Page 1

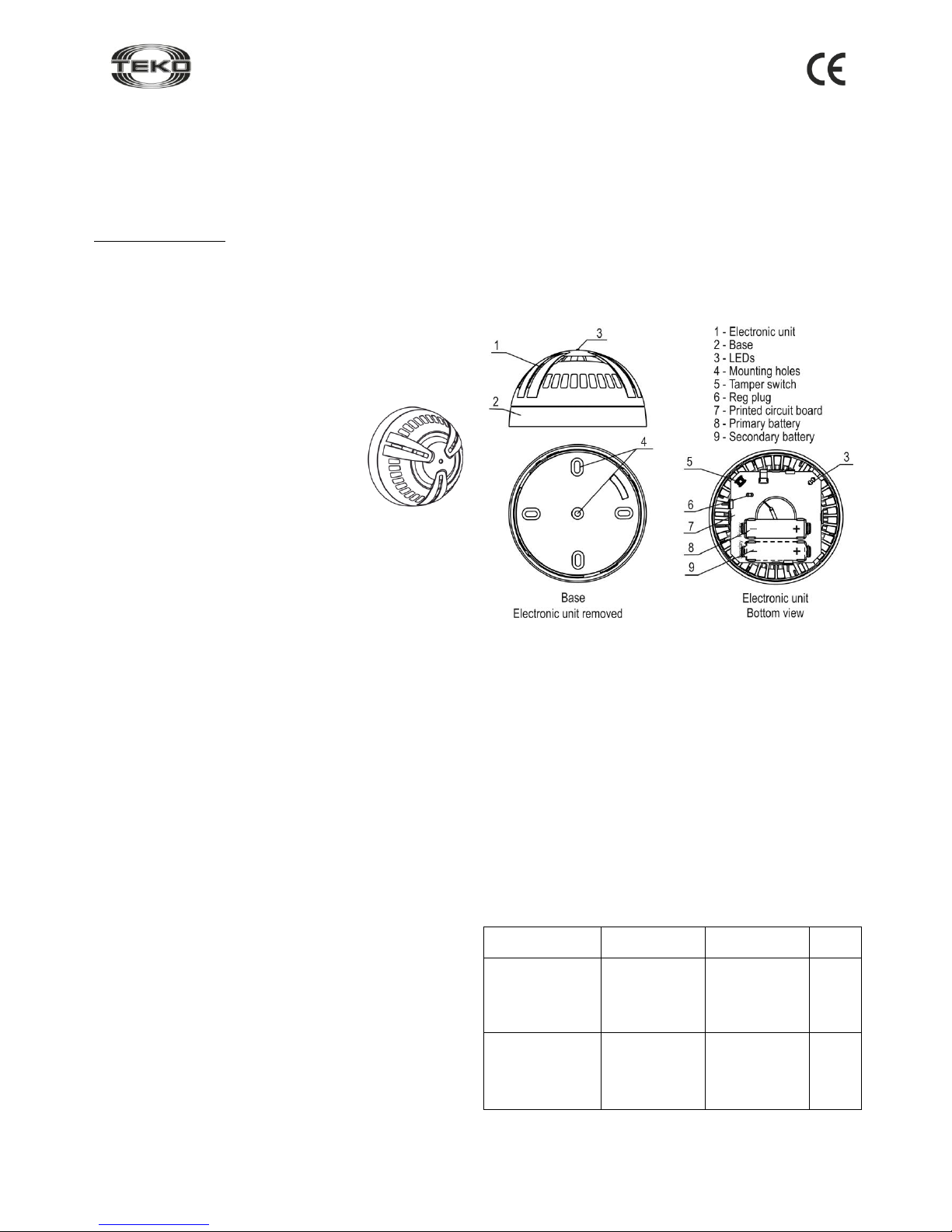

Astra-Z-4245

Wireless Optic-Electronic Fire Smoke Detector

Operation Manual

This operation manual is intended for studying the operating

principles, proper use, storage, and maintenance of the

Wireless Optic-Electronic Fire Smoke Detector Astra-Z-4245

(hereinafter referred to as detector) (Figure 1).

The manufacturer reserves the right to make changes to

improve the detector without prior notification. All changes will

be included in the new revision of the operation manual.

List of Abbreviations:

Astra-Zitadel System: Astra-Zitadel on-site wireless intrusion /

fire detection and alarm system;

Astra-Zitadel System Control Panel: Astra-Z-812M, Astra-Z8945 ver.A, Astra-8945 Pro or Astra-812 Pro Control Panel

(with connected Astra-Z Wireless Extender);

LT: Laser Tester Astra-942;

MSS Astra-Z: Astra-Z Monitoring Software Suite;

MSS Astra Pro: Astra Pro Monitoring Software Suite.

1 Function

1.1 The detector is intended for detecting

fire accompanied by smoke, forming and

transmitting «Fire» notification to the AstraZitadel system control panel via radio.

1.2 Power is supplied to the detector from

one or two lithium-thionyl-chloride batteries

(primary and secondary), size AA, voltage

3,6 V.

2 Operating Principle

The detector’s operating principle is based on registering

infrared radiation (hereinafter IR) that is reflected from smoke

particles in a smoke chamber by a photodetector. Further the

electric signal formed by the photodetector is amplified and

sent to microcontroller in order to analyze the smoke density

value. The microprocessor forms smoke density value and

«Fire» notification in accordance with specified operating

algorithm.

3 Specification

Detector sensitivity, dB/m ........................................ 0.05 to 0.2

Response time, s, max ......................................................... 10

Detection area, m2, max ..................................................... 110

Installation height, m, max .................................................... 10

Technical Parameters of Radio Channel

Operating frequency range, MHz .................. 2 400 to 2 483. 5

Number of operating channels at 5 MHz intervals ................ 16

Channel width, MHz ............................................................... 2

Wireless coverage range, line-of-sight, m, min ................... 300

General Technical Parameters

Current consumption, mA, max:

- with radio module OFF .................................................... 0.05

- with radio module ON ....................................................... 105

Battery replacement

indication threshold, V ......................................................... 2.6

Power supply voltage lower threshold (programmed

deactivation threshold retaining

battery discharge indication), V ........................................... 2.1

Technical readiness time, s, max ......................................... 40

Standby mode recovery time, s, max ....................................... 60

Overall dimensions, mm, max:

- diameter ........................................................................... 106

- height ................................................................................. 60

Weight (without battery), kg, max ...................................... 0.13

Primary battery average life time, year, min ........................... 3

Primary+Secondary batteries average life time, year, min ..... 5

Operating Conditions

Temperature range, °C ..................................... from -30 to +55

Relative air humidity, % ............................... up to 93 at +40 °C

without moisture condensation

4 Delivery Set

Astra-Z-4245 Wireless

Optic-Electronic Fire Smoke Detector ................................ 1 pcs.

Battery ............................................................................... 2 pcs.

Screw 3.9×32 ..................................................................... 2 pcs.

Dowel 6×30 ........................................................................ 2 pcs.

Operation Manual ............................................................. 1 copy

5 Structure

Batteries from delivery package are inserted.

Figure 2

5.1 The detector consists of a removable electronic unit and a

base (Figure 2).

5.2 Inside the electronic unit is a smoke chamber, printed

circuit board (PCB) with radio elements, radio module and

batteries.

5.3 Mounted on PCB is a tamper switch (S1 button), which

results in the «Tampering» notification when the cover is

removed.

5.4 Mounted on PCB are red and white LEDs for detector

operability / wireless network status supervision respectively.

Note - It is not recommended to disassemble the detector’s electronic

unit, as this could damage the detector tuning.

6 Notification Types

Table 1: Notifications processed by LEDs and Control Panel

(or MSS interface)

Notification

Type

Red

LED

White

LED

Control

Panel

Standby

mode start

Lights up for 1

to 40

seconds

Not lit

−

Normal

Lights up for

0.2 seconds

one time per

(60±5)

seconds

Not lit

+

Figure 1

Page 2

Rev. 4245-v3_2_en

2

Fire

Lights up one

time for 10

seconds when

the smoke

density

reaches the

activation

threshold

Not lit

+

Detector failure

Triple blink

every 25

seconds

Not lit

+

Powering up

Not lit

Any

Primary battery

failure

Not lit

Any

+

Secondary

battery failure*

Not lit

Any

+

Power failure

Triple blink

every 25

seconds

Not lit

+

Tampering/

Tamper recovery

Lights up

one time for

0.2 seconds

Not lit

+

Network search

Not lit

Blinks with

frequency of

5Hz for 1 to

60 seconds

−

No network

Not lit

Double blink

every 25

seconds

−

Radio module

failure

Not lit

Triple blink

every 25

seconds

+

+: notification issued; –: notification not issued

*: with secondary battery installed

Notes

1 The «Power failure» notification is processed by the red LED

if both batteries are discharged or if one of the batteries is

missing and the second battery is discharged.

2 If «Primary battery failure» notification appears, replace

the battery within two months.

7 Operating Modes

The detector provides for «Registration» and «Test» modes.

7.1 «Registration» mode is intended for registering the

detector in the wireless network in which it supposed to

operate (see p.8.3).

7.2 «Test» mode is intended for testing electronic and

optical circuits of the detector.

The mode is activated upon a command from the control panel

or LT. Within 5 seconds after the command receipt, the

detector should issue «Test fire» notification (in case of

detector normal operation) or «Detector failure» or «Power

failure» notifications (in case of corresponding failures).

8 Pre-Starting Procedure

8.1 After transportation in conditions differing from those of

operation, keep the detector unpacked for 4 hours in the

expected operating conditions.

8.2 Running Detector. Replacing Batteries

WARNING! Lithium-thionyl-chloride batteries have an effect of

«passivation» to provide the possibility of long-term storage. To

provide battery normal operation after long-term storage, hold

an «activation» procedure.

Step-1

Turn the detector’s electronic unit

counter-clockwise. Remove the

electronic unit from the detector

base.

Step-2

When using one battery to switch the detector ON, insert

the Primary battery.

Note – When using two batteries, it is recommended to

insert the Secondary battery first, and then the Primary

battery. The Secondary battery can be inserted up to 1

minute after inserting the Primary battery.

To replace the battery, remove the old one, and after at

least 30 seconds insert the new one.

The red LED lights up for 1 to 40 seconds – the battery

activation and checking period.

If after 40 seconds the red LED flashes triply every 25

seconds, re-activate the battery by removing it, and after at

least 30 seconds reinserting it.

Warning! If two batteries have been inserted, replace

both batteries.

8.3 Registering the Detector in the Wireless

Network

Detector registration procedure is required for detector

identification in the wireless network in which it is supposed

to operate.

Step-1

According to Astra-Zitadel System Control Panel`s

Operating Manual * perform the following procedure:

1) Install Software ** (MSS Astra-Z, Pconf-Z or MSS Astra

Pro) intended for configuring Control Panel.

2) Create wireless network

Step-2

Perform par.8.2

Step-3

Switch the control panel to Wireless device registration

mode by the method described in the appropriate Control

Panel Operating manual *

Step-4

Initiate detector registration procedure by one of 2

methods:

a) using the LT (step-5);

b) using the Reg plug and the tamper switch (step-6)

WARNING!

Avoid to initiate registration procedure on several

detectors simultaneous

Step-5

Initiating Detector

Registration Using the LT:

- Press the lower button on the

LT and hold until a beam

appears.

- Direct the laser beam at the

detector LED.

- Irradiate the LED for 1 second.

The detector red LED lights up for 2 seconds, and then

the detector switches to wireless network search mode and

the detector white LED blinks at a frequency of 5 Hz.

No more than 10 m

At least 0.1 m

Page 3

Rev. 4245-v3_2_en

3

Step-6

Initiating Detector Registration

Using the Reg Plug and Tamper

Switch:

1) Shortly (for 1-2 seconds) close

the Reg plug with a screwdriver.

The detector switches to registration in wireless network

mode for 60 seconds.

2) Within 60 seconds, shortly (for 0,2-2

seconds) press the tamper switch

on the detector. The detector switches

to wireless network search mode and

the detector`s white LED blinks at a

frequency of 5 Hz.

Step-7

Verify registration procedure:

Once registration procedure completed successfully, the

abbreviated name of detector «SD» appears on the screen

or «SDxxx registered» notification appears on the control

panel`s screen.

Assemble the detector:

- Place the detector’s electronic unit on the base, aligning

the projections on the detector base with the button on the

electronic unit circuit board.

- Press the housing of the detector’s electronic unit against

the base and turn it clockwise firmly.

In case registration procedure failed repeat the

registration procedure, i.e. perform steps 3 and 5 or 3 and

6.

Step-8

After successful registration of the detector, for long term

storage before its installation, it is allowed to switch the

detector OFF by removing the battery or installing a soft

isolator.

When power is supplied, there is no need to re-register the

detector in the same wireless network if it was not intentionally

removed from the network through software or control panel`s

menu.

8.4 Deleting Detector from Wireless Network

Deletion the detector from wireless network is performed

using Software ** or through Control Panel`s menu.

When deleting detector from wireless network, Control Panel

transmits notification about deletion to detector within two

periods of RF supervision time. After receiving the

notification detector issues "No network" notification.

To speed up the deletion procedure:

- remove detector`s cover

- shortly close Reg plug

- press and hold down tamper switch for 8-10 sec.

The detector issues "No network" notification to LED and is

available for registration.

9 Installation

9.1 Location

9.1.1 Install the detector on the ceiling.

9.1.2 The area covered by one detector, as well as the maximum

distance between detectors and between the detector and the

wall, must be determined according to Table 2.

Table 2

Secured room

height,

m

Average area

covered

by one detector, m2

Maximum distance, m

between

detectors

from detector

to wall

up to 3.5

up to 85

9.0

4.5

> 3.5 to 6.0

up to 70

8.5

4.0

> 6.0 to 10.0

up to 65

8.0

4.0

9.1.3 When installing the detector on a sloped ceiling, it should

be installed at the highest point.

9.1.4 Do not cover the detector; smoke particles must freely

penetrate the grating into the smoke chamber.

9.2 Installation Procedure

Step-1

Turn the detector’s electronic

unit counter-clockwise.

Remove the electronic unit

from the detector base.

Step-2

Mark a place on the ceiling,

using the detector base as a

template.

Fasten the base to the

ceiling.

Step-3

Install the detector’s electronic unit onto the fastened base:

- Align the projections on the detector base with the button

on the electronic unit circuit board.

- Press the housing of the detector’s electronic unit against

the base and turn it clockwise firmly.

- Make sure the detector LED issues «Standby mode»

notification.

Page 4

Rev. 4245-v3_2_en

4

Step-4

Activate «Test» mode in accordance

with the appropriate Astra-Zitadel

System Control Panel`s Operating

Manual* or using the LT:

- Press the upper button on the LT;

- Direct the laser beam at the

detector LED;

- Irradiate the LED for 1 second:

In 5 seconds make sure «Fire» notification appears on the

LED – the red LED lights up for 10 seconds. A «Test fire»

event is recorded in the control panel (or MSS interface)

event log.

9.3 To ensure the alarm system reliable operation, testing

and maintenance of the detector is recommended.

Testing should be carried out as follows:

- Check absence/output of the «Failure» notification on the

LED at least once a week;

- Check the detector operability by using a laser tester at least

once a month.

Perform technical maintenance at least once in 3 months

as follows:

- Inspect the detector housing integrity and reliability of its

mounting;

- Purge the detector from contamination;

- Clean the detector’s smoke chamber with compressed air.

Detecting severe dust of smoke chamber (dust level value

greater than 50 units) during the process of testing or issuing

the "Failure" notification requires unscheduled cleaning of the

smoke chamber.

Dust level value is displayed:

- in the “Engineer menu / 2 Wireless network / 5 W/devices

status” for Astra-Z-812M Control Panel;

- in the “Wireless devices / Device type” tab of Monitor

module from Astra-Z MSS for Astra-Z-8945 ver.A Control

Panel, or in the “Wireless devices / Device type” tab of

Monitor module from Astra Pro MSS for Astra-8945 Pro and

Astra-812 Pro Control Panels. Launch test of the detector from

right-click menu (Launch SD/HD test), observe dust level value

in the “Dust level value / Temperature” column.

10 Labeling

The following information is marked on the label attached to the

detector housing:

- manufacturer trademark;

- abbreviated detector designation;

- firmware version;

- month and year (last two digits) of manufacture;

- conformity mark (if the conformity certificate is available);

- bar-code that duplicates textual information.

11 EC Conformity Declarations

This product is in conformity with the provisions of:

R&TTE Directive 1999/5/EC, Article 10.5;

EN 60950: 2001 Safety of information technology equipment;

EN 50371 Generic standard to demonstrate the compliance of lowpower electronic and electrical apparatuses with the basic restrictions

related to human exposure to electromagnetic fields (10 MHz - 300

GHz) – General public;

EN 301489-17 V1.1.1 (09-2000) Electromagnetic Compatibility and

radio spectrum Matters (ERM); Electromagnetic Compatibility (EMC)

standard for radio equipment and services; Part 17: Specific conditions

for wideband data Hiperlan equipment;

EN 300220-1 V1.3.1 (2000-09) Electromagnetic compatibility and

Radio spectrum Matters (ERM); Short range devices; Technical characteristics and test methods for radio equipment to be used in the 25

MHz to 1 000 MHz frequency range with power levels ranging up to

500 mW; Part 1: Parameters intended for regulatory purposes.

Construction of the detector provides for protection class IP41.

12 Recycling

12.1 The detector poses no threat to human life, health or to the

environment; after its service life is over, it can be disposed of without

any special environmental protection measures.

12.2 Recycling of battery cells should be done by delivering used

cells to a trading organization, service centre, manufacturer, or to any

organization accepting used batteries.

13 Warranty Terms

13.1 Quality Management System meets provisions of ISO 9001-2011.

13.2 The manufacturer guarantees the compliance of the detector to

specifications if the user observes required conditions of

transportation, storage, installation and operation.

13.3 The storage warranty period is 5 years and 6 months from the

date of manufacture.

13.4 The operating warranty period is 5 years from the startup date,

but not more than 5 years and 6 months from the date of manufacture.

13.5 The manufacturer guarantees replacement or repair of the

product during the warranty period.

13.6 The warranty doesn’t come into effect in the following

cases:

- not adherence to the operating manual;

- mechanical damage to the detector;

- repair of the detector by any third-party service except for the

manufacturer.

13.7 The warranty applies to the detector only. All equipment from

other manufacturers used with the detector, including batteries, is

covered by its own warranties.

The manufacturer bears no responsibility for death, injury,

property damage or other incidental or premeditated loss based

on user's statement that the device failed to implement its

functions.

* Available for free downloading from www.controlex.eu

and/or integrated with configuring software.

** Available for free downloading from www.controlex.eu.

Sales:

Controlex GmbH

Warranty service and

technical support:

ТЕКО-TD

Philosophenweg 31-33

47051 Duisburg, Germany

Phone: +49 (0) 203 / 393 91 188

Fax: +49 (0) 203 / 393 91 189

GSM: +49 (0) 178 / 218 48 22

E-mail: info@controlex.eu

Web: www.controlex.eu

Prospekt Pobedy str. 19

420138 Kazan, Russia

Phone: +7 (843) 261-55-75

Fax: +7 (843) 261-58-08

E-mail: info@teko.biz

support@teko.biz

Web: www.teko.biz

Made in Russia

Loading...

Loading...