Page 1

Astra-642

Ultrasonic Volumetric Detector

Operating Manual

Rev. 642-v2_6_en 1

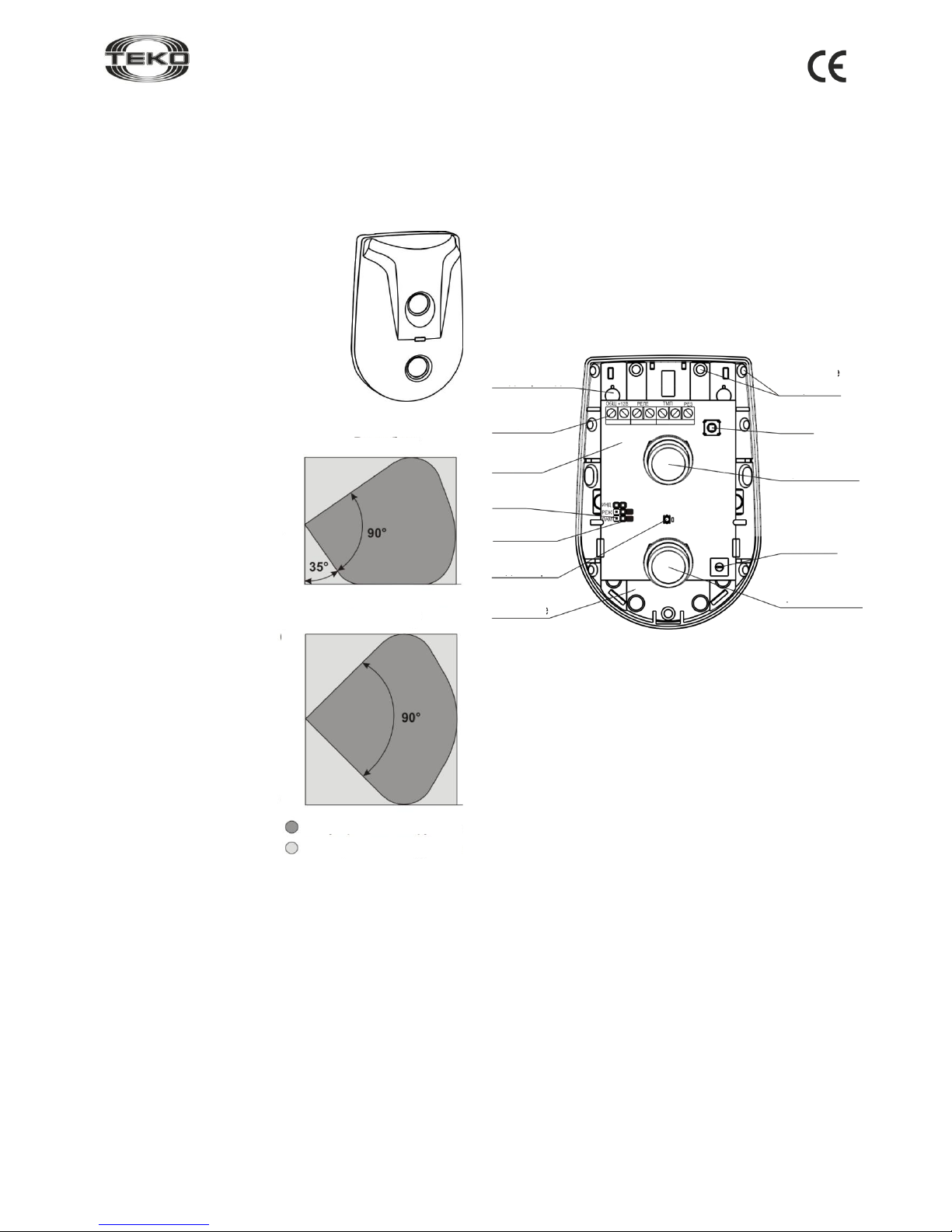

The operating manual describes the operating principle, operational and maintenance conditions pertaining to ultrasonic volumetric detector Astra-642 (hereinafter “detector”) (Fig.1).

The manufacturer reserves the right to introduce changes

which update and retrofit the detector without prior notice. All

such changes will be described in an updated revision of the

operating manual.

1 Function

The detector detects intrusion into a protected volume of a closed room and generates an alarm notification by opening output contacts of the signaling relay.

The detector is powered by any DC

source with rated voltage of 12V and pulsation amplitude not exceeding 0.1V.

2 Operating Principle

2.1 The operating principle of

the ultrasonic channel (hereinafter referred to as the USchannel) is based on the

Doppler Effect – changes in

frequency of ultrasonic

waves emitted by the detector, when they are reflected

from a moving object.

An electric signal from the ultrasonic sensor is sent to a

microcontroller, which – if signals are present in both channels and in accordance with a

present operation algorithm –

generates the “Alarm” notification by opening the output circuit of the optic-electronic relay.

2.2 Schematics of the detection zone are shown in Fig. 2.

Note – The US-channel de-

tection zone depends on a

specific room: some objects

absorb or reflect ultrasound,

thus distorting the detection

zone.

3 Specifications

Technical Parameters of US-channel

Intrusion detection range, m, min................................................... 10

Confident detection area angle

in horizontal and vertical plane, о ............................................ 90

Operating frequency, kHz ....................................................... 25

Movement speed detection range, m/s................ from 0.3 to 2.0

Recommended mounting height, m ....................................... 2.2

General Technical Parameters

Power supply voltage, V .......................................... from 8 to 15

Current consumption, mA, max .............................................. 25

Readiness time, s, max .......................................................... 20

Permissible current through relay contacts, А, max............. 0,08

Permissible voltage on relay contacts, V, max ..................... 100

Resistance of the circuit, included in the alarm loop

in standby mode, Ohm ........................................................... 16

Overall dimensions, mm, max ............................... 106.5×72×38

Weight, kg, max ................................................................... 0.08

Operating Conditions

Temperature range, °С ................................. from -10 up to +50

Relative air humidity, % ...................................... up to 95 at + 35 °С

no moisture condensation

4 Delivery Set

Ultrasonic volumetric detector Astra-642 ........................... 1 pcs.

Bracket ............................................................................... 1 pcs.

Screw 2,9х25 (or 2-3x30) ................................................... 2 pcs.

Dowel 5х25 ........................................................................ 2 pcs.

Sealing material ................................................................. 1 pcs.

User Instruction ................................................................ 1 copy.

5 Structure

Fig. 3

Structurally, the detector is a unit comprised of a base and a

removable cover.

The unit houses a printed circuit board with radio elements,

screw terminal blocks for external connections, ultrasonic

transmitter and receiver (Fig. 3).

A switch installed on the printed circuit board generates a

“Tampering” notification when the cover is detached by open-

ing the ТМР circuit (irrespective of whether or not the detector

power supply is switched on).

The following indicators are mounted on the printed circuit

board: red – for detector status monitoring, blue – for interference indication.

The US-channel detection range can be adjusted using the

US-channel range controller.

Fig. 1

Fig. 2

Side view

Top view

Confident detection area

Probable detection area

10m

2.2m

10m

6m

0

6m

Wire

insertion holes

Mounting

holes

Screw

terminals

Tamper

Switch

PCB

Ultrasonic

transmitter

Plugs

Jumpers

US-channel

range

controller

Indicators

Ultrasonic

transmitter

Base

Cover removed

Page 2

Rev. 642-v2_6_en

2

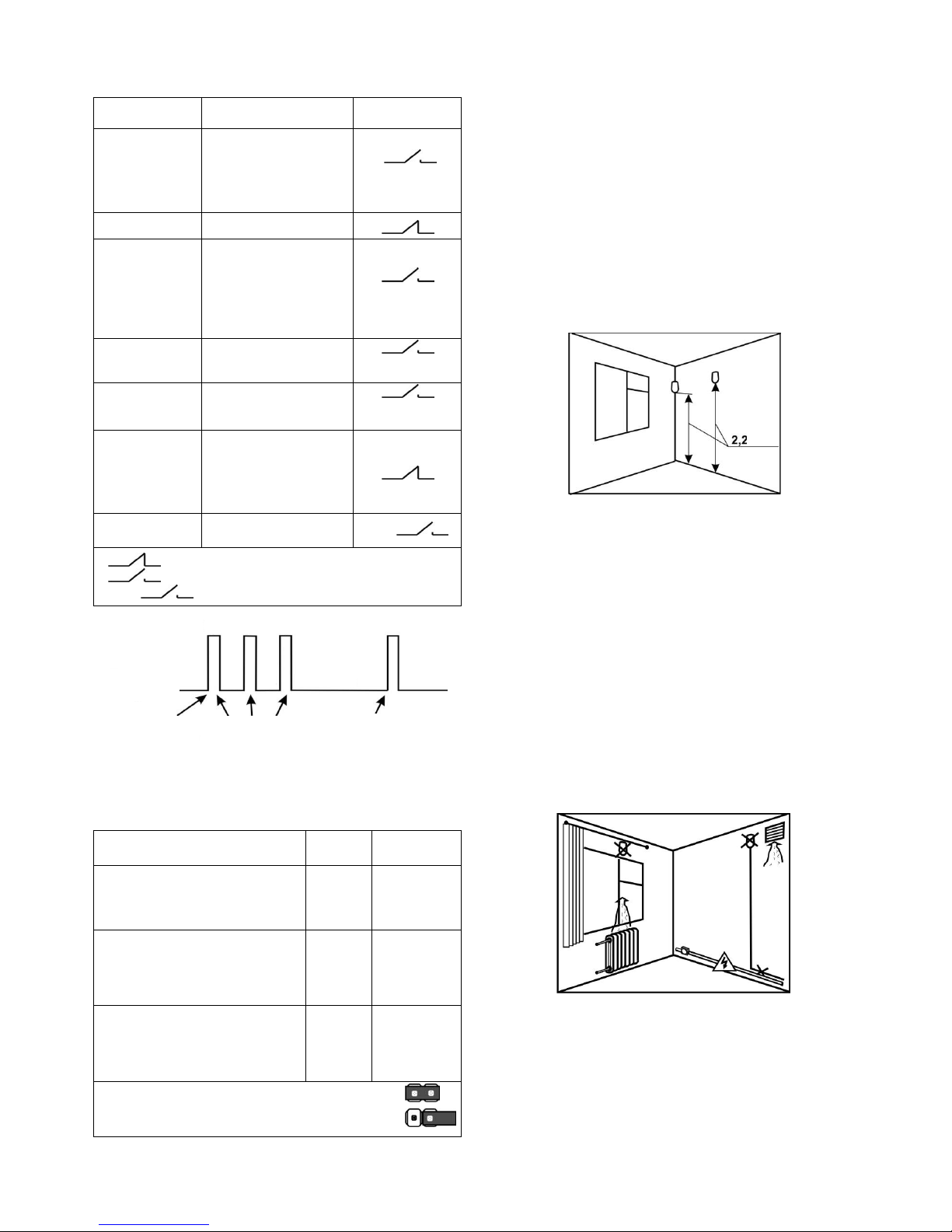

6 Information Capacity

Table 1 – Notification – Indicator and relay

Type of

notification

Indicator

Relay

Detector

standby mode

start

Blinks red and blue

alternatively after

power up.

Duration – up to 20 s

For up to 20 s

Norm

Not lit

Alarm

Lights up red once for

4 s if a person is detected moving in the

detection area (if indication is permitted)

For 4 s

Alarm in “Alarm

memory” mode

Fig. 4

For 4 s

Failure

Lights up red until failure is eliminated

Until failure elimination

Interference

Blinks blue for as long

as interference is

present (if indication is

permitted)

Tampering

Not lit

ТМП

" " –relay is closed,

" " –relay is open,

"ТМП " – ТМР circuit is open

Fig. 4

7 Operating Modes

Table 2 – Operating modes and settings

Operating mode

Plug

Jumper

position

Indication ON

Indication OFF

ИНД

+

–

High detectability

Normal detectability

РЕЖ

+

–

“Alarm memory” ON

“Alarm memory” OFF

ПАМ

+

–

"+" - jumper is installed on both plug pins

"–" - jumper is removed (or installed on one plug pin)

The “Alarm memory” mode allows registering the fact

and number of zone violations in prortected area, and is

reflected in corresponding notification .

The mode is activated in 1 minute after installation of ПАМ

plug or in 1 min. after starting of detector stand-by mode with

jumper installed previously on ПАМ plug. “Alarm” notification

is indicated in 1 min. after violation of protected area. To

switch the mode off and reset indication, remove jumper from

ПАМ plug or switch power off.

8 Installation and Pre-starting Procedure

8.1 Works on installation, mounting, maintenance and

operation of detector should be performed by only qualified

persons.

8.2 After transportation in conditions differing from those of

operation keep detector unpacked under supposed operation

conditions for at least 4 hours.

8.3 Selecting a Location

8.3.1 Recommended mounting height

8.3.2 The detector shall be mounted on load-bearing, vibra-

tion-free structural elements.

8.3.3 Alarm loop and power circuit wires shall not be located near

power cables.

8.3.4 This detector type allows mounting several detectors in

the same room. Detectors shall be placed not closer than 5

m from each other.

8.3.5 It is not permitted to operate the detector in a room with

noise levels exceeding 75 dB.

8.3.6 Do not mount the detector near curtains (blinds) and

other object which may move when air currents move through

the room.

8.3.7 When a room is being protected, it is recommended to

close doors and ventilation windows, switch off fans, air conditioners and other possible sources of strong air currents, and

make sure there are no animals and insects in the room.

8.3.8 Non-recommended mounting locations

m

Indication is

ON

Indication

Is OFF

Start of

indication

Number of alarm

events (up to 3)

Reiterated indication

0.5s 0.5s 0.5s

1s

1s

4s

Page 3

Rev. 642-v2_6_en

3

8.4 Installation Procedure

Step-1

Push out cover lock from

base slot.

Remove cover

Step-2

Unbend hook on the base.

Remove PCB

Step-3

Press out blanks of selected wire holes

Step-4 Choose mounting option: a, b or c

Step-5а

WALL-MOUNTED

Step-5c

BRACKET-MOUNTED

Press the slot blank for

bracket mounting

Step-5b

CORNER-MOUNTED

Step-6a,b

Bring the base against a wall

at a required height and mark

the wall.

The detector base shall be

positioned in strict

accordance with item 4a

figure

Step-6c

Bring the bracket against

a place you want to

mount the detector on

and mark the mounting

holes.

Mount the bracket on a

wall or on the ceiling

Mounting holes

Step-7a,b

Pull power supply and

alarm loop wires

through the dedicated

wire insertion hole in

the detector base.

Attach the base to the

wall or the corner

Proceed to step 9

Step-7c

Superpose bracket clamp with

base slot of the detector. Drive a

screw partially into the bracket

clamp from the inside of the detector base.

Position the detector as required

and tighten the screw. The

bracket provides for detector

rotation for 87º in horizontal

plane

Step-8

Pull power supply and alarm loop wires through the dedicated wire insertion hole in the detector base

Step-9

Place the printed circuit

board back into the

base, match the PCB

slots with guides on the

base. Press on the PCB

until it clicks in position

Step-10 Connect the wires to detector terminals.

A reserve terminal РЕЗ is provided for connection of a

terminal resistor

Step-11

Seal the wire insertion hole and other holes with the sealing

materials included in the delivery set to prevent air currents

and insects from getting into the detector

Step-12

Install jumper on ИНД and РЕЖ

plugs.

Remove jumper from the ПАМ plug

Step-13

Place the detector cover back

into its position (until it clicks

shut)

Hook

Clamp

Screw

Press out

blanks of

selected

mounting

holes

Press out

blanks of

selected

mounting

holes

c

b

Page 4

Rev. 642-v2_6_en

4

Step-14

Switch on the detector power supply, red and blue indicators

shall alternatively blink for not more than 60 s – it means the

detector is being switched to the standby mode.

If within 30 s after switching to the standby mode the detec-

tor gives the “Interference” notification:

1 Make sure there is no extra emission on the operating fre-

quency of the detector and exclude such emission if

present.

2 Remove any object, vibrating/moving rhythmically by the

detector.

Step-15

Make a TEST-pass through a

protected area with speed of 0.3 m/s

and 2 m/s.

Make sure the “Alarm” notification is

given for every movement (the indicator lights up red for 4 s).

Repeat the TEST-pass in different

directions

Step-16

Push out cover lock from

base slot.

Remove detector cover

Step-17

If required, adjust the US-channel

detection range in accordance with

protected room dimensions using

the US-channel range controller

min – 5 m range;

max – 10 m range

Step-18

Depending on a selected operating

mode, install jumpers on ИНД and

ПАМ plugs

Step-19

Place the detector cover back

into its position (until it clicks

shut)

Step-20

If during alarm system testing in the initial operating period

(1-2 weeks) you receive false “Alarm” notifications due to

specific characteristics of a protected room, remove jumper

from РЕЖ plug

8.5 To provide for reliable operation of the alarm system it is

recommended to test and maintain the detector at least

once a month.

The detector shall be tested in the following way:

- walk through the detection zone;

- make sure that the “Alarm” notification is present on the

control panel and, if indication is permitted, on the detector

indicator (lights up once for 4 s for each movement).

The detector shall be maintained in the following way:

- inspect integrity of the detector body, reliability of contacts

and mounting, clean the detector from any dirt accumulated.

9 Labeling

The following data are shown on the label glued to the body:

- manufacturer trademark;

- detector abbreviated designation;

- firmware version;

- month and year of manufacture (last two digits);

- conformity mark (if the conformity certificate is available);

- bar code, duplicating textual data.

10 EC Conformity Declarations

This product is in conformity with the provisions of:

EMC 89/336/EEC

EN 61000-6-3:2005 Electromagnetic compatibility (EMC) - Part 6-3:

Generic standards - Emission standard for residential, commercial

and light-industrial environments

EN 50130-4/1995 + A1:1998 + A2:2003 + Corrig. 2003 Alarm systems - Part 4: Electromagnetic compatibility - Product family standard: Immunity requirements for components of fire, intruder and

social alarm systems

EN 60950-1: 2001+A11:2004+Corrig.2004 Safety of information

technology equipment

11 Recycling

The detector does not pose any life or health risk to individuals or to

the environment. Once its service life is complete, the detector may

be utilized with no special environment protection measures.

12 Manufacturer Warranties

12.1 Quality Management System meets provisions of ISO 9001-

2011.

12.2 The manufacturer warrants that the detector will meet requirements of technical specifications if a user follows all shipping,

storage, mounting and operating guidelines.

12.3 Guaranteed storage life – 5 years and 6 months from the

manufacture date.

12.4 Guaranteed service life – 5 years from the commissioning, but

not more than 5 years and 6 months from the manufacture date.

12.5 The manufacturer shall repair or replace a faulty detector during the warranty period.

12.6 The warranty becomes void if:

- the user does not follow guidelines of the operating manual;

- the detector is mechanically damaged;

- the detector is repaired by a party other than the Manufacturer.

12.7 The warranty covers the detector only. All equipment manu-

factured by other parties and used with the detector is covered by its

respective warranty.

The manufacturer shall not be responsible for personnel death,

injury, and damage to equipment or other accidental or delibe-

rate losses based on user’s claims that the detector failed to

function properly.

Sales:

Controlex GmbH

Warranty service and

technical support:

ТЕКО-TD

Philosophenweg 31-33

47051 Duisburg, Germany

Phone: +49 (0) 203 / 393 91 188

Fax: +49 (0) 203 / 393 91 189

GSM: +49 (0) 178 / 218 48 22

E-mail: info@controlex.eu

Web: www.controlex.eu

Prospekt Pobedy str. 19

420138 Kazan, Russia

Phone: +7 (843) 261-55-75

Fax: +7 (843) 261-58-08

E-mail: info@teko.biz

support@teko.biz

Web: www.teko.biz

Made in Russia

Top view

Indication OFF

Indication ON

“Alarm memory” OFF

“Alarm memory” ON

c

b

Loading...

Loading...