Page 1

COMMITTED TO EXCELLH~CE

Tektronix, Inc ..

P.O. Box

Beaverton, Oregon 97077

070-3986-00

Product Group 20

500

PLEASE CHECK FOR CHANGE INFORMATION

AT THE REAR OF THIS

MANUAL

067-1 039-00

PATTERN

GENERAT R

INSTRUCTION MANUAL

Serial Number ______ _

First Printing JUL 1982

Page 2

1982Tektronix, Inc. All rights reserved.

Copyright©

Contents of this publication may not be reproduced in

any form without the written permission of Tektronix, Inc.

Products of Tektronix, Inc. and its subsidiaries are

covered by U.S. and foreign patents and/or pending

patents.

1981,

TEKTRONIX, TEK, SCOPE-MOBILE, and

registered trademarks of Tektronix, Inc. TELEQUIPMENT is a registered trademark of Tektronix U.K.

Limited.

Printed in U.S.A. Specification and price change

privileges are reserved.

~

are

Page 3

067-1039-00

TABLE OF CONTENTS

LIST OF ILLUSTRATIONS

OPERATORS SAFETY

Section 1

GENERAL INFORMATION AND

SUMMARY •••••••••••••• , • • • • • • • • • • • • • • • • • • • • • • • • •

SPECIFICATIONS

INTRODUCTION

OVERVIEW

OPERATORS PART

SERVICING PART

ST AND ARDS

SPECIFICATION •

ELECTRICAL

CHARACTERISTICS •••••••••••••••••••••••••••

ENVIRONMENTAL CHARACTERISTICS ••••••••••••••••••••••••

PHYSICAL CHARACTERISTICS •••••••••••••••••••••••••••••

Section

2

OPERATING INSTRUCTIONS

INTRQDUCTIQN

ABOUT THE PATTERN GENERATOR ••••••••••••••••••••••••••

INSTALLATION •

REPACKAGING

FUNCTIONS OF THE CONTROLS AND CONNECTORS

Controls

Indicators

Connectors

OPERATORS

CHECKOUT PROCEDURE•••••••••••••••••••••••••

USING THE PATTERN GENERATOR TO CHECK

6 9QSR: MAINFRAME

@ •

e e s

4l G

@

;ii

Ell

@ •

e c

0 • 0 0 e,

o

@

e

\!I w

oeoee@oet1eeoai@fleeoelillae@ot1eeeeoseeeeee

s,

e •

41 •

o o

10

o

G

@

e e " e e e e "

®

@

e e

Q

o.

e o e

II

o a • • ,. u

e

ei •

s e e e o e e e

o o es

,sc

e.

9IIIIII00GGCIEIO@eeeoe61eGIIOGlll811CG8e@6eeeeQIIGeee

Ill.

8 9 0 0 G Cl

II

o

ei •

o o a o e e e • e e s e • • e o o e e •

a

9@

<!I

(ll

ea e e e

ti

e • • e •

a e

<J

Cl

1:11

o e • e e o

e

O O Cl Cl

o

<!ii •

41

u

@

11

QI

e,

II

o o • o o o

g

@

e • •

e

@

11 •

e e e • e

8

Q

8

e

1111

o

III

e a c

l!il

o

,s

e

Q

e

,a •

@

~

ei

G

,a

41

c

,a

e e o o a

ai

Cl •

e • e • • • e e e o o •

<11

c,

61 6

Q

11!1

'5

a

THE

@ •

Q

e- e • • • o

ll II

6i!I

o

e

e

O Cl

o

I'll

G 11 •

111 0

Q

e

6 G

11 •

~

e o

e

6 S 411 0

G

<Ill

e

e e •

s

ie

0

«i

e • e

@ •

<lil

Q

o»

c • • • e o

fl

~

•

0 •

e

fl

Q •

0

G

e

111

e

18 9 8

o • •

e s

o e

Ill •

«1

e

0

V

vi

1-1

1-2

1-2

1-2

1-3

1-4

1-4

1-6

1-7

2-1

2-1

2-1

2-2

2-2

2-3

2-5

2-5

2-6

2-8

i

Page 4

067-1039-00

WARNING

FOLLOWING SERVICING INSTRQCTIONS ARE FOR USE BY

THB

QUALIFIED PERSONNEL

NOT

OPERATING

PERFORM ANY

INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO

ONLY. TO AVOID PERSONAL INJURY, DO

SERVICING OTHER THAN THAT CONTAINED IN

I

so.

SERVICING SAFETY SUMMARY•••••••••••••••••••••••••••••••••••••••• S-1

Section 3 THEORY OF OPERATION

HORIZONTAL SYNC GENERATOR (Diagram 1) •••••••••••••••• 3-1

Horizontal Oscillator ••••••••••••••••••••••••••••• 3-1

Vertical Line Generator ••••••••••••••••••••••••••• 3-1

Vertical Bar Generator••••·•••••••·••••·•·•·••·•·· 3-2

Horizontal Interval Timing••••···••·•··•••••···••• 3-2

2H (Interlace) Generator••••••••·••••••••••••••••• 3-3

H Sync Output Buffers••••·•··••··•••····•···•··••• 3-4

Power Supplies

VIDEO LOGIC AND DRIVERS (Diagram 2) •••••••••••••••••• 3-5

Power Supplies••••·•••··•••··•••·•·•··•··•·•·••••· 3-5

Video Logic••••••••••••·•••••·•••·••····••••·•··•·

Video Output Drivers·•••••••••••··••·····••·••···• 3-5

HORIZONTAL LINE GENERATOR (Diagram 3) •••••••••••••••• 3-8

Current State Registers and Remainder Up-Counter •• 3-8

Line Spacing Increment and Line Spacing Reset ••••• 3-9

Line Spacing Memory••••••••••··•·•···••••••••••••• 3-10

Scan Line Counter and White Line Generator·••••••• 3-10

H Bar Generator and Staircase Generator•·•••·••••• 3-11

Bounce Generator and Program Logic •••••••••••••••• 3-13

VERTICAL SYNC, POWER SUPPLY (Diagram 4) •••••••••••••• 3-13

Power Supply••••••••••••·····•••···•···••••••••••• 3-14

End-of-Field Pulse Generator••••··•••·•····•••••·• 3-15

Vertical Blanking Generator•••••••••••·•···••••··· 3-15

Composite Sync Driver·•·••••·••···••····••••••·•·• 3-16

External Video Input••••·•••••••••··•••••••••••••• 3-17

·•••••····••·····••••·•·••••••·•••••-3-4

3-5

ii

Page 5

067-1039-00

r

i

Section 4

PERFORMANCE CHECK AND ADJUSTMENT

INTRODUCTION•••••••••••••••••••••••••••••••••••••••••

HISTORY INFORMATION••••••••••••••••••••••••••••••••••

RECOMMENDED TEST EQUIPMENT•••••••••••••••••••••••••••

PERFORMANCE CHECK ••••••••••••••••••••••••••••• ; ••••••

INCOMING INSPECTION••••••••••••••••••••••••••••••••••

PRELIMINARY PREPARATION••••••••••••••••••••••••••••••

PERFORMANCE CHECK PROCEDURE••••••••••••••••••••••••••

Check White Level•••••••••••••••••••••••••••••••••

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check Interlace

ADJUSTMENT ••••••••••••••••••••••••••••••••••••••• • • • •

PRELIMINARY PREPARATION••••••••••••••••••••••••••••••

Adjust Power Supply··••••·•·•·•••••••••··•••••••••

Adjust Horizontal Active Time•••••••·•··•·••••••·•

Adjust Internal Horizontal Timing·•••·•·•••••••••·

Ajust Levels••••·····•••·•·•··•·••••••······••••·•

Adjust Staircase•·•••·••·••••···••••••··•·••••·••·

Adjust Crosshatch Width•••·••••·•••··•··••••••···•

Adjust Interlace•·•••••··••••••·····••••••·•••••••

Grey Level·•••••····••••••••••······•···•·••

Blanking Level ..............................

Blanking Level Shift••••••••••••••••••••••••

Sync Level·•••••···••••········•••·····••••·

Staircase Steps••·•···••••·••·····•••••••···

Horizontal Active Time••··•···•••·•·····••••

Horizontal Blanking Time·•·•······••••••····

Horizontal Sync Width •••••••••••••••••••••••

TTL White Level•••••••••••••••••••••••••••••

TTL Black Level•••••••••••••••••••••••••••••

...................................

4-1

4-1

4-1

4-3

4-3

4-3

4-3

4-3

4-4

4-5

4-5

4-5

4-5

4-5

4-6

4-7

4-7

4-8

4-9

4-11

4-12

4-13

4-14

4-14

4-15

4-16

4-16

4-16

r

iii

Page 6

067-1039-00

Section 5

MAINTENANCE

PREVENTIVE MAINTENANCE

Cleaning

••••e•••••••eoo•o••aie0oeaee&eoel$easo@0e11ee

Lubrication

Adjustment

TROUBLESHOOTING AIDS

Theory of Operation

Diagrams

eeeaa,•••••••••••eeeeeeooeeeeaoacieoee•ea<&&;i

•••••••••••••efilo~•o•o"61eooee•ee11,1Q@

··········••oeeeeeee•••oeSOQ@OG

Circuit Board Illustrations

Component and Wiring Color Codes ••••••••••••••••••

Testing Equipment

•••••••••eoeooeeooeooe@filGtieeooee@

TROUBLESHOOTING TECHNIQUES •••••••••••••••••••••

Control Settings

Visual Check

Static-Sensitive Components

•••• ., ........... lll41419.tllG0$80090~$1i11a0

eeee<1seeeoai11eoe('leeeea<11eeeeega90Q@O

oe@eoeoooeeeee®aiao@c@eo

Test Equipment

Circuit Isolation

Voltages and Waveforms

Component Checking

Transistors and Integrated Circuits

Diodes

Resistors

Circuit Board Removal

••••••Q••••e••••o•••

e e,eve e e o ••• o •me

o

e e

PARTS ORDERING AND REPLACING

Ordering

USING THE REAR INTERFACE

Input

Output

•••••••••••••••••••••eee111eaa111e@eoeC1oesooee

CONNECTOR

e

0880 O

,a

e

00 O O O O GI Cl O Ge 9 89 e 9 O

•••e•••••••••••••••••oeeeeos1teG8e$eaie0111&oee1a

!I

e e El S

Iii

&11

e

!Iii

&

e

(110

Q

O 9 9 0 GI eeo gee

5-1

5-1

5-1

5-1

5-2

5-2

5=2

5-2

5-2

5-2

5-3

5-3

5-3

5-4

5-5

5=5

5-6

5-6

5-6

5-8

5-8

a•

11

5-8

5-9

5-9

5-10

5-10

5-10

Section 6

Section

REPLACEABLE ELECTRICAL PARTS

7

DIAGRAMS

CHANGE INFORMATION

iv

Page 7

067-1039-00

LIST OF ILLUSTRATIONS

f

Fig. 1-1

Fig. 2-1

Fig. 2-2

Fig. 3-1

Fig. 4-1

Fig. 4-2

Fig. 4-3

Fig. 4-4

Fig. 4-5

Fig. 4-6

Fig. 4-7

Fig. 4-8

Fig. 4-9

Fig. 4-10

Fig. 4-11

Fig.

5-1

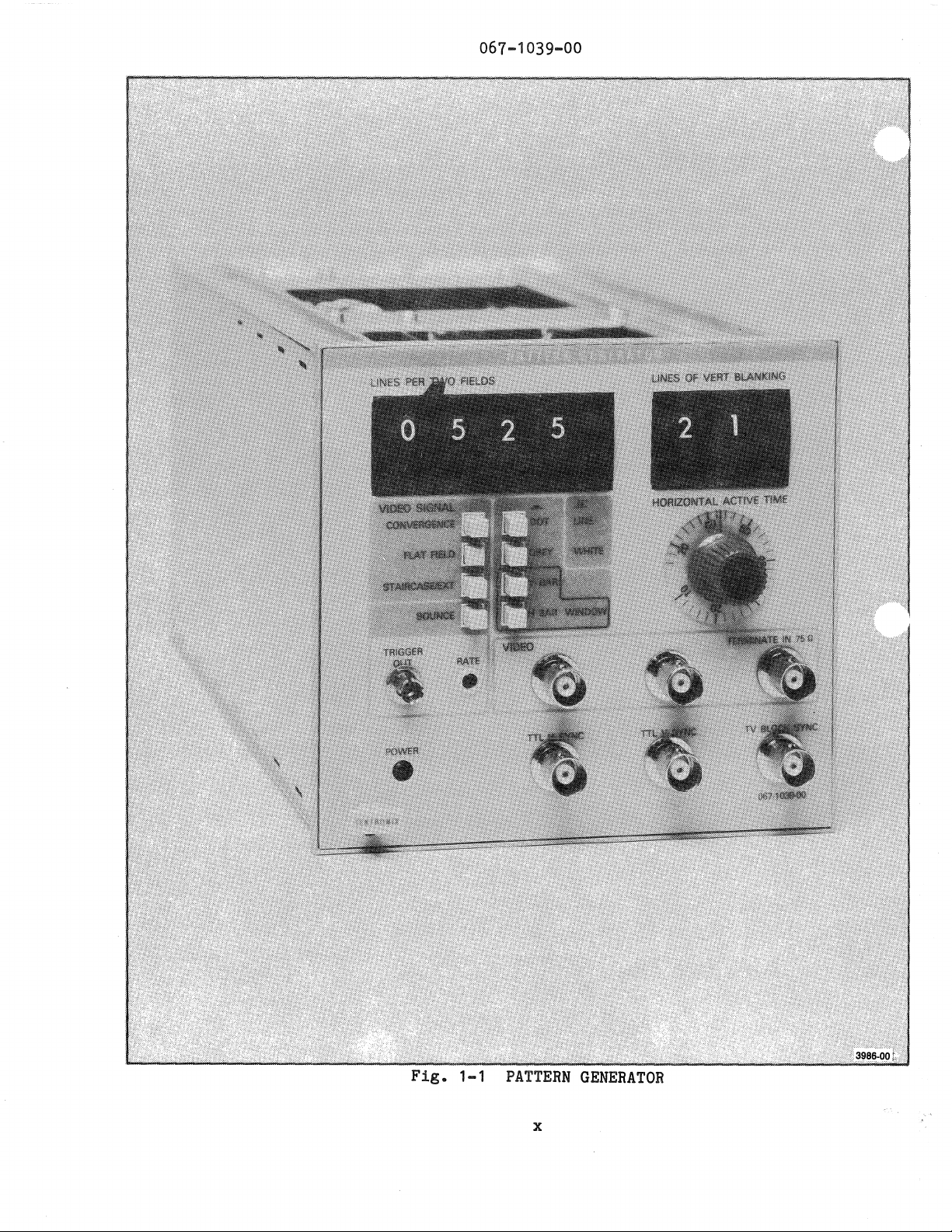

PATTERN GENERATOR•••••••••••••••••••••••••••••••• ix

PATTERN GENERATOR Controls and Connectors••••••••

PATTERN GENERATOR Connections

Monitor with Video Decoder Module •••••••••••• 2-8

Field Rate Staircase Signal•·•••••••••••••••••••· 3-7

Test Equipment Setup for Performance Checks •••••• 4-4

Horizontal Active Time·(70 us) ••••••••••••••••••• 4-6

Horizontal Active Times (10 us) •••••••••••••••••• 4-6

Horizontal Blanking Time•••••••••••••••••••·••··• 4-7

Horizontal Sync Width•••••••••···••·••••••••••··· 4-7

TV to TTL Signal Level Adjustment•••••··•··•·•••• 4-8

Interlace••••·•••••·•••·•·••·•••••••••••••••··••· 4-9

Test Equipment Setup for Adjustment Procedure •••• 4-12

+15 V Adjustment Locations on the Vertical

Sync Generator Board•••••••••·••••••·•••••••· 4-13

Test points and Adjustments Locations on the

Horizontal Sync Generator Board••••·••••••••• 4-15

Adjustments on the Horizontal Line

Generator Board••••••••••·•••·•••·••···•··••· 4-17

Semiconductor Components Basing••••••••••••·••••· 5-7

to

Display

2-4

l

l

l

V

Page 8

Page 9

067-1039-00

OPERATORS SAFETY SUMMARY

The general safety information in this part of the summary is for

both operating and service personnel. Specific warnings and cautions

will be found throughout the manual where they apply, but may not

appear in this summary.

TERMS

In This Manual

CAUTION statements identify conditions or practices that could result

in damage to the equipment or other property.

l

I

l

WARNING statements identify conditions or practices that could result

in personal injury or loss of life.

A1 Marked on lquipment

CAUTION indicates a personal injury hazard not immediately accessible

as one reads the marking, or a hazard to property including the

equipment itself.

DANGER indicates a personal injury hazard immediately accessible as

one reads the marking.

SYMBOLS

In This Manual

This symbol indicates where applicable

cautionary or other information is to

be found.

vii

Page 10

067-1039-00

As Marked On Equipment

DANGER - High Voltage.

Protective ground (earth) terminal.

ATTENTION - Refer to manual.

Power Souroe

This product is intended to operate from a power source that will not

apply more than 250 volts rms between the supply conductors or between

either supply conductor and ground. A protective ground connection by

way of the grounding conductor in the power cord is essential for safe

operation.

Grounding the Produot

This product is grounded through the grounding conductor of the power

cord in the mainframe. To avoid electrical shock, plug the mainframe

power cord into a properly wired receptacle before connecting to the

mainframe input terminals. A protective ground connection

the grounding conductor in the mainframe power cord is essential for

safe operation.

by way

of

na111•r Al'iai111 rrom Losa ot Ground

Upon loss of the protective-ground connection,

conductive parts (including nobs and controls that may

insulating) can render an electric shock.

all accessible

appear to be

Uae the Proper Fuse

To avoid fire hazard, use only a fuse of the proper type, voltage

rating, and current rating as specified in the parts list for your

product.

viii

Page 11

067-1039-00

Do Not

To avoid explosion, do not operate this product in an atmosphere of

explosive gases unless it has been specifically certified for such

operation.

Do Hot Remove Covers or Panels

To avoid personal injury, do not remove the product covers or panels.

Do not operate the product without the covers and panels properly

installed.

Operate

In Explosive Atmospheres

r

ix

Page 12

067-1039-00

Fig.

1-1 PATTERN GENERATOR

X

Page 13

Section1 - 067-1039-00

GENERAL INFORMATION AND SPECIFICATIONS

INTRODUCTION

The 067-1039-00 PATTERN GENERATOR provides a series of video test

signals required to calibrate a multi-rate display monitor (such as

the 690SR Color Display Mainframe). The 690SR can be used with

computer display or television signal sources that use a wide variety

of scanning systems. The PATTERN GENERATOR emulates these scan

systems and provides a selection of test signals for calibrating the

display monitor.

r

l

l

f

l

The PATTERN GENERATOR has three front panel controls that allow it

to emulate the line and field rates of many scan systems, present or

future. The Horizontal Active Time adjustment varies the interval

between the horizontal blanking periods (blanking itself is nominally

6.75 us); the Lines per Two Fields is set to the number of scan lines

of the chosen standard (an odd number generates 2:1 interlace, an even

number is non-interlaced); and the Lines of Vertical Blanking is set

to the number of blanked lines in each field. The Frame Period is

(6.75 us+ Horizontal Active Time) times Lines per Two Fields.

There are

operation of the display monitor. These switches generate the

following patterns:

1. Flat Field (White). Tests purity and colorimetry.

2. Flat Field (Grey). Tests low light level calibration.

3. Convergence (Lines/Dots). Tests convergence, geometry,

linearity, and video amplifier pulse response.

4. Vertical Bar. Tests the video amplifier for line time

distortion and integrity of step response.

5. Horizontal Bar. Tests high voltage supply regulation.

8 pushbutton switches that provide patterns to test the

r

6. Window. Tests crt purity error due to shadow mask heating.

7. Staircase. Tests color balance, nonlinear

video amp limiting. With an external ohrominanoe

differential

gain and differential phase.

1-1

distortion, and

signal, tests

Page 14

General Information - 067-1039-00

8. Bounce. Tests video clamp response and feedback stability in

the beam feedback loop.

OVERVIEW

The Operators part of this manual is intended to help the user

obtain maximum performance from the PATTERN GENERATOR. This part

covers General Information, Specifications, and Operating

Instructions.

The Service Part of this manual covers the Theory of Operation,

the Performance Check and Adjustment section, the Maintenance section,

and. other service information, including the block and schematic

diagrams of the PATTERN GENERATOR.

The eight sections of the manual are:

OPERATORS PART

Section 1 - General Information and Specifications; contains the

instrument description and a listing of the PATTERN GENERATOR

Characteristics and Performance Requirements.

Section 2 - Operating Instructions; introduces the user to the

PATTERN GENERATOR/Display Monitor system and demonstrates the

functions of the front panel controls.

SERYICIIG PART

Section

the PATTERN GENERATOR.

Section 4 - Calibration, Part 1: Performance Check; this

subsection is used to verify all of the Performance Requirements in

the Specification, and to determine the need for recalibration

(adjustment) of the PATTERN GENERATOR.

Section

Procedure; this subsection is used to return the PATTERN GENERATOR to

conformance with the Performance Requirements. The procedure is

arranged in functional blocks to facilitate referencing from the

Performance Check and the Maintenance Instructions.

3 -

Theory of Operation; describes all major circuits of

4 -

Performance Check and Adjustment, Part 2: Adjustment

1-2

Page 15

l

General Information - 067-1039-00

Section 5 - Maintenance Instructions; describes routine and

corrective maintenance with detailed instructions for replacing

assemblies, subassemblies, and individual components.

Section 6 - Replaceable Electrical Parts; provides information

necessary to order replaceable parts and assemblies related to the

electrical functions of the instrument.

Section 7 - Diagrams; provides functional block diagram and

circuit schematics.

Section 8 - Replaceable Mechanical Parts; provides information

necessary to order mechanical parts that are being replaced. The list

is cross-referenced to replaceable electrical parts where appropriate.

The Exploded Diagram shows the assembly sequence and identifies the

assemblies. The Accessories page lists the standard and optional

accesories. (Not present in the interim manual.)

Changes and Corrections; provides updating information for the

manual in the form of inserts. These inserts are incorporated into

the manual text and diagrams when the manual is revised.

r

l

l

l

STANDARDS

The abbreviations

diagrams are based on

Y32.14-1973 (American

Street, New York, N.

and graphic symbols

ANSI Y1.1-1972, ANSI

National Standards

Y. 10017)

used in the

Y32.2 1970,

Institute, 345

text and

and ANSI

East 47

1-3

Page 16

Specification - 067-1039-00

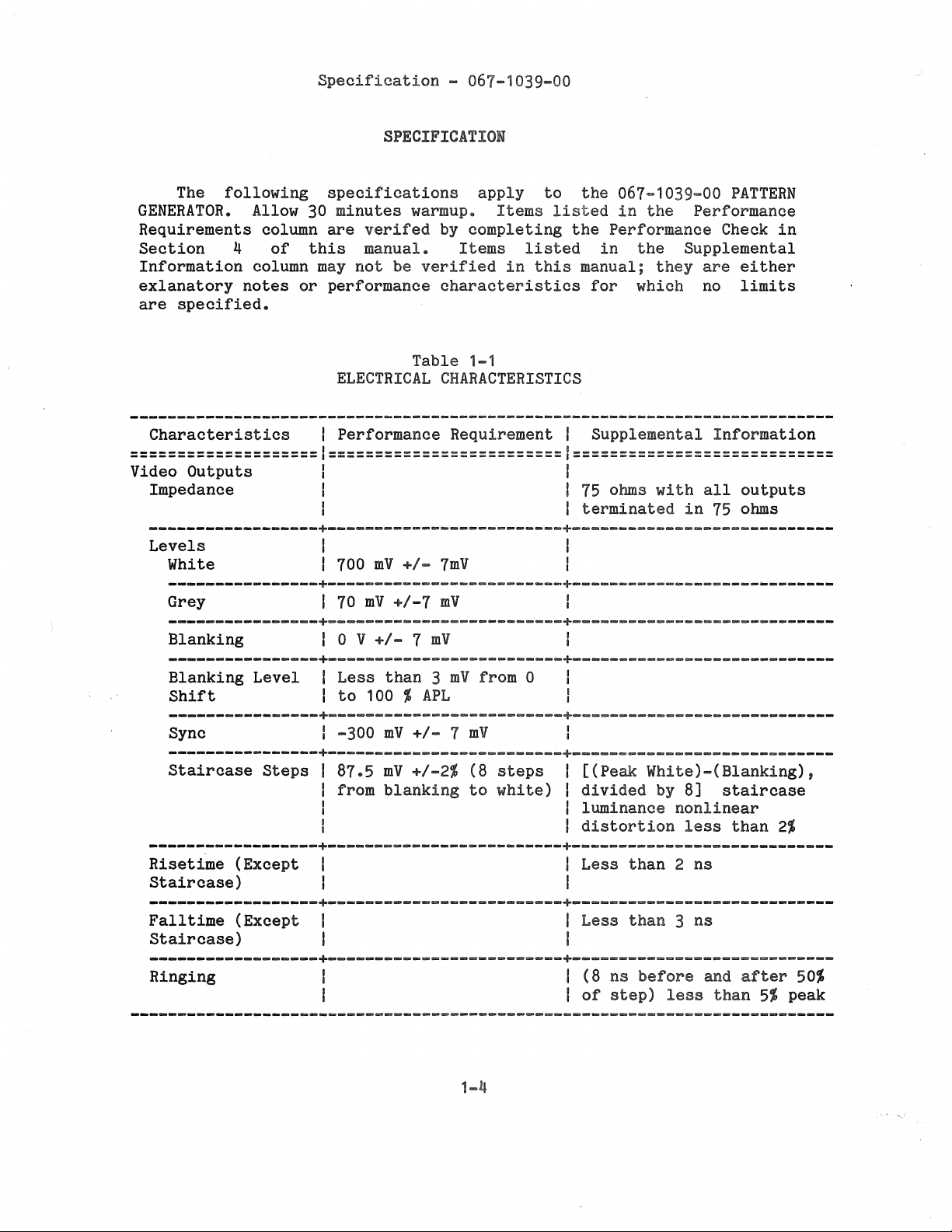

SPECIFICATION

The following specifications apply to the 067-1039-00 PATTERN

GENERATOR. Allow 30 minutes warmup. Items listed in the Performance

Requirements column are verifed by completing the Performance Check in

Section 4 of this manual. Items listed in the Supplemental

Information column may not be verified in this manual; they are either

exlanatory notes or performance characteristics for which no limits

are specified.

Table 1-1

ELECTRICAL CHARACTERISTICS

Characteristics

I Performance Requirement I Supplemental Information

====================l=========================I============================

Video Outputs I I

Impedance I I 75 ohms with all outputs

I I terminated in 75 ohms

------------------+-------------------------+----------------------------

Levels

White

----------------+-------------------------+----------------------------

Grey

----------------+-------------------------+----------------------------

Blanking

----------------+-------------------------+----------------------------

Blanking Level

Shift

----------------+-------------------------+----------------------------

Sync

----------------+-------------------------+----------------------------

Staircase Steps

------------------+-------------------------+----------------------------

Risetime (Except

Staircase)

I

I 700 mV +/- 7mV

I 70 mV +/-7 mV

I O V +/- 7 mV

I Less than 3 mV from 0

I to 100 % APL

I -300 mV +/- 7 mV

87.5 mV +/-2% (8 steps

from blanking to white)

[(Peak White)-(Blanking),

divided by 8] staircase

luminance nonlinear

distortion less than 2%

I Less than 2 ns

I

------------------+-------------------------+----------------------------

Falltime (Except

Staircase)

------------------+-------------------------+----------------------------

Ringing

1-4

I Less than 3 ns

I

I (8 ns before and after 50%

I of step) less than 5% peak

Page 17

Specification - 067-1039-00

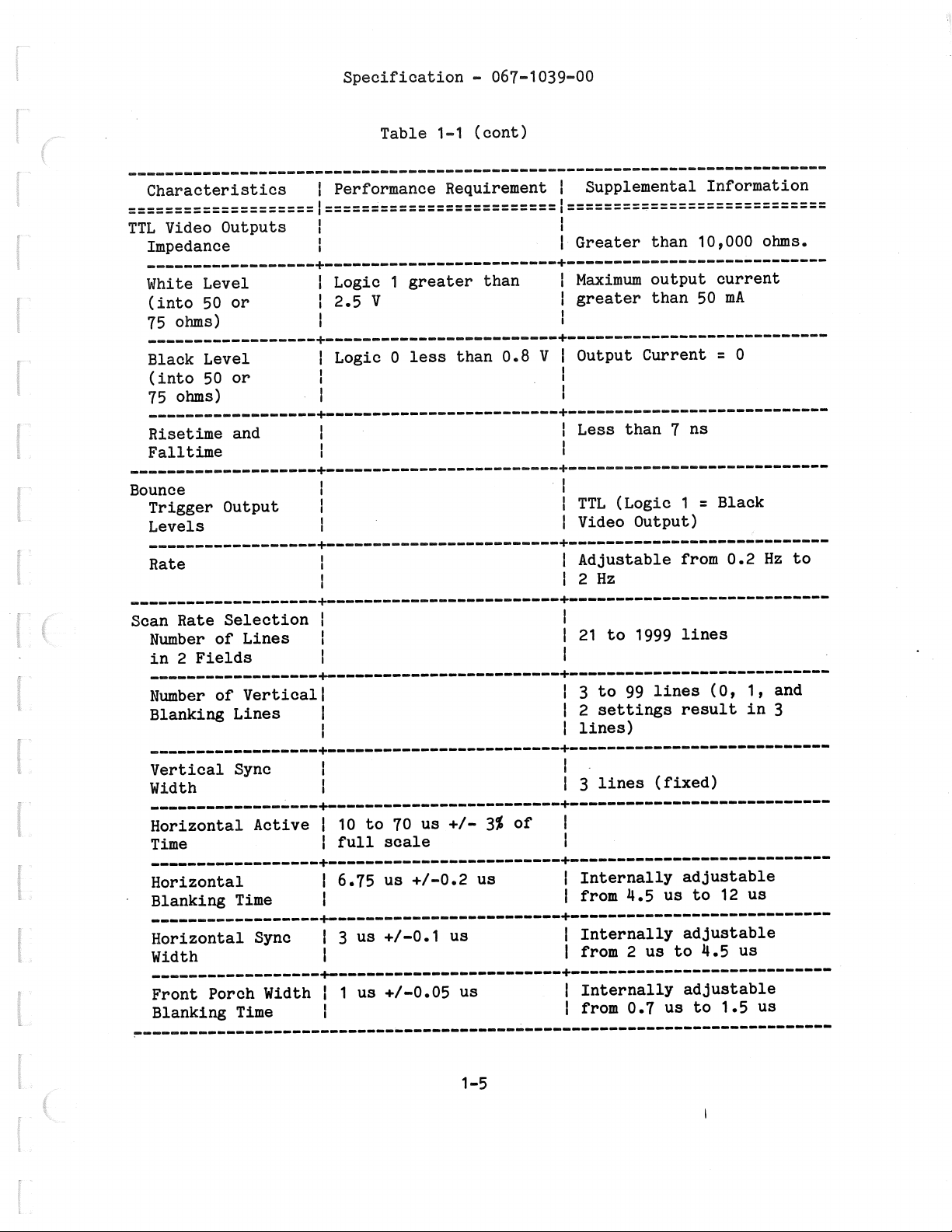

Table 1-1 (cont)

Characteristics I Performance Requirement I Supplemental Information

====================l=========================I======== ===========-=~=====

TTL Video Outputs

Impedance

I I

Greater than 10,000 ohms.

I

[

l

------------------+-------------------------+----------------------------

White Level

(into 50 or

75 ohms)

------------------+-------------------------+---------------------------~

Black Level

(into 50 or

75 ohms)

------------------+-------------------------+----------------------------

Risetime and

Fall time

--------------------+-------------------------+----------------------------

Bounce

Trigger Output

Levels

------------------+-------------------------+----------------------------

Rate

--------------------+-------------------------+----------------------------

Scan Rate Selection

Number of Lines

in 2 Fields

------------------+-------------------------+----------------------------

Number of Vertical!

Blanking Lines

Logic 1 greater than

I

2.5 V

I

Logic O less than 0.8 V Output Current= 0

I

I Maximum output current

I greater than 50 mA

I

Less than 7 ns

I

I

I

TTL (Logic 1 = Black

I

Video Output)

I

Adjustable from 0.2 Hz to

I

Hz

2

I

I

21 to 1999 lines

I

I

3 to 99 lines

I

2 settings result in 3

I

lines)

I

(O,

'

1, and

I

[

------------------+-------------------------+----------------------------

Vertical Sync

Width

------------------+-------------------------+----------------------------

Horizontal Active

Time

------------------+-------------------------+----------------------------

Horizontal

Blanking Time

------------------+-------------------------+----------------------------

Horizontal Sync

Width

------------------+-------------------------+----------------------------

Front Porch Width

Blanking Time

10 to 70 us+/- 3% of

I

full scale

I

6.75 us +/-0.2 us

I

I

us +/-0.1 us

I 3

I

1 us +/-0.05 us

l

I

3 lines (fixed)

I

Internally adjustable

I

from 4.5 us to 12 us

I

Internally adjustable

I

from 2 us to 4.5 us

I

Internally adjustable

I

from 0.7 us to 1.5 us

I

~--------------------------------------------------------------------------

1-5

Page 18

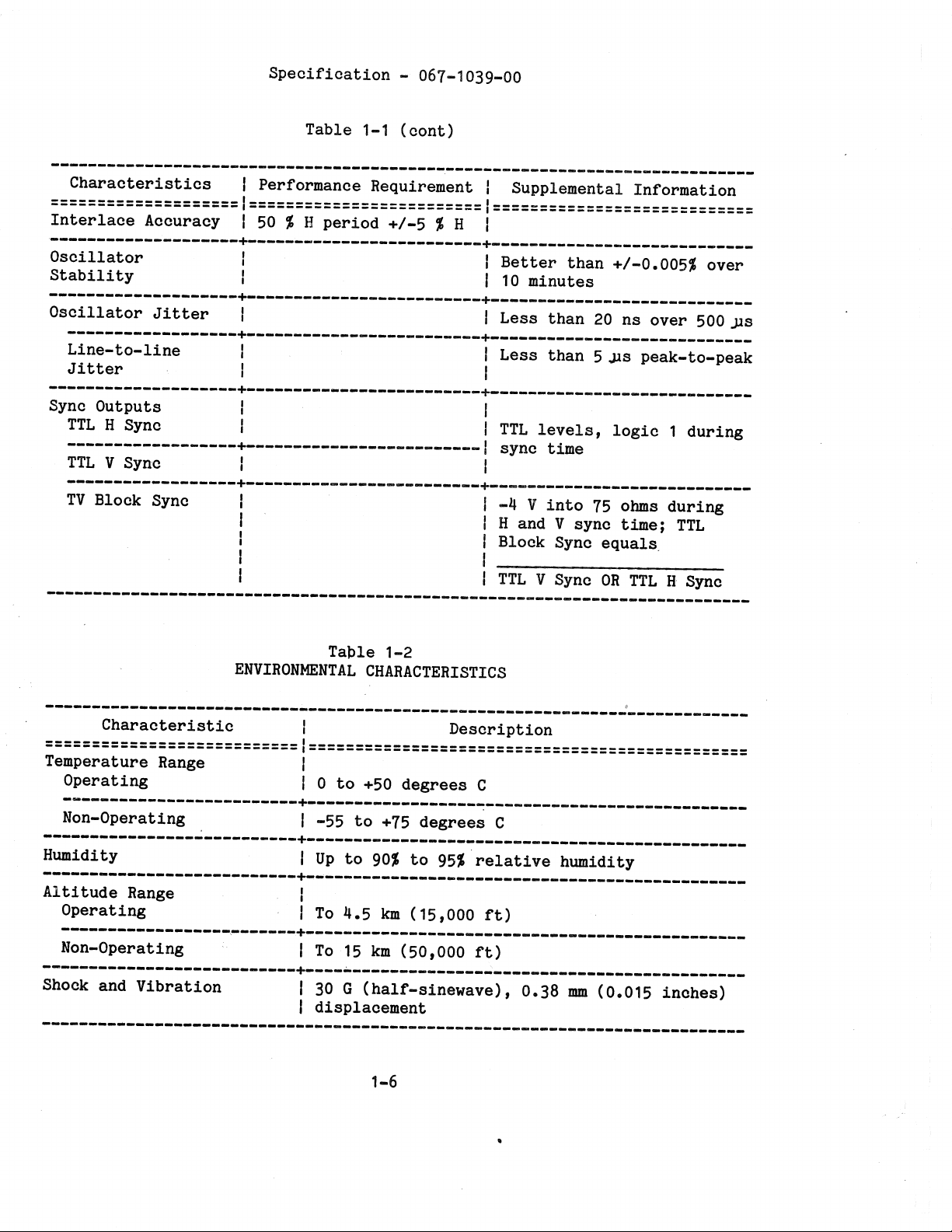

Specification -

Table 1-1 (cont)

067-1039-00

Characteristics

I

Performance Requirement

I

Supplemental Information

====================l=========================I============================

Interlace Accuracy

--------------------+-------------------------+----------------------------

Oscillator

Stability

--------------------+-------------------------+----------------------------

Oscillator Jitter

------------------+-------------------------+----------------------------

Line-to-line

Jitter

--------------------+-------------------------+----------------------------

Sync Outputs

TTL H Sync

------------------+-------------------------1

TTL V Sync

------------------+-------------------------+----------------------------

TV Block Sync

I

50

%

H

period

I I

I I

I I

I I

I I

+/-5

%

H

I

Better than

10

minutes

Less than

I

Less than

I

TTL levels, logic

sync time

-4 V

Hand

Block Sync equals

TTL V Sync OR TTL H Sync

into

V

+/-0.005%

20

ns over

5

JlS

peak-to-peak

1

75

ohms during

sync time; TTL

over

500

during

ps

Table

ENVIRONMENTAL CHARACTERISTICS

---------------------------------------------------------------------------

Characteristic

I

1-2

'

Description

===========================I=====~=========================================

Temperature Range

Operating

-------------------------+------------------~----------------------------

Non-Operating

---------------------------+-----------------------------------------------

Humidity

---------------------------+-----------------------------------------------

Altitude Range

Operating

I

I

Oto

I

-55

I

Up to

I

I

To

+50

to

90%

4.5

degrees C

+75

degrees C

to

km

(15,000

95%

relative humidity

ft)

-------------------.-------+-----------------------------------------------

Non-Operating

---------------------------+-----------------------------------------------

Shock and Vibration

I

To

15

km

I

30

G (half-sinewave),

I

displacement

1-6

(50,000

ft)

0.38

mm

(0.015

inches)

Page 19

Specification - 067-1039-00

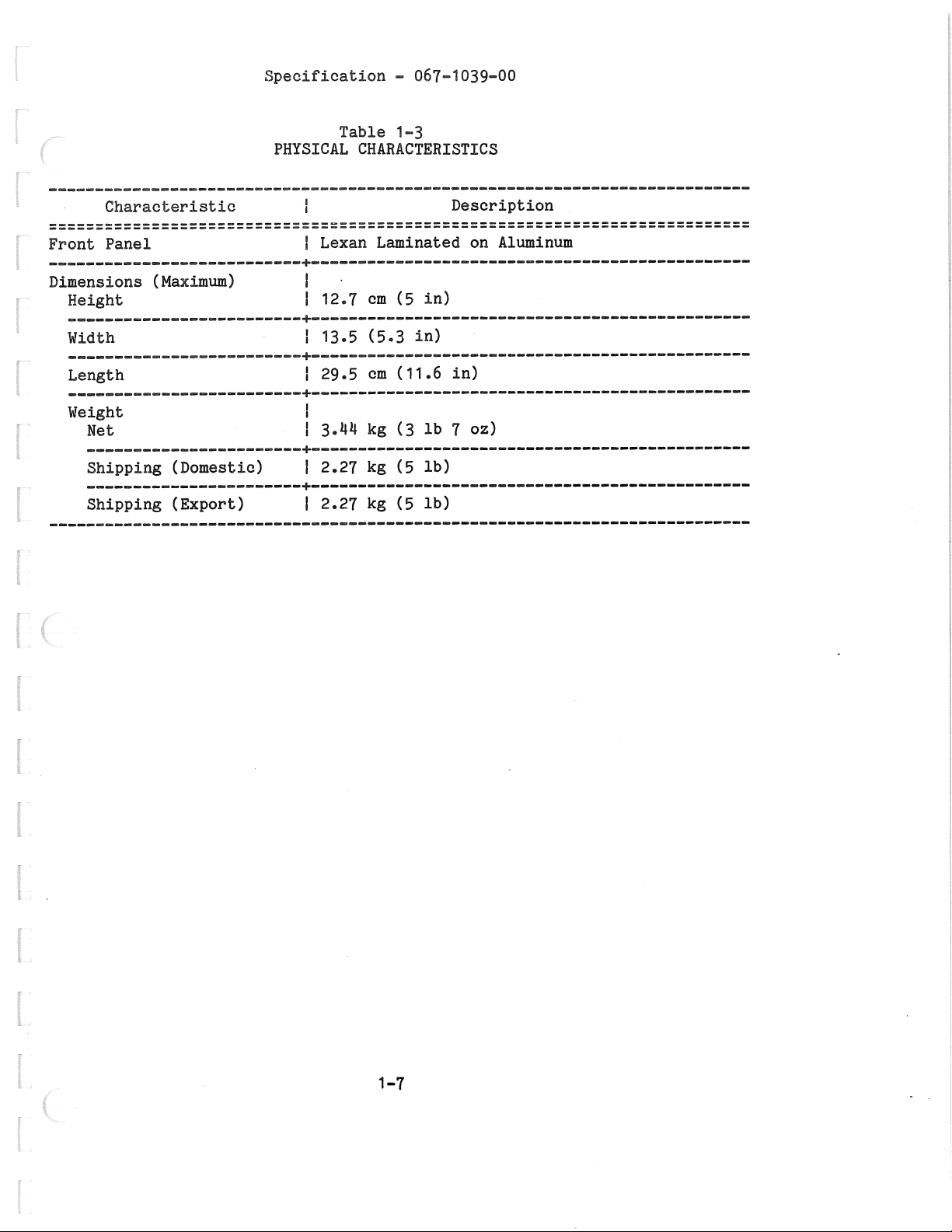

Table 1-3

PHYSICAL CHARACTERISTICS

Characteristic

------------------------------~--------------------------------------------

---------------------------------------------------------------------------

Front Panel Lexan Laminated on Aluminum

---------------------------+-----------------------------------------------

Dimensions (Maximum)

(5

Height 12.7

--------------------=----+-----------------------------------------------

Width

-------------------------+-----------------------------------------------

Length 29.5

-------------------------+-----------------------------------------------

Weight

Net

-----------------------+-----------------------------------------------

Shipping (Domestic) 2.27 kg (5 lb)

-----------------------+-----------------------------------------------

Shipping (Export)

I

cm

13.5 (5.3 in)

(11.6 in)

cm

(3

kg

3.44

2.27 kg (5 lb)

Description

in)

oz)

7

lb

1-7

Page 20

Page 21

Section 2 - 067-1039-00

OPERATING INSTRUCTIONS

INTRODUCTION

This section describes the functions of the PATTERN GENERATOR,

the installation procedure, the controls and connectors, and the

checkout procedure.

ABOUT THE PATTERN GENERATOR

f

r

l

l

The 067-1039-00 PATTERN GENERATOR is a two-wide instrument that

plugs into a TM 500 mainframe. It provides a series of video test

signals required to test a multi-rate display monitor (such as the

690SR Color Display Mainframe). This monitor is suitable for computer

displays and broadcast television; with the aid of the PATTERN

GENERATOR, it can be calibrated to any scan rate within its operating

range.

By setting Horizontal Active Time, Lines per Two Fields, and Lines

of Vert Blanking, the PATTERN GENERATOR can emulate the scan system

that will be used with display monitor. The monitor can then be

calibrated with the pushbutton-selected signals provided by the

PATTERN GENERATOR.

INSTALLATION

The PATTERN GENERATOR was inspected both mechanically and

electrically before shipment. It should be free of mars or scratches

and electrically meet or exceed all specifications. Inspect the

instrument for physical damage incurred in transit and check the

electrical performance by following the Operators Checkout Procedure

in this section. If there is a problem, contact your local Tektronix

Field Office or representative.

I

2-1

Page 22

Operating Instructions - 067-1039-00

NOTE

If the PATTERN GENERATOR is used with a NTSC display

monitor, the Horizontal Blanking Time should be changed

from 6.75 .usec. to 11.1 ..usec. This is an internal

adjustment and should be performed by a qualified

technician. Refer to Section 4 for the °Calibrate

Internal Horizontal Timing

0

procedure.

REPACKAGING

Save and re-use the PATTERN GENERATOR shipping container. If the

original container is not available or is damaged, repackage the

PATTERN GENERATOR as follows:

1. Attach a tag to the PATTERN GENERATOR that shows: name and

address of the firm, name of the person responsible for the PATTERN

GENERATOR, serial number, and a description of the service required.

2. Obtain a shipping container made of heavy corrugated cardboard

or wood. To allow for cushioning, make sure that the inside

dimensions are no less than 12 by 12 by 18 inches (300 by 300 by 450

mm). This container should have a carton test strength of no less

than 275 pounds (605 kg).

3. To protect the finish of the PATTERN GENERATOR, wrap it in

heavy· paper or polyethylene. Protect the front panel with urethane

foam or strips of cardboard.

4. Cushion the PATTERN GENERATOR by tightly packing urethane foam

or dunnage between the PATTERN GENERATOR and the shipping container.

Allow at least

5. Seal the container with shipping tape or an industrial

stapler.

If there are any questions, contact the nearest Tektronix Field

Office or representative.

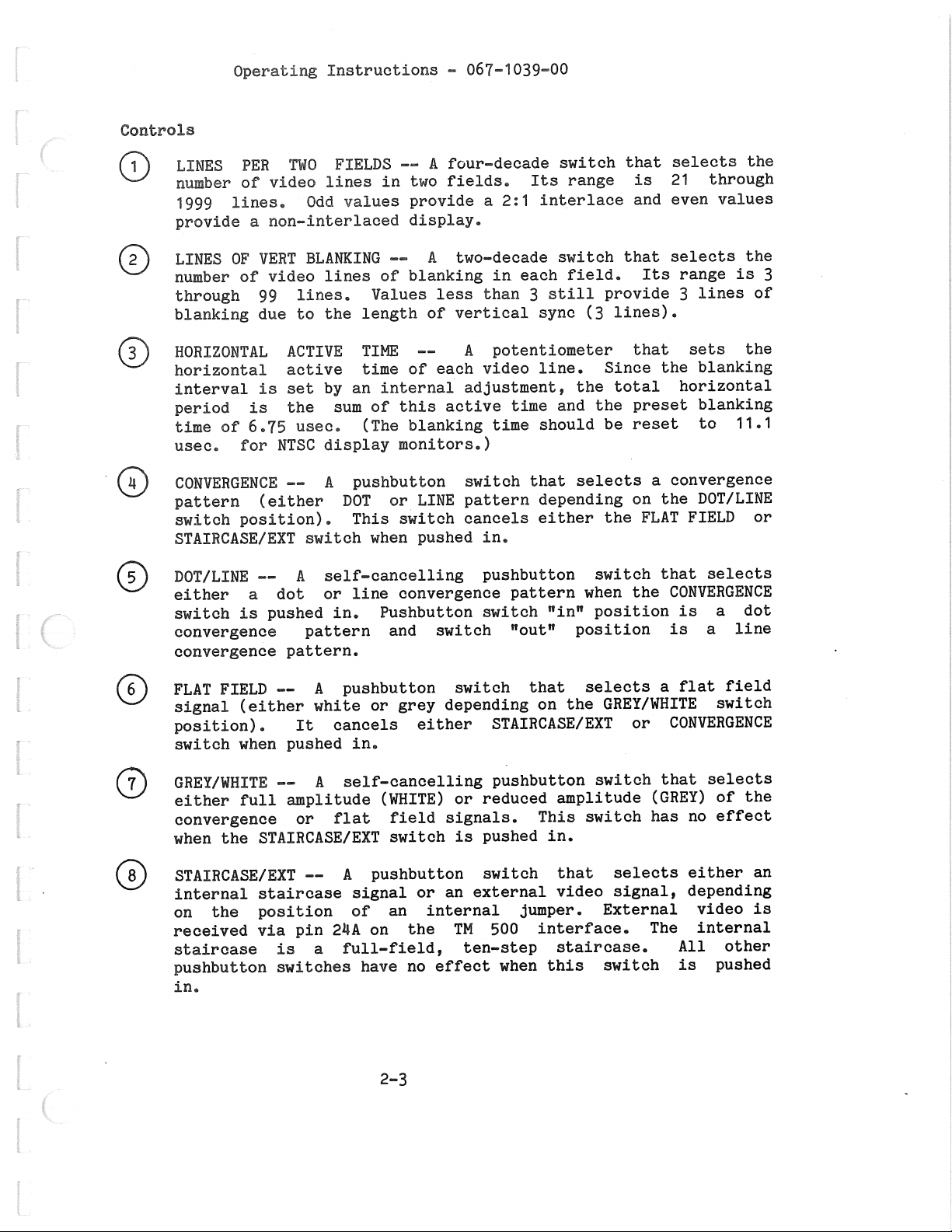

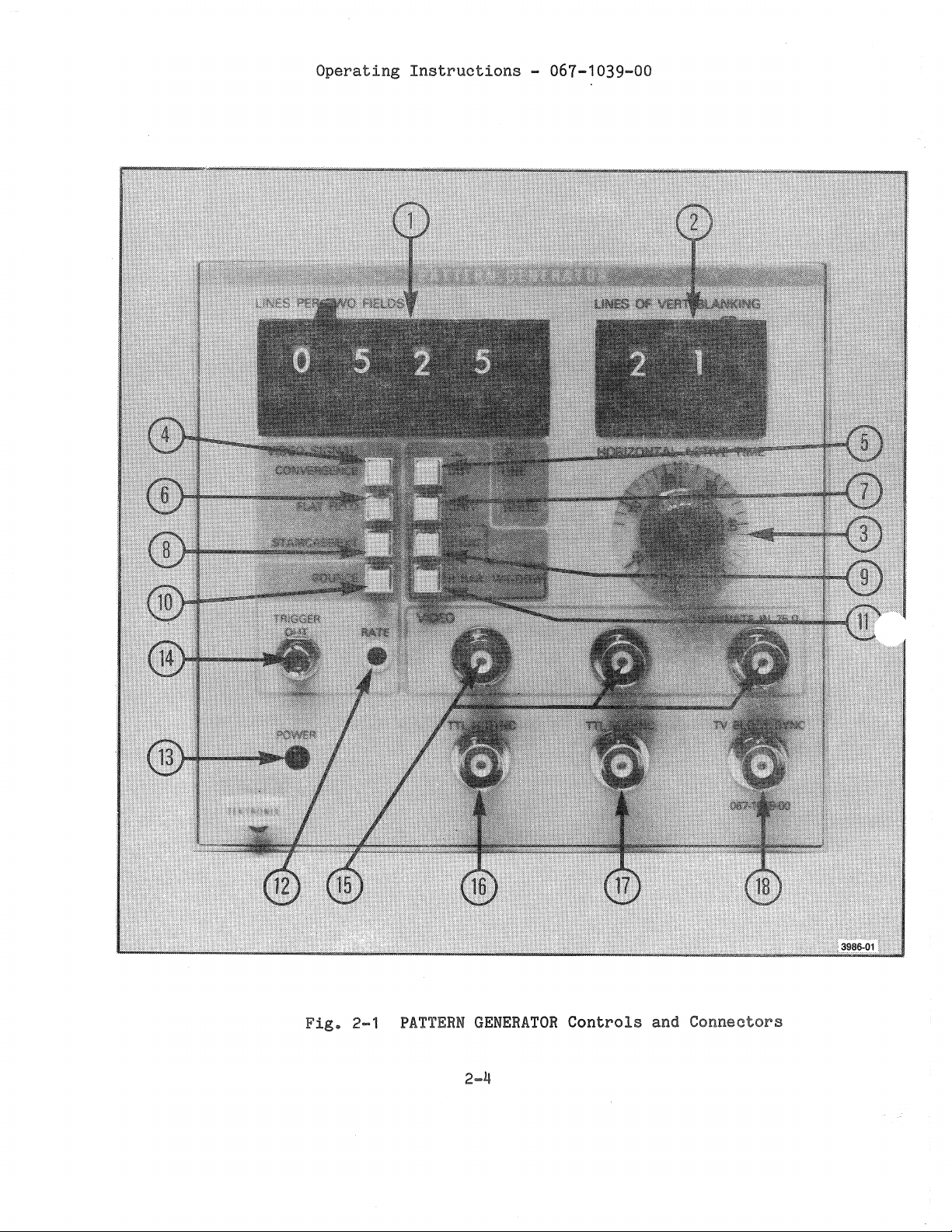

FUNCTIONS OF CONTROLS, INDICATORS, AND CONNECTORS

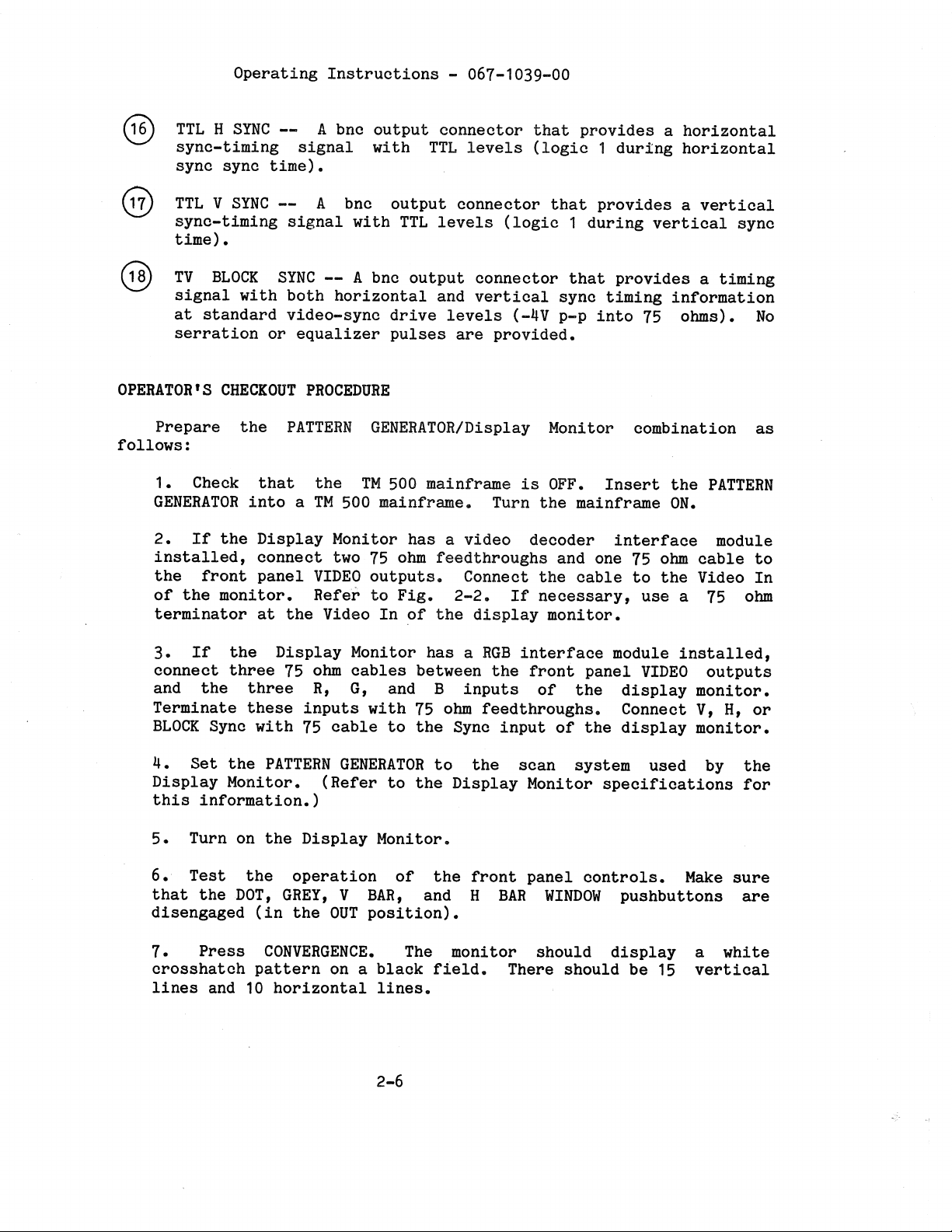

The front panel controls and connectors are shown in Fig. 2-1 and

numbered to match the text.

3 inches (75 mm) on all sides.

2-2

Page 23

Controls

Operating Instructions - 067-1039-00

f

0

0

0

©

LINES PER TWO FIELDS -- A four-decade switch that

number of video lines in two fields. Its range is

1999 lines. Odd values provide a 2:1 interlace and

provide a non-interlaced display.

LINES OF VERT BLANKING -- A two-decade switch that selects the

number of video lines of blanking in each field. Its range is 3

through 99 lines. Values less than 3 still provide 3 lines of

blanking due to the length of vertical sync (3 lines).

HORIZONTAL ACTIVE TIME A potentiometer that sets the

horizontal active time of each video line. Since the blanking

interval is set by an internal adjustment, the total horizontal

period is the sum of this active time and the preset blanking

time of 6.75 usec. (The blanking time should be reset to 11.1

usec. for NTSC display monitors.)

CONVERGENCE -- A pushbutton switch that selects a convergence

pattern (either DOT or LINE pattern depending on the DOT/LINE

switch position). This switch cancels either the FLAT FIELD or

STAIRCASE/EXT switch when pushed in.

DOT/LINE -- A self-cancelling pushbutton switch that selects

either a dot or line convergence pattern when the CONVERGENCE

switch is pushed in. Pushbutton switch "in" position is a dot

convergence pattern and switch "out" position is a line

convergence pattern.

selects the

21 through

even values

l .

i

t

l

©

0

0

FLAT FIELD -- A pushbutton switch that selects a flat field

signal (either white or grey depending on the GREY/WHITE switch

position). It cancels either STAIRCASE/EXT or CONVERGENCE

switch when pushed in.

GREY/WHITE -- A self-cancelling pushbutton switch that selects

either full amplitude (WHITE) or reduced amplitude (GREY) of the

convergence or flat field signals. This switch has no effect

when the STAIRCASE/EXT switch is pushed in.

STAIRCASE/EXT -- A pushbutton switch that selects either an

internal staircase signal or an external video signal, depending

on the position of an internal jumper. External video is

received via pin 24A on the TM 500 interface. The internal

staircase is a full-field, ten-step staircase. All other

pushbutton switches have no effect when this switch is pushed

in.

2-3

Page 24

Operating Instructions - 067-1039-00

Fig. 2-1 PATTERN GENERATOR Controls and Connectors

2-4

Page 25

V BAR A self-cancelling pushbutton switch that inserts a

vertical bar into the convergence-pattern signal or adds a

vertical bar to

STAIRCASE/EXT switches in the "out" position). When both the

BAR and

resulting signal is a WINDOW signal.

@

@

@

Indicators

H BAR

horizontal bar in the same manner as the

BOUNCE

video pattern to be periodically blanked to black with a 50

squarewave whose period (RATE) is adjustable from 0.2

Hz. This switch does not affect the video pattern when the

STAIRCASE/EXT switch is in the "in" position.

RATE (BOUNCE)

varies the bounce rate from 0.2

Operating Instructions - 067-1039-00

black pattern (CONVERGENCE, FLAT FIELD, and

a

BAR switches are depressed at the same time, the

H

self-cancelling pushbutton switch that inserts a

A

self-cancelling pushbutton switch that causes the

A

front-panel screwdriver adjustment that

A

2 Hz.

to

Hz

BAR switch.

V

Hz

to

V

%

2

@

Connectors

@

@

POWER

whenever power is applied to the instrument.

TRIGGER OUT -- A probe tip output connector that provides a TTL

signal that is synchronous with the bounce transition. This

signal is used to trigger a test oscilloscope so that the clamp

response and beam current feedback stability of the 690SR can be

easily measured.

VIDEO -- Three bnc output connectors driven at TTL or composite

video levels depending on the position of an internal jumper.

Each connector is intended to drive a 75 ohm load, and all three

connectors are driven by a common driver to eliminate any timing

errors. Source-termination resistors provide proper reflection

termination when each connector is terminated in 75 ohms.

These connectors are provided to drive RGB monitors. Monitors

with only one input would use one of the output connectors with

the other two output connectors terminated in 75 ohms.

red light-emitting dioe (LED) that illuminates

A

NOTE

The unit receives its power from any TM 500 mainframe.

2-5

Page 26

Operating Instructions - 067-1039-00

@

@

OPERATOR'S CHECKOUT PROCEDURE

follows:

TTL H SYNC -- A bnc output connector that provides a horizontal

sync-timing signal with TTL levels (logic 1 during horizontal

sync sync time).

TTL V SYNC -- A bnc output connector that provides a vertical

sync-timing signal with TTL levels (logic 1 during vertical sync

time).

TV BLOCK SYNC -- A bnc output connector that provides a timing

signal with both horizontal and vertical sync timing information

at standard video-sync drive levels (-4V p-p into 75 ohms). No

serration or equalizer pulses are provided.

Prepare the PATTERN GENERATOR/Display Monitor combination as

1. Check that the TM 500 mainframe is OFF. Insert the PATTERN

GENERATOR into a TM 500 mainframe. Turn the mainframe ON.

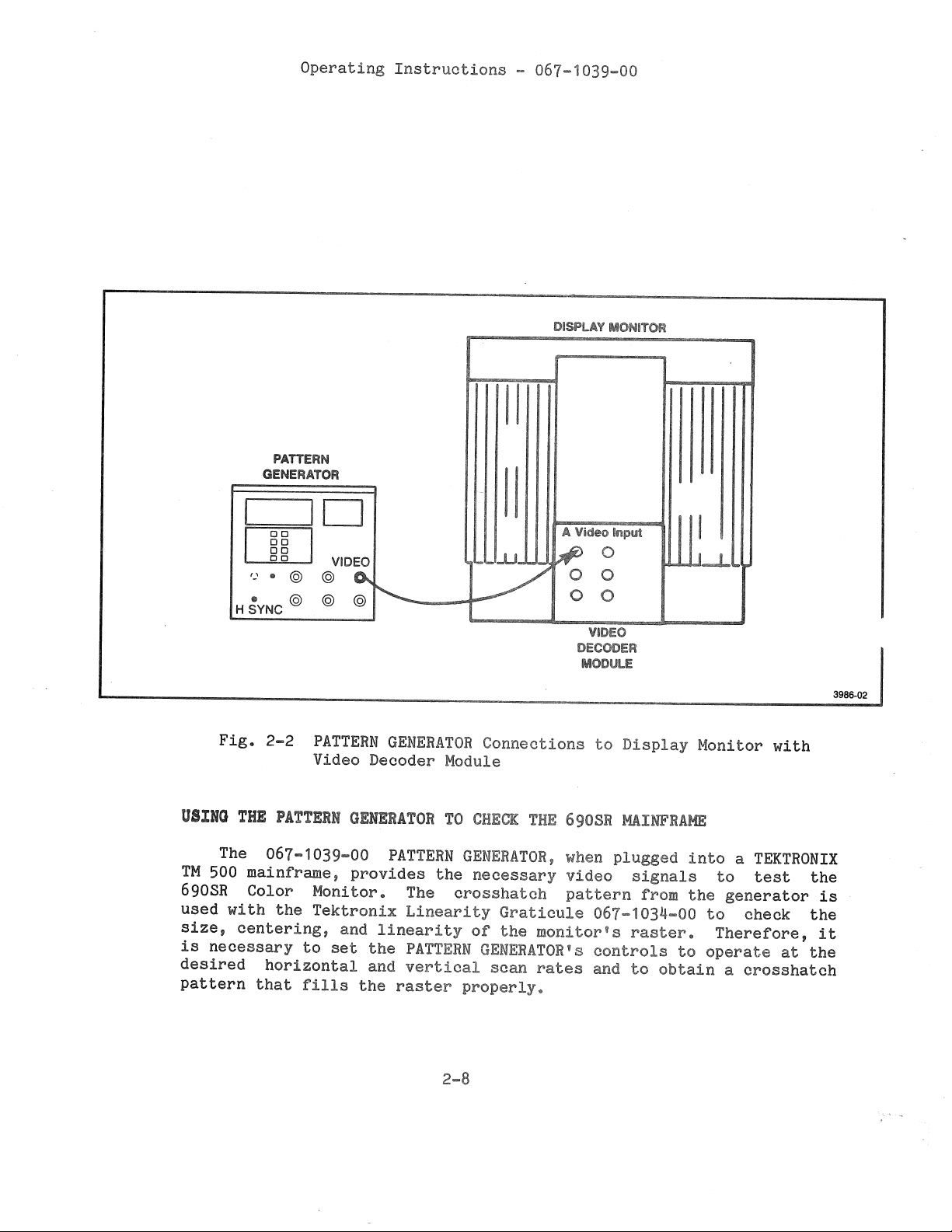

2. If the Display Monitor has a video decoder interface module

installed, connect two 75 ohm feedthroughs and one 75 ohm cable to

the front panel VIDEO outputs. Connect the cable to the Video In

of the monitor. Refer to Fig. 2-2. If necessary, use a 75 ohm

terminator at the Video In of the display monitor.

3.

If the Display Monitor has a RGB interface module installed,

connect three 75 ohm cables between the front panel VIDEO outputs

and the three R, G, and B inputs of the display monitor.

Terminate these inputs with 75 ohm feedthroughs. Connect V, H, or

BLOCK Sync with 75 cable to the Sync input of the display monitor.

4. Set the PATTERN GENERATOR to the scan system used by the

Display Monitor. (Refer to the Display Monitor specifications for

this information.)

5. Turn on the Display Monitor.

6.

Test the operation of the front panel controls. Make sure

that the DOT, GREY, V BAR, and H BAR WINDOW pushbuttons are

disengaged (in the OUT position).

7.

crosshatch pattern on a black field. There should be 15 vertical

lines and 10 horizontal lines.

Press CONVERGENCE. The monitor should display a white

2-6

Page 27

Operating Instructions - 067-1039-00

Press DOTS. The crosshatch should change into a pattern of

8.

dots. Disengage DOTS.

Press

9.

crosshatch pattern.

10. Press

center of the crosshatch pattern. Disengage

horizontal bar should appear across the crosshatch pattern.

Disengage

11. Press FLAT FIELD. The monitor should display a flat field at

white level (700 mV).

12. Press GREY. The monitor should display a grey field (10% or

70 mV). Disengage GREY.

13. Press BOUNCE. The monitor should display an alternating

black and white field at a rate controlled by the RATE adjustment.

The adjustment covers a range of 0.2 Hz to 2 Hz. Disengage

BOUNCE.

14. Press STAIRCASE/EXT. A full-field monochrome staircase

should appear on the monitor.

This completes the Operators Checkout Procedure. For further

information on calibrating the Display Monitor with these test

signals, consult the manual of the Display Monitor.

V BAR. A

H BAR

BAR WINDOW.

H

white vertical bar should appear across the

white window should appear in the

WINDOW.

A

V BAR;

a white

2-7

Page 28

Operating Instructions - 067-1039-00

11

PATTERN

GENERATOR

'=I

~ID

1

CID

,_, &l

@

©

H SYNC

Fig. 2-2 PATTERN GENERATOR Connections

@

•.J.~UJ~,.&'I~ 0

~b..A..i'

A Vici@@

0 0

0 0

VIDEO

DECOD~R

MODULE

to

ifl!)Ut

Display Monitor with

Video Decoder Module

USING THE PATTERN GENERATOR TO CHECK THE

690SR MAINF'RAME

The 067-1039-00 PATTERN GENERATOR, when plugged into a TEKTRONIX

TM 500 mainframe, provides the necessary video signals to test the

690SR

Color Monitor. The crosshatch pattern from the generator is

used with the Tektronix Linearity Graticule 067-1034-00 to check the

sizep centering, and linearity of the mm1itor's raster. Therefore,

is

necessary

to set the PATTERN GENERATORWs controls to operate at the

it

desired horizontal and vertical scan rates and to obtain a crosshatch

pattern that fills the raster properly.

3986-02

Page 29

Operating Instructions - 067-1039-00

NOTE

Simply setting the PATTERN GENERATOR controls to provide

signals that are equivalent to the user's system may not

permit checking the 690SR mainframe performance

properly.

The PATTERN GENERATOR front-panel control settings given in the

equipment setup illustrations are set to generate a 31.5 kHz scan rate

and a 60.6 Hz field rate. The Horizontal Active Time control is set

to 25 .,us since 25 JJ.S active time plus 6. 75 .J.IS horizontal blanking time

horizontal period to generate a 31.5 kHz scan

is equal to 31.75

.JlS

rate. (The PATTERN GENERATOR blanking time is factory set at 6.75 .).ls

to match the 690SR raster blanking time.) The Lines of Vertical

Blanking switch is set to obtain approximately 600 J.lS vertical

blanking time. (The 18 lines chosen times 31.75.J.ls is equal to 572

ps.) The Lines Per Two Fields switch is set to obtain an approximate

60 Hz field rate and at the same time produce full top and bottom

crosshatch lines that coincide with the top and bottom edges,

respectively, of the raster.

NOTE

If the Lines Per Two Fields switch is set to an odd

number; for example, 1039, the display may appear to

flicker because the display is interlaced. To obtain a

non-interlaced display, set the switch to an even

number. When preparing this manual, the Lines Per Two

Fields switch was set to 1040.

If the 690SR mainframe is being operated at a horizontal and/or

vertical scan rate other than 31.5 kHz and approximately 60 Hz

respectively, or if the horizontal blanking time is not 6.75.JJ.s, then

use the following procedure as an aid for setting the PATTERN

GENERATOR controls to properly check the 690SR mainframe.

Measure the vertical scan period, the horizontal scan period,

1.

and horizontal blanking time of the monitor's intended signal

source or obtain their specification.

Compute the horizontal active time

2.

blanking time from the H scan period.

by subtracting

For example:

the H

31.75JlS - 6.75JlS: 25.)J.S.

2-9

Page 30

Operating Instructions - 067-1039-00

a. Set the Horizontal Active Time control on the PATTERN

GENERATOR to the computed horizontal active time value.

b. If the H blanking time is other than 6.75,J.ls and precise

linearity adjustment is required, recalibrate the PATTERN

GENERATOR's horizontal blanking time. (Refer to step 11

in the Adjustment Procedure of this 690SR manual.) (For

quick monitor setups when the linearity requirement is

less critical, the horizontal blanking time need not be

recalibrated. Instead, use 6.75Jls during the Performance

Check Procedure. Then, readjust the 690SR H Size control,

R925, on A8A1 after completing the Performance Check

Procedure so the displayed picture from the monitor's

intended signal source will be the proper width.)

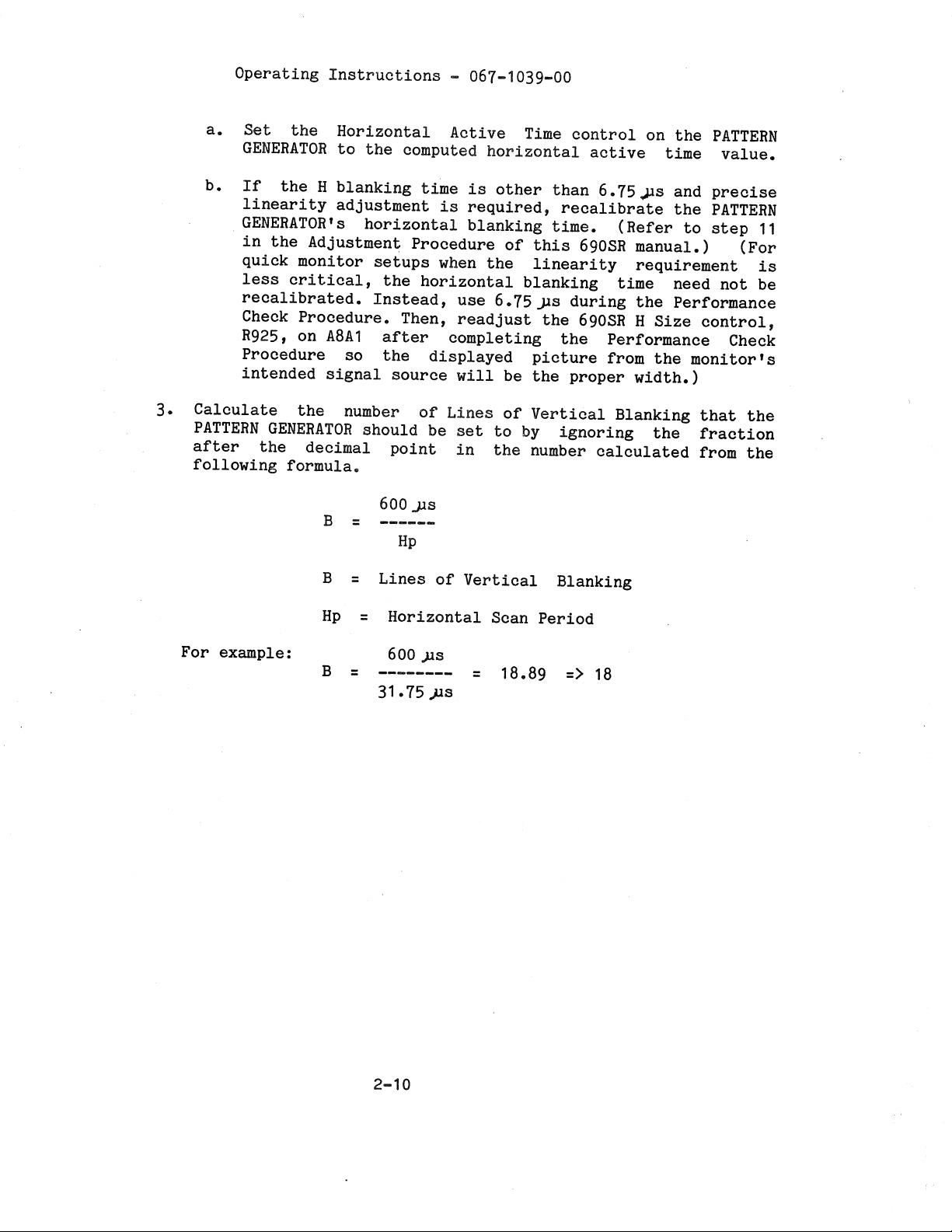

3. Calculate the number of Lines of Vertical Blanking that the

PATTERN GENERATOR should be set to

after the decimal point in the number calculated from the

following formula.

600

J.lS

B

------

=

Hp

by

ignoring the fraction

For example:

B

Hp

B

Lines of Vertical

=

Horizontal Scan Period

=

600

)lS

---------

=

31. 75 ..us

=

18.89

Blanking

18

=>

2-10

Page 31

Operating Instructions - 067-1039-00

4. Calculate the approximate number of Lines Per Two Fields that

the PATTERN GENERATOR should be set to by using the following

formula.

(Vp)

2

LA

=

------

Hp

r

f

f_

l

LA

Vp

Hp

For example:

LA

5. Find the exact number of Lines Per Two Fields that the PATTERN

GENERATOR should be set to by first setting Lin the formula

below or equal to LA that was calculated previously. Then,

increment L up or down one digit at a time until the

calculated value for x becomes a whole number.

L - 2B - 24

X: ----------

x

=

Must be a whole number (i.e., an integer) to

obtain a full screen display so that the last

horizontal crosshatch. line is at the bottom of

the raster. The whole number is the number of

black horizontal scan- ning lines between any

two white horizontal lines of the displayed

crosshatch pattern.

The approximate Lines Per Two Fields

=

setting (truncate this

Vertical Scan Period

=

Horizontal Scan

=

2(16.67 ms)

=

-----------

31.75

20

J.l.S

=

Period

1050.08

number)

=>

1050

L

B

For example:

x

Hence, L

=

=

Lines Per Two Fields

=

Lines of Vertical Blanking

1040 - 2(18) - 24

= ----------------- =

1040

20

2-11

49 lines

Page 32

Page 33

Page 34

Page 35

r

•

067-1039-00

SERVICING SAFETY SUMMARY

FOR QUALIFIED SERVICE PERSONNEL ONLY

Refer also to the preceding Operators Safety Summary

Do Not Service Alone

Do not perform internal service or adjustment of this product unless

another person capable of rendering first aid and resuscitation is

present.

Use Care When Servicing With Power On

Dangerous voltages exist at several points in this product. To avoid

personal injury, do not touch the exposed connections and components

while power is on.

Disconnect power before removing protective panels, soldering, or

. replacing components.

r

I -

Power Source

This product is intended to operate from a power source that does not

apply more than 250 volts rms between the supply conductors or between

either supply conductor and ground. A protective ground connection by

way of the grounding conductor in the power cord is essntial for safe

operation.

S-1

Page 36

Page 37

Section 3

=

067-1039-00

THEORY OF OPERATION

HORIZONTAL SYNC GENERATOR

<!)

Horizontal Oscillator

The ACTIVE TIME control R682 varies

source consisting of

current

is

ramp (on pin 1

toggles

charges

compared

to a low

holding capacitor C684 to generate a ramp@

to a de level on pin 2 of U580,

of

U580)

state

Q680 into saturation and

One-shot

generates

approximately

before it starts charging up again. The output at pin

drives a

circuit block.

While the ramp

the input of

The comparison voltage at the input of

at the input of

a

binary

0580,

multivibrator

pulse

80

nse

counter,

it is also compared

U580.

Q688, Q685,

crosses that threshold voltage, pin

and

resets the ramp

discharging

U575A

at

output

This ensures that

U564

signal

on

C684 is

and the associated circuitry. The

is

pin

in the Horizontal Interval Timing

the current out of a current

a comparator. When the

by

causing

U670A

C684 ..

triggered

·7

which keeps

being compared to a de level at

to a

U587

at

the

same time, and

Q680

C684

de level at pin

is slightly less than that

is fully discharged

That

5

6

2

ramp

of

U580

to drive

iron" for

of U575A

of

0587.

Since the ramp is positive-going,

Horizontal Oscillator resets the ramp, and then remains in that state

as

long

voltage at the input. This results in a pulse at the outputs of U587.

The width of this pulse is determined

amplitude of the ramp signal exceeds the comparison voltage. As the

frequency of the Horizontal Oscillator changes and the slope of the

ramp changes, the width of the output pulse remains a constant

percentage of the horizontal period. As a result, this vertical line

pulse appears to have a constant spatial width even as the horizontal

scan rate is varied. On the schematic diagram, this pulse is labelled

as the amplitude of the ramp signal exceeds the comparison

U587 toggles just before the

by

the amount of time that the

V Linee

The pulse at the output of U587 is used to generate the effective

address on the crt of a display monitor from left to right. For

example, the vertical bar

signal

is determined

by

counting the number

3-1

Page 38

Theory of Operation - 067-1039-00

of vertical lines that have occurred since the start of that

particular horizontal line.

Vertical Bar Generator

Counter U462 and the logic associated with

Vertical Bar Generator. It counts vertical lines

combined with an "EXCLUSIVE OR" gate, resulting in

width is approximately six vertical lines. Logic

U556C, and U556D form an "EXCLUSIVE OR" gate.

If this bar signal were displayed on a picture monitor, the crt

would display a light bar extending from the top to the bottom and

dark at the left and right sides.

Horizontal Interval

The output of the Horizontal Oscillator's one-shot multivibrator

U575A is counted by U564, and when the count reaches 14 (pins 11, 12,

and 13 all high; pin 14 low), the output of U670B triggers another

one-shot multivibrator U575B which controls the horizontal hold-off

and blanking times. The output of U575B is clocked by V Line to

generate the horizontal blanking time (labeled H Blank at the output

of U457D).

The output of U670C (pin 8) forces the Horizontal Oscillator ramp

at C684 to be clamped to ground, stopping the Horizontal Oscillator

during the horizontal interval hold-off time. Horizontal blanking

time is equal to the sum of the horizontal interval hold-off time and

the Horizontal oscillator period.

Timing

it constitutes the

and its outputs are

a bar signal whose

gates U457A, U457B,

The output of U670C (inverted output of U575B) is fed to a

circuit which determines the front porch timing and sync timing. The

output of that circuit is horizontal sync. The circuit consists of

two cascaded one-shot multivibrators, U552A and U552B together with the associated circuitry. The first multivibrator, U552A, determines

the offset of the horizontal sync leading edge from the start of the

blanking time which is the front porch time. The second

multivibrator, U552B, determines the width of the horizontal sync

pulse, and that output pulse (pin 10 of U552B) is fed to the 2H

(Interlace) Generator circuit block and to several buffer circuits.

3-2

Page 39

Theory of Operation - 067-1039-00

2H (Interlace) Generator

The heart of this circuit is a constant-amplitude ramp generator.

It generates a ramp which starts at the end of one horizontal sync

pulse, ramps up until the next horizontal sync pulse comes along,

resets and starts up again. A comparator is used to compare this ramp

with a de level whose amplitude is automatically adjusted to one half

the peak amplitude of the ramp. Each time the ramp amplitude crosses

that threshold voltage, the output of the comparator changes states.

This results in a square wave output that has a transition halfway

between the two horizontal sync pulses. This transition is then used

to generate a pulse occuring midway between the two horizontal sync

pulses; and the pulse and the horizontal sync pulses are combined

with a "NAND" gate to produce a signal having twice the frequency of

the horizontal sync signal. This is the 2H signal that is used to

generate interlace.

Operational amplifier 0420, C420, Q420, and R422 comprise the

ramp generator. Operational amplifier 0420 is connected as an

integrator. A constant de level applied to R422 supplies a constant

current to C420, charging it up until a reset pulse from 0328A turns

Q420 "on" to discharge C420. The slope of the ramp is- determined by

the de level that is applied to R422, and that voltage is determined

by sampling the output of the ramp generator. The sampled output of

the ramp generator is peak-detected through CR425 and C533, and

coupled to the non-inverting input of 0530. Capacitor C523 together

with 0530 form a much slower integrator, essentially making 0530 a

power source.

i

l

A horizontal sync signal from pin 10 of 0552B drives one-shot

multivibrator 0328A. One-shot multivibrator 03~8A produces horizontal

at the output.

rate pulses with a duration of approximately 0.5

These pulses are are used to momentarily turn "on" Q420 in order to

discharge C420. That is, the output of 0328A resets the ramp

generator.

The inverting input of 0530

temperature-stabilized power supply.

temperature compensation for CR425.

If the peak amplitude of the ramp gets too high at the output of

U420, the signal coupled back to pin 3 of 0530 gets bigger. That

drives the output level at pin 6 higher than it was before. The de

level at pin 6 of 0530 is normally negative, and this de level is made

more positive. Consequently, less current flows through R422,

resulting in a ramp at the output of 0420 that has a lower slope.

That is, a lower ramp peak amplitude results. The signal being fed

back to pin 3 of 0530 will reach a steady state (equilibrium)

ramp's sampled peak amplitude equals the de level at pin 2 of 0530.

3-3

is connected

The diode CR525

JlS

'

to a

provides

when

the

Page 40

Theory of Operation - 067-1039-00

This constant

discharged.

Comparator U330 compares the ramp at the input with a de level

whose amplitude is equal to one half the peak amplitude of the ramp.

Potentiometer R332 (2H Interlace) is used to set the comparison

voltage at pin 2 of U330. When the ramp crosses this threshold

voltage, the output of U330 changes states resulting in a transition

midway between two horizontal sync pulses. This transition is used to

trigger one-shot multivibrator U328B. The result at the output of

U328B, is a signal with pulses occuring midway between horizontal sync

pulses. That is, a pulse occurs once every line in the middle of the

horizontal line with a duration of approximately 3)1s.

The output of U328B and the horizontal sync signal from pin 10 of

U552B are combined with a "NAND" gate U234B which acts like an "OR"

gate. The output of U234B is the 2H signal, and is routed to the

Vertical Sync Generator board.

amplitude is independent of how often C420 is

H S1no output Butters

The Horizontal Sync Output Buffers consist of two "NAND" gates

connected as inverters. An inverted horizontal sync signal from U552B

drives U538A, resulting in a normal polarity signal at the output.

This signal is available at the front panel as TTL H SYNC.

Depending on the position of the jumper for J542, U538B may be

driven with a normal polarity or inverted horizontal sync signal from

U552B. The output (TTL H Sync) is available at pins 26A and 28A at

the TM500 interconnect jack.

Power Supplies

Power

Generator

diagram 1, VR474 and VR647

respectively.

provides power to 0552.

supply inputs

board are shown in schematic

DC

supply

and

are used

+5

regulators on the Horizontal

vc

to

provides power

diagram

derive

2.

On schematic

vc

+5

to U575 and +5 VD

and

+5

Sync

VD

3-4

Page 41

Theory of Operation - 067-1039-00

VIDBO LOGIC AND DRIVERS 0

This schematic diagram consists of Power Supplies, Video Logic,

and Video Drivers.

Power Supplies

The Power Supplies provide the following de voltages: +15 V, +12

V, +11.7 V, +10 V, +5 VA, +5 VB, -10 V, -12 V, and -15 V.

f

[

l

[

The +15 V and -15 V supplies together with a +8 V supply provided

by the TM500 host mainframe are used to derive the rest of the

supplies.

The +12 V, +5 VA, +5 VB, and -12 V supplies are obtained through

the use of 1% regulators. The rest of the supplies are obtained by

placing the appropriate zener diodes across the proper de busses, with

the exception of the +15 V and -15 V.

Video Logic

The Video Logic circuitry combines a number of video signals

generated in other parts of the Horizontal Sync Generator board, and

other video signals from the Horizontal Line Generator and Vertical

Sync Generator boards. These signals consist of the Vertical Bar;

Horizontal Blanking; Vertical Blanking; Bounce (alternate "on" and

"off" blanking signal); V Line, and signals resulting from the

positions of the program switches (front panel controls) such as V Bar

Enable (labeled GG), V Line Enable (labeled AA), Horizontal Video

(labeled VV); and External Video. These signals are combined with a

series of gates resulting in a drive signal at the output of U355C.

A Vertical Sync signal from U238A on the Vertical Sync Generator

board is buffered by U495B resulting in TTL V SYNC available at the

front panel.

The output of the Video Logic circuit (pin 8 of U355C) drives the

Video Output Drivers.

L

l

Video Output Drivers

This circuitry consists of a TTL video driver (U495A, Q396, and

Q398) and a television video driver.

3-5

Page 42

Theory of Operation - 067-1039-00

The

TTL

video drives

5 V

11

ones

11

and "zeros".

It

has no sync,

just the video with blanking. The TTL video is amplified by a pair of

VMOS

transistors,

Q396

and Q398. These two transistors are connected

in parallel in order to produce enough current to drive three 50 ohm

loads at the video outputs on the front panel. This circuit is

enabled when pins 1 and 2, and pins 3 and 4 of J394 are jumpered;

that is, by moving the jumper for J390 to J394. Jumper pins for J390

and J394 are installed side-by-side on the Horizontal Sync Generator

board. Either one or the other set of pins is jumpered at any one

time, but never both. Therefore, either the TTL video or the

television video is available at any one time by placing a jumper on

J394 or J390 respectively.

The television video driver consists of one fast and three very

fast current sources. The circuit associated with Q188 is the fast

white current source; the circuitry associated with R270 (Grey Level

adjustment) is the grey current source; the circuitry associated with

R178 (Black Level adjusment) is the black current source; and the

circuitry associated with R486 (Sync Level adjustment) is the sync

current source. The white current source is normally "on" all the

time, and sets the output to

terminated

in

75

ohms, and the other current sources are normally

700

mV when all three video outputs are

"off".

The grey current source is turned

11

on" in order to obtain a grey

output level, and most of the current from the white source that would

normally go to the output is diverted to the grey current source

circuit. That is, the current from the white source now divides

between the output load and the grey current source. This is

accomplished by turning

"on". Transistor

cathode of

CR276

Q276

(activating the GREY button on the front panel).

Q276

"off" which causes Q286 and

may be turned

11

off

11

Q288

by applying ground to the

to turn

The black current source operates in the same manner as the grey

currrent source. It robs additional current from the white current

source whenever a black level is desired. During that time, both the

grey current source and the black current source circuits are "on".

Thus, the sum of the grey current source output and the black current

source output is equal to the white current source output. That

leaves no current for the output load, and the voltage at the output

is zero.

The sync level is

accomplished by sinking additional current in

the sync current source circuit. Since the white current cannot

provide any more current, this current is drawn from the output load,

and in

thi.s

way the output is brought down to -300 mV.

3-6

Page 43

Theory of Operation - 067-1039-00

In the case of the staircase signal, the video output is set to a

condition that would normally produce a black flat field, essentially

sync pulses and no video. However, the staircase circuit on the

Horizontal Line Generator is enabled and the resulting signal

modulates the current produced by the white current source. The

staircase drive signal biases the base of Q188 more negative, causing

Q188 to produce additional current. This additional current is sent

to the output load instead of being sunk to -12 Vin the grey, black,

and sync current sources. The staircase drive signal is a result of a

digital-to-analog conversion which is proportional to the horizontal

line scan number, and as it goes down the field, the current in the

white current source undergoes step changes resulting in the staircase

signal at the output. See Fig. 3-1.

-2

2V

~

-

-

-

-

-

-

~

-F""

--

"

"

Staircase Signal

(Field)

Fig. 3-1 Field Rate Staircase Signal

.

3986-14,

3-1

Page 44

Theory of Operation - 067-1039-00

HORIZONTAL LINE GENERATOR

The main input signals are H Sync and V Blank. A horizontal

line-generating circuit comprises most of the circuit board. This

circuit produces a white line in the raster which will be a horizontal

line when displayed. The circuit guarantees that there will be eleven

white lines from the top to the bottom of a crosshatch display. Since

the Vertical Line Generator on the Horizontal Line Generator board

generates fifteen vertical lines, the crosshatch display will be an

11 X 15 pattern. The 11 X 15 pattern is guaranteed regardless of the

number of horizontal scan lines the circuit uses. There is circuitry

which automatically adjusts the spacing between these white lines to

guarantee that there will be fifteen lines that fit the best in that

number of scan lines.

The main output from the line generating circuit is H Line. It is

available at the output of U665 pin 13. The H Line signal and the

H Bar signal (which is a result of that generator as well) are

combined with the control panel switch settings to produce three

signals namely VV (H Video), AA (V Line Enable, and GG (V Bar Enable).

The three signals are routed to the Horizontal Sync Gnererator board.

Another circuit located on the Horizontal Line Generator board is

the Bounce Generator which is a timer whose rate is adjustable from

the control panel. Its output acts as an additional blanking signal

to the video, and is routed to the Horizontal Sync board where it is

combined with vertical and horizontal blanking signals to produce a

blanking signal that varies slowly with time.

0

A third circuit located on this circuit board is the Staircase

Generator.

Current State Registers

The current state number is CBA where C is U145, Bis U265A, and

A is U265B. Inputs to the registers are V Blank, H Sync, and All

White Lines generated signals.

Register C, a field discriminator, is a divide-by-two T flip-flop

[Q

output equals zero for Field O (1) and one for Field 1 (2)]. Its

outputs change states at the end of each vertical blanking period

(beginning

(U265A).

Register B, clocked vertical blanking, is a J-K flip-flop

connected to appear as a D-Type flip-flop. The J-K inputs are V

Blanking and inverted V Blanking respectively, and the clock input is

of pattern). It is clocked by the Q output of register B

and Remainder Up-Counter

3-8

Page 45

l

J

Theory of Operation - 067-1039-00

H Sync. The clocked V Blanking signal eliminates the one half line

offset which may be present when the number of lines per two fields is

odd. This guarantees that the white lines will never start in the

middle of a horizontal. line. The Q output of U265A is high during

clocked

in one field have been displayed. The

White Lines pulse that occurs after the last white line in the field,

and has a pulse duration of approximately

transition of the clock pulse sets the

input pulse comes along and resets the flip-flop. During the time

that the

analyzed.

line is generated. It then counts the number of scan lines remaining

in the pattern ,that is, until

lines have been counted in both fields that would allow the pattern to

enlarge, the counter sends out a pulse that may be used to increase

the spacing between white lines by one. If the spacing is increased,

the remainder counter is cleared and the remainder-counting is

resumed.

V

Blanking.

The

Q

output of register A (U265B) is high after all white lines

J

input is driven with an All

3:ps.

Q

output high (one) until a

Q

output is high, the remainder of the scan lines are

The Remainder Up-Counter, U255, is enabled after the last white

V

Blanking starts. Each time enough

The negative-going

K

r

r.

[

[_

l

L

Line Spacing Increment and Line Spacing Reset

(Pattern Too Small and Pattern Too Big)

Logic gates U375A, U375B, U375C, U375D, U575A, and U575B comprise

the Line Spacing Increment circuit; and U365A, U365B, U365C, U365D,

U355B, U355C, U355D, U275A, and U275B comprise the Line Spacing Reset

circuit. Logic gates U375B and U375C form one set-reset flip-flop

hereinafter referred to as FF1; and U355B and U355C form another

set-reset flip-flop referred to as FF2.

The Line Spacing Increment logic increments the line spacing

memory when the pattern is too small. The Remainder Up-Counter (U255)

informs the Line Spacing Increment logic with the number of remaining

dark lines at the end of the pattern (after the last white line) that

it is large enough to increment the Spacing Counter for the pattern

field just scanned. (For the 11 white lines, each 10 remaining lines

may be distributed into the pattern, one per space between white

lines.)

The Line Spacing Memory is

fields agree that the pattern is

when the Q output for register C

Counter signals •pattern too

incremented

too small.

(U145) is

small", the

only if both pattern

During pattern field zero

zero and the Remainder

decision is remembered by

3-9

Page 46

Theory of Operation - 067-1039-00

setting FF1 to 1, but the Remainder Counter is not incremented.

During pattern field 1, when the Remainder Counter signals

"pattern too small" and FF1 is set, the Line Spacing Memory is

incremented each time the signal is received.

Flip-flop FF1 is reset during vertical blanking at the end of

pattern field 1.

The Line Spacing Reset logic clears the Line Spacing Memory when

the pattern is too big. The pattern is too big when the start of

vertical blanking occurs before the last white line is generated in

both fields. This condition occurs when the number of LINES PER TWO

FIELDS swith is decreased by more than- [2(Remainder)].

Flip-flop FF2 remembers if the pattern in field zero was too big.

If V Blanking starts before the last white line is generated in

field 1 and FF2 is se~, the Line Spacing Memory is cleared. The

correct spacing is then set by the Line Spacing Increment circuit.

Flip-flop FF2 is cleared whenever all white lines have been

output (A= 1).

Line Spacing Memory

The Line Spacing Memory is an eight-bit binary up-counter

consisting of U555 and U545. It contains the number of dark scan

lines between white lines. For example, if the memory contains the

number 10 and scan line number (i

number (i

+ 11) is also a white line.

+ 1) is a white line, then scan line

Soan Line Counter and White Line Generator

This circuit consists of an eight-bit binary up-counter (U775 and

U565), an eight-bit comparator (U655), a set-reset flip-flop (U675B

and U675C, and another eight-bit comparator (White Line Generator

U665).

The Scan Line Counter is reset to zero during vertical blanking

or after the last white line of the current field has been generated.

When not reset, the Scan Line Counter counts up from zero each

horizontal scan line until the counter value equals the Line Spacing

Memory. These two values are compared by U655. The output pin 13 of

this comparator goes to a high state when the counter equals the Line

Spacing Memory and sets the set-reset flip-flop U675B and U675C. The

3-10

Page 47

f

Theory of Operation - 067-1039-00

flip-flop resets the Scan Line Counter to zero, a white line is

generated, and the sequence repeats until either the last white line

is generated or vertical blanking occurs. Either of these conditions

sets the Strobe-NOT pin 11 of 0655 to a high state, which forces the

output high, holding the set-reset flip-flop set, the Scan Line

Counter reset, and disabling the White Line Generator.

The flip-flop is reset one line after vertical blanking ends,

that is, at the start of the next pattern field.

The White Line Generator generates a "high" each time the Scan

Line Counter is equal to zero during the pattern time (last white line

not yet generated and no vertical blanking). The H Sync signal on pin

23 of 0665 gates the signal "low" during sync time.

H Bar Generator and Staircase Generator

Integrated circuits 0455 and 0465C comprise a white line counter.

The counter (0455) is enabled during pattern time, and counts the

number of white lines generated in the current field. When eleven

white lines have been counted, the Max/Min output goes to a high state

signaling the end of pattern time. This signal sets register A

(0265B) high. The white line counter value is used to generate the

Bar and staircase signals.

H

l

f

r

I

l

E,

Bar Generator circuit consists of 0465B,

H

The

0475A, B, and C. The white line counter value is used to

horizontal bar which is centered vertically in the display.

ten vertical sections between the eleven white lines. The

bar occupies the middle six sections (states 7 through 12).

3-1.

D,

0675A,

F,

generate a

There are

horizontal

See Table

l

3-11

Page 48

Theory of Operation -

067-1039-00

Table 3-1

Counter States

Number of Counter

White Lines

Counted

-----------------------------------------------------

-----------------------------------------------------

0

1

2

3

4

5

6

7

8

9

10

11

-----------------------------------------------------

-----------------------------------------------------

Value

D C B A

0

0

0

0

1

1

1

1

1

1

1

0

1

0

1 0

1

0

1 1

1 1

1

0 0 0

0 0

1 1

0

1

0

0

1 1

1

0

0

1

0

1

1

0 0 0

1

1

1 1

C D

0

A B D A B D H Bar

0 0 0

0 0 0 0

0

0

1

1

1

0

0

0

0 0 0

0

0

0

0

0

1

0 0

0

1 1

0

0

0

0

0

0 0

0 0

1

1

1

1

1

0

H Bar= CD+ AB D +AB D

The rest of the circuitry in this circuit block comprises the

Staircase Generator and a staircase amplfier, 0595.

The value of the white line counter is used to generate an

eight-level, analog staircase signal. States 6 through 13 of counter

0455 enable the inputs to a digital-to-analog converter (D/A) 0685

when

the STAIRCASE/EXT control is pushed in and the St En (2) signal

line is logic high. Binary adder 0385 increments the state value so

that the input to the D/A varies from 7 through 14 (the D/A input is

equal to 15 for all other states).

An inverted staircase signal is present at pin 2 of 0685. Note

that pin 2 of U685 (lout-NOT) is equal to zero when the input to the

D/A is 15 since the other four input bits are also high.

Pin

2 of

0685 is at maximum negative amplitude when the input to the D/A is

equal to 7. Potentiometer R789 (Staircase Amplitude) is used to

adjust this amplitude, which sets the overall staircase amplitude.

Pin 2 of 0685 equals zero when the STAIRCASE/EXT control is not

activated.

Operational amplifier

non-inverting amplifier. It

in the Video Output Drivers

board (diagram 2). The

U595 (staircase amplifier) is a

modulates the white current source (Q188)

circuit on the Horizontal Sync Generator

negative-going staircase causes the white

3-12

Page 49

r

Theory of Operation - 067-1039-00

current to further increase, moving the video signal closer to white.

If the white current source was not varied during the staircase

signal, a black flat field would be displayed because the grey and

black current source are "on" while the staircase is being generated.

For signals other than a staircase, 0595 sets the white current

to a constant value determined by R791 (White Level).

Bounce Generator and Program Logic

The Bounce Generator circuit consists of 0552, U435A, and the

associated circuitry. The output of 0552, a timer, is a square wave

signal whose period is determined by R516, the parallel combination of

R514 and R518, and C626. This signal is buffered by U435A and is

available at the control panel as the BOUNCE TRIGGER. The output of

the buffer (U435A) is al~o routed to the Video Logic circuit on the

Horizontal Sync Generator board. BOUNCE RATE control (R514 accessible

on the control panel) is used to set the bounce rate.

The Program Logic consists of control panel switches and a series

of logic gates. This circuit combines signals and switching logic to