Page 1

Technology Solutions

TEK-FLEX 4100A

Explosion Proof Guided Wave

Radar Level Transmitter

Instruction Manual

Document Number: IM-4100A

www.tek-trol.com

Page 2

www.tek-trol.com

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

For technical assistance, contact

Customer Support

796 Tek-Drive

Crystal Lake, IL 60014

USA

Tel: +1 847 857 6076, +1 847 655 7428

© COPYRIGHT Tek-Trol LLC 2019

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer language, in any form or by any means,

electronic, mechanical, manual, or otherwise, or disclosed to third parties without the express

written permission. The information contained in this manual is subject to change without notice.

Page 3

Tek-Flex 4100A

Instruction Manual

Technology Solutions

CONTENTS

1 Safety instructions 7

1.1 Software history ............................................................................................................... 7

1.2 Intended use ..................................................................................................................... 7

1.3 Certification ...................................................................................................................... 8

1.4 Electromagnetic compatibility ......................................................................................... 8

1.5 Safety instructions from the manufacturer ..................................................................... 9

1.5.1 Copyright and data protection ................................................................................................ 9

1.5.2 Disclaimer ............................................................................................................................... 9

1.5.3 Product liability and warranty .............................................................................................. 10

1.5.4 Information concerning the documentation......................................................................... 10

1.5.5 Warnings and symbols used................................................................................................. 11

1.6 Safety instructions for the operator............................................................................... 11

2 Device description 12

2.1 Scope of delivery............................................................................................................. 12

2.2 Device description .......................................................................................................... 14

2.3 Visual Check ................................................................................................................... 15

2.4 Nameplates .................................................................................................................... 16

2.4.1 Non-Ex nameplate ................................................................................................................ 16

3 Installation 17

3.1 General notes on installation ......................................................................................... 17

3.2 Storage ........................................................................................................................... 17

3.3 Transport ........................................................................................................................ 18

3.4 Pre-installation requirements ....................................................................................... 19

3.5 How to prepare the tank before you install the device.................................................. 19

3.5.1 Pressure and temperature ranges....................................................................................... 19

3.5.2 General information for nozzles........................................................................................... 21

3.5.3 Installation requirements for concrete roofs....................................................................... 23

3.6 Installation recommendations for liquids...................................................................... 24

3.6.1 General requirements .......................................................................................................... 24

3.6.2 How to attach probes to the bottom of the tank................................................................... 25

3.6.3 Standpipes............................................................................................................................. 28

3.6.4 Typical applications............................................................................................................... 32

3.7 Installation recommendations for solids....................................................................... 34

3.7.1 Nozzles on conical silos........................................................................................................ 34

3.7.2 Traction loads on the probe.................................................................................................. 35

3.8 How to install the device on the tank ............................................................................. 36

3.8.1 How to assemble the single rod probe (single-piece probe)............................................... 36

3.8.2 How to assemble the single rod probe (segmented probe)................................................. 40

3.8.3 How to assemble the segmented coaxial probe .................................................................. 43

3.8.4 How to install a device with a flange connection ................................................................. 46

3.8.5 How to install a device with a threaded connection............................................................. 47

3.8.6 How to install a cable probe in the tank............................................................................... 48

3.8.7 Recommendations for pits and tanks made of non-conductive materials.......................... 49

3.8.8 How to assemble the remote version................................................................................... 50

www.tek-trol.com

03

Page 4

Tek-Flex 4100A

4 Electrical connections 56

4.1 Safety instructions.......................................................................................................... 56

4.2 Electrical installation: outputs 1 and 2 .......................................................................... 56

4.3 Electrical connection for current output ....................................................................... 57

4.4

4.5 Networks ........................................................................................................................ 59

Instruction Manual

Te gy Solutionschnolo

3.8.9 How to turn or remove the signal converter ........................................................................ 53

3.8.10 How to attach the weather protection to the device........................................................... 54

3.8.11 How to open the weather protection .................................................................................. 55

Non-Ex devices ..................................................................................................................... 57

4.3.1

4.3.2 Devices for hazardous locations........................................................................................... 57

Protection category ........................................................................................................58

4.5.1 General information.............................................................................................................. 59

4.5.2 Point-to-point networks ....................................................................................................... 59

4.5.3 Multi-drop networks ............................................................................................................. 60

5 Start-up 61

5.1

Start-up checklist........................................................................................................... 61

5.2 Operating concept ..........................................................................................................61

5.3 Digital display screen .....................................................................................................62

5.3.1

Local display screen layout .................................................................................................. 62

5.3.2 Keypad buttons ..................................................................................................................... 62

5.3.3 Help screens ......................................................................................................................... 62

5.3.4 How to start the device ......................................................................................................... 63

Remote communication with PACTware™ .................................................................... 63

5.4

5.5 Remote communication with the AMS™ Device Manager............................................. 64

6 Operation 65

6.1

User modes .................................................................................................................... 65

6.2 Operator mode................................................................................................................ 65

6.3 Supervisor mode ............................................................................................................68

6.3.1

General notes........................................................................................................................ 68

6.3.2 How to get access to the supervisor mode .......................................................................... 68

6.3.3 Keypad functions................................................................................................................... 69

6.3.4 Menu overview ...................................................................................................................... 72

6.3.5 Function description ............................................................................................................. 73

6.4 Further information on device configuration................................................................. 86

6.4.1

Protection of the device settings .......................................................................................... 86

6.4.2 Network configuration .......................................................................................................... 86

6.4.3 Linearisation ......................................................................................................................... 87

6.4.4 Distance measurement ........................................................................................................ 87

6.4.5 Level measurement .............................................................................................................. 88

6.4.6 How to configure the device to measure volume or mass................................................... 89

6.4.7 How to make the device follow the correct level or interface signal .................................. 90

6.4.8 Thresholds and parasitic signals.......................................................................................... 92

6.4.9 How to use the snapshot function to filter parasitic signals ............................................... 96

........................................... 97

6.4.10 How to measure products with a low dielectric constant (e

6.4.11 How to decrease the length of probes................................................................................ 98

)

r

ww.tek-trol.com

04w

Page 5

Tek-Flex 4100A

Instruction Manual

Technology Solutions

6.5 Service mode .................................................................................................................. 99

6.6 Errors............................................................................................................................ 100

6.6.1 General information............................................................................................................ 100

6.6.2 Error handling..................................................................................................................... 102

7 Service 106

7.1 Periodic maintenance................................................................................................... 106

7.2 Keep the device clean................................................................................................... 106

7.3 How to replace device components ............................................................................. 107

7.3.1 Service warranty ................................................................................................................. 107

7.3.2 Replacement of the display cover....................................................................................... 108

7.3.3 Replacement of the complete electronic module .............................................................. 110

7.3.4 Replacement of the terminal module................................................................................. 112

7.3.5 Replacement of the BM 100 signal converter .................................................................... 114

7.3.6 Replacement of the BM 102 signal converter .................................................................... 120

7.4 Spare parts availability................................................................................................. 1

7.5 Availability of services .................................................................................................. 1

7.6 Returning the device to the manufacturer................................................................... 1

7.6.1 General information............................................................................................................ 1

7.6.2 Form (for copying) to accompany a returned device.......................................................... 1

7.7 Disposal ........................................................................................................................ 1

11

11

11

11

12

13

8 Technical data

8.1 Measuring principle...................................................................................................... 1

8.2 Technical data............................................................................................................... 1

8.3 Pressure/temperature table for probe selection ........................................................ 1

8.4 Guidelines for maximum operating pressure (CRN certification) .............................. 1

1

14

14

17

22

23

8.5 Dimensions and weights .............................................................................................. 126

9 Description of HART interface 158

9.1 General description ...................................................................................................... 1

9.2 Software history ........................................................................................................... 1

9.3 Connection variants...................................................................................................... 1

9.3.1 Point-to-Point connection - analogue / digital mode......................................................... 1

9.3.2 Multi-Drop connection (2-wire connection) ....................................................................... 1

9.4 HART® device variables............................................................................................... 1

9.5 Field Communicator 375/475 (FC 375/475) ................................................................. 1

9.5.1 Installation .......................................................................................................................... 1

9.5.2 Operation............................................................................................................................. 136

9.6 Asset Management Solutions (AMS) ............................................................................ 137

9.6.1 Installation .......................................................................................................................... 137

9.6.2 Operation............................................................................................................................. 137

9.6.3 Parameter for the basic configuration ............................................................................... 137

9.7 Field Device Tool / Device Type Manager (FDT / DTM) ................................................ 137

9.7.1 Installation .......................................................................................................................... 137

9.7.2 Operation............................................................................................................................. 1

33

33

34

34

34

36

36

36

37

www.tek-trol.com

05

Page 6

Tek-Flex 4100A

Instruction Manual

Technology Solutions

9.8 HART menu tree for Basic-DD .................................................................................. 1

9.8.1 Overview Basic-DD menu tree (positions in menu tree).................................................... 1

9.8.2 Basic-DD menu tree (details for settings).......................................................................... 1

9.9 HART menu tree for AMS

9.9.1 Overview AMS menu tree (positions in menu tree) ............................................................ 1

9.9.2 AMS menu tree (details for settings).................................................................................. 1

10 Appendix

10.1 Order code ...............................................................................................................

10.2 List of spare parts ......................................................................................................

10.3 List of accessories......................................................................................................

10.4 Glossary .................................................................................................................

®

®

38

38

38

140..........................................................................................

40

41

144

144

147

149

151

www.tek-trol.com

06

Page 7

Tek-Flex 4100A

Instruction Manual

Technology Solutions

1. SAFETY INSTRUCTION

1.1 Software history

Data about software revisions is shown in the Supervisor menu. Go to Test > Information >

Device ID

Device ID. For more data, refer to

Device IDDevice ID

Function description

on page 73. If it is not possible to refer to

Test > Information >

Test > Information > Test > Information >

the device menu, record the serial number of the device (given on the device nameplate) and

speak to the supplier.

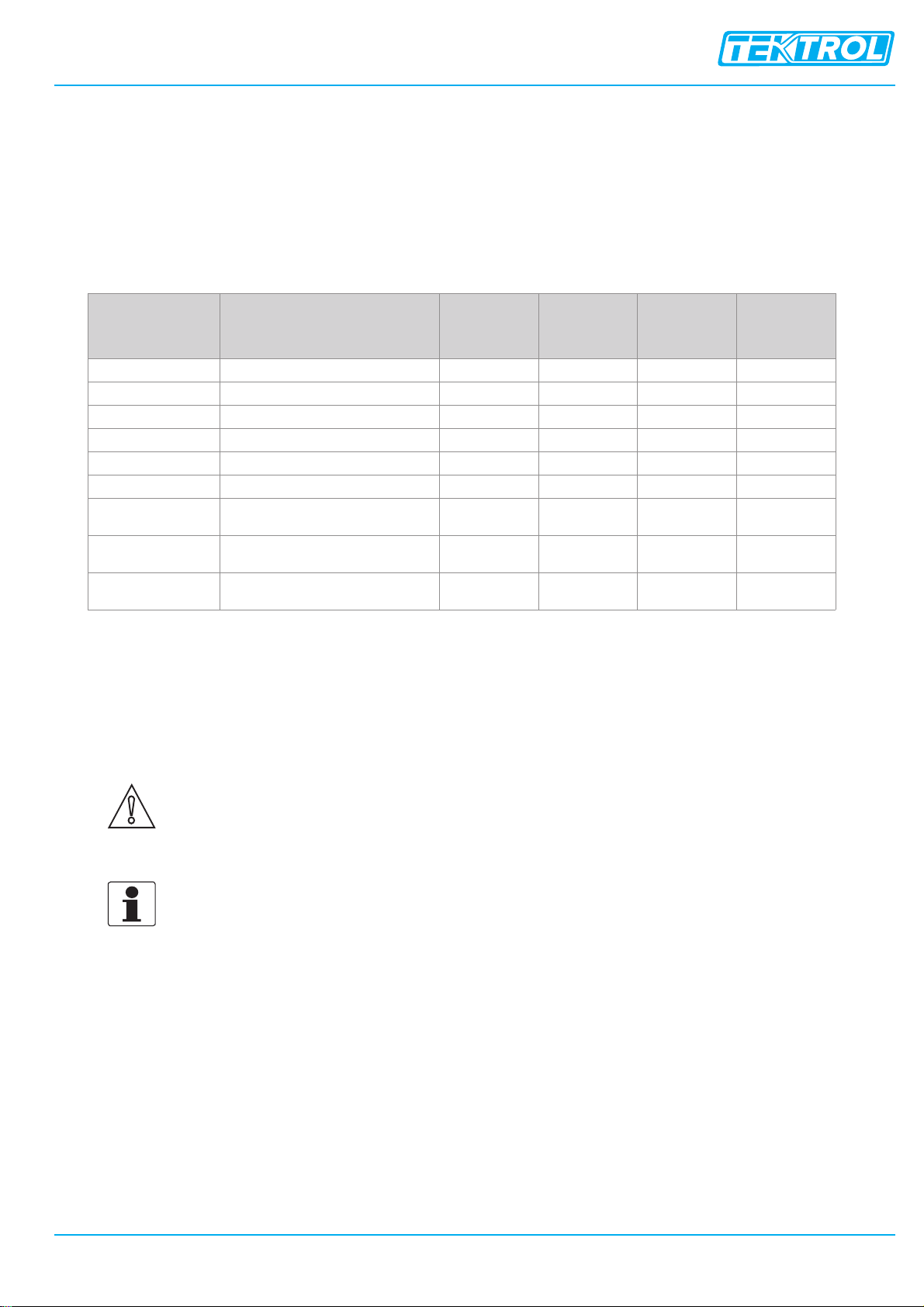

Release date

Back end Front end DTM revision Hardware NE 53 level

(back end)

[YYYY-MM-DD]

2005-10-18 1.0.2.73 1.0.0.22 1.0.0.24 2139590100 n/a

2006-02-27 1.02.75 1.0.0.22 1.0.0.24 2139590100 3

2006-05-29 1.02.75 1.0.0.25 1.0.0.24 2139590100 3

2006-09-01 1.02.77 1.0.0.26 1.0.0.32 2139590100 3

2007-11-21 1.02.79 1.0.0.27 1.0.0.33 2139590100 3

2008-06-22 1.02.80 1.0.0.27 1.0.0.34 2139590100 3

2010-03-01 2.02.82

2010-05-01 2.02.83

2012-03-05 2.02.84

1 This back end firmware revision is only used for device upgrades

2 It is possible to upgrade the hardware (revision 2139590100) with back end firmware revision 1.02.82

3 If your computer uses the Windows XP operating system, install DTM revision V 1.0.0.35. If your computer uses the Windows 7 operating

system, install DTM revision V 1.0.0.37.

4 It is possible to upgrade the hardware (revision 2139590100) with back end firmware revision 1.02.83

5 It is possible to upgrade the hardware (revision 2139590100) with back end firmware revision 1.02.84

1.02.82

1.02.83

1.02.84

1

1

1

1.0.0.28 1.0.0.35 4000659401

1.0.0.28 1.0.0.37

1.0.0.28 1.0.0.37

3

3

2

4000659401

4

4000659401

5

1

3

3

n/a

3

3

1.2 Intended use

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

This TDR level transmitter measures distance, level, mass and volume of liquids, pastes,

slurries, granulates and powders. It can also measure level and interface of liquids at the same

time.

It can be installed on tanks, silos and open pits.

www.tek-trol.com

07

Page 8

Tek-Flex 4100A

Instruction Manual

Te gy Solutionschnolo

1.3 Certification

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

In accordance with the commitment to customer service and safety, the device

described in this document meets the following safety requirements:

• Electromagnetic Compatibility (EMC) Directive 2004/108/EC in conjunction with EN 61326-1

(2013).

All devices are based on the CE marking and meet the requirements of NAMUR Guideline NE 21

and NE 43.

1.4 Electromagnetic compatibility

The device design agrees with European Standard EN 61326-1 (2013) when installed in metallic

tanks.

You can install the device on open-air tanks and tanks that are not made of metal. Refer also to

the note that follows.

CAUTION!

If you install a device with a rod or cable probe in a non-metallic tank or open-air pit, a strong

electromagnetic field near to the device can have an unwanted effect on the accuracy. Use a

device with a coaxial probe for this type of installation.

INFORMATION!

Device operation agrees with residential-class (class B) and industrial-class (class A) emissions.

The device fulfils immunity requirements when it is installed in industrial areas.

The device agrees with these conditions if:

•

the device has a single or double probe (rod or cable probe) and is used in a closed tank made

of metal or

•

the device has a coaxial probe.

www.tek-trol.com

08

Page 9

Tek-Flex 4100A

Instruction Manual

Technology Solutions

1.5 Safety instructions from the manufacturer

1.5.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.5.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

www.tek-trol.com

09

Page 10

Tek-Flex 4100A

Instruction Manual

Technology Solutions

1.5.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation or operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.5.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of icons as shown below.

www.tek-trol.com

10

Page 11

Tek-Flex 4100A

Instruction Manual

Technology Solutions

1.5.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

RESULT

RESULT

i

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.6 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.tek-trol.com

11

Page 12

Tek-Flex 4100A

Instruction Manual

Technology Solutions

2. DEVICE DESCRIPTION

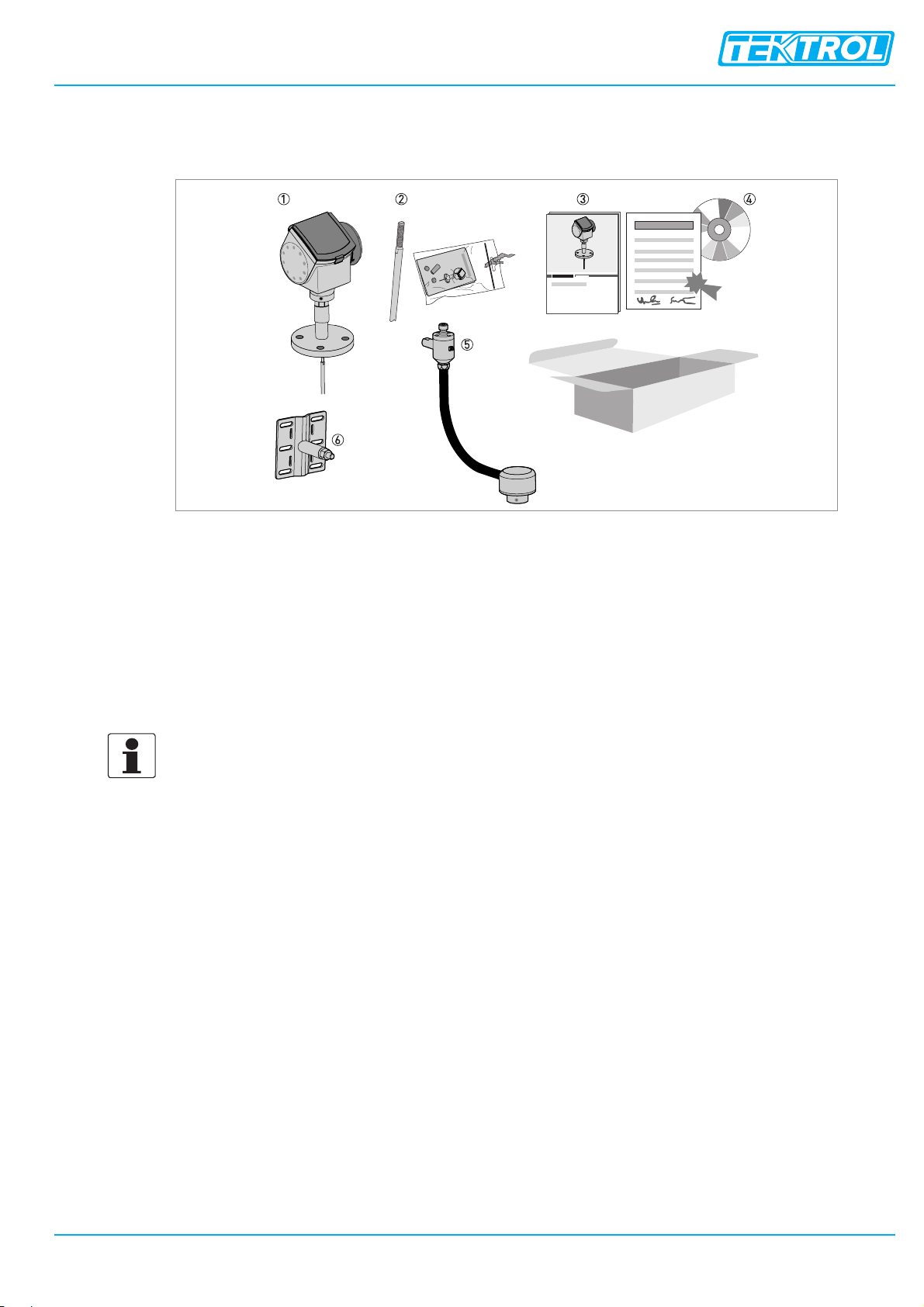

2.1 Scope of delivery

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

Figure 2-1: Scope of delivery for compact version

1 Signal converter and probe – compact version.

2 Probe segments. For the assembly procedure of the single rod probe, refer to

(single-piece probe)

option, only part of the probe is attached to the device. For the assembly procedure of the segmented single rod probe,

How to assemble the single rod probe (segmented probe)

refer to

mented coaxial probe, refer to

The assembly instructions and small parts are in a bag attached to the signal converter.

3 Quick Start

4 CD-ROM. This contains the Handbook, the Quick Start, the Technical Datasheet and related software.

on page 36. If a single rod or coaxial probe is attached and you ordered the "segmented probe"

on page 40. For the assembly procedure of the seg-

How to assemble the segmented coaxial probe

How to assemble the single rod probe

on page 43.

www.tek-trol.com

12

Page 13

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Figure 2-2: Scope of delivery for the remote version

1 Signal converter and probe

2 Probe segments. For the assembly procedure of the single rod probe, refer to

(single-piece probe)

option, only part of the probe is attached to the device. For the assembly procedure of the segmented single rod, refer

to

How to assemble the single rod probe (segmented probe)

coaxial probe, refer to

The assembly instructions and small parts are in a bag attached to the signal converter.

3 Quick Start

4 CD-ROM. This contains the Handbook, the Quick Start, the Technical Datasheet and related software.

5 Flexible conduit. For the assembly procedure, refer to

6 Wall bracket (also for installation on pipes)

on page 36. If a single rod or coaxial probe is attached and you ordered the "segmented probe"

on page 40. For the assembly procedure of the segmented

How to assemble the segmented coaxial probe

How to assemble the remote version

on page 43.

How to assemble the single rod probe

on page 50.

INFORMATION!

No special tools, no training required!

www.tek-trol.com

13

Page 14

Tek-Flex 4100A

Instruction Manual

Technology Solutions

2.2 Device description

The TDR level transmitter is designed to measure the distance, level, interface, mass and

volume of liquids, pastes, slurries, granulates and powders.

TDR level transmitters use a probe to guide a signal to the surface of the measured product. The

device has a large choice of probes. Thus, it can measure most products in difficult conditions.

For more data, refer to

The device has a set-up wizard, fully-potted electronic sub-assemblies and online help

functions. You usually will not need this document to install, set up and operate the device.

Technical data

You can order these accessories:

• Stainless steel weather protection.

• RS232 / HART® converter (VIATOR).

• USB / HART® converter (VIATOR).

• ESD protection (30 kV).

• Metaglas® dual process sealing system for dangerous products.

on page 127.

INFORMATION!

For more data on accessories, refer to List of accessories on page 182

.

www.tek-trol.com

14

Page 15

Tek-Flex 4100A

Instruction Manual

Technology Solutions

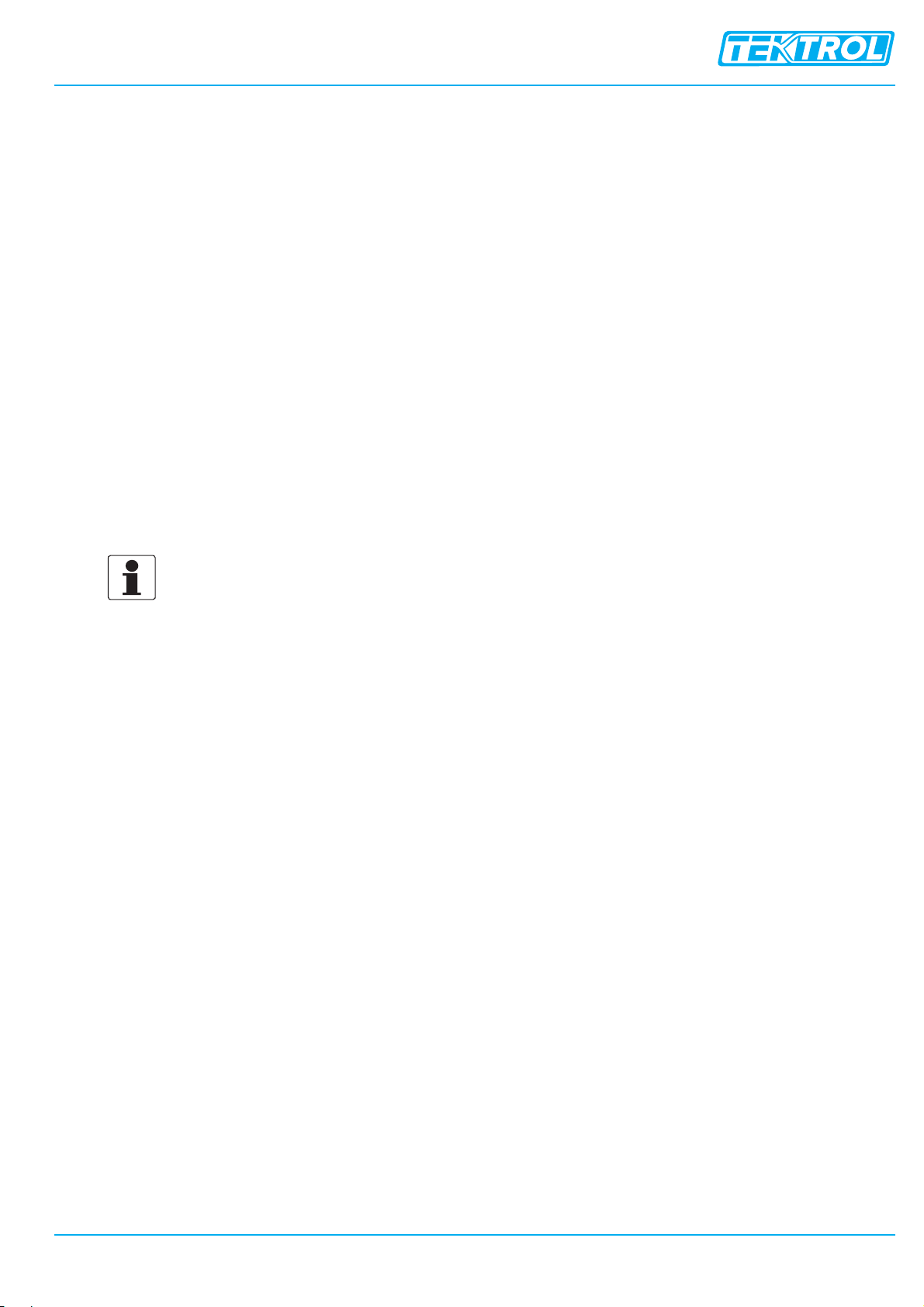

2.3 Visual Check

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

Figure 2-3: Visual check

1 Device nameplate (for more data, refer to

2 Process connection data (size and pressure rating, material reference and heat number)

3 Gasket material data - refer to the illustration that follows

Figure 2-4: Symbols for the supplied gasket material (on the side of the process connection)

1 EPDM

2 Kalrez® 6375

Non-Ex nameplate

on page 16)

If the device is supplied with an FKM/FPM gasket, there is no symbol on the side of the process

connection.

WARNING!

•

If the display screen glass is broken, do not touch.

•

If the device has to measure the level of dangerous products (ammonia etc.), we recommend

that the device has the Metaglas® option.

•

If the device has to measure the level of products where there is a risk of electrostatic

discharge, we recommend that the device has the ESD (electrostatic discharge) protection

option.

www.tek-trol.com

15

Page 16

Tek-Flex 4100A

Instruction Manual

Technology Solutions

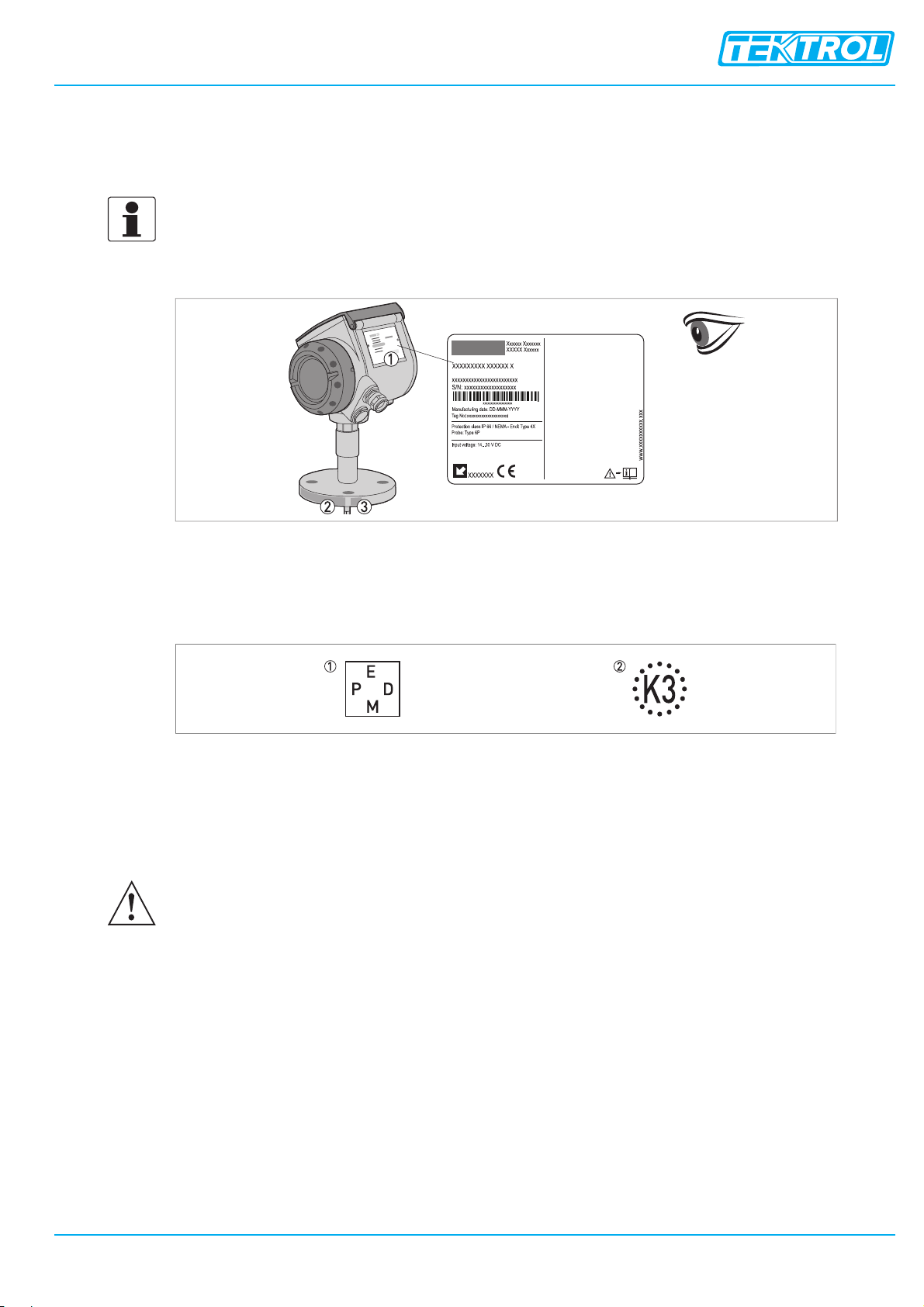

2.4 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

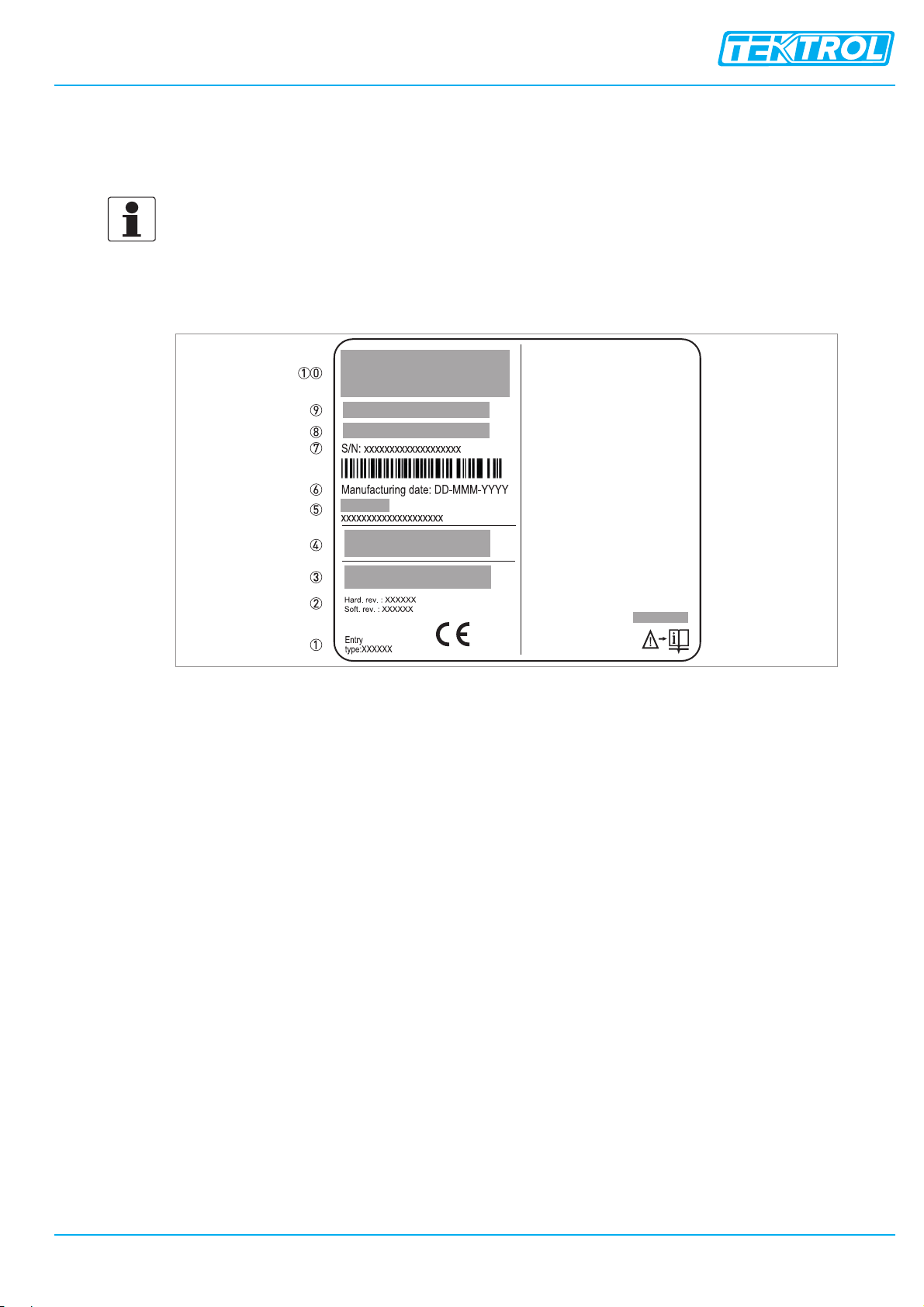

2.4.1 Non-Ex nameplate

Figure 2-5: Non-Ex nameplate

1 Indicator arrow to cable entry / cable entry size. Notified body for radio approval.

2 Hardware revision / Software revision

3 Nominal voltage for operation. For further information, refer to

4 Degree of ingress protection (according to EN 60529 / IEC 60529)

5 Customer tag number

6 Date of manufacture

7 Order number

8 Type code (defined in order)

9 Model name and number

10 Company name and address

Non-Ex devices

on page 57.

www.tek-trol.com

16

Page 17

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3. INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

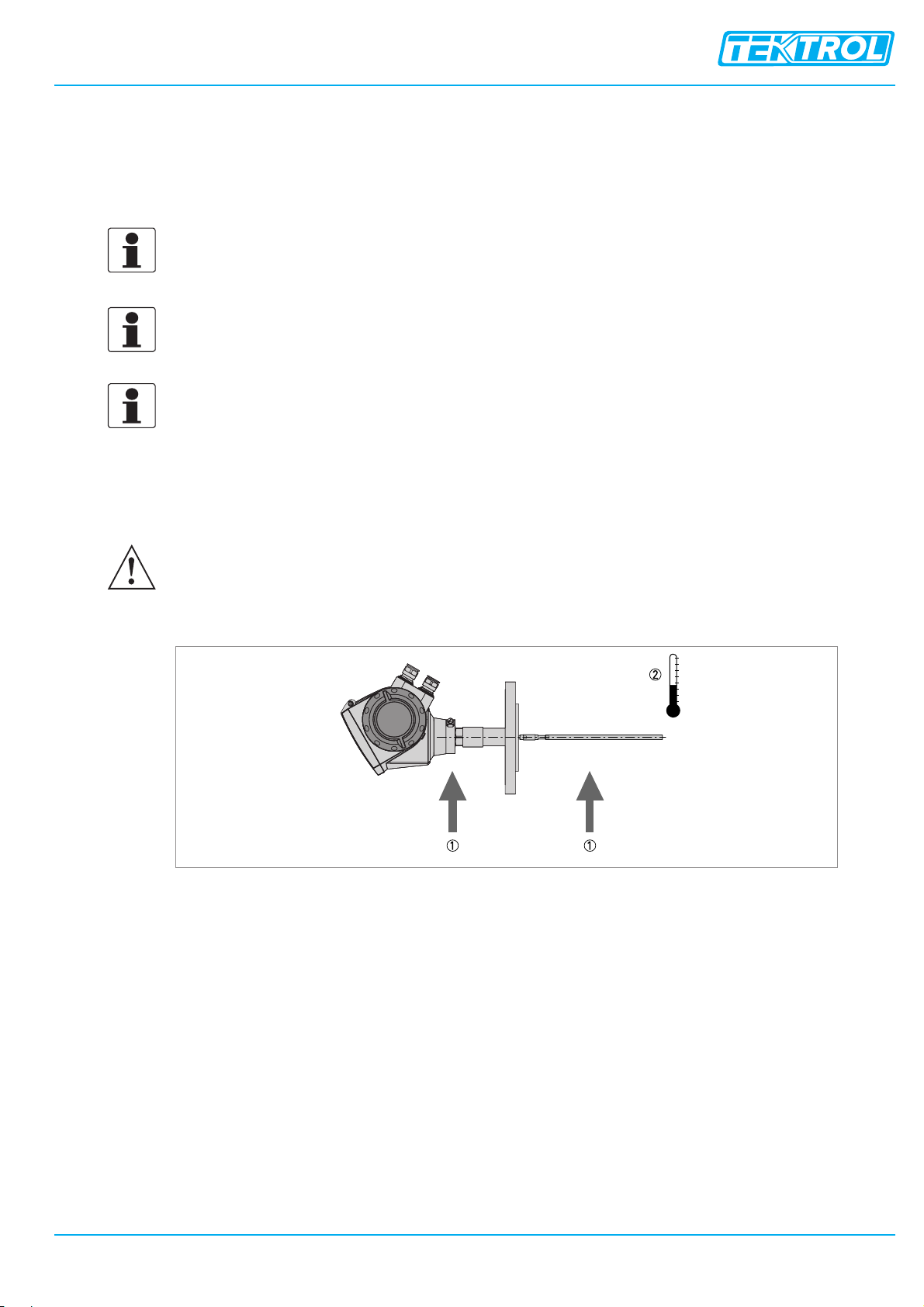

3.2 Storage

WARNING!

Do not keep the device in a vertical position. This will damage the probe and the device will not

measure correctly.

Figure 3-1: Storage conditions

1 Do not bend rod and coaxial probes – support here

2 Storage temperature range: -50…+85°C/ -60…+185°F (min. -40°C/ -40°F for devices with the integrated LCD display

option)

• Store the device in a dry and dust-free location.

• Store the device in its original packing.

www.tek-trol.com

17

Page 18

Tek-Flex 4100A

Instruction Manual

Technology Solutions

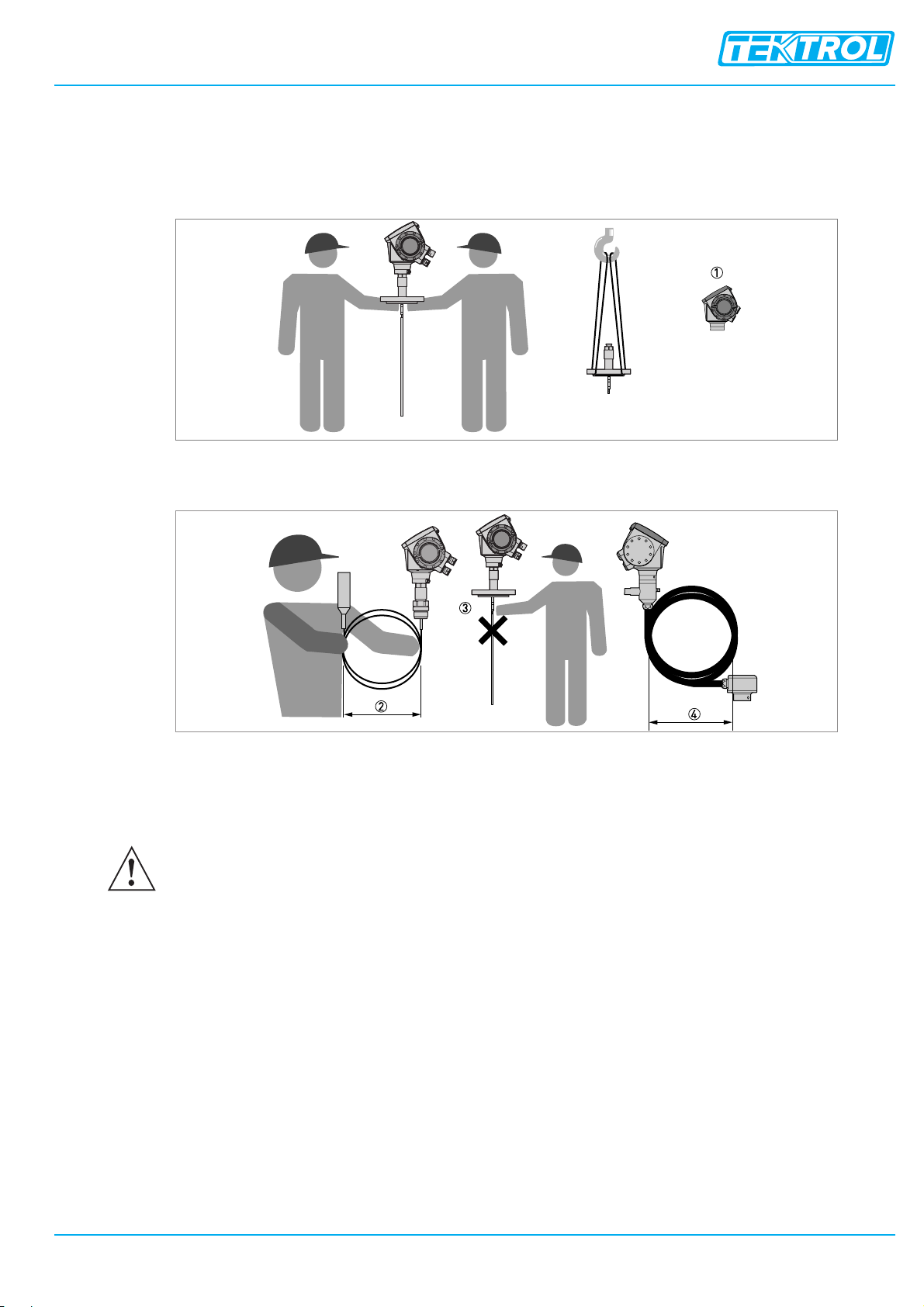

3.3 Transport

Figure 3-2: How to hold the device

Figure 3-3: How to hold the device

1 Remove the converter before you lift the device with a hoist.

2 Wind cable probes greater than 400 mm / 16¨ in diameter.

3 Do not hold the probe when you lift the device.

4 Do not wind the flexible conduit less than 330 mm / 13¨ in diameter.

WARNING!

If you do not lift the device carefully, you can cause damage to the probe.

www.tek-trol.com

18

Page 19

Tek-Flex 4100A

Instruction Manual

Technology Solutions

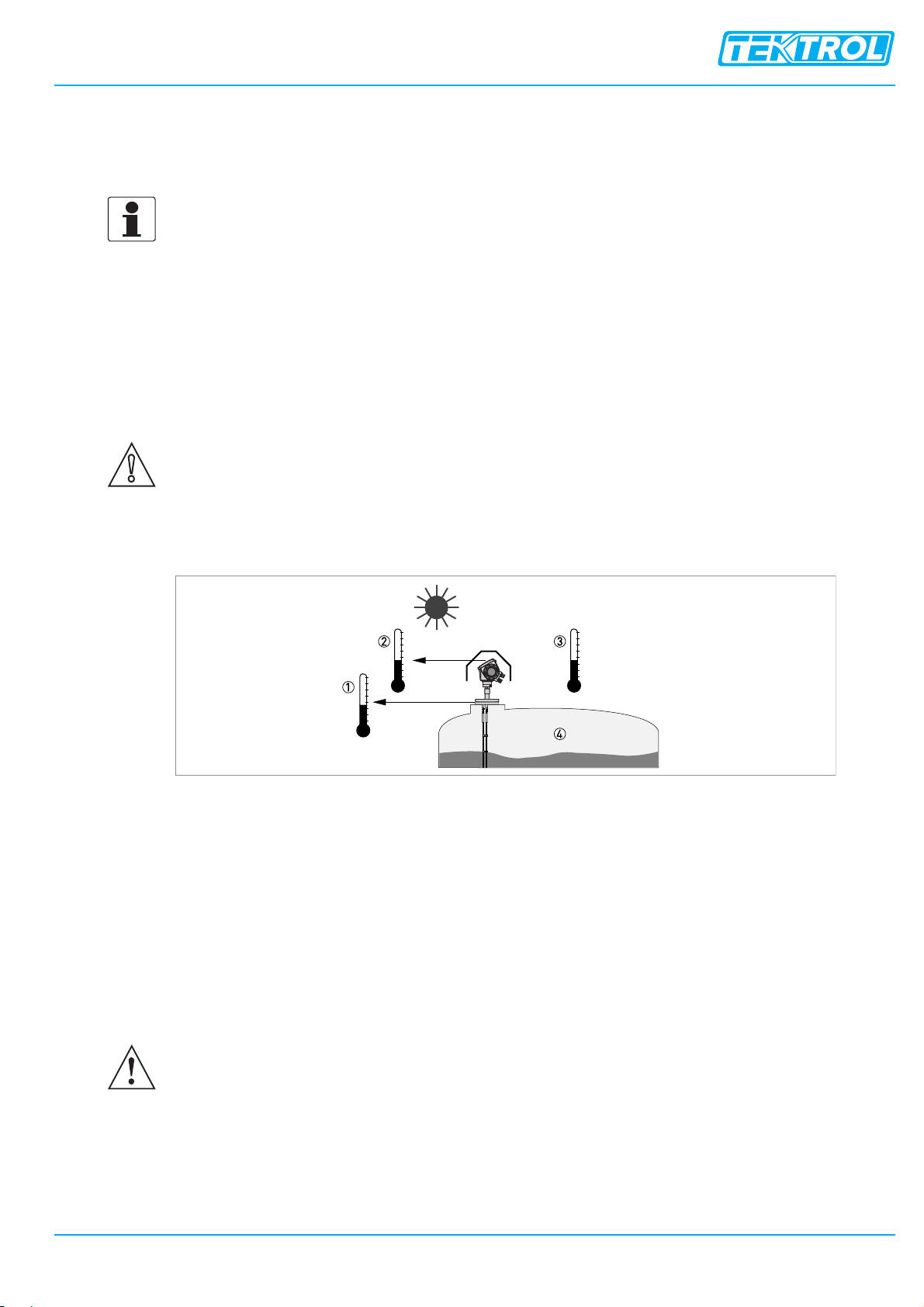

3.4 Pre-installation requirements

INFORMATION!

Obey the precautions that follow to make sure that the device is correctly installed.

• Make sure that there is sufficient space on all sides.

• Protect the signal converter from direct sunlight. If necessary, install the weather protection

accessory.

• Do not subject the signal converter to heavy vibrations. The devices are tested for vibration

and agree with EN 50178 and IEC 60068-2-6.

3.5 How to prepare the tank before you install the device

CAUTION!

To avoid measuring errors and device malfunction, obey these precautions.

3.5.1 Pressure and temperature ranges

Figure 3-4: Pressure and temperature ranges

1 Process connection temperature

The process connection temperature must stay in the temperature range of the gasket material unless the device is

a High-Temperature version. Refer to the table "Temperature ranges for gaskets" that follows and to "Technical data"

on page 130.

Ex devices: see supplementary operating instructions

2 Ambient temperature for operation of the display

-20...+60°C / -5...+140°F

If the ambient temperature is not between these limits, the display screen switches off automatically

3 Ambient temperature

Non-Ex devices: -40...+80°C / -40...+176°F

Ex devices: see supplementary operating instructions

4 Process pressure

Refer to the table "Process pressure limits" that follows and "Pressure/temperature table for probe selection" on

page 136.

WARNING!

The process connection temperature range must agree with the temperature limits of the

gasket material. The operating pressure range is subject to the process connection used and the

flange temperature.

www.tek-trol.com

19

Page 20

Tek-Flex 4100A

Instruction Manual

Technology Solutions

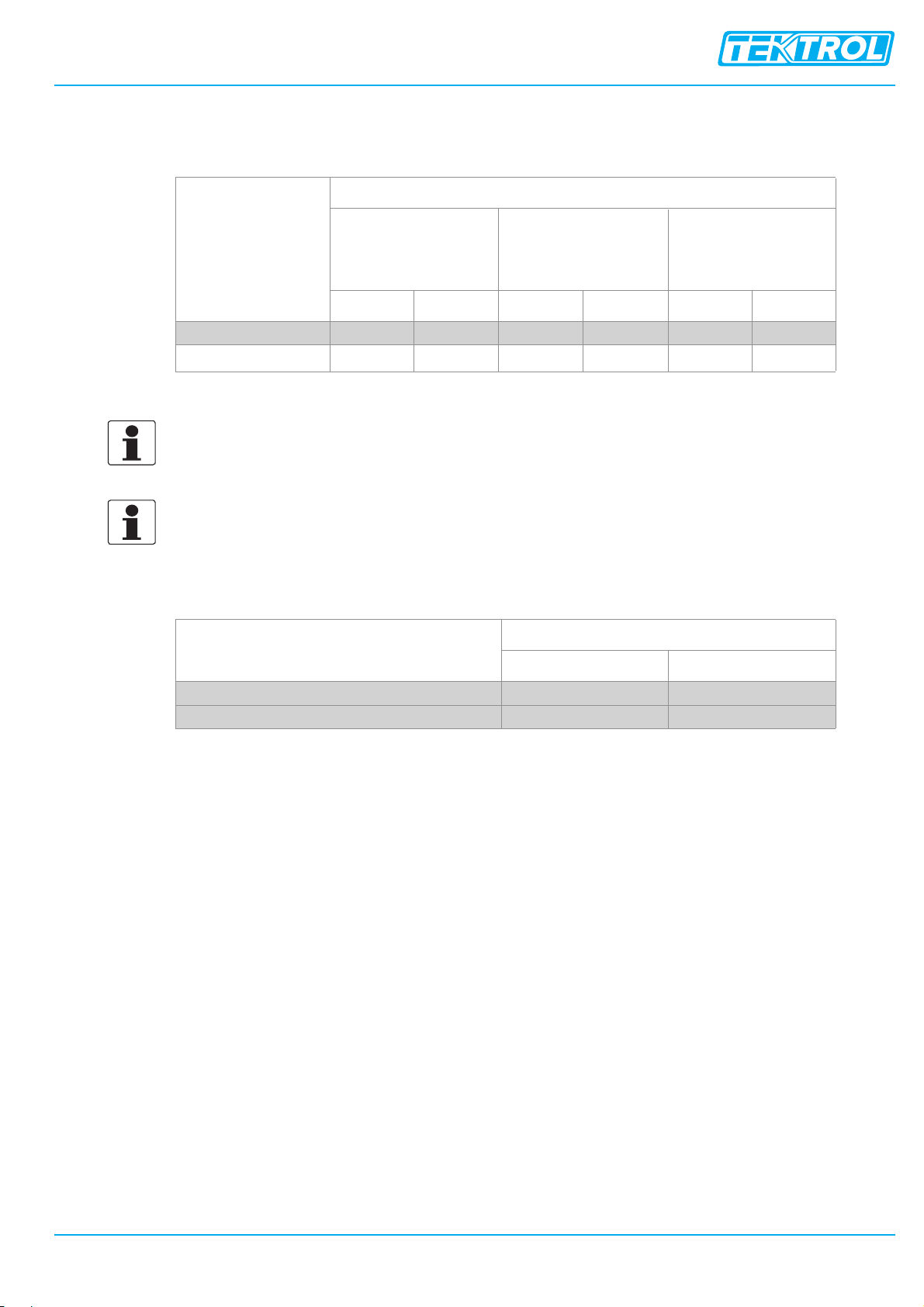

Temperature ranges for gaskets

Gasket material Process connection temperature

Standard version High-Pressure version High-Temperature and

High-Temperature /

High-Pressure

versions

[°C] [°F] [°C] [°F] [°C] [°F]

FKM/FPM -40…+200 -40…+392 -40…+150 -40…+302 -40…+300 -40…+572

Kalrez® 6375

-20…+200 -4…+392 -20…+150 -4…+302 -20…+300 -4…+572

INFORMATION!

Ø4 mm / 0.16

Ø4 mm / 0.16¨ single cable probe with FEP coating option only:

Ø4 mm / 0.16Ø4 mm / 0.16

single cable probe with FEP coating option only: The process connection

single cable probe with FEP coating option only: single cable probe with FEP coating option only:

temperature range is -20...+150°C / -4...+302°F

INFORMATION!

Single rod probes with protective sheath option only:

Single rod probes with protective sheath option only: The process connection temperature range

Single rod probes with protective sheath option only:Single rod probes with protective sheath option only:

depends on the protective sheath material selected.

°

PP: -40...+90

C/ -40…+194°F; PVDF: -40...+150°C/ -40…+302°F; PVC: -15...+80°C/ +5…+176°F

Process pressure limits

Device version Maximum process pressure

[barg] [psig]

Ø8 mm / 0.32¨ single cable 40

All other probe types

Refer also to "Pressure / temperature table for probe selection" in the "Technical data" section

1

and device versions 100

1

1

580

1450

1

1

www.tek-trol.com

20

Page 21

Tek-Flex 4100A

Instruction Manual

Technology Solutions

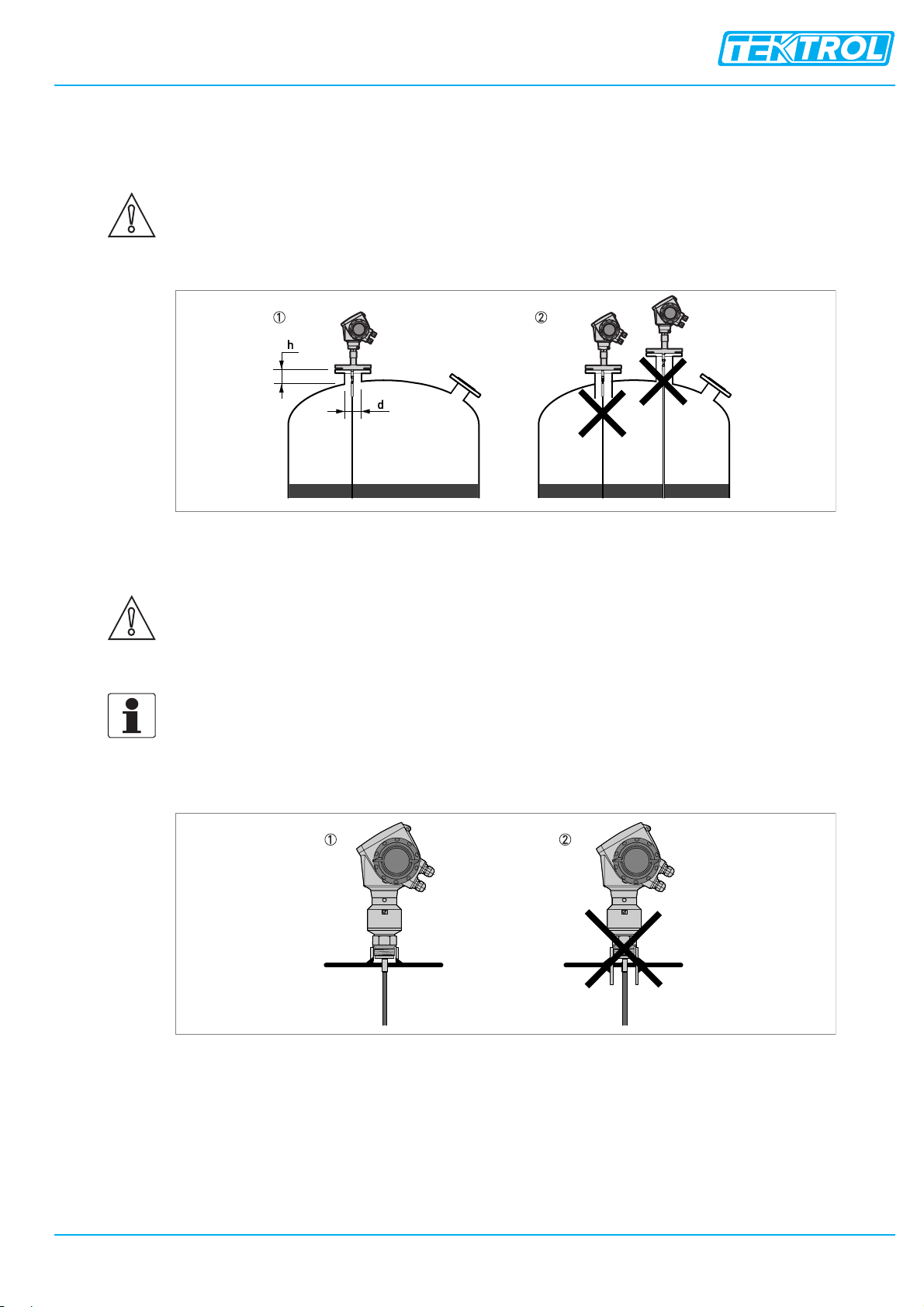

3.5.2 General information for nozzles

CAUTION!

Follow these recommendations to make sure that the device measures correctly.

Figure 3-5: Recommended nozzle dimensions for single rod and single cable probes

1 Recommended conditions: h ≤ d, where h is the height of the tank nozzle and d is the diameter of the tank nozzle.

2 The end of the nozzle must not have an extension into the tank. Do not install the device on a high nozzle.

CAUTION!

If the device is installed on a high nozzle, make sure that the probe does not touch the side of the

nozzle (attach the probe end, ...). We recommend that you use a coaxial probe (this solution is

applicable only to liquids).

INFORMATION!

It is possible to measure in these conditions with a minimum top dead zone. Use the snapshot

function to filter the parasite signals from long nozzles. For more data, refer to How to use the

snapshot function to filter parasitic signals on page 96

.

Figure 3-6: Sockets for threaded process connections

1 Recommended installation

2 The end of the socket must not have an extension into the tank

www.tek-trol.com

21

Page 22

Tek-Flex 4100A

Instruction Manual

Technology Solutions

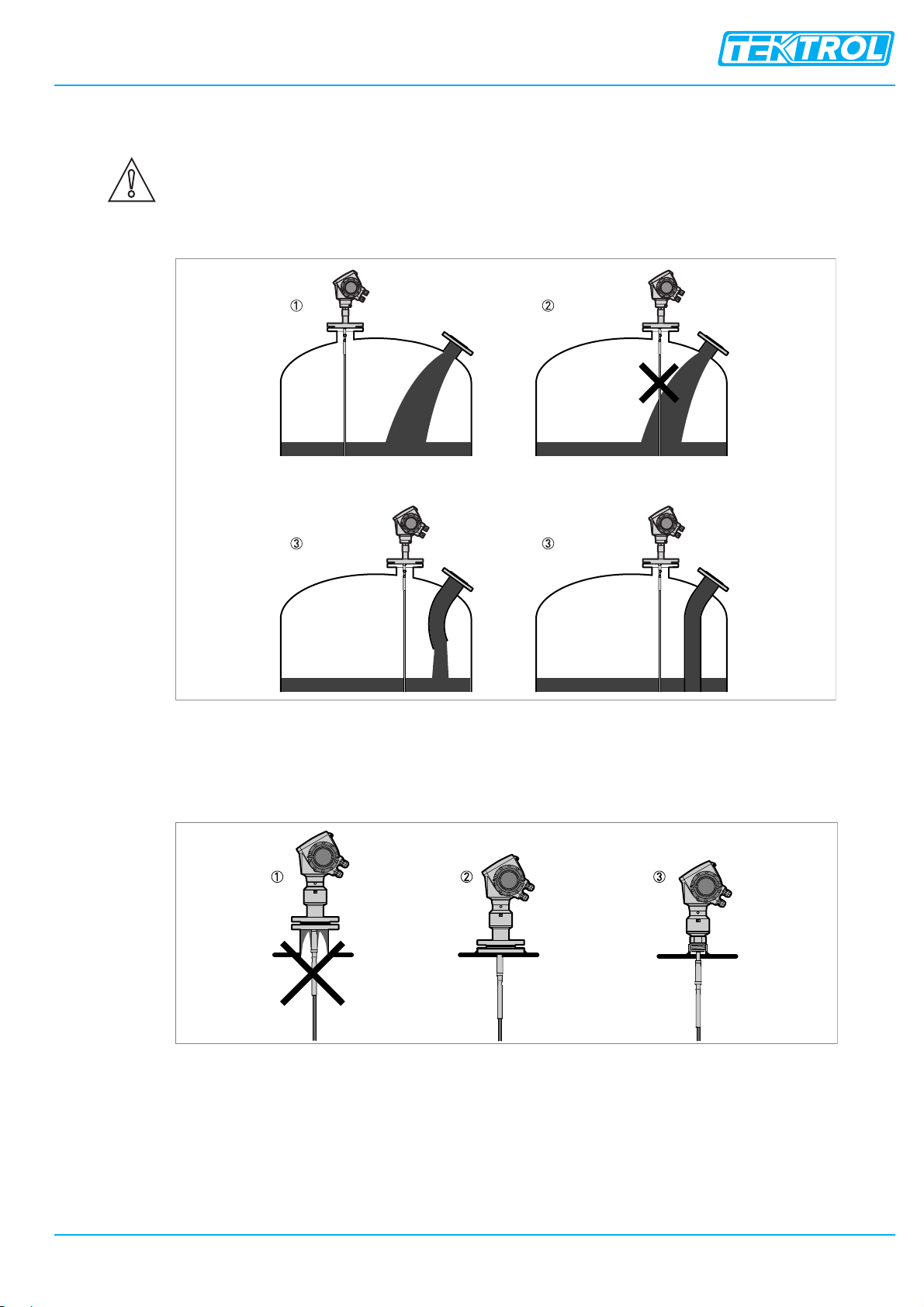

CAUTION!

Do not put the process connection near to the product inlet. If the product that enters the tank

touches the probe, the device will measure incorrectly.

Figure 3-7: Do not put the device near to a product inlet

1 The device is in the correct position.

2 The device is too near to the product inlet.

3 If it is not possible to put the device in the recommended position, install a deflector pipe.

Figure 3-8: How to prevent build-up of product around the process connection

1 If product particles are likely to collect in holes, a nozzle is not recommended.

2 Attach the flange directly to the tank.

3 Use a threaded connection to attach the device directly to the tank.

www.tek-trol.com

22

Page 23

Tek-Flex 4100A

Instruction Manual

Technology Solutions

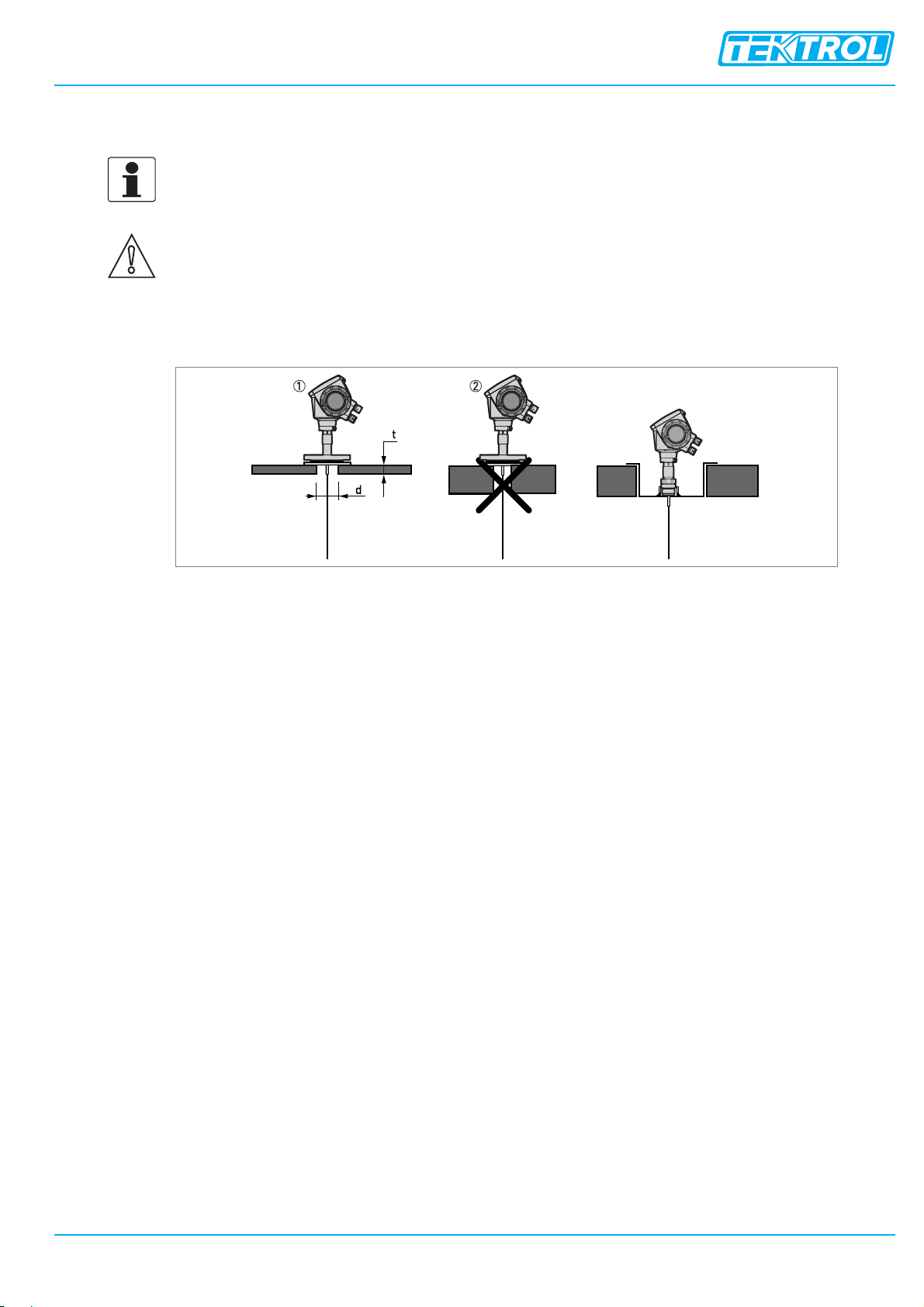

INFORMATION!

If your device has a coaxial probe, you can ignore these installation recommendations.

CAUTION!

Install coaxial probes in clean liquids that are not too viscous.

3.5.3 Installation requirements for concrete roofs

Figure 3-9: Installation on a concrete roof

1 The diameter, d, of the hole must be greater than the thickness, t, of the concrete.

2 If the thickness, t, of the concrete is greater than the diameter, d, of the hole, install the device in a recess.

www.tek-trol.com

23

Page 24

Tek-Flex 4100A

Instruction Manual

Te gy Solutionschnolo

3.6 Installation recommendations for liquids

3.6.1 General requirements

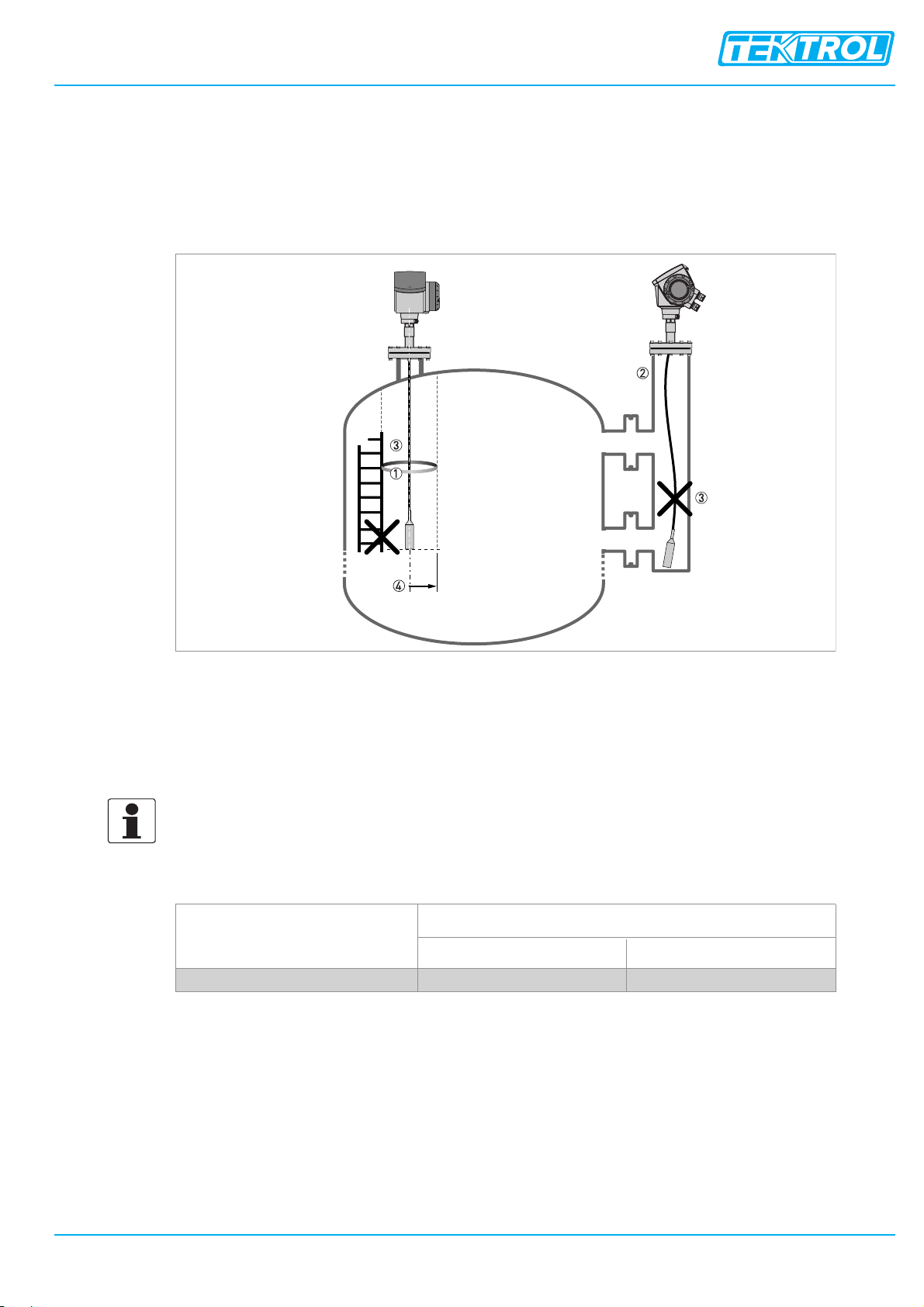

Figure 3-10: Installation recommendations for liquids

1 The electromagnetic (EM) field generated by the device. It has a radius of R

objects and product flow. Refer to the table that follows.

2 If there are too many objects in the tank, install a bypass chamber or stilling well.

3 Keep the probe straight. If the probe is too long, shorten the probe length. M ake sure t hat the de vice is configur ed with

the new probe length. For more data on the procedure, refer to

4 Empty space. Refer to the table that follows.

How to decrease the length of probes

. Make sure that the EM field is clear of

min

on page 98.

INFORMATION!

If the device has to measure the level of dangerous products (ammonia etc.), we recommend

that you use a device with the Metaglas® option.

Clearance between the probe and other objects in the tank

Probe type Empty space (radius, R

[mm] [inches]

Single rod / cable

300

), around the probe

min

12

www.tek-trol.com

24

Page 25

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.6.3 Standpipes

Use a standpipe if:

• There is highly conductive foam in the tank.

• The liquid is very turbulent or agitated.

• There are too many other objects in the tank.

• The device is measuring a liquid (petro-chemicals) in a tank with a floating roof.

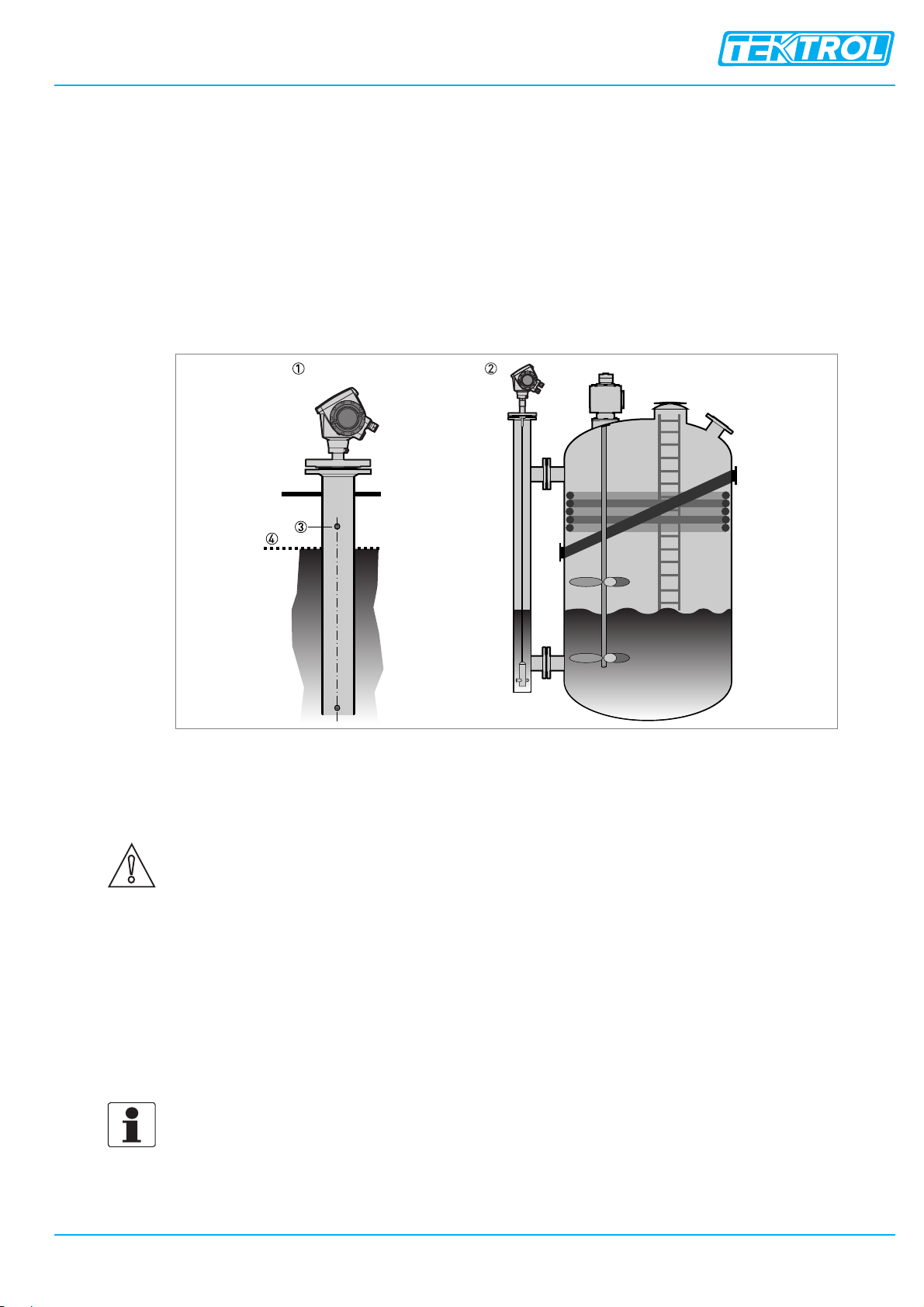

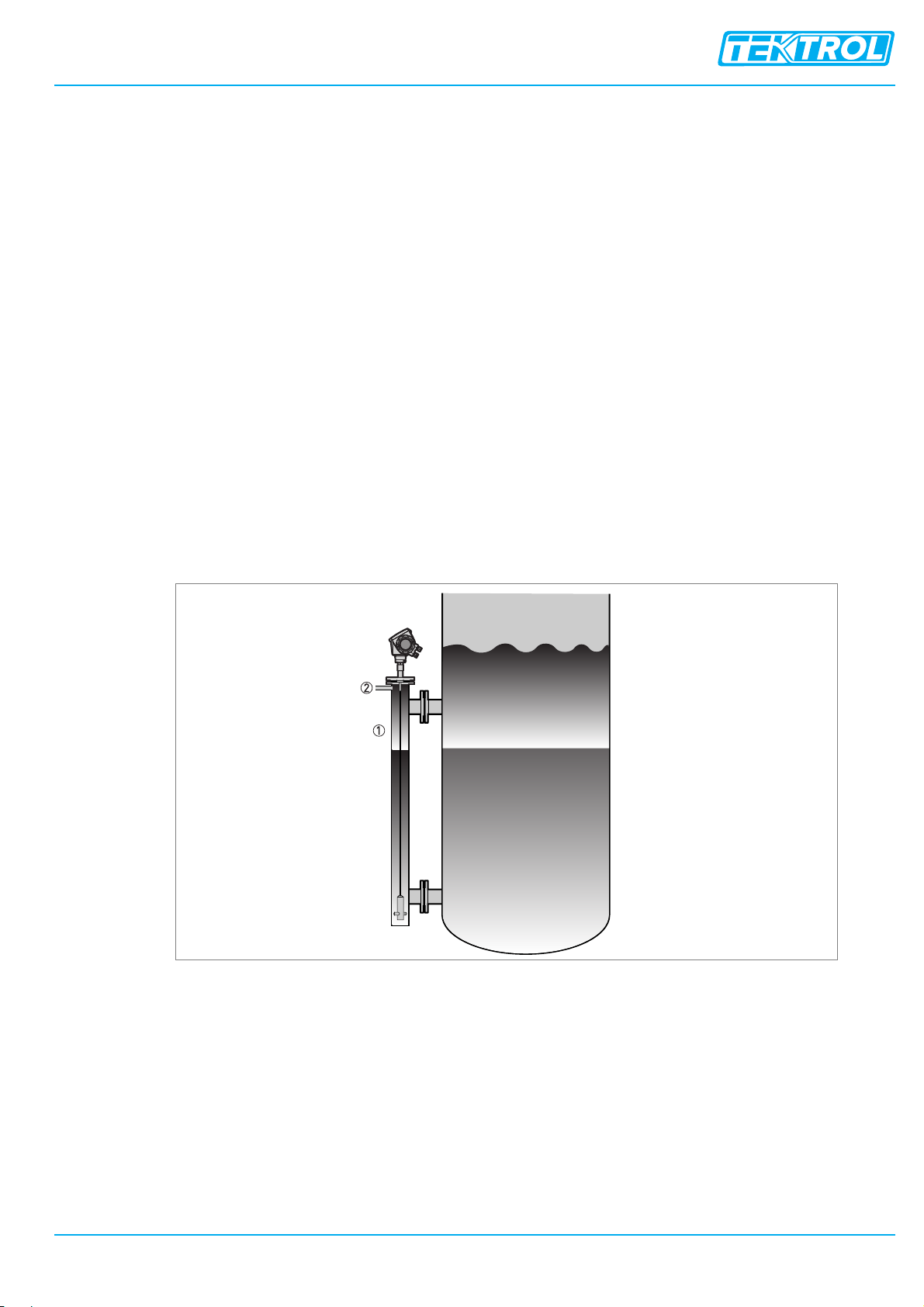

Figure 3-17: Basic installation recommendations for standpipes (stilling wells and bypass chambers)

1 Stilling well

2 Bypass chamber

3 Air circulation hole

4 Level of the liquid

CAUTION!

Installation requirements

•

The standpipe must be electrically conductive.

•

The standpipe must be straight. There must be no sudden changes in internal diameter

¨

greater than 1 mm / 0.04

•

The standpipe must be vertical.

•

Recommended surface roughness: <±0.1 mm / 0.004¨.

•

Stilling well only: The bottom of the stilling well must be open.

•

Adjust the probe to the center of the standpipe.

•

Make sure that there are no deposits at the bottom of the standpipe.

•

Make sure that there is liquid in the standpipe.

INFORMATION!

Standpipes are not necessary for devices with coaxial probes. But if there is a sudden change in

diameter in the standpipe, we recommend that you install a device with a coaxial probe.

.

www.tek-trol.com

25

Page 26

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Figure 3-18: Installation recommendations for stilling wells

1 Stilling well in tanks containing one liquid

2 Stilling well in tanks containing more than one liquid

3 Air circulation hole

4 Maximum level of the liquid

5 Liquid circulation hole

6 Distance between holes ≥ 25 mm/1¨ (depends on the minimum layer to be measured)

Installation in tanks containing one liquid and foam

• Drill a pressure equalization hole in the stilling well above the maximum level.

• Deburr the hole.

• If the probe has a counterweight, make sure that there is enough space between the

counterweight and the wall of the stilling well.

Installation in tanks containing more than one liquid

• Drill a pressure equalization hole in the stilling well above the maximum level of the top liquid.

• Drill more holes along the length of the stilling well. Distance between holes ≥ 25 mm / 1¨

(depends on the minimum layer to be measured)

These holes help the liquids to move freely.

i

• Deburr the holes.

• If the probe has a counterweight, make sure that there is enough space between the

counterweight and the wall of the stilling well.

Floating roofs

If the device is for a tank with a floating roof, install it in a stilling well.

www.tek-trol.com

26

Page 27

Tek-Flex 4100A

Instruction Manual

Technology Solutions

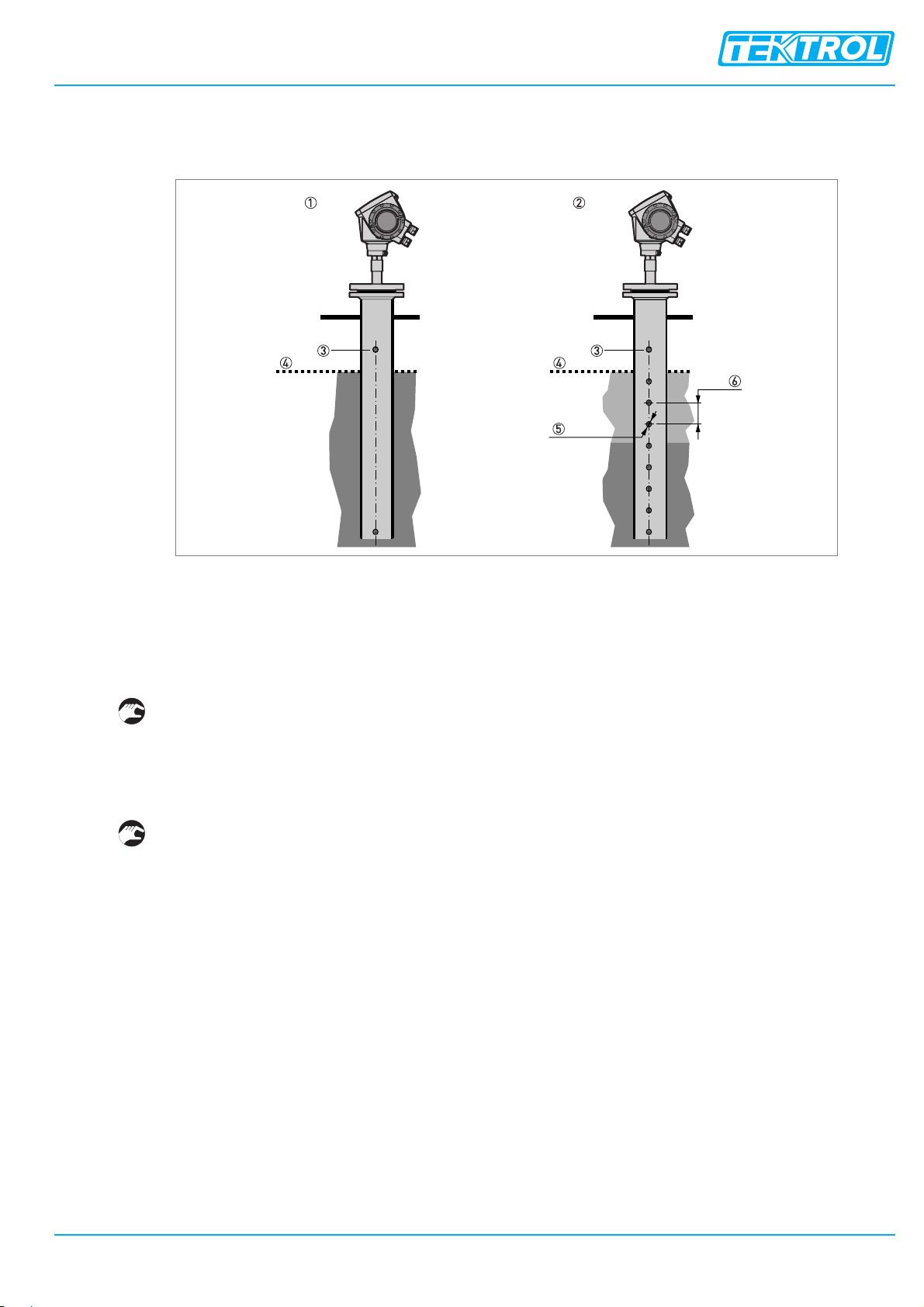

Figure 3-19: Floating roofs

1 Sediment

2 Support fixtures

3 Stilling well

4 Floating roof

5 Product

6 Tank

Bypass chamber - general notes

Figure 3-20: Installation recommendations for bypass chambers

1 Bypass chamber for tanks that contain one liquid

2 Bypass chamber for tanks that contain more than one liquid

3 Distance between holes ≤ minimum level of each liquid in the tank

4 Additional process connection

www.tek-trol.com

27

Page 28

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Installation on tanks containing one liquid and foam

• The bypass chamber must have a process connection that is above the maximum level of

liquid.

• The bypass chamber must have a process connection that is below the lowest measured level

of liquid.

Installation on tanks containing more than one liquid

• The bypass chamber must have a process connection that is above the maximum level of

liquid.

• The bypass chamber must have a process connection that is below the lowest measured level

of liquid.

• There must be more process connections along the length

must have a minimum diameter of 25 mm / 1¨ with a minimum distance of 100 mm / 4¨

between the holes.

• If the probe has a counterweight, make sure that there is enough space between the

counterweight and the wall of the stilling well.

• If the interface liquid does not have a layer of air above it, fit a vent at the top of the bypass

chamber. Refer to the illustration that follows:

of the bypass chamber. These

Figure 3-21: Installation recommendations for bypass chambers with no air gap

1 Bypass chamber with no air gap

2 Air vent

www.tek-trol.com

28

Page 29

Tek-Flex 4100A

Instruction Manual

Technology Solutions

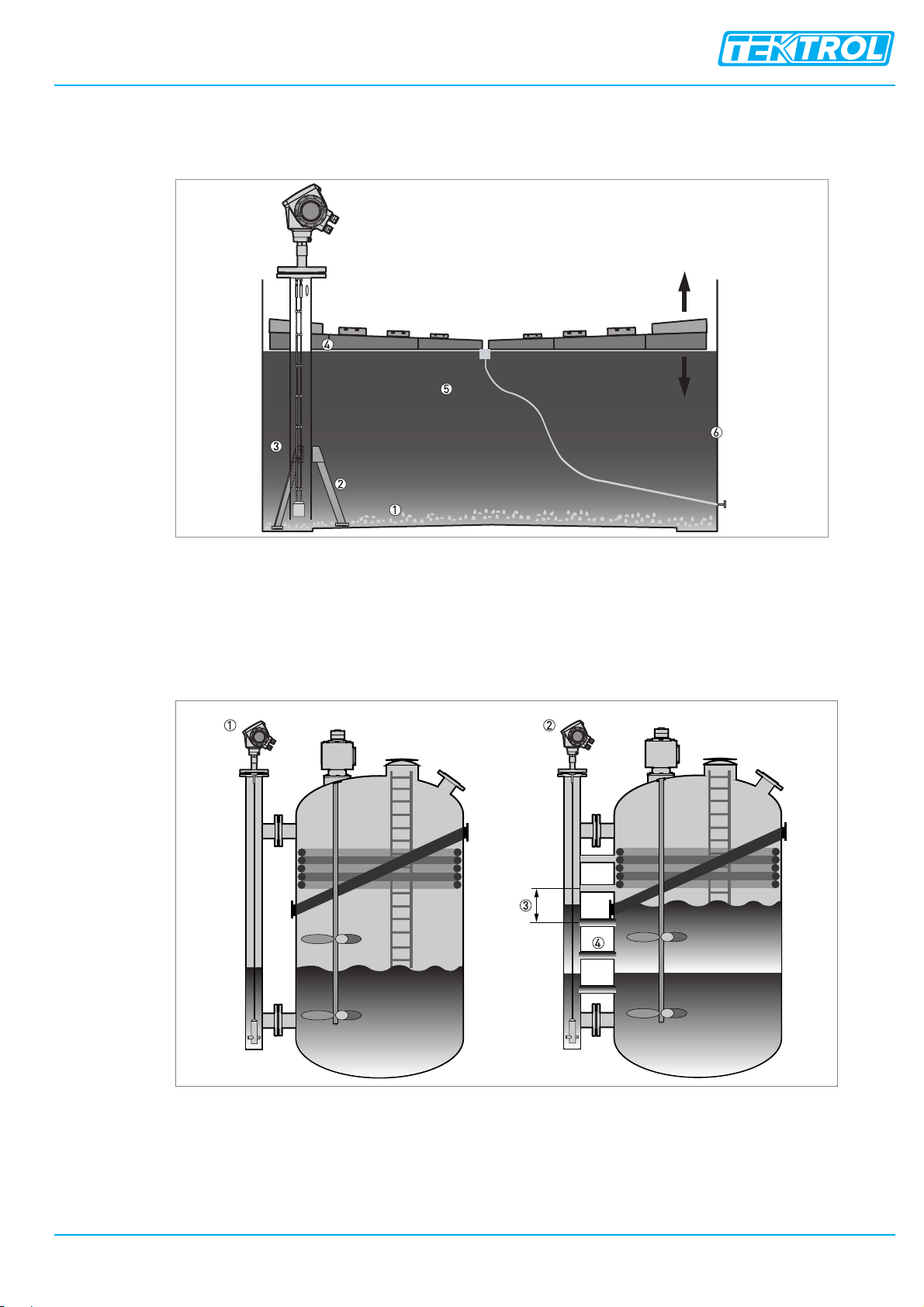

3.6.4 Typical applications

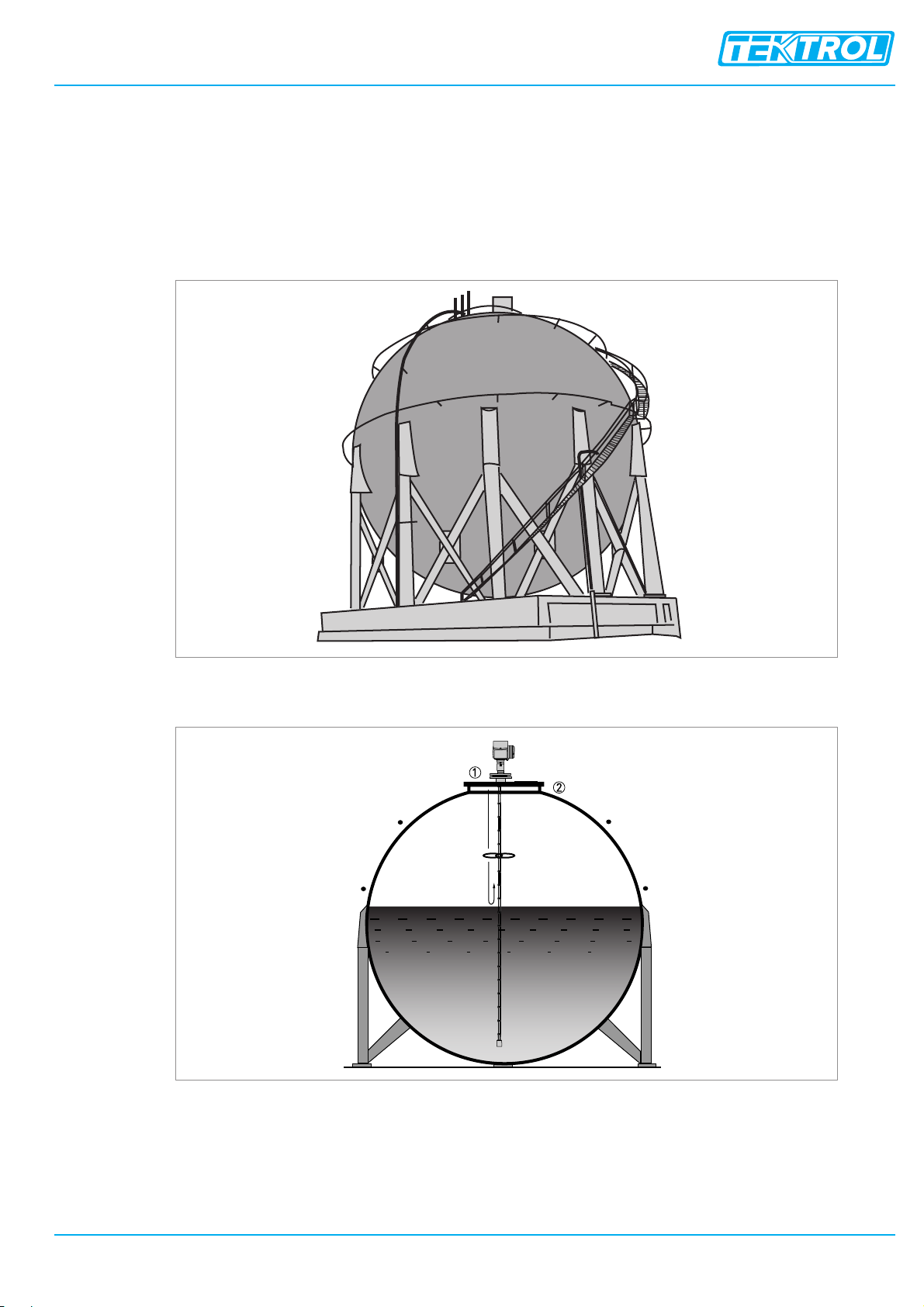

Spherical tanks

The device can measure liquid petroleum gas (LPG). This product is stocked in spherical tanks.

Figure 3-22: A spherical tank

Figure 3-23: How to install the device on a spherical tank

1 Install the device on top of the tank

2 If the top platform has the shape of a nozzle, do not install the process connection too near to the wall. For more data,

refer to

General requirements

on page 24.

www.tek-trol.com

29

Page 30

Tek-Flex 4100A

Instruction Manual

Technology Solutions

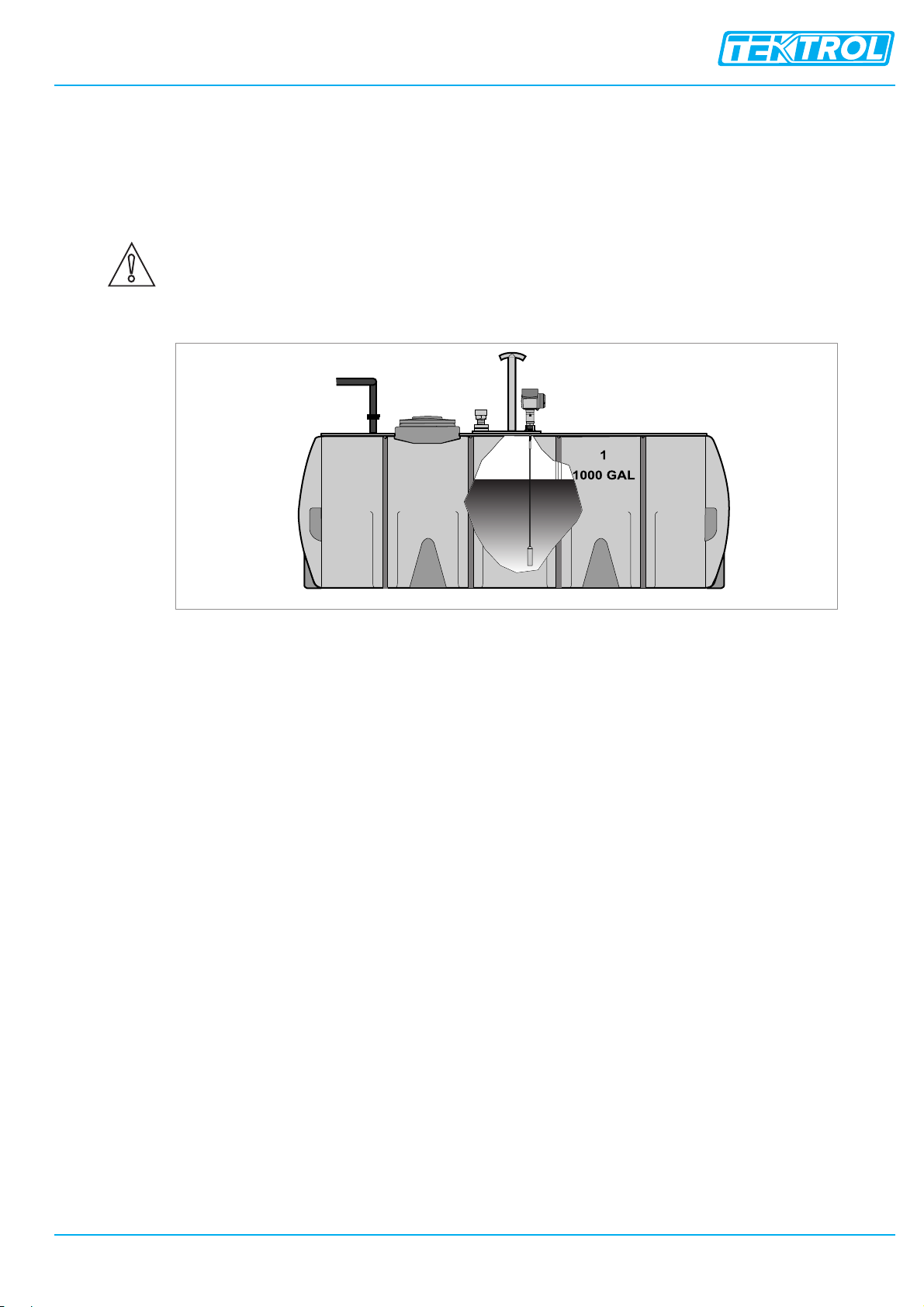

Horizontal cylindrical tanks

The installation requirements and procedures for vertical tanks are also applicable to horizontal

cylindrical tanks.

CAUTION!

Calculate volume and mass values carefully for conversion tables. Volume does not increase in

the same proportion as level.

Figure 3-24: How to install the device in a horizontal cylindrical tank

www.tek-trol.com

30

Page 31

Tek-Flex 4100A

Instruction Manual

Te gy Solutionschnolo

3.7 Installation recommendations for solids

3.7.1 Nozzles on conical silos

We recommend that you prepare the installation when the silo is empty.

DANGER!

Risk of electrostatic discharge (ESD): The device is resistant to electrostatic discharges of up to

15 kV (30 kV with the ESD protection option – recommended for solid applications), but it is the

responsibility of the fitter and the user to prevent ESD.

CAUTION!

Install the device at the correct location to measure level correctly and prevent too much

bending and traction. If necessary, attach the probe to the bottom of the tank.

Figure 3-25: Installation recommendations for solids

1 We recommend installation without a nozzle. If not, h ≤50 mm / 2¨.

2 The end of the probe must be more than 300 mm / 12¨ above the tank bottom.

3 Empty space (radius, R

4 The electromagnetic (EM) field generated by the device. It is also the measurement zone of the probe. Make sure that

5 Ground the tank, the product and the probe (if attached).

6 If possible, put the process fitting ≥300 mm / 12¨ from the tank wall

www.tek-trol.com

) around the probe.

min

the EM field is clear of objects and product flow.

31

Page 32

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Clearance between the probe and other objects in the tank

Probe type Empty space (radius, R

Single cable Ø4 mm / 0.16¨ 4 300 12

Single cable Ø8 mm / 0.32¨ 4 300 12

INFORMATION!

If the probe is longer than 10 m / 33 ft, we recommend that you do not attach the end of the

probe.

3.7.2 Traction loads on the probe

Traction load depends on:

• The height and shape of the tank.

• The particle size and density.

• The rate at which the tank is emptied.

CAUTION!

Risk of damage to the cable probe. High loads can break the cable.

If the load on the Ø8 mm / 0.32

supplier.

) around the probe

min

[mm] [inches]

¨

single cable probe is more than 3500 kg / 7700 lb, contact your

CAUTION!

Make sure that the tank roof is resistant to deformation at high loads.

Estimated traction load on the probe in kg

Material Probe length, 10 m Probe length, 20 m Probe length, 30 m

[kg]

Cement 1000 2000 3000

Fly ash 500 1000 1500

Wheat 300 500 1200

Estimated traction load on the probe in lb

Material Probe length, 33 ft Probe length, 65 ft Probe length, 98 ft

[lb]

Cement 2200 4410 6520

Fly ash 1100 2200 3300

Wheat 660 1100 2650

www.tek-trol.com

32

Page 33

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8 How to install the device on the tank

3.8.1 How to assemble the single rod probe (single-piece probe)

INFORMATION!

This procedure is for devices with single rod probes that are not segmented (single-piece

probes).

Figure 3-26: Equipment needed to assemble the device

1 Union nut

2 2 locking nuts

3 Housing assembly

4 Single rod probe

5 Tools: two 8 mm open-ended wrenches (not supplied)

6 Tools: one 7 mm open-ended wrench (not supplied)

www.tek-trol.com

33

Page 34

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Part 1: Check the order number on each component

Figure 3-27: Part 1: Check the order number on each component

• Make sure that the housing and the single rod have the same ID numbers.

• Remove the sticker from the probe.

www.tek-trol.com

34

Page 35

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Part2: How to attach the locking nut and union nut

Figure 3-28: Part2: How to attach the locking nut and union nut

1 Attach a locking nut to the housing assembly.

2 Make sure that the nut is fully engaged on the thread.

3 Attach the union nut to the housing assembly.

4 Tighten these nuts with the two 8 mm open-ended wrenches.

5 Continue the assembly procedure on the page that follows.

www.tek-trol.com

35

Page 36

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Part 3: How to attach the locking nut and union nut

Figure 3-29: Part 3: How to attach the locking nut and union nut

CAUTION!

Support the probe.

1 Attach a locking nut to the single rod.

2 Make sure that the locking nut is engaged ¾ along the length of the thread.

3 Attach the single rod to the union nut. Make sure the probe touches the housing assembly.

4 Tighten the single probe with a 7 mm open-ended wrench.

5 Tighten the locking nut against the union nut with two 8 mm open-ended wrenches.

www.tek-trol.com

36

Page 37

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.2 How to assemble the single rod probe (segmented probe)

INFORMATION!

This procedure is for devices with single rod probes that are segmented.

Figure 3-30: Equipment needed to assemble the single rod probe (segmented)

1 Converter and process connection

2 Bottom (quantity: 1) segment of the rod probe

3 Top and middle (if more than one) segments of the rod probe

4 Tools: two 8 mm open-end wrenches (not supplied)

5 Lock nuts (2 lock nuts per segment)

6 Union nut (1 union nut per segment)

CAUTION!

Make sure that the housing and the single rod have the same ID numbers.

www.tek-trol.com

37

Page 38

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Part 1: How to assemble the segmented single rod probe

Figure 3-31: Part 1: How to assemble the segmented single rod probe

CAUTION!

Make sure that the nuts are tight and the rod probe cannot loosen.

1 Attach a lock nut to the threaded rod below the process connection. Turn the nut until it is ¾

along the length of the rod.

2 Attach a union nut to the threaded rod below the process connection.

3 Use two 8 mm open-end wrenches to tighten the union nut against the lock nut.

www.tek-trol.com

38

Page 39

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Part 2: How to assemble the segmented single rod probe

Figure 3-32: Part 2: How to assemble the segmented single rod probe

WARNING!

Put a support below the probe to prevent deformation.

CAUTION!

Make sure that the nuts are tight and the rod probe cannot loosen.

1 Attach a lock nut to each end of the rod probe segments.

2 Attach a union nut to the bottom end of each rod probe segment, but not to the bottom seg-

ment. Use two 8 mm open-end wrenches to tighten the union nut against the lock nut.

3 Attach the top segment of the rod probe to the union nut below the process connection. Use

two 8 mm open-end wrenches to tighten the union nut against the lock nut on the rod probe.

4 Attach the middle segment of the rod probe to the union nut on the top segment (if there are

middle segments). Use two 8 mm open-end wrenches to tighten the union nut against the lock

nut. Repeat this step for the other segments.

5 Attach the bottom segment of the rod probe to the union nut on the top segment. Use two

8 mm open-end wrenches to tighten the union nut against the lock nut.

www.tek-trol.com

39

Page 40

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.3 How to assemble the segmented coaxial probe

Figure 3-33: Equipment needed to assemble the coaxial probe

1 Converter and process connection

2 HC M4×20 screws (1 screw per probe segment)

3 Lock washers (1 pair of washers per probe segment)

4 Top (quantity: 1), middle (quantity: 1 or more) and bottom (quantity: 1) segments of the signal rod

5 PTFE spacer (1 spacer per probe segment)

6 Middle (quantity: 1 or more) and bottom (quantity: 1) segments of the coaxial tube

7 Union nut with 2 socket set screws M5×5 (1 union nut per segment of the coaxial tube)

8 Tools: two 7 mm open-end wrenches (not supplied)

9 Tools: two pipe (Stillson) wrenches (not supplied)

10 Tools: one 2.5 mm Allen wrench and one 2 mm Allen wrench (not supplied)

CAUTION!

Make sure that the housing and the single rod have the same ID numbers.

www.tek-trol.com

40

Page 41

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Part 1: How to assemble the segmented coaxial probe

Figure 3-34: Part 1: How to assemble the segmented coaxial probe

CAUTION!

Do not attach the screw to the end of the rod segment that has a groove for the attachment of a

PTFE spacer.

1 Use a 2 mm Allen wrench to attach and tighten a HC M4×20 screw at the top of each rod seg-

ment (intermediary and end rod segments)

2 Attach a PTFE spacer to the end of each rod segment that has a groove.

3 Attach a pair of lock washers at the top of each rod segment (intermediary and end rod seg-

ments)

4 Assemble one of the middle rod segments (with a pair of lock washers on the attached screw)

and the signal rod below. Use two 7 mm open-ended wrenches to tighten the assembled parts

to a torque of 2…3Nm.

www.tek-trol.com

41

Page 42

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Part 2: How to assemble the segmented coaxial probe

Figure 3-35: How to assemble the segmented coaxial probe: part 2

WARNING!

Be careful when you use the pipe wrenches. Make sure that the measuring tubes have no

deformation.

CAUTION!

•

Make sure that the screws are tight and the measuring tube cannot loosen.

•

Make sure that the fitting for the lock screw is not aligned with a hole in the coaxial tube.

1 Attach a union nut to each coaxial tube (middle and end tubes)

2 Attach a middle tube segment to the coaxial probe stem. Do not use tools to tighten the as-

sembled parts.

3 Assemble the next middle rod segment (with a pair of lock washers on the attached screw)

and the top rod segment. Use two 7 mm open-ended wrenches to tighten the assembled parts

to a torque of 2…3Nm.

4 Assemble the next coaxial tube segment and the top coaxial tube segment. Do not use tools

to tighten the assembled parts. Do steps (9) thru (10) again until the end rod segment and end

coaxial tube are attached.

5 Use the 2 pipe wrenches to tighten the coaxial tubes in the lock nuts.

6 Use a 2.5 mm Allen wrench to attach and tighten the two HC M5×5 screws (lock screws) to the

union nut.

www.tek-trol.com

42

Page 43

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.4 How to install a device with a flange connection

Equipment needed:

• Device

• Gasket (not supplied)

• Wrench (not supplied)

Figure 3-36: Flange connection

• Make sure that the flange on the nozzle is level.

• Make sure that you use the applicable gasket for the flange and the process.

• Align the gasket correctly on the flange facing of the nozzle.

• Lower the probe carefully into the tank.

i

For more data on cable probes, refer to

• Tighten the flange bolts.

Refer to local rules and regulations for the correct torque to apply to the bolts.

i

How to install a cable probe in the tank

on page 48.

www.tek-trol.com

43

Page 44

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.5 How to install a device with a threaded connection

Equipment needed:

• Device

• Gasket (not supplied)

• 50 mm / 2¨ wrench (not supplied)

Figure 3-37: Threaded connection

• Make sure the tank connection is level.

• Make sure that you use the applicable gasket for the connection and the process.

• Align the gasket correctly.

• If the device is installed on a tank made of plastic or other non-conductive material, refer to

Recommendations for pits and tanks made of non-conductive materials

• Lower the probe carefully into the tank.

i

For more data on cable probes, refer to

• Use 50 mm / 2¨ wrench to attach the process connection to the tank.

• Tighten the nut.

i

Refer to local rules and regulations for the correct torque to apply to the connection.

How to install a cable probe in the tank

on page 49.

on page 48.

INFORMATION!

If there is not sufficient clearance to install the device, remove the housing. Install the probe and

then put the housing back on the process connection. For more data, refer to How to turn or

remove the signal converter on page 53

.

www.tek-trol.com

44

Page 45

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.6 How to install a cable probe in the tank

Figure 3-38: Wind cable probes carefully

1 Do not wind cable probes less than 400 mm / 16¨ in diameter.

WARNING!

If you bend the probe too much, you will damage the device and it will not measure accurately.

Figure 3-39: Installation of devices with cable probes

1 >1 m / 3½ ft

• Use two persons to lift the housing and the probe above the process connection.

• Hold the device 1 m / 3½ ft above the tank.

• Unwind the probe carefully into the tank.

www.tek-trol.com

45

Page 46

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.7 Recommendations for pits and tanks made of non-conductive materials

If you have a device with a single rod or a single cable probe and a thread connection,

obey these instructions:

• Put a metal sheet between the device and the process connection.

i

It must have a diameter greater than 200 mm / 8¨.

• Make sure that the metal sheet is in contact with the thread stop on the device.

We recommend that you use DN≥200 / ≥8¨ for flange connections.

If you have a device with a double rod, double cable or coaxial probe, you can ignore these

instructions.

Figure 3-40: Installation in a non-metallic tank or pit with a thread connection

1 Non-metallic (plastic...) tank or pit

2 Metal sheet, Ø ≥200 mm / 8¨

CAUTION!

When the device is installed, make sure that the tank roof has no deformation.

www.tek-trol.com

46

Page 47

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.8 How to assemble the remote version

Figure 3-41: Part 1 of assembly procedure

• Attach the wall bracket 1 to the flexible conduit.

• Tighten the locking nut 2 with a 24 mm wrench.

• Attach the wall bracket to a wall or pipe (DN50...100 / 2¨...4¨) 3.

• Loosen the housing locking screw 4 with a 5 mm Allen wrench.

• Remove the housing 5.

www.tek-trol.com

47

Page 48

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Figure 3-42: Part 2 of the assembly procedure

• Attach the housing to the flexible conduit 6.

• Tighten the housing locking screw 7.

• Attach the flexible conduit to the probe 8.

• Tighten the flexible conduit locking screw 9.

www.tek-trol.com

48

Page 49

Tek-Flex 4100A

Instruction Manual

Technology Solutions

You can attach the wall bracket of the remote housing to a wall or pipe (DN50...100 / 2¨...4¨).

These are the dimensions:

Figure 3-43: Dimensions of the wall bracket

Dimensions in mm

Dimensions [mm]

a b c d e f g h i j

Wall bracket 120 60 20 11 90 150 6 67.4 126.4 150.4

Dimensions in inches

Dimensions [inches]

a b c d e f g h i j

Wall bracket 4.7 2.4 0.8 0.4 3.5 5.9 0.2 2.65 4.98 5.92

www.tek-trol.com

49

Page 50

Tek-Flex4100A

Instruction Manual

Technology Solutions

3.8.9 How to turn or remove the signal converter

The converter turns 360°. The converter can be removed from the process connection assembly

under process conditions.

Figure 3-44: How to turn or remove the signal converter

1 Tool: 5 mm Allen wrench (not supplied) for the lock screw on the signal converter

2 Cover for the coaxial hole on top of the process connection assembly (not supplied)

CAUTION!

If you remove the housing, put a cover on the coaxial hole on top of the process connection

assembly.

When the housing is attached to the process connection assembly, tighten the lock screw with

the 5 mm Allen wrench 1.

www.tek-trol.com

50

Page 51

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.10 How to attach the weather protection to the device

Equipment needed:

• Device

• Weather protection (option)

• 10 mm wrench (not supplied)

Refer to "Technical data: Dimensions and weight", for the overall dimensions of the weather

protection.

Figure 3-45: Installation of the weather protection

• Loosen the bracket nuts on the weather protection. Remove the bracket.

• Lower the weather protection onto the device. Turn the weather protection so that the keyhole

points forward.

• Attach the bracket.

• Lift the weather protection to the top of the housing support pillar. Hold the weather

protection in the correct position and tighten the bracket nuts.

www.tek-trol.com

51

Page 52

Tek-Flex 4100A

Instruction Manual

Technology Solutions

3.8.11 How to open the weather protection

Equipment needed:

• Weather protection attached to the device.

• Large slotted tip screwdriver (not supplied).

Figure 3-46: How to open the weather protection

1 Weather protection in its closed position

2 Weather protection in its open position. Minimum clearance in front of the device: 300 mm / 12¨.

• Put a large slotted tip screwdriver into the keyhole at the front of the weather protection. Turn

the screwdriver counterclockwise.

• Pull the top of weather protection up and forward.

This will open the weather protection.

i

www.tek-trol.com

52

Page 53

Tek-Flex 4100A

Instruction Manual

Te gy Solutionschnolo

4. ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Electrical installation: outputs 1 and 2

Figure 4-1: Electrical installation

1 Terminal compartment cover

2 Output 1: current output -

3 Output 1: current output +

4 Grounding terminal in the housing

5 Output 2: current output - (option)

6 Output 2: current output + (option)

7 Grounding terminal between the process connection and the converter

Output 1 energizes the device and is used for HART® communication. If the device has the

second current output option, use a separate power supply to energize output 2.

www.tek-trol.com

53

Page 54

Tek-Flex 4100A

Instruction Manual

Technology Solutions

Procedure:

• Remove the housing terminal compartment cover 1.

• Connect the wires to the device. Obey the national electrical codes.

• Make sure that the polarity of the wires is correct.

• Attach the ground to 4 or 7. Both terminals are technically equivalent.

INFORMATION!

If the polarity is not correct, this will not cause damage to the device. But the device will not

operate and the output will be 0 mA.

4.3 Electrical connection for current output

4.3.1 Non-Ex devices

Figure 4-2: Electrical connections for non-Ex devices

1 Power supply

2 Resistor for HART® communication

3 Output 1: 14...30 VDC for an output of 22 mA at the terminal

4 Output 2: 10...30 VDC for an output of 22 mA at the terminal

4.3.2 Devices for hazardous locations

DANGER!

For electrical data for device operation in hazardous locations, refer to the related certificates of

compliance and supplementary instructions (ATEX, IECEx, FM, CSA etc.). You can find this

documentation on the DVD-ROM delivered with the device or it can be downloaded free of charge

from the website (Download Center).

www.tek-trol.com

54

Page 55

Tek-Flex 4100A

Instruction Manual

Technology Solutions

4.4 Protection category

INFORMATION!

The device fulfils all requirements per protection category IP66 / IP67. It also fulfils all

requirements per NEMA type 4X (housing) and type 6P (probe).

DANGER!

Make sure that the cable gland is watertight.

Figure 4-3: How to make the installation agree with protection category IP67

• Make sure that the gaskets are not damaged.

• Make sure that the electrical cables are not damaged.

• Make sure that the electrical cables agree with the national electrical code.

• The cables are in a loop in front of the device 1 so water does not go into the housing.

• Tighten the cable feedthroughs 2.

• Close unused cable feedthroughs with dummy plugs 3.

www.tek-trol.com

55

Page 56

Tek-Flex 4100A

Instruction Manual

Technology Solutions

4.5 Networks

4.5.1 General information

The device uses the HART® communication protocol. This protocol agrees with the HART®

Communication Foundation standard. The device can be connected point-to-point. It can also

have a polling address of 1 to 15 in a multi-drop network.

The device output is factory-set to communicate point-to-point. To change the communication

mode from point-to-point

point-to-point to multi-drop

point-to-pointpoint-to-point

4.5.2 Point-to-point networks

multi-drop, refer to

multi-dropmulti-drop

Network configuration

on page 86.

Figure 4-4: Point-to-point connection (non-Ex)

1 Address of the device (0 for a point-to-point connection)

2 4...20 mA + HART

3 Resistor for HART® communication

4 Power supply

5 HART® modem

6 HART

®

communication device

®

www.tek-trol.com

56

Page 57

Tek-Flex 4100A

Instruction Manual

Technology Solutions

4.5.3 Multi-drop networks

Figure 4-5: Multi-drop network (non-Ex)

1 Address of the device (n+1 for multidrop networks)

2 Address of the device (1 for multidrop networks)

3 4mA + HART

4 Resistor for HART® communication

5 Power supply

6 HART

7 HART® communication device

®

modem

®

www.tek-trol.com

57

Page 58

Tek-Flex 4100A

Instruction Manual

Technology Solutions

5. START-UP

5.1 Start-up checklist

Check these points before you energize the device:

• Are all the wetted components (probe, process connection and gaskets) chemically resistant

to the product in the tank?

• Does the information on the signal converter nameplate agree with the operating data?

• Did you correctly install the device on the tank?

• Do the electrical connections agree with the national electrical codes?

DANGER!

If the device has a Hazardous Locations approval, make sure that the device and the installation

agrees with the requirements of the certificate of compliance.

5.2 Operating concept

You can read measurements and configure the device with:

• A digital display screen (optional).

• A connection to a system or PC with PACTware™. You can download the Device Type

Manager (DTM) file from the website. It is also supplied on the DVD-ROM delivered with the

device.

• A connection to a system or PC with AMS™. You can download the Device Description (DD)

file from the website. It is also supplied on the DVD-ROM delivered with the device.

®

• A connection to a HART

file from the website. It is also supplied on the DVD-ROM delivered with the device.

Field Communicator. You can download the Device Description (DD)

www.tek-trol.com

58

Page 59

Tek-Flex 4100A

Instruction Manual

Technology Solutions

5.3 Digital display screen

5.3.1 Local display screen layout

Figure 5-1: Local display screen layout

1 Error / Warning icon

2 Tag number or menu name

3 Selected menu item (gray text cannot be selected)

4 []/ []: scroll up/scroll down

5 Keypad buttons (refer to the table below)

5.3.2 Keypad buttons

For data on keypad functions, refer to

Keypad button Description

Right [>>>>]

Enter [^^^^]

Down []

Up []

Esc (Escape) [>>>>] + []

Operator mode

on page 65.

5.3.3 Help screens

When you are in supervisor mode, the local display helps you to configure the device. If you do

not touch any keys after 30 seconds, a help message is displayed. This will explain what the

menu is and what the parameters do. Push [>>>>] and [] (Esc) at the same time to go back to the

menu. If you do not touch the display for another 30 seconds, the message is shown again.

www.tek-trol.com

59

Page 60

Tek-Flex 4100A

Instruction Manual

Technology Solutions

5.3.4 How to start the device

• Connect the converter to the power supply.

• Energize the converter.

After 30 seconds the screen will display "booting up", "starting up" and then the default

i

screen will appear.

• The device will display readings.

Measurements agree with specifications given in the customer order.

i

CAUTION!

If the manufacturer received information about the installation, the device will display readings

correctly. If not, refer to the quick setup procedures on page 73

.

5.4 Remote communication with PACTware™