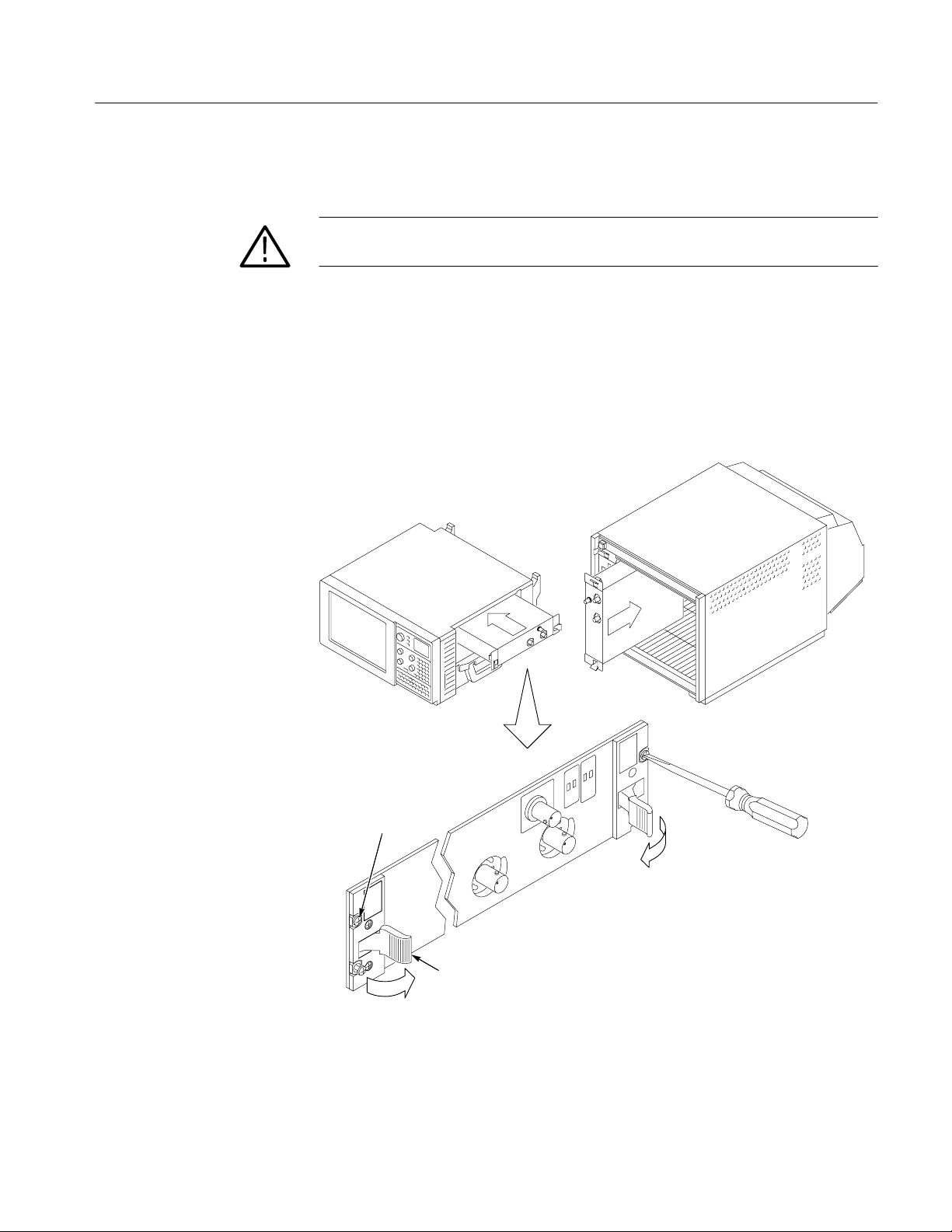

Install the Modules

Basic Installation

CAUTION. Do not install or remove any modules while the mainframe is powered

on; doing so can damage the modules or the logic analyzer.

If your logic analyzer does not have the modules preinstalled, install the modules

as shown in Figure 2. You can install the modules in any slot. Use a Phillips

screwdriver with a Number 1 tip to tighten the retaining screws after seating the

modules in place.

If you want to merge two logic analyzer modules to create a wider module, refer

to Appendix A: Merging Logic Analyzer Modules on page 33.

Figure 2: Installing modules

TLA 700 Series Installation Manual

Portable mainframe Benchtop mainframe

Retaining screws

Injector/ejector handles

5

Page 22

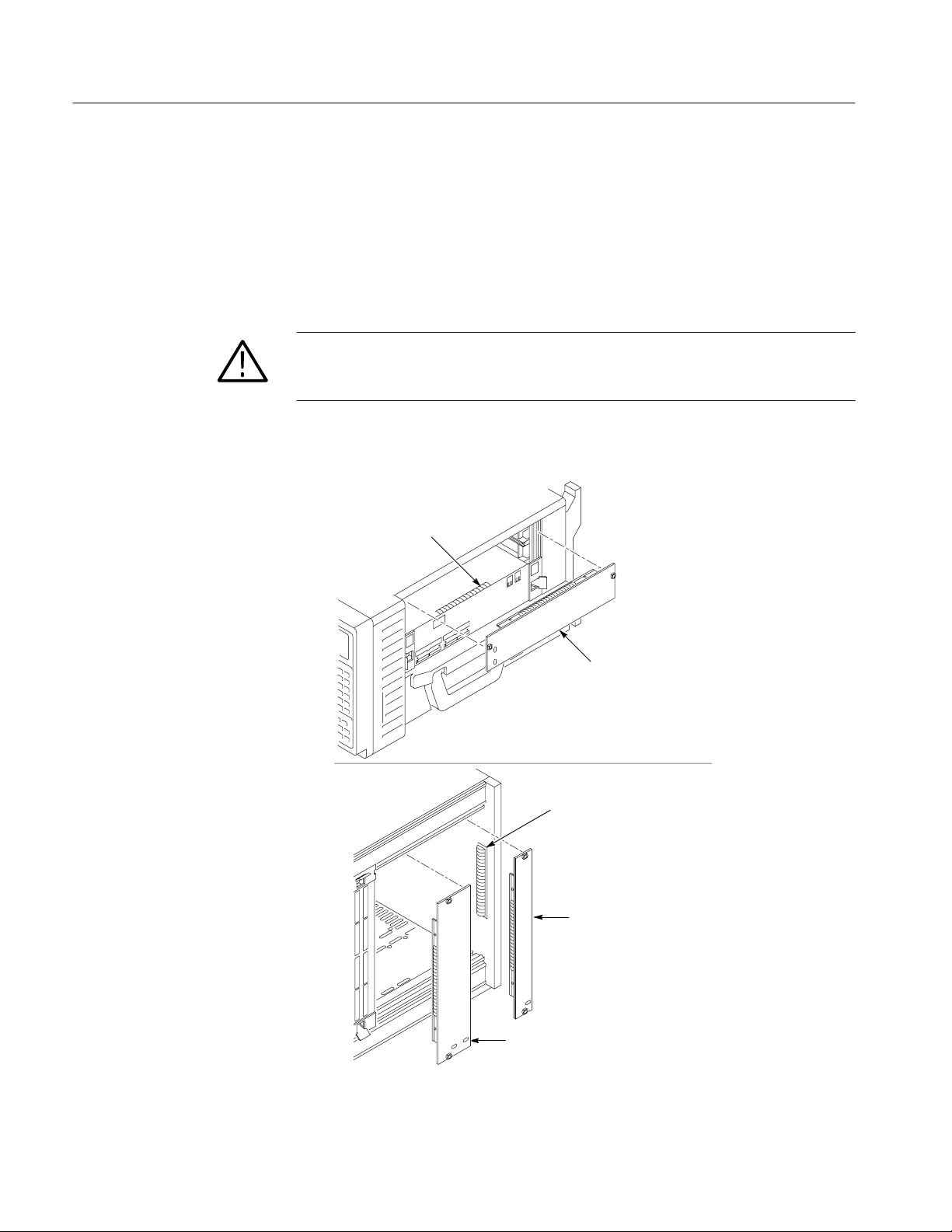

Basic Installation

Cover Empty Slots

If you have any unused (empty) slots in your mainframe, you must install blank

slot panel covers to meet EMC specifications. Install a blank slot panel cover for

each empty slot as shown in Figure 3. Make sure that the EMI shielding is in

contact with the adjacent panel or module cover. Installing the covers provides

proper EMI shielding and reduces audible noise.

CAUTION. Use only Tektronix TLA 700 Series slot panel covers on the benchtop

mainframe. Do not use non-Tektronix covers, otherwise the mainframe may not

meet cooling and EMC requirements.

EMI shielding strip

Double slot panel cover

EMI shielding strip

Single slot panel cover

Double slot panel cover

Figure 3: Installing the empty slot panel covers

6

TLA 700 Series Installation Manual

Page 23

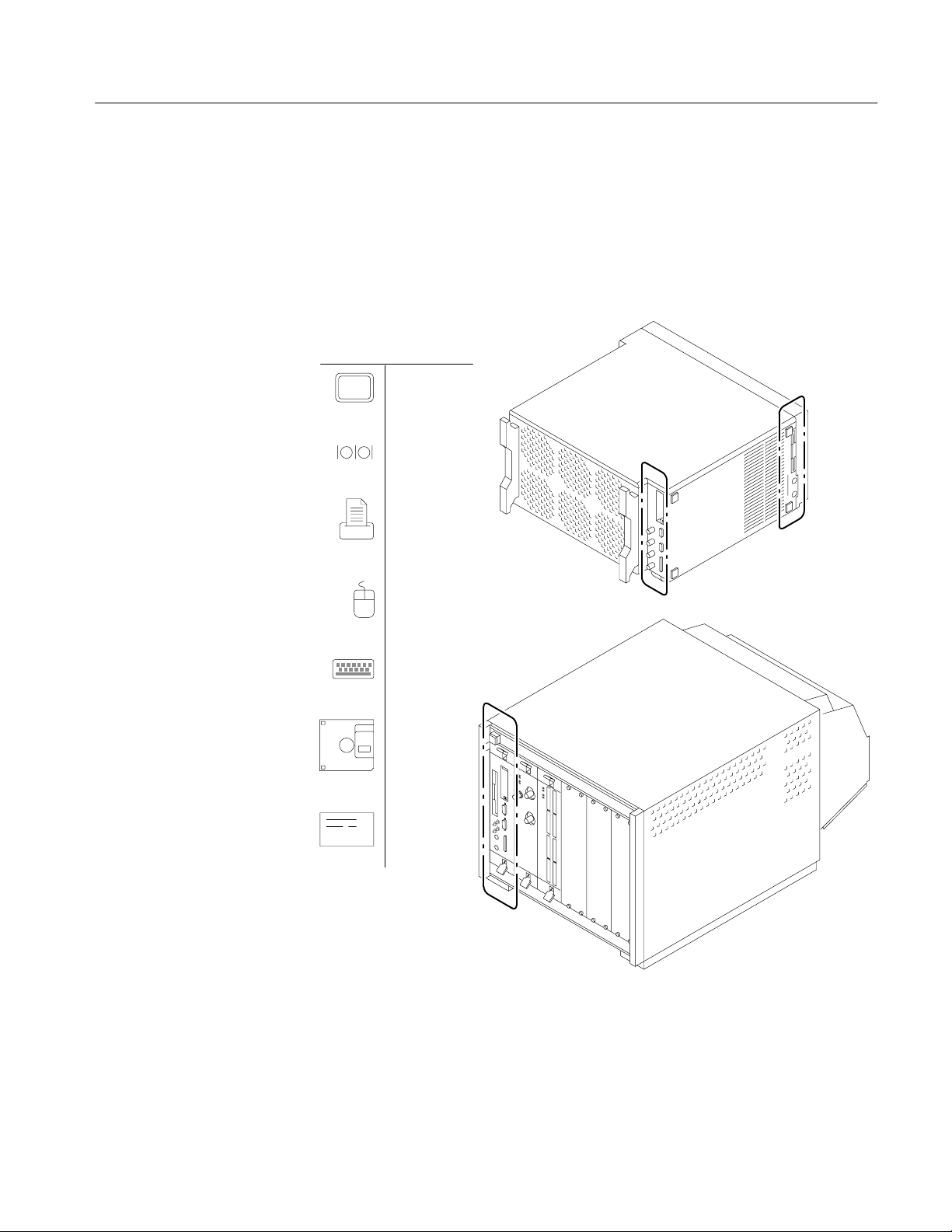

Connect the Standard and Other Accessories

The accessory connections are the same as those you would make on a personal

computer. The connection points are shown in Figure 4. Use the icons that

appear in the circled areas as a guide. See Table 2 on page 8 for additional

connection information.

Icon Description

Monitor

RS-232

Printer

Basic Installation

Mouse

Keyboard

Floppy

disk drive

PC card

(LAN or other)

Figure 4: Locations of external connectors

TLA 700 Series Installation Manual

7

Page 24

Basic Installation

T able 2: Additional accessory connection information

Item Description

Monitor If you use a non-standard monitor, you may need to change the

the Windows 95 display settings to achieve the proper

resolution for your monitor. Refer to Set the Display Driver on

page 58 or to Adjust the Display Desktop Settings for an

External Monitor on page 62. Y ou may also want to refer to the

documentation for your display monitor for installation

information.

Printer Connect the printer to the EPP (enhanced parallel port)

connector directly. If your printer has a DB–25 connector, use

the adapter cable that came with your logic analyzer to connect

to the EPP connector.

Rackmount Refer to the TLA 71 1 Benchtop Mainframe Rackmount

Installation Instructions for information on installing the

rackmount kit.

Other Refer to the TLA 700 Series Application online release notes

for additional accessory installation information not covered in

this manual. Y ou should also refer to the user or installation

documentation that came with your accessory.

8

TLA 700 Series Installation Manual

Page 25

Connect the Probes

Basic Installation

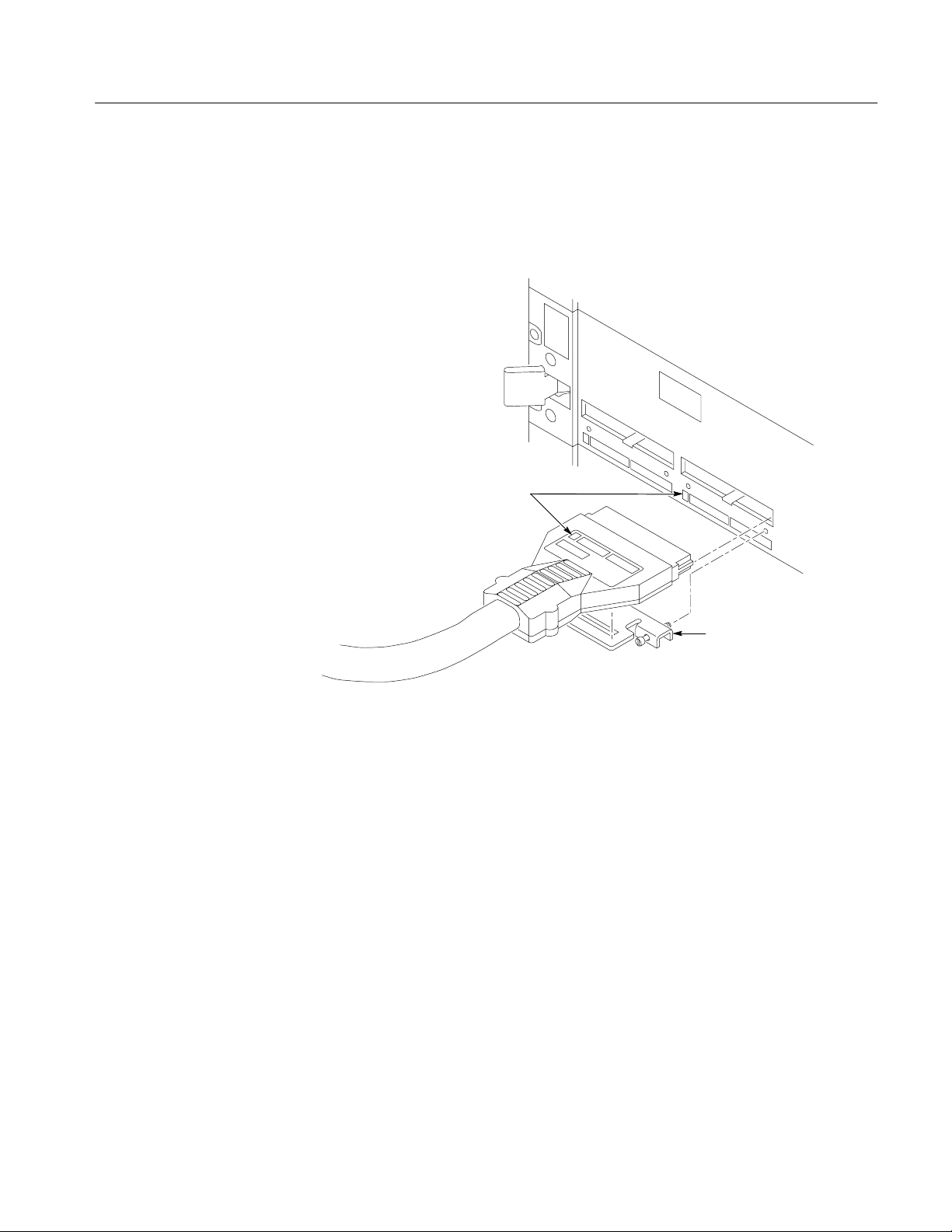

Connect the logic analyzer probes and the optional retaining brackets as shown

in Figure 5. Then connect the oscilloscope probes.

Match color-coded labels

Figure 5: Connecting the logic analyzer probes

Attach optional

probe retainer

brackets

TLA 700 Series Installation Manual

9

Page 26

Basic Installation

Power On the Logic Analyzer

Follow these steps to power on the logic analyzer for the first time.

1. Check that the line fuse is correct for your application. See Table 3 and

Figure 6.

T able 3: Line fuses

Line voltage Rating Tektronix part number

Portable mainframe

90 V to 132 V operation 8 A, fast blow, 250 V 159-0046-00

207 V to 250 V operation 6.3 A, fast blow, 250 V 159-0381-00

Benchtop mainframe

90 V to 132 V operation 20 A, slow blow, 250 V 159-0379-00

103 V to 250 V operation 15 A, fast blow, 250 V 159-0256-00

207 V to 250 V operation 6.3 A, fast blow, 250 V 159-0381-00

AC power and fuse

Figure 6: Line fuse and power cord connector locations

CAUTION. Connect the keyboard, mouse, and other accessories before applying

power to the mainframe. Connecting the accessories after powering on the

mainframe can damage the accessories. Refer to Figure 4 on page 7 for

connection information.

10

TLA 700 Series Installation Manual

Page 27

Basic Installation

2. Connect the power cord.

CAUTION. Although the benchtop mainframe can use the power cord with the

15 A plug, mainframes operating at low line (90 VAC) with four or more

instrument modules may require the power cord with the 20 A plug. If you have

four or more modules in your mainframe, you must determine the correct fuse

and power cord combination to avoid overloading the power distribution system.

Refer to Power Cord and Line Fuse Requirements for the Benchtop Mainframe

on page 65 for further information.

3. If you have an external monitor, connect the power cord and power on the

monitor.

4. Press the On/Standby switch to power on the logic analyzer (see Figure 7 for

the switch location).

Figure 7: On/Standby switch locations

5. Wait for the boot routine and low-level self test to complete.

6. Follow the instructions on the screen and enter the Windows 95 Product

7. Restart your logic analyzer when the setup program is complete.

The next time you power on the mainframe, the logic analyzer application starts

automatically.

TLA 700 Series Installation Manual

Identification number (located above the bar code) on the Windows 95

software package that came with your logic analyzer. Enter other information

as required.

The internal setup software will automatically configure your logic analyzer

and install all required devices depending on the installed accessories.

11

Page 28

Basic Installation

Powering Off the Logic Analyzer

The portable mainframe has a built-in soft power-off function that safely powers

off the mainframe when you press the On/Standby switch. If you have the

benchtop mainframe, you must power off the mainframe using the Windows 95

shutdown process before depressing the On/Standby switch.

CAUTION. When powering off the benchtop mainframe, use the Windows 95 shut

down procedure. Powering off the benchtop mainframe prematurely can corrupt

the software on the hard disk.

Perform the Incoming Inspection

Incoming inspection consists of verifying the basic operation of the logic

analyzer. The Power-on diagnostics check the basic functionality. These

diagnostics run every time you power on the logic analyzer.

Checking the Logic

Analyzer Probes

(Optional)

You can also verify more detailed functionality by running the self calibration

and extended diagnostics.

NOTE. Allow a 30-minute warm-up before running the self calibration.

Disconnect any attached probes from the modules. Then select the System menu,

and point to Calibration and Diagnostics. Run the self calibration followed by

the extended diagnostics by selecting the proper tab. Results of the tests display

on the individual property page.

NOTE. The time required to run the self calibration on the logic analyzer

modules depends on the number of acquisition channels. Modules with a large

number of channels may take several minutes to run the self calibration.

If you want to perform detailed performance verification procedures, refer to the

TLA 700 Series Performance Verification and Adjustment Technical Reference

Manual (available as an optional accessory).

Connect the logic analyzer probes to a signal source, start an acquisition, and

verify that the acquired data is displayed in either the listing or waveform

windows.

12

TLA 700 Series Installation Manual

Page 29

Basic Installation

Checking the DSO Probes

(Optional)

Checking the Mainframe

(Optional)

Connect the oscilloscope probes to the Probe Compensation connector on the

front panel of the DSO module. You can then run the Calibrate Probe function in

each vertical setup page for the module.

To check the mainframe diagnostics not covered by the TLA 700 Series

Application software. Run the QAPlus diagnostics or the TLA 700 Mainframe

Diagnostics located under the Windows 95 Start menu under the Tektronix

TLA 700 programs. Exit the TLA 700 Series Application before running the

external diagnostics.

Create an Emergency Startup Disk

Now that you have completed the basic installation process, you should create an

emergency startup disk that you can use to restart your logic analyzer in case of a

major hardware or software failure. You should create this disk and then store it

in a safe place.

The emergency startup disk contains basic files to restart your logic analyzer. It

also contains files to check and format the hard disk.

Follow these steps to create the emergency startup disk:

Back Up User Files

1. Exit the TLA 700 Series application.

2. Click on the Windows 95 Start button, point to Settings, and click Control

Panel.

3. In the Control Panel window, double-click Add/Remove Programs.

4. Select the Startup Disk property page.

5. Insert a floppy disk into the disk drive and follow the on-screen instructions

to create the startup disk.

You should always back up your user files on a regular basis. Use the Windows 95 Back Up tool to back up files stored on the hard disk. The Back Up tool

is located in the System Tools folder in the Accessories folder. Start the tool and

determine which files and folders that you want to back up. Use the Windows 95

online help for information on using the Back Up tool.

TLA 700 Series Installation Manual

13

Page 30

Basic Installation

14

TLA 700 Series Installation Manual

Page 31

Installing Microprocessor Support Software

Each microprocessor support package comes with setup software and required

support files. Install the microprocessor software using the setup program on the

floppy disk (the following procedure assumes the instrument is already

powered on).

NOTE. Before you install any software, verify that microprocessor support

software is compatible with the logic analyzer software.

1. Insert the floppy disk in the disk drive.

2. Click the Windows 95 Start button, point to Settings, and click Control

Panel.

3. In the Control Panel window, double-click Add/Remove Programs.

4. Follow the instructions on the screen for installing the software from the

floppy disk.

Similarly, you can remove or uninstall software by following the above

instructions and selecting Uninstall.

TLA 700 Series Installation Manual

15

Page 32

Installing Microprocessor Support Software

16

TLA 700 Series Installation Manual

Page 33

The Next Step

Online Help

Now that you have set up your logic analyzer, you are ready to learn how to use

the logic analyzer for various applications. This chapter provides information on

other documentation that you may need to operate your logic analyzer.

The online help is the primary source of information for the logic analyzer. The

online help provides operational details on the screen without having you refer to

printed documentation. Most of the online help information overlaps basic

operating information found in the user manual.

The online help also contains basic operating information for microprocessor

support products.

An online example is provided to guide you through the basic steps in using your

logic analyzer. To access the online help example, start the TLA 700 Series

Application, click on Help, Help Topics, and Welcome.

TLA 700 Series QuickStart Training Board and Manual

The TLA 7QS Training Manual is intended to be used with the TLA 700 Series

QuickStart Training Board to provide examples of how to use the logic analyzer

to solve typical problems. The TLA 700 Series QuickStart Training Board

provides a means of connecting the logic analyzer to signal sources for exercises

described in the training manual. The training board can be used with the logic

analyzer module and the DSO module.

A TLA 7QS Technical Reference Manual is also available to provide technical

and service information on the TLA 700 Series QuickStart Training Board.

Other Documentation

Refer to Related Documentation in the Preface for a list of printed documentation for your TLA 700 Series Logic Analyzer.

TLA 700 Series Installation Manual

17

Page 34

The Next Step

18

TLA 700 Series Installation Manual

Page 35

In Case of Problems

This chapter provides information that addresses problems that you may

encounter while installing your logic analyzer. This chapter does not identify

module-specific problems relating to performance verification or adjustments.

For information on running performance verification procedures or adjustment

procedures, refer to the instructions in the TLA 700 Series Performance

Verification and Adjustment Technical Reference Manual, available as an

optional accessory to your logic analyzer.

Diagnostics

The following diagnostic tools are available with your logic analyzer:

Power on diagnostics. These diagnostics run when you first power on the

logic analyzer or when you first start the TLA 700 Series application. If any

diagnostic failures occur during power on, the Calibration and Diagnostics

property page appears.

NOTE. Before running the extended diagnostics on the logic analyzer module,

disconnect any attached probes.

Extended diagnostics. These diagnostics test the logic analyzer more

thoroughly than the power on diagnostics. The TLA 700 Series extended

diagnostics test the DSO module as well as the logic analyzer module. You

can use the extended diagnostics to isolate problems down to an individual

module. The extended diagnostics are part of the TLA 700 Series Application.

TLA 700 Mainframe diagnostics. The TLA Mainframe diagnostics are a

separate Windows 95 application located in the TLA 700 program group.

These diagnostics check operation of the mainframe beyond the basic PC

circuitry. These diagnostics also check the front panel controls of the

portable mainframe.

QAPlus diagnostics. The QAPlus diagnostics are a separate Windows 95

application located in the Windows 95 Start Programs menu. The diagnostics

check the basic operation of the controller including the following items:

system board, video, hard and floppy disks, memory, communications port,

printer port, mouse and keyboard.

Use the diagnostics to isolate problems to software or hardware within the logic

analyzer. For additional help on the diagnostics, contact your local Tektronix

representative.

TLA 700 Series Installation Manual

19

Page 36

In Case of Problems

Software Problems

Your TLA 700 Series Logic Analyzer comes with most software already

installed. For any suspected software problems, try to isolate the problem to the

TLA 700 Series application software or to other installed software.

Before running any of the diagnostics, you should check the online release notes

to verify the logic analyzer software matches the module firmware.

Run the QAPlus diagnostics software to identify hardware or software problems.

Follow the QAPlus online help instructions for running the diagnostics software.

The diagnostics are located in the Start menu under Programs/ QAPlus_WinWin.

Many software problems can be due to corrupted or missing software files. In

most cases the easiest way to solve software problems is to reinstall the software

and follow the on-screen instructions. Refer to Upgrading Software on page 41

for instructions on reinstalling or upgrading software.

Refer to Table 4 on page 21 for a list of software and hardware troubleshooting

information and recommended action.

Hardware Problems

If you suspect problems with the TLA 700 Series software, contact your local

Tektronix representative or refer to Contacting Tektronix on page xii.

Hardware problems can have several causes. The first step to identifying a

problem is to review the installation instructions in this manual to verify that you

have properly installed the logic analyzer.

If you are certain that you have installed the logic analyzer correctly, run the

TLA 700 Series extended diagnostics (located under the System menu) to

identify any problems with the individual modules.

If your logic analyzer powers up so that you have access to the desktop, run the

QAPlus diagnostics software to identify possible controller hardware problems.

Follow the QAPlus online help instructions for running the diagnostics software.

The diagnostics are located in the Start menu under Programs/ QAPlus_WinWin.

You can also run the external TLA 700 Mainframe diagnostics to identify

problems not covered by other diagnostics. The TLA 700 Mainframe diagnostics

are located under the Start menu under the Tektronix TLA 700 programs.

20

Table 4 lists some of the symptoms of hardware problems and possible solutions.

TLA 700 Series Installation Manual

Page 37

In Case of Problems

CAUTION. Do not attempt to remove or reinstall modules in the logic analyzer

while the logic analyzer is receiving power. Power off the logic analyzer and

disconnect the power cord before removing and installing modules. Failure to do

so can damage the logic analyzer or the individual modules.

T able 4: Troubleshooting

Symptom Possible causes and recommended action

Mainframe does not power on Verify that all power cords are connected to the mainframe and to the power source.

Check that the mainframe receives power when you press the On/Standby switch; check that fans

start and that front-panel indicators light.

Check that power is available at the power source.

Check for failed fuses (see Table 3 on page 10 for mainframe fuse information).

Mainframe failure; contact your local Tektronix service center.

Monitor does not power on Check the monitor power cord connection.

Check for failed fuse.

Monitor failure; contact the vendor of your monitor for corrective action.

Monitor display is blank Check that the monitor is connected to the mainframe; replace the cable if necessary.

If portable mainframe display is blank, try connecting external monitor; if both displays are blank,

contact your local Tektronix service center.

External monitor controls turned down; adjust monitor controls for brightness and contrast.

Check the controller BIOS setups for the monitor.

Faulty monitor; contact the vendor of your monitor for corrective action.

Mainframe powers on but does

not complete the power-on

sequence

Power-on diagnostics fail Isolate problem to faulty mainframe or to faulty module. Multiple diagnostic failures across modules

Power off mainframe and check that all modules are fully inserted.

If mainframe is a benchtop mainframe, check the status of the SYSTEM FAIL and TEST LEDs on

the benchtop controller . If either LED stays on, contact your local Tektronix service center.

Check the status of the READY and ACCESSED LEDs on the front panel of the application

modules. The READY LED turns on when the module passes the power on diagnostics and when

the module is ready to communicate with the controller. The ACCESSED LED turns on any time the

controller accesses the module.

Check for disk in floppy disk drive; make sure mainframe boots from the hard disk drive.

Check for faulty module. Remove modules one at a time and power on the mainframe. If mainframe

completes the power-on sequence, replace faulty module.

Possible software failure or corrupted hard disk; see Software Problems at the beginning of this

chapter.

indicate a faulty mainframe. Diagnostic failures confined to an single module most likely indicate a

faulty module. Contact your local Tektronix service center.

TLA 700 Series Installation Manual

21

Page 38

In Case of Problems

T able 4: Troubleshooting (Cont.)

Symptom Possible causes and recommended action

Mainframe does not recognize

accessories such as monitor,

printer, or keyboard

LA Module merge not recognized

Windows 95 comes up but the

TLA 700 application does not

Windows 95 comes up in Safe

mode

TLA 700 application starts but

modules do not display in

System window

Portable Mainframe will not

power off with On/Standby

switch

Check that accessories are properly connected or installed. Try connecting other standard PC

accessories or contact your local Tektronix service center.

Modules not merged; check merge connection.

Faulty module; replace with known-good module or contact your local Tektronix service center.

Mainframe not set up to start TLA 700 application at power on. Start application from the desktop, by

double-clicking on the TLA 700 icon; see the TLA 700 application online help on Powering On and

Off for setting the startup sequence.

Faulty or corrupt software; reinstall the TLA 700 application software.

Exit the Safe mode and restart the mainframe.

Incompatible hardware and hardware driver software. Either install hardware driver or remove the

incompatible hardware.

Power off mainframe and check that all modules are fully inserted.

Flash programming jumper installed. Power off mainframe and remove module. Remove jumper (see

Figure 21 on page 50), and reinstall module.

Module address switches not set correctly. Power of f mainframe and remove module. Set address

switches to FF and reinstall module (refer to Figure 21 on page 50 for address switch locations).

Module failure; replace with known-good module or contact your local Tektronix service center.

Mainframe failure; contact your local Tektronix service center.

The Mainframe Utilities may be set up to disable hard power off. Check the setting of the Mainframe

Utilities (the Mainframe Utilities are located in the Windows 95 Control Panel).

The Windows 95 operating system problem. Try powering off the mainframe using the Windows 95

shutdown procedure. If the mainframe still does not power off, disconnect power cord and reconnect

after 10 seconds to reboot the mainframe.

22

TLA 700 Series Installation Manual

Page 39

TLA 700 Startup Sequence

The following information is intended to provide troubleshooting hints in case

the logic analyzer fails to complete the startup sequence. You may want to refer

to Figure 8 on page 24 while reading the following paragraphs.

At power on, the logic analyzer starts the mainframe and module kernel tests. If

the mainframe passes the kernel tests, it begins to boot the Windows 95

operating system. If the mainframe fails the kernel tests, it displays the error

codes, beeps, and terminates the startup sequence.

The Windows 95 operating system starts the resource manager. The resource

manager performs the following tasks:

Starts the mainframe power-on self tests

Verifies the power-on self test status

Inhibits any failed modules

Records the power-on self test failures

In Case of Problems

Determines the logic analyzer configuration

Executes the system controller power-on diagnostics

After completing all of the above tasks, the logic analyzer starts the TLA 700

application. The TLA 700 application performs the following tasks:

Performs the power-on diagnostics on all installed modules

Performs the power-on diagnostics on the TLA 700 system

Records the Pass/Fail status in the Calibration and Diagnostics property

sheet

If no failures occur, the TLA 700 application is ready to use for regular tasks.

TLA 700 Series Installation Manual

23

Page 40

In Case of Problems

Power on

Terminate and

display error

code

Mainframe kernel test

Fail

Pass/Fail ?

Pass

MS Windows 95

boot

Start resource

manager

System controller

tests

Module 1

kernel test

Pass/Fail

Log failures and build configuration

Module power-on diagnostics

TLA 700 system power-on diagnostics

Records failures in Calibration and

Module 2

kernel test

Pass/Fail

Verify kernel self test status

Inhibit failed modules

Start TLA 700 application

Diagnostic property sheet

Module 3

kernel test

Pass/Fail

Module n

kernel test

Pass/Fail

Figure 8: TLA 700 startup sequence

24

TLA 700 ready

TLA 700 Series Installation Manual

Page 41

Replacing Podlets on the P6417 Logic Analyzer Probe

Although your logic analyzer was fully tested at the factory prior to shipment,

there may be reasons to move or replace podlets on your logic analyzer probes.

In Case of Problems

Moving Probe Podlets

Depending on your application, you can move or reposition probe podlets as

shown in Figure 9. When moving podlets in the podlet holder keep the ground

side of the podlets together.

Remove podlet

cables

Pull open the podlet holder

Figure 9: Moving probe podlets

TLA 700 Series Installation Manual

25

Page 42

In Case of Problems

Replacing Probe Podlets

The podlet replacement procedure consists of identifying the faulty podlet and

replacing it with a new one. A podlet replacement kit is available as an optional

accessory.

NOTE. Refer to the TLA 700 Online Help for part numbers of the TLA 700

accessories.

Equipment and Required Material. You will need the following equipment and

material:

Replacement podlet

Masking tape

Small diagonal cutters

Screwdriver with #1 Phillips tip

Replacement Procedure. Perform the following steps to replace a faulty probe

podlet:

1. Identify and mark the faulty podlet.

2. Disconnect the probe from the logic analyzer and set the probe cable on a

clean working surface.

NOTE. If you need to replace more than one podlet, replace the podlets one at a

time to avoid mixing them up.

26

TLA 700 Series Installation Manual

Page 43

In Case of Problems

3. Using the screwdriver with the #1 Phillips tip, remove the four screws on the

probe housing on the module end of probe cable (see Figure 10).

Top housing

Cable header

housing

Bottom housing

Rubber comb

Podlet holder

Figure 10: Disassembling the probe cable

4. Remove the top and bottom probe housings and set them aside.

TLA 700 Series Installation Manual

27

Page 44

In Case of Problems

5. Remove the remaining top and bottom probe housings and set them aside.

Do not mix the probe connector-end housings with the podlet connector

housings; the labels are different at each end of the probe.

6. Identify the faulty probe channel at the module end of the cable.

7. Refer to Figure 11 and use a small pointed tool, such as a straightened paper

clip or a mechanical pencil, to release the faulty cable from the cable header

housing. Discard the small plastic retaining snap.

Paper clip

Cable header housing

Retaining snap

Podlet cable

Figure 11: Removing the faulty channel from the probe cable header housing

8. Identify the faulty probe channel at the podlet end of the probe.

CAUTION. Be sure that you have identified the correct podlet cable before you cut

the cable.

9. Cut the faulty podlet just above the color-coded ring.

10. Remove the color-coded ring and set it aside; you will need to install it on

the replacement cable later in this procedure.

28

TLA 700 Series Installation Manual

Page 45

In Case of Problems

11. Refer to Figure 12 and bend the rubber comb to remove the faulty podlet

cable from the comb.

Remove faulty podlet cable from rubber comb

Cut above color-coded ring

Figure 12: Removing a podlet cable from the rubber comb

12. Attach the module end of the replacement podlet cable to the cut end of the

faulty podlet cable in the following manner:

a. Lay the two cables in parallel with a four-inch (10 cm) to six-inch

(15 cm) overlap.

b. Wrap the overlapping portion of the two podlet cables tightly with

masking tape to temporarily splice them together.

13. Pull the faulty cable from the module end through the mesh sleeve so that

the replacement cable is drawn through the mesh sleeve. Stop pulling when

the replacement cable is located at the proper position in the cable wire

bundle.

TLA 700 Series Installation Manual

29

Page 46

In Case of Problems

14. Remove the faulty podlet cable from the podlet holder and replace it with the

new cable as shown in Figure 13.

Align the ground connectors

Pull open

Figure 13: Replacing a podlet in the podlet holder

15. Take the color-coded ring that you removed in step 10 on page 28 and slide

it onto the installation tool. (The installation tool is included in the podlet

replacement kit.)

CAUTION. Do not damage the cable with the installation tool when installing the

color-coded ring.

16. Refer to Figure 14 and place the installation tool over the replacement podlet

cable as shown. Slide the color-coded ring down the installation tool onto the

replacement cable. Position the ring so that it is in the same relative position

as the other color-coded rings (approximately 0.5-inch from the podlet).

30

TLA 700 Series Installation Manual

Page 47

Replacement

cable

In Case of Problems

Installation tool

Install color-coded ring on

the replacement cable and

slide the ring down the tool.

Figure 14: Installing the color-coded ring

17. Push the new podlet cable into the rubber comb.

18. Unwrap and remove the masking tape from the splice of the two cables and

discard the faulty cable.

19. Remove the protective 1x2 housing from the new podlet cable. Use the same

procedure as in Step 7 on page 28 to remove the plastic retaining snap.

Discard the retaining snap and the protective housing.

TLA 700 Series Installation Manual

31

Page 48

In Case of Problems

20. Insert the new podlet cable partially into the cable header housing. Place a

new retaining snap (included with the kit) on the podlet cable as shown in

Figure 15 and fully insert the cable and retaining snap into the cable header

housing. Tug lightly on the podlet cable to ensure the retaining snap is in

place.

Cable header housing

Retaining snap

Podlet cable

Figure 15: Installing the cable in the cable header housing

21. Reinstall the top and bottom probe housings on the module end of the probe

cable in the following manner (refer to Figure 10 on page 27 if necessary):

a. Line up the two tabs on the probe header with the two embedded slots in

the bottom (deep) probe housing.

NOTE. It may be necessary to push or pull the cables in the sleeve so that the

probe header lines up properly with the slots in the bottom probe housing.

b. Place the two metallic guides on the probe sleeve in the slots in the

bottom probe housing.

c. Line up the three tabs of the probe header with the three embedded slots

in the top probe housing.

d. Install and tighten the four screws in the probe housing.

e. Smooth the sleeve by hand to ensure the sleeve fully covers the cables

when replacing the probe housing over the comb.

22. Repeat step 21 to install the probe housing over the rubber comb on the

podlet end of the probe cable.

32

TLA 700 Series Installation Manual

Page 49

Appendix A: Merging Logic Analyzer Modules

This appendix describes how to merge two logic analyzer modules to form a

wider module.

There are no specific rules to merging modules. However, the following

guidelines may be helpful.

You can merge modules with 102 channels or greater.

The maximum merged module width is two modules.

The two modules should have the same firmware version.

The two modules should have the same state speed.

When merging modules of unequal channel widths, place the module with

the higher number of channels in the lower numbered slot.

Merged modules of unequal memory depths will assume the depth of the

shallower module.

Equipment Required

Merge Procedure

You will need the following equipment to complete these procedures:

Torque screwdriver with a size T-10 Torx tip

Two logic analyzer modules

CAUTION. Static discharge can damage any semiconductor component in the

logic analyzer module. Discharge the static voltage from your body by wearing a

grounded antistatic wrist strap while performing the Merge Procedure.

Perform the following steps to merge two logic analyzer modules:

1. Power off the logic analyzer and remove the modules.

2. Determine which module will be designated as the slave module (this

module will be placed in the higher numbered slot).

3. Lay the slave module on the right side (as viewed from the front panel).

TLA 700 Series Installation Manual

33

Page 50

Appendix A: Merging Logic Analyzer Modules

4. Use the screwdriver with the T-10 Torx tip and remove the eight screws from

the cover (Six screws on the cover, and two screws on the rear panel, see

Figure 16).

5. Remove the four flat-head screws near the front of the module (102-channel

modules only have two flat-head screws).

6. Remove the two screws holding the Merge cable bracket to the cover.

7. Remove the top part of the cable bracket and set it aside.

8. Remove the cover and locate the Merge cable.

Merge cable bracket

Remove screws (2)

Remove screws (8)

Remove screws (4)

Module cover

Chassis

34

Figure 16: Removing the cover

TLA 700 Series Installation Manual

Page 51

Appendix A: Merging Logic Analyzer Modules

9. Replace the cover while feeding the Merge cable through the hole in the

cover (see Figure 17). Do not twist the cable while feeding it through the

hole, otherwise the cable will not connect properly to the adjacent module.

Remove screws (2)

Merge cable bracket

Merge cable

Figure 17: Feeding the Merge cable through the cover

10. Turn the Merge cable bracket over so that the guide pins point up and place

the bracket over the Merge cable connector.

11. Install the two screws that hold the Merge cable bracket in place.

CAUTION. To prevent damage to the module during the installation process,

reinstall the cover exactly as described in steps 12 through 16. If the cover is not

properly seated, the module can be damaged when you install it in the logic

analyzer or it will not meet EMC requirements.

TLA 700 Series Installation Manual

35

Page 52

Appendix A: Merging Logic Analyzer Modules

12. Push forward on the cover so the tab on the front edge of the cover inserts

into the rear of the front subpanel. Make sure that the cover is fully seated

(no gaps) against the front and rear chassis flanges (see Figure 18).

Make sure tab inserts into

slot on rear of front panel

Leave no vertical gap

Figure 18: Seating the cover on the chassis

13. While holding the cover in place, install the four screws nearest the front of

the module (two on the top and two on the bottom), to secure the cover to

the chassis.

14. Install the flat-head screws near the front of the module.

15. Slide the rear panel on the chassis and install the two rear panel screws.

16. Install the top and bottom rear screws.

36

TLA 700 Series Installation Manual

Page 53

Appendix A: Merging Logic Analyzer Modules

17. Check and tighten all screws to 4 in lbs.

18. Place the Master module adjacent to the Slave module so that the two guide

pins from the Slave module line up with the guide pin holes in the Master

module (see Figure 19).

Guide pins

Master module

Figure 19: Lining up the two modules

19. Gently push the two modules together so that the Merge cable of the Slave

module mates with the Merge cable connector on the Master module.

Installing the Merged Modules in the Logic Analyzer

After merging the two modules, perform the following steps to install the

module pair in the logic analyzer:

1. Hold the module pair such that the two modules do not become separated

and line up the modules with the slot guides in the logic analyzer.

2. Push both of the modules in the logic analyzer until they rest against the rear

panel connector. Use the injector/ejector handles to fully seat the modules

one at a time. Tighten the module retainer screws.

Slave module

TLA 700 Series Installation Manual

37

Page 54

Appendix A: Merging Logic Analyzer Modules

3. Verify that the modules are fully seated before powering on the logic

analyzer.

4. After powering on the logic analyzer, run the merge calibration to calibrate

the module pair (select the system menu, point to Calibration and Diagnos-

tics, point to the Self Calibration property page, and select the merged pair in

the list box).

Removing Merged Modules from the Logic Analyzer

Perform the following steps to remove merged modules from the logic analyzer:

1. Identify the two logic analyzer modules that you want to remove.

2. Loosen the retainer screws for both modules (top and bottom).

NOTE. Use the ejector handles to just loosen the modules from the rear panel

connector before sliding both modules out of the logic analyzer.

Storing the Merge Cable

3. Use the ejector handles to disconnect the first module from the rear panel

connector.

4. Use the ejector handles to disconnect the second module from the rear panel

connector.

5. Slide both modules out of the logic analyzer at the same time.

6. Gently pry the two modules apart.

Perform the following steps to store the Merge cable inside the logic analyzer

module:

1. Use the screwdriver with the T-10 Torx tip to remove the two screws that

hold the Merge cable bracket in place.

2. Remove the Merge cable bracket.

3. Use the screwdriver with the T-10 Torx tip to remove the screws from the

side cover and rear cover (see Figure 16 on page 34).

4. Push the Merge cable through the side cover and remove the cover.

38

5. Dress the Merge cable as shown in Figure 20.

TLA 700 Series Installation Manual

Page 55

Appendix A: Merging Logic Analyzer Modules

Merge cable

Figure 20: Dressing the Merge cable before installing the cover

CAUTION. To prevent damage to the module during the installation process,

reinstall the cover exactly as described in steps 6 through 8. If the cover is not

properly seated, the module can be damaged when you install it in a mainframe

or it will not meet EMC requirements.

6. Push forward on the cover so the tab on the front edge of the cover inserts

into the rear of the front subpanel. Make sure that the cover is fully seated

(no gaps) against the front and rear chassis flanges (see Figure 18 on

page 36).

7. While holding the cover in place, install the four screws nearest the front of

the module (two on the top and two on the bottom), to secure the cover to

the chassis.

8. Install the flat-head screws near the front of the module.

9. Slide the rear panel on the chassis and install the two rear panel screws.

10. Install the top and bottom rear screws.

11. Install the Merge cable bracket so that the guide pins point into the module.

12. Install and tighten the two screws on the Merge cable bracket.

13. Verify that you have installed and tightened all screws to 4 in lbs on the

TLA 700 Series Installation Manual

module.

39

Page 56

Appendix A: Merging Logic Analyzer Modules

40

TLA 700 Series Installation Manual

Page 57

Appendix B: Upgrades

This appendix describes procedures for upgrading your logic analyzer software

or firmware. The following sections are included:

Restoring or upgrading software in your logic analyzer

Installing TPI, the TLA 700 Programmatic Interface (page 43)

Restoring or upgrading firmware in your logic analyzer module or DSO

module (page 50)

Restoring or changing the Controller BIOS setup (page 52)

Reinstalling Software (page 56)

Customizing the TLA 700 Series setups (page 61)

Upgrading Software

This section provides information for restoring or upgrading software in your

logic analyzer. In addition to the TLA 700 software, there are other software

programs that are installed separately; Table 5 lists some of the software and

installation information.

T able 5: Software not covered by the TLA 700 Series software setup

Software Installation information

Microsoft Windows 95 OS

QAPlus Diagnostic Software Refer to the QAPlus online documentation or to Reinstall the

Logic Analyzer Module & DSO

Module Performance Verifica-

tion and Adjustment

Microprocessor Support Soft-

ware

PC Card Software Refer to the instructions that come with your PC Card.

Other software Refer to the instructions that come with your software.

1

For information on installing Microsoft Windows 95 software not available on the

Windows 95 backup floppy disks, refer to the MS Web Site at http://www.microsoft.com/windows/software/cdextras.htm

1

Refer to the Windows 95 documentation or contact your local

Microsoft representative.

QAPlus Diagnostic Software on page 59.

Refer to the TLA 700 Series Performance Verification and

Adjustment T echnical Reference Manual for instructions on

installing and using the PV/Adjust software.

Refer to Installing Microprocessor Support Software beginning

on page 15 in this manual.

TLA 700 Series Installation Manual

41

Page 58

Appendix B: Upgrades

Upgrading or Reinstalling

TLA 700 Software

You can update or reinstall the TLA 700 software by executing the setup.exe

program on the Disk #1 of installation disks or by performing the following

steps.

NOTE. The following instructions assume that you are reinstalling the TLA 700

application software only. If you are installing the software on a new hard disk

drive, refer to the instructions under Reinstalling Software on page 56.

1. If the TLA 700 application is running, exit the application before continuing.

2. Insert the TLA 700 application floppy disk 1 in the disk drive.

3. Click Start, point to Settings, and click Control Panel.

4. In the Control Panel window, double-click Add/Remove Programs.

5. Click on the Install button and follow the instructions on the screen for

installing the software from the floppy disk.

If the setup program finds an earlier version of the TLA 700 Application, the

program will ask you to confirm your selection and then will remove the

software. At the end of the removal process, the program will ask you to

remove the floppy disk and then restart the logic analyzer to complete the

file removal process.

Uninstalling TLA 700

Software

6. After the logic analyzer restarts, reinsert the floppy disk and repeat steps 1

through 5 to install the application software.

When executed, the setup program will replace old versions of the software after

you have confirmed your choice. The program also offers to delete shared files

which appear to be no longer needed by any application.

The program will not remove saved TLA files or microprocessor support

packages.

You can also remove or uninstall the TLA 700 software using the Uninstall

program. Use the Add/Remove Programs tool under the Control Panel to

uninstall software.

NOTE. The TLA 700 Software Setup program automatically invokes the Uninstall

program before reinstalling the TLA 700 software.

42

TLA 700 Series Installation Manual

Page 59

Installing TPI

Appendix B: Upgrades

Use these procedures to install the TLA 700 Programmatic Interface (TPI). In

these procedures, client refers to the user written application that controls the

logic analyzer through the TPI. Server refers to the TLA 700 application

software. For additional information on installation, refer to the online help.

You have two methods of using TPI with your client application:

You can run the client application locally on the logic analyzer. No special

setup is required. To verify that a client application can connect to the

TLA 700 server, see Running a Client Application on the Logic Analyzer.

You can run your client application remotely across the network. In this case,

both the logic analyzer and the remote host require special setup procedures.

See Setting Up TPI for Remote Access on the Logic Analyzer to begin this

setup procedure.

In the following procedures, <install directory> refers to the directory where the

TPI client is installed on your client machine. This directory is C:\Program

Files\TLA 700 by default.

Running a Client

Application on the Logic

Analyzer

Setting Up TPI for Remote

Access on the Logic

Analyzer

If you need to use the type library (tla700.tlb), this file will be located in

C:\Program Files\TLA 700\System\TPI on the logic analyzer and/or in the

<install directory>\System\TPI on your client machine.

To verify that a client application on the logic analyzer can connect to the

TLA 700 application, do the following steps:

1. Start the TLA 700 application on the logic analyzer.