Page 1

Oct. 10, 2012

VE Series Printer

Operation Manual

600T00120

(Primary Edition)

Version 1.0

Page 2

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 1 -

Preface

Thank you very much for purchasing ME series wide format printer.

In order to use this printer correctly and safely and understand this product’s capability, please read this

manual carefully.

The manual includes equipment structure, Description, technical parameters, operation manual, safety

information and application of software, etc.

This manual is subject to change without notice.

Contents here in contained are believed to be correct, however, please contact us if you find any error or

something not clear enough.

To ensure safe and correct use

To ensure the safe and correct use of your printer, read this manual thoroughly prior to use.

After reading this manual, store it in a safe place for reference as necessary.

Do not allow small children to touch the printer.

The following describes are important points for safe operation. Be sure to observe them strictly.

Conventions used in this manual

To ensure the safe and correct use of the printer as well as to prevent human injury and property damage, the

safety precautions provided in this manual are ranked in the three categories described below. Be sure to gain a

full understanding of the difference between each of the categories before reading the Manual.

DANGER

This category provides information that, if ignored, is highly likely to cause fatal or

serious injury to the operator.

WARNING

This category provides information that, if ignored, is likely to cause fatal or serious

injury to the operator.

CAUTION

This category provides information that, if ignored, could cause injury to the operator or

damage to the printer.

Description of safety symbols

The symbol indicates information that requires careful attention (including warnings).

The symbol indicates an action that is prohibited.

The symbol indicates an action that must be performed.

Page 3

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 2 -

Safety precautions

To ensure the safe and correct use of your printer, be sure to observe the following points.

Installation precautions

WARNING

Do not install the printer in the vicinity of volatile solvents such as alcohol or thinner

。。。。

A volatile solvent coming into contact with any of internal electrical components may

result in a fire hazard or electric shock.

Do not place objects such as those listed below on top of the printer.

Objects such as these coming into contact with any of internal electrical components

may result in a fire hazard or electric shock..

·Metallic objects such as necklaces.

·Objects such as glasses, vases, houseplants, etc. that contain water or other fluids.

CAUTION

Do not use the printer in an unstable location such as on a slope or a location

that is subject to a lot of vibration.

Such locations may cause the printer to tip over and cause injuries.

Do not place heavy objects on top of the printer.

Such objects may tip over or fall off, causing injuries.

If the printer is mounted on its dedicated stand, be sure to use the caster stoppers

to fix the stand in place and prevent it from moving while the printer is being used

If the stand is not fixed in place, the printer may tip over and cause injuries.

Avoid using the printer in the following locations.

Use in such locations may result in a fire hazard or electric shock.

·Excessively humid or dusty locations.

·Locations exposed to direct sunlight.

·Locations exposed to high temperatures.

·Locations near flames or moisture.

Use at the following places may result in malfunction or failure.

·Near equipment which generate a strong magnetic force or magnetic field.

Use this printer in places where the ambient temperature is between 20 to 28°C centigrade and humidity is

between 40 to 70%.

Leave plenty of space around the printer.

Leave sufficient space for operations around the printer.(rear and front about 2 meters, left and right about

3 meters)

Page 4

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 3 -

Power supply precautions

WARNING

Do not damage the power cable, or modify it in any way. Moreover, do not place heavy

objects on the power cable, pull on the cable, or bend it excessively.

There may be current leakage from the damaged parts, resulting in a fire hazard or

electric shock.

Do not unplug or plug in the power cable when your hands are wet, such action may

result in electric shock.

Do not connect multiple devices to the same power outlet.

Use of the printer in such a condition may result in a fire hazard or short circuit.

Do not bundle or tie-wrap the power cable.

Use of a bundled power cable may result in a fire hazard or short circuit.

Make sure that the power cable is firmly inserted into the power outlet.

Use of a power cable when the plug is not completely inserted into the power outlet

may result in a fire hazard or short circuit.

Do not use a power cable other than the one supplied with your printer.

Use of a different power cable may result in a fire hazard or short circuit.

Be careful of the following when connecting a ground wire.

Items which allow connection to a ground wire

·

Ground terminals of electric outlets

·

Ground terminals after completion of grounding work (type D)

Items which do not allow connection to a ground wire

• Water pipes

Water pipes may have plastic parts in the middle which do not serve as grounding.

It is possible to connect a ground wire to water pipes which are approved by the waterworks

department to use for grounding.

• Ground terminals for telephone lines and lightning conductors

These may get a high-voltage current from lightning which may cause fires or short circuit.

CAUTION

Use an appropriate power source and voltage for the specifications of this printer.

Using this printer with a power source and voltage which are not compatible with

the specifications may result in a fire or an short circuit.

When disconnecting the power cable, be sure to hold on to the plug, and not pull

on the cable itself.

Page 5

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 4 -

As a general rule, do not use additional power cables.

If you use additional cable, please make sure that total amperage of the equipment

connecting with cable shall not exceed the amperage of the power supply. Moreover,

the amperage of all equipment connecting with wall socket does not exceed the amperage of the wall

socket.

Make sure that the power plug can be readily unplugged at any time, and that

there are no objects placed in its vicinity.

Be sure to ground the earth terminal.

Avoid the socket in the same circuit with copy machine or air conditioner.

Avoid using the socket controlled by the wall switch or by automatic timer.

Put your computer system away from potential sources of electromagnetic interference.

Such as reproducers and cordless telephones.

Do not use damaged or attrited power cable.

Handling precautions

WARNING

Do not disassemble or modify printer.

If the printer makes an unusual noise, generates smoke, overheats, emits a strange odor, or otherwise

functions abnormally, immediately turn off the power, remove the plug from the power outlet, and either

contact the store where you purchased your printer or your nearest Graphtec representative.

Do not use flammable aerosols or similar products in the vicinity of the printer.

Before moving the printer, make sure that the power switch is in the “off" position

and that the power plug has been removed from the power outlet.

Use power switch to close your printer. If the power switch is in the “off” position,

power will be cut off. Before cut off the power, do not pull out the printer plug and

data lines.

Before moving the printer, make sure that the print heads are fixed on the original

locations

Do not touch any metallic parts on the print heads after a printing operation.

Page 6

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 5 -

● Printing malfunctions may occur.

● There is a risk of damage from static electricity.

CAUTION

Prevent metal objects or liquid contact to the internal electrical components, otherwise will result in a fire

hazard or electric shock.

On the print procedure, prohibit putting hand to the printer.

Do not move the print heads by hand, otherwise will result in a damage.

Make sure that power cables be connected correctly.

In the face of the following situations, please cut off the power supply for the experienced maintenance staff

to maintain:

power cables or plug have be damaged;

liquid splashing into the printer;

printer fall down or damaged;

Printer is not in normal operation or performance are changed obviously.

Maintenance and inspection precautions

WARNING

Be sure to turn off the power and remove the power plug from the power outlet before

performing any cleaning operations.

Failure to do so may result in a fire hazard or electric shock.

To clean the printer, use a cloth that has been dampened with neutral detergent and then well wrung out. Do

not use volatile solvents such as alcohol, benzene or thinner to clean the printer.

Do not apply any lubricant to mechanical sections of this printer.

CAUTION

At least once a year, remove the power plug from the power outlet and clean the prongs and surrounding

areas.

A build-up of dust may result in a fire hazard.

Page 7

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 6 -

When cleaning or checking the inside of the printer, make sure that a metallic object such as a necklace or

bracelet does not come into contact with any of the internal components.

Such actions may result in injuries or an electric shock.

Precaution on Handling the Consumable Items.

WARNING

Take care not to ingest ink or get it into your eyes.

This may cause breathing difficulty or damage to your eyes.

If ink gets into your eyes, immediately rinse with clear water, and consult a doctor.

If you ingest ink accidentally, do not try inducing vomiting; immediately consult a doctor.

Leakage ink may cause damage to the surface coating of this printer.

CAUTION

As a safety precaution, store the print heads and ink cartridges in a location out of the reach of small children.

If ink is licked or ingested accidentally, consult a doctor immediately.

Do not use any ink other than those specified because it may not only disturb printing quality, but also cause a

malfunction which will prevent appropriate maintenance procedures.

Do not use ink after the expiration date because it may cause a malfunction.

Please comply with relative applicable rules to dispose waste ink.

Take care not to get ink on your skin or clothing. If ink gets on your skin, immediately rinse it off by using soap

and water.

Periodically check the amount of the waste ink in waste ink bottles to avoid an overflow.

Store ink in a dark cold place. Never store it at locations exposed to high temperatures or direct sunlight. This

may affect its performance.

Page 8

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 7 -

Index

Chapter 1 Introduction

1.1 Technical Parameters................................................................................................................................... …….9

1.2 Components and Features................................................................................................................................10

Chapter 2 Installation Guide

2.1 Open package and remove printer ......................................................................................................... …….14

2.2 Check packing list ..............................................................................................................................................16

2.3 Install Printer ..............................................................................................................................................18

2.4 Install Drier…………………………………………………………………………………………………………………………………………………..20

2.5 Install Waste Ink Tank……………………………………………………………………………………………………………………………….....22

2.6 Install Print-head................................................................................................................................................23

2.7 Ink Initializing.....................................................................................................................................................25

2.8 Turn On Pinter………………………………………………………………………………………………………………………..…………………....27

2.9 Load Media and Nozzle Checking………………………………………………………………………………………………….……………...28

Chapter 3 Control Panel & Parameter Setting

3.1 Control Panel ..................................................................................................................................................32

3.2 Manu Tree..........................................................................................................................................................33

3.3 Manu Description...............................................................................................................................................35

Chapter 4 Software & Operation Instruction

4.1 Software Instruction ...................................................................................................................................38

4.2 Operation Procedure......................................................................................................................................38

4.2.1 Install RIP and Printer Set up....................................................................................................................38

4.2.2 Print Task and Image Edit..........................................................................................................................42

4.2.3 Print Mode and Parameter Setting...........................................................................................................45

4.2.4 Printer Task Manager…………………………………………………………………………………………………………………………..50

4.3 Printer Set-up ....................................................................................................................................................52

Chapter 5 Ink Supplying and Capping System

5.1 Introduction...................................................................................................................................................60

5.2 Operation Diagram.........................................................................................................................................60

5.3 System Structure............................................................................................................................................60

Chapter 6 Media Heating System

6.1 Introduction......................................................................................................................................................62

Page 9

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 8 -

6.2 Operation Diagram............................................................................................................................................62

6.3 Features.............................................................................................................................................................62

6.4 Structure and Description..................................................................................................................................63

Chapter 7 Media Take-up System (Optional )

7.1 Instruction......................................................................................................................................................65

7.2 Structures.......................................................................................................................................................65

7.3 Operation Description....................................................................................................................................66

Chapter 8 Maintenance

8.1 Daily maintenance..........................................................................................................................................68

8.2 Linear Rail maintenance.................................................................................................................................68

8.3 Pint-head maintenance..................................................................................................................................68

8.4 Ink supply maintenance.................................................................................................................................69

Page 10

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 9 -

Chapter 1 Introduction

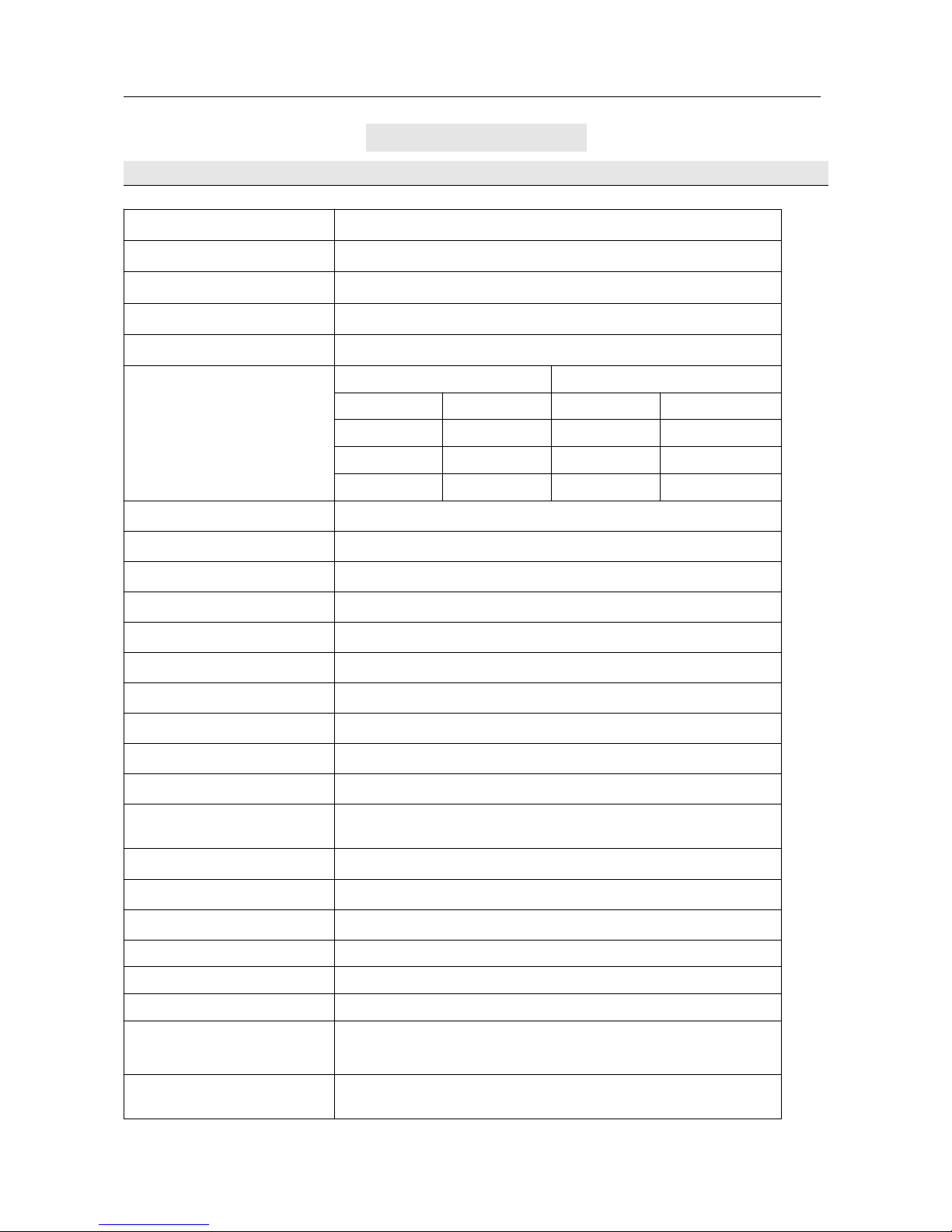

1.1 Technical Parameters

Model ME Series: ME901 ME1301 ME1601

Print-Head Type & Qty

EPSON DX5 1

pieces

Printing Width

1600 mm

Resolution

720DPI / 1080DPI / 1440DPI

Drops Fixed dot or variable dot control

Speed

1 Head

3PASS 18

m

2

/h

4PASS 14

m

2

/h

6PASS 10

m

2

/h

8PASS 7.6

m

2

/h

Ink Type Water Base Dye Ink; Water Base Pigment Ink; Eco Solvent Dye Ink

Colors

4 color: CMYK; 8 color optional

Ink Supply

Ink Cartridge. Optional CISS

Ink Capacity

Standard 220ml *2 * 4 color; Optional 220ml * 8 color

Media Type

PP, Photo Paper, Lamp Pieces, PVC, Vinyl ,Mesh, Banner

Media Release

Standard Passive Release. Optional Auto feeding & Take up

Maximum Media Width

1640mm

Maximum Media Wight

< 30kg

Print-Head Height 1.5mm~3.0mm Adjustable

Head Clean/Capping Auto cleaning & Capping system

Media Heater

Front & Real: Constant Temperature control.

Printing Platen: Adjustable

Media Drier

Standard: Fans Drier; Optional: Hot Air (PTC+Fans Array)

Control Panel 9Key LCD Display Panel;

Interface

USB2.0 (Window2000、NT、XP etc)

RIP Software

Standard:

MainTop

RIP,Support third party RIP

Operation System

(Window2000、NT、XP etc

Power Supply

AC110 or 220V,50HZ/ 60HZ

Operation Environment

Temperature:20°C ~ 28°C

Humidity:40% ~ 70%

Printer Size / Weight

Net:

Gross:

The Parameter might be varied without notice.

Page 11

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 10 -

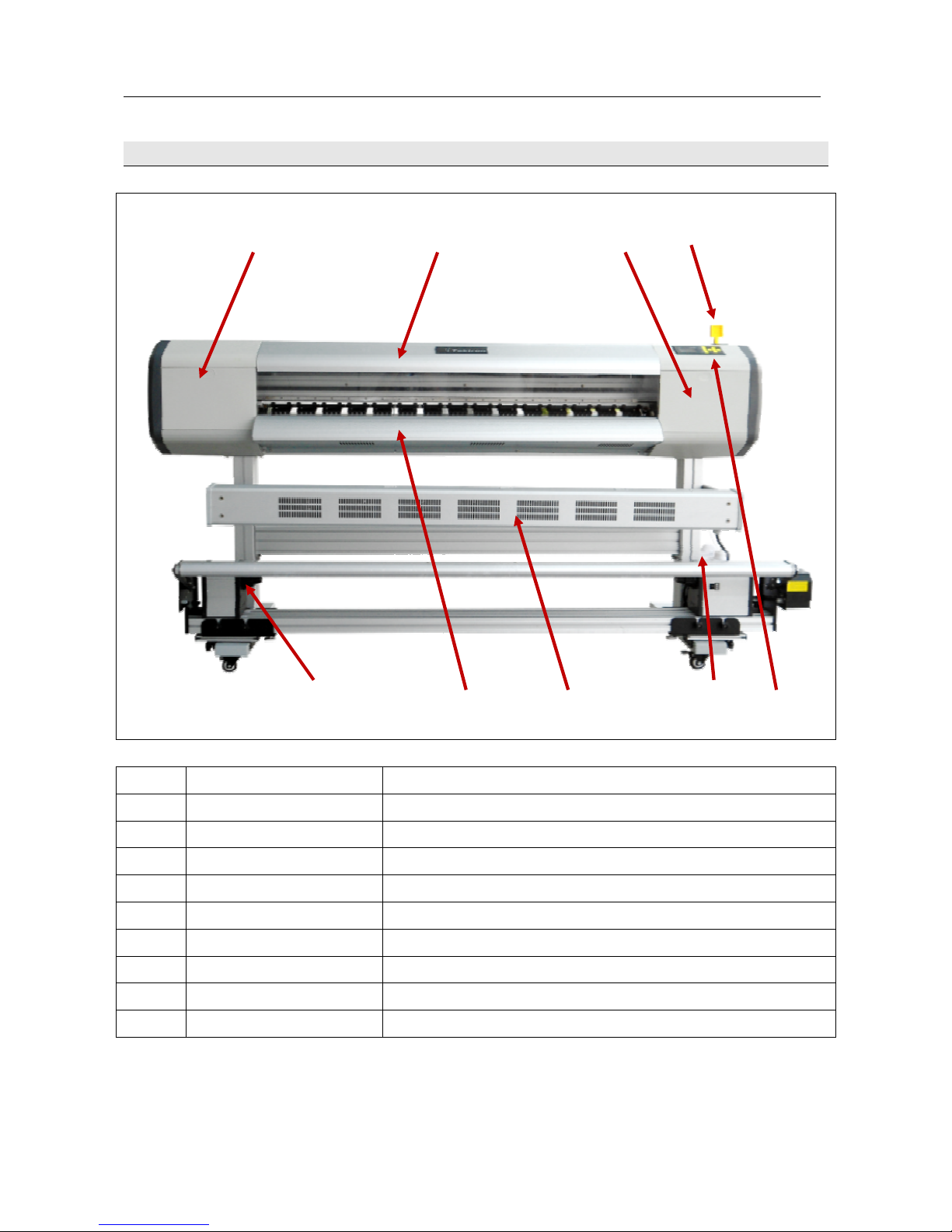

1.2 Components And Features

1 2 3 4

5 6 7 8 9

Item # Description Function

1 Left Cover Open this cover when do head maintenance manually.

2 Front Cover Open this cover to observe carriage movement and printing quality.

3 Right Cover Open this cover to check head cleaning and capping station.

4 Press handle To be used for releasing and loading media.

5 Media taking-up Holder To holder the paper core for rewinding the media after printing.

6 Front Media Guide This is the guide for media exiting and drying after printing.

7 Media Drier This is used for drying media after printing.

8 Waste Ink Bottle This is used for storing the waste ink coming from clean station.

9 Control Panel This is the key panel for printer basic operation.

Page 12

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 11 -

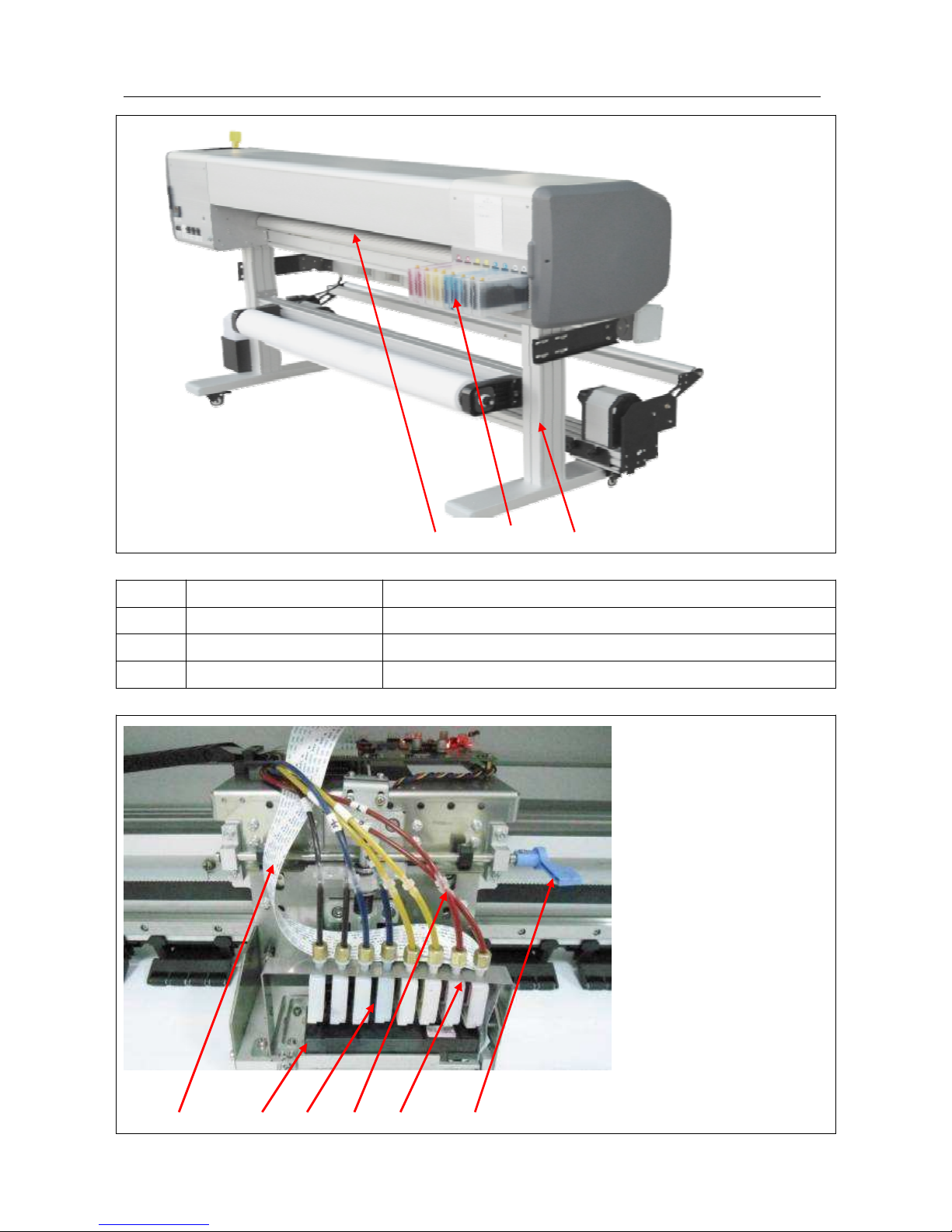

1 2 3

Item # Description Function

1 Rear Media Guide This is the guide for media feeding and pre-heating.

2 Ink Cartridge This is the bulk ink storage for ink supplying.

3 Media Release Holder This is media holder for passive release.

1 2 3 4 5 6

Page 13

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 12 -

Item # Description Function

1 Print-head cable This is the cable for connecting print-head drive board and print-head.

2 Print-Head This is print-head (DX5)

3 Damper This is a damper for ink storage and absorb the pressure fluctuation

while carriage moving.

4 Ink Tube Connector This is used to connect damper and ink tube.

5 Damper Holder This is a clip to hold the damper and avoid it loose during carriage

moving.

6 Head Height Adjust Handle This is used to adjust the head height. There are 3 positions, each step

is 0.5mm.

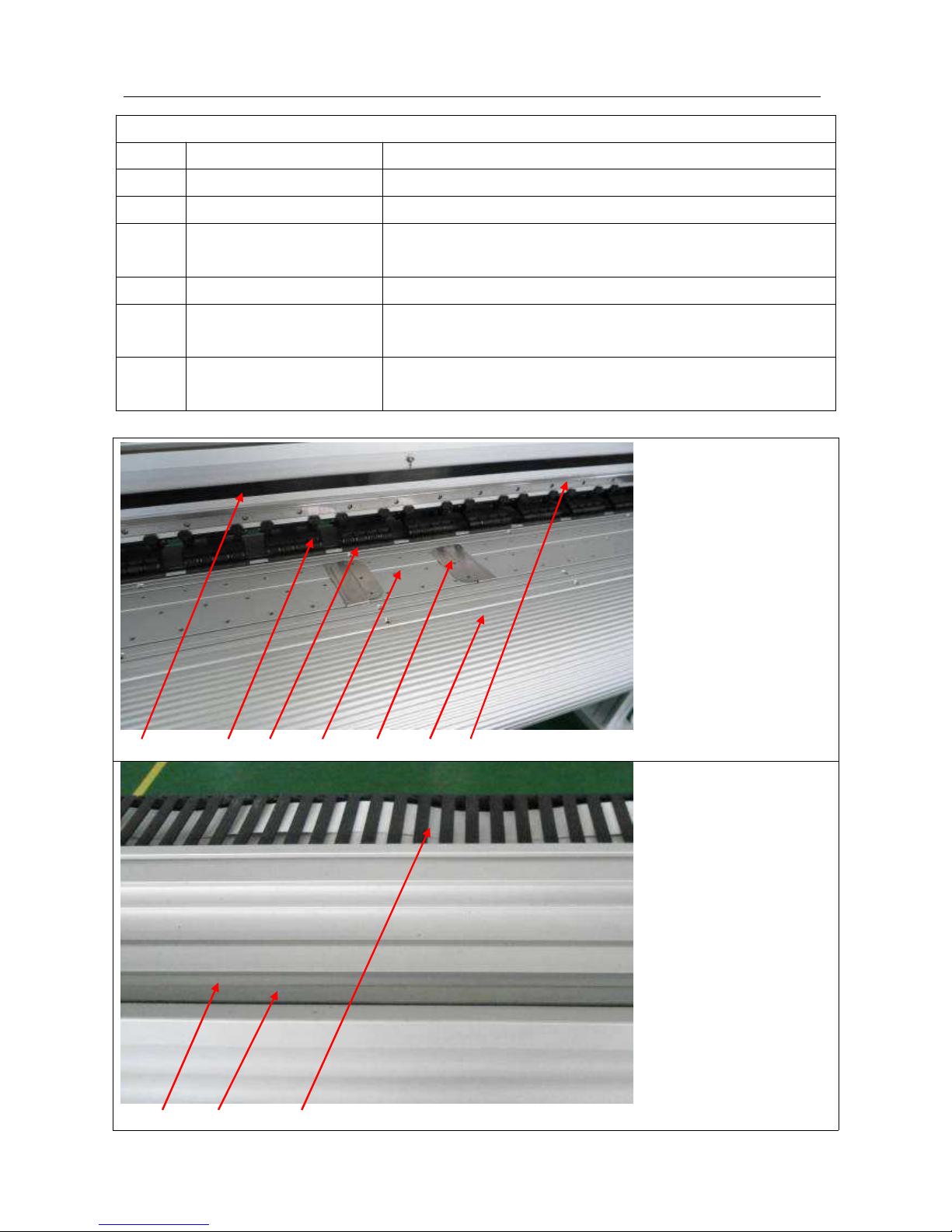

1 2 3 4 5 6 7

8 9 10

Page 14

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 13 -

Item # Description Function

1 Syncro Timing Belt This is the belt for driving the carriage moving.

2 Press Roll This is the roller to press the media touching the pinch roll firmly.

3 Pinch Roll This is pinch roll for driving the media moving.

4 Printing Platen This is the plate for supporting the media while printing.

5 Media Edge Guide This is the guide to prevent media edge rising and touch the head.

6 Front Media Guide This is the guide for media exiting and drying out after printing.

7 Linear Rail This is the guide for carriage movement.

8 Encoding Strip This is used for jetted dots allocating in scan direction.

9 Encoding Strip Shield This is a cover for protecting encoding strip.

10 Cable Chain This is the chain for holding cables and ink tubes.

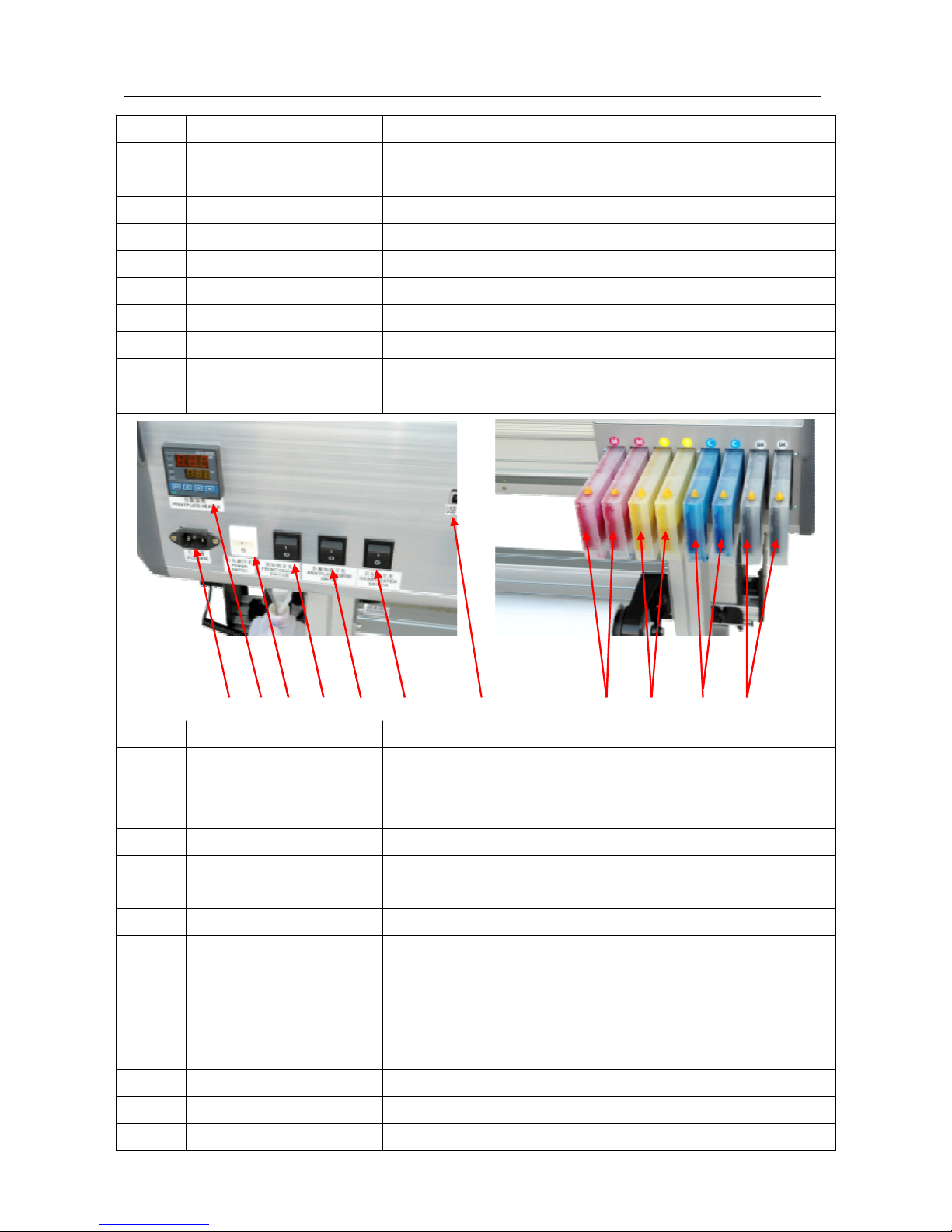

1 2 3 4 5 6 7 8 9 10 11

Item # Description Function

1

Power Cord Socket

This is the socket for supplying electrical power from the power

source.

2 Heater controller This is a digital controller for control the Printing Platen temperature

3 Main Power Switch This is main switch for turn on & off the printer

4 Front Media Guide heater

switch

This is a switch for turn on & off the front Media Guide heater

5 Printing Platen heater switch This is a switch for turn on & off the printing Platen heater

6 Rear Media Guide heater

switch

This is a switch for turn on & off the rear Media Guide heater

7 USB Port

This is used for connecting the cable for communication and data

transfer between printer and PC.

8 M main ink tank This is a ink tank for contain the M color ink. Double 220ML

9 Y main ink tank This is a ink tank for contain the Y color ink. Double 220ML

10 C main ink tank This is a ink tank for contain the C color ink. Double 220ML

11 K main ink tank This is a ink tank for contain the K color ink. Double 220ML

Page 15

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 14 -

Chapter 2 Installation Guide

Read the safety guide more carefully before install the printer.

2.1 Open Package and Remove Printer

DANGER

Be careful while use fork-lift to remove printer from the packaging.

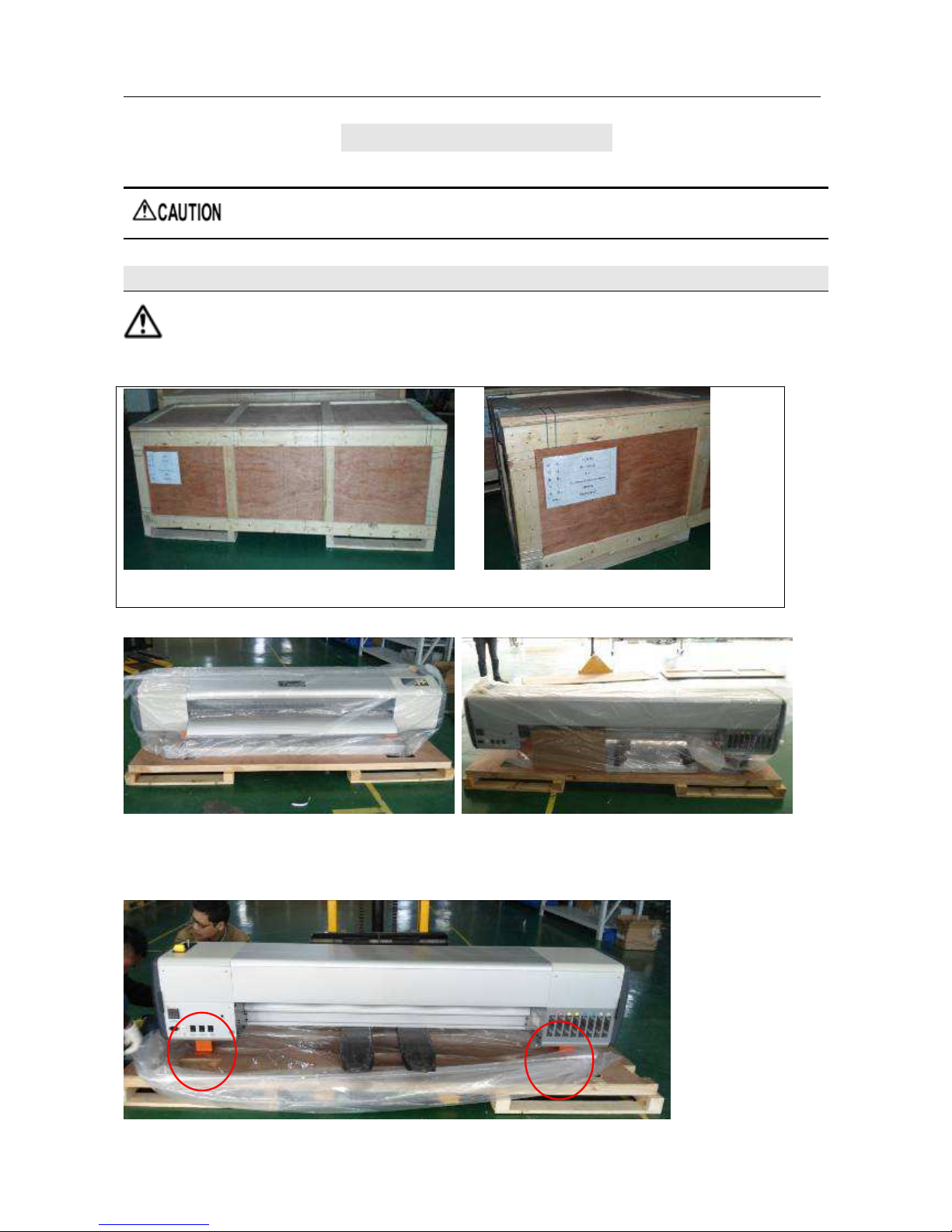

2.1.1 Open the wooden box

2.1.2 Remove the modules

2.1.3 Remove printer

Remove all side plate of wooden box, as the fig below:

Page 16

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 15 -

Remove fixing screws on the pallet.

2.1.4 Remove 4 screw nuts, lift printer up .

Remove shipping bracket fixing screws, and remove Orange brackets.

Page 17

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 16 -

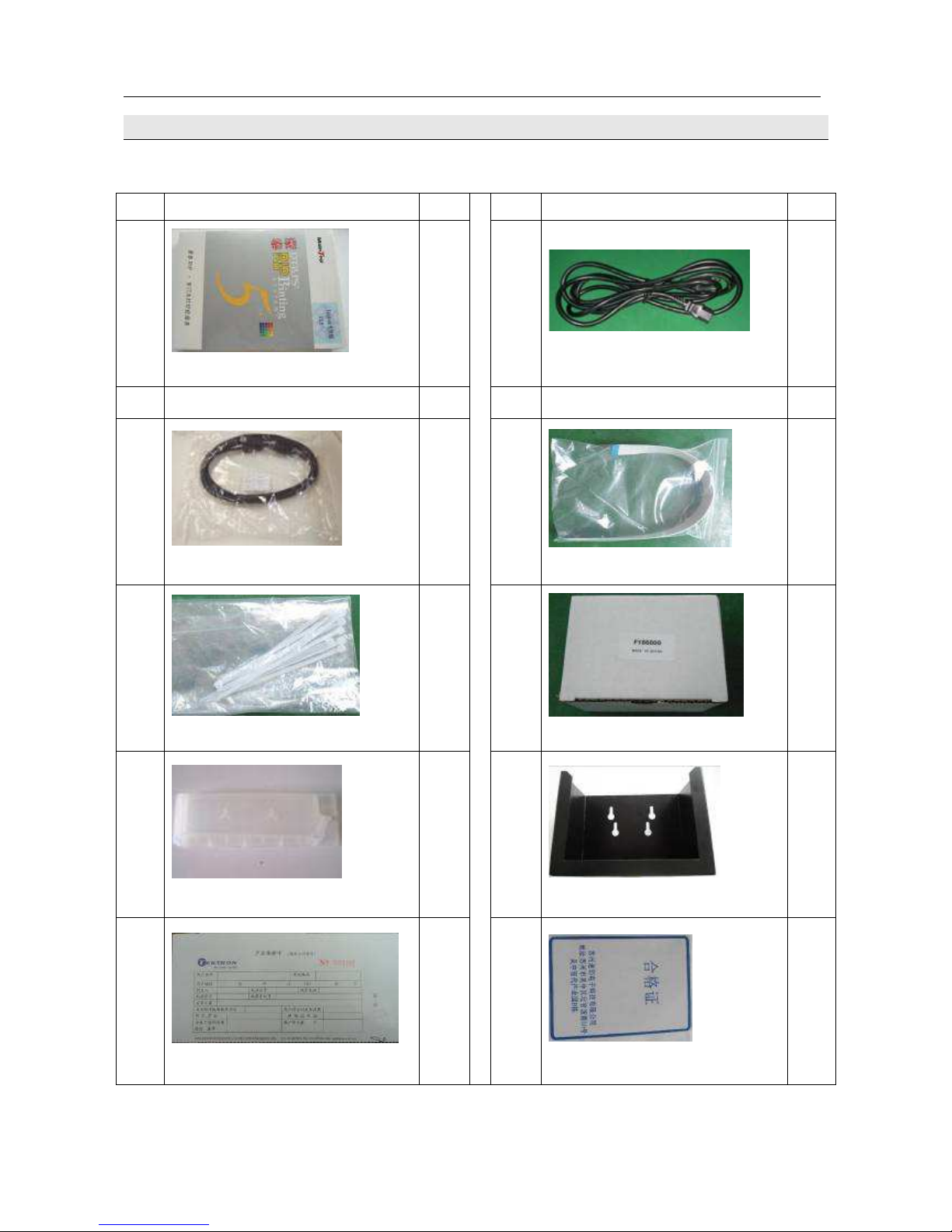

2.2 check Packing List

Check the items on the list. Please contact seller if there is any thing missing.

Item Description Qty Item Description Qty

1

RIP Software

1 2

Power Cord

1

Item Description Qty Item Description Qty

3

USB Cable

1 4

Print Head Cable

2

5

Tier

10 6

Print Head

1

7

220ml Ink Cartridge

8 8

Waste Ink Tank Holder

1

9

Warranty Card

1 10

Quality Certificate

1

Page 18

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 17 -

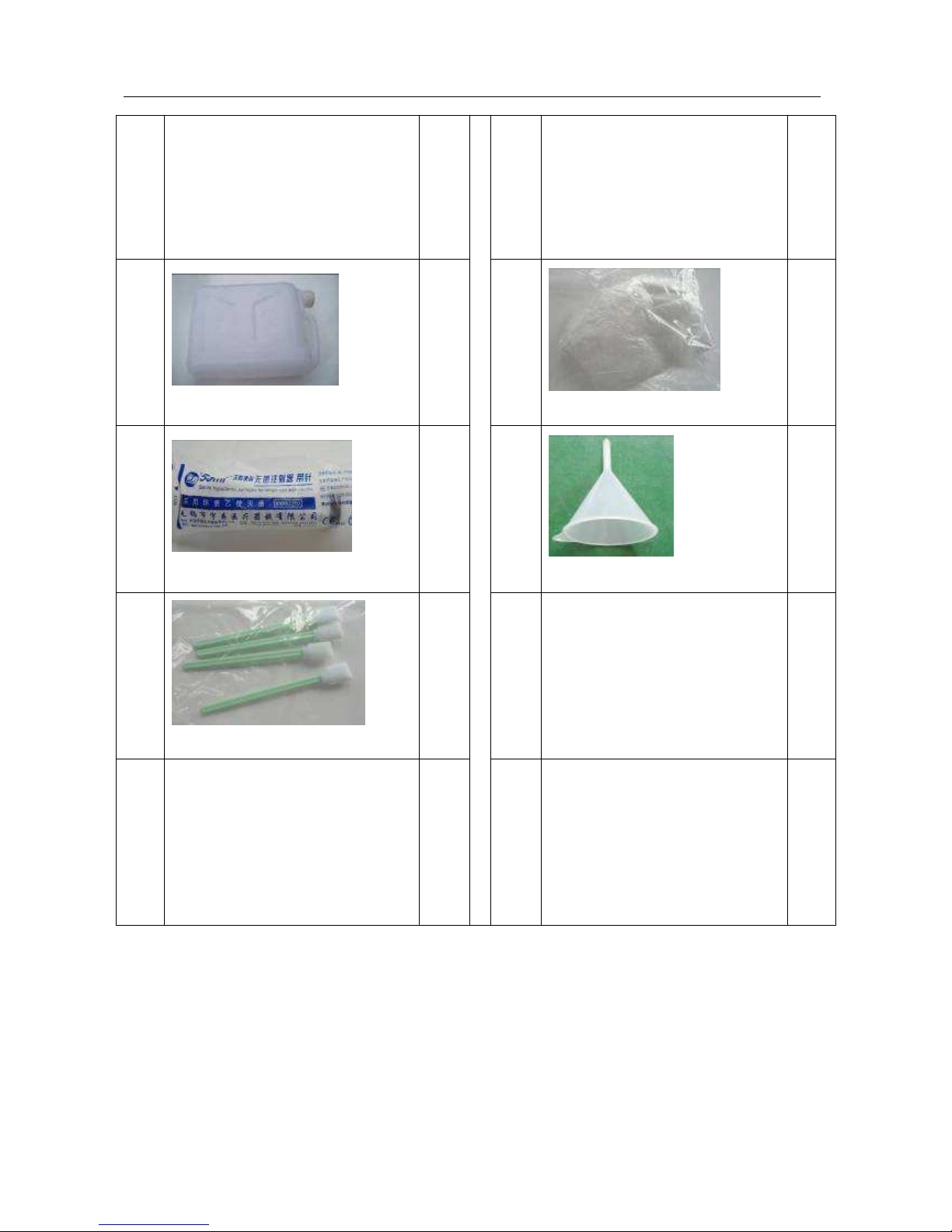

11

Operation Manual

1 12

Quick Start Instruction

1

13

Waste Ink Tank(5L

)

1 14

Glove Pack

1

15

Injector

1 16

Funnel

4

17

Clean Stick

4

Page 19

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 18 -

2.3 Install Printer

WARNING

Two person required when install printer.

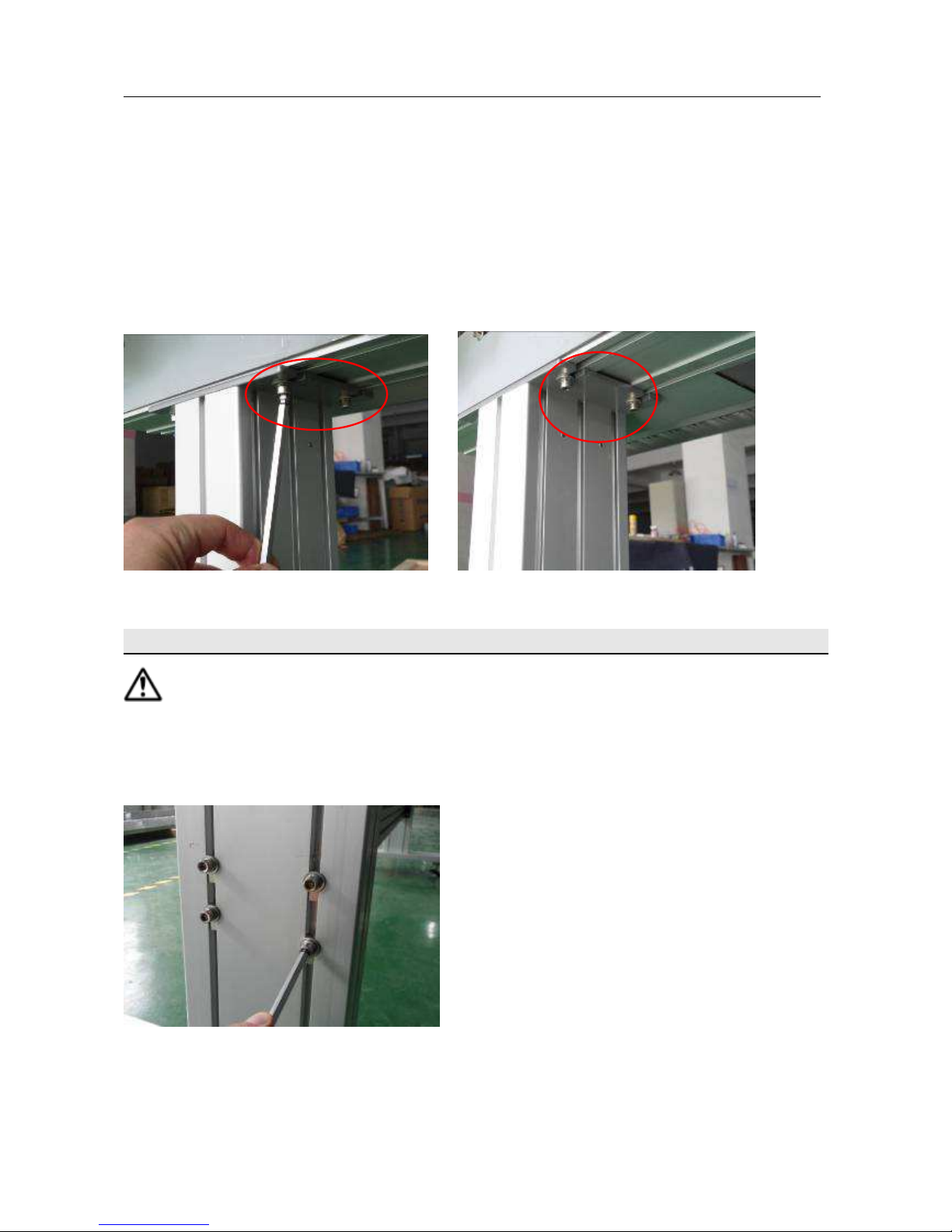

2.3.1 Install Leg Assembly

Take leg parts from the packaging.

Take low support beam, insert the fixing screw on the end of beam into fixing hole on the legs.

Fixing the beam by 6 pcs of M6X16 Hex screws, see below fig

:

Do the same for another side of leg.

Page 20

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 19 -

2.3.2 Install Printer

Install the printer body on leg stand

Note: As the printer is heavy, please use fork-lift to left the printer. Or two persons to do the procedure is

necessary.

With the help of fork-lift, put the printer on the stand and fix it by 4 pieces of M6X18 Hex screws in each side.

Please be sure that the fixing screw on the top of the leg is inserted in to the fixing hole in low beam of printer.

See the picture below.

2.4 Install Drier

WARNING

Two people required while install the drier.

2.4.1 Install Drier Bracket

Take the bracket from the packaging. Remove 4pcs of M8X14 Hex screws from each side of leg stand.

Page 21

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 20 -

Install the bracket. Make sure two brackets in both side are in the same level.

2.4.2 Install Drier Assembly

Install the drier on the bracket and fix it by two screws.

Do the same way for another side.

Remove two M5X12 Hex Screws

in both side of drier.

Page 22

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 21 -

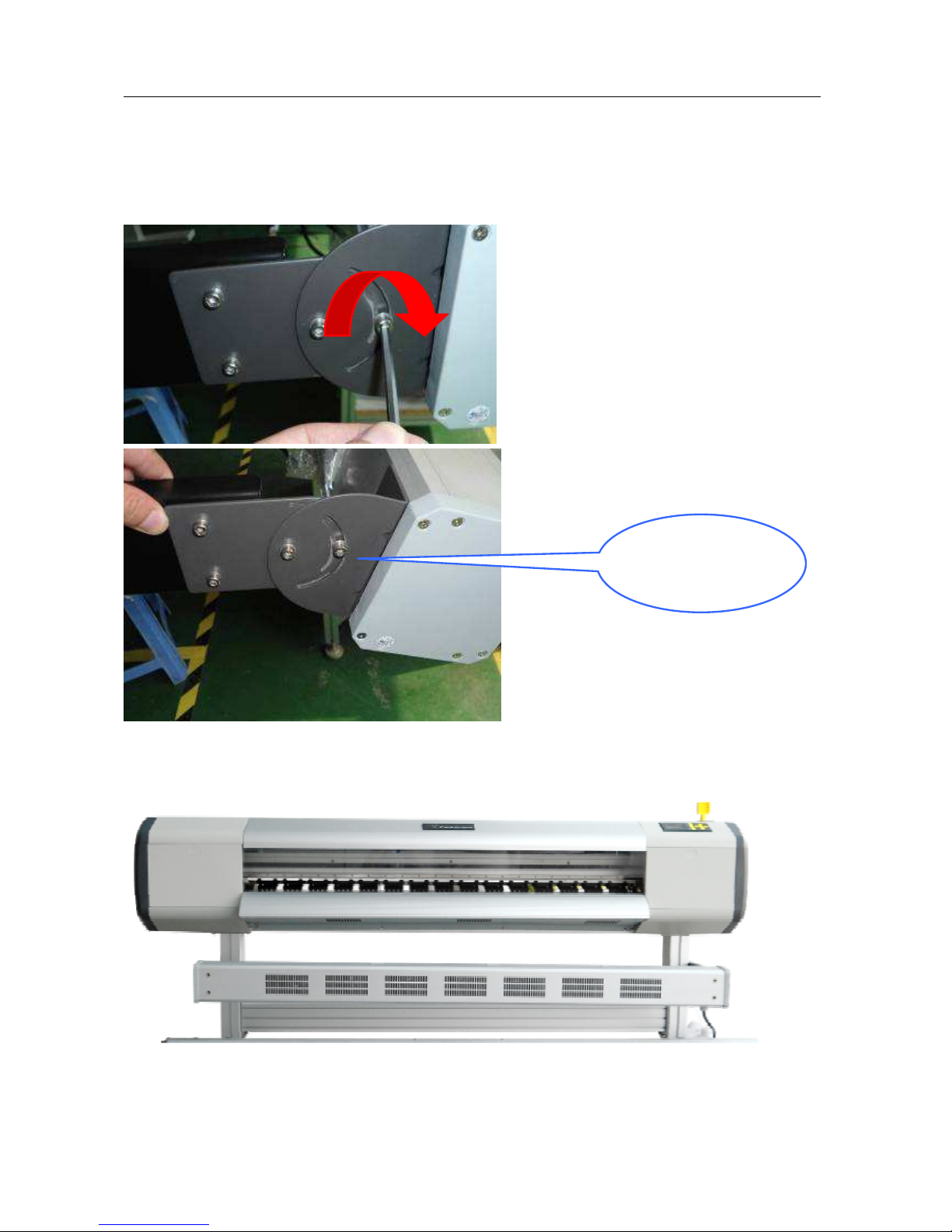

The hot air direction is adjustable as follow:

Use Hex screw driver to loose the fixing screw in both side, turn the drier to a certain angle, then fasten the

screw.

After installation.

Turn the drier to

proper angle.

Page 23

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 22 -

2.5 Install Waste Ink Tank Holder

Take the waste ink tank holder and install it on right side of leg assembly. Remove two screws on the leg.

Install waste ink tank holder on the right side leg. Fix it by 4 pcs of M6X16 Hex screws.

Push the holder down to

the end and fix it by two

M8X14 Hex screws.

Page 24

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 23 -

2.6 Install Print-Head

2.6.1 Connect flat cables to print head. Make sure the cable are in the right direction. See below fig.

The blue color of two cables have to be faced each other. Recommend to use same width

paper to cover the connector to avoid circuit short by sprayed ink

2.6.2 Use two M3X6 Hex screws to fix print head on holding plate. See the fig below

3 fixing holes

Page 25

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 24 -

2.6.3 put the head assembly on the carriage and fix it by 3 pcs of M#X6 Hex screws on head plate.

2.6.4 Install head adjustment screw

Note::::The screws are used to adjust the straightness of the head.

Fix the head on the

plate by using 3 pcs

of M3X6Hex screws.

Page 26

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 25 -

Turn the left screws in to push the head turn in CW direction. Turn the right screws to pull the head turning in

CCW direction.

2.6.5 Connect head cables to Pint-head drive board.

2.7 Ink Initializing

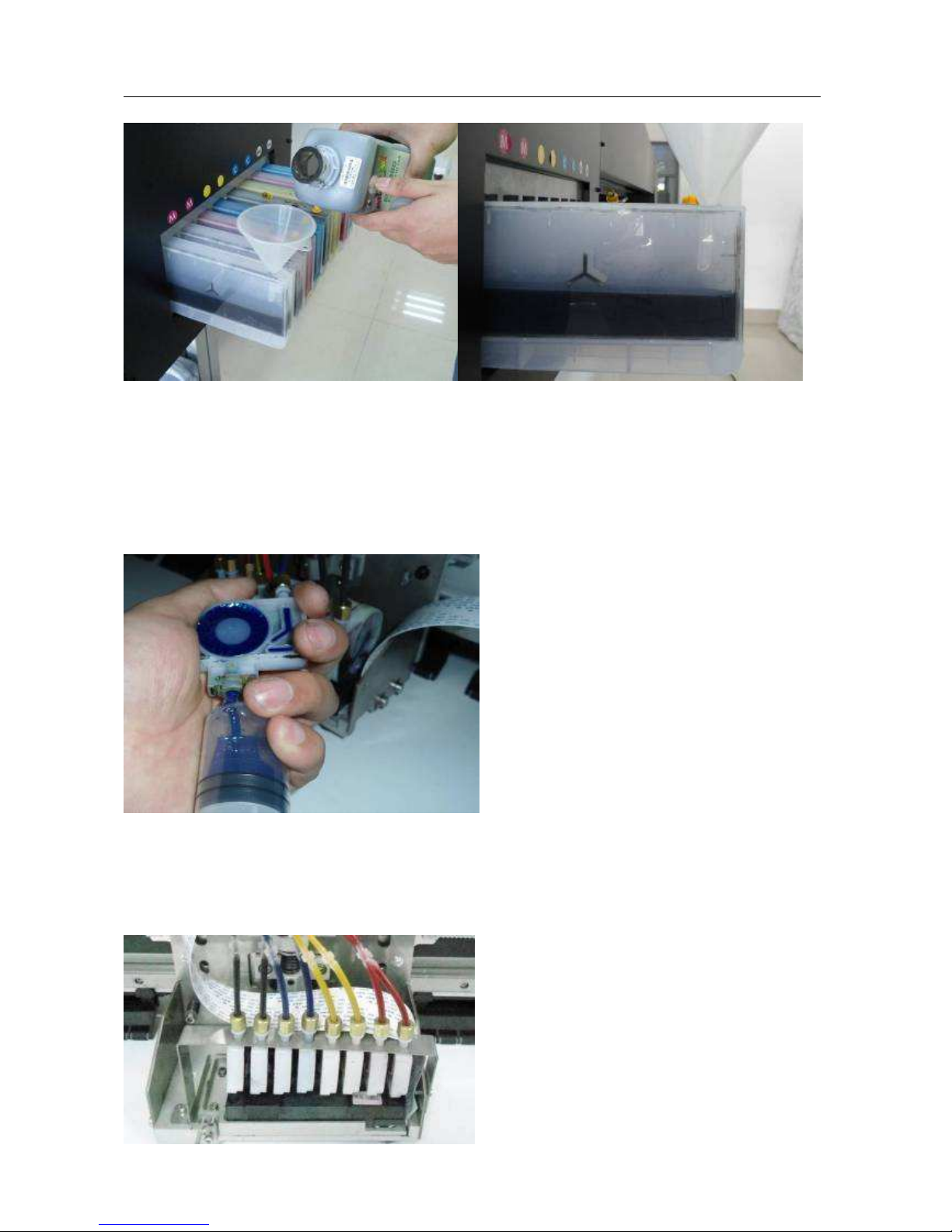

2.7.1 Insert 8 empty cartridges into the slots.

2.7.2 Remove rubber cap on each cartridge, fill the ink in to the cartridge by using funnel. Please make sure

the ink color should be match with the marks on the cartridge.

Please be sure the ink level should be within the level limit lines on the cartridge.

Note: while the ink level is below the low limit line of the cartridge, the ink should be added on time

otherwise the air could be gotten into the ink tube and cause ink supplying interrupted.

Page 27

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 26 -

2.7.3 Connect the injector with the damper, draw the ink out from the cartridge into the damper.

Note: the ink level in the damper should be not less than 50%, otherwise it will cause ink

interrupted during printing.

2.7.4 Connect each damper to individual ink inlet on print head

Note: please make sure the color order should be in correct: K,K,C,C,,Y,Y,M,M. from left to right.

Page 28

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 27 -

2.7.5 Install and fix damper holder after all dampers are connected with the head correctly.

2.8 Turn On Printer

2.8.1 Choose correct power supply

1) Power supply required:

Printer:AC 220V/50Hz or AC 110V/60Hz; Heater:AC 220V/50Hz or AC 110V/60Hz ;

PC: as per the instruction on PC

The printer requires good grounding.

Please use correct power supply as per the requirement otherwise may damage the equipment.

2) Please remove any un-necessary remains in the printer before switch on power.

3) Connect printer and heater to power supply by two power cords.

2.8.2 Booting printer and self checking

Note: Please move the carriage and check the gap between the head and printing plate by manually.

Make sure there is no substance on the platen. Make sure there is no problem for carriage move freely.

1)Turn on the machine by push main power switch. The printer starts self booting for checking the status of the

machine. The carriage would move back to home position after checking.

2)The printer will be online after booting.

Page 29

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 28 -

2.9 Load Media and Nozzle Checking

2.9.1 put the media on the holder and fix well.

Note: the holder can fit 3 inch paper core, or 2 inch paper core by removing the core adapter.

see below:

This is the holder for 3 in

paper core.

Push the clips in for

position, remove 3 in core

adaptor.

Now the holder will fit 2

in paper core.

Page 30

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 29 -

Fix one side holder on low support beam, move anther holder to fit media core.

2.9.2 Lift press roller by push back Press Handle. Put the media going through press roller. Pull and smooth the

media equably from the front of printer. Pull back the handle to release press roller.

Push the holder then

fasten the fixing

screw.

Make sure the media

is on the platen

Page 31

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 30 -

2.9.3 Move media edge guide to cover the media edge in both side.

2.9.4 Head Initializing and nozzle checking

Enter head cleaning procedure, choose Standard, press OK. The ink is being sucked into the head and

sucked out by vacuum. While the process completed, the display will back to Main Manu. Press Nozzle Check,

the carriage will move left and a nozzle status bar will be printed. Observe each nozzle status, and do clean

process again if necessary.

Note: if there still have some nozzles don’t jetting well, please stop clean and do some printing for while, then

do the clean process again.

While all process is done, the machine is ready to run for further adjustment and calibration.

Please be noted that the first installation should be done by service engineer, or under the guide

of service engineer.

Observe the media edge is

under the middle of three

holes.

Page 32

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 31 -

Chapter 3 Control Panel & Parameter Setting

3.1 Control Panel

1 2 3 4 5 6 7 8 9

Item # Description Function

1 Exit Press this button to cancel, Back to previous Manu.

2 Manu Press this button to enter the main Manu

3 Nozzle Checking Press this button to do nozzle checking print.

4 On Line Press this button for linking the PC.

5 Left Press this button for reduce the value, or move the carriage left

toward.

6 Up Press this button to go up on displayed Manu. Or move the media

in backward.

7 OK Press this bottom to confirm for next step

8 Down Press this bottom for choose next item on the displayed Manu, or

move the media forward.

9 Right Press this button to increase the value, or move the carriage right

forward.

Page 33

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 32 -

3.2 Manu Tree

Main Manu

1:Media_Move

1. Media_Move

2. Margin_Set

3. Media_Detect

2:Head_Clean

1. Heavy_Mode

2. Std_Mode

3. Light_Mode

4. Cap_Clean

5. Capping

3:Param_Set

1. Wiper_Pos

2. Wiper_Cycle

3. Carriage_Spd

4. Vacuum_Adj

5. Auto_Purge

6. Auto_Clean

7. Vacuum_Mode

4:System_Set

1. Head_Qty

2. LCD_Cntrst

3. Language

4. Media_Detect

5. Cutter_Enab;

6. Media_End

7. Load_Default

8. About...

5:Engr_Mode

1. Motion_Test

2. Speed

3. Print_Width

4. PurgePosition

5. Voltage_Adj

Page 34

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 33 -

3.3 Manu Description

Main Manu

Next Manu Description

Media_Move

Media_Move

Lighten this item by using Up or Down key, press OK to confirm. Press

Down Key the media will move forward, press Down Key again, the media

moving stops.

Press Up Key, the media moves backward, press again the moving stops.

Press Left Key, the carriage moves leftward. Press Left Key again, the

carriage moving stops.

Press Right Key, the carriage moves rightward. Press the key again, the

carriage moving stops.

Press Exit to back.

Margin_Set

Lighten this item by using Up or Down kay, press OK to confirm, the

carriage moves to printing origin position. Press Left or Right key to move

the carriage to the new origin position, then press OK to confirm, the

carriage will move to home position and standby. The next printing will be

stated from the new origin position.

Press Exit to back.

Media_detect

Lighten this item by using Up or Down kay, press OK to confirm, the

carriage will move left to detect the paper edges, then record the paper

width. (this function is not available for this printer)

Head_Clean

Heavy_Mode

Lighten this item by using Up or Down Key, press OK key to confirm. The

printer starts head clean process automatically. The clean time is longer in

this mode. This clean mode is chose while the nozzles are clogged in

seriously.

Std_Mode

Lighten this item, press OK to confirm. The printer starts head clean

process automatically. The clean time is in normal. This mode is chose for

regular clean request.

Light_Mode

Lighten this item and press OK to confirm. The printer starts head clean

process. The clean time is shorter in this mode. This is chose for a tender

clean while start printer in second day.

Cap_Clean

Lighten this item, press OK to confirm, the carriage move left. Press Down

key to start sucking the waste ink from head capper by vacuum generated

by pump. The operator can add some solution into the capper and let

them sucked out. Put the solution again until the form pad in the capper

becomes clean.

Page 35

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 34 -

Press Up key again to stop.

Press Exit key, the carriage will move to home position, the display back to

last Manu.

Do this clean procedure every week.

Capping

Lighten this item, press OK to confirm, the carriage moves right to capping

station. The capper will rise up to cover the head. Please observe the

rubber edge of copper touches the head surface well, there is no gap

between the surface and rubber edge.

It is must to do before switch off the printer. Otherwise the nozzle of head

would not be wet well and gets dried out and damaged.

Press Exit key, the carriage will move to home position and standby.

Param_Set

Wiper_Pos

Lighten this item, press OK to confirm. The wiper will turn to working

position. Press Left or Right key to change to position of the wiper. The

number displayed indicates the angle of the wiper turned.

The position of the wiper has been set in the factory. This procedure is

done by service engineer while the wiper is worn out and change.

Wiper_Cycle

Lighten this item, press OK to confirm. The number displayed indicates the

times the wiper wipes the head after cleaning. Use Left or Right key to

change the number. The range is 1 to 3.

The default is” 1”. Mean the wiper wipes one time after cleaning.

This procedure is done by service engineer only.

Carriage_Spd

Lighten this item, press OK to confirm. Use Up or Down key to select the

speed mode.

Produ: the productivity is high but the image quality is little low

Fine: the productivity is little low but the image quality is better

Vacuum_Adj

Lighten this item, press OK to confirm. The vacuum fan starts run. Use Left

or Right key to change the vacuum strength on printing platen.

0 is Disable, there is no vacuum generated on the platen.

1~9 indicates the vacuum strength from weak to strong. This value is

depending on the thickness of the media, in most case, thin material

requires weaker vacuum.

Press Exit key to stop the fan and back.

Auto_Purge

This is the function to keep nozzles wet by periodic jetting process while

printer is in standby.

Lighten this item, press OK to confirm. Use Left or Right key to change the

value. Larger number indicates more strong head purging.

Page 36

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 35 -

For water base ink, 3 is recommended.

For Eco-solvent ink, 5 is recommended.

Auto_Clean

This is the function to keep nozzle wet by periodic jetting process during

printing. All nozzles will jet while head pass through the purging pad in

clean station after certain passes.

Lighten this item, press OK to confirm. Use Left or Right key to change the

value.

1:indicates all nozzles are purged after 36 passes.

9:indicates all nozzles are purged every pass.

The default value is 0 (Disable).

Vacuum_Mode

Lighten this item, press OK to confirm. Use Left or Right key to change the

vacuum mode.

1:Auto: the vacuum is controlled by the system. The vacuum is generated

with printing starts. The vacuum is off if there is no printing task existed.

2:Enabl: The vacuum is generated while the printer is on.

3:Disab: There is always no vacuum on the platen.

Syetem_Set

Head_Qty

Lighten this item, press OK to confirm. Use Left or Right key to choose the

head number.

“1” indicates that one head is used.

“2” indicates that two head are used.

The default number is 1.

LCD_Cntrst

Lighten this item, press OK to confirm. Use Left or Right key to change LCD

display contrast

Press Left key, the display background will be more dark

Press Right key, the display background will be more bright

Language

Lighten this item, press OK to confirm. Use Left or Right key to select

language.

The default language is Chinese.

Media_detect

Lighten this item, press OK to confirm. Use Left or Right key to enable or

disable..

The default is Disable

Cutter_Enabl

This is the function to cut off the media while finish printing task. ( it is not

available for this model)

Lighten this item, press OK to confirm. Use Up or Down key to enable or

disable the cutter.

The default is Disable.

Page 37

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 36 -

Media_End

This is the function to detect the media usability. When the media end is

detected, the system will alarm and pause the printer. ( this function is no

available on this model).

Lighten this item, press OK to confirm. Use Up or Down key to enable or

disable the function.

The default is Disable.

Load_Default

This makes all parameter back to default setting.

Lighten this item, press OK to confirm. Use Up or Down key to choose the

action. “No” indicates to keep the current setting. “Yes” indicates to

re-set the parameter to default.

Press OK key again to execute the action.

About…

Lighten this item, press OK to confirm. The display will show firmware

reversion and memory size

Engr_Mode

(Press OK

key, enter

the

password

98766, press

OK key to

enable this

feature)

Motion_Test

Lighten this item, press OK to confirm. The carriage starts moving left

and right and repeat.

This is used for carriage moving test.

Speed

Lighten this item, press OK to confirm. This is used to set up the value of

printing speed. Use Up or Down key to choose mode, use Left and right key

to change the value. The bigger number indicates the carriage moves

faster.

9 is the default value of Prod mode

6 is default number of Fine mode.

Press OK key to confirm the setting and back.

Print_Width

This function is used to set up maximum printing width of the printer.

Lighten this item, press OK to confirm, press Left key to move the carriage

to left side until the carriage is 10mm away from the mechanical limit,

press OK again to save the value. The carriage will move back to home

position, the display back to previous Manu.

Note: the new data will be in effective after restart the printer.

PurgePosiyion

This is used to define the position of head purge.

Lighten this item, press OK to confirm, the carriage will move to flushing

position.

Use Left and Right key to move the carriage. Make sure the head is in the

right position above head capper.

Press OK to save the value, the carriage will move to capping position.

Voltage_Adj This function is used to change head firing voltage. Please be noted that

Page 38

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 37 -

there is a minor difference for different type of ink.

Lighten this item, press OK to confirm, use Up and Down key to change the

value. The range is 0 to +3.

For water based ink the default value is 0

For eco-solvent ink, the default value is +1.7

Press OK to back.

Page 39

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 38 -

Chapter 4 Software & Operation Instruction

4.1 Software Instruction

4.1.1 Operation Environment

Hardware:CPU Intel Pentium4 and above - 2GHZ , 1G Memory,

Display Resolution: 1024X768 and above

Operation System: Windows2000, XP, WIN7.

4.2 Operation Procedure

4.2.1 Install RIP and Printer Set-up

1.Insert MainTop CD into driver, the program will be auto run and display as below:

2. Click“MAINTOP DTP ”,

Note:The system recommends to install the software in default route.

Restart computer after finish installation.

Page 40

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 39 -

Page 41

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 40 -

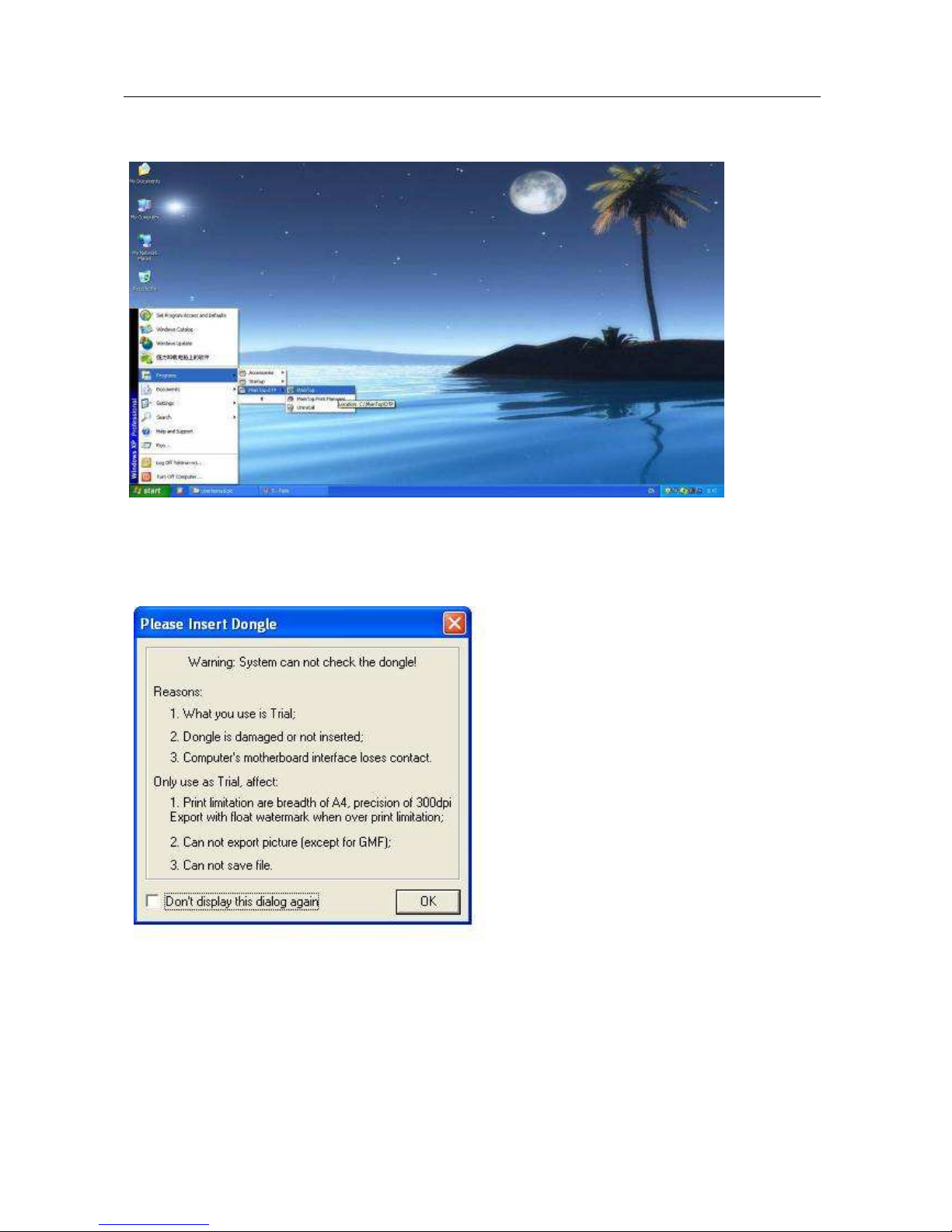

3. Start the program. Refer to follow fig:

Note:Please make sure the MainTop RIP Dongle is inserted in USB port otherwise

the follow massage will be displayed:

4 Open RIP software and make printer setting.

Click “File”, choose “Printer Setup”

Page 42

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 41 -

Click ”Install”

Choose “TEKTRON” in Printer Type list

Page 43

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 42 -

Choose Printer Name. (ME1601-E for example)

Click “OK” back to precious Manu. Click ” Set As Default Printer”.

4.2.2 Print Task and Image Edit

1:Create a new print task, Click “New…” refer to below:

2:Set printing media width

Click “Custom” under Page; Here we set the width as 1600mm, the length is

Page 44

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 43 -

1000mm for example:

Page 45

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 44 -

3:Load the image

Click “ Load Image” shortcut:

Choose the image from the file:

Choose “Off” under Page of Image Picture Setting:

Page 46

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 45 -

4.2.3 Print Mode and Parameter Setting

1:After finish image editing, click “Printer” to set up print parameter:

The below dialogue window displays:

Please refer to RIP user manual for detailed instruction. The operator can keep

default parameter set.

Page 47

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 46 -

Click “Properties…”, below window will be displayed:

Choose ICC profile

The Pinter Ports is “Tektron”

Select print resolution

V360X1080DPI 3PASS Production Mode

V720X720DPI 4PASS Standard Mode

V720X1080DPI 6PASS Quality Mode

V720X1440DPI 8PASS High Quality Mode

Page 48

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 47 -

Click ”Auto ” , the system would recall the media size while image size edited.

In example, the window will show Customized 1600mmX1000mm”

Choose ICC Profile

Note:ICC profile shall match with

the

resolution

selected.

The default media size

is “Auto”

Page 49

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 48 -

Click “OK” to back to previous Manu, see below fig:

There are two printing methods while print an image:

One method is that the system will convert the image into RIPed format, then

print.

Click “Print To File”, the software starts to convert the image.

As the image data has been converted in RIPed file before print, so while the

printer prints a RIPed file, the printer would not be interrupted and wait the

data processed by the PC.

The disadvantage is the printer is not printing the image in real time. The

RIPed file will take big space on memory.

Page 50

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 49 -

Anther method is real print

Click “OK”, the system will transfer the data to “Print Manager, see below fig,

Page 51

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 50 -

Note: While choose real print method, the Print Management System will run

automatically. The data will be transferred Print Management System while RIPing.

4.2.4 Printing Management System

1: when set Printing Management System first time, the operator has to use Real

Print method to open Printing Management System, otherwise Printing Manager

will not find Tektron Printer Port. See follow

2:Printing Management System

(Please refer to MainTop User Manual for further information)

The Printing Management System is showed as below:

The system is sending the

data to print manage…

Page 52

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 51 -

The listed Print Job Name are the images to be printed.

The operator shall select and lighten the task, then click print button, the printing

will start.

Progress Status Bar:

The data format is AA/BBB. BBB indicates the date volume has been transferred to

Printing Management System. AA indicates the data volume that being transferred

to printer through USB.

Tips : if there is no progress data indicates, that mean there is problem in data

transition. You can re-start Printing Management System or printer to solve.

Page 53

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 52 -

4.3 Printer Property

Click “Printer Property ” shortcut:

Set Printer Parameter:

Page 54

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 53 -

Item Description Function

1 Print Direction

Choose printing mode in scan direction. There are two mode: UNI

means the printer print while carriage moves from right to left, and

doesn’t print while carriage moves from left to right. BiD mean that

the printer prints in both directions while carriage moves.

2 Color Channel

Choose the color to be jetted. There are C,M,Y,K four ink channels

can be chose.

3 Head Array Choose head quantity.

4 Position

Select the color checking bar position. “No” mean there is no checking

bar printed beside image. “Left” mean the checking bar printed in left

side of image. “Right” mean the checking bar printed in right side of

image. Both mean checking bar in both side.

5 Margin The distance of checking bar from printing origin

6 Distance The distance of checking bar from the image

7 Width The width of each color of checking bar

8 Effect Mode

Line Mode This is regular printing mode without discount of speed.

Wave Mode

This is a wave processing method applied on each printing pass to

recover the image problem (banding) caused by missing stepping or

nozzle clogged. The printing productivity will be lower than

normal.

Feather Mode

This is a feather processing method applied on each printing pass to

recover the image problem (banding) caused by missing stepping or

nozzle clogging. The printing productivity will be lower than

normal.

Wave +

Feather

This is a wave plus feather processing method applied on each printing

pass to recover the image problem (banding) caused by missing

stepping or nozzle clogging. The printing productivity will be lower

than normal.

9 Altitude

Mini Wave The Wave or Feather effect in less percentage

Middle Wave The Wave or Feather effect in little more percentage

Big Wave The Wave or Feather effect in more percentage

10 BlankSkip

The carriage or media moving will be quickly pass through none color

or blank area in the image.

11 Roll Diameter This is system parameter, the operator can not change

12 Ration This is system parameter, the operator can not change

13 Encoder This is system parameter, the operator can not change

Page 55

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 54 -

Set Calibration::::

Item Description Function

1 Print Head Slant Adjust: Print test chart for checking the head if there is any slant.

2 Media Feeding Calibration Print test image for different pass mode, to verify stepping parameter.

3 Media Choose

The calibration parameter might be variable for different media. Once

finish a calibration, save the data on the name of the media used.

recall the file before print on this type of media in the future.

4 Bid Calibration Print the checking chart for bi-direction printing calibration.

Page 56

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 55 -

Print Head Alignment

Click “Slant Adjust”, the printer will print the head check chart as below:

Loose three head fixing screws, turn head adjust screw slightly, print again until the

Page 57

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 56 -

line for each printing pass align well:

Page 58

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 57 -

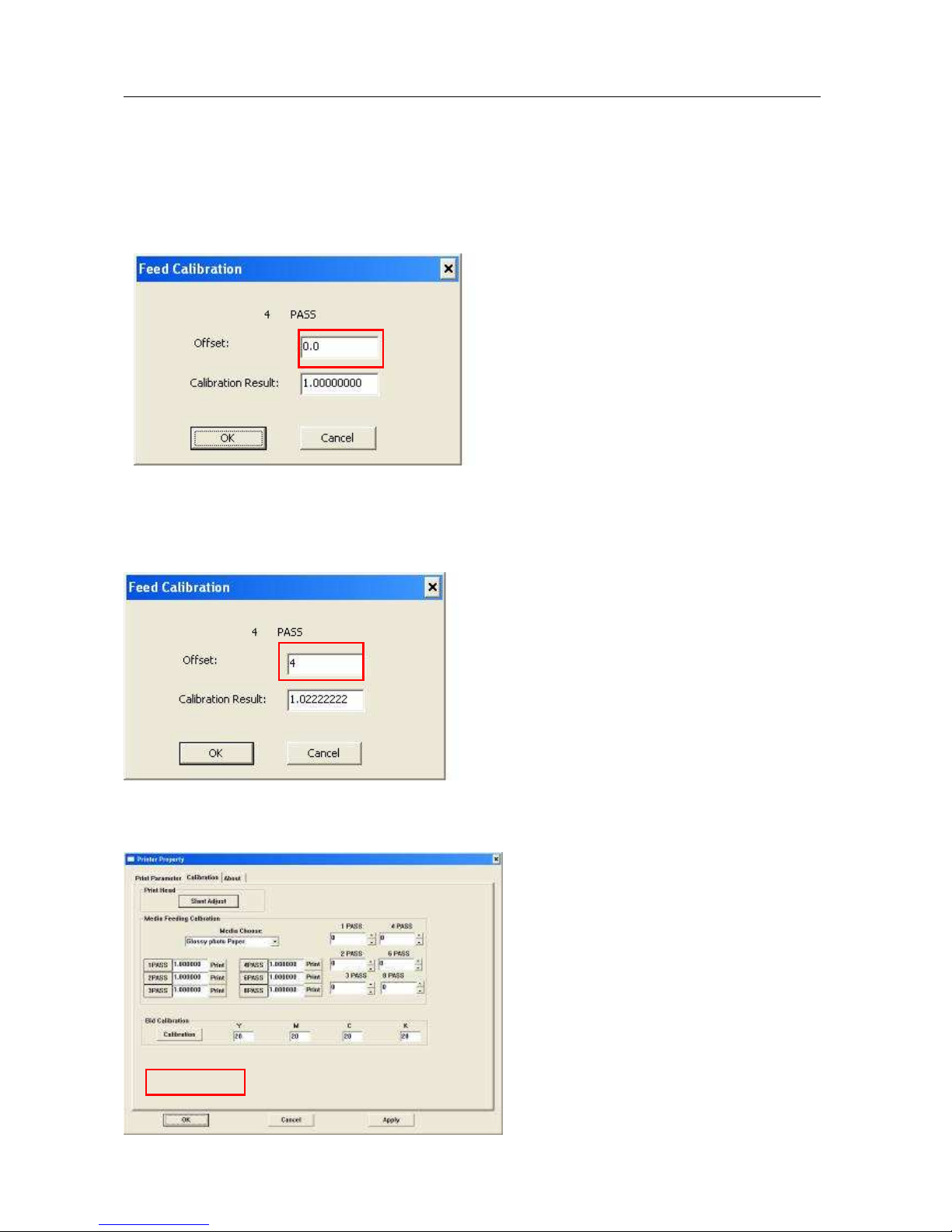

Media Feeding Calibration Procedure::::

Do calibration for each Pass mode to achieve the best printing quality.

Take example for 4 Pass to instruct the procedure:

Click “Print” in 4 PASS mode, the printer will print calibration image as below:

Read the deviation value from the chart. Check all line pairs in the chart, figure out

Page 59

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 58 -

the number under the most matched line pairs, which is the value to be fill in

calibration.

Click “ 4Pass” , the widow displays as below:

Fill the value read in the chart ( assume the value is 4 for example) to offset window,

click OK to save and back to previous Manu.

Bi-direction calibration procedure:

Page 60

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 59 -

Click “Calibration” on Bid calibration, the printer will print the checking chart as

below:

Look at the chart printed, find the each line of individual color that is most matching

black line, the value under the line is the deviation to be filled in related color.

Fill the value to the window for each color, then click “Apply” to save.

Page 61

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 60 -

Chapter 5 Ink Supplying and Capping System

5.1 Introduction

The ink supplying is nature siphonic method from the bulk cartridge to print head.

There are three clean methods for head cleaning that can be selected during printing.

5.2 Operation Diagram

Fig 5-1 Clean System Diagram

Page 62

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 61 -

5.3 System Structure

5.3.1 Introduction

1 2 3 4

5 6 7 8 9 10

11

Page 63

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 62 -

Item # Description Function

1 Ink Cartridge Magenta (2) Main ink store for magenta color ink, capacity is 220ML

2 Ink Cartridge Yellow (2) Main ink store for yellow color ink, capacity is 220ML

3 Ink Cartridge Cyan (2) Main ink store for cyan color ink, capacity is 220ML

4 Ink Cartridge Black (2) Main ink store for black color ink, capacity is 220ML

5 Wiper

This is a wiper for removing the remain ink on the surface of nozzle

after purging.

6 Waste Ink Tube This is the tube for connecting the head capper with waste ink tank.

7 Capper

This is the capper for seal the head for keep wetting. It is also a

container for store the ink such from nozzle while cleaning.

8 Capping Pad This is a pad for waste ink or clean solution storage.

9 Capping Container

This is the main case for holding wiper, capper, pad, and collect the

waste ink.

10 Vacuum Pump tube

The vacuum pump from this tube suck the ink from print head then

let the waste ink go through to the waste ink tank

11 Waste ink tank This part is used to contain the waste ink

Page 64

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 63 -

Chapter 6 Media Heating System

6.1 Introduction

The media heating system is an independent system, witch includes front, rear heater, and printing platen heater.

The user can choose the heater for particular media to achieve the best printing results.

6.2 Operation Diagram

Fig 6-1 Heating System Diagram

6.3 Features

The front and rear heater are constant temperature controlled.

The printing platen heater’s temperature is controlled by a separate PID controller. The user can set the

temperature as required.

All of the heater has a over heating protection for 70 ˚C. the power will be switched off while over

temperature occurs. It can be recovered while the temperature is down.

The input voltage is selectable for 110V AC or 220VAC.

Page 65

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 64 -

6.4 Structure And Description

1 2 3 4 5 6

Item # Description Function

1 SET key For Function change and confirm

2 Shift key This is used to change the digit that would be changed

3 Down key This is used for reducing the count

4 Up key This is used for increase count

5 SV Set Value This displays the temperature to be reached.

6 PV Presnt Value This displays the actual temperature measured.

Procedure

:

Switch on heater power switch after turn on the main power switch of printer. The heater starts warming up.

The default control point is 40℃.

To adjust the control point ( for example, set to 50℃):

Step 1. Press SET,

Page 66

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 65 -

Step 2: Press shift key, Lighten the digit to be changed.

Step 3 : Press or key to change the value.

Step 4 : Press SET again to save the value and exit

Page 67

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 66 -

Page 68

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 67 -

Chapter 7 Media Take-up System (Optional)

7.1 Instruction

The take up device is a separate operation system, it has independent DC power supply.

7.2 Structure

1 2 3 4 5 6

7 8 9

Item Description Function

1 Passive Media Holder This is a holder for fix the media.

2 Supporting Slot Guide The holder can be moved along with the slot to fit the length of

media.

3 Tension Bar It give the media take up system a constant tension and also give the

sensor signal for media auto control system

4 Active Media Holder This is a holder driven by DC motor for media rewinding.

5 Take up support This is a sheet metal to fasten the media take up system on the leg

assy

6 Electrical box The electrical control part is install in the box

Page 69

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 68 -

7 Auto/manual switch The switch used to transfer the control system by manual or by sensor

to auto control

8 Power Cord This is the power card for taking up system.

9 Direction Switch This is used to change the winding direction.

7.3 Operation Description

7.3.1 Install Paper Core

Install paper core, stick a double side adhesive in horizontal on the surface of the paper core.

7.3.2 Pull the media to paper core equably, slight press the media and stick it on paper core.

Page 70

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 69 -

7.3.3 Put the tension bar down

7.3.4 Switch on take up system, select winding direction.

Page 71

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 70 -

Chapter 8 Maintenance

8.1 Daily Maintenance

Daily maintenance is very important for normal work of the printer.

8.1.1 Daily work

Check waste ink tank, clean up if necessary;

Check the ink level in ink cartridge, keep the level between ½ to 2/3 of of the capacity.

Check the waste ink groove on the clean station. clean it if necessary;

Check the wetness of head capper , clean or replace it if necessary;

Check wiper and clean it if necessary;

Clean feeding and pinch rollers with PM acetate.

Do normal clean for the printer everyday.

8.1.2 Weekly work

Clean the dust on the surface of fans on dry board. Assemble them after ensure clearness of the leafages.

Check pump route if there is any loose.

Check power socket and USB connector.

Check the tension of X/Y driving belt. Do adjustment if necessary.

Check the tension of carriage driving belt. Do adjustment if necessary.

Check the status of encoding strip. Clean the dust on the strip if necessary.

Check press roller and pinch roll. Clean the gap to keep the roll turning freely.

Check media guide slot. Clean the slot to keep guide moving freely.

8.1.3 Monthly work

Clean the floating switch;

Clean the filters of C、M、Y and K;

Observe the three-way valve of the positive pressure cleaning if has ink in it. If necessary, use flush solution

to cleaning;

Check the tension of straps;

Clean dust in the power tank.

8.1.4 Six Months Work

Replace ink filters;

Blow the dust out of electrical chassis with compress air;

Clean or replace ink pad on clean station.

Clean the ink supply routes;

Change wiper;

Clean or replace vacuum pump.;

Check whole circuit if there is any loosen or broken. Repair it in time if necessary;

Check if there is any tear on the tube and wire in the towline set and replace it if necessary.

Page 72

ME

MEME

ME Series

SeriesSeries

Series Printer

PrinterPrinter

Printer Operation

OperationOperation

Operation Manual

ManualManual

Manual

- 71 -

8.2 Linear Rail Maintenance

Add lubricating oil to the rail daily. The details as below:

Turn off the power supply;

Add a few lubricating oil on a cotton fabric and move the print head to original position.

Brush the rail with the cotton fabric to create an average oil layer on the Rail;

Power the printer and move the print head unit left and right repeatedly;

Erase the oil smear on the both ends of the rail. Erase the oil drops on the rail again before printer running。

8.3 Print-head Maintenance

Always keep the print head surface wet with flush solution. If the printer is left unused, the print head must be

move to clean station and covered by capper ,to keep it wet and in a good condition..

If there would be two or more days not use the printer, please do follow procedure to keeping the nozzle of the

head be tried out.

Apply flush solution on the pad of head capper. Initial head capping procedure to park the head on clean

station.

If more than four days not using, disconnect the damper from the head, flush the head by using flush

solution. Initial capping procedure.

Unload print head

Do as follows when you are going to unload print head:

Suck the ink out from print head and clean it with flush solution by using injector;

Power off the printer and plug out power line from socket;

Check static on the machine with a multi-meter and release the static if necessary;

Loosen Right screws, and take out the right screw;

Take out the print head and put it on an unwoven fabric soaked with flush solution

Please wear the anti-static wrist strap when connect the print heads onto the print heads

driven board, otherwise will result in a damage to the print heads or print heads driven board.

8.4 Ink Supply Maintenance

Clean out the ink in all tubes and cartridges

Remove 8 cartridges from the printer, clean the remains out from the cartridge..

Check the rubber seal on the cartridge. Replace a new one if necessary.

Re-install the sensor and cap.

Loading...

Loading...