Page 1

067-2431-xx

Deskew Fixtur

ZZZ

Instructions

Internal circui

between –1.5 and +4 volts, with a rise time of

40 ps. The fixture

ports of the oscilloscope.

Connectors on the fixture accept the coax

adapters and solder tips that are available for the

e

P7600 Series probes.

NOTE. You cannot deskew probes with coax

connectors to probes with solder tips; only

coax-to-coax or tip-to-tip probes can be

deskewed together.

CAUTION. The deskew fixture is ESD

sensitive. To avoid damaging the fixture,

only use it at an antistatic workstation and

observe proper ESD practices.

Standard Accessories

The following

deskew fixture:

try conditions the input signal to

is powered by one of the USB

accessories are included with the

Deskew Procedur

compensates for signal delays that occur between

probes due to dif

The oscilloscope deskew feature applies deskew

values after it

deskew values do not affect logic triggering.

Deskew has no af

formats.

e. The deskew function

ferent tips or cable lengths.

completes each acquisition. The

fect on XY and XYZ display

*P071302900*

071-3029-00

Deskew Fixture

The probe deskew fixture provides an edge

source to time-align (deskew) signals at the

inputs of P7600 Series probes. It allows you

to deskew the probes when you are using

P76CA-xxx probe adapters with coax cables or

the P76TA solder tip adapter with P7500 Series

TriMode Probe solder tips.

The edge signal input voltage is internally

adjustable to accommodate different logic levels,

and is provided by the oscilloscope FAST EDGE

output or by an external source. The edge signal

input voltage must be between –2 and +5 volts,

with a 1 ns or faster rise time.

Accessory

USB cable, A to B, 6 ft

SMA cable, male-to-male, 36 in

Adjustment tool 003-1890-xx

Instructions 071-3029-xx

Overview

For best performance, you should do the DC

Calibrati

Deskew procedure. Refer to your probe manual

for detail

Probe Calibration Procedure.

You should also check the calibration status of the

probes that you intend to use prior to performing

the deskew procedure. Use the procedure below.

Check the Calibration Status.

1. Select Probe Cal... from the Vertical menu.

2. Select the channel to which the probe is

If the te

problem; do not continue with the deskew

procedu

on procedure before performing the

ed instructions for performing the DC

attached and then check the Probe Status

readout:

Initialized. The probe has not been

ed on the selected channel; perform

calibrat

the DC probe calibration procedure.

Compensated. The probe has been

calibrated on the selected channel.

Fail. The probe has not been calibrated;

repeat the procedure.

st continues to fail, troubleshoot the

re.

Tektronix

part number

174-5194-xx

174-5631-xx

1. Connect the deskew fixture to a USB power

source. The power LED lights and the

solder tip retainer clips illuminate.

2. Connect the probes to the oscilloscope.

3. Connect th

connectors that match your probe. Leave

the 50 Ω ter

connectors.

NOTE. If y

solder tips, use the same solder tips with

the desk

measurements.

NOTE. You cannot deskew probes with coax

connect

coax-to-coax or tip-to-tip probes can be

deskewe

e probes to the fixture, using the

minations on any unused SMA

Connect the P76CA–292 or

P76CA–292C coax adapters to

the SMA connectors on the fixture.

Connect the P76CA–SM P coax

adapters to SMP-to-SMA adapters, and

then to the SMA connectors on the

fixture.

Attach the P76TA probe solder tip

adapter w

Probe solder tips beneath the

spring-l

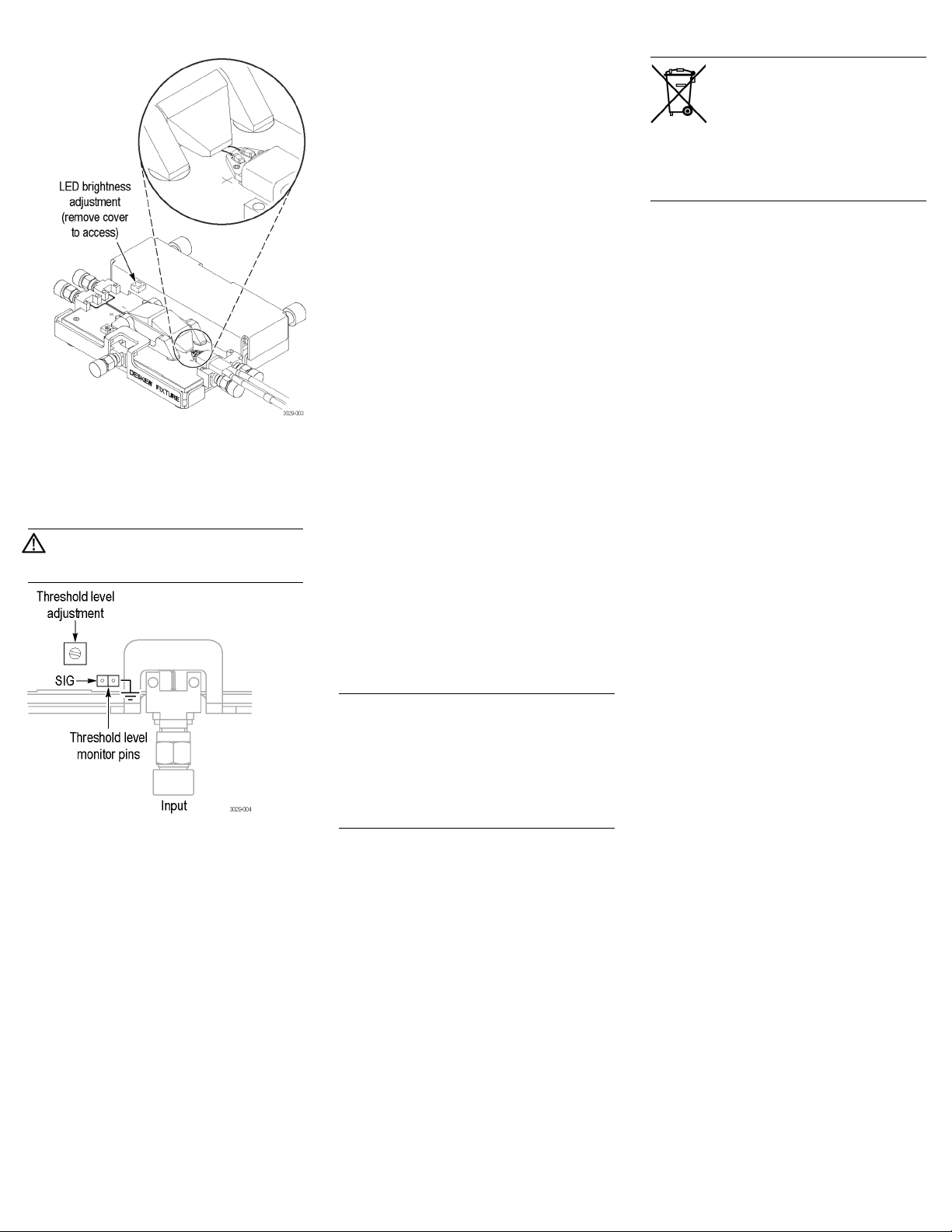

LEDs with adjustable brightness help

you align

fixture contacts. See figure below.

ith P7500 Series TriMode

oaded retainers on the fixture.

the probe tip leads to the

ou are deskewing probes with

ew fixture that you will use to take

ors to probes with solder tips; only

d together.

Page 2

4. Connect th

e edge signal input to the fixture.

Use either the FAST EDGE output on the

oscillosc

ope, or connect an external source.

The external signal source voltage must be

between –2

and+5volts,witha1nsor

faster rise time.

CAUTION. D

o not exceed the input voltage

limits of the fixture. Damage to the fixture

and probes

may result.

7. Select a referen

ce channel with which all

other channels will be deskewed. This is

typically Chann

el 1, but can vary depending

on your setup.

8. Select Deskew from the Vertical menu.

9. Select Channel 1 and set the Deskew to

0.0 s.

10. Display all channels to deskew, including

the reference c

hannel.

11. Set the Display Persistence to Infinite

Persistence mode.

12. Set the Record View Palette to Temperature

Grading.

13. Adjust the trigger level to get a stable

trigger.

14. Adjust the vertical SCALE, POSITION,

and OFFSET for each channel so that the

signals overlap and are centered on screen.

Make sure all channels being deskewed are

at the same volts/div setting. Deskew the

channels at the same level as your planned

signal measurement.

15. Adjust the horizontal POSITION so that

a triggered rising edge of the reference

channel is at center screen.

16. Adjust the horizontal SCALE so the

differences

in the channel delays are clearly

visible.

17. Adjust the horizontal POSITION again so

that the first rising edge of the reference

channel is at center screen.

18. Select Deskew from the Vertical menu.

19. Select one of

the channels to match to the

reference channel.

Equipment Recyc

complies with the European Union’s

requirements according to Directive

2002/96/EC on waste electrical and

electronic equipment (WEEE). For

more information about recycling

options, check

section of the Tektronix Web site

(www.tektronix.com).

ling. This product

the Support/Service

Contacting Tektronix

Web site: www.tektronix.com

Phone: 1-800-833-9200

Address: Tektronix, Inc.

Email:

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077 USA

techsupport@tektronix.com

Warranty Information

For warranty information, go to

www.tektronix.com/warranty.

5. Connect a DMM or oscilloscope to the

threshold level monitor pins.

6. Using an insulated tool, adjust the threshold

level on the fixture to the appropriate logic

level (for example, 1.4 V for TTL circuits).

NOTE. Do the n

ext step at a signal amplitude

within the same attenuator range (vertical scale)

as your plan

ned signal measurements. A ny

change to the vertical scale after the deskew is

complete ca

n change the attenuator setting and

give a slightly different signal path. This signal

path differ

ence can cause as high as 100 ps

variation in timing skew between channels.

20. Adjust the d

eskew time for that channel

so that its signal a ligns with that of the

reference c

hannel.

21. Repeat steps 19 and 20 for each additional

channel that you want to deskew.

opyright © Tektronix, Inc. A ll rights reserved. www.tektronix.com

C

Loading...

Loading...