Page 1

Instructions

013-0278-XX

Video Display Clamp

070-8762-01

www.tektronix.com

*P070876201*

070876201

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are prot ected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications a nd price c hange privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Warranty 5

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of three

(3) months from the date of shipment. If any such product proves defective during the warranty period, Tektronix,

at its option, either will repair the defective product without charge for part s and labor, or will provide a

replacement in exchange for the defective product. Parts, modules and replacement products used by Tektronix for

warranty work may be new or reconditioned to like new performance. All replaced parts, m odules and products

become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the respective warranty period and make suitable arrangements for the performance of service. Customer shall

be responsible for packa ging and shipping the defective product to the service center designated by Tektronix,

with shipping cha rges prepaid. Tektronix shall pay for the return of the product to Customer i f the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shal l not appl y to any defect , failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligate d to furnish service under this warranty a) to repair dam age

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product .

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY .

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE OR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary iii...................................

Environmental Considerations v...............................

The Video Display Clamp 1...................................

Product Description 1..............................................

Features 2........................................................

Using the Video Display Clamp 2.....................................

Specifications 5...................................................

Performance Verification 7...................................

General Instructions 7..............................................

Conventions 7.................................................

Equipment Required 7..........................................

Procedures 8......................................................

Back Porch Correction Check 8...................................

Gain Error Check 11.............................................

Crosstalk and Timing Checks 13...................................

Bandwidth Check 16............................................

60 Hz Rejection Check 17........................................

Maintenance 21..............................................

Service Information 21..............................................

Replacing the Contact Pins 21.....................................

013-0278-XX Video Display Clamp

i

Page 6

Table of Contents

List of Figures

Figure 1: The video display clamp 1............................

Figure 2: Video waveform disrupted by 60 Hz hum 2.............

Figure 3: Viewing a video signal directly with the video display

clamp 3................................................

Figure 4: Monitoring a video signal with the video display clamp 3..

Figure 5: Probing circuits with the video display clamp 4..........

Figure 6: Back porch test setup 9..............................

Figure 7: Back porch correction check (negative) 10...............

Figure 8: Back porch correction test (positive) 11..................

Figure 9: Gain error test setup 12...............................

Figure 10: Gain check 13......................................

Figure 11: Crosstalk test setup 14...............................

Figure 12: Measuring interference 15............................

Figure 13: Measuring timing intervals 15........................

Figure 14: Bandwidth test setup 16..............................

Figure 15: 60 Hz rejection test setup 18..........................

Figure 16: 60 Hz rejection check (negative) 19....................

Figure 17: 60 Hz rejection check (positive) 19.....................

Figure 18: Replacing the contact pins 21.........................

List of Tables

ii

Table 1: Warranted Characteristics — Signal Pass Through

(Insertion Characteristics) 5...............................

Table 2: Warranted Characteristics — Signal Input Impedance

(Return Characteristics) 5....................................

Table 3: Warranted Characteristics — Video Display Clamp 5.....

T able 4: Warranted Characteristics — Environmental 6..........

Table 5: Typical Characteristics — Video Display Clamp 6........

T able 6: Nominal Traits — Mechanical 6.......................

Table 7: Test Equipment 7...................................

013-0278-XX Video Display Clamp

Page 7

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

ToAvoidFireor

Personal Injury

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

013-0278-XX Video Display Clamp

iii

Page 8

General Safety Summary

Terms in this Manual

Symbols and Terms

on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

H DANGER indicates an injury hazard immediately accessible as you read the

marking.

H WARNING indicates an injury hazard not immediately accessible as you

read the marking.

H CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

CAUTION

Refer to Manual

iv

013-0278-XX Video Display Clamp

Page 9

Environmental Considerations

This section provides information about the environmental impact of the

product.

Product End-of-Life

Handling

Restriction of Hazardous

Substances

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive.

013-0278-XX Video Display Clamp

v

Page 10

Environmental Considerations

vi

013-0278-XX Video Display Clamp

Page 11

The Video Display Clamp

Product Description

The Tektronix 013-0278-00 Video Display Clamp is an active signal processor

designed to increase your ability to monitor video signals.

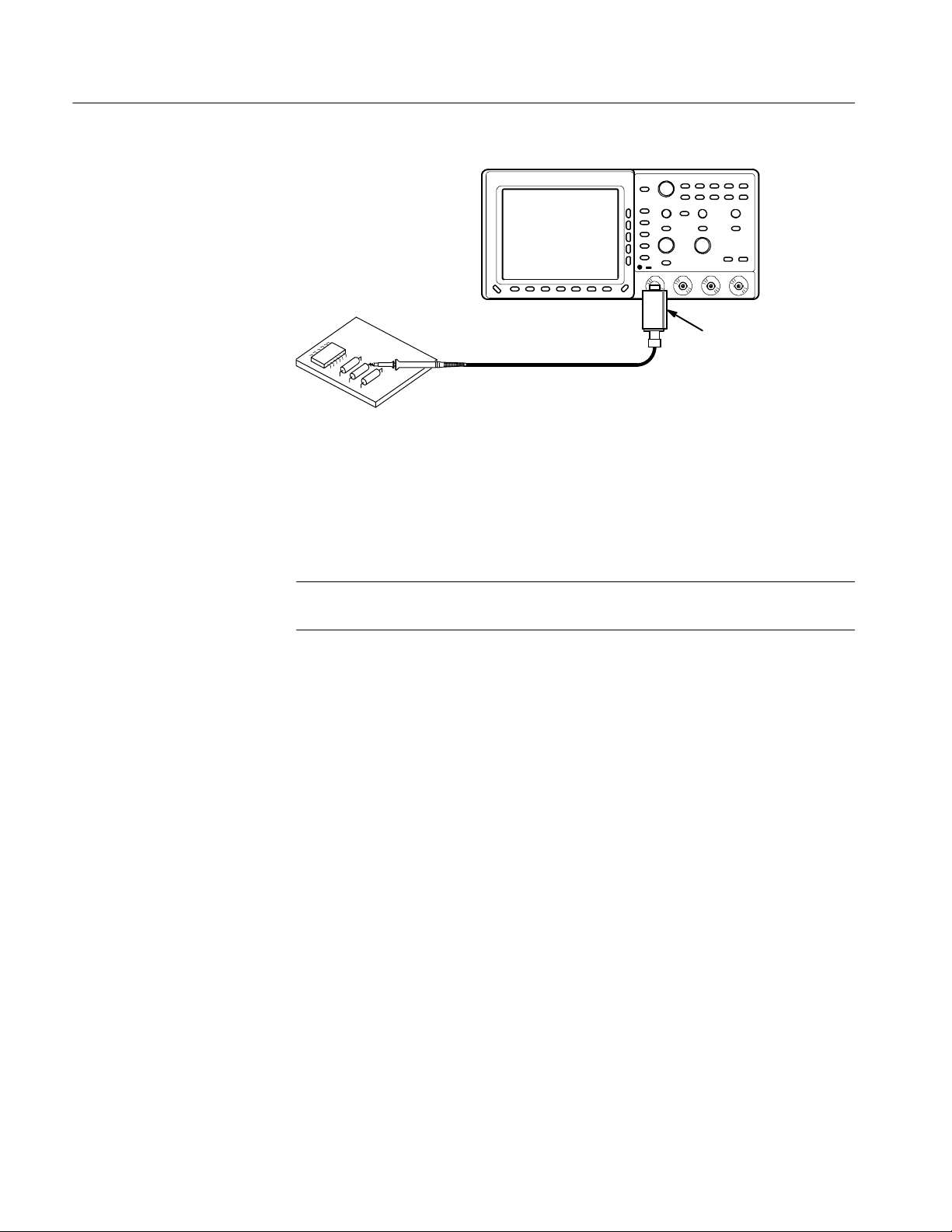

Figure 1: The video display clamp

Video signals containing a 60 Hz ripple or a DC offset make it difficult to view

the video signal with an oscilloscope. The Video Display Clamp provides a

stable signal to the oscilloscope by clamping the back porch of the video signal

to ground reference. This does not affect the signal source.

Figure 2 gives an example of how a 60 Hz hum disrupts the capability to view

the video signal. Figure 2 also shows the same signal stabilized by using the

Video Display Clamp. You can see how this enhances your ability to take

measurements of the video signal.

013-0278-00 Video Display Clamp

1

Page 12

The Video Display Clamp

Video Signal Disrupted with 60 Hz Hum Video Signal Stabilized using the Video Display Clamp

Figure 2: Video waveform disrupted by 60 Hz hum

Features

The Video Display Clamp receives its power from the host instrument. The host

instrument must have a TEKPROBE

TDS400, TDS500, and TDS600 Series Oscilloscopes).

The video display clamp works with most popular signal formats including the

following:

H NTSC

H PAL

H HDTV (component and composite)

Features of the video display clamp (other than setting the back porch to ground

reference) include the following items.

CLAMP FILTER. When ON, the Video Display Clamp ignores the presence of a

color burst signal. This helps ensure a ground level for the back porch. The filter

does not remove the color burst signal from the video waveform.

SYNC POLARITY. Select + to match sync pulses having a positive leading edge.

Select -- to match sync pulses having a negative leading edge.

TM

Level 2 interface (such as the Tektronix

Using the video display clamp

Signals passing through cables often pick up stray 60 Hz hum (from the line

voltage) or a small DC offset might be generated by the video equipment.

Although these signals may not affect the quality of the information contained in

2

013-0278-00 Video Display Clamp

Page 13

The Video Display Clamp

the signal, it makes it nearly impossible to obtain a viewable display of the video

information.

Use the Video Display Clamp to reduce or eliminate this type of interference to

view the video signal.

Viewing the video signals can be accomplished with several methods.

H Connect a video signal directly to the video display clamp (see Figure 3).

H Tap into a video signal line with a T-connector to monitor the signal without

causing loading interference to the signal (see Figure 4).

H Connect a 1X probe directly to the video display clamp to probe video

circuits (see Figure 5). The bandwidth of the video display clamp may be

compromised due to the probes characteristics.

Device

Under Test

Video display clamp

75 Ω coaxial cable75 Ω terminator

Figure 3: Viewing a video signal directly with the video display clamp

Signal

Load

Video display clamp

Coaxial cable

T-connector

Coaxial Cable

Signal

Source

Figure 4: Monitoring a video signal with the video display clamp

013-0278-00 Video Display Clamp

3

Page 14

The Video Display Clamp

Video display clamp

Figure 5: Probing circuits with the video display clamp

Procedure

Use the following short procedure to install and use the Video Display Clamp.

Attaching the video display clamp to an oscilloscope with a TEKPROBE

TM

Level 2 interface automatically turns on the video display clamp.

STOP. The use of this clamp requires that the test oscilloscope has a TEK-

TM

PROBE

Level 2 interface and the vertical input impedance is 1 MΩ.

1. Attach the video display clamp to the input of the oscilloscope and apply the

test signal to the input of the video display clamp. See the examples

provided in Figures 3 through 5.

2. Set the input impedance of the oscilloscope to 1 MΩ.

3. Set the S YNC POLARITY of the video display clamp to match the polarity

of the signal source.

H Set to -- for video signals with negative sync pulses.

H Set to + for video signals with positive sync pulses.

4. Set the CL AMP FILTER of the video display clamp.

H Set to OFF for video signals without a color burst signal.

H Set to ON for video signals with a color burst signal.

5. Set the controls of the test oscilloscope as you normally would to view the

signal.

4

013-0278-00 Video Display Clamp

Page 15

Specifications

The electrical characteristics found in these tables of warranted characteristics

apply when operating at an ambient temperature between 0 _C and +50 _C.

Table 1: Warranted Characteristics — Signal Pass Through (Insertion Characteristics)

Name Description

Bandwidth

The bandwidth of the video clamp signal path with the

oscilloscope input coupling set to 1 MΩ and the input of

the clamp is terminated into 75 Ω.

Gain Error

Error does not include the vertical error of the

oscilloscope or the error in the terminator.

--3 dB at 70 MHz (100 MHz typical), ±1 dB out to 30 MHz (60 MHz

typical)

±2.5%

The Video Display Clamp

Table 2: Warranted Characteristics — Signal Input Impedance (Return Characteristics)

Name Description

Input Resistance

Only applies when the video display clamp is operating. ≥15 kΩ

Table 3: Warranted Characteristics — Video Display Clamp

Name Description

60 Hz Rejection

Measured with 1 V

60 Hz interference signal.

60 Hz Modulation

The maximum amount of 60 Hz interference that the

clamp functions under.

Video Input Amplitude 240 mV to 570 mV sync tip height (measured from the top of the sync

NTSC video signal with 1 V

p-p

p-p

21 dB (NTSC or PAL, typical) worst case. Faster speed standards have

better rejection.

1V

(NTSC and PAL)

p-p

0.5 V

tip to the back porch).

If the video information does not extend below the back porch, these

limits translate to approximatel y 0.85 V

amplitude.

p-p

(HDTV)

p-p

to2V

of video signal

p-p

Back Porch Correction

The maximum voltage between the back porch and

ground the video clamp can correct.

013-0278-00 Video Display Clamp

±1V

5

Page 16

The Video Display Clamp

Table 3: Warranted Characteristics — Video Display Clamp (Cont.)

Name Description

Crosstalk

The maximum crosstalk interference created on the back

porch.

Line Rates/Standards

The video display clamp works with any bi-level sync

pulse standard that has a back porch at least 3 s long.

The clamp works with any tri-level sync pulse standard

as long as the sync tip is shorter than 1.8 s and the

back porch is at least 1 s long.

Offset Error ±16 mV

The difference between the back porch and ground. Offset error may increase up to 40 mV for certain standards (such as

10 mV

p-p

525/59.94/2:1 1050/59.94/2:1

525/59.94/1:1 1050/59.94/1:1

625/50/2:1 1250/50/2:1

625/50/1:1 1250/50/1:1

787/59.94/1:1

787/59.94/1:1) due to timing considerations of the vertical interval sync

pulses. This increase is resolved by the fourth line.

Table 4: Warranted Characteristics — Environmental

Name Description

Operating Temperature 0 _Cto+50_C

Nonoperating Temperature -- 5 5 _Cto+75_C

Humidity 90% +5% --0% humidity, 60 _C non-operating, 50 _C operating

Table 5: Typical Characteristics — Video Display Clamp

Name Description

Maximum Input Voltage

The maximum input voltage allowed for proper

operation.

±3V

Table 6: Nominal Traits — Mechanical

Name Description

Weight 500 grams

6

013-0278-00 Video Display Clamp

Page 17

Performance Verification

This Performance Verification subsection confirms the performance of the

013-0278-00 Video Display Clamp to its warranted specifications.

General Instructions

These General Instructions describe the conventions used in the test procedures

and provides a list of the required test equipment.

Conventions

The procedures in this section provide the following information:

H Title of test

H Equipment required (if applicable)

H Procedure

The procedures check all the characteristics designated as checked in the

Specifications subsection. (The checked characteristics appear in boldface type.)

Equipment Required

These procedures use external, traceable signal sources to directly check

warranted characteristics. Table 7 lists the required test equipment.

Table 7: Test Equipment

Item Number and Description Minimum Requirements Example Purpose

1. Oscilloscope TEKPROBETMLevel 2 interface,

100 MHz bandwidth

2. Cable, Precision Coaxial 50 Ω, 36 in, male to male BNC connectors

3. Termination, 50 Ω Impedance 50 Ω; connectors: female

BNC input, male BNC output

4. Attenuator, 2.5X Ratio: 2.5X; impedance 50 Ω; connectors: female BNC input, male BNC output

5. Coupler, Dual-input

(two required)

6. Generator, Leveled Sine

Wave

Female BNC to dual male BNC Tektronix part number

30 MHz; Variable amplitude from 5 mV to

4V

into 50 Ω.

p-p

Tektronix TDS460 Signal display

Tektronix part number

012-0482-00

Tektronix part number

011-0049-01

Tektronix part number

011-0076-02

067-0525-02

TEKTRONIX SG503 Leveled Sine Wave Genera-

1

tor

Signal interconnection

Signal interconnection

Signal attenuation

Signal interconnection

Bandwidth check

013-0278-00 Video Display Clamp

7

Page 18

Performance Verification

Table 7: Test Equipment (Cont.)

Item Number and Description PurposeExampleMinimum Requirements

7. Generator, Leveled Sine

Wave

8. Generator, Pulse 0 to 3 V, 15 kHz pulses with independent

1

Requires a TM500 or TM5000 Series Power Module Mainframe.

60 Hz; Variable amplitude from 5 mV to

4V

into 50 Ω

p-p

controls of the top and bottom pulse

levels; Variable pulse duration and pulse

period; Normal output and its complement

Procedures

These procedures check the characteristics of the Video Display Clamp listed as

checked under Warranted Characteristics in the Specifications section.

Back Porch Correction

Check

These procedures check those characteristics that relate to the back porch

correction capability of the Video Display Clamp listed as checked under

Warranted Characteristics in the Specifications section.

Equipment Required: One test oscilloscope (Item 1), one pulse generator

(Item 8), one 2.5X attenuator (Item 4), one 50 Ω terminator (Item 3), one

dual-input coupler (Item 5), and one precision coaxial cable (Item 2).

TEKTRONIX SG502 Leveled Sine Wave Genera-

1

tor

TEKTRONIX PG502 Pulse

Generator

1

60 Hz rejection check

Back porch correction and

gain accuracy checks

1. Set the test oscilloscope as follows:

H Set the sec/div scale to 10 s

H Set the channel 1 volts/div scale to 100 mV, DC coupled

H Set the channel 2 volts/div scale to 500 mV, DC coupled

H Position both channel 1 and 2 traces to center screen

H Display channel 2 (channel 1 off)

2. Connect the output of the pulse generator to the test oscilloscope as shown in

Figure 6.

NOTE. This test setup provides a display of the test signal on channel 2 and a

clamped test signal on channel 1.

8

013-0278-00 Video Display Clamp

Page 19

Pulse

Generator

Performance Verification

Video display clamp

Dual-input

coupler

50 Ω terminator

Coaxial cable

Figure 6: Back porch test setup

3. Set the pulse generator as follows (viewed with channel 2):

H Set the compliment to --

H Adjust the period to 15 kHz

H Adjust the pulse duration to 5 s

H Set the high level to 1.0 volts

H Set the low level to 0.75 volts

4. Set the Video Display Clamp as follows:

H Polarity to -- (negative)

H Filter to Off

5. Set the test oscilloscope to display channel 1 (channel 2 off).

2.5X attenuator

6. Verify that the positive portion of the pulse is within ±14 mV of the ground

013-0278-00 Video Display Clamp

reference (see Figure 7).

9

Page 20

Performance Verification

Test signal (channel 2) Corrected signal (channel 1)

Figure 7: Back porch correction check (negative)

7. Set the test oscilloscope to display channel 2 (channel 1 off).

8. Set the pulse generator as follows:

H Set the high level to --0.8 volts

H Set the low level to --1.0 volts

H Set the compliment to +

9. Set the Video Display Clamp Polarity to + (positive).

10. Set the test oscilloscope to display channel 1 (channel 2 off).

11. Verify that the negative portion of the pulse is within ±14 mV of the ground

reference (see Figure 8).

10

013-0278-00 Video Display Clamp

Page 21

Test signal (channel 2) Corrected signal (channel 1)

Figure 8: Back porch correction test (positive)

Performance Verification

Gain Error Check

These procedures check those characteristics that relate to the gain error of the

Video Display Clamp listed as checked under Warranted Characteristics in the

Specifications section.

Equipment Required: One test oscilloscope (Item 1), one pulse generator

(Item 8), one precision coaxial cable (Item 2), one 2.5X attenuator (Item 4), one

50 Ω terminator (Item 3), and one dual-input coupler (Item 5).

1. Set the test oscilloscope as follows:

H Set the sec/div scale to 10 s

H Set the channel 1 volts/div scale to 200 mV, DC coupled

H Set the channel 2 volts/div scale to 500 mV, DC coupled

H Position both channel 1 and 2 traces to center screen

H Display channel 2 (channel 1 off)

2. Connect the output of the pulse generator to the test oscilloscope as shown in

Figure 9.

NOTE. This test setup provides a display of the test signal on channel 2 and a

clamped test signal on channel 1.

013-0278-00 Video Display Clamp

11

Page 22

Performance Verification

Pulse

Generator

Video display clamp

Dual-input

coupler

50 Ω terminator

Coaxial cable

Figure 9: Gain er ror test setup

3. Set the pulse generator as follows:

H Set the compliment to --

H Adjust the period to 15 kHz

H Adjust the pulse duration to 5 s

H Set the high level to 500 mV

H Set the low level to --500 mV

4. Set the Video Display Clamp as follows:

H Polarity to -- (negative)

H Filter to Off

5. Set the test oscilloscope to display channel 1 (channel 2 off).

2.5X attenuator

12

6. Vertically position the channel 1 display to view the entire signal.

7. Verify that the pulse amplitude is between 975 mV

and 1.025 V

p-p

Figure 10).

013-0278-00 Video Display Clamp

p-p

(see

Page 23

Test signal (channel 2) Corrected signal (channel 1)

Figure 10: Gain check

Performance Verification

Crosstalk and Timing

Checks

These procedures check those characteristics that relate to crosstalk interference

and timing of the Video Display Clamp listed as checked under Warranted

Characteristics in the Specifications section.

Equipment Required: One test oscilloscope (Item 1), one pulse generator

(Item 8), one precision coaxial cable (Item 2), one 2.5X attenuator (Item 4), and

one 50 Ω terminator (Item 3), and one dual-input coupler (Item 5).

1. Set the test oscilloscope as follows:

H Set the sec/div scale to 10 s

H Set the channel 1 volts/div scale to 5 mV, DC coupled

H Set the channel 2 volts/div scale to 100 mV, DC coupled

H Position both channel 1 and channel 2 traces to center screen

H Display channel 2 (channel 1 off)

2. Connect the output of the pulse generator to the test oscilloscope as shown in

Figure 11.

013-0278-00 Video Display Clamp

13

Page 24

Performance Verification

Pulse

Generator

Video display clamp

Dual-input

coupler

50 Ω terminator

Coaxial Cable

Figure 11: Crosstalk test setup

3. Set the pulse generator as follows:

H Set the compliment to --

H Adjust the period to 15 kHz

H Adjust the pulse duration to 5 s

H Set the high level to 0 V

H Set the low level to --300 mV

4. Set the Video Display Clamp as follows:

H Polarity to -- (negative)

H Filter to Off

5. Set the test oscilloscope to display channel 1 (channel 2 off).

2.5X attenuator

14

6. Verify that any interference on the high level of the pulse is <10 mV

Figure 12).

013-0278-00 Video Display Clamp

p-p

(see

Page 25

Test signal (channel 2) Corrected signal (channel 1)

Figure 12: Measuring interference

Performance Verification

7. Switch the Video Display Clamp Polarity to + (positive) then back to --

(negative).

8. Verify that the pulse display returns to its original position within ±1mV.

9. Set the test oscilloscope sec/div scale to 500 ns.

10. Using Figure 13 as a reference, measure the time intervals marked A and B.

H Verify that interval A is between 2.08 s and 2.28 s.

H Verify that interval B is between 600 ns and 700 ns.

Interval A Interval B

Figure 13: Measuring timing intervals

013-0278-00 Video Display Clamp

15

Page 26

Performance Verification

Bandwidth Check

These procedures check those characteristics that relate to the bandwidth of the

Video Display Clamp listed as checked under Warranted Characteristics in the

Specifications section.

Equipment Required: One sinewave generator (Item 6), one precision coaxial

cable (Item 2), one 50 Ω terminator (Item 3), and one dual-input coupler

(Item 5).

1. Set the test oscilloscope as follows:

H Set the sec/div scale to 10 ns

H Set the channel 1 and channel 2 volts/div scales to 200 mV, AC coupled

H Position both the channel 1 and channel 2 traces to center screen

H Display channel 2 (channel 1 off)

2. Connect the output of the sinewave generator to the test oscilloscope as

shown in Figure 14.

NOTE. This test setup provides a display of the test signal on channel 2 and a

clamped test signal on channel 1.

Sinewave

Generator

Video display clamp

Coaxial cable

Figure 14: Bandwidth test setup

3. Set the sinewave generator as follows:

H Adjustthefrequencyto30MHz

H Adjust the amplitude for a 1 V

p-p

Dual-input

coupler

display.

50 Ω terminator

16

013-0278-00 Video Display Clamp

Page 27

Performance Verification

4. Set the Video Display Clamp as follows:

H Polarity to -- (negative)

H Filter to Off

5. Set the test oscilloscope to display channel 1 (channel 2 off).

60 Hz Rejection Check

6. Verify that the signal display amplitude is greater than 892 mV

p-p

.

These procedures check those characteristics that relate to the 60 Hz rejection

capability of the Video Display Clamp listed as checked under Warranted

Characteristics in the Specifications section.

Equipment Required: One test oscilloscope (Item 1), one pulse generator

(Item 8), one sinewave generator (Item 7), one 2.5X attenuator (Item 4), two

dual-input couplers (Item 5), and one precision coaxial cable (Item 2).

1. Set the test oscilloscope as follows:

H Set the sec/div scale to 10 s

H Set both channel 1 and channel 2 volts/div scales to 200 mV, DC

coupled.

H Position both channel 1 and 2 traces to center screen

H Display channel 2 (channel 1 off)

2. Connect the output of the pulse generator and the sinewave generator to the

test oscilloscope as shown in Figure 15.

NOTE. This test setup provides a display of the test signal on channel 2 and a

clamped test signal on channel 1.

013-0278-00 Video Display Clamp

17

Page 28

Performance Verification

Sinewave

Generator

Dual-input

coupler

Pulse

Generator

2.5X attenuator

Video display clamp

Coaxial cable

Figure 15: 60 Hz rejection test setup

3. Set the Video Display Clamp as follows:

H Polarity to -- (negative)

H Filter to Off

4. Set the sinewave generator as follows:

Dual-input

coupler

H Set the frequency to 60 Hz

H Adjust the amplitude to 0 V

5. Set the pulse generator as follows:

H Set the compliment to --

H Adjust the period to 15 kHz

H Adjust the pulse duration to 5 s

H Set the high level to 150 mV

H Set the low level to --420 mV

6. Set the test oscilloscope sec/div to 2 ms.

7. Set the sinewave generator amplitude to create a 1 V

display of the 60 Hz

p-p

sinewave.

8. Set the test oscilloscope to display channel 1 (channel 2 off).

9. Verify that the amplitude of the 60 Hz sinewave component of the waveform

is ≤70 mV

(see Figure 16).

p-p

18

013-0278-00 Video Display Clamp

Page 29

Test signal (channel 2) Corrected signal (channel 1)

Figure 16: 60 Hz rejection check (negative)

Performance Verification

10. Set the compliment of the pulse generator to +.

11. Set the Video Display Clamp Polarity to + (positive).

12. Verify that the amplitude of the 60 Hz sinewave component of the waveform

is ≤70 mV

(see Figure 17).

p-p

Figure 17: 60 Hz rejection check (positive)

013-0278-00 Video Display Clamp

19

Page 30

Performance Verification

20

013-0278-00 Video Display Clamp

Page 31

Maintenance

Service Information

This subsection provides you with the service information for the Video Display

Clamp.

Replacing the Contact

Pins

There are no user serviceable parts inside the case of the Video Display Clamp.

The TEKPROBE

Video Display Clamp.

If the contact pins become damaged, obtain replacement pins through your

nearest Tektronix Field Office or representative. Use the following procedure to

replace a damaged contact pin.

1. Using a pair of needle-nosed pliers, grasp the damaged pin and pull the pin

straight out of the assembly (see Figure 18). Note the location of the

removed pin.

2. Using the needle-nosed pliers, grasp the replacement pin and carefully insert

the pin into the assembly. Use care to avoid crushing or bending the new pin

during installation.

3. Verify that the new pin is installed to the same depth as the other pins.

TM

interface contact pins are the only replaceable part of the

Remove Pin

with Pliers

Figure 18: Replacing t he contact pins

013-0278-00 Video Display Clamp

21

Page 32

Maintenance

22

013-0278-00 Video Display Clamp

Loading...

Loading...