Page 1

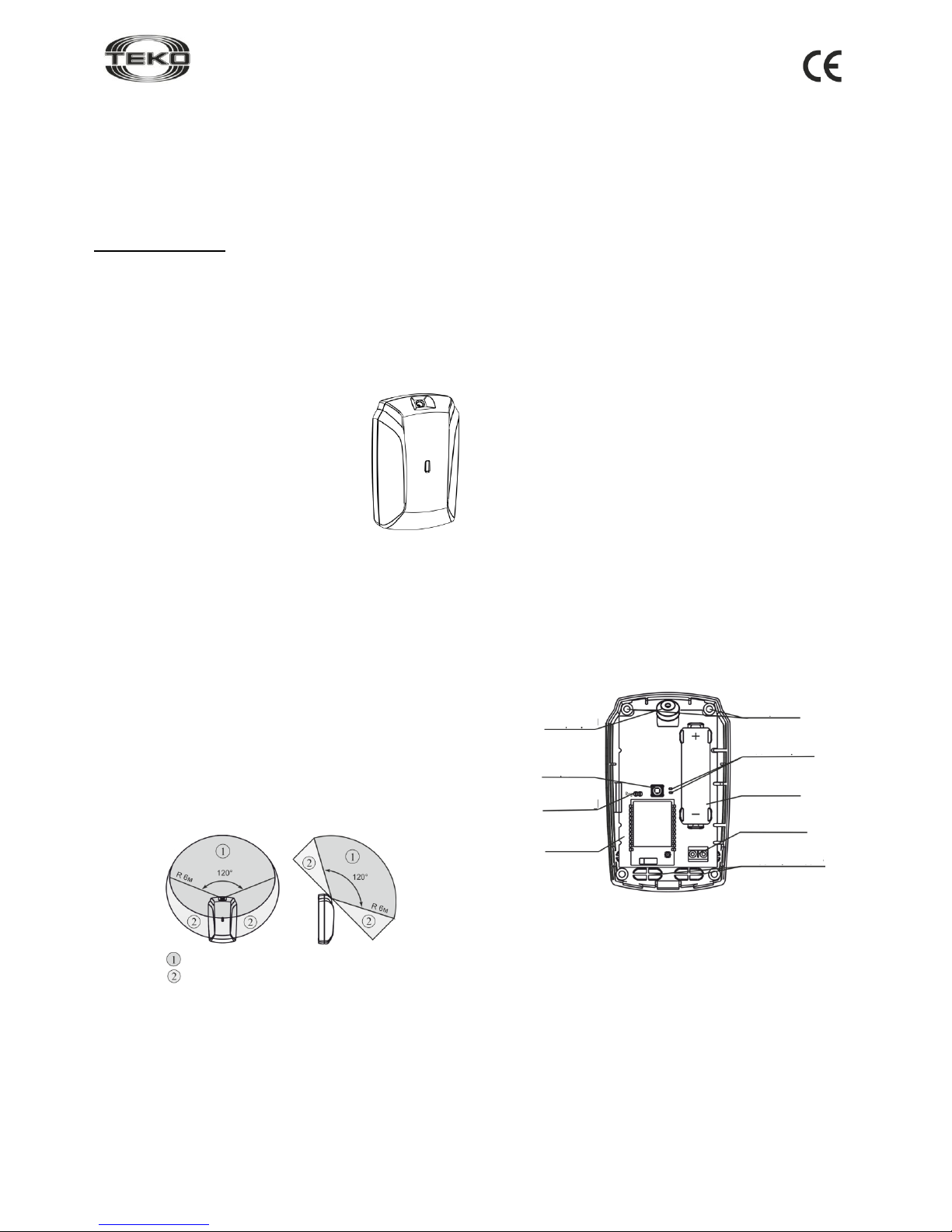

Astra-Z-6145

Wireless Surface Acoustic Glass Break Detector

Operating Manual

Fig. 1

This manual is intended for studying principles of operation,

correct use, operating conditions and maintenance of the Wireless Surface Acoustic Glass Break Detector Astra-Z-6145

(hereinafter “detector”) (Fig. 1).

The manufacturer reserves the right to make alteration regarding refinement of the product without prior notification. All

changes will be imported into new edition of the operation

manual.

List of Abbreviations

Astra-Zitadel System – the on-site Wireless Intrusion / Fire

Detection and Alarming System Astra-Zitadel;

Astra-Zitadel System Control Panel – Astra-Z-812M, Astra-Z-

8945 ver.A, Astra-8945 Pro or Astra-812 Pro Control Panel (with

connected Astra-Z Wireless Extender);

MSS Astra-Z – Astra-Z Monitoring Software Suite;

MSS Astra Pro: Astra Pro Monitoring Software Suite;

LT – Laser Tester Astra-942;

Battery – power supply battery.

1 Function

1.1 The detector detects the breaking of

glass in closed glassed rooms, generates the

alarm notification and sends the notification to

the Control Panel of the Astra-Zitadel System

via radio channel.

Types of glass:

- conventional and protected with a polymer

film, thickness from 2,5 mm to 8 mm;

- armored glass, thickness from 5,5 mm and

6 mm;

- figure glass, thickness from 4 mm to 7 mm;

- laminated construction glass, thickness from 6 mm to 8 mm;

- tempered glass, thickness from 4 mm to 6 mm space is at

least 0,1 m2 (length of one of the sides is at least 0,3 m).

1.2 The detector supports connection of external hard-wired

detectors with NO/NC outputs of «dry contact»-type.

Note: Zone-GND Input does not have current control.

1.3 The detector is powered by lithium-thionyl- chloride bat-

tery of AA size with voltage of 3.6 V (included in the delivery

set).

2 Operating Principle

2.1 The principle of operating is based on the registration of

breaking glass by means of analysis of an acoustic signal in

the sound frequency range. The microphone is a sensor. An

electric signal proceeds from the microphone comes to microcontroller, which forms an alarm notification in accordance with

specified operation algorithm.

2.2 Schematics of the detection zone are shown in Fig. 2.

Fig. 2

3 Specifications

Technical Parameters of Acoustic Channel

Two operating frequency bands:

- first (high), kHz ............................................................. 4 to 6

- second (low), Hz .................................................... 100 to 200

Detector coverage range, m, min ............................................... 6

Detection area angle, degrees, min .................................... 120

Technical Parameters of Radio Channel

Operating frequency range, MHz ...................... 2400 to 2483.5

Number of active channels with 5 MHz increment ................ 16

Channel width, MHz ................................................................ 2

Wireless coverage range, line-of-sight, m, min ................... 300

General Technical Parameters

Detector current consumption, mA, max:

- radio module OFF ............................................................ 0.13

- radio module ON .............................................................. 105

Battery replacement indication threshold, V .................... 2.7

-0.2

Power supply voltage lower threshold (deactivating

threshold retaining battery discharge indication), V ............. 2.1

Overall dimensions, mm, max ............................. 101.56332

Weight (without battery), kg, max ...................................... 0.07

Average battery service life, years, min ..................................... 2

Operating Conditions

Temperature range, °С ................................ from -20 up to +50

Relative air humidity, % .............................. up to 95 at + 35 °С

no moisture condensation

4 Delivery Set

Wireless Surface Acoustic

Glass Break Detector Astra-Z-6145 ................................... 1 pcs.

Battery ER14505 ............................................................... 1 pcs.

Screw 2.9×25 ..................................................................... 4 pcs.

Dowel 5х25 ........................................................................ 4 pcs.

Operating Manual ............................................................ 1 copy.

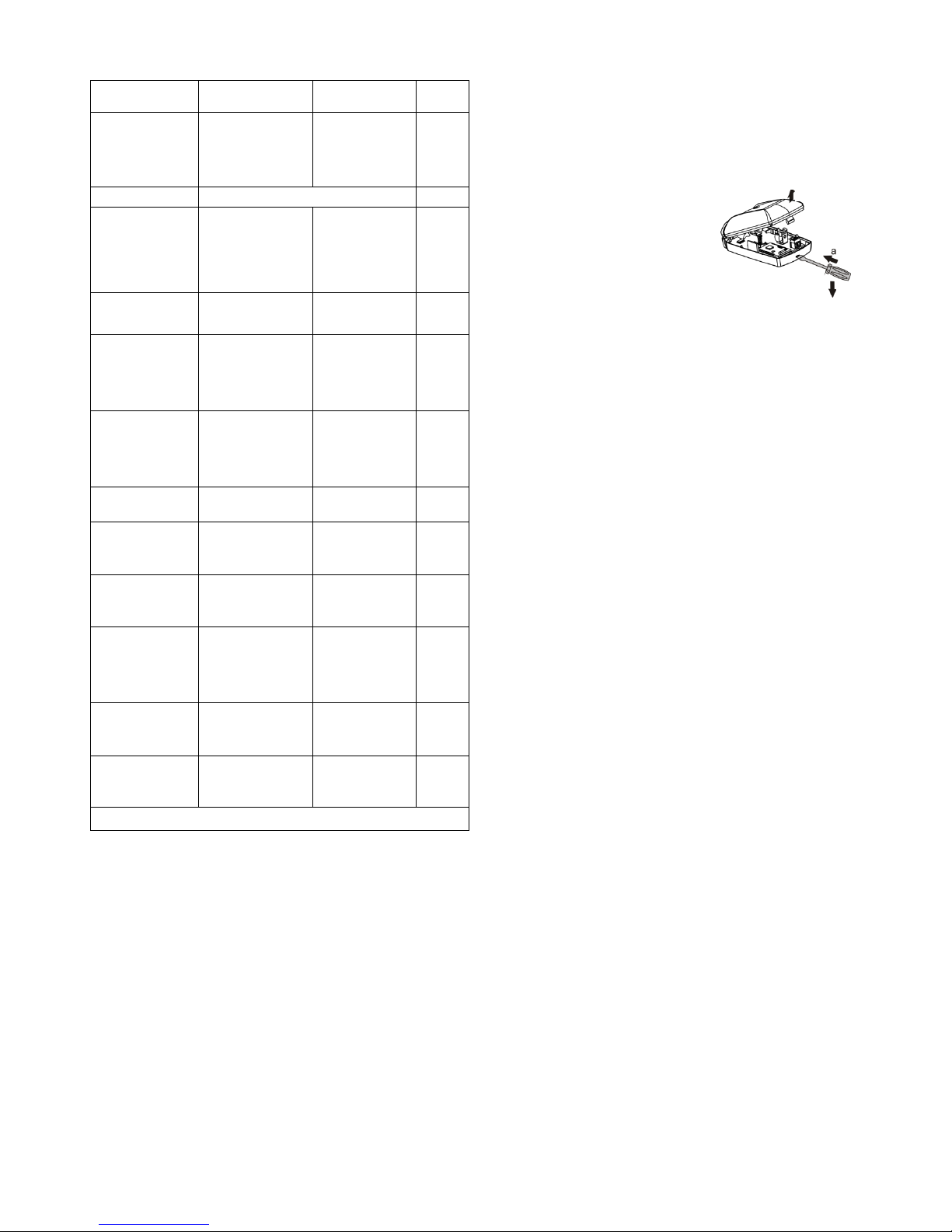

5 Structure

Fig. 3

5.1 Structurally, the detector is designed as a unit consisting of a

base and a removable cover. The unit houses a printed circuit

board with radio elements (Fig. 3).

5.2 Mounted on PCB is a Zone-GND terminal block for con-

necting external emergency detectors (gas leak, water leak,

etc.). Wire length is 3 m max.

5.3 Mounted on PCB is a Tamper Switch (S1button), which

results in the «Tampering» notification when the cover is removed.

5.4 Mounted on PCB are LEDs: red (for monitoring the detec-

tor’s operability) and white (for wireless network status supervision).

Confident detection area

Probable detection area

(in case of positive testing with a steel ball)

Cover removed

Battery installed

Mounting

holes

Microphone

LED indicators

Tamper

switch

Battery

Reg plug

Screw

terminal block

PCB

Wire insertion

holes

Page 2

Rev. 6145-v3_1_en

2

6 Information Capacity

Table 1 – Notification – Detector indicators and control panel

Type of

notification

Red

indicator

White

indicator

Control

panel

Detector

standby mode

start

Lights up once for

1 to 20 s after

power is up

Not lit

−

Norm

Not lit

+

Alarm

Lights up once

for 2 s when the

protected glass

is being broken

Not lit

+

Zone-GND

input violation

Lights up once

for 0.2 s

Not lit

+

Low-frequency

(LF) interference

in the acoustic

channel

Lights up for 0.5 s

with 1 s pause for

as long as interference is present

Not lit

−

High-frequency

(HF) interference

in the acoustic

channel

Blinks twice with

1 s pause for as

long as interference is present

Not lit

−

Powering up

Not lit

Any

Power supply

failure

Blinks 3 times

every 25 s

Not lit

+

Tampering/

Tampering

restored

Lights up once for

0.2 s

Not lit

+

Network

search

Not lit

Blinks with

frequency of 5

Hz for 1 to 60

s

−

No network

Not lit

Blinks 2 times

every 25 s

−

Radio module

failure

Not lit

Blinks 3 times

every 25 s

+

“+” – the notification is given, “–” – the notification is not given

Notes

1 If «Power failure» notification appears, change the battery

within three weeks.

2 Indication of notification on HF and LF interference, “Viola-

tion”, “Network search” is initiated for 10 to 250 minutes by a

command from the control panel or MSS interface and then

automatically ceases to save energy.

7 Operating Modes

The detector operating modes are set via radio upon a command from the control panel in accordance with appropriate

Astra-Zitadel System Control Panel`s Operating Manual *.

Upon a command from Control Panel it is possible to:

1) set detector sensitivity to normal or high;

2) switch on indication for 10 to 250 min;

3) switch Zone-GND terminals channel on/off;

4) set RF supervision time;

5) set operating channel.

The normal sensitivity mode is used when the distance to

protected glass with thickness of more than 3 mm is less than

3 meters.

8 Pre-Starting Procedure

8.1 After transportation in conditions differing from those of

operation, the detector must be kept unpacked for at least 4

hours in the operating conditions.

8.2 Running Detector. Battery Replacement

WARNING! Lithium-thionyl-chloride batteries have an effect of

«passivation» to provide the possibility of long-term storage. To

provide battery normal operation after long-term storage, hold

an «activation» procedure.

Step-1

Push cover lock from base slot.

Remove cover

Step-2

Insert the battery (To replace battery remove the old one and

after no less than 10 sec install the new one).

The LED will light up one time for 1 to 20 seconds - battery

activation and check period.

If after 20 seconds the red LED flashes with a triple blink

every 25 seconds, re-activate the battery by removing, and

after at least 10 seconds reinserting it.

As a last resort, use a piece of wire to close the battery’s

positive and negative poles for 2-3 seconds.

WARNING! Closing the poles for more than 3 seconds leads

to battery discharge

8.3 Registering the Detector in the Wireless Network

Detector registration is required for detector identification in the

wireless network in which it shall operate.

Step-1

According to Astra-Zitadel System Control Panel`s Operating

Manual * perform the following procedure:

1) Install Software ** (MSS Astra-Z, Pconf-Z or MSS Astra

Pro) intended for configuring Control Panel.

2) Create wireless network

Step-2

Perform p. 8.2

Step-3

Switch the control panel to Wireless device registration

mode by the method described in the appropriate Control

Panel Operating manual *

Step-4

Initiate detector registration procedure by one of 2 methods:

а) using the LT (step-5);

b) using the Reg plug and the Tamper switch (step-6)

WARNING!

Avoid to initiate registration procedure on several detectors simultaneously

Step-5

Initiating Detector Registration Procedure Using LT:

- press the lower LT button and wait until the beam appears;

- shine the laser beam on the detector indicator;

- illuminate the indicator for 1 s.

The detector`s red LED lights up for 2 seconds, then the

detector switches to wireless network search mode and the

white LED blinks at a frequency of 5 Hz

b

c

Page 3

Rev. 6145-v3_1_en

3

Step-6

Initiating Detector Registration

Using Reg Plug and Tamper

Switch:

1) Using a screwdriver, shortly

(for 1-2 s) close the Reg plug

The “Waiting for detector registration in

the network” mode switches ON for 60 s

2) Shortly press the Tamper switch on the detector.

The detector switches to the wireless network search mode, and

its white indicator blinks with frequency of 5 Hz.

Step-7

Verify registration procedure:

Once registration procedure

completed successfully, the

abbreviated name of detector «AC»

appears on the screen or «ACxxx

registered» notification appears on the

control panel`s screen Assemble the detector.

In case registration procedure failed, the control panel

screen displays «Registration time expired» notification. In

this case, repeat the registration procedure, i.e. perform operations 3 and 5 or 3 and 6.

Step-8

After successful registration of the detector, for long term

storage before its installation, it is allowed to switch the

detector OFF by removing the battery or installing a soft

isolator.

When power is supplied, there is no need to re-register the detector in the same wireless network if it was not intentionally

removed from the network through software or control panel`s

menu.

8.4 Deleting Detector from Wireless Network

Deletion the detector from wireless network is

performed using Software ** or through Control Panel`s

menu.

When deleting detector from wireless network, Control Panel

transmits notification about deletion to detector within two

periods of RF supervision time. After receiving the

notification detector issues "No network" notification.

To speed up the deletion procedure:

- remove detector`s cover

- shortly close Reg plug

- press and hold down tamper switch for 8-10 sec.

The detector issues "No network" notification to LED and is

available for registration

9 Installation

9.1 Selecting a Location

9.1.1 Recommended height of installation on a wall and fur-

thermost distance from secured glass

9.1.2 Installation options

9.1.3 Non-recommended installation places

9.1.4 It is prohibited the detector in a room with high levels of

sound interference.

9.1.5 For the period of protection it is recommended to close

doors, windows of secured space, switch off ventilators and

other possible sound interference sources.

9.1.6 Make sure that the entire space of secured glass is

covered by detection area. It is not allowed to drape the detector with curtains etc. Otherwise sensitivity can be limited.

9.2 Installation Procedure

Step-1

Push cover lock from base slot.

Remove cover

Step-2

Unbend hooks on the

base. Remove PCB

Step-3

If Zone-GND input is used for

connection of external emergency detectors, remove

blanks from the selected wire

insertion holes

Hook

Page 4

Rev. 6145-v3_1_en

4

Step-4

Press out blanks of selected

mounting holes

Make markings on the wall at

an appropriate height by using

the applied base.

Attach the base

Step-5

Replace PCB matching

PCB slots with guides on

the base. Press on PCB

until it clicks in position

Step-6

Lead wires from external emergency detectors

through the selected hole on the detector base.

Connect wires to the terminal block.

Step-7

Set a detector operating mode in accordance with appropriate

Control Panel Operating Manual *

Step-8

Carry out testing of the detector by knocking on the furthermost part of the secured glass. Please, don´t break secured

glass:

1) place a test steel ball with diameter of 21-22 mm and

weight of 32-48 g, suspended from a 35 cm thread, right by

the glass surface without touching it;

2) deflect the ball by 3070 (Table 3) in the plane perpendicu-

lar to the glass surface without changing the suspension point

and not allowing the thread to go slack. Release the ball.

The test operator shall not obstruct the detector during the

impact;

3) during the test impact the detector red LED lights up for 2

s, and an “Alarm” notification shall be sent to the control

panel.

Table 3 – Angle of steel ball inclination

Glass thickness, mm

Less

than

3

34

45

56

67

More

than

7

Angle of inclination for

glass conventional and

protected with a polymer film, deg

45

50

55

60

65

70

Angle of inclination for all

other glass types, refer to

p.1.1.deg

30

35

40

45

50

55

Step-9

Replace the detector cover (until it

clicks)

9.3 To provide for reliable operation of the alarm system it is

recommended to test and maintain the detector.

The detector shall be tested at least once a week using the

test ball.

Perform technical maintenance at least once a month as

follows:

- inspect integrity of the detector body,

- inspect reliability of mounting,

- clean the detector from any dirt accumulated.

10 Labeling

The following data are shown on the label glued to the body:

- manufacturer trademark;

- detector abbreviated designation;

- firmware version;

- month and year of manufacture (last two digits);

- conformity mark (if the conformity certificate is available);

- bar code, duplicating textual data.

11 EC Conformity Declarations

This product is in conformity with the provisions of:

R&TTE Directive 1999/5/EC, Article 10.5;

EN 60950: 2001 Safety of information technology equipment;

EN 50371 Generic standard to demonstrate the compliance of lowpower electronic and electrical apparatuses with the basic restrictions

related to human exposure to electromagnetic fields (10 MHz - 300

GHz) – General public;

EN 301489-17 V1.1.1 (09-2000) Electromagnetic Compatibility and

radio spectrum Matters (ERM); Electromagnetic Compatibility (EMC)

standard for radio equipment and services; Part 17: Specific conditions for wideband data Hiperlan equipment;

EN 300220-1 V1.3.1 (2000-09) Electromagnetic compatibility and

Radio spectrum Matters (ERM); Short range devices; Technical characteristics and test methods for radio equipment to be used in the 25

MHz to 1 000 MHz frequency range with power levels ranging up to

500 mW; Part 1: Parameters intended for regulatory purposes.

Construction of the detector provides for protection class IP41.

12 Recycling

12.1 Detector is not a danger to life, human health and the environ-

ment. On expiry of its lifetime recycling is done without taking special

measures to protect the environment.

12.2 Recycling of battery cells should be done by delivering used cells

to a trading organization, service centre, manufacturer, or to an organization accepting used batteries.

13 Manufacturer Warranties

13.1 Quality Management System meets provisions of ISO 9001-2011.

13.2 The manufacturer guarantees the compliance of the detector to

specifications on condition that user observes required conditions of

transportation, storage, installation and operation.

13.3 The storage warranty period is 5 years and 6 months from the

date of manufacture.

13.4 The operating warranty period is 5 years from the date of com-

missioning, but not more than 5 years and 6 months from the date of

manufacture.

13.5 The manufacturer shall repair or replace a faulty detector during

the warranty period.

13.6 The warranty becomes void if:

- the user does not follow guidelines of the operating manual;

- the detector is mechanically damaged;

- the detector is repaired by a party other than the Manufacturer.

13.7 The warranty covers the detector only. All equipment manufac-

tured by other parties and used with the detector, including batteries, is

covered by its respective warranty.

The manufacturer bears no responsibility for death, injury, property damage or other incidental or premeditated loss based on

user's statement that the device failed to implement its functions.

* Available for free downloading from www.controlex.eu

and/or integrated with configuring software.

** Available for free downloading from www.controlex.eu.

Sales:

Controlex GmbH

Warranty service and

technical support:

ТЕКО-TD

Philosophenweg 31-33

47051 Duisburg, Germany

Phone: +49 (0) 203 / 393 91 188

Fax: +49 (0) 203 / 393 91 189

GSM: +49 (0) 178 / 218 48 22

E-mail: info@controlex.eu

Web: www.controlex.eu

Prospekt Pobedy str. 19

420138 Kazan, Russia

Phone: +7 (843) 261-55-75

Fax: +7 (843) 261-58-08

E-mail: info@teko.biz

support@teko.biz

Web: www.teko.biz

Made in Russia

Directed at protected

glass

cm

Glass

Loading...

Loading...