Page 1

Service Manual

1780R-Series

Video Measurement Set

SN B030000 & Up

070-8030-01

This document supports firmware version 1.16

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

Service Assurance

If you have not already purchased Service Assurance for this product, you may do so at any time during the product’s

warranty period. Service Assurance provides Repair Protection and Calibration Services to meet your needs.

Repair Protection extends priority repair services beyond the product’s warranty period; you may purchase up to three

years of Repair Protection.

Calibration Services provide annual calibration of your product, standards compliance and required audit documentation,

recall assurance, and reminder notification of scheduled calibration. Coverage begins upon registration; you may purchase

up to five years of Calibration Services.

Service Assurance Advantages

H Priced well below the cost of a single repair or calibration

H Avoid delays for service by eliminating the need for separate purchase authorizations from your company

H Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your T ektronix representative and provide the information

below . Service Assurance may not be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City , State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Page 4

Page 5

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of three (3) years from the date of shipment. If a product proves defective during this warranty period,

T ektronix, at its option, either will repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY T O

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY . TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 6

Page 7

Table of Contents

Specifications

Operating Information

General Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CR T Options 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Options 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Qualification 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat Dissipation 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packaging 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel Connectors 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Requirements 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Source 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mains Frequency and Voltage Ranges 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Options 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floating Video Input Connectors 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE Connector 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Operation 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERIAL Interface Connector 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Remote Information 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25-Pin to 9-Pin RS232D Adapter 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Set 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XY INPUT Connector 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Mounting The 1780R-Series 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Installation 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Portable Case Installation 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Calibration 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Menu Information 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waveform Calibration Information 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waveform Calibration Procedure 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vectorscope Calibration Information 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vectorscope Calibration Procedure 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identification T ag 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging for Shipment 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1780R-Series Service Manual

i

Page 8

Table of Contents

Theory of Operation

Operating Information 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front-panel Controls 2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Measurement Controls 2–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagrams 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic Diagrams 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 1 & 2 Input Amplifiers 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

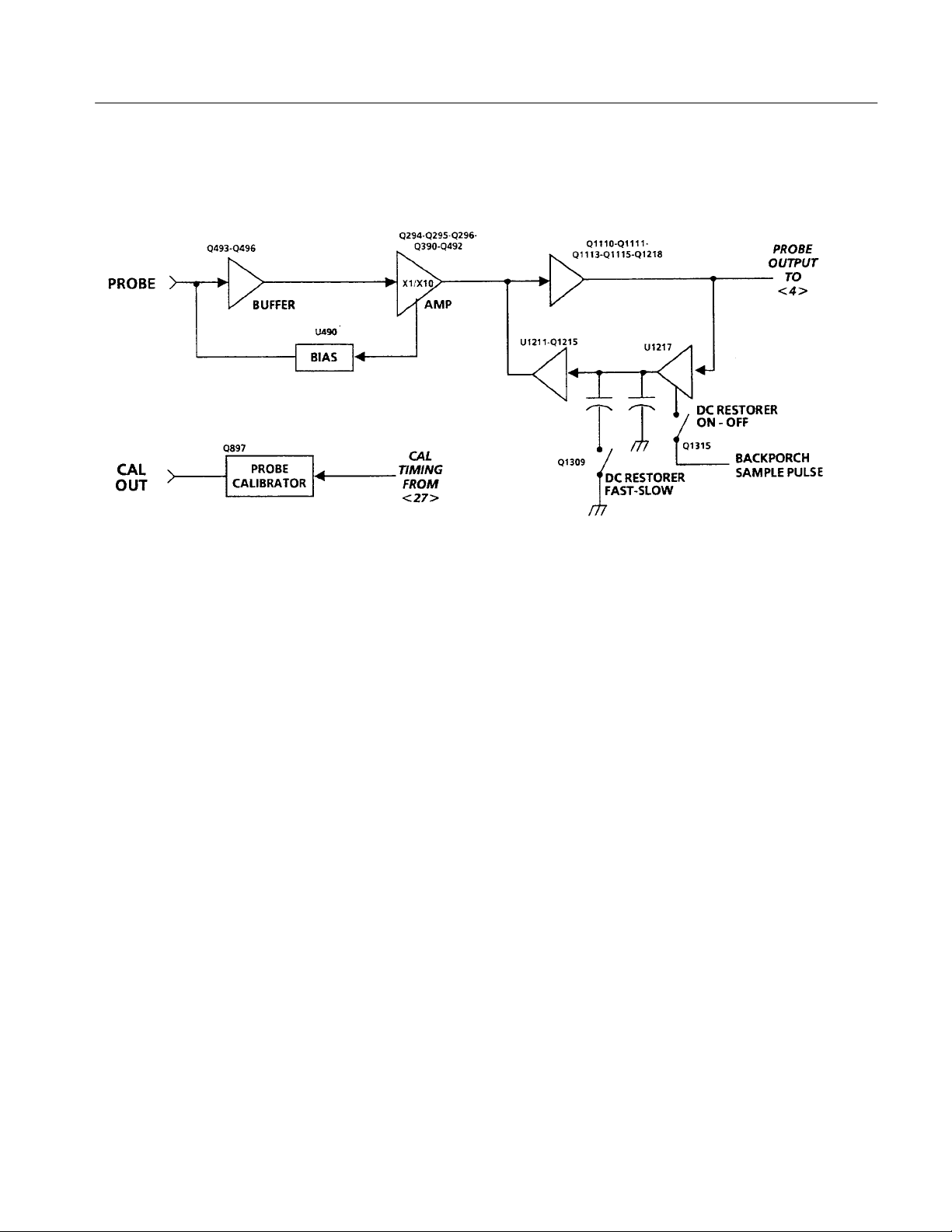

Diagram 3 Probe Input and DC Restorer 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 4 Input & Reference Selection 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 5 Difference Amplifier & Video Filters 3–12. . . . . . . . . . . . . . . . . . . . . . . .

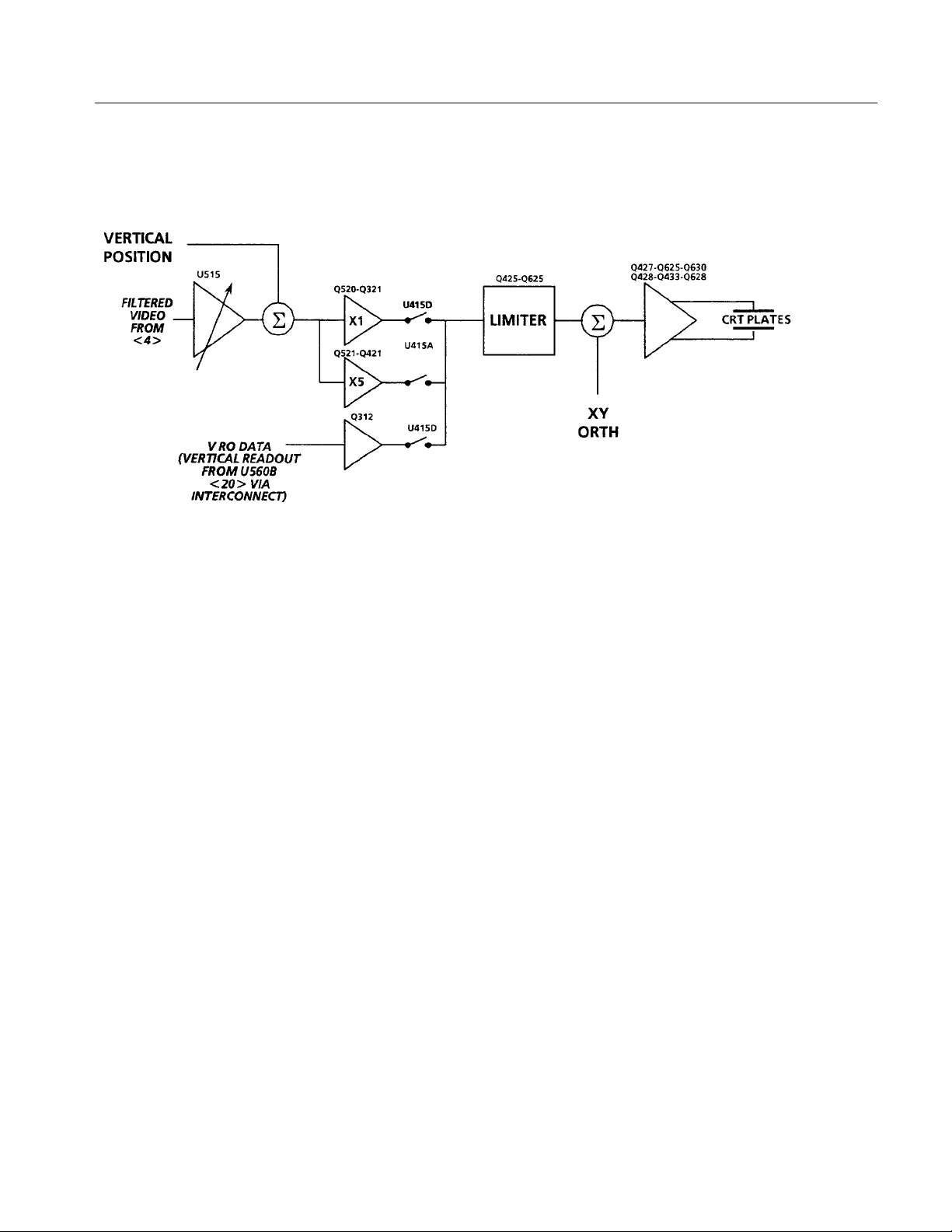

Diagram 6 Vertical Deflection 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 7 Vertical Control Logic, Calibrator, & Cursors 3–17. . . . . . . . . . . . . . . . . .

Diagram 8 Reference Sync Generation 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 9 H & V Sync Generators 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 10 Ramp Generator 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 11 Horizontal Magnifier & Output Amplifiers 3–32. . . . . . . . . . . . . . . . . . .

Diagram 12 Horizontal Latches & DAC 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 13 Slow Sweep & Ext Horiz Input 3–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 14 & 15 SCH Phase Timing & Sync Locked Oscillator 3–39. . . . . . . . . . .

Diagrams 16 & 17 Master MPU, ROM & NVRAM 3–44. . . . . . . . . . . . . . . . . . . . . .

Diagram 17 Dynamic RAM 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 18 Line Rate Controller 3–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 19 UART & A/D 3–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 20 Readout Engine & Read Output 3–57. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 21 Interconnect 3–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 22, 23, & 24 MPU Annex, Front Switch Panel, & T ouch Panel 3–62. . . . .

Diagram 25 Vectorscope Input & Gain 3–65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 26 Diff Phase/Gain 3–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 27 Vector Timing & Blanking 3–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 28 Demodulators 3–73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 29 XY Inputs & PIX Monitor 3–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 30 Vector Deflection Amps 3–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 31 Subcarrier Regenerator 3–80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 32 Digital Phase Shifter 3–84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 33 Horizontal AFC & Post Regulators 3–87. . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 34 Diff Gain/Phase Alt Mode Switch 3–89. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 35 Digital Recursive Filter 3–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 36 Z-Axis 3–95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 37 & 38 Timing Cursors & Counters 3–97. . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 39 CRT Display DAC 3–102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 40 & 45 Scale Illum & Trace Rotation – Graticule Lights 3–104. . . . . . . . .

Diagram 41 Vector High V olts 3–107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 42 Waveform High Volts 3–1 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 43 Low Voltage Power Supply 3–113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Recommended Equipment List 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Form Procedure 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Check Procedure 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

1780R-Series Service Manual

Page 9

Adjustment Procedures

Maintenance

Table of Contents

General Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Equipment List 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment List 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning or Changing the Fan Filter 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Checks and Readjustments 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Visual Inspection 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static-Sensitive Components 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corrective Maintenance 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Obtaining Replacement Parts 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Disassembly/Assembly 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inner Bezel Frame Removal 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graticule Light Removal 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Removal from Rack Mounting Cabinet or Portable Case 6–8. . . . .

CR T Removal 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CR T Replacement 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Input & BNC Board 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Fuse Board 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Waveform HV Supply Board 6–12. . . . . . . . . . . . . . . . . . . . . . . .

Removing the Microprocessor (MPU) Board 6–12. . . . . . . . . . . . . . . . . . . . . . . .

Removing the MPU Annex Board 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the LV Power Supply Board 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Vectorscope Board 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Oscillator Board 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Z-Axis Board 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Aids 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foldout Pages 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Lists 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selected Components 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Troubleshooting Techniques 6–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedures 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board Accessibility 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Z Axis and Oscillator Boards 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LV Power Supply Board 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Equipment 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Limit Adjustment (A1R466) 6–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ouch Panel Sensitivity Adjustment (A9R292) 6–29. . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required List 6–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1780R-Series Service Manual

iii

Page 10

Table of Contents

Options

Electrical Parts List

Diagrams

Mechanical Parts List

CR T Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

1780R-Series Service Manual

Page 11

List of Figures

Table of Contents

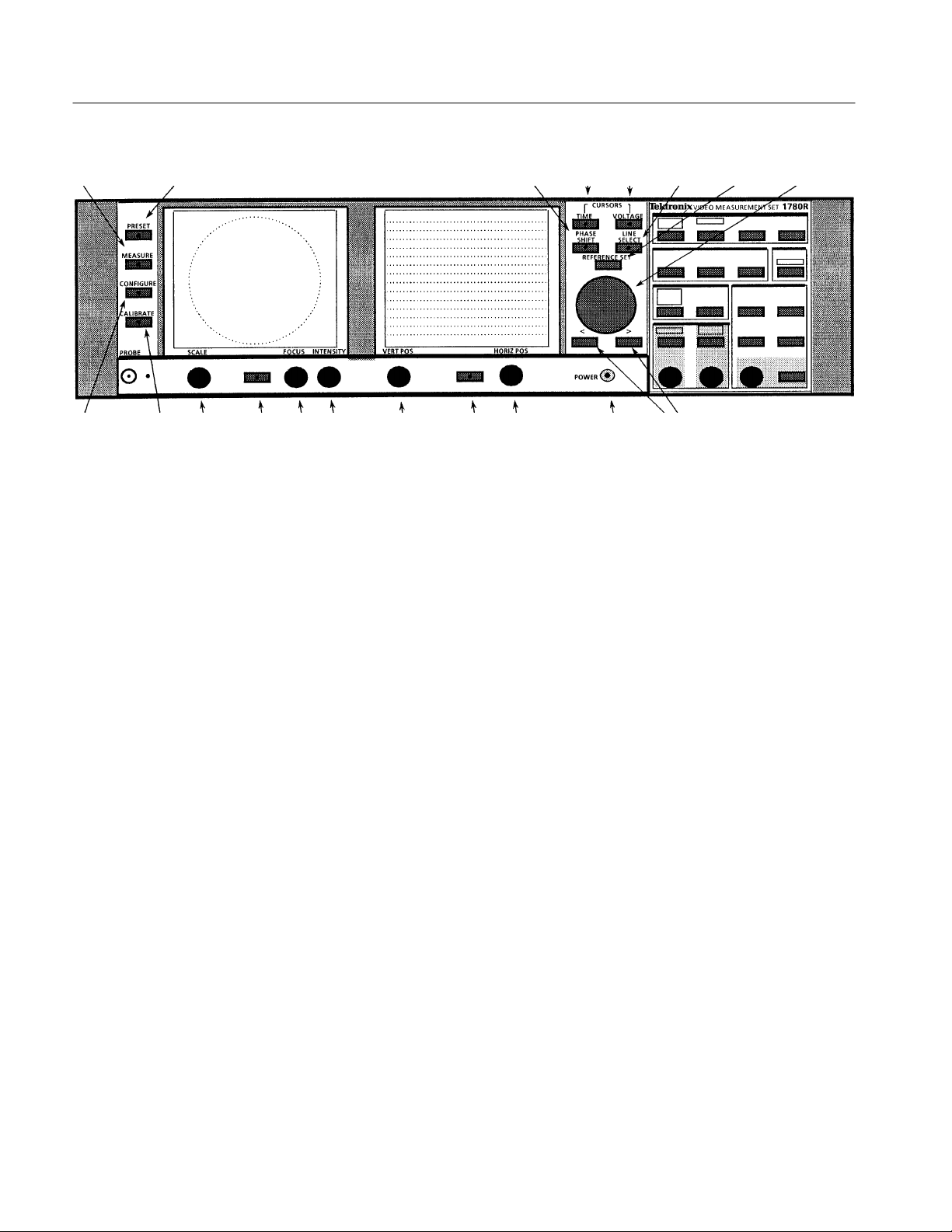

Figure 1–1: Simplified representation of the 1780R-Series

Video Measurement Set 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Rear panel for the Tektronix 1780R-Series

Measurement Set 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Settings for the rear-panel mains selector switch 2–5. . . . . .

Figure 2–3: Upper right portion of the 1780R-Series rear panel,

showing the location of the four loop-through signal inputs 2–8. . . .

Figure 2–4: Remote connector and the function of each pin.

A / before a function indicates a low to activate 2–9. . . . . . . . . . . . . . .

Figure 2–5: Serial interface connector showing the function of

each pin 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: RS232D serial interface adapter diagram 2–11. . . . . . . . . . . .

Figure 2–7: Rear-panel XY connector diagram showing the function

of each pin 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: Location of the four screws that secure the instrument

to rack mounting cabinet or portable case 2–14. . . . . . . . . . . . . . . . . . .

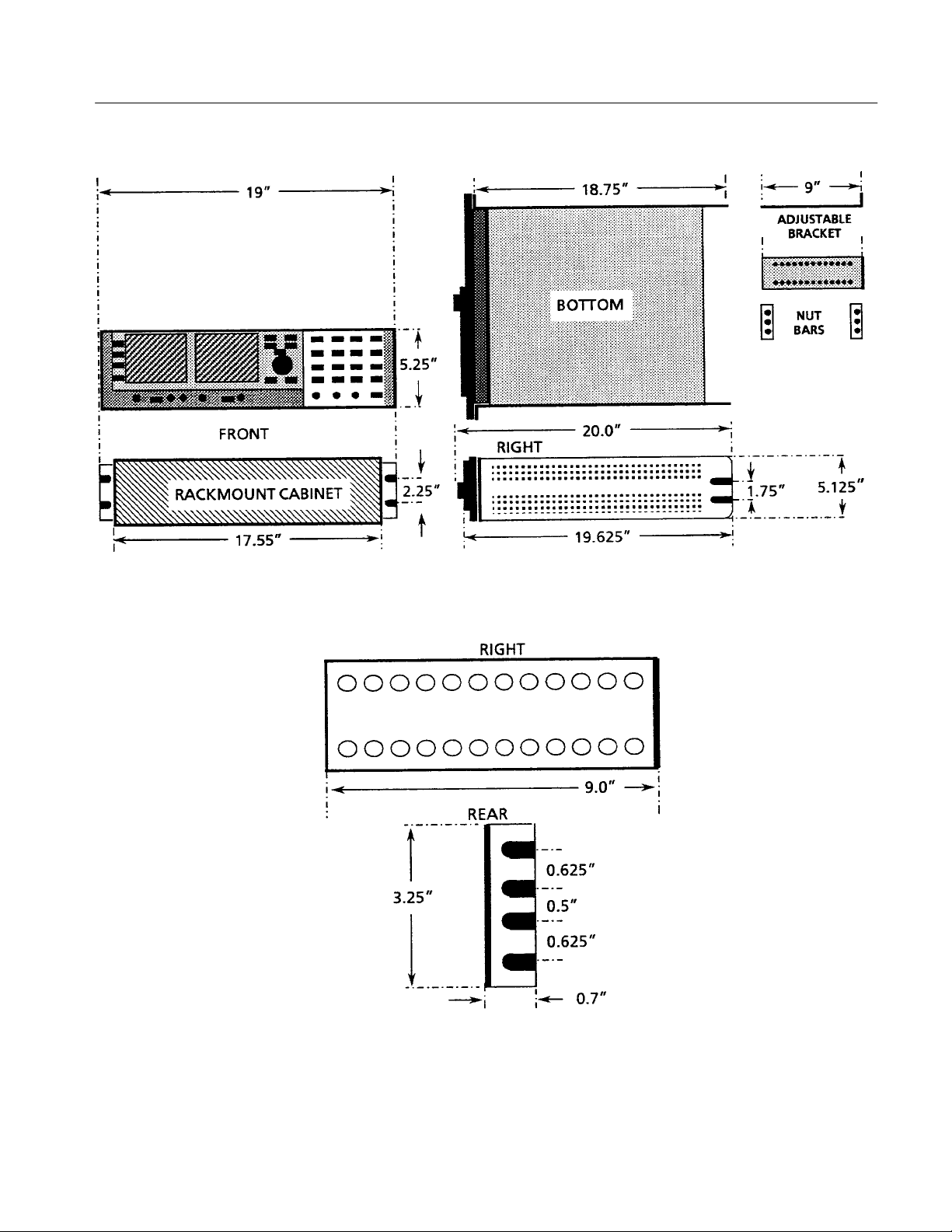

Figure 2–9: Dimensions used for rack mounting the 1780R-Series

Video Measurement Set 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–10: Dimensions of the adjustable rear rackmounting

bracket 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–11: Installing rear rack-mounting brackets for rack

applications of depths from 18 to 24 inches 2–16. . . . . . . . . . . . . . . . . .

Figure 2–12: Portable case for the 1780R-Series Video Measurement

Set. Case has handle, feet, and an elevating bail along with two

panel covers 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–13: Waveform Calibration menu display 2–20. . . . . . . . . . . . . . .

Figure 2–14: 1780R (NTSC) Vectorscope Calibration menu display

with CAL OSC on 2–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–15: 1781R (PAL) Vectorscope Calibration menu display 2–23. .

Figure 2–16: 1780R-Series repackaging 2–25. . . . . . . . . . . . . . . . . . . . . . . .

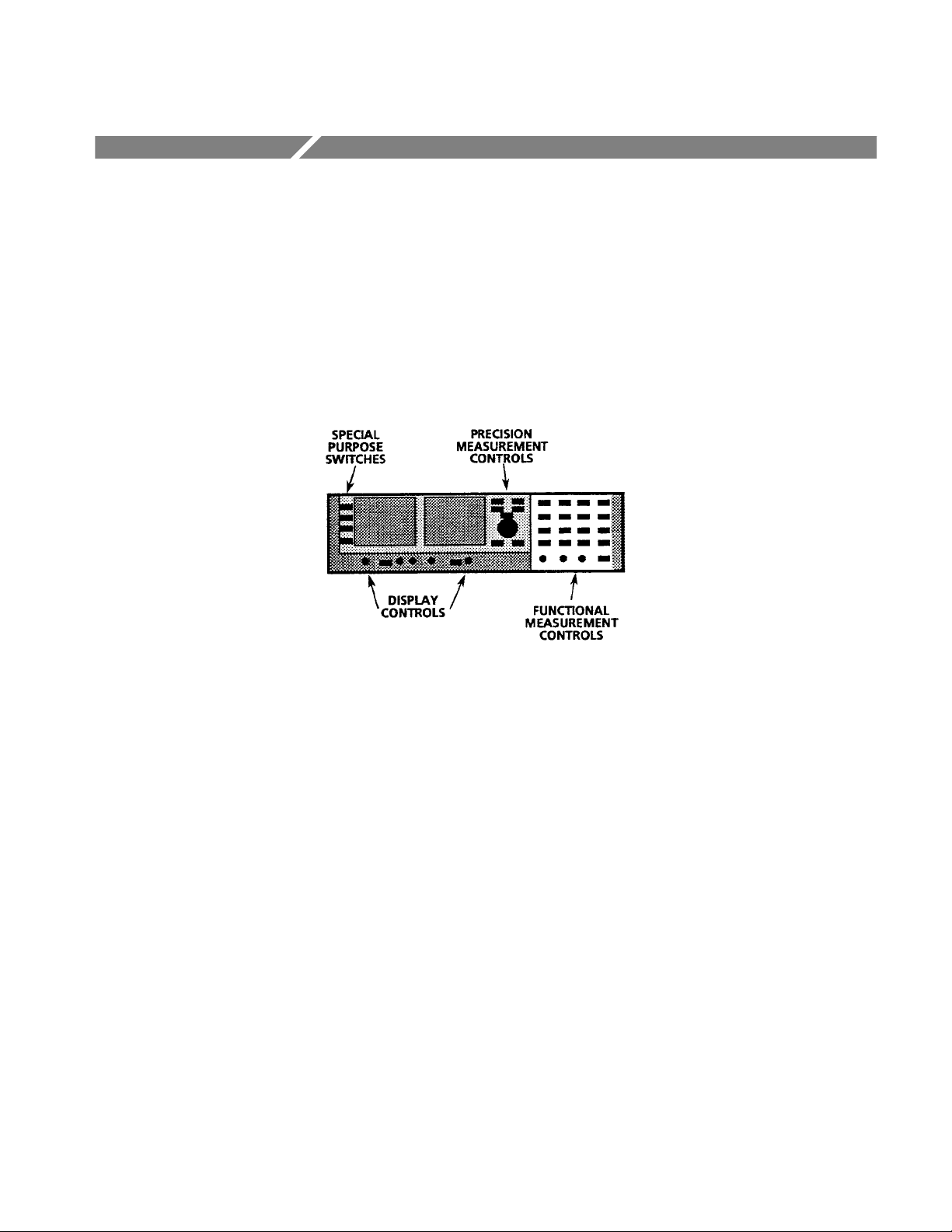

Figure 2–17: Simplified representation of the 1780R Series showing

the location of the control groups 2–27. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–18: Front panel of the 1780R-Series Video Measurement

Set 2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–19: The right front panel for the Tektronix 1780R-Series,

showing the Functional Measurement Controls 2–31. . . . . . . . . . . . . .

1780R-Series Service Manual

v

Page 12

Table of Contents

Figure 4–1: 5% signal Attenuator for checking differential gain 4–4. . . .

Figure 4–2: Rear view of the X Y plug connections. (Pins 2, 4, 6,

10, 12, and 14 can be used to make ground connections.) 4–5. . . . . . .

Figure 4–3: REMOTE connector modified for Remote Sync input 4–5. .

Figure 4–4: RGB Parade Display Test Connector 4–6. . . . . . . . . . . . . . . .

Figure 4–5: Initial equipment hook-up for the Performance Check

Procedure 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–6: Test equipment connections for checking calibrator

amplitude accuracy 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–7: Identification of marks and divisions on the graticule

baseline 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–8: Test equipment connections for checking CH A

frequency response 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–9: Connections for checking AUX OUT frequency response.

(Only Ch 1 of the test oscilloscope dual-trace unit is used.) 4–27. . . . .

Figure 4–10: Vector graticule showing the –3 dB points for checking

frequency response 4–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–11: Properly adjusted xy input gains 4–61. . . . . . . . . . . . . . . . . . .

Figure 4–12: Connections for checking line strobe pulse timing 4–63. . . .

Figure 4–13: Setting up the Return Loss Bridge: a) setup 500 mV

amplitude; b) Nulling the bridge 4–66. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–14: Measuring return loss of 1780R-Series CH A INPUT 4–67. .

Figure 5–1: Simplified representation of the 1780R-Series Video

Measurement Set, showing the location of the four control

groups 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–2: Calibrate menu as displayed on the Vectorscope CRT 5–2. .

Figure 5–3: 1780R-Series circuit board assembly locations 5–3. . . . . . . .

Figure 5–4: Rear view of the X Y plug connections. (Pins 2, 4, 6,

10, 12, and 14 can be used to make ground connections.) 5–7. . . . . . .

Figure 5–5: RGB Parade Display Test Connector 5–7. . . . . . . . . . . . . . . .

Figure 5–6: Initial signal connections for re-adjustment of the

1780R-Series 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–7: Adjustment and test point locations on the

Waveform HV Supply circuit board (Assembly 16.) 5–15. . . . . . . . . . .

Figure 5–8: Adjustment locations on the Vectorscope HV Supply

circuit board (Assembly A3) 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–9: Adjustment locations on the Microprocessor circuit

board (Assembly A5) 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–10: Waveform circuit board (Assembly A2) adjustment,

test point, and jumper locations. 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

1780R-Series Service Manual

Page 13

Table of Contents

Figure 5–11: Adjustment locations on the Vectorscope circuit board

(Assembly A6) 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–12: Connections for adjusting the calibrator amplitude 5–22. . .

Figure 5–13: Input & BNC circuit board (A8) adjustments, shown as

they would appear with the instrument on its left side 5–25. . . . . . . . .

Figure 5–14: Test equipment connections for matching CH A and

CH B1 input gains. 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–15: Test equipment connections for adjusting CH A

frequency response 5–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–16: Adjustment and test point (TP) locations for the

Oscillator circuit board (Assembly A7). 5–41. . . . . . . . . . . . . . . . . . . . .

Figure 5–17: Noise Reduction–ON. DAC offset properly adjusted 5–47. .

Figure 5–18: Noise Reduction–OFF. Demod offset properly adjusted 5–48

Figure 5–19: Z-Axis circuit board (A4) adjustment and test

point locations 5–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–20: Vector graticule x- and y-axis markings for adjusting

xy input gains 5–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–21: Properly adjusted xy input gains 5–54. . . . . . . . . . . . . . . . . . .

Figure 6–1: Front panel parts 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Positions of the waveform CRT deflection leads 6–9. . . . . . .

Figure 6–3: Rear panel for the Tektronix 1780R-Series Video

Measurement Set showing the location of sub-assembly

mounting screws 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Using foldout pages 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: 1780R-Series circuit board assembly locations 6–18. . . . . . . .

Figure 6–6: Connections for the external power supply leads 6–23. . . . . .

Figure 6–7: Connecting the AC mains to the 1780-R Series for

troubleshooting 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: A. Q250 collector waveform. B. Q250 base waveform.

C. Q350–Q451 emitter waveform. D. U460 pin 3 waveform.

E. U460 pin 4 waveform 6–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–9: +5 V supply output waveform when over voltage

protection is operating 6–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–10: Power supply load used when adjusting current limit

(A1R466). Load can be connected between the top end of

A2L638 and ground 6–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1780R-Series Service Manual

vii

Page 14

Table of Contents

List of Tables

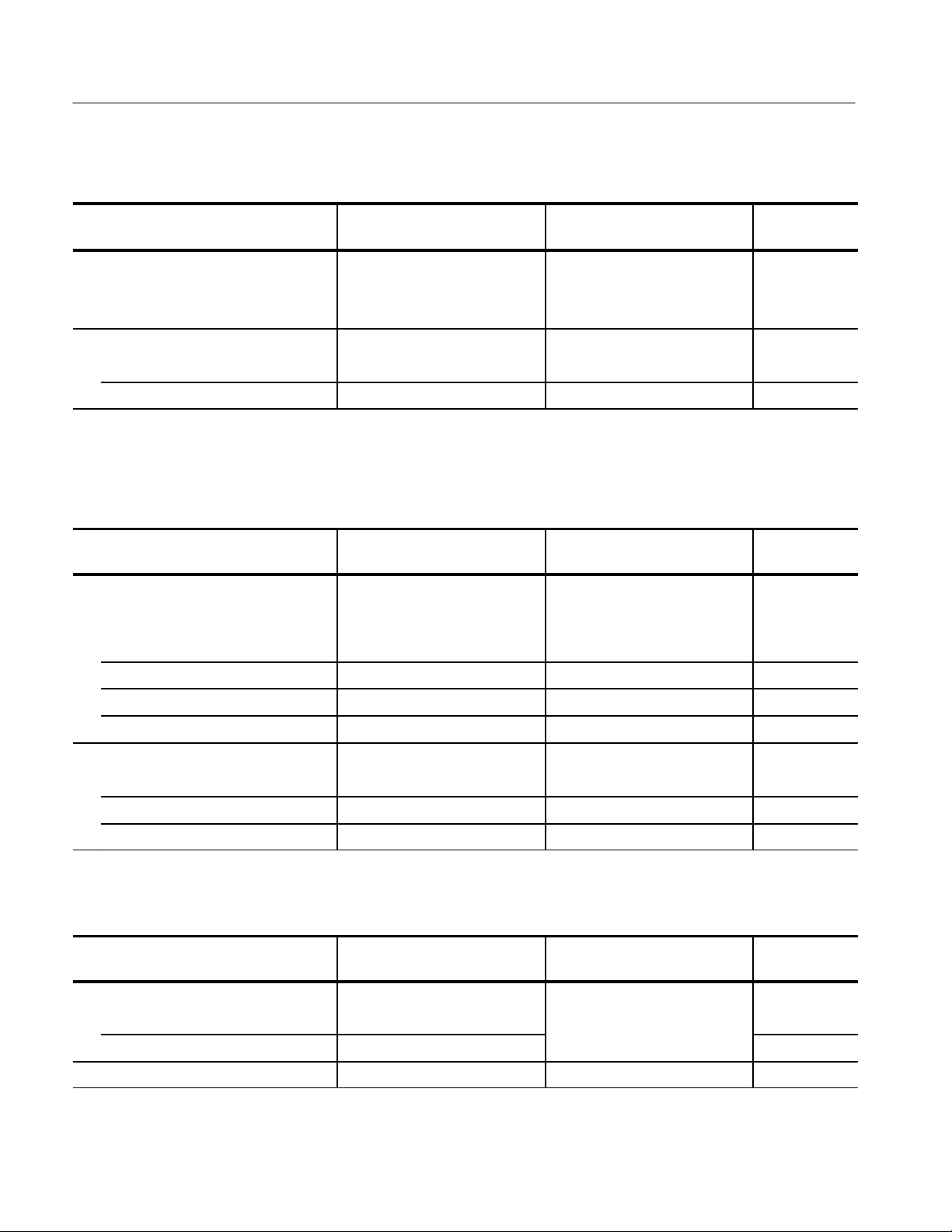

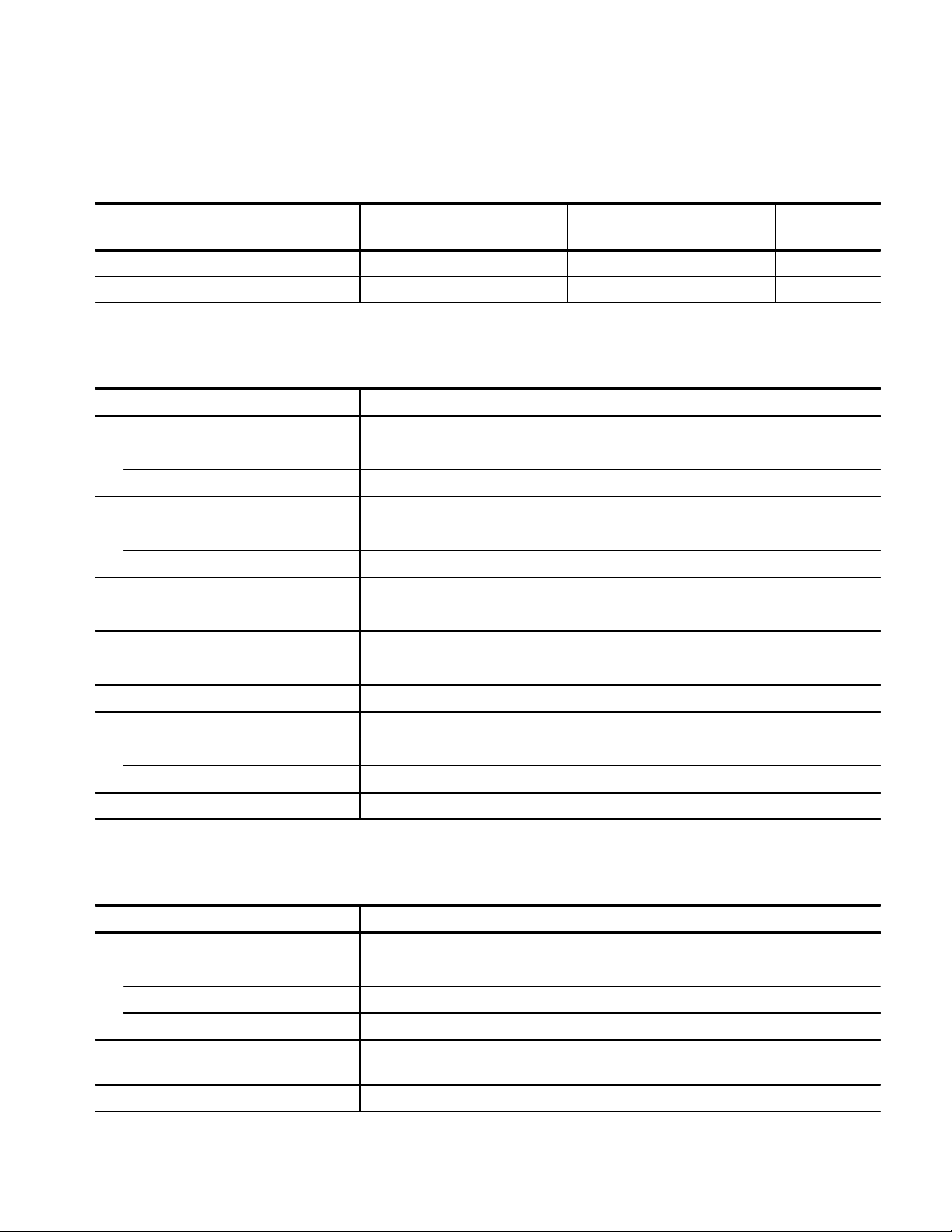

Table 1–1: Input/Output 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Waveform Monitor Vertical System 1–5. . . . . . . . . . . . . . . . .

Table 1–3: Waveform Monitor Probe Input 1–8. . . . . . . . . . . . . . . . . . . .

Table 1–4: Waveform Monitor Horizontal Deflection System 1–8. . . . . .

Table 1–5: Waveform Monitor dG and dP Display 1–11. . . . . . . . . . . . . . .

Table 1–6: Synchronization 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Vectorscope Vector Display 1–13. . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Vectorscope X-Y Display 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–9: Vectorscope SCH Phase Display 1–15. . . . . . . . . . . . . . . . . . . . .

Table 1–10: CRTs and High Voltage Supplies 1–16. . . . . . . . . . . . . . . . . . .

Table 1–11: Power Requirements 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–12: Environmental Summary 1–17. . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–13: Physical Characteristics 1–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–14: Certifications and Compliances 1–18. . . . . . . . . . . . . . . . . . . .

Table 2–1: 1780R-Series Standard Accessories 2–1. . . . . . . . . . . . . . . . . .

Table 2–2: Partial List of Optional Accessories Available for the

1780R-Series 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Plug Jumpers for Waveform Board (Assembly A2)

(Schematic Diagrams 3 through 15) 2–6. . . . . . . . . . . . . . . . . . . . . . . .

Table 2–4: Plug Jumpers and DIP Switch on the Microprocessor

Board (Assembly A5) (Schematic Diagrams 16 through 19) 2–7. . . .

Table 2–5: Plug Jumpers for Vectorscope Board (Assembly A6)

and Oscillator Board (Assembly A7) 2–7. . . . . . . . . . . . . . . . . . . . . . .

Table 2–6: Serial Remote Commands 2–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–7: Serial Remote Responses 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: Schematics and Circuit Board Assemblies 3–3. . . . . . . . . . . .

Table 3–2: Input Channel Selection Logic 3–18. . . . . . . . . . . . . . . . . . . . . .

Table 3–3: Filter Selection Logic 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–4: Memory Switch Outputs 3–93. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Recommended Equipment 4–1. . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–2: 1780R-Series Initial Control Settings 4–10. . . . . . . . . . . . . . . . .

Table 4–3: Common Mode Rejection 4–35. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–4: Sweep Timing and Linearity 4–42. . . . . . . . . . . . . . . . . . . . . . . .

viii

1780R-Series Service Manual

Page 15

Table of Contents

Table 5–1: Recommended Equipment 5–4. . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: 1780R-Series Adjustments for Calibration Procedure 5–8. .

Table 5–3: 1780R-Series Initial Control Settings 5–12. . . . . . . . . . . . . . . . .

Table 5–4: Low Voltage Power Supply Tolerance 5–14. . . . . . . . . . . . . . . .

Table 6–1: Static Susceptibility 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–2: Test Selectable Components 6–16. . . . . . . . . . . . . . . . . . . . . . . .

Table 6–3: Circuit Board Assemblies 6–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–4: Power Supply External Load Resistances 6–25. . . . . . . . . . . . .

1780R-Series Service Manual

ix

Page 16

Table of Contents

x

1780R-Series Service Manual

Page 17

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Recharge Batteries Properly. Recharge batteries for the recommended charge

cycle only.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

1780R-Series Service Manual

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

xi

Page 18

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

Not suitable for

connection to

the public telecom-

munications network

xii

1780R-Series Service Manual

Page 19

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

1780R-Series Service Manual

xiii

Page 20

Service Safety Summary

xiv

1780R-Series Service Manual

Page 21

Preface

This Service Manual is part of a 2-volume set. Its companion manual is the

Operator’s Manual, which is aimed primarily at operating personnel. Information

in this volume is intended for those who are required to maintain the 1780R-Series Video Measurement Set.

Specific instructional procedures can be found in the Performance Check,

Adjustment Procedures, Maintenance and Installation sections. In addition, the

lists of Replaceable and Mechanical Parts along with circuit board component

locating dollies and schematic diagrams are at the back of this manual.

Operating Information is a very simple explanation of the controls and connectors. If there is a question involving one of the specific measurement applications, it may be necessary to consult the Operator’s Manual to determine if there

is an instrument malfunction or simply an operator error.

Special techniques are required to service the 1780R-Series Low Voltage Power

Supply. Consult Troubleshooting before attempting to work on the Low Voltage

Power Supply.

To assist in locating information in this volume there is a complete Table of

Contents, augmented by a List of Illustrations and a List of Tables.

1780R-Series Service Manual

xv

Page 22

Preface

xvi

1780R-Series Service Manual

Page 23

Page 24

Product Description

The Tektronix 1780R-Series Video Measurement Set is a 19-inch wide,

5 1/4-inch high, 18-inch deep dual-CRT Waveform Monitor/Vectorscope. It

weighs approximately 28 pounds and is intended for rack-mount applications,

but can also be configured as a full (rack) width cabinet model for bench and

portable applications. See Figure 1–1. The remainder of the front-panel area

contains controls and switches that manually configure the instrument for

measurements. Both CRTs have alphanumeric readout and touch-screen control

to simplify measurement tasks and operating menus.

Figure 1–1: Simplified representation of the 1780R-Series Video Measurement Set

The left CRT is selectively used for vectorscope, picture monitor, SCH phase,

and XY displays, while the right one is used for the waveform monitor displays.

The picture monitor display has a bright-up strobe; when the instrument is in a

line select mode, that makes its display identical to that of a picture monitor

driven from the rear-panel Pix Mon Out.

1780R-Series Service Manual

The right CRT is used for the normal filtered waveform monitor displays.

Waveform monitor measurements can have voltage and time cursors added to the

display to improve measurement accuracy. The elapsed time or amplitude

difference between cursors is displayed as alphanumeric CRT readout. Besides

the typical waveform monitor displays the right CRT is used for high-resolution,

high-accuracy differential gain and phase measurements.

Signal and reference input is through 75 W bridging loop-through inputs. There

are four composite video inputs, making it possible to use the 1780R-Series to

measure analog component signals, if desired. In addition to the normal 1- or

2-line, and 1- or 2-field displays, both component and composite signals can be

displayed in parade or overlay mode. The external reference can be either

composite sync or black burst. The 1780R-Series can also be operated with an

external subcarrier reference input, similar to the Tektronix 520-Series.

All instruments in the series have a front-panel, high impedance (1 MW) probe

input. Signals input through the probe can be displayed as single or multiple

lines or fields and can also be overlayed or paraded with the rear-panel input

1–1

Page 25

Product Description

signals. The probe input has gain and input compensation for both X1 and X10

probes.

The instrument control system is based on a National Semiconductor 32CG16

Microprocessor, with an additional line rate processor that makes line-by-line

measurement decisions. Front-panel switching and CRT touch-screen selections

are acted upon by the processors. The front-panel switches are momentary

touch-type, which toggle through a short list of functions and provide additional

selections when held in. Each switch has a back-lighted functional indicator or

built-in indicator to relay switch status to the operator. In addition to sensing and

acting on switch and touch panel changes, the Microprocessor controls the

alphanumeric CRT readout for menu selections and measurement results.

The current front-panel configuration (switch and touch screen) is always stored

in non-volatile memory allowing the instrument to power back up in its previous

measurement configuration. In addition, front-panel configurations can be stored

and recalled (one-button measurement), like the Tektronix 1730-Series.

The use of touch screens and an assignable, multi-function control greatly

simplifies the operator interface. The control is an optical encoder that is used for

line selection, voltage measurements, timing measurements, and subcarrier phase

measurements, along with other menu/touch screen assigned tasks. A pair of

push buttons, adjacent to the control, can be used to duplicate the function of the

control when individual steps are desired.

CRT Options

Power Cord Options

The waveform monitor has reduced spot size and provides a bright display for

showing an individual line. The left CRT provides the vectorscope, picture

monitor, SCH phase and XY displays. Both CRTs have internal measurement

graticules, and can accommodate external graticules that are used for specialized

measurements and some photographic applications. Variable graticule scale

illumination provides uniform lighting over the usable area for both the internal

and external graticules.

Option 74 provides a P4 (white) phosphor tube.

Any of the power cord options described in Maintenance can be ordered for the

1780R-Series. If no power cord option is ordered, instruments are shipped with a

North American 125 V power cord and one replacement fuse.

1–2

1780R-Series Service Manual

Page 26

Specifications

This section of the manual contains the specifications for the 1780R-Series.

Tabular information is divided into two categories. First there are the Performance Requirements which is assured by Tektronix Inc. Second are the items in

the Supplemental Information column, which due to a number of reasons may be

only typical numbers or could vary slightly from one instrument to the next.

The Performance Verification is provided to verify listed Performance Require-

ments. If a step for a specific requirement is not included in this procedure, it is

because the performance has been built into the instrument and is therefore

assured by either the fact that the instrument is operational or is proven correct

by other performance check steps. In a few instances, the procedure to verify a

specification can be extremely difficult or require extremely expensive equipment to verify, which might also cause them to be omitted from the procedure. In

these cases the factory has a procedure, that can be provided if necessary.

The step numbers, that can be used to verify the Performance Requirements and

some critical Supplemental items, are in a column following the Supplemental

Information.

Performance Qualification

The Performance Requirements listed in the Electrical Specification apply over

an ambient temperature range of 0_ C to +50_ C. The rated accuracies are valid

when the instrument is calibrated at an ambient temperature range of +20_ C to

+30_ C, after a warm-up time of 20 minutes. Test equipment used to verify

Performance Requirements must be calibrated and working within the limits

specified under the Equipment Required list.

Heat Dissipation

Maximum heat dissipation is 120 Watts (410 BTU/ Hour).

1780R-Series Service Manual

1–3

Page 27

Specifications

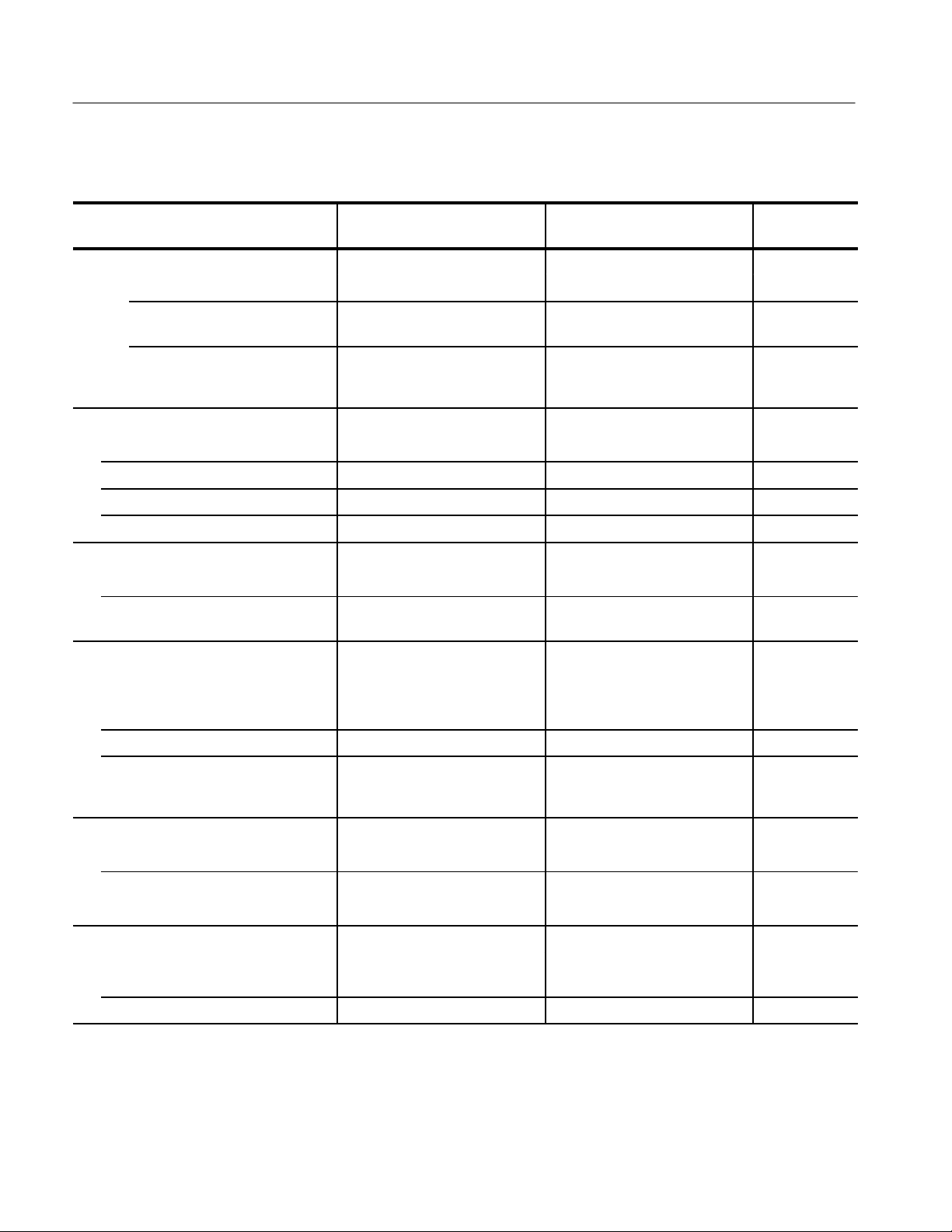

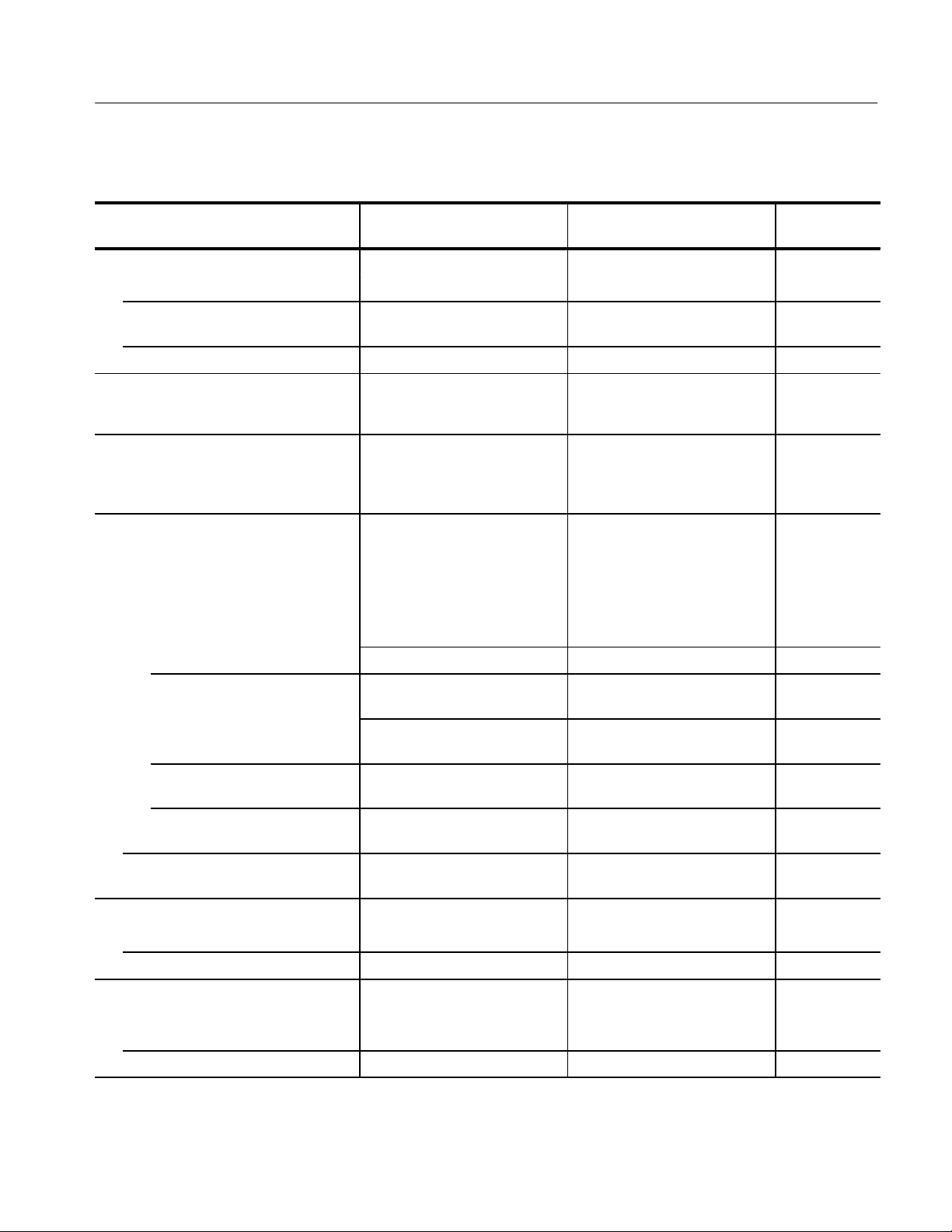

T able 1–1: Input/Output

Characteristic Performance Requirement Supplemental Information

Vertical Ranges

Volts Full Scale Accuracy

Performance

Check Step

1.0 1.0 V ±0.007 V. Peak-to-peak Amplitude for Full

Graticule 1.0 volt/140 IRE.

Var ≤0.5:1 to ≥1.5:1 (0.67 V to 2.0 V

input signal can be made full

scale).

Input Gain Ratios

A to B 1 to 1 ±0.002 (0.998 – 1.002). 10

Auxiliary Video Input to A Input 1.5 dB ±0.3 dB. 10

Input A to Auxiliary Video Output 1 to 1 ±0.005 (0.995 – 1.005). 10

Input A to Picture Monitor Output 1 to 1 ±0.02 (0.98 – 1.02). 10

Vertical Magnifier

X5 Accuracy 0.2 V ±0.007 V .

Peak-to-peak Amplitude for Full

Graticule

Maximum Input Signal

AC Coupled All Inputs 2.0 V , peak-to-peak, 10%–90%

APL.

DC Coupled All Inputs ±1.5 V (DC + peak AC).

0.2 V/28 IRE.

Aux Video Out and Pix Mon

(terminated), 1.0 V peak-to-peak,

10%–90% APL.

4

5

Max volts from Loop-Thru common

terminal to chassis

Max DC Output Voltage

Aux Video Out ±0.5 V into 75 W.

Pix Mon Out ±0.5 V into 75 W.

Remote Control

Interface Standard RS422, RS232 (subset of all

Control Enable Ground closures and presets.

2 V

at mains frequency. Rejection ratio of common-to-

RMS

chassis in floating ground mode,

≥34 dB at mains frequency.

Line strobe but no input signal.

controls).

1–4

7

1780R-Series Service Manual

Page 28

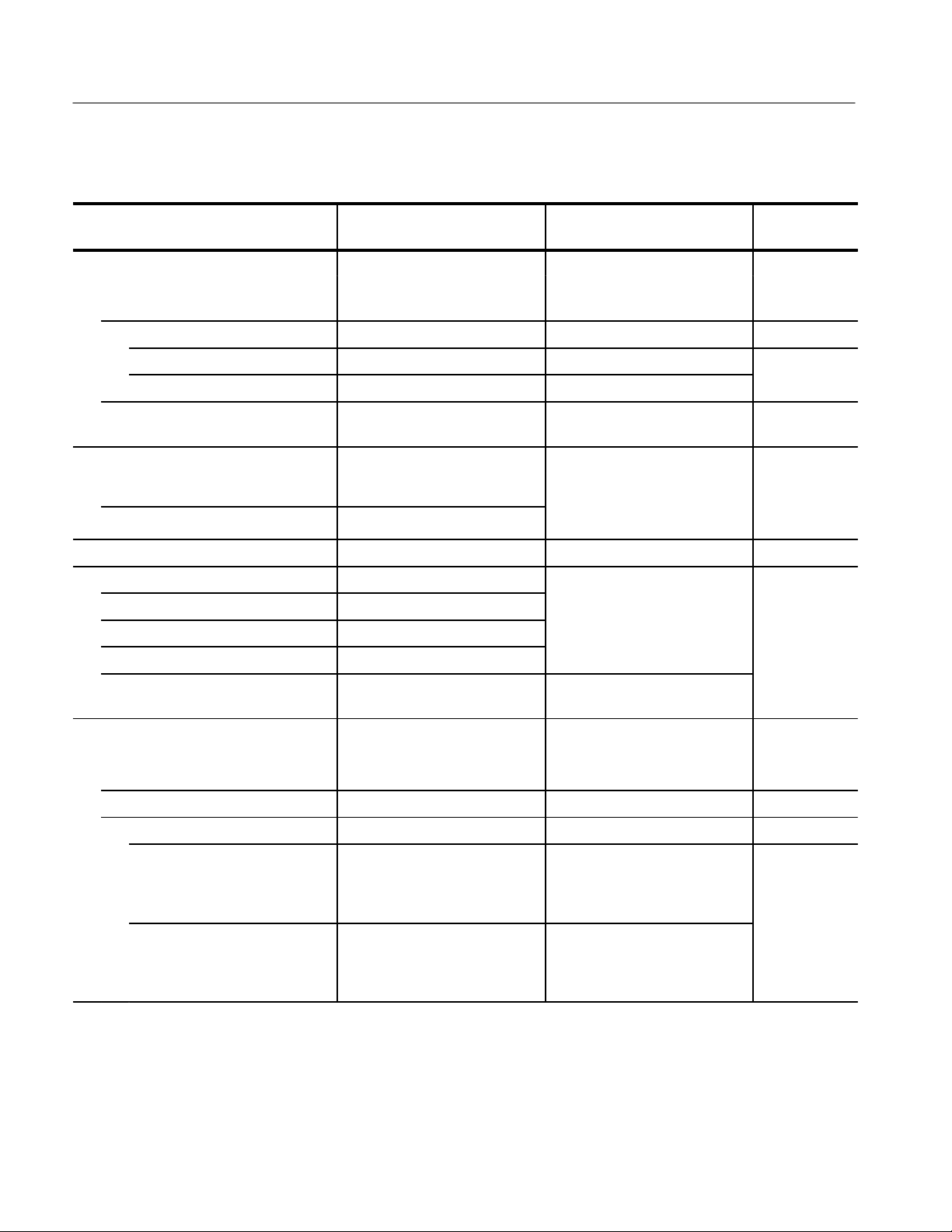

T able 1–2: Waveform Monitor Vertical System

Characteristic Performance Requirement Supplemental Information

Return Loss

CH A, B1, B2, or B3 >40 dB DC to 5 MHz. (Terminated in 75 W.) 58

Specifications

Performance

Check Step

Aux Video In, Aux Video Out, & Pix

Mon Out

Ext. Sync Input >46 dB to 5 MHz. 58

Loop-Through Isolation >80 dB at FSC, between channels

Crosstalk Typically 70 dB isolation between

Frequency Response

Flat (X1)

50 kHz – 5 MHz ±1%. All inputs, 1 V Full Scale, Var.

5 MHz – 10 MHz ±1%. CH A, 1 V Full Scale, Var. Gain

>34 dB DC to 5 MHz. Instrument On only. 58

and each channel and EXT REF.

Measured externally.

channels. Measured at F

between channels and each

channel and EXT REF .

Gain off. Adjusted for min. lum/

chroma gain error. T ypically

<0.5%.

±2%. Aux In, and Aux Out. 15–16

off.

±2%. Ch B1, Ch B2, Ch B3, Aux In, and

Aux Out.

SC

11–15

11

12–16

10 MHz – 15 MHz +2% –5%. All Inputs, 1 V Full Scale, Var.

Gain off.

15 MHz – 20 MHz +2% –15%. All Inputs, 1 V Full Scale, Var.

Gain off. –3 dB at >20 MHz.

Lum/Chroma Gain ±0.5%. X5 Gain with Modulated Sin

Pulse (12.5T NTSC, 10T PAL).

Voltage Cursor

Accuracy ±0.2%. 6

Resolution 1 mV .

Cal Amplitude

Accuracy 1.00 V ±0.2%. NTSC = 0.714 V ±0.5%.

PAL = 0.700 V ±0.5%.

Resolution 1 mV at 1.00 V.

1780R-Series Service Manual

11–15

11–15

2

19

3

1–5

Page 29

Specifications

Adjusted

e

1

error

1

de

s

.

0

T able 1–2: Waveform Monitor Vertical System (Cont.)

Characteristic

DC Restorer

Performance

Supplemental InformationPerformance Requirement

Check Step

Clamp Point Backporch or Sync Tip.

(All clamps controlled together.)

Mains Hum Atten.

Slow Clamp ≤0.9 dB. Attenuation ≤10%.

Fast Clamp ≥26 dB.

Shift caused by presence or absence

of burst

Lum/Chroma Gain Ratio

NTSC (50 kHz – 3.58 MHz) 1:1 ±1%.

PAL (50 kHz – 4.43 MHz) 1:1 ±1%.

DC Channel Matching Typically within 30 mV. 8

Common Mode Rejection AB1 B1B2 / B1B3

60 Hz ≥46 dB ≥46 dB

15 kHz (Lum) ≥46 dB ≥46 dB

1 MHz ≥40 dB ≥34 dB

3.58 or 4.43 MHz (Chroma) ≥34 dB ≥34 dB A – B1 typically >46 dB to

Filters

NTSC = 1 IRE.

PAL = ≤7 mV.

to minimize luminanc

to chrominance gain

Full Scale, typically ≤0.5%.

V peak-to-peak common mo

ignal

6.0 MHz and >40 dB to 10.0 MHz.

at 1 V

21

22

24

9

26

Luminance <3 dB down at 1 MHz. ≥40 dB

down at 3.58 or 4.43 MHz.

Low Pass ≥14 dB down at 500 kHz. Typically –3 dB at 300 kHz.

Chrominance

3.58 MHz ±1% of flat at 3.58 MHz.

3 dB points:

Lower: 2.83 ±0.15 MHz.

Upper: 4.33 ±0.15 MHz.

4.43 MHz ±1% of flat at 4.43 MHz.

3 dB points:

Lower: 3.68 ±0.15 MHz.

Upper: 5.18 ±0.15 MHz.

1–6

2

1780R-Series Service Manual

Page 30

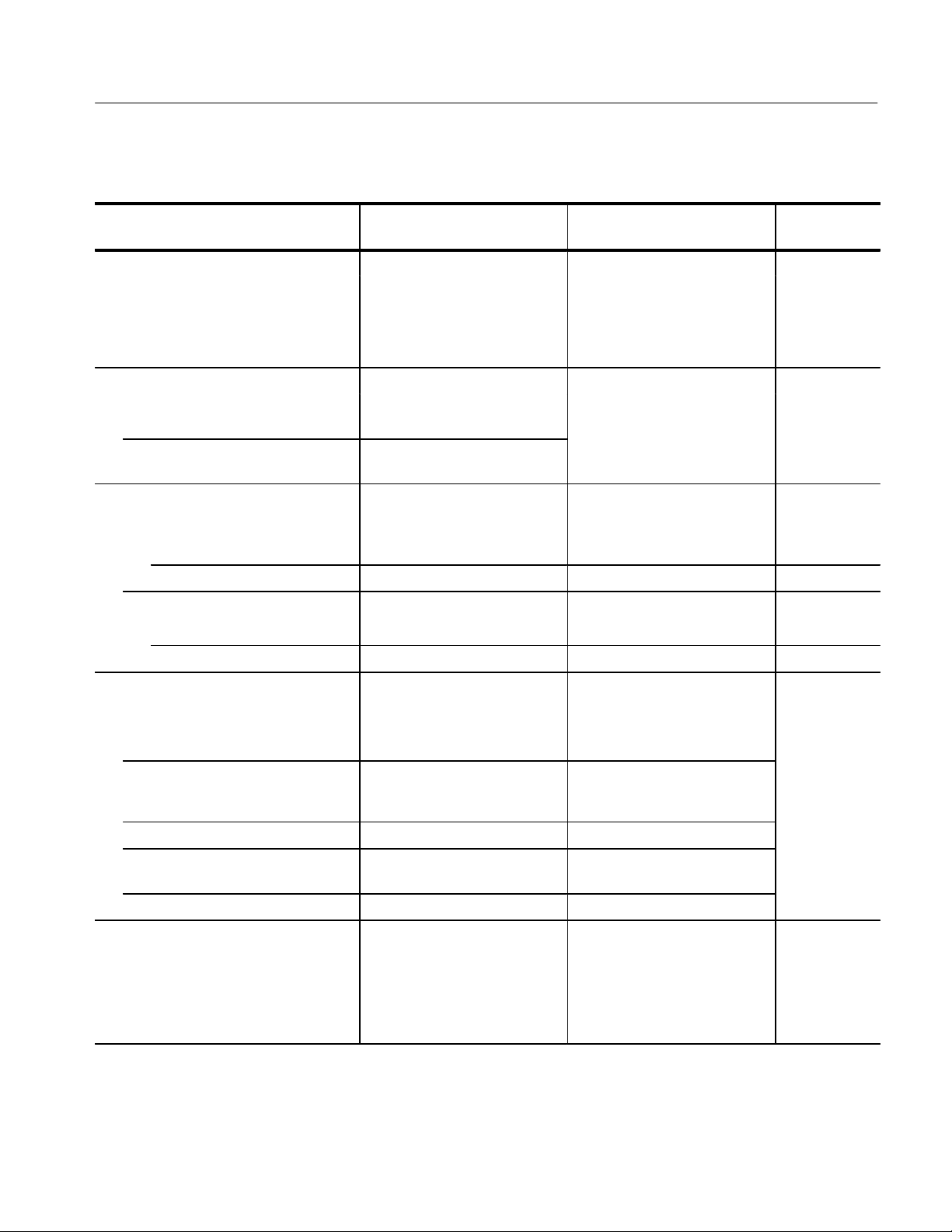

T able 1–2: Waveform Monitor Vertical System (Cont.)

Re

Characteristic

Diff Steps

Specifications

Performance

Supplemental InformationPerformance Requirement

Check Step

(Differentiated Steps Attenuation) >40 dB at 3.58 MHz

(4.43 MHz PAL).

Noise Measurements

Accuracy To 56 dB within 1 dB; 60 dB

within 2 dB.

Offset Accuracy To 56 dB within 0.5 dB; 60 dB

within 1 dB.

Non-Linear Waveform Distortion

Differential Gain

Aux Video Out ≤0.25%, 10% – 90% APL. W aveform modes.

Pix Mon Out ≤0.25%, 10% – 90% APL.

Differential Phase

Aux Video Out ≤0.25°, 10% – 90% APL.

Pix Mon Out ≤0.25°, 10% – 90% APL.

Linear Waveform Distortion

Pulse Overshoot & Ringing ≤1% of applied pulse amplitude. Typically

Pulse and Bar ≤1% of applied pulse amplitude. Typically

25 ms Bar Tilt ≤1% of applied bar amplitude.

5 step, 20 IRE staircase within

2% of flat display.

Vertical Gain increase approx. 5X

to compare staircase risers.

lative to 700 mV

set to maximum.

<0.5% on T Pulse, and

<1.0% on T/2 Pulse.

<0.5% on T Pulse, and

<1.0% on T/2 Pulse.

RMS

, Var Gain

27

9

29

Field Square Wave Tilt ≤1% of applied square wave

amplitude.

2T Sin2 Pulse-to-Bar Ratio 1:1 ±1%.

Vertical Overscan

Baseline Distortion <7 mV variation in baseline of

chroma when positioned anywhere between sync tip and

100% white.

1780R-Series Service Manual

Typically <0.5%.

1 V p-p PAL or NTSC Modulated

2

composite video signal

Sin

(12.5T NTSC, 10T PAL). X1 or

X5, Variable Gain of f. Typically

<0.5%.

23

1–7

Page 31

Specifications

1

T able 1–3: Waveform Monitor Probe Input

Characteristic Performance Requirement Supplemental Information

Input Resistance 1 MW.

Input RC Product 20 ms (20 pF).

Performance

Check Step

Gain Unity ±3%. With gain adjusted for equivalent

1 V peak-to-peak display.

Frequency Response

25 Hz to 10 MHz

Tilt Less than 5% on 50 Hz square

Probe Calibrator

Waveform

Period

Output Voltage

Impedance Out

±3%. Referenced to 50 kHz. 17, 18

Fast DC Restorer eliminates low

wave.

1.0 V ±0.5%. 0.995 to 1.005 V.

frequency tilt on a comp video

signal.

50% Duty Cycle square wave.

4 horizontal lines.

≈950 W.

T able 1–4: Waveform Monitor Horizontal Deflection System

Characteristic Performance Requirement Supplemental Information

Sweep Rates & Timing Accuracy 1 MW.

30

32

3

Performance

Check Step

1 Line (5 ms/Div.) ±2%. Center 10 divisions.

2 Line (10 ms/Div.) ±2%. Center 10 divisions.

3 Line (15 ms/Div.) ±2%. Center 10 divisions.

1-Field Sweep Displays 1 full field including field

rate sync.

2-Field Sweep Displays 2 full fields, and the field

rate sync between them. First

sweep is selectable between the

even or odd field.

3-Field Sweep Displays 3 full fields, and the

2-field rate sync intervals between

them (3/4 of the color frame). First

sweep is selectable between the

even or odd field, third field

polarity is the same as the first

field’s.

1–8

1780R-Series Service Manual

34

Page 32

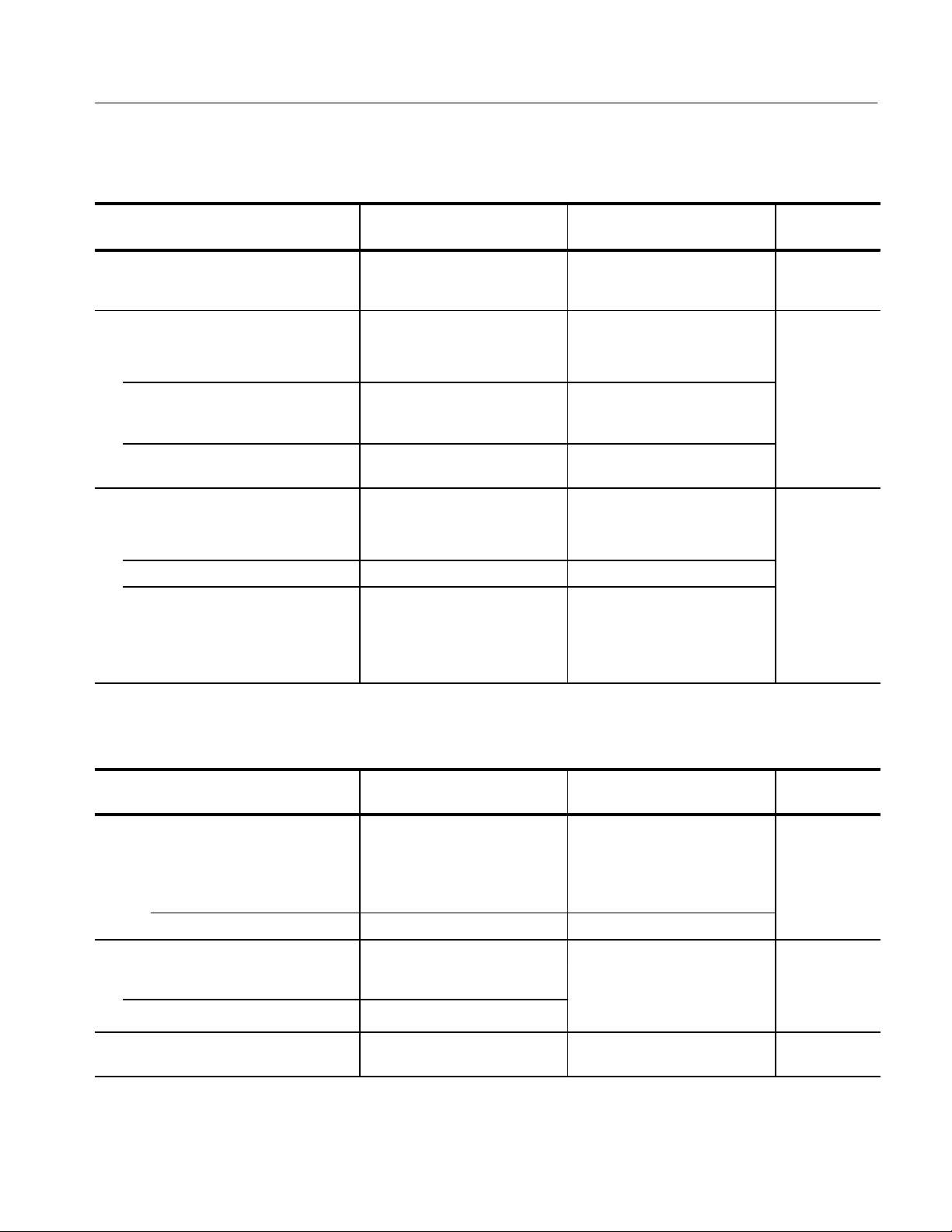

T able 1–4: Waveform Monitor Horizontal Deflection System (Cont.)

A

des

-

-

A

des

-

-

Waveform m

r-

s

ffere

es.

Characteristic

Sweep Linearity

Specifications

Performance

Supplemental InformationPerformance Requirement

Check Step

1 Line (5 ms/Div.) ±1%.

2 Line (10 ms/Div.) ±1%.

3 Line (15 ms/Div.) ±1%.

1-Field Sweep ±0.5 division.

2-Field Sweep ±0.5 division.

3-Field Sweep ±0.5 division.

Slow Sweep ±5% of full screen over the length

of the sweep.

Magnified Sweep Accuracy

X5 (1 ms/Div.) ±1%.

X10 (0.5 ms/Div.) ±2%.

X20 (0.25 ms/Div.) ±3%.

X25 (0.2 ms/Div.) ±3%.

X50 (0.1 ms/Div.) ±3%.

X100 (50 ns/Div.) ±5%.

Magnified Sweep Linearity

X5 (1 ms/Div.) ±1 minor division (2%).

X10 (0.5 ms/Div.) ±1 minor division (2%).

X20 (0.25 ms/Div.) ±1 minor division (2%).

pplies to the center 10 divisions34

of unmagnified sweep. Exclu

the first 2 divisions of the magni

the first 2 divisions of the magni

fied display.

pplies to the center 10 divisions34

of unmagnified sweep. Exclu

the first 2 divisions of the magni

the first 2 divisions of the magni

fied display.

34

X25 (0.2 ms/Div.) ±1 minor division (2%).

X50 (0.1 ms/Div.) ±1 minor division (2%).

X100 (50 ns/Div.) ±1 minor division (2%).

Variable Sweep Range >±20%. Expands sweep around center of

sweep.

Slow Sweep Duration 4 to 12 seconds. Front panel

variable control.

Timing Cursor Accuracy Within 5 ns, any delay within 1

line (64 ms).

Line Select

Range Full Field.

Field Selection 1 of 4 for NTSC or 1 of 8 for PAL.

Even or Odd and All Fields.

cope may select di

CRT alphanumeric identification.

onitor and vecto

nt lin

1780R-Series Service Manual

35

45

33

36

1–9

Page 33

Specifications

T able 1–4: Waveform Monitor Horizontal Deflection System (Cont.)

Characteristic

RGB/YRGB

Performance

Supplemental InformationPerformance Requirement

Check Step

Staircase Input Amplitude A +10 V input will result in a

horizontal display of 9 divisions

±1.4 major divisions.

Staircase Operating Signal DC Signal levels plus peak AC,

not to exceed _–12 to +12 V .

Max AC Signal Volts 12 V peak-to-peak. Field or line rate sweeps.

Sweep Length

RGB 2 Fld = 27 – 33% of normal.

YRGB 2 Fld = 20 25% of normal.

Sweep Repetition Rate Field or line rate of displayed

video or external sync signal as

selected by front-panel HORI-

ZONT AL controls.

External Horiz. Input Used for ICPM measurements.

Sensitivity Direct coupled 0 – 5 V. Sawtooth

Input Impedance ≈10 kW.

Ground to +10 V . +10 V corresponds to left side of CRT.

1 Line = 27 – 33% of normal.

2 Line = 27 – 33% of normal.

1 Line = 20 – 25% of normal.

2 Line = 20 – 25% of normal.

Requires 1H or 1Fld sweep

selection.

input of up to 5 V is nominally a

10 division horizontal sweep.

37

38

1–10

1780R-Series Service Manual

Page 34

T able 1–5: Waveform Monitor dG and dP Display

CRT read

.

CRT read

.

0

1

Characteristic Performance Requirement Supplemental Information

Differential Gain

Specifications

Performance

Check Step

Deflection Factor 5% dG deflects the trace 50 IRE

(NTSC) or 500 mV (PAL) ±5%.

Residual dG (10 – 90% APL) ≤0.2%, last 90% of trace. 39

Calibrated dG

Resolution 0.1%.

Accuracy 0.1% ±10% of reading.

Range ±5%.

Differential Phase

Deflection Factor 5_ dP deflects the trace 50 IRE

(NTSC) or 500 mV (PAL) ±5%.

Residual dP (10 – 90% APL) ≤0.1_, last 90% of trace. 40

Calibrated dP

Resolution 0.05_.

Accuracy ±0.1_ over any 10_ increment.

±0.1_ over full 360_, Ext. Ref.

±0.2_ burst lock.

Range 360_.

Waveform gain X1, Var. Gain off.

Vector gain adjusted to place

chroma at compass rose.

out

Waveform gain X1, Var. Gain off.

Vector gain adjusted to place

chroma at compass rose.

out

39

39

40

4

Recursive Filter

Noise Reduction ≈15 dB signal-to-noise reduction

with filter selected. Assumes

white noise source.

Cross-Luminance Rejection ≈30 dB with filter selected. 0 dB

in dual dP/dG mode.

Unit Sample Response Settles to within 1 dB in <50 lines

with a step in APL. Settles to

within 1 dB in <50 frames in line

select.

Chrominance Bandwidth 500 kHz ±100 kHz baseband.

1780R-Series Service Manual

4

1–11

Page 35

Specifications

T able 1–6: Synchronization

Characteristic Performance Requirement Supplemental Information

Sync Input

Internal

Performance

Check Step

Ref. Sync Separator 0.2 to 2.0 V peak-to-peak com-

posite video.

Int. Sync Separator 0.5 to 2.0 V peak-to-peak com-

posite video.

External

Black Burst –14 dB to +6 dB. Black Burst signal of 0.2 to 5

Composite Sync 0.2 to 8.0 V peak-to-peak. Composite sync applied to EXT

SCH Modes 286 mV (300 mV PAL) Sync and

Burst ±3 dB.

Direct Sync

Horiz. Freq. Range 15.75 kHz ±1 kHz. Frequencies much below

Sync Jitter

Comp sync or video ≤12 ns with respect to input sync. 44

Variable APL (10–90%) ≤20 ns; with the addition of 36 dB

Composite video applied to Inputs

A, B1, B2, or B3 or probe.

times amplitude applied to EXT

SYNC input.

SYNC input locks waveform

monitor; vectorscope also requires CW signal.

Composite Video or Black Burst. 56

15.75 kHz will not permit a normal

TV display.

white noise ≤90 ns.

42

42

43

43

Noise Immunity <250 ns jitter , 1 V composite

video with _–26 dB white noise.

AFC Sync

Horiz. Freq. Range 15.75 kHz ±200 Hz.

Lock-In Time <1 second.

Sync Jitter

Comp sync or video

Variable APL (10–90%)

Jitter with respect to white noise ≤30 ns. Doubles with each 6 dB increase

Noise Immunity <90 ns jitter , 1 V composite video

1–12

≤10 ns; with the addition of 36 dB

white noise ≤12 ns.

in white noise.

with _–26 dB white noise.

1780R-Series Service Manual

44

Page 36

T able 1–6: Synchronization (Cont.)

NTSC

.

Characteristic

Jitter from missing line sync pulses <15 ns per missing sync pulse.

Slow Sweep Triggering

Supplemental InformationPerformance Requirement

Maximum of 10 consecutive line

sync pulses.

Specifications

Performance

Check Step

Signal APL change from 10% to ≤90%. Front panel selectable for either +

or _– level change.

Sensitivity 0.4 V to 2.0 V peak-to-peak

composite video with APL

change.

Rate 0.2 Hz. Free runs at rates less than

0.2 Hz or with no triggering signal.

Remote Sync

Amplitude 2.0 to 5.0 V square wave, or 4.0 V

composite sync.

Input Impedance 1 MW.

Frequency 30/60 Hz (NTSC), 25/50 Hz (PAL)

Input enabled through rear-panel

REMOTE connector.

square wave will synchronize a

2-field sweep. Remote sync

bypasses the sync stripper and

field ID circuits.

T able 1–7: Vectorscope Vector Display

Characteristic Performance Requirement Supplemental Information

Phase Control

45

46

Performance

Check Step

Digital Phase Shifter

Phase Accuracy ±0.1_. (External CW signal.) 0.25_ Burst

Lock.

Resolution 0.05_.

Chrominance Bandwidth

Upper –3 dB Point FSC +500 kHz, ±100 kHz.

Lower –3 dB Point FSC _–500 kHz, ±100 kHz.

Chrominance Transient Response Modulated Sin2 pulse in R-Y

FSC (Subcarrier Frequency)

– 3.579545 MHz

PAL – 4.43361875 MHz.

mode.

1780R-Series Service Manual

47

48

1–13

Page 37

Specifications

0

10

1

T able 1–7: Vectorscope Vector Display (Cont.)

Characteristic

Display

Performance

Supplemental InformationPerformance Requirement

Check Step

Vector Phase Accuracy ±1.25_. Measured with color bar signal.

Vector Gain Accuracy ±2.5% (1.25 IRE).

Quadrature Phasing ±0.5_.

Subcarrier Regenerator

Pull-In Range

(NTSC) ±50 Hz of FSC.

(PAL) ±10 Hz of FSC.

Pull-In Time Within 1 second, with subcarrier

Phase Shift with Subcarrier Frequency

Change

(NTSC) ±0.5_ from FSC to (FSC +50 Hz),

(PAL) ±0.5_ from FSC to (FSC + 10 Hz),

Phase Shift with Burst Amplitude

Change

Phase Shift with Input Channel

Change

Phase Control Range 360_ continuous rotation. 50

±2_ from nominal burst amplitude

to ±3 dB.

±2_. CH A to CH B1 or CH B1, CH B2,

PAL instruments are tested to

Hz, but typically lock to within

50 Hz.

frequency within 50 Hz (10 Hz for

PAL instruments) of FSC.

or FSC to (FSC –50 Hz).

or FSC to (FSC –10 Hz).

Internal or External burst refer-

ence.

and CH B3 to each other. With

EXT REF selected.

49

5

50

50

Vector Display

Differential Phase ≤1.

Differential Gain ≤1%.

Measured with 140 IRE (1 V)

linearity signal with 40 IRE

(300 mV) of subcarrier.

Position Control Range

Horizontal ≥1/4 inch (6 mm) from center.

Vertical ≥1/4 inch (6 mm) from center .

Clamp Stability 1/64 inch (0.4 mm) or less. Center Spot movement with

rotation of PHASE control.

1–14

1780R-Series Service Manual

5

51

Page 38

T able 1–7: Vectorscope Vector Display (Cont.)

Characteristic

Variable GAIN Range +14 dB to –6 dB of 75% color bar

preset gain.

Max Gain >X5.

Supplemental InformationPerformance Requirement

Unterminated color bar signal can

be brought to appropriate targets.

Burst from a triple terminated

signal can be moved to the

compass rose.

Specifications

Performance

Check Step

52

Variable GAIN Phase Shift ±1_ as gain is varied from +3 dB

to – 6 dB.

T able 1–8: Vectorscope X-Y Display

Characteristic Performance Requirement Supplemental Information

Input DC coupled differential inputs

through rear-panel connector.

Input Amplitude 2 to 9 V peak-to-peak. Adjustable full scale deflection

0 dBm to +12 dBm for 600 W

system. Factory set to 0 dBm.

Maximum Input Voltage ±15 V combined peak signal and

DC.

Frequency Response DC to >500 kHz. 3 dB point. 55

X and Y Input Phase Matching < a trace width of separation at

20 kHz.

Single-ended. Phase matching

above 20 kHz may be improved

by adjusting Vertical Deflection

Amplifier VHF Compensation.

53

Performance

Check Step

54

T able 1–9: Vectorscope SCH Phase Display

Characteristic Performance Requirement Supplemental Information

Accuracy

Absolute ±5_ phase at 25_ C.

Relative ±2_.

Acquisition Time ≤1 sec. 56

Display Phase Error caused by CRT

Geometry Variations

±1.25_ calibrated for zero display

phase error at zero SCH phase.

1780R-Series Service Manual

Performance

Check Step

56

1–15

Page 39

Specifications

.

T able 1–9: Vectorscope SCH Phase Display (Cont.)

Characteristic

Input Timing Correct relative SCH operation

Display Range

Ext Reference 360_.

Int Reference ±70_. Typically >80_. 56

Supplemental InformationPerformance Requirement

with displayed video delayed up

to 2 ms or advanced up to 1.5 ms

relative to external reference.

T able 1–10: CRTs and High Voltage Supplies

Performance

Check Step

Characteristic Performance Requirement Supplemental Information

Waveform Monitor

Viewing Area 80 × 100 mm. Horizontal Scale

12.5 Divisions. Vertical Scale 170

IRE (NTSC), 1.19 V (PAL).

Accelerating Potential Nominally 20 kV .

Orthogonality ±1_. 57

Trace Rotation Range ≥±1_ from horizontal. Typical adjustment range is ≈8_. 57

Vectorscope

Viewing Area 80 × 100 mm.

Accelerating Potential Nominally 13.75 kV .

Orthogonality ±1_. 57

T able 1–11: Power Requirements

Characteristic Performance Requirement Supplemental Information

Mains Voltage Ranges

Performance

Check Step

Performance

Check Step

110 VAC 90 – 132 V .

220 VAC 200 – 250 V .

Mains Frequency Range 48 – 66 Hz.

1–16

Selected by rear-panel switch

1780R-Series Service Manual

1

Page 40

T able 1–11: Power Requirements (Cont.)

Characteristic

Crest Factor ≥1.3.

Power Consumption 120 Watts maximum.

Supplemental InformationPerformance Requirement

T able 1–12: Environmental Summary

Characteristic Performance Requirement

Temperature

Operating 0_ C to +50_ C.

Non-Operating 55_ C to +75_ C.

Altitude

Operating To 15,000 feet (4.5 km) maximum.

Specifications

Performance

Check Step

Non-Operating To 50,000 feet (15 km) maximum.

Vibration

Operating 0.015 inch (0.38 mm) peak-to-peak 10–55 Hz, 75 minutes total.

Shock

Non-Operating 30 g acceleration 3 times each major axis. 11 ms halfsine.

Bench Handling 4 inch drop to table top on each of the four bottom corners.

Transportation

Vibration Qualified under National Safe Transit Association (NST A) Test Procedure 1A-B-1.

Drop Test Qualified under NSTA Test Procedure 1A-B-2.

Humidity 90 to 95% Noncondensing

T able 1–13: Physical Characteristics

Characteristic Supplemental Information

Dimensions

Height 5 1/4 inches (133.4 mm).

Width 19 inches (483 mm).

Length 18 inches (460 mm).

Net Weight Approximately 28 lbs (approximately 12.7 kg). Add 7 lbs (3.2 kg) for accessories and

manuals.

Shipping Weight Approximately 45 lbs (approximately 20.3 kg).

1780R-Series Service Manual

1–17

Page 41

Specifications

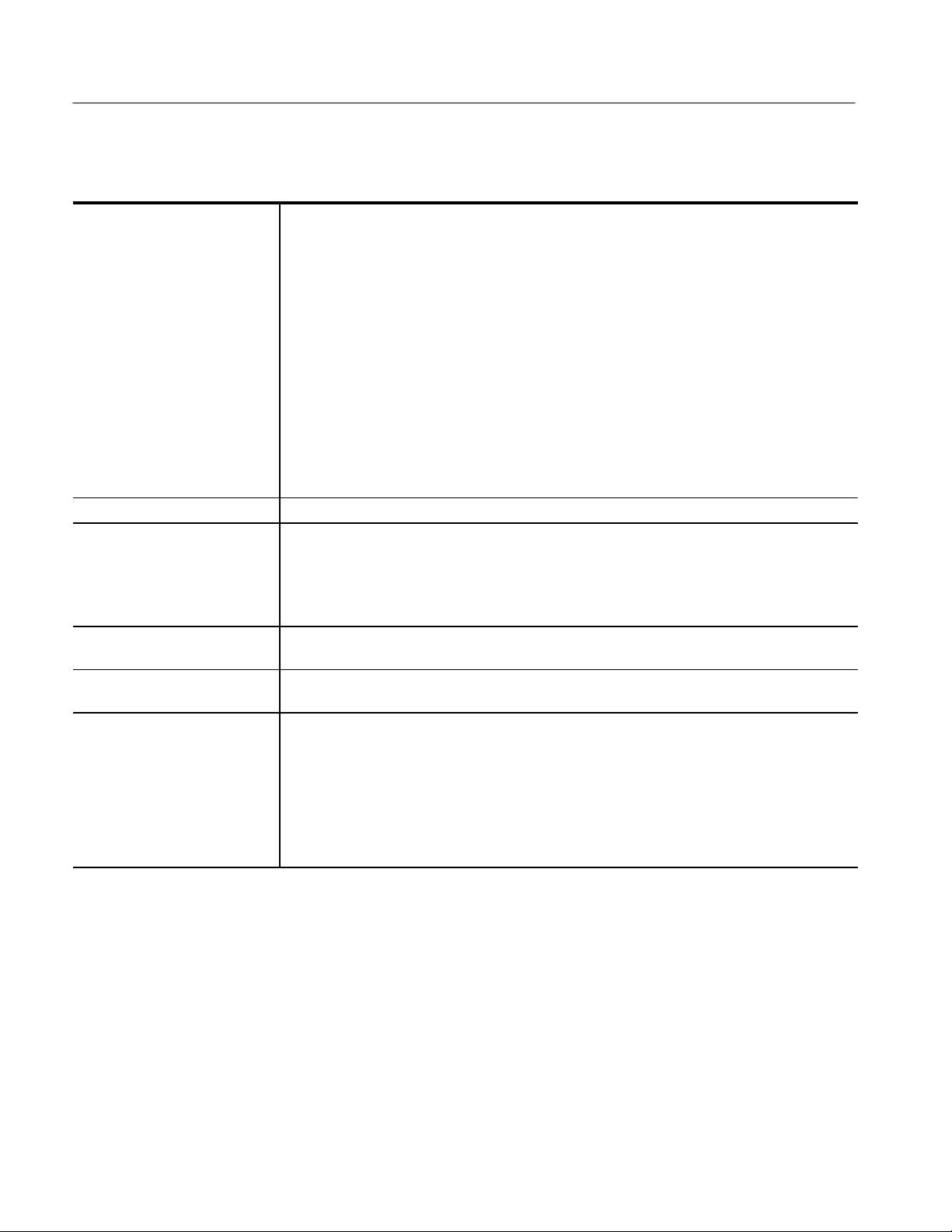

T able 1–14: Certifications and Compliances

EC Declaration of Conformity –

EMC

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A Limits

EC Declaration of Conformity –

Low Voltage

U.S. Nationally

Recognized Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 231 CSA Safety Requirements for Electrical and Electronic Measuring and

Installation Category Descriptions Terminals on this product may have different installation category designations. The installation

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

High-quality shielded cables must be used to ensure compliance to the above listed

standards.This product complies when installed into any of the following Tektronix

instrument enclosures:

1700F00 Standard Cabinet

1700F02 Portable Cabinet

1700F05 Rack Adapter

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Low Voltage Directive 73/23/EEC

HD401 S1 Safety requirements for electronic measuring apparatus

UL1244 Standard for Electrical and Electronic Measuring and Testing Equipment.

T est Equipment.

categories are:

CA T III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location

CA T II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected

CA T I Secondary (signal level) or battery operated circuits of electronic equipment

1–18

1780R-Series Service Manual

Page 42

Page 43

Installation

Assembly

Overview

This section provides information on both mechanical and electrical installation

of the 1780R-Series Video Measurement Set. Be sure to read this material prior

to physically mounting the instrument in either a rack mount or portable

configuration.

Packaging

Accessories

The shipping carton and pads provide protection for the instrument during

transit, and should be retained in case subsequent shipment becomes necessary.

Repackaging instructions, including an illustration, can be found at the end of

this section.

The 1780R-Series comes with a set of standard accessories, which includes items

such as manuals, rack-mounting hardware, external graticules, power cord, spare

fuse, etc. Table 2–1 is a list of these standard accessories. Not all of the items in

the table (especially power cables and graticules) are appropriate for all

instruments. Part numbers for these accessories are located at the back of the

manual in the Replaceable Mechanical Parts List.

T able 2–1: 1780R-Series Standard Accessories

Item Description

1 Manual 1 – Operator Manual

3 External Graticules per Standard 1– IEEE STD 511 Visual (1780)

1– IEEE STD. 511 Photo (1780)

1– PAL K-Factor V isual (1781)

1– PAL K-Factor Photo (1781)

1780R-Series Service Manual

Power Cable

(1 of 5 options)

1 Spare Fuse 250 V 2A T-type Cartridge fuse

3 Incandescent Bulbs Spare Graticule Lights

1 Air Filter For rear-panel fan

2 Mounting Brackets For rear rack-mounting

Option Country of Use

––– North Amer. (115 V)

A1 European (220 V)

A2 U K (240 V)

A3 Australian (240 V)

2–1

Page 44

Installation

In addition to the standard accessories in Table 2–1 there are a number of

optional accessories that can be purchased, such as a portable case, maintenance

kits, etc., to complement the 1780R-Series Video Measurement Set. For more

information contact a Tektronix Inc. field office or distributor.

Table 2–2 is a partial list of optional accessories that are available for the

1780R-Series instruments.

T able 2–2: Partial List of Optional Accessories Available for the

1780R-Series

Item Description

Cabinet 1780F02 Portable Carrying Case with front and rear panel

covers

Circuit Bd. Extender Kit Used to service Oscillator and Z-Axis etched circuit boards

Viewing Hood T ektronix Catalog Accessory

Manual Service Manual

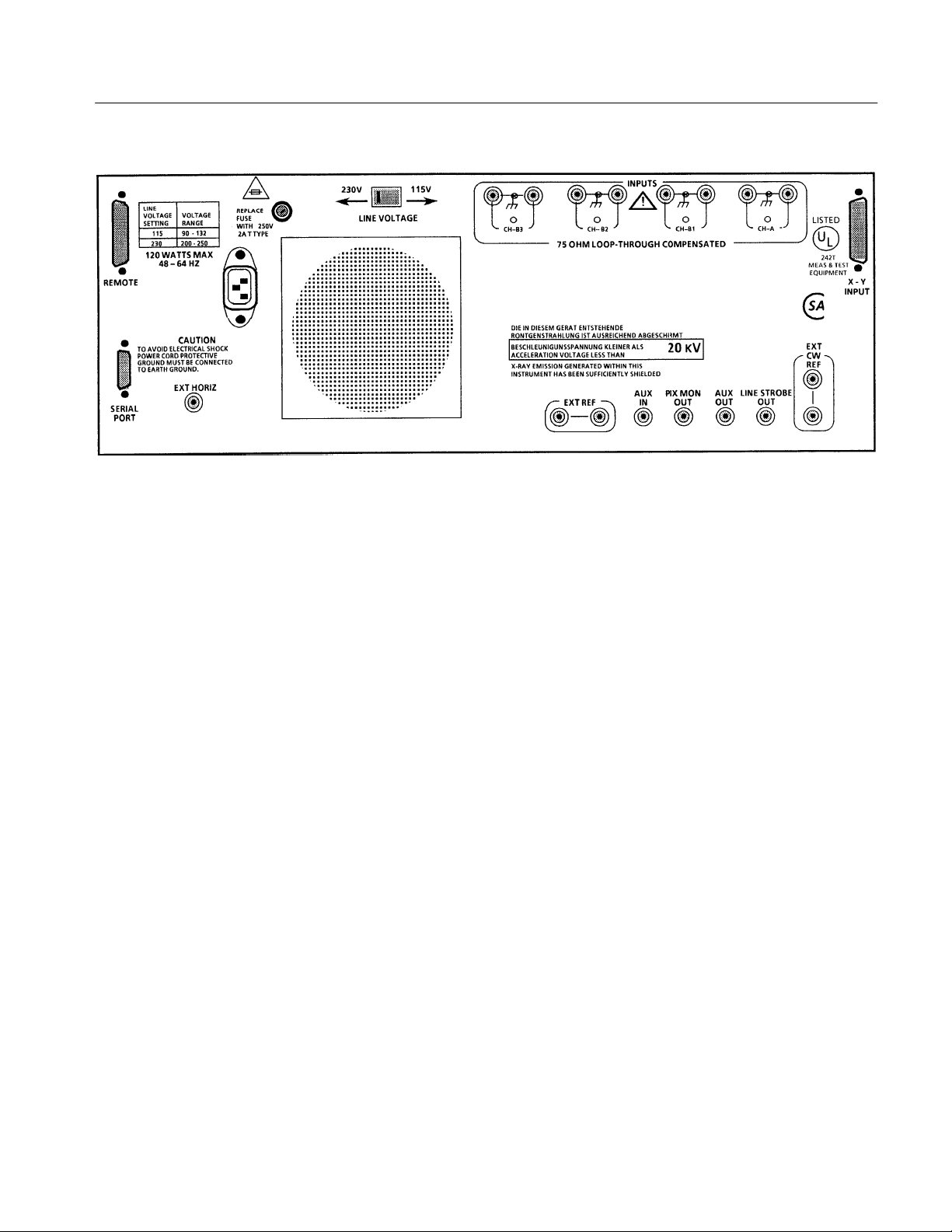

Rear Panel Connectors

Figure 2–1 shows the rear panel of the 1780R-Series. The following connectors

are on the rear panel

CH A. High impedance bridging loop-through input for composite video signal.

Shield can be grounded or floating depending on the position of the grounding

screw (located between the BNC connectors).

CH B1. High impedance bridging loop-through input for composite video signal.

Shield can be grounded or floating depending on the position of the grounding

screw (located between the BNC connectors).

CH B2. High impedance bridging loop-through input for composite video signal.

Shield can be grounded or floating depending on the position of the grounding

screw (located between the BNC connectors).

CH B3. High impedance bridging loop-through input for composite video signal.

Shield can be grounded or floating depending on the position of the grounding

screw (located between the BNC connectors).

EXT HORIZ. High impedance input through BNC connector. Positive-going

signal deflects the sweep from left to right. Requires a 0 to +5 V signal for full

scale deflection.

.

2–2

1780R-Series Service Manual

Page 45

Figure 2–1: Rear panel for the Tektronix 1780R-Series Measurement Set

Installation

EXT REF. High impedance bridging loop through connector for either composite

sync or black burst.

AUX IN. 75 W input for video signals. Insertion point follows the internal filters.

AUX OUT. 75 W video signal output just prior to the filters. Can be used with

the AUX IN to design custom filters.

PIX MON. 75 W output to drive a picture monitor, signal is output prior to filters

and has a bright-up pulse added when line select is used.

LINE STROBE. A 75 W output that provides a pulse for the selected line(s)

when line select is used. Can also be configured to output the Field 1 pulse, see

Table 2–3 (J1103).

CW. High impedance bridging loop-through input for continuous subcarrier

signal. Provides an external phase reference signal.

REMOTE. 15-pin D-type connector used as a ground closure interface for

remote control of key functions. See Figure 2–4.

SERIAL PORT. 9-pin D-type connector that provides a serial interface, using

RS422A or RS232D control, for remote control of Microprocessor-controlled

functions. See Figure 2–5.

1780R-Series Service Manual

X – Y. A 15-pin D-type connector used as a high impedance input for the 600 W

balanced audio. See Figure 2–6.

2–3

Page 46

Installation

Installation Requirements

The 1780R-Series is designed for efficient use of rack space. It can be mounted

flush with other equipment, eliminating the need for air circulation above and

below the cabinet. It should not be mounted flush with equipment that is a

significant heat source, because heat conducted through the cabinet can raise the

internal temperature of the instrument beyond its ability to cool itself.

Cooling air for the 1780R-Series is pulled into the instrument through a

rear-panel fan and exhausted through the cabinet sides. Most equipment racks

provide enough space, along side the instruments, to allow heated air to escape

from this instrument.

Before installing the instrument in the rack, be sure that the cooling fan blades

are un-obstructed and turn freely.

A minimum rear panel clearance of 1-1/2 inches is required to connect BNC

cables.

Front-panel clearance of at least 20 inches is required to remove the instrument